Patents

Literature

234 results about "Calcium sulfate crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

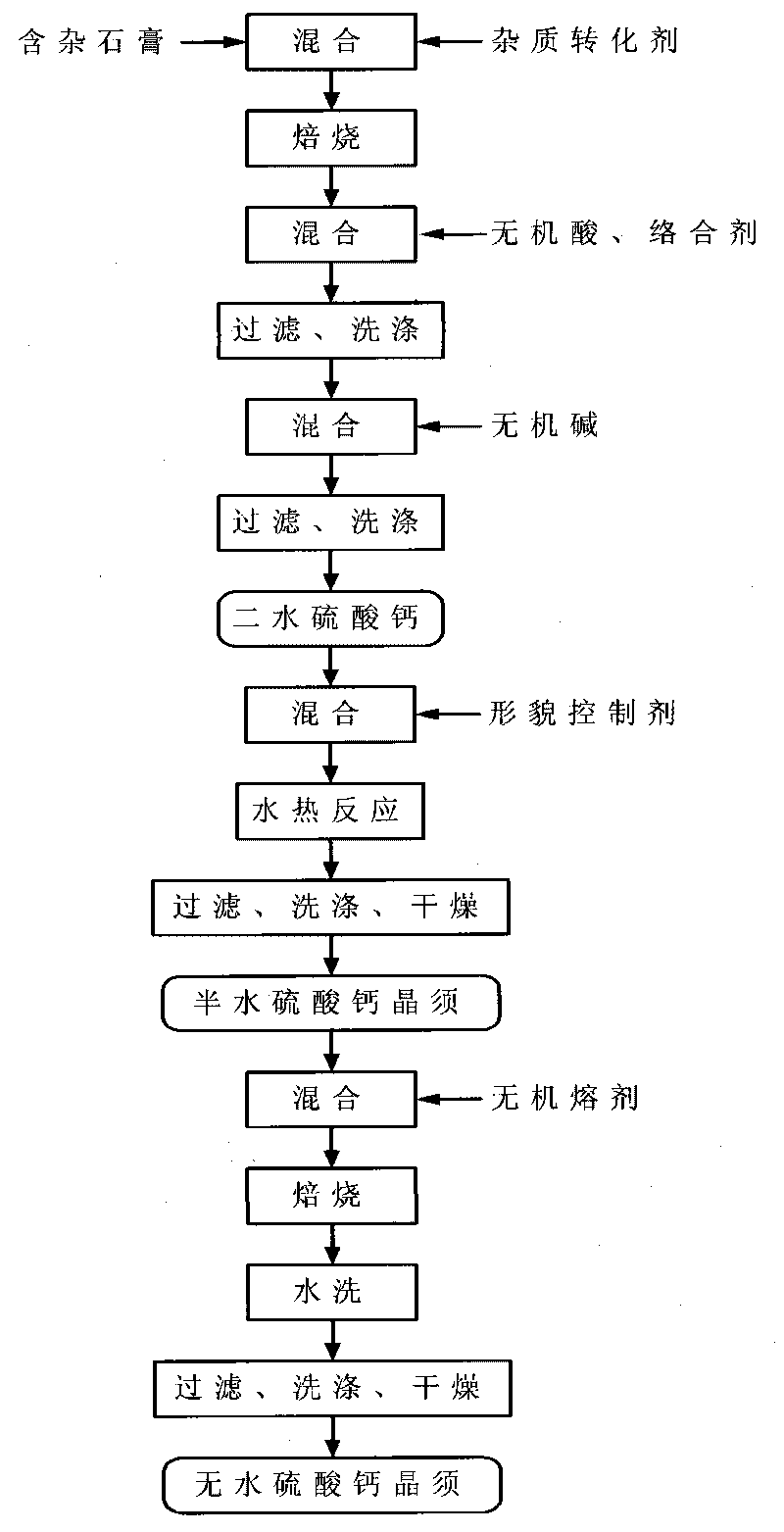

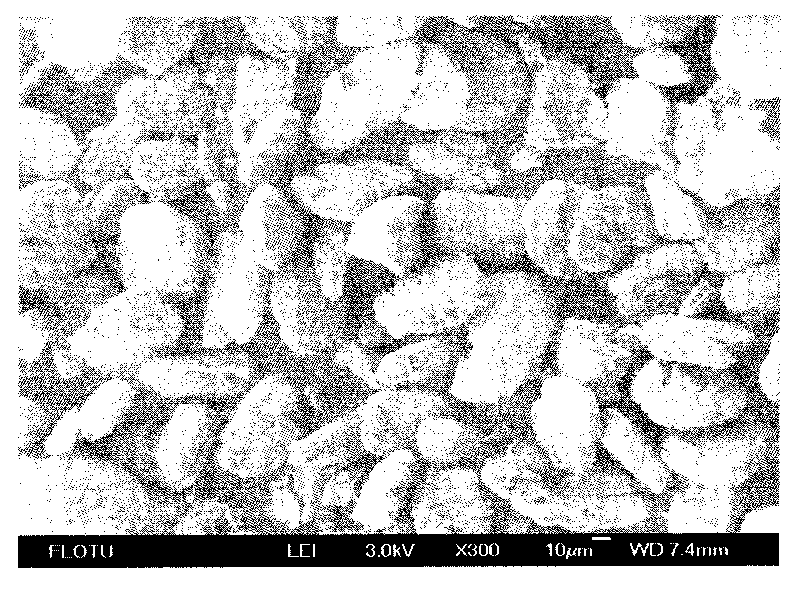

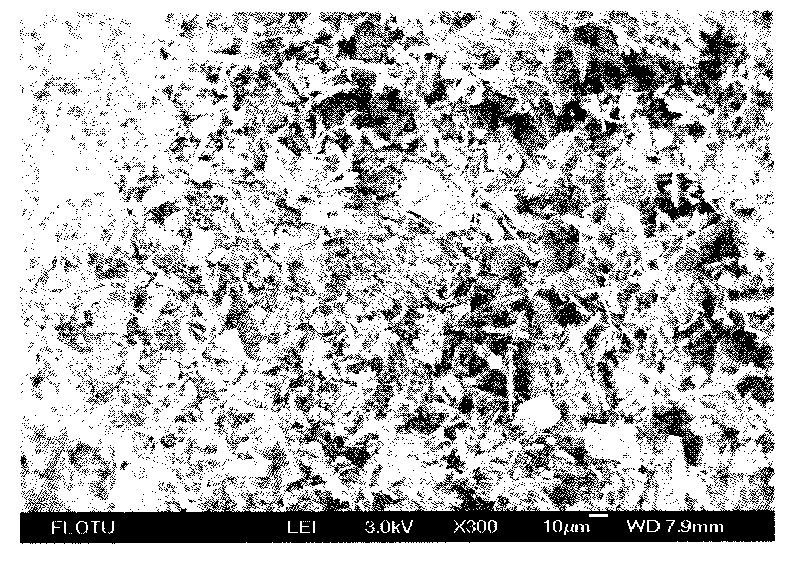

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

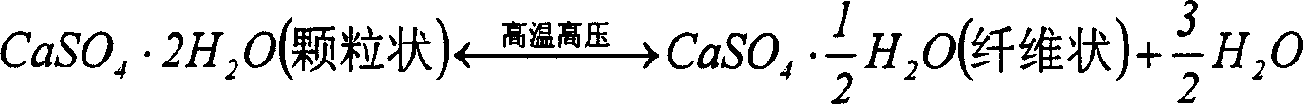

InactiveCN101736403AHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

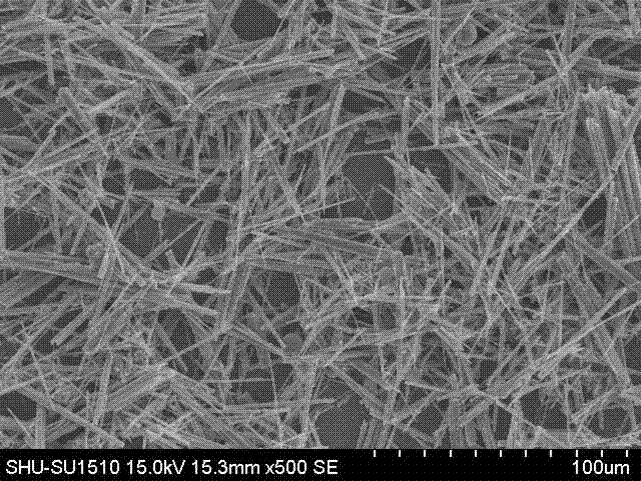

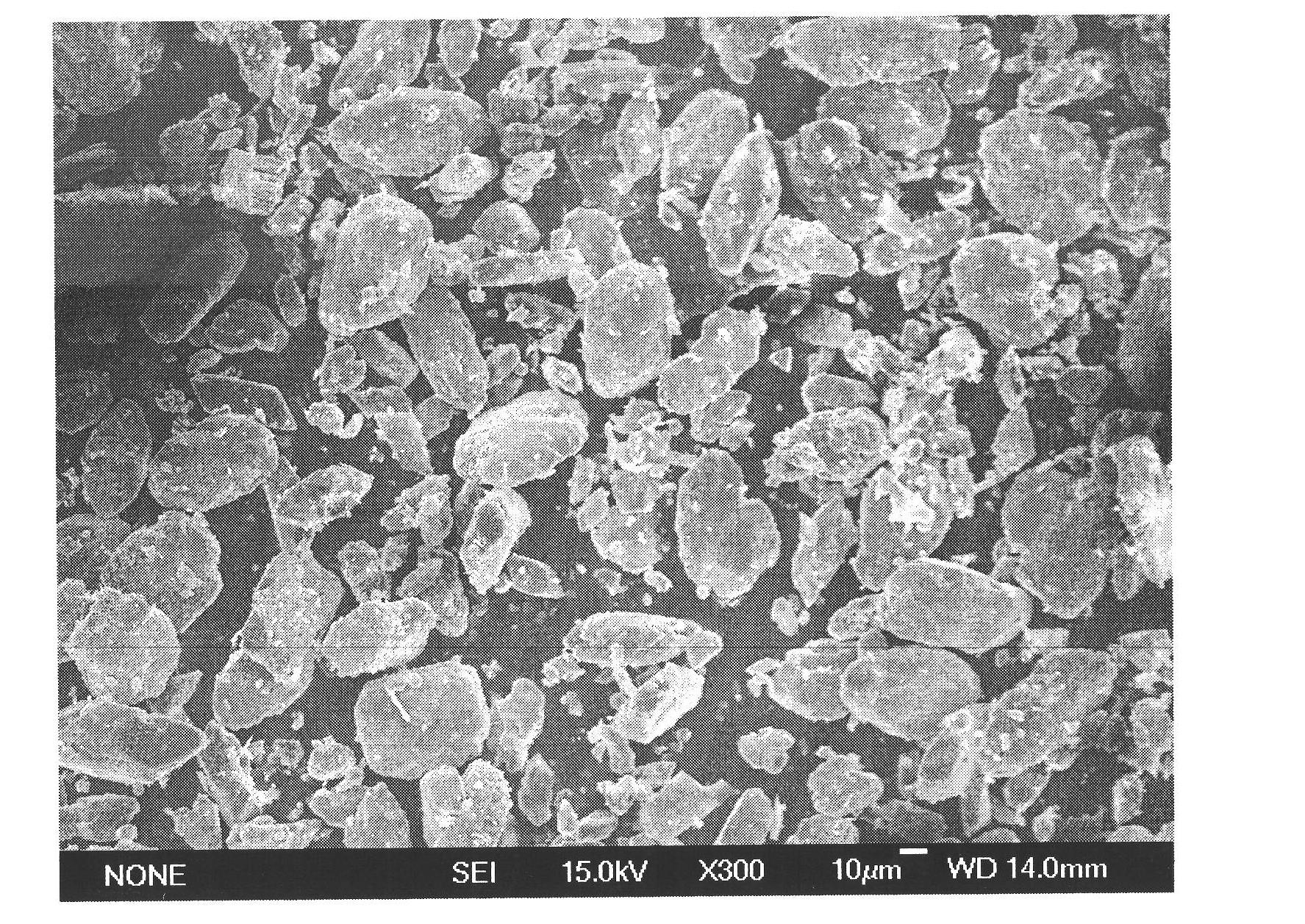

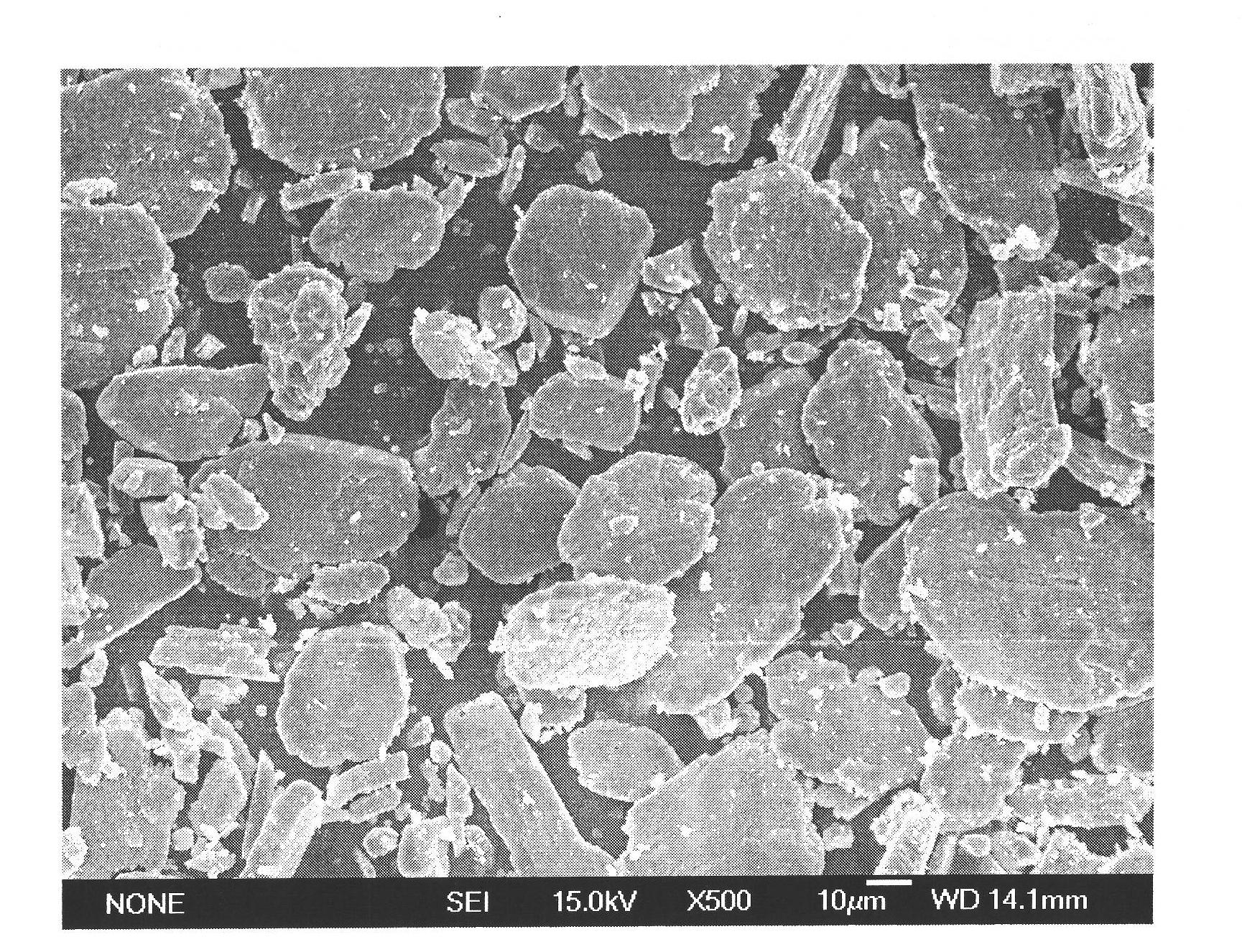

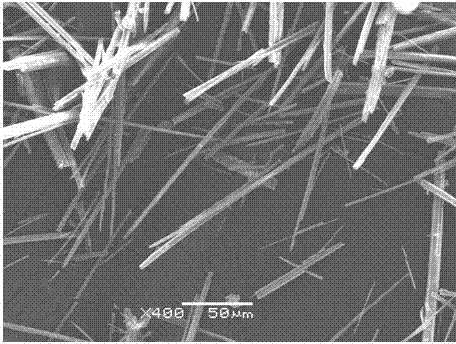

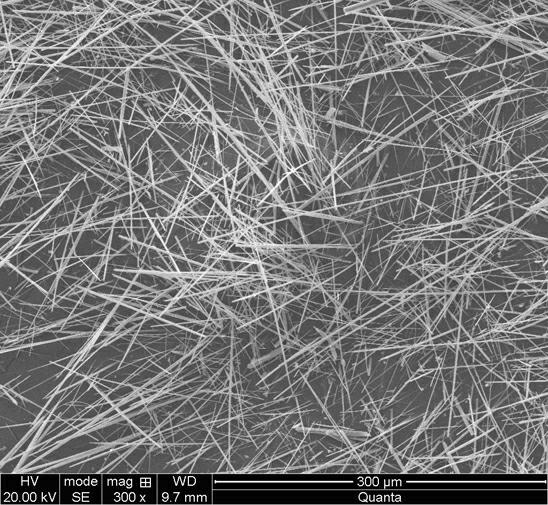

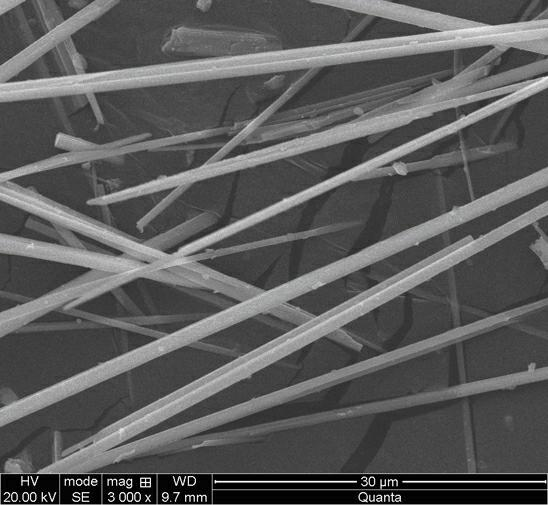

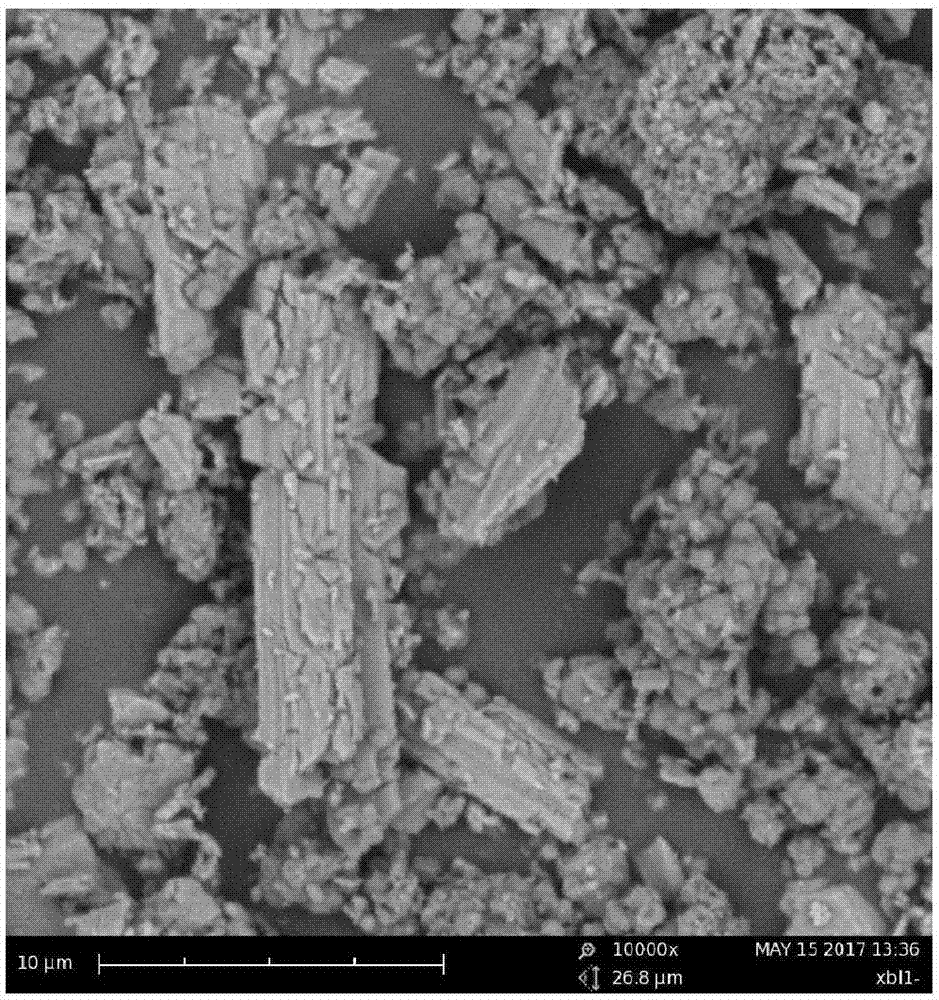

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

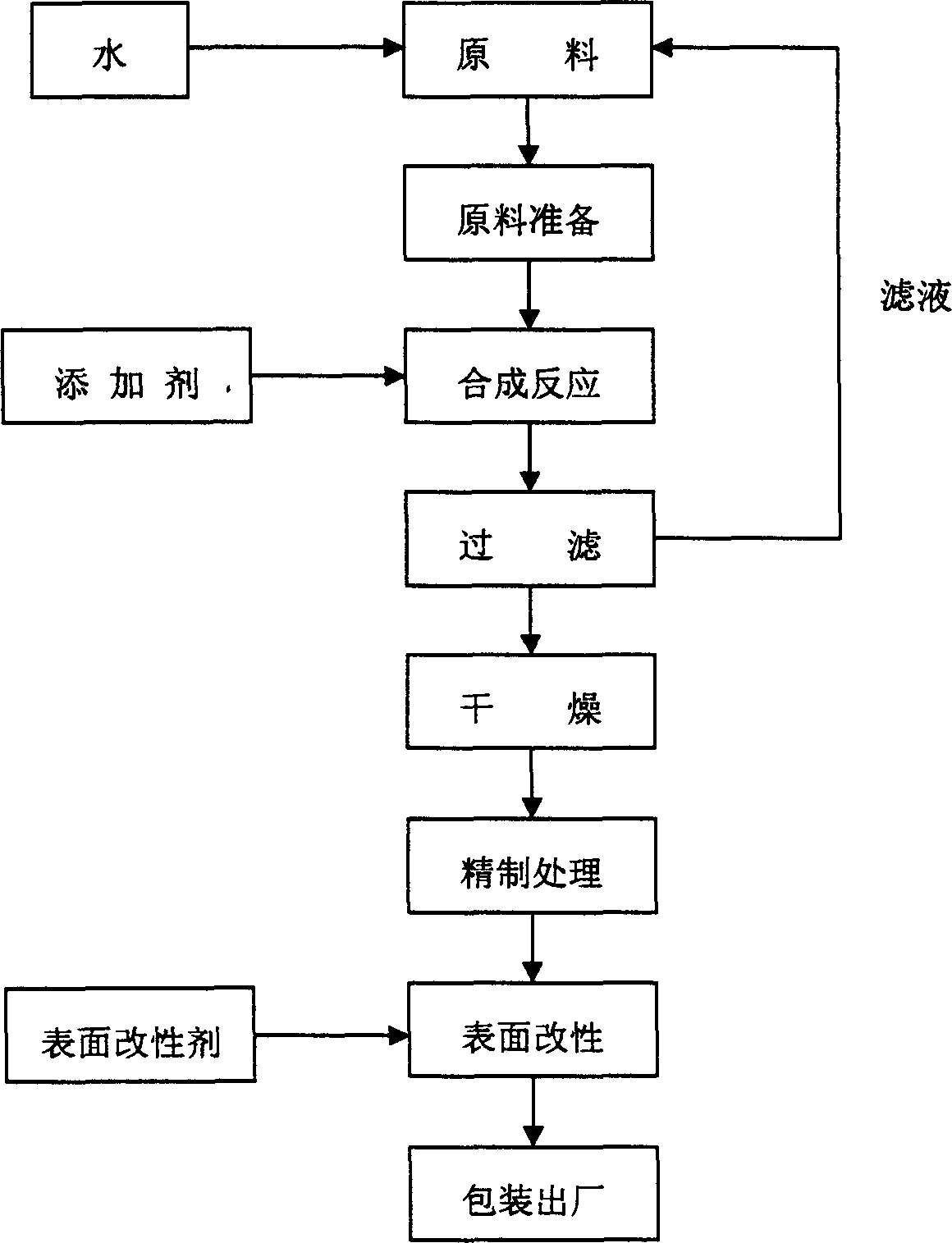

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

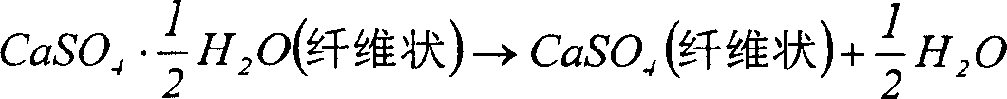

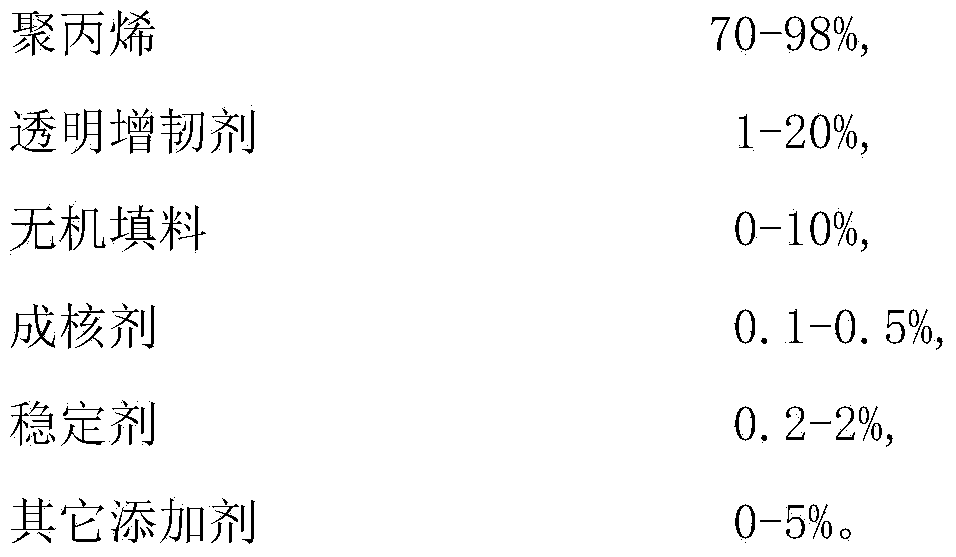

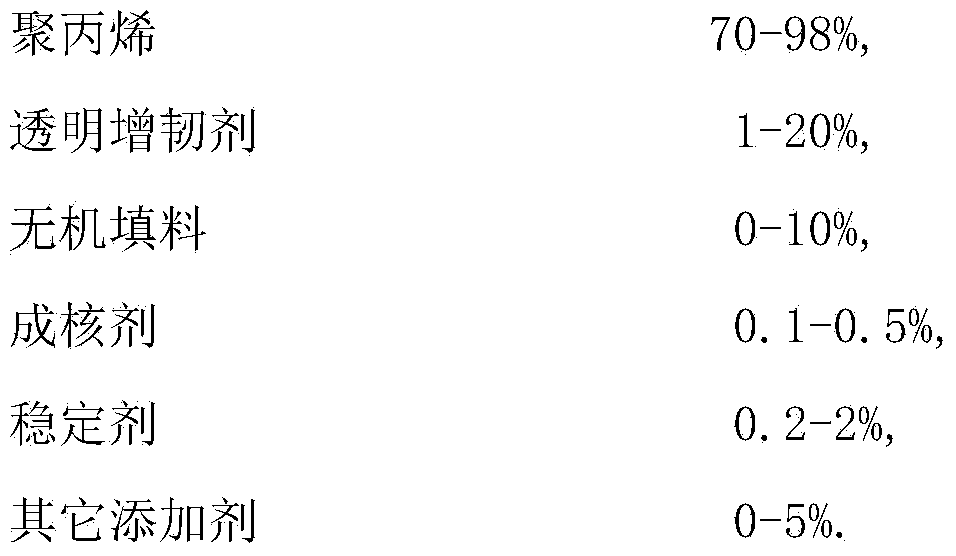

Polypropylene composite material for 3D (Three Dimensional) printing and preparation method thereof

The invention discloses a polypropylene composite material for 3D (Three Dimensional) printing and a preparation method thereof. The polypropylene composite material is composed of following raw materials in percentage by weight: 70%-98% of polypropylene, 1%-20% of a transparent toughening agent, 0-10% of inorganic fillers, 0.1%-0.5% of a nucleating agent, 0.2%-2% of a stabilizing agent and 0-5% of other additives. The polypropylene composite material has the advantages that 1 a propylene-based elastic body is used as the toughening agent for processing polypropylene so that the roughness of materials can be improved and the shrinkage rate of the materials is reduced; the transparency is not greatly influenced; a beta nucleating agent is used for accelerating a crystallization speed; the molding speed is improved, the size of a spherical crystal is thinned and the transparency is improved; the density of a crystal region is reduced and the shrinkage rate is reduced; super-pure and superfine talcum powder or calcium sulfate crystal whiskers with a high mesh number and the like are adopted so that the shrinkage rate is reduced and the good transparency is