Patents

Literature

357results about "Alumino-thermic welding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manual thermit welding electrode and preparation and using methods thereof

ActiveCN101444876AFirmly connectedEasy to weldWelding/cutting media/materialsAlumino-thermic welding apparatusSlagEngineering

The invention discloses a manual thermit welding electrode and preparation and using method thereof which belong to the technical field of welding. A welding compound of the welding electrode comprises a thermit, a slag forming constituent and an alloying agent. Raw materials are weighed according to the proportion and arranged in a ball mill, a grinding ball and a milling medium are added, and the welding compound is obtained by drying after wet grinding; the welding compound is filled in a cylinder which is made of paper, a lead wire is arranged at one end of the cylinder, and the other end is sealed by a plastic plug, thereby forming the thermit welding electrode; the welding electrode is arranged in a sleeve which is made of paper and sealed for preservation. When in use, the sleeve is fixed on the plug at the back end of the welding electrode, the sleeve is held by a hand, and the lead wire at the front end of the welding electrode is ignited, and then the manual welding or cutting operation can be carried out. The welding electrode is small, lightweight and portable, the welding and the cutting operations are simple, rapid and safe, the welding and the cutting operations can be carried out anytime and anywhere, and the welding electrode can be applied in the welding and the cutting of steels, stainless steels or copper alloy materials.

Owner:TSINGHUA UNIV

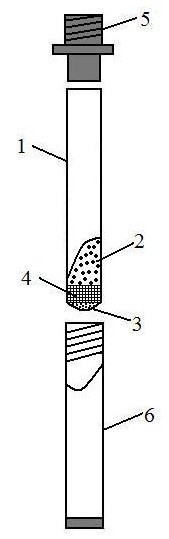

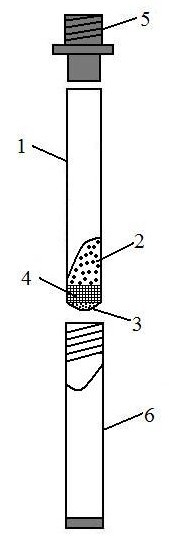

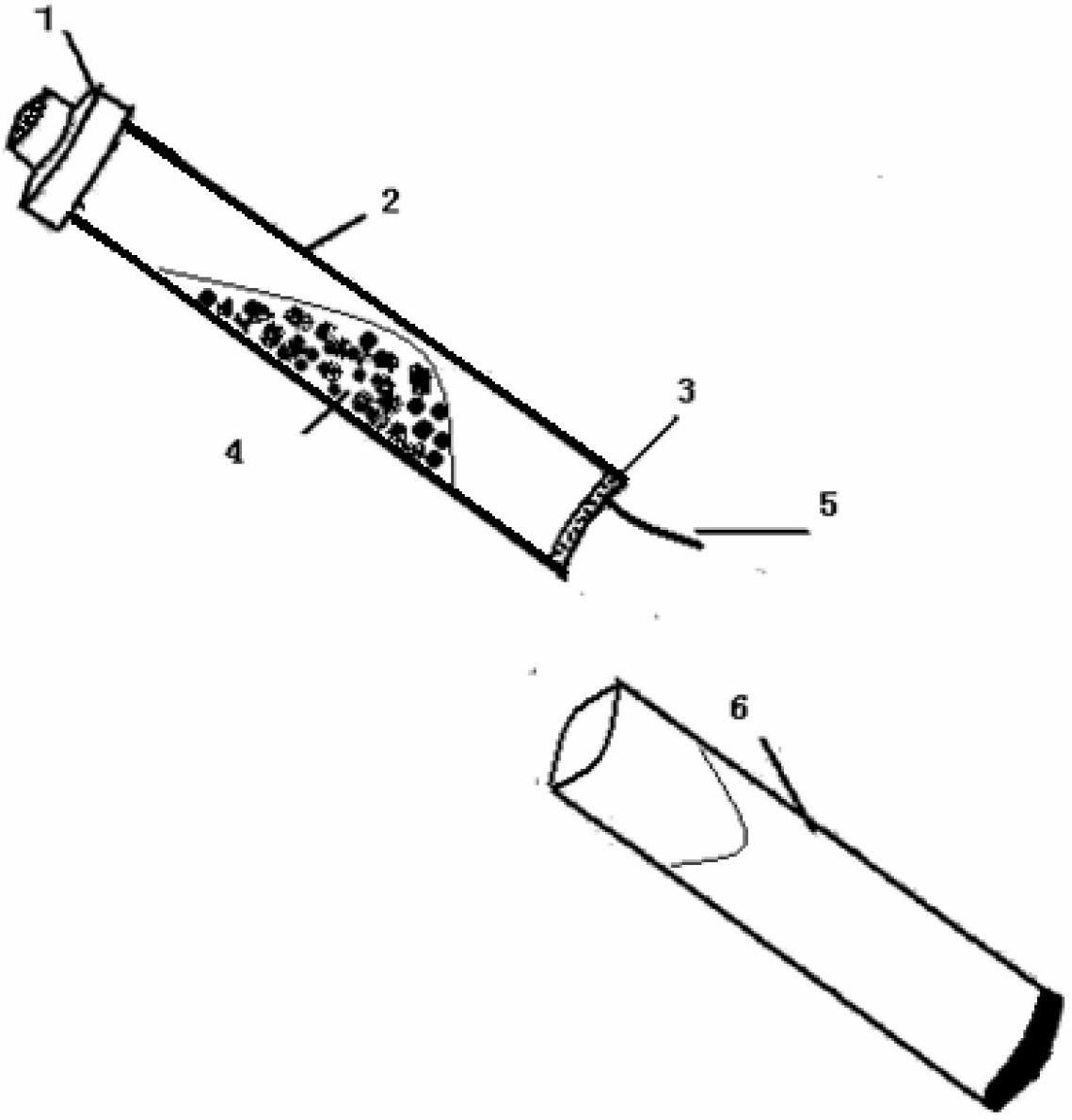

Portable welding pen

ActiveCN102151982ASimple ingredientsEnsure consistencyAlumino-thermic welding apparatusAl powderEngineering

The invention discloses a portable welding pen, which belongs to the field of welding and cutting technique. The portable welding pen comprises a powder tube filled with a thermit, an ignition head on the head part of the powder tube, and an ignition segment between the ignition head and the thermit, wherein the tail part of the powder tube is closed by a clamping end with external threads on one end; the ignition head is made of red phosphorus; the ignition segment adopts thermit welding pyrophoric powder; the thermit contains an exothermic agent, a slagging flux and an alloying agent; the exothermic agent contains CuO powder 60 to 70 wt% and Al powder 15 to 20 wt%; the slagging flux contains CaF2 powder 4 to 8 wt% and CaSO4 powder 5 to 7 wt%; and the alloying agent contains ferromanganese powder 1 to 3 wt% and ferronickel powder 2 to 4 wt%. When in use, the welding pen can be used for welding and cutting workpieces by withdrawing the pen tube, screwing the pen tube on the clamping end, holding the pen tube and then igniting the ignition head at the front end of the welding pen. The welding pen has low manufacture cost, and is small and portable. The welding pen is particularly suitable for the welding and cutting operation of steel and copper materials under emergence conditions, and has the advantages of high welding quality and high cutting speed.

Owner:常熟紫金知识产权服务有限公司

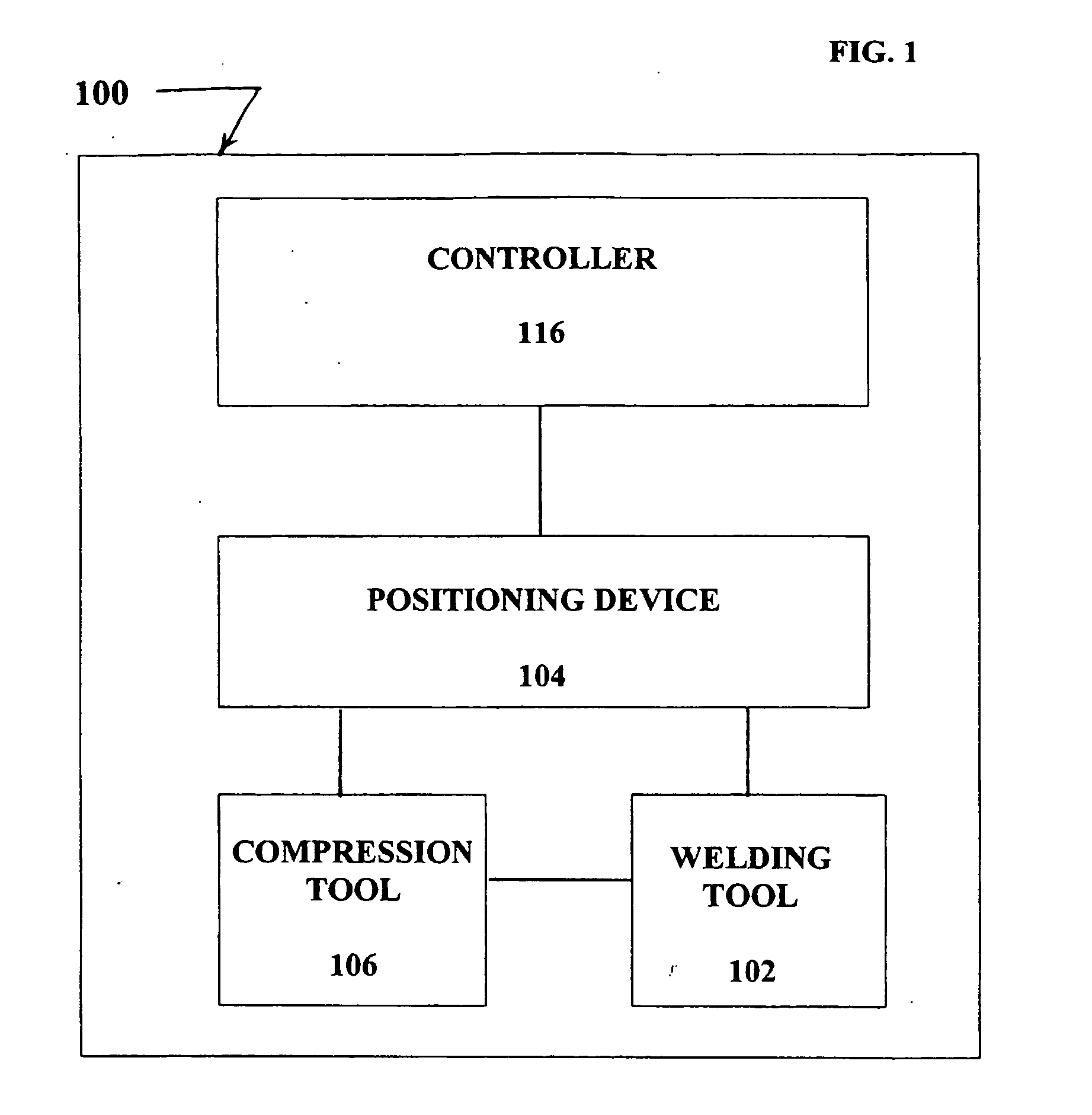

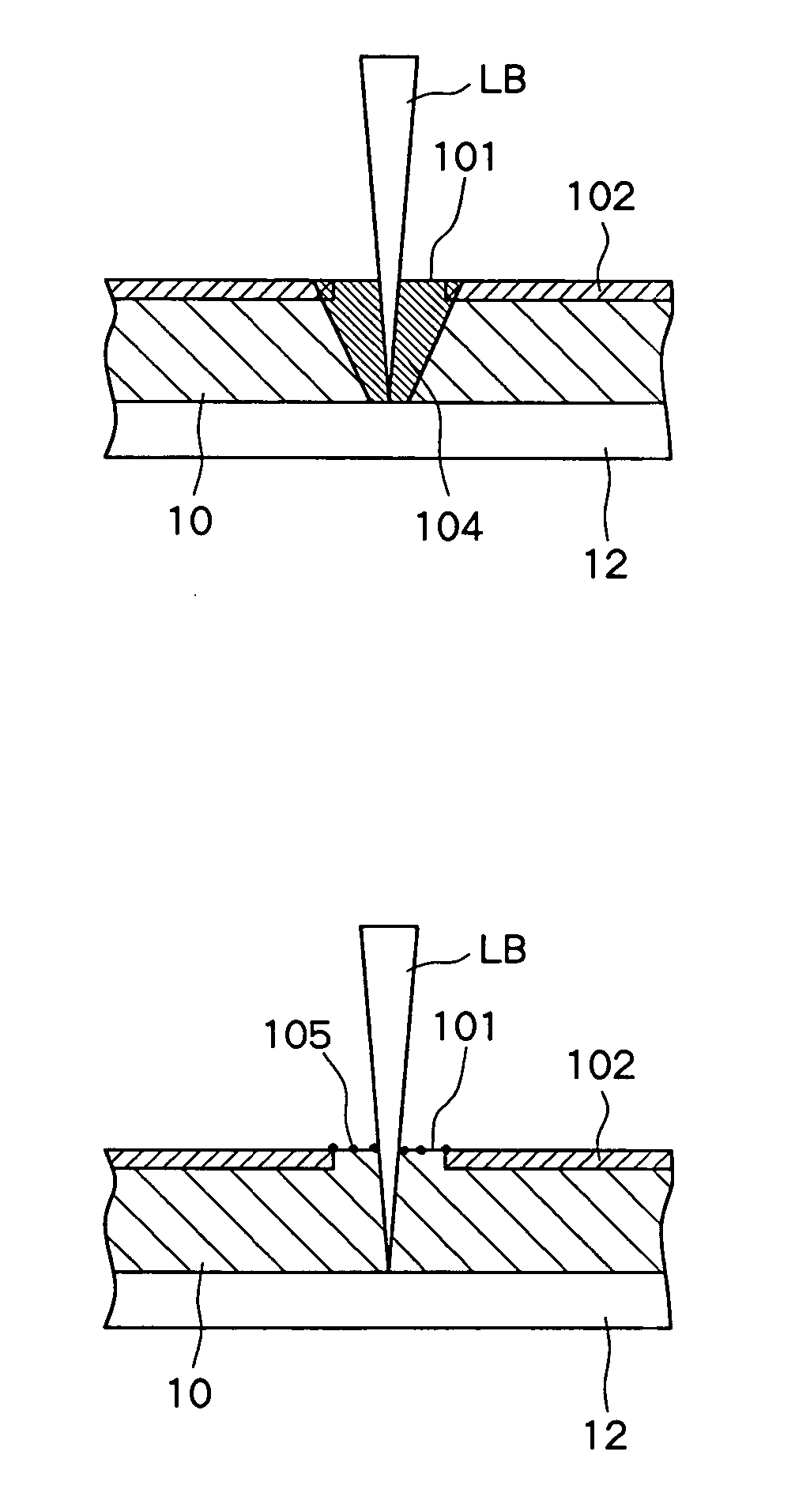

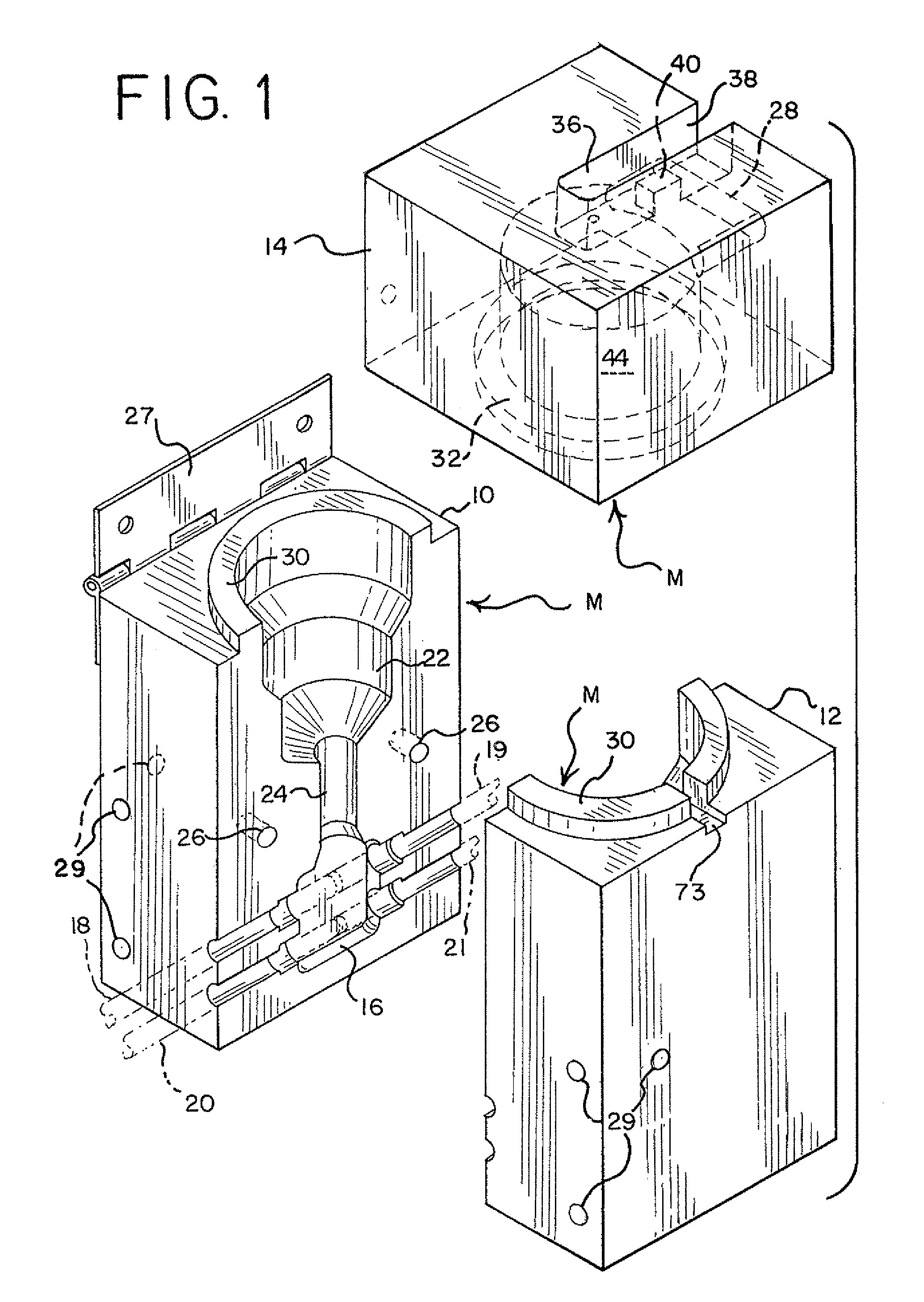

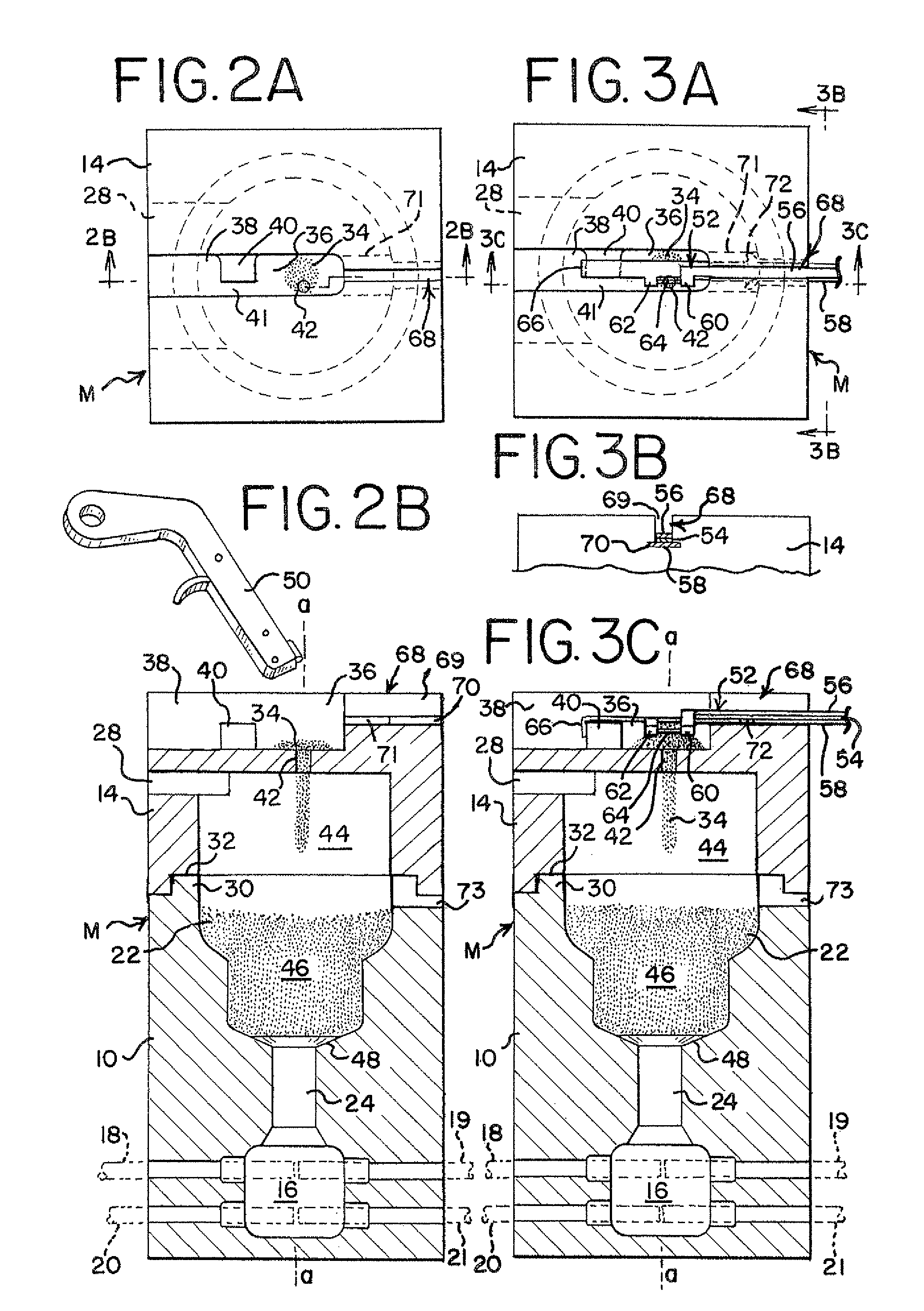

Apparatus and method for forming a weld joint having improved physical properties

InactiveUS20050224562A1Improve material performanceDeep compressionArc welding apparatusFurnace typesHeat-affected zoneEngineering

