Patents

Literature

179results about How to "Avoid bulky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

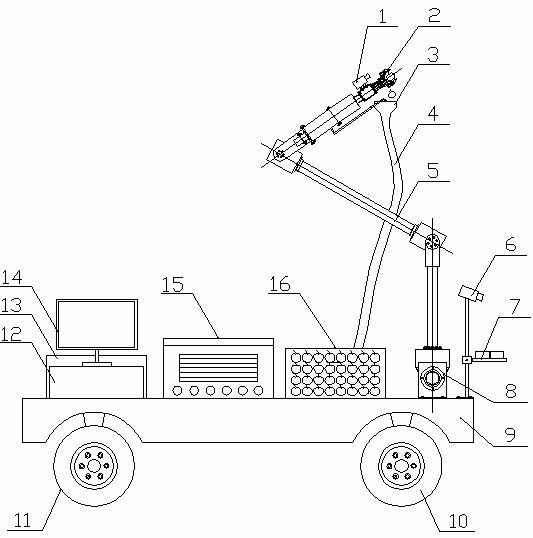

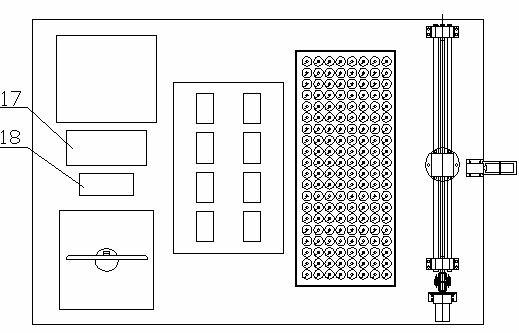

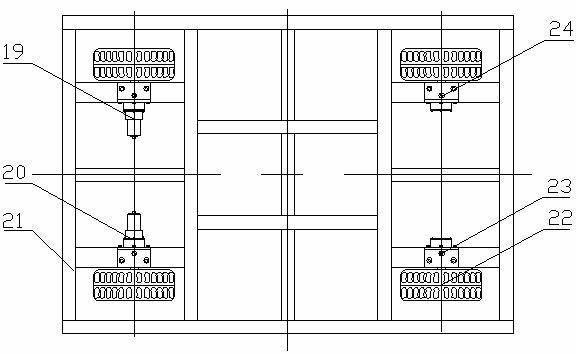

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

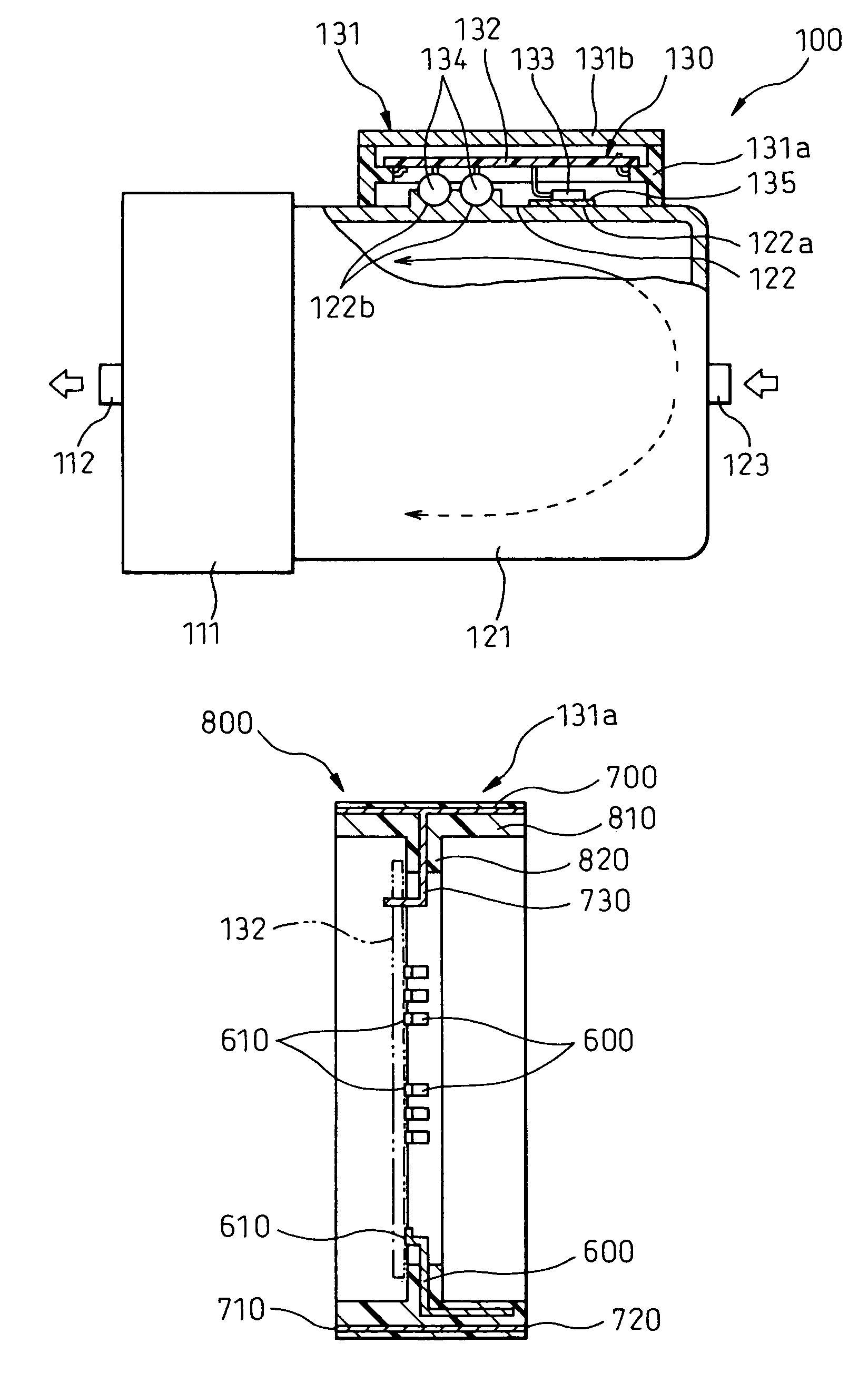

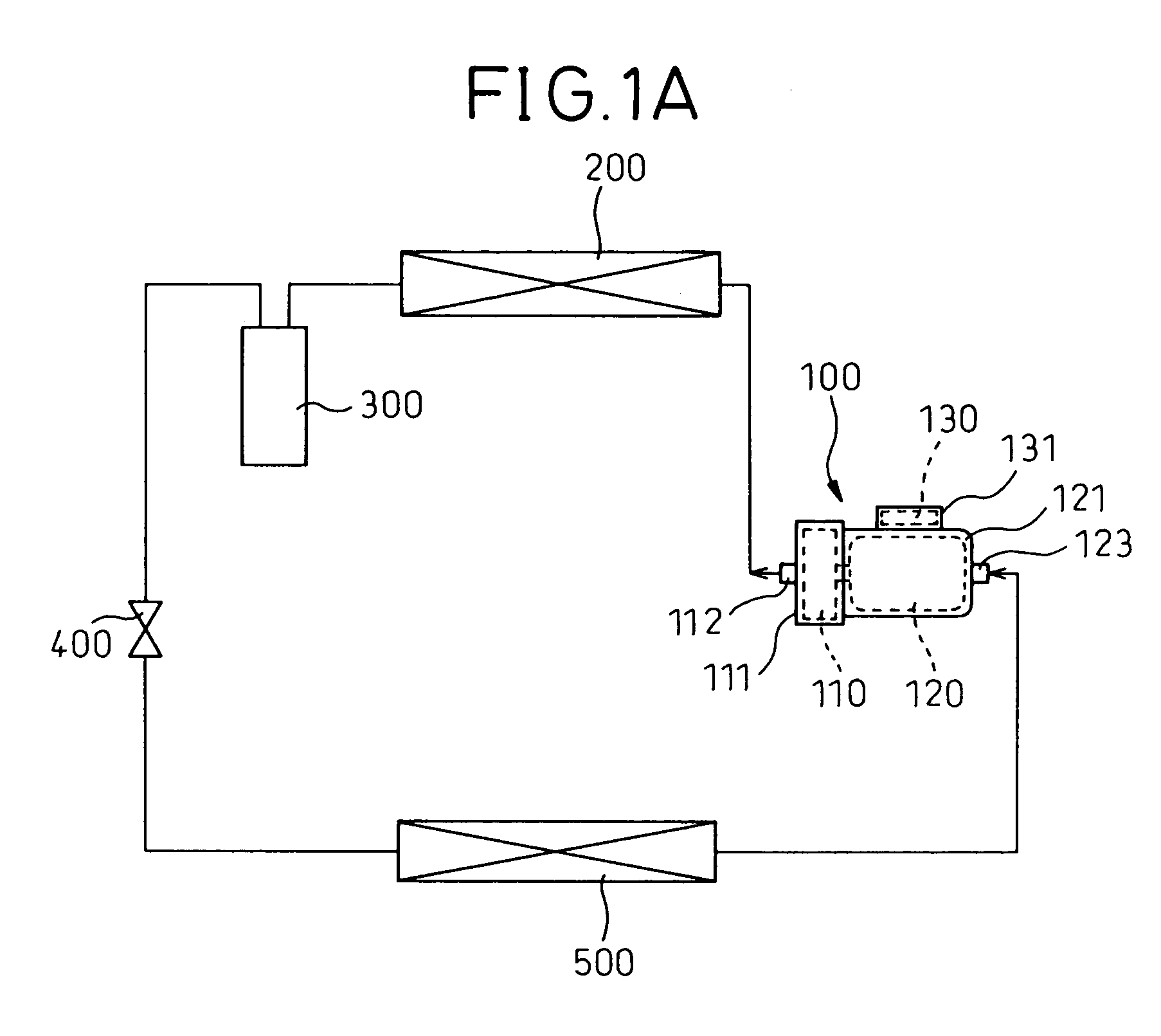

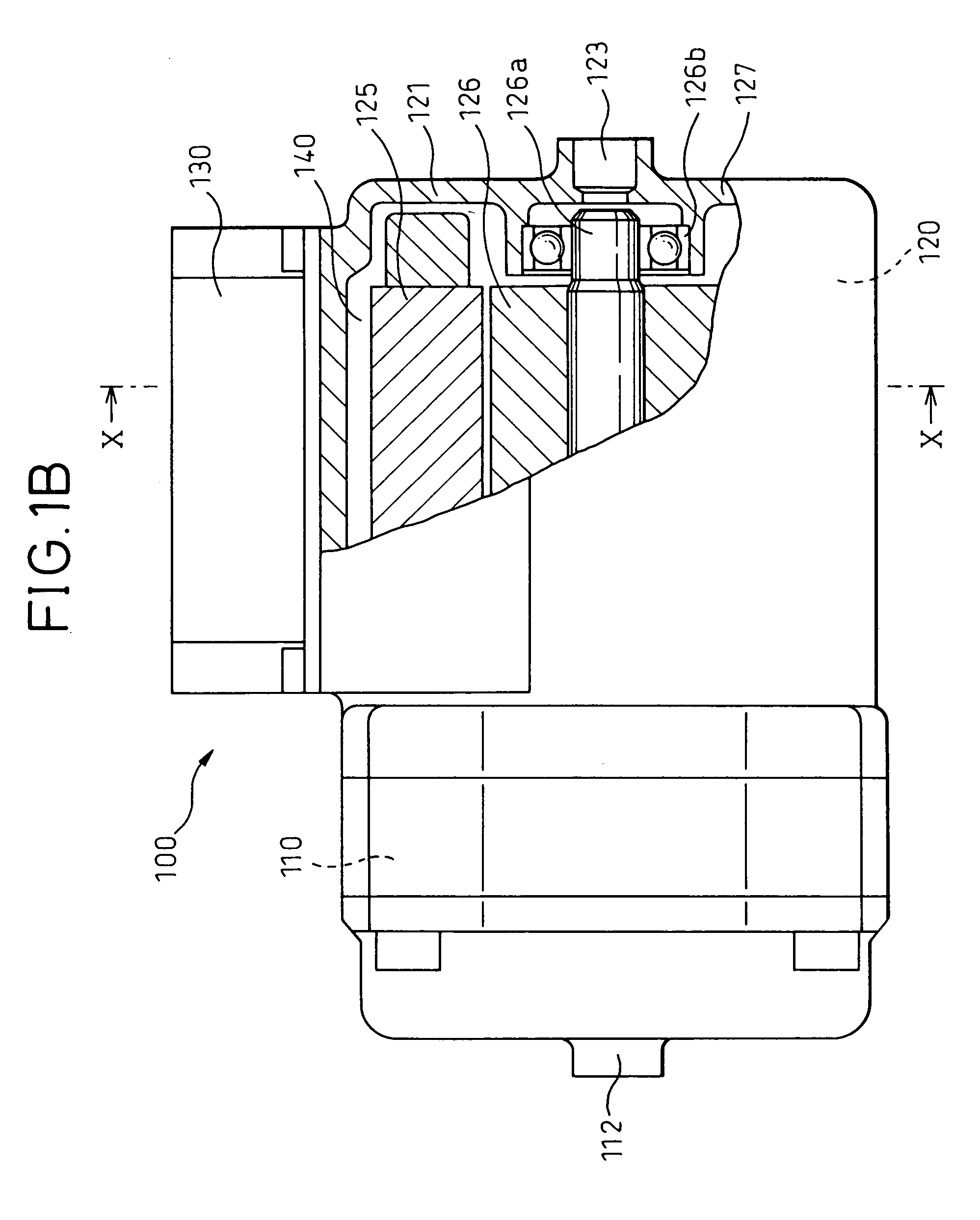

Housing for electronic circuit

InactiveUS7122928B2Avoid bulkyImprove rigidityMagnetic/electric field screeningCooling/ventillation arrangementElectronic circuitEngineering

A box unit is a housing having a space for containing a circuit board therein. Bus bars are insert-molded in a resin body of the box. A metal shield plate is insert-molded around the entire periphery of the box and outside the bus bars. As a result, the box has a shield and is reduced in size compared with a metal box.

Owner:DENSO CORP

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

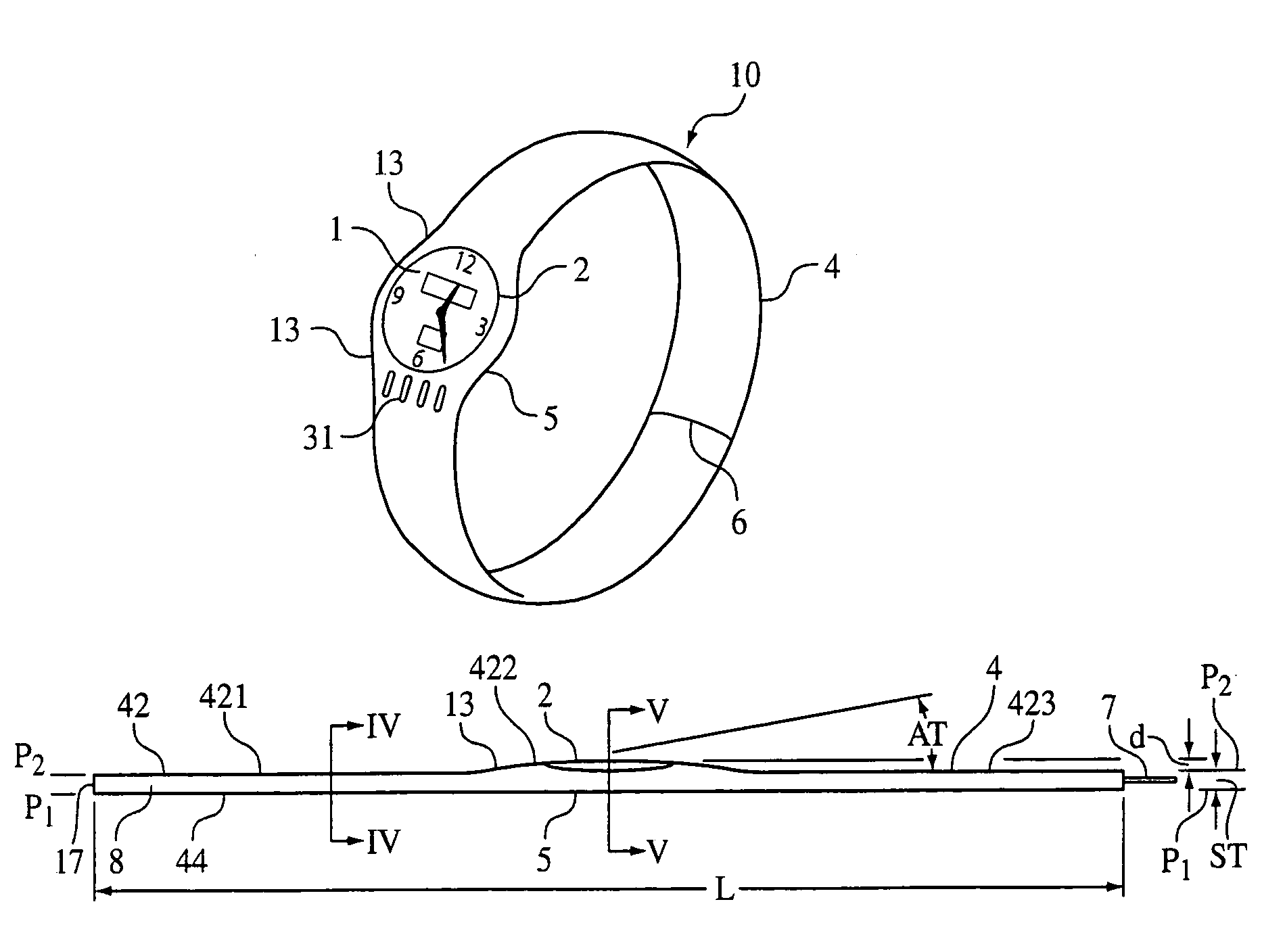

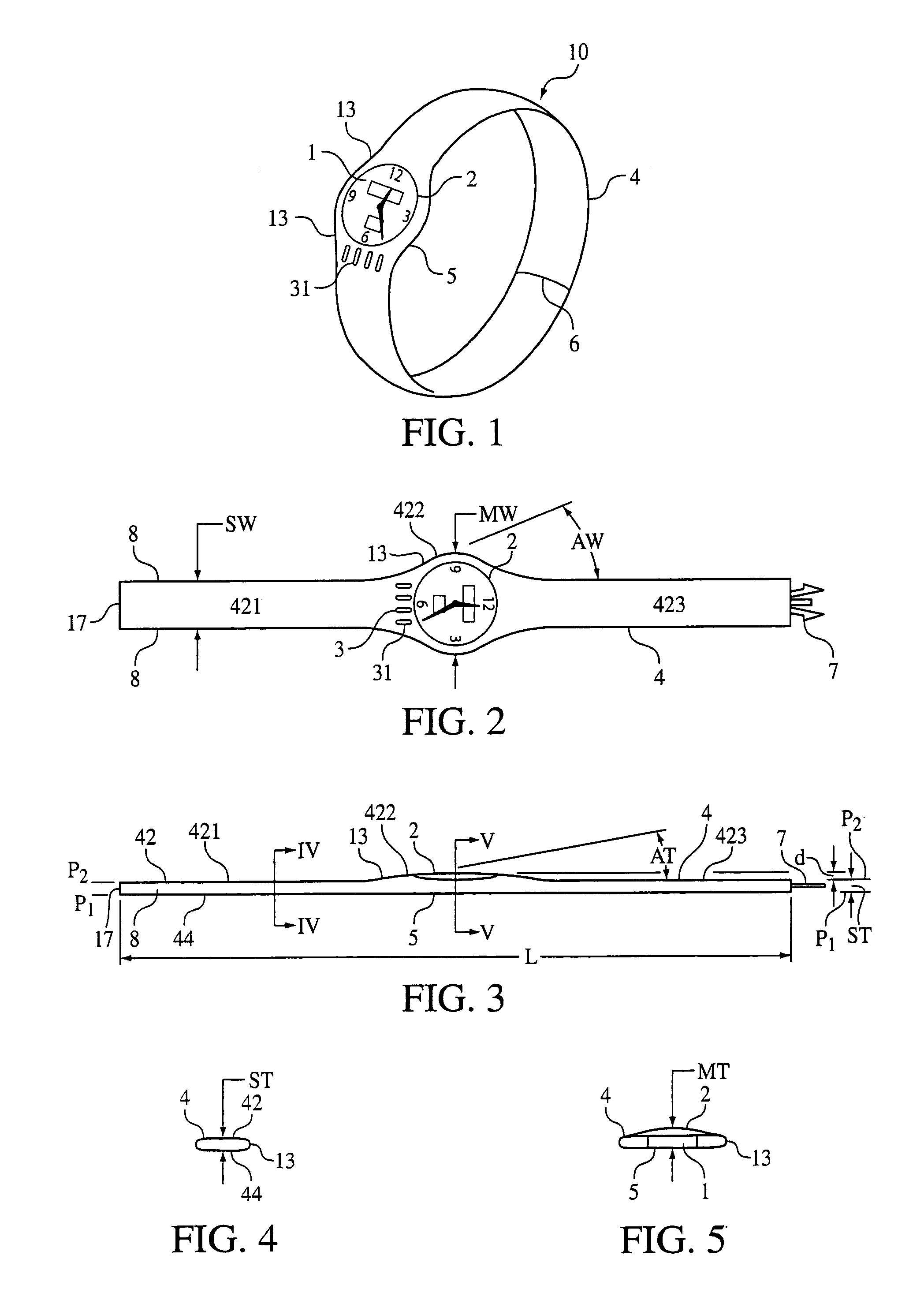

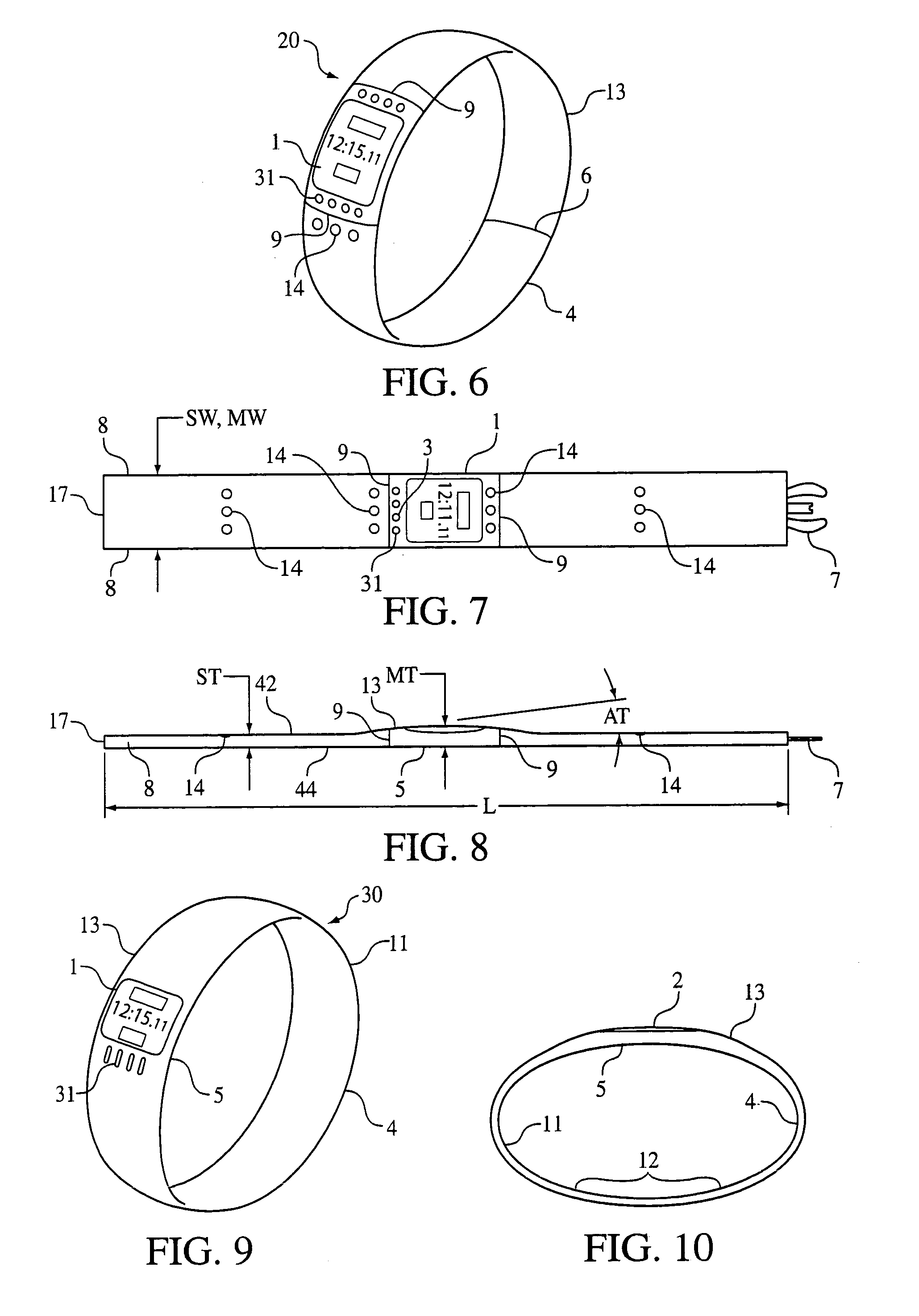

Safety wristwatch system

A snag-free or safety instrument, such as a wristwatch, having substantially smooth and flowing contours and being free of stems and protrusions eliminates or greatly reduces the potential of state of the art wristwatches to scratch, puncture or tear the skin of persons other than the wearer whom the watch may contact, when worn in normal use and in situations involving possible close contacts as in care giving and sports activities.

