Method for manufacturing luminous optical cable

A production method and optical cable technology, applied in cable/conductor manufacturing, cable, optics, etc., can solve problems such as difficulty in identifying optical cables and cables at the same time, failure to identify with bright light, and troublesome construction and maintenance personnel, so as to facilitate construction and maintenance. Simple structure, easy to test the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

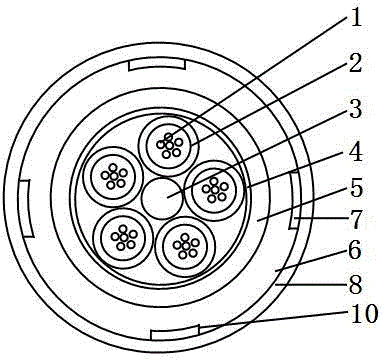

[0034] please see figure 1, light-emitting optical cable, which includes an optical cable core, a protective layer 5 coated outside the optical cable core, an inner sheath 6 that is extruded and coated outside the protective layer, and the optical cable core is composed of a central strengthening member 3, parallel It is composed of a plurality of loose tubes 2 distributed outside the reinforcement in a twisted manner, and a wrapping layer 4 that wraps the multiple loose tubes. Each loose tube has at least one optical fiber 1; it is characterized in that the There is a light-emitting layer 7 outside the inner protective layer, and a protective layer 8 is extruded and coated on the outer surface of the light-emitting layer; the light-emitting layer covers the inner protective layer as a whole; the protective layer is transparent.

[0035] The light-emitting optical cable described above has five loose tubes, and each loose tube has six optical fibers. It can have other loose tu...

Embodiment 2

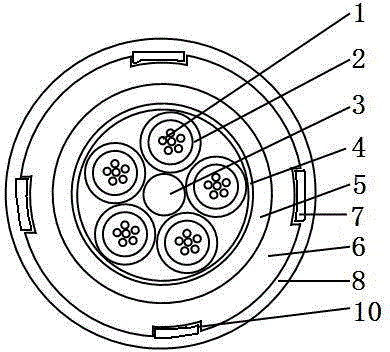

[0056] please see figure 2 , light-emitting optical cable, which includes an optical cable core, a protective layer 5 coated outside the optical cable core, an inner sheath 6 that is extruded and coated outside the protective layer, and the optical cable core is composed of a central strengthening member 3, parallel Or at least one loose tube 2 and at least one filling rope 9 distributed outside the reinforcement in a stranded manner, and a wrapping layer 4 that wraps multiple loose tubes and filling ropes. In each loose tube, at least It has an optical fiber 1; it is characterized in that there is a luminous layer 7 outside the inner sheath, and the outer sheath is extruded and coated with a protective layer 8; the luminous layer covers the inner sheath as a whole; the protective layer is transparent .

[0057] The light-emitting optical cable described in this implementation example has three loose tubes, and each loose tube has six optical fibers. It can have other loose ...

Embodiment 3

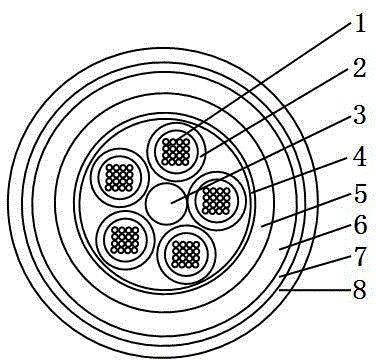

[0061] please see image 3 , light-emitting optical cable, which includes an optical cable core, a protective layer 5 coated outside the optical cable core, an inner sheath 6 that is extruded and coated outside the protective layer, and the optical cable core is composed of a central strengthening member 3, parallel It is composed of a plurality of loose tubes 2 distributed outside the reinforcement in a twisted manner, and a wrapping layer 4 that wraps the multiple loose tubes. Each loose tube has at least one optical fiber 1; it is characterized in that the There are a plurality of luminescent layers 7 distributed at intervals outside the inner sheath, and the inner sheath and the luminescent layer are extruded and coated with a protective layer 8; the protective layer is transparent.

[0062] The light-emitting optical cable described above has five loose tubes, and each loose tube has six optical fibers. It can have other loose tubes as required, and each loose tube can ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com