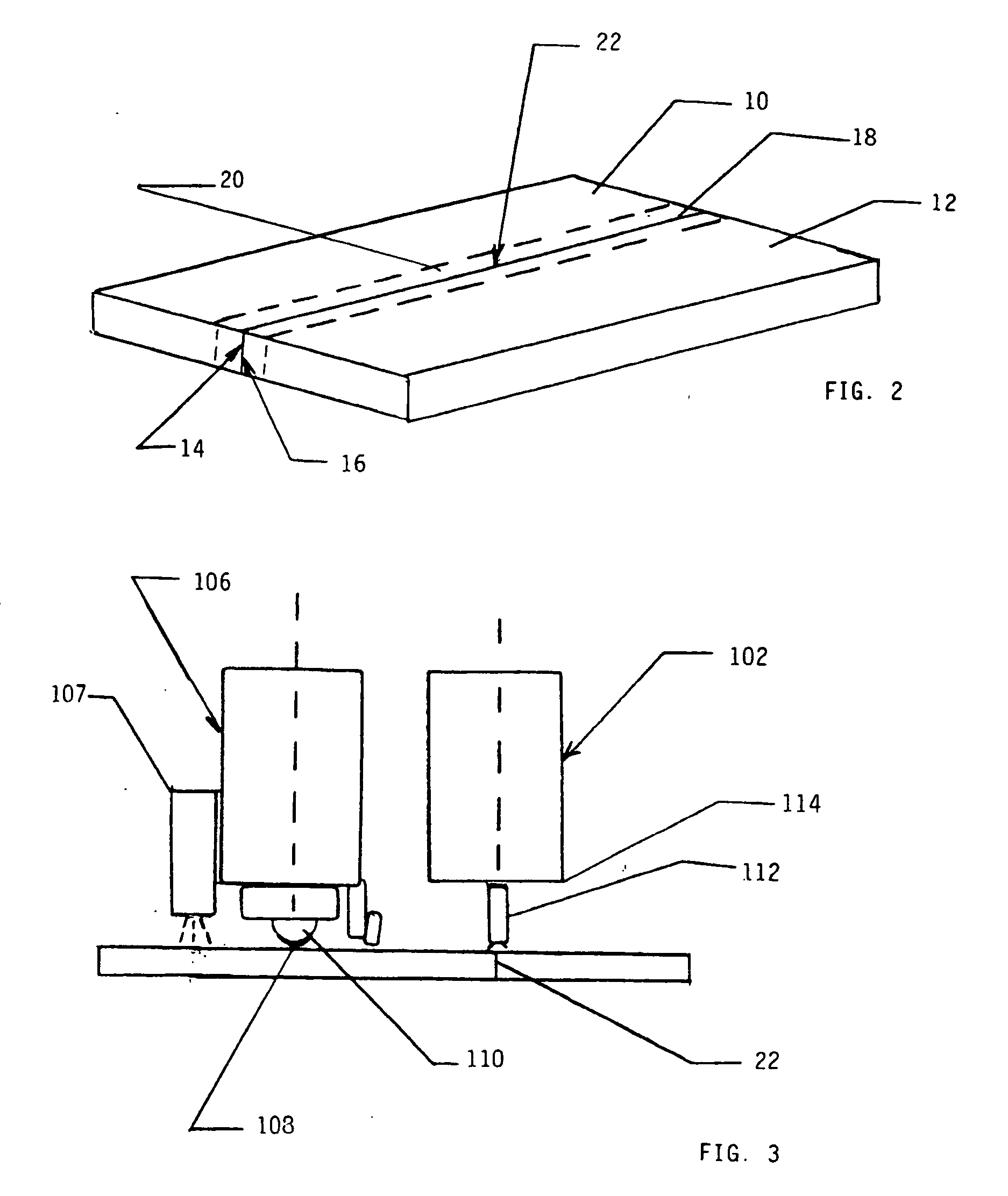

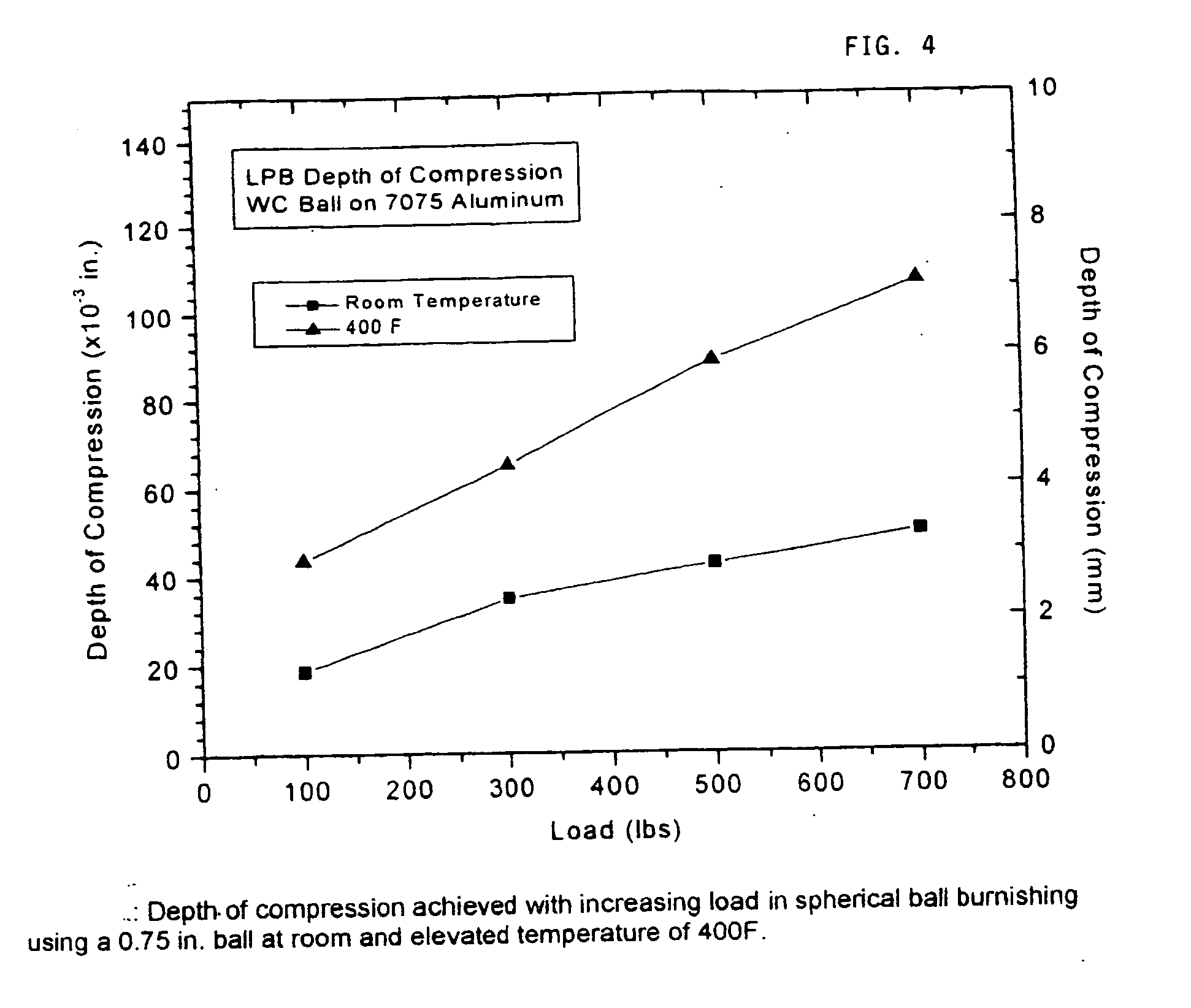

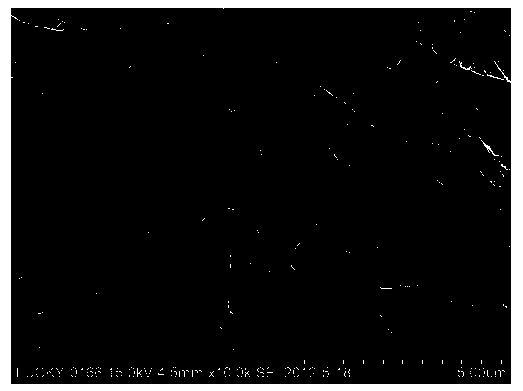

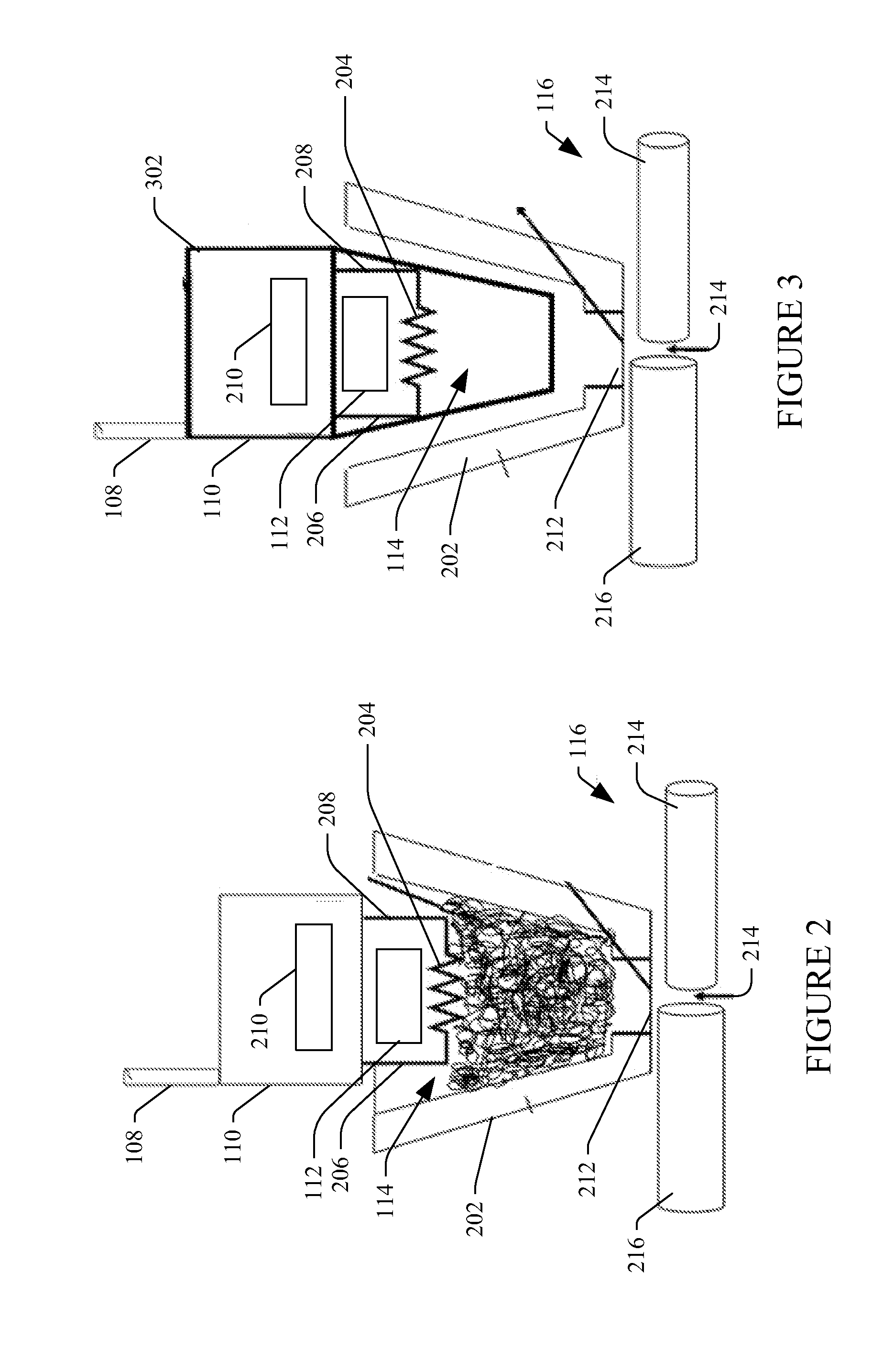

The method and apparatus for performing the method of forming a weld joint of the present invention utilizes welding apparatus (100) having welded tool (102) and a compression tool (106) for inducing a layer of residual compressive stress along the surface of the weld line (18) and any heat affected regions with a controlled amount of cold working and surface hardening. In a preferred embodiment of the invention the compression tool (106) utilizes a single-point burnishing process to provide deep compression within the weld joint (20) with a minimal amount of cold working and surface hardening.

Owner:SURFACE TECH HLDG

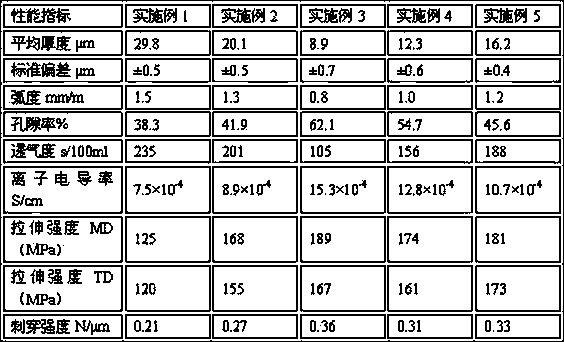

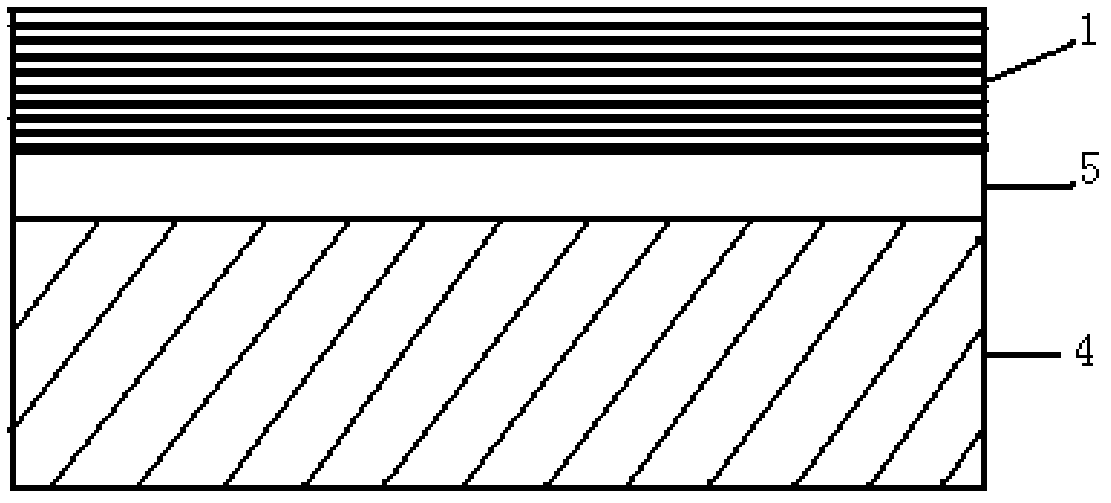

Polyolefin microporous film preparation method for lithium ion battery and microporous film

InactiveCN103522550AReduce unclampingReduce edge tearingCell component detailsFlat articlesPolymer sciencePolyolefin

The invention discloses a polyolefin microporous film preparation method for a lithium ion battery and a microporous film. A mode of twice bidirectional drawing is adopted, and the overall rate of the twice drawing is 16 to 100 times. The preparation method comprises the following steps of (a) extruding a casting piece; (b) performing primary bidirectional drawing at a bidirectional drawing rate which is controlled to be 4 to 10 times to obtain an oily thin film; (c) performing extraction to obtain a microporous film A; (d) performing secondary bidirectional drawing at a bidirectional drawing rate which is controlled to be 4 to 10 times to obtain a thinner microporous film B; (e) performing heat setting to obtain a polyolefin microporous film. The polyolefin microporous film microcosmically has a completely drawn fiber structure, is uniform in aperture and high in performance consistency, and has higher mechanical performance, higher air permeability and enhanced ionic conductivity; the yield can be greatly improved; the lithium ion battery adopting the microporous film has high assembling performance, and the performance and the stability of the battery are enhanced.

Owner:乐凯胶片股份有限公司

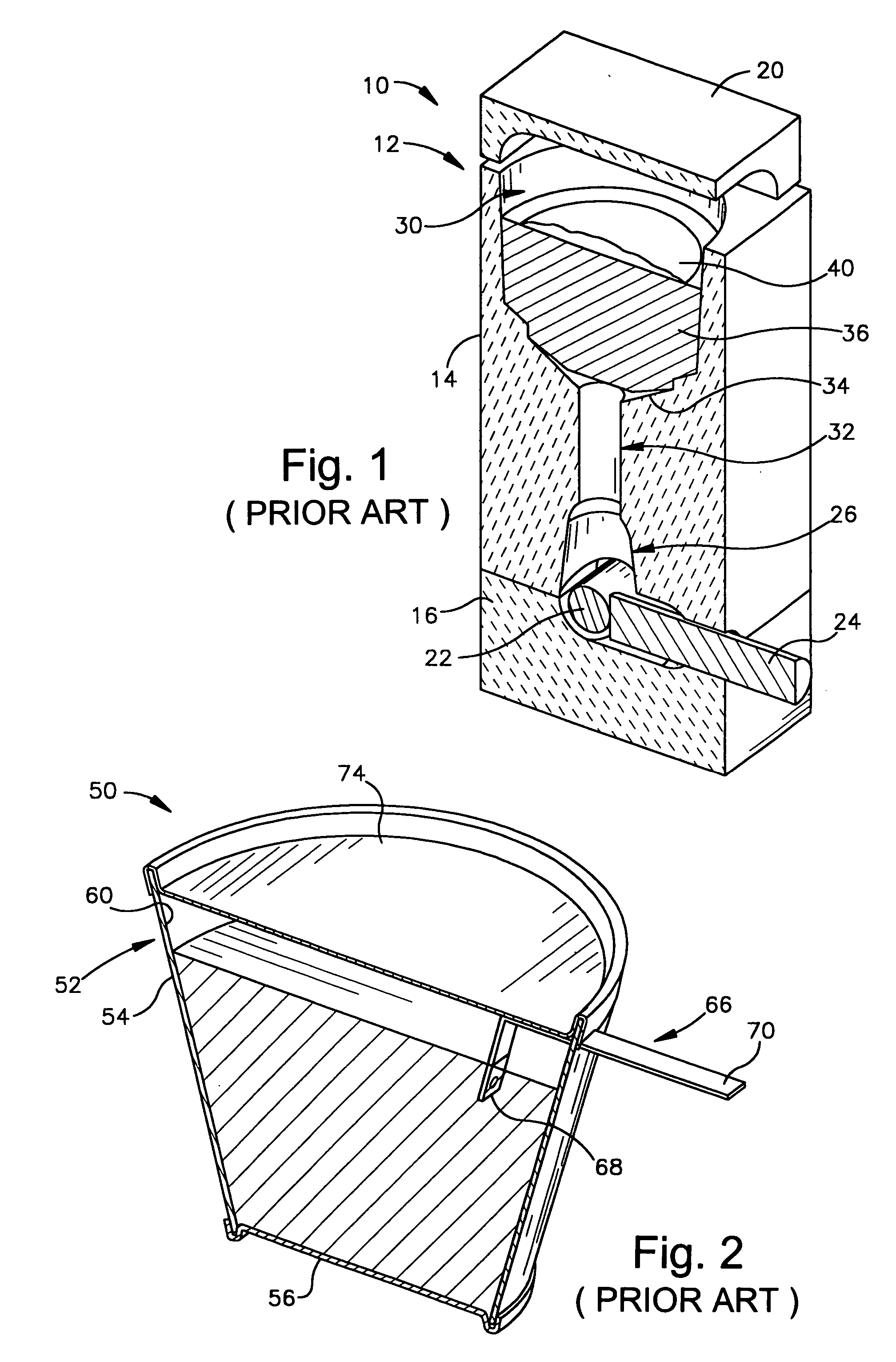

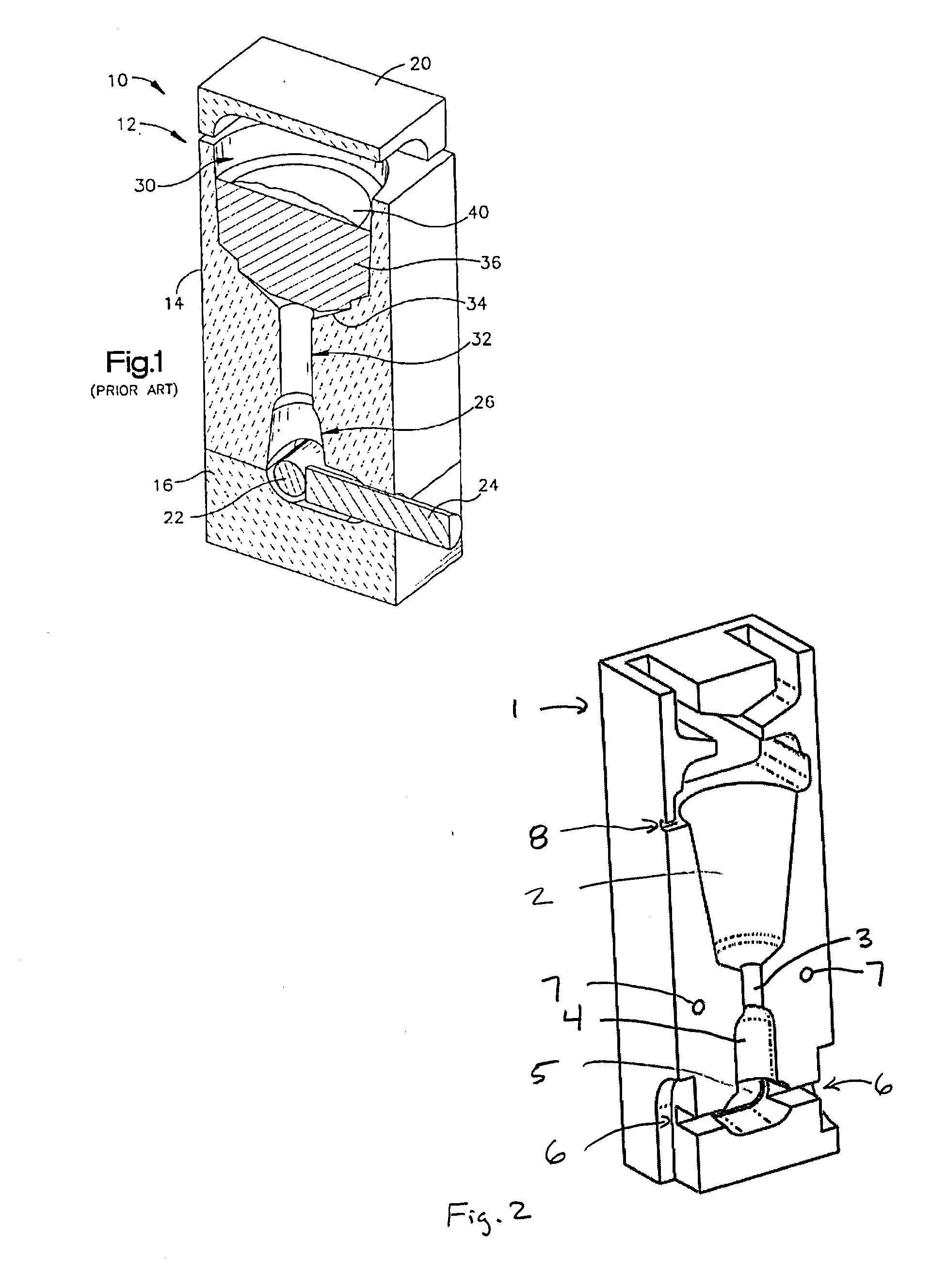

Exothermic welding

ActiveUS6994244B2Eliminate needImprove the immunityWelding/soldering/cutting articlesMetal working apparatusExothermic weldingEngineering

An assembly and method are disclosed for exothermic welding including a mold which is formed of a material which withstands exothermic welding temperatures, and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together adjacent to each other, and an ignition cavity communicating with the first cavity. The members which are to be exothermically welded together are positioned adjacent to each other using the weld cavity, and a weld metal cartridge is positioned in the ignition cavity. The cartridge comprises a container having copper walls which define a chamber therein, and a particulate weld metal in the chamber. The tip of an electrical igniter is positioned into the chamber of the container and particulate weld material therein, the igniter is electrically fired while the container is in the ignition cavity of the mold to melt the particulate weld material, and the contents of the ignition cavity are passed after melting the particulate weld metal to the weld cavity to weld the members together.

Owner:HARGER

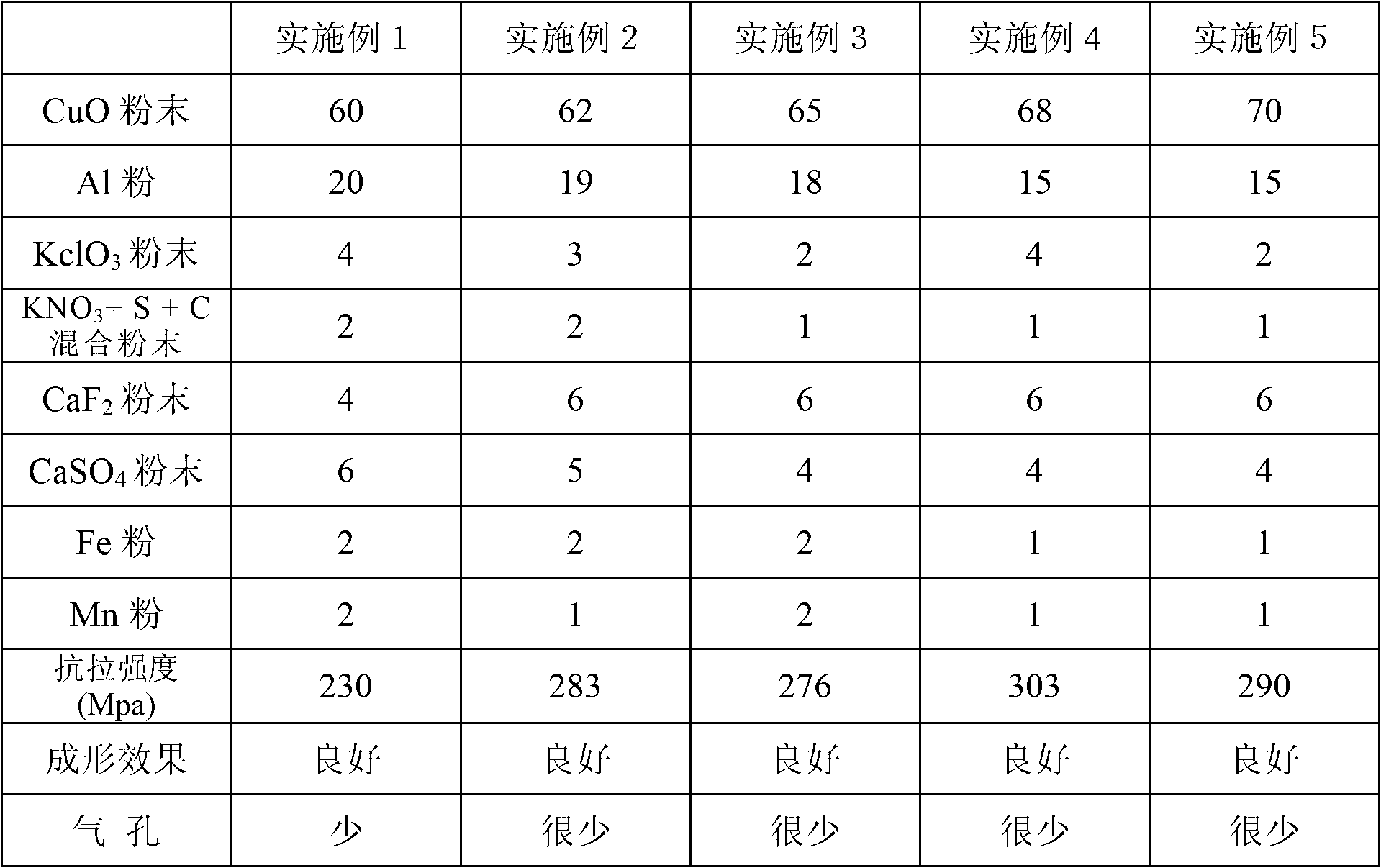

Simple electroless welding pen and preparation method of electroless welding pen

InactiveCN102699521AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a simple electroless welding pen, which comprises a cartridge, welding flux and a lead. The welding flux is thermite; the simple electroless welding pen comprises the raw material constituents by weight percent: 60-70% of CuO (cupric oxide) powder, 15-20% of Al (aluminum) powder, 2-4% of KClO3 (potassium chlorate), 1-2% of KNO3 (potassium nitrate)+S (sulfur)+C (carbon) mixed powder, 4-6% of CaF2 (calcium fluoride) powder, 4-6% of CaSO4 (calcium sulfate) powder, 1-2% of Fe (Ferrum) powder and 1-2% of Mn (manganese) powder; and the mixed powder is KNO3, S and C freely mixed. According to the method disclosed by the invention, the problems of inexhaustive slag separation and more welding line defects in the welding lines in the prior art are solved without any welding device and power supply. The preparation method has the advantages of simple preparation process and simple, fast and safe welding operation, and is particularly suitable for field emergency operation.