Owner:FIELD GERALD P

Method for combined welding of austenitic stainless steel moderate thickness plate

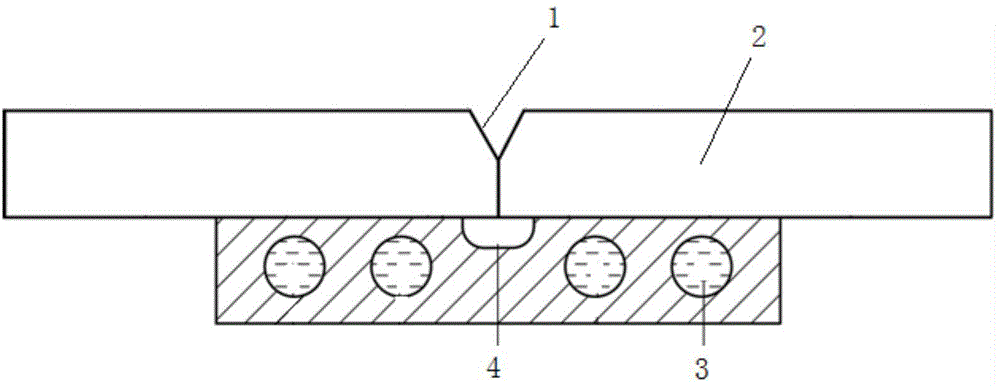

InactiveCN104858557ALittle thermal impactNo crackWelding/soldering/cutting articlesWelding apparatusButt weldingButt joint

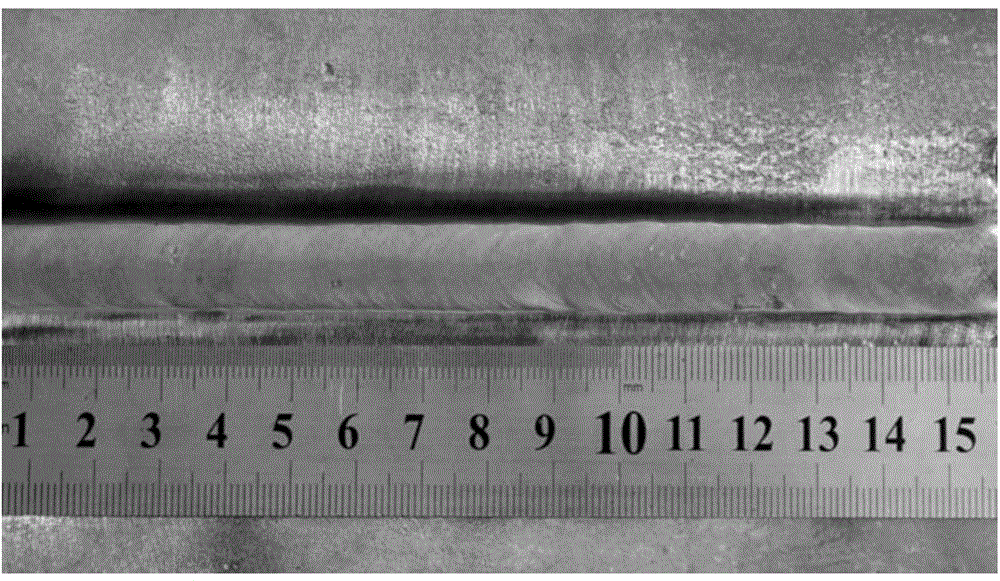

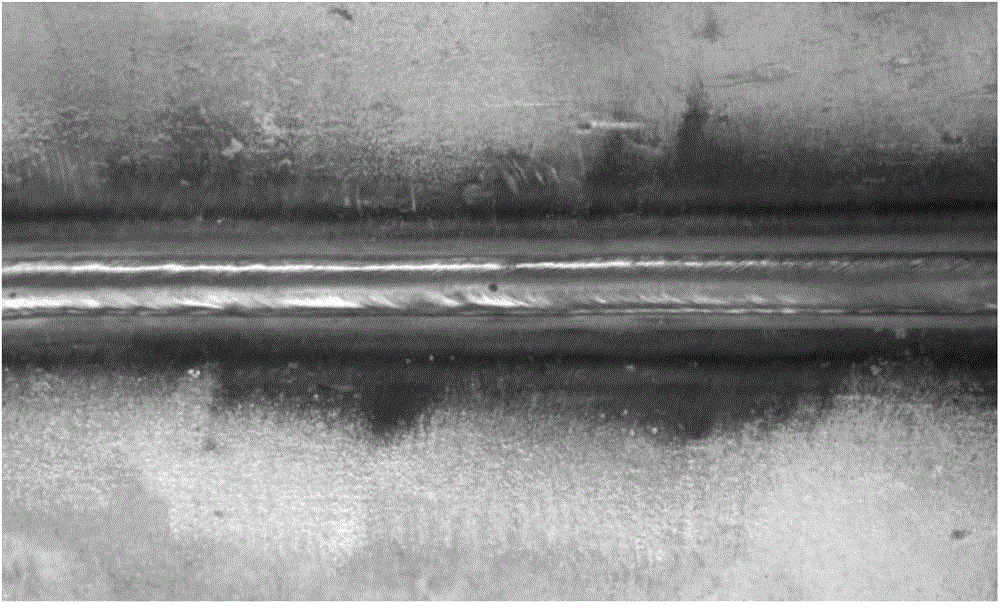

The invention relates to a method for combined welding of an austenitic stainless steel moderate thickness plate. The method comprises the steps of opening a V-shaped groove at the position of the to-be-welded butt joint surface of austenitic stainless steel; polishing and cleaning the surface of a to-be-welded workpiece and the position of the V-shaped groove; performing gapless tight fixed assembly of the workpiece, performing spot welding fixation on a run-on plate, an arc blowout plate and a test plate; pre-leading in protective gas prior to butt welding, guaranteeing that sufficient protective atmosphere is formed on the surface of the stainless steel groove and the bottoms of the weld joints; adopting pulsed plasma arc welding to perform bottoming welding; adopting low carbon welding wires to perform cosmetic welding of pulse wire filling argon tungsten-arc welding, performing the bottoming welding of the pulsed plasma arc welding and cosmetic welding of the pulse wire filling argon tungsten-arc welding simultaneously, and cooling the workpiece while performing the welding. The PC-PAW bottoming welding is adopted, the micropore effect is utilized to achieve one-side welding and double-sided free forming of the moderate thickness plate, the backs of the weld joints are smoothly formed and are free of cracks and edge snapping defects, the process is stable and easy to achieve, and the quality is reliable.

Owner:SHANDONG UNIV

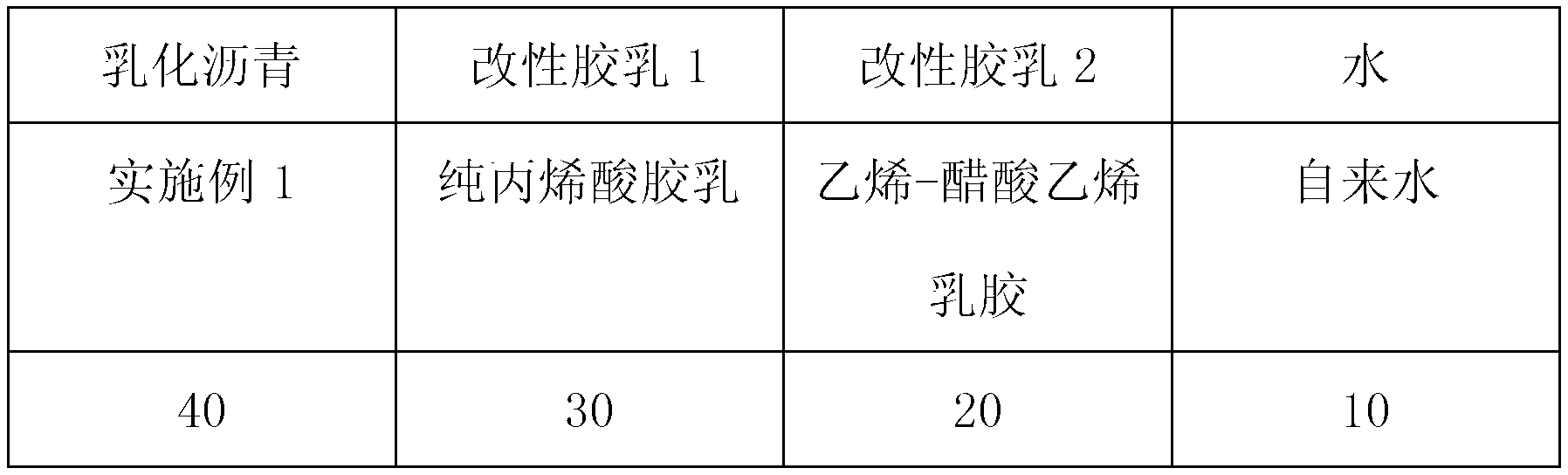

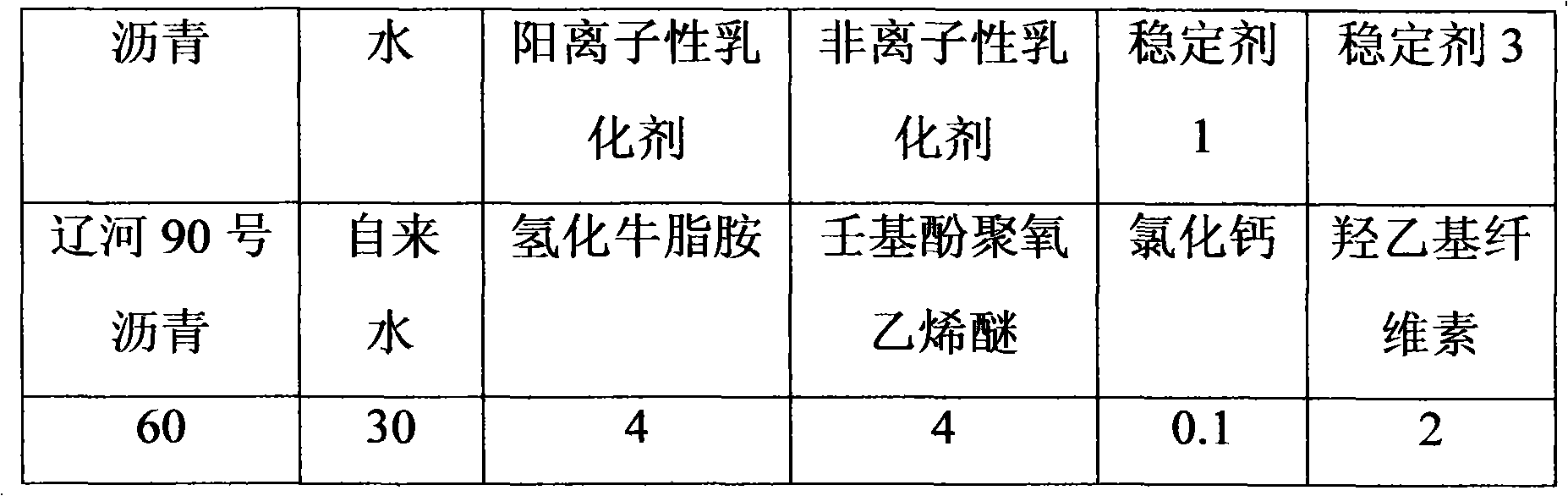

Asphalt polymer cement waterproof coating

The invention relates to an asphalt polymer cement waterproof coating which consists of a component A and a component B. The component A comprises the raw materials in percentage by weight as follows: 20-50% of emulsified asphalt, 30-50% of modified latex and 10-30% of water. The component B comprises the raw materials in percentage by weight as follows: 40-60% of cement, 20-40% of staffing and 1-5% of assistant. The coating provided by the invention is low in price, good in waterproofness and good in flexibility, and can resist corrosion caused by low concentration inorganic acid, base and salt. The asphalt polymer cement waterproof coating can be independently used as a film waterproof layer in waterproof and corrosion resisting projects of kitchens and bath rooms, basements and bridge floors.

Owner:KUNMING FENGXING WATERPROOF MATERIAL

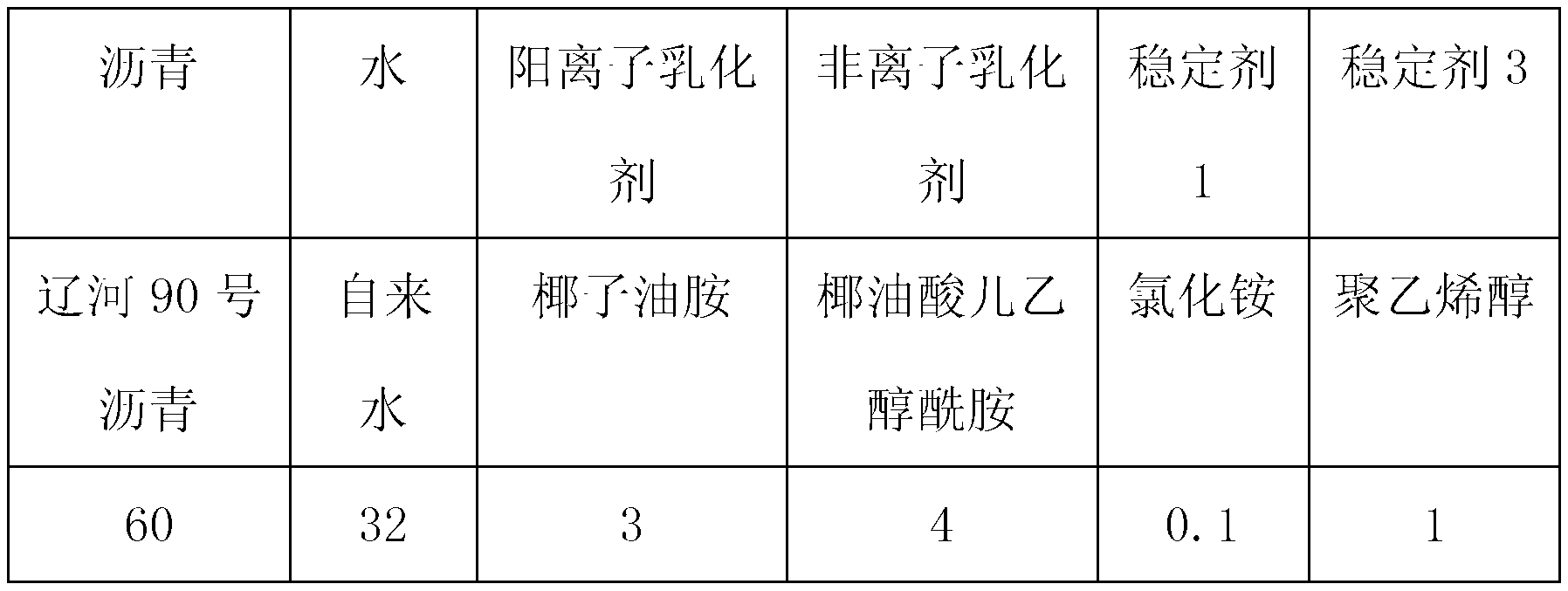

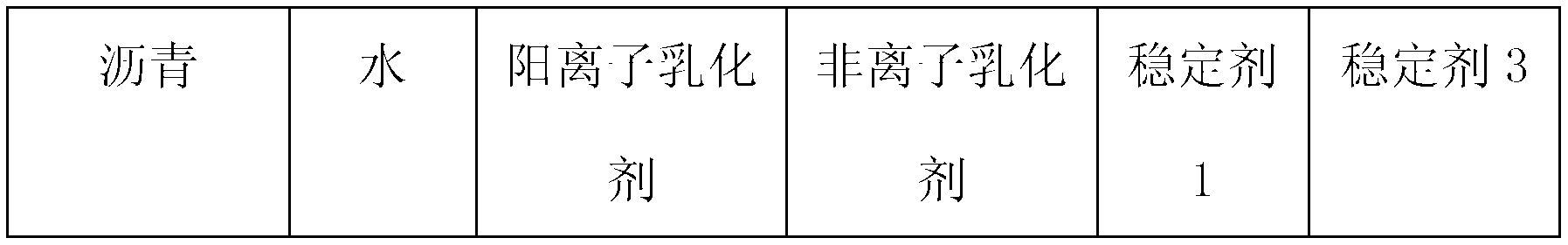

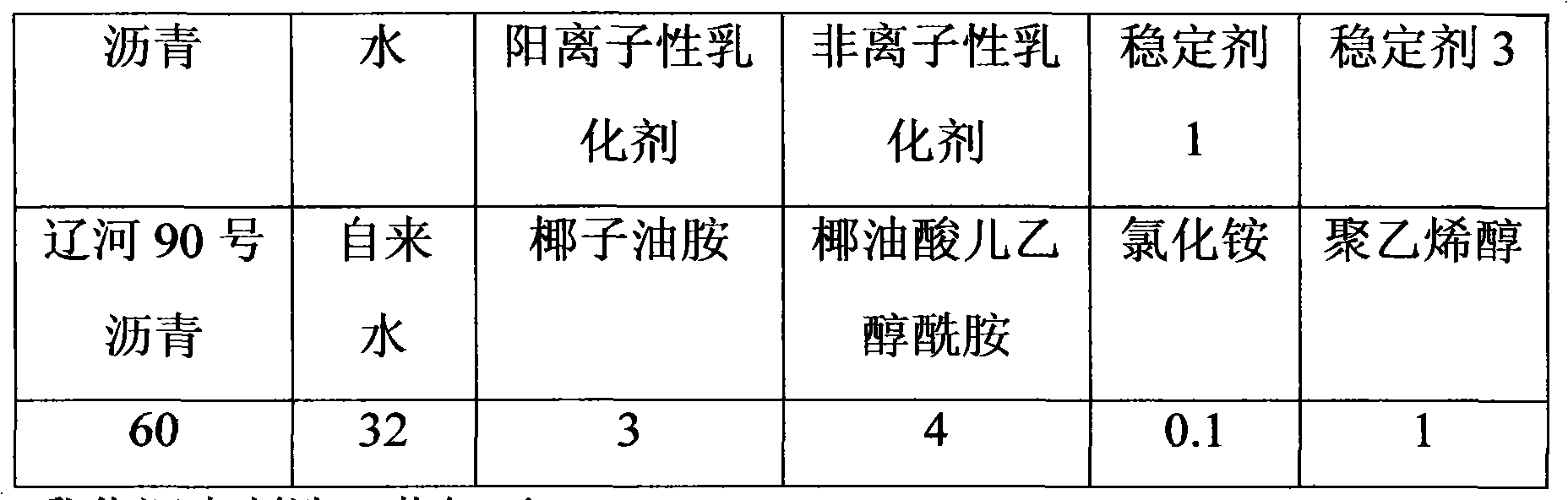

Self-hardening rubber asphalt paint

InactiveCN102108257AEliminates prone to low cloud point problemsLow densityConjugated diene hydrocarbon coatingsNatural rubber coatingsEmulsionSpray coating

The invention provides self-hardening rubber asphalt paint which comprises the following components by weight percent: 50%-65% of asphalt, 3%-6% of cationic emulsifier, 3%-6% of nonionic emulsifier, 25%-35% of modified latex, 1%-3% of stabilizer and 5%-10% of filler. The invention further provides a preparation method of the self-hardening rubber asphalt paint, the rubber asphalt paint is modified through normal-temperature self-crosslinking emulsion, has the prominent characteristics of normal temperature spray coating, manual scrape-coating, instant shaping, perfect joint, high elastic force, zero joints and the like, and can fundamentally solve the technical difficulty of leakages at side angles, gaps and junction of irregular structures and the like, thereby thoroughly updating the traditional construction process and the method of waterproof material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

