Double heat flux gauge steady state method for measuring material heat conductivity

A measurement method and technology of heat flow meter, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of heat flow density error, non-sample thermal conductivity, lack of quantitative criteria for one-dimensional heat flow conduction, etc., to overcome the inaccurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Using a group of quartz glass samples with known thermal conductivity, the thermal conductivity testing device of the present invention is used to test the thermal conductivity of the samples. The test results are shown in Table 1. The upper and lower surfaces of the sample are kept parallel and carefully ground and polished. At the same time, the upper and lower surfaces of the sample are coated with thermal conductive silicone grease to reduce the interface thermal resistance. The test sample is placed between the upper and lower heat flow metering plates, and the pressure (generally not greater than 0.7MPa) is applied through the pressure bolt on the top of the instrument.

[0086] Table 1 Test samples and test results

[0087]

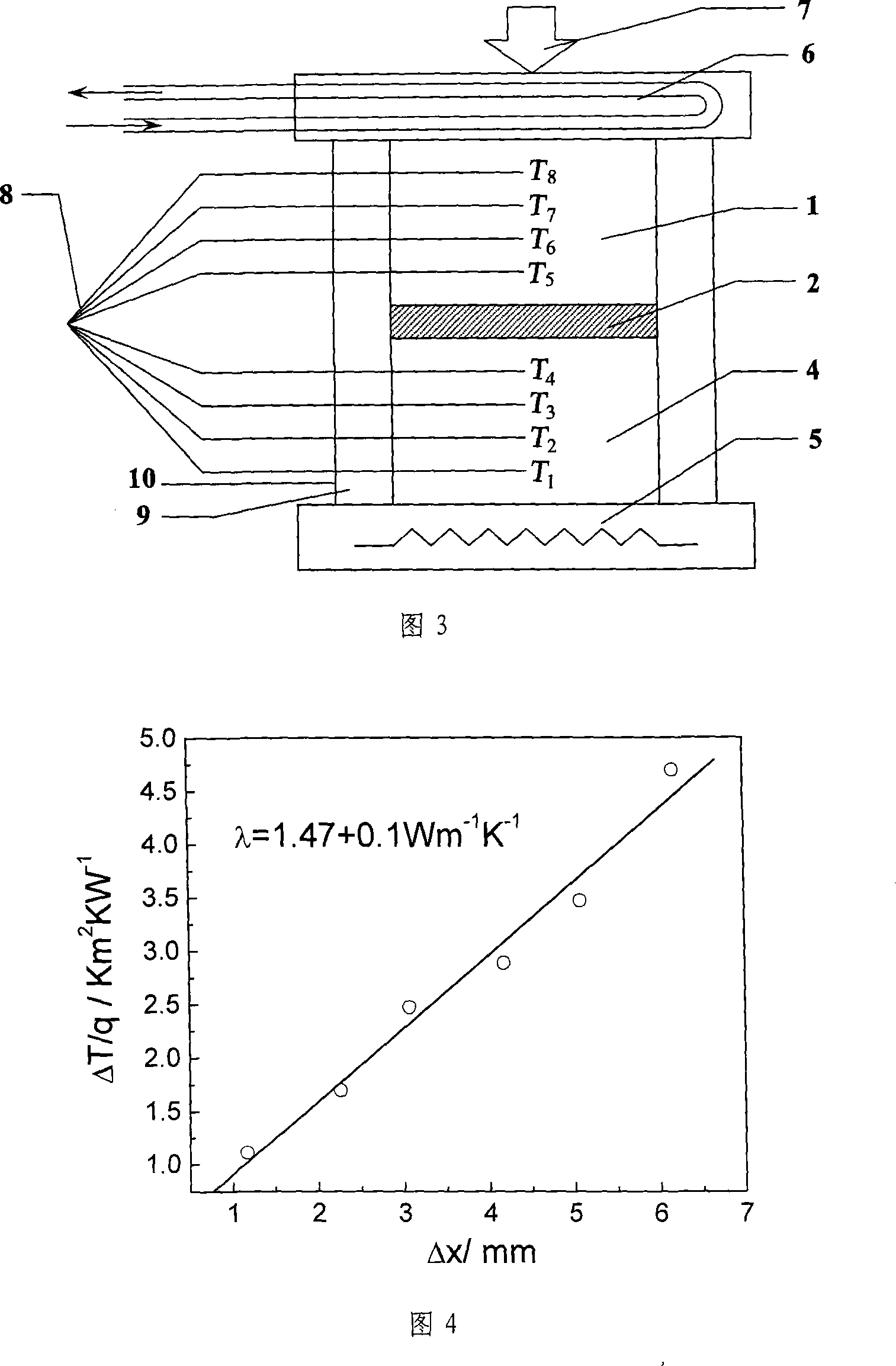

[0088] Figure 4 shows the relationship curve between ΔT / q and Δx data of the quartz glass test sample, and the thermal conductivity of the quartz glass is 1.47Wm obtained from the slope of the curve in the figure -1 K -1 , with ...