Owner:TIANJIN UNIV

In situ self-spread welding repair method of aluminum mother plate

InactiveCN101474719AQuick Weld RepairUnique process methodAlumino-thermic welding apparatusFusible plugGraphite

The invention relates to a welding repairing method for aluminum parent metal, in particular to an in-situ self-propagting welding repairing method for aluminum parent metal. The method is characterized in that: self-propagting medical preparation is firstly prepared, and cleaning, oil removal, oxide film removal are carried out on parts to be welded of aluminum parent metal, then welding fluid is coated on a groove face; according to the shape and size of the groove, a mould with lower holes is made by graphite and is fixed on the upper part of the groove, and a graphite plate is clamped at the two sides of the groove by a clamping device and forms a melting chamber together with the mould, an automatic fusible plug is laid at the bottom part of the mould, then the self-propagting medical preparation is poured into the mould, pyrophoric powder is coated above the self-propagting medical preparation, after the parent metal is preheated to a certain temperature, the pyrophoric powders is lighted, thus realizing in-situ self-propagting welding repairing of the aluminum parent metal. By the method provided by the invention, intense magnetic field interference can be avoided, welding quality can be improved, labor intensity can be relieved, and the operation is easy and rapid.

Owner:QINGTONGXIA ALUMINUM IND GROUP +1

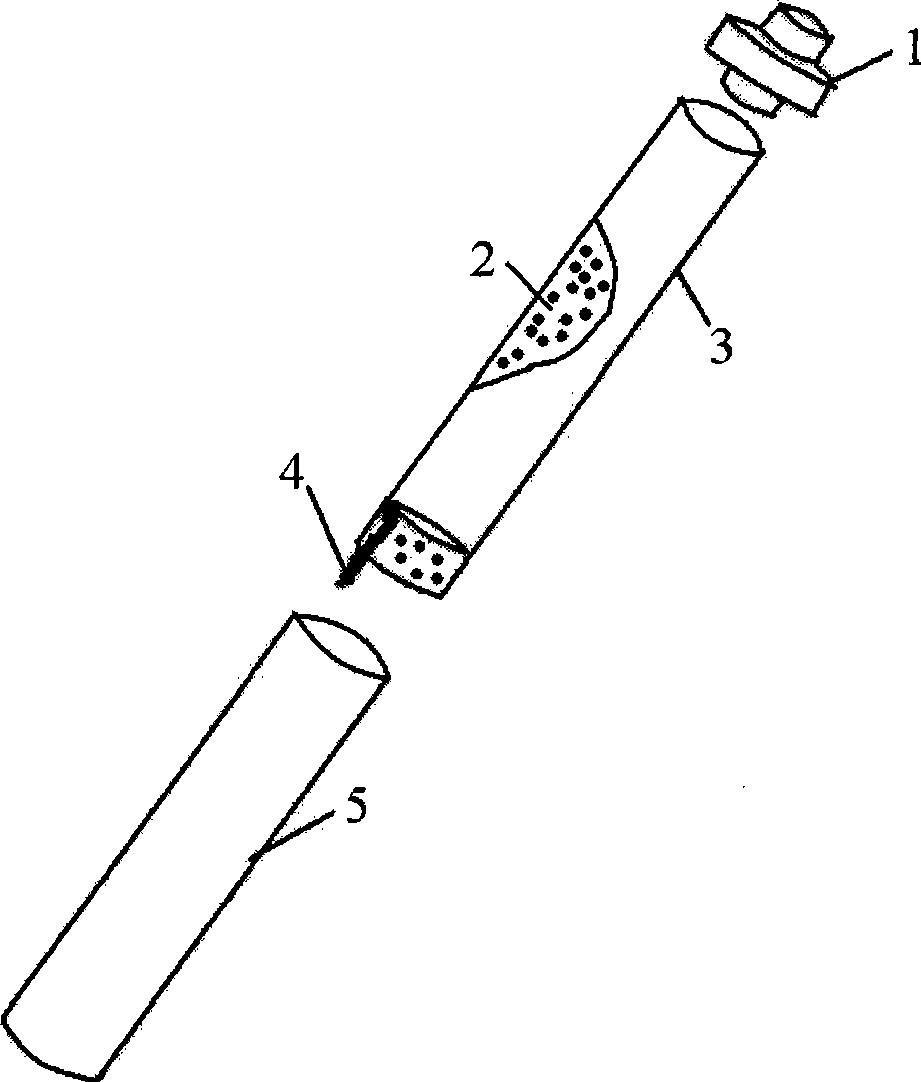

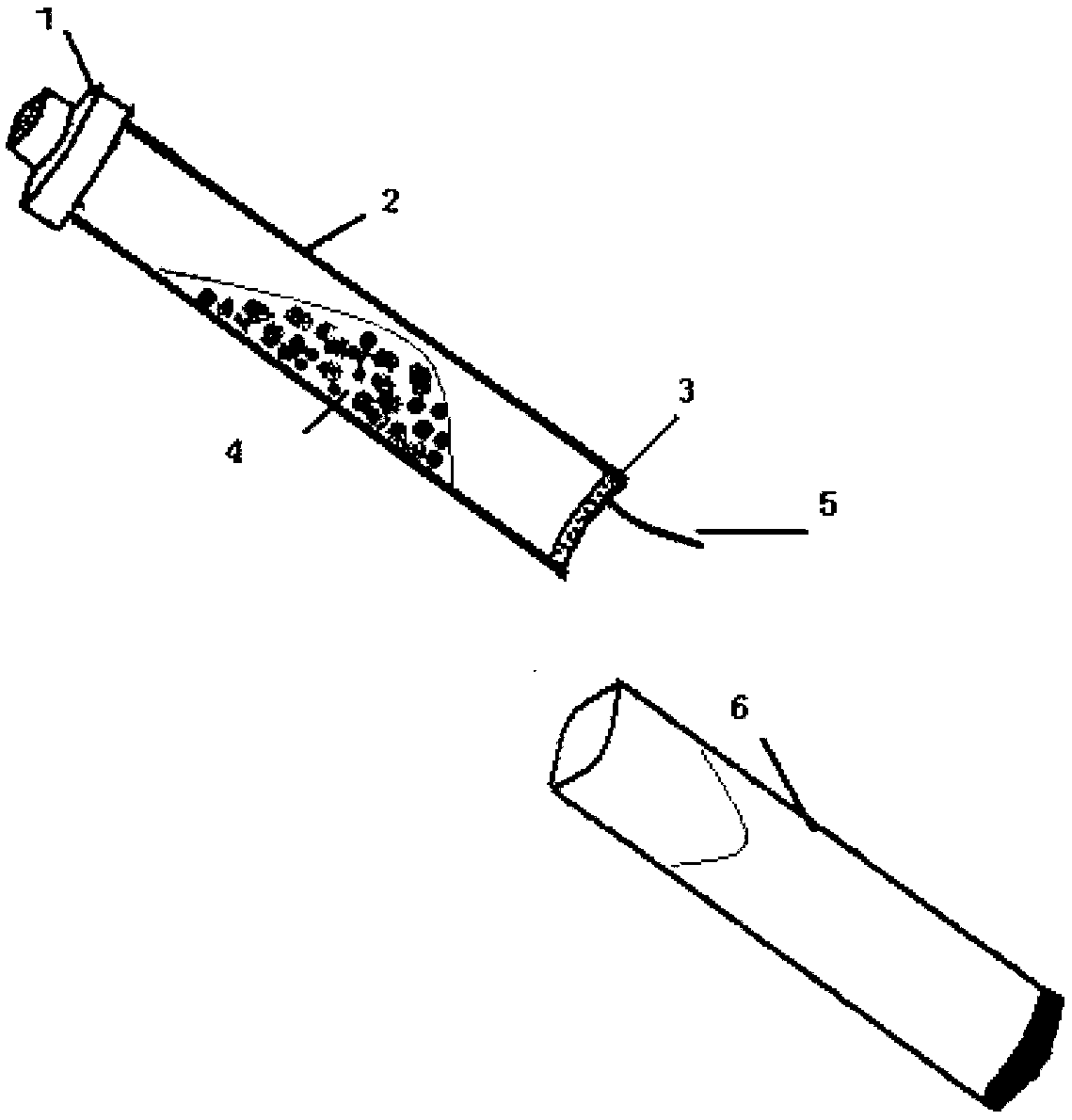

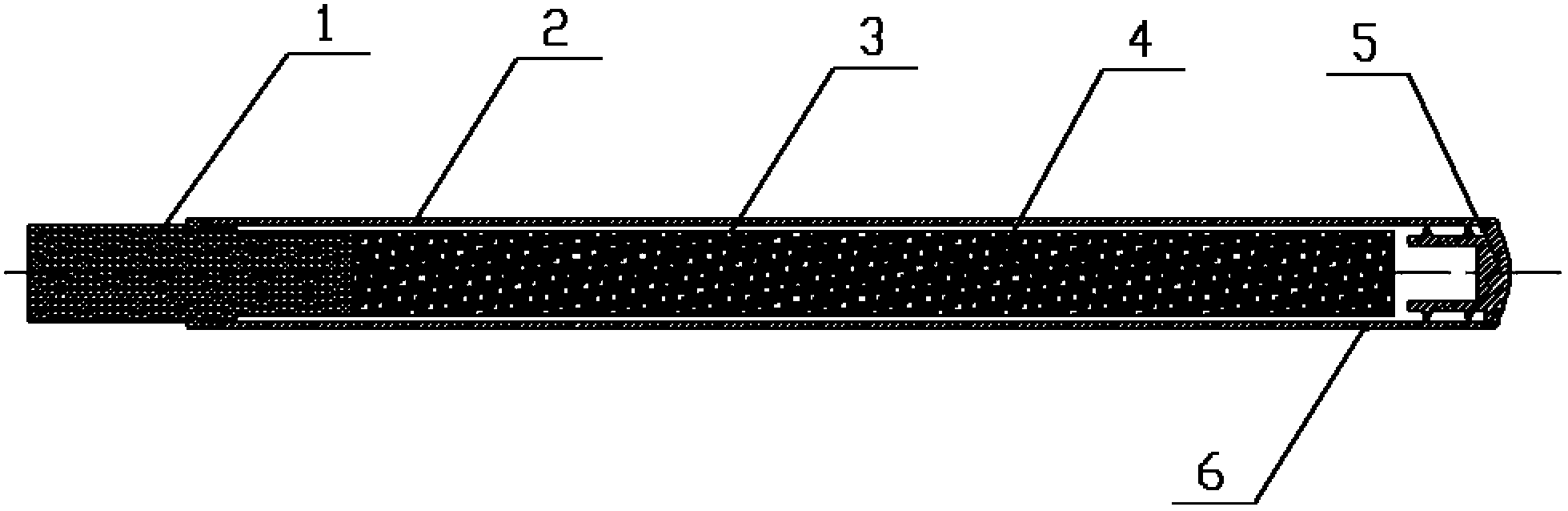

Electroless welding type welding rod and preparation and welding method thereof

InactiveCN102990240ASolving Quick Weld RepairsTackling Emergency Welding RepairsWelding/cutting media/materialsAlumino-thermic welding apparatusEmulsionThermite

The invention discloses an electroless welding type welding rod and a preparation and welding method thereof. The electroless welding type welding rod comprises a plug, a grain, a paper pipe, an igniting cap, a pipe plug and a sleeve pipe, wherein the plug and the paper pipe are coaxially adhered together through emulsions; the grain and the igniting cap are formed in the paper pipe; the sleeve pipe is sleeved on the paper pipe; one end of the sleeve pipe is connected with the plug in a close fit way, and the other end of the sleeve pipe is sealed through the pipe plug. According to the electroless welding type welding rod, a welding material is manufactured into a special hand-held pencil, the special hand-held pencil can initiate reaction by being only ignited through matches, a reaction product and a parent material are molten by taking the self-releasing chemical energy of a thermite as a welding heat source, and the firm connection of the welded parent material is realized through mechanisms such as wetting, diffusion and reaction crystallization.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

A kind of solder and its igniter for exothermic welding of grounding body in grounding system

InactiveCN102267024AWelding/cutting media/materialsAlumino-thermic welding apparatusHigh resistanceExothermic welding

The invention discloses a solder for exothermic welding of a grounding body in a grounding system and an ignition agent of the solder, relates to the solder for the exothermic welding and the ignition agent of the solder and solves the technical problem of poor welding performance caused by impurities contained in a welding joint which is obtained by the conventional exothermic welding hot-melting soldering agent. The solder for the exothermic welding of the grounding body in the grounding system consists of copper oxide powder, copper powder, industrial pure aluminum powder, zinc powder, zirconium powder, silicon iron powder, fluorite powder, marble powder and lanthanum cerium alloy powder. The ignition agent of the solder for the exothermic welding of the grounding body in the groundingsystem consists of magnesium powder, the copper oxide powder, the industrial pure aluminum powder, potassium permanganate powder and red phosphorus powder. When the solder and the ignition agent are used, the mass ratio of the solder for the exothermic welding of the grounding body in the grounding system to the ignition agent is (78-82):1. All elements in the solder and rare-earth elements can purify the welding joint. The invention is applicable to welding of copper, copper alloy, steel, galvanized steel, copper-clad steel, stainless steel and high-resistance heating source materials.