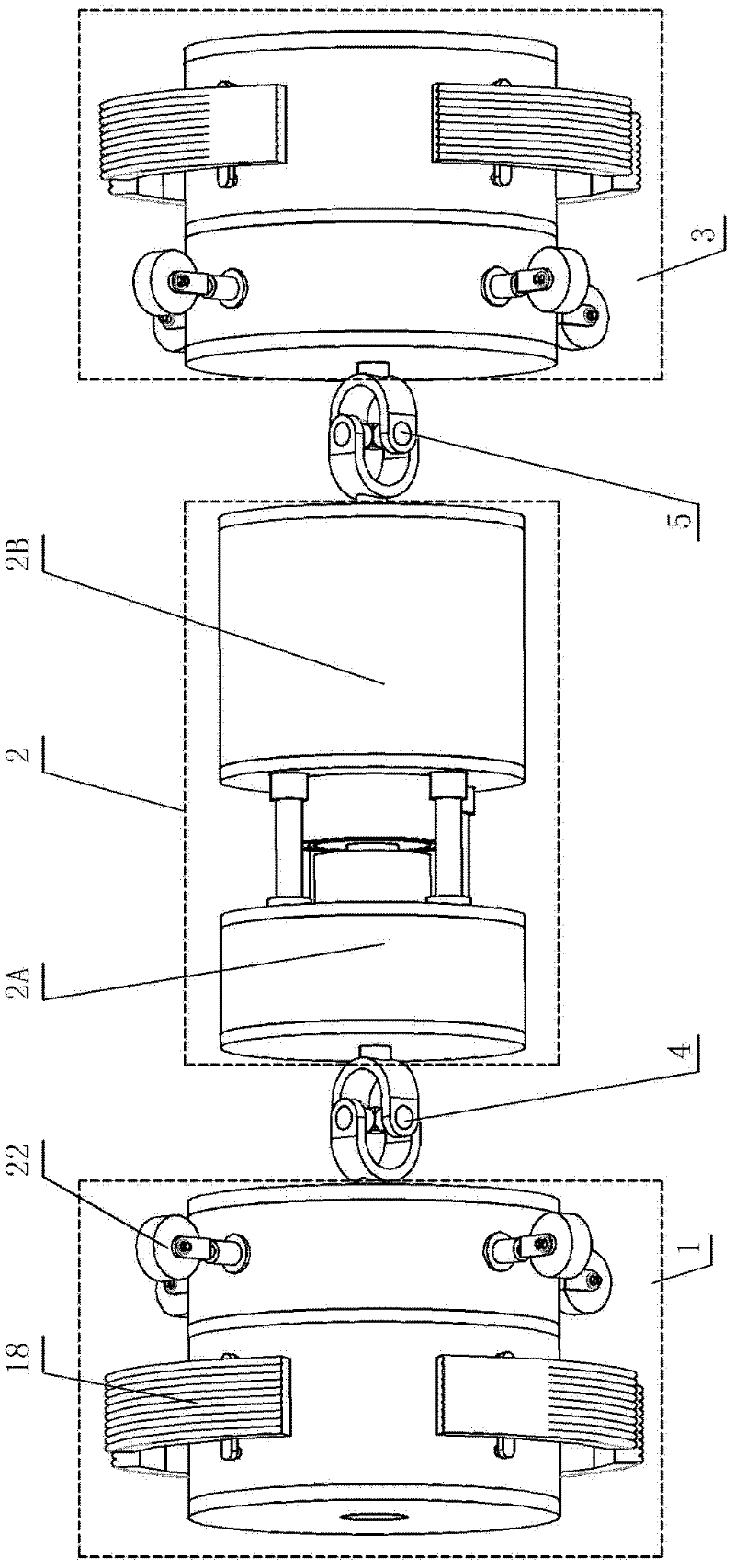

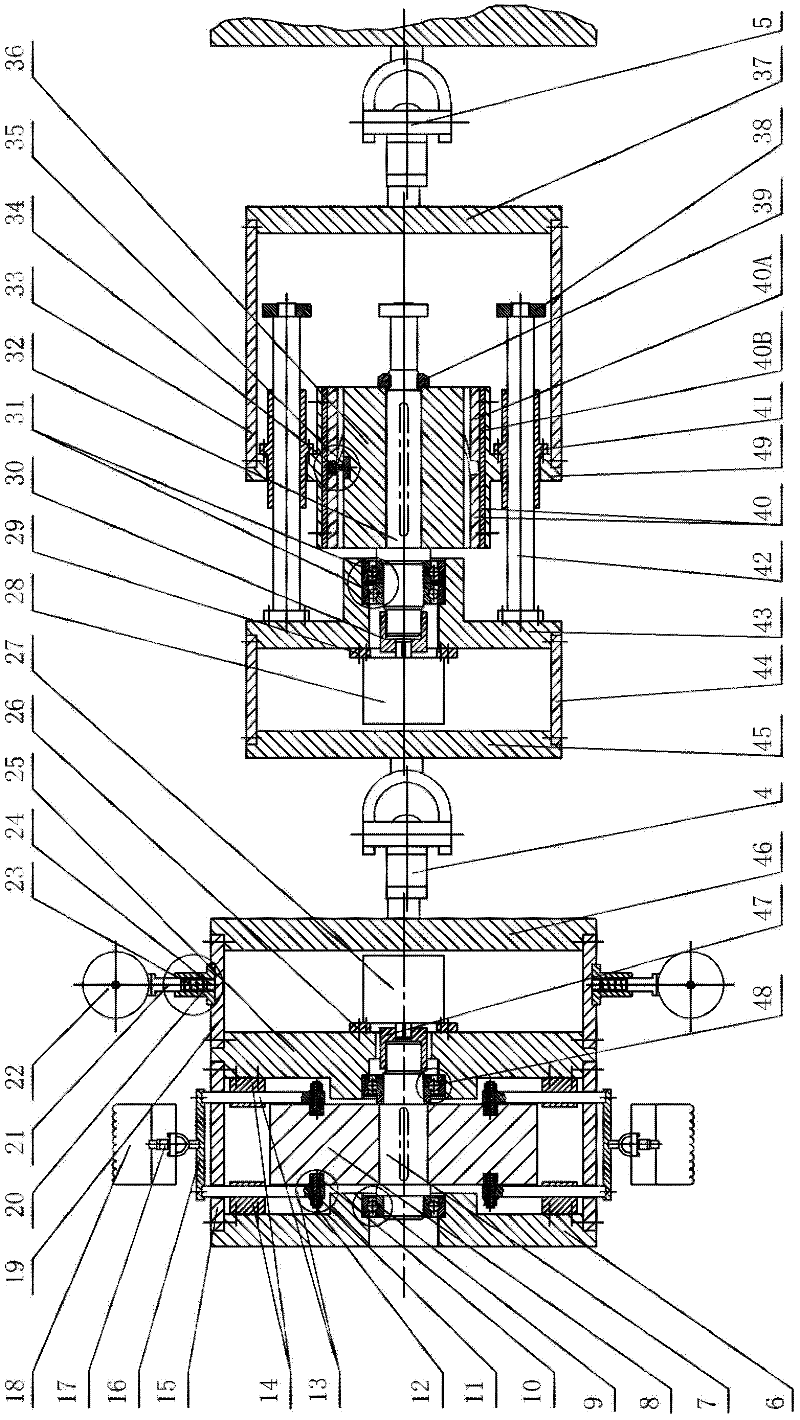

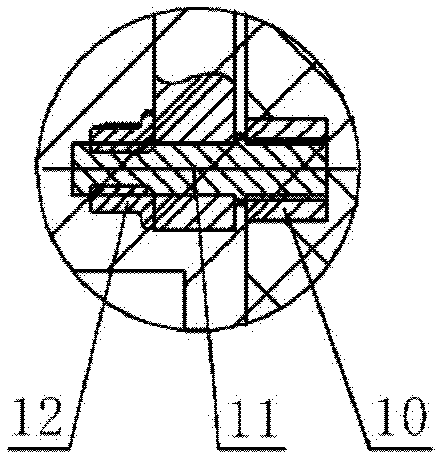

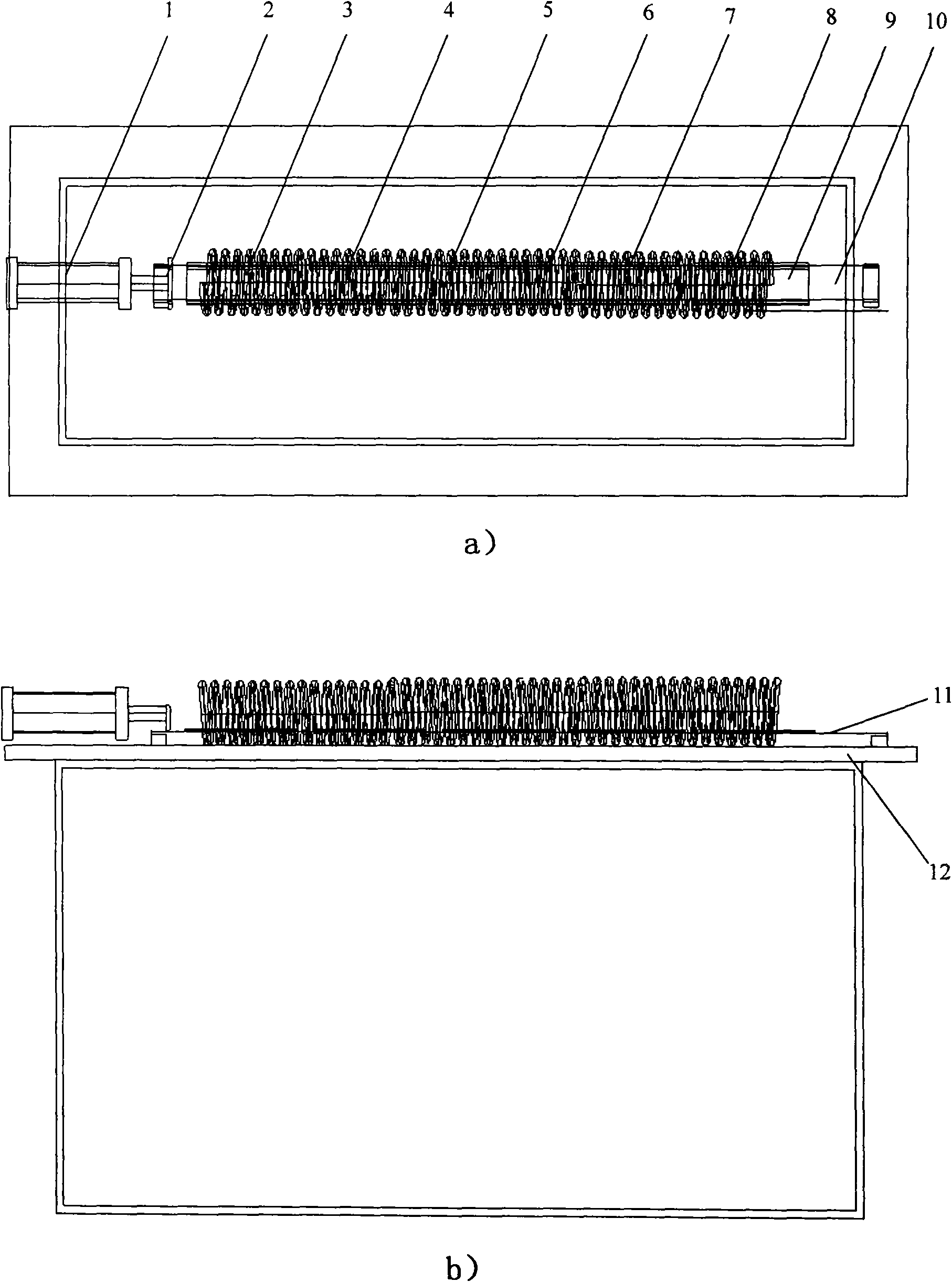

Bionic squirm type pipeline travelling mechanism and control method thereof

The invention relates to a bionic squirm type pipeline travelling mechanism and a control method thereof. The travelling mechanism is characterized in that a forebody section radial support unit and an afterbody section radial support unit are symmetrically arranged on the two ends of a middle axial input unit; a periodicity intermittent radial breathing motion between the radial support unit andthe inner wall of a pipeline and a periodicity intermittent axial stretching motion of the middle axial input unit are adjusted, and the travelling mechanism imitates motion gait and a rule of a wormsomite in the pipeline to walk in a squirm manner; and the travelling mechanism can replace labour to carry out different pipeline job tasks through carrying corresponding instrument, and missions ofvertical underground mine disaster detection and rescue and the like can be implemented. The travelling mechanism provided by the invention has the advantages of simple compact body, reliable stable operation, easiness in control, cheap manufacturing cost, and can be suitable for multiple occasion applications and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Dedicated welding active agent for deep penetration TIG welding and using method

InactiveCN103990919ASimple welding processIncrease productivityArc welding apparatusWelding/cutting media/materialsActive agentMechanical property

The invention discloses a dedicated welding active agent for deep penetration TIG welding. The welding active agent is composed of, by mass, five percent to 15 percent of NaCl powder, 10 percent to 20 percent of CaO powder, 15 percent to 20 percent of MgF2 powder, 10 percent to 15 percent of Fe2O3 powder, seven percent to 10 percent of SiO2 powder, eight percent to 10 percent of TiO2 powder, 17 percent to 20 percent of Cr2O3 powder, four percent to five percent of La2O3 powder and four percent to five percent of Y2O3 powder. The using method of the active agent comprises the steps that calculation is carried out according to the mass percent, 92 percent to 95 percent of the powder of the dedicated welding active agent for deep penetration TIG welding is mixed with five percent to eight percent of acetone to form the pasty or grease-shaped welding active agent, the surface of a workpiece is evenly coated with the welding active agent through a brush, and welding is carried out after the acetone is fully volatilized. According to the welding active agent, complete penetration is achieved on AISI316 austenitic stainless steel and X70 pipeline steel with the thickness of 14 mm through deep penetration TIG welding, the welding process is simplified, a coarse structure is avoided, the mechanical property of a welding joint is improved, production efficiency is improved, and production cost is lowered.

Owner:ZHANGJIAGANG HUABAO MACHINERY MFG

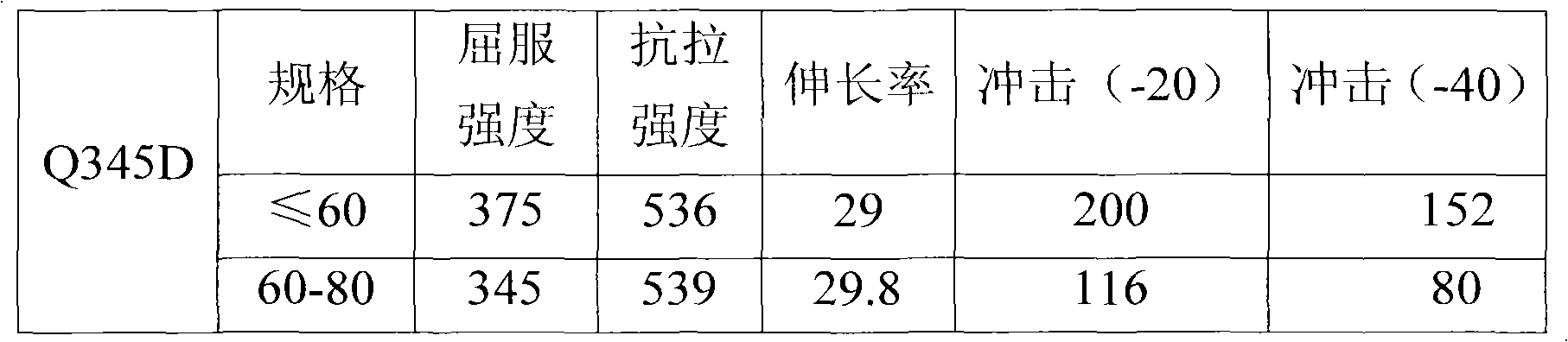

Low-alloy Q345D thick plate produced without adding micro-alloy elements and production method thereof

ActiveCN102080181AGuaranteed purityGuaranteed Performance RequirementsTemperature control deviceThick plateDegasser

The invention discloses a low-alloy Q345D thick plate produced without adding micro-alloy elements and a production method thereof. The method disclosed by the invention is characterized in that on the premise of not adopting vacuum decarburization equipment such as an RH and the like, through using the existing equipment such as a VD (vacuum degasser) and the like of enterprises, the requirements for smelting low-carbon steel plates and extreme low carbon steel plates are met, therefore, under the condition that the profits of the enterprises at the present stage are not high, a heavy investment in large-scale equipment replacement and remodeling is avoided, thereby saving the investment for the enterprises, completely using the existing equipment of the enterprises, greatly reducing the capital investment of the enterprises at the present stage, and providing abundant preparation time for equipment replacement after the market situation takes a favorable turn in the future and the profits of the enterprises are improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

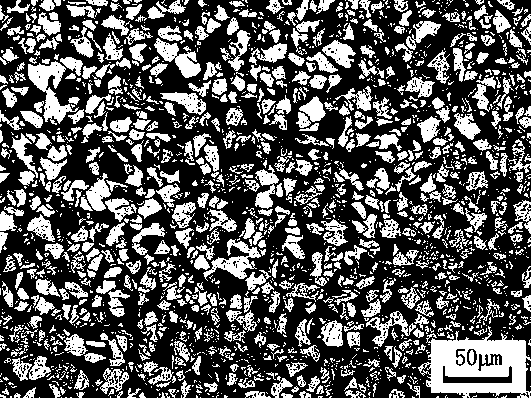

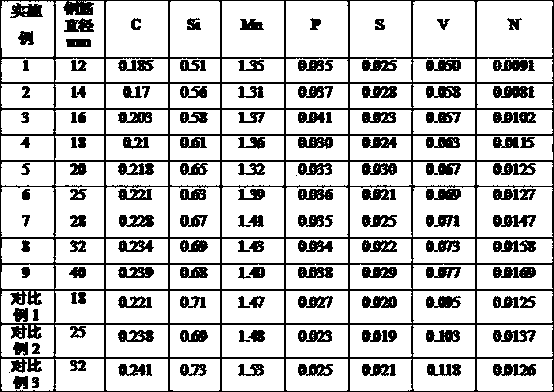

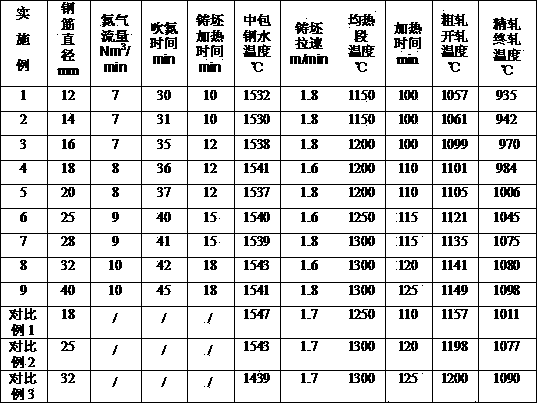

Hot-rolled ribbed steel bar having strength-to-yield ratio of 1.25 or more, and production method thereof

A hot-rolled ribbed steel bar having a strength-to-yield ratio of 1.25 or more comprises 0.17-0.25wt% of C, 0.4-0.8wt% of Si, 1.2-1.5wt% of Mn, 0.045wt% or less of P, 0.045wt% or less of S, 0.05-0.08wt% of V, 0.006-0.018wt% of N, and the balance of Fe and impurity elements, and has a specification diameter of 12-40mm. A production method of the hot-rolled ribbed steel bar comprises the following steps: desulfurizing molten iron; carrying out top-bottom blowing of a converter; carrying out component fine-adjustment at an argon station, and blowing in nitrogen; refining an LF furnace, and blowing nitrogen into the LF furnace; continuously casting; carrying out stacking cooling; heating casted blanks; carrying out rough rolling and finish rolling; and naturally cooling to room temperature. Nitrogen is blown to realize greatly reduced cost, greatly reduced vanadium alloy consumption, increased V (C,N) amount and dispersity with the increase of the content of N in steel, substantial reinforcement effect and stable mechanical performances on the premise that mechanical performances comprising a hot-rolled yield strength of above 530MPa, a strength-to-yield ratio of 1.25-1.30, an A value of 18% or more and an Agt value of 10 or more are guaranteed.

Owner:武汉钢铁有限公司

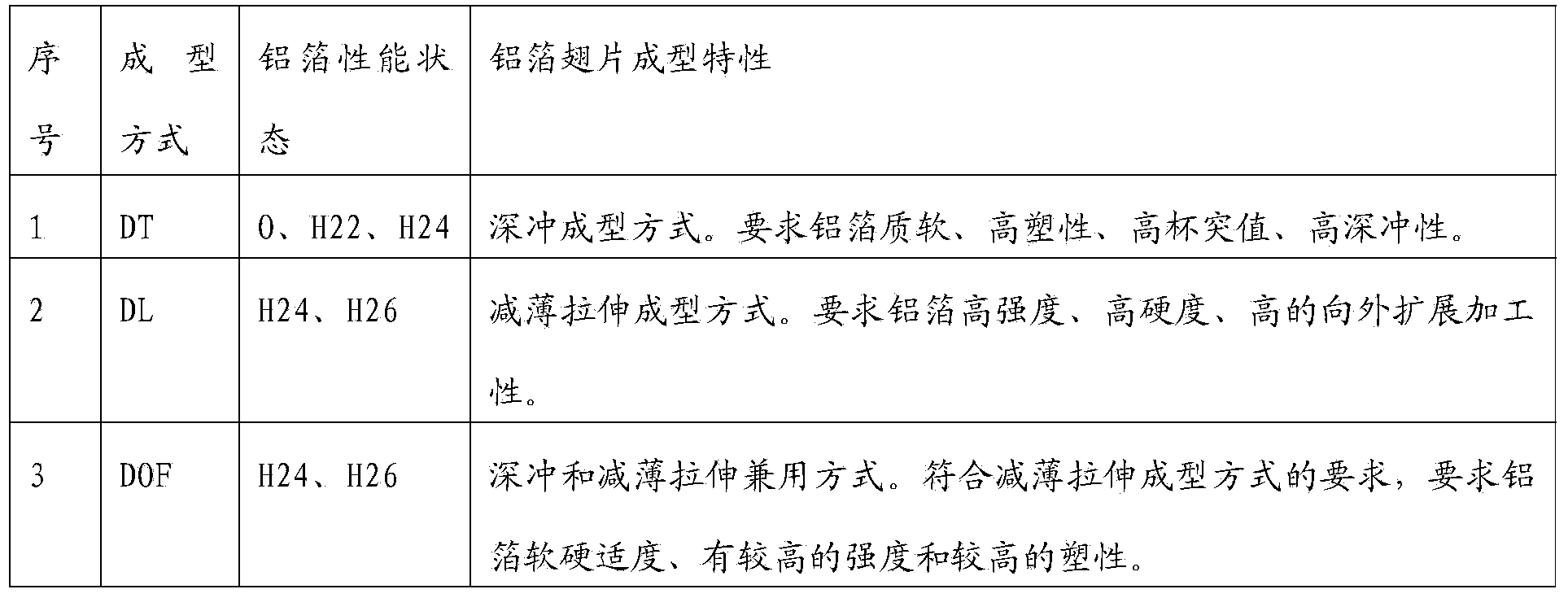

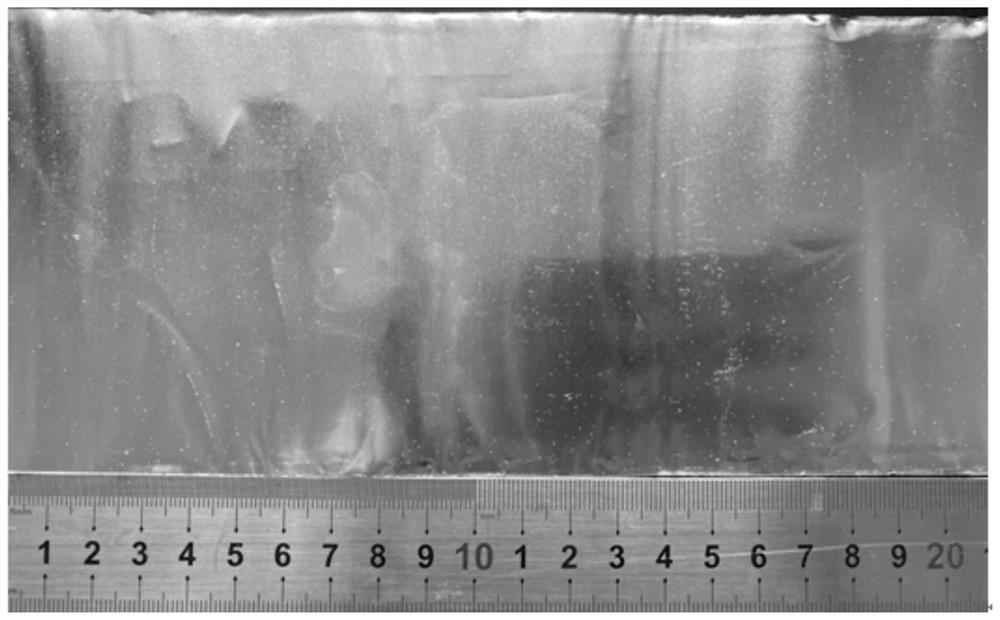

Novel aluminum alloy and method for manufacturing aluminum foil with high deep-drawing performance by continuous cast-rolling

InactiveCN104060132AIncreased recrystallization temperature rangeHigh strengthMaterials processingPre treatment

The invention relates to the field of processing and manufacturing of metal materials and particularly relates to a novel aluminum alloy and a method for manufacturing an aluminum foil with high deep-drawing performance by continuous cast-rolling. The novel aluminum alloy contains the following components in percentage by mass: 0.1-0.3% of Si, 1.0-1.5% of Fe, 0.3-0.6% of Mn, not greater than 0.05% of Ti and the balance of Al. According to the novel aluminum alloy and the method for manufacturing the aluminum foil with high deep-drawing performance by continuous cast-rolling, which are provided by the invention, cast-rolled aluminum coils are pre-processed by increasing the content of Mn and Fe in a blank and optimizing a continuous cast-rolling process, so that defects that the aluminum foil produced by the cast-rolling blank is low in plasticity and insufficient in deep-drawing performances are overcome; the produced aluminum foil can achieve and can even exceed performances of the hot-rolled blank aluminum foil, and can solve a universality problem of the fin aluminum foil and a thinning problem of the deep-drawing aluminum foil very well.

Owner:山东邹平长城能源科技有限公司

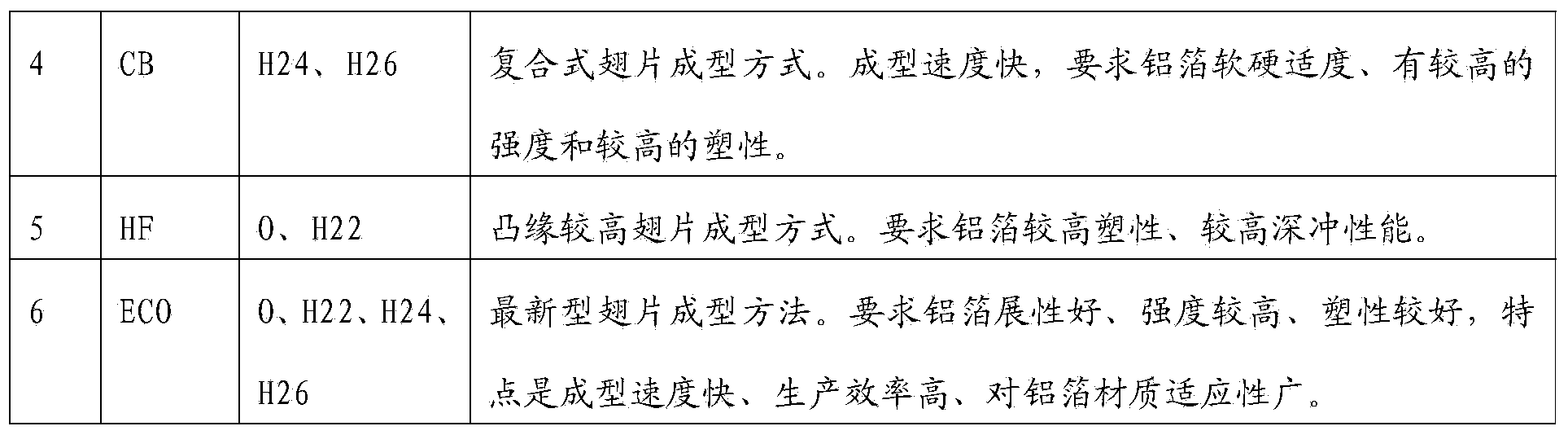

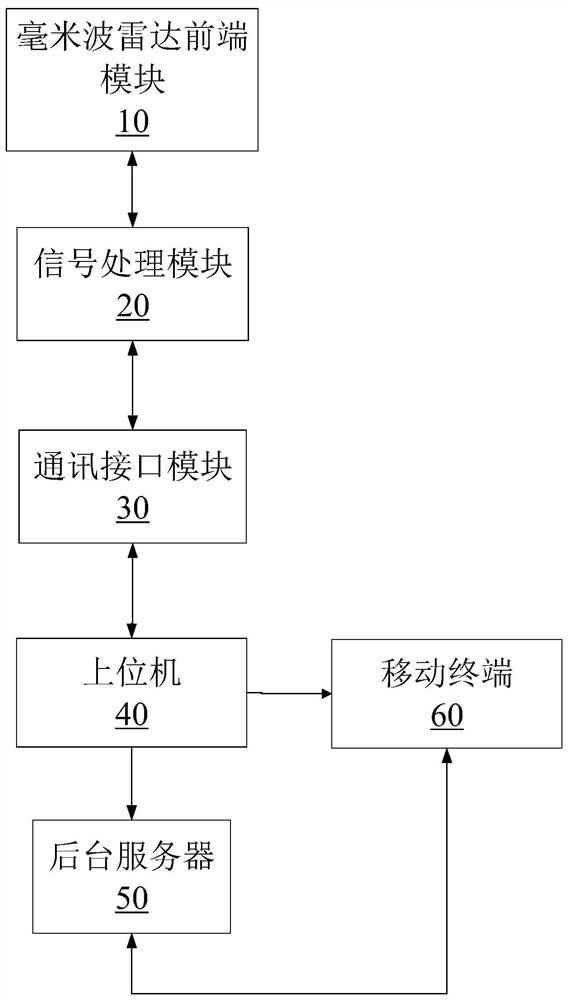

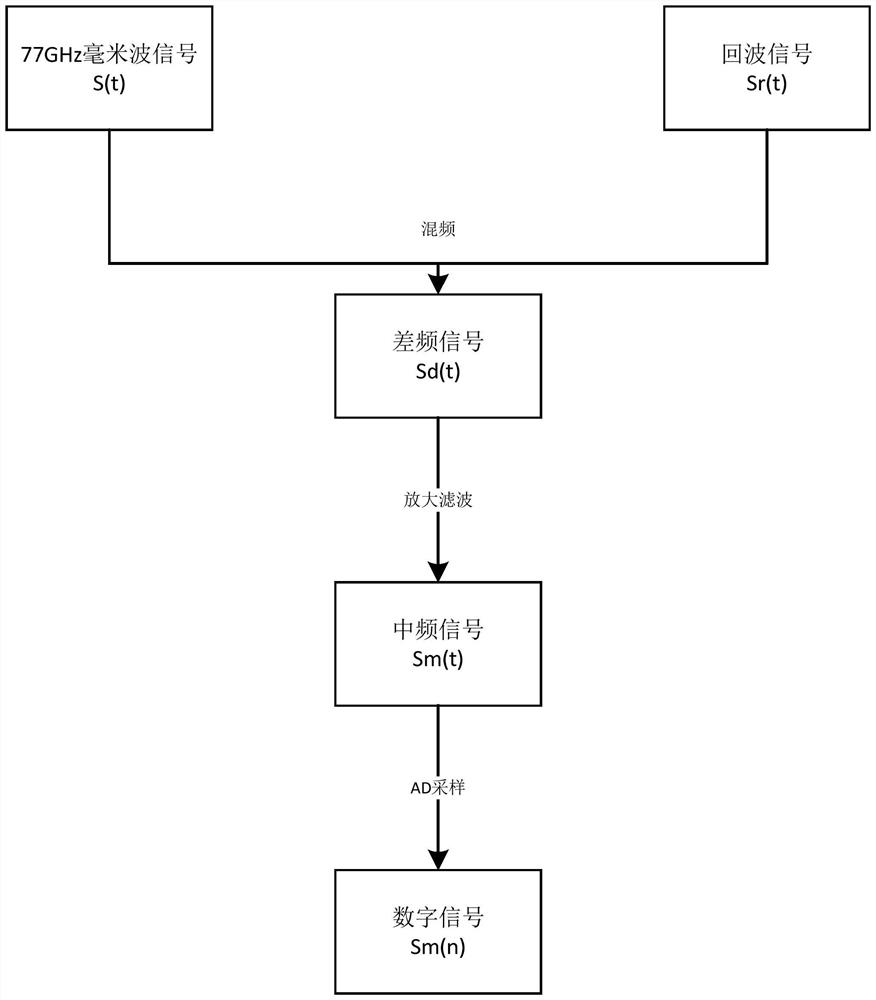

Physical sign non-contact intelligent monitoring system based on millimeter-wave radar

ActiveCN112014837AAvoid cumbersomeAvoid bulkySensorsMeasuring/recording heart/pulse rateCommunication interfaceTelecommunications

The invention discloses a physical sign non-contact intelligent monitoring system based on a millimeter-wave radar. A millimeter-wave radar front-end module transmits and receives a millimeter-wave radar signal, and the millimeter-wave radar front-end module is connected with a signal processing module; a signal processing module is connected with a communication interface module, analyzes the echo signals after sampling quantification to obtain vital sign data, including frequency parameters of respiration and heartbeat, of a tested person, and transmits a processed information result to an upper computer through the communication interface module; and the upper computer compares the received vital sign data with preset data, uploads the data and a comparison result to a background server, gives an alarm to the mobile terminal if the comparison result is abnormal, and automatically gives an alarm when the comparison result exceeds a preset maximum value. According to the invention, the real-time intelligent monitoring of vital signs of indoor old people is realized, including monitoring of breathing and heartbeat parameters, and real-time alarm is carried out in case of abnormality so as to prevent accidents.

