Patents

Literature

702results about "Film/foil adhesive primer layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

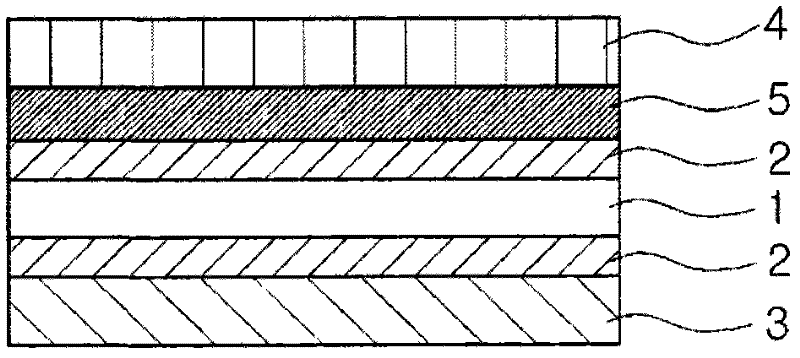

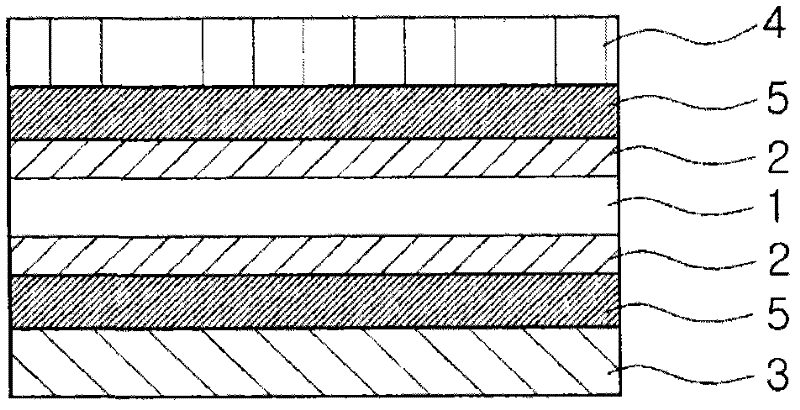

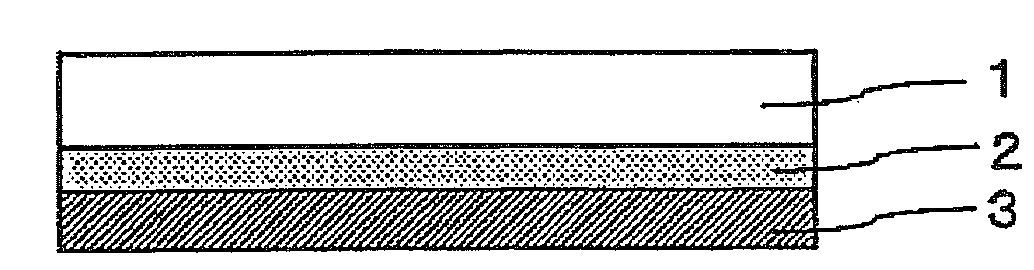

Layered body and method for manufacturing thin substrate using the layered body

InactiveUS20090017248A1Reduce pressureBubble contamination preventedFilm/foil adhesive primer layersSolid-state devicesPhotothermal conversionAcrylate polymer

