Patents

Literature

2284results about "Solution crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

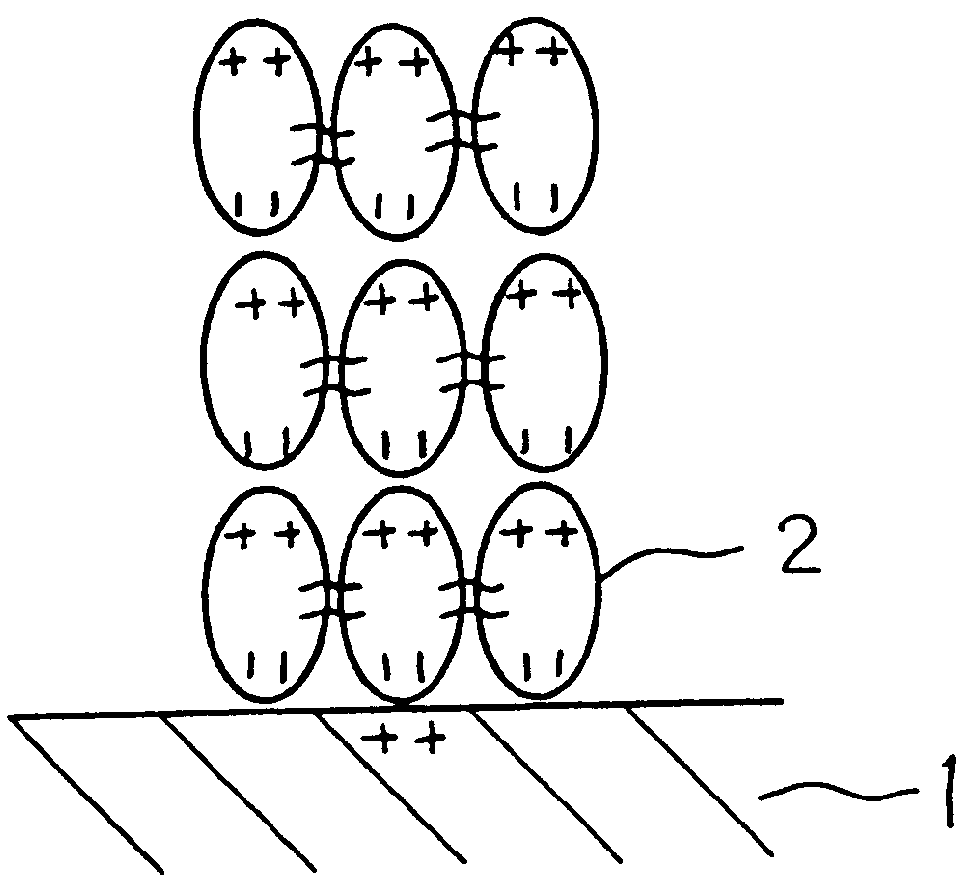

Crystallization control method for organic compound and crystallization control solid-state component employed therefor

InactiveUS6123769APolycrystalline material growthFrom normal temperature solutionsValence electronBiopolymer

A method which can control crystallization of a biopolymer such as protein is provided. A silicon crystal (15) whose valence electrons are controlled to be capable of controlling the concentration of holes or electrons of the surface part in response to the environment of a buffer solution (14) containing the biopolymer such as protein is brought into contact with the solution (14), for getting a crystal of the biopolymer deposited on the surface of the silicon crystal (15). Crystallization is controlled by an electrical state which is generated by the controlled valence electrons on the surface of the silicon crystal (15).

Owner:SUMITOMO METAL IND LTD

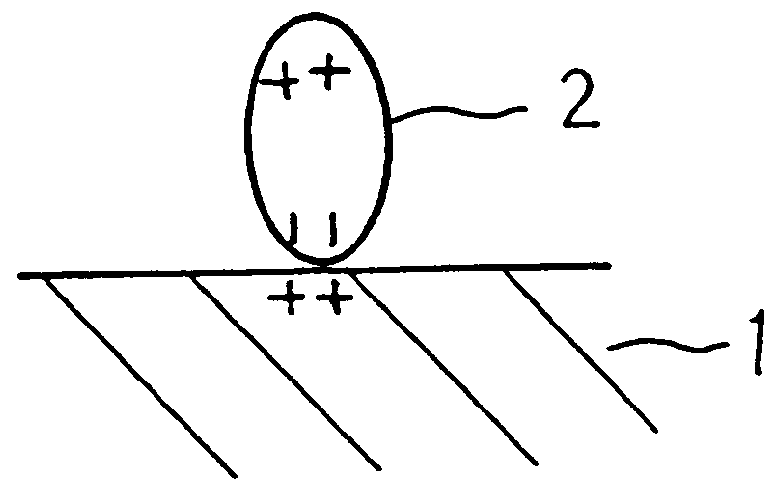

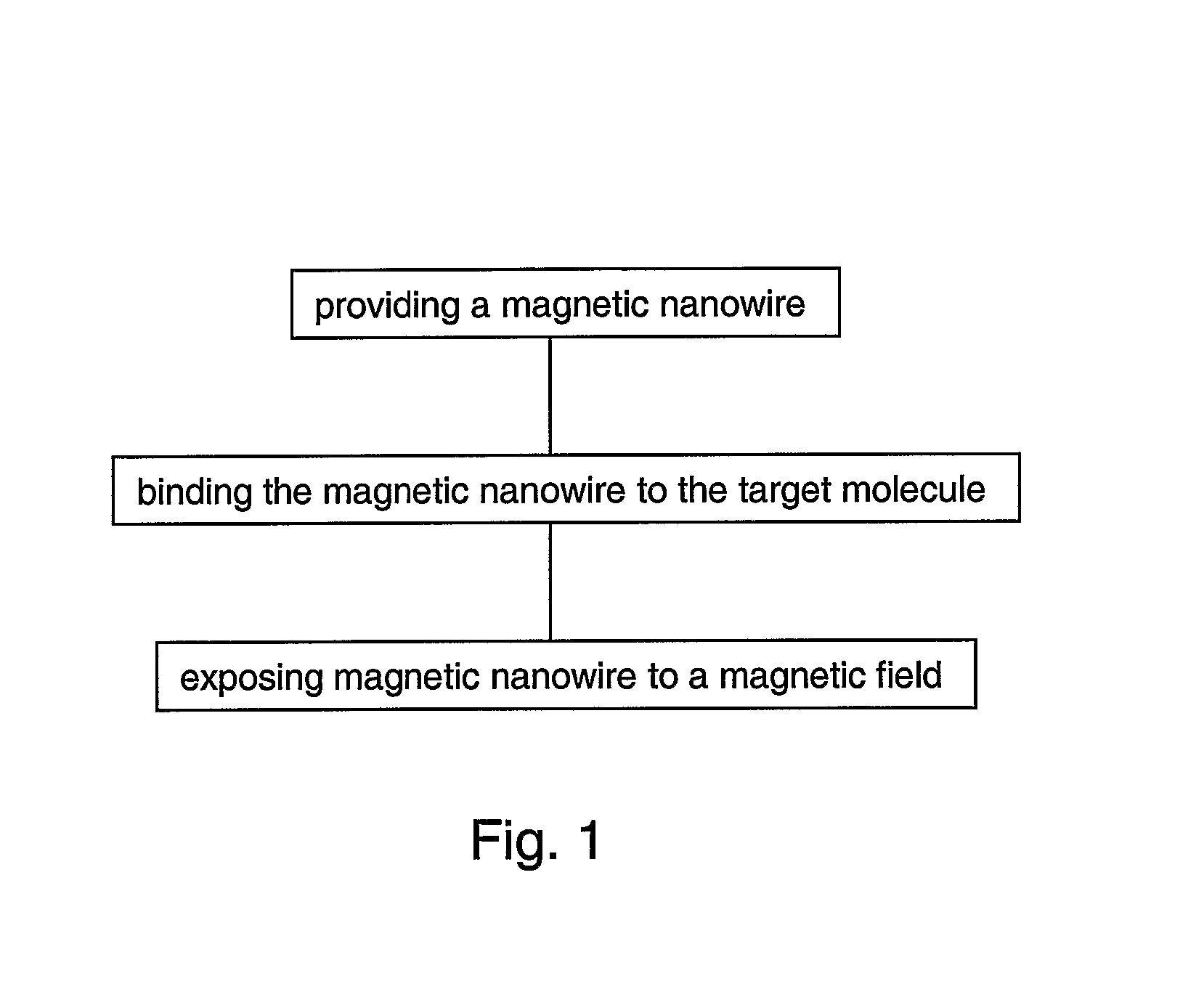

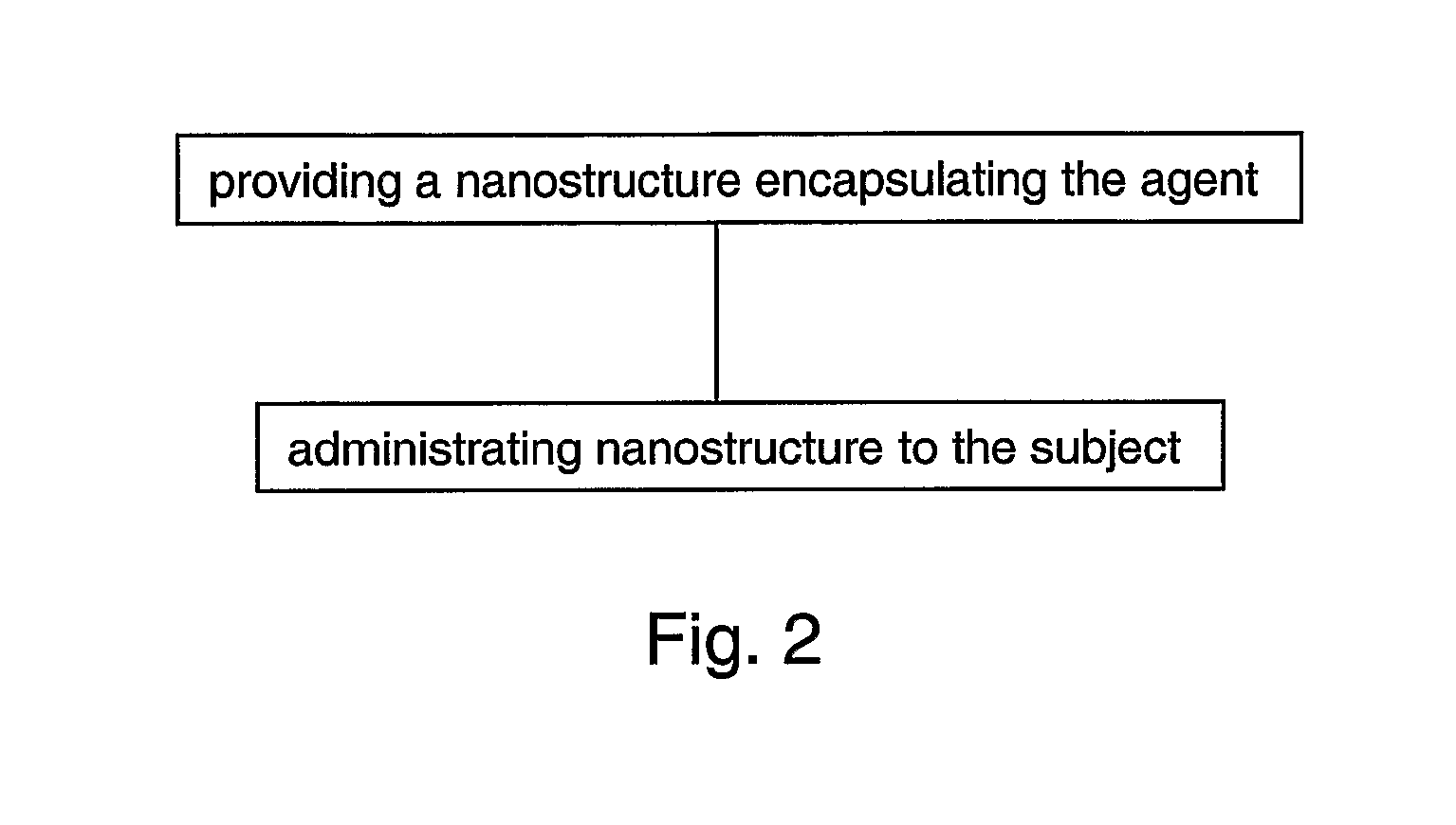

Peptide Nanostructures Containing End-Capping Modified Peptides And Methods Of Generating And Using The Same

InactiveUS20080009434A1Peptide/protein ingredientsSpace heating and ventilationEndcappingCrystallography

A nanostructure composed of a plurality of peptides, each peptide containing at least one aromatic amino acid, whereby one or more of these peptides is end-capping modified, is disclosed. The nanostructure can take a tubular, fibrillar, planar or spherical shape, and can encapsulate, entrap or be coated by other materials. Methods of preparing the nanostructure, and devices and methods utilizing same are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

