Patents

Literature

1344results about How to "Good yellowing resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

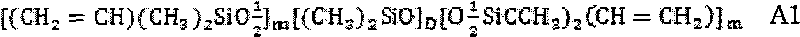

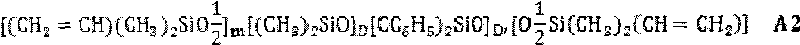

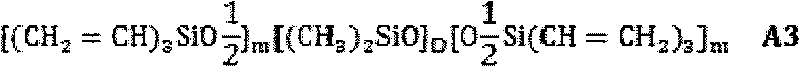

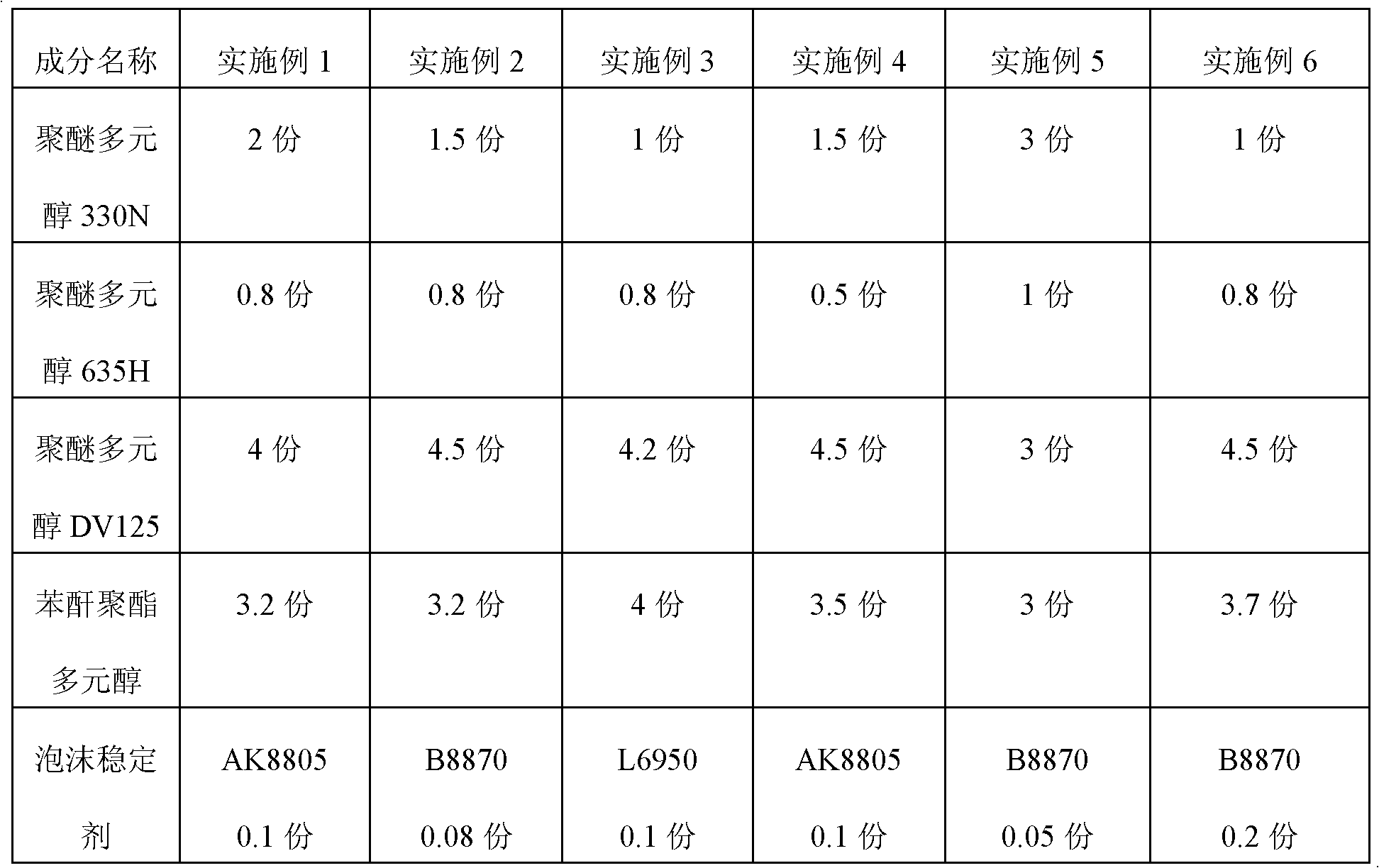

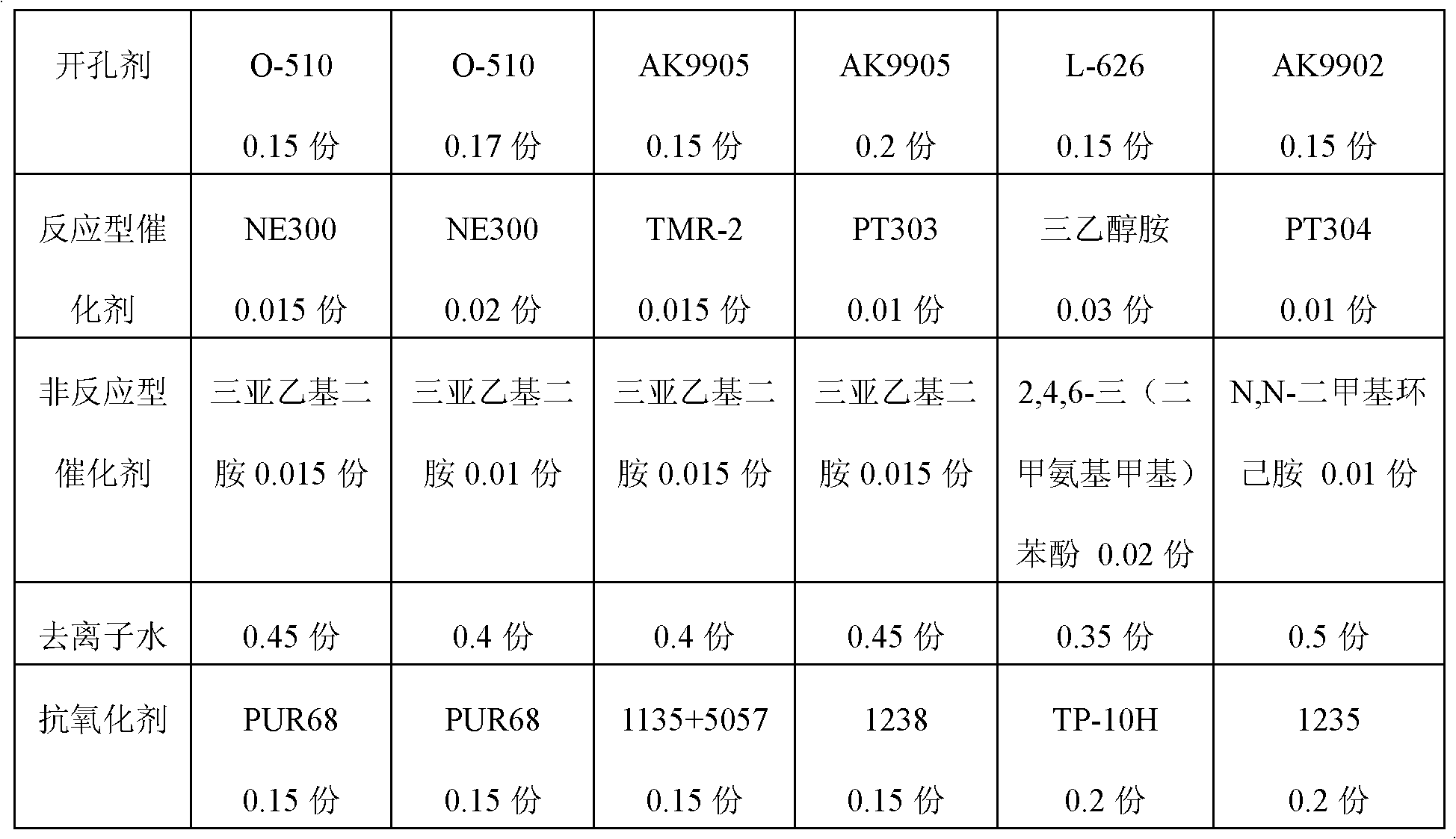

Composite polyether, polyurethane rigid foam as well as raw material composition and usage thereof

InactiveCN102093527AGood dimensional stabilityGood resistance to yellowingPolyesterBenzoic anhydride

The invention relates to a composite polyether which comprises 1-3 parts of polyether polyol 330N, 0.5-1 part of polyether polyol 635H, 3-5 parts of polyether polyol DV125, 3-4 parts of benzoic anhydride polyester polyol, 0.05-0.2 part of foam stabilizer, 0.05-0.2 part of cell opener, 0.02-0.1 part of polyurethane synthetic catalyst and 0.3-0.5 part of water. The invention also relates to polyurethane rigid foam as well as a raw material composition and usage thereof. The polyurethane rigid foam material can simultaneously have excellent cell opening property, size stability, bending strength and compression mildness, thus the polyurethane rigid foam material has the effects of light weight, heat isolation, sound absorption and the like and can well meet use requirements of car roof foam. Besides, the polyurethane rigid foam also has excellent yellowness resistance and prolonged service life.

Owner:SHANGHAI DONGDA POLYURETHANE

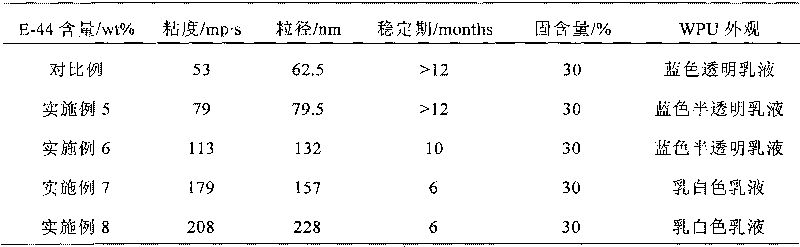

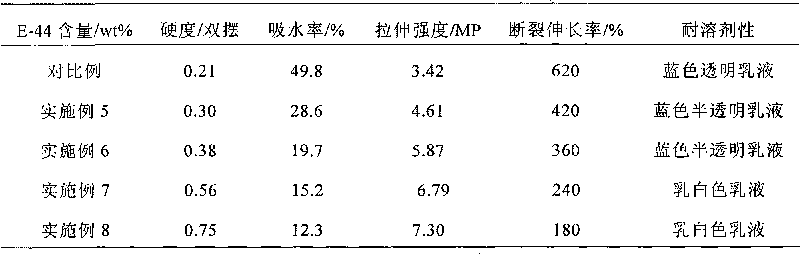

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

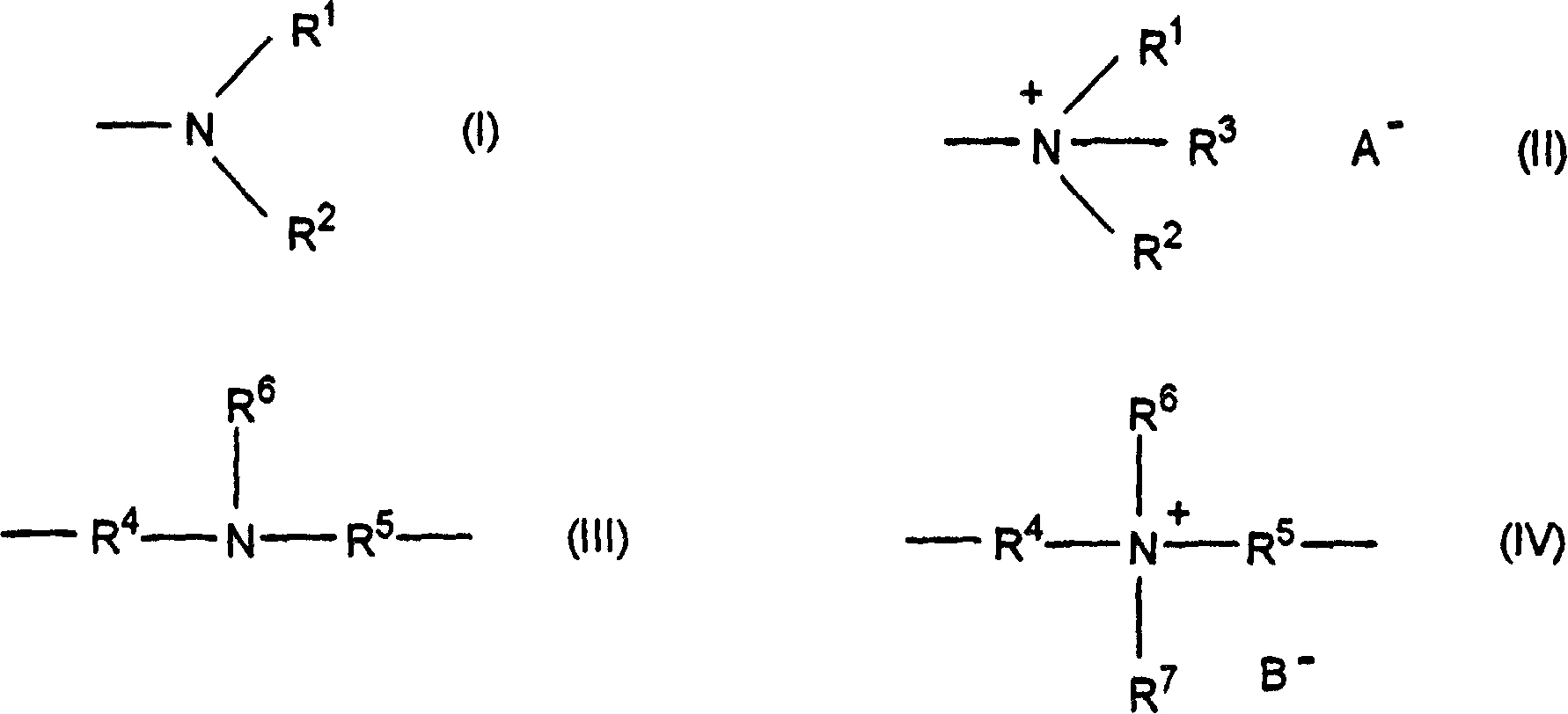

Surface treatment agent for metal, surface treatment method for metallic material, and surface-treated metallic material

InactiveCN101048476AImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsMetallic material coating processesVanadium CompoundsEmulsion

An agent for treating metal surfaces which comprises an aqueous medium and, incorporated therein, (A) a cationic urethane resin which is water-soluble or in an aqueous emulsion form, (B) a cationic polycondensation product obtained from a phenol compound and an aldehyde, and (C) a zirconium compound and / or titanium compound. A coating film formed from the treating agent imparts excellent corrosion resistance and alkali resistance to a metallic material. When the proportion of the urethane resin (A) is equal to or higher than that of the polycondensation product (B), yellowing resistance can be also imparted. By incorporating a metal compound (D) containing a specific metal, excellent blacking resistance also can be imparted. Furthermore, by incorporating an acid ingredient (E) and a vanadium compound (F), a further improvement in performances can be attained.

