Patents

Literature

516results about "Conductor/cable marking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

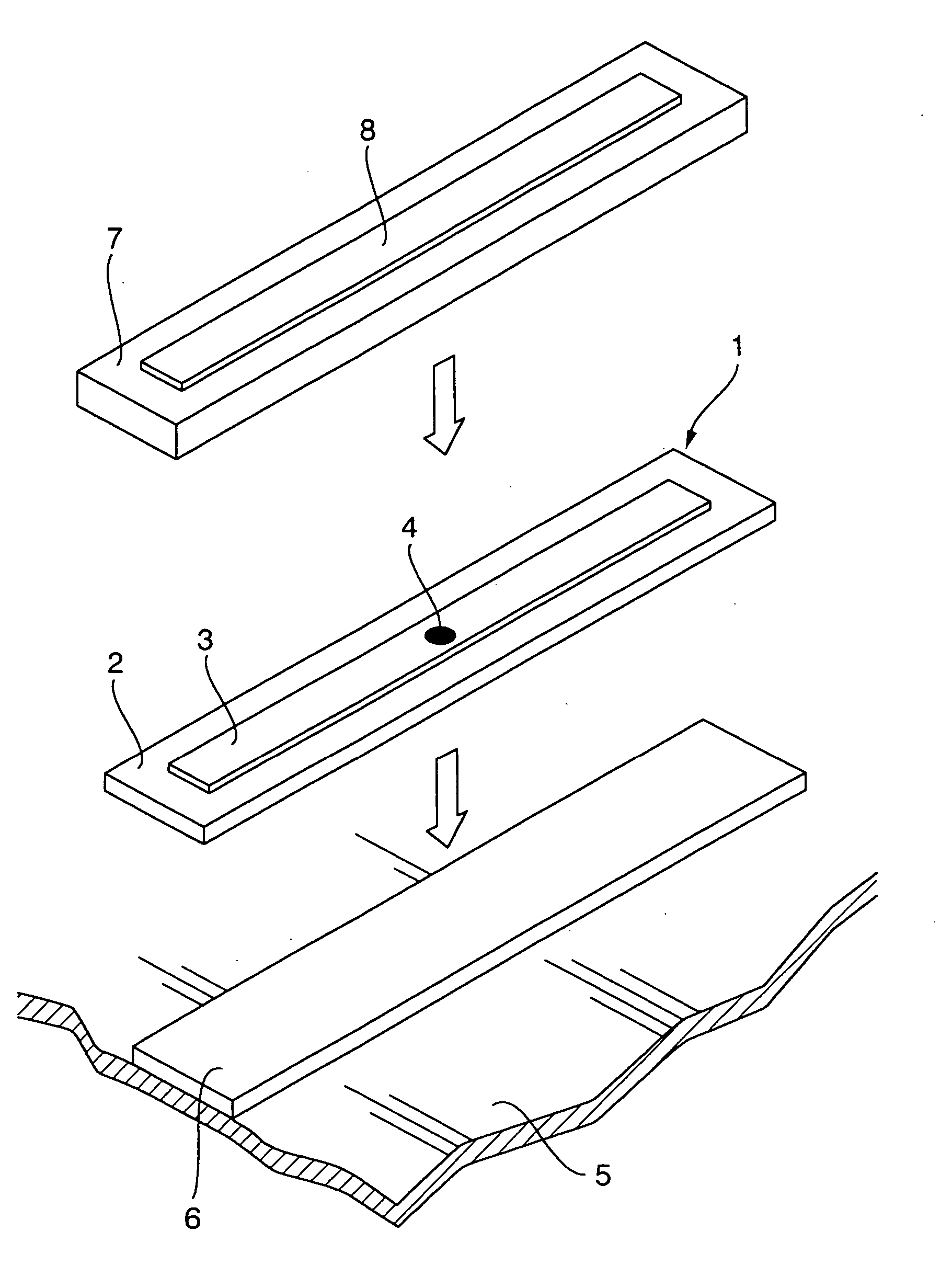

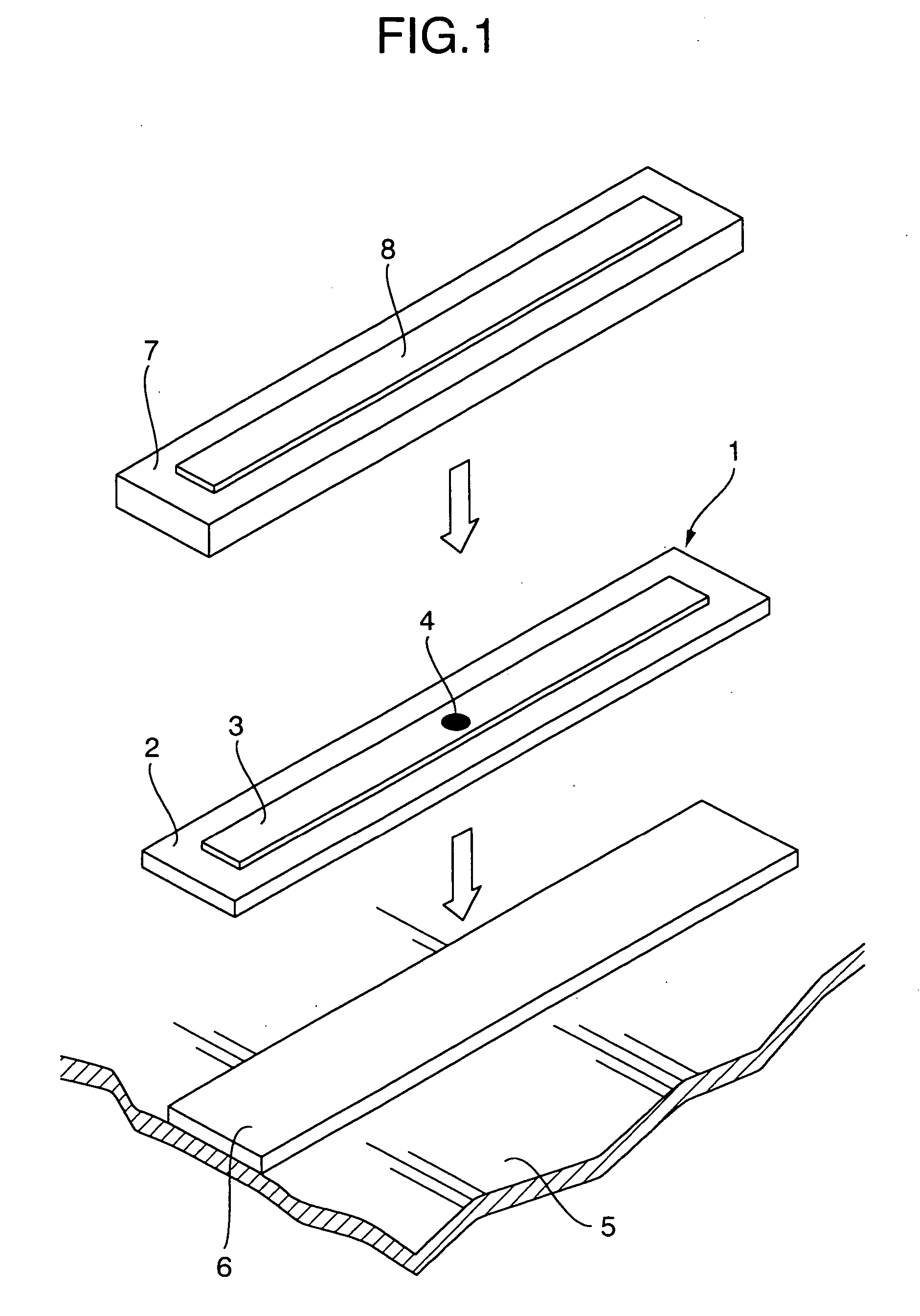

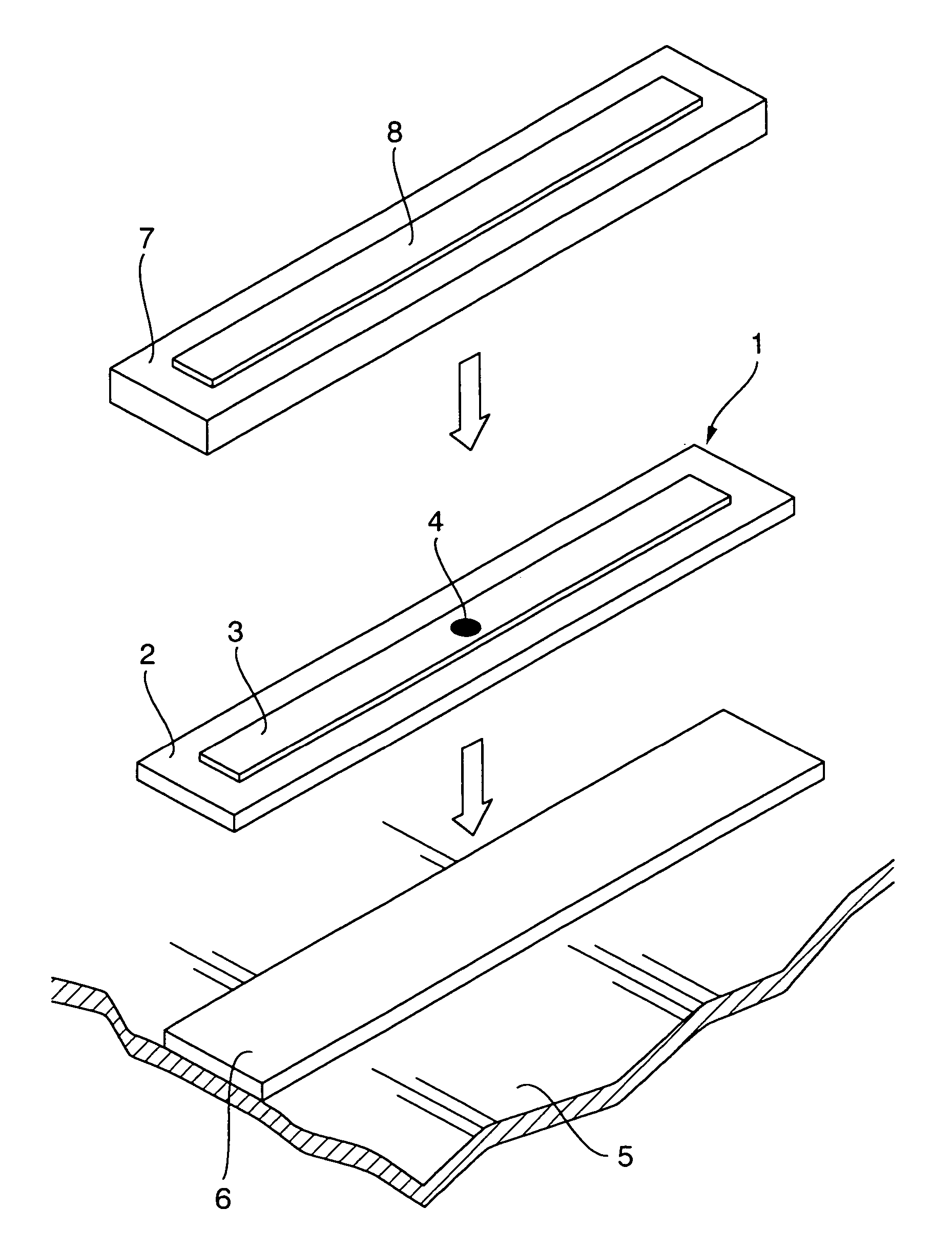

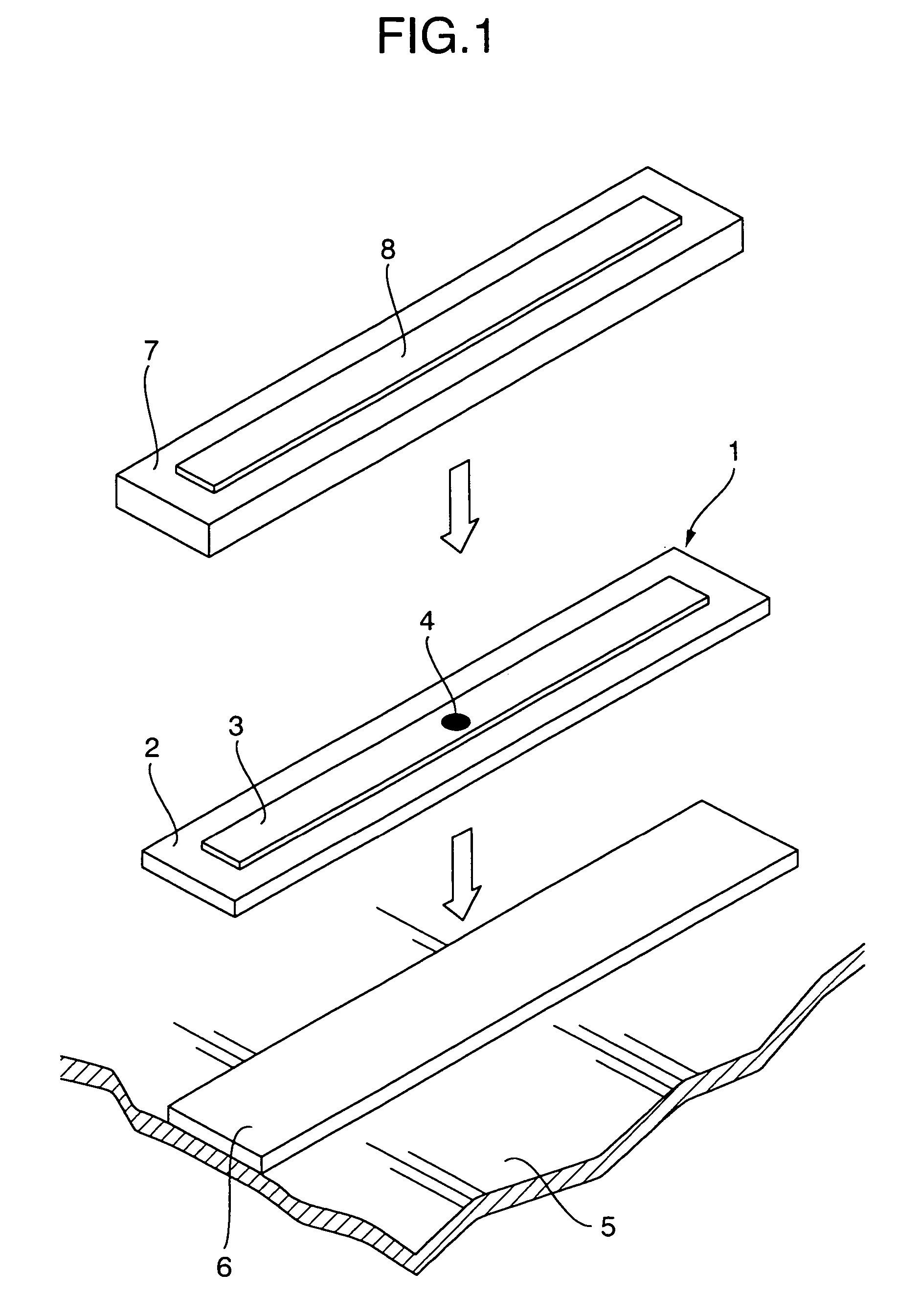

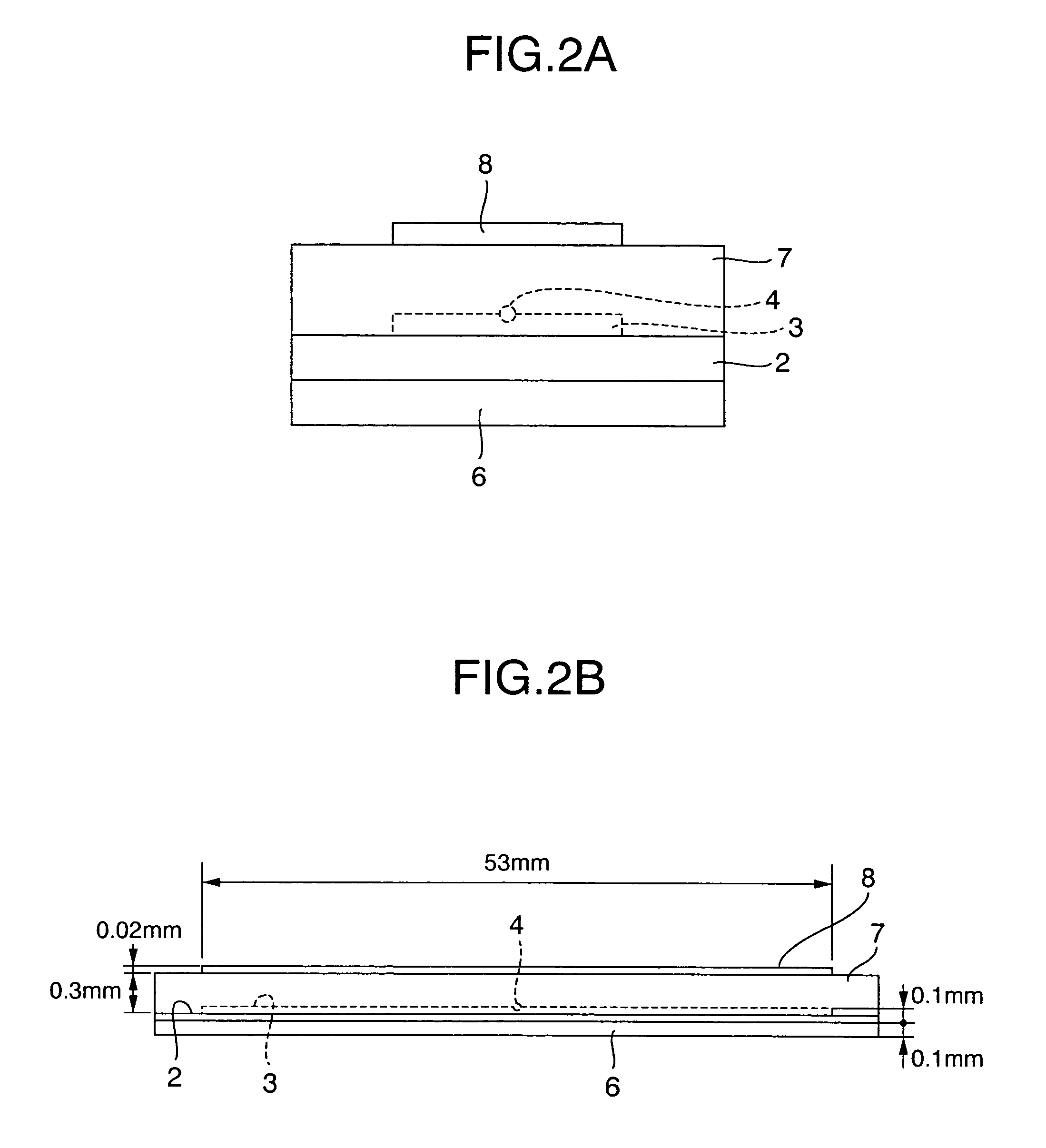

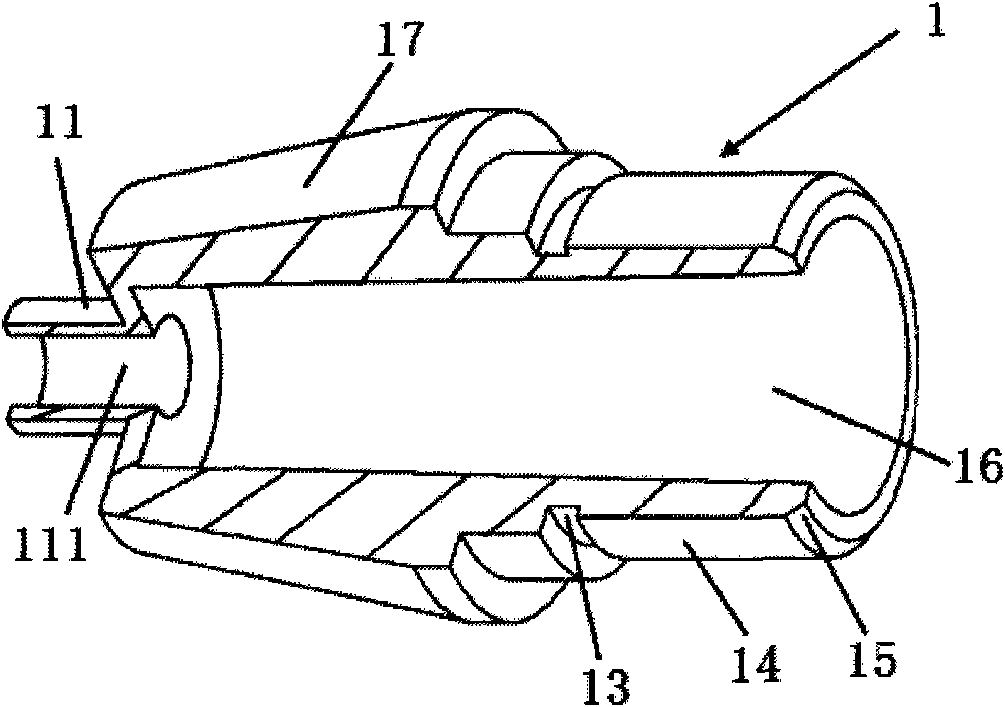

Wireless IC tag, and method and apparatus for manufacturing the same

InactiveUS20050140512A1Reduced durabilityImprove communication distanceSimultaneous aerial operationsAntenna supports/mountingsDielectricWireless

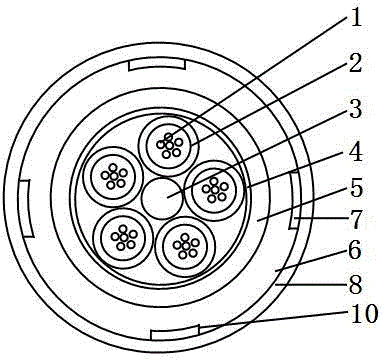

In a wireless IC tag, metallic antennas are deposited as thin films on the front and back surfaces of a spacer, made of a heat-resistant glass epoxy material having a desired dielectric constant, to form a first antenna and a second antenna. An IC chip is mounted in the center of the first antenna. The second antenna functions as an auxiliary antenna for resonating to a desired frequency of a transmission radio wave of the first antenna to strengthen the intensity of the radio wave. Accordingly, even when the IC tag is mounted to a cable or the like, the tag can be mounted in the interior of the enclosure of the cable and thus the radio wave intensity of the first antenna can be prevented from being weakened by a metallic member in the cable.

Owner:HITACHI LTD

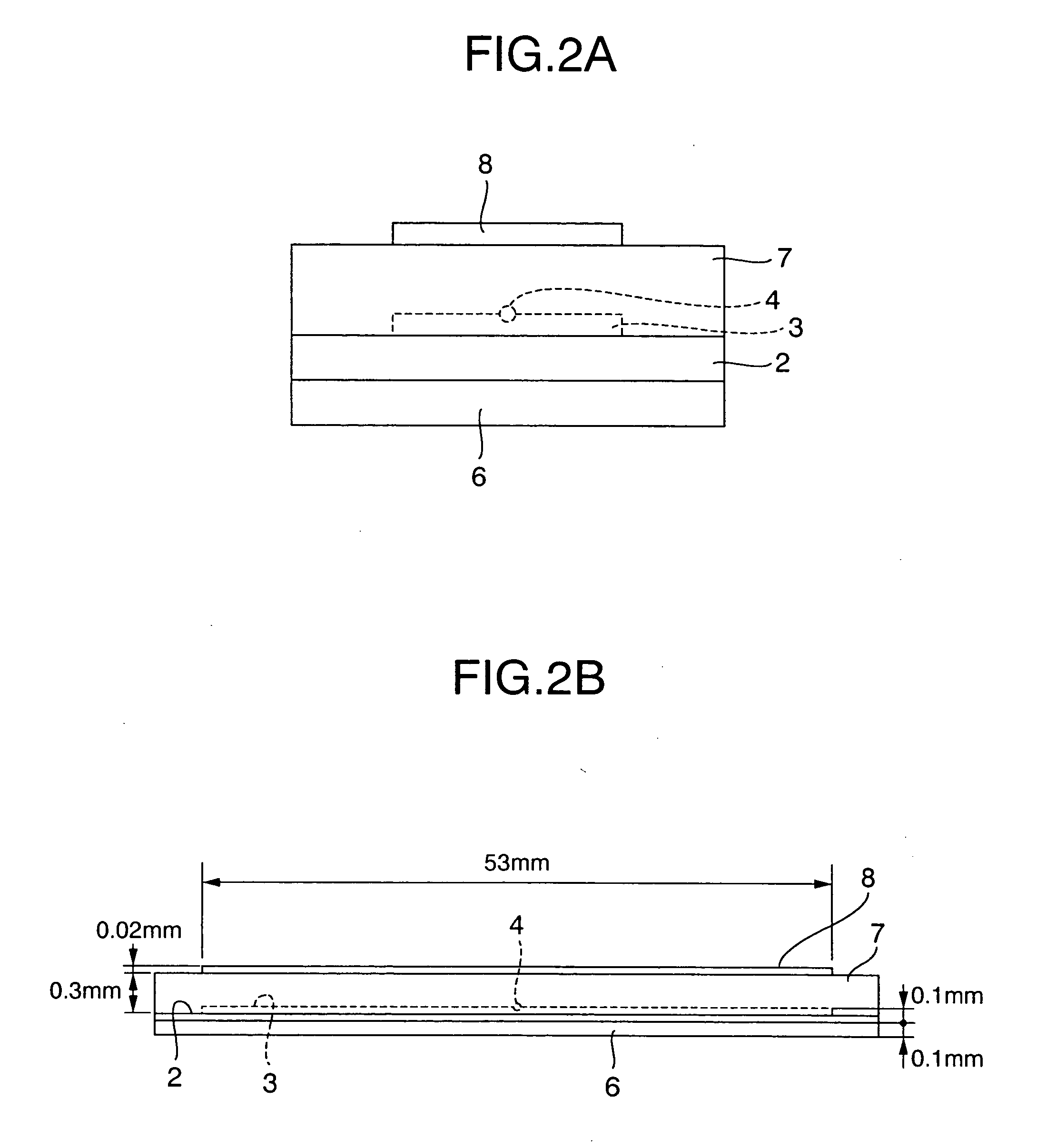

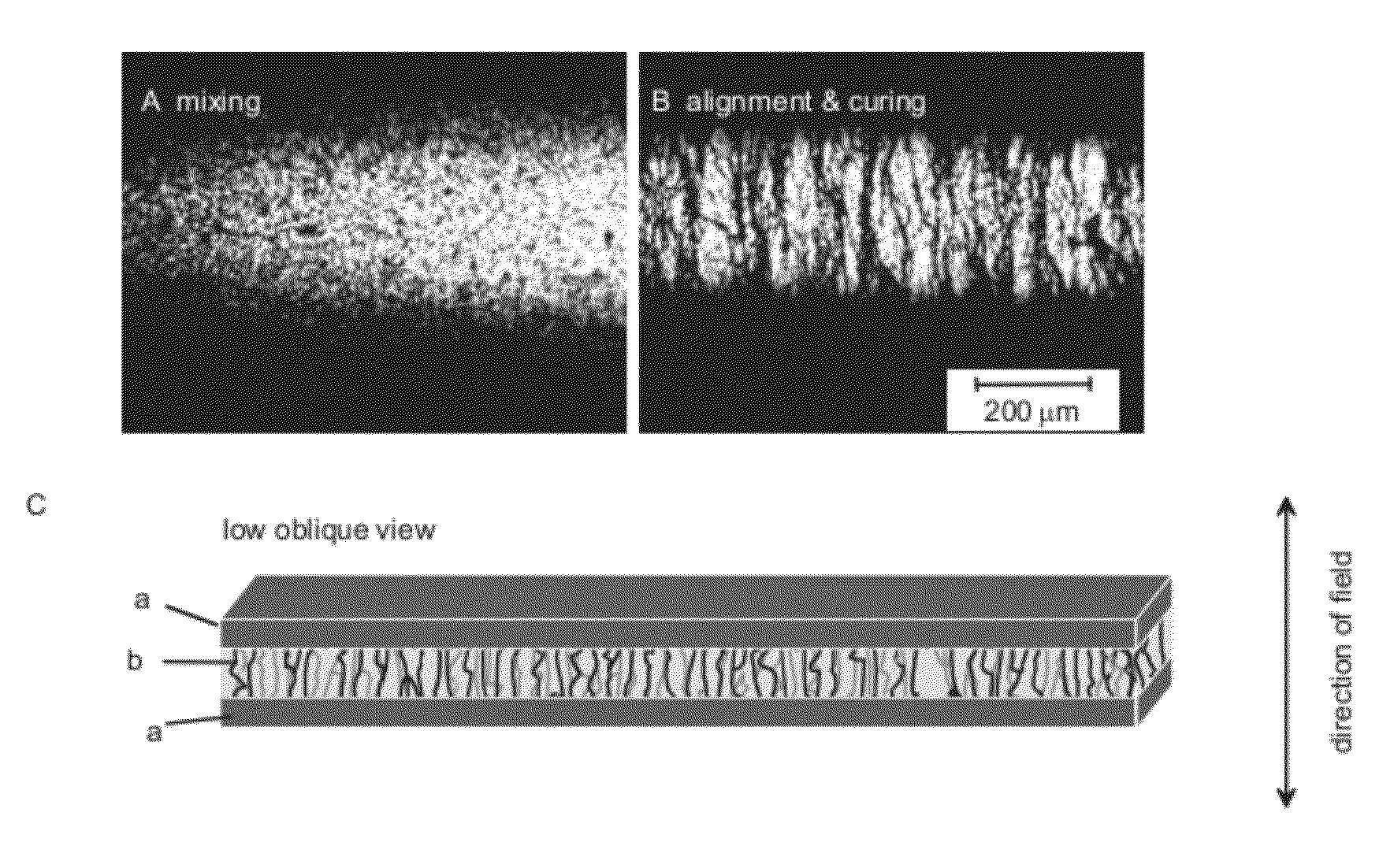

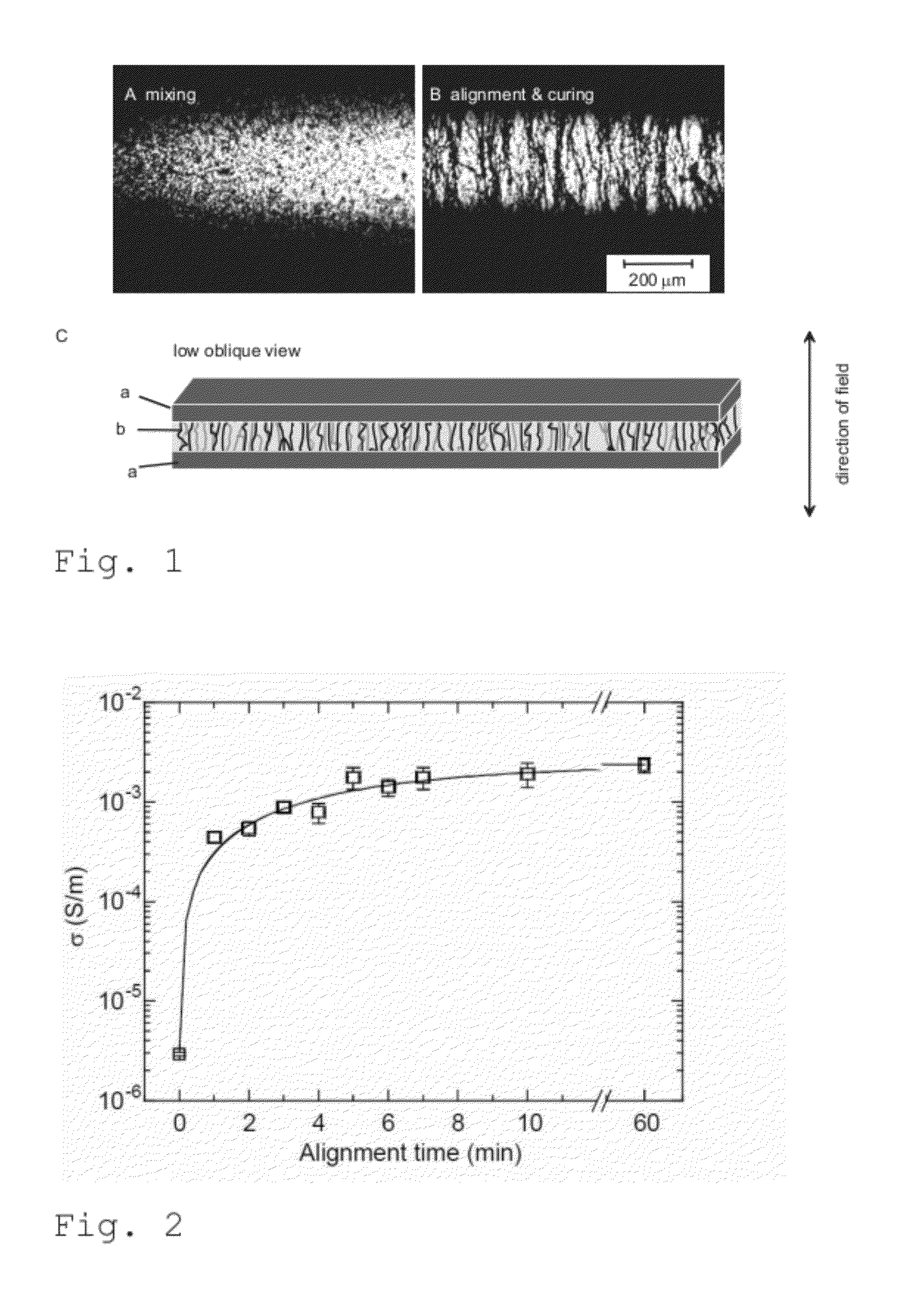

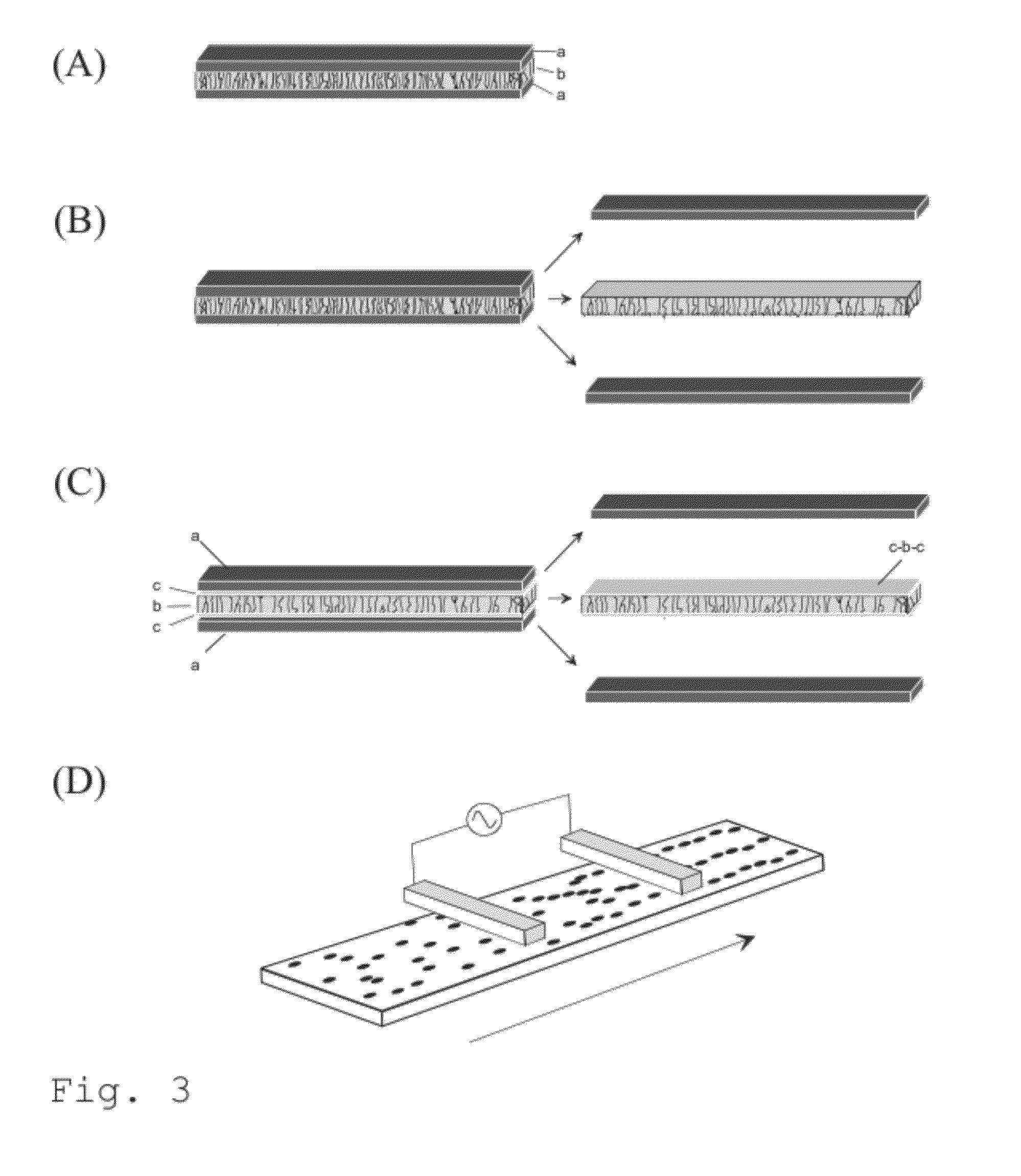

Anisotropic conductive polymer material

ActiveUS20120145315A1Fast curing timeHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesConductive polymerPercolation threshold