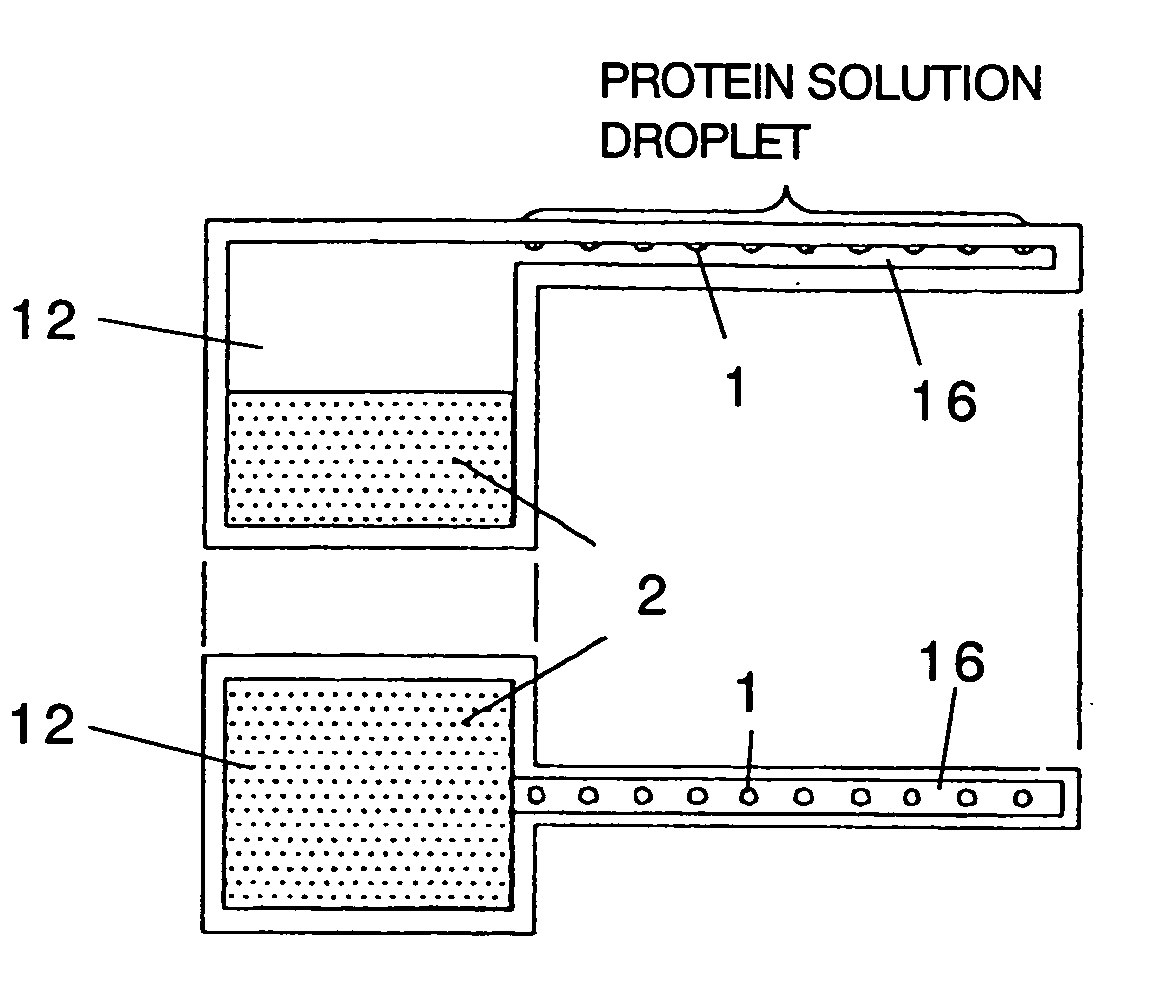

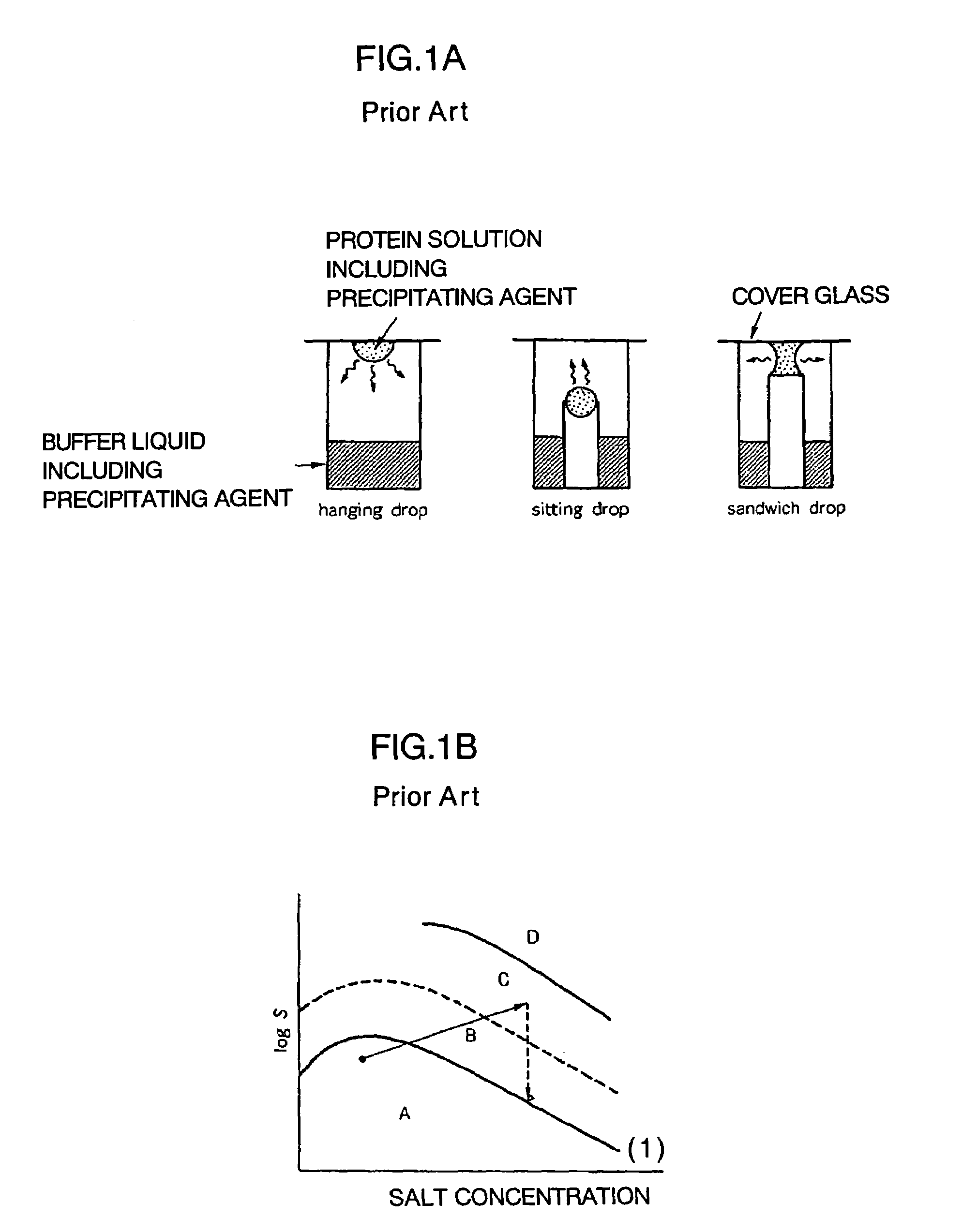

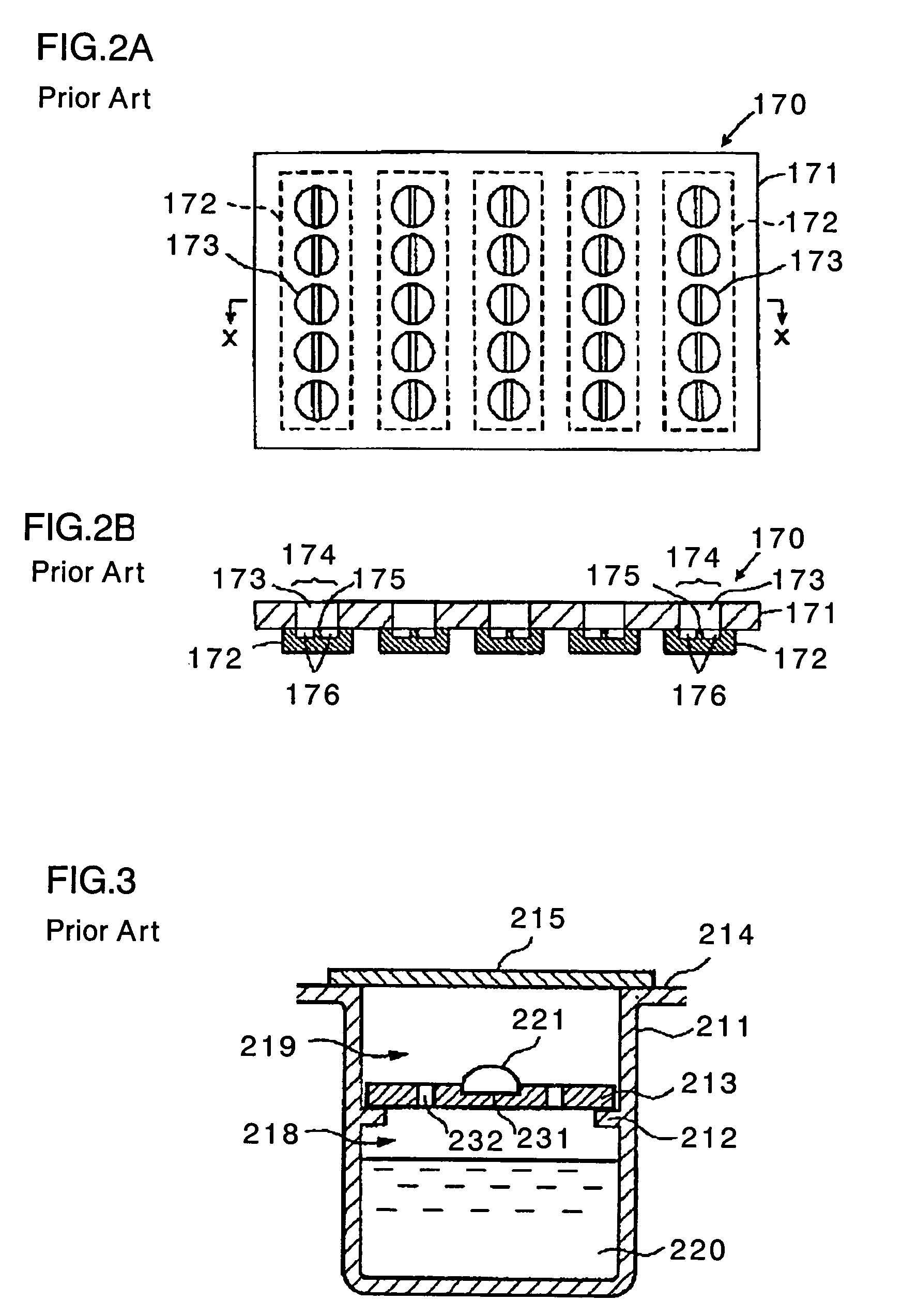

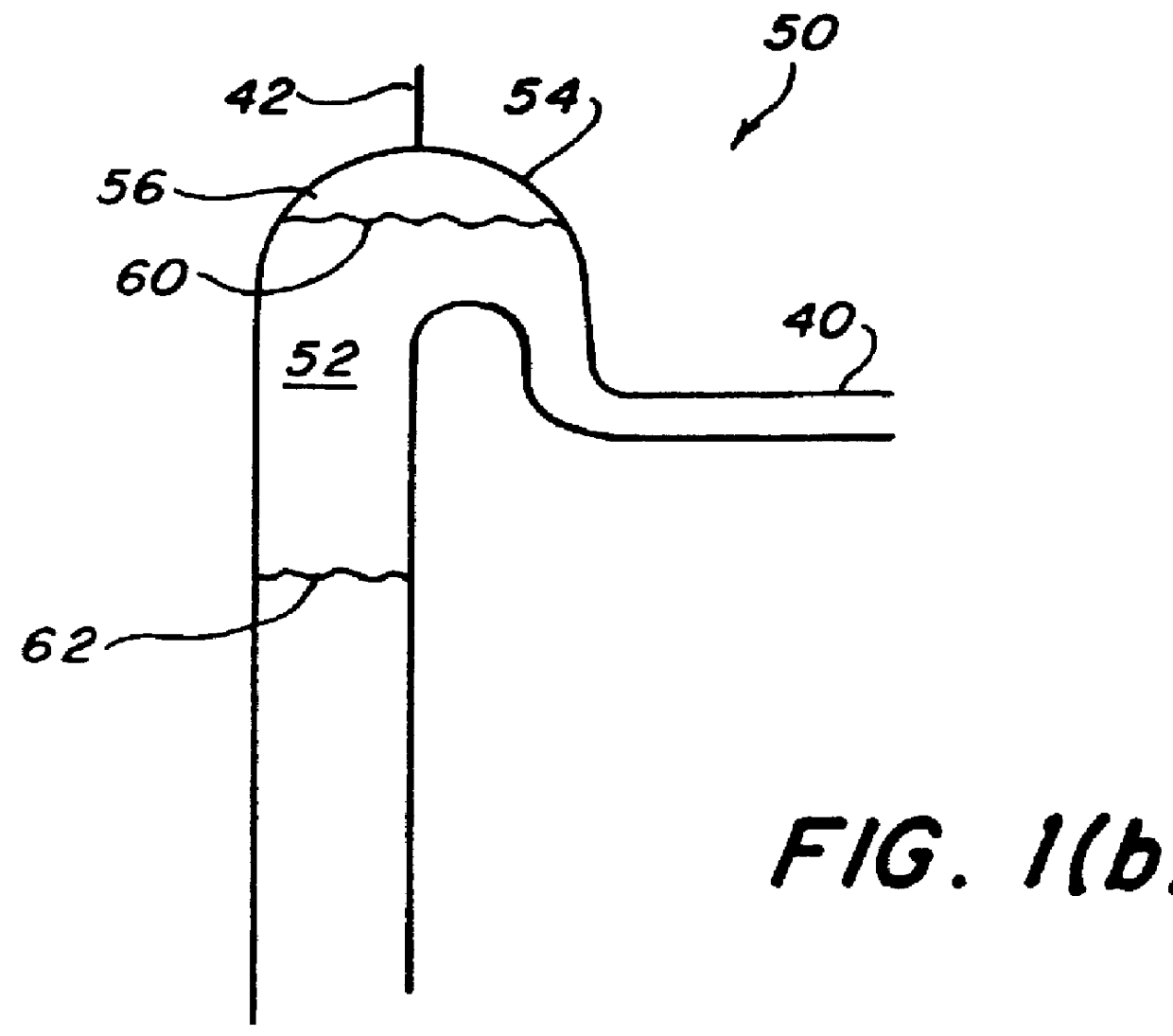

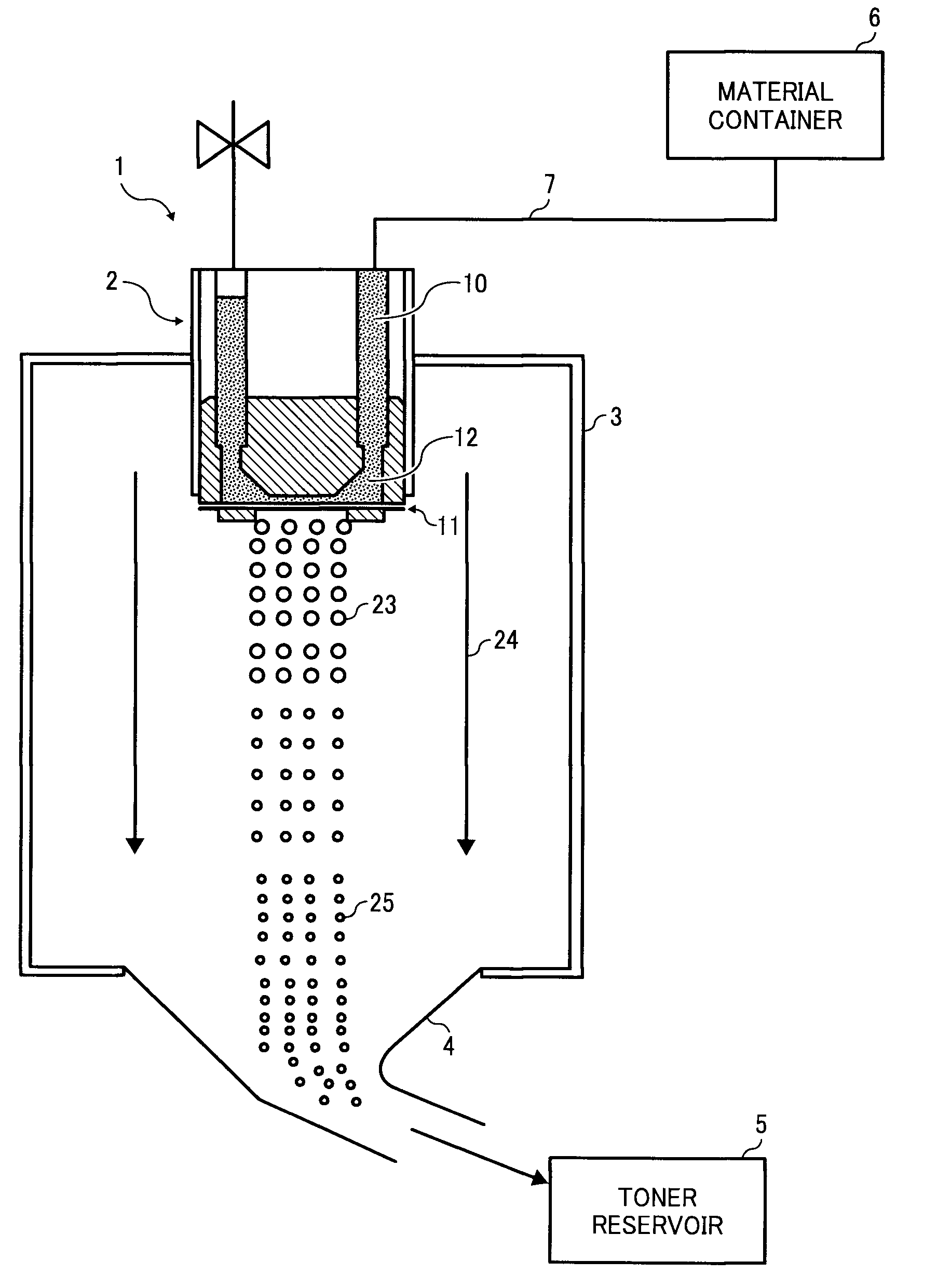

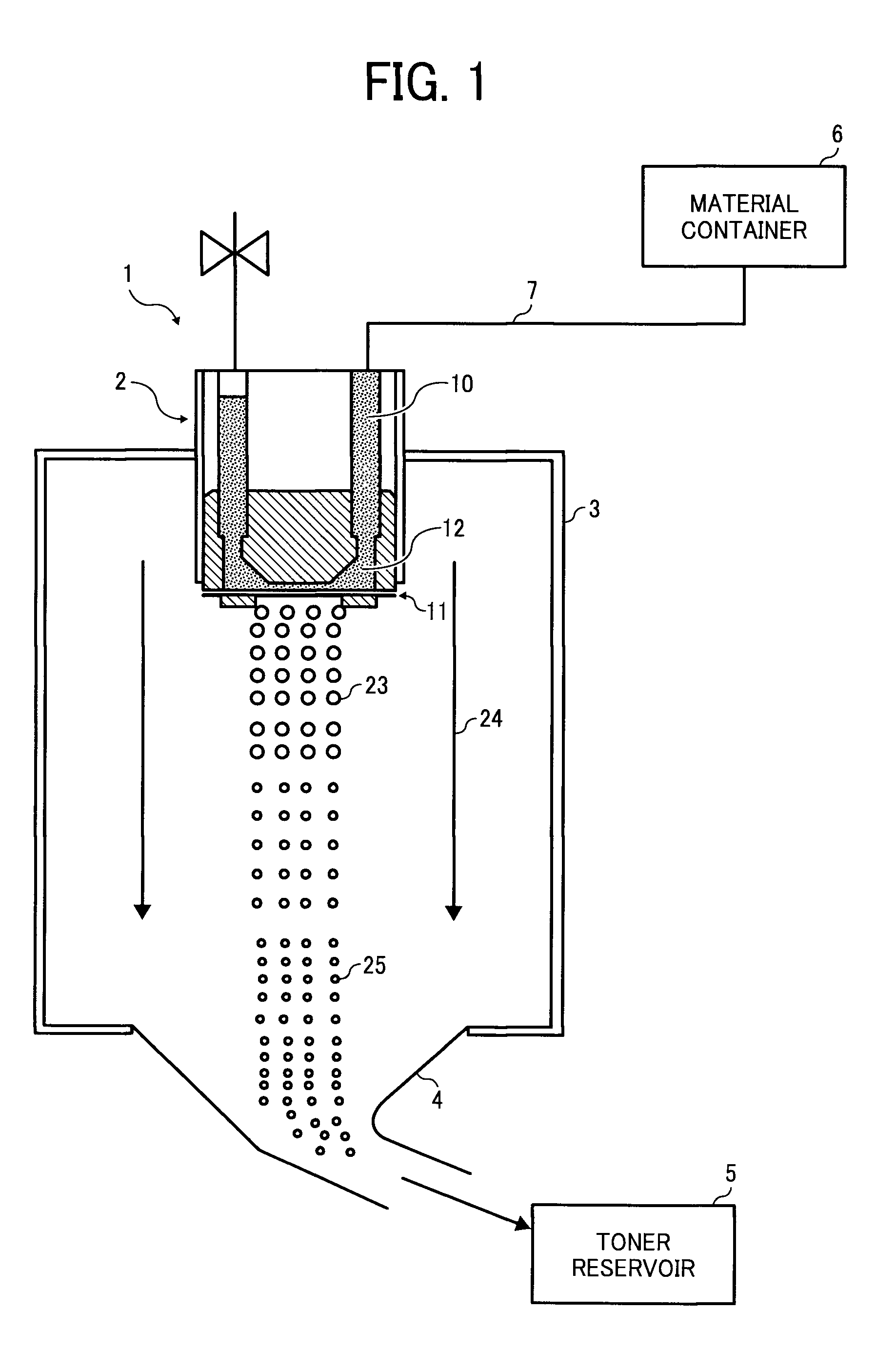

Apparatus and method for growing crystal, and apparatus and method for analyzing crystal

InactiveUS7156917B2Easy to implementPolycrystalline material growthFrom normal temperature solutionsEngineeringBiological macromolecule

An apparatus for growing a biological macromolecular crystal by vaporizing biological macromolecular solution into an oversaturated state. The apparatus includes a first sealed room that receives first crystallizing agent solution, and a communicating tube that communicates with the first sealed room and has a small sectional area for suppressing convection of air. A plurality of droplets of solution dissolving a biological macromolecule and a crystallizing agent therein are held in the communicating tube with the plurality of droplets being separated from each other.

