Tail end executor of fragrant pear picking robot, and picking method

A technology of end effector and picking robot, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problem of limited cutting range of cutters and scissors, growth of rot bacteria and penicillium, and high labor intensity in time periods, etc. problems, to achieve the effect of improving the successful picking rate, reducing the positioning accuracy, and avoiding the blind area of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

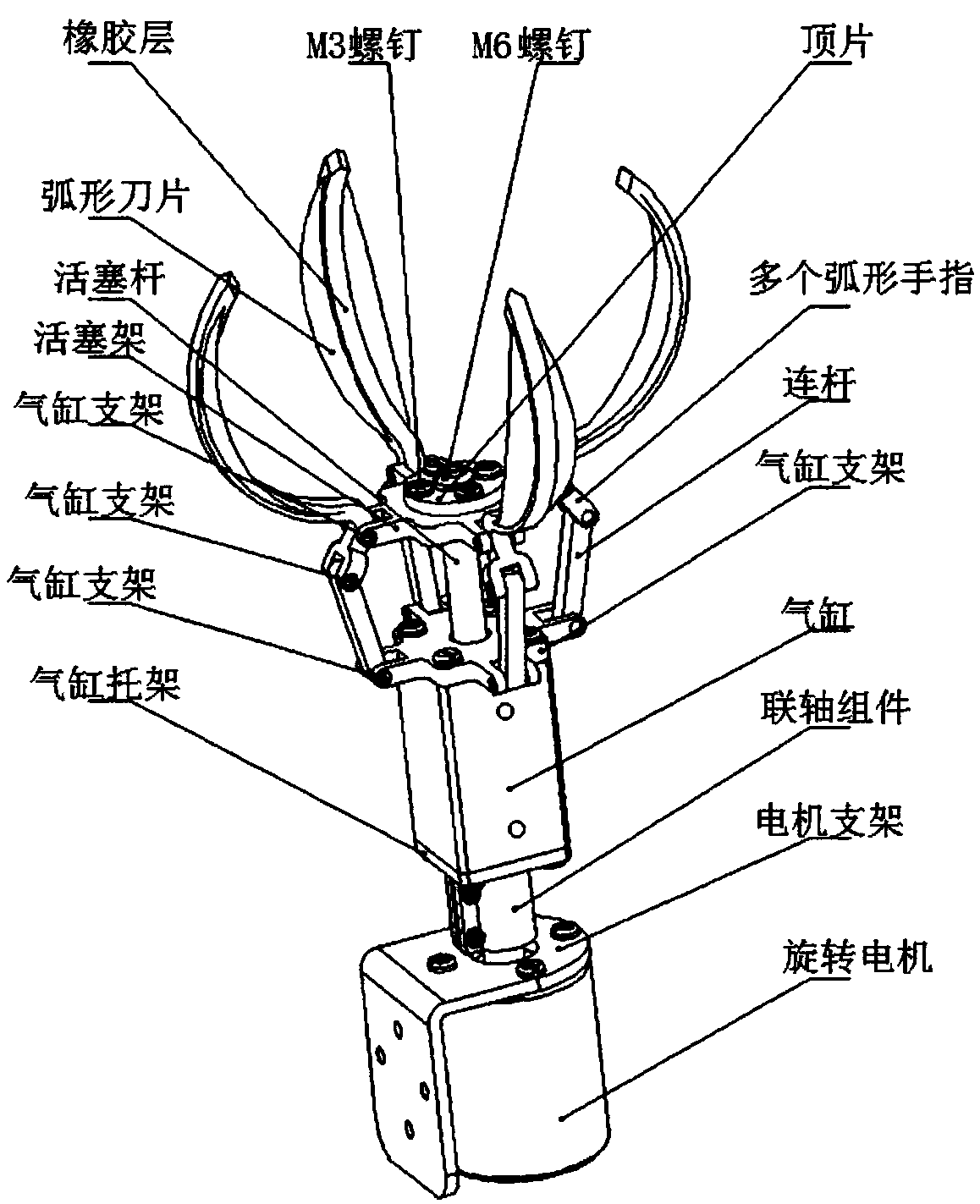

[0057] An end effector of a fragrant pear picking robot is composed of a manipulator docking plate 1, a transmission mechanism 2, an execution mechanism 3 and a sensing mechanism.

