Patents

Literature

41results about How to "Quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

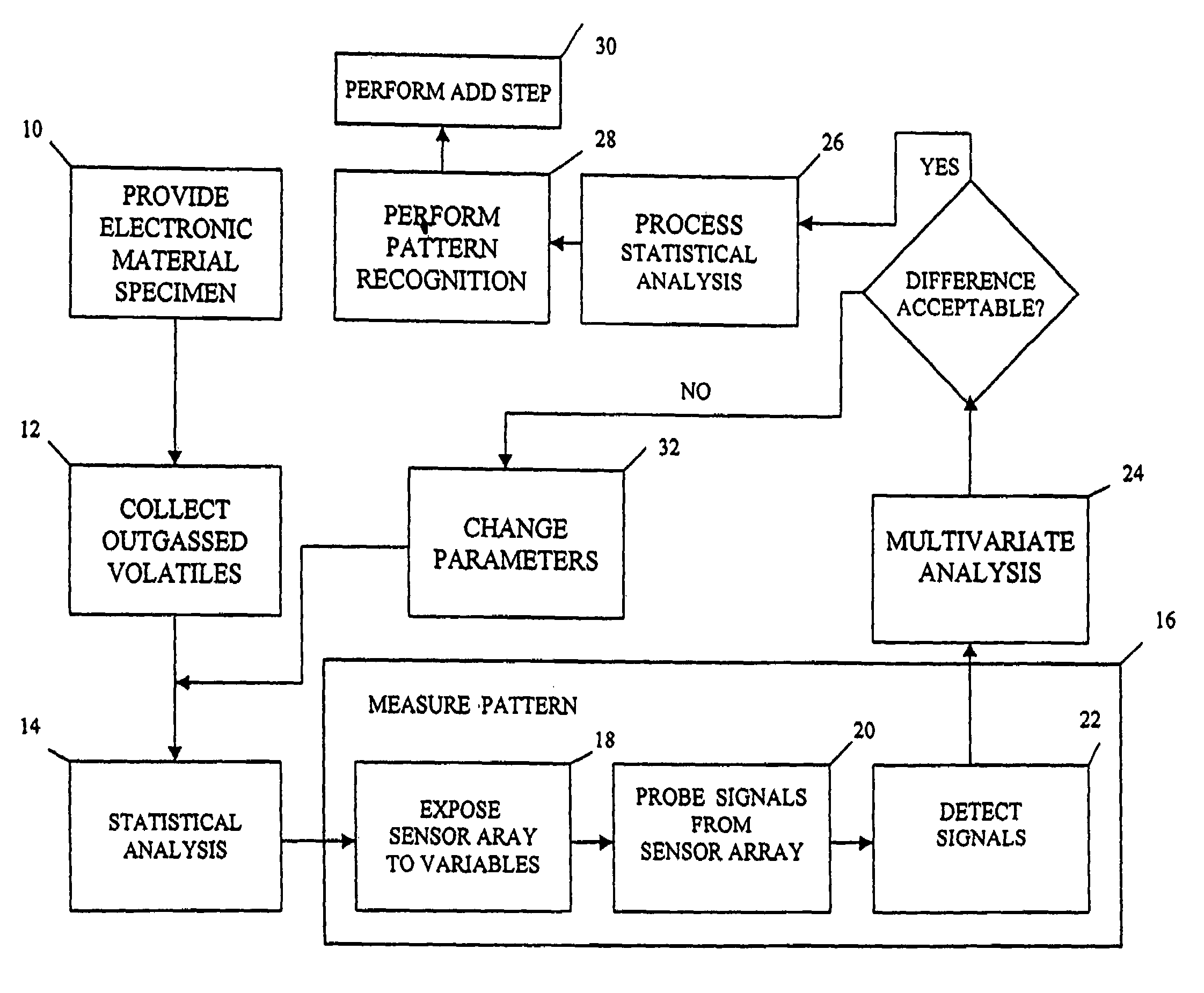

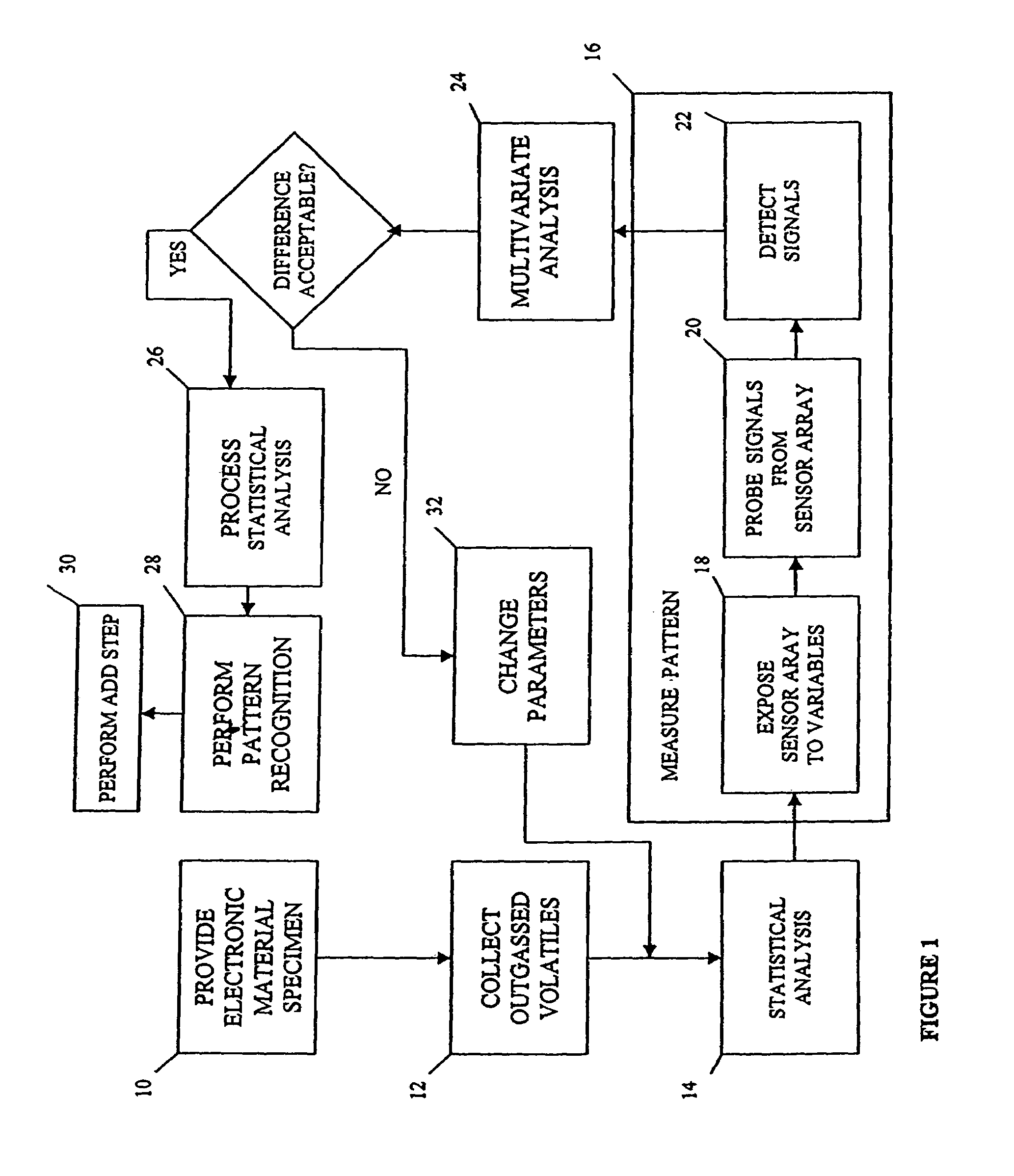

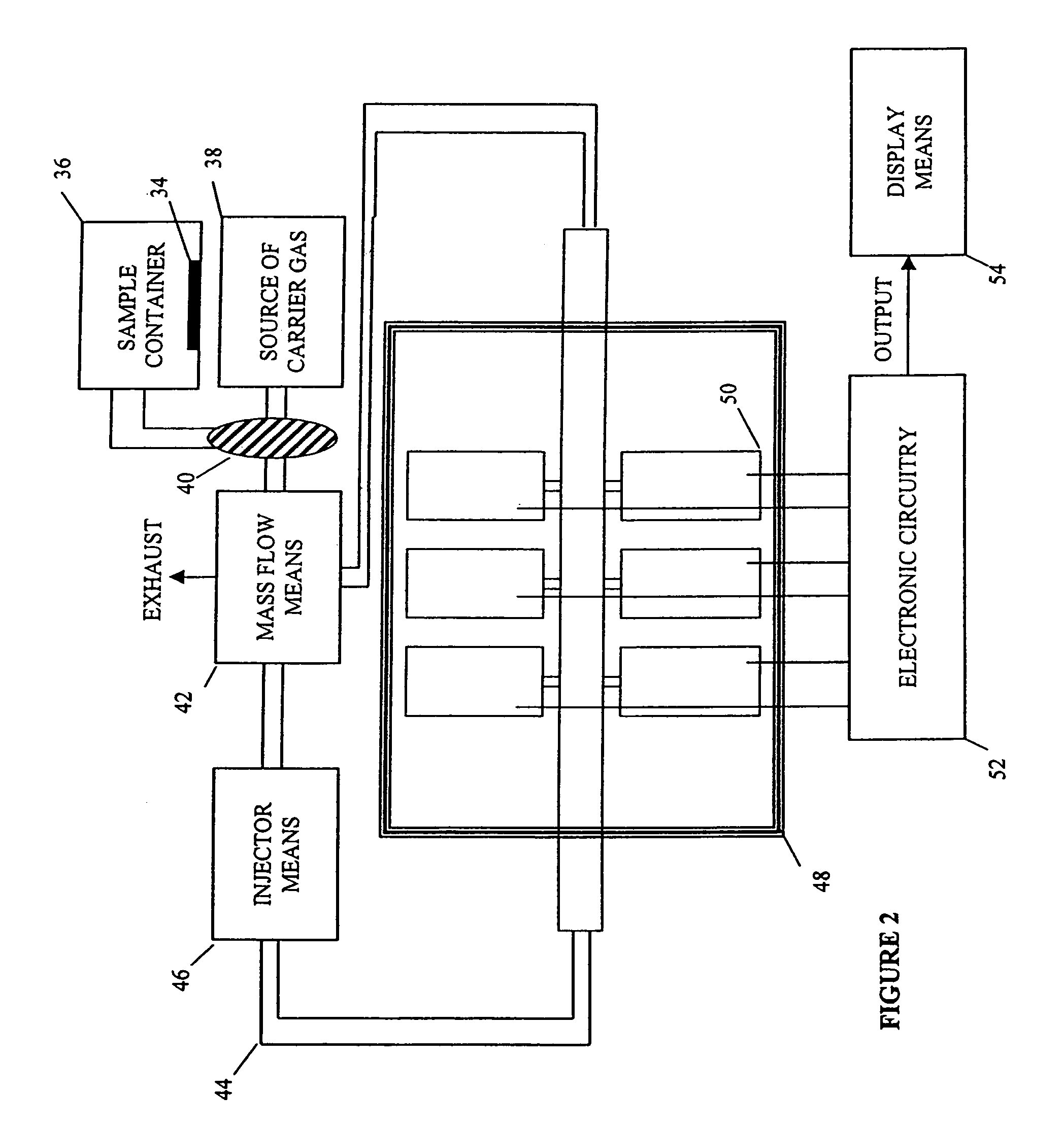

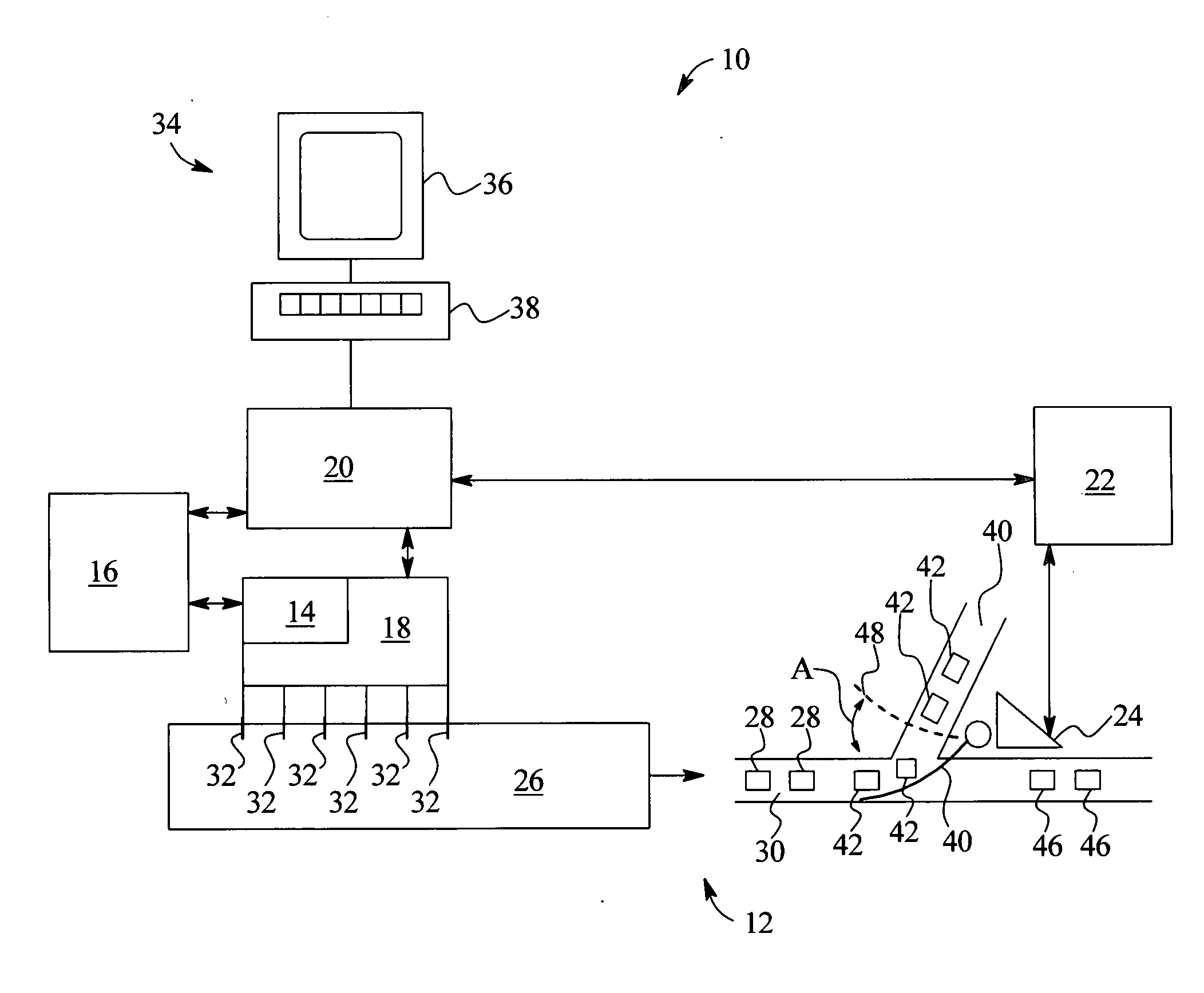

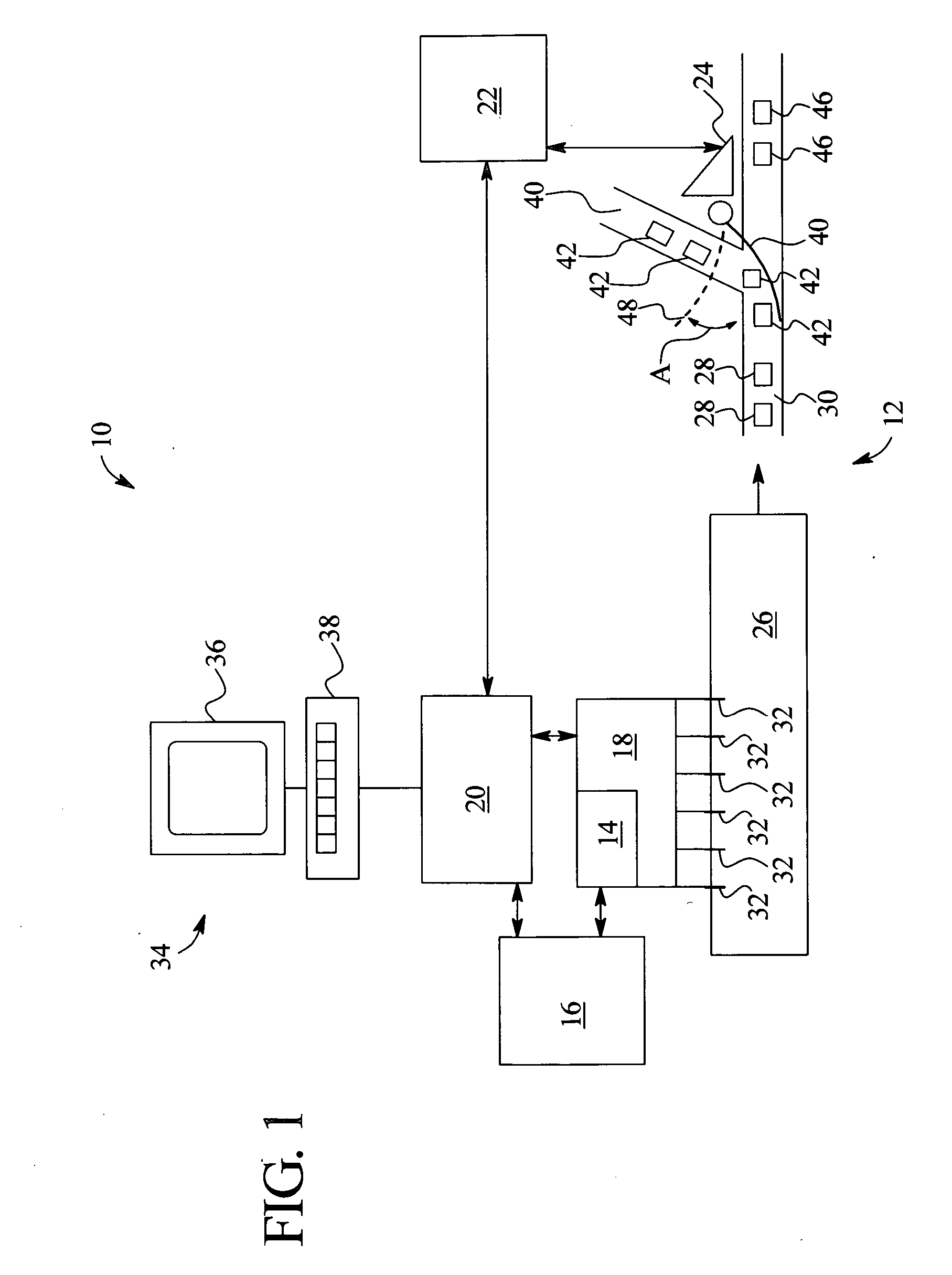

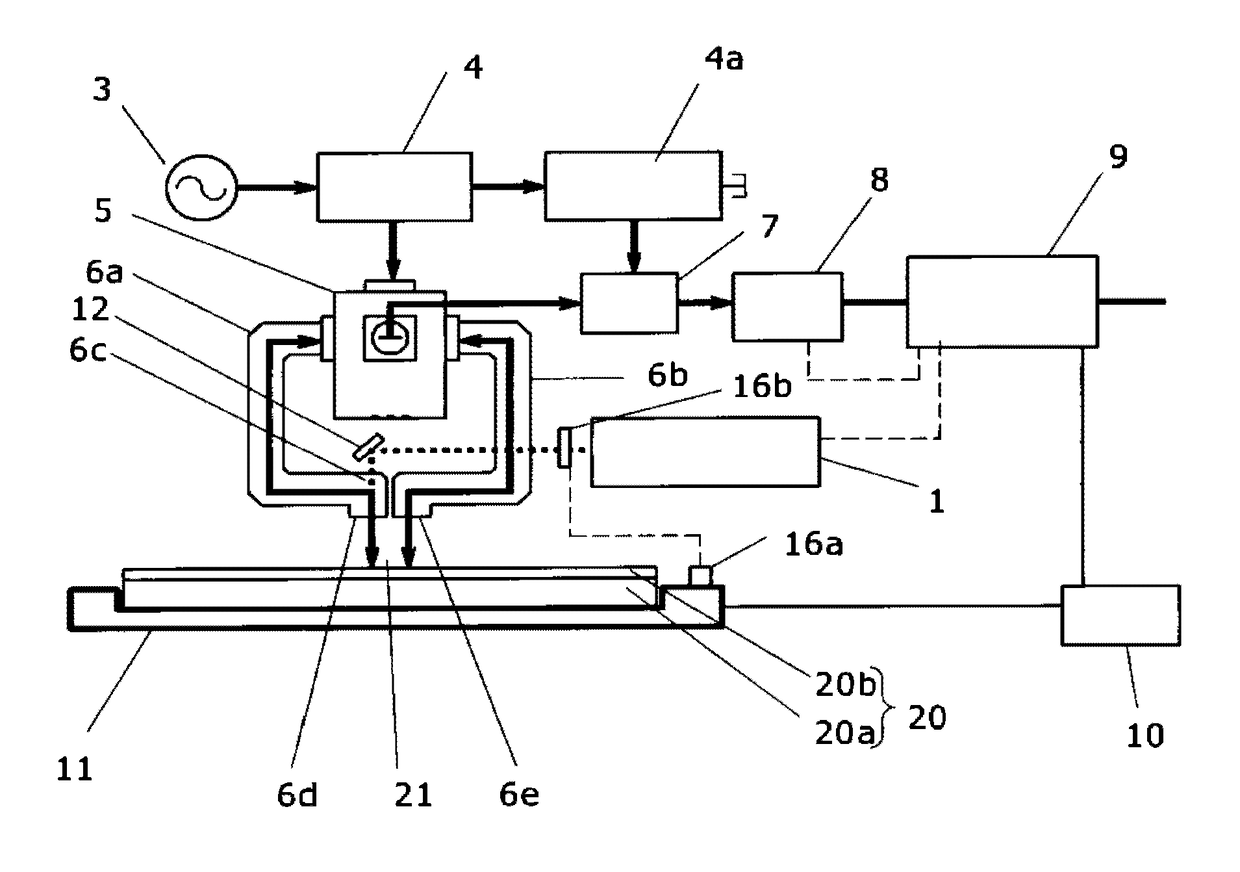

Method and apparatus for monitoring materials used in electronics

InactiveUS6975944B1Quality controlFast and conveniently curableMaterial resistanceSpecial data processing applicationsIntegrated circuitSensor array

A method and apparatus suitable for monitoring the quality and / or performance of a processing aid or a component during manufacture, storage, or use of electronics or electronic assemblies is provided. The apparatus incorporates a sampling device, a multivariate sensing system (e.g., a multi-sensor array or at least one sensor capable of measuring multiple variables) capable to process an analysis of low vapor pressure or vaporizable constituents in electronics by detecting some changes in the physico-chemical properties of the sensor and / or electronics and applying multivariate analysis. In one embodiment, the sensing system comprises an array of metal oxide sensors and a multivariate analysis algorithm for data processing. This method and apparatus can be employed for various quality control purposes such as contamination analysis or failure analysis of integrated circuits components.