Owner:MORIYAMA HIDEAKI +1

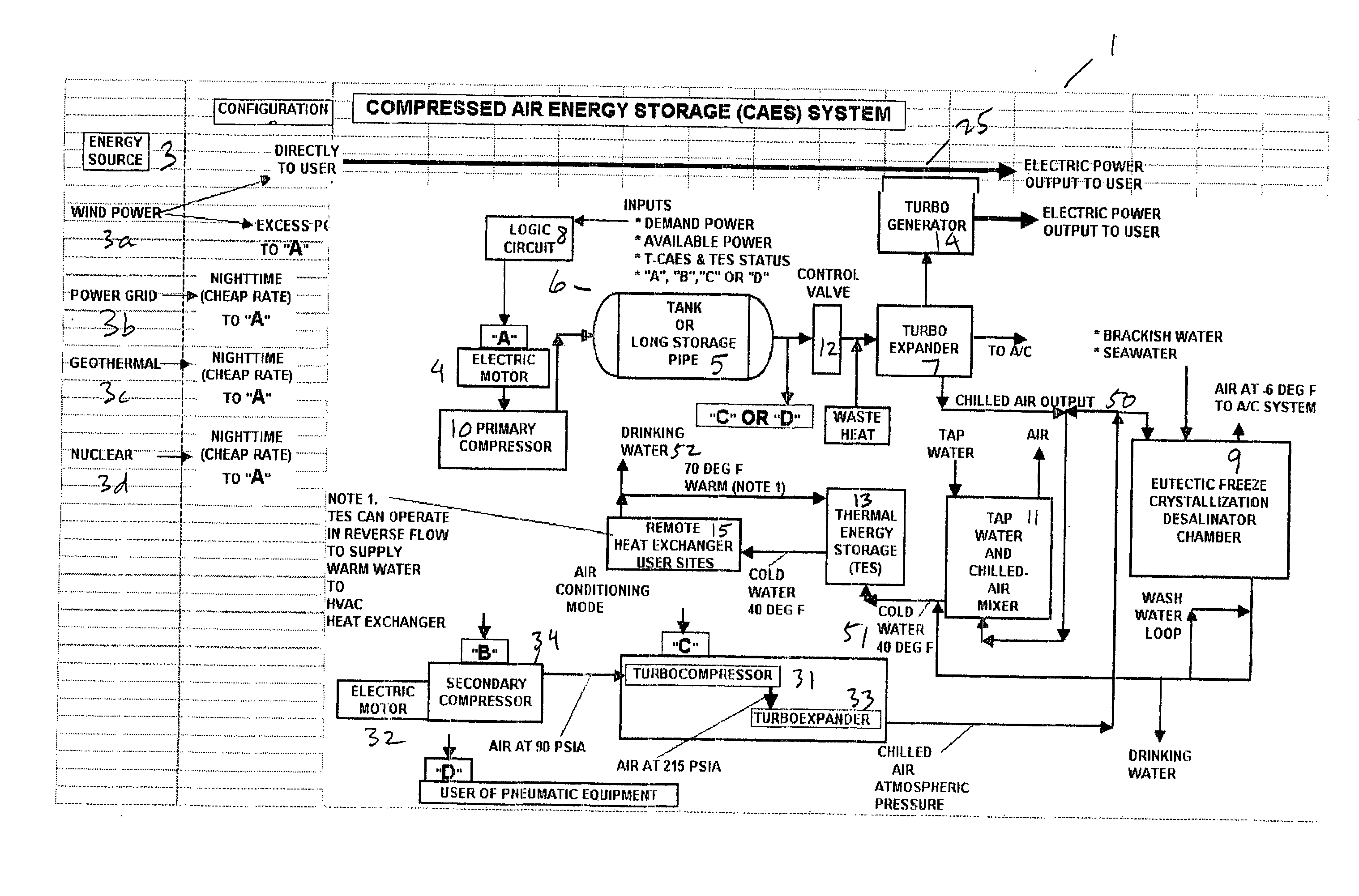

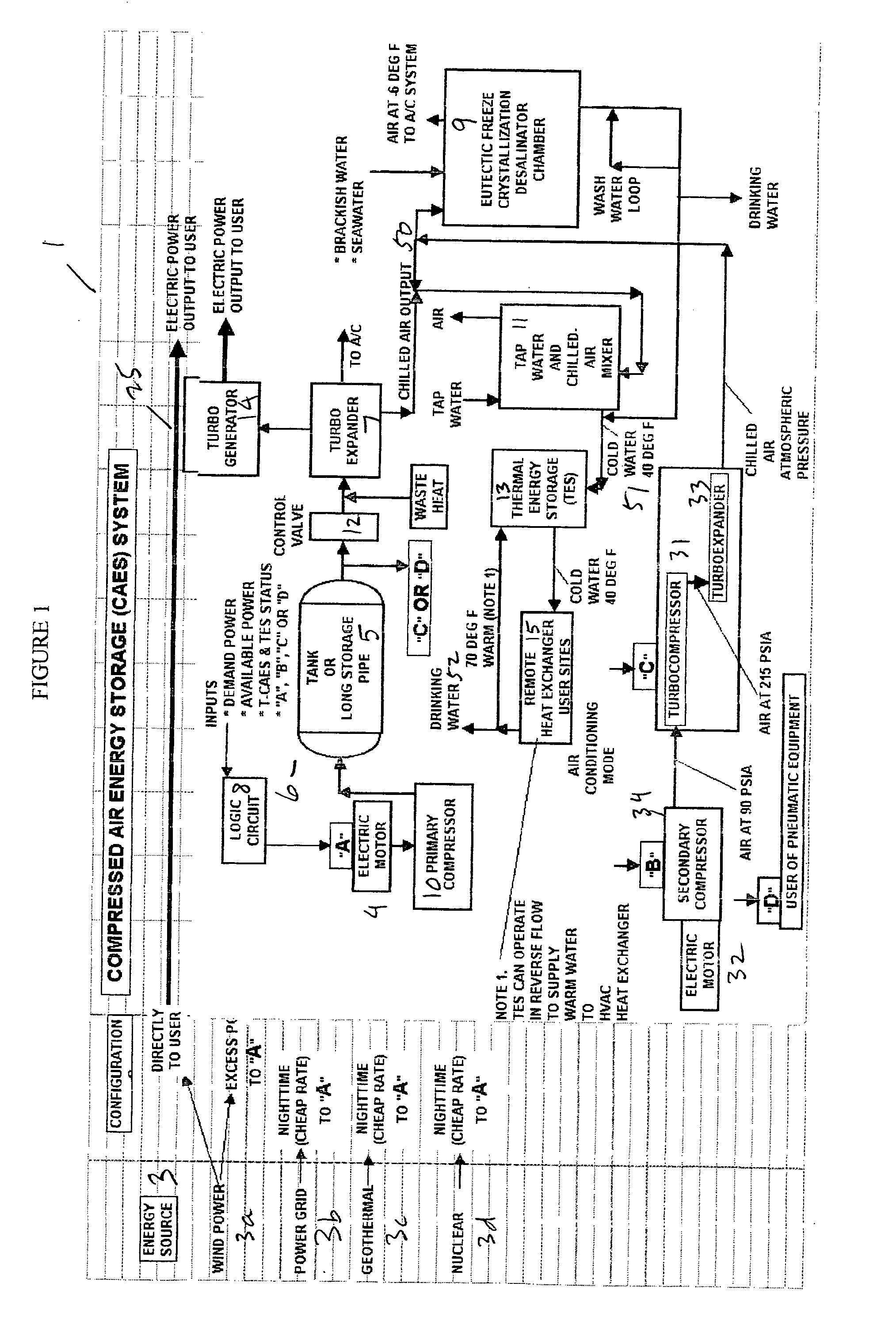

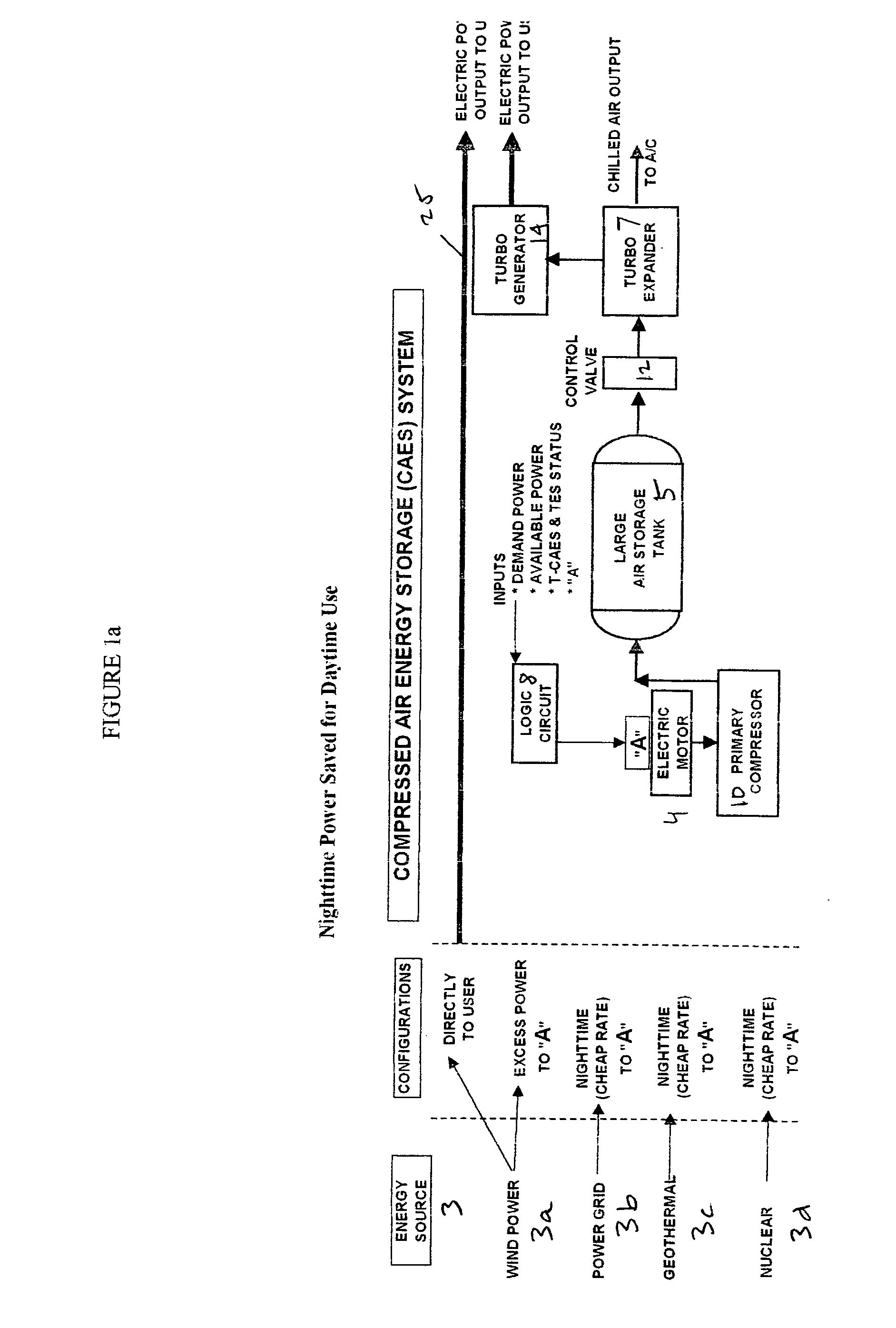

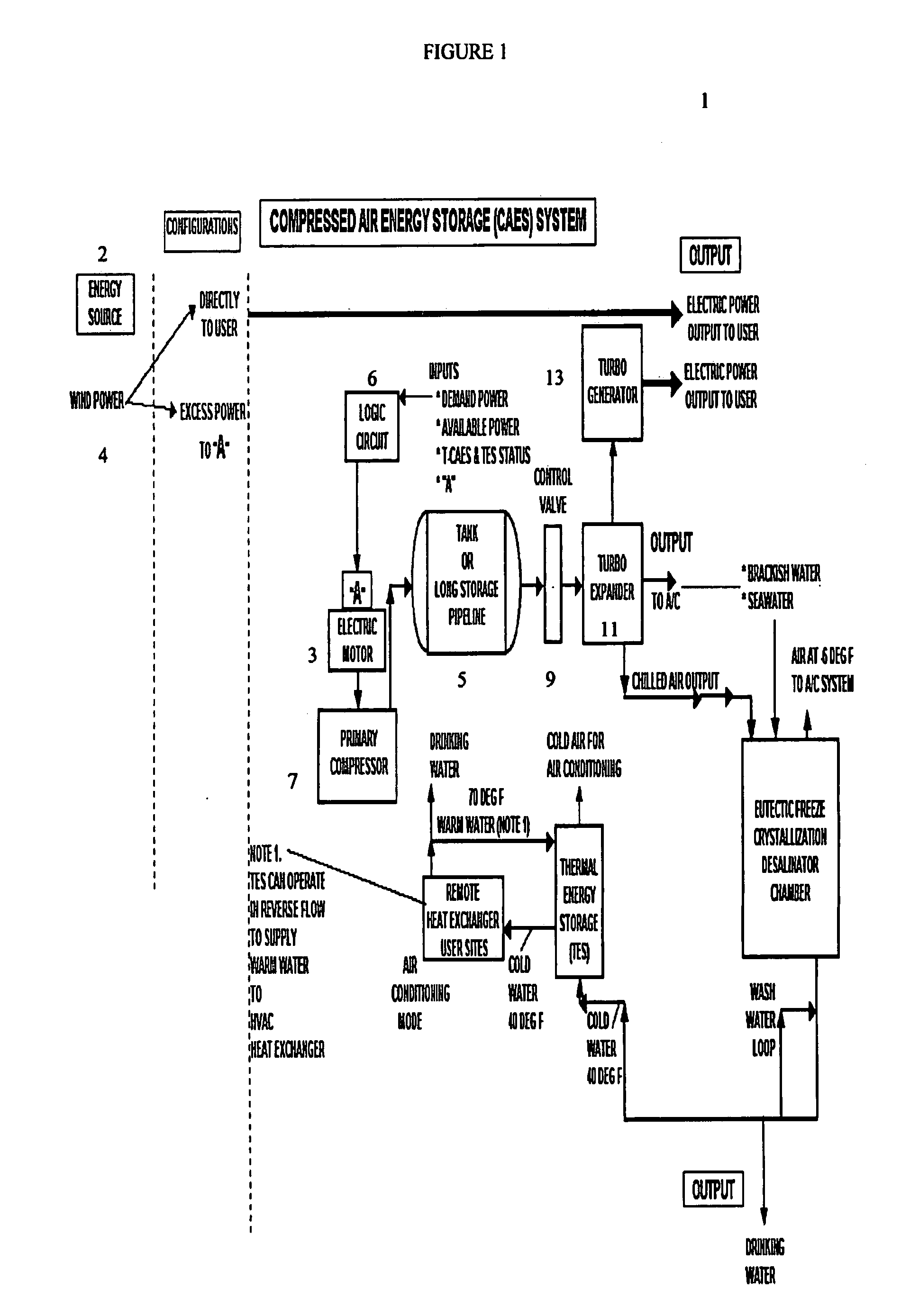

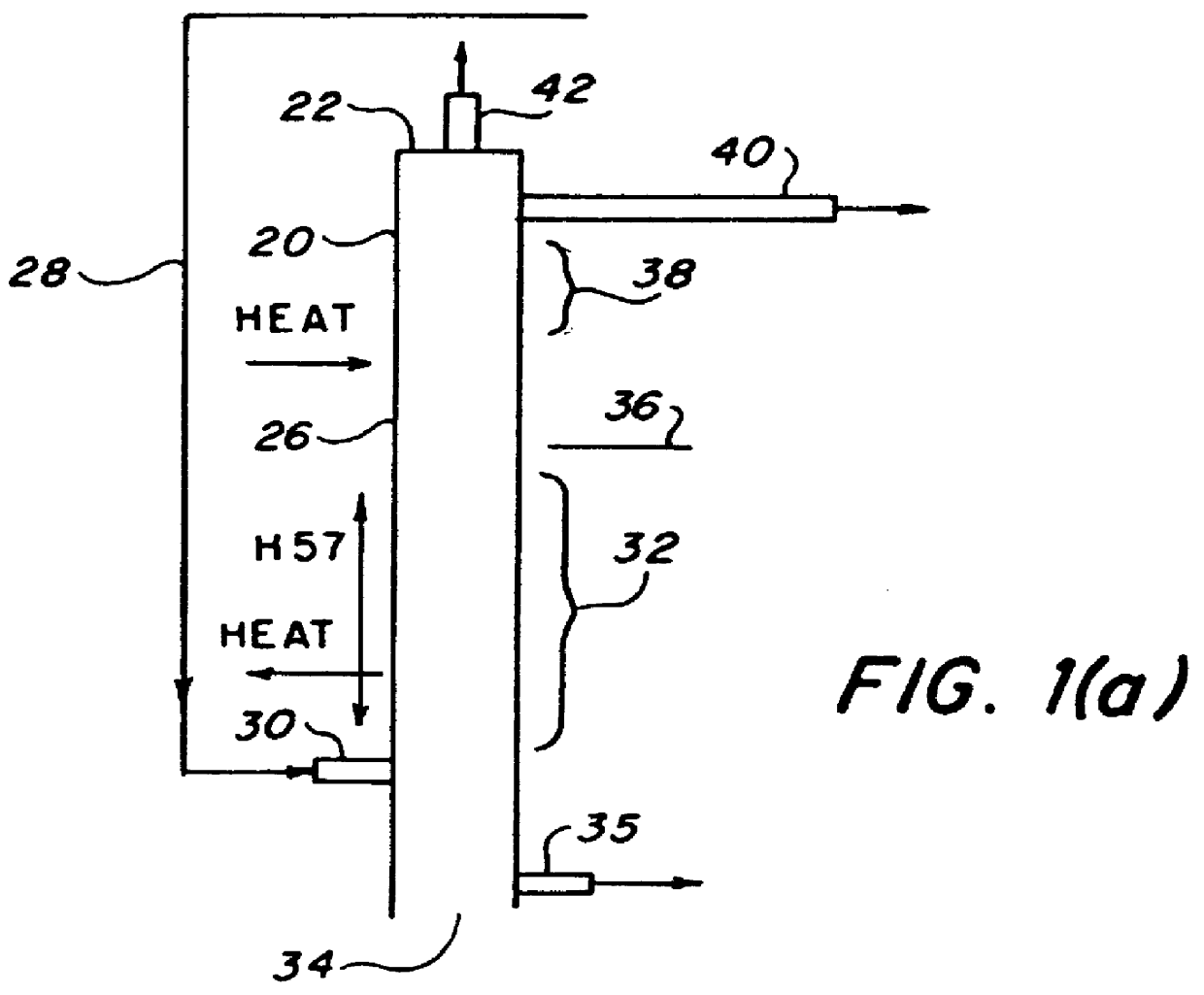

Thermal energy storage system using compressed air energy and/or chilled water from desalination processes

InactiveUS20070234749A1Reducing end-user cost of energyEnergy efficiencyWater treatment parameter controlGeneral water supply conservationThermal energyThermal energy storage system

The invention relates to a universal system for producing cost effective energy particularly for cooling purposes. In one embodiment, wind turbines are used to generate electricity and compressed air energy, wherein the compressed air energy is used to co-generate electricity and chilled air. The chilled air is then used to chill water in either a mixing chamber, or a desalination system, wherein the chilled water is stored in a separation tank, wherein it can later be used to provide cooling for an air conditioning system for a facility. When desalination is used, the system produces chilled fresh drinking water which can be used for air conditioning, and then used as fresh drinking water. Any exhaust chilled air can be used directly for air conditioning.

Owner:ENIS BEN M +1

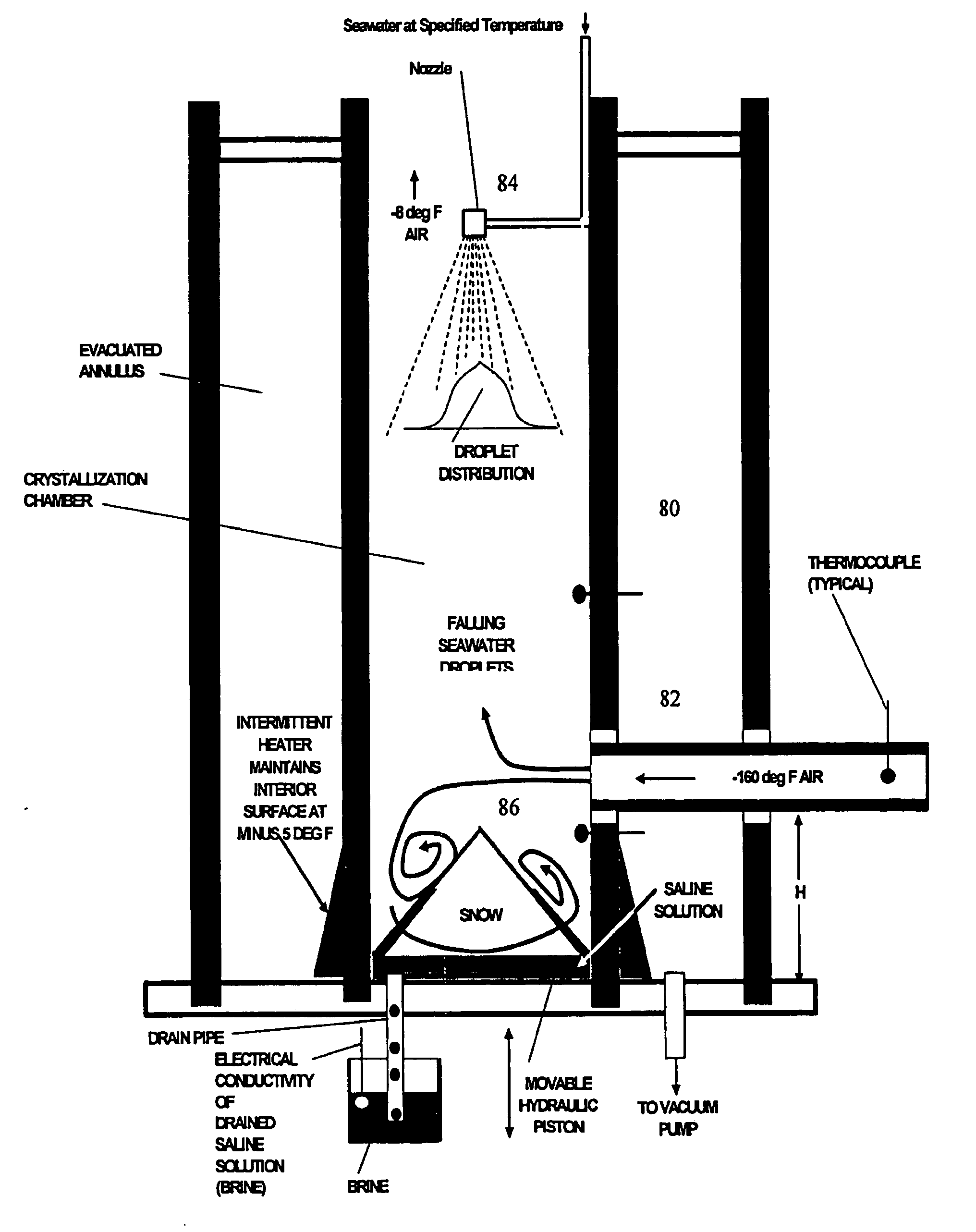

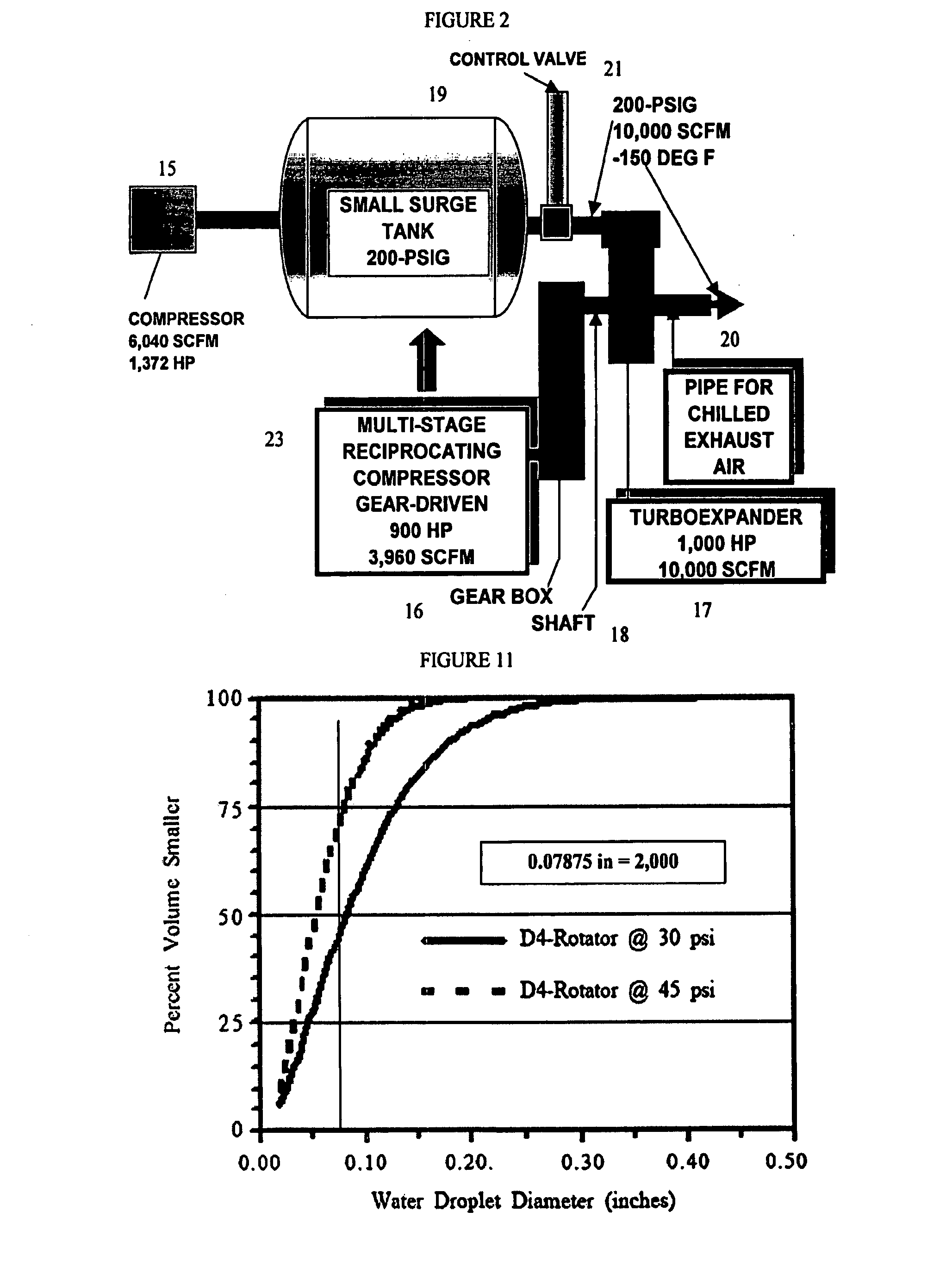

Desalination Method and System Using Compressed Air Energy Systems

InactiveUS20100037653A1Facilitate runoffClean the ice massGeneral water supply conservationSeawater treatmentDesalinationSalt water

