Patents

Literature

2040results about How to "Improve picking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

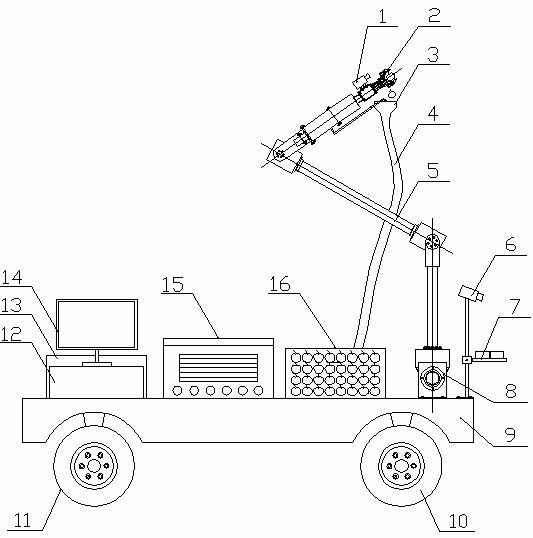

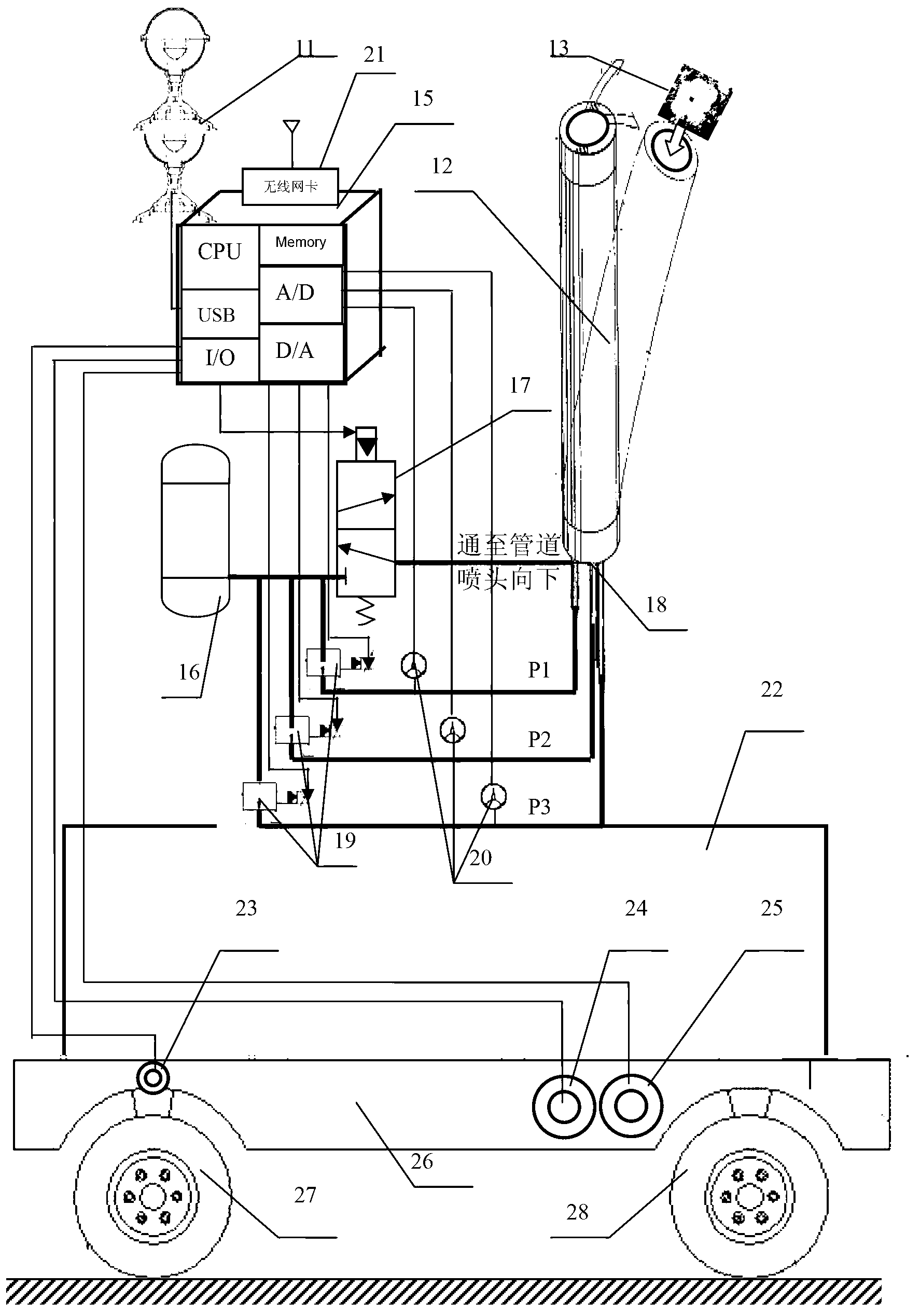

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

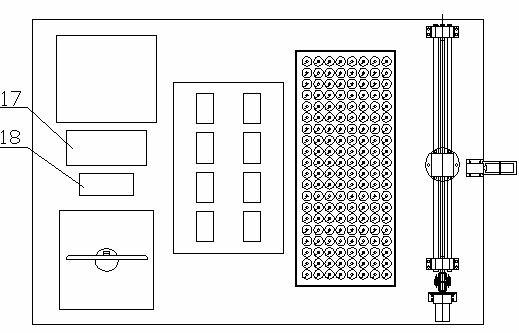

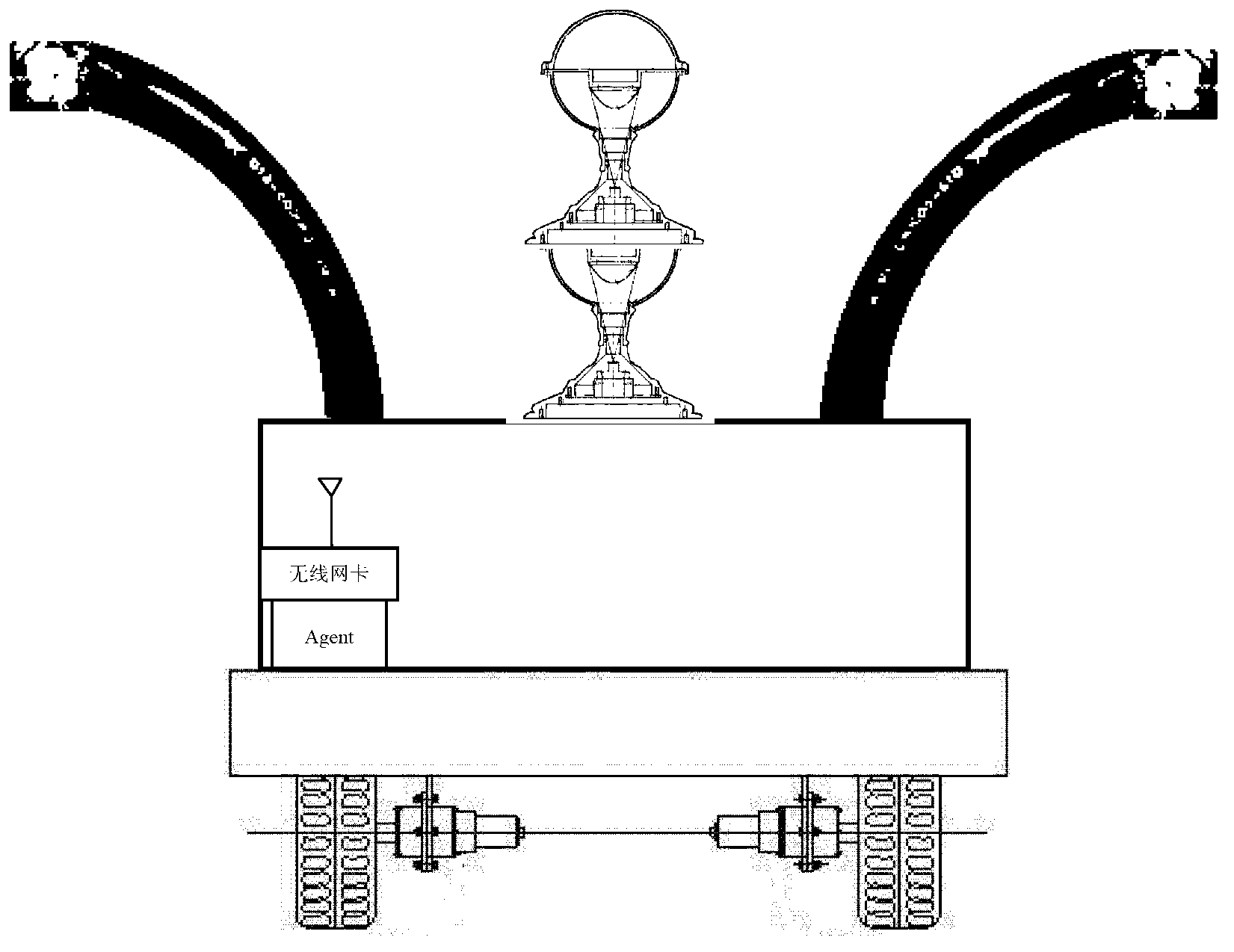

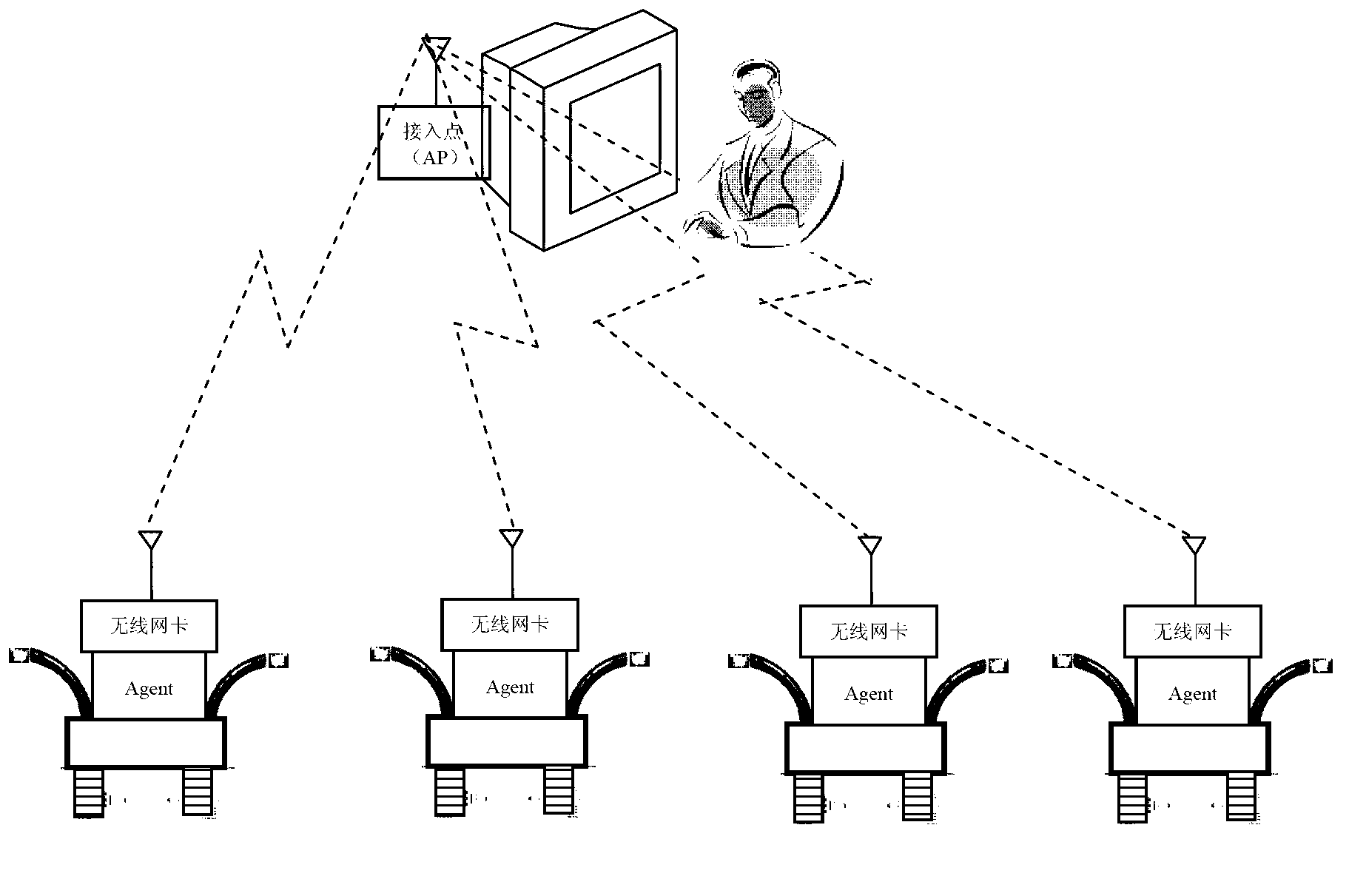

Autonomous navigation and man-machine coordination picking operating system of picking robot

ActiveCN102914967AImprove practicalityReduce the level of intelligent control requiredPicking devicesAdaptive controlStereoscopic videoMan machine

An autonomous navigation and man-machine coordination picking operating system of a picking robot comprises a travelling unit of the picking robot, a picking robot arm, an Agent, a wireless sensor network, a computer and a panoramic stereoscopic visual sensor. The Agent has functions of autonomous navigation, obstacle avoidance, positioning and path planning and the like, the wireless sensor network is used for completing man-machine coordination picking information interaction, the computer is used for providing long-distance intervention and management for picking administrators during man-machine coordination picking operation, and the panoramic stereoscopic visual sensor is used for acquiring panoramic stereoscopic video images in a picking area. The autonomous navigation and man-machine coordination picking operating system of the picking robot is fine in natural flexibility, simple in mechanism, low in control complexity, limited intelligent, high in picking efficiency, fine in environmental adaptation, and low in manufacturing and maintenance costs., Picking objects and crop are not damaged during picking.

Owner:ZHEJIANG UNIV OF TECH

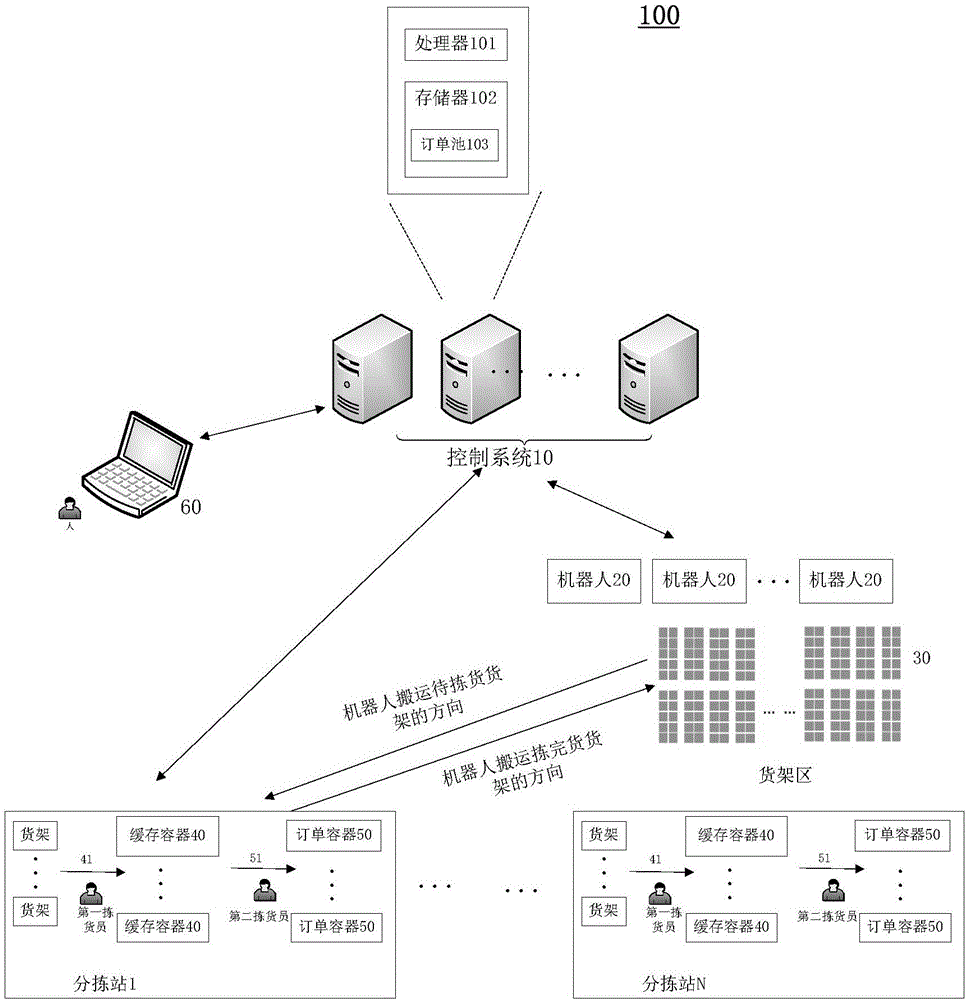

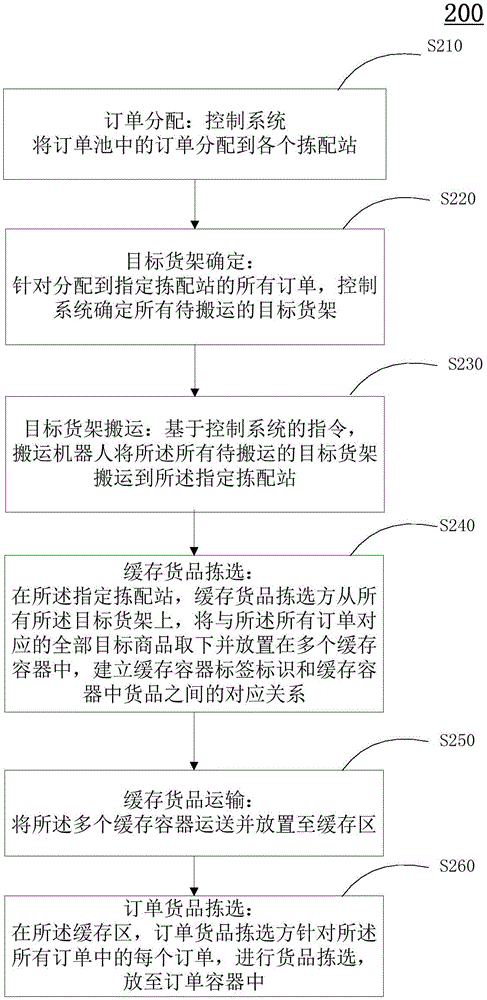

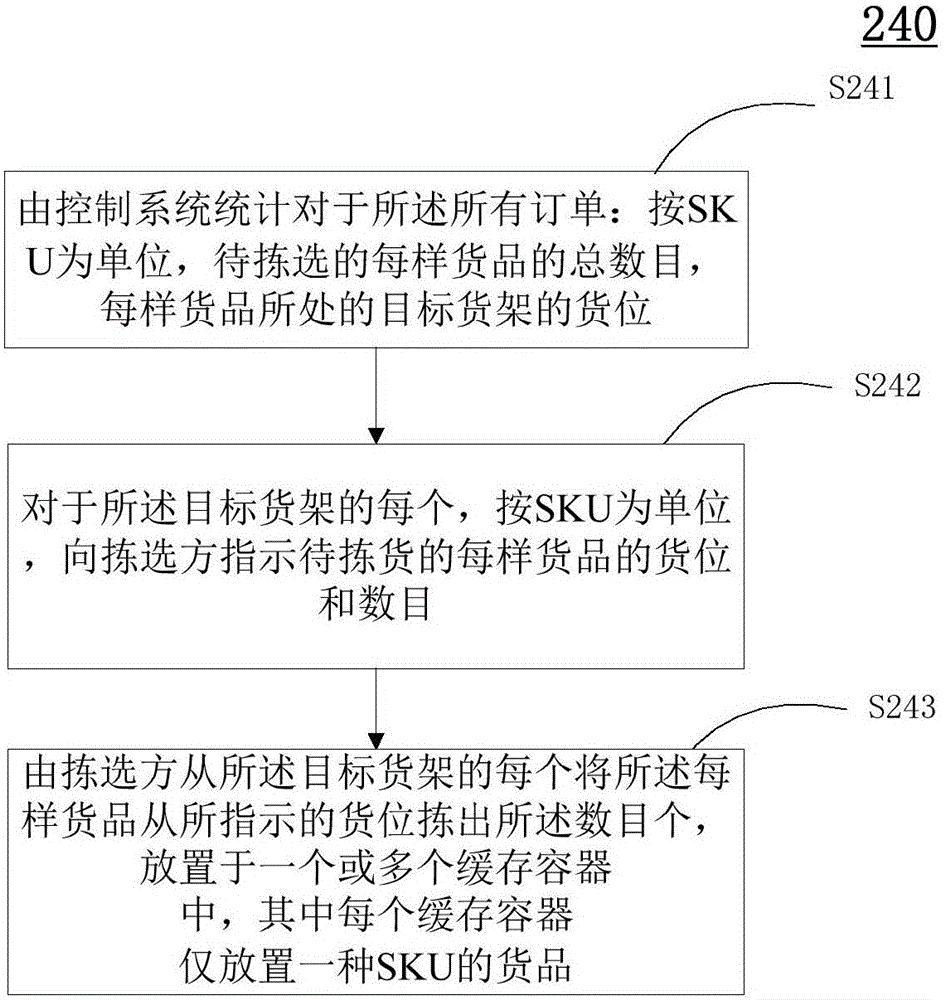

Layering goods picking method and system and calculating device

ActiveCN106311615AReduce the frequency of repeated handlingShorten the transportation distanceSortingControl systemTransport engineering

The invention discloses a layering goods picking method and system and a calculating device, wherein in the layering goods picking method, robots are utilized, and a goods-to-man manner is adopted. The goods picking method comprises the steps that orders in order pools are distributed to all picking and distributing stations; according to all the orders distributed to the designated picking and distributing stations, control systems determine target goods shelves to be carried; the target goods shelves are carried to the designated picking and distributing stations through the transfer robots; at the designated picking and distributing stations, a buffer goods picking party takes down all target goods corresponding to all the orders from all the target goods shelves and places the target goods in a plurality of buffer containers, and the corresponding relationship between labels of the buffer containers and goods in the buffer containers is built; the multiple buffer containers are conveyed to and placed in a buffer area; and in the buffer area, an order goods picking party carries out goods picking according to each order, and the goods are placed in order containers. By means of the above layering picking manner that order picking is carried out after buffer picking, the repeated carrying frequency of the goods shelves is greatly reduced, the carrying distance is greatly shortened, and the order picking efficiency is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

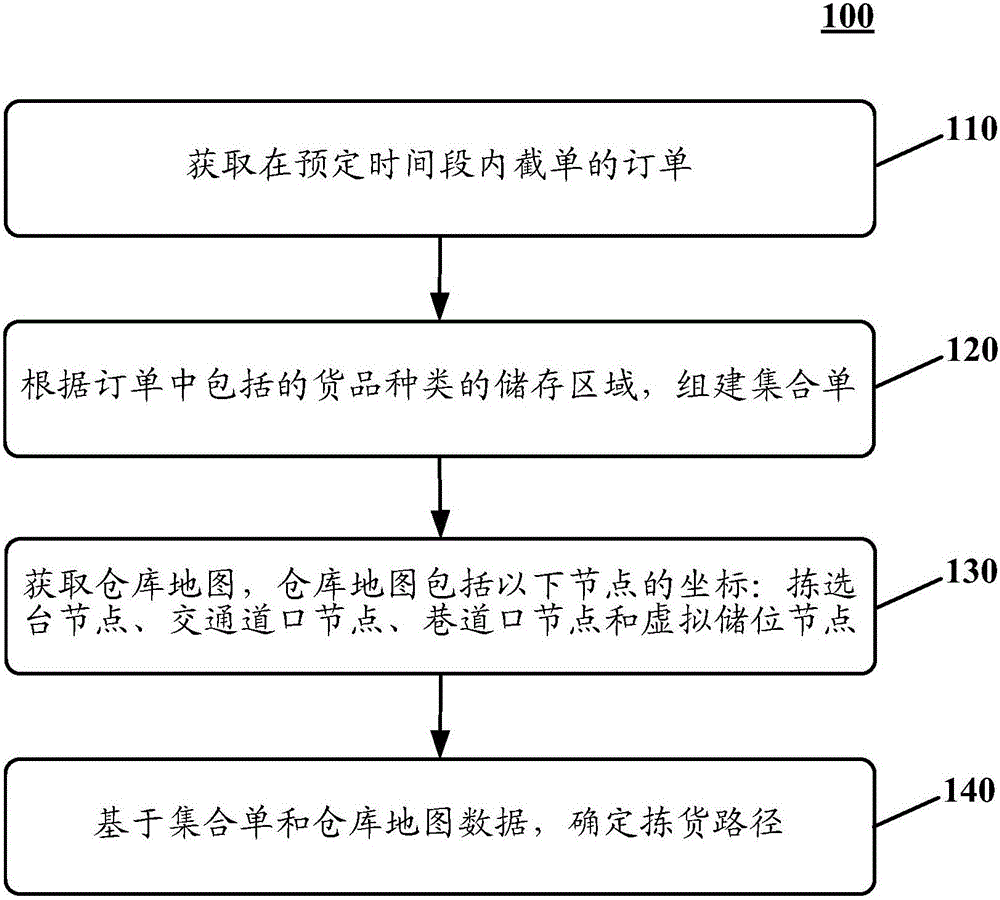

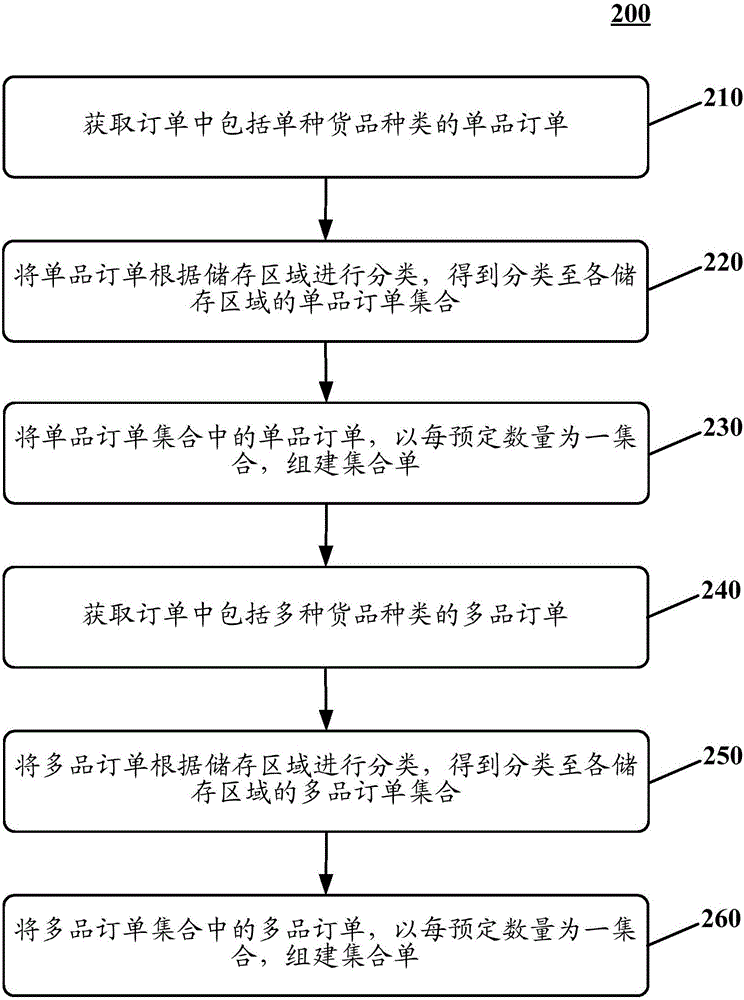

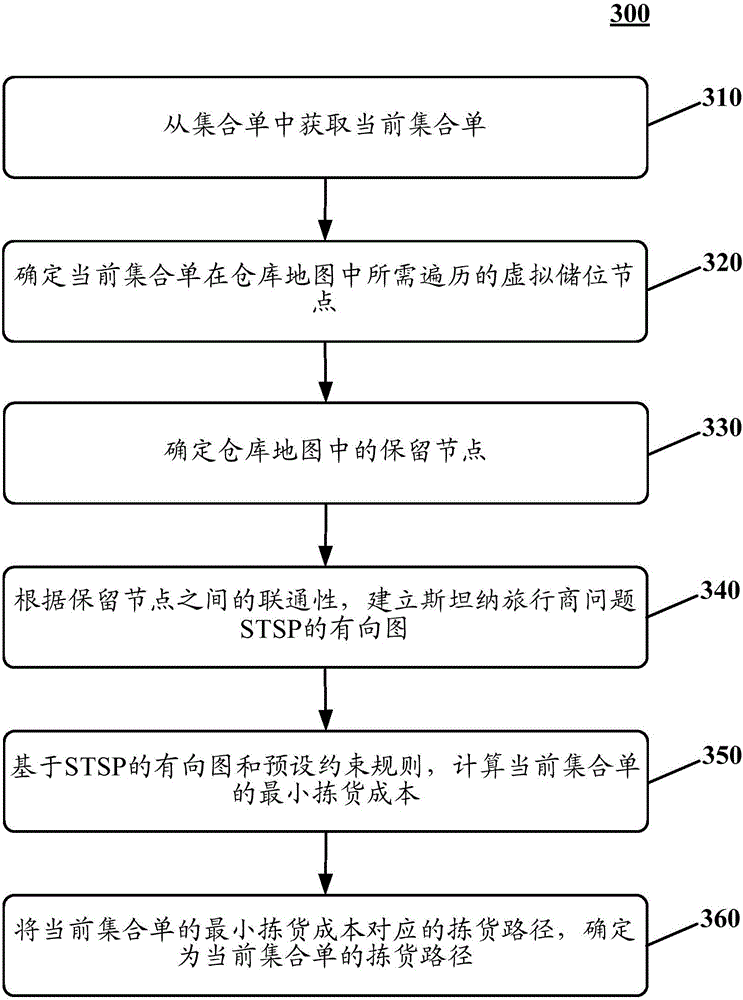

Method and device used for determining picking route

ActiveCN106809586AImprove total picking efficiencyReduce picking costsLogisticsStorage devicesProduct typeComputer science

The invention discloses a method and device used for determining a picking route. The method comprises the steps that orders cut off in a preset time period are obtained; an aggregation order is built according to storage areas of product types contained in the orders; a warehouse map is obtained, wherein the warehouse map comprises coordinates of following nodes including the picking table node, the traffic crossing node, the alley crossing node and the virtual storage location node; based on the aggregation order and the warehouse map, the picking route is determined. By means of the method, the aggregation order is built according to the storage areas of the product types, and when conducting order picking according to the aggregation order, the required picking route is short, so that the picking cost of the picker is reduced and the picking efficiency of the picker is improved; the picking route is determined based on the aggregation order and the warehouse map so that it can be determined that the route from which storage locations of products in the aggregation order are traversed is shortest, accordingly the total picking route is short, and the total picking efficiency of the warehouse is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

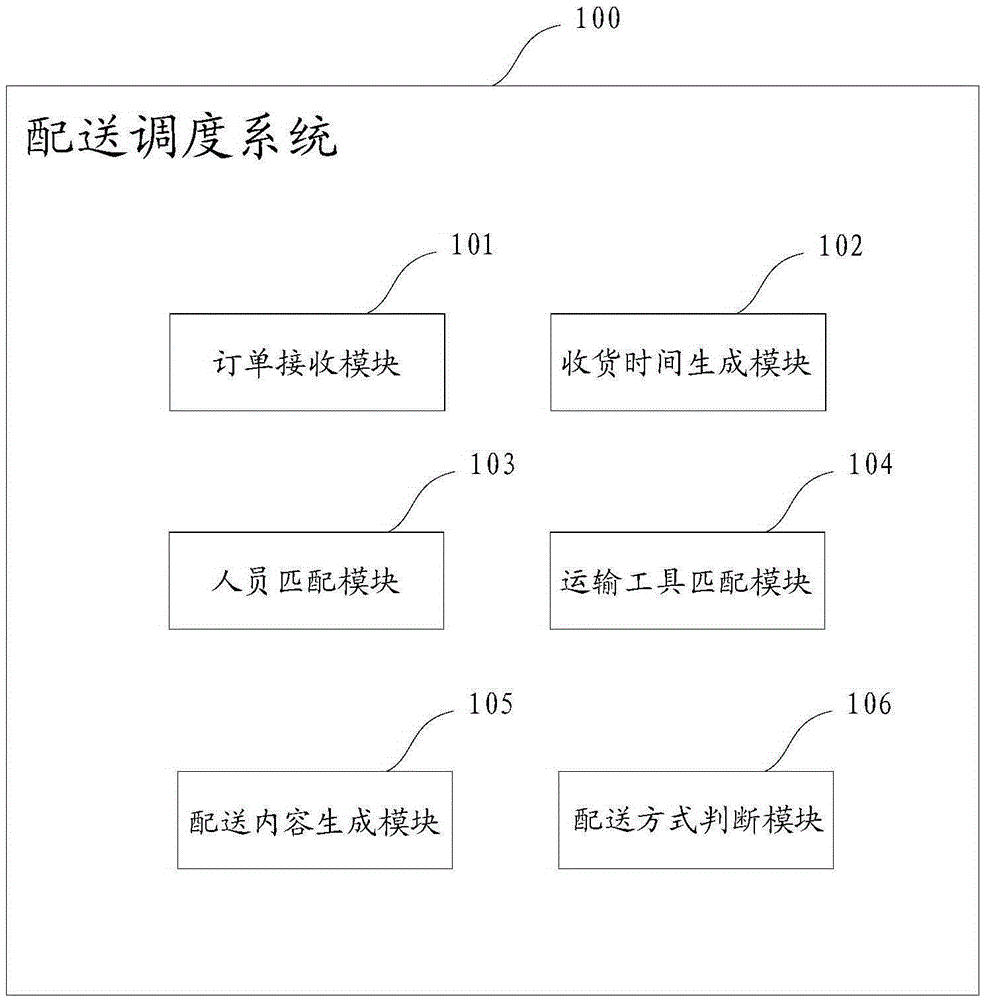

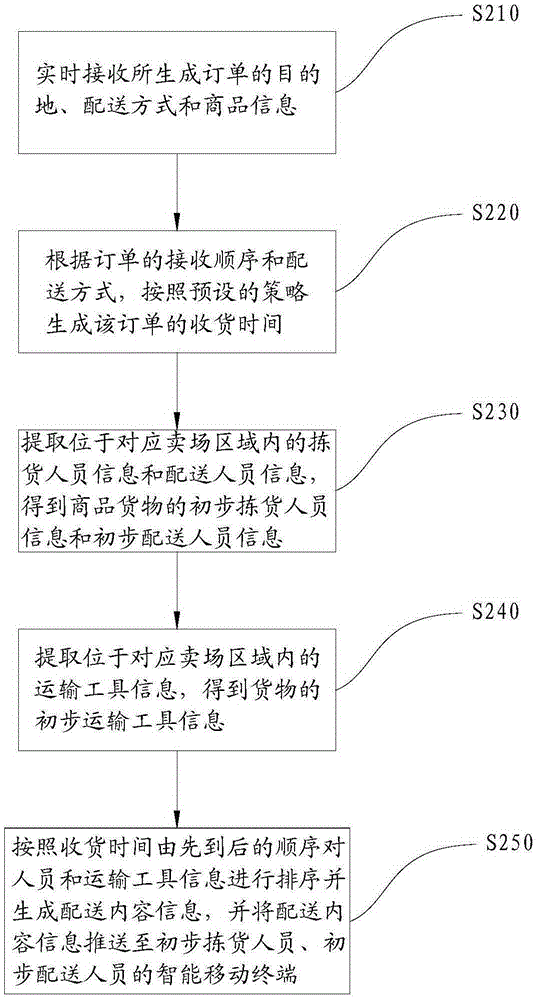

Delivery scheduling method and system based on O2O mode

ActiveCN105260873AReduce delivery costsReduce labor intensityLogisticsLogistics managementDelivery cost

The invention provides a delivery scheduling method and system based on the O2O mode. The method comprises the following steps that the scheduling system receives a destination, a delivery mode and commodity information of a generated order in real time; delivery taking time of the order is generated in a preset strategy according to the reception sequence and delivery mode of the order; preliminary picking staff information and preliminary delivery staff information of the commodity are obtained according to the delivery taking time and the commodity information; preliminary transport means information of the commodity is obtained according to the destination, delivery mode, delivery taking time and commodity information; and according to sequence of the delivery taking time, the preliminary picking staff information, the preliminary delivery staff information and the preliminary transport means information are ordered, and delivery content information is generated and pushed to intelligent mobile terminals of preliminary picking and delivery staff. The method and system can be used to effectively improve the time efficiency and picking efficiency of delivery, reduces the logistics delivery cost to the largest extent, and greatly reduces mistake of orders.