kept. The polypropylene composite material for the 3D printing has the advantages that 1 the comprehensive performance is good; 2 a manner of wholly feeding from a main feeding opening is adopted so that the dispersion effects of the toughening agent, the talcum powder and the like are improved, and the performance of the composite material is further improved.

Owner:CHONGQNG PRET NEW MATERIAL +2

Method for preparing calcium sulfate crystal whisker from many kinds of industrial waste residue gypsum serving as raw materials

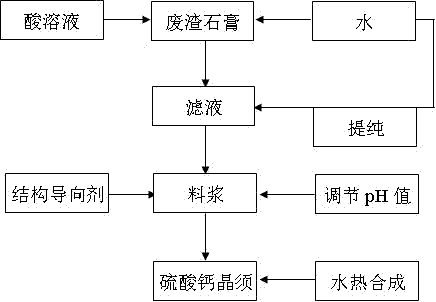

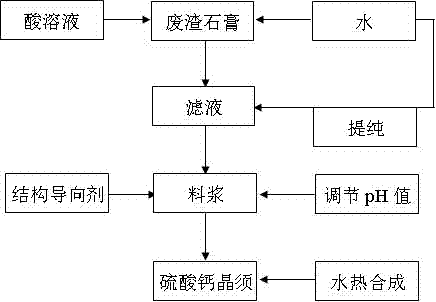

InactiveCN102212884AIncrease added valueTo achieve the purpose of turning waste into treasurePolycrystalline material growthFrom normal temperature solutionsSolubilityLiquid ratio

The invention relates to a method for preparing a high-quality calcium sulfate crystal whisker, which comprises the following steps of: purifying industrial waste residue gypsum serving as a raw material by utilizing the characteristic of the obvious change of the solubility of calcium sulfate in specific acid solution with temperature, adjusting the solid-to-liquid ratio and pH value of purified filter liquor, and synthesizing the high-purity and high-whiteness calcium sulfate crystal whisker in a hydrothermal mode under the action of a structural guiding agent. In a process for preparing the calcium sulfate crystal whisker from many kinds of industrial waste residue gypsum, the bottleneck problem of the large-scale industrial utilization of complex varieties of waste residue gypsum impurities is solved fundamentally, and the aims of saving energy, reducing emission and recycling waste materials are fulfilled, and the method has a bright application and market prospect.

Owner:SHANGHAI UNIV

Method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure

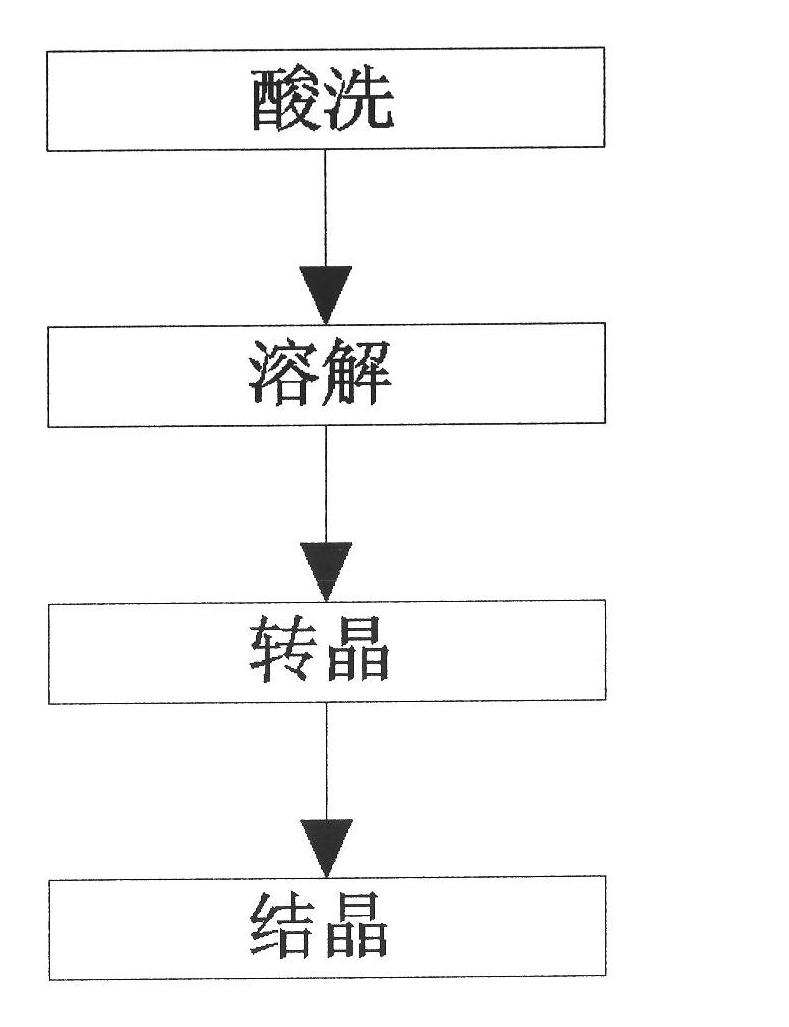

ActiveCN102352535ASimple manufacturing processEasy to implementPolycrystalline material growthFrom normal temperature solutionsDispersityCalcium sulfate crystals

