Manual thermit welding electrode and preparation and using methods thereof

A welding rod and hot agent technology, applied in the direction of thermite welding equipment, welding equipment, welding equipment, etc., can solve the problems of cumbersome process and insufficient convenience, and achieve the effect of simple cutting operation and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

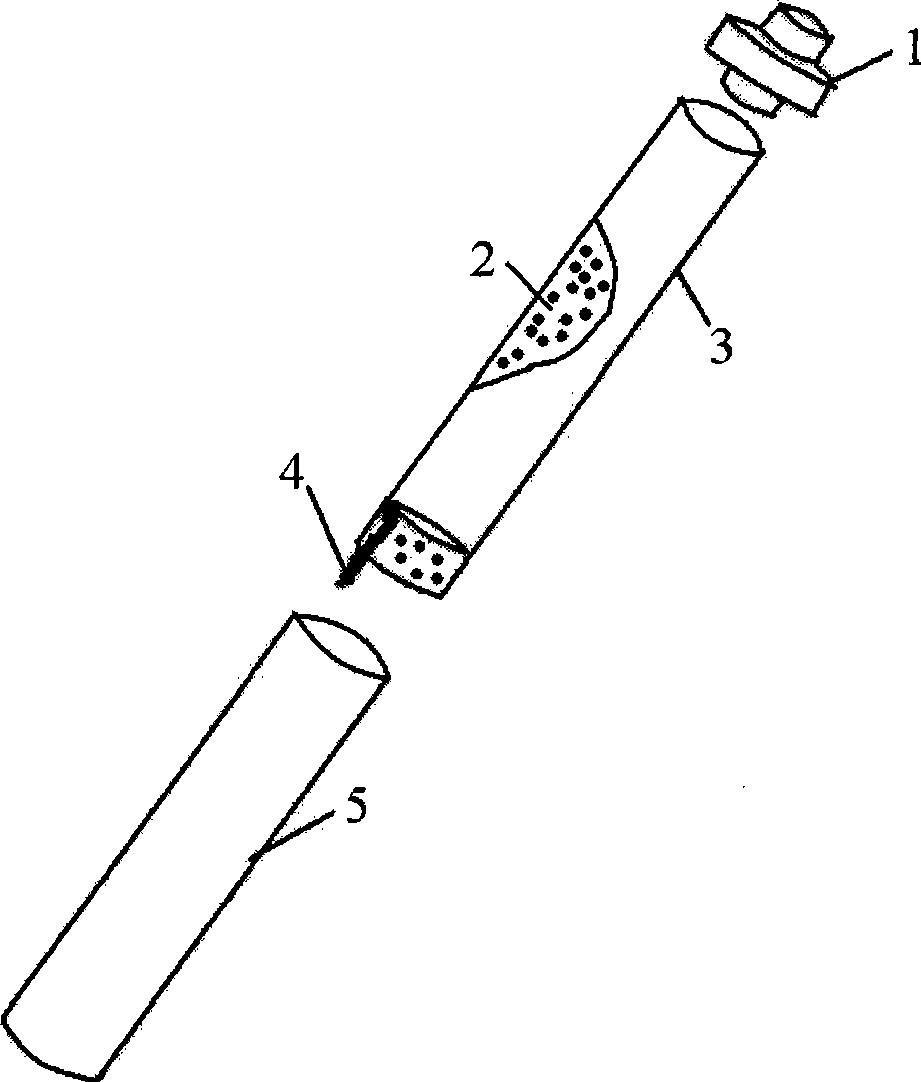

Image

Examples

Embodiment 1

[0025] A manual hot flux welding rod, the welding flux of the electrode is composed of a thermite, a slag-forming agent and an alloying agent. 2 O powder: 10%, NiO powder: 8%, Al powder: 13%, the composition of the slag-forming agent and the percentage of the quality of each component in the total mass of the flux is: B 2 O 3 Powder: 13%, SiO 2 Powder: 9%, CaO powder: 2%, the composition of the alloying agent and the percentage of the mass of each component in the total mass of the flux are: Fe powder: 1%, Mn powder: 1%, the particle size of the raw materials used are all less than 100μm.

[0026] A preparation method of manual hot flux welding rod, the method steps are:

[0027] (1) Weigh the raw materials in proportion, put them into the ball mill tank, and add ZrO according to the ratio of balls to material 1:1 2 Grinding ball, the ball milling medium is acetone, after wet grinding for 24 hours, and drying to obtain flux 2;

[0028] (2) Fill the solder 2 into a paper cy...

Embodiment 2

[0032] A manual hot flux welding rod, the welding flux of the electrode is composed of a thermite, a slag-forming agent and an alloying agent. 2 O powder: 4%, NiO powder: 10%, Al powder: 12%, the composition of the slag-forming agent and the percentage of the quality of each component in the total mass of the flux is: B 2 O 3 Powder: 11%, SiO 2 Powder: 10%, CaO powder: 3%, the composition of the alloying agent and the percentage of the mass of each component in the total mass of the flux are: Fe powder: 1%, Mn powder: 1%, and the particle size of the raw materials used is less than 100μm.

[0033] A preparation method of manual hot flux welding rod, the method steps are:

[0034] (1) Weigh the raw materials in proportion, put them into the ball mill tank, and add ZrO according to the ratio of balls to material 1:1 2 Grinding ball, the ball-milling medium is ethanol, after wet grinding for 12 hours, and drying to obtain flux 2;

[0035] (2) Fill the solder 2 into a paper cy...

Embodiment 3

[0039] A manual hot flux welding rod, the welding flux of the electrode is composed of a thermite, a slag-forming agent and an alloying agent. 2 O powder: 4%, Fe 2 O 3 Powder: 12%, Al powder: 15%, the composition of the slag-forming agent and the percentage of the quality of each component in the total mass of the flux is: B 2 O 3 Powder: 15%, SiO 2 Powder: 6%, CaO powder: 2%, the composition of the alloying agent and the percentage of the mass of each component in the total mass of the flux are: Fe powder: 1%, Mn powder: 1%, the particle size of the raw materials used are all less than 100μm.

[0040] A preparation method of manual hot flux welding rod, the method steps are:

[0041] (1) Weigh the raw materials in proportion, put them into the ball mill tank, and add ZrO according to the ratio of balls to material 1:1 2 Grinding ball, the ball-milling medium is acetone, after wet grinding for 18 hours, and drying to obtain flux 2;

[0042] (2) Fill the solder 2 into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com