Patents

Literature

1067 results about "Cold side" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cool design data center

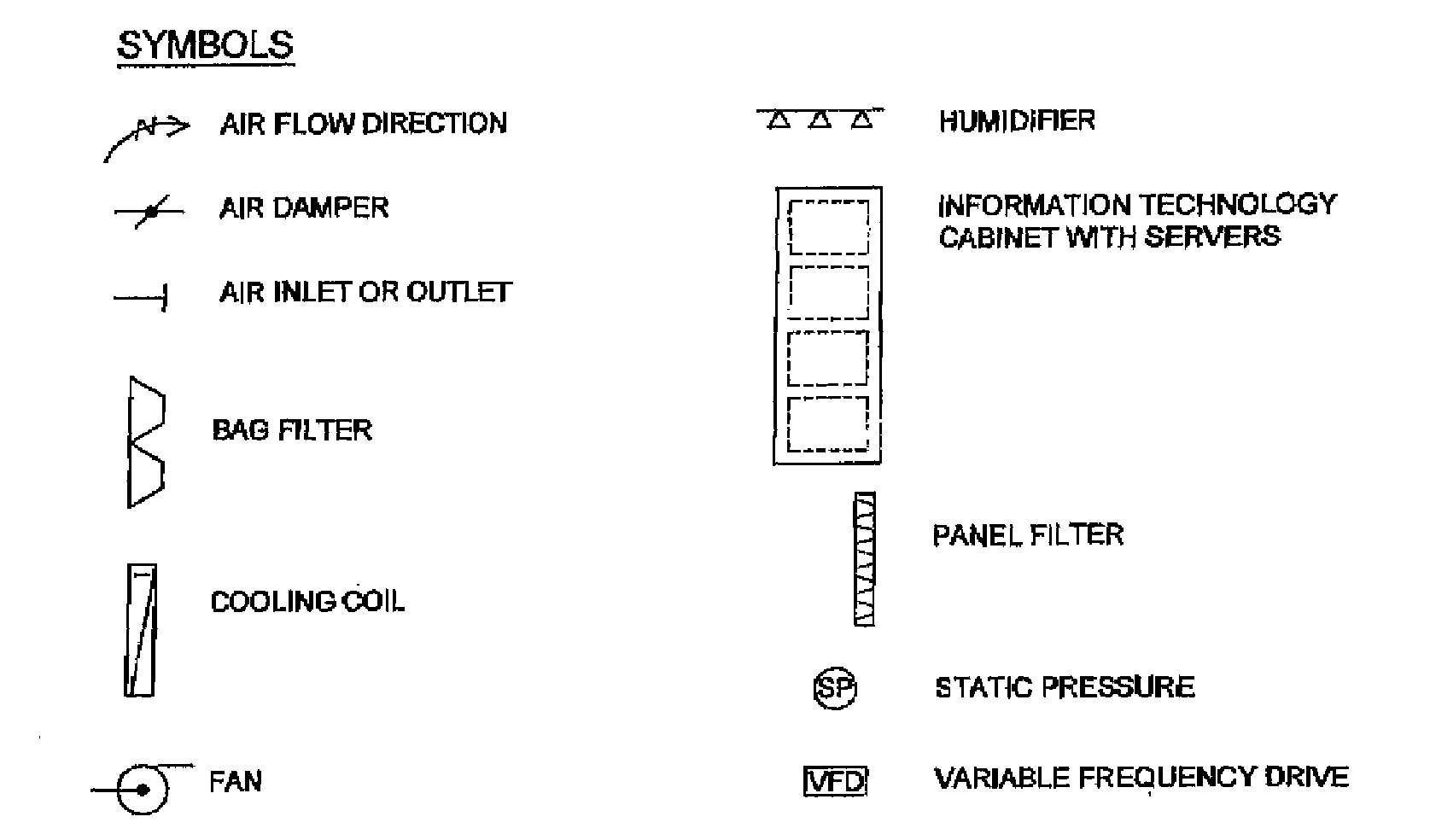

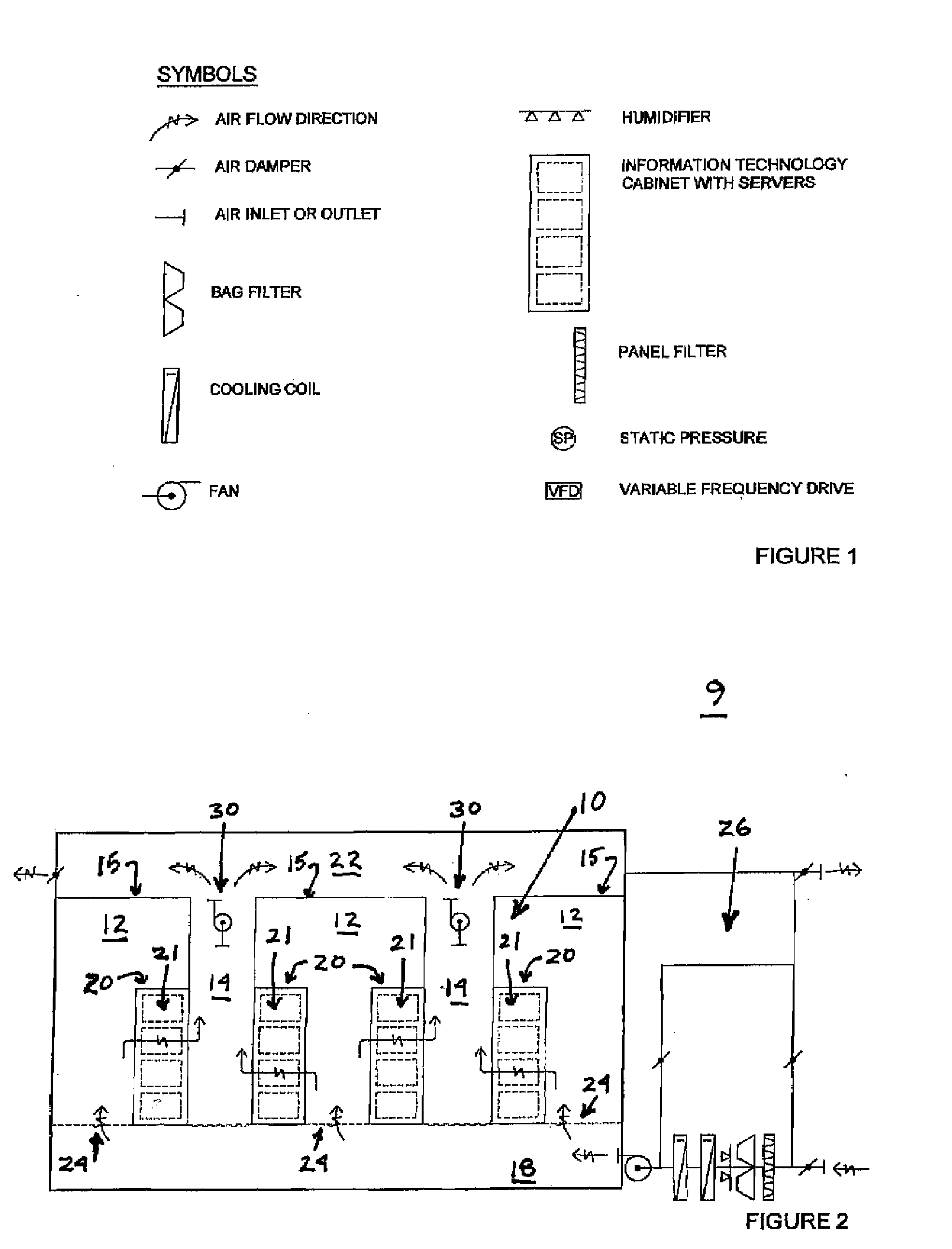

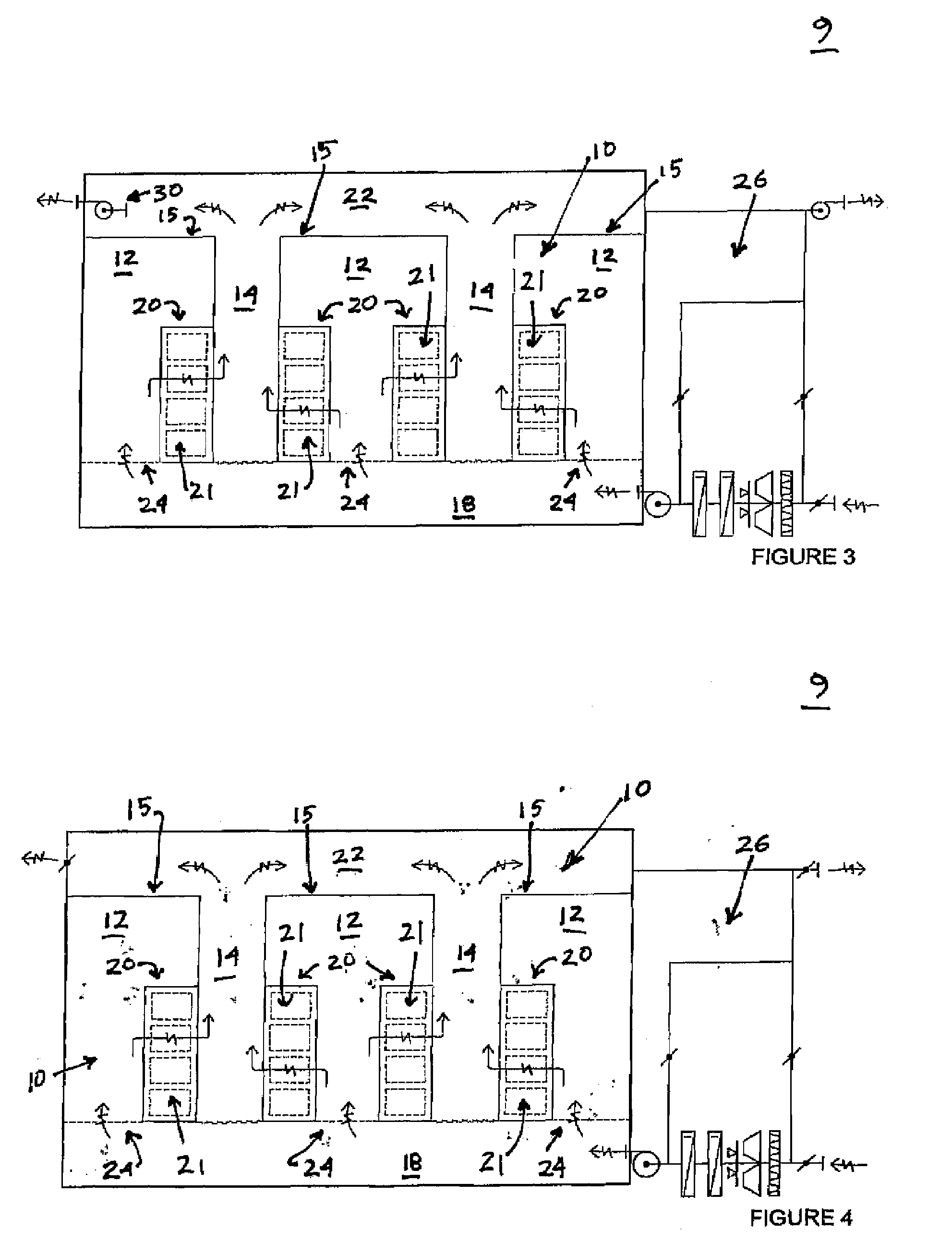

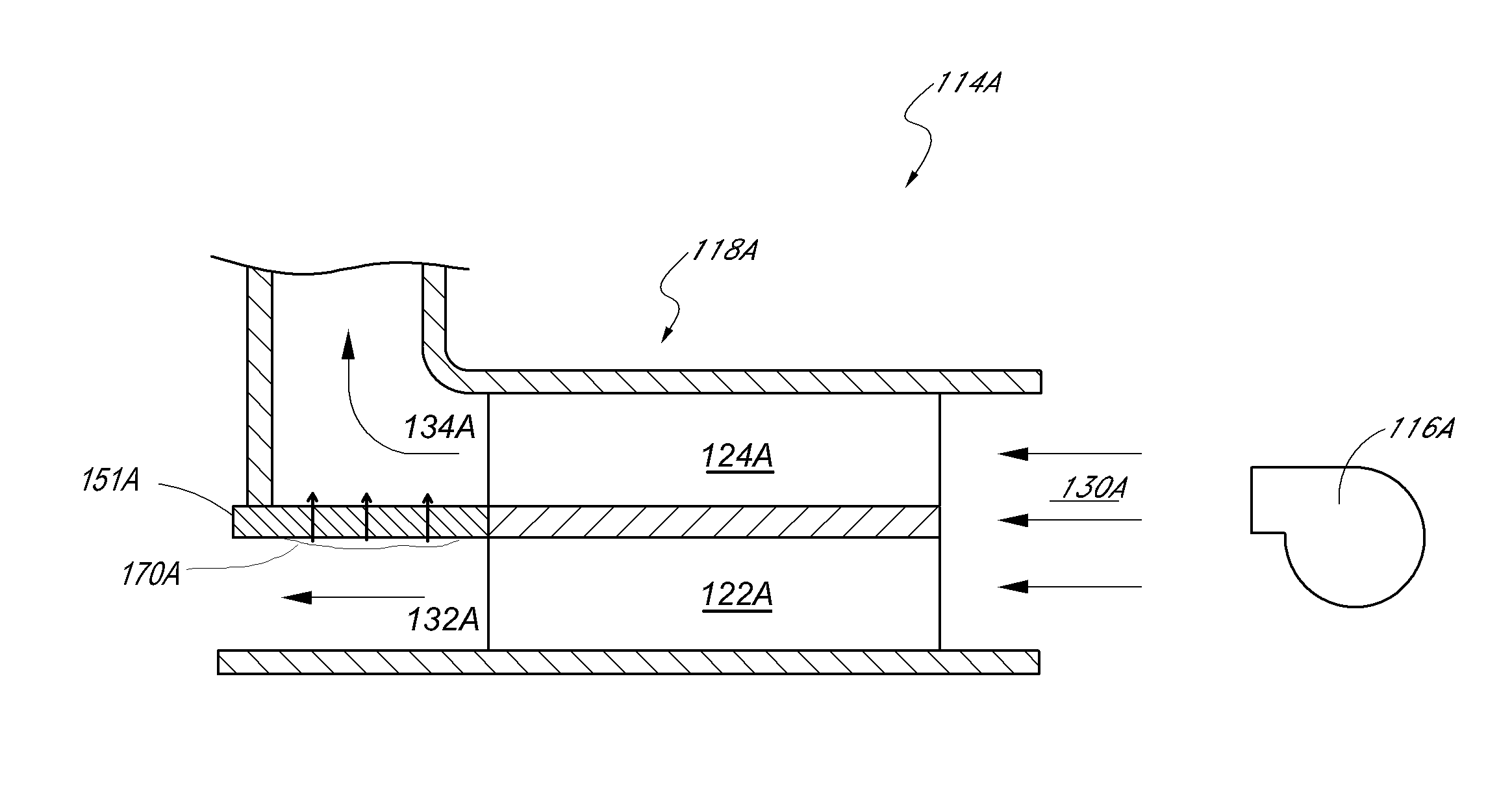

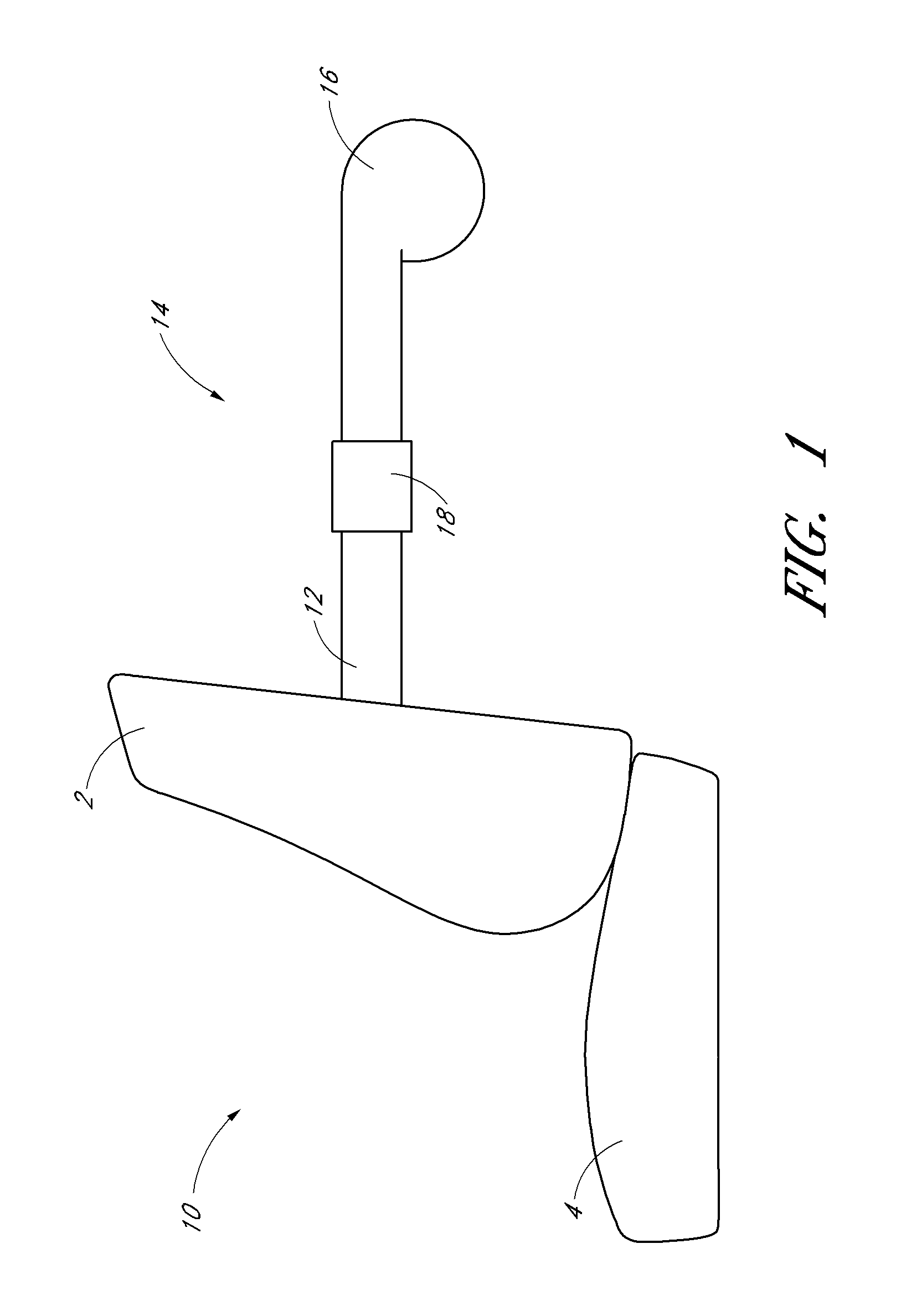

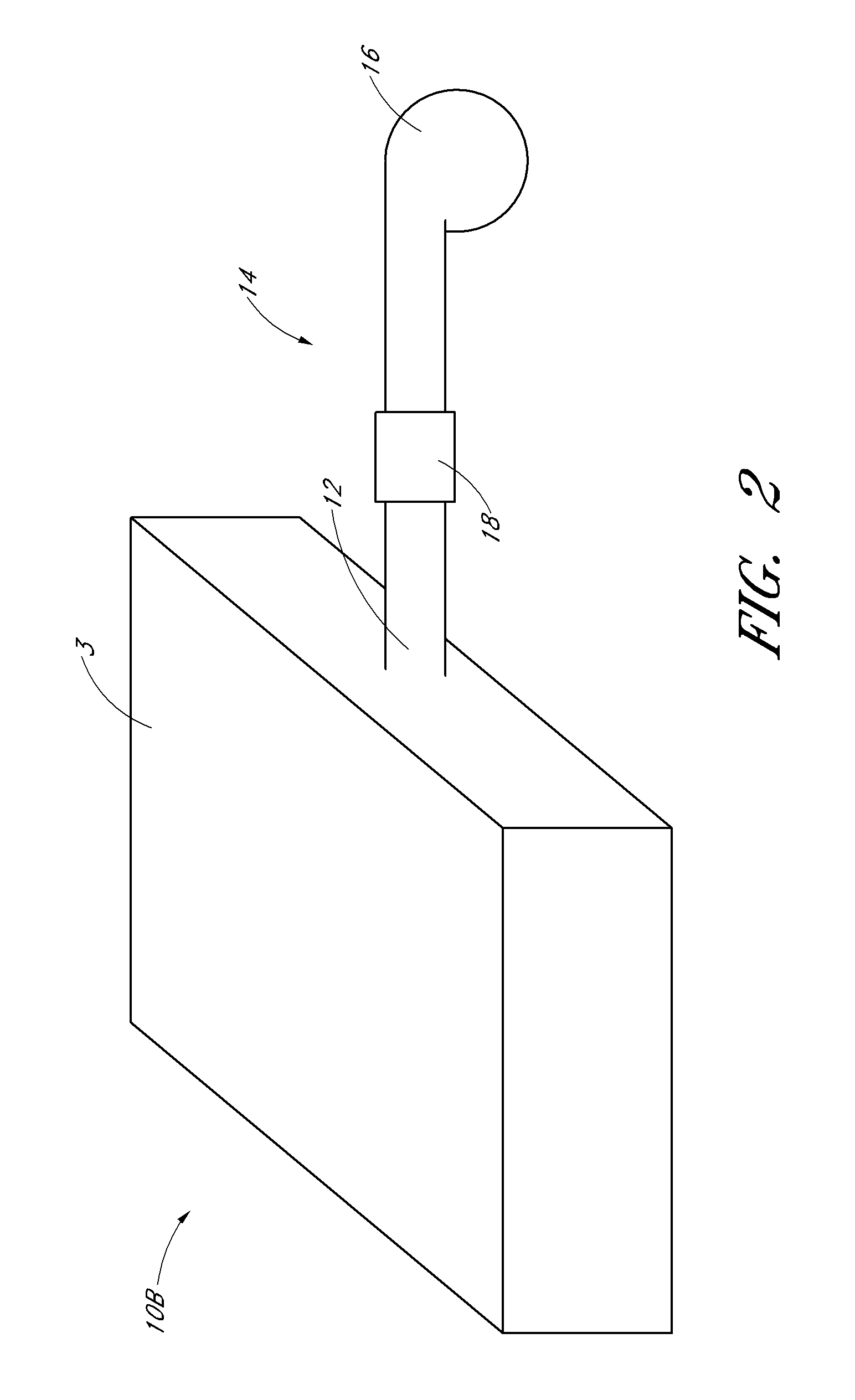

ActiveUS20080185446A1Easy to solveAvoid uneven loadLighting and heating apparatusElectrical apparatus contructional detailsAir managementAir volume

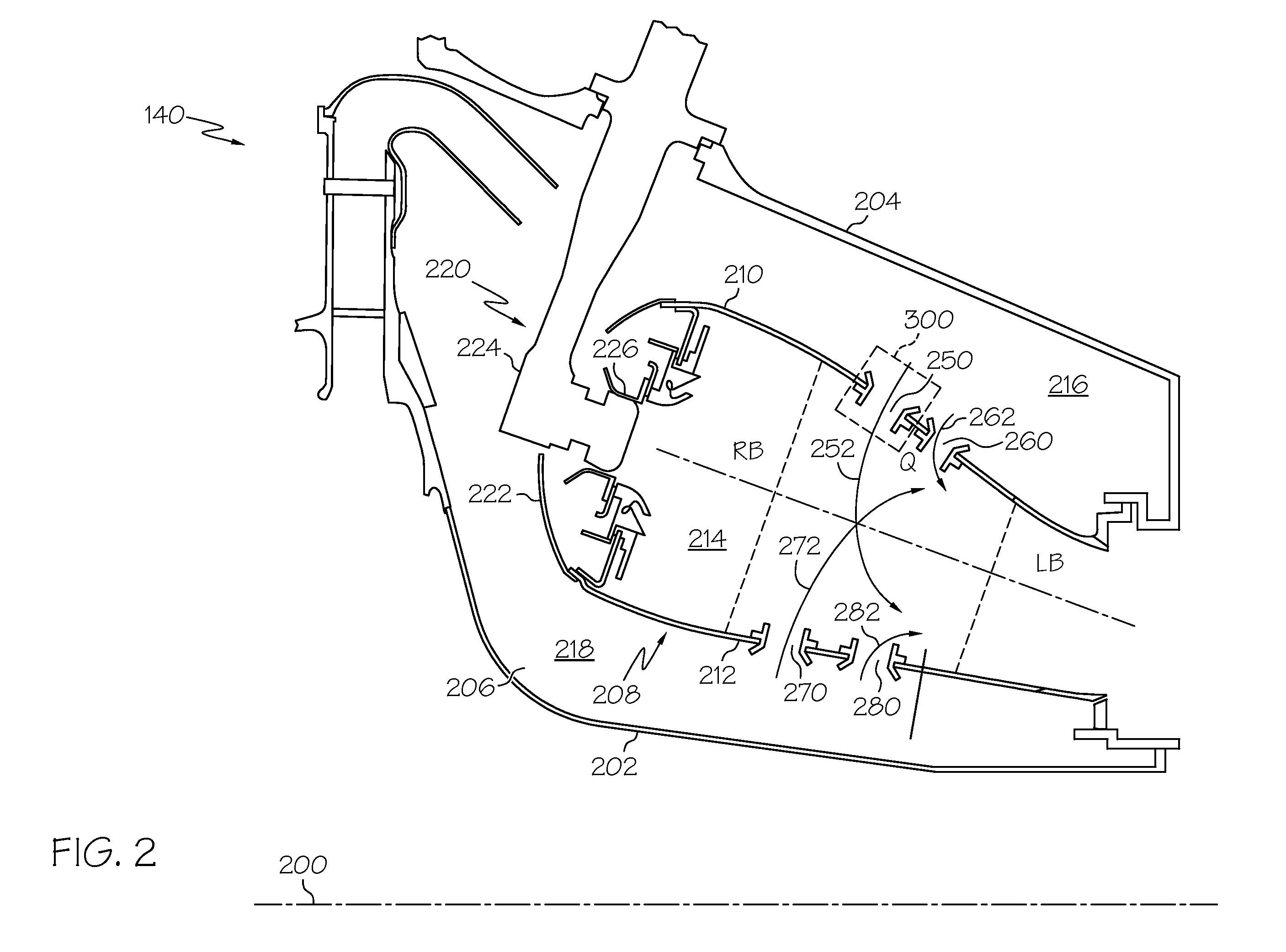

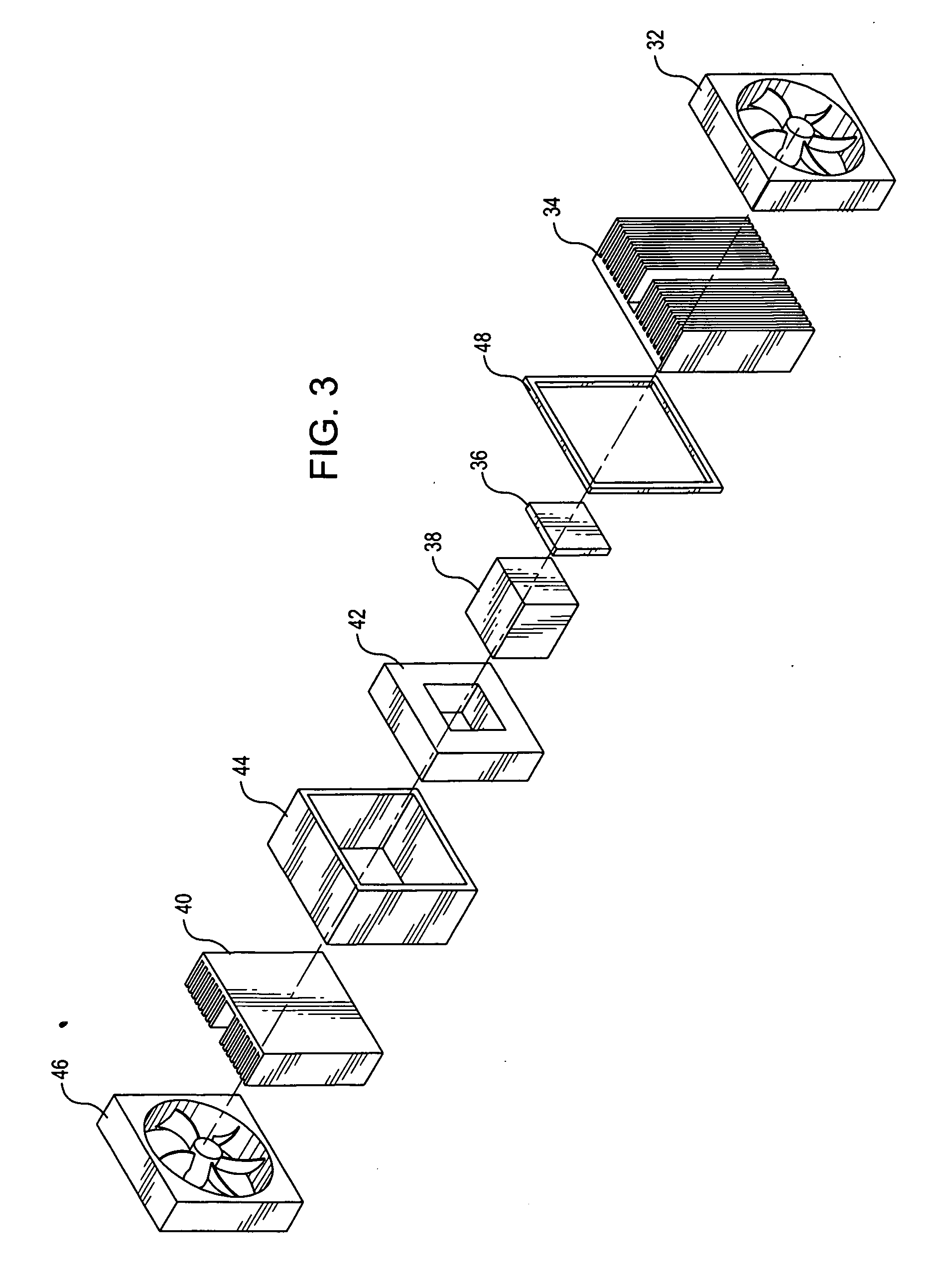

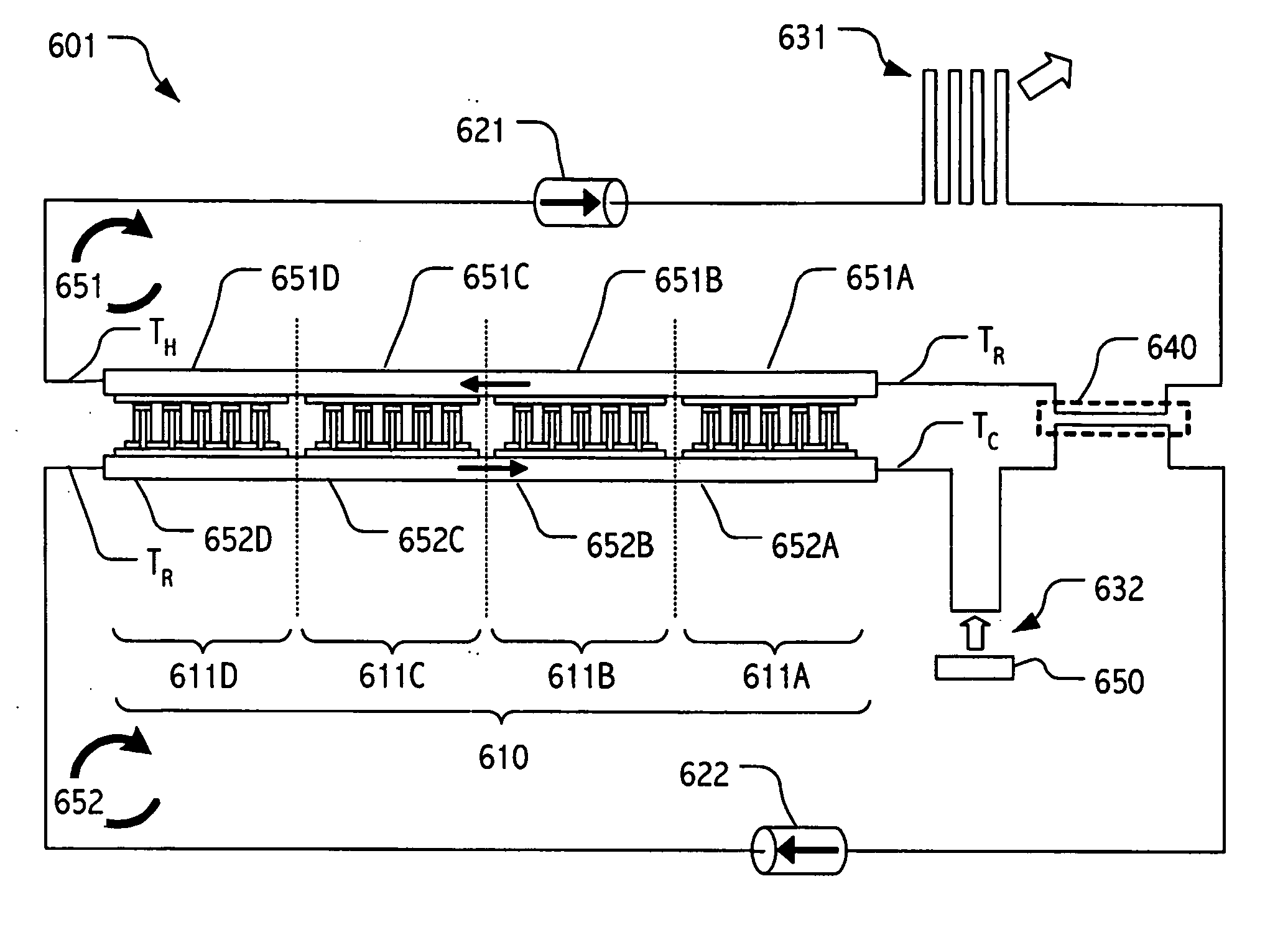

An improved solution for cooling a data center is provided. In an embodiment of the invention, a data center design that combines physical segregation of hot and cold air streams together with a data hall variable air volume system is provided. The invention is a data center design that resolves air management issues of re-circulation, bypass and load balance. Bypass is airflow supplied by the cooling units that directly returns without cooling servers. Recirculation airflow is server discharge warm air that returns directly without being cooled. Load balance is supplying the required server airflow. An embodiment includes physical segregation of cold and hot air streams and by providing variable air volume to match server load. Air segregation is done by enclosing the hot aisle end and above the cabinets. The air conditioning system provides variable air volume to the data hall (cold side) to meet server demands. The cooling plant consists of variable-air-volume air-cooling system, which cools air by air free cooling (economizer) and is supplemented with mechanical cooling in the warmer seasons.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

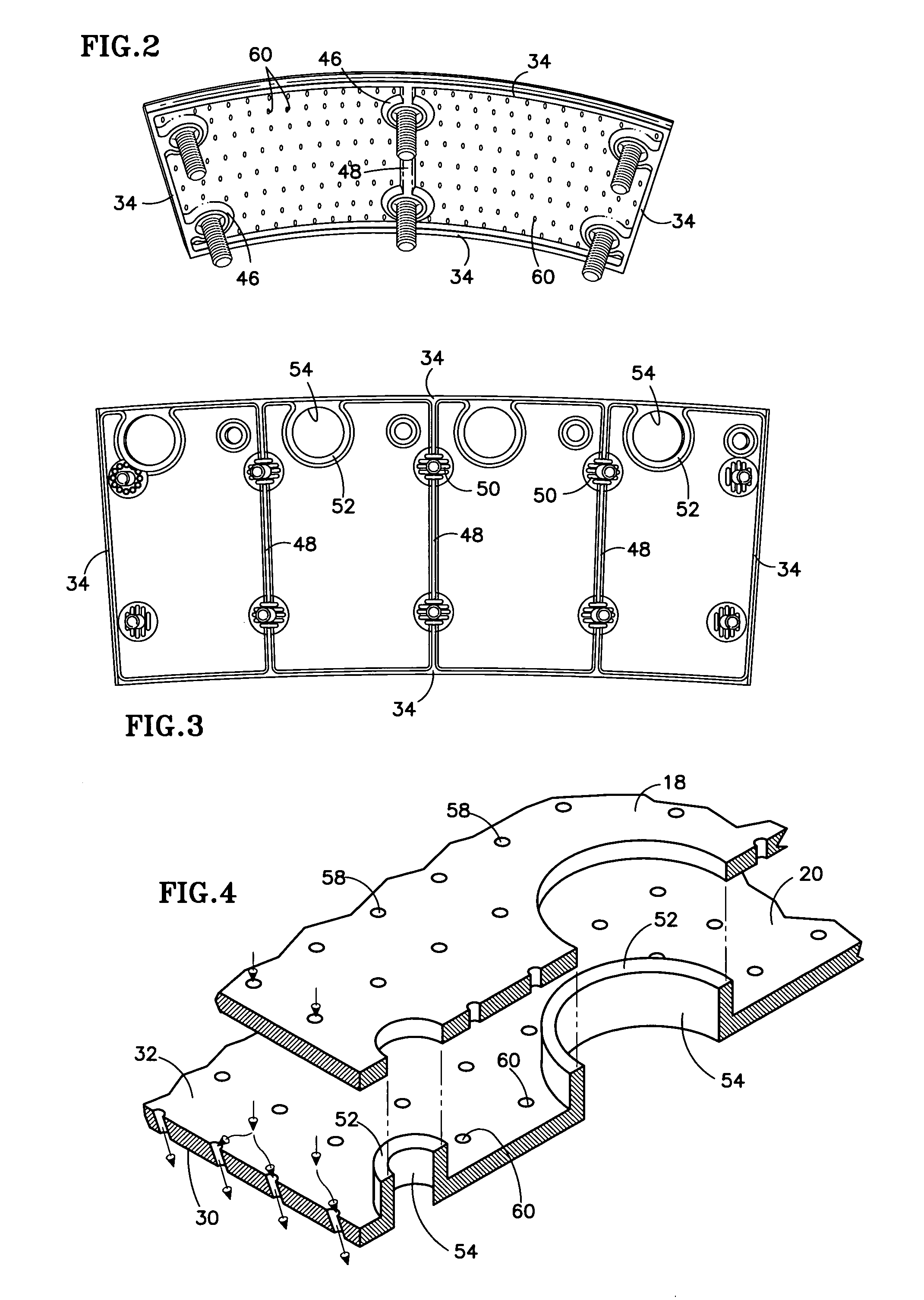

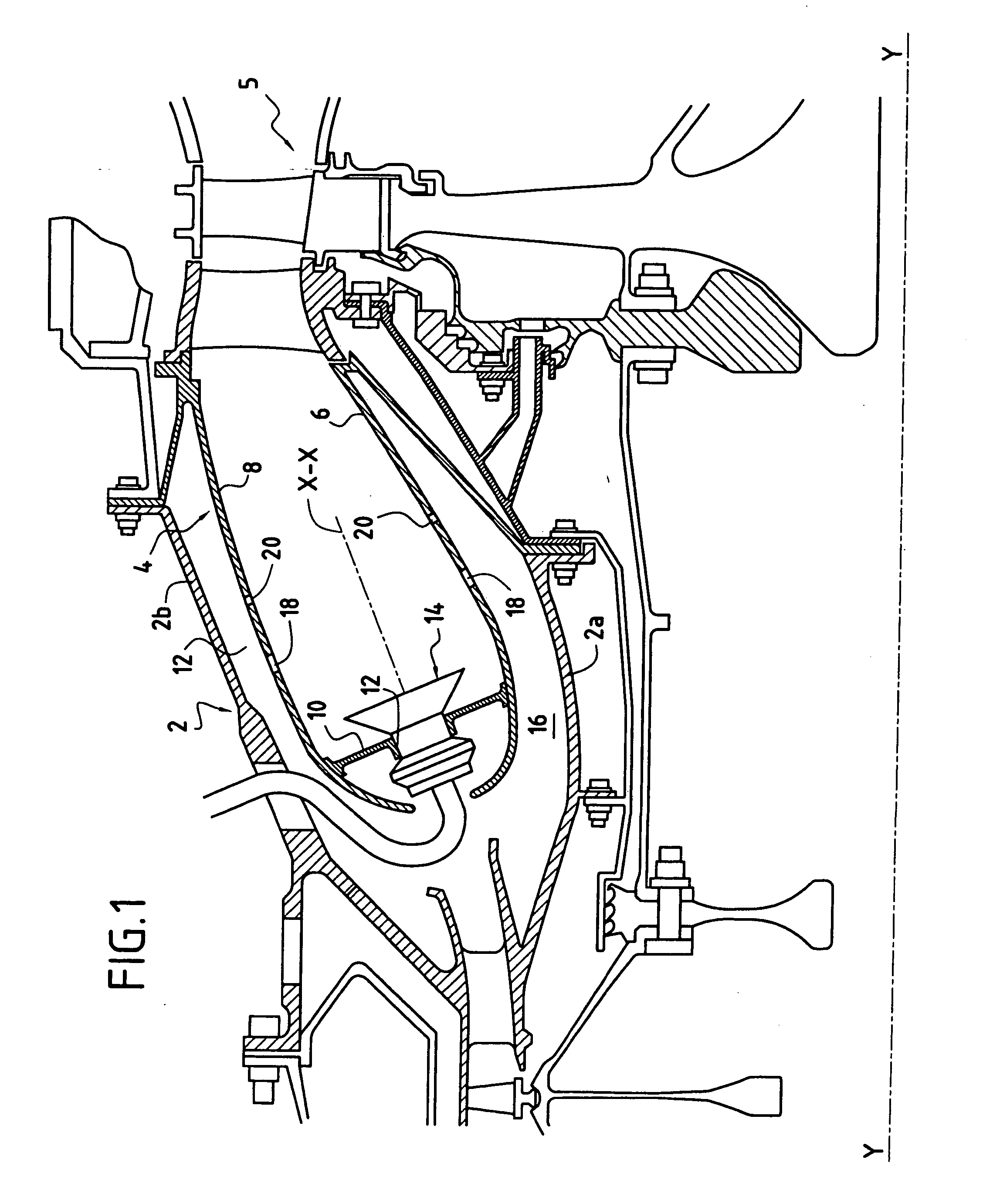

Heat shield panels for use in a combustor for a gas turbine engine

ActiveUS7093439B2Extended service lifeContinuous combustion chamberGas turbine plantsCold sideCombustor

The present invention relates to heat shield panels or liners to be used in combustors for gas turbine engines. The heat shield panels each comprise a hot side and a cold side and at least one isolated cooling chamber on the cold side. Each cooling chamber has a plurality of cooling film holes for allowing a coolant, such as air, to flow from the cold side to the hot side. A combustor having an arrangement of heat shield panels or liners is also described.