The invention discloses a method for preparing calcium sulfate crystal whiskers from desulfurized gypsum under normal pressure. The method comprises the following steps: 1) pickling; 2) dissolving; 3) rotating crystal; and 4) crystallizing, after crystallizing, carrying out solid-liquid separation, washing filter cake with water, and drying to obtain calcium sulfate crystal whiskers. The method disclosed by the invention has the advantages that: the preparation process is simple and is easy to achieve, and the production efficiency is high; higher-purity and higher-whiteness calcium sulfate crystal whiskers are prepared by adopting a normal-pressure recrystallization method, controlling related process conditions and utilizing the characteristic that the dissolubility of main component calcium sulfate dihydrate of desulfurized gypsum in specific solution changes obviously along with the temperature; obtained calcium sulfate crystal whisker product has regular morphology, low agglomeration and good dispersity; and in addition, inorganic acid solution used for recrystallization can be recycled, and inorganic acid solution is not consumed in the reaction process, thereby creating better economic benefit, environmental benefit and social benefit, reducing the burden of coal-fired power plant and increasing enterprise benefits.

Owner:上海大学浙江嘉兴新兴产业研究院

Method for preparing ultra-fine calcium sulfate crystal whisker by using phosphogypsum

ActiveCN101792932ALarge diameterSmall diameterPolycrystalline material growthSingle crystal growth detailsFiltrationWhiskers

The invention discloses a method for preparing ultra-fine calcium sulfate crystal whiskers by using phosphogypsum. The method comprises that the phosphogypsum is ultra-fine treated to powder with grain size of 0.1-100 mum, water is added into the powder to prepare slurry with weight percent of 5-15 percent, pH value is regulated to be 3-5, reaction is kept for 3-5h at 125-145 DEG C and under 2-3MPa, pumping filtration is conducted when the obtained product is hot, and the filtered product is dried at 120-250 DEG C to obtain the calcium sulfate crystal whiskers. Moreover, crystal promoter with weight 0.10-0.20 time of the weight of the phosphogypsum and seed crystal with weight 0.1-0.2 time of the weight of the phosphogypsum can be added. The invention has the advantages of low production cost, simple production method and good comprehensive performance.