Owner:多点生活(中国)网络科技有限公司

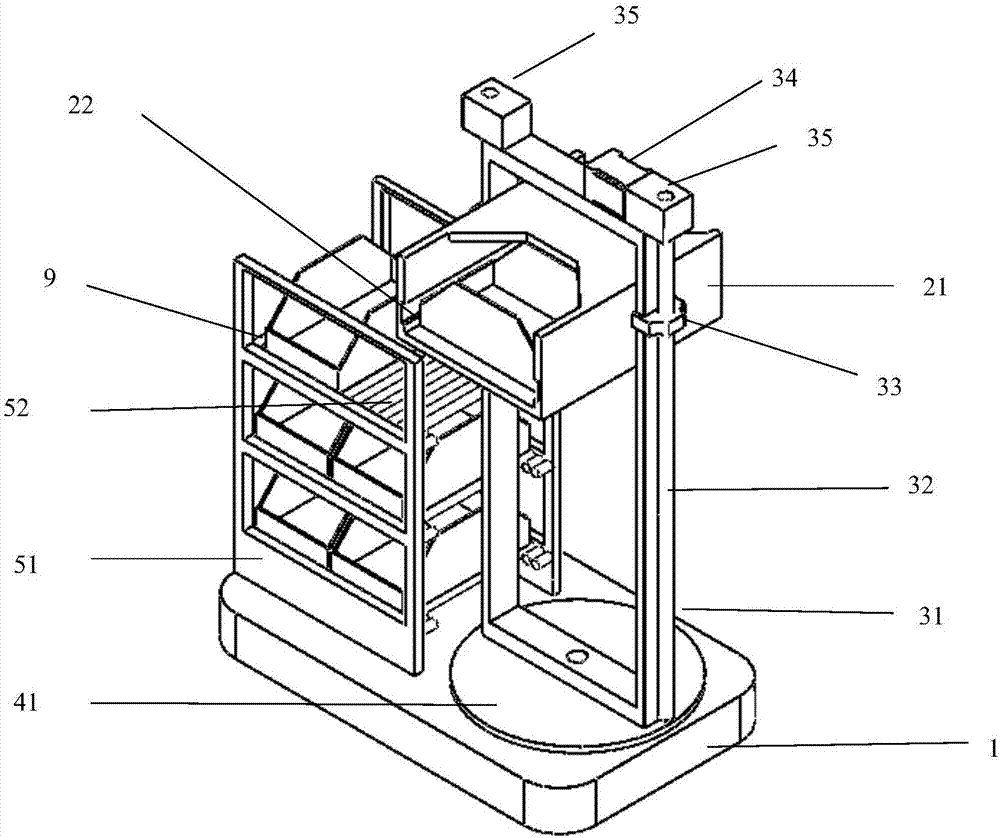

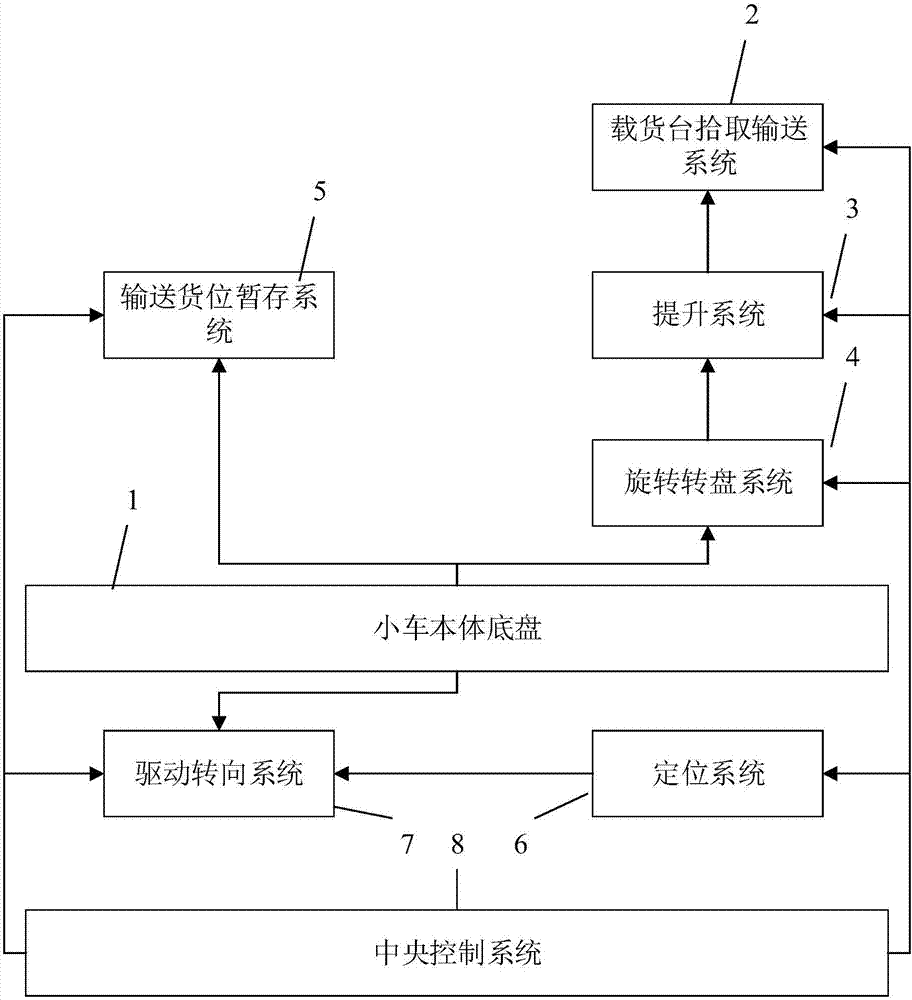

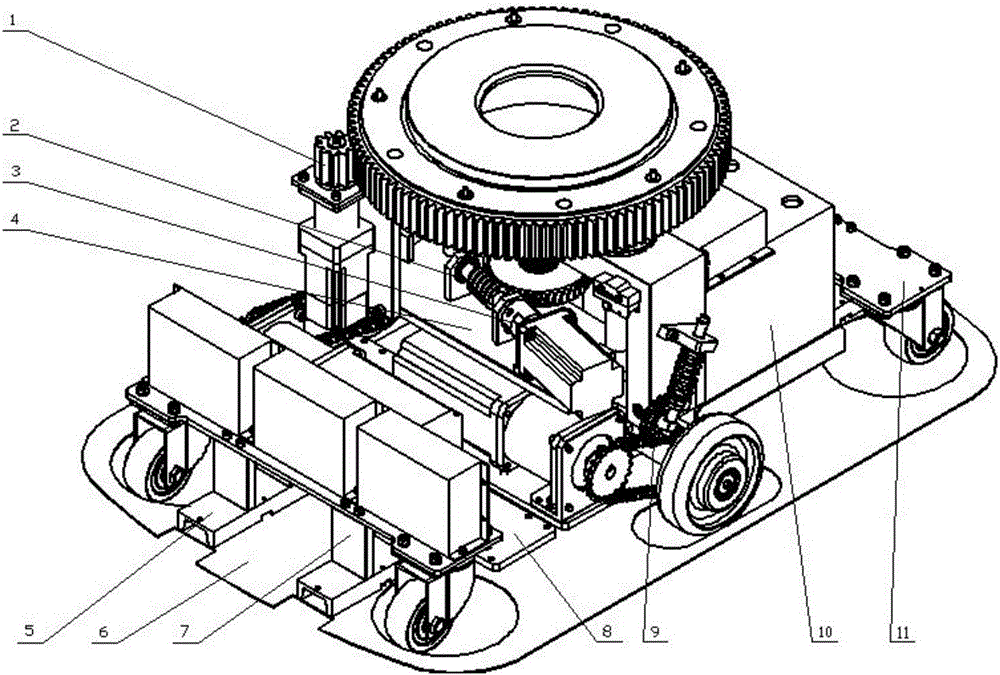

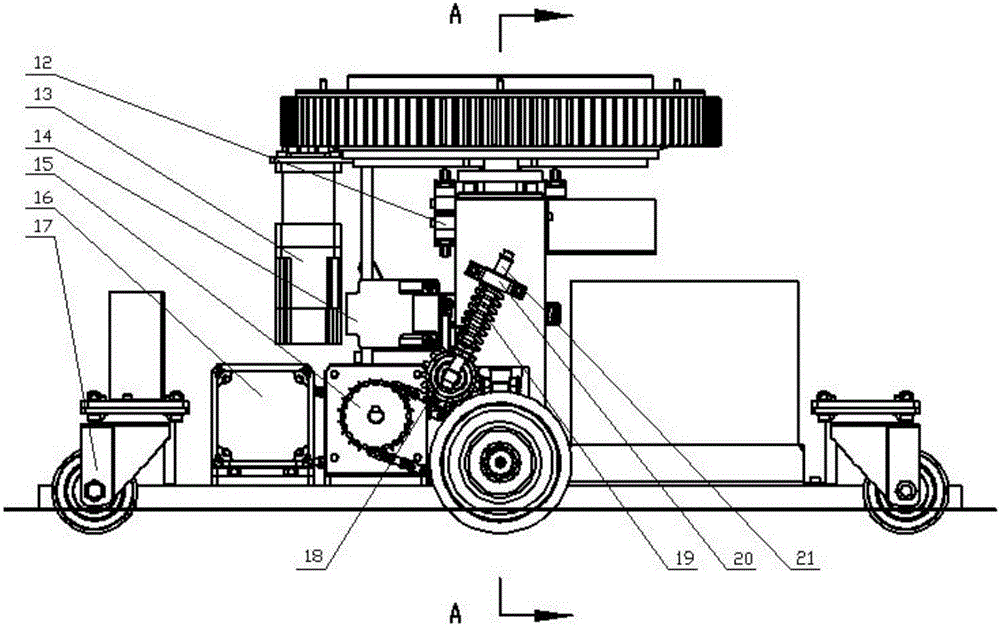

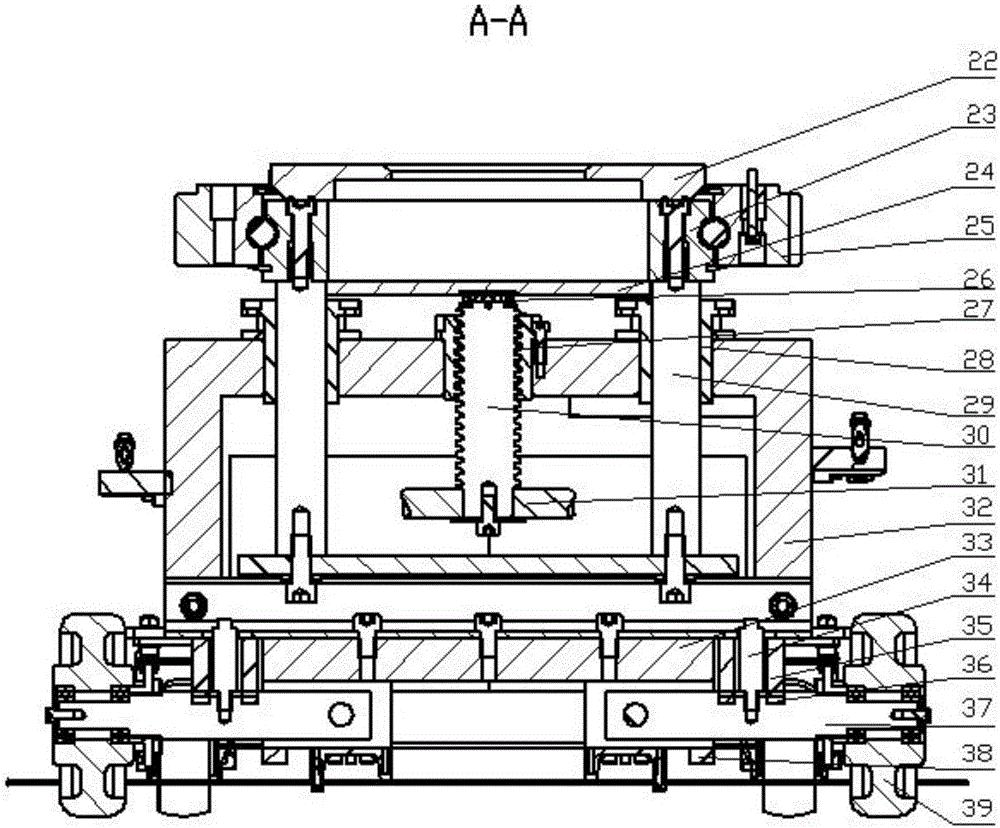

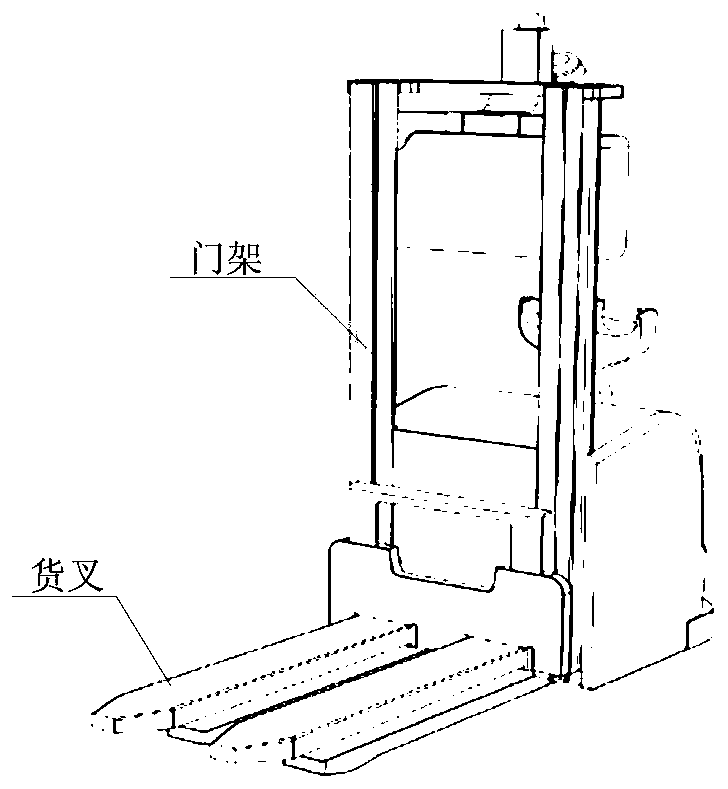

AGV (Automatic Guided Vehicle) and method

PendingCN107226310AImprove picking efficiencyImprove accuracyControl devices for conveyorsStorage devicesEngineeringTemporary storage

The invention discloses an AGV (Automatic Guided Vehicle) and a method. The AGV (Automatic Guided Vehicle) comprises a vehicle body chassis, a cargo bearing platform picking-up and conveying system, a lifting system, a rotary rotary-table system and a delivered cargo temporary storage system; the rotary rotary-table system and the delivered cargo temporary storage system are fixed to the two sides of the upper portion of the vehicle body chassis correspondingly; the lifting system is fixed to the upper portion of the rotary rotary-table system, and the control end of the lifting system is connected with the cargo bearing platform picking-up and conveying system; the delivered cargo temporary storage system comprises a plurality of layers of temporary storage racks, and each layer of the temporary storage racks is provided with a plurality of temporary storage cargo positions; and the lifting system is used for controlling the sliding height of the cargo bearing platform picking-up and conveying system, and the rotary rotary-table system is used for controlling the rotation angle of the lifting system. By means of the AGV (Automatic Guided Vehicle) and the method, operation of manual picking-up of workbins is omitted, manpower and time are saved, and meanwhile workbin picking-up efficiency and accuracy are also improved.

