Corrosion-resistant aluminothermic welding flux suitable for U68CuCr steel rail and welding method thereof

An aluminothermic flux and corrosion-resistant technology, which is applied in the direction of aluminothermic welding equipment, welding equipment, welding media, etc., can solve the problems of deepening welding head corrosion, endangering driving safety, and poor corrosion resistance, so as to prolong service life and improve Corrosion resistance, the effect of simple welding operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

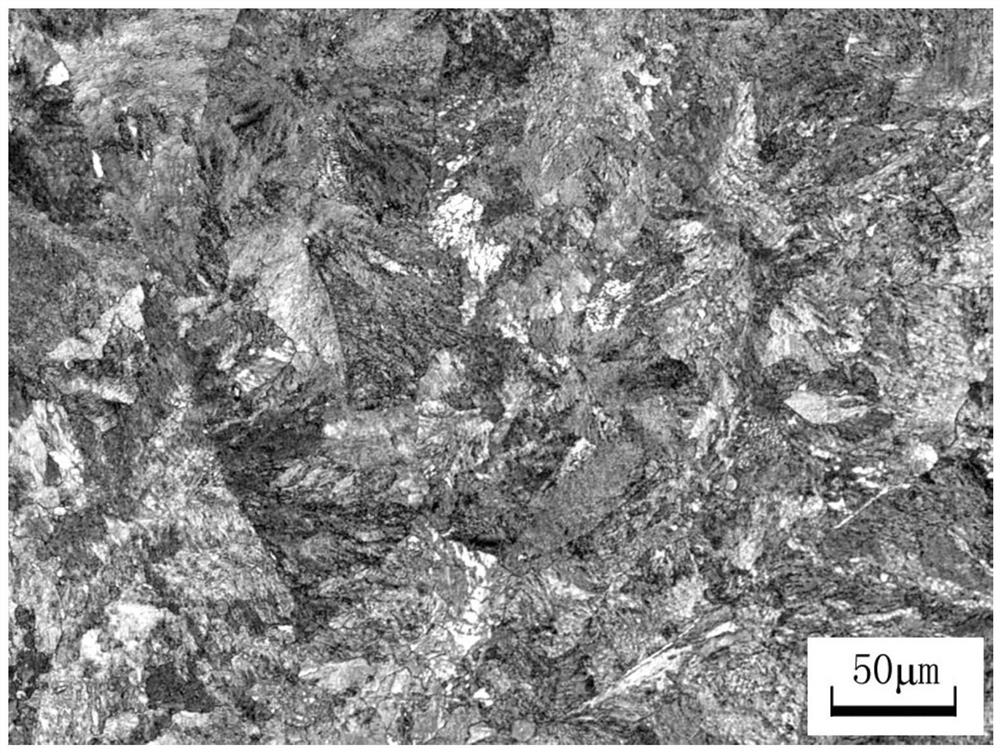

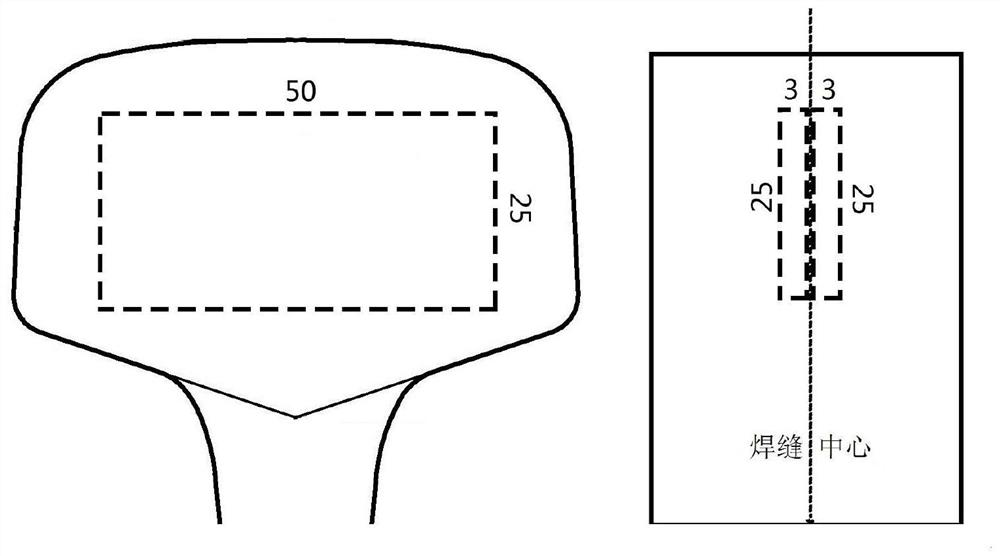

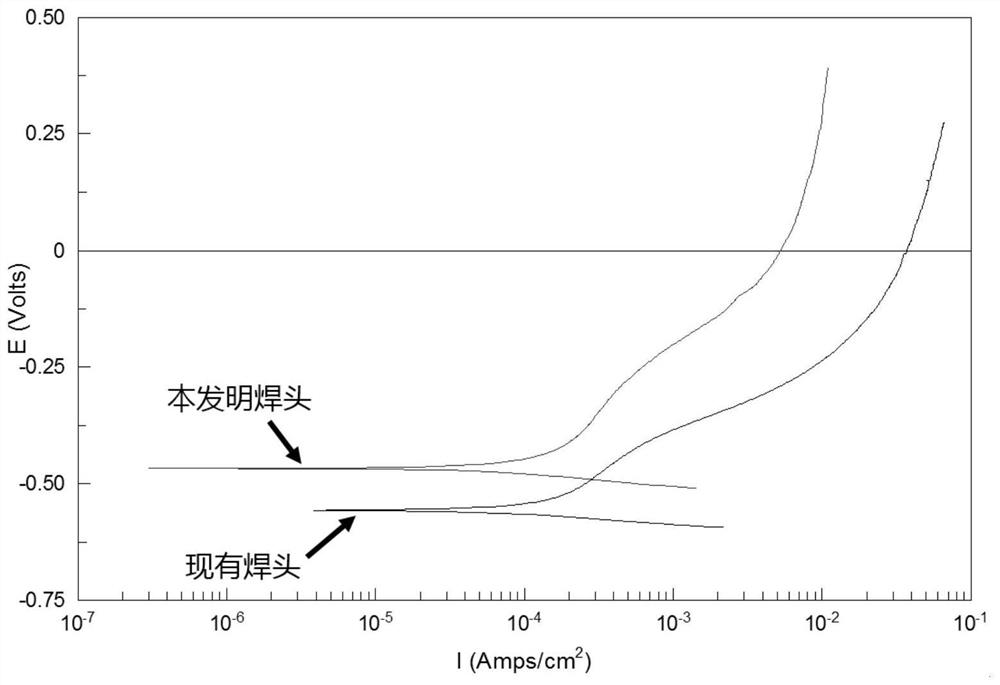

Embodiment 1

[0029] A kind of anti-corrosion thermite flux, the formula is as follows in dry state according to weight percentage: aluminum powder 17.4%, iron oxide 63.3%, cast iron grain 9.6%, Mn 0.62%, Cu 0.21%, Cr 0.25%, Nb 0.13% , Iron scraps 8.49%. Among them, the particle size of aluminum powder is 40-60 mesh, the particle size of iron oxide is 18-60 mesh, the particle size of cast iron shot is 10-30 mesh, the particle size of Mn is 10-80 mesh, the particle size of Cu is 10-80 mesh, and the particle size of Cr is 10-80 mesh. The particle size of Nb is 10-80 mesh, and the particle size of Nb is 10-80 mesh. The above raw materials are uniformly mixed at room temperature according to the stoichiometric ratio, and then sealed and stored.

[0030] In addition, an existing conventional thermite flux has been prepared, and the formula in dry state is as follows: 17% of aluminum powder, 65% of iron oxide, 9% of cast iron particles, 0.4% of Si, 0.8% of Mn, iron shavings 7.8%. The powder ra...

Embodiment 2