Owner:NIHON PARKERIZING

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

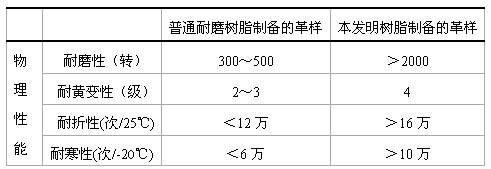

Cold-resistant high-wear-resistant polyurethane resin for synthetic leather

ActiveCN102060973AImprove wear resistanceGood yellowing resistanceFibre treatmentPolyurethane elastomerAlcohol

The invention belongs to polyurethane elastomeric materials, and particularly relates to a cold-resistant high-wear-resistant polyurethane resin for synthetic leather. The technical scheme is as follows: the cold-resistant high-wear-resistant polyurethane resin for synthetic leather is characterized by mainly comprising isocyanate, polyalcohol compound, reactive silicone oil, alcohol chain extender of which the molecular weight is lower than 150, and solvent. By using the scheme, the invention overcomes the defects in the prior art, and provides a novel cold-resistant high-wear-resistant polyurethane resin for synthetic leather.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Polyurethane matt woodenware paint

InactiveCN102382564AGood leveling by brushingImprove levelingPolyurea/polyurethane coatingsSOYBEAN SEED OILToluene diisocyanate

The invention discloses polyurethane matt woodenware paint. The polyurethane matt woodenware paint comprises a paint main agent component, a polyurethane curing agent component and a diluent component, wherein a weight ratio of the paint main agent component to the polyurethane curing agent component to the diluent component is 1: 0.5: 0.6. The paint main agent component comprises: by weight, 32.5 to 39 % of short-oil soybean oil alkyd resin, 9 to 15% of medium-oil castor oil alkyd resin, 2% of vinyl chloride-vinyl acetate copolymer, 3 to 5% of flatting powder and 0.3 to 1.0% of polyethylene wax. The polyurethane curing agent component comprises: by weight, 30 to 40% of toluene diisocyanate trimer and the balance an addition product of toluene diisocyanate and trimethylol propane. The diluent component comprises: by weight, 70 to 80% of butyl acetate, 10 to 20% of propylene glycol monomethyl ether propionate and 10 to 15% of propylene glycol monoethyl ether acetate. The polyurethane matt woodenware paint has the advantages of good brush coating levelability, good mechanical properties, and environmentally friendly and health characteristics.

Owner:NIPPON PAINT CHENGDU

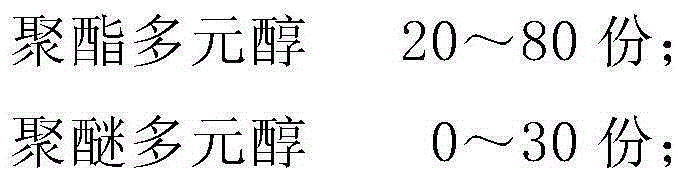

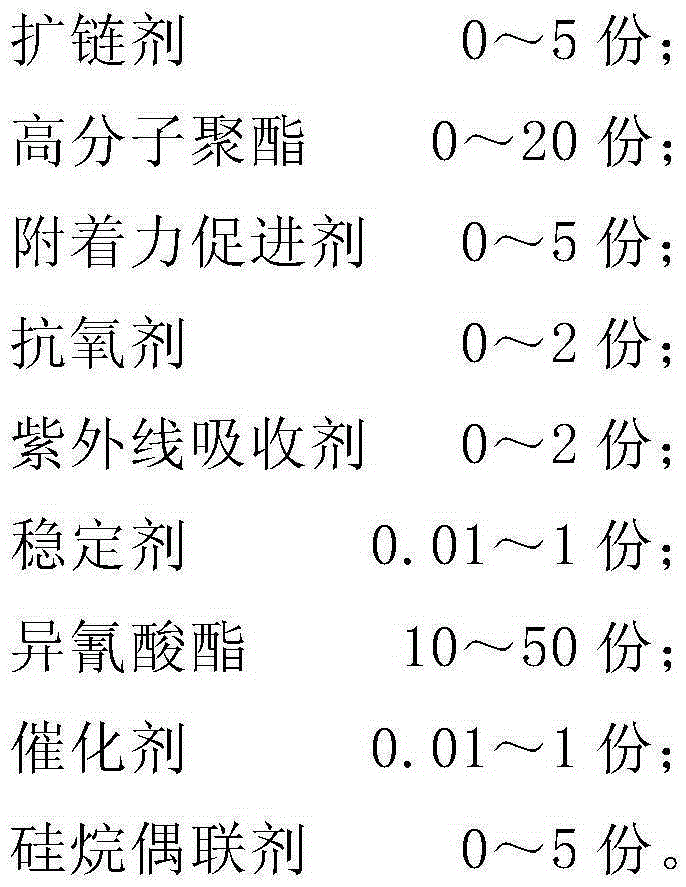

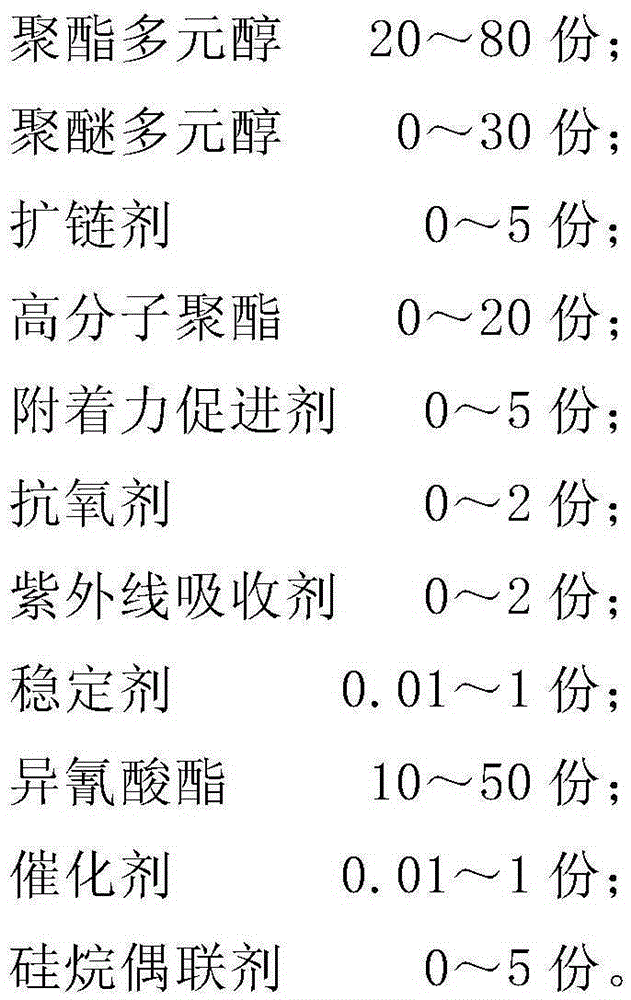

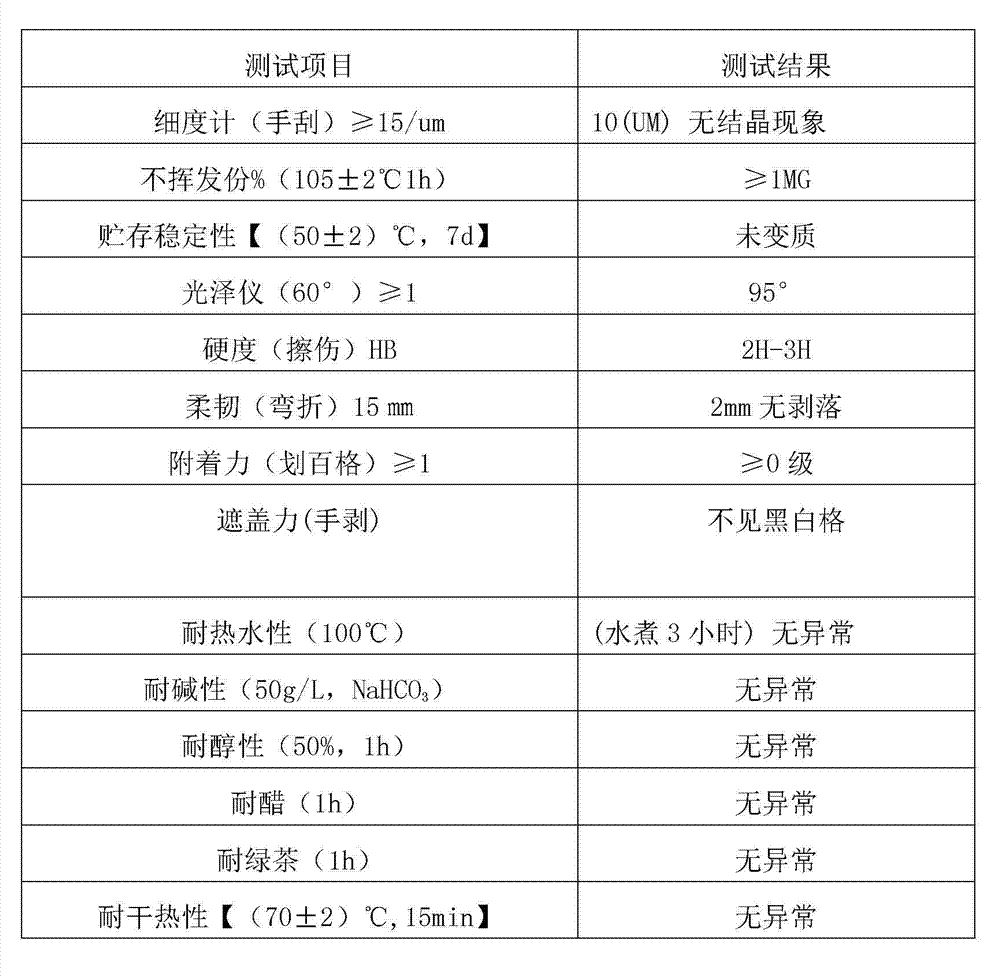

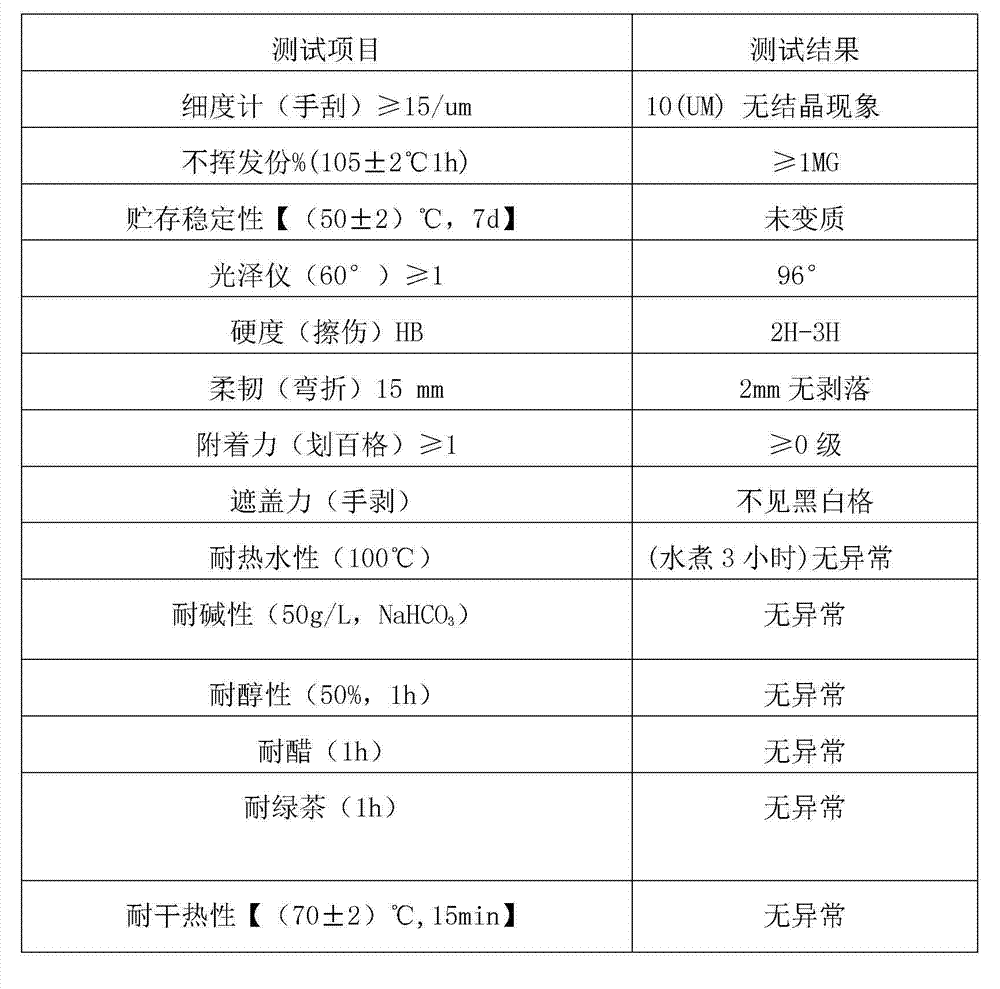

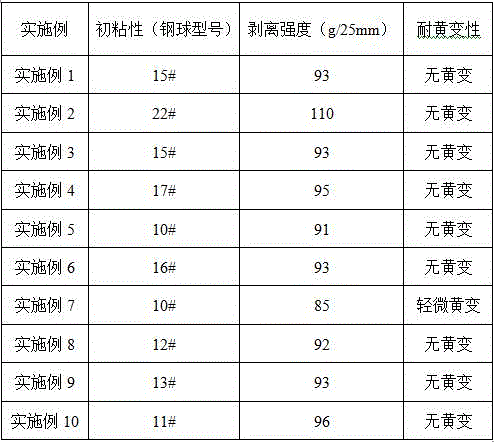

Reactive polyurethane hot melt adhesive for reflective fabric and preparation method thereof

ActiveCN105295815AImprove antioxidant capacityGood yellowing resistancePolyureas/polyurethane adhesivesSolventChemistry

The invention discloses a reactive polyurethane hot melt adhesive for a reflective fabric. The reactive polyurethane hot melt adhesive is prepared from polyester polyol, polyether polyol, a chain extender, high polymer polyester, an adhesion promoter, an anti-oxidant, an ultraviolet ray absorber, a stabilizing agent, isocyanate, a catalyst and a silane coupling agent. The invention also discloses a preparation method for the reactive polyurethane hot melt adhesive used for the reflective fabric. The reactive polyurethane hot melt adhesive for the reflective fabric has high initial-stage strength, good soft handle, good washing performance, solvent resistance, heat resistance, storage stability and excellent environmental protection performance and is applicable to bonding of a variety of materials including a reflective material.

