Anchor-layer-forming coating liquid, adhesive layer-carrying optical film and method for producing the film

A technology of optical film and adhesive layer, which is applied in the direction of film/sheet adhesive, device for coating liquid on the surface, optics, etc. It can solve the problem of solvent cracks in optical films, the influence of optical properties, and the inability to meet high durability requirements. problems such as resistance, to achieve the effect of inhibiting the decrease of monomer transmittance, reducing the content, and improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

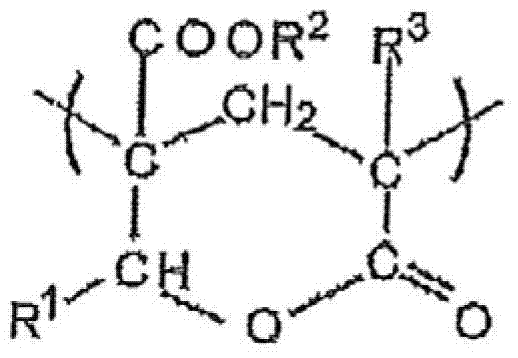

Method used

Image

Examples

Embodiment 1

[0159] Production of optical films (polarizing films)

[0160] Polarizer

[0161] A polyvinyl alcohol film having an average degree of polymerization of 2400 and a degree of saponification of 99.9 mol % and a thickness of 75 μm was immersed in warm water at 30° C. for 60 seconds to swell. Next, the film was immersed in an aqueous solution of iodine / potassium iodide (weight ratio = 0.5 / 8) with a concentration of 0.3%, and the film was dyed while being stretched to 3.5 times. Then, it stretched so that the total stretch ratio might become 6 times in the borate ester aqueous solution of 65 degreeC. After stretching, drying was performed in an oven at 40° C. for 3 minutes to obtain a PVA-based polarizer (thickness: 23 μm).

[0162] Transparent protective film

[0163] As the transparent protective film, a triacetate cellulose film (TAC) having a thickness of 80 μm was used without saponification and corona treatment (hereinafter, TAC without saponification and corona trea...

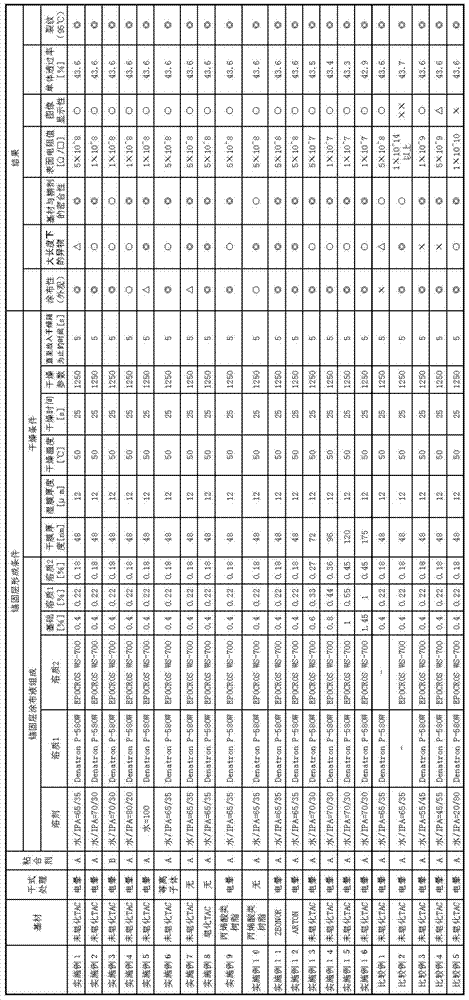

Embodiment 2~16 and comparative example 1~5

[0187] In the optical film (polarizing film), the type of transparent protective film on the side on which the anchor layer is formed (the side on which the pressure-sensitive adhesive layer is laminated) is laminated (the side opposite to the side on which the pressure-sensitive adhesive layer is laminated) It was produced by the same method as in Example 1, except that there are unsaponified TAC films), base concentration, mixed solvent composition, type of binder solution, and / or binder composition as shown in Table 2 Optical film with adhesive layer.

[0188] In Table 2, "substrate" represents the transparent protective film on the anchor layer forming surface side, "dry treatment" represents the type of treatment performed on the anchor layer forming surface side of the substrate, and,

[0189] "Unsaponified TAC" means an optical film (manufactured by Konica Minolta, Inc.) formed of unsaponified cellulose triacetate,

[0190] "Saponified TAC" means an optical film (manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com