Owner:WENGFU (GRP) CO LTD +1

Modified calcium sulfate crystal whisker papermaking filler, preparation method and applications thereof

ActiveCN102852031AHigh whitenessHigh strengthPolycrystalline material growthInorganic compound additionPlant fibrePapermaking

The present invention discloses a modified calcium sulfate crystal whisker papermaking filler, a preparation method and applications thereof, wherein a modified calcium sulfate crystal whisker papermaking filler is prepared, and then the modified calcium sulfate crystal whisker papermaking filler is applied in papermaking industry. The application of the modified calcium sulfate crystal whisker papermaking filler in the papermaking industry comprises: 1) selection a papermaking slurry, (2) use of the modified calcium sulfate crystal whisker papermaking filler and related auxiliary materials, 3) papermaking, and 4) white water circulation. According to the present invention, the calcium sulfate crystal whisker raw material source is wide, conditions are wide, and solid waste pollution can be effectively solved; the modified calcium sulfate crystal whisker product has characteristics of high whiteness, low abrasion, effectively-controlled solubility, high papermaking retain rate, and low white water load, the problem of pipe scale is eliminated, and the product can completely replace calcium carbonate, kaolin, talc powder, and other papermaking fillers, and partial plant fiber raw materials; and the method has characteristics of low equipment investment, simple modification process, strong operability and low cost, and is applicable for large scale production.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

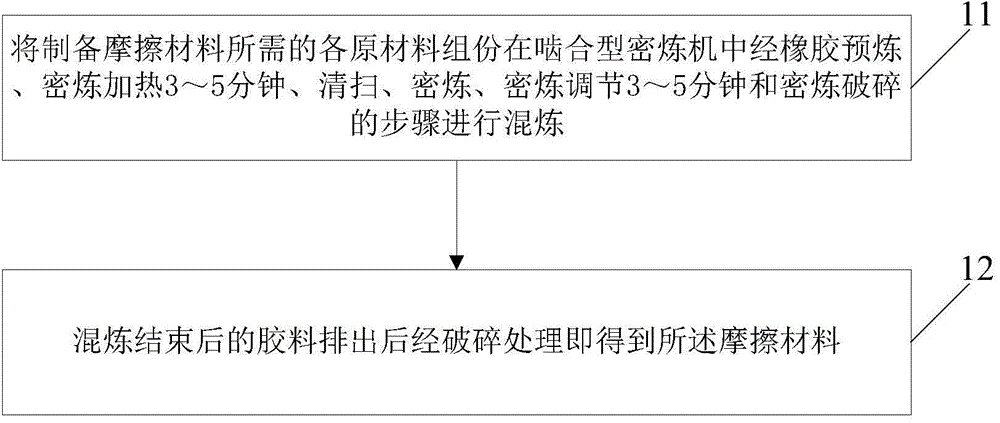

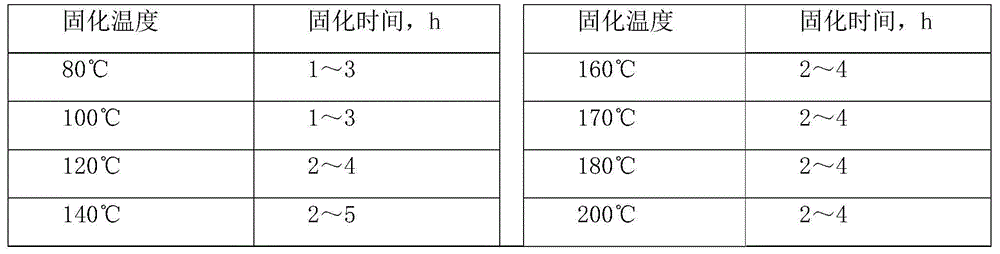

Friction material for brake-shoe of heavy axle-load wagon and preparation method of friction material

InactiveCN104087245AMeet the friction performanceMeet the mechanicsOther chemical processesFiberKyanite

The invention discloses a friction material for a brake-shoe of a heavy axle-load wagon. The friction material is prepared from the following components in percentage by mass: 6-12 percent of nitrile rubber, 1-4 percent of butadiene styrene rubber, 3-8 percent of A-stage phenolic resin, 0.4-1 percent of insoluble sulfur, 0.1-0.6 percent of an accelerant, 0.1-0.6 part of a curing agent, 2-6 percent of carbon black, 8-18 percent of barite, 1-4 percent of kyanite, 17-40 percent of hybrid fibers, 7-14 percent of magnesium oxide, 2-6 percent of petroleum coke, 2-8 percent of calcium sulfate crystal whiskers, 1-4 percent of molybdenum disulfide, 1-5 percent of crystalline flake graphite, 1-4 percent of artificial graphite, 1-4 percent of mica iron oxide and 1-3 percent of antimony sulfide. The friction material can satisfy the friction performance and mechanical property required by the brake-shoe of the heavy axle-load wagon and can meet the high speed operating requirement on heavy load of the wagon.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Method for preparing calcium sulfate crystal whisker in low cost

InactiveCN102965721AIncrease profitReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateHigh pressure

The invention discloses a method for preparing calcium sulfate crystal whisker in low cost and relates to a method for preparing the calcium sulfate crystal whisker. The method comprises the following steps of: crushing raw materials consisting of ground limestone and anhydrite, treating the crushed ground limestone and anhydrite by a sulfuric acid solution, adding a crystal growth substance to prepare a mixture solution, preparing calcium sulfate hemihydrate crystal whisker with higher length-diameter ratio by a hydrothermal synthesis method at high temperature under high pressure, and carrying out filtering, washing and high-temperature crystal water removing steps on the calcium sulfate hemihydrate crystal whisker to obtain high-quality anhydrous calcium sulfate crystal whisker products. The calcium sulfate crystal whisker prepared by the method disclosed by the invention can be applied to high polymer material such as plastic and rubber to improve the performances of polymer materials by serving as a reinforcing material. The method disclosed by the invention has the advantages of low production cost, simple operation and high additional value of products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

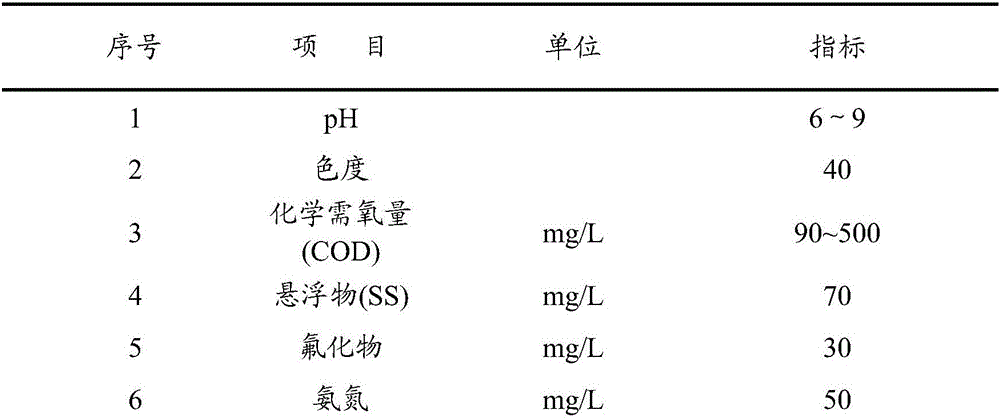

Power plant flue gas desulfurization wastewater treatment process

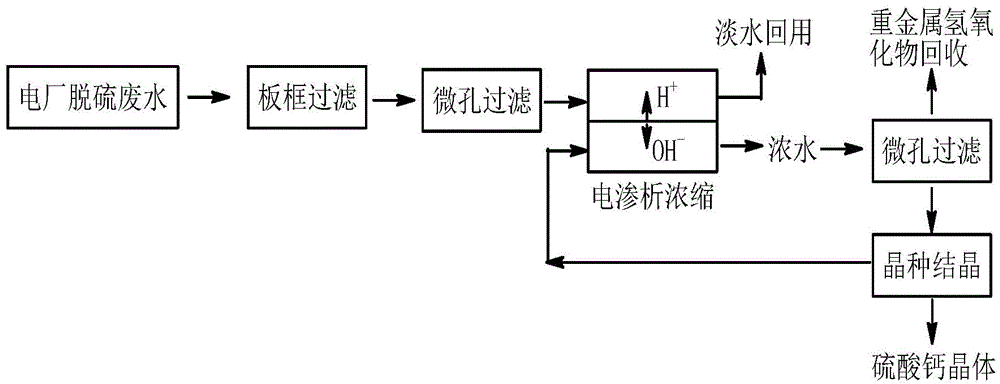

ActiveCN104478141AOvercoming complexityOvercome the disadvantage that heavy metals cannot be recycled and will form waste solidsTreatment involving filtrationWaste water treatment from gaseous effluentsFiltrationFresh water

The invention relates to a wastewater treatment process, and in particular relates to a power plant flue gas desulfurization wastewater treatment process. The process comprises three steps as follows: I, carrying out plate frame filtration on desulfurated wastewater in a power plant, and implementing microporous filtration so as to obtain a clear filtrate without suspended solids; II, concentrating the clear filtrate by virtue of an electrodialysis membrane unit having a pH value regulating function, and recycling concentrated fresh water; and III, carrying out microporous filtration on a mixture in a concentrated water room, recovering filter residue, crystallizing the filtrate in a calcium sulfate crystal seed crystallizing device, and separating out calcium sulfate crystal. The wastewater treatment process disclosed by the invention is simple in process, and capable of effectively recovering heavy metals and achieving a purpose of zero discharge of desulfurized wastewater in a real sense.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Preparation of hydrophobic nature calcium sulphate crystal whisker with liquid phase method of sodium sulfate wastewater in situ

InactiveCN101343773ASimple production processLow costPolycrystalline material growthFrom normal temperature solutionsLiquid wasteSurface-active agents

The invention relates to a normal-pressure low-temperature liquid phase in situ hydrophobic calcium sulfate crystal whisker preparation method, in which sodium sulfate waste water is adopted as a raw material. The preparation method comprises the steps: a certain amount of calcium salt of 0.5 to 1mol / L is added in a three-necked bottle, a surface active agent is added thereto, and after the mixture is evenly blended, a certain amount of sodium sulfate waste water is added, the temperature is increased to 30 to 70 DEG C, the mixture is blended at a constant temperature to cause the crystallizing reaction for 3 to 7 hours, the obtained white product is dried and treated byheat at the temperature of 60 to 200 DEG C after being filtered and cleaned, the calcium sulfate crystal whisker powder with the diameter of 1 to 2 micron, the length of 30 to 50 micron, and the length-diameter ratio of 15 to 50 is obtained, the filtered fluid is a salt solution as much again as the raw material, sodium chloride is produced based thereon, and the secondary utilization of the waste fluid is realized. The invention has the advantages that the sodium sulfate waste water is simply treated during the preparation process, the process is simplified, the energy resources are saved, the cost is reduced, the recycling and utilization of the renewable resources are realized, and the product is provided with higher economic value and social value.

Owner:JILIN UNIV

Method for preparing high-purity calcium sulfate dihydrate crystal whisker by using metallurgic flue gas desulfurization gypsum recrystallization process

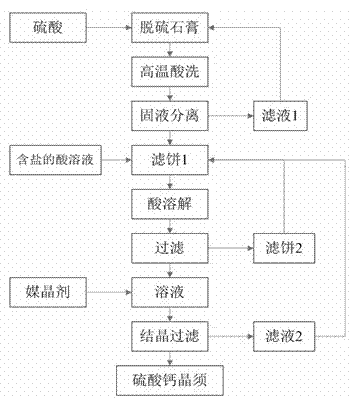

ActiveCN104846440APromote conversionImprove Calcium UtilizationPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryCalcium Sulfate Dihydrate

The invention discloses a method for preparing a high-purity calcium sulfate dihydrate crystal whisker by using a metallurgic flue gas desulfurization gypsum recrystallization process. The method comprises the steps of pickling metallurgic flue gas desulfurization gypsum to remove a small deal of calcium carbonate or calcium oxide and soluble impurities; dissolving the gypsum by using a salt-containing acid solution to obtain a product used as a raw material for preparing the high-purity calcium sulfate dihydrate crystal whisker; adding a medium crystal agent to control the controllable growth of a calcium sulfate crystal whisker to form a calcium sulfate crystal whisker with controllable length-to-diameter ratio and complete crystal appearance, filtering and drying to obtain the calcium sulfate dehydrate crystal whisker. The recycling of the high-added-value calcium sulfate crystal whisker prepared from the metallurgic flue gas desulfurization gypsum is realized under normal-pressure and mild conditions according to the recrystallization principle. The raw material adopted in the method is available, the production process condition is simple, the added value of the high-purity crystal whisker is high, and the produced calcium sulfate dihydrate crystal whisker has the characteristics of small diameter, high length-to-diameter ratio, complete and uniform appearance and stable performance, can be used as a reinforcing material to be applied to an additive for industries such as plastics, rubber, papermaking, ceramics and the like and has a wide application prospect.

Owner:KUNMING METALLURGY INST

Method for preparing modified calcium sulfate crystal whisker papermaking filler

InactiveCN102337703AWide variety of sourcesWide conditionPolycrystalline material growthInorganic compound additionFlocculationPlant fibre

The invention discloses a method for preparing a modified calcium sulfate crystal whisker papermaking filler. The method is characterized by comprising the following steps of: (1) calcining a crystal whisker; (2) performing organic dissolution restraint modification; (3) drying; and (4) grinding for flocculation elimination. In the method, the used calcium sulfate crystal whisker has a wide raw material source and a wide condition, and can effectively solve the problem of solid pollution caused by various industrial gypsum waste residues or metal waste residues; the prepared modified calcium sulfate crystal whisker filler has the characteristics of high whiteness, low abrasion, high retention rate and the like and can effectively replace the conventional calcium carbonate fillers or plantfibers; simultaneously, the solubility of the prepared modified calcium sulfate crystal whisker filler is effectively controlled, and the filler is easy to disperse in papermaking aqueous pulp, so that the problems that the calcium sulfate has high water solubility and has a low retention rate, high content of white water waste ions, high possibility of scaling in a pipeline and the like when used as the papermaking filler are solved, the application field of the crystal whisker is expanded, and the additional value of the crystal whisker is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Continuous technological process for producing calcium sulfate whiskers on a large scale

ActiveCN102330152AReduce the workload of manual operationsLow technical requirementsPolycrystalline material growthFrom normal temperature solutionsLow speedSulfate

The invention discloses a continuous technological process for producing calcium sulfate whiskers on a large scale. The problem that the continuous flow operation is unavailable in the traditional mass production of the calcium sulfate whiskers is solved. According to the invention, through improving the calcium sulfate crystal synthesis condition, the calcium sulfate whiskers can be continuously synthesized on a large scale according to five general requirements (dilute solution, stable salt contained low speed, uniform mixing and long ageing (time)) which must be followed in the production of the calcium sulfate whiskers. According to the invention, the workload of manual operation is further reduced and the technical requirements are reduced; and the continuous technological process for producing the calcium sulfate whiskers on a large scale, disclosed by the invention, has the special advantages of simplicity, high efficiency, energy conservation, environment friendliness and extremely excellent whisker quality.

