Patents

Literature

113results about How to "Reduce picking costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

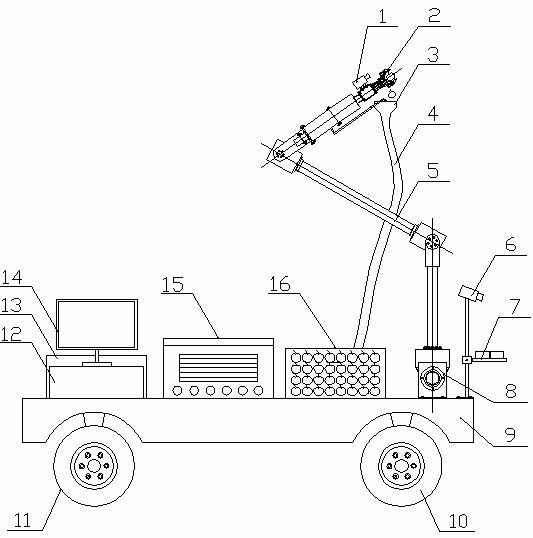

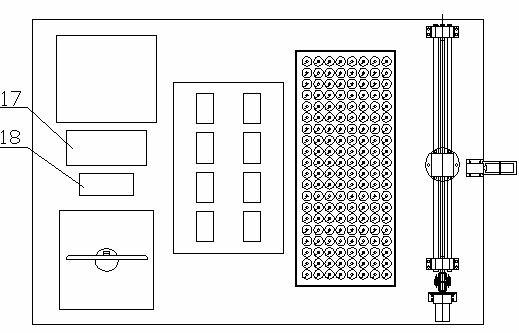

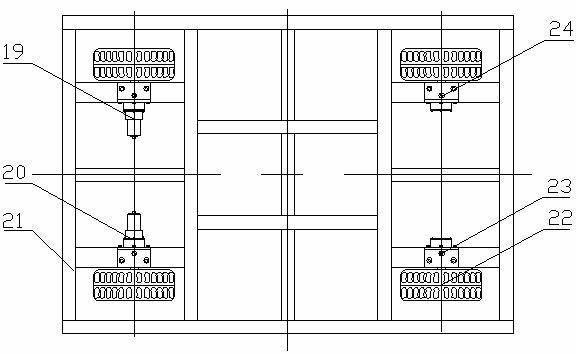

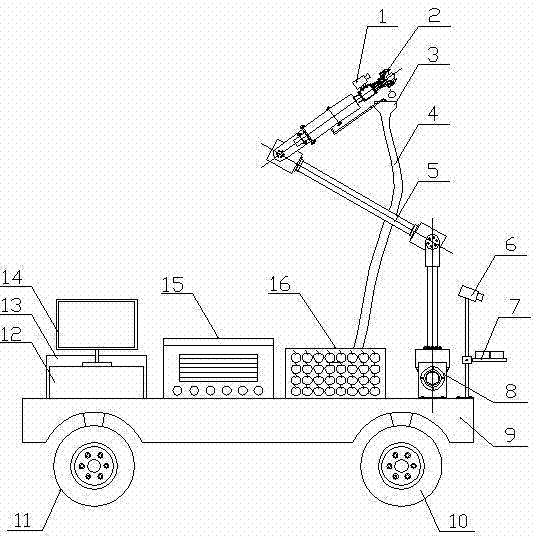

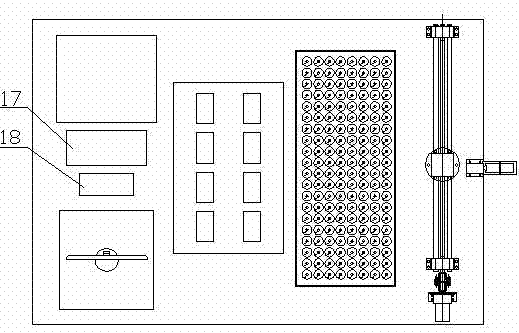

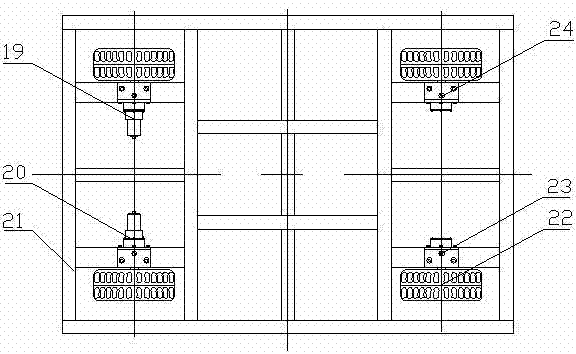

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

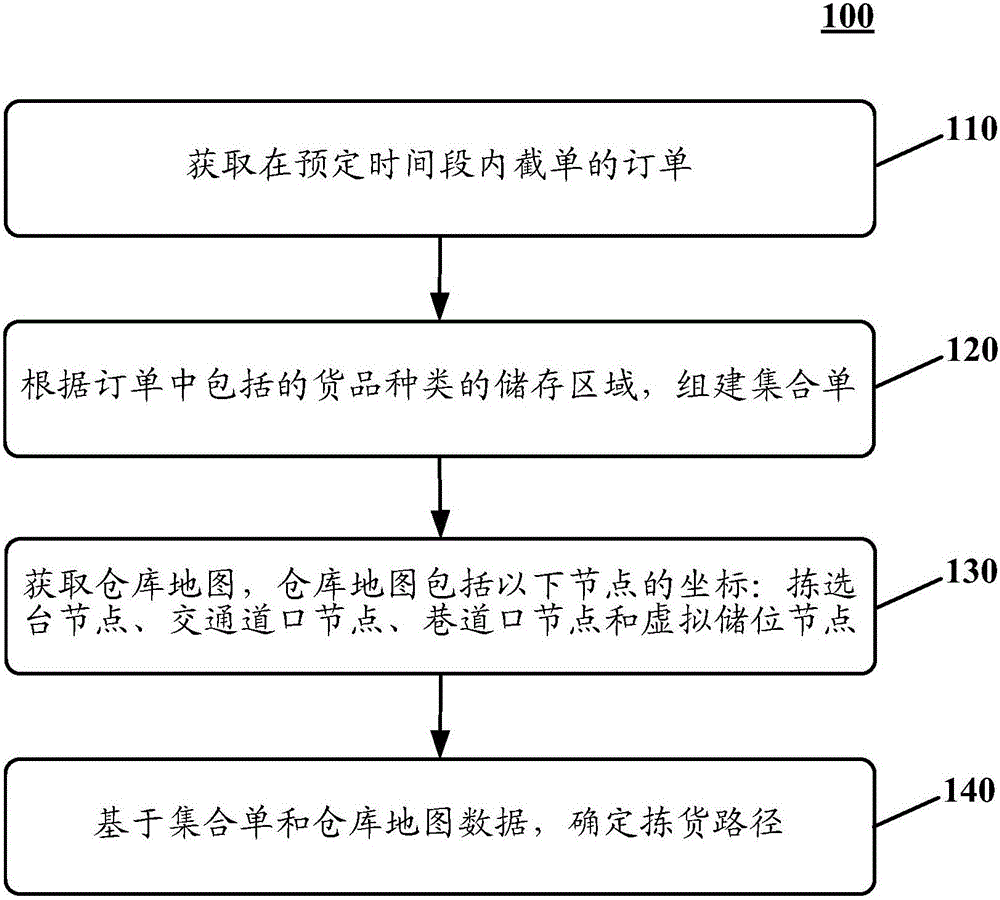

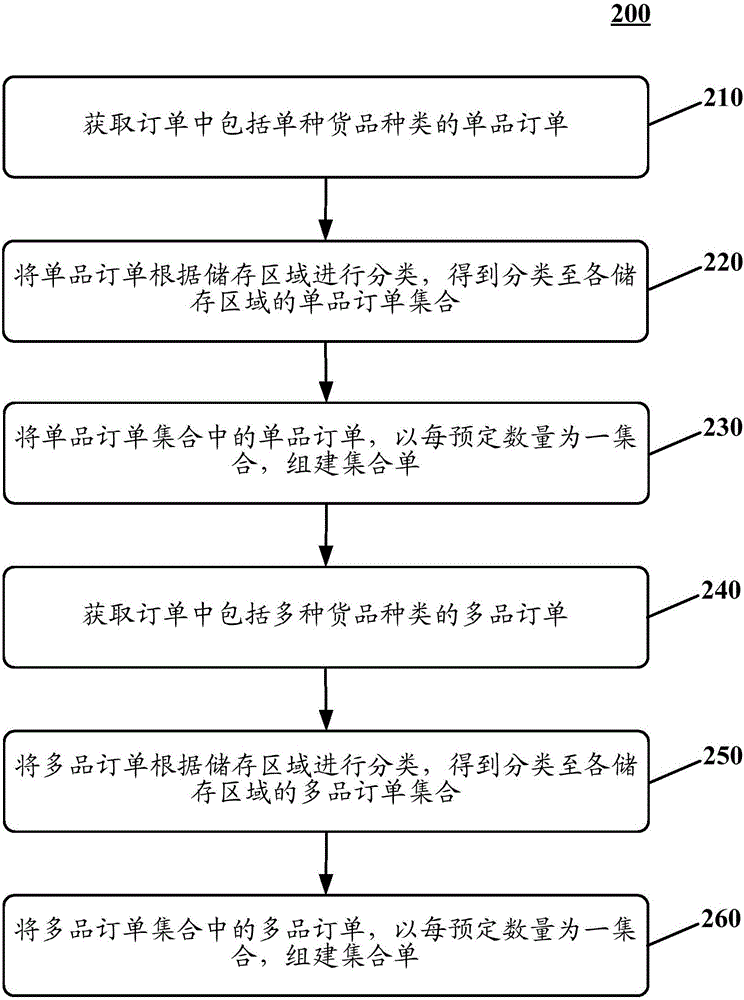

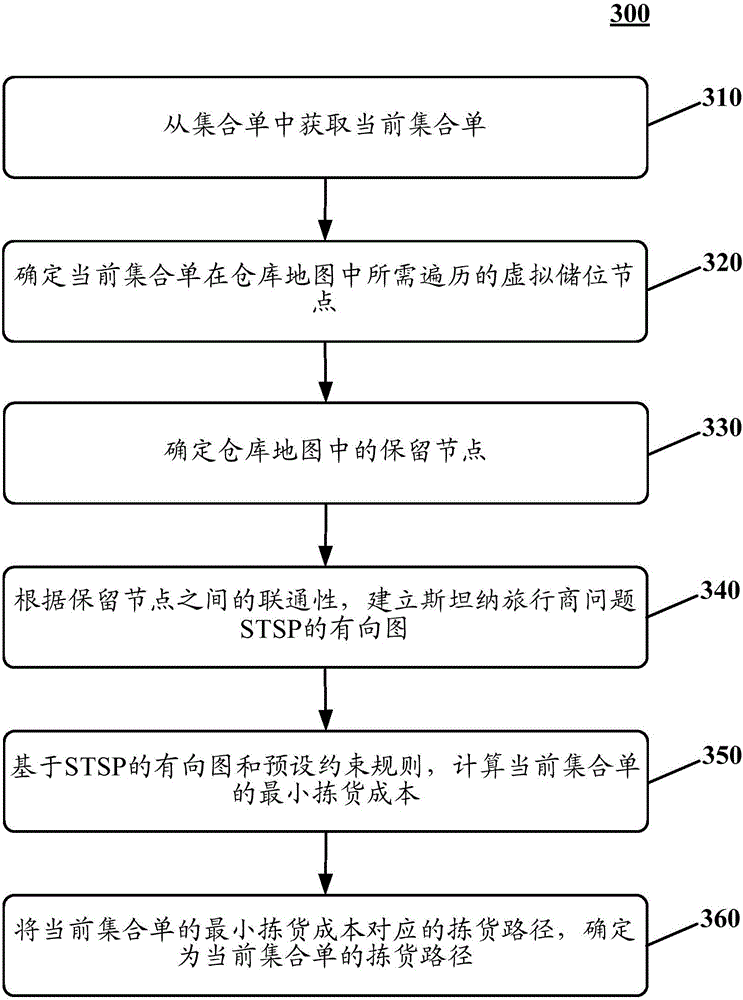

Method and device used for determining picking route

ActiveCN106809586AImprove total picking efficiencyReduce picking costsLogisticsStorage devicesProduct typeComputer science

The invention discloses a method and device used for determining a picking route. The method comprises the steps that orders cut off in a preset time period are obtained; an aggregation order is built according to storage areas of product types contained in the orders; a warehouse map is obtained, wherein the warehouse map comprises coordinates of following nodes including the picking table node, the traffic crossing node, the alley crossing node and the virtual storage location node; based on the aggregation order and the warehouse map, the picking route is determined. By means of the method, the aggregation order is built according to the storage areas of the product types, and when conducting order picking according to the aggregation order, the required picking route is short, so that the picking cost of the picker is reduced and the picking efficiency of the picker is improved; the picking route is determined based on the aggregation order and the warehouse map so that it can be determined that the route from which storage locations of products in the aggregation order are traversed is shortest, accordingly the total picking route is short, and the total picking efficiency of the warehouse is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

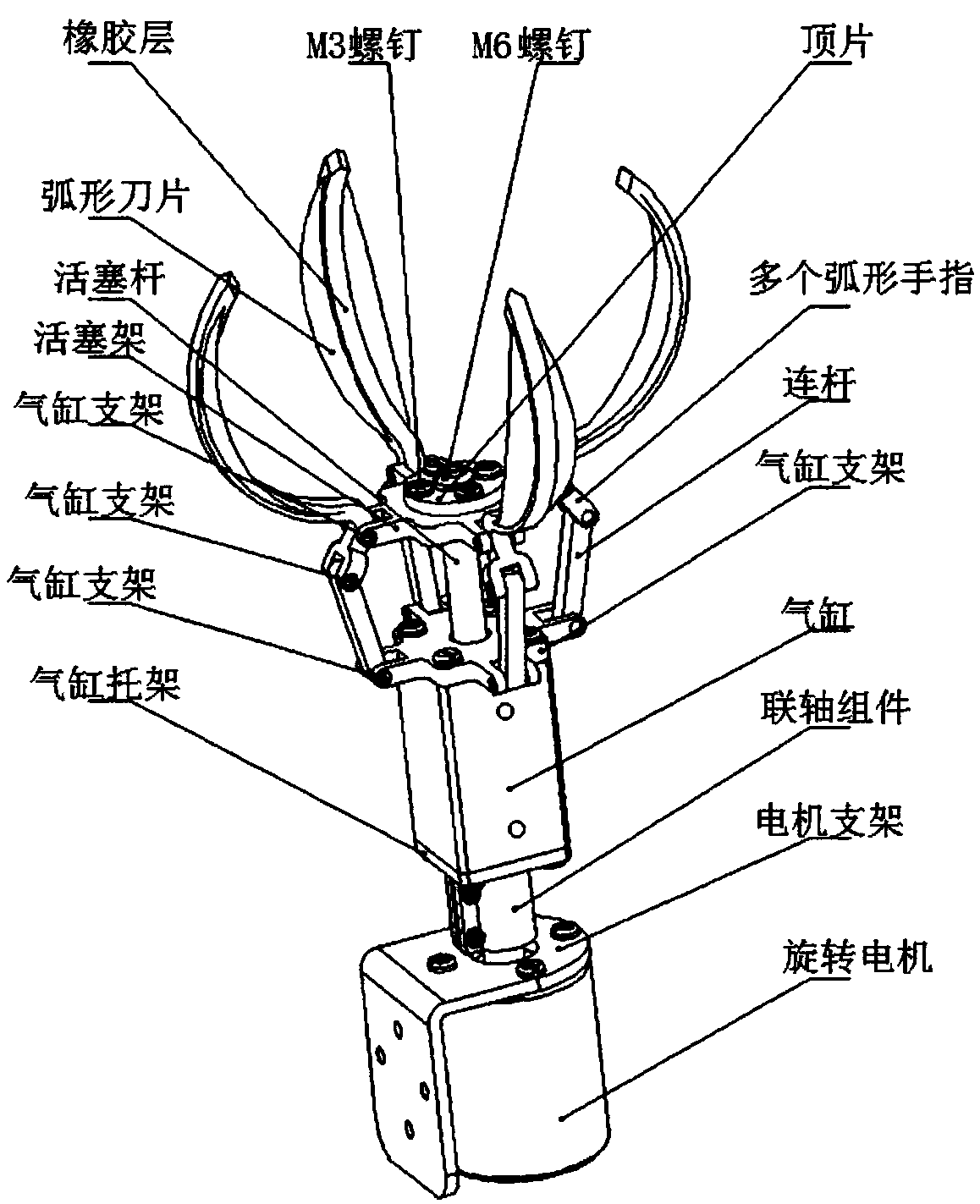

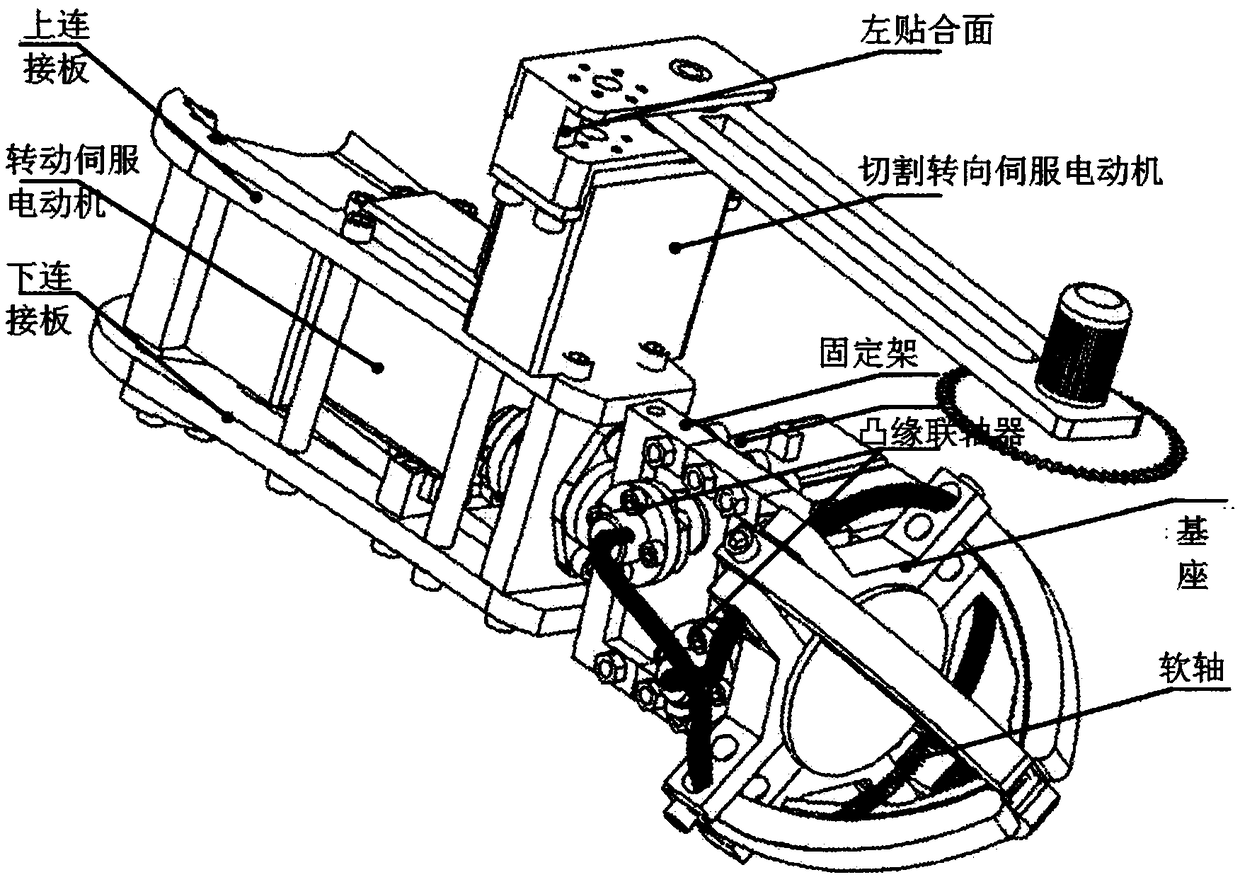

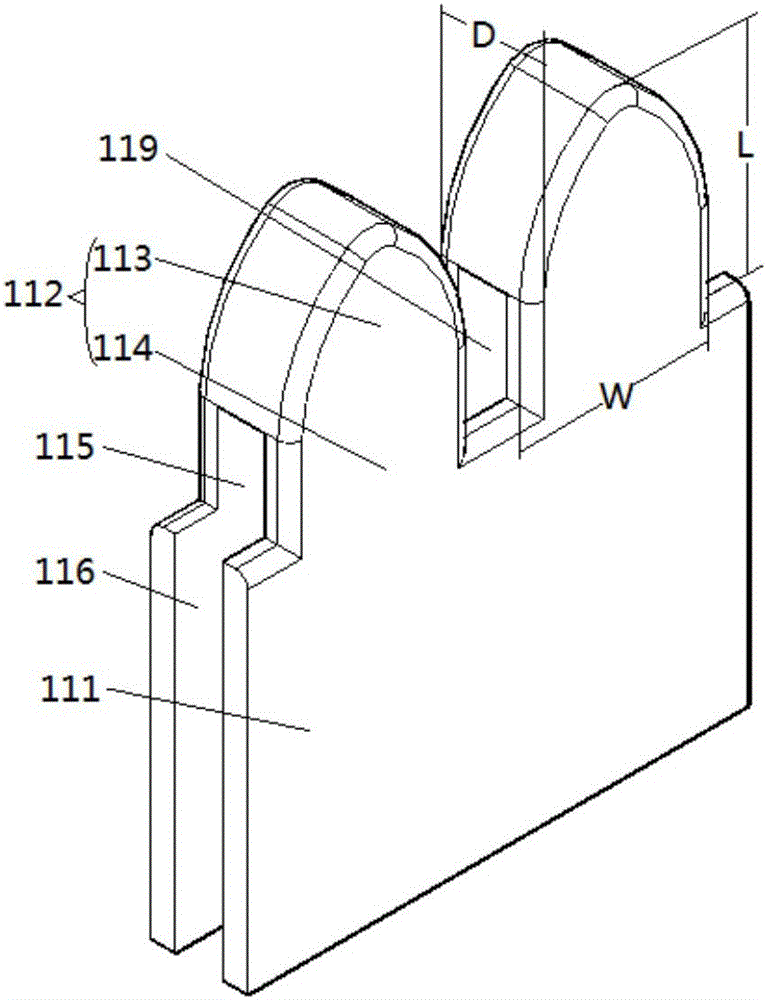

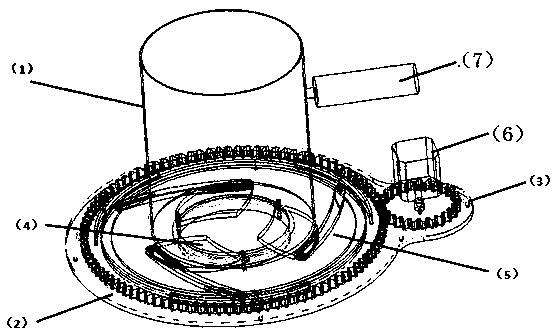

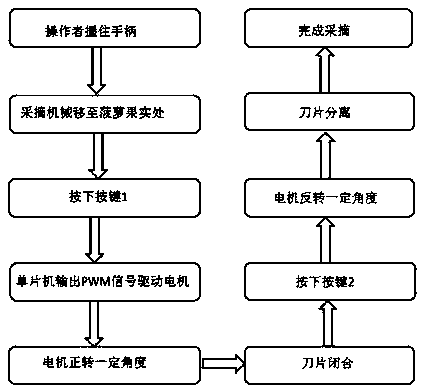

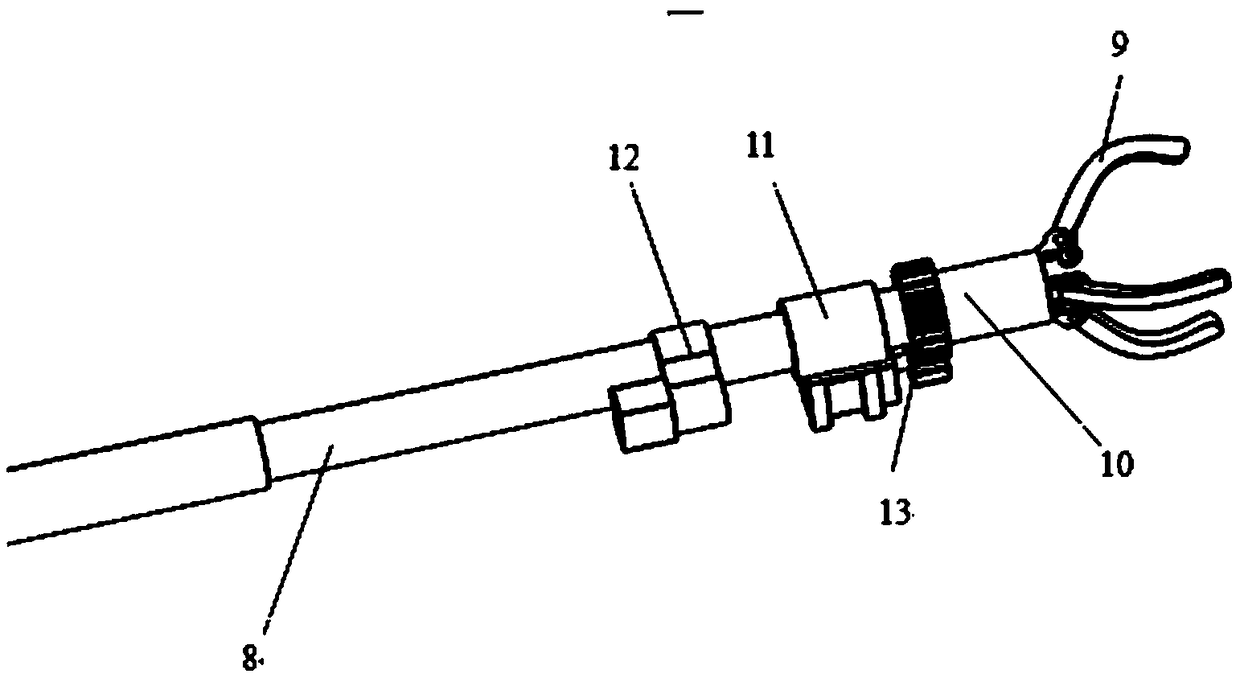

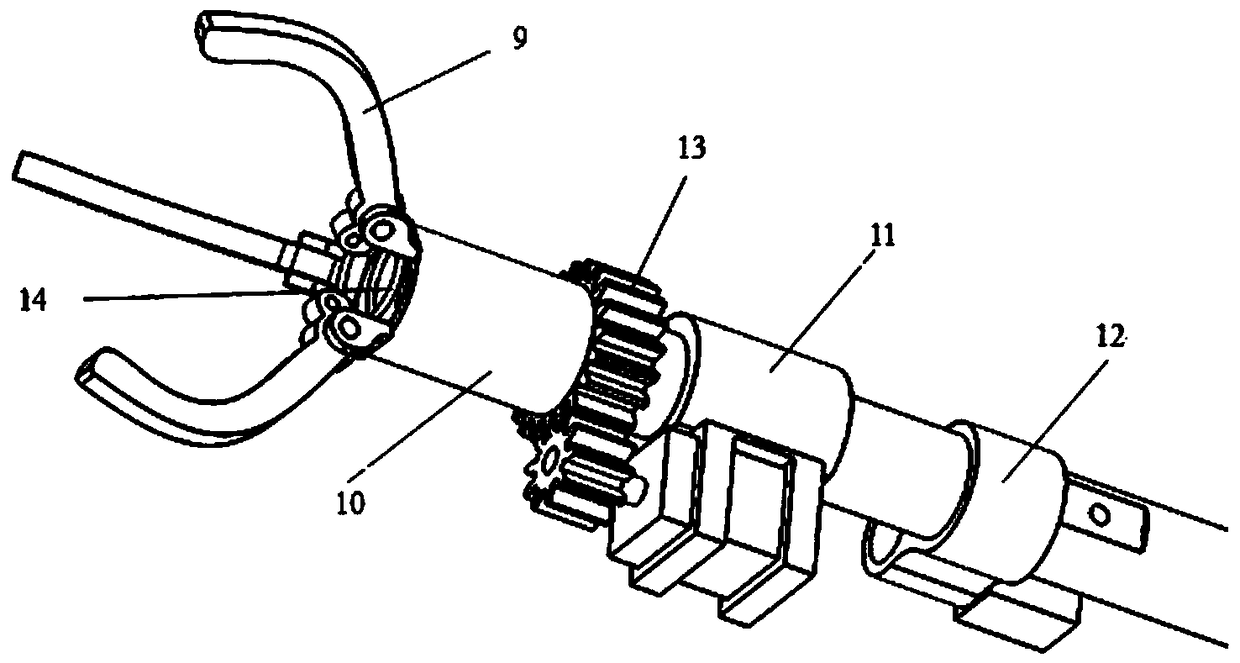

Tail end executor of fragrant pear picking robot, and picking method

PendingCN109105001ANovel methodCompact structurePicking devicesRenewable energy machinesPEARButt joint