Owner:HANGZHOU DIANZI UNIV

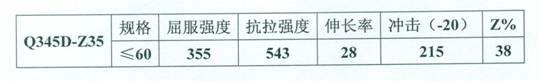

Low-alloy medium-thickness steel plate Q345D-Z35 and production process thereof

InactiveCN102041441AMatching strengthMatching plasticityTemperature control deviceSheet steelChemical composition

The invention discloses a low-alloy medium-thickness steel plate Q345D-Z35 produced without adding microalloy elements and a production process thereof. The steel plate contains the following chemical components in percentage by mass (with wt% as a unit): 0.10 to 0.18 percent of C, 0.20 to 0.45 percent of Si, 1.20 to 1.60 percent of Mn, less than or equal to 0.018 percent of P, less than or equal to 0.005 percent of S, 0.015 to 0.050 percent of Als and the balance of Fe and residual elements. The production method comprises the following steps of: pretreatment with high-quality molten iron or KP molten iron, blowing in a top and bottom combined blown converter, ladle furnace (LF) refining, vacuum degassing treatment, casting blank cooling in pile, treatment in a heating furnace, rolling, ACC (Active Calcium Carbonate) laminar cooling, treatment in a hot straightening machine, cooling in pile, finishing, external inspection, flaw detection and warehousing. The steel plate has the advantages that: compared with the traditional Q345D-Z35, under the conditions that the carbon equivalent is not changed and precious alloys of Nb, Ti and the like are not added, the various performance indexes of the Q345D-Z35 are ensured to meet the national standard requirements, and the production cost is greatly reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

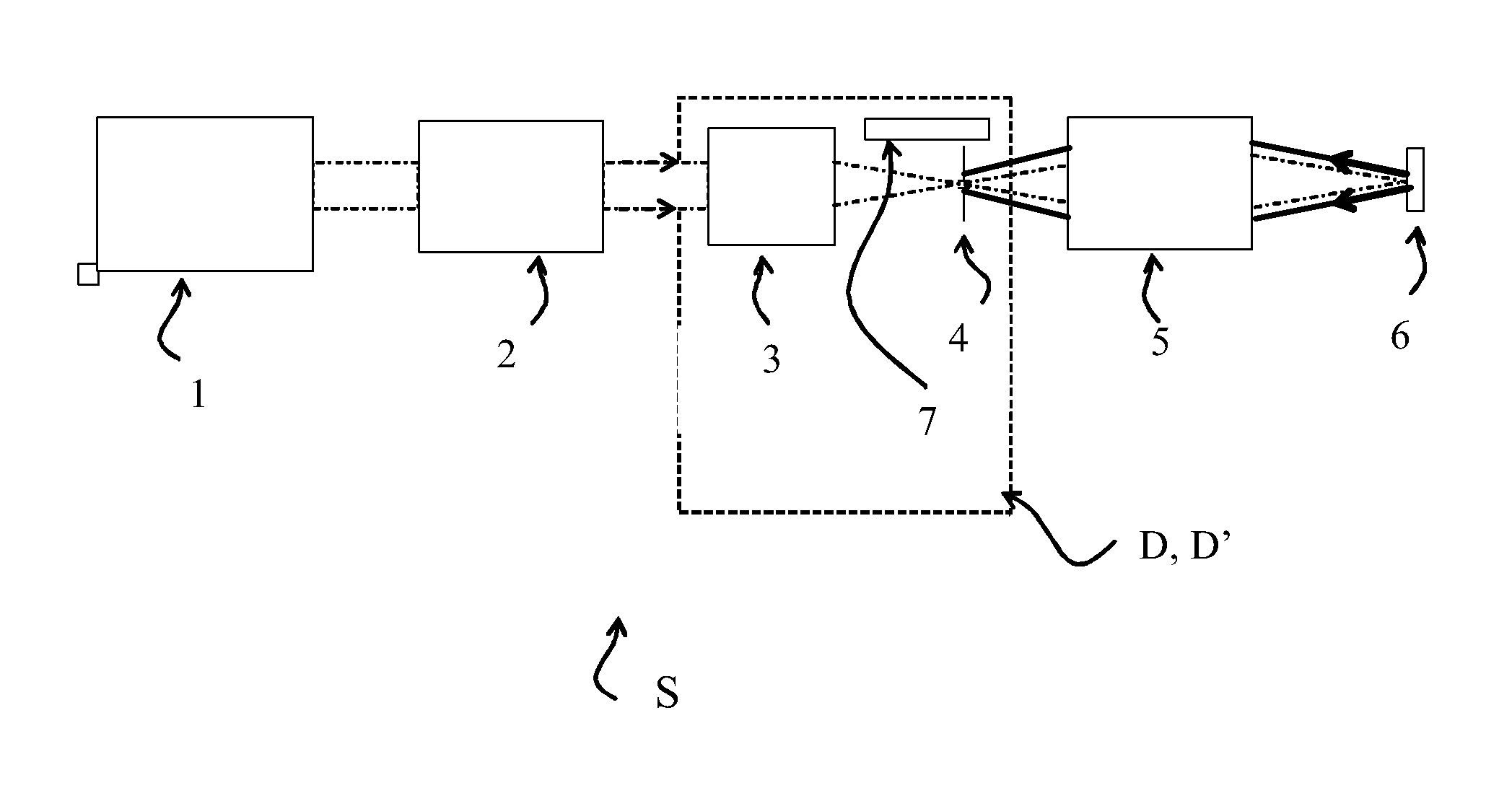

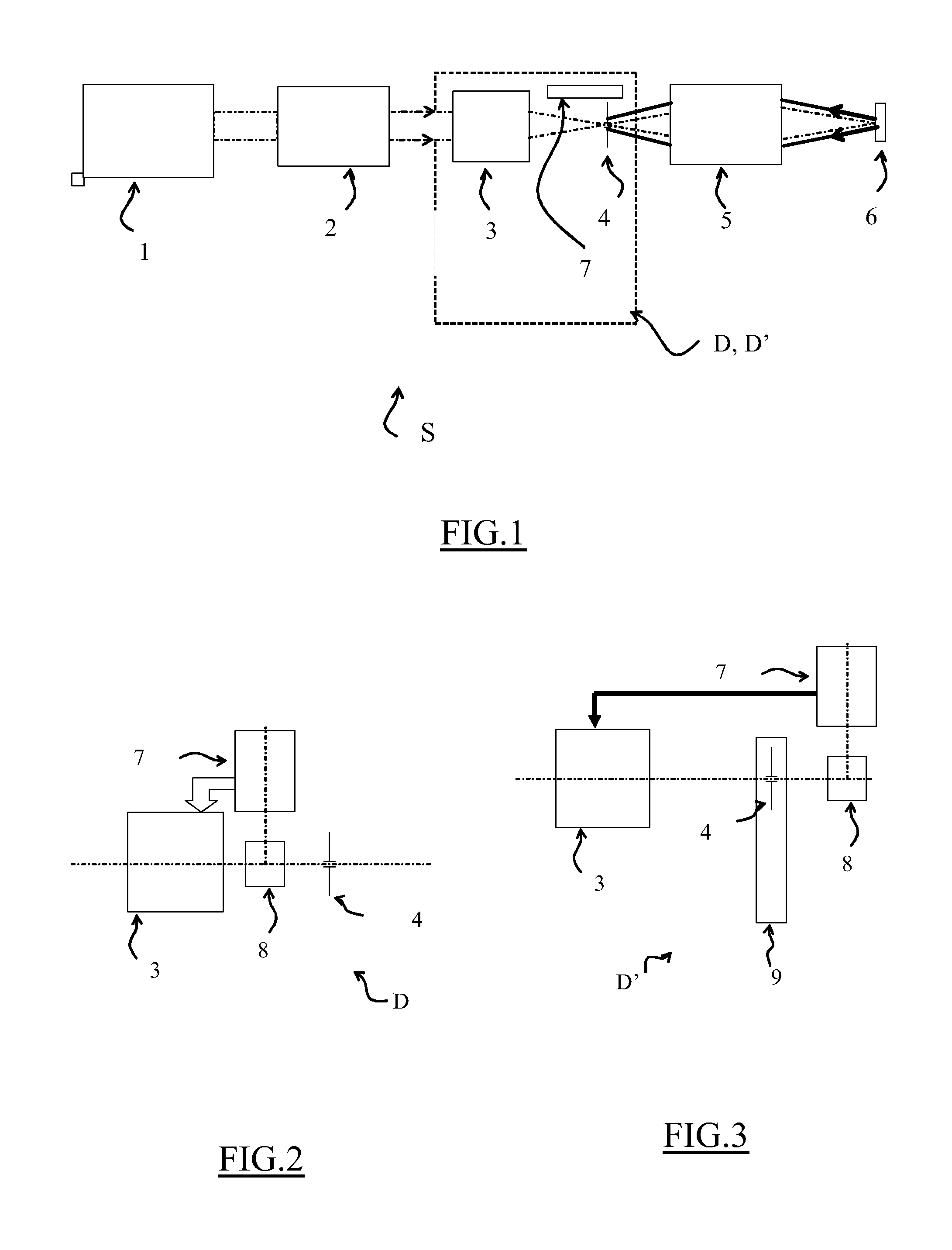

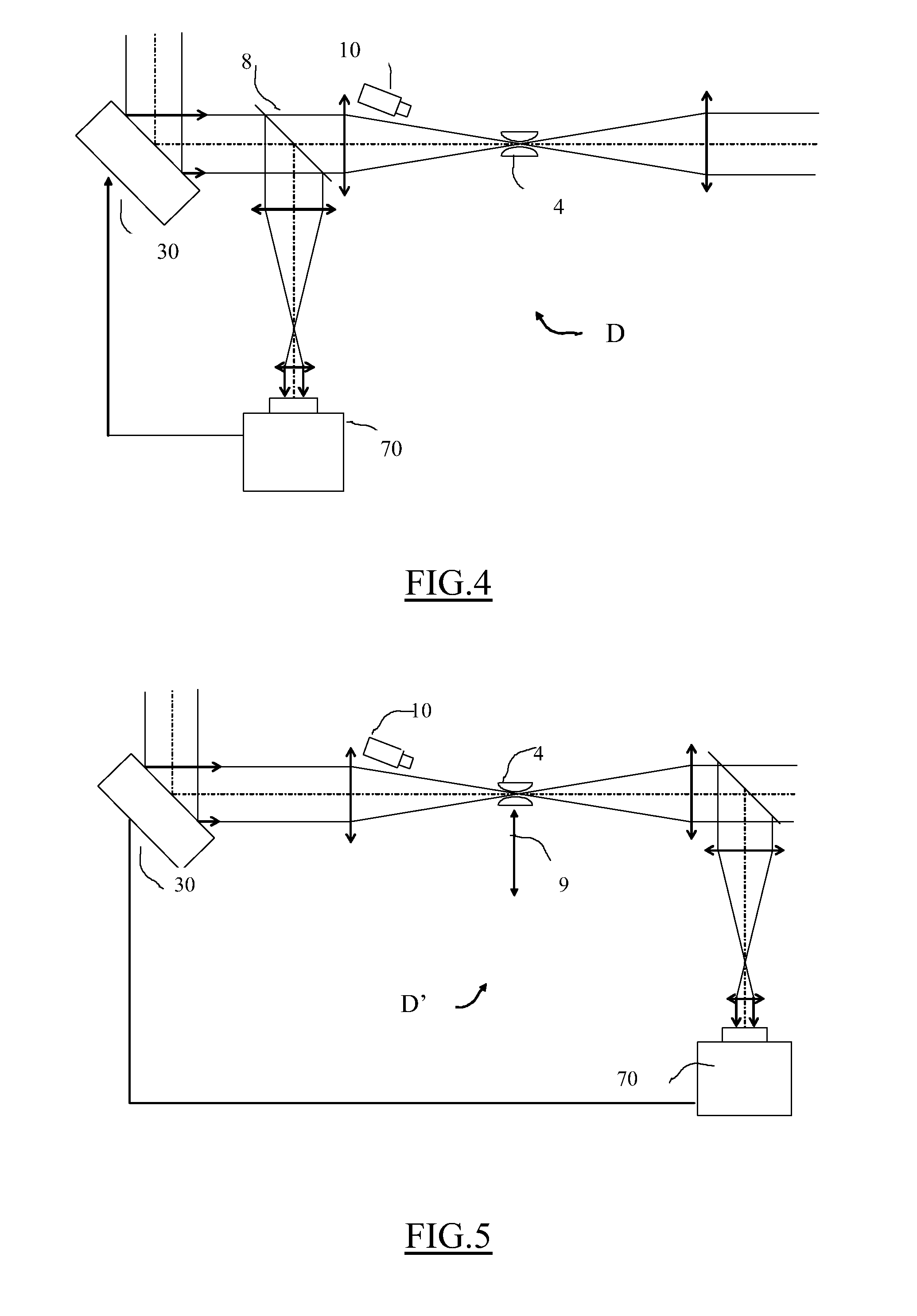

Method and device for shielding a high-power laser apparatus and high-power-laser optical system employing such a device

InactiveUS8971363B2Control damageEasy to controlLaser arrangementsOptical devices for laserPhase correctionHigh power lasers

Method for shielding a high-power laser apparatus (S) in which a laser beam is generated and then amplified in at least a first amplification stage, including spatial filtering (4) of the amplified laser beam, phase correction (3) carried out on the laser beam before it is spatially filtered, and a measurement of the aberrations (7) on the laser beam. The phase of the beam is corrected so as to produce a beam having minimal aberrations after spatial filtering. The shielding device (D, D′) implementing this method may in particular be employed in apparatus using an intense laser beam of high (terawatt) peak power and in proton therapy units.

Owner:IMAGINE OPTIC +1

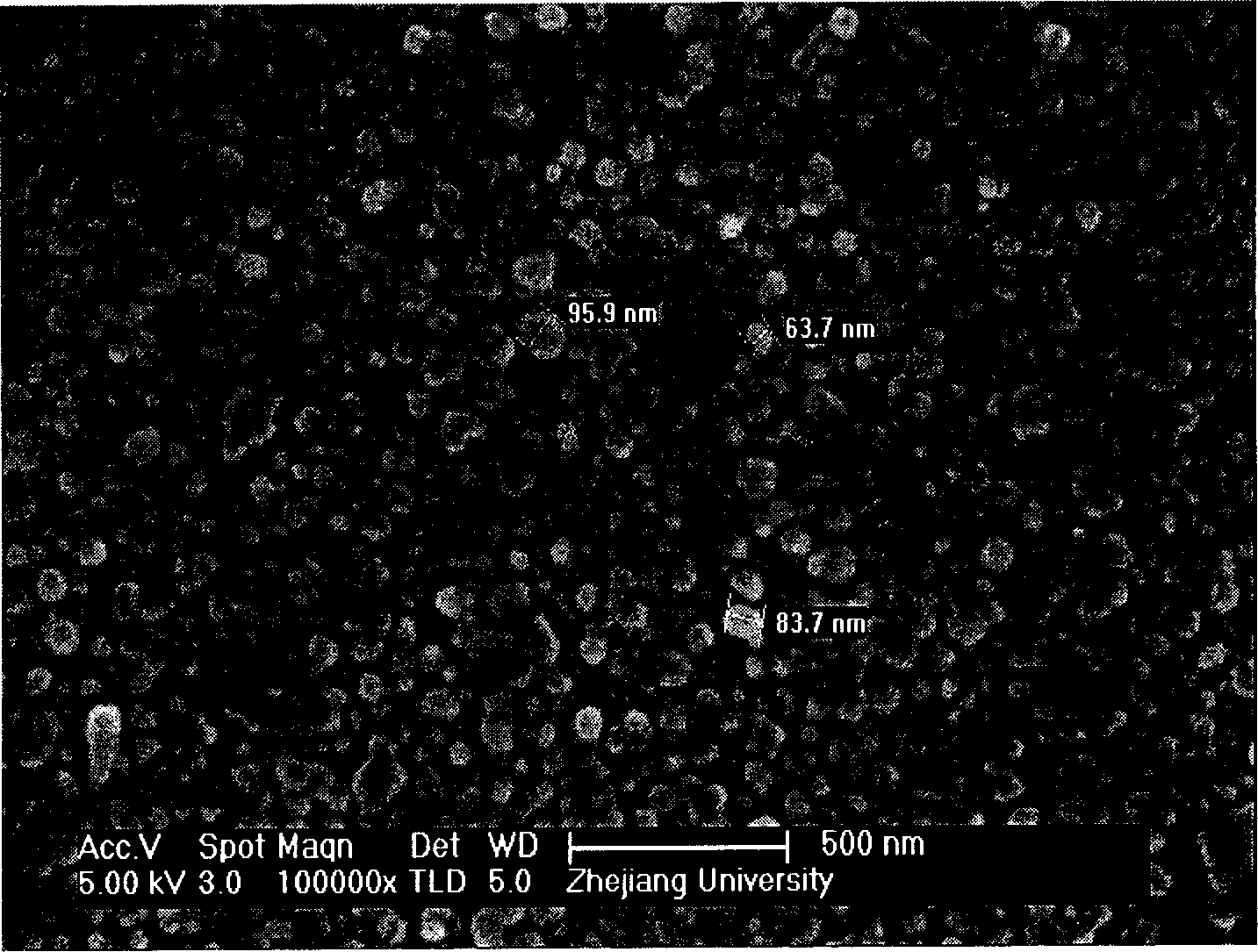

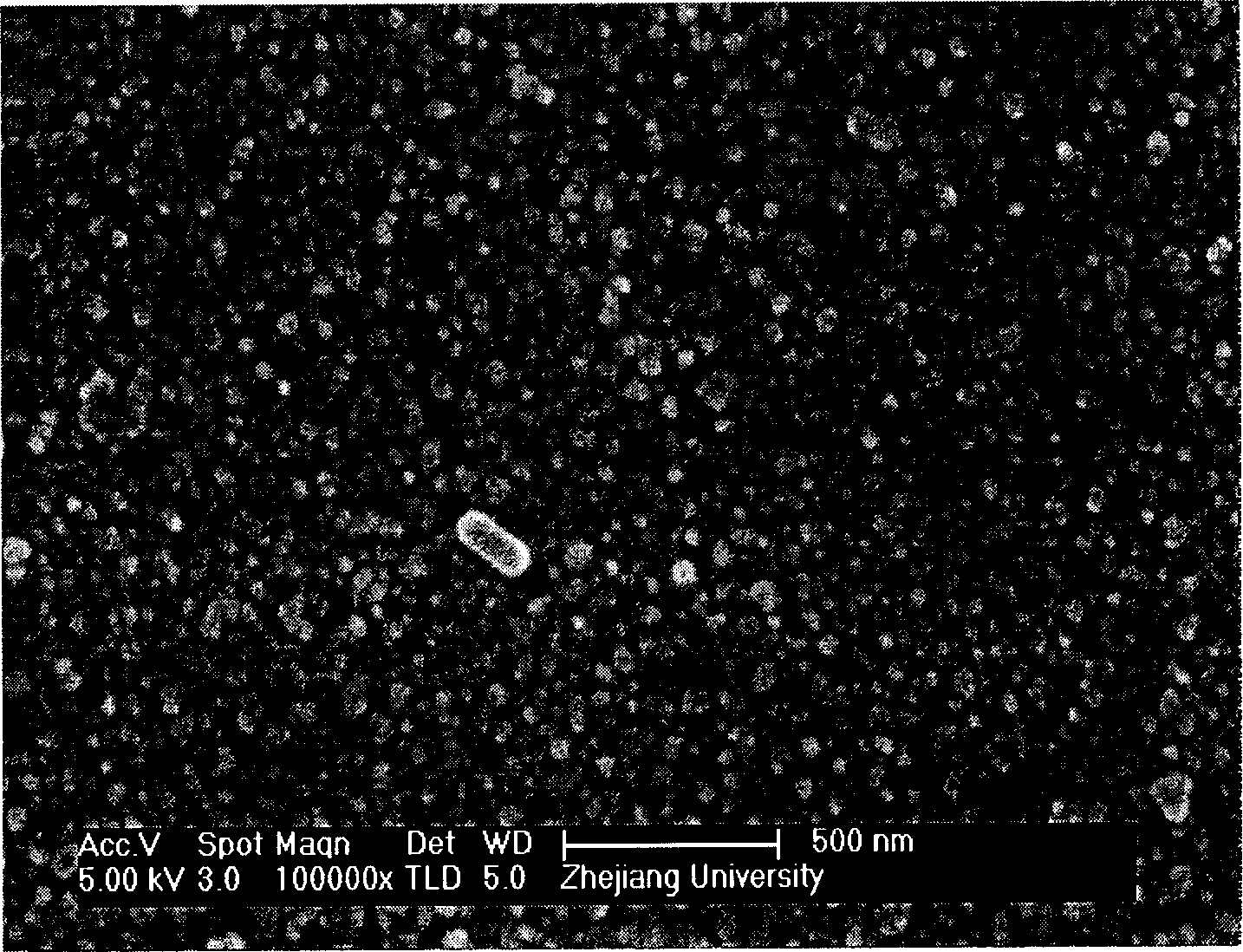

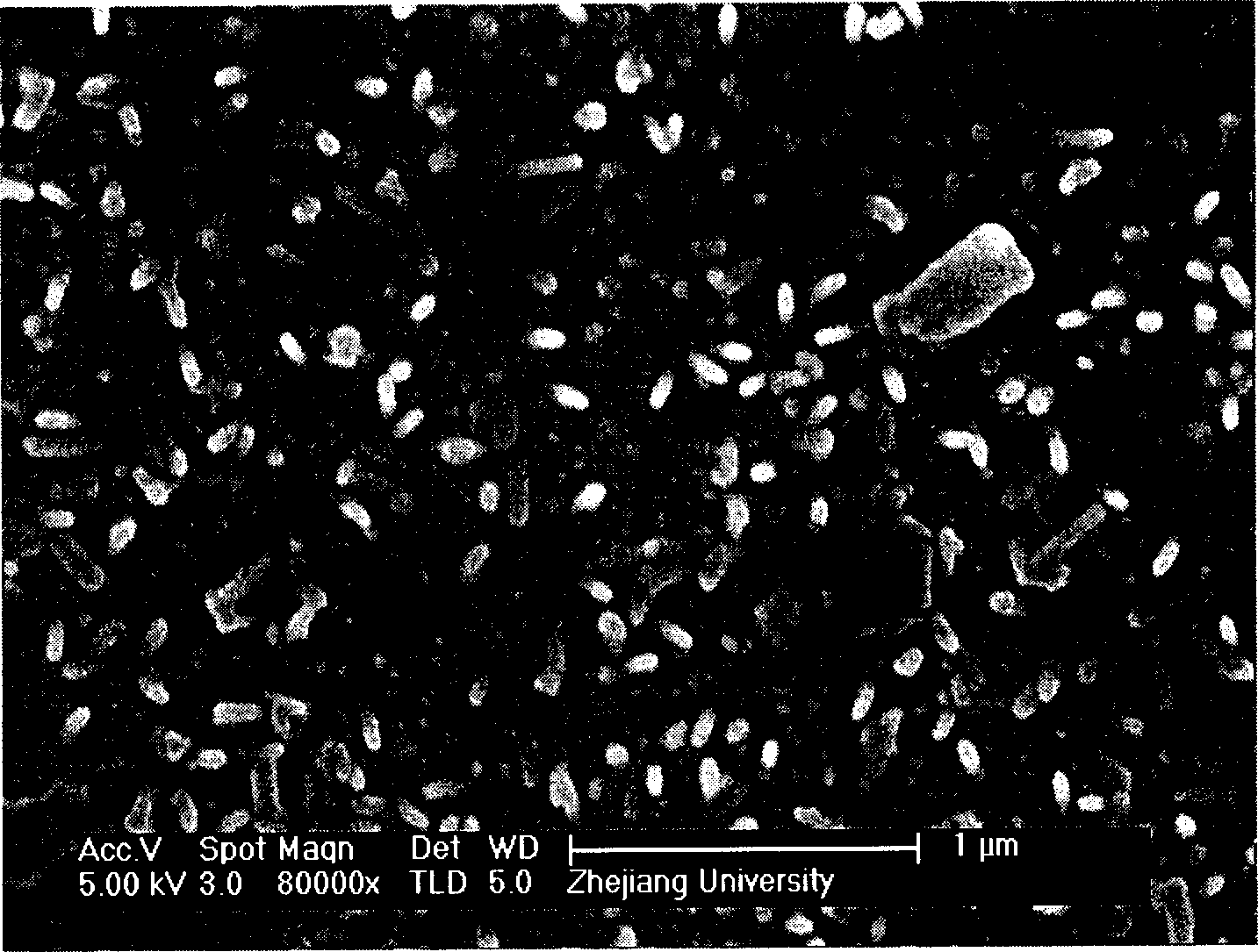

Nano-multicrystal phase glass ceramics and its production method

The present invention discloses a nano multicrystal phase glass-ceramic. Its composition includes (by wt%) 70% of silicon dioxide, 3.1%-4% of lithium oxide, 15% of aluminium oxide, 0.7%-1.2% of magnesium oxide, 0.8%-1.4% of zinc oxide, 0.4%-0.7% of calcium oxide, 0.2% of boron oxide, 1.8%-3.2% of titanium oxide, 1.5%-2.3% of zirconium oxide, 1.8%-2.1% of mixture of potassium oxide and sodium oxide, 0.1%-2.0% of lithium fluoride and / or phosphorus pentoxide and 0.8%-0.9% of mixture of arsenium oxide and antimony oxide. Its production method includes the following steps: grinding the above-mentioned components, uniformly mixing them to obtain mixed material, melting at 1350-1650deg.C, forming, annealing, nucleating for 1-4hr at 500-800deg.C, then heating to 700-1000deg.C and making crystallization treatment for 1-12hr so as to obtain the invented product.