Owner:湖北九州云仓科技发展有限公司

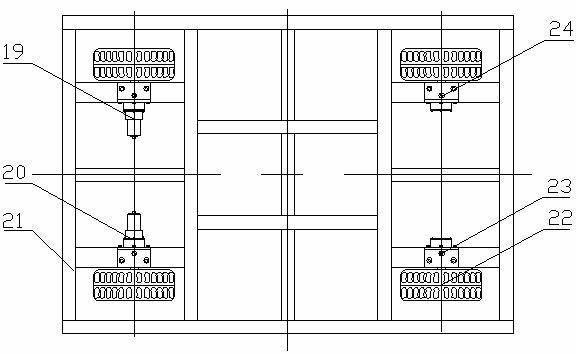

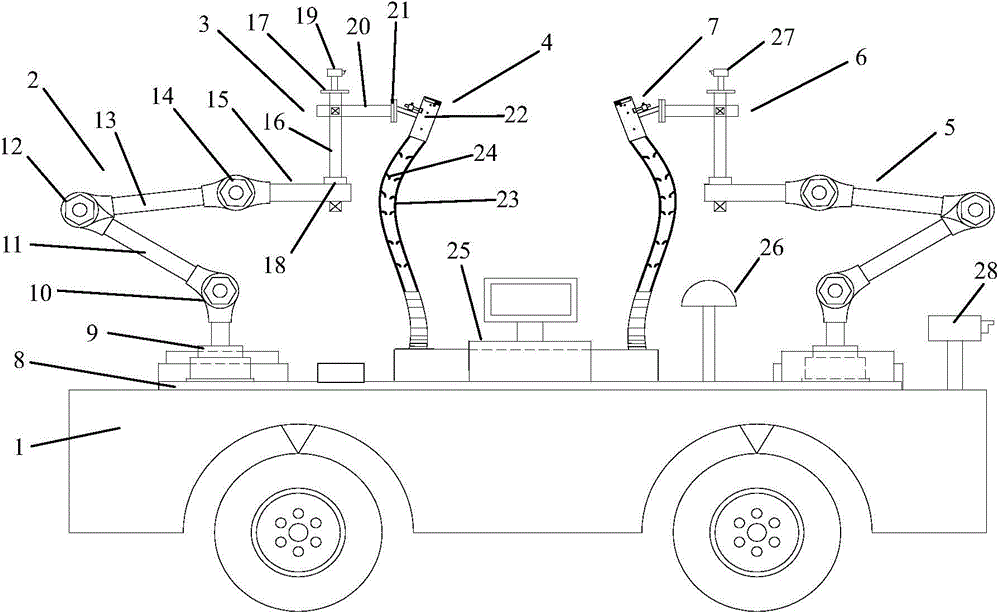

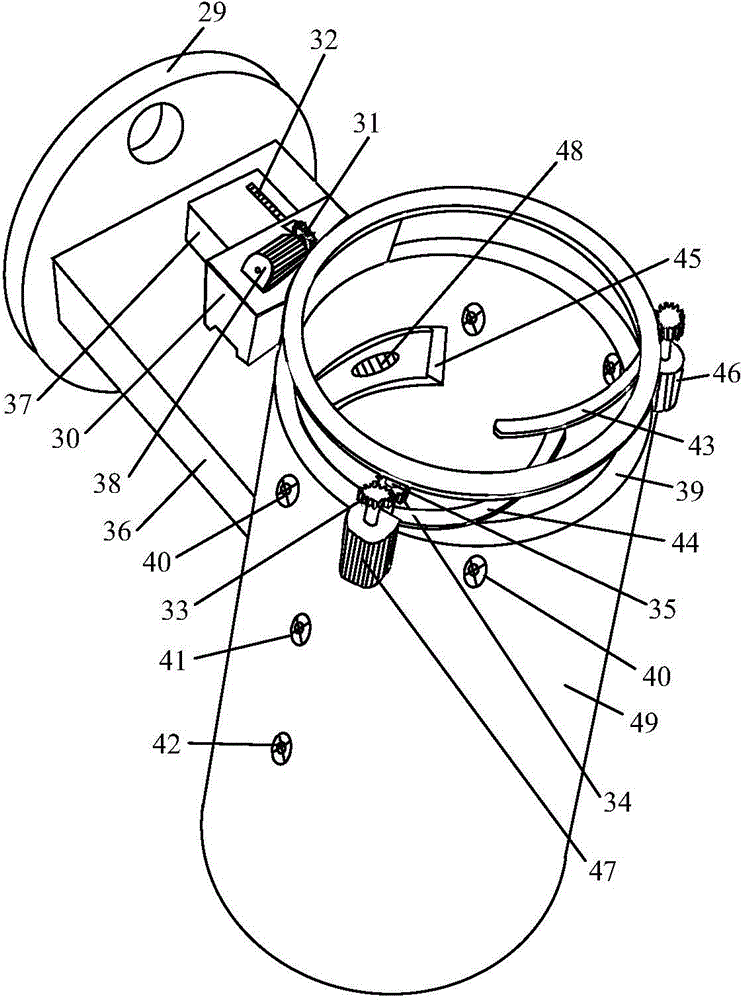

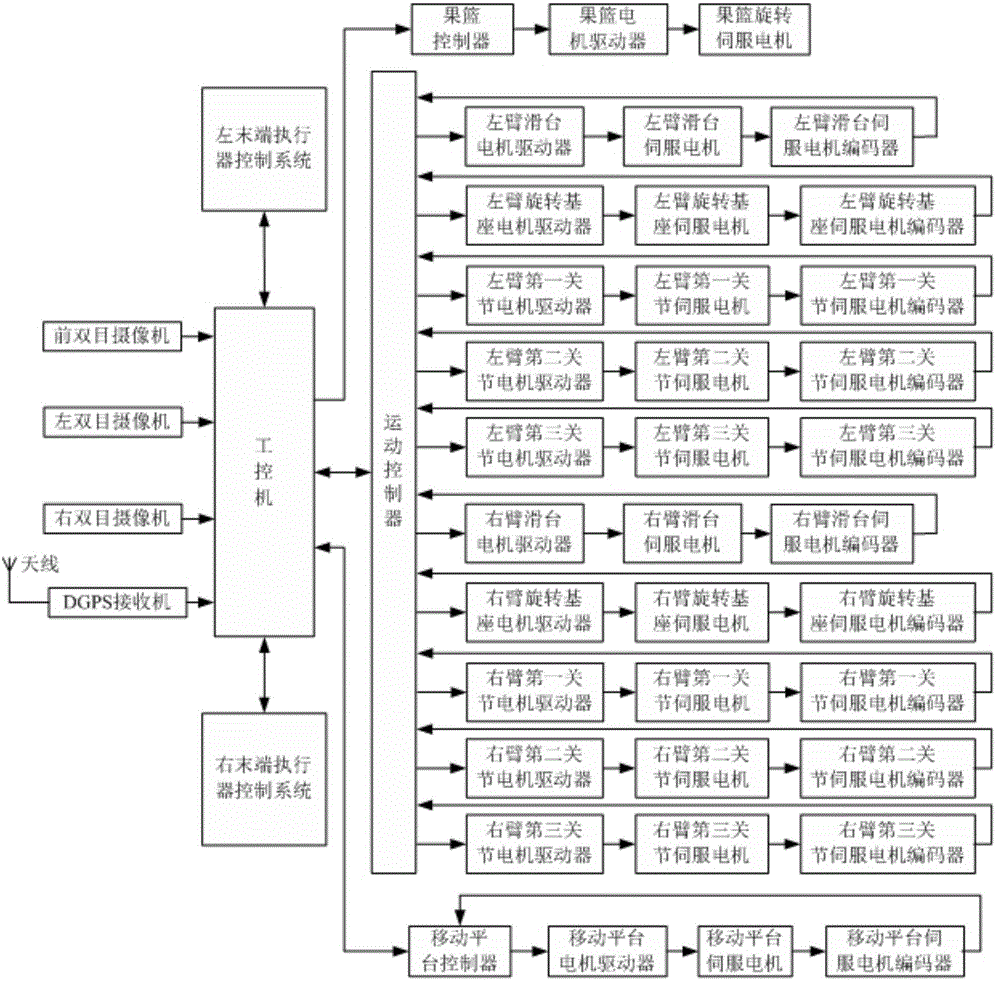

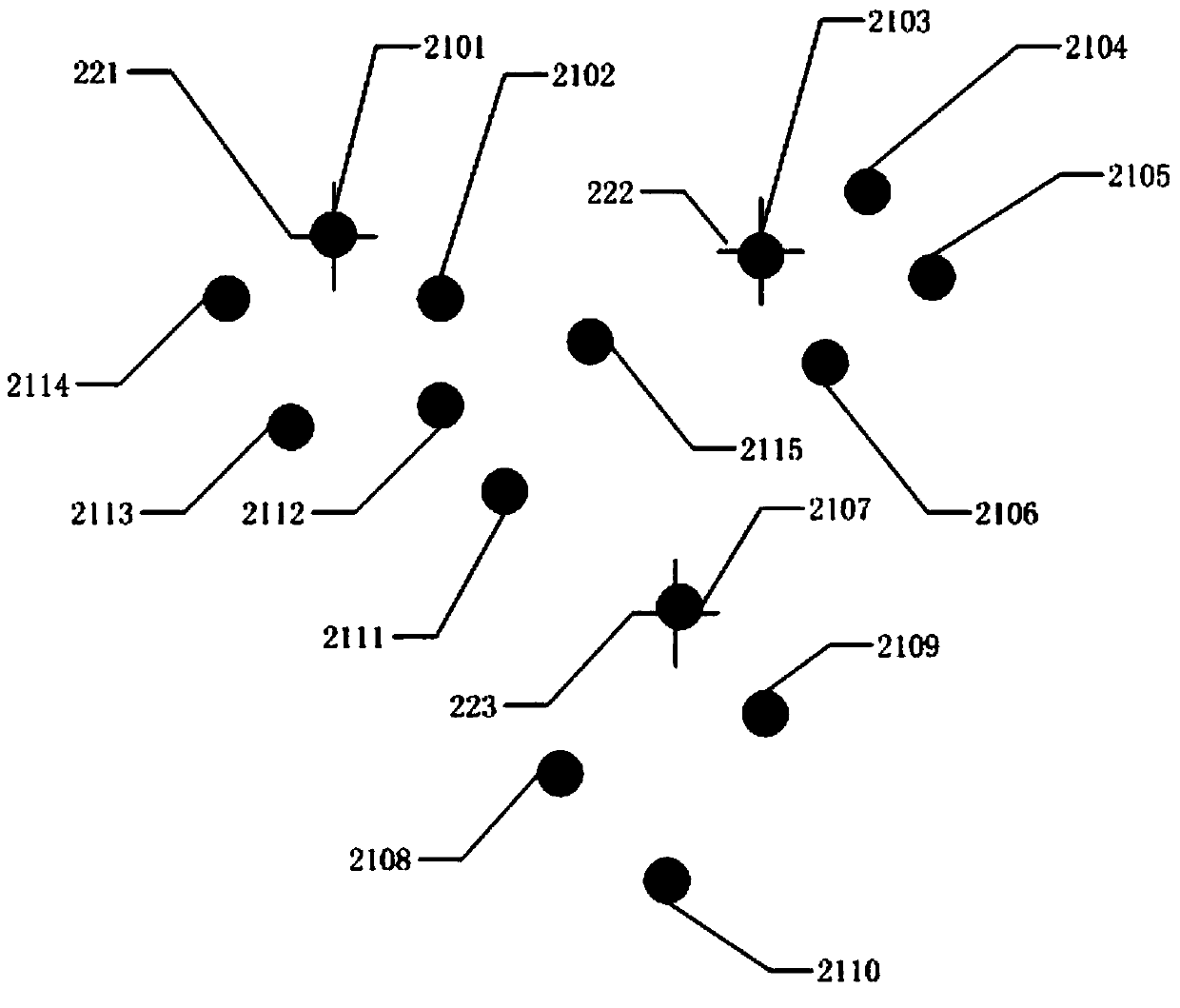

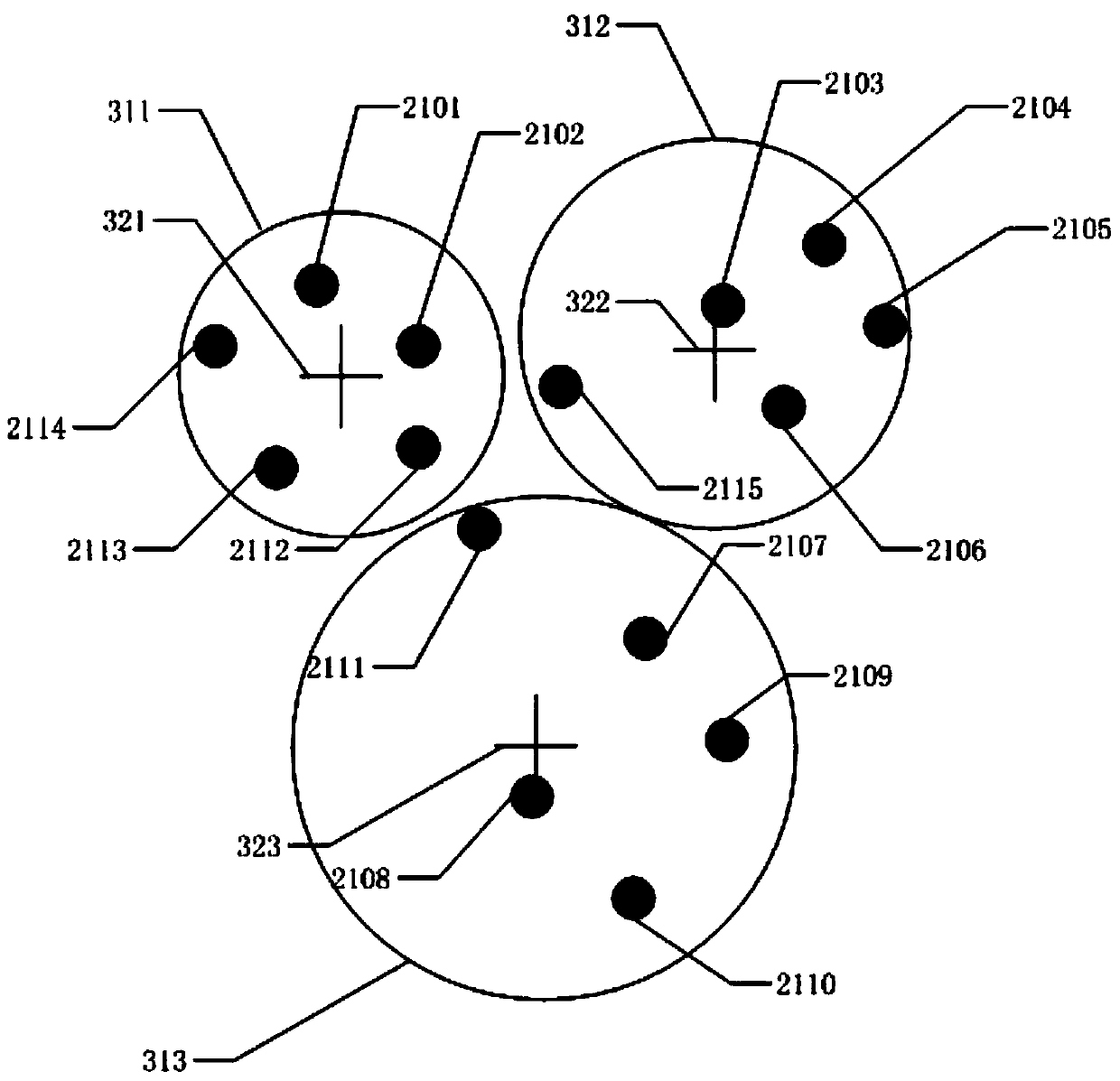

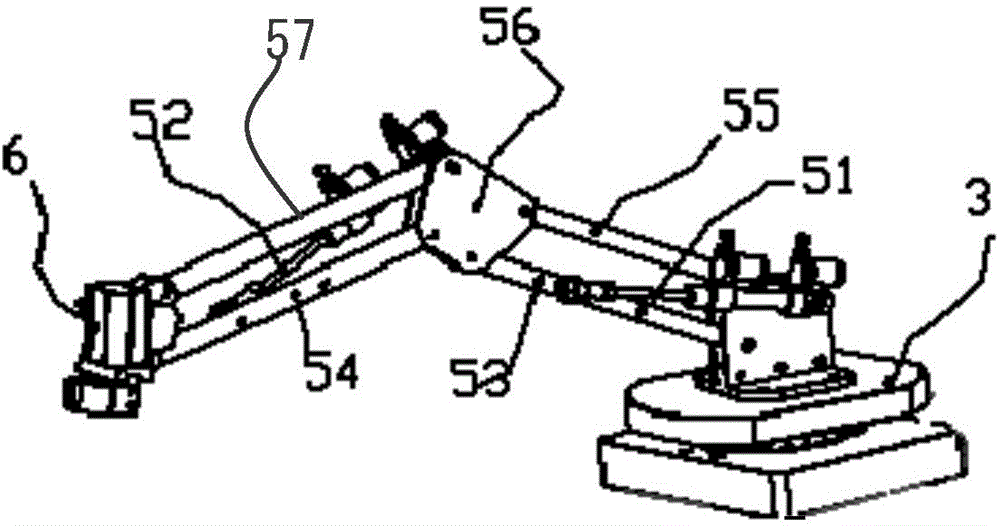

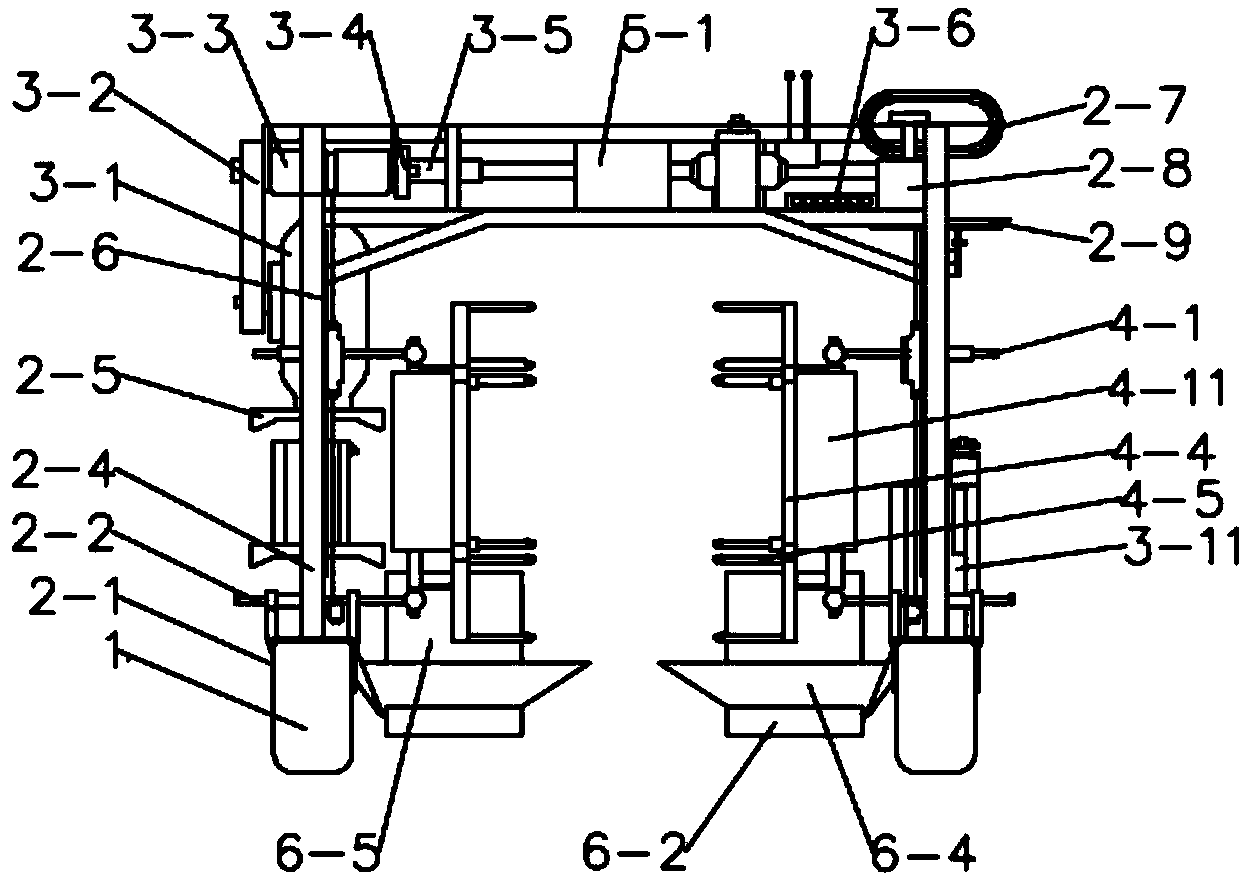

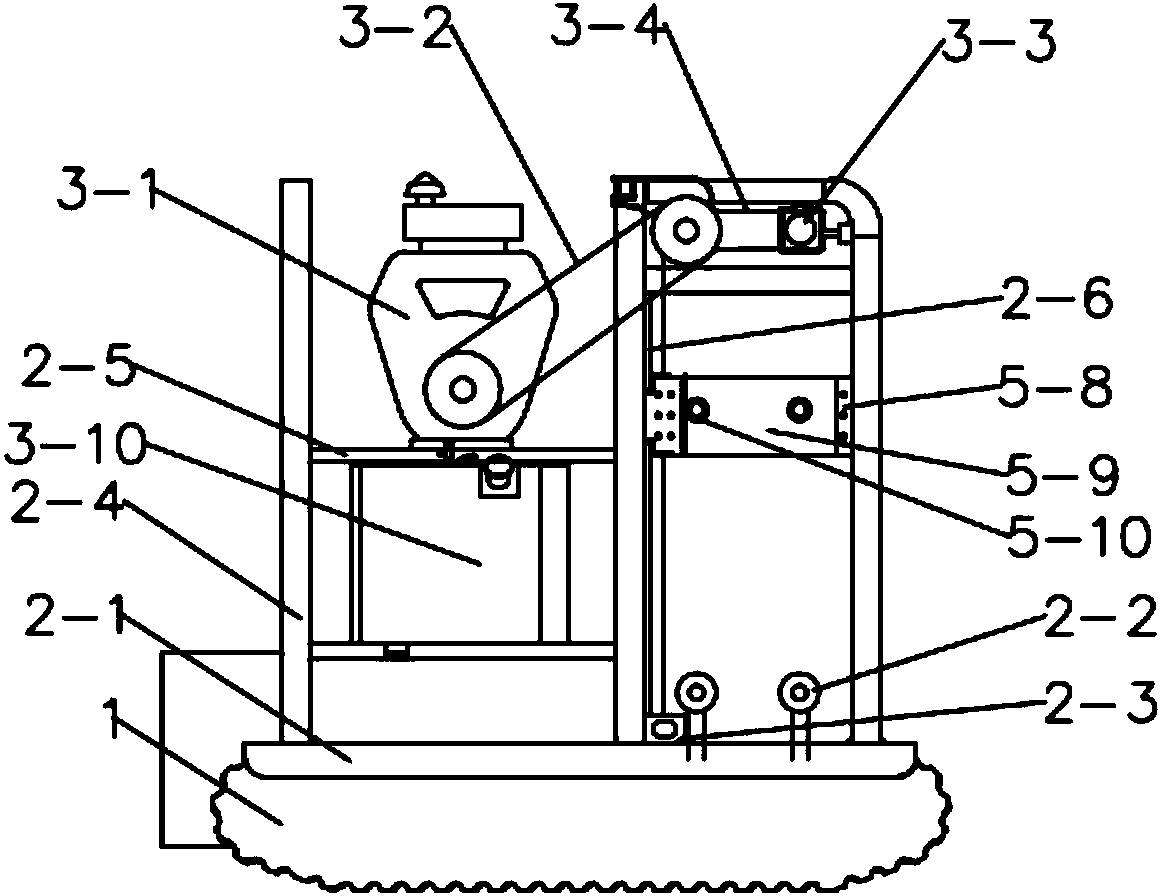

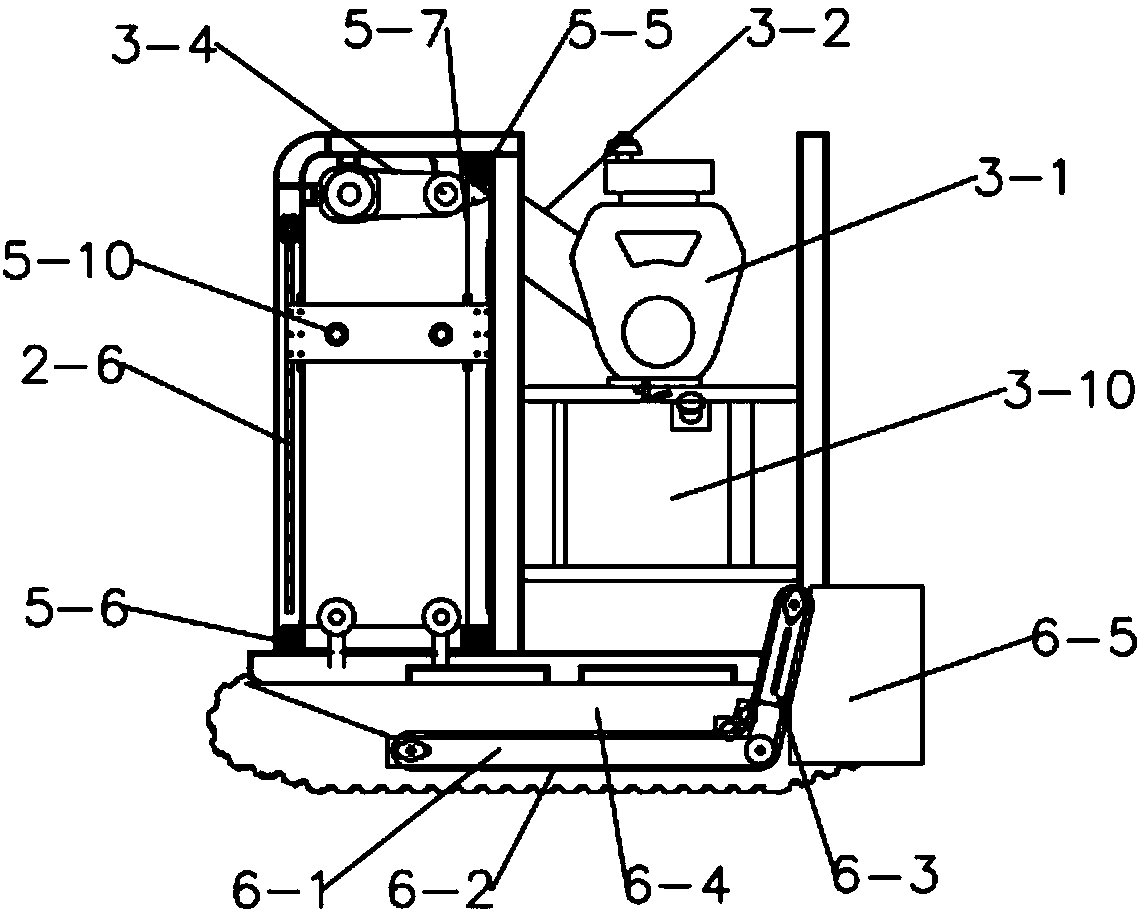

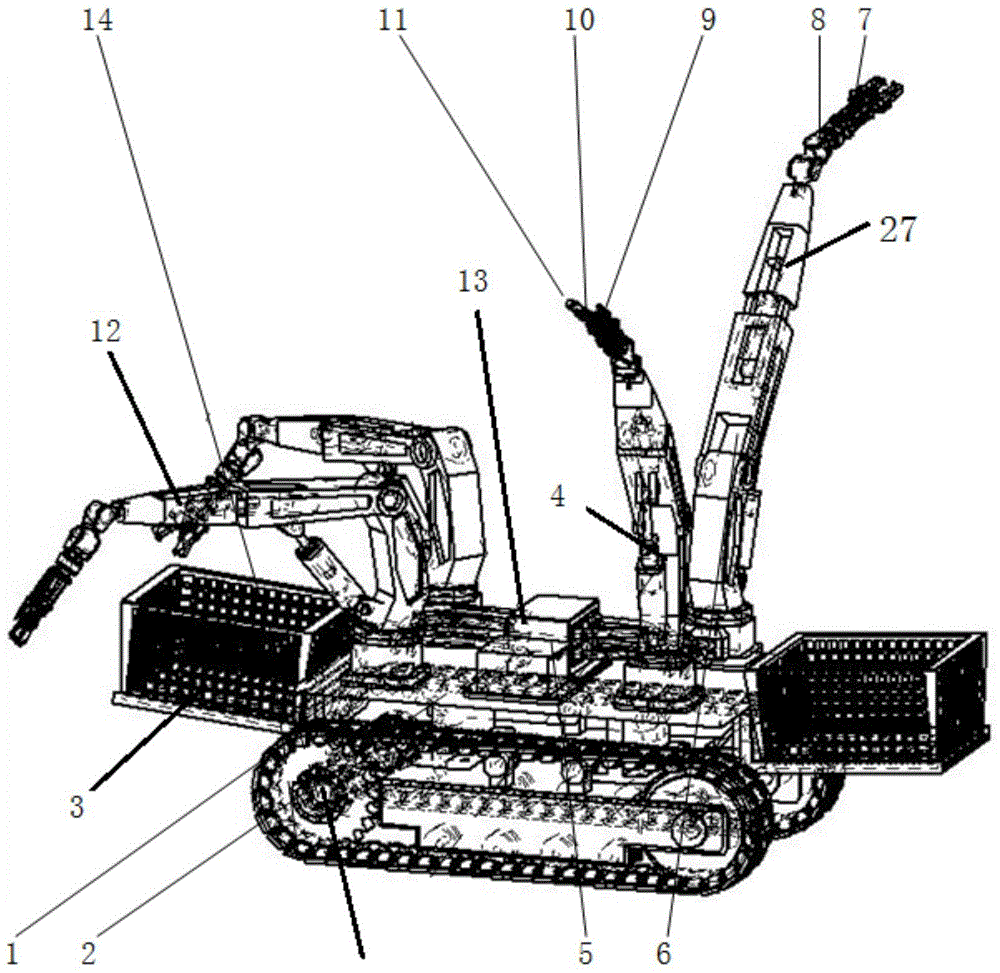

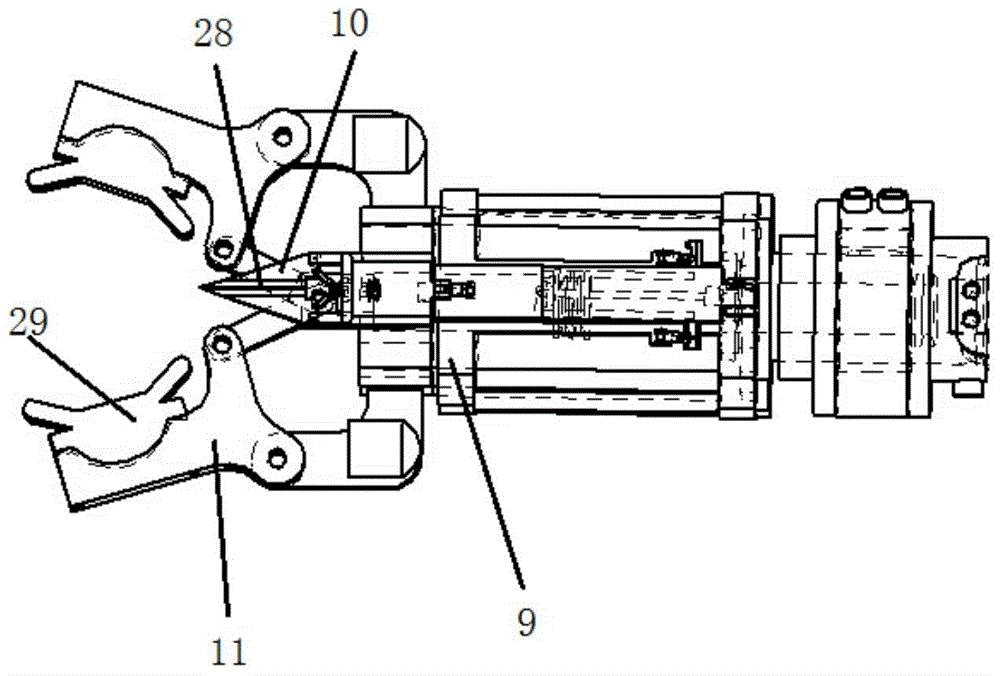

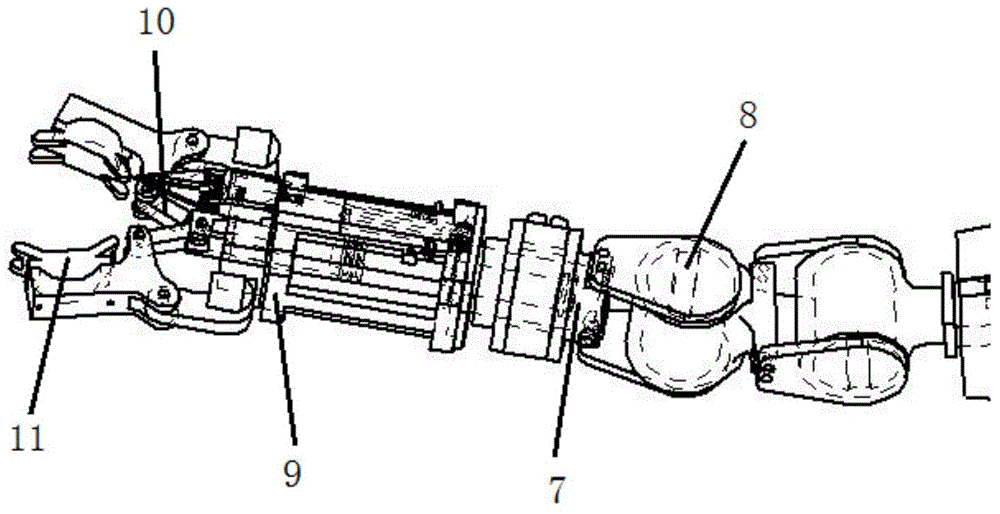

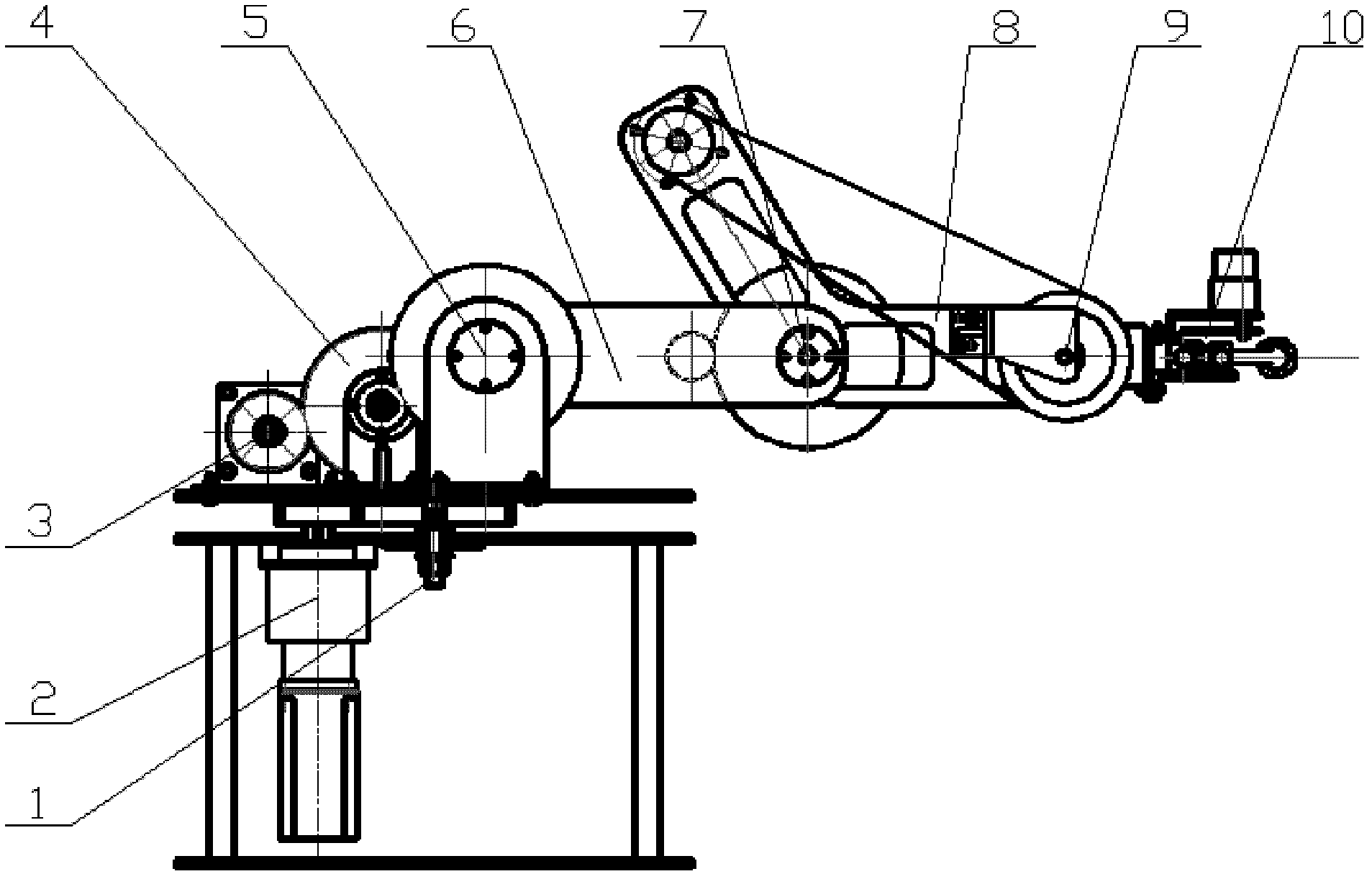

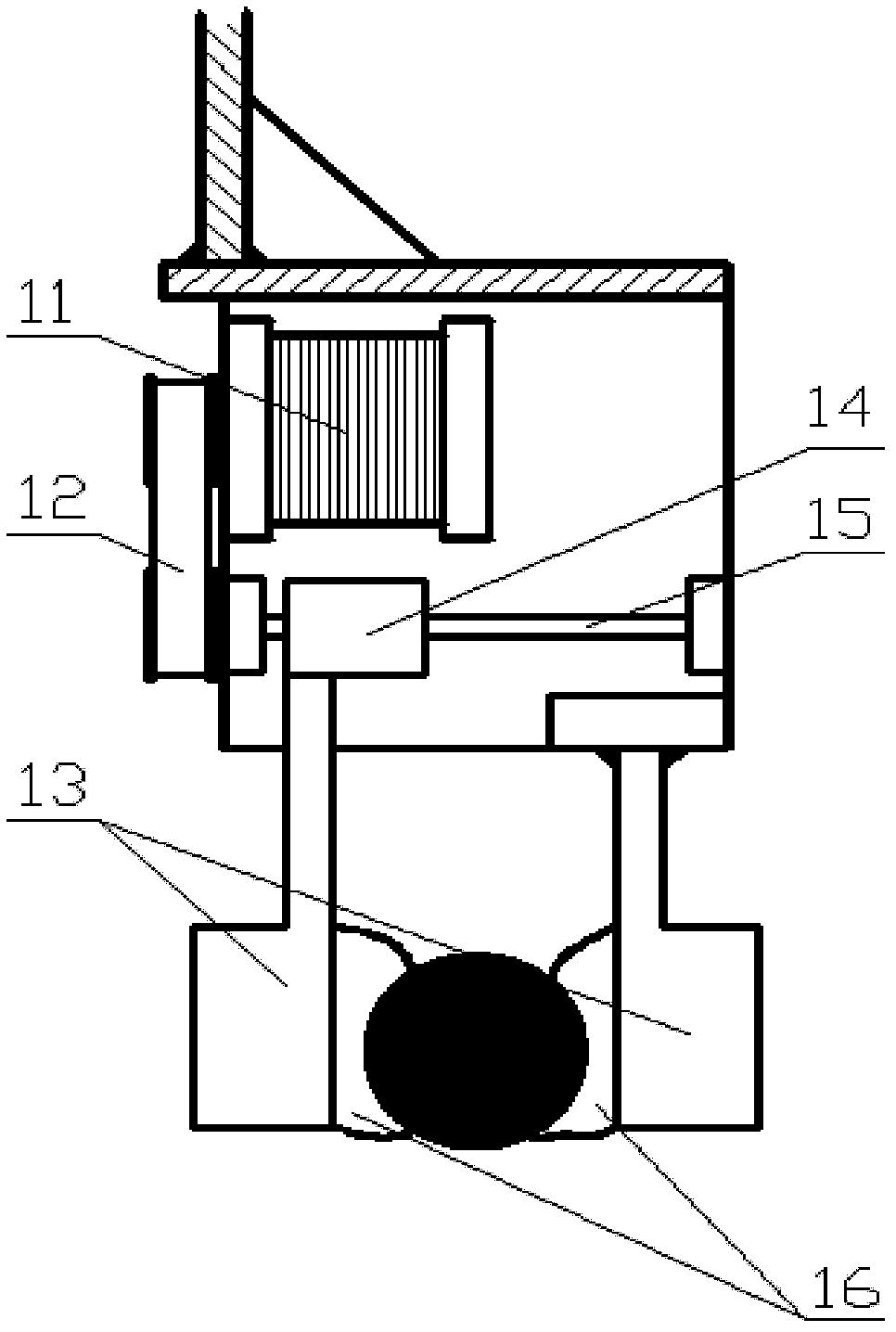

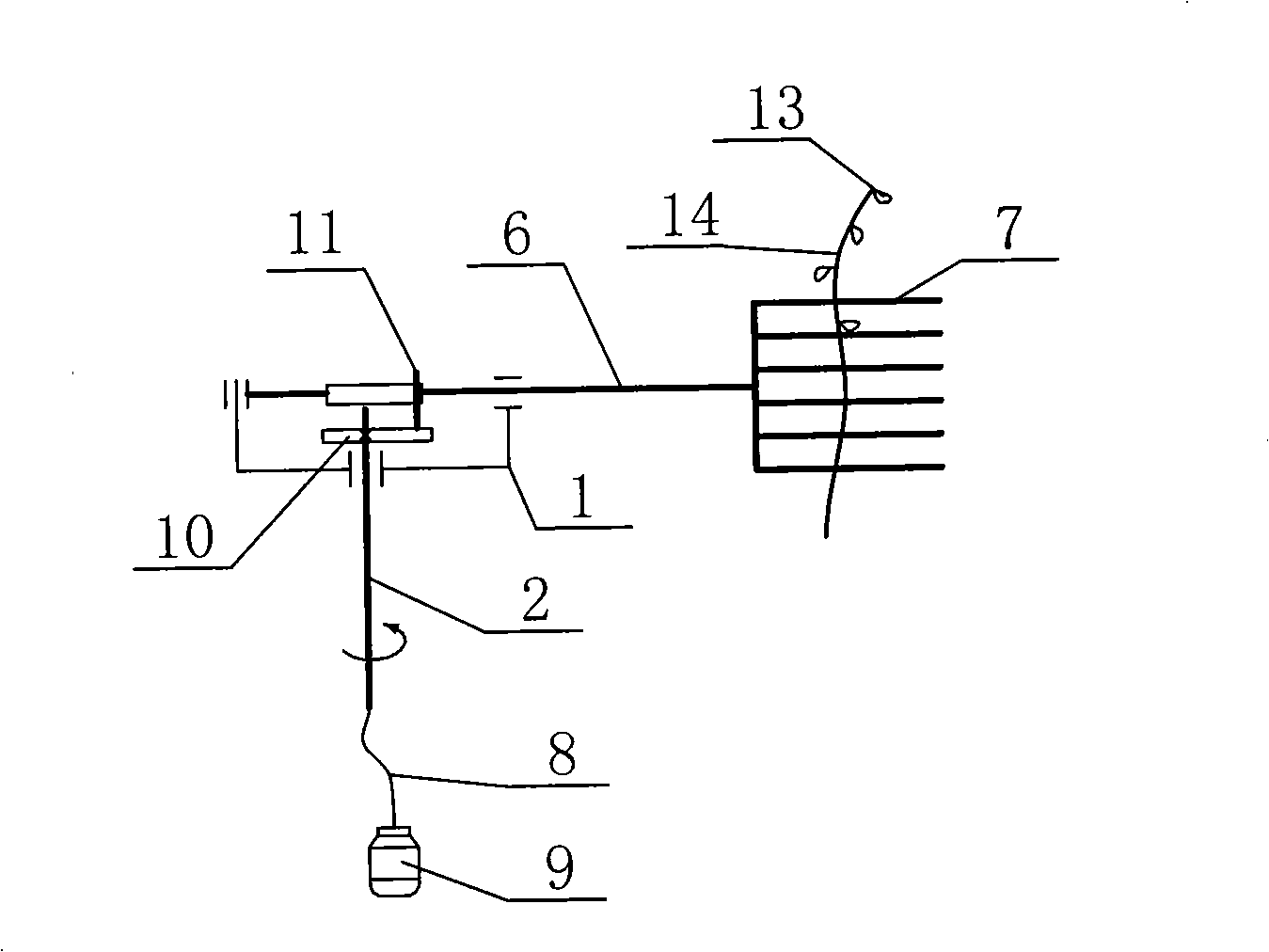

Double-arm fruit picking robot and fruit picking method

ActiveCN103947380AThe average picking period is shortImprove picking efficiencyPicking devicesFruit treeControl system

The invention discloses a double-arm fruit picking robot and a fruit picking method. The double-arm fruit picking robot comprises a fruit picking mechanical device and a control system, wherein the fruit picking mechanical device comprises a left mechanical arm, a right mechanical arm, a left tail end actuator, a right trail end actuator, a moving platform and a fruit basket, the left mechanical arm and the right left mechanical arm are of the same structures, are respectively arranged at the left side and the right side of the moving platform, and respectively complete the work of conveying the left tail end actuator and the right trail end actuator to specified picking points, the left tail end actuator and the right trail end actuator are of the same structures, are respectively arranged at the front end of the left mechanical arm and the front end of the right mechanical arm, and respectively complete the work of obtaining and recovering fruits of fruit trees at the left side and the right of the advancing direction of the robot, and a control system completes the control tasks of robot navigation, walking and picking. The invention also discloses a fruit picking method of the double-arm fruit picking robot. According to the method, the mechanical arms carry out picking in different picking points, and the continuous and respective picking of a plurality of fruits can be realized in one picking point.