Owner:RAYTHEON TECH CORP

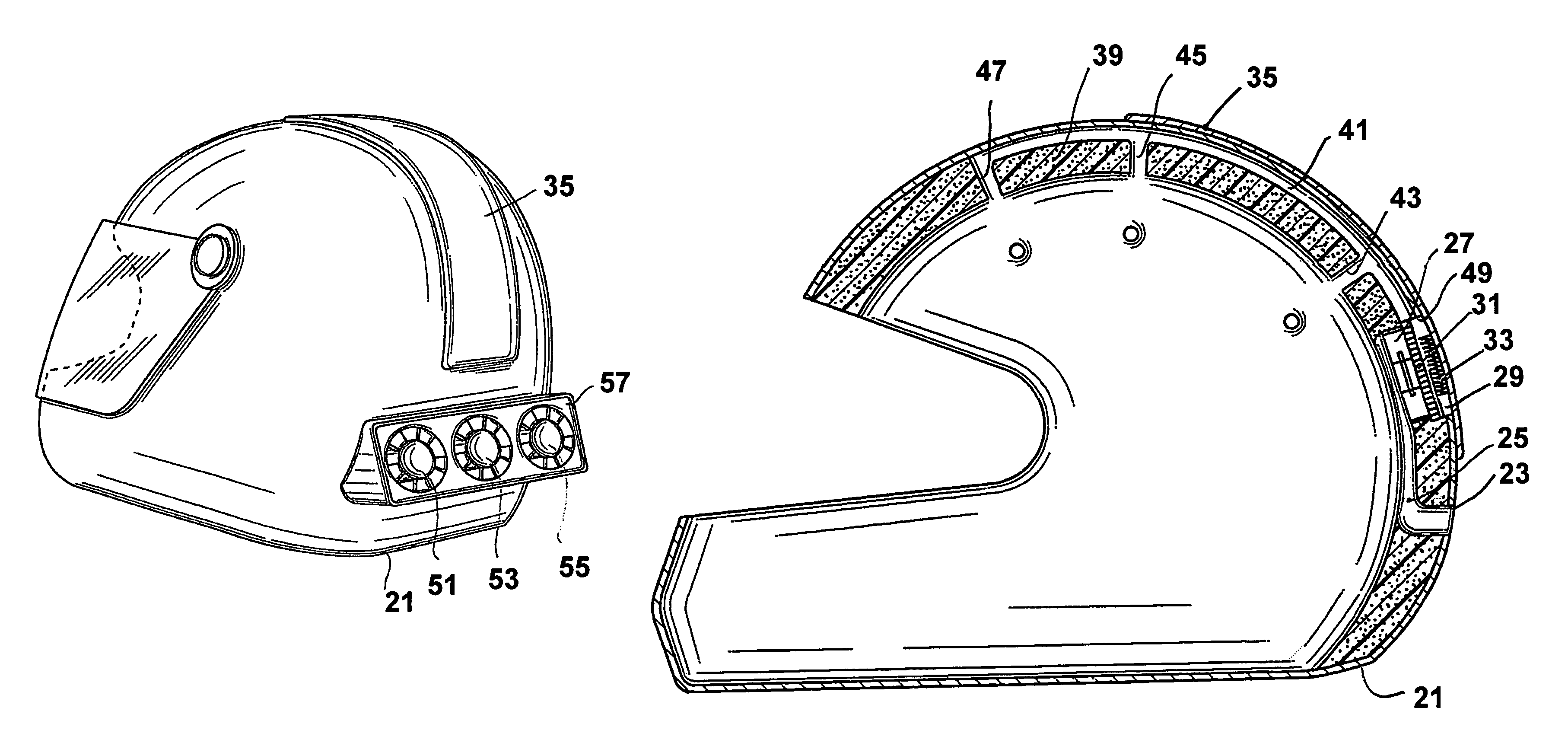

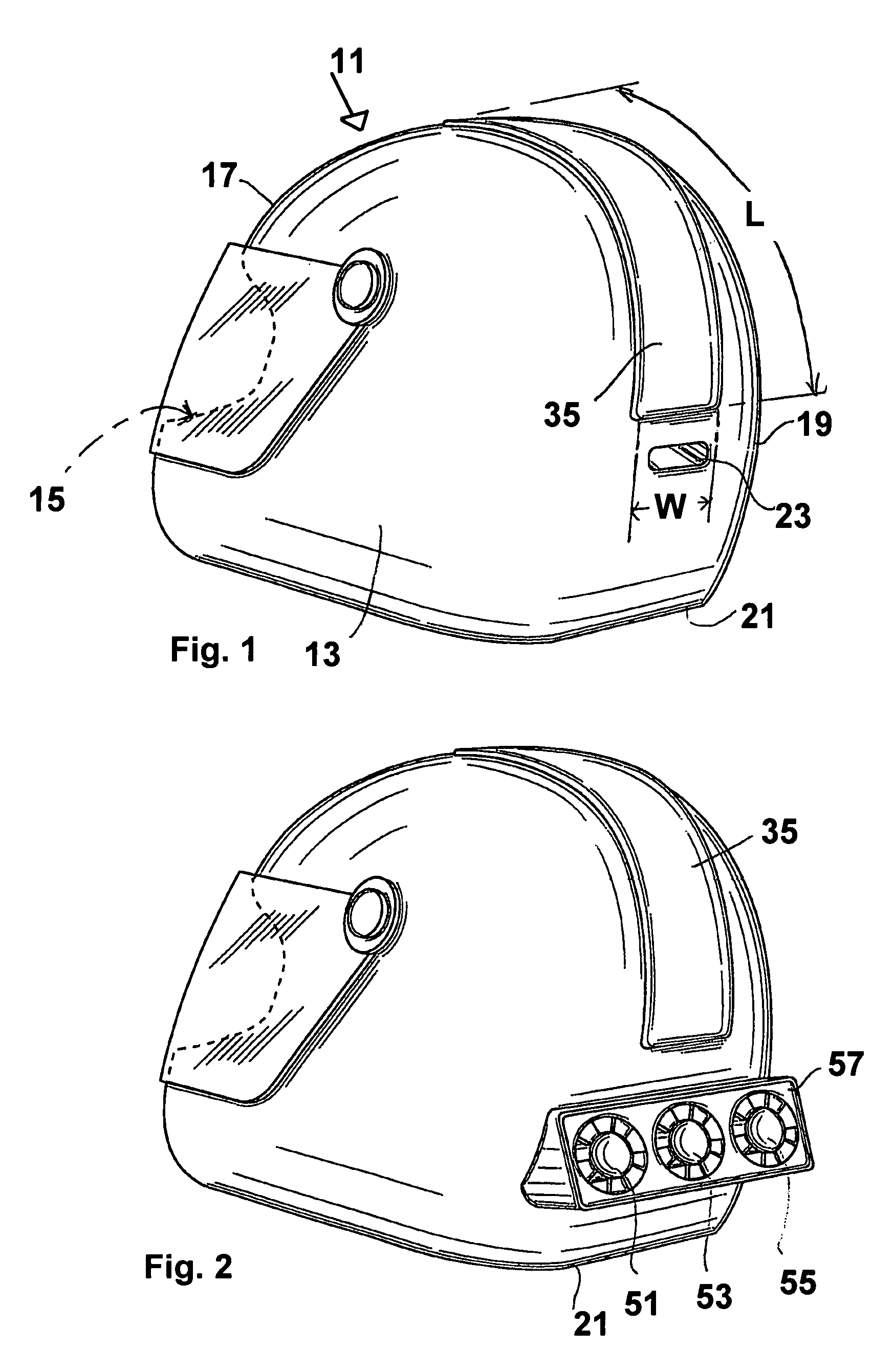

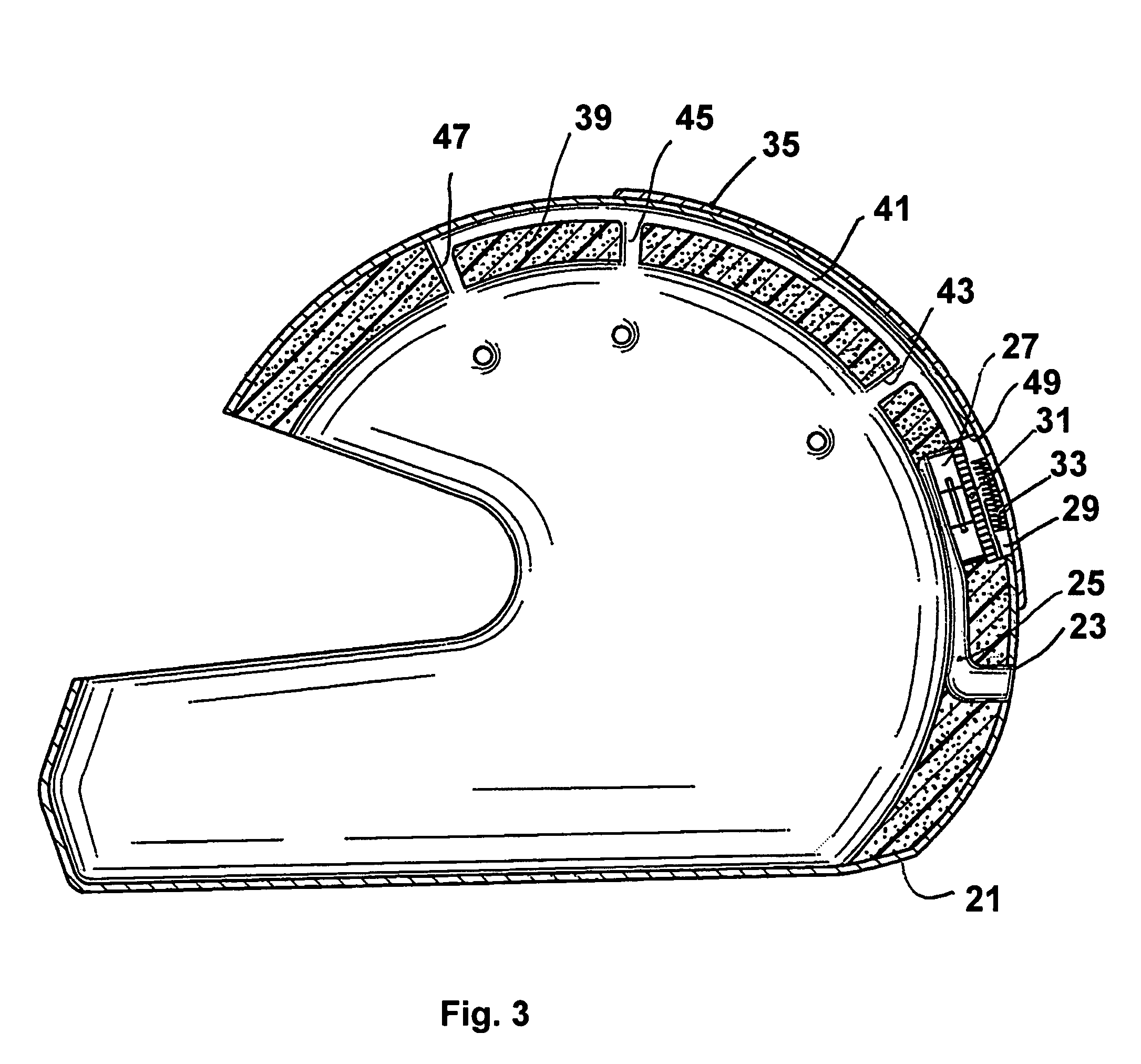

Crash helmet with thermoelectric cooling

InactiveUS7296304B2Increase airflowConvenient ArrangementHatsHeadwear capsThermoelectric coolingCold side

An conditioning system is shown for a helmet having an impact resistant body with an exterior, an interior which defines a head receiving cavity, a front region and having a back region which is located adjacent a lower edge of the helmet body. A first opening is provided in the helmet body located at the back region of the helmet body adjacent a lower edge thereof which acts as an air intake opening. A blower fan communicates with the air intake passage for drawing air into the intake passage and forcing the air from the back region of the helmet in the direction of the front region thereof. A thermoelectric cooling element is located in the helmet interior in communication with the intake passage downstream of the blower fan. The thermoelectric cooling element has a cold side and a hot side. A DC power source is provided for powering the thermoelectric cooling element. An external heat sink is located on the helmet exterior and is connected to the hot side of the thermoelectric cooling element by means of a second opening in the helmet body. Air passing over the thermoelectric cooling element is cooled and air conditions the head receiving region of the helmet.

Owner:R & G MACHINE TOOL

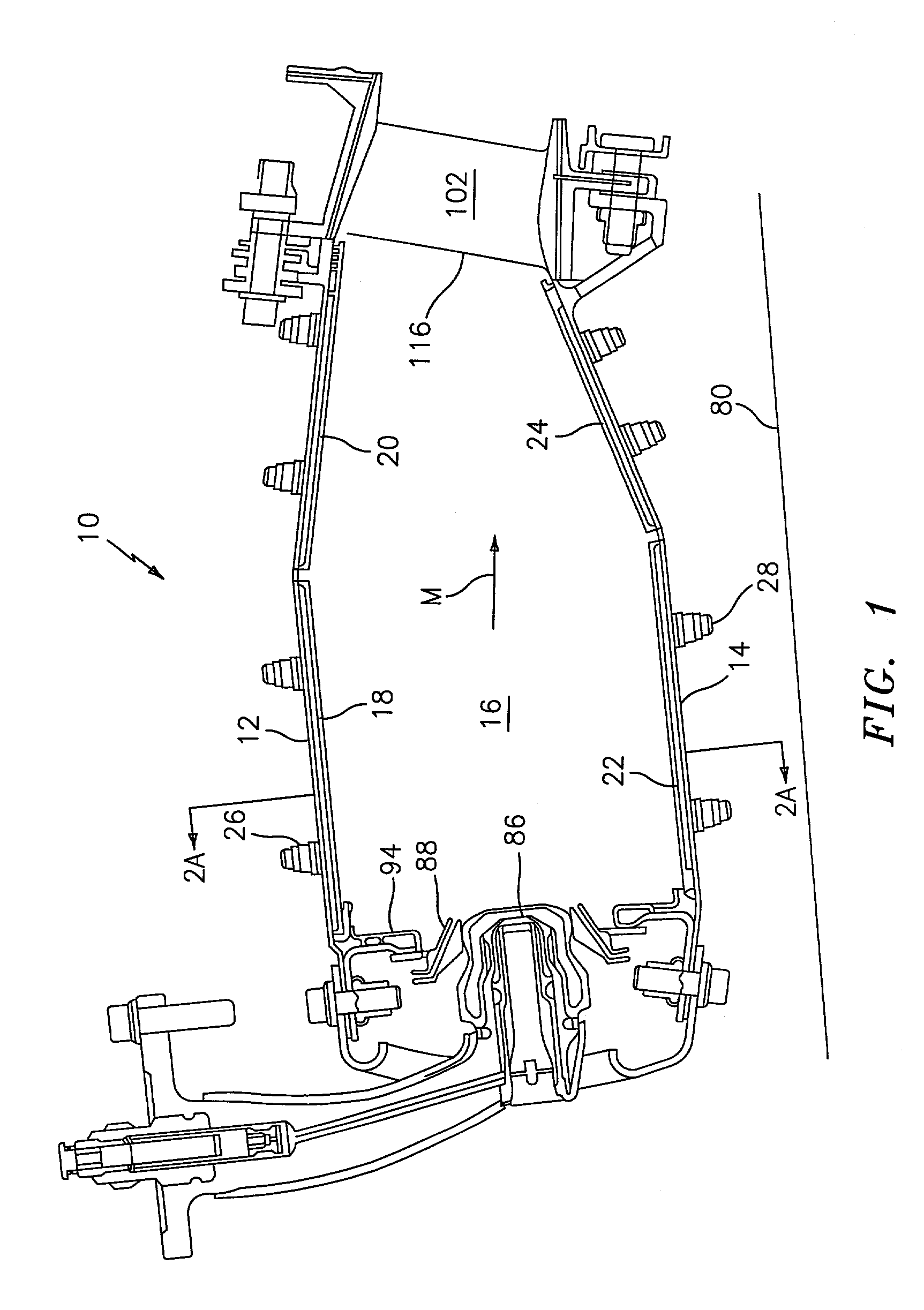

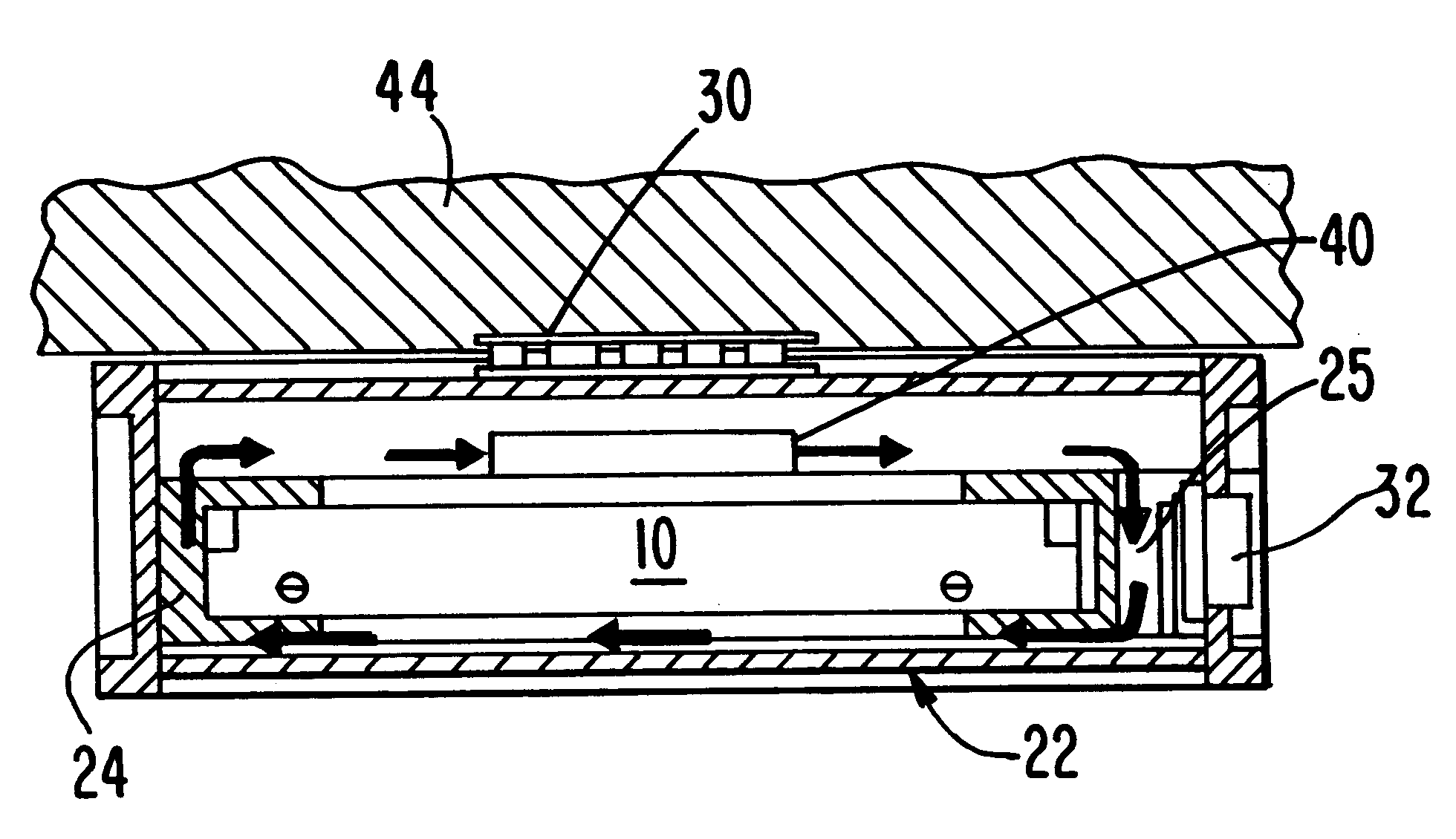

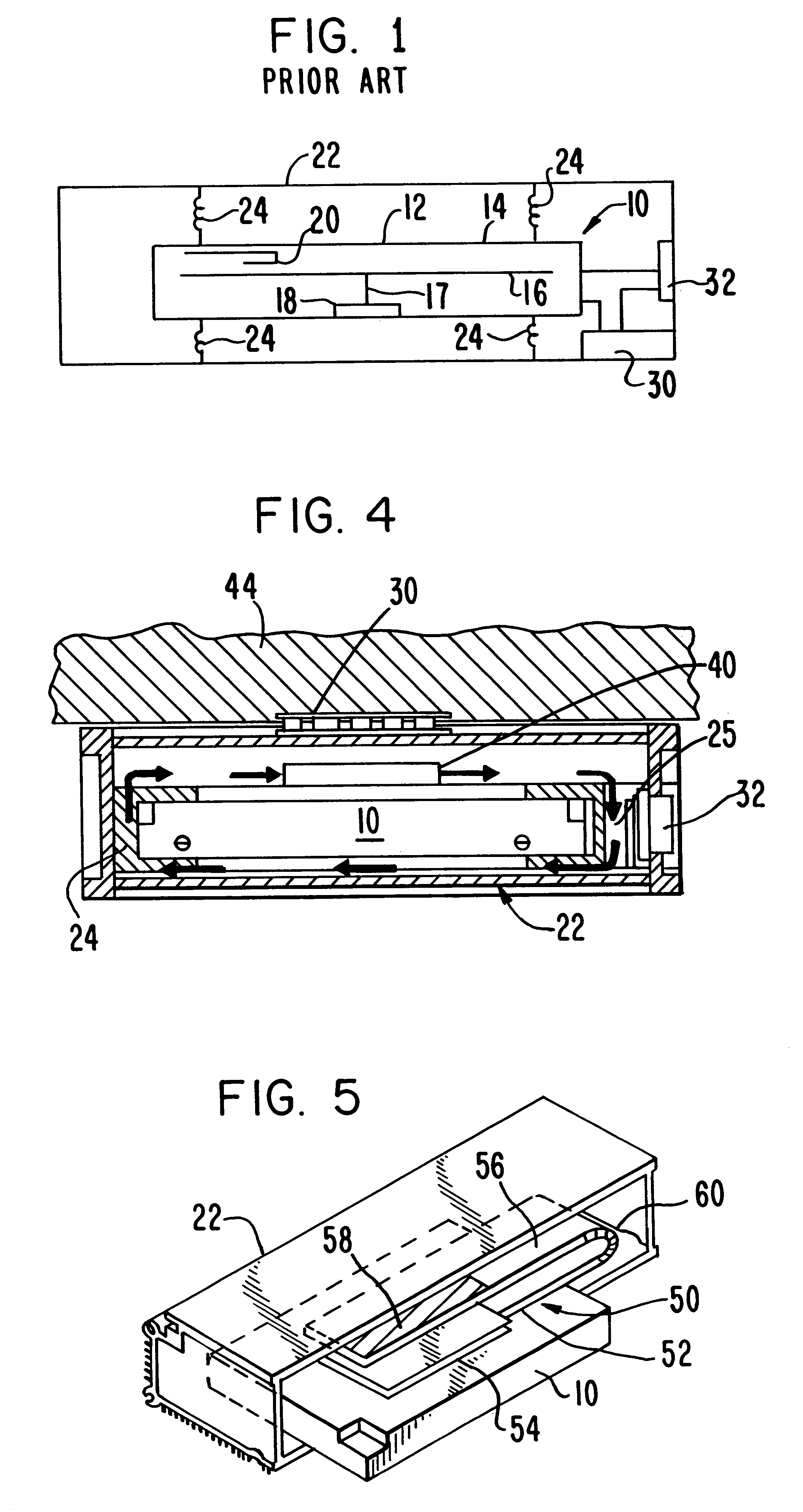

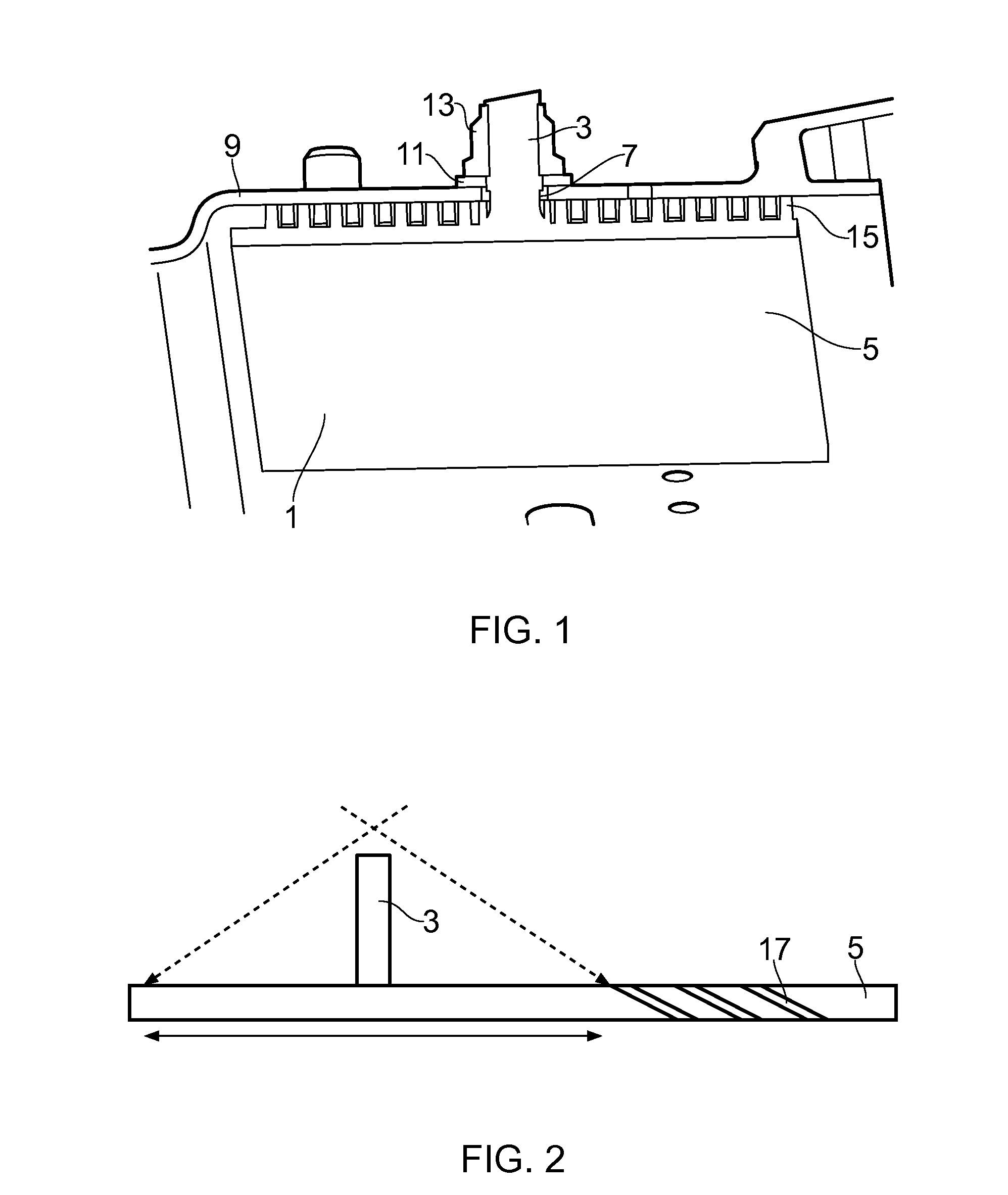

Environmental system for rugged disk drive

InactiveUS6289678B1Reducing temperature influence on carrierDigital data processing detailsCold sideShock mount

A hard disk system having a disk housing shock mounted in an environmental housing employs a device to transfer heat from the disk housing while avoiding any mechanical connection that would impose significant rigidity between the disk housing and the environment housing so as to defeat the shock mounting. In one embodiment, a Peltier effect heat pump has a cold side in contact with the disk housing and a hot side in contact with heat-conducting spring fingers contacting the environmental housing. In another embodiment, a fan is positioned in a space between the outside of the disk housing and the inside of the environmental housing to circulate air around the disk housing, while a Peltier effect heat pump moves heat to the environmental housing. In yet another embodiment, the fan is positioned in the space between the disk housing and the environmental housing, and the Peltier effect heat pump has a cold side in contact with an exterior surface of the environmental housing and a hot side in contact with a heat sink. In still another embodiment, a flexible heat pipe comprising a shell containing a low vapor-point liquid is positioned in the space between the outside of the disk housing and the inside of the environmental housing with respective ends in contact with each of the housings.