A method for forming a body comprising a mixture of a matrix and conductive particles, whereby the conductive particles are formed into aligned conductive pathways in an alignment step by applying an electric field between alignment electrodes and thereafter stabilizing the mixture wherein the conductive particles have a low aspect ratio; and a polymeric composition and method for producing such composition which is curable by UV light to an anisotropic electrically conductive polymer layer, comprising i) providing a non-conductive matrix of a flowable polymer composition having inherent photocurability, ii) adding to matrix conductive particles having low aspect ratio in an amount to allow the concentration of the conductive particles to be maintained at a level lower than the percolation threshold, and iii) placing the formed composition in a receptacle where exposure to UV light is prevented, and a method for establishing an anisotropic electrically conductive, optionally thermally conductive

Owner:CONDALIGN AS

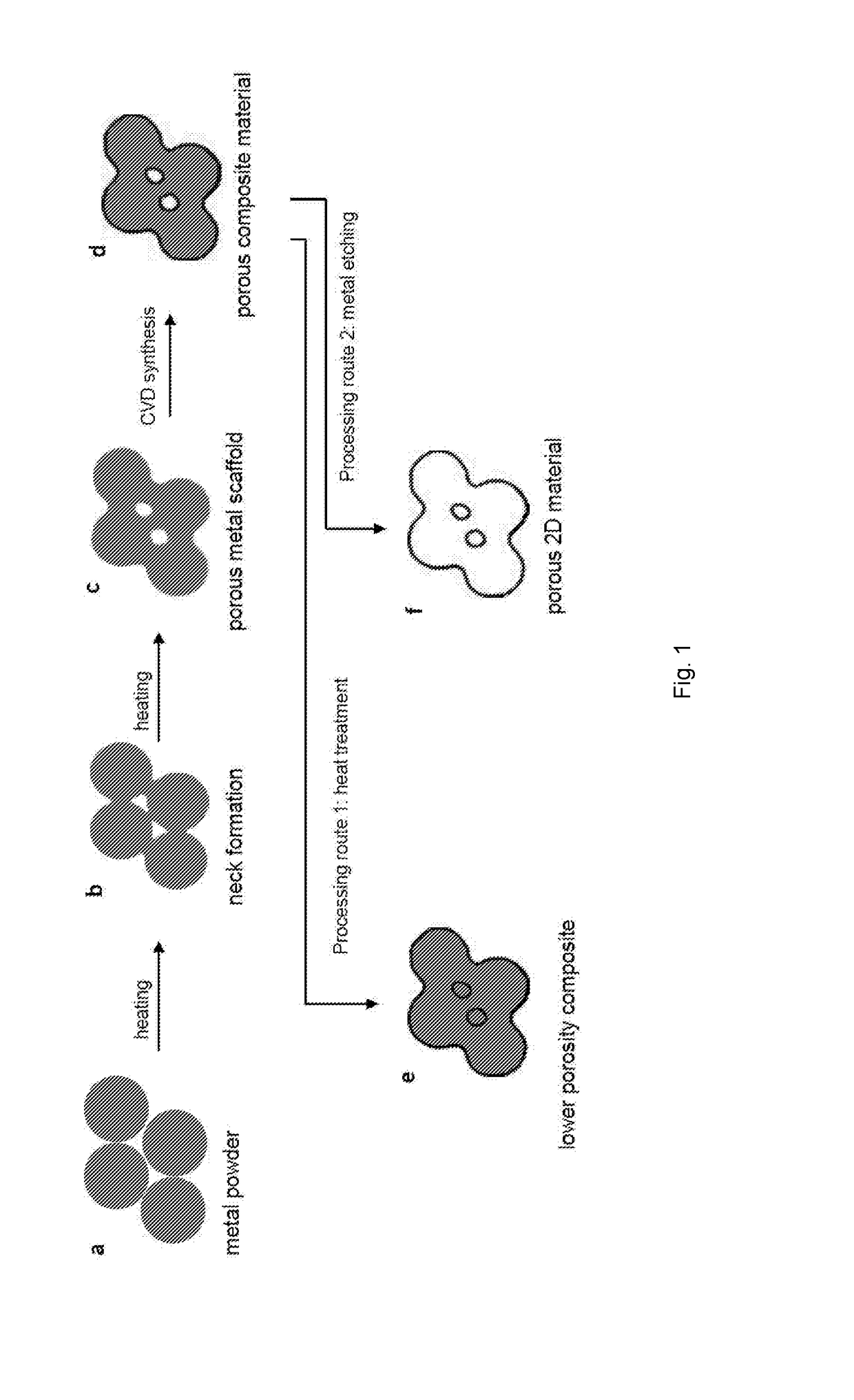

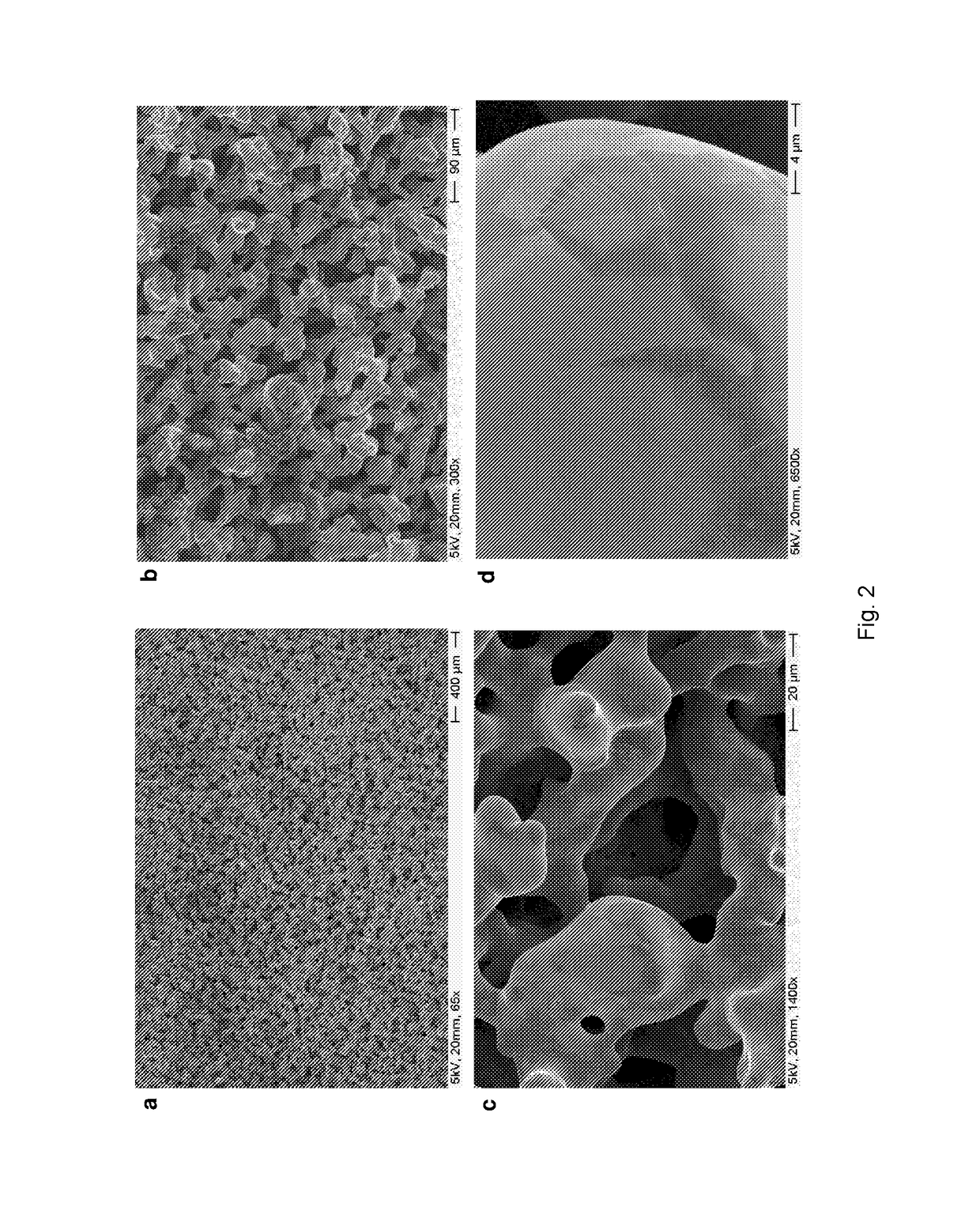

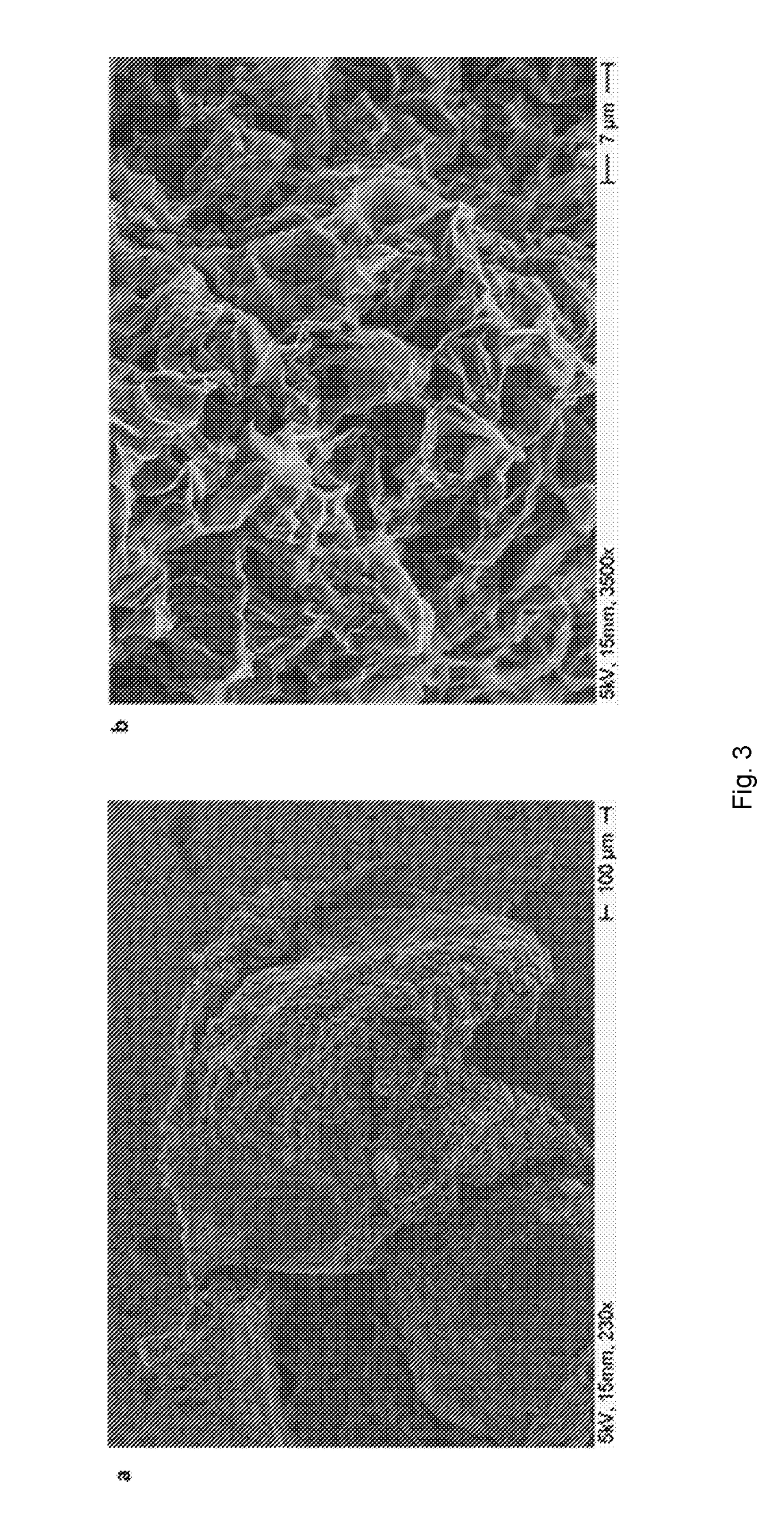

Porous materials comprising two-dimensional nanomaterials

ActiveUS20170216923A1Low costImprove scalabilityNitrogen compoundsElectrode thermal treatmentCompound (substance)Metal particle

According to the present invention, there are provided processes for preparing a porous composite material comprising a metal and a two-dimensional nanomaterial. In one aspect, the processes comprise the steps of: providing a powder comprising metal particles; heating the powder such that the metal particles fuse to form a porous scaffold; and forming a two-dimensional nanomaterial on a surface of the porous scaffold by chemical vapour deposition (CVD). Also provided are materials obtainable by the present processes, and products comprising said materials.

Owner:OXFORD UNIV INNOVATION LTD

Wireless IC tag, and method and apparatus for manufacturing the same

InactiveUS7250867B2Improve communication distanceLong communication distanceSimultaneous aerial operationsAntenna supports/mountingsDielectricEngineering

In a wireless IC tag, metallic antennas are deposited as thin films on the front and back surfaces of a spacer, made of a heat-resistant glass epoxy material having a desired dielectric constant, to form a first antenna and a second antenna. An IC chip is mounted in the center of the first antenna. The second antenna functions as an auxiliary antenna for resonating to a desired frequency of a transmission radio wave of the first antenna to strengthen the intensity of the radio wave. Accordingly, even when the IC tag is mounted to a cable or the like, the tag can be mounted in the interior of the enclosure of the cable and thus the radio wave intensity of the first antenna can be prevented from being weakened by a metallic member in the cable.

Owner:HITACHI LTD

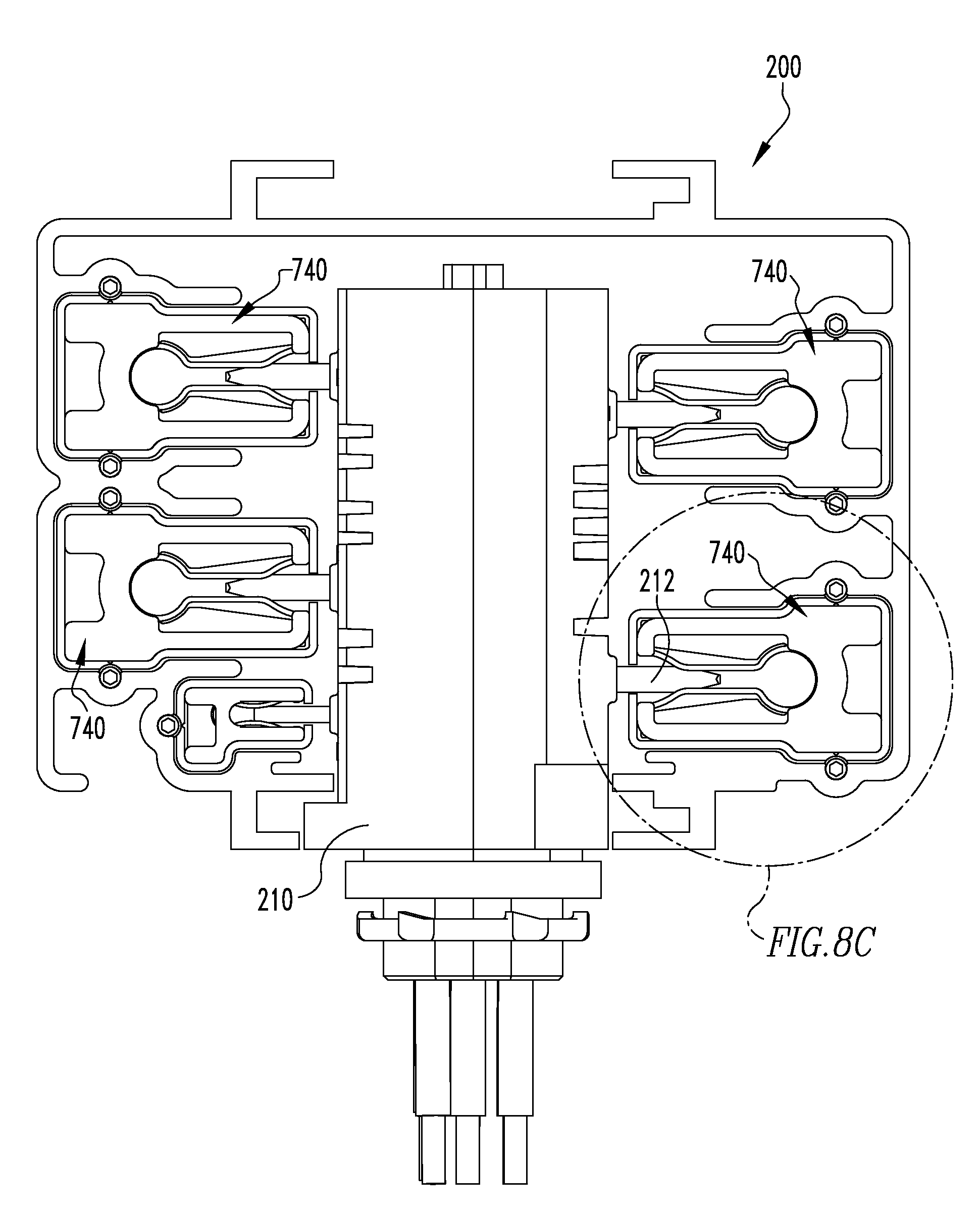

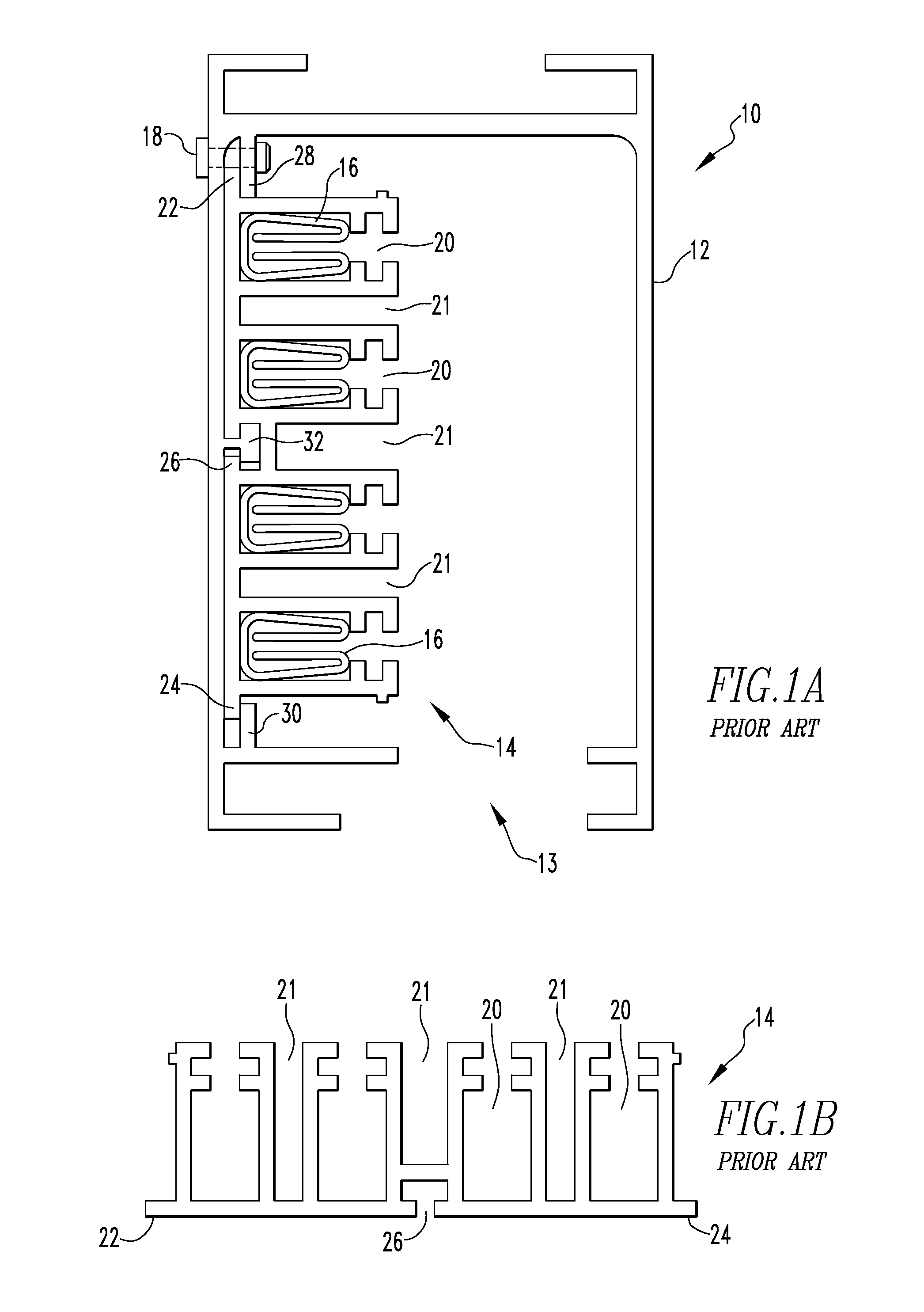

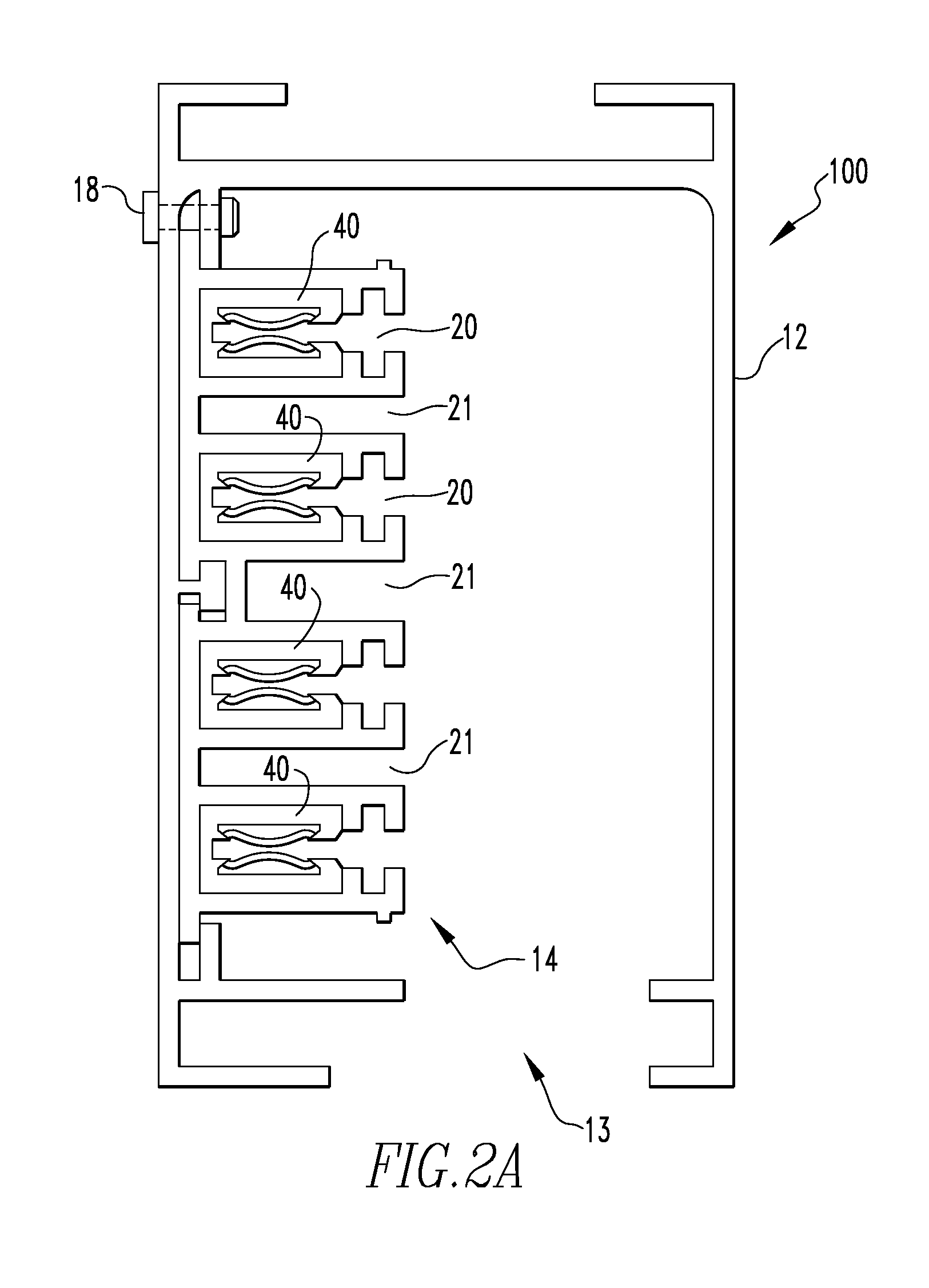

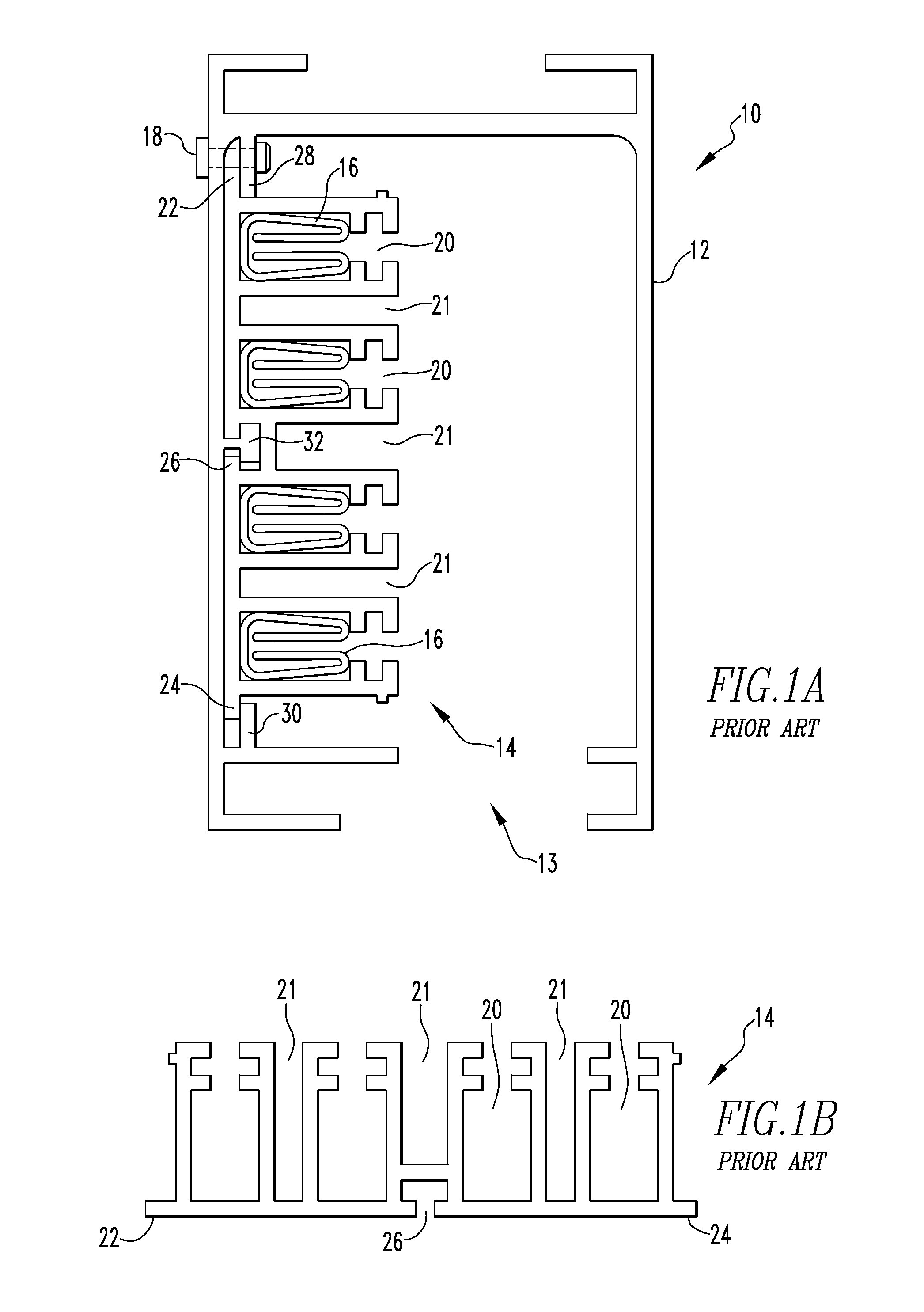

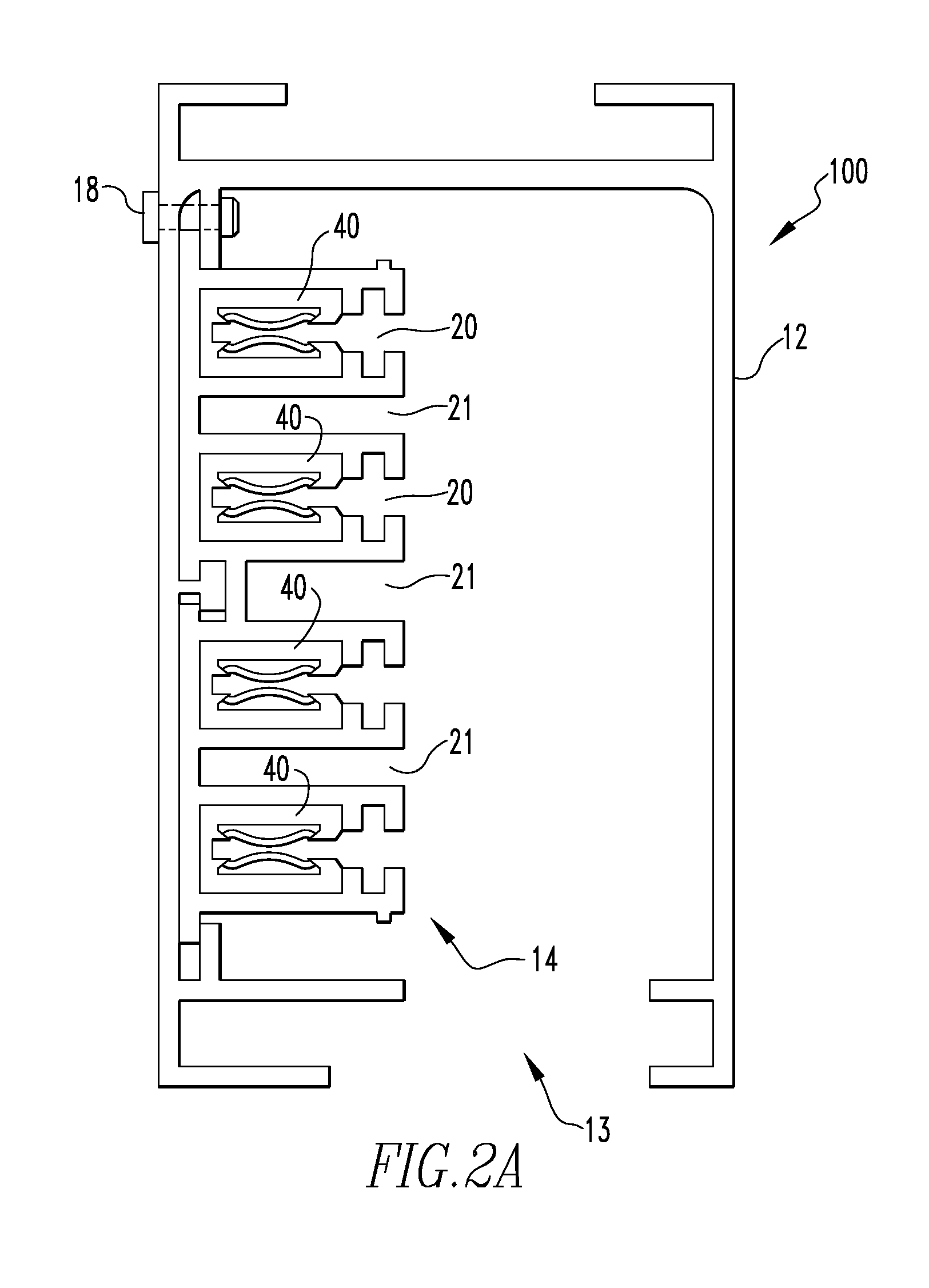

Press-fit busbar and busway employing same

ActiveUS20110261508A1Increase current capacityGood electrical contactCoupling device connectionsBus-bar/wiring layoutsBusbarElectrically conductive

An improved conductive busbar assembly and power distribution track utilizing the improved conductive busbar assembly. The busbar assembly including an inner component adapted to engage a stab member of a plug-in unit and an outer component disposed about, and in contact with, the inner component. The inner and outer components are both formed from an electrically conductive material. The busbar assembly provides greater current-carrying capacity and permits take-off devices to be installed at any point along the busway run.