Owner:ZHEJIANG UNIV

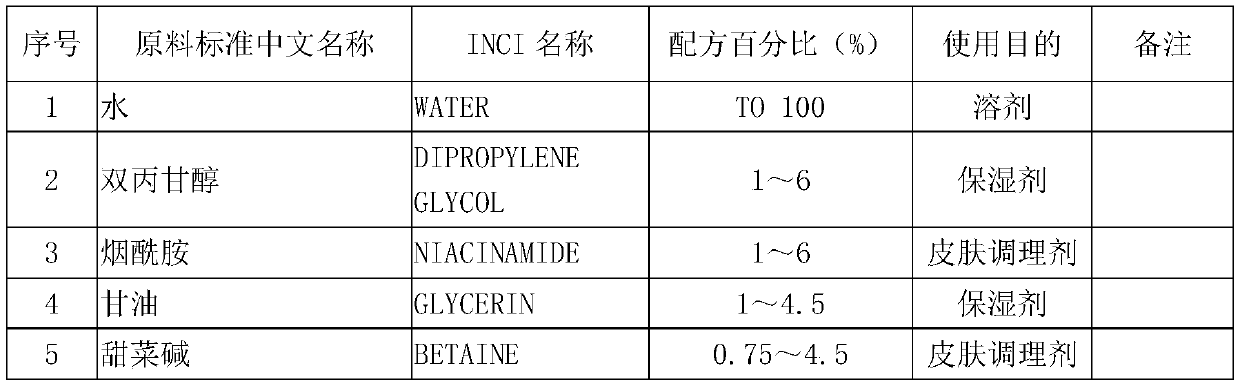

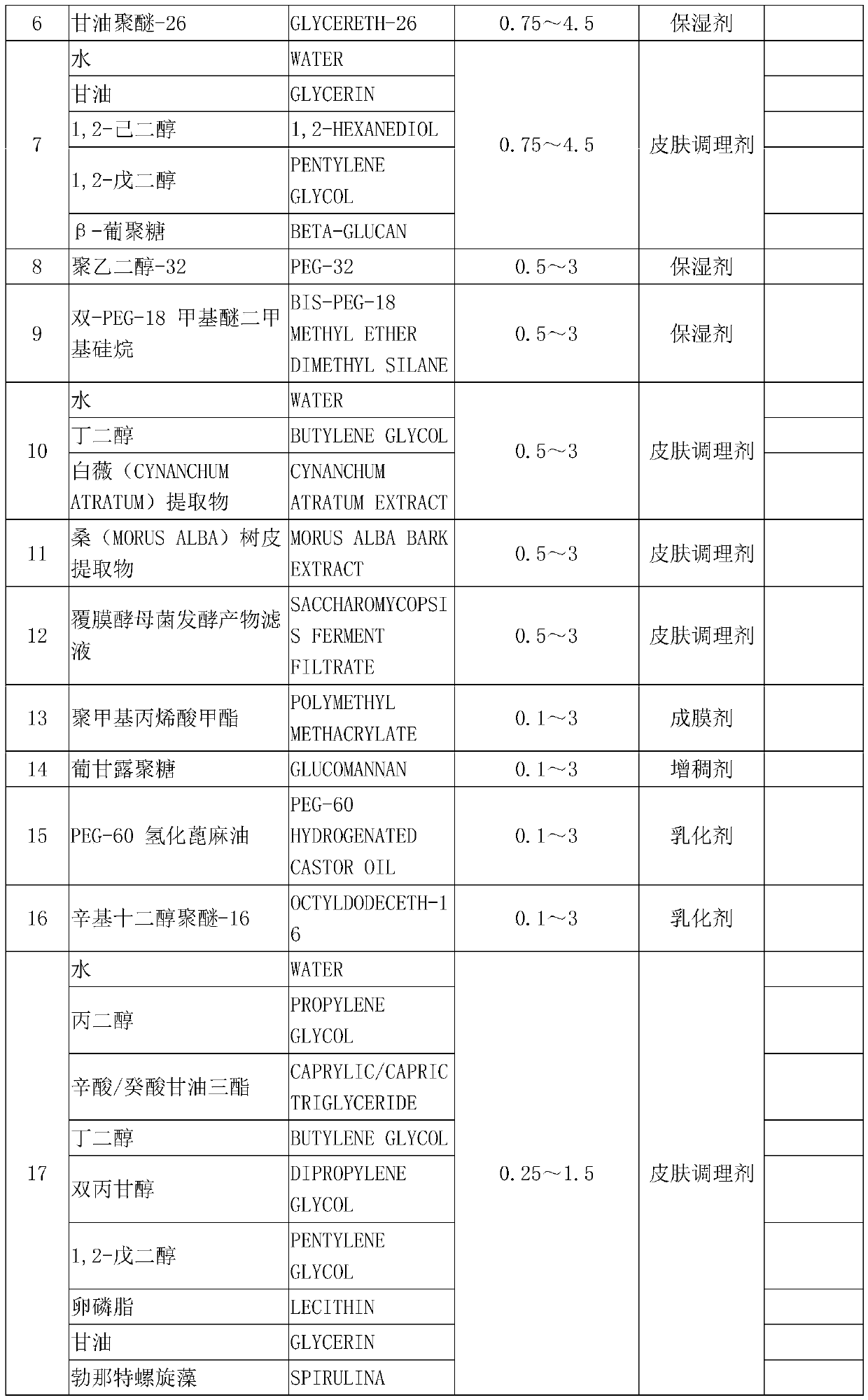

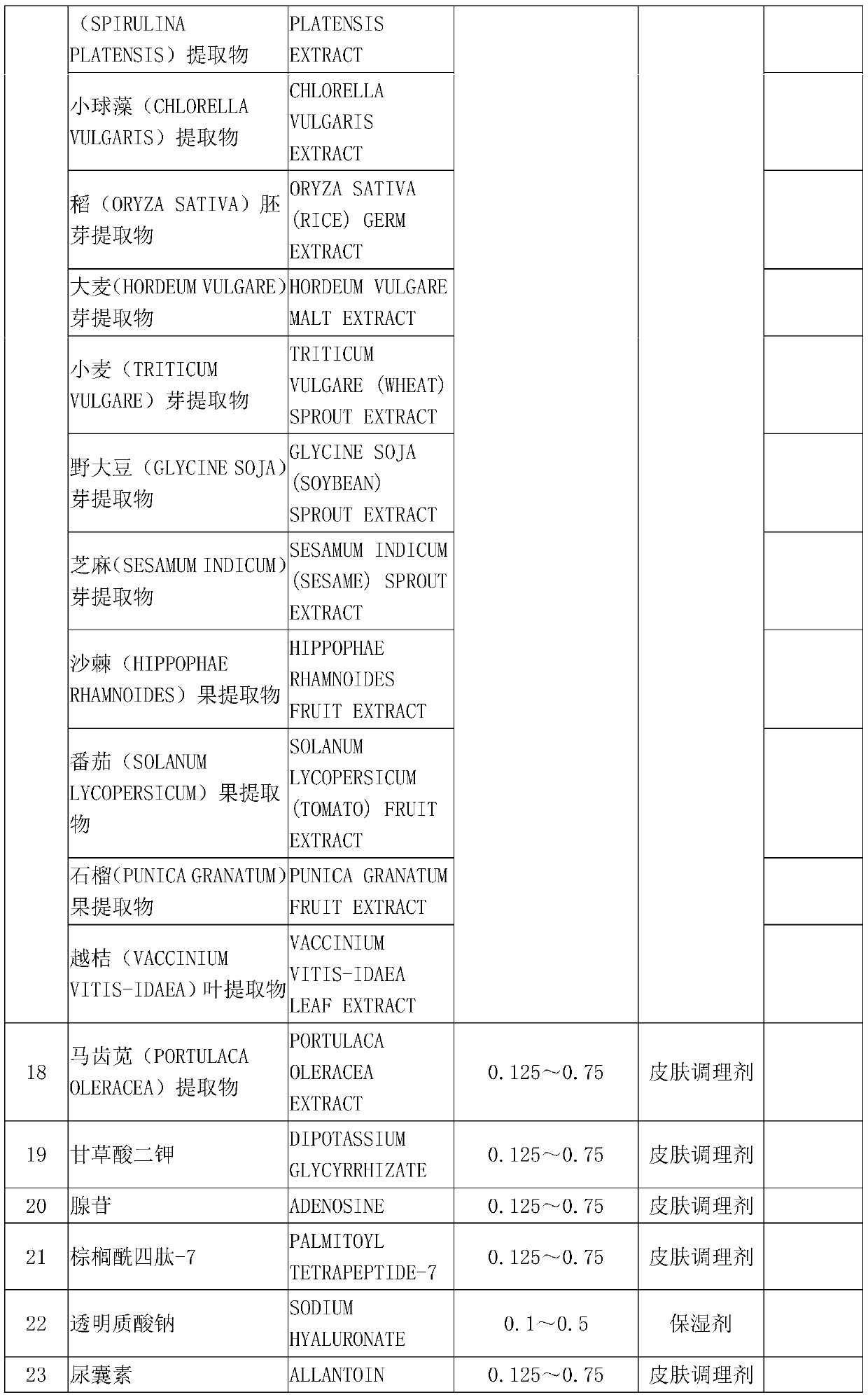

Whitening and freckle-removing skin care product capable of blocking, inhibiting and reducing melanin and preparation method of skin care product

InactiveCN109893464AGood whitening effectPrevent agingCosmetic preparationsToilet preparationsWrinkle skinMorus alba bark

The invention relates to a whitening and freckle-removing skin care product capable of blocking, inhibiting and reducing melanin and a preparation method of the skin care product, in particular to a whitening and freckle-removing formula capable of blocking, inhibiting and reducing melanin. The formula comprises niacinamide, betaine, beta-glucan, a cynanchum atratum extract, a morus alba bark extract, coated saccharomyces fermentation product filtrate, a spirulina platensis extract, a chlorella vulgaris extract, an oryza sativa germ extract, a hordeum vulgare germ extract, a triticum vulgare germ extract and the like. The skin care product can block, inhibit and reduce melanin, accelerate cell metabolism, accelerate falling of melanin keratinocyte, eliminate skin aging, inhibit, delay andreduce wrinkles and have skin conditioning functions of promoting skin regeneration. The skin care product is not limited by product dosage forms, can be added to aqueous solutions, emulsions, cream,essence and the like, can have multiple purposes and makes up the obvious defect that commercial products are single in function.

Owner:中美杜克(广州)护肤研究中心(普通合伙)

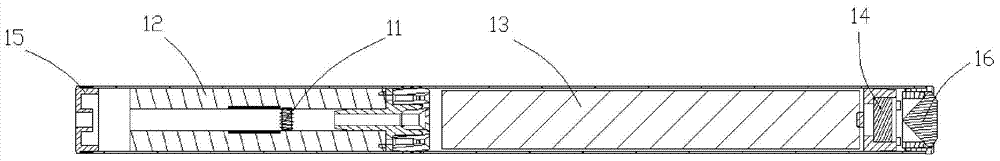

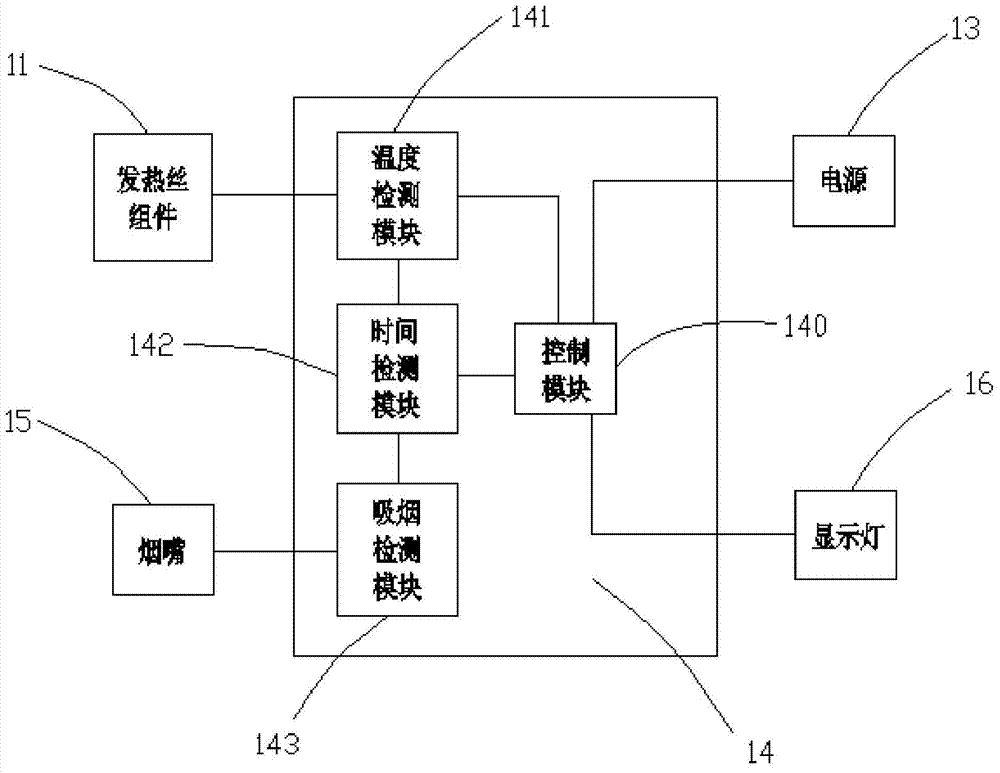

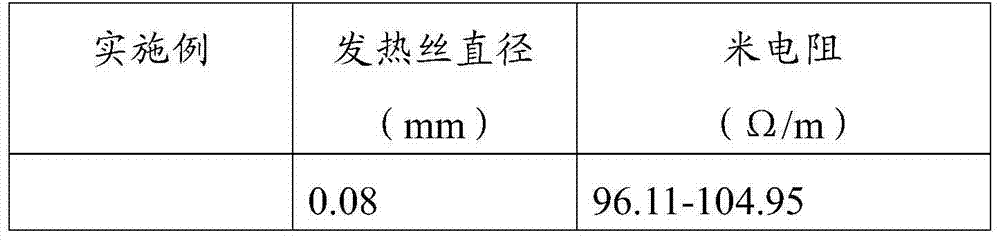

Electronic cigarette and heating wire thereof

The invention relates to an electronic cigarette and a heating wire thereof. The heating wire comprises the following components in percentage by mass: 46-78% of nickel, 0.005-0.4% of cerium and the balance of iron. The heating wire can reduce the temperature increase speed when in use.