Owner:PHOENIX GROUP

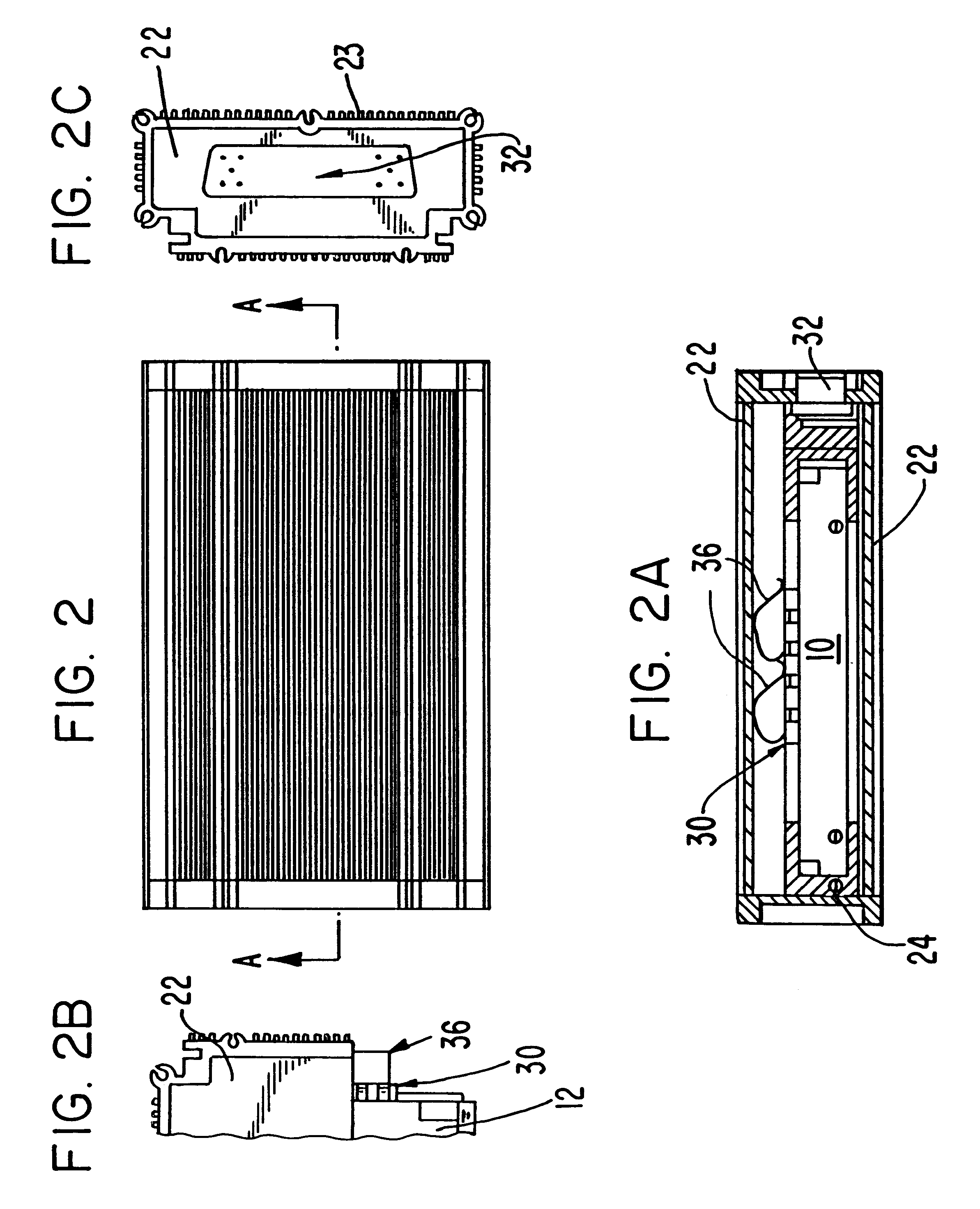

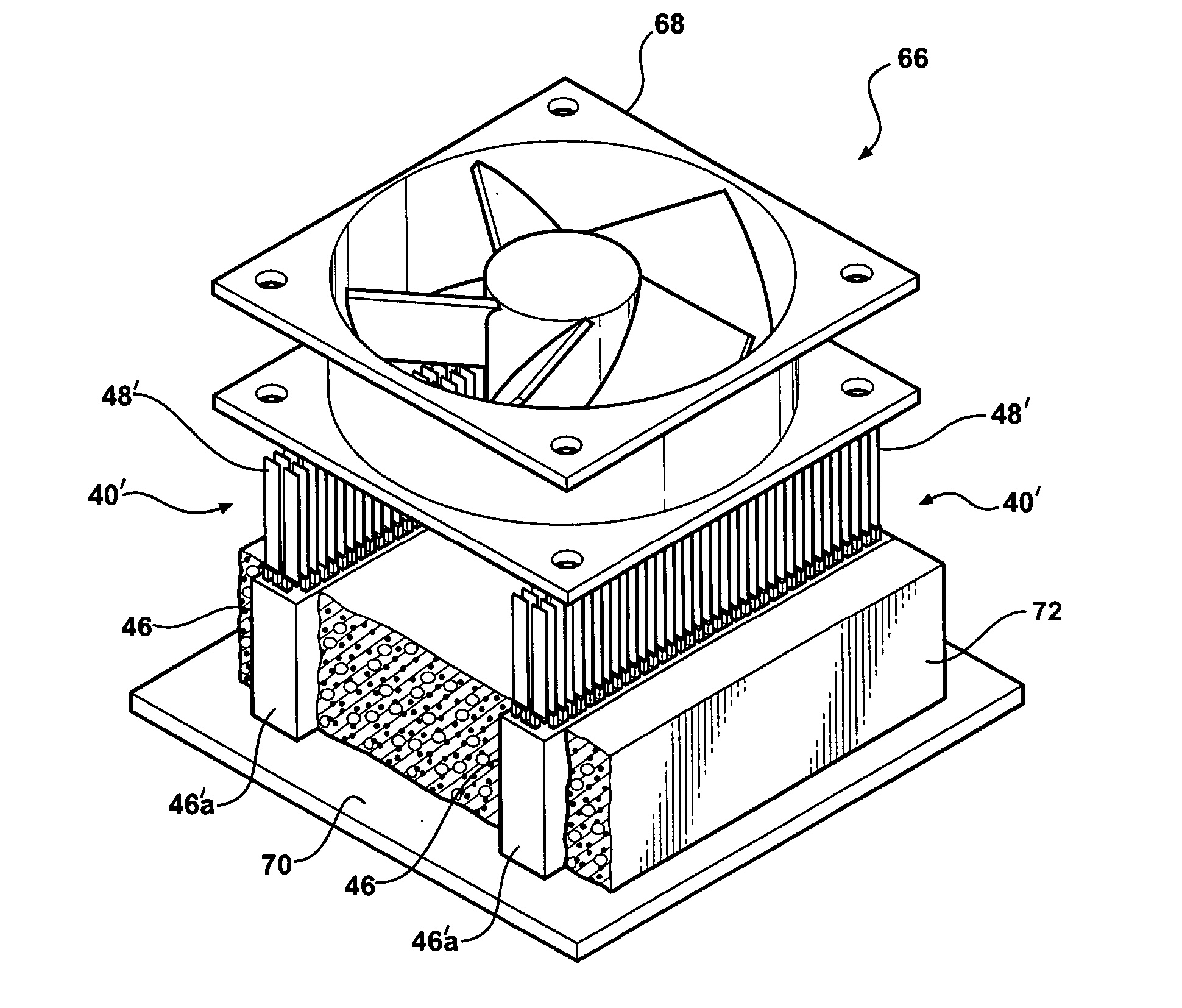

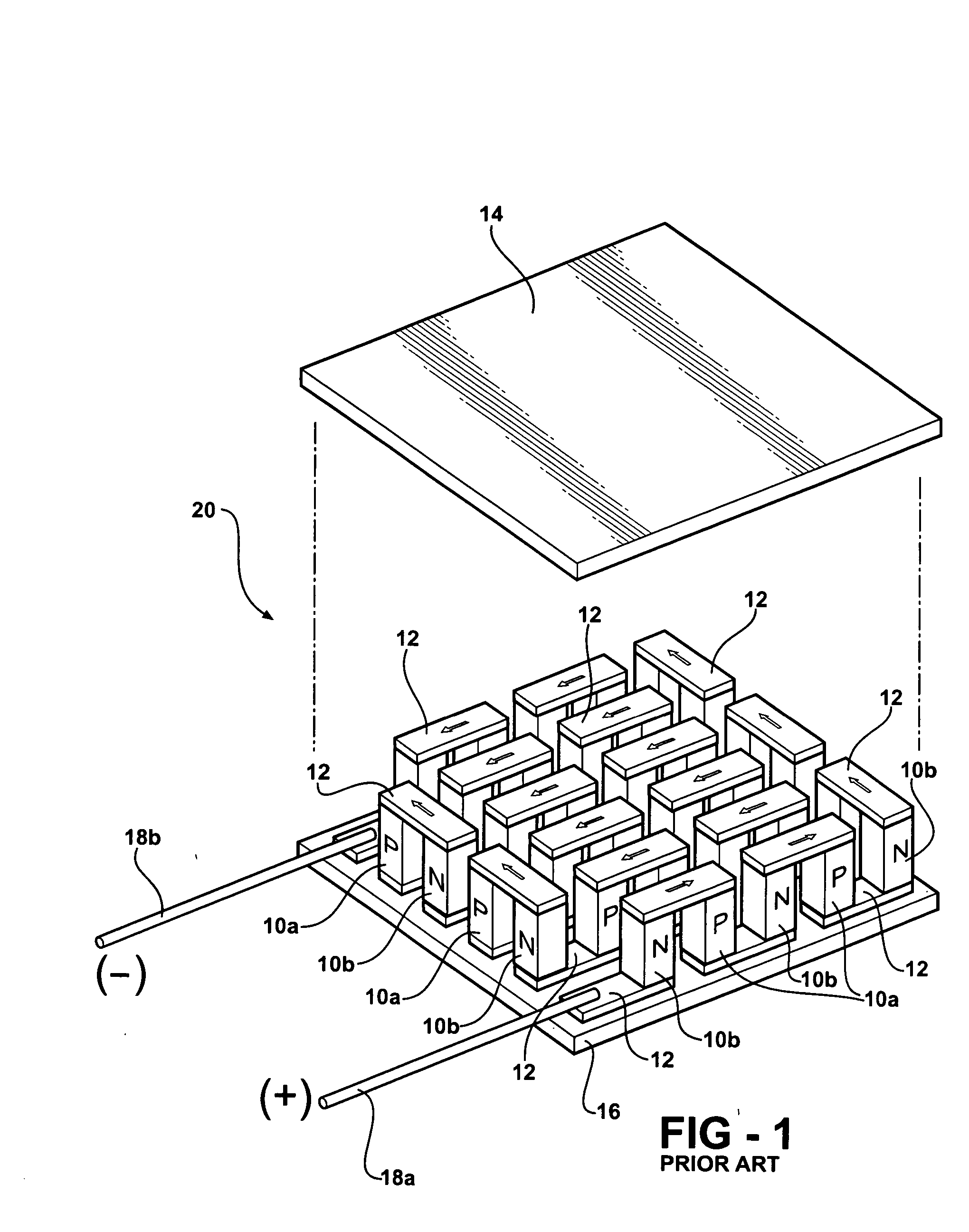

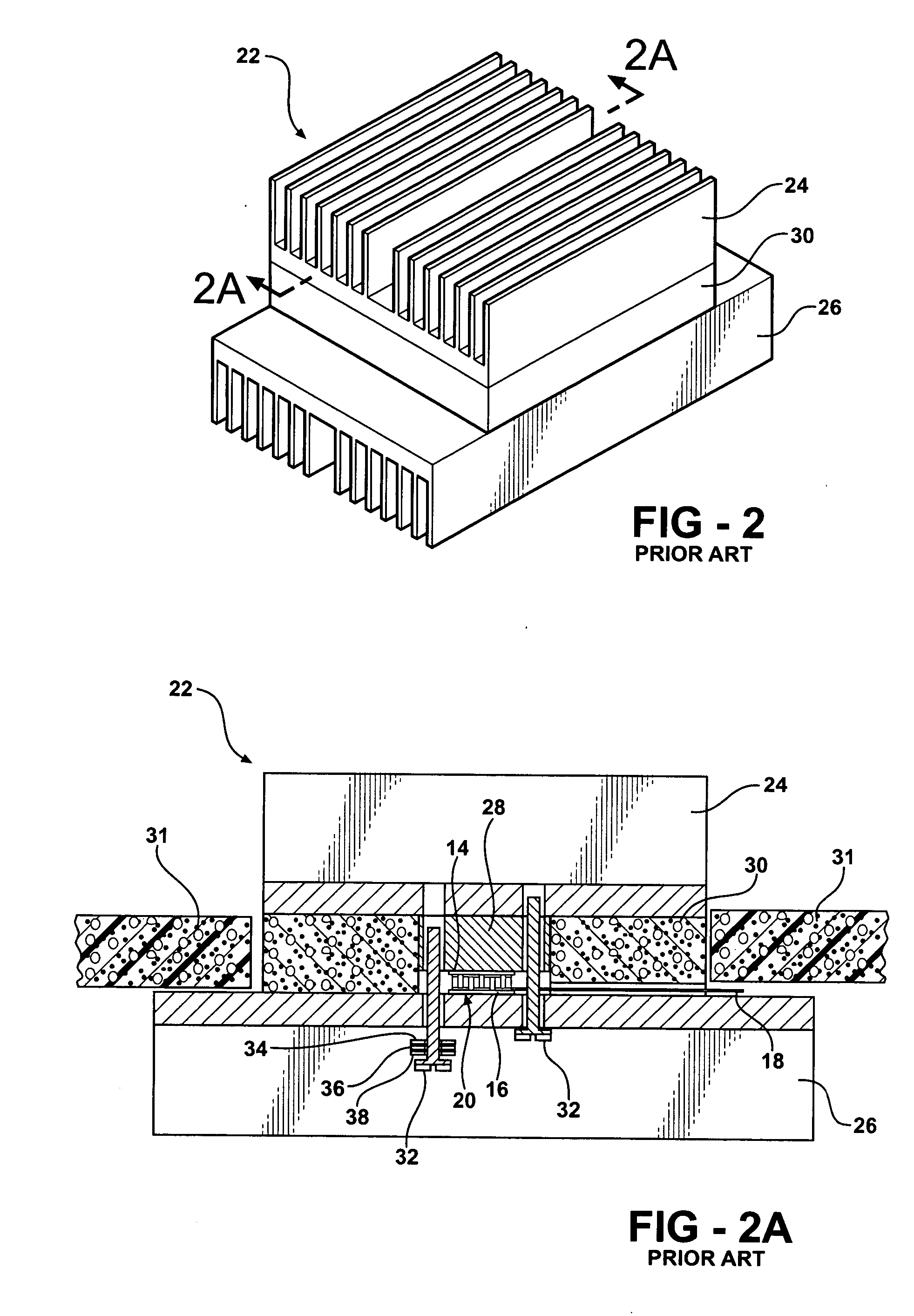

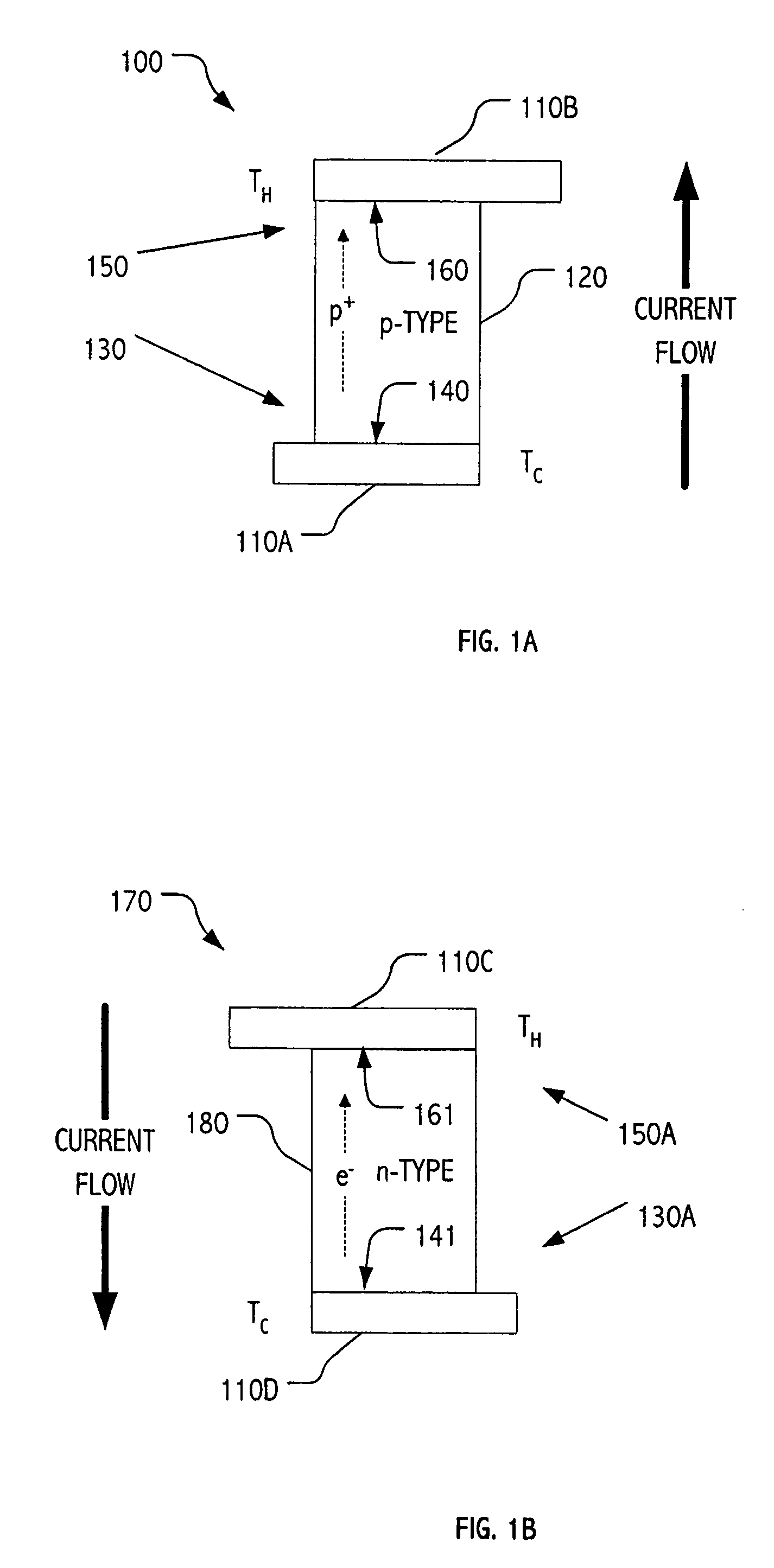

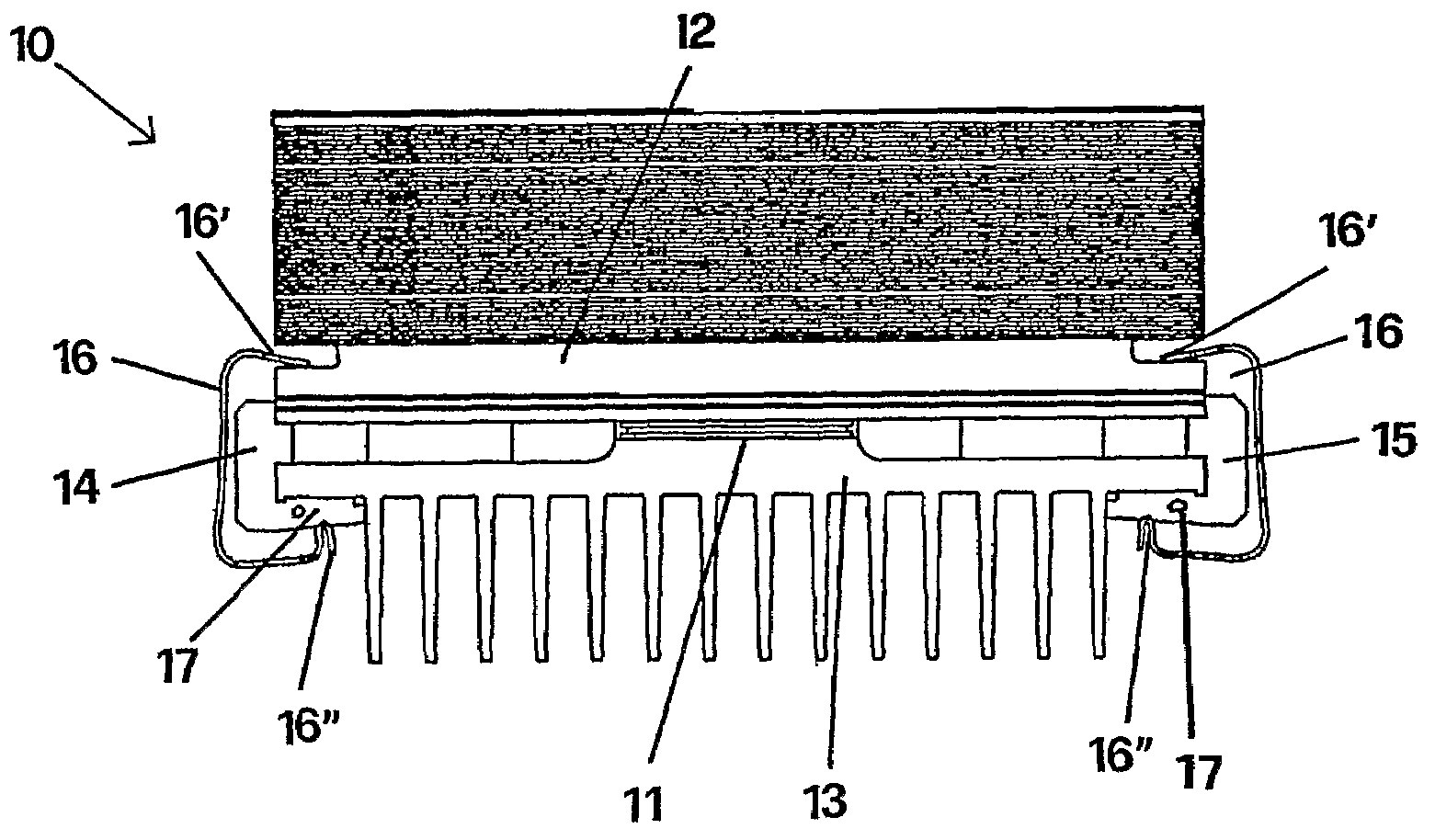

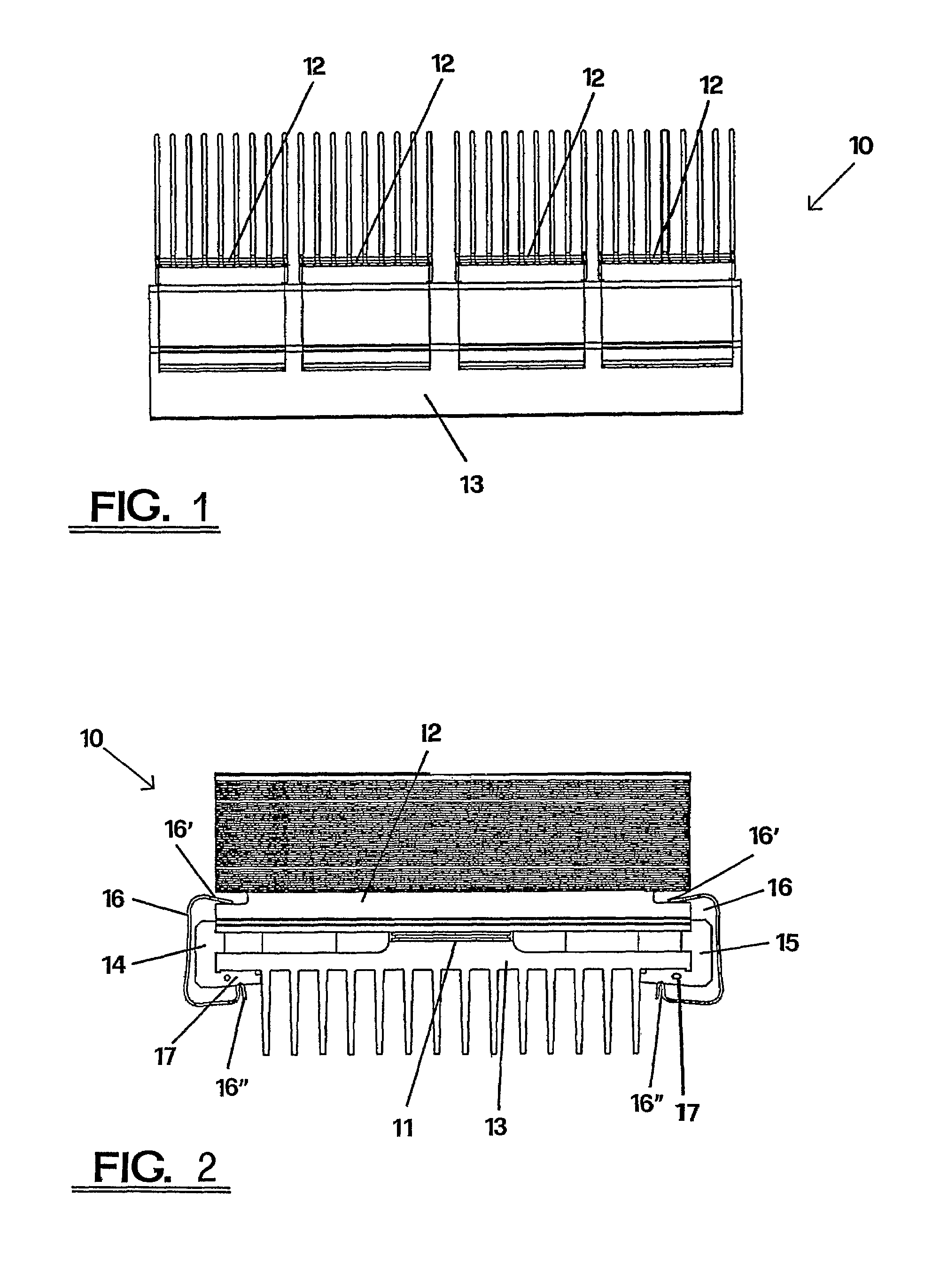

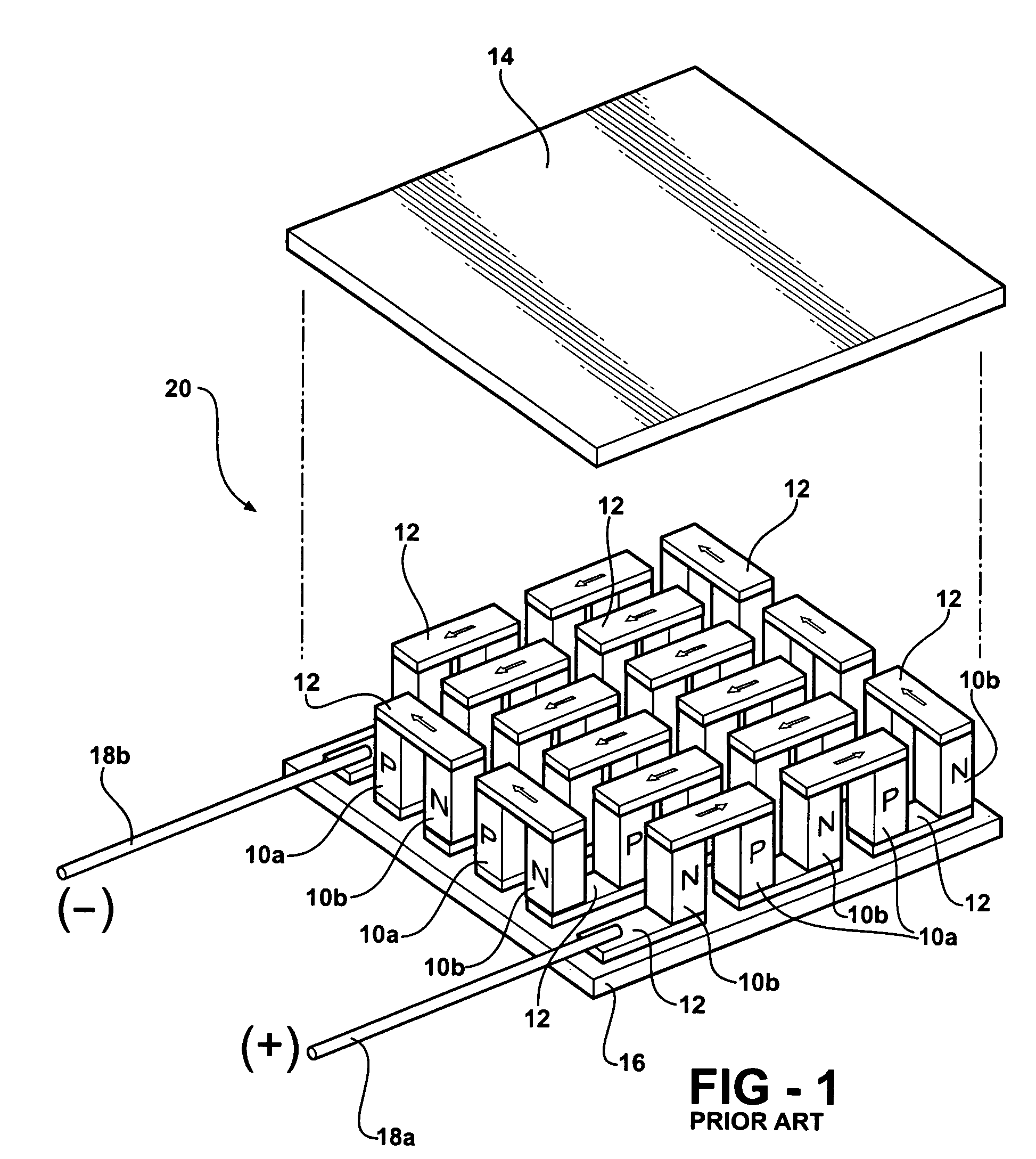

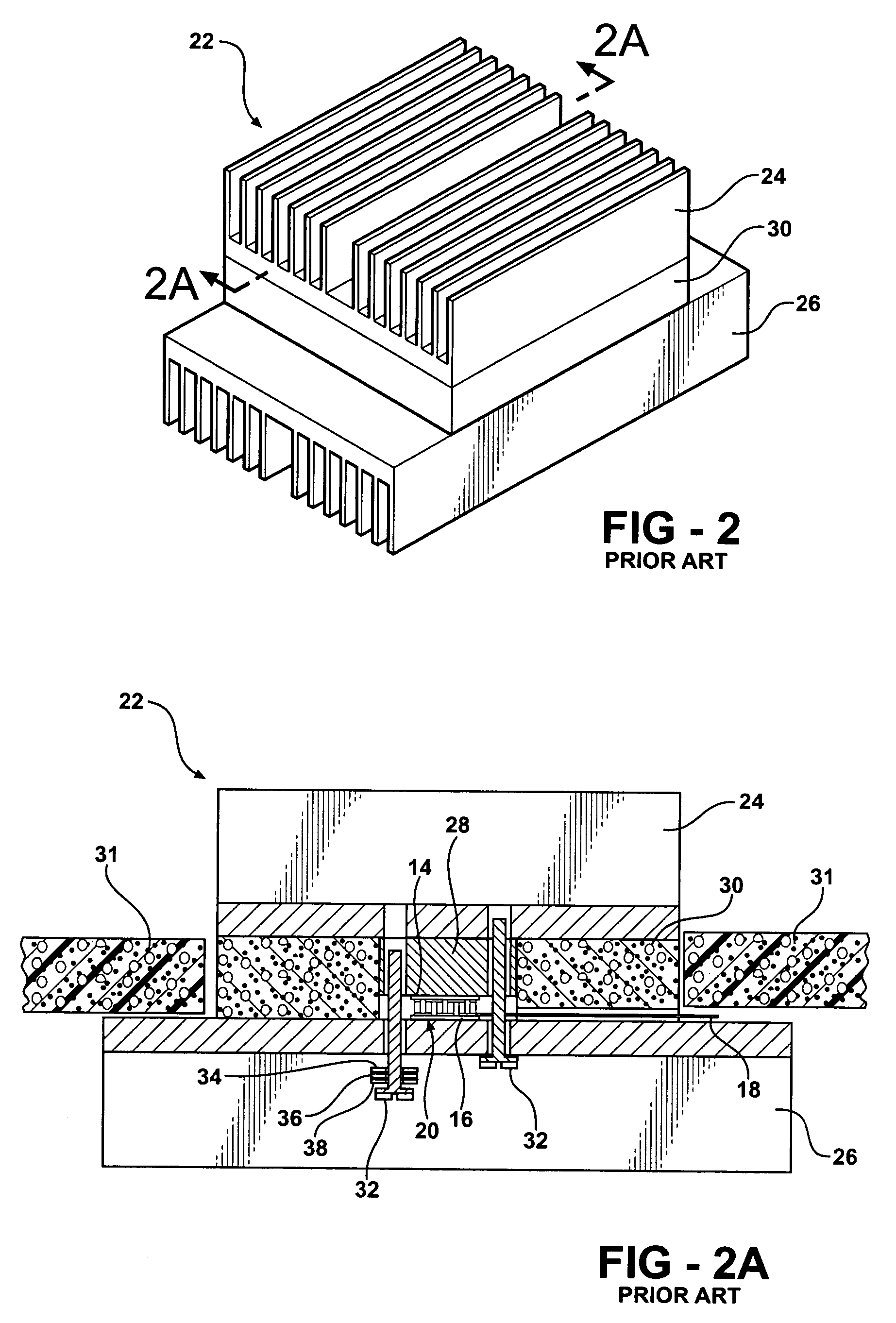

Thermoelectric heat pump with direct cold sink support

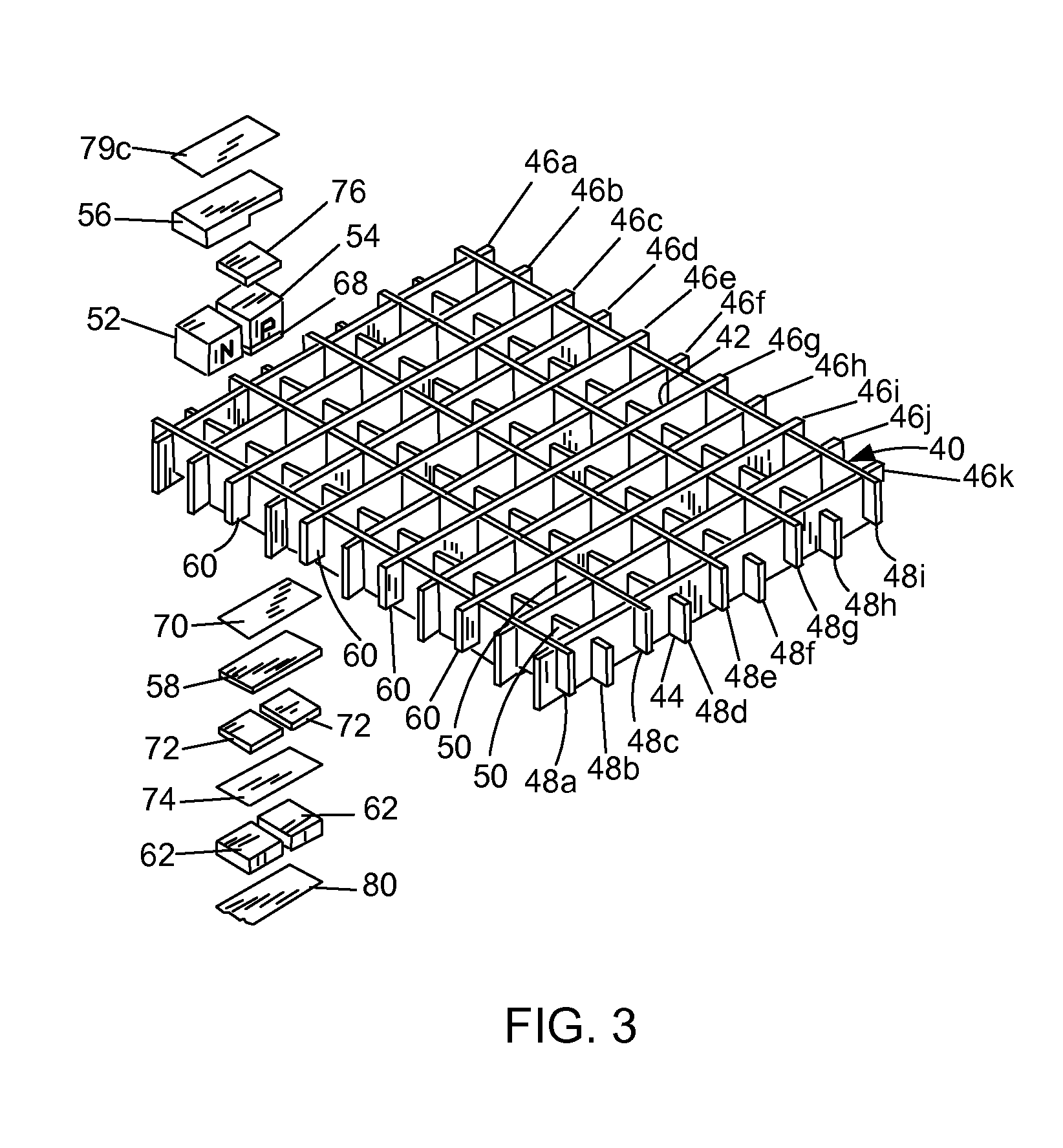

InactiveUS20050126184A1Eliminates expensiveEliminates thermally inefficientThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsCold sideEngineering

A thermoelectric heat pump module of the type used in small cooling applications and appliances, such as a thermoelectric picnic cooler. The module comprises an array of thermoelectric elements with cold-side connectors directly bonded to a large, unitary cold sink for support, and hot-side connectors each having an integrated heat exchange fin to form a small, lightweight, but efficient hot sink array directly bonded to the elements without thermal stress. The cold sink is larger than the hot sink array. The cold-side connectors and at least portions of the thermoelectric elements are sealed and supported with a layer of potting material built up from the surface of the cold sink, and optionally insulated with an additional layer of sealed foam, eliminating moisture vapor transmission, condensation, and corrosion in the module. In a preferred form, the elements and their finned hot-side connectors are arranged in an elongated, narrow-depth array designed to be placed perpendicular to a flow of cooling air, and allowing multiple modules to be used in a distributed pattern with a single air-mover such as a fan.

Owner:THERMOELECTRIC DESIGN

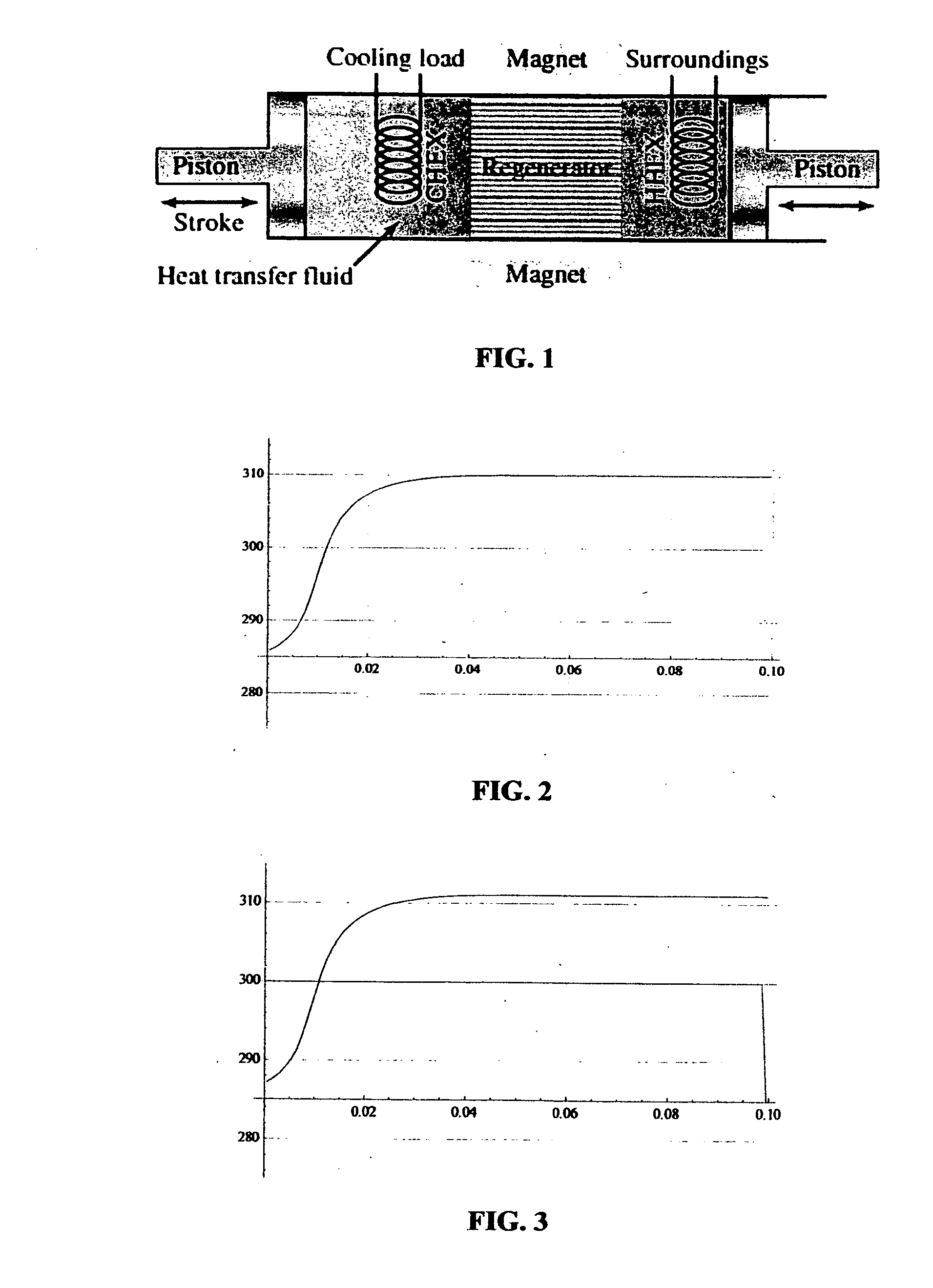

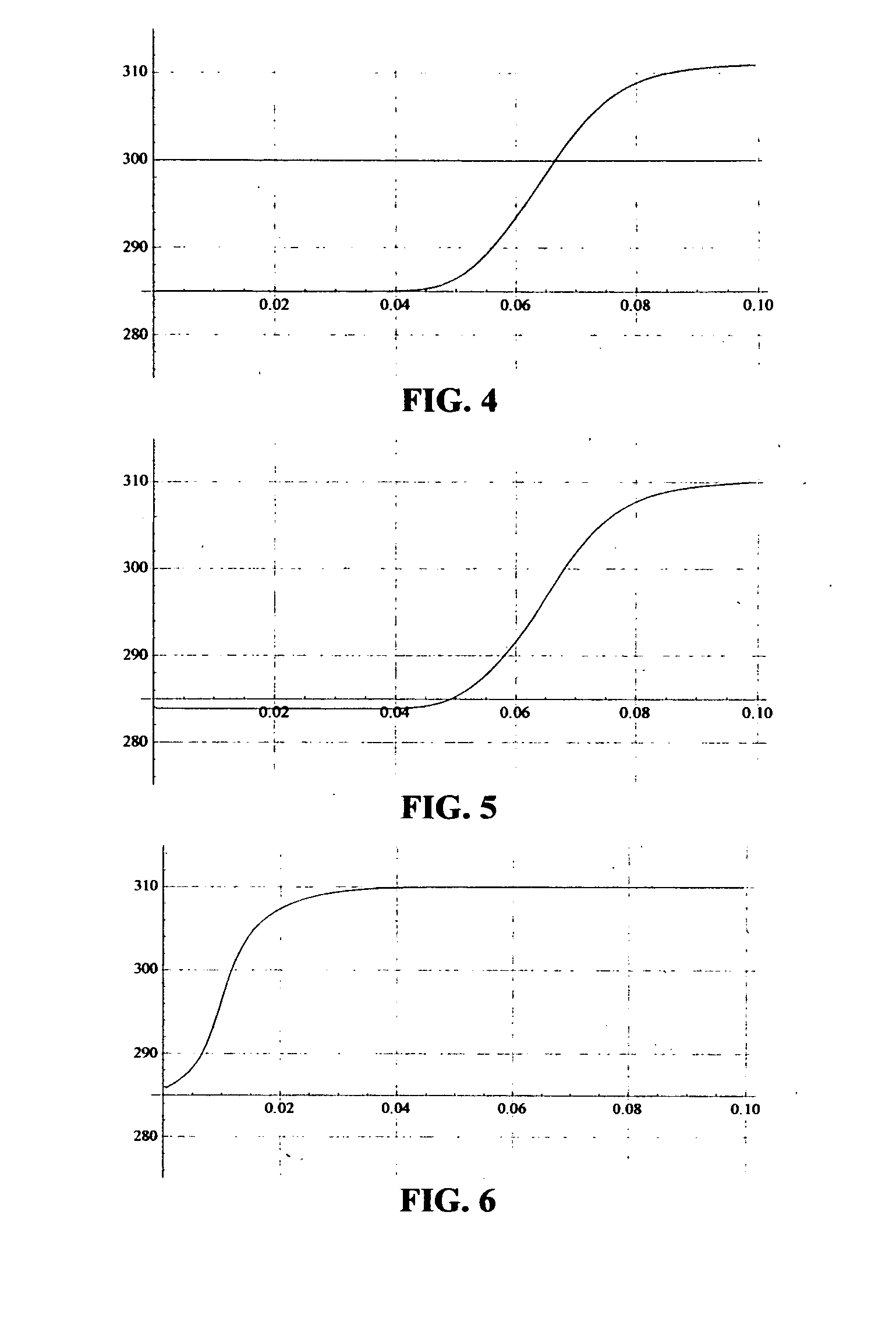

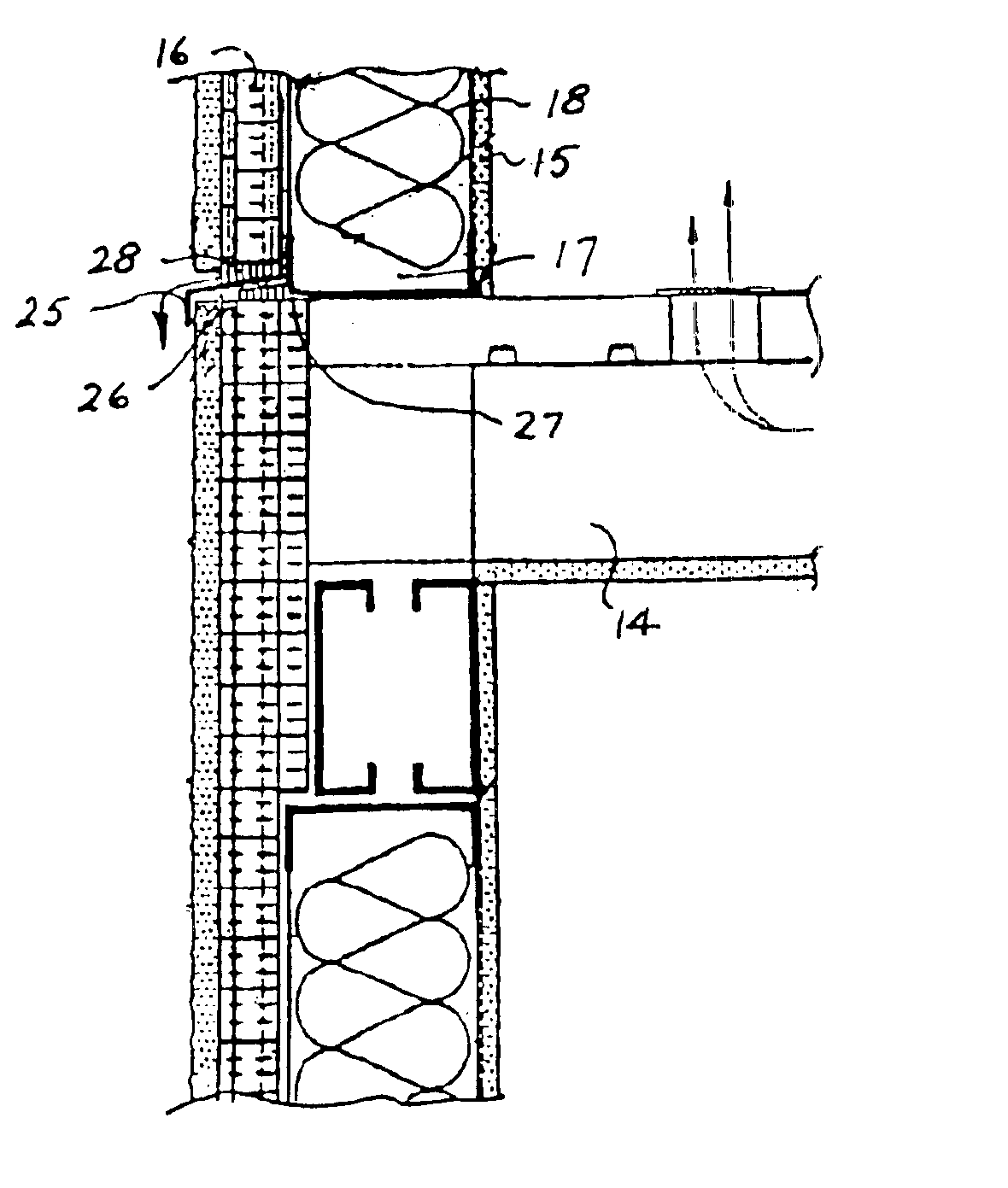

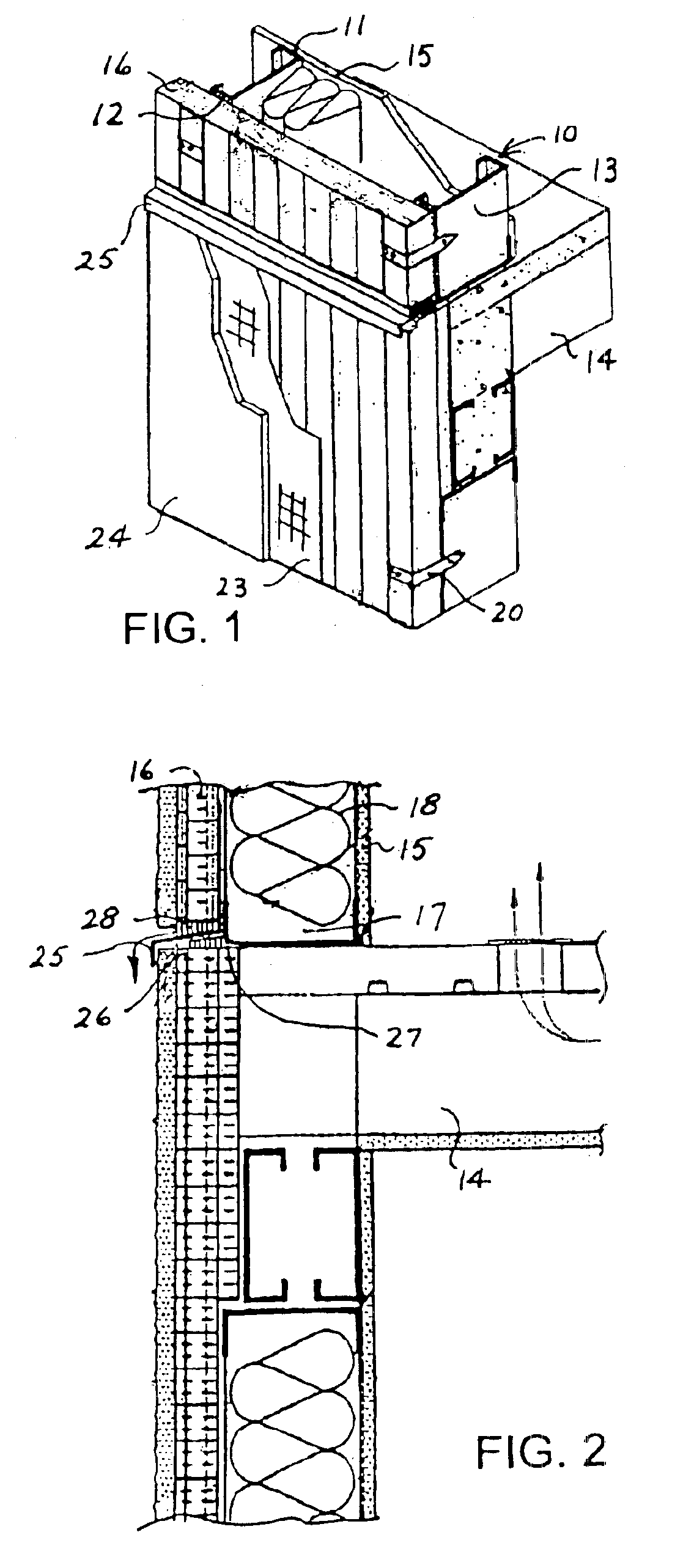

Flow-synchronous field motion refrigeration

Owner:HASSEN CHARLES N

Exterior building cladding having rigid foam layer with drain channels

InactiveUS6886301B2Reduce conductivityStructural failureCeilingsConstruction materialInsulation layerSteel frame

A novel building construction is described for exterior building walls. The construction comprises an interior frame formed of a plurality of laterally spaced studs or beams, a layer of rigid insulation adjacent to the exterior side of this steel frame, exterior building cladding adjacent the exterior side of the rigid insulation and a plurality of low conductivity connectors, e.g. insulating plastic connectors or thin metal strips having an insulating plastic foam coating, extending through the layer of rigid insulation and connecting together the exterior cladding and the interior steel studs or beams. Vertical channels are formed adjacent both the inside and outside faces of the insulation layer to remove moisture. This provides the required structural strength with a minimum of thermal conductivity from the warm side to the cold side of the building envelope, while providing exterior drain channels and interior moisture removing channels.