Owner:UNIVERSAL ELECTRIC

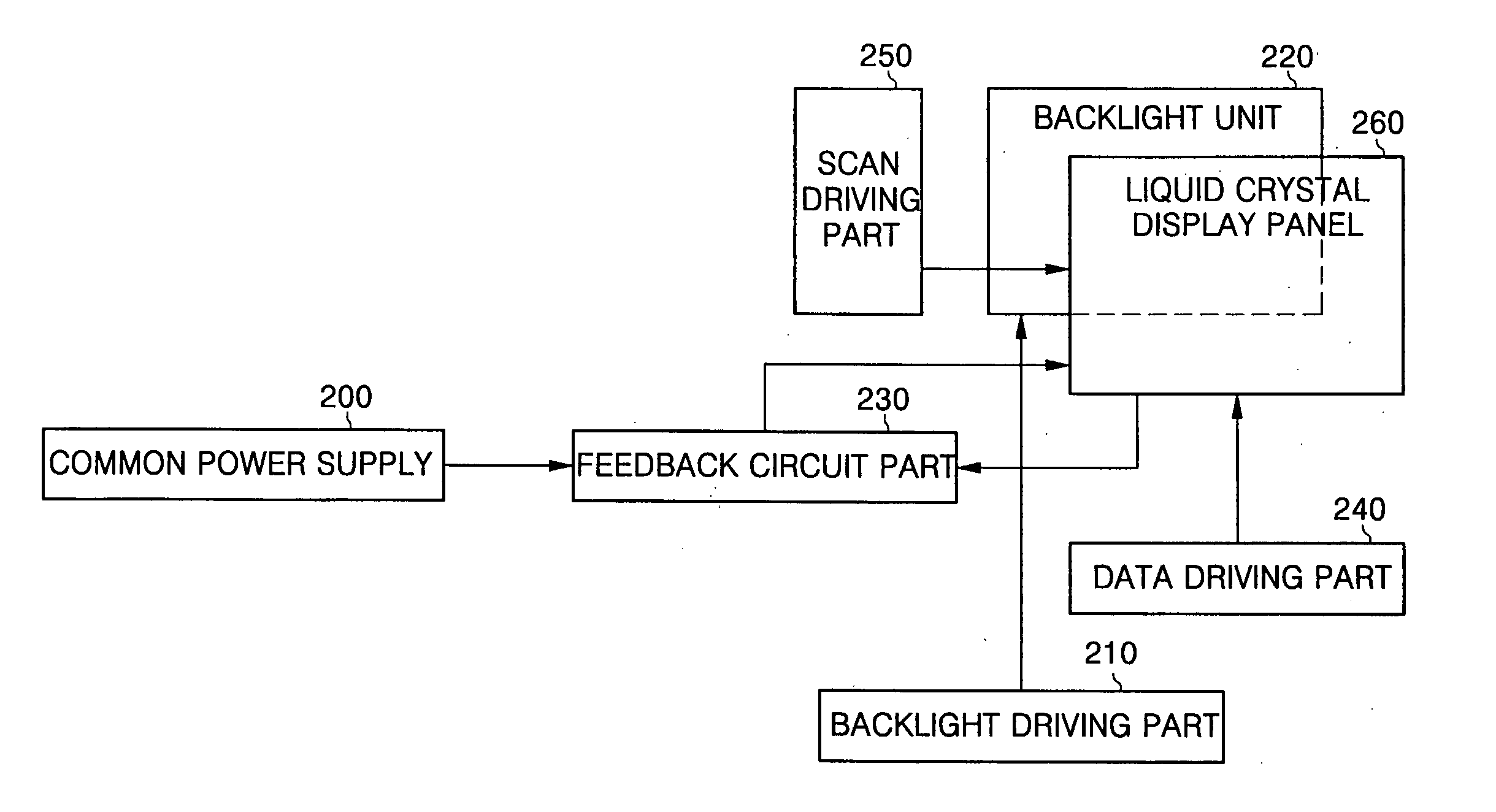

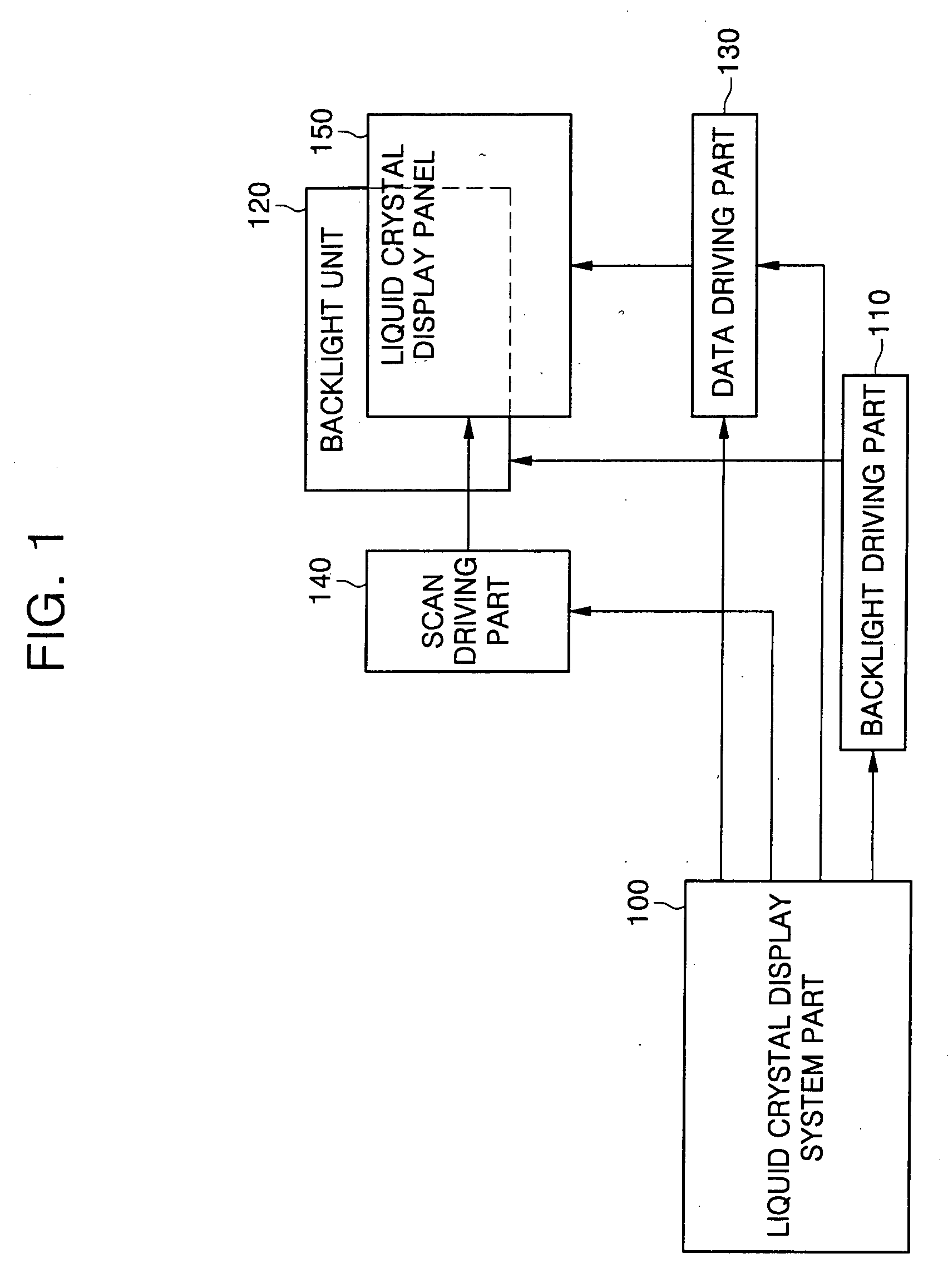

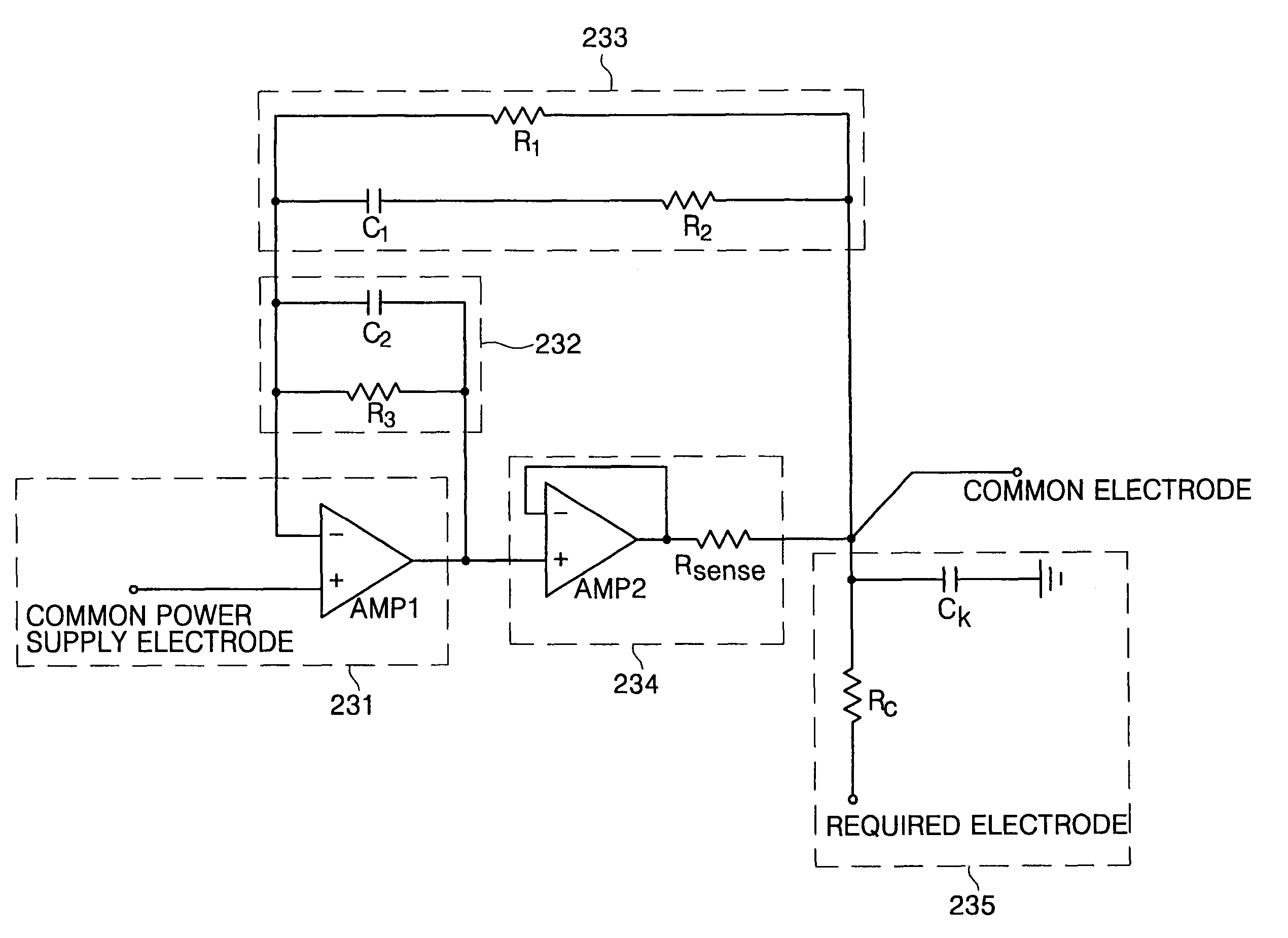

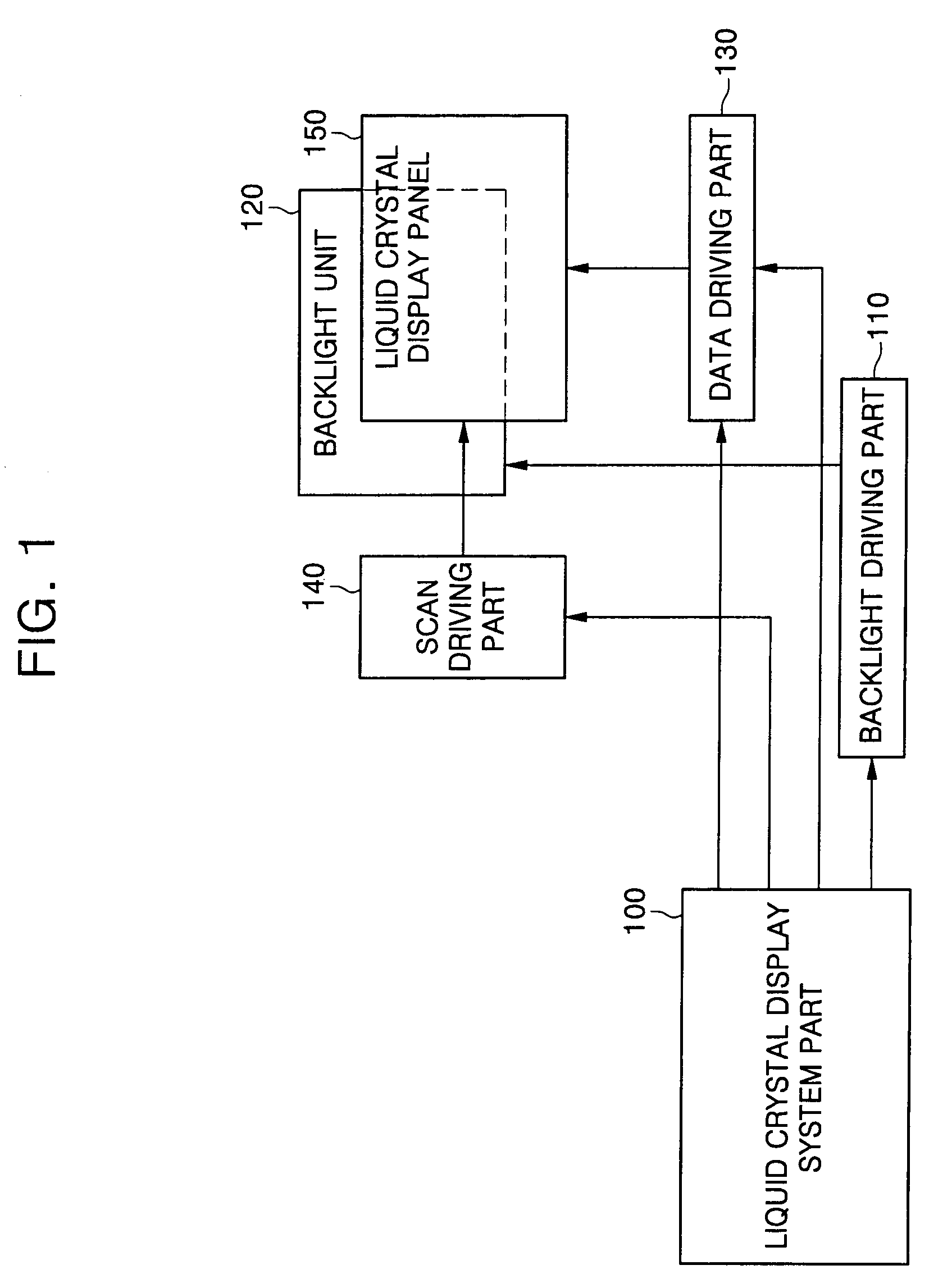

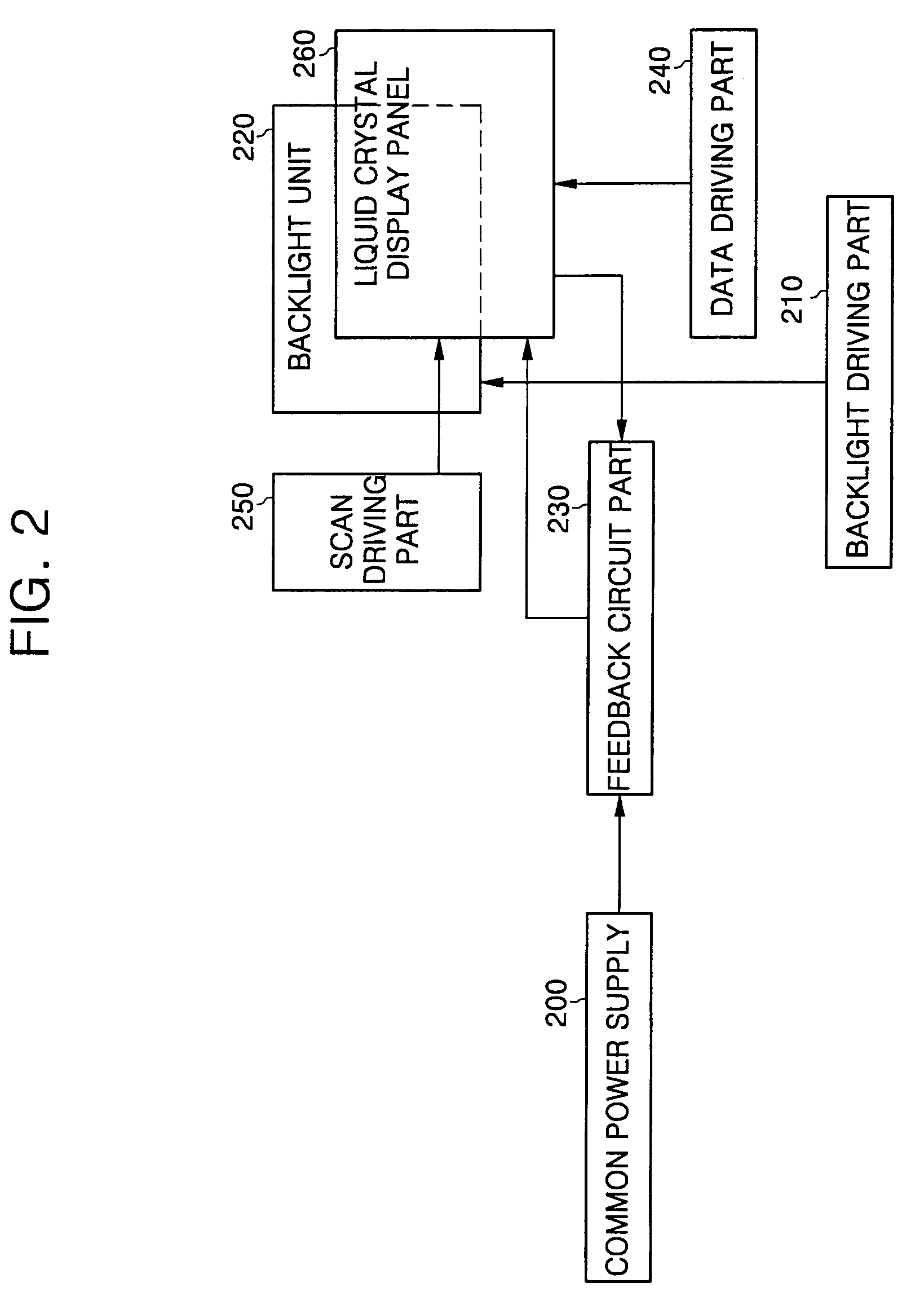

Liquid crystal display with feedback circuit part

InactiveUS20060170640A1Electroluminescent light sourcesInsulated cablesNegative feedbackLiquid-crystal display

In a liquid crystal display device having a feedback circuit part, the feedback circuit part prevents black points and blinking pixels from being generated on a liquid crystal display panel by compensating ripple voltages generated from a common electrode of a common substrate. The feedback circuit part comprises a negative feedback part, a buffer part, a low-pass filter part, and first and second impedances interconnecting the low-pass filter part and the negative feedback part.