Owner:ALPHA MOS

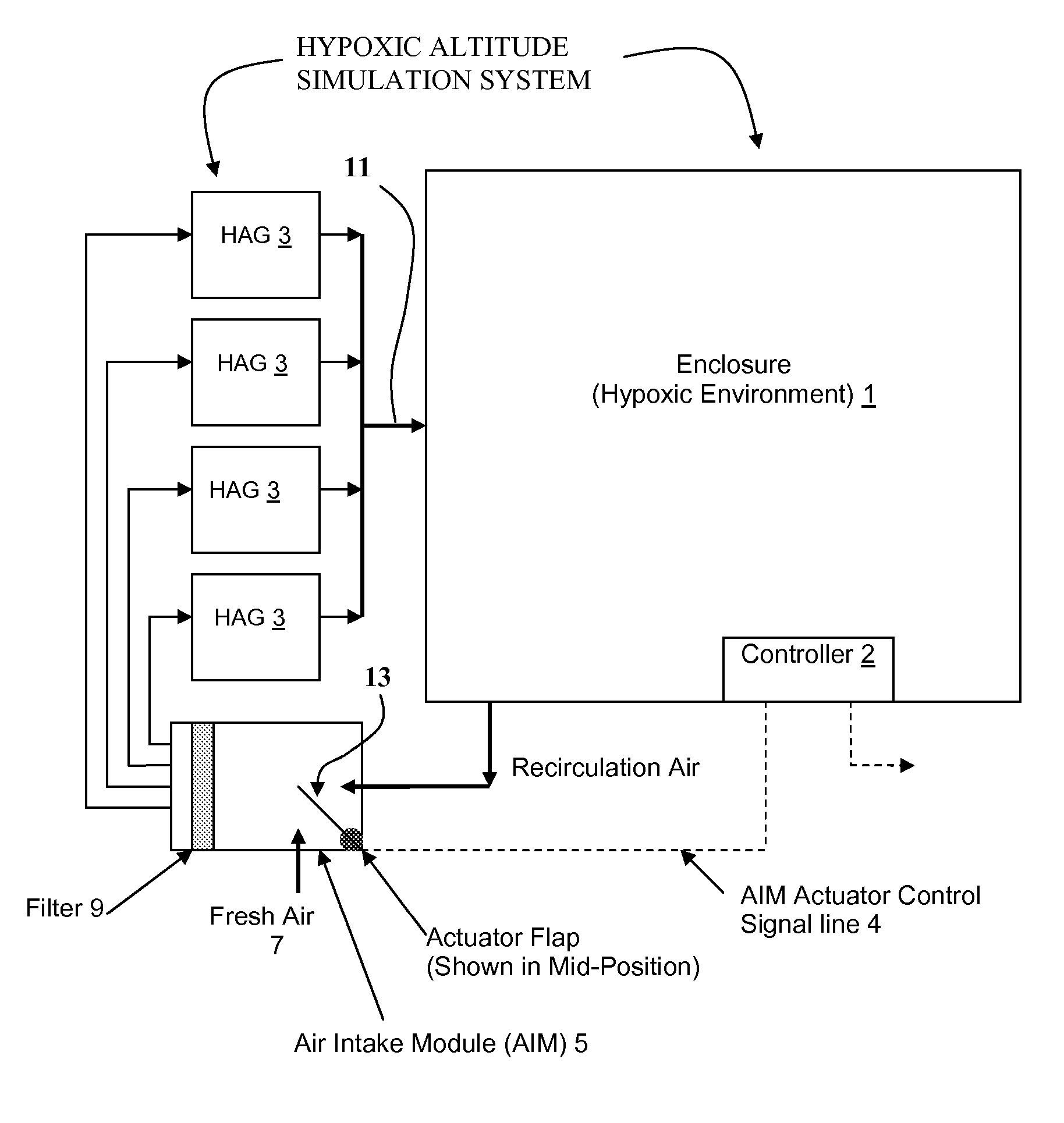

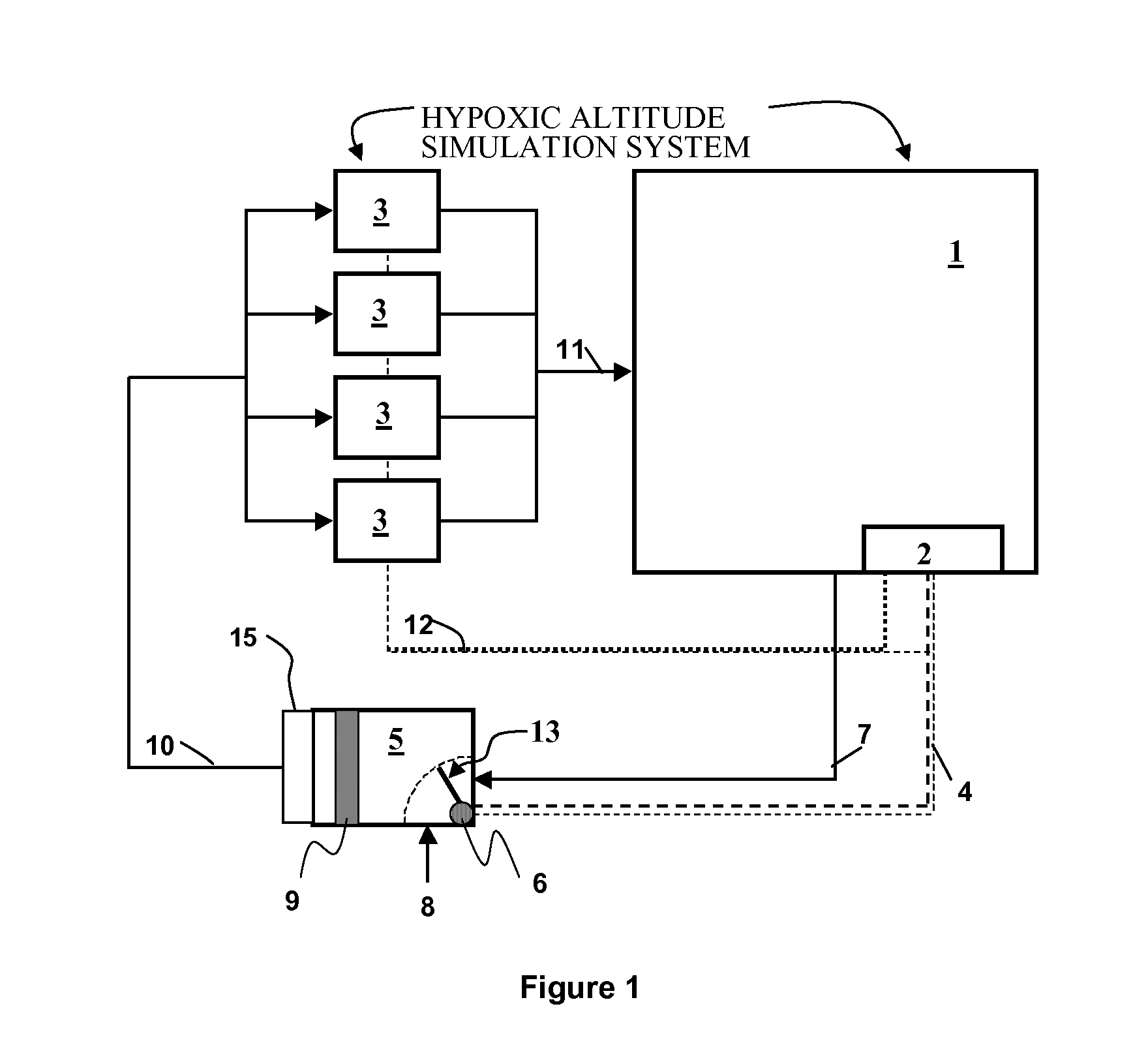

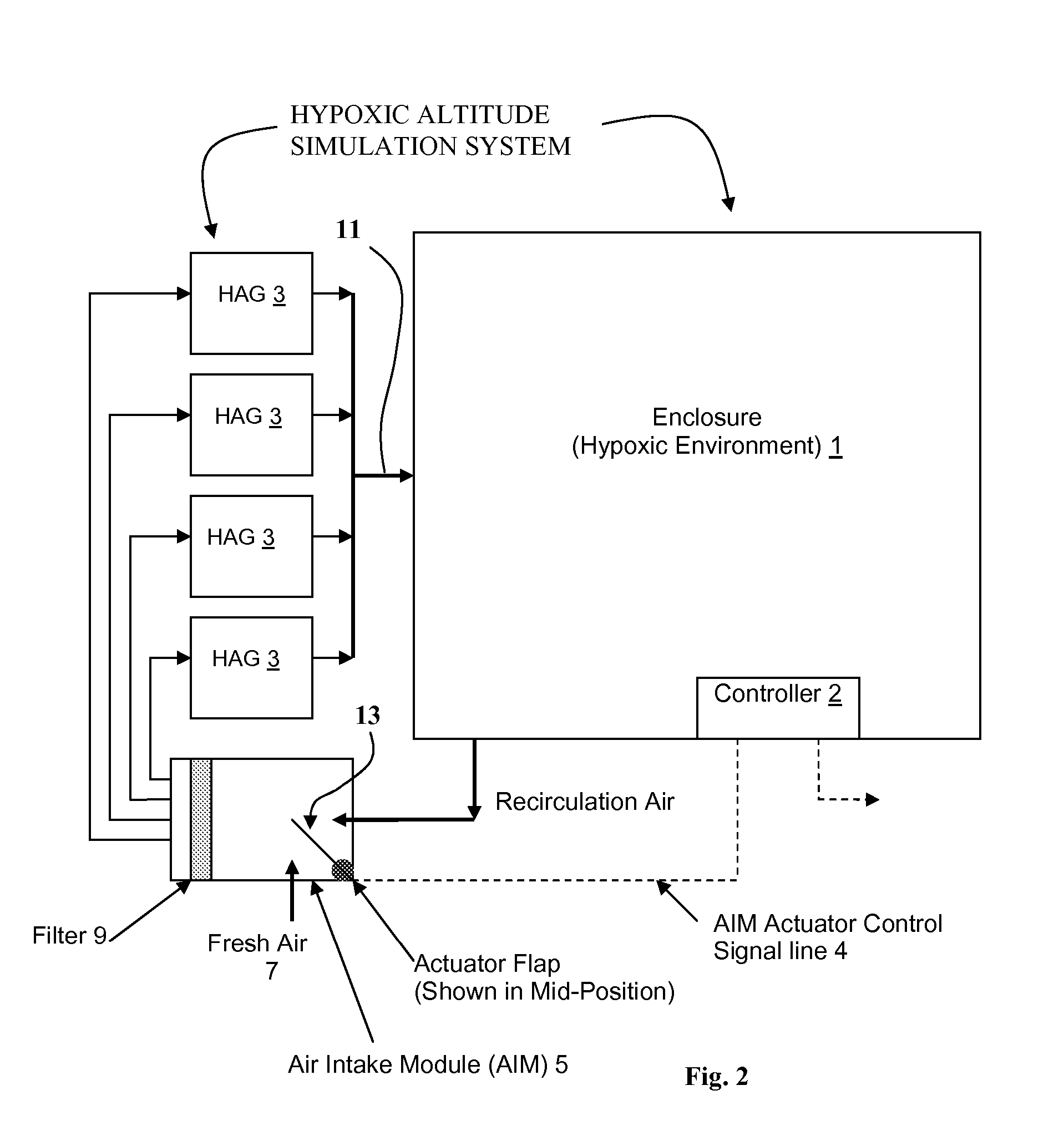

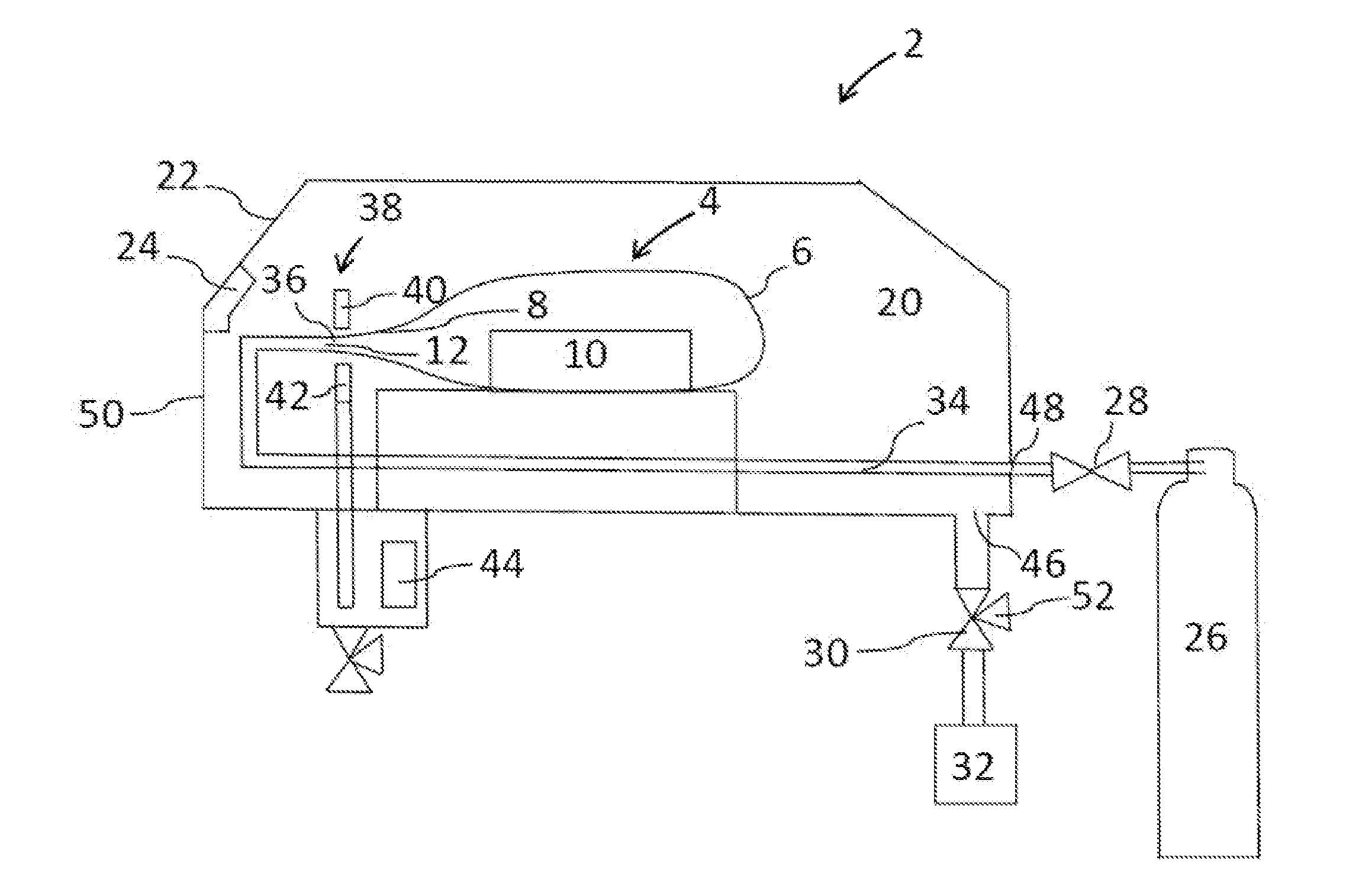

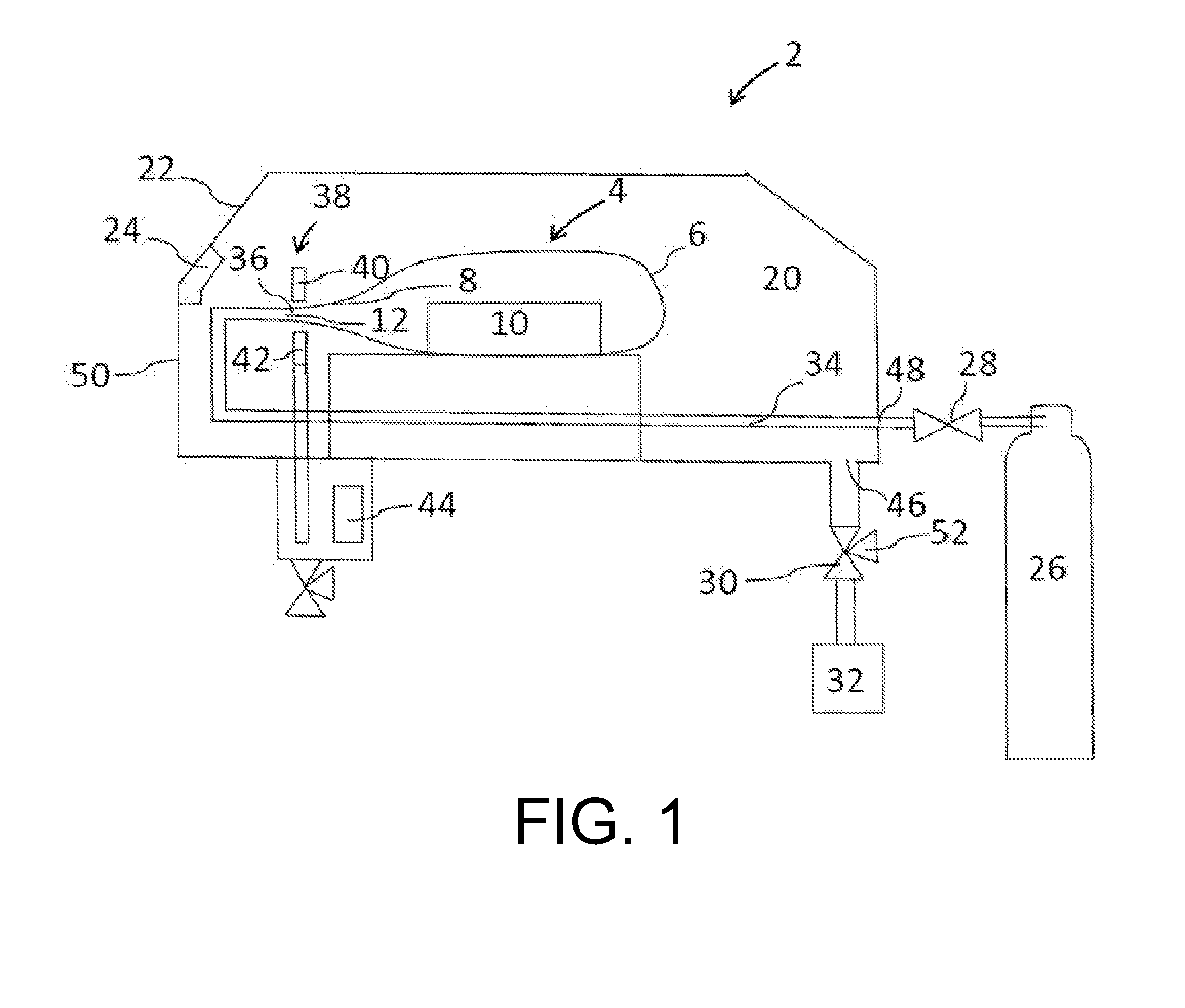

Simulated Altitude Method and Apparatus

InactiveUS20070221225A1Adapt wellQuality controlRespiratorsBreathing protectionSimulated altitudeEngineering

An altitude simulation system is disclosed for simulating an altitude within an enclosure or mask, wherein various improvements are provided, including: (a) a more effective use hypoxpic air generated by the system via recirculating techniques and improvements in air leakage, (b) improvements in determining when a simulated altitude is reached, (c) improvements in controlling hypoxic air generators so that peak electrical power loads are reduced and there are enhanced failsafe features for protecting the health of users, (d) using a pulse oximetry device for measuring oxygen saturation in a user's blood to thereby vary the oxygen content in the air provided to the user.

Owner:COLORADO ALTITUDE TRAINING

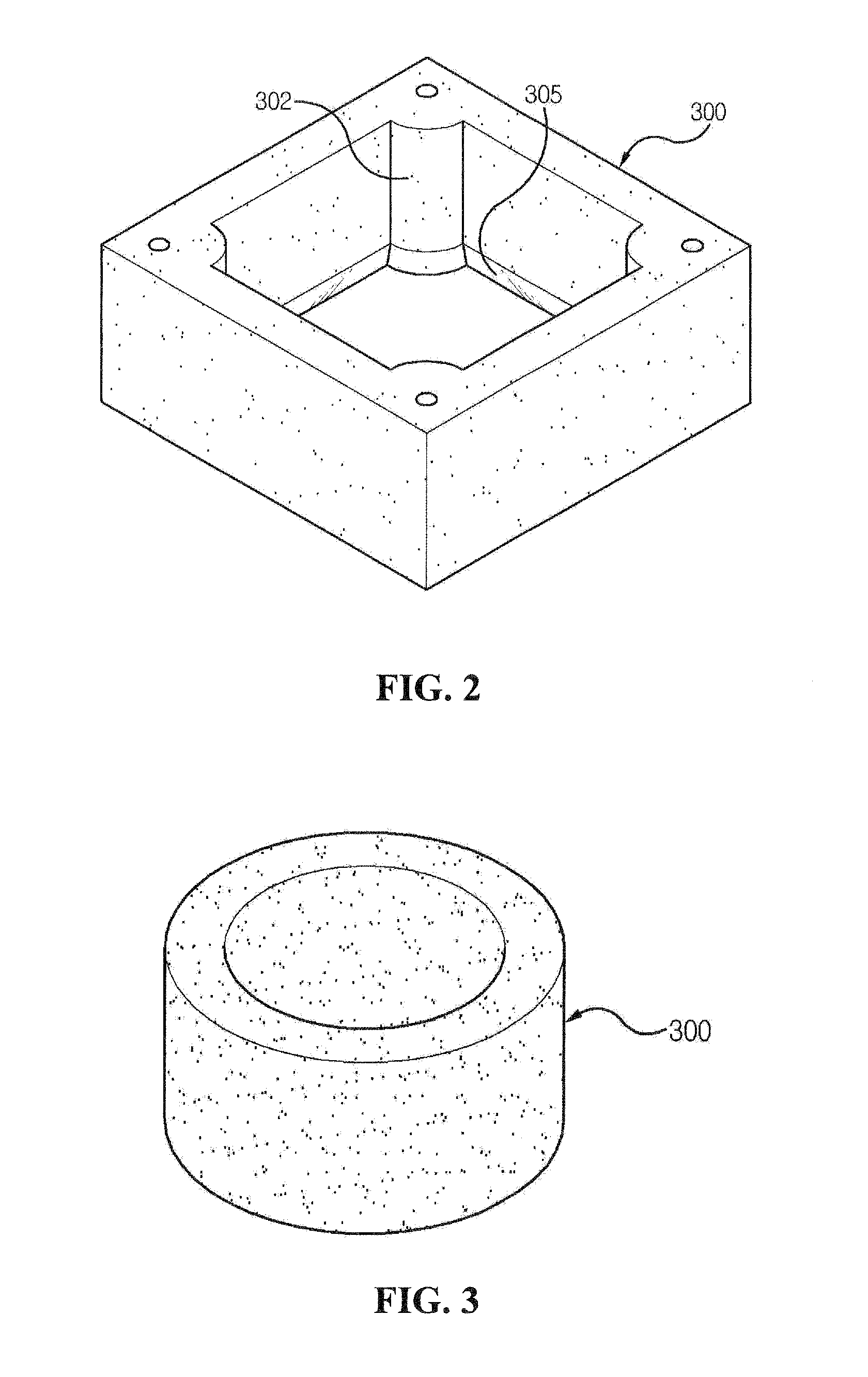

Parametric injection molding system and method

ActiveUS20060012064A1Quality controlDischarging arrangementMouldsInjection molding processMultivariate analysis

The present invention provides a method and system for controlling the quality of a product produced by an injection molding production process. The invention includes performing a multivariate analysis on injection molding process data collected real-time and determining whether the real-time data is within a predetermined production control limit. When the real-time production data exceeds the control limit, the process is considered out of control and product produced during the out of control condition is removed real-time from the injection molding production process.

Owner:BAXTER INT INC +1

Terminal apparatus and controlling method for optical output power

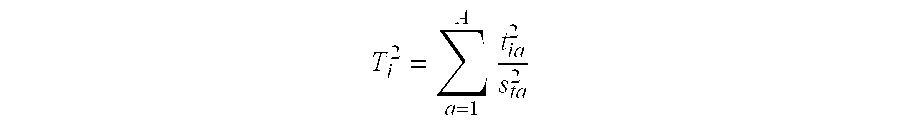

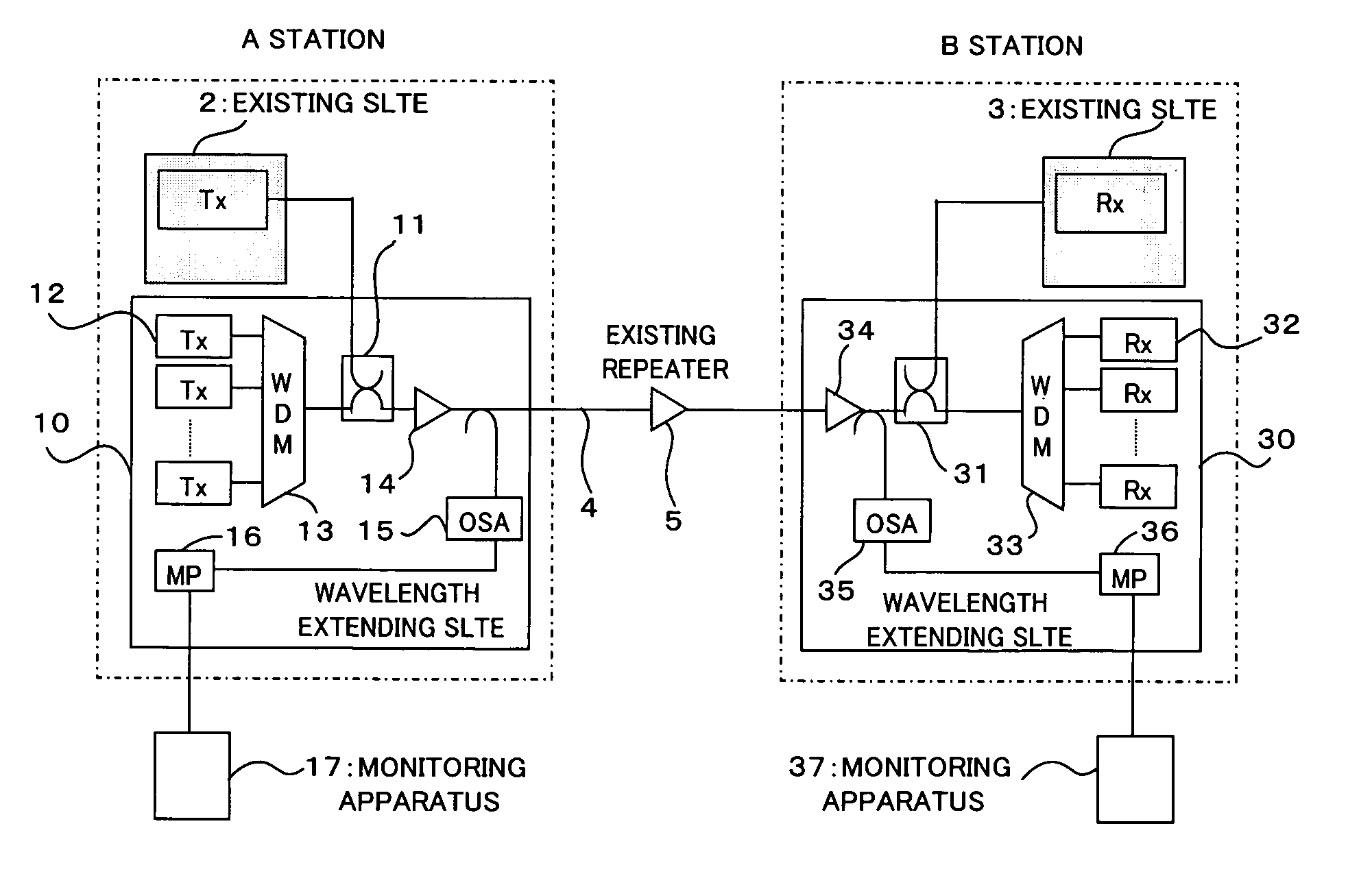

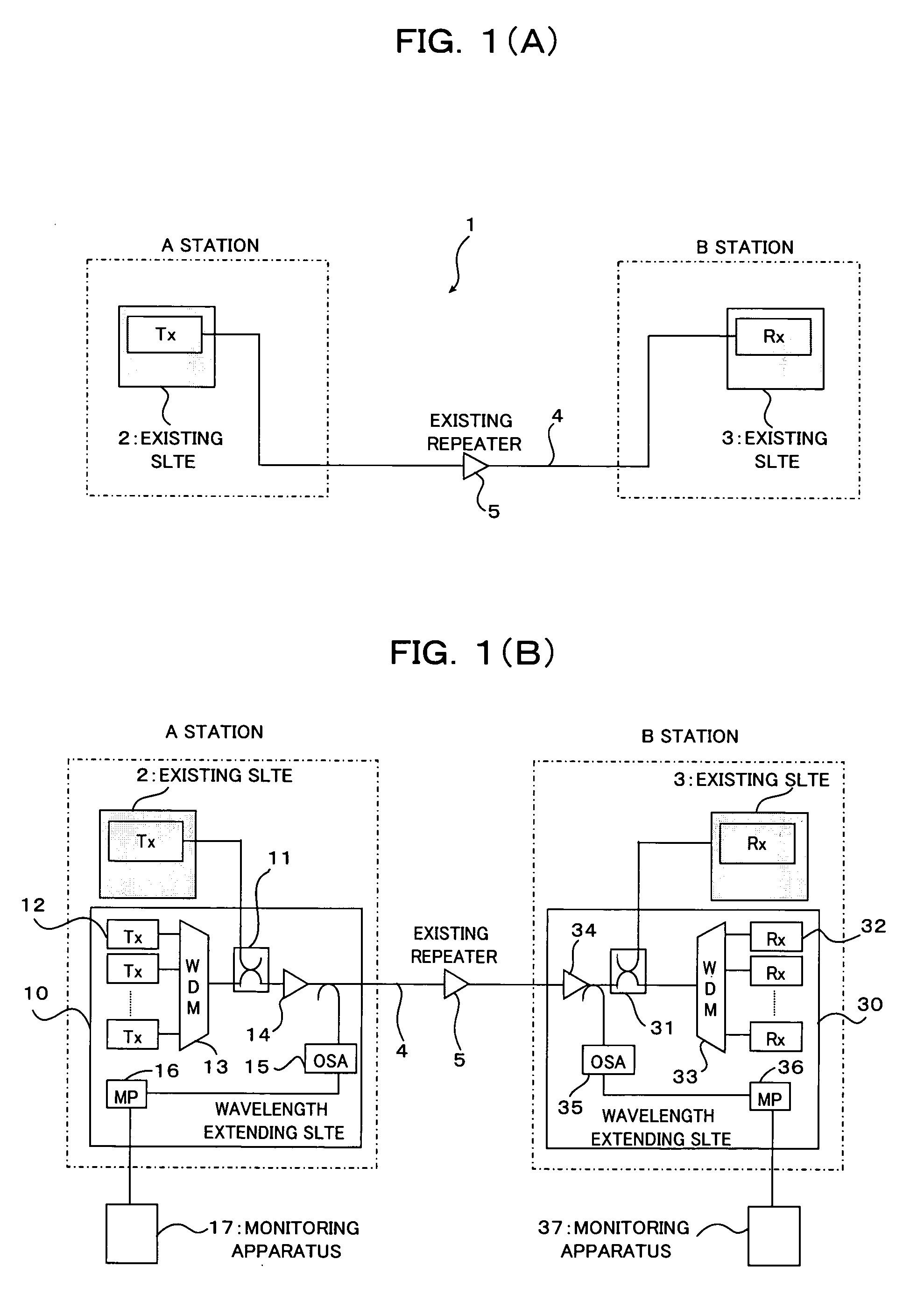

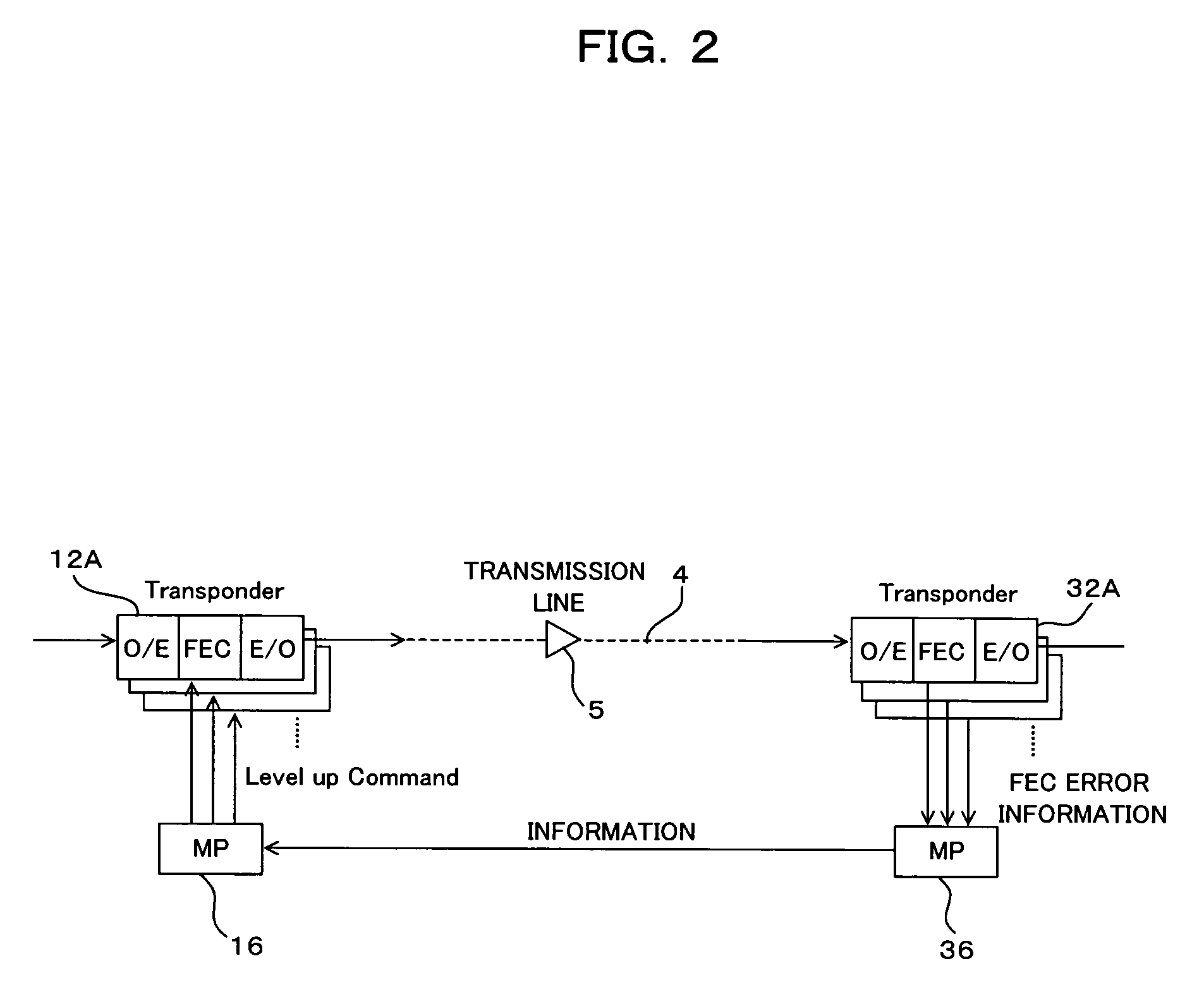

InactiveUS20050207754A1Improve levelQuality controlWavelength-division multiplex systemsTransmission monitoringPower controlTerminal equipment

A terminal apparatus by which, even where BER data, for example, of an optical signal of an existing wavelength cannot be utilized, the optical output powers of the existing wavelength and an extension wavelength can be adjusted in a short period of time while eliminating quality degradation of the existing circuit. The terminal apparatus includes a level controlling section for controlling a total optical output power of an existing wavelength signal light and an extension wavelength signal light to a fixed level, a monitoring unit capable of monitoring the optical output power for each wavelength, and a controller for controlling the optical output power of the extension wavelength signal light so that the optical output power of the existing wavelength signal light monitored by the monitoring unit may not be lower than a minimum permissible optical output power.

Owner:FUJITSU LTD

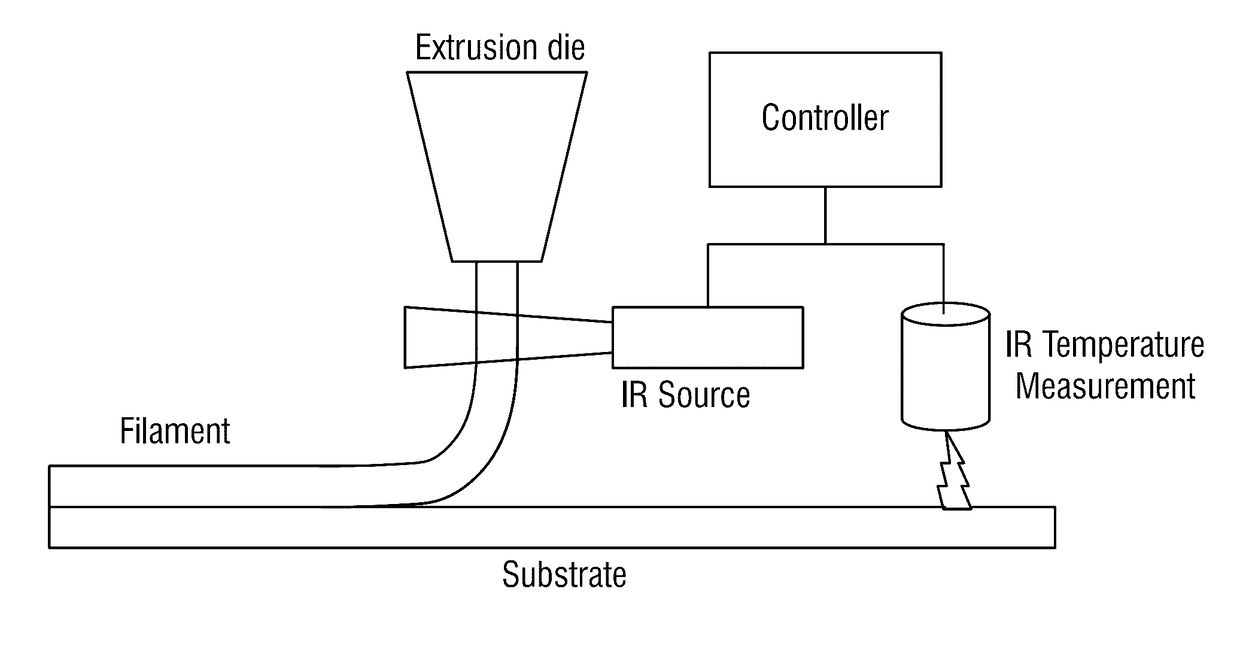

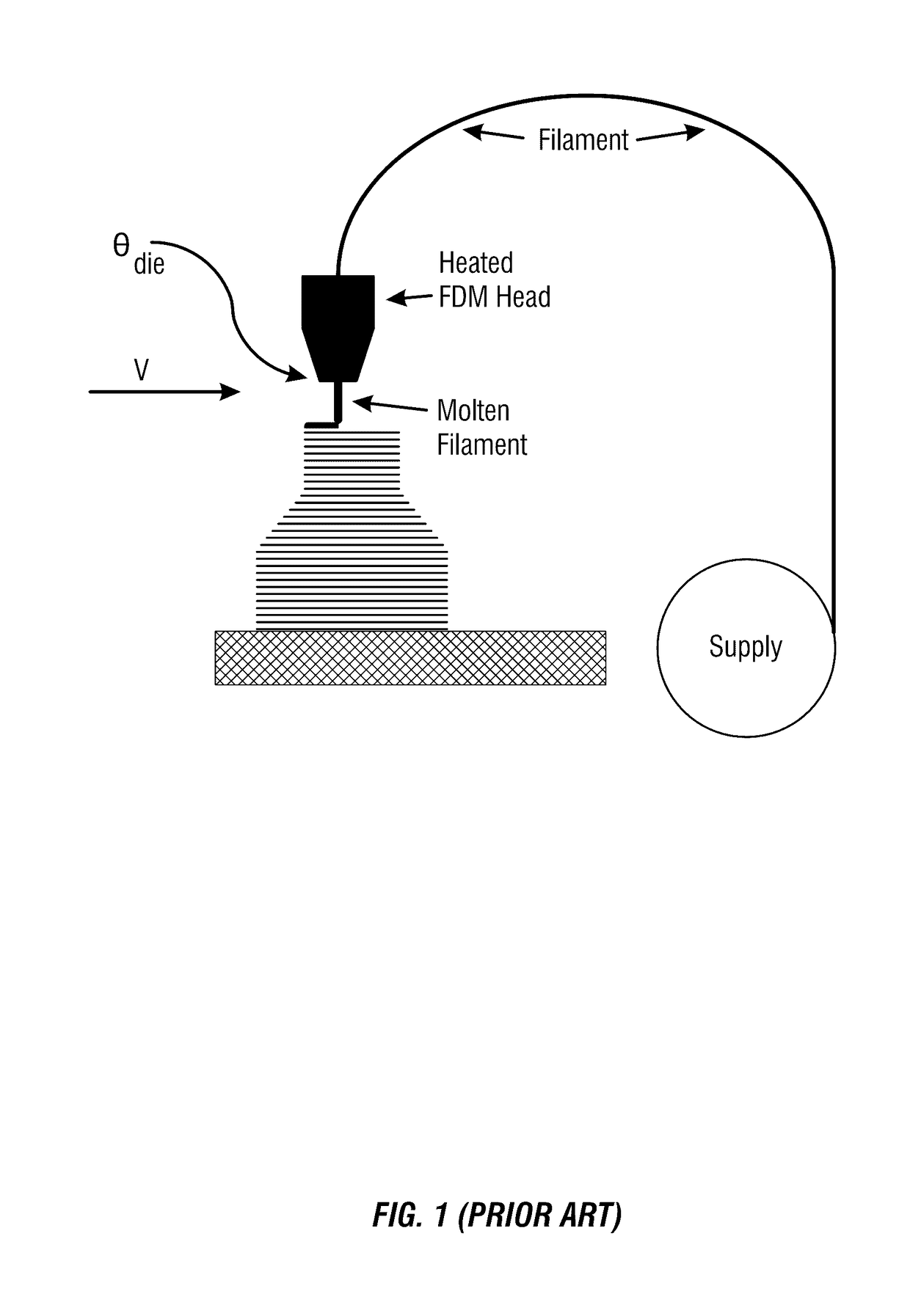

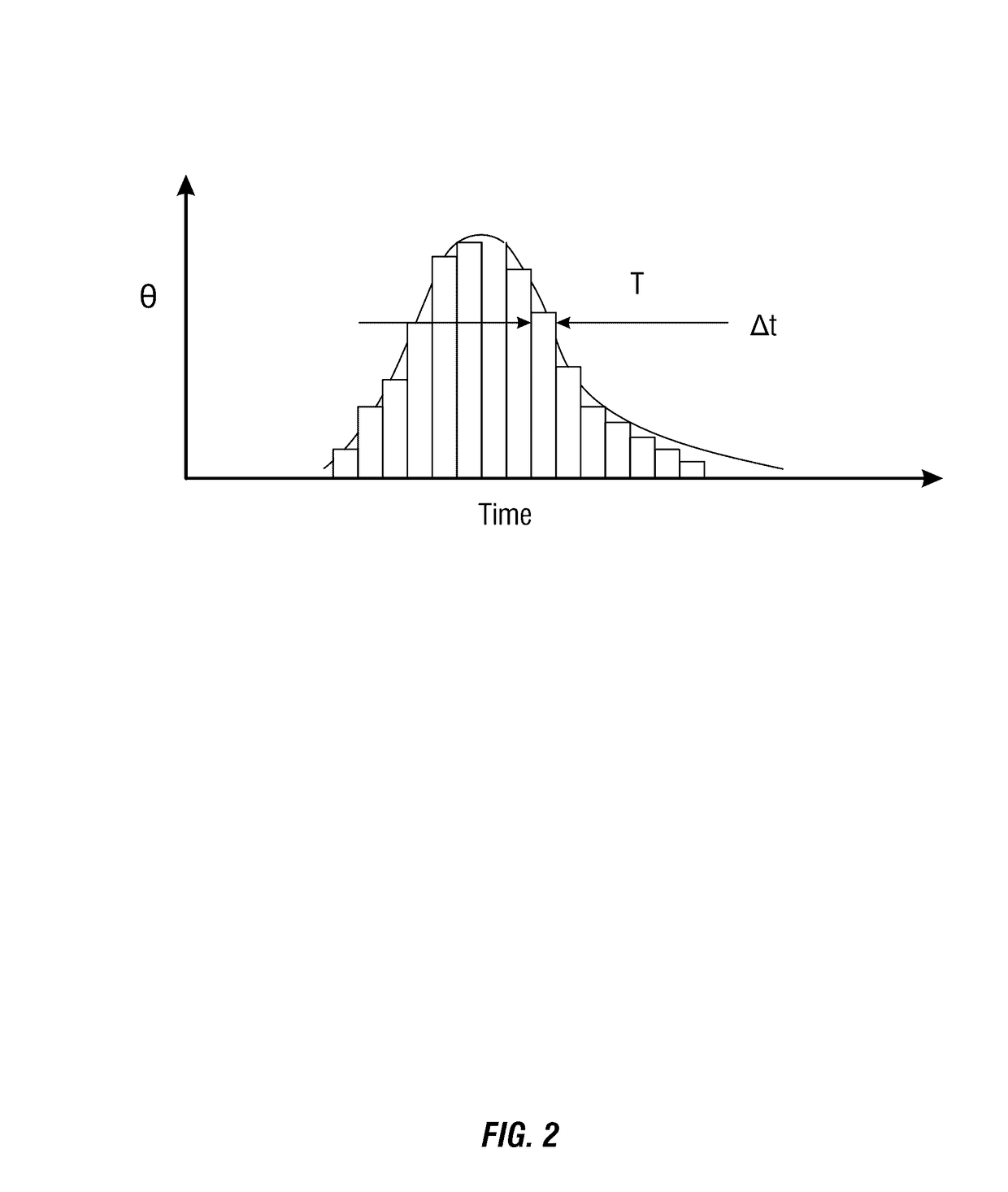

Closed loop 3D printing

ActiveUS20170087767A1Temperature of to varyQuality controlManufacturing heating elementsAdditive manufacturing with liquidsEngineeringIntelligent control

To better control part quality of 3D printed parts, the temperature of an extruder filament using a secondary heat source is provided. A heat source, such as an infrared heat source, can be used to heat the filament of a 3D printer to the optimum temperature that will enhance welding of the filament to a substrate that it is being printed on or to. Such an optimum temperature can be based upon, in part, the temperature of the substrate. A controller or other intelligent control can be used to receive temperature readings of the substrate and / or filament and then can adjust the temperature of the heating source to optimize the temperature of the filament to better combine the filament to the substrate.