Owner:SCHILGER HERBERT K

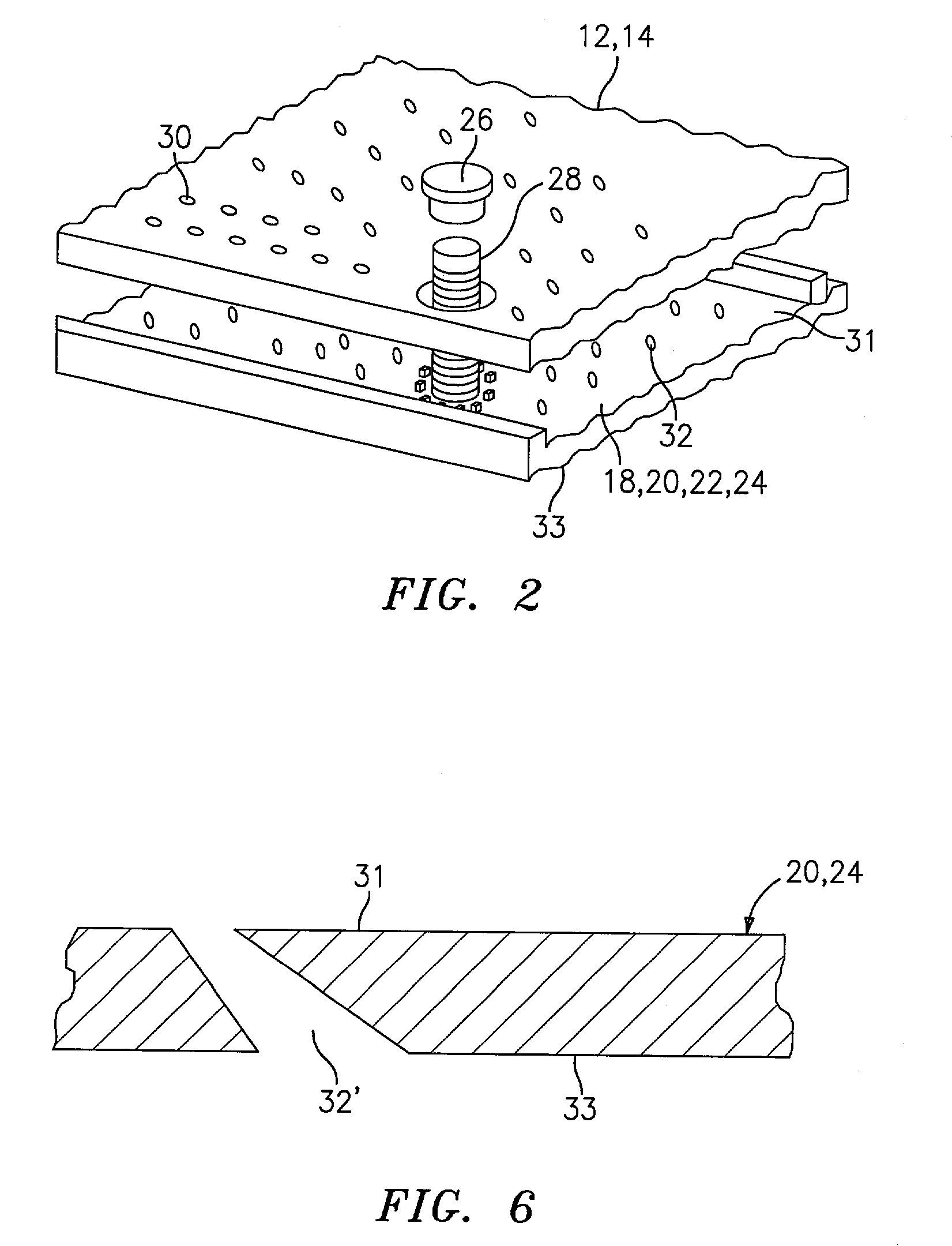

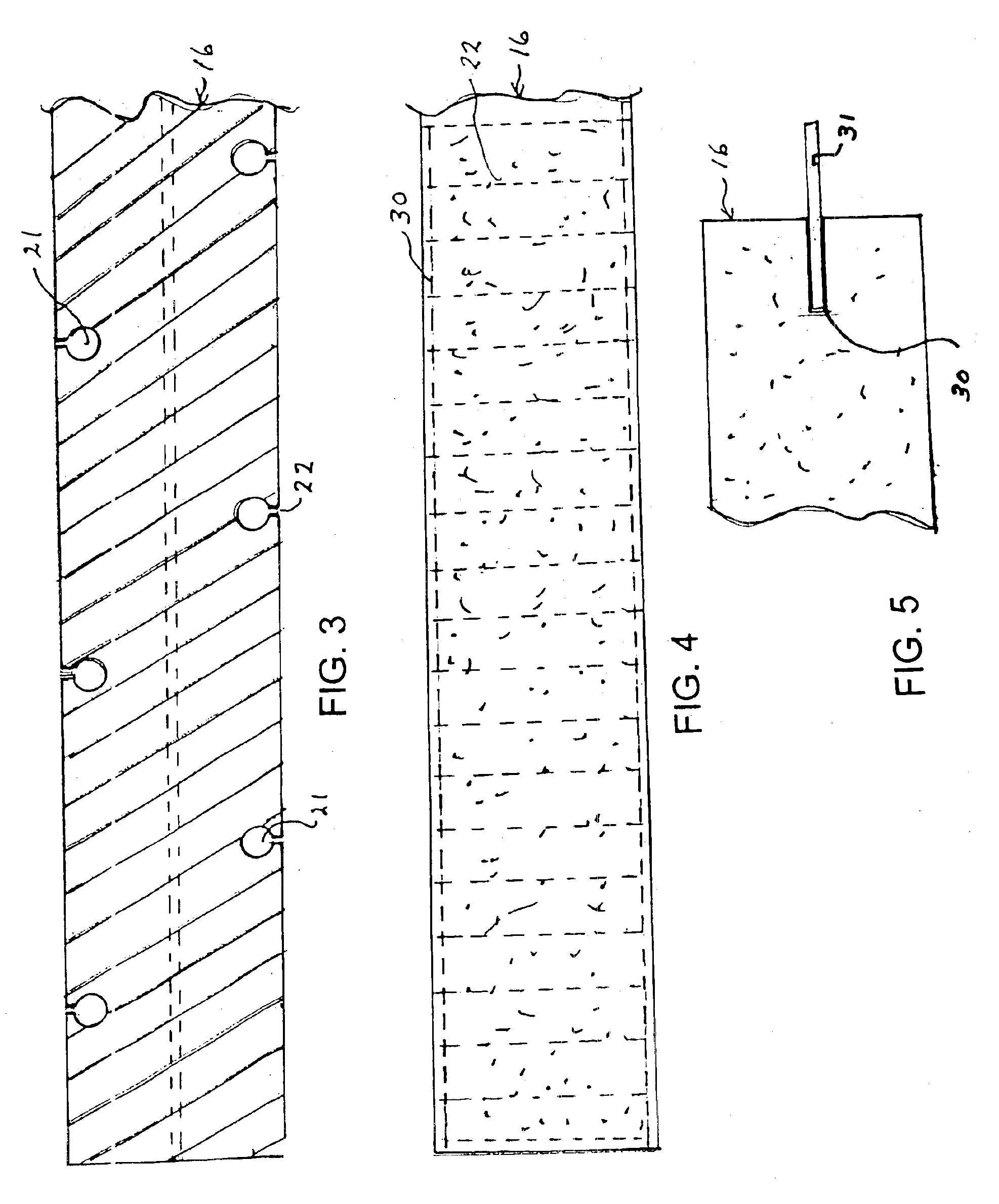

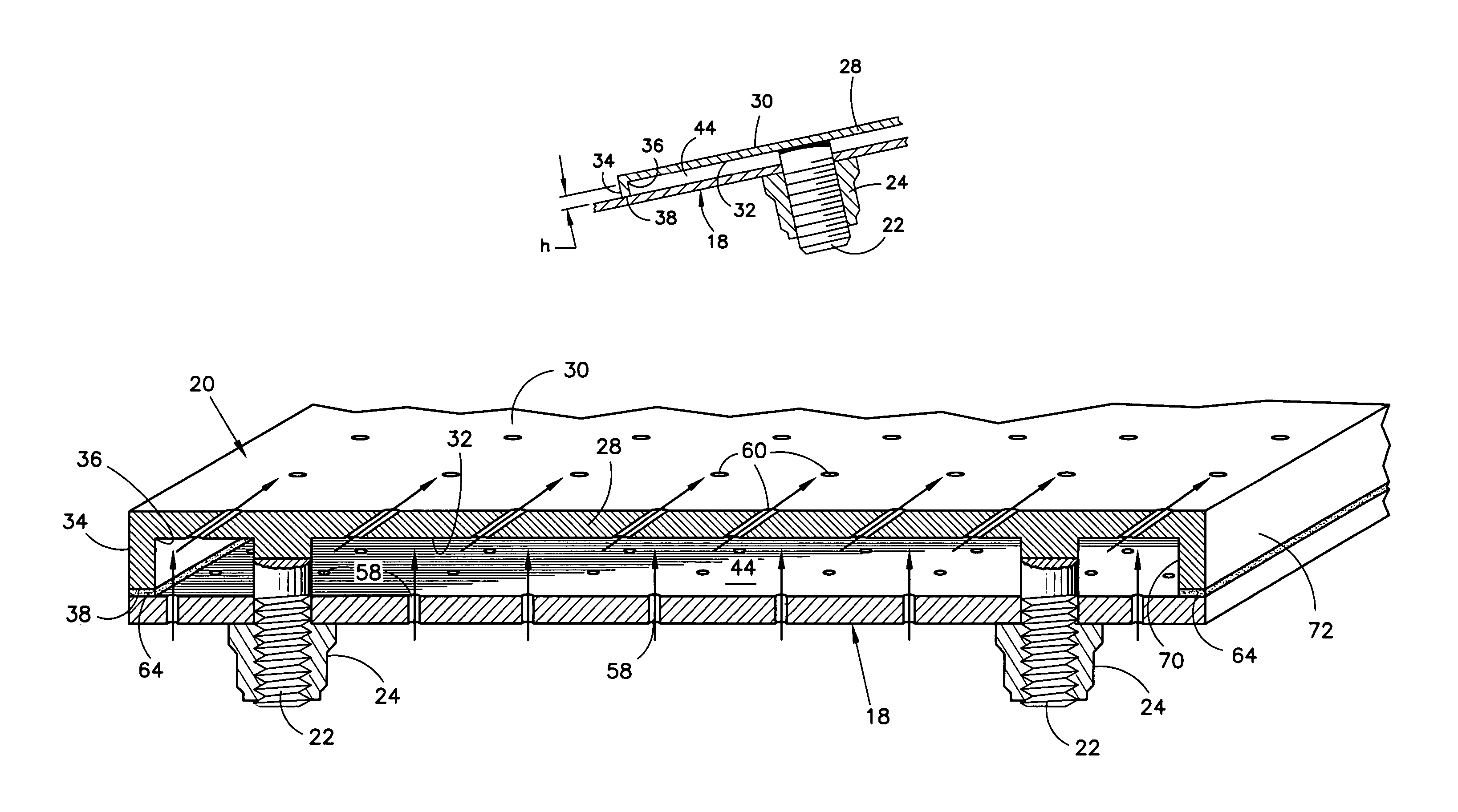

Heatshielded article

InactiveUS7140185B2Change heightEasily and inexpensively changedContinuous combustion chamberGas turbine plantsCold sideEngineering

A heatshielded article includes a support 18 and at least one heatshield 20 secured adjacent to the support. The heatshield includes a shield portion 28 spaced from the support. The shield portion includes a hot side 30 and an uncoated cold side 32. A projection projects from an origin 36 at the shield portion to a terminus 38 remote from the shield portion. The terminus includes a protective coating 64 along at least a portion of its length.

Owner:UNITED TECH CORP

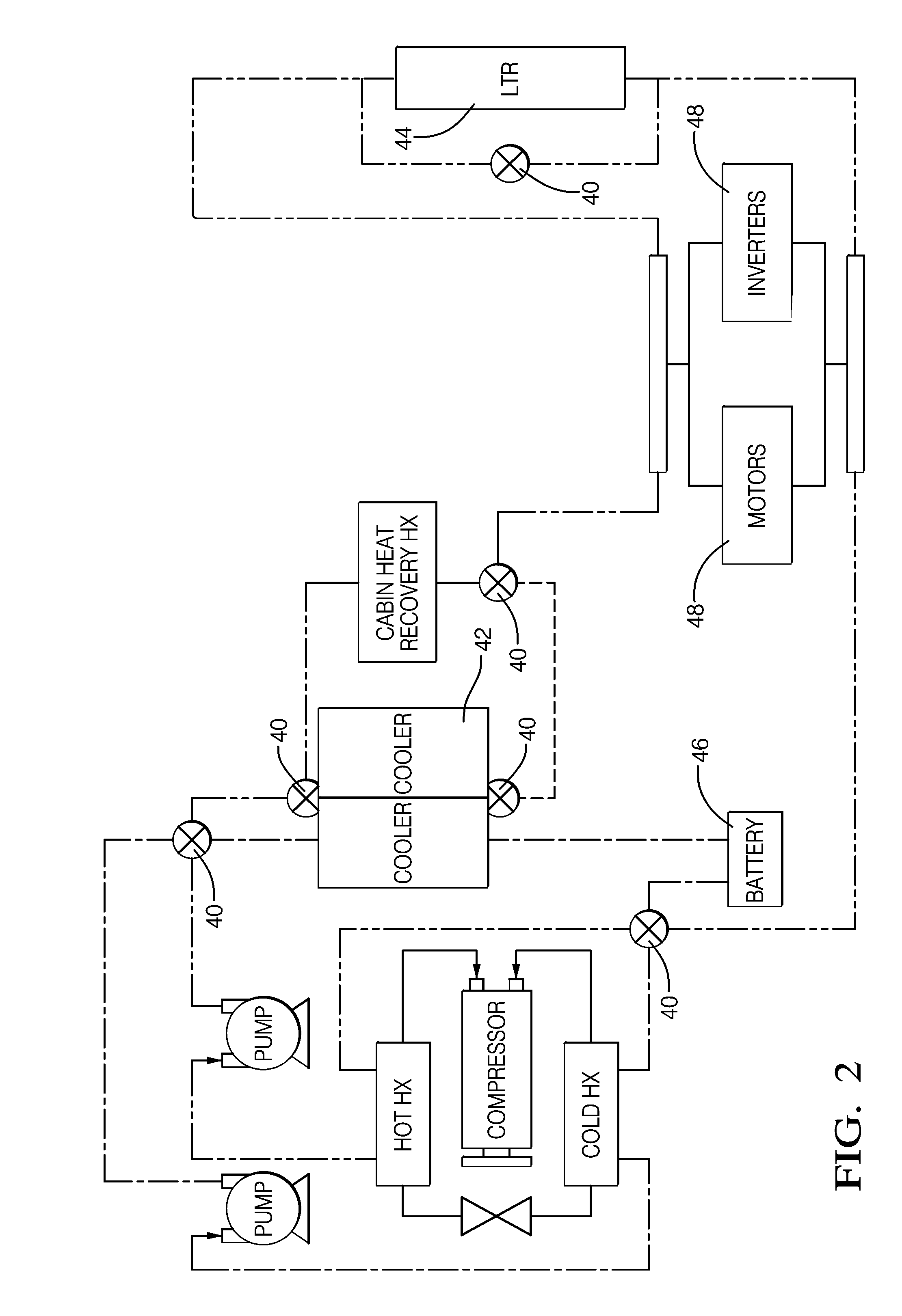

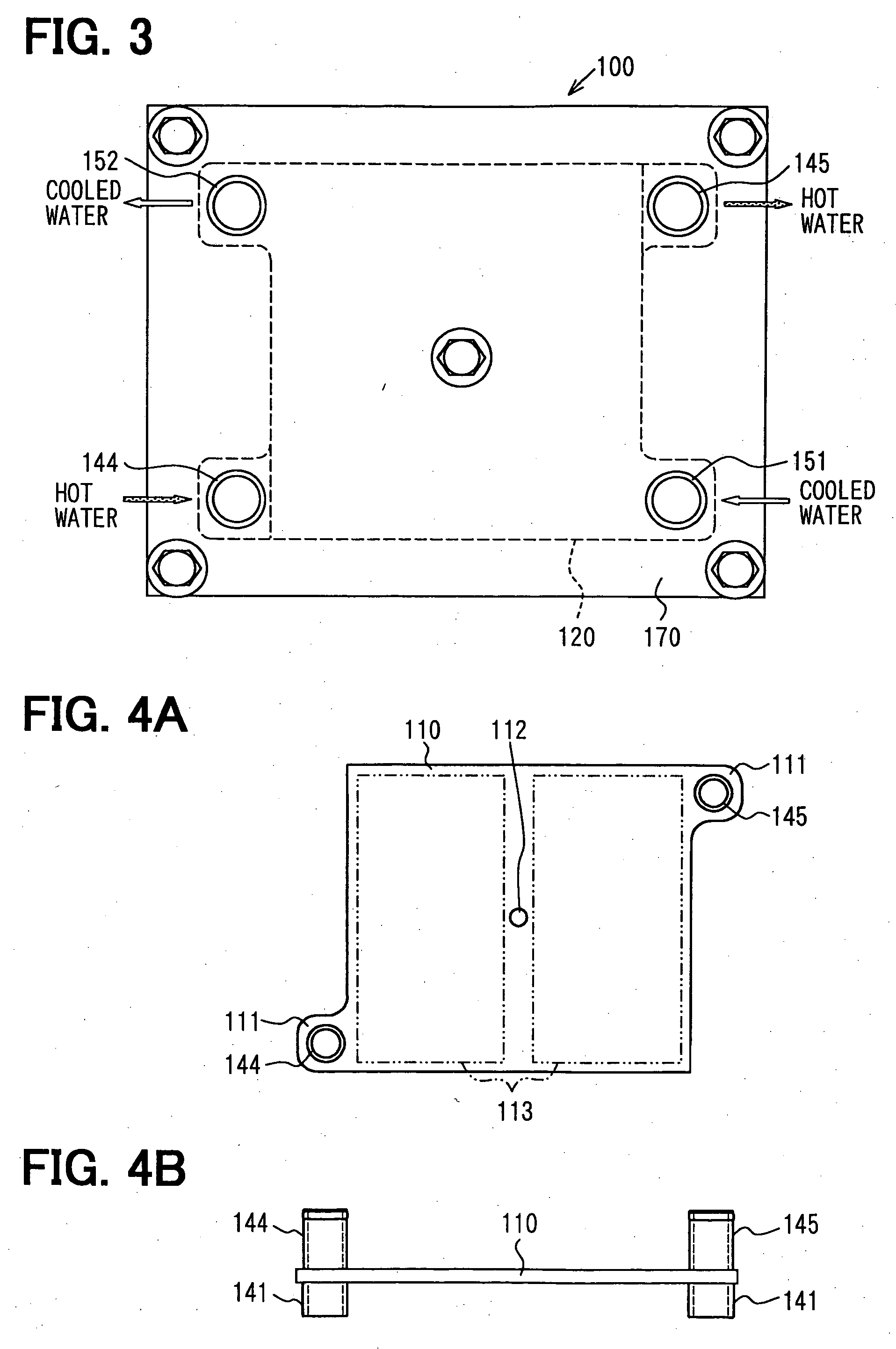

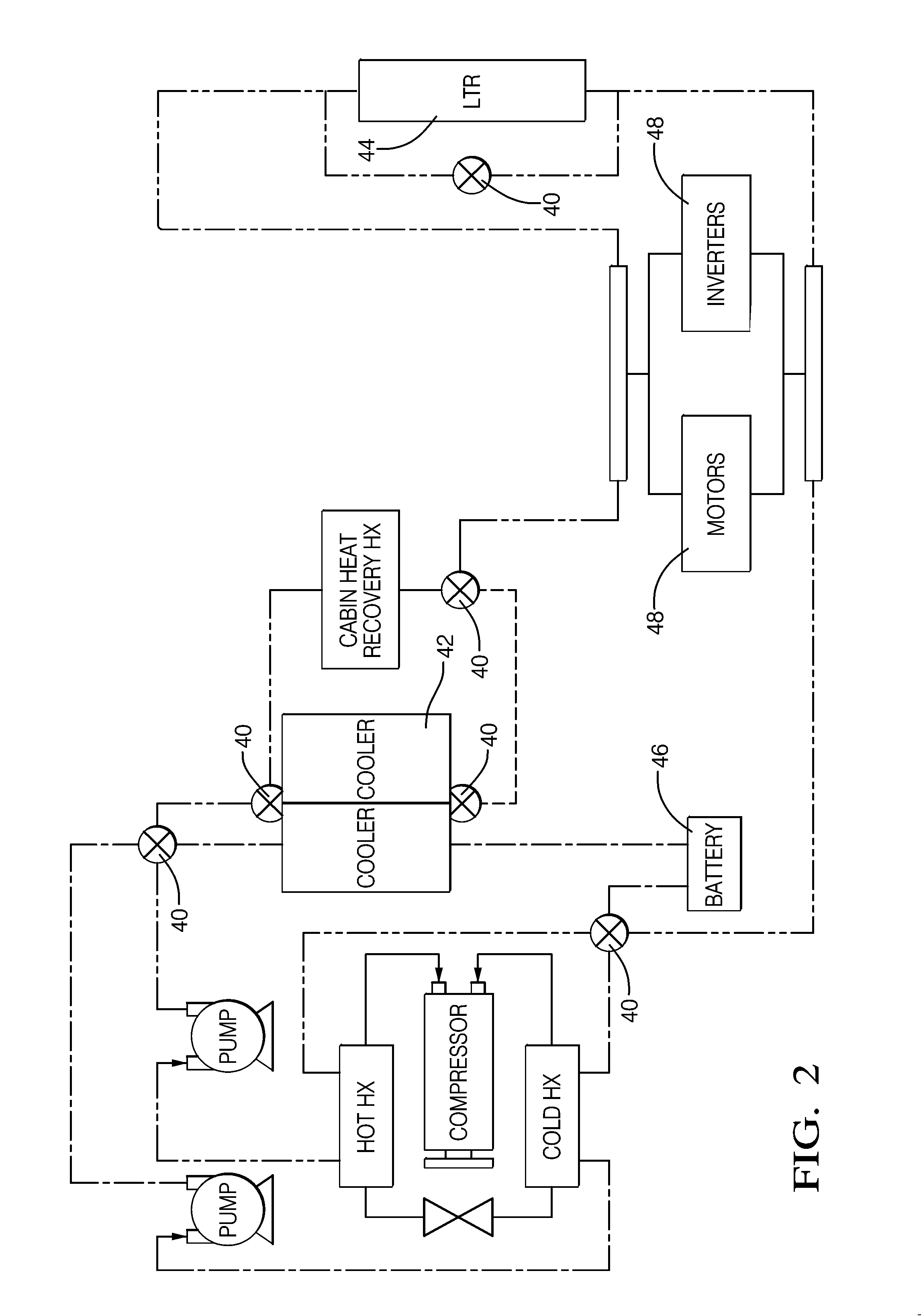

Plate-type heat pump air conditioner heat exchanger for a unitary heat pump air conditioner

ActiveUS20120210746A1Increase temperatureHeat pumpsCompression machines with non-reversible cycleCold sideThermal energy

A plate-type heat exchanger having a first heat exchanger portion configured to receive a refrigerant flow and a hot side coolant flow having a lower temperature than the refrigerant flow, a second heat exchanger portion configured to receive the refrigerant flow exiting from the first heat exchanger portion and a cold side coolant flow having a higher temperature than the refrigerant flow exiting from the first heat exchanger portion, and an internal heat exchanger portion sandwiched between the first heat exchanger portion and the second heat exchanger portion. The refrigerant flow through the plate type heat exchanger is in non-contact thermal communication with the hot side coolant flow and the cold side coolant flow. The cold side coolant flow transfers heat energy to the refrigerant, which in turn transfer that heat energy to the hot side coolant flow.

Owner:MAHLE INT GMBH

Moisture abatement in heating operation of climate controlled systems

ActiveUS20130206852A1Reduce the temperatureReduce the required powerVehicle seatsAir-treating devicesCold sideControl system

Embodiments related to moisture abatement during a heating operation of a climate control system are disclosed. In some embodiments, the climate control system includes a thermoelectric device (TED) or other thermal condition device having a hot side and a cold side. In certain embodiments, the thermal conditioning device is operated (e.g., by a processor or a condensate switch) to inhibit or prevent the occurrence of condensation, and / or to abate condensation that has already occurred, on the cold side of the thermal conditioning device during the heating operation.

Owner:GENTHERM INC

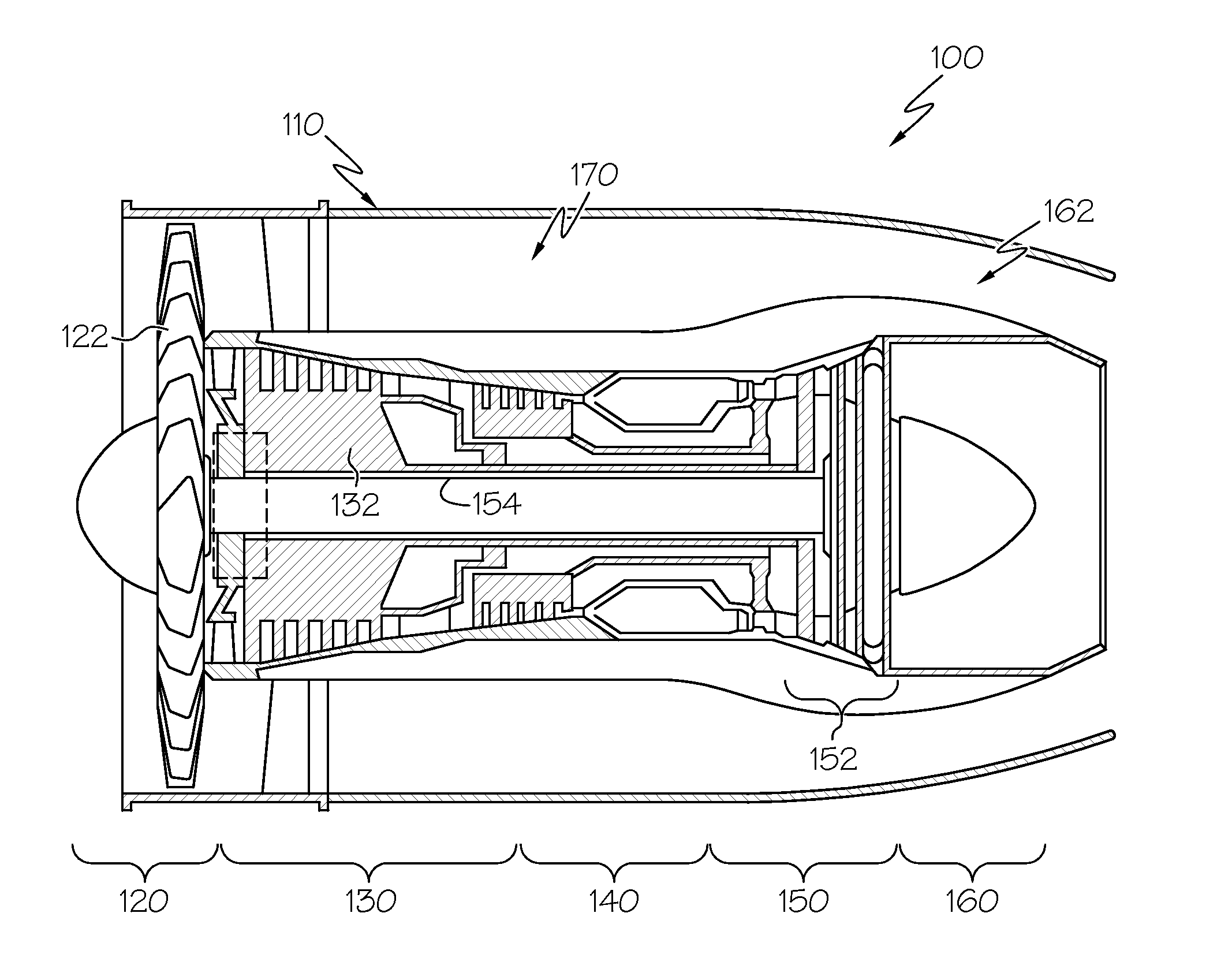

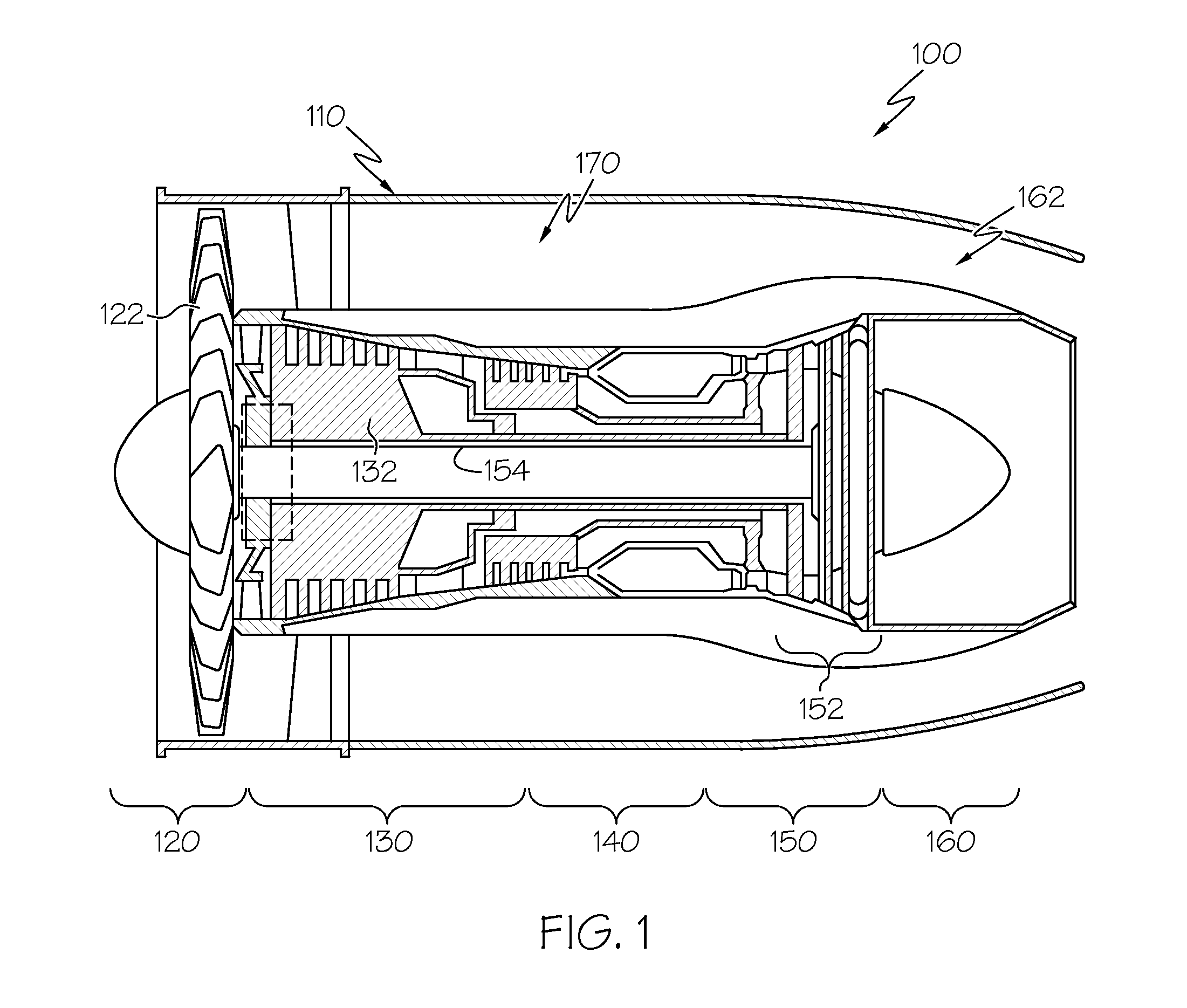

Combustors with quench inserts

ActiveUS20120297778A1Continuous combustion chamberMetal-working apparatusCold sideCombustion chamber

A combustor is provided for a turbine engine. The combustor includes a first liner having a first hot side and a first cold side; a second liner having a second hot side and a second cold side, the second hot side and the first hot side forming a combustion chamber therebetween. The combustion chamber is configured to receive an air-fuel mixture for combustion therein. The combustor further includes an insert having a body portion extending through the first liner and terminating at a tip, the body portion configured to direct air flow into the combustion chamber. The insert further includes a cooling hole defined in the body portion and configured to direct a first portion of the air flow toward the tip as cooling air.

