Patents

Literature

1374 results about "Heat flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat flux or thermal flux, sometimes also referred to as heat flux density, heat-flow density or heat flow rate intensity is a flow of energy per unit of area per unit of time. In SI its units are watts per square metre (W⋅m⁻²). It has both a direction and a magnitude, and so it is a vector quantity. To define the heat flux at a certain point in space, one takes the limiting case where the size of the surface becomes infinitesimally small.

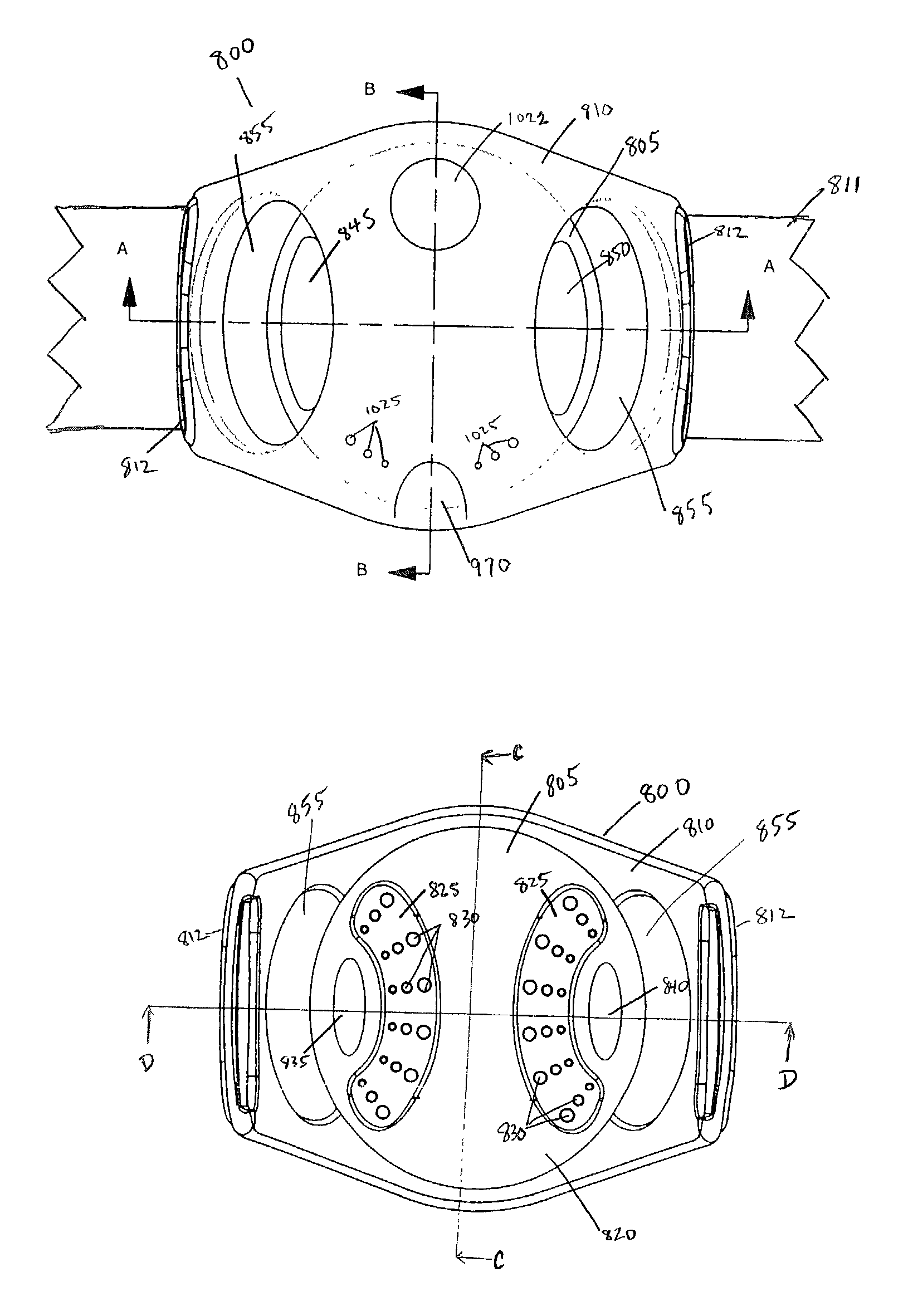

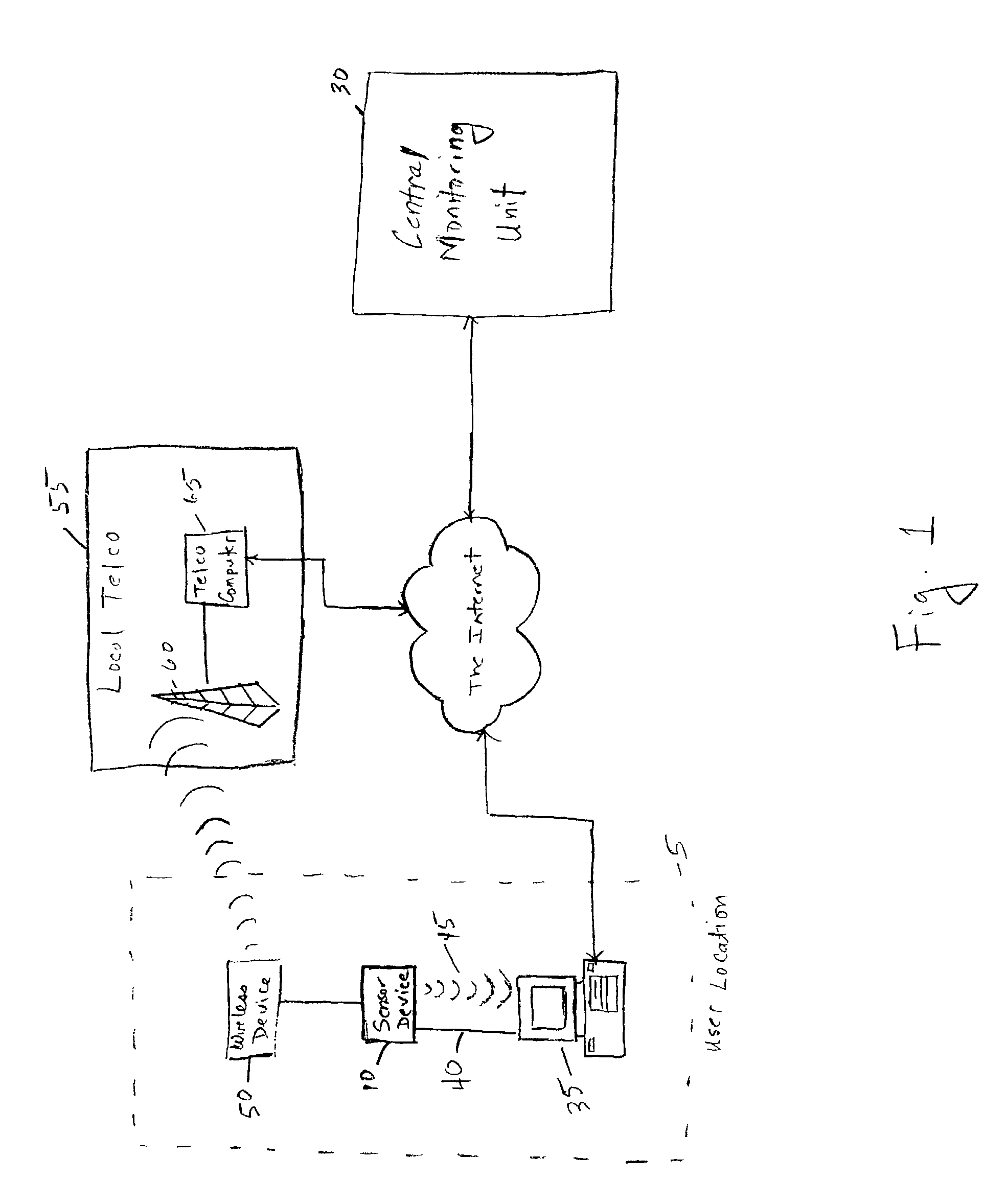

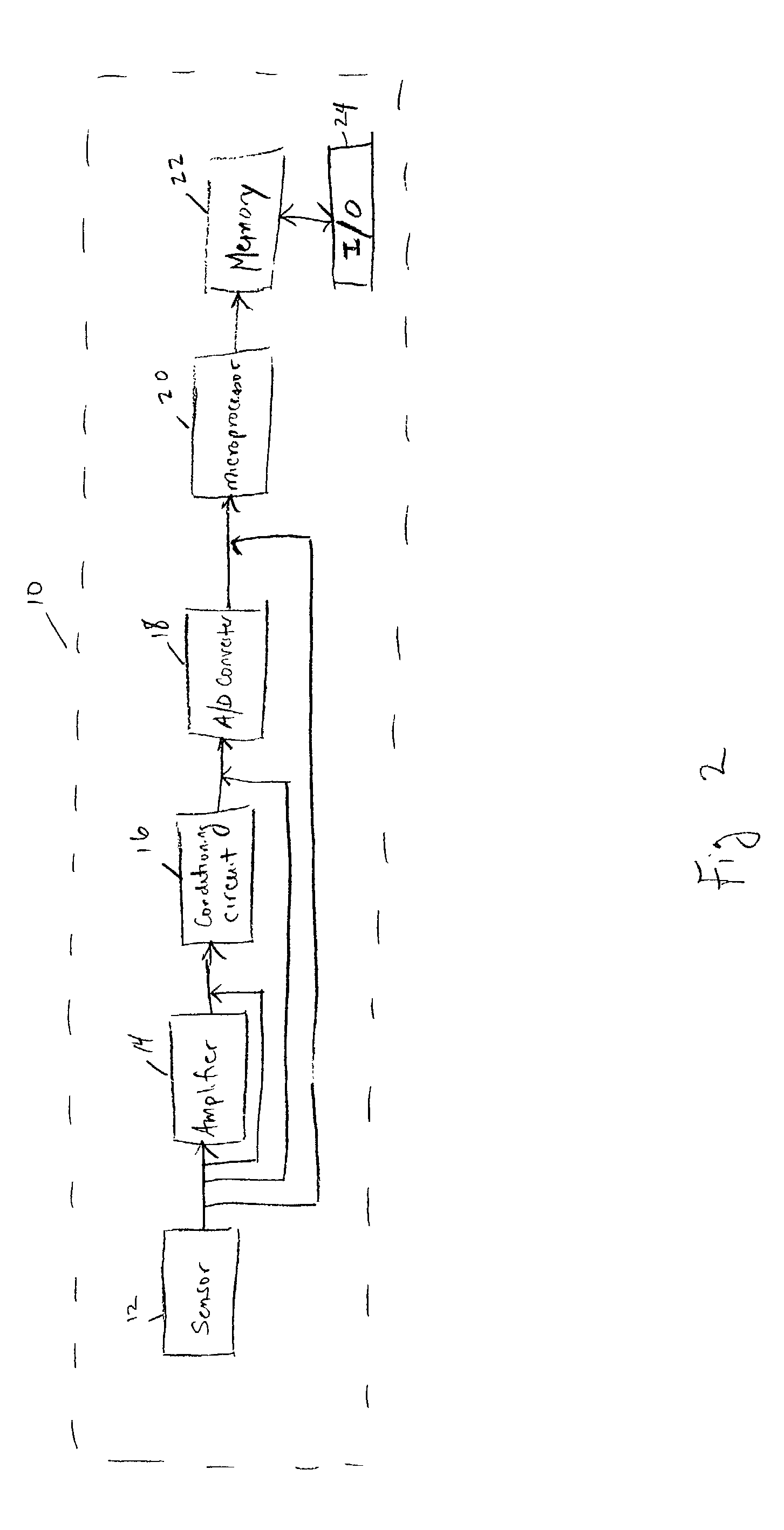

Apparatus for detecting human physiological and contextual information

InactiveUS7020508B2Promote generationWidth dimensionElectrocardiographyDiagnostics using lightThermal energyHeat flux

A detecting apparatus includes a housing support section(s), a housing removably attached thereto, one or more sensors and a processor. An alternate apparatus measures heat flux and includes a known resistivity base member, a processing unit and two temperature measuring devices, one in thermal communication with the body through a thermal energy communicator and the other in thermal communication with the ambient environment. A further alternate apparatus includes a housing or flexible section having an adhesive material on a surface thereof for removably attaching the apparatus to the body. A further alternate apparatus includes a housing having an inner surface having a concave shape in a first direction and convex shape in a second direction substantially perpendicular thereto. Also, an apparatus for detecting heart related parameters includes one or more filtering sensors for generating filtering signals related to the non-heart related motion of the body.

Owner:J FITNESS LLC

Radiation shield

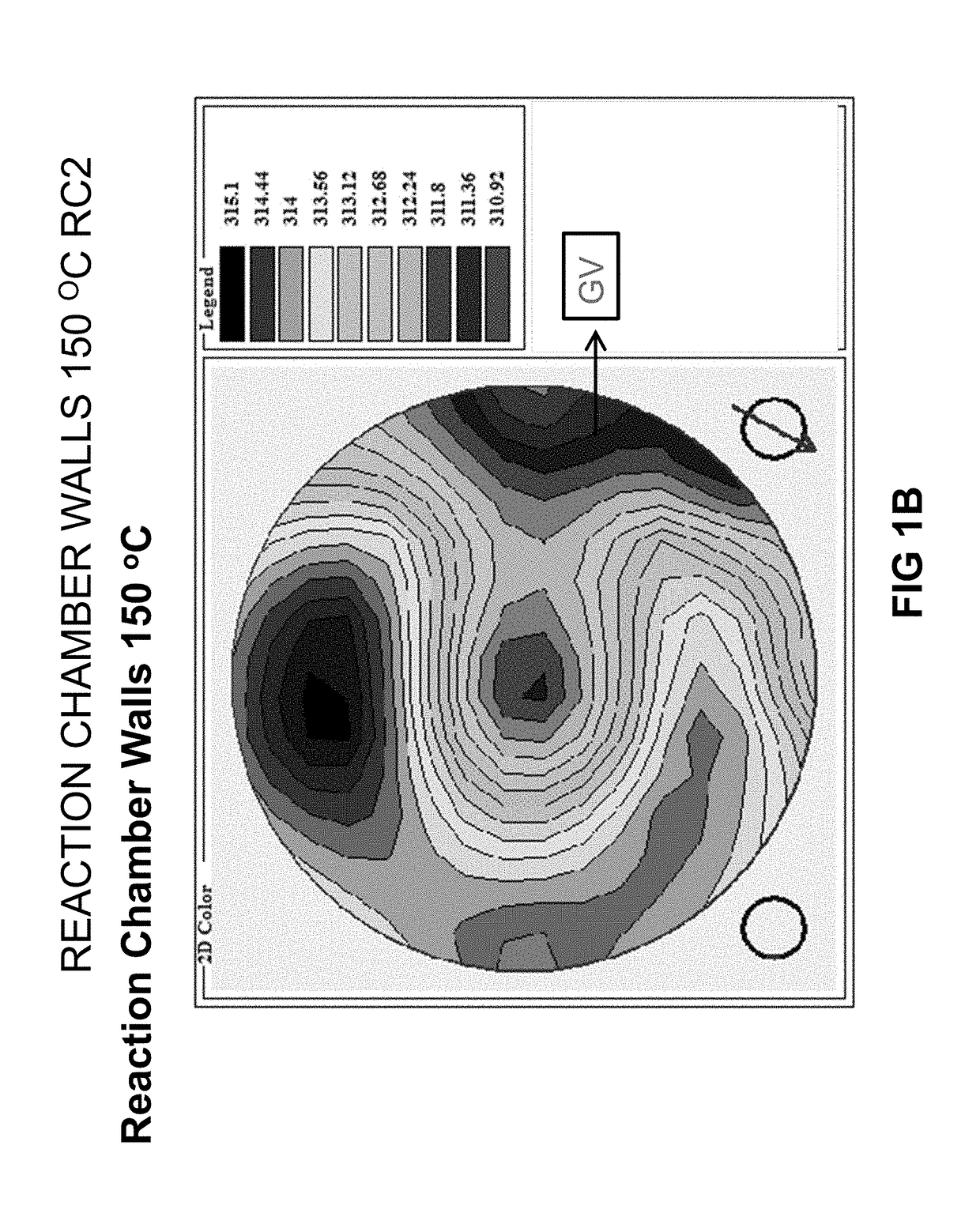

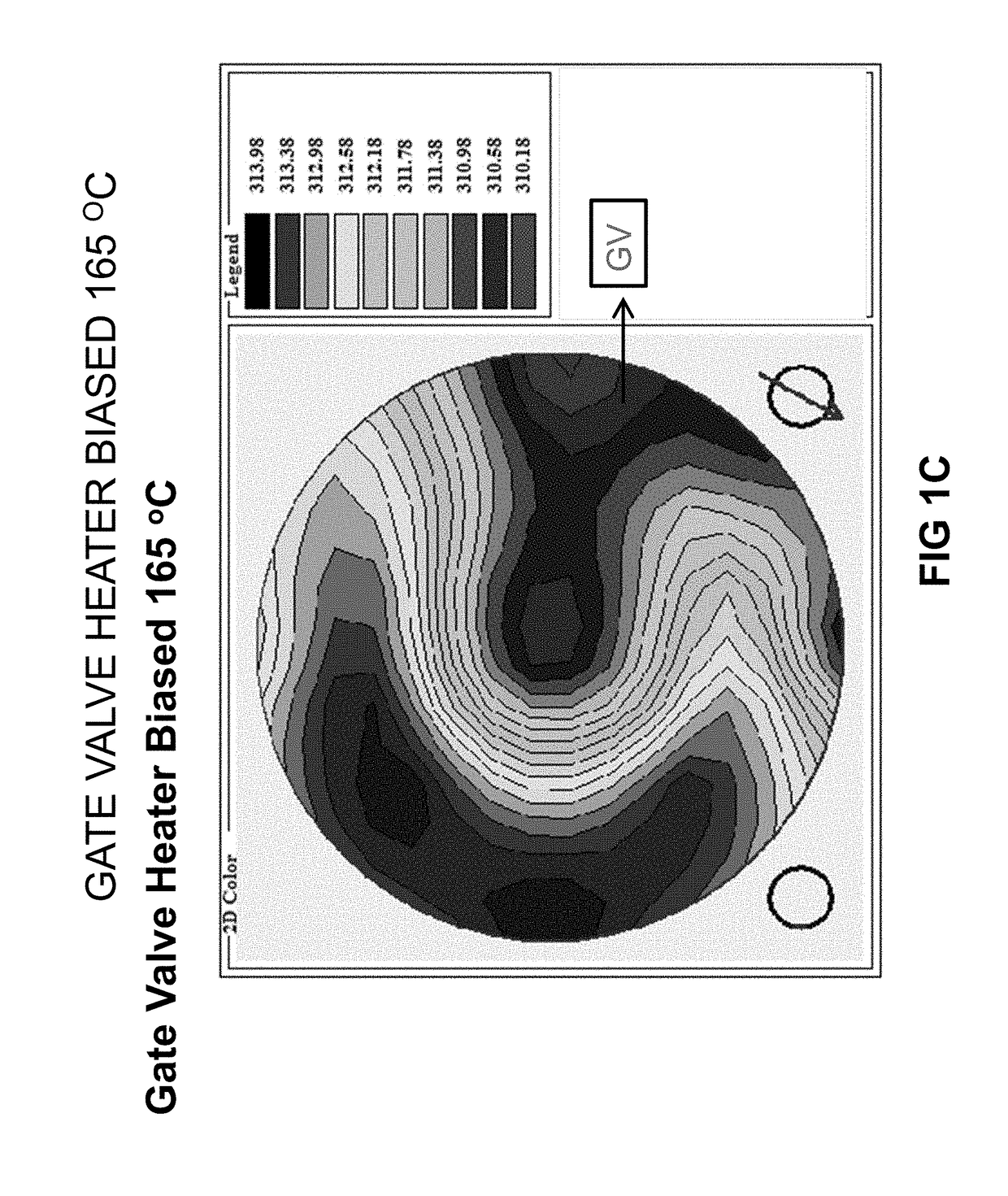

ActiveUS20190051544A1Reduce heat fluxQuality improvementGaseous chemical processesElectric discharge tubesSusceptorHeat flux

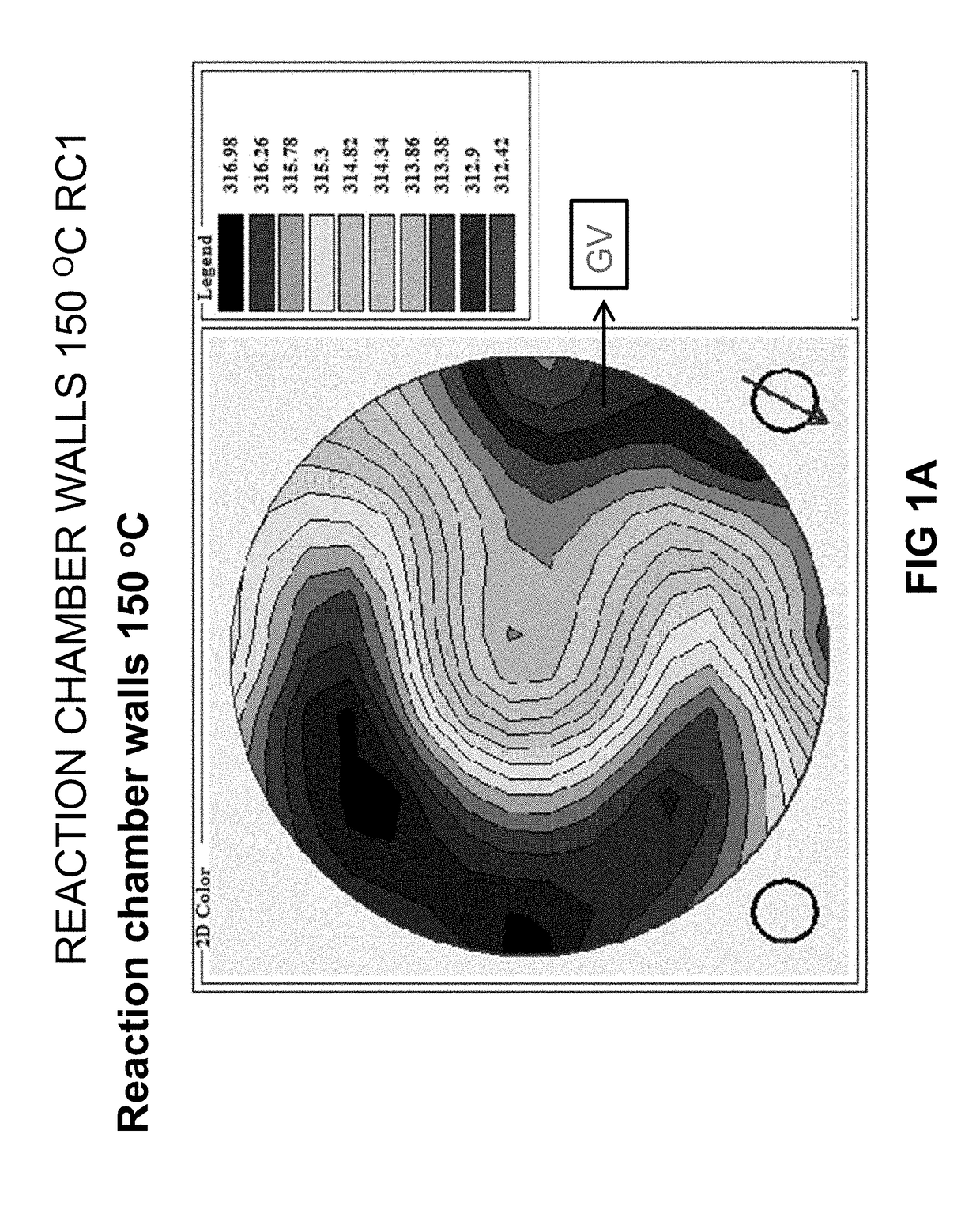

A radiation shield and an assembly and a reactor including the radiation shield are disclosed. The radiation shield can be used to control heat flux from a susceptor heater assembly and thereby enable better control of temperatures across a surface of a substrate placed on a surface of the susceptor heater assembly.