Owner:SAMSUNG DISPLAY CO LTD

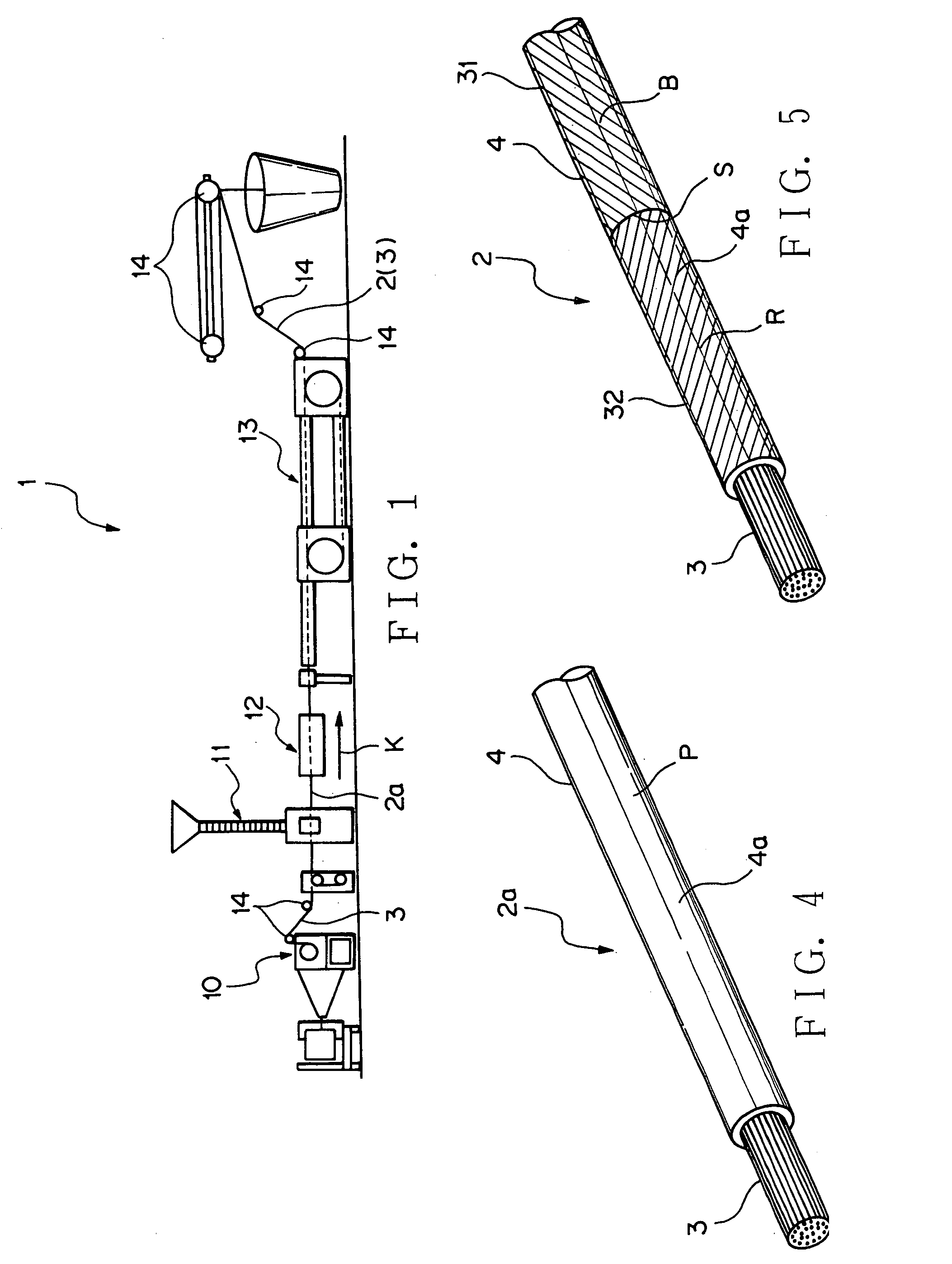

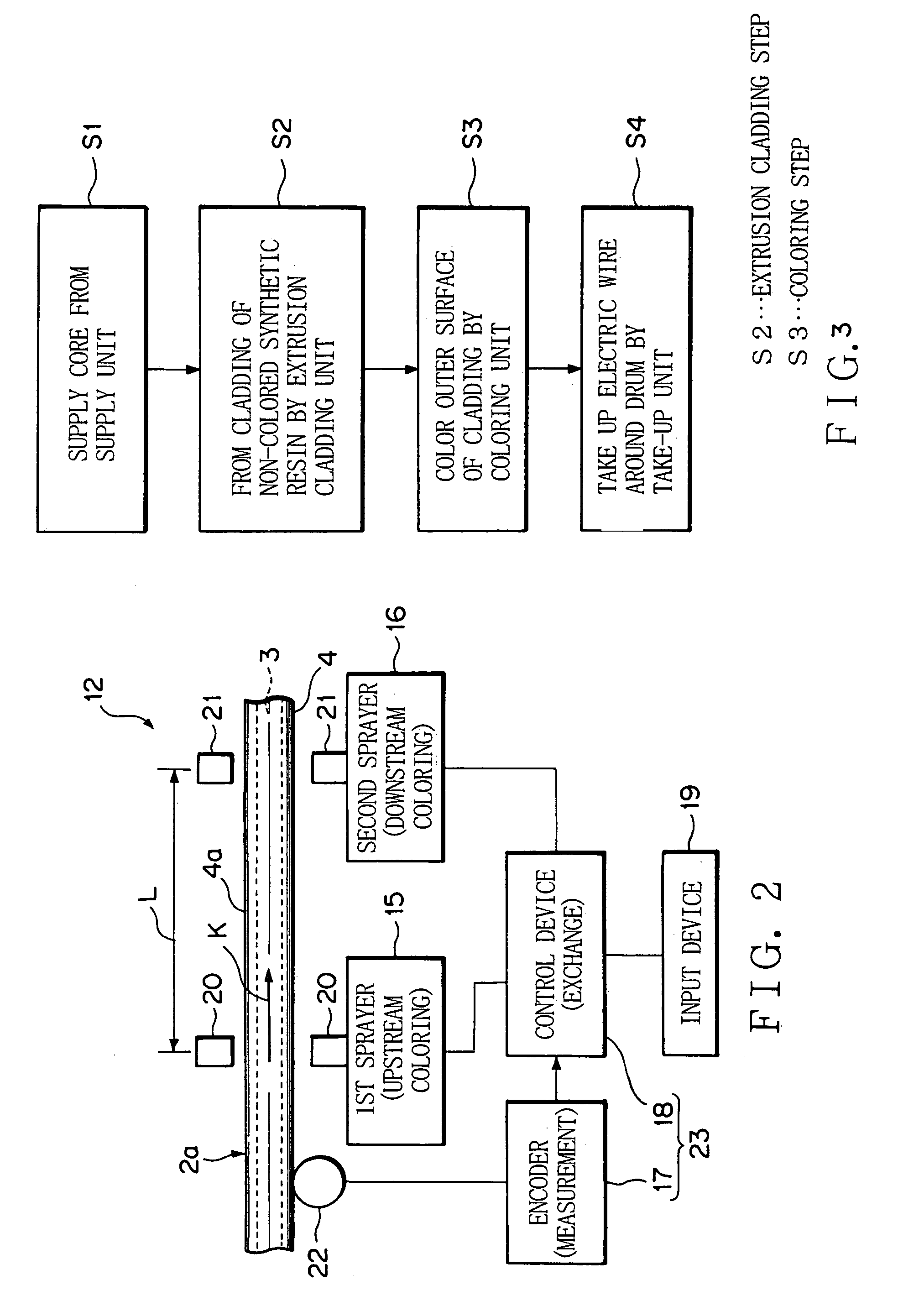

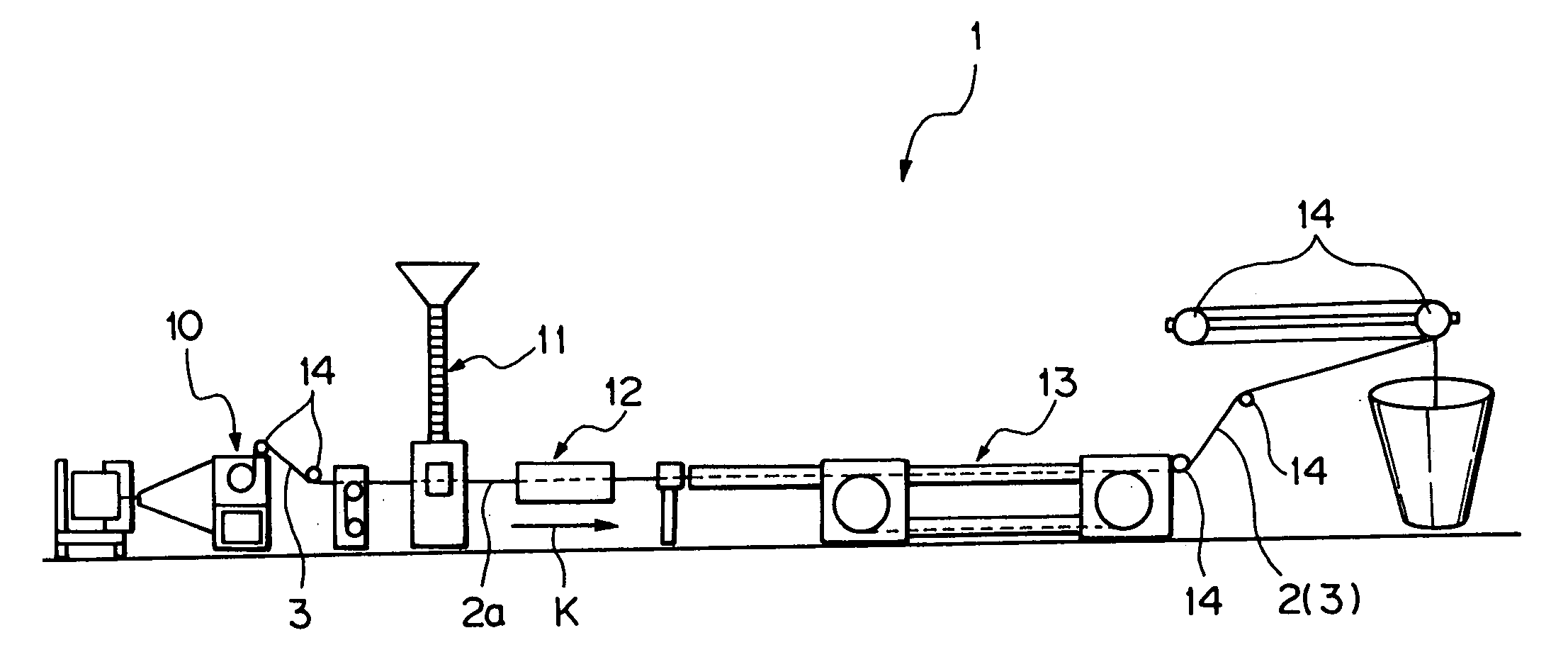

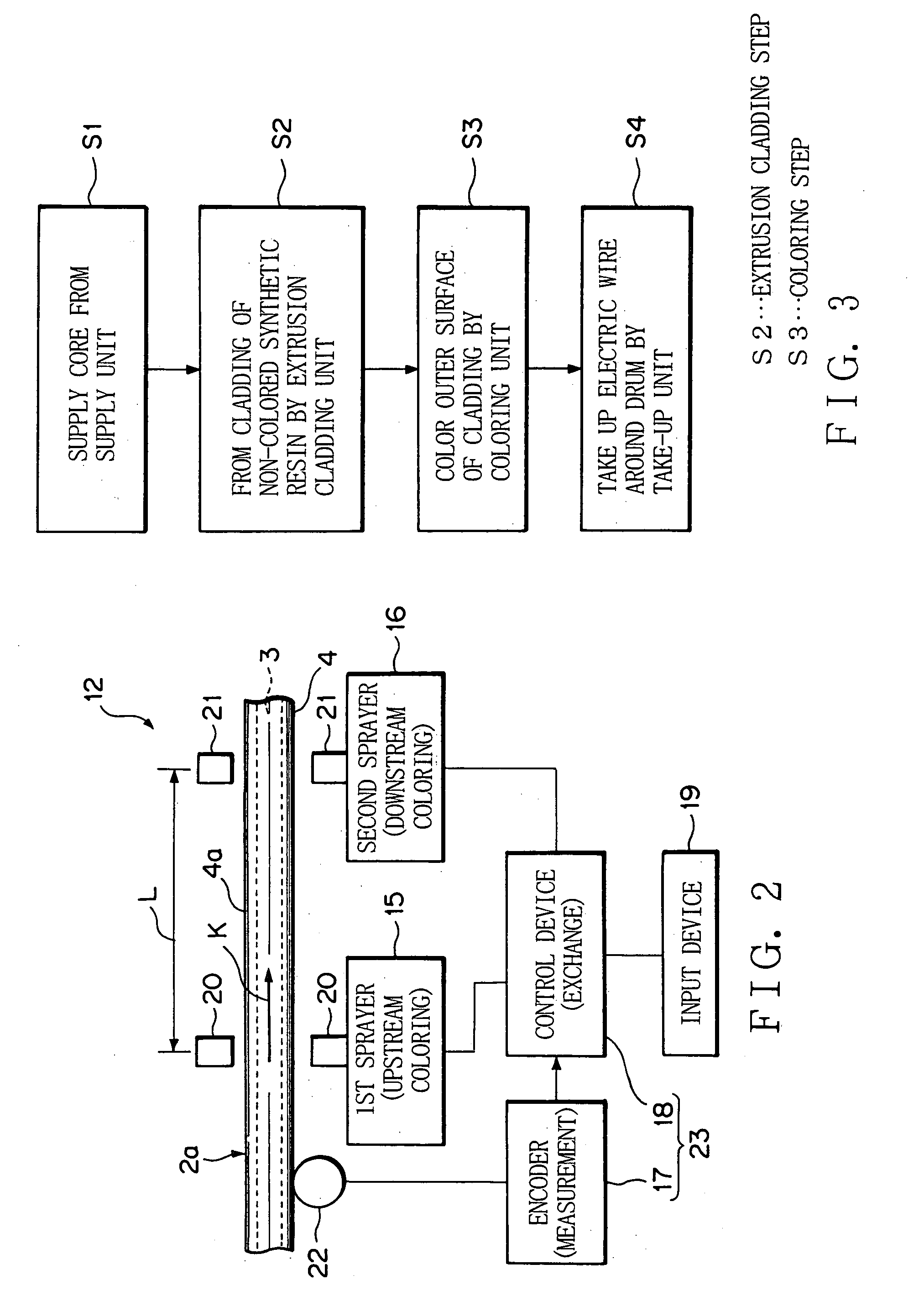

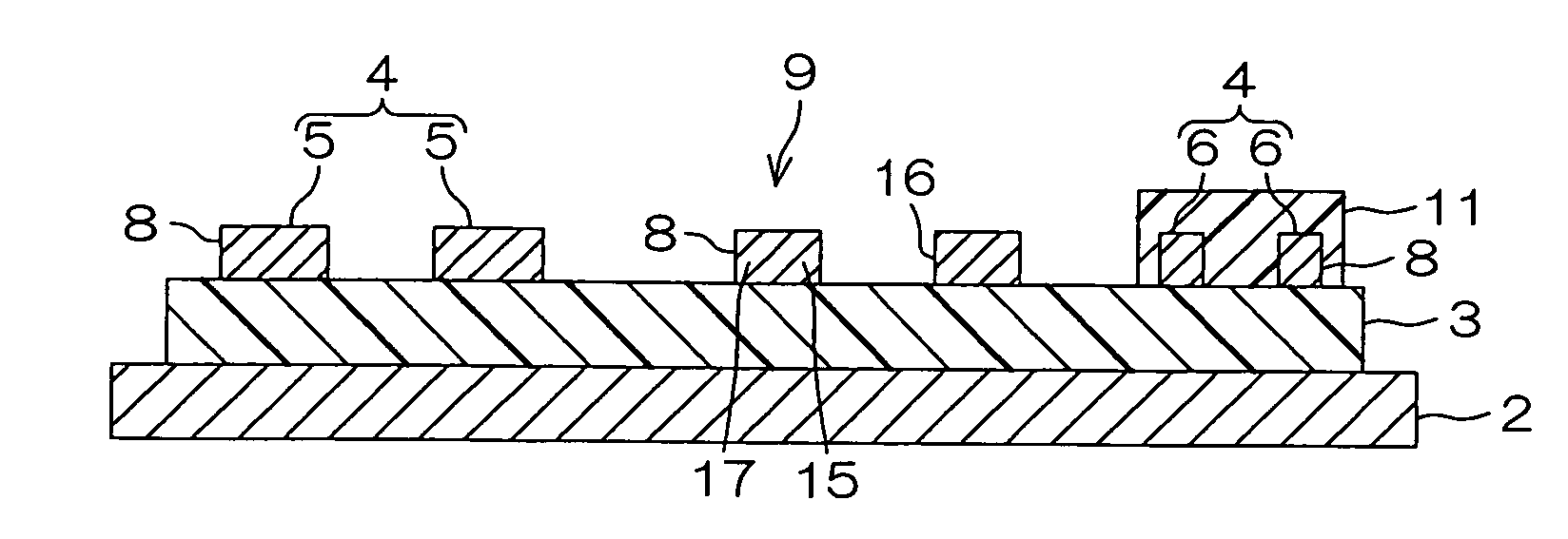

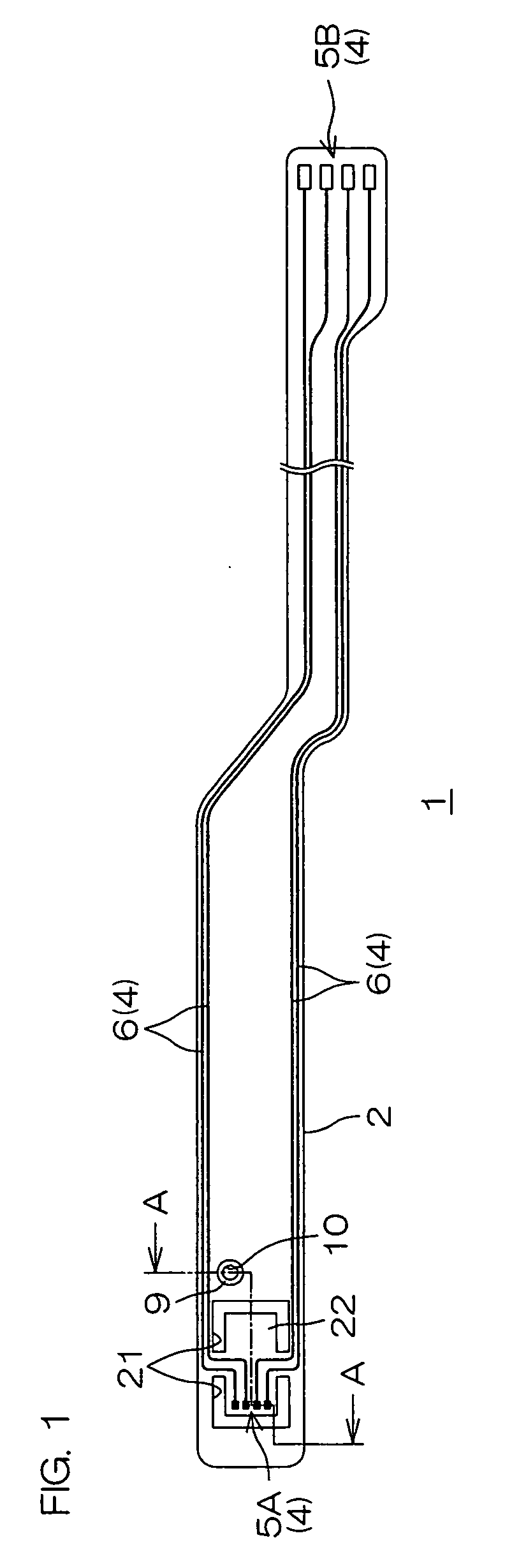

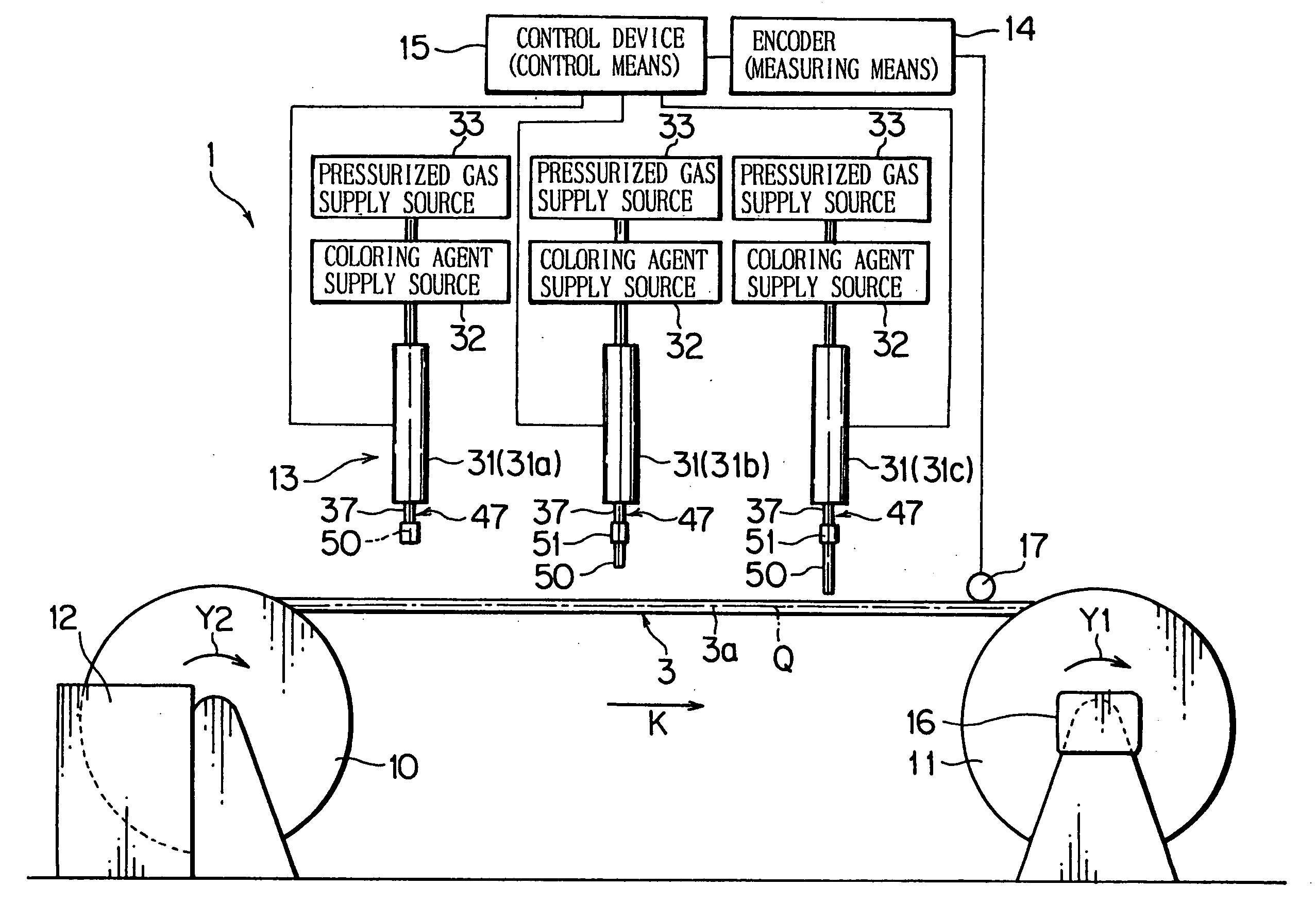

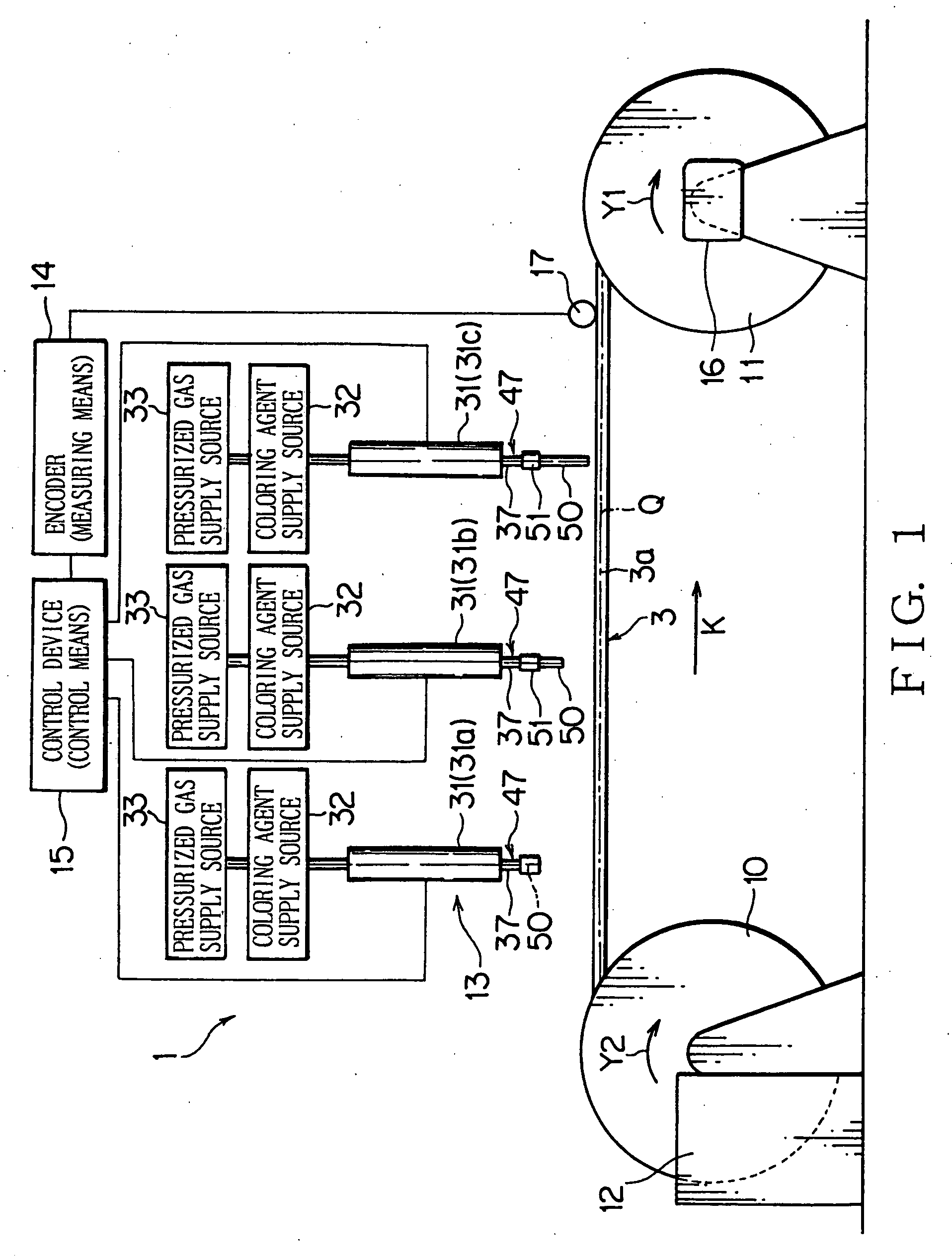

Wire manufacturing method wire manufacturing apparatus and wire

InactiveUS7442877B2Easy to changeReduce the number of productsPlastic/resin/waxes insulatorsPretreated surfacesManufactured apparatusEngineering

This invention intends to provide a method and apparatus for manufacturing an electric wire, capable of easily changing a color applied to the electric wire. The electric wire manufacturing apparatus intends to manufacture an electric wire composed of a core and a cladding. In step S1, the core is supplied from a supply unit. In step S2, in an extrusion cladding unit, the outer periphery of the core is coated with non-color synthetic resin by extrusion cladding to form the cladding. In step S3, the outer surface of the cladding is colored by a coloring unit. The coloring unit includes a plurality of sprayers 15 and 16. In step S3, the sprayers 15 and 16 are exchanged to operate as necessary. In step S4, in a take-up unit, the electric wire is cut into segments each having a desired length, which are wound around a drum.

Owner:YAZAKI CORP

Press-fit busbar and busway employing same

ActiveUS8664530B2Good electrical contactImprove manufacturabilityCoupling device connectionsElectrically conductive connectionsBusbarConductive materials

Owner:UNIVERSAL ELECTRIC

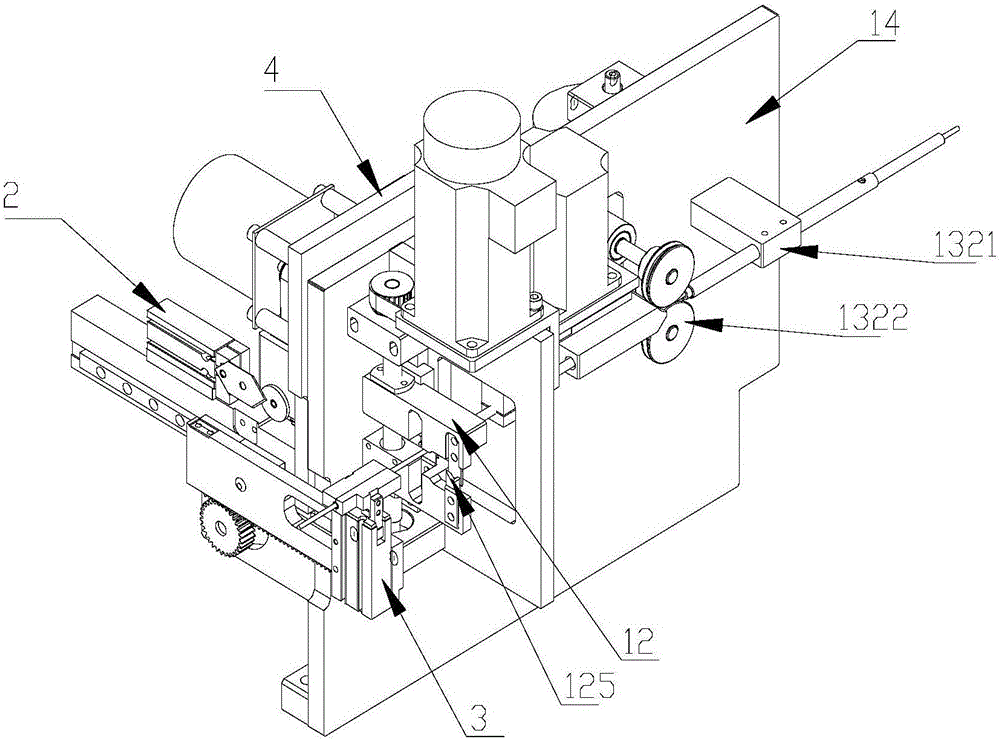

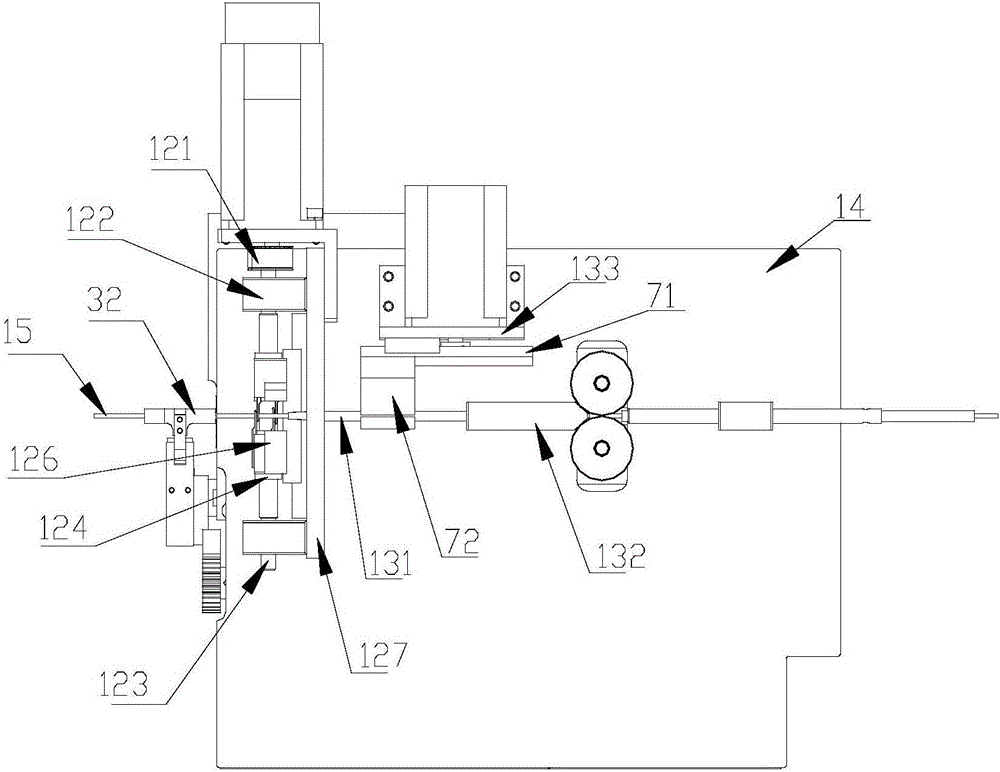

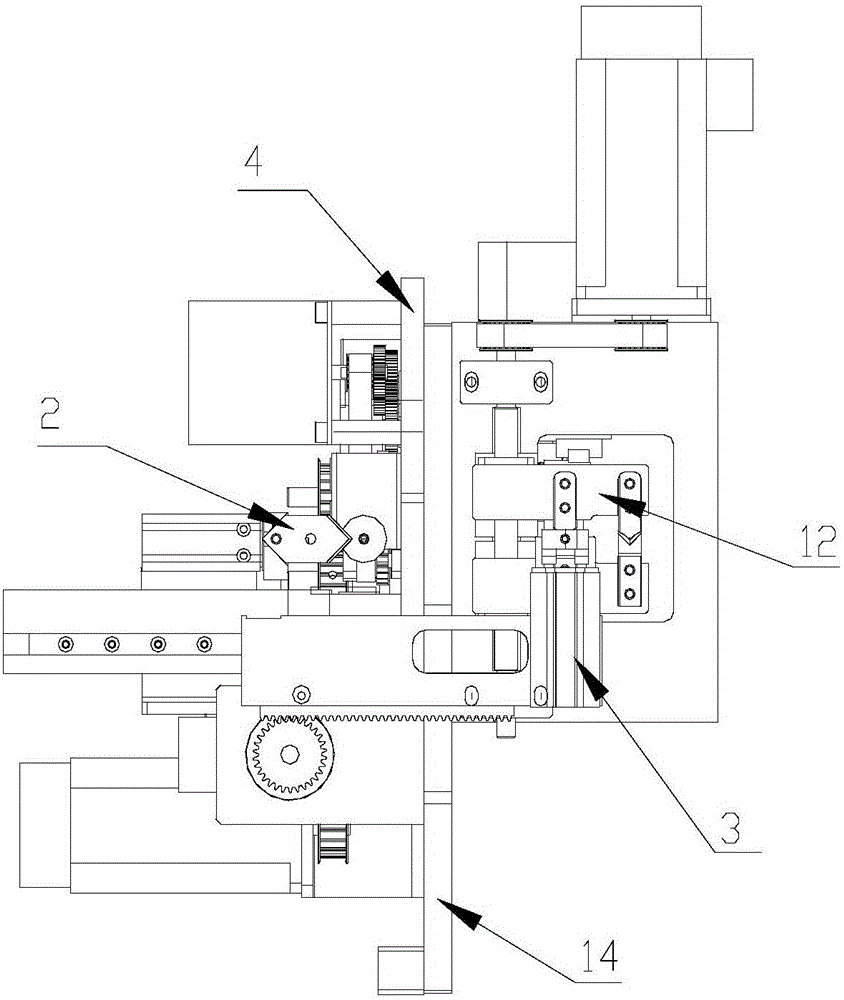

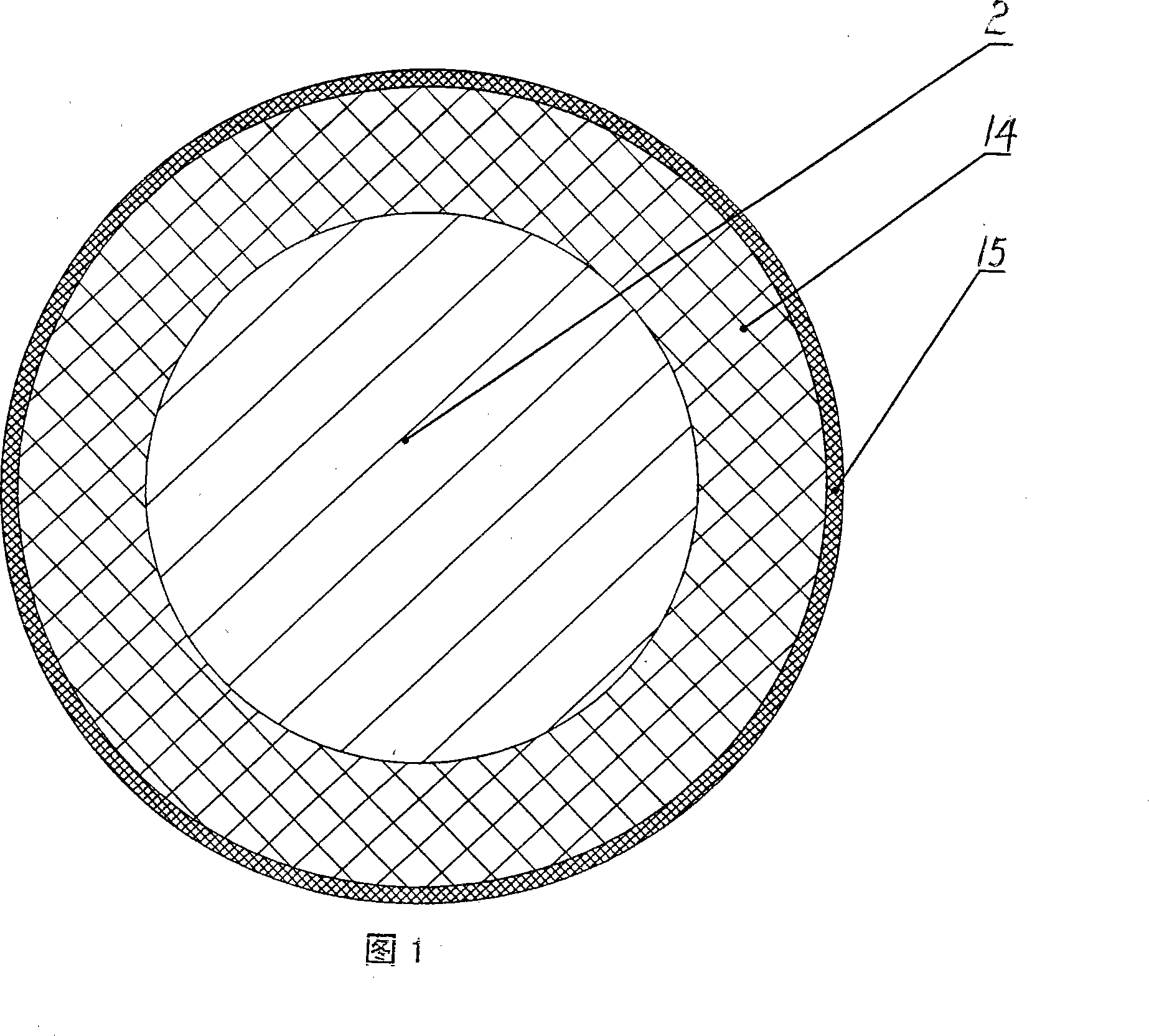

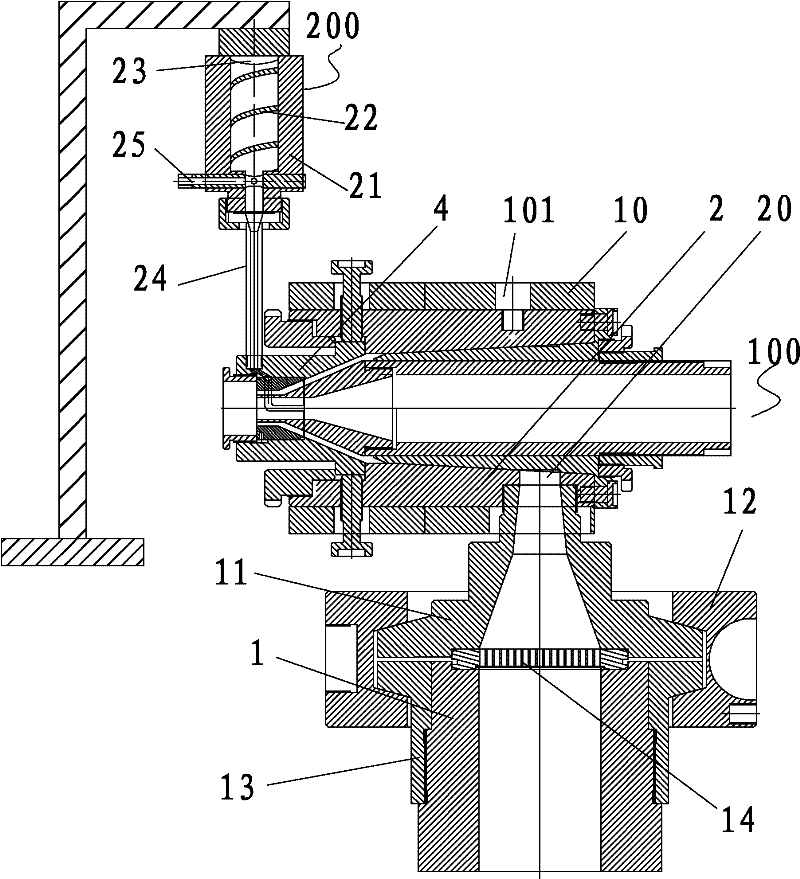

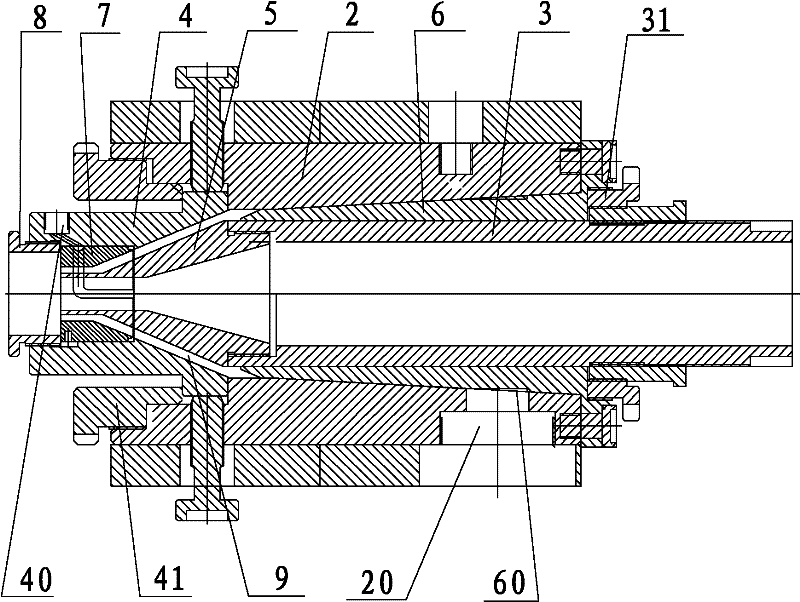

Cable marker printing and threading machine

ActiveCN106373675AAvoid alignment problemsPrevent insertionConductor/cable markingWire cuttingEngineering

The invention relates to a cable marker printing and threading machine. The cable marker printing and threading machine comprises a movable clamping component, a threading component, a wire cutting component, a first mounting plate and a printing main panel; the printing main panel is arranged on the first mounting plate; the threading component and the wire cutting component are arranged on the first mounting plate; the movable clamping component is arranged on the printing main panel; the threading component comprises a threading pipe, a wire feeding structure, a guiding structure, a mounting block, a moving structure and a fourth mounting plate; a wire is arranged in the threading pipe; the wire feeding structure is located behind the mounting block and comprises at least a pair of wire feeding friction wheels used for transferring the wire; the wire cutting component is located in front of the threading component and is used for cutting off the wire; the movable clamping component comprises a cable marker mould which can be opened and closed, a clamping hole is formed in the cable marker mould, and the clamping hole is coaxial with the threading pipe. The cable marker printing and threading machine solves a calibration problem of the wire penetrating the cable marker and guarantees accuracy of the wire penetrating the cable marker.

Owner:GUANGZHOU CHANGLI MACHINERY EQUIP CO LTD

A production method for color cable core with color insulation layer

InactiveCN101236808AReduce in quantityRealize linkage operationInsulated cablesConductor/cable markingElectrical conductorInsulation layer

The invention relates to a manufacturing method for a dichroic cable core provided with a colored insulation material layer on the outside, wherein, when the insulation material layer is extruded on a conductor, two plastic extruding machines are used; one is a plastic extruding machine for uncolored insulation materials and the other is a plastic extruding machine for colored insulation materials; the two plastic extruding machines share a double-layer coextrusion handpiece; the uncolored insulation materials are taken as inner layer insulation materials, and the colored insulation materials are taken as outer layer insulation materials; two layers of insulation materials are combined in the same handpiece, and simultaneously extrusion of double-layer insulation materials is completed on a cable conductor. By adoption of the method for color changing of the insulating core, users only need to extrude colored insulation materials in a donkey engine completely, and obviously the means can greatly reduce the number of color changing wastes. By adoption of the method of the invention, the interlocking operation of the two plastic extruding machines is realized and the operating procedure is simplified.

Owner:高荣富

Wire manufacturing method wire manufacturing apparatus and wire

InactiveUS20050129855A1Easy to changeReduce the number of productsPretreated surfacesInsulated cablesWire rodSprayer

This invention intends to provide a method and apparatus for manufacturing an electric wire, capable of easily changing a color applied to the electric wire. The electric wire manufacturing apparatus intends to manufacture an electric wire composed of a core and a cladding. In step S1, the core is supplied from a supply unit. In step S2, in an extrusion cladding unit, the outer periphery of the core is coated with non-color synthetic resin by extrusion cladding to form the cladding. In step S3, the outer surface of the cladding is colored by a coloring unit. The coloring unit includes a plurality of sprayers 15 and 16. In step S3, the sprayers 15 and 16 are exchanged to operate as necessary. In step S4, in a take-up unit, the electric wire is cut into segments each having a desired length, which are wound around a drum.