Owner:康达新材料(集团)股份有限公司

White finish coat photocurable UV (ultraviolet) paint and preparation method thereof

ActiveCN103031034AHigh glossNot easy to yellowPolyurea/polyurethane coatingsEpoxy resin coatingsChemical industryReactive diluent

The invention belongs to the field of chemical industry, and particularly discloses white finish coat photocurable UV (ultraviolet) paint and a preparation method thereof. The photocurable UV paint comprises the following components in percentage by weight: 20-60% of epoxy acrylate, 20-60% of polyurethane acrylate, 2-5% of phenyl acetone photoinitiator, 0.2-1% of diphenyl phosphine oxide photoinitiator, 0.2-1% of dispersant, 0.2-1% of leveling agent, 1-40% of titanium white TiO2, 5-15% of two-functional-group reactive diluent and 5-30% of three-functional-group reactive diluent. The paint has the characteristics of favorable gloss, adhesive force and leveling property, thus ensuring that the white UV paint can be better applied.

Owner:AODA KOALA PAINT HUIZHOU

Two-component epoxy resin adhesive for stone skin patching and preparation thereof

ActiveCN101314704AHigh surface glossGood yellowing resistanceEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a double-component epoxy resin adhesive for repairing stone surface and the preparation method thereof. The double epoxy resin adhesive is composed of a component A consisting of epoxy resin and diluting agent, and a component B consisting of curing agent, optical stabilizer and UV absorber. The double-component epoxy resin adhesive is used for repairing microcrack on stone surface and ant road, and has the advantages of moderate curing speed, good yellowing-resistant performance, good permeability, high glossiness after cured and polished, easily-obtained environment-friendly material, simple process, etc.

Owner:HUNAN SHENLI IND

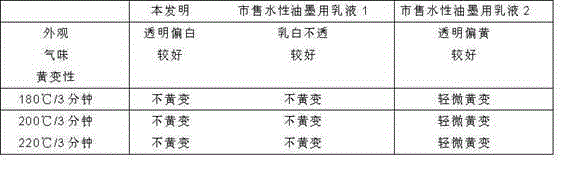

Water-based polyurethane elastomer emulsion, and preparation method and application thereof

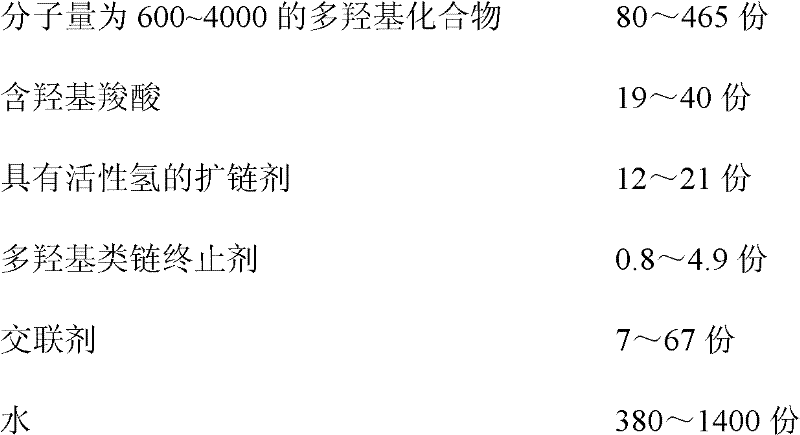

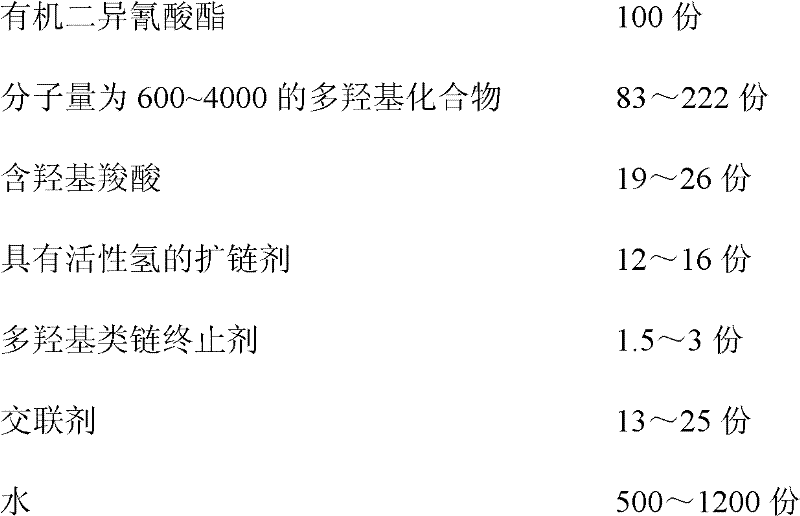

The invention discloses water-based polyurethane elastomer emulsion, and a preparation method and application thereof. The preparation method comprises the following steps of: (1) mixing organic diisocyanate, polyol with the molecular weight of 600-4,000, hydroxy carboxylic acid and an organotin-containing catalyst, and reacting at the temperature of between 60 and 90DEG C for 2 to 5 hours; (2) adding an active hydrogen-containing chain extender, and continuously reacting until a theoretical value of residual NCO percent is reached; (3) adding a polyhydroxy chain terminator to make the residual NCO percent equal to 0; (4) adding organic amine for neutralization reaction at the temperature of between 30 and 55DEG C, wherein the neutralization degree is 70 to 100 molar percent of hydroxy carboxylic acid; and (5) adding a crosslinking agent and water to obtain aqueous dispersion, namely the water-based polyurethane elastomer emulsion. Products prepared from the emulsion have low modulus, weak bondage feel, and high resistance to yellowing, and can be stably stored.

Owner:SHANGHAI HUAMING HI TECH GRP +1

Low-energy electron beam radiation curing coating and use method thereof

The invention discloses a low-energy electron beam radiation curing coating, which comprises the following components in percentage by weight: 40-90 percent of reactivity oligomer, 10-60 percent of reactivity monomer, 0.3-5 percent of additive, 0-30 percent of thermoplastic resin, 0-15 percent of photoinitiator and 0-30 percent of pigment and filler. The coating is particularly suitable for coating processing on substrate made of plastic or paper. A use method of the low-energy electron beam radiation curing coating comprises the following steps of: (a) printing at least one layer of the electron beam radiation curing coating on the plastic or paper substrate; (b) radiating the coating by adopting an electron beam of no more than 200+ / -10kV; or repeating the use steps. The coating has low cost and good environment protection property. The coating obtained by using the low-energy electron beam radiation curing coating has good abrasive resistance, scratching resistance and solvent resistance.

Owner:恒昌涂料(惠阳)有限公司

High-heat-conductivity white adhesive composition, high-heat-conductivity white cover film made from same and preparation method thereof