Owner:武善东 +1

Method for preparing brake block by calcium sulfate crystal whisker

InactiveCN101177601AEasy to compressImproved high-temperature heat-fading propertiesOther chemical processesFriction liningAdhesiveAramid

The invention relates to a method of using calcium sulfate whisker in the friction material field to prepare a brake block. The technical proposal of the invention consists of the following materials by weight: 5-18 portions of adhesive which is produced by employing modified phenolic resin; 20-40 portions of strengthening materials which are mixed by one or several of calcium sulfate whisker and one of aramid fiber, steel fiber, ceramic fiber and mineral fiber and glass fiber; 1-15 portions of grinding agent which is compounded by one or several of aluminum oxide , ferric oxide and magnesium oxide; 5-15 portions of lubricant which is compounded by one or several graphite, molybdenum disulfide and mica; and 10-30 portions of fillers which are compounded by one or several barium sulfate, potassium titanate and vermiculite powder. The brake block prepared by the method is able to lower the thermal fading of organics caused by thermal decomposition under high temperature, and has stable friction coefficient; when in use, the brake block has comfortable brake, being quiet, small abrasion and more than 70,000 kilometers of service life.

Owner:信义集团公司

Process for preparing calcium sulfate crystal whisker by desulfurized gypsum as well as calcium sulfate crystal whisker

InactiveCN102605430ASolve the costSolve problems that are not conducive to sustainable developmentPolycrystalline material growthFrom normal temperature solutionsCopper chlorideDiameter ratio

The invention discloses a process for preparing calcium sulfate crystal whisker by desulfurized gypsum as well as calcium sulfate crystal whisker, which can be used for solving the problems that the conventional process for preparing the calcium sulfate crystal whisker by the desulfurized gypsum has the defects of lower quality of the prepared calcium sulfate crystal whisker, higher used reagent price, and higher production cost. The process for preparing the calcium sulfate crystal whisker by the desulfurized gypsum is realized by the steps of material taking, ball-milling, slurry preparation, habit modifier feeding, hydrothermal reaction, dehydration and drying. The calcium sulfate crystal whisker prepared by the desulfurized gypsum has higher quality, has diameter of 1-3 mu m and has a length-diameter ratio of 100-150. Furthermore, the diameter distribution and the length-diameter variation of the calcium sulfate crystal whisker are smaller; and the calcium sulfate crystal whisker is crystallized well on the surface. The process provided by the invention has the advantages of simple process, and convenience in control. The used habit modifier is copper chloride and has lower cost, so that the production cost is effectively reduced and the process provided by the invention is good for development of enterprises. The conversion rate of the desulfurized gypsum reaches to be more than 80%. The prepared calcium sulfate crystal whisker has lower impurity content. The invention provides a novel route with high extra value, high technology and high quality utilization for the treatment of the desulfurized gypsum.

Owner:HENAN UNIV OF URBAN CONSTR

Method for preparing micron-sized calcium sulfate particles and crystal whiskers from phosphogypsum

InactiveCN102634843AReduce contentHigh whitenessPolycrystalline material growthFrom normal temperature solutionsPhosphogypsumToxic industrial waste

The invention discloses a method for preparing micron-sized calcium sulfate particles and crystal whiskers from phosphogypsum, which comprises the following steps: treating phosphogypsum with a hot sulfuric acid mixed solution; then separating while the solution is hot; cooling the leach solution to obtain calcium sulfate crystal whiskers; and pickling the solid phase to obtain micron-sized calcium sulfate particle products having a phosphorus-fluorine content of less than 0.1% and a higher whiteness, wherein the pickling process conditions are as follows: the temperature is 60-90 DEG C, the mixed solution is a sulfuric acid solution containing assistants, the concentration of the sulfuric acid is 15-40%, the pickling time is 0.5-4.0h, and the stirring speed is 200-500rpm. The method disclosed by the invention is simple and easy to operate, can take full advantage of industrial waste phosphogypsum, develops a new application way for the utilization of phosphogypsum, changes the waste into valuables, reduces environment pollution and saves resources.

Owner:KUNMING UNIV OF SCI & TECH

Calcium sulfate crystal whisker glass fiber composite reinforcing nylon material and preparation method thereof

The invention relates to a calcium sulfate crystal whisker glass fiber composite reinforcing nylon material and a preparation method thereof. The material is prepared by the following raw materials in weight percent: 50-70% of nylon 6, 5-20% of calcium sulfate crystal whisker, 5-30% of alkali-free glass fiber, 0.2-5% of silane coupling agent, 0.1-0.5% of antioxidant, and 0.1-0.5% of lubricant. The preparation method comprises the following steps: weighing raw materials according to the above weight percent; placing the calcium sulfate crystal whisker and the silane coupling agent into a high mixing machine to process for 2-5min; discharging; and placing the evenly-mixed raw materials into a screw machine for extrusion and pelletizing. The invention is characterized in that the prepared nylon material has higher mobility and higher strength, can improve surface floating fiber and can be used for manufacturing surface materials with higher surface requirements such as cars, electronics and the like.

Owner:SHANGHAI SUNNY

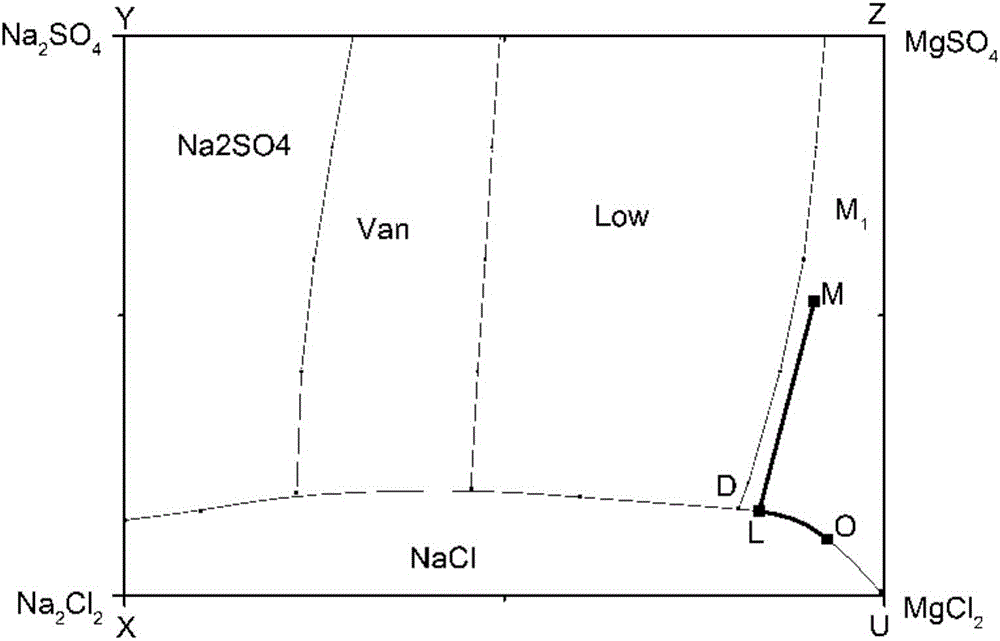

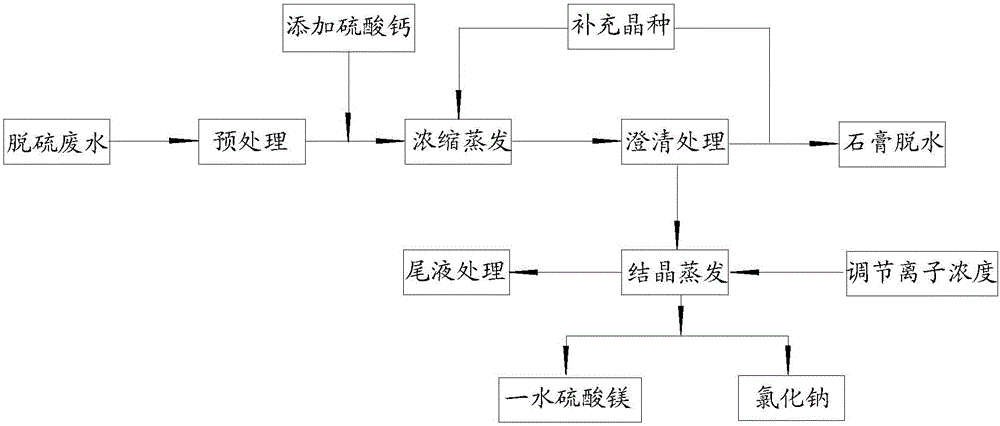

Desulfurization wastewater resourceful treatment method

ActiveCN105906125ALow running costLow investment costWaste water treatment from gaseous effluentsMultistage water/sewage treatmentEvaporationPre treatment

The invention relates to a desulfurization wastewater resourceful treatment method. The method comprises the following steps of 1, pretreatment, wherein suspended solids in desulfurization wastewater are removed; 2, concentration evaporation, wherein wastewater is subjected to evaporation treatment, in the initial stage of evaporation, calcium sulfate crystals are put into the wastewater, and after evaporation is ended, wastewater is cleared up; 3, crystallization evaporation, wherein the concentration of ions in wastewater is adjusted, crystallization points of the solution are made to fall into a crystallization region of a magnesium sulfate monohydrate salt or crystallization regions of magnesium sulfate monohydrate and sodium chloride salts, and then wastewater is subjected to evaporation crystallization; 4, crystallization salt separation, wherein the obtained mixed salt is separated to obtain a magnesium sulfate monohydrate crystallization salt and a sodium chloride crystallization salt. According to the desulfurization wastewater resourceful treatment method, the investment and operation costs are low, and two high-value industrial salts of magnesium sulfate and sodium chloride can be obtained.

Owner:GUANGDONG DEGA POWER ENVIRONMENTAL PROTECTION TECH CO LTD

Clay green sand for high-pressure molding and preparation method thereof

The invention discloses clay green sand for high-pressure molding and a preparation method thereof. The clay green sand is prepared from the following raw materials in parts by weight: 50-70 parts of zircon sand, 30-40 parts of chromite sand, 8-12 parts of bentonite, 5-10 parts of pottery, 3-6 parts of calcium sulfate crystal whiskers, 2-3 parts of calcium lignosulphonate, 1-2 parts of lauryl alcohol polyoxyethylene, 1.5-2.5 parts of polyoxyethylene, 1-2 parts of iron oxide red, 4-8 parts of stove ash slag, 3-5 parts of aluminum silicate fibers, 2-4 parts of composite powder and 5-10 parts of water. The molding sand disclosed by the invention is added with the aluminum silicate fibers and the calcium sulfate crystal whiskers, so that strength and toughness of the molding sand can be improved, damages to a sand mould during drawing are reduced; moreover, the molding sand further has good ability of preventing burnt-on sand and sand inclusion as well as low evolution rate, good gas permeability, and the like, can be used for effectively avoiding the defects such as gas pores and sand inclusion of a casting piece, and improving the production efficiency of a high-pressure molding line and the quality of the casting piece.

Owner:TONGLING JINGWEI FLUID SCI & TECH

High impact resistance and aging resistance PVC-M pipe

The present invention relates to the technical field of PVC pipes, and discloses a high impact resistance and aging resistance PVC-M pipe, which comprises, by weight, 60-85 parts of a PVC resin, 3-7 parts of light calcium carbonate, 1-3 parts of MBS, 1-3 parts of chlorinated polyethylene, 1-3 parts of a processing aid, 1-3 parts of calcium sulfate crystal whisker, 2-4 parts of a calcium zinc stabilizer, 0.1-0.3 part of a lubricant, 0.1-0.3 part of carbon black, 0.1-0.4 part of hindered phenol, and 0.1-0.4 part of mercaptan. According to the present invention, based on the aging mechanism of the pipe, through the synergy effect of 2,6-tert-butyl p-phenol and ethyl mercaptan, the mechanisms that the free radical transfers and the non-activated stable product alcohol is produced are used to terminate the chain reaction and inhibit the free radical generation, such that the PVC product produces the good light stability so as to improve the aging resistance of the PVC plastic finished product.