Owner:YAZAKI CORP

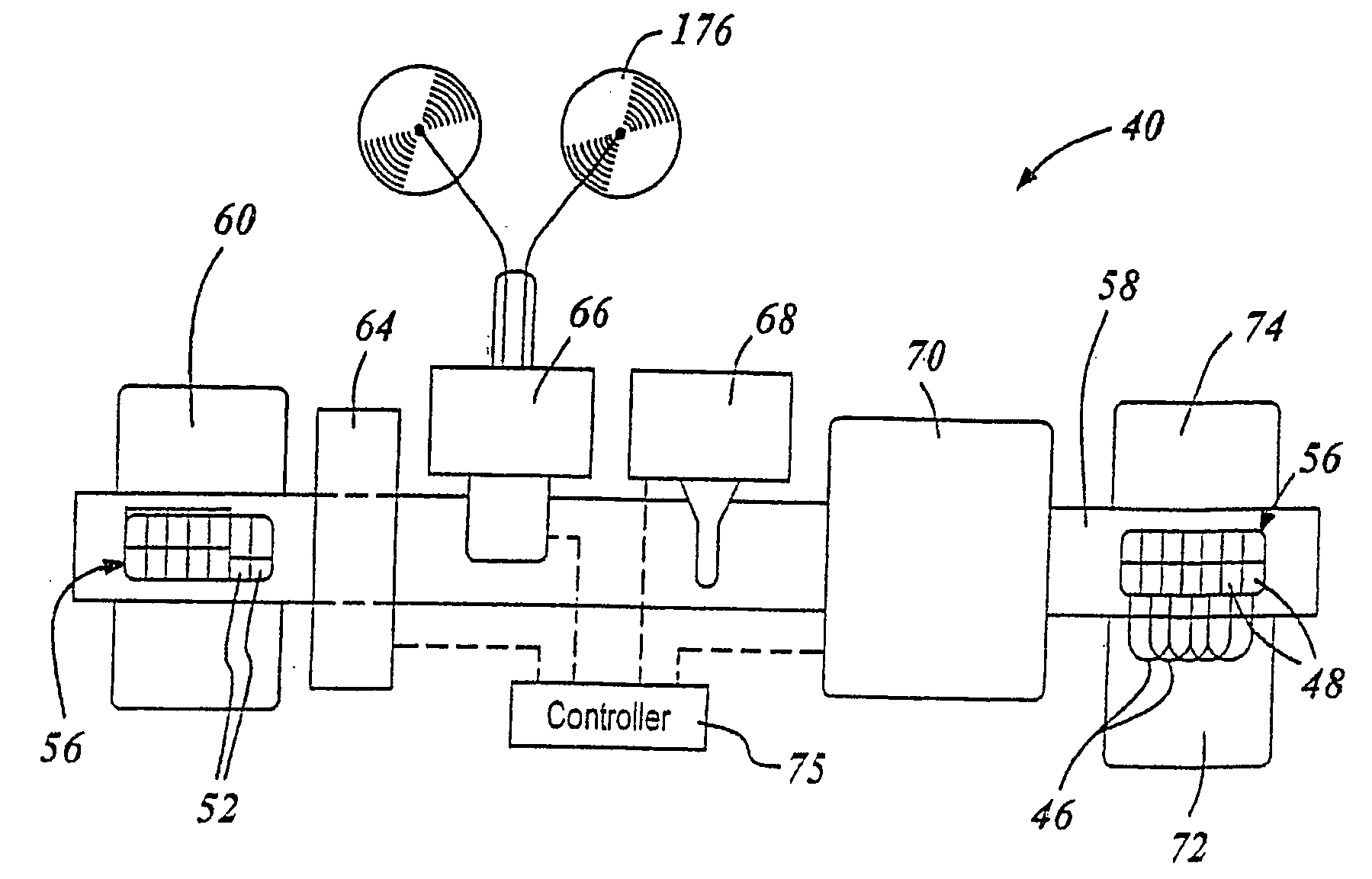

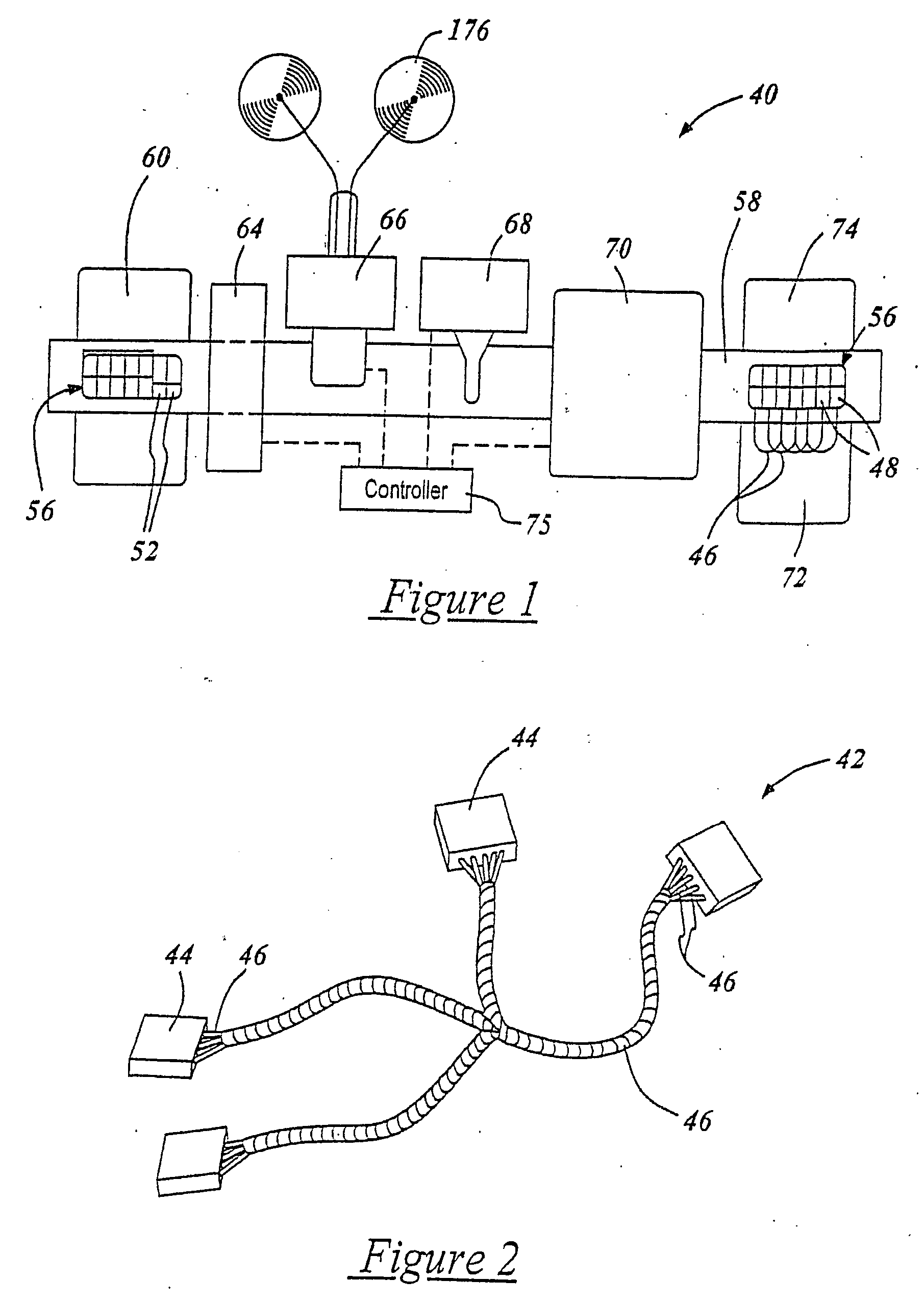

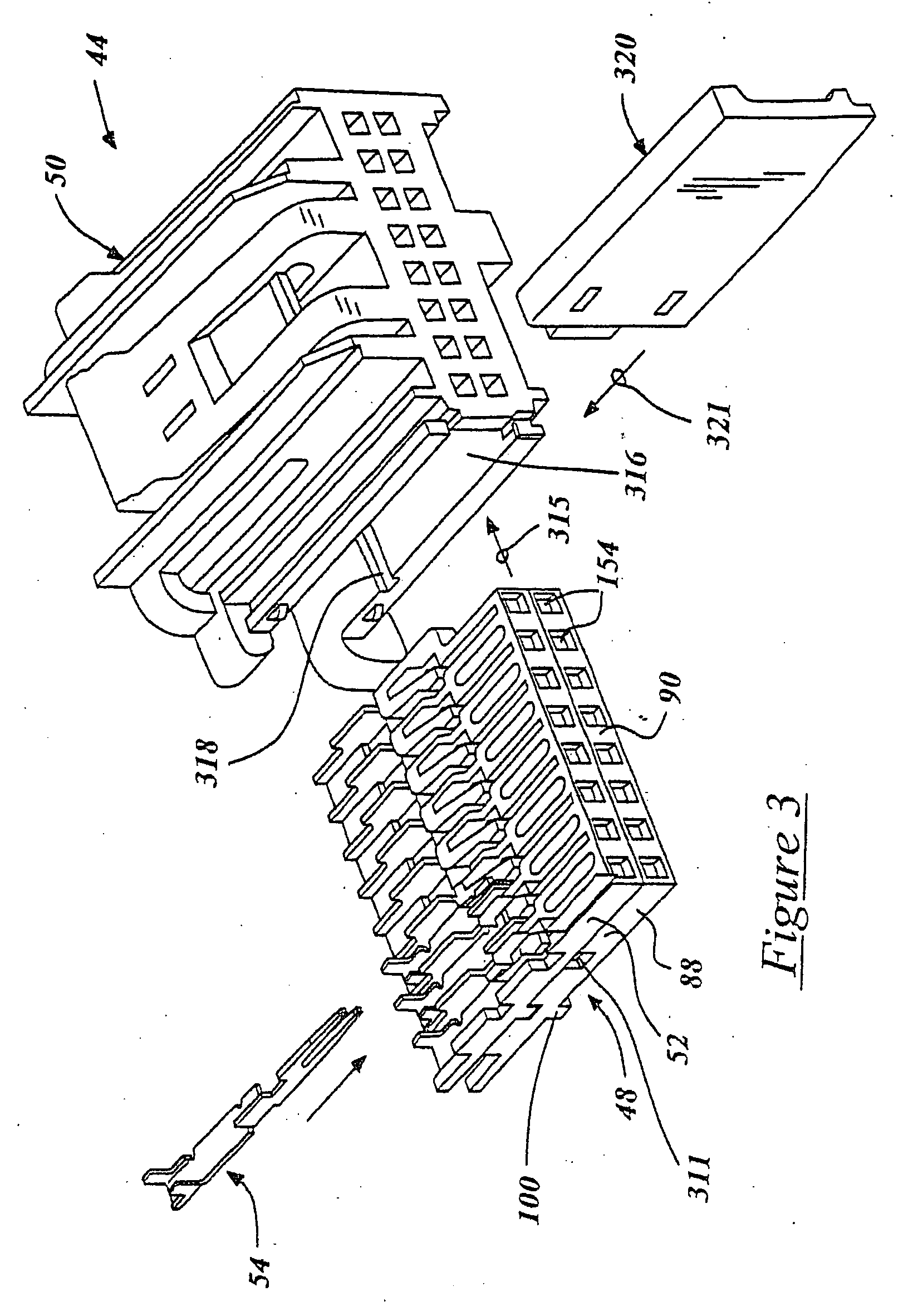

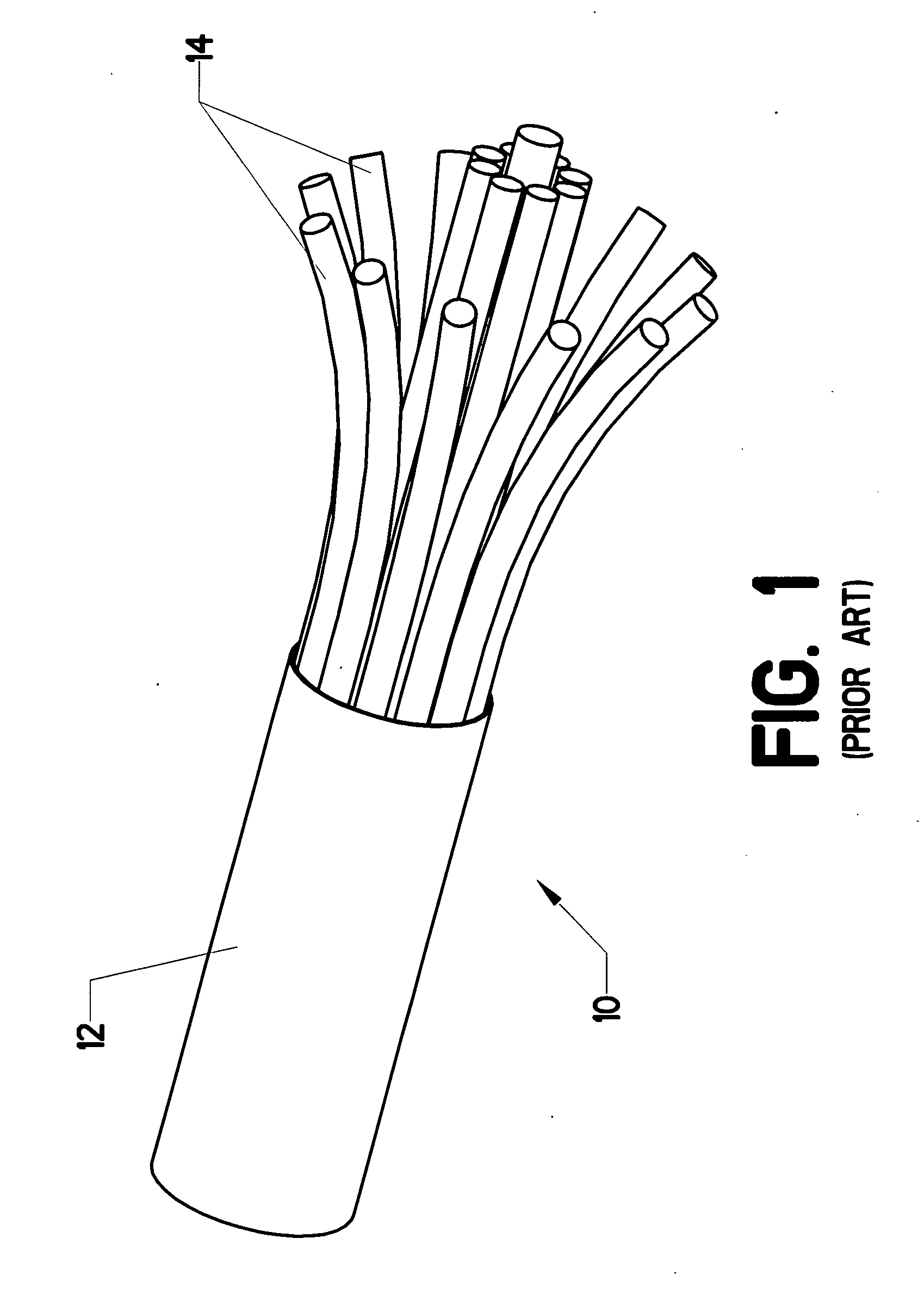

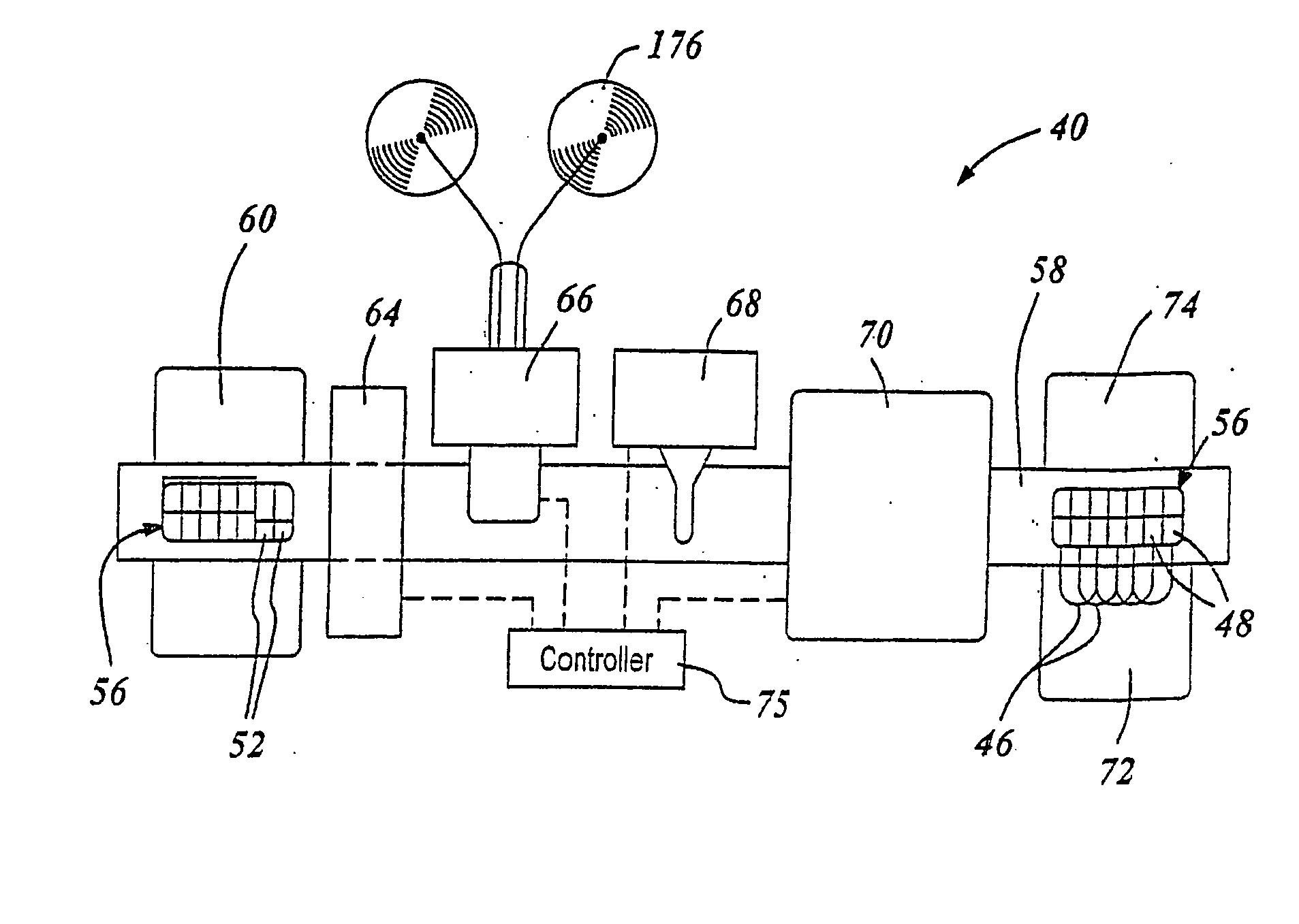

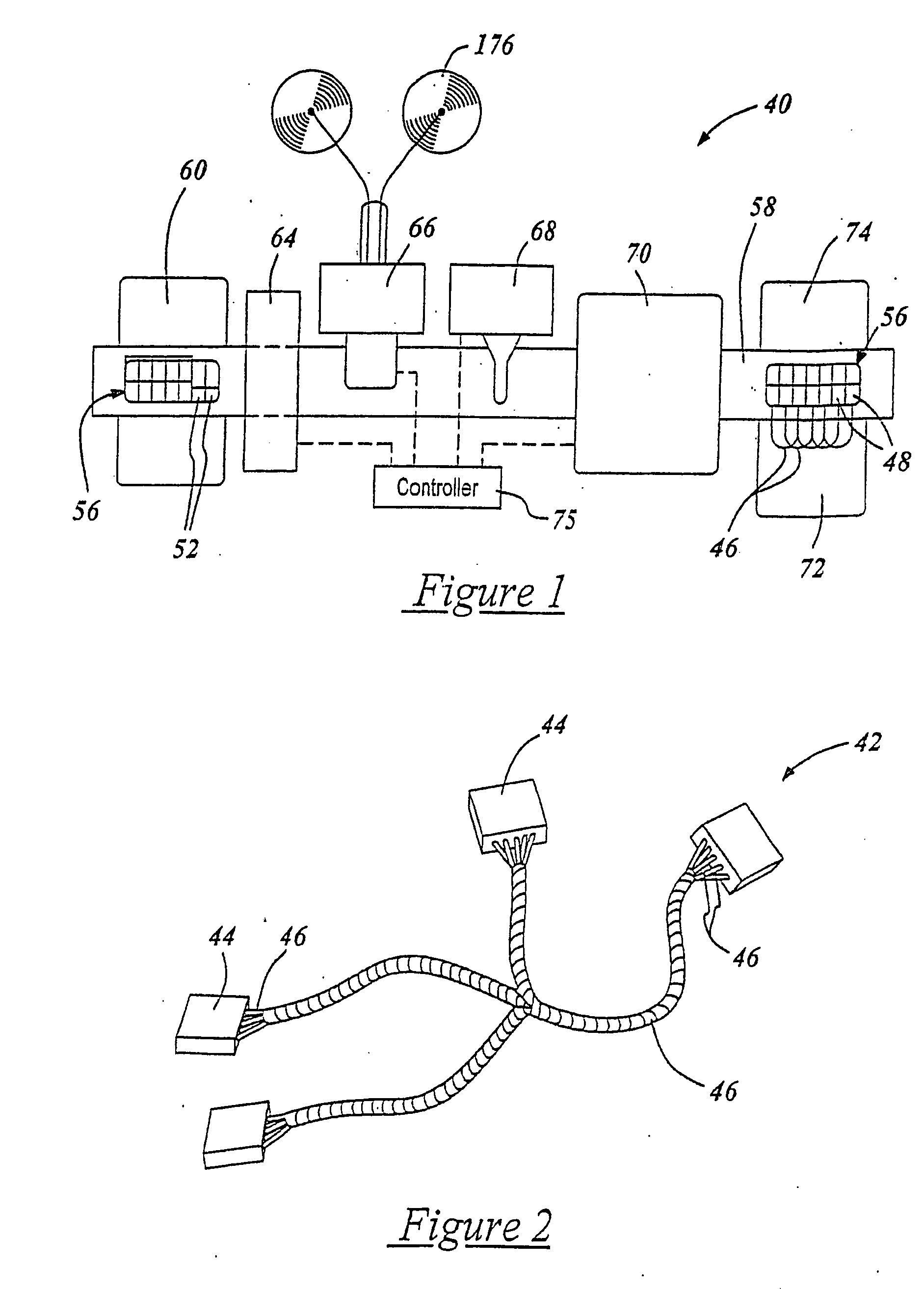

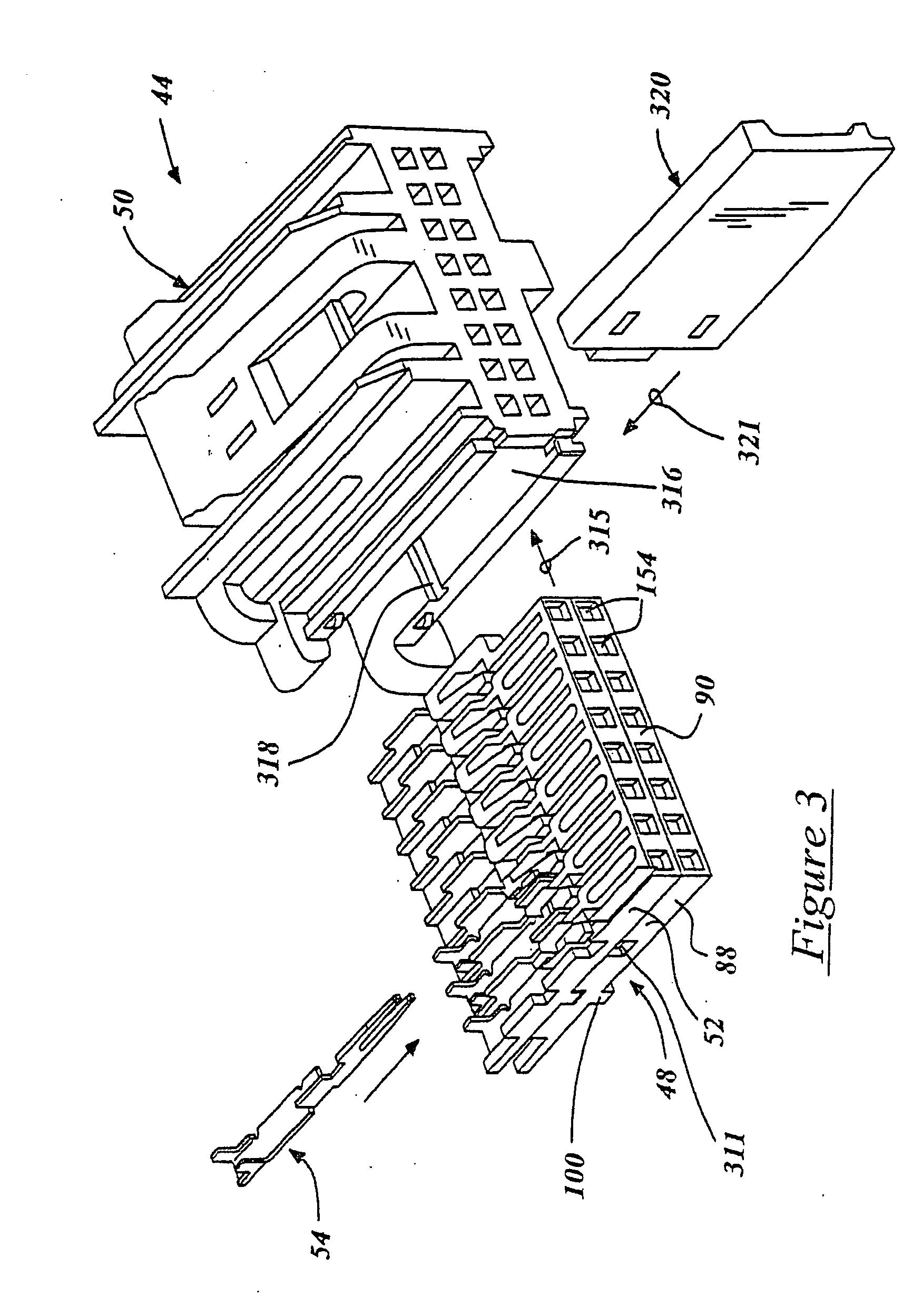

Wire loader

InactiveUS20050210670A1Contact member assembly/disassemblyWelding/cutting auxillary devicesEngineeringElectrical connector

An automated wire harness machine is capable of manufacturing a wire harness in an automated process. The wire harness is generally a plurality of bundled, preferably un-stripped, insulated wires. Each un-stripped end portion of each wire is preferably terminated by an electrical terminal in one of a series of electrical connectors of the wire harness. Each connector has at least one wafer which houses a plurality of terminals. The wire harness machine utilizes a pallet that holds all of the wafers of one wire harness. A conveyor transports the pallet and wafers through a series of stations which perform automated manufacturing steps. The first station is a terminal inserter which inserts and locks the terminals within pre-assigned cavities of the wafers. The next station is an automated wire loader which measures, cuts and crimps the two ends of each wire into the respective terminals of the loaded wafer assembly. A third station, or ultrasonic welder, then galls an un-stripped non-ferrous core of the crimped wire to the terminal. The pallet with the loaded wafers, crimped terminals, and terminated wires are then transported to a wire marker station which marks each wire, preferably via a laser, for identification purposes.

Owner:DELPHI TECH INC

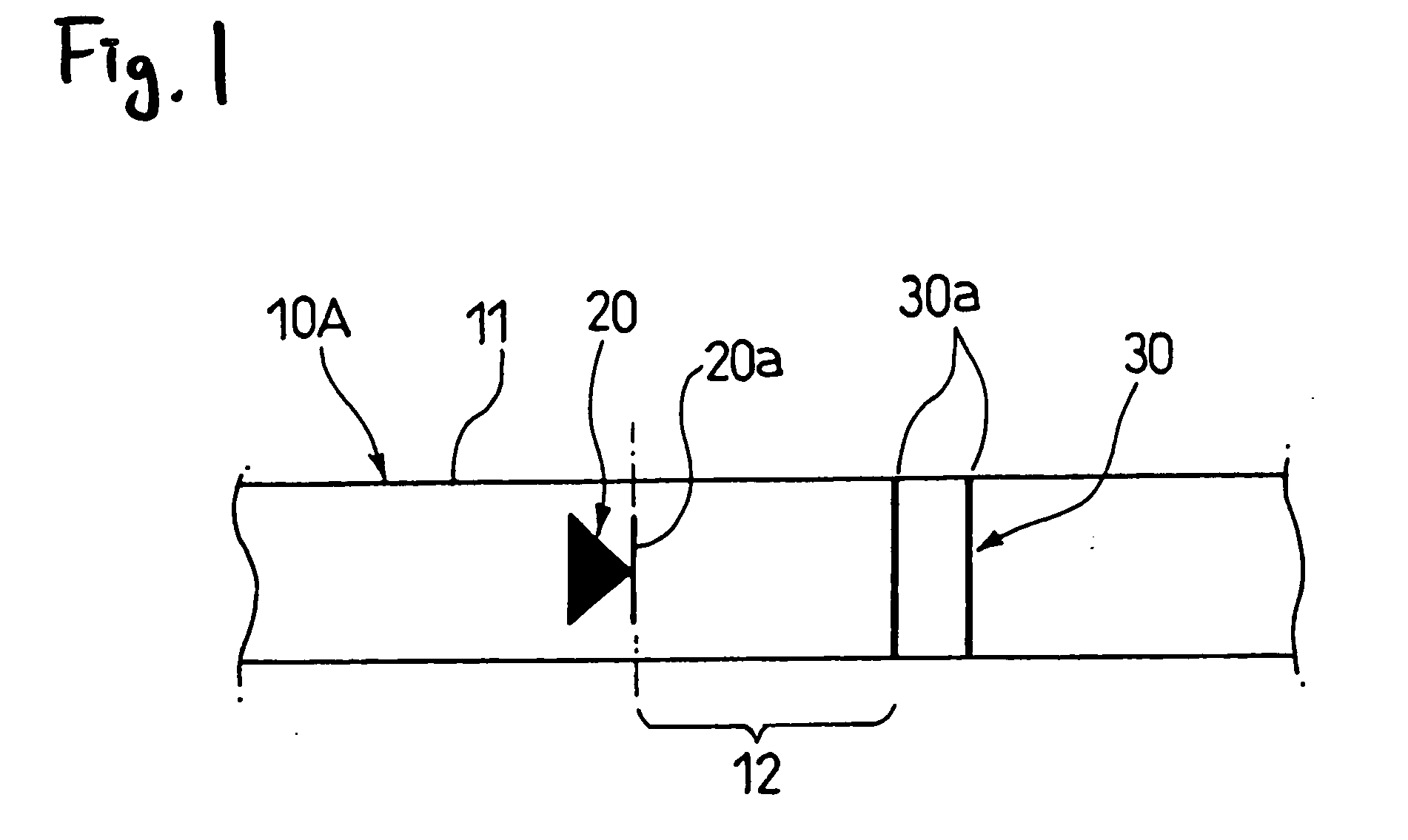

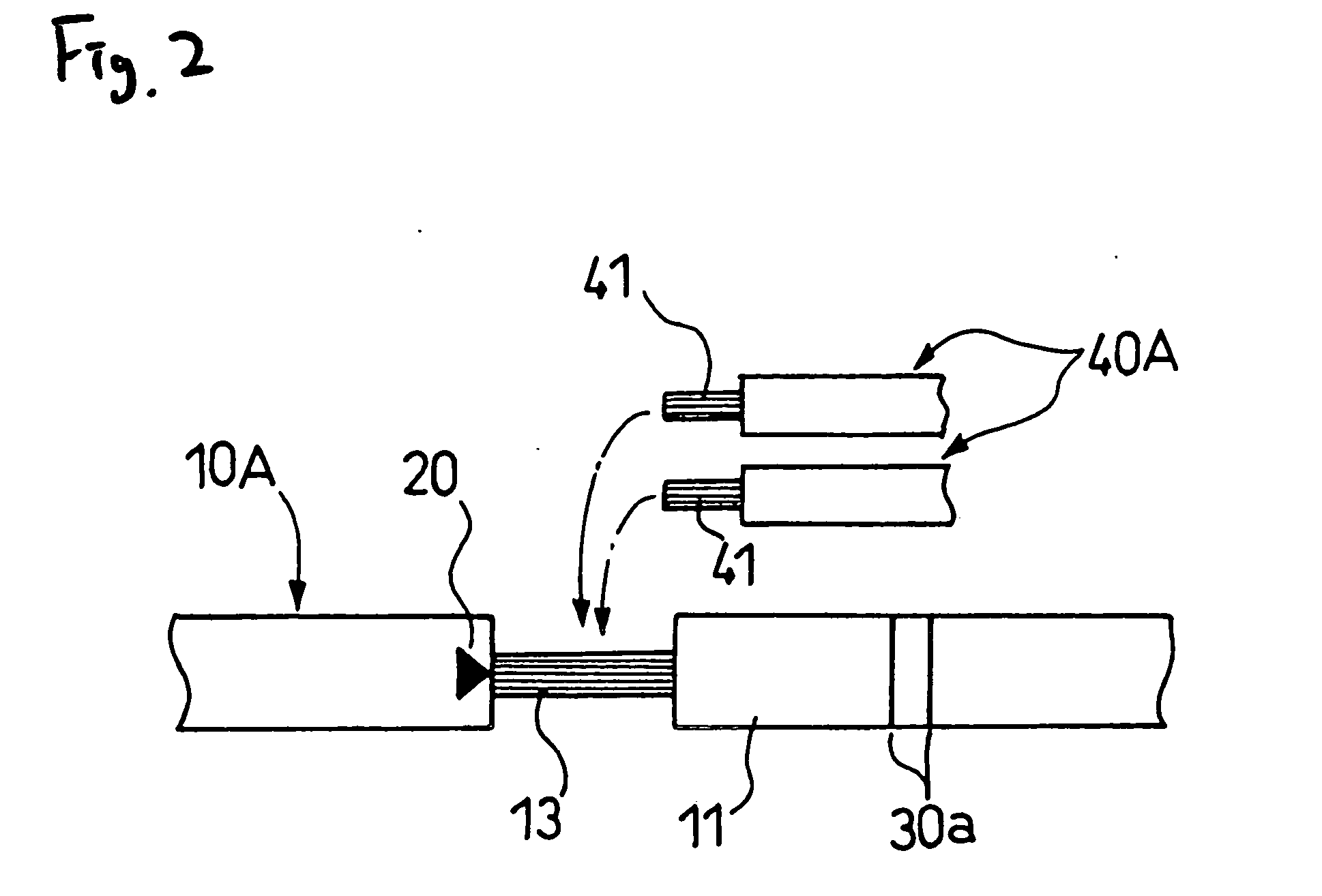

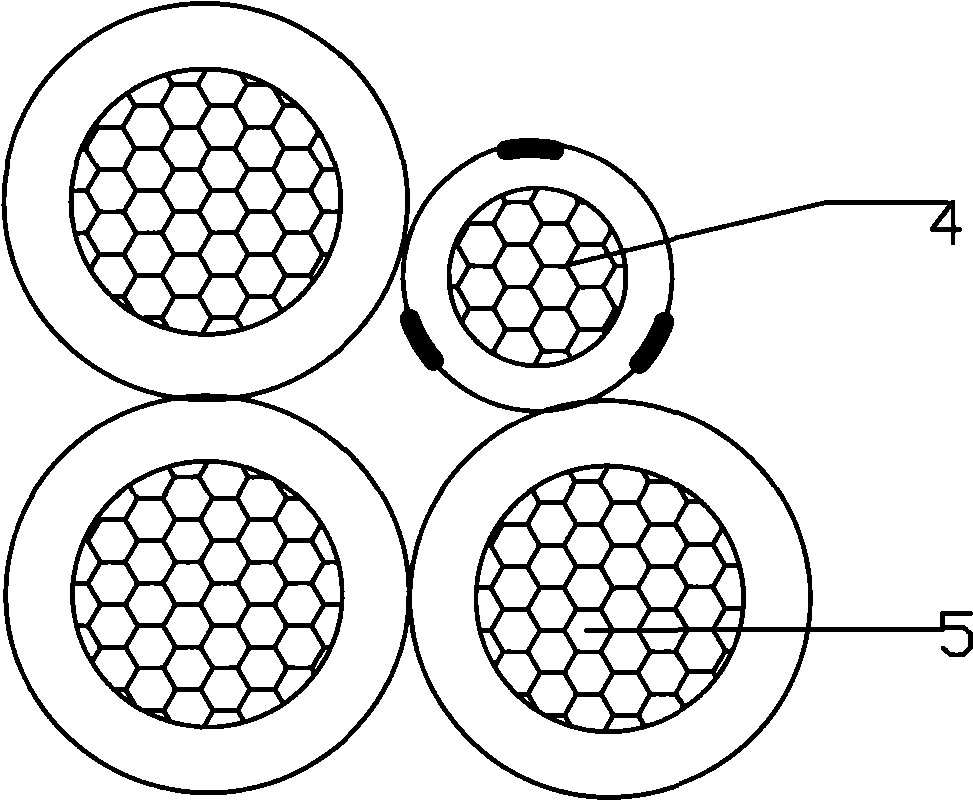

Electric wire, electric wire connection method and wire harness

InactiveUS20060225909A1Easy to identifyAccurate operationInsulated cablesConnections effected by permanent deformationConnection formCable harness

A first marking 20 and a second marking 30, indicating a connection form, are provided on a covering sheath 11 at a connection position of a first wire 10 serving as a main wire. Therefore, an operation is carried out at a region between the first marking 20 and the second marking 30 of the first wire 10 according to an operation form indicated by the second marking 30. Therefore, the predetermined form of operation can be carried out errorlessly at the predetermined position of the first wire 10 without consulting a manual or the like.