Owner:IOWA STATE UNIV RES FOUND

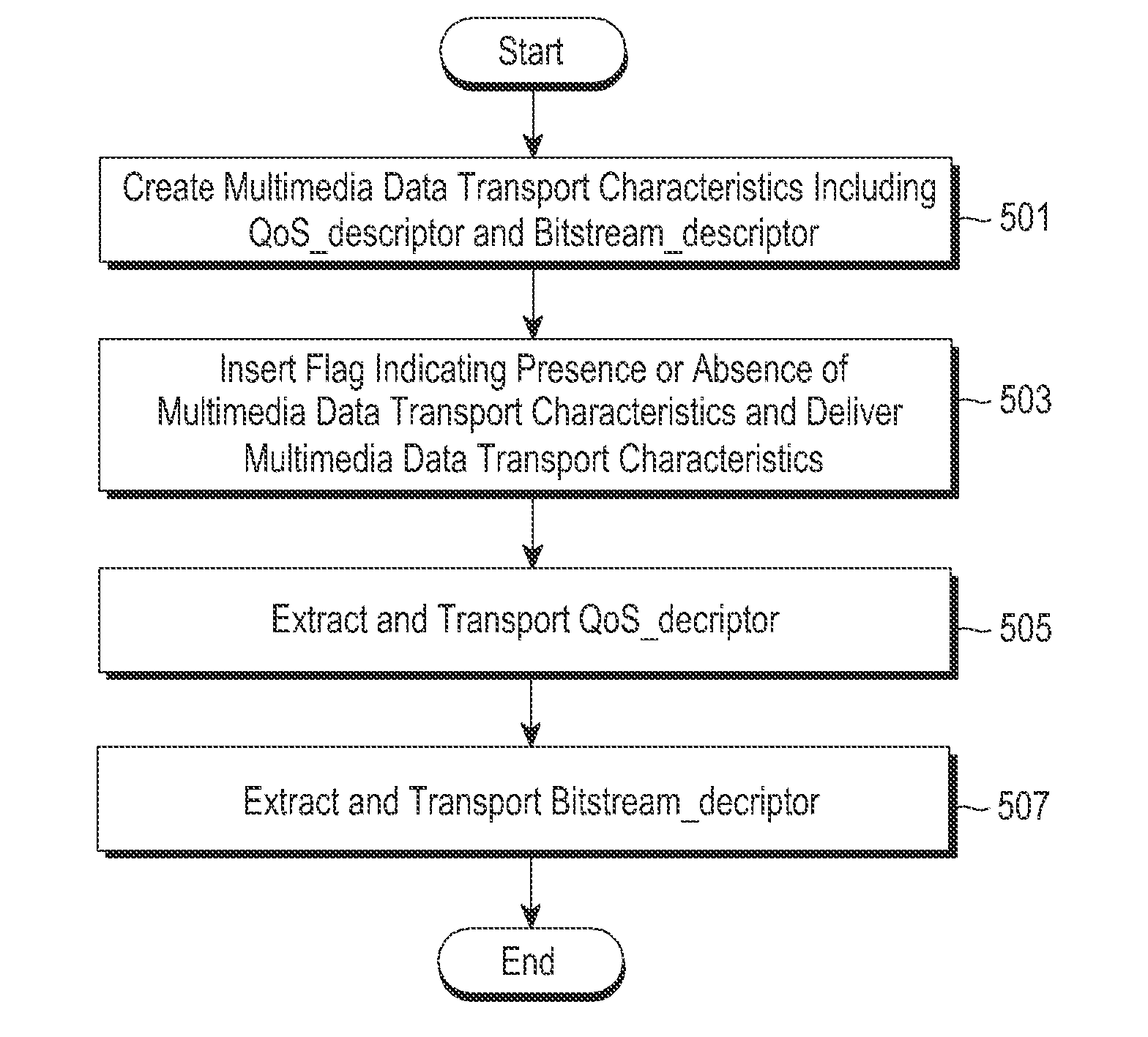

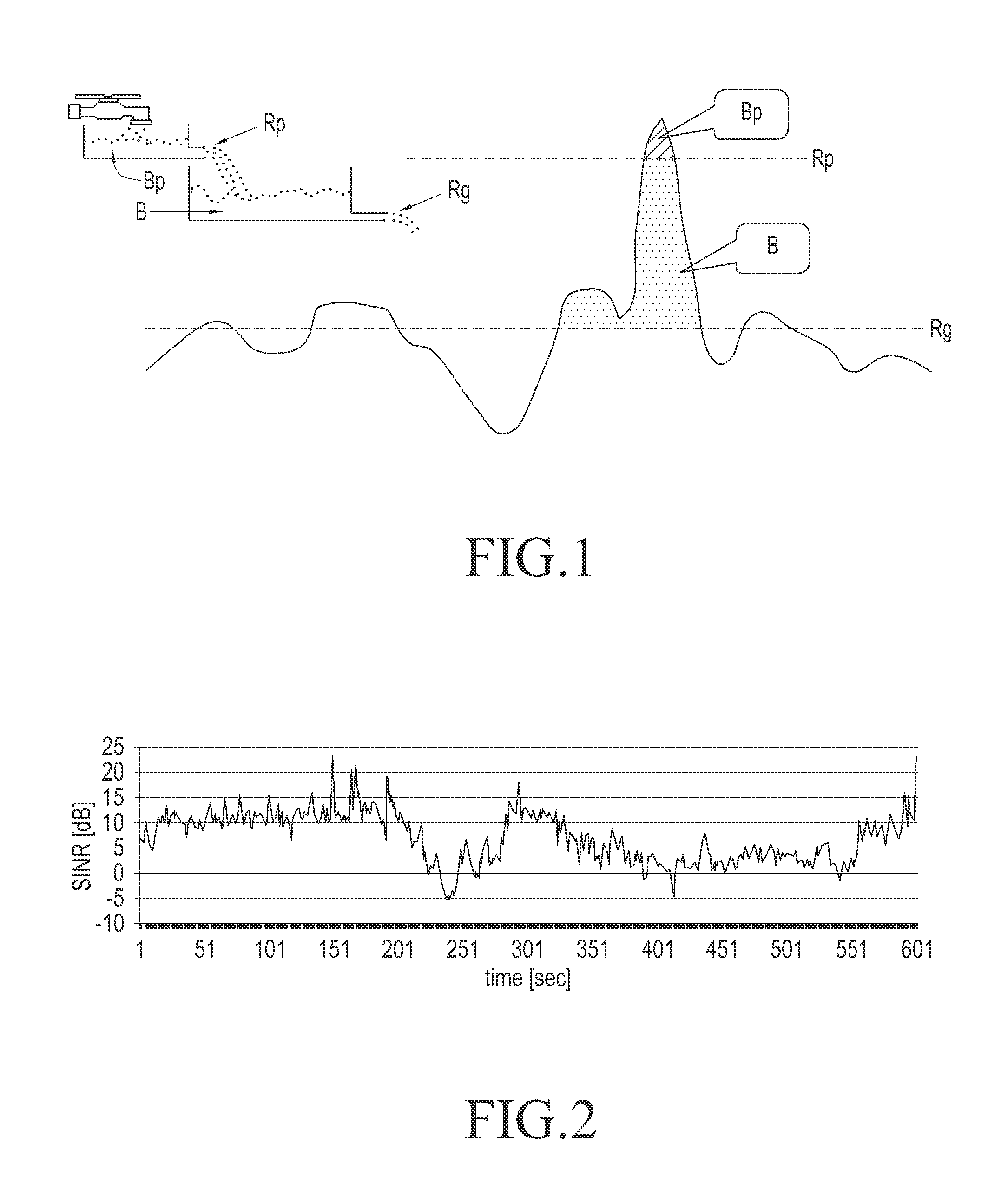

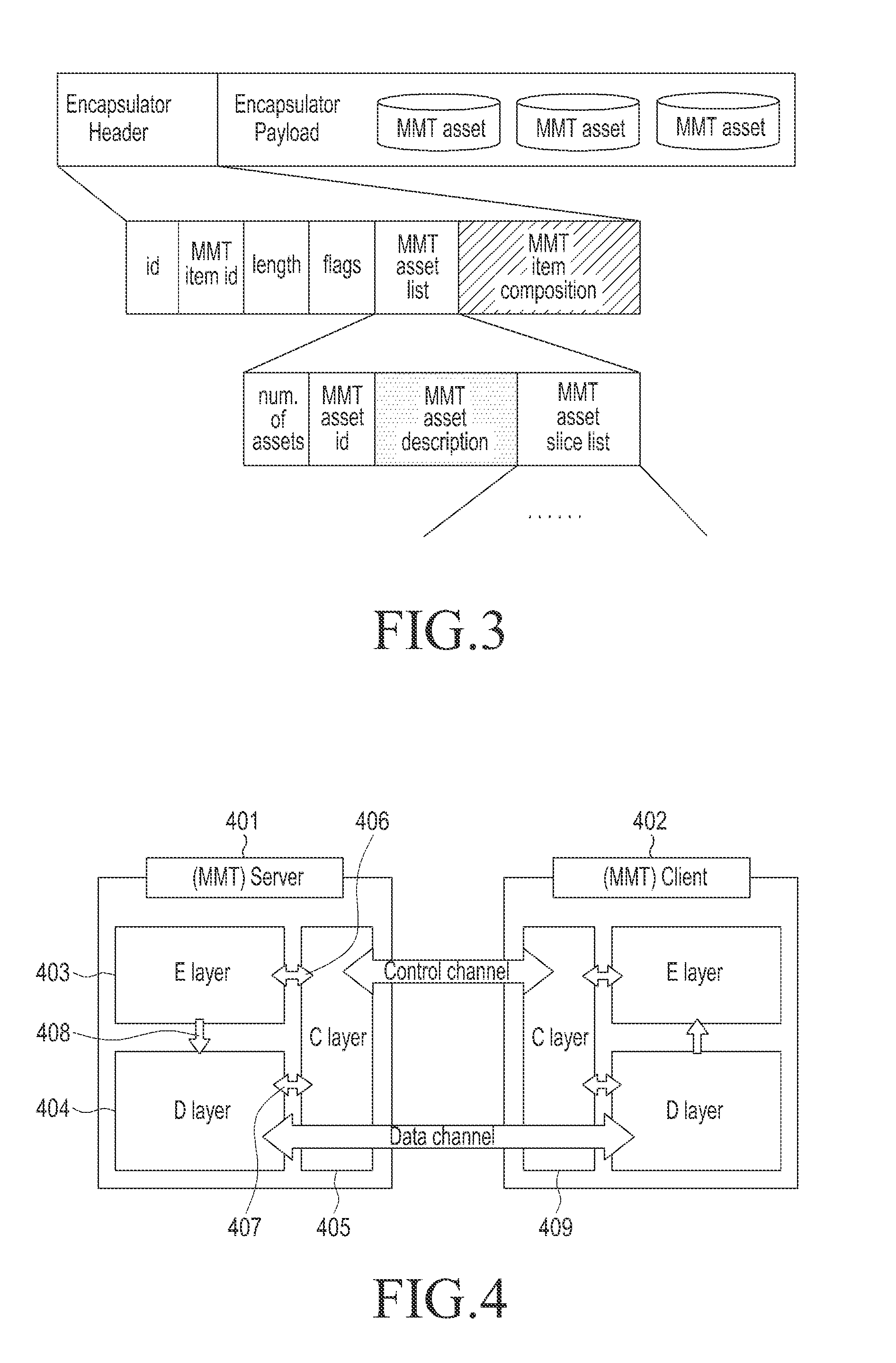

Apparatus and method for delivering transport characteristics of multimedia data

ActiveUS20140023071A1Quality controlEffectively control Quality of Service (QoS)Error preventionNetwork traffic/resource managementMobile WebMedia processing unit

There are provided a method and apparatus for delivering transport characteristics of multimedia data. According to an aspect of the present invention, transport characteristics of media data that can be divided in a unit of a Media Processing Unit (MPU) are created in a unit of a predetermined number of MPUs, the created transport characteristics and a flag indicating presence or absence of the created transport characteristics are inserted into the media data, and the resultant media data is delivered. Accordingly, by using transport characteristics in units of media data unit groups, each media data unit corresponding to a short time length, it is possible to effectively control Quality of Service (QoS) in a dynamically changing transport environment, like a mobile network.

Owner:SAMSUNG ELECTRONICS CO LTD +1

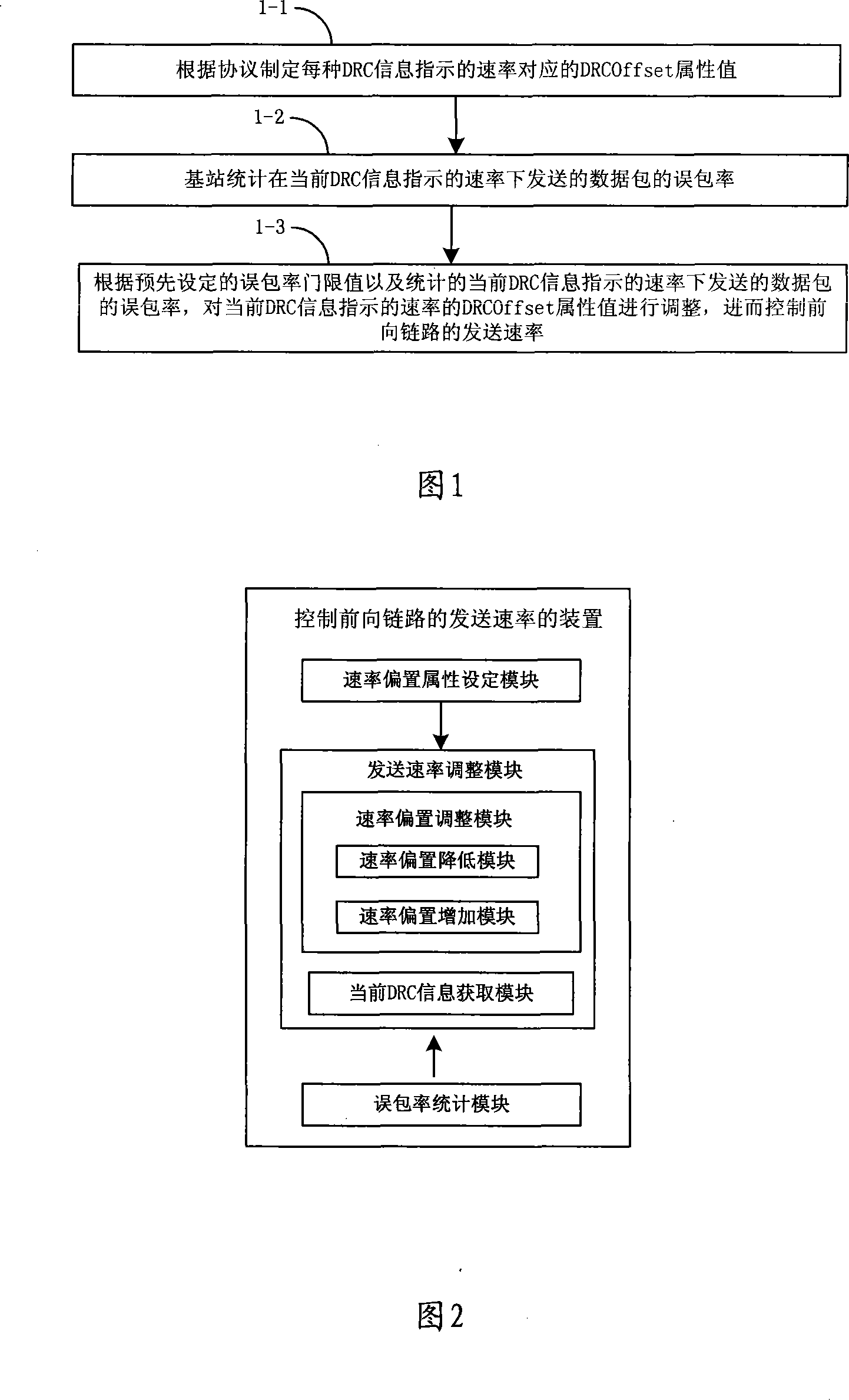

Method and device for controlling transmission rate of the forward link data packets

InactiveCN101170381AQuality controlPacket Error Rate ControlError prevention/detection by using return channelRadio/inductive link selection arrangementsTransmission delayTransmission rate

The invention provides a method and a device to control transmission rate of data packets on a forward chaining path. The method mainly includes the steps of: according to the rate indicated by received DRC (data rate control) information, transmitting data packets by a base station to terminals on the forward chaining path, and calculating mistaken packet ratio of the data packets sent at the rate indicated by the DRC information according to the right and wrong response messages returned from terminals; comparing the mistaken packet ratio of the data packets sent at the rate indicated by the DRC information with the pre-established mistaken packet ratio of threshold, and adjusting the transmission rate of the data packets on the forward chaining path according to the comparative result. The invention can adjust the transmission rate of the data packets on the forward chaining path of the base station through coordination of the base station and the terminals, further controls the mistaken packet rate of the data packets sent at the rate indicated by the DRC information, and thereby controlling the quality of the forward chaining path.

Owner:杨江

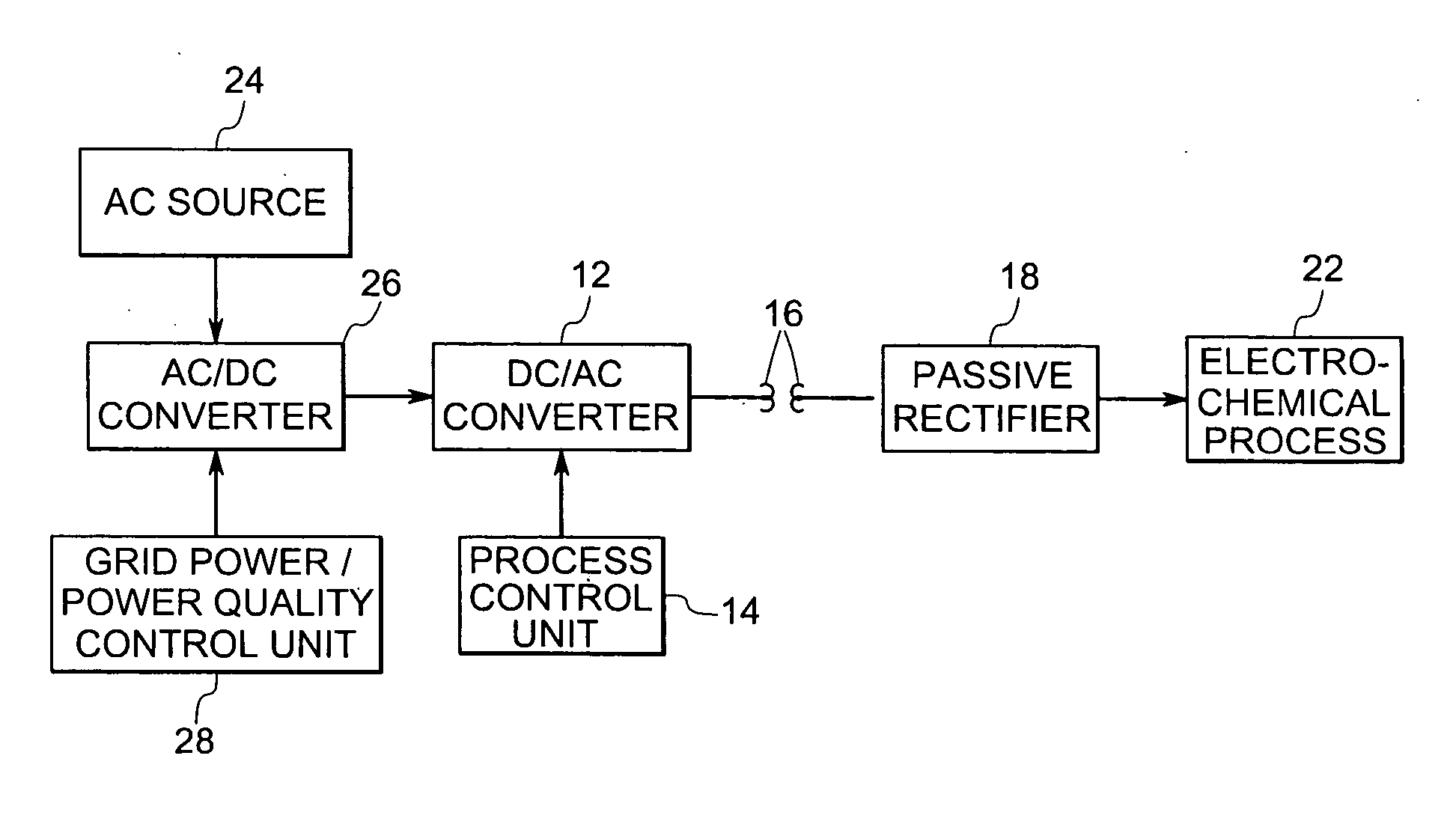

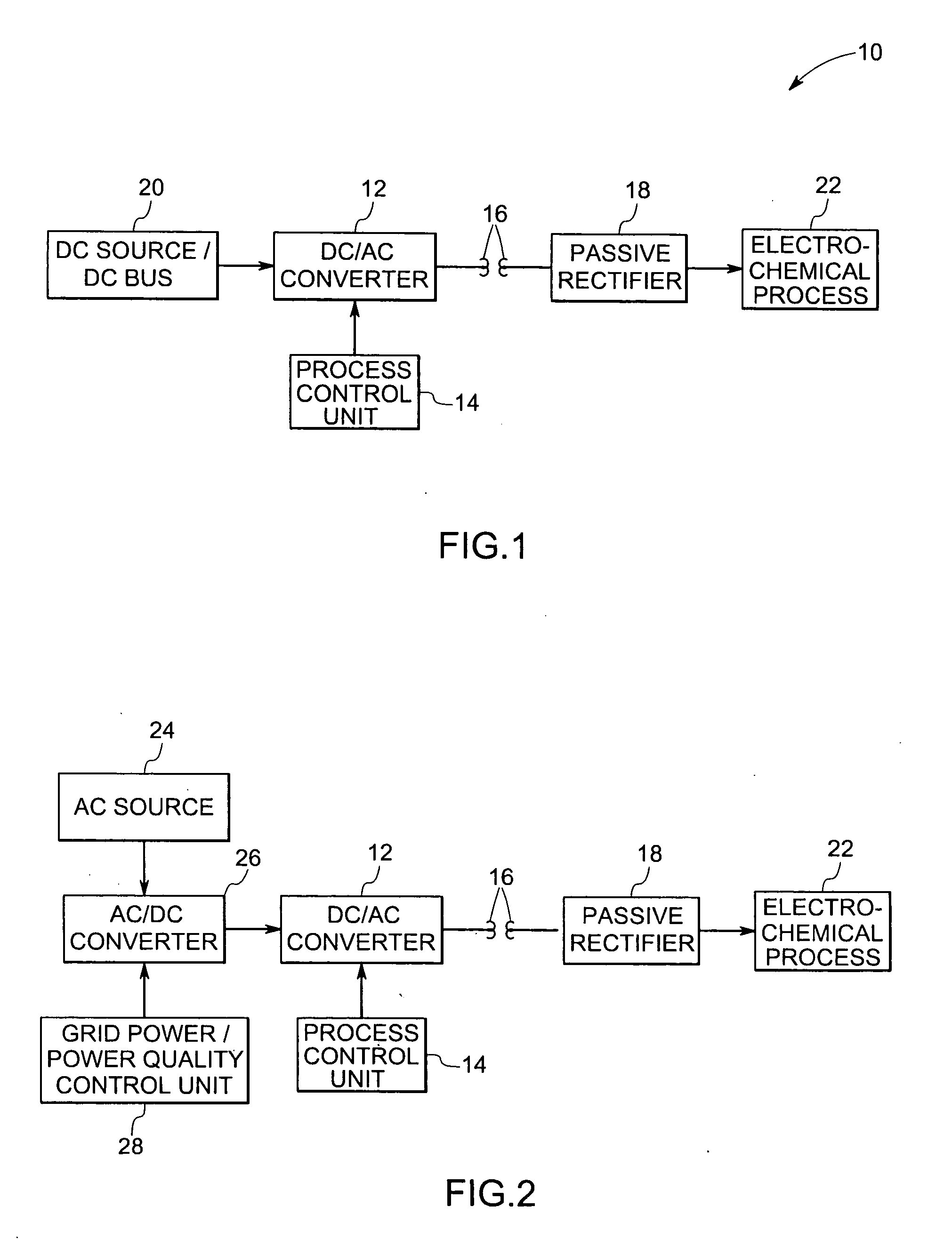

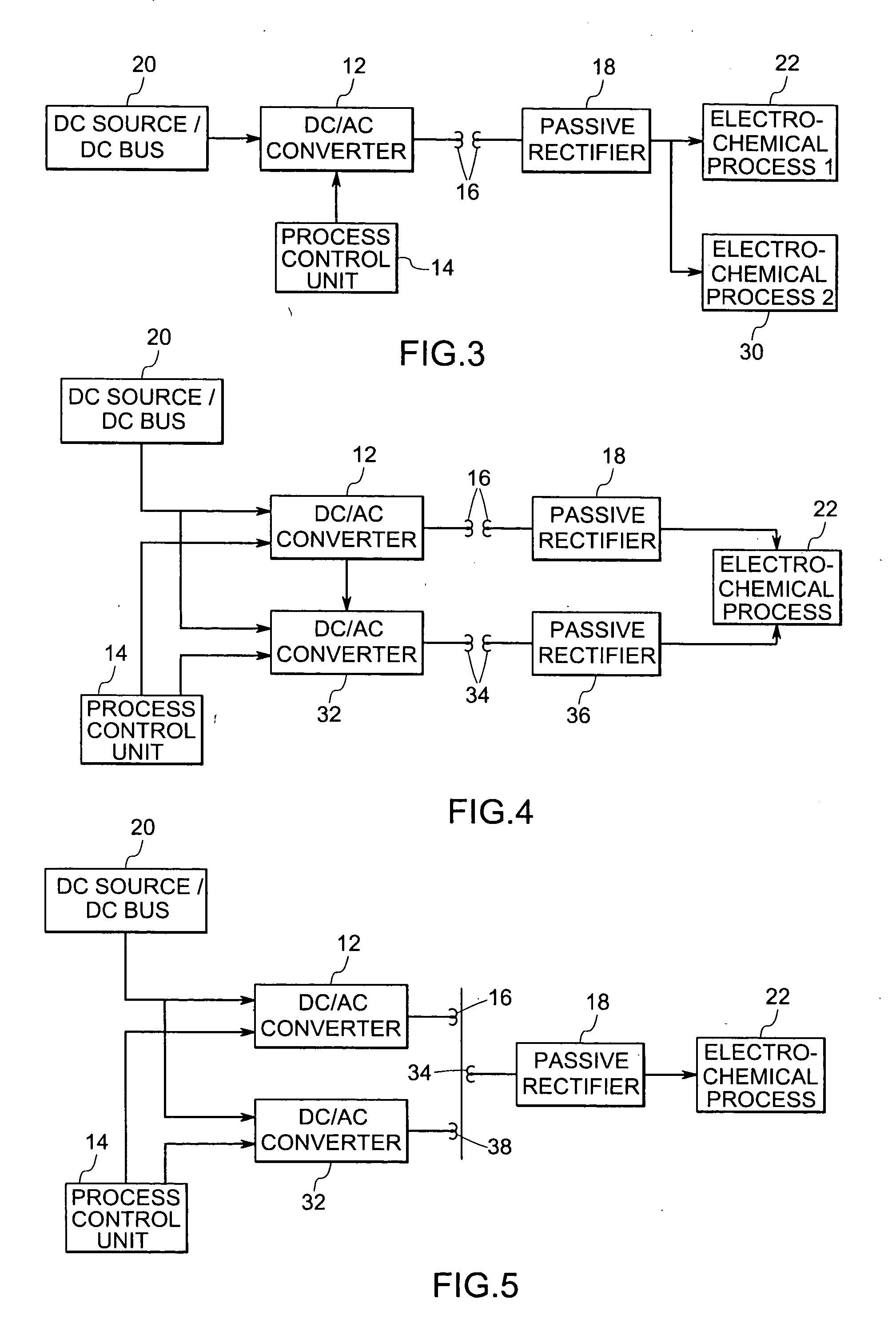

Power conversion system and method

InactiveUS20050286268A1Quality controlAc-dc conversion without reversalMachining electric circuitsChemical processAC power

A power conversion system comprises a converter coupled to a power source and configured to convert a DC power to a variable AC power signal. The power conversion system may further comprise a process control unit coupled to the converter and configured to control the variable AC power signal. The power conversion system may also further comprise a transformer having a primary side and a secondary side, the primary side receiving the variable AC power signal from the converter and a passive rectifier coupled to the secondary side of the transformer. The transformer may be adapted to provide galvanic isolation between the power source and an electro-chemical process. The passive rectifier is adapted to convert the variable AC power to the variable DC power and to deliver the variable DC power to the electro-chemical processing unit.

Owner:GENERAL ELECTRIC CO

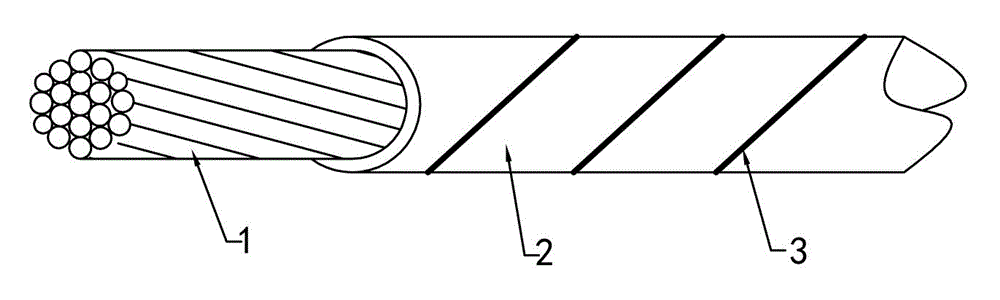

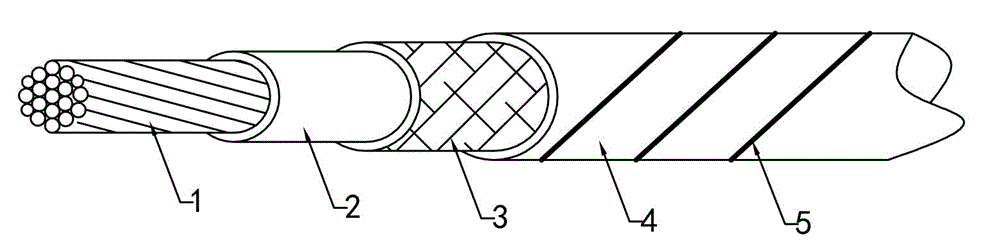

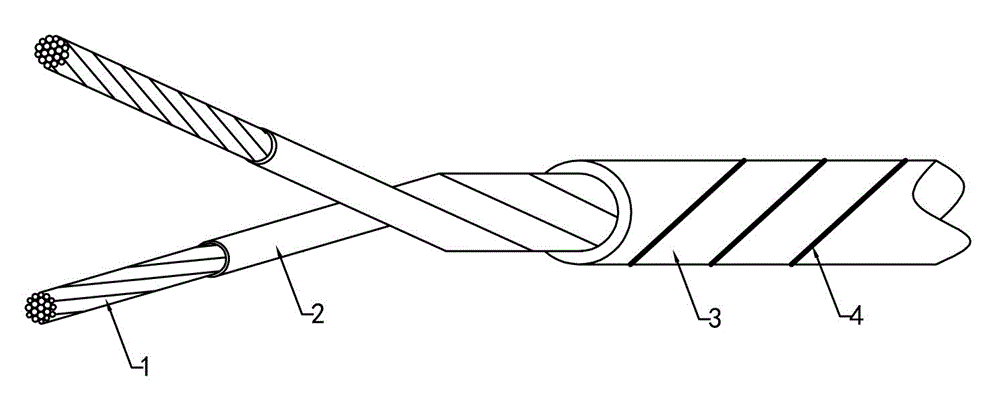

X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and preparation process for insulating wire or cable

InactiveCN102723135AQuick distinctionAccurate distinctionInsulated cablesConductor/cable markingTetrafluoroethyleneWire rod

The invention discloses an X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and a preparation process for the insulating wire or cable. The preparation process for the insulating wire or cable includes steps of: printing spiral stripe identifications on an insulating layer of an X-ETFE insulating wire directly formed by a single insulating core wire; printing spiral stripe identifications on a sheath layer of an X-ETFE insulating cable formed by a single insulating core wire, a shielding layer and the sheath layer; printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires, the shielding layer and the sheath layer; and printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires and the sheath layer. The insulating core wires consist of conductors and the insulating layers which wrap the conductors. The X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace is easy to be distinguished and identified, convenient to trace back and rapid in checking, and is beneficial to waste wire recovery. In addition, the X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace has excellent high-temperature resistance, low-temperature resistance and radiation resistance, and the mechanical performance of the insulating layer is quite good.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