Owner:HEILONGJIANG PATENT TECH DEV

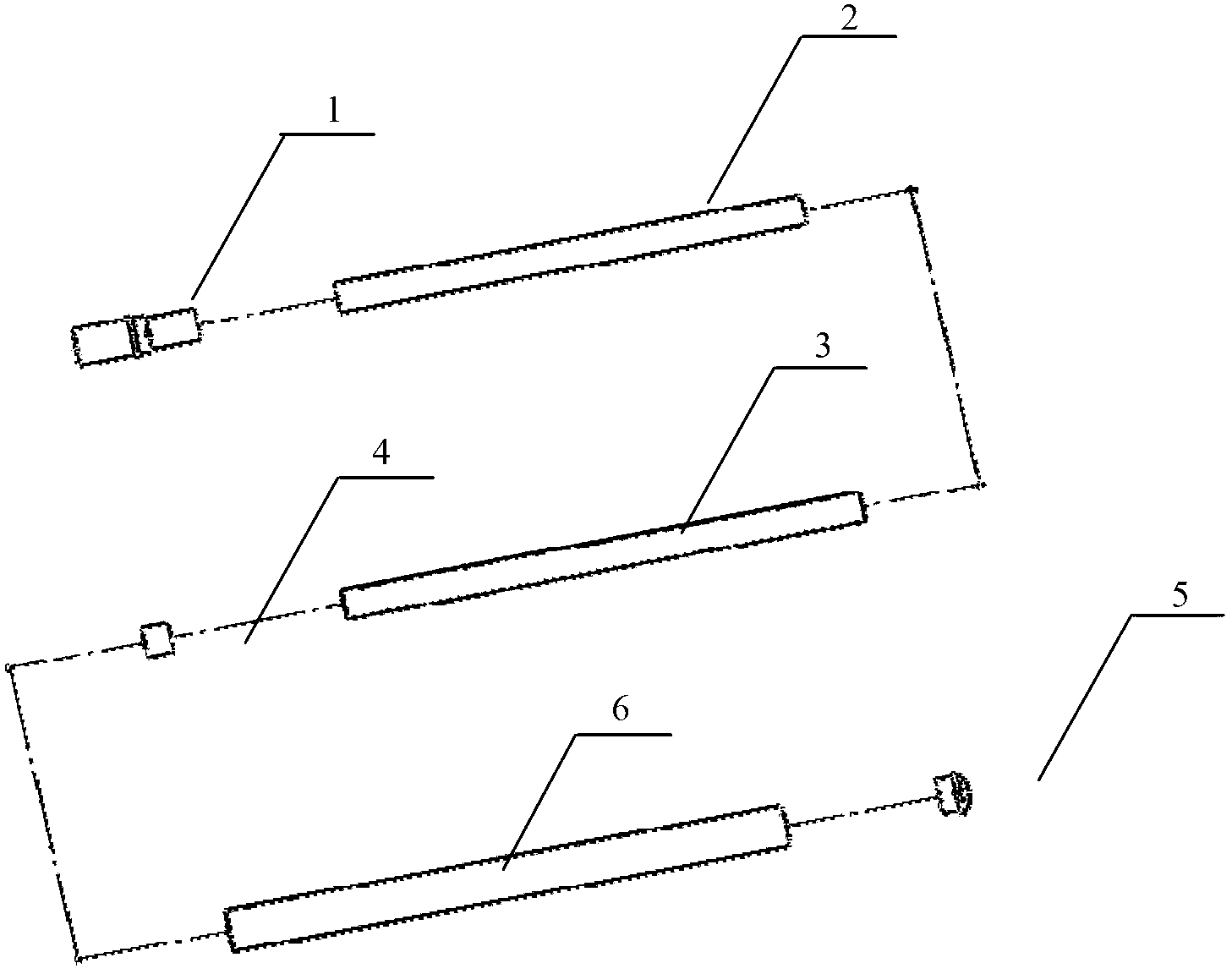

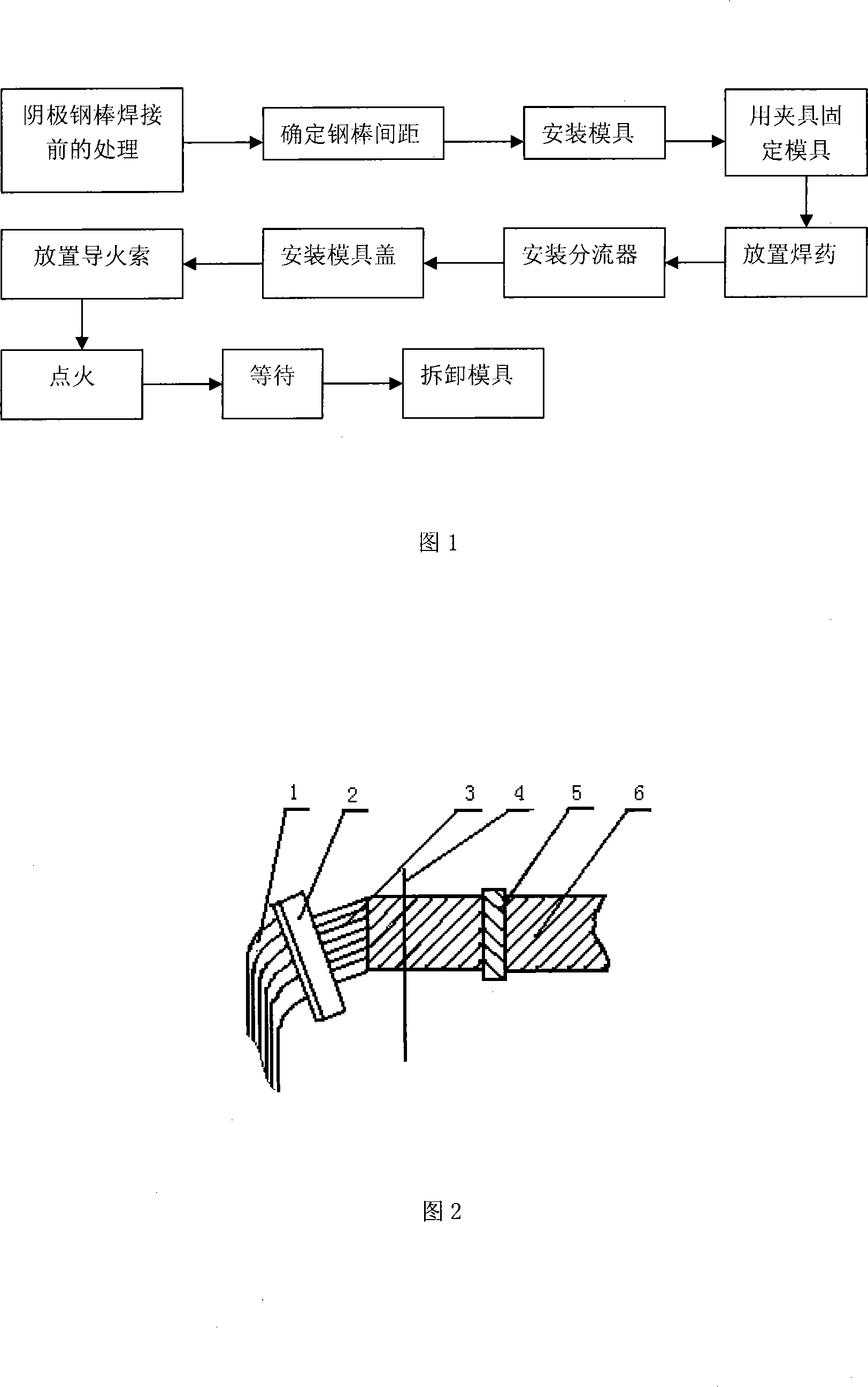

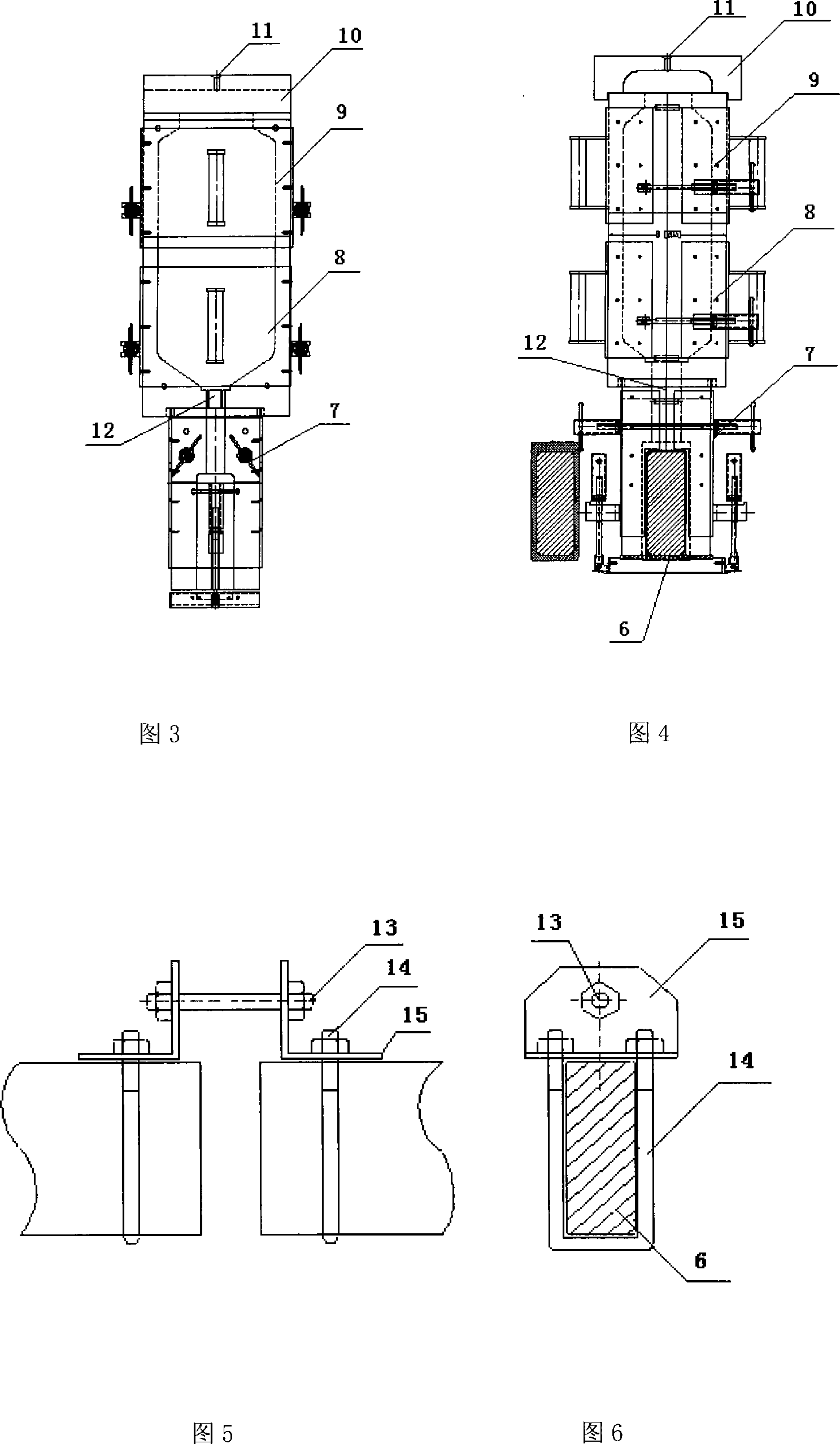

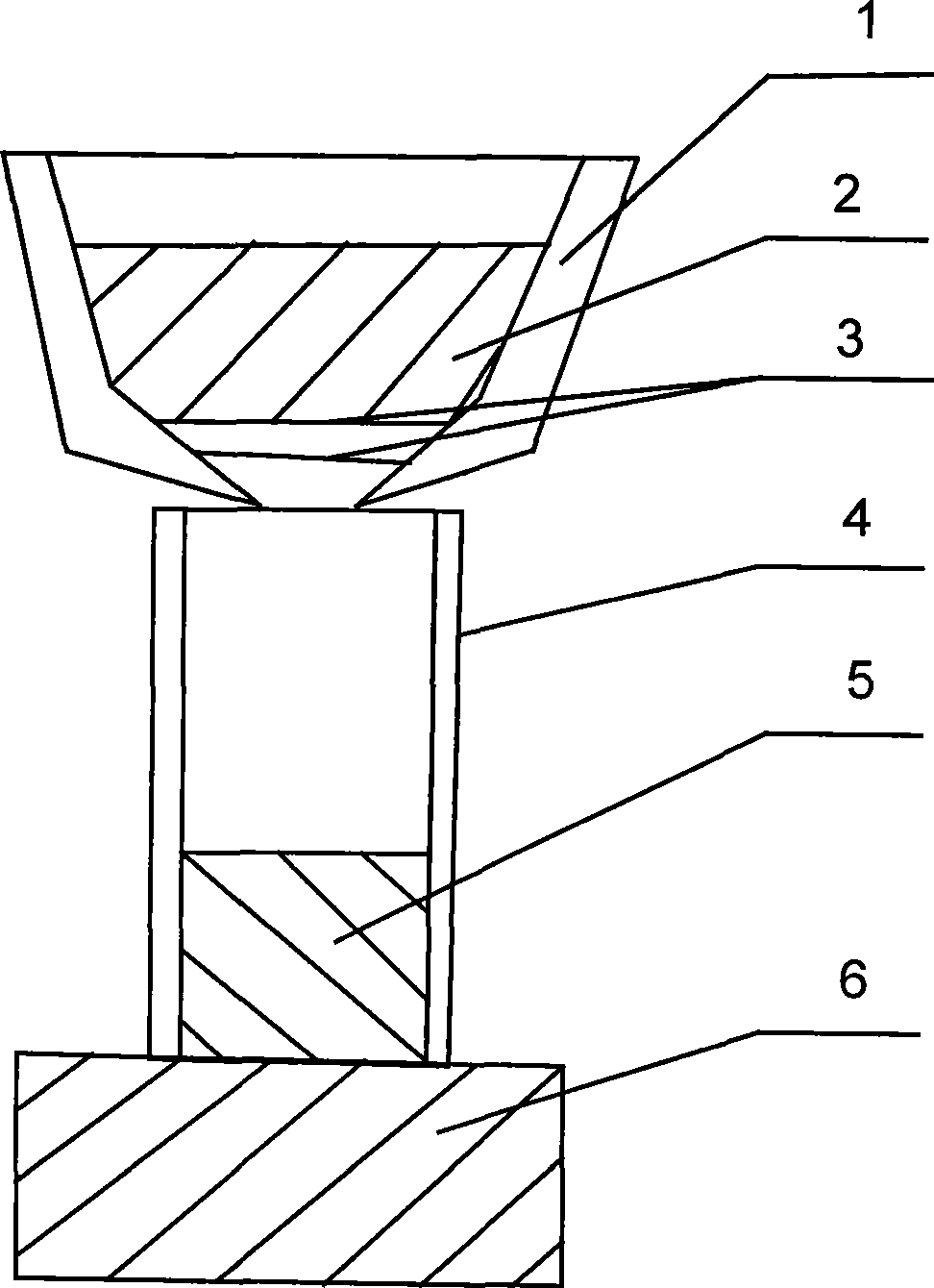

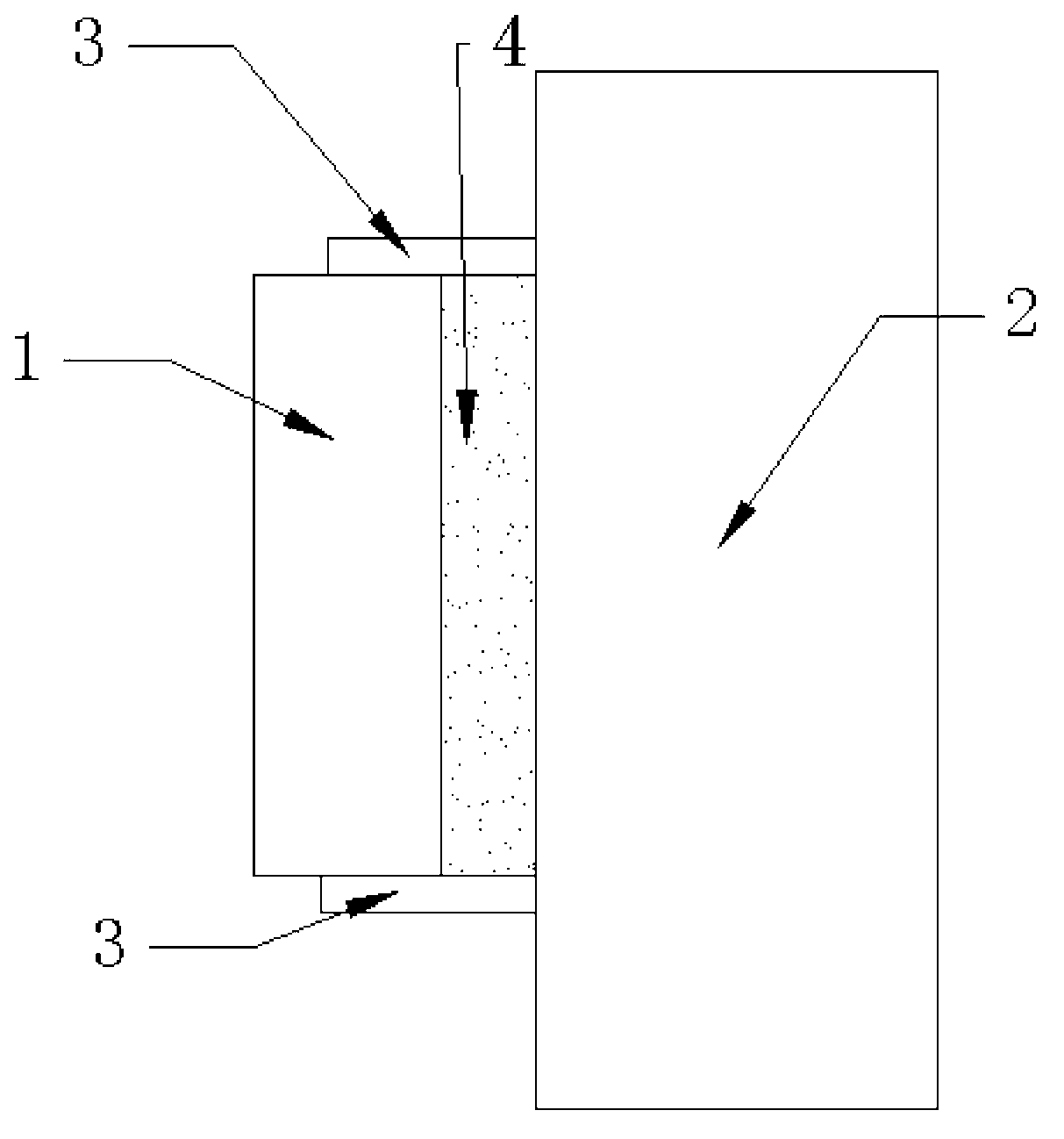

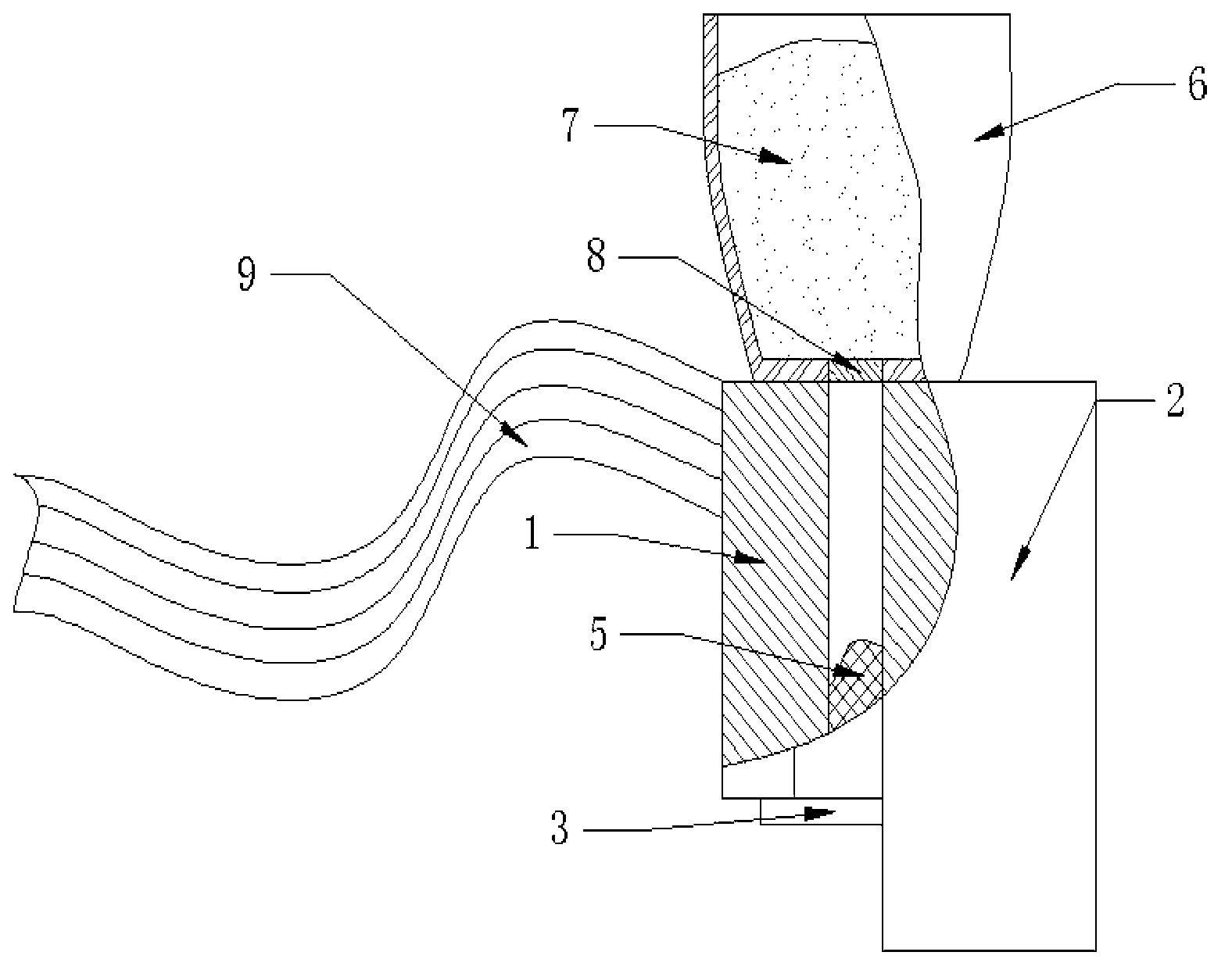

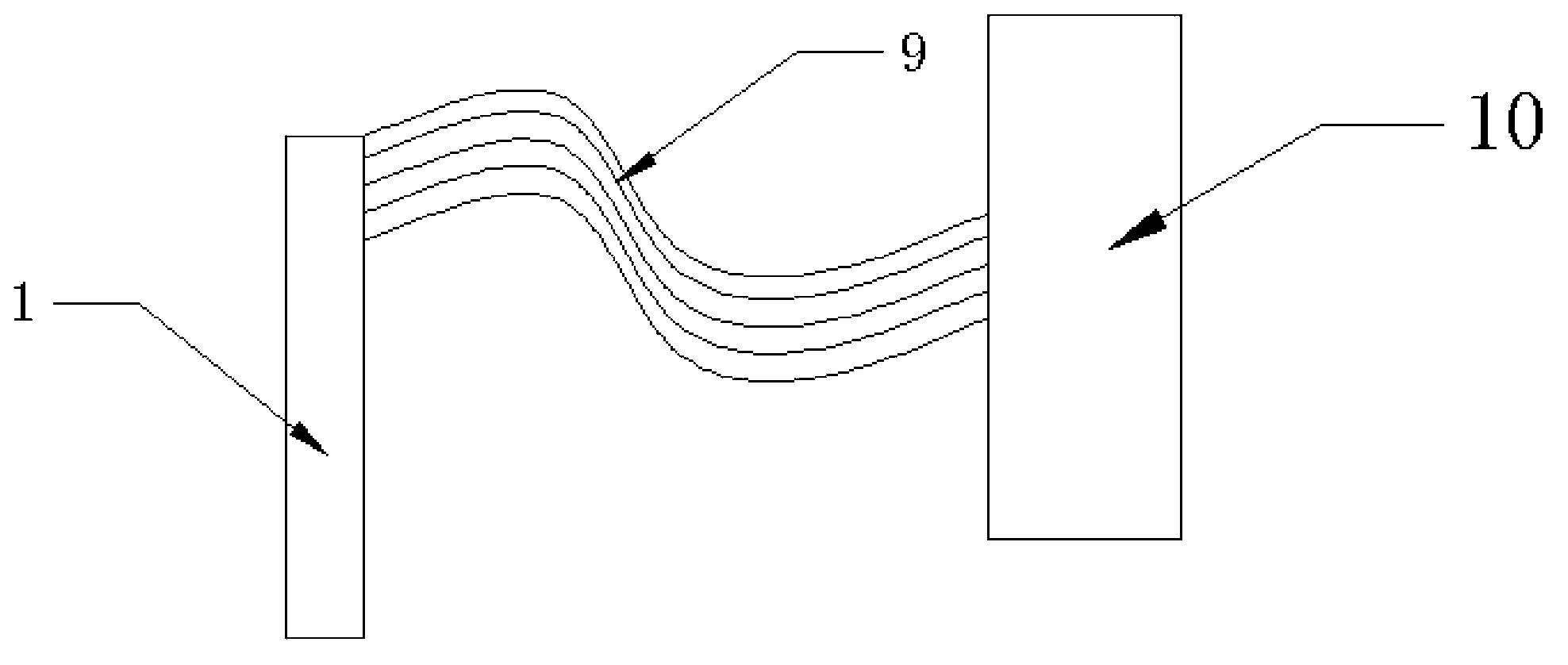

Electrified welding method of aluminum cell cathode steel bar

ActiveCN101249585AFirmly connectedHigh tensile strengthWelding/cutting auxillary devicesAuxillary welding devicesChemical reactionElectrolysis

The invention relates to an overhaul process of an aluminum electrolytic tank, in particular to a live welding method of steel cathode bars during overhaul of aluminum electrolytic tank. The live welding method of the steel cathode bars comprises the following steps of: arranging a mold on a steel cathode bar; arranging a crucible on the mold; adding flux and ignition composition into the crucible; arranging a splitter on the crucible; arranging a mold cover on the splitter; adding the ignition composition and a blasting fuse in an ignition hole on the mold cover; igniting the blasting fuse to start burning; injecting molten metal generated by chemical reaction into a cavity formed by the gap between a new and a used steel cathode bars and the pedestal of the mold by a guide channel holes to weld the two steel cathode bars; waiting for 5 min; and demolding to achieve the live welding of steel cathode bar of the aluminum electrolytic tank. The live welding method can be used for welding steel cathode bars without switching off power supply, and the operator operates in the tank to solve the safety problem. The voltage drop on furnace bottom is 299 mV while starting the aluminum electrolytic tank.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

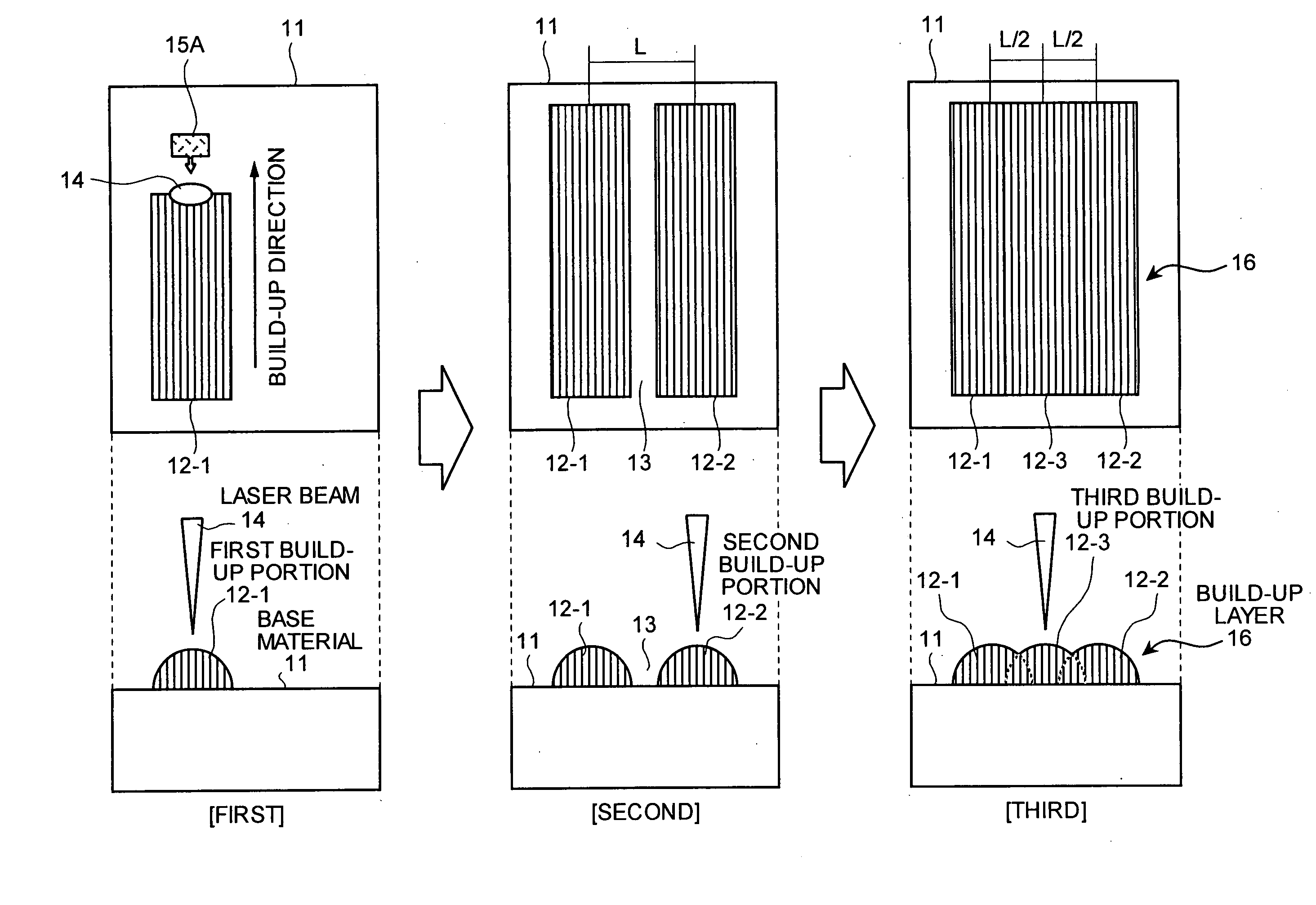

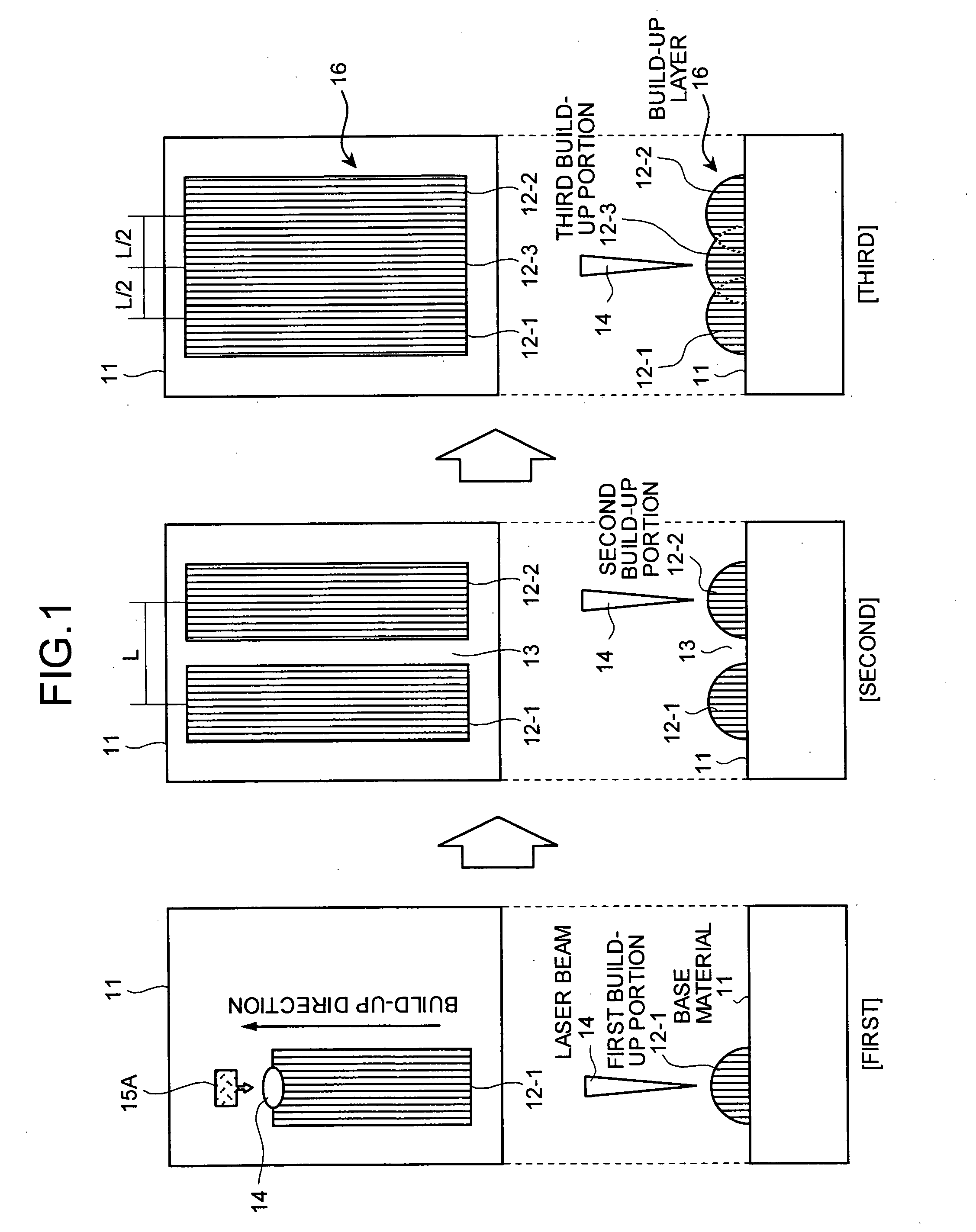

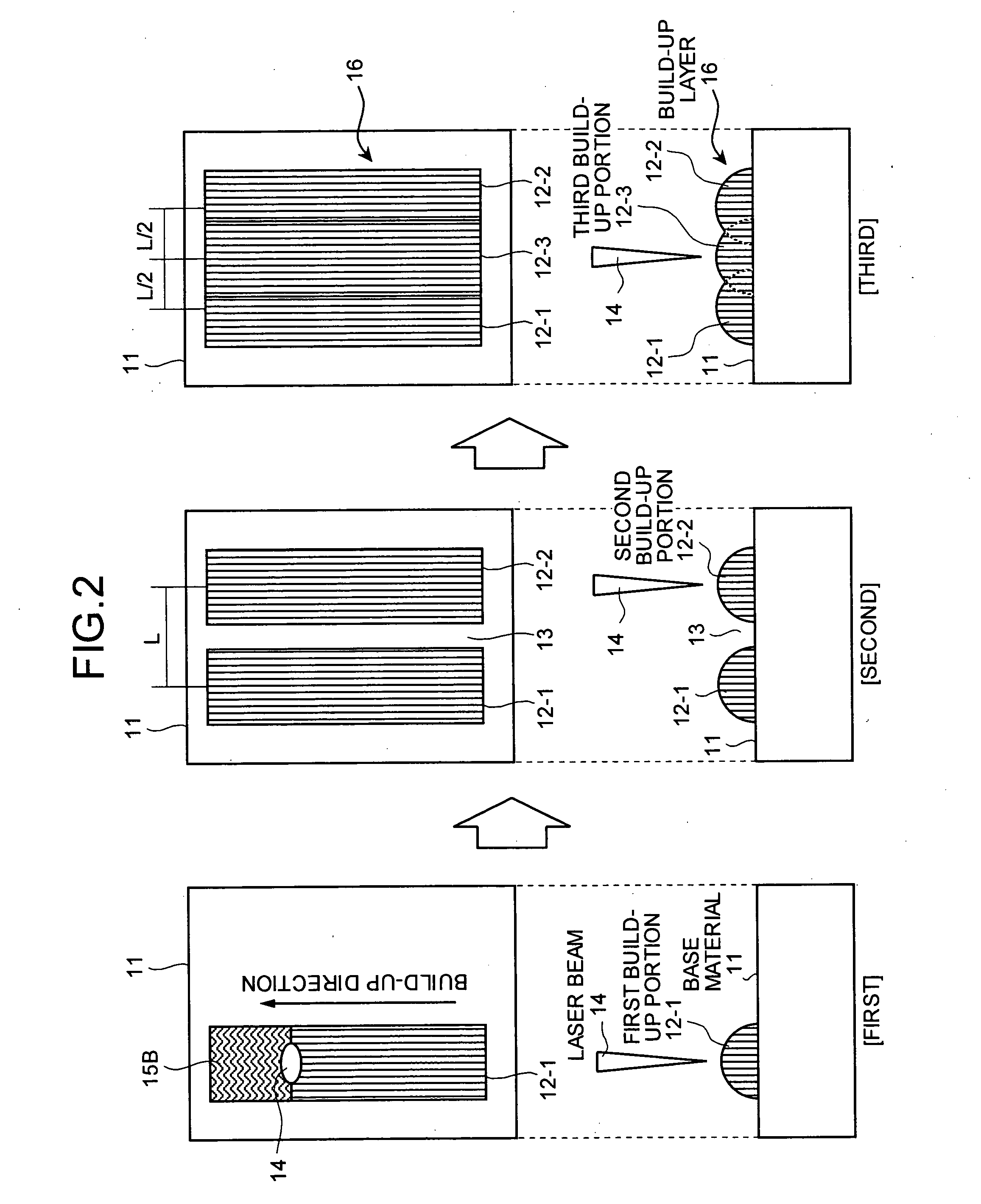

Welding method

A welding method forms a molten build-up portion on a base material that is any one of a single crystal material and a unidirectionally solidified crystal material. The method includes forming a plurality of build-up portions on the base material while maintaining a predetermined gap between adjacent build-up portions; and forming a build-up portion in each of the predetermined gaps.