Owner:SHENZHEN SMOORE TECH LTD

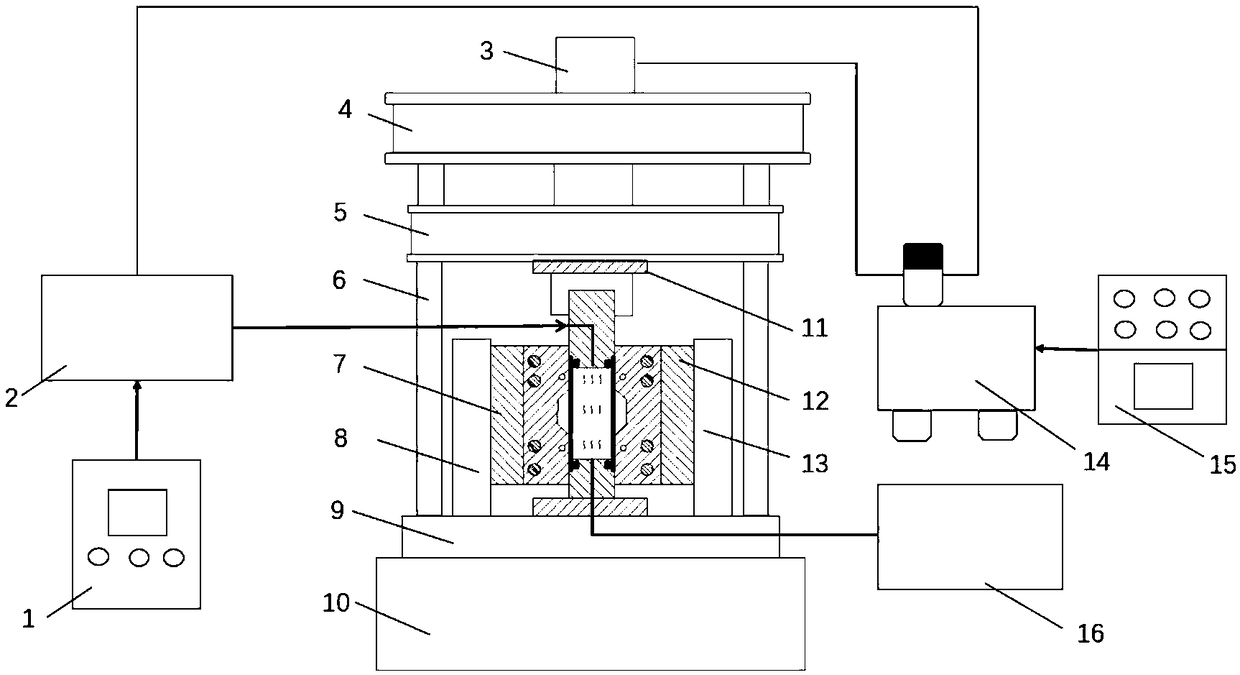

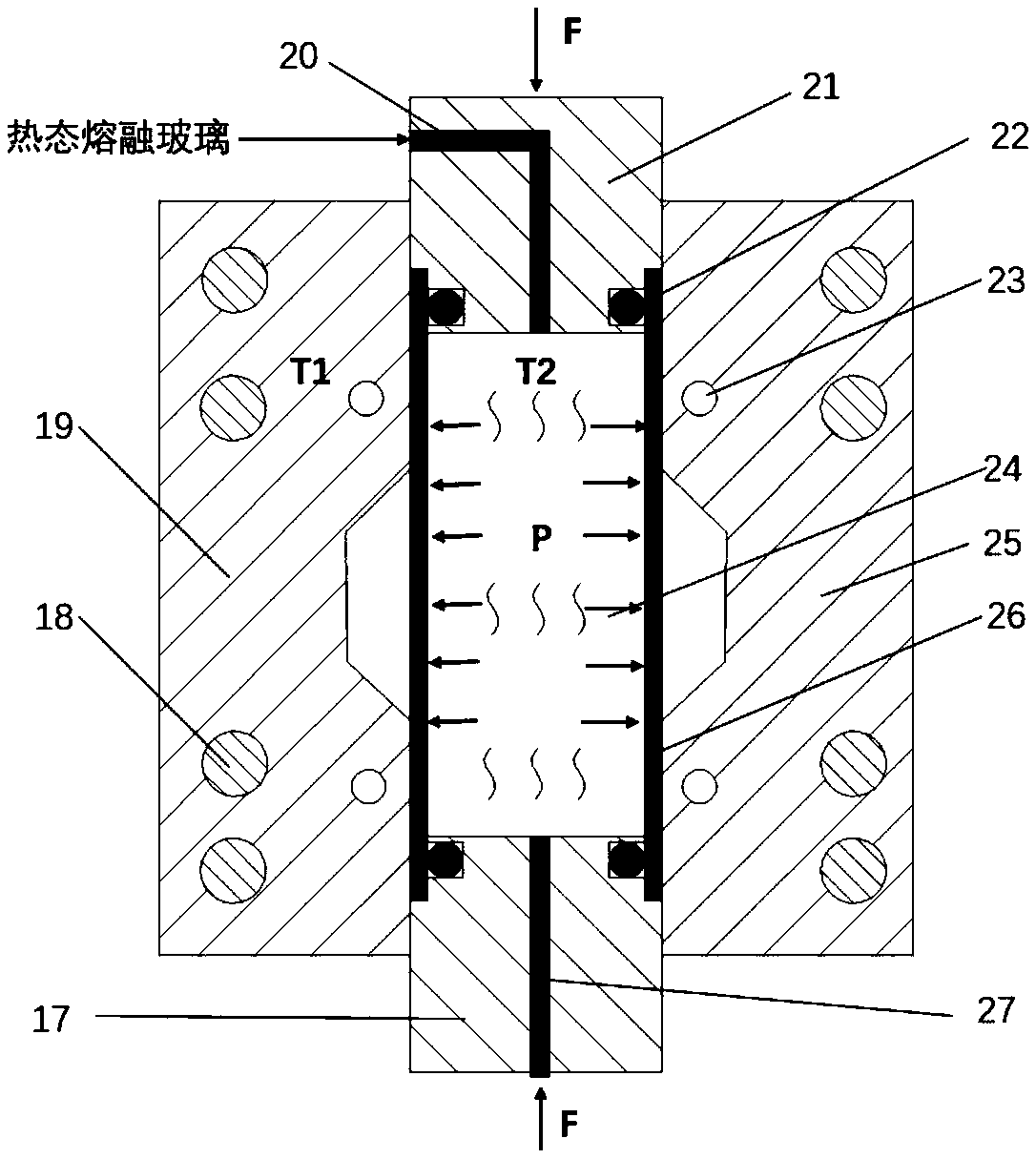

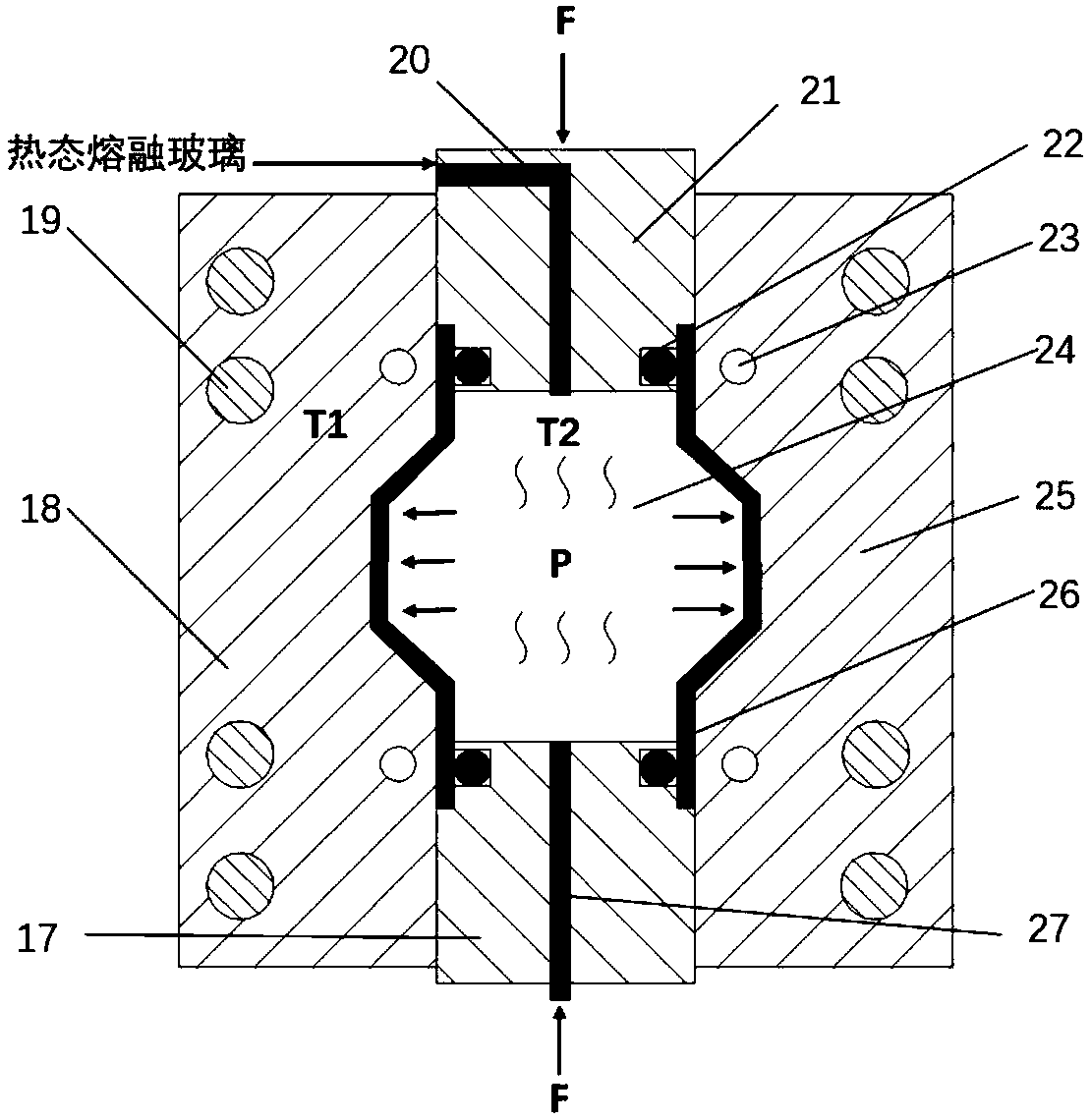

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

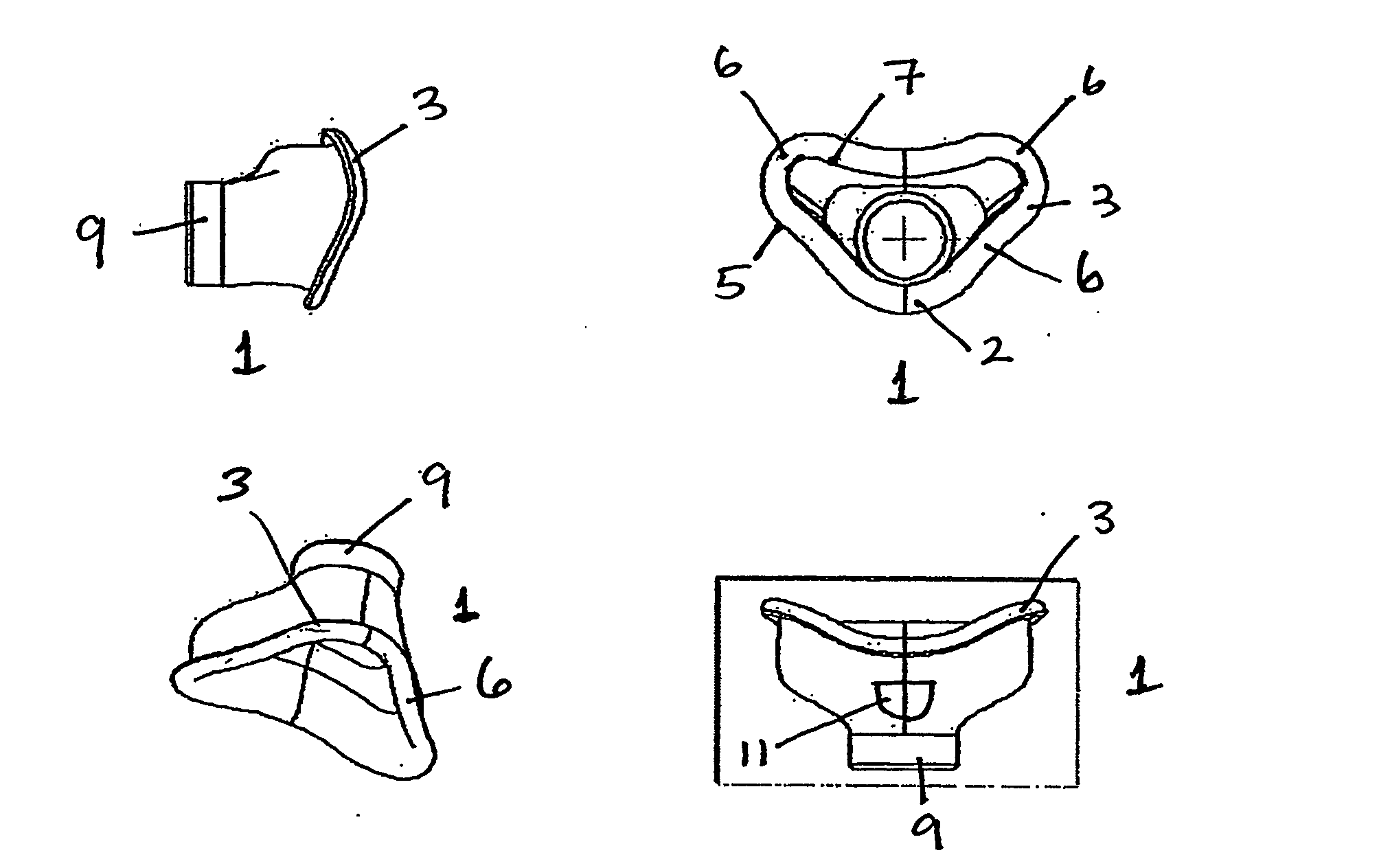

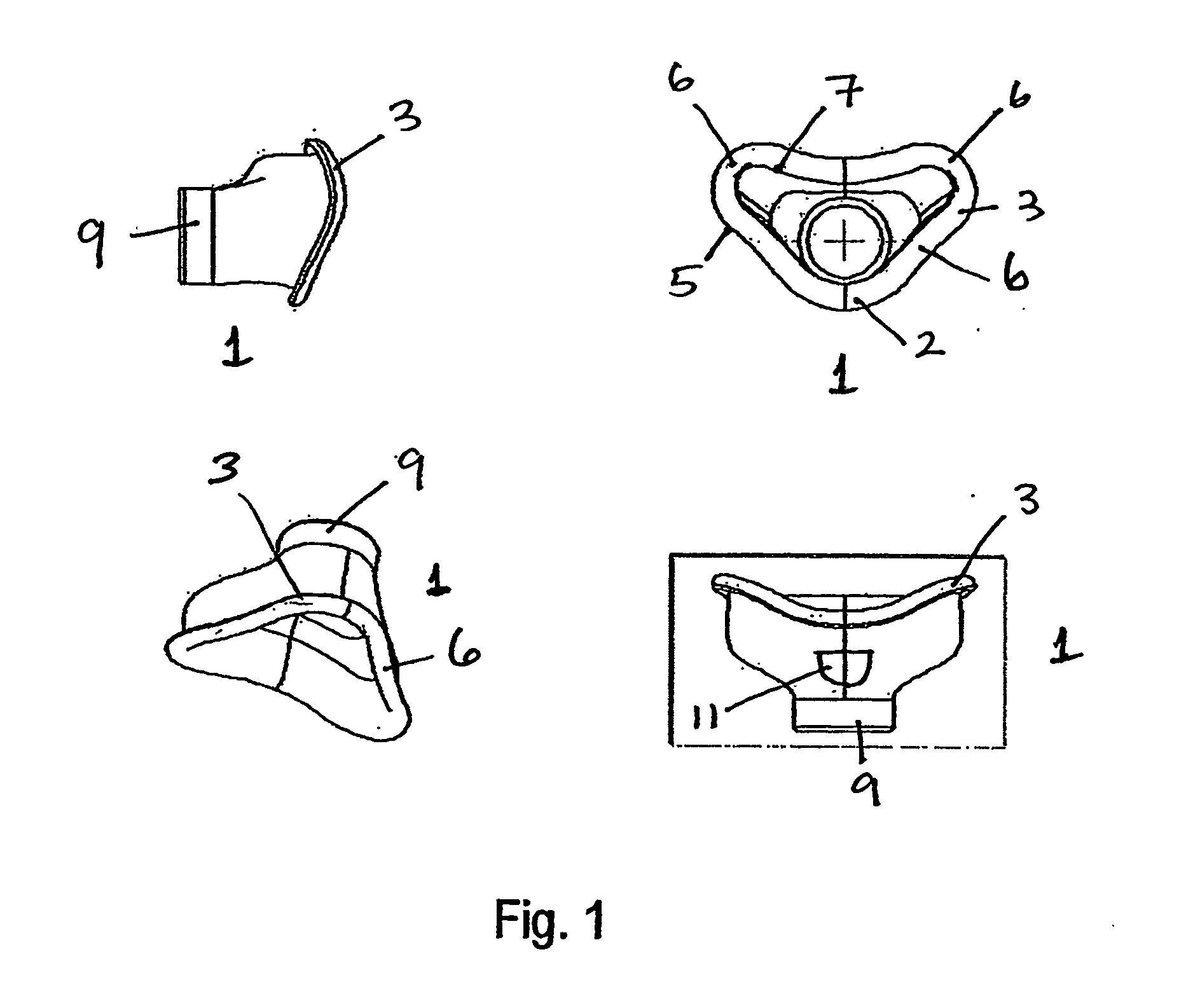

Nasal adapter for the base of the nose

InactiveUS20070131230A1Easily communicateEasy to useBreathing filtersBreathing masksDual deliveryAirborne particle

A novel nasal adapter is provided that conforms to, and seals with the base (underside) of a nose. Upward pressure exerted against the inventive nasal adapter compressibly conforms an adapter lip to seal with the underside of the nose. The nasal adapter provides for the comfortable, discreet, and effective transmission of deliverable flow (e.g., fluid, gas, airborne particles and medicament, etc.) to the nasal chambers with minimal leakage. In preferred embodiments, the nasal adapter is formed of a single molded piece made of flexible material and can be made in various sizes to adaptably conform to a broad range of nose sizes, and conformations. Particularly preferred embodiments comprise dual delivery channels with dual outflow apertures that are in communication with at least one lip that is proportioned and disposed to provide for separate delivery channels to each nostril.

Owner:KURVE THERAPEUTICS INC

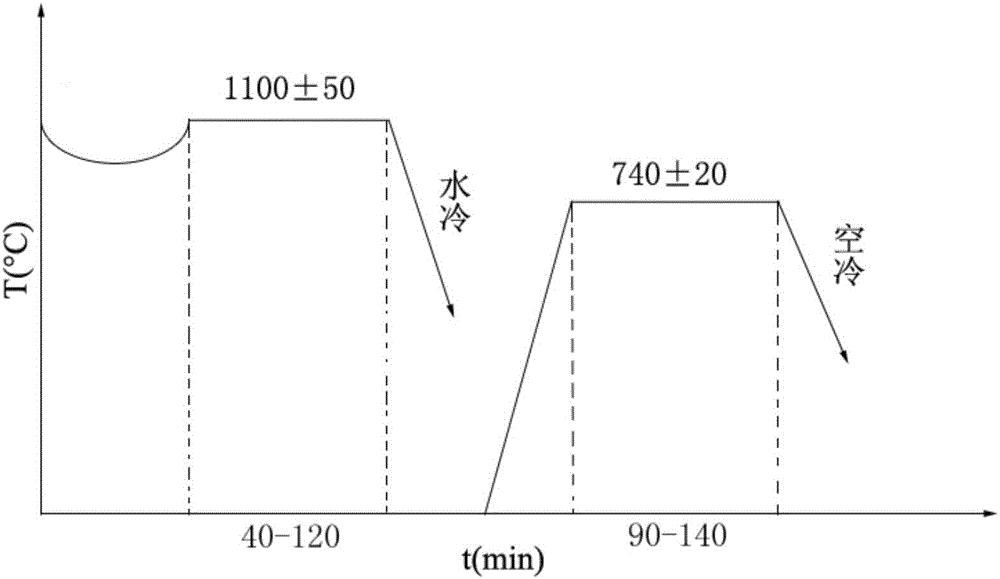

Low-activity martensitic steel with high-temperature mechanical performance and heat treatment process

The invention relates to low-activity martensitic steel with high-temperature mechanical performance and a heat treatment process. The low-activity martensitic steel comprises main components of 8.5-9.5% of Cr, 1.2-1.7% of W, 0.15-0.25% of V, 0.12-0.18% of Ta, 0.4-0.5% of Mn, (C+N) not more than 0.17% and not less than 0.09%, N less than 0.07% (wt.%), and the balance of Fe elements; and the purpose of controlling C and N is to form fine dispersed carbonitride in subsequent treatment to enhance the material high-temperature performance. Low-activity martensitic steel plates molded by rolling are heated to 1100+ / -50 DEG C, are insulated by 40-120 min according to different thicknesses and sizes to discharge from a furnace, are quickly cooled by water to reach the room temperature, are reheated to 740+ / -20 DEG C, are insulated by 90-140 min according to different thicknesses and sizes to discharge from the furnace, and are cooled by air to reach the room temperature. The high-temperature strength and the high-temperature durability of radiation-resistance low-activity steel are prominently improved to lay the foundation to the use temperature of the radiation-resistance low-activity steel.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

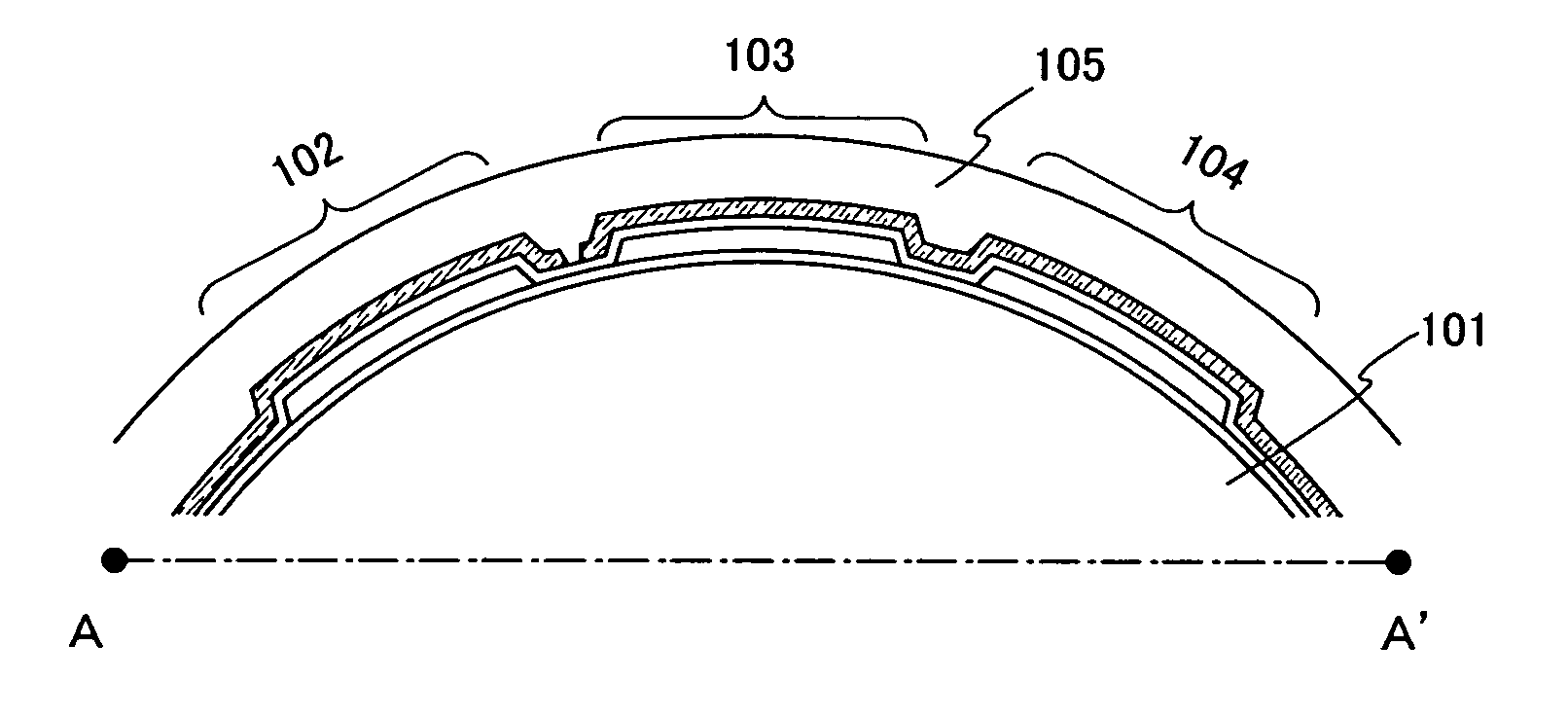

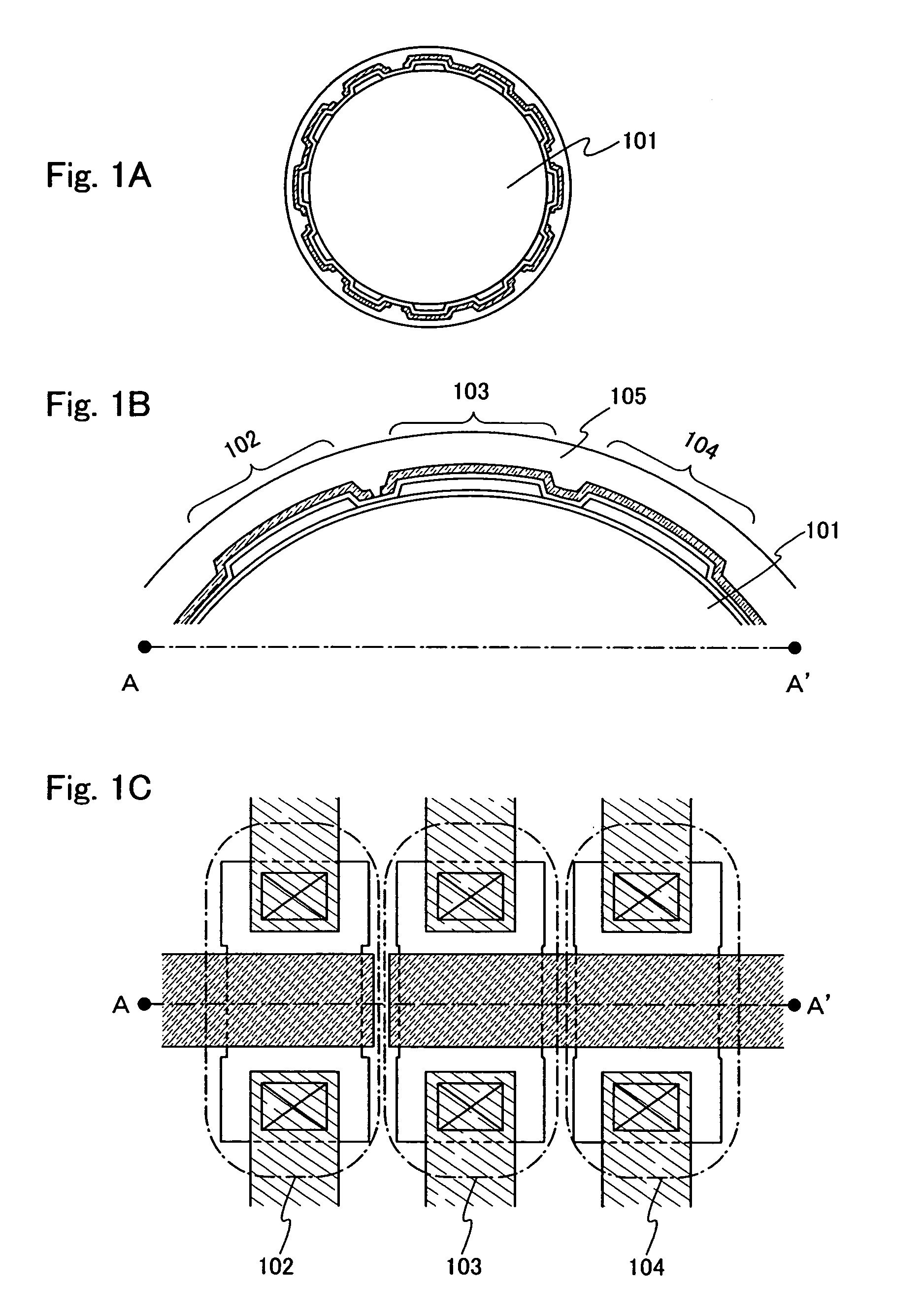

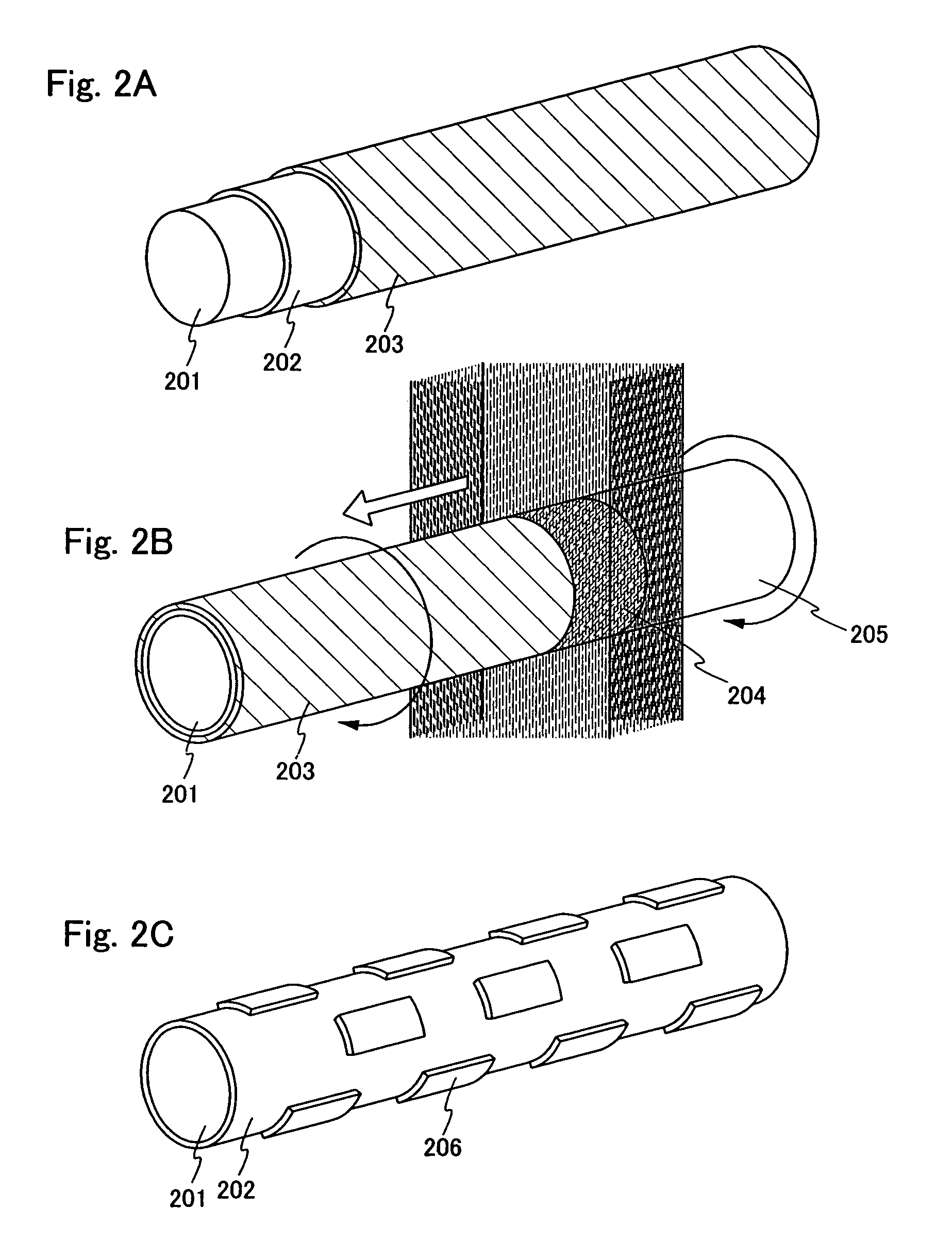

Semiconductor device and method for manufacturing the same

The present invention provides a semiconductor device using a support of new form which can further expand the range of design and enlarge a circuit size while restraining volume of a substrate than a flexible flat-plate substrate. A method for manufacturing a semiconductor device comprising the steps of: forming an insulating film on a fibrous support; forming a semiconductor film so as to be in contact with the insulating film; and forming a semiconductor device using the semiconductor film; wherein the step of forming the insulating film or the step of forming the semiconductor film is performed with the support rotating, using a rotational axis parallel to a longitudinal direction of the support as a center.