Owner:大禹节水(天津)有限公司

Method for preparing calcium sulfate crystal whiskers

InactiveCN102230226AImprove protectionLow costPolycrystalline material growthFrom normal temperature solutionsSulfateDistilled water

The invention relates to a method for preparing calcium sulfate crystal whiskers, which comprises the following steps of: mixing white mud and water according to a weight ratio of 1:(3-10), stirring for 5 to 10 minutes, standing for 8 to 12 hours, and filtering to obtain filter residues; mixing the filter residues and distilled water, stirring in a stirring container, and spraying dilute sulphuric acid solution continuously; when the pH value of the solution is 7, stopping stirring and spraying, and filtering to obtain filter liquor; putting the filter liquor into a high-pressure reaction kettle, adding calcium sulfate seed crystals, and crystallizing; and after crystallizing, filtering and drying to obtain the calcium sulfate crystal whiskers. In the method for preparing the calcium sulfate crystal whiskers, the white mud serving as industrial pollutants is recycled and is low in cost, so environmental protection is facilitated; a preparation process is simple, short in period and easy to control, and large-scale production can be realized; and products are large and uniform in a slenderness ratio, and stable in quality. The method can be used for the modification of rubber, plastics and coatings.

Owner:刘立文

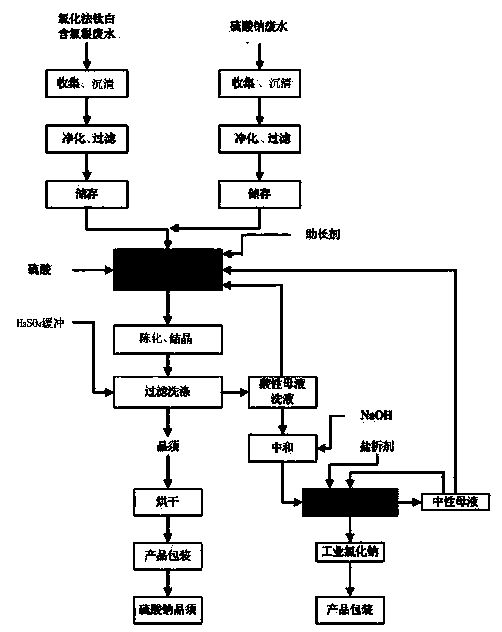

Process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production

ActiveCN103834989AImprove the level of cleaner productionSolve processing problemsPolycrystalline material growthFrom normal temperature solutionsFluidized bed dryingAnhydrous Calcium Sulfate

The invention relates to a process of producing calcium sulfate crystal whiskers from chloride-containing wastewater generated in chloride process titanium dioxide production. The process comprises the following steps: respectively colleting, clarifying, purifying and filtering chloride-containing wastewater generated in chloride process titanium dioxide production and sodium sulfate-containing wastewater, mixing for reacting, stirring, heating and adding sulfuric acid to adjust the pH value; meanwhile, adding magnesium chloride as a growth substance; placing in a crystallization tank to age and crystallize to obtain calcium sulfate crystals; filtering, and adding H2SO4 to be buffered and heated to be boiled; thermally filtering and washing by deionized water at the same time to obtain calcium sulfate crystal whiskers; feeding to a fluidized bed dryer to be dried and hydrated, and packaging to obtain anhydrous calcium sulfate crystal whiskers. The process is simple and low in cost, and is suitable for industrialized production, so that wastewater is comprehensively utilized.

Owner:中信钛业股份有限公司

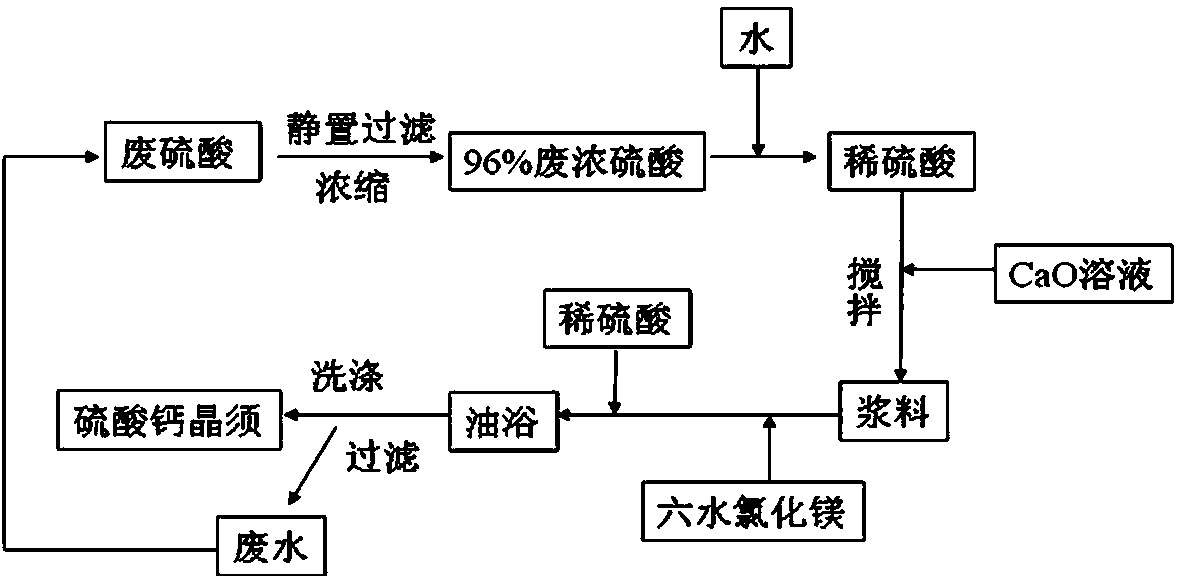

Method for processing waste sulfuric acid in graphene production process

ActiveCN103696015ASimple filterEasy to washPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryGraphite

The invention discloses a method for processing waste sulfuric acid in a graphene production process. The method is characterized by comprising the following steps: collecting the waste sulfuric acid, filtering and settling the waste sulfuric acid to obtain the transparent sulfuric acid, diluting the waste sulfuric acid with water to obtain a dilute sulfuric acid solution, and utilizing the obtained dilute sulfuric acid solution to synthesize calcium sulfate crystal whiskers. The waste sulfuric acid can be utilized to prepare the calcium sulfate crystal whiskers in the graphene production process, so that the pollution source can be eliminated; the environment can be obviously improved; the method benefits generation by generation, turns waste into valuable things, can achieve obvious economic benefits, and is simple in process and easy to operate.

Owner:山东金利特新材料有限责任公司

High-strength and heat-resistant polylactic acid material for 3D printing

ActiveCN104987680AImprove heat resistanceReduce heat warpageAdditive manufacturing apparatusEpoxyAntioxidant

The present invention relates to a high-strength and heat-resistant polylactic acid material for 3D printing, wherein the components comprise, by mass, 100 parts of a L-polylactic acid resin, 1-20 parts of an inorganic filler, 0.01-5 parts of a polycarboxylic acid metal salt, 0.1-5 parts of an amide compound, 0.1-5 parts of a plasticizer, 0.1-1 part of an antioxidant, and 0.1-2 parts of an anti-hydrolyzing agent, wherein the molecular weight of the L-polylactic acid resin is 100000-400000, the anti-hydrolyzing agent is mixing at least one or more than two selected from a Polycarbodiimide compound, a single carbodiimide compound and a compound having an active group epoxy, the inorganic filler is a mixture formed from one or at least two selected from nanometer silica, talc powder, calcium sulfate crystal whisker and mica, and the diameter of the inorganic filler is 0.05-5 [mu]m. According to the present invention, the tensile strength achieves more than or equal to 60 MPa, the bending strength achieves more than or equal to 100 MPa, the Vicat softening temperature is more than or equal to 120 DEGC, the mechanical property and the heat resistance are substantially improved compared with the commonly used PLA, and the practicality and the application range of the PLA supplies are substantially improved.

Owner:中广核三角洲(江苏)塑化有限公司

Method for surface modification of calcium sulfate crystal whisker

ActiveCN102634847AProtective structureMaintain aspect ratioPolycrystalline material growthAfter-treatment detailsAlcoholPolycaprolactone