Owner:JINLING INST OF TECH

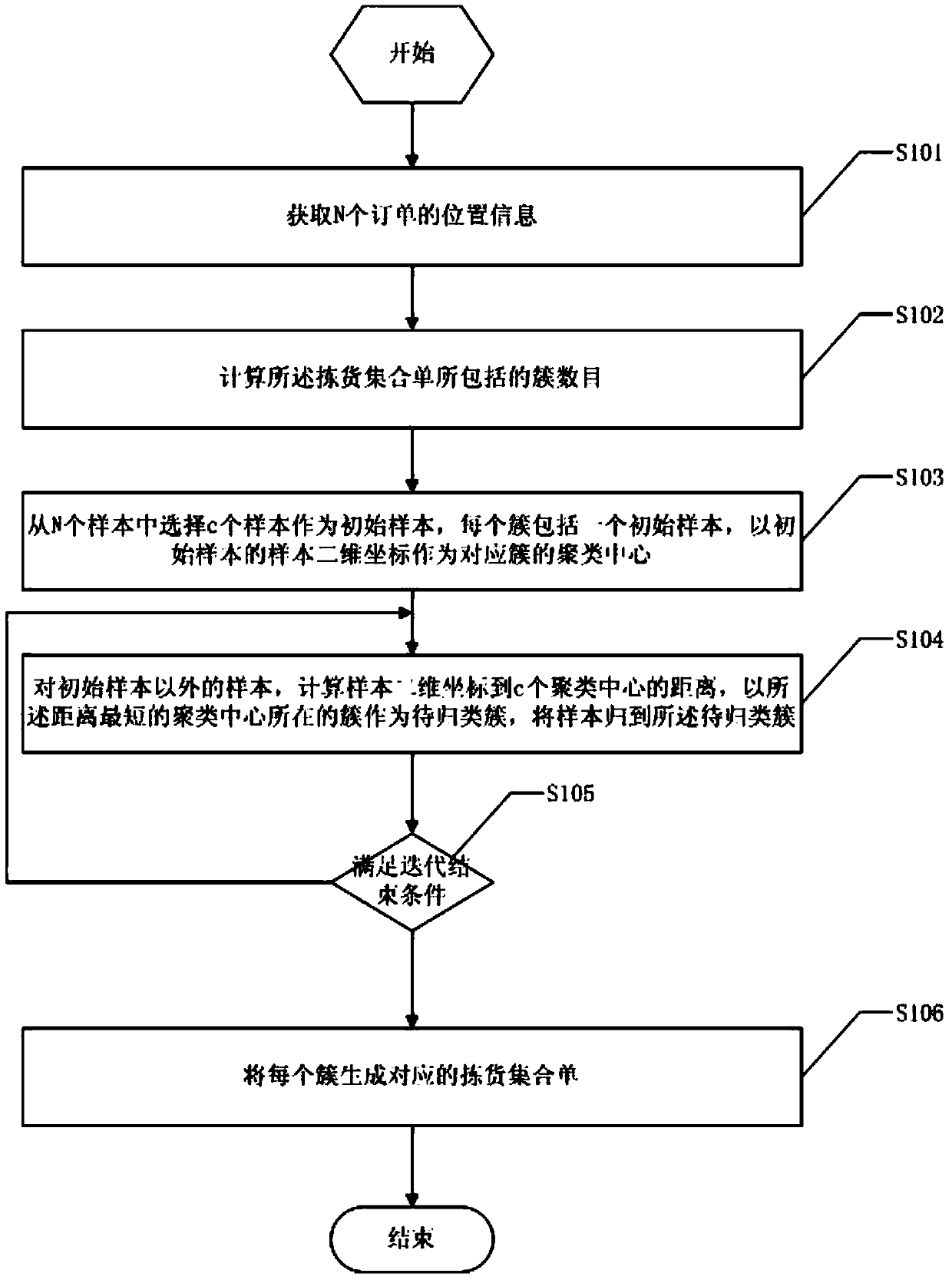

Method and device for generating order picking collection lists and method for optimizing order picking route

The invention relates to the correlation technical field of order picking operation, in particular to a method and device for generating order picking collection lists and a method for optimizing an order picking route. The generation method comprises the steps: obtaining position information of N order forms, using the order forms as samples, and using the position information of the order forms as sample two-dimensional coordinates of the corresponding samples, wherein N is greater than one; computing the number of clusters included by the order picking collection lists; selecting c samples from the N samples as initial samples; computing the distances between the sample two-dimensional coordinates of (N-c) samples except for the initial samples and c clustering centers, regarding the cluster where the clustering center with the shortest distance is located as a cluster to be classified, and returning the samples to the cluster to be classified; generating the corresponding order picking collection lists by the clusters if the iteration end condition is met, and continuing to perform iteration if the iteration end condition is not met. According to the order picking route generated by the optimized order picking collection lists, the order picking efficiency is improved greatly compared with the order picking efficiency in the prior art.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD

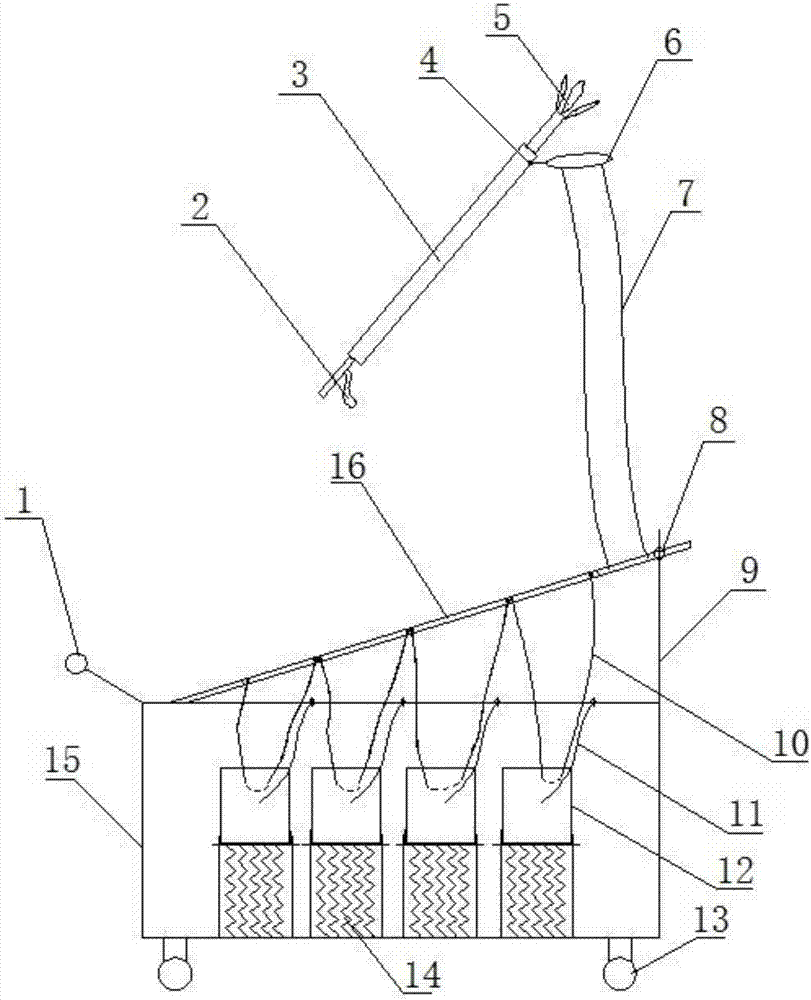

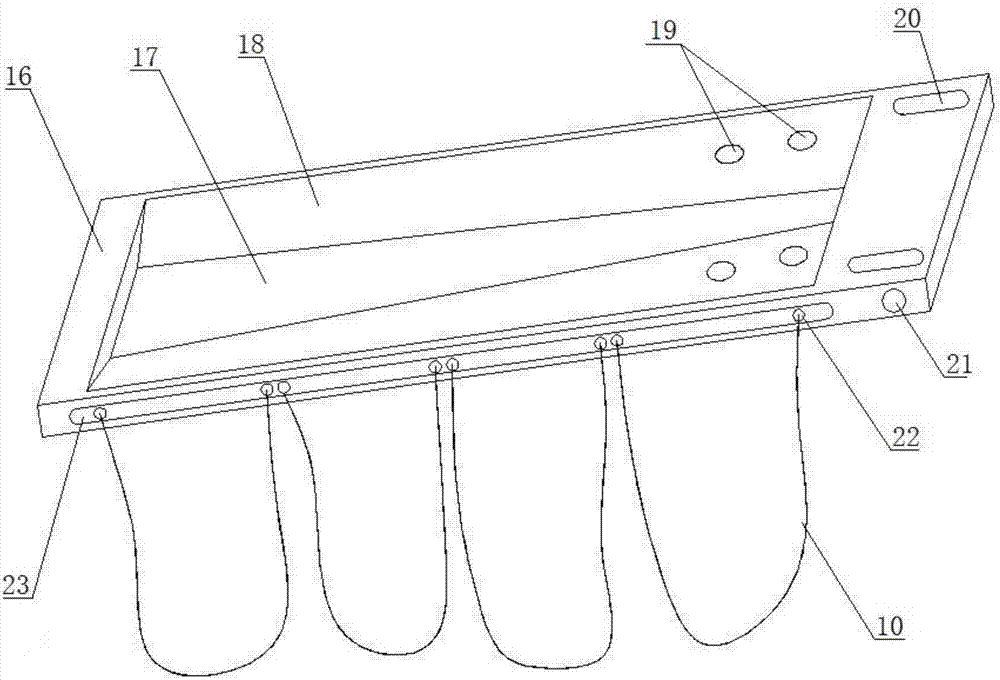

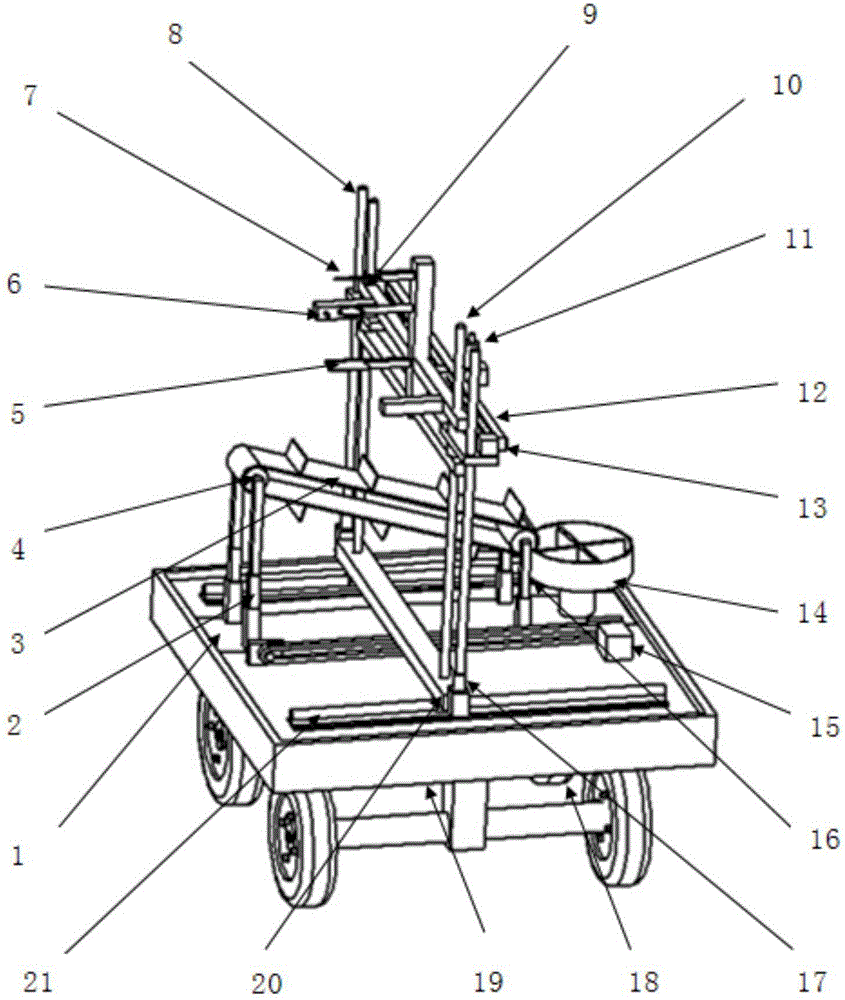

Automatic grading device and application thereof for apple picking

The invention relates to an automatic grading device and application thereof for apple picking. The automatic grading device for apple picking comprises a mobile vehicle, a picking device, a grading device, a storage box and a sleeve, and the picking device is arranged above the mobile vehicle and used for picking fruits; the grading device is arranged on the top of a vehicle body and located below the picking device and used for conducting size grading on the picked fruits; the storage box is arranged in the vehicle body and used for containing the graded fruits; one end of the sleeve is connected to the picking device, the other end of the sleeve is connected to the grading device, and the picked fruits enter the grading device through the sleeve in an undamaged mode. The automatic grading device for apple picking is exquisite in conception, reasonable in structural design and convenient to use, the picking efficiency can be improved, real-time grading can be conducted, the subsequent operation procedures of conducting grading on the fruits again are omitted, and meanwhile on-site boxing can be conducted in the process of conducting grading on the fruits. The picking grading vehicle can be widely applied to multiple planting environments such as orchards and mountainous regions.

Owner:山东鲁果现代设施果树科技有限公司

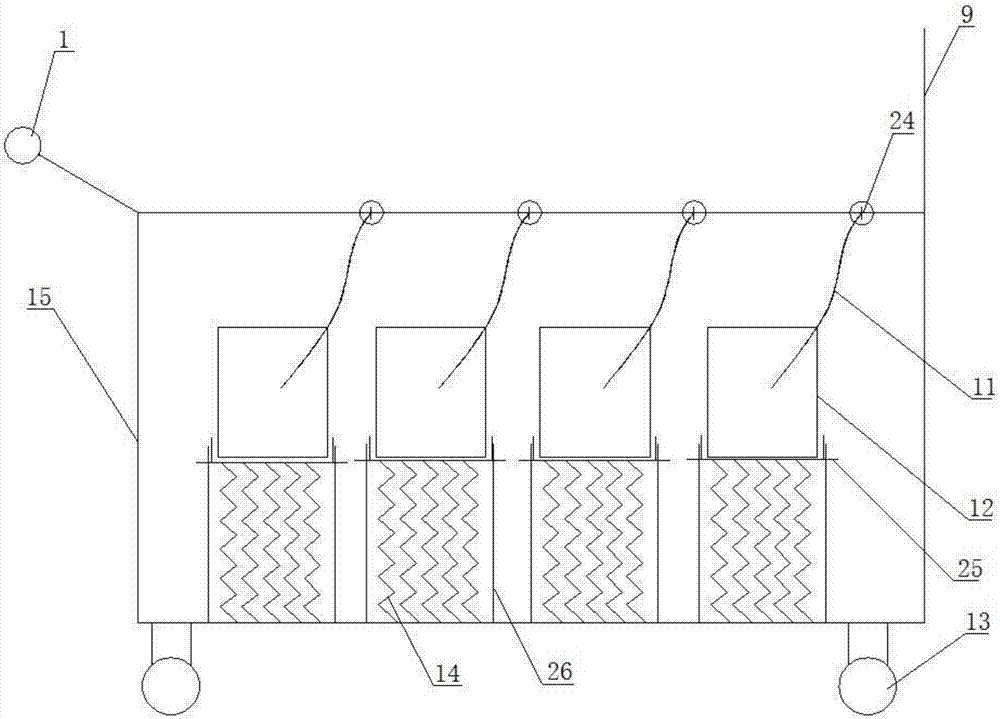

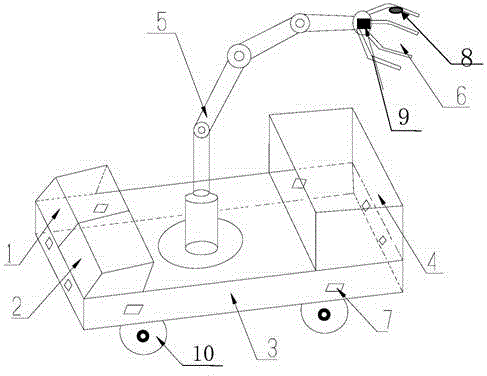

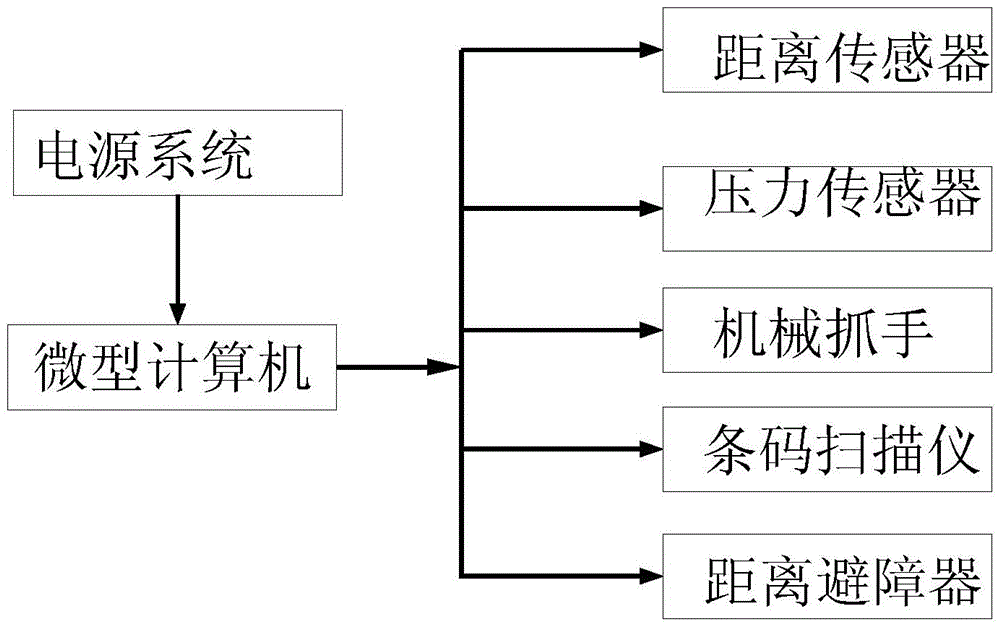

Full-automatic picking car for warehouse and control method of full-automatic picking car

InactiveCN104924288ASimple structureInnovative designProgramme-controlled manipulatorGripping headsMicrocomputerWorkload

The invention discloses a full-automatic picking car for a warehouse and a control method of the full-automatic picking car. The full-automatic picking car comprises a picking car body, a microcomputer, a power supply system, a storage box, a mechanical arm, a mechanical finger, a range sensor, a pressure sensor, a bar code scanner and wheels, wherein the microcomputer and the power supply system are fixedly mounted at one end of the picking car body; the storage box is fixedly arranged at the other end of the picking car body; one end of the mechanical arm is fixed on the picking car body; the mechanical finger is mounted at the other end of the mechanical arm; and the pressure sensor and the bar code scanner are arranged at one end, connected with the mechanical finger, of the mechanical arm. The car can achieve automatic picking, placement and classification of goods after ordering, changes the shortages of manual picking of the goods, high workload and long time consumed in the existing warehouse, and improves picking and loading efficiency.

Owner:JIANGSU UNIV

Method for improving precision and efficiency of first-arrival wave pickup

The invention relates to a method for improving the precision and the efficiency of first-arrival wave pickup in oil seismic exploration. The method comprises the following steps: selecting the first-arrival time of a seed gun line and a seed shot; dividing an observation region covered by the seed shot into small sub-regions; carrying out elevation correction on the first-arrival time of each track; obtaining a beeline slope through fitting; using the reciprocal of the slope as the visual speed of a section first-arrival curve; establishing a visual speed field; carrying out first-arrival pickup through the non-seed shot first-arrival time calculated by the seed shot; and gradually completing the first-arrival pickup of the whole shot line to further complete the first-arrival time pickup of the whole working region. The method adopts batch pickup, reduces the workload of manual intervention and improves the efficiency and the accuracy of the first-arrival time pickup.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

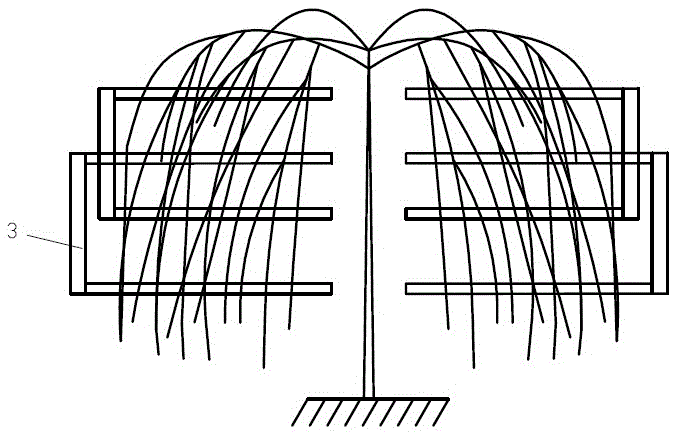

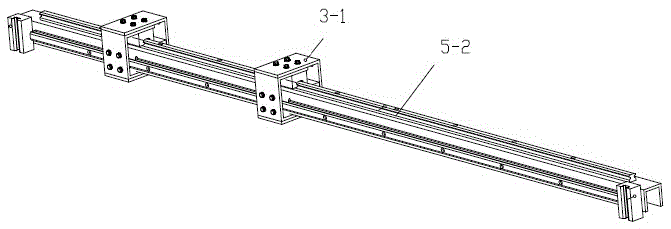

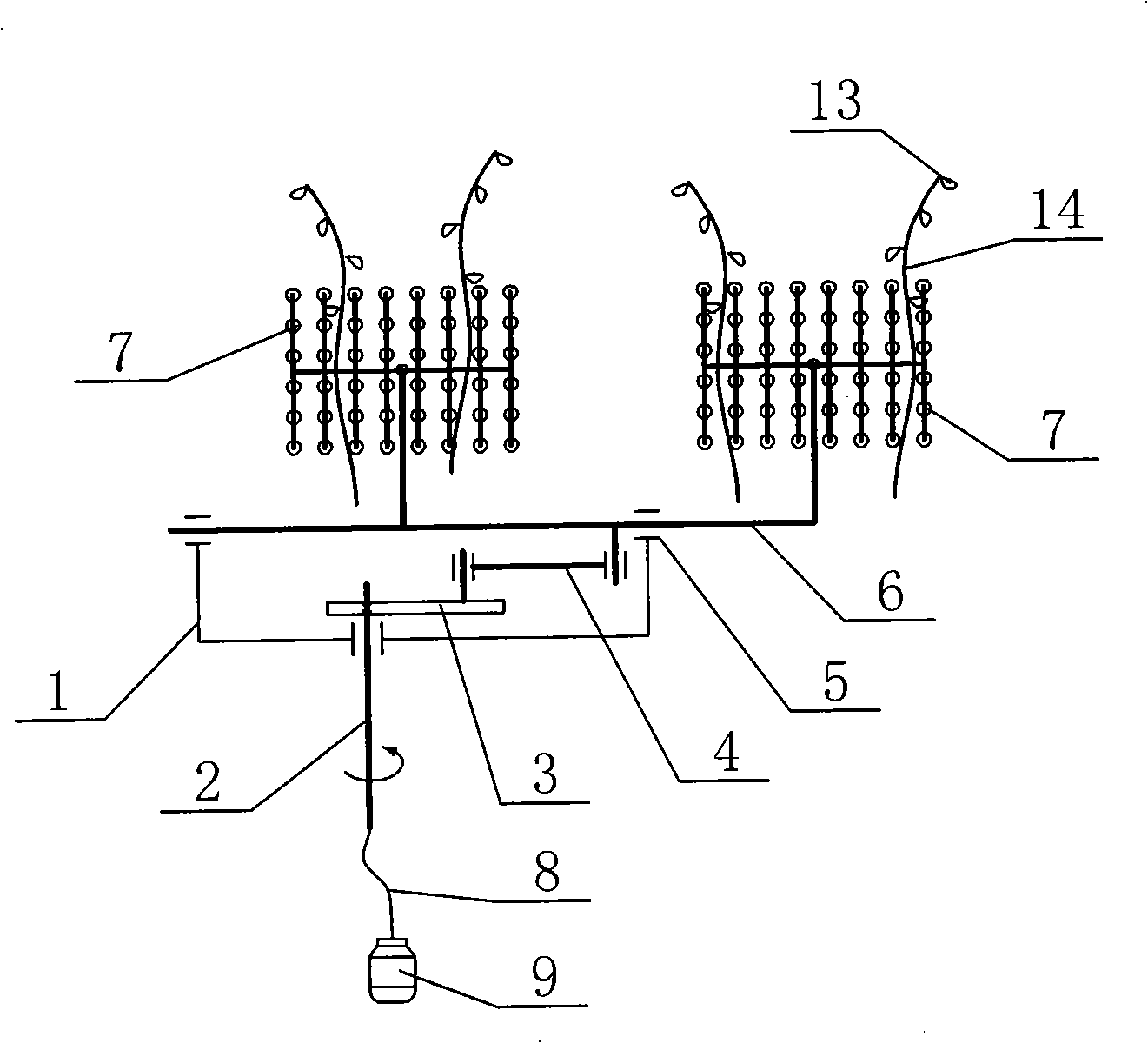

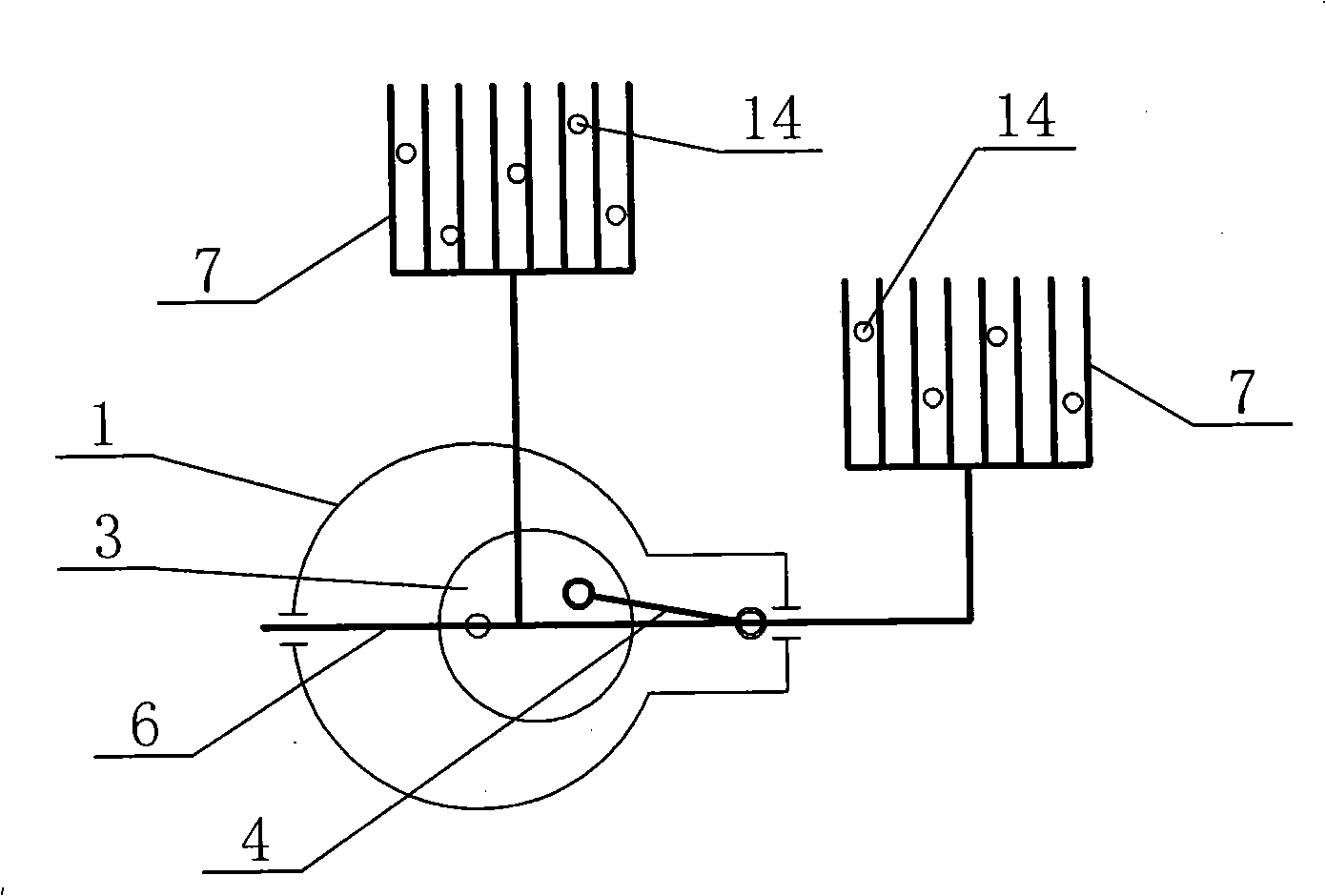

Vibration-type wolfberry fruit picking mechanism

ActiveCN105594374AEliminate avoidance of vibrating rodsReduce harmPicking devicesHydraulic motorFixed frame

The invention relates to a vibration-type wolfberry fruit picking mechanism and belongs to the technical field of agricultural machinery. A fixed frame of the mechanism is formed by fixedly connecting door-shaped brackets on the left and right sides, front and rear slide ways and a middle connecting beam; the two sides of the front and rear slide ways, and left and right hoisting opening / closing frames from left and right horizontal movement pair respectively; two opening / closing air cylinders are mounted in the middle of the middle connecting beam; stretching-out piston rod ends of the opening / closing air cylinders are fixedly connected with the left and right hoisting opening / closing frames respectively; each hoisting opening / closing frame is a rectangular framework; front and rear vertical beams, and upper and lower vibration rod mechanisms with opposite vibration directions form vertical movable pairs respectively; a hoisting air cylinder is mounted in the middle of an upper transverse beam; a piston rod end of the hoisting air cylinder is fixedly connected with the vibration rod mechanisms; each vibration rod mechanism comprises horizontal slide rails, and the horizontal slide rails, and upper and lower rows of vibration rod rows form front and rear horizontal movement pairs; the vibration rod rows are in transmission connection with an output shaft mounted on a hydraulic motor. By virtue of the vibration-type wolfberry fruit picking mechanism, the picking efficiency and the picking rate are effectively improved; a needed excitation force is relatively small, and injuries to branches, caused by the picking excitation force, is remarkably reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

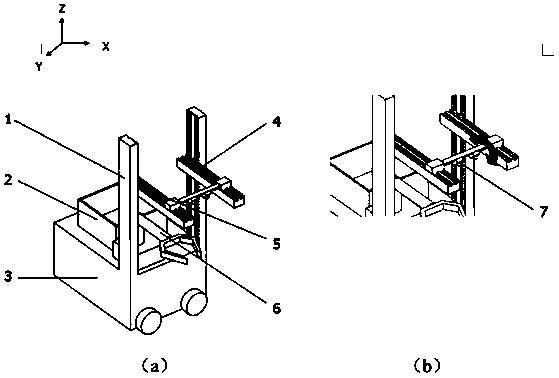

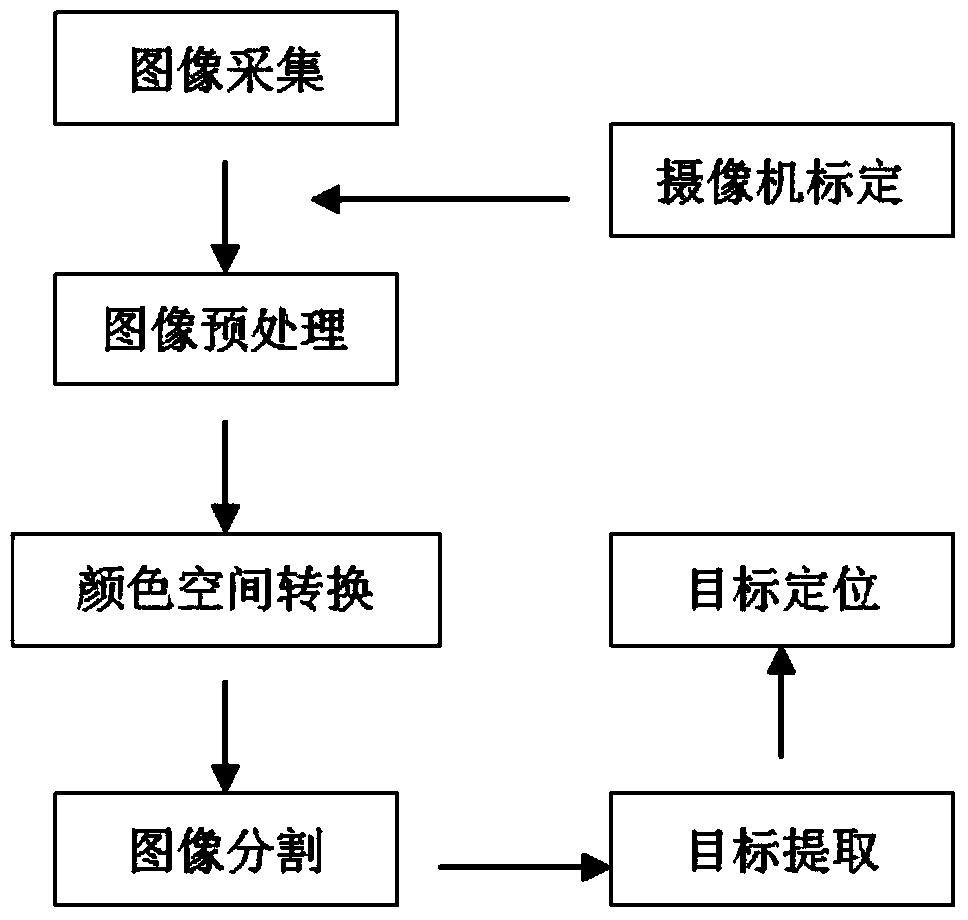

Rotary adjustable binocular vision target recognition and positioning device and application thereof in agricultural fruit harvesting machinery

ActiveCN103529855ARealize identification and positioningOptimize the recognition and positioning effectCharacter and pattern recognitionPicking devicesImaging processingThree-dimensional space

The invention discloses a rotary adjustable binocular vision target recognition and positioning device and application thereof in agricultural fruit harvesting machinery. The target recognition and positioning device comprises a support, cameras and an image processing system, wherein the support comprises two longitudinal guide rails and two transverse guide rails; the transverse guide rails and the longitudinal guide rails are in sliding connection to realize movement of the cameras in Z-axis direction; the cameras are two cameras which are fixedly arranged on the support through a pedestal and are symmetrically arranged left and right; the pedestal can rotate around Y-axis; the pedestal and the transverse guide rails are in sliding connection to realize movement of the cameras in X-axis direction. The target recognition and positioning device can realize multi-degree-of-freedom movement of binocular vision three-dimensional cameras in a three-dimensional space, realize binocular vision multi-angle recognition and positioning and optimize the recognition and positioning effects; the device is applied to the agricultural fruit harvesting machinery, can adapt to various agricultural fruits and has certain universality.