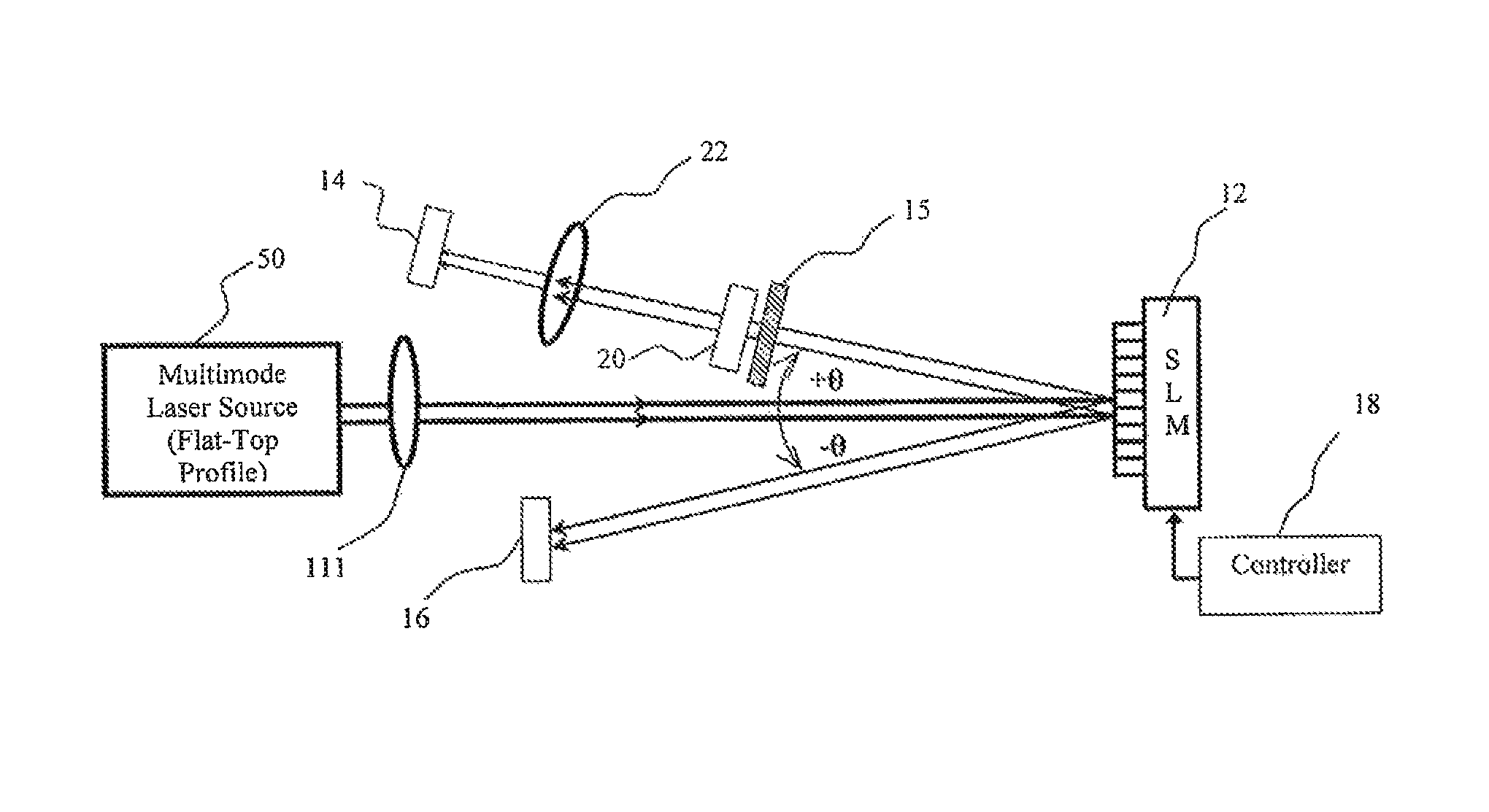

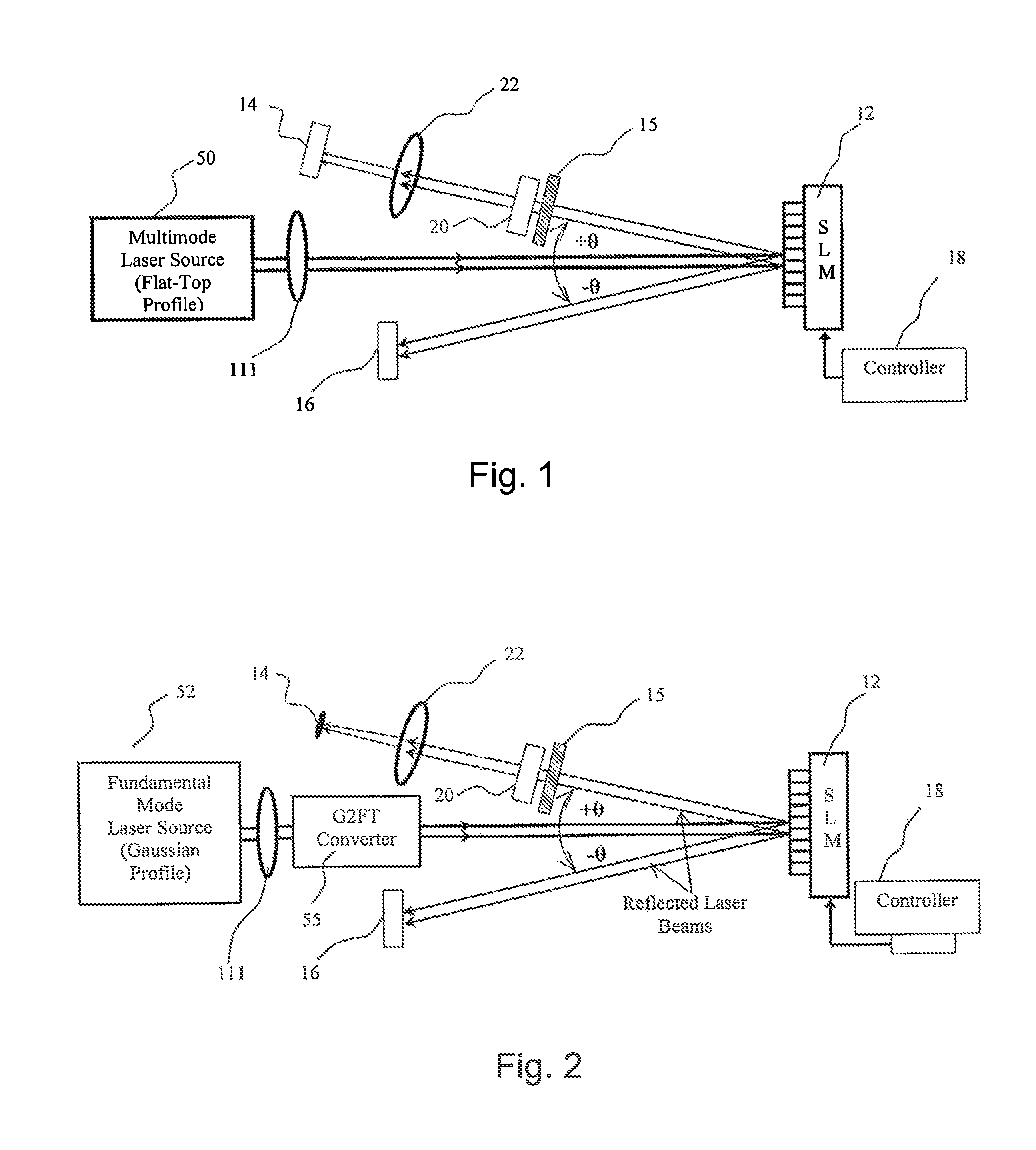

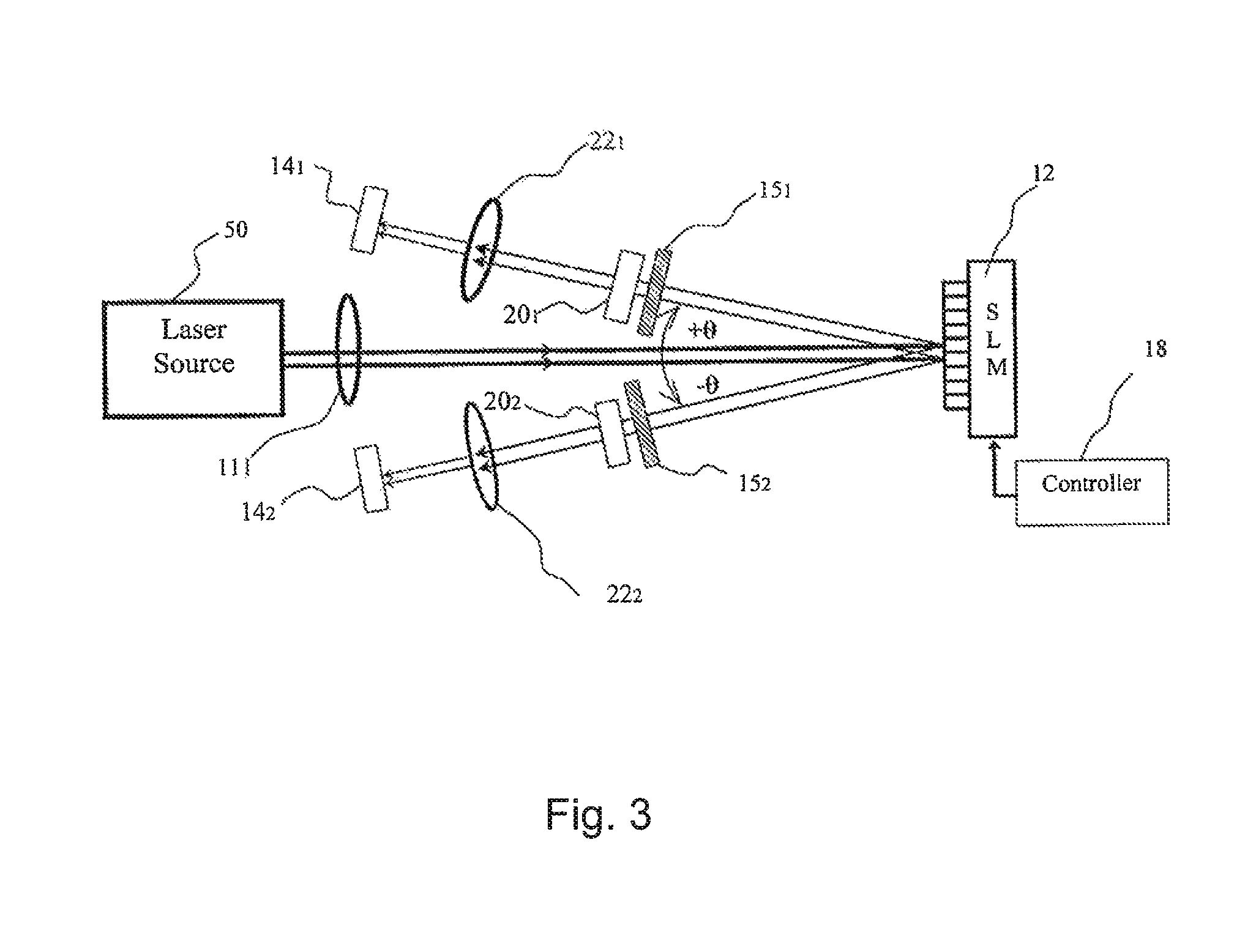

System for laser-based digital marking of objects with images or digital image projection with the laser beam shaped and amplified to have uniform irradiance distribution over the beam cross-section

ActiveUS9570874B1Quality controlUniformly amplifyLaser detailsThermographyPulse durationOptical amplifier

An optical system including a laser apparatus, a spatial light modulator to receive a laser beam, an optical-conditioning system to capture a propagating diffracted beam of the optical pattern and to form at least one of a magnified version and a demagnified version of the optical pattern and to control a quality of the optical pattern, a uniformity maintaining optical amplifier to receive the laser beam output from the spatial light modulator and generate an amplified laser beam such that a final optical pattern is an amplified version of the optical pattern as generated by the spatial light modulator, the amplified laser beam having a substantially uniform amplification across the cross-section of the beam, and at least one of a time-bandwidth pulse duration control mechanism including at least one of a pulse stretching element and pulse compression element, and a frequency conversion device.

Owner:VARDEX LASER SOLUTIONS

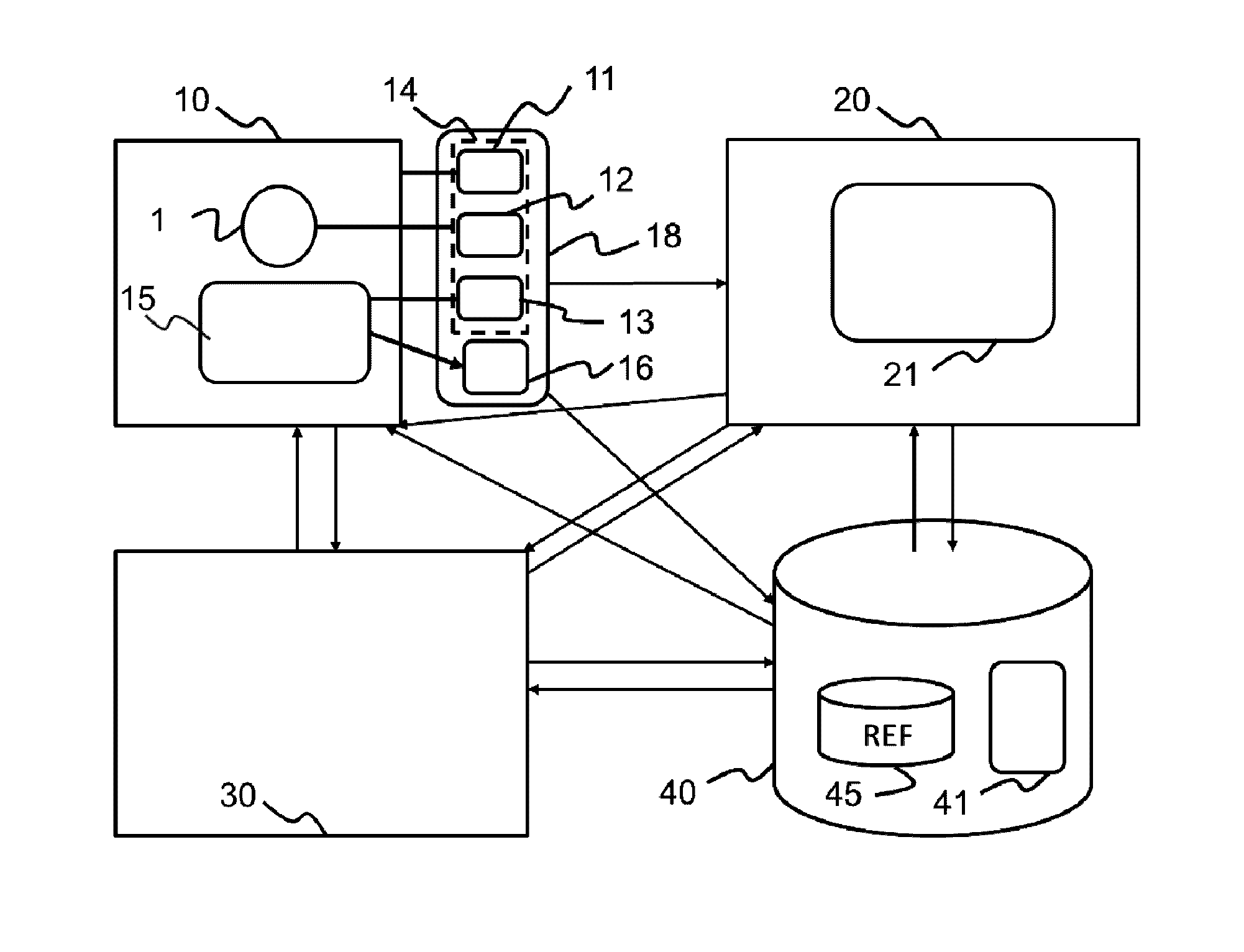

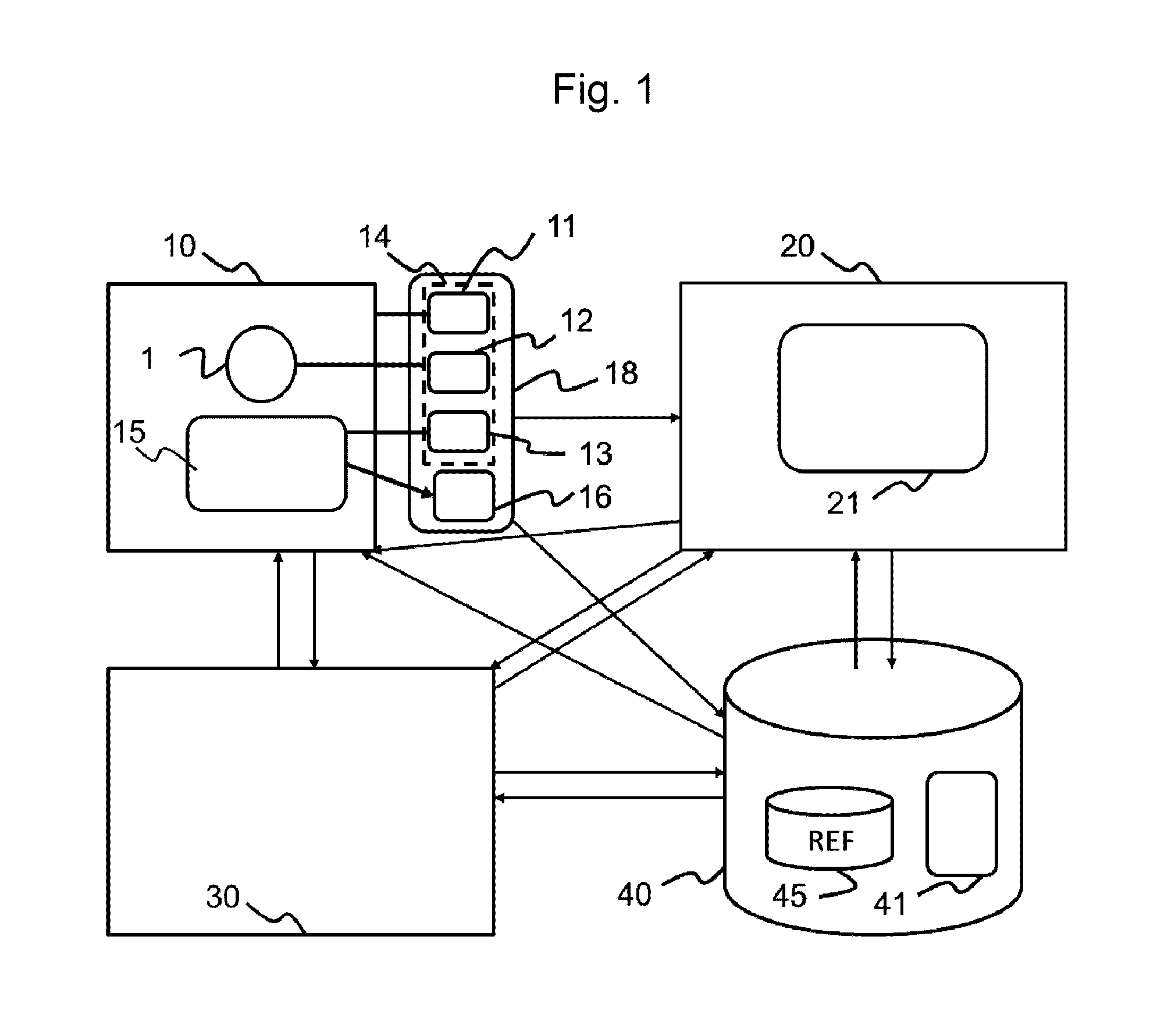

Quality control method for optometric measurements

ActiveUS20160353985A1Quality controlQuality improvementSpectales/gogglesDiagnostic recording/measuringOptical measurementsDigital data

A quality control method for optometric measurements includes the following steps: (a) recording, via computer, a first record (14) that includes at least one first value of a first identifier (12), enabling identification of a glasses wearer (1), and at least one other value of another identifier (13) enabling identification of an optometric apparatus (15) on a first optometric measuring site (10); (b) carrying out at least one optometric measurement (16) of the wearer; (c) sending, to a second site (20), a digital measurement data set (18) including the optometric measurement result from step (b), the digital data set being linked, via computer, to the first record; and (d) digitally processing the optometric measurement result from the first record (14) on the basis of a digital data reference system (45) and the values of the respective identifiers of the glasses wearer and the optometric apparatus of the first record.

Owner:ESSILOR INT CIE GEN DOPTIQUE

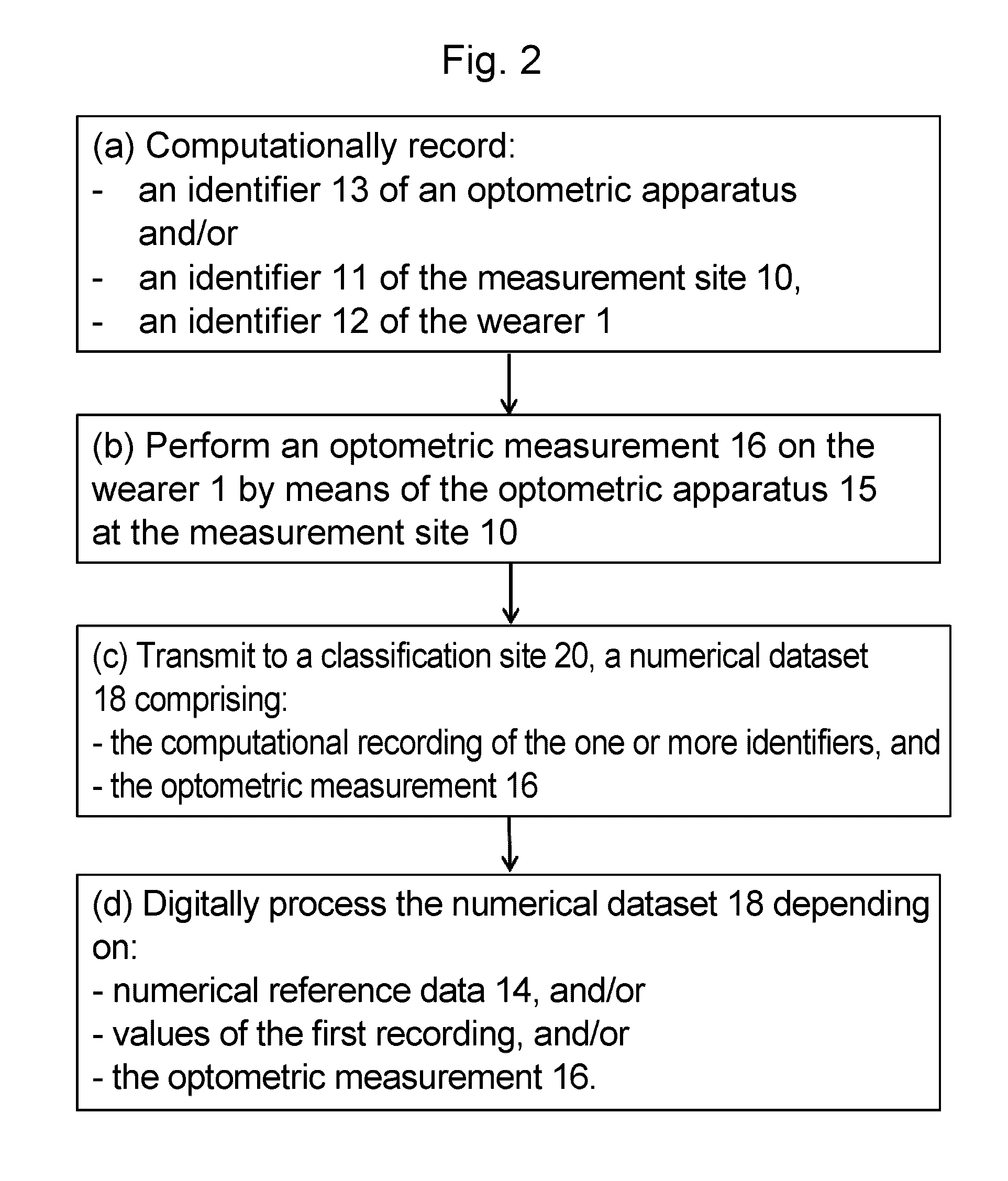

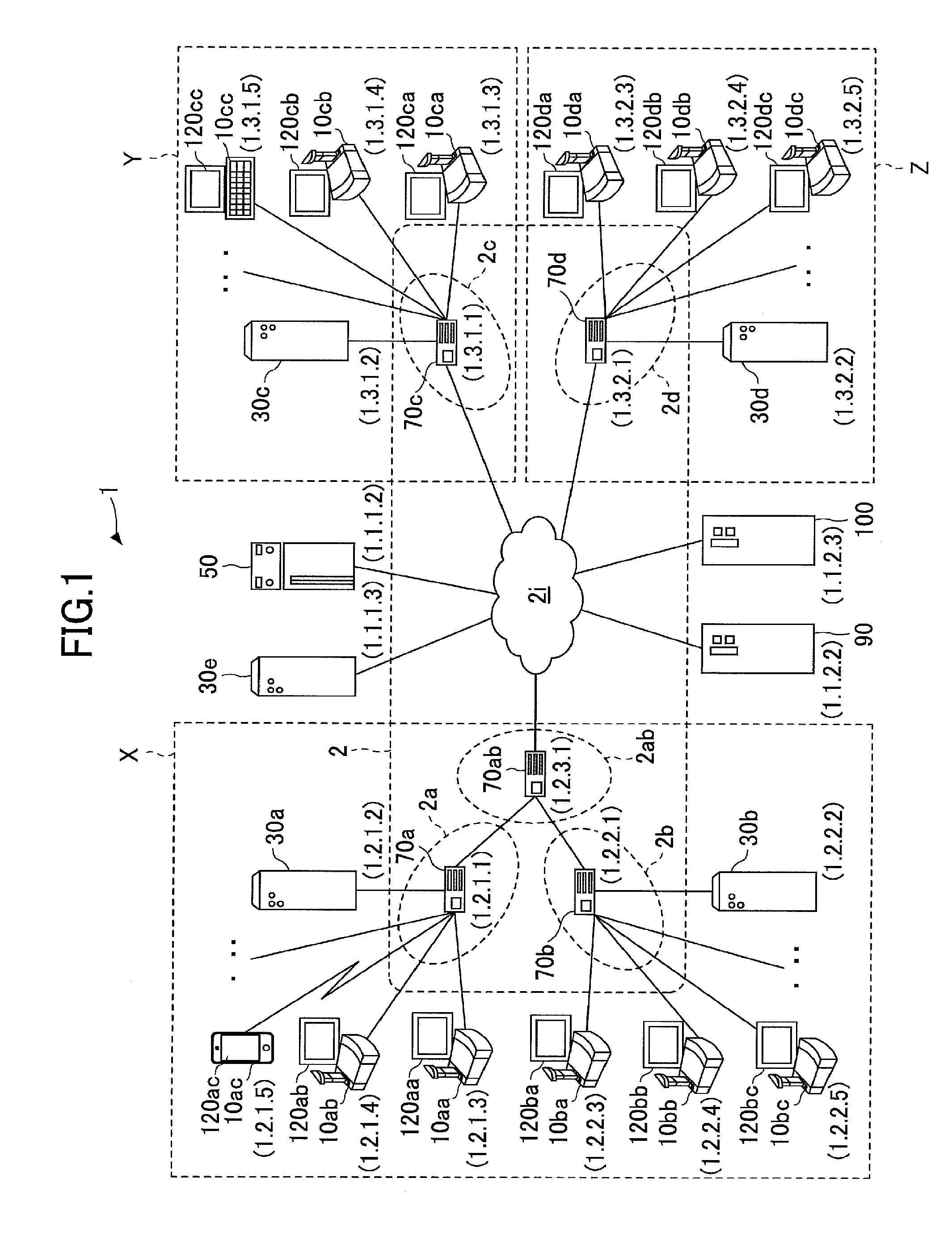

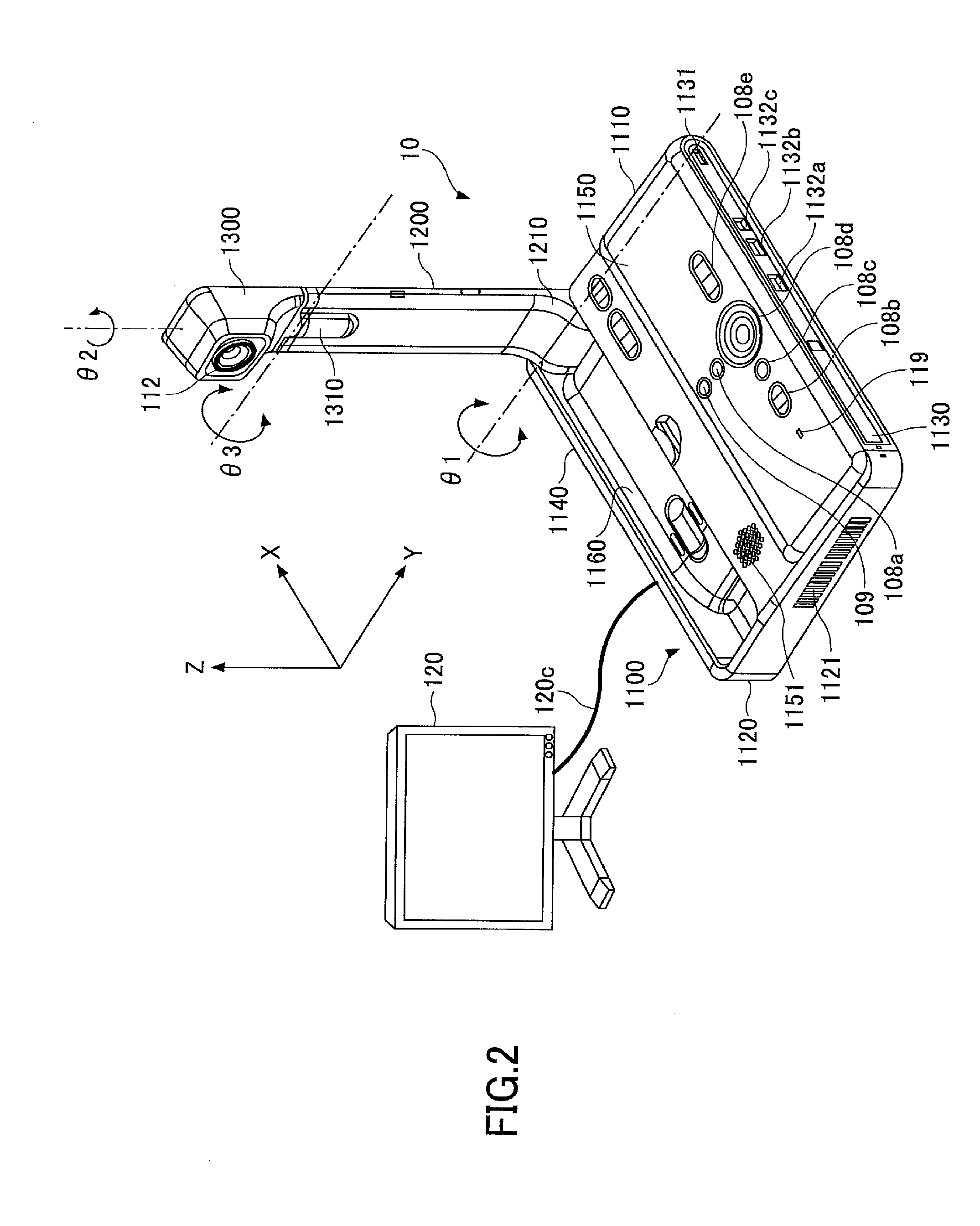

Control system, communication system, control method, and recording medium

ActiveUS20160248819A1Possible to determineQuality controlTelevision conference systemsTwo-way working systemsState managementReal-time computing

A control system is provided. The control system includes a state management unit configured to control state information indicating a state of a communication terminal and a control unit configured to, when a first communication terminal and a second communication terminal communicate, determine whether content data should be transmitted from the first communication terminal to the second communication terminal and whether content data should be transmitted from the second communication terminal to the first communication terminal based on a set of the state information indicating the state of the first communication terminal and the state information indicating the state of the second communication terminal controlled by the state management unit.