Owner:ASM IP HLDG BV

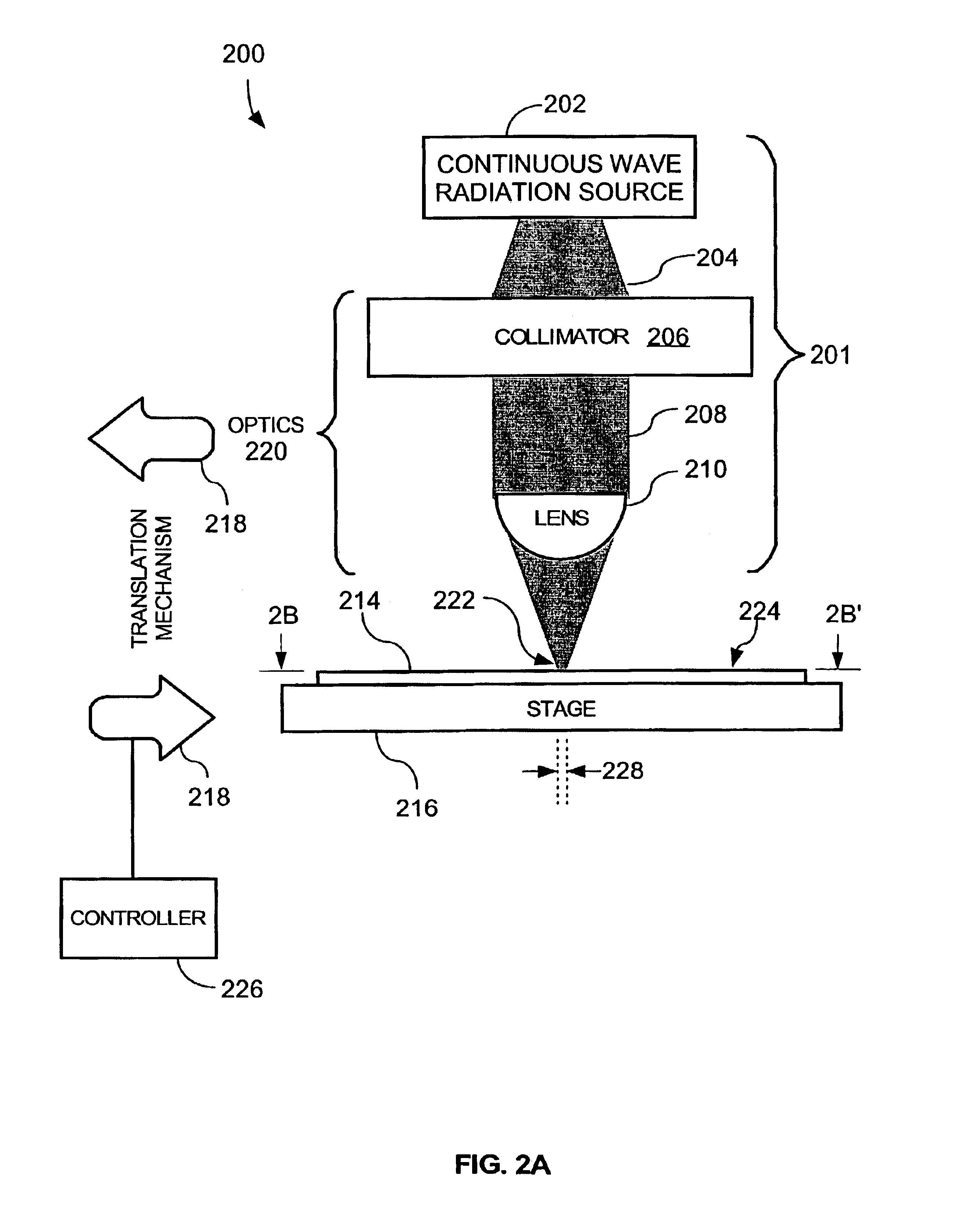

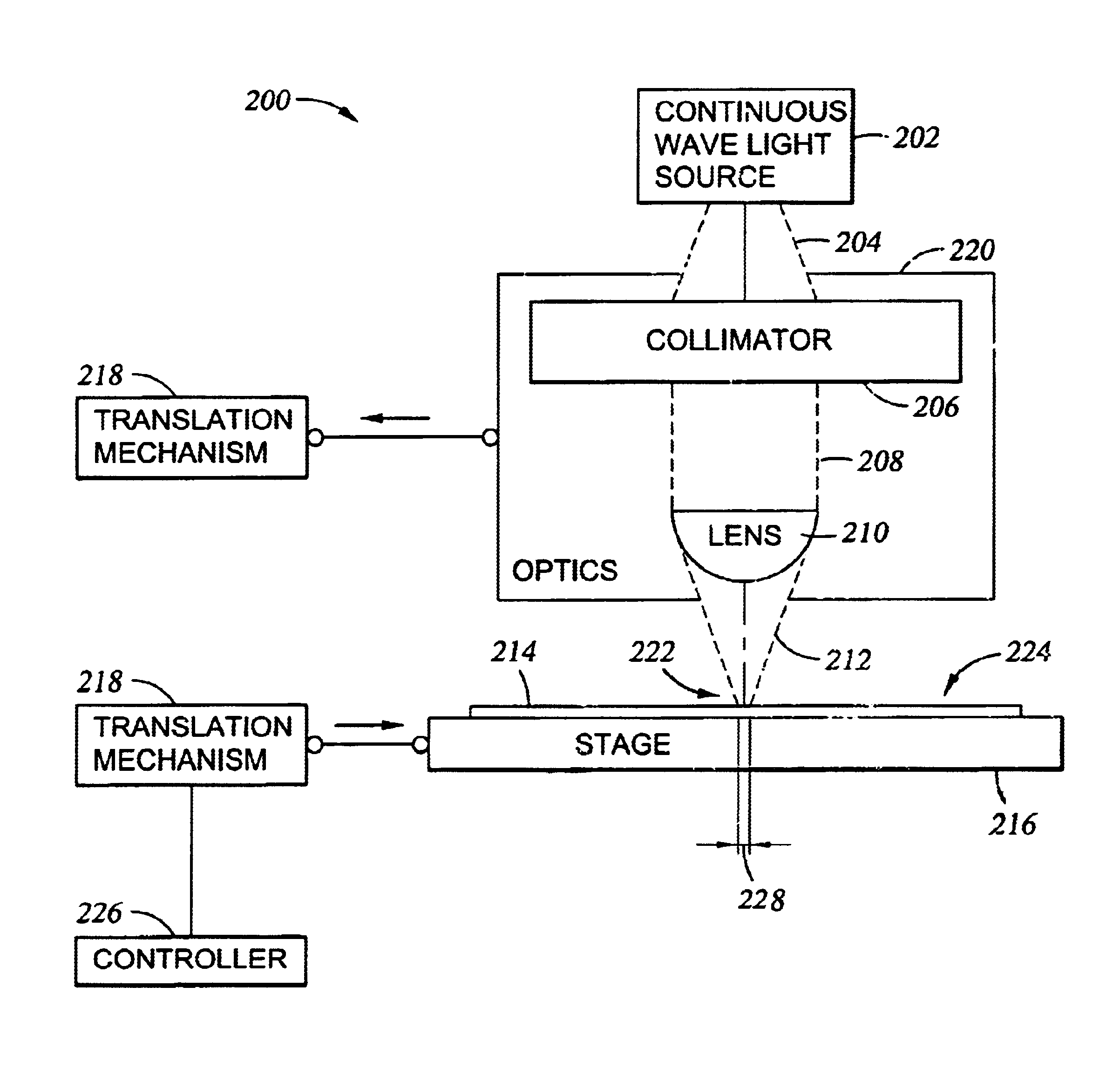

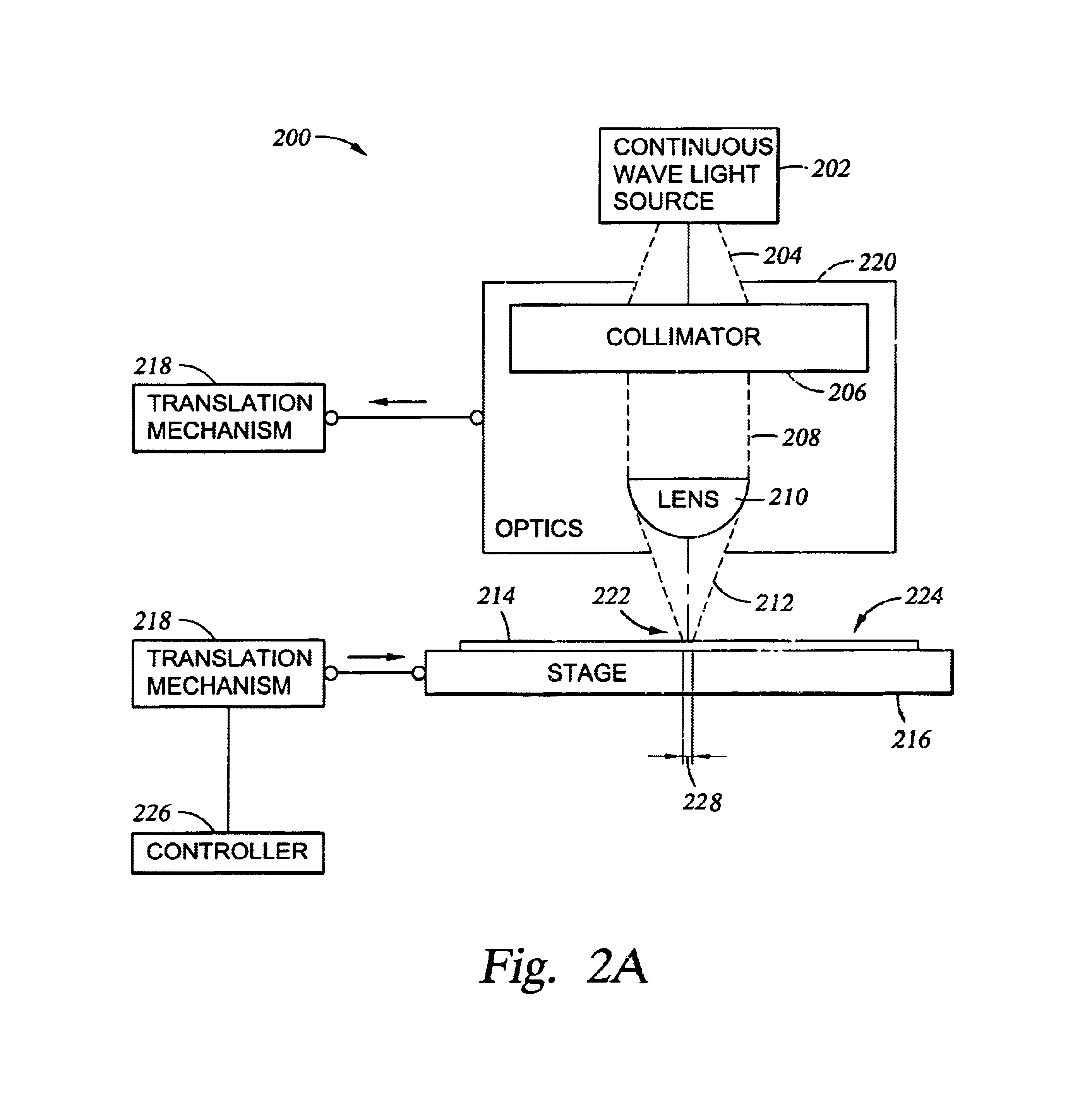

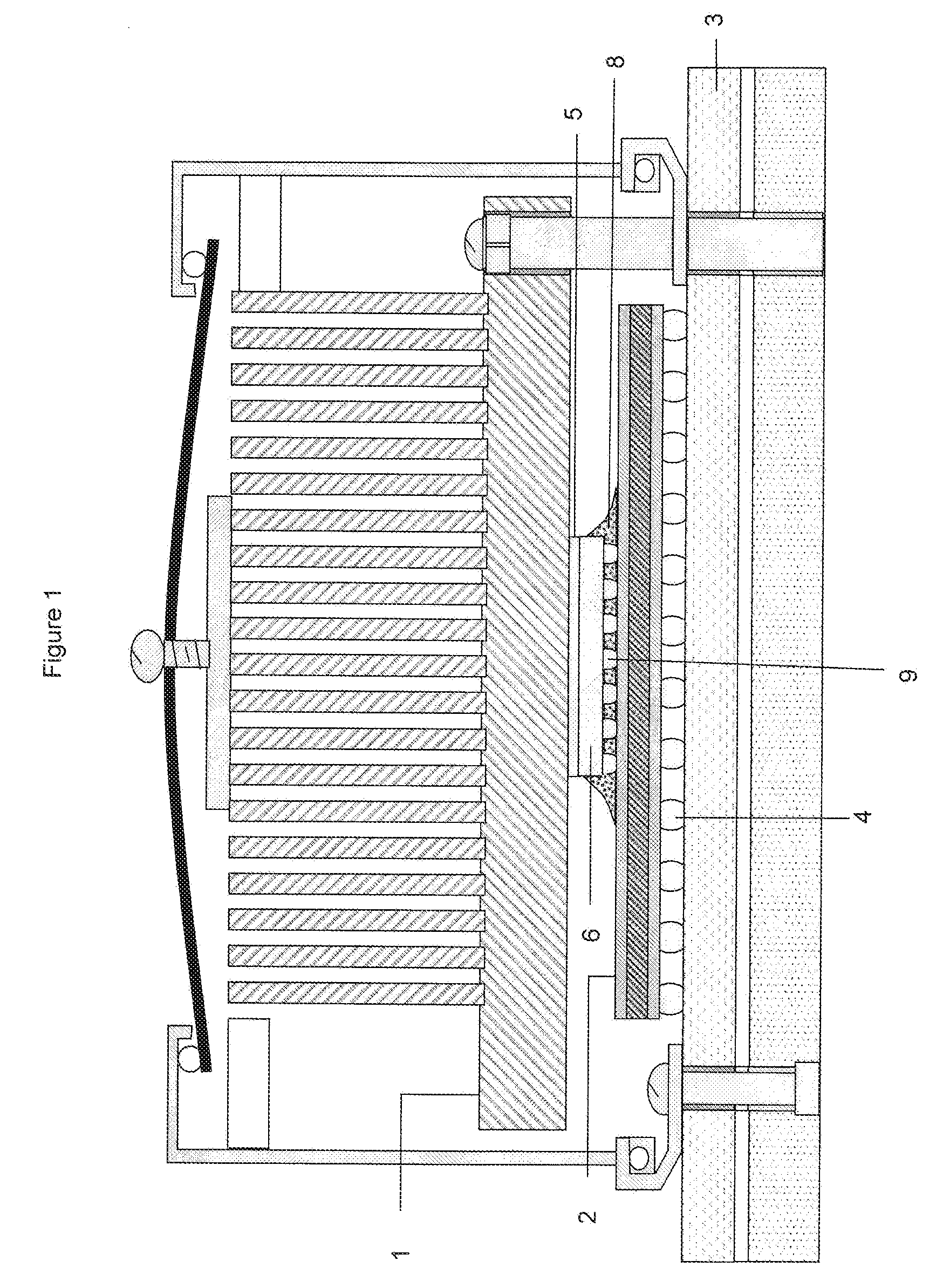

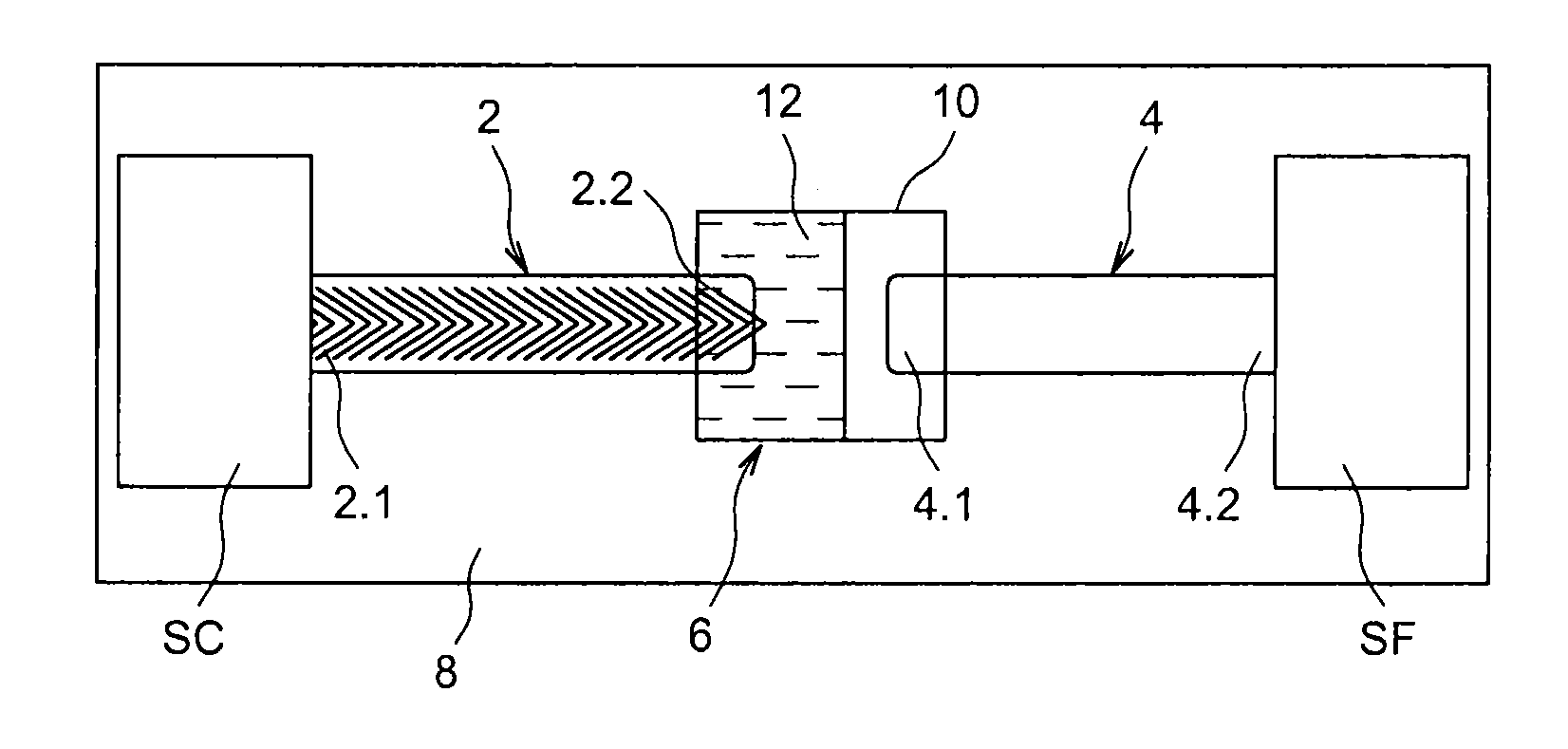

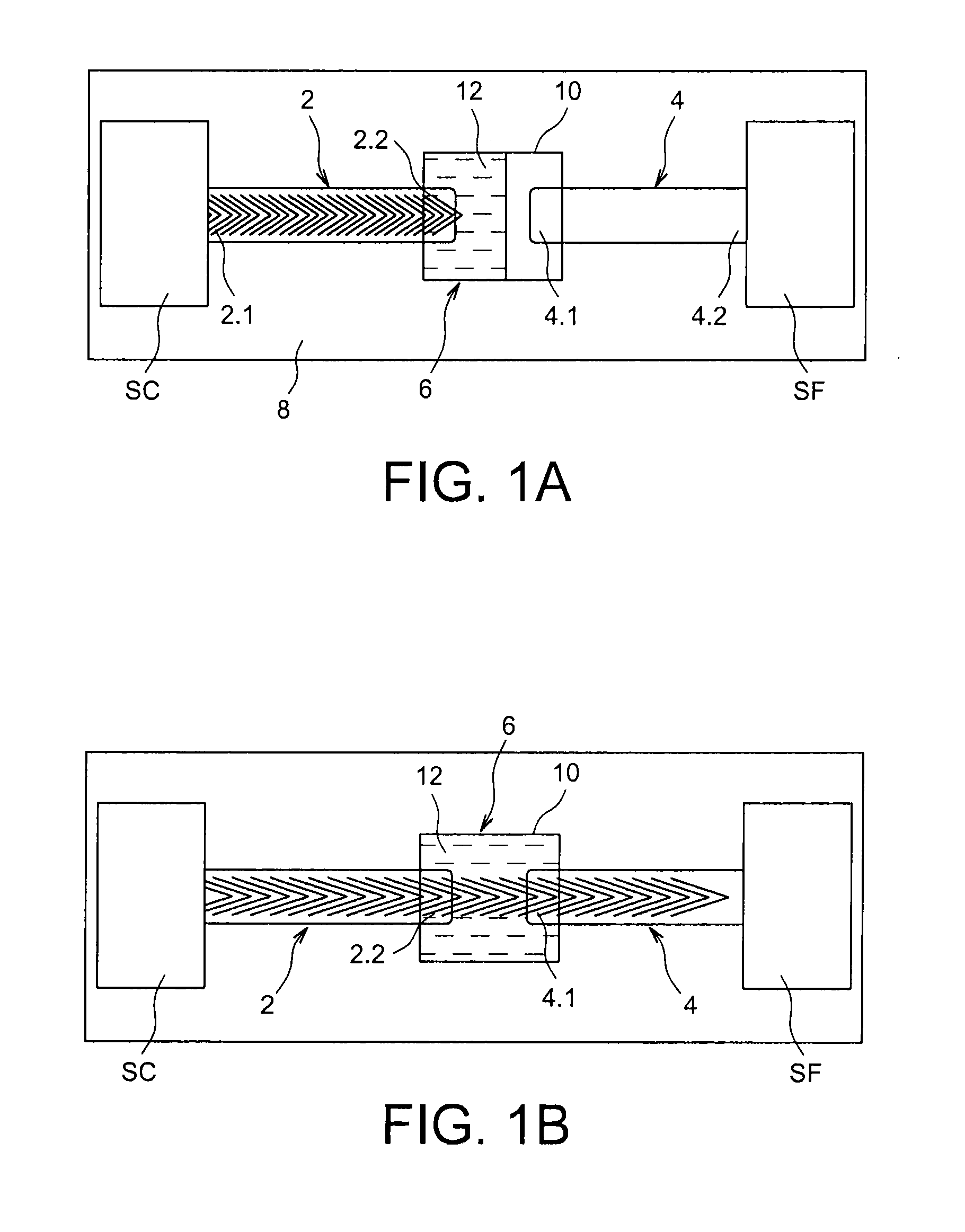

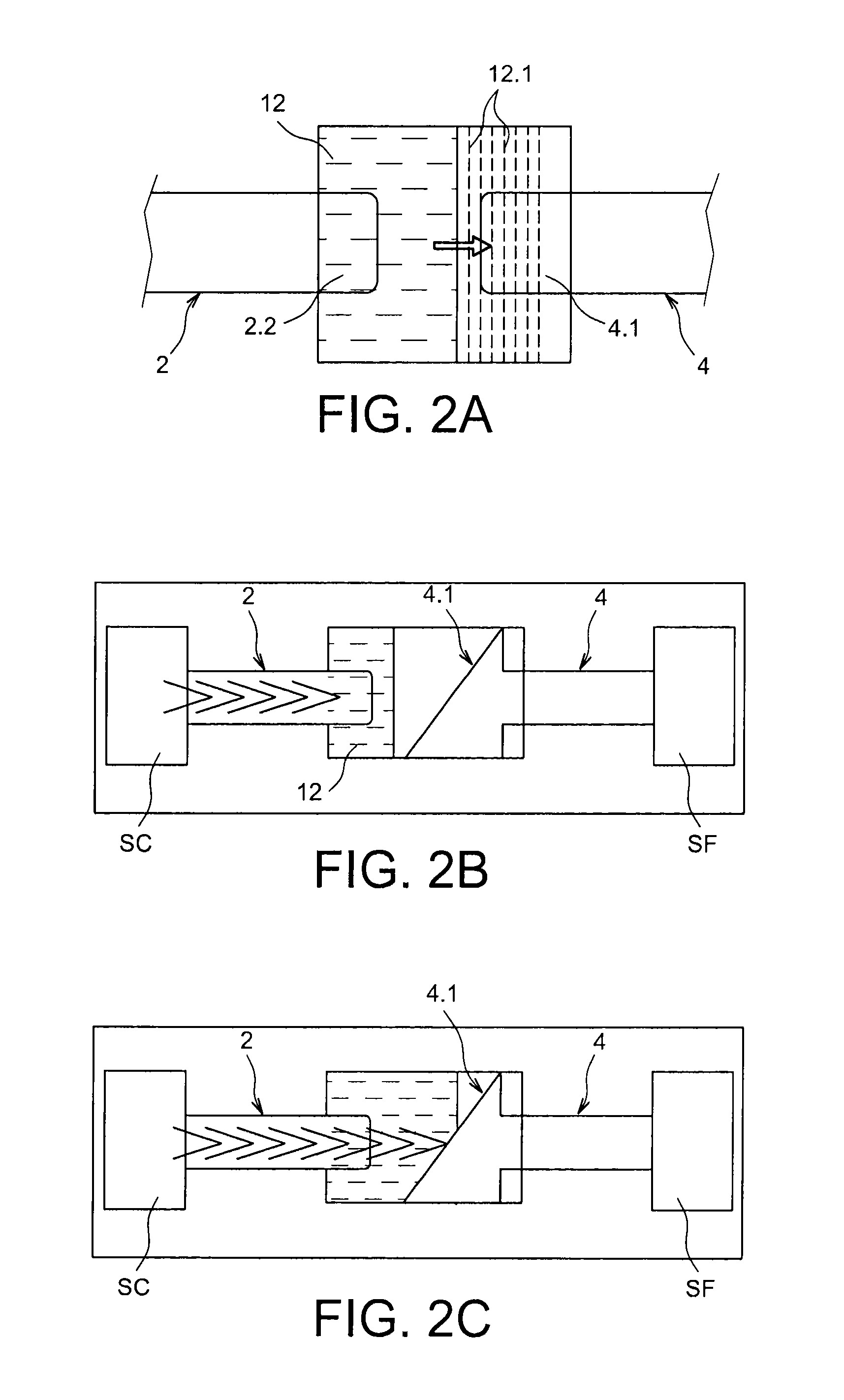

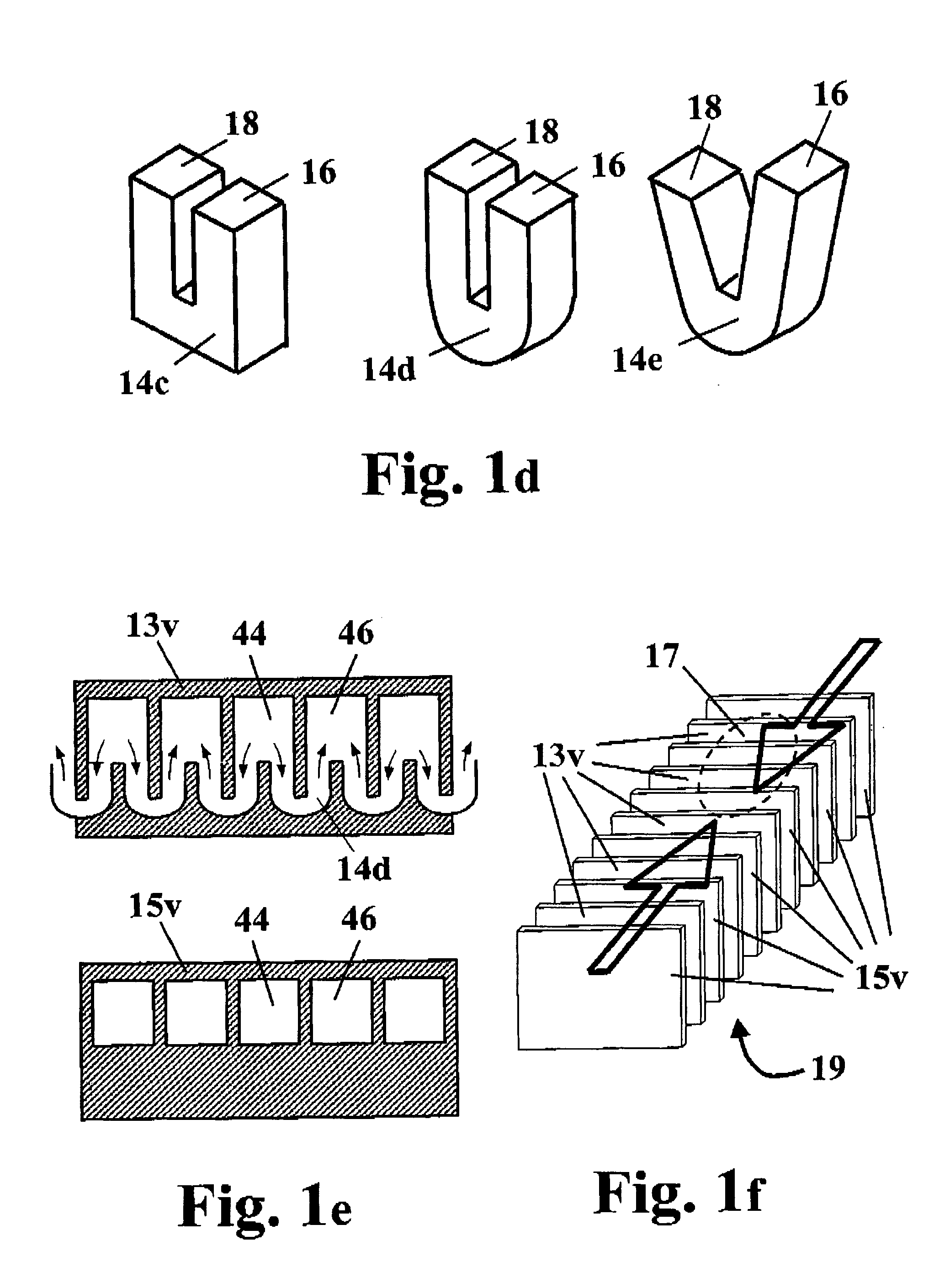

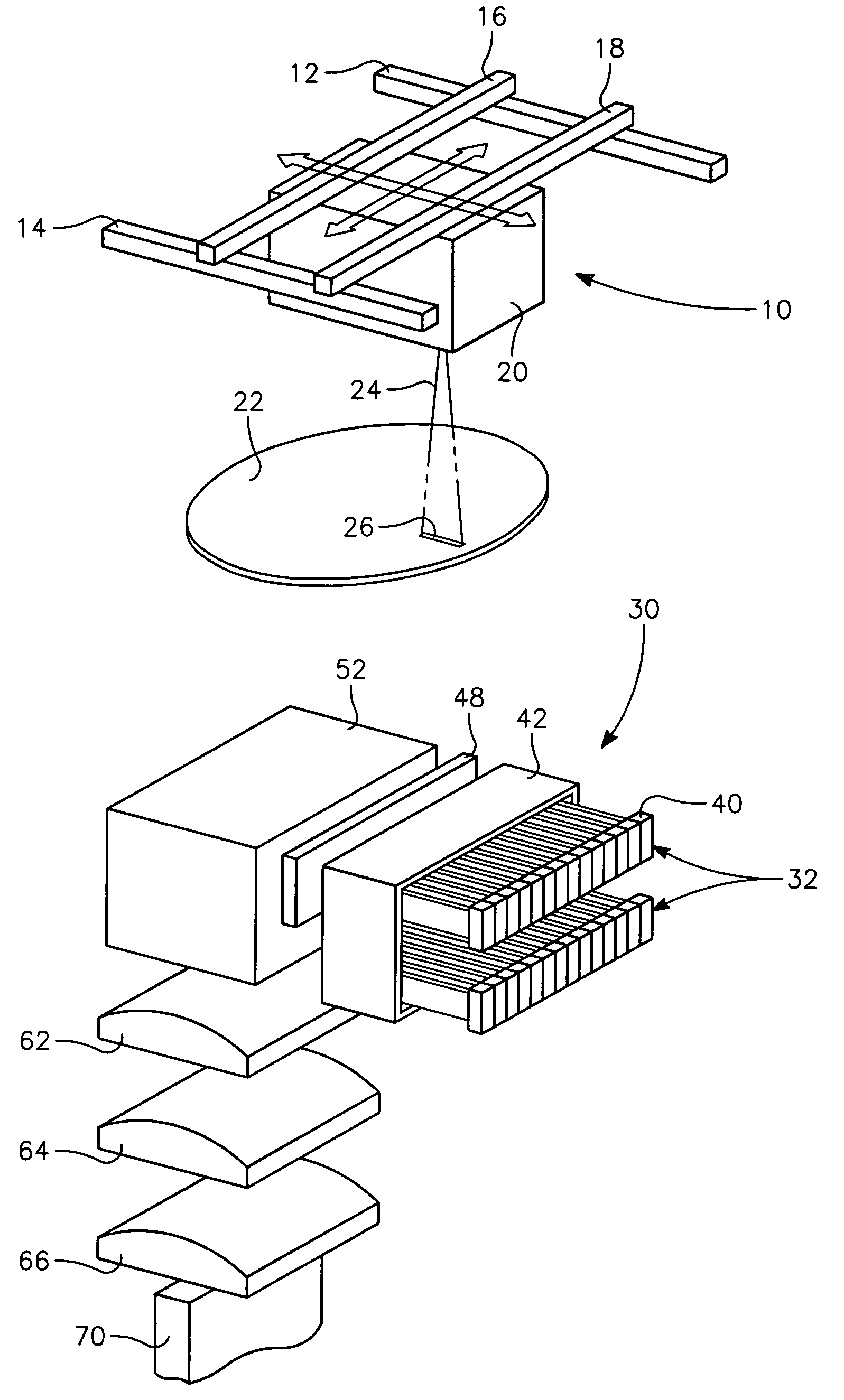

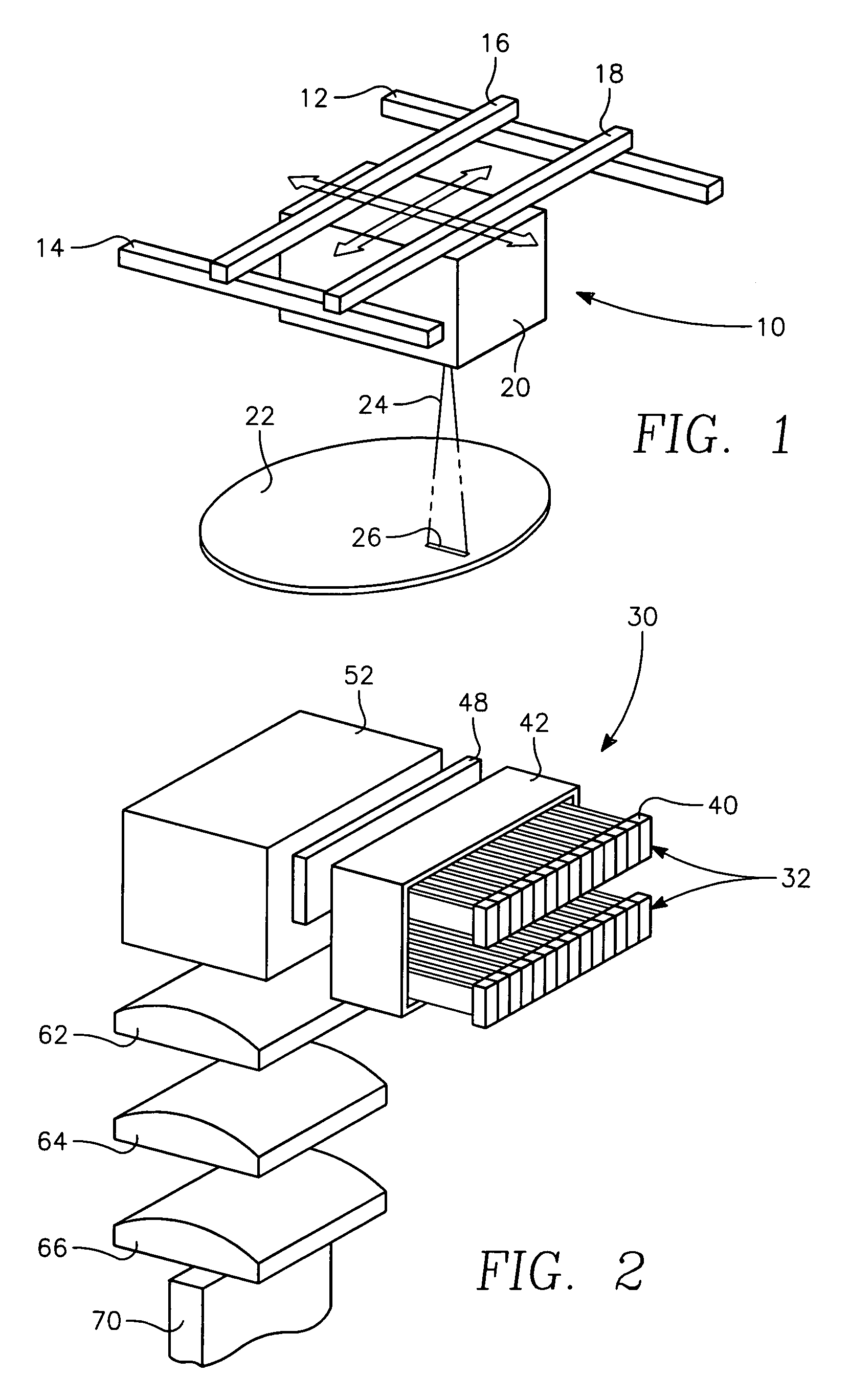

Thermal flux processing by scanning

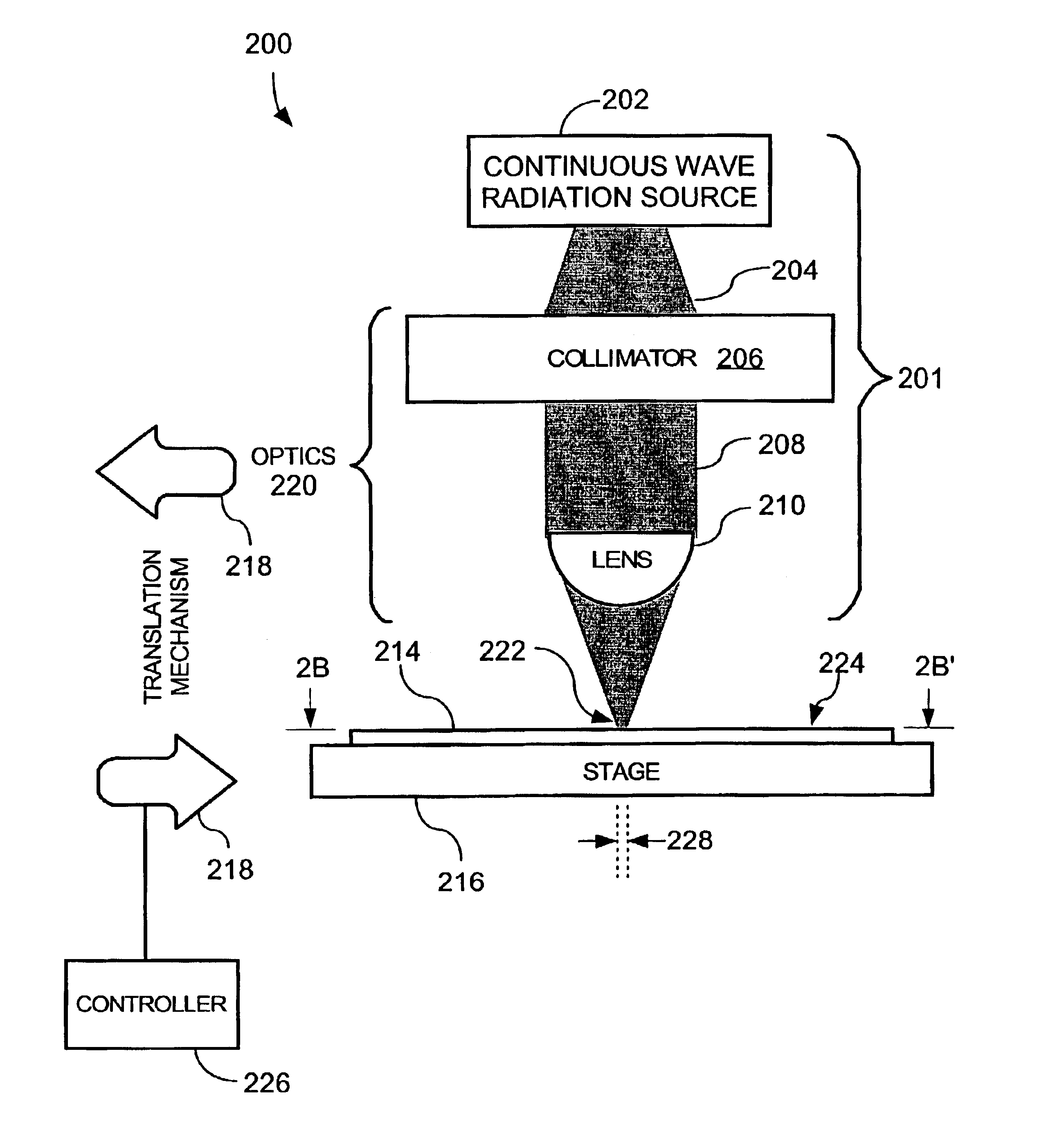

InactiveUS6987240B2Easy to controlReduced Power RequirementsSemiconductor/solid-state device manufacturingSolid state diffusion coatingHeat fluxComputerized system

The thermal processing device includes a stage, a continuous wave electromagnetic radiation source, a series of lenses, a translation mechanism, a detection module, and a computer system. The stage is configured to receive a substrate thereon. The continuous wave electromagnetic radiation source is disposed adjacent the stage, and is configured to emit continuous wave electromagnetic radiation along a path towards the substrate. The series of lenses is disposed between the continuous wave electromagnetic radiation source and the stage, and are configured to condense the continuous wave electromagnetic radiation into a line of continuous wave electromagnetic radiation on a surface of the substrate. The translation mechanism is configured to translate the stage and the line of continuous wave electromagnetic radiation relative to one another. The detection module is positioned within the path, and is configured to detect continuous wave electromagnetic radiation. The computer system is coupled to the detection module.

Owner:APPLIED MATERIALS INC

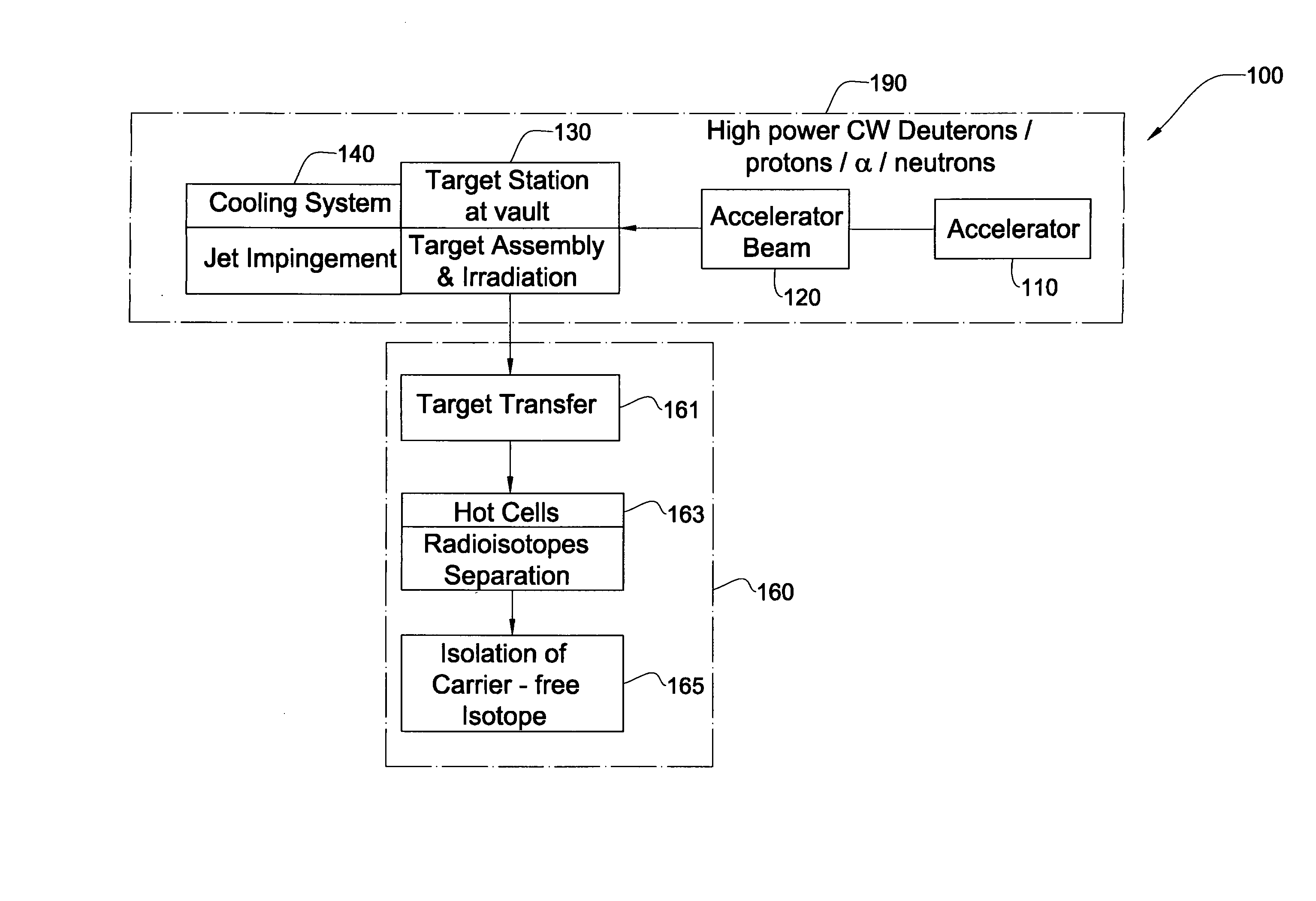

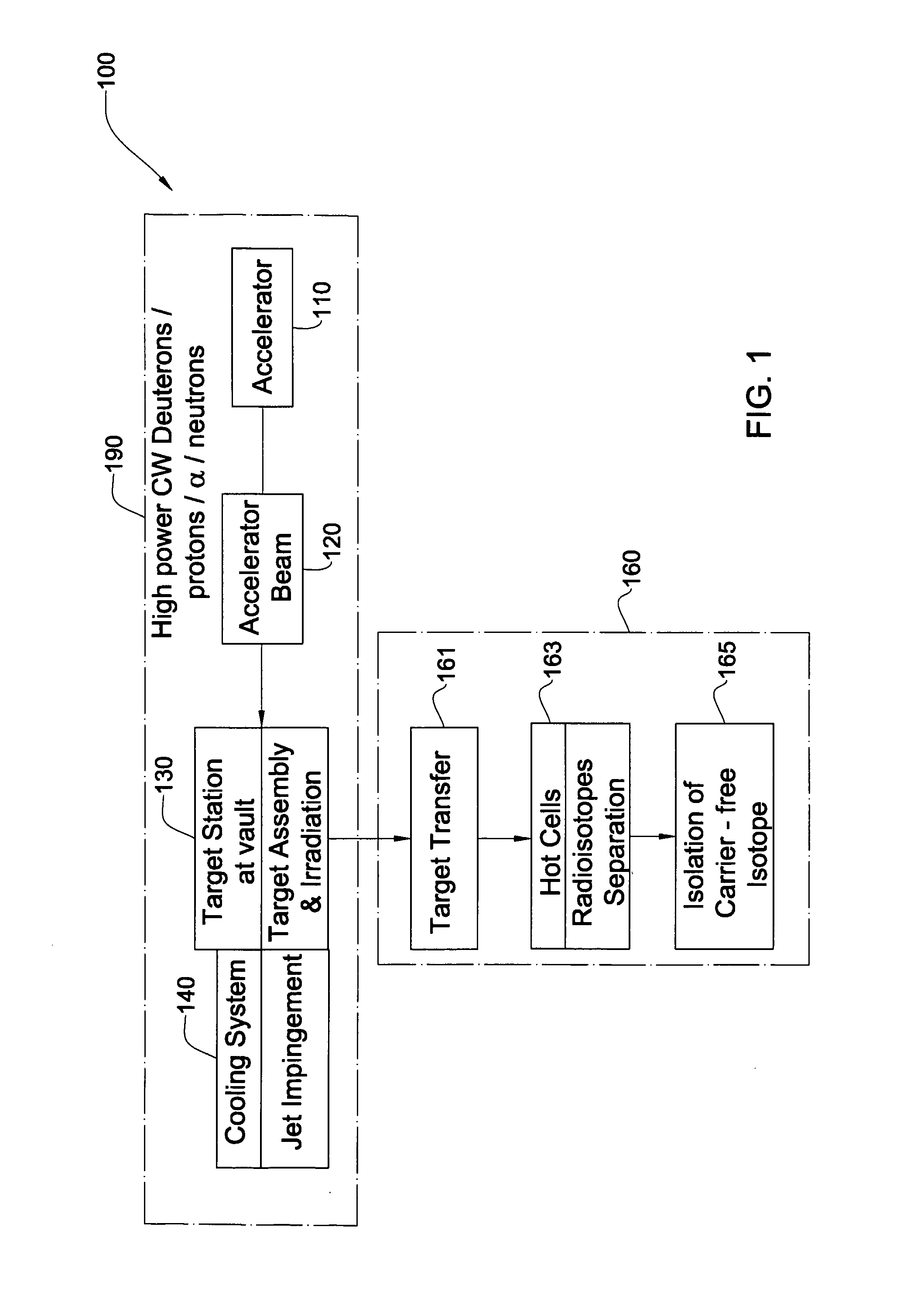

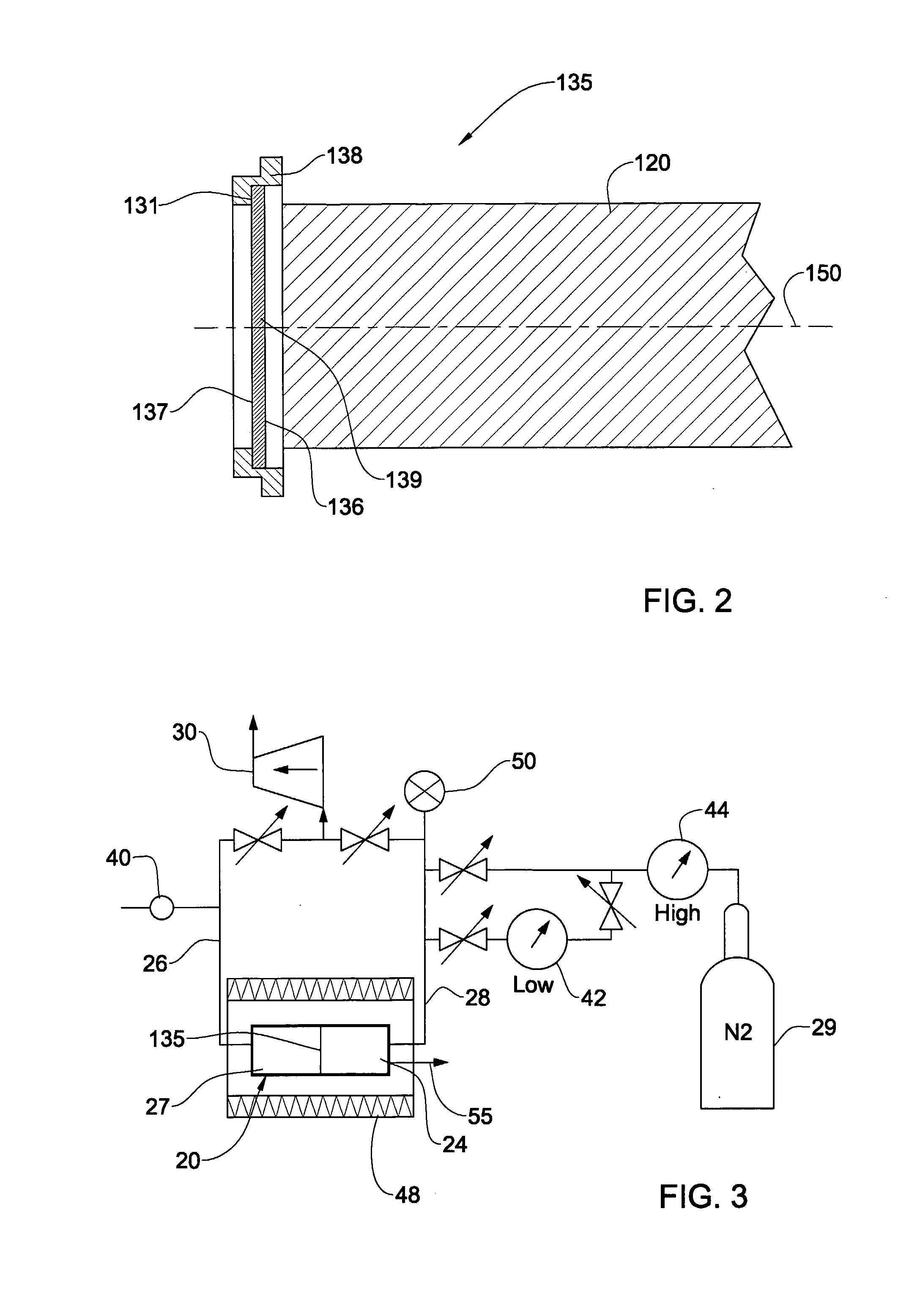

Method And System For Production Of Radioisotopes, And Radioisotopes Produced Thereby

InactiveUS20070297554A1Avoid communicationAvoid contaminationConversion outside reactor/acceleratorsNuclear targetsHeat fluxParticle beam

A system and method for the production of radioisotopes by the transmutation of target isotopic material bombarded by a continuous wave particle beam. An ion source generates a continuous wave ion beam, irradiating an isotope target, which is cooled by transferring heat away from the target at heat fluxes of at least about 1 kW / cm2.