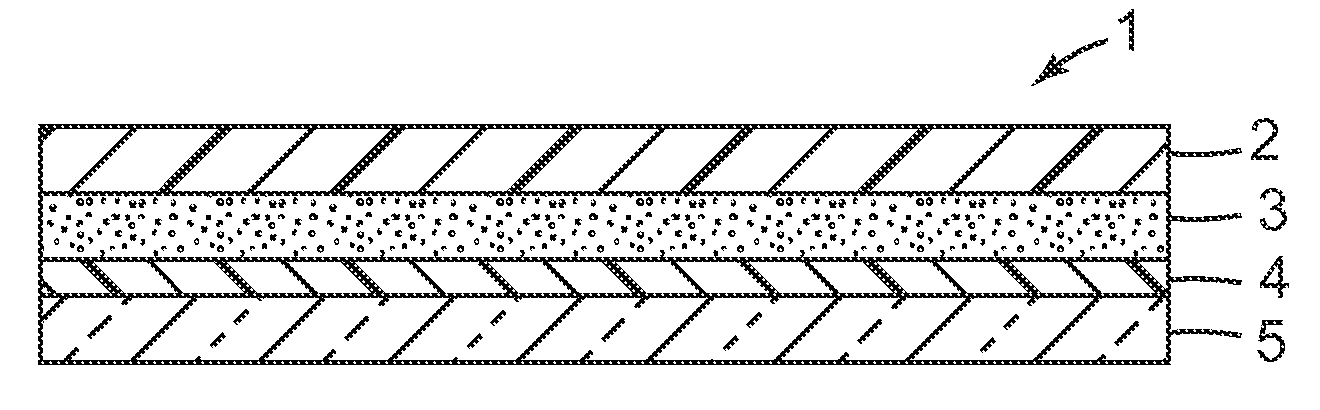

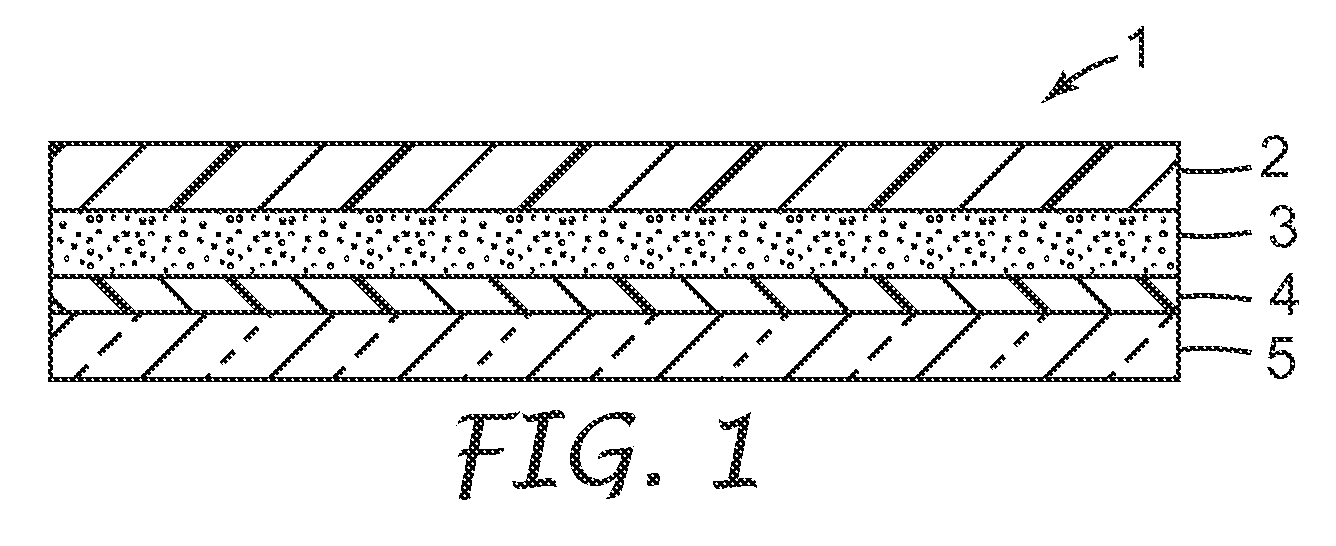

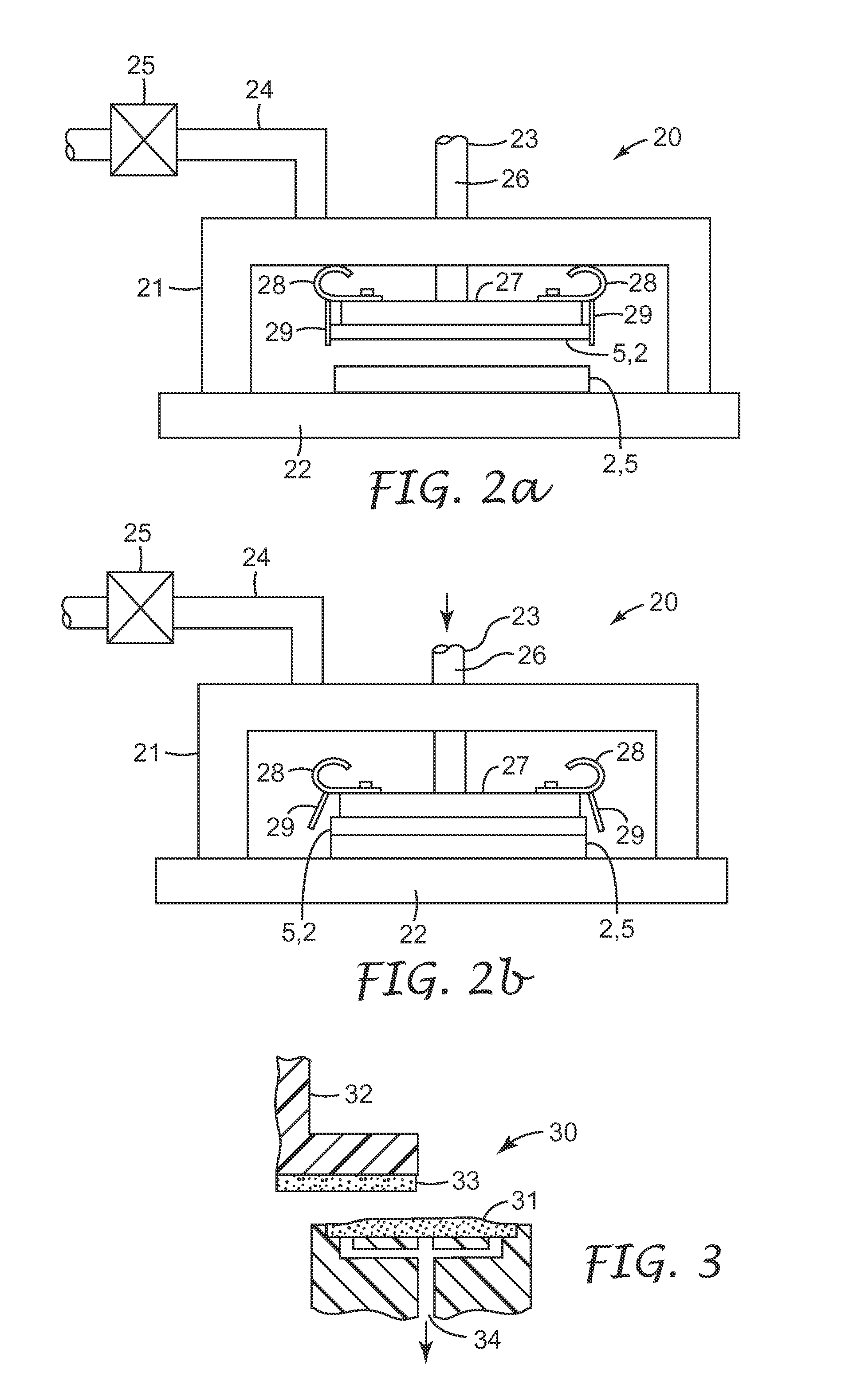

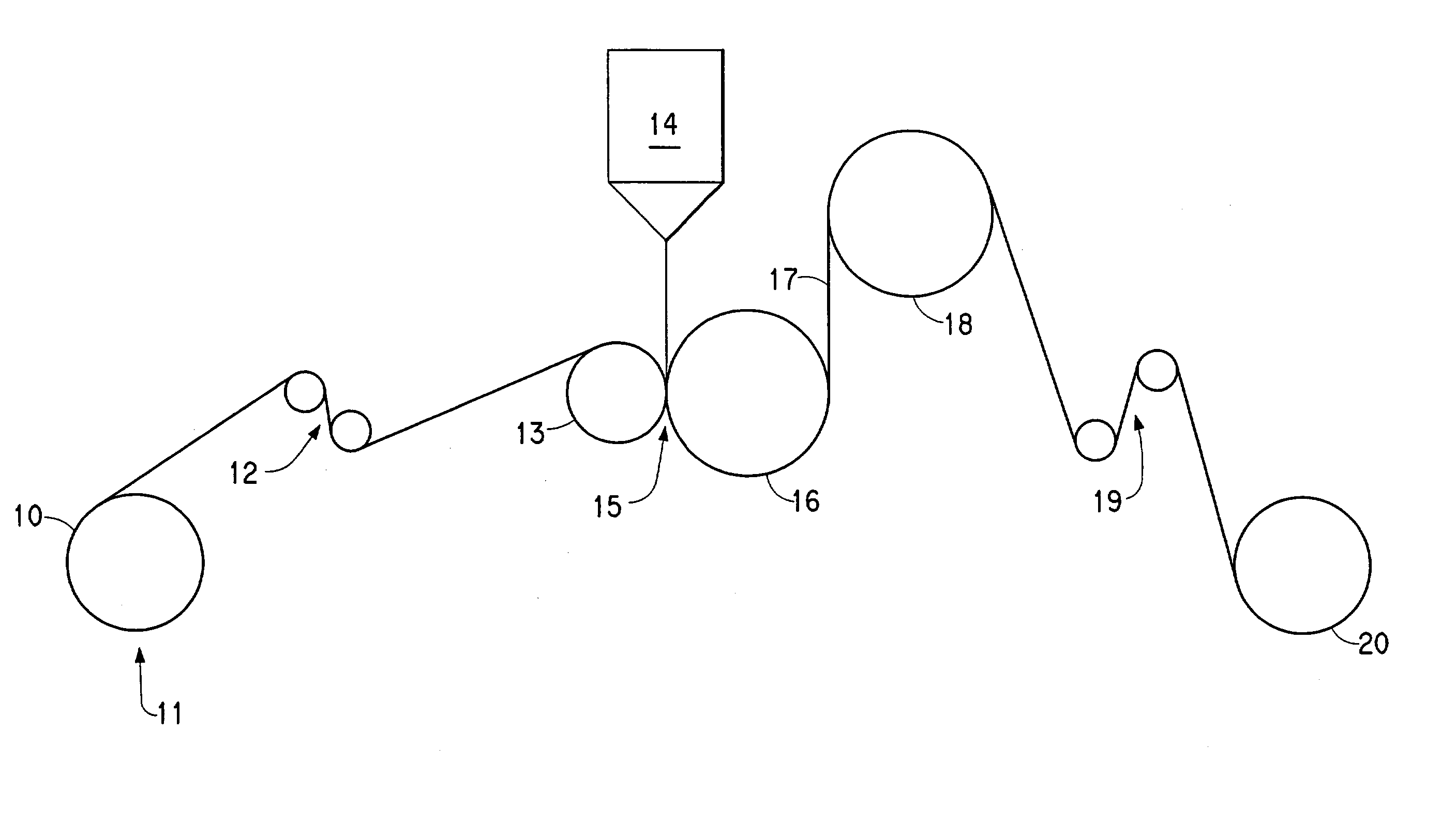

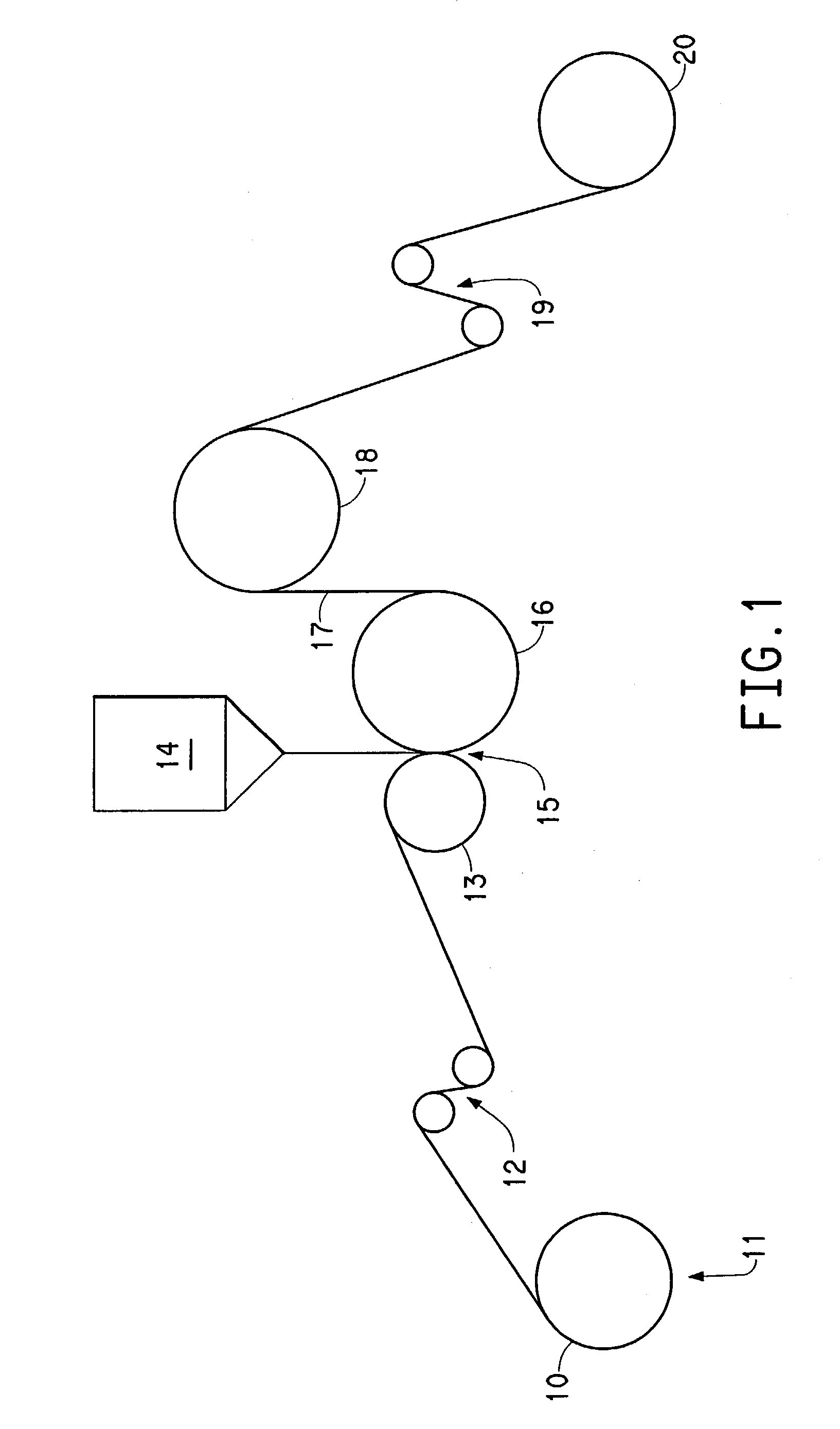

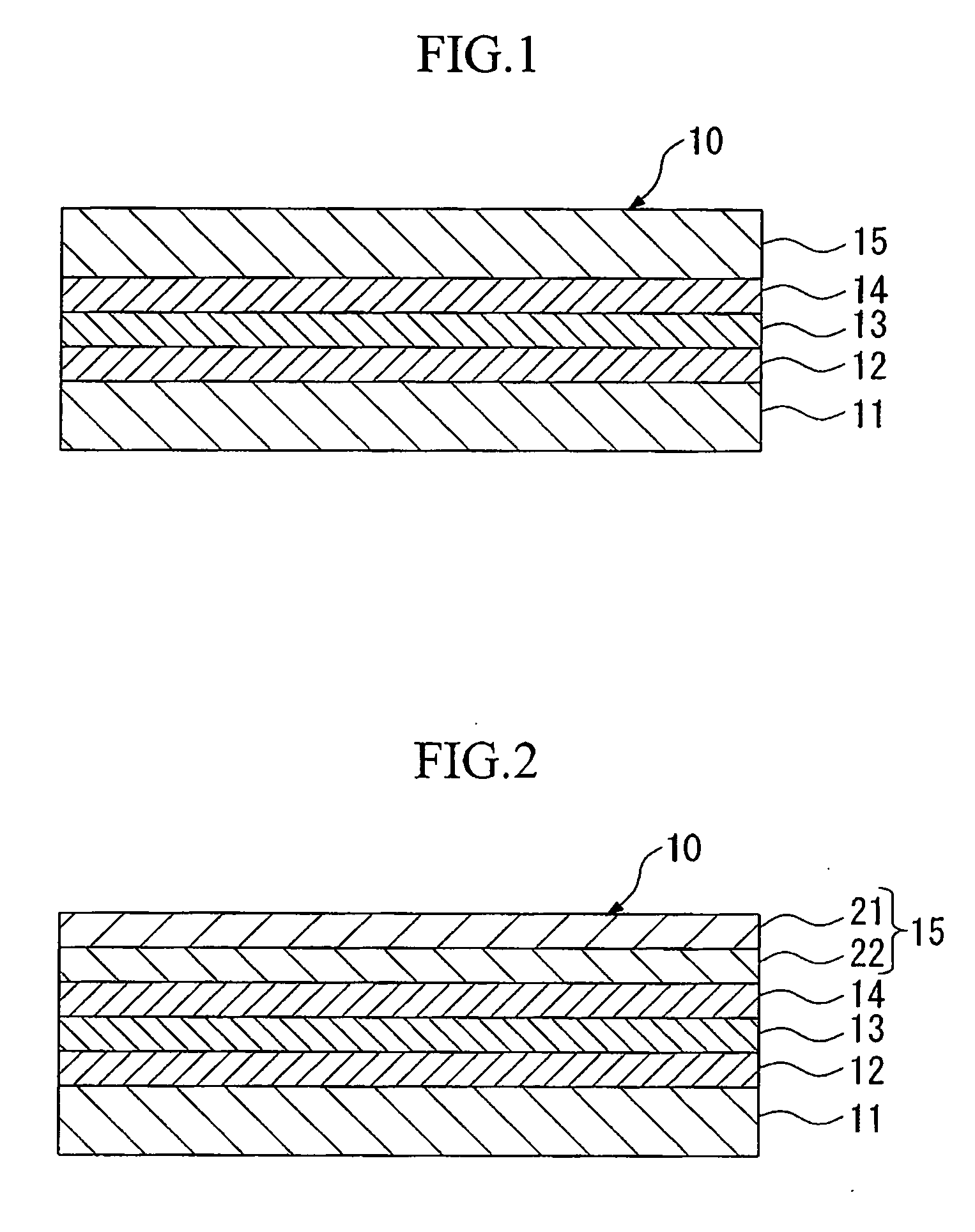

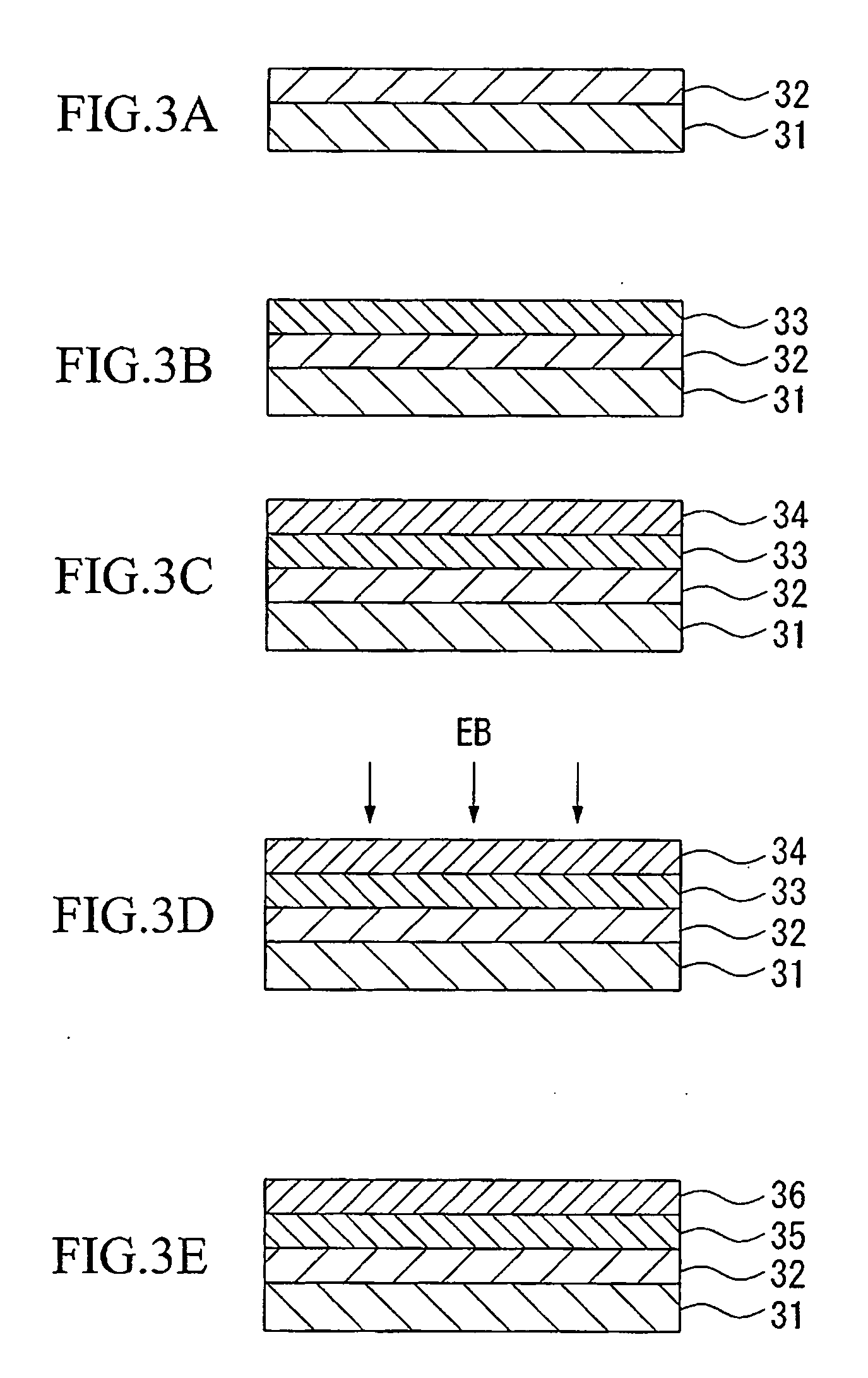

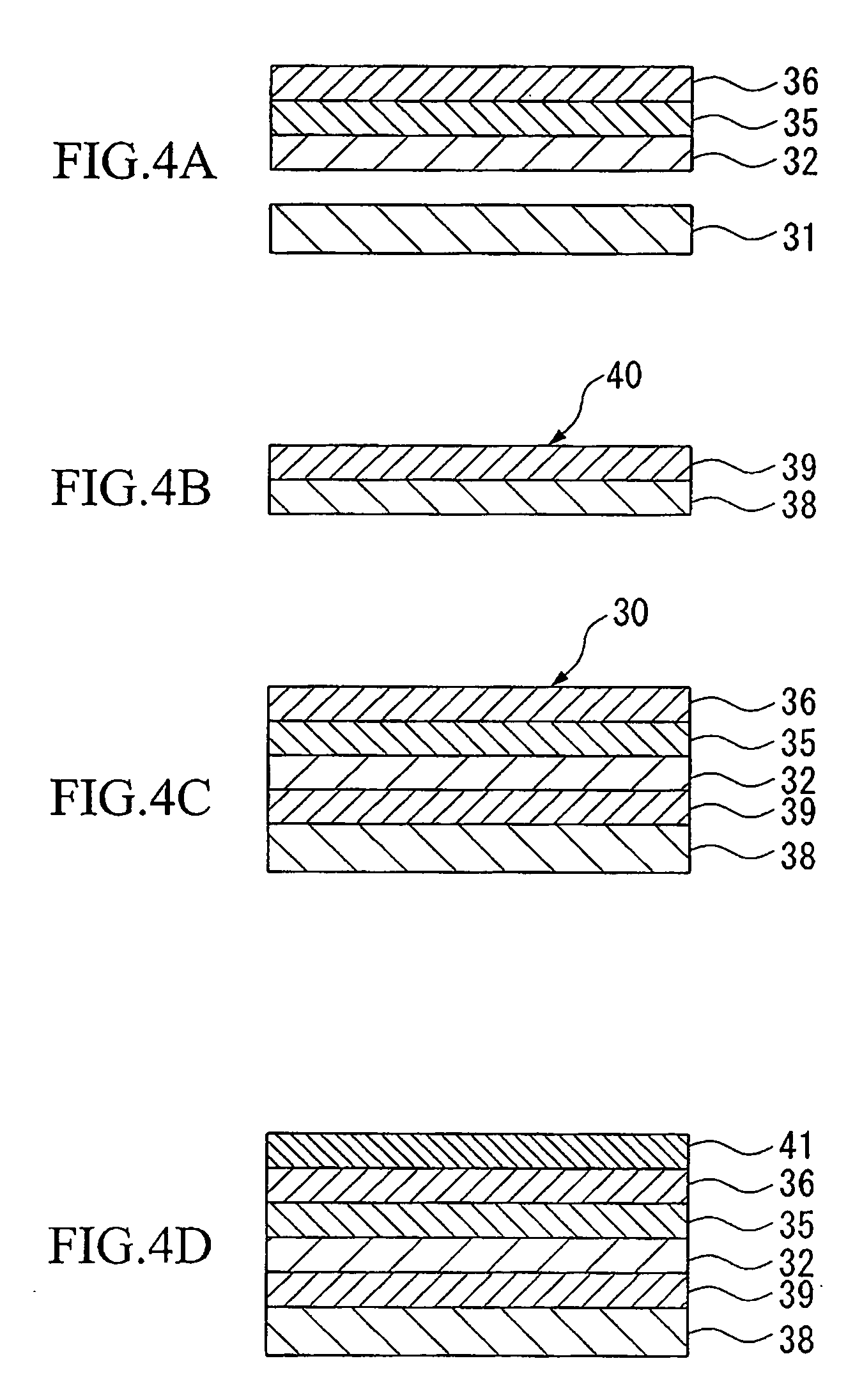

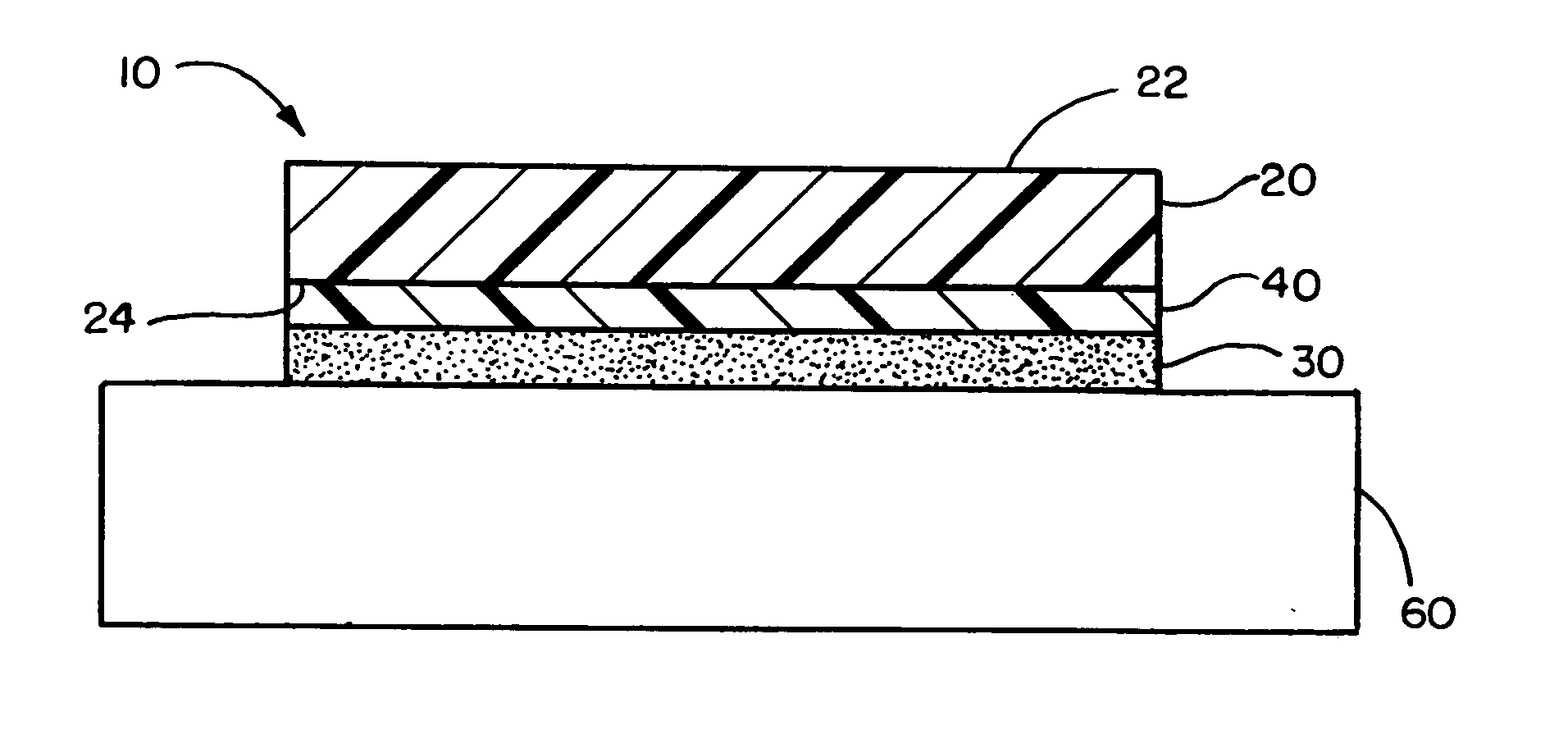

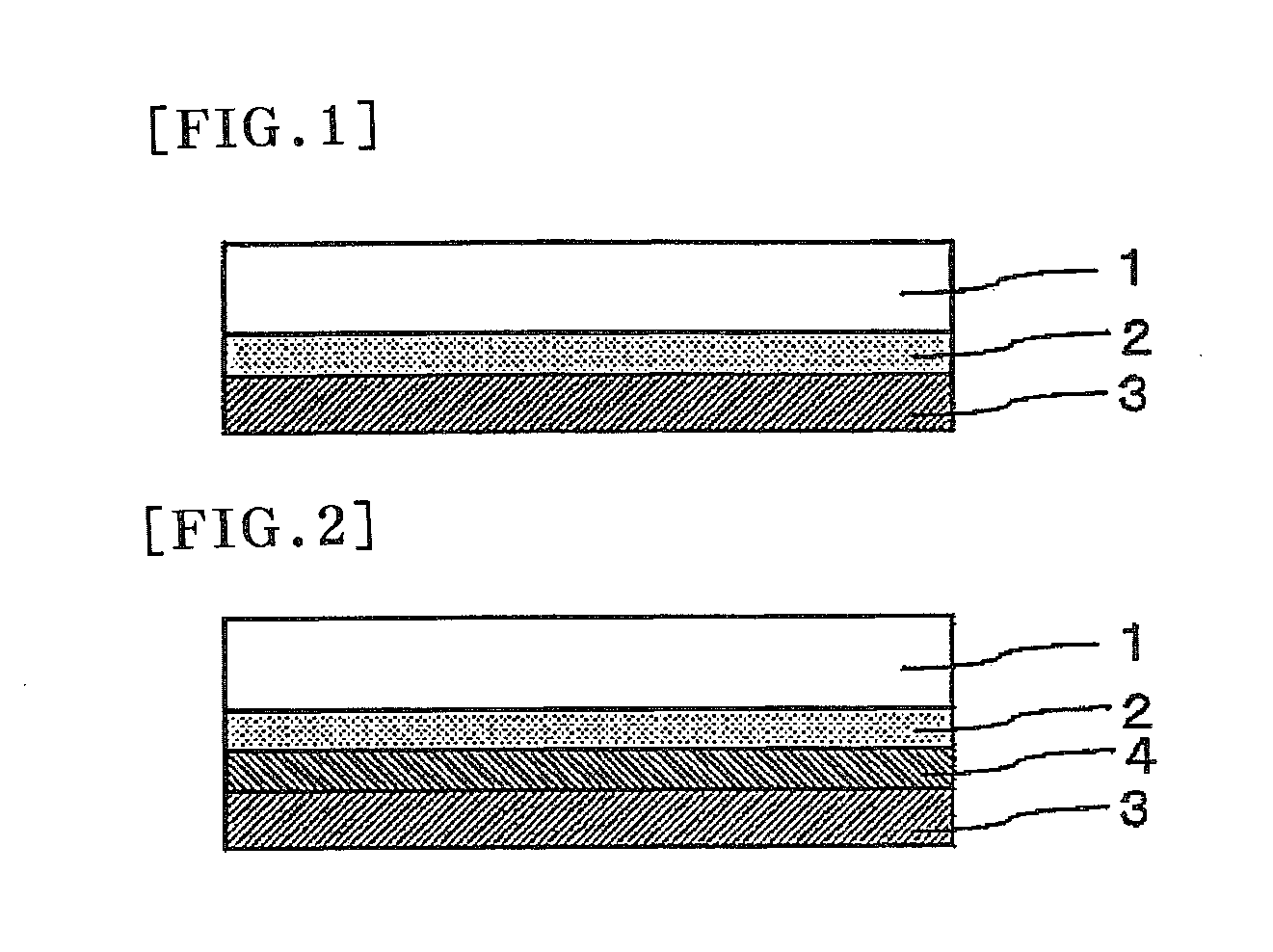

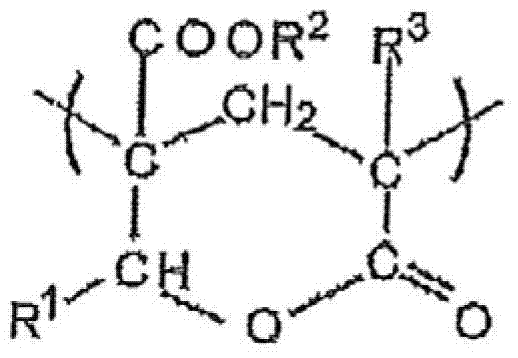

Provided is a layered body including a substrate to be ground and a support, where the substrate may be ground to a very small (thin) thickness and can then be separated from the support without damaging the substrate. One embodiment is a layered body including a substrate to be ground, a joining layer having a curable acrylate polymer and a curable acrylate adhesion modifying agent in contact with the substrate to be ground, a photothermal conversion layer having a light absorbing agent and a heat decomposable resin, and a light transmitting support. After grinding the substrate surface which is opposite that in contact with the joining layer, the layered body is irradiated through the light transmitting layer and the photothermal conversion layer decomposes to separate the substrate and the light transmitting support.

Owner:3M INNOVATIVE PROPERTIES CO

Fluoropolymer film structures and laminates produced therefrom

InactiveUS7070675B2Easy to useAdhesive processesFilm/foil adhesive primer layersPolymer sciencePolyolefin

Fluoropolymer films which combine the attributes of outdoor durability, chemical resistance and thermoformability with paint-like aesthetics are formed into film structures which have at least one surface coated with a primer of amine functional polymer and an overcoat of a thermoplastic adhesive of acid modified polyolefin. Fluoropolymer films so coated are securely bonded to a variety of thermoplastic substrates forming a laminated film structure which resists delamination when exposed to moisture and humidity.

Owner:EI DU PONT DE NEMOURS & CO

Decorative sheet and process for producing the same

InactiveUS20050175818A1Excellent designability and abrasion resistanceEfficient use ofFilm/foil adhesive primer layersDecorative surface effectsEngineeringSolvent

A decorative sheet with excellent designability, abrasion resistance, weather resistance, and solvent resistance, which is easy to apply and displays low levels of adhesive transferability is provided. A decorative sheet (50) comprises a pressure sensitive adhesive layer (52), a first primer layer (53) that contacts this layer (52), a decorative layer (54) that contacts this layer (53), a second primer layer (55) that contacts this layer (54), and a radiation cured coating layer (56) that contacts this layer (55), wherein the first primer layer (53) comprises at least 25% by weight of at least one thermoplastic resin selected from a group consisting of vinyl chloride-vinyl acetate copolymer resins, acrylic based resins and urethane based resins.