Owner:MITSUBICHI HEAVY IND AERO ENGINES LTD

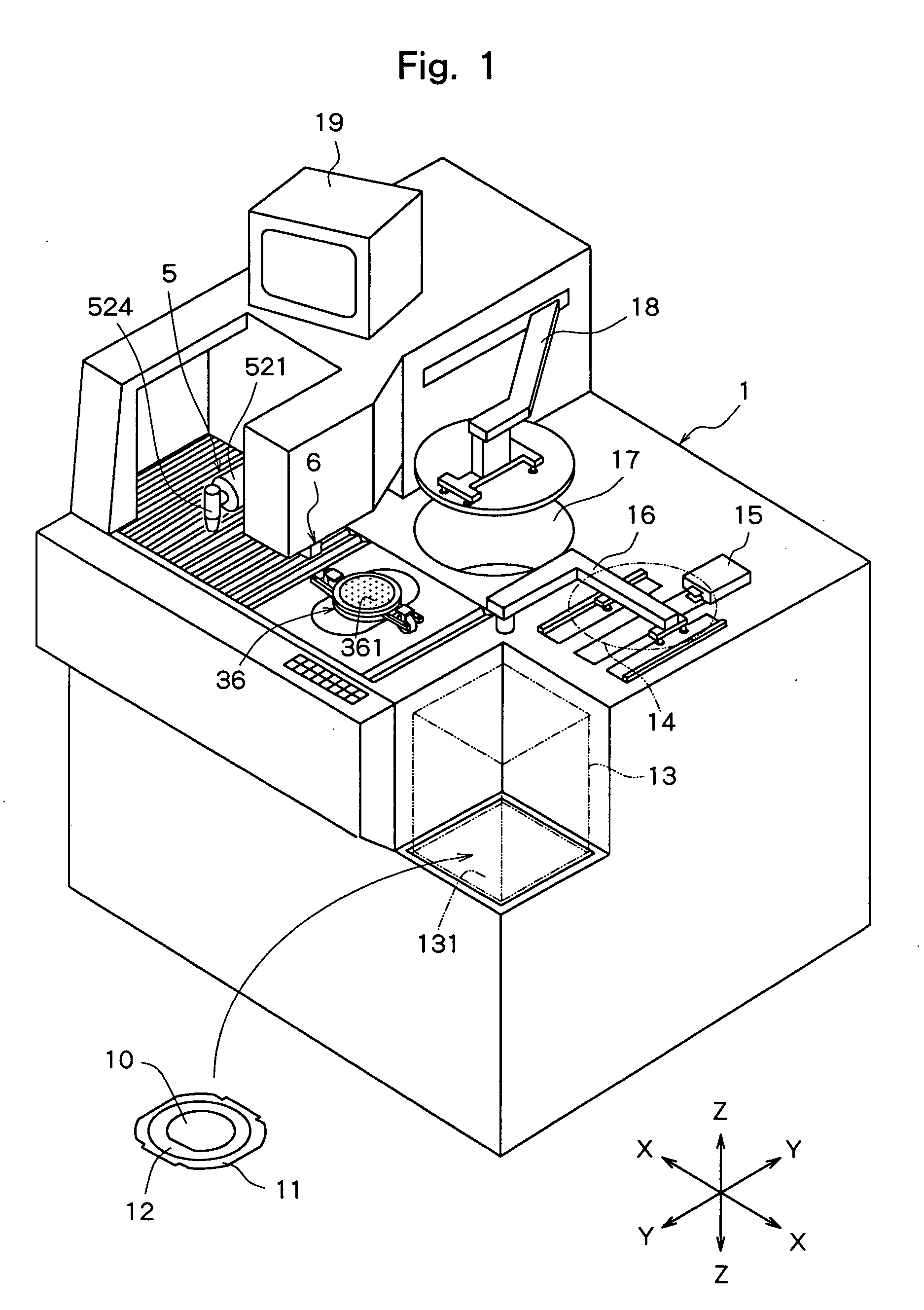

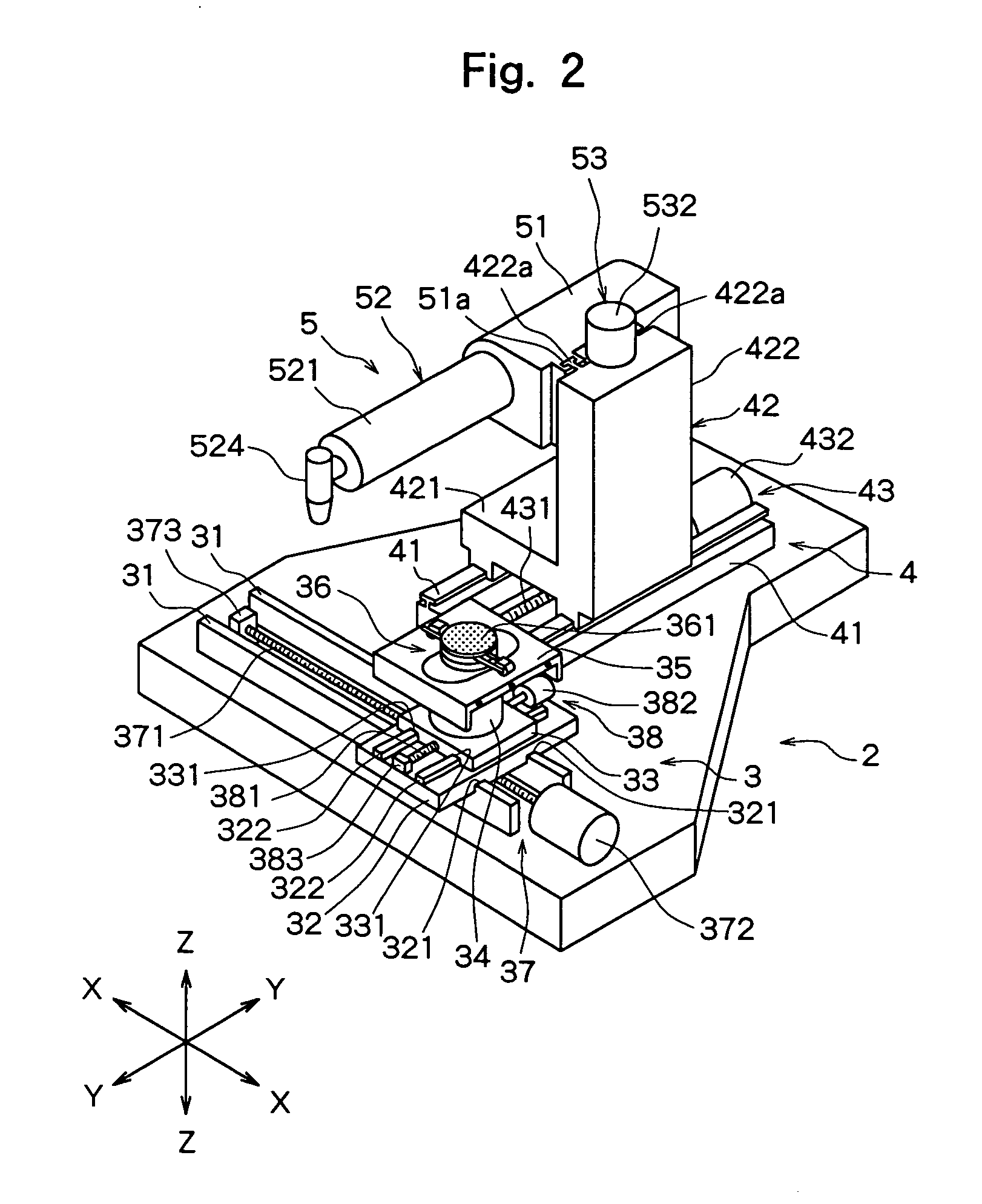

Method and apparatus for splitting semiconductor wafer

InactiveUS20050054179A1Decorative surface effectsSemiconductor/solid-state device manufacturingLaser beamsSemiconductor

A method of dividing a semiconductor wafer having circuits formed in a plurality of areas defined by streets arranged on the front surface in a lattice form along the streets, comprising the step of detecting the streets from the back surface of the semiconductor wafer and the step of cutting the semiconductor wafer along the streets detected in the street detection step by applying a laser beam to the back surface of the semiconductor wafer along the streets.

Owner:DISCO CORP

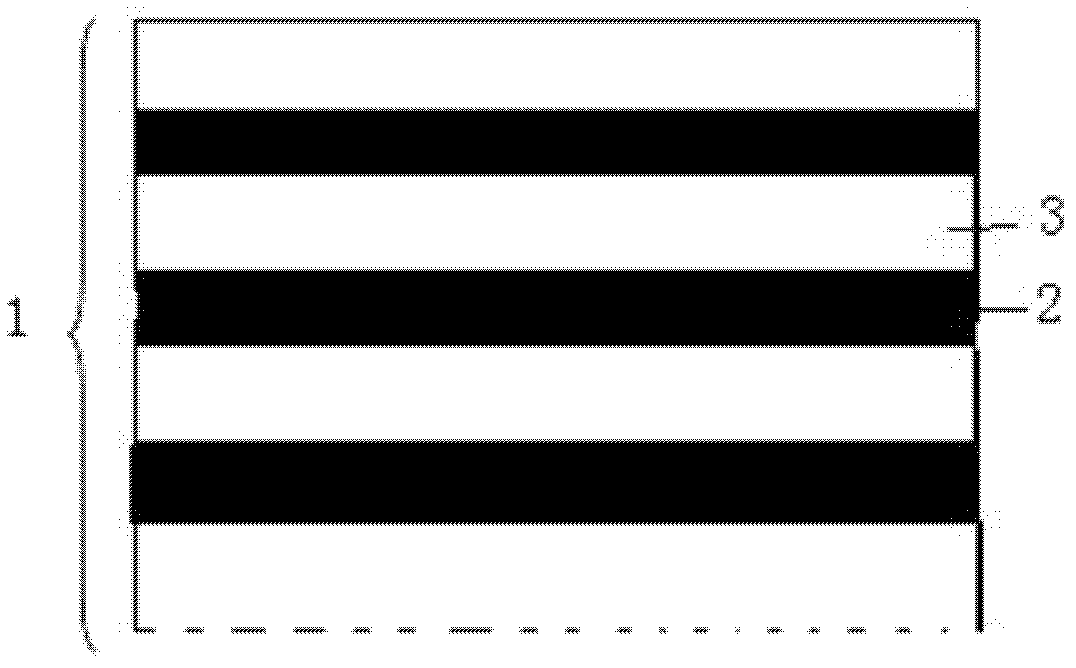

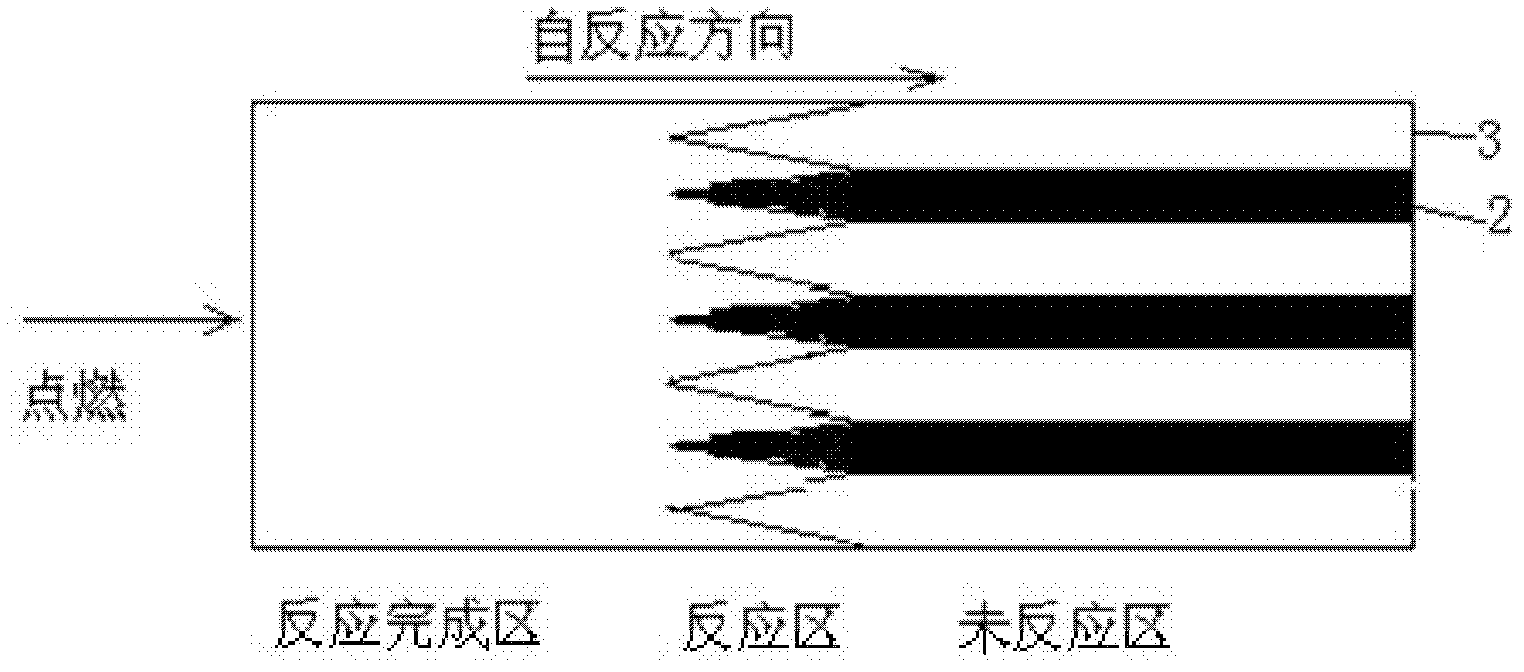

Thermit reaction foil, manufacturing method thereof and application thereof to welding process

InactiveCN102248280AQuick responseFast welding speedWelding/cutting media/materialsSoldering mediaThermal expansionUltimate tensile strength

The invention belongs to the technical field of thermit welding and discloses a thermit reaction foil. The thermit reaction foil consists of aluminum and a metal oxide capable of generating the thermit reaction with the aluminum, wherein each of the aluminum and the metal oxide has a laminated structure with at least one layer; and the aluminum layer and the metal oxide layer are arranged sequentially in an overlapping mode. When excitation with certain heat is applied to one end face of the thermit reaction foil, the thermit reaction foil generates self-propagating reaction instantly and other thermite or melting solder is ignited by heat released by the reaction, so that materials are welded. Therefore, compared with the prior art, the thermit reaction foil has reaction time of only several milliseconds, high reaction heat release, high welding speed and high welding strength, can weld the materials with different coefficient of thermal expansion, and is easy to operate, applicable to welding of various armors and parts and emergent welding repair of battlefields and also applicable to welding of various fine parts.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for laying ballastless track long steel rail

ActiveCN101215813ARich laying technologyMeet construction requirementsRailway track constructionAlumino-thermic welding apparatusDedicated lineBuilding construction

A ballastless long rail laying method of the invention relates to a construction method of rail laying after welding regular length-fixed rail into a long rail. The invention aims to provide a construction method to weld the length-fixed rail into the long rail for rail laying, which comprises a technical scheme that after welding the length-fixed rail into the long rail, the long rail is transported to the construction field of rail laying and then is welded to meet the requirement of the whole rail seamless line. The method of the invention is mainly applied in ballastless rail laying of high-speed railways and passenger transportation dedicated lines.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Weld metal material apparatus and method

InactiveUS20070017955A1Lower the volumeWelding/cutting media/materialsSoldering mediaSlurrySodium silicate

A solid weld-metal-producing material is formed by agglomerating weld metal material powder. An igniter may be integrally formed in or on the agglomerated weld metal material. In addition to typical components of a weld metal material mixture, such as a reductant metal and a transition metal oxide, the agglomerated weld metal mixture may include a binder material, such as sodium silicate. In addition to functioning as a binder to help hold the agglomerated weld metal material together, the binder material may aid in the exothermic reaction that occurs when the weld metal material is ignited. The agglomerated weld metal material may be made by mixing together a reductant metal powder, a transition metal oxide powder, and possibly a binder solution. A slurry of the components may be pressed together, for example, using a die and a ram, and then may be dried.

Owner:ERICO INT

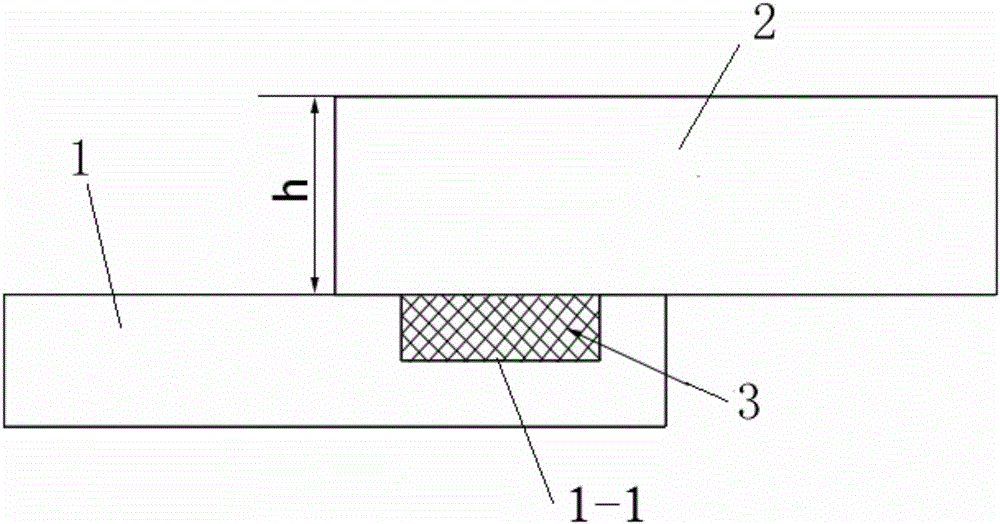

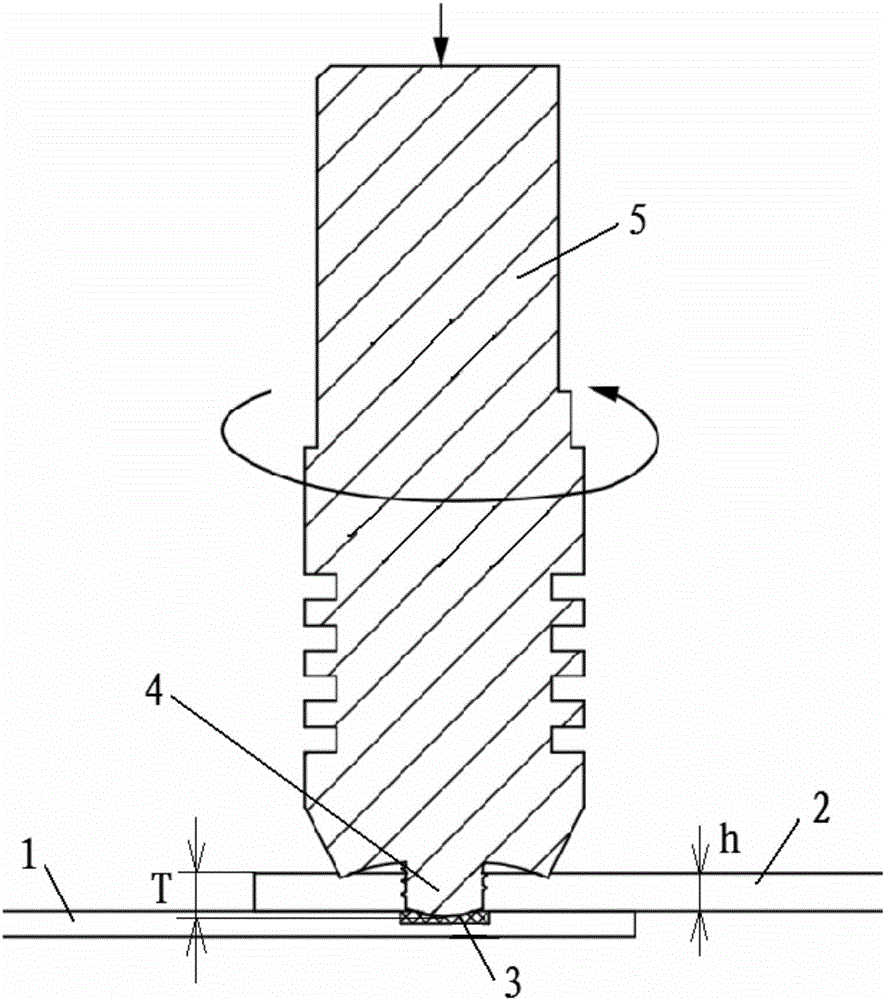

Friction deformation-triggered self-propagating assistant aluminum/steel friction stirring overlapping method

ActiveCN105945419AReduce wearWith preheating effectWelding/soldering/cutting articlesAlumino-thermic welding apparatusSheet steelOrganic solvent

The invention provides a friction deformation-triggered self-propagating assistant aluminum / steel friction stirring overlapping method which is capable of solving the problem that severe abrasion to a soldering set is caused when a stirring needle is inserted into a steel plate during light aluminum / steel dissimilar material friction stirring overlapping in the prior art. The friction deformation-triggered self-propagating assistant aluminum / steel friction stirring overlapping method comprises the following steps: 1, forming a square groove in a central line of an overlapping part on the steel plate 1; 2, cleaning up the contact surfaces and the peripheries of the steel plate to be welded and an aluminum plate to be welded; 3, wiping the surfaces of the steel plate and the aluminum plate with an organic solvent; 4, filling the square groove with a mixture; 5, combining and clamping the aluminum plate and the steel plate in such an overlapping manner that the aluminum plate is above the steel plate; and 6, performing friction stirring welding on the steel plate and the aluminum plate, wherein the shaft shoulder of a stirring head rubs with the aluminum plate, heat generated in plastic deformation of the aluminum plate is transmitted to the mixture, gunpowder is ignited, a thermite reaction between aluminum powder and Fe2O3 is triggered, the gunpowder burns, the thermite reaction spreads from one end of the steel plate to the other end of the steel plate fast to soften the steel plate, and Fe, which is a product of the thermite reaction, sinks to the bottom of the square groove and is combined with steel. The friction deformation-triggered self-propagating assistant aluminum / steel friction stirring overlapping method is used for dissimilar material friction stirring overlapping.

Owner:安徽万宇机械设备科技有限公司

Faster welding method for armored vehicle aluminium alloy part for emergency in battlefield

InactiveCN101372068AHigh densityEasy to carryAlumino-thermic welding apparatusFerrosiliconEmergency situations

The invention relates to a quick welding method used for aluminium alloy part of armored vehicle when being emergent in battlefield, comprising the process steps: thermit casting welding flux is prepared; the thermit casting welding flux is arranged inside a resin crucible with a lower hole; the lower hole of the resin crucible is plugged by an asbestos cushion of 3-5mm; Ti powders of 2mm thick are arranged between the asbestos cushion and the thermit casting welding flux; TiC igniter is embedded inside the thermit casting welding flux and part of the TiC igniter is exposed and can be ignited; the thermit casting welding flux initiates a self-propagating reaction in the crucible, thus gaining mixed melts of iron and Ti which are poured into the aluminium alloy surface to be welded; when the melts is just concreted, knocking and pressurizing are carried out so as to achieve the welding object; the thermit casting welding flux used by the welding method, according to the weight percentage, comprises 19-25% of aluminium powders of 200-300 meshes, 55-60% of ferric oxide with the granularity less than 100 meshes and the carbon content less than 0.5%, 3-12% of alloying additive of ferromanganese, ferrosilicon and iron nailhead, residual quantity of CaCO3-CaF2-Al2O3 slagging flux and 2-5% of alkalescent auxiliary flux; the welding method is mainly applicable to the emergent quick welding of aluminium alloy parts of armored vehicles in battlefield.

Owner:江阴东大新材料研究院

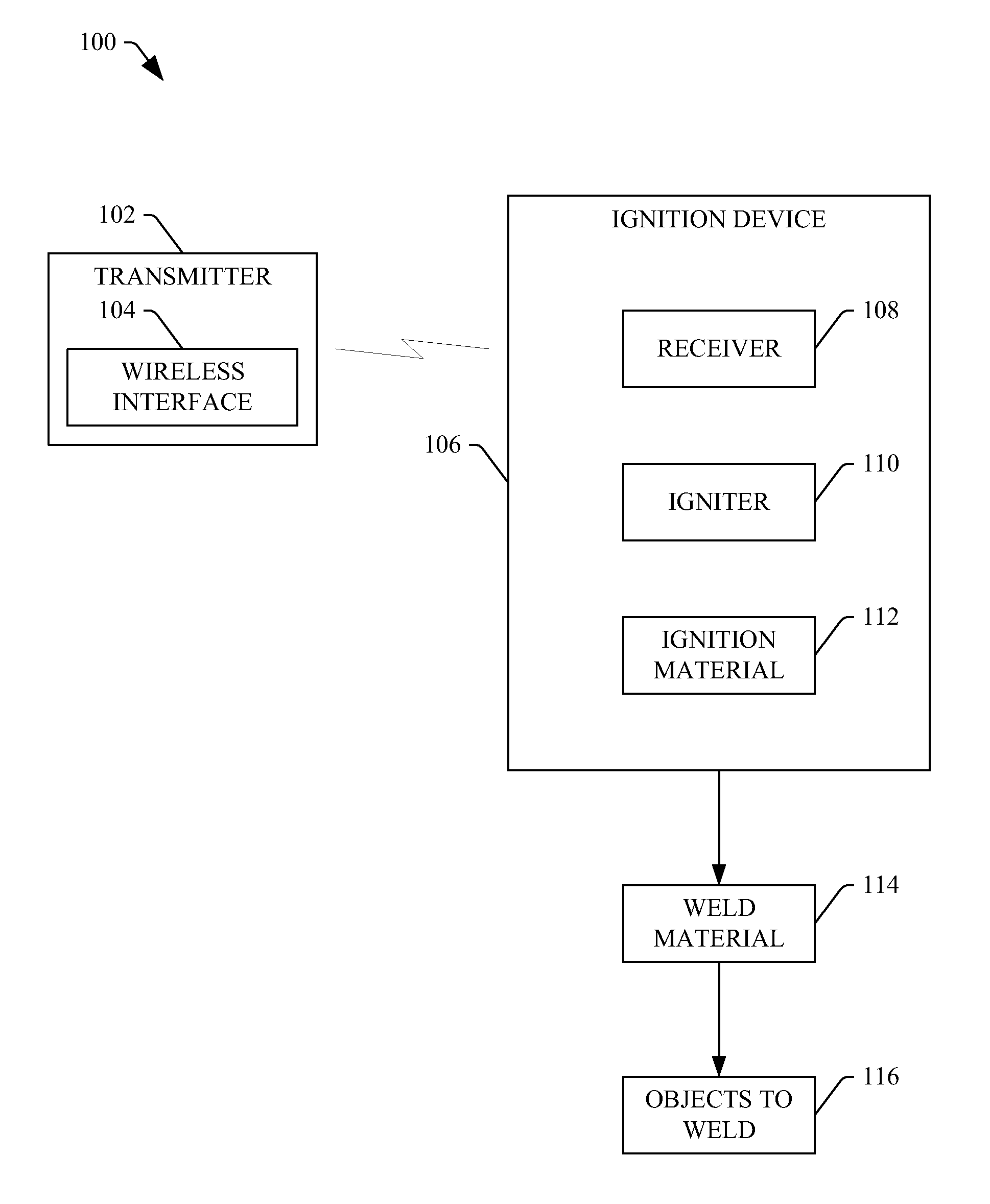

Weld material ignition

A weld ignition system includes a wireless receiver that wirelessly receives a weld ignition activation signal. The weld ignition system further includes igniter that ignites a weld ignition material in response to the wireless receiver wirelessly receiving the weld ignition activation signal. The ignited weld ignition material initiates exothermic based welding of a weld material.

