High performance repairing adhesive tape used for photovoltaic module backboards, and preparation method thereof

A photovoltaic module and repair tape technology, applied in photovoltaic modules, photovoltaic power generation, adhesive products, etc., can solve the problems of backplane yellowing, high cost, functional failure, etc., and achieve small peeling force attenuation and high bonding strength , Improve the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

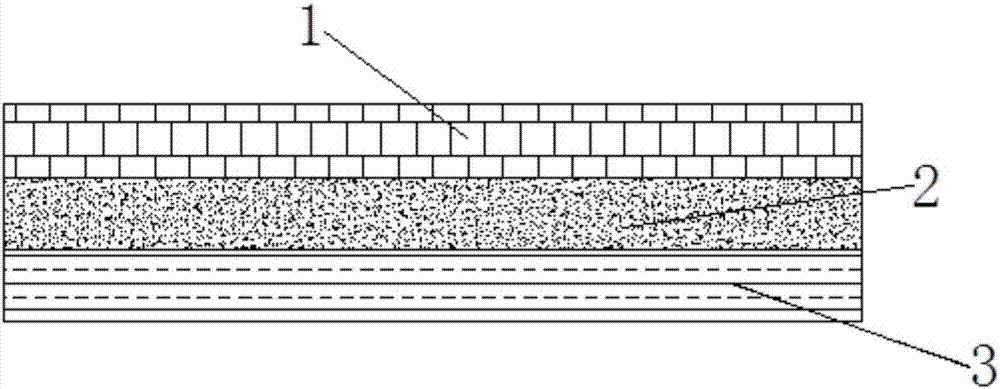

[0030] Such as figure 1 As shown, a high-performance repair tape for a photovoltaic module backplane in this embodiment includes a substrate layer 1, a functional adhesive layer 2, and a release material layer 3 arranged in sequence from top to bottom, and the substrate layer 1 is 300 μm The composite polyester film consists of a core layer in the middle and a weather-resistant polymer film pasted on both sides of the core layer. The core layer is a polyester film, and the weather-resistant polymer film is a fluorine film. The fluorine film is a 50 μm polyester film Vinylidene fluoride (PVDF). The functional adhesive layer 2 includes acrylic pressure-sensitive adhesive, the added curing agent is epoxy curing agent, the tackifying resin is rosin, the antioxidant is aromatic amine antioxidant, and the ultraviolet absorber is salicylate ultraviolet absorber.

[0031] According to the preparation method of any one of the above-mentioned high-performance repair tapes for photovolt...

Embodiment 2

[0036] Such as figure 1 As shown, a high-performance repair tape for a photovoltaic module backplane in this embodiment includes a substrate layer 1, a functional adhesive layer 2, and a release material layer 3 arranged in sequence from top to bottom, and the substrate layer 2 is 250 μm Composite polyester film, including a core layer in the middle, a weather-resistant polymer film pasted on one side of the core layer, and a polymer weather-resistant coating directly coated on the other side of the core layer. The core layer is nylon film, and the weather resistance The polymer film is a 50μm UV-resistant polyolefin film, and the polymer weather-resistant coating is formed by curing fluorocarbon resin to the surface of the core layer through a curing agent. The functional adhesive layer 2 is composed of acrylic pressure-sensitive adhesive and thermosetting structural adhesive. The added curing agent is epoxy curing agent and isocyanate curing agent. The tackifying resin is ro...

Embodiment 3

[0042] Such as figure 1 As shown, a high-performance repair tape for a photovoltaic module backplane in this embodiment includes a base material layer 1, a functional adhesive layer 2, and a release material layer 3 arranged sequentially from top to bottom, and the base material layer 1 is coated Covered polyester film, including a core layer in the middle, and coatings directly coated on both sides of the core layer; the core layer is a high-barrier film, and the coating includes organic resins, curing agents and inorganic fillers. The organic resin is fluorine Silicone resin, curing agent is isocyanate curing agent, inorganic filler is titanium dioxide. The functional adhesive layer 2 is a polyurethane pressure-sensitive adhesive, the added curing agent is an imidazole curing agent, the tackifying resin is a terpene resin, the antioxidant is an auxiliary antioxidant, and the ultraviolet absorber is a benzotriazole ultraviolet absorber.

[0043] According to the preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com