Owner:SOREQ NUCLEAR RES CENT ISRAEL ATOMIC ENERGY COMMISSION

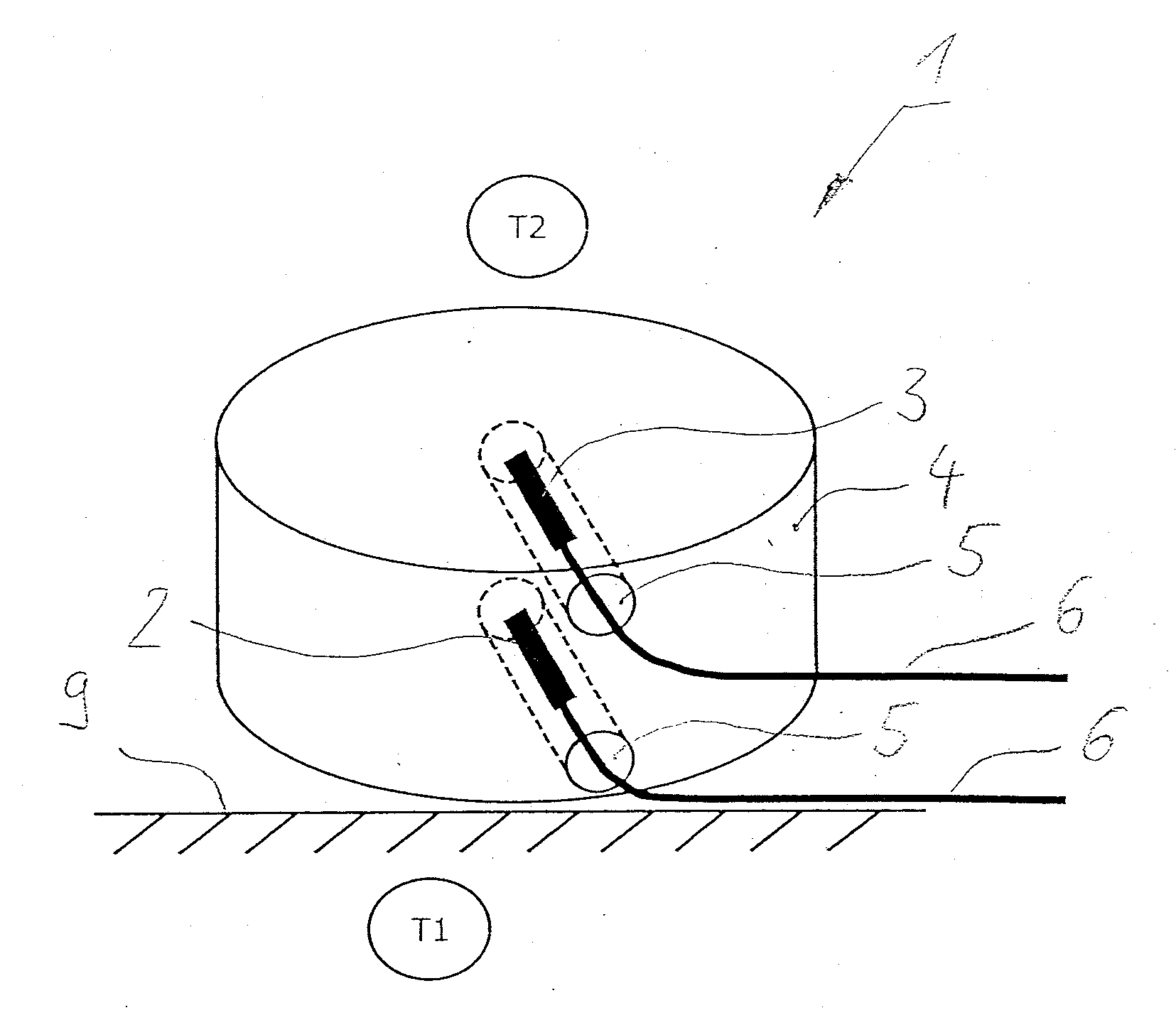

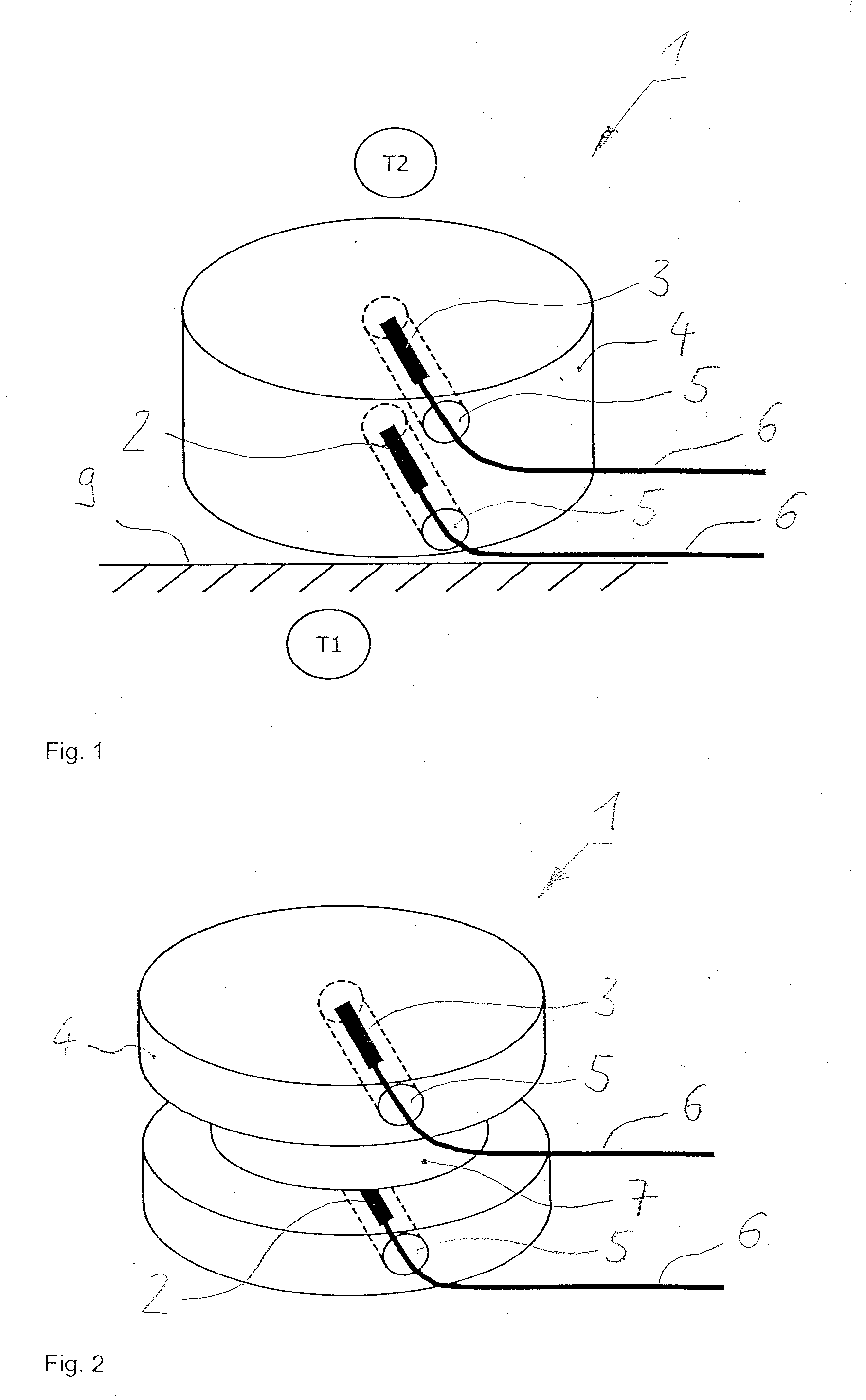

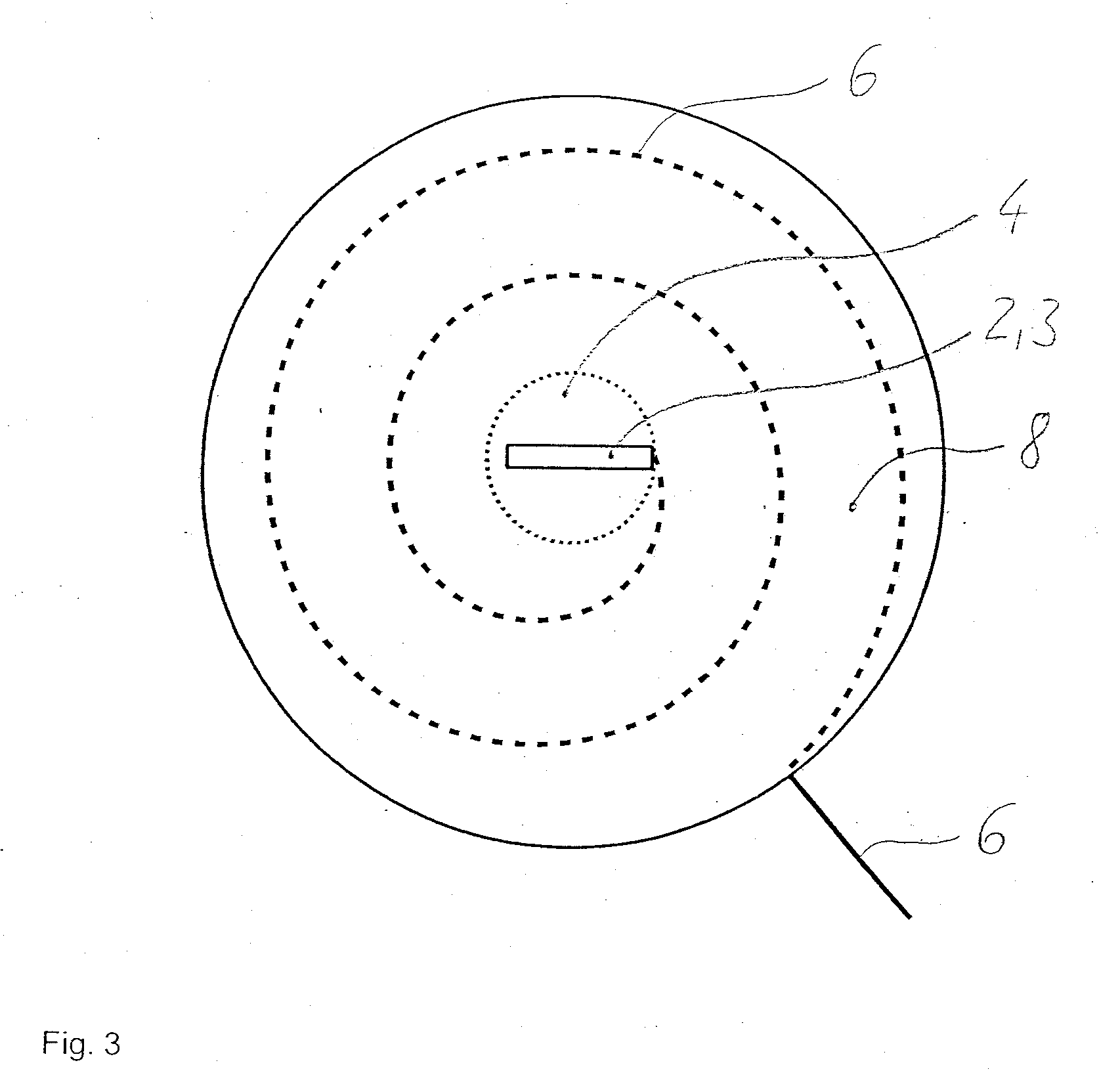

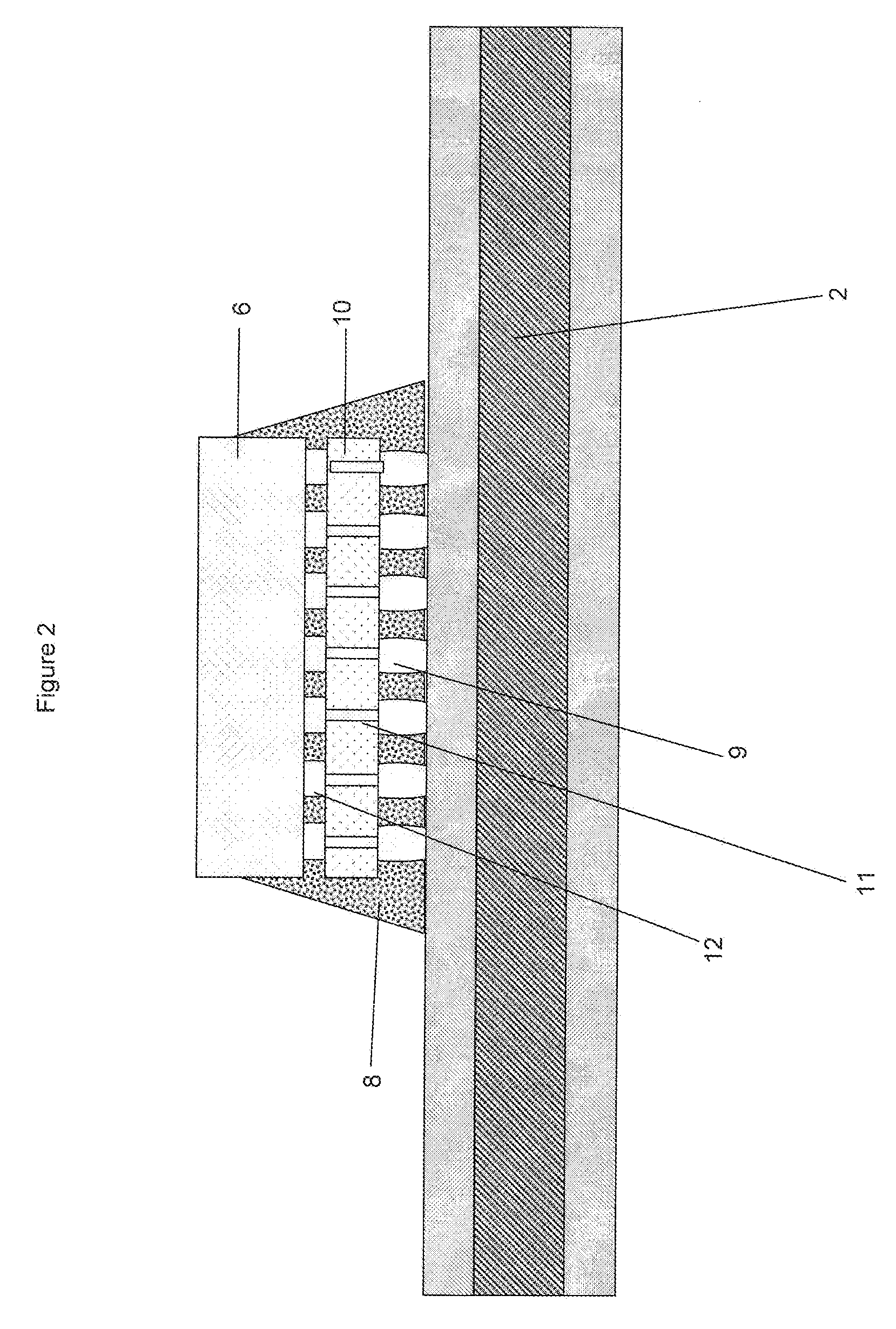

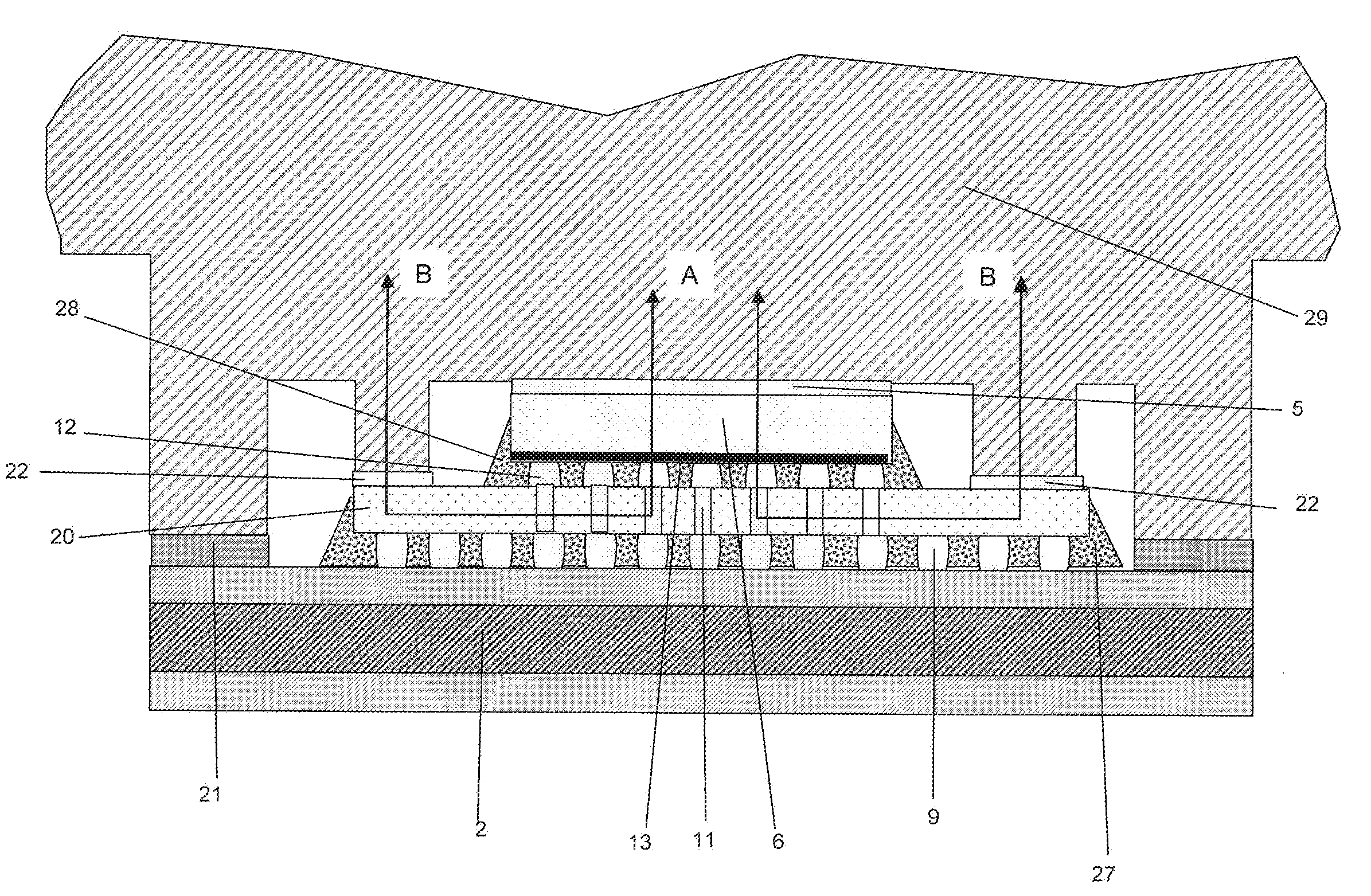

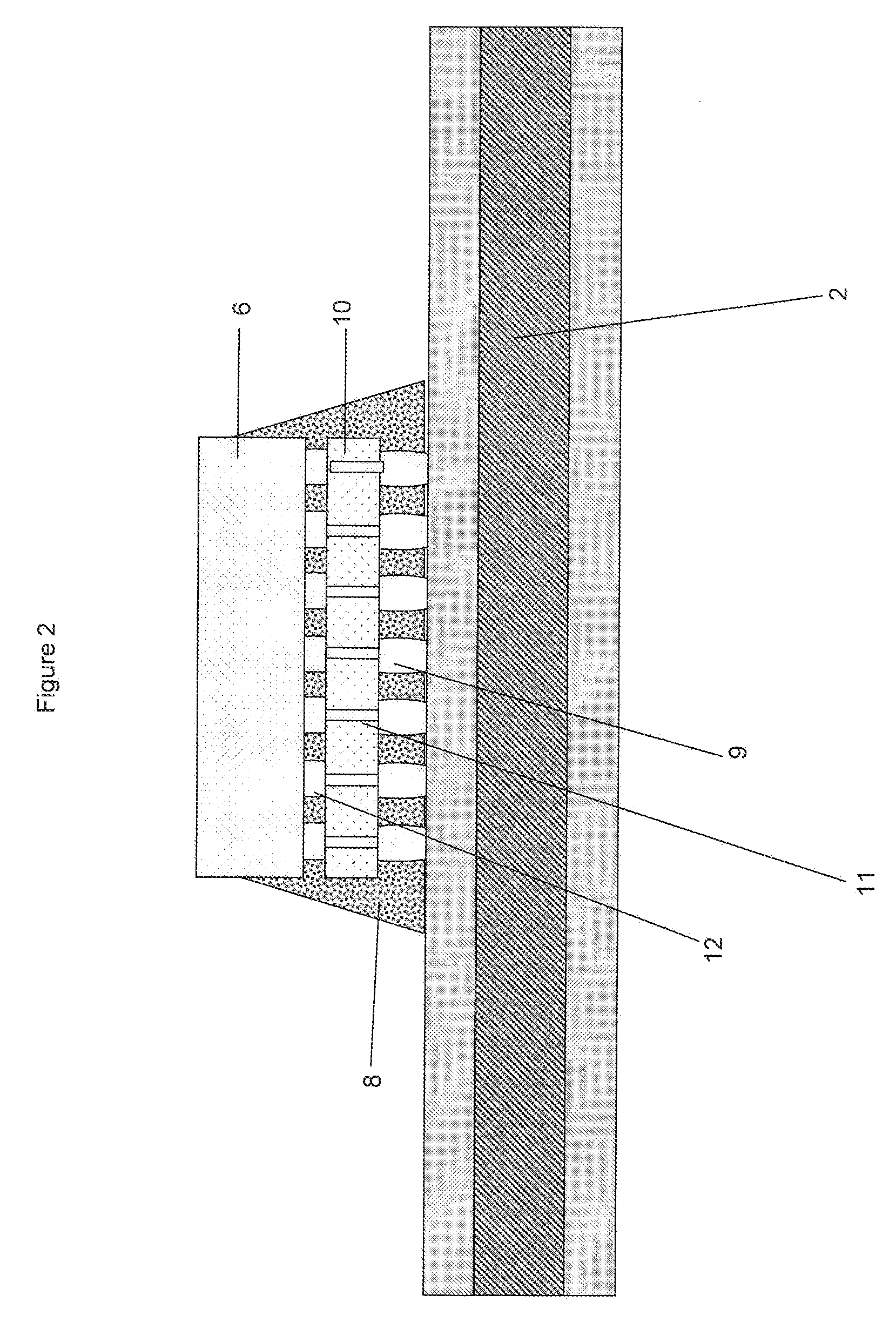

Double temperature sensor

ActiveUS20080170600A1Easy to manufactureTolerances of the heat transfer coefficient can be minimizedThermometer detailsThermometers using electric/magnetic elementsElectricityHeat flux

A double temperature sensor is provided for measuring a near-surface temperature of the ambient air and the temperature of the skin surface (9). A heat flux insulation block (4) is made of an insulation material in one piece as a housing. Two temperature sensor elements (2, 3) with respective electric connections (6) belonging to them are arranged in the heat flux insulation block (4) one on top of another at spaced locations from one another and near the surface.

Owner:DRAGERWERK AG

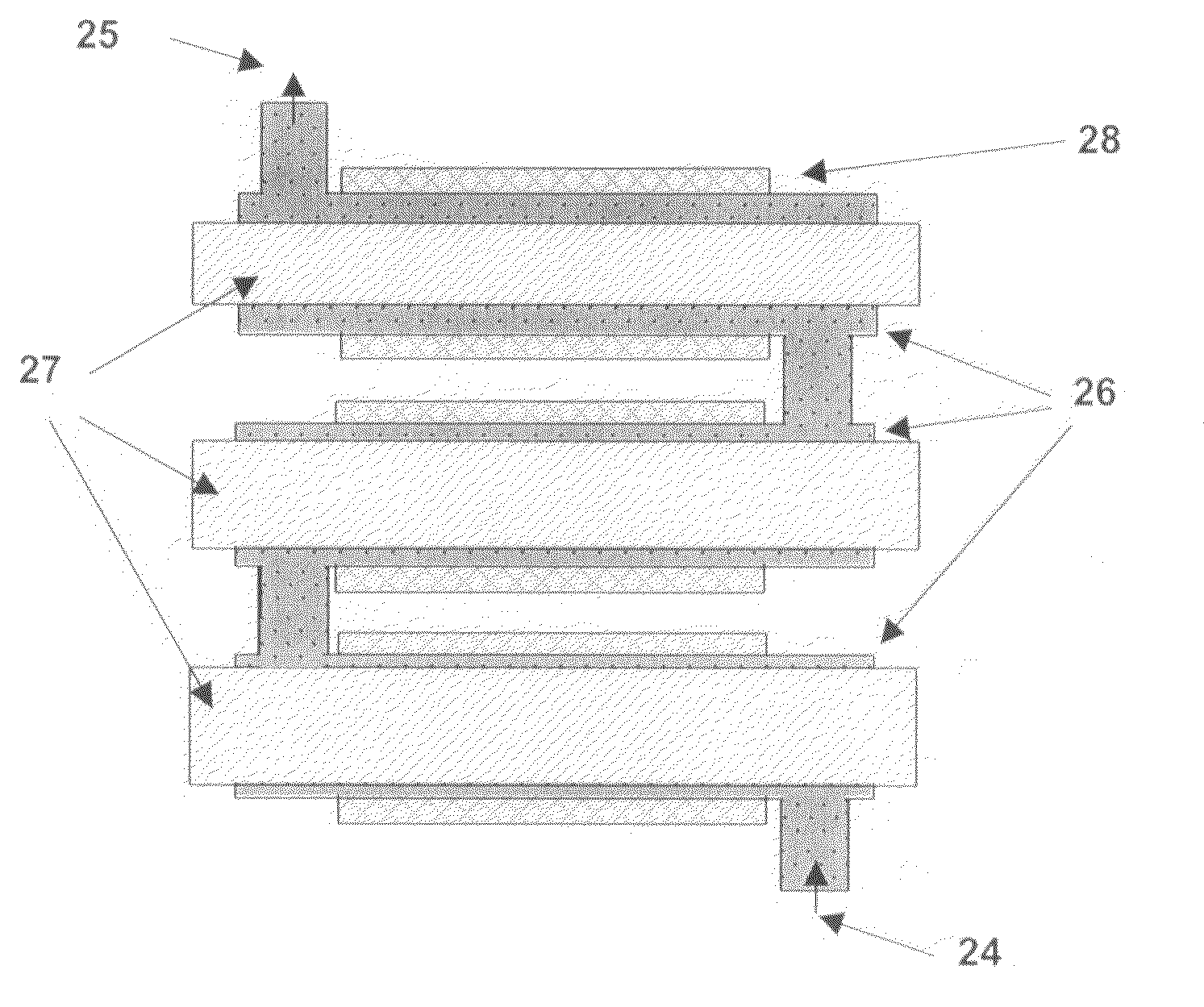

Thermally conductive composite interface, cooled electronic assemblies employing the same, and methods of fabrication thereof

ActiveUS7967062B2Enhanced couplingImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesHeat fluxElectronic assemblies

A composite interface and methods of fabrication are provided for coupling a cooling assembly to an electronic device. The interface includes a plurality of thermally conductive wires formed of a first material having a first thermal conductivity, and a thermal interface material at least partially surrounding the wires. The interface material, which thermally interfaces the cooling assembly to a surface to be cooled of the electronic device, is a second material having a second thermal conductivity, wherein the first thermal conductivity is greater than the second thermal conductivity. At least some wires reside partially over a first region of higher heat flux and extend partially over a second region of lower heat flux, wherein the first and second regions are different regions of the surface to be cooled. These wires function as thermal spreaders facilitating heat transfer from the surface to be cooled to the cooling assembly.

Owner:INT BUSINESS MASCH CORP

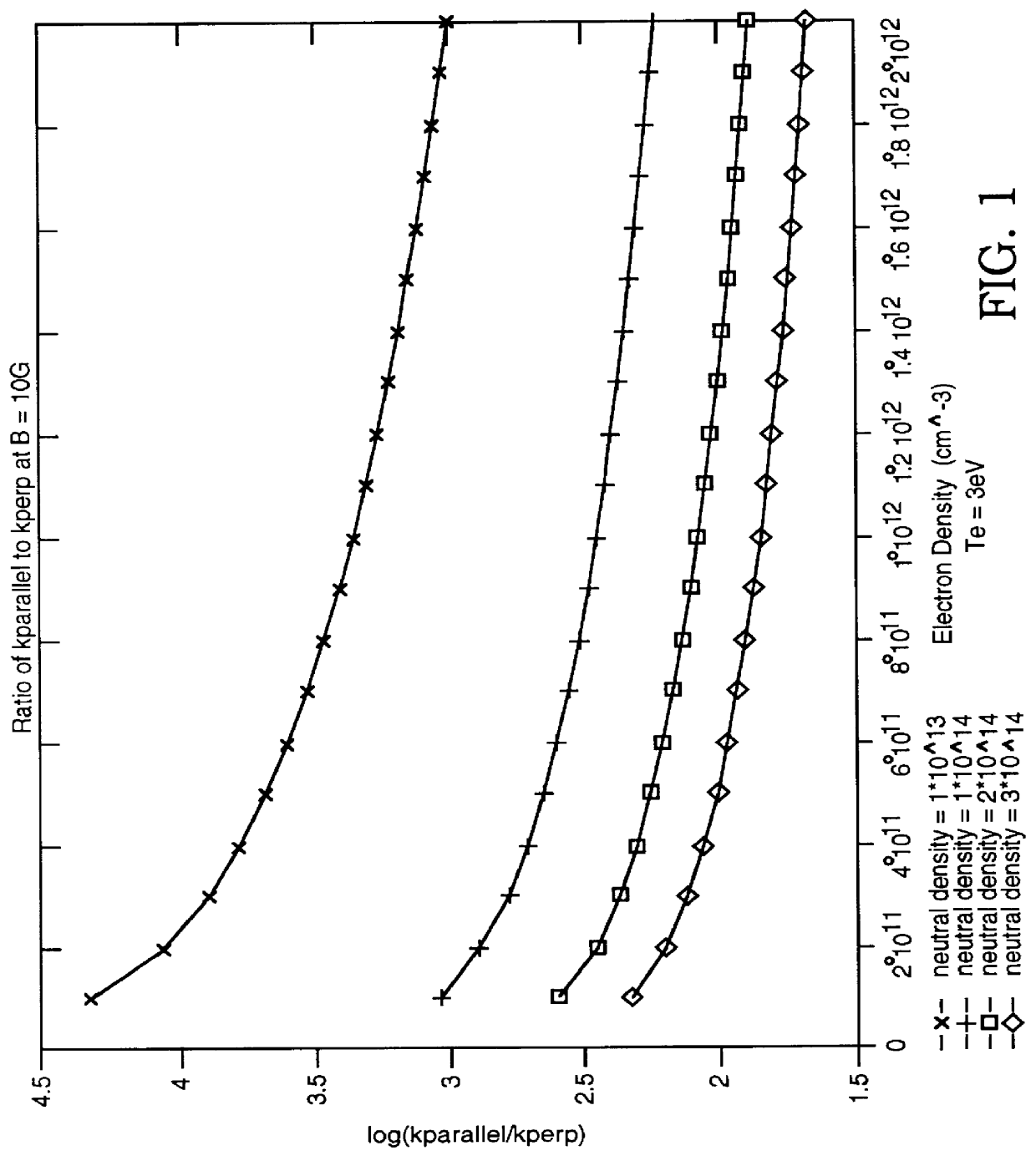

Method and structure for controlling plasma uniformity

InactiveUS6110395AMinimal effectIncrease inertiaDecorative surface effectsVacuum evaporation coatingElectron temperatureHeat flux

The present invention relates to a method and structure for controlling plasma uniformity in plasma processing applications. Electron thermal conductivity parallel and perpendicular to magnetic field lines differs by orders of magnitude for low magnetic fields (on the order of 10 gauss). This property allows the directing of heat flux by controlling the magnetic field configuration independent of ions since the effect of modest magnetic fields upon the transport of ions themselves is minimal. Heat is preferentially conducted along magnetic field lines with electron temperatures on the order of 0.1 to 1 eV / cm being sufficient to drive kilowatt-level heat fluxes across areas typical of plasma processing source dimensions.

Owner:SPTS TECH LTD

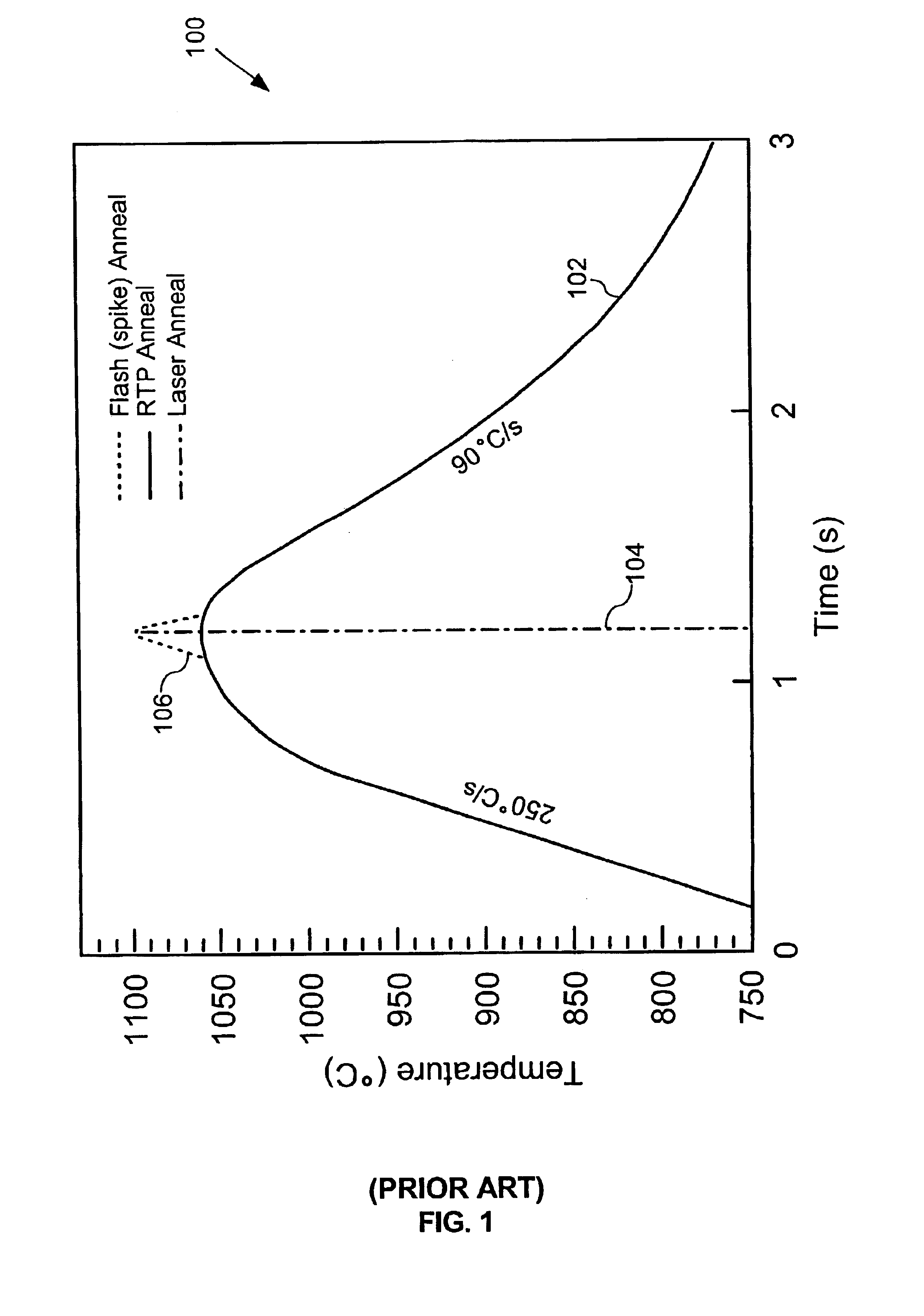

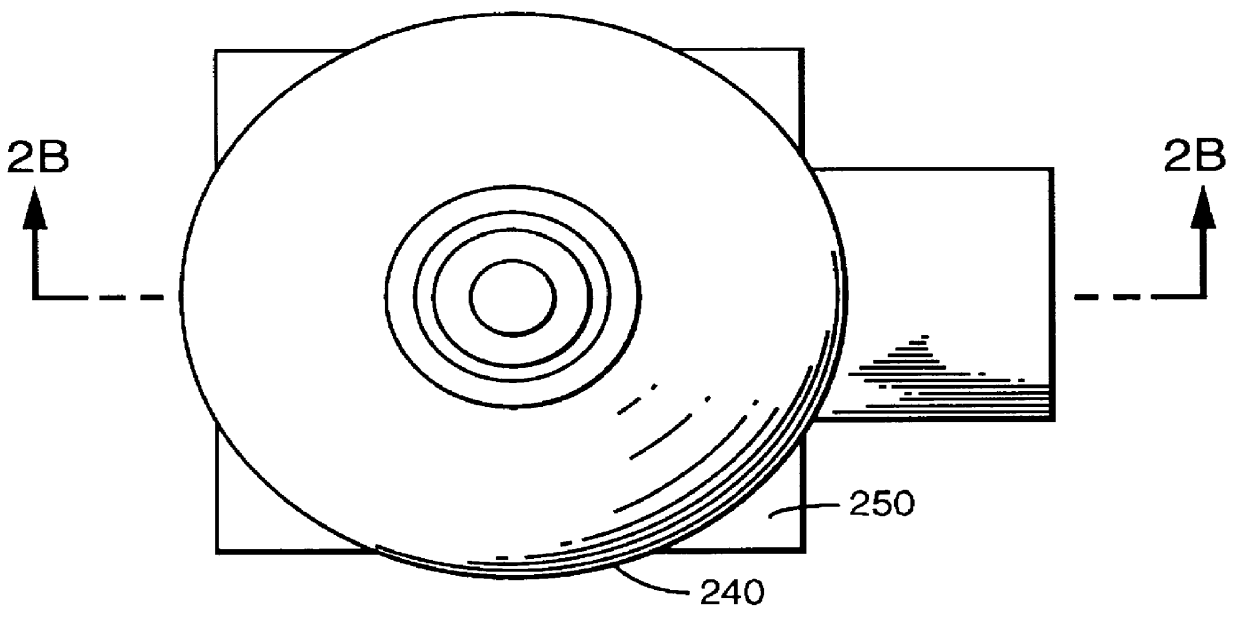

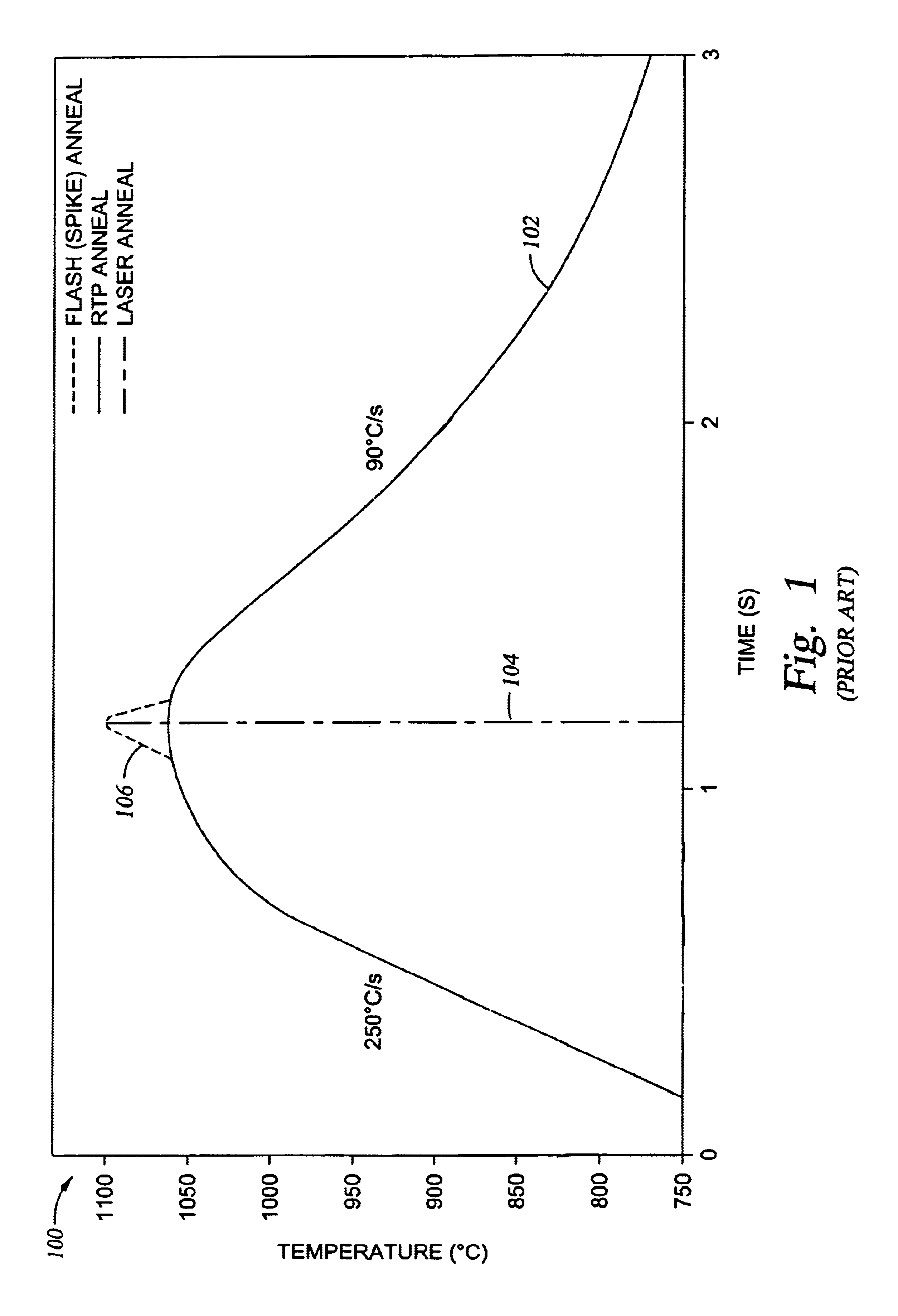

Thermal flux processing by scanning

InactiveUS7005601B2Easy to controlShort annealing timeSemiconductor/solid-state device manufacturingSolid state diffusion coatingHeat fluxContinuous wave

The thermal flux processing device includes a continuous wave electromagnetic radiation source, a stage, optics, and a translation mechanism. The continuous wave electromagnetic radiation source is preferably a diode / s. The stage is configured to receive a semiconductor substrate thereon. The optics are preferably disposed between the continuous wave electromagnetic radiation source and the stage. Also, the optics are configured to focus continuous wave electromagnetic radiation from the continuous wave electromagnetic radiation source into a line of continuous wave electromagnetic radiation on an upper surface of the semiconductor substrate. A length of the line of continuous wave electromagnetic radiation extends across an entire width of the semiconductor substrate. The translation mechanism is configured to translate the stage and the line of continuous wave electromagnetic radiation relative to one another, and preferably includes a chuck for securely grasping the substrate. A method for thermally processing a semiconductor substrate is also provided.