Owner:KUNMING UNIV OF SCI & TECH

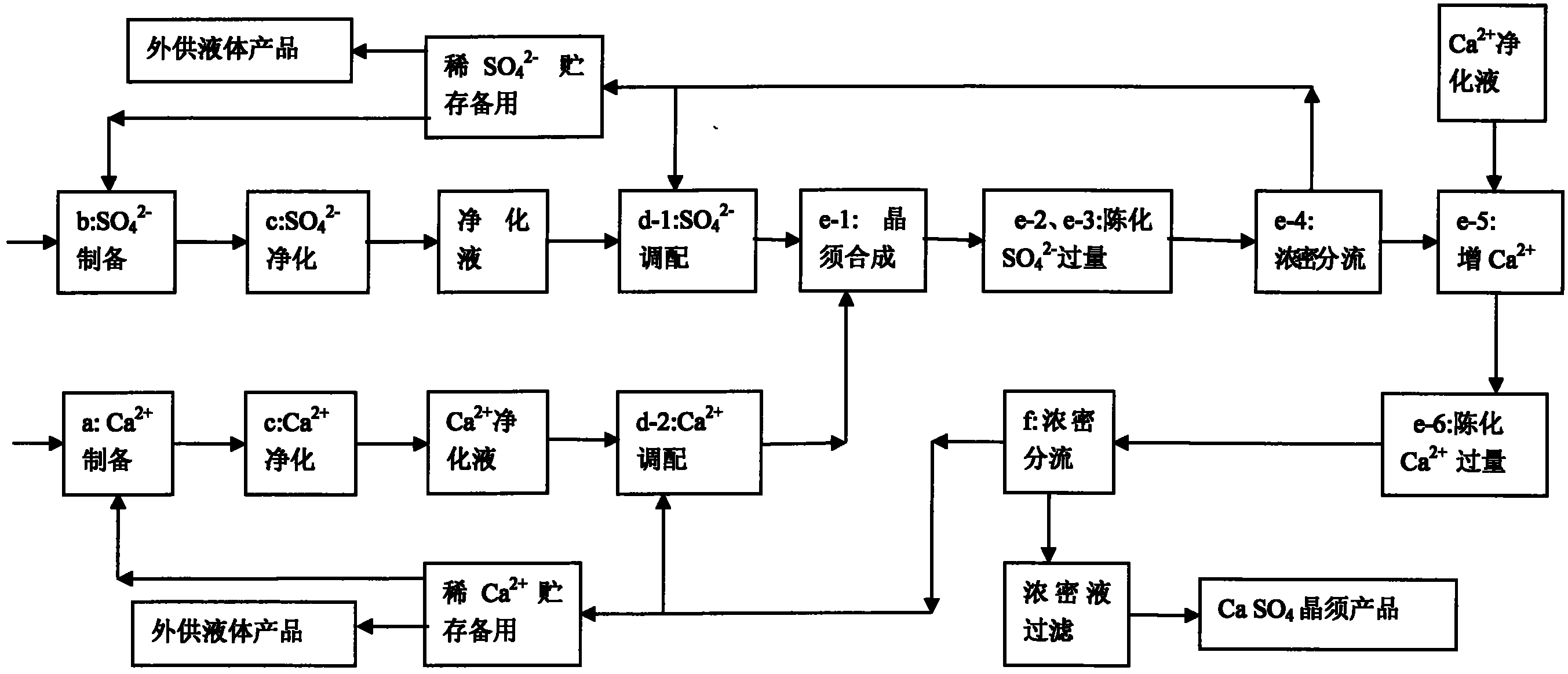

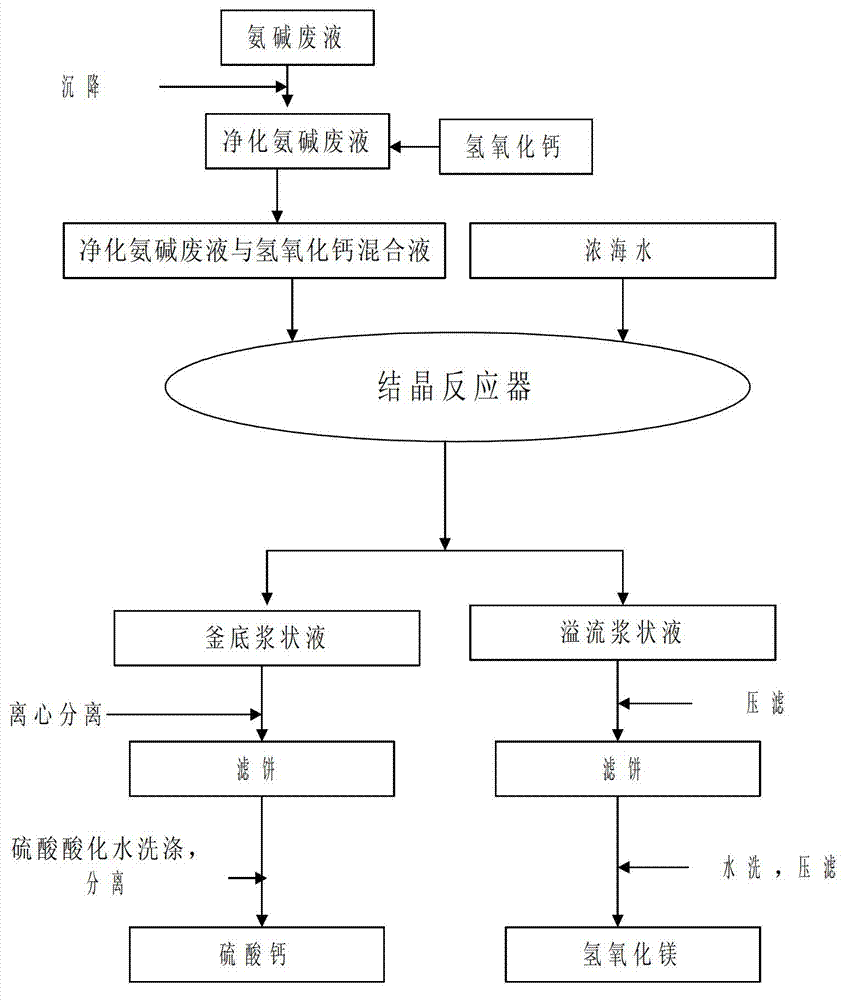

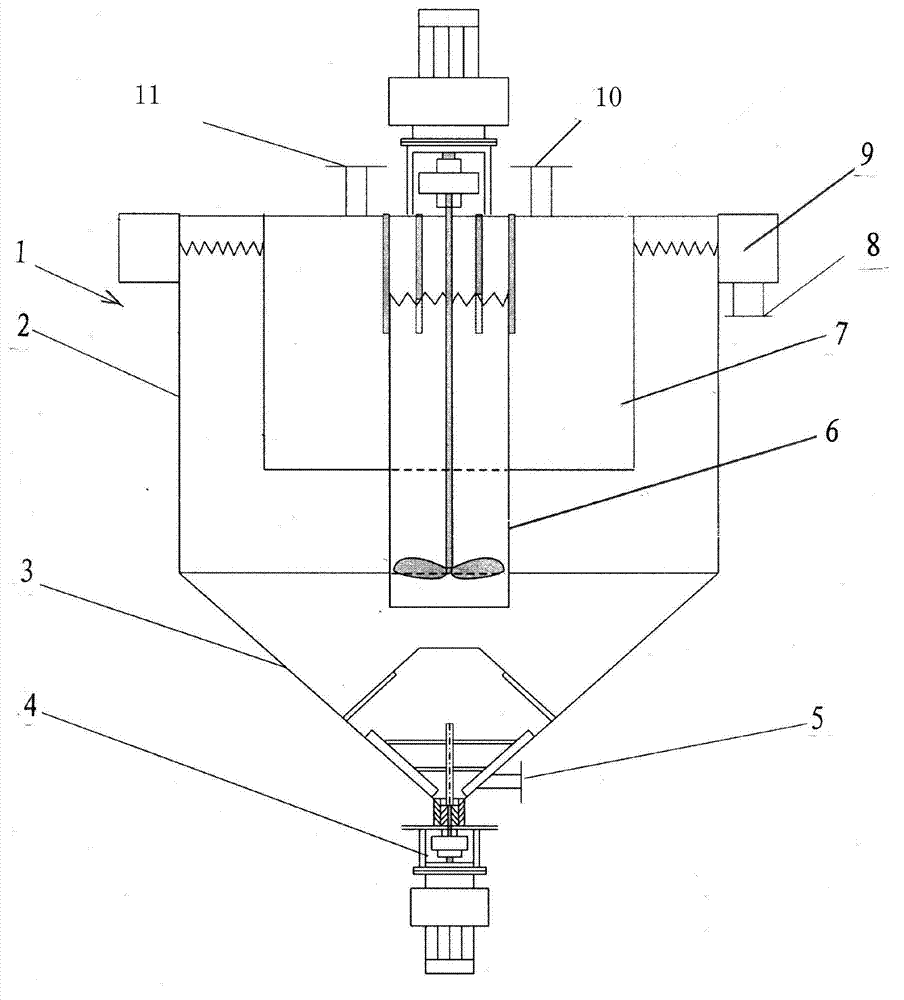

Method for co-producing calcium sulphate and magnesium hydrate by ammonia alkali waste liquid and concentrated seawater

ActiveCN102951668AReduce supersaturationInhibition of spontaneous nucleationCalcium/strontium/barium sulfatesMagnesium hydroxideCalcium hydroxideCalcium ion binding

The invention discloses a method for co-producing calcium sulphate and magnesium hydrate by ammonia alkali waste liquid and concentrated seawater. The method comprises the technical steps of ammonia alkali waste liquid purification, calcium hydroxide dissolving, crystallization reaction, kettle bottom slurry liquid separation washing and overflowing slurry liquid filtering washing. The calcium sulphate is dissolved in the purified ammonia alkali waste liquid, formed mixed solution and the concentrated seawater are respectively and continuously added into a crystallization reactor, the circulation mixing is carried out under the effect of a circulation lifting device arranged in the crystallization reactor, sulfate ions and calcium ions are combined to form large-grain-diameter calcium sulfate crystals to be settled to the bottom of the crystallization reactor, magnesium ions and hydroxyl ions are combined to form magnesium hydrate with smaller grain diameter, and the magnesium hydrate is lifted in the crystallization reactor through the circulation lifting device and overflows from an overflowing opening. The method has the characteristics of simple work procedure, high separation efficiency and the like, and the comprehensive utilization of resources is further realized.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