Owner:YAZAKI CORP

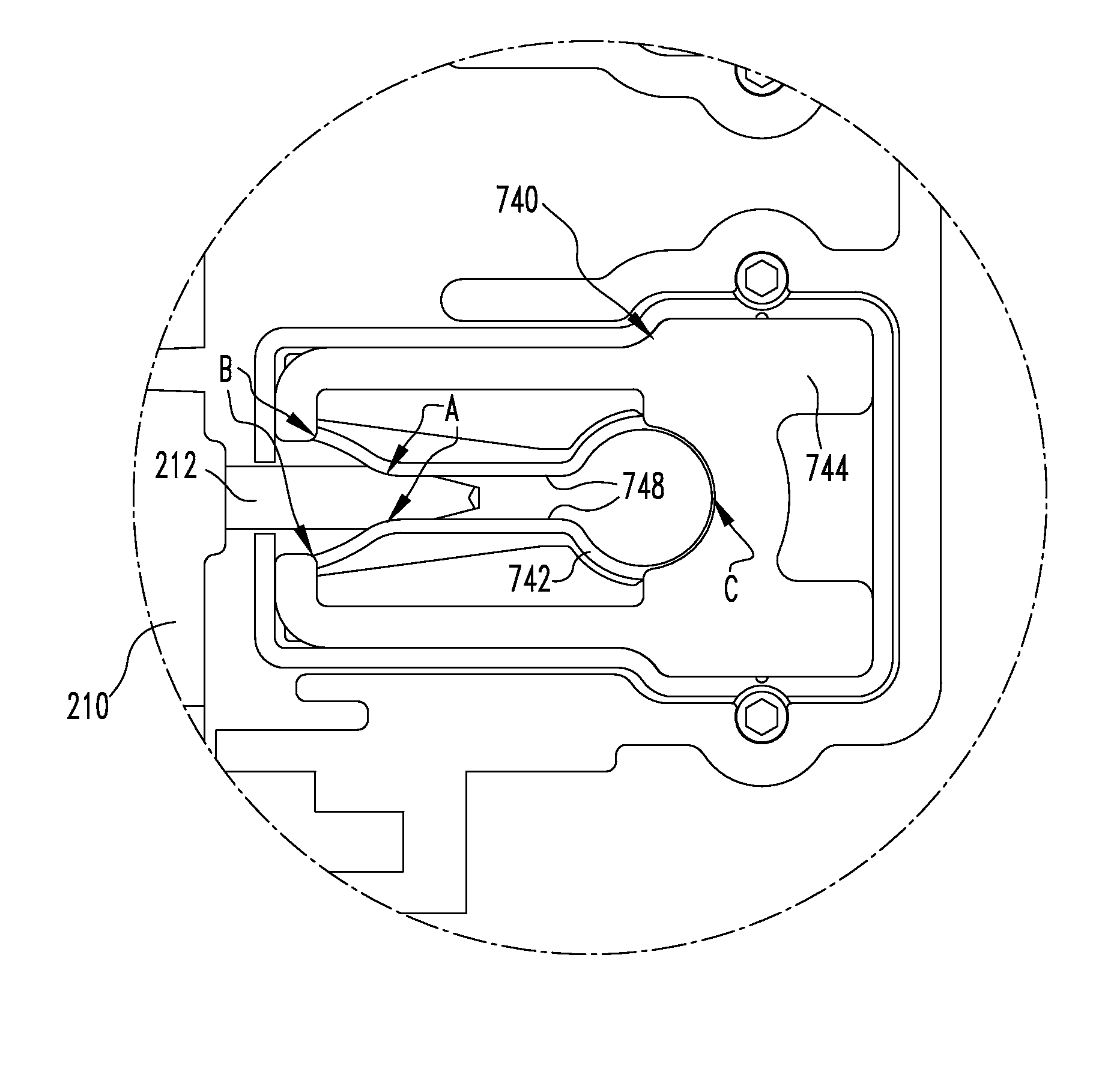

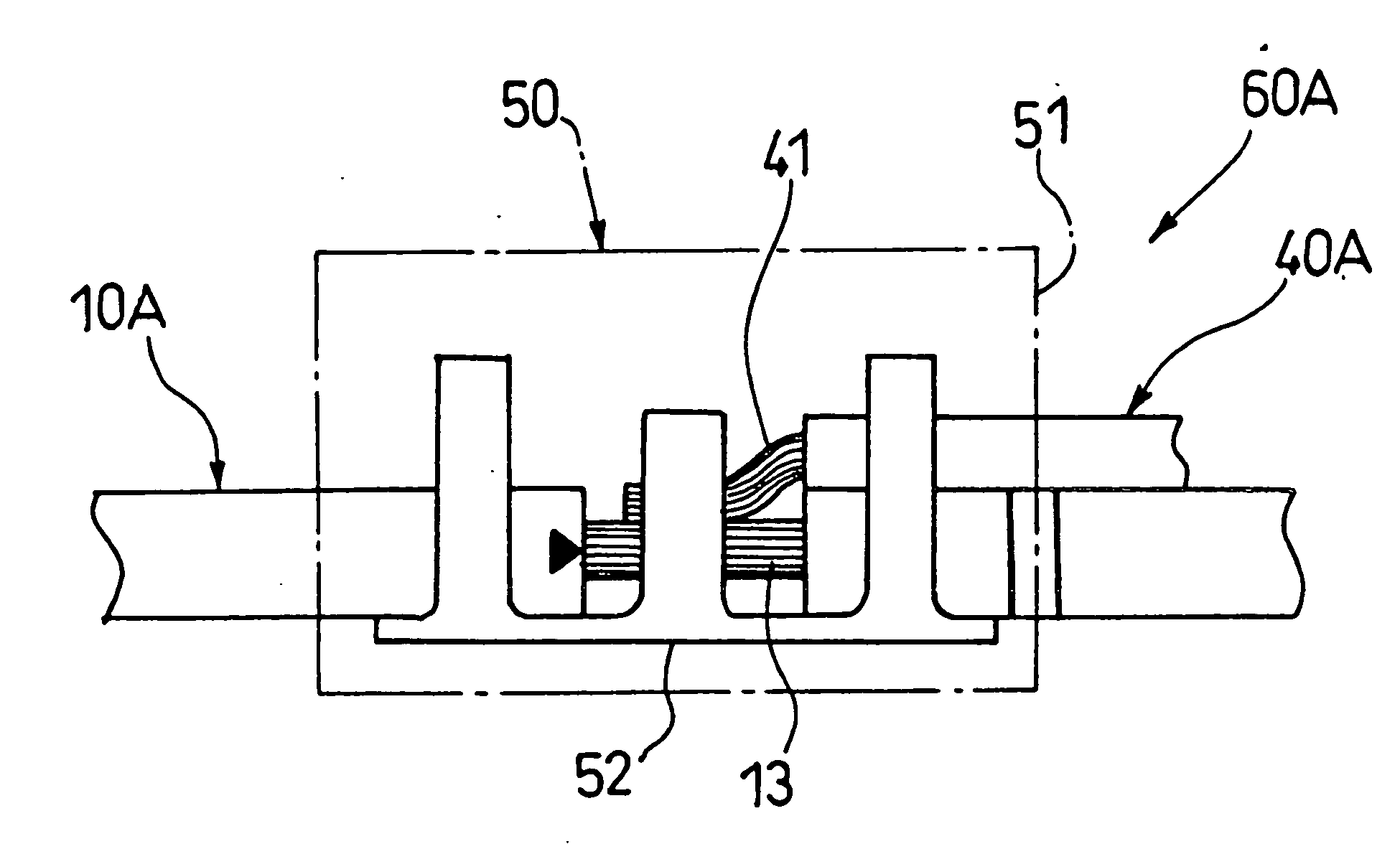

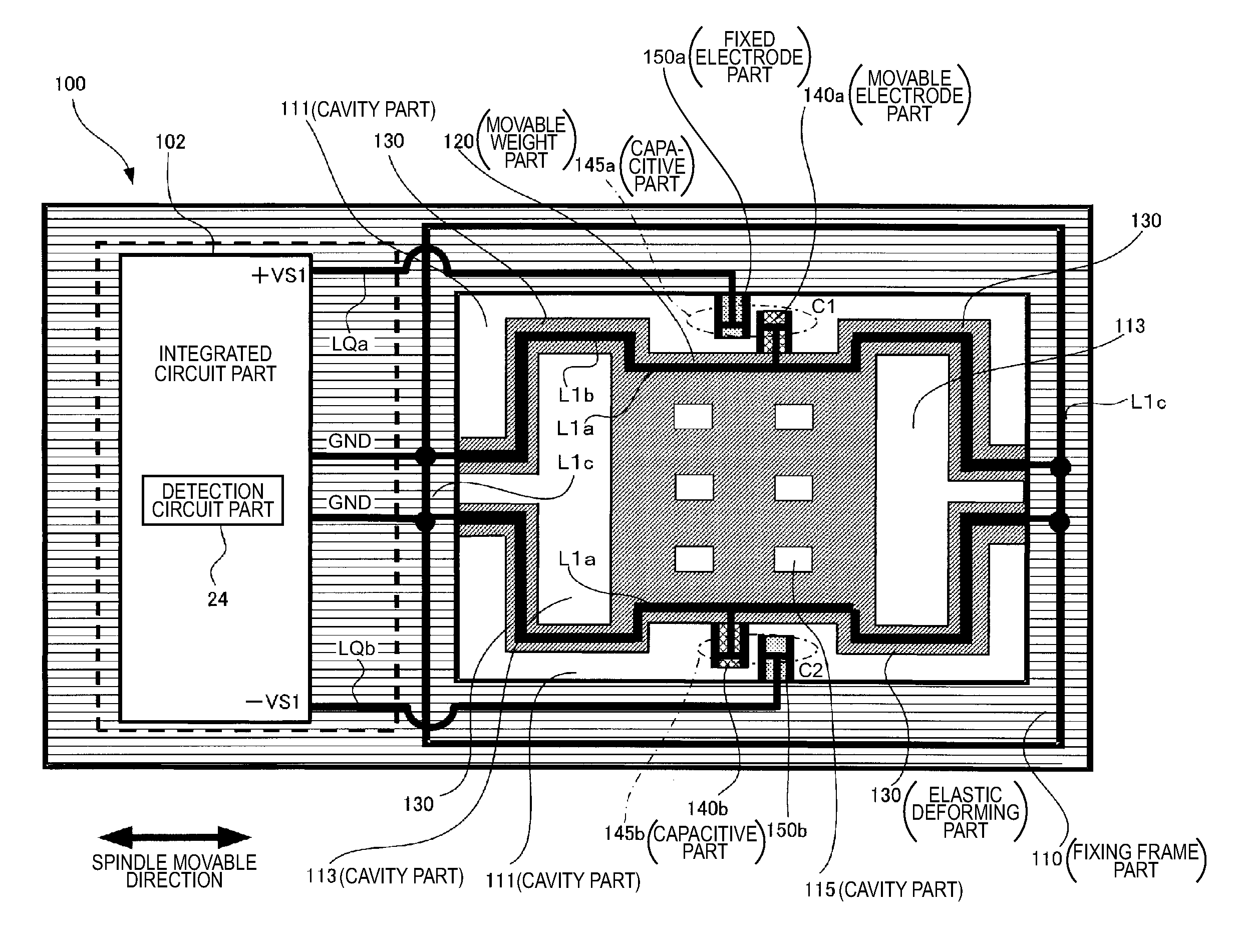

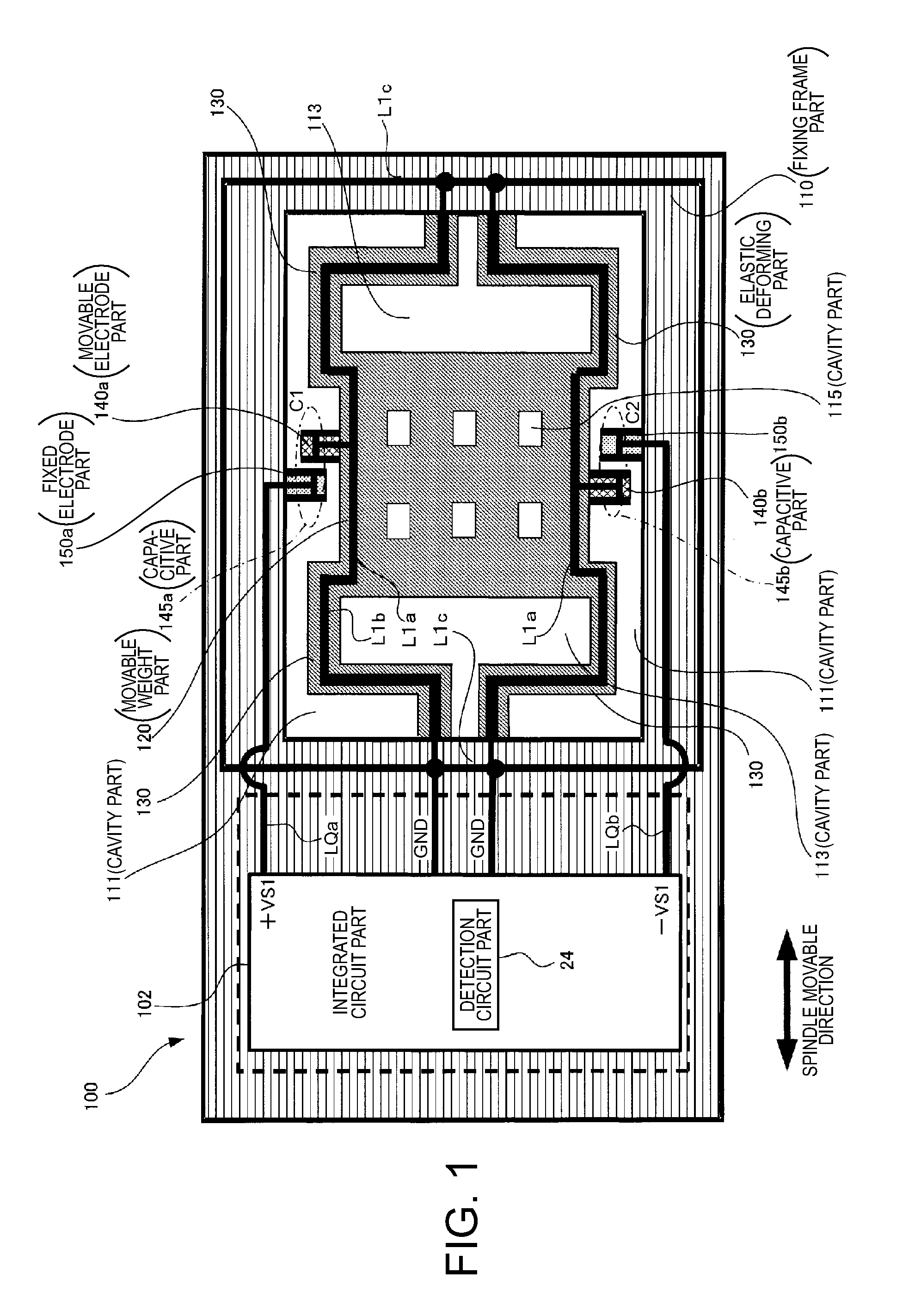

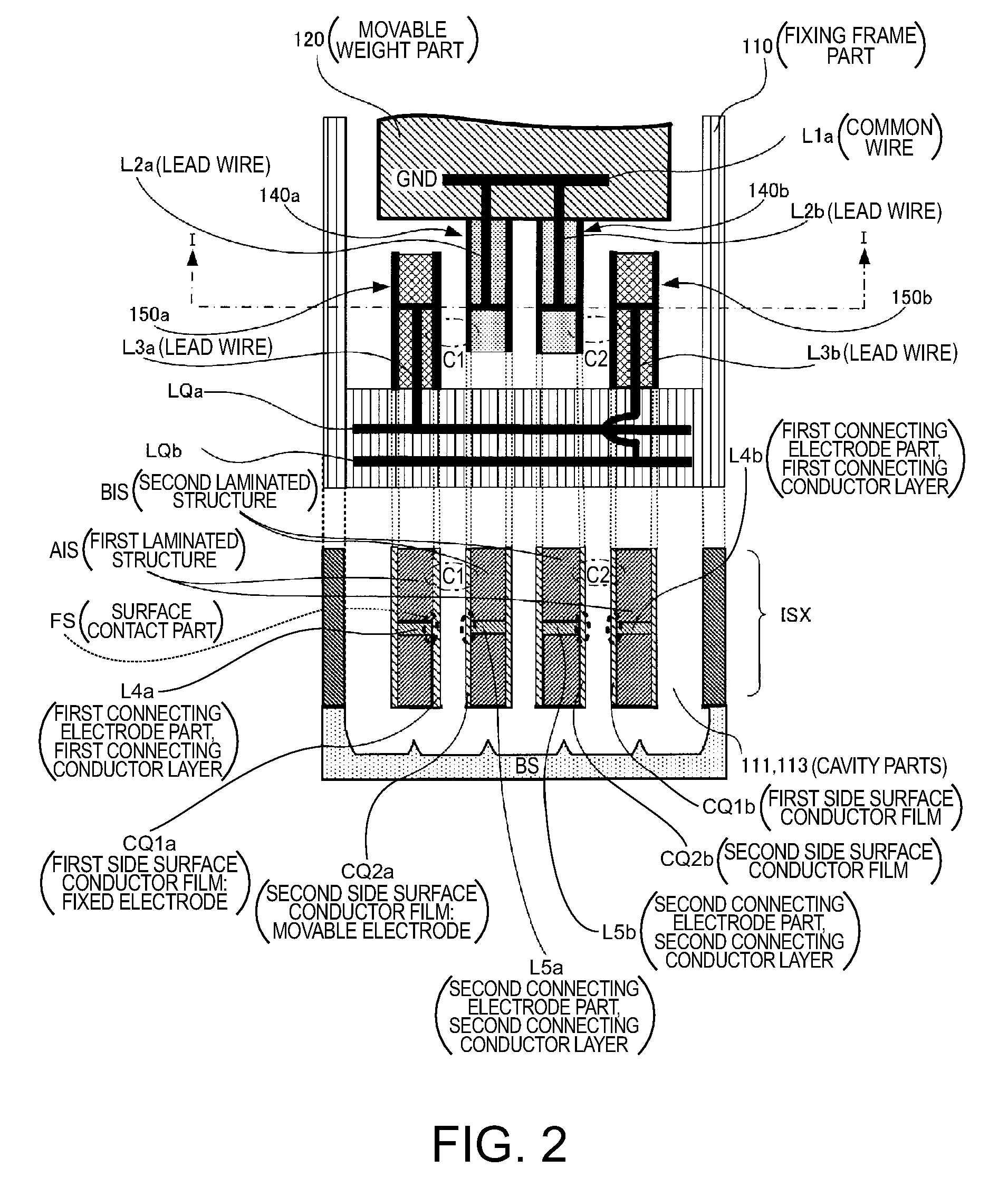

Physical quantity sensor, manufacturing method of physical quantity sensor, and electronic apparatus

InactiveUS20110056296A1Low costEasy to provideAcceleration measurementConductor/cable markingElectrical conductorElectron

A physical quantity sensor includes: a fixing part; an elastic deforming part; a movable weight part coupled to the fixing part via the elastic deforming part; a fixed arm part extended from the fixing part; and a movable arm part extended from the movable weight part and provided to face the fixed arm part via a gap, wherein the fixed arm part and the movable arm part are laminated structures containing insulating layers and conductor layers, the fixed arm part has a first side surface conductor film provided on a side surface of the fixed arm part and a first connecting electrode part using the conductor layer and electrically connected to the first side surface conductor film, and the movable arm part has a second side surface conductor film provided on aside surface opposed to the first side surface conductor film and a second connecting electrode part using the conductor layer and electrically connected to the second side surface conductor film.

Owner:SEIKO EPSON CORP

Production equipment for dual-color insulated wire

InactiveCN102446593AReduce wasteGuarantee product qualityConductor/cable markingInsulating conductors/cablesRadial positionEngineering

The invention discloses production equipment for a dual-color insulated wire, which consists of a horizontal plastic extruding machine and a vertical stripping extrusion machine. The horizontal plastic extruding machine comprises a machine body, a machine head body and a mold. A main material input hole is arranged on the machine head body. The machine body is connected with the main material input hole of the machine head body. The mold comprises a mold core seat, a mold sleeve, a mold core, a flue dispensing body and an outer mold. A pigment input hole is arranged in the radial direction ofthe highest radial position of the external surface of the front part of the mold sleeve. A pigment filling opening which is communicated with the pigment input hole is arranged at the highest radialposition of the external surface of the front part of the outer mold. A pigment trench which is communicated with the inner cavity of the outer mold is arranged on the external surface of the outer mold. A pigment output through hole is arranged in the axial direction of the center of the bottom surface of a spiral drum. A stripping extrusion nozzle which is abutted with the pigment input hole ofthe mold sleeve is connected onto the pigment output through hole. A through hole is arranged in the radial direction of the bottom surface of the spiral drum. A bar-shaped change-over switch is inserted into the through hole. By turning the change-over switch, the pigment output through hole can be communicated with or isolated from the stripping extrusion nozzle.

Owner:SHANGHAI NANDA GROUP

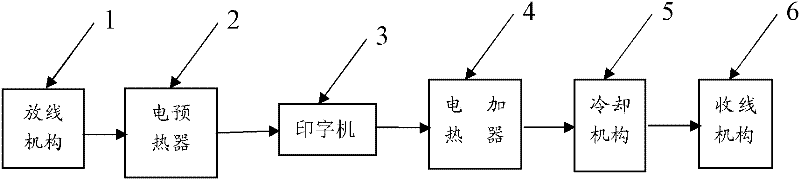

Fluoroplastic electric wire and cable surface lettering method and device

The invention provides a fluoroplastic electric wire and cable surface lettering method. The method comprises the following steps of: preheating a fluoroplastic electric wire in an electrical heating preheater, lettering on a high-temperature printing ink lettering wheel, heating the lettered electric wire in an electric heater, cooling the electric wire and the like. The invention also provides a corresponding lettering device which comprises a paying-out mechanism, the electric preheater, a high-temperature printing ink roll wheel lettering machine, the electric heater, a cooling mechanism and a cable coiling mechanism through which the electric wire successively passes. The method has the beneficial effects that the fluoroplastic surface of the electric wire is preheated to a required temperature firstly, then lettering is carried out on the fluoroplastic surface of the electric wire by use of high temperature printing ink, then the lettered fluoroplastic surface of the electric wire is heated to the required temperature so as to be firmly adhered to the fluoroplastic surface of the electric wire and cable, and subsequently, and cooling is performed, so that the lettering is firm and clear, the price is economic and cheap. Thus, the method and device provided by the invention are suitable for national conditions of China.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

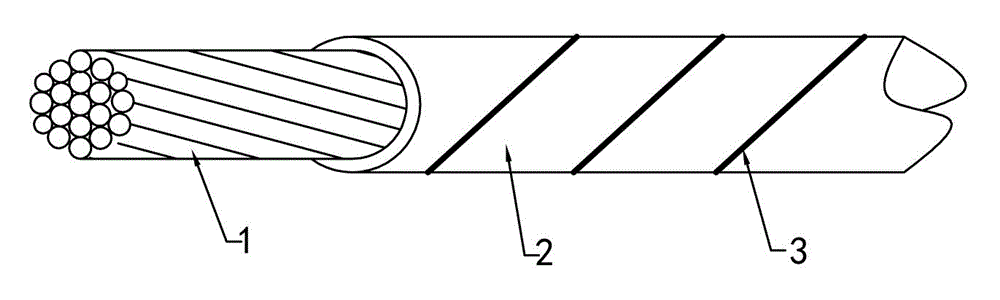

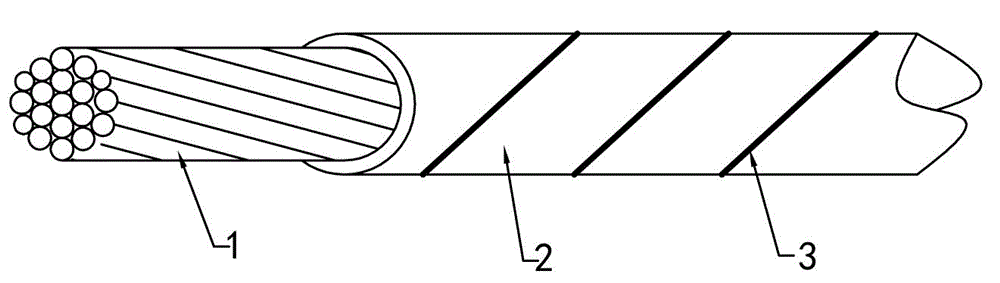

X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and preparation process for insulating wire or cable

InactiveCN102723135AQuick distinctionAccurate distinctionInsulated cablesConductor/cable markingTetrafluoroethyleneWire rod

The invention discloses an X-ETFE (crosslinked ethylene-tetrafluoroethylene) insulating wire or cable with spiral stripe identifications for aerospace and a preparation process for the insulating wire or cable. The preparation process for the insulating wire or cable includes steps of: printing spiral stripe identifications on an insulating layer of an X-ETFE insulating wire directly formed by a single insulating core wire; printing spiral stripe identifications on a sheath layer of an X-ETFE insulating cable formed by a single insulating core wire, a shielding layer and the sheath layer; printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires, the shielding layer and the sheath layer; and printing spiral stripe identifications on an insulating layer and / or a sheath layer of an X-ETFE insulating cable formed by a plurality of insulating core wires and the sheath layer. The insulating core wires consist of conductors and the insulating layers which wrap the conductors. The X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace is easy to be distinguished and identified, convenient to trace back and rapid in checking, and is beneficial to waste wire recovery. In addition, the X-ETFE insulating wire or cable with the spiral stripe identifications for aerospace has excellent high-temperature resistance, low-temperature resistance and radiation resistance, and the mechanical performance of the insulating layer is quite good.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

