High-heat-conductivity white adhesive composition, high-heat-conductivity white cover film made from same and preparation method thereof

A technology of high thermal conductivity and composition, which is applied in the field of high thermal conductivity white adhesive composition and high thermal conductivity white cover film, can solve the problems of limited application, and achieve the effects of good yellowing resistance, high thermal conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

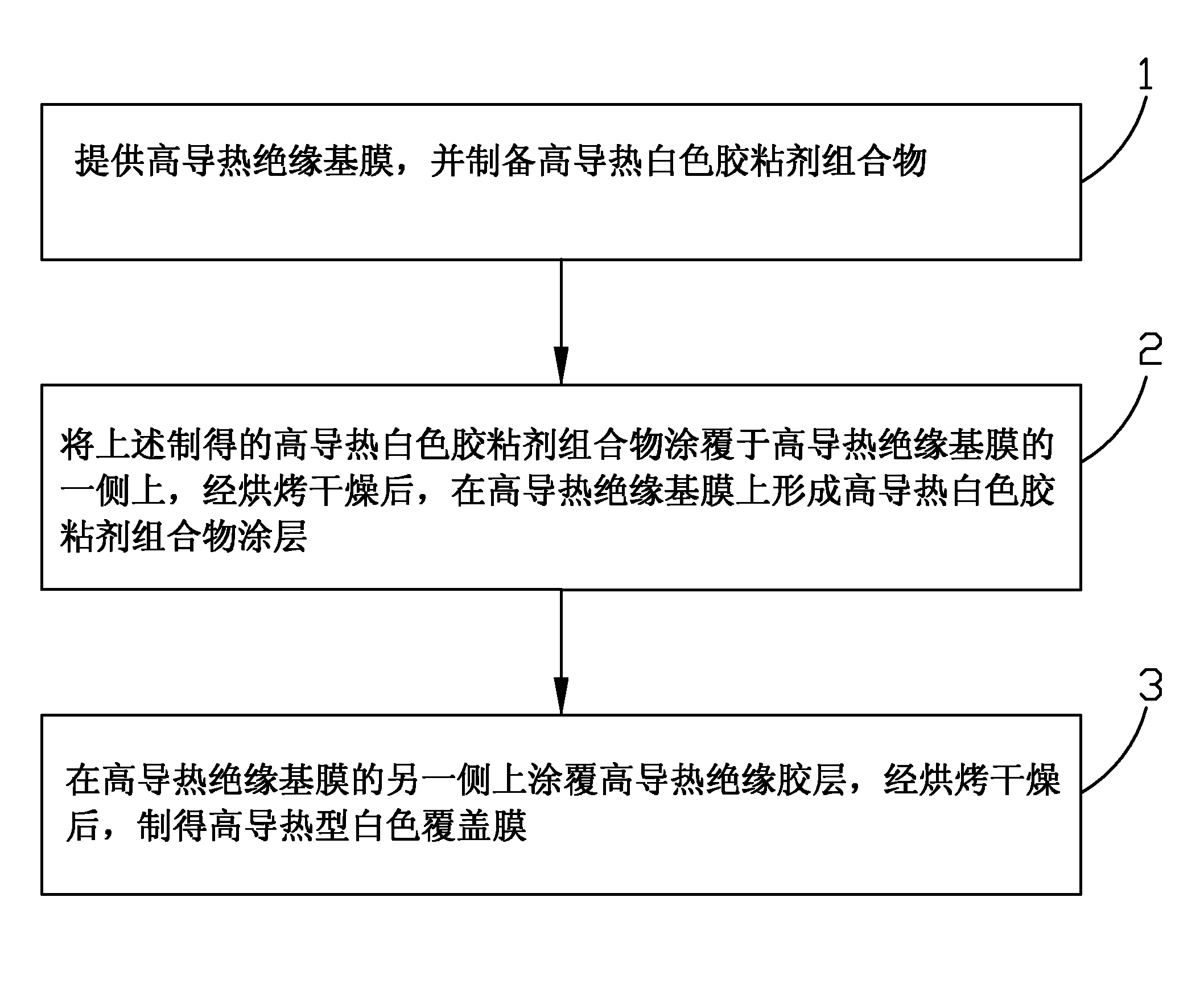

Method used

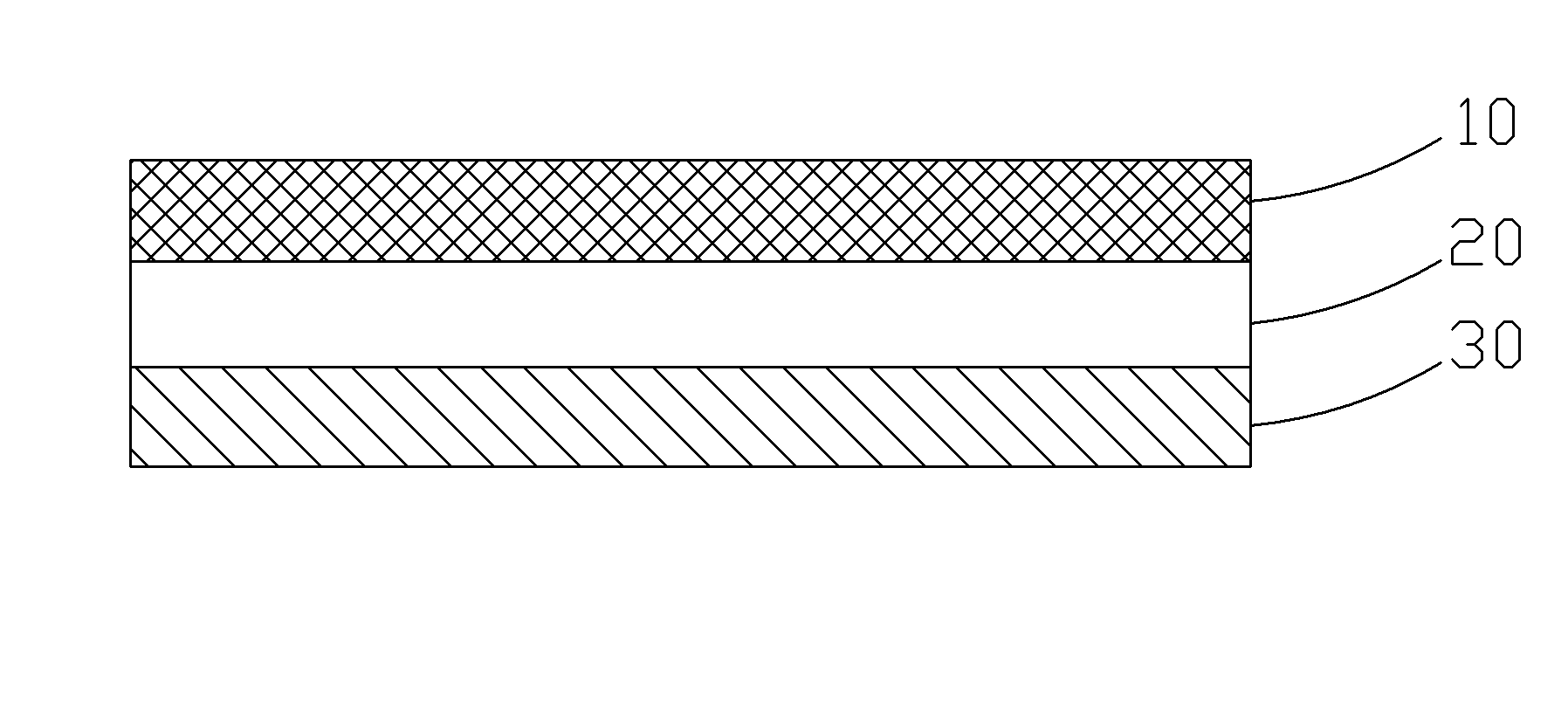

Image

Examples

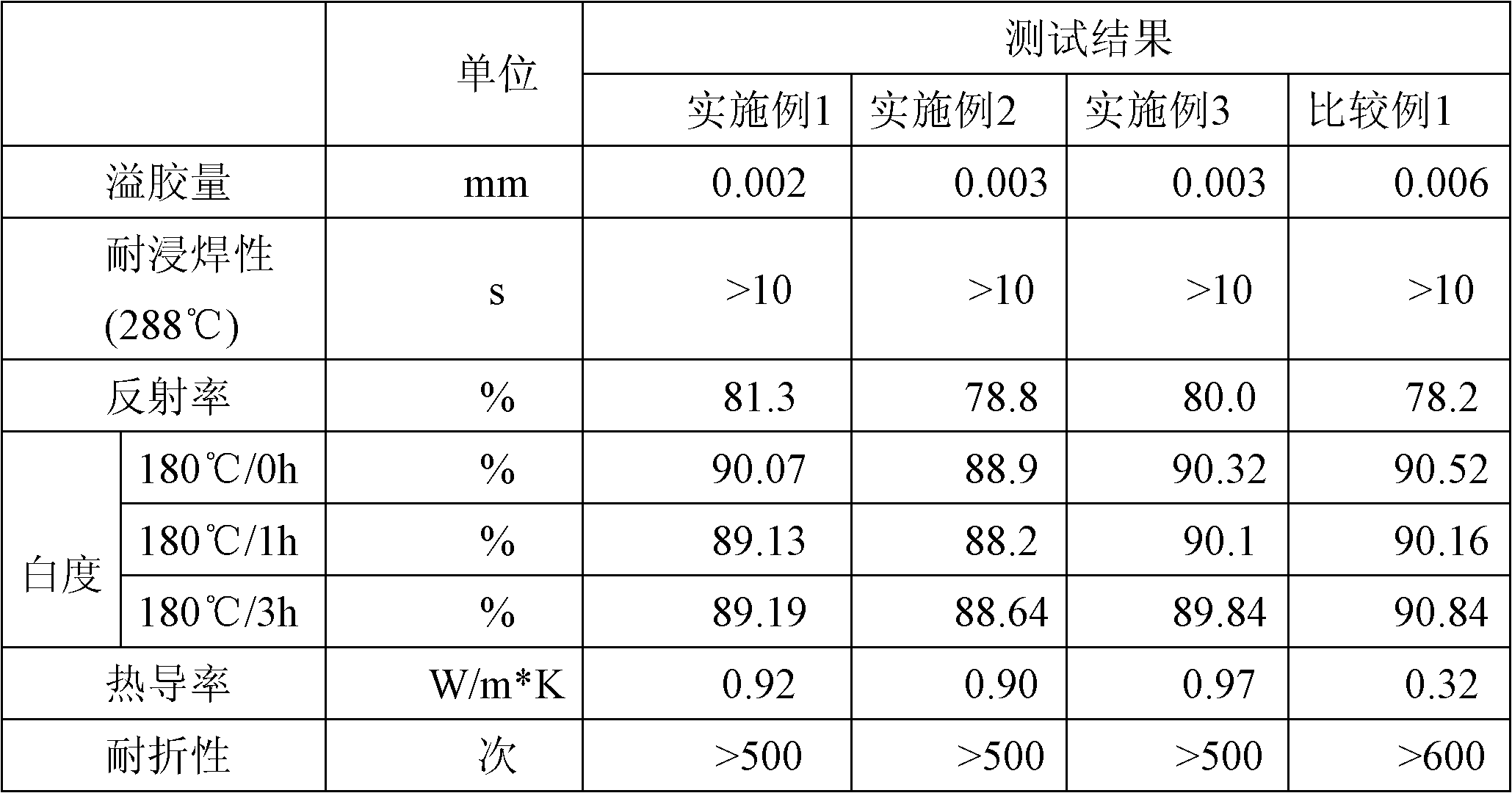

Embodiment 1

[0052] Flexible linear saturated polyester (commodity model Vitel3300B, manufactured by Bostik Company) 68 parts by weight; Rigid linear saturated polyester (commodity model Vitel2200B, manufactured by Bostik Company) 32 parts by weight; Manufacture) 10 parts by weight; Rutile type titanium dioxide (commodity model TRONOX CR828, product of Ke Meiji Company, Australia) 90 parts by weight; Aluminum oxide (commercial model VK-L04R, Wanjing material) 40 parts by weight; Fluorescent whitening agent (commercial product Model OB-1, product of Eastman Company, USA) 0.08 parts by weight; defoamer (product model BYK-57, product of BYK Company) 0.4 parts by weight.