Owner:APPLIED MATERIALS INC

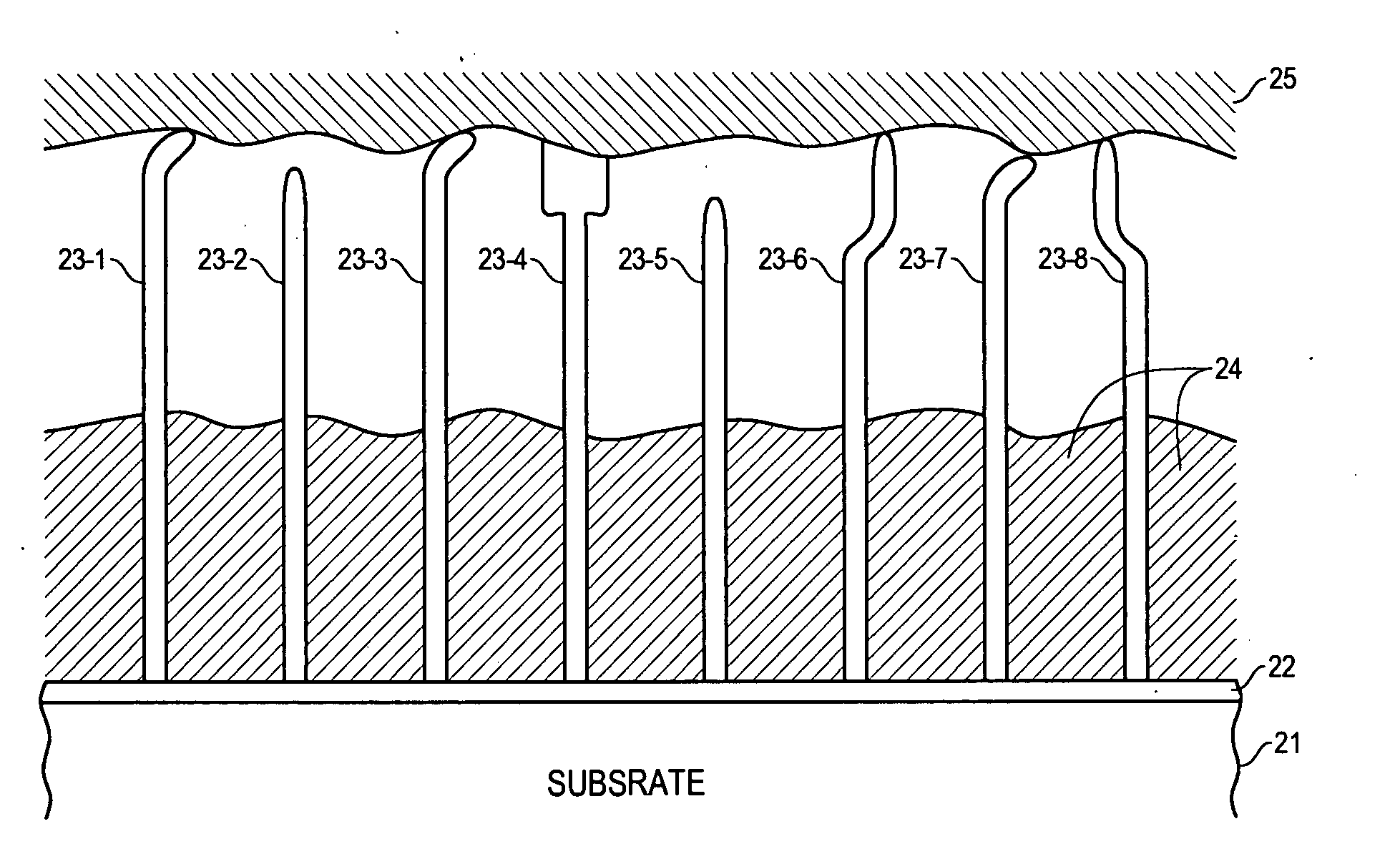

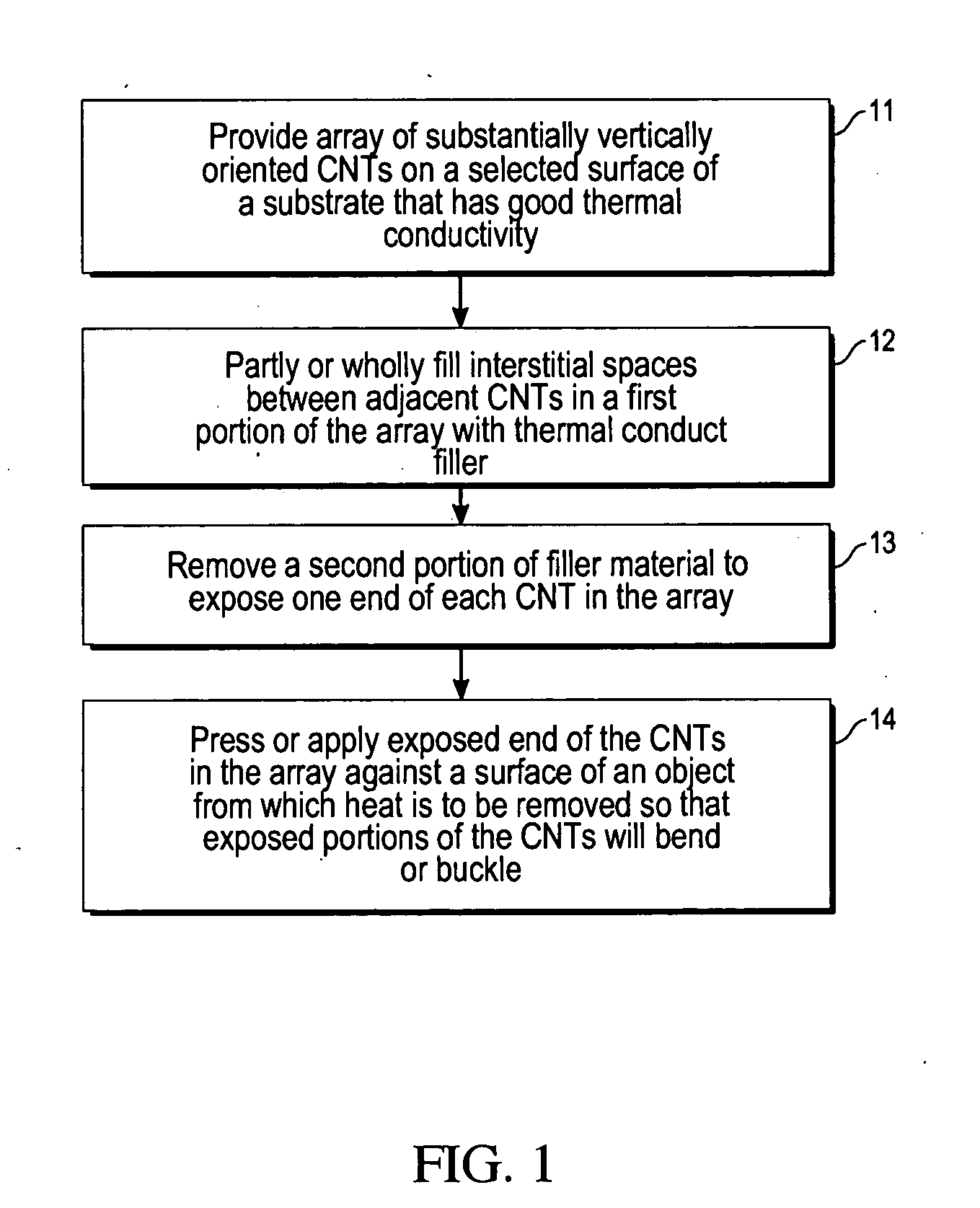

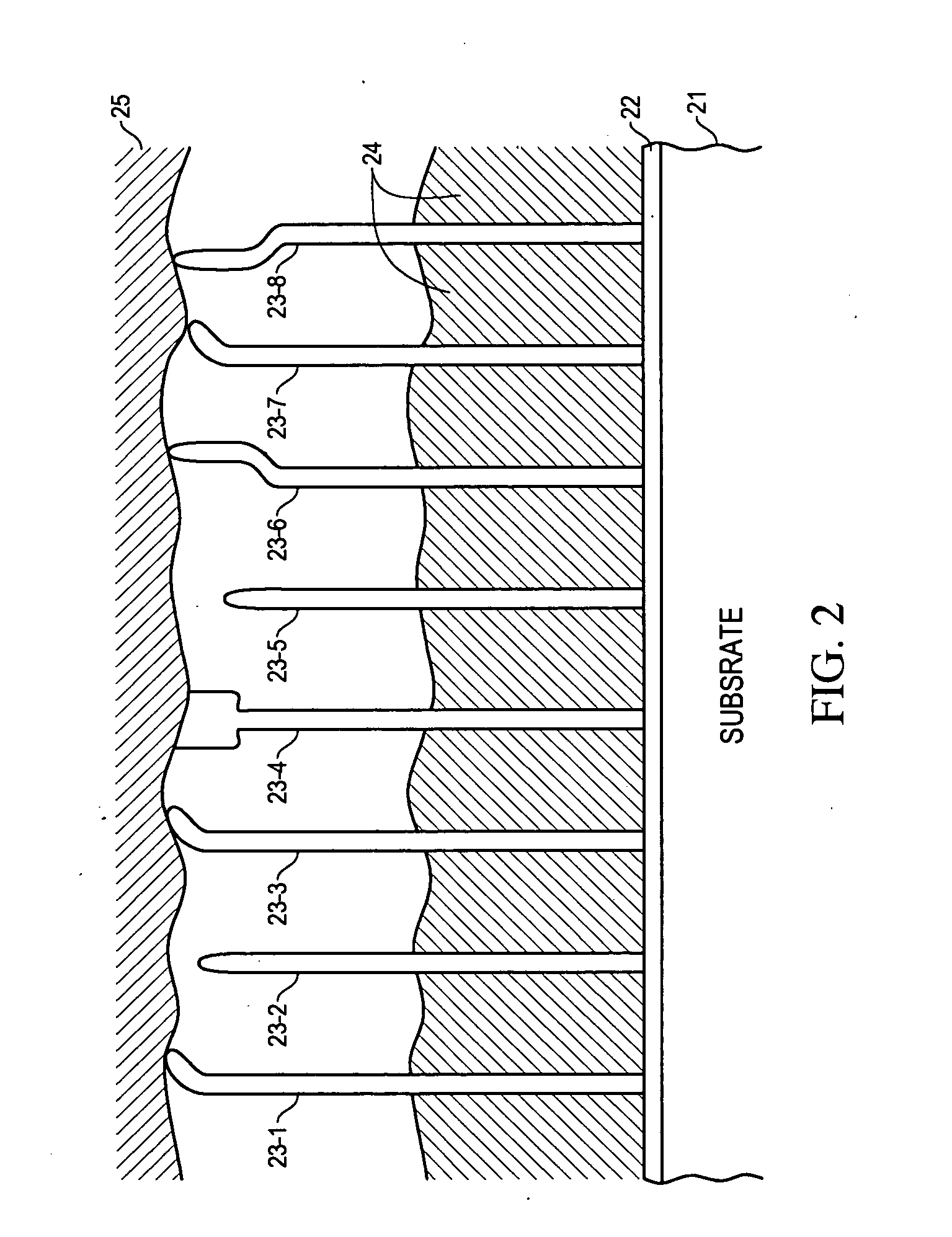

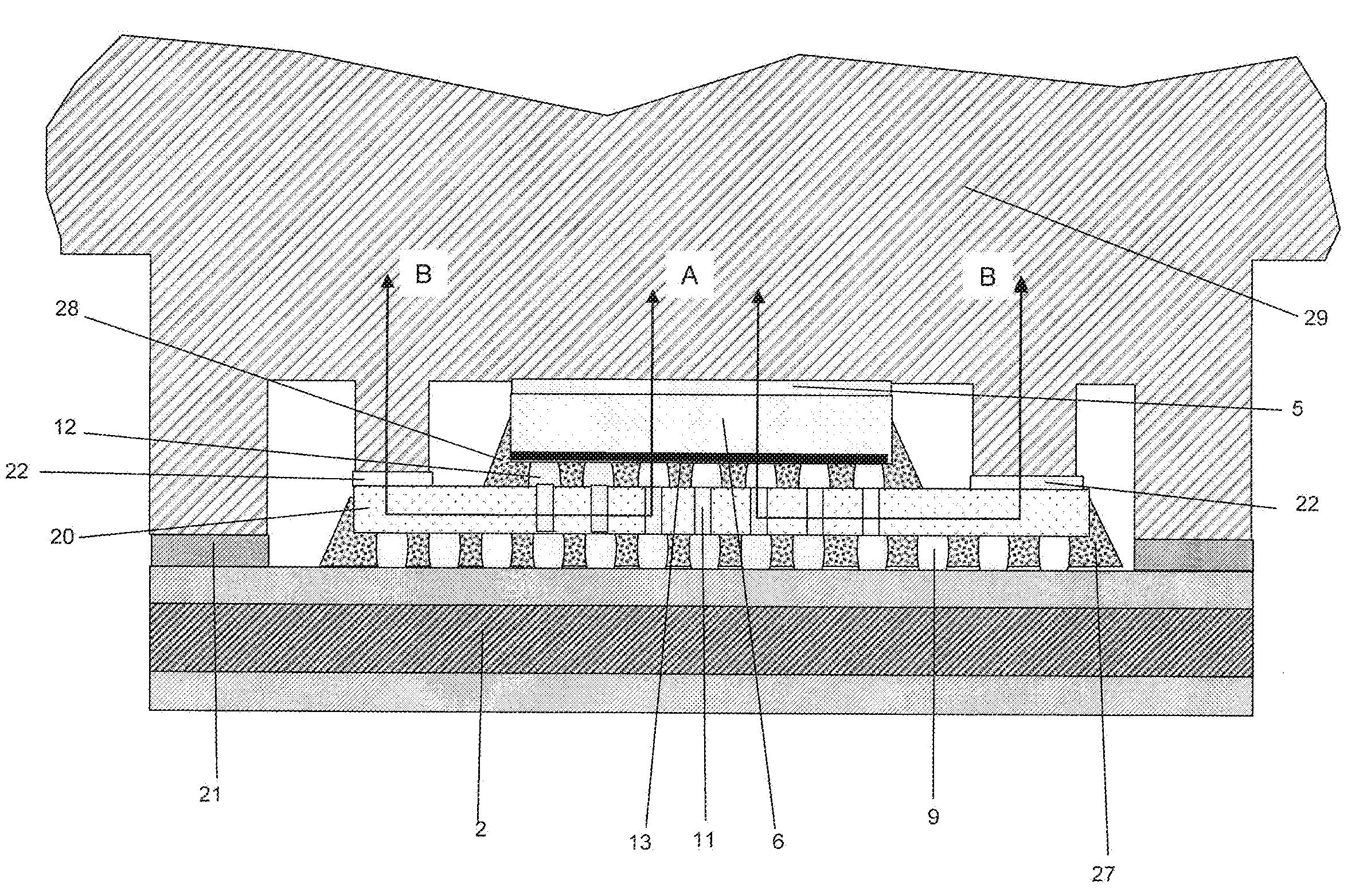

Nanoengineered thermal materials based on carbon nanotube array composites

InactiveUS20050224220A1High mechanical strengthImprove cooling effectMaterial nanotechnologySemiconductor/solid-state device detailsHeat fluxFilling materials

A method for providing for thermal conduction using an array of carbon nanotubes (CNTs). An array of vertically oriented CNTs is grown on a substrate having high thermal conductivity, and interstitial regions between adjacent CNTs in the array are partly or wholly filled with a filler material having a high thermal conductivity so that at least one end of each CNT is exposed. The exposed end of each CNT is pressed against a surface of an object from which heat is to be removed. The CNT-filler composite adjacent to the substrate provides improved mechanical strength to anchor CNTs in place and also serves as a heat spreader to improve diffusion of heat flux from the smaller volume (CNTs) to a larger heat sink.

Owner:SAMSUNG ELECTRONICS CO LTD +1

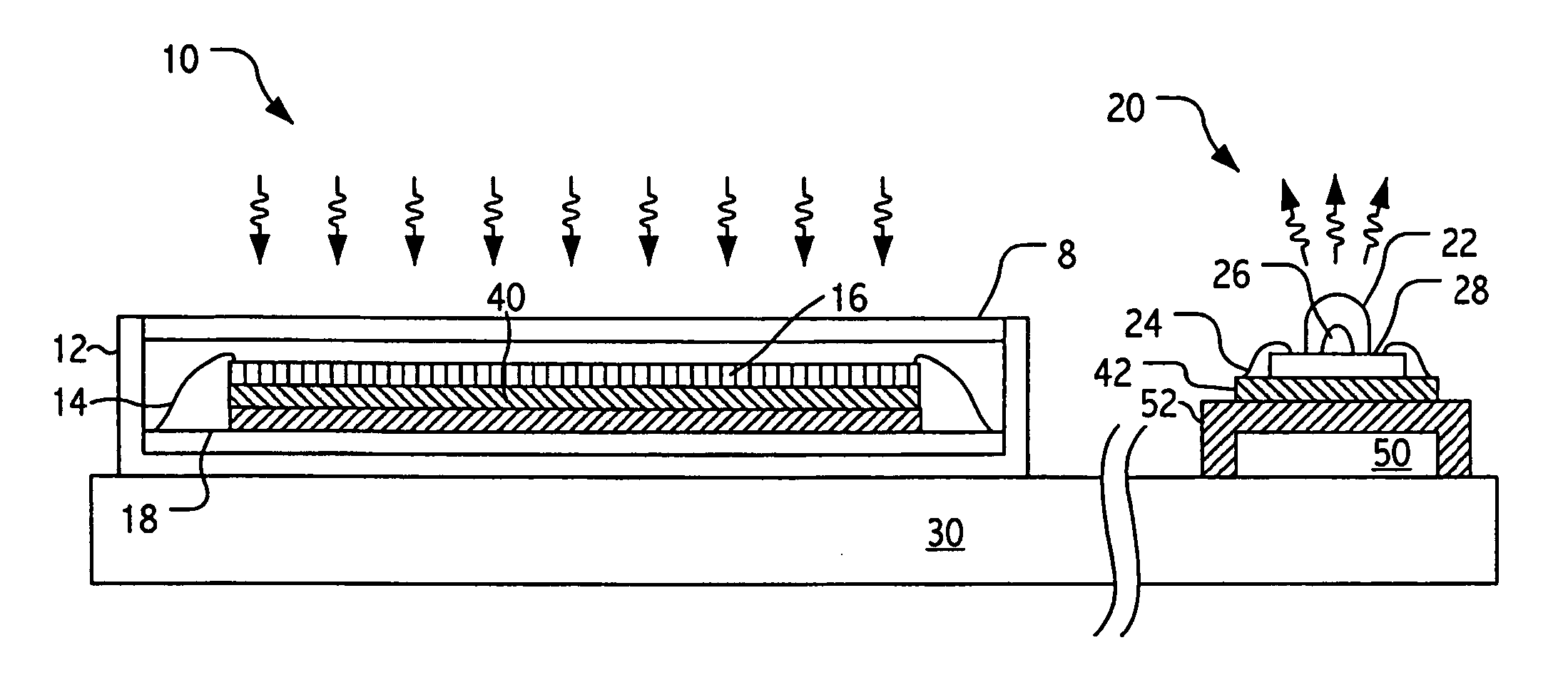

Electronic package with a thermal interposer and method of manufacturing the same

ActiveUS20100044856A1Reduce heatInhibit transferSemiconductor/solid-state device detailsSolid-state devicesHeat fluxInterposer

Owner:GLOBALFOUNDRIES US INC

Variable heat flux heat exchangers

InactiveUS20090120629A1Easy to adaptMinimal modificationChemical/physical/physico-chemical processesHeat transfer modificationHeat fluxHeat transmission

A system for heat exchange is provided in which process material flows through a heat exchanger comprising multiple heat transfer stages and the heating and or cooling power applied to each stage can be modified independently. The system comprises a unitary heat exchanger comprising a heat transfer surface comprising a plurality of elements or zones over which a process material can flow wherein each element or zone has independent means to set or control the level of heating or cooling within that zone.

Owner:ASHE MORRIS LTD

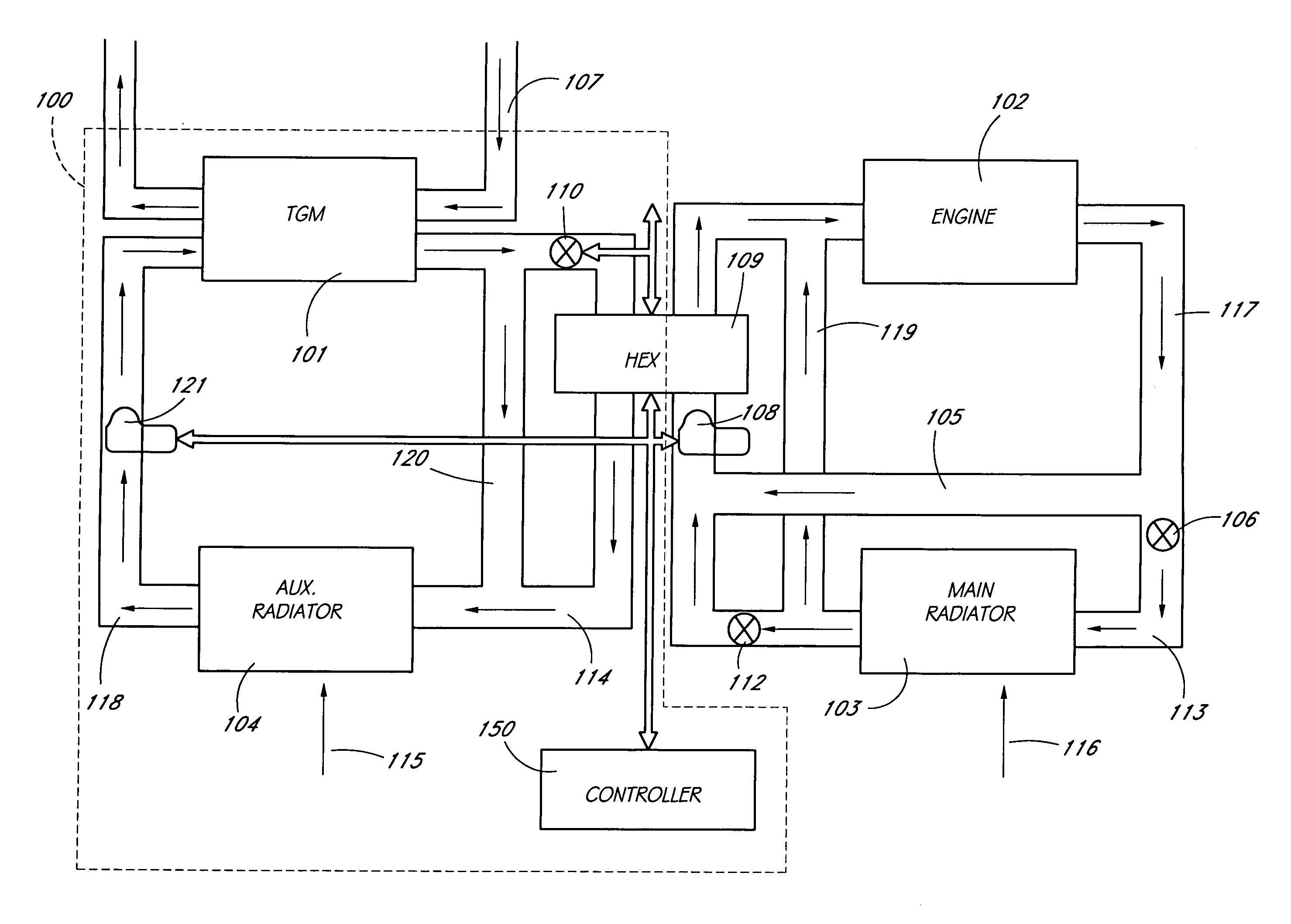

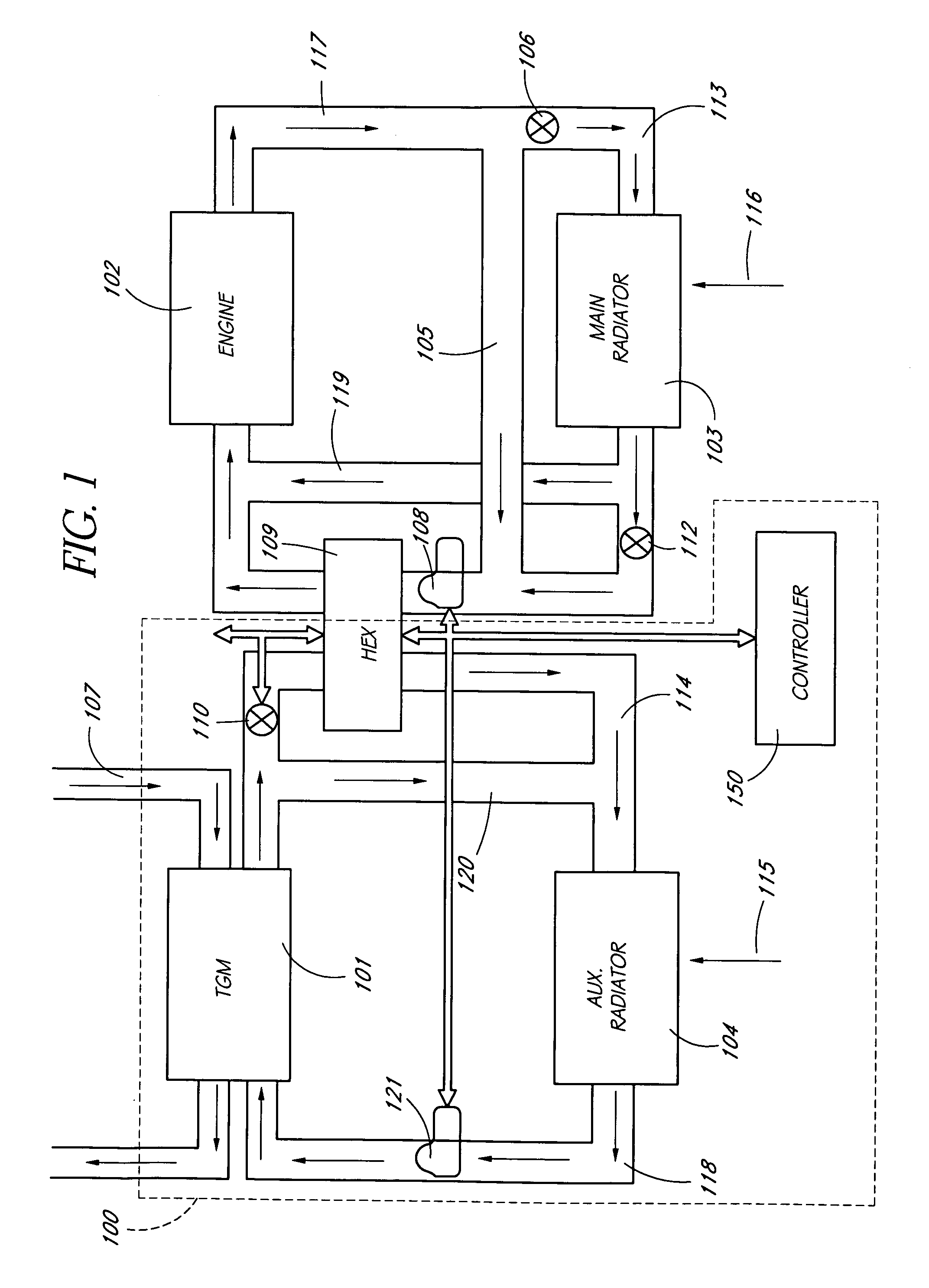

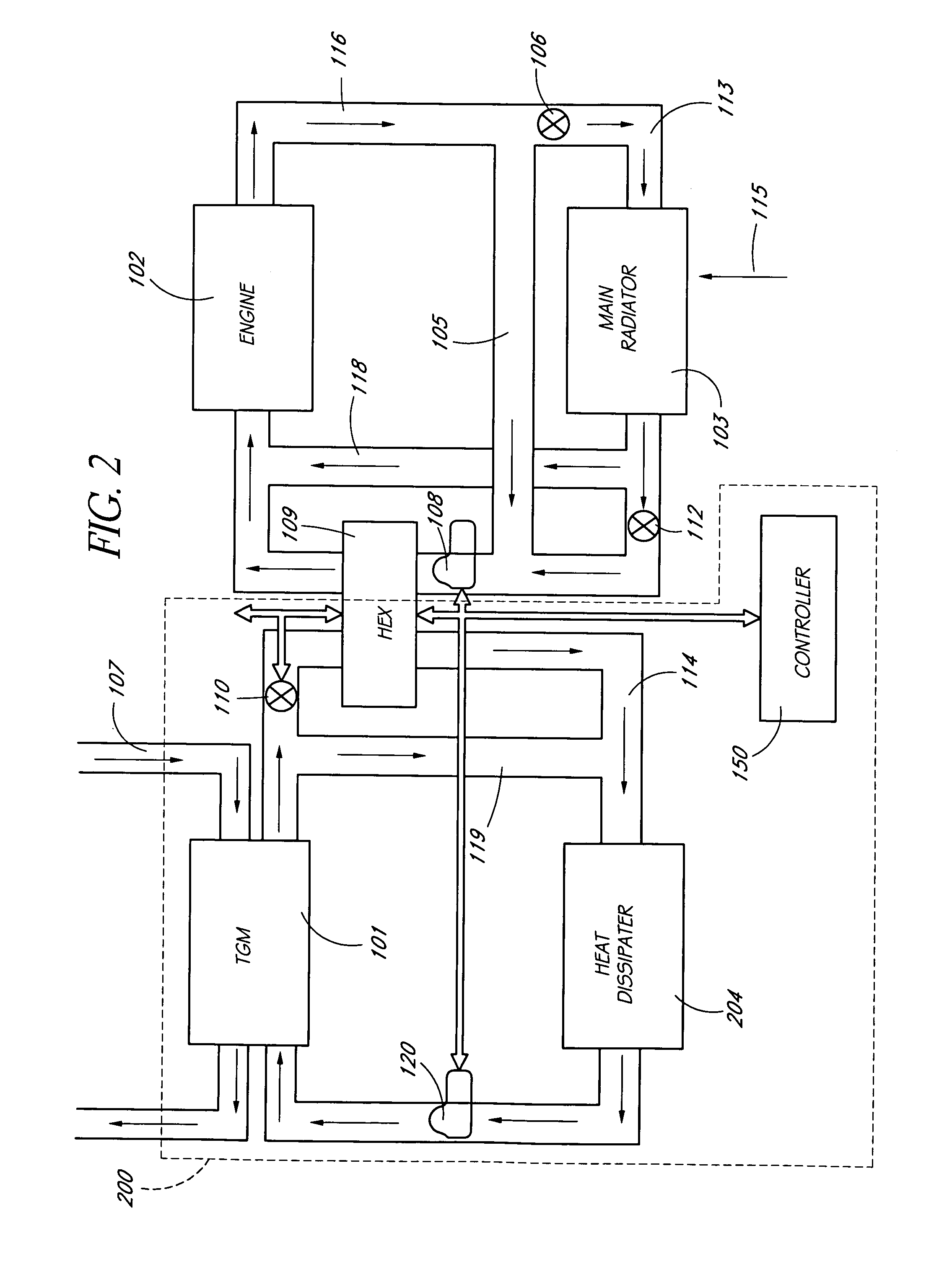

Thermoelectric power generator with intermediate loop

InactiveUS7608777B2Performance maximizationIncrease temperature differenceThermoelectric device with peltier/seeback effectMachines/enginesHeat fluxNuclear engineering

A thermoelectric power generator is disclosed for use to generate electrical power from heat, typically waste heat. An intermediate heat transfer loop forms a part of the system to permit added control and adjustability in the system. This allows the thermoelectric power generator to more effectively and efficiently generate power in the face of dynamically varying temperatures and heat flux conditions, such as where the heat source is the exhaust of an automobile, or any other heat source with dynamic temperature and heat flux conditions.

Owner:GENTHERM INC

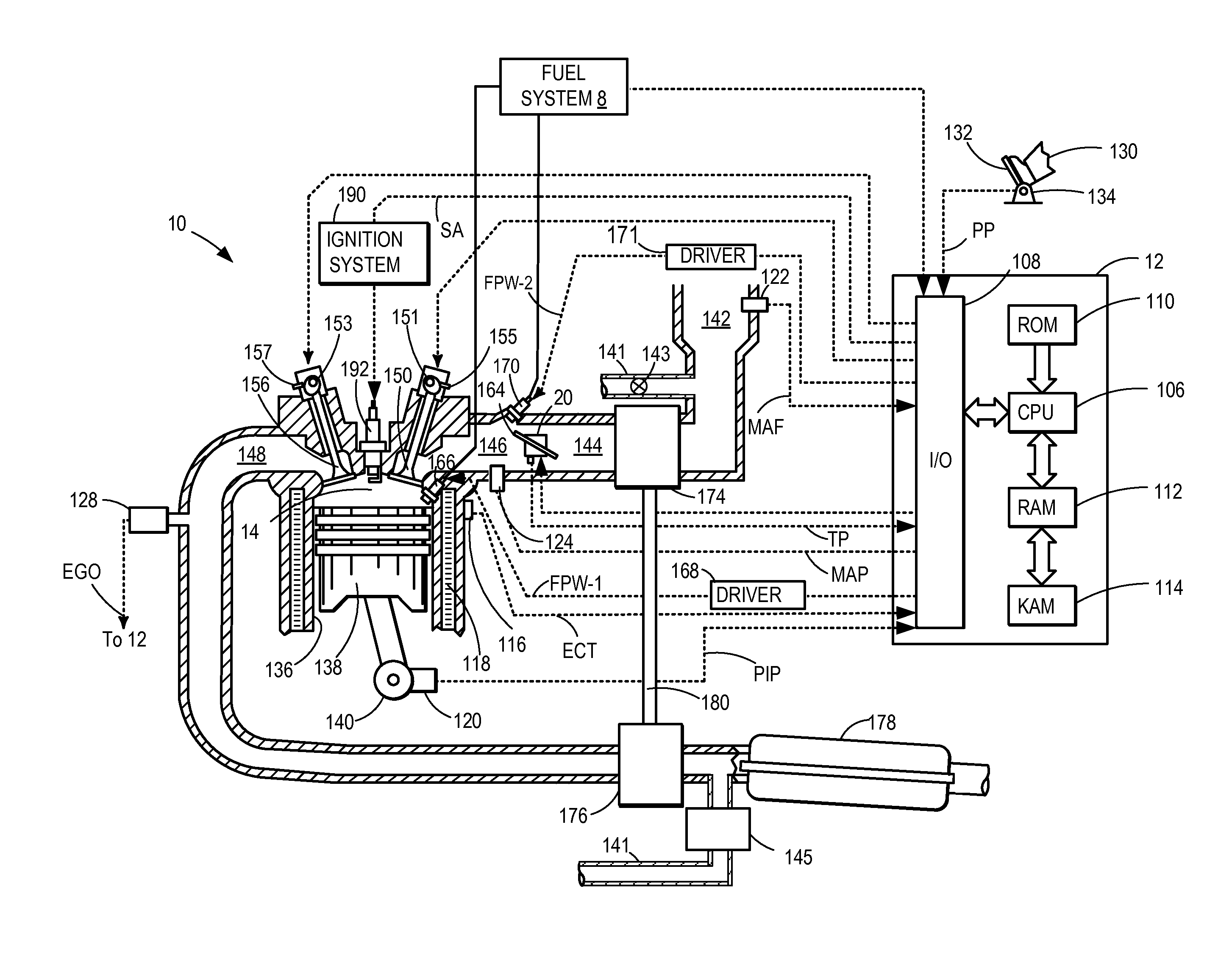

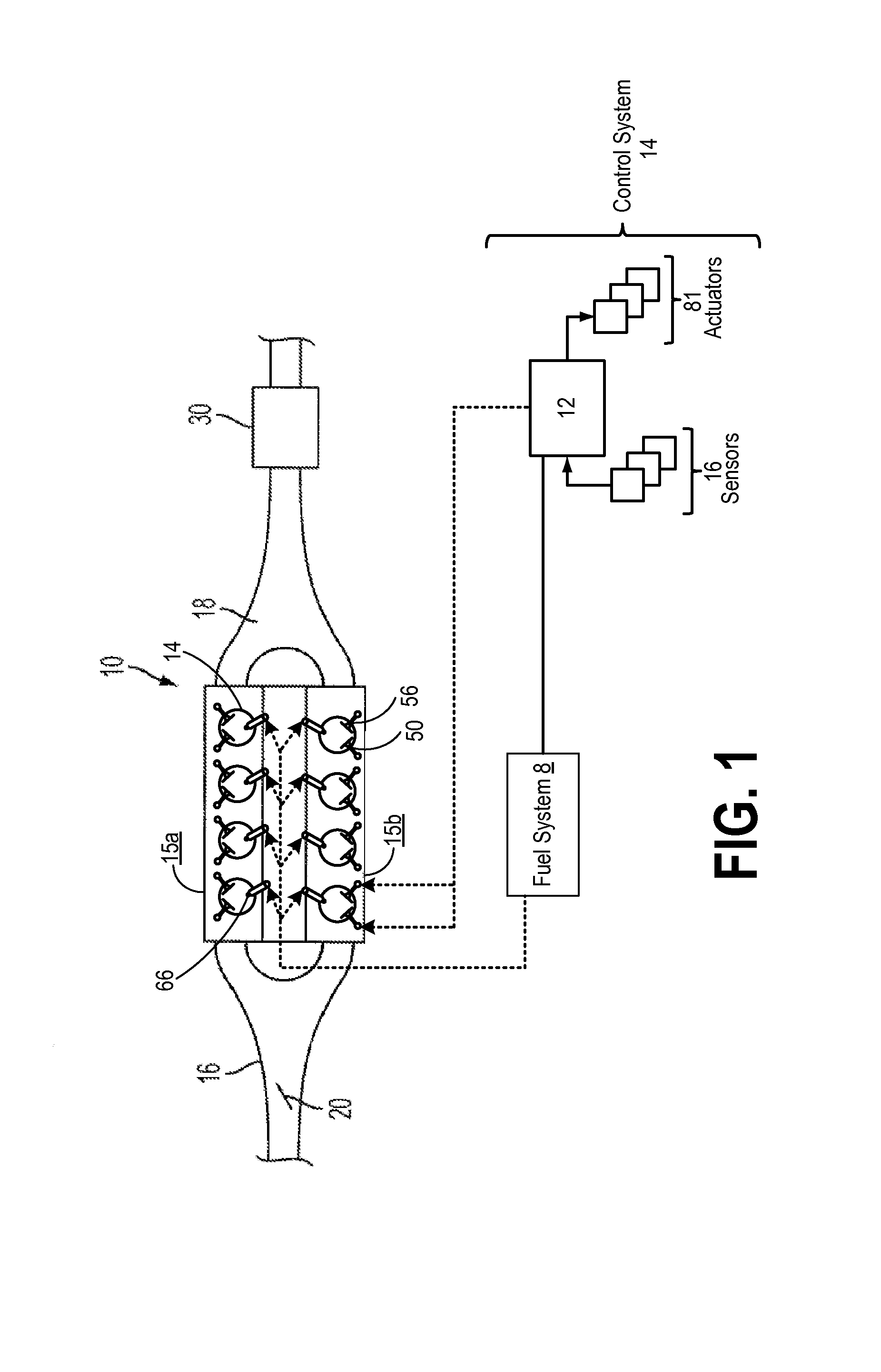

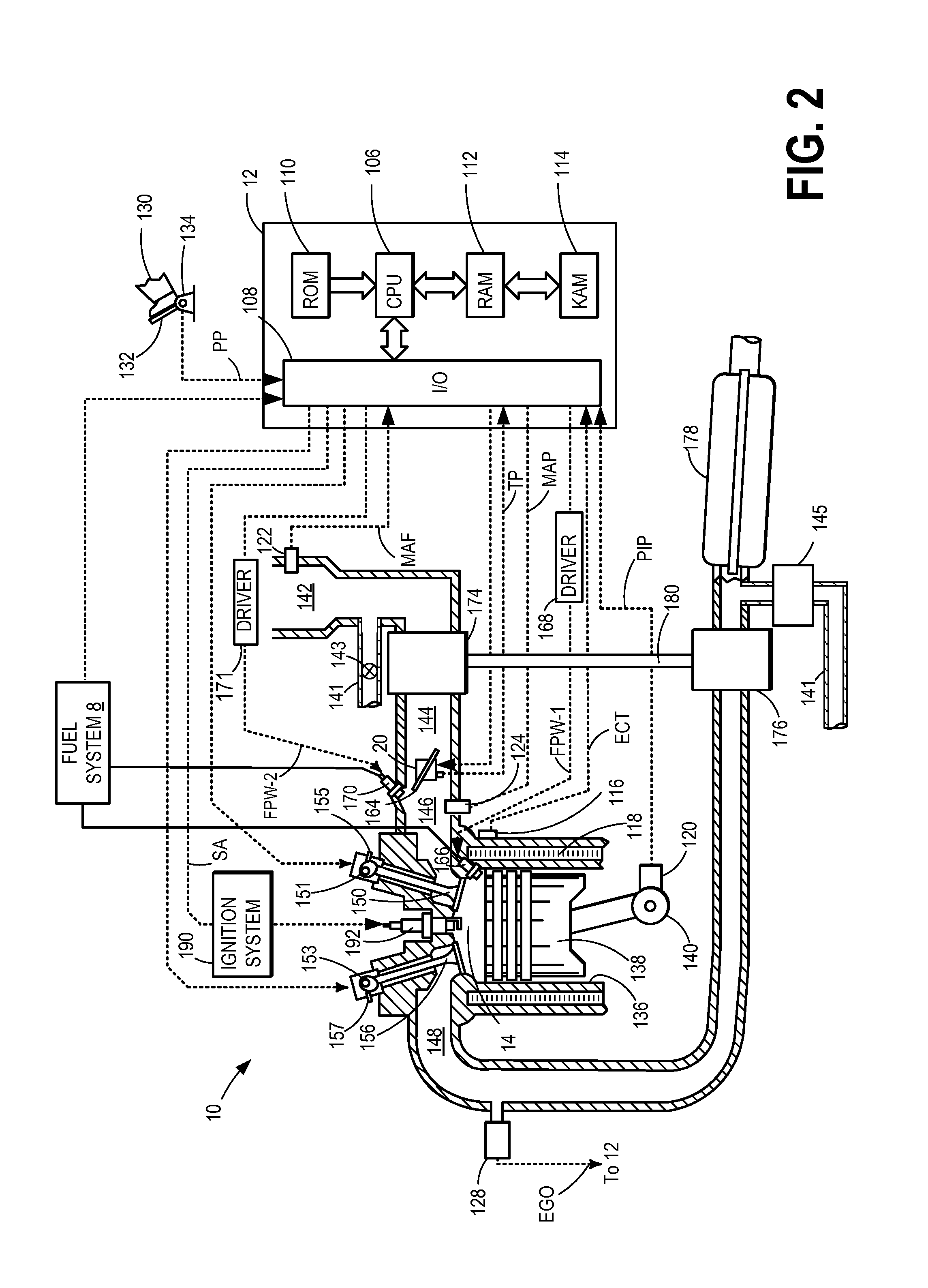

Method and system for exhaust catalyst warming

ActiveUS20160222899A1Improve fuel economyFew contactsElectrical controlInternal combustion piston enginesHeat fluxAutomotive engineering

Methods and systems are provided for leveraging engine skip-fire operation during an engine cold-start to expedite catalyst heating. Based on the heat flux required, the engine may be operated with a group of cylinders selectively deactivated, with spark retard on remaining active cylinders increased, and with engine speed increased to reduce NVH issues during the skip-fire operation. The combination of parameters may be adjusted based on changes in exhaust temperature and NVH limits of the engine.

Owner:FORD GLOBAL TECH LLC

Electronic package with a thermal interposer and method of manufacturing the same

ActiveUS7781883B2Relieve pressurePrevent inadvertent transferSemiconductor/solid-state device detailsSolid-state devicesHeat fluxInterposer

An electronic package includes a die including a thermal interface material through which a primary heat flux path is enabled for conducting heat from the die, an organic substrate, and a thermal interposer provided between the organic substrate and the die, the thermal interposer having an area extending beyond a footprint of the die, the area including the thermal interface material, the thermal interposer conducting heat generated by the die through the thermal interface material such that an auxiliary heat flux path for conducting heat generated in the die is enabled.

Owner:GLOBALFOUNDRIES US INC

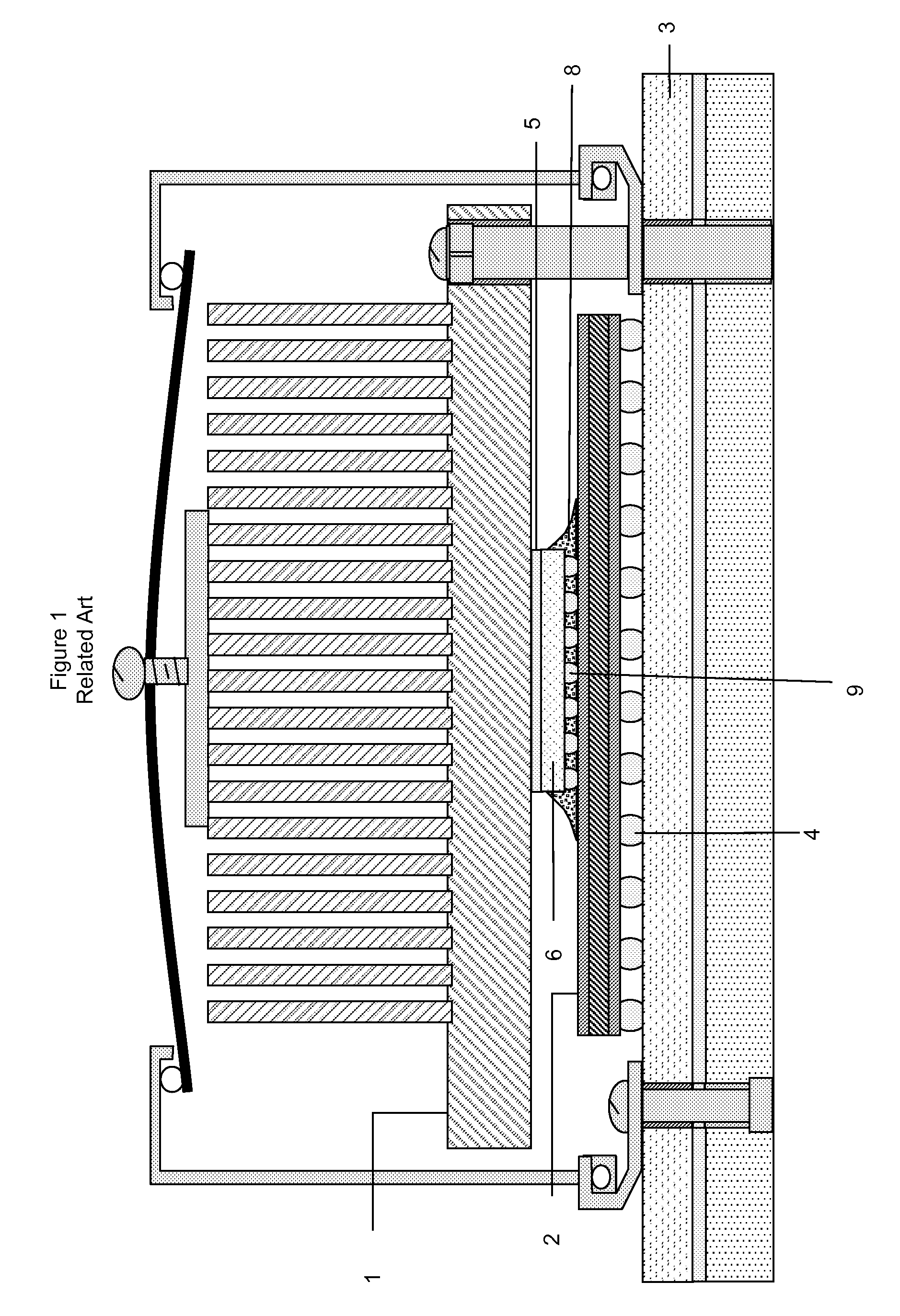

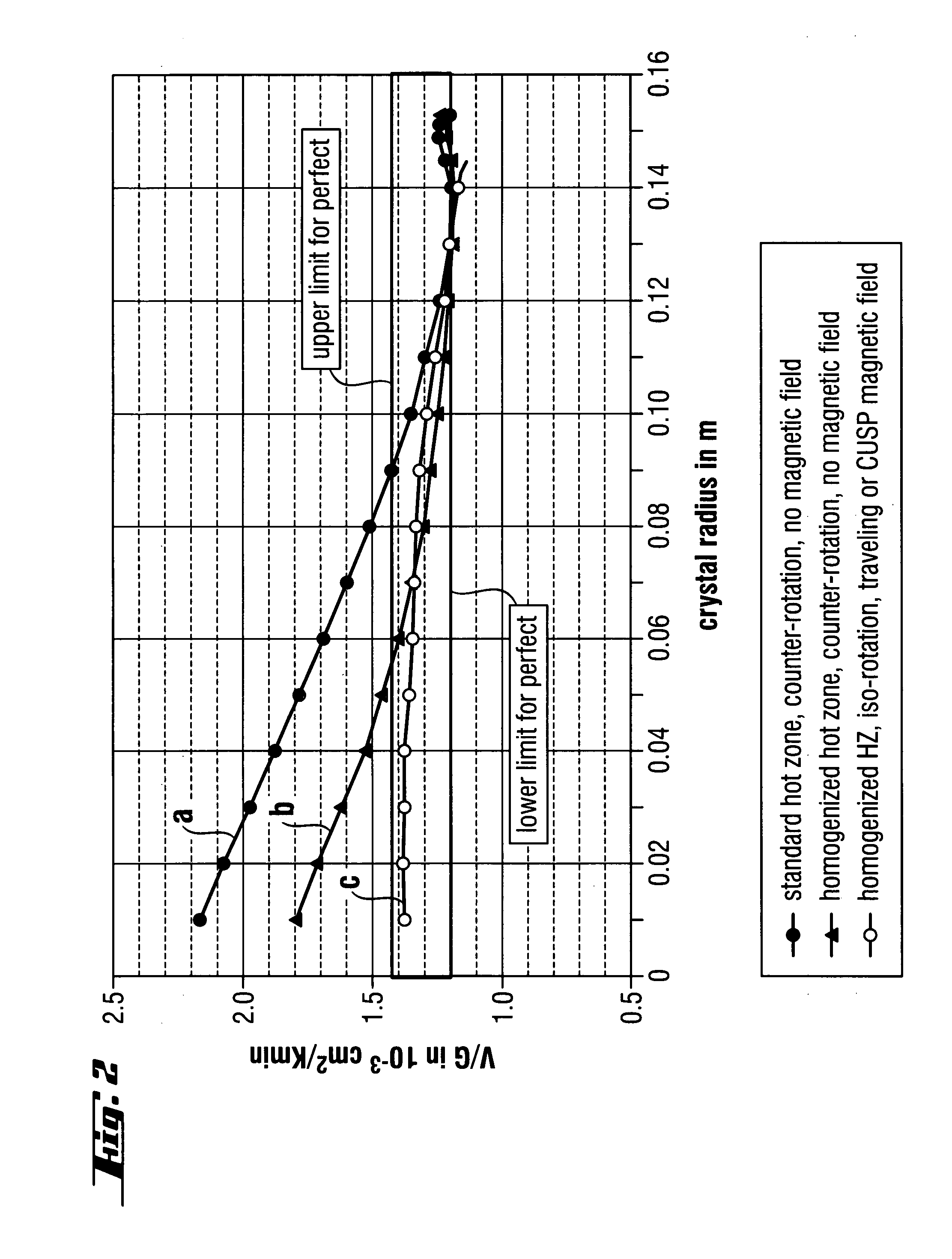

Method and device for the production of a silicon single crystal, silicon single crystal, and silicon semiconductor wafers with determined defect distributions

InactiveUS20040192015A1Increase productionMinimize thermal dissipationPolycrystalline material growthFrom solid stateVacancy defectHeat flux

A method for the production of a silicon single crystal by pulling the single crystal, according to the Czochralski method, from a melt which is held in a rotating crucible, the single crystal growing at a growth front, heat being deliberately supplied to the center of the growth front by a heat flux directed at the growth front. The method produces a silicon single crystal with an oxygen content of from 4*10<17 >cm<-3 >to 7.2*10<17 >cm<-3 >and a radial concentration change for boron or phosphorus of less than 5%, which has no agglomerated self-point defects. Semiconductor wafers are separated from the single crystal. These semiconductor wafers have may have agglomerated vacancy defects (COPs) as the only self-point defect type or may have certain other defect distributions.