Owner:ALGHUSAIN FADY AMEER

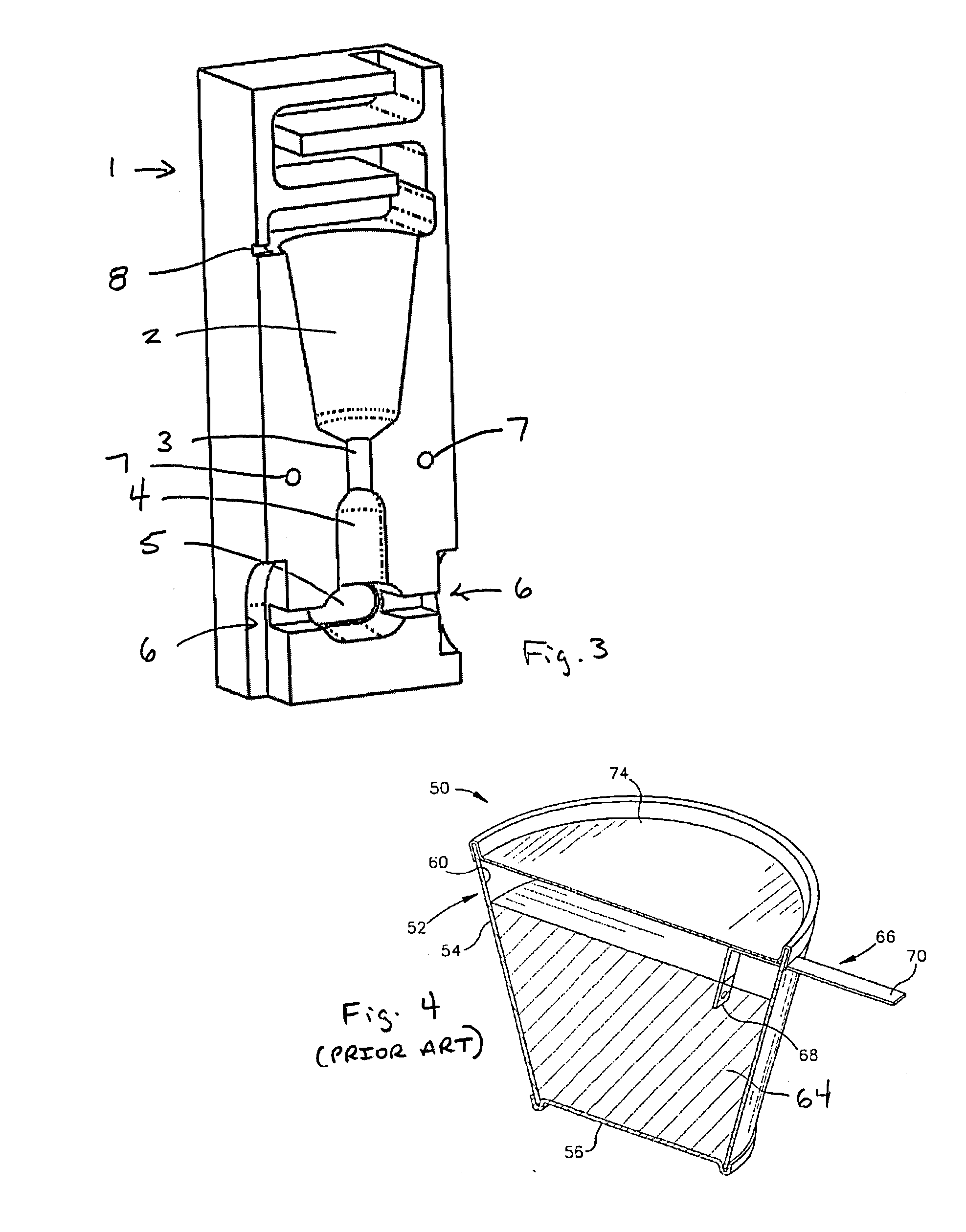

Exothermic welding mold with integral cover

InactiveUS20110240244A1Increased exothermic welding reaction containmentIncreased gas-venting controlMelt-holding vesselsAlumino-thermic welding apparatusExothermic weldingCrucible

An exothermal weld mold includes a mold section with an integral cover portion, made as part of a single piece of material with the rest of the mold section. The mold section may be a mold half of a vertically split mold, or may constitute most of a half of the mold. The cover portion may be part of an integral cover that covers substantially all of a reaction chamber or crucible of the mold. The cover may have one or more vent holes, in the top and / or side of the mold. The cover may have a baffled passage for expansion of gases produced by reaction of the weld material, before the gases are expelled from the mold at an opening in the top or side of the mold. The passage may be a serpentine passage. A filter may be placed in the passage.

Owner:ERICO INT

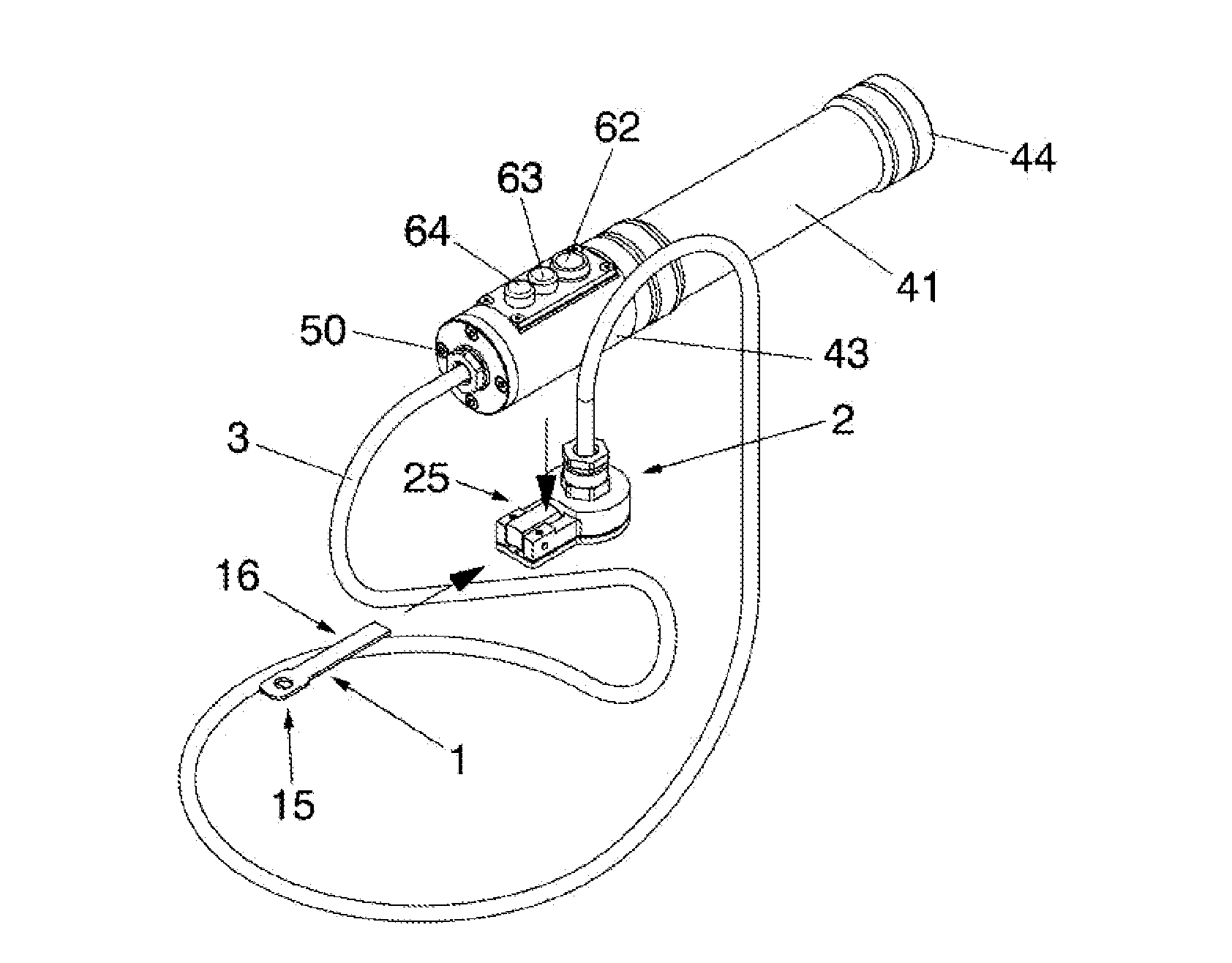

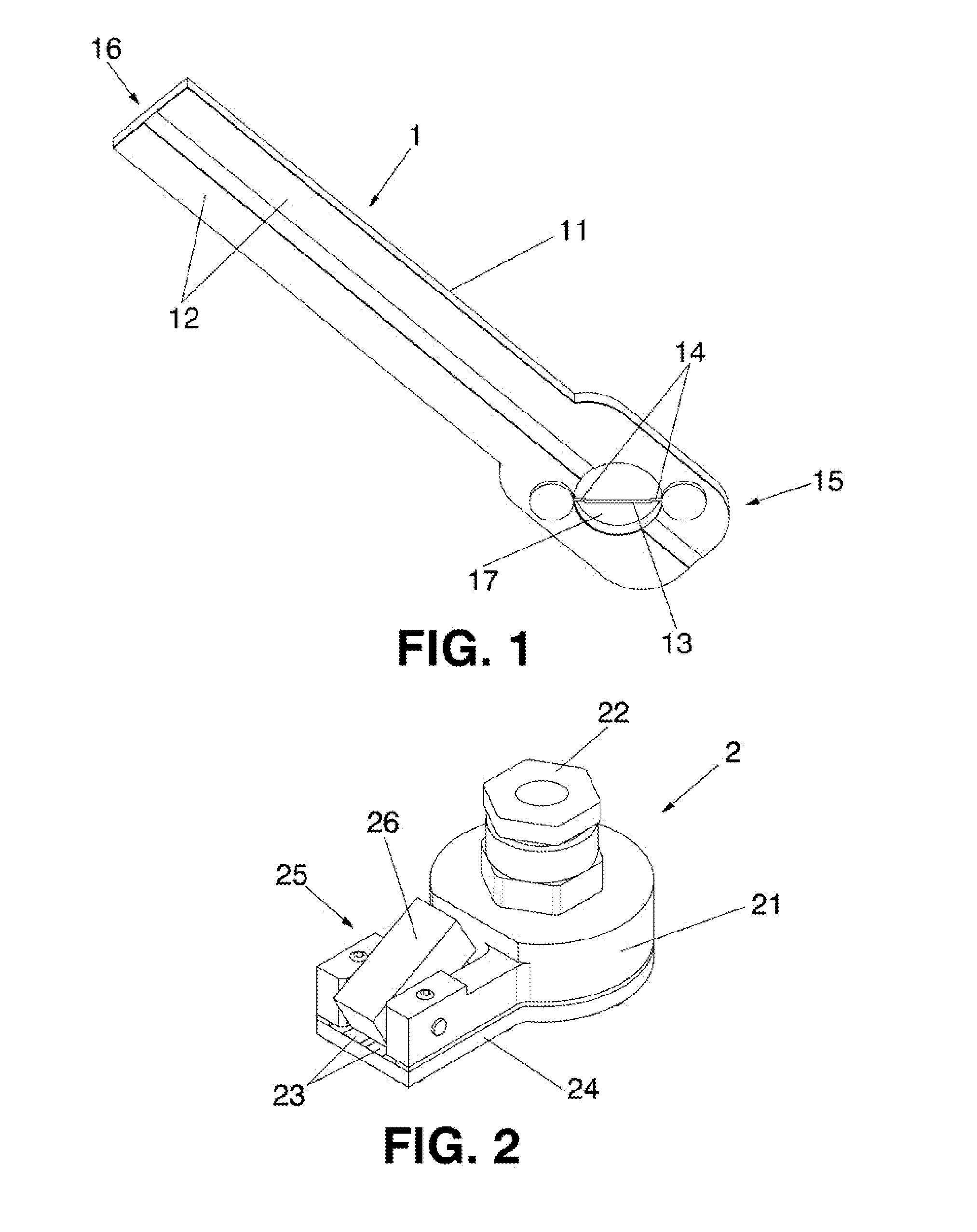

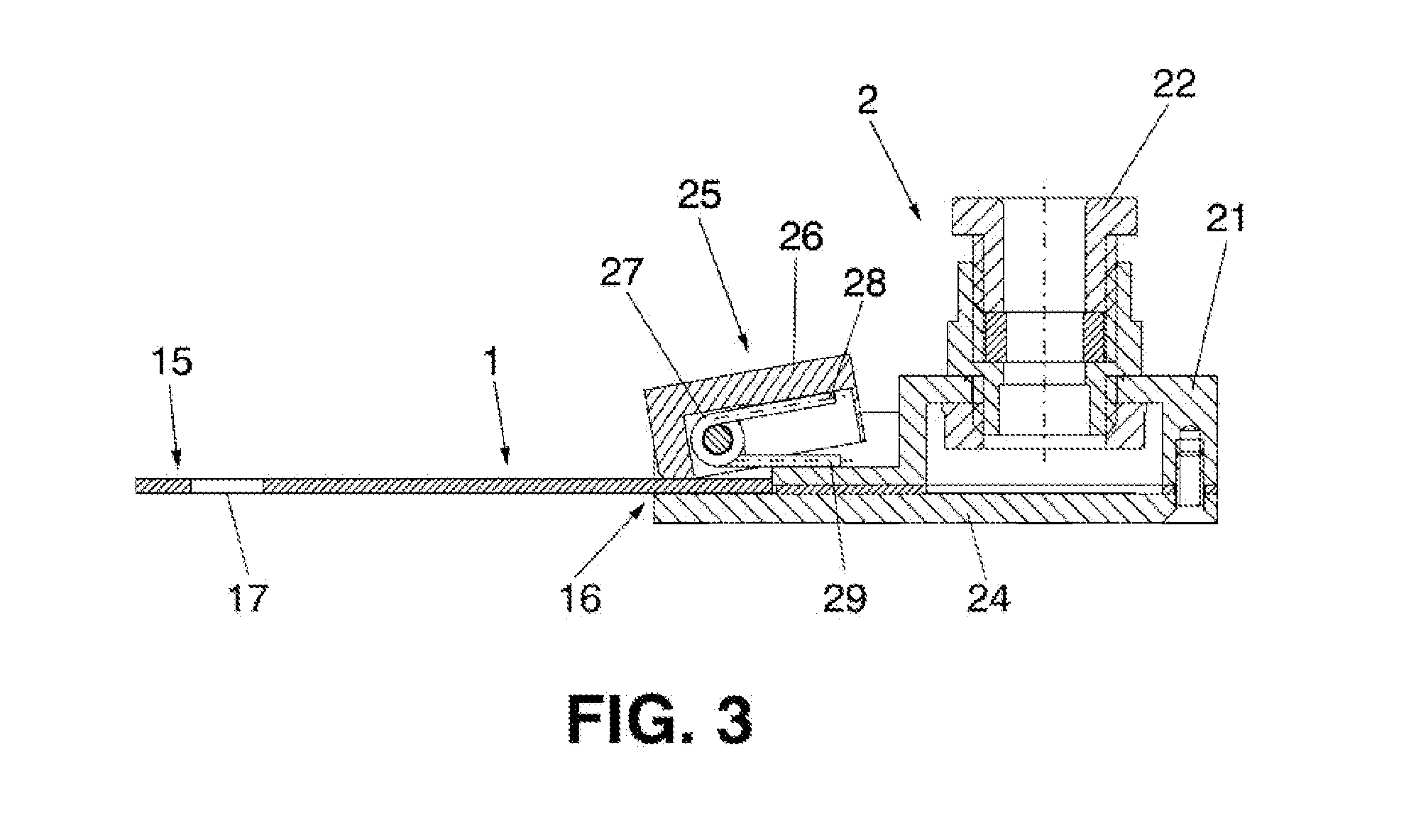

Device and process for remote ignition in aluminothermic welding

ActiveUS20150328716A1Incandescent ignitionBlasting cartridgesElectrical resistance and conductanceElectricity

It enables to use very limited energy and an easily transportable device. Comprises: a) a consumable ignition element with a resistive wire to be heated as the electric current passes through it and cause a remote ignition; b) a reusable intermediate element, provided with fitting means to be electrically connected with the ignition element; c) a portable case to house a portable power source and, d) an ignition switch that is housed in the case, with a push button to activate the power source, as well as a first indicator adapted to turn on if the power source is available and a second indicator adapted to turn on if the contact between the first tracks and the second tracks is correct.