The invention provides a tail end executor of a fragrant pear picking robot, and a picking method. The tail end executor comprises a manipulator butt joint disc, a shell of a motor A and four knife rests, wherein the manipulator butt joint disc is in butt joint with a robot mechanical arm, the shell of the motor A is connected with the manipulator butt joint disc and is positioned in a transmission mechanism, and the four knife rests are connected with connecting rods of the transmission mechanism and an installation frame. The method comprises the following steps of accessing points by usinga camera, carrying out fixation by using a sucking disc, carrying out cutting by utilizing arc-shaped blades, withdrawing the mechanical arm to release fragrant pears, and the like. According to the invention, shearing efficiency is improved, time consumption for carrying out image recognition and segmentation on fruit contours and fruit stems by a sensing mechanism is reduced, precision quality of picking operation is guaranteed, picking difficulty is lowered, and operation efficiency is improved

Owner:SHIHEZI UNIVERSITY

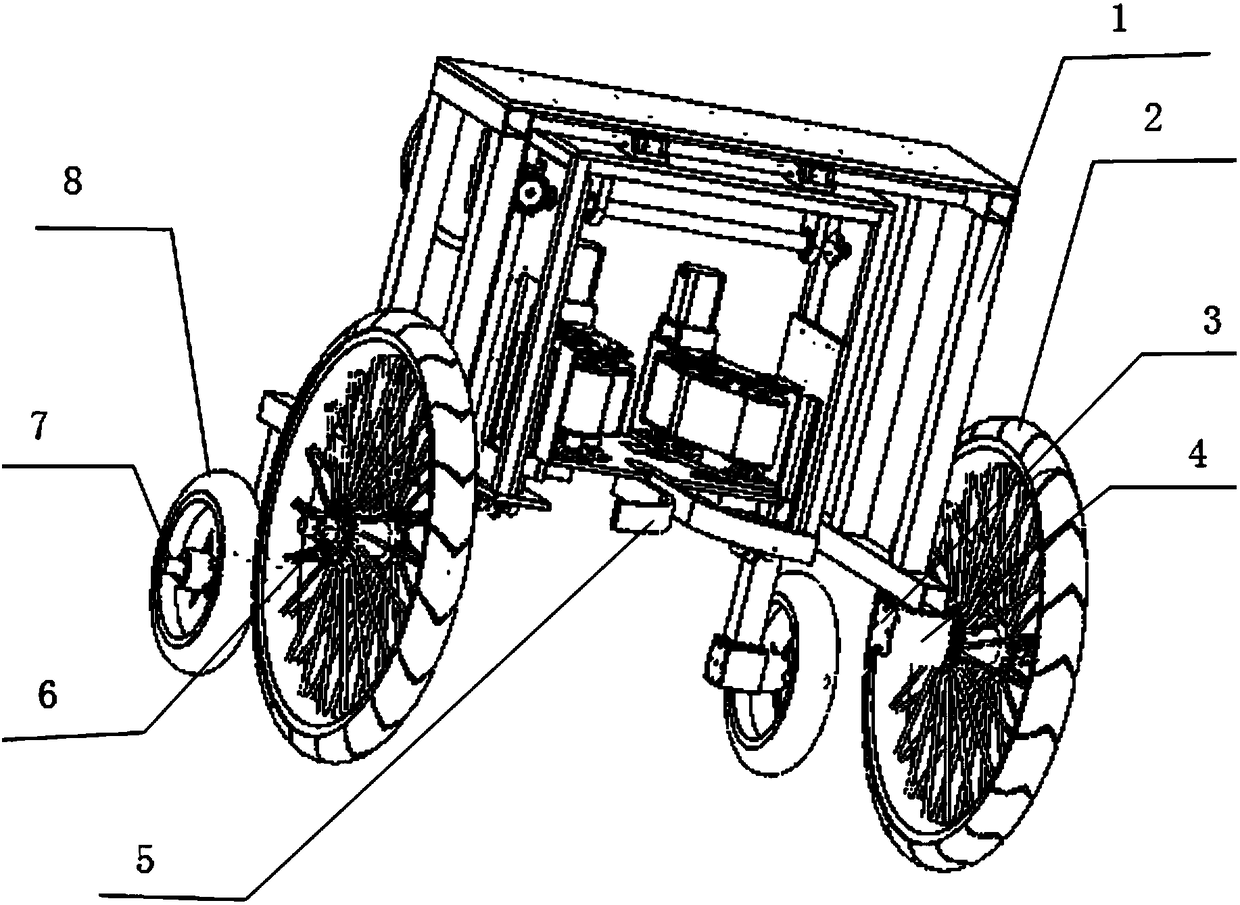

Blueberry picking vehicle

InactiveCN102150516AImprove work efficiencyRealize large-scale plantingPicking devicesDesign draftsmanEngineering

The invention relates to a blueberry picking vehicle which is characterized in that the vehicle body has a shape of door. When the vehicle works, the vehicle is driven by a drafter and longitudinally runs along the blueberry cluster. Two sets of metal teeth rows are respectively arranged on two side walls in a door-shaped compartment, wherein the teeth rows can rotate following teeth row pillars, so as to beat and flutter down the blueberries; the fluttered down blueberries drop onto conveyor belts having slots at two sides under the stopping action of a fruit-receiving plate and inside wall of the compartment; and then the blueberries are conveyed to a fruit box on the rear part of the compartment by the conveyor belts. In order to fully utilize the space of the compartment, the outer side of the compartment is designed into a fruit box frame which is used for storing the fruit boxes, thereby increasing the transporting efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Intelligent recognition medlar picking device

InactiveCN105309131AGuaranteed timely harvestQuality assurancePicking devicesControl systemManipulator

The invention provides an intelligent recognition medlar picking device provided with a distributed machine vision system for solving the problems existing in the prior art. The medlar picking device comprises a rack, a power source system, a control system, a driving system, the machine vision system, a medlar picking mechanical hand, a branch positioning mechanical hand, a medlar picking head and a fruit collecting device, wherein the power source system, the control system, the driving system, the machine vision system, the medlar picking mechanical hand, the branch positioning mechanical hand, the medlar picking head and the fruit collecting device are arranged on the rack. The control system is connected with the machine vision system, the medlar picking mechanical hand, the branch positioning mechanical hand, the medlar picking head and the fruit collecting device through the driving system. The invention further provides a medlar picking method based on the intelligent recognition medlar picking device. The medlar picking device automatically and efficiently collects medlar fruits, solves the problems that the medlar fruits are prone to breakage in the harvesting process, and the picking device is prone to be blocked by leaves, greatly reduces production cost and has good practical application prospects.

Owner:QINGDAO AGRI UNIV +1

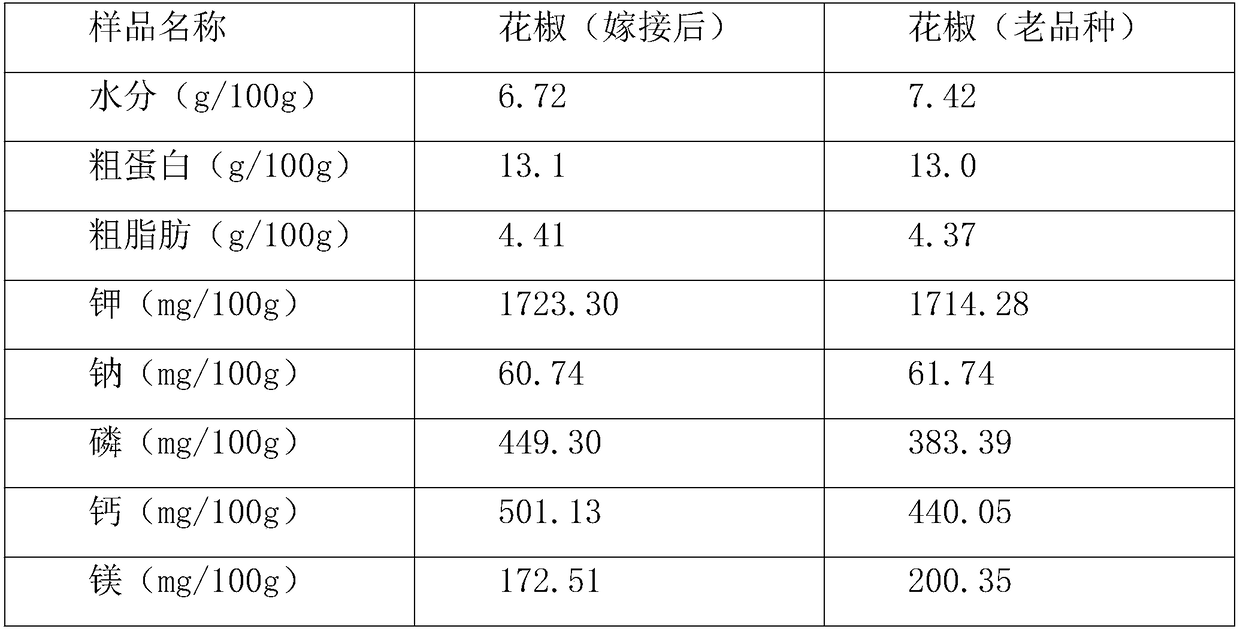

Method for graft-cultivating high-quality stingless pepper tree

InactiveCN108450167AImprove stress resistanceExtend your lifeGraftingCultivating equipmentsDiseaseInsect pest

The invention belongs to the field of economic tree grafting technologies, and provides a method for graft-cultivating a high-quality stingless pepper tree. The method comprises the following steps: (1) cultivating a stock seedling; (2) cultivating a grafting seedling; (3) cultivating a stingless pepper strain; (4) establishing a garden and planting; (5) managing the garden; (6) pruning; and (7) preventing and treating plant diseases and insect pests. The method is capable of using eight months of a pepper tree as a stock, graft-improving six months of a Da Hong Pao tree and five months of a Mei Hua pepper tree, and acquiring a stingless pepper seedling with stable characters, and using a wild pepper seedling as a stock again before establishing the garden and planting, enabling a breedingstingless pepper seedling scion to obtain a second-turn-grafted stingless pepper seedling through the grafting, wherein the stress resistance of the second-turn-grafted stingless pepper seedling is remarkably enhanced, the lifetime, the yield and the quality of the second-turn-grafted stingless pepper seedling are remarkably improved, the age of the pepper tree is about 25 years, the single treeyield in a full productive stage is up to 3.2 Jin in average, the stingless pepper tree has the characteristics of strong disease resistance, drought resistance and water logging resistance, the stingless pepper tree can be generally grown in drought or damp areas below 1800 meters of an altitude, and can be planted and survived in a site where an original pepper tree is dead, and an occurring rate of root rot is remarkably reduced.

Owner:王全奎

Crossover type pineapple picking vehicle

The invention relates to the field of fruit picking, in particular to a crossover type pineapple picking vehicle. The crossover type pineapple picking vehicle has the advantages that the translation mechanism of the vehicle regulates a picking mechanism and a lifting mechanism to an appropriate horizontal picking position; a guide mechanism guides a pineapple to the front end of the picking mechanism; the lifting mechanism ascends the picking mechanism to an appropriate picking height through a sprocket to fix the pineapple; the picking mechanism uses the friction force of a belt and the shearing force of a blade to apply backward acting force to the pineapple so as to cut the pineapple off from a stem to achieve pineapple picking. By the crossover type pineapple picking vehicle which is simple in structure, convenient to operate, high in picking efficiency and the like, the problem that existing manual picking or robot picking is low in efficiency and complex in operation is solved.

Owner:HUBEI UNIV OF TECH

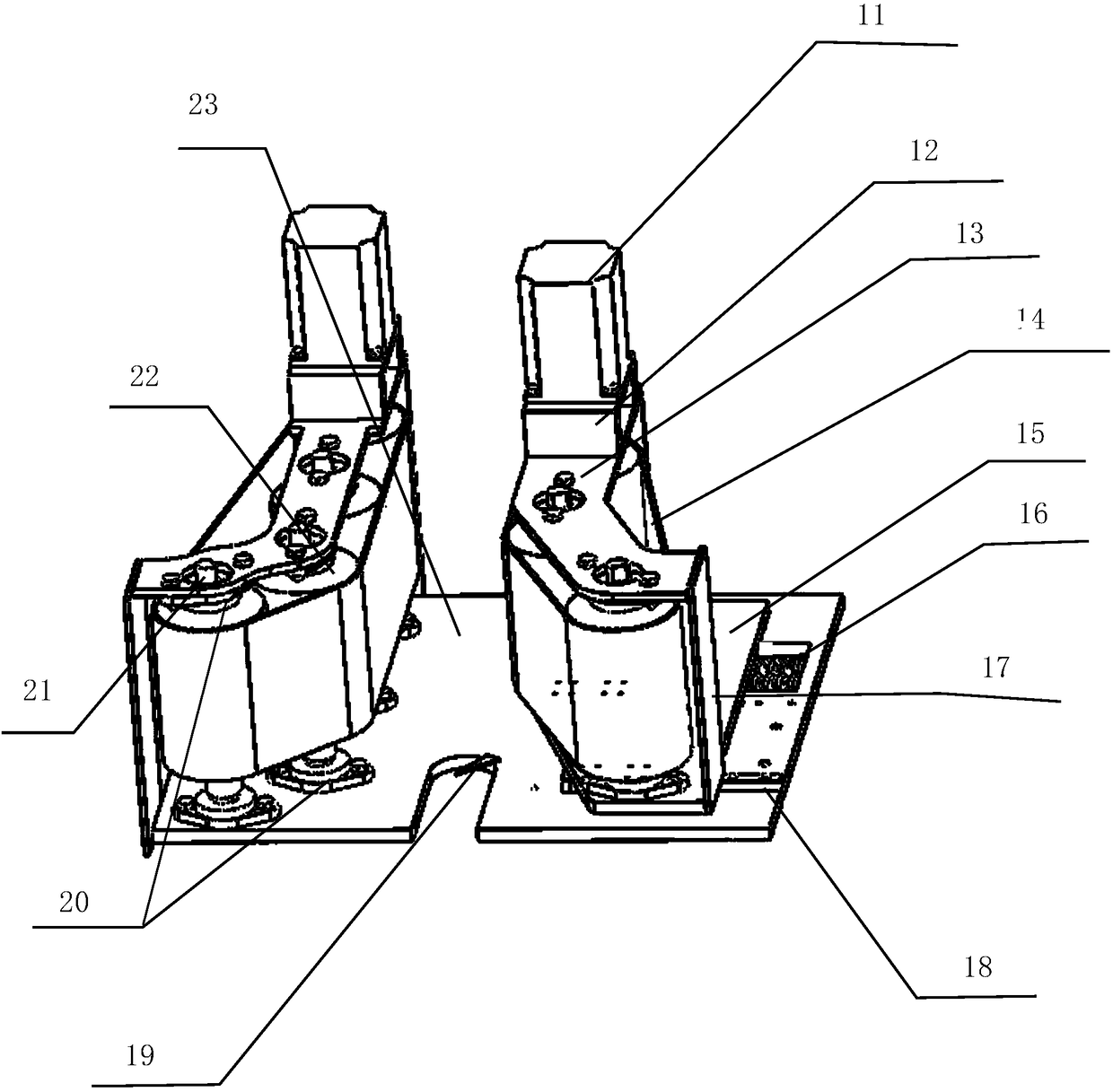

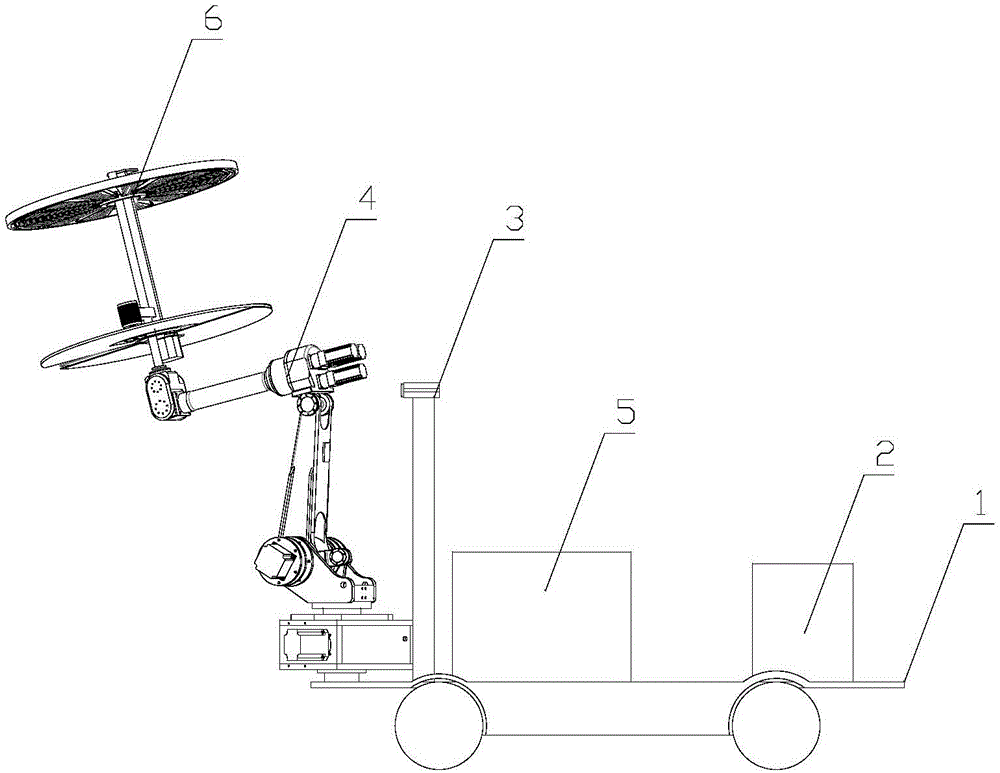

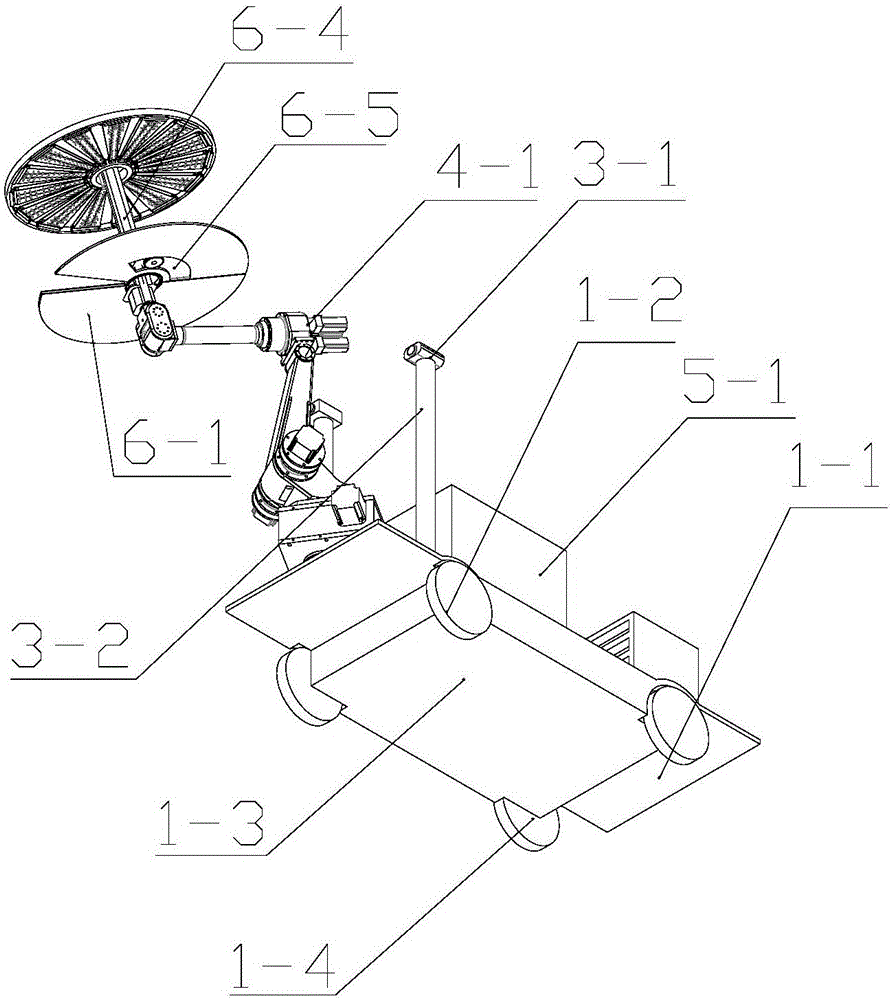

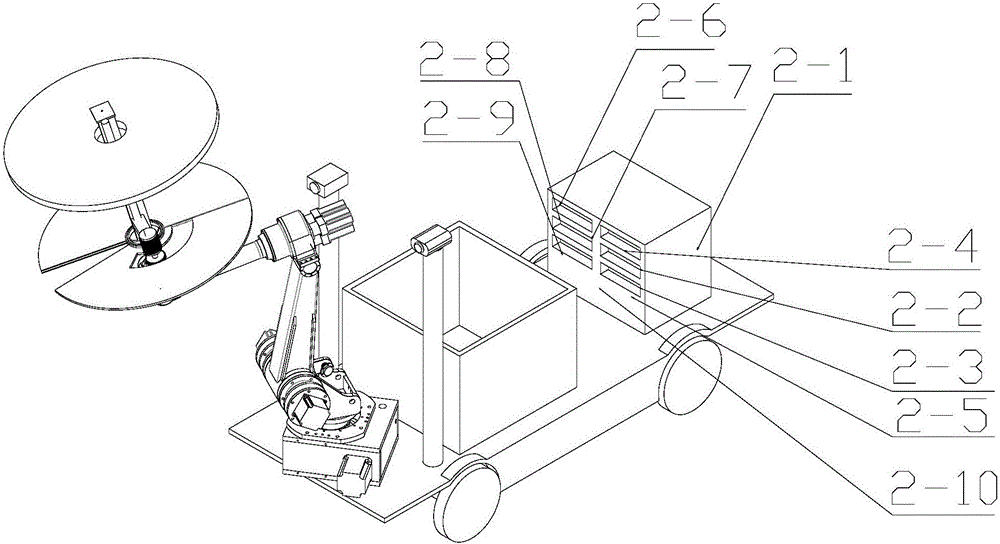

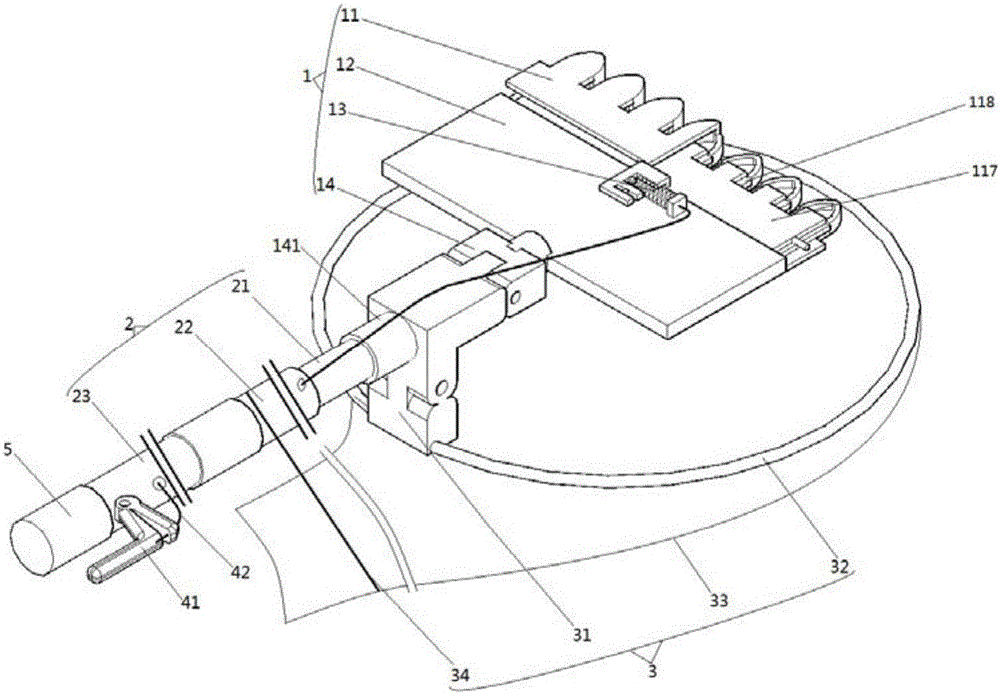

Carding type branched fruit picking robot

The invention relates to a carding type branched fruit picking robot which is used for efficiently picking fruits such as wolfberries, glossy privet fruits and the like which are produced on low-level branches and distributed in a strip shape and belongs to the technical field of agricultural automation and robots. The robot comprises a mobile picking platform, a control cabinet, a machine vision system, a mechanical picking arm, a fruit collecting box and a carding type picking disk, wherein the mechanical picking arm, the control cabinet, the fruit collecting box and the machine vision system are mounted on the mobile picking platform, and the carding type picking disk is mounted on the mechanical picking arm. Existing general mechanical picking arms are abandoned, the self-developed carding type picking disk for branched fruit picking is used for picking the fruits, the robot is simple, reliable and efficient, and the picking efficiency can be greatly improved. The robot greatly promotes rural economic development and has inestimable significance in improving modernization and intelligentialization of Chinese agriculture and accelerating scientific progress of agriculture.