Owner:CI KASEI COMPANY +2

Protection film and method of making the same

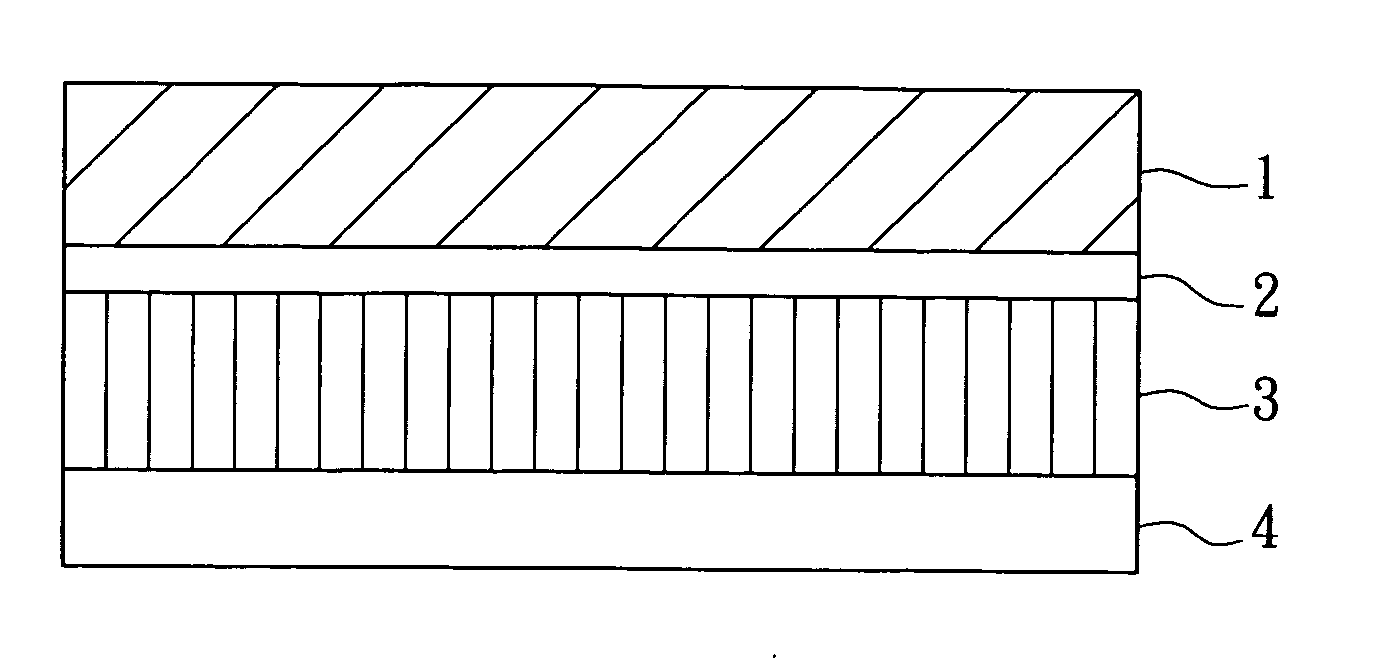

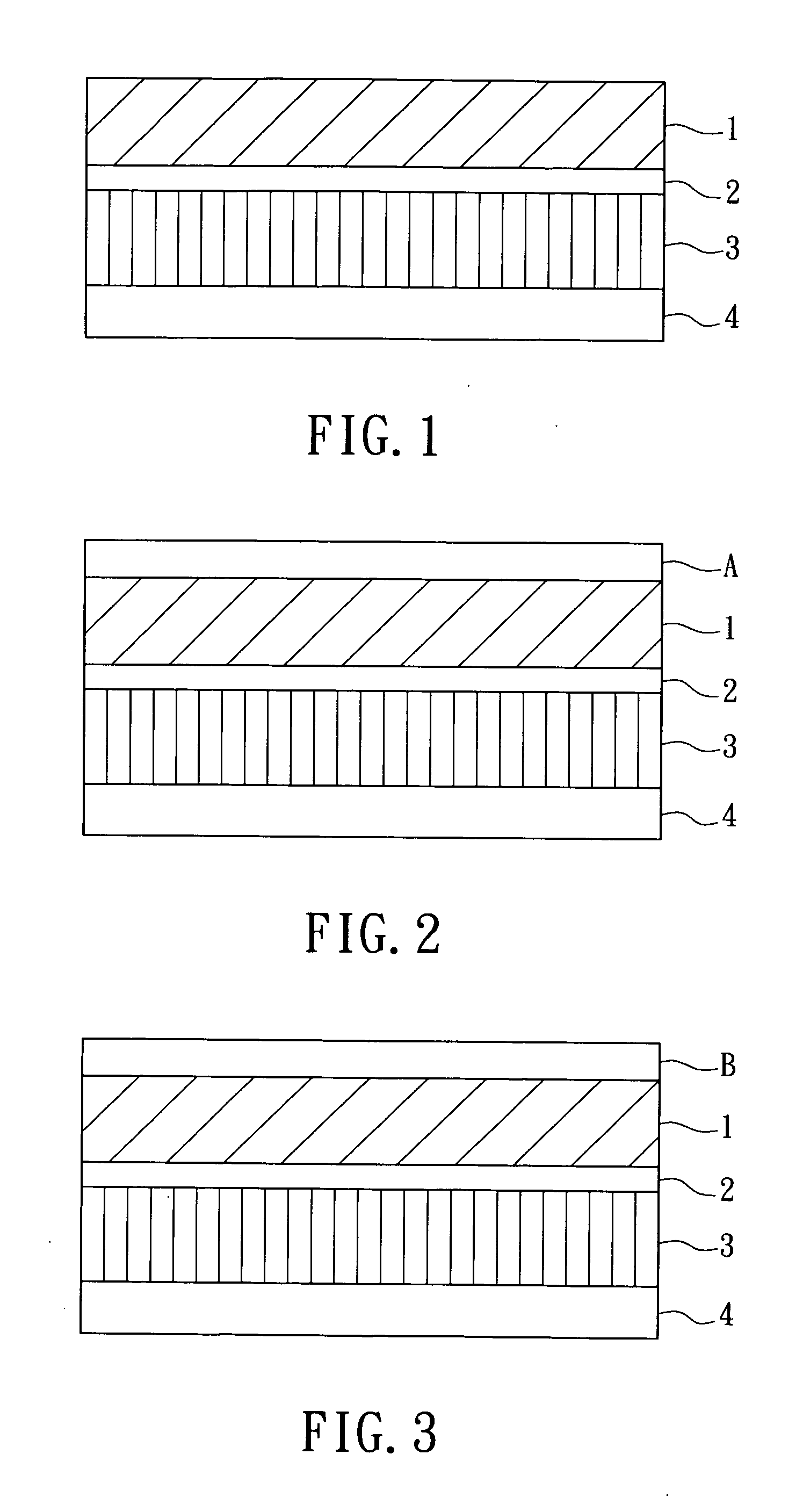

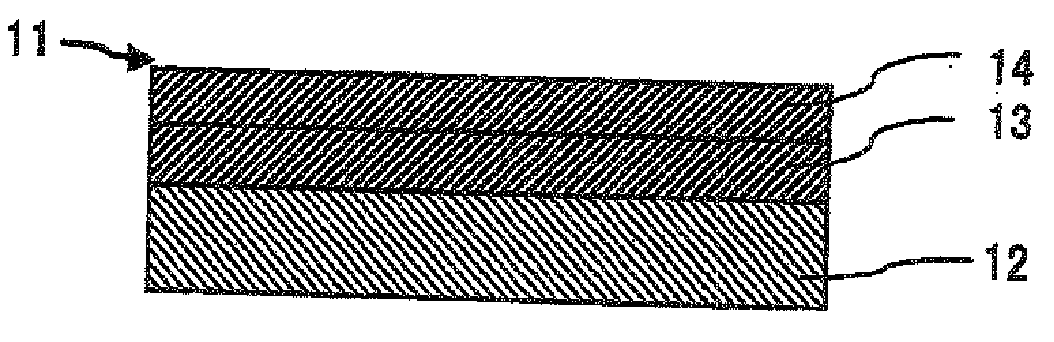

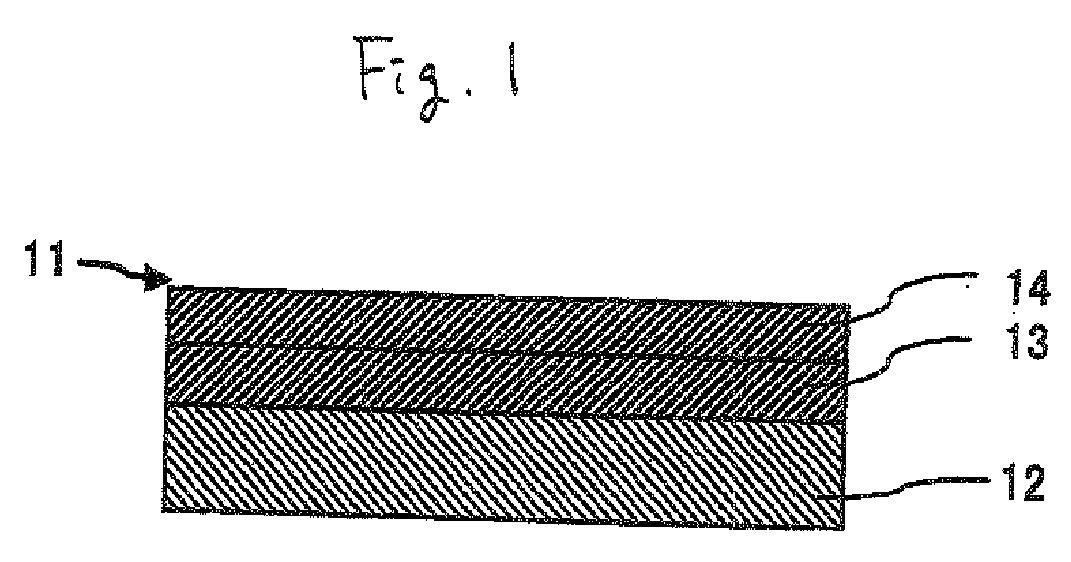

InactiveUS20050249946A1Improve cohesionCapabilityFilm/foil adhesive primer layersSemiconductor/solid-state device detailsPolycarbonatePolypropylene

The present inventions provide a protection film and the method of making the same. The protection film comprises a substrate, made of a compound selected from the group consisting of polycarbonate (PC), polyethylene (PE), polypropylene (PP), and aryl polyester (PET); an adhesive layer, attached on at least one of the surfaces of the substrate; and an acrylic primer, arranged between the substrate and the adhesive layer for enhancing the cohesiveness. The protection film not only has a better anti-stress capability, but also is capable of reduce the thickness of the adhesive layer so as to reduce the manufacturing cost of the protection film.

Owner:OPTIMAX TECHNOLOGY CORPORATION

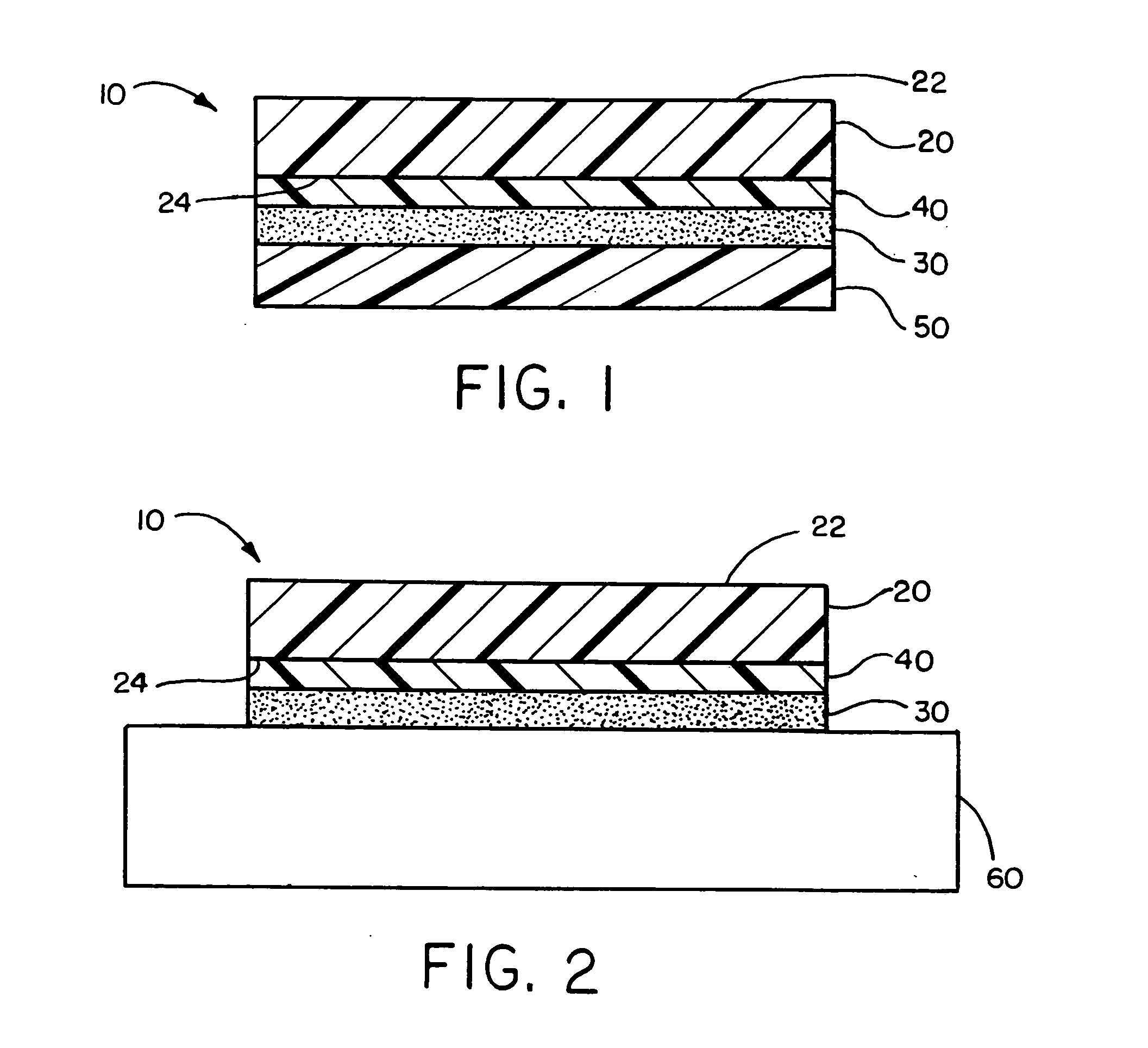

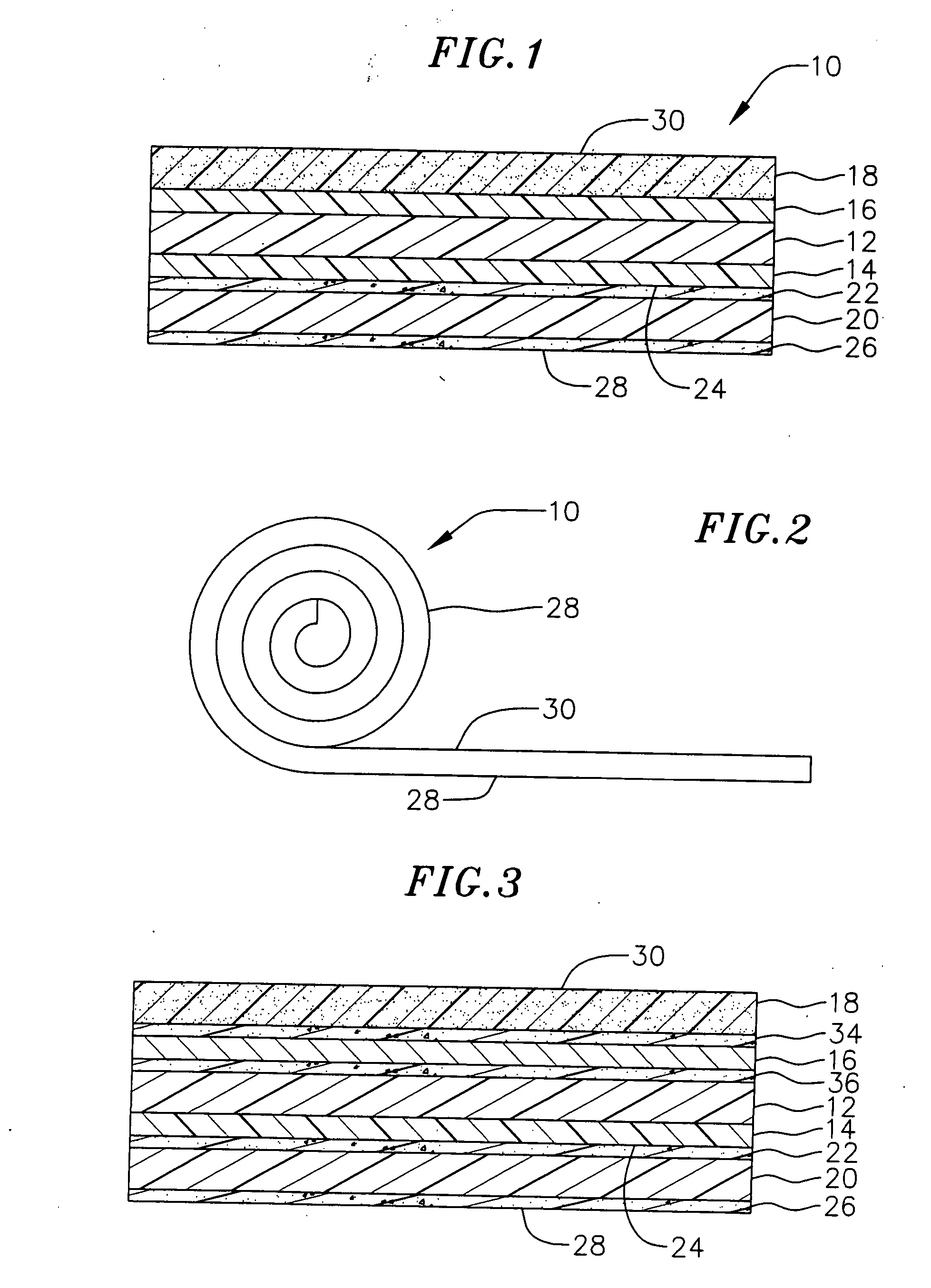

Composite construction containing barrier layer

This invention relates to a composite construction for use as a label or a tape to be adhered to a second substrate comprising a rubber-based material (e.g., vehicular tire), said composite construction comprising: a first substrate (e.g., paper, polymer film or combination thereof), said first substrate having a face side and an underside opposite said face side; an adhesive layer; and a barrier layer adhered to the underside of said first substrate and positioned between said first substrate and said adhesive layer, said barrier layer comprising a radiation cured acrylated epoxy derived from at least one acrylated epoxy oligomer and at least one reactive diluent selected from N-vinyl-2-pyrrolidone and N-vinylcaprolactam, said barrier layer being substantially impervious to migratory components in said adhesive layer and said second substrate. In one embodiment, a release liner is adhered to the adhesive layer. In one embodiment, the composite construction is adhered to the second substrate.