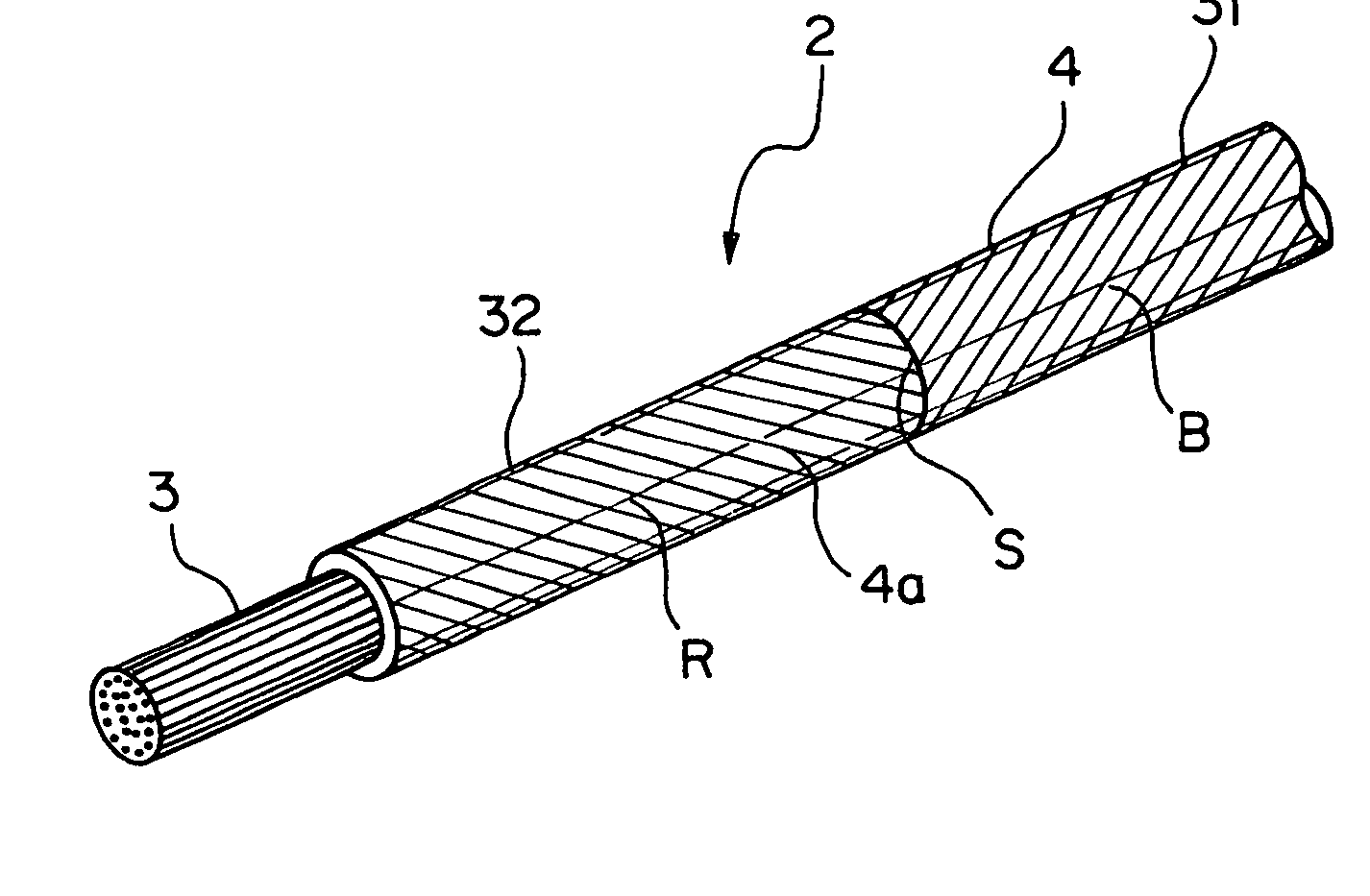

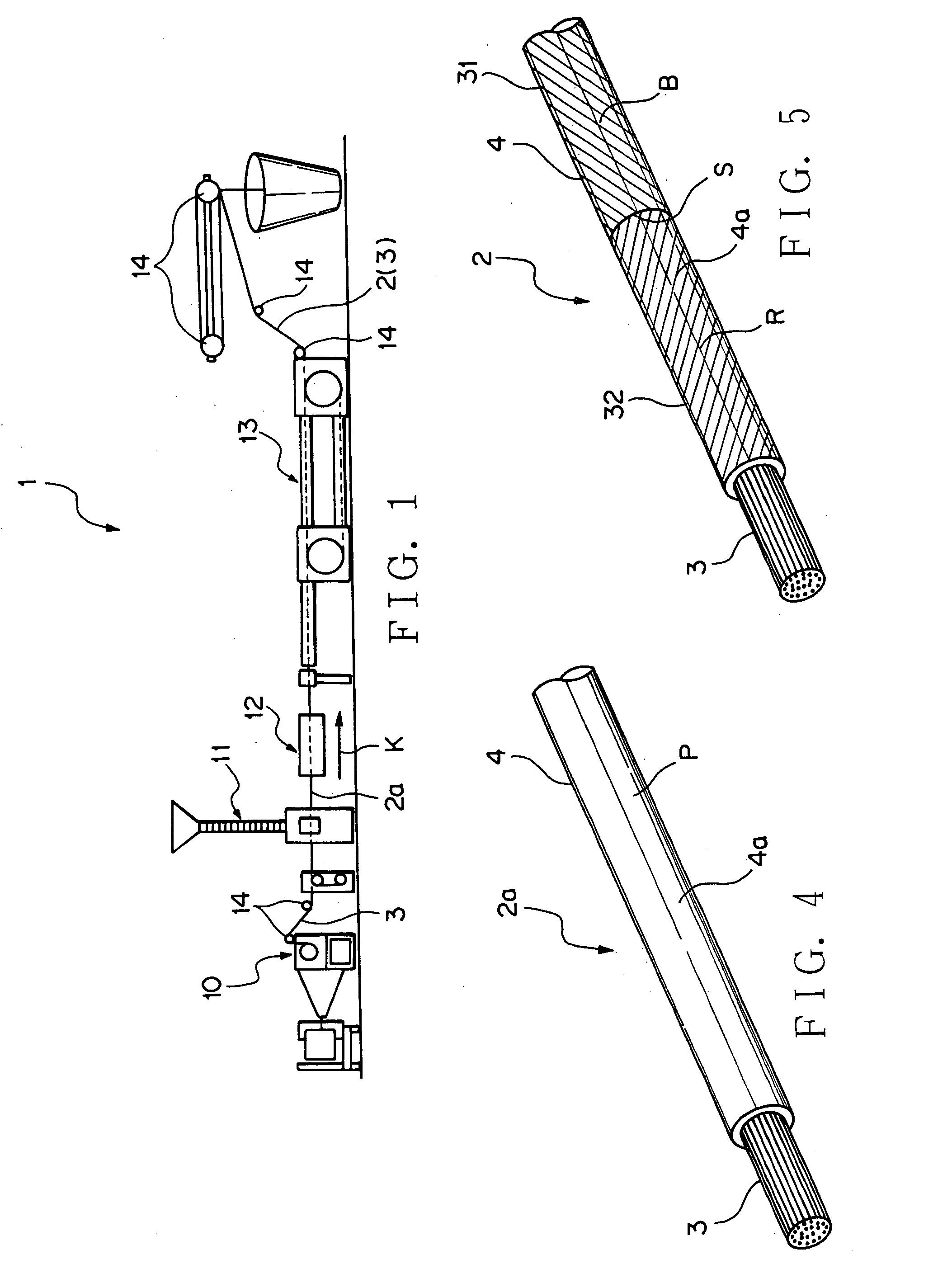

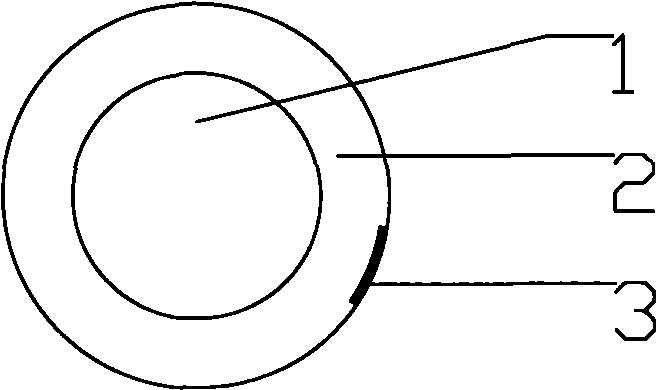

Electric wire

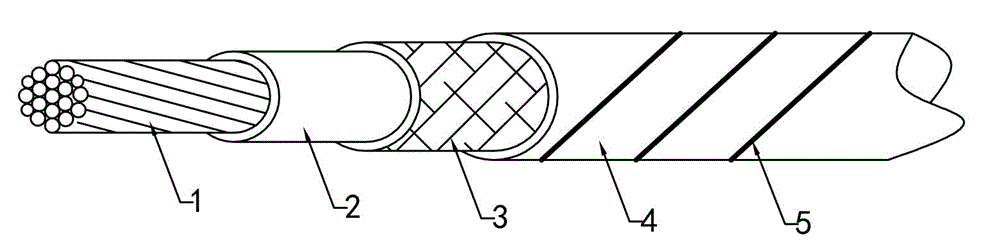

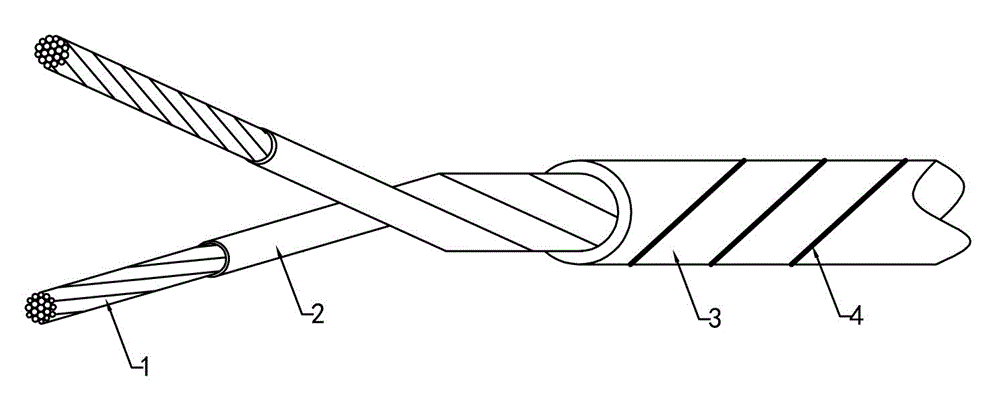

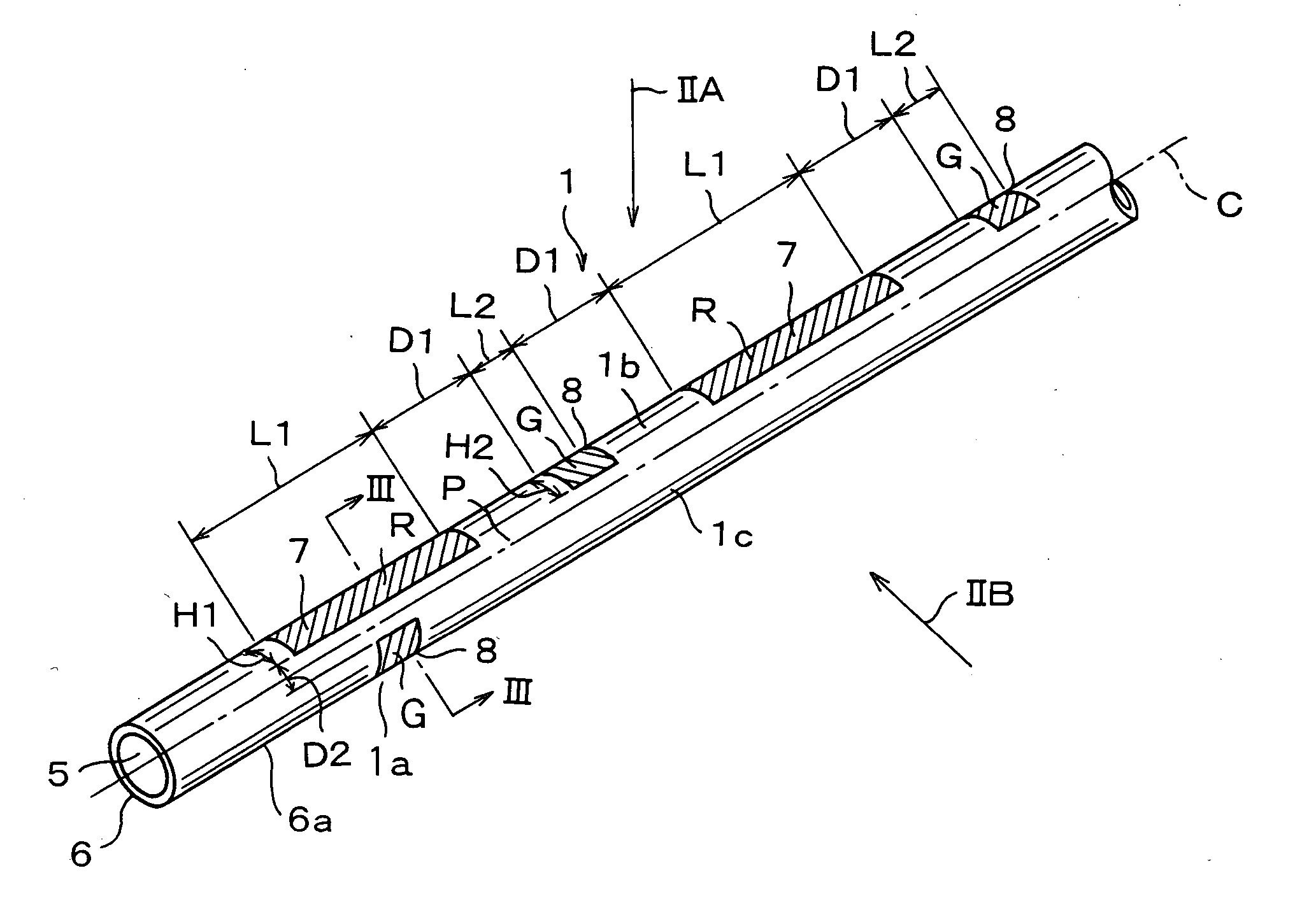

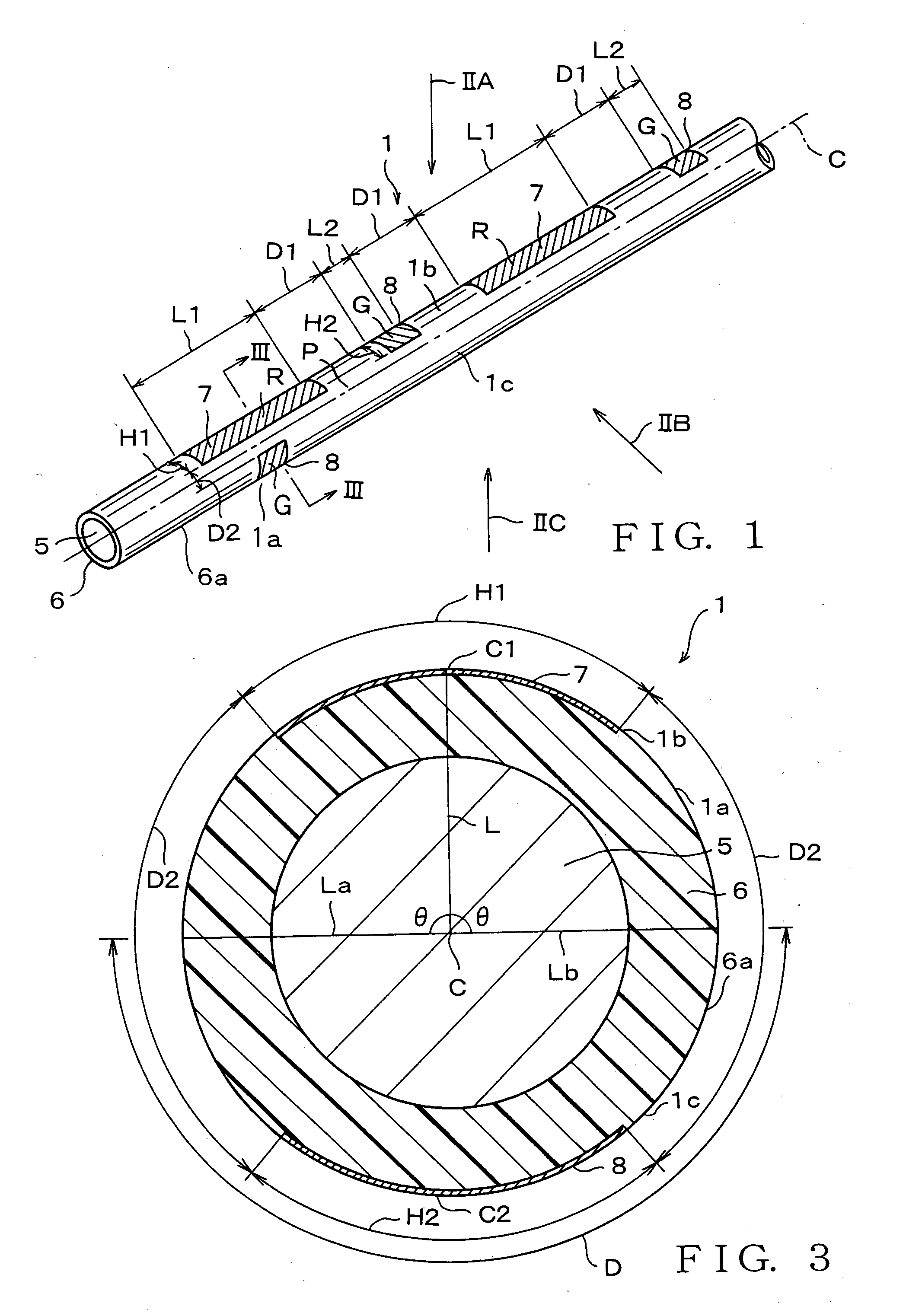

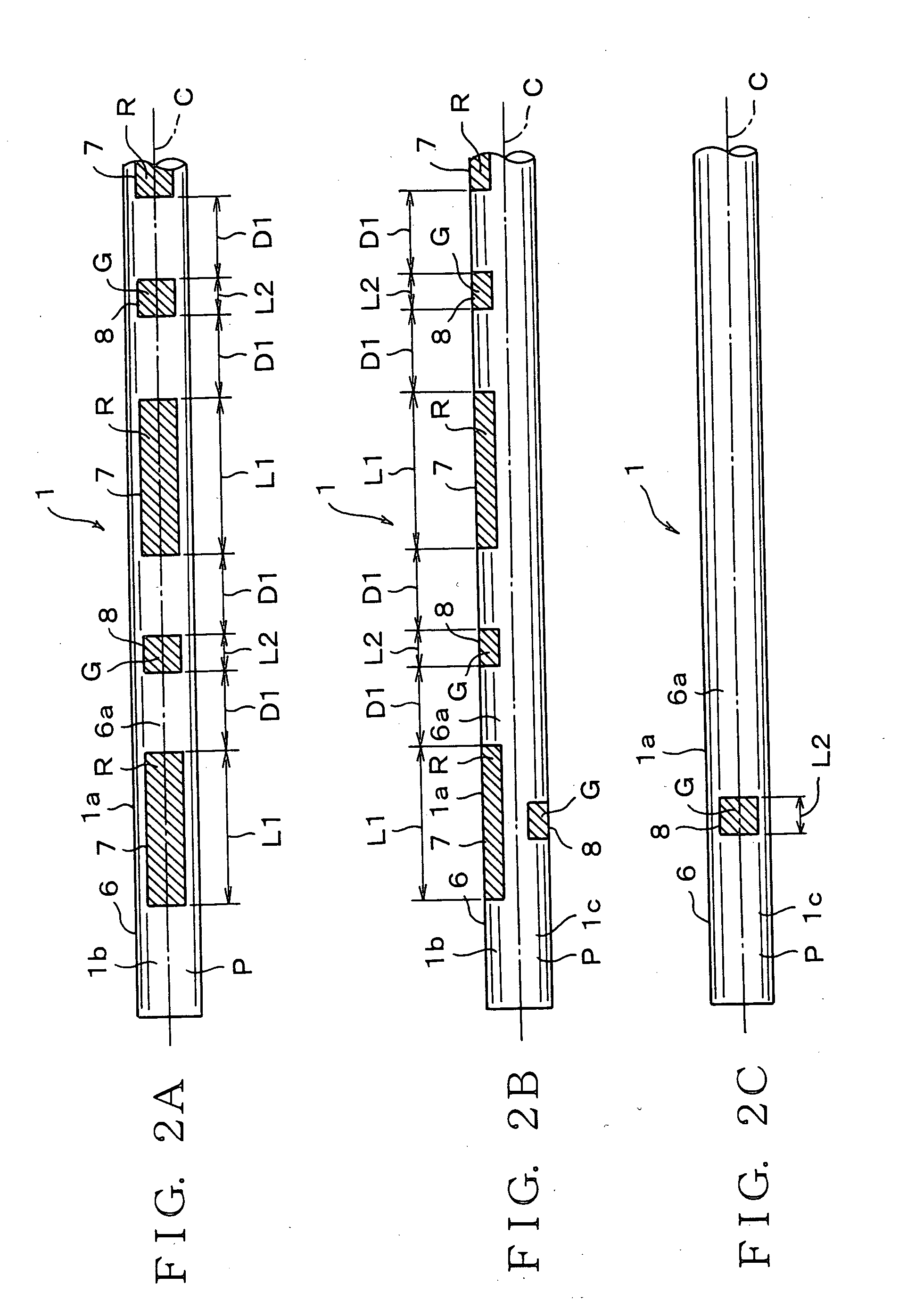

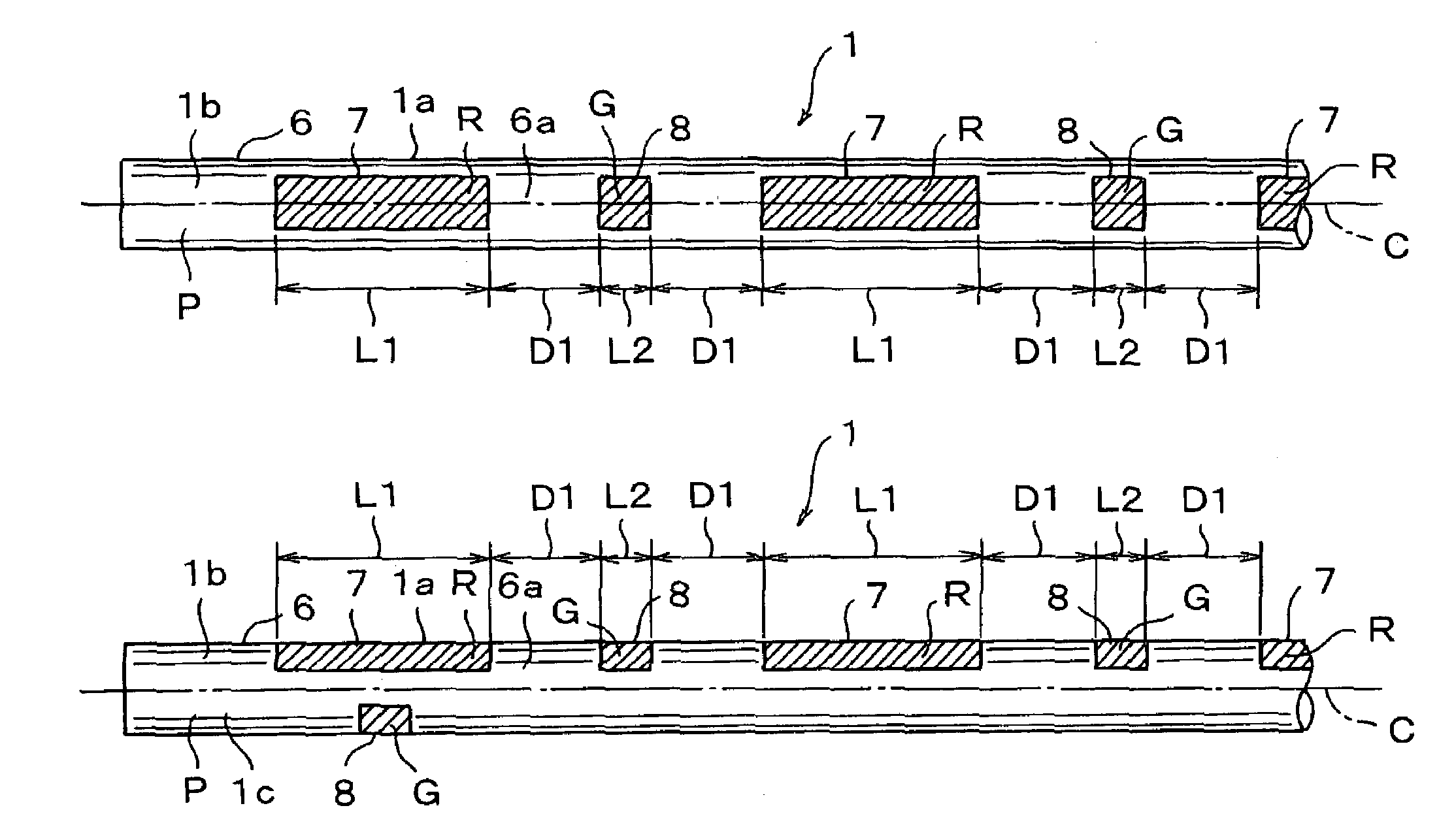

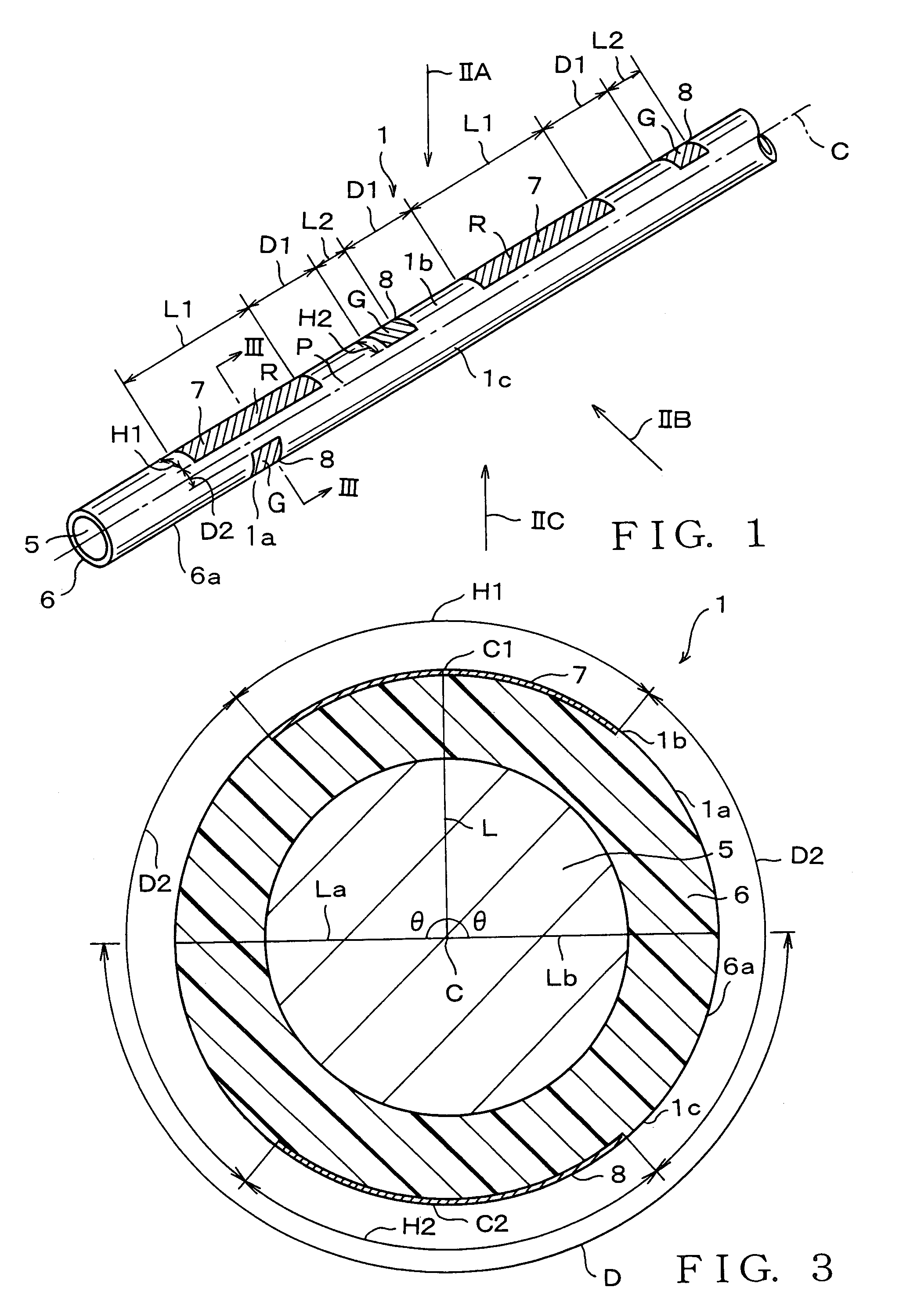

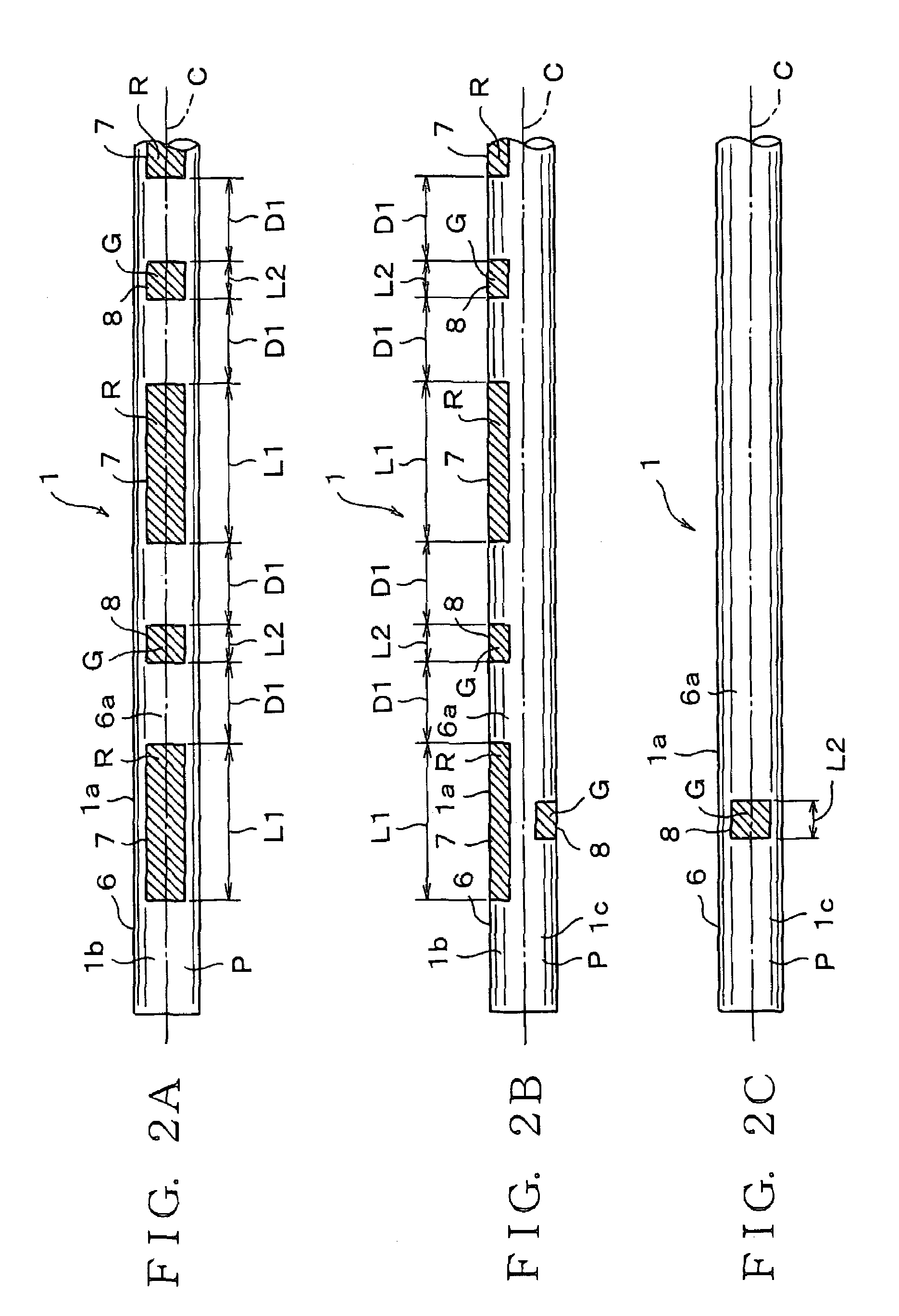

ActiveUS20060070766A1Insulated cablesConductor/cable markingElectrical and Electronics engineeringElectrically conductive

The present invention provides electrical cables that can be surely discriminated from one another, even when only a part of an outer surface of each cable is exposed. An electrical cable 1 has an electrically conductive core 5 and a sheathing layer 6 covering the core 5. The sheathing layer 6 has an outer surface 6a with a mono-color. On the outer surface 6a, a first mark 7 and a second mark 8 are provided. At an end 1a of the cable 1, the first mark 7 is provided on a first outer surface 1b while the second mark 8 is provided on a second outer surface 1c positioned oppositely to the first surface 1b of the sheathing layer 6. On the first outer surface 1b, a plurality of the first and second marks 7, 8 are provided to be alternately positioned in a longitudinal direction of the cable 1. The first mark 7 has a first color R while the second mark 8 has a second color G different from the first color R. Desirable variation in hue of the first and second colors R, G allows discrimination of the cables 1 from each other.

Owner:YAZAKI CORP

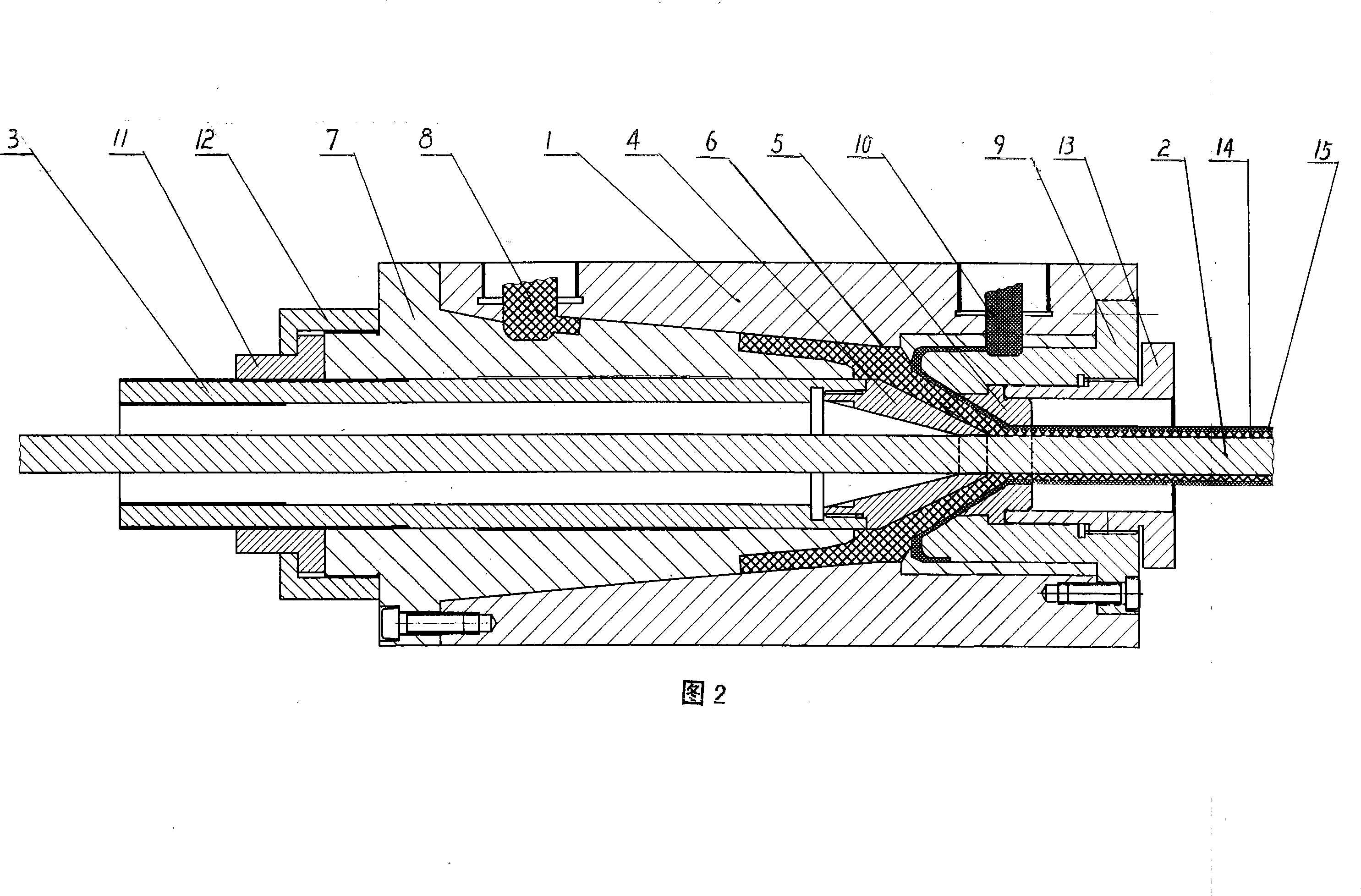

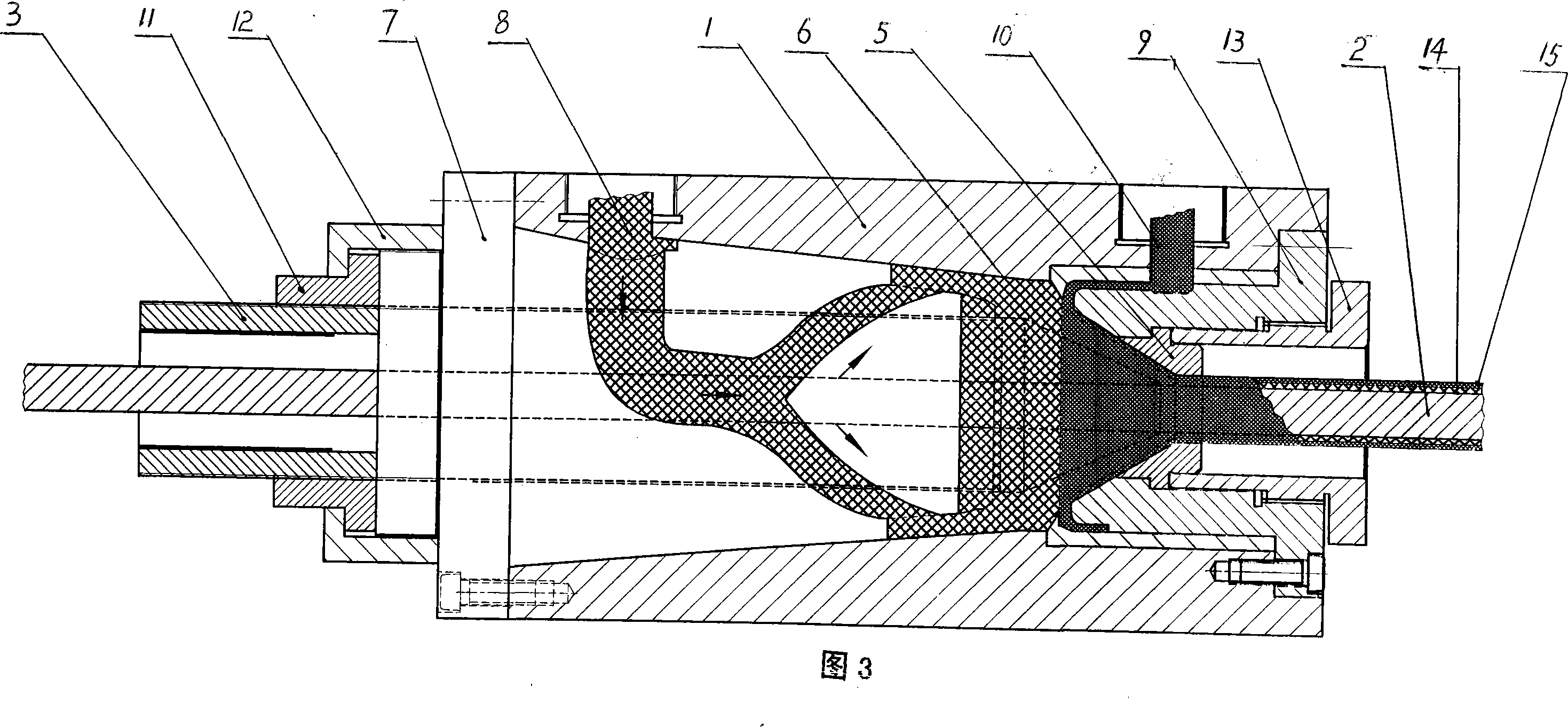

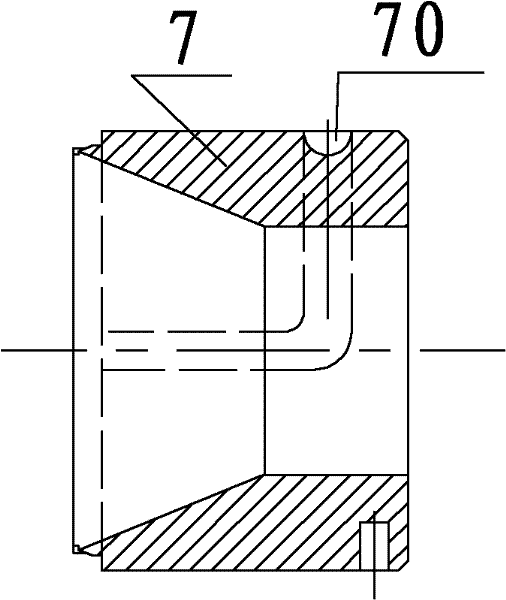

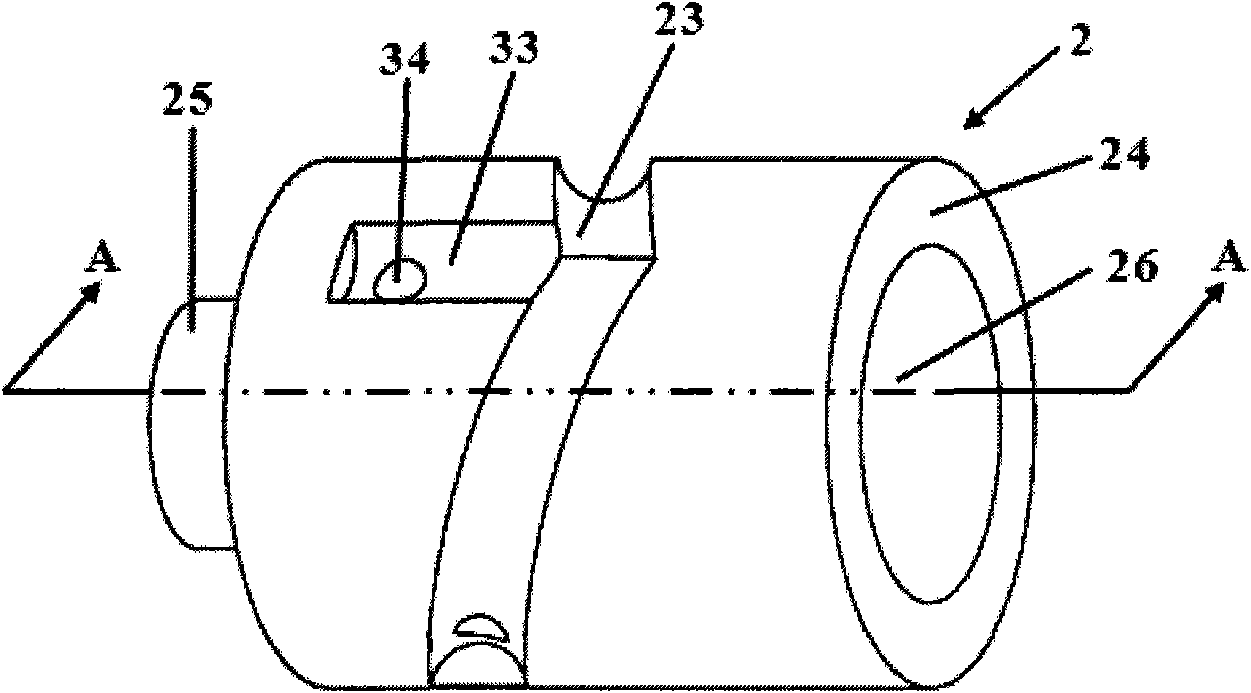

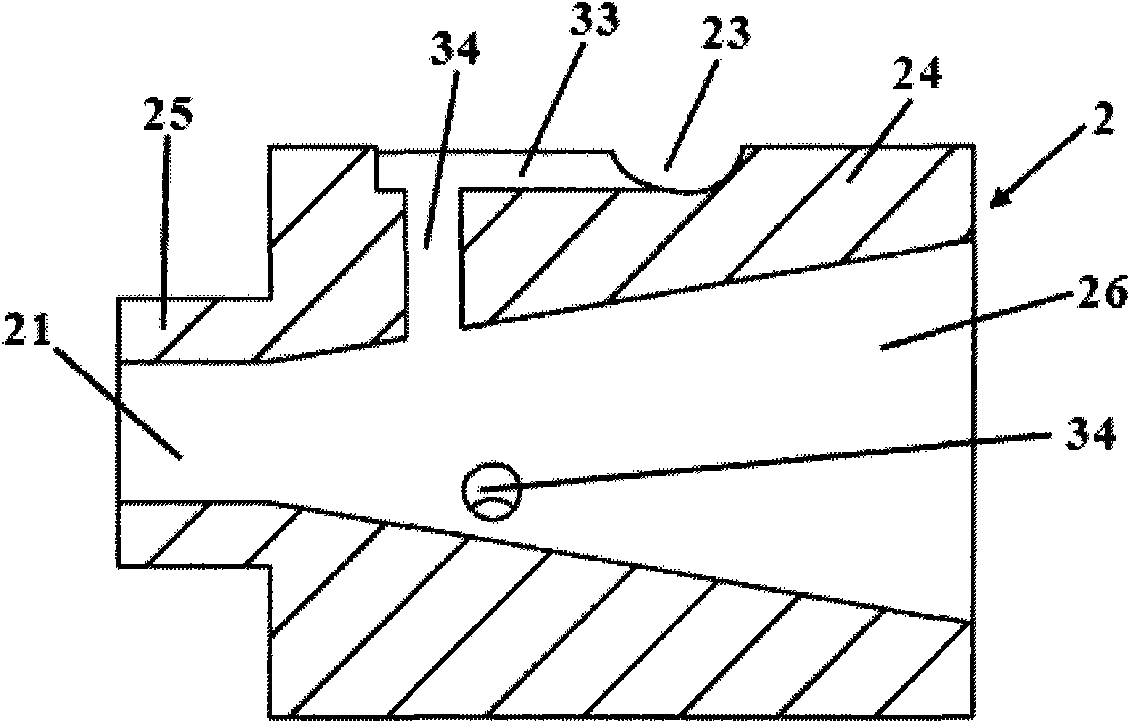

Two-color cable sheath extruded mould with improved structure

InactiveCN101635190AEasy to identifyGood symmetryConductor/cable markingInsulating conductors/cablesScrew threadPolymer chemistry

The invention relates to a two-color cable sheath extruded mould with an improved structure, comprising a mould core unit (1) and a mould cover unit (2). The two-color cable sheath extruded mould with the improved structure is characterized by also comprising a mould sleeve unit (3), wherein a mould sleeve side wall (334) is provided with an injection molding hole (333) longitudinally passing through the mould sleeve side wall (334), and a mould sleeve hole (336) formed inside the mould sleeve side wall (334) is communicated with a mounting hole (331) on the front end surface (335) of the mould sleeve unit (3); the surface of the mould cover unit (2) is provided with a diffluent groove (33) and a color separation ring (23), and both of the diffluent groove (33) and the color separation ring (23) are provided with color separation holes (34) passing through the wall of a mould cover body (24) from top to bottom; the diffluent groove (33) and the color separation ring (23) are converged into the mould cover body (24), and the diffluent groove (33) and the color separation ring (23) both does not pass through the wall body of the mould cover body (24); the color separation ring (23) is spirally distributed along the surface of the mould cover body (24); and the inner surface of the mould sleeve side wall (334) is provided with a thread matched with screw teeth on the outer surface of the mould cover body (24). The invention has the advantages of simple structure, more even distribution of colored bands and more beautiful produced light, cables and pipelines and easy installing and debugging, and conforms to the principle of viscous body hydromechanics.

Owner:NANTONG BEICHENG SCI & TECH ENTREPRENEURIAL MANAGEMENT

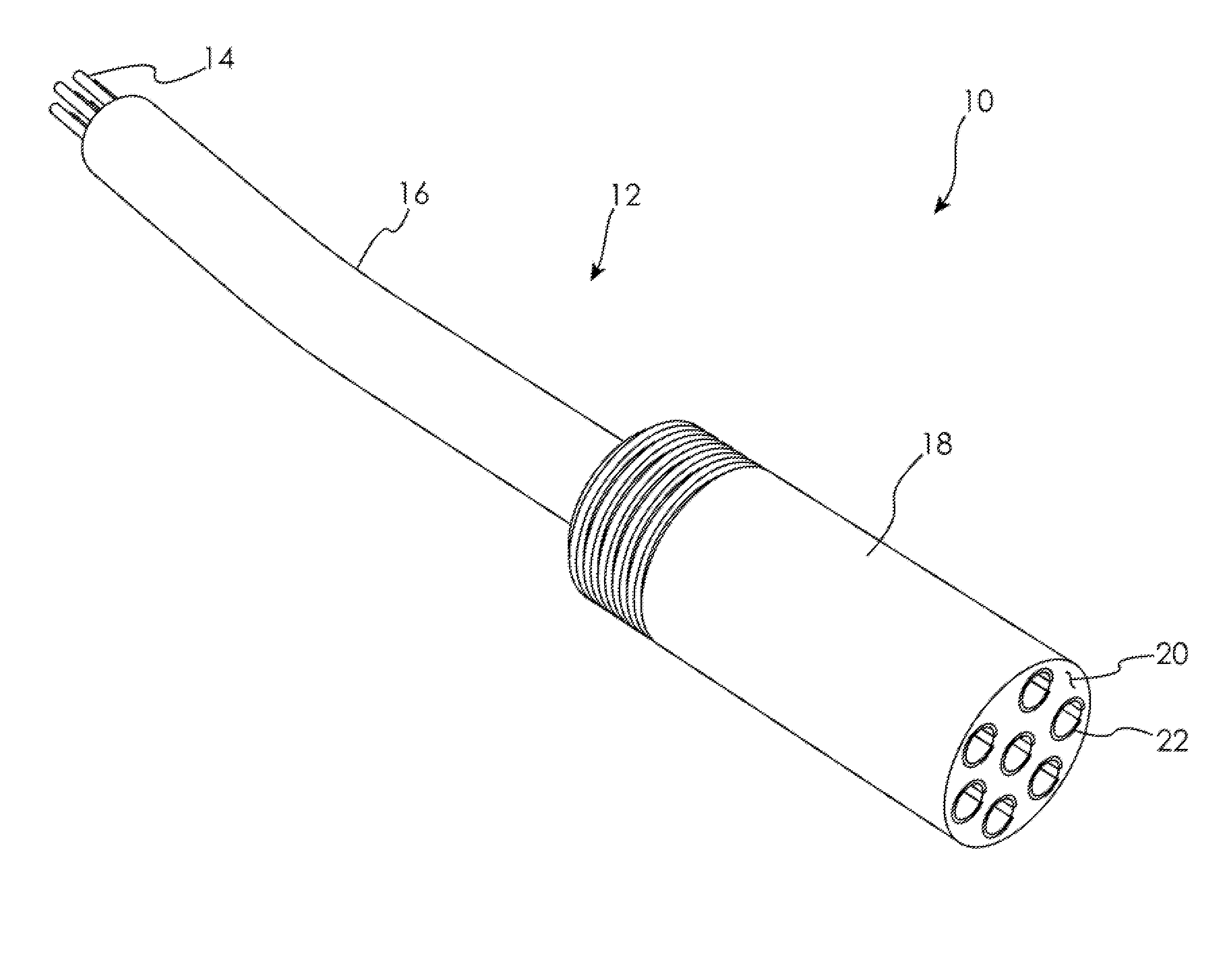

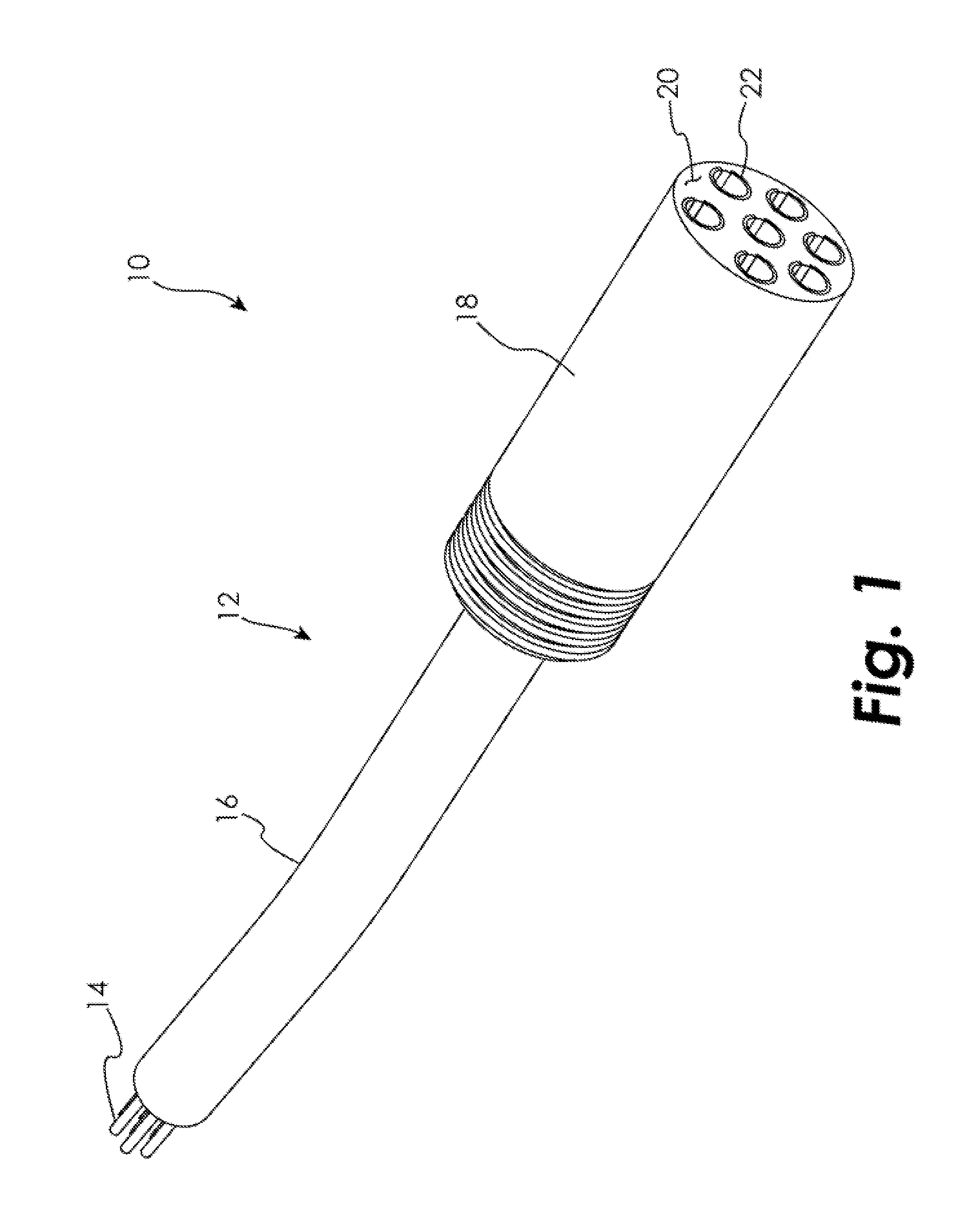

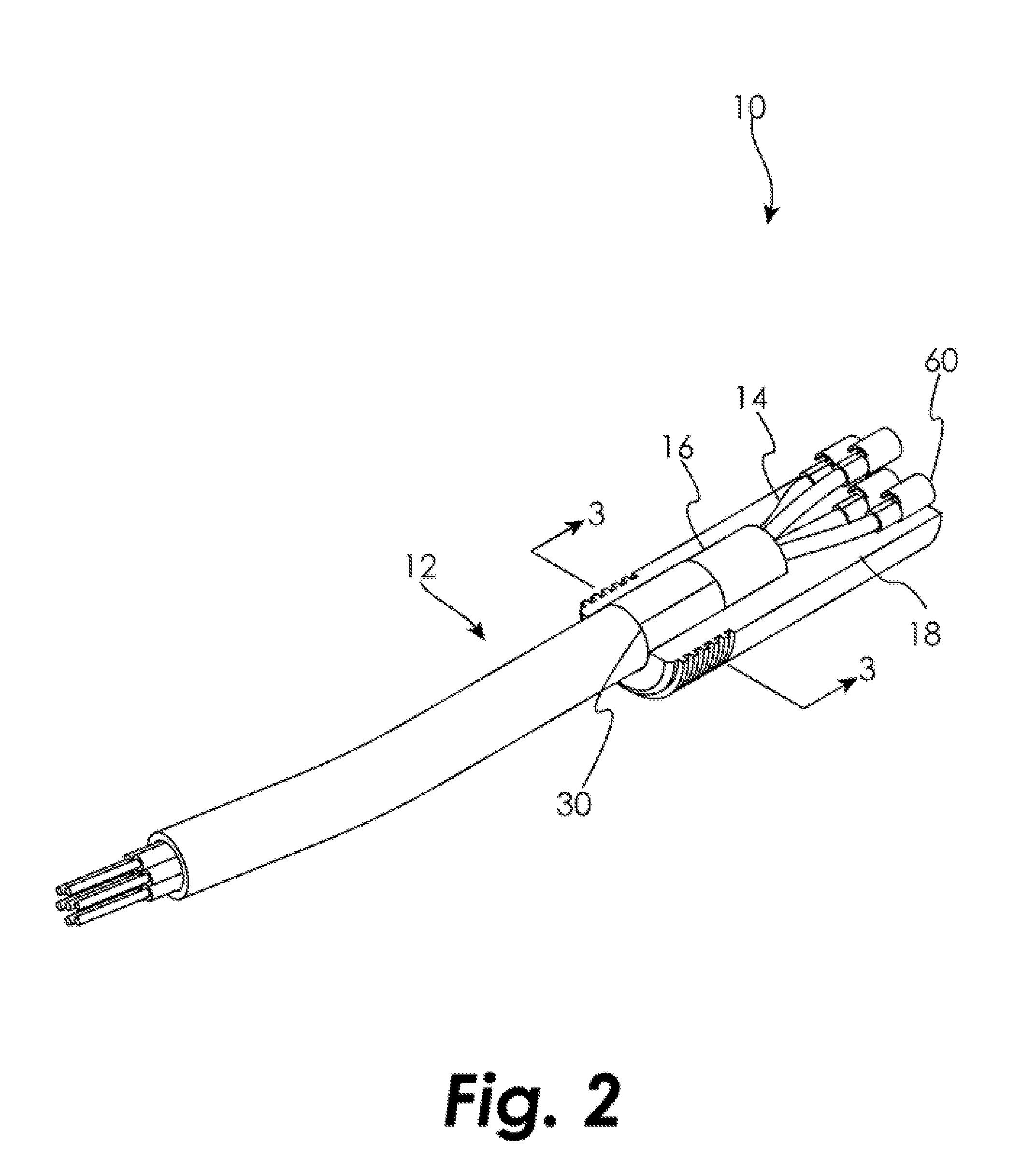

System and Method for Polyurethane Bonding During and After Overmolding

ActiveUS20110177720A1Electrically conductive connectionsContact member assembly/disassemblyEngineeringElectric wire

An electrical apparatus according to the present disclosure comprises a molded device having a molded portion and being formed via an overmolding process. The electrical apparatus includes a wire set at least partially overmolded within the device, the wire set having an outer sheath surrounding a plurality of wires. The molded portion surrounds a portion of the wire set. The electrical apparatus further includes polyurethane bonding material occurring between the outer sheath and the molded portion. The polyurethane bonding material bonds at least a portion of the wire set to the molded portion during the overmolding process.

