Desulfurization wastewater resourceful treatment method

A technology for desulfurization wastewater and treatment method, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high softening agent, high cost, low crystalline salt, etc. The effect of running costs and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

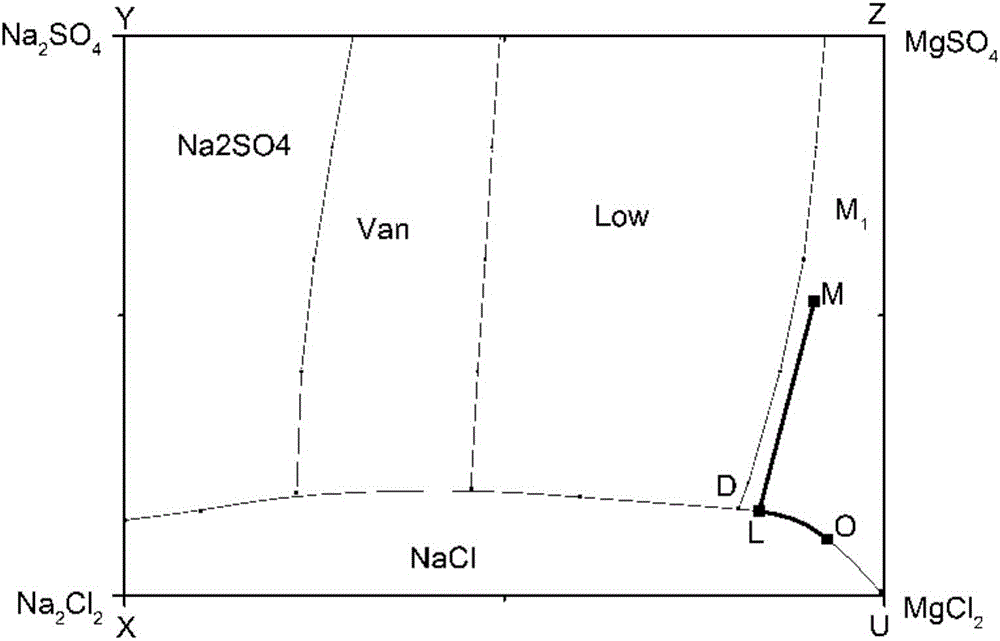

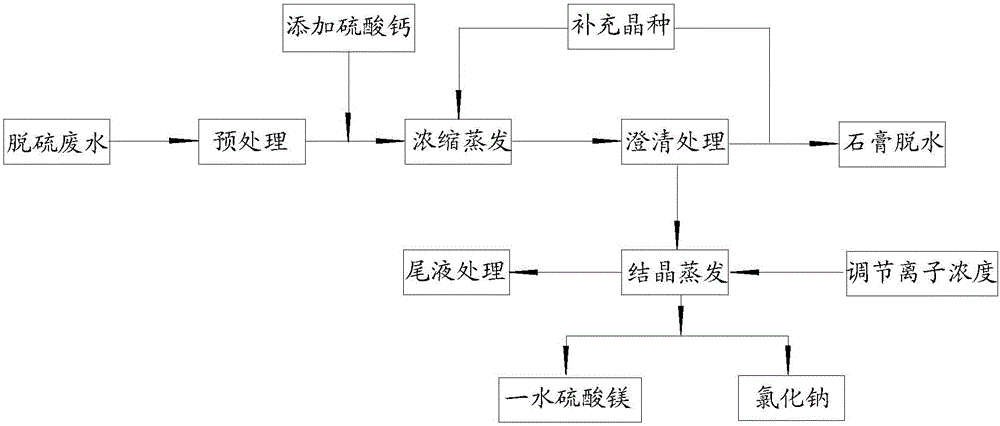

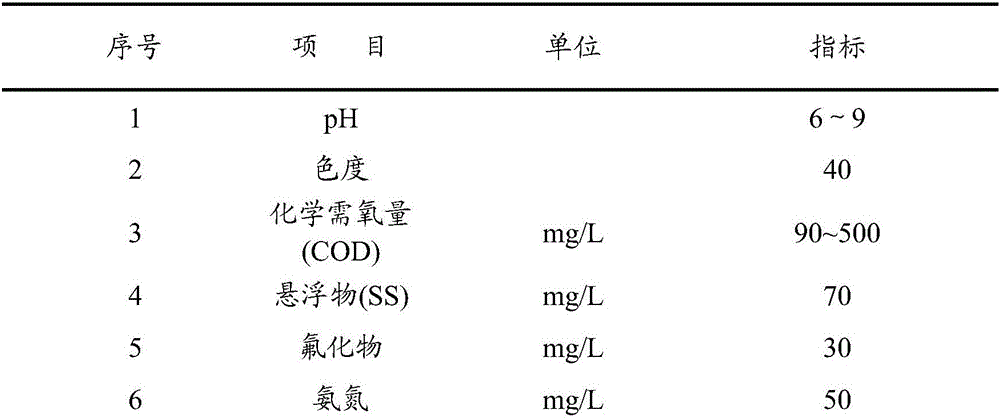

[0044] Such as Figure 1-2 As shown, a resource treatment method for desulfurization wastewater comprises the following steps:

[0045] 1) Pretreatment: Add alkali and coagulant aid respectively to the wastewater, and remove the precipitate after the suspended solids settle; the dosage of the alkali is 2g / L, and the dosage of the coagulant aid is 2mg / L , the alkali is slaked lime, and the coagulant aid is polyacrylamide;

[0046] 2) Concentration and evaporation: the waste water treated in step 1) is passed into the evaporator, and the waste water is evaporated. In the initial stage of evaporation, calcium sulfate crystals are added to the waste water as crystal seeds for crystallization, so that the sulfuric acid in the waste water The concentration of calcium crystals is greater than 10g / L; when the amount of waste water is reduced to 5% of the incoming amount, the evaporation is stopped, and the obtained concentrated solution is passed into the clarification tank for clari...

Embodiment 2

[0050] Such as Figure 1-2 As shown, a resource treatment method for desulfurization wastewater comprises the following steps:

[0051] 1) Pretreatment: add a coagulant aid to the wastewater, and after the suspended matter settles, perform Fenton chemical oxidation treatment on the wastewater, and finally add alkali and coagulant aid to the oxidized wastewater, and remove the wastewater after standing The sediment in; the dosage of described alkali is 1g / L, and the dosage of described coagulant aid is 5mg / L, and described alkali is caustic soda, and described coagulant aid is polyacrylamide;

[0052] 2) Concentration and evaporation: the waste water treated in step 1) is passed into the evaporator, and the waste water is evaporated. In the initial stage of evaporation, calcium sulfate crystals are added to the waste water as crystal seeds for crystallization, so that the sulfuric acid in the waste water The concentration of calcium crystals is greater than 10g / L; when the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com