Owner:RICOH KK

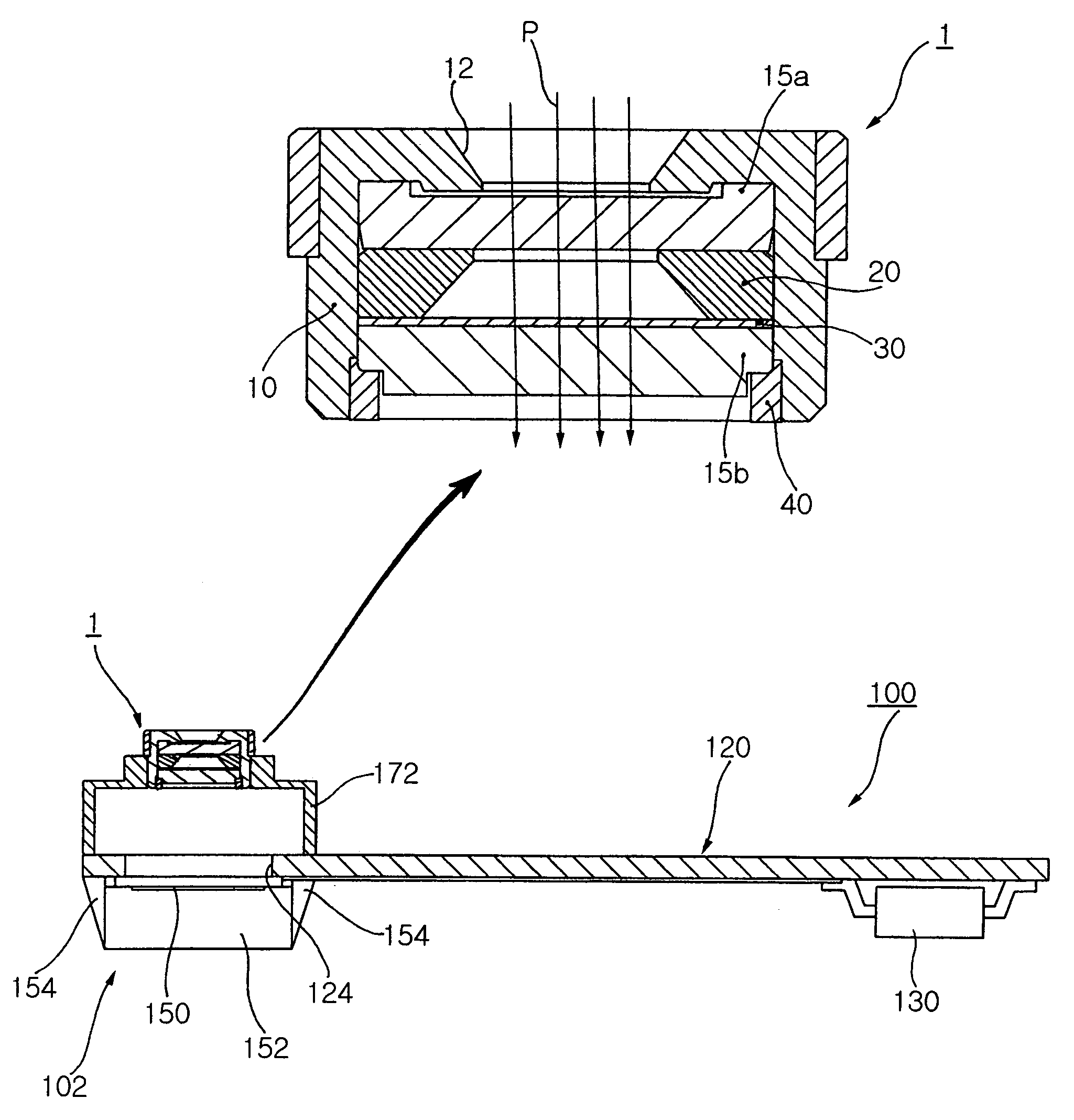

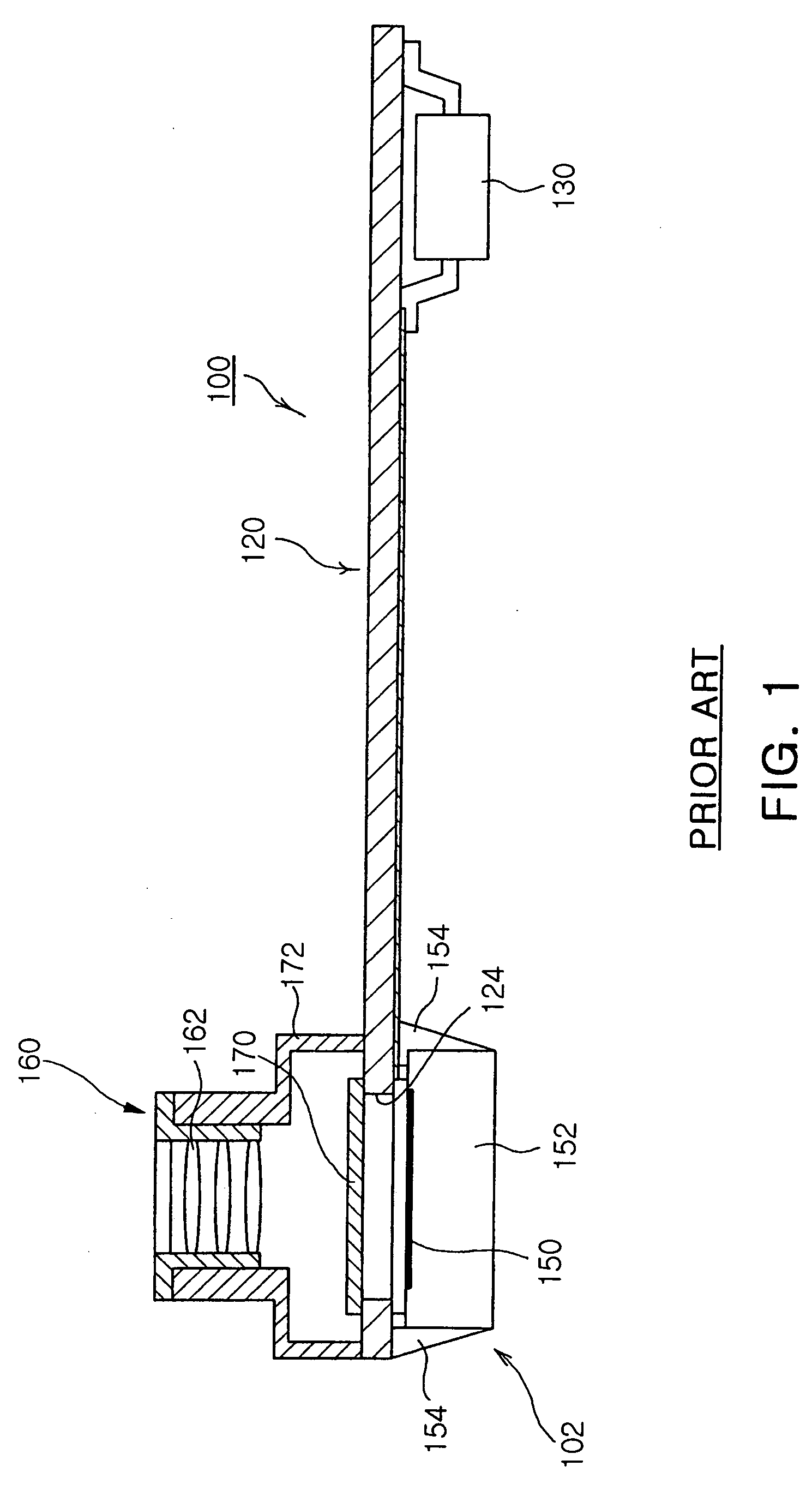

Lens unit used for camera module having optical filter therein

InactiveUS20060171701A1Quality controlReduce overall heightTelevision system detailsSecondary cellsPhysicsLight filter

A lens unit for a camera module having an optical filter therein is provided. The lens unit includes a casing, a plurality of lenses, an optical filter, and a fixing member. The casing has a light-receiving hole formed in one side thereof and has a structure in which a cavity is formed. The lenses are aligned in the inside of the casing to transmit light that passes through the light-receiving hole. The optical filter is disposed in the inside of the casing to block a partial wavelength of light and the fixing member maintains the lenses and the optical filter at an aligned state in the inside of the casing. A separate optical filter doesn't need to be mounted in the camera module but is integrally formed in the inside of the casing, so that inflow of foreign substance during the manufacturing process is minimized.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

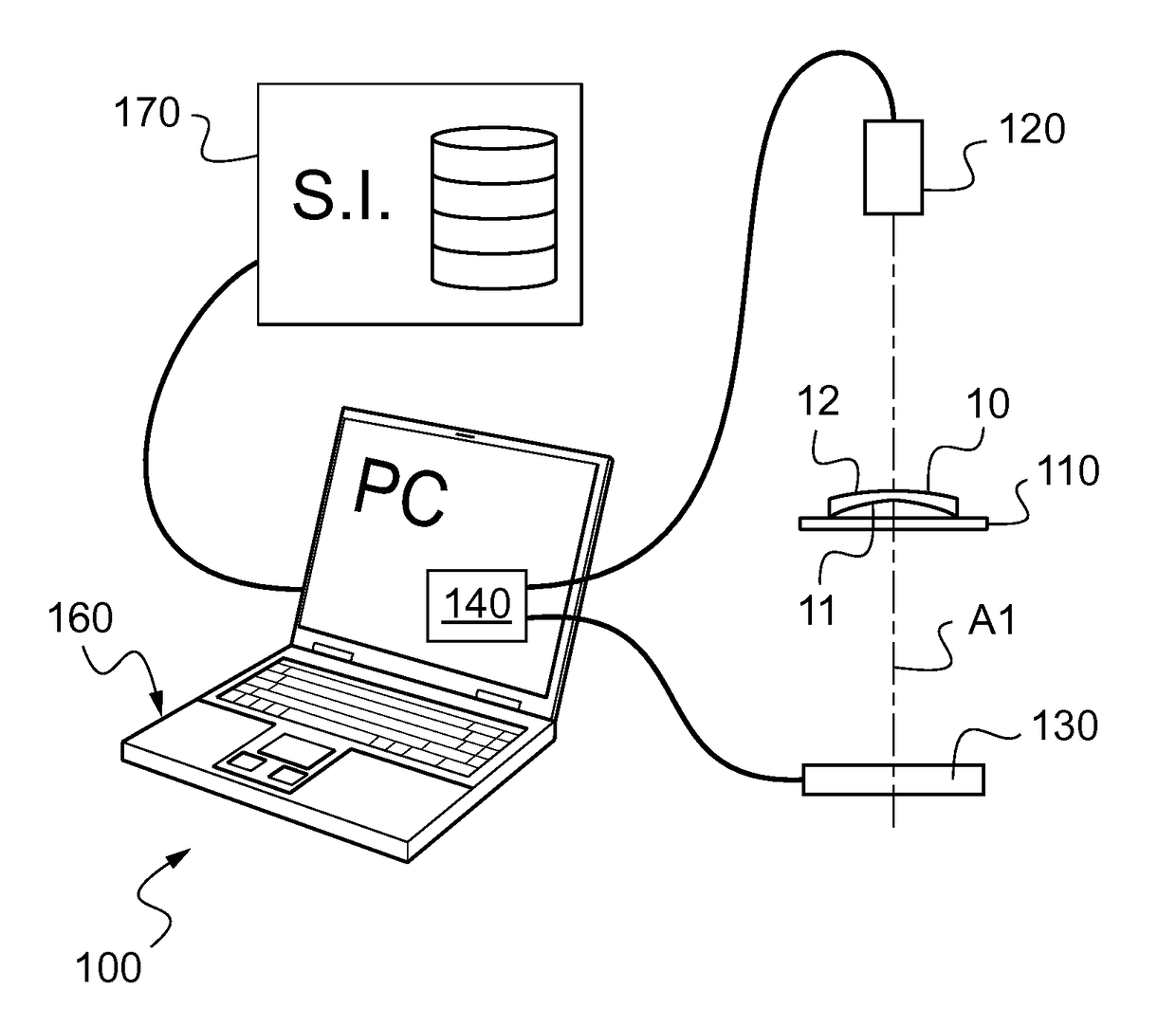

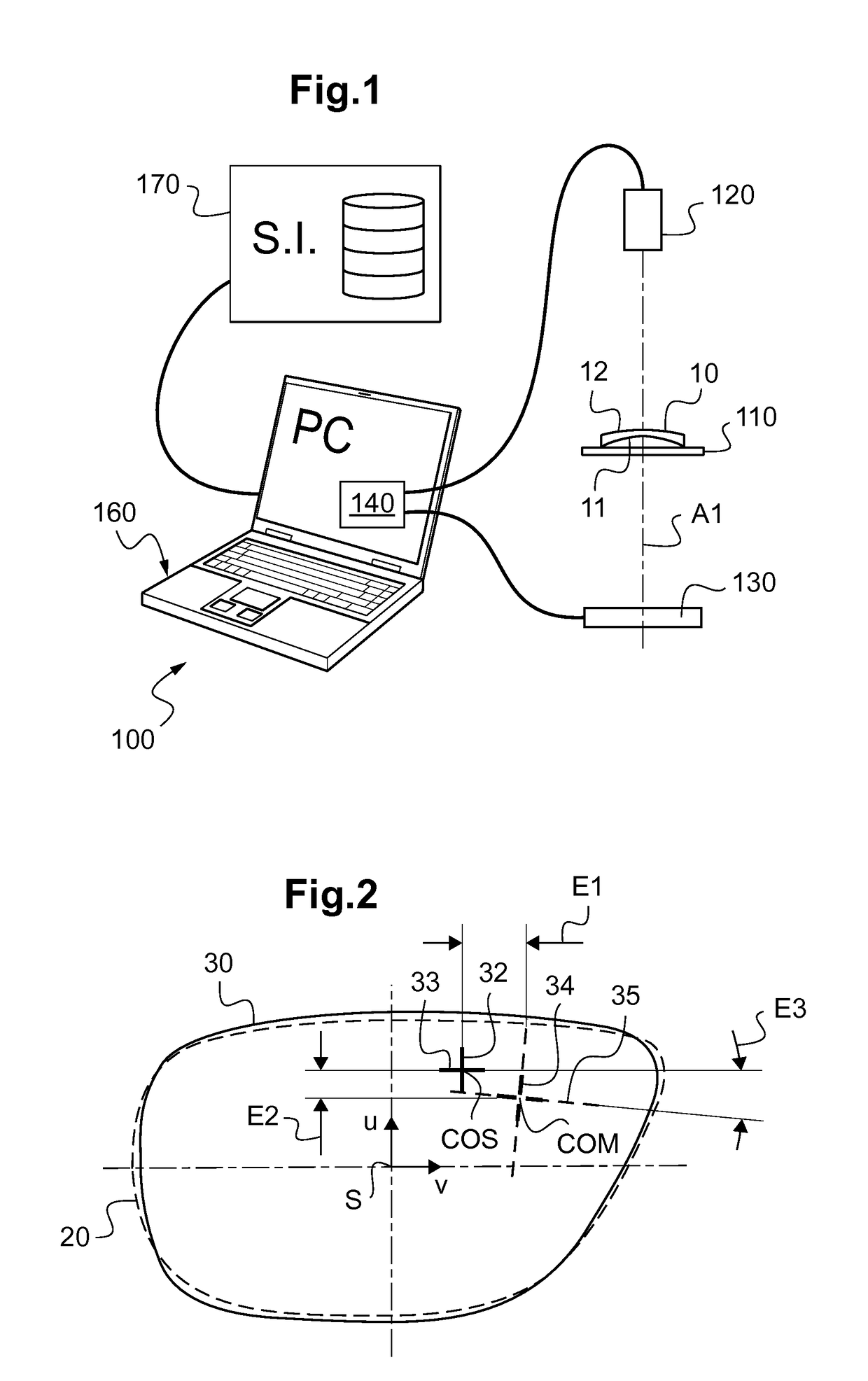

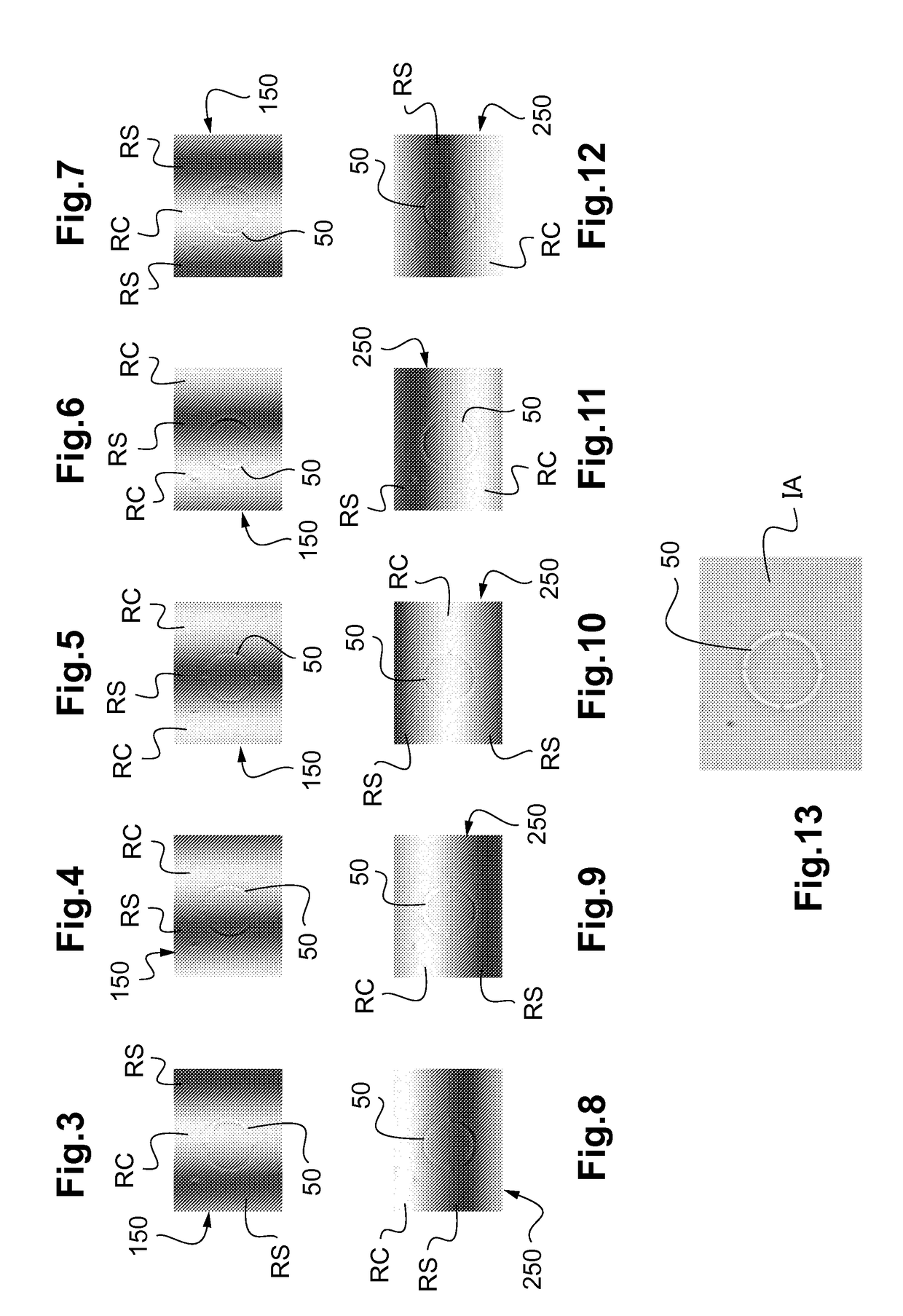

Method for checking a geometric characteristic and an optical characteristic of a trimmed ophthalmic lens and associated device

ActiveUS20180195931A1Quality controlHigh precisionSpectales/gogglesMaterial analysis by optical meansImage captureLens plate

Disclosed is a method for checking at least one geometric characteristic and one optical characteristic of a trimmed ophthalmic lens (10) including the following steps: a) arranging the trimmed ophthalmic lens on a support (110), b) capturing at least one image of the trimmed ophthalmic lens, c) determining, from the image, a measured geometric characteristic of the trimmed ophthalmic lens, d) determining at least one measured optical characteristic of the trimmed ophthalmic lens in a reference frame of the image captured in step b), e) comparing the measured geometric characteristic associated with the measured optical characteristic to a predefined desired ophthalmic lens model, including at least one desired geometric characteristic and one associated desired optical characteristic. Also disclosed is an associated checking device.

Owner:ESSILOR INT CIE GEN DOPTIQUE

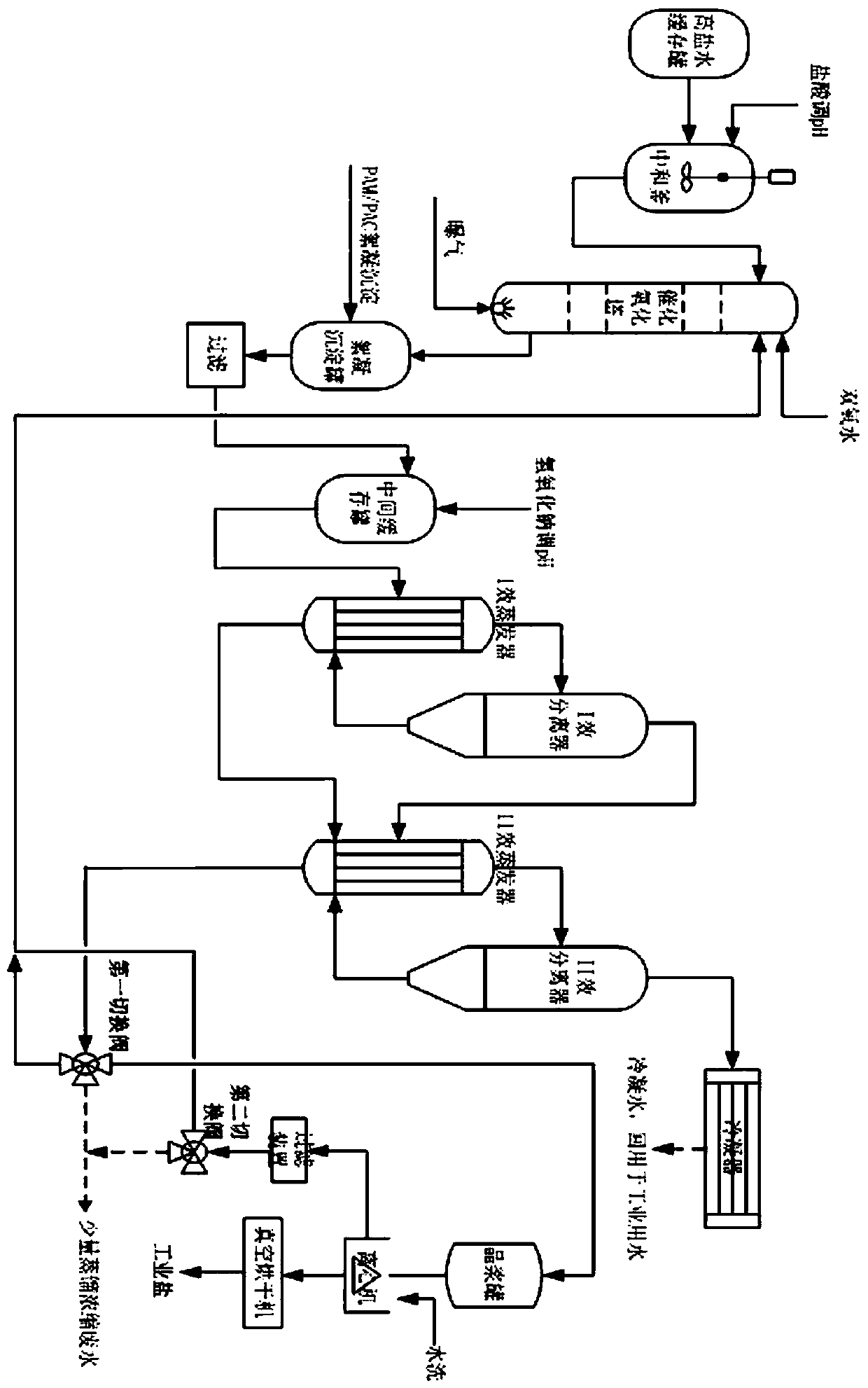

Resource processing method and device for preparing industrial salt from high-concentration and high-salt chemical wastewater

InactiveCN107651804AQuality controlWater/sewage treatment by centrifugal separationTreatment involving filtrationChemistryHigh concentration

The invention discloses a resource processing method and device for preparing an industrial salt from high-concentration and high-salt chemical wastewater. The resource processing methodcomprises thefollowing steps ofa homogenization step, a neutralization step, a three-phase catalytic oxidation step, a flocculation and sedimentation step, a double-effect evaporation and concentration step and acentrifugal filtration step. The resource processing method and device adopt the above scheme to remove or destroy organic substances in the waste water, recover an inorganic salt tobe refinedinto theindustrial salt and finally achieve the resource utilization of the high-concentration and high-salt waste water.

Owner:昌邑市瑞海生物科技有限公司

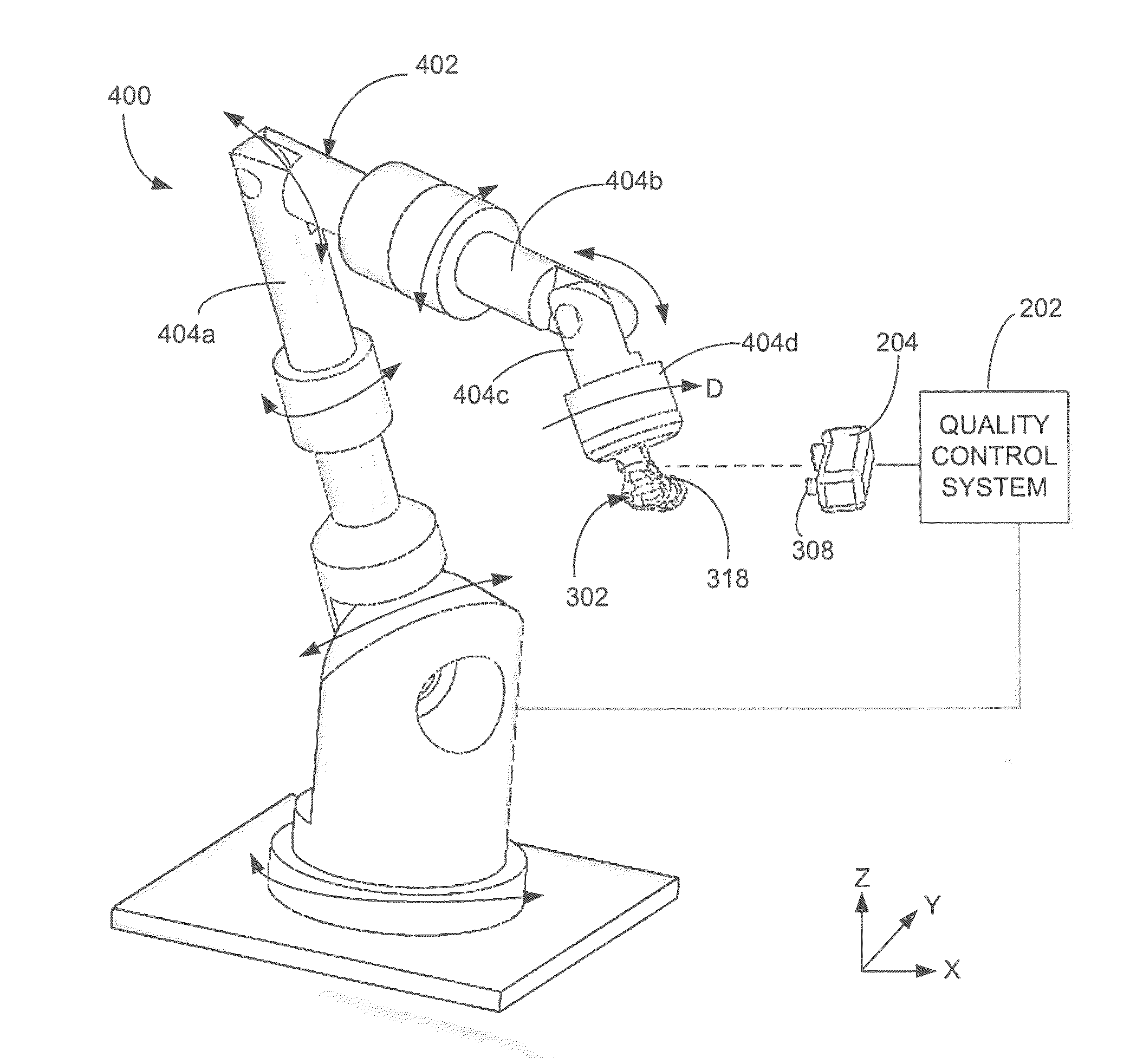

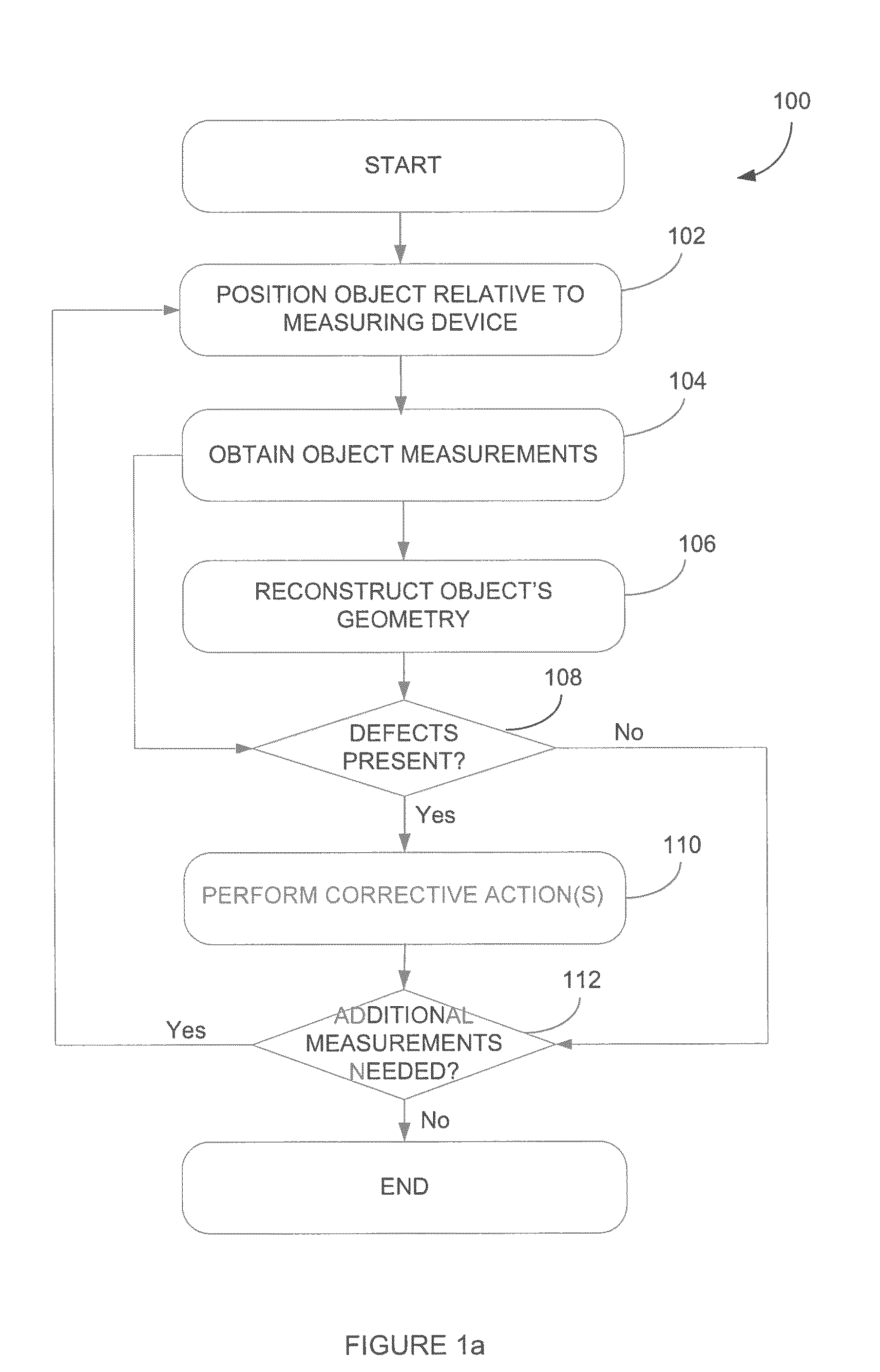

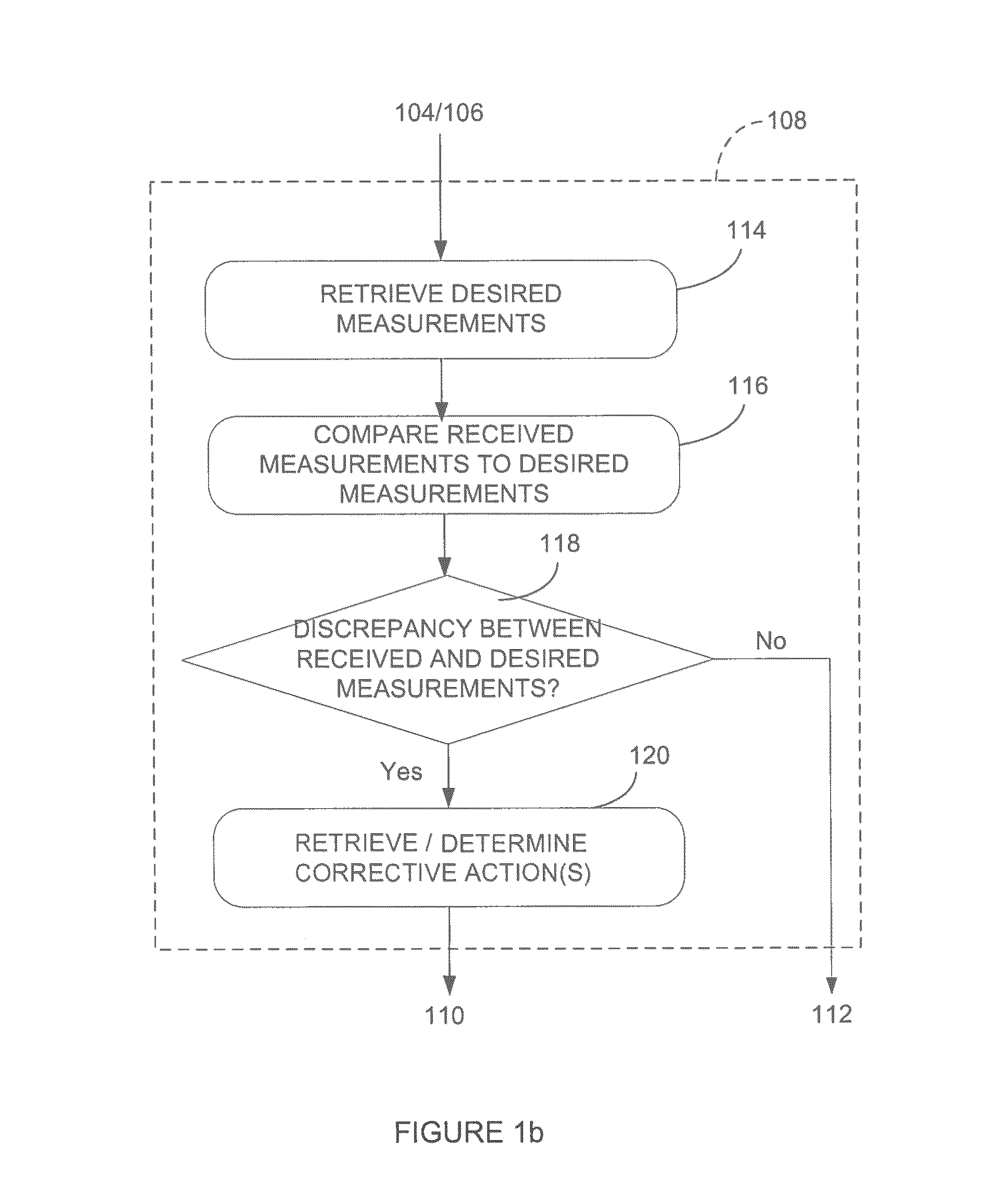

Quality control of an object during machining thereof

InactiveUS20140156051A1Quality controlSpecial data processing applicationsProgramme total factory controlMeasurement deviceQuality control

A system and method for controlling the quality of an object during machining thereof with a machine. Measurement data is received from a measuring device during the machining, the measurement data comprising at least one measurement of the object. It is determined from the received measurement data whether the object comprises a defect. An output signal is then generated to cause the machine to correct a detected defect.