Owner:AVERY DENNISON CORP

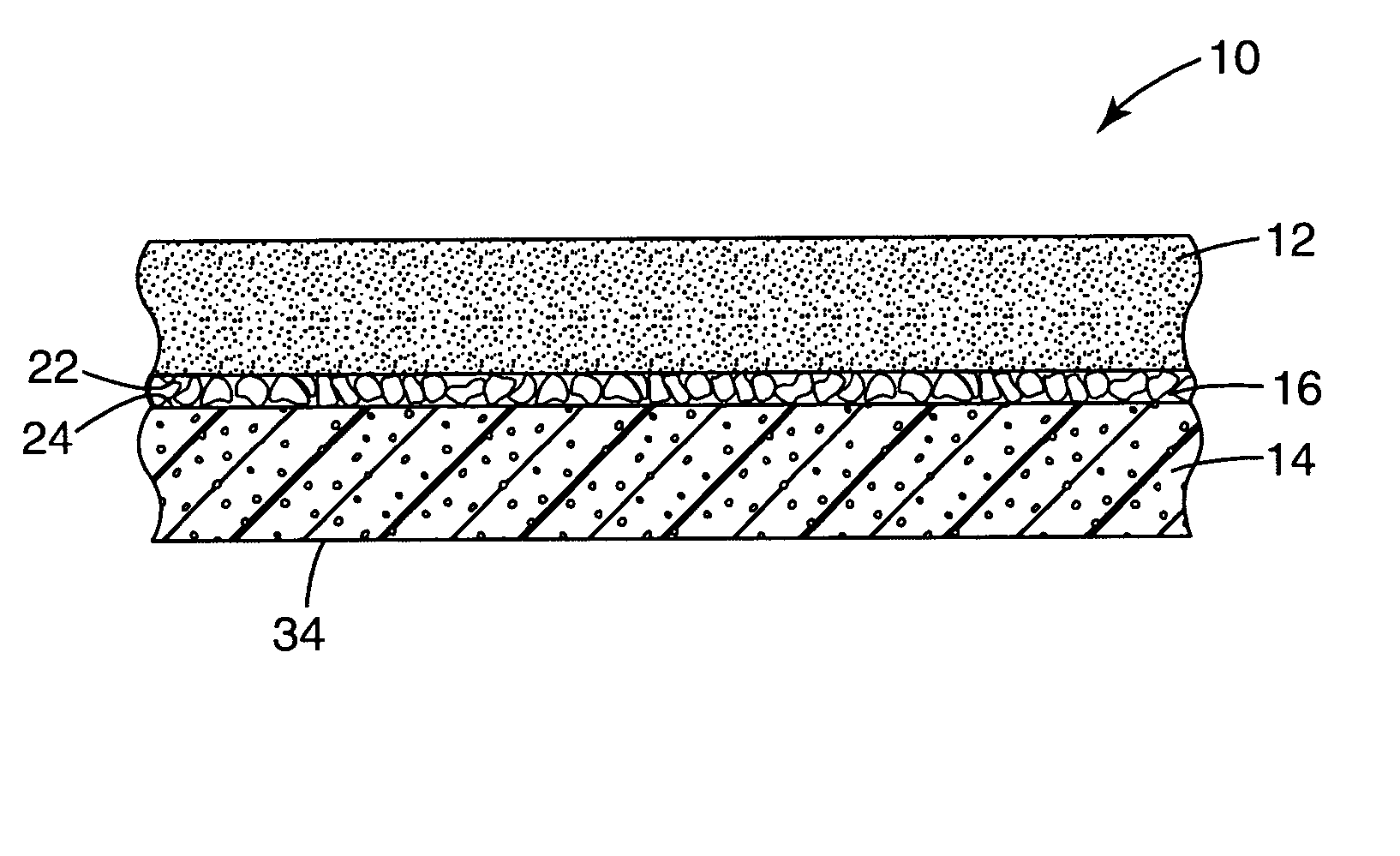

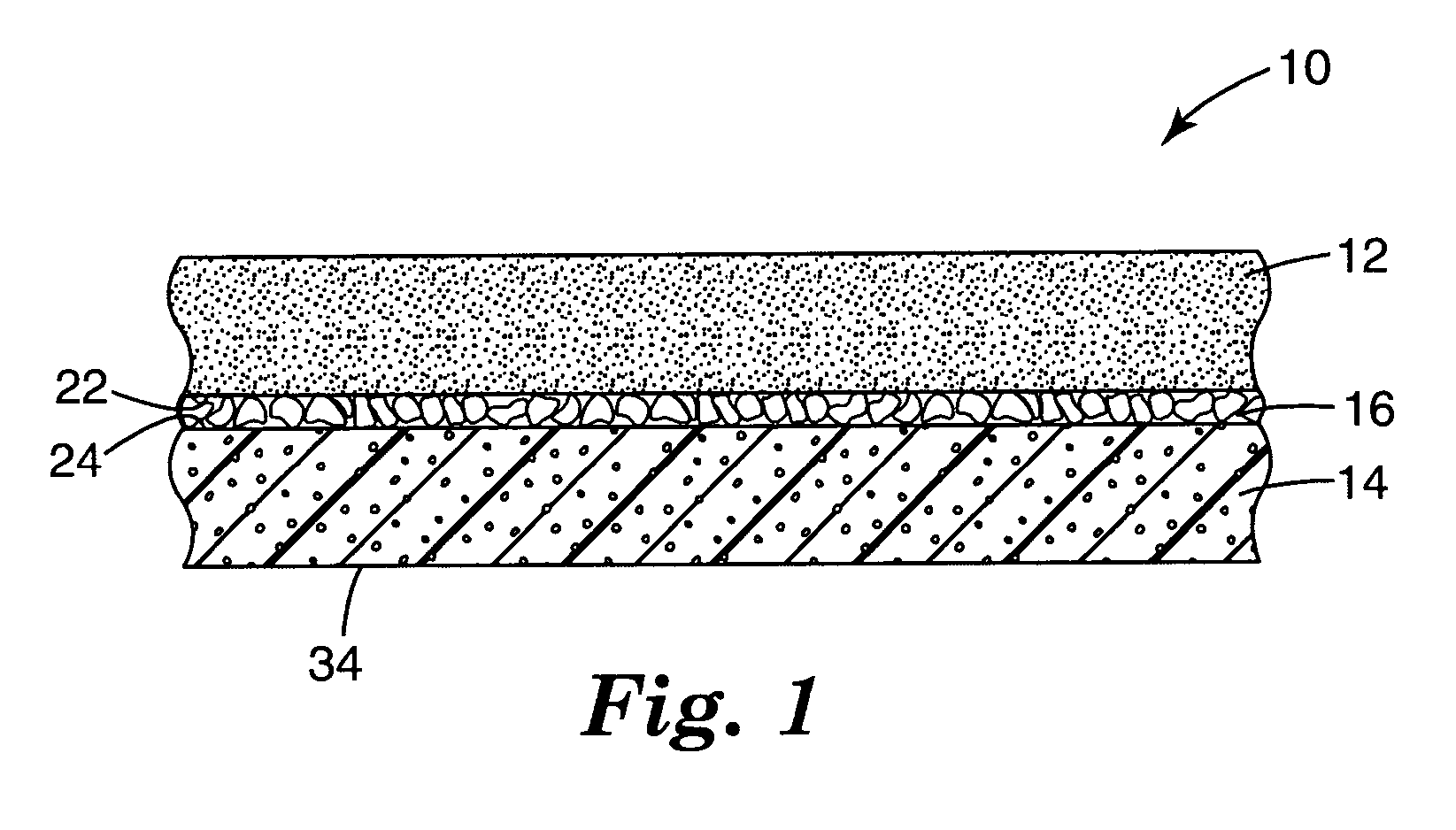

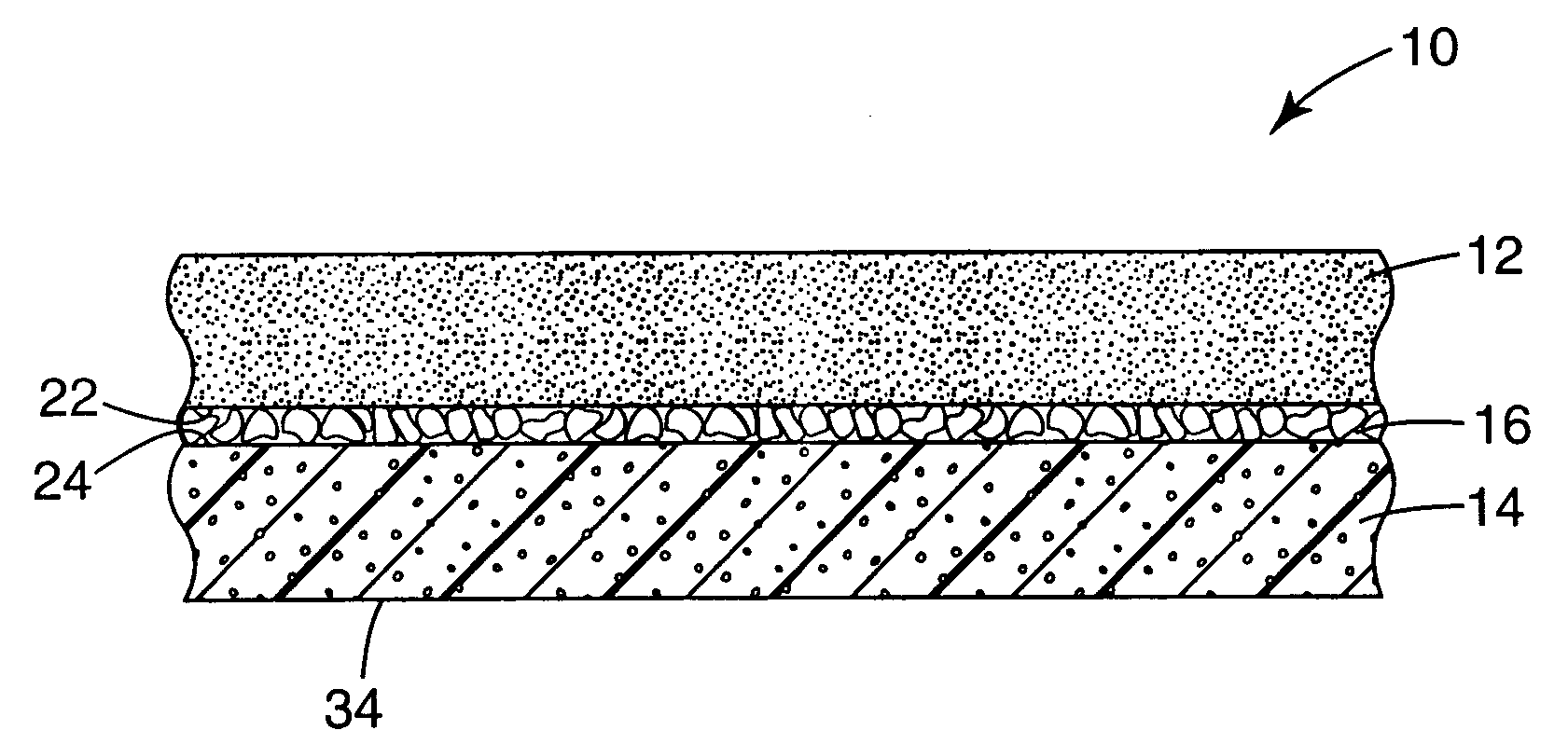

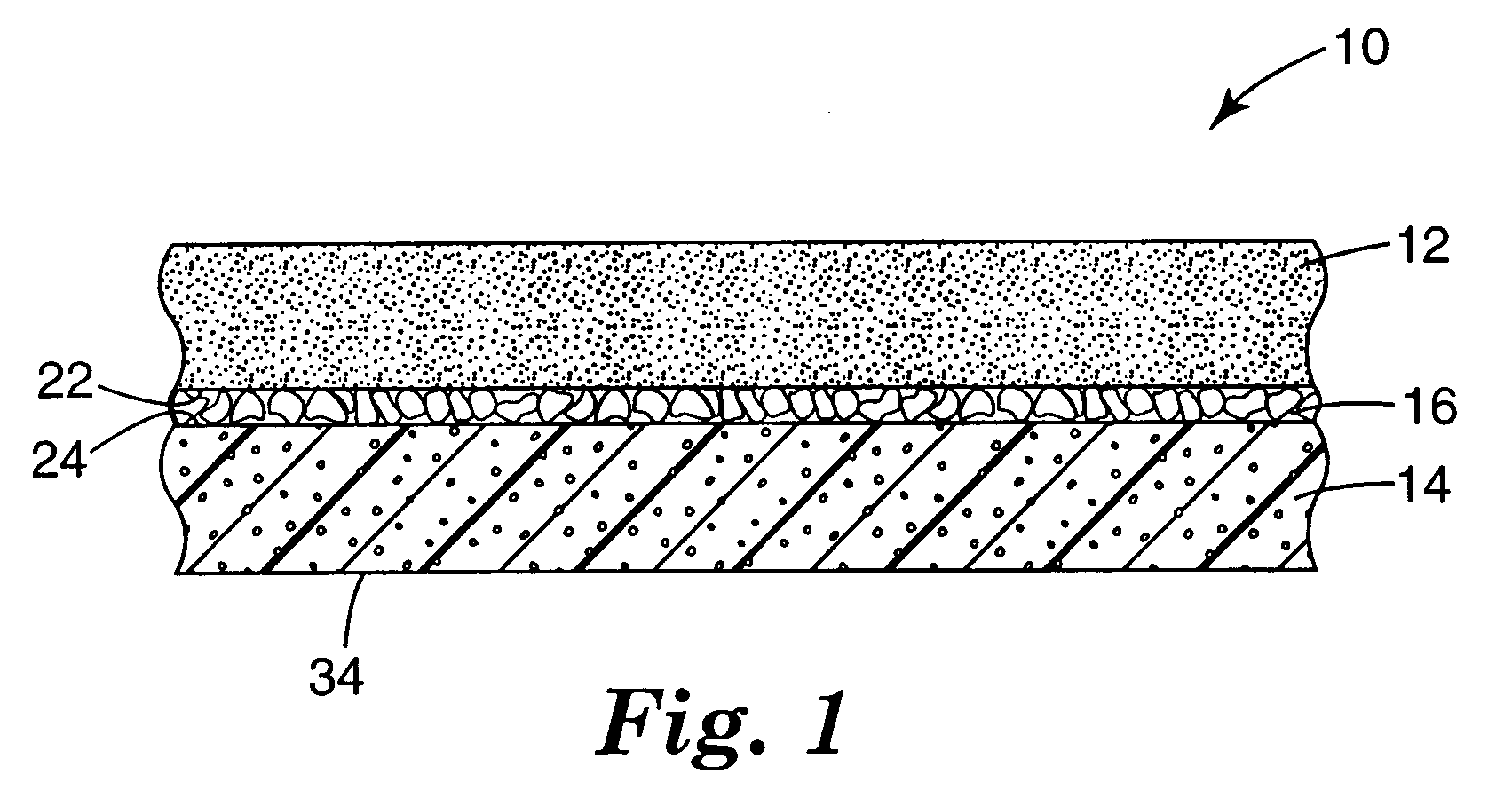

Adhesive articles including a nanoparticle primer and methods for preparing same

Adhesive articles comprising a primer consisting essentially of nanoparticles and methods of making the adhesive articles are provided. The adhesive article may include a polymeric foam substrate and / or an adhesive comprising less than 5% by weight of acrylic acid units.

Owner:3M INNOVATIVE PROPERTIES CO

Adhesive articles including a nanoparticle primer and methods for preparing same

Adhesive articles comprising a primer consisting essentially of nanoparticles and methods of making the adhesive articles are provided. The adhesive article may include a polymeric foam substrate and / or an adhesive comprising less than 5% by weight of acrylic acid units.

Owner:3M INNOVATIVE PROPERTIES CO

Waterborne priming coating compound, polarizing plate containing compound, and preparation method of optical film containing priming coating

InactiveCN102417807AFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesWater dispersibleAdditional procedure

The invention relates to a waterborne priming coating compound, a polarizing plate containing the waterborne priming coating compound, and a preparation method of an optical film containing the priming coating. For the priming coating compound has 100 parts of weight, the priming coating compound includes 1 to 30 parts by weight of polyurethane polymer, 0.1 to 10 parts by weight of water dispersible particles, and the balance water. The polarizing plate is arranged between the optical film and the priming coating formed by the priming coating compound. The method includes the steps of coating the priming coating compound on at least one side of the optical film and drying the optical film coated with the priming coating compound. The priming coating compound has excellent bonding performance, and can be contained in the polarizing plate without reducing the transparency of the polarizing plate and using additional procedures or devices.

Owner:LG CHEM LTD

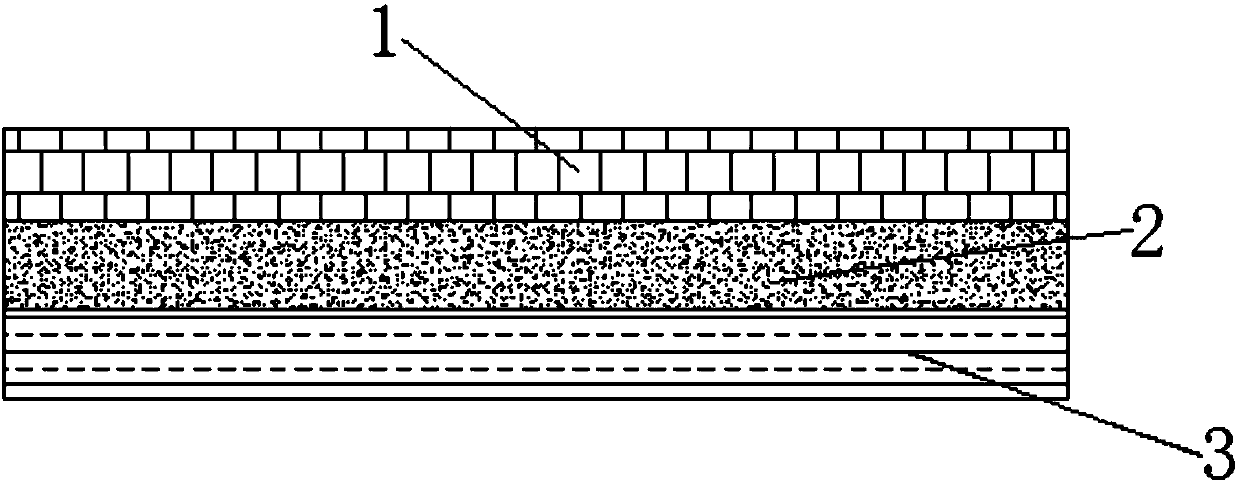

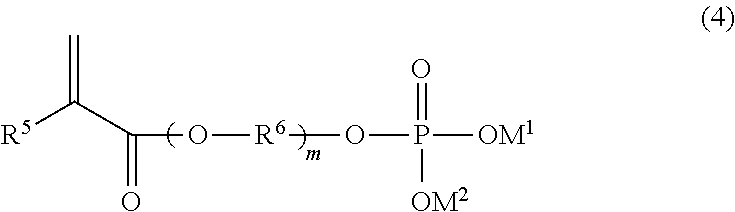

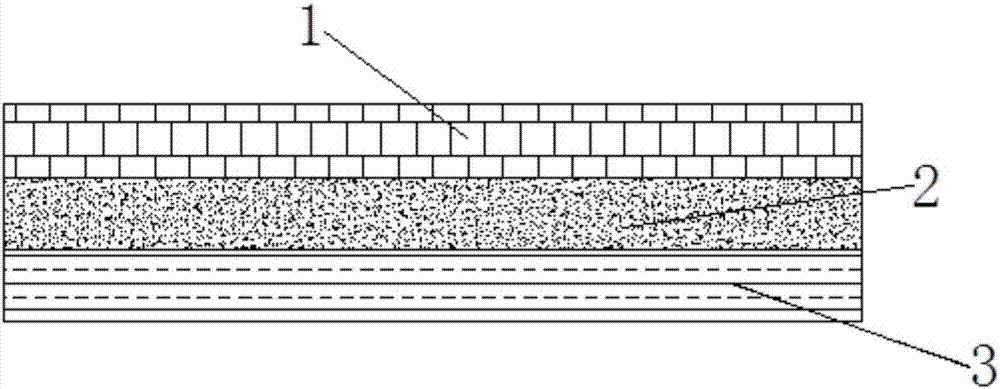

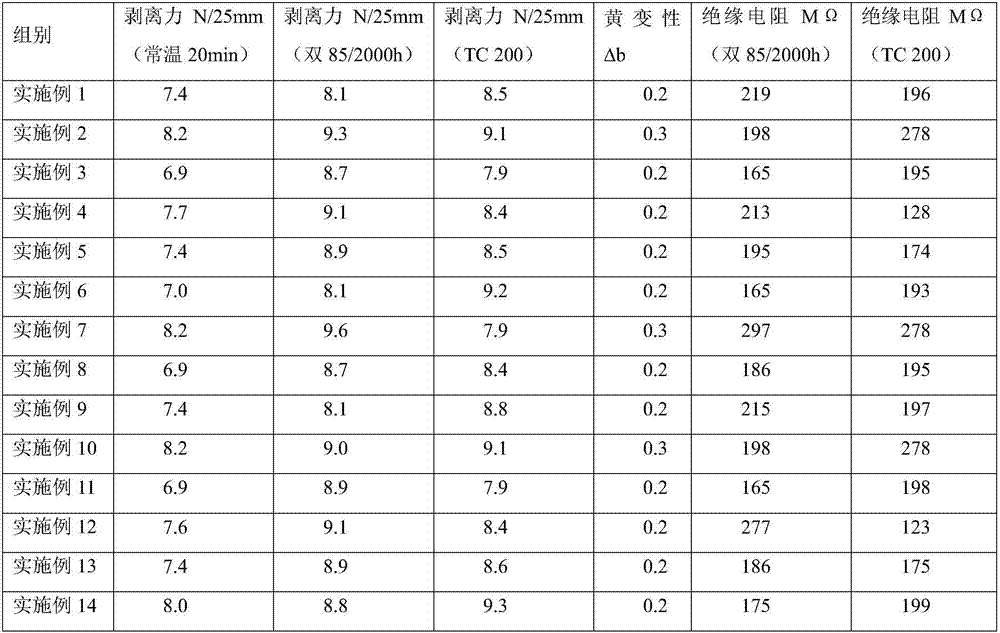

High-performance repairing adhesive tape for photovoltaic module back panel and preparation method

InactiveCN107841259AGood weather resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAdhesive cement

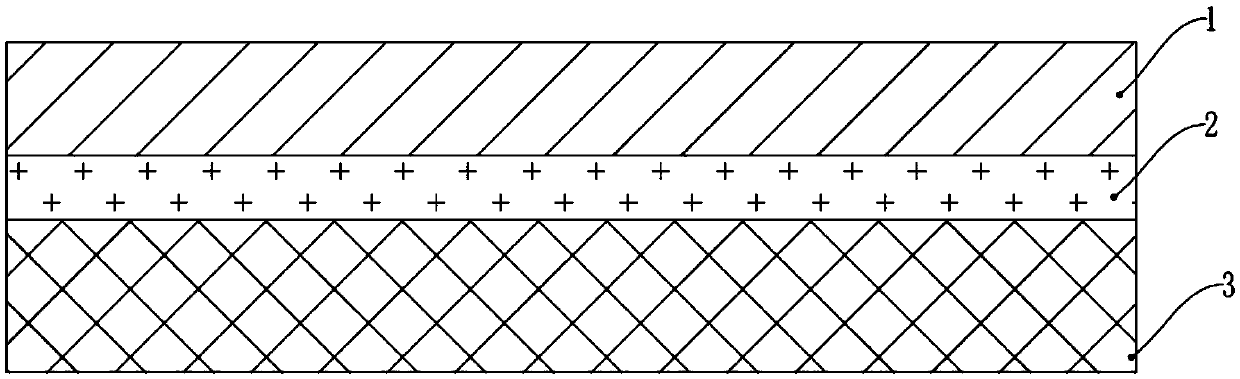

The invention discloses a high-performance repairing adhesive tape for a photovoltaic module back panel. The high-performance repairing adhesive tape comprises a base material layer, a functional adhesive layer and a release material layer which are arranged in sequence from top to bottom, wherein the base material layer is composed of a polyester thin film type material; the functional adhesive layer is composed of a high-weather-resistance adhesive. According to the high-performance repairing adhesive tape for the photovoltaic module back panel and the preparation method, disclosed by the invention, the weather-resistance base material layer is selected so that the effects of water resistance, insulation, ultraviolet radiation resistance and the like can be realized and the effect of anindependent back panel is realized; the high-weather-resistance adhesive is selected for the functional adhesive layer, so that the weather resistance, high temperature resistance and yellowing resistance of the adhesive tape can be improved; the adhesive tape has great bonding strength and is not easy to fall off; meanwhile, the adhesive tape is convenient to stick and convenient to construct.