Owner:SILTRONIC AG

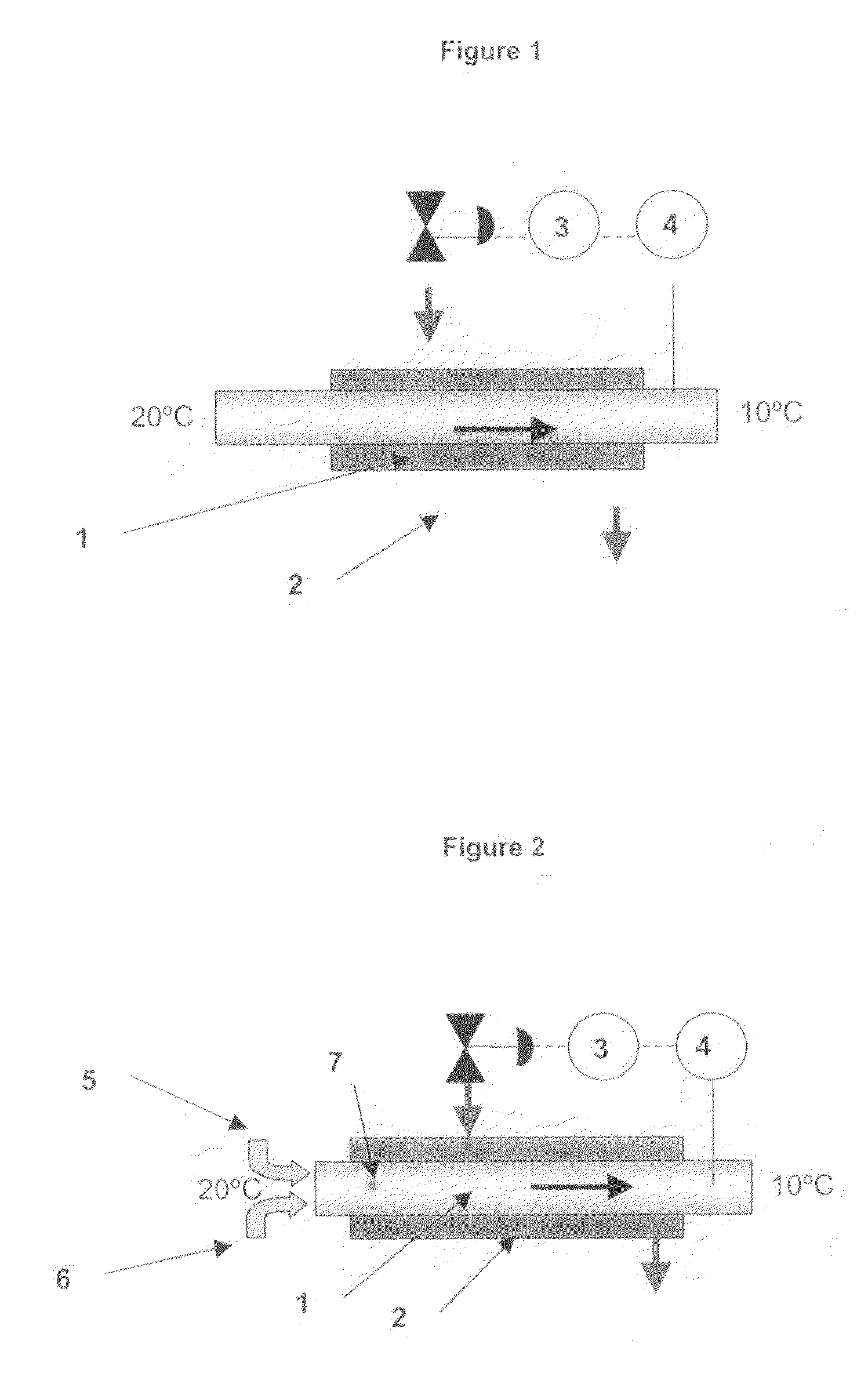

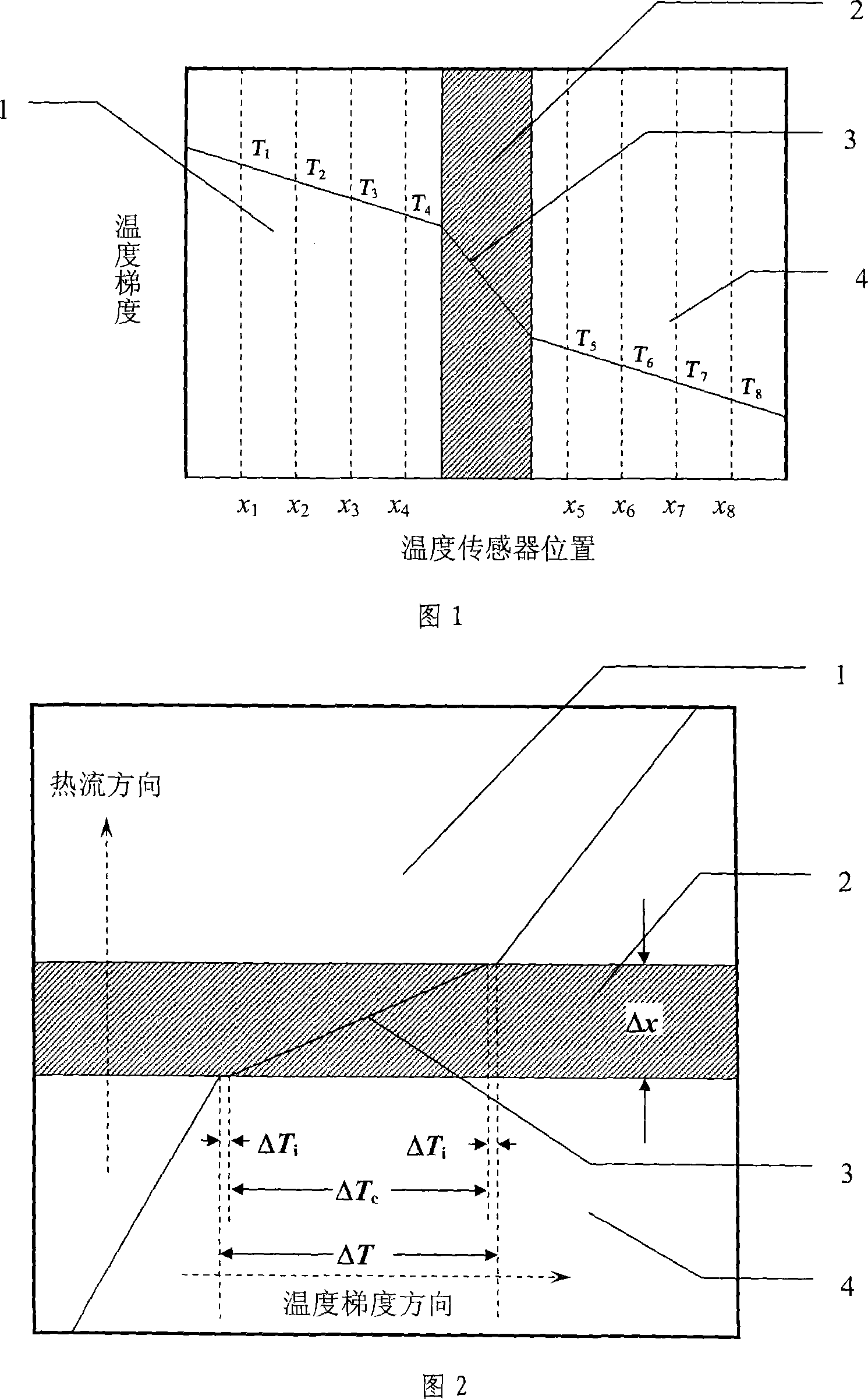

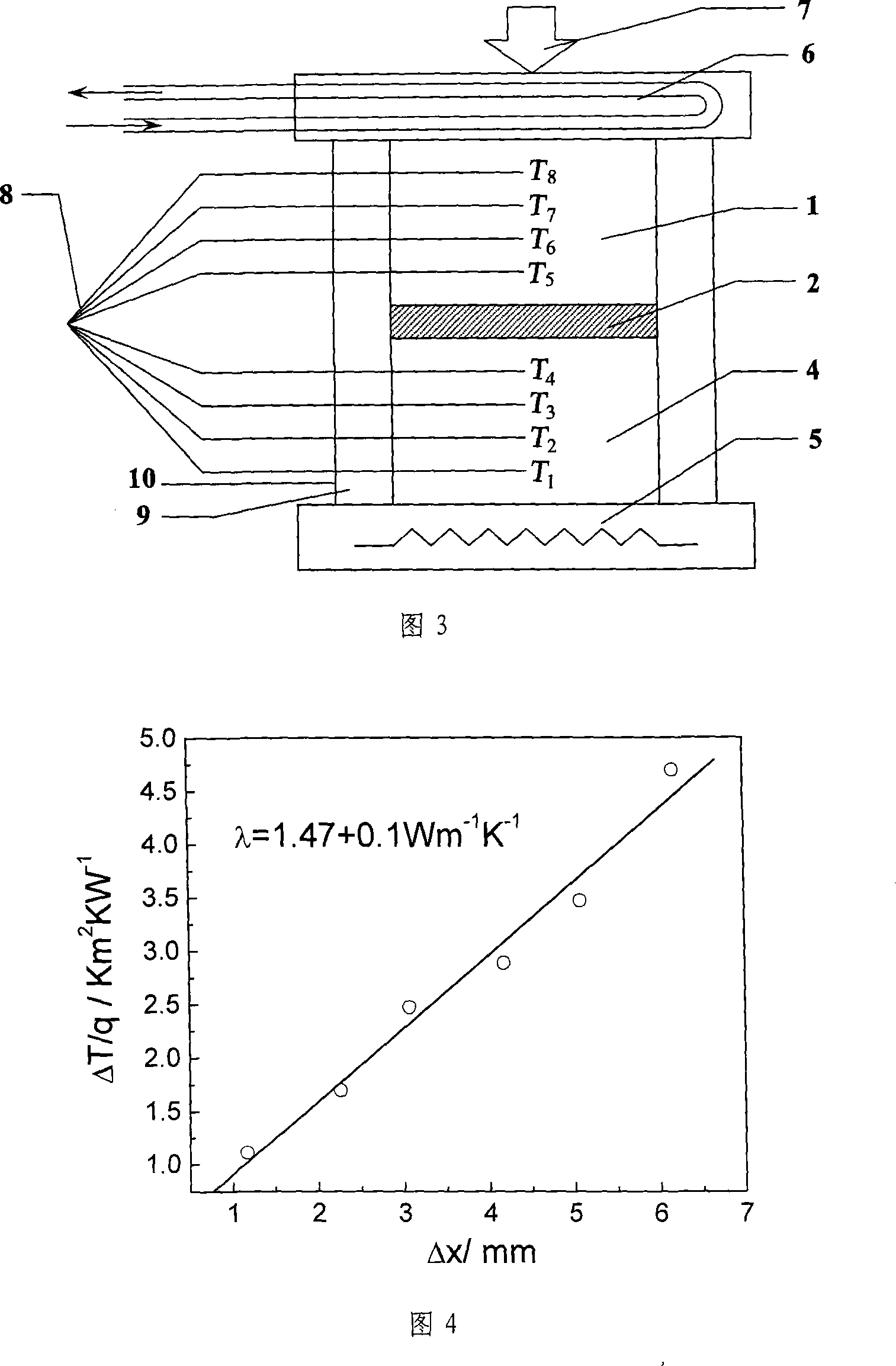

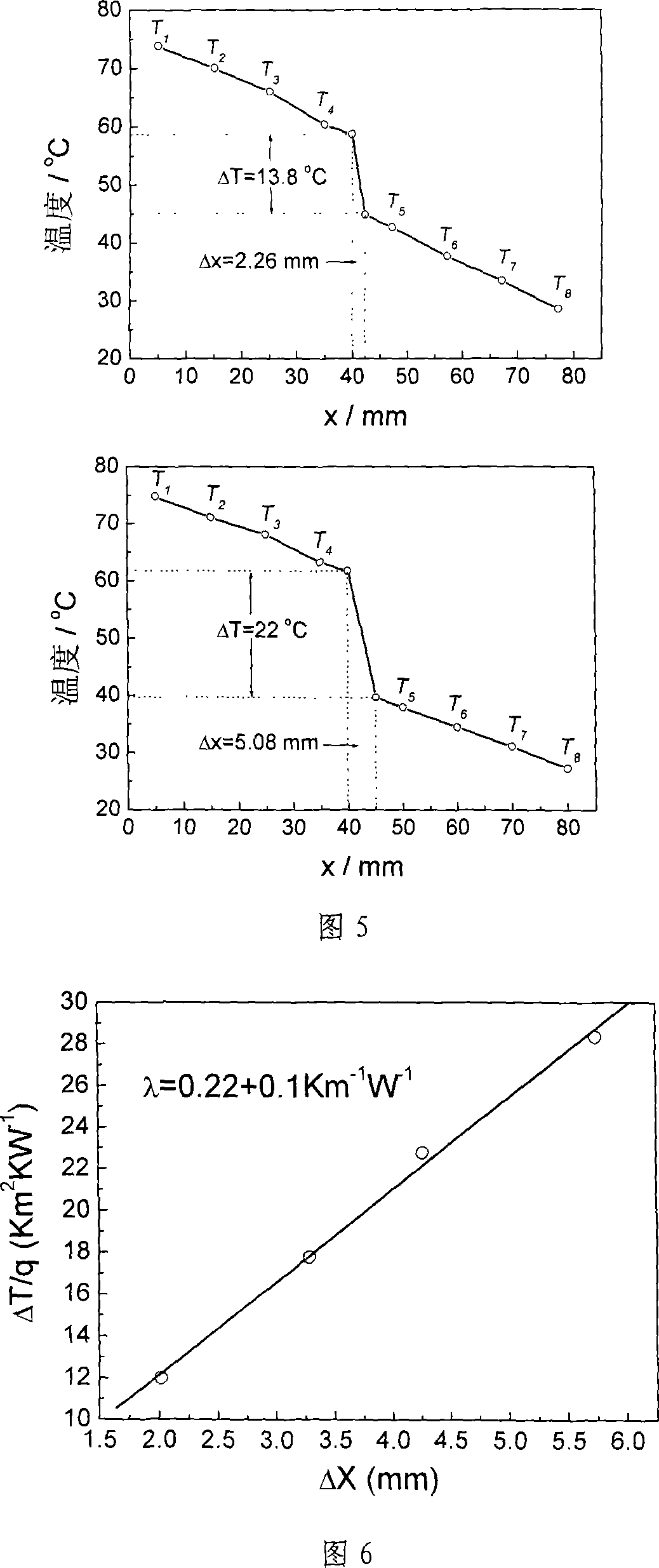

Double heat flux gauge steady state method for measuring material heat conductivity

InactiveCN101126729AOvercoming Difficulties of Inaccurate MeasurementsMaterial thermal conductivityMaterial heat developmentHeat flowHeat flux

The utility model relates to a material thermal conductivity measuring method of double heat-flux meter steady-state method, belonging to the technical field of material heat conduction performance testing. Based on the analysis of one-dimensional heat conduction in multilayer flat plate, the utility model proposes the adoption of the method of double heat-flux meter and samples with different thickness for heat conduction measurement, and gives quantitative criterion of one-dimensional heat conduction. The utility model adopts multi-point temperature measurement in heat-flux meter, calculates the average heat flux density with one-dimensional heat conduction formula of multi-layer flat plate, overcomes the difficulty of inaccurate heat flux density measurement, and makes alignment-fitting calculation for the actual thermal conductivity coefficient and the interface thermal resistance with test data of samples with different thickness. In addition, the utility model can test not only the thermal conductivity of solid material, but also the thermal conductivity coefficient of film material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Thermal management system with variable-volume material

InactiveUS20140158334A1Simple and robustEasy to returnTemperatue controlHeat storage plantsThermal energyHeat flux

A thermal management system configured to be installed between a heat source and a heat sink, including a first heat conductor and a second heat conductor, a thermal switch configured to allow or prevent thermal connection between the first and second heat conductors, the thermal switch including at least one thermally conductive material that can connect the first and second conductors by a change in its volume, and the thermal switch including a controller configured to transfer thermal energy to the phase-change material to change a connection state. The connection is made when the heat source goes above a critical temperature, since the connection enables a heat flux to be established between the heat source and the heat sink.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

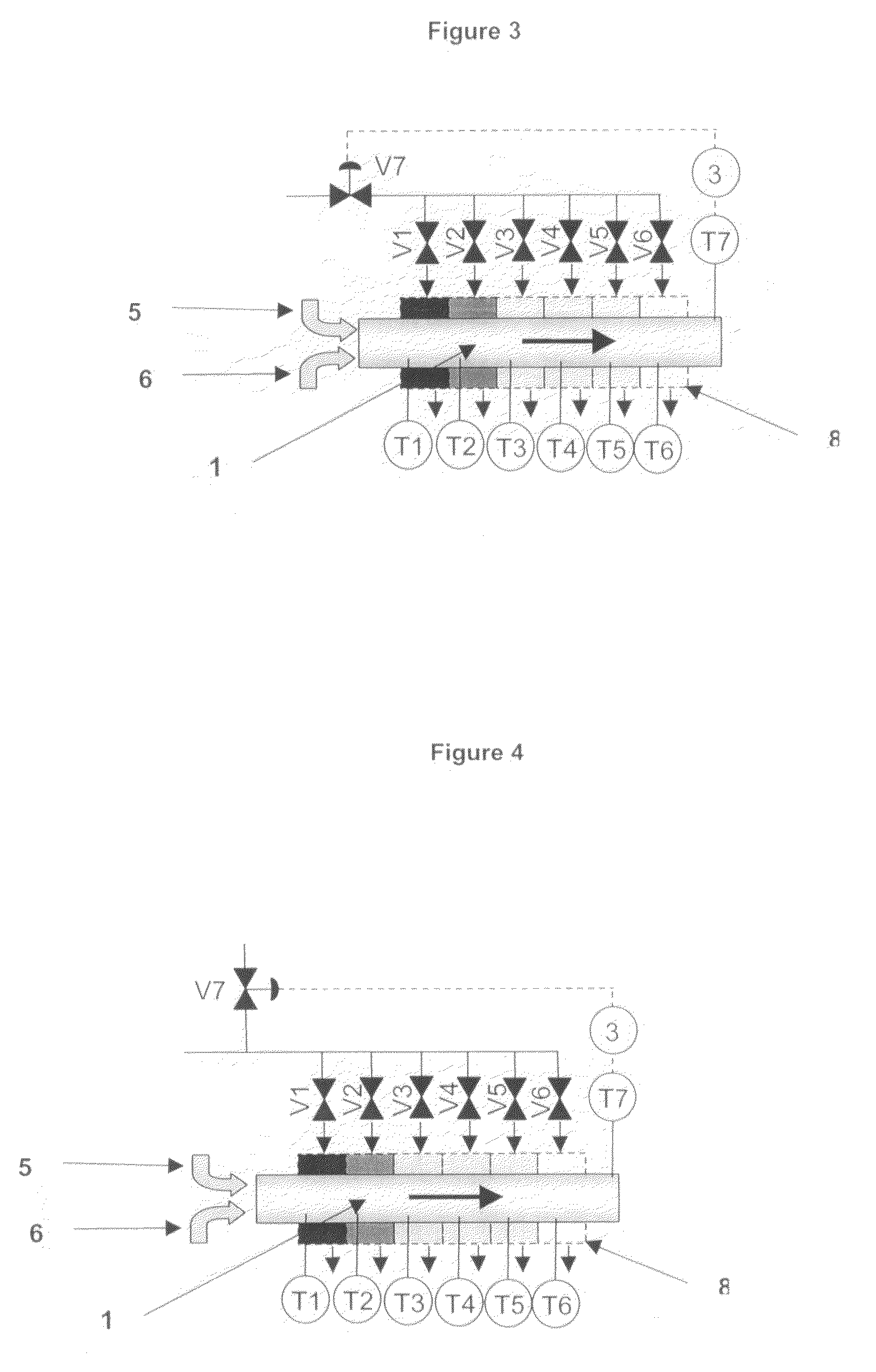

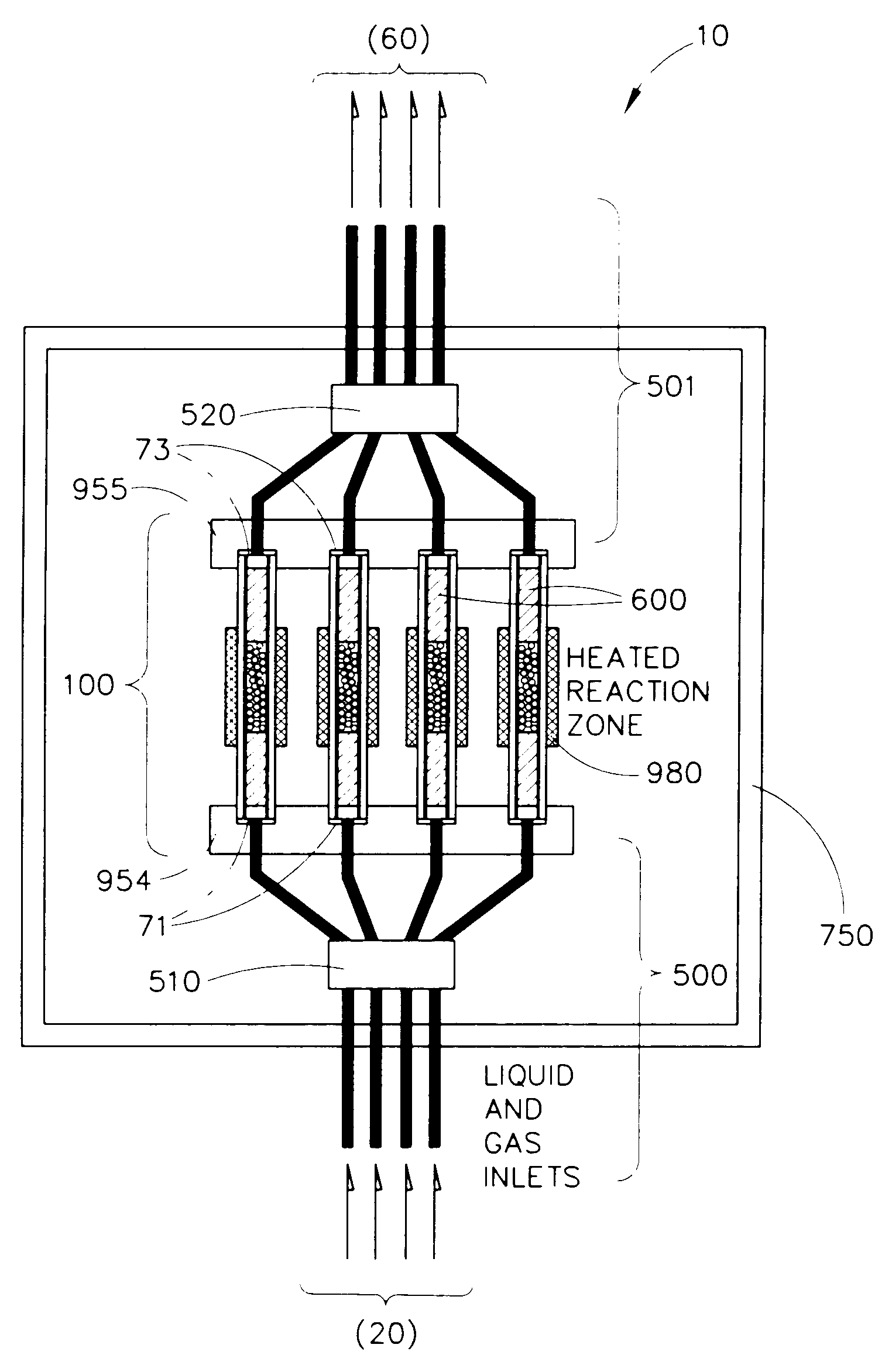

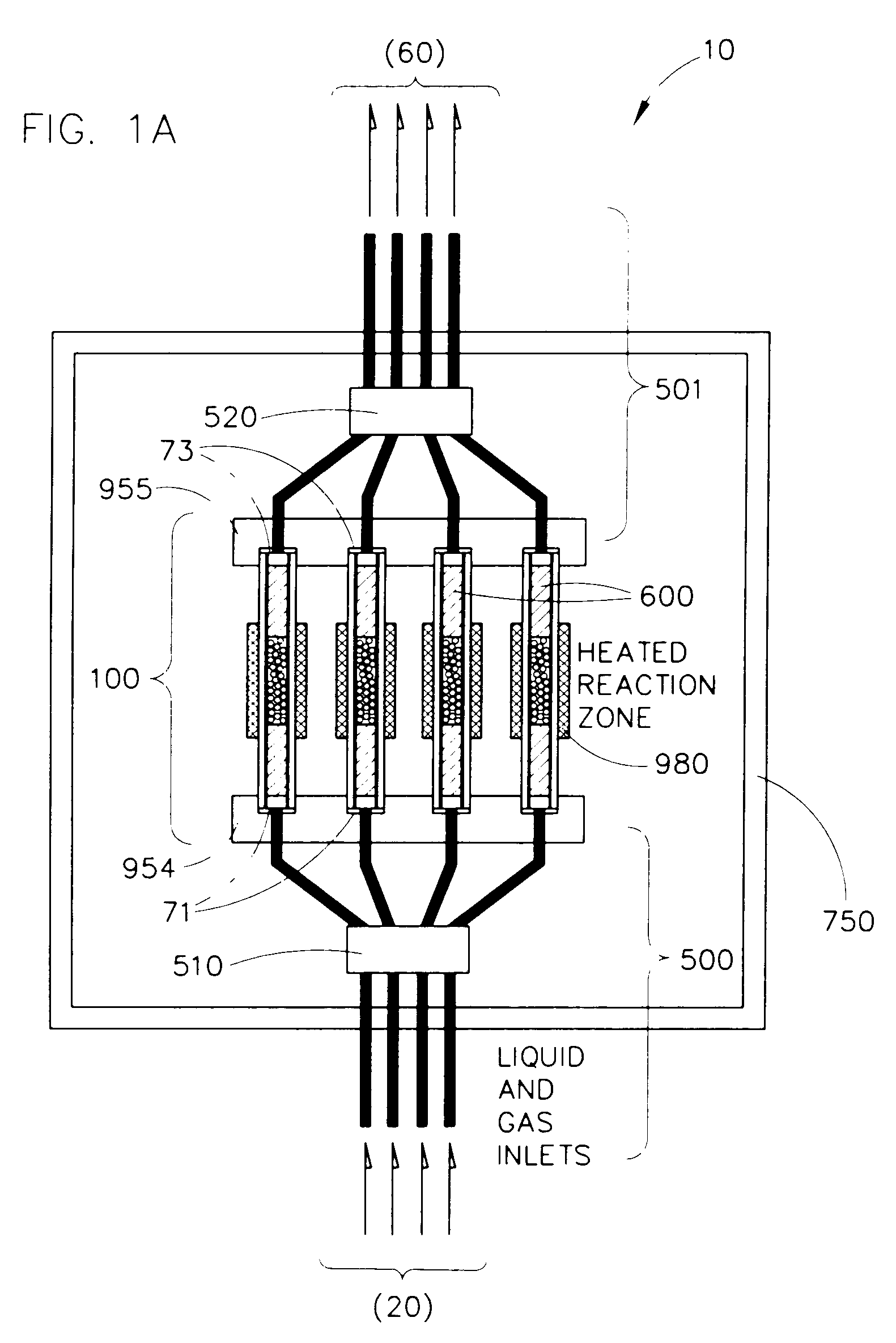

Parallel flow reactor having improved thermal control

InactiveUS7118917B2Efficient identificationEfficiency optimizationSequential/parallel process reactionsLighting and heating apparatusChemical treatmentThermal isolation

Parallel flow chemical processing systems, such as parallel flow chemical reaction systems are disclosed. These systems are adapted to simultaneously and independently vary temperature between separate flow channels, preferably by employing separate, individual heating elements in thermal communication with each of four or more parallel flow reactors. The flow reactors are preferably isolated from each other using a thermal isolation system comprising fluid-based heat exchange. In preferred embodiments, the axial heat flux can be fixedly or controllably varied.