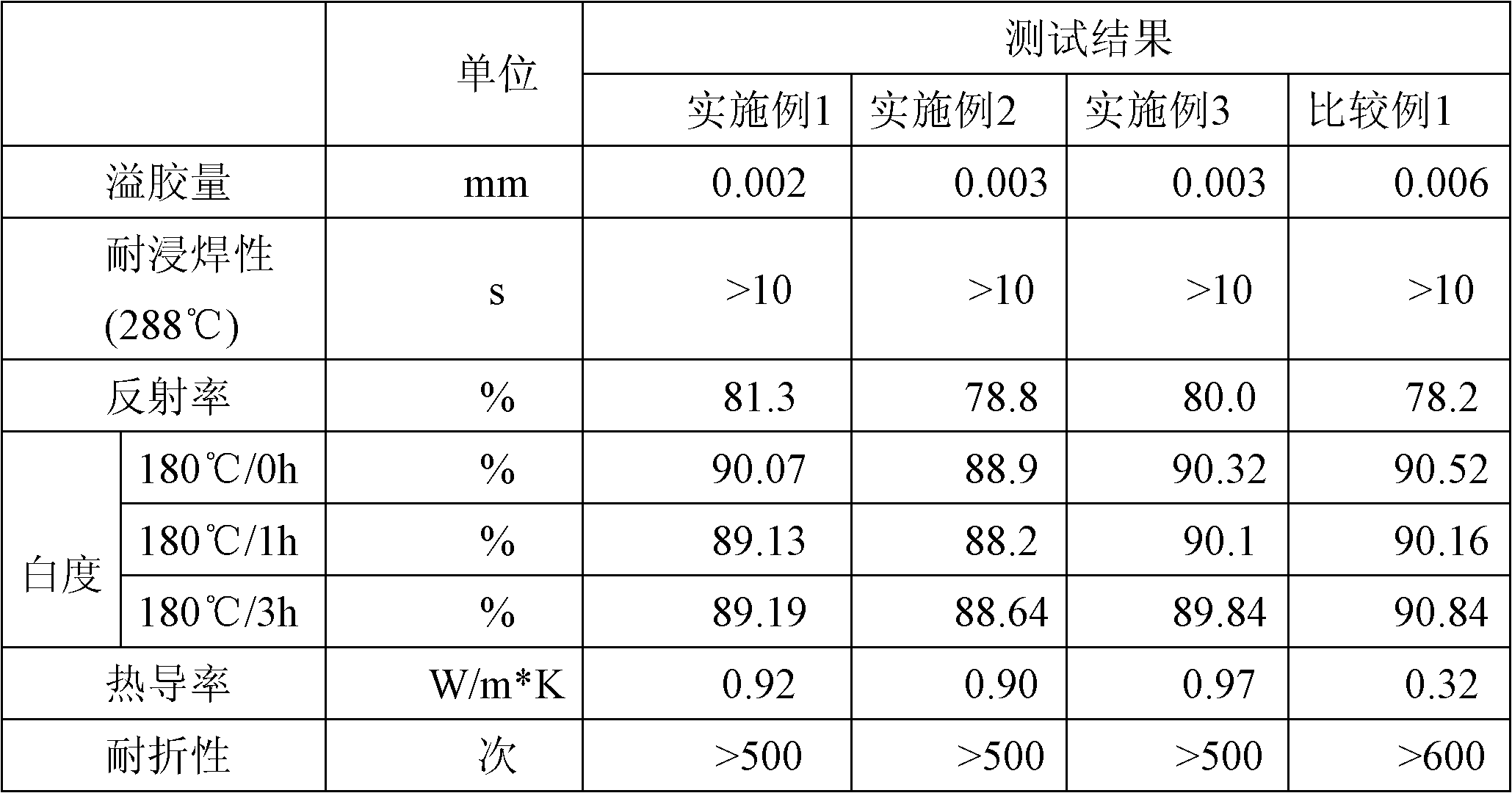

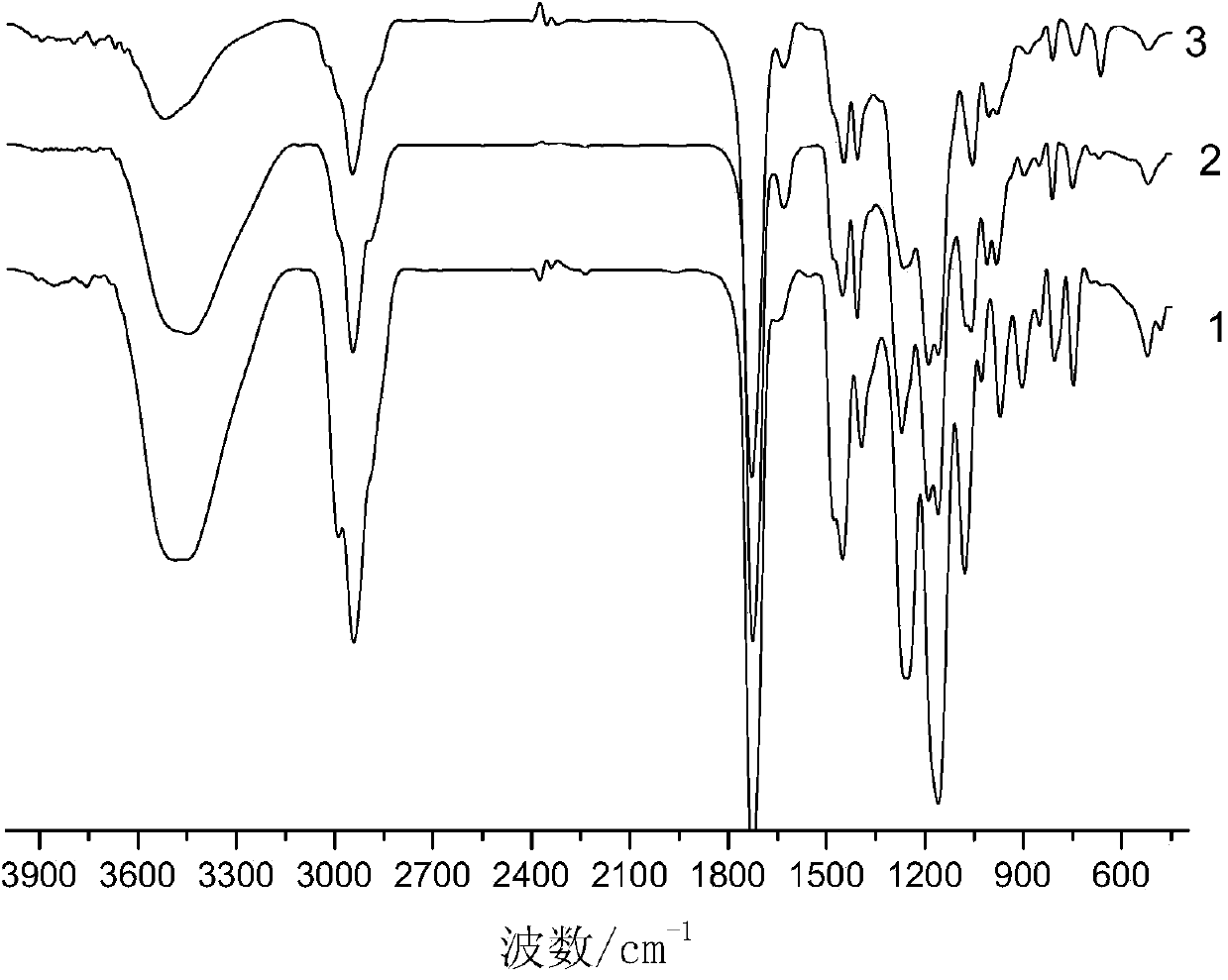

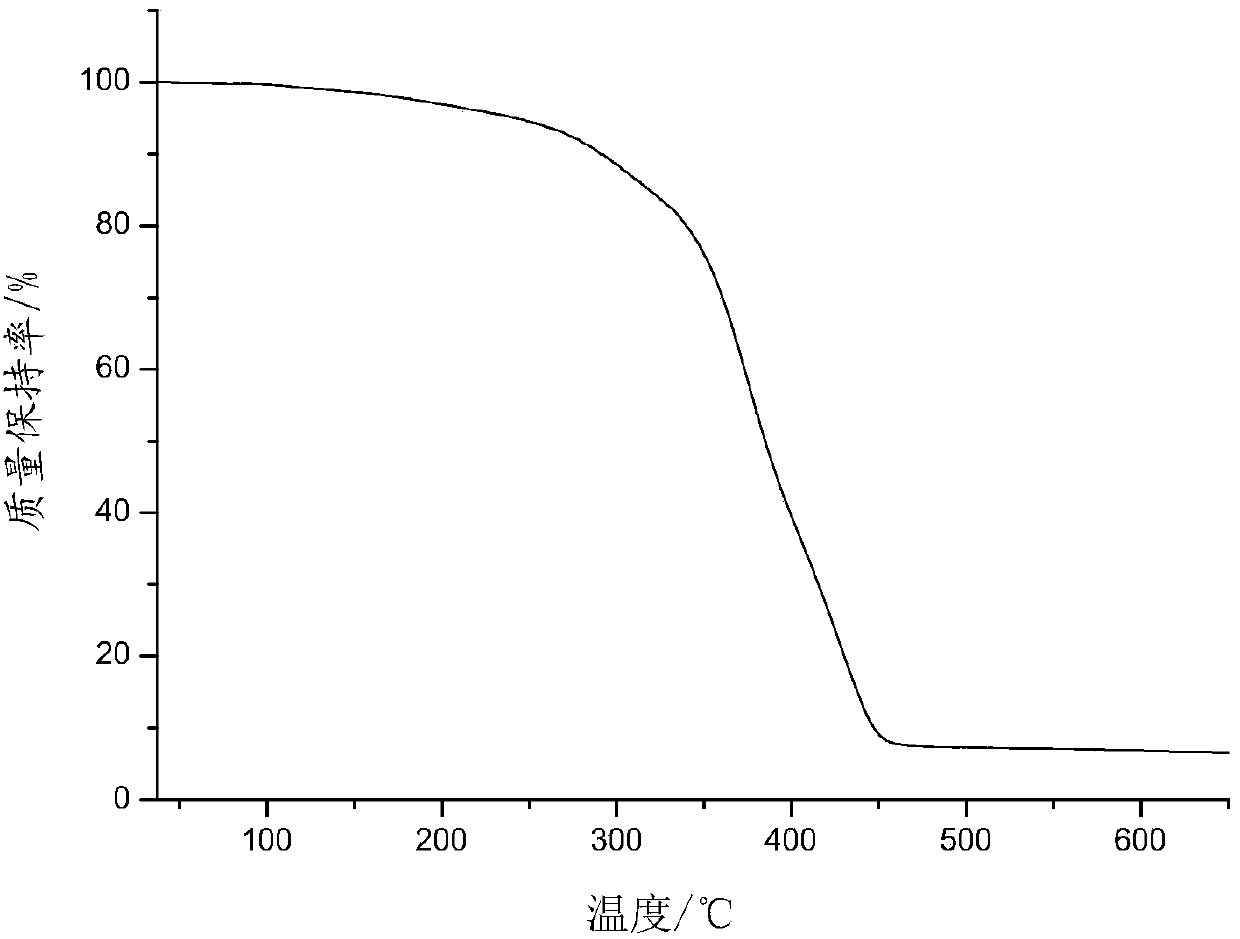

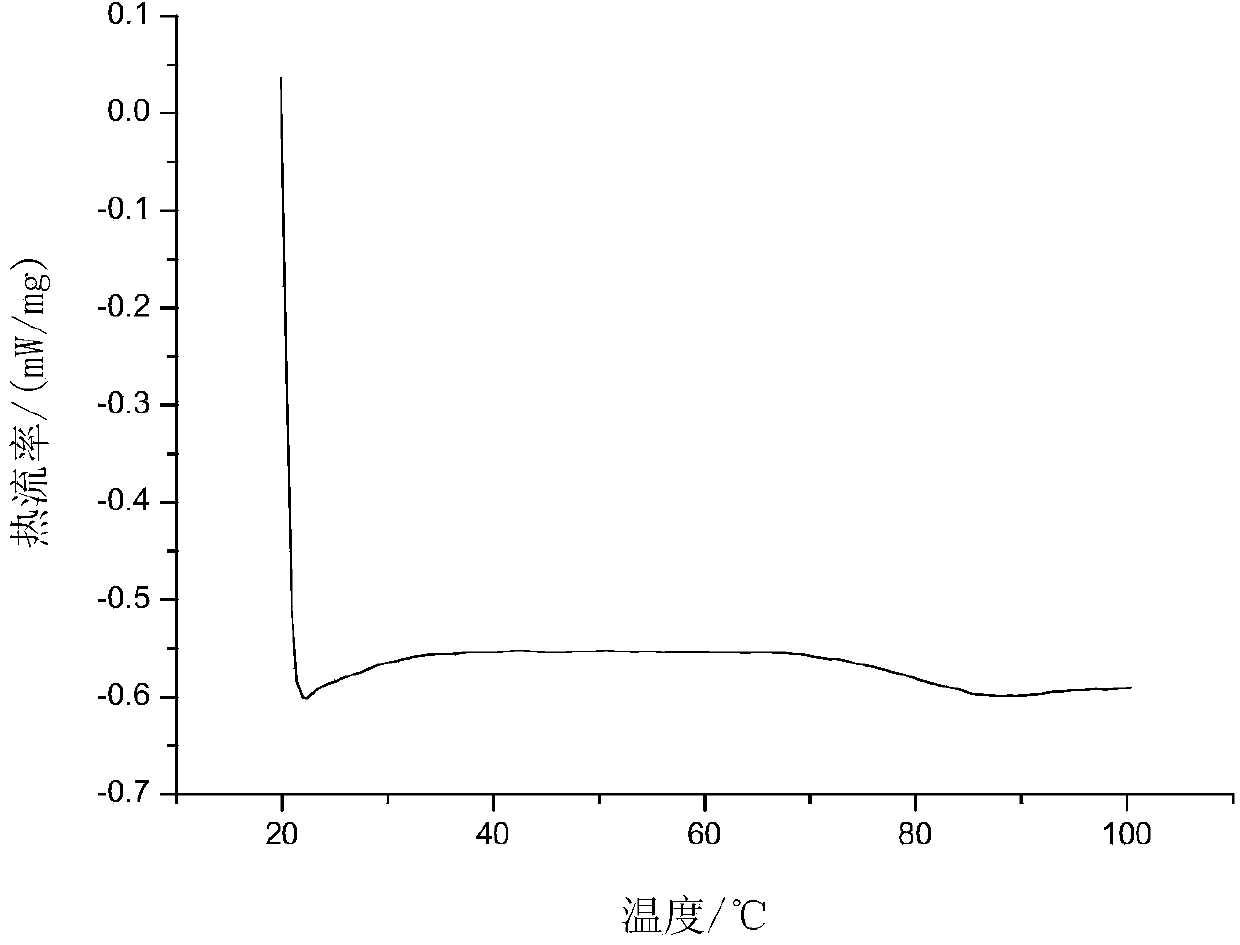

ActiveCN102079959AHigh whitenessImprove reflectivityPrinted circuit detailsFilm/foil adhesivesPolyesterAdhesive