Owner:GROTE IND

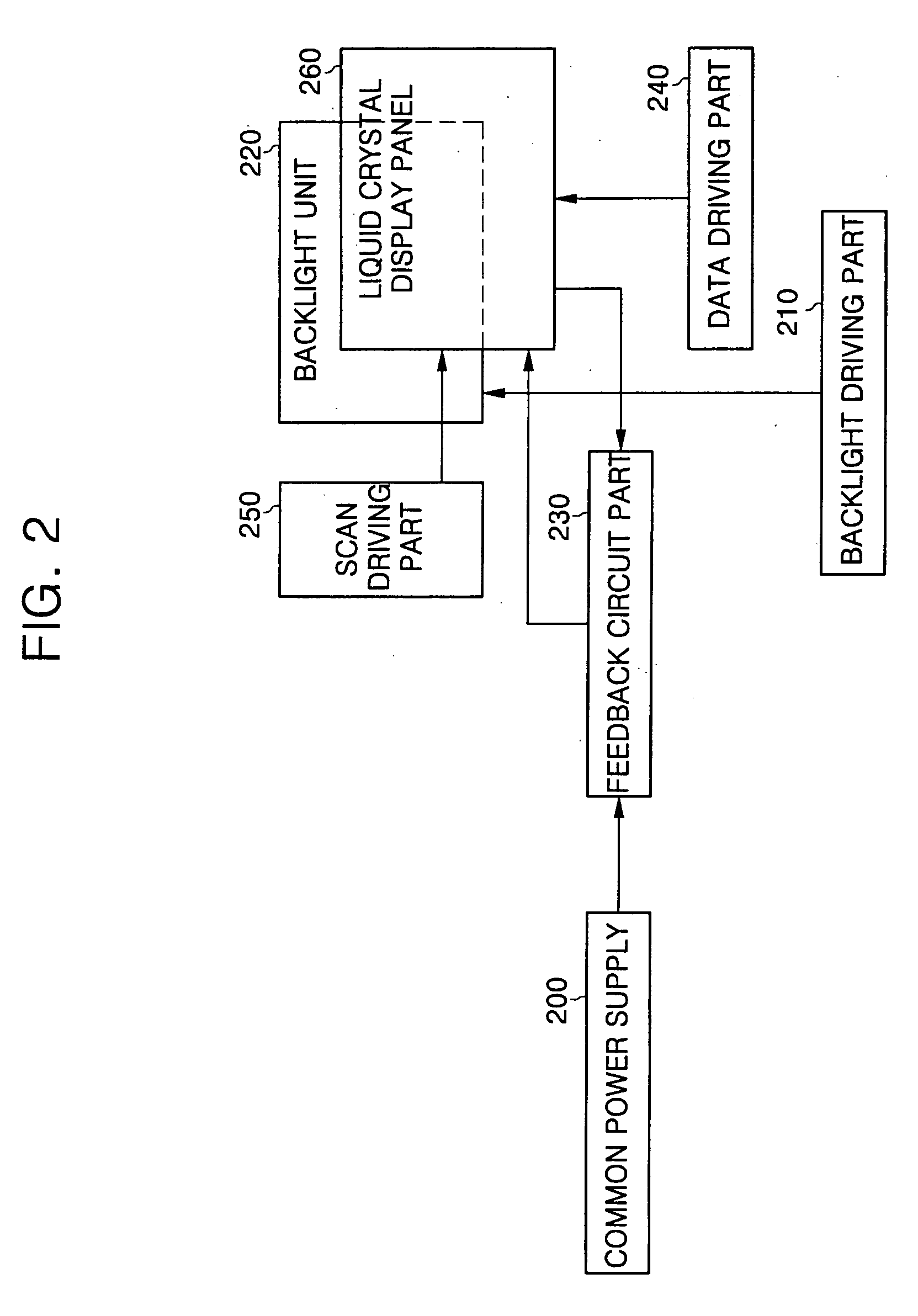

Liquid crystal display with feedback circuit part

InactiveUS7843447B2Electroluminescent light sourcesInsulated cablesNegative feedbackLiquid-crystal display

In a liquid crystal display device having a feedback circuit part, the feedback circuit part prevents black points and blinking pixels from being generated on a liquid crystal display panel by compensating ripple voltages generated from a common electrode of a common substrate. The feedback circuit part comprises a negative feedback part, a buffer part, a low-pass filter part, and first and second impedances interconnecting the low-pass filter part and the negative feedback part.

Owner:SAMSUNG DISPLAY CO LTD

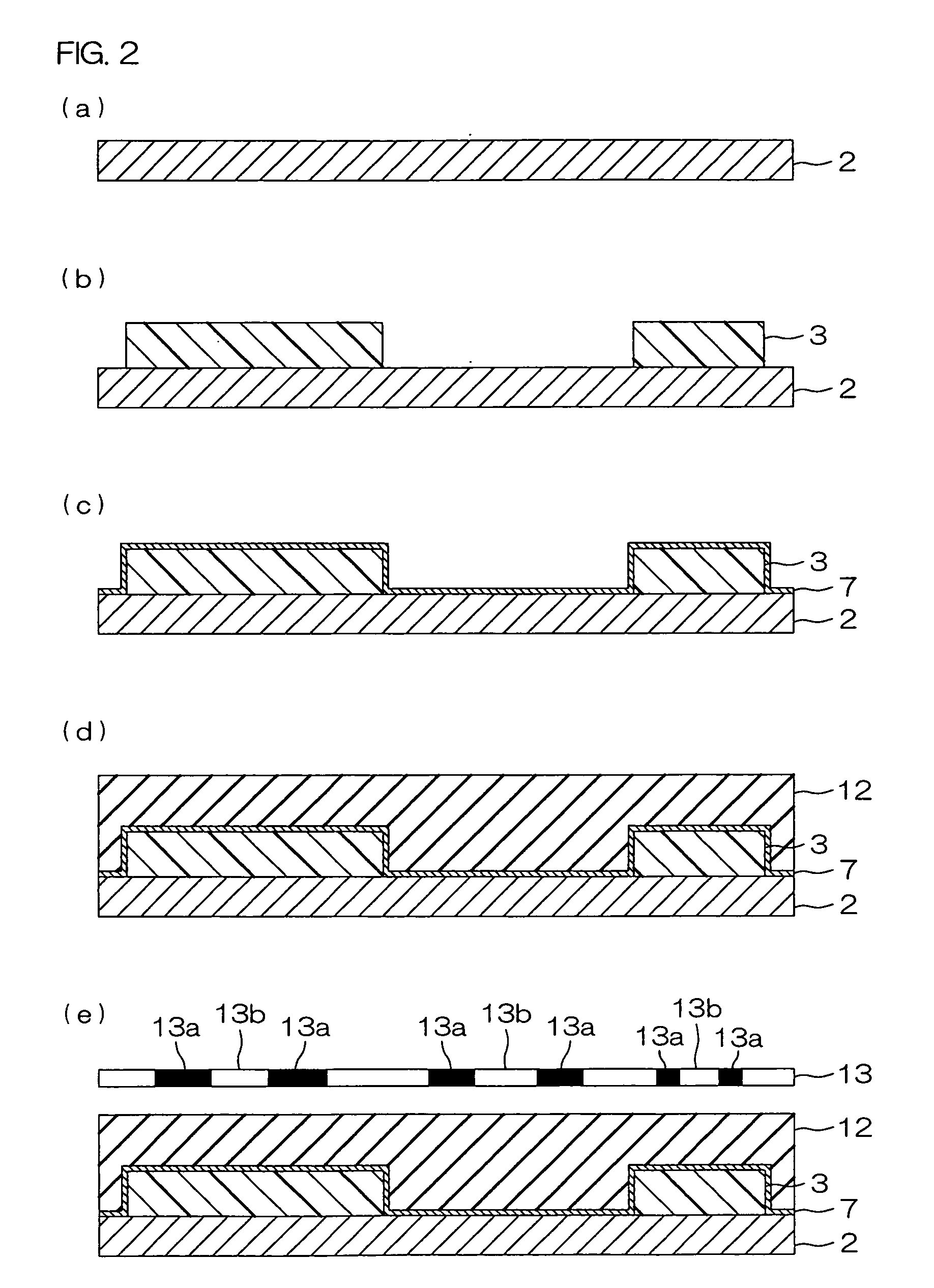

Producing method of suspension board with circuit

InactiveUS20090014410A1Precise positioningAccurate mounting of an electronic componentElectrical connection between head and armPrinted circuit aspectsElectronic componentMetal

A producing method of a suspension board with circuit includes simultaneously forming a conductive pattern formed on an insulating layer formed on a metal supporting board and having a terminal portion for connecting to an electronic component, and a mark formed on the metal supporting board, or on the insulating layer and having an opening for forming a reference hole for mounting the electronic component, and forming the reference hole by etching the metal supporting board disposed in the opening of the mark, or the insulating layer and the metal supporting board each disposed in the opening of the mark.

Owner:NITTO DENKO CORP

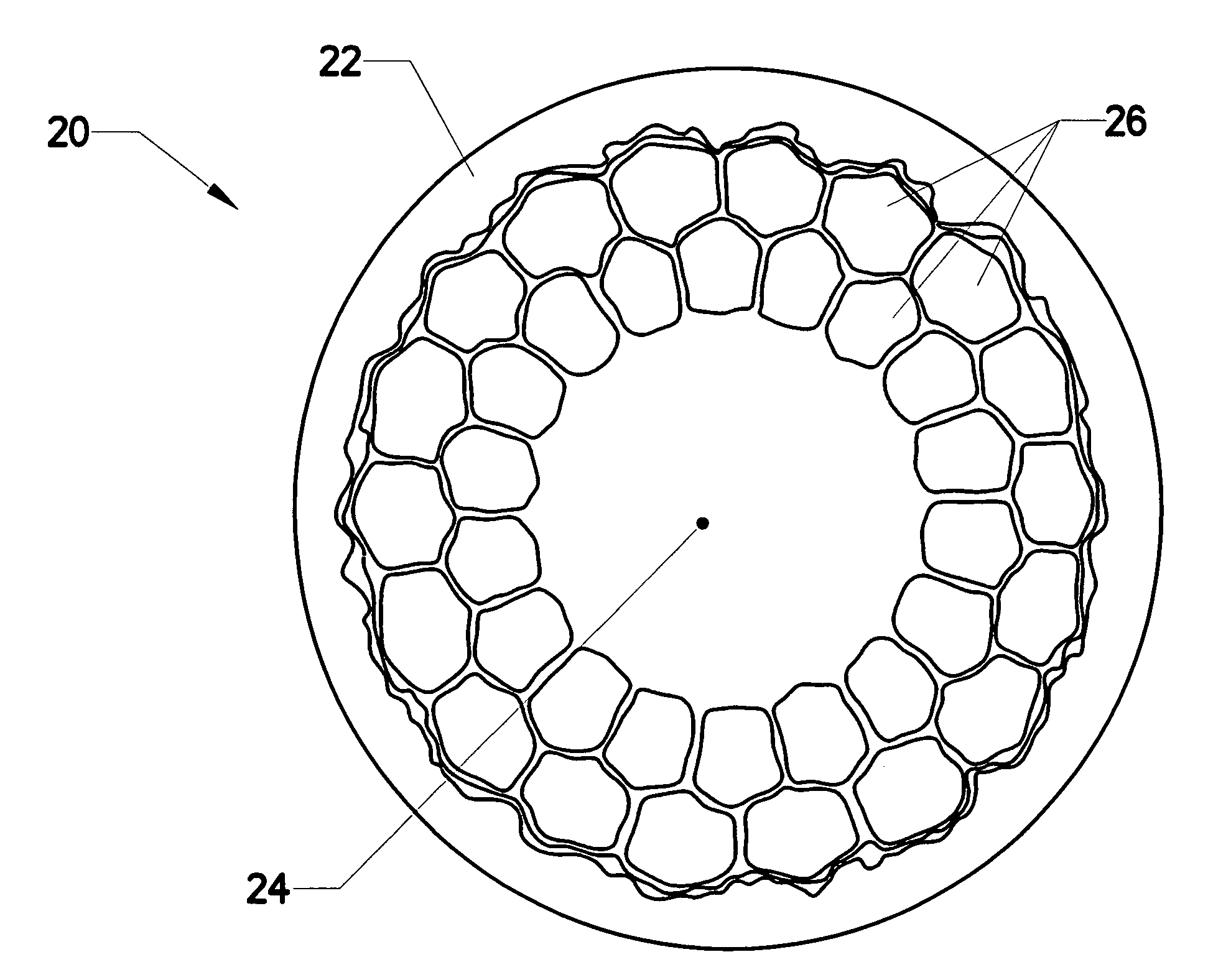

Aluminum oxide particle strengthened niobiumtin superconducting composite wire

ActiveUS20080146451A1Shorten heat treatment timeSave energySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentNiobiumUltimate tensile strength

A composite superconducting wire and a method of manufacturing the wire is disclosed. Nano-particle dispersion strengthened copper is co-drawn with Niobium rod to produce DSC-1Nb wire. n numbers of DSC-1Nb wires are then stacked in a hollow DSC tube and drawn to form a DSC-n.Nb hexagonal wire. In a separate preliminary process, Tin rod is co-deformed with Copper tube to form a Cu-1Sn wire. m DSC-n Nb wires and 1 Cu-1Sn wires are then wrapped by Niobium foil and placed into a Copper tube. This entire assembly is then drawn to a finished size. The drawn composite is then subjected to heat treatment with a final stage at 650-700° C. for about 100 hours or longer. The new wire has higher electric critical current and higher mechanical strength than the controlled conventional ones.

Owner:FLORIDA STATE UNIV RES FOUND INC

Wire marker

InactiveUS20050204595A1Coupling device connectionsWelding/cutting auxillary devicesWaferingInterposer

An automated wire harness machine is capable of manufacturing a wire harness in an automated process. The wire harness is generally a plurality of bundled, preferably un-stripped, insulated wires. Each un-stripped end portion of each wire is preferably terminated by an electrical terminal in one of a series of electrical connectors of the wire harness. Each connector has at least one wafer which houses a plurality of terminals. The wire harness machine utilizes a pallet that holds all of the wafers of one wire harness. A conveyor transports the pallet and wafers through a series of stations which perform automated manufacturing steps. The first station is a terminal inserter which inserts and locks the terminals within pre-assigned cavities of the wafers. The next station is an automated wire loader which measures, cuts and crimps the two ends of each wire into the respective terminals of the loaded wafer assembly. A third station, or ultrasonic welder, then galls an un-stripped non-ferrous core of the crimped wire to the terminal. The pallet with the loaded wafers, crimped terminals, and terminated wires are then transported to a wire marker station which marks each wire, preferably via a laser, for identification purposes.

Owner:DELPHI TECH INC

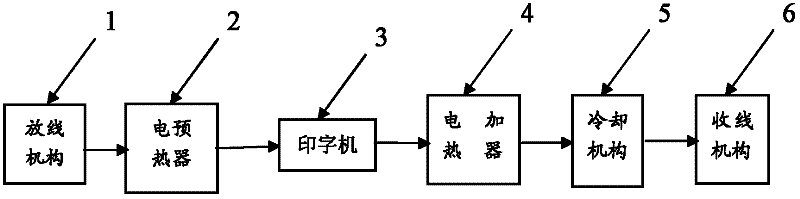

Inkjet printing identification process for fluorine plastic sheath phase-stabilized cable

InactiveCN104021894AImprove marking resistance to abrasion testHigh fastnessConductor/cable markingPolymer scienceFluoroplast

The invention discloses an inkjet printing identification process for a fluorine plastic sheath phase-stabilized cable. The process includes the first step of carrying out plasma treatment on a fluorine plastic sheath so that ink can be easily immersed in scattered molecular structures of treated materials, the second step of adopting an inkjet printer with high ink adhesive force to carry out inkjet printing on the surface of the fluorine plastic sheath of the fluorine plastic sheath phase-stabilized cable, and the third step of adopting an electric heater to heat and solidify ink inkjet printing identifications on the surface of the fluorine plastic sheath after inkjet printing is conducted on the surface of the fluorine plastic sheath of the fluorine plastic sheath phase-stabilized cable. A plasma treatment machine is utilized, so that ink is prone to adhering to the surface of the sheath of the fluorine plastic sheath phase-stabilized cable; the electric heater is used for heating and solidifying, so that firmness and productivity of the identifications are improved.

Owner:安徽宏源特种电缆集团有限公司

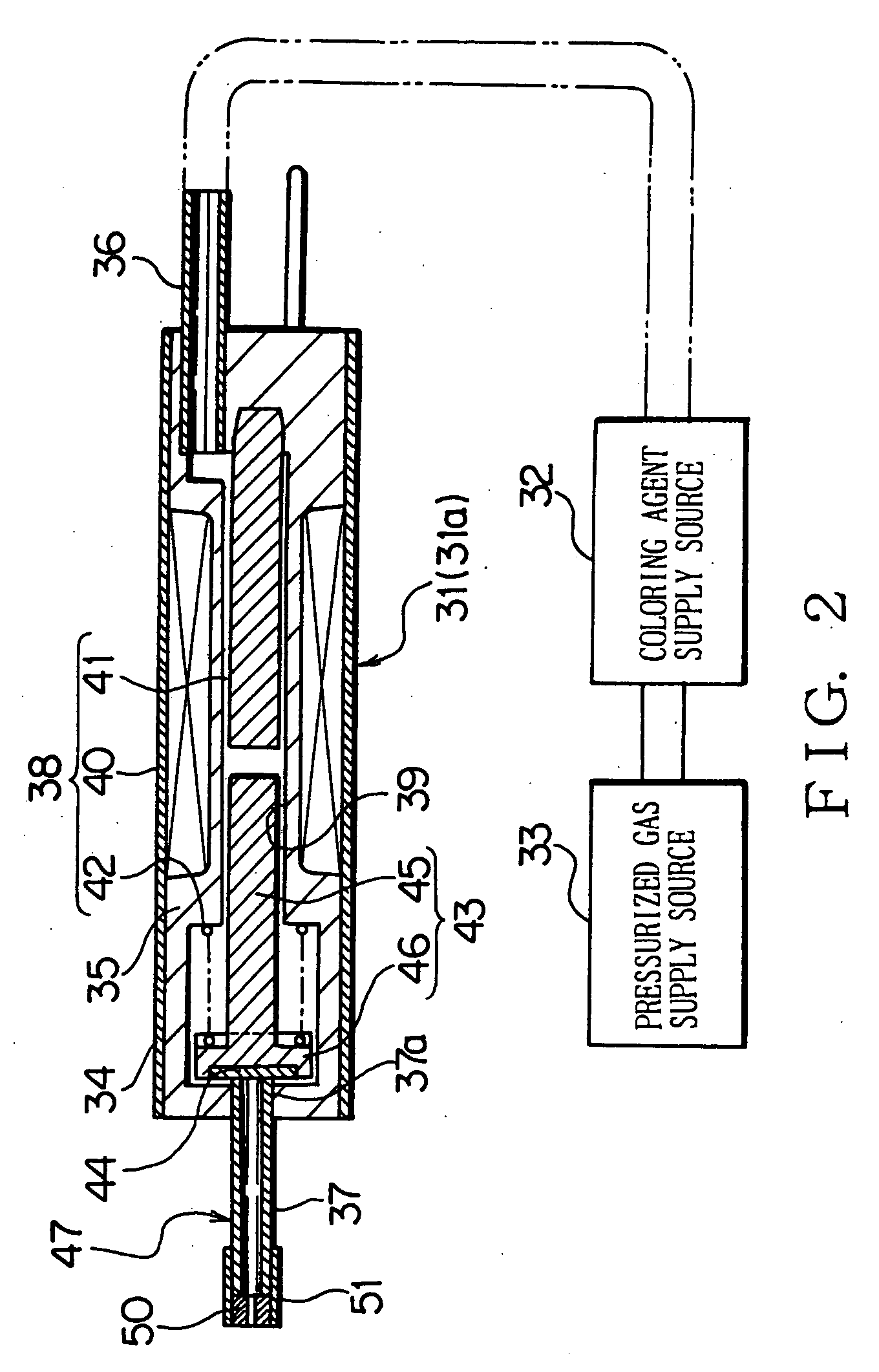

Apparatus and method for coloring electric wire

InactiveUS20050003077A1Simple structureGood colorSpray nozzlesLiquid spraying apparatusEngineeringElectric wire

The apparatus for coloring a wire includes a plurality of coloring nozzles, each of which spouts a liquid coloring agent toward an outer surface of a wire with a specific amount thereof per spouting so as to allow the liquid drop of the coloring agent to adhere to the outer surface of the wire, thereby coloring the wire. The coloring agent adheres on the outer surface of the wire so as to form a spot. Each coloring nozzle includes an insert member for receiving the coloring agent therein and a nozzle member that communicates with the insert member. The length of the nozzle member is different from each other. The apparatus selects one coloring nozzle from a plurality of the coloring nozzles in response to the size of the spot to be formed on the outer surface of the wire and spouts the coloring agent.

Owner:YAZAKI CORP

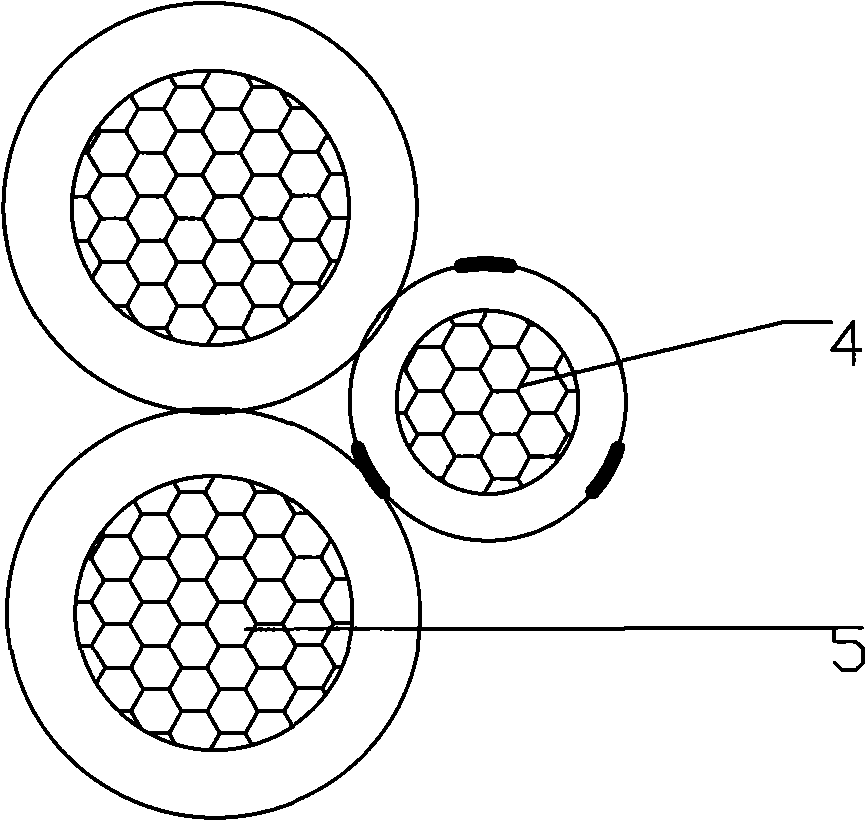

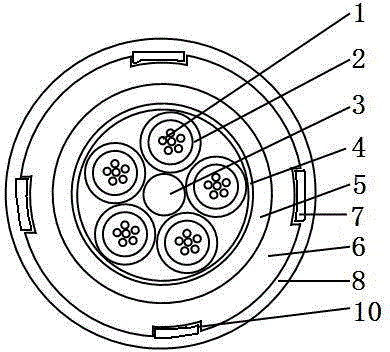

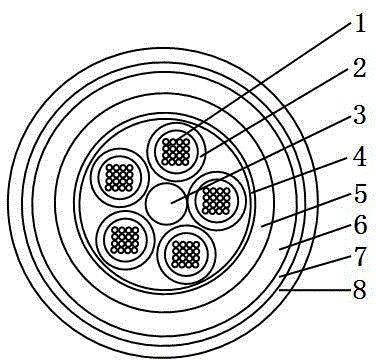

Recognizable cable, extrusion die and manufacture method thereof

ActiveCN101546625ANovel structureSimple structureInsulated cablesConductor/cable markingState of artEngineering

The invention discloses a recognizable cable, an extrusion die and a manufacture method thereof. The recognizable cable is formed by extruding longitudinal color stripes with colors different from a body on the surface of a protective sleeve and / or an insulated layer so as to form an obvious identification mark on the surface of the cable and / or a cable core. The extrusion die is formed by arranging a circular shunt groove along the circumference of the die body and longitudinally arranging a pigment feeding groove which is communicated with the circular shunt groove; the die body is also longitudinally provided with an extrusion pigment groove communicated with the circular shunt groove, and an outlet is circularly provided with a pigment extrusion opening communicated with the extrusion pigment groove. The invention not only enables the color strips to be firmly clearly attached and be rapidly accurately identified and have high identification rate, but also keeps the physical mechanical performance of the protective sleeve and / or the insulated layer so as to have good economy, can directly identify various characteristics of the color strips, such as voltage stages, waterproofness, fireproofness, and the like, can add a black pigment to an insulated base pigment and overcomes the defect of carbon black addition incapability of the prior art so that a cable without a protective layer has weatherability and can be used for outdoor overhead laying.

Owner:WUXI JIANGNAN CABLE

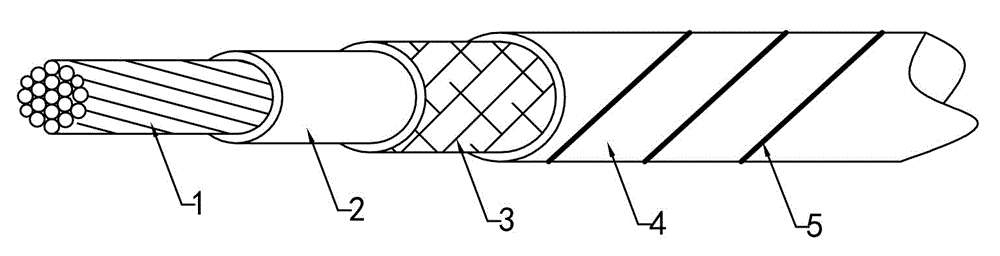

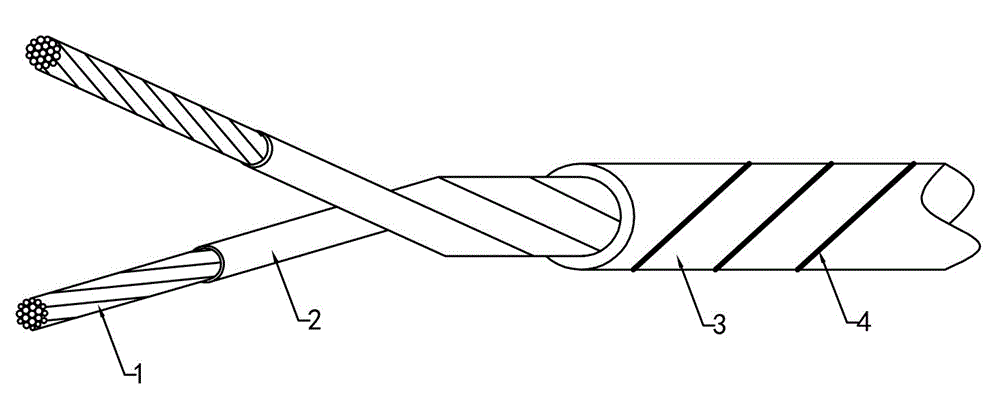

Strip marked polyimide composite membrane wire and cable for aerospace and preparation technology

InactiveCN102723136AQuick distinctionAccurate distinctionInsulated cablesConductor/cable markingInsulation layerEngineering

The invention discloses a strip marked polyimide composite membrane wire and cable for aerospace, the wire and cable are characterized in that in terms of the strip marked polyimide composite membrane wire for aerospace formed directly by single insulation core wire, spiral strip marks are arranged on the insulation layer; in terms of the strip marked polyimide composite membrane cable for aerospace consisting of a single insulation core wire, a shielding layer and a sheath layer, spiral strip marks are arranged on the sheath layer; in terms of the strip marked polyimide composite membrane cable for aerospace consisting of multiple insulation core wires, a shielding layer and a sheath layer, spiral strip marks are arranged on the insulation layer and / or sheath layer; and in terms of the strip marked polyimide composite membrane cable for aerospace consisting of a plurality of insulation core wire and a sheath layer, the spiral strip marks are arranged on the insulation layer and / or sheath layer. The wire or cable provided by the invention is easily identified; the quality problem of the wire can be conveniently tracked; and meanwhile, the wire and cable provided by the invention have good mechanical performance, flame retardant performance and excellent radiation resistance.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Electric wire

ActiveUS7482539B2Plastic/resin/waxes insulatorsInsulated cablesEngineeringElectrical and Electronics engineering

The present invention provides electrical cables that can be surely discriminated from one another, even when only a part of an outer surface of each cable is exposed. An electrical cable 1 has an electrically conductive core 5 and a sheathing layer 6 covering the core 5. The sheathing layer 6 has an outer surface 6a with a mono-color. On the outer surface 6a, a first mark 7 and a second mark 8 are provided. At an end 1a of the cable 1, the first mark 7 is provided on a first outer surface 1b while the second mark 8 is provided on a second outer surface 1c positioned oppositely to the first surface 1b of the sheathing layer 6. On the first outer surface 1b, a plurality of the first and second marks 7, 8 are provided to be alternately positioned in a longitudinal direction of the cable 1. The first mark 7 has a first color R while the second mark 8 has a second color G different from the first color R. Desirable variation in hue of the first and second colors R, G allows discrimination of the cables 1 from each other.

Owner:YAZAKI CORP

Method for manufacturing luminous optical cable

InactiveCN104698559AStrong reflectionEasy to identifyInsulated cablesFibre mechanical structuresEngineeringProtection layer

The invention belongs to the technical field of cables and materials, and particularly relates to a luminous optical cable. The luminous optical cable comprises an optical cable core, a protective layer which wraps the optical cable core, and an inner protective layer which wraps the protective layer in an extrusion molding mode. The optical cable core is composed of a reinforcer located at the center of the optical cable core, a plurality of loose tubes which are distributed outside the reinforcer in parallel or in a twisted mode, and a binding layer which binds up the loose tubes. At least one light-guide fiber is arranged in each loose tube. The luminous optical cable is characterized in that a luminous layer is arranged outside the inner protective layer, the luminous layer is wrapped with a protection layer in an extrusion molding mode, the luminous layer wraps the inner protective layer integrally, and the protection layer is transparent. The invention further discloses the luminous optical cable and a method for manufacturing the luminous optical cable. The luminous optical cable and the method for manufacturing the luminous optical cable have the advantages that the product structure is simple, manufacturing is easy, the optical cable can be recognized in bright light and night light conveniently, and construction and maintenance are facilitated.

Owner:重庆成瑞光电科技有限公司

Popular searches

Radiating elements structural forms Insulators Subscribers indirect connection Burglar alarm by hand-portable articles removal Sensing by electromagnetic radiation Antenna feed intermediates Record carriers used with machines Waveguide type devices Burglar alarm electric actuation Insulated conductors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com