Owner:FREESLATE

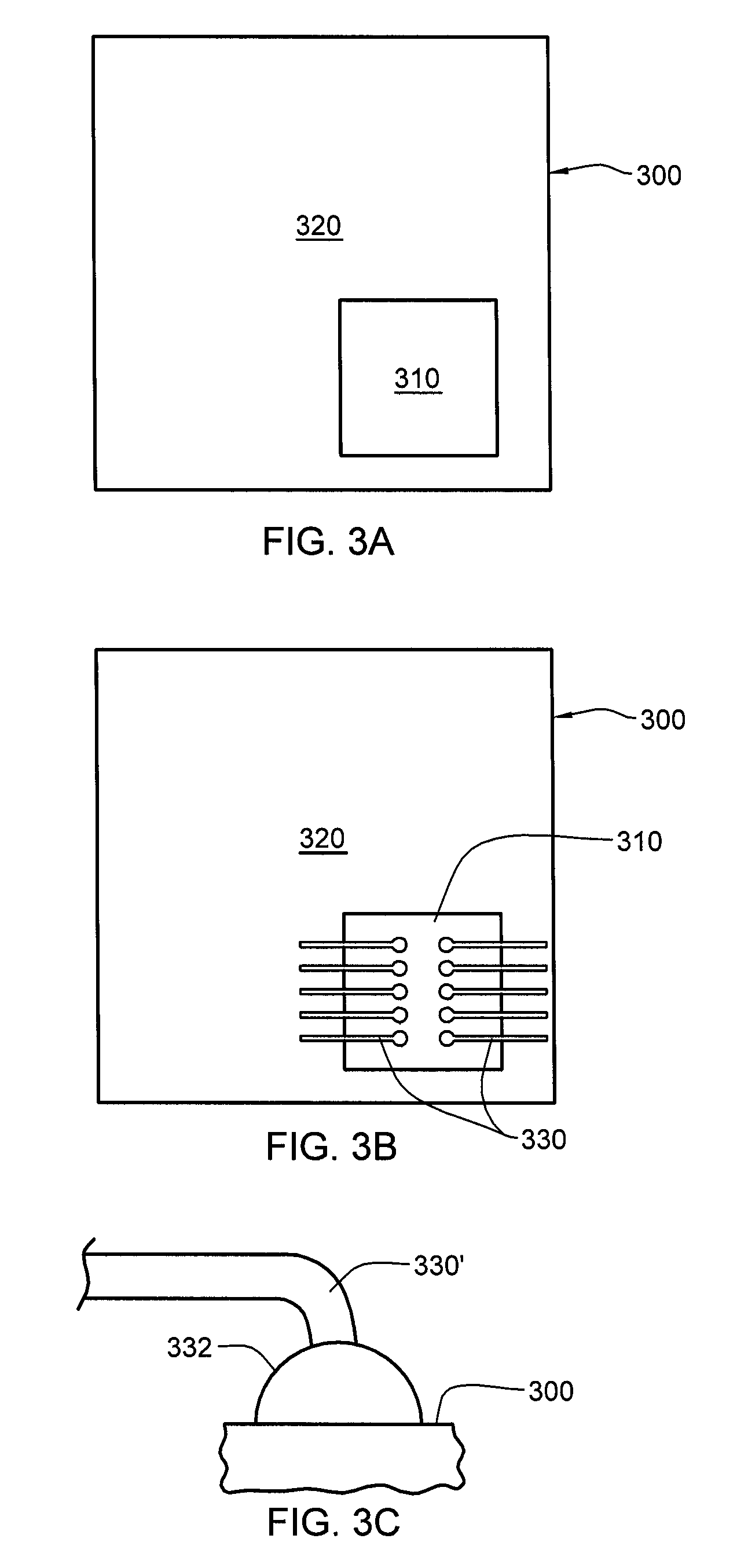

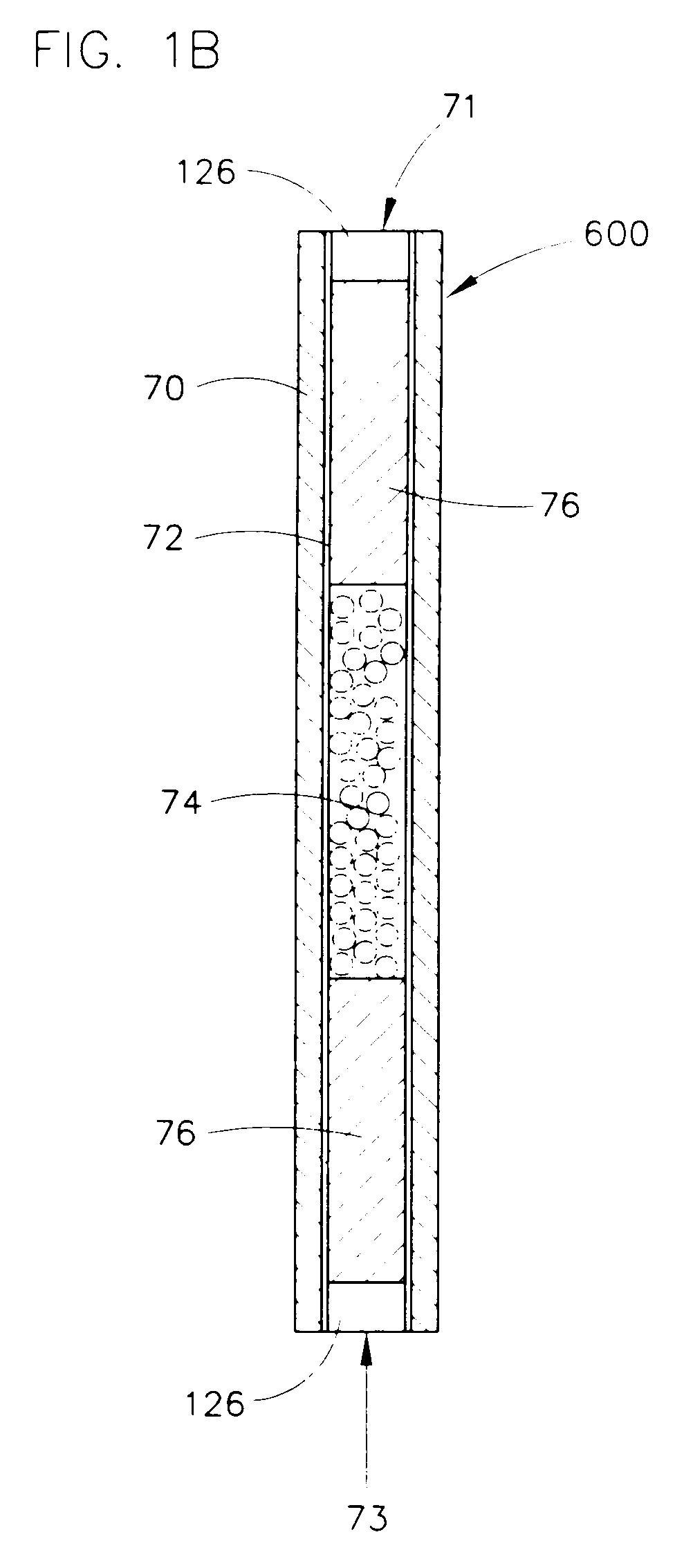

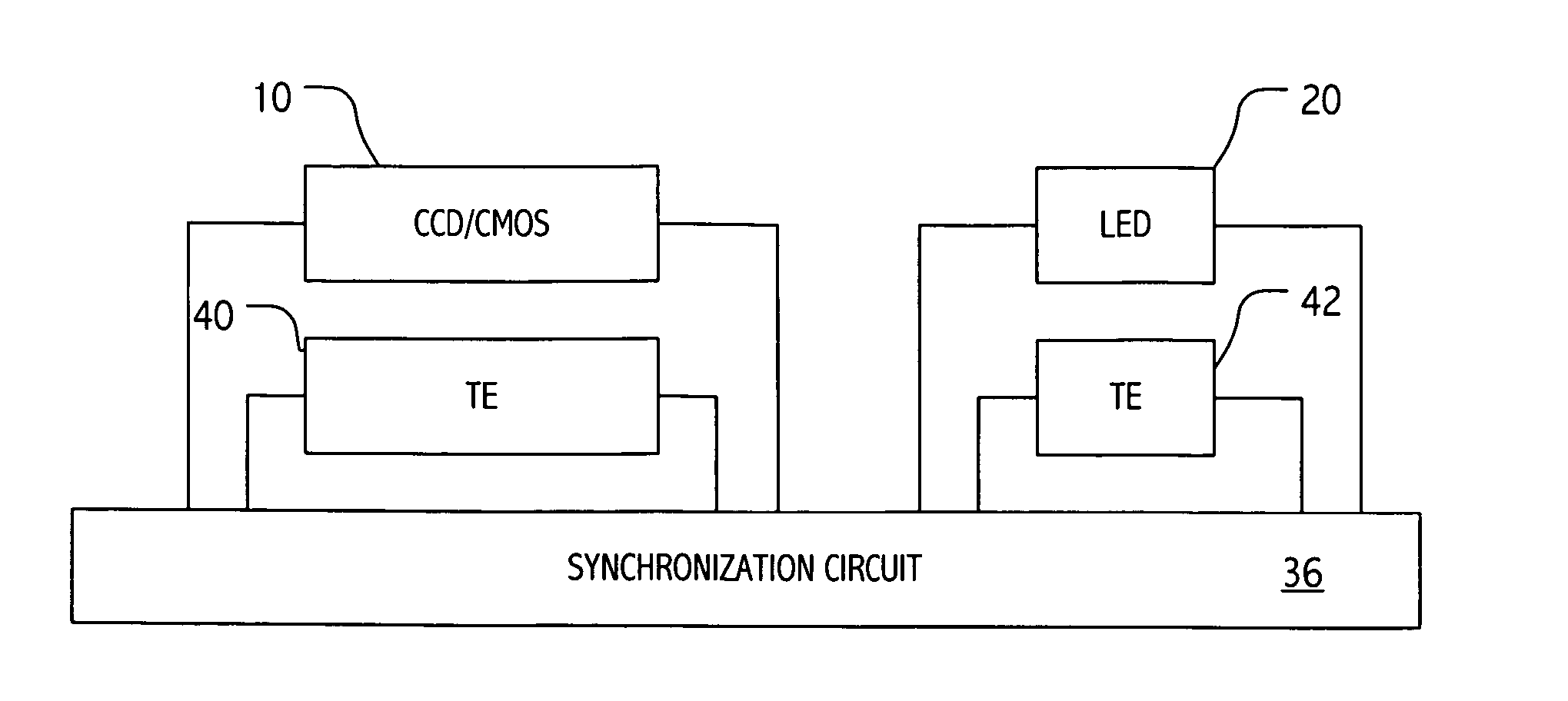

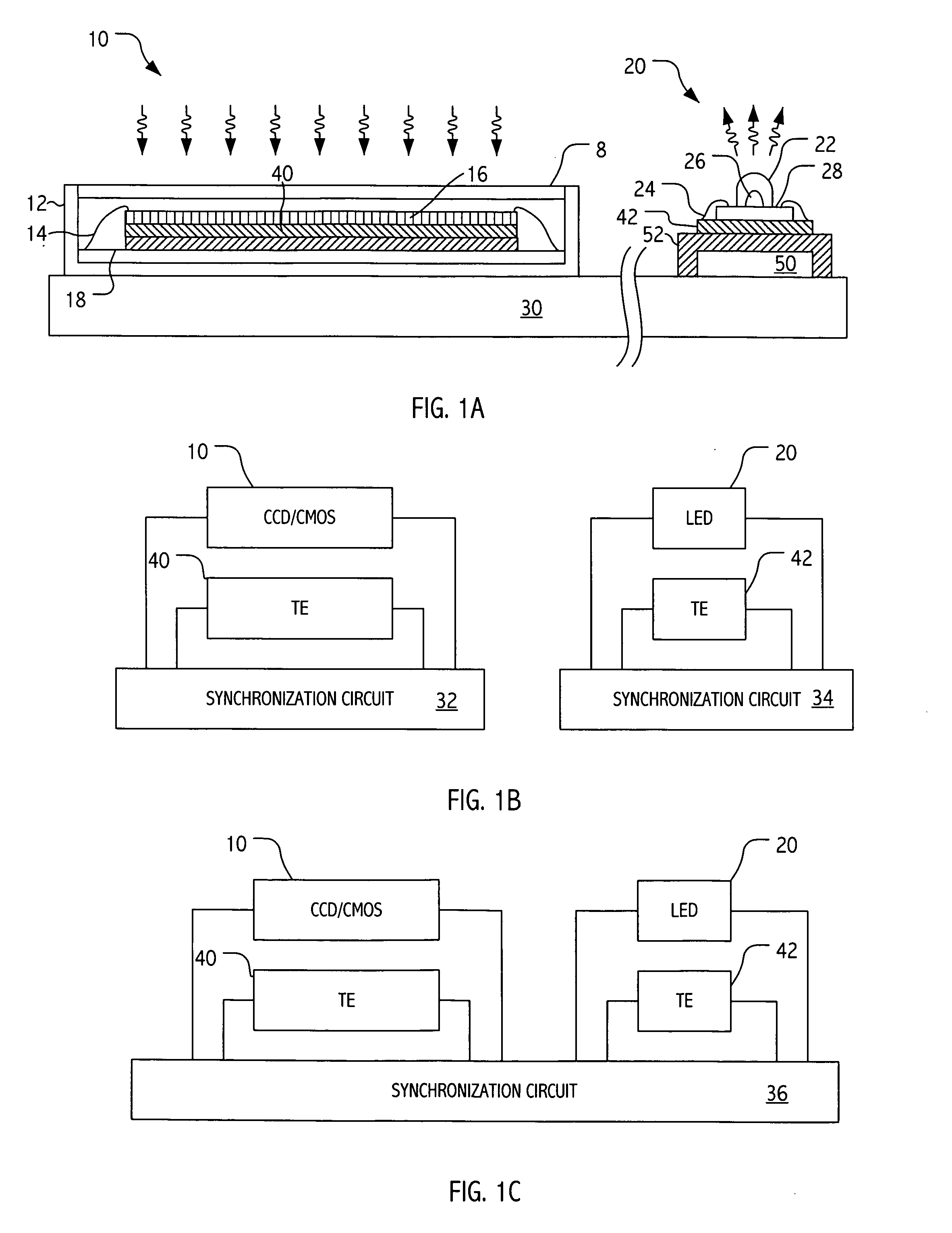

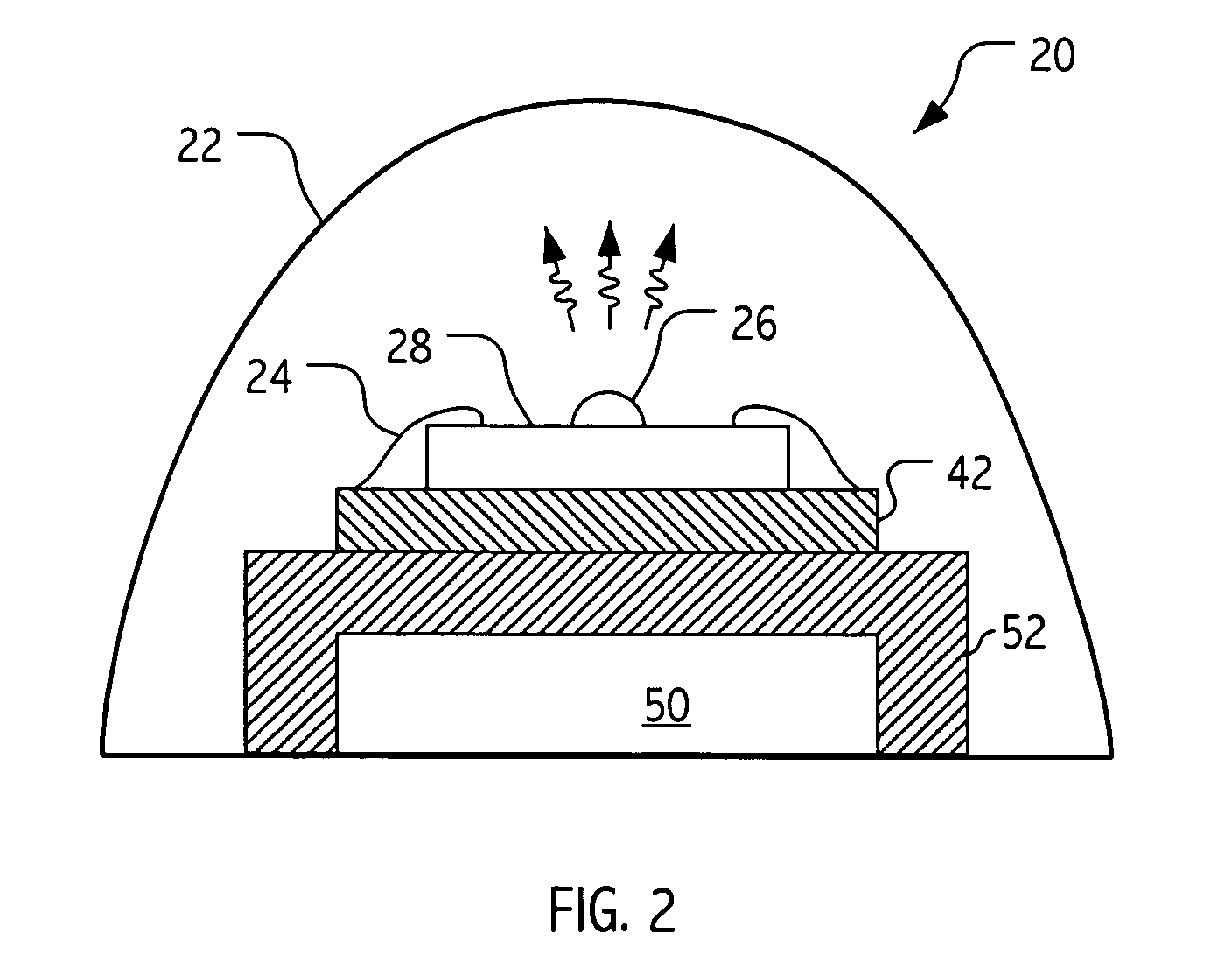

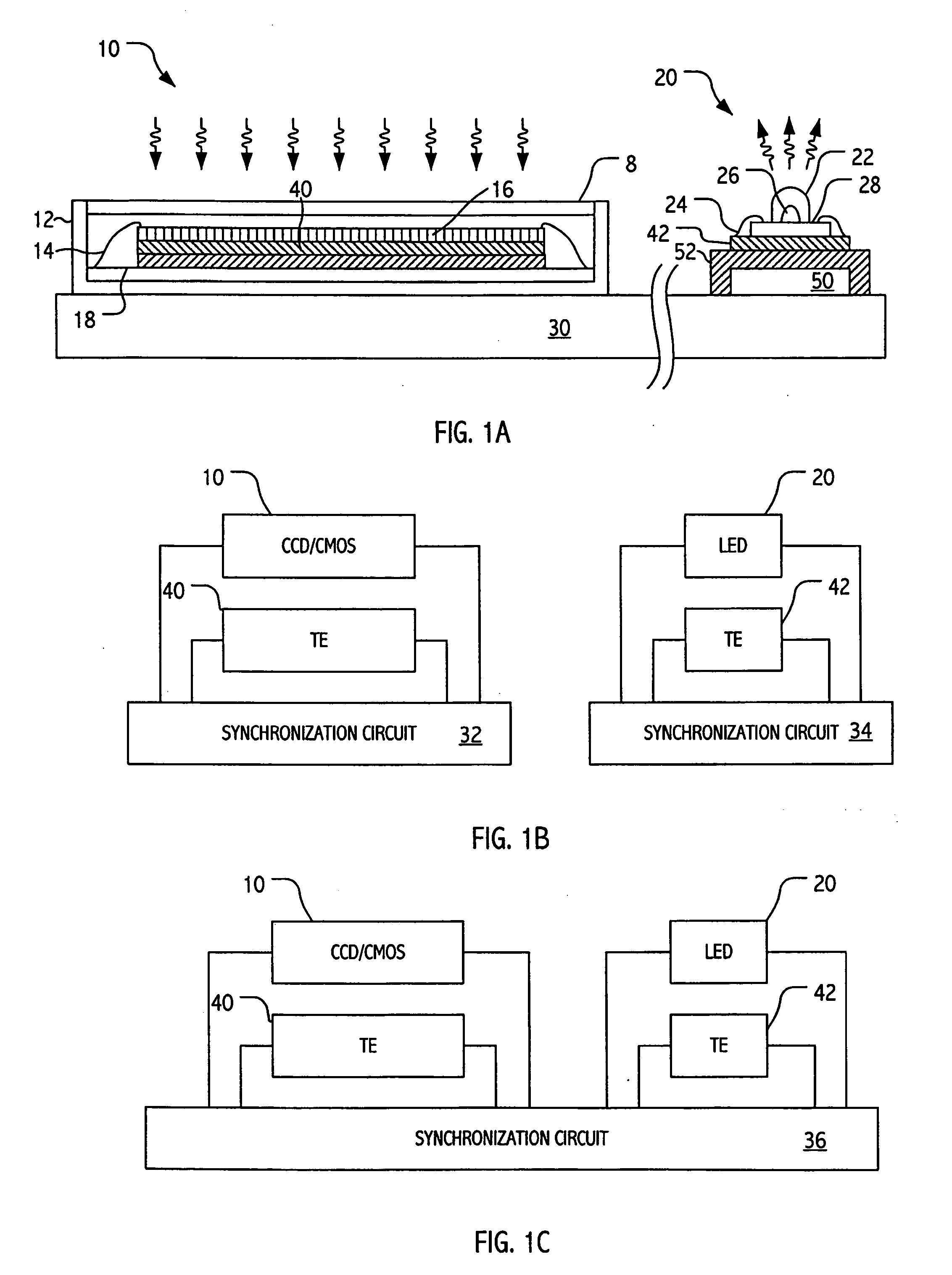

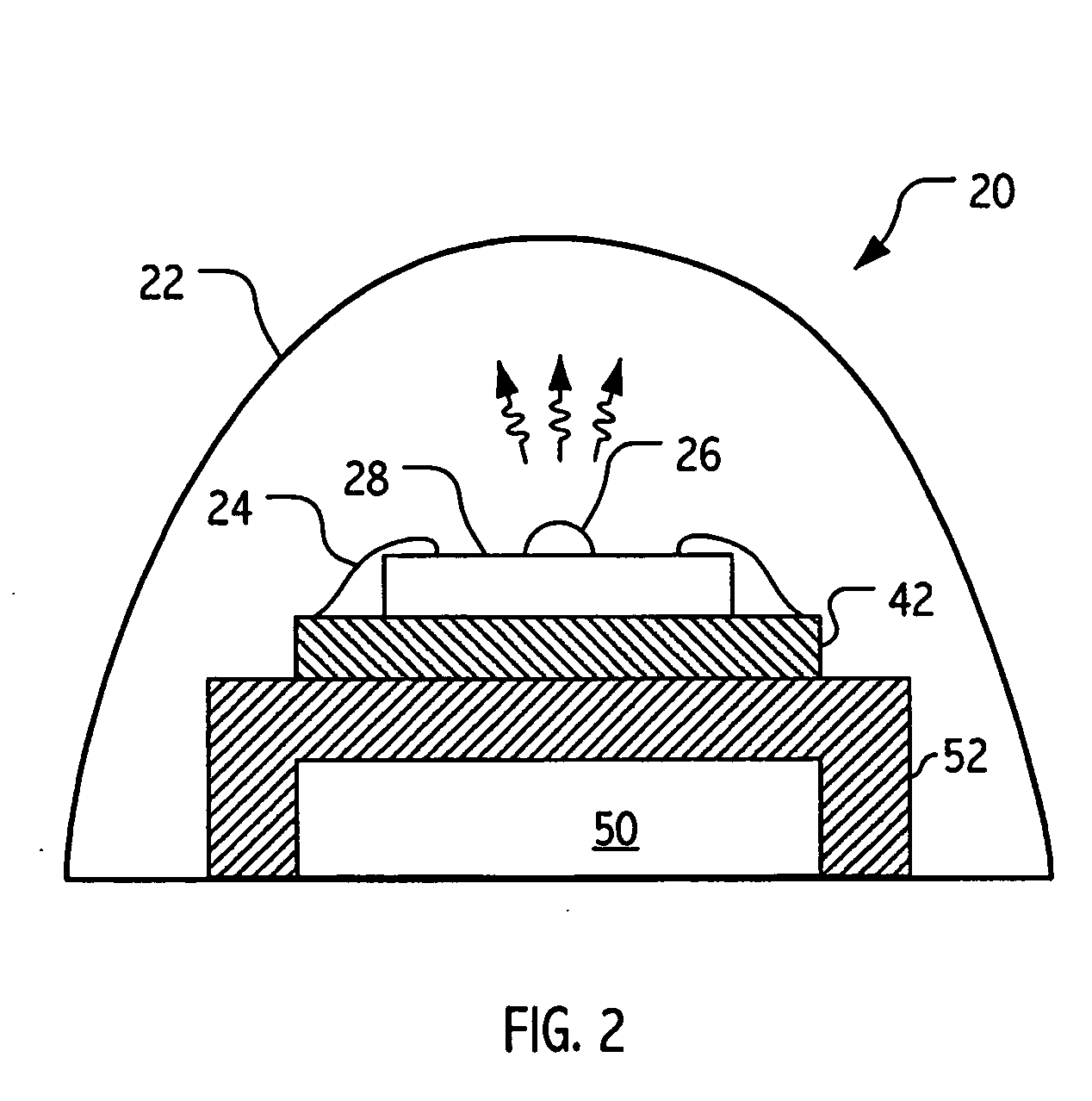

Transient thermoelectric cooling of optoelectronic devices

InactiveUS20060088271A1Reduce the temperatureEffective clampingPrinted circuit aspectsSolid-state devicesThermoelectric coolingHeat flux

A thermoelectric cooler may be transiently operated in substantial synchronization with operation of an optoelectronic device to provide extremely high density and intensity spot cooling when and where desired. The invented techniques described and illustrated herein can permit high luminous flux and / or longer lifetimes for a class of emissive device configurations and / or uses that generate intense highly localized, but transient heat flux. For example, certain Light Emitting Diode (LED) applications, e.g., white LEDs for flash illumination, certain solid state laser configurations and other similar configurations and uses may benefit from the developed techniques. In addition, the invented techniques described and illustrated herein can be employed in sensor configurations to provide greater device sensitivity. For example, in photosensitive device applications, e.g., CCD / CMOS imagers, the invented techniques may be employed to provide greater photon sensitivity and lower dark currents.

Owner:NANOCOOLERS

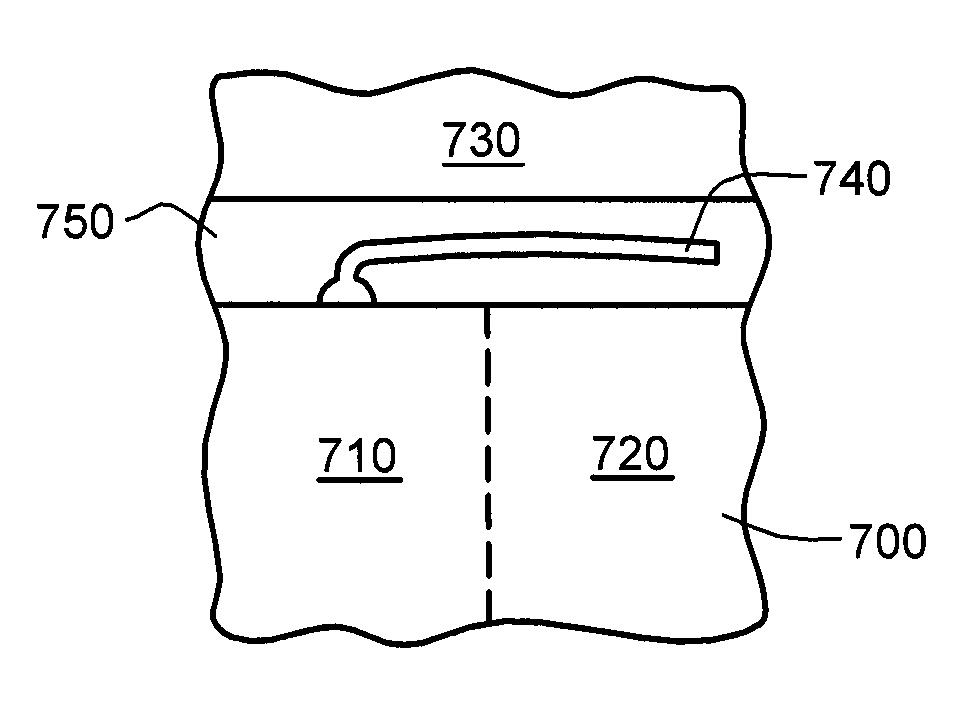

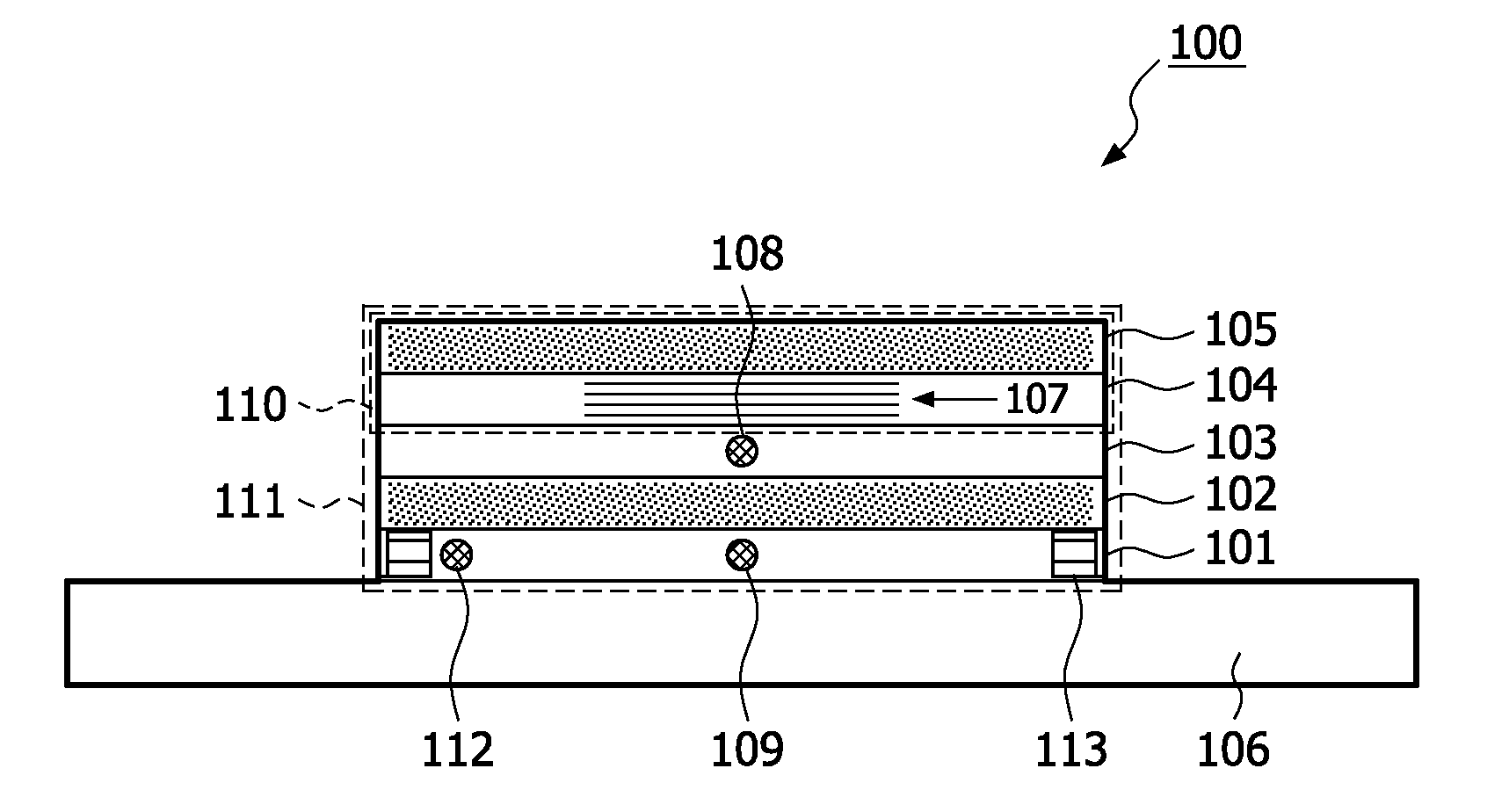

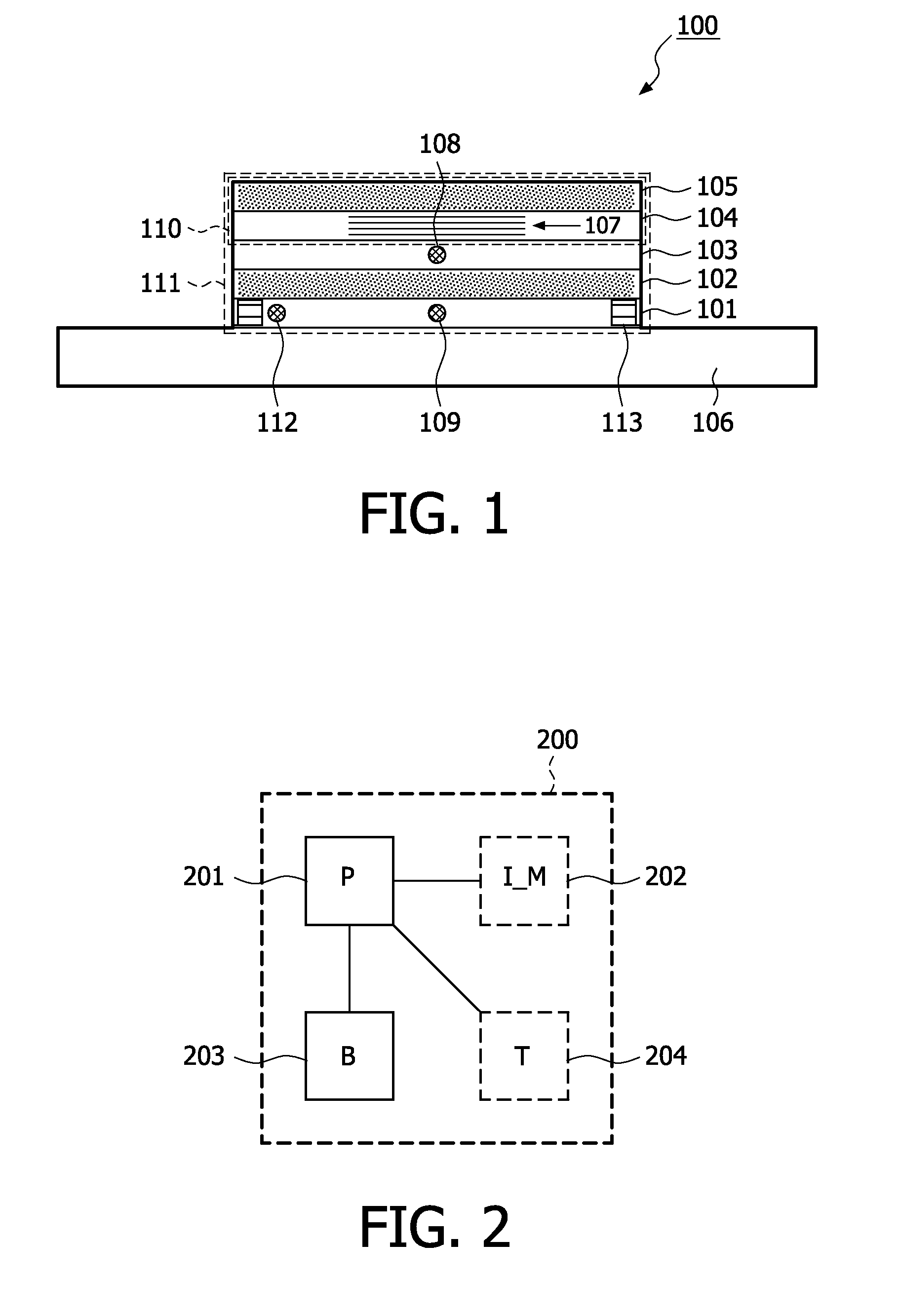

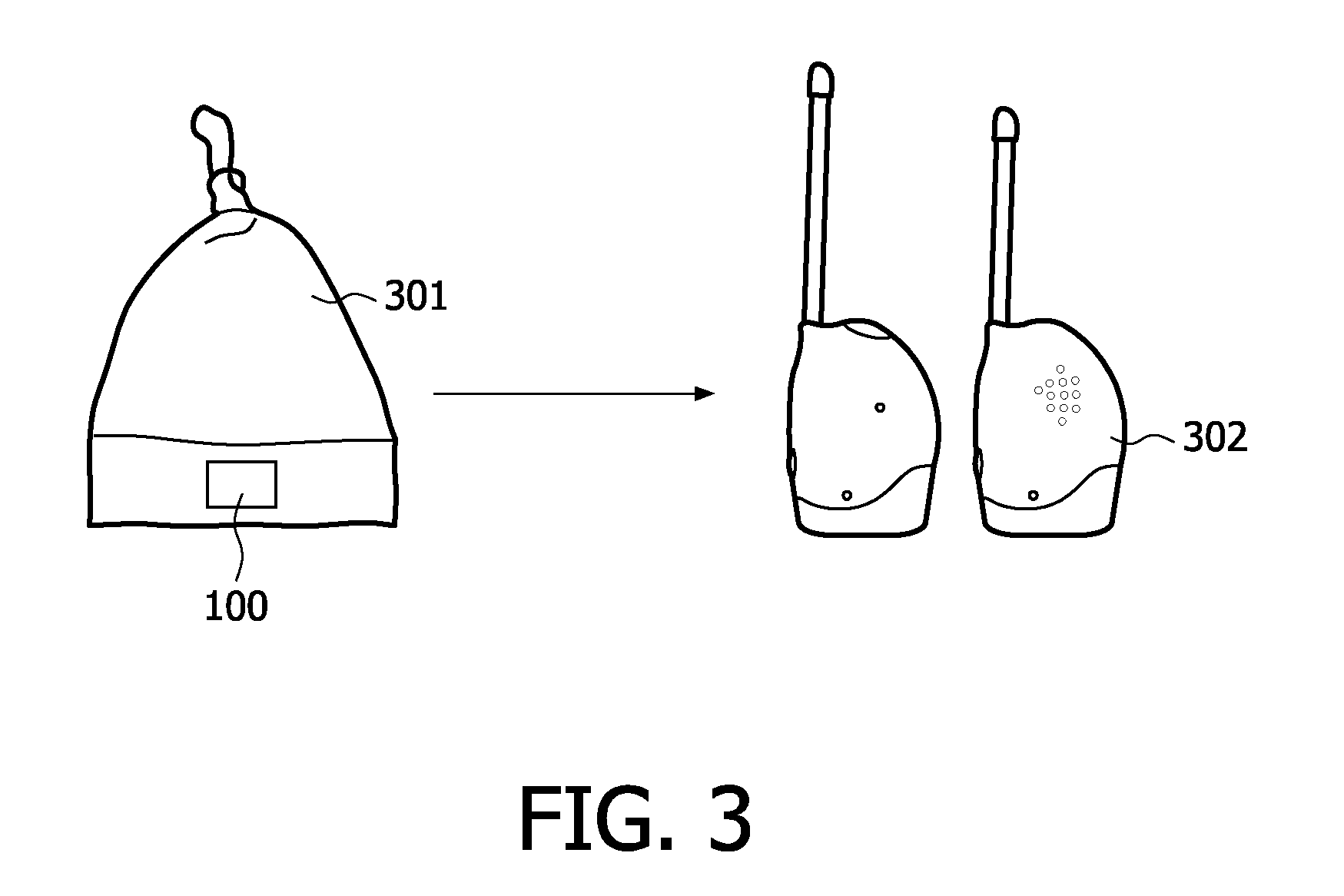

Temperature sensor for body temperature measurement

ActiveUS20120024833A1Prevent lateral heat lossReduce decreaseThermometer detailsThermometers using electric/magnetic elementsHeat fluxBody temperature measurement

This invention relates to a temperature sensor for body temperature measurements. The temperature sensor is made of several layers, where a first layer has a central heater embedded therein, a second layer which is attached to the first layer has at least one first thermistor embedded therein for measuring a first temperature value, a third layer has at one ore second thermistor embedded therein separated from the first thermistor for measuring at least one second temperature value, but this third layer is adapted to be in contact to the skin of the surface of the body for conducting the heat escaping from the body through the layers. The difference between the first and the second temperature values indicates the heat flux from the body. The heat emitted from central heater is tuned oppositely to the heat flux until a zero heat flux is reached, where the temperature at the at least one second thermistor at zero heat flux indicates the body temperature. These layers are fabric layers.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

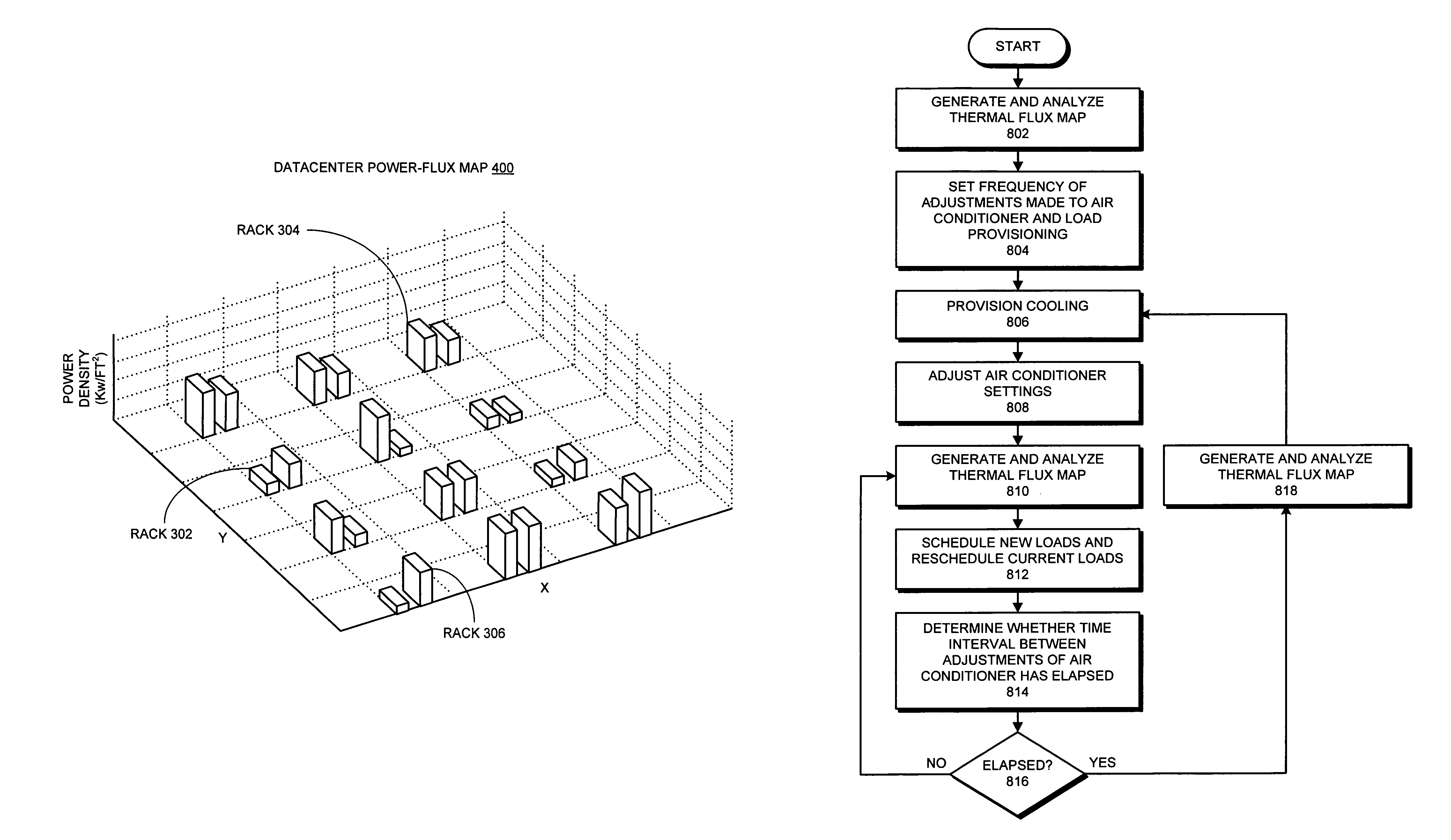

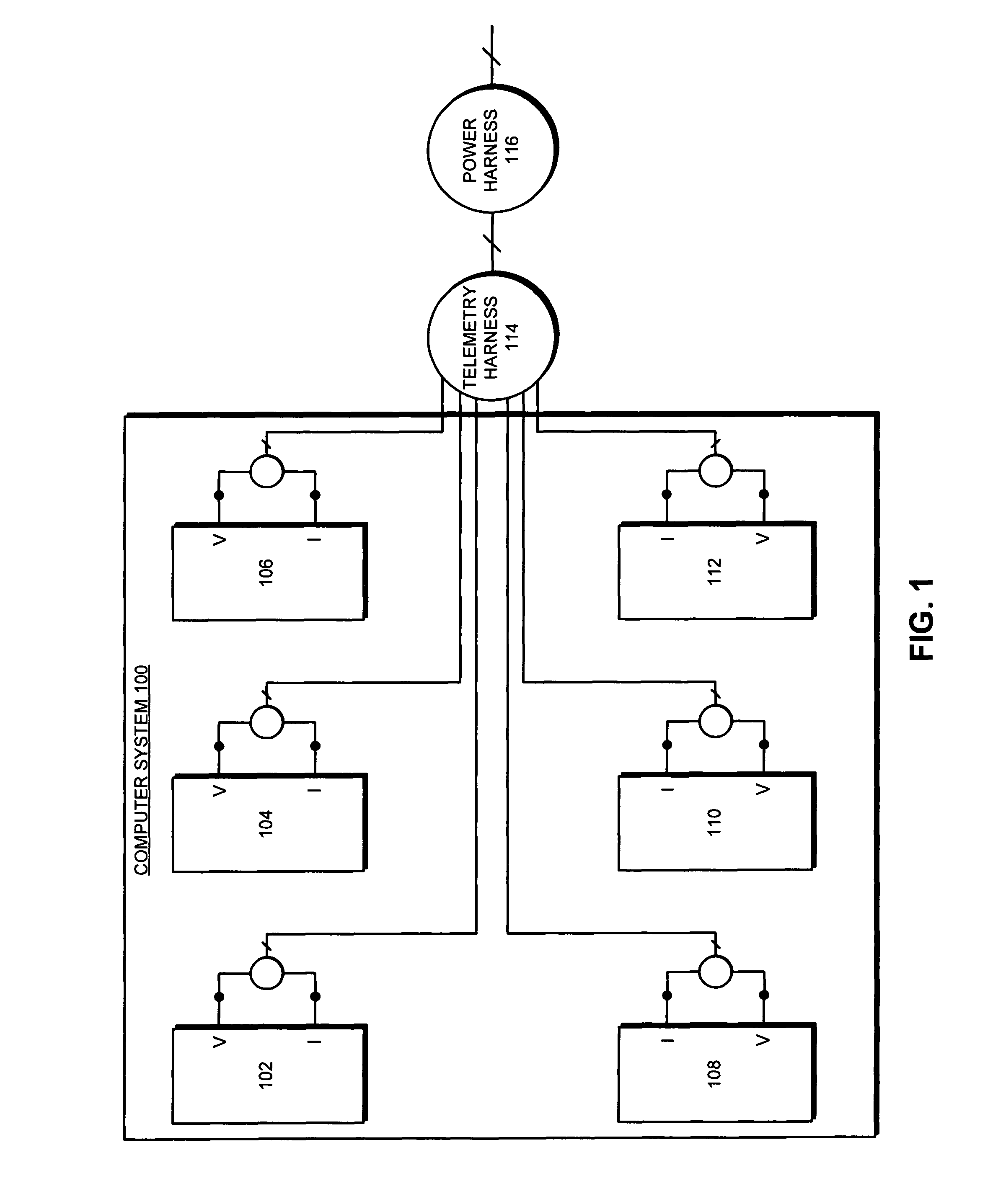

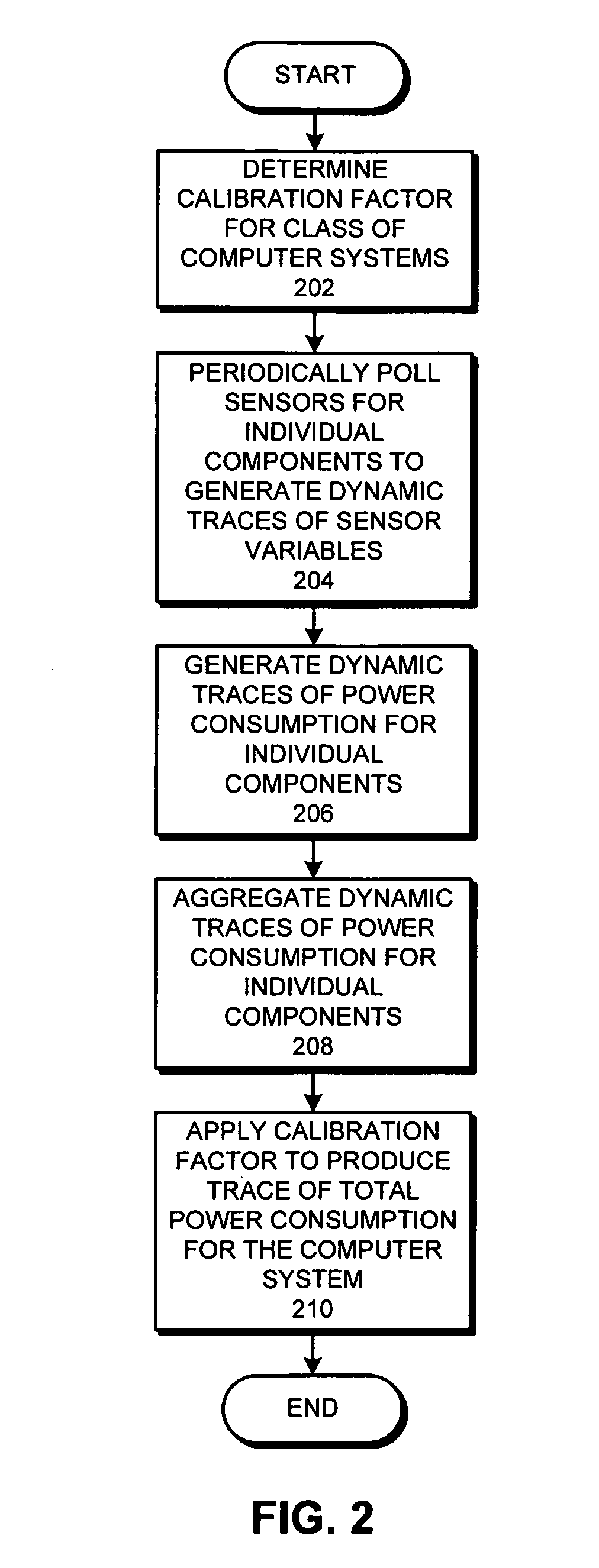

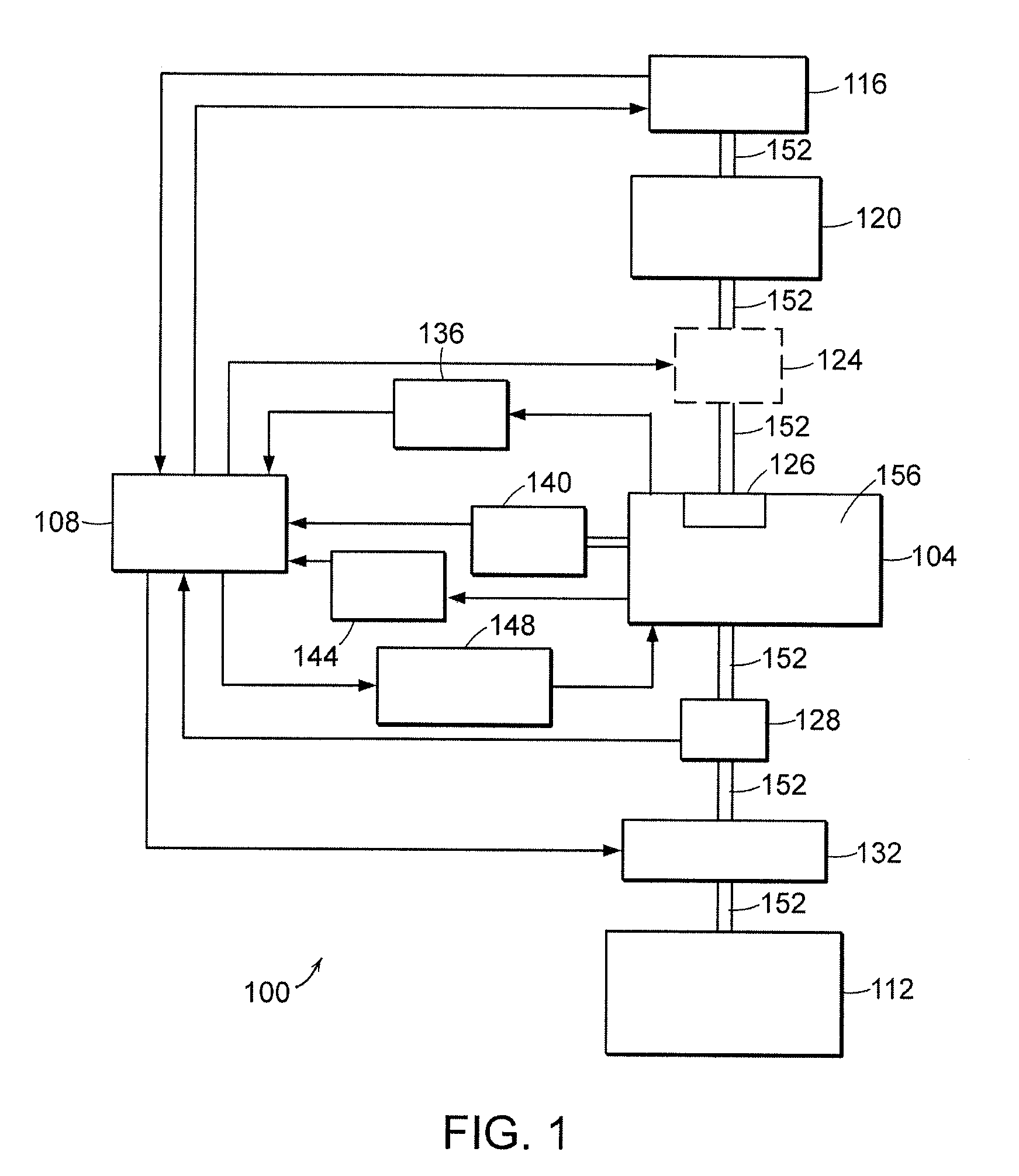

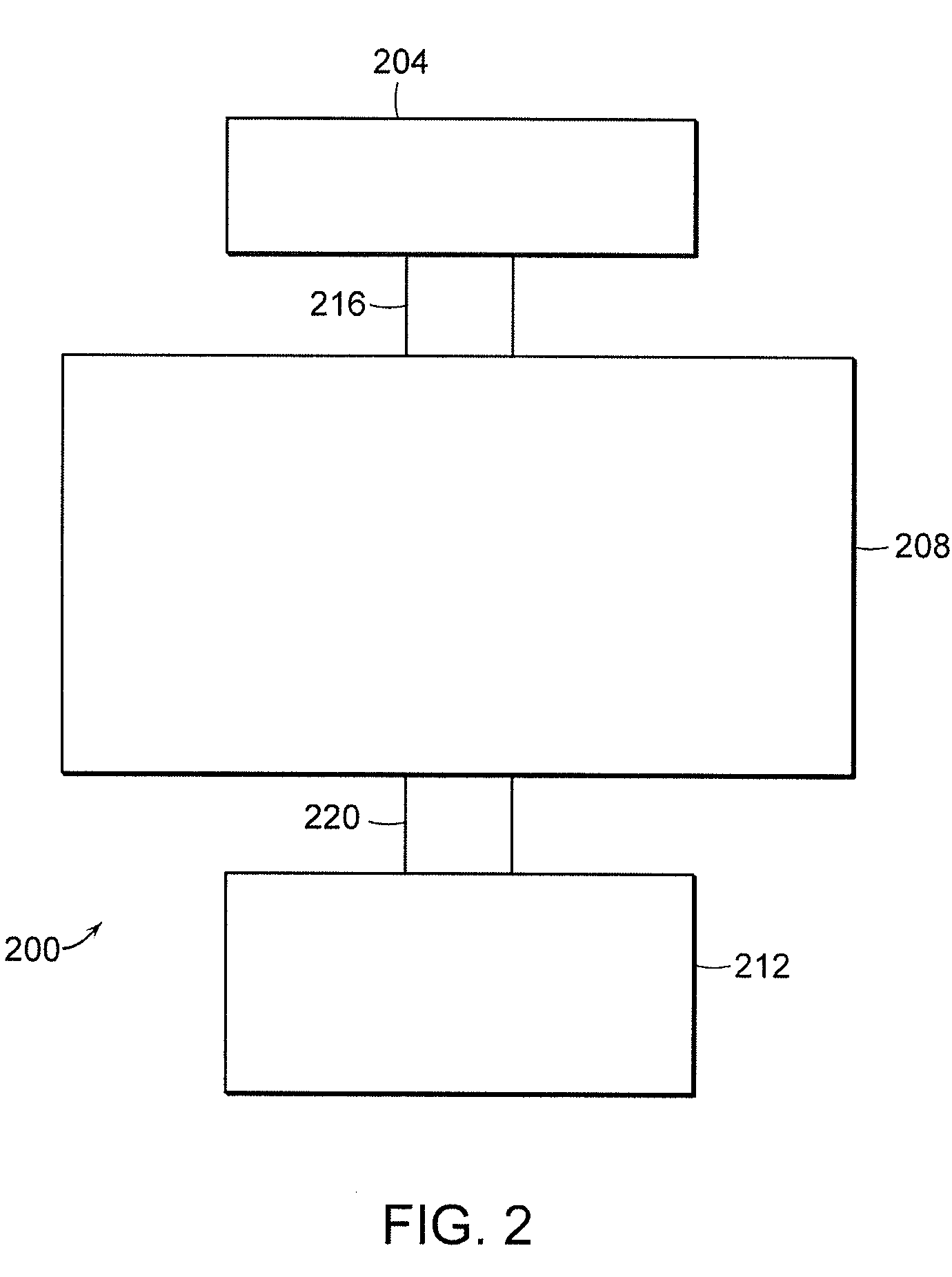

Method and apparatus for balancing thermal variations across a set of computer systems

ActiveUS8684802B1More balancedSpeed up the flowSampled-variable control systemsComputer controlHeat fluxSystems analysis

A system that balances thermal variations within a set of computer systems in a datacenter. During operation, the system obtains a thermal flux map for the set of computer systems. The system then analyzes the thermal flux map to determine whether imbalances exist in the thermal flux across the set of computer systems. If so, the system can adjust: (1) the scheduling of loads across the set of computer systems, and / or (2) air conditioning within the datacenter, so that the thermal flux is more balanced across the set of computer systems.