Owner:SHANDONG GUOXING SMARTECH CO LTD

Rotary fruit picker

ActiveCN107371608ASimple and flexible operationReduce labor intensityPicking devicesMechanical engineeringFruit rot

Owner:NORTHEASTERN UNIV

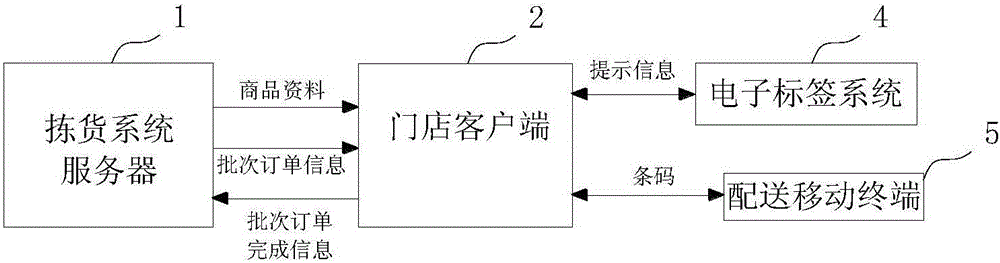

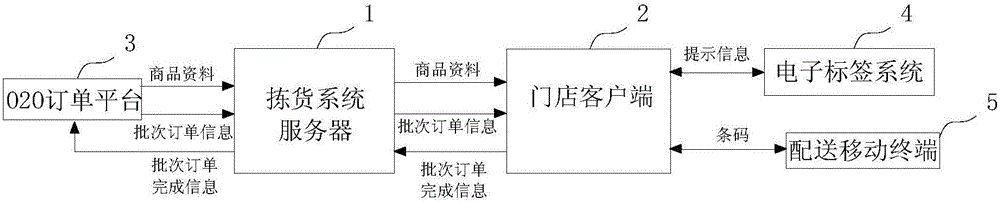

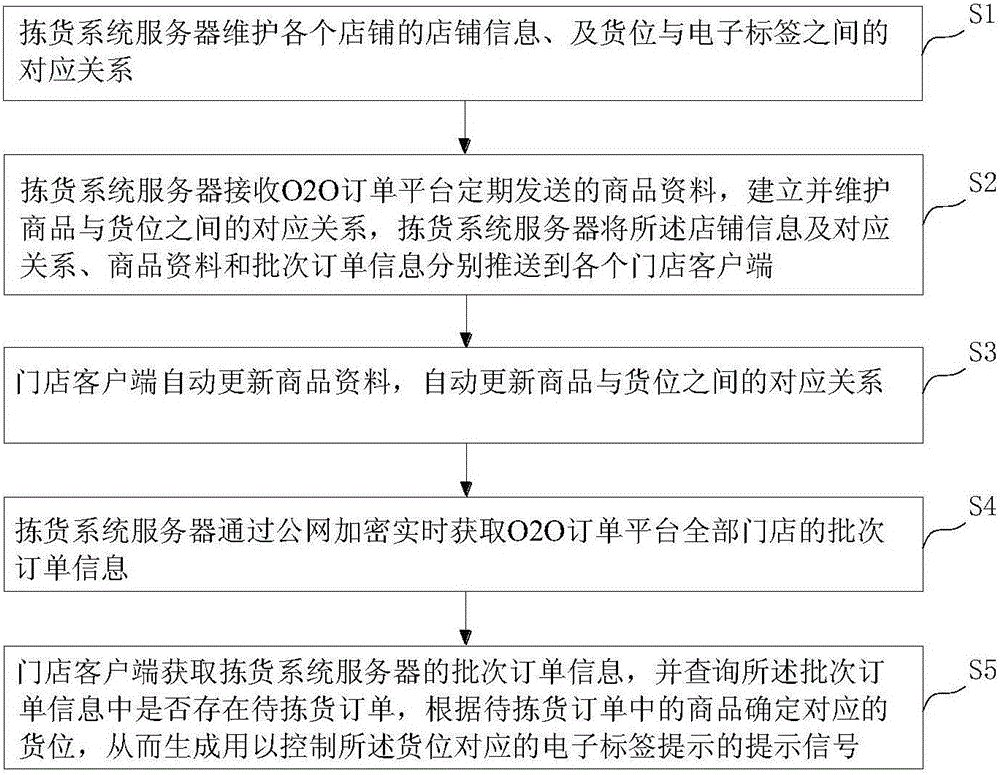

Order picking system applied to catering O2O (online to offline) mode and method

The invention provides an order picking system applied to a catering O2O (online to offline) mode and an order picking method applied to the catering O2O (online to offline) mode. The system includes a picking system server and at least one store client; the picking system server is used for maintaining store information, maintaining corresponding relationships between commodities of each store and commodity locations, maintaining corresponding relationships between the commodity locations and electronic labels, obtaining commodity information and batch order information from an O2O order platform, and pushing the above information to each store client; and the at least one store client is used for obtaining the above information from the picking system server, querying whether orders to be picked exists in the batch order information and determining corresponding commodity locations according to commodities in the orders to be picked so as to generate prompting signals used for controlling electronic label prompts corresponding to the commodity locations. With the order picking system and method of the invention adopted, order picking efficiency can be improved, operation personnel can be decreased, and labor cost can be saved. The order picking system and method can be applied to factory type stores with a larger quantity of orders.

Owner:上海海鼎信息工程股份有限公司

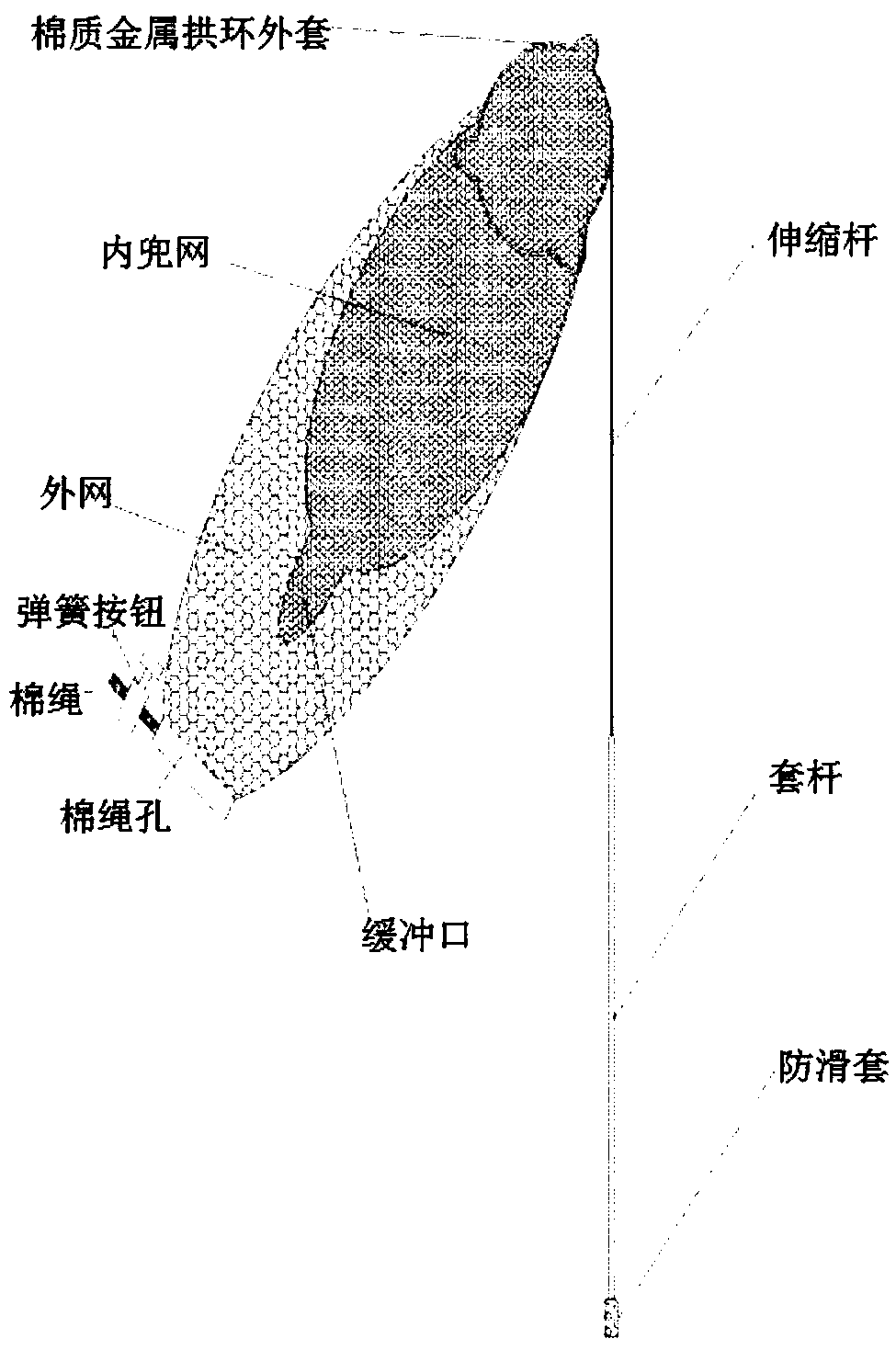

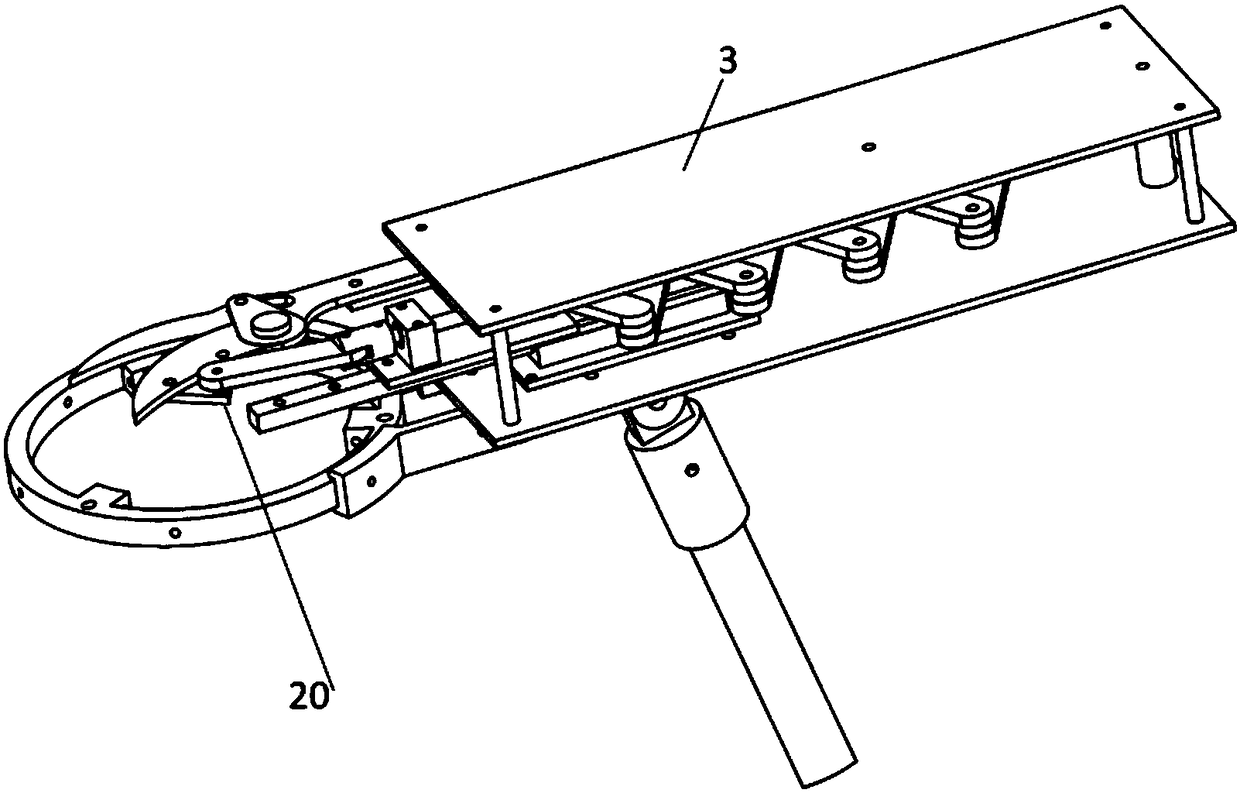

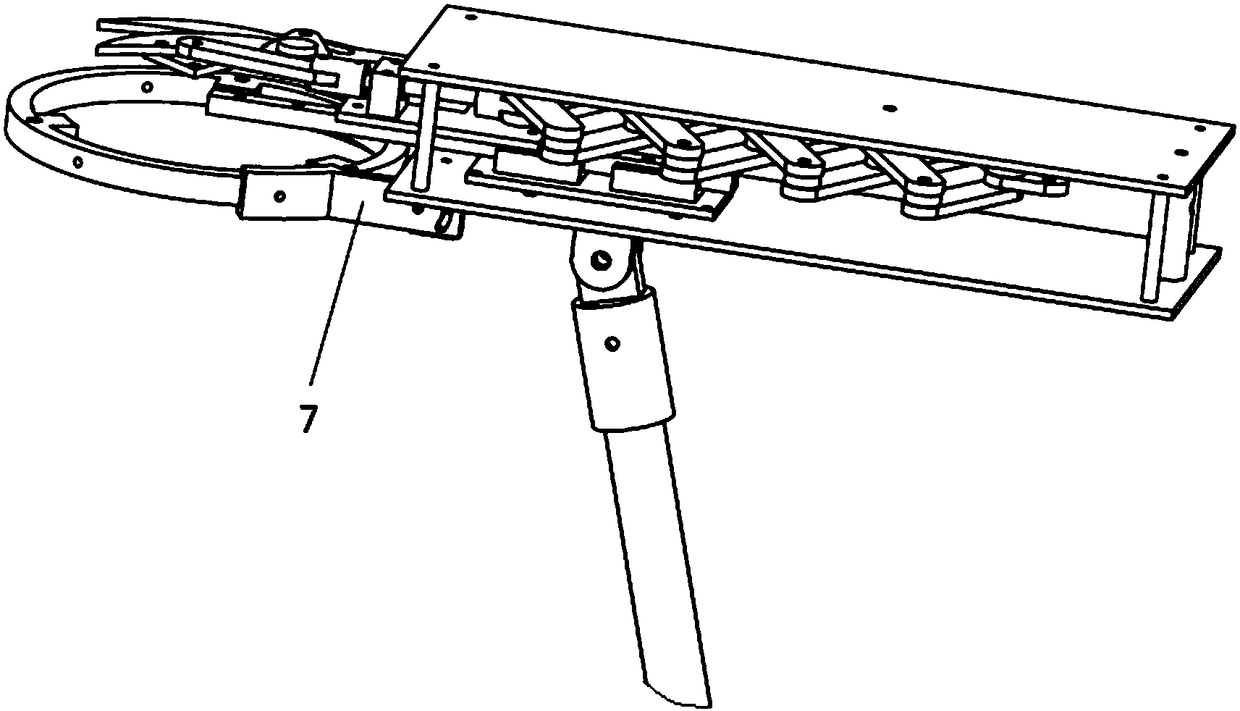

Self-adaption auxiliary picking device for oranges

The invention discloses a self-adaption auxiliary picking device for oranges. Presently, an exclusive picking device for the oranges does not exist. The device comprises a self-adaption circular ringmechanism, a telescopic cutting mechanism, an upper base plate, a lower base plate, a telescopic rod, a net bag and an angle adjusting mechanism; the self-adaption circular ring mechanism is arrangedbelow the telescopic cutting mechanism, the telescopic rod is used for extending the telescopic cutting mechanism, and the angle adjusting mechanism is used for adjusting the included angle of the telescopic rod and the telescopic cutting mechanism; a closing and opening plate of the self-adaption circular ring mechanism is driven by the orange gravity to open, and the automatic closing of the self-adaption circular ring mechanism is achieved by a spring; the telescopic cutting mechanism comprises a refitted round fruit scissor, a fruit scissor connecting piece, a cutting stroke amplificationmechanism, a steel wire rope limit piece, a steel wire rope connecting piece and a support rod; the refitted round fruit scissor comprises a first blade, a second blade, a pushing rod, a pushing block, a sleeve connecting rod, a sliding seat, a sliding rod and a sliding passage. The integrated picking and collection is achieved, the electricity is not needed, selective picking on higher positionsor lower positions is achieved, and the working range is increased.

Owner:HANGZHOU DIANZI UNIV

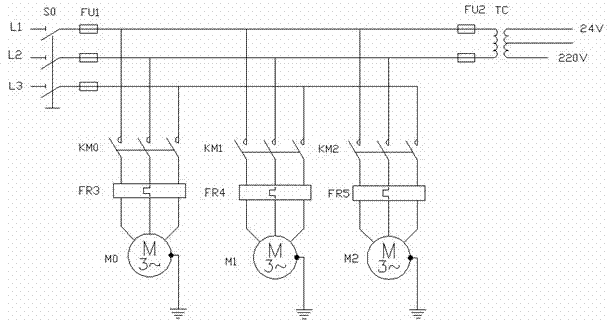

Automatic fruit-picking and leave-removing device

InactiveCN103609258ARealize automatic pickingRealize automatic picking and removing leavesPicking devicesImaging processingProgrammable logic controller

The invention relates to an automatic fruit-picking and leave-removing device, and belongs to the technical field of agricultural mechanical equipment. The automatic fruit-picking and leave-removing device comprises a manipulator, a monitoring scanner, a mechanical arm I, a rotary fulcrum, a rotary shaft, a receiver, an opening and closing valve, a shock absorber, a buffer device, an image processing device, a mechanical arm II, a leave cutting knife, a conveying belt, a container, an oil tank, a brake, a shock absorber II, a driving motor I, a relay I, a PLC (programmable logic controller), a transmission shaft, a relay II, a relay III, wheels, a driving motor II, a vehicle body, a driving motor III and a supporting rod. The automatic fruit-picking and leave-removing device is convenient to operate; and leaves can be removed effectively after fruits are automatically picked, the picking cost is saved, the picking efficiency is improved, and the fruit picking quality is guaranteed.

Owner:KUNMING UNIV OF SCI & TECH

Comb-shaped fruit-and-vegetable picking device

InactiveCN105723939AEasy to control the lengthEasy to eatPicking devicesEngineeringFruits and vegetables

The invention discloses a comb-shaped fruit-and-vegetable picking device.The comb-shaped fruit-and-vegetable picking device comprises a comb-shaped separating cover, a harvesting cutter, a connecting rod and a storage bag.The comb-shaped separating cover comprises a base, and separating teeth are arranged on the base at intervals; the harvesting cutter is arranged inside the comb-shaped separating cover, and the cutting face of the cutter is exposed at tooth gaps between the adjacent separating teeth; the connecting rod is connected with a picking head; a bag opening of the storage bag is formed below the comb-shaped separating cover.In the fruit-and-vegetable picking process, fruit-and-vegetable stalks are slid into the tooth gaps between the adjacent separating teeth and cut through the harvesting cutter, and the harvested fruits and vegetables are fallen into the storage bag below the comb-shaped separating cover.According to the comb-shaped fruit-and-vegetable picking device, the comb-shaped separating cover structure is adopted, in the fruit-and-vegetable picking process, branches and leaves can be automatically separated, only the fruit-and-vegetable stalks are cut, the fruits, the vegetables, the branches and the leaves are not damaged, the length of the fruit-and-vegetable stalks is controllable, the picked fruits and vegetables are more beautiful and more convenient during eating.Meanwhile, the comb-shaped fruit-and-vegetable picking device further has the advantages that picking is safe and efficient, and picking cost can be greatly reduced.

Owner:李学恩

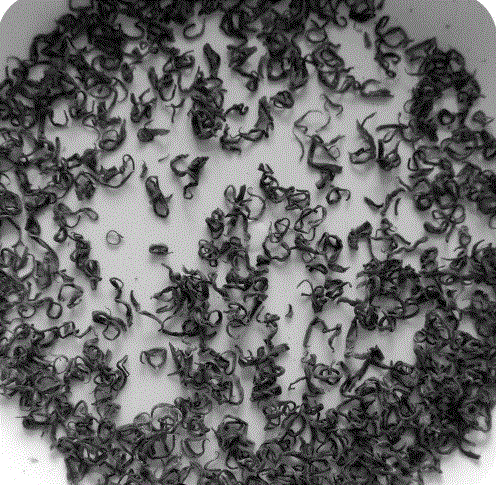

Making process of curly white leaf tea

InactiveCN105767275ALower requirementImprove tree down ratePre-extraction tea treatmentFlavorCooking & baking

The invention discloses a making process of curly white leaf tea. The making process includes steps of picking, spreading for water removing, water removing, kneading and twisting, shaping and baking. Requirements on tea leaf raw materials are low during picking, and one-sprout one-leaf, one-sprout two-leaf and one-sprout three-leaf can be picked at the same time, so that picking cost is lowered and white tea off-tree rate is increased to maximum extent; the white leaf tea made by the making process is thin and beautiful in appearance, curly, small in size and convenient to carry and transport; after tea leaves are kneaded and twisted, tea leaf cell damage rate is increased, so that dry tea is stronger in fragrance, brewed tea is stronger in fragrance, quality factors like water extract, soluble sugar and theaflavin are increased, and the curly white leaf tea is better in flavor.