Embodiment 2

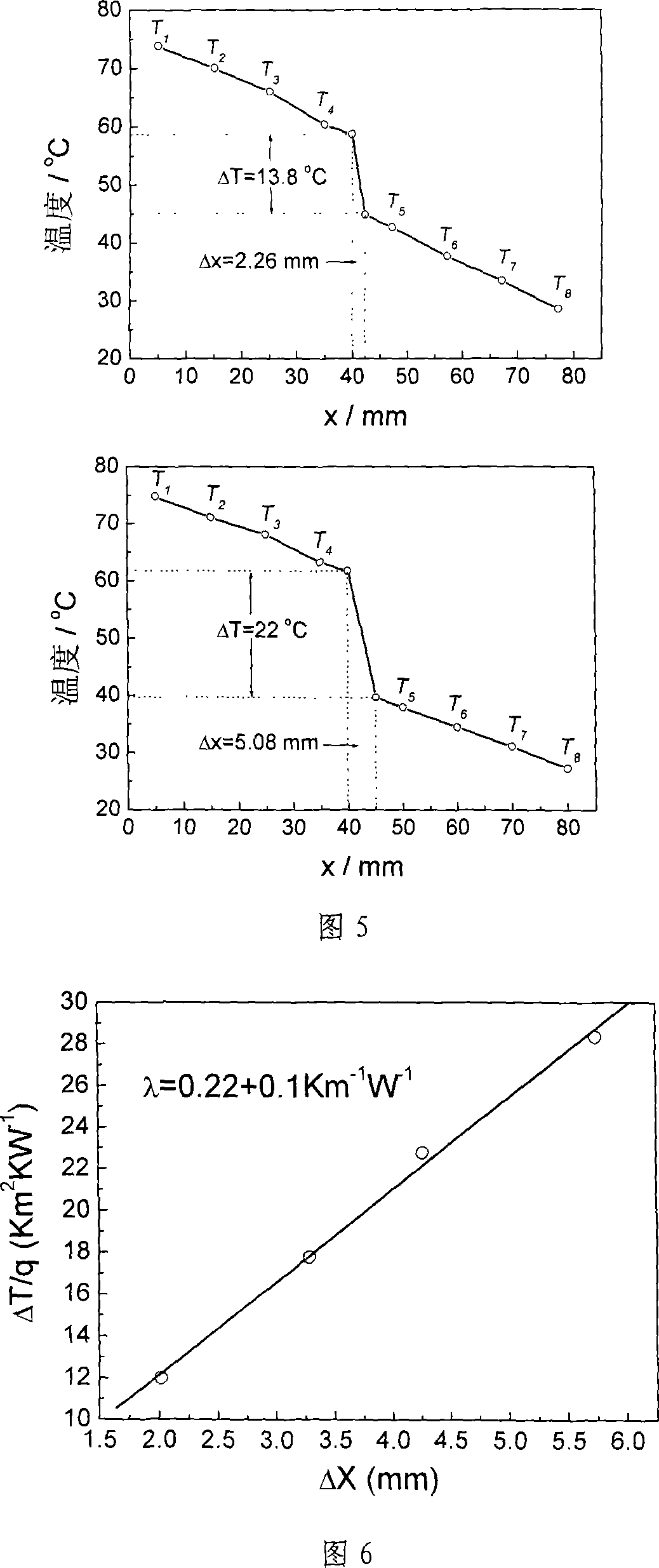

[0090] Using a group of polystyrene samples with known thermal conductivity, the thermal conductivity testing device of the present invention is used to test the thermal conductivity of the samples. The test results are shown in Table 1. Figure 6 shows the relationship curve between ΔT / q and Δx data of polystyrene test samples, and the thermal conductivity of polystyrene obtained from the slope of the curve in the figure is 0.22Wm -1 K -1 , and test data reported in literature 0.15~0.20Wm -1 K -1 In comparison, the experimental test values are also in good agreement with the reported values in the literature. Figure 7 shows the temperature gradient curves of heat flow through the heat flow meter and test samples with different thicknesses when the test device reaches a steady state.

Embodiment 3

[0092] Using a group of common carbon steel samples with 0.45% carbon content known to the thermal conductivity, the thermal conductivity testing device of the present invention is used to test the thermal conductivity of the samples. The test results are shown in Table 1. Figure 8 shows the relationship curve between ΔT / q and Δx data of 45 steel test samples, and the thermal conductivity of 45 steel is 41.7Wm obtained from the slope of the curve in the figure -1 K -1 , with test data reported in the literature 47.68Wm -1 K -1 In comparison, the experimental test values are also in good agreement with the reported values in the literature. Figure 7 shows the temperature gradient curves of heat flow through the heat flow meter and test samples with different thicknesses when the test device reaches a steady state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com