[0053] Feed saturated polyester and blocked isocyanate curing agent according to the above weight ratio with methyl ethyl ketone, stir evenly at high speed, then add pre-ultrasonic treated alumina, titanium dioxide, whitening agent, defoamer, etc., and stir for about 6 hours. Mixed into a highly thermally conductive white ad...

Embodiment 2

[0057] Except changing the consumption of blocked isocyanate curing agent, other proportioning is identical with embodiment 1. 15 parts by weight of blocked isocyanate curing agent (product model BL3475, manufactured by Bayer).

[0058] Feed saturated polyester and blocked isocyanate curing agent according to the above weight ratio with methyl ethyl ketone, stir evenly at high speed, then add pre-ultrasonic treated alumina, titanium dioxide, whitening agent, defoamer, etc., and stir for about 6 hours. Mixed into a highly thermally conductive white adhesive composition.

[0059] The composition is coated on the surface of a high thermal conductivity PI base film with a thickness of 25 μm by a glue coating machine, and the thickness of the coating is 25 μm, and then baked in an oven at 180 ° C for 2 minutes to obtain a high thermal conductivity white adhesive composition coating .

[0060] Then a high thermal conductivity epoxy resin adhesive composition with a thickness of 25...

Embodiment 3

[0062] Except for changing the amount of high thermal conductivity filler, other proportions are the same as in Example 1. Aluminum oxide (commodity model VK-L04R, Wanjing material) 50 parts by weight;

[0063] Feed saturated polyester and blocked isocyanate curing agent according to the above weight ratio with methyl ethyl ketone, stir evenly at high speed, then add pre-ultrasonic treated alumina, titanium dioxide, whitening agent, defoamer, etc., and stir for about 6 hours. Mixed into a highly thermally conductive white adhesive composition.

[0064] The composition was coated on the surface of a high thermal conductivity PI base film with a thickness of 25 μm by a coating machine, and the coating thickness was 25 μm, and then baked in an oven at 180° C. for 2 minutes to obtain a white adhesive layer.

[0065] Then a high thermal conductivity epoxy resin adhesive composition with a thickness of 25 μm was coated on the surface of the high thermal conductivity white adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com