Owner:佛山市中科农业机器人与智慧农业创新研究院

Medlar harvesting machine

The invention relates to a medlar harvesting machine and belongs to the technical field of agricultural machinery. The machine is mounted on a door-shaped framework on a walking mechanism and is provided with a vertical slide rail; the vertical slide rail is provided with a hoisting sliding plate and a vibration assembly; a collection assembly is mounted under the vibration assembly; a hoisting plate is mounted at the upper part of the hoisting sliding plate; the upper and lower ends of a fixed bracket of the vibration assembly are hinged to one end of an upper sliding rod and one end of a lower sliding rod respectively; the other end of the upper sliding rod penetrates through a horizontal perforated hole of the hoisting plate to form a lockable movable pair and the other end of the lower sliding rod penetrates through a sliding rod support at the lower part of the hoisting sliding plate to form a lockable movable pair; a frame-shaped vibration tooth bracket is mounted on the inner side of the fixed bracket and a horizontal movable pair is composed of the frame-shaped vibration tooth bracket and the fixed bracket; horizontal vibration teeth which are distributed at intervals are arranged on the inner side of the vibration tooth bracket by extending; a vibration motor is in transmission connection with the vibration tooth bracket through an eccentric wheel mechanism. The medlar harvesting machine can avoid a branch breaking phenomenon and is conveniently wound on a tree shed so that the movement of the medlar harvesting machine is not influenced by the impeding of branches, and medlar branches can be further prevented from being damaged.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

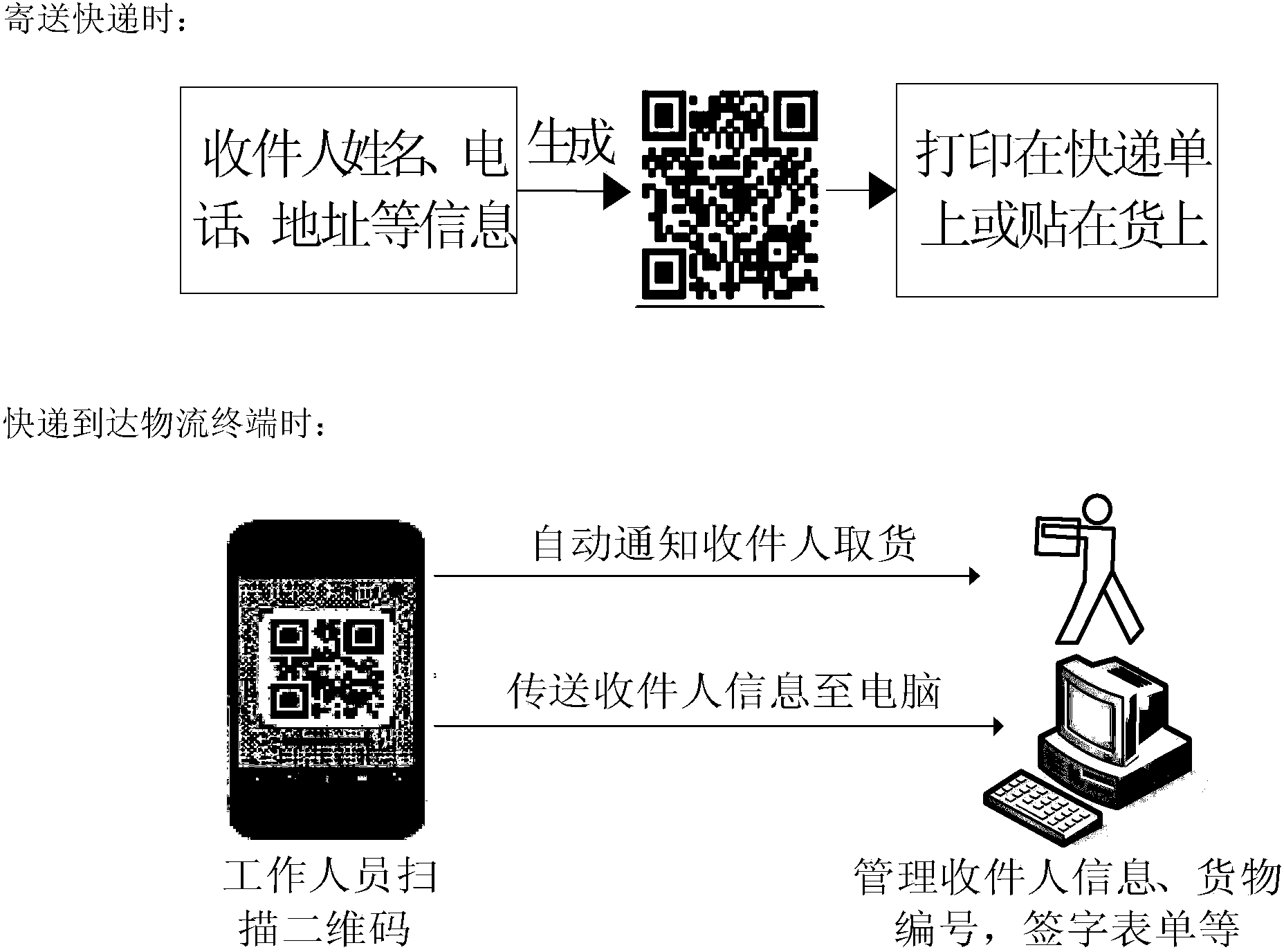

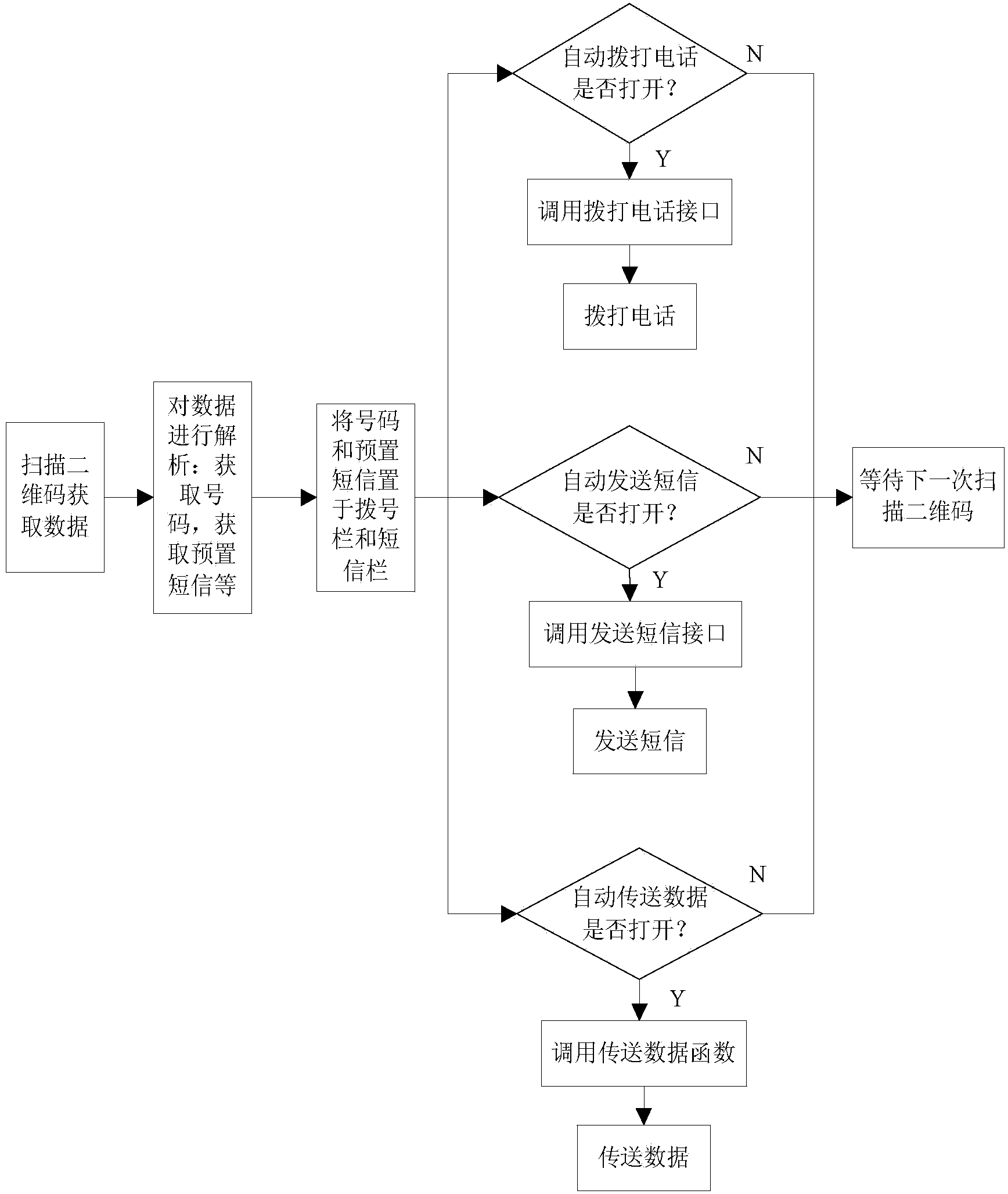

Logistic terminal application method based on two-dimensional code

InactiveCN103679423AFault-tolerantAvoid causingSensing record carriersLogisticsData informationSoftware

The invention discloses a logistic terminal application method based on a two-dimensional code. Different from a traditional one-dimensional code which needs a special database server to store corresponding goods information, the two-dimensional code can store a large capacity of Chinese character information, and the two-dimensional code can be applied to logistics and express so as to improve delivery efficiency of a logistic and express terminal. By means of the characteristic that the two-dimensional code is large in storage capacity, text Chinese information such as a goods addressee is directly stored in the two-dimensional code. A two-dimensional code module, an intelligent mobile phone two-dimensional code recognition processing module and a computer data receiving module are included. A name, a phone number, an address and other information of the addressee are generated into the two-dimensional code to be printed on or attached to express goods. When the goods reaches the logistic and express terminal, data information is analyzed and processed by means of two-dimensional scanning and processing software, so that the functions of calling the addressee automatically, sending a short message to the addressee automatically and sending data to a computer end are achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

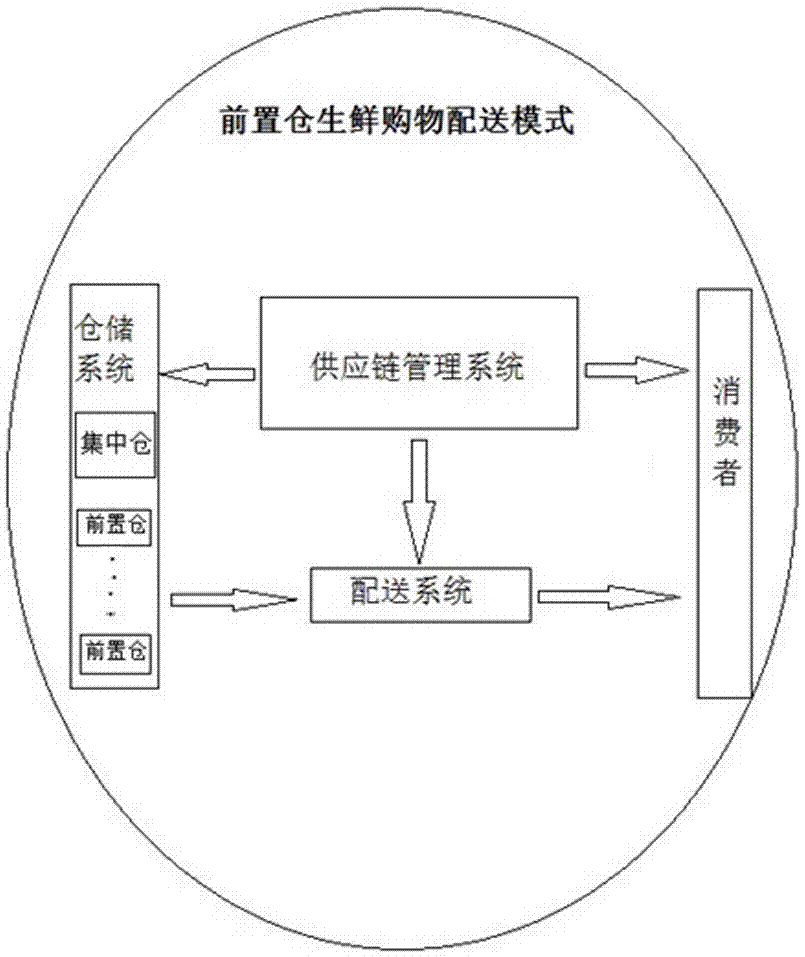

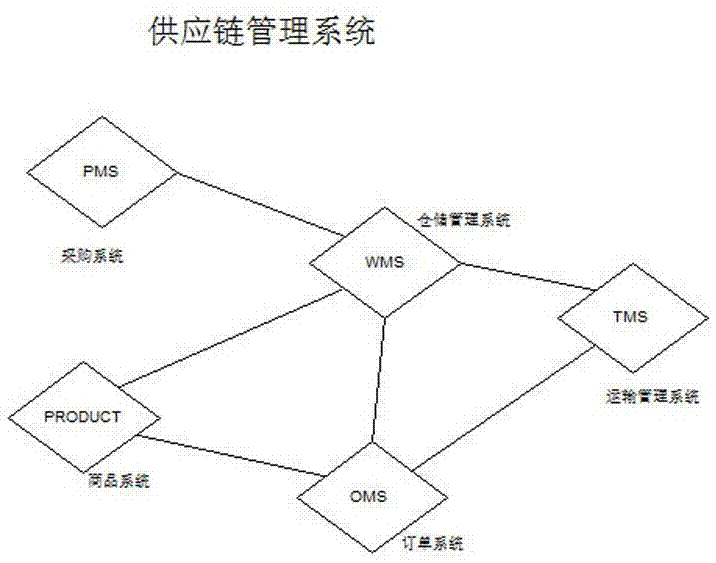

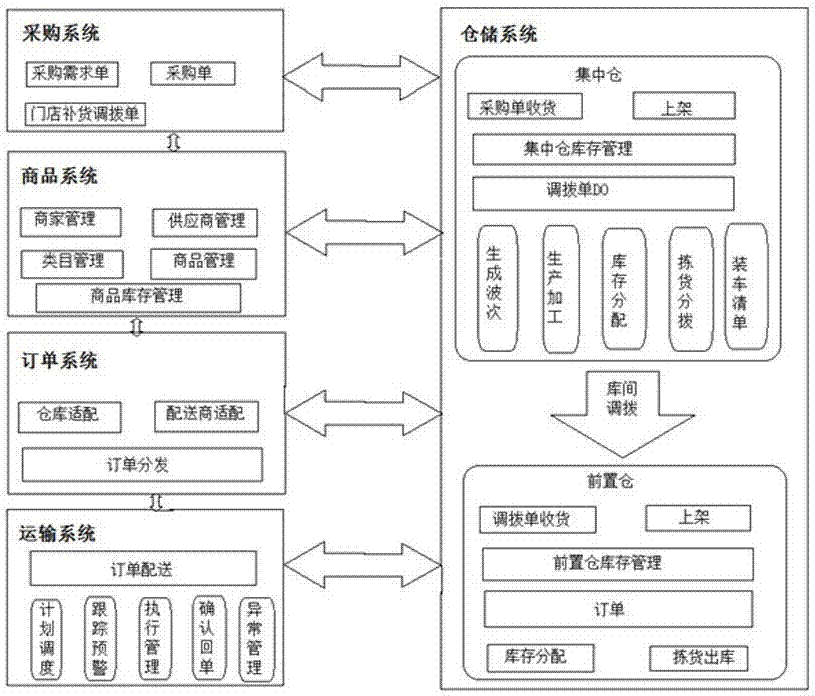

Preposed warehouse fresh food shopping and distribution mode

InactiveCN107292565ATimely distributionImprove on-time deliveryBuying/selling/leasing transactionsLogisticsOrder management systemDistribution system

The invention relates to the field of fresh food supply chain management, and specifically relates to a preposed warehouse fresh food shopping and distribution mode. The preposed warehouse fresh food shopping and distribution mode comprises a warehousing system, a distribution system and a supply chain management system, and the supply chain management system comprises five subsystems of a purchasing system, a warehouse management system, a commodity system, an order management system and a transportation management system. A centralized + distributed management mode is employed, a centralized warehouse and several preposed warehouses are arranged in the urban area, goods are stored in the preposed warehouses, a customer places an order through a mobile phone APP, goods are sent to the customer from the closest preposed warehouse, and therefore one-hour delivery is achieved. Beneficial effects of the preposed warehouse fresh food shopping and distribution mode are that a centralized + distributed warehousing mode is employed, efficient distribution of one-hour deliver in the last one kilometer is achieved; compared with a conventional mode, the intermediate links are less, the distribution efficiency is high, time is short, and the cost is low; by means of distributed storage, supply chain steps can be greatly reduced, the distribution cost of each order can be reduced to 11 yuan, and the distribution time is reduced to one hour.

Owner:浙江优展信息科技有限公司

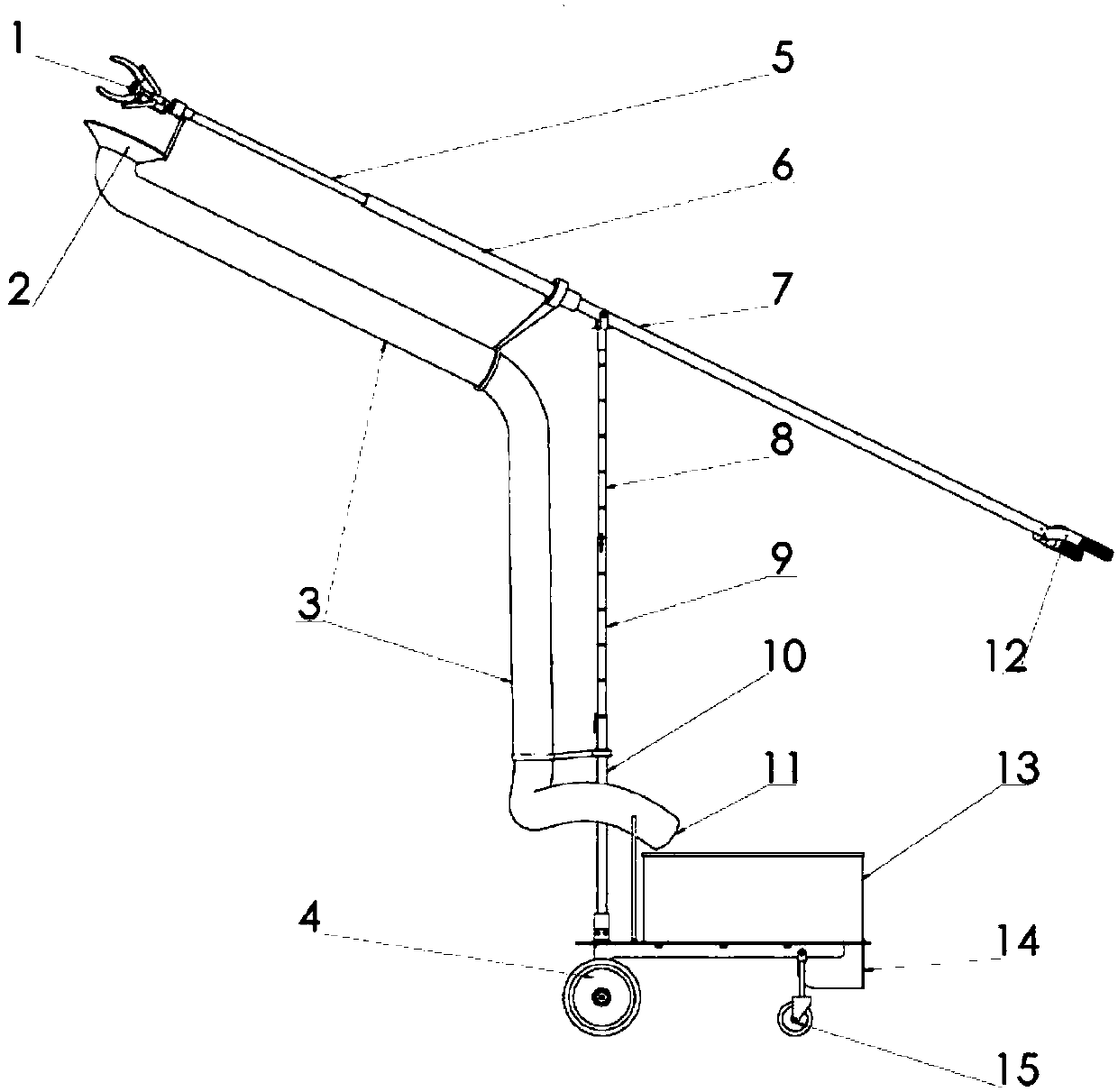

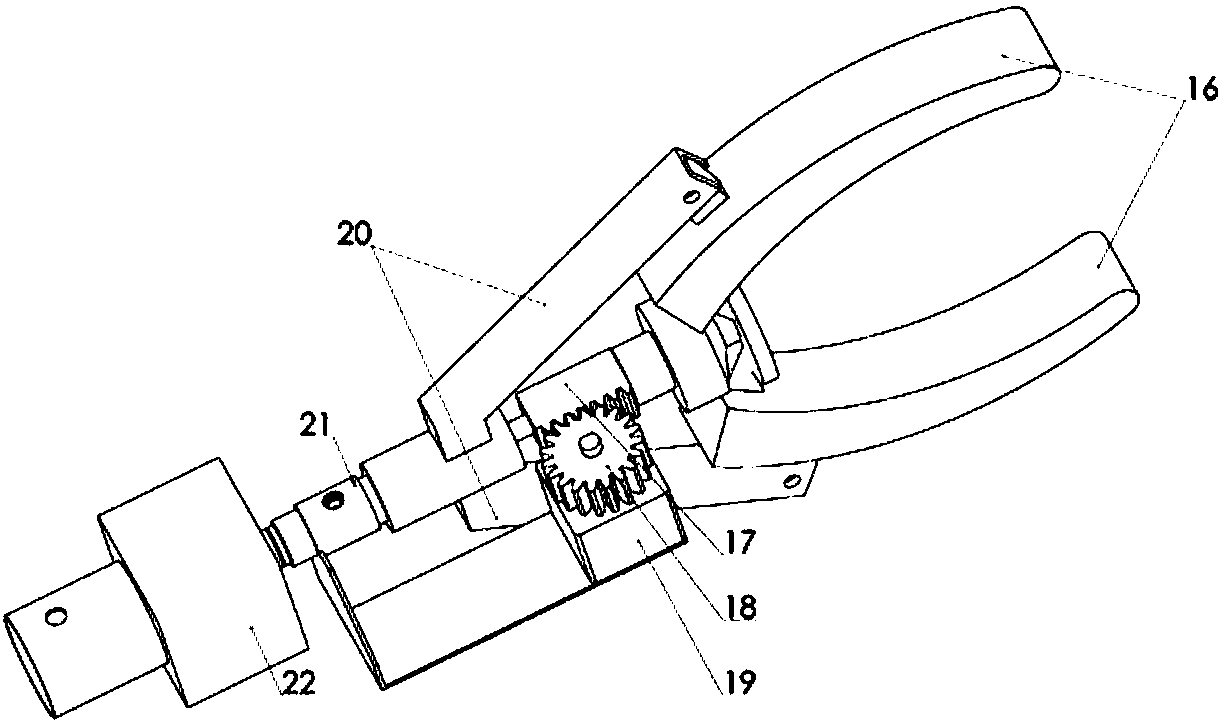

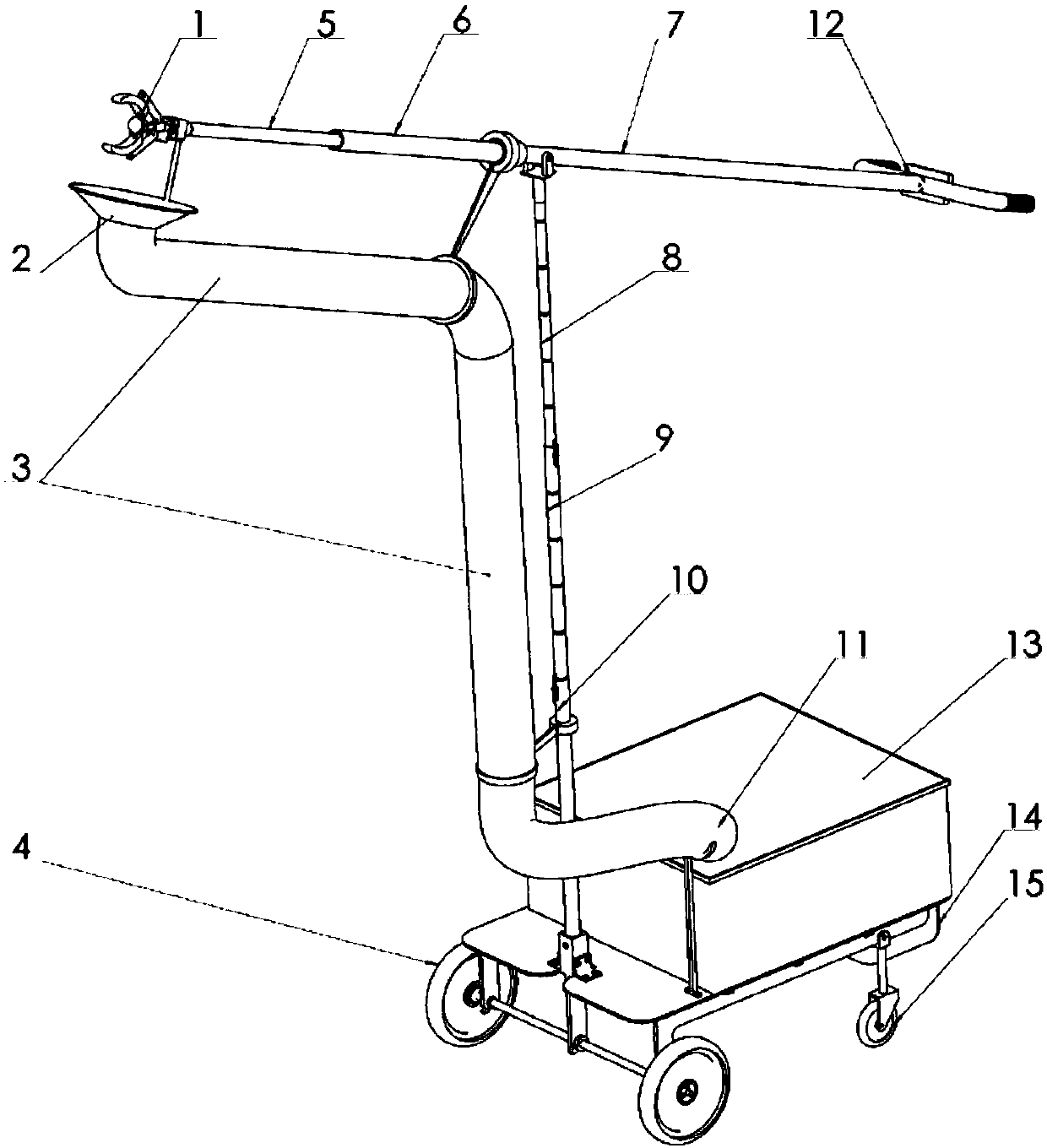

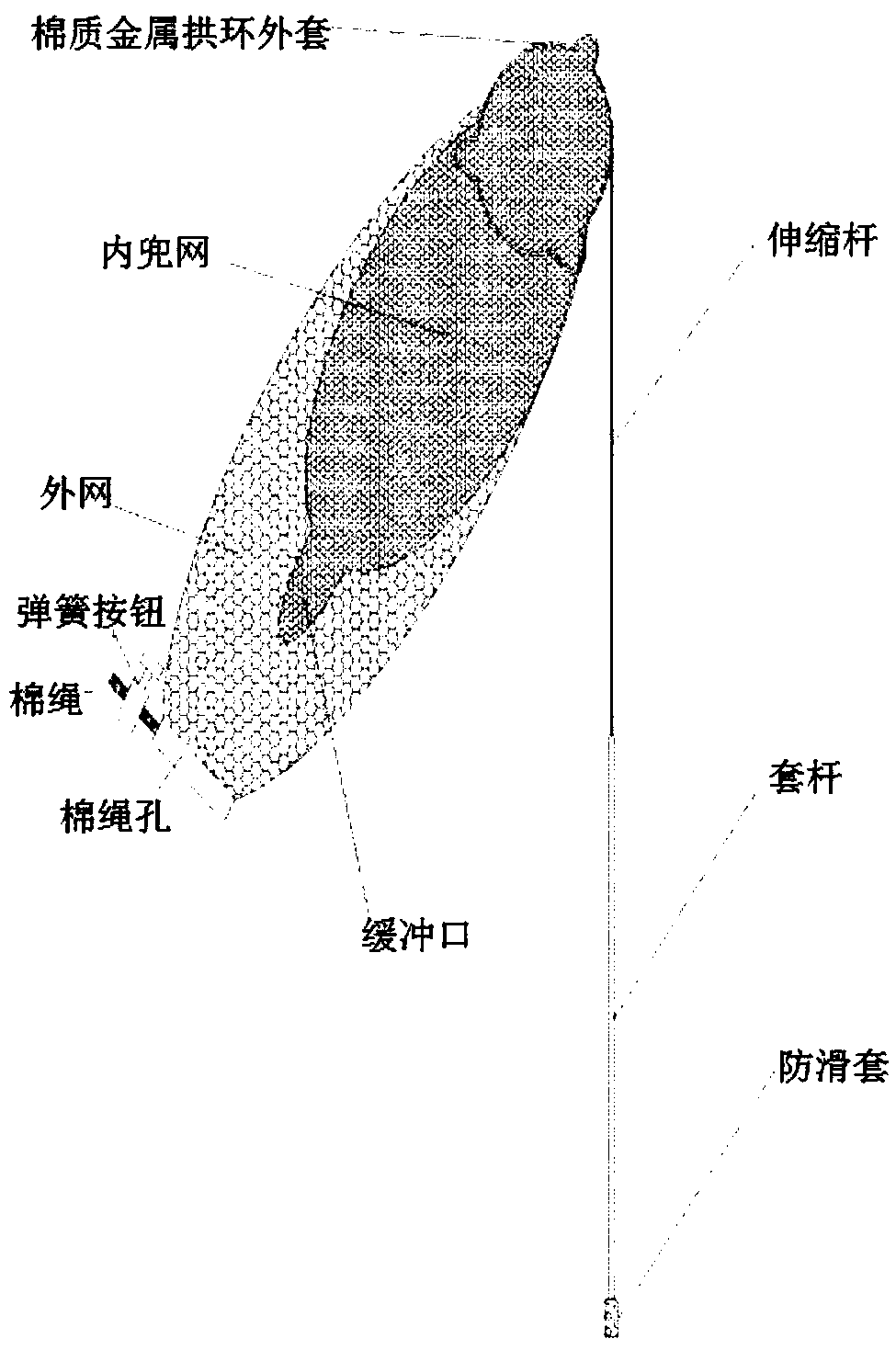

Novel detachable auxiliary artificial fruit picking machine

InactiveCN107711072ARapid positioningFast locationGripping headsPicking devicesElectric machineryEngineering

The invention relates to a novel detachable auxiliary artificial fruit picking machine comprising a base. A collection box is fixed to the base. Front wheels and a universal wheel are fixed to the lower portion of the base, a fixed supporting rod is fixed to the front end of the top of the base and concentrically connected with a first supporting rod, the first supporting rod is concentrically connected with a second supporting rod, the top end of the second supporting rod is connected with a picking rod through a rotating sleeve, the front end of the picking rod is connected with a fixed rod,and the fixed rod is matched with a telescopic rod. The novel detachable auxiliary artificial fruit picking machine is convenient to use. By meshing between a gear and a rack, the contraction and opening of a picking hand claw are controlled; fruits are twisted down through the rotation of a second motor, picking and collection are performed simultaneously through a telescopic pipe, labor time isgreatly saved in the actual production process, and the novel detachable auxiliary artificial fruit picking machine has very high practicality.