Owner:LAB BODYCAD

Method for controlling antiviral oral liquid

A quaility control method for the antiviral oral liquid features that on the basis of existing quality control standards, the gas-phase chromatography method is additionally used to measure the content for patchoulic alcohol to ensure that it is not less than 10 micrograms per 10 ml.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD

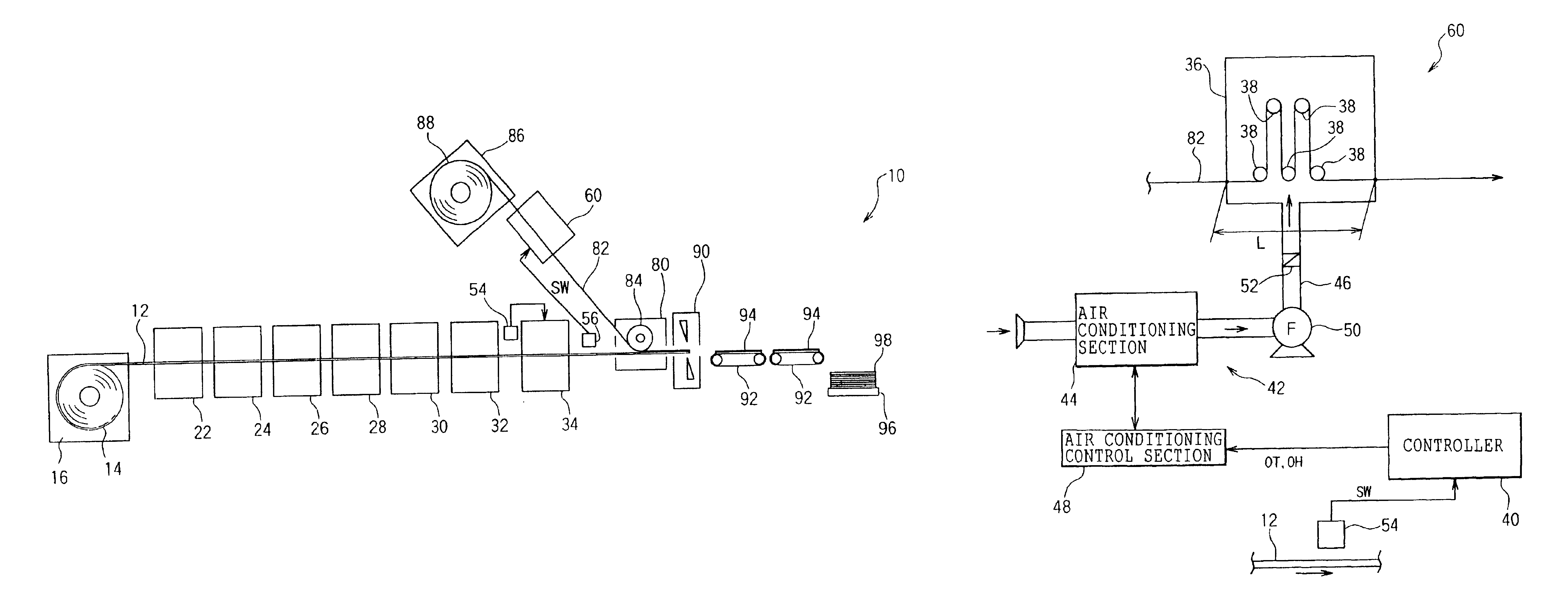

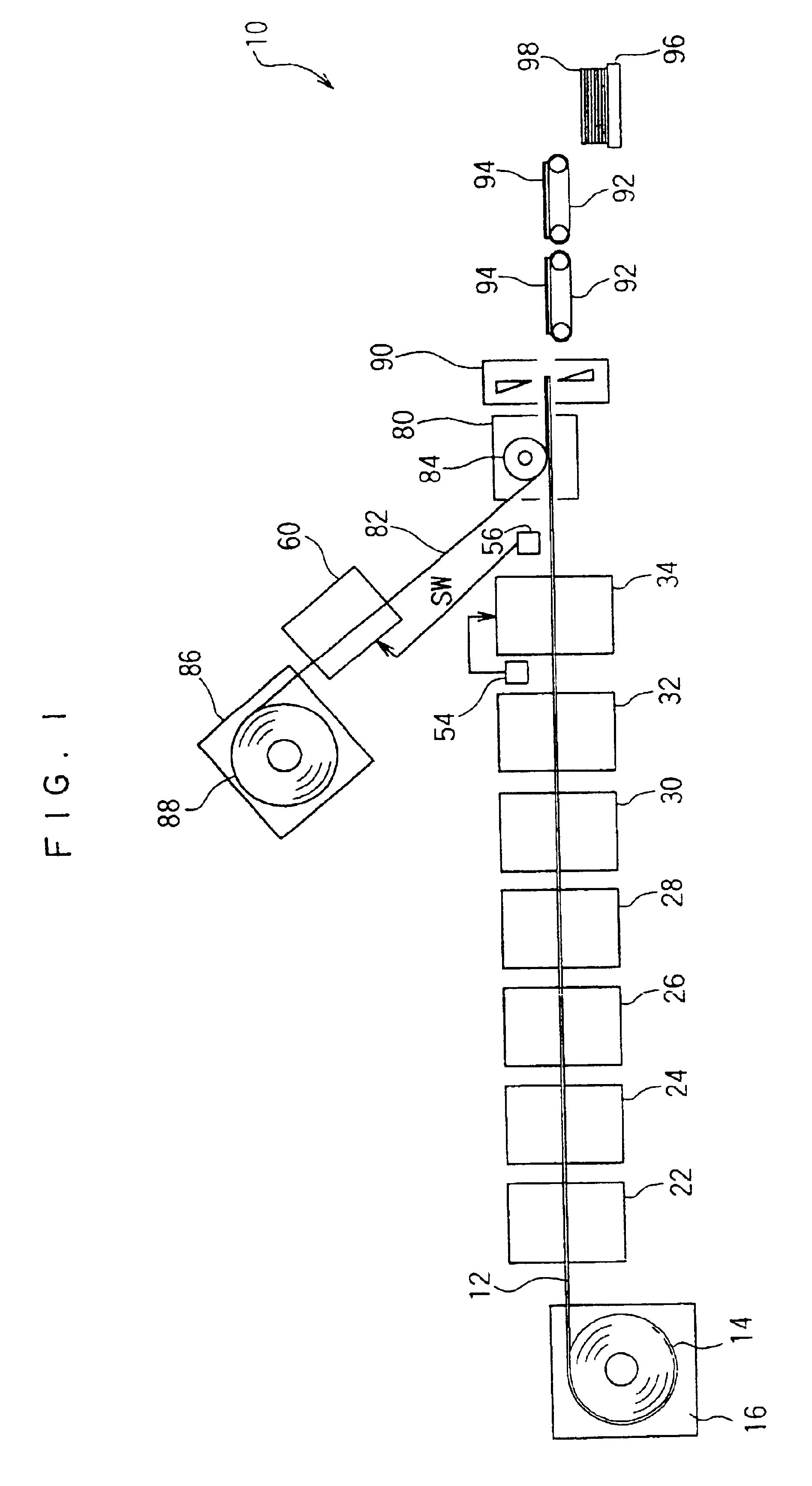

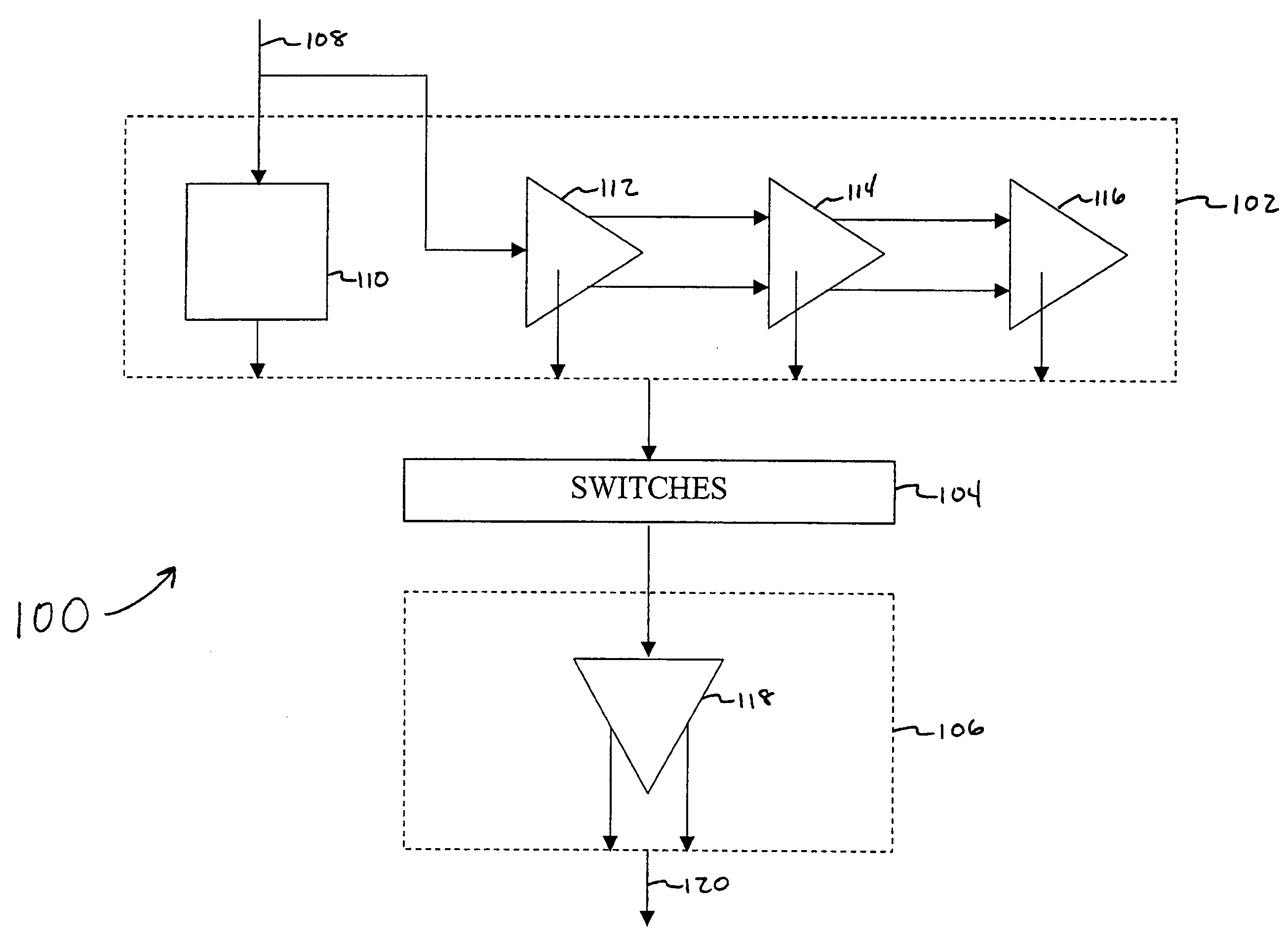

Coating film layer moisture adjusting device and planographic printing plate producing method

InactiveUS6855206B2High precisionQuality controlLiquid surface applicatorsElectrographic process apparatusControl periodEngineering

A controller for a moisture adjusting device of the present invention reads out a target moisture content set in advance in a data table in accordance with a type of a planographic printing plate; determines, every predetermined control period, a moisture content of an overcoat layer (measured moisture content) based on a measured signal SW; and calculates a difference (deviation) between the measured moisture content and the target moisture content. For example, if the measured moisture content of the overcoat layer is lower than the target moisture content, the controller sets an adjusted moisture content which is higher than the measured moisture content and controls the humidity and the temperature within a humidity conditioning zone so that an interposing paper web (protective sheet material) attains the adjusted moisture content within the humidity conditioning zone.

Owner:FUJIFILM HLDG CORP +1

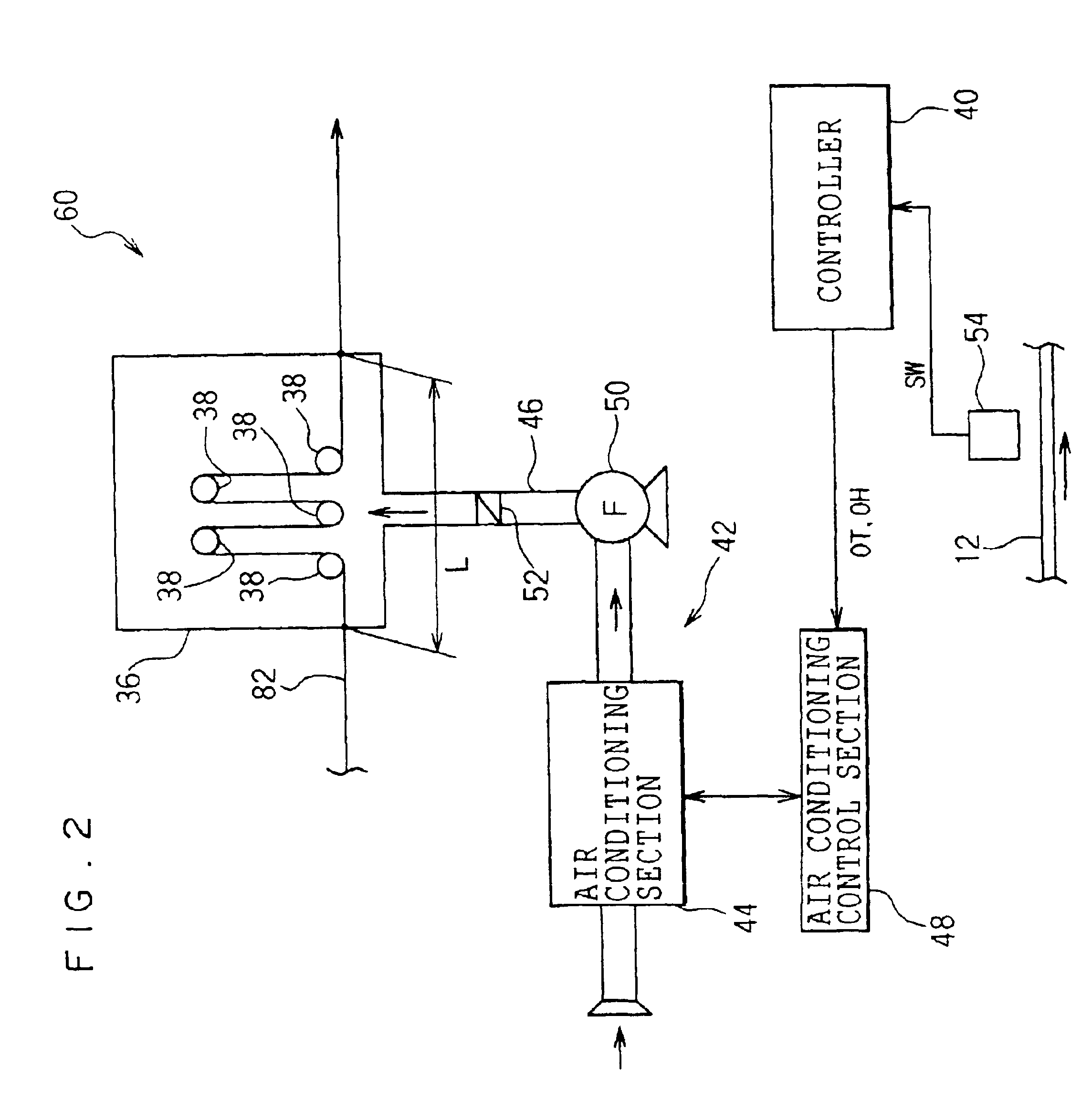

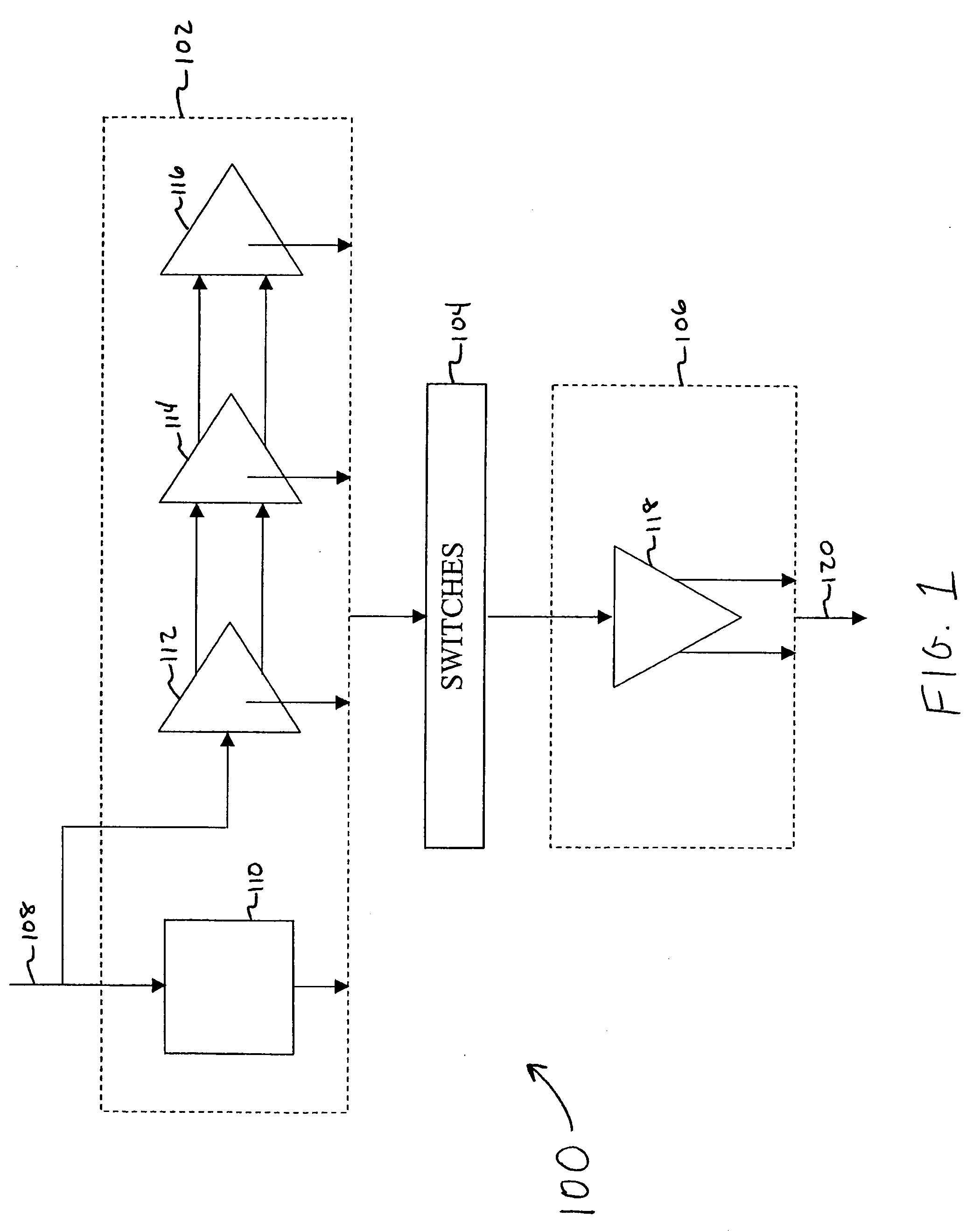

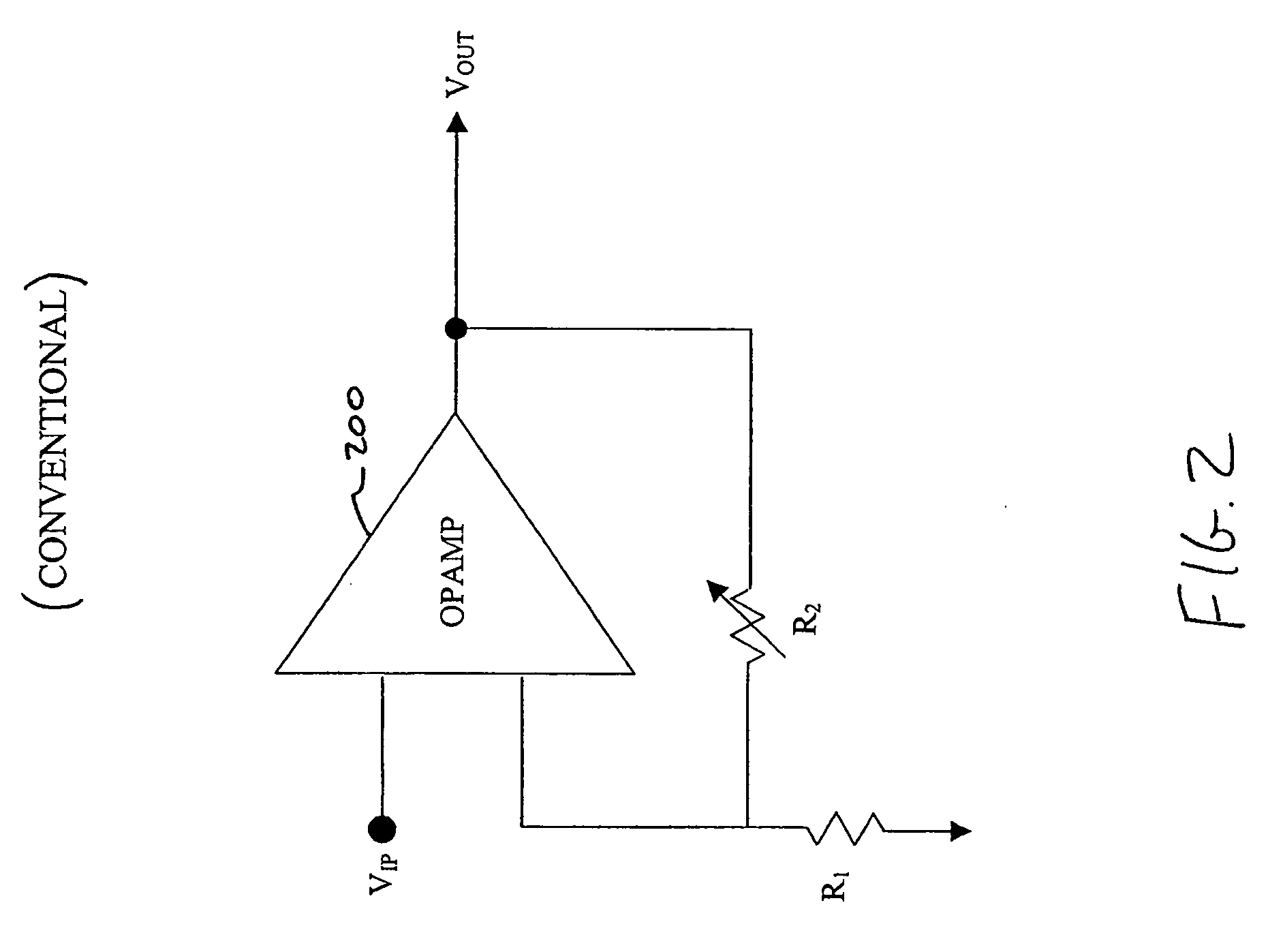

Fine step and large gain range programmable gain amplifier

ActiveUS20050140451A1Quality controlImprove signal-to-noise ratioGain controlAmplifier with semiconductor-devices/discharge-tubesProgrammable-gain amplifierEngineering

A programmable gain amplifier with three stages uses fine steps, has a large gain range, and is monotonic. The first stage comprises several amplifiers, each including a resistive feedback loop. The feedback loop comprises a series of resistors, with each resistor acting as a tap. Since the number of resistors in the loop is unchanging, monotonicity and stability is guaranteed when resistance is increased using successive taps. A switch system connects two taps at a time to an interpolation stage. Each of these taps corresponds to a specific resistor level, and thus a gain level. The interpolation stage uses a plurality of current sources inside a feedback amplifier to control the interpolation, in order to provide fine gain steps.

Owner:AVAGO TECH INT SALES PTE LTD

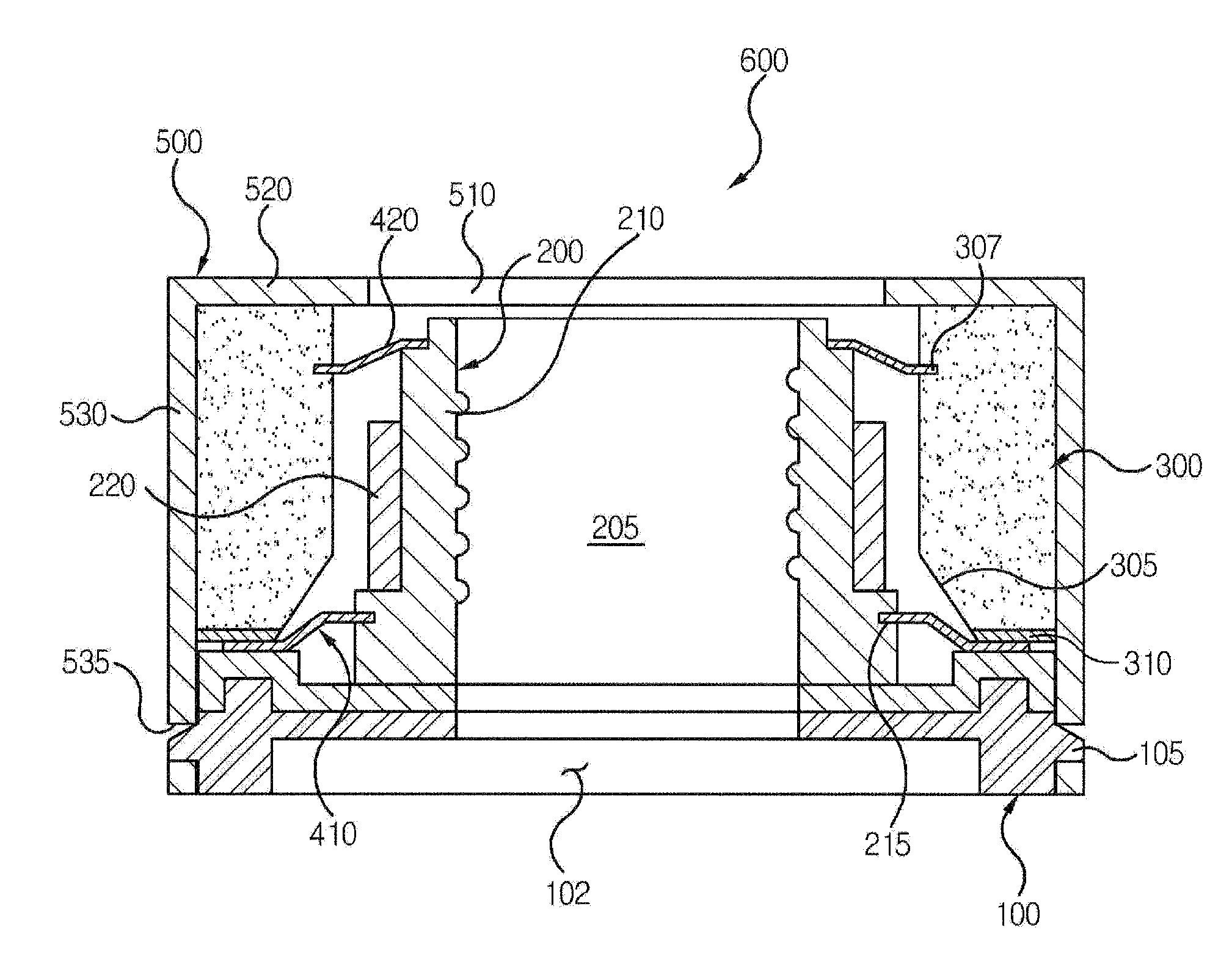

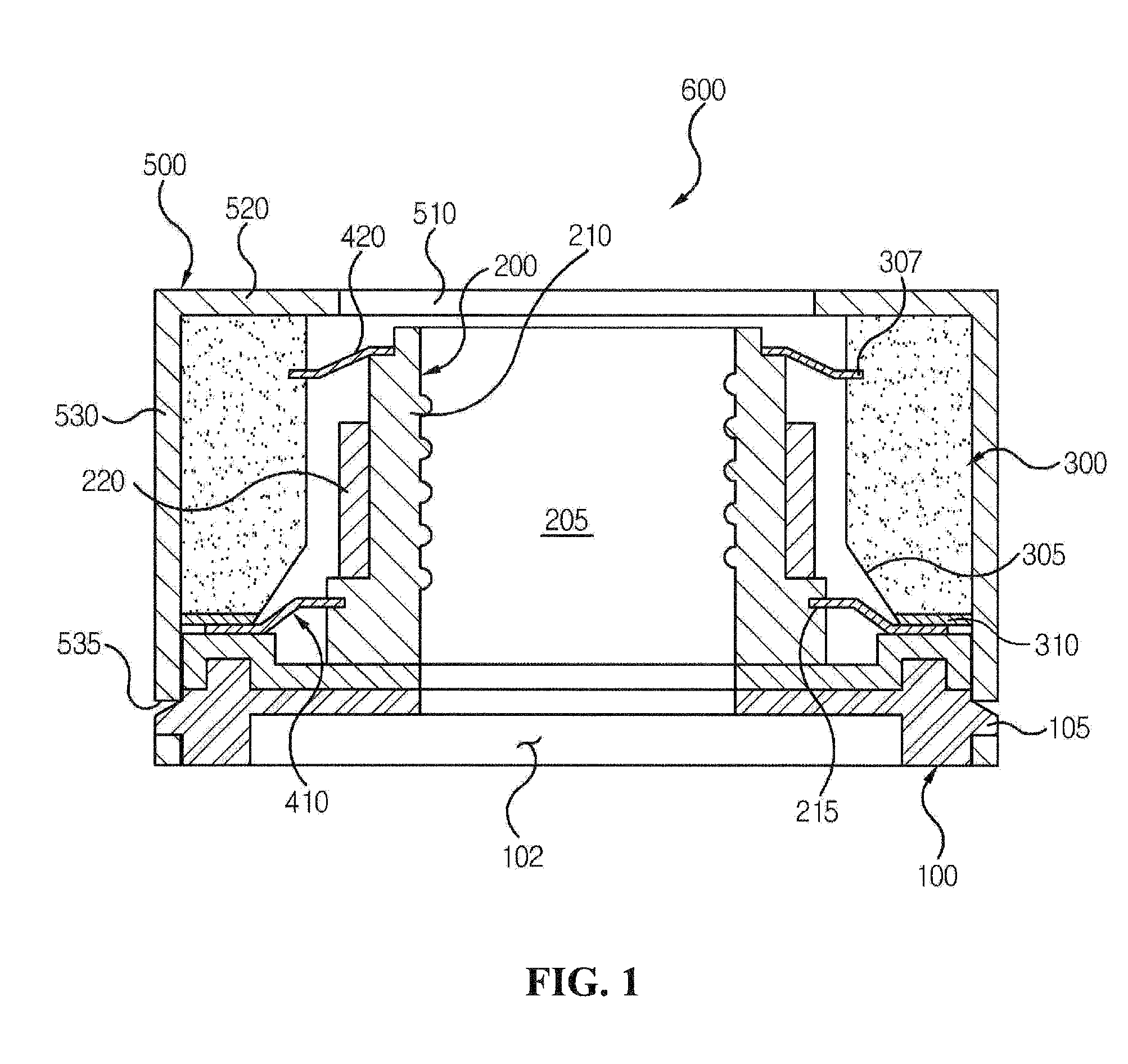

Voice coil motor

ActiveUS20110204731A1Manufacturing cost be reduceQuality controlProjector focusing arrangementCamera focusing arrangementBobbinVoice coil

A voice coil motor (VCM) is disclosed. The VCM includes a base formed with an opening; a movable body including a bobbin arranged on the base and formed with a hollow hole and a coil arranged along a periphery of the bobbin; a stator including a frame-shaped magnet arranged on the base, the magnet being discrete from the coil and wrapping a periphery of the coil; and a case covering an upper surface and an outer surface of the magnet, the case being coupled to the base.

Owner:LG INNOTEK CO LTD

Media container and media protection apparatus

The invention discloses a media container (4) adapted to protect a medium (10) havingan opening (12) adapted to allow that a medium (10) is put into the media container (4) ; anda closure (8) by which the opening (12) may be closed; wherein the closure (8) is adapted such that in its opened state air from the media container (4) may be exhausted, that in its opened state protective gas may flow into the media container (4) and that in its closed state entering and / or exiting of a fluid from the media container (4) and / or into the media container (4) is prevented.

Owner:BALGA WOLFGANG

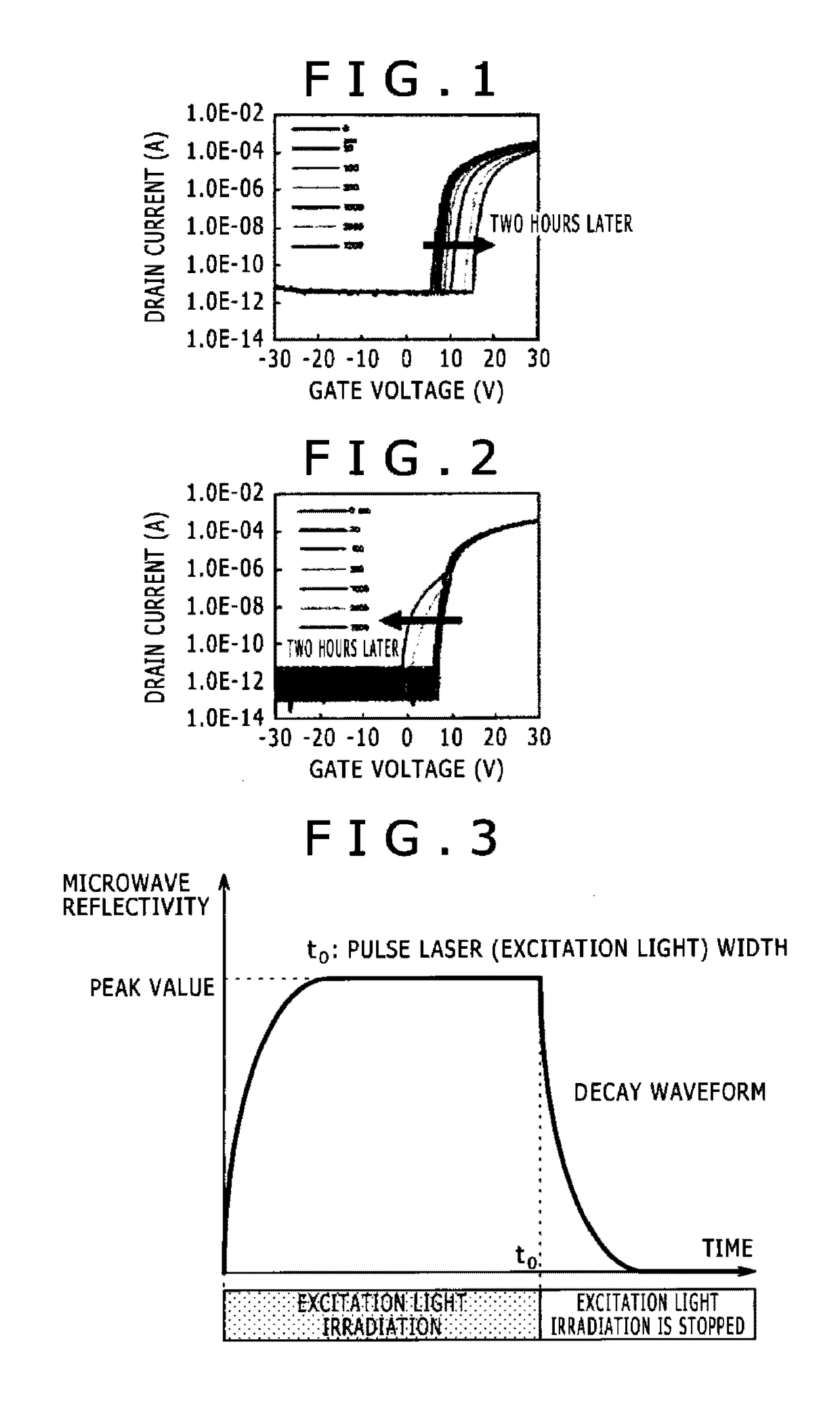

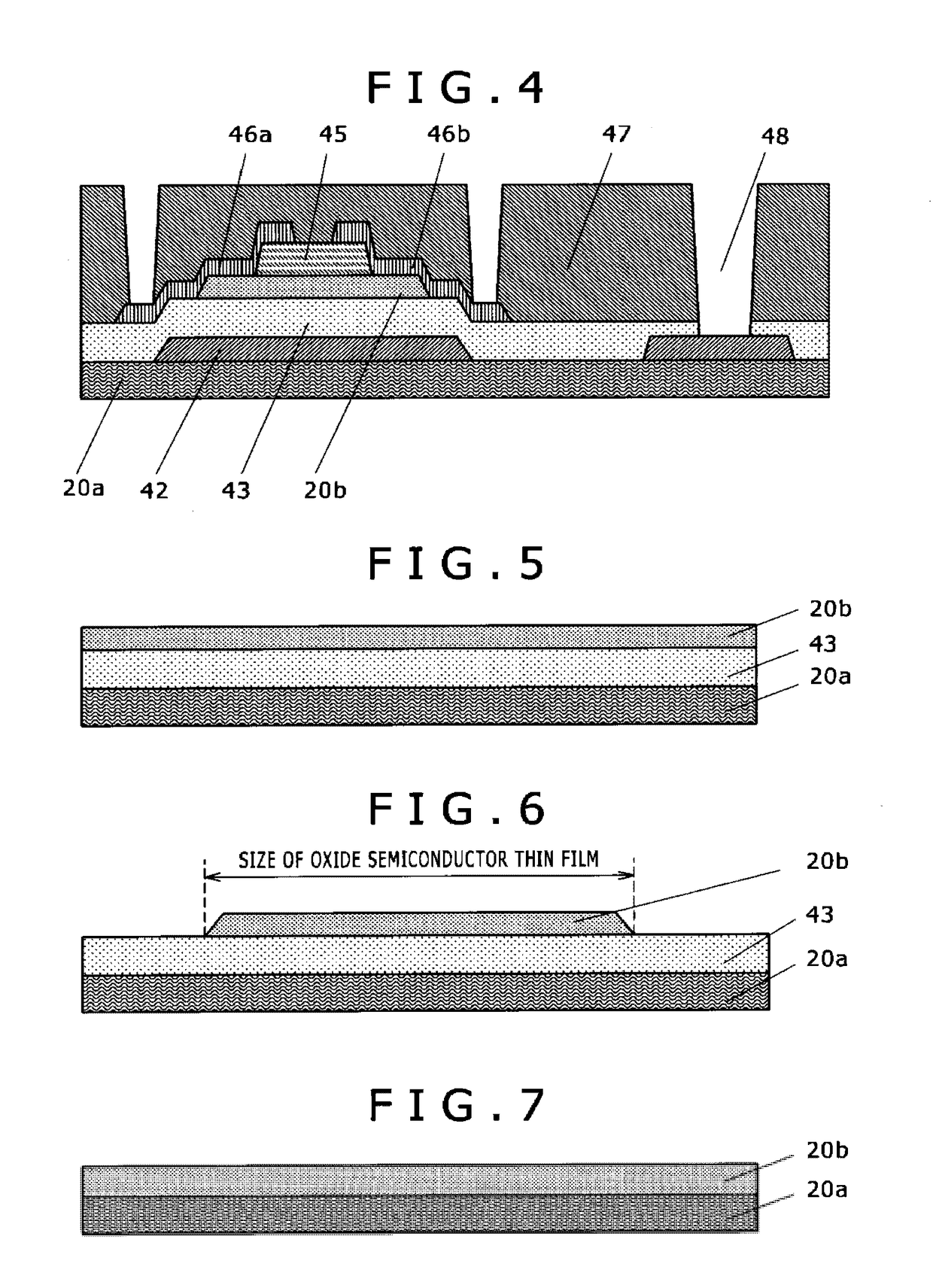

Method for evaluating quality of oxide semiconductor thin film and laminated body having protective film on surface of oxide semiconductor thin film, and method for managing quality of oxide semiconductor thin film

ActiveUS20170194218A1Accurately and simply evaluatedQuality controlSemiconductor/solid-state device testing/measurementSolid-state devicesOxide semiconductorContact method

Provided is a method for reliably and simply evaluating the quality of an oxide semiconductor thin film and a laminated body having a protective film on the surface of this oxide semiconductor thin film. Also provided is a method for reliably and simply managing the quality of an oxide semiconductor thin film. This method, which is for evaluating the quality of an oxide semiconductor thin film and a laminated body having a protective film on the surface of this oxide semiconductor thin film, has: a first step, wherein an oxide semiconductor thin film is formed on a substrate, after which the electron state of the oxide semiconductor thin film is measured by a contact method or a noncontact method, thereby evaluating defects arising from in-film defects in the oxide semiconductor thin film; and a second step, wherein the oxide semiconductor thin film is processed on the basis of a condition determined on the basis of that evaluation, after which a protective film is formed on the surface of the oxide semiconductor thin film, and then the electron state of the oxide semiconductor thin film is measured by a contact method or a noncontact method, thereby evaluating defects arising from defects at the interface between the oxide semiconductor thin film and the protective film.