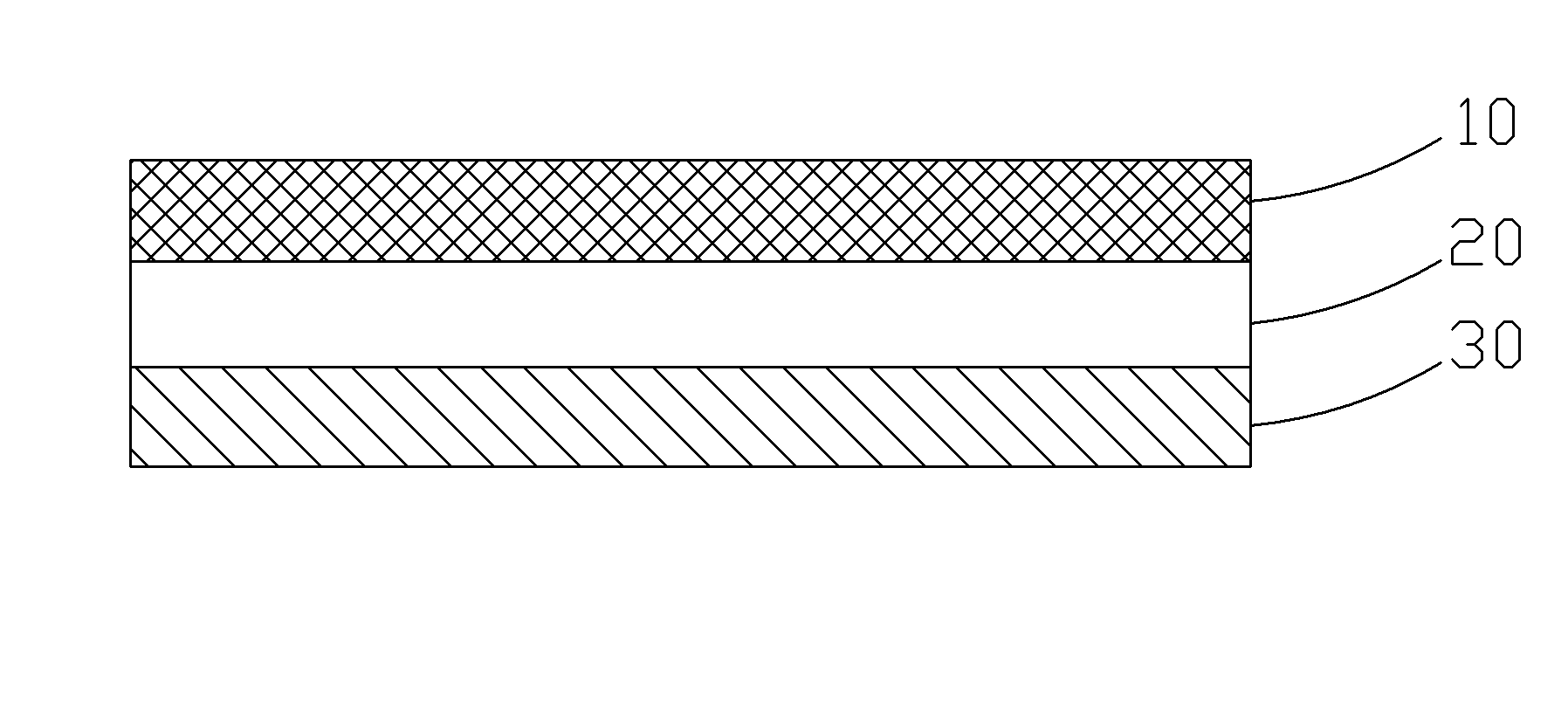

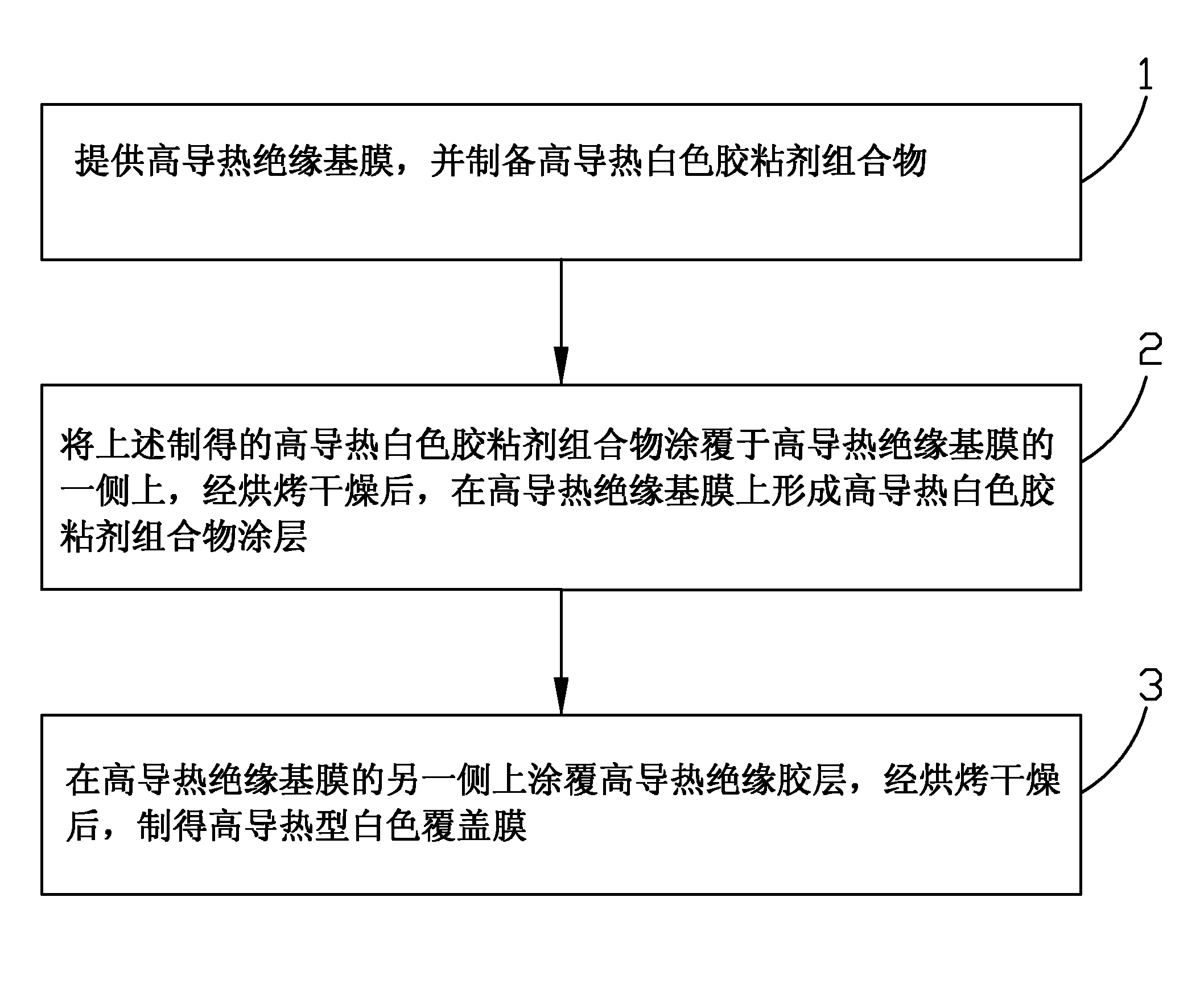

The invention relates to a high-heat-conductivity white adhesive composition, a high-heat-conductivity white cover film made from the same and a preparation method thereof. The high-heat-conductivity white adhesive composition comprises flexible saturated polyester, hard saturated polyester, blocked isocyanate curing agent, pigment, high-heat-conductivity filler, fluorescent brightener, defoaming agent and solvent. The high-heat-conductivity white cover film comprises a high-heat-conductivity insulation basal film, a high-heat-conductivity white adhesive composition coating applied onto one side of the high-heat-conductivity insulation basal film, and a high-heat-conductivity insulation adhesive layer applied onto the other side of the high-heat-conductivity insulation basal film. By applying the heat-conduction adhesive layers onto the two sides of the high-heat-conductivity insulation basal film, the high-heat-conductivity white cover film has the advantages of high whiteness and high reflectivity of the cover film surface, low cost, favorable yellowing resistance, excellent folding resistance and high heat conductivity, and can be widely used in the fields of high-power LEDs (Light Emitting Diodes), backlight sources and the like.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin

InactiveCN104086701AHigh glass transition temperatureImprove heat resistanceInksCoatingsGlycidyl methacrylate(Hydroxyethyl)methacrylate

The invention discloses a preparation method of a high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin. The preparation method comprises the following steps: carrying out free radical polymerization on an alicyclic epoxy acrylate monomer, glycidyl methacrylate, and hydroxyethyl methacrylate or hydroxypropyl methacrylate to prepare an alicyclic epoxy acrylate copolymer; reacting acrylic acid with an epoxy group in the above epoxy acrylate resin, and introducing a double bond to make the resin have photosensitive activity; and reacting acid anhydride with a hydroxy group, and introducing a carboxyl group to make the resin alkali-soluble in order to prepare the high temperature and yellowing resistant alkali-soluble epoxy acrylate UV resin with a carboxyl group. The glass transition temperature of the resin finally obtained in the invention is 65-100DEG C, and the finally obtained resin has the characteristics of good high temperature resistance, yellowing resistance, acid and alkali resistance of a curable film, solvent resistance, excellent mechanical performances and the like, and can be widely applied in yellowing resistant optical imaging solder resistant inks, photoresist, yellowing resistant UV inks and coatings, adhesion promoters, ink crosslinking agents and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