[0046] A kind of anti-corrosion thermite flux, the formula is as follows in dry state according to weight percentage: aluminum powder 17.2%, iron oxide 63.1%, cast iron shot 9.2%, Mn 0.55%, Cu 0.16%, Cr 0.22%, Nb 0.11% , Iron scraps 9.46%. The above raw materials are uniformly mixed at room temperature according to the stoichiometric ratio, and then sealed and stored. The selected powder raw materials all meet the particle size requirements.

[0047] With reference to the method of Example 1, two sections of U68CuCr steel rails were welded with the above-mentioned corrosion-resistant thermite flux, and the joints were sampled for corrosion resistance. The results showed that its corrosion resistance and other properties were similar to those of Example 1 samples. See Table 4-6.

[0048] Table 4 Different corrosion sheets Experimental results comparison table

[0049]

[0050] Table 5 Comparison table of electrochemical experiment results in different weld center region...

Embodiment 3

[0055] A kind of anti-corrosion thermite flux, the formula in dry state is as follows according to the weight percentage: aluminum powder 17.5%, iron oxide 63.6%, cast iron grain 9.6%, Mn 0.65%, Cu 0.24%, Cr 0.28%, Nb 0.15% , Iron scraps 7.98%. The above raw materials are uniformly mixed at room temperature according to the stoichiometric ratio, and then sealed and stored. The selected powder raw materials all meet the particle size requirements.

[0056] With reference to the method of Example 1, two sections of U68CuCr rails were welded with the above-mentioned corrosion-resistant thermite flux, and the joints were sampled for corrosion resistance. The results showed that its corrosion resistance and other properties were similar to those of Examples 1 and 2. The experimental results are shown in Table 7-9.

[0057] Table 7 Different corrosion sheets Experimental results comparison table

[0058]

[0059] Table 8 Comparison table of electrochemical experiment results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com