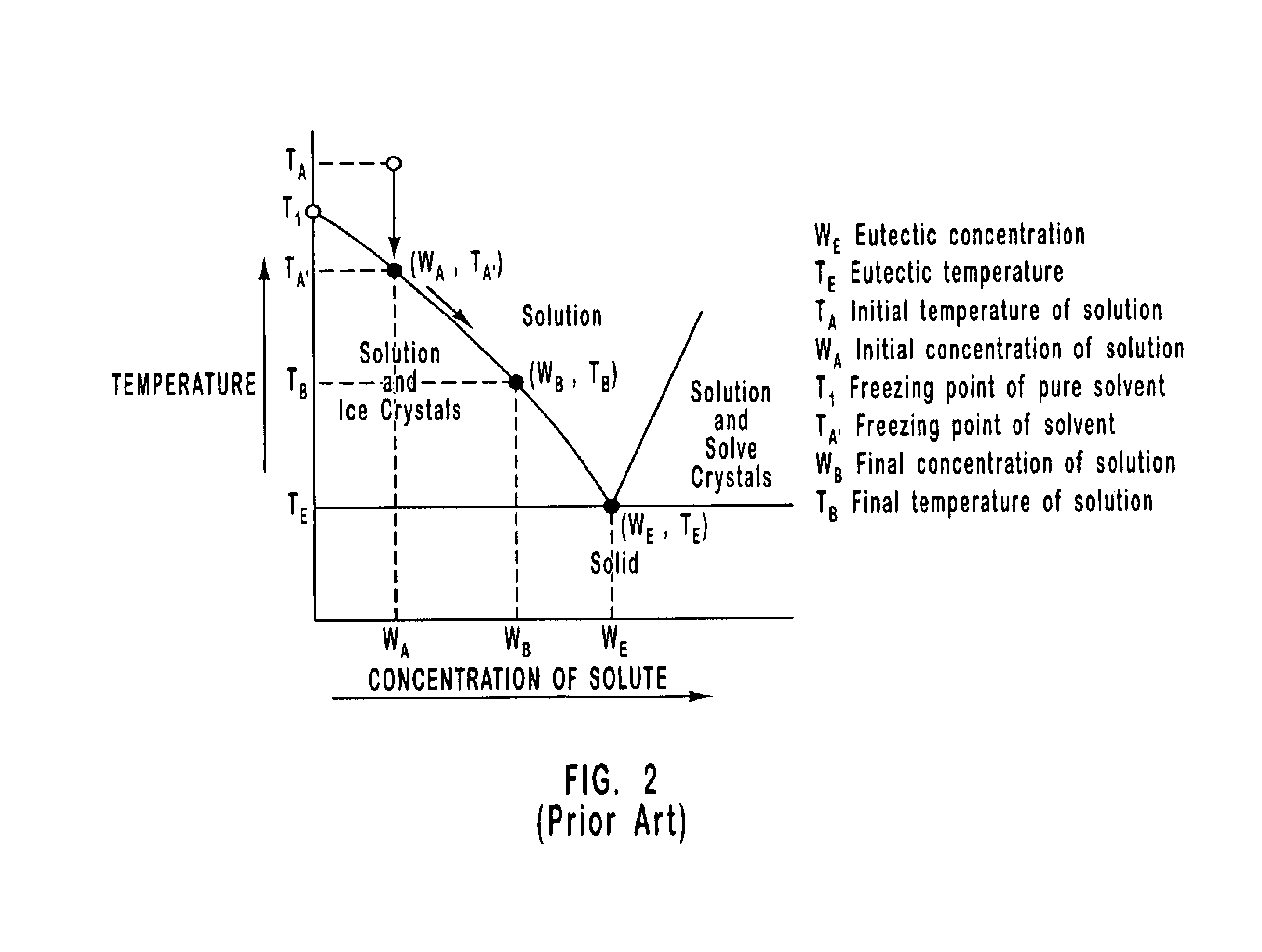

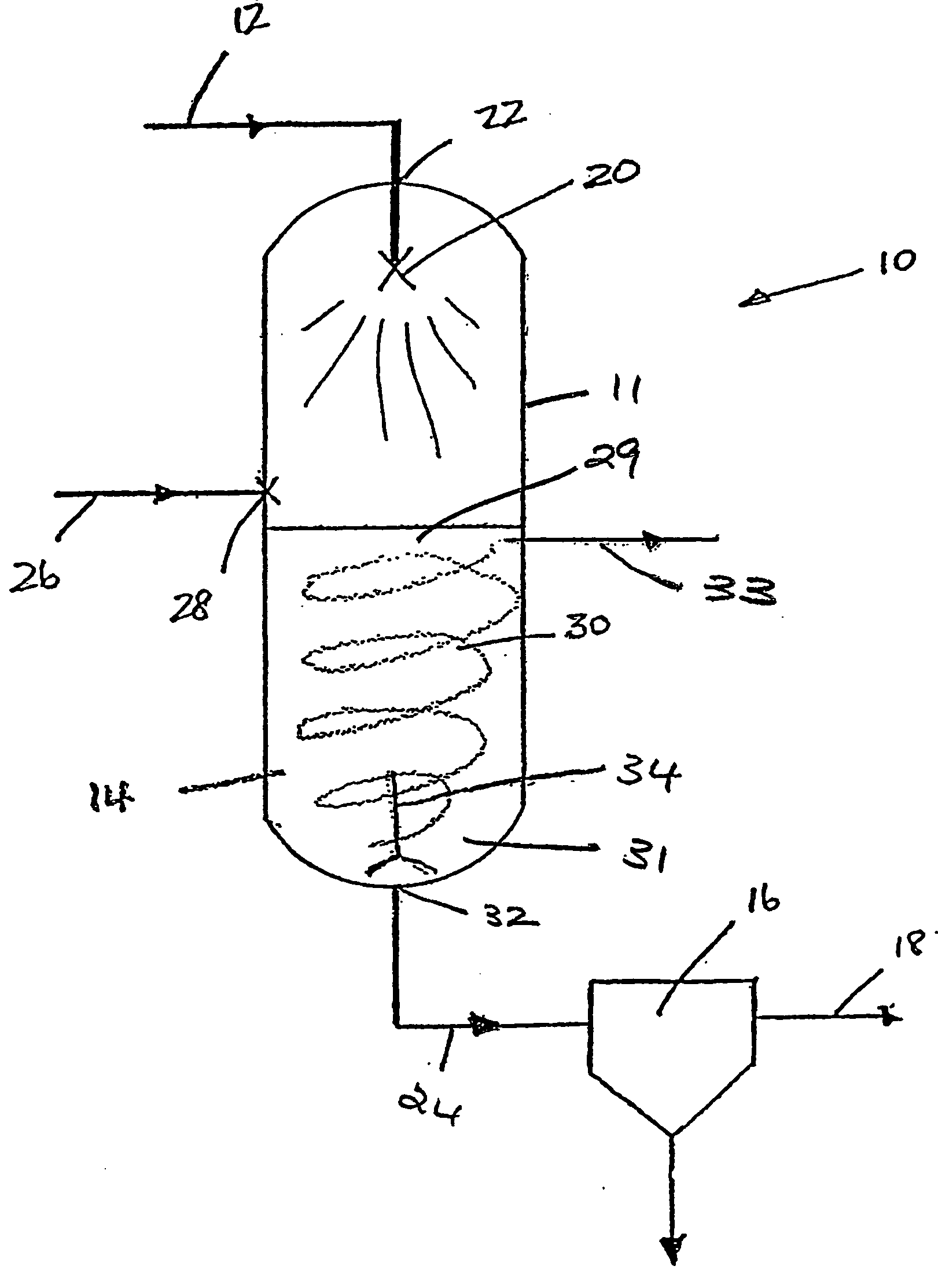

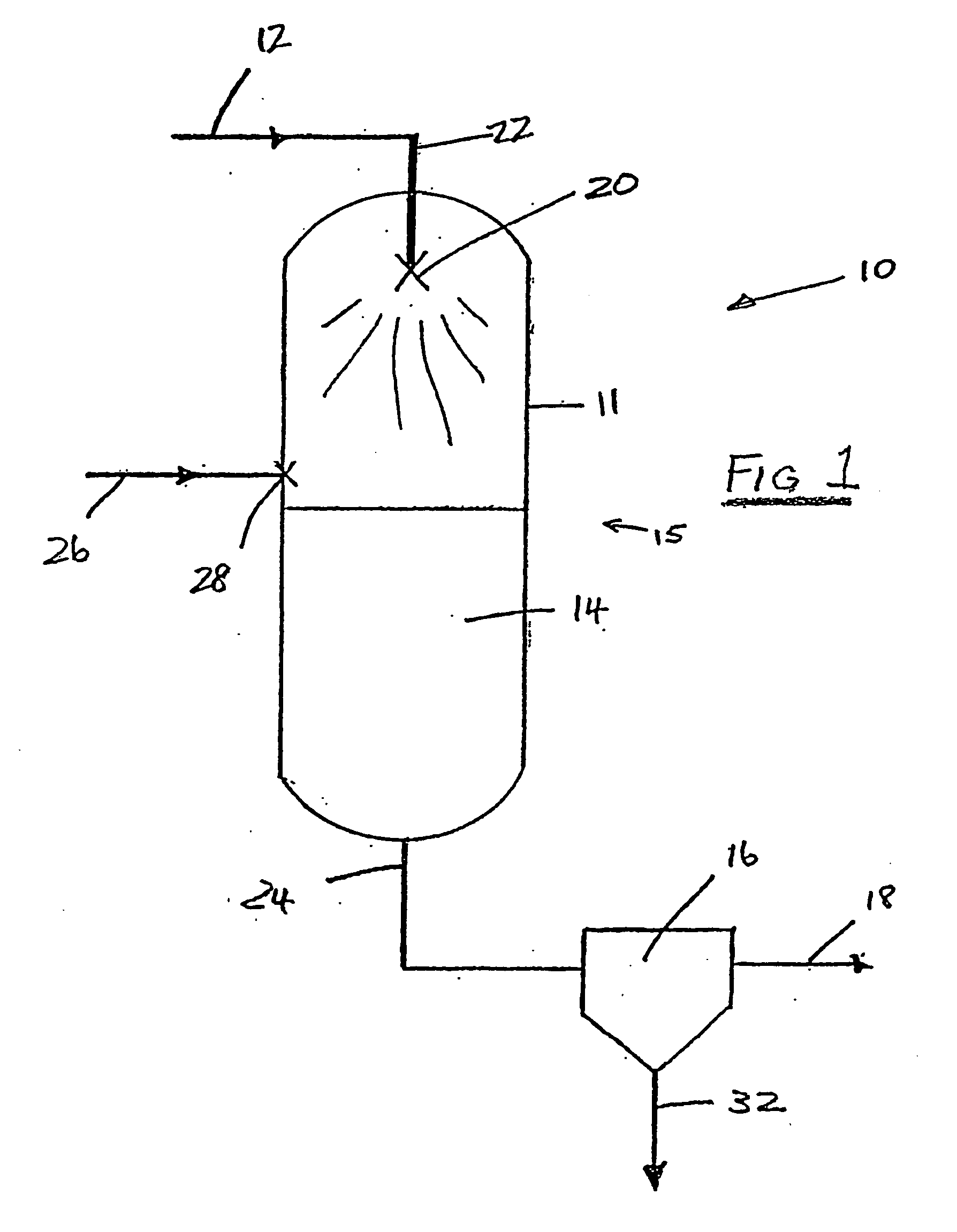

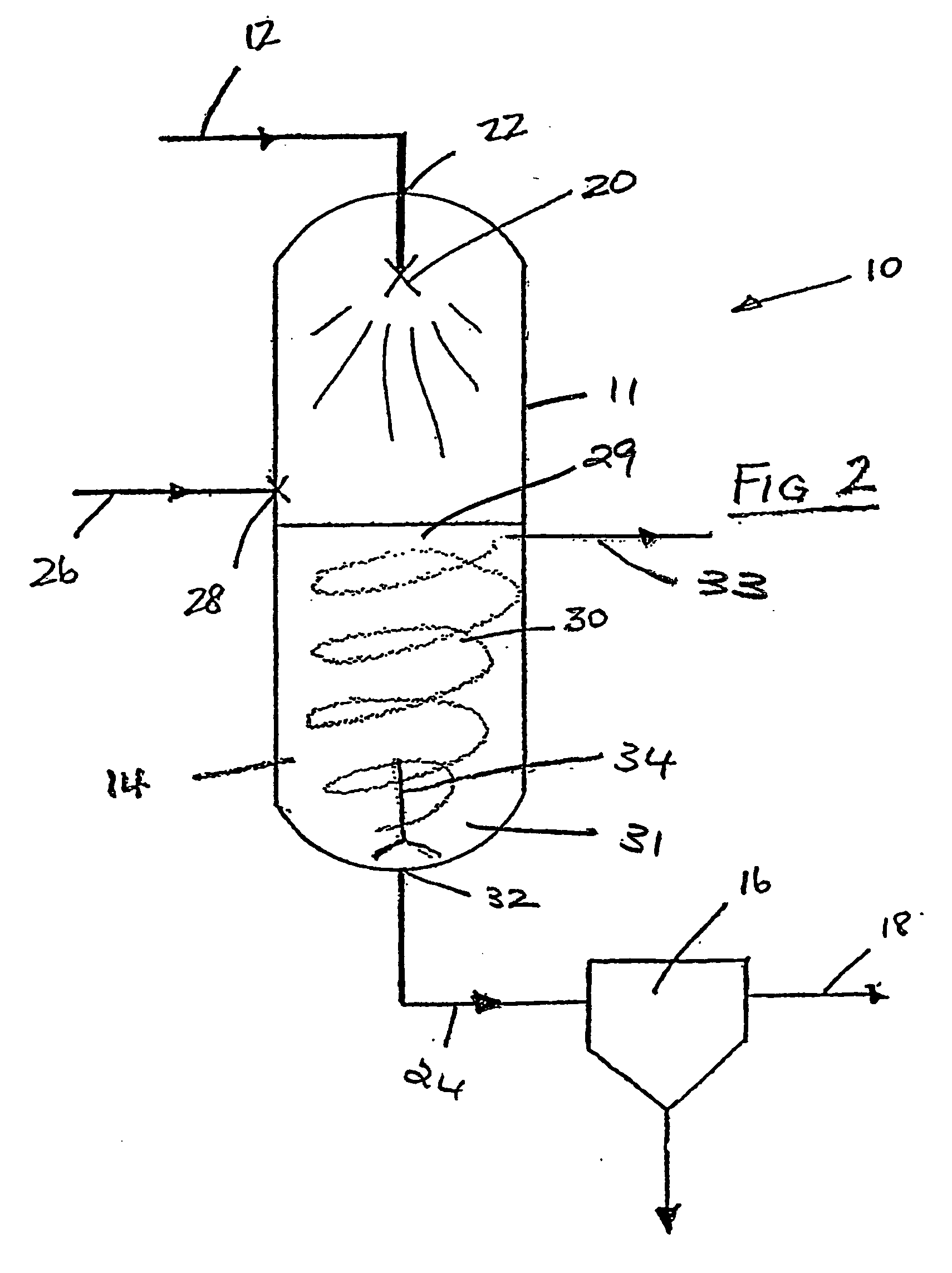

The invention relates to a desalination method and system that uses freeze crystallization technology that incorporates the use of compressed air energy as the source for freezing temperatures. When compressed air is released by a turbo expander, chilled air is produced as a by-product, wherein the chilled air is introduced into a crystallization chamber. Also injected into the chamber is a spray cloud of seawater droplets, which has been pre-chilled by heat exchange with the cold chamber walls, and which is then circulated and exposed to the chilled air in the chamber. The sizes of the droplets can vary, but are preferably predetermined, along with the relative temperatures, flows and speeds of the spray and chilled air, such that when the droplets are circulated within the chilled air, and settle at the bottom of the chamber, they are deposited at slightly above the eutectic temperature. This way, the ice / snow mass that forms at the bottom of the chamber will consist of frozen ice crystals, and a residue of salt water brine, which can runoff from the mass, either from the sides, or through any voids or channels that may form within the mass.

