Steel rail aluminothermy welding flux and welding method thereof

An aluminothermic flux and rail technology, applied in aluminothermic welding equipment, rails, welding media, etc., can solve problems such as hardness matching of weld metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Effect contrast of the thermite flux of the present invention and traditional flux

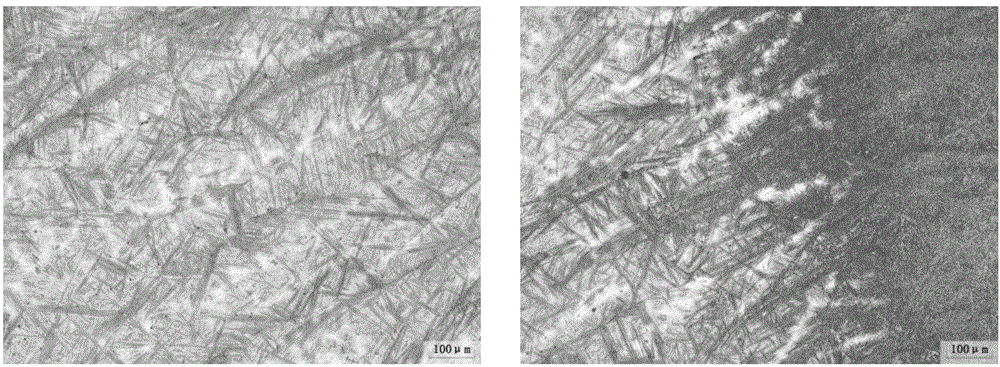

[0036] In percent by weight, aluminum powder 18.6%, iron oxide 67.3%, Cr 1.5%, Ni0.32%, Mo 0.15%, and the balance are cast iron grains, uniformly mixed to obtain the thermite flux of the present invention; The thermite flux is welded according to the welding method of the present invention, and the obtained weld metal structure is bainite structure, as shown in the attached Figure 4 As shown, the weld metal of this organization has good comprehensive properties of strength and toughness;

[0037] Using traditional flux, its composition is: aluminum powder, iron oxide, cast iron particles and a small amount of iron alloy are evenly mixed, and welded according to the welding method of the present invention, the weld metal structure obtained is pearlite structure, its strength and hardness Limited and cannot match high-strength steel rails. Although the strength of the joint metal can b...

Embodiment 2

[0039] Performance comparison of the weld metal obtained by the thermite flux of the present invention

[0040] By weight percent, aluminum powder 18.6%, iron oxide 67.3%, Cr 1.5%, Ni0.32%, Mo 0.15%, and the balance are cast iron grains, uniformly mixed to obtain the thermite flux of the present invention, and the present invention The above-mentioned thermite flux is welded according to the welding method of the present invention, and the weld metal obtained is according to Figure 6 The way of processing, testing its performance, test results are shown in Table 2;

[0041] Evenly mix aluminum powder, iron oxide, cast iron particles and a small amount of iron alloy to obtain traditional flux, which is welded according to the welding method described in the present invention, and the obtained weld metal is obtained according to Figure 6 The way of processing, testing its performance, test results are shown in Table 2;

[0042] The tensile strength contrast of the weld metal...

Embodiment 3

[0048] Screening test of the content ratio of each component in the thermite flux of the present invention

[0049] Groups 1 to 3 are the composition ratios of the thermite fluxes of the present invention, and groups 4 to 6 are comparative examples.

[0050] Table 3 The performance comparison of the weld metal obtained by the content ratio of each component of the thermite flux according to the present invention

[0051]

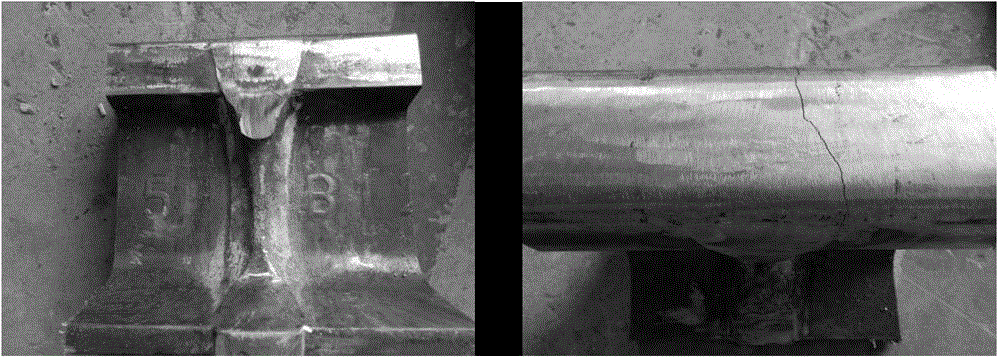

[0052] Table 3 shows that Groups 1 to 3 are the composition ratios of the thermite flux described in the present invention, and the weld metal structure obtained by it is a bainite structure, as shown in the attached Figure 4 As shown, the weld metal with this organizational structure has good comprehensive properties of strength and toughness; the aluminothermic flux adopts the composition ratio shown in group 4, and the weld metal obtained by it will cause cracks due to the abnormal chemical composition of the weld, as shown in attached figure 1 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com