Owner:ANHUI UNIV OF SCI & TECH

Vegetable and fruit picking robot and control method thereof

InactiveCN105027834ARealize simultaneous movementAccurate identificationPicking devicesRobotic armControl theory

The invention discloses a vegetable and fruit picking robot and a control method thereof. The vegetable and fruit picking robot comprises a walking mechanism. A base is arranged on the walking mechanism. Storage baskets are arranged at the front and rear ends of the base respectively. An execution mechanism, a recognition system, a first driving mechanism, a second driving mechanism and a controller are arranged on the base. The controller is connected with the recognition system, the first driving mechanism and the second driving mechanism through wires. Both fruits on trees and plant fruits at low positions can be picked, and therefore the picking object range is wide; the crawler-type walking mechanism drives a plurality of mechanical arms to work at the same time, and therefore the picking efficiency is high; a small arm is flexible and continuous in movement, the stretching range of the mechanical arms is wide, and therefore the vegetable and fruit picking robot can adapt to various operating environments; the multi-sensor function and the digital imaging technology are adopted, and therefore the fruits can be accurately recognized and positioned; clamping force is controlled through sensor detection, and therefore the fruits are prevented from being damaged.

Owner:平顶山工业职业技术学院

Intelligent transfer robot for warehouse

InactiveCN105947506AImprove picking efficiency and logistics efficiencyReduce tally staffStorage devicesCushionEngineering

The invention belongs to the technical field of AGV (Automatic Guided Vehicle), and relates to an intelligent transfer robot for a warehouse. The intelligent transfer robot for the warehouse comprises a trolley located on the bottom part and contacted with the ground. The trolley comprises a bottom plate, bottom frameworks, a motor base plate, universal wheel supporting plate cushion blocks, universal wheel supporting plates and universal wheels, wherein the bottom framework are fixedly arranged on the bottom plate; the motor base plate and the universal wheel supporting plate cushion blocks are fixedly arranged on the bottom framework; the universal wheel supporting plates are fixedly arranged on the supporting plate cushion blocks; the universal wheels are connected with the universal wheel supporting plates; a drive mechanism, a motor, a driver and a storage battery are sequentially arranged on the bottom framework from bottom to top; a rotatable lifting mechanism and a chain compressing mechanism are also arranged on the drive mechanism. The invention provides the intelligent transfer robot for the warehouse, which is reasonable in design, stable in performance, and applicable to the AGV and turns flexibly.

Owner:芜湖智久机器人有限公司

Magnetorheological conformable clamp holder and robot for picking multiple types of fruits and vegetables

The invention discloses a magnetorheological conformable clamp holder and a robot for picking various kinds of fruits and vegetables. The magnetorheological conformable clamp holder comprises a clamping handle, a magnetorheological liquid bag, a shell and a clamping handle translation mechanism; the magnetorheological liquid bag is arranged at the inner side of one end of the clamping handle, is filled with magnetorheological liquid, is connected with a control circuit, and fulfills the function of forming a shape most appropriate for clamping the fruits and vegetables by means of electric magnetization regulation. The robot for picking various kinds of fruits and vegetables comprises a working table, a manipulator and an end effector arranged at the tail end of the manipulator, and the end effector consists of the magnetorheological comformable clamp holder and a shearing mechanism. According to the magnetorheological conformable clamp holder and the robot, when the fruits and vegetables of different kinds are picked, the picking of the fruits can be well performed without replacing clamping devices, and the picking efficiency is high; the picking requirements on different positions within the space can be met, the movement is flexible, and compared with a stepping motor used by the traditional picking manipulator, servo motors can be used for controlling more accurately.

Owner:佛山市中科农业机器人与智慧农业创新研究院

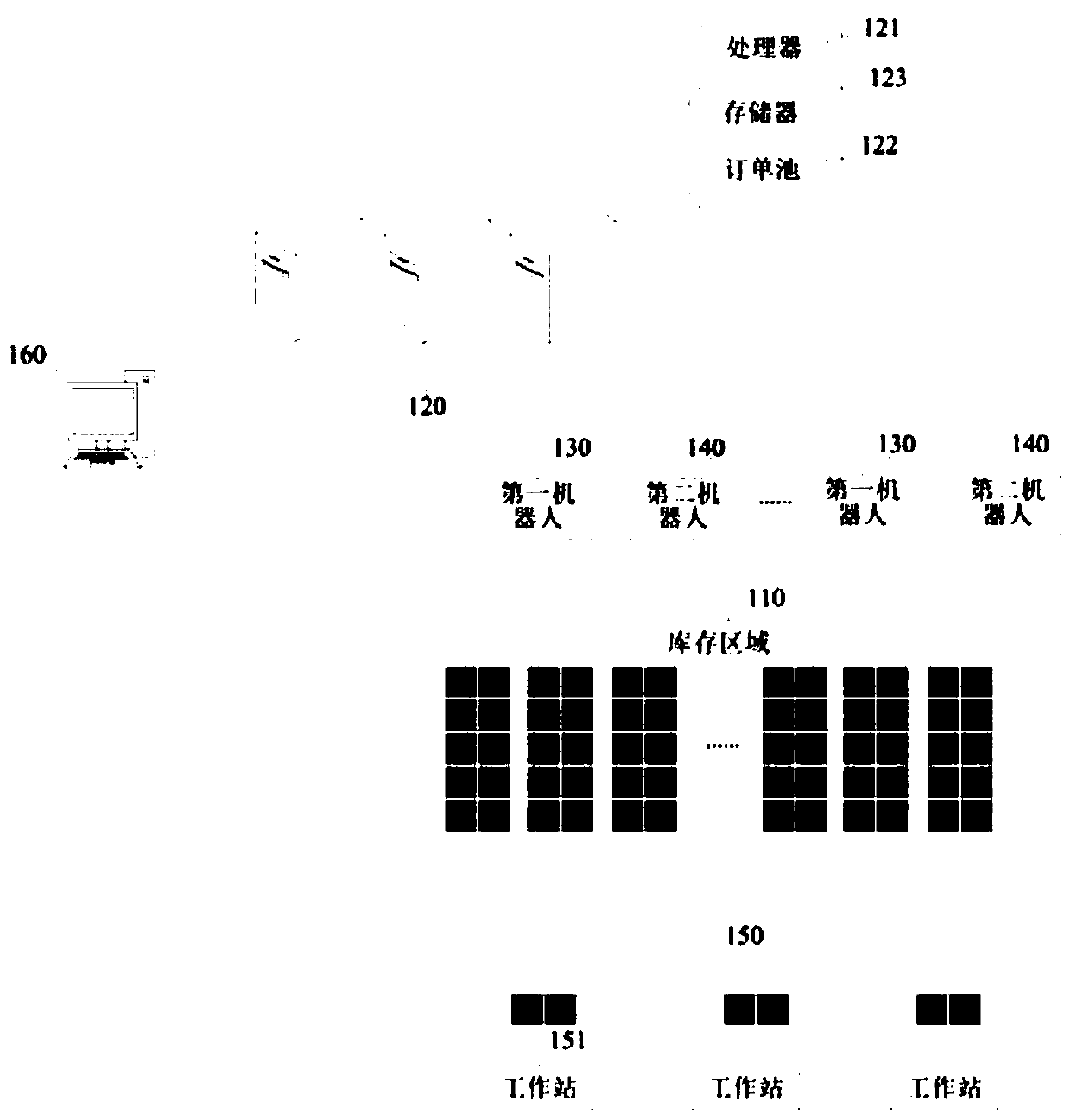

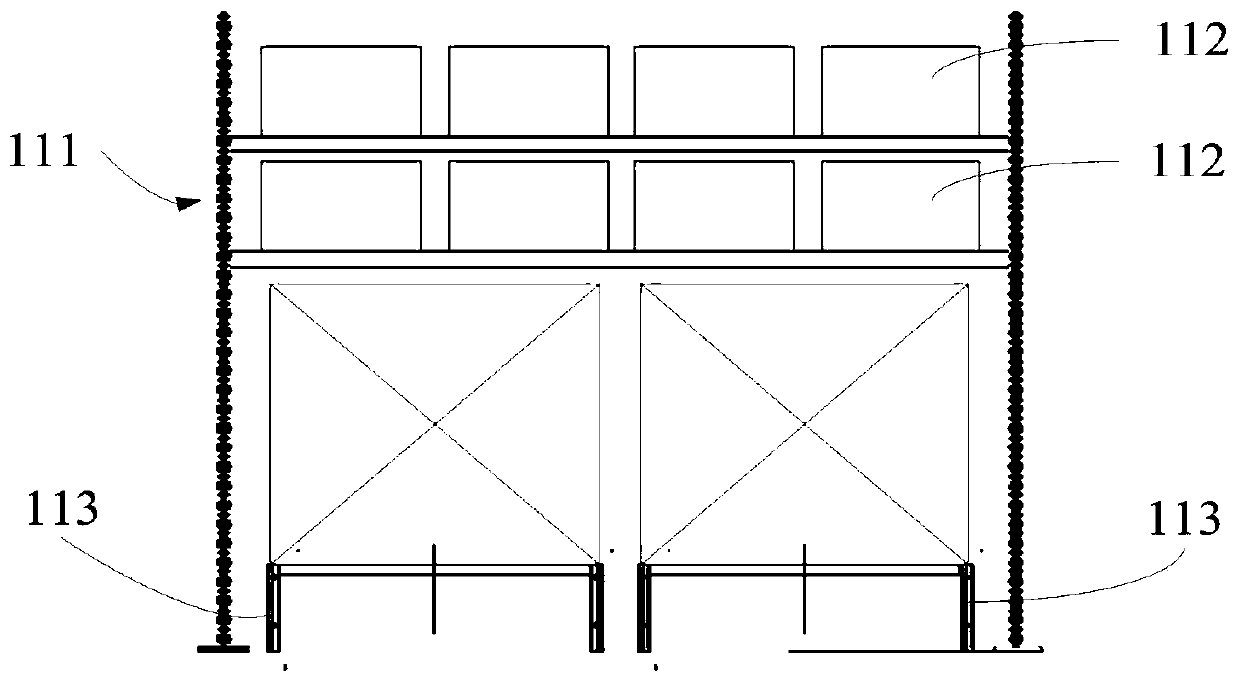

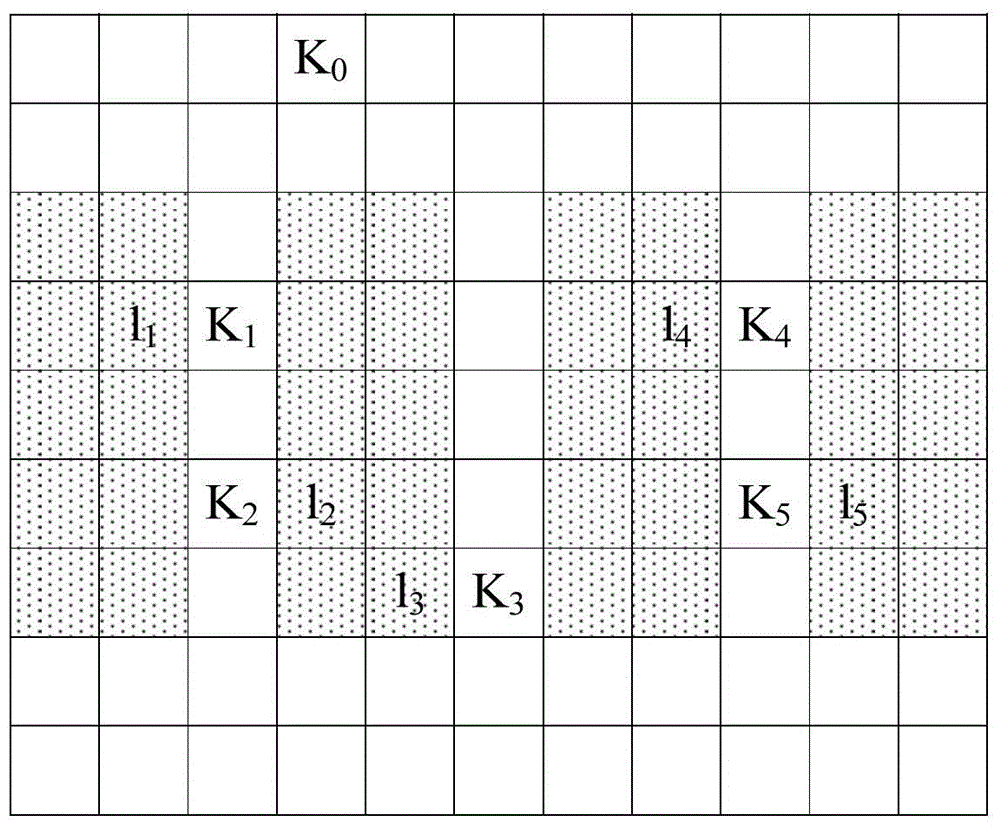

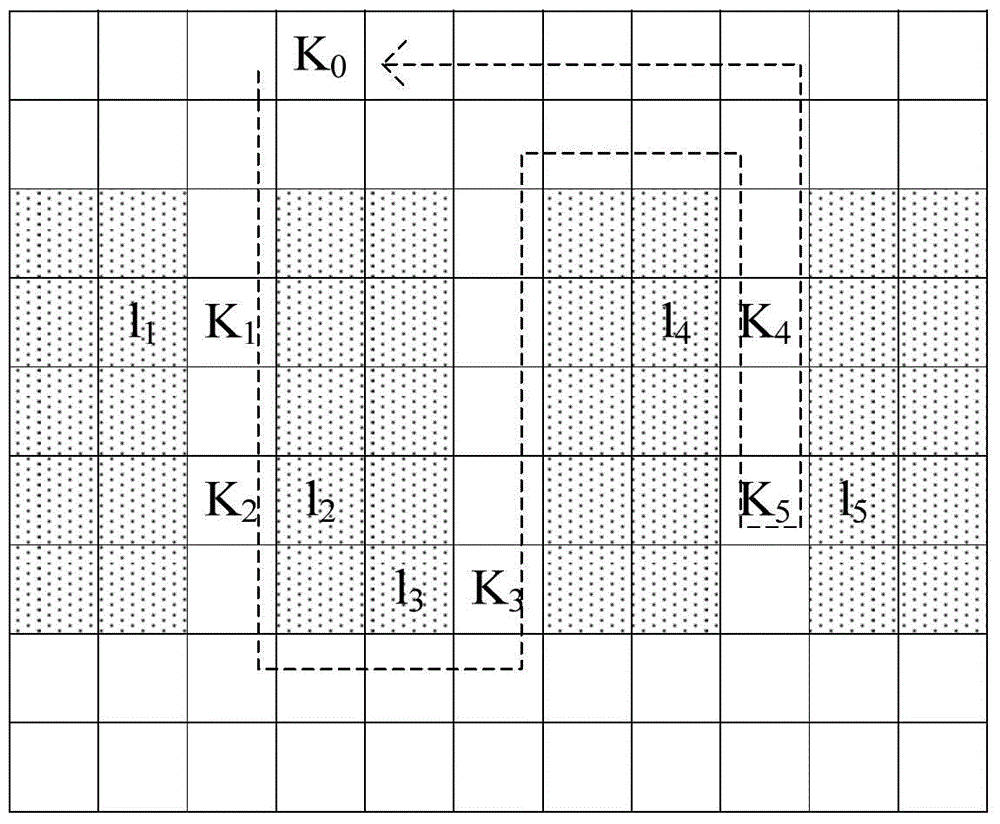

Stock rack set, storage system, robot control method, and robot

ActiveCN110949923AReduce the number of handlingReduce in quantityStorage devicesSimulationRobot control

The invention provides a stock rack set, a storage system, a robot control method, and a robot. The storage system includes a stock area, a control server, a first robot, a second robot, and a workstation, the first robot and the second robot are in wireless communication with the control server respectively; the stock area includes a plurality of stock racks, the layers other than bottom layers of the stock racks are for the placement of first storage containers capable of being transported, scattered goods are placed in the first storage containers, second storage containers capable of beingtransported are placed at bottom layers of the stock racks, full container loads are placed on the second storage containers, through a mix running method of two types of robots, carrying of target storage containers is achieved for sorting the full container loads and the scattered, the number of carrying times of the robot is significantly decreased, the number of robots is decreased, and thusthe sorting efficiency is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

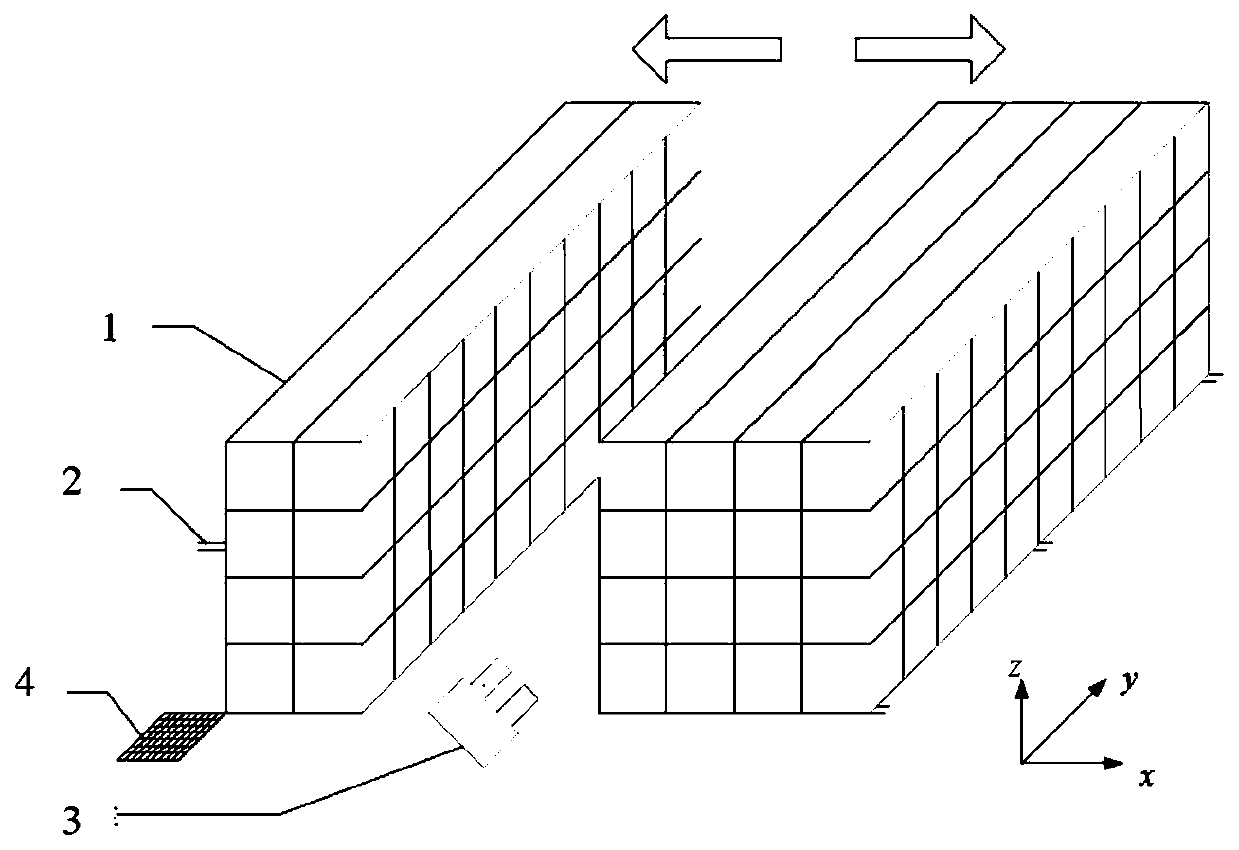

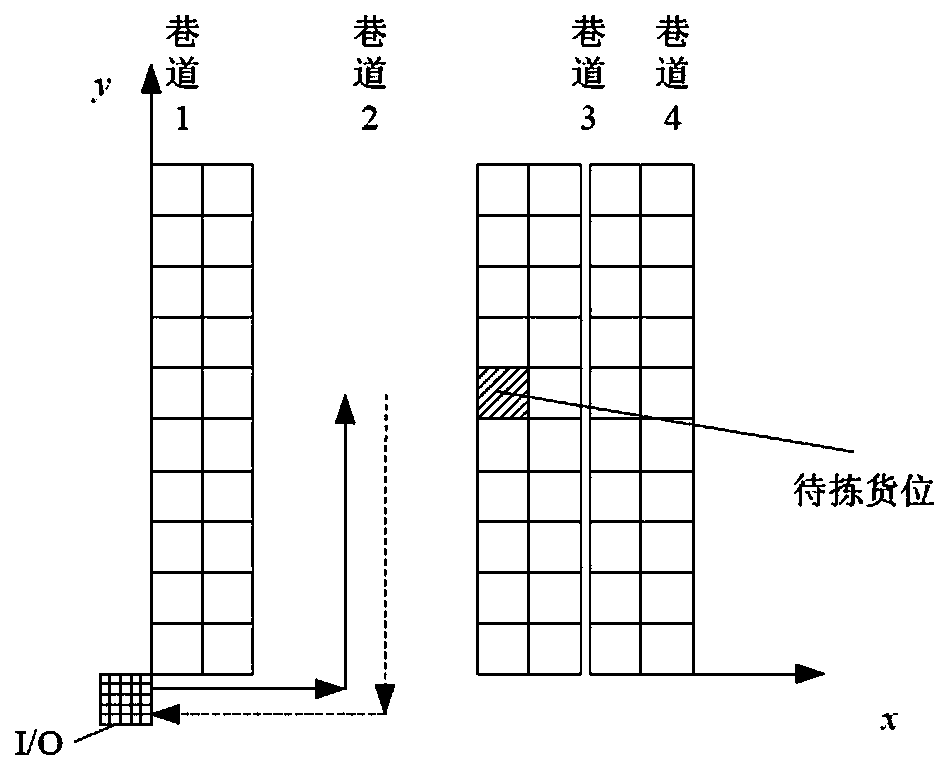

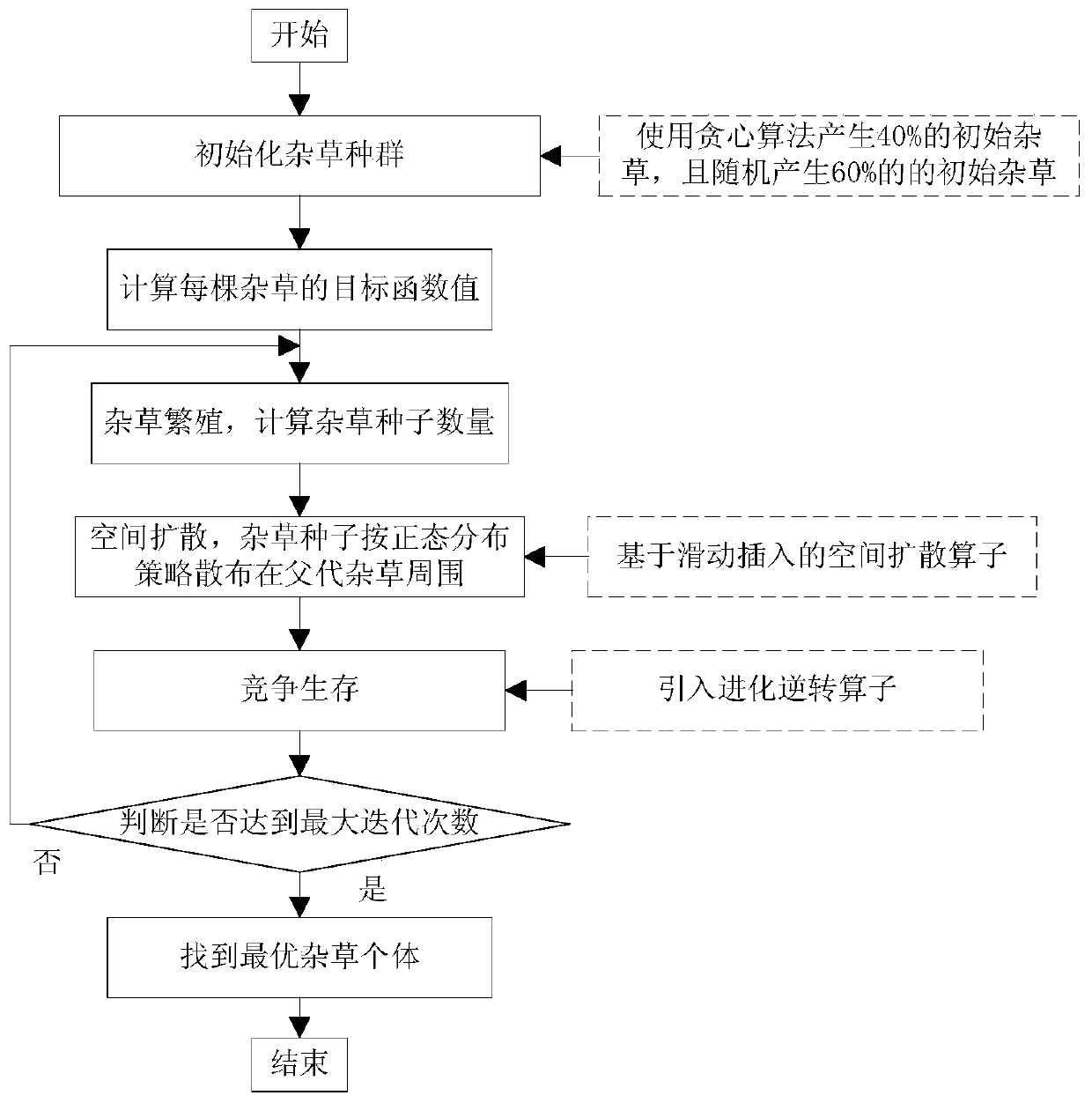

Goods location distributing method of mobile shelf warehousing system for refrigeration house

ActiveCN110909930AImprove picking efficiencyImprove stabilityForecastingResourcesLocal search (optimization)Greedy algorithm

The invention discloses a goods location distributing method of a mobile shelf warehousing system for a refrigeration house. The goods location distributing method includes the steps: distributing items with strong correlation to the same sorting roadway, thus reducing the possibility of repeatedly opening the sorting roadway; taking the similarity coefficient of the order item as the basis of thecorrelation; establishing a multi-target goods allocation optimization model by comprehensively considering item sorting frequency and goods shelf gravity center; solving by adopting an improved invasive weed algorithm to obtain an optimal storage position of goods; generating a part of initial population by adopting a greedy algorithm; setting a reasonable spatial diffusion operator; and finallyintroducing an evolutionary reversal operation of a genetic algorithm. According to the goods location distributing method, the global search capacity and the local search capacity are high, and theoptimization effect is remarkable, and the warehouse sorting efficiency and the shelf stability are effectively improved.

Owner:ZHEJIANG UNIV OF TECH

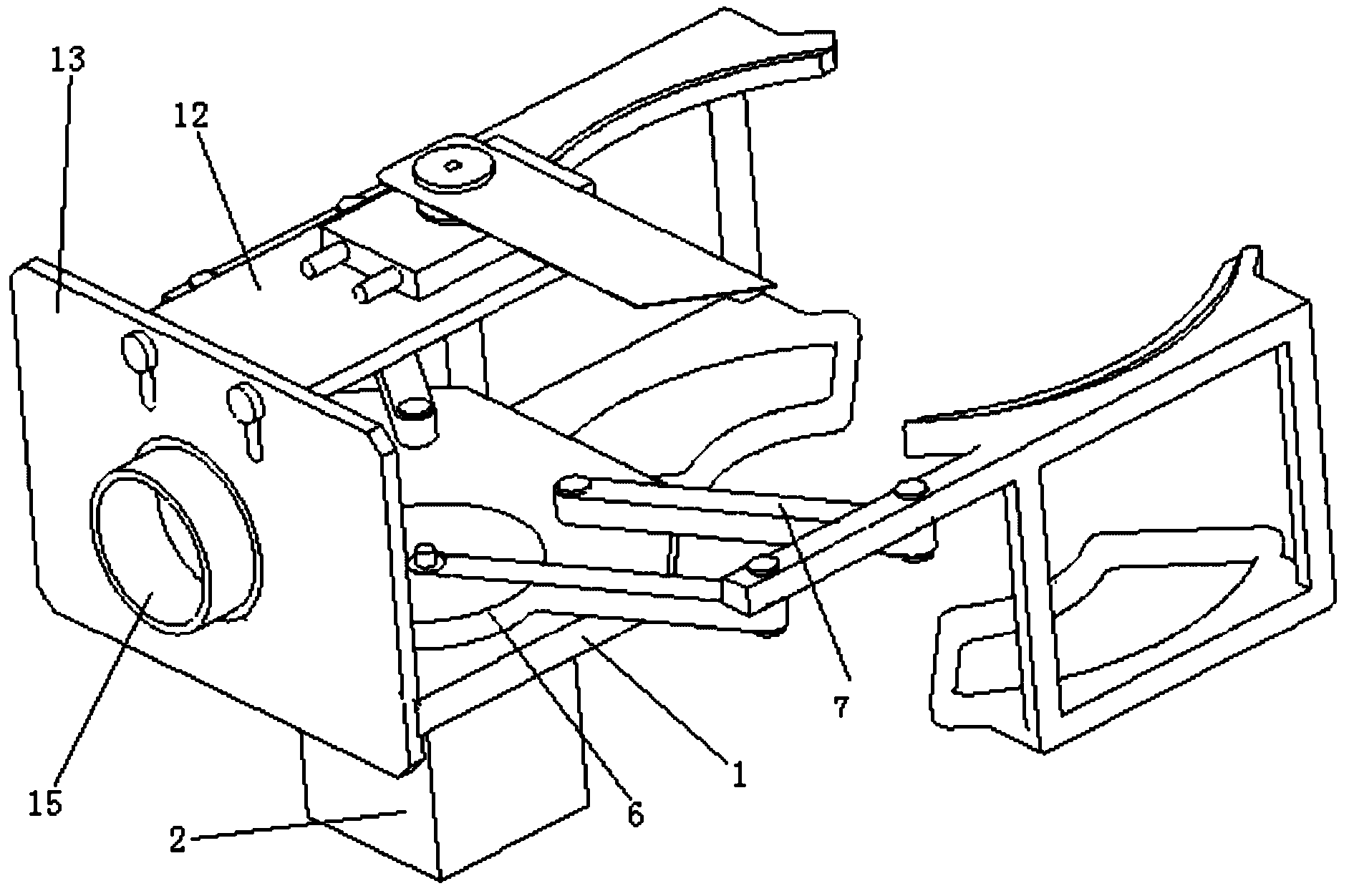

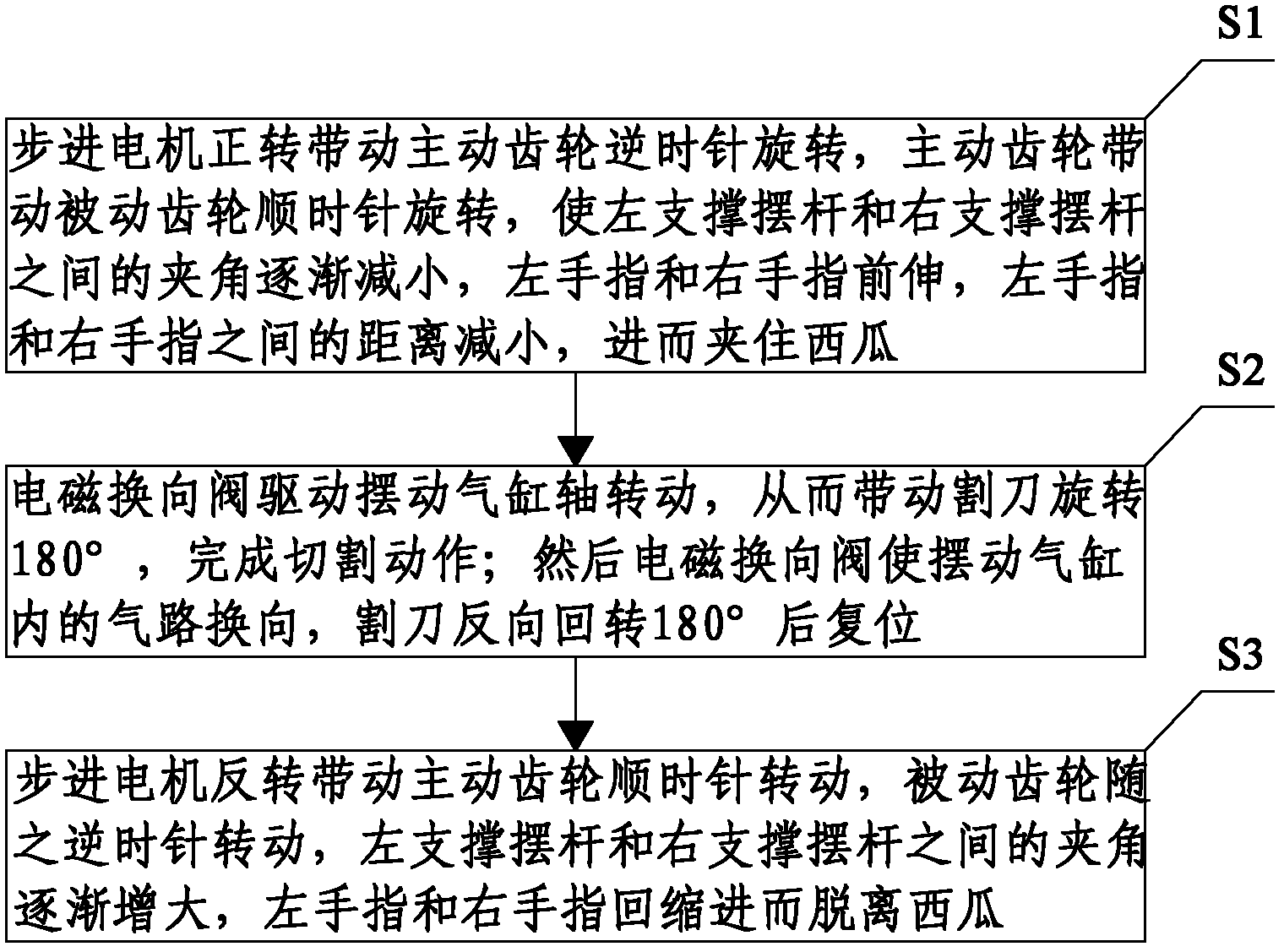

Melon and fruit picking device and picking method thereof

The invention discloses a melon and fruit picking device and a picking method thereof, which relate to the technical field of agricultural equipment. The melon and fruit picking device comprises a clamping device, a cutting device and a control device, wherein the clamping device comprises a step motor, a driven gear, a left support swinging rod, a left finger, a driving gear, a right support swinging rod, a right finger and supporting blocks, the supporting blocks are arranged under the left finger and the right finger, the driving gear and the step motor are connected, the driving gear and the driven gear are connected through a gear pair, the left finger is arranged at the end parts of the left support swinging rod and the driven gear, the right finger is arranged at the end parts of the right support swinging rod and the driving gear, the cutting device comprises a cutter, a swinging air cylinder and an electromagnetic reversing valve, the cutter is arranged on an output shaft of the swinging air cylinder, the electromagnetic reversing valve is arranged on the swinging air cylinder, the swinging air cylinder is arranged on a cutter frame, and the cutter frame is arranged on a back seat vertically and fixedly arranged on a base. The melon and fruit picking device and the method can be used for automatically picking melons and fruits, and a large amount of time and labor canbe saved for laborers.