Owner:KLK ELECTRO MATERIALES S L U

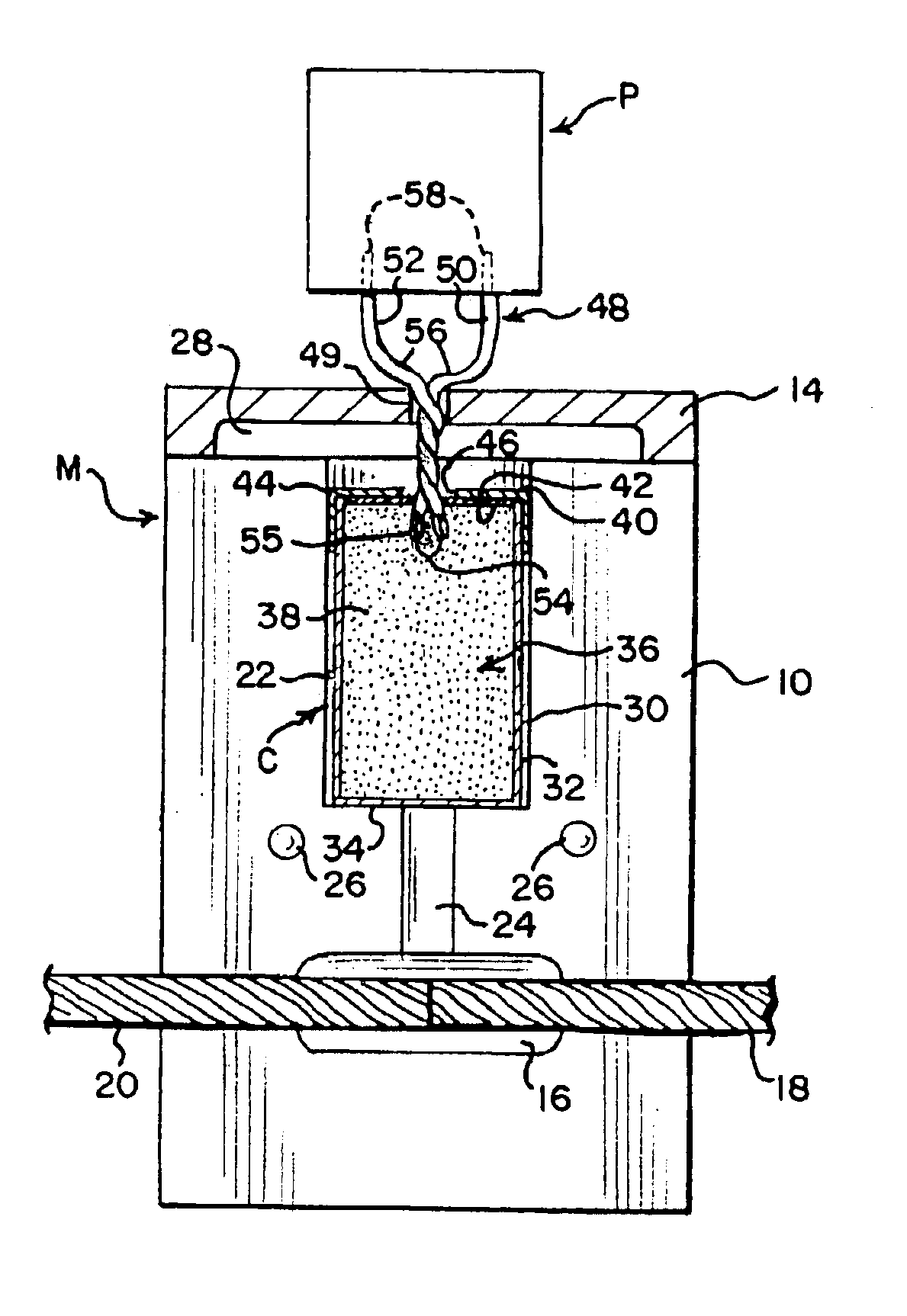

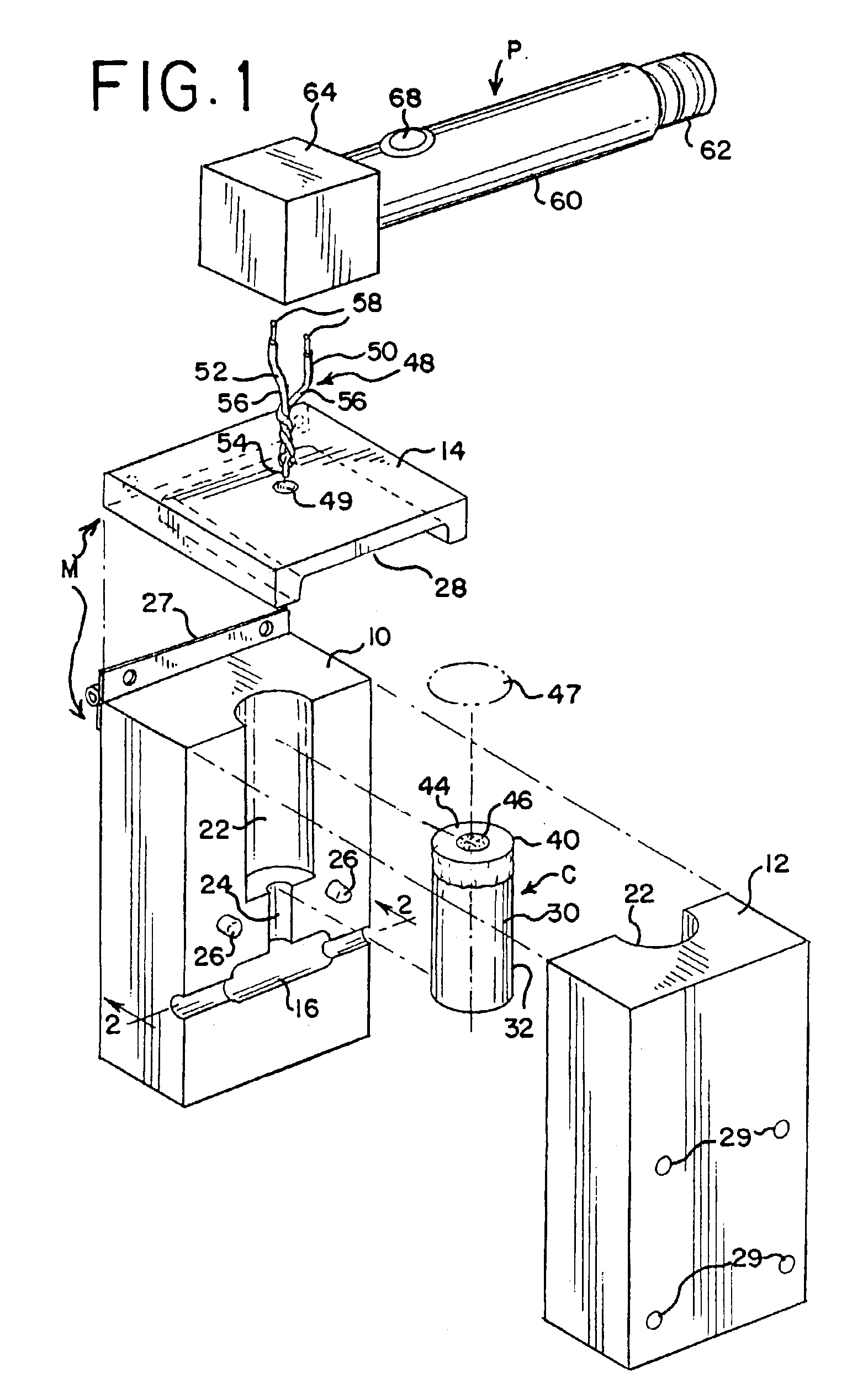

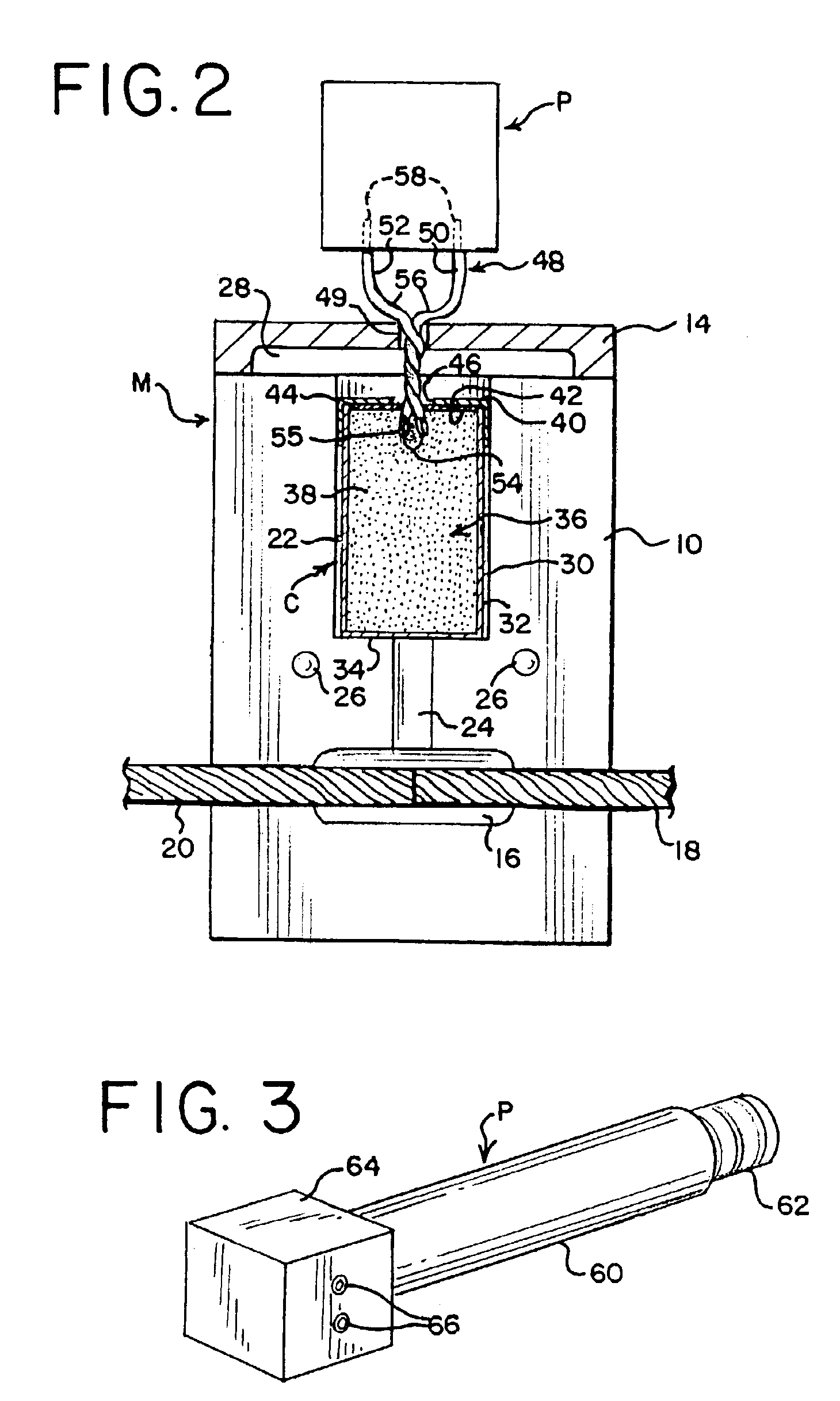

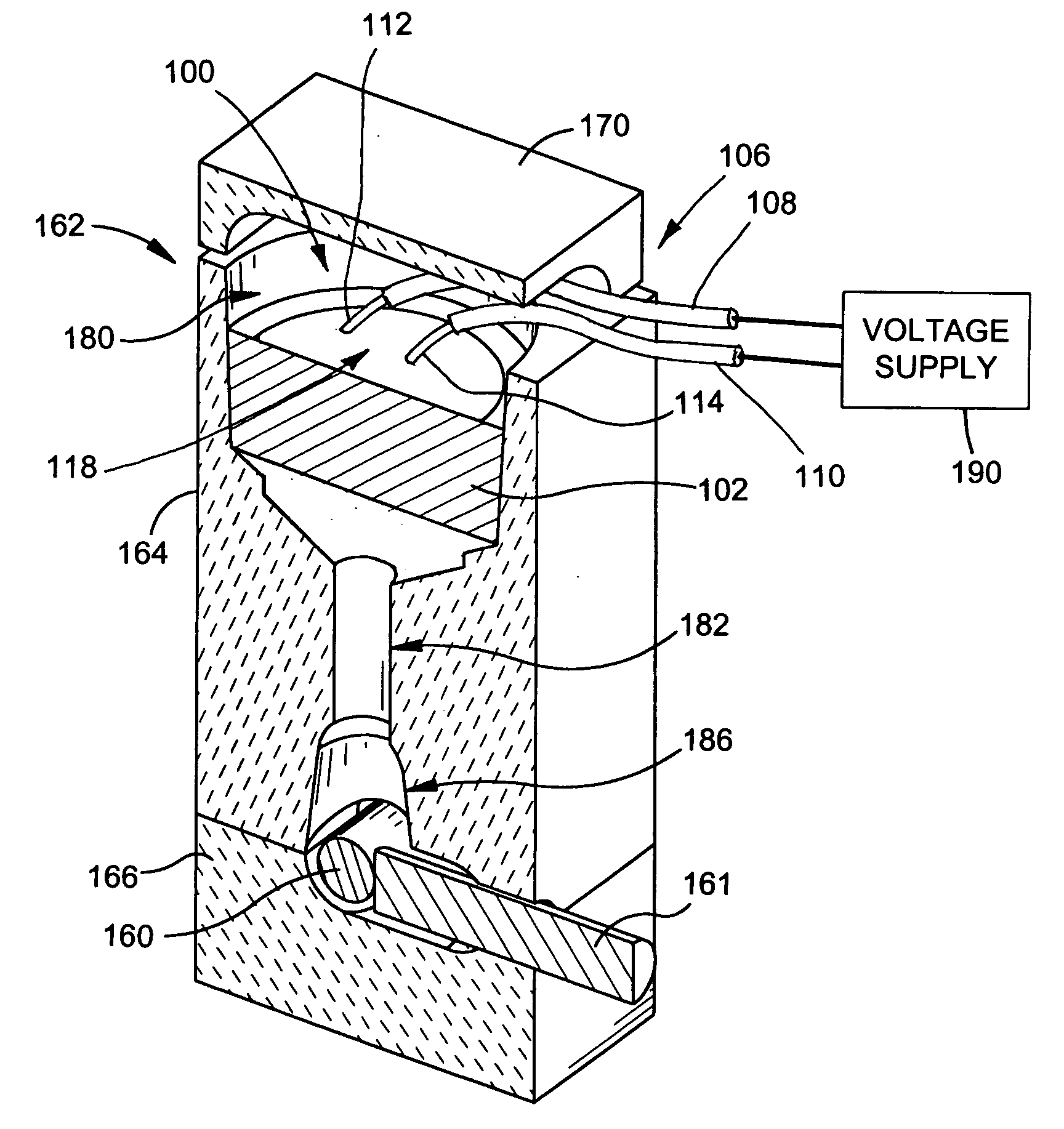

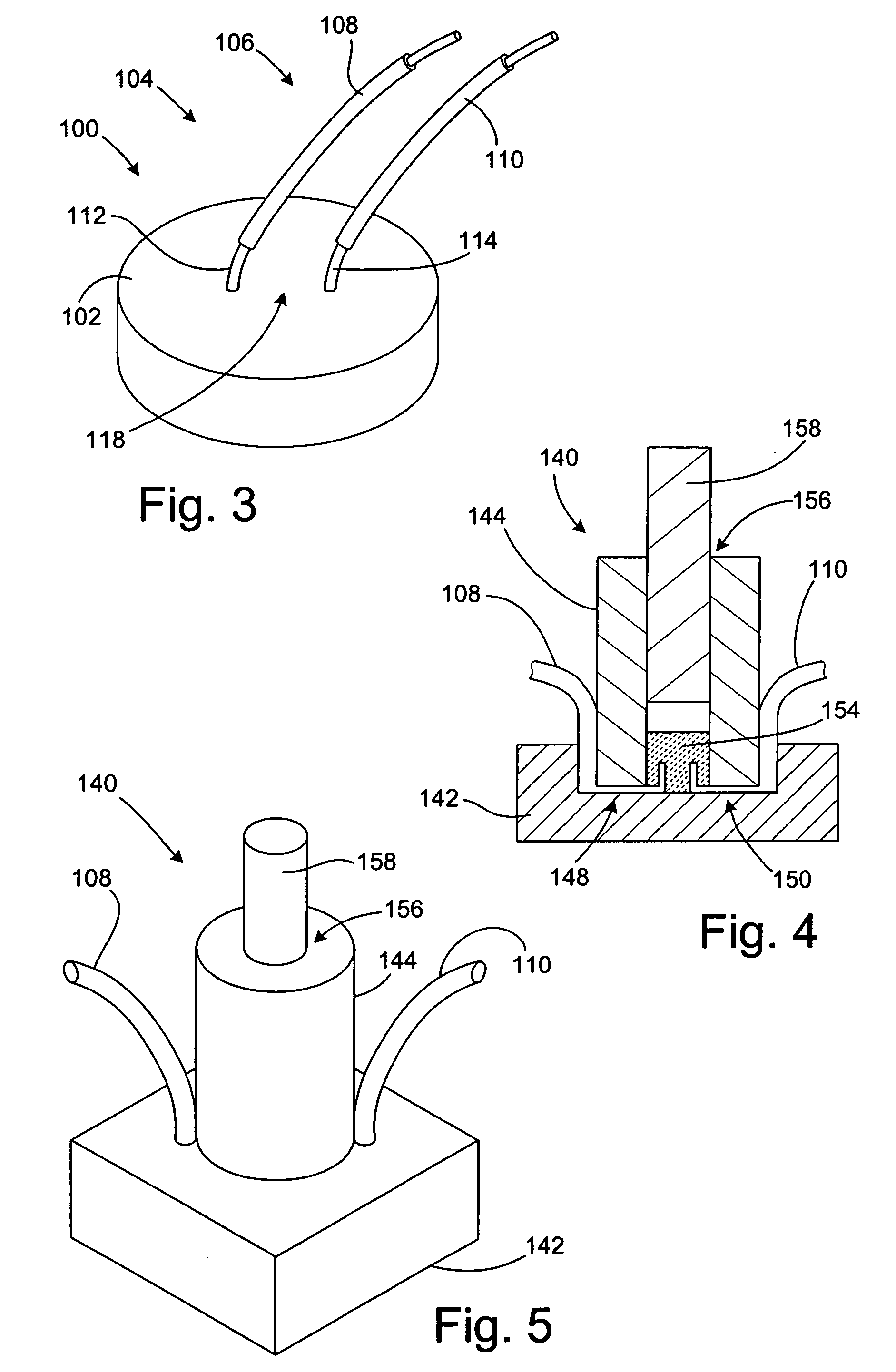

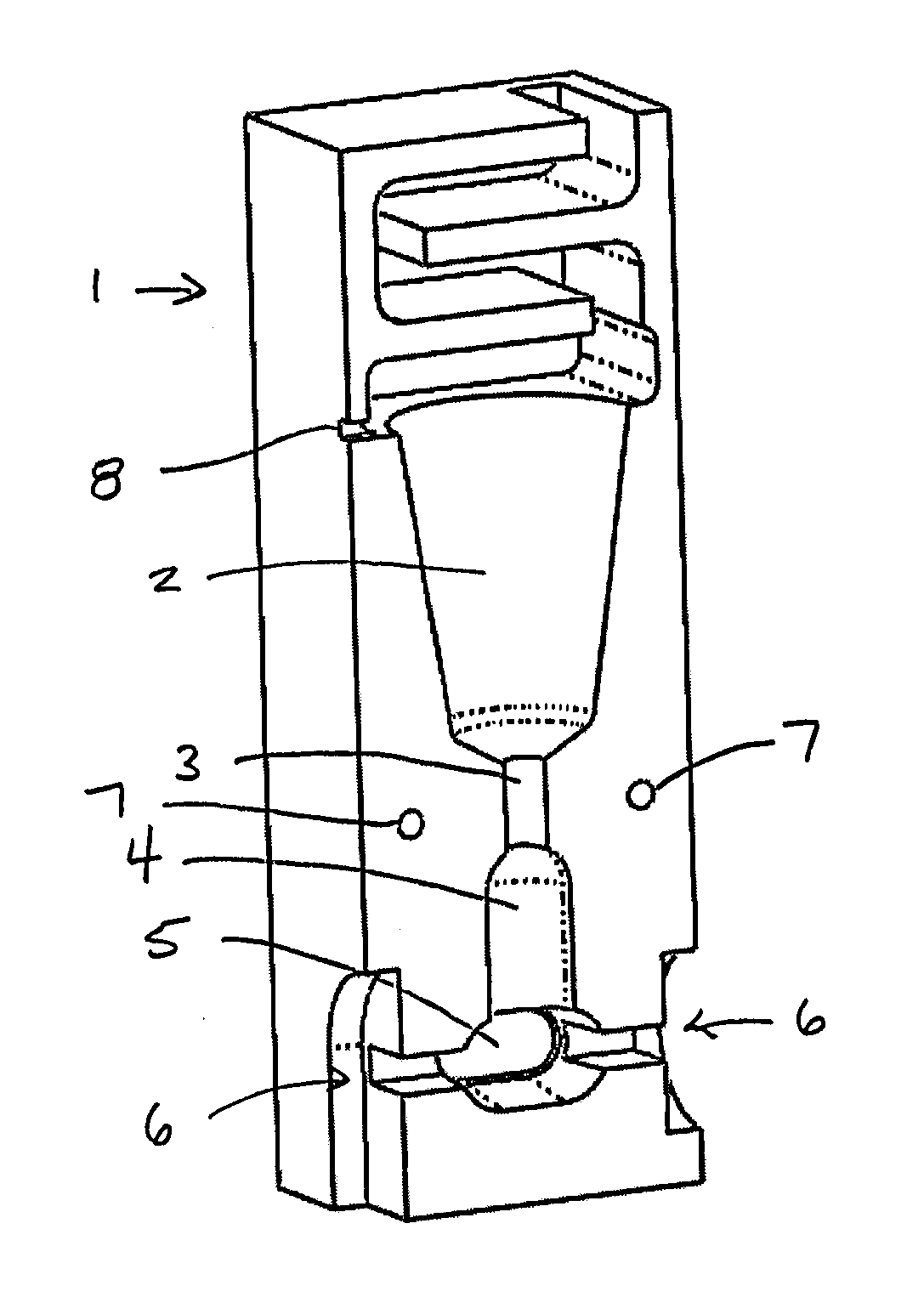

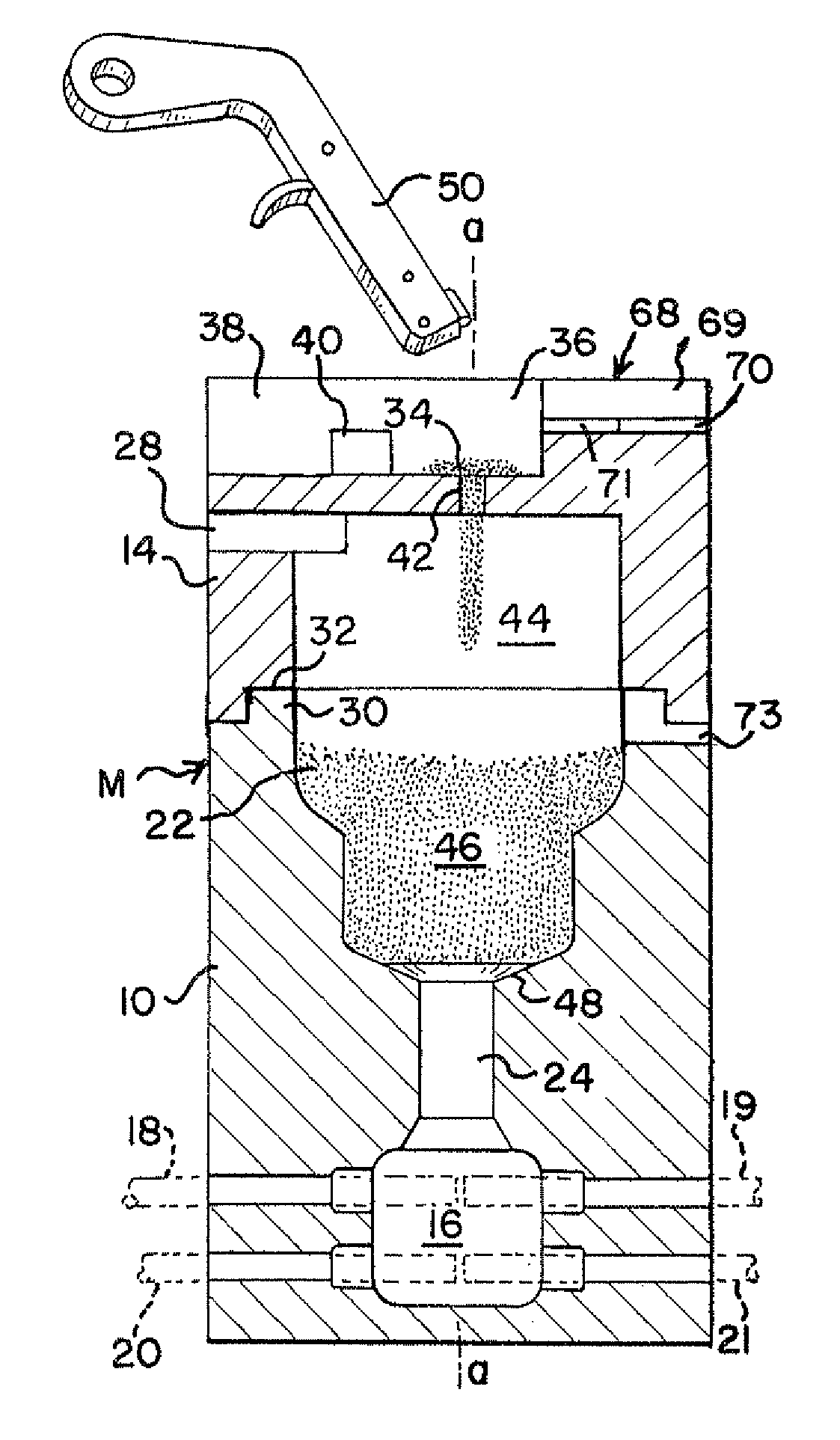

Exothermic welding assembly

ActiveUS7950568B2Improve the immunityEliminate needMould separation apparatusBlasting cartridgesExothermic weldingElectrical conductor

An assembly is disclosed for exothermic welding comprising a mold which is formed of a material which withstands exothermic welding temperatures and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together, and an ignition cavity communicating with the weld cavity. The mold is capable of accommodating any one of several exothermic welding procedures which may involve either a flint igniter or the use of an electrical igniter which is readily accommodated by the mold in the performance of several of the procedures. The electrical igniter is formed of a pair of flat, longitudinally extending conductor strips with a sheet of insulation laminated therebetween, a filament adjacent one end of the strips, and one or more positioning tabs adjacent one end of the strips. A cartridge is also provided which contains the weld metal and the electrical igniter and which may be positioned in the ignition cavity of the mold. The cartridge is formed of a material which is consumed during the welding procedure and may contain a plate of a different material adjacent its bottom which melts at a higher temperature than the materials of the cartridge.

Owner:HARGER

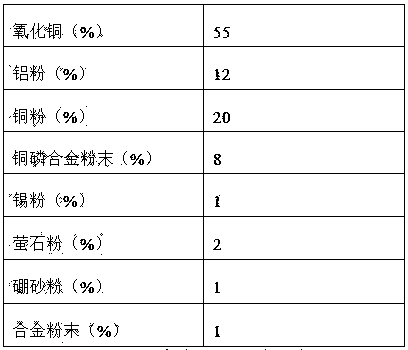

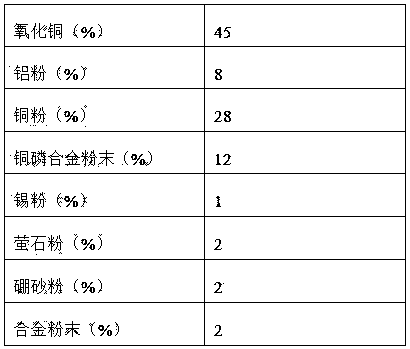

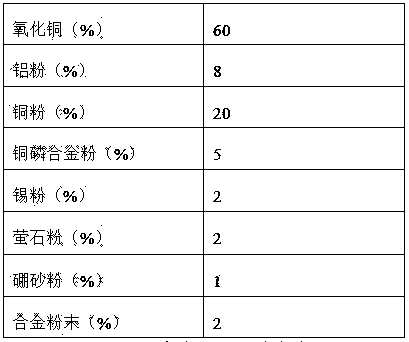

Exothermic welding powder for welding novel grounding grid materials

ActiveCN104043913AQuality improvementLower connection costsWelding/cutting media/materialsAlumino-thermic welding apparatusExothermic weldingAl powder

The invention discloses exothermic welding powder for welding novel grounding grid materials. The exothermic welding powder comprises, by weight, 45%-60% of copper oxide, 8%-13% of aluminum powder, 20%-30% of copper powder, 5%-15% of copper-phosphorus alloy powder, 1%-5% of tin powder, 2%-6% of fluorite powder, 1%-4% of borax powder and the balance alloy powder. The alloy powder comprises, by weight, 8%-12% of Ca, 40%-47% of Si, 28%-32% of Ba and the balance impurities. According to the exothermic welding powder, raw materials are low in price and easy to get, the problems that pores, slag inclusion, hot tear and the like can be easily generated in the welding process by using the exothermic welding powder are solved, the quality of welded joints is reliable, the connecting cost of the novel grounding grid materials is lowered, and the development of a grounding system in electric power engineering in China is facilitated.

Owner:STATE GRID CORP OF CHINA +3

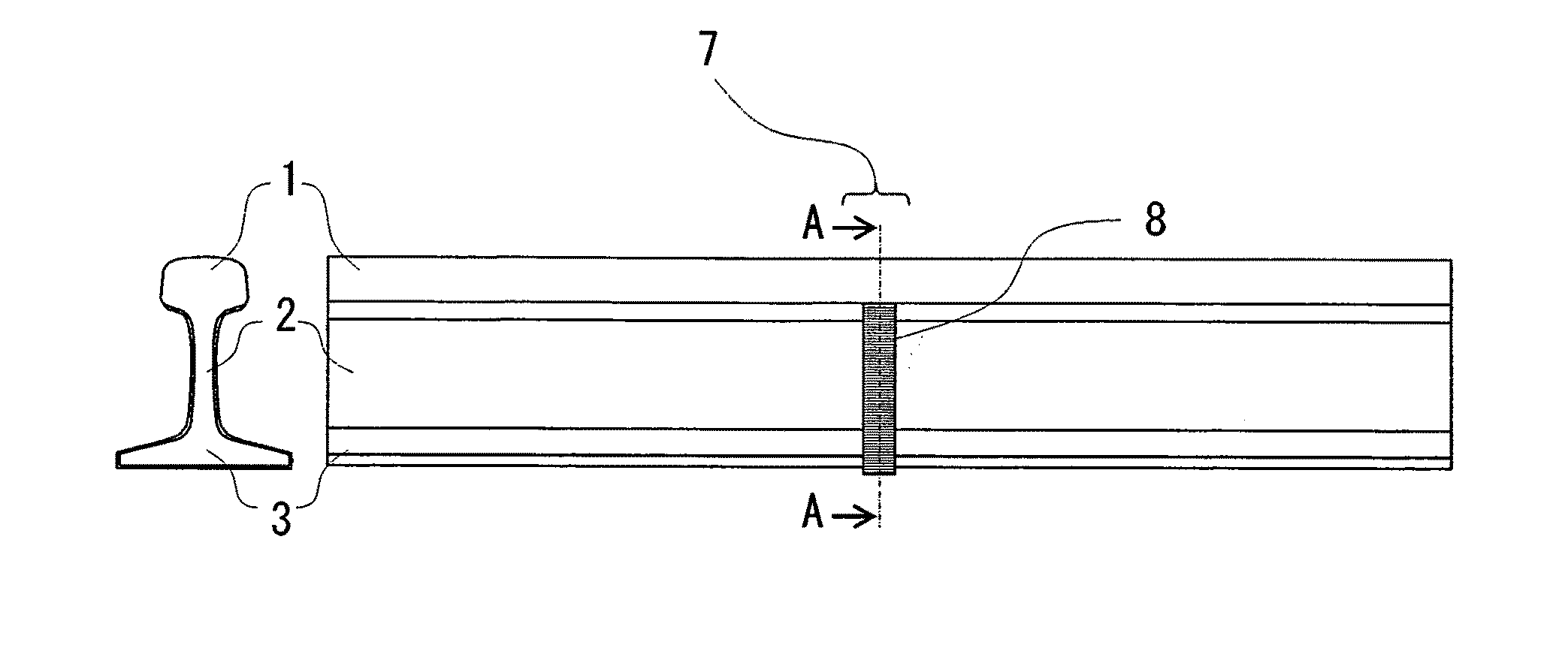

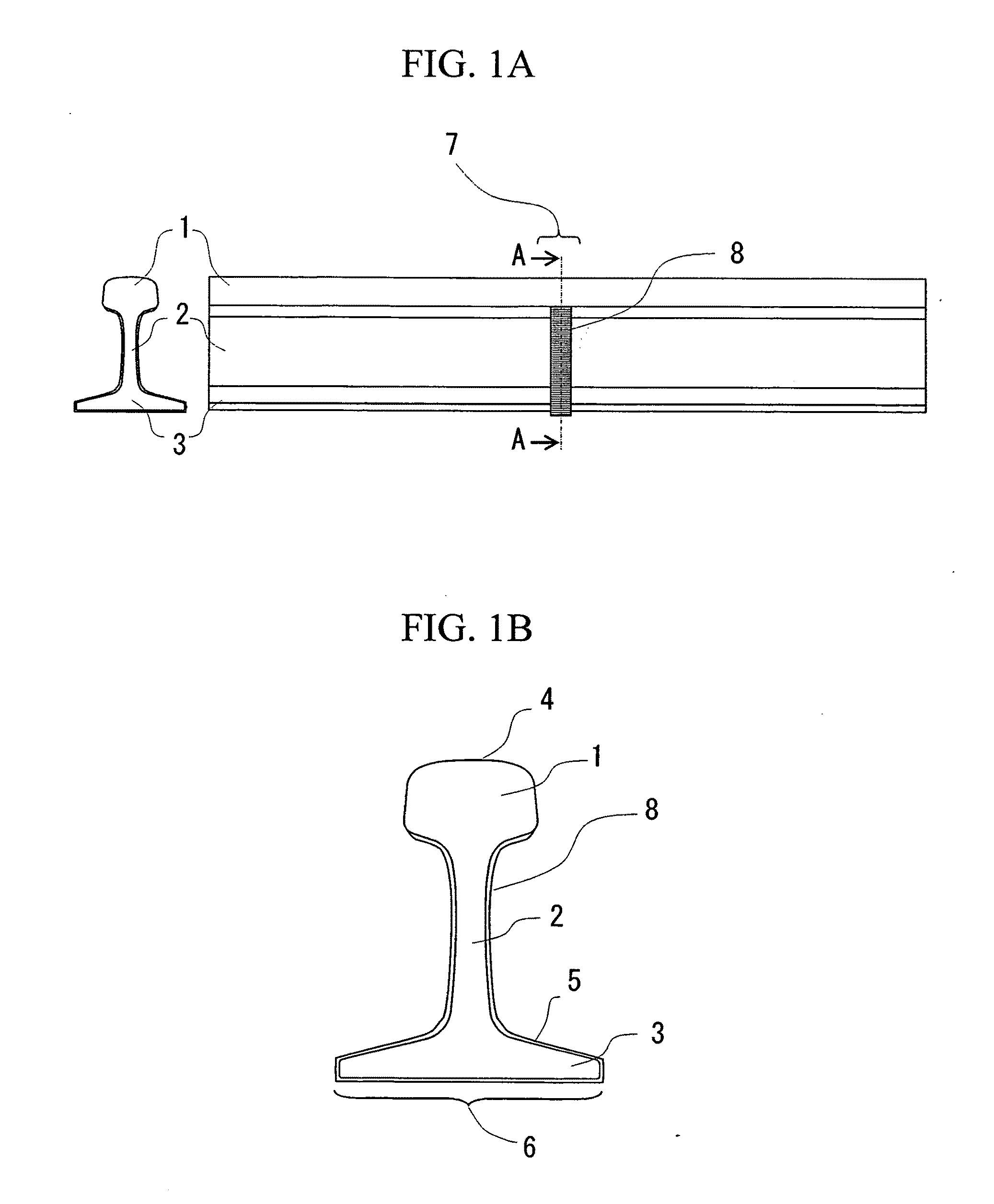

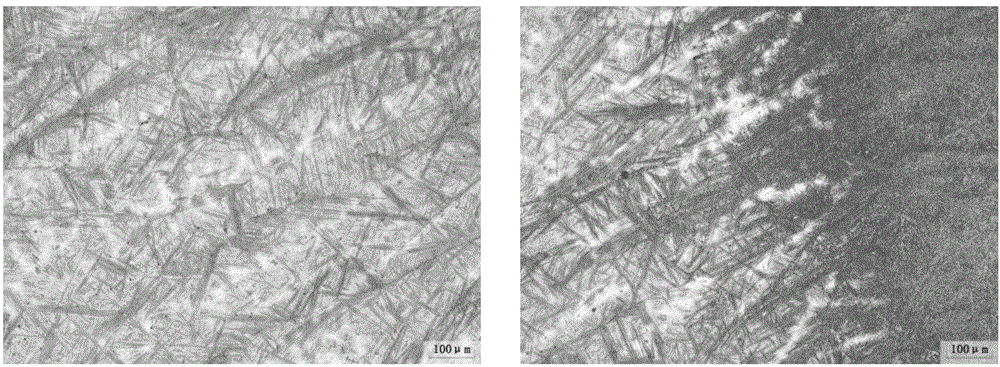

Method of cooling rail weld zone, device for cooling rail weld zone, and rail weld joint