Owner:HONEYWELL INT INC

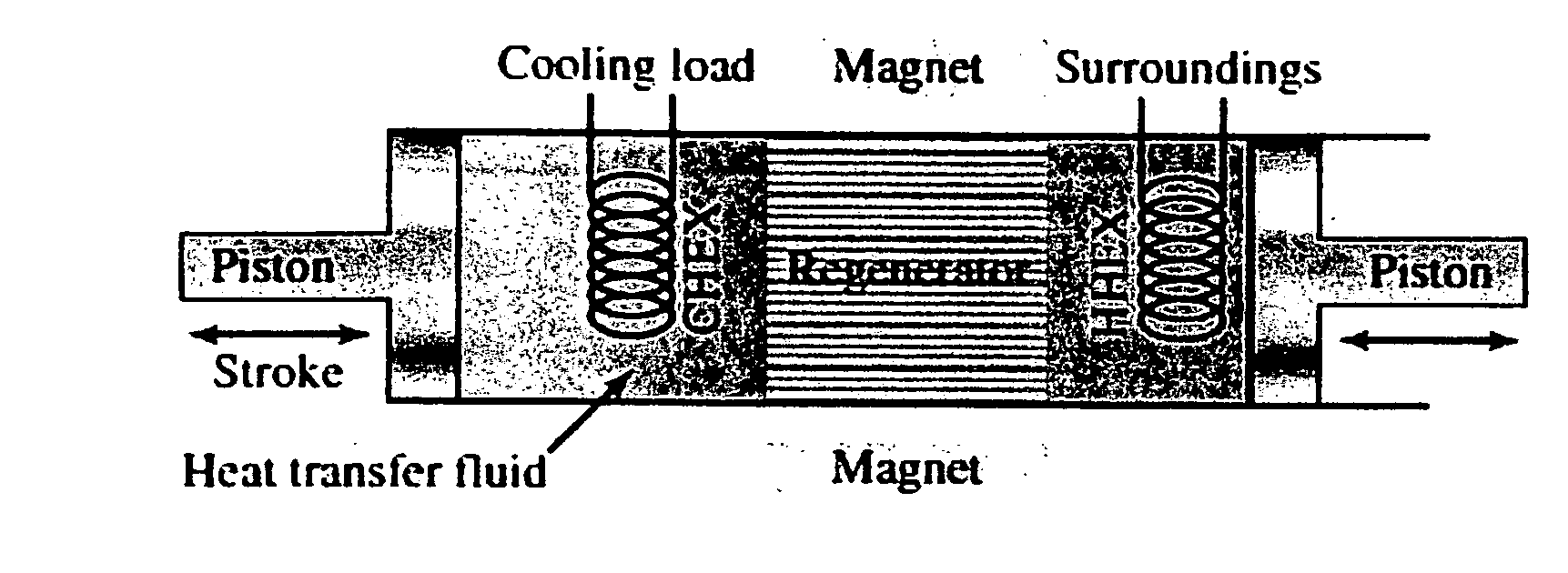

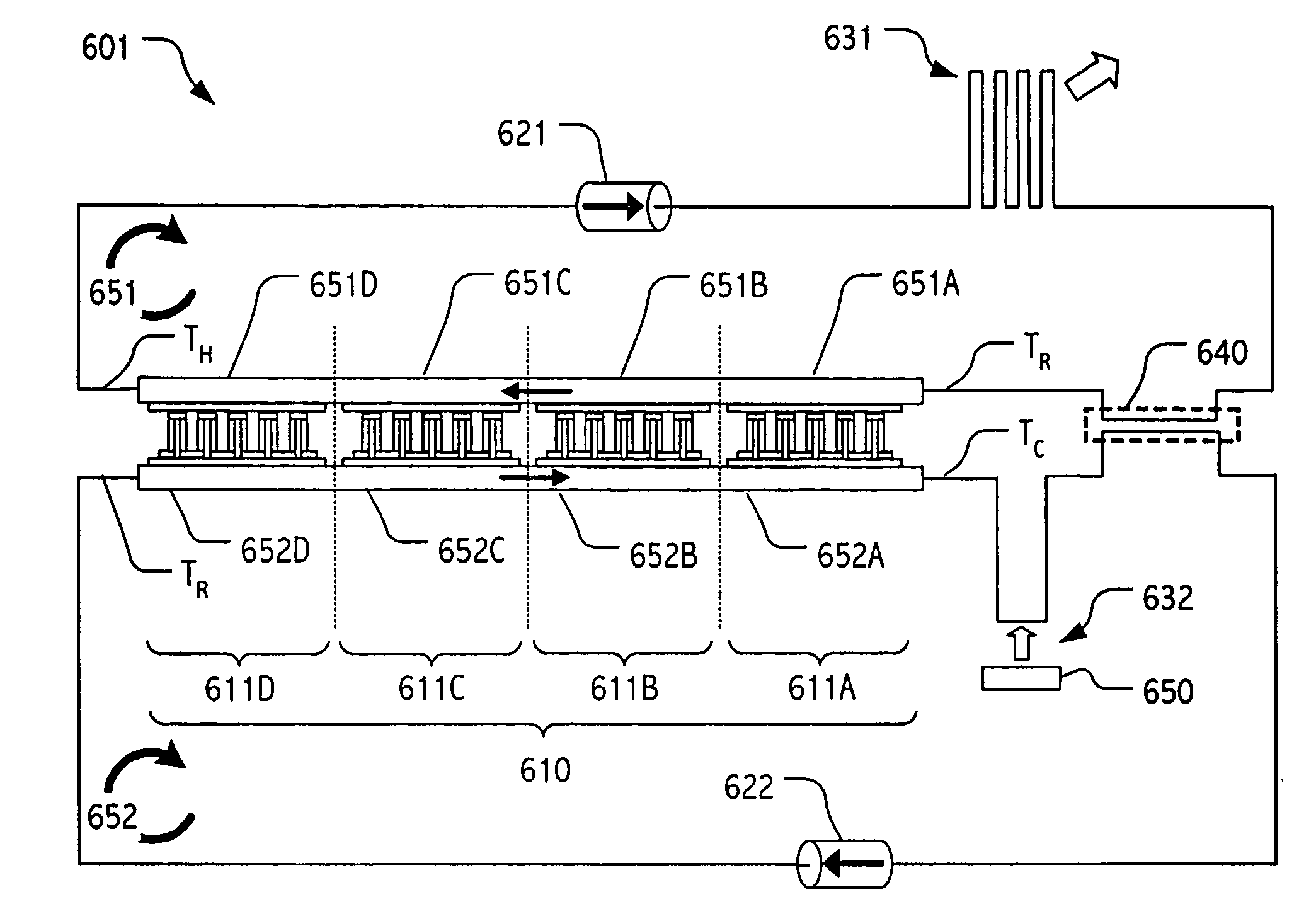

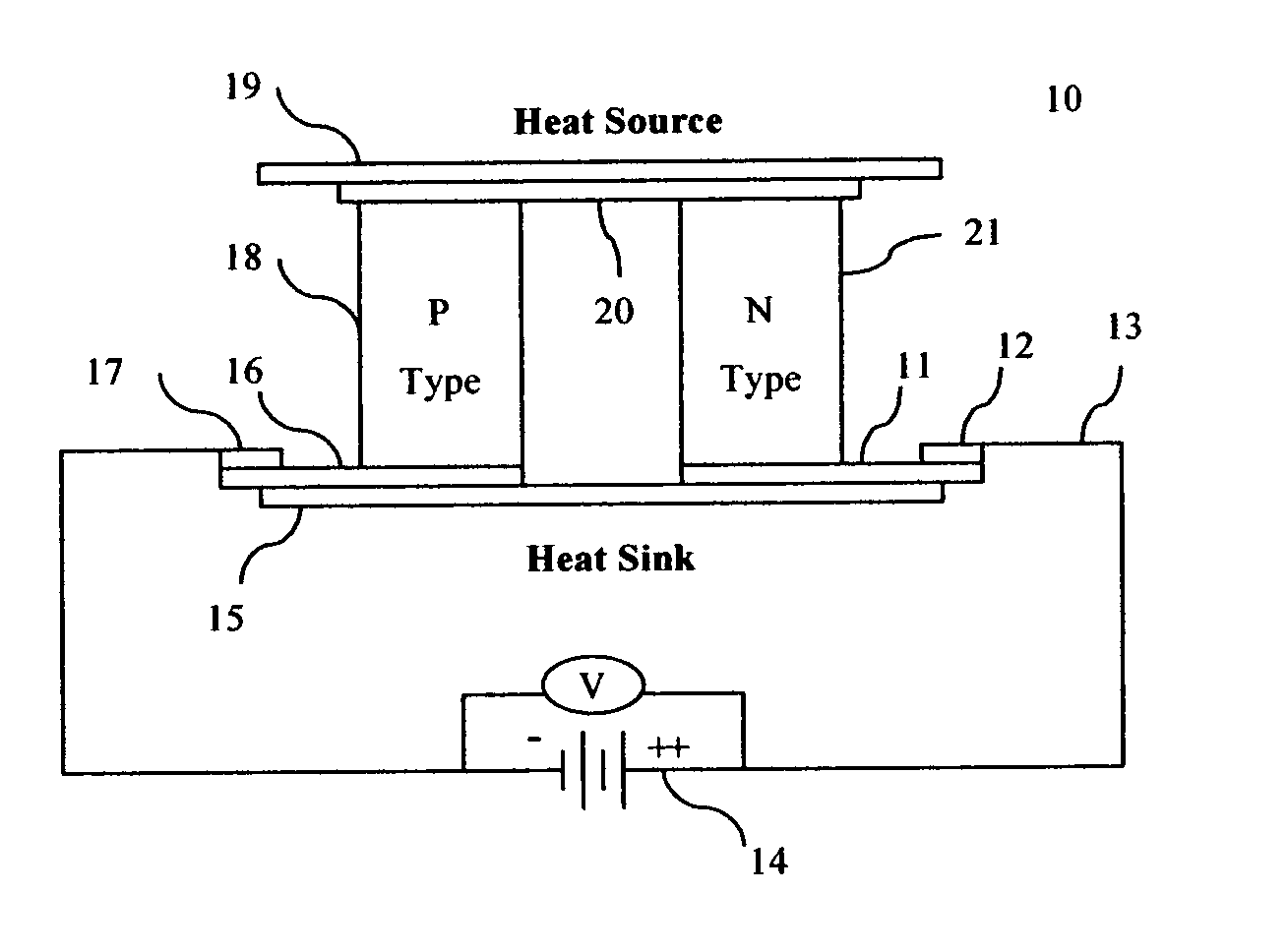

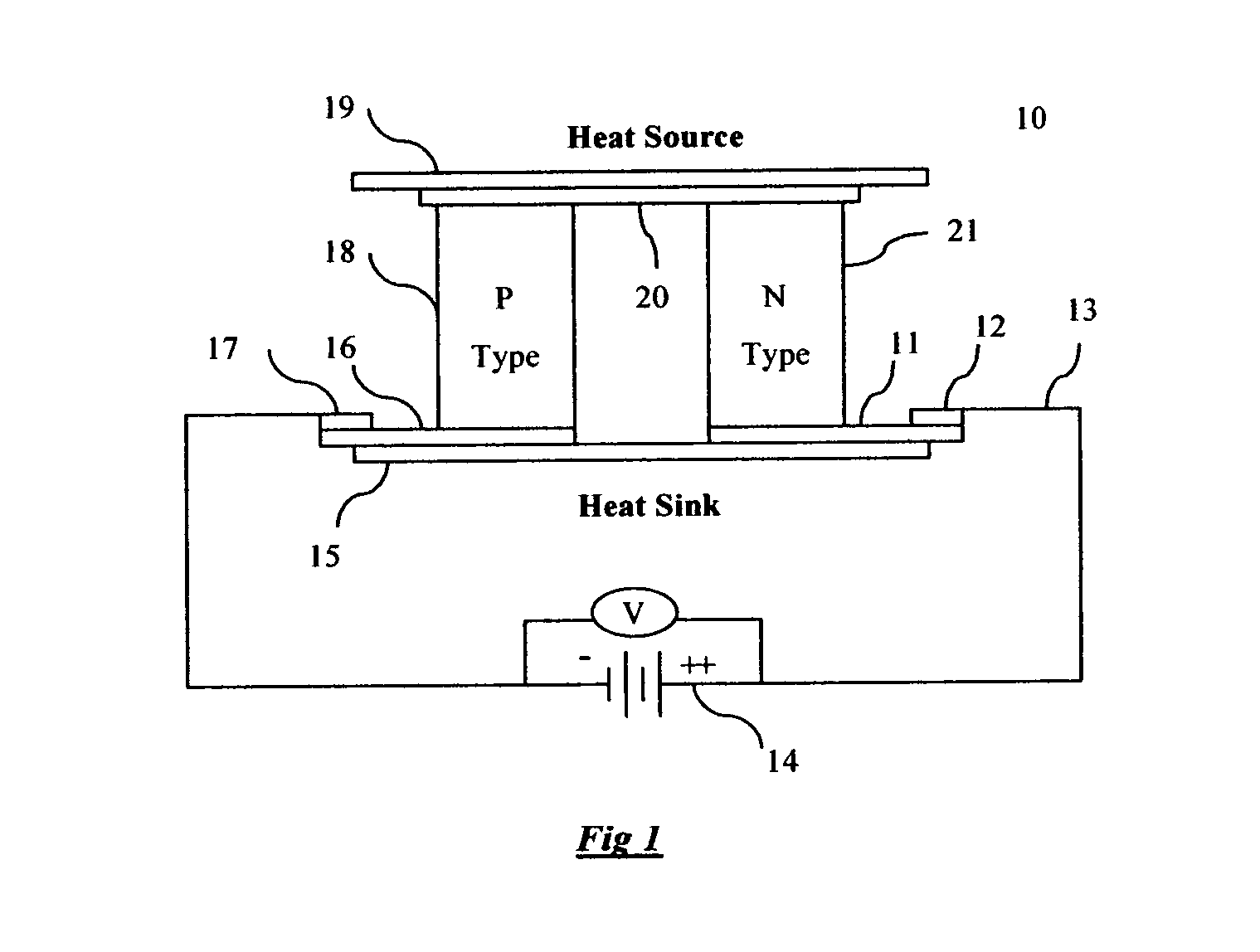

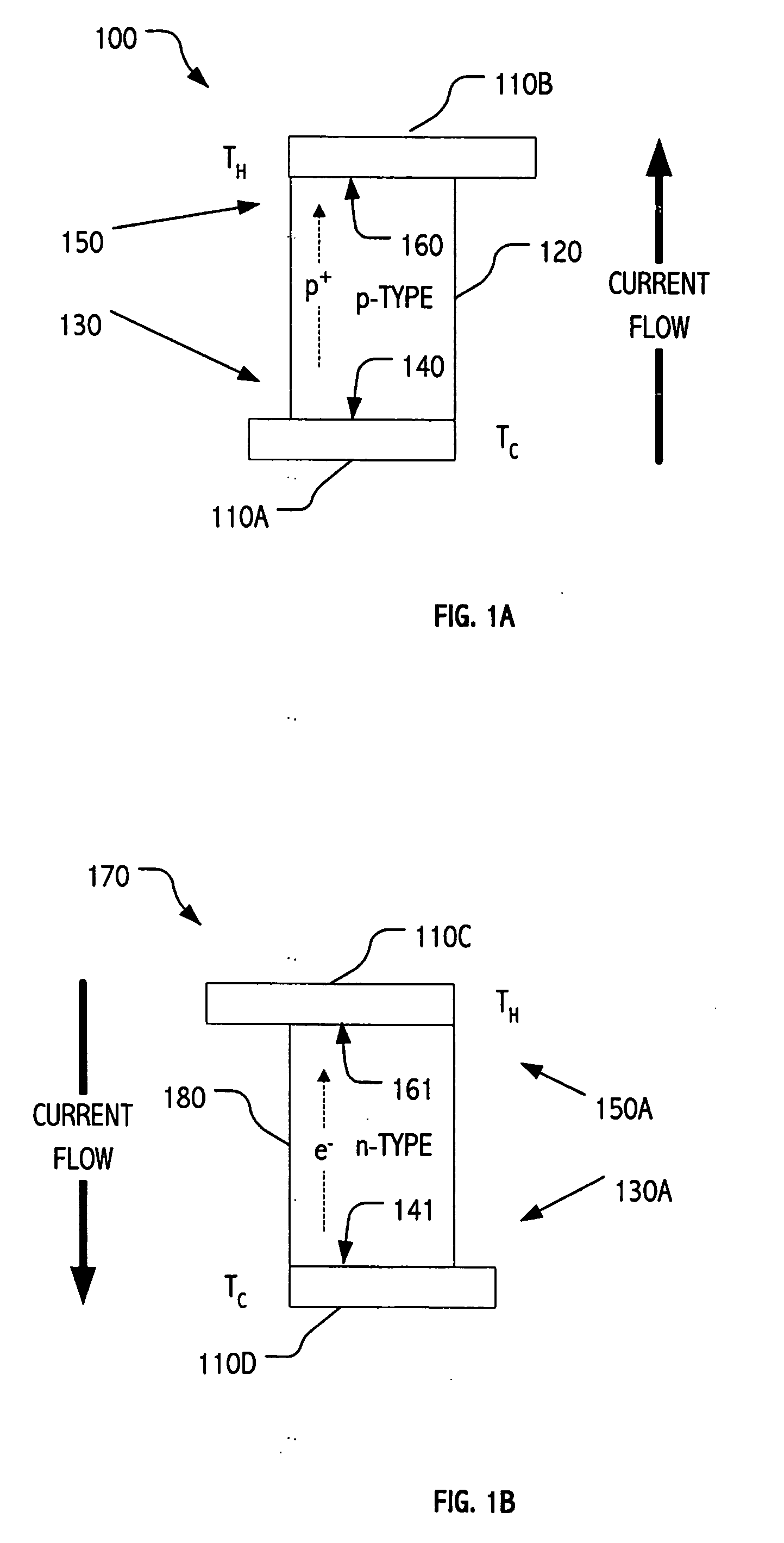

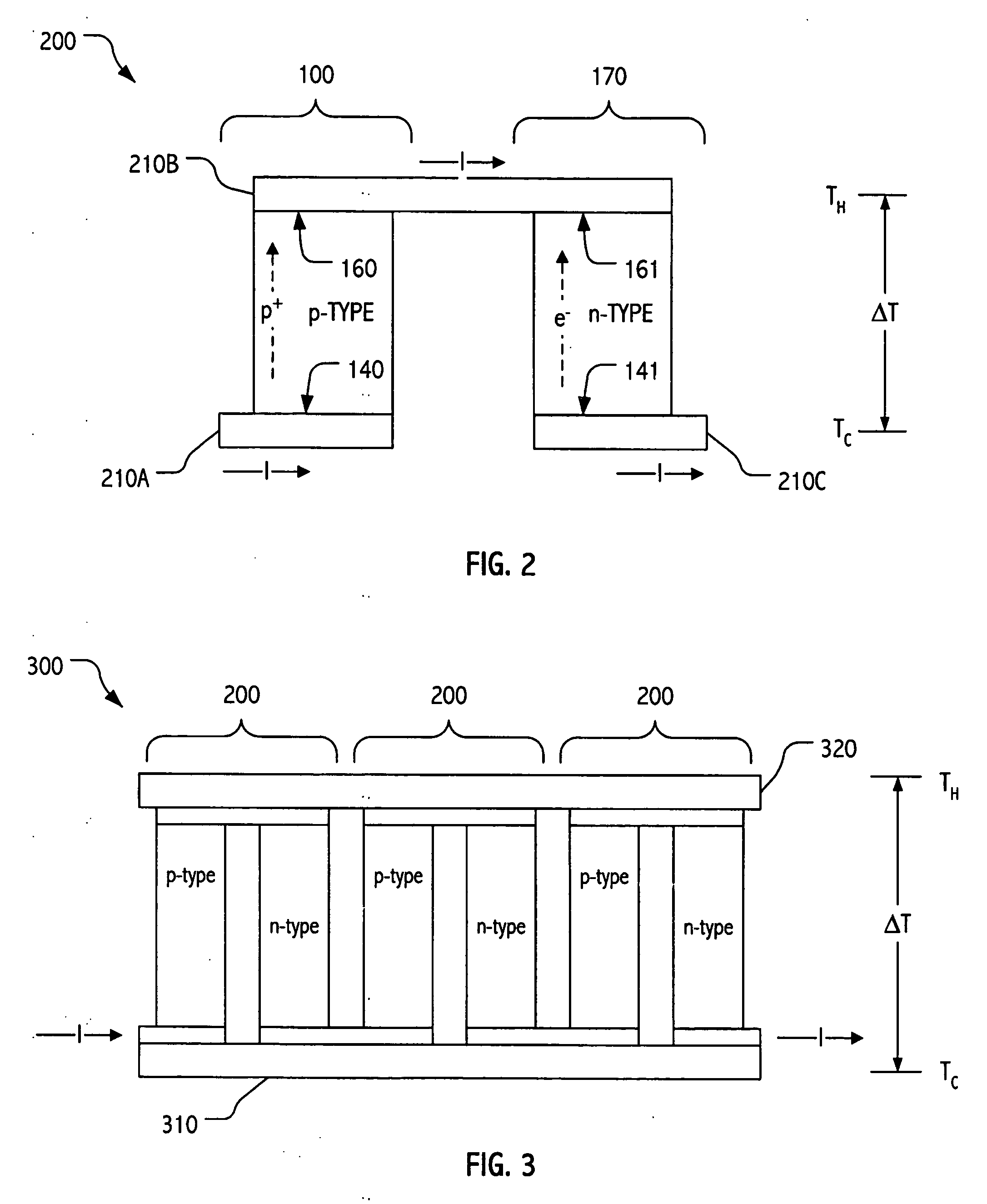

System employing temporal integration of thermoelectric action

InactiveUS7475551B2Thermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsThermoelectric materialsCold side

Active cooling technologies such as thermoelectrics can be used to introduce thermal “gain” into a cooling system and, when employed in combination with forced flow cooling loops, can provide an attractive solution for cooling high heat flux density devices and / or components. In such configurations, it can be advantageous to discontinuously flow thermal transfer fluid into thermal contact with the hot or cold side of a thermoelectric module (TEM), allow it to dwell while heat is transferred from or to the TEM, and resume the flow. In configurations in which the TEM operation is itself discontinuous, various relationships between thermal transfer fluid flow and TEM operation can be advantageously employed to temporally integrate thermoelectric action.

Owner:ZAGORIN OBRIEN GRAHAM

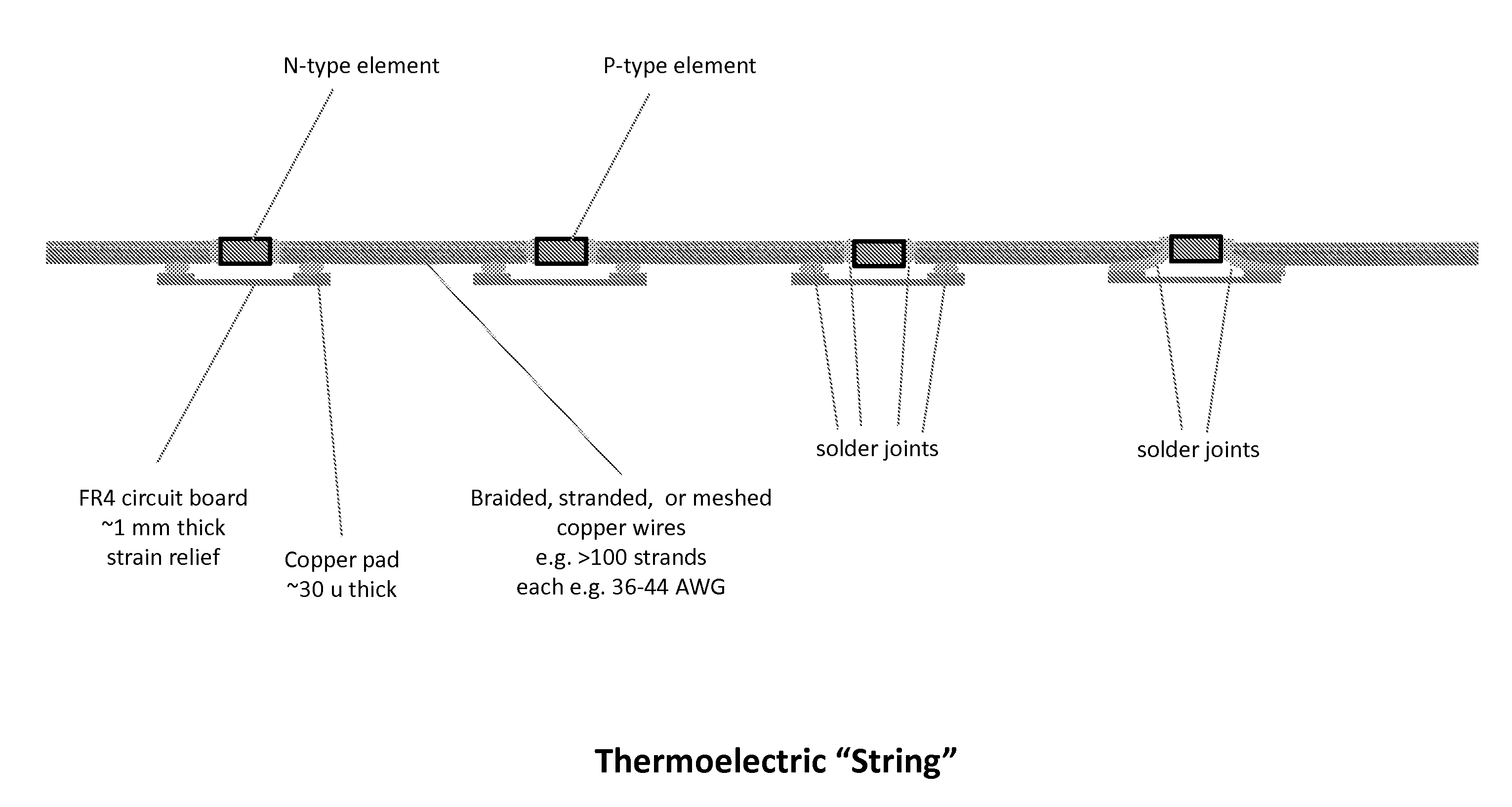

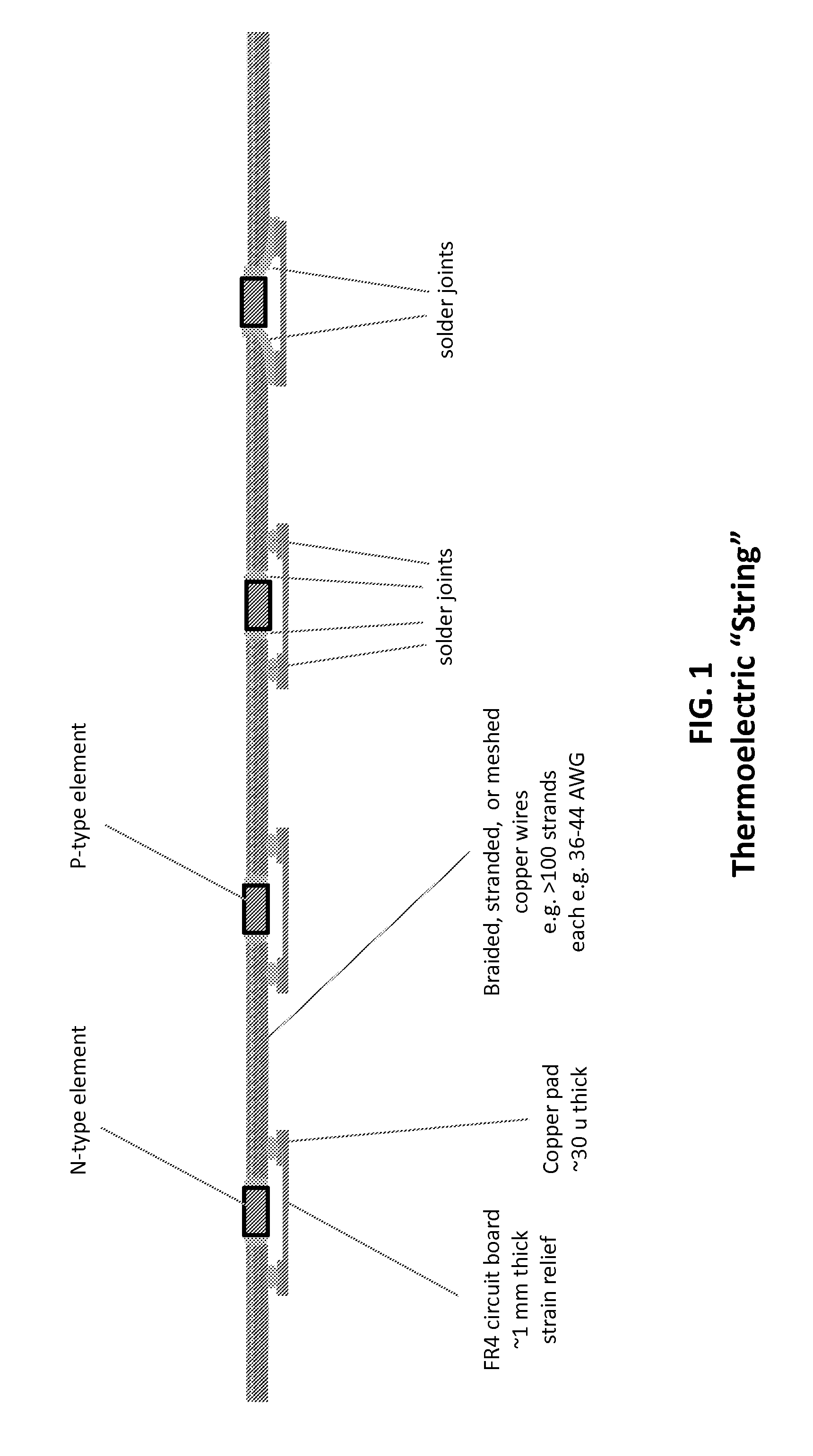

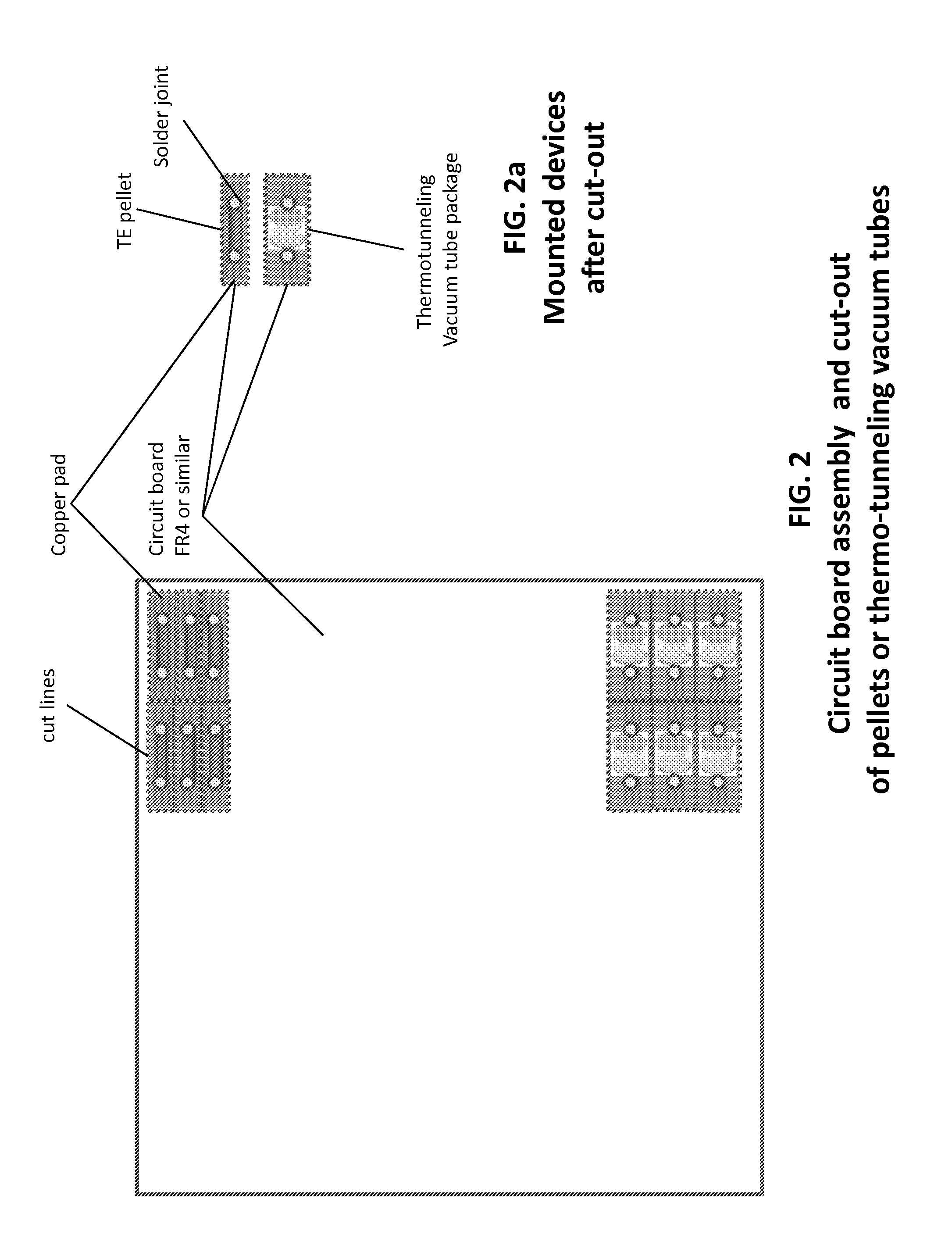

Distributed thermoelectric string and insulating panel

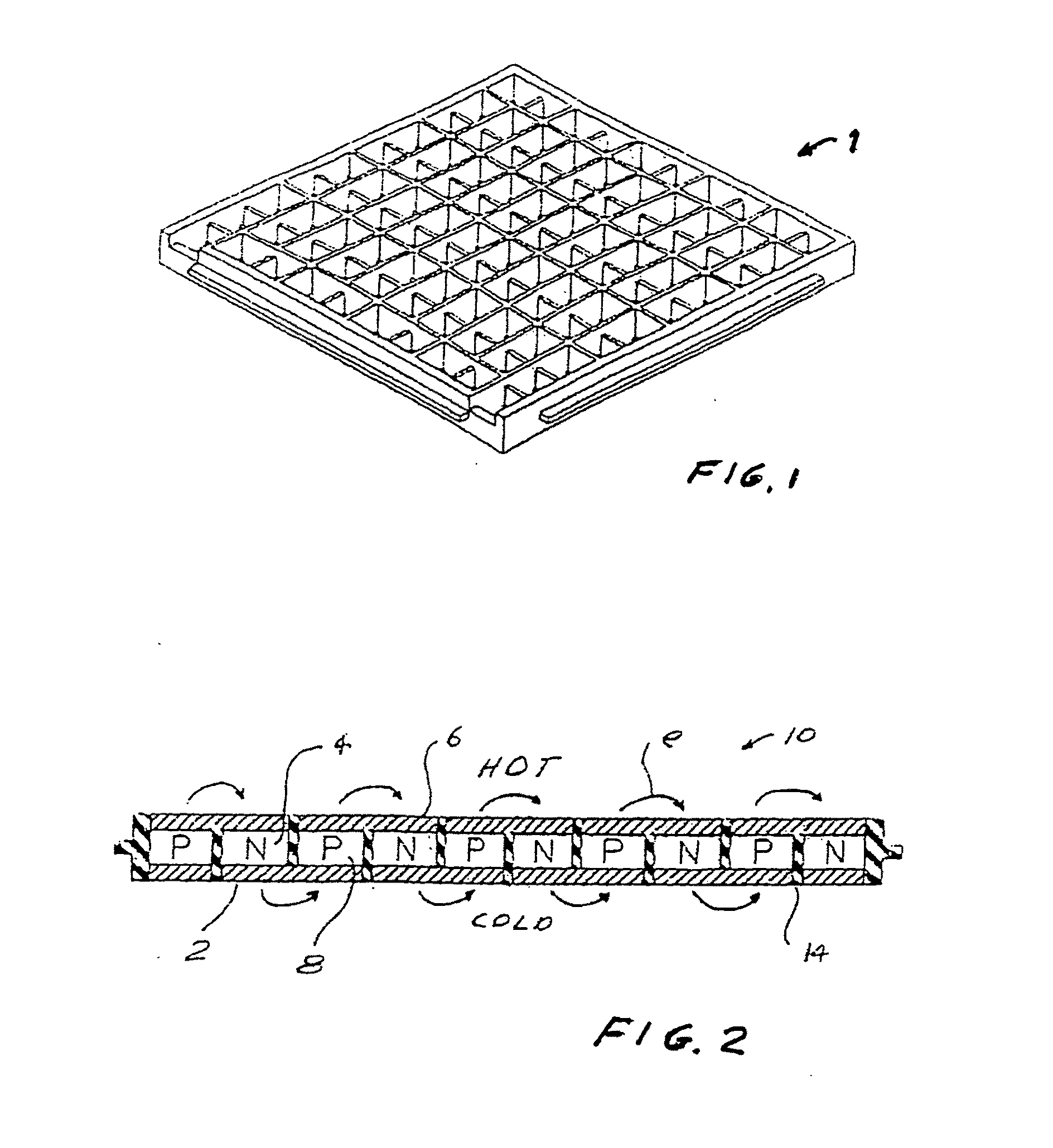

ActiveUS20120060885A1Reduce energy consumptionConserve costOther resistor networksThermoelectric device with peltier/seeback effectCold sideElectrical conductor

Inexpensive, lightweight, flexible heating and cooling panels with highly distributed thermoelectric elements are provided. A thermoelectric “string” is described that may be woven or assembled into a variety of insulating panels such as seat cushions, mattresses, pillows, blankets, ceiling tiles, office partitions, under-desk panels, electronic enclosures, building walls, refrigerator walls, and heat conversion panels. The string contains spaced thermoelectric elements which are thermally and electrically connected to lengths of braided, meshed, stranded, foamed, or otherwise expandable and compressible conductor. The elements and a portion of compacted conductor are mounted within the insulating panel On the outsides of the panel, the conductor is expanded to provide a very large surface area of contact with air or other medium for heat absorption on the cold side and for heat dissipation on the hot side.

Owner:LEAR CORP

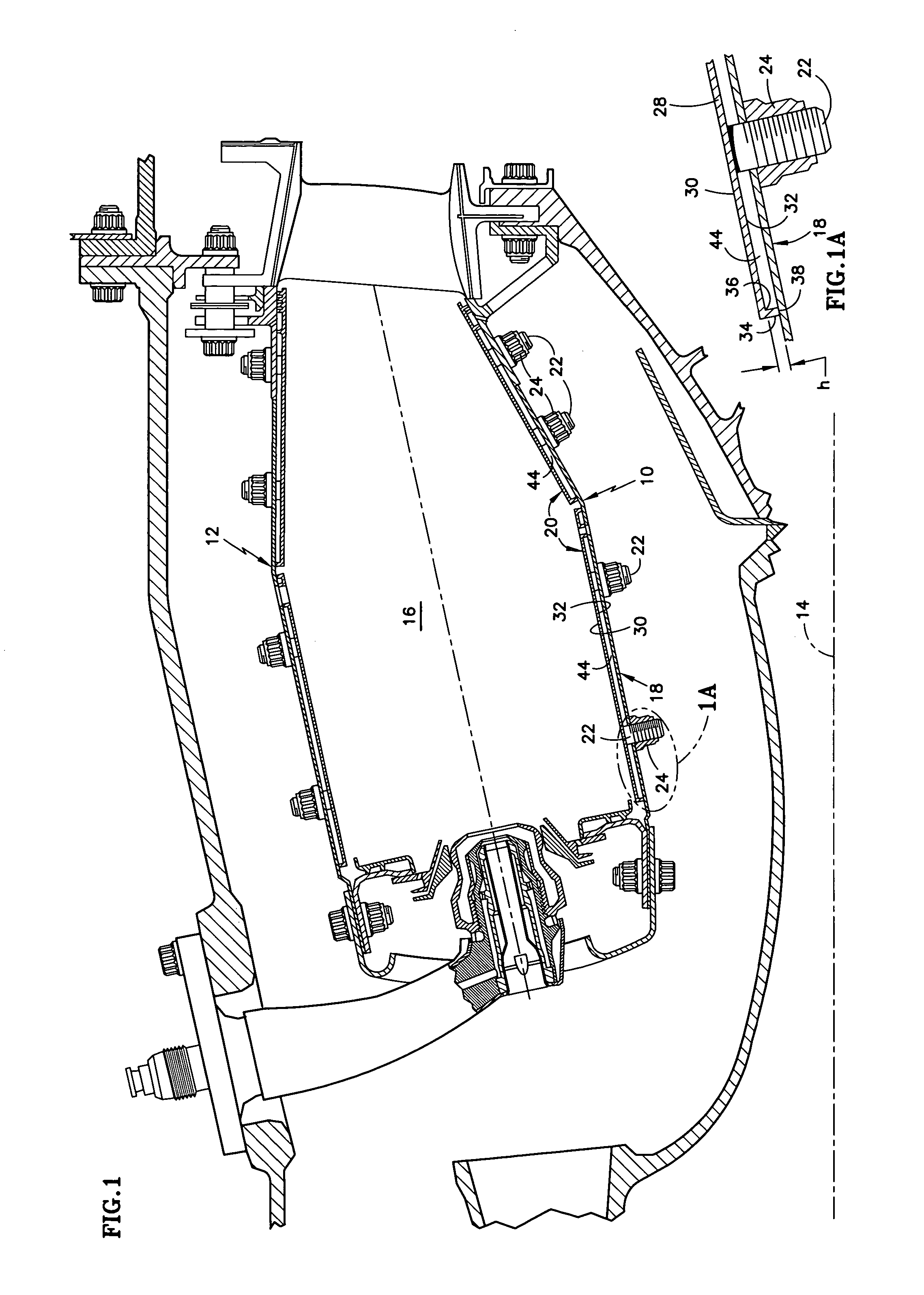

Combustor tile mounting arrangement

ActiveUS20110030378A1Inhibition setting spaceReduce the overall heightContinuous combustion chamberTurbine/propulsion engine coolingCold sideCombustor

A tile is provided for lining the hot side of a wall of a combustor. The tile has a tile body with one or more bosses protruding from the cold side thereof. The or each boss extends, in use, through the wall of the combustor and has a threaded recess formed therein for threadingly connecting with a bolt which is inserted into the recess from the cold side of the combustor wall. The bolt fastens the tile to the combustor wall.

Owner:ROLLS ROYCE PLC

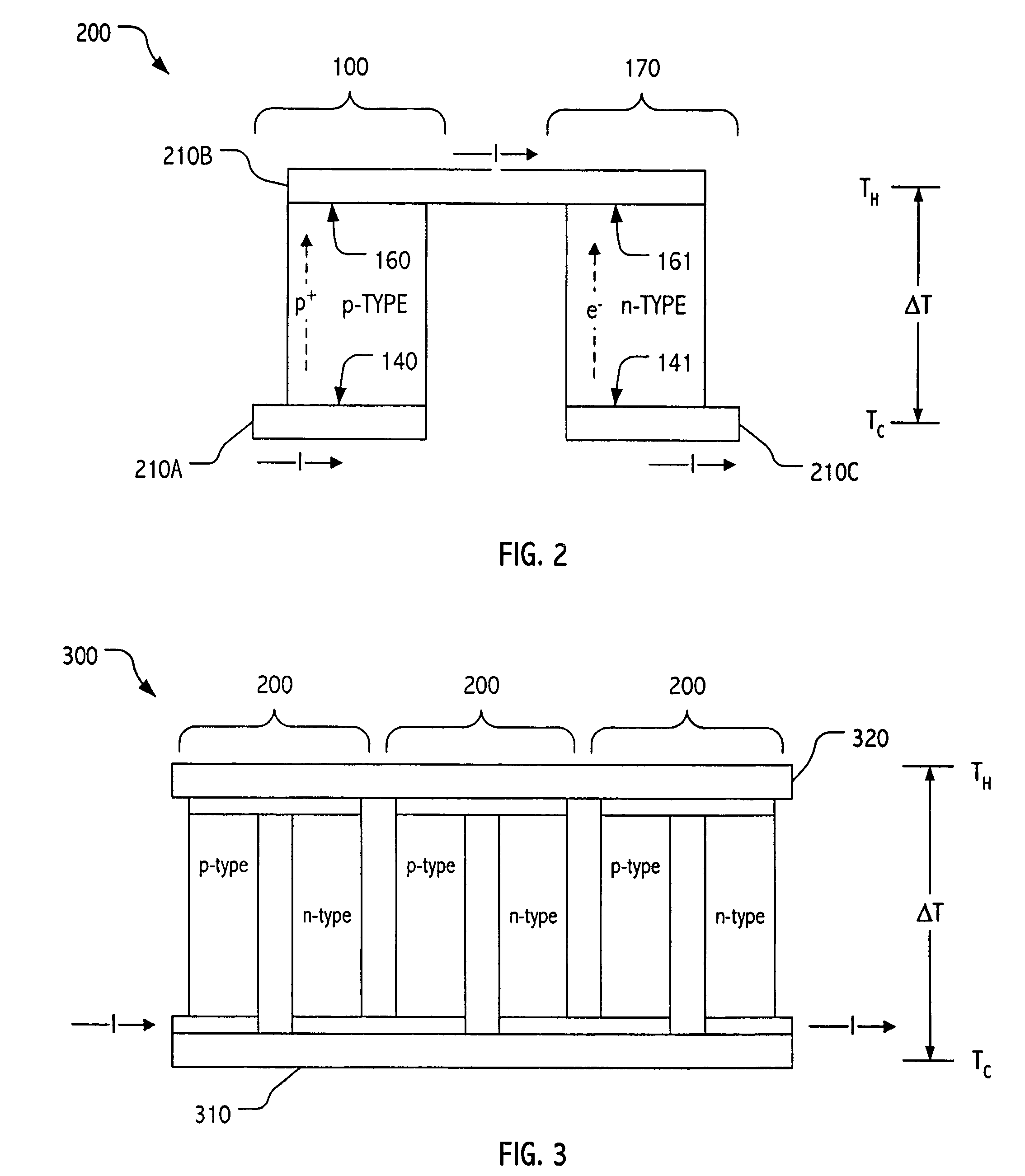

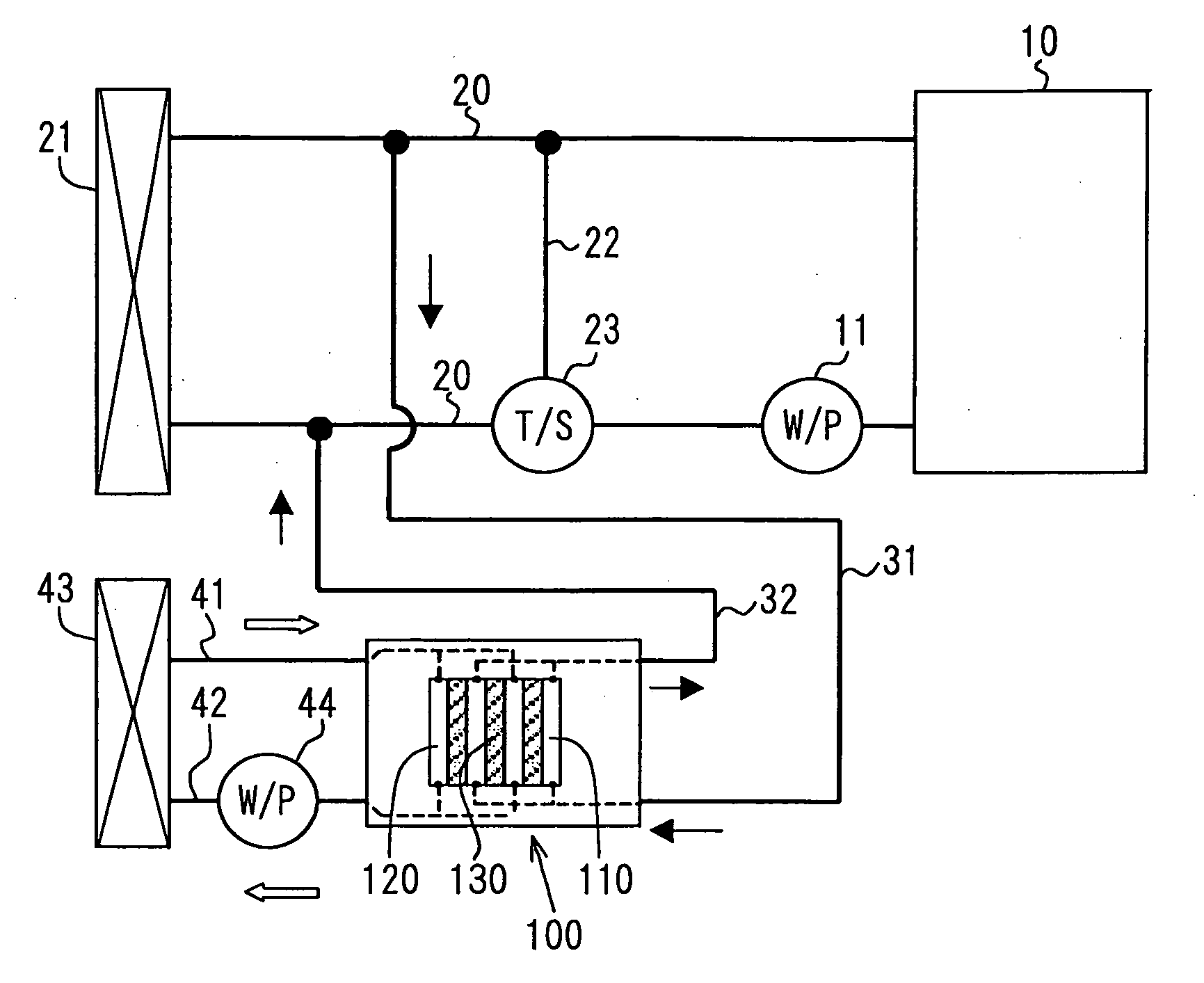

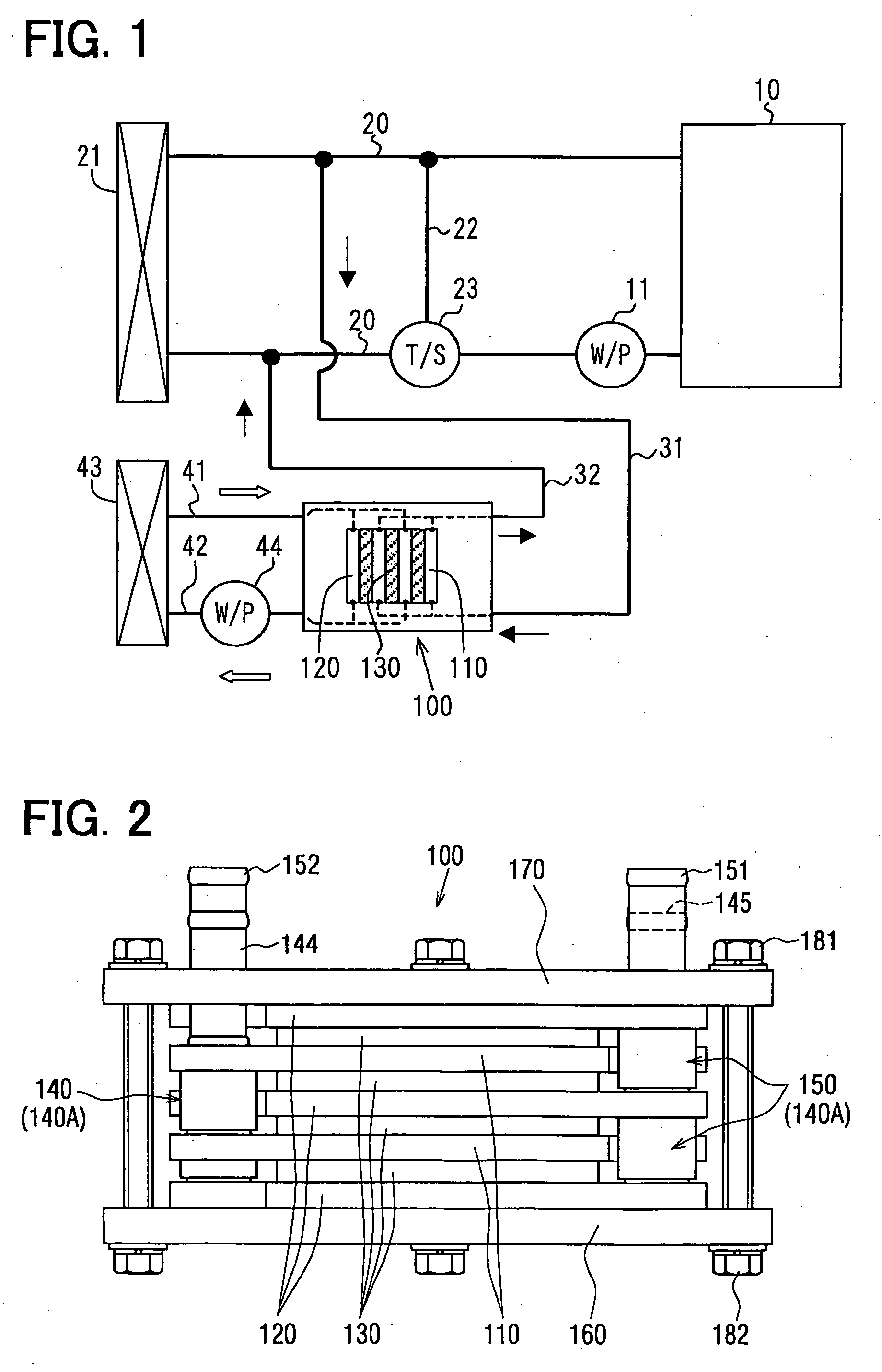

Thermoelectric generator

InactiveUS20050194034A1Liquid coolingThermoelectric device with peltier/seeback effectCold sideEngineering

A thermoelectric generator has a plurality of hot-side heat source portions, a plurality of cold-side heat source portions, a thermoelectric element, a hot-side communicator and a cold-side communicator. Hot fluid flows in the plurality of hot-side heat source portions, and cold fluid colder than the hot fluid flows in the plurality of cold-side heat source portions. The heat source portions are alternately stacked in such a manner of interposing the thermoelectric element between the hot-side heat source portion and the cold-side heat source portion. The hot-side communicator communicates the hot-side heat source portions, and the cold-side communicator communicates the plurality of cold-side heat source portions. Each of the hot-side communicator and the cold-side communicator has a distance adjuster for adjusting distances between the hot-side heat source portions and the cold-side heat source portions so as to bring them in contact with the thermoelectric elements in the stacking direction thereof.