Owner:CHINA AGRI UNIV

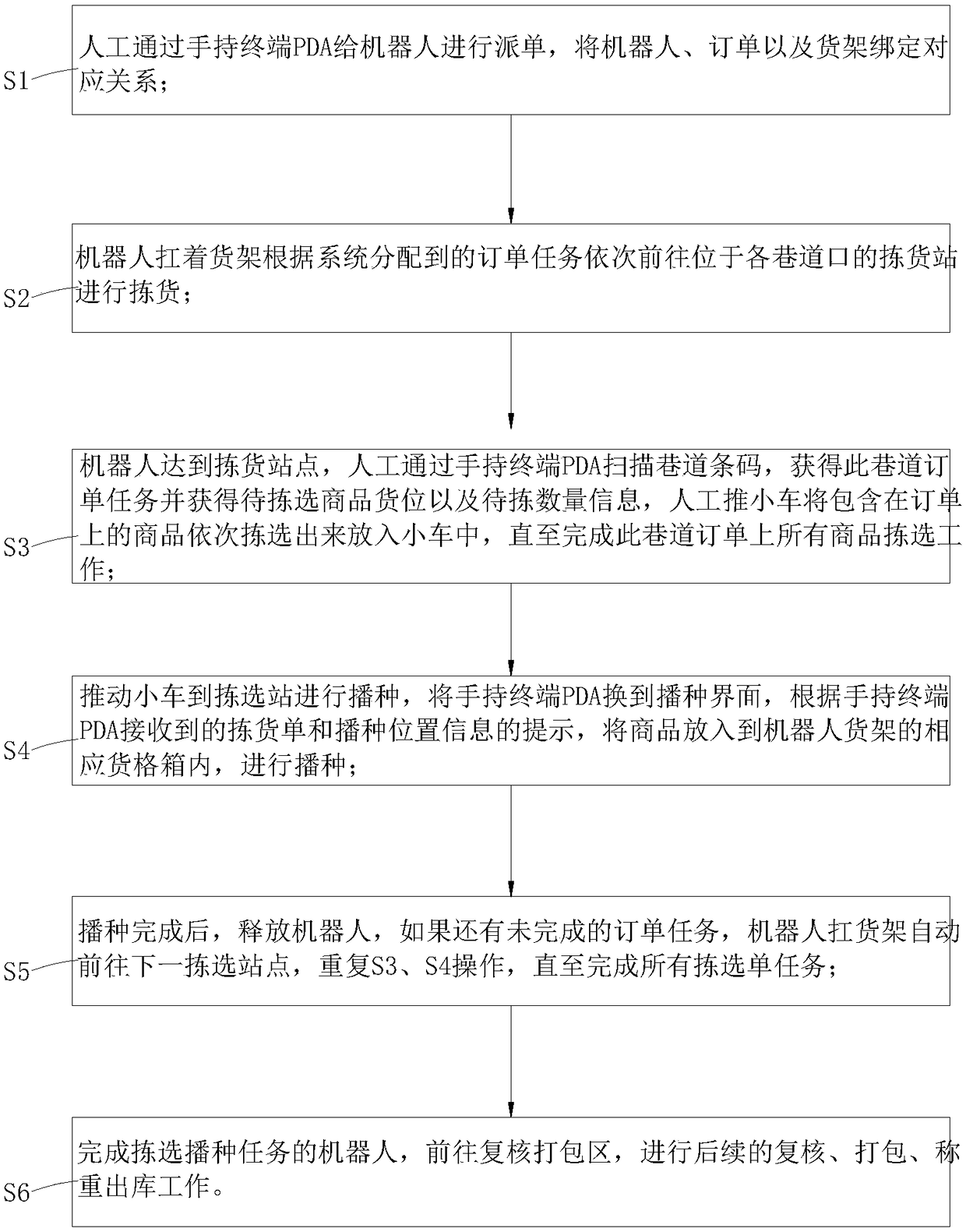

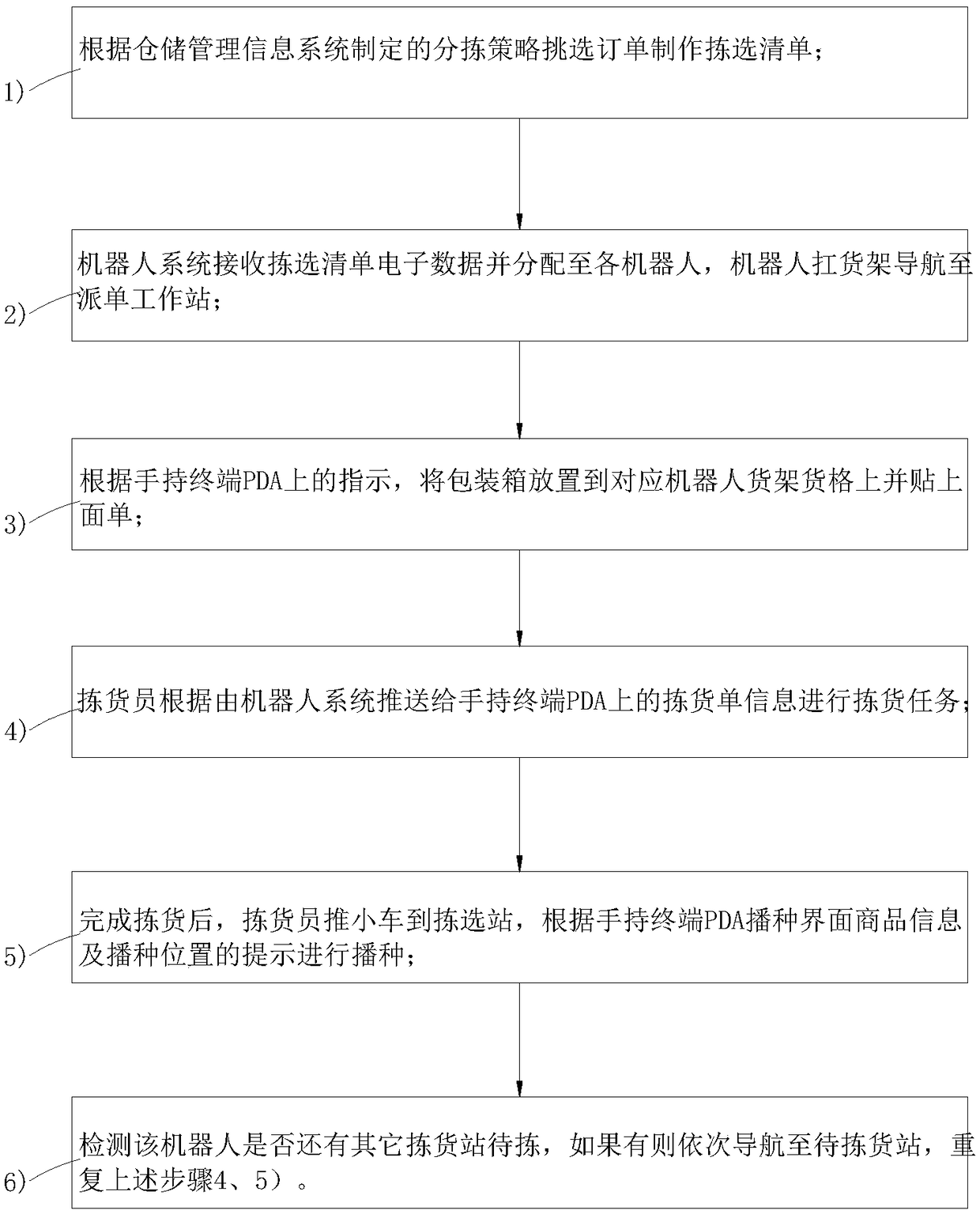

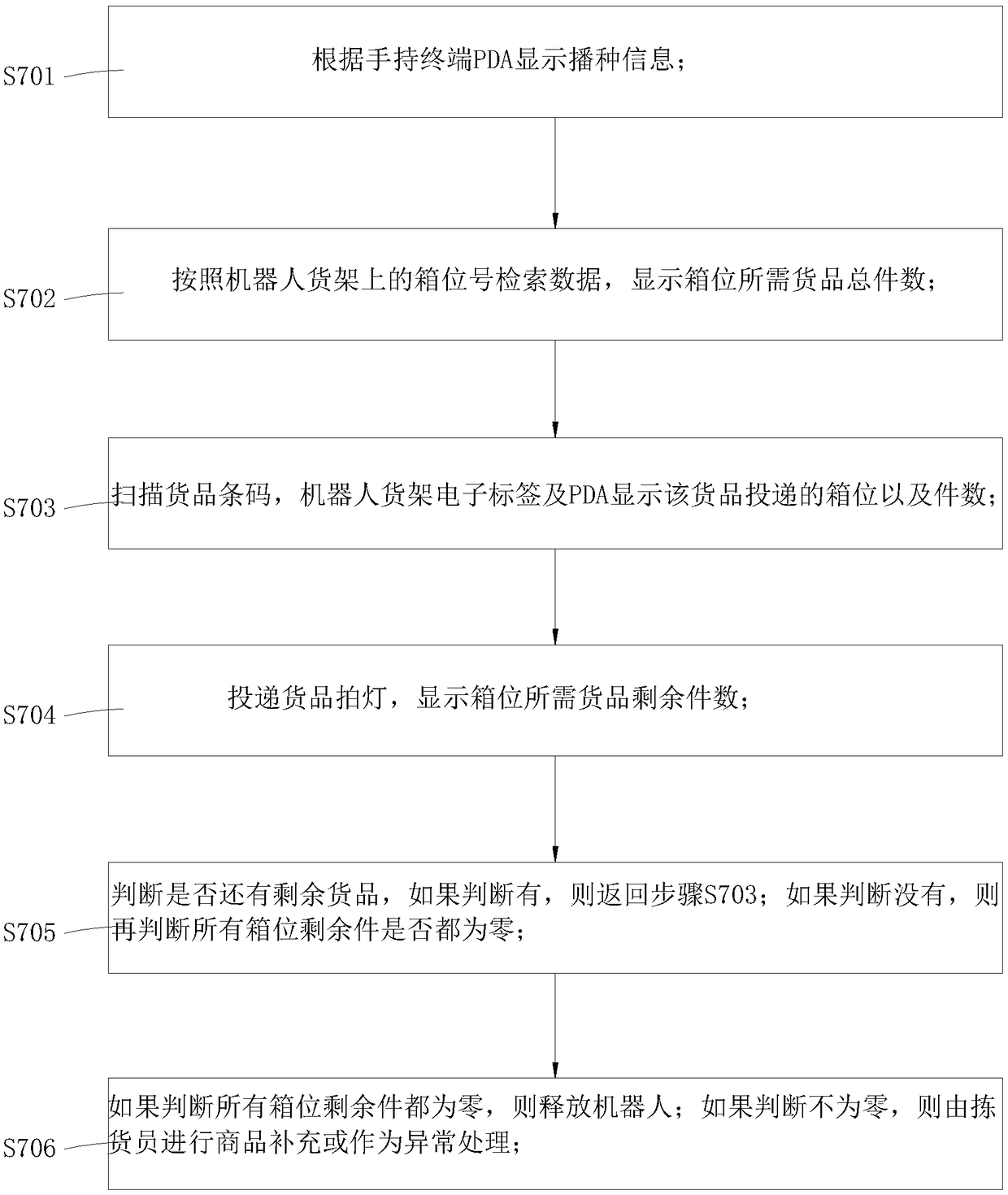

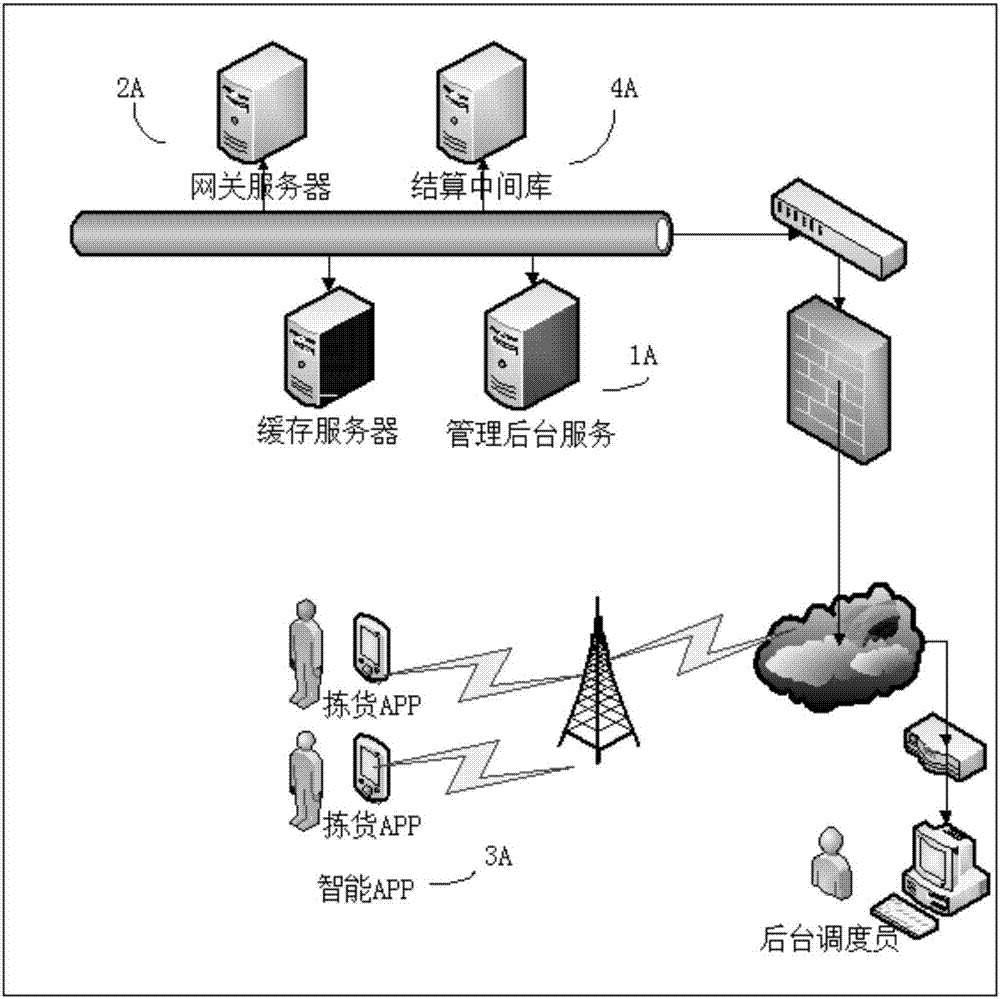

Robot automatic sorting method and system based on simultaneous picking and sorting

PendingCN109160163AHigh sorting hit rateImprove picking efficiencyStorage devicesIndustrial engineeringReal-time computing

The invention discloses a robot automatic sorting method and system based on simultaneous picking and sorting. The robot automatic sorting method comprises the following steps that a robot is dispatched by manually operating a handheld terminal PDA; S2, the robot carries a goods shelf to leave for a sorting station to conduct sorting according to distributed dispatching information; S3, the robotarrives at the corresponding laneway sorting station to acquire a laneway order task until completing all commodity sorting work on a laneway order; S4, a trolley is pushed to the sorting station to conduct seeding and puts commodities into corresponding goods grids of the goods shelf of the robot to conduct seeding; S5, after completion of seeding, the robot is released; if there is uncompleted order tasks, the robot carries the good shelf to automatically leave for the next sorting station to repeat operations in the steps S3 and S4 until completing all the sorting order tasks. Through the robot automatic sorting method, manpower participates in sorting; sorting and seeding tasks are completed simultaneously at the sorting station; as sorting and seeding are completed at the sorting station simultaneously, the number of seeding personnel is reduced while the procedures are reduced, and the labor cost is reduced.

Owner:BEIJING IT LOGISTICS CO LTD

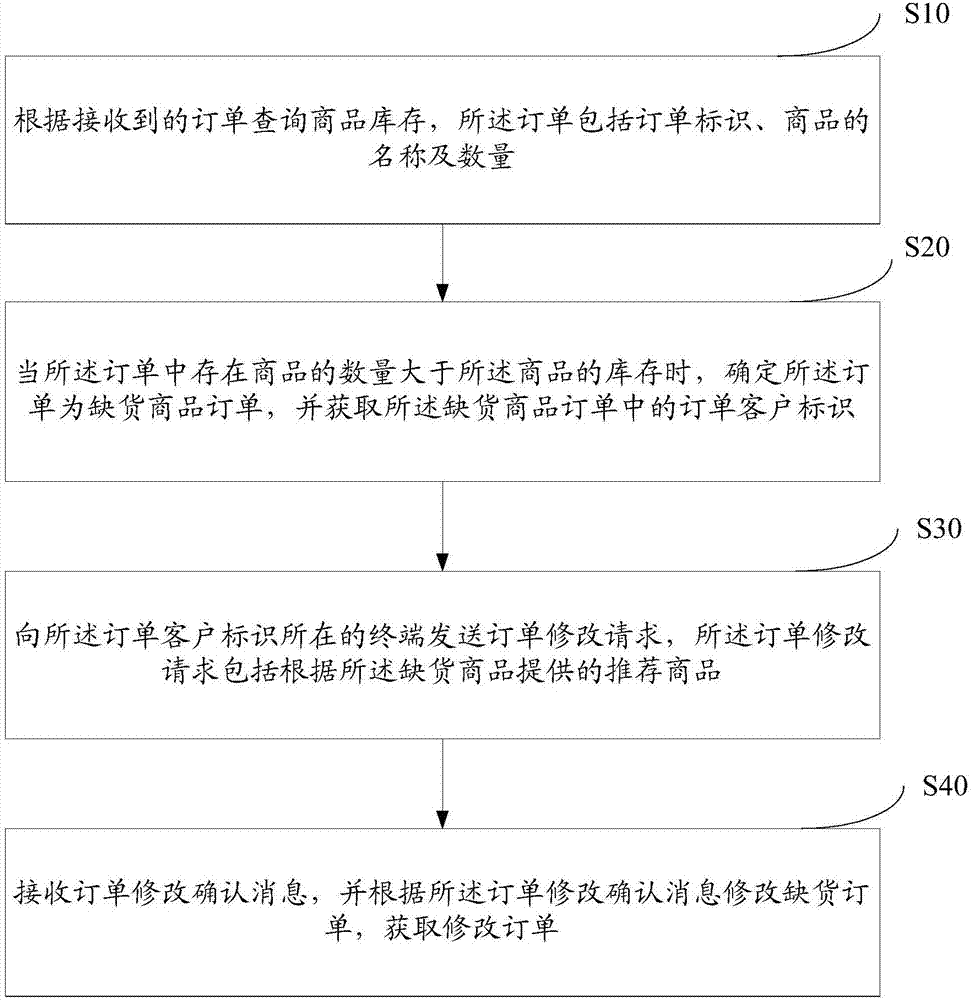

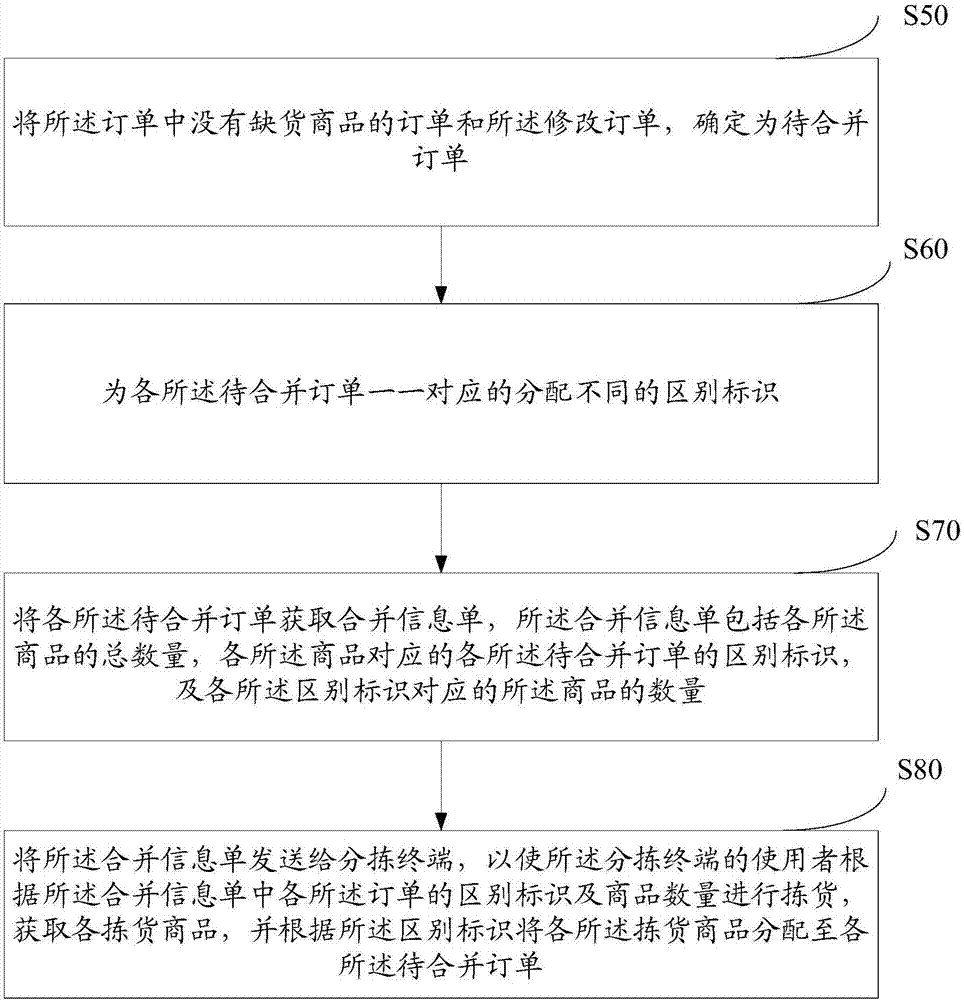

Order processing method and system

InactiveCN107248096AImprove picking success rateImprove completion rateBuying/selling/leasing transactionsOrder processingComputer science

The invention relates to an order processing method and a system. The method includes the following steps: checking the commodity inventory according to an order received, wherein the order includes an order identity and the name and number of each commodity; when the number of a commodity in the order is greater than the number of the commodity in the inventory, determining the order as an out-of-stock commodity order, and acquiring an order customer identity in the out-of-stock commodity order; sending an order modification request to a terminal represented by the order customer identity, wherein the order modification request includes a recommended commodity provided according to the out-of-stock commodity; and receiving an order modification confirmation message, modifying the out-of-stock commodity order according to the order modification confirmation message, and acquiring a modified order. According to the order processing method provided by the invention, recommended commodities can be provided for order customers, and an order can be modified after generation. Therefore, the success rate of picking by order and the completion rate of orders are increased, and the degree of satisfaction of order customers is enhanced.

