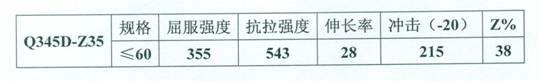

Low-alloy medium-thickness steel plate Q345D-Z35 and production process thereof

A Q345D-Z35, thick steel plate technology, applied in the field of medium and heavy plate production, can solve the problems of complex process and high production cost, and achieve the effect of reducing production cost and ensuring the matching of strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme adopted in the present invention is: the low-alloy Q345D-Z35 medium-thick steel plate contains the following chemical components in mass percentage (unit, wt%): C: 0.10-0.18, Si: 0.20-0.45, Mn: 1.20-1.60, P ≤0.018, S≤0.005, Als: 0.015~0.050, others are Fe and residual elements;

[0014] Carbon equivalent [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]: ≤0.44.

[0015] In the above method, the thickness of the produced steel sheet is 80mm and below.

[0016] In order to obtain the steel plate of the present invention, the production method adopted comprises the following steps: high-quality molten iron, KR molten iron pretreatment, top-bottom double-blowing converter, LF furnace refining, vacuum degassing treatment, billet stack cooling, heating furnace, rolling, ACC laminar cooling, thermal straightener, stack cooling, finishing, external inspection, flaw detection, storage; in the refining step, argon is blown throughout the refining process, refining slag is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com