Owner:DENSO CORP +1

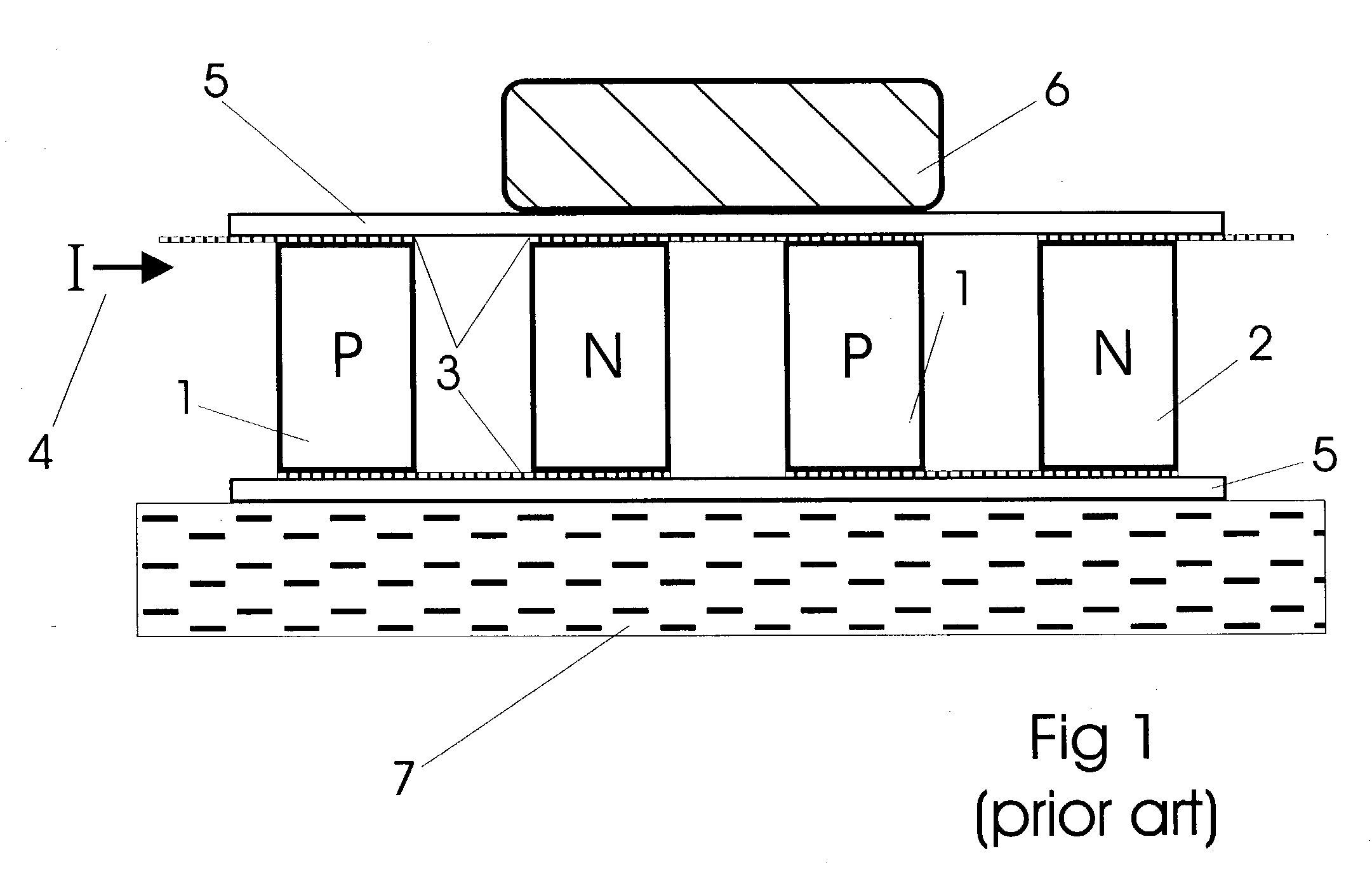

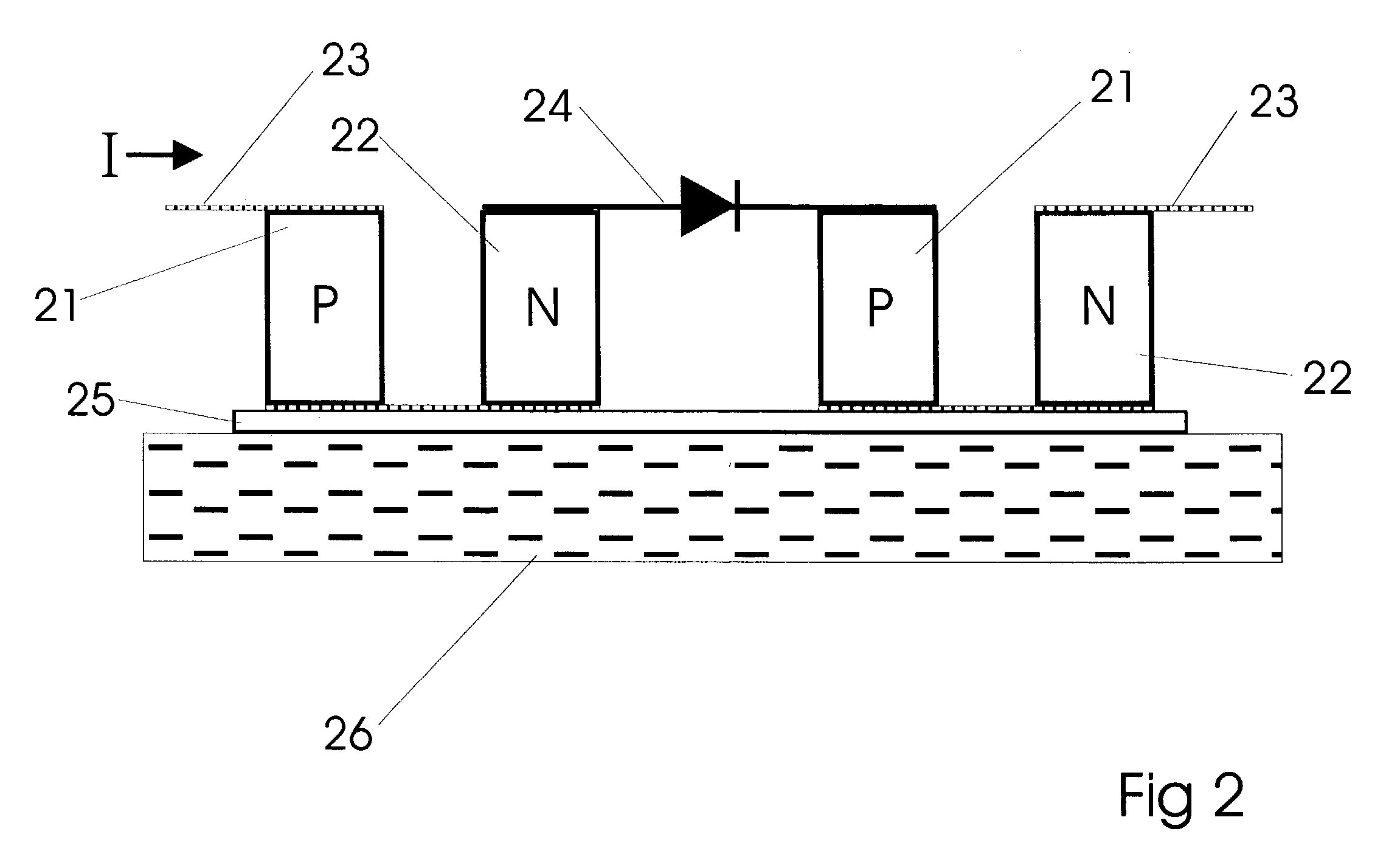

Thermoelectric heat pumps

InactiveUS7360365B2Thermoelectric device with peltier/seeback effectSolid-state devicesCold sidePlate heat exchanger

The thermoelectric heat pump comprises one or more thermoelectric modules having a hot side connected to a first heat exchanger and a cold side connected to a second heat exchanger, and is characterized in that it comprises a pair of elongated bar-like elements made of an electrically and thermally insulating material which are arranged at two parallel sides of the heat exchangers, at least partly interposed between facing flanges of said heat exchangers, at least one of said elongated bar-like elements including electric conductors for supplying power to the thermoelectric modules, as well as conductors for supplying control signals therefor, and that said heat exchangers contacting the thermoelectric modules are linked one another via a plurality of fasteners, each fastener being formed of a substantially C-shaped metal clip.

Owner:PELTECH

Thermoelectric heat pump with direct cold sink support

InactiveUS7032389B2Eliminates expensive and thermally inefficientInexpensively and effectively sealed against moistureThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsCold sideEngineering

A thermoelectric heat pump module of the type used in small cooling applications and appliances, such as a thermoelectric picnic cooler. The module comprises an array of thermoelectric elements with cold-side connectors directly bonded to a large, unitary cold sink for support, and hot-side connectors each having an integrated heat exchange fin to form a small, lightweight, but efficient hot sink array directly bonded to the elements without thermal stress. The cold sink is larger than the hot sink array. The cold-side connectors and at least portions of the thermoelectric elements are sealed and supported with a layer of potting material built up from the surface of the cold sink, and optionally insulated with an additional layer of sealed foam, eliminating moisture vapor transmission, condensation, and corrosion in the module. In a preferred form, the elements and their finned hot-side connectors are arranged in an elongated, narrow-depth array designed to be placed perpendicular to a flow of cooling air, and allowing multiple modules to be used in a distributed pattern with a single air-mover such as a fan.

Owner:THERMOELECTRIC DESIGN

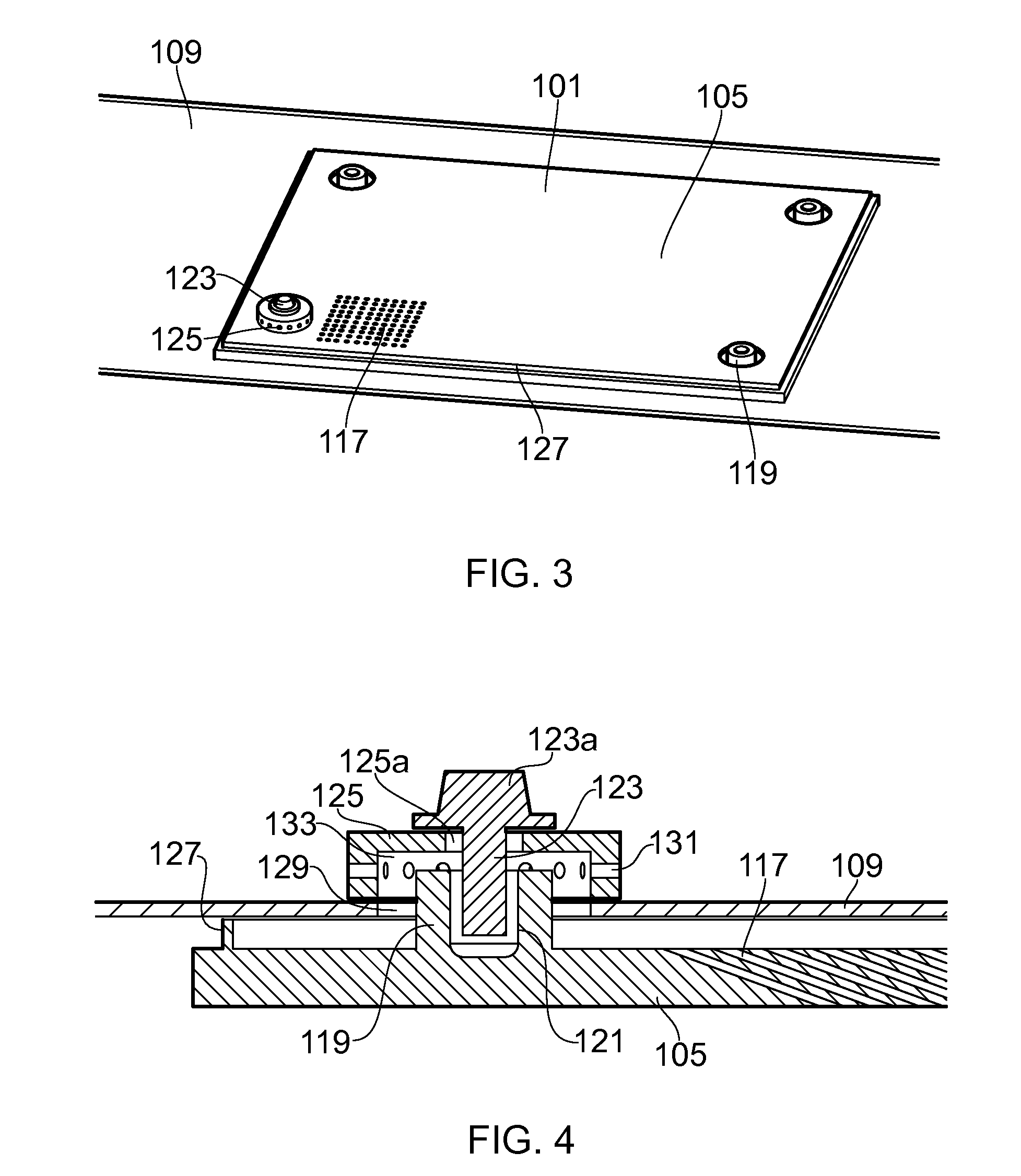

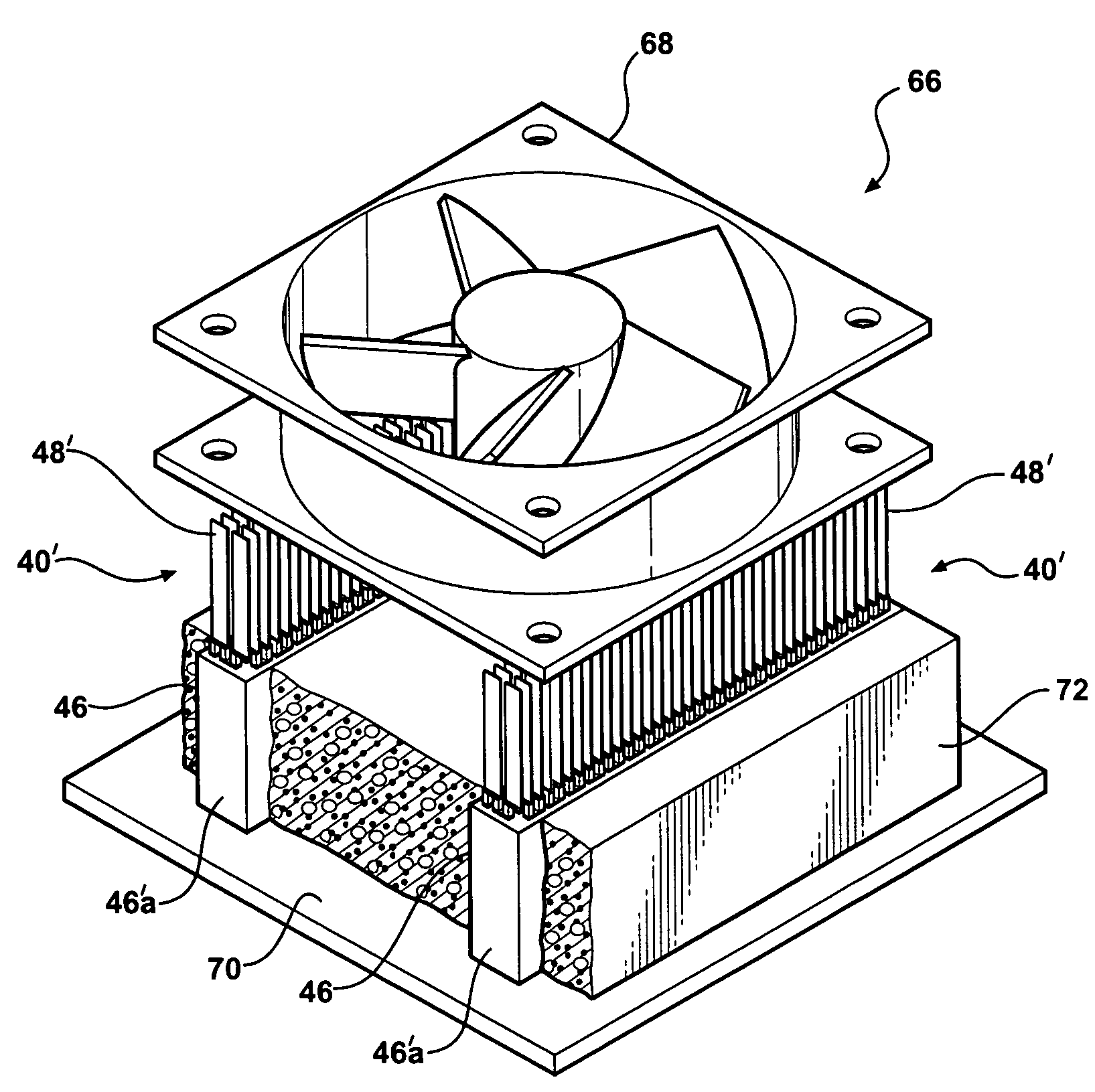

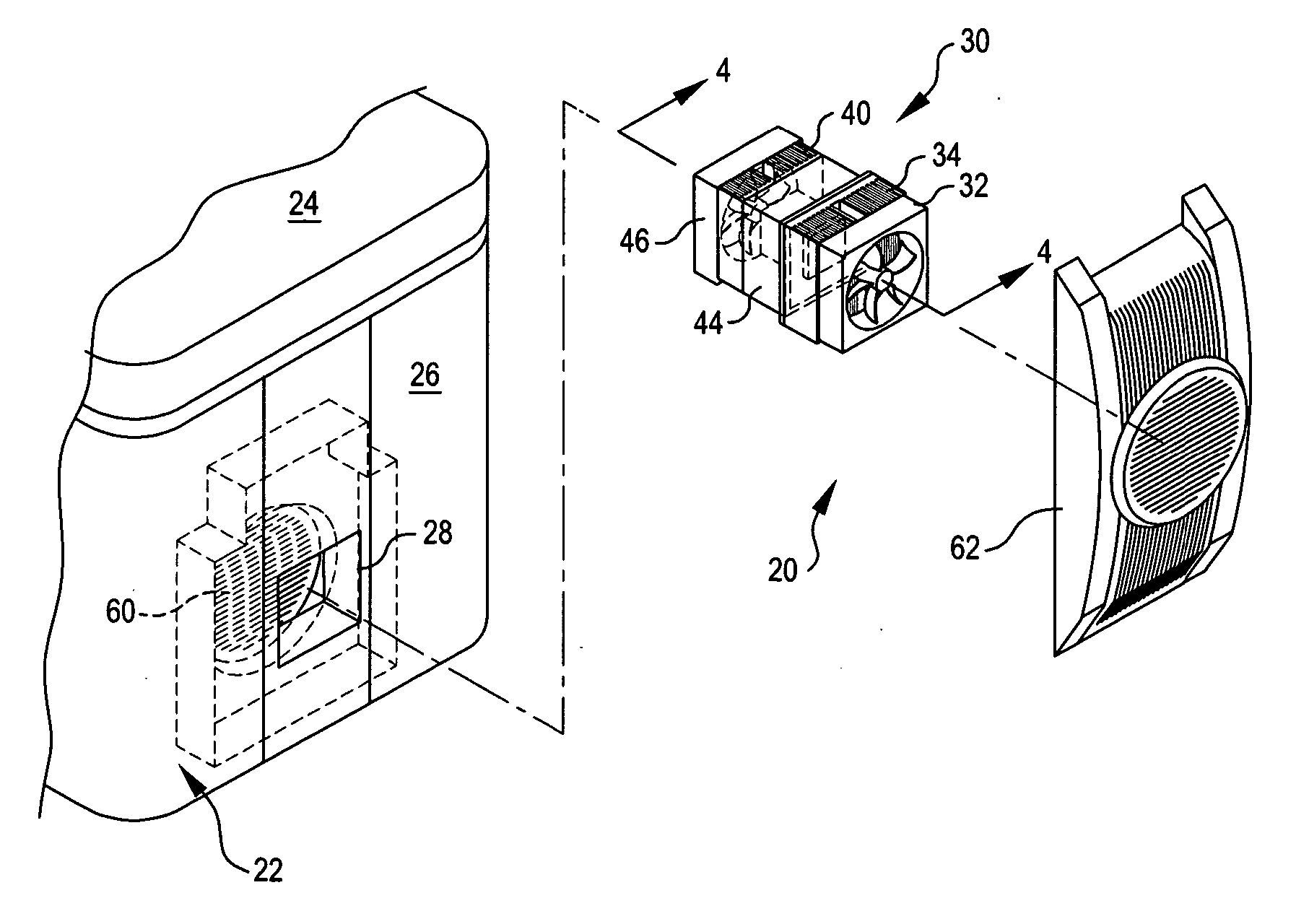

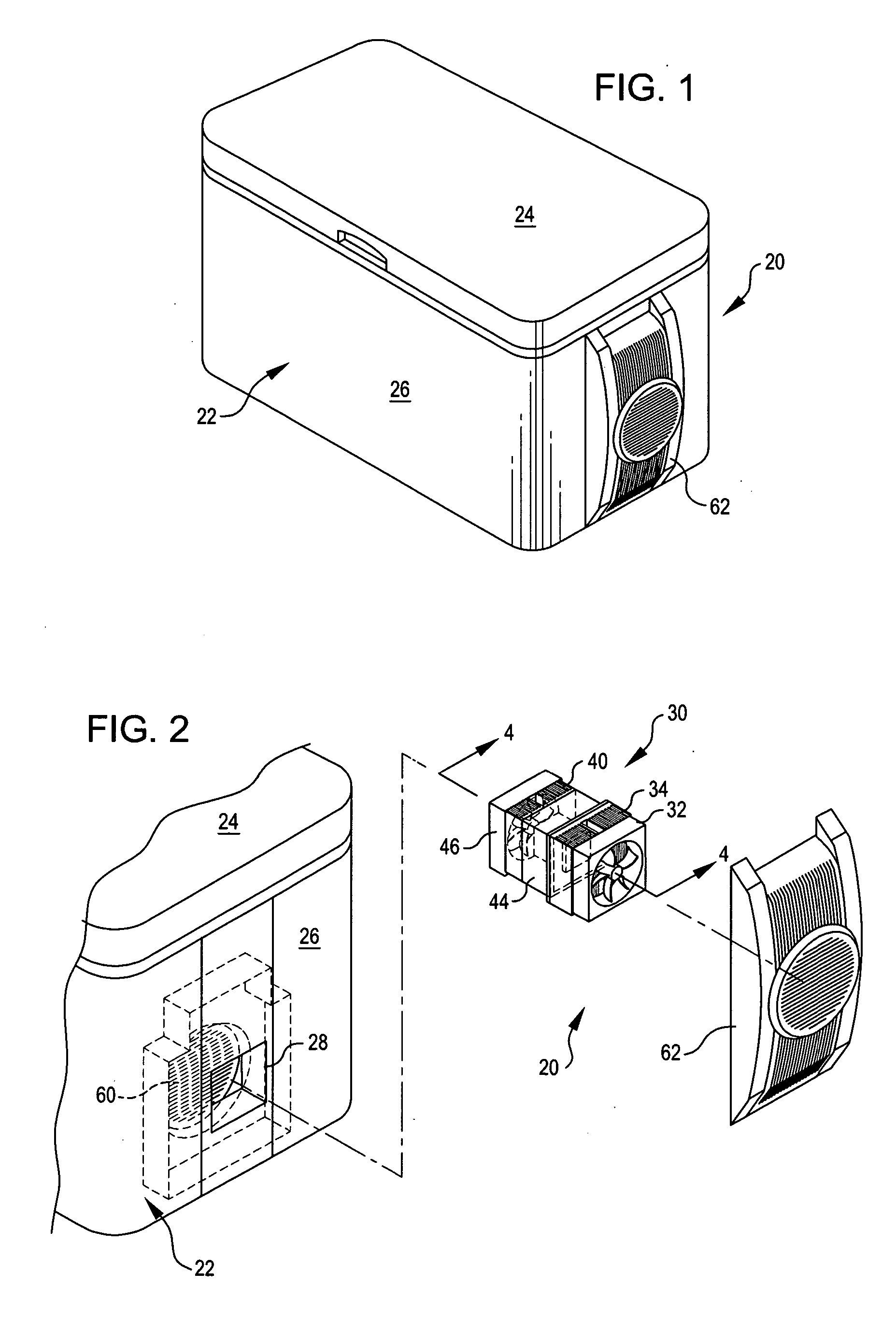

Insulated container with thermoelectric unit

ActiveUS20060000221A1Minimized in sizeReduce Freight CostsThermoelectric device with peltier/seeback effectContainer filling methodsCold sideEngineering

A thermoelectric unit for a thermoelectric insulated container. The thermoelectric unit is configured to be inserted in a small opening in the insulated container. A cold side heat sink is mounted on the portion of the thermoelectric unit that extends inside of the insulated container, and a hot side heat sink is mounted on a portion of the thermoelectric unit that extends outside. The thermoelectric unit is arranged so that a thermoelectric module for the thermoelectric unit, the cold side heat sink, and the hot side heat sink are aligned linearly. A hot side fan and motor unit is mounted on the outside of the hot side heat sink and a cold side fan and motor unit is mounted on the outside of the cold side heat sink. The hot and cold side fan and motor units may also be mounted linearly with the hot and cold side heat sinks.

Owner:THE COLEMAN CO INC

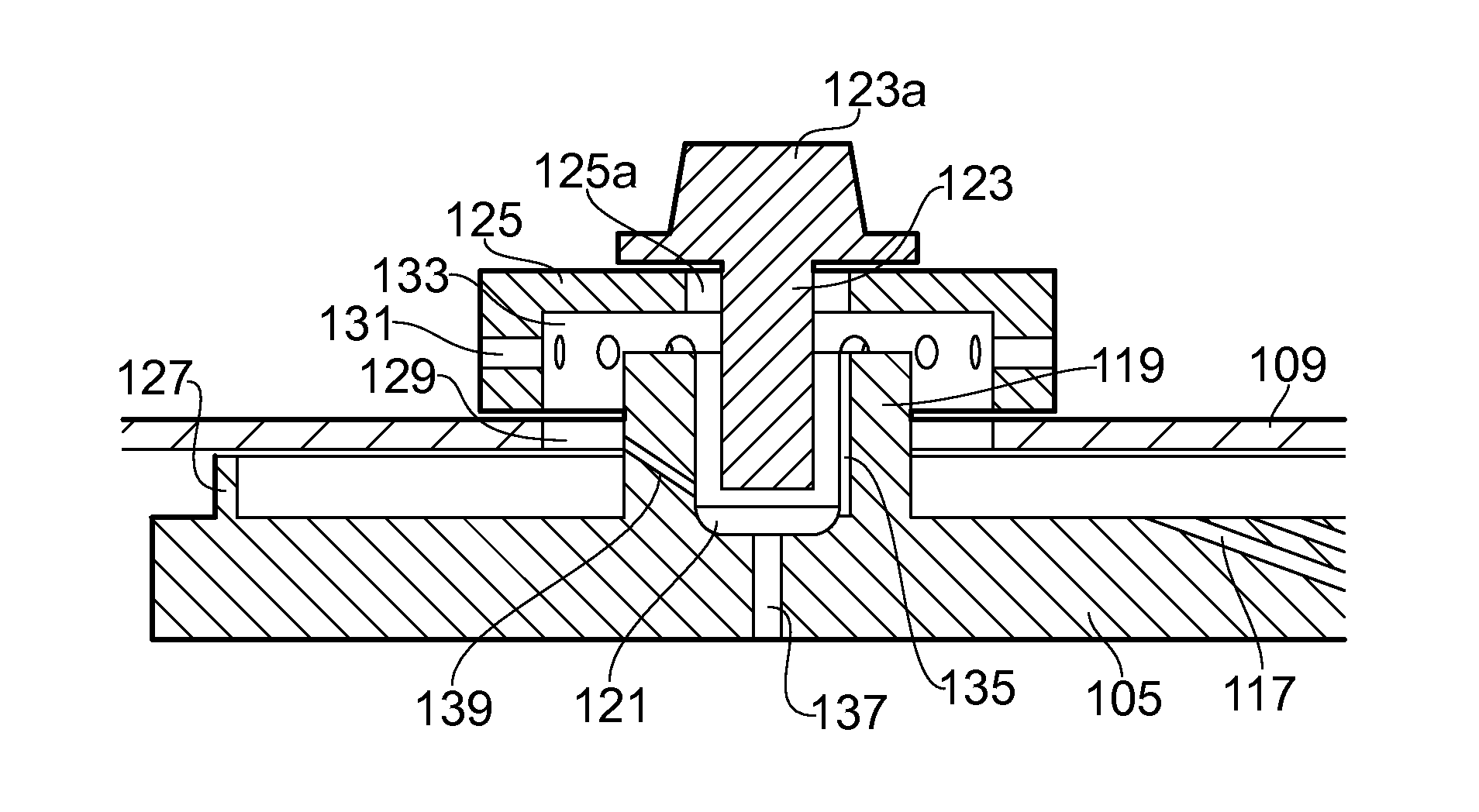

High temperature, high efficiency thermoelectric module

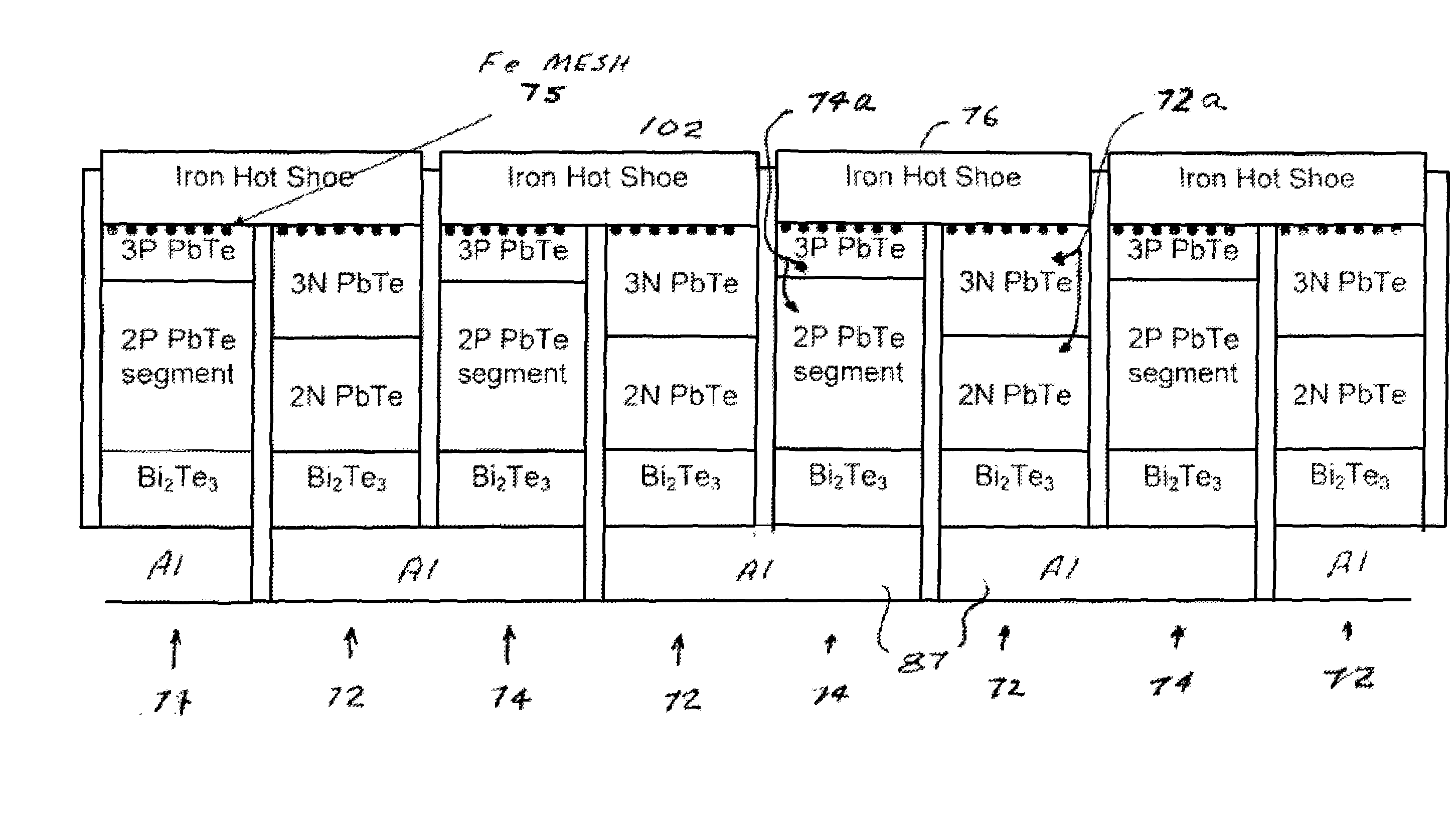

InactiveUS20100229911A1Low thermal conductivityImprove ZTThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsElectrical connection

A long life, low cost, high-temperature, high efficiency thermoelectric module. Preferred embodiments include a two-part (a high temperature part and a cold temperature part) egg-crate and segmented N legs and P legs, with the thermoelectric materials in the three segments chosen for their chemical compatibility or their figure of merit in the various temperature ranges between the hot side and the cold side of the module. The legs include metal meshes partially embedded in thermoelectric segments to help maintain electrical contacts notwithstanding substantial temperature variations. In preferred embodiments a two-part molded egg-crate holds in place and provides insulation and electrical connections for the thermoelectric N legs and P legs. The high temperature part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 500° C. and the cold temperature part is comprised of a thermoplastic material having very low thermal conductivity.