Owner:ENIS BEN M +1

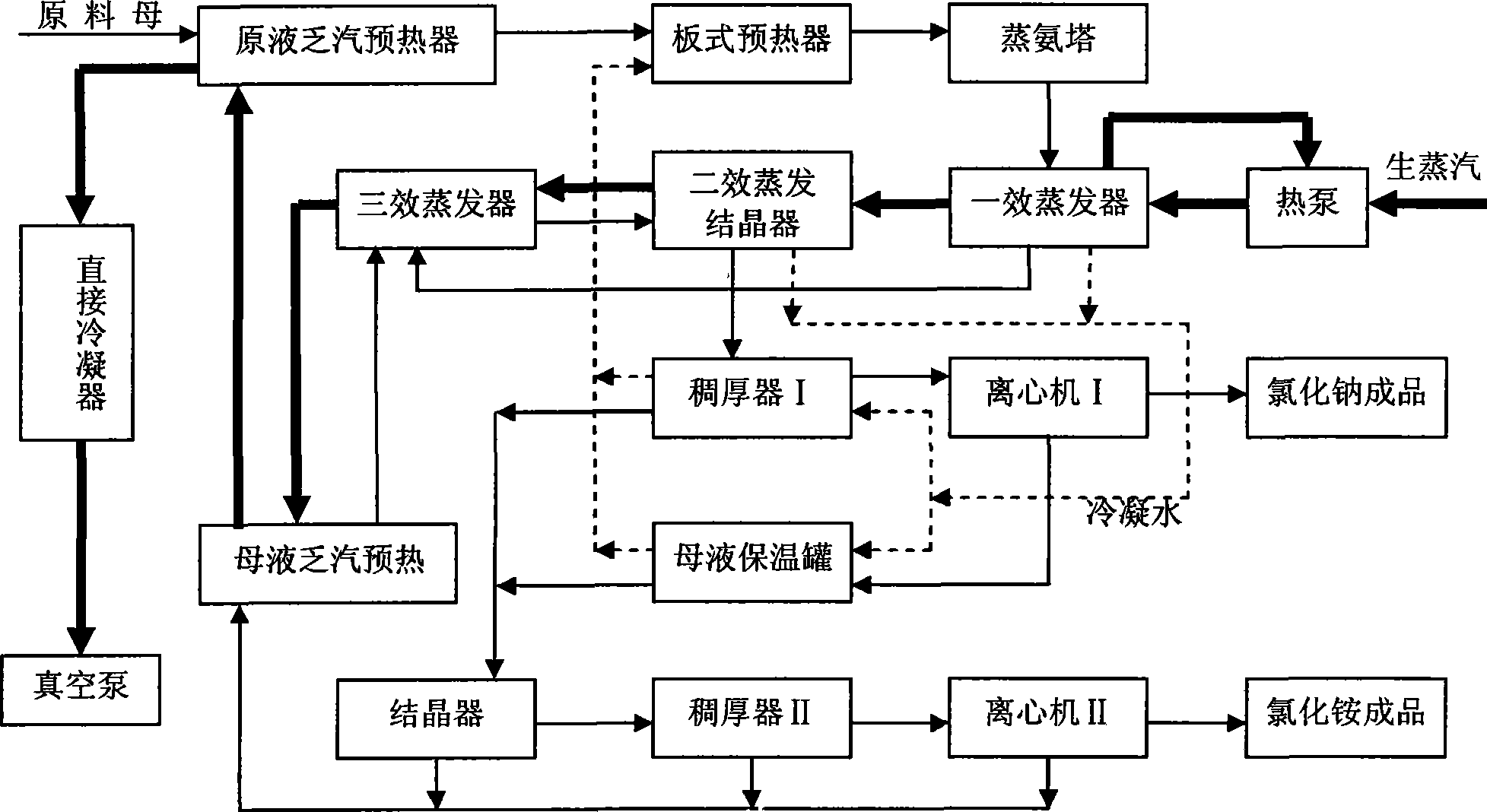

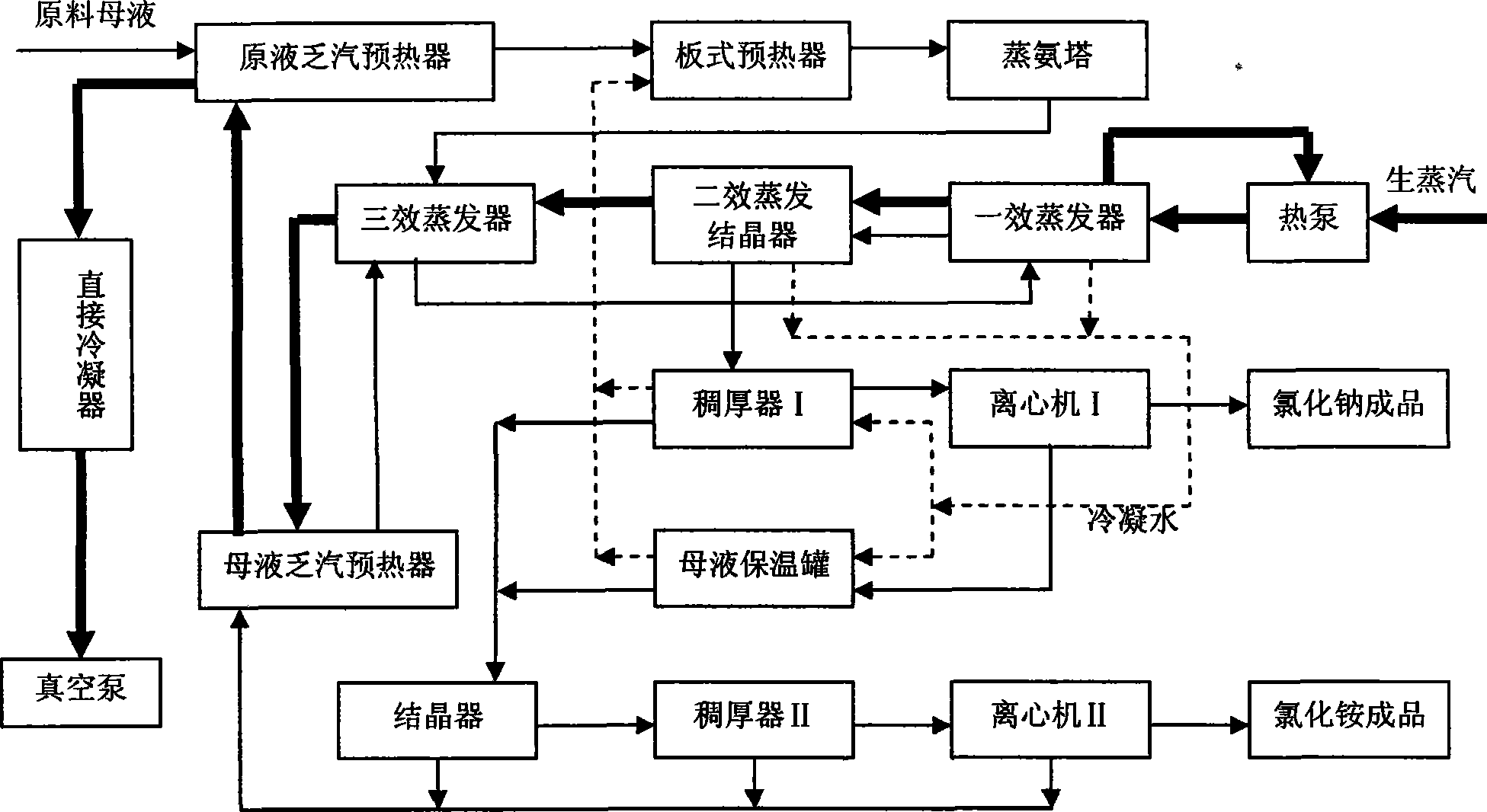

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

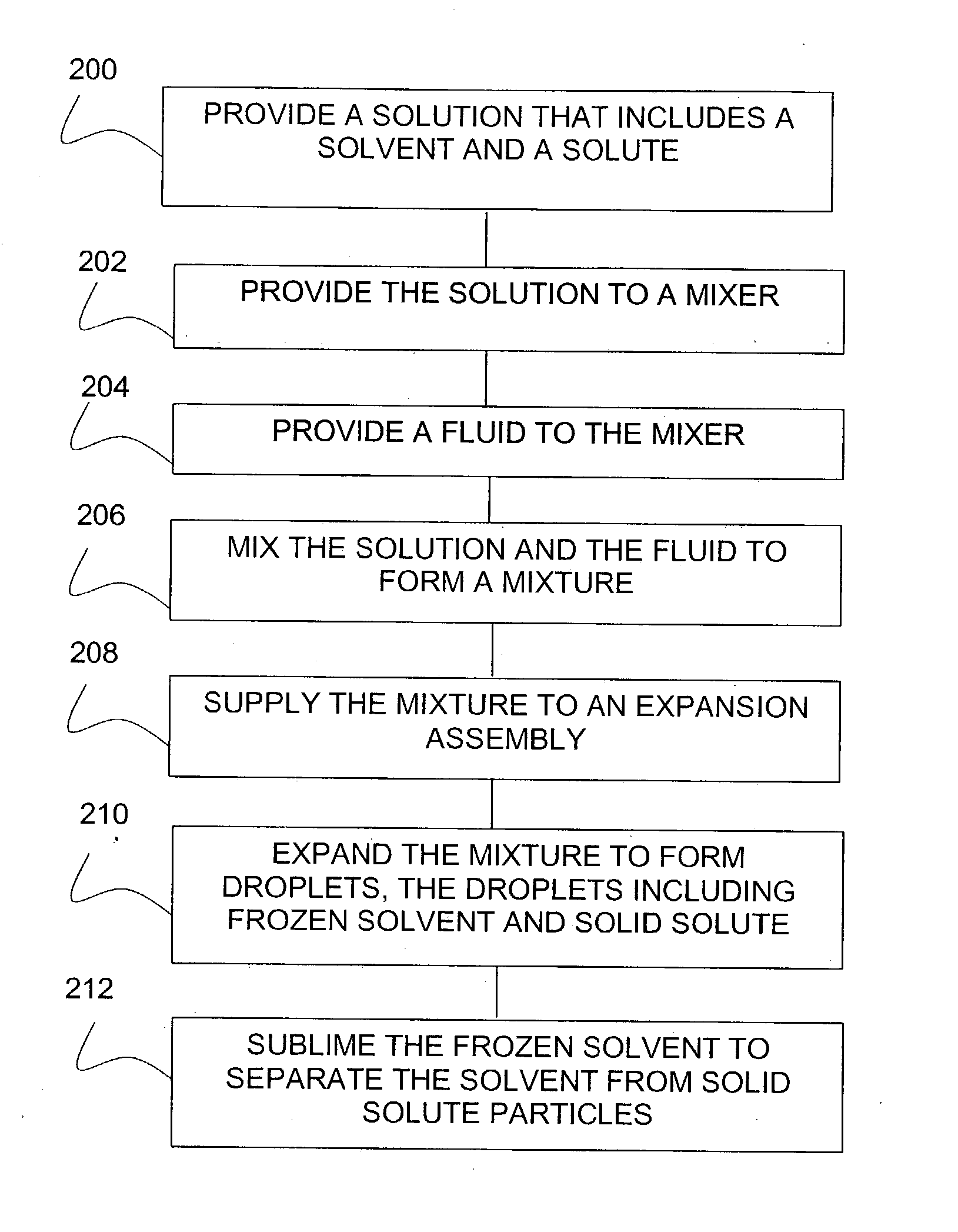

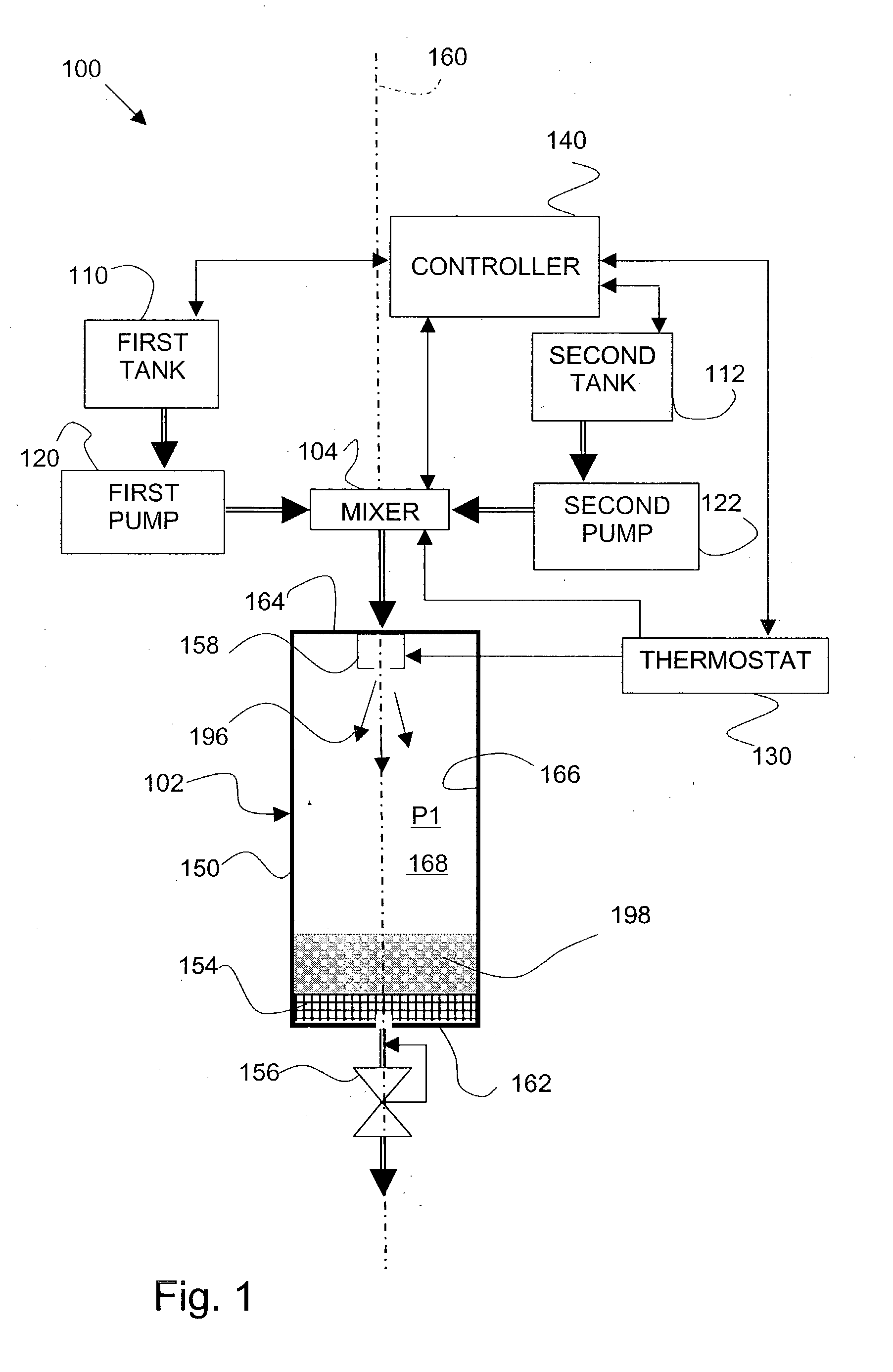

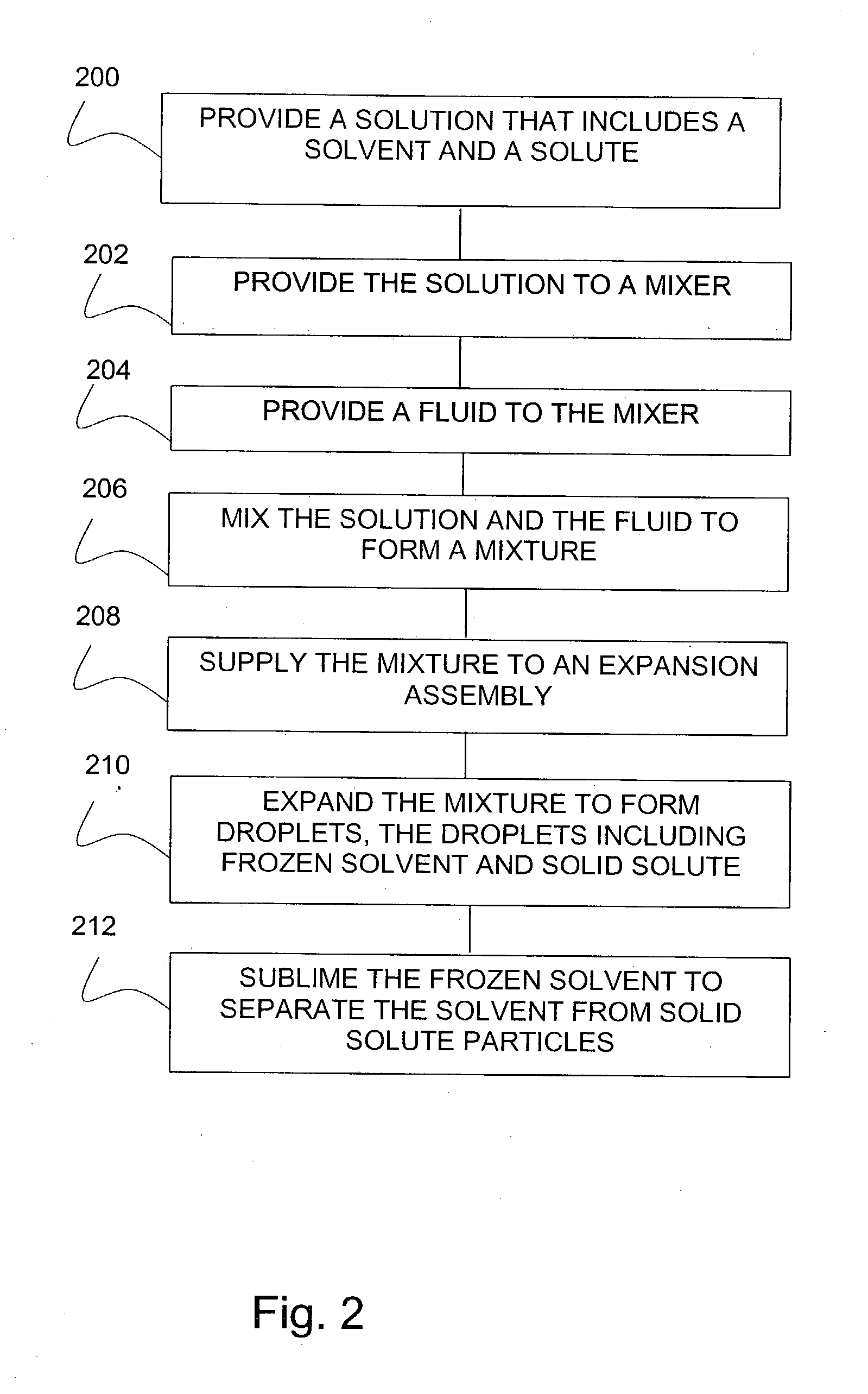

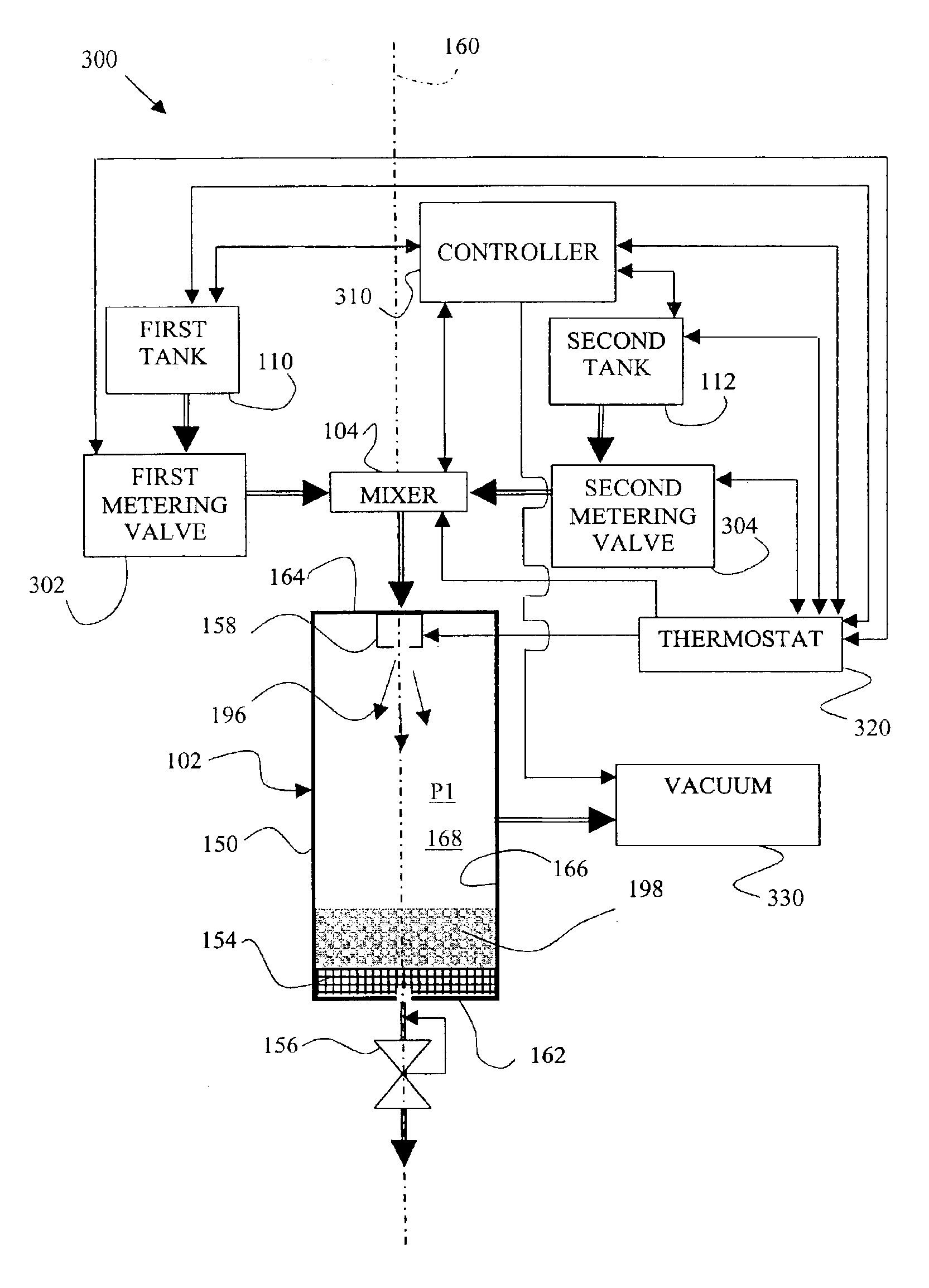

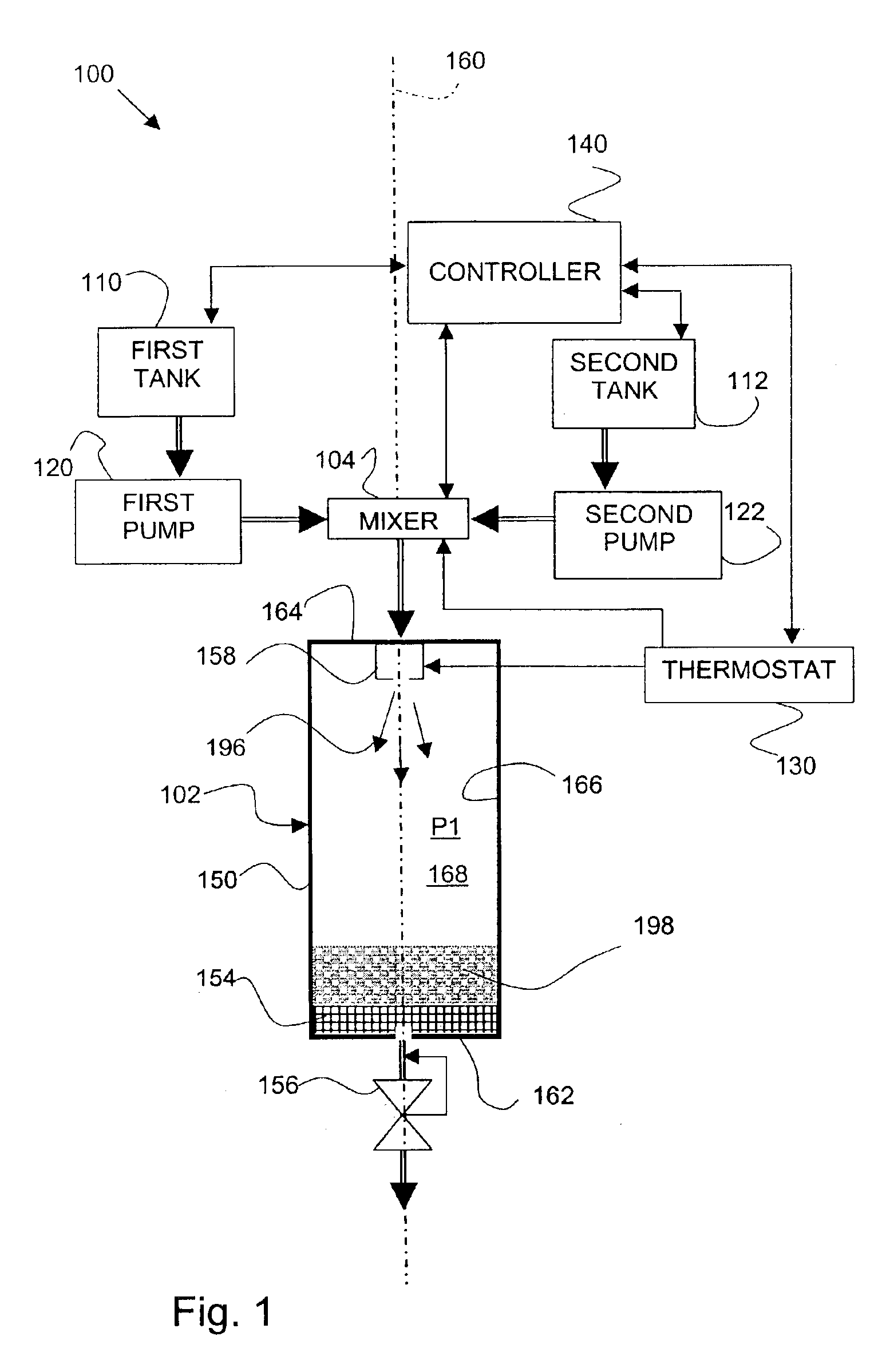

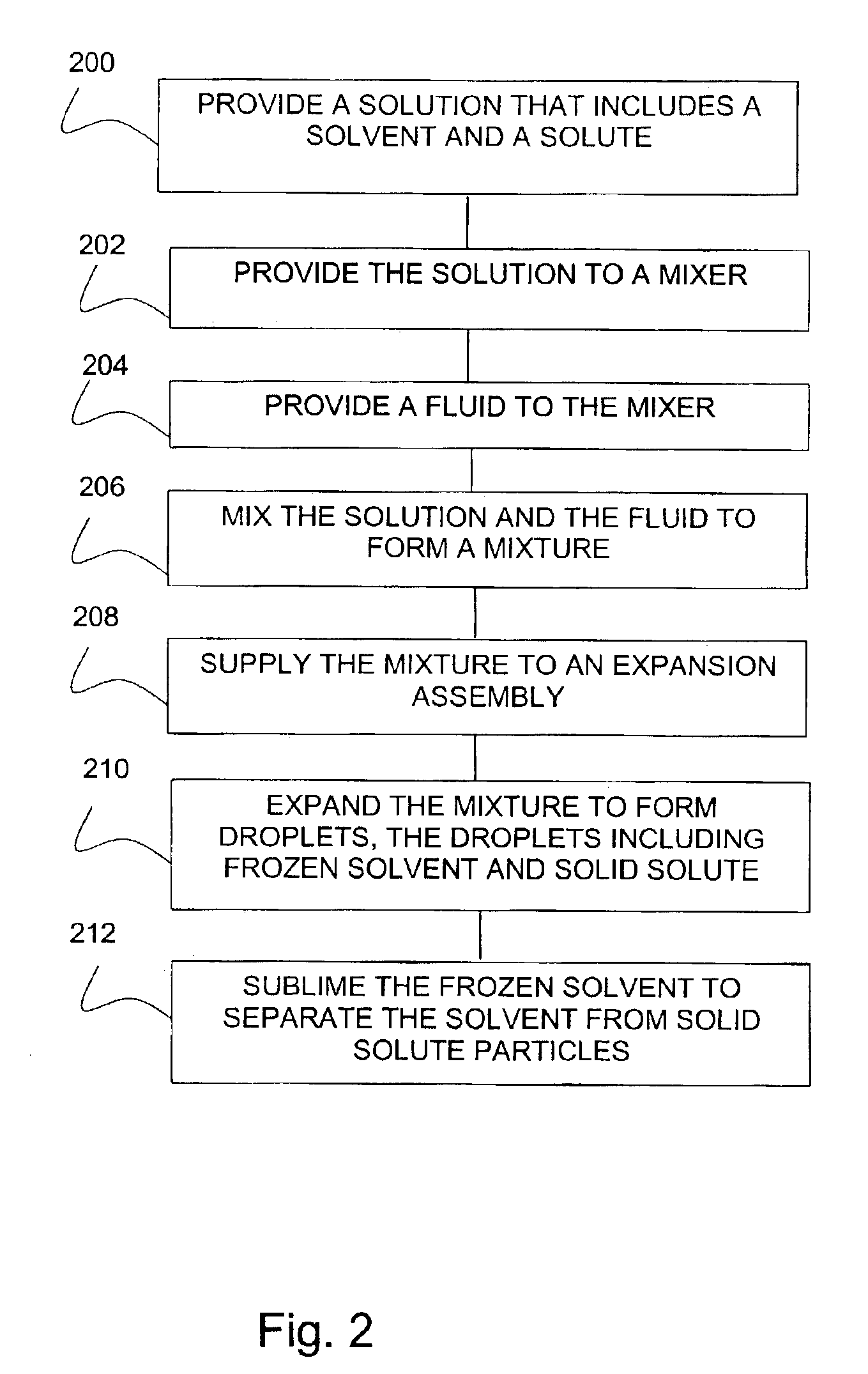

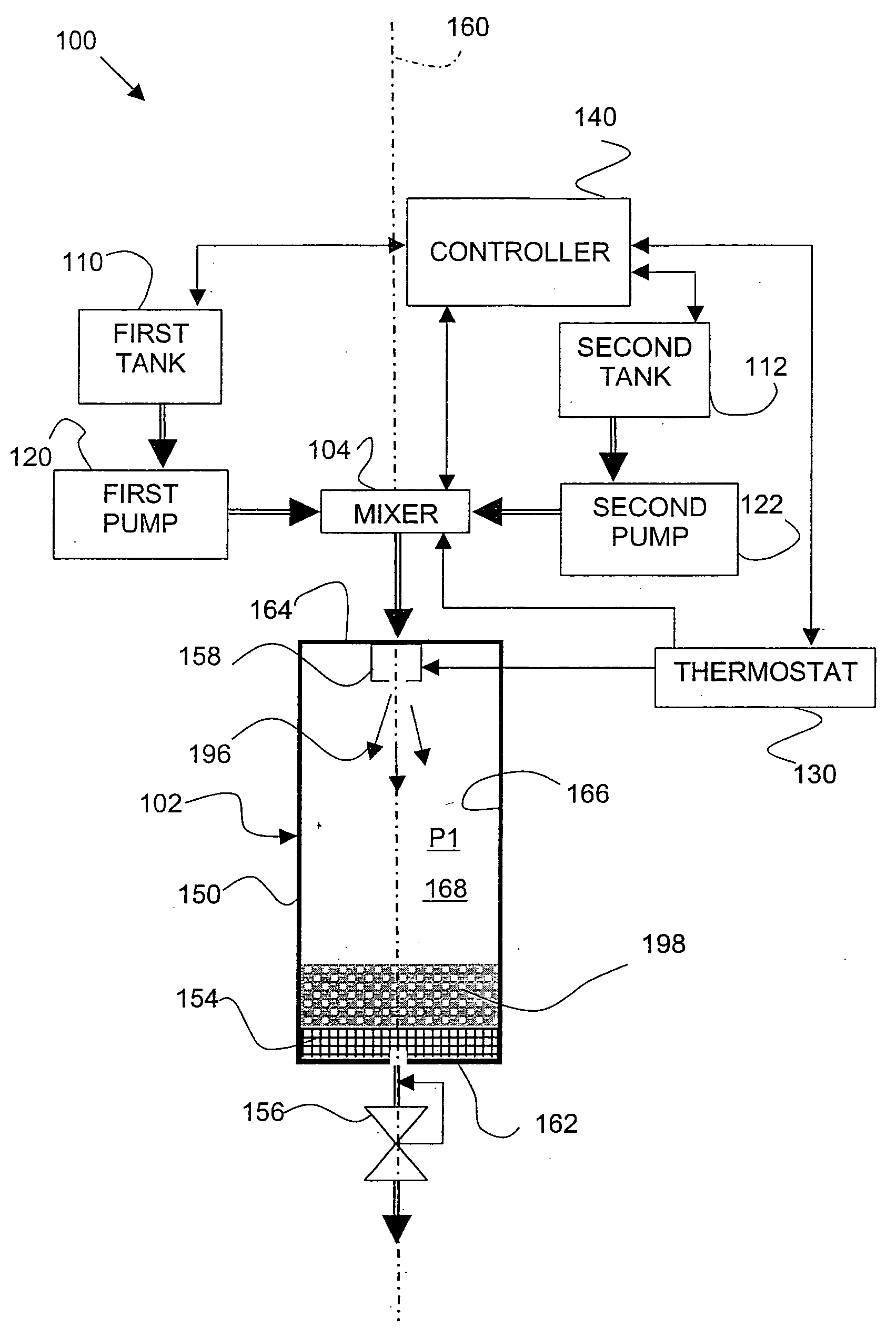

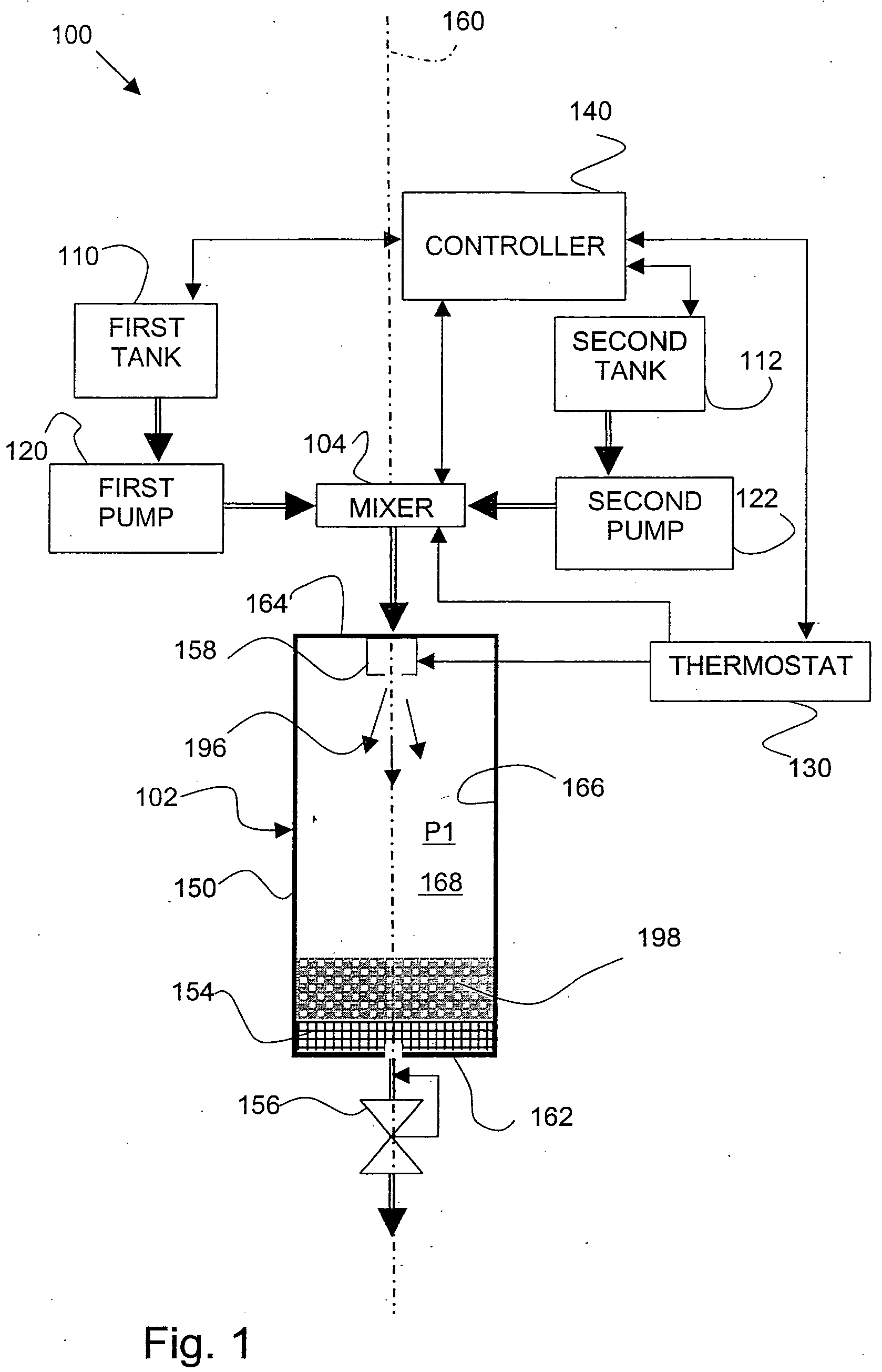

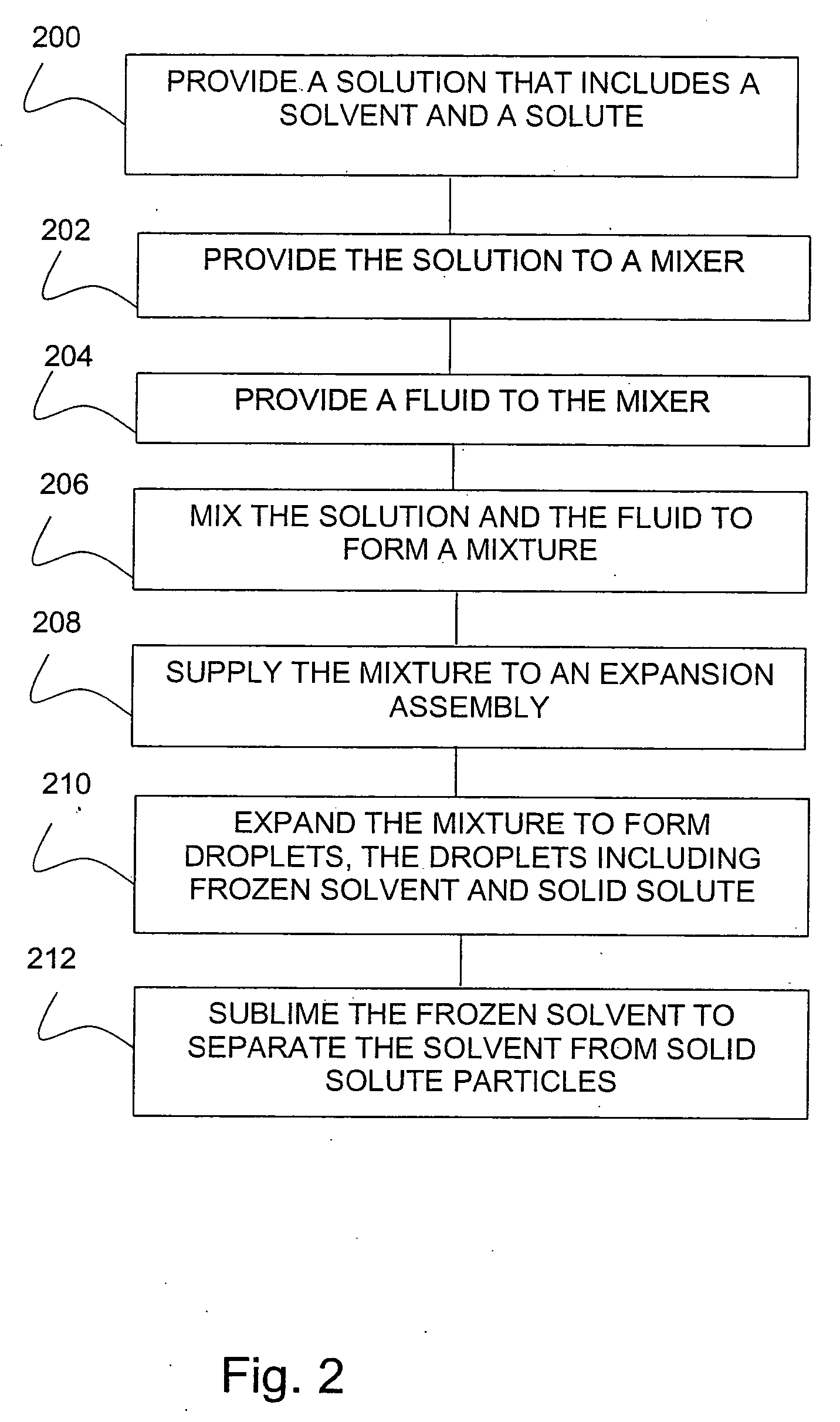

Lyophilization method and apparatus for producing particles

InactiveUS20040154317A1Powder deliveryDrying solid materials without heatFreeze-dryingSolid particle