Owner:CYBRID TECHNOLOGIES INC

Primer for improving the adhesion of adhesive tapes on plastics and metals which are difficult to bond

InactiveUS20140113070A1Improve adhesionFilm/foil adhesive primer layersOrganic non-macromolecular adhesivePolymer sciencePolyolefin

Primer comprising a mixture, dissolved or dispersed in one or more solvents, of I) a pressure sensitive adhesive obtained by copolymerization of a) at least one acrylic ester of a linear primary alcohol, b) at least on acrylic ester of a branched, acyclic alcohol, and d) acrylic acid, II) at least one thermal crosslinker, and III) at least one chlorinated polyolefin.

Owner:TESA SE

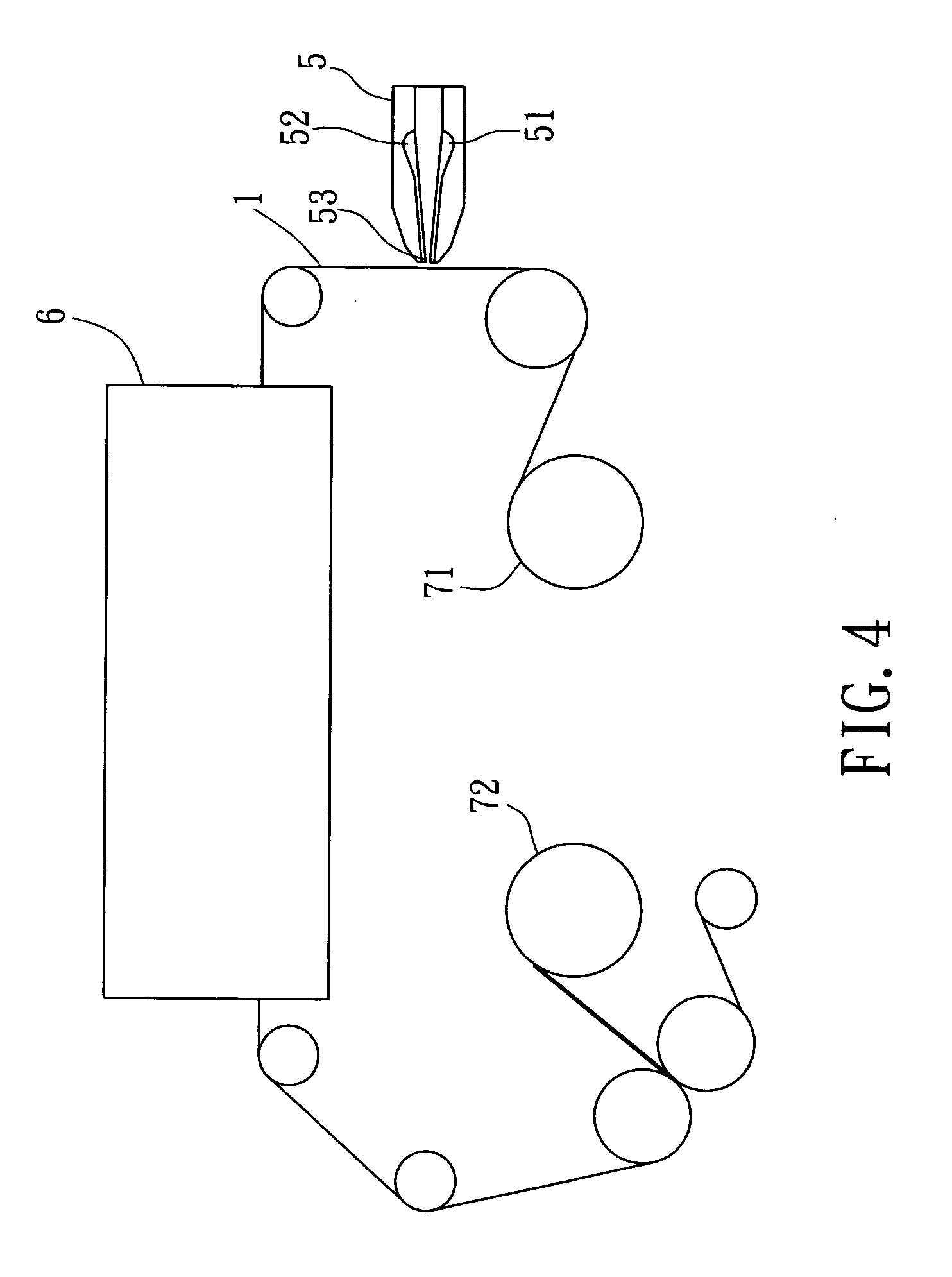

Anti-broken hot melt adhesive membrane used for automobile decoration and preparation method of anti-broken hot melt adhesive membrane

InactiveCN109135605AImprove the adhesion effectImprove surface wear resistanceFilm/foil adhesive primer layersHeat-activated film/foil adhesivesSurface layerWear resistant

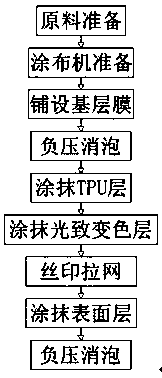

The invention discloses an anti-broken hot melt adhesive membrane used for automobile decoration and a preparation method of the anti-broken hot melt adhesive membrane. The anti-broken hot melt adhesive membrane comprises a PVB base adhesive, a TPU adhesive layer is stuck to the outer wall on one side of the PVB base adhesive, a photochromic layer is stuck to the outer wall on the side, away fromthe PVB base adhesive, of the TPU adhesive layer, a nylon mesh cloth layer is stuck to the outer wall on the side, away from the TPU adhesive layer, of the photochromic layer, and a membrane surface layer is stuck to the outer wall on the side, away from the photochromic layer, of the nylon mesh cloth layer. The preparation method comprises the following steps of preparation of raw materials, wherein a PVB adhesive solution, an EVA adhesive solution and a TPU adhesive solution which are needed during production are mixed and stirred respectively, and then sampled and inspected respectively; preparation of coating machines, wherein the three coating machines are prepared, and adhesive storage cylinders and coating heads of the three coating machines are cleaned. By means of the anti-brokenhot melt adhesive membrane, improvement of the wear-resistant performance of the surface of the hot melt adhesive membrane is facilitated, by cooperatively arranging the nylon mesh cloth layer, improved of the adhesion effect of the surface layer of the membrane can be facilitated, the box stretching performance of the hot melt adhesive membrane is improved, and improvement of the elasticity of the hot melt adhesive membrane is facilitated.

Owner:安徽天念材料股份有限公司

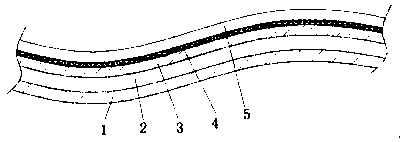

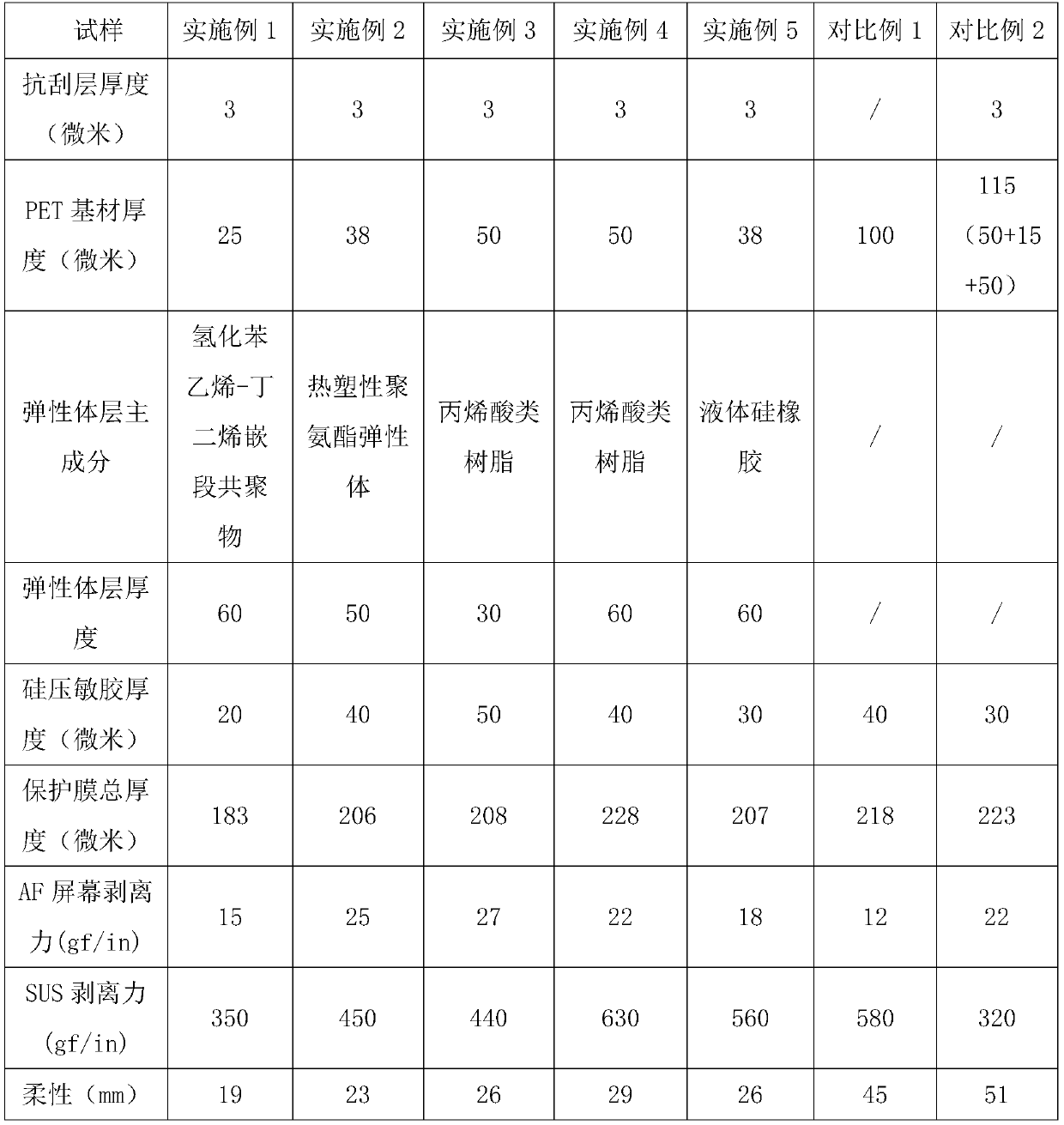

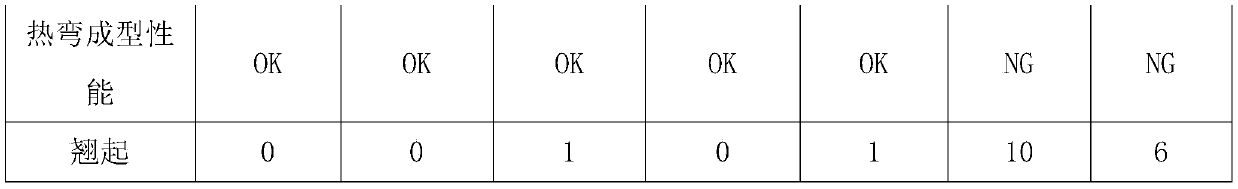

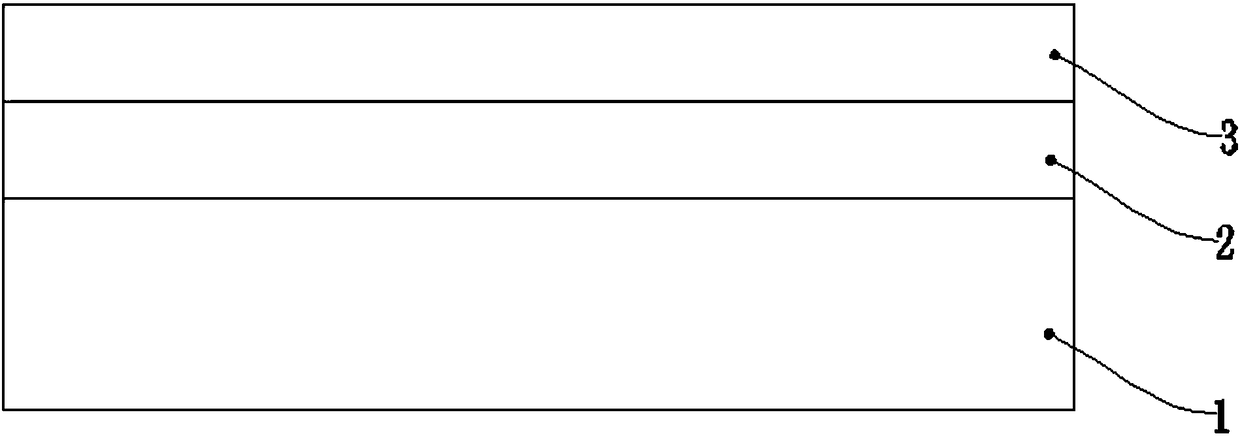

Curved screen protection film and preparation method thereof

ActiveCN110105896AImprove bendabilityImprove impact performanceFilm/foil adhesive primer layersPolyurea/polyurethane coatingsElastomerTectorial membrane

The invention relates to the technical field of curved screen protection films, in particular to a screen protection film for protecting curved liquid crystal screens and a manufacturing method of thescreen protection film. The curved screen protection film structurally comprises an anti-scratching layer, a PET base material, an elastomer layer, a silica gel layer and a fluorine release film which are sequentially arranged. According to the protection film, the arranged elastomer layer is beneficial to improving the bending property and drop resistance of the protection film, and under cooperation with the silica gel layer arranged on a protection film body, improvement of the fixing and fitting property of the protection film is facilitated, so that the problem of edge warping is effectively solved, and the protection film is suitable for the design of large angles and radians of the edge positions of mobile phone screens. Through the reasonable arrangement of the structure and thickness of each layer, the protection film has the basic performance of a PET screen protection film, and meanwhile, the flexibility, drop resistance and edge warping resistance of the protection film are further improved.

Owner:佛山固泰明科技有限公司

Anchor layer formation composition, anchor layer, optical film provided with adhesive layer, and image display device

InactiveUS20170183543A1Improve adhesionIncreased durabilityLiquid surface applicatorsAntifouling/underwater paintsDisplay devicePolymer

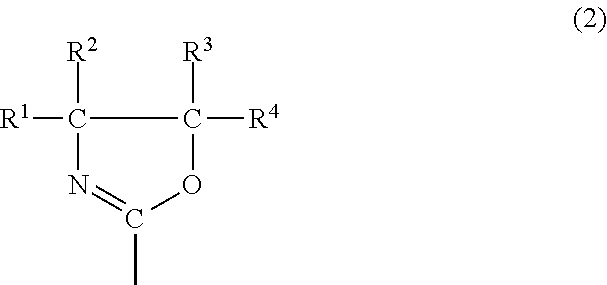

An anchor layer formation composition, a pressure-sensitive adhesive layer-attached optical film, and an image display device are provided, in which the composition includes an oxazoline group-containing polymer and an ionic compound including a cation component and a sulfonyl group-containing anion component and is capable of forming an anchor layer that can improve the adhesion between a pressure-sensitive adhesive layer and an optical film when interposed therebetween, the pressure-sensitive adhesive layer-attached optical film has high durability and good reworkability and allows the pressure-sensitive adhesive layer to resist chipping, and the image display device has the pressure-sensitive adhesive layer-attached optical film.

Owner:NITTO DENKO CORP

High performance repairing adhesive tape used for photovoltaic module backboards, and preparation method thereof

InactiveCN107267086AGood weather resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAdhesive

The invention discloses a high performance repairing adhesive tape used for photovoltaic module backboards. The high performance repairing adhesive tape comprises a substrate layer, a functional glue layer, and a release material layer from top to bottom successively; the substrate layer is composed of a polyester film material; the functional glue layer is composed of a high weatherability adhesive. According to a preparation method, the substrate layer with weatherability is capable of providing the high performance repairing adhesive tape with water resistance, insulation performance, and ultra violet radiation resistance, and backboard independence effect is achieved; the functional glue layer is prepared from the weatherability adhesive, so that the weatherability, high temperature resistance, and yellowing resistance of the functional glue layer are improved, the adhesive tape bonding force is increased, shedding is not easily caused, fitness is improved, and construction is convenient.

Owner:CYBRID TECHNOLOGIES INC

Pressure sensitive adhesive tape containing natural rubber latex

InactiveUS6489024B2Film/foil adhesive primer layersThin material handlingPolymer sciencePolymer thin films

