Device and method for making a multi-layer nonwoven fabric from at least one loose fiber web

A fiber mesh and fiber layer technology, applied in the field of inclined screen mesh forming machines, can solve the problems of low productivity, reduced quality, and high requirements, and achieve the effects of avoiding quality loss, reducing space requirements, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

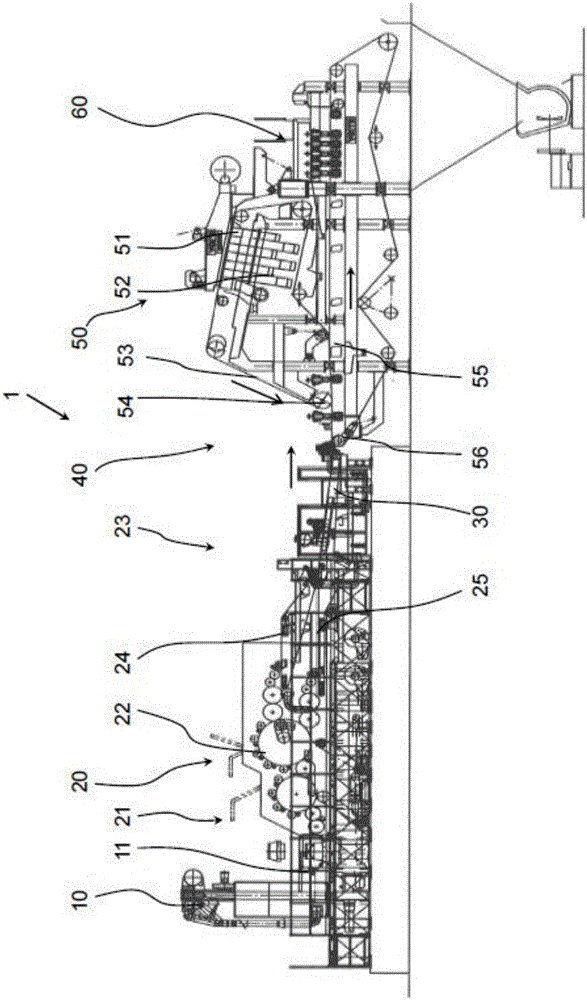

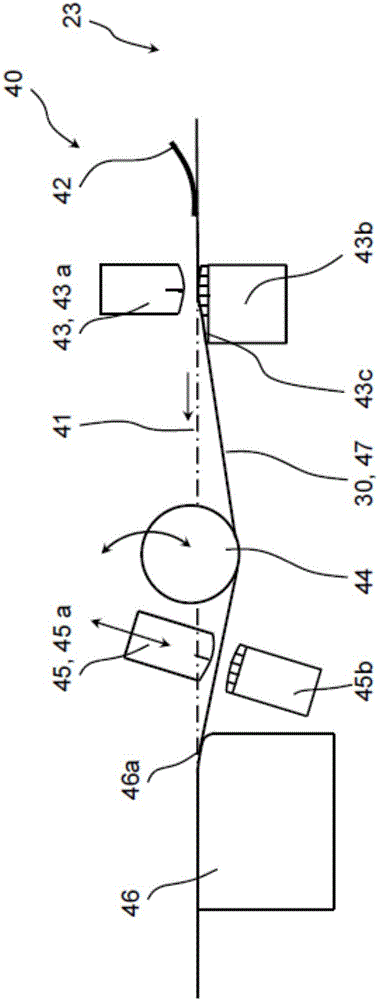

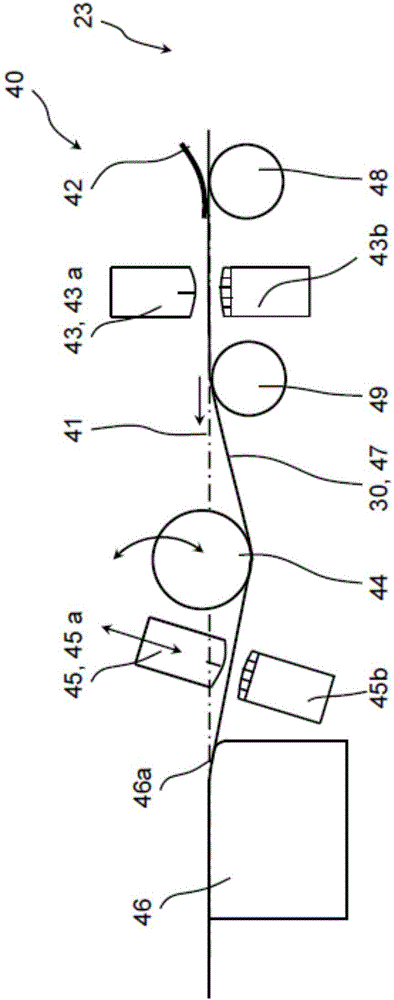

[0030] exist figure 1 shows a part of a device 1 for producing fibrous nonwovens with a known card 20 having an input side 21 for fiber bundles and one or more outputs for fiber webs 30 side 23. Arranged upstream of the input side 21 of the card 20 is a feeder 10 , for example a vibrating vertical feeder (Rüttelschachtspeiser), with which the fiber bundles are deposited onto the conveyor belt 11 . In addition to the vibrating vertical feeder, the card 20 can also be equipped with a card feeder with an integrated nonwoven thickness measuring device, in which the weight is determined via the nonwoven thickness measuring device .

[0031] In the carding machine 20, the fiber bundle is fed on the input side 21 of the device and is guided to the main cylinder (Tambour) 22 by elements not depicted in more detail, such as feed rollers, pre-combing cylinders and transport units, so that the fibers are The bundles are opened into individual fibers and oriented. During the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com