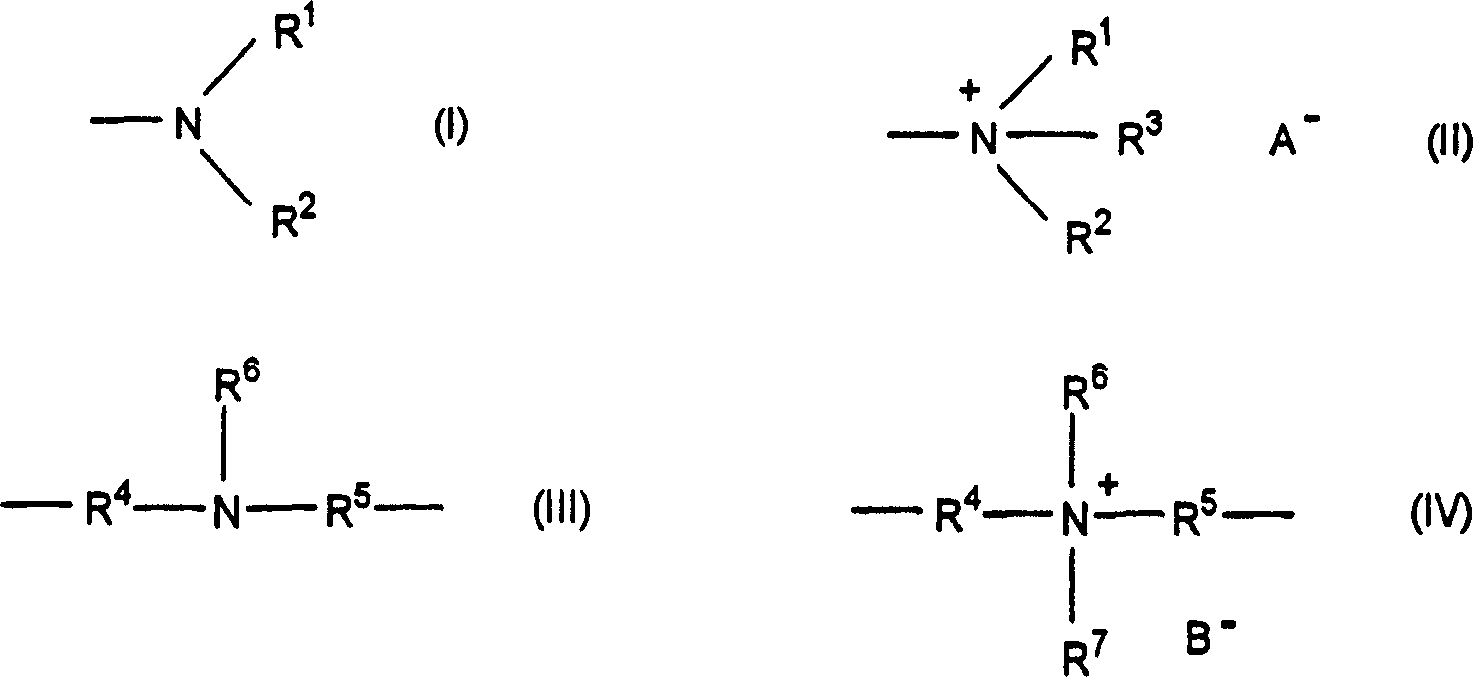

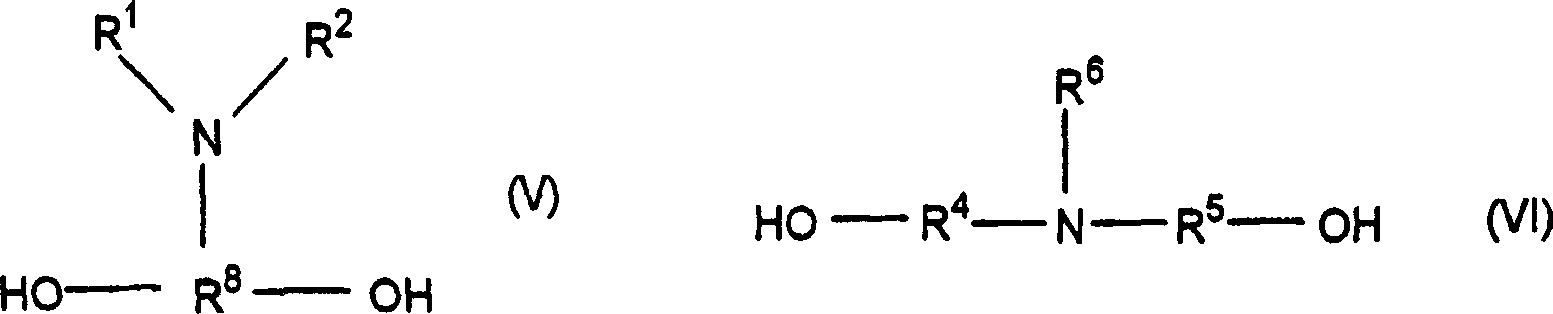

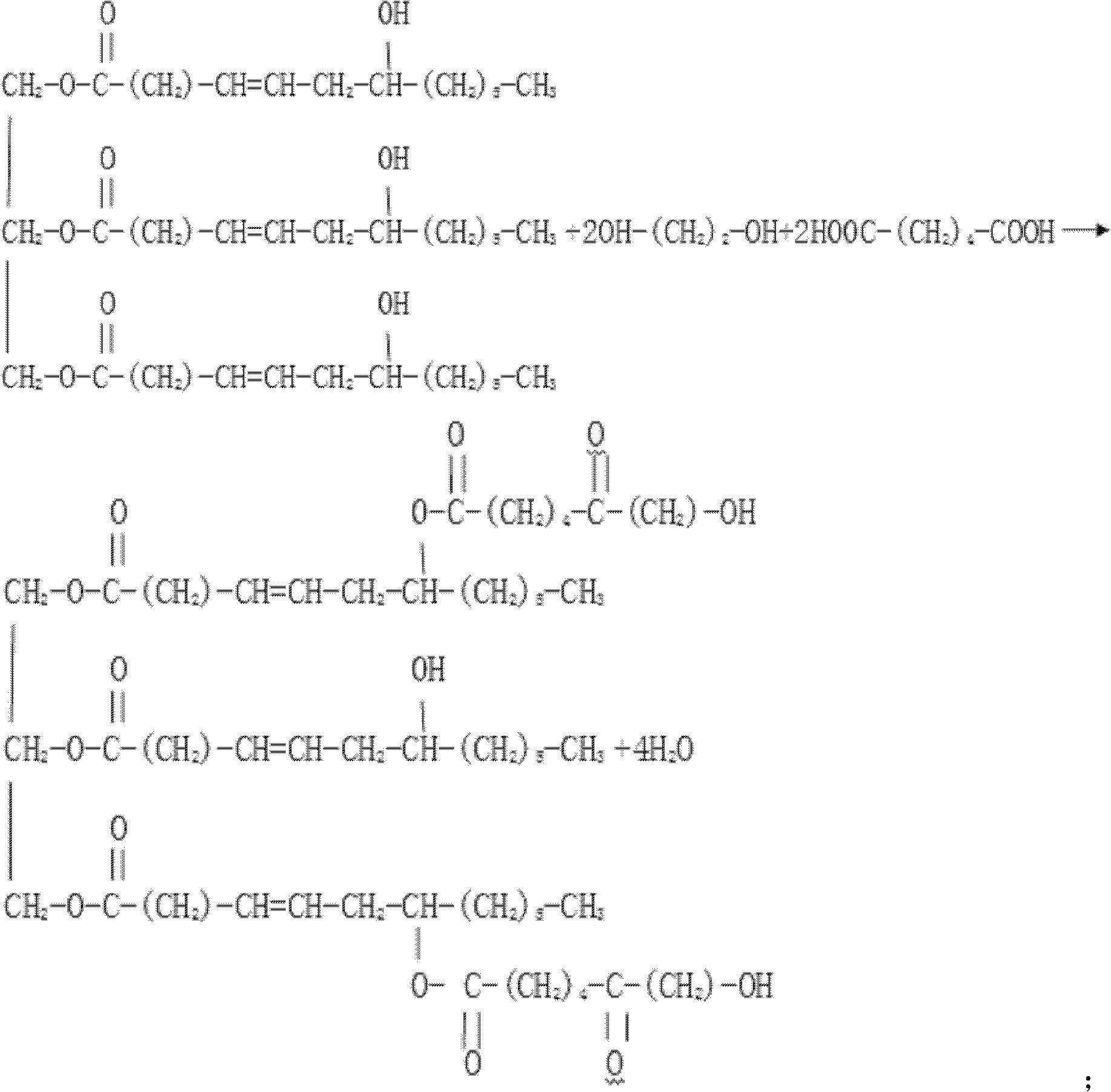

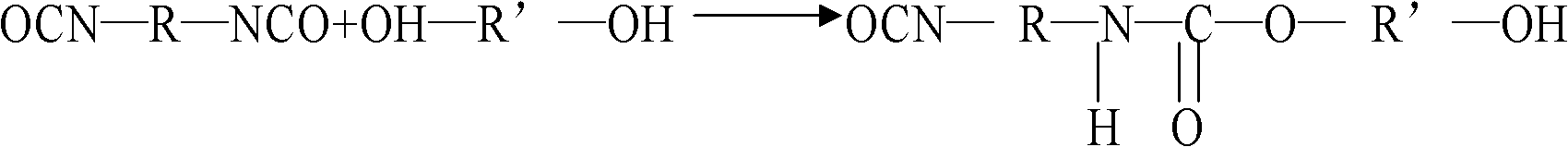

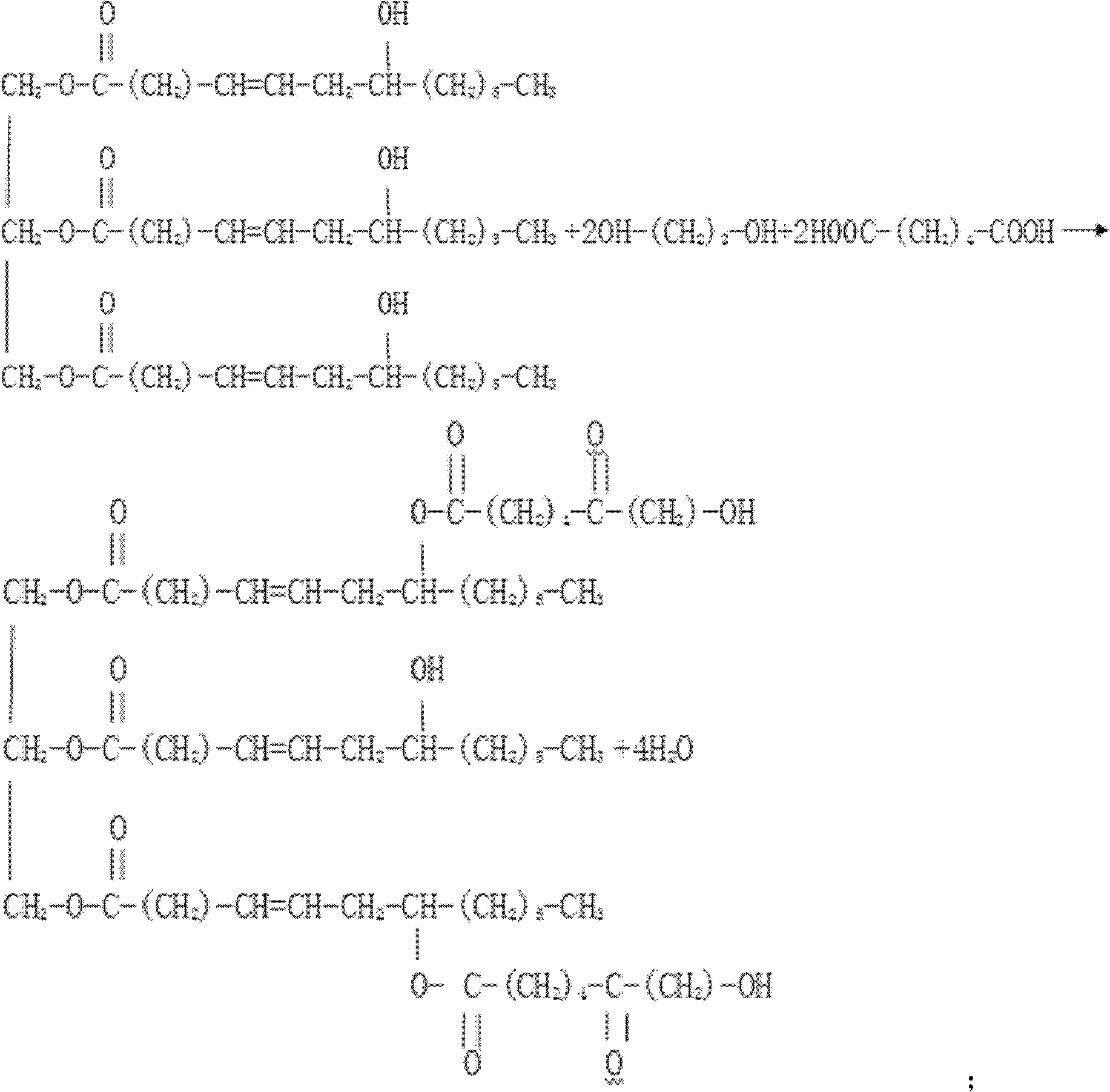

Aromatic yellow-stain resistant polyurethane resin for synthetic leather and preparation thereof

The invention discloses an aromatic yellowing-proof polyurethane resin for synthetic leather and a preparation method thereof. The aromatic yellowing-proof polyurethane resin comprises the following raw material components: aromatic isocyanate, polylol compound, diol chain extender of which molecular weight is 62 to 500 grams per mol, catalyst, antioxidant, ultraviolet absorbent and solvent. Through adjusting the polylol compound in the polyurethane resin, increasing usage of a polyether polylol compound, improving the hydrolysis resistance of the polyurethane resin, and adjusting variety and dosage of assistants such as antioxidant, ultraviolet absorbent and the like, the yellowing resistance of the synthetic leather prepared by the polyurethane resin can reach a level of more than grade 4.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

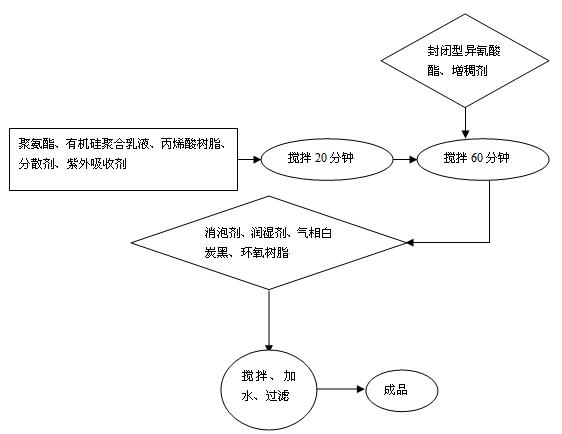

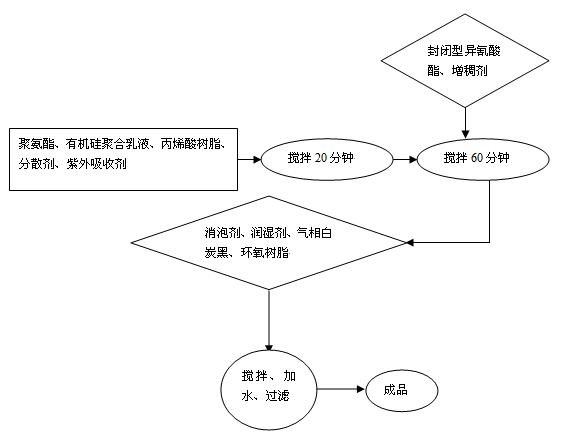

Coating for automobile sealing strip and preparation method thereof

ActiveCN102585681AGood flexibilityImprove aging resistanceAntifouling/underwater paintsPaints with biocidesEpoxySolvent

The invention discloses coating for an automobile sealing strip and a preparation method thereof. The coating comprises a film forming material, at least one curing agent, a plurality of auxiliaries, at least one packing and solvent. The film forming material comprises organic silicon polymer emulsion, epoxy resin and polyurethane. The curing agent is closed isocyanate. The auxiliaries include a dispersing agent, a wetting agent, a thickening agent, an antifoaming agent and an ultraviolet absorber, and the solvent is water. The coating for the automobile sealing strip has excellent abrasion-resistance, yellow degeneration resistance at high temperature, flexibility, pollution resistance, environmental friendliness, and is convenient to transport and use and easy to store.

Owner:云南三恩汽车新材料有限公司

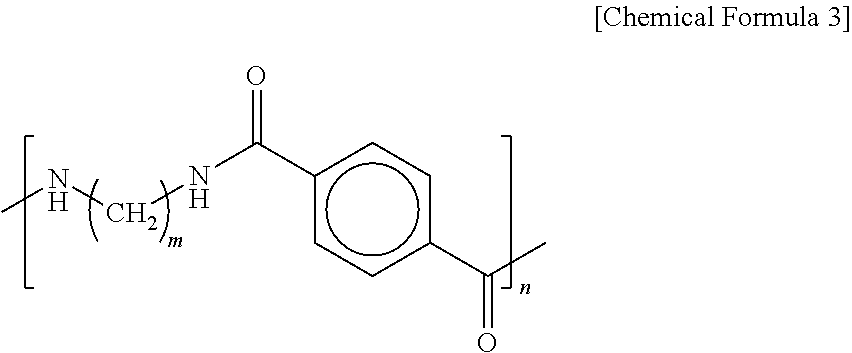

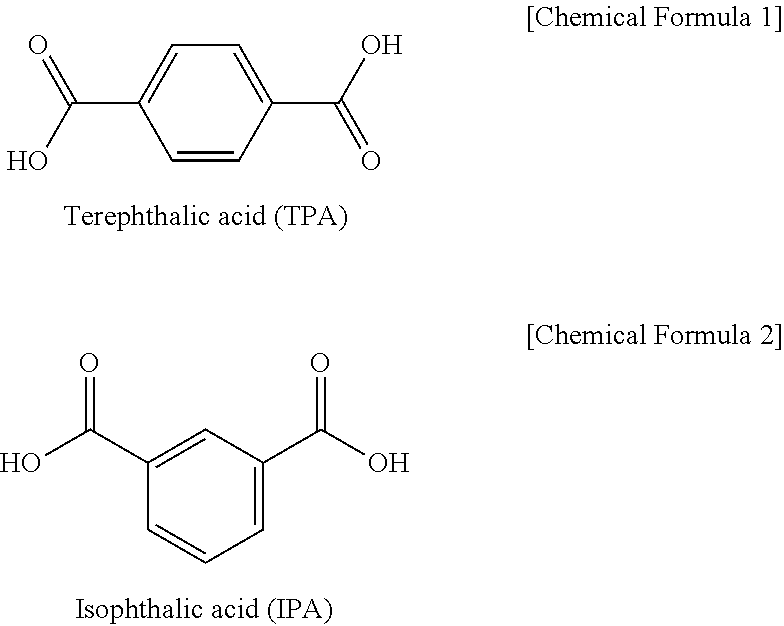

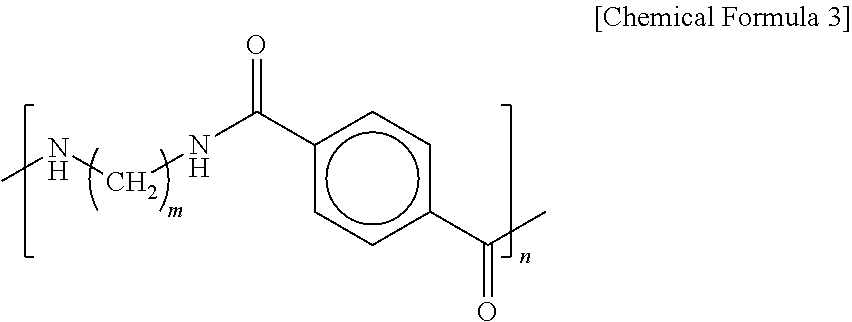

Polyamide Resin Composition Having Improved Physical Properties Including Thin-wall Moldability

ActiveUS20130172453A1Good thin-wall moldabilityImprove mechanical propertiesAlkaline-earth metal silicatesHeat resistancePolyamide

A polyamide resin composition comprises (A) about 10 to about 70% by weight of a crystalline polyamide resin, (B) about 10 to about 70% by weight of an amorphous polyamide resin, (C) about 5 to about 30% by weight of an inorganic filler, and (D) about 10 to about 50% by weight of a white pigment. The polyamide resin composition can have good thin-wall moldability, light reflectance, yellowing resistance, impact strength and heat resistance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