Owner:HI Z TECH +1

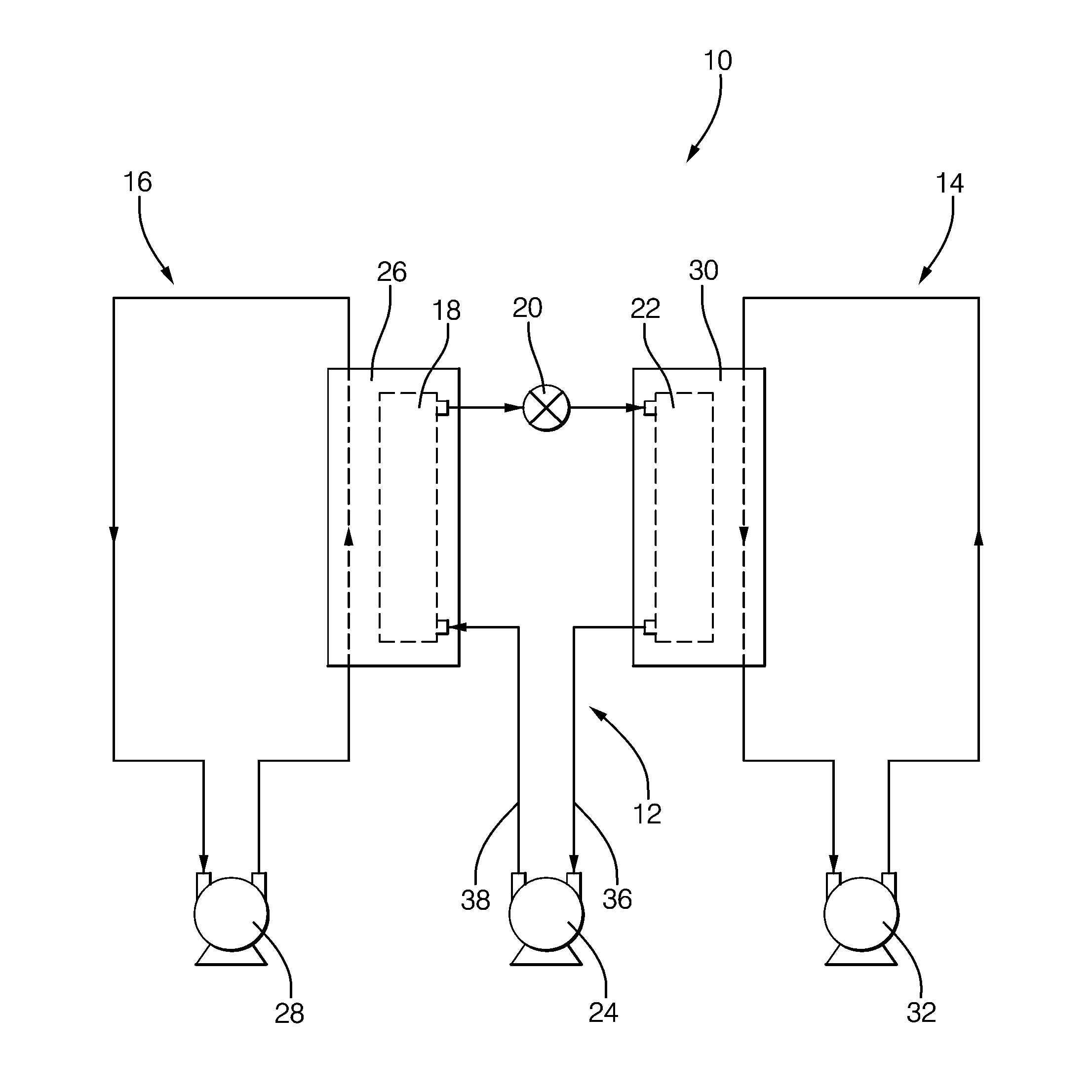

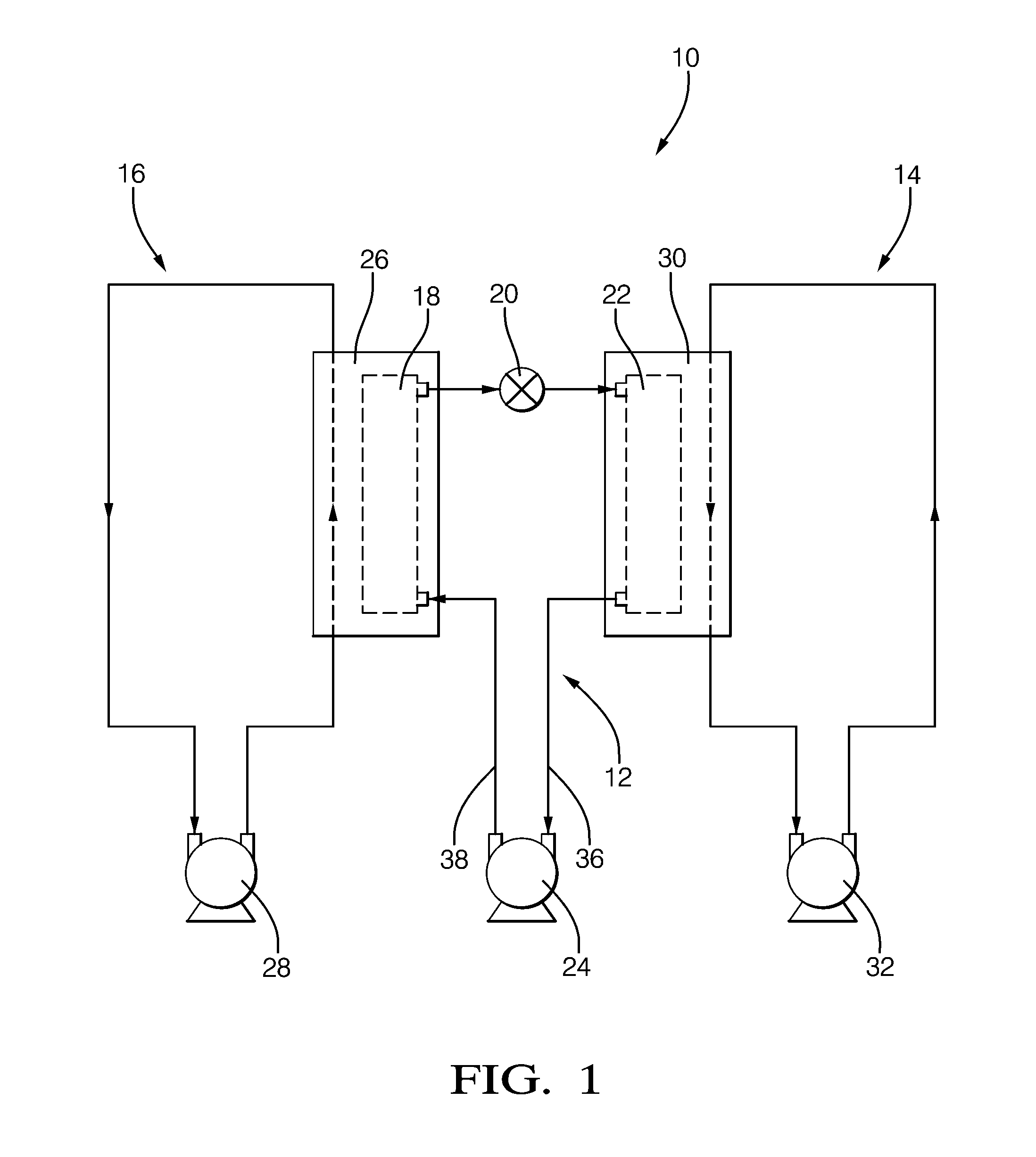

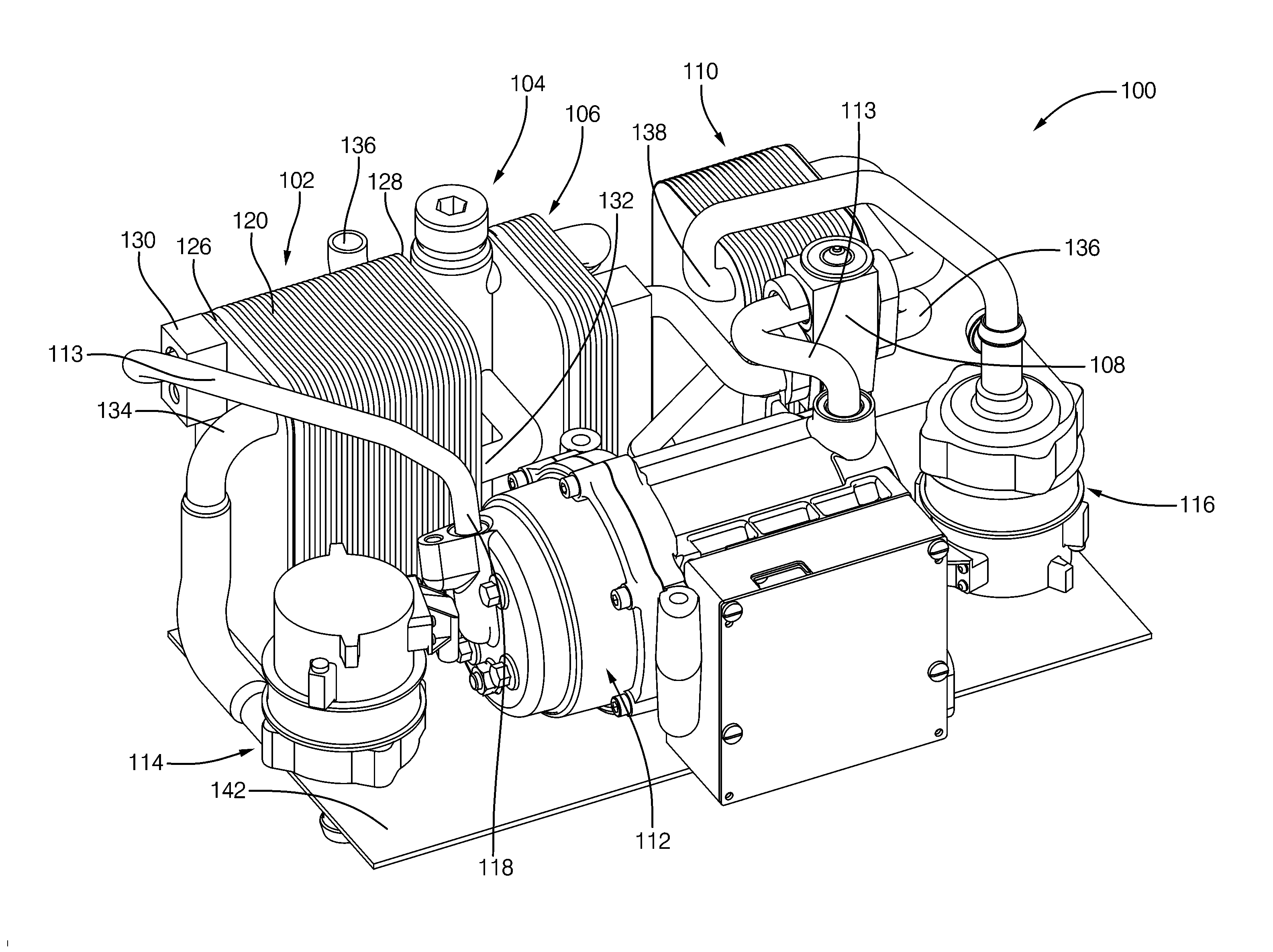

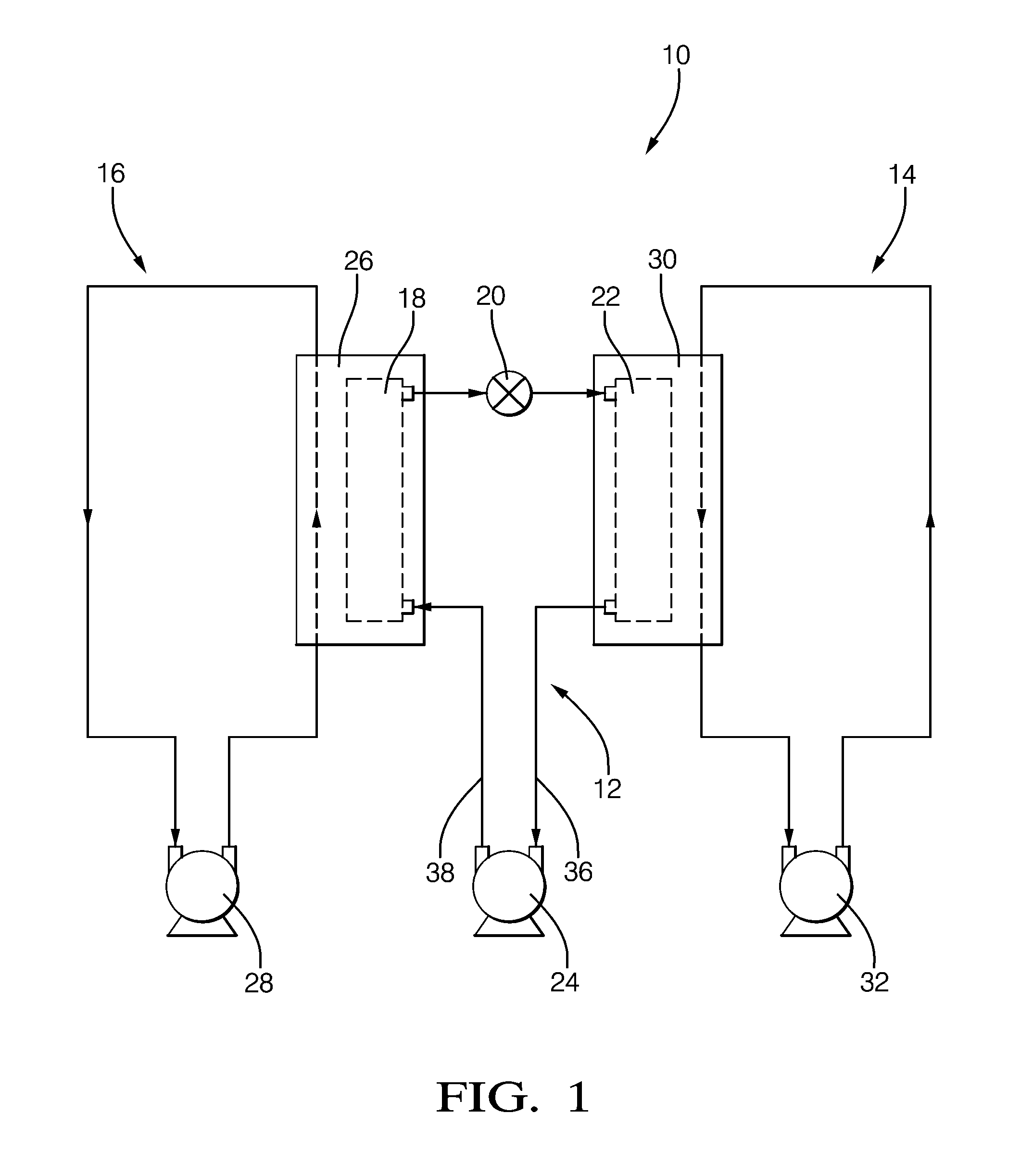

Unitary heat pump air conditioner

InactiveUS20130283838A1Easy to installIncrease mileageHeat pumpsCompression machines with non-reversible cycleCold sideEngineering

The disclosure relates to a unitary heat pump air conditioner (Unitary HPAC) that includes a refrigerant loop having a condenser, a refrigerant expansion device, and an evaporator hydraulically connected in series. An electrically driven compressor is provided to circulate a two-phase refrigerant through the refrigerant loop to transfer heat from the evaporator to the condenser. The unitary HPAC also includes a cold side chiller configured to hydraulically connect to a cold side coolant loop and is in thermal communication with the evaporator. The unitary HPAC further includes a hot side chiller configured to hydraulically connect to a hot side coolant loop and is in thermal communication with the condenser. The refrigerant loop transfer heat from the cold side chiller to the hot side chiller, thereby cooling the cold side coolant loop and heating the hot side coolant loop. The components of the unitary HPAC are mounted on a common platform.

Owner:MAHLE INT GMBH

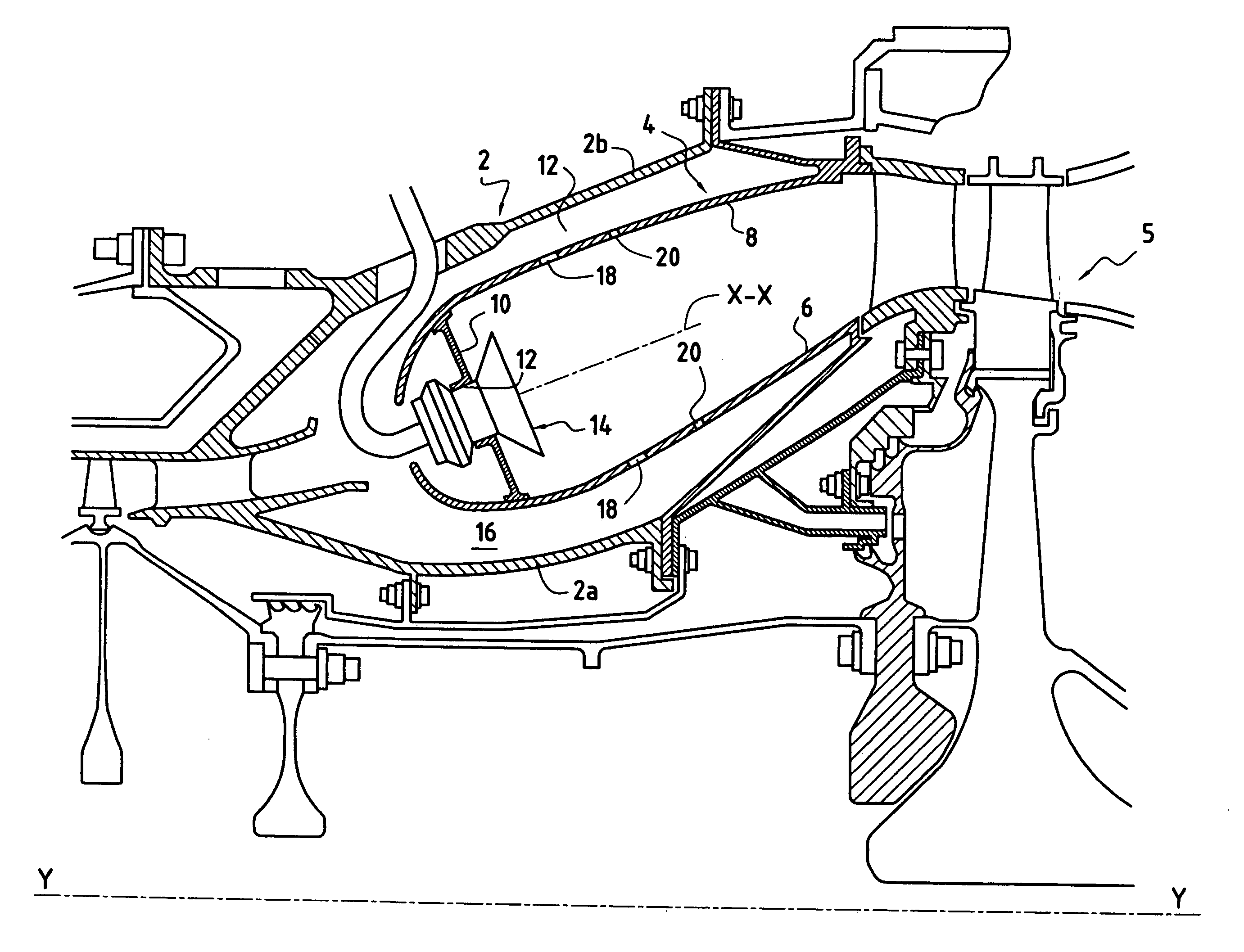

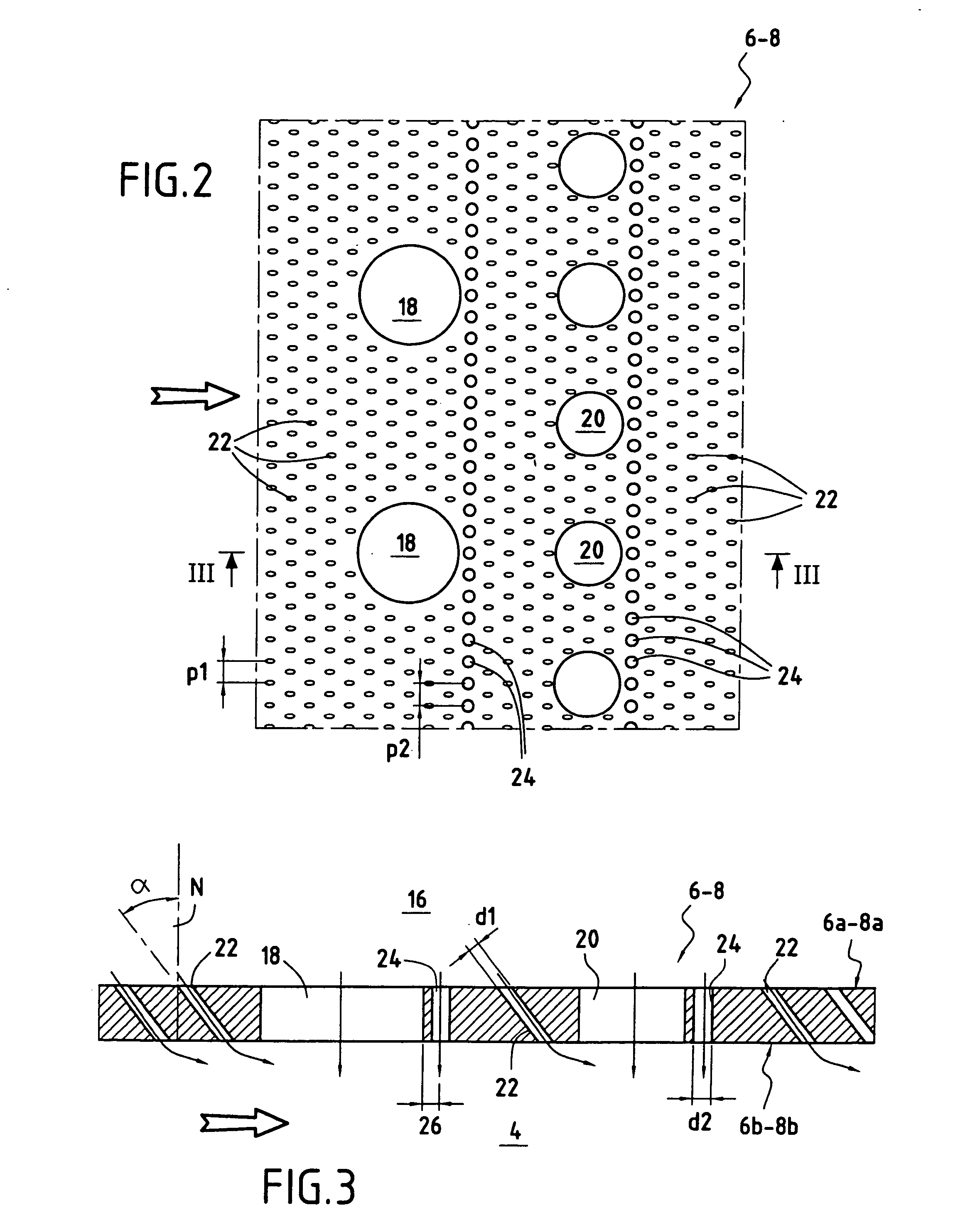

Performance of a combustion chamber by multiple wall perforations

ActiveUS20070084219A1Mitigate such drawbackAvoid risk of crackingContinuous combustion chamberGas turbine plantsCold sideCombustion chamber

An annular wall for the combustion chamber of a turbomachine has a cold side and a hot side, said wall being provided with a plurality of primary holes and a plurality of dilution holes distributed in circumferential rows, together with a plurality of cooling orifices that are distributed in a plurality of circumferential rows that are spaced apart axially from one another, the number of cooling orifices being identical in each row thereof, and the wall further including bores disposed immediately downstream from the primary holes and from the dilution holes and distributed in circumferential rows, the bores in any one row presenting a substantially identical diameter, being spaced apart at a pitch that is constant, and presenting intrinsic characteristics that are different from the intrinsic characteristics of the cooling orifices of the adjacent rows.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

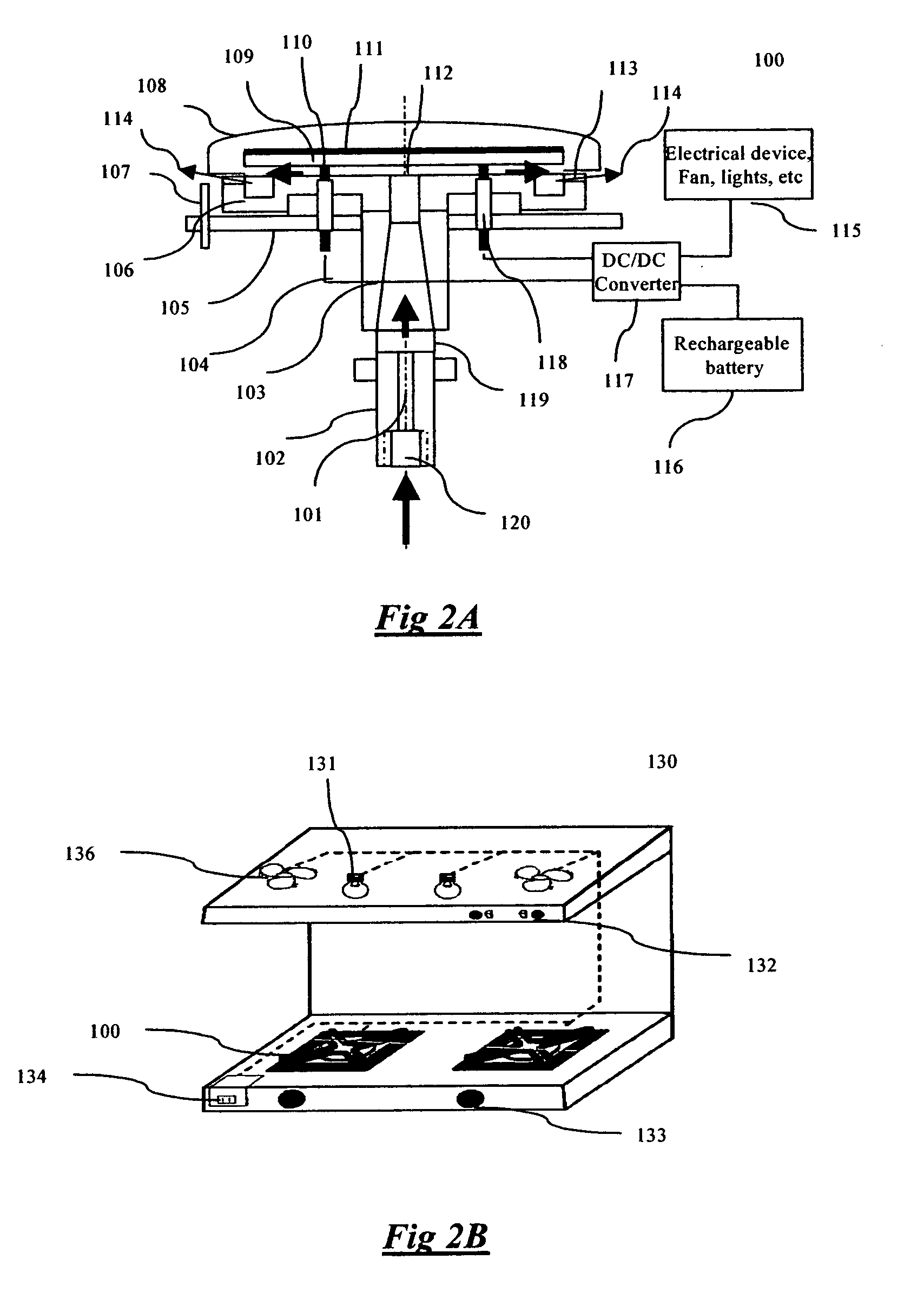

Gas stove with thermoelectric generator

InactiveUS20060016446A1Wasted thermal energyDomestic stoves or rangesGaseous heating fuelElectrical batteryEngineering

A gas burner generates electricity with waste heat energy. At least one thermoelectric unit is installed underneath the burner cap of the gas burner. Gas flame at the edge of the burner cap creates heat sources (hot side) for the thermoelectric unit. A gas-mixing chamber underneath the thermoelectric unit functions as heat sinks (cold side) for the thermoelectric unit. An insulation plate is inserted in between the thermoelectric unit and the burner cap to control the hot side temperature. The thermoelectric unit generates electricity while the gas burner is in use and the flame heats up the burner cap. The thermoelectric unit connects to an electric circuit and provides electricity to power devices such as electric fans, lights, TVs, battery chargers etc.

Owner:HU CAROLINE K +1

Method for cooling automated storage library media using thermoelectric cooler

InactiveUS6854275B2Reduce heat lossReducing temperature influence on carrierDomestic cooling apparatusThermoelectric coolingCold side

An automated storage library including: an enclosure having a cartridge storage area in an interior of the enclosure; a plurality of media cartridges disposed in the cartridge storage area; and a cooling unit operatively connected to the enclosure for cooling at least the cartridge storage area of the enclosure. Preferably, the enclosure has an exterior wall and the cooling unit is at least partially disposed in the exterior wall. More preferably, the cooling unit is a thermoelectric cooler having a hot side disposed on an exterior of the enclosure and a cold side disposed in the interior of the enclosure.

Owner:IBM CORP

System, method, and apparatus for providing a thermal bypass in electronic equipment

ActiveUS7134288B2Reduce the temperatureReduce cooling effectDomestic cooling apparatusMachines using electric/magnetic effectsCold sideThermoelectric cooling

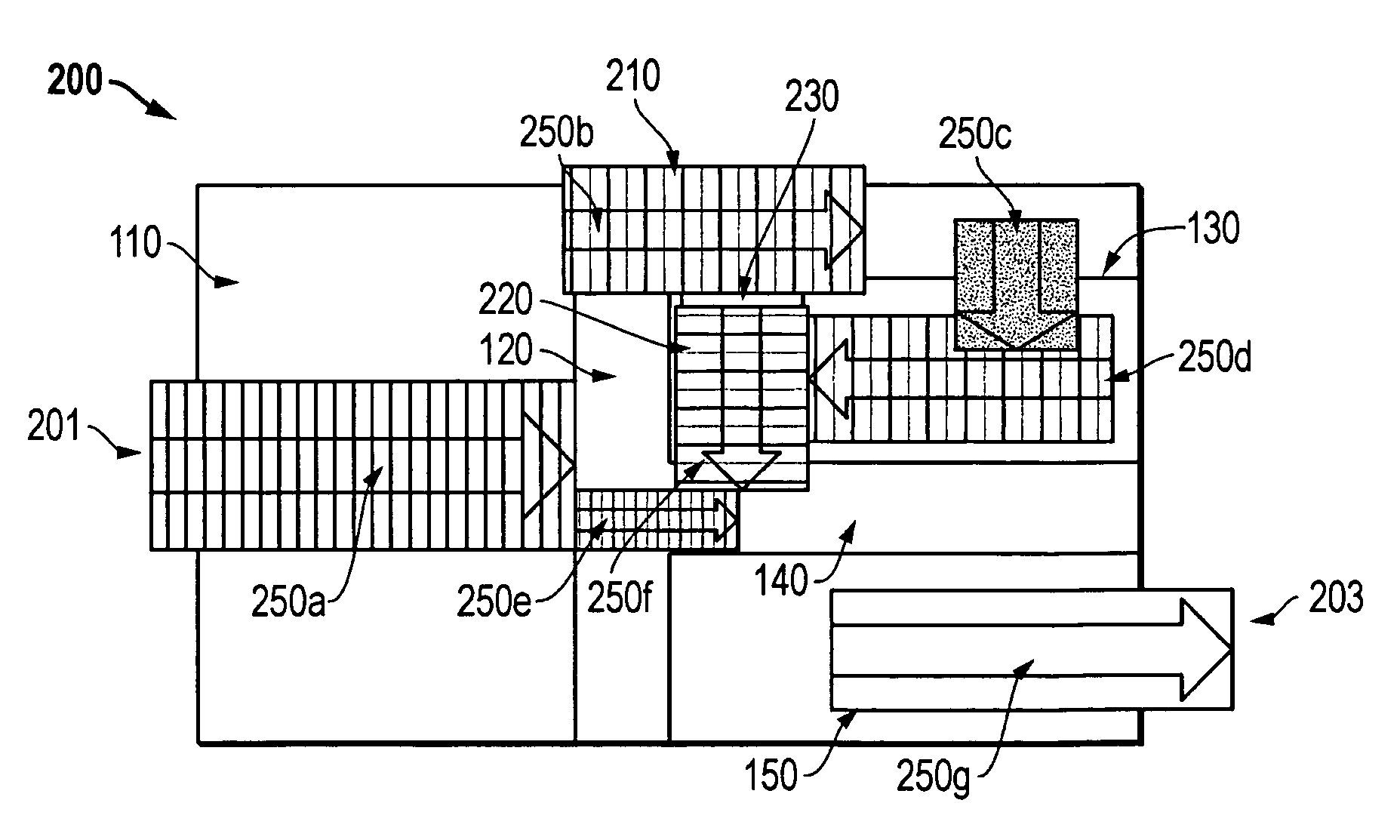

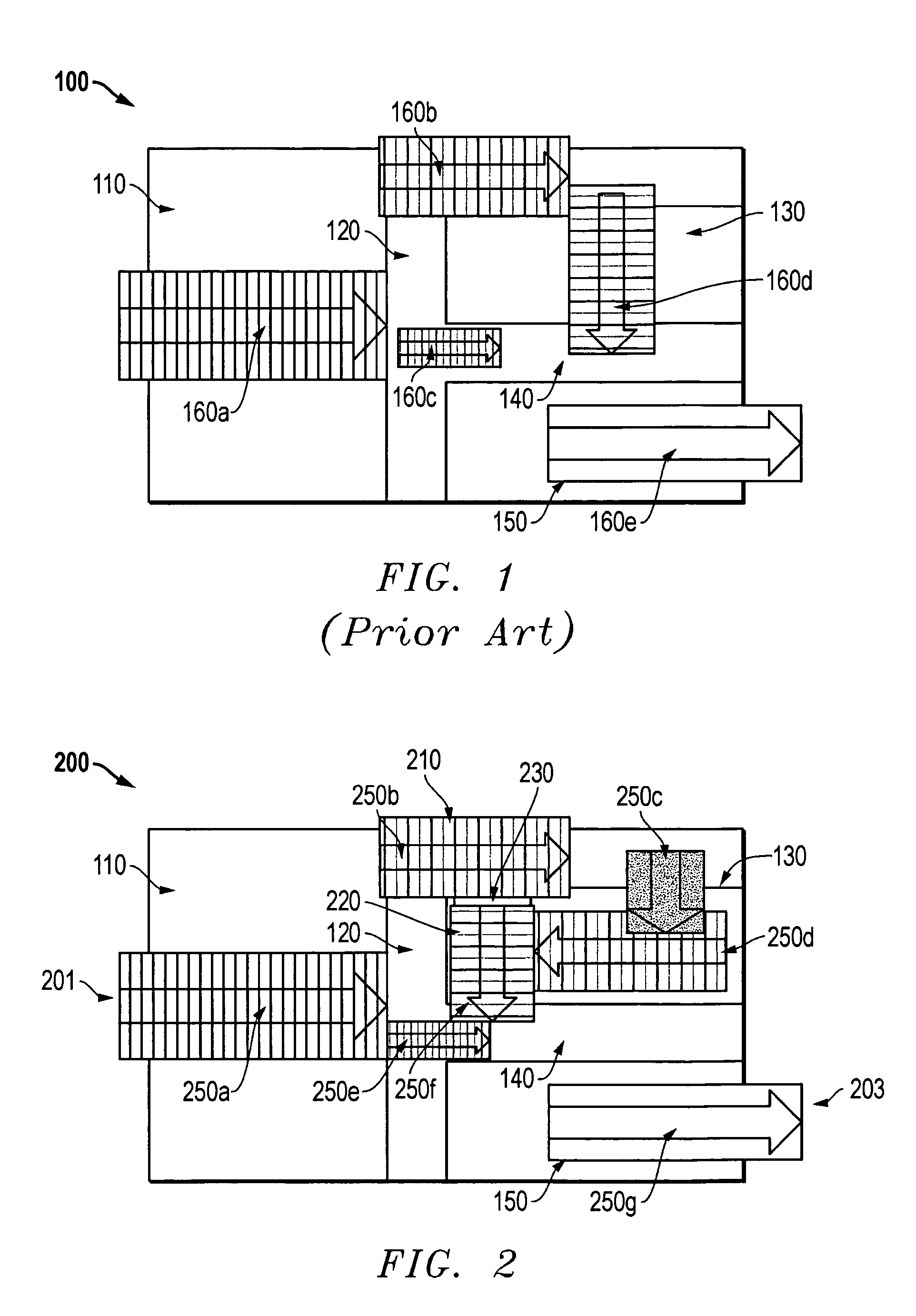

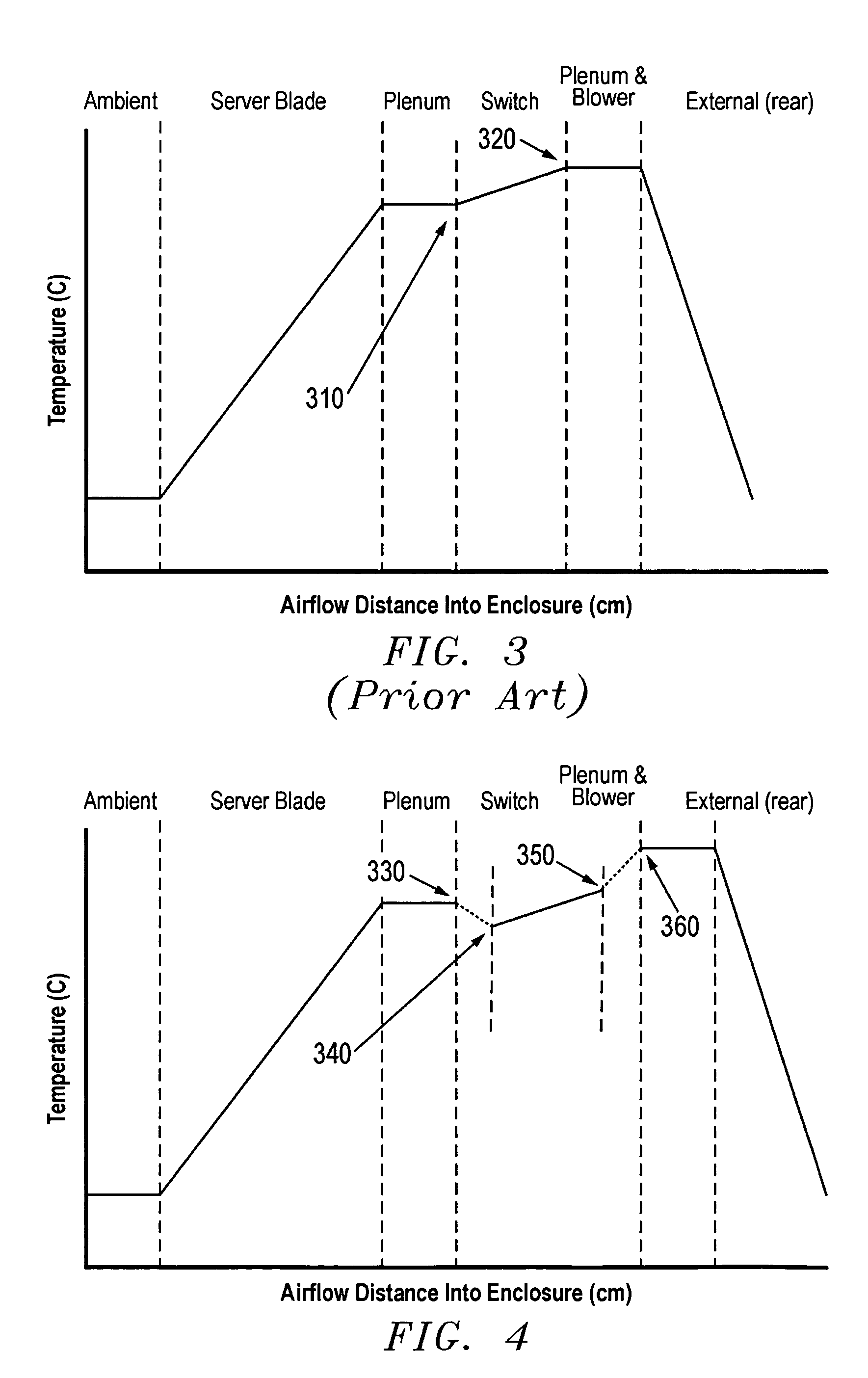

A system enclosure uses two heat exchangers and a thermoelectric cooling module to manage heat within the system. An airflow enters the system and is heated by server blades. Portions of the airflow split and travel to various portions of the system enclosure. Some heat is removed from the airflow by passing through the first heat exchanger before circulating around downstream subsystems. The first heat exchanger contacts the cold side of a TEC module, to reduce the temperature of that airflow. The air then enters the network switch module or other subsystem where it is further heated. Thereafter, the second heat exchanger ‘bypasses’ those components by reinserting the upstream heat back into the downstream airflow. The second heat exchanger contacts the hot side of the TEC module. The mixture of all heated air is then expelled from the system enclosure.

Owner:INT BUSINESS MASCH CORP

Peltier cooler integrated with electronic device(s)

InactiveUS20040155251A1Improve cooling effectIncrease productionThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsEngineeringThermal contact

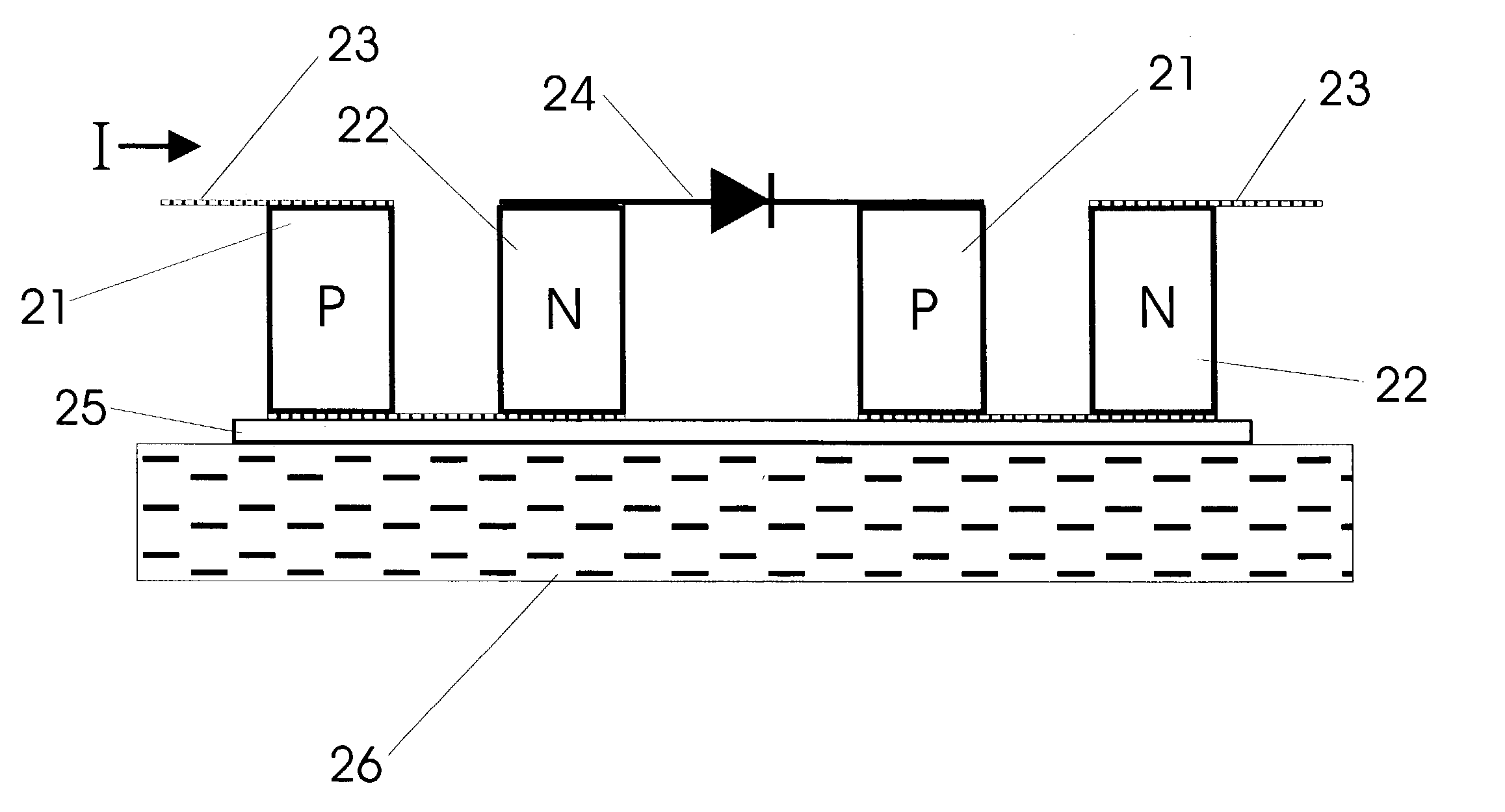

A Peltier effect cooling device is formed in combination with an electronic device to form a unique thermal and electrical relationship. An electronic device to be cooled is placed in a serial electrical relationship between at least two thermoelectric couples while simultaneously being in thermal contact with a cold side of the cooler arrangement. The same current which produces the thermoelectric effect in the Peltier thermocouples also drives the electronic device. A balanced effect results as a higher driving current through the electronic device causes greater heating, it is offset by the added cooling due to a greater current in the thermocouples. In addition, a unique spatial arrangement provides improved heat distribution and transfer to a heat sink. Due to the unique shapes of Peltier elements, heat is pulled radially from a heat generating source and distributed at a peripheral region. Shaped Peltier elements are tapered from a small cold area to a large hot area to further magnify the transfer of heat.