A method and apparatus for producing particles, the apparatus includes a solution source that supplies a solution, and a fluid source that supplies a fluid. The solution includes a solvent and a solute. A mixer receives the solution and the fluid from the sources, and mixes the solution and the fluid together to form a mixture. The mixture is supplied from the mixer to an expansion assembly at first pressure. The expansion assembly sprays and expands the mixture substantially simultaneously to form frozen droplets, and preferably to form a low-density powder of frozen droplets. A freeze-dry apparatus sublimes the solvent from the particles. A high mass-transfer rate and a uniform open-structure of the powder bed enhances the freeze-drying process. Solid particles having a controlled size distribution are obtained. The particles preferably have a hollow or porous morphology suitable for differing drug delivery applications to include aerosol formulations.

Owner:FERRO CORP

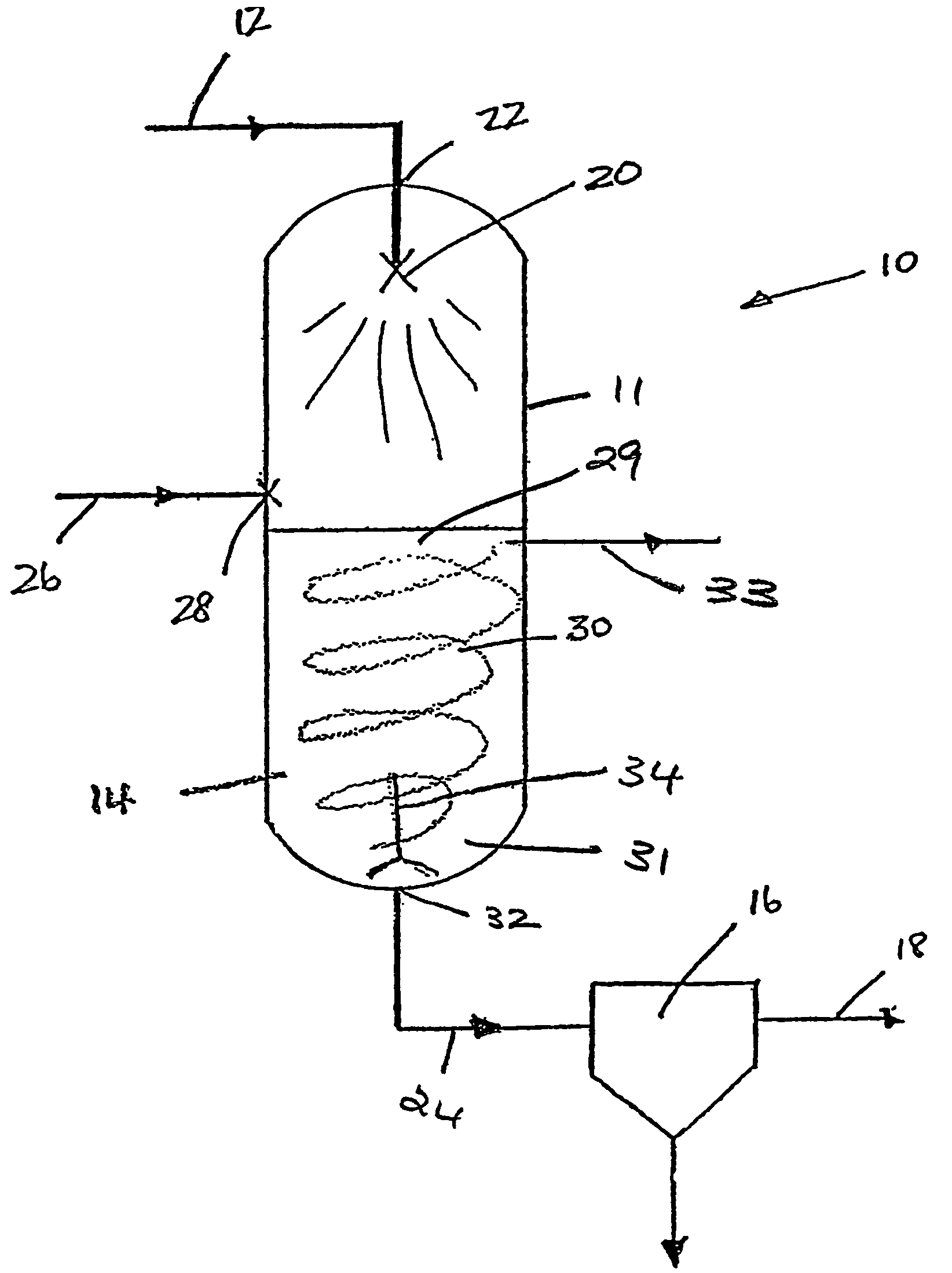

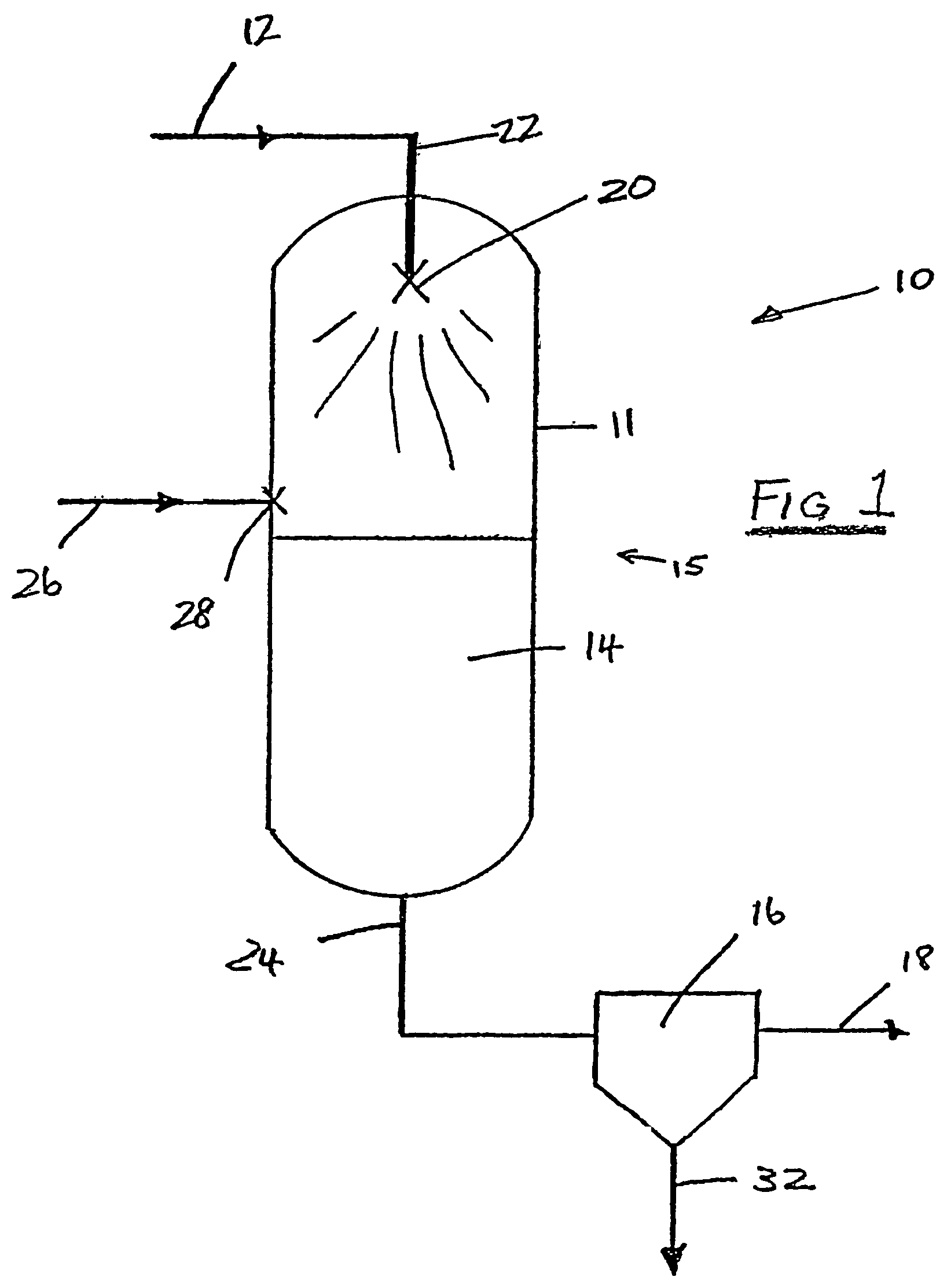

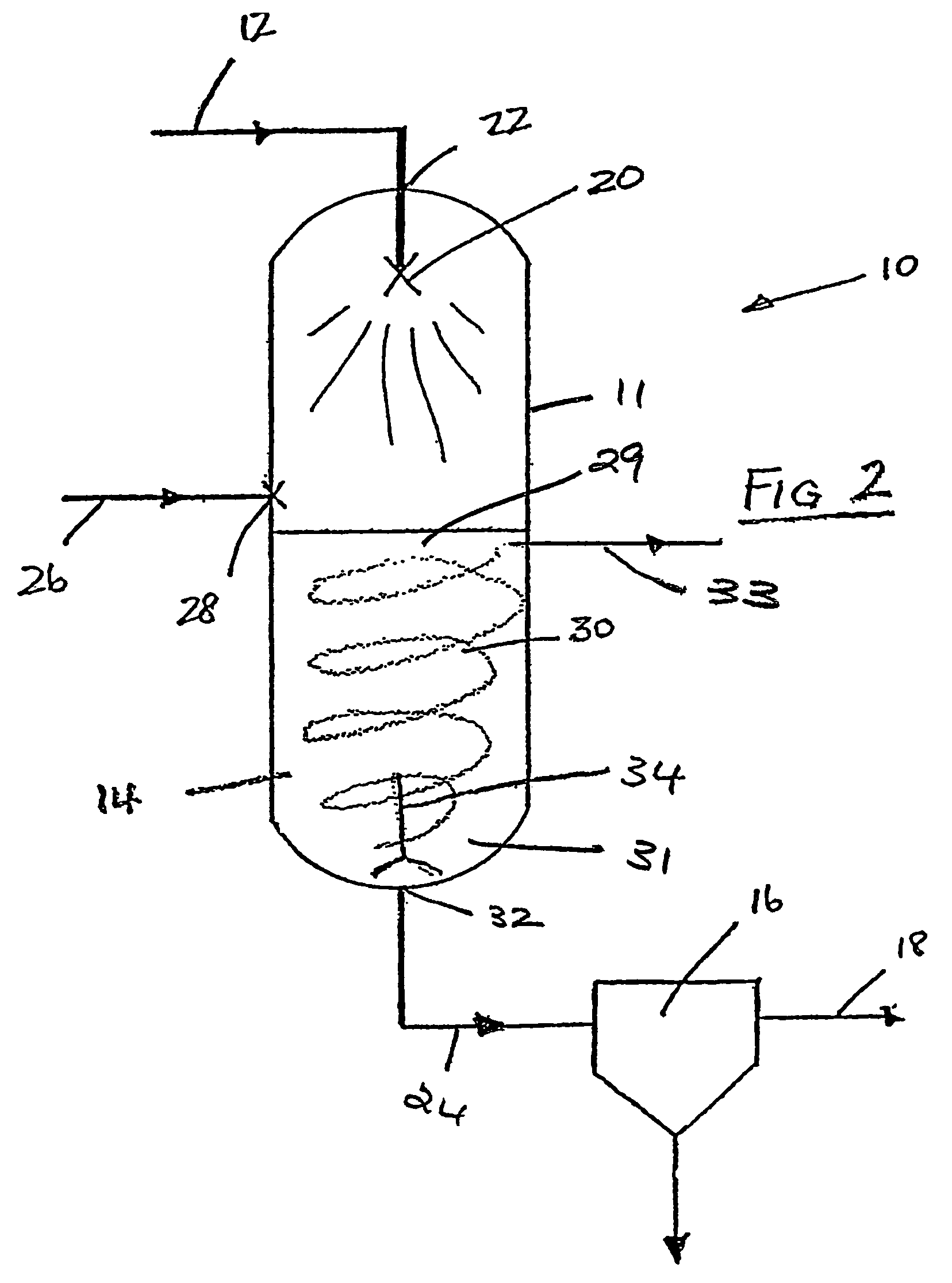

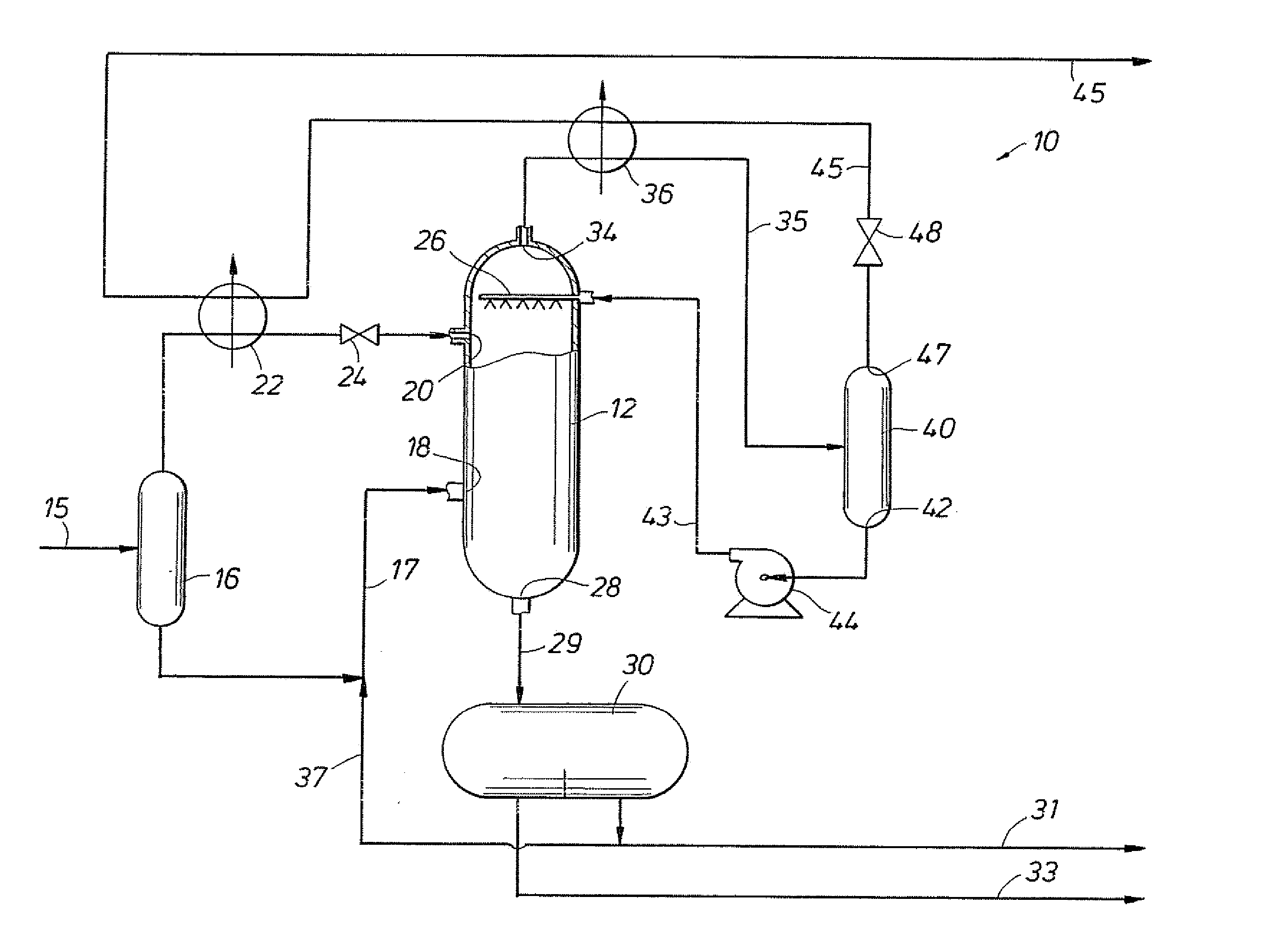

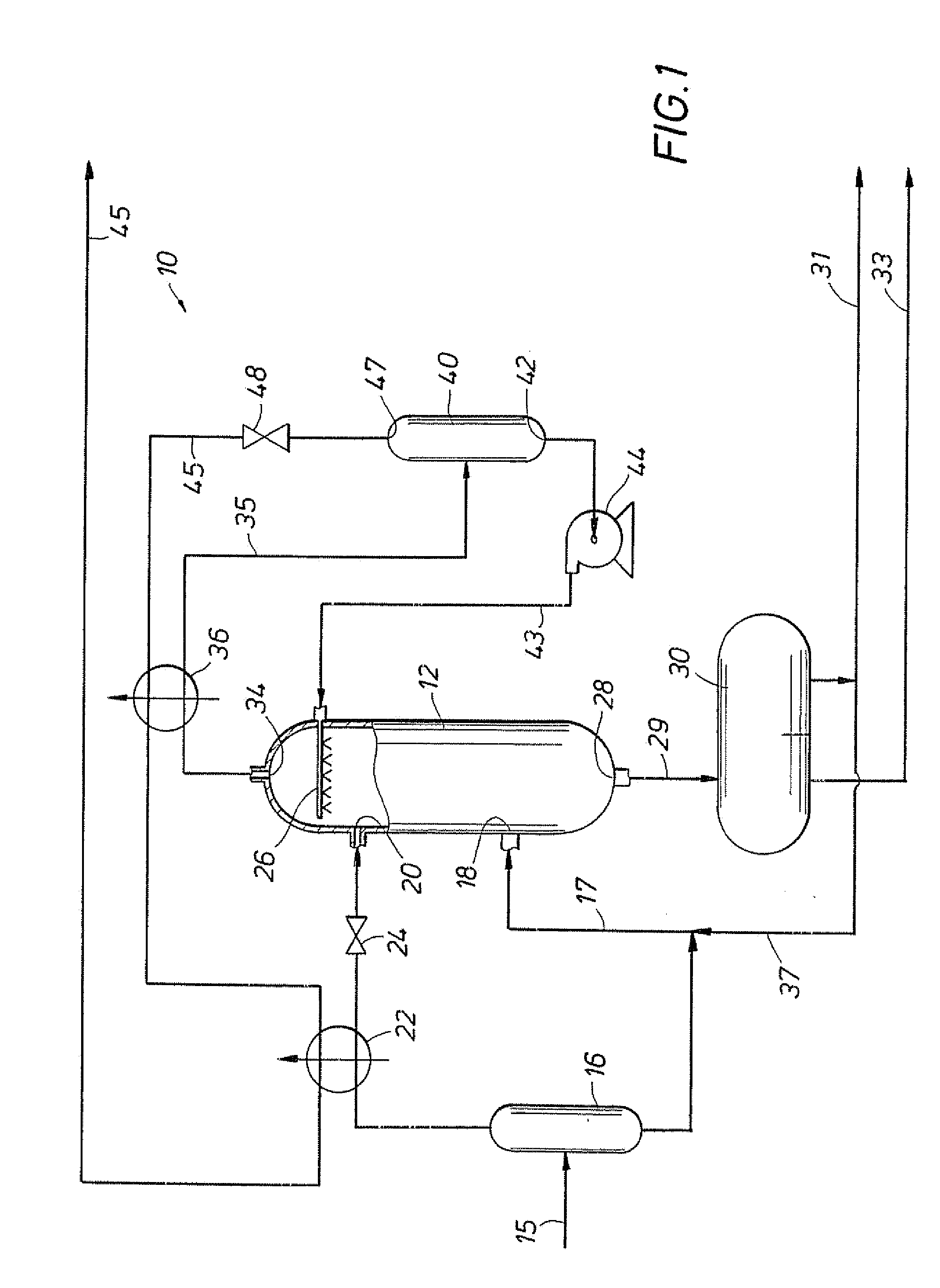

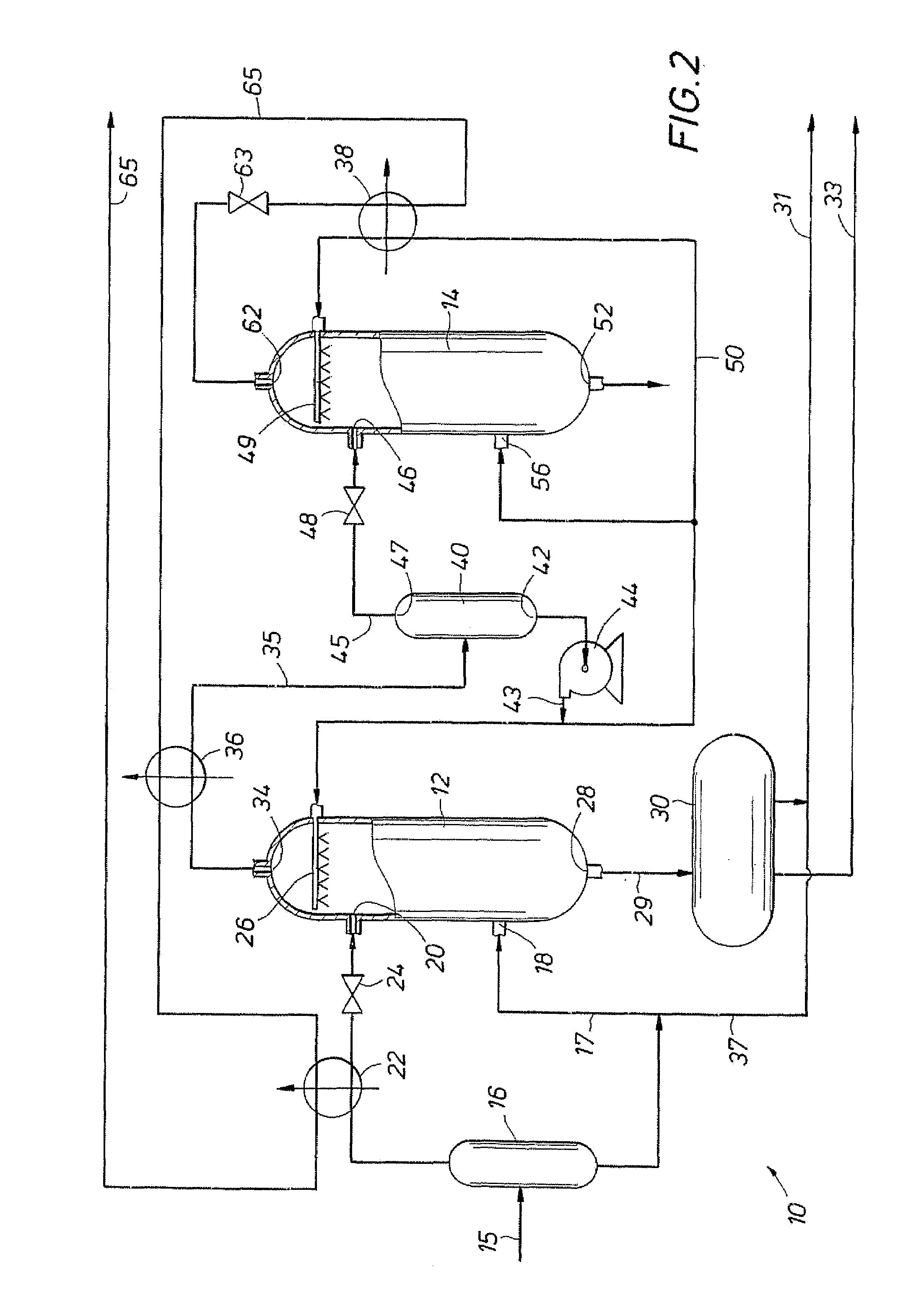

Process and device for production of LNG by removal of freezable solids

ActiveUS7325415B2Reducing and eliminating foulingSolidificationLiquefactionWorking pressureAmount of substance