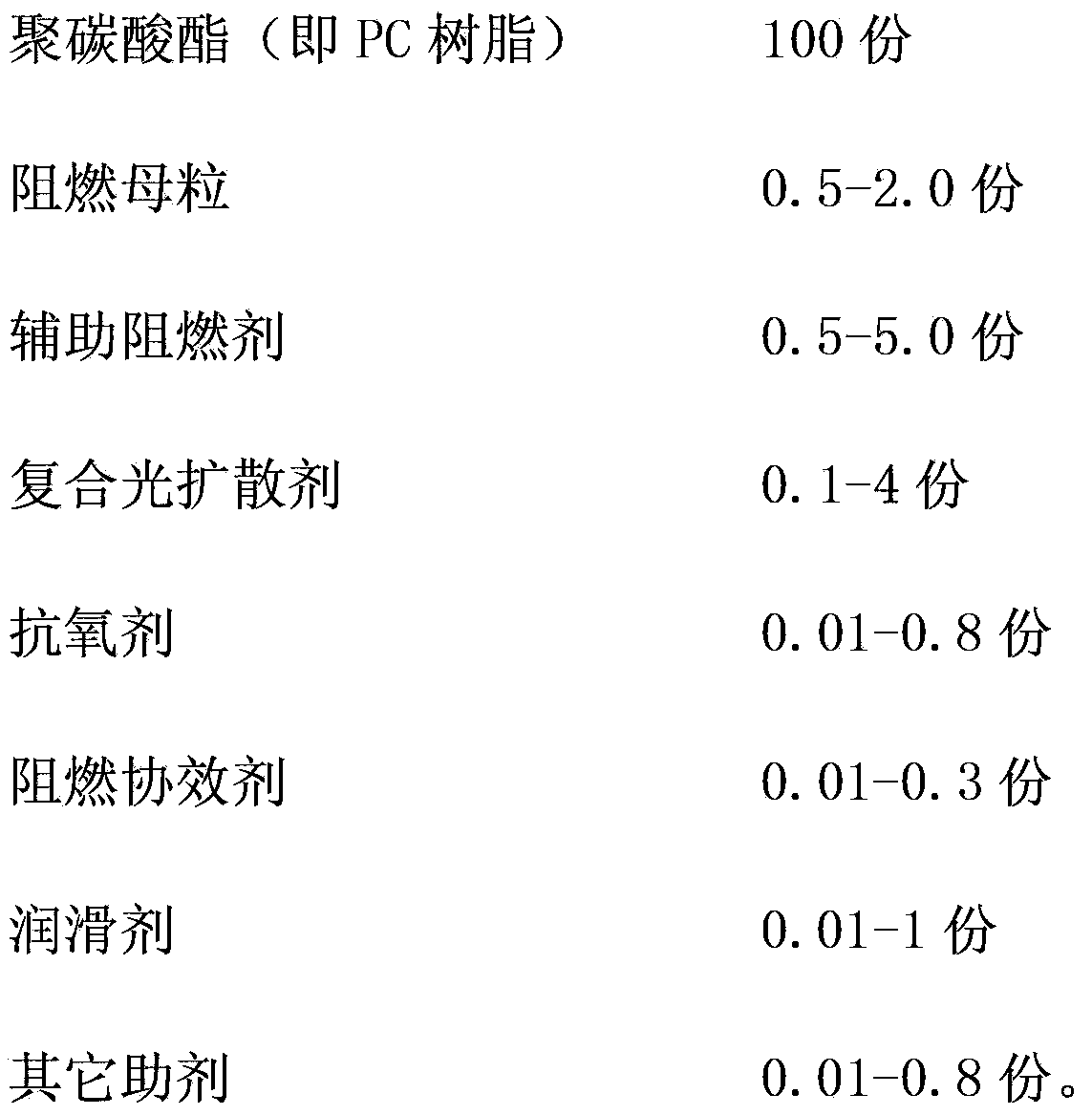

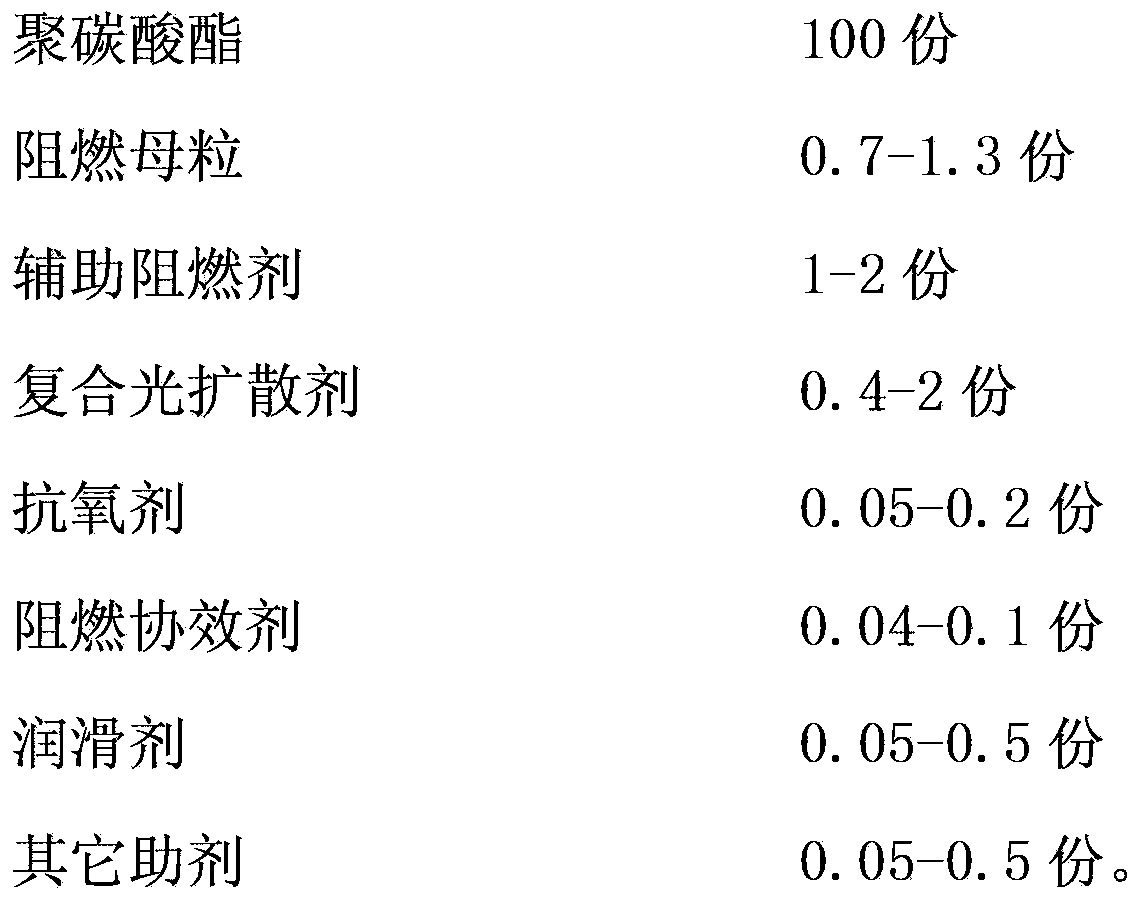

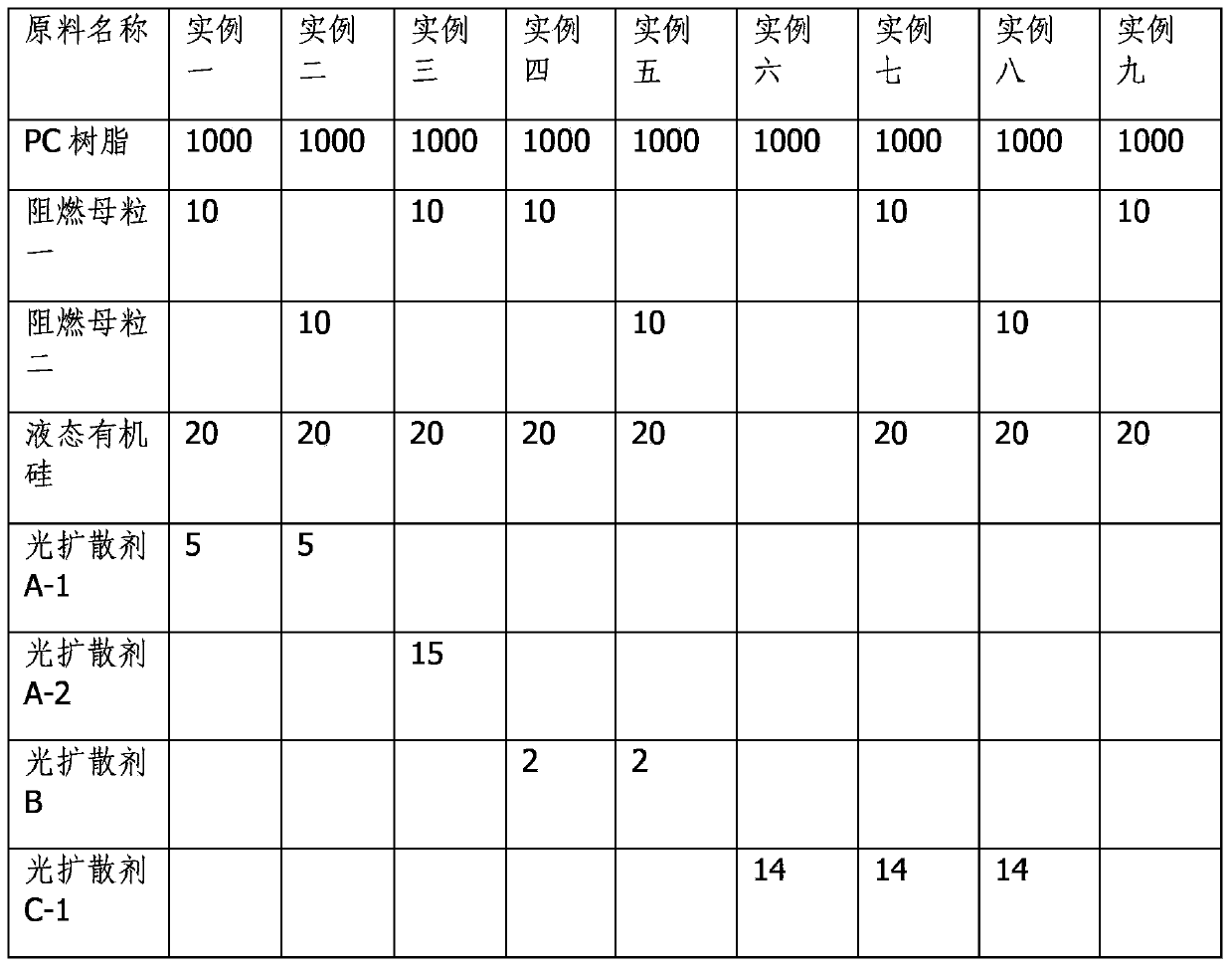

Polycarbonate material with excellent transparent light diffusion function and preparation method thereof

The invention discloses a PC (Polycarbonate) material with an excellent transparent light diffusion function and a preparation method thereof. The PC material is composed of polycarbonate, flame retardant masterbatch, an auxiliary flame retardant, a compound light diffuser, an antioxidant, a flame retardant synergist, a lubricant and other auxiliaries. The principle ingredient of the PC material is PC resin; the PC material is extruded by two steps, wherein the first step is to blend a sulfonate type major flame retardant and an organic silicon flame retardant with the PC resin by melting and granulate the mixture through extrusion by virtue of a twin-screw extruder so as to obtain the light diffusible flame retardant masterbatch, and the second step is to add the compound light diffuser, the flame retardant masterbatch, the antioxidant, the flame retardant synergist, the lubricant and other auxiliaries for further melting blending by taking PC as the major ingredient, and then extrude and granulate the mixture. The flame-retardant light diffusible PC material provided by the invention can be widely applied to an LED (Light-Emitting Diode) lamp, the backlight of a liquid crystal display, a transmission type screen, a decorative lighting billboard, an advertisement lamp box and the like in the lighting field.

Owner:NANTONG DONGFANG PLASTIC CO LTD

Thermoplastic polyester resin composition and molded article

InactiveCN1717452AImprove hydrolysis resistanceImprove heat resistancePolymer sciencePhenolic antioxidant

Owner:DAICEL CHEM IND LTD

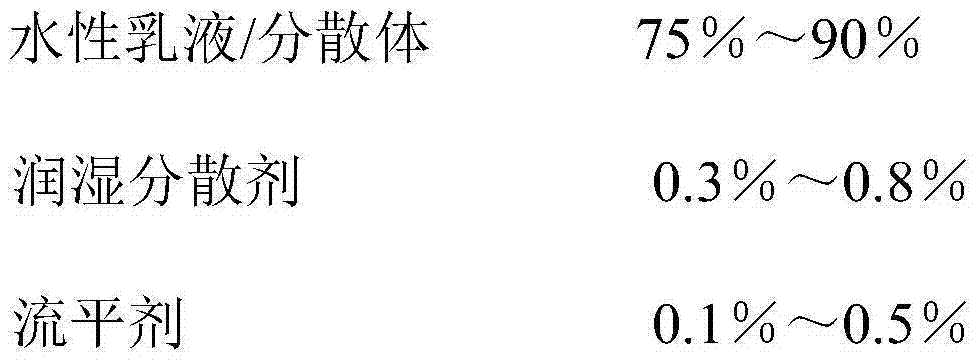

Water-based transparent colored paint for wooden ware and preparation method of paint

ActiveCN103881502AGood yellowing resistanceHigh gloss retentionAntifouling/underwater paintsPaints with biocidesWaxWater based

The invention discloses a water-based transparent colored paint for wooden ware and a preparation method of the paint. The water-based transparent colored paint is applied to decoration of the surface of a wood material (cabinets, tables, chairs, chair rails and the like). The water-based transparent colored paint comprises components including water-based emulsion / dispersoid, a water-based color concentrate, pure water, a film forming aid, a wetting dispersant, a foam killer, a flatting agent, a bactericide, a mildew preventive, an anti-freezing agent, a thickening agent, a multi-functional additive, a matting agent and wax emulsion. The water-based transparent colored paint for the wooden ware is bright in color and clear in texture and has the effects of greatly reducing the content of VOC, guaranteeing the application performance of the product and realizing the environmental protection characteristics of the product.

