Sucking disc assembling bracket for float glass production line cold side glass stacking

A float glass and production line technology, applied in the field of palletizers, can solve the problems of broken glass, heavy weight of a single piece of glass, and difficulty in manual adjustment, and achieve the effects of preventing breakage, improving yield, and ensuring connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

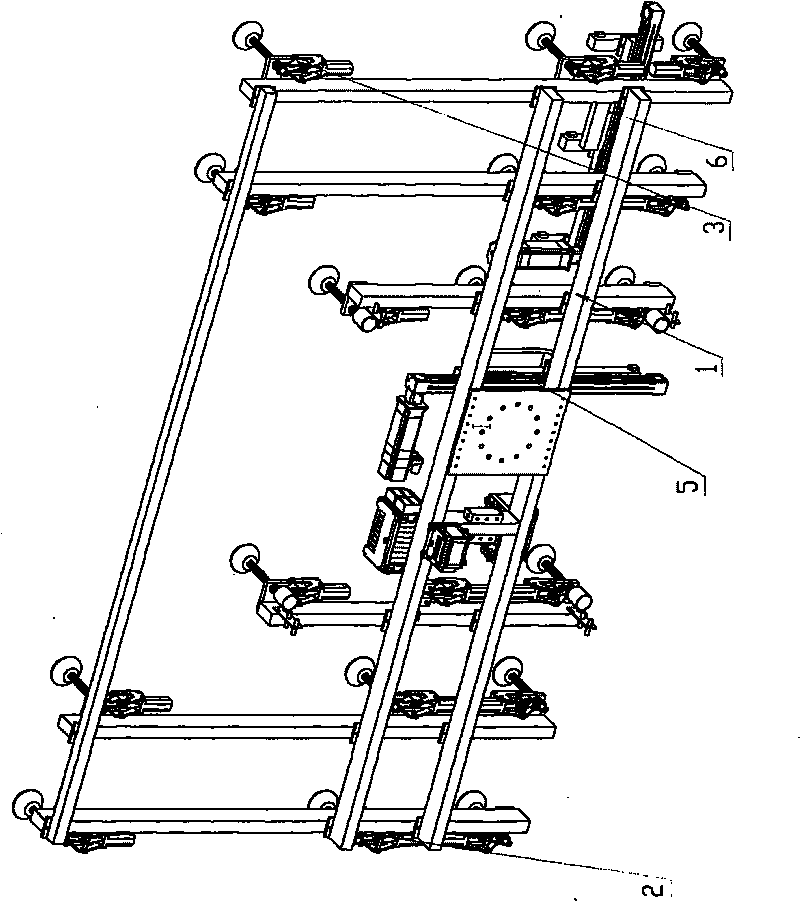

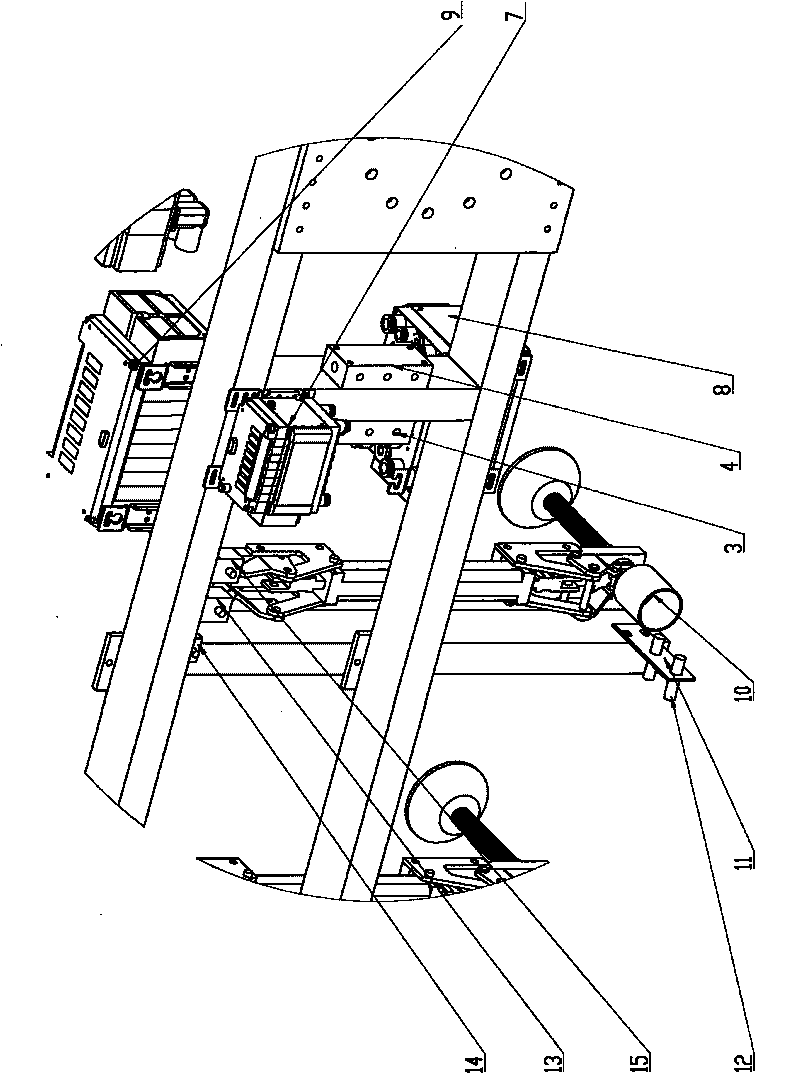

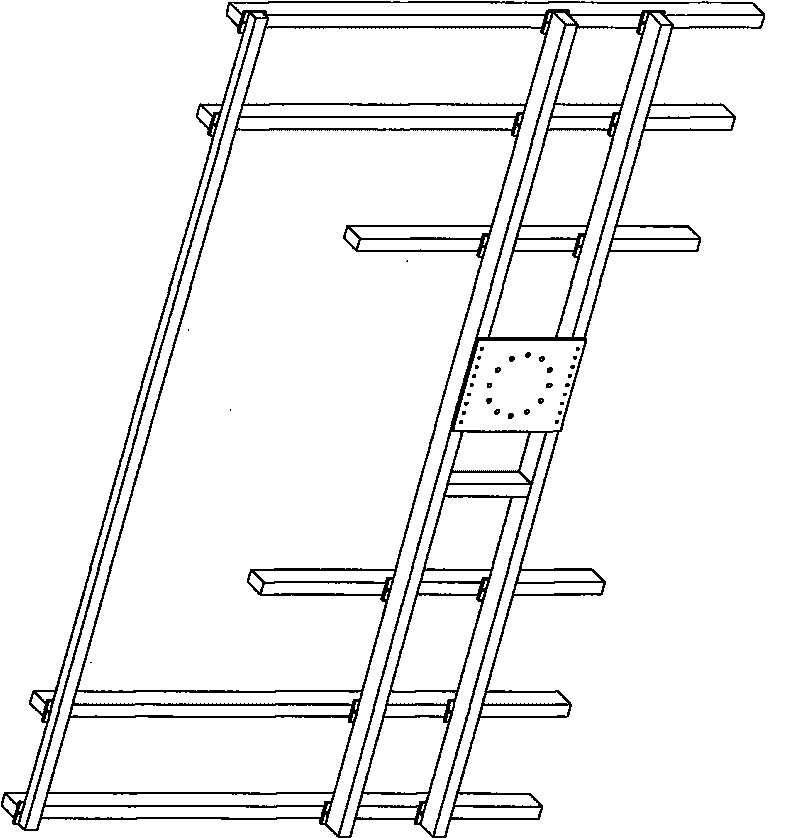

[0031] see Figure 1~2 , figure 1 It is a schematic diagram of the suction cup assembly frame used for palletizing glass at the cold end of the float glass production line according to the present invention. figure 2 for figure 1 A partial enlargement of the . Depend on figure 1 with figure 2 It can be seen that the suction cup assembly frame used for palletizing glass at the cold end of the float glass production line in the present invention includes a suction cup frame 1, eighteen sets of suction cup mechanisms 2, a first air circuit board 3, a second air circuit board 4, a A group of valve islands 7, a second group of valve islands 8, a third group of valve islands 9, a set of two-point detection components 6, a set of one-point detection components 5, four sets of anti-collision detection components 10, 11, 12 and three pressure And vacuum detection elements 13,14,15. The eighteen groups of sucker mechanisms 2 are all mounted on the bottom of the sucker frame 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com