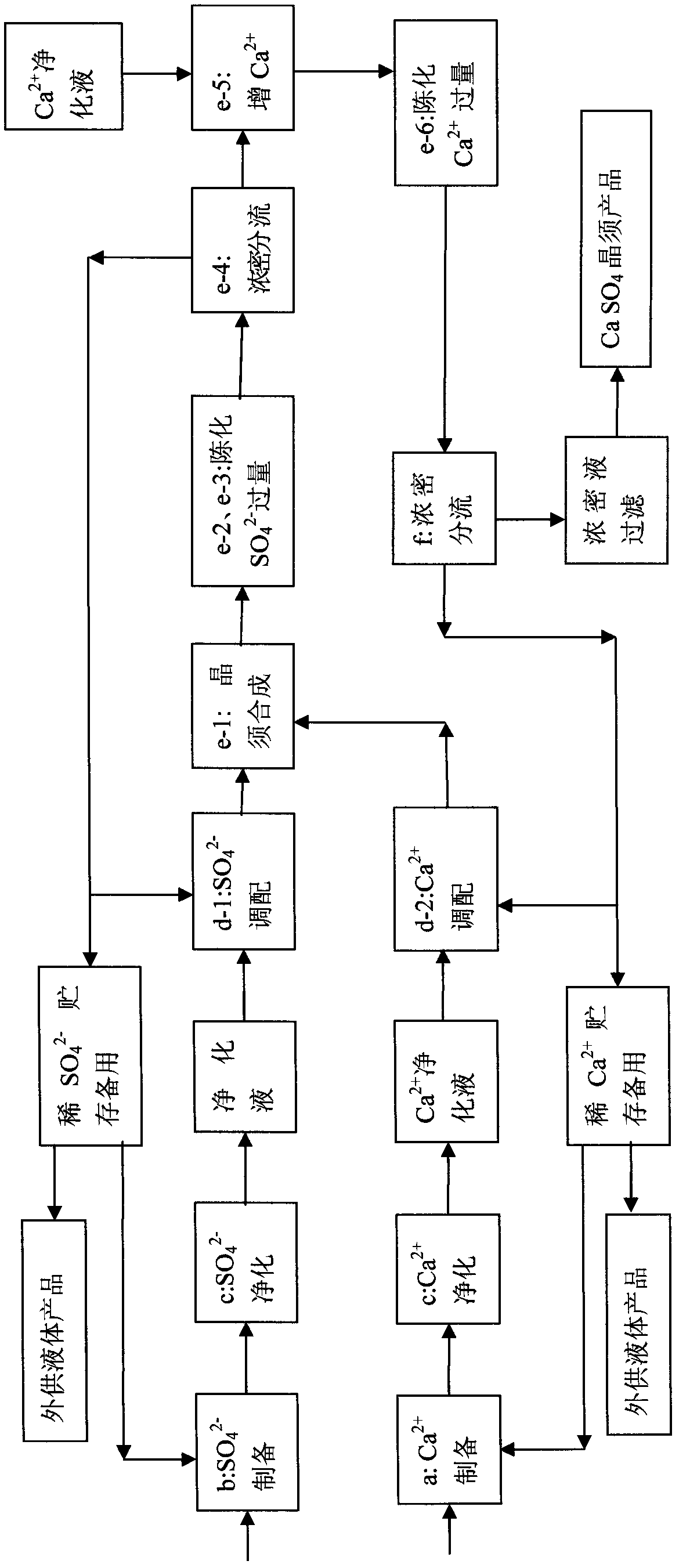

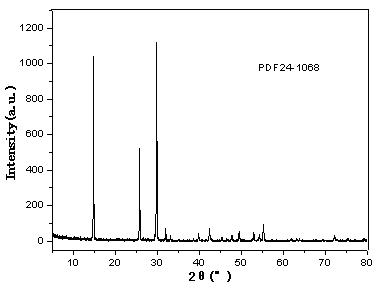

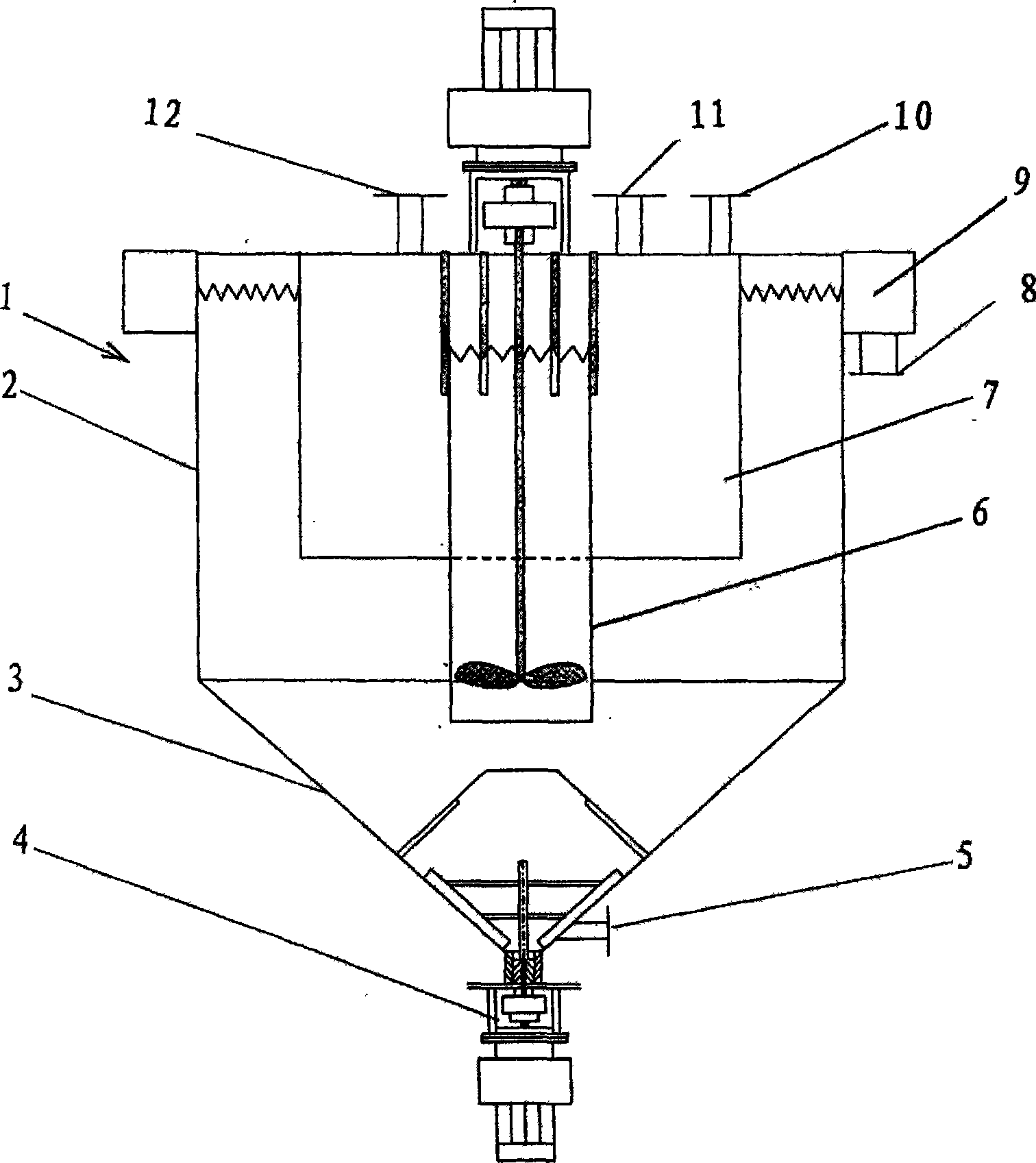

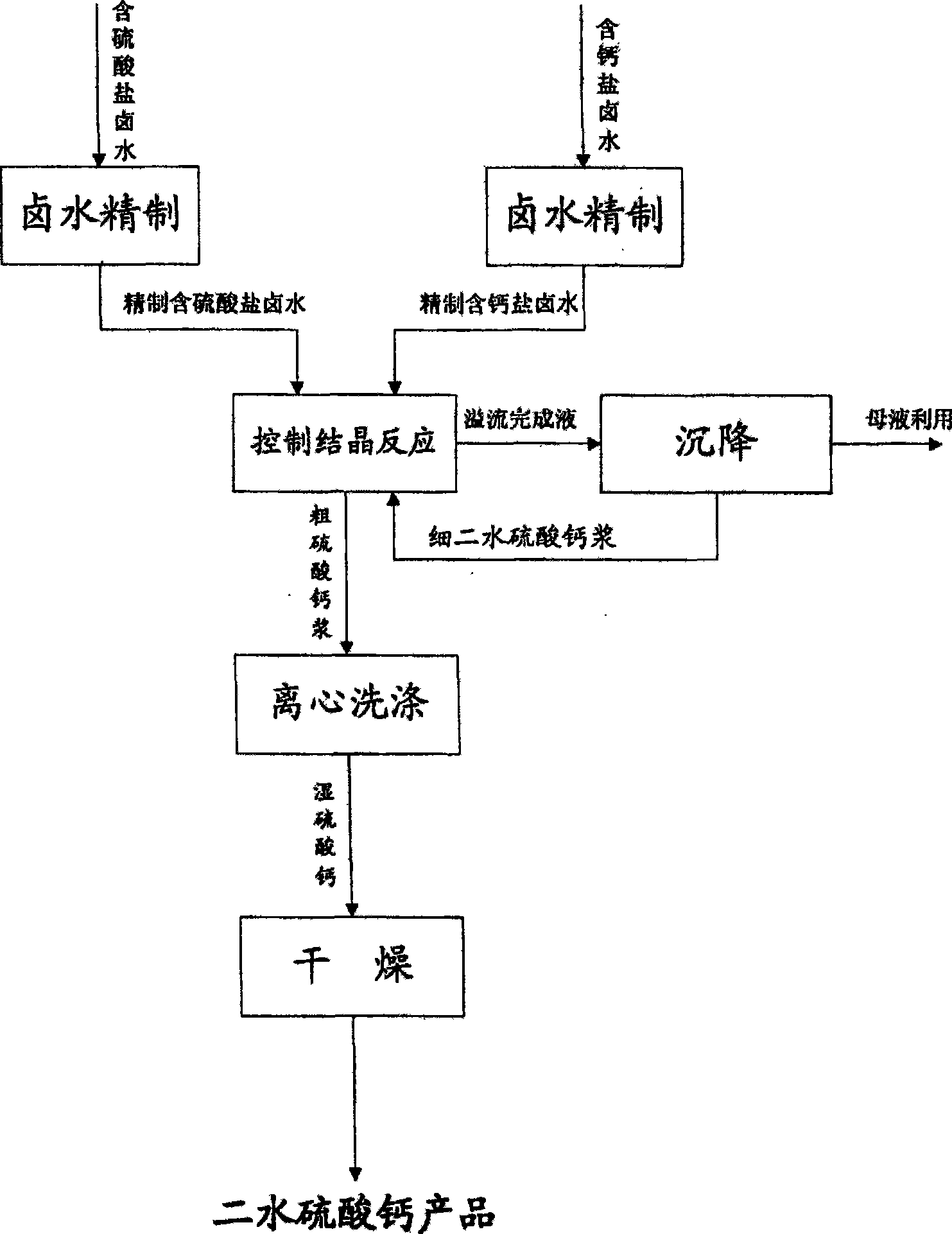

Method for preparing calcium sulphate with sulfate containing bittern and calcium containing bittern

ActiveCN101367538AReduce supersaturationLarge crystalsCalcium/strontium/barium sulfatesSulfate radicalsDihydrate Calcium Sulfate

The invention relates to a method for preparing the calcium sulfate with the sulfate-contained brine and the calcium-salt-contained brine; the two refined brines in a crystallization control reactor are uniformly and consecutively mixed with the cycling liquid inside a cycling lifting device to form dihydrate calcium sulfate crystal with large grain diameter; the dehydrate calcium sulfate crystal is centrifugally washed and dried to prepare the product of the high-purity dehydrate calcium sulfate. The flow rate of the refined sulfate-contained brine that is continuously added in a reaction crystallization barrel is determined according to the ratio between the flow rate of the refined sulfate-contained brine and the flow rate of the cycling liquid in the cycling lifting device in the reactor of 1:10 to 1:30. The flow rate of the refined calcium-salt-contained brine that is consecutively added is determined according to the mol ratio of 1:1 between the sulfate radical ion and the calcium ion in the refined sulfate-contained brine and the calcium-salt-contained brine.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

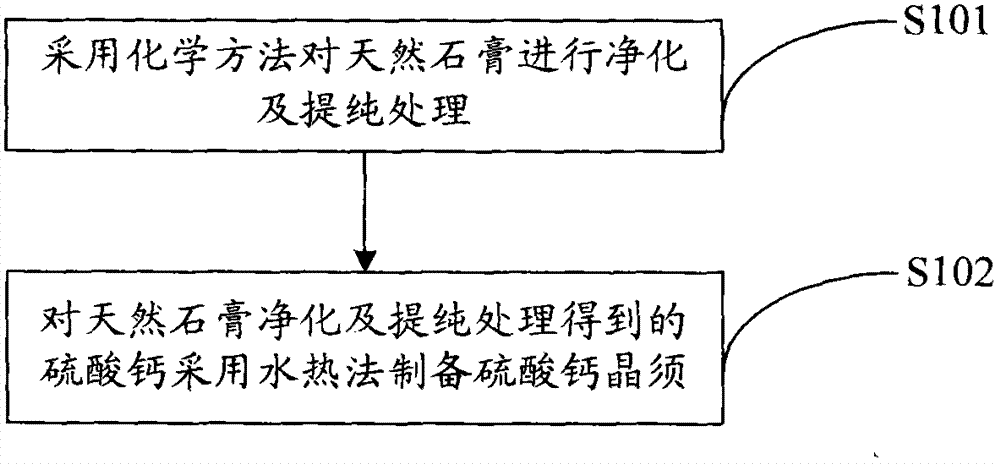

Method for preparing calcium sulfate crystal whiskers by using natural gypsum

InactiveCN102776569ATake advantage ofReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsDecompositionImpurity

The invention belongs to the technical field of chemical production and provides a method for preparing calcium sulfate crystal whiskers by using natural gypsum. The method comprises the steps of: firstly treating and purifying the natural gypsum by adopting a chemical method, enabling the natural gypsum to have double decomposition reaction with ammonium hydrogen carbonate and ammonia water to obtain ammonium sulfate and calcium carbonate, conducting solid-liquid separation to obtain ammonium sulfate solution and crude calcium carbonate, using hydrochloric acid to treat the byproduct crude calcium carbonate to obtain calcium chloride solution, removing impurities, and enabling the calcium chloride to react with the ammonium sulfate to obtain pure calcium sulfate; and then preparing the calcium sulfate crystal whiskers through a hydrothermal method by using the purified calcium sulfate. The method for preparing the calcium sulfate crystal whiskers by using the natural gypsum has the advantages that since the rich natural gypsum and low-cost chemical raw materials are used for producing high-added-value chemical products calcium sulfate crystal whiskers and byproducts ammonium chloride and carbon dioxide, the raw materials are fully utilized, the production cost is effectively reduced, the production process is clean and environmental-friendly, and the promotion and application values are very great.

Owner:TAISHAN MEDICAL UNIV

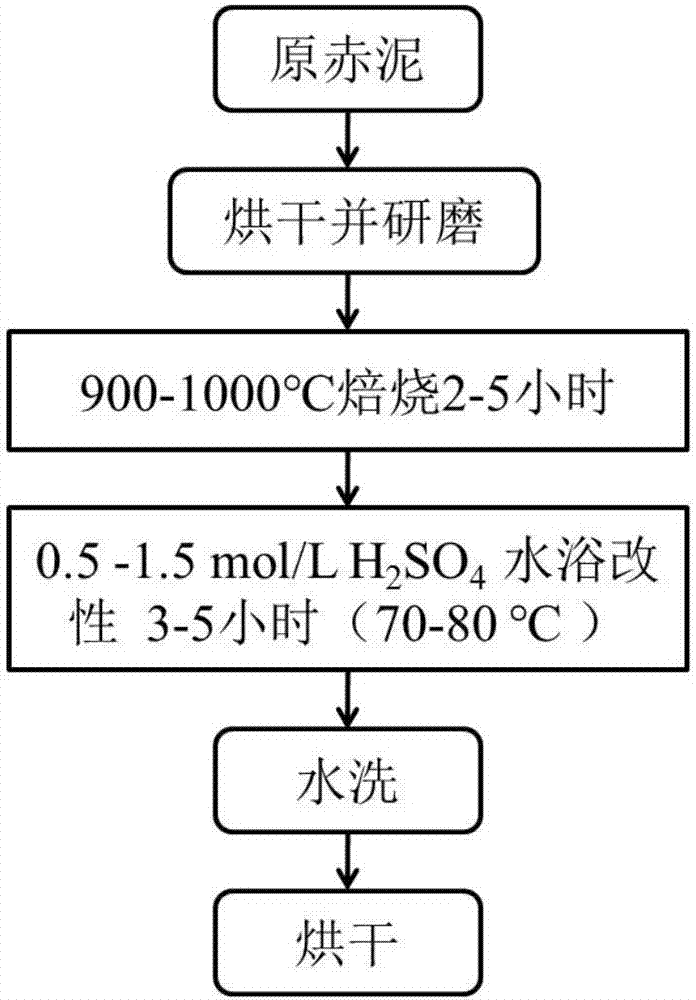

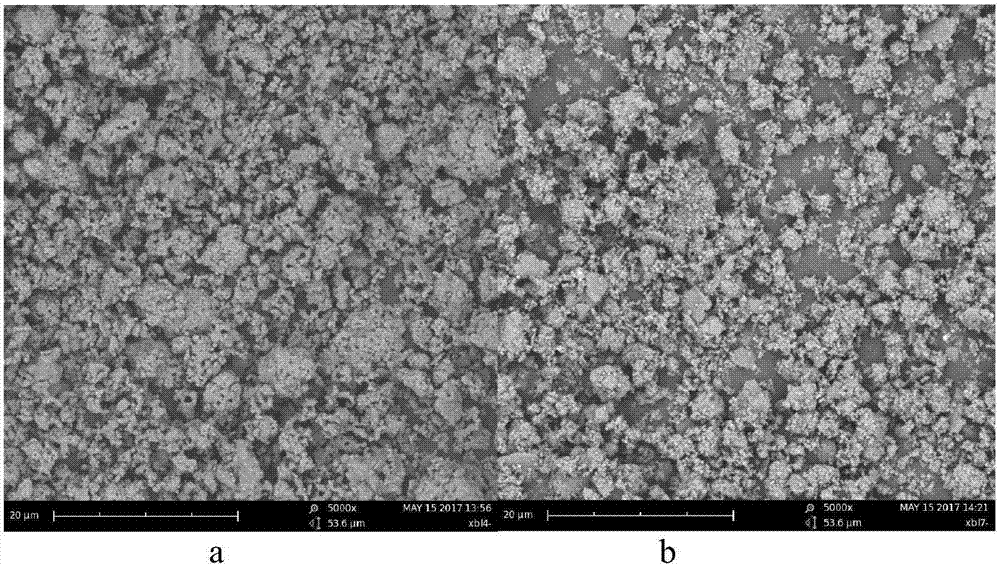

Modified red mud and its preparation method and application

ActiveCN107262019AReduce contentIncrease contentOther chemical processesWater contaminantsSulfate radicalsSlag

The invention provides a preparation method of modified red mud, and belongs to the technical field of water disposal. The modified red mud is prepared by roasting waste slag red mud, acquiring a roasting product and performing acid immersion on the roasting product by sulfuric acid. Through the roasting treatment, the content of impurities in the waste slag red mud can be reduced, and method is good for the reaction of sulfate radical and calcium ion in the subsequent acid immersion process, and can improve the content of effective component CaSO4 (H2O)2 (plaster stone) of a final product; the waste slag red mud surface after roasting is in porous state, thus it is good for the sufficient contact between the waste slag red mud and sulfuric acid, thereby benefiting the formation of the calcium sulfate crystal. Data of an embodiment shows that the removal rate of fluorine in the waste water by the modified red mud is up to 99% above in 1h, and the arsenical removal rate is over 99%, thus the synchronous removal of fluorine and arsenic can be realized; the water quality after absorbing can completely meet the national Hygienic Standard for Drinking Water.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com