InactiveUS20120015212A1Improve residual stressAvoid fatigue crackingRailsFurnace typesEngineeringMechanical engineering

The invention provides a method of cooling a rail weld zone. The method includes a first rail web portion cooling process of cooling a rail web portion cooling region of the rail weld zone in a part of a temperature range until the completion of transformation from austenite to pearlite, a second rail web portion cooling process of cooling the rail web portion cooling region after the entire rail web portion of the rail weld zone is transformed to pearlite, a foot portion cooling process of cooling a foot portion of the rail weld zone, and a head portion cooling process of cooling a head portion of the rail weld zone. When cooling time of the first and second rail web portion cooling processes is t minute, a k value satisfies an expression represented as −0.1t+0.63≦k≦−0.1t+2.33.

Owner:NIPPON STEEL CORP

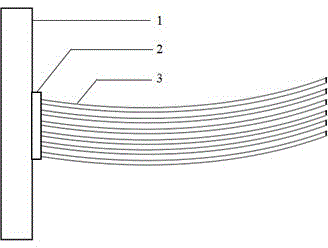

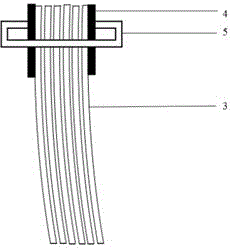

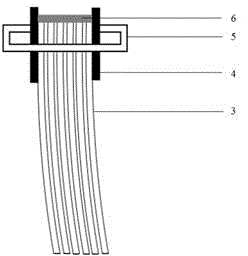

Secondary self-propagating welding method for cathode soft belt and large bus for aluminum electrolysis cell

InactiveCN103317226AQuick Weld RepairUnique process methodWelding/cutting media/materialsAlumino-thermic welding apparatusCrucibleWeld seam

The invention relates to a secondary self-propagating welding method for a cathode soft belt and a large bus for an aluminum electrolysis cell. The method includes first taking down a waste cathode soft belt, welding an aluminum plate at one end of a new soft belt beam, welding a steel aluminum explosion block at the other end, coating aluminum welding flux on the groove face, arranging a crucible above a welding seam, arranging a self-fluxing plug in the crucible, preheating a bus material and the crucible, arranging welding powder into the welding seam and the crucible, evenly scattering pyrophoric powder on the surface of welding powder at the two positions, igniting the pyrophoric powder in the welding seam, erecting the crucible above the welding seam quickly after the welding powder finishes reaction and igniting the pyrophoric powder in the crucible at the moment to enable the welding powder in the crucible to react. When a metal solution enters the welding seam, welding of the aluminum plate at the end of the soft belt and the bus can be finished, and the steel aluminum explosion block at the other end of the soft belt is connected with a steel rod on a groove casing through arc welding. A workpiece with different sections has good conductivity and strength when the workpiece is welded through the method.

Owner:QINGTONGXIA ALUMINUM GRP +1

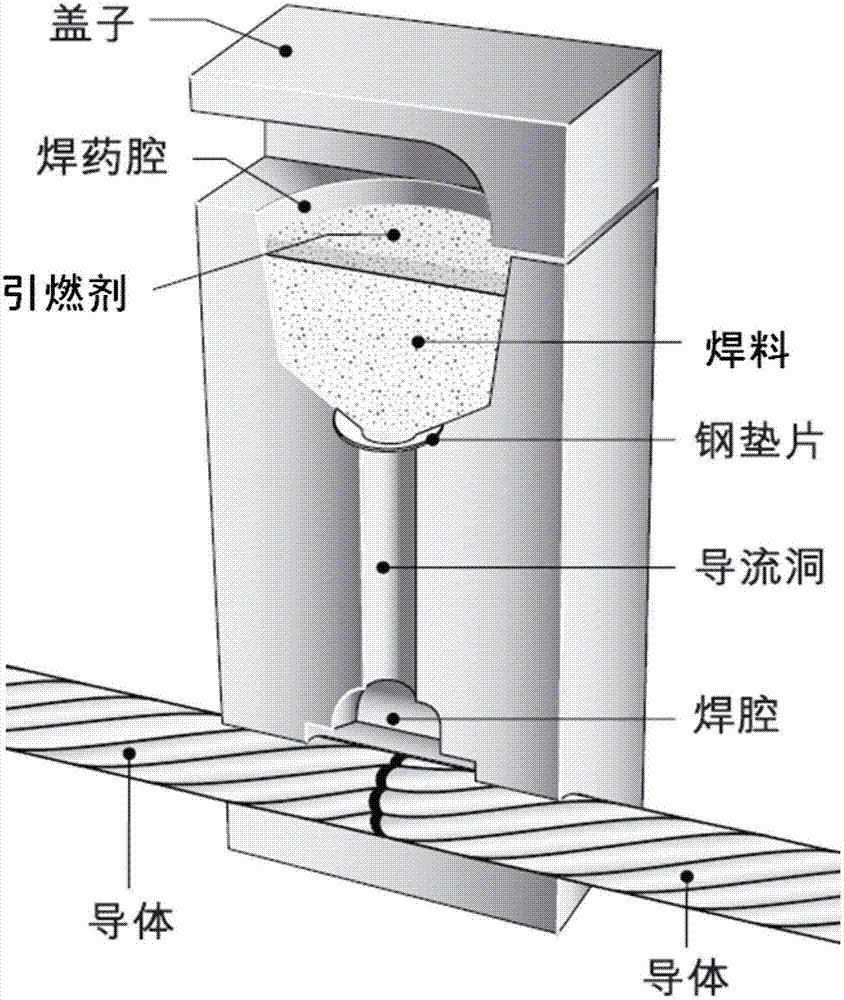

Metal fusion welding method

ActiveCN103071919AEasy to operateReduce sensitivityWelding/cutting media/materialsSoldering mediaElectrical conductorPetrochemical

The invention discloses a metal fusion welding method, which comprises the following steps that a fire striking gun is used for igniting ignition agents, the ignition agents ignite heat release welding fluxes, a graphite mold is applied, a welding form is formed in a mold cavity, and a workpiece is melt for welding. The metal fusion welding method has the advantages that the operation is simple, and the metal fusion welding method can be widely applied to the welding in various aspects including railway rail guide, electric equipment grounding engineering processing, lightning protection grounding, surge protection, intelligent mansion building, petrochemical industry engineering building, cathode anticorrosion protection and the like. When the welding method is used, the occurrence of hydrogen-induced pinholes and air holes in workpiece joints can be inhabited, the sensitivity to the humid environment in the welding process is lowered, the workpiece joint completed through welding is stable and firm, the electric performance is excellent, and the high-current surge impact resistance capability is higher than that of the workpiece (conductor) per se.

Owner:XINCHANG COUNTY RENTONG ELECTRIC POWER TECHLIMITED

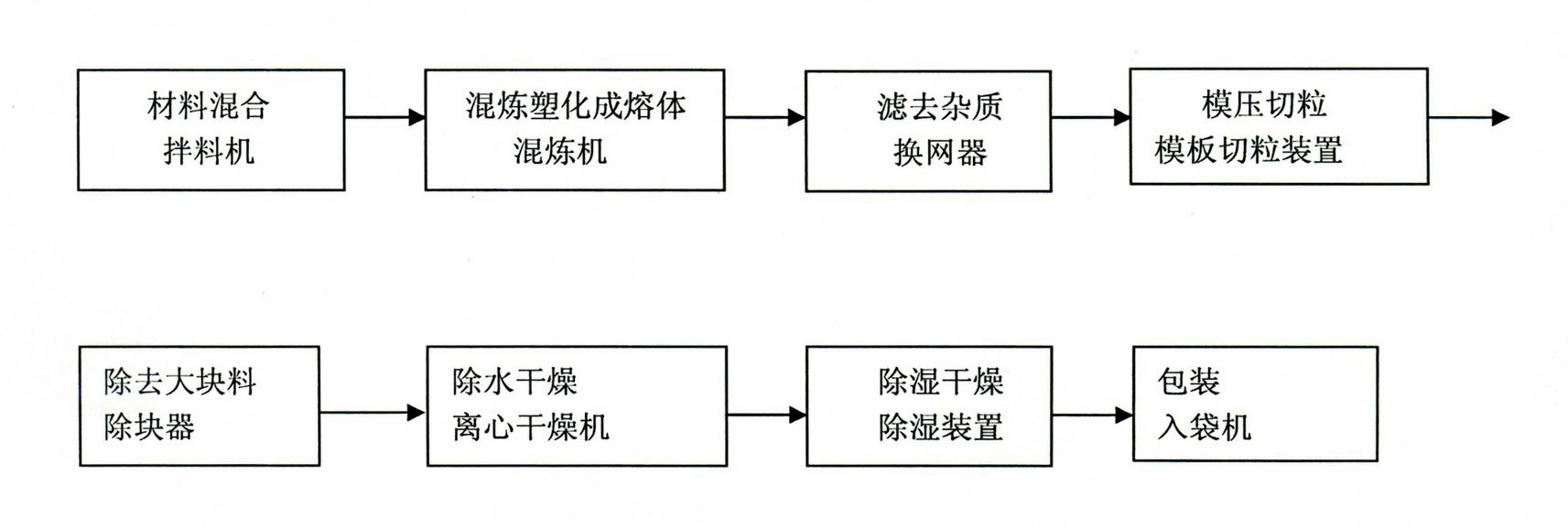

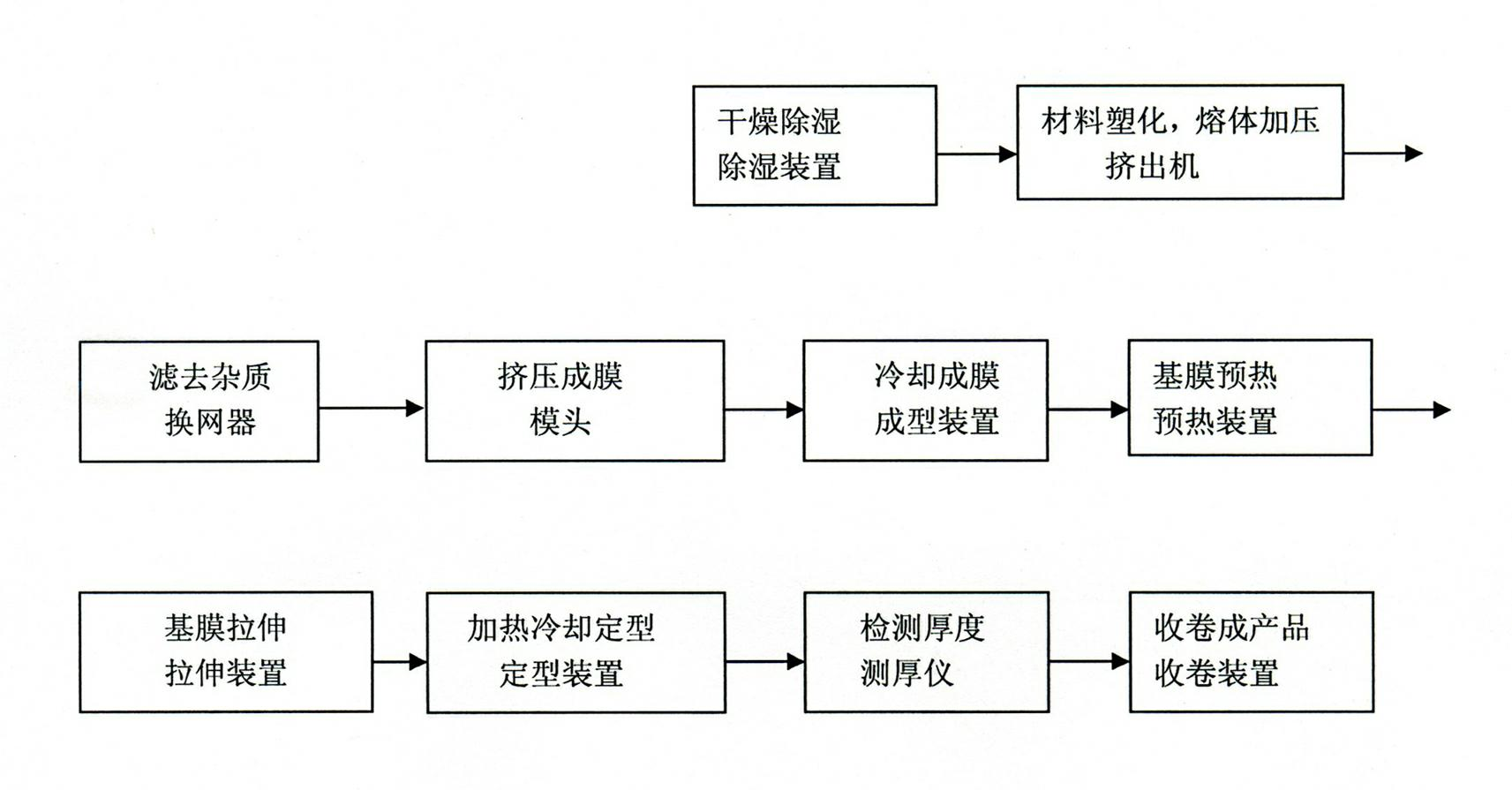

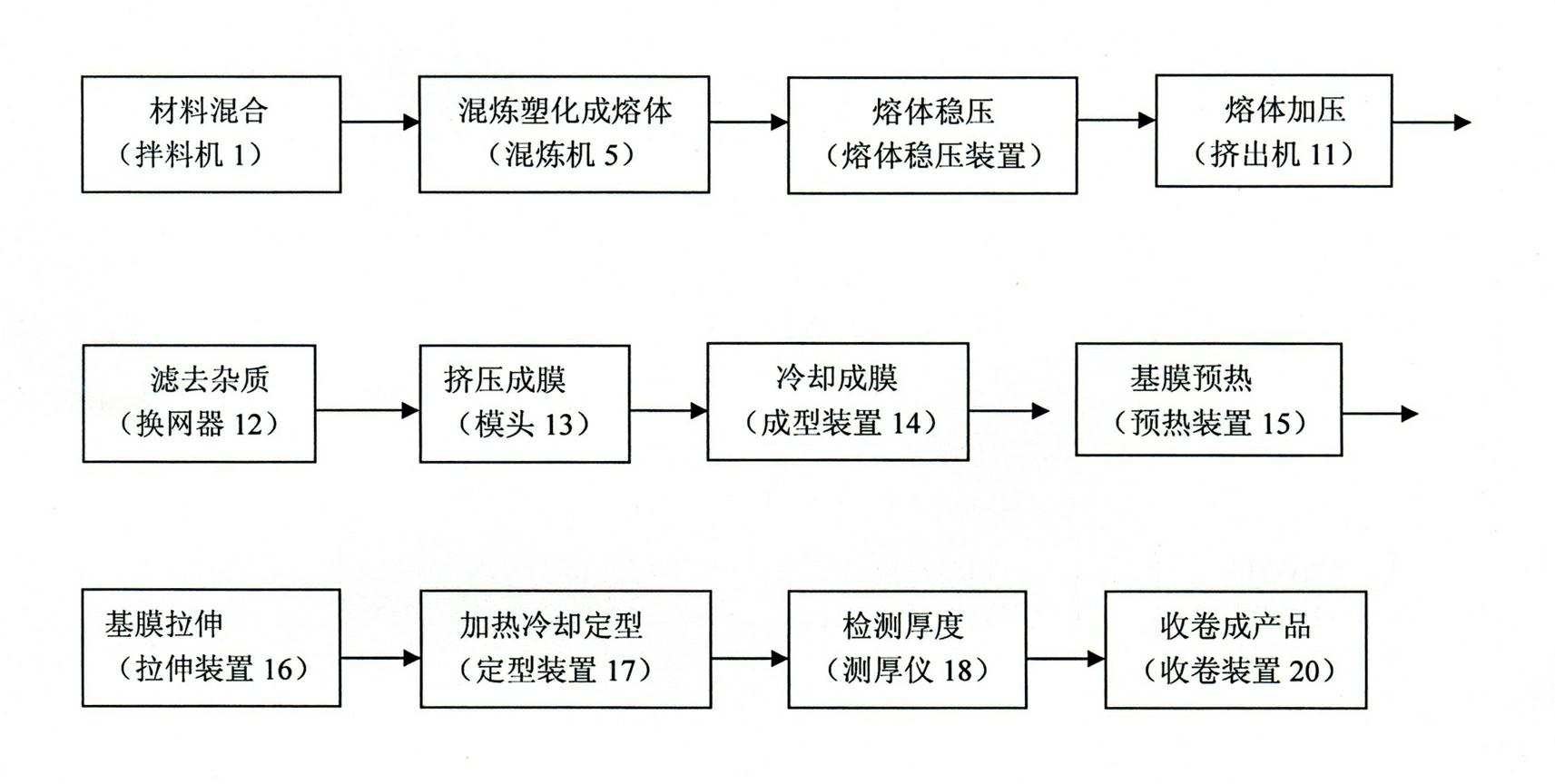

Continuous production process of polyethylene (PE) breathable film

ActiveCN102205655AEliminate the granulation processEliminate dehumidification processFlat articlesAlumino-thermic welding apparatusEngineeringContinuous production

The invention discloses a continuous production process of a polyethylene (PE) breathable film. By the continuous production process, granulation and dehumidification flows in the conventional production process of the PE breathable film are eliminated. The production of the PE breathable film from a raw material to a finished product is finished on a production line, so the production process provided by the invention has the advantages of energy conservation, high efficiency, low cost and high quality. The production process of the PE breathable film comprises the following steps of: mixingmaterials; mixing and plastifying to form a melt; pressurizing and stabilizing the melt; filtering out impurities; extruding to form a film; cooling to form the film; pre-heating a base film; stretching the base film; heating, cooling and setting; detecting thickness; and rolling to obtain the PE breathable film. An extruder which only has a feeding section and a metering section and a melt pressure-stabilizing device are arranged between an evacuation section of a mixing roll and a mould head on the production line, so the continuous production of the PE breathable film is realized.

Owner:吴国逵

Steel rail aluminothermy welding flux and welding method thereof

ActiveCN104625480AMeet the requirements of on-site construction and useRailsWelding/cutting media/materialsHardnessIron oxide

The invention provides steel rail aluminothermy welding flux which is used for a railway steel rail and is of a bainite structure and high in strength and a welding method of the steel rail aluminothermy welding flux. The steel rail aluminothermy welding flux comprises, by weight, 18.4% to 18.8% of aluminum powder, 67.0% to 67.6% of ferric oxide, 1.4% to 1.6% of Cr, 0.31% to 0.33% of Ni, 0.14% to 0.16% of Mo and the balance cast iron particles. By the adoption of the steel rail aluminothermy welding flux, a weld metal structure is bainite, the hardness of the welding flux can be matched with that of a bainite steel rail base metal, and meanwhile the requirements for field construction use can be completely met.

Owner:CHINA RAILWAYS CORPORATION +2

Thermit iron welding flux special for welding steel grounding materials and welding method thereof

ActiveCN102862005AOperational securityEasy to carryWelding/cutting media/materialsSoldering mediaExternal energyAlloy

The invention discloses a thermit iron welding flux special for welding steel grounding materials. The thermit iron welding flux is prepared by aluminum powder, iron oxide powder and alloy additives through even mixing. The thermit iron welding flux and a welding method thereof have the advantages that the operation is safe, professional technical knowledge and special protection are not needed, and the welding method is simple and easy to learn; external energy resources are not needed, tools are convenient to carry, and the construction efficiency is high; and unification of parent metal and welded joint materials can be achieved, and the problem of fracture of a joint caused by electrochemical corrosion and the fact that thermal stress is easy to produce in a welding process and when impulse currents are born due to differences in melting point, coefficient of linear expansion, thermal conductivity and specific heat capacity between the parent metal and the welded joint is solved.

Owner:SICHUAN SUNLIGHT INTELLIGENT ELECTRIC EQUIP CO LTD

In-situ power-cut-free welding method for soft mother belts and aluminum bus of cathode of aluminum electrolysis cell

ActiveCN104972220ASolve technical problemsAvoid the defect that exothermic welding cannot be used directlyWelding/cutting media/materialsSoldering mediaExothermic weldingEconomic benefits

The invention relates to the electrolytic aluminum industry, in particular to an in-situ power-cut-free welding method for soft mother belts and an aluminum bus of the cathode of an aluminum electrolysis cell. The method comprises the following steps of 1 in-situ grinding, 2 in-situ fixing, 3 in-situ fusion, 4 pre-welding treatment, 5 preheating, 6 exothermic welding and 7 post-welding treatment. By means of the method, in-situ connection between the soft mother belts and the aluminum bus is directly completed through exothermic welding, the defect that the soft mother belts of a sheet type structure cannot be directly welded in a magnetic field is overcome, the economic benefits of an aluminum electrolysis enterprise are increased, and repairing of the soft mother belts for the aluminum electrolysis enterprise is realized. The operation can be completed under the condition that serial aluminum electrolysis cells are powered all the time, and the repairing purpose can be achieved on the promise of not affecting production of the serial aluminum electrolysis cells. The method is suitable for welding of the soft mother belts and the aluminum bus in various cell types, and is good in universality, easy to operate and high in welding repair efficiency.

Owner:WUHAN UNIV

Balanced high-heat type aluminum hot-welding agent

InactiveCN102152026AAchieve redistributionUniform heat generationWelding/cutting media/materialsSoldering mediaElectricityAl powder

The invention discloses a balanced high-heat type aluminum hot-welding agent. MgO is added into components and is reduced into elementary substance Mg under high temperature and heat is absorbed; and then Mg is oxidized into MgO under low temperature and the heat is released. Through this process, the redistribution of the heat during thermit reaction is realized and the purpose of uniform heat production is reached. The balanced high-heat type aluminum hot-welding agent comprises the components by weight portions as follows: 80-85 percent of CuO powder, 6-12 percent of Al powder, 6-9 percent of MgO, 0-1 percent of CaF2, and 0-1 percent of SiO2. The balanced high-heat type aluminum hot-welding agent has the characteristics of high heat, balance, and safety. The heating volume of the balanced high-heat type aluminum hot-welding agent is not sensitive to component parameters, thus being convenient for scale batch production, and being capable of being broadly used for quickly and reliably connecting metal structures or connection under outdoor power-less conditions.

Owner:RAINBOWALLY CHENGDU LIGHTNING PROTECTIVE TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com