Owner:GUIZHOU PROVINCE WENGAN COUNTY GUISHAN TEA BUSINESS CO LTD

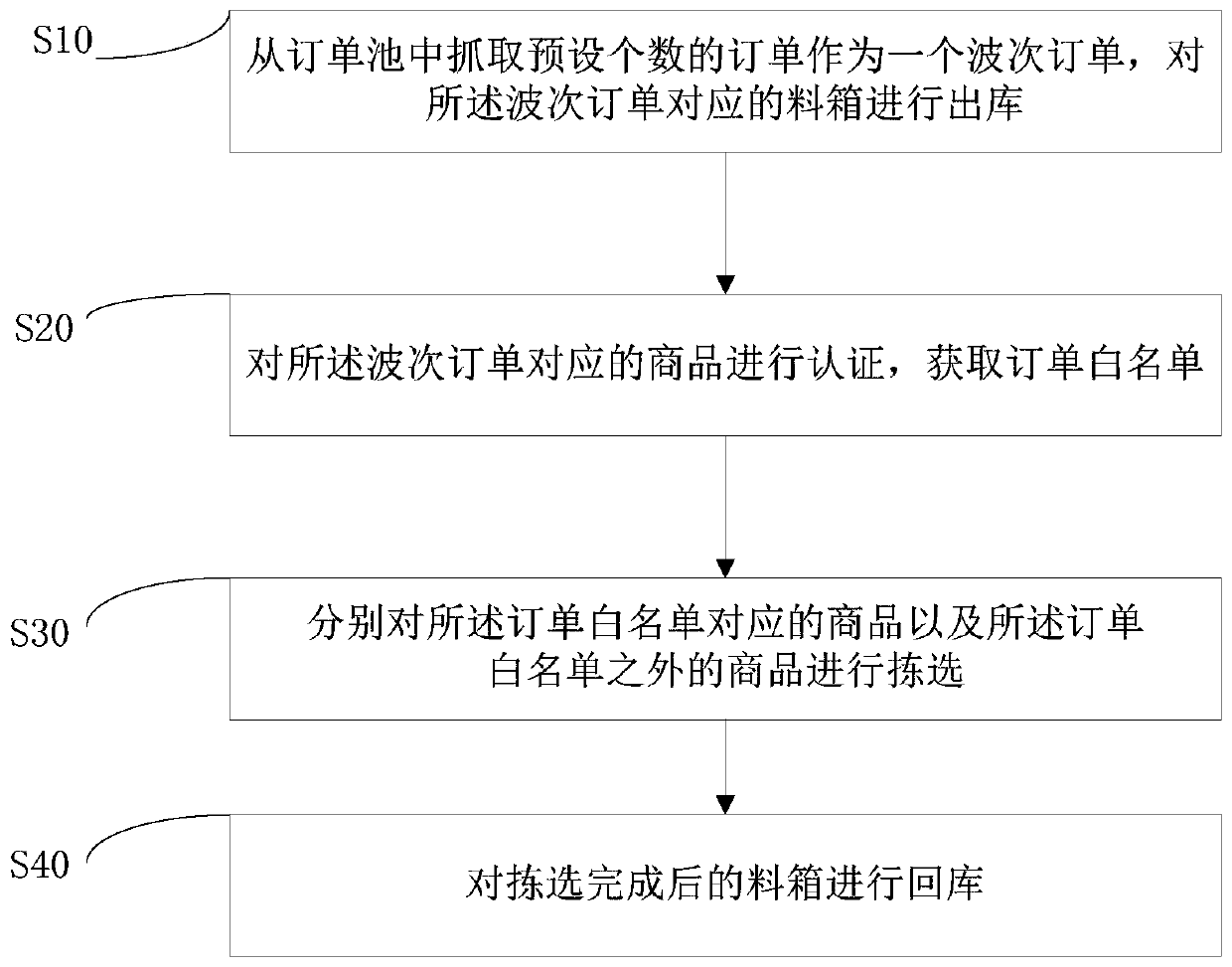

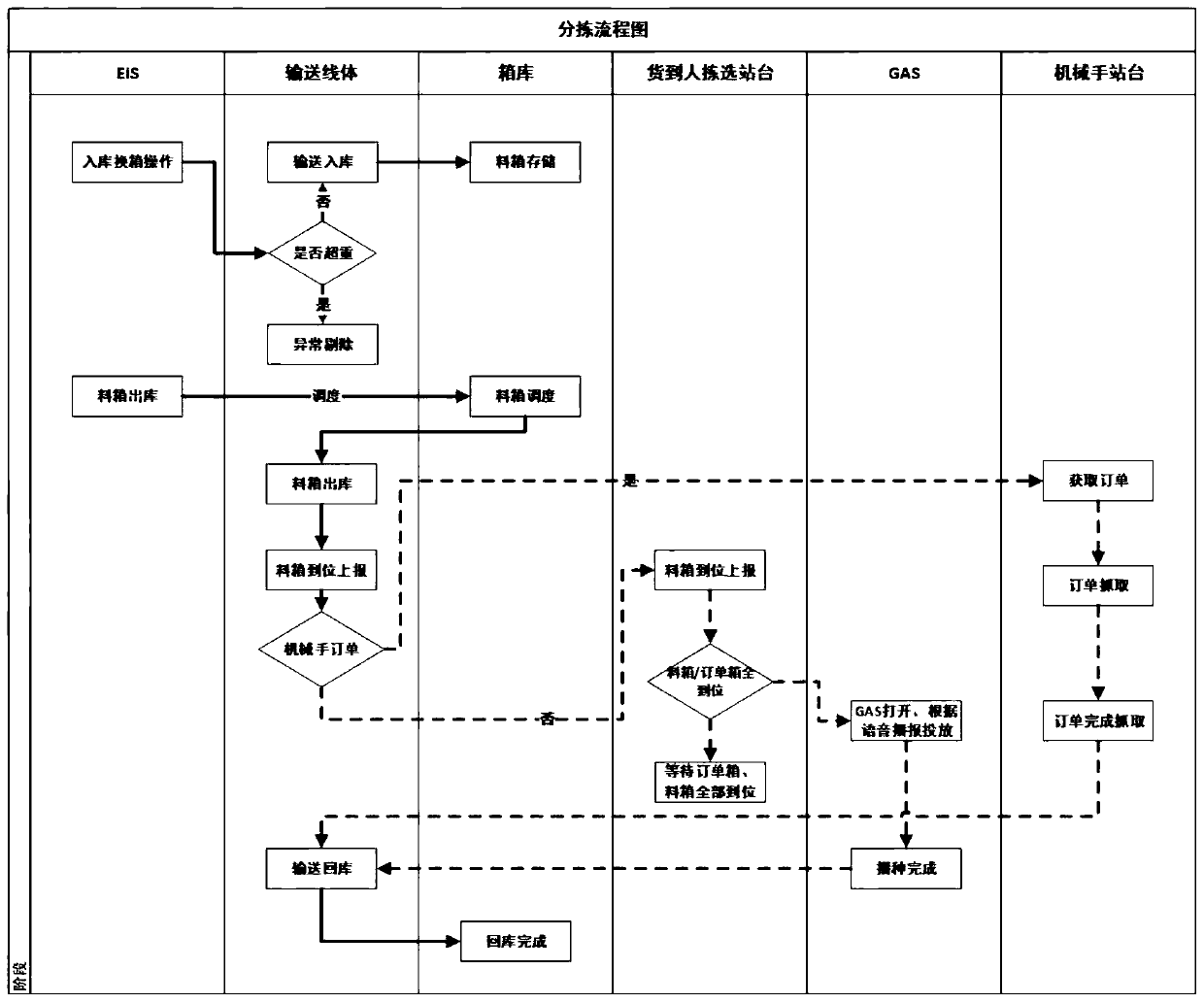

Intelligent sorting method and system

ActiveCN110264323AImprove order picking timeImprove order picking efficiencyBuying/selling/leasing transactionsResourcesSorting timeComputer science

The invention discloses an intelligent sorting method and system, belongs to the field of logistics automation, and the intelligent sorting method and system solve the problems of low sorting time efficiency, low labor efficiency, low efficiency per square meter and high sorting cost in the prior art. The method comprises the steps that orders with the preset number are grabbed from an order pool to serve as a wave picking order, and material boxes corresponding to the wave picking order are delivered out of a warehouse; a commodity corresponding to the wave picking order is authenticated to obtain an order white list; commodities corresponding to the order white list and commodities outside the order white list are picked respectively; and the sorted material boxes are returned to the warehouse. The time efficiency of order picking, the labor efficiency of order picking and the storage efficiency are improved, and meanwhile the picking cost is reduced.

Owner:智芯科技(湖北)有限公司

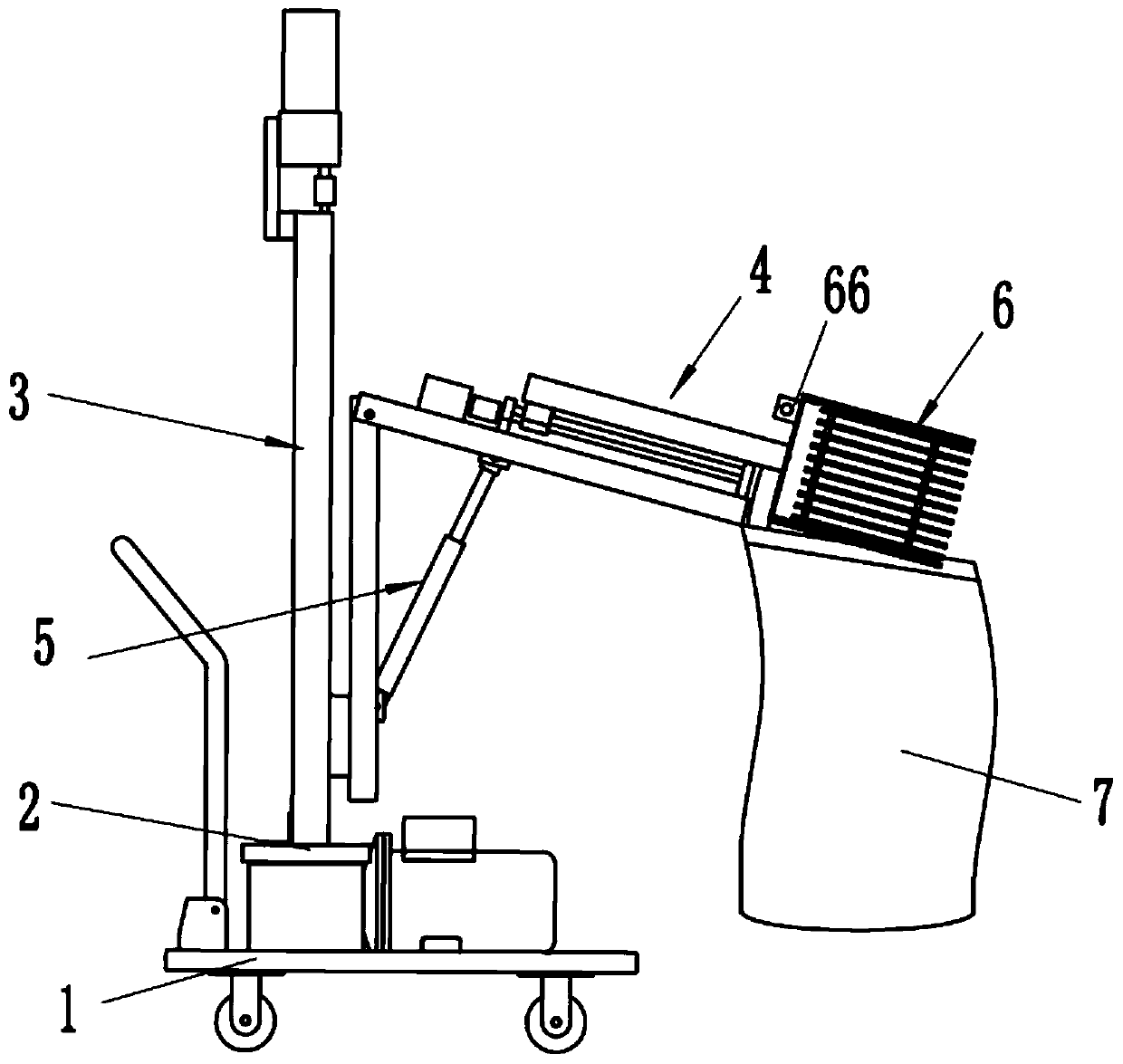

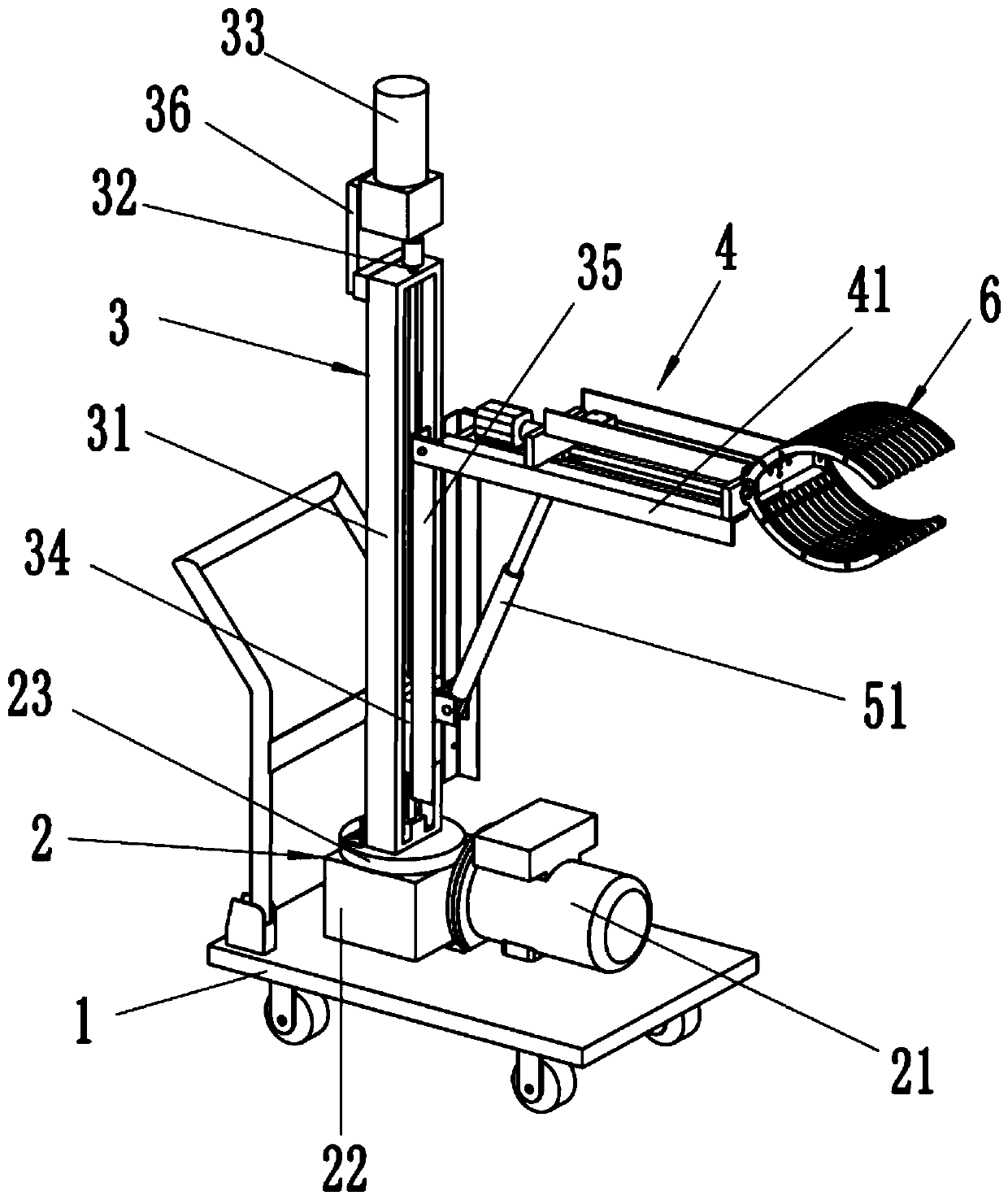

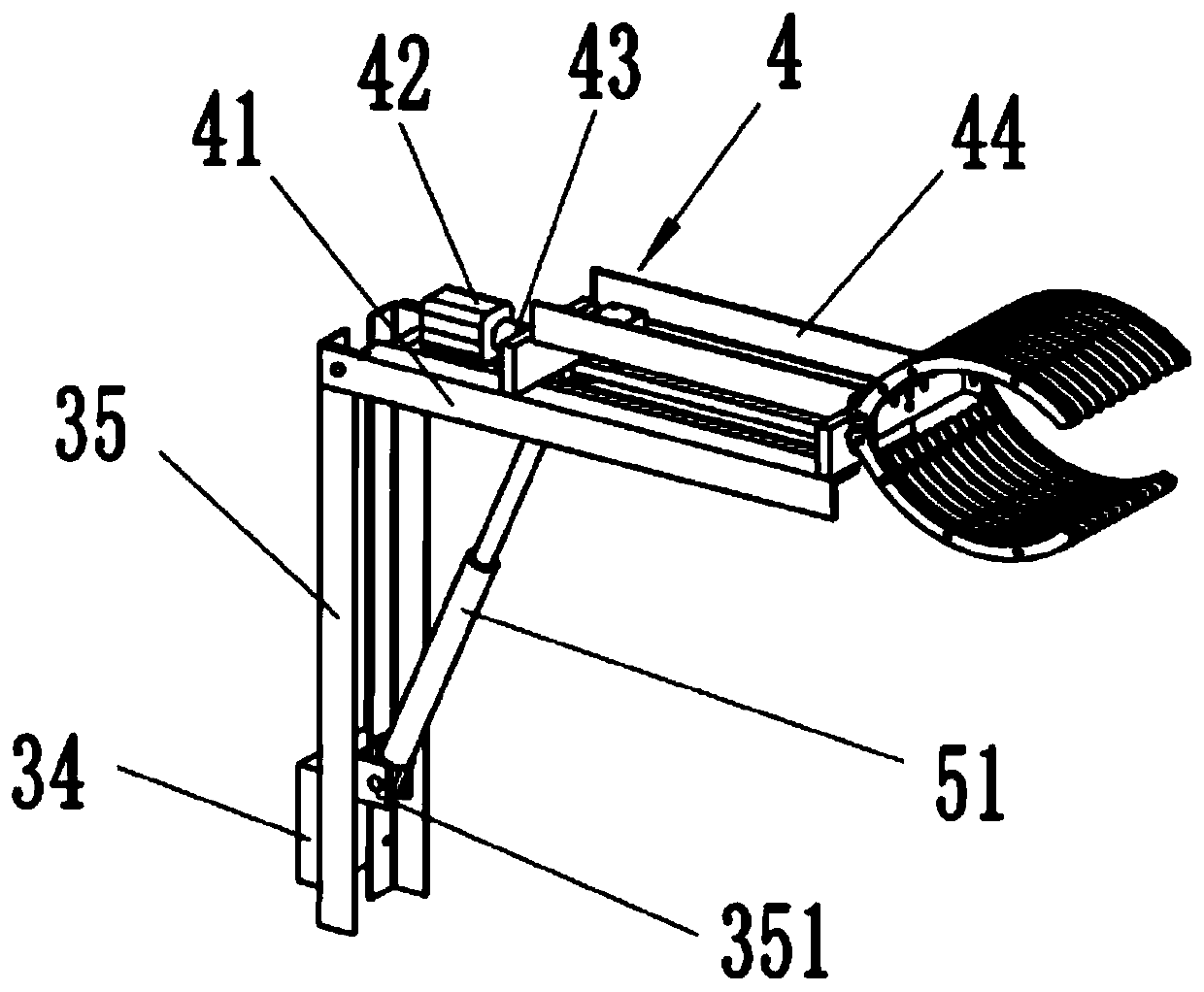

Fruit picking machine

The invention provides a fruit picking machine, which comprises a mobile cart, a steering mechanism, a lifting mechanism, a transverse telescopic mechanism, a jacking mechanism and a picking mechanism. The steering mechanism is fixed to the mobile cart, and a rotary disc is arranged at the upper end of the steering mechanism; the lifting mechanism is arranged on the rotary disc; the transverse telescopic mechanism is arranged on the upper part of the lifting mechanism, and the lifting mechanism drives the transverse telescopic mechanism to go up and down; the jacking mechanism comprises a telescopic rod, one end of the telescopic rod is hinged to the lower part of the lifting mechanism, the other end of the telescopic rod is hinged to the lower end of the transverse telescopic mechanism, and the telescopic rod drives the transverse telescopic mechanism and the lifting mechanism to change the included angle therebetween; the picking mechanism is connected to one end of the transverse telescopic mechanism. The fruit picking machine is small in size, low in price, flexible and convenient, and solves the technical problems of low fruit picking efficiency and difficult picking for small-scale orchard workers.

Owner:DSP TECH DEV WENZHOU CO LTD

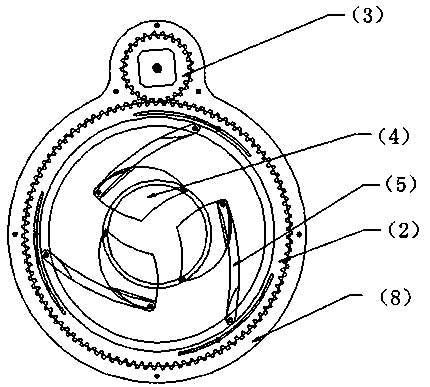

Pineapple picking device

The invention discloses a pineapple picking device. The device picks up pineapples in a gear transmission mode and comprises a micro processing chip, a motor, a drive wheel, a driven wheel, a chassisand N blades, N is a positive number greater than 2, and the output end of the micro processing chip is electrically connected with the input end of the motor; a rotor of the motor is in transmissionconnection with a shaft hole of the drive wheel; gear teeth of the drive wheel are in transmission connection with gear teeth of the driven wheel; the blades are connected with the driven wheel; the driven wheel is connected with the chassis; the drive wheel is connected with the chassis; a through hole is formed in the chassis. The working technology of the device comprises the processes that pineapples pass through the through hole of the chassis, the fruit stems of the pineapples penetrate through the through hole of the chassis, the rotation of the motor drives the drive wheel to rotate, and the drive wheel drives the driven wheel to rotate. The blades are arranged on the driven gear, the rotation of the driven wheel drives the blades to make shearing motions, the fruit stems are cut off, and the separation between the pineapples and the fruit stems is achieved.

Owner:LINGNAN NORMAL UNIV

Apple picking tool

ActiveCN108718688AImprove picking efficiencyGuarantee the quality of finished productsPicking devicesEngineeringUltimate tensile strength

The invention discloses an apple picking tool which comprises a bearing box, wherein a control rod is arranged on the side face of the straps of the bearing box; the control rod is connected with a telescopic rod by virtue of a connecting rod mechanism; the control rod is used for controlling the telescopic rod to rotate and pitch; a support is arranged at the front end of the telescopic rod; multiple claws are connected to the front end of the support; the claws are circularly and uniformly arranged in a surrounding manner; the support can rotate relative to the claws; a pulley is arranged onthe telescopic rod; the pulley is connected with the claws by virtue of a steel wire rope. The apple picking tool disclosed by the invention has the characteristics that the apple picking efficiencyis improved, the labor intensity and picking cost are reduced, and the quality of finished apples is ensured.

Owner:SHAANXI UNIV OF SCI & TECH

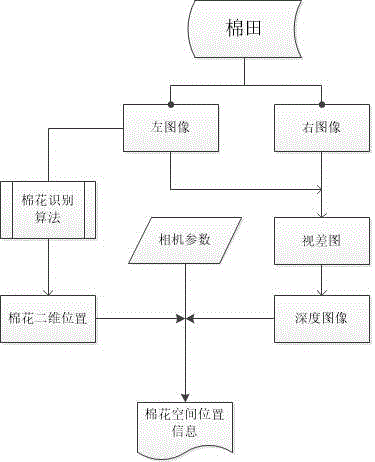

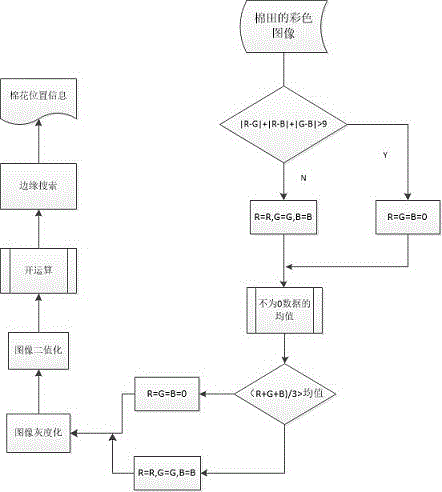

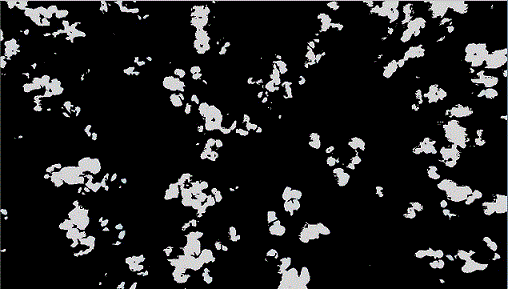

Cotton identifying and positioning method based on binocular camera

PendingCN107527367AImprove picking efficiencyLow costImage enhancementImage analysisPattern recognitionDepth map

The invention discloses a cotton identifying and positioning method based on a binocular camera, comprising the steps of calibrating the binocular camera and obtaining the internal and external parameters of the camera; collecting the left and right images of cotton field by means of the binocular camera, and calculating the depth images; finding the position of cotton among colored images through the cotton identification algorithm; calculating the 3D information of all cotton by combining the camera parameter, the depth images, and the 2D image positions of cotton. The cotton identifying and positioning method based on a binocular camera is advantageous in that labor intensity is reduced and work efficiency is improved; cotton-picking cost is declined; cotton quality is enhanced.