[0058] The docking plate 1 of the manipulator and the motor A housing 22 of the transmission mechanism 2 are fixed by bolts.

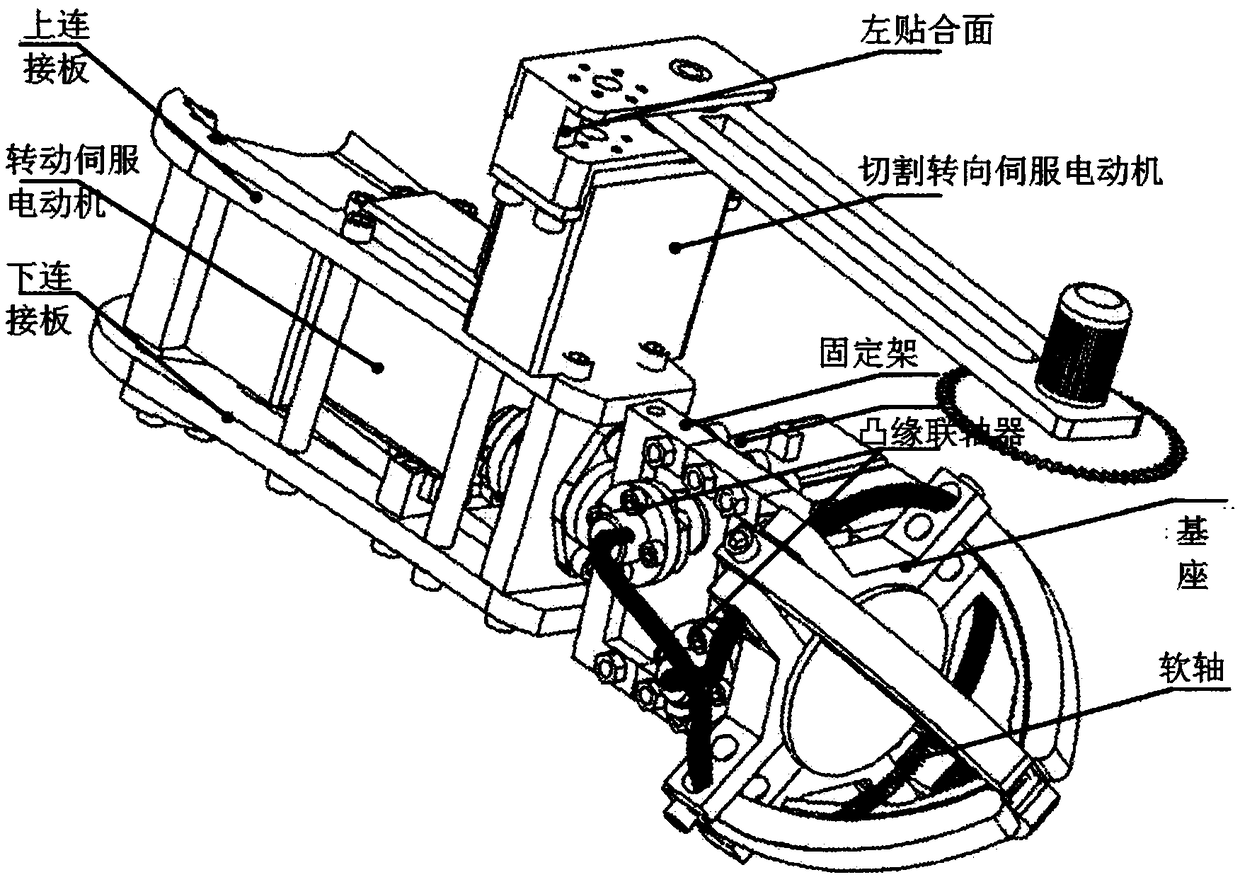

[0059] The servo motor A21 in the transmission mechanism 2 is installed in the inner cavity of the motor A casing 22, the O-ring 26 is installed on the end face of the motor shaft (that is, the O-ring is installed on the motor shaft), and the motor flange 23 is installed on the servo motor A21 through screws. on the shaft end face; the servo motor A21 is connected with the signal line through the reducer 24, the reducer 24 is installed inside the connecting shell 25, and the connecting shell 25 is fixedly connected with the motor B shell 28 through the connecting plate 215 and the connecting screw 214; the servo motor B27 is installed In the inner cavity of the motor B shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com