Novel processes and devices for the removal of freezable species such as carbon dioxide, water and heavy hydrocarbons from a natural gas feed stream during liquefaction to produce LNG are disclosed. The freezable species are able to be removed as a solid, avoiding the costly step of pretreatment to remove the freezable species from the natural gas feed stream prior to the liquefaction stage. The freezable species may be removed on a continuous basis being separated as solids following liquefaction of the natural gas feed stream with subsequent separation of the solids. The solid freezable species may then be liquefied on a continuous basis if required with natural gas recycled to the process. Continuous removal of the freezable species from the natural gas feed stream is achievable by maintaining cooling and separation apparatus at the same working pressure. Advantageously, at least part of the cooling vessel is constructed from a material having a low thermal conductivity which discourages formation of the solids of the freezable species on the walls of the cooling vessel.

Owner:SHELL USA INC

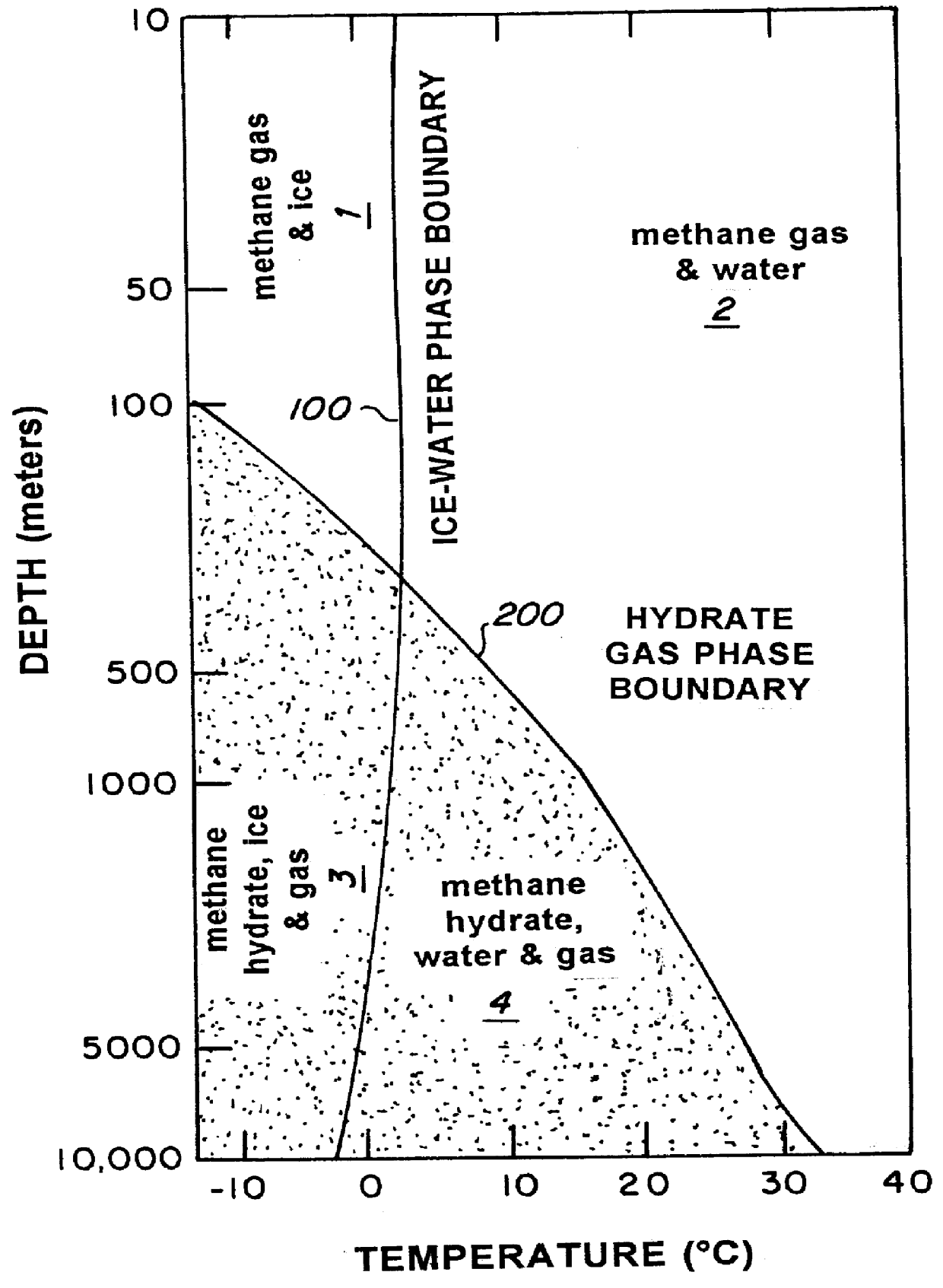

Desalination through gas hydrate

In one embodiment, this invention pertains to desalination of seawater by feeding methane into seawater at a depth generally exceeding 100 meters to form methane hydrate which rises to where it is decomposed into methane and water, and recoverig water. Methane is recycled to depth to form more buoyant hydrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

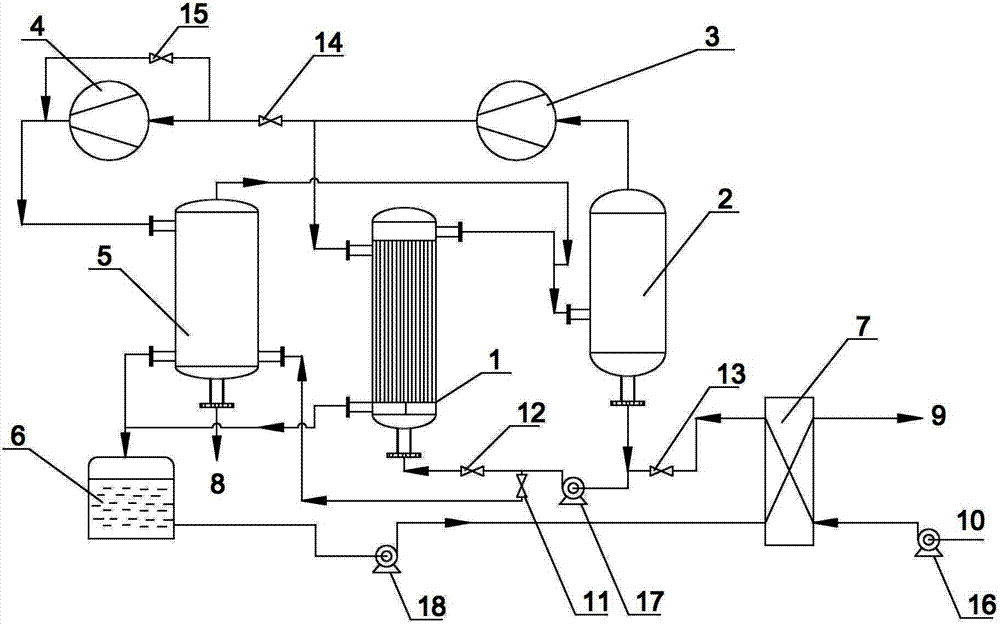

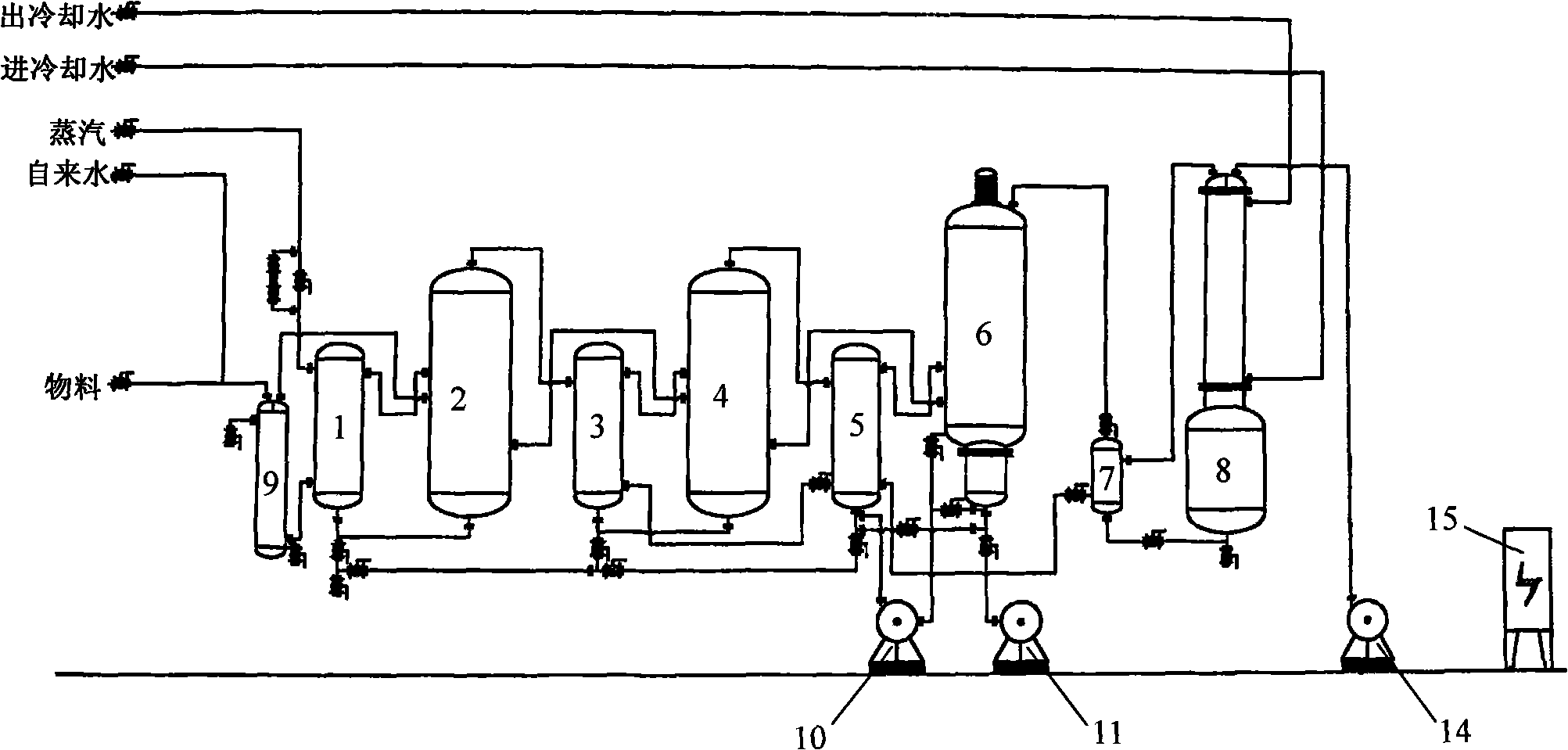

MVR (Mechanical Vapor Recompression) continuous evaporative crystallization system and continuous evaporative crystallization method

ActiveCN103203116ATake advantage ofSmall footprintEvaporation with vapour compressionSolution crystallizationEvaporatorEngineering

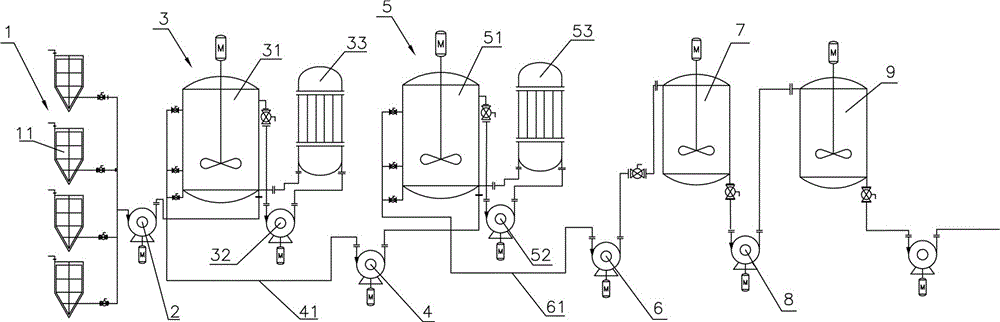

The invention relates to an MVR (Mechanical Vapor Recompression) continuous evaporative crystallization system and a continuous evaporative crystallization method. The system comprises an evaporator, a steam-liquid separator, a main steam compressor, an assistant steam compressor and a crystallizer. The outlet of the evaporator is connected with the inlet of the steam-liquid separator. The top outlet of the steam-liquid separator is connected with the main steam compressor which is further communicated with the top inlet of the evaporator. The communicating pipeline of the main steam compressor with the top inlet of the evaporator is provided with a branched pipeline connected to the crystallizer. The branched pipeline is provided with the assistant steam compressor which is provided by a bypass. The bottom outlet of the steam-liquid separator is respectively connected with the inlets of the evaporator and the crystallizer. The top of the crystallizer is connected with the inlet of the steam-liquid separator. The method is carried out by the system. Through reasonable design, the energy-saving economical benefit, the integrity, the reasonability and the agility of the evaporative crystallization technology are further improved. Secondary steam in the evaporating and crystallizing process is adequately utilized, and latent heat is recovered, so that the thermal efficiency is improved.

Owner:江苏迪飞生物技术有限公司

Lyophilization method and apparatus for producing particles

Owner:FERRO CORP

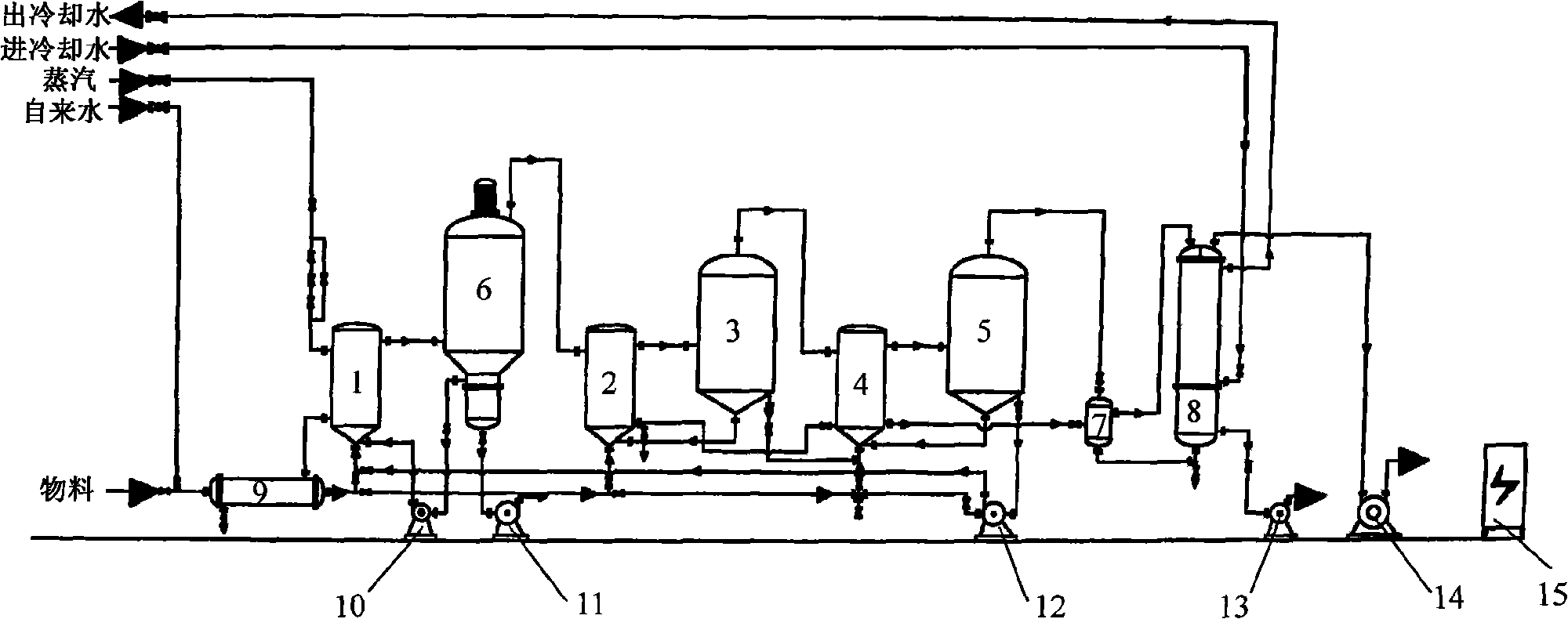

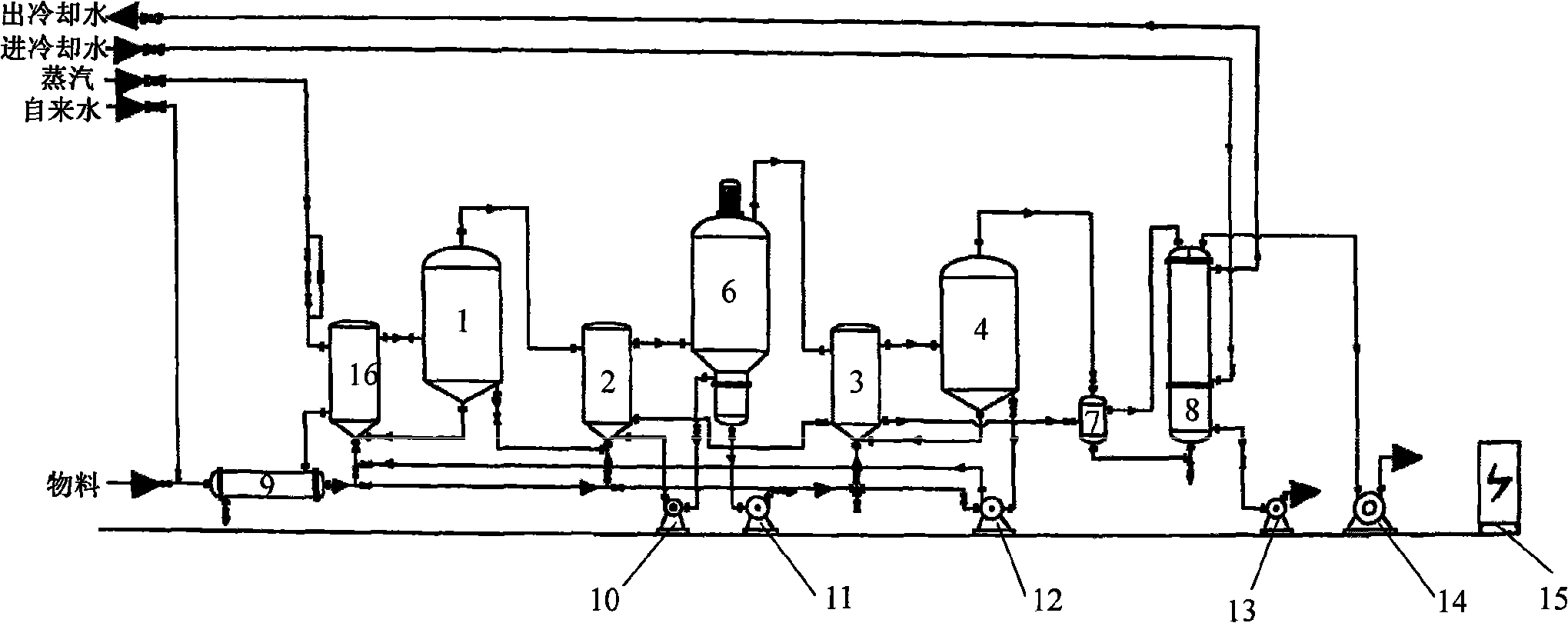

Multifunctional multiple-effect automatic continuous evaporative crystallization technique and crystallization device

InactiveCN101306260AEasy to separateReduce manufacturing costSolution crystallizationMultiple-effect evaporationOrganic solventEconomic benefits

The invention relates to an evaporative crystallization process, in particular to the multifunctional multi-effect automatic continuous evaporative crystallization process and a crystallization device. The process preheats unsaturated water solution or organic solution of materials and carries out the continuous evaporation to the material liquid by a multi-effect evaporator, the temperature of the multi-effect evaporator is gradually reduced and the vacuum degree is gradually increased; when the concentration of the material liquid achieves the saturation, the material liquid enters a crystallizer for the flash evaporation crystallization, and products after the crystallization are subjected to the solid-liquid separation in a centrifuge; the unsaturated solution after the centrifugalization is sent back to the device for the further evaporation crystallization, and the evaporated water or the organic solvent is recycled for use after cooling, thereby realizing the continuous production. The evaporative crystallization process can greatly reduce the labor use and improve the productivity, thereby directly bringing economic benefits to enterprises which use the device and simultaneously reducing the national energy consumption.