Owner:SEMICON ENERGY LAB CO LTD

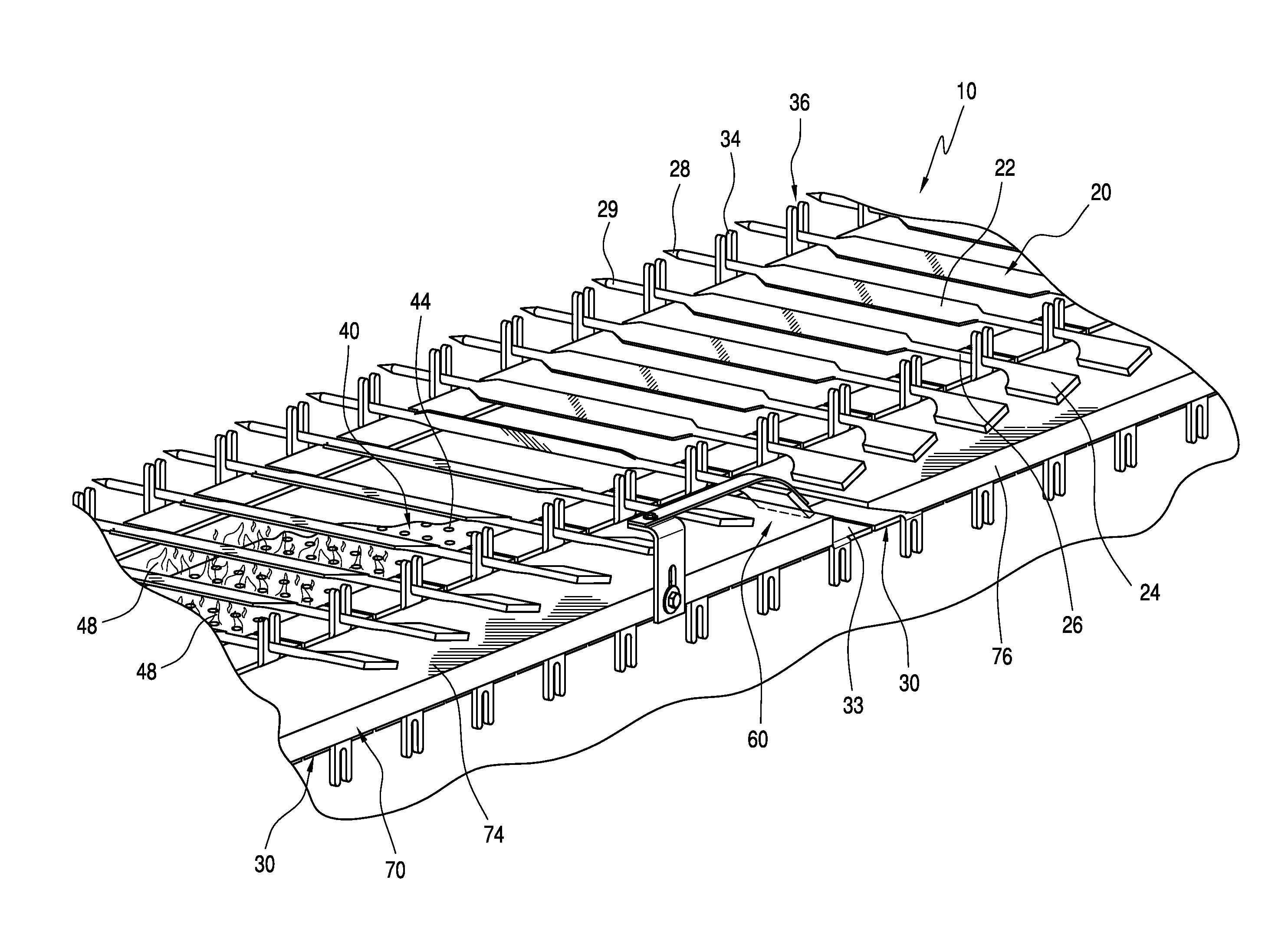

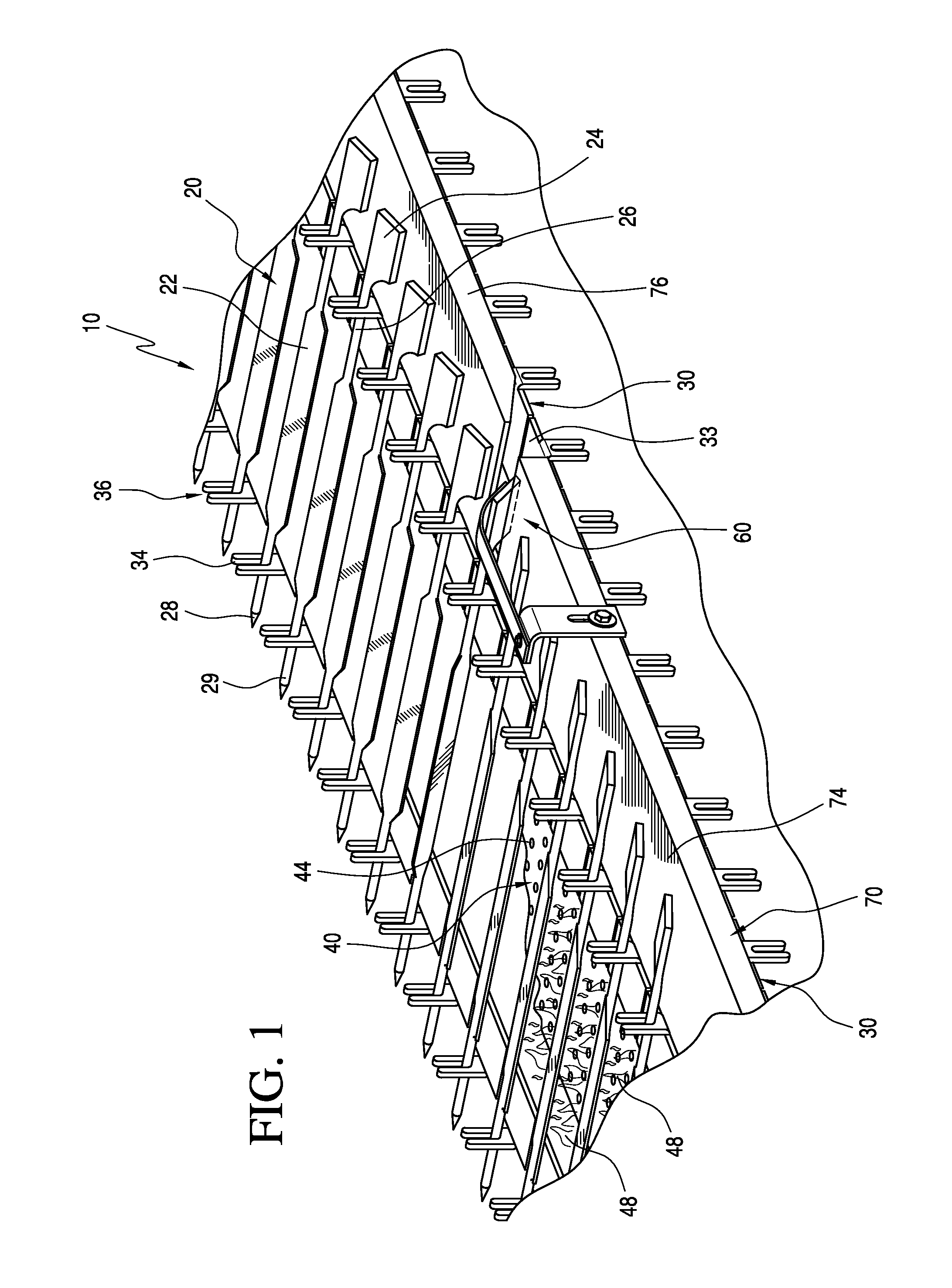

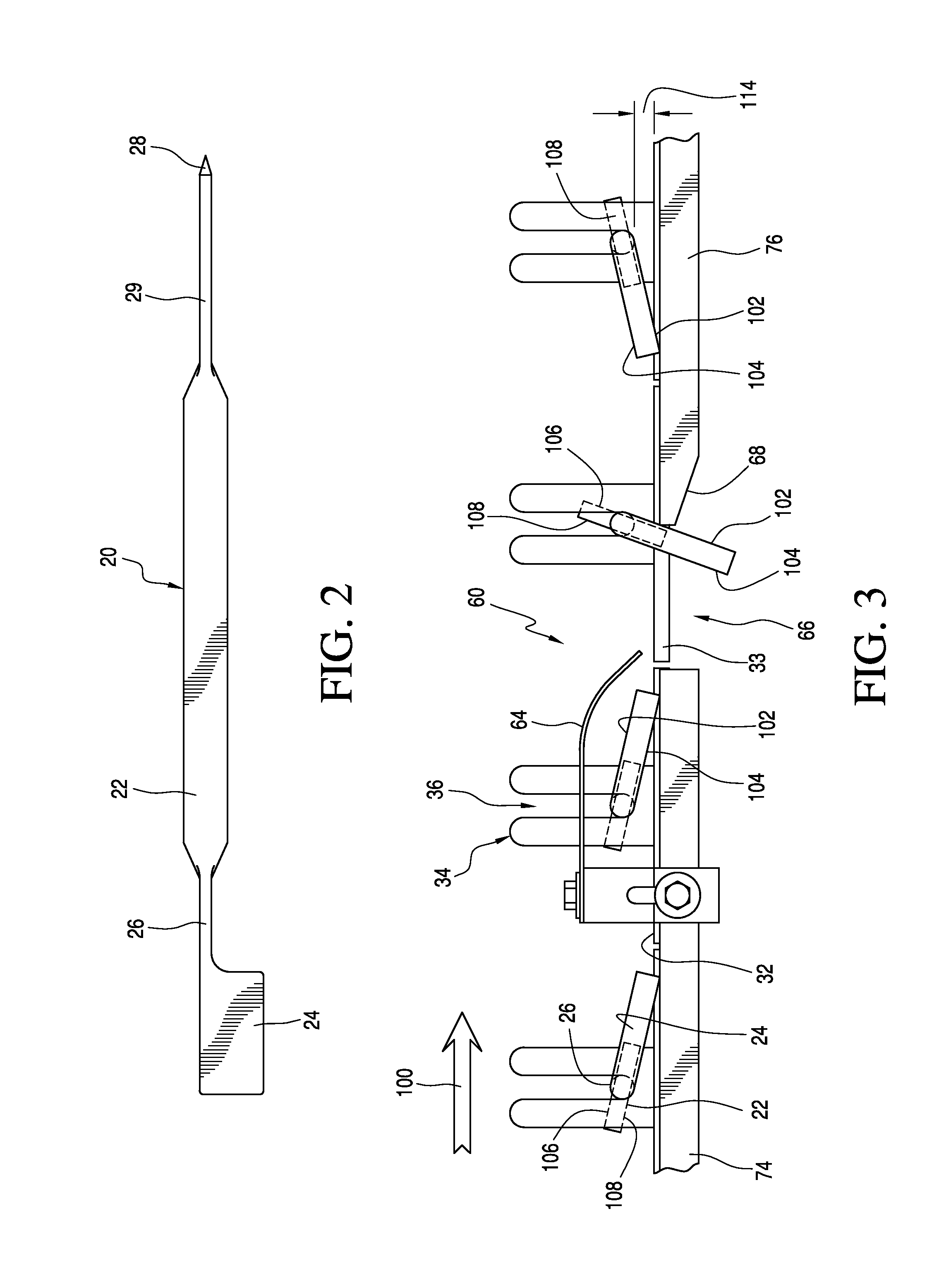

Automatic grill, in particular an automatic grill for evenly cooking food

InactiveUS20150196162A1Avoids unwieldy sprocket and gearEasy to useRoasting apparatusRoasters/grillsEngineering

Device for cooking food includes a food securing element, such as a skewer, for securing food to be cooked. A conveying element is provided for moving the food securing element relative to a heating device, such as a gas or electric grill, the conveying element moving at a predetermined rate of speed. Heating device may be provided for heating and cooking food on the food securing element, and a turning device is provided for turning the food securing element once as food securing element moves relative to the heating device, such as a gas burner. The turning device may be a rotating device which automatically turns the food securing element once in the range of 150 to 210 degrees, and, indeed, exactly 180 degrees, depending on the intended use.

Owner:WOODBEES S A L

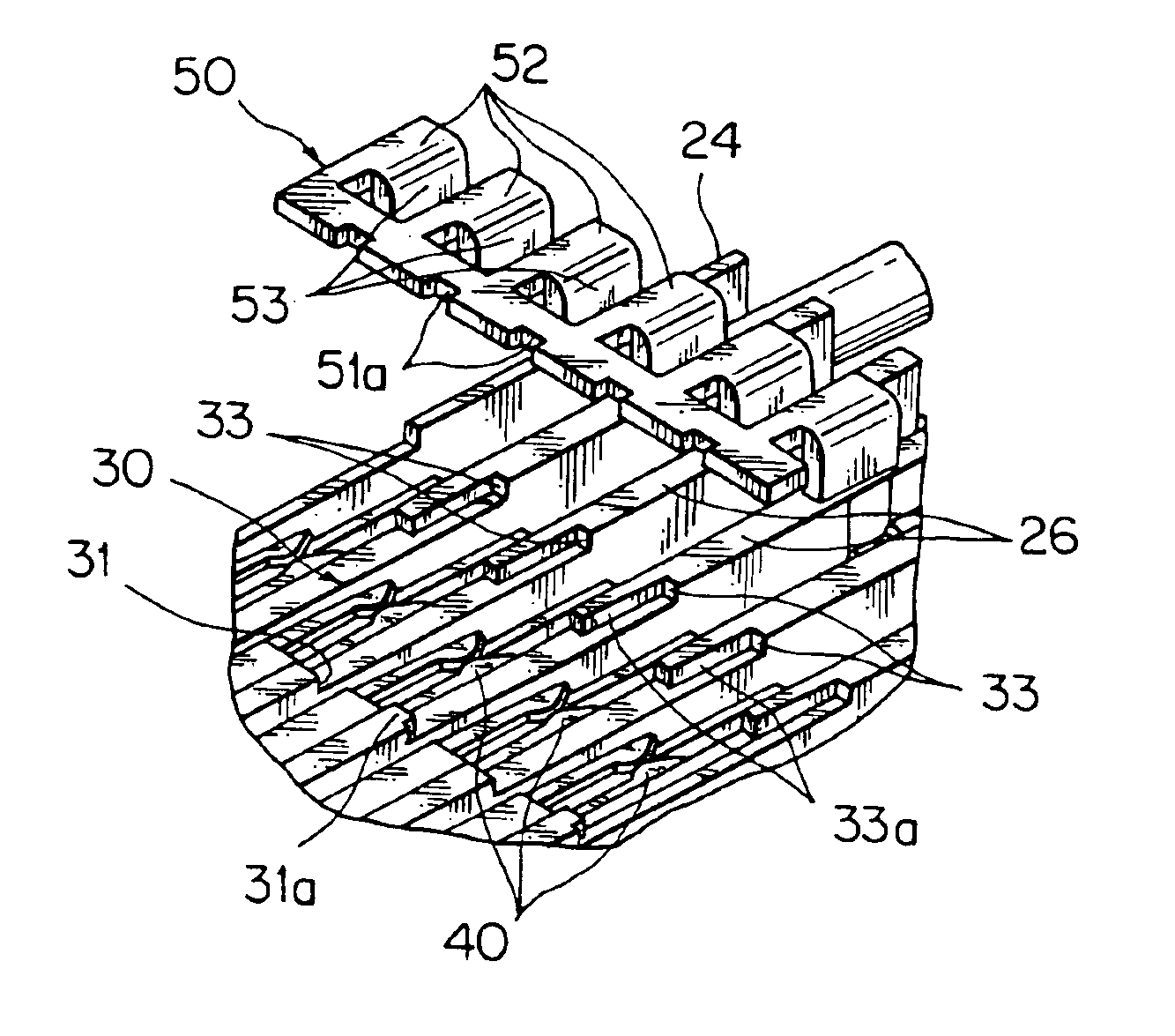

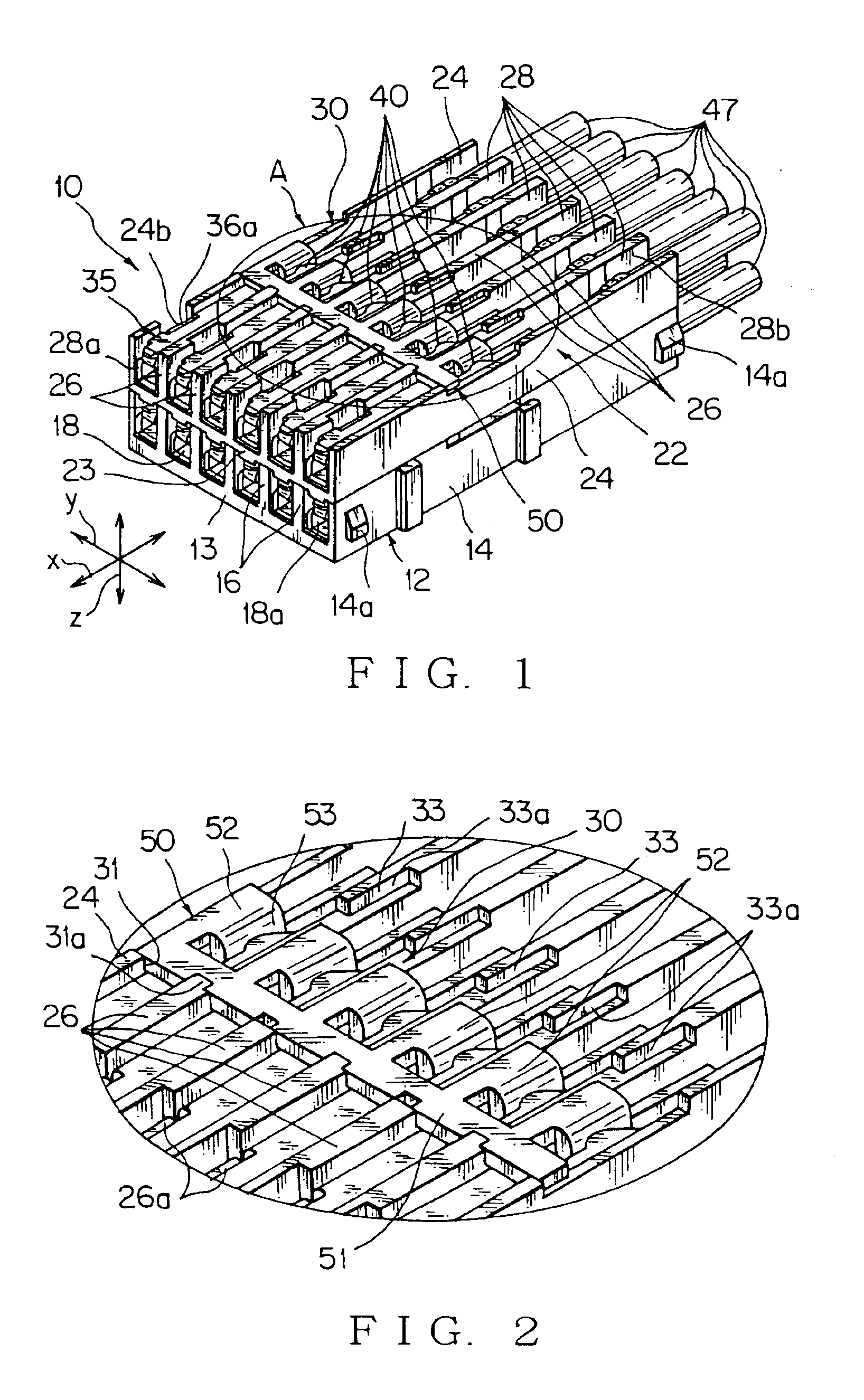

Joint connector and its terminals

InactiveUS6921289B2Reduce depthAttachability and reliabilityCoupling contact membersLateral displacementMechanical engineering

A notch 30 is provided at partitions 16, 26 and side walls 14, 24 to support slidably a coupling member 50 from a slide start to a slide end of the notch 30, said partitions and side walls partitioning terminal receiving chambers 18, 28. A resiliently clipping member 40 is provided at a terminal 35 to clip the coupling member 50 at the slide end of the notch 30. Further, the coupling member 50 has a thin joint piece, slidably contacting piece continued to the joint piece in a same plane, and a vertically contacting piece formed perpendicular to the slidably contacting piece. A wall to prevent the coupling member 50 from lateral displacement is provided at the notch 30, said wall being contacted with a side part of the coupling member 50.

Owner:YAZAKI CORP

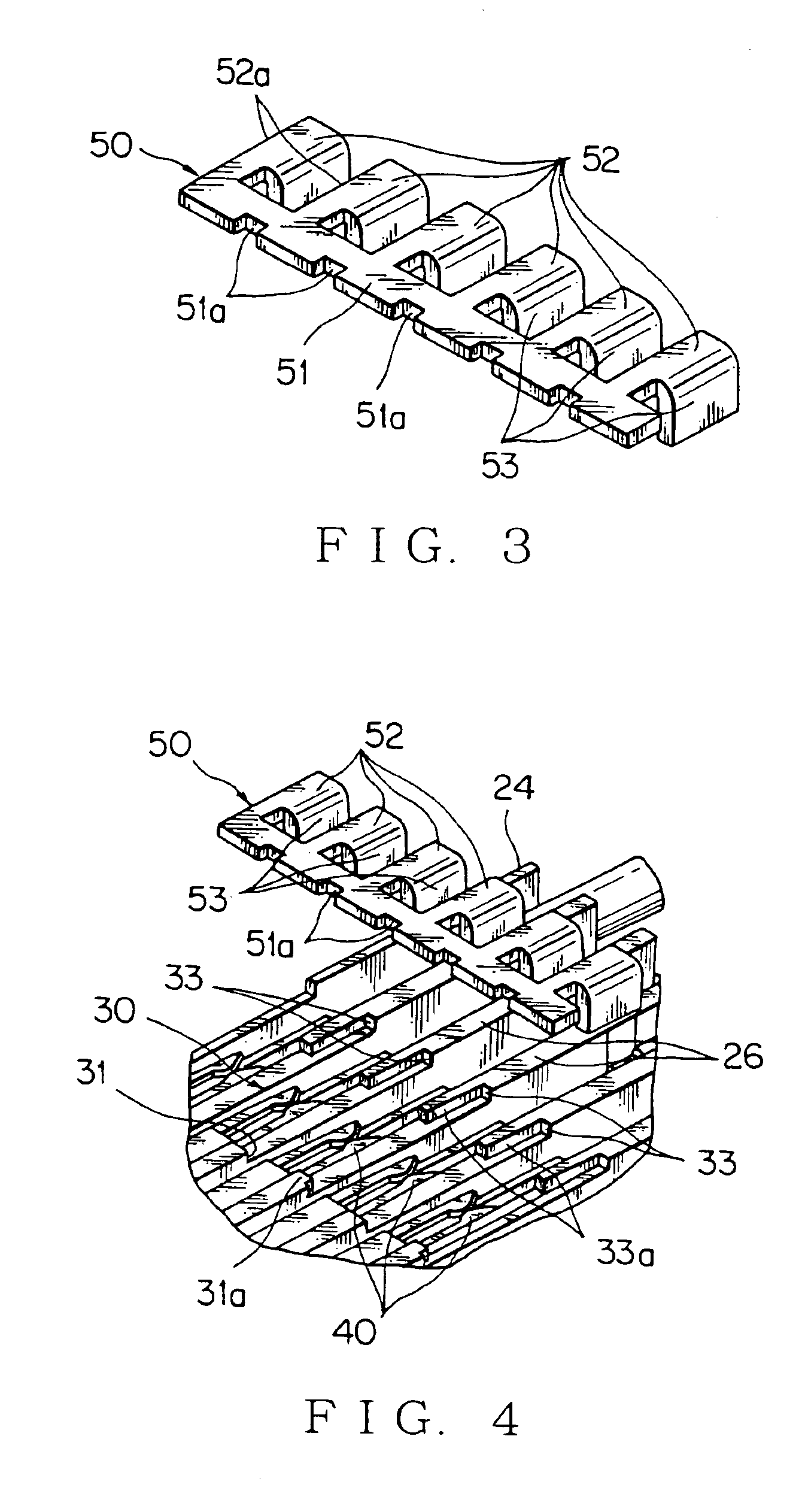

Horizontal type device for reheating semi-solid metal blank material

The invention relates to a horizontal type device for reheating a semi-solid metal blank material, which comprises an induction heating power supply, an induction heating mechanism, and a blank material carrying mechanism, and is provided with five stations, such as at least three material heating stations, a material placing station and a material discharging station, wherein the induction heating mechanism adopts three sections of induction heating coils which are separately and horizontally arranged, and all the induction heating coils are mutually electrically communicated and arranged on the three material heating stations respectively; the blank material carrying mechanism comprises a feed mechanism and a blank material transporting device; the blank material transporting device is a delivering device processing in front of each station; and the feed mechanism is positioned in front of each induction heating coil. The induction heating three-section heating mode is selected to make the heating of the blank material and the distribution of the temperature field more even and reasonable. The horizontal structure is adopted, the blank material cannot collapse or discharge fluid, and the blank material transportation is simple and convenient because of a large contact surface between the blank material and a supporting part. The blank material is allowed to have a higher liquid phase fraction, which is convenient for the thixotropic forming of more complicated parts.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

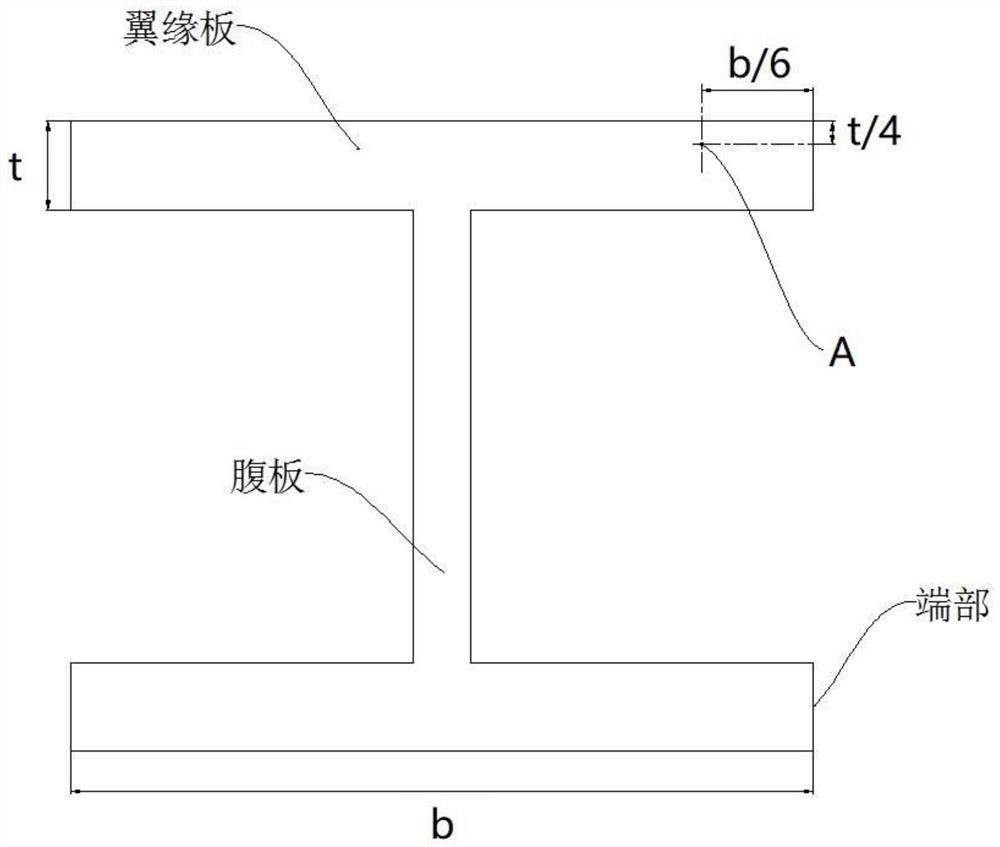

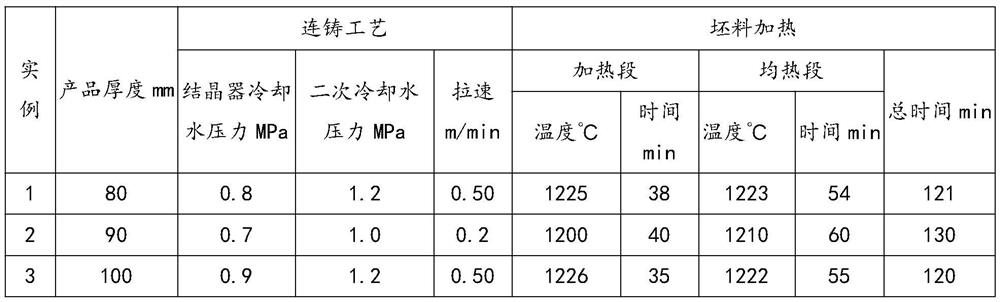

Super-thick Q355-grade hot-rolled H-shaped steel with good low-temperature toughness and production method thereof

ActiveCN112359289AReduce manufacturing costImprove mechanical propertiesTemperature control deviceMetal rolling arrangementsEconomic benefitsToughness

The invention discloses super-thick Q355-grade hot-rolled H-shaped steel with good low-temperature toughness and a production method thereof. The H-shaped steel comprises the following chemical components of, in percentage by mass, 0.12-0.18% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, 0.02-0.06% of Al, 0.02-0.06% of Nb, 0.0040-0.0100% of N, less than or equal to 0.015% of P, less than or equal to 0.005% of S, the balance Fe and inevitable impurities, with flange thickness of 80-150mm, less than or equal to 0.42% of CEV, and less than or equal to 0.25% of Pcm. The invention further provides an Nb and Al microalloying low-cost component design scheme. With reasonable continuous casting process and rolling process, distribution of AlN and NbC in a continuous casting billet and the H-shaped steel is controlled, a beam blank structure is improved, a H-shaped steel structure is refined, the product mechanical performance is good, and the economic benefits are good.