Owner:NIPPON PAINT YASHILI

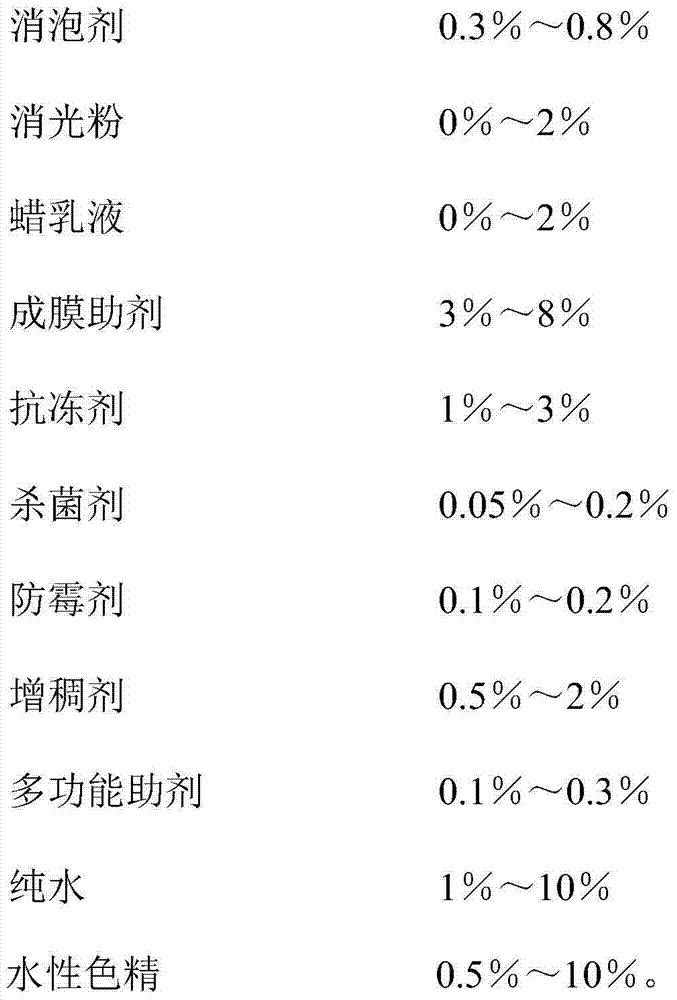

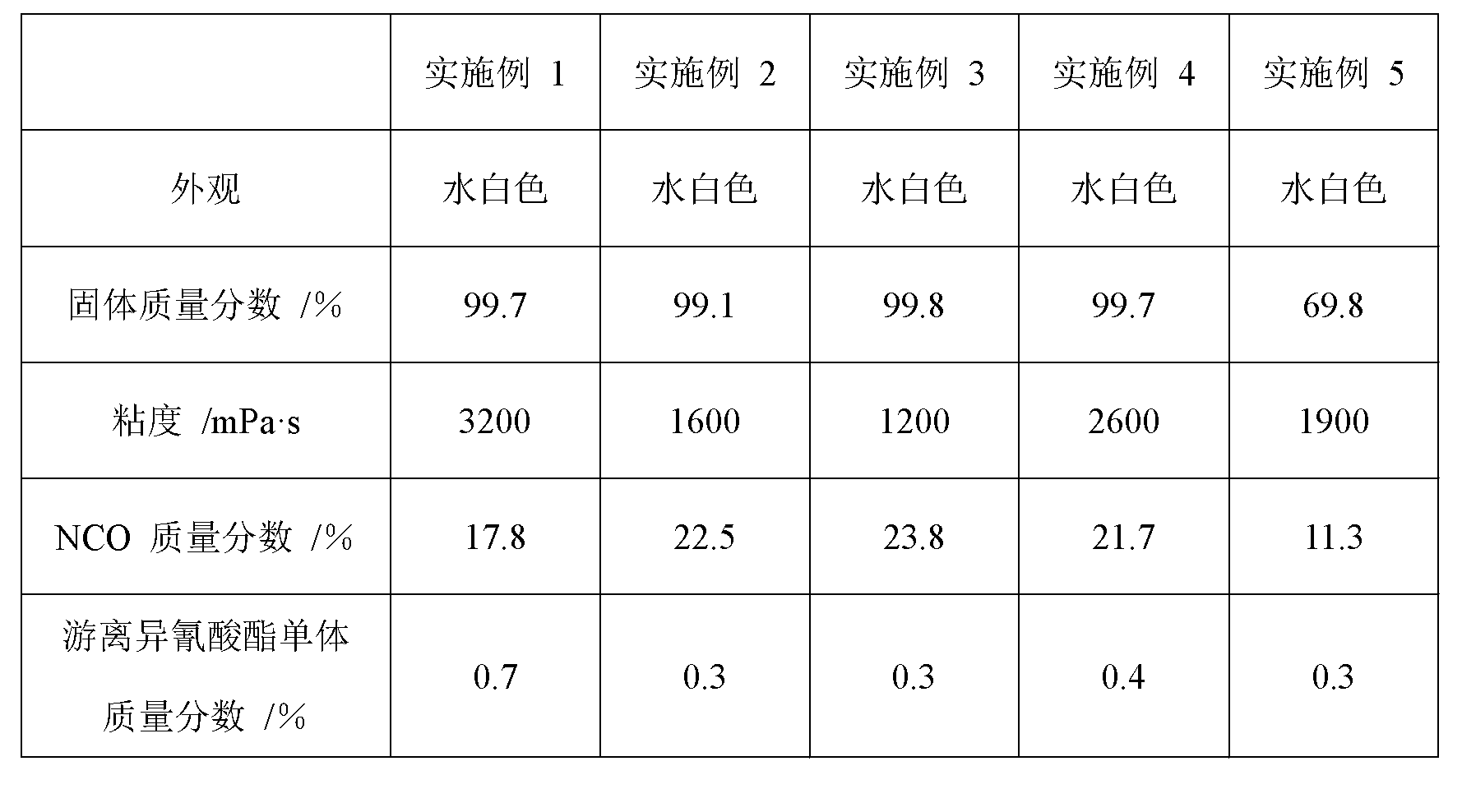

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

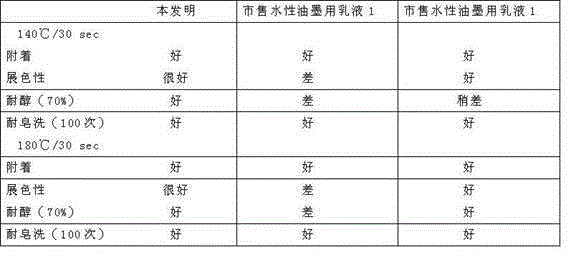

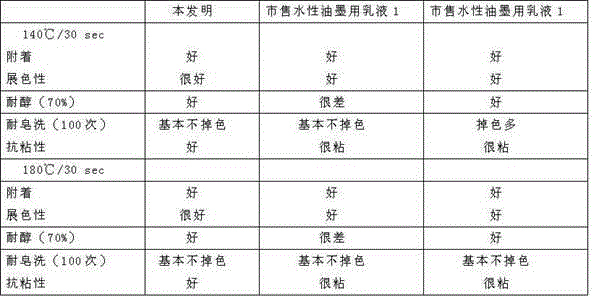

Anti-after tack acrylic latex for water-based ink

ActiveCN102911559AGood yellowing resistanceExcellent color paste stabilityInksMethacrylatePolymer science

The invention discloses anti-after tack acrylic latex for water-based ink. The latex comprises 5-18% of water, 0.1-0.8% of initiator, 40-60% of self-made alkali-soluble resin solution, 4-20% of C4-C12 alkyl acrylate monomer, 15-40% of C4-C20 methacrylate monomer and 0.2-5% of functional monomer. In a preparation method of the latex, firstly (methyl) acrylic acid, methyl methacrylate and C4-C12 alkyl acrylate are used as comonomers, persulfate is used as the initiator, a chain transfer agent is adopted, and then the alkali-soluble resin solution is obtained through emulsion polymerization; and then, the C4-C12 alkyl acrylate unsaturated monomer, the C4-C20 methacrylate unsaturated monomer and the functional monomer are used as comonomers, the alkali-soluble resin serves as a protective colloid, and then the anti-after tack acrylic latex is prepared by soap-free emulsion polymerization. According to the invention, the technology is simple, the operation is convenient, and the energy consumption and cost of production are reduced; and the latex has excellent yellowing resistance and color paste stability, and can effectively improve the alcohol resistance, soaping resistance, color development property and anti-after tack property of the water-based ink.

Owner:NANJING REGAL POLYMER +1

Modified polyurethane resin and benzene-free and ketone-free composite plastic ink containing same, as well as preparation methods thereof

The invention relates to benzene-free and ketone-free composite plastic ink which comprises 25-35 parts of modified polyurethane resin, 5-10 parts of matching resin (polyketone resin), 0.5-1 part of dispersant, 7-15 parts of pigment, 2-4 parts of adhesion promoter, 0.1-0.3 part of wax powder, 10-15 parts of ethanol, 20-30 parts of acetic ether and 10-20 parts of isopropyl alcohol, wherein the matching resin is L-872 polyketone resin, the contents of the ethanol, the isopropyl alcohol and the acetic ether are all above 99%, the content of benzene and ketone substances is below 0.01%, the dispersant is TM-950, the adhesion promoter is a titanate coupling agent HY-201, and the wax powder is polyethylene wax. The benzene-free and ketone-free composite plastic ink takes the isopropyl alcohol, the acetic ether and the ethanol as diluents without the assistance of the benzene and ketone substances for dissolving. The benzene-free and ketone-free composite plastic ink has no harm to operators, society and environment from preparation and production to printing and use and has excellent safe and healthy property.

Owner:新东方油墨有限公司

Polyurethane retanning filler

InactiveCN103030769APromote environmental protectionImprove hydrophobicityTanning treatmentPolymer scienceEmulsion

The invention relates to a polyurethane retanning filler. The preparation method of the polyurethane retanning filler comprises the following steps: preparing a prepolymer from raw materials IPDI (isophorone diisocyanate), PEG (polyethylene glycol), castor oil and DMBA (dimethylbenzanthracene); adding triethylamine to carry out neutralization reaction to generate salt; and adding an ethylenediamine water solution to carry out emulsification and chain extension to prepare the water-based polyurethane emulsion. The coated film of the water-based polyurethane emulsion has favorable water resistance and yellowing resistance.

Owner:QINGDAO WINCHANCE TECH

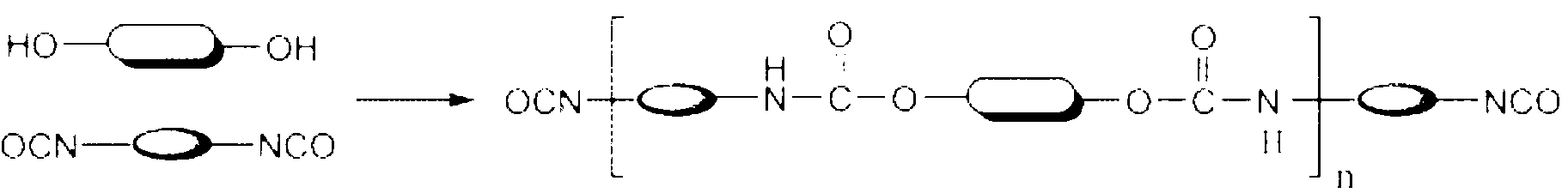

Preparation method of polyurethane trimer curing agent of low free isocyanate monomer

ActiveCN102718944AGood compatibilityRapid curing at room temperatureOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceNitrogen

The invention discloses a preparation method of a polyurethane trimer curing agent of a low free isocyanate monomer, comprising the following steps of: under the protection of nitrogen, firstly putting an isocyanate monomer and an esters solvent into a reaction container to evenly stir, wherein the temperature is kept at 50-90DEG C; dropwise adding diamine into the reaction container under the condition of stirring, wherein the dropwise adding time is 1-1.5 hours; and after dropwise adding, adding a catalyst of which the mass is 0.1-0.5% of that of the isocyanate monomer once, continuing stirring and reacting at the temperature of 70-100DEG C for 3-6hours, when the NCO base content is 20%-25%, immediately adding the polymerization inhibitor of which the mass is 0.1-1% of that of the isocyanate monomer, keeping the temperature for 1-2hours, and discharging in a cooling way. The polyurethane trimer curing agent prepared by the preparation method can be better compatible with the resin, can be quickly solidified under normal temperature, and has the advantages of being higher in mechanical strength, modulus, adhesion, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

Anti-seismic epoxy dipping glue and preparation method thereof

ActiveCN104293266AEasy constructionLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesAliphatic amineDiluent

The invention discloses anti-seismic epoxy dipping glue and a preparation method thereof. To be specific, the dipping glue comprises a component A and a component B in a weight part ratio of 3 to 1; the component A comprises 50.0-75.0 parts of bisphenol A epoxy resin, 5.0-20.0 parts of epoxy acrylate, 10.0-20.0 parts of hydrogenated bisphenol A epoxy resin, 2.0-8.0 parts of diluents, 5.0-15.0 parts of toughening agents, 1.0-6.0 parts of a thixotropic agent, 0.1-0.5 parts of an anti-aging agent, 0.5-1.0 part of peroxides, and 0.1-1.0 part of rheological additives; the component B comprises 20.0-40.0 parts of an aliphatic amine curing agent, 40.0-60.0 parts of an alicyclic amine curing agent, 0.5-2.0 parts of accelerants, 1.0-4.0 parts of coupling agents and 1.0-15.0 parts of a thixotropic agent. The dipping glue is prepared by respectively preparing the component A and the component B, and mixing the components A and B, and is mainly used for gluing carbon fiber composite materials used for reinforcing buildings in areas with the seismic fortification intensity of not less than level 7; the intensity index of the dipping glue is in line with performance indexes in Engineering Structure Strengthening Material Security Identification Technical Specification of GB50728-2011.

Owner:苏州市姑苏新型建材有限公司

Emulsion pressure sensitive adhesive for anti-yellowing surface protective film and preparation method thereof

ActiveCN105884964AGood yellowing resistanceMeet performance requirementsNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneFunctional monomer

The invention provides an emulsion pressure sensitive adhesive for an anti-yellowing surface protective film. The emulsion pressure sensitive adhesive is prepared by polymerization of various raw material components in a reaction still in percentage by weight: 40.5-45.5 percent of a soft monomer, 1.3-4.3 percent of a hard monomer, 1.7-3.3 percent of a functional monomer, 0.8-2.2 percent of an emulsifier, 0.2-0.5 percent of an initiator, 0.1-0.2 percent of a buffering agent, 0.4-1.3 percent of neutralizer, 0.05-0.2 percent of oxidizing agent, 0.05-0.2 percent of a reducing agent and 47.5-52.5 percent of deionized water. The protective film prepared by the invention is excellent in anti-yellowing property and favorable in adhesion property with color plates and aluminium plates, is free from phenomena such as degumming and adhesive residue after being stripped, has no pollution on substrates and meets the use performance requirements of the protective film.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

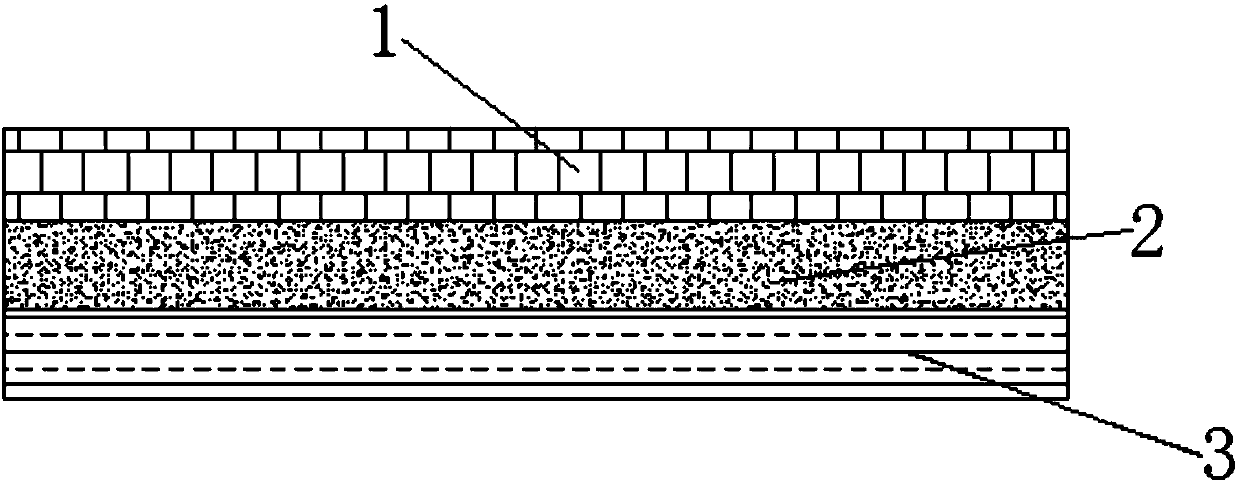

High-performance repairing adhesive tape for photovoltaic module back panel and preparation method

InactiveCN107841259AGood weather resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyesterAdhesive cement

The invention discloses a high-performance repairing adhesive tape for a photovoltaic module back panel. The high-performance repairing adhesive tape comprises a base material layer, a functional adhesive layer and a release material layer which are arranged in sequence from top to bottom, wherein the base material layer is composed of a polyester thin film type material; the functional adhesive layer is composed of a high-weather-resistance adhesive. According to the high-performance repairing adhesive tape for the photovoltaic module back panel and the preparation method, disclosed by the invention, the weather-resistance base material layer is selected so that the effects of water resistance, insulation, ultraviolet radiation resistance and the like can be realized and the effect of anindependent back panel is realized; the high-weather-resistance adhesive is selected for the functional adhesive layer, so that the weather resistance, high temperature resistance and yellowing resistance of the adhesive tape can be improved; the adhesive tape has great bonding strength and is not easy to fall off; meanwhile, the adhesive tape is convenient to stick and convenient to construct.

Owner:CYBRID TECHNOLOGIES INC

UVLED light-curing wood coating

InactiveCN108314911AGood storage stabilityFast curingEpoxy resin coatingsChemistryCycloaliphatic epoxy

The invention discloses an UVLED light-curing wood coating and application thereof, the coating comprises an oxetane compound, an epoxy compound selected from the group consisting of at least one of bisphenol A type epoxy resin, bisphenol F type epoxy resin or an alicyclic epoxy compound, a (methyl) acrylate compound, a cationic and a radical photoinitiator, and optionally a sensitizer. The coating has excellent response to an UVLED light source in the wavelength range of 200 to 450 nm, and the curing speed is fast. The cured coating is excellent in hardness, wear resistance, flexibility, adhesion, alcohol resistance and yellowing resistance and the like. The coating is odorless and has strong technical and market competitiveness.

Owner:CHANGZHOU GREEN PHOTOSENSITIVE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com