Owner:项公浩

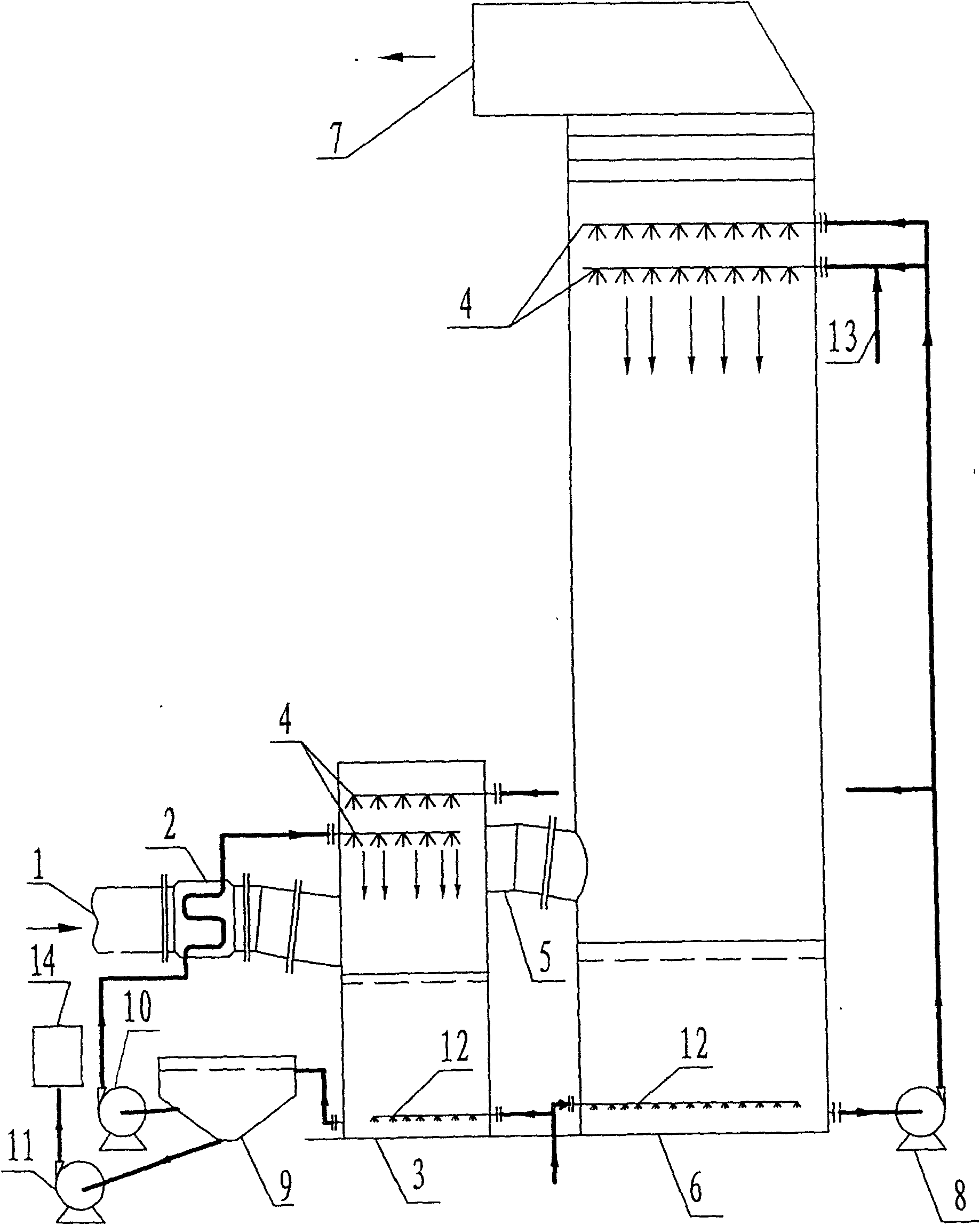

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

ActiveCN101670231ASolve the strength problemSolve highDispersed particle separationSolution crystallizationMagmaDistributor

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, andthe upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

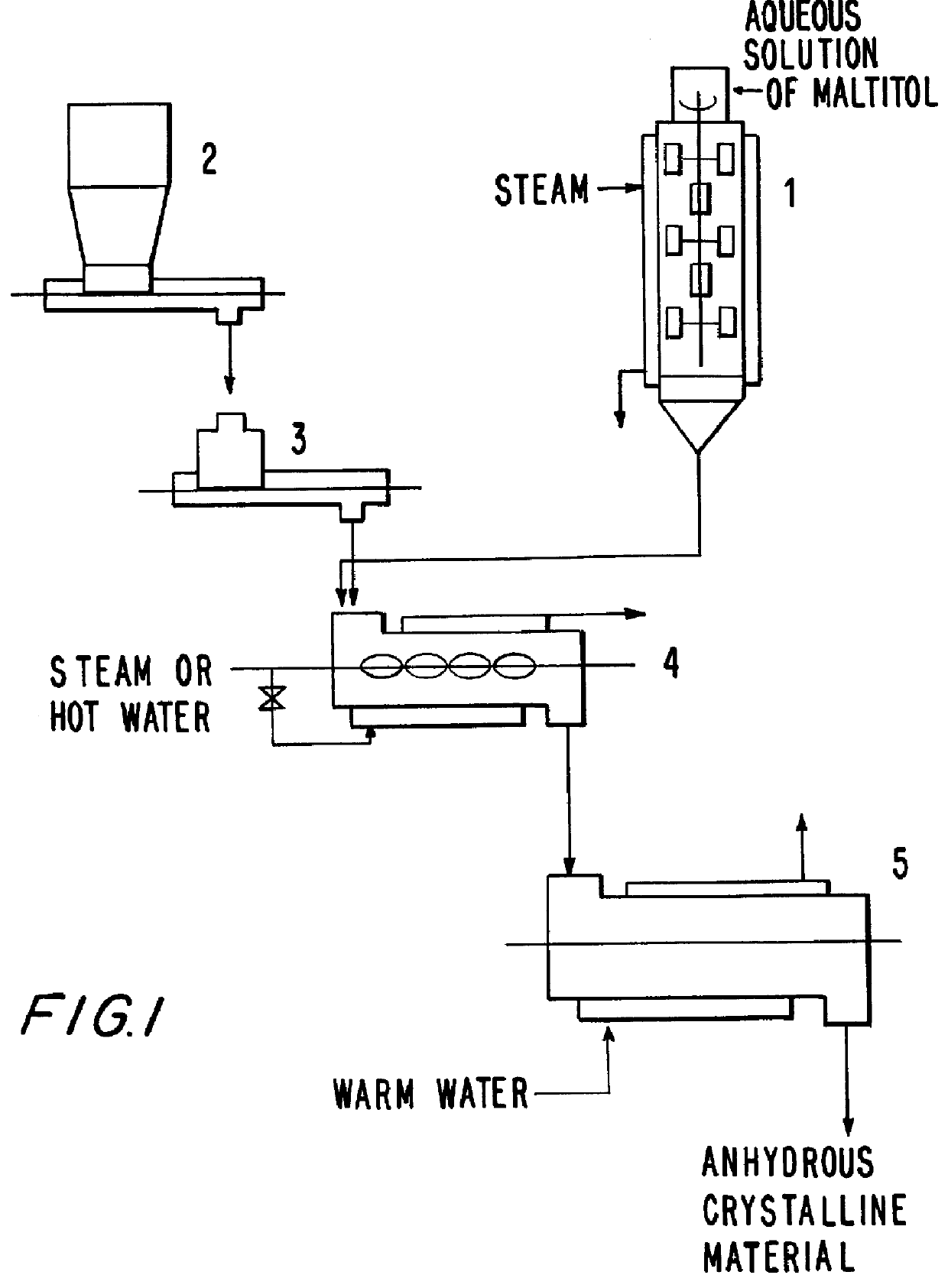

Method for the continuous manufacture of anhydrous crystalline maltitol and a manufacturing apparatus therefor

InactiveUS6120612ALow production costLabor expenseSugar derivativesSugar crystallisationHigh concentrationPolymer science

Disclosed herein is a continuous manufacturing method for anhydrous crystalline maltitol comprising the following steps: (i) a heating and concentrating step where an aqueous solution containing maltitol in which maltitol is a main ingredient is continuously heated and concentrated to give a concentrated solution having a high concentration; (ii) a seed crystal adding and mixing step where the seed crystals are added to and mixed with the above concentrated solution with heating to give a massceuite containing the seed crystals; and (iii) a crystal aging step where the massceuite is subjected to disintegration, mixing, stirring and transfer in an atmosphere in which temperature and moisture are adjusted to proceed the crystallization.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC +1

Method for separating magnesium from lithium and extracting lithium from brine

InactiveCN101538057ASolve the difficult technical problems of filtrationSimple technical processMultistage water/sewage treatmentSolution crystallizationFiltrationHigh energy

The invention provides a method for separating magnesium from lithium and extracting the lithium from high magnesium-lithium ratio brine (brine from a saline lake, from underground and from an oil-gas field). The method comprises: sodium salt and potassium and magnesium mixed salt are separated from the brine by evaporation of a saltpan; after boron extraction, sodium hydroxide is used for precipitating Mg<2+> from obtained old brine, and crystallized Mg(OH)2 is obtained by modification and precipitation condition control; filtration and separation are carried out to remove the Mg(OH)2 to realize separation of magnesium and lithium; after filtered mother solution is vaporized and concentrated for 2-4 times, Na2SO4 and NaCl are separated by crystallization, and pure caustic soda can be added to form lithium carbonate from lithium; or the operation of further evaporation is carried out until Na2SO4 and NaCl are separated by multiple times of natural evaporation or forced evaporation concentration and multiple times of cooling crystallization; the operations of evaporation and concentration are carried out until LiCl saturation, and LiCl products can be prepared after the operation of cooling crystallization is carried out. Compared with the prior art for separating the magnesium from the lithium and extracting the lithium from the brine, the method obtains the crystallized Mg(OH)2 by modification and precipitation condition control, solves the existing technical problem of hard filtration of Mg(OH)2, solves the defects of high energy consumption, complex process and high cost of the existing calcination method, and solves the fundamental defects of low Li<2+> recovery ratio and complex technical process of the traditional precipitation method. The Li<2+> recovery ratio ranges from 85-93%, Mg<2+> removal ratio is more than 99.5%, and the method solves the problem of extracting Li<+> and Mg<2+> from high-magnesium and low-lithium brine with Mg<2+> / Li<+>>=20 mass ratio.

Owner:钟辉

(Meth)acrylic acid crystal and method for the production and purification of aqueous (meth)acrylic acid

ActiveUS20050222459A1High water concentrationHigh purityOrganic compound preparationSolution crystallizationMeth-Purification methods

The present invention relates to processes for purifying a composition containing (meth)acrylic acid, at least one impurity and water, wherein the composition has a water content in the range of 0.55 to 90, based on the composition, to form a purified phase containing (meth)acrylic acid and at least one impurity, wherein, in the purified phase, the quantity of at least one impurity is less than 7% by weight, based on (meth)acrylic acid in the purified phase.

Owner:EVONIK SUPERABSORBER GMBH

Freeze concentration process

The use of an improved method for freeze concentration is disclosed. The method provides for first freezing components of a pulpy slurry of Morinda citrifolia. More dilute components are extracted after the initial freezing. A secondary freezing process at a lower temperature allows more concentrated portions of a Morinda citrifolia slurry to be removed. Flavor and therapeutic oils remain in the resulting concentrate for improved flavor and health benefits.

Owner:TAHITIAN NONI INT INC

Nanostructured aerogel-thermoelectric device, making and using the same

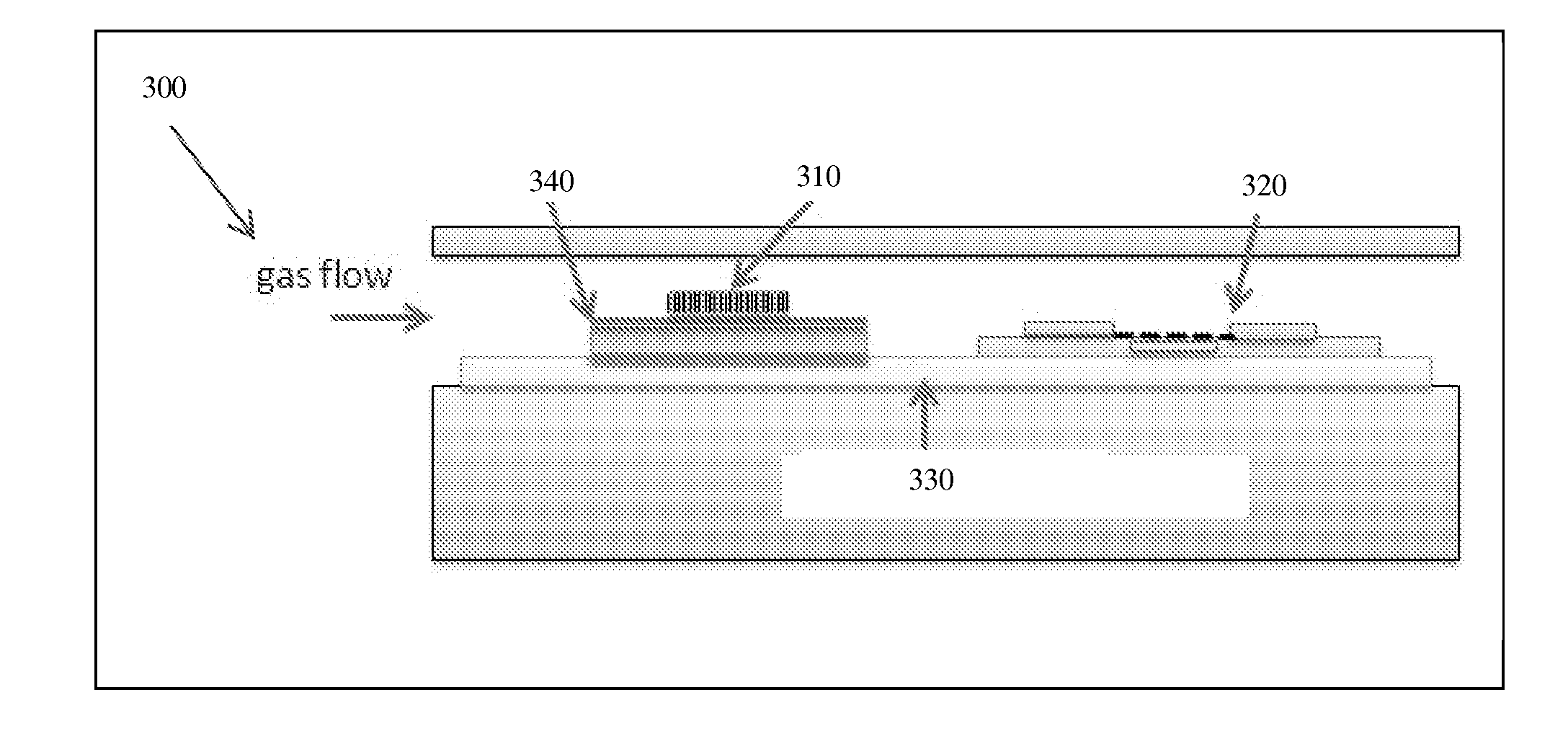

InactiveUS20120301360A1Material analysis using sonic/ultrasonic/infrasonic wavesDrying solid materials without heatThermoelectric materialsAnalyte

Devices used in conjunction with detecting analytes and methods of their manufacture are disclosed. A pre-concentrator device includes a thermoelectric material and an aerogel which includes a nanostructured material disposed on, and in thermal communication with, the thermoelectric material. Such a pre-concentrator is part of a detection system including a sensor. The detection system is used in a method for detecting analytes.

Owner:LOCKHEED MARTIN CORP

Method of removing solid carbon dioxide

The invention provides a method of removing solid carbon dioxide from cryogenic equipment, including the steps of: (a) introducing a stream including ethane to the cryogenic equipment to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. In particular, the method can be used in a liquefied natural gas (LNG) plant wherein cryogenic equipment contains LNG, and the method includes the steps of: (a′) removing the LNG from the cryogenic equipment; (a) introducing a stream including ethane to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. The result is an effective cleaning method for fouled LNG equipment.

Owner:SHELL OIL CO

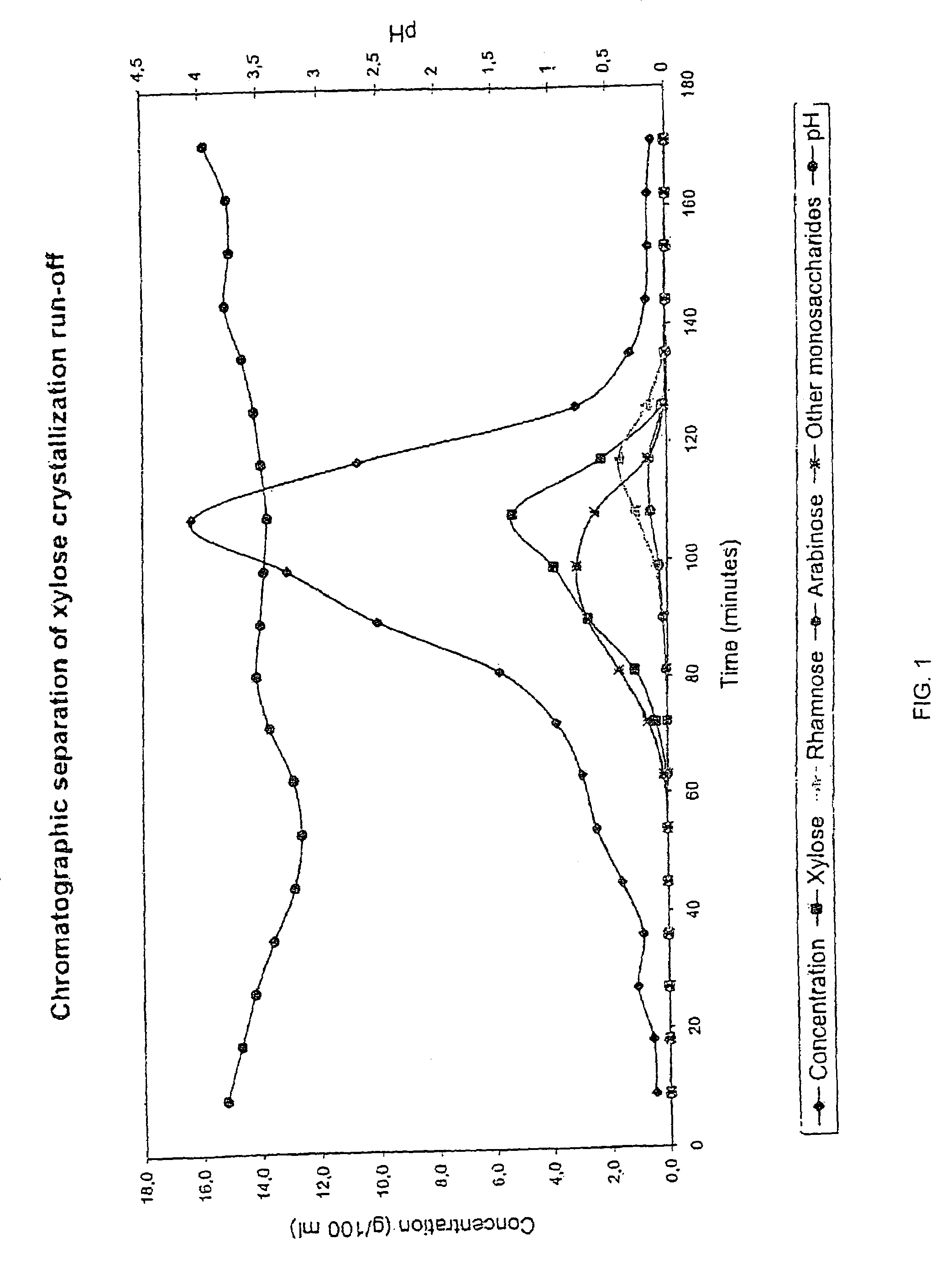

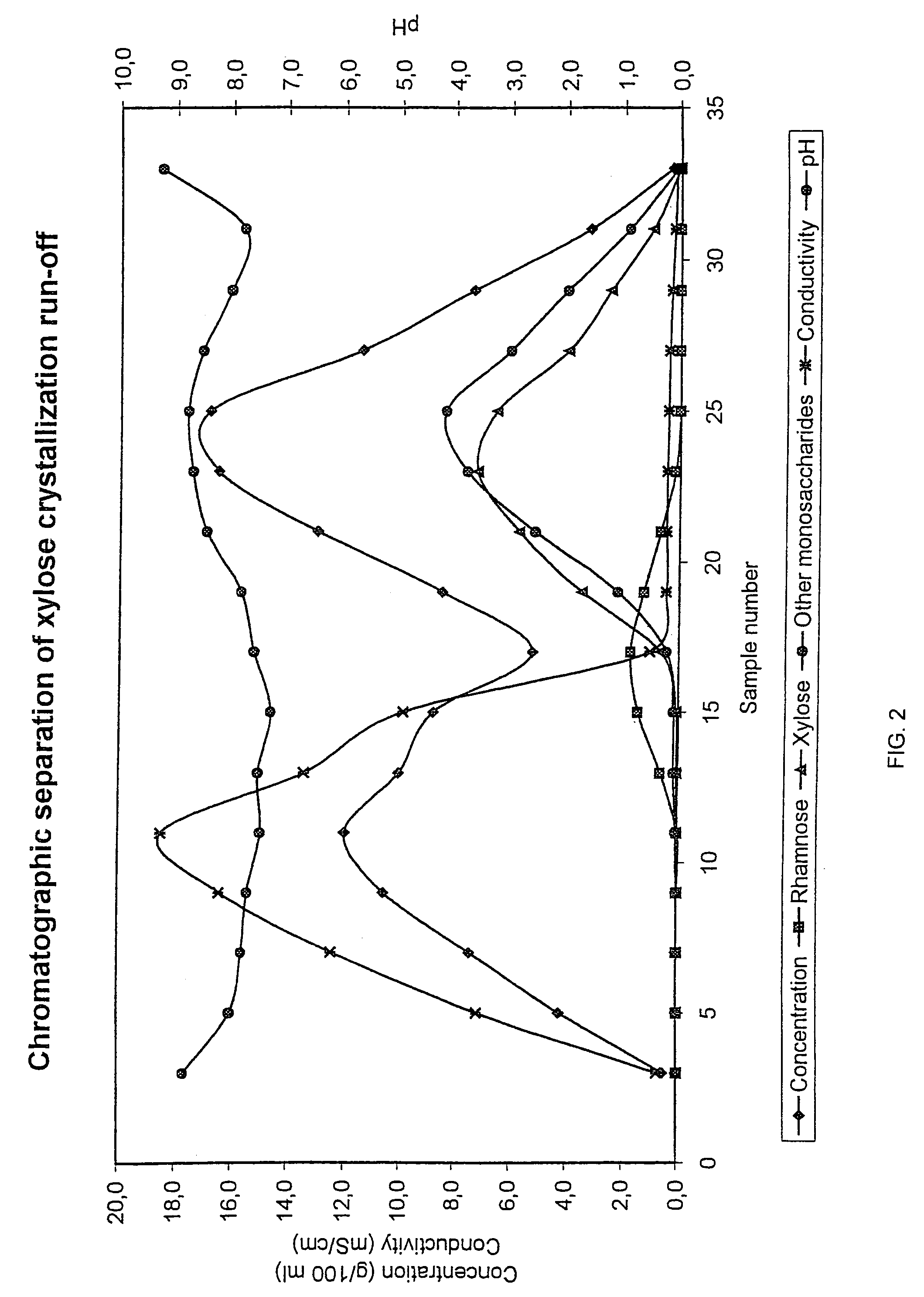