Owner:XINJIANG QINYU CONSTR EQUIP INSTALLATION

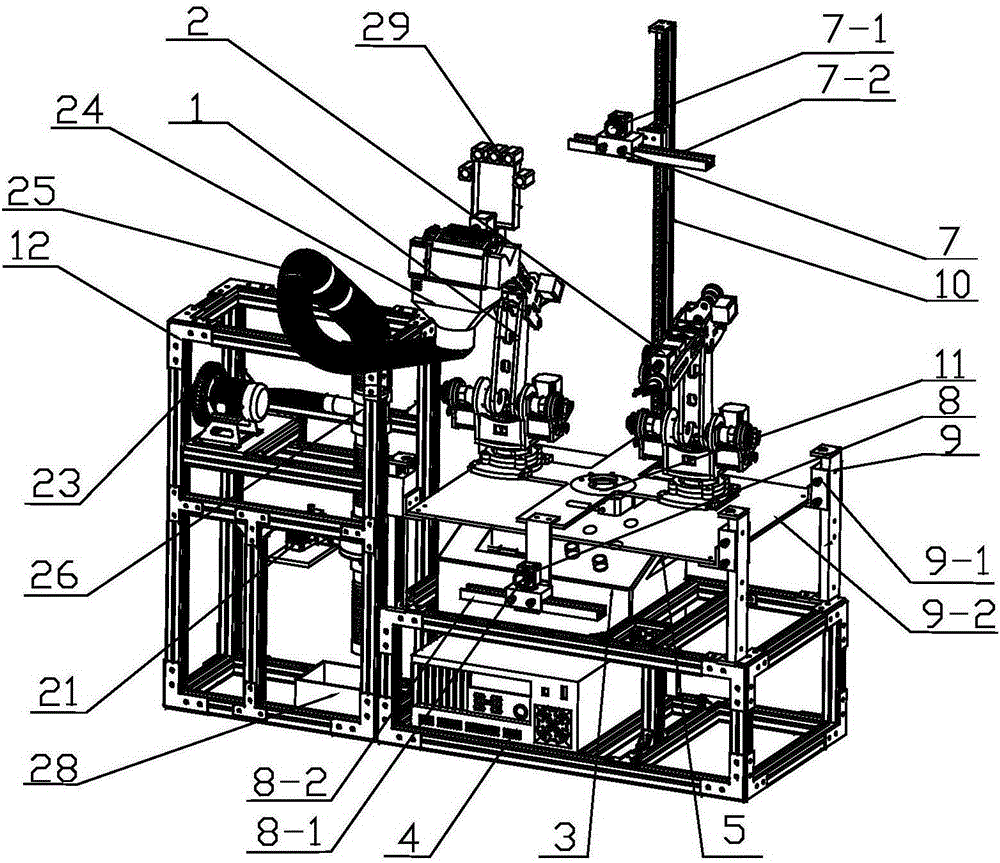

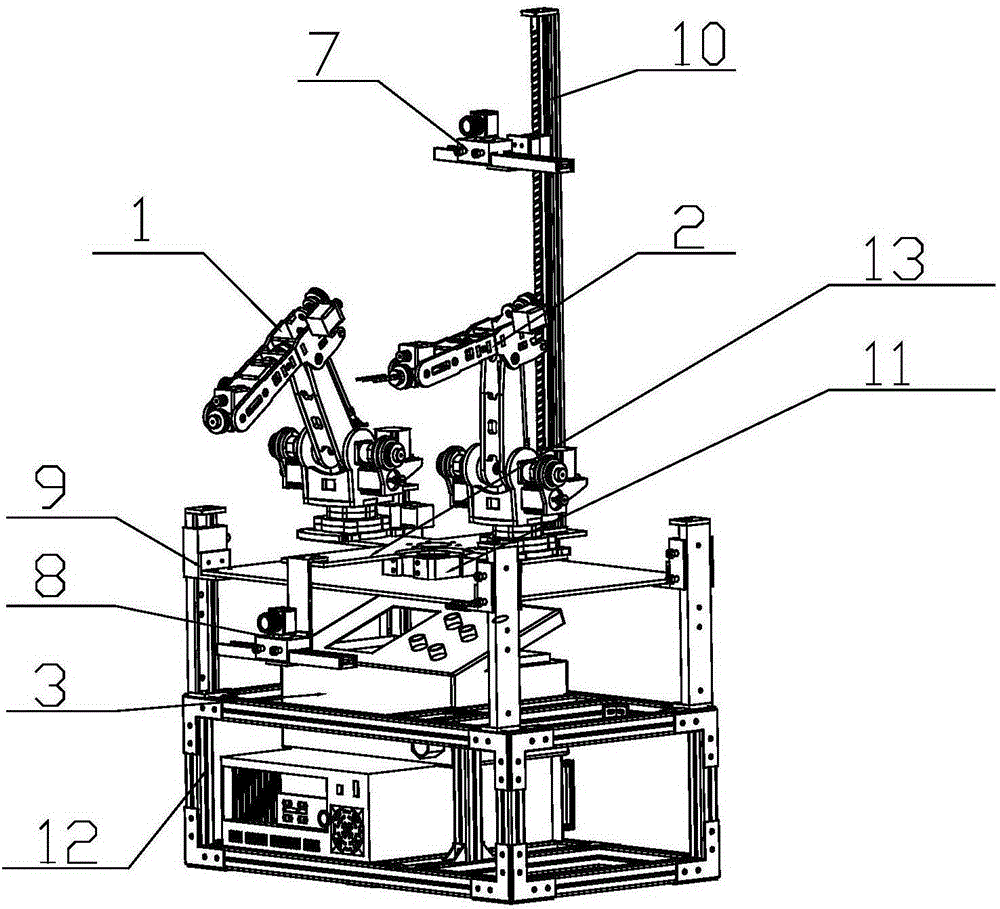

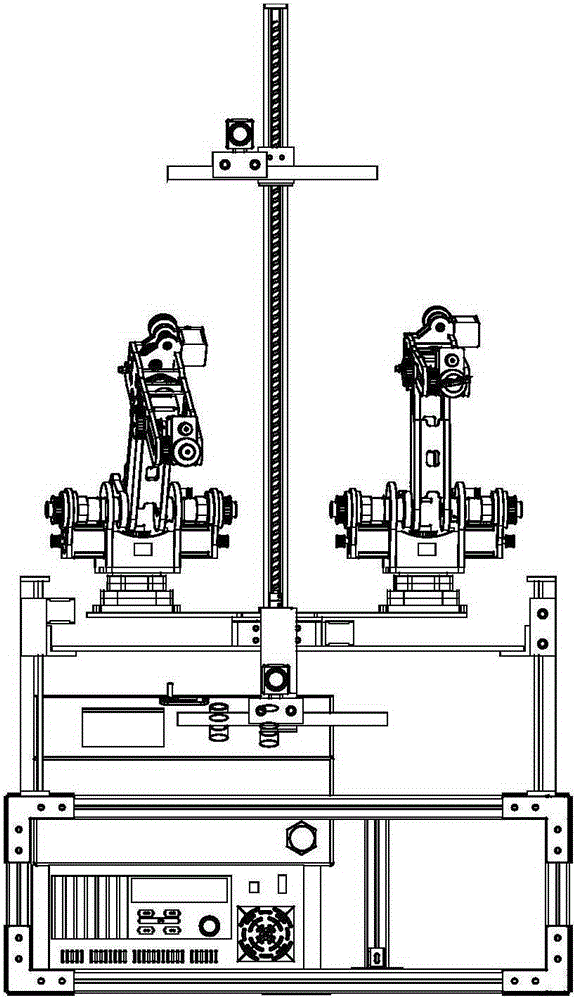

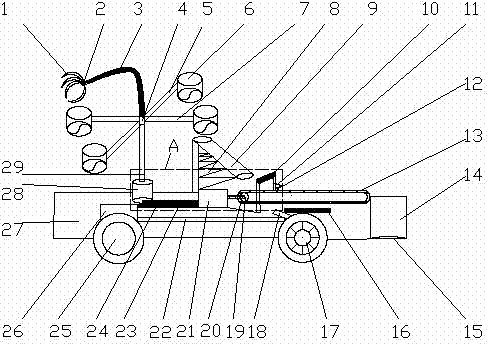

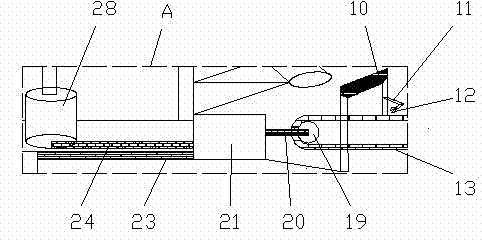

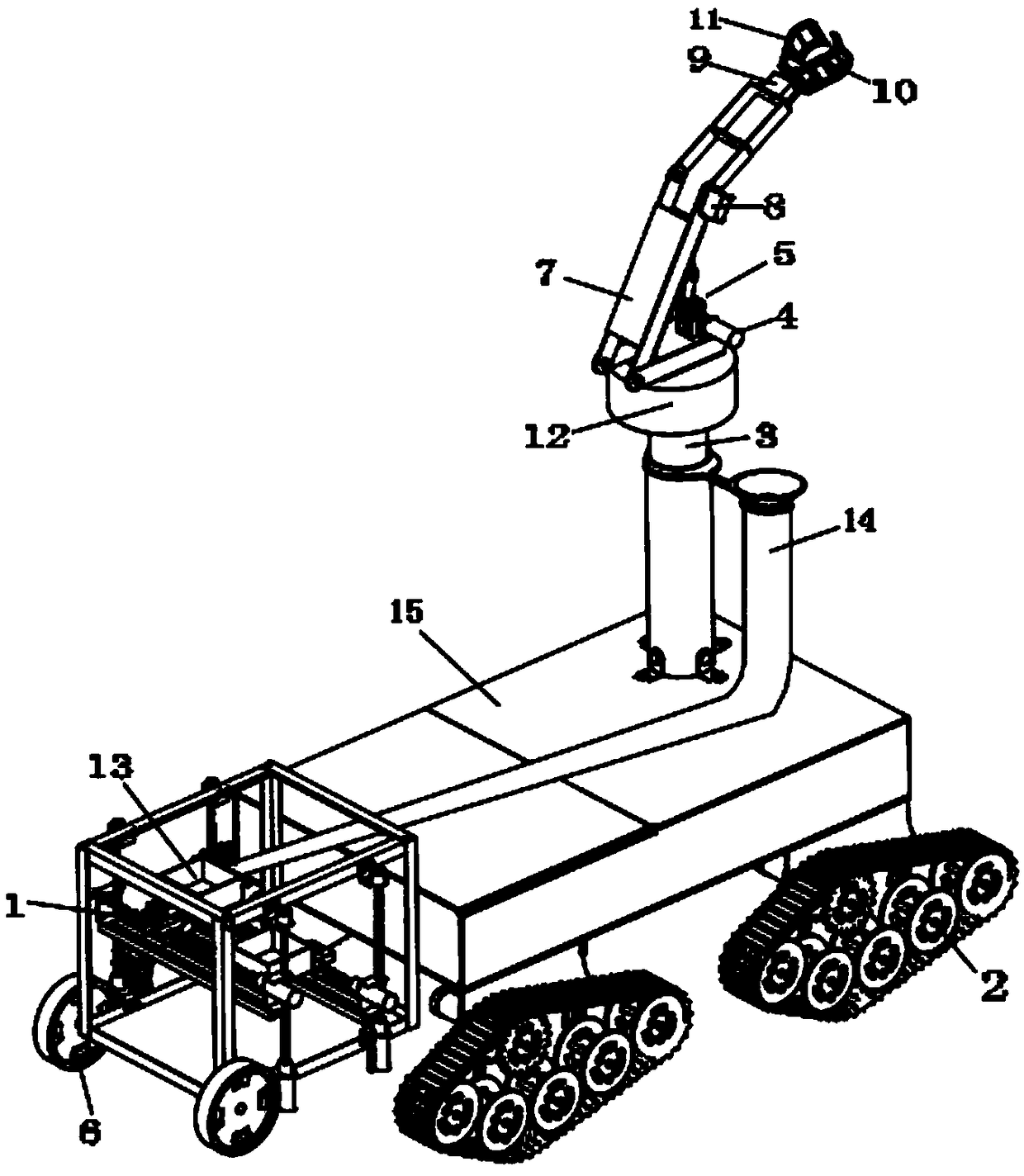

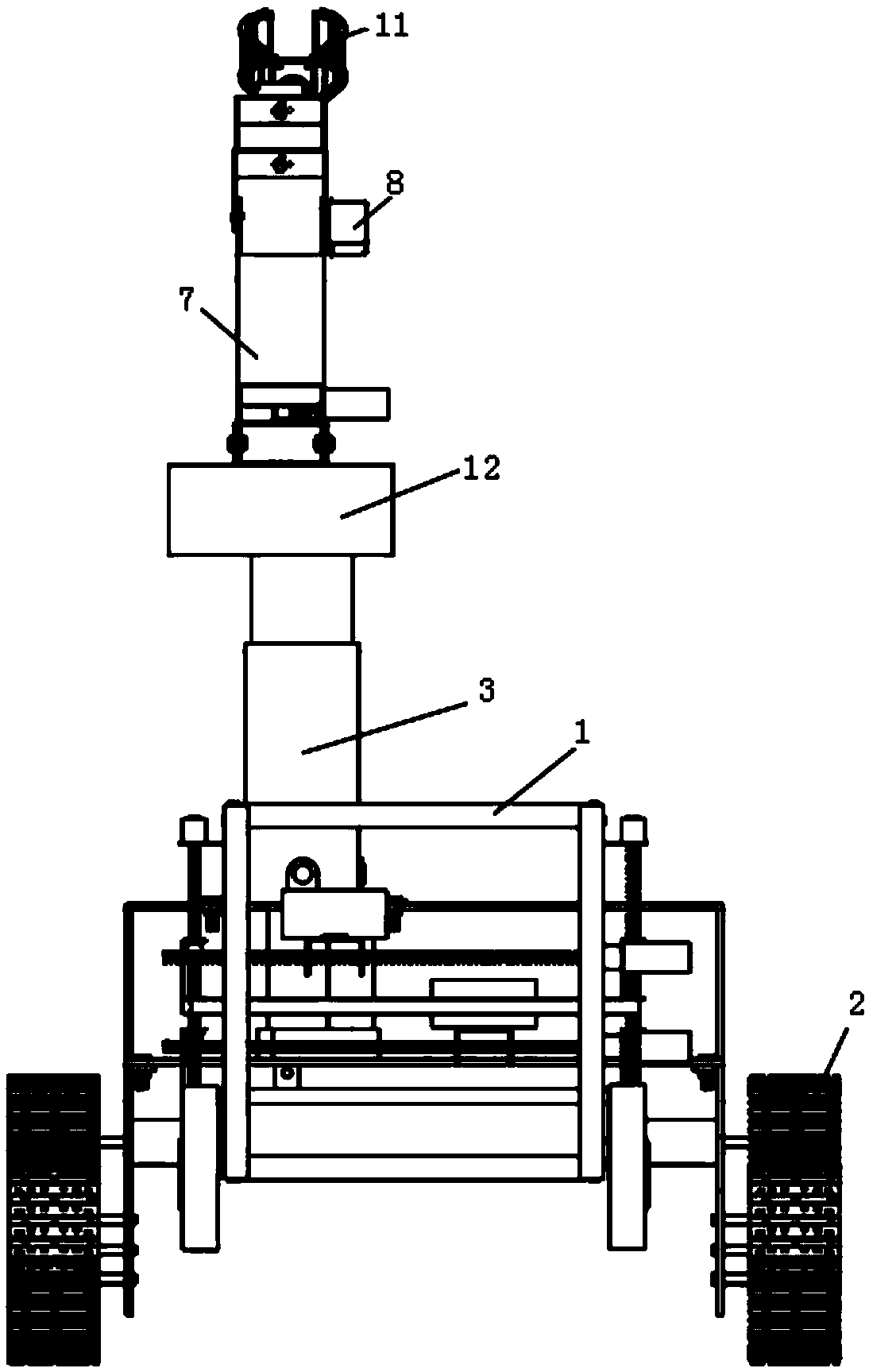

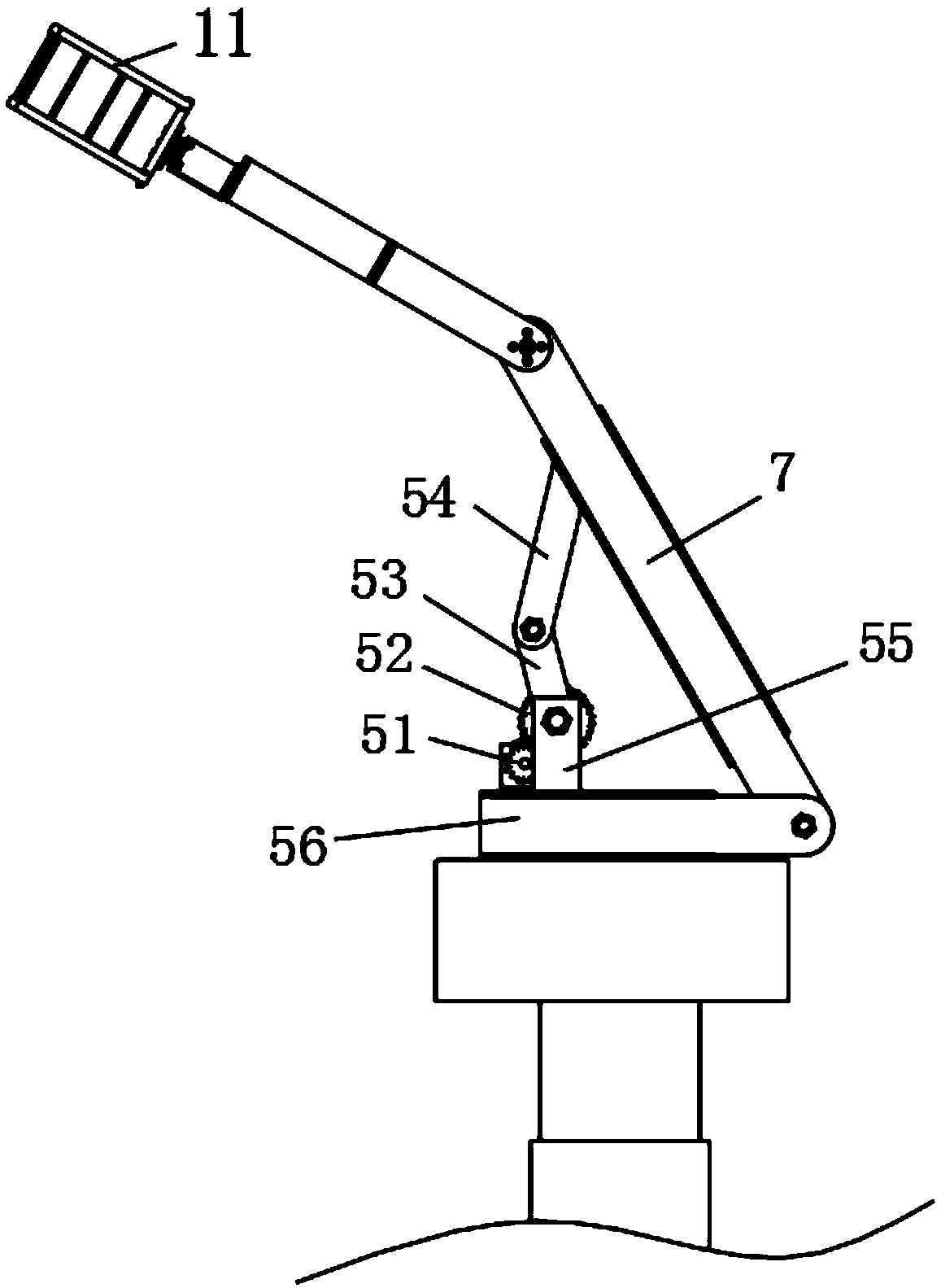

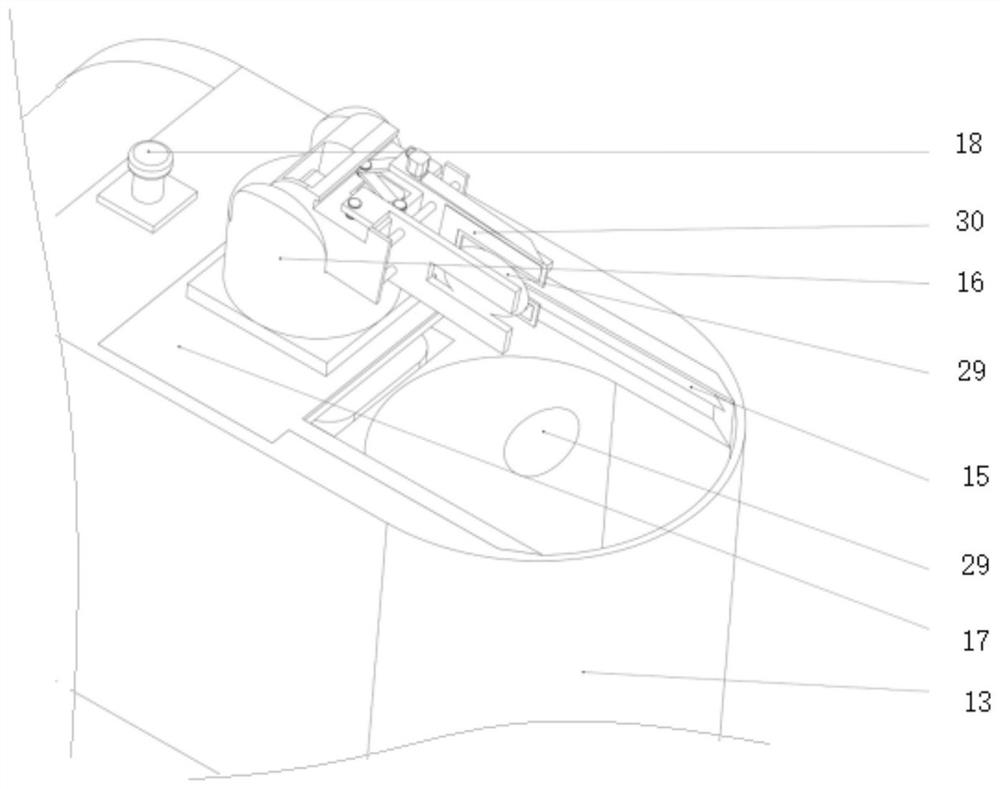

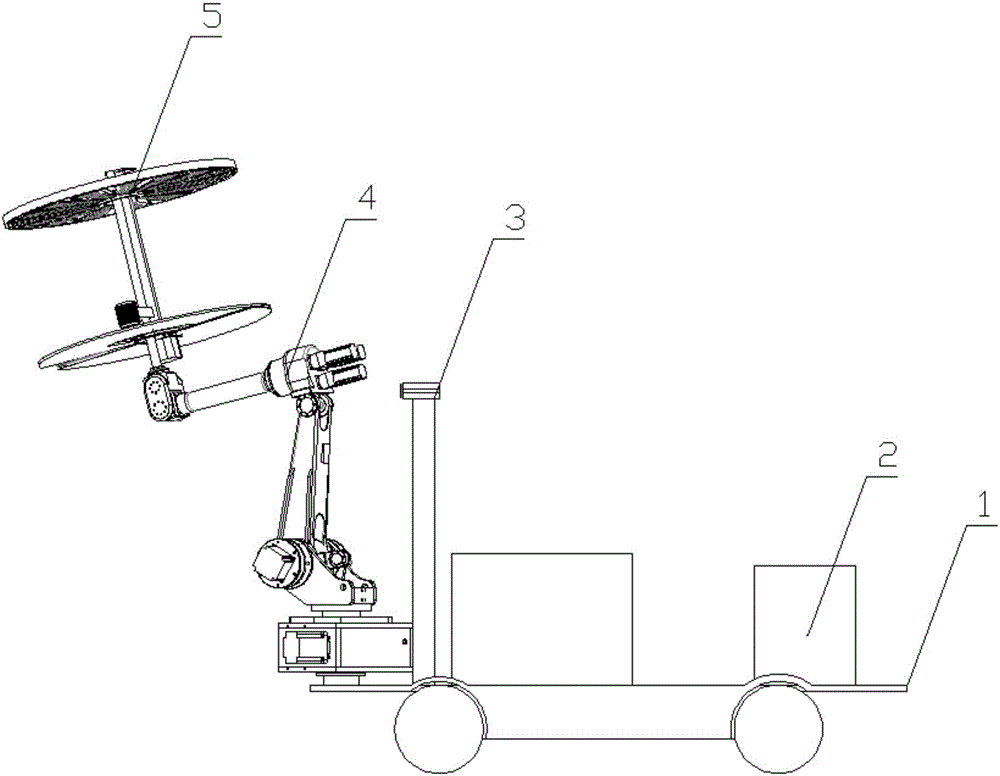

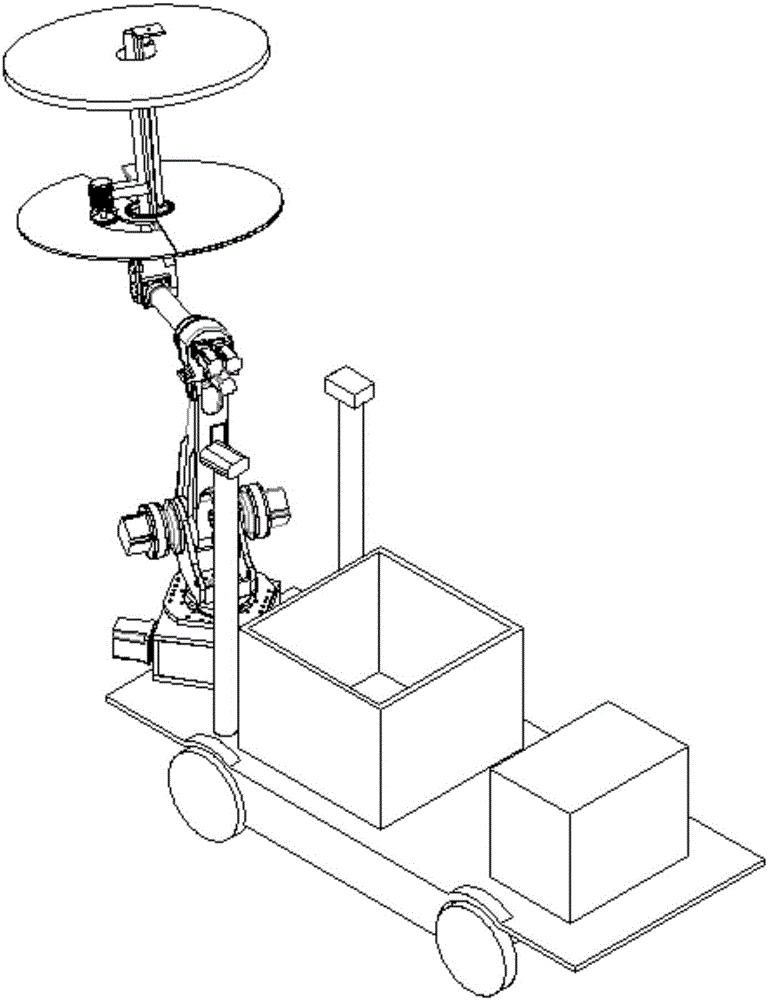

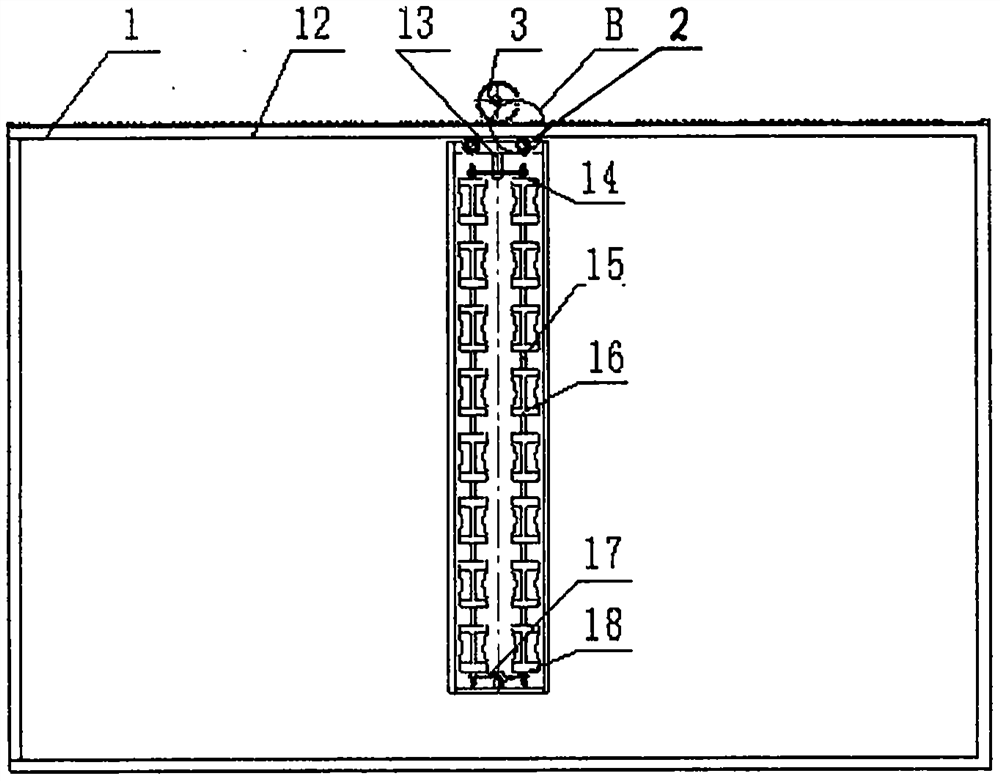

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866BReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

The invention discloses a picking method and picking robot device aiming at fruits which are in size of an apple and is similar to a sphere. The picking robot device comprises a mechanical actuating device, control system hardware and control system software. The mechanical actuating device comprises a picking mechanical arm, an underactuated manipulator, an electric sliding table and an intelligent mobile platform, wherein the control system hardware comprises an IPC (industrial personal computer), a motion control card, a data acquisition card, an AHRS (attitude and heading reference system), a coder, a monocular camera, a binocular camera, a force sensor, a slipping sensor and the like. During operation, the IPC fuses information of the coder, the AHRS, monocular camera components and an ultrasonic sensor to enable the mobile platform to independently navigate and avoid obstacles. A binocular vision system collects images of mature fruits and obstacles and extracts the characteristics of the images so as to realize obstacle avoidance of the mechanical arm and fruit positioning. Finally, the IPC fuses the information of the force sensor, the slipping sensor and the position sensor, thereby further reliably gripping the mature fruits and separating the fruits from fruit branches.

