Thermoelectric cooling and/or moderation of transient thermal load using phase change material

a phase change material and thermal load technology, applied in the direction of domestic cooling devices, lighting and heating devices, semiconductor lasers, etc., can solve the problems of sensitivity being typically limited by background noise, most sensors, ccd's (and cmos devices) susceptible to noise, etc., and achieve the effect of avoiding large localized excursions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

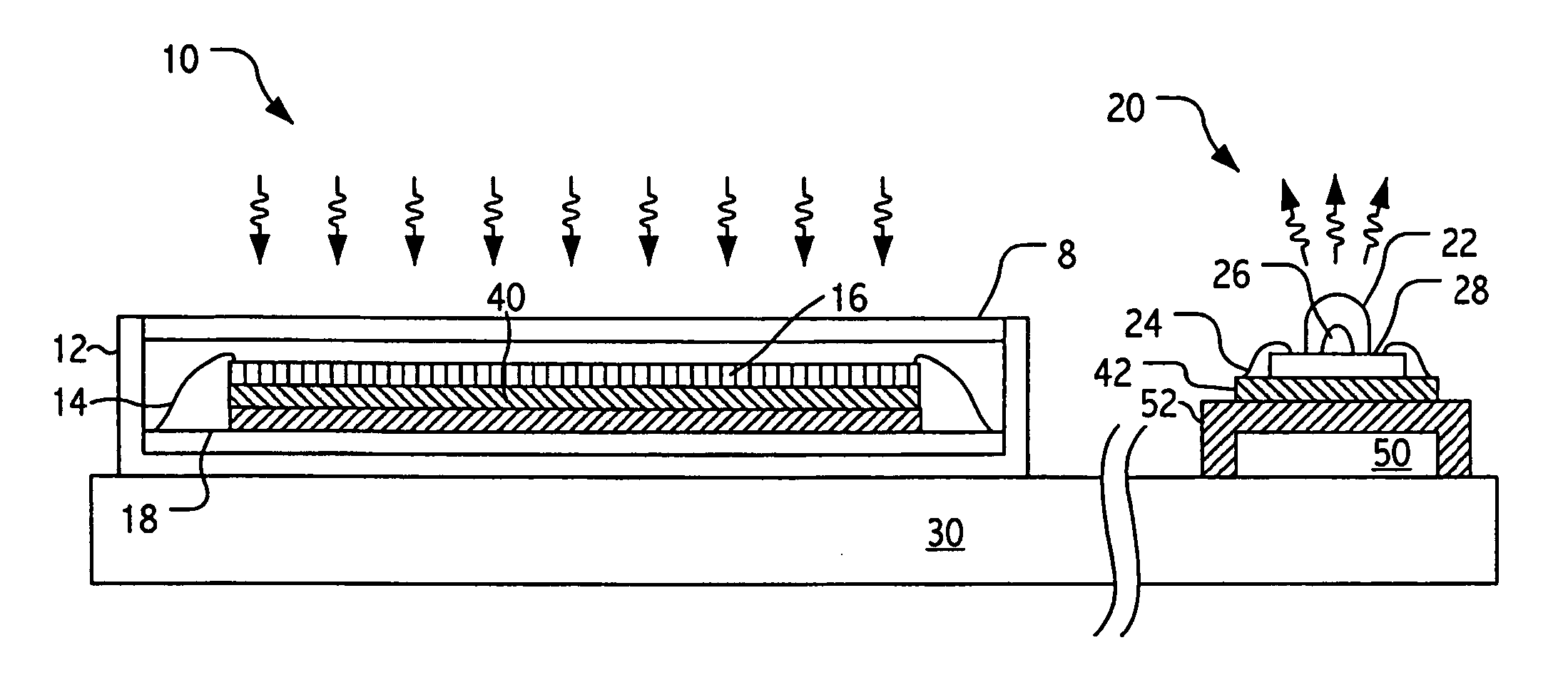