Owner:ORACLE INT CORP

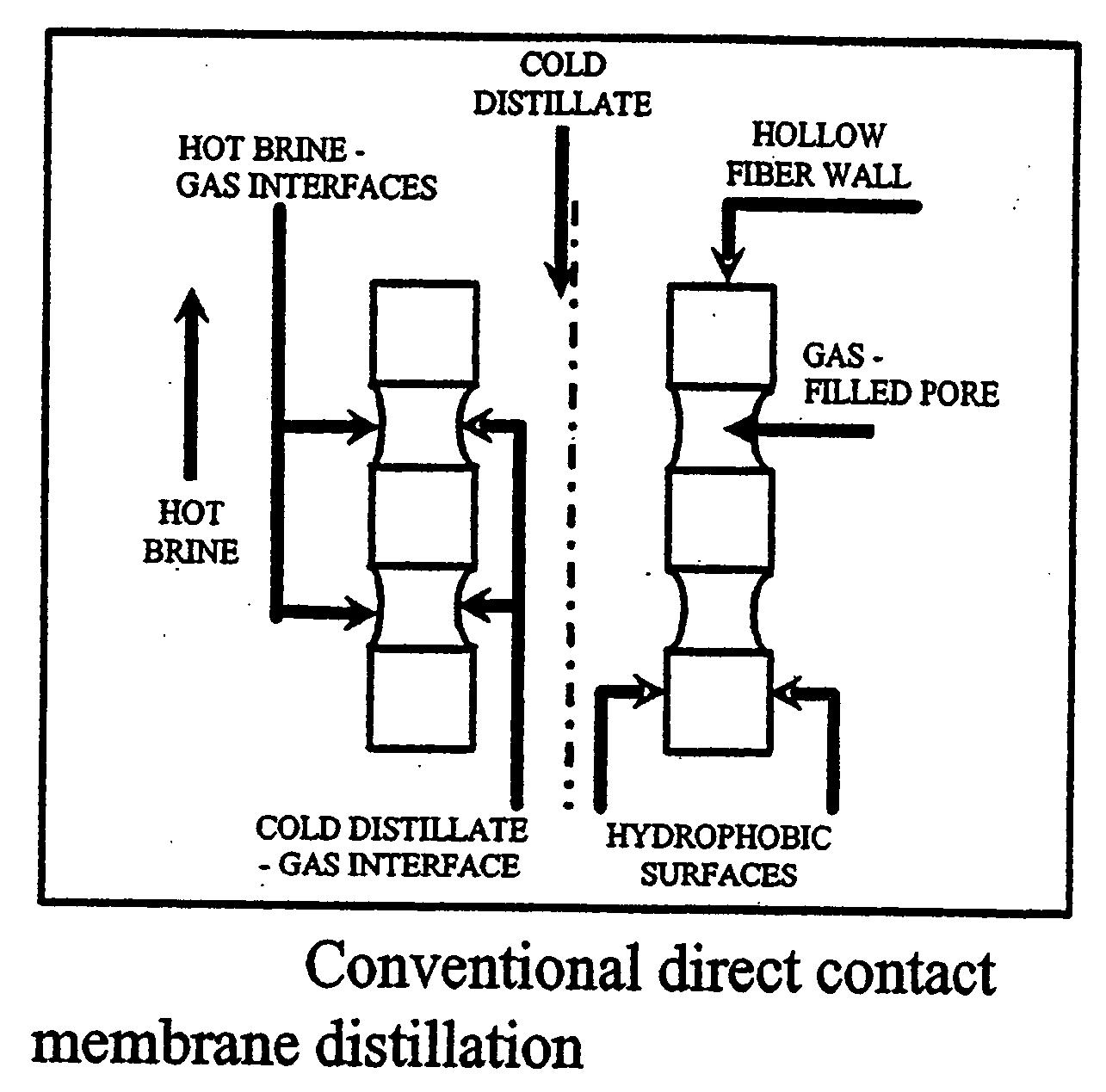

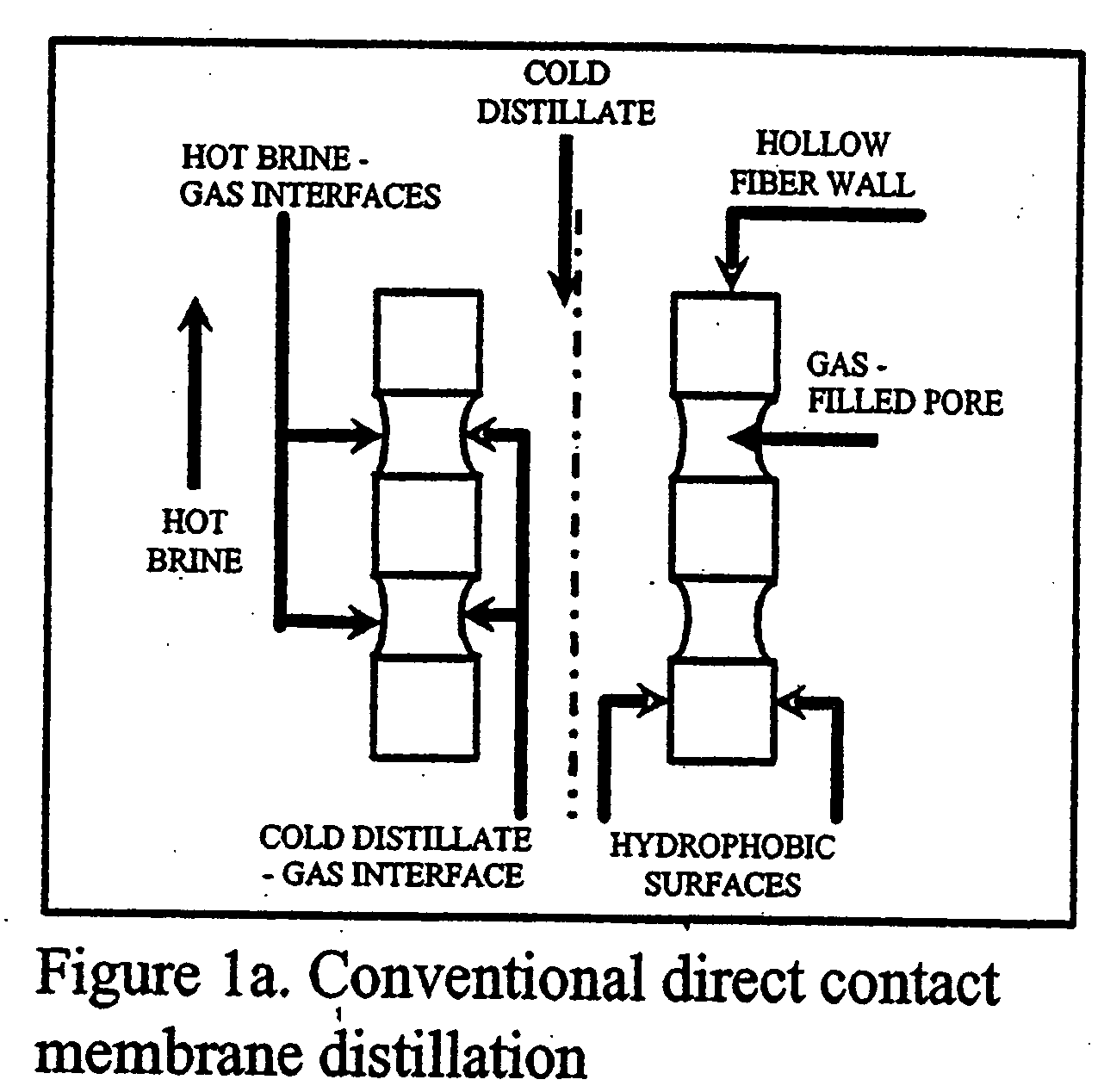

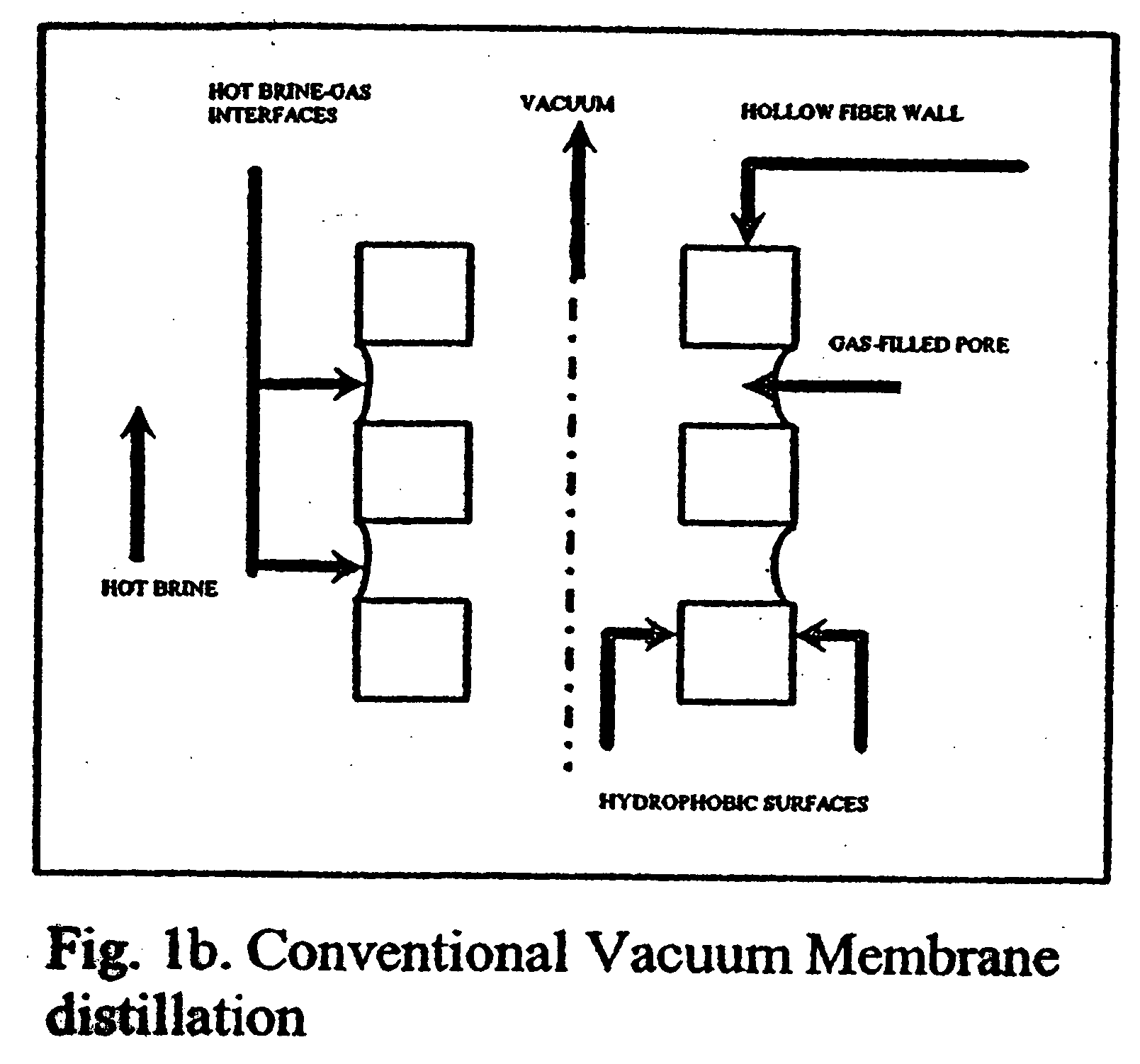

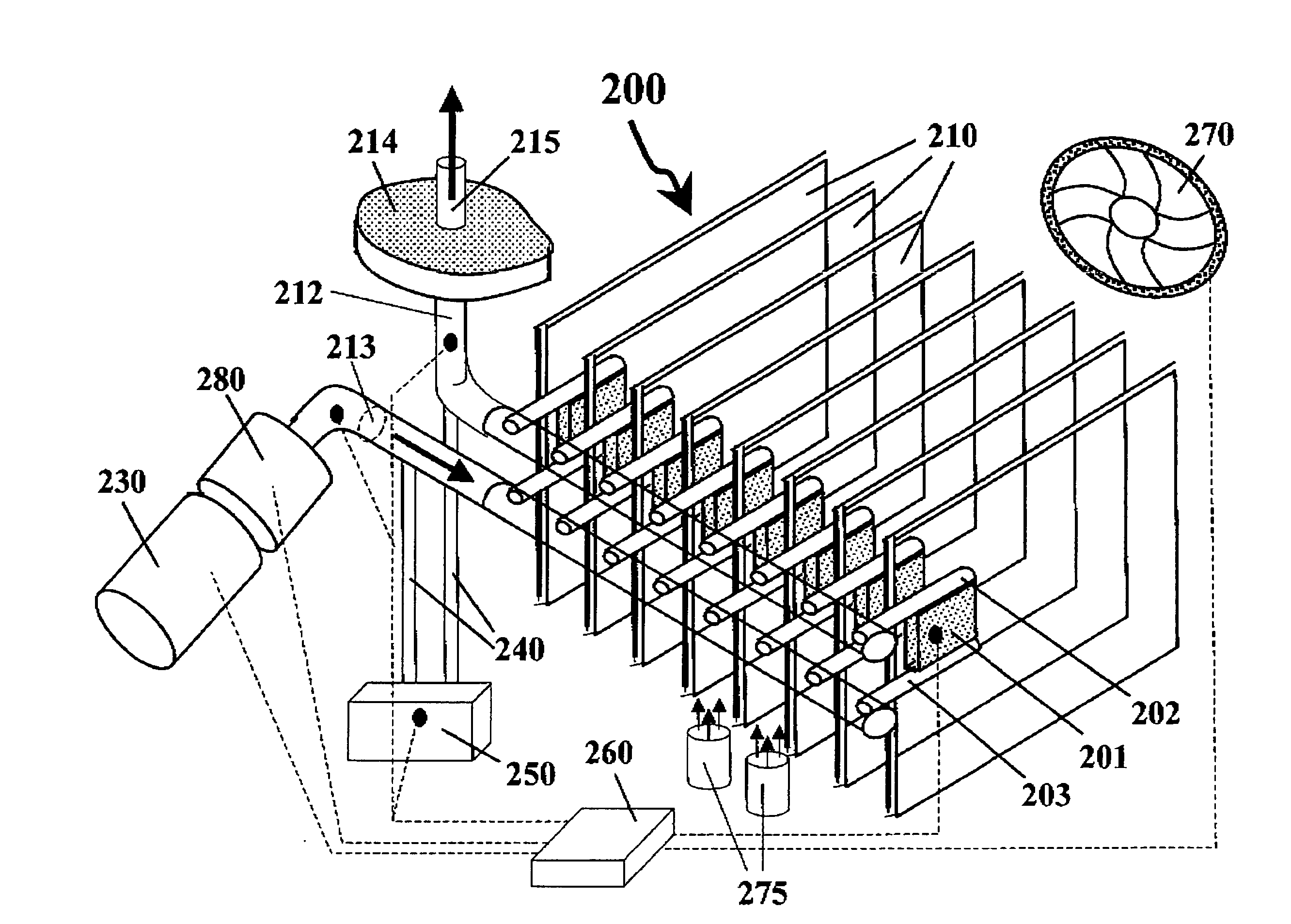

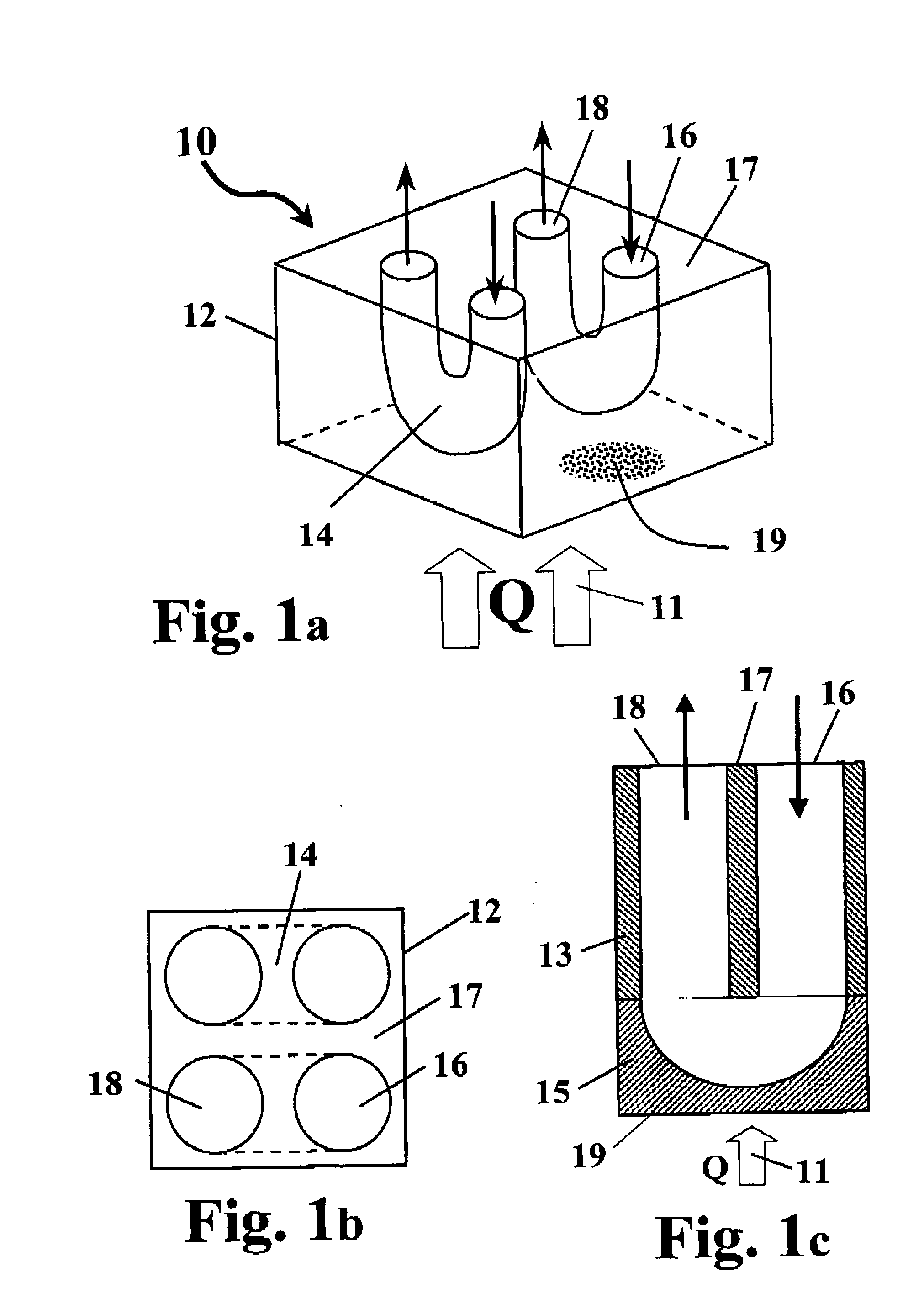

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

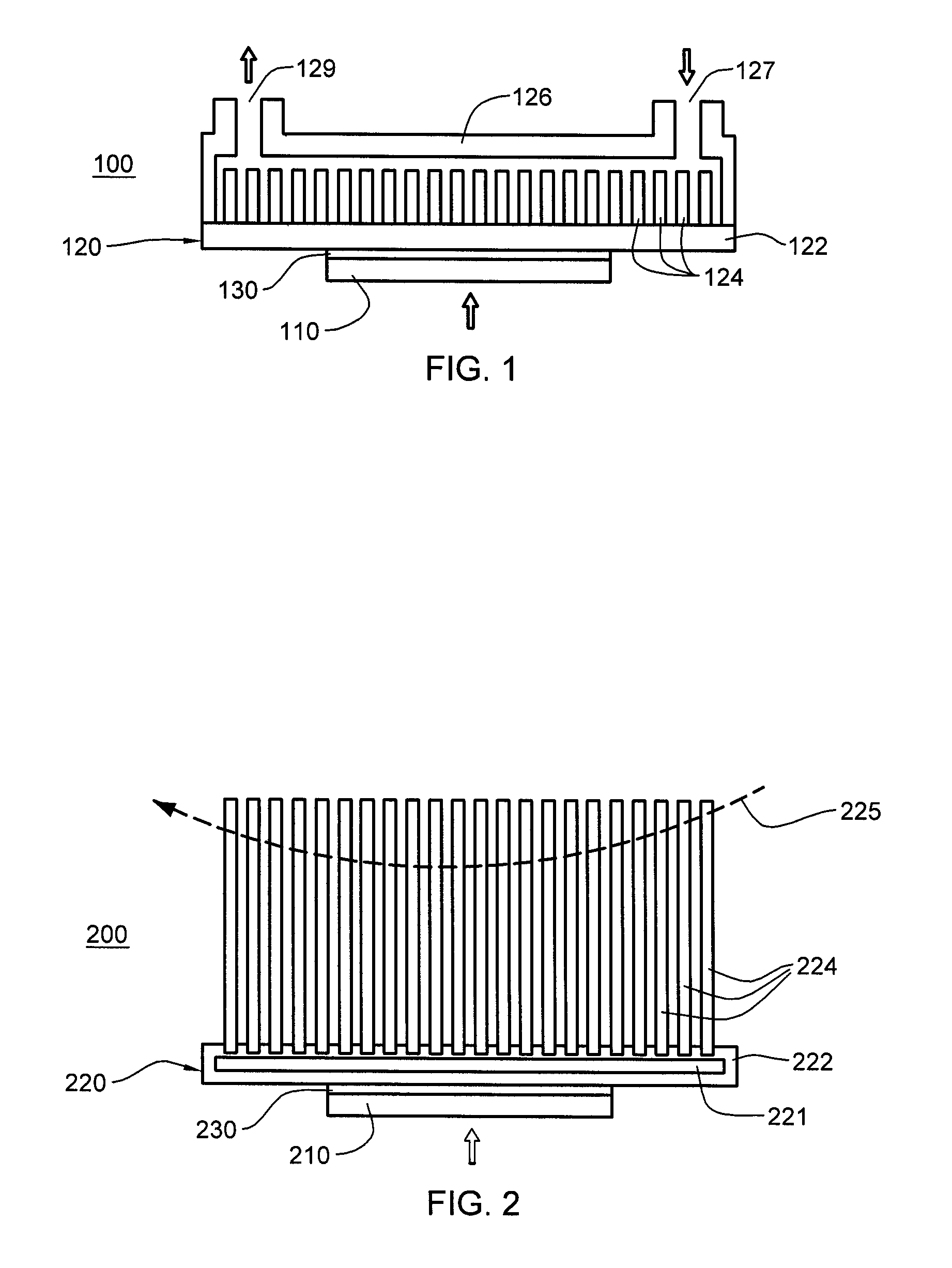

Heat-exchanger device and cooling system

InactiveUS20060011326A1Semiconductor/solid-state device detailsSolid-state devicesHeat fluxHeat conducting

A heat-exchanging device. The device comprises a block made from a heat-conducting material with a plurality of cooling tubes provided in it. Each of the cooling tubes has an inlet for receiving an inflow of a coolant fluid and an outlet for evacuating the coolant fluid, the inlet and the outlet of each cooling tubes are distributed on at least one active surface, which is substantially opposite a heat-transfer surface of the heat-exchanging device. Each cooling tube is designed to direct the coolant fluid towards and then away from said at least one heat-transfer surface. When subjected to a heat flux through the heat-transfer surface and when coolant fluid passes through the cooling tubes it absorbs heat from the block and evacuates it away.

Owner:OPTHERM - THERMAL SOLUTIONS

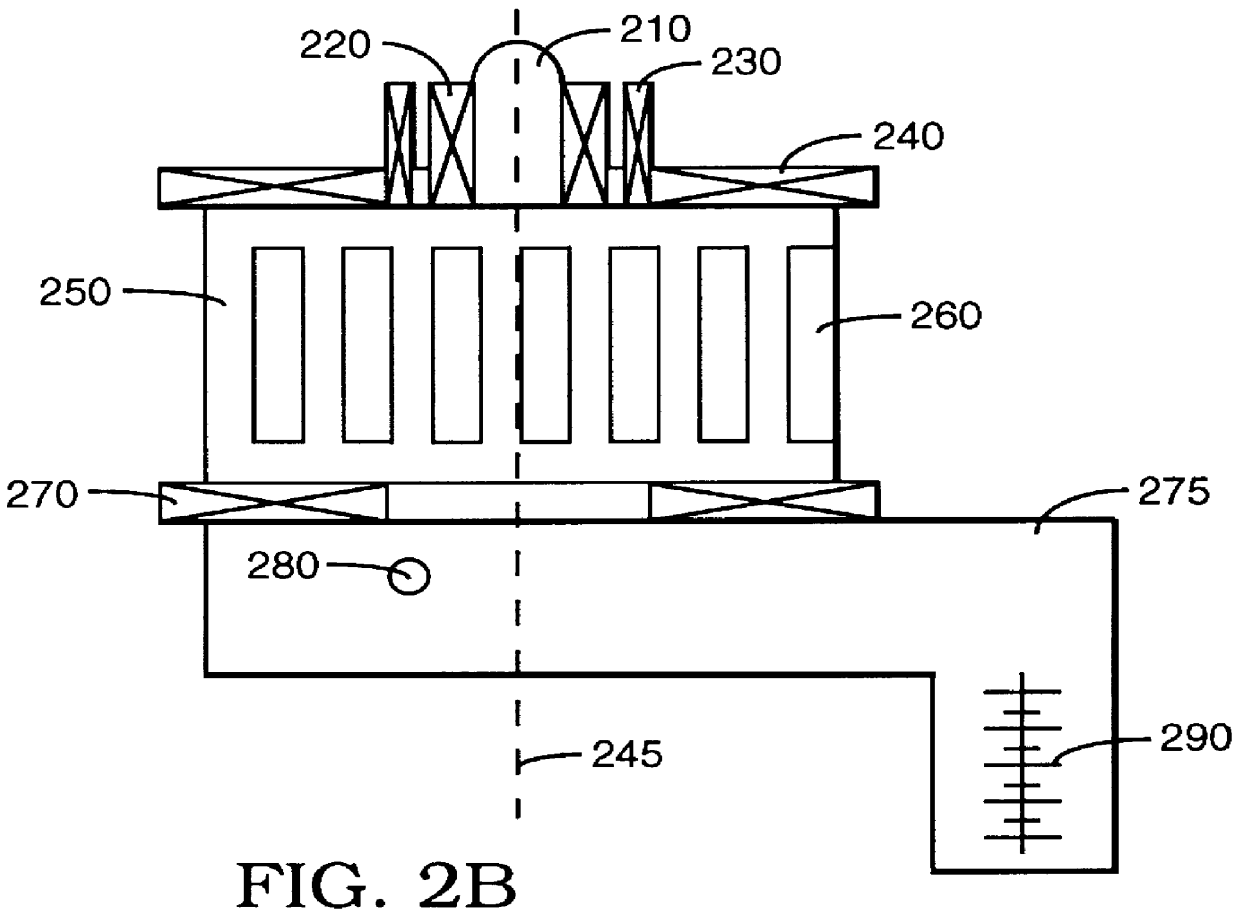

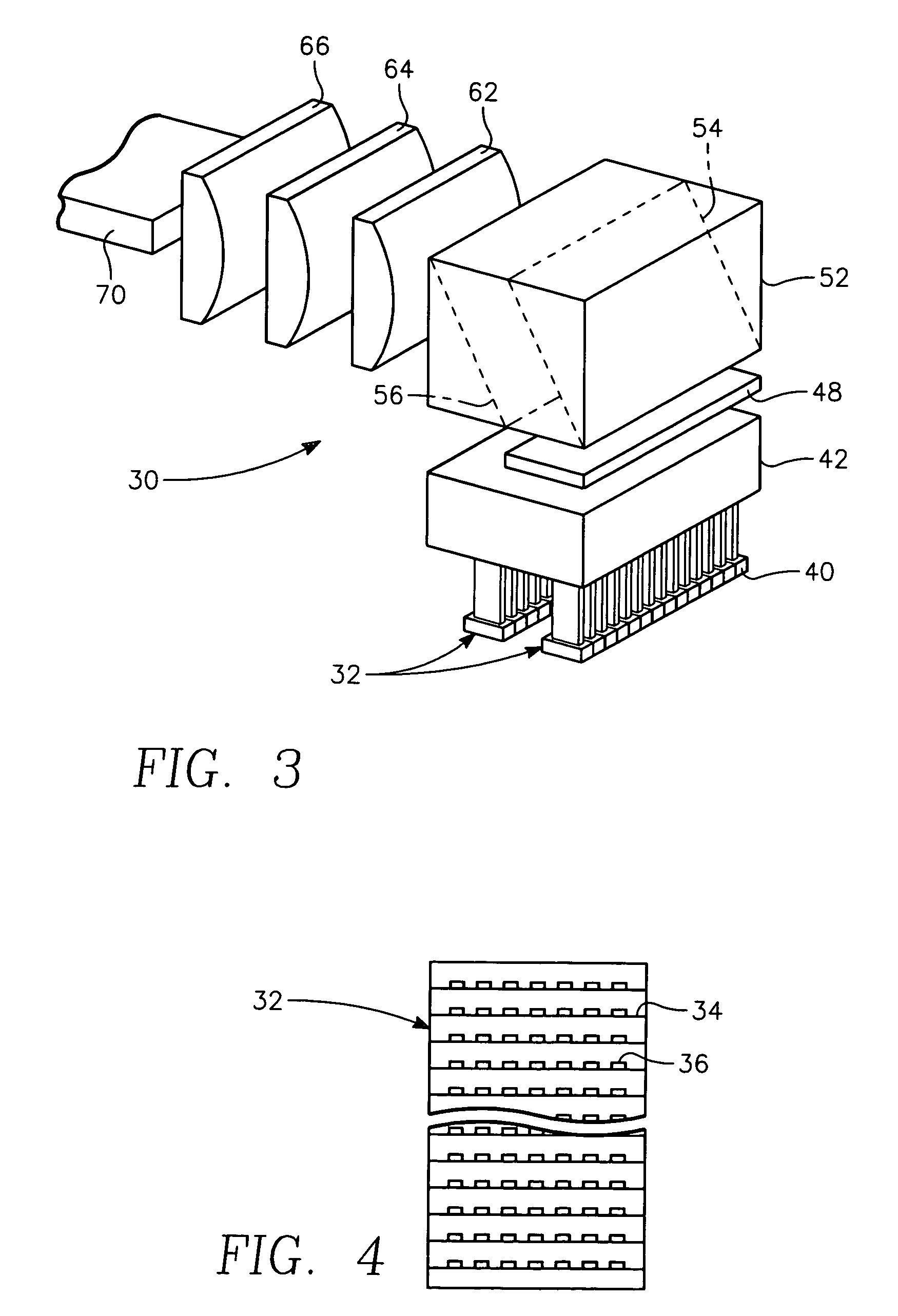

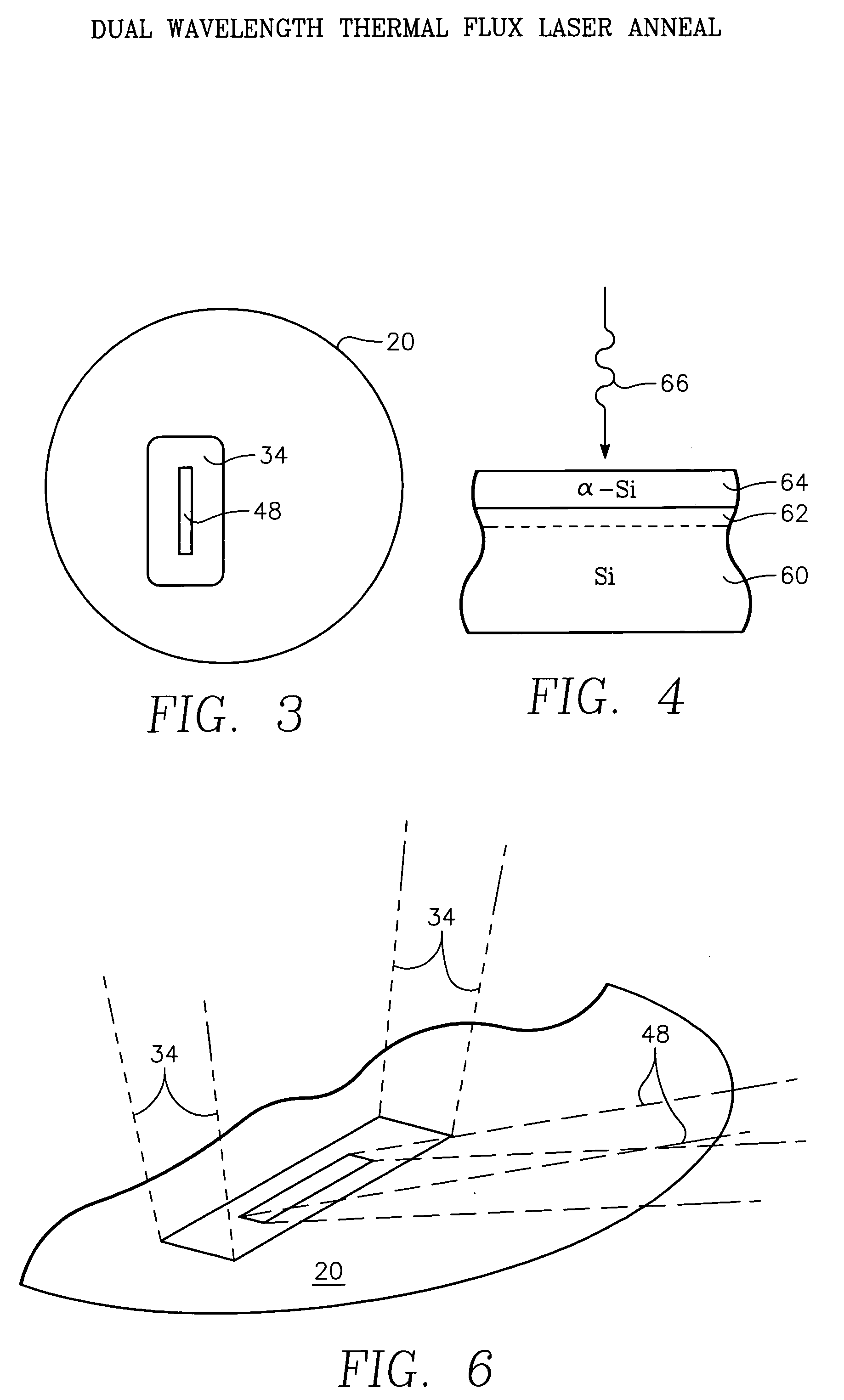

Thermal flux laser annealing for ion implantation of semiconductor P-N junctions

ActiveUS7135392B1Facilitate multiple reflectionSemiconductor/solid-state device manufacturingSemiconductor lasersLaser transmitterHeat flux

A method for forming P-N junctions in a semiconductor wafer includes ion implanting dopant impurities into the wafer and annealing the wafer using a thermal flux laser annealing apparatus that includes an array of semiconductor laser emitters arranged in plural parallel rows extending along a slow axis, plural respective cylindrical lenses overlying respective ones of the rows of laser emitters for collimating light from the respective rows along a fast axis generally perpendicular to the slow axis, a homogenizing light pipe having an input face at a first end for receiving light from the plural cylindrical lenses and an output face at an opposite end, the light pipe comprising a pair of reflective walls extending between the input and output faces and separated from one another along the direction of the slow axis, and scanning apparatus for scanning light emitted from the homogenizing light pipe across the wafer in a scanning direction parallel to the fast axis.