Owner:NANJING AGRICULTURAL UNIVERSITY

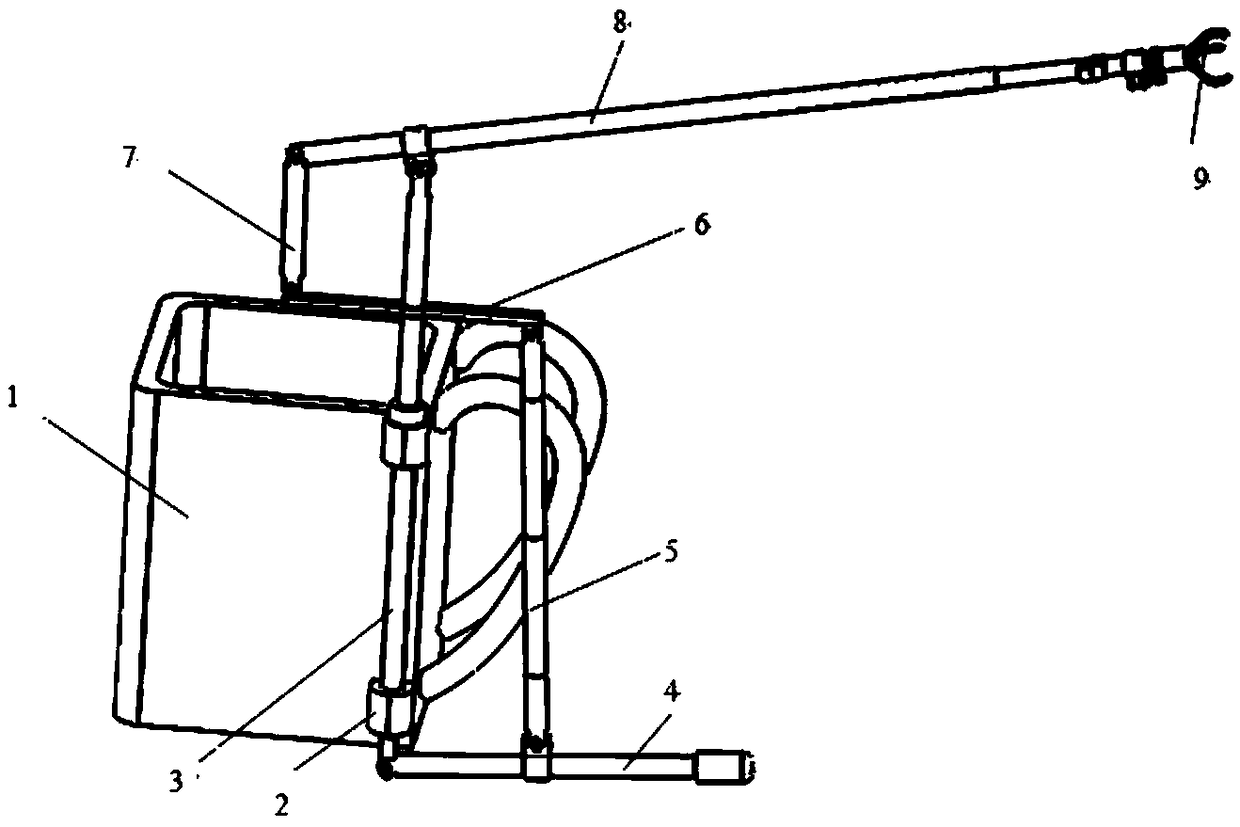

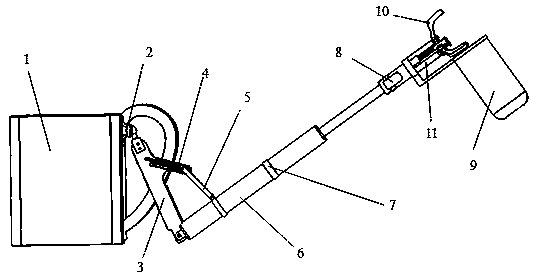

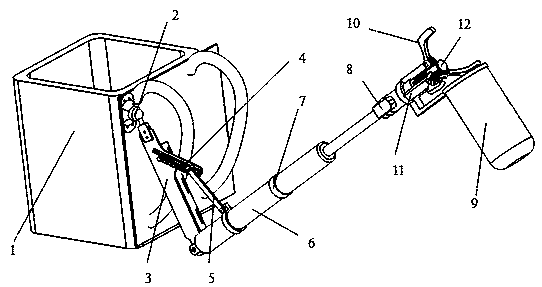

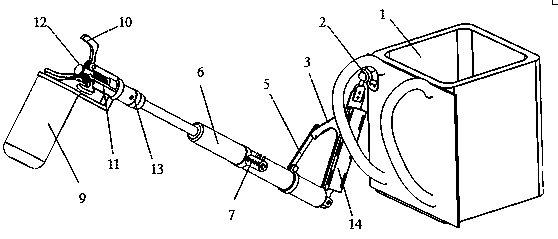

Knapsack apple auxiliary picking device

ActiveCN109076789AImprove picking efficiencyGuarantee the quality of finished productsPicking devicesArchitectural engineering

The invention discloses a knapsack apple auxiliary picking device. An auxiliary fixed end of the spherical pair is rigidly fixed at the upper end of the backpack box, the other end of the auxiliary fixed end of the spherical pair is fixed with a supporting plate; one side of the supporting plate is provided with a U-shaped plate; the other side of the supporting plate is provided with a sliding rail and a synchronizing wheel; the synchronizing wheel is provided with a synchronous belt; the sliding rail is provided with a sliding block; one end of the connecting rod is connected with the sliding block, the lower end of the supporting plate is connected with a telescopic rod, the other end of the supporting plate is connected with the middle part of the telescopic rod through a fixing ring,a handle is arranged at the middle part of the telescopic rod, a hollow fixing rod is fixed with the telescopic rod, the motor is fixed with the hollow fixing rod, a roller seat is fixed with the hollow fixing rod, the roller is fixed on the roller base, the roller is connected with the motor shaft, a fixing support base, a string bag and a rod is fixed with the front end of the hollow fixing rod,the string bag is connected with the hollow fixing rod through a fixing ring, and the front end of the support is connected with the claws; a rack is fixed at the front end of the rod, a spring is arranged in the middle part, and a convex platform is arranged at the rear end, one end of the spring is contacted with the rod, the other end of the spring contacts the sliding bearing so that the apple picking efficiency is improved, the labor intensity and the picking cost are reduced, and the quality of the apple finished product is ensured.

Owner:SHAANXI UNIV OF SCI & TECH

Apple picking robot

The invention discloses an apple picking robot, which comprises a robot body, a multi-stage adjusting arm, an adjusting device, a claw and a sorting device. One end of the robot body is vertically provided with an electric push rod, and the other end of the robot body is provided with the sorting device; a crawler walking device is disposed under the robot body; the electric push rod is provided with a torsion steering gear; the torsion steering gear is provided with the adjusting device and the multi-stage adjusting arm; the upper end of the multi-stage adjusting arm is provided with the clawand a second stepping motor for driving the claw; the upper surface of the sorting device is provided with a collecting box, and the bottom of the sorting device is provided with rollers; and the collecting box is provided with a conveying pipe fixed to the electric push rod and having an upward opening. The apple picking robot has reasonable structure design, conducts integrated picking, sortingand collecting of the apples in a high place, improves the efficiency of collecting and sorting, and causes no damage to the fruits; and the apple picking robot has is simple in operation, high in safety, and greatly reduces labor intensity and picking costs.

Owner:TONGLING UNIV

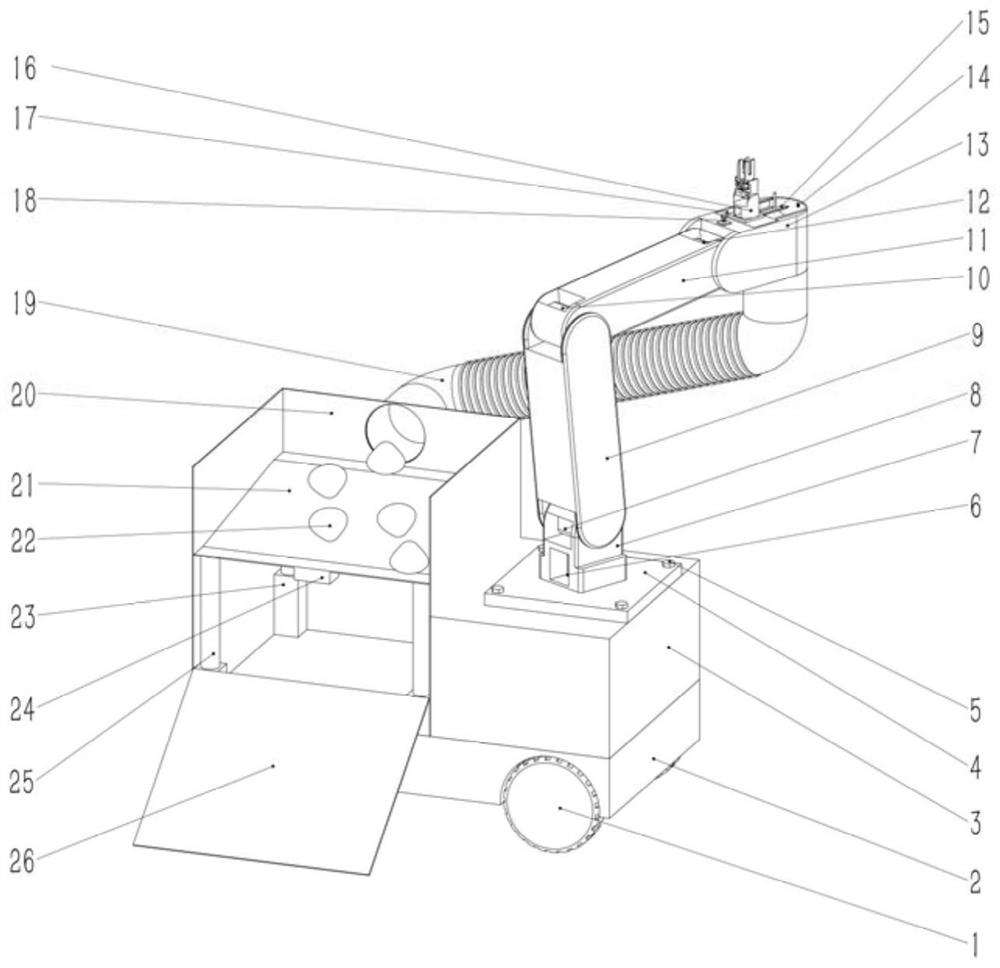

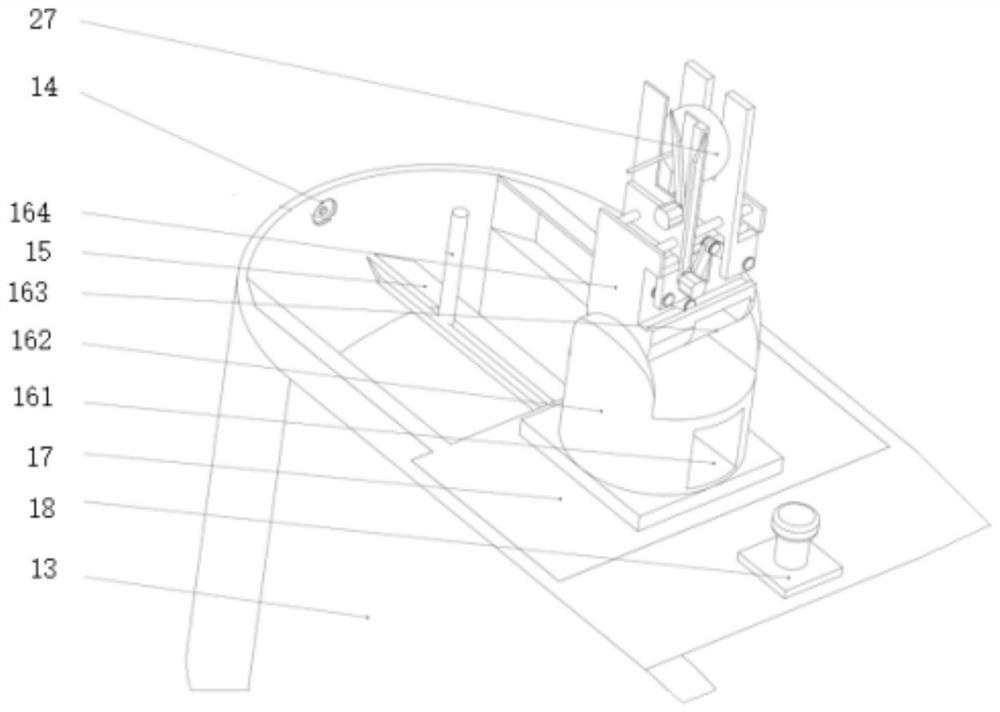

Spherical-like fruit picking robot based on machine vision and fruit picking method thereof

PendingCN113843810ACost-effectiveReduce picking costsProgramme-controlled manipulatorGripping headsRobot controlAgricultural engineering

The invention discloses a spherical-like fruit picking robot based on machine vision and a fruit picking method thereof. The spherical-like fruit picking robot comprises a picking device, a collecting device, a driving device, a console and a telescopic hose, the picking device comprises a mechanical arm base, a base rotating motor, a mechanical arm device, an end effector, an internal visual sensor, a large fruit shearing device, a small and medium fruit clamp and an external visual sensor, the end effector is connected with the collecting device through the telescopic hose, and the picking robot controls the picking device, the driving device and the collecting device to work through the console so as to complete fruit picking operation. According to the fruit picking robot, efficient picking of spherical-like fruits such as apples, pears, oranges, lemons, grapefruits, durians, kiwi fruits and grapes which grow and are distributed sparsely can be achieved, the cost performance of the picking robot is greatly improved, the fruit picking cost is reduced, and the fruit picking quality is greatly improved.

Owner:ZHENGZHOU UNIV

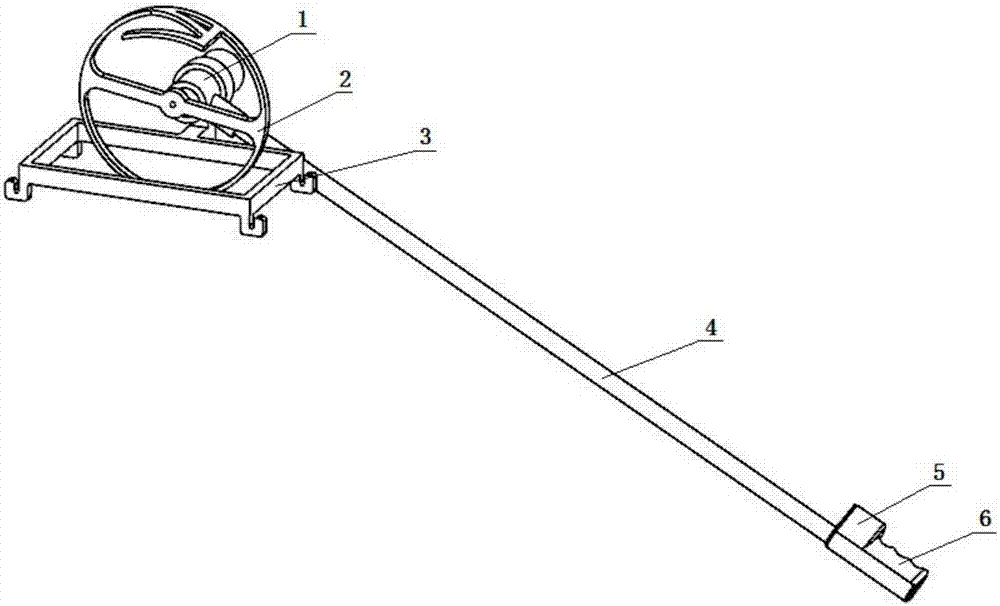

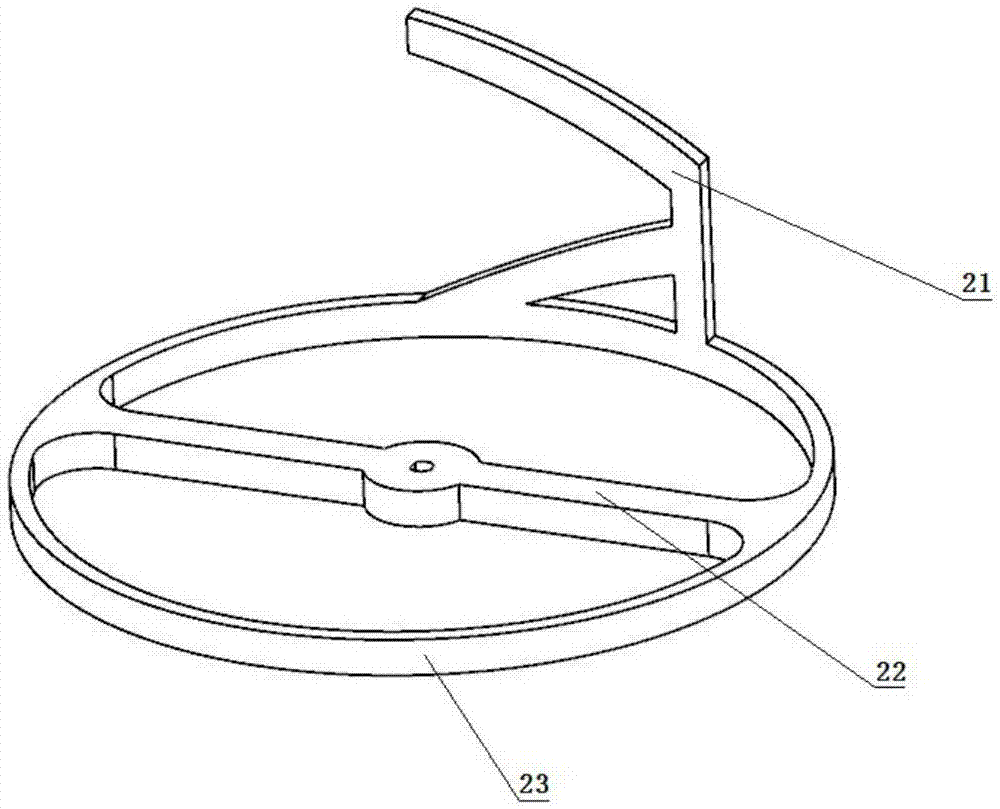

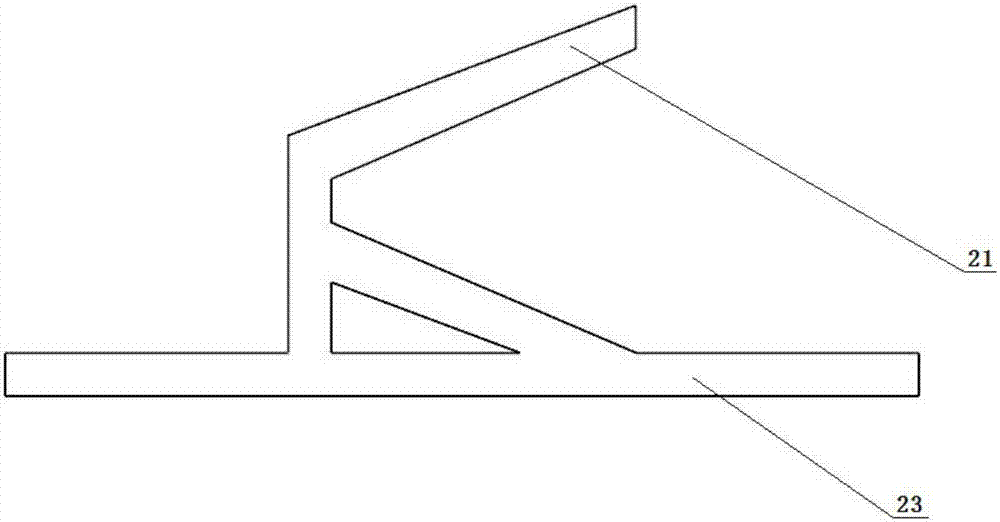

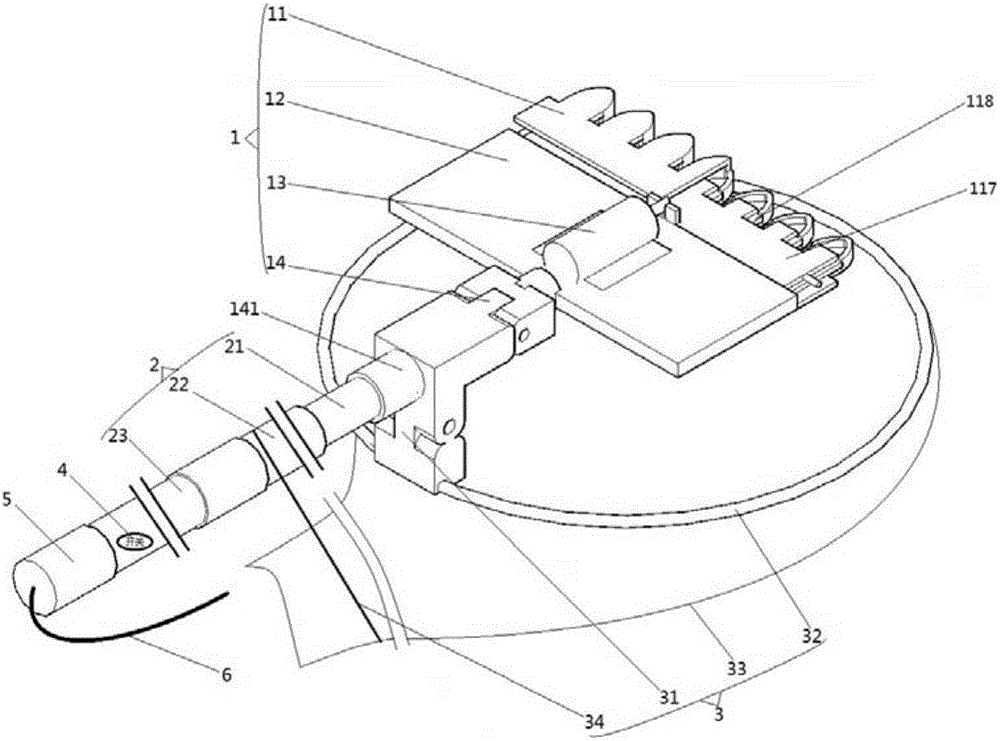

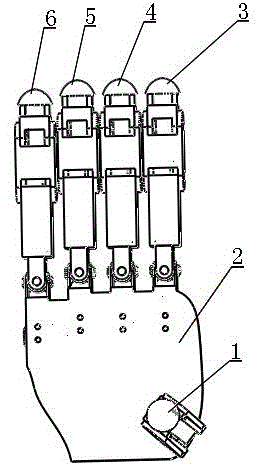

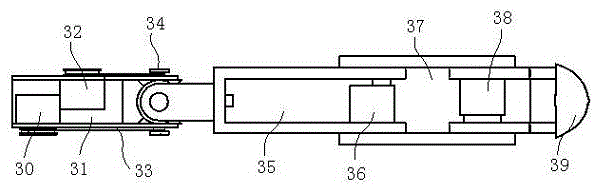

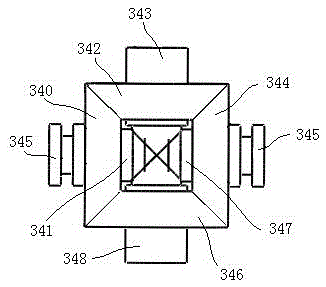

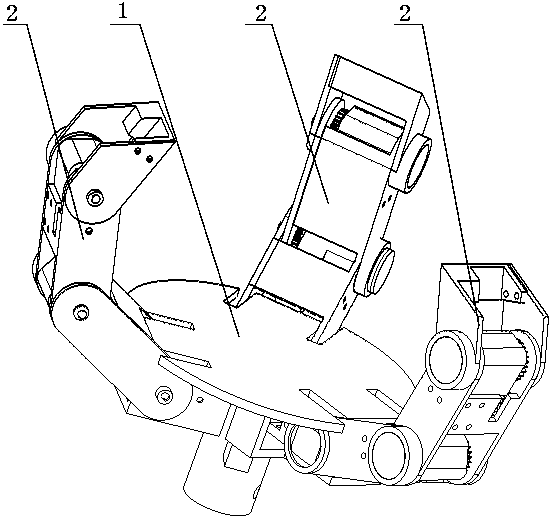

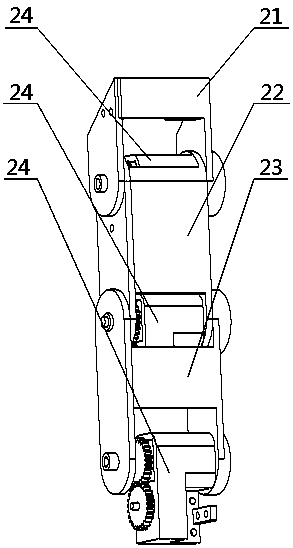

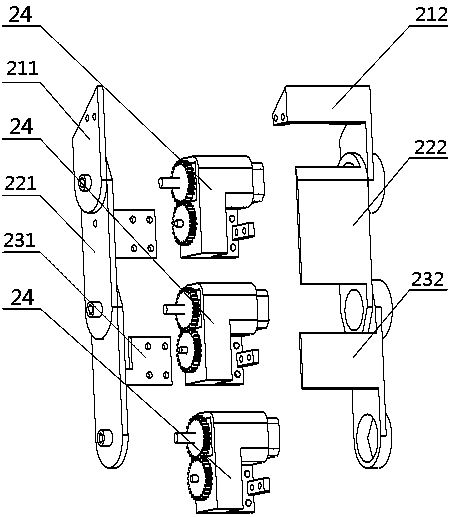

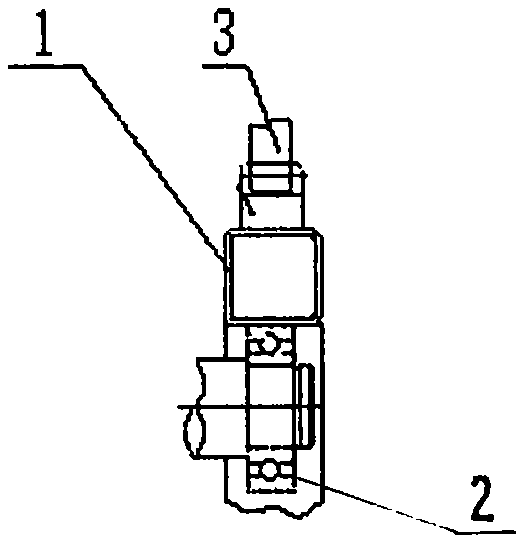

Five-finger end effector

InactiveCN105643643AReduce picking costsLarge space for exerciseGripping headsPicking devicesEngineeringRing finger

The invention relates to a five-finger end effector which comprises a thumb (1), a palm (2), an index finger (3), a middle finger (4), a ring finger (5) and a little finger (6). The five-finger end effector is characterized that the index finger (3), the middle finger (4), the ring finger (5) and the little finger (6) are identical in structure, each of the index finger (3), the middle finger (4), the ring finger (5) and the little finger (6) is provided with a base joint first motor (30), a base joint second motor (32) and a differential mechanism (34), each base joint first motor (30) and the corresponding base joint second motor (32) are fixed on the palm (2), a near joint of each finger is connected with the palm (2) through the corresponding differential mechanism (34), and each base joint first motor (30) and the corresponding base joint second motor (32) drive the corresponding differential mechanism (34) to lateral swing movement and pitching movement of the corresponding finger.