Owner:KOBE STEEL LTD

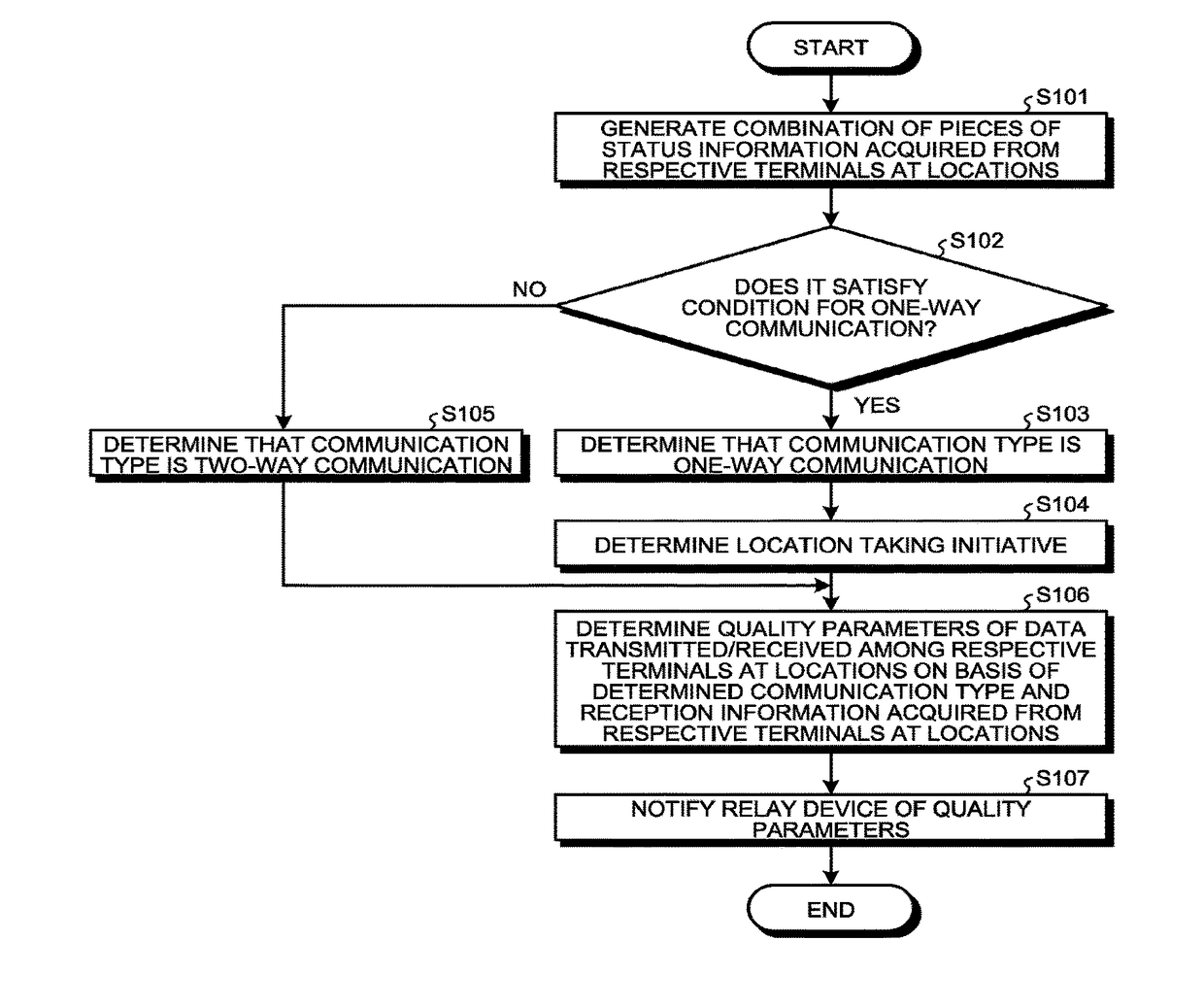

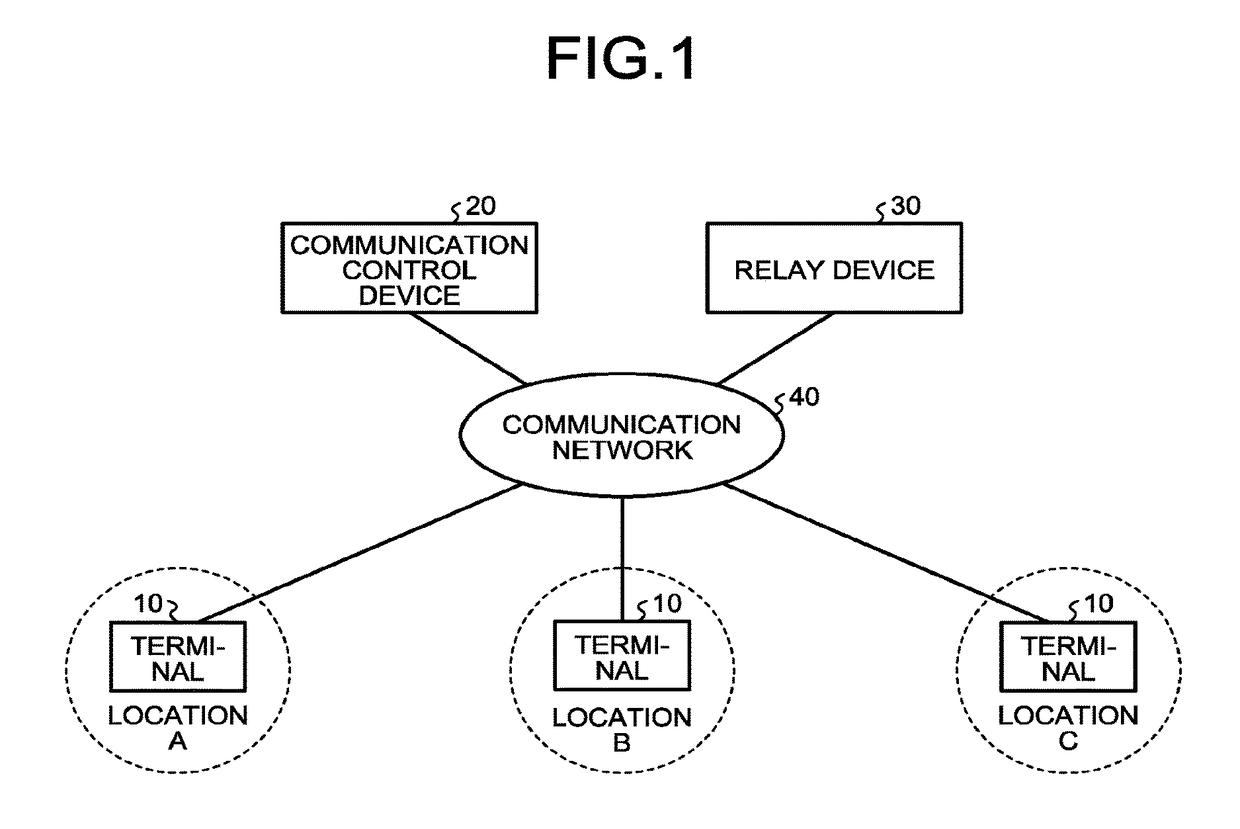

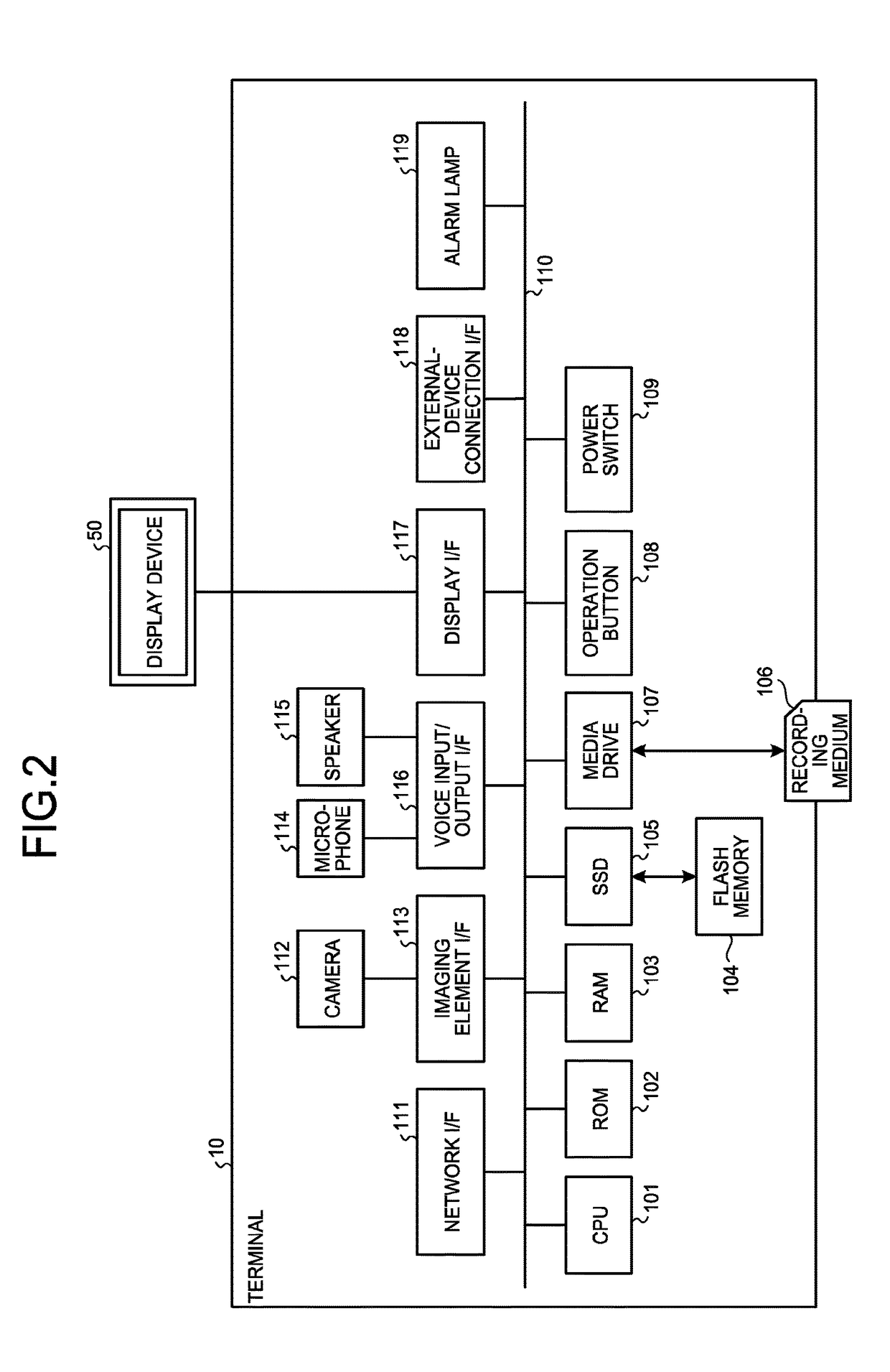

Communication control device, communication system, and communication control method

ActiveUS20180007095A1Quality controlTelevision conference systemsHybrid transportQuality controlReal-time computing

A communication control device is configured to control data communication between terminals using a communication network. The communication control device include: a status-information acquiring unit configured to acquire respective pieces of status information which represent operating states of the terminals; a reception-information acquiring unit configured to acquire respective pieces of reception information which represent states of the communication network when the terminals have received data; a communication determining unit configured to determine a type of communication on the basis of a combination of pieces of status information of multiple terminals that participate in the same communication; and a quality control unit configured to control quality of data that each terminal transmits or receives on the basis of the determined type of communication and the acquired reception information.

Owner:RICOH KK

Preparation method of ethionamide tablet

InactiveCN103462912ALittle difference in tablet weightQuality controlAntibacterial agentsPill deliverySolventSieve

The invention discloses a preparation method of an ethionamide tablet, and the preparation method comprises the following steps: (1) weighing the following raw materials by weight: 250 parts of ethionamide; 40-55 parts of a filler; 15-25 parts of a disintegrating agent; 10-15 parts of a binder; 6.25 parts of a flow aid and 1 part of a lubricant; and (2) mixing the ethionamide and the flow aid, crushing, sieving by a 100 mesh standard sieve, adding the filler, the disintegrating agent and the binder for mixing, adding an auxiliary solvent with an amount being 6% of the total amount of the formula for wet granulation, baking at the temperature of 60DEG C for 20min, trimming granules by a 16-20 mesh standard sieve, adding the lubricant, and tabletting to obtain the ethionamide tablet. By using the preparation method of the invention, crushing and sieving of ethionamide raw material drug is convenient, the prepared tablet is small in tablet weight difference, and the quality of the drug is well controlled.

Owner:TIANJIN KUNJIAN BIOLOGICAL PHARMA

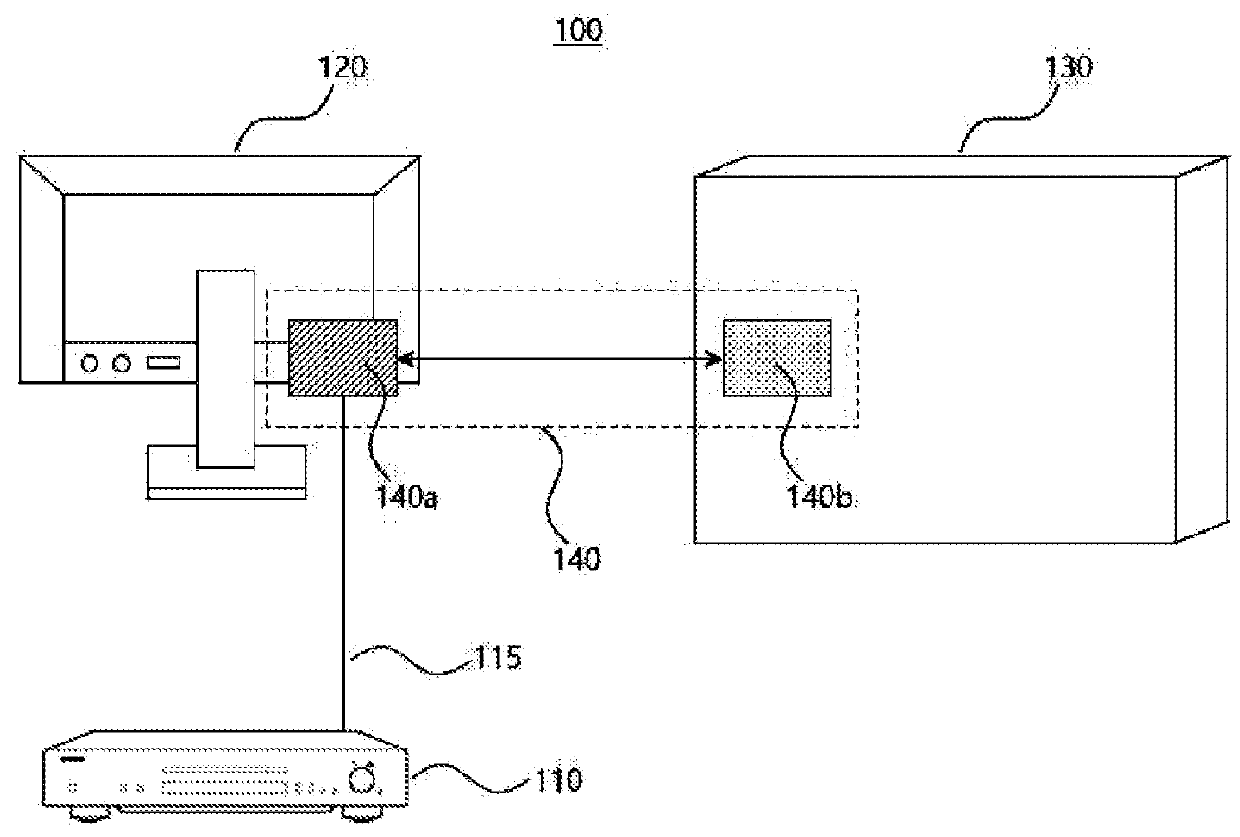

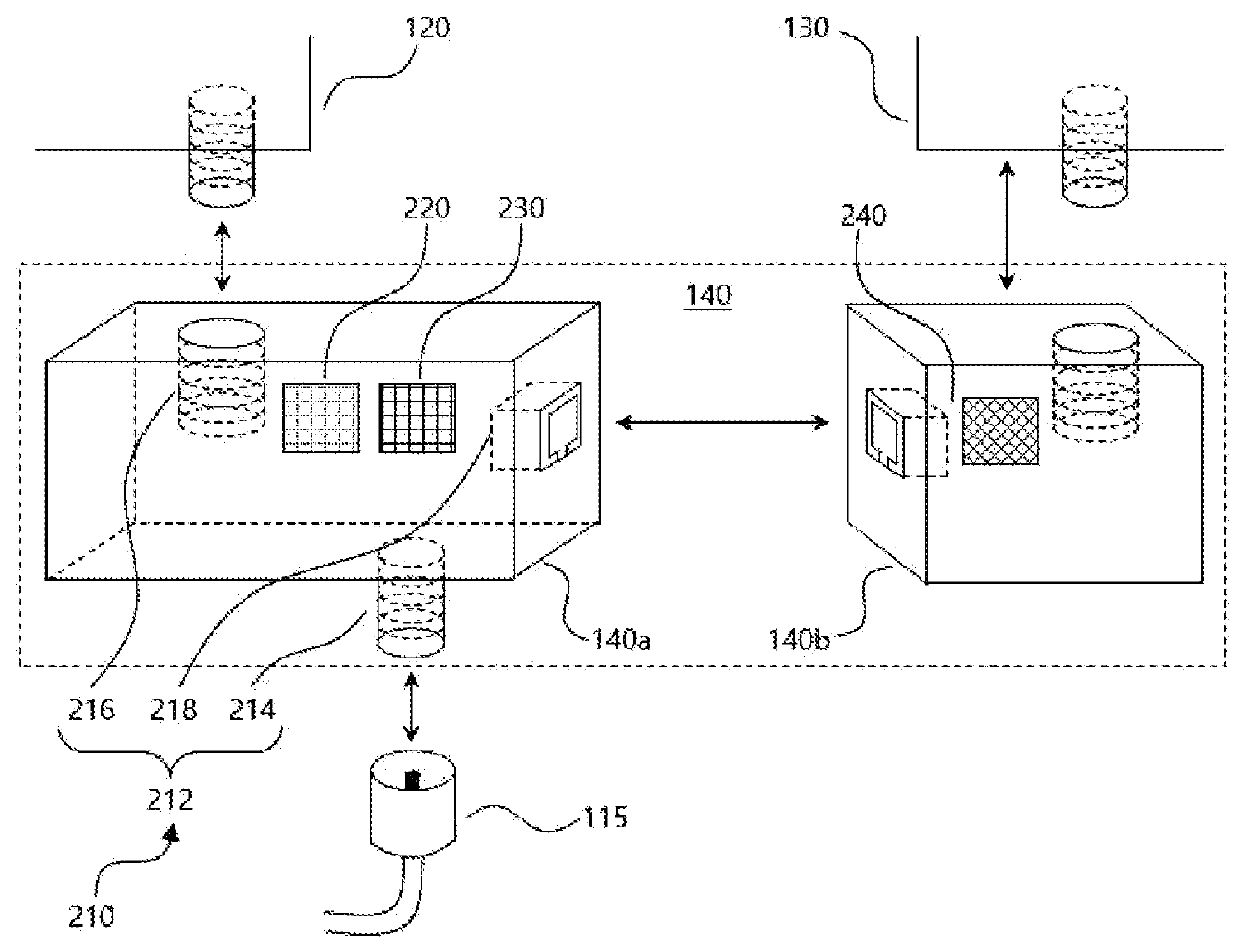

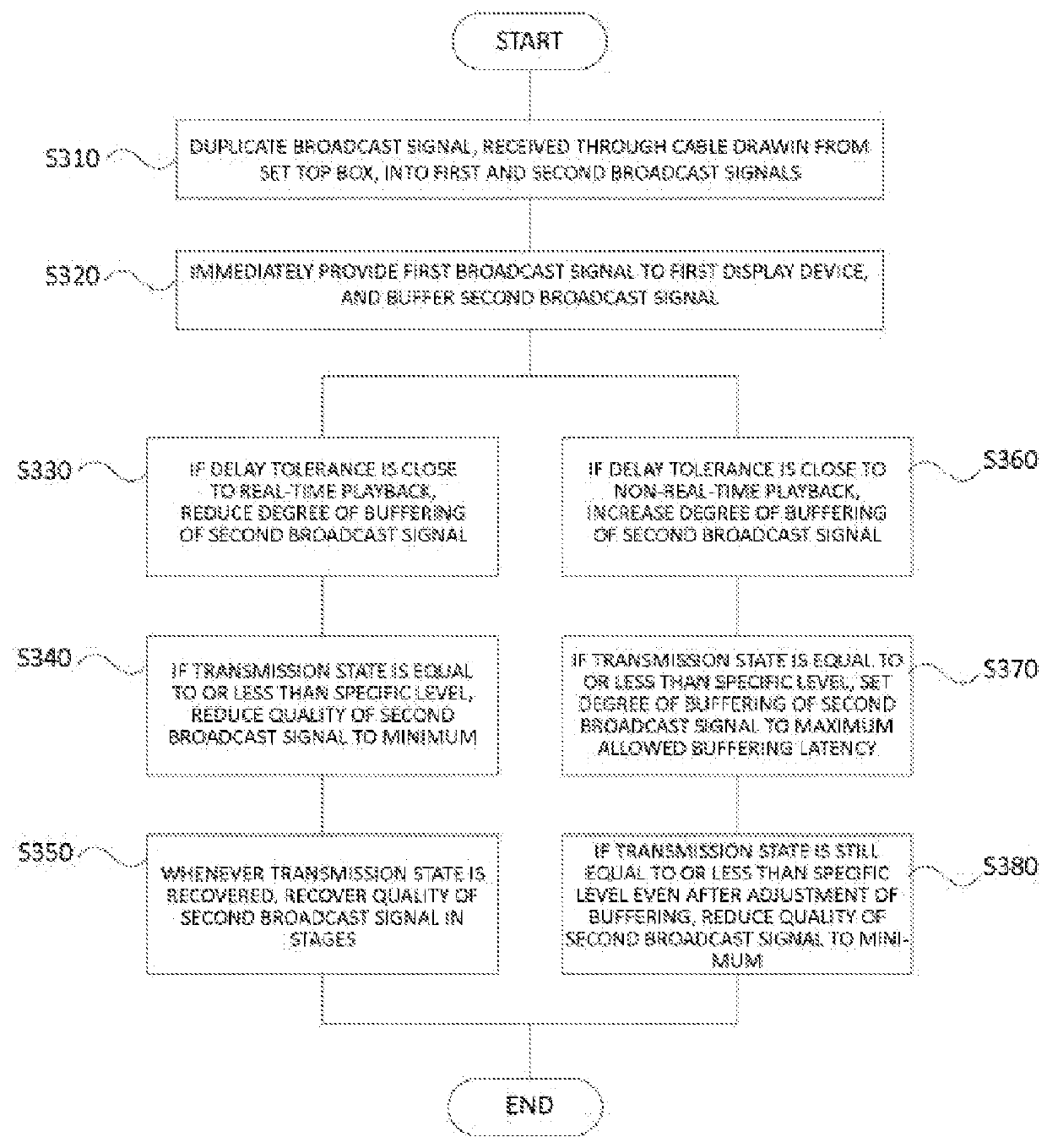

Multi-display control apparatus

InactiveUS20180098130A1Quality controlEfficiently provideSelective content distributionWi-FiDisplay device

Disclosed is a multi-display control apparatus including: a broadcast signal splitter connected to a cable, which is a medium for receiving broadcast content, and configured to duplicate a broadcast signal received through the cable into first and second broadcast signals and immediately provide the first broadcast signal to a first display device; a buffer configured to buffer the second broadcast signal; a transmitter configured to perform digital encoding of the duplicated second broadcast signal based on a state of transmission to a second display device, and transmit the encoded data over Ethernet or Wi-Fi; a broadcast signal provision unit configured to receive and decode the encoded data, and provide the decoded data as an input to the second display device.

Owner:QUOPIN

Method, system, and non-transitory computer readable record medium for video quality control

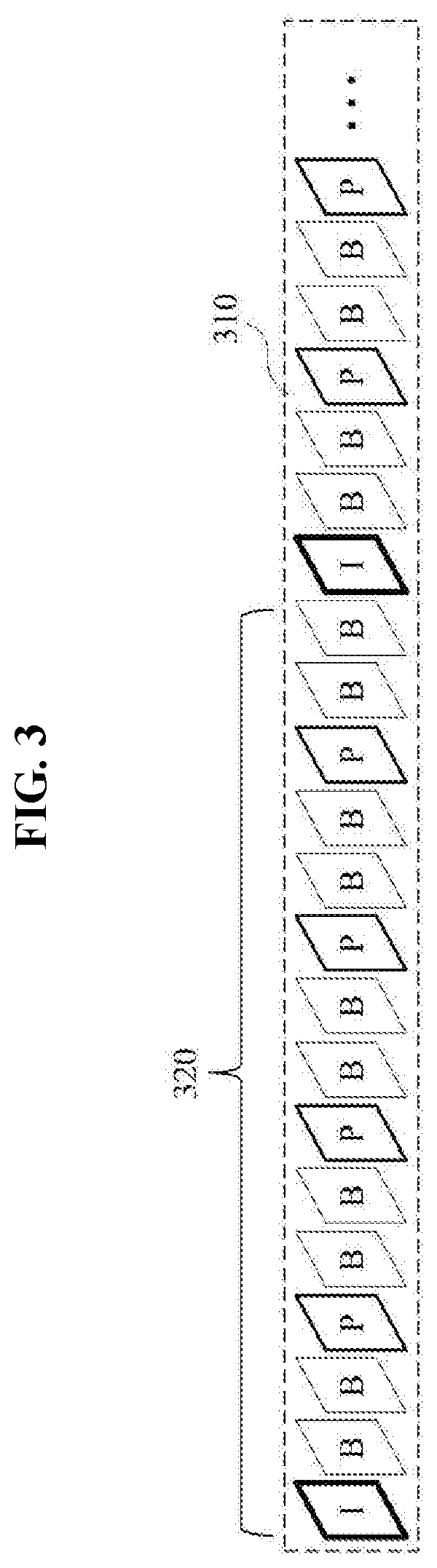

Provided are a method, a system, and a non-transitory computer readable record medium for video quality control. A quality control method may include: receiving a video stream including frames classified into a plurality of frame types based on a reference relationship between the frames for decoding; selecting a frame type among the plurality of frame types; and controlling a quality of the video stream by multiplexing the frames included in the video stream and by outputting one or more of the frames that have the selected frame type.