Owner:MAANSHAN IRON & STEEL CO LTD

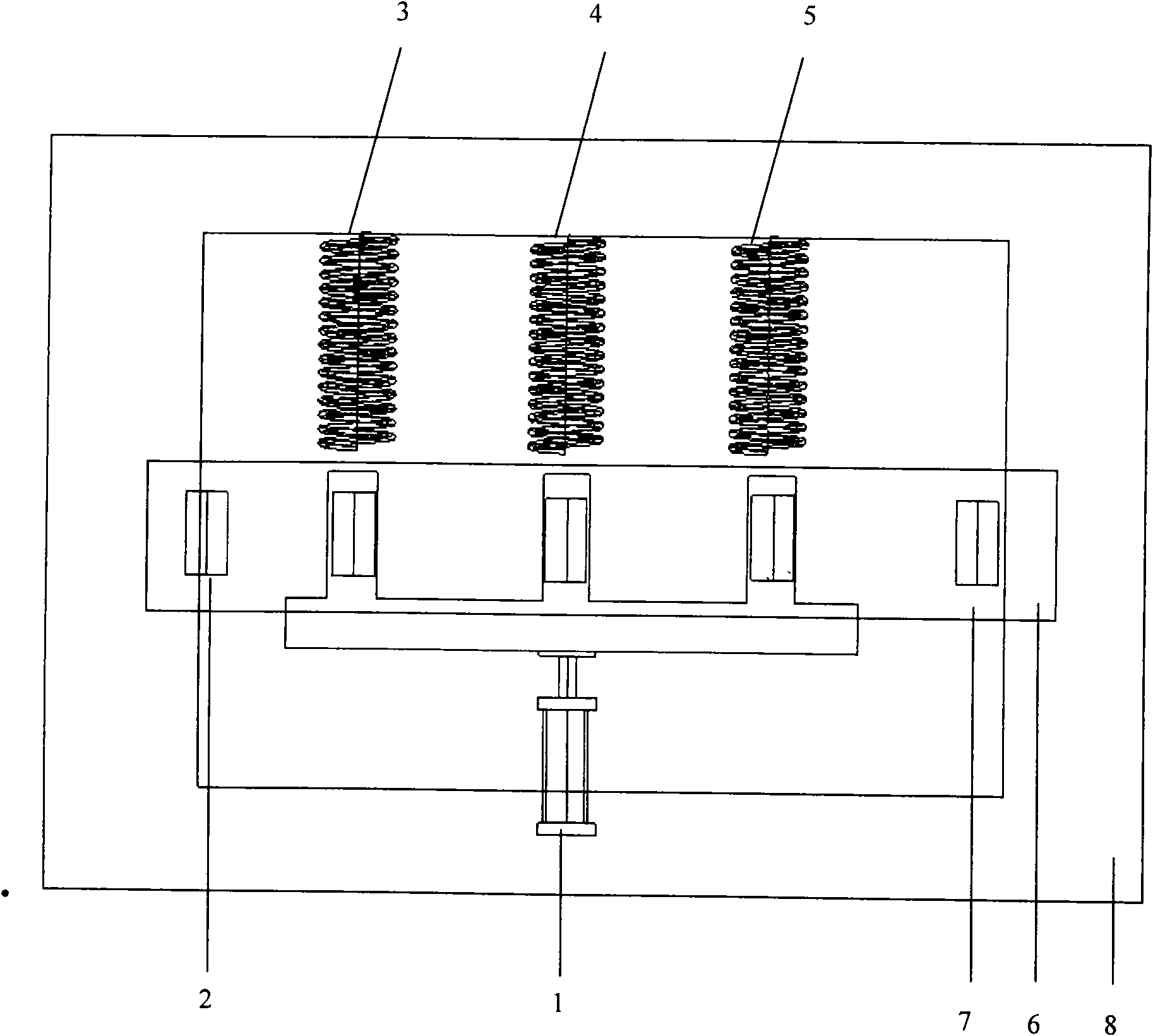

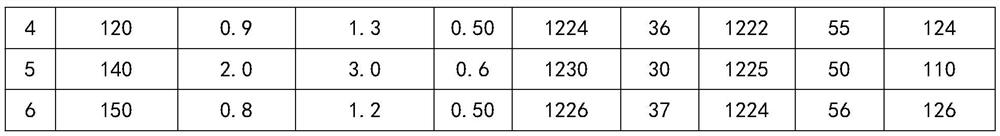

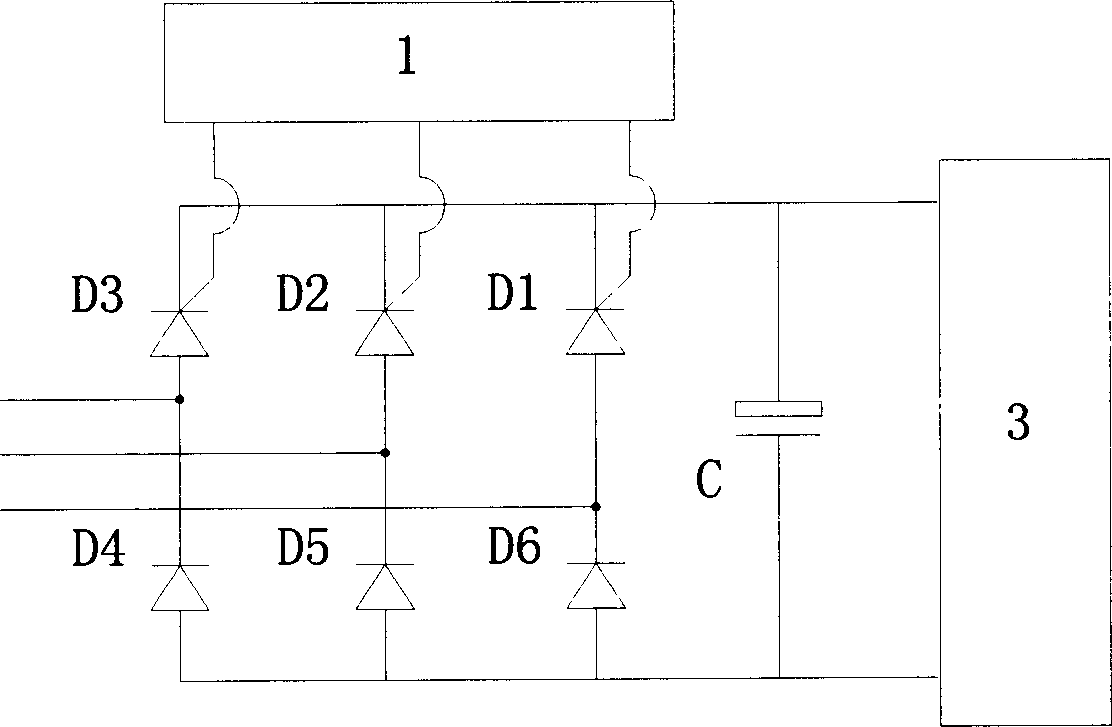

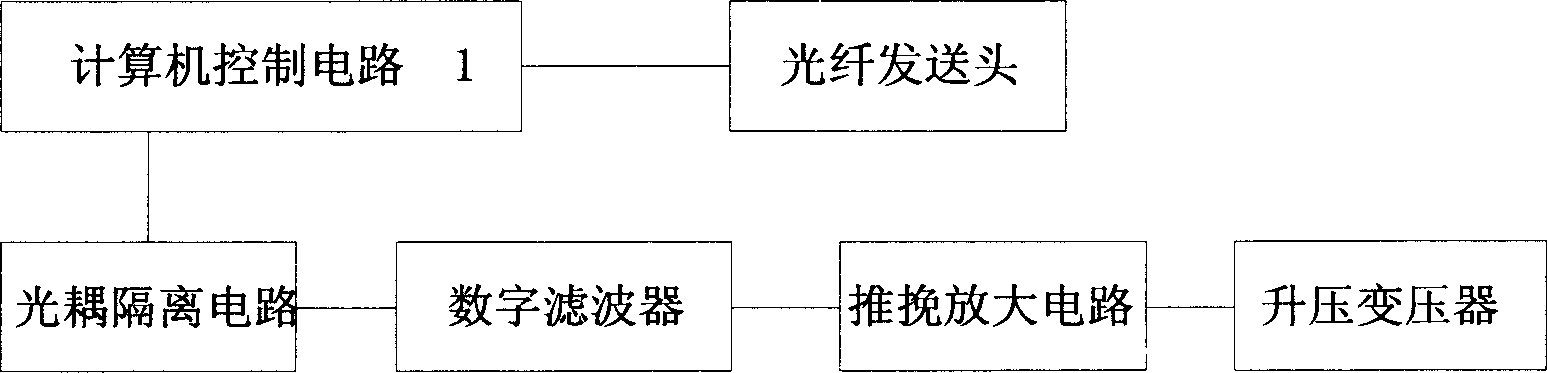

Low interference frequency change power for high-voltage testing

ActiveCN1719709AAvoid bulkyAvoid powerConversion with intermediate conversion to dcAc-dc conversionElectric power systemControl signal

This invention relates to a low disturbance conversion supply, in which, a three-phase AC input is sent to a trigger control and rectified circuit of a thyristor, the control signal of which is generated by a computer control circuit, its rectified output is sent to a bridge output circuit, the output signal of which is sent to a short circuit box and sent to an output sampling and testing circuit, which sends the sampled signal for testing then sends the tested signal to a computer control circuit, At the same time, the system voltage is also sent to a computer control circuit via the system voltage input and measurement circuit, which generates an input control signal needed by a synchronous and blanking signal generation circuit.

Owner:SIEYUAN ELECTRIC CO LTD

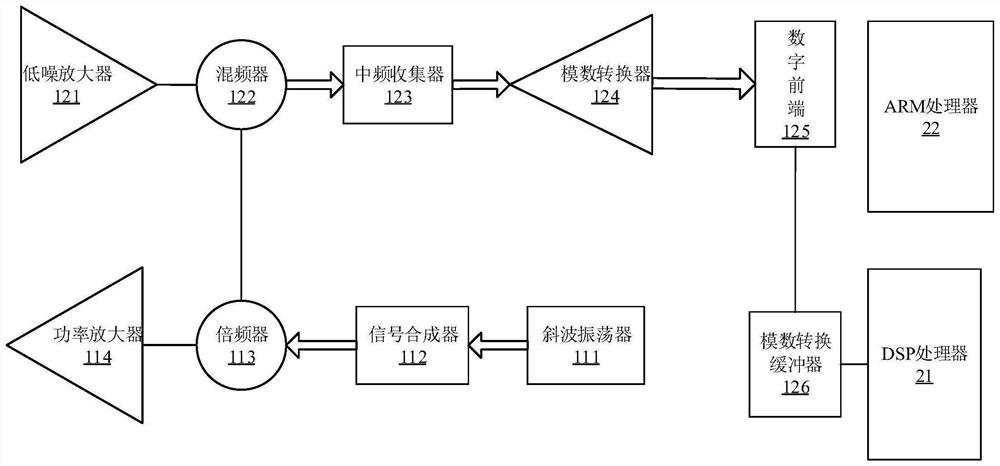

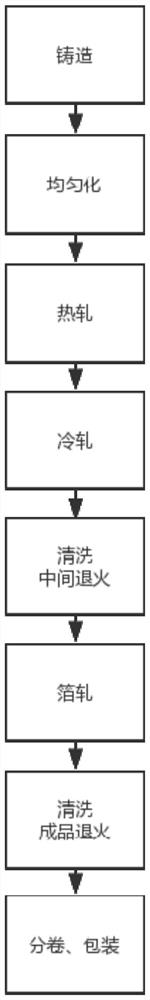

Medium-high-voltage electronic aluminum foil for high-capacity and high-strength capacitor and preparation method thereof

ActiveCN113234907AIncrease capacityIncrease the proportionElectrolytic capacitorsFurnace typesAluminum foilCapacitor

The invention discloses a medium-high-voltage electronic aluminum foil for a high-capacity and high-strength capacitor and a preparation method thereof. Through the production modes of casting and a continuous air cushion furnace, the specific volume is increased, and the production period is shortened; and the continuous air cushion furnace is used for multiple times for homogenization and annealing, and the problem that a casting structure is not uniform is solved, so that the performance and the cubic texture are improved, and the medium-high-voltage high-purity aluminum foil for the high-capacity and high-strength capacitor is obtained.

Owner:广西广投正润新材料科技有限公司

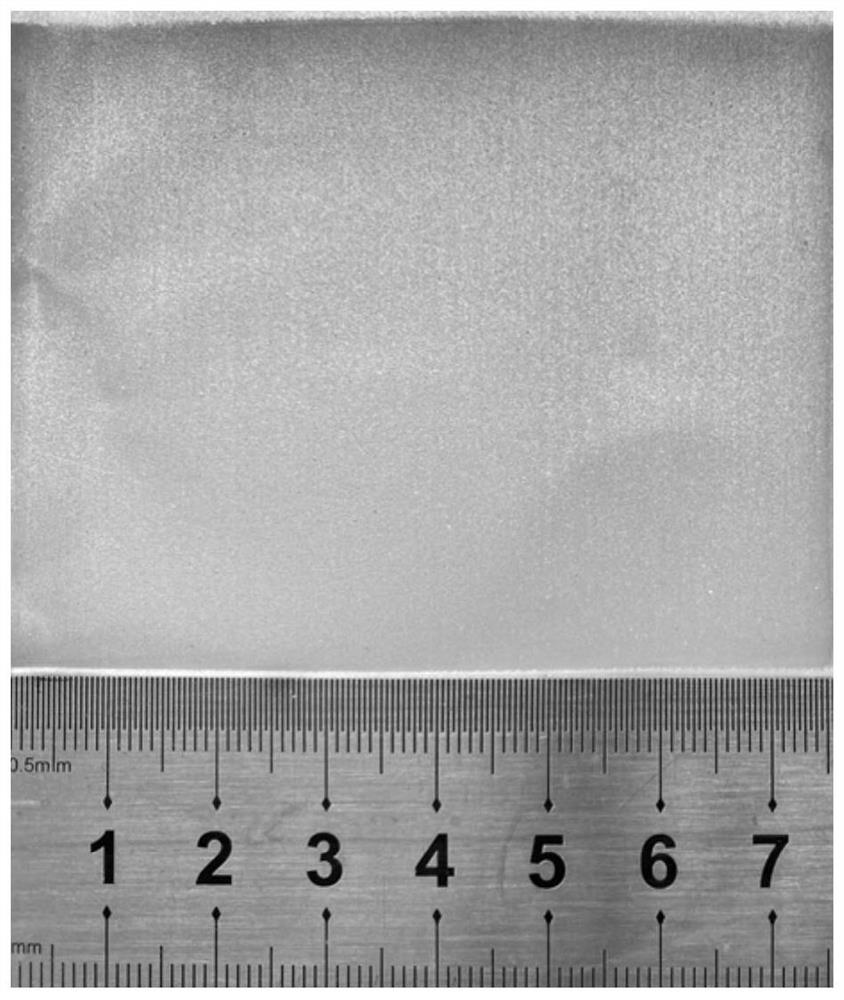

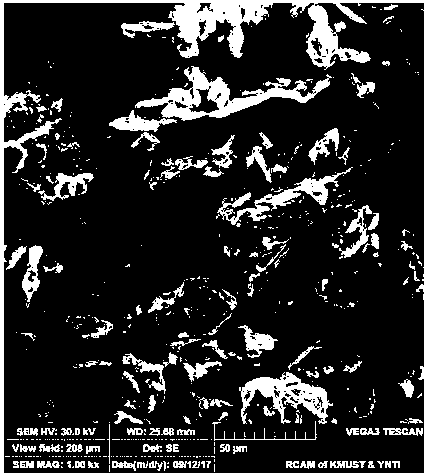

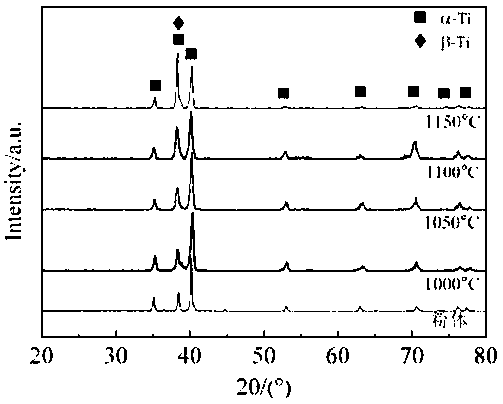

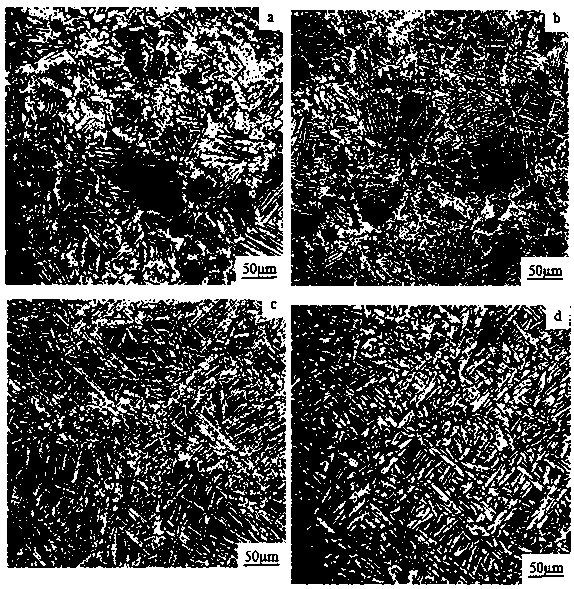

Preparation method of titanium, aluminum, niobium, zirconium and molybdenum alloy

The invention discloses a preparation method of a titanium, aluminum, niobium, zirconium and molybdenum alloy, and belongs to the technical field of preparation of titanium alloys. The method comprises the following steps: weighing Ti, Al, Nb, Zr and Mo metal powder according to certain proportions, mixing the metal powder, performing intermittent dry type ball grinding through a ball grinder to obtain mixed powder, putting the obtained mixed powder into a graphite mold, prepressing the mixed powder, placing the graphite mold into a discharge plasma sintering furnace, applying axial pressure of 10 to 50 MPa for sintering under the condition that the vacuum degree is 2 to 8 Pa, heating the mixed powder in a multi-stage heating mode to 1,000 to 1,150 DEG C, preserving the heat for 3 to 8 min, cooling the mixture to room temperature, and demolding the mixture, thus obtaining the titanium, aluminum, niobium, zirconium and molybdenum alloy material. The titanium, aluminum, niobium, zirconium and molybdenum alloy prepared by the method disclosed by the invention has the advantages of uniform component, high compactness, high intensity, high plasticity and the like; and in addition, the method is easy to operate, short in time, energy-saving and environmentally friendly and has a good popularization value.

Owner:KUNMING UNIV OF SCI & TECH

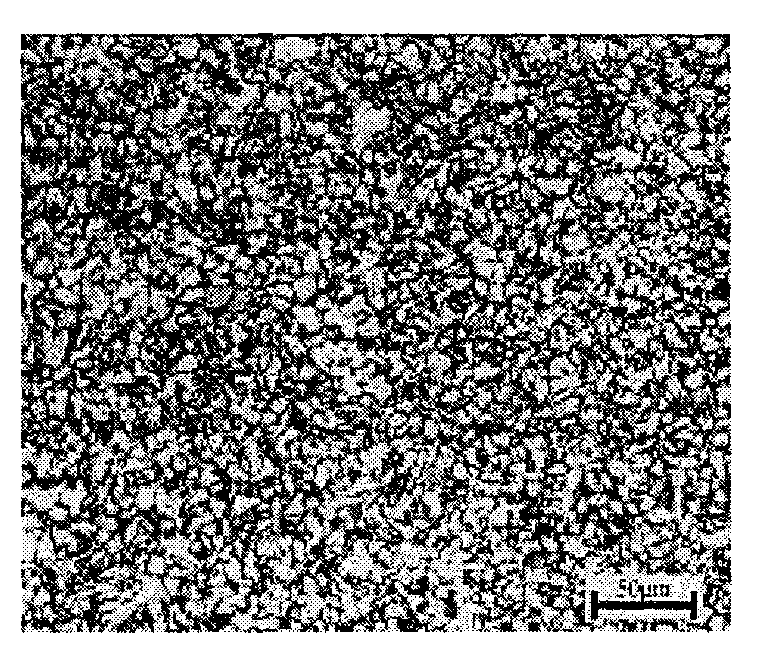

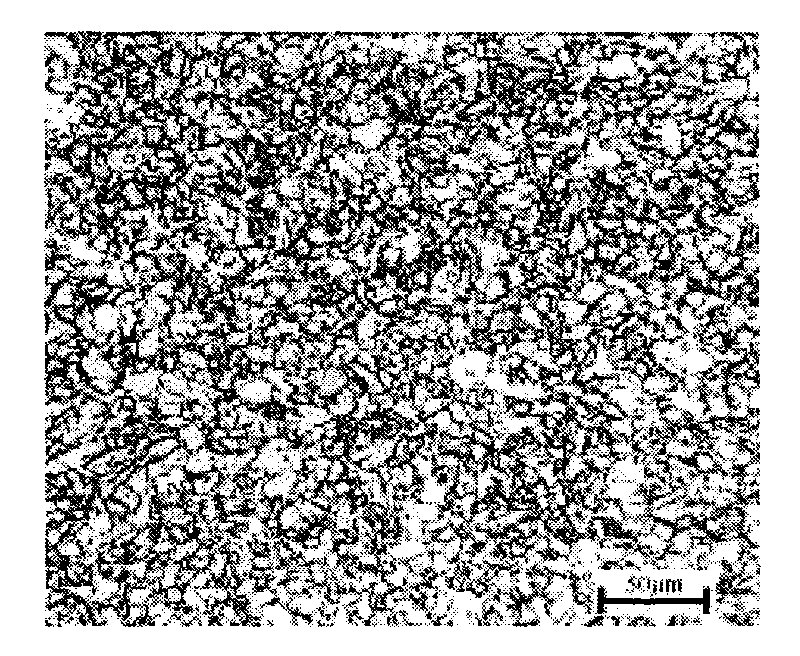

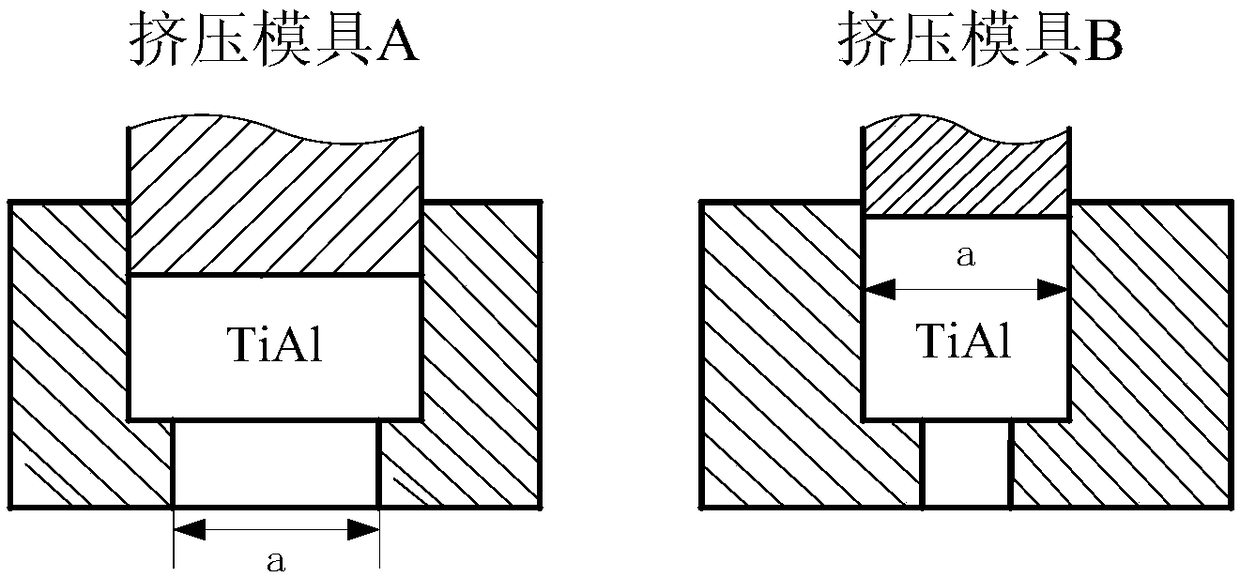

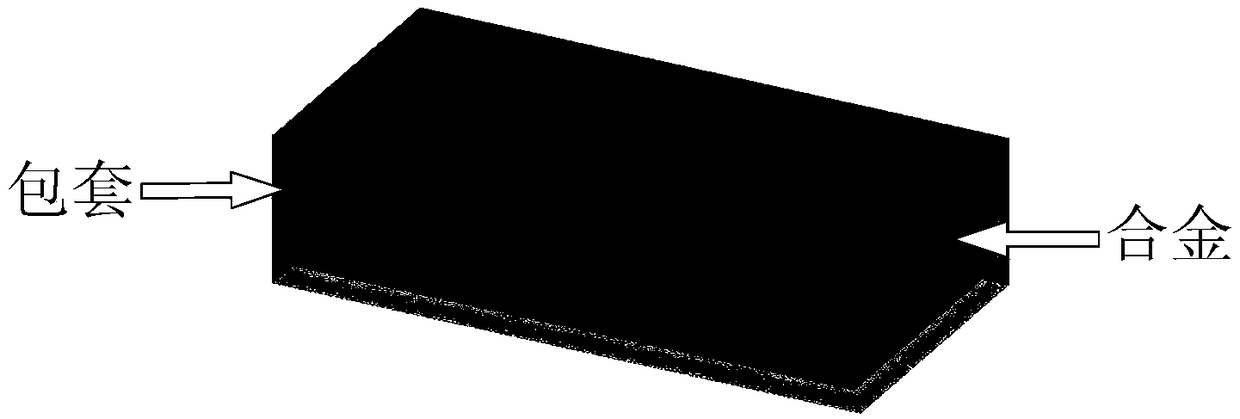

One-step large-deformation rolling method of beta solidification TiAl alloy plate

ActiveCN108787750AAvoid bulkyAvoid small amount of deformation in a single passForging/pressing devicesFurnace typesBeta phaseRoom temperature

The invention provides a one-step large-deformation rolling method of a beta solidification TiAl alloy plate. The method comprises the following steps that 1, raw materials are weighed; 2, a TiAl alloy casted ingot is manufactured by utilizing a vacuum induction melting technology, and heat treatment is carried out; 3, two-step hot extrusion deformation is carried out on the alloy; and 4, one-steplarge-deformation packing rolling is carried out on the alloy, and a pack is removed so as to obtain the TiAl alloy plate which is uniform and fine in structure. According to the one-step large-deformation rolling method of the beta solidification TiAl alloy plate, the beta solidification TiAl alloy with excellent high-temperature deformation capability is adopted, the beta phase content is controlled to be 15%-25%, and the excellent high-temperature deformation capability of the TiAl alloy is ensured; meanwhile, the alloy structure of a blank is refined violently through the two-step extrusion so as to remarkably improve the structure uniformity of the alloy, and therefore, one-step large-deformation rolling of the blank can be guaranteed, finally, the TiAl alloy plate with the uniform and fine structure and good room temperature plasticity is obtained, and the problems that in the prior art, a TiAl alloy rolled blank is coarse in structure, plate forming is difficult, and the platestructure uniformity is poor are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com