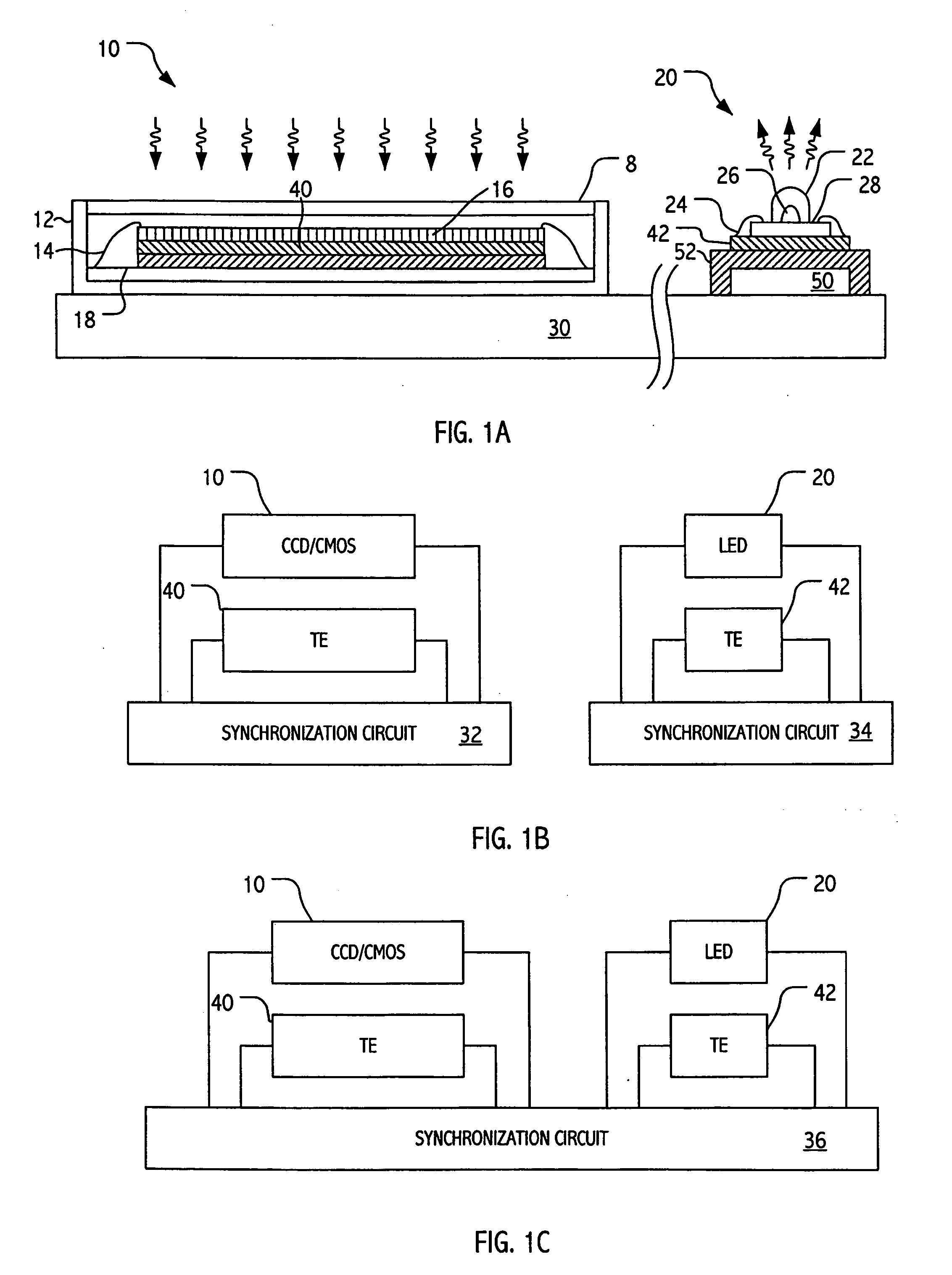

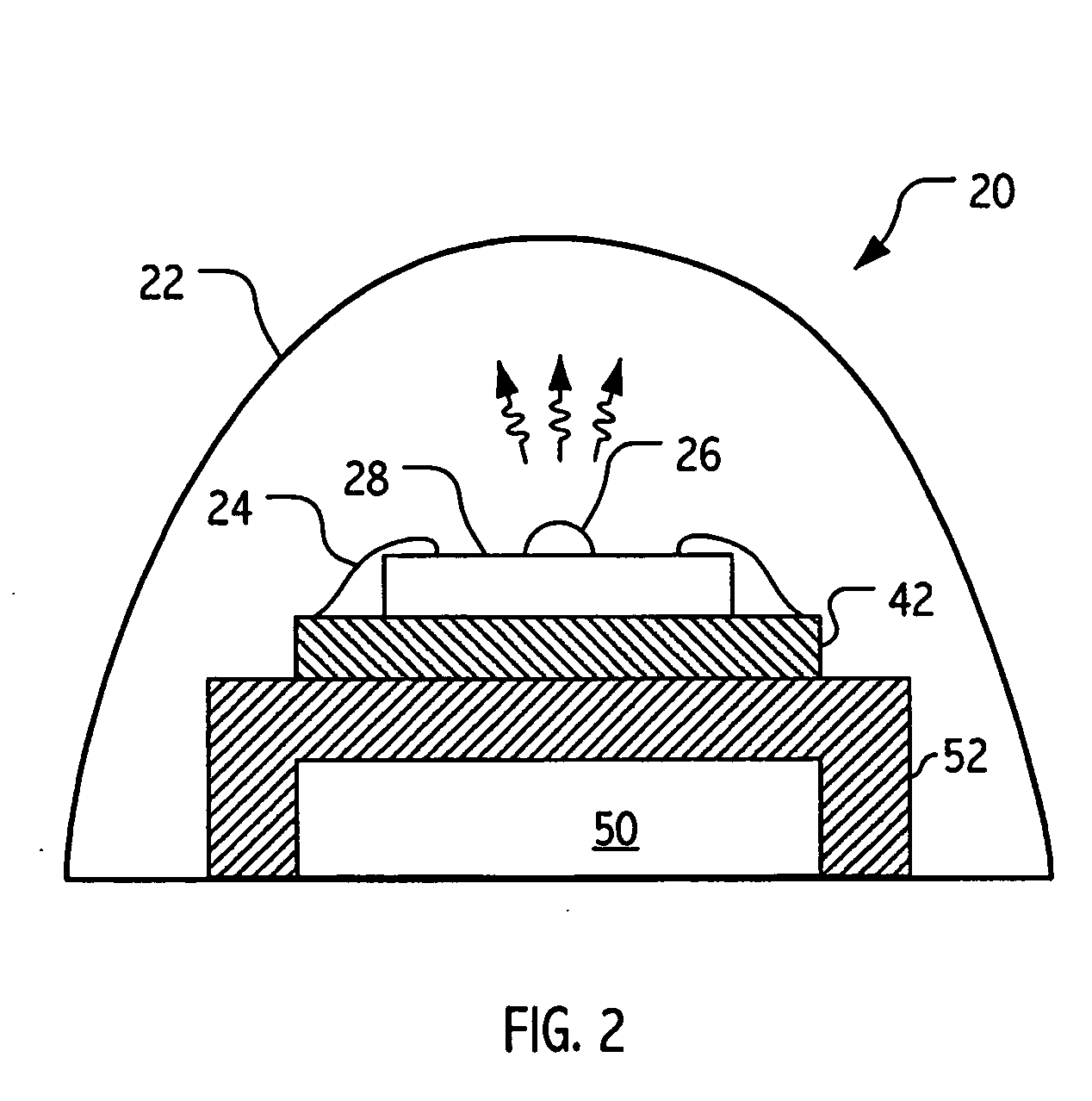

[0028] While not limited thereto, the invented techniques described and illustrated herein can permit high luminous flux and greater lifetimes for flash LEDs, and greater photon sensitivity and lower dark currents for CCD / CMOS imagers. Accordingly, we describe aspects of the inventive concepts in the context of configurations, optoelectronic devices, materials and heat fluxes typical of consumer electronics such as digital cameras and mobile phones that incorporate similar technologies. However, as more completely described herein, the invention is not limited to such exploitations.

[0029] In particular, the description that follows emphasizes exploitations of the present invention in which a light emitting diode, e.g., a white LED, or other photoemissive device is used in a flash mode of operation, e.g., as flash illumination to support digital imaging. In such exploitations, extremely high transient thermal flux can be generated. Particularly for white LEDs, quality of the lumina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com