Owner:LINE CORPORATION

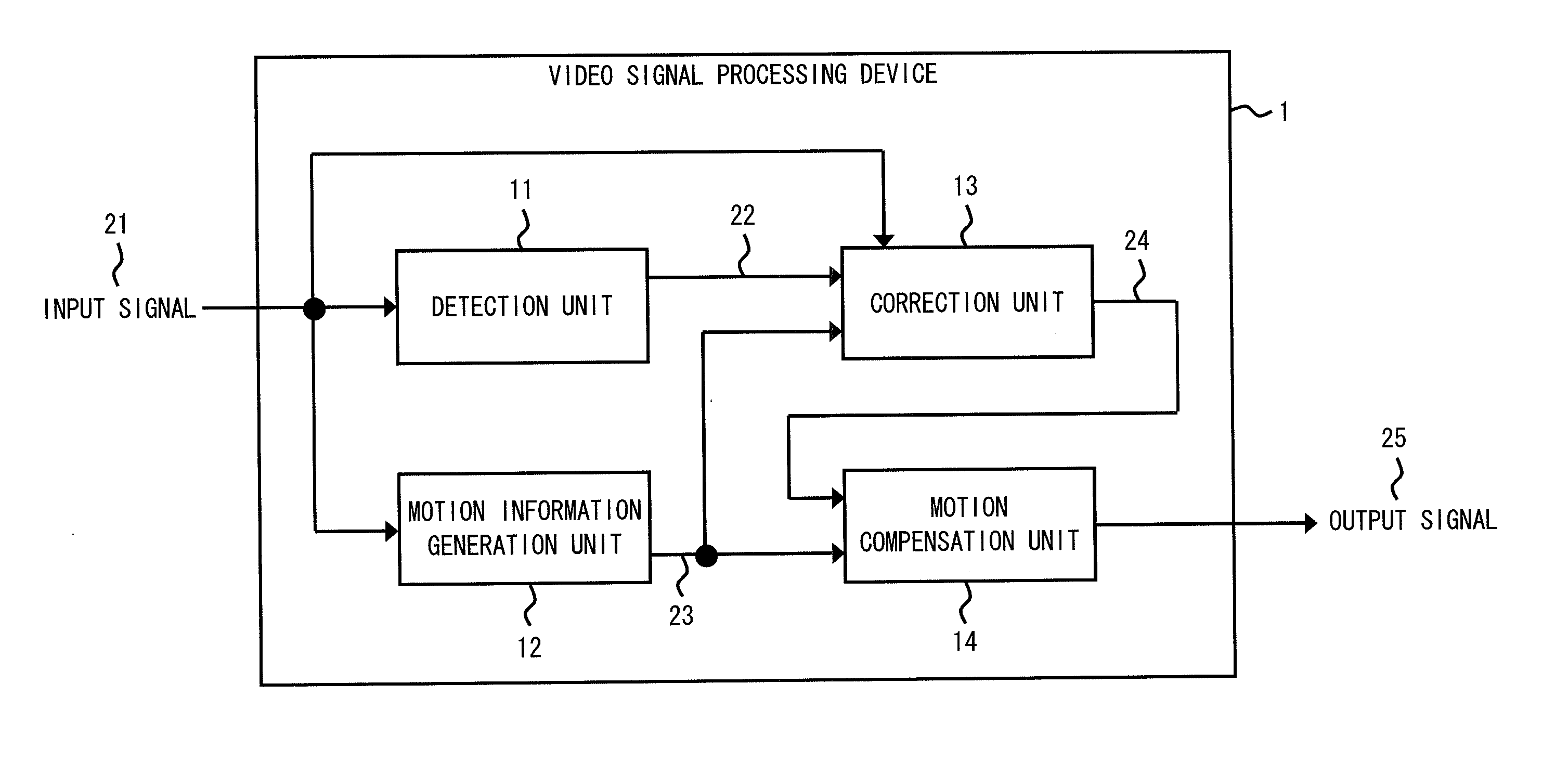

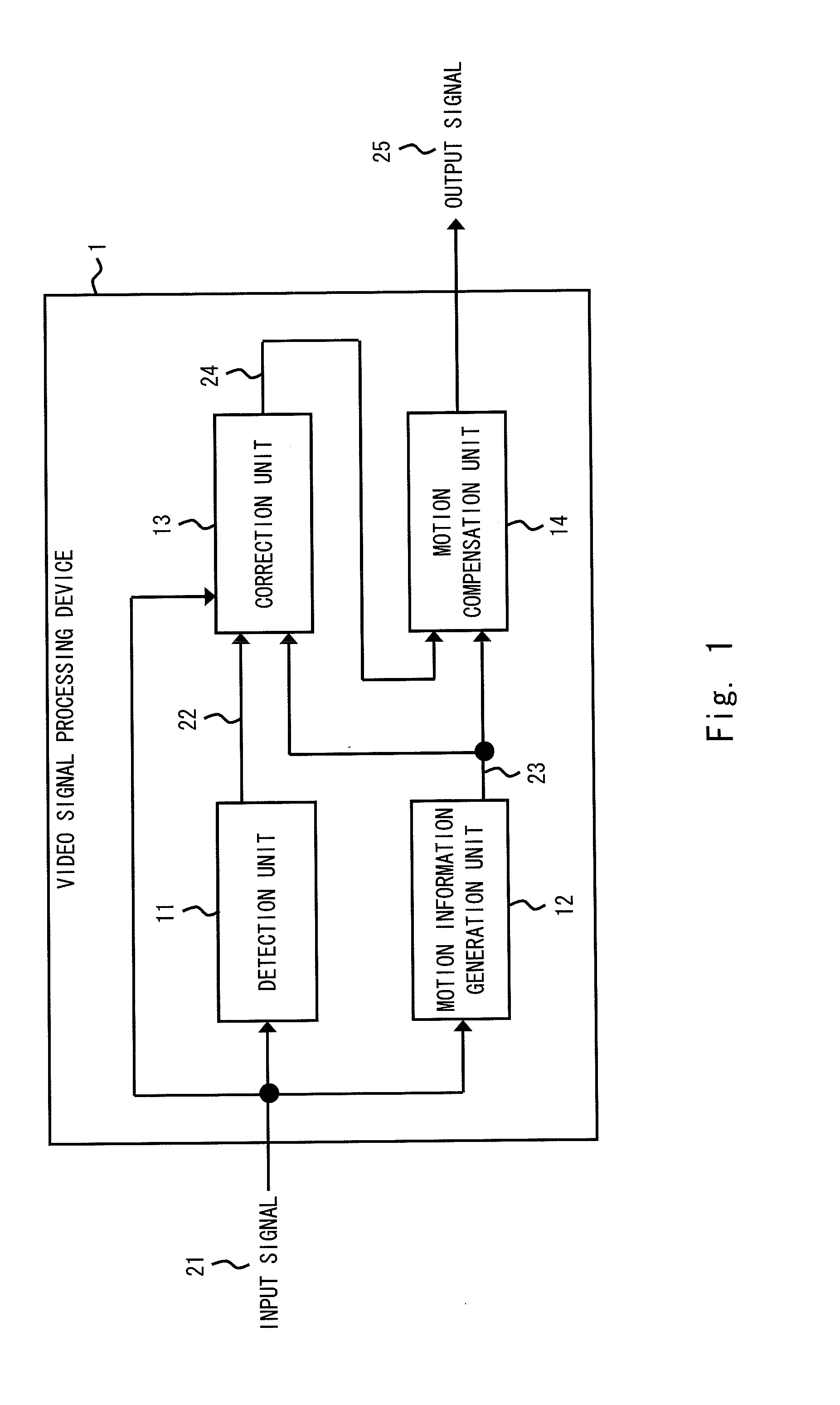

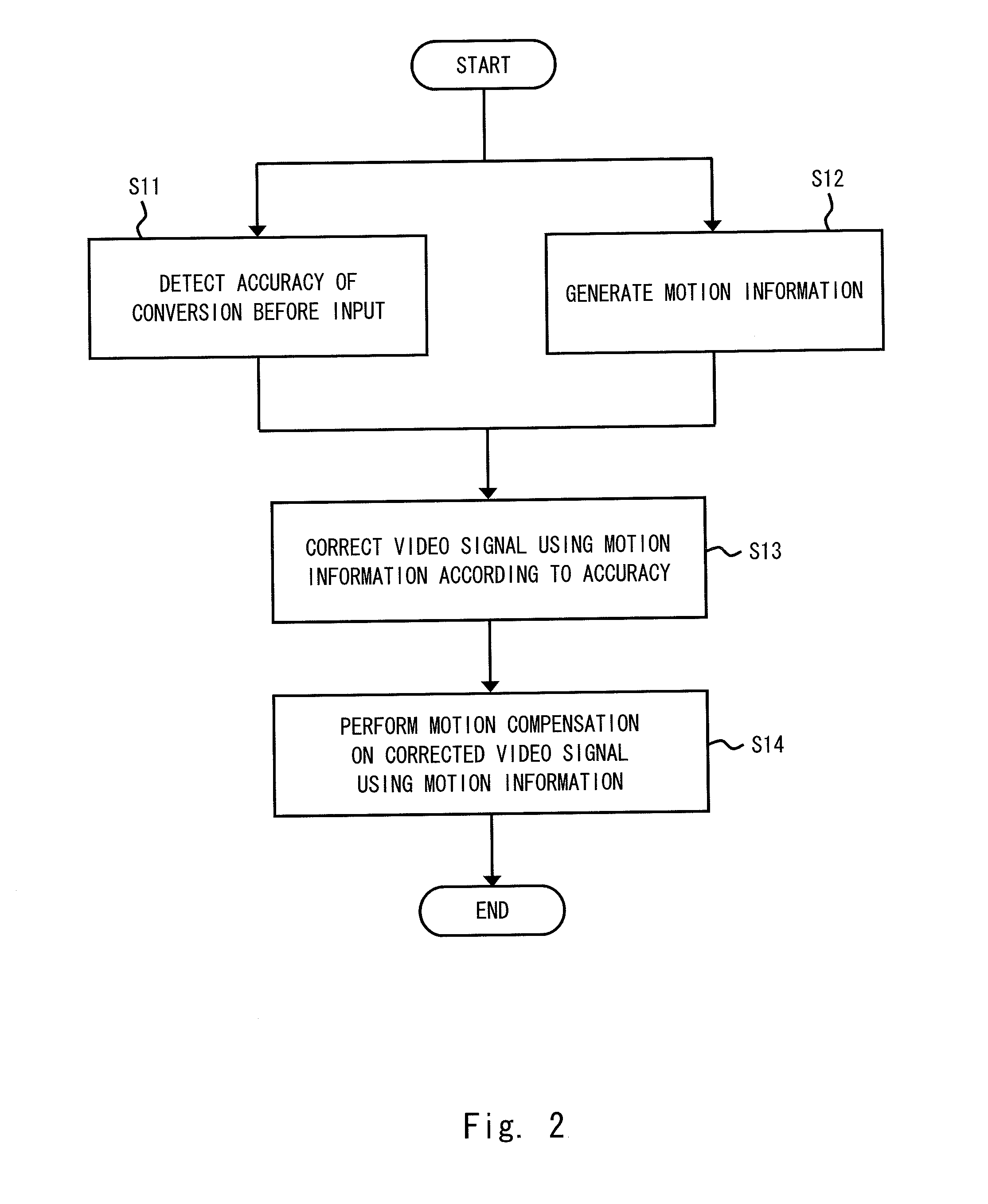

Video signal processing device, video signal processing method, and non-transitory computer readable medium storing image processing program

ActiveUS20110141369A1Significant effectQuality controlTelevision system detailsColor television detailsSignal processingImaging processing

A video signal processing device includes: a correction unit which performs correction such that when a first frame to be displayed at a first time includes a pixel different from a pixel to be included in the first frame, the pixel different from the pixel to be included in the first frame is corrected to the pixel to be included in the first frame, and when a second frame to be displayed at a second time prior to the first time includes a pixel different from a pixel to be included in the second frame, the pixel different from the pixel to be included in the second frame is corrected to the pixel to be included in the second frame; and a motion compensation unit which generates an interpolation frame to be displayed at a time between the first and second times by referring to the first and second frames.

Owner:RENESAS ELECTRONICS CORP

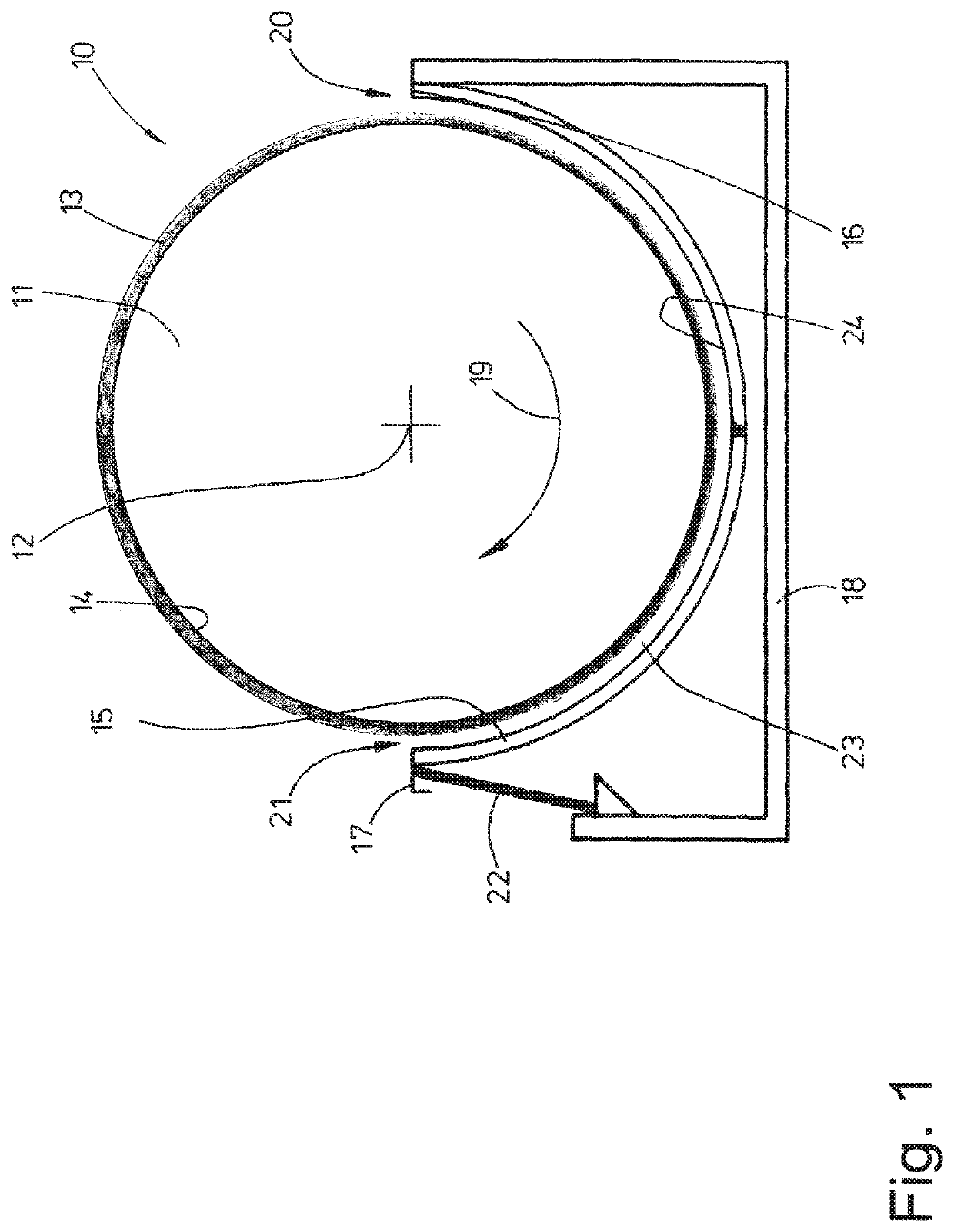

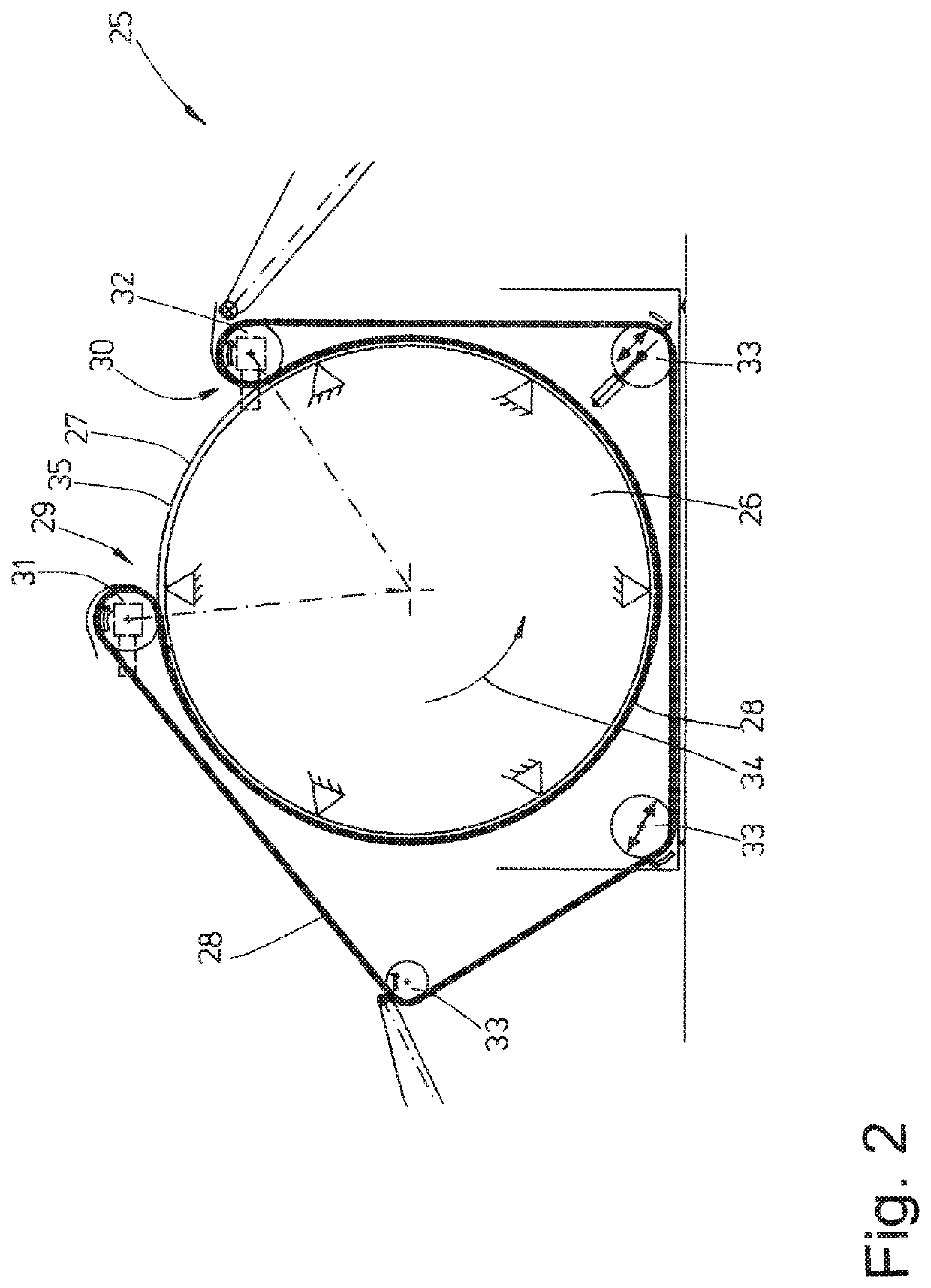

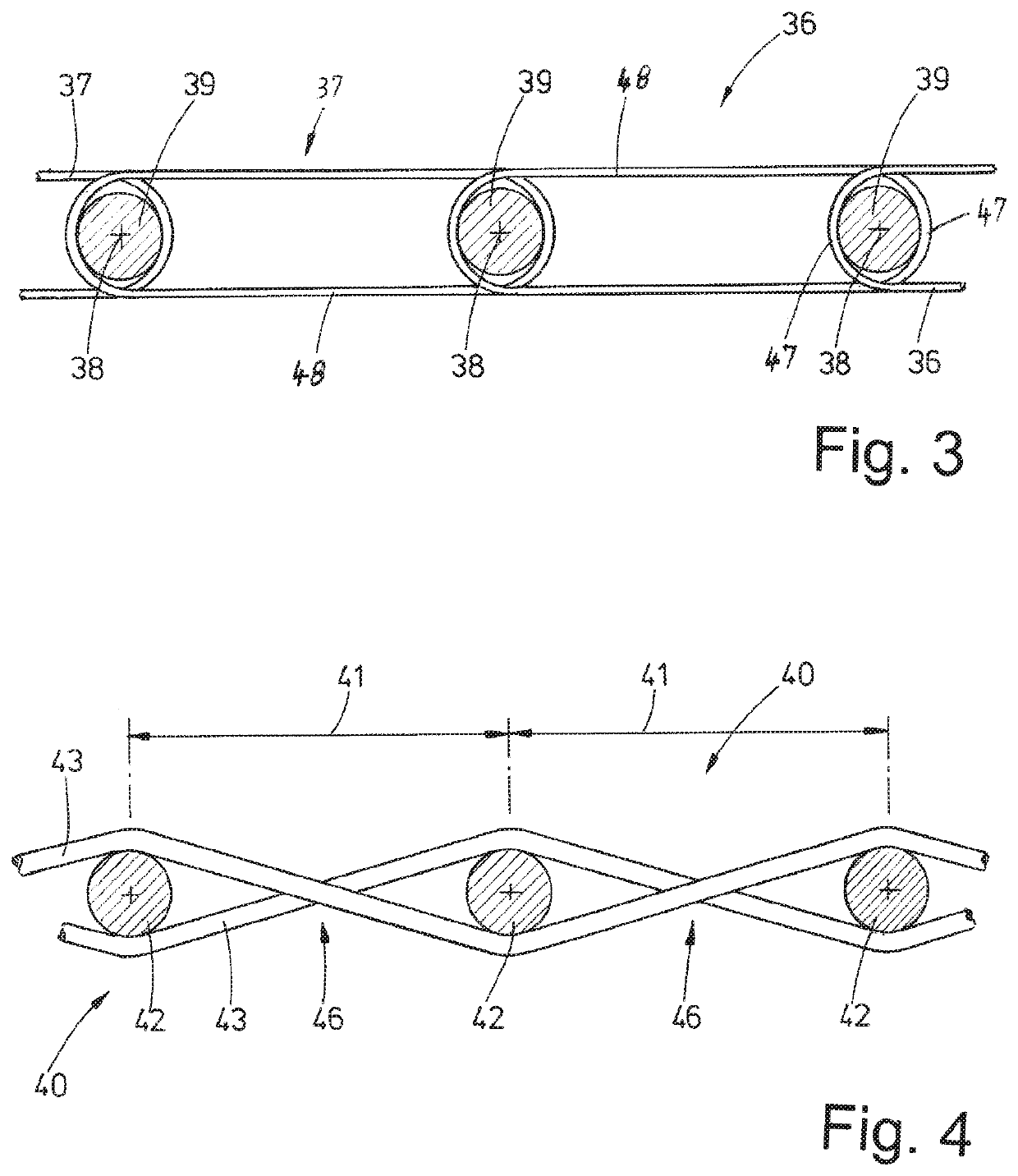

Device for ironing laundry items

InactiveUS20200102693A1Increase flexibilityQuality controlIroning padsIroning machinesPhysicsWoven fabric

Ironers are provided with spiral wrappings for the ironer roll thereof and ironer belts which are subjected to significant stress during the ironing process. This leads to settling phenomena and to warpage in the known spiral wrappings and ironer belts, whereby the ironing quality is impaired. The object of the invention is to form the spiral wrapping and / or the ironer belt from a base layer and a non-woven fabric layer assigned to this base layer on at least one side. The non-woven fabric layer is preferably connected to the base layer by needling. The base layer forms a stable three-dimensional support layer for the non-woven fabric layer, whereby the ironer belt and / or the spiral wrapping may be effectively stabilized and as a result may be used for a longer period of time without settling phenomena and warpage.

Owner:KANNEGIESSER GMBH CO HERBERT

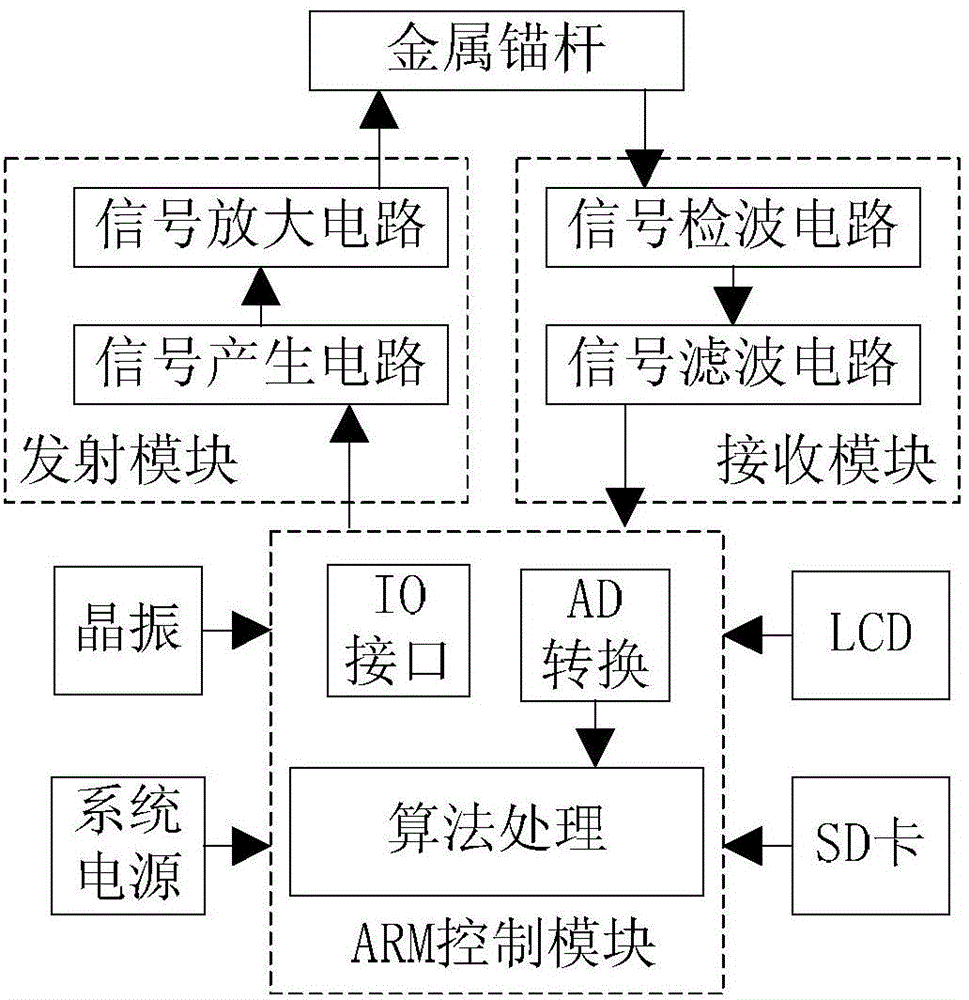

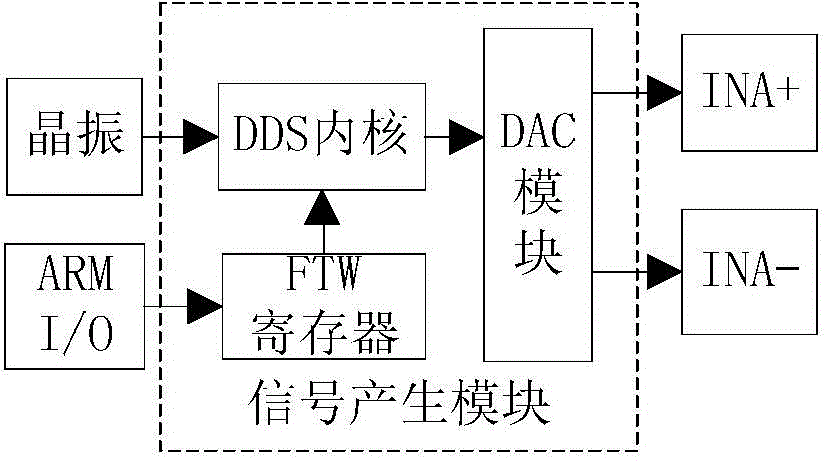

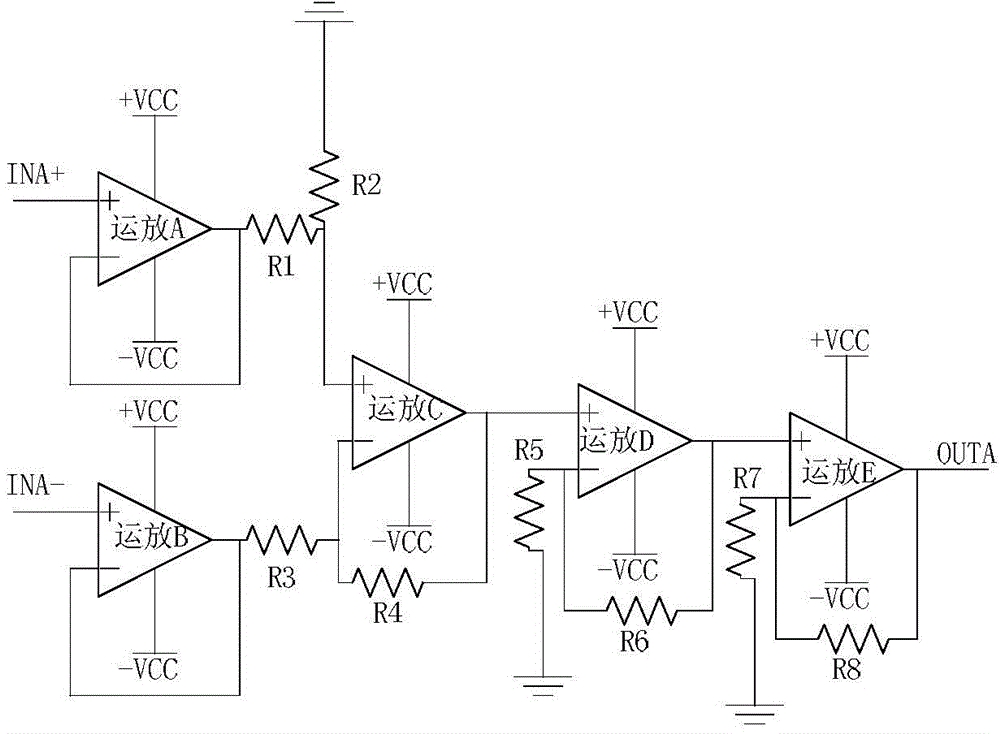

Anchor rod length measuring method and anchor rod length measuring instrument

ActiveCN104406549AEnhanced couplingImprove stabilityUsing wave/particle radiation meansWave troughStanding wave

The invention discloses an anchor rod length measuring method and an anchor rod length measuring instrument. The anchor rod length measuring method comprises the following steps: a transmitting module is used for generating a plurality of sinusoidal signals with different frequency values according to a set frequency interval and transmitting the sinusoidal signals to an anchor rod in sequence; each sinusoidal signal is transmitted from the starting end of the anchor rod and is reversely transmitted to the starting end of the anchor rod after being reflected at the tail end of the anchor rod, so that incident waves and reflecting waves at the starting end of the anchor rod can be superposed to form standing wave signals; a receiving module is used for receiving the standing wave signals at the starting end of the anchor rod in sequence; a control module is used for mapping voltage values and frequency values of all the standing wave signals onto a two-dimensional curve; the length measurement of the anchor rod is realized through finding out a frequency value corresponding to a first wave trough point of the two-dimensional curve. The anchor rod length measuring method and the anchor rod length measuring instrument have the benefits that measuring signals are electromagnetic waves, so that non-destructive detection can be realized; the anchor rod length measuring instrument has he advantages of great coupling convenience, wide length measurement scope, high measurement accuracy and the like.

Owner:LIUZHOU YUANCHUANG EFI TECH

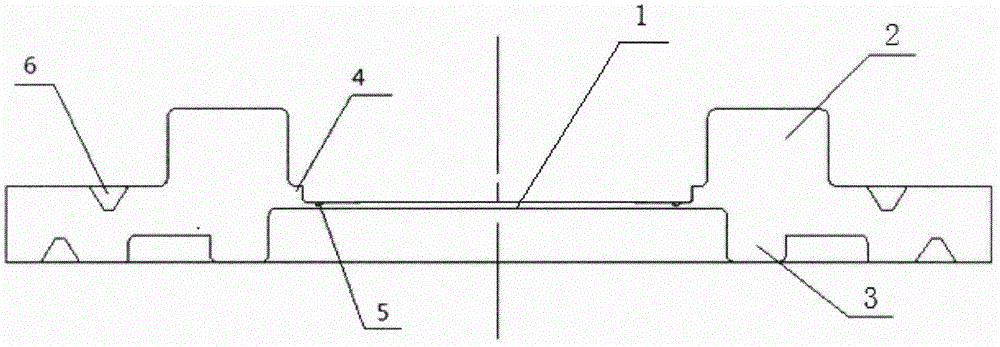

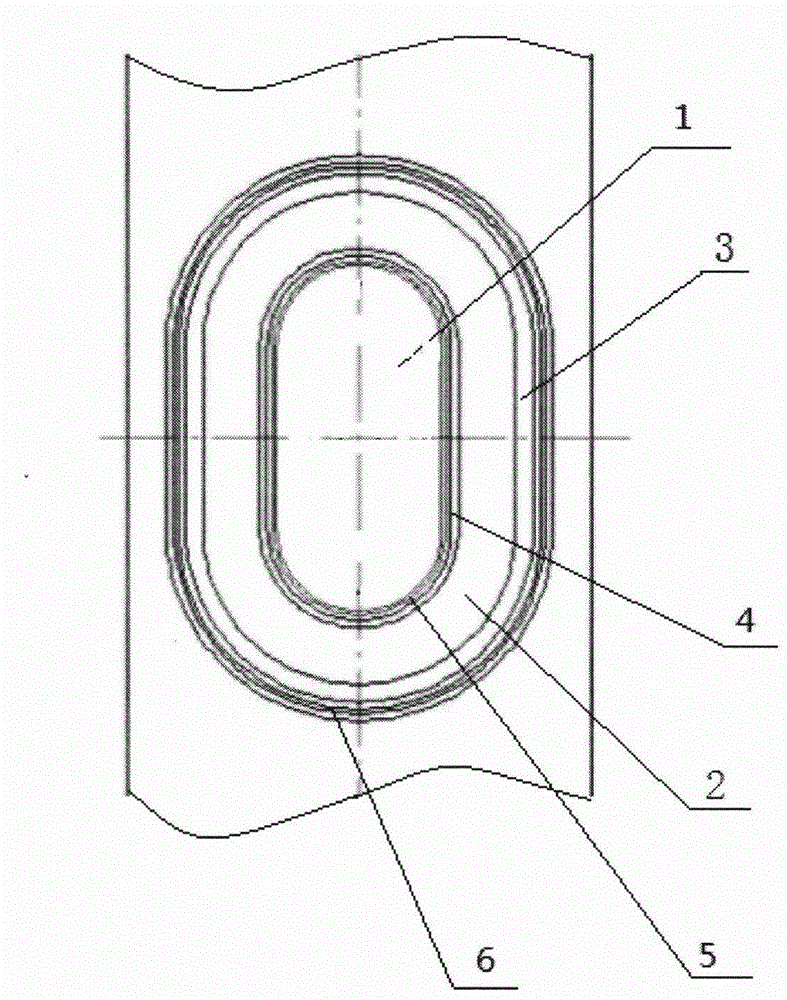

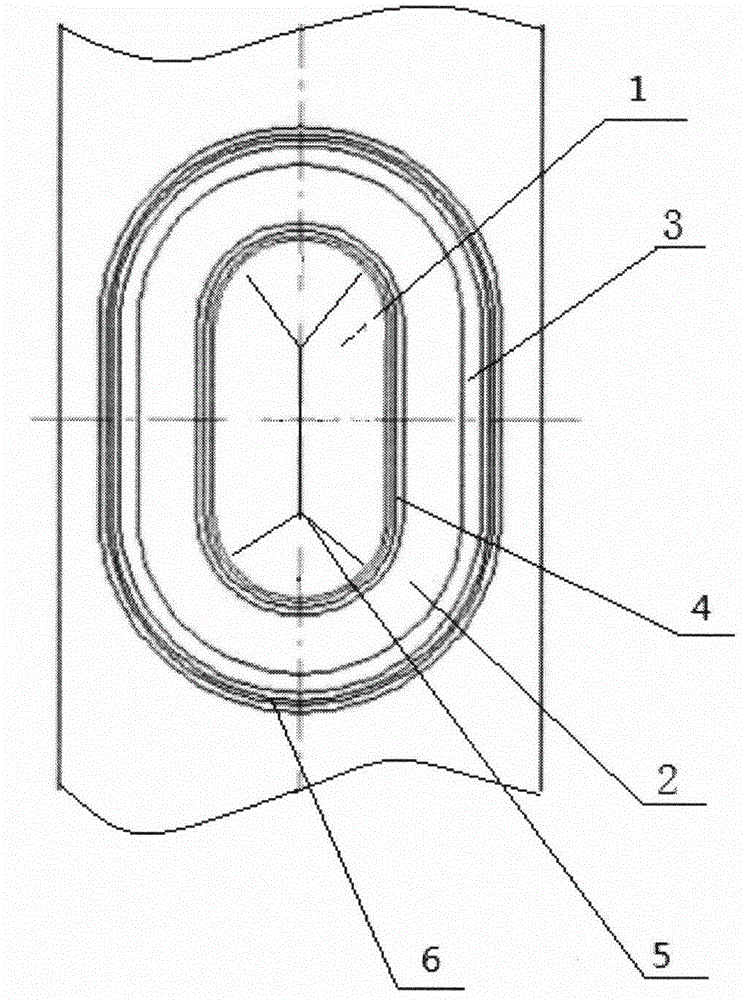

Integrally-formed explosion-proof membrane used on top cover of automobile lithium battery, and preparation method for explosion-proof membrane

ActiveCN106129301AAvoid meltdownAvoid security issuesCell component detailsEngineeringLithium battery

The invention discloses an integrally-formed explosion-proof membrane used on a top cover of an automobile lithium battery, and a preparation method for the explosion-proof membrane. The explosion-proof membrane is characterized in that the overall explosion-proof membrane and the top cover of the lithium battery are manufactured and formed concurrently; the explosion-proof membrane is oval; an oval enclosure wall is arranged around the explosion-proof membrane; a protruding small enclosure wall is arranged on the lower surface, close to the lower surface of the inner edge, of the enclosure wall; a transitional small lug boss is arranged on the inner side of the enclosure wall; a pressing rib explosion-proof groove is formed in the oval part on the edge of the small lug boss; and trapezoid grooves are formed in the upper and lower surfaces, which are connected with the top cover of the lithium battery, outside the oval enclosure wall respectively. The explosion-proof membrane has the advantages that the explosion-proof membrane and the top cover of the lithium battery are manufactured and formed concurrently, so that a step of welding is omitted; and therefore, the safety problem of the product caused by melt-through of the explosion-proof membrane, or insecure welding and the like can be avoided consequently.

Owner:NINGBO ZHENYU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com