Owner:APPLIED MATERIALS INC

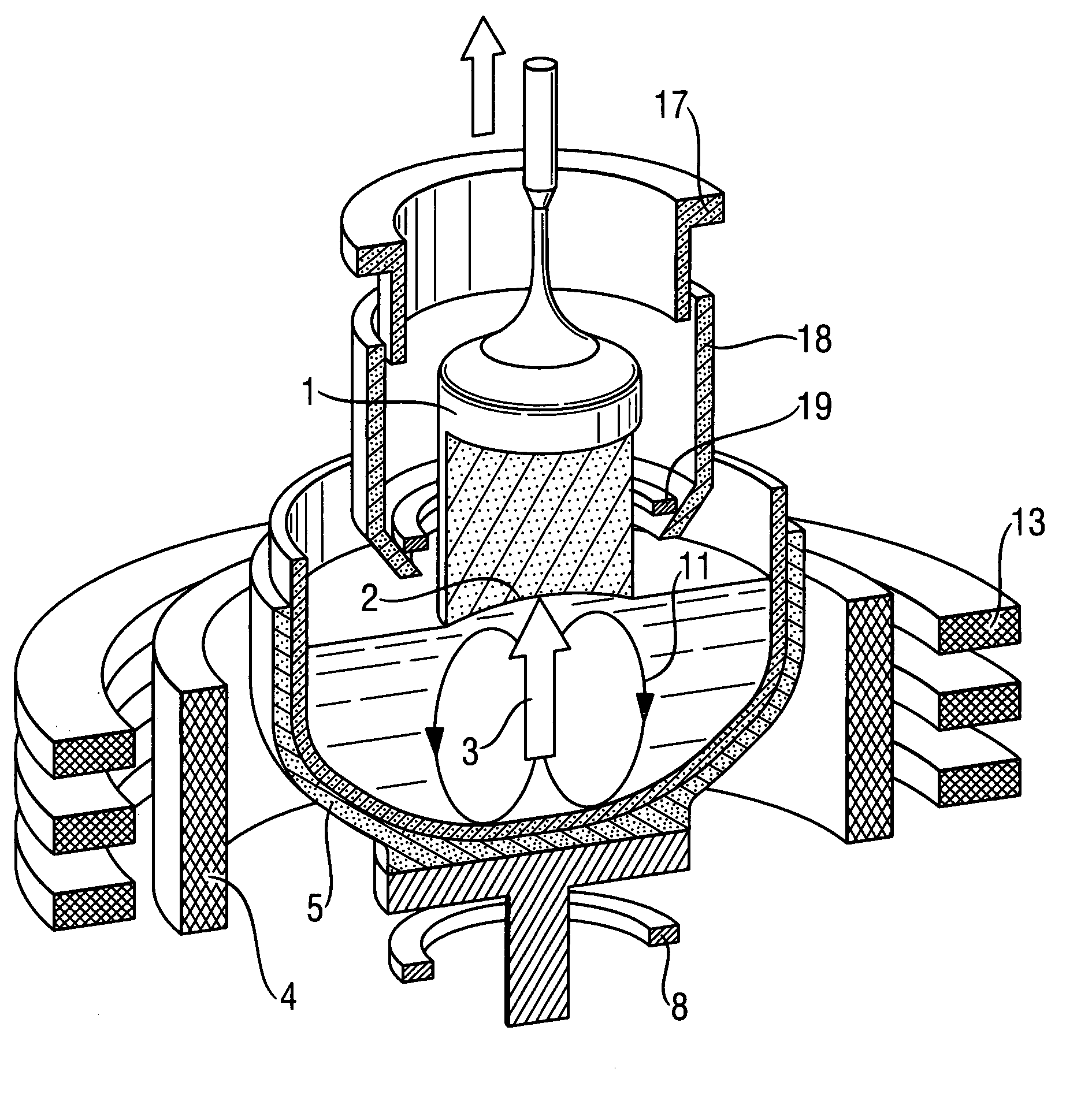

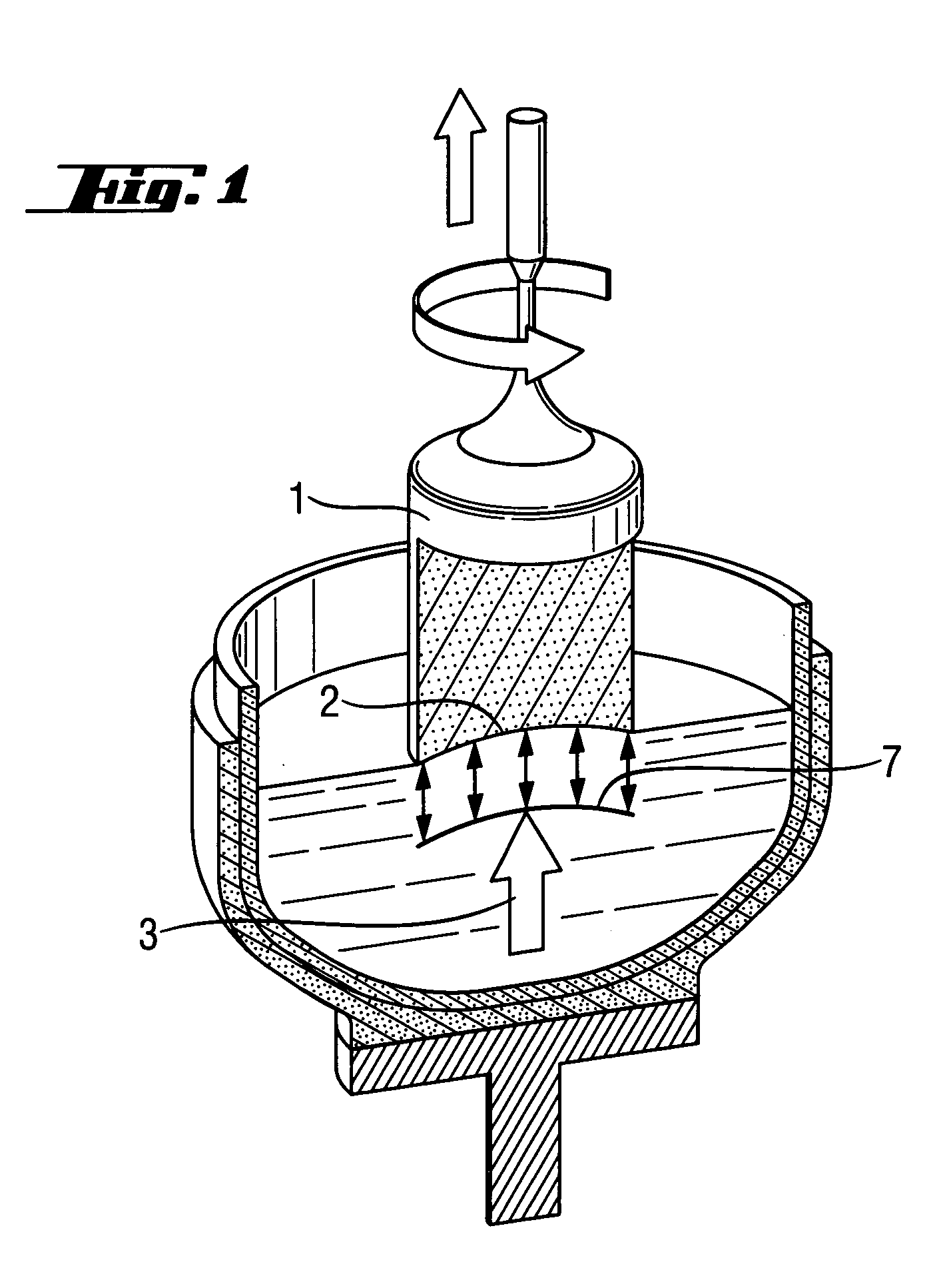

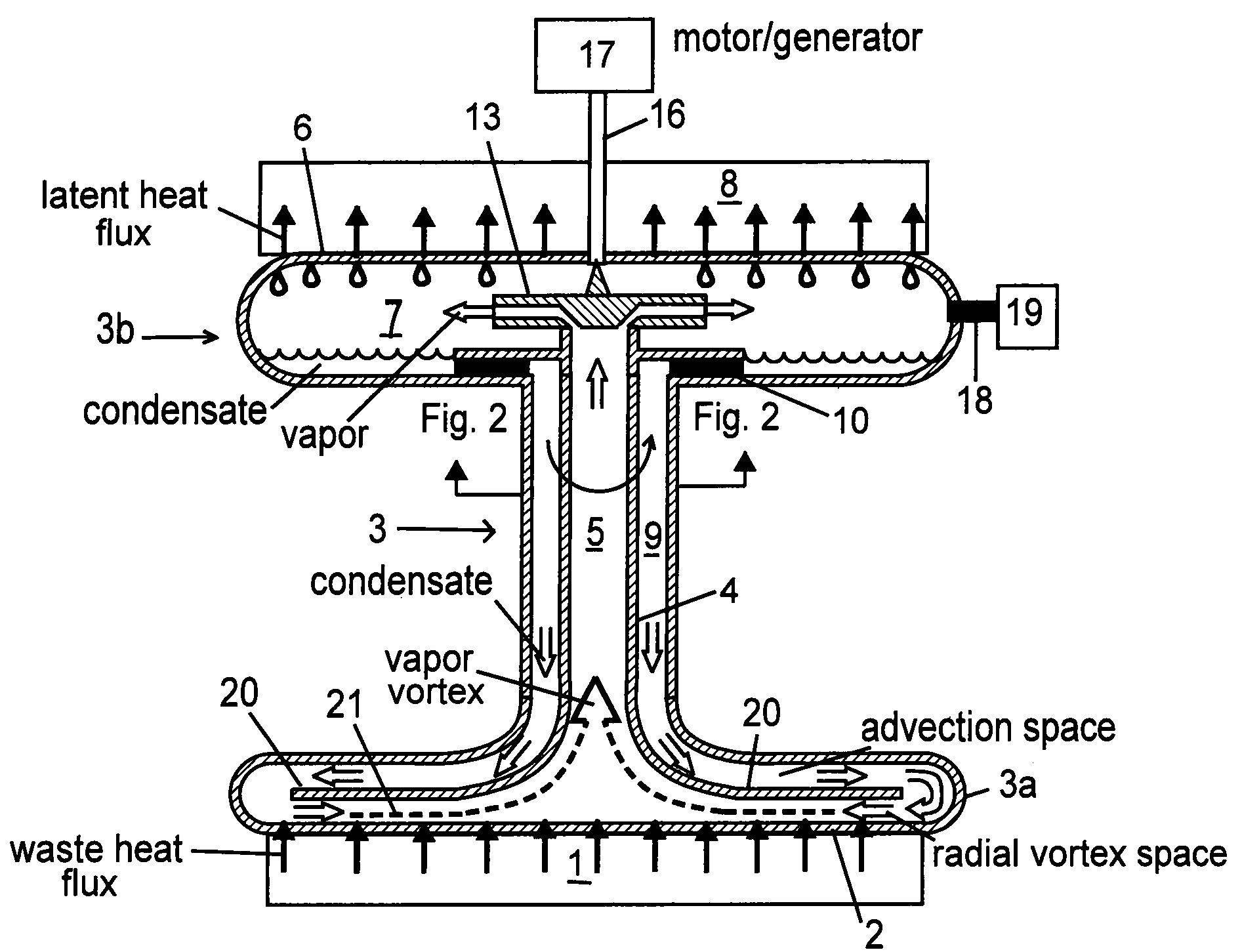

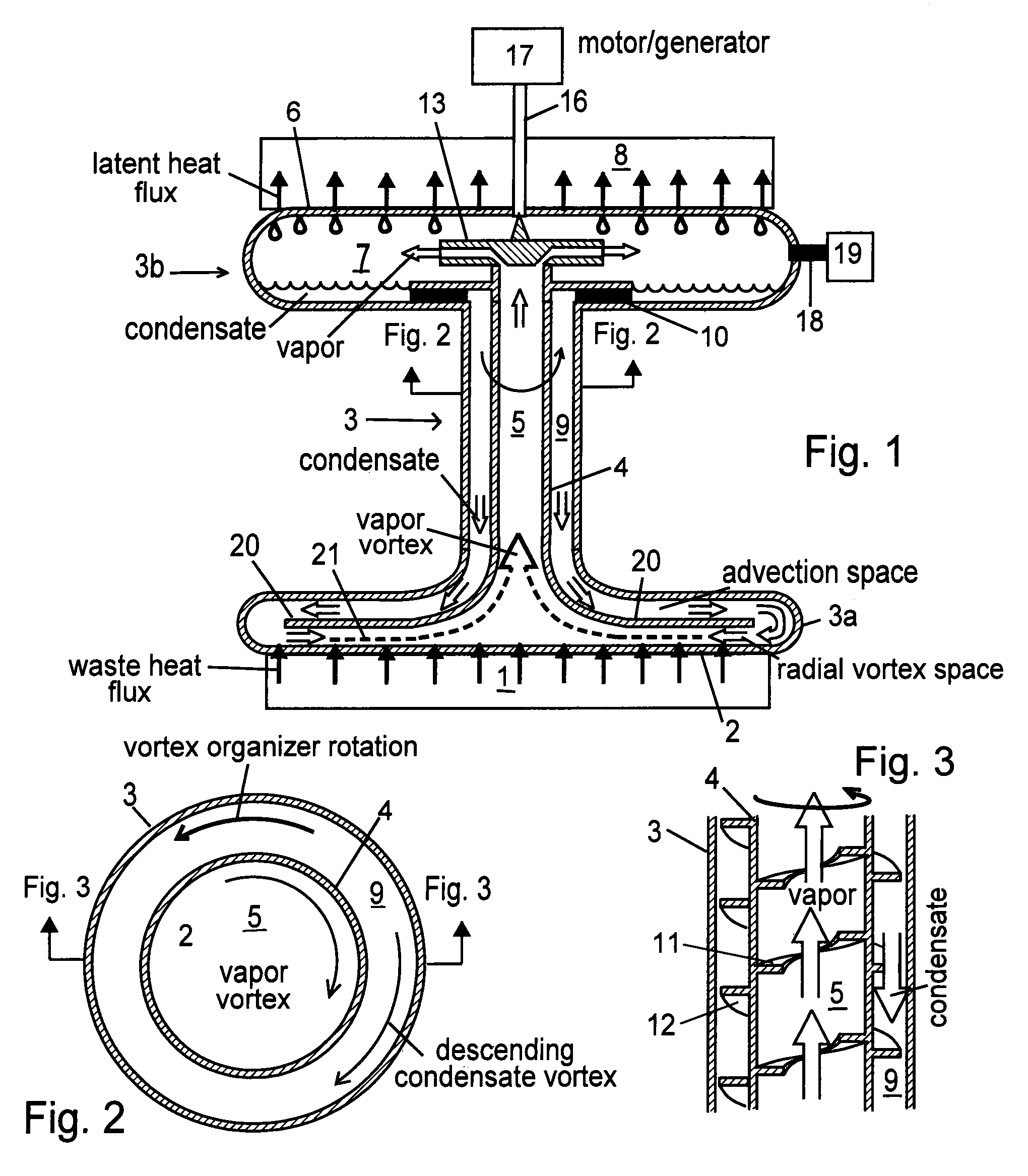

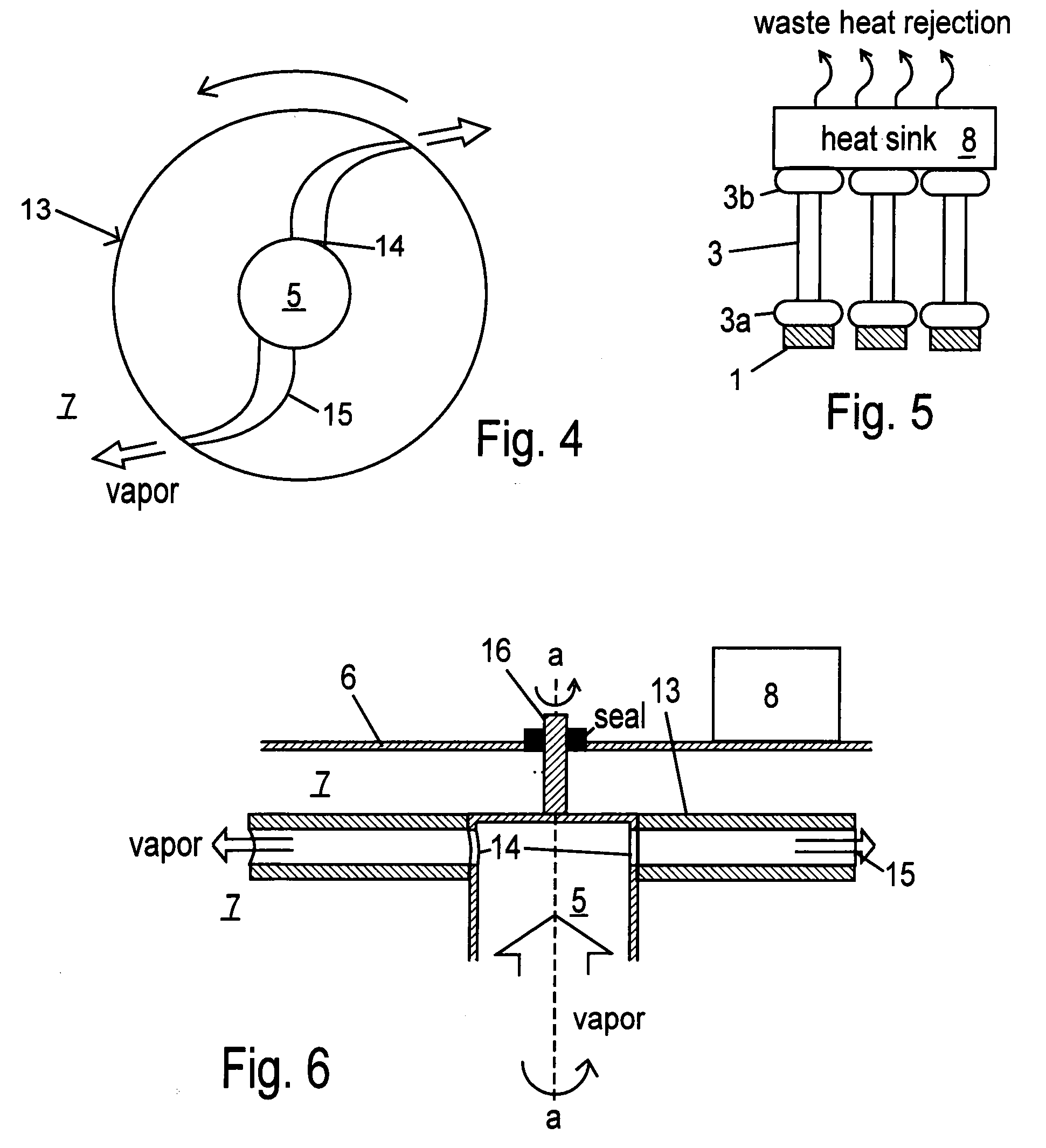

Vapor vortex heat sink

ActiveUS20090242174A1Powerful power generationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat flux

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

Particle Reduction Through Gas and Plasma Source Control

A system for producing excited gases for introduction to a semiconductor processing chamber. The system includes a plasma source for generating a plasma. The plasma source includes a plasma chamber and a gas inlet for receiving process gases from a gas source. A gas flow rate controller is coupled to the gas inlet for controlling an inlet flow rate of the process gases from the gas source to the plasma chamber via the gas inlet. The system includes a control loop for detecting a transition from a first process gas to a second process gas and for adjusting the inlet flow rate of the second process gas from about 0 sccm to about 10,000 sccm over a period of time greater than about 300 milliseconds to maintain transient heat flux loads applied by the plasma to an inner surface of the plasma chamber below a vaporization temperature of the plasma chamber.

Owner:MKS INSTR INC

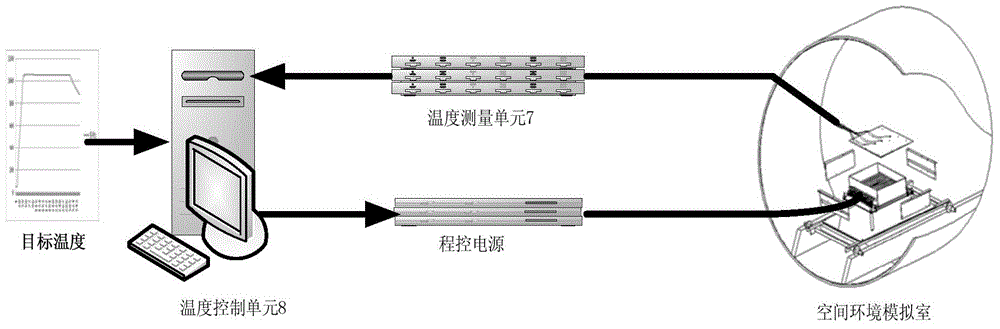

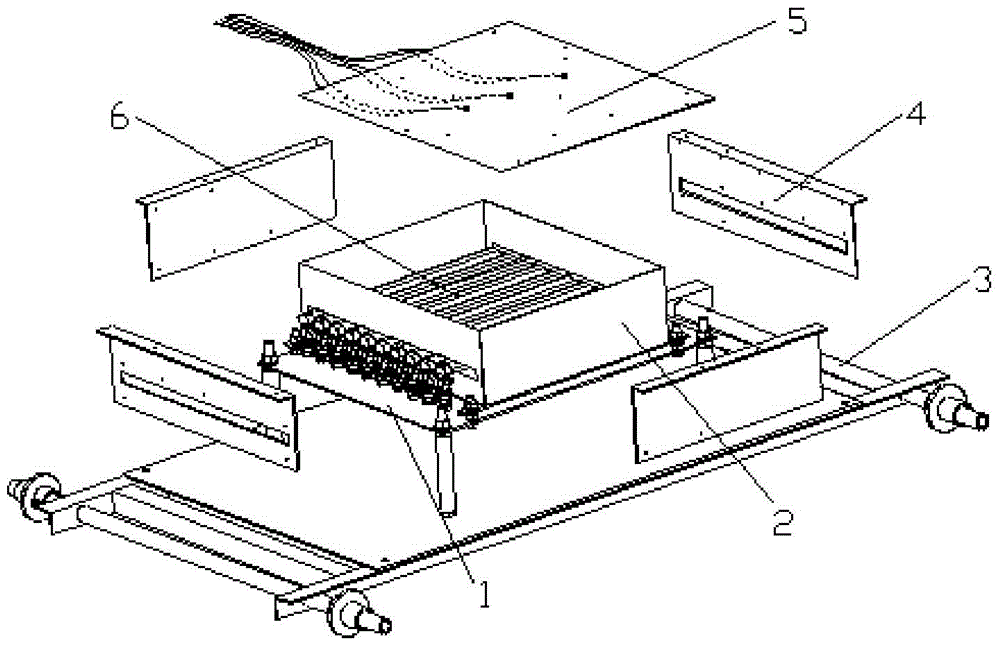

High heat flow simulator for spacecraft vacuum heat tests

InactiveCN103600851ASolve high temperatureSolve the technical difficulties of high heat flow simulationCosmonautic condition simulationsAircraft components testingHeat fluxInfrared lamp

The invention discloses a high-temperature high heat flow simulator for spacecraft vacuum heat tests in a space environment simulating chamber. The simulator mainly comprises infrared light arrays, a high-temperature insulation component unit, moving units, a temperature measuring unit and a temperature controlling unit. A plurality of infrared lights in the infrared light arrays are provided with reflective screens, the infrared lights are arrayed and combined to form the infrared light arrays according to requirements of heat flux density and uniformity, baffles surround the periphery of the infrared light arrays, high-temperature multi-layer insulation components are mounted among the infrared lights, a mounting baseplate and the baffles, and a high temperature region is limited in region formed through specimen irradiated face and the infrared light array high-temperature insulation components. According to the high-temperature high heat flow simulator, by means of unique design of the infrared light arrays and the high-temperature insulation components, technical difficulties of high-temperature high heat flow simulation when vacuum heat tests are performed on a spacecraft are solved, high-temperature high heat flow space environment can be simulated when vacuum heat tests are performed on spacecrafts in series of deep space exploration and space shuttles, and the spacecrafts can be tested.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

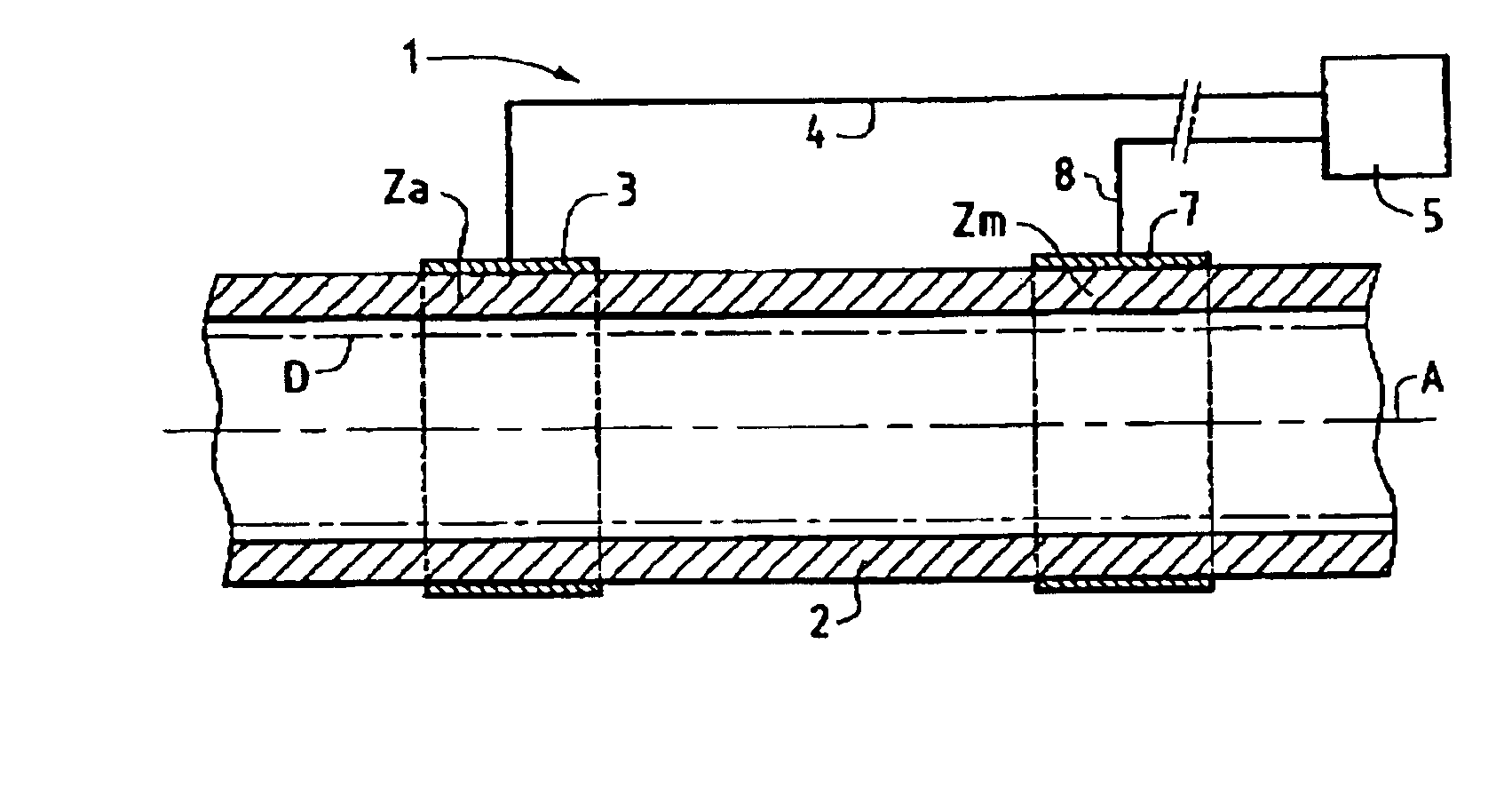

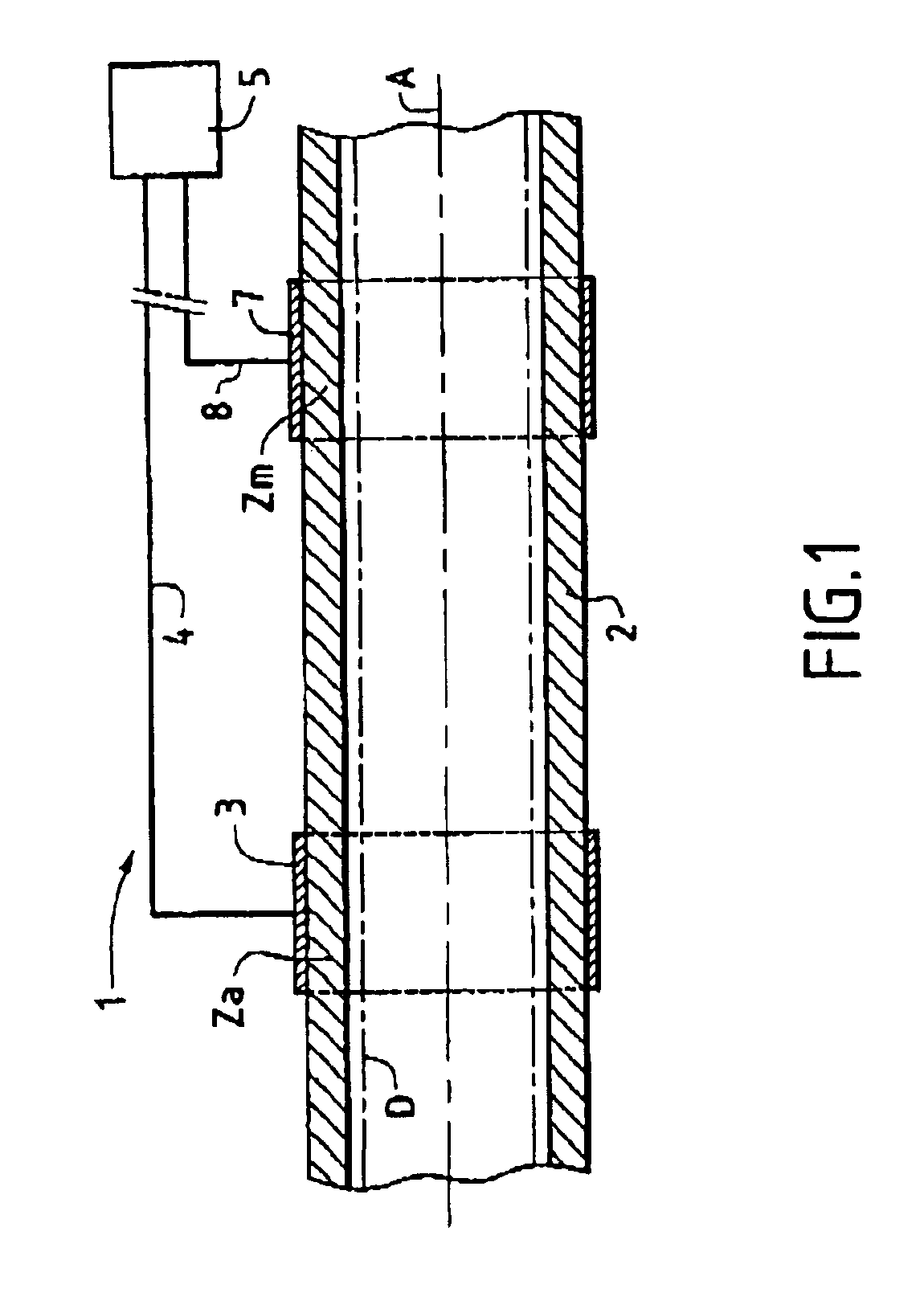

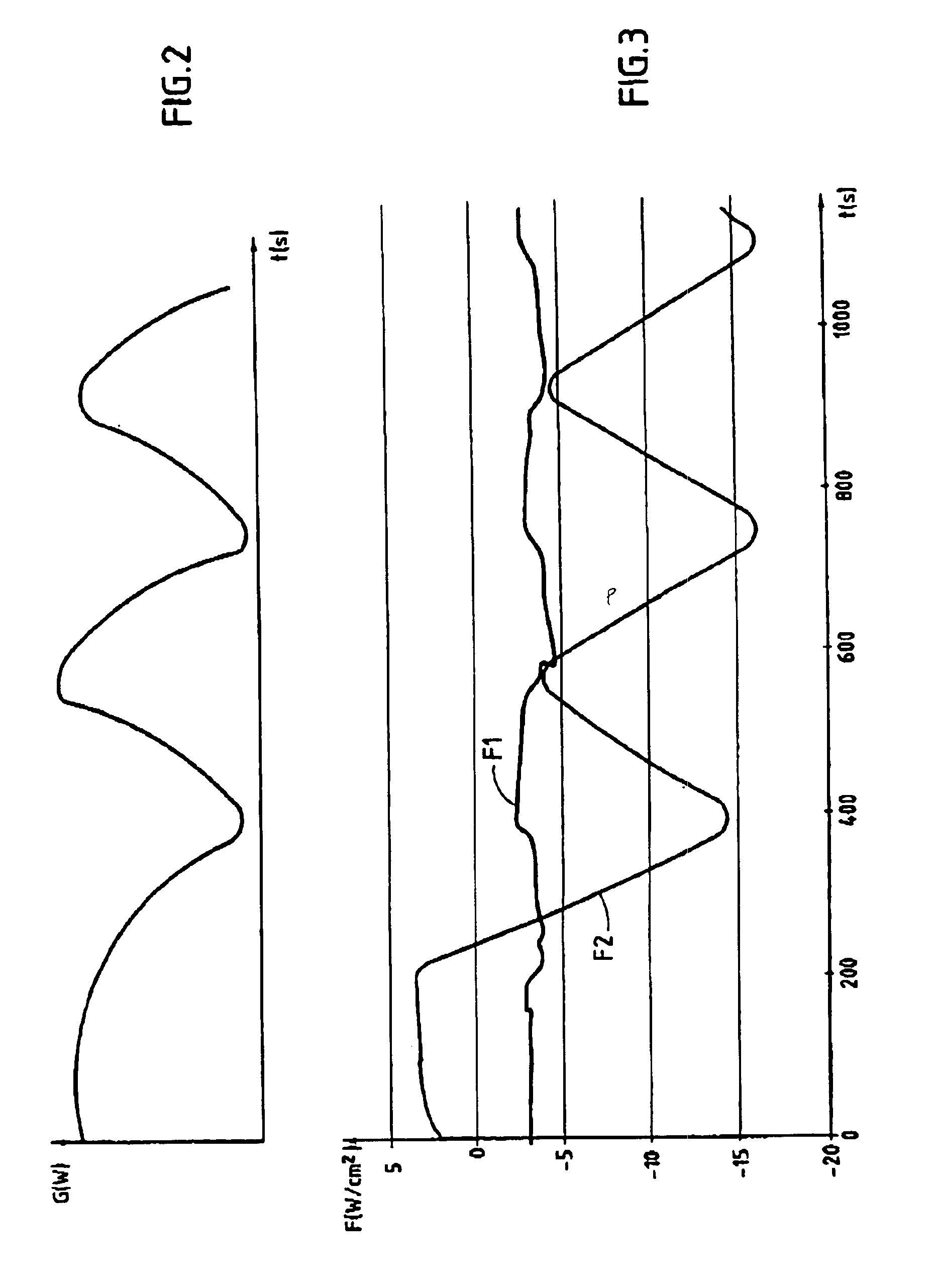

Method and device for detecting deposit in a conduit

The invention relates to an installation for implementing a method for detecting a deposit (D) that might form inside a fluid transport pipe (2). According to the invention, the installation comprises:at least one production source (3) for producing a thermal gradient, the source being for mounting on an “active” zone (Za) of the outside surface of the pipe;at least one measurement sensor (7) for measuring heat flux, the sensor being for mounting on a zone (Zm) of the outside surface of the pipe situated relative to the active zone at a given distance in consideration of the length of the pipe; andcontrol and monitoring means (5) connected to the production source (3) and to the measurement sensor (7), and adapted to detect when the heat flux corresponding at least in part to the applied thermal gradient and transmitted by the pipe exceeds a determined threshold indicative of the presence of a deposit inside the pipe.

Owner:INST FR DU PETROLE +1

Thermoelectric cooling and/or moderation of transient thermal load using phase change material

InactiveUS20060086096A1High densityEffective clampingDomestic cooling apparatusPrinted circuit aspectsThermoelectric coolingHeat flux

Techniques described and illustrated herein can permit high luminous flux and / or longer lifetimes for a class of photoemissive device configurations and / or uses that generate intense highly localized, but transient heat flux. For example, certain Light Emitting Diode (LED) applications, e.g., for flash illumination, certain solid state laser configurations and other similar configurations and uses may benefit from the developed techniques. In particular, it has been discovered that by locating an amount of appropriate phase change material in close thermal proximity to such a photoemissive device, substantial generated heat fluxes may be “absorbed” into a phase transition of the phase change material. In some configurations, a thermoelectric is employed in conjunction with the phase change material. For example, the thermoelectric may at least partially define a heat transfer path from the photoemissive device to the phase change material. Similar configurations may be employed for photosensitive devices. In such configurations, the phase change material may effectively clamp one side (typically the hot side) of the thermoelectric as heat transferred across the thermoelectric is absorbed into the transition of at least some of the phase change material from a first state thereof to a second state. The thermoelectric may be transiently operated in substantial synchrony with operation of the photoemissive or photosensitive device to provide extremely high density spot cooling when and where desired.

Owner:NANOCOOLERS

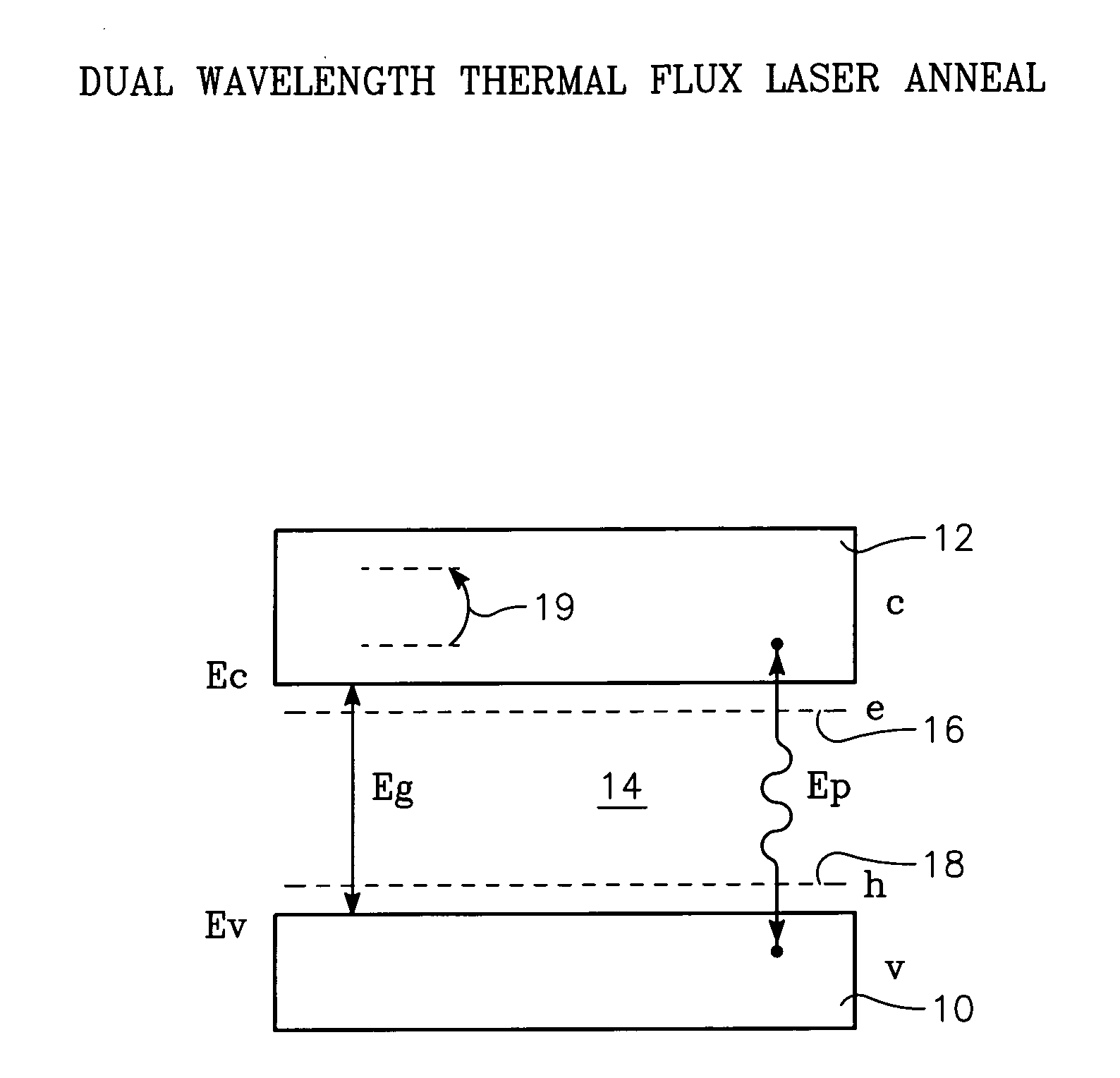

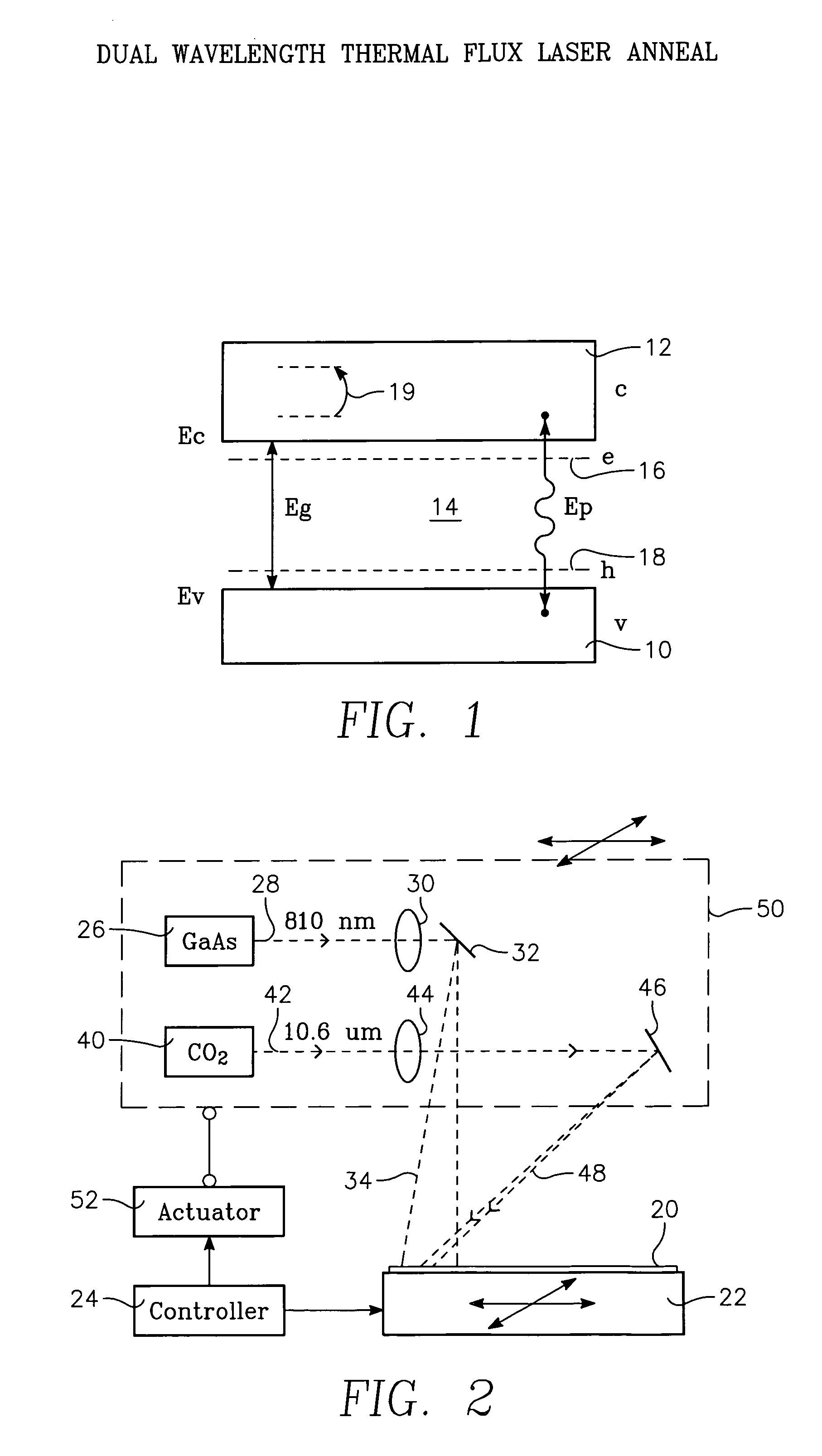

Dual wavelength thermal flux laser anneal

ActiveUS20060234458A1Effective radiationSemiconductor/solid-state device manufacturingLaser beam welding apparatusHeat fluxLaser source

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com