Owner:ROHM & HAAS CO

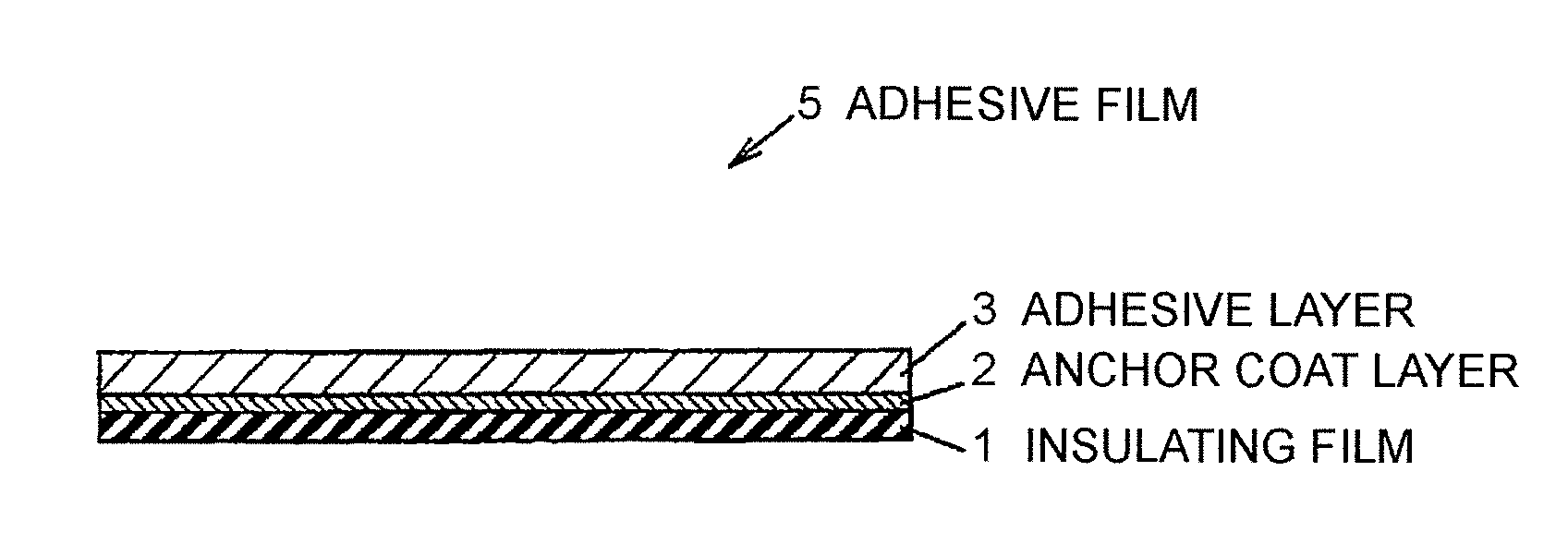

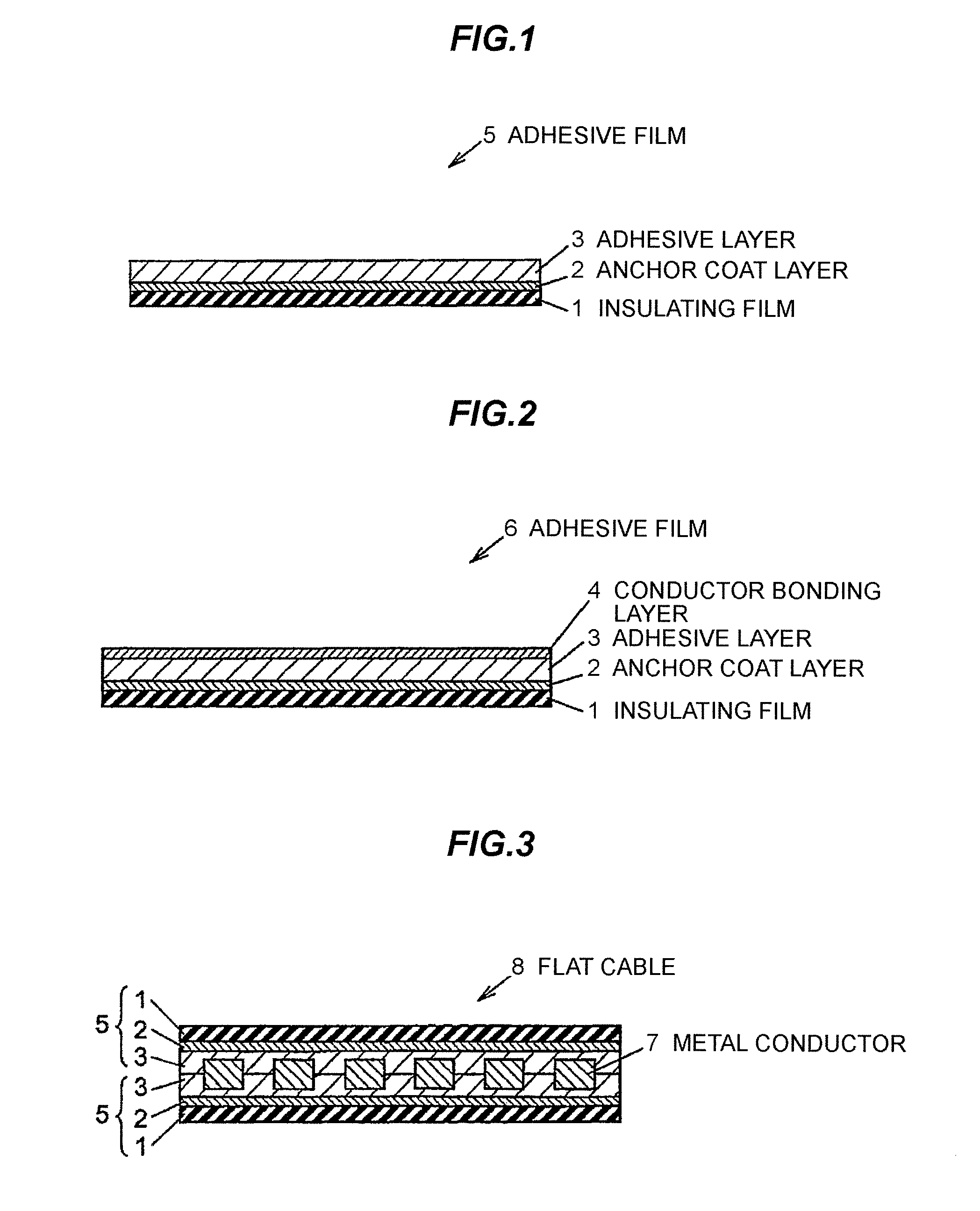

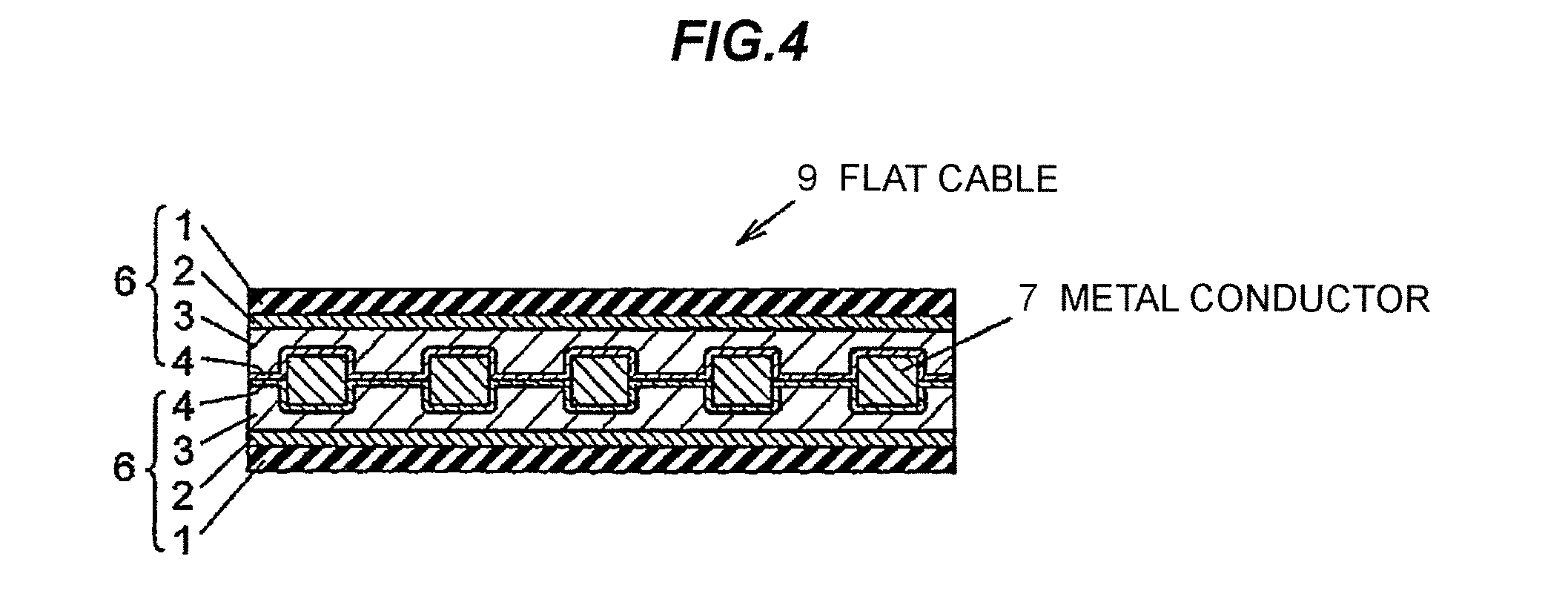

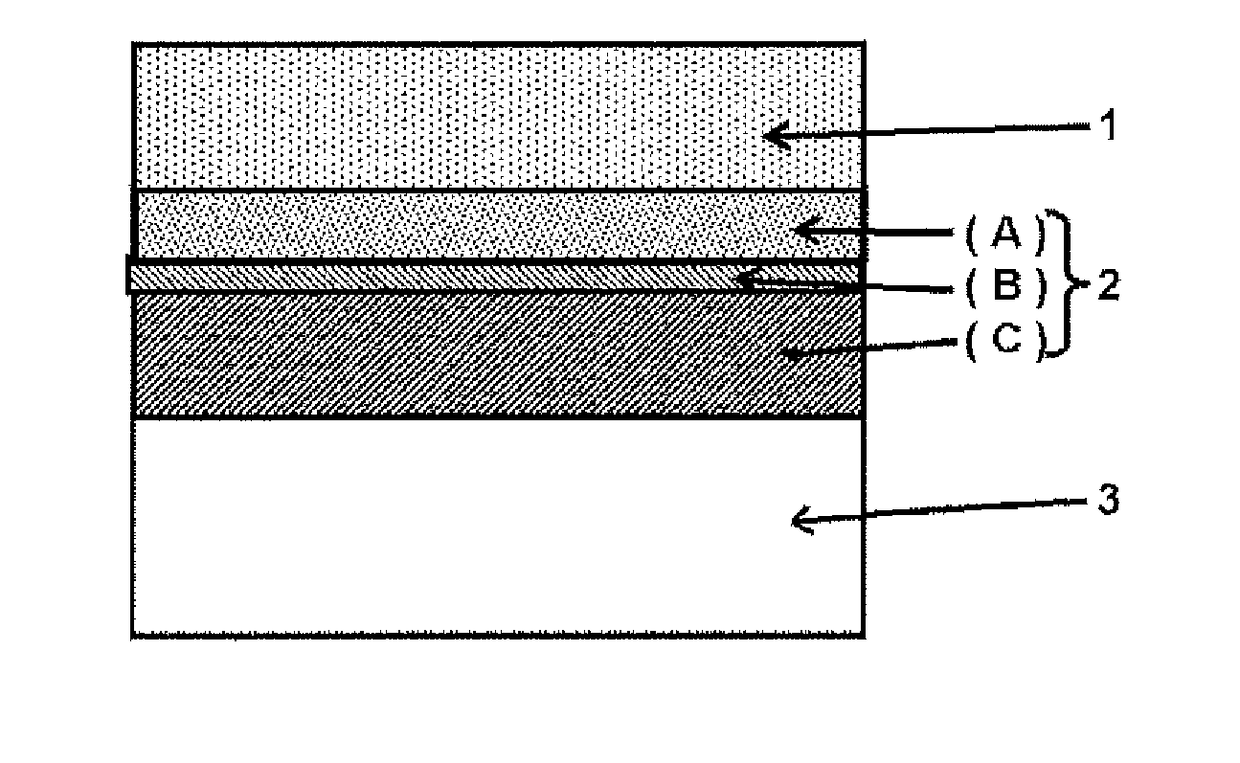

Adhesive film and flat cable using same

InactiveUS20120255761A1Improve heat resistanceImprove adhesionFilm/foil adhesive primer layersSynthetic resin layered productsCelsius DegreePolyamide

The adhesive film includes an insulating film, an adhesive layer provided over one side of the insulating film, and an anchor coat layer provided between the one side of the insulating film and the adhesive layer. The adhesive layer is a copolymer polyamide resin which is soluble in a solvent at 25 degrees Celsius and has a melting point of 100 degrees Celsius or more and 150 degrees Celsius or less. The anchor coat layer enhances the adhesion between the insulating film and the adhesive layer.

Owner:HITACHI METALS LTD

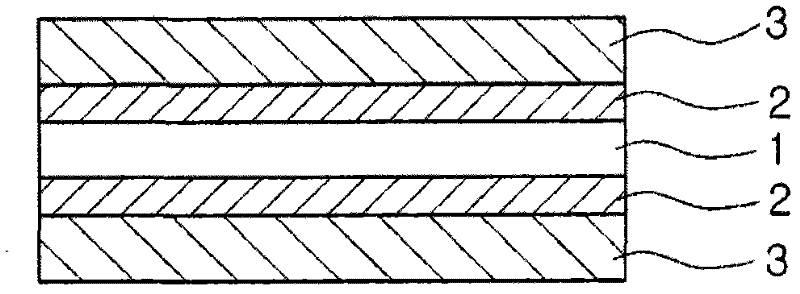

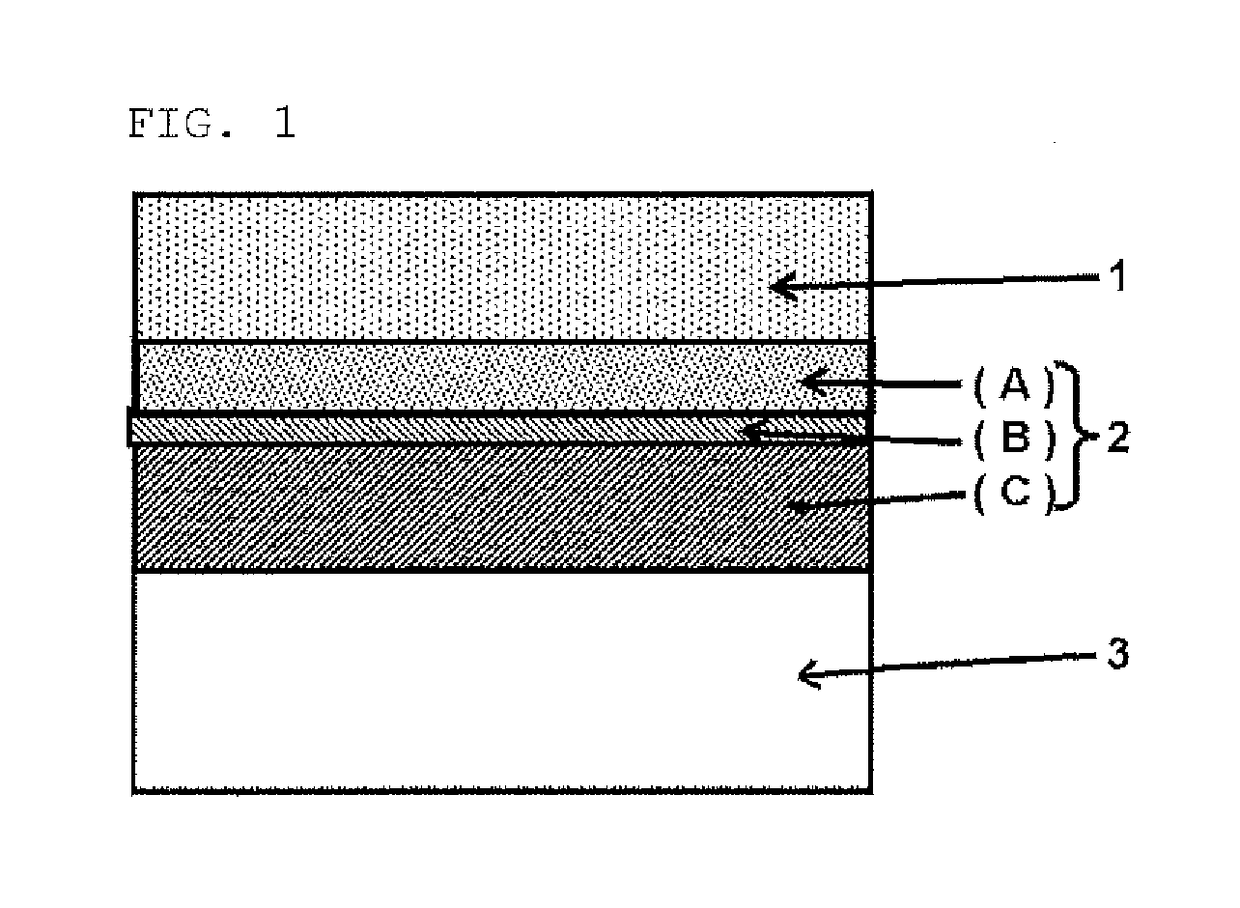

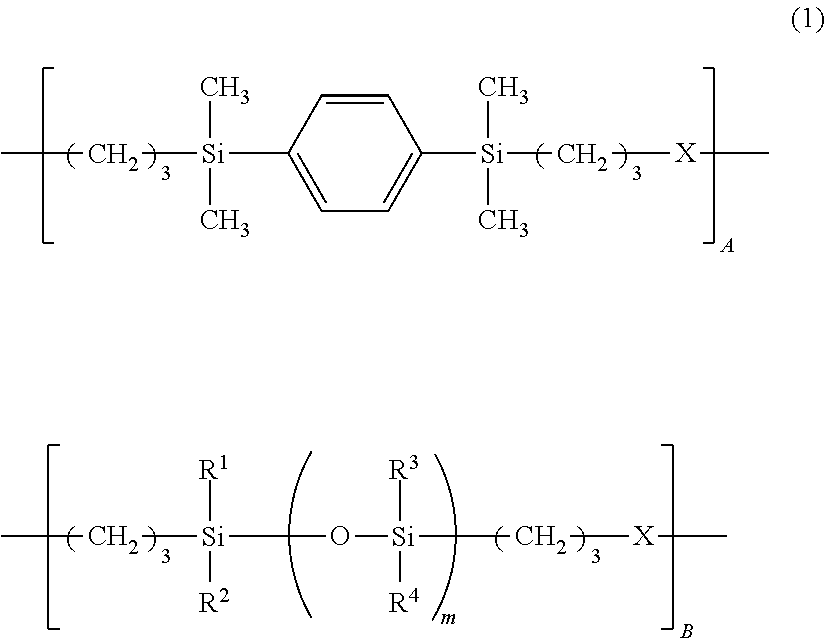

Wafer processing laminate, temporary adhesive material for wafer processing, and method for manufacturing thin wafer

ActiveUS20170069521A1Improve heat resistanceEasy to manufactureNon-macromolecular adhesive additivesFilm/foil adhesive primer layersEngineeringAdhesive materials

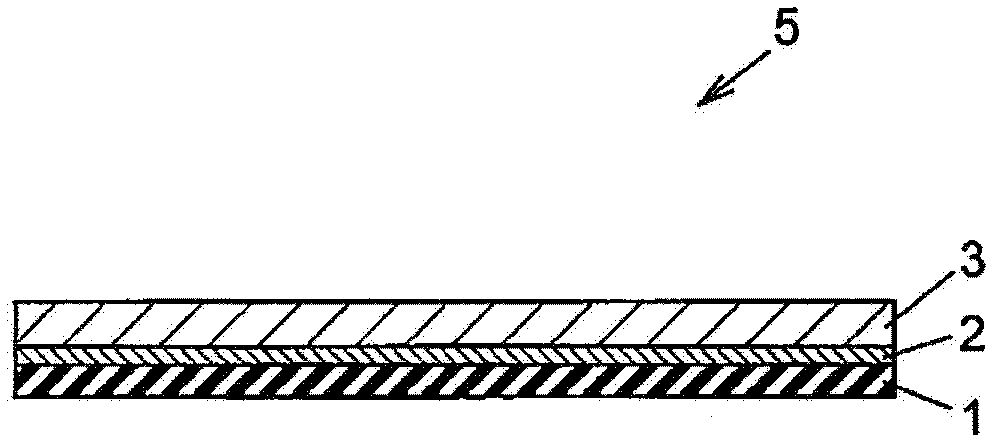

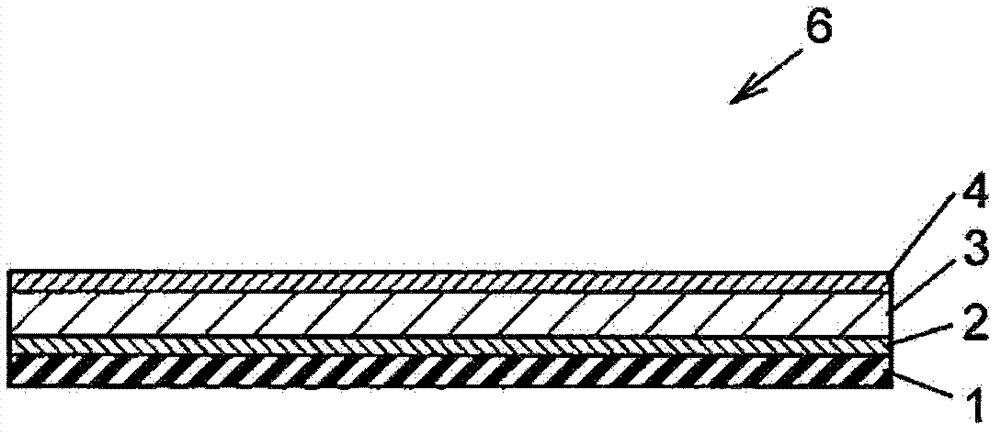

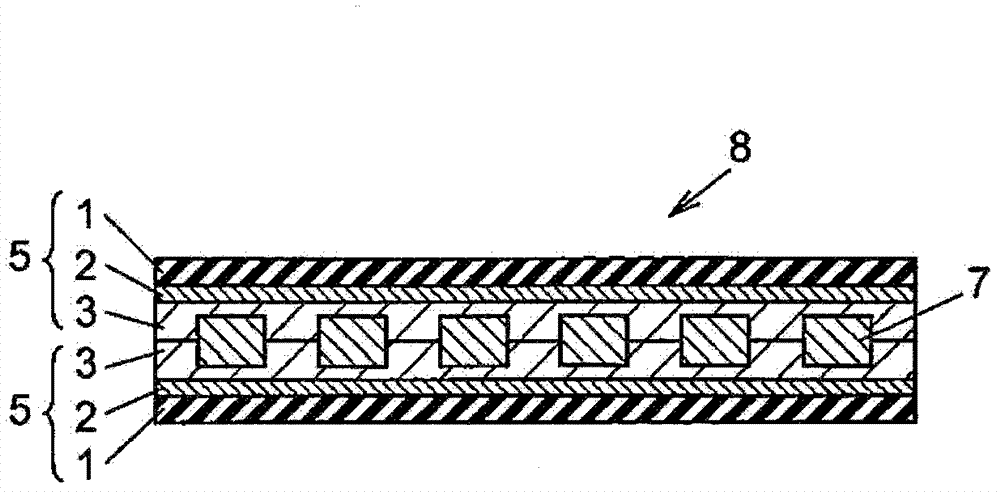

A temporary adhesive material for a wafer processing, used for temporarily bonding a support and a wafer having a circuit-forming front surface and a back surface to be processed, contains a complex temporary adhesive material layer having a three-layered structure that includes a first temporary adhesive layer composed of a non-silicone thermoplastic resin layer capable of releasably adhering to the front surface of the wafer, a second temporary adhesive layer composed of a thermosetting siloxane polymer layer laminated on the first temporary adhesive layer, and a third temporary adhesive layer composed of a thermosetting siloxane-modified polymer layer laminated on the second temporary adhesive layer and capable of releasably adhering to the support. A wafer processing laminate and temporary adhesive material for a wafer processing facilitate temporary adhesion and separation, have excellent CVD resistance, and can increase productivity of thin wafers, and a method manufactures a thin wafer using the same.