Owner:SHISHOV ALEXANDER

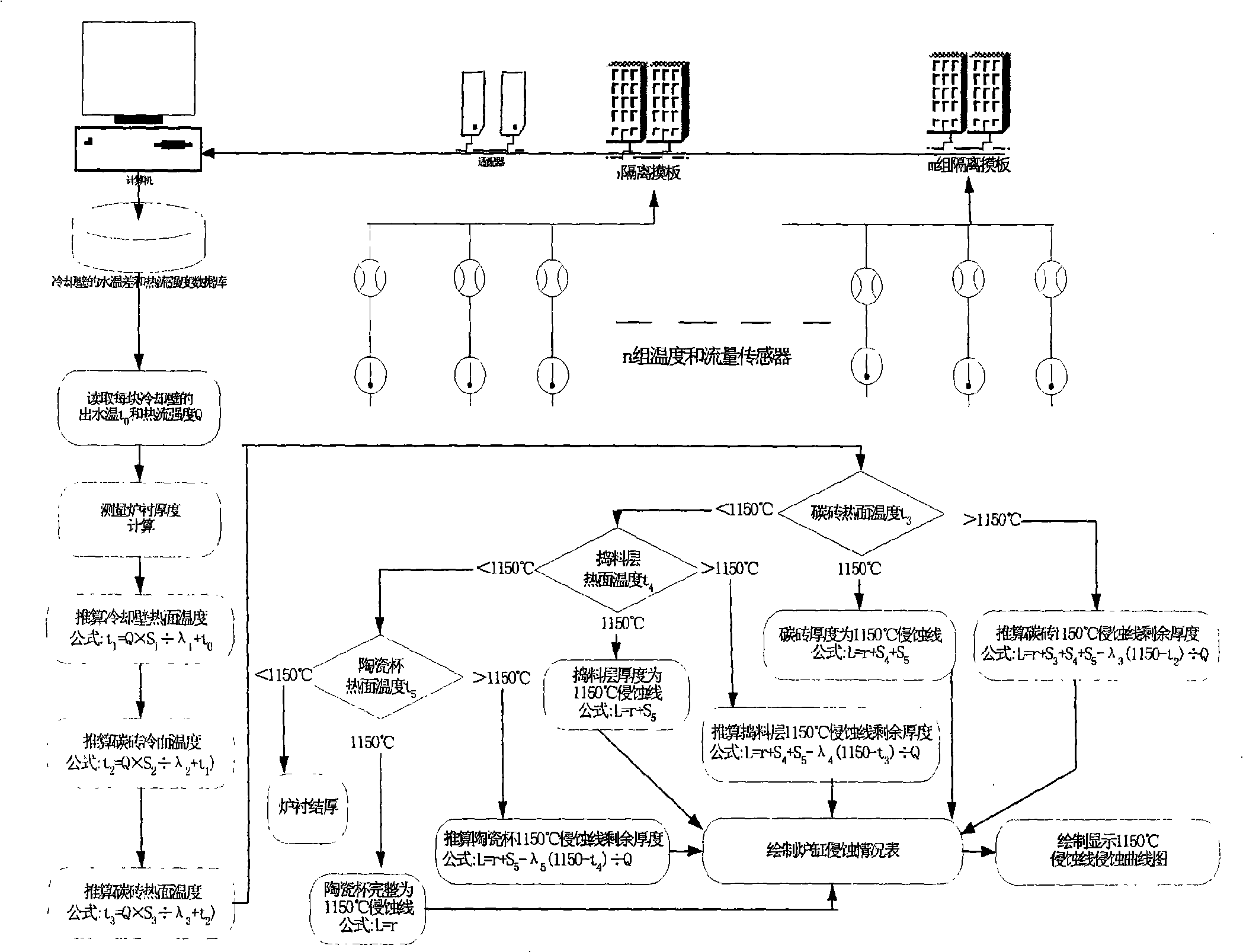

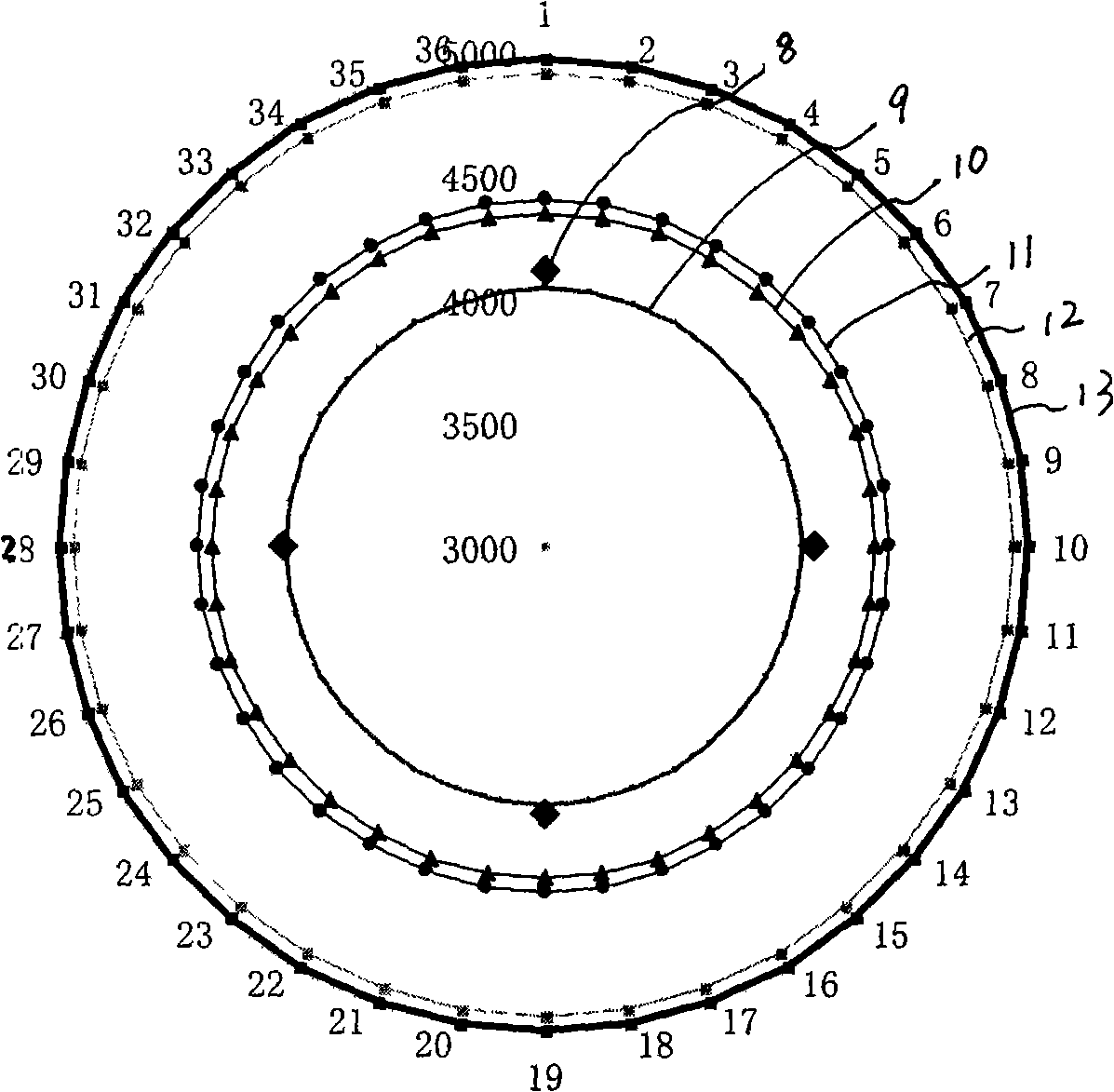

Method for measuring blast furnace lining corroding thickness

InactiveCN101275829ASmooth renderingLarge reckoning coverageThermometers using electric/magnetic elementsUsing electrical meansCold sideHeat flow

The invention relates to a method for measuring corrosion thickness, especially a method for measuring corrosion thickness of blast furnace lining, aiming to solve technical problems that the bull couple can not cover circumferential direction when being previously embedded in blast furnace hearth causing large limitation for calculating corrosion thickness of blast furnace hearth according to the couple detecting data. A method for measuring corrosion thickness of blast furnace lining, comprising: a, a temperature and flow rate sensor on the cooling wall collects and inputs data into a computer via an isolation baffle and an adaptor, reads flow temperature t<0> and heat flow intensity Q of each cooling wall from the cooling wall water temperature difference and heat flow intensity database, b, measuring the cooling wall heat side temperature according to Fourier formula: t<1>=Q*S<1> / lambda <1>+t<0>; c, measuring carbon brick cold side temperature: t<2>=Q*S<2> / lambda<2>+t<1>; d, measuring carbon brick heat side temperature: t<3>=Q*S<3> / lambda <3>+t<2>, determining position of blast furnace hearth iron solidification corrosion line at 1150 degrees centigrade, and finally surveying and drawing corrosion curve of blast furnace hearth at 1150 degrees centigrade. The invention can automatically measure blast furnace lining corrosion degree in each part of the blast furnace and draw the corrosion curve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

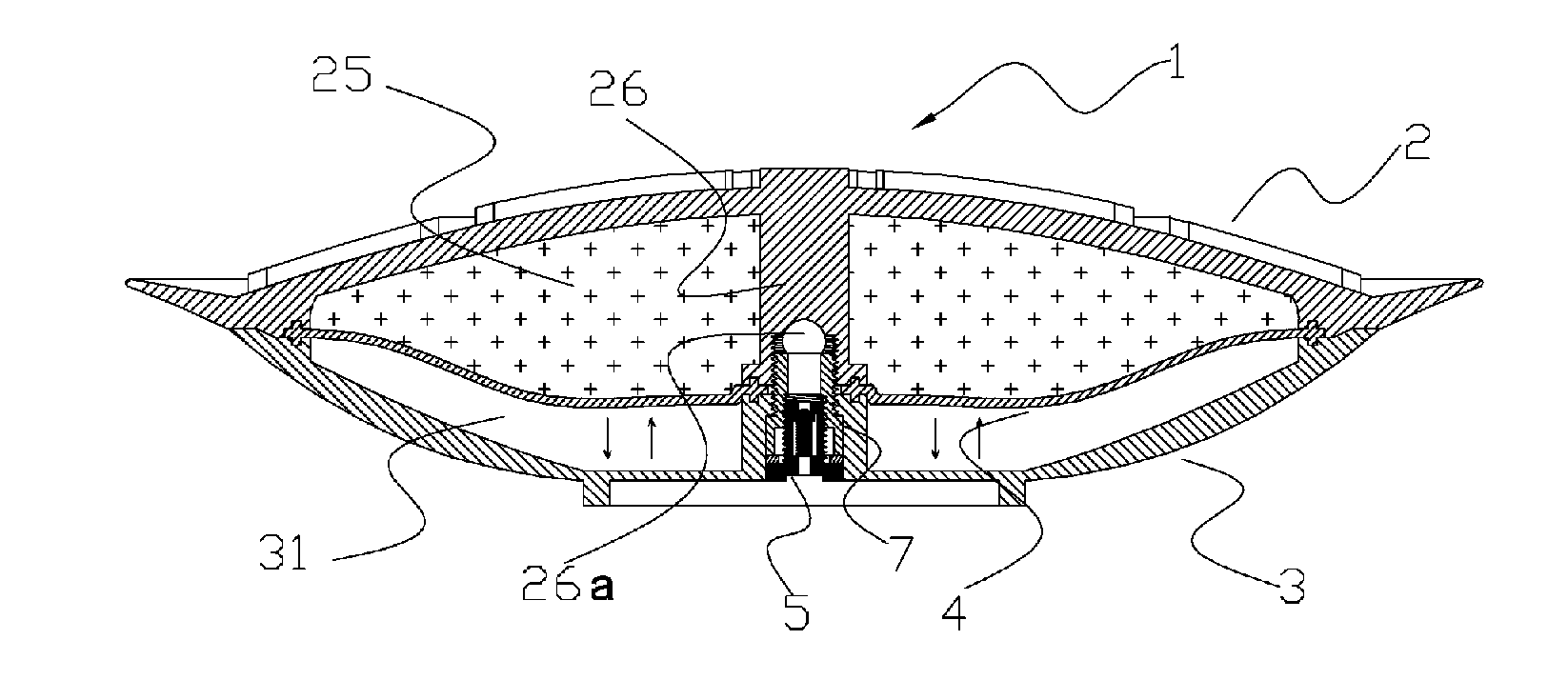

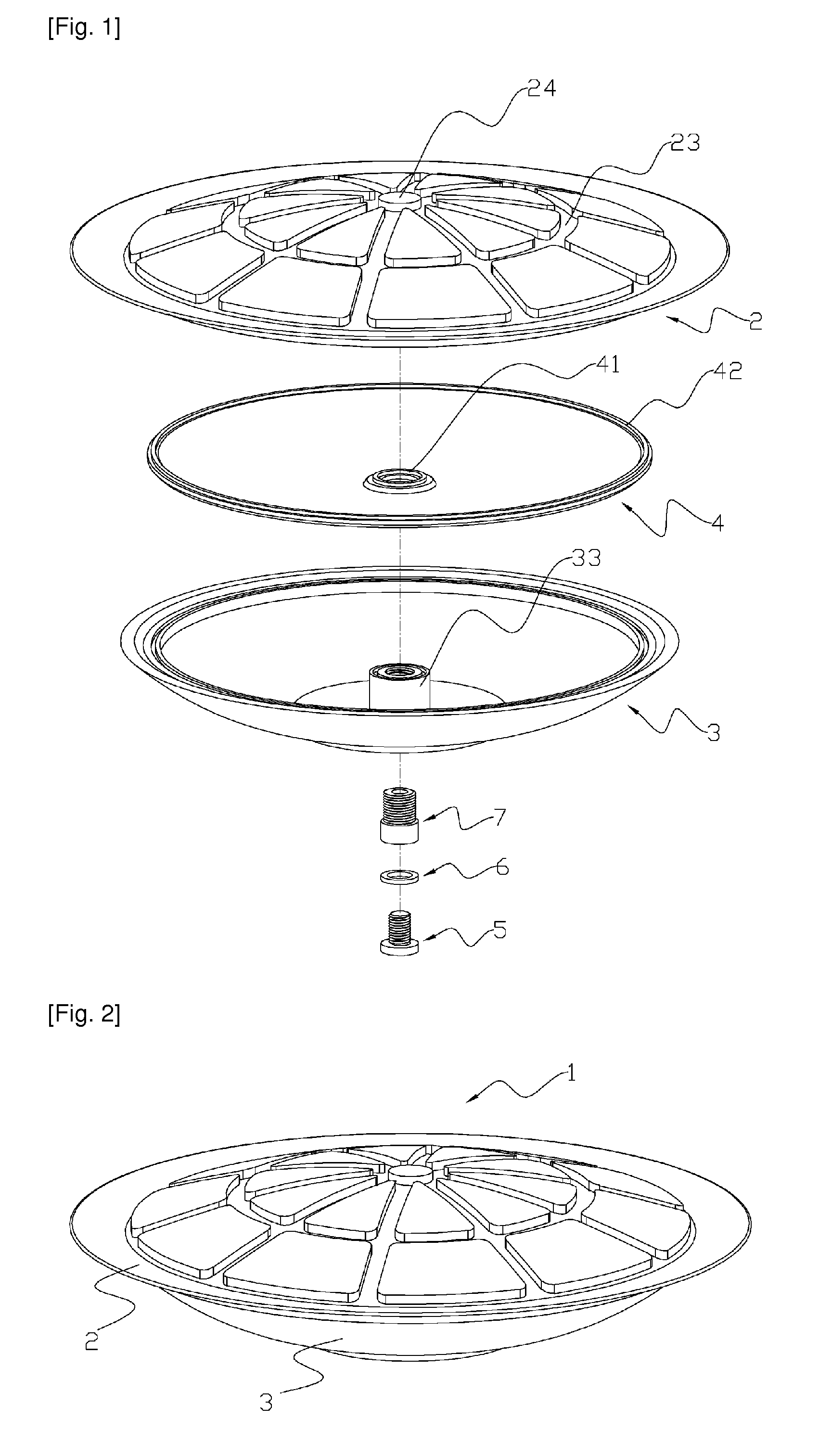

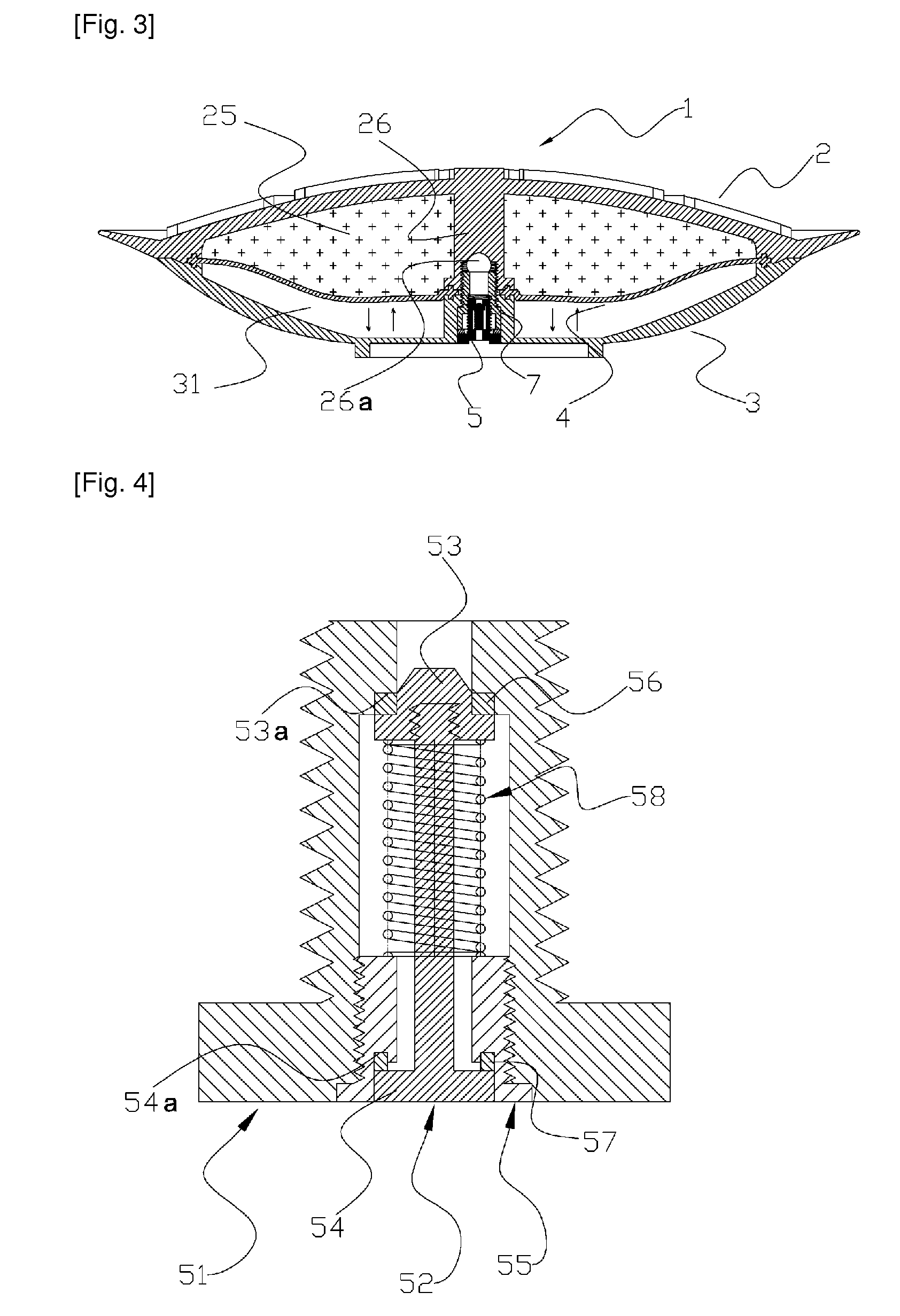

Freezing crack or distortion proof cooling utensil

InactiveUS20100147014A1Reduce manufacturing costSimple configurationLighting and heating apparatusPlatesVacuum gapEngineering

The present invention relates to a cooling utensil, which is a proof of freezing-crack and distortion. More particularly, an internal cavity of the utensil is fully filled the water to freeze in the freezer for cooling the serving food, such as a law fish, fruit, cold noodle or beer to feel fresh and tasty. For using the cooling bowl, the cooling cavity is filled the water or coolant for freezing. The cooling bowl is using for serving food. The cooling cavity is formed between the upper part and the lower part. The lower part is used a base to support the upper part. The upper part has same shape and size of the lower part for placing over the lower part. The elastic plate having flexibility and elastically restoring force is attached to the lower part, the upper part for assembling. Further, the cooling bowl having a cooling cavity is filled the water or coolant and freeze to use serving food. The lower part has built a dual wall to form a vacuum gap between the inner wall and the outer wall for insulation, so that the outer wall has no condensed water gained. The elastic tube (4k) having elastically restoring force is inserted through the water inlet (33). the plug bolt (5k) mounted at the mouth of the water inlet (33), for sealing the water filled cavity.

Owner:KIM EE

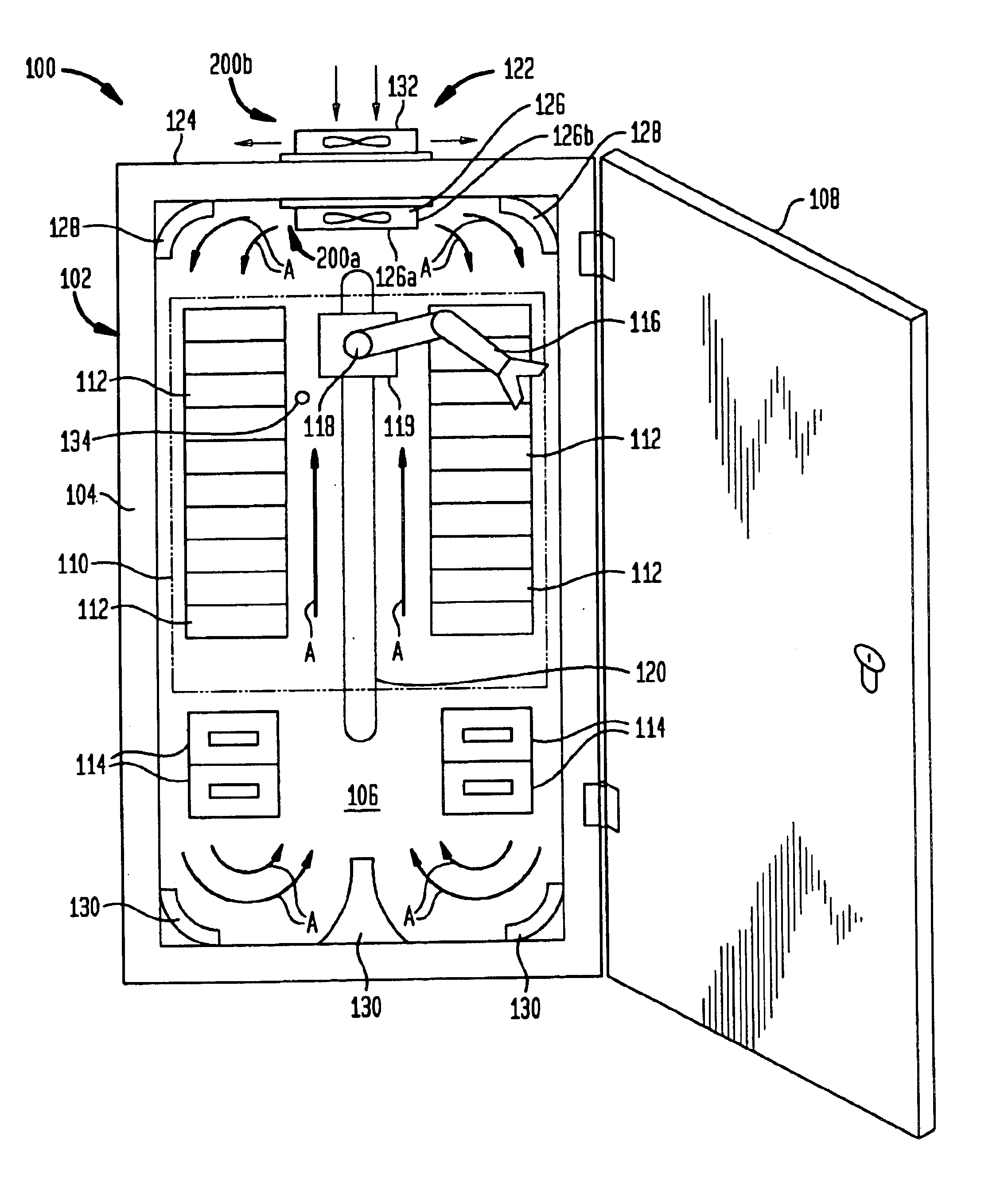

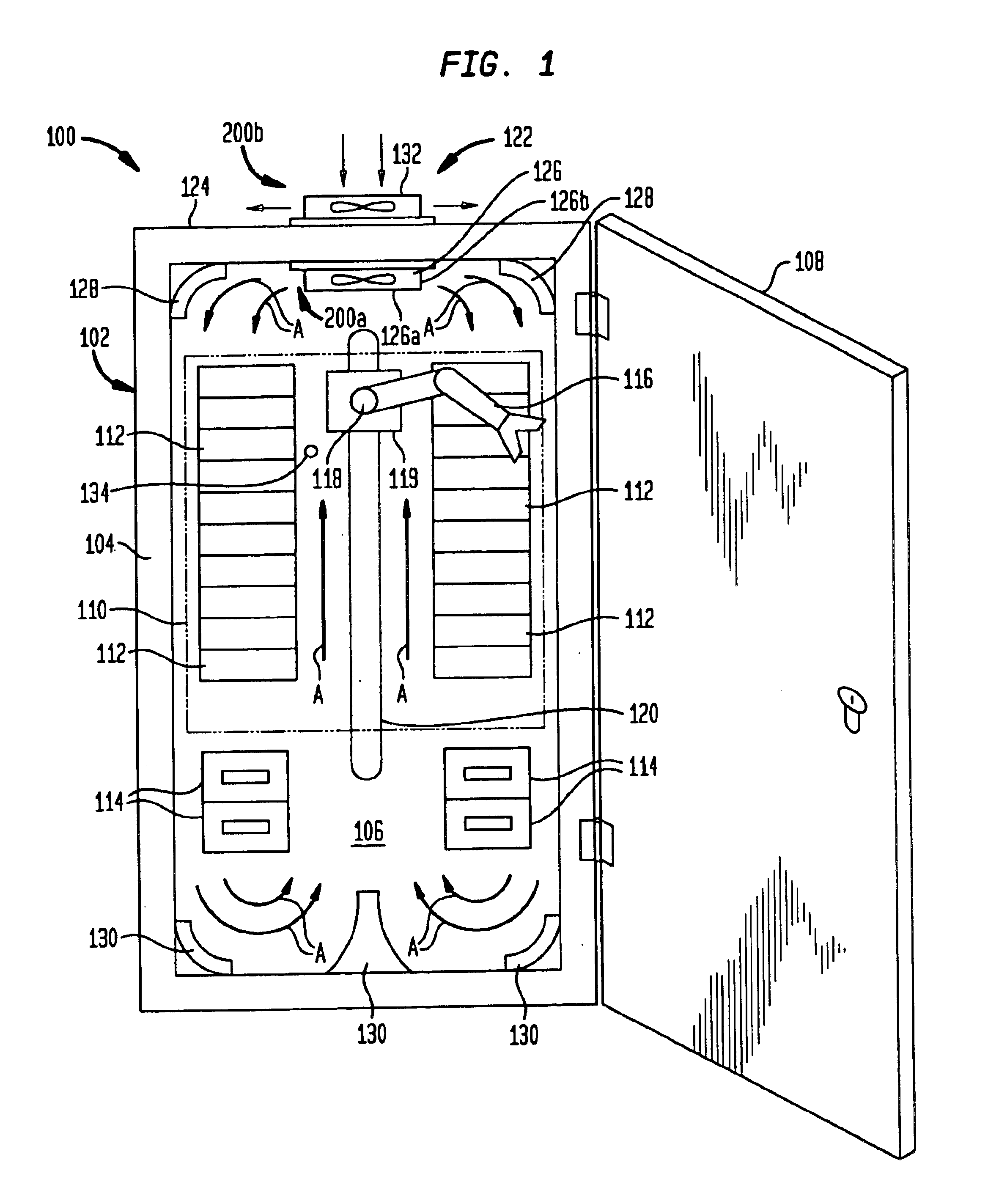

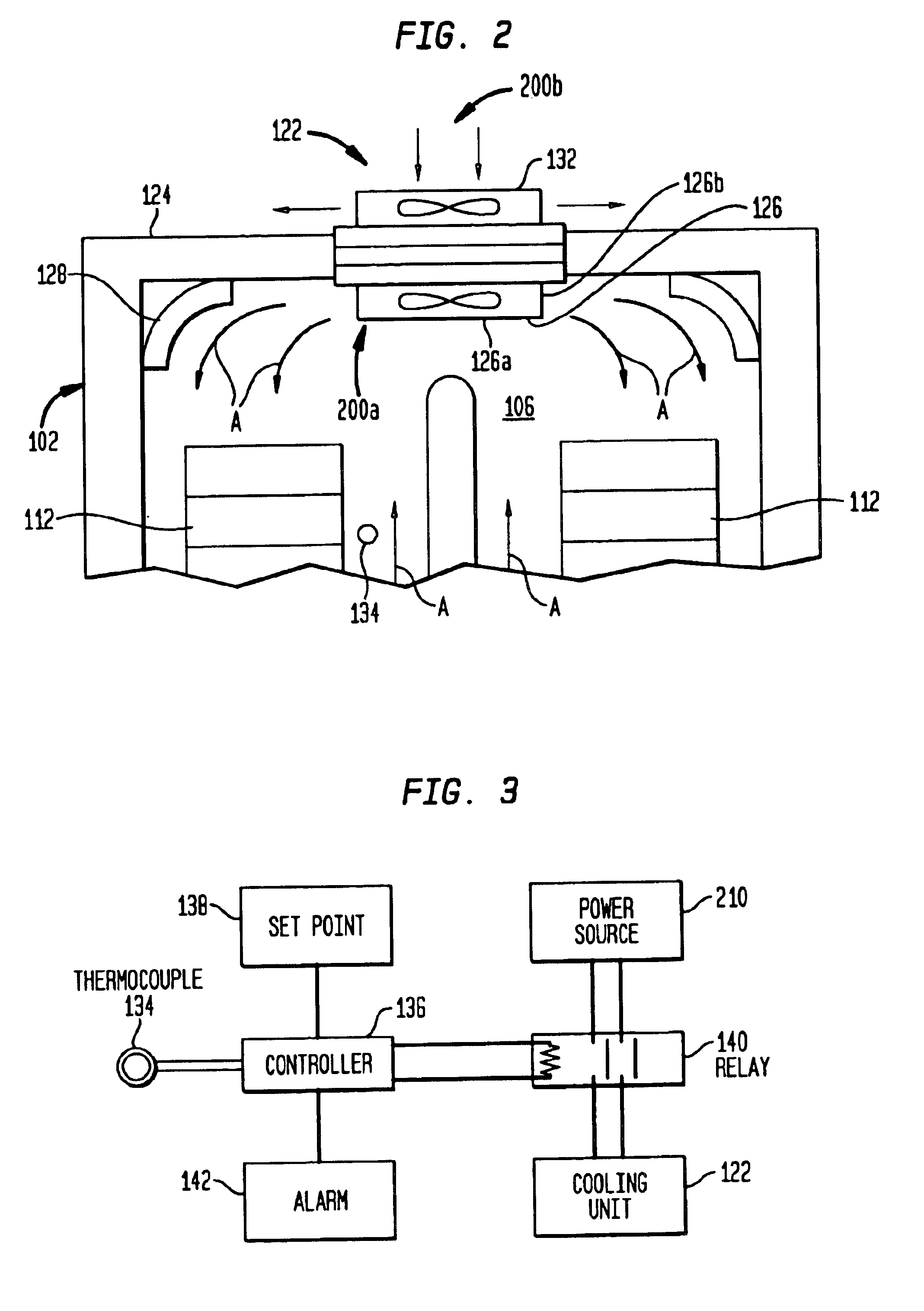

Switch cupboard with a cooling device which is subject to a rotation and cooling device for this

Owner:PFANNENBERG GMBH

Thermoelectric configuration employing thermal transfer fluid flow(s) with recuperator

ActiveUS20060137360A1High thermoelectric efficiencyHigh heat fluxMachines using electric/magnetic effectsCold sideActive cooling

Active cooling technologies such as thermoelectrics can be used to introduce thermal “gain” into a cooling system and, when employed in combination with forced flow liquid metal cooling loops, can provide an attractive solution for cooling high heat flux density devices and / or components. In such configurations, it can be advantageous to configure fluid flows to provide heat transfer between hot-side and cold-side flows. For example, it can be desirable to substantially equilibrate temperature of liquid metal flows entering hot-side and cold-side paths. In this way, thermal differential (ΔT) across individual thermoelectric elements can be reduced, thereby improving efficiency of the thermoelectric. Various suitable recuperator designs are described including designs that provide heat exchange with and without mixture of respective flows.

Owner:SHEETAK INC

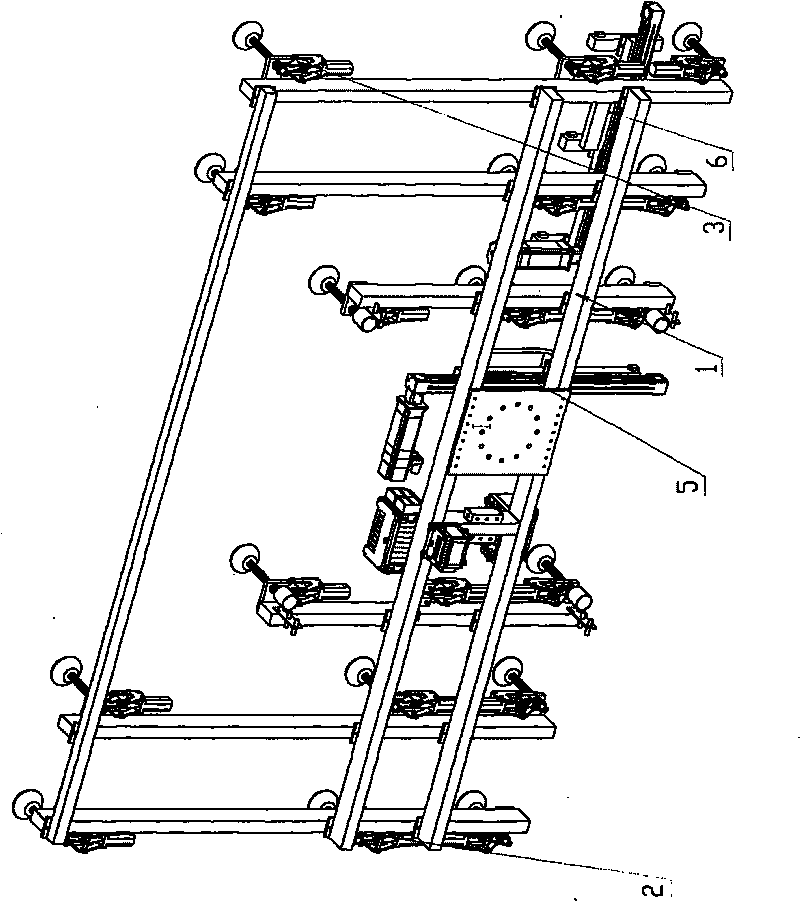

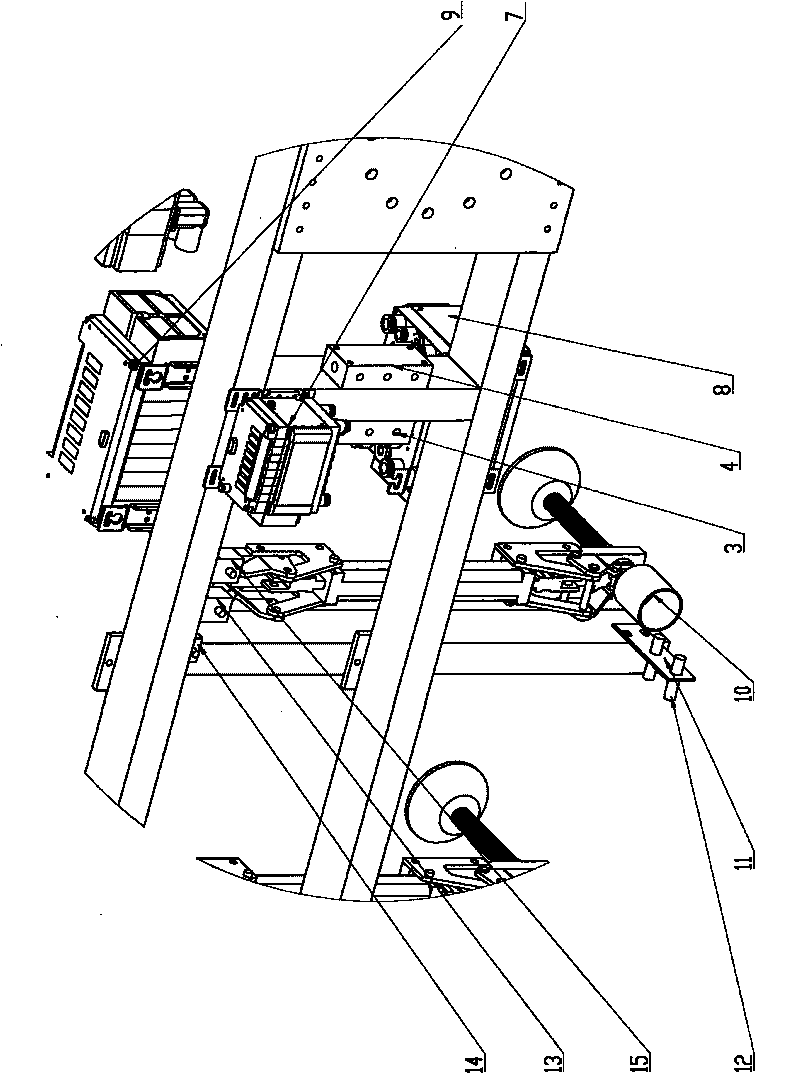

Sucking disc assembling bracket for float glass production line cold side glass stacking

ActiveCN101723182ARelative position deviation correctionAvoid smashingGlass transportation apparatusCharge manipulationCold sideProduction line

The invention relates to a sucking disc assembling bracket for float glass production line cold side glass stacking, comprising a sucking disc bracket (1), a plurality of groups of sucking disc mechanisms (2), a set of two-point detection component (6), a set of one-point detection component (5) and four sets of anti-collision detection components (10, 11, 12); a plurality of groups of the sucking disc mechanisms (2) are arranged at the bottom part of the sucking disc bracket (1), each group of the sucking disc mechanism (2) comprises a bottom plate (2.1), a bracket(2.2), a movable plate (2.3),an air cylinder (2.4), a sucking disc (2.5), a sucking disc rod (2.6), a sucking disc rod guide sleeve (2.7), a guide sleeve fixed nut (2.8) and a spring (2.9); the two-point detection component (6) is laterally arranged at the bottom part of the sucking disc bracket (1); the one-point detection component (5) is longitudinally arranged at the bottom part of the sucking disc bracket (1), and four sets of the anti-collision detection components are arranged on the sucking disc bracket (1) in a rectangle way. The sucking disc assembling bracket for float glass production line cold side glass stacking can automatically suck the glass, after suction is carried out, the glass is detected and placed on the bracket, and the anti-collision detection is carried out in the whole process.

Owner:JIANGSU JINMING IND ROBOT AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com