Owner:NORTHWEST A & F UNIV

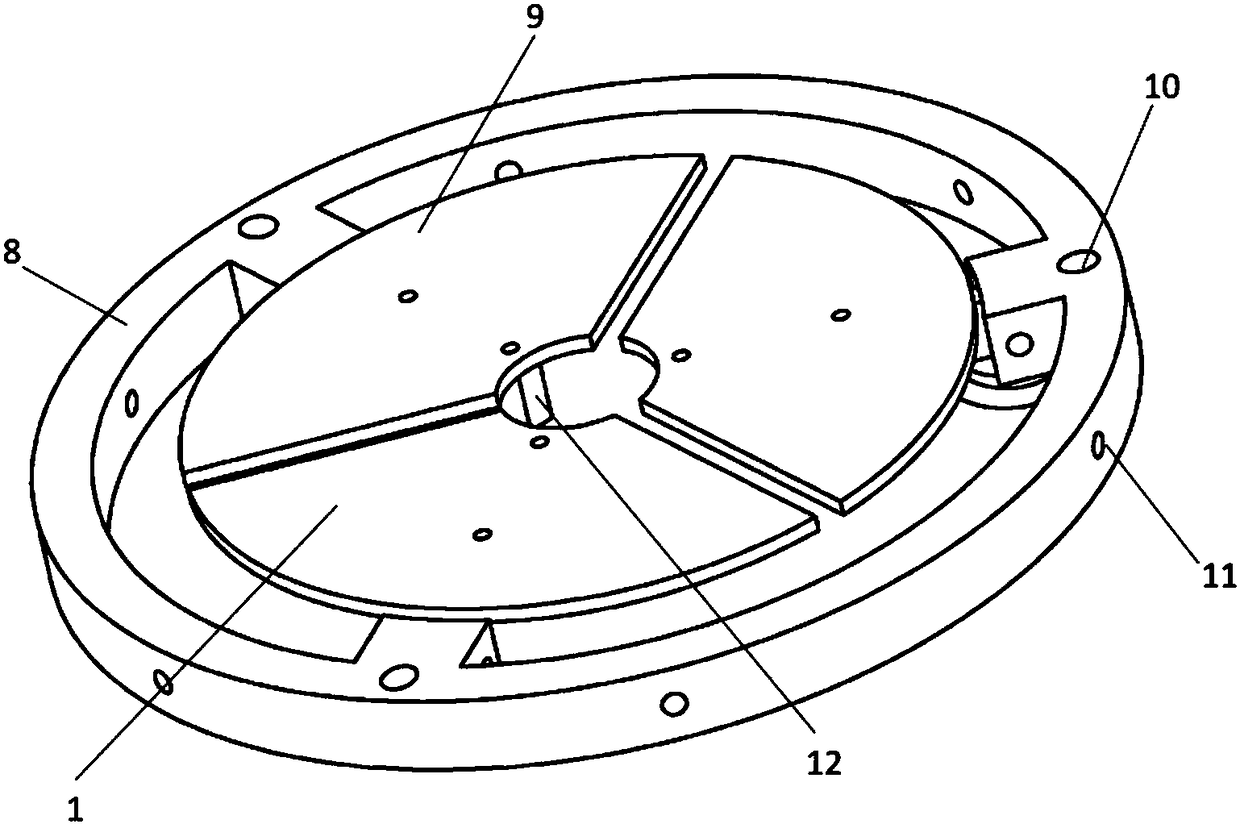

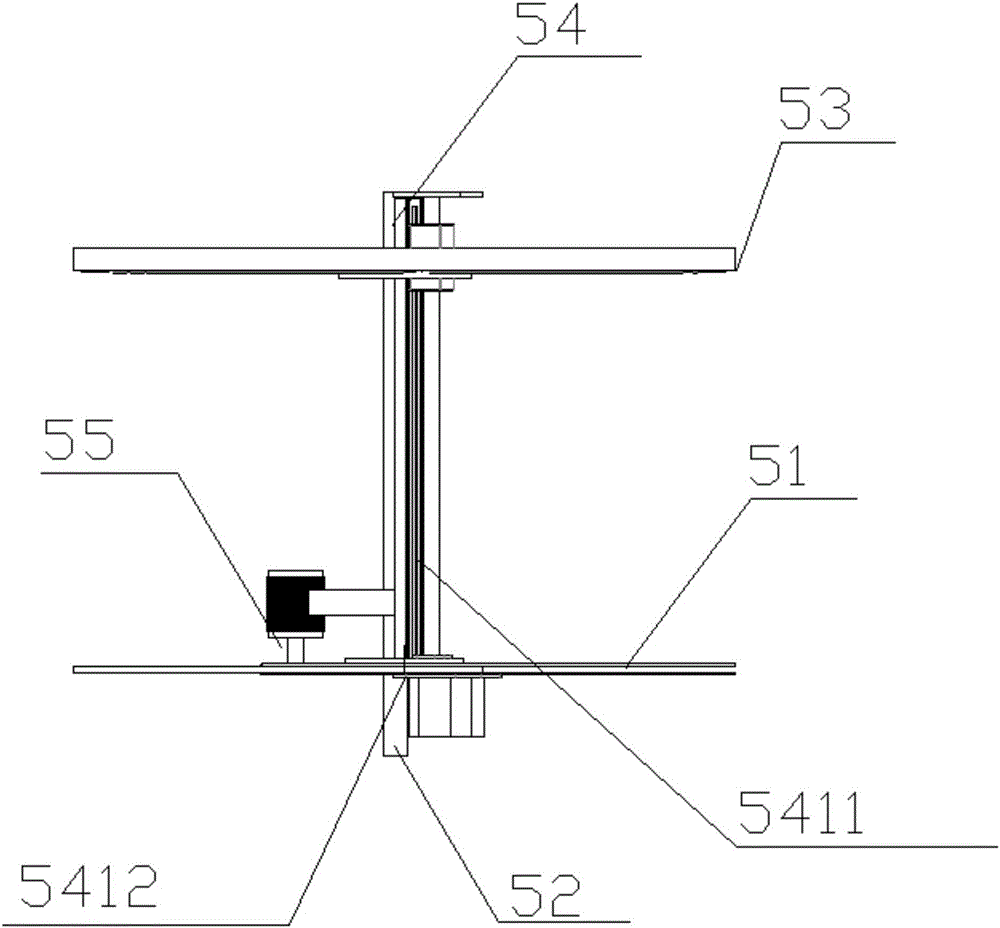

Fruit picking robot based on efficient picking disc

The invention relates to the technical field of agricultural automation and robots, in particular to a fruit picking robot based on an efficient picking disc. The fruit picking robot comprises a four-wheeled intelligent platform, a control system, an image identification system, a picking arm and the picking disc. The picking disc comprises a chassis, a support, a top body disc, a top body disc lifting mechanism and a chassis rotating mechanism. The chassis comprises a left half chassis, a right half chassis, a conical bearing and an outer edge housing. The top body disc is of a branch-shaped fruit carding and picking structure. The top body disc lifting mechanism achieves convergence and separation of the top body disc and the chassis and accordingly achieves branch clamping and loosening. The fruit picking robot improves the picking labor productivity of branch-shaped distributed fruits of dogwoods, hot peppers, Chinese wolfberry, glossy privets and the like, reduces the labor intensity and picking costs of peasants, ensures timely harvesting and picking quality of the fruits and has the immeasurable significance on promotion of rural economic development, improvement of agricultural modernization and intelligentization of our country and acceleration of agricultural scientific progress.