Owner:多点生活(中国)网络科技有限公司

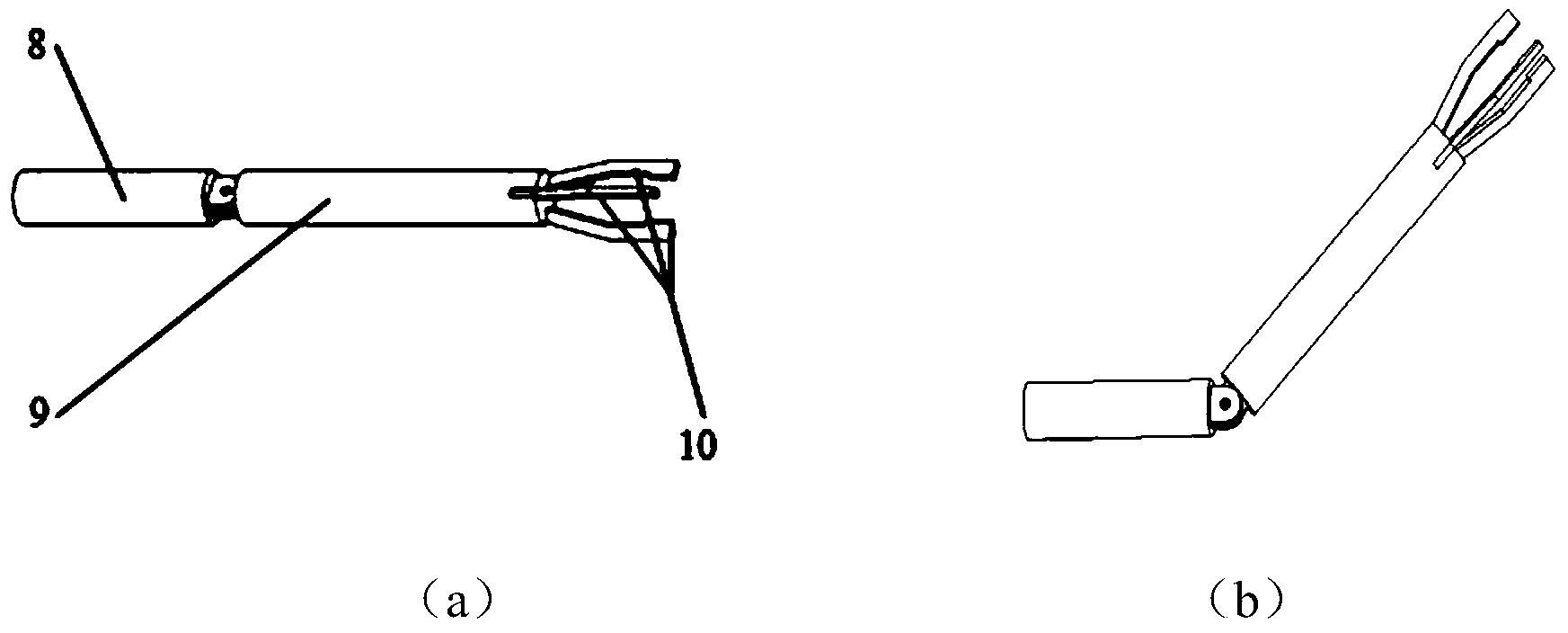

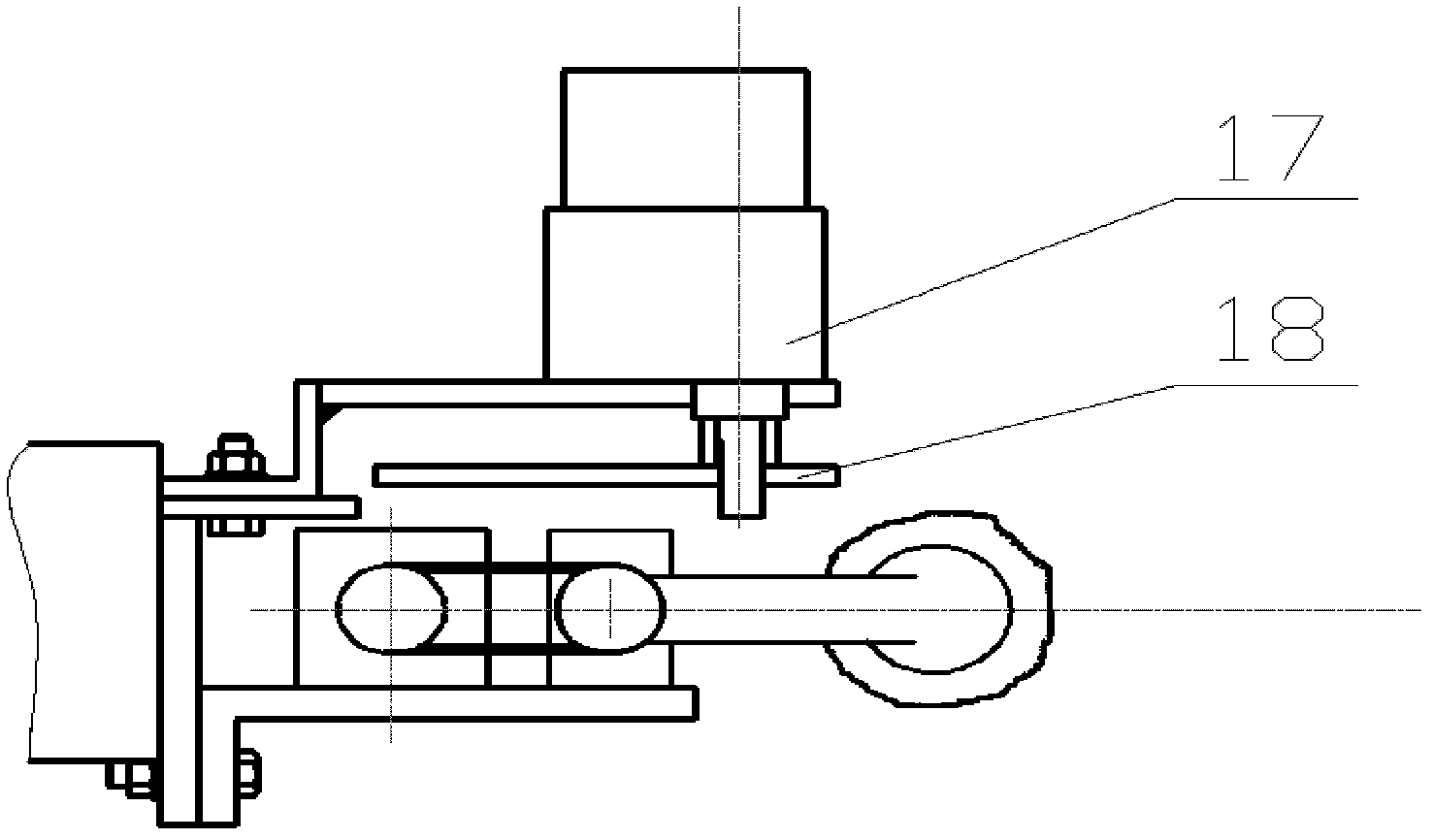

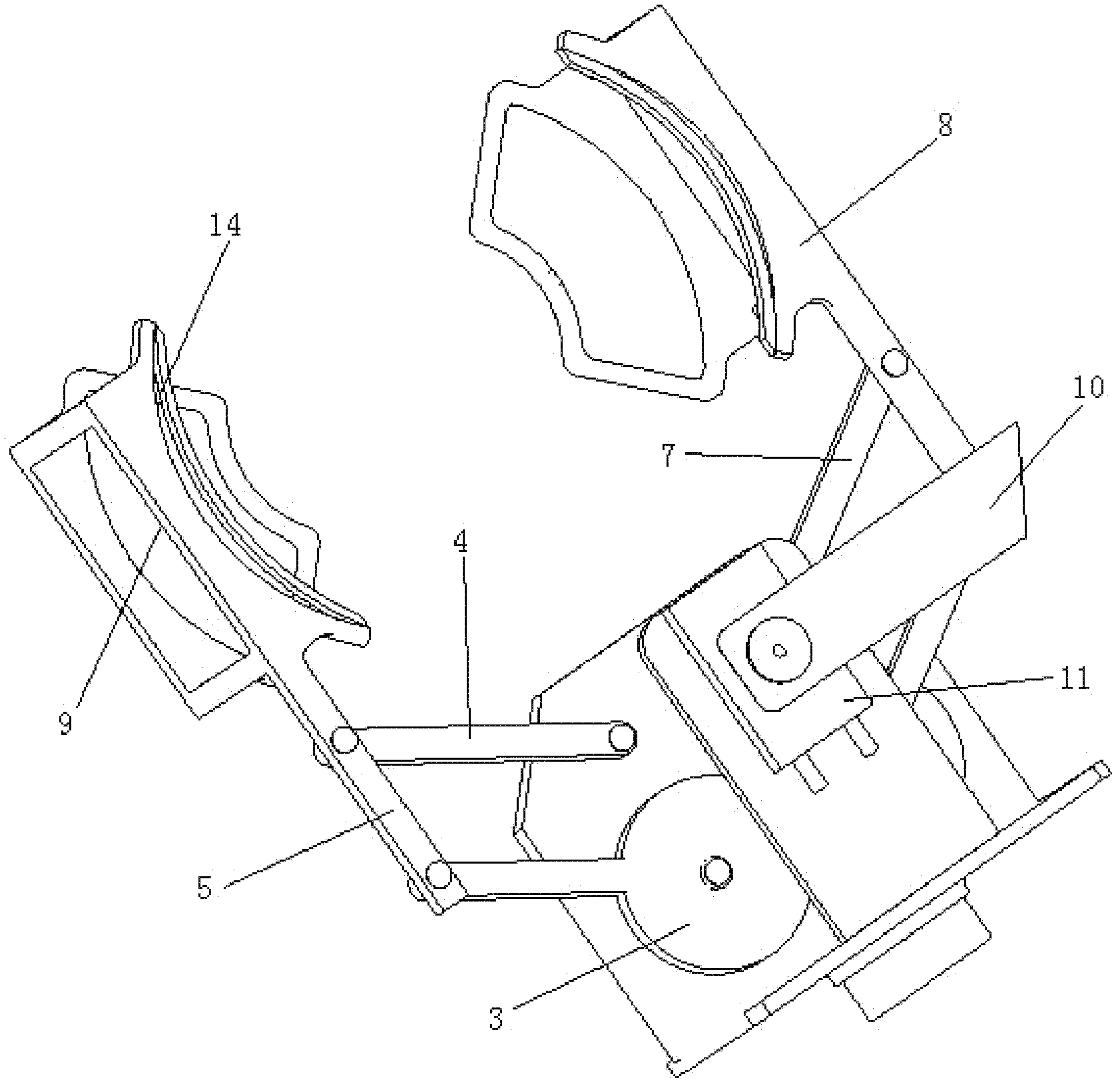

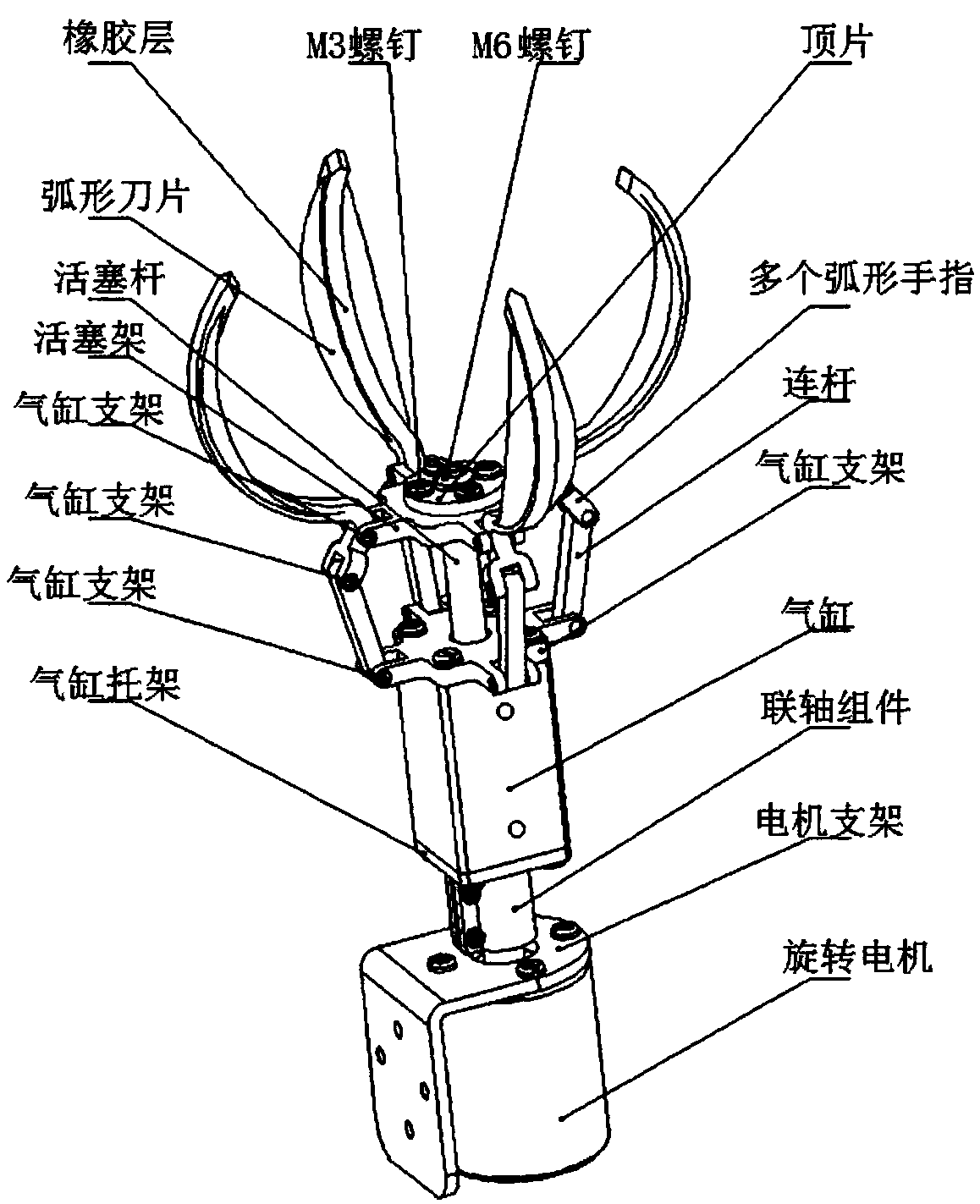

Tail end executor of fragrant pear picking robot, and picking method

PendingCN109105001ANovel methodCompact structurePicking devicesRenewable energy machinesPEARButt joint

The invention provides a tail end executor of a fragrant pear picking robot, and a picking method. The tail end executor comprises a manipulator butt joint disc, a shell of a motor A and four knife rests, wherein the manipulator butt joint disc is in butt joint with a robot mechanical arm, the shell of the motor A is connected with the manipulator butt joint disc and is positioned in a transmission mechanism, and the four knife rests are connected with connecting rods of the transmission mechanism and an installation frame. The method comprises the following steps of accessing points by usinga camera, carrying out fixation by using a sucking disc, carrying out cutting by utilizing arc-shaped blades, withdrawing the mechanical arm to release fragrant pears, and the like. According to the invention, shearing efficiency is improved, time consumption for carrying out image recognition and segmentation on fruit contours and fruit stems by a sensing mechanism is reduced, precision quality of picking operation is guaranteed, picking difficulty is lowered, and operation efficiency is improved

Owner:SHIHEZI UNIVERSITY

Fruit picking machine

InactiveCN101326878AReduce weightImprove picking efficiencyPicking devicesElectric machineryEngineering

The invention relates to an agricultural machine, in particular to a machine used for picking fruits. A picking machine comprises a picking head and a driving device which can drive the picking head to swing, and is characterized in that the driving device arranged inside a housing is a plane connecting rod mechanism; the crank of the plane connecting rod mechanism is fixedly connected with the upper end of an input shaft which can be rotatably arranged inside the housing, and the lower end of the input shaft is connected with a motor through a flexible connection; the rocker of the plane connecting rod mechanism is connected with the picking head. The invention is characterized by simple structure and convenient use; the device adopts the plane connecting rod mechanism with great simple structure to drive the picking head for vibration, and simultaneously adopts a steel wire flexible shaft connection, thus reducing the weight of picking with convenient use; because two or more than two picking heads are distributed parallely with a pectination structure, when picking, the picking head is inserted into branches of medlar or sea backthern, and then mature fruits drop inside a collecting device through the swinging of the pectination picking head, thus increasing the picking efficiency.

Owner:雷泽民 +2

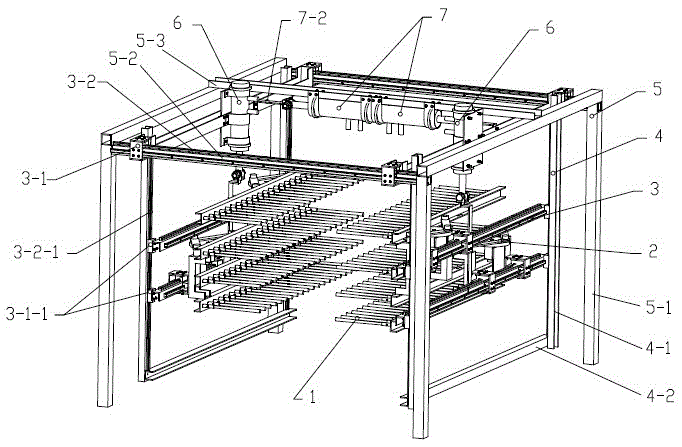

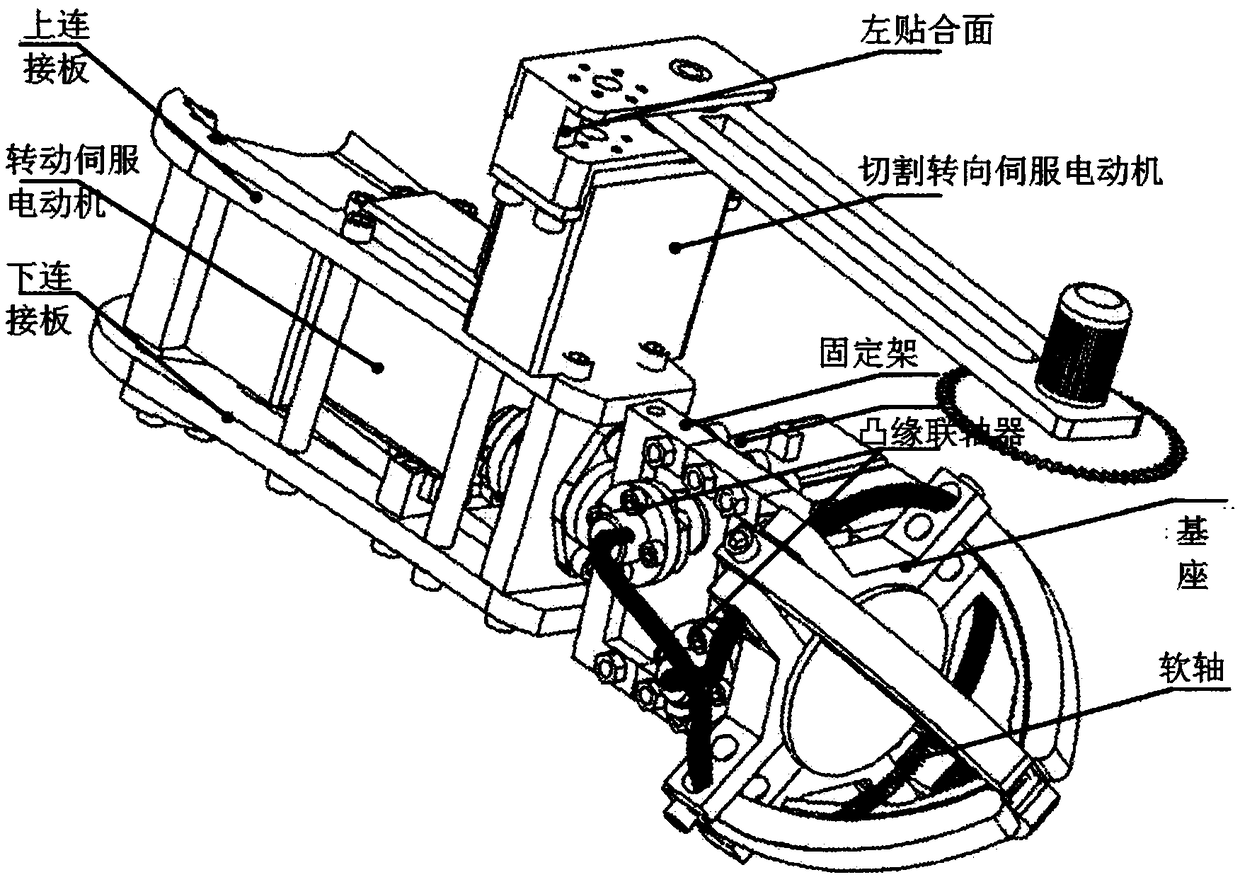

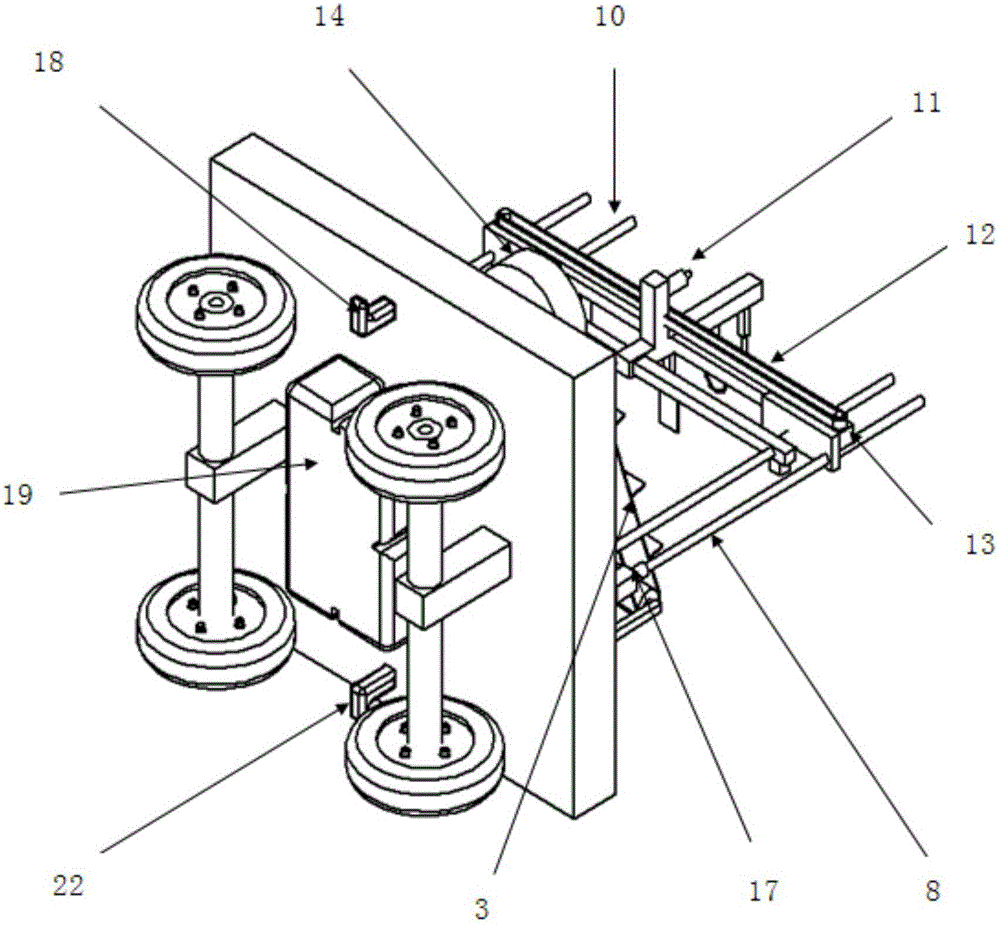

Intelligent integrated machine for intactly picking and grading table grapes and control method thereof

ActiveCN105900610AMeet the requirements of sustainable developmentAvoid secondary damageFood treatmentPicking devicesImage detectionEngineering

The invention provides an intelligent integrated machine for intactly picking and grading table grapes and a control method thereof. The intelligent integrated machine comprises a three-dimensional motion platform, a picking point positioning system, a picking system and a grading and subpackaging system. The three-dimensional motion platform comprises a walking motor controller, a position sensor and the like; the picking point positioning system is composed of a grading image detecting camera, system software and a data transmission module; the picking system is a top end structure of the three-dimensional motion platform and is composed of an infrared geminate transistor set, a picking cutter, a net bag and a rotary buffering plate; the grading and subpackaging system is composed of a conveying belt front lifting device, a conveying crawler belt, a conveying belt driving motor, a grading image detection camera and a controllable rotary box. The grape pickup integrated machine improves grape pickup efficiency and grading accuracy, reduces secondary damage to the grapes, ensures freshness and has wide market popularization prospects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

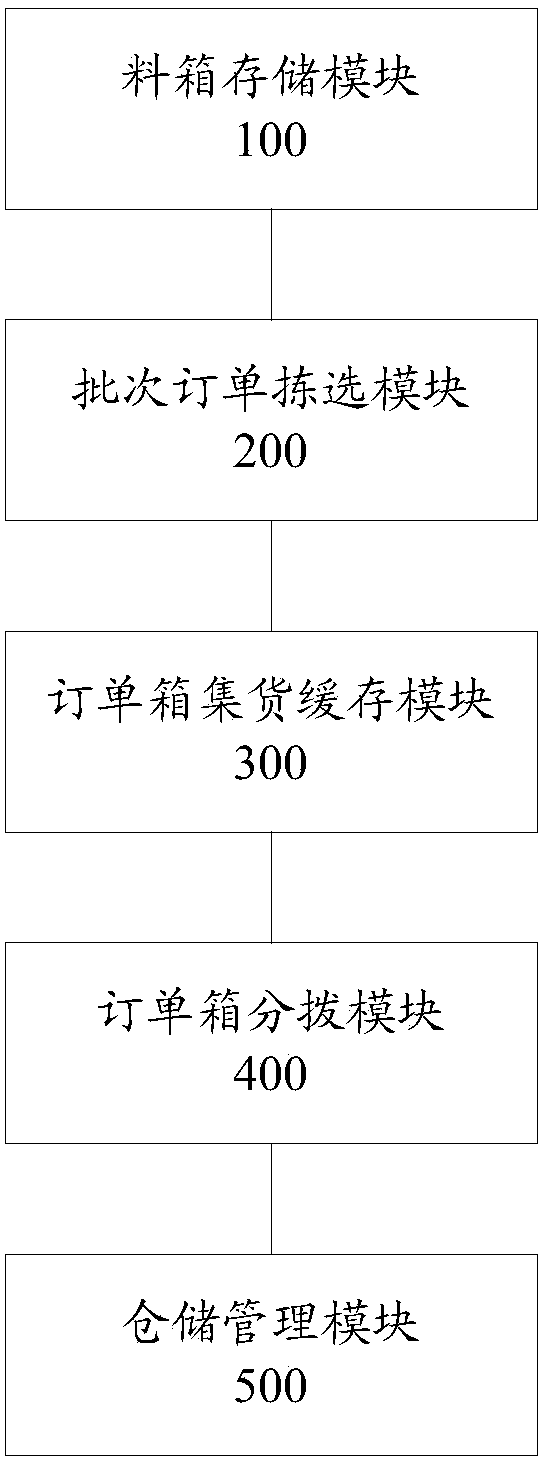

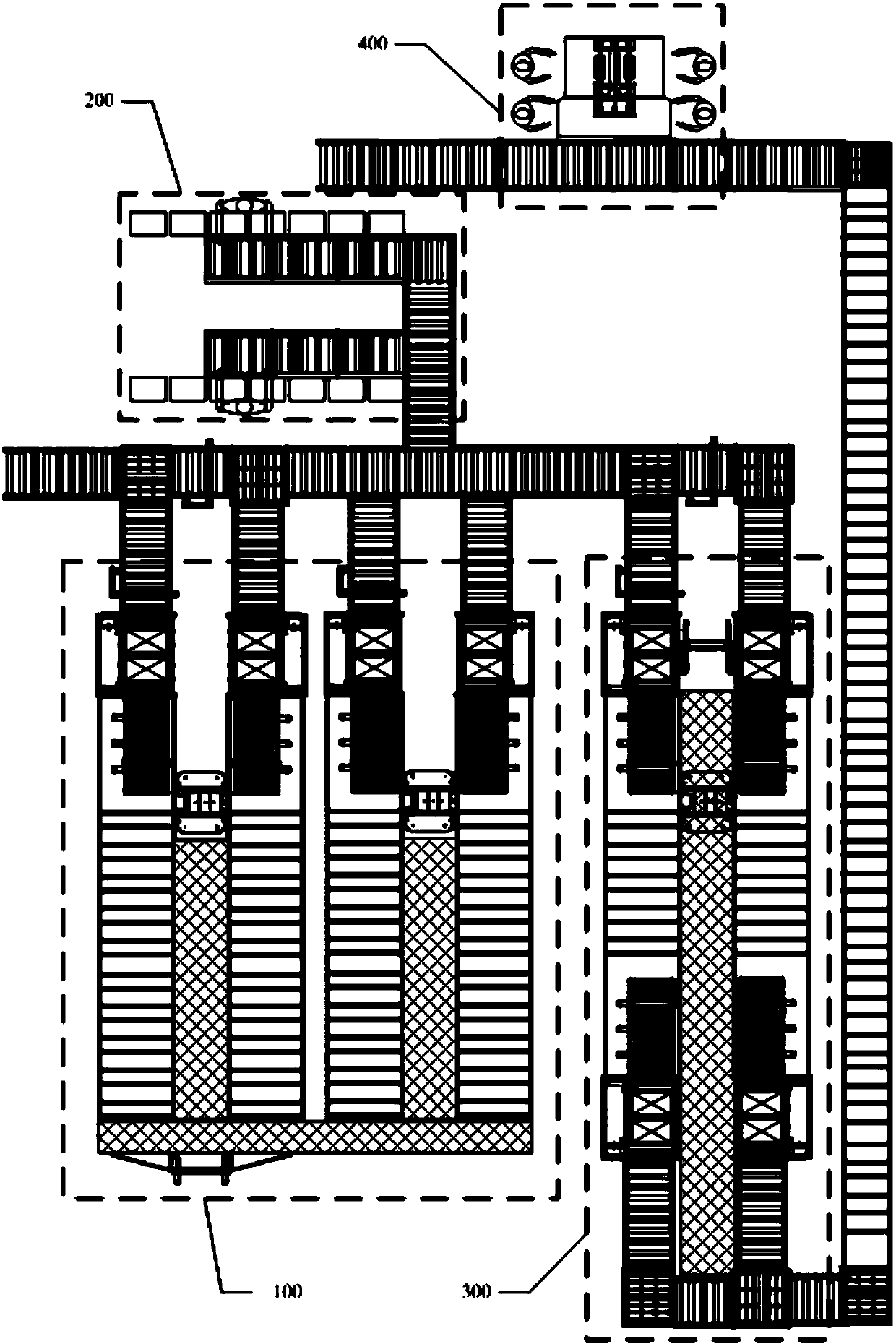

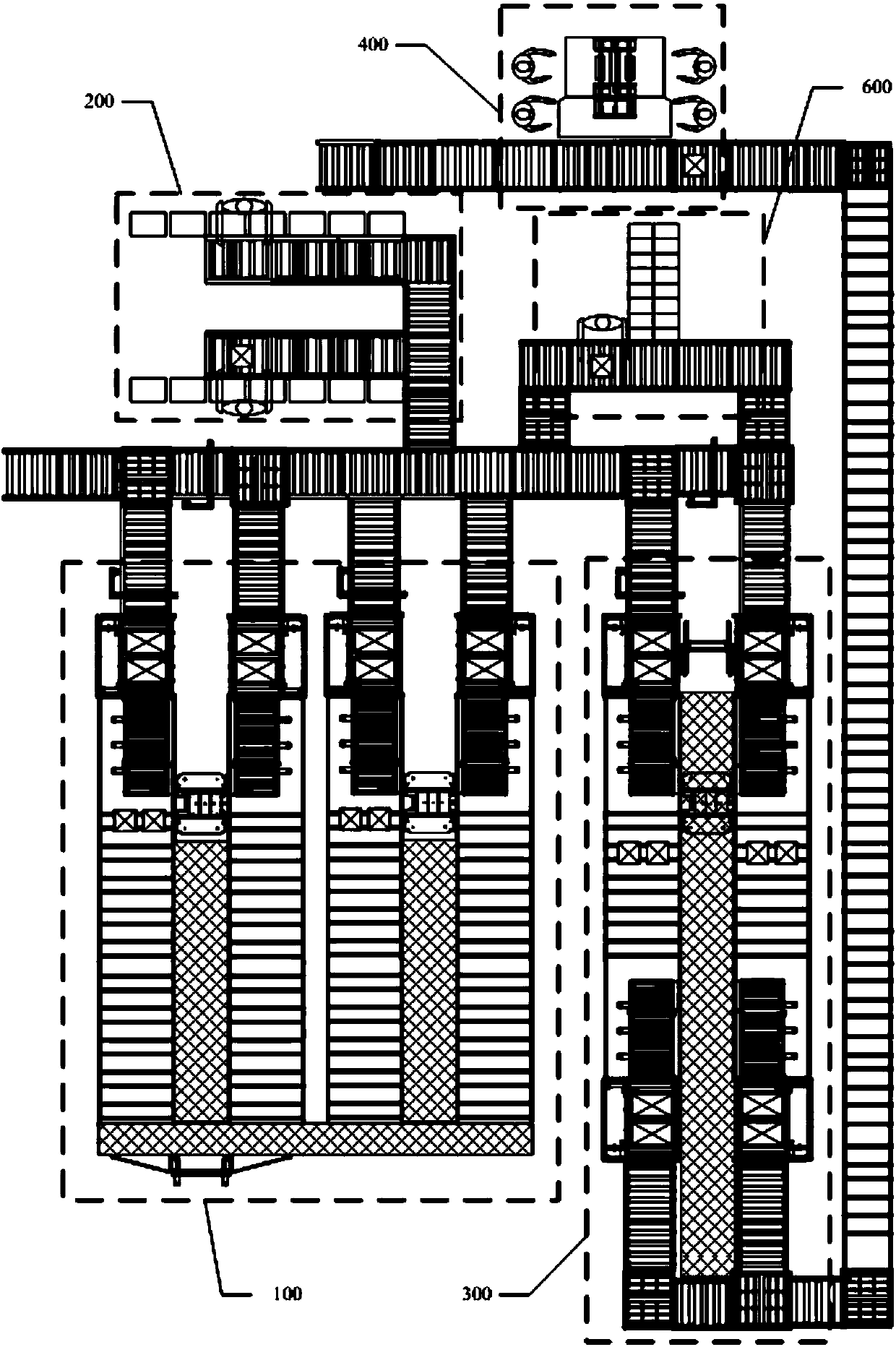

Material box storing and sorting system and storing and distributing integrated system

PendingCN107555056AImprove resupply efficiencyIncrease the number ofConveyorsPackagingParallel sortingOrder form

The invention provides a material box storing and sorting system and a storing and distributing integrated system and relates to the technical field of intelligent sorting. The material box storing and sorting system comprises a material box storing module, a batch order sorting module, an order box collecting and caching module, an order box distributing module and a storage management module, wherein the material box storing module is used for storing material boxes; material boxes are used for storing goods; the batch order sorting module is used for the parallel sorting of batch orders soas to sort goods in the material boxes to order boxes; batch orders comprise a plurality of user orders; the order box collecting and caching module is used for caching and transferring the order boxes; and the order box distributing module is used for receiving the order boxes cached and transferred by the order box collecting and caching module and distributing according to information of the user orders to complete the goods sorting of the batch orders. According to the system provided by the invention, the parallel sorting of the batch orders and the collecting and the caching of the orderboxes are adopted, so that the sorting efficiency of the batch orders is increased.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

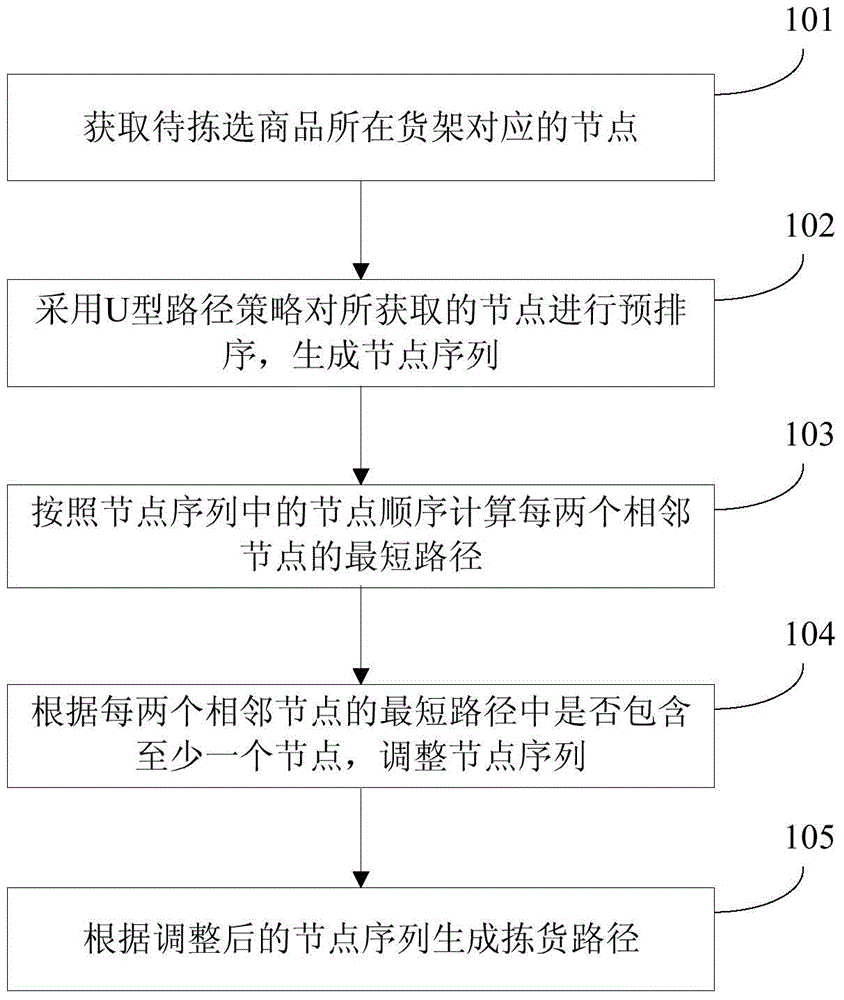

Goods picking path generation method and generation apparatus, and corresponding storage management system

ActiveCN104992241AQuick buildAvoid going the wrong wayForecastingLogisticsPath generationStorage management

The embodiments of the invention provide a goods picking path generation method and generation apparatus, and a corresponding storage management system. The method comprises the following steps: obtaining nodes corresponding to a shelf where a goods to be picked up is disposed; pre-ordering the obtained nodes by use of a U-shaped path strategy to generate a node sequence; according to the node order in the node sequence, calculating a shortest path between every two adjacent nodes; according to whether the shortest path between the two adjacent nodes includes at least one node, adjusting the node sequence; and according to the adjusted node sequence, generating a goods picking path. Through adoption of the technical scheme provided by the invention, a conventional U-shaped goods picking path is optimized, when the shortest path between the two adjacent nodes includes other nodes, the node order can be adjusted, goods corresponding to the included nodes are preferentially picked up, goods picking personnel is prevented from going a wrong way, and the goods picking efficiency is improved. Besides, the algorithm employed by the scheme is simple, and the goods picking path can be rapidly generated.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com