Owner:SHIN ETSU CHEM IND CO LTD

Pressure-sensitive adhesive sheet and method of processing articles

InactiveUS20070059903A1High precision machiningFilm/foil adhesive primer layersSolid-state devicesNitrogenAcrylic polymer

To provide a pressure-sensitive adhesive that is used in processing an article such as a semiconductor wafer, the pressure-sensitive adhesive sheet is one that has a base, an intermediate layer and a pressure-sensitive adhesive layer in order, wherein the intermediate layer has an elastic modulus at elongation at 23° C. of 1 MPa or more and 100 MPa or less, the intermediate layer includes an acrylic polymer obtained by polymerization of a (meth) acrylic monomer mixture containing 1% by weight or more and 20% by weight or less of a nitrogen-containing acrylic monomer, the acrylic polymer containing 20% by weight or less of a polymer component having a molecular weight of 100,000 or less, and the base includes at least one film having an elastic modulus at in tension at 23° C. of 0.6 GPa or more.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive optical film and image display

ActiveUS20090123718A1Improve dispersion stabilityGood dispersionNon-macromolecular adhesive additivesFilm/foil adhesive primer layersWater dispersibleOptical property

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film; and a pressure-sensitive adhesive layer laminated on at least one side of the optical film with an anchor layer interposed therebetween, wherein the anchor layer has a thickness of 5 to 300 nm, the pressure-sensitive adhesive layer has a thickness of 5 to 50 μm, at least one of the anchor layer and the pressure-sensitive adhesive layer is made from a ammonia-containing water-dispersible material, the layer made from the ammonia-containing water-dispersible material contains ammonia in an amount of 10 ng or more per 1 cm2 of the pressure-sensitive adhesive optical film, wherein the amount is a measurement derived from the layer, and the pressure-sensitive adhesive optical film contains ammonia in a total amount of 2000 ng or less per 1 cm2 of the pressure-sensitive adhesive optical film. The pressure-sensitive adhesive optical film has good appearance and high durability with which alterations in optical properties can be kept small even in high-temperature, high-humidity environments.

Owner:NITTO DENKO CORP

Adhesive film and flat cable using same

InactiveCN102732171AImprove heat resistanceImprove flame retardant performanceFilm/foil adhesive primer layersFlat/ribbon cablesOrganic solventCelsius Degree

The adhesive film includes an insulating film, an adhesive layer provided over one side of the insulating film, and an anchor coat layer provided between the one side of the insulating film and the adhesive layer. The adhesive layer is a copolymer polyamide resin which is soluble in a solvent at 25 degrees Celsius and has a melting point of 100 degrees Celsius or more and 150 degrees Celsius or less. The anchor coat layer enhances the adhesion between the insulating film and the adhesive layer.

Owner:PROTERIAL LTD

Anchor-layer-forming coating liquid, adhesive layer-carrying optical film and method for producing the film

ActiveCN103483987AImprove conductivityGood dispersionFilm/foil adhesive primer layersLayered productsTransmittanceOptical thin film

Owner:NITTO DENKO CORP

Scratch-resistant and anti-fouling TPU vehicle body protection film and production process thereof

InactiveCN109837036AImprove scratch resistanceExcellent anti-scratch and anti-fouling performanceAntifouling/underwater paintsFilm/foil adhesive primer layersPolyesterMicro nano

The invention discloses a scratch-resistant and anti-fouling TPU vehicle body protection film, which comprises a base material layer and a glue layer arranged on the lower portion of the base materiallayer, the base material layer is a TPU film, the upper surface of the TPU film is provided with an scratch-resistant and anti-fouling coating, the scratch-resistant and anti-fouling coating comprises, by mass, 50-85 parts of a main body resin, 0.01-5 parts of an initiator or / and cross-linking agent, 5-50 parts of a filler, 0-20 parts of an auxiliary agent, and 0-30 parts of a solvent, the fillercomprises nanometer polymer micro-beads self-assembled into micro-nano clusters, and the main body resin is a composition of polyester type polyurethane or / and acrylic resin. According to the presentinvention, the novel scratch-resistant and anti-fouling TPU vehicle body protection film is formed by improving the formula of the scratch-resistant and anti-fouling coating, such that the TPU vehicle body protection film can integrate the effects of scratch resistance and stain resistance through the scratch-resistant and anti-fouling coating compared with the existing protection film.

Owner:SHANGHAI NAR INDAL +1

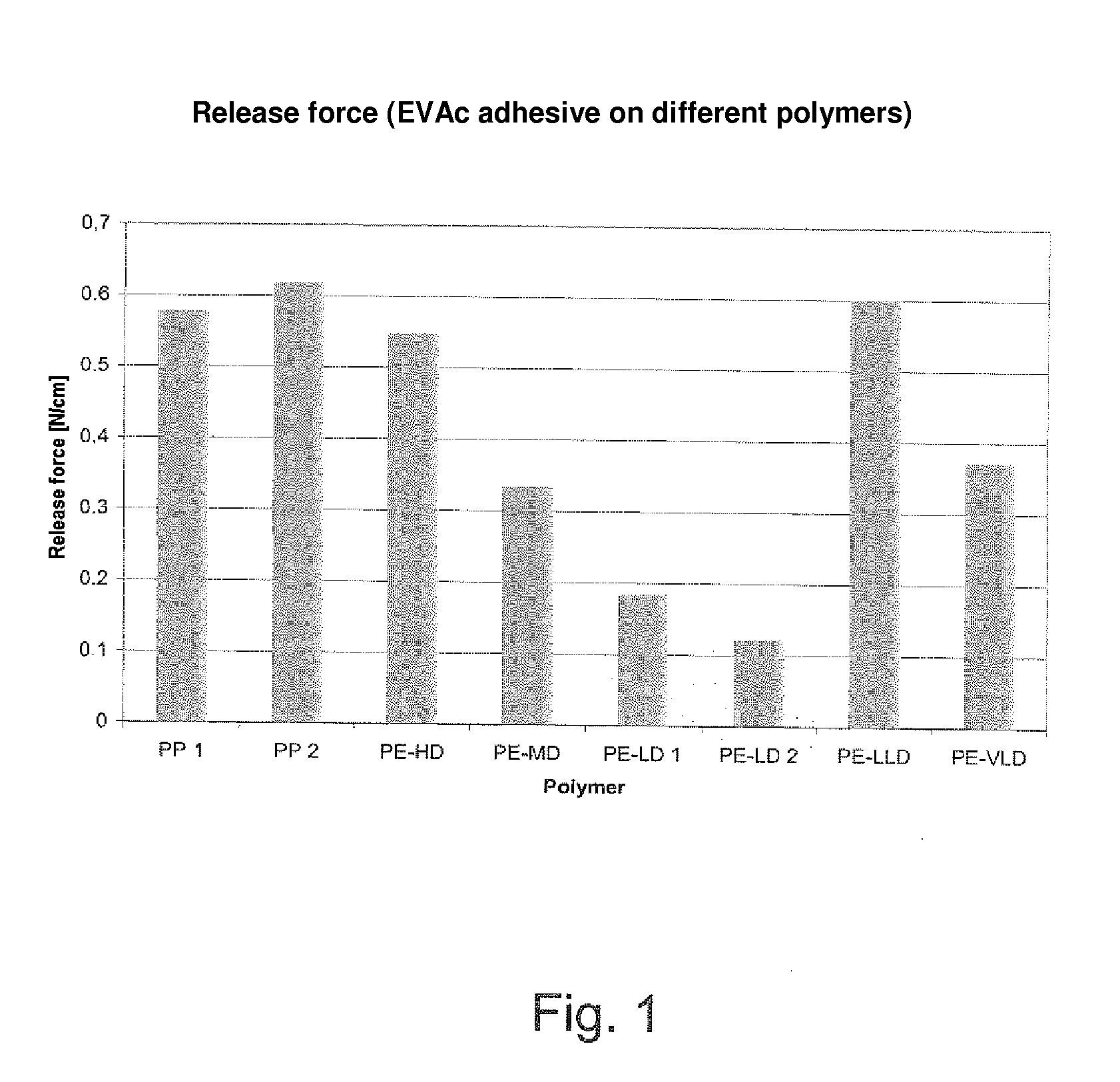

Surface protecting film with low unwind capability

InactiveCN101255320AMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsLow-density polyethyleneCopolymer

The invention relates to a self-adhesive protective film composed of a backing to one side of which an adhesive is applied, characterized in that the backing has at least two layers: a first layer, facing the adhesive, comprising an unoriented film which comprises at least one propylene block copolymer with an amount of 10% to 95% (w / w), and a second layer, facing away from the adhesive, comprising a film which contains at least 75% (w / w), preferably at least 80% (w / w), of a low-density polyethylene.

Owner:TESA SE

Coloring layer coating suitable for silver alumite hot stamping foils and preparation method thereof

ActiveCN108059858AHigh hardnessStructural solutionFilm/foil adhesive primer layersCoatingsHot stampingSolvent

The invention discloses coloring layer coating suitable for silver alumite hot stamping foils and a preparation method thereof. Paint films of silver alumite hot stamping foils in the prior art are prone to efflorescence; in gold stamping, the defects of gold flying, powder falling and the like are prone to happening; thus, hot stamping quality and a production efficiency are affected. The coloring layer coating disclosed by the invention is prepared from the following raw materials in parts by weight: 15 to 25 parts of thermoplastic methacrylic resin, 1 to 5 parts of chloride-acetate resin, 1to 8 parts of styrene-maleic anhydride copolymer, 1 to 10 parts of cellulose acetate butyrate, 1 to 10 parts of methyl isobornyl acrylate, 1 to 5 parts of impact modifier and 50 to 70 parts of solvent. According to the coloring layer coating disclosed by the invention, the impact modifier is added into the formula ingredients, so that paint film toughness is effectively improved; meanwhile, the coloring layer coating has the characteristics of moderate viscosity, good adhesion with aluminum layers, simple production technology easy to control, stable quality, convenience in long-time storageand the like; a coloring layer paint film of alumite containing the coloring layer coating has the characteristics of high glossiness, large hardness, toughness, wear resistance and the like.

Owner:云南玉溪东魅包装材料有限公司

Surface protection film with low unwind force

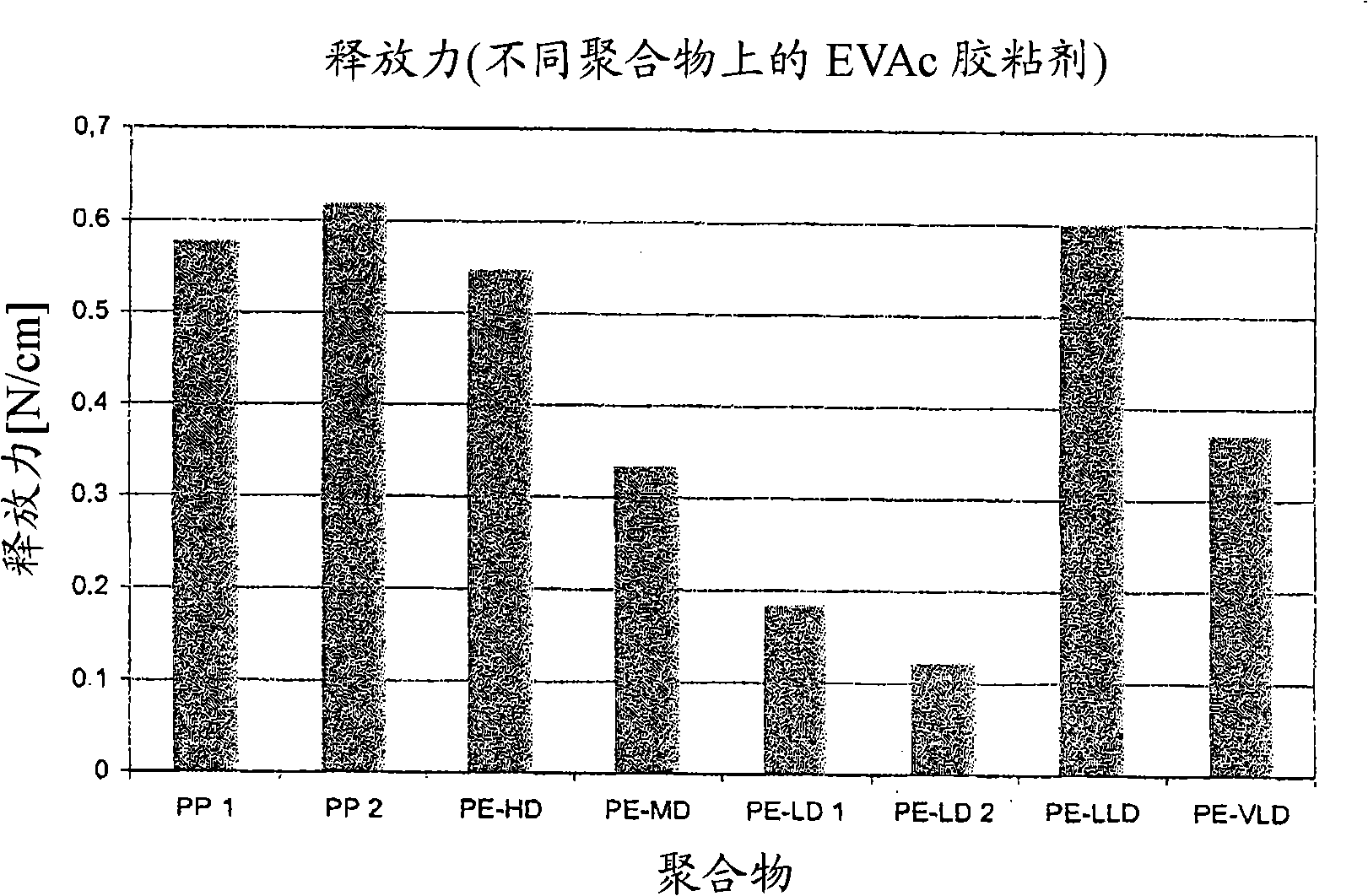

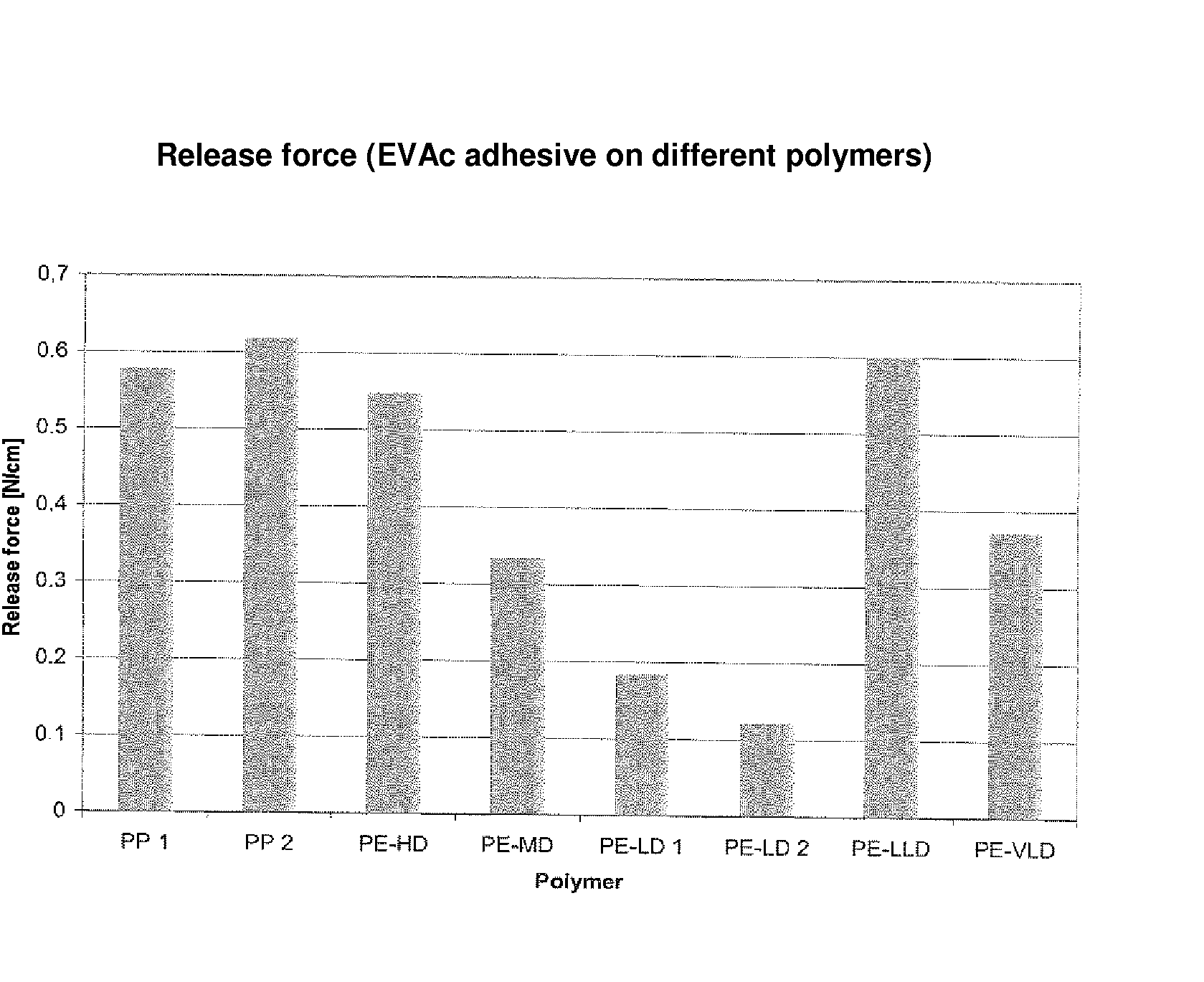

InactiveUS20080202663A1Bond strength of the protective film may be characterized more effectivelyMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsLow-density polyethyleneEngineering

The invention relates to a self-adhesive protective film composed of a backing to one side of which an adhesive is applied, characterized in that the backing has at least two layers: a first layer, facing the adhesive, comprising an unoriented film which comprises at least one propylene block copolymer with an amount of 10% to 95% (w / w), and a second layer, facing away from the adhesive, comprising a film which contains at least 75% (w / w), preferably at least 80% (w / w), of a low-density polyethylene.

Owner:TESA SE

Pressure-sensitive adhesive sheet for processing

InactiveUS20080248296A1Increase expansibilityMaintain good propertiesNon-macromolecular adhesive additivesFilm/foil adhesive primer layersVitrificationGlass transition

The present invention relates to a pressure-sensitive adhesive sheet for processing, which includes a substrate; a pressure-sensitive adhesive layer containing a radiation-polymerizable compound; and an interlayer containing an acrylic polymer having a glass transition temperature of 20° C. or higher as a main component, the interlayer being disposed between the substrate and the pressure-sensitive adhesive layer. The pressure-sensitive adhesive sheet of the invention is excellent in pressure-sensitive adhesive properties, releasability, and expansibility.