Owner:SHANDONG GUOXING SMARTECH CO LTD

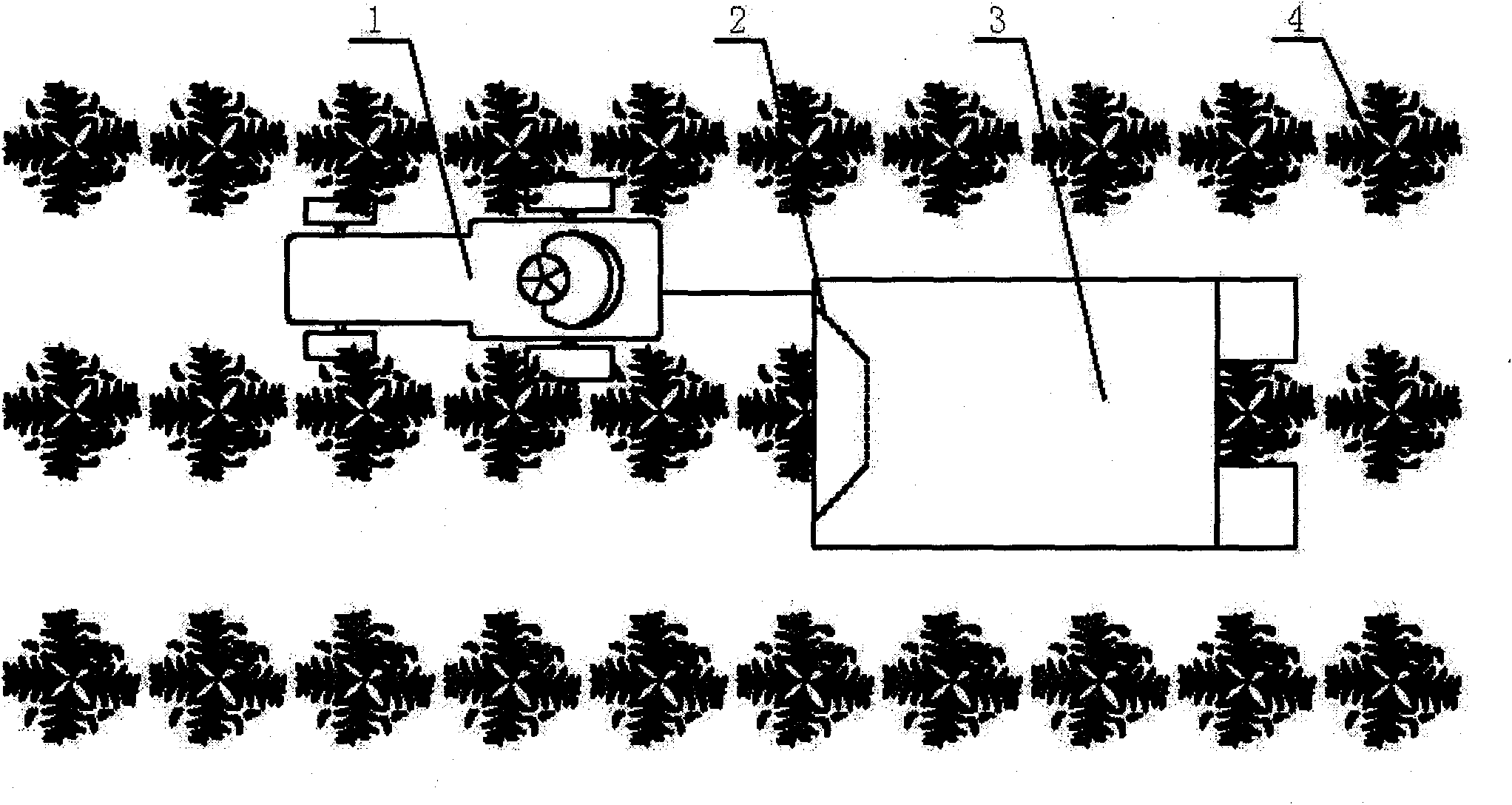

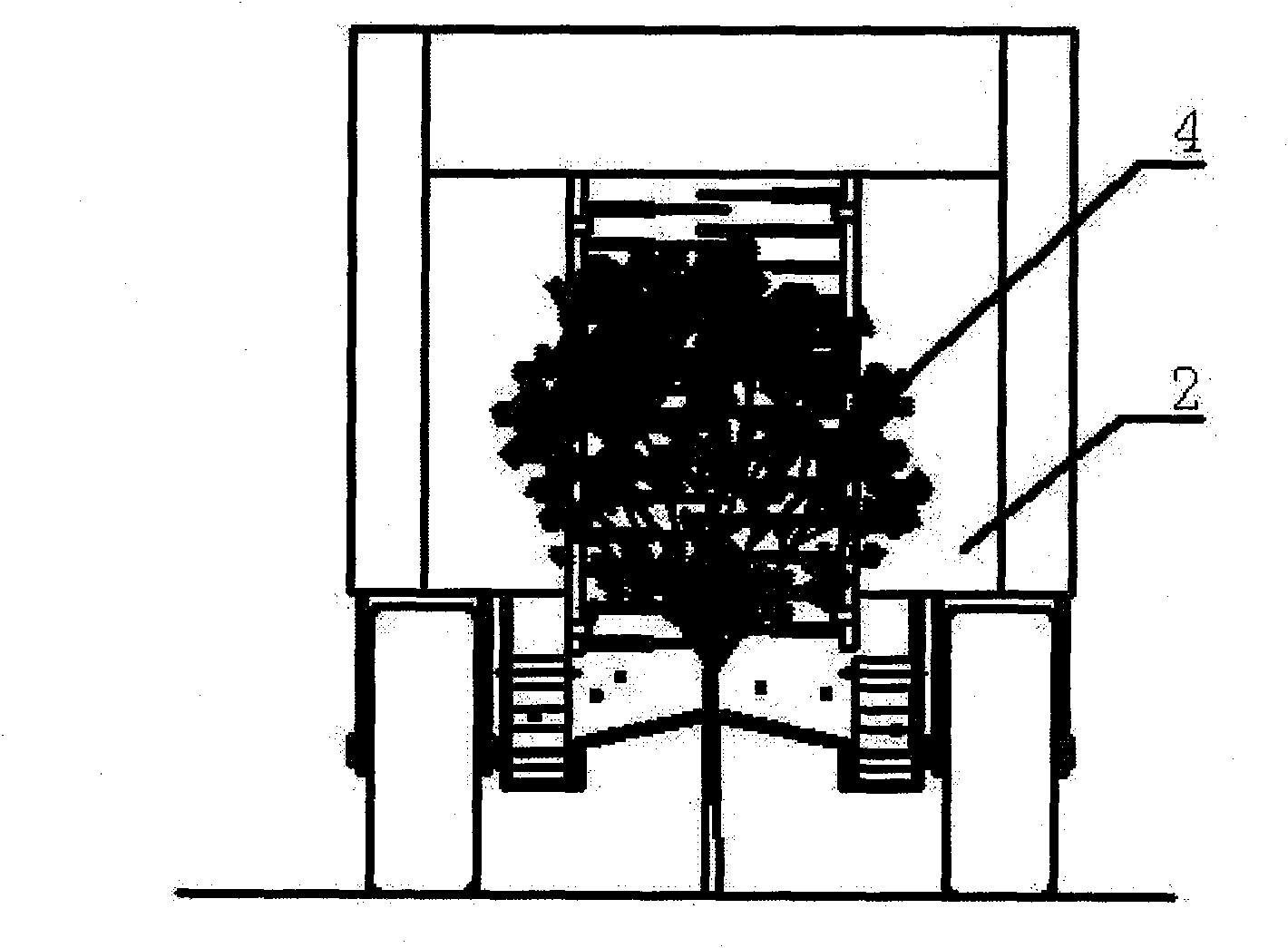

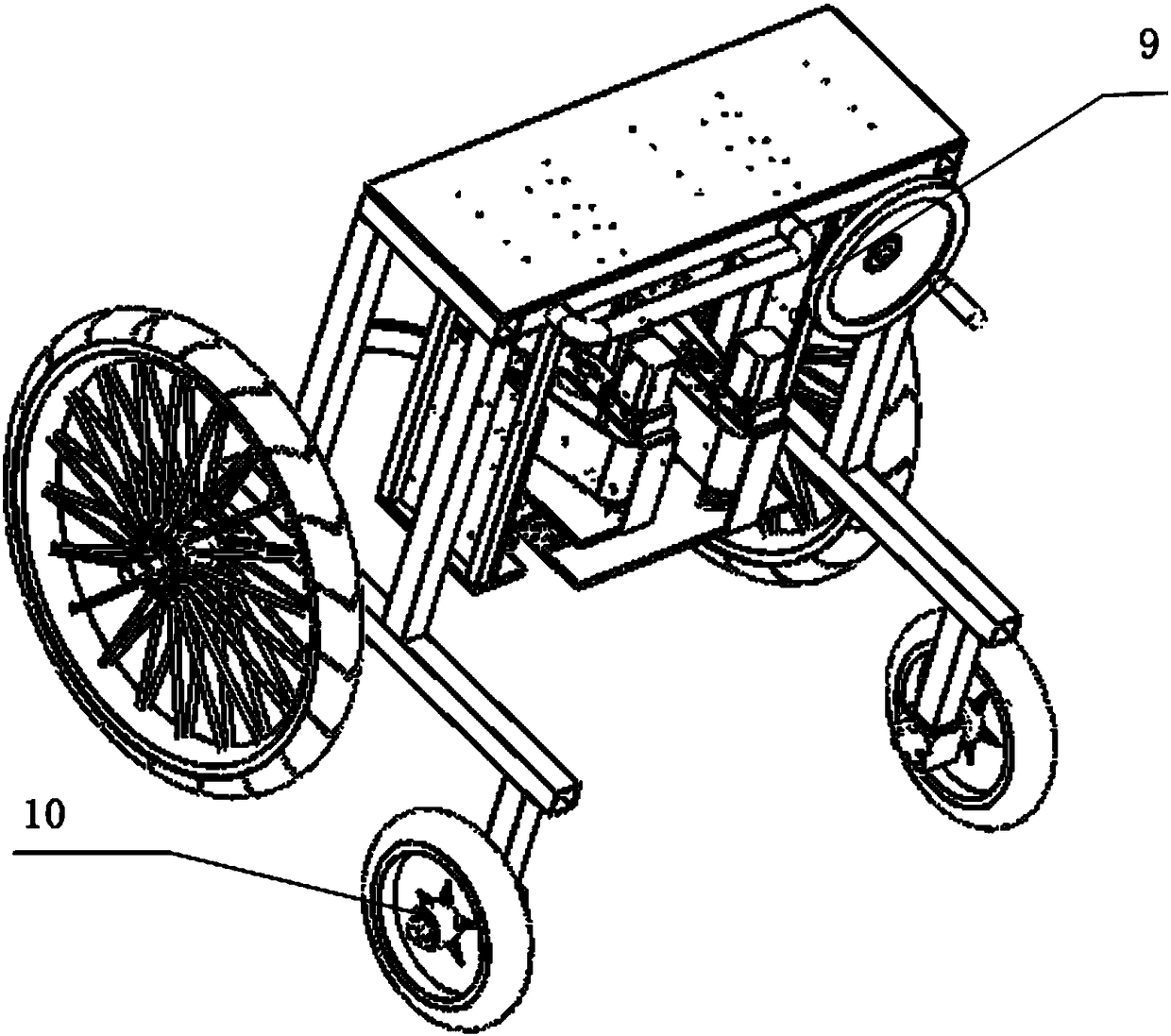

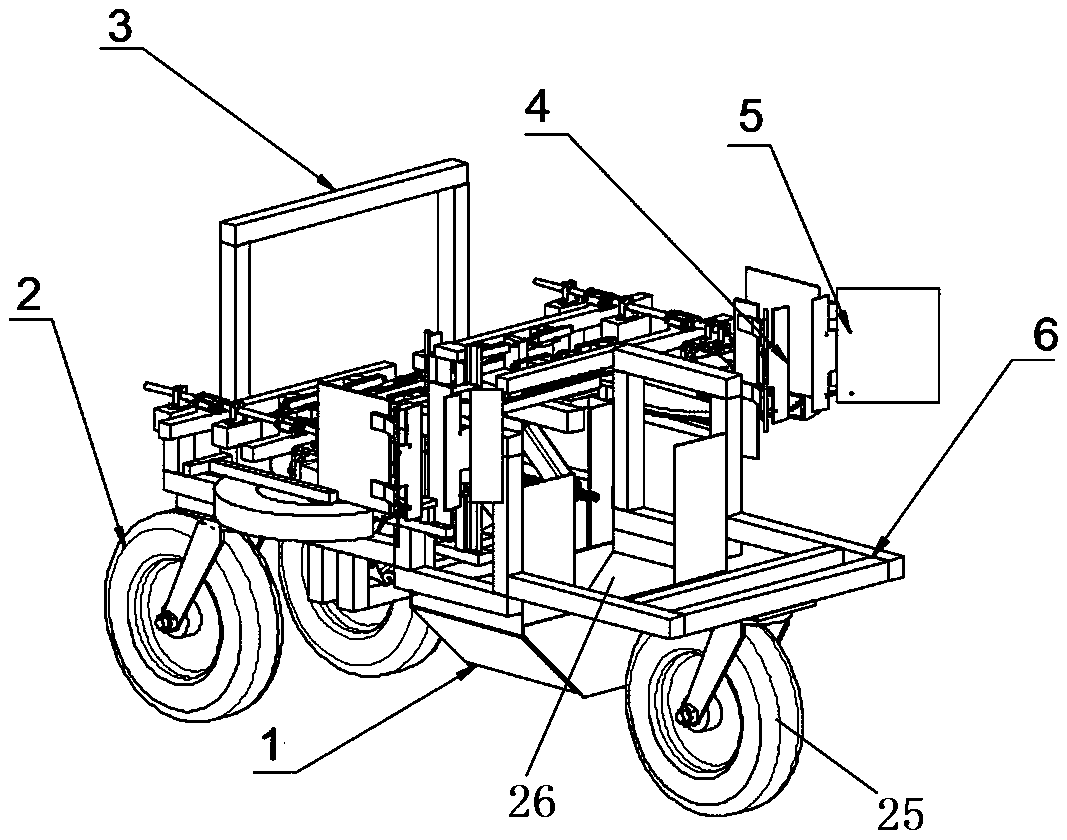

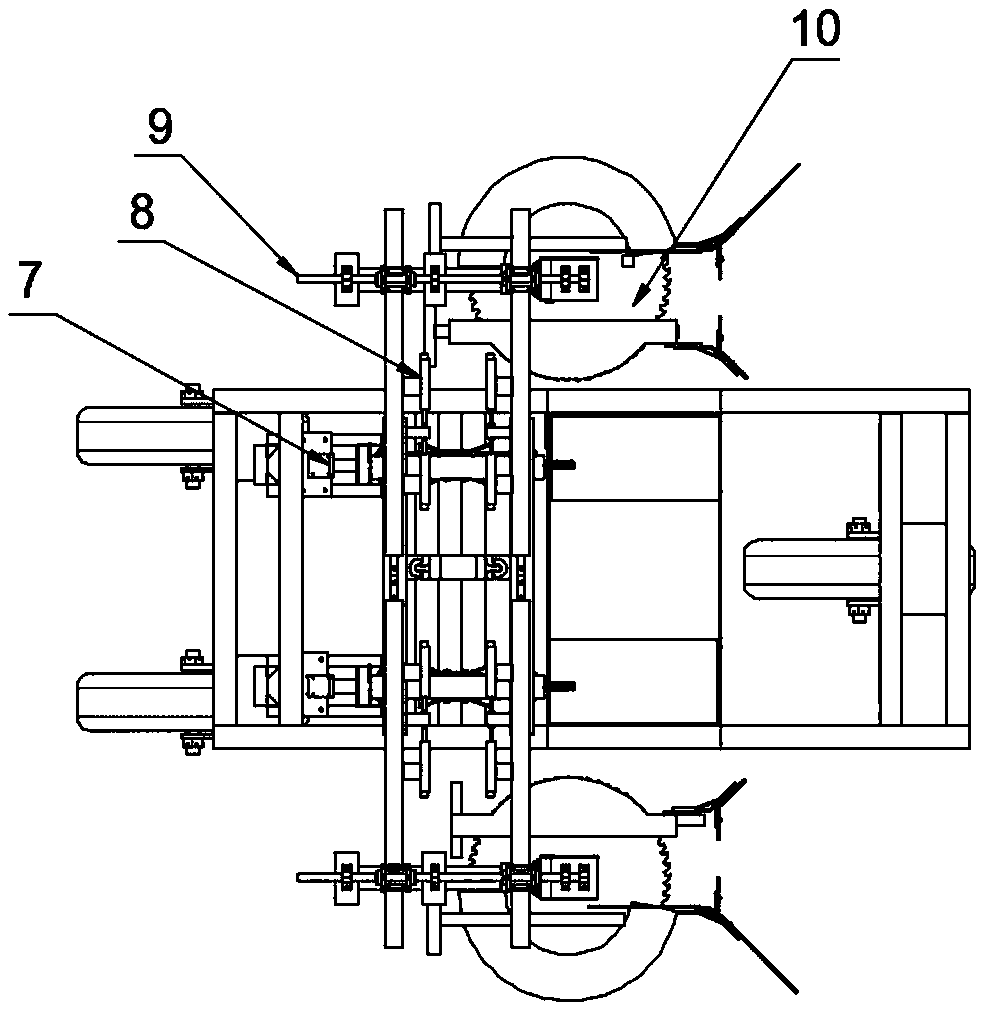

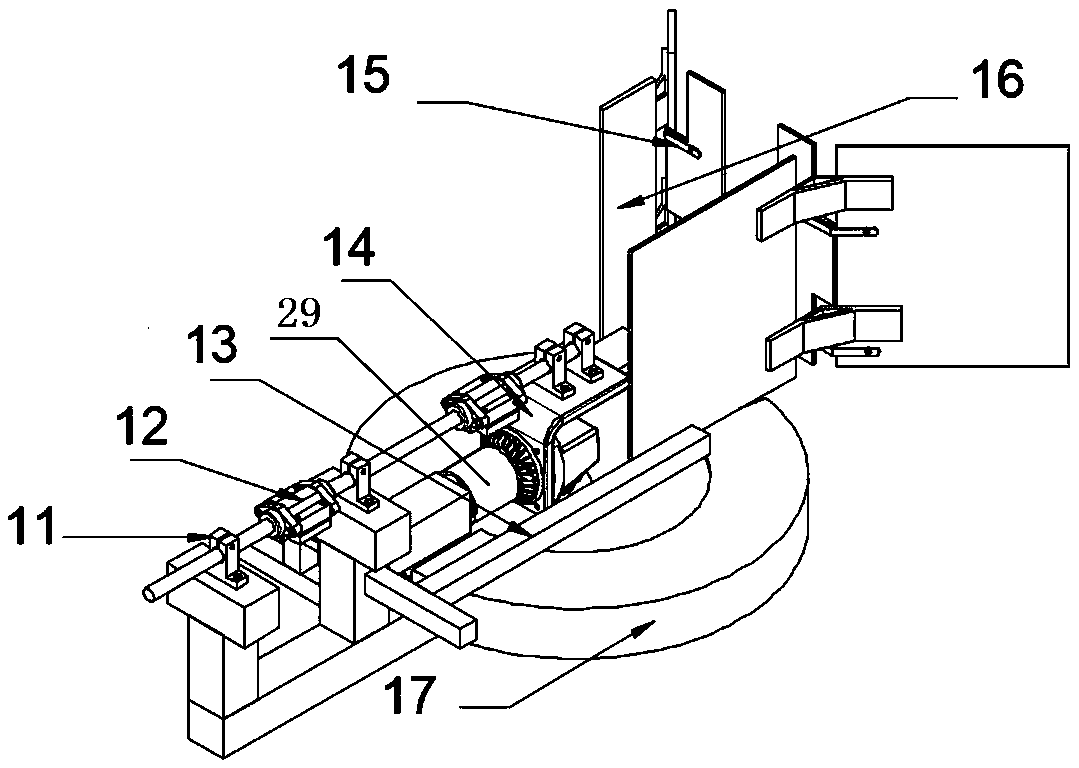

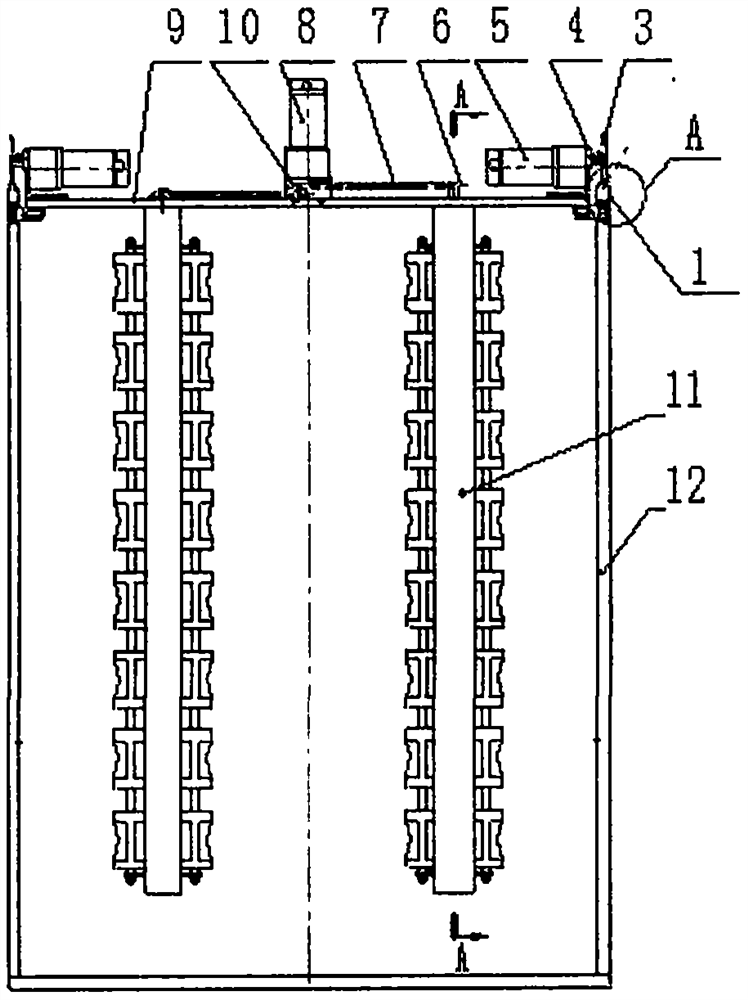

Adaptive double-row pineapple automatic harvester and harvesting method thereof

ActiveCN109258089AEasy to harvestImprove harvesting efficiencyHarvestersPineapple PlantHigh volume manufacturing

The invention discloses an adaptive double-row pineapple automatic harvester. The automatic harvester comprises a supporting device and at least one cutting device installed on the supporting device;each cutting device is connected with an angle adapting device for adjusting the cutting angle of the cutting device, each angle adapting device is connected with a transverse adapting device for adjusting the transverse position of the corresponding cutting device, and each transverse adapting device is connected to the supporting device through a lifting device; collecting and sorting devices are further arranged on the supporting device, and the positions of the collecting and sorting devices correspond to the cutting positions of the cutting devices. The automatic harvester can fill up thedomestic blank of pineapple harvesting and collecting integration and improve the pineapple harvesting efficiency greatly; by widely using the automatic harvester in the process of harvesting pineapples in pineapple planting bases after mass production, pineapples can be conveniently harvested, the labor intensity of farmers can be reduced, the picking efficiency can be improved, the picking costcan be reduced, and the economic benefit of farmers can be increased.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nine-freedom-degree picking mechanical arm

PendingCN108098825AImprove interchangeabilityPicking achievedGripping headsPicking devicesFinger jointDegrees of freedom

The invention relates to a nine-freedom-degree picking mechanical arm. The nine-freedom-degree picking mechanical arm is characterized in that the nine-freedom-degree picking mechanical arm includes apalm and three fingers, each finger has three rotation freedom degrees; the palm is of a circular plate shaped structure or a circular disk shaped structure or a circular bowl shaped structure, the three fingers are evenly distributed on the periphery of the palm; each finger includes a fingertip, a middle finger section, and a base finger section; the fingertip, the middle finger section, and the base finger section are rotationally connected with one another in sequence through corresponding finger joints; and the base finger sections and the palm are rotationally connected through corresponding finger joints. According to the nine-freedom-degree picking mechanical arm, crawl is flexible, working space is large, picking of various kinds of round fruit can be achieved, interchangeabilityof the mechanical arm is improved, and the picking cost is reduced.

Owner:NORTHWEST A & F UNIV

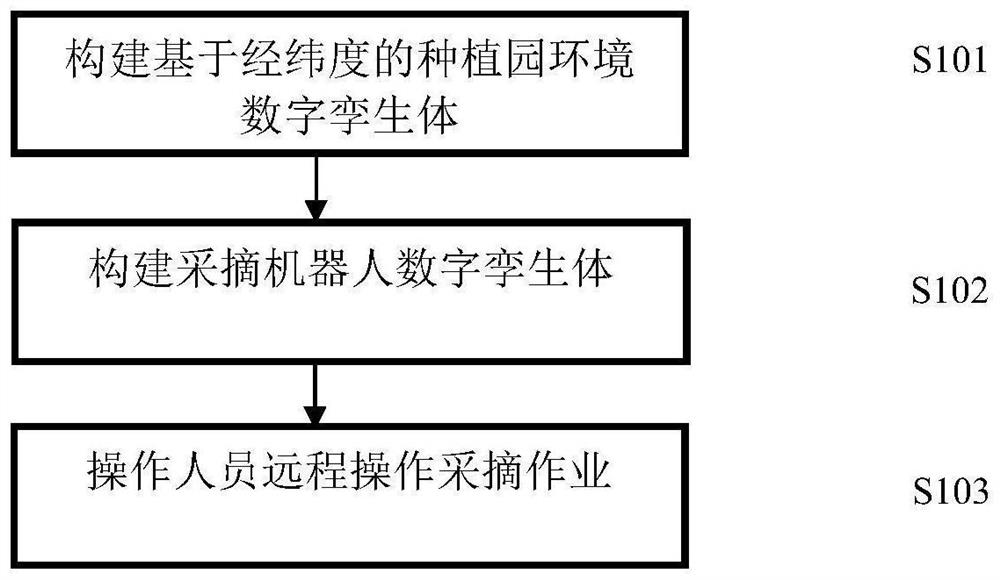

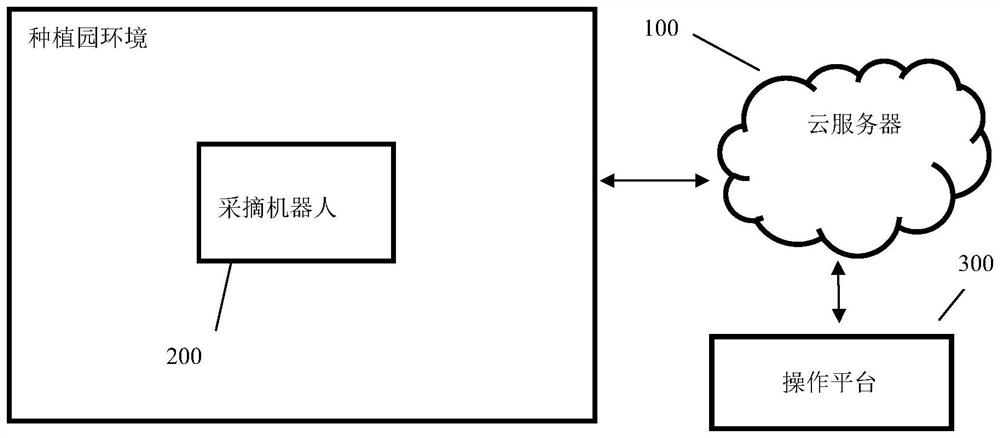

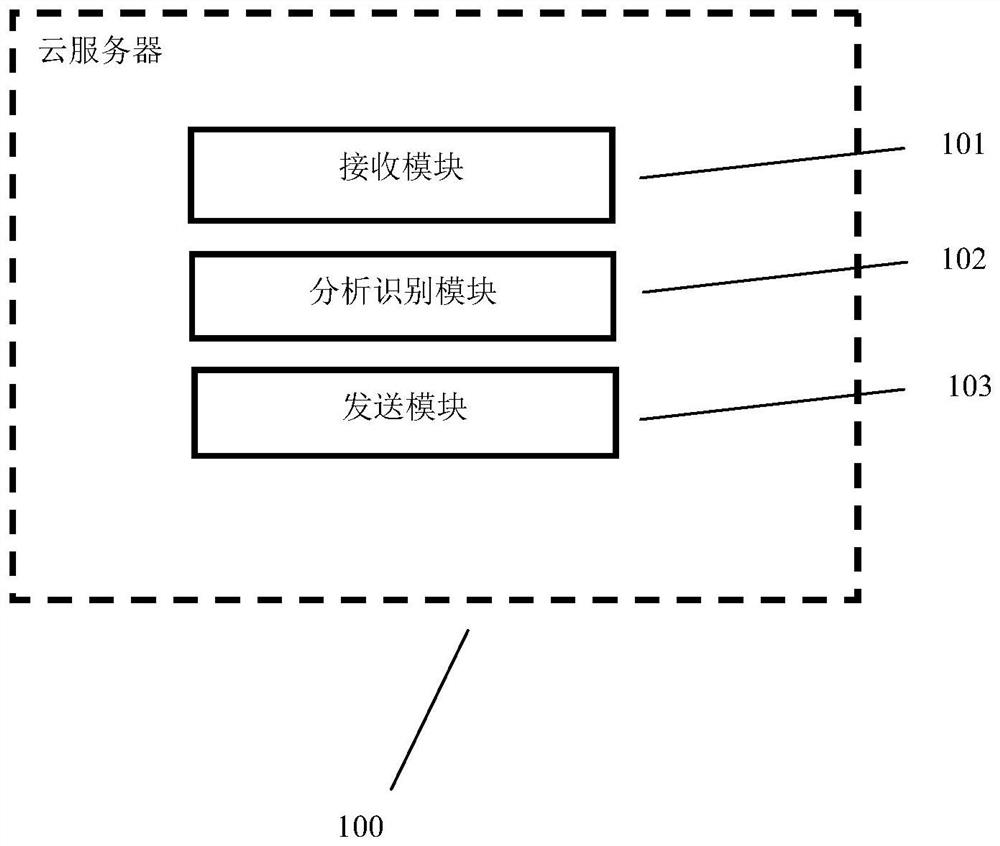

Picking method based on digital twins and cloud picking robot system

ActiveCN114080905AIncrease productivityReduce picking costs and staffing requirementsProgramme-controlled manipulatorPicking devicesComputer visionEngineering

The invention provides a picking method based on digital twins and a cloud picking robot system. A plantation environment digital twinborn body and a picking robot digital twinborn body are constructed through a cloud server in the cloud picking robot system; and an operator remotely controls the picking robot to perform picking operation according to the visual information presented by the cloud server. Through the technical scheme of the invention, the plantation picking environment is virtually reconstructed based on the digital twin technology, the picking operation can be remotely and visually completed through the cloud server, a plurality of picking tasks can be remotely completed under the condition of one operator, and the dependence of the current picking robot on the field operator is reduced.

Owner:HANGZHOU QOGORI TECH

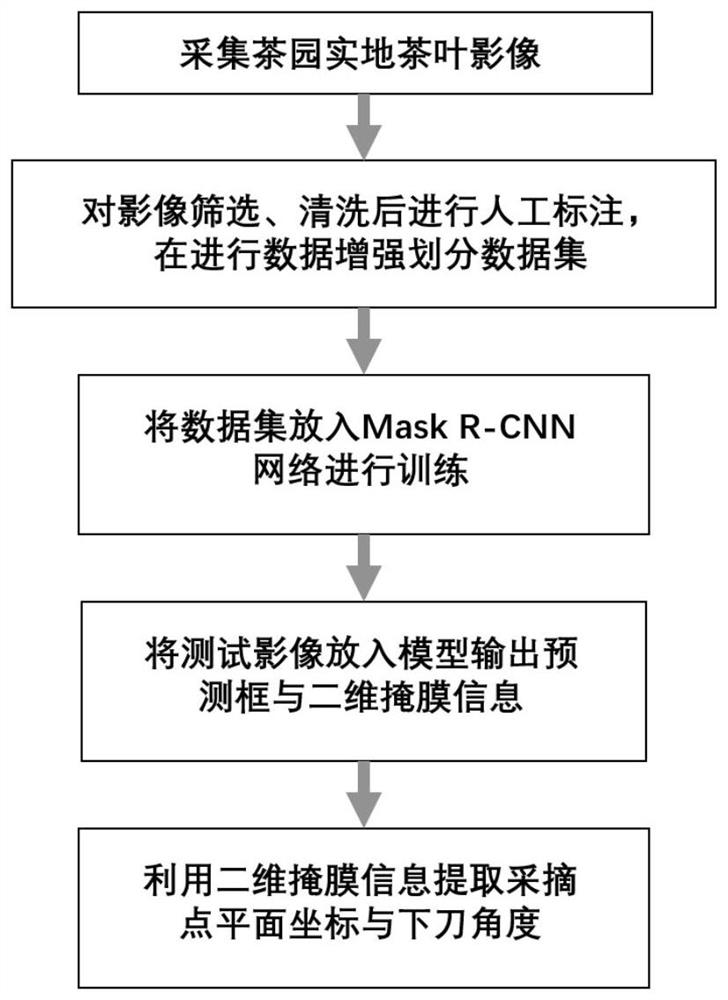

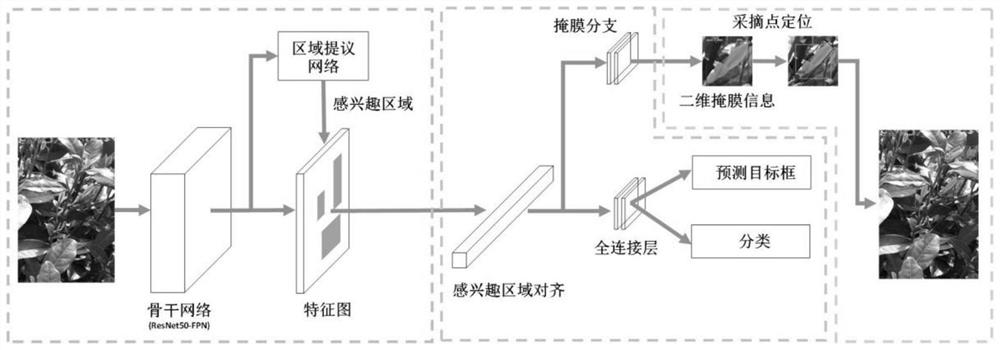

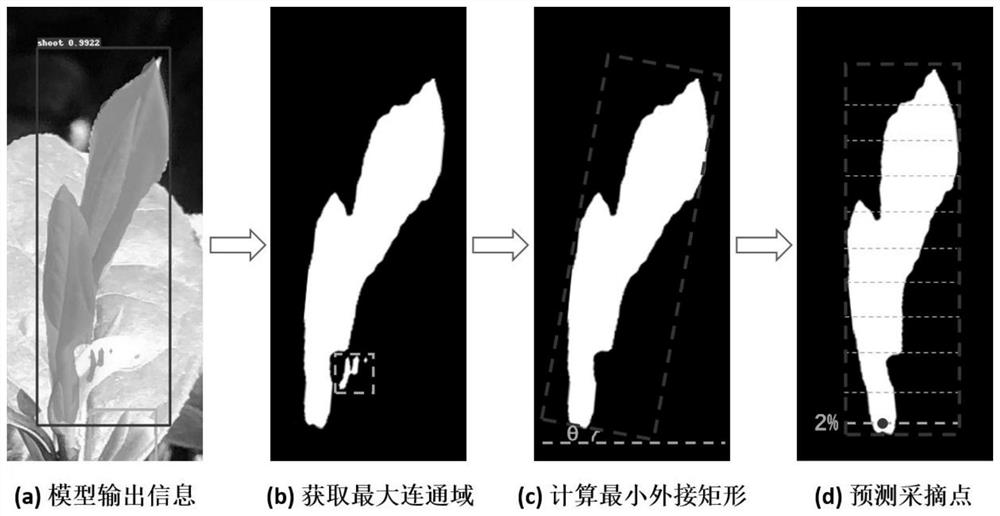

Machine vision-based famous high-quality tea tender shoot identification and picking point positioning method

ActiveCN114708208AAccurate extractionImprove efficiencyImage enhancementImage analysisMachine visionAlgorithm

The invention discloses a famous high-quality tea tender shoot recognition and picking point positioning method based on machine vision. The method comprises the following specific steps: step 1, making an original data set of famous high-quality tea tender shoots; step 2, training an original data set, solidifying obtained parameters into a model after training is finished, and outputting the model; step 3, acquiring a test image of famous high-quality tea tender shoots, inputting the test image into the model output in the step 2, and outputting a prediction frame and two-dimensional mask information of the tea tender shoots in the test image; step 4, acquiring areas of different connected domains in the two-dimensional mask information, calculating a minimum enclosing rectangle of a maximum connected domain, acquiring a rotation angle of the minimum enclosing rectangle, taking the rotation angle of the minimum enclosing rectangle as a bud axis direction, and acquiring a cutting angle along the tangential direction of the bud axis; 5, taking 2% of the position from bottom to top along the bud axis as a picking point. An instance segmentation algorithm is used to directly output a mask region of a tender shoot through deep features between model learning pixels, and tea bud edge extraction is accurate.

Owner:HANGZHOU DIANZI UNIV

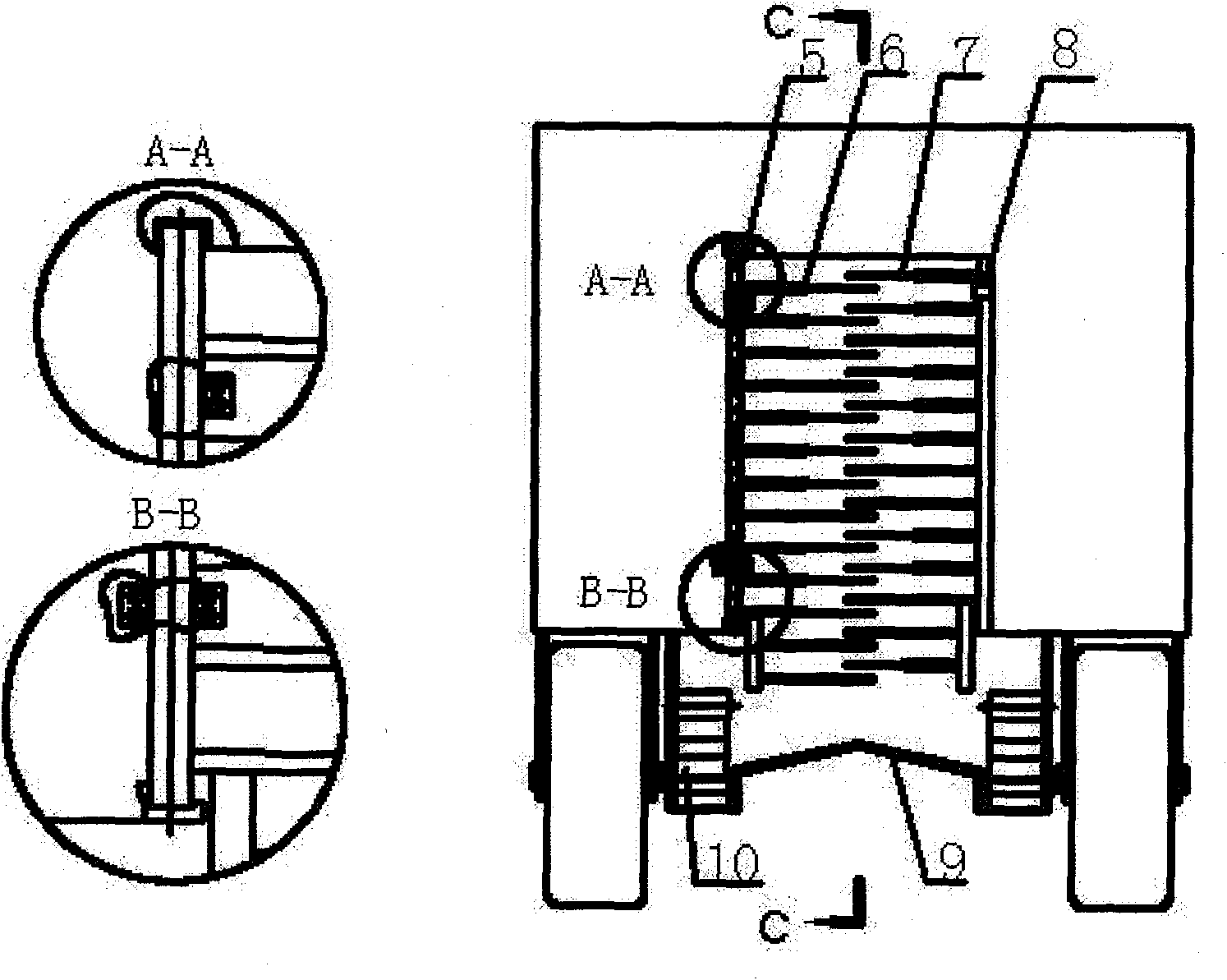

Automatic picking device suitable for horizontal centralized three-dimensional cultivation of agaric bags

PendingCN111990182AMeet and realize mechanized automatic picking operationReasonable structureCultivating equipmentsMushroom cultivationGear wheelAgricultural engineering

The invention discloses an automatic picking device suitable for horizontal centralized three-dimensional cultivation of agaric bags, and belongs to fungus production and harvesting equipment. A walking driving motor with a seat plate and a gear is mounted on a walking plate frame; a limiting roller is mounted on the seat plate; the walking plate frame is supported and mounted on the upper longitudinal beam of a supporting frame through the clamping fit of the gear and the limiting roller; the gear is meshed with the teeth on the upper longitudinal beam; a picking driving motor equipped with adriving chain wheel is mounted on the walking plate frame; a rectangular frame type picking component frame is fixedly arranged on the lower side part of the walking plate frame; a driving half shaftfixedly provided with a follow-up chain wheel and a driving disc is inserted into the walking plate frame and the rectangular frame type picking component frame; a chain is sleeved on the driving chain wheel and the follow-up chain wheel; and a shaft rod with an agaric picking component is fixedly arranged between a follow-up disc fixedly provided with a follow-up half shaft and the driving disc.The device realizes the mechanized automatic picking operation of the horizontal centralized three-dimensional configured agaric bags, and is reasonable in structure, high in applicability, high in operation efficiency and good in picking quality.

Owner:黑龙江省农业机械工程科学研究院牡丹江农业机械化研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com