Owner:NITTO DENKO CORP

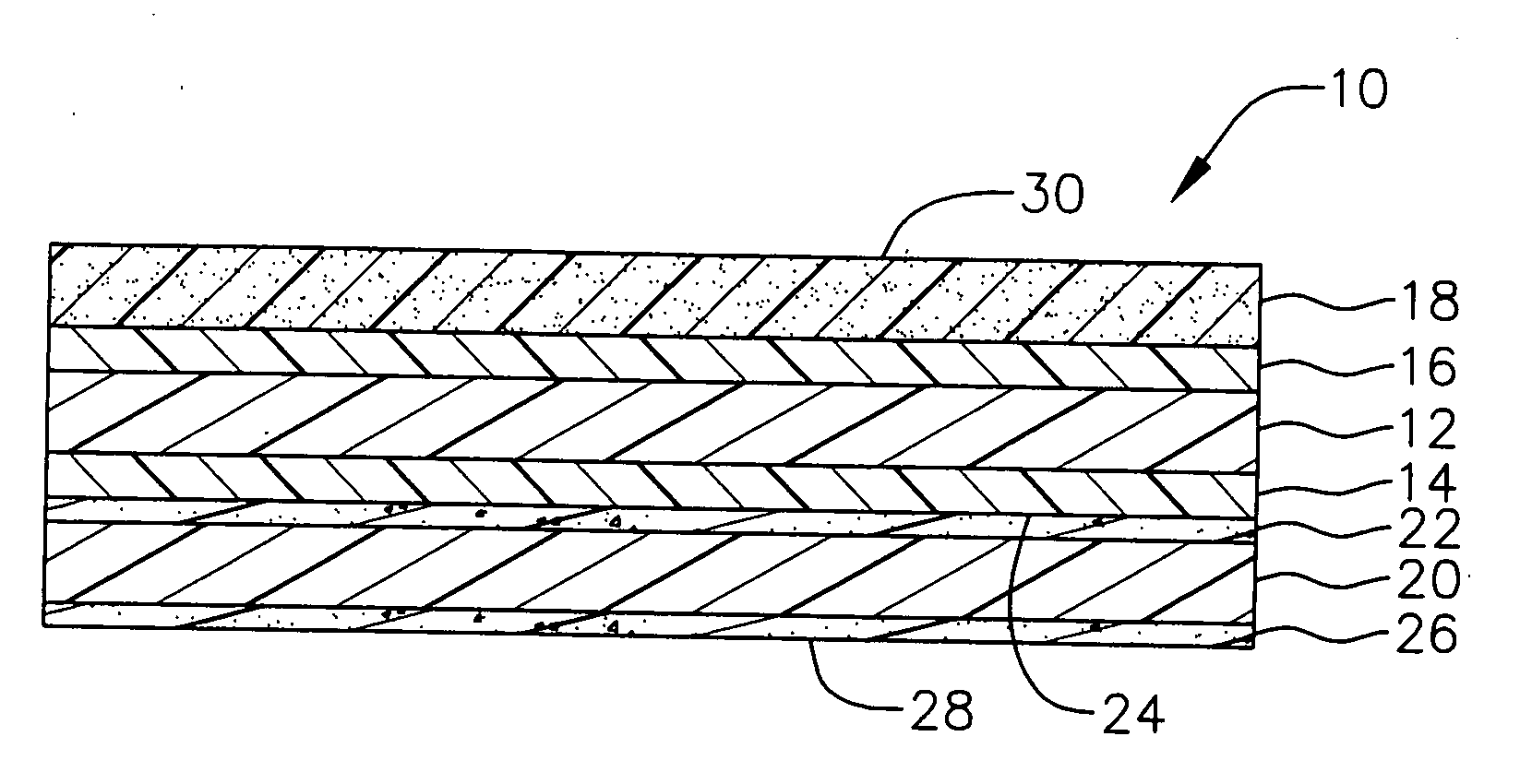

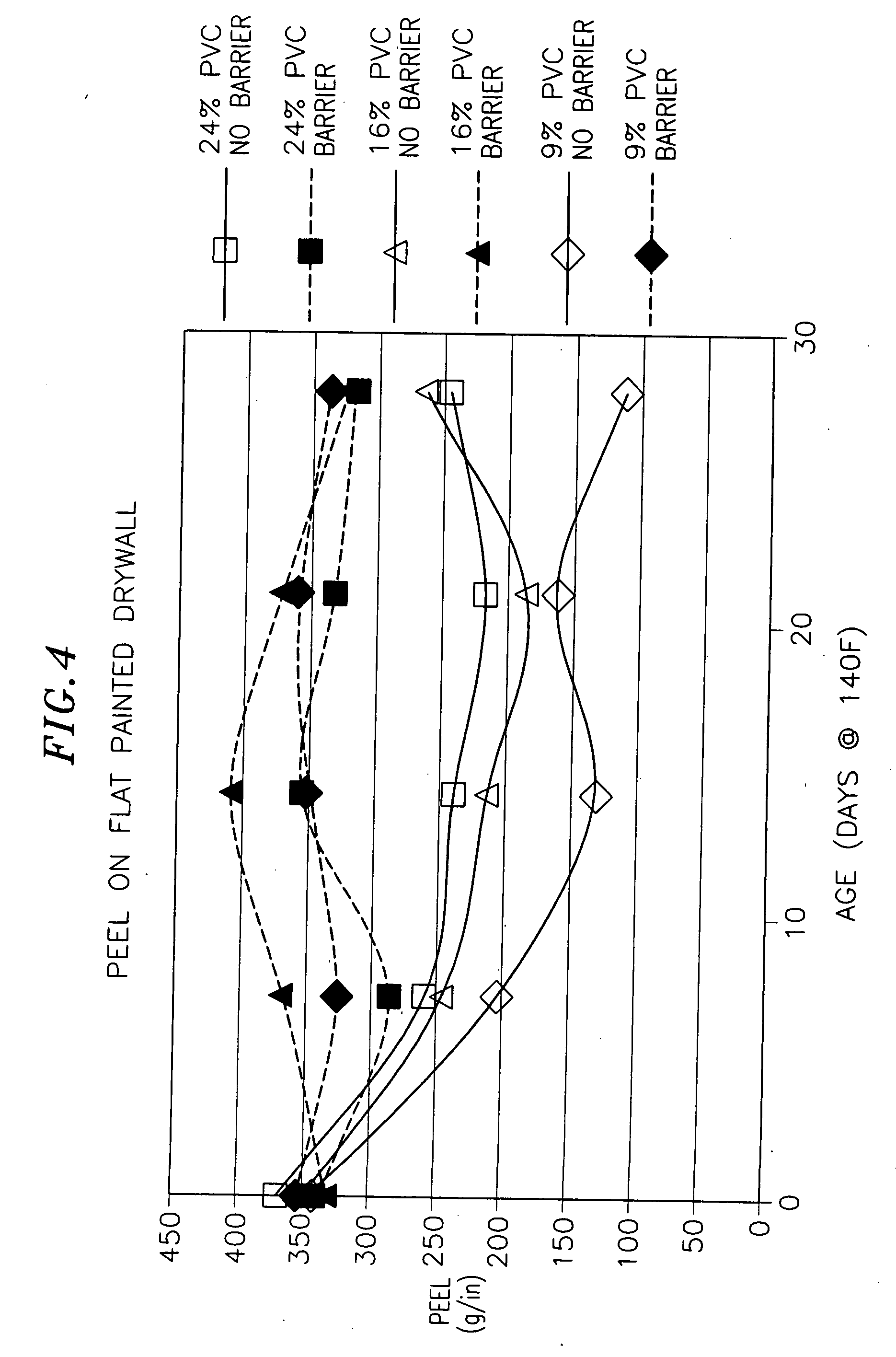

Multi-layer dry paint decorative laminate having discoloration prevention barrier

InactiveUS20070154671A1Slow and stop discolorationSlow orCovering/liningsFilm/foil adhesive primer layersEmulsionLacquer

A decorative dry paint wall film includes a layer of dry paint, a pressure-sensitive adhesive layer on one side of the dry paint layer, and a release liner in releasable contact with the dry paint layer on a side opposite from the pressure-sensitive adhesive (PSA). The release liner has a matte release coat layer that contacts the dry paint layer. The release liner is released from the dry paint layer after the PSA side is attached to a wall. The matte release coat transfers a matte finish to the dry paint layer when the release liner is removed. The wall film includes a barrier layer to protect against significant discoloration of the color in the dry paint layer caused by migration of azo-type pigments from a painted wall surface. The barrier layer in one embodiment comprises a dry emulsion containing ethylene-vinyl alcohol and a dispersed polymeric material which in one embodiment comprises a urethane material.

Owner:PROCTER & GAMBLE CO

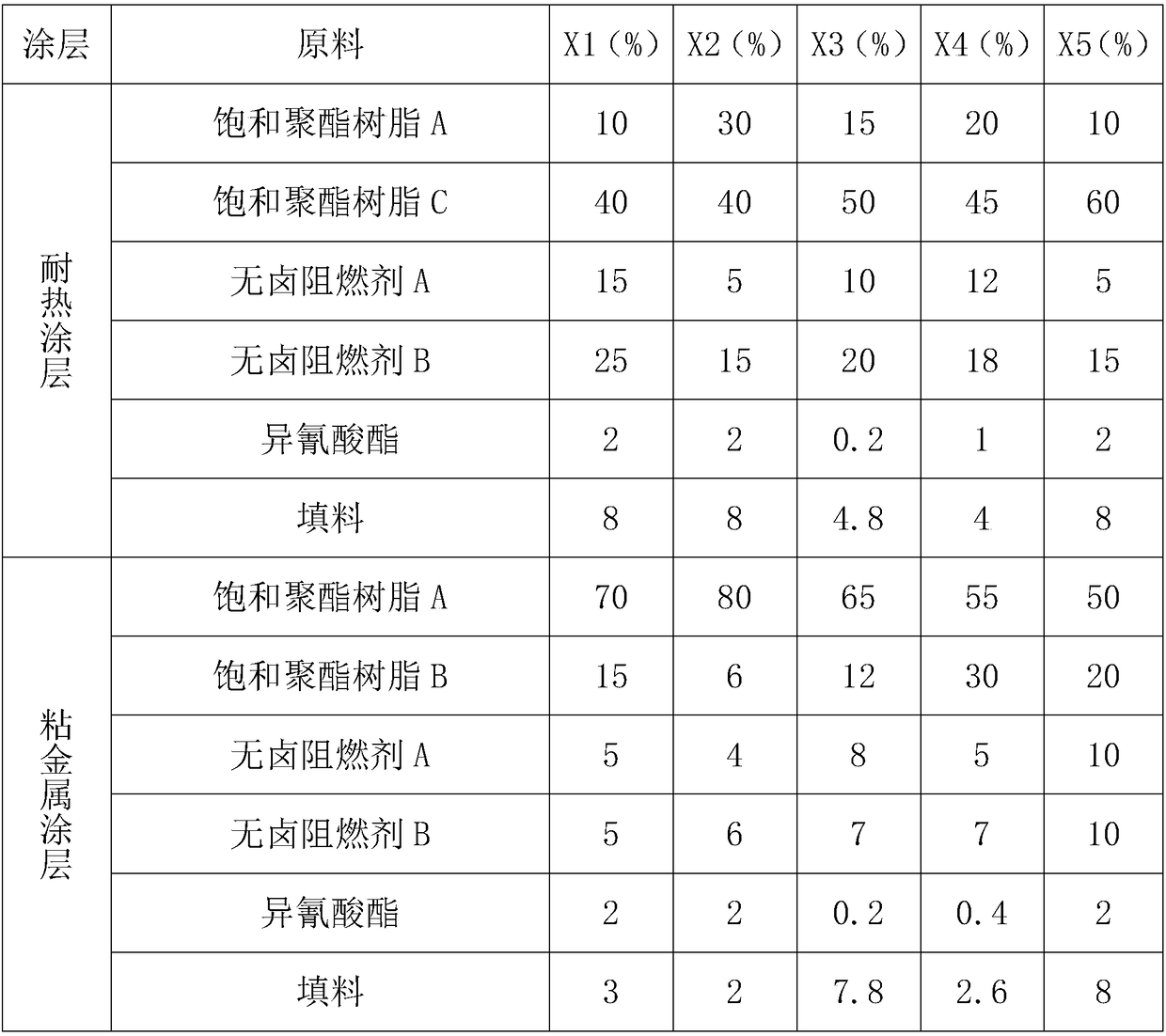

Halogen-free hot-melt adhesive film with high metal-bond force and good fire resistance and preparing method thereof

InactiveCN108084902AReduces total solvent residueFireproof paintsNon-macromolecular adhesive additivesHalogenBond coating

The invention discloses a halogen-free hot-melt adhesive film with high metal-bond force and good fire resistance and a preparing method thereof. The halogen-free hot-melt adhesive film comprises a polyester film, a refractory coating and a metal-bond coating, wherein the refractory coating is arranged between the polyester film and the metal-bond coating; the metal-bond coating is prepared from,by mass, 50-80% of saturated polyester resin A, 5-30% of saturated polyester resin B, 4-10% of halogen-freefire retardant A, 6-10% of halogen-freefire retardant B, 0.2-2% of isocyanate and 0.5-8% of filler. The polyester film serves as a base film and is coated with the refractory coating and the metal-bond coating, the metal-bond coating arranged on the outer layer has high bonding force for metal, the refractory coating arranged on the inner layer has high fire resistance, accordingly the fire resistance is improved, and the halogen-free hot-melt adhesive film still has high metal-bond forcefor wrapped tinned flat copper wires at the same time.

Owner:广东莱尔新材料科技股份有限公司

Method for producing pressure-sensitive adhesive layer-carrying optical film

InactiveUS20130330544A1Improve wettabilityProduction of binder-derived contaminants can be suppressedFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesPolymer scienceOptical thin film

A method for producing a pressure-sensitive adhesive layer-carrying optical film includes at least: an adhesion facilitating treatment step comprising performing an adhesion facilitating treatment on a surface of the optical film where the anchor layer is to be formed, before a step of forming the anchor layer is performed; and an application step comprising applying an anchor layer-forming coating liquid to the surface of the optical film having undergone the adhesion facilitating treatment, wherein the anchor layer-forming coating liquid contains a mixed solvent, a binder resin, and a polyoxyalkylene group-containing polymer, and the mixed solvent contains 65 to 100% by weight of water and 0 to 35% by weight of an alcohol or contains 0 to 35% by weight of water and 65 to 100% by weight of an alcohol.

Owner:NITTO DENKO CORP

Preparation method of hot melt adhesive film for vehicle flexible flat cable (FFC) wire and hot melt adhesive film

ActiveCN109536078ANon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAnti-Adhesion Agent

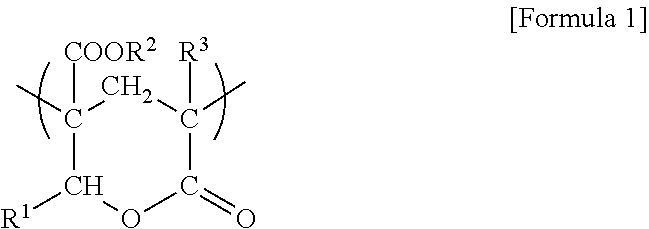

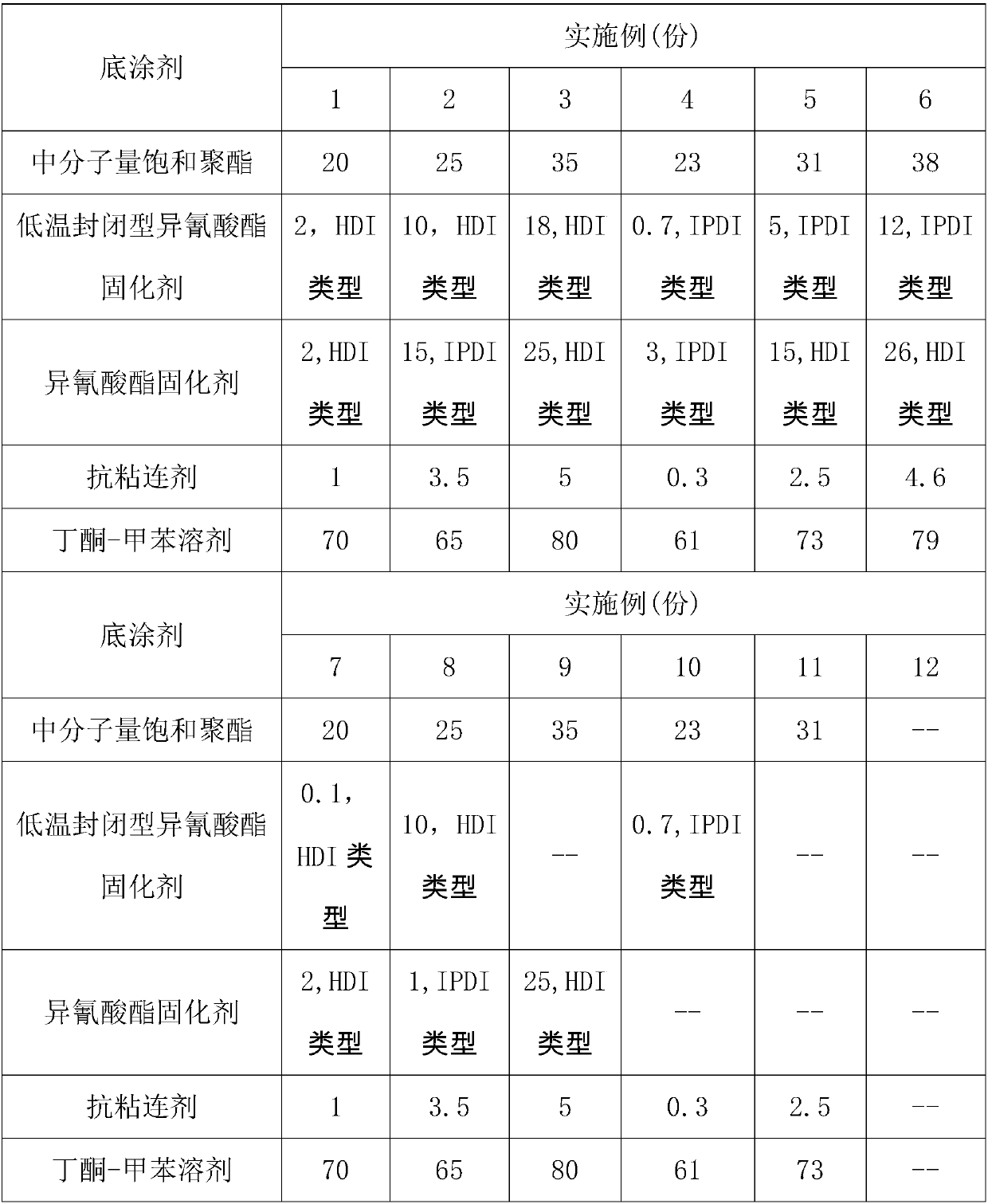

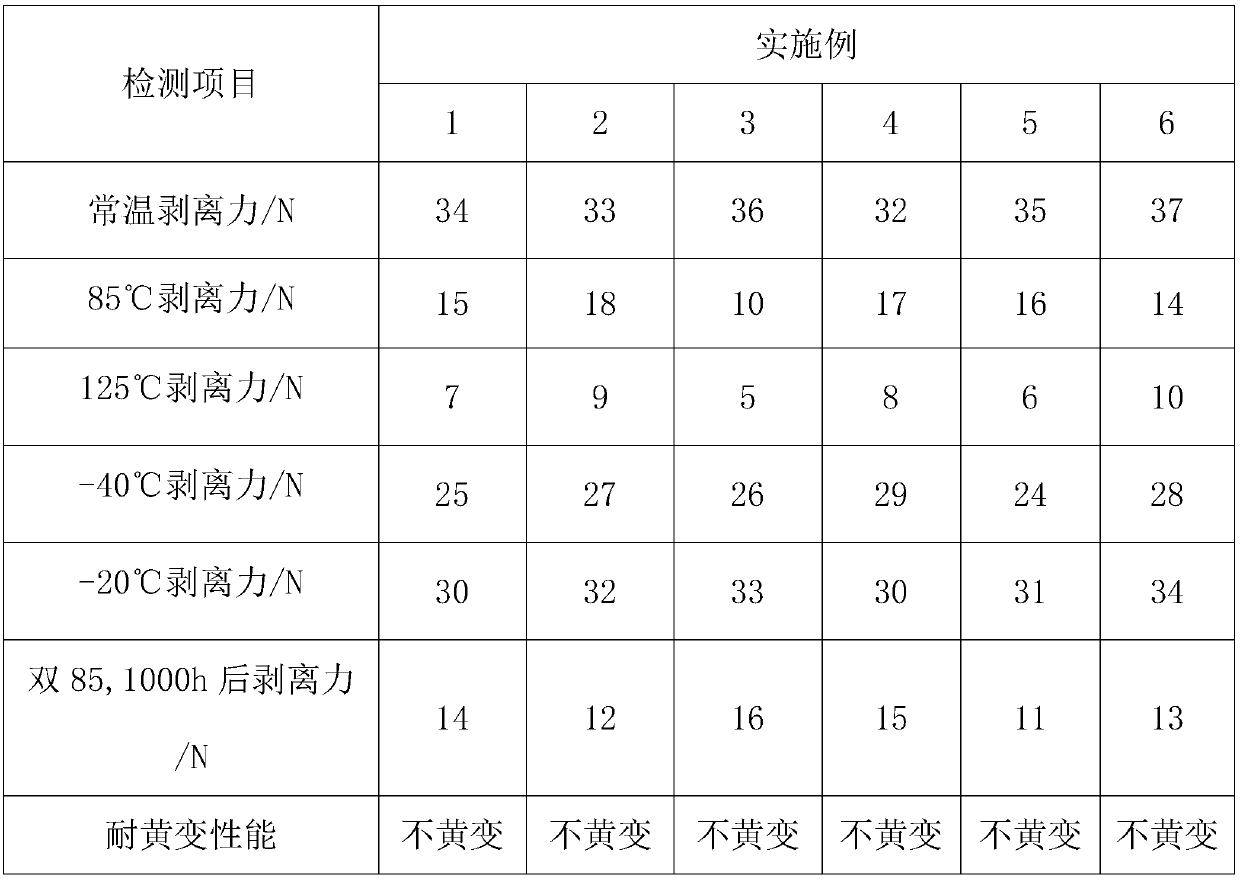

The invention discloses a preparation method of a hot melt adhesive film for a vehicle flexible flat cable (FFC) wire and the hot melt adhesive film. The preparation method comprises the following steps: A, preparing a primer coating agent: step A1, adding 20-40 parts by mass of medium-molecular-weight saturated polyester and 60-80 parts by mass of a butanone-toluene solvent into a reaction kettle, and carrying out dissolving by stirring, wherein the stirring speed is 500-1000 r / min; and step A2, after the mixture in the reaction kettle in the step A1 is uniformly dissolved by stirring, carrying out cooling to the room temperature, then adding 0.1-5 parts by mass of an anti-adhesion agent and 0.5-20 part by mass of a low-temperature closed isocyanate curing agent, and uniformly carrying out dispersing by stirring. The low-temperature closed isocyanate curing agent is added into the primer coating agent, so that chemical cross-linking of the primer coating agent to a polyethylene terephthalate PET polyester film and a hot melt adhesive is increased, and the adhesive force of the primer coating agent to the PET polyester film and the hot melt adhesive under a high-temperature condition and a low-temperature condition is improved. A closed type latent curing agent is adopted in the hot melt adhesive, so that the cross-linking degree and cohesion of the hot melt adhesive are increased, heat resistance and hydrolysis resistance are improved, cracking of the hot melt adhesive is avoided, and blistering and layering between the PET polyester film and the hot melt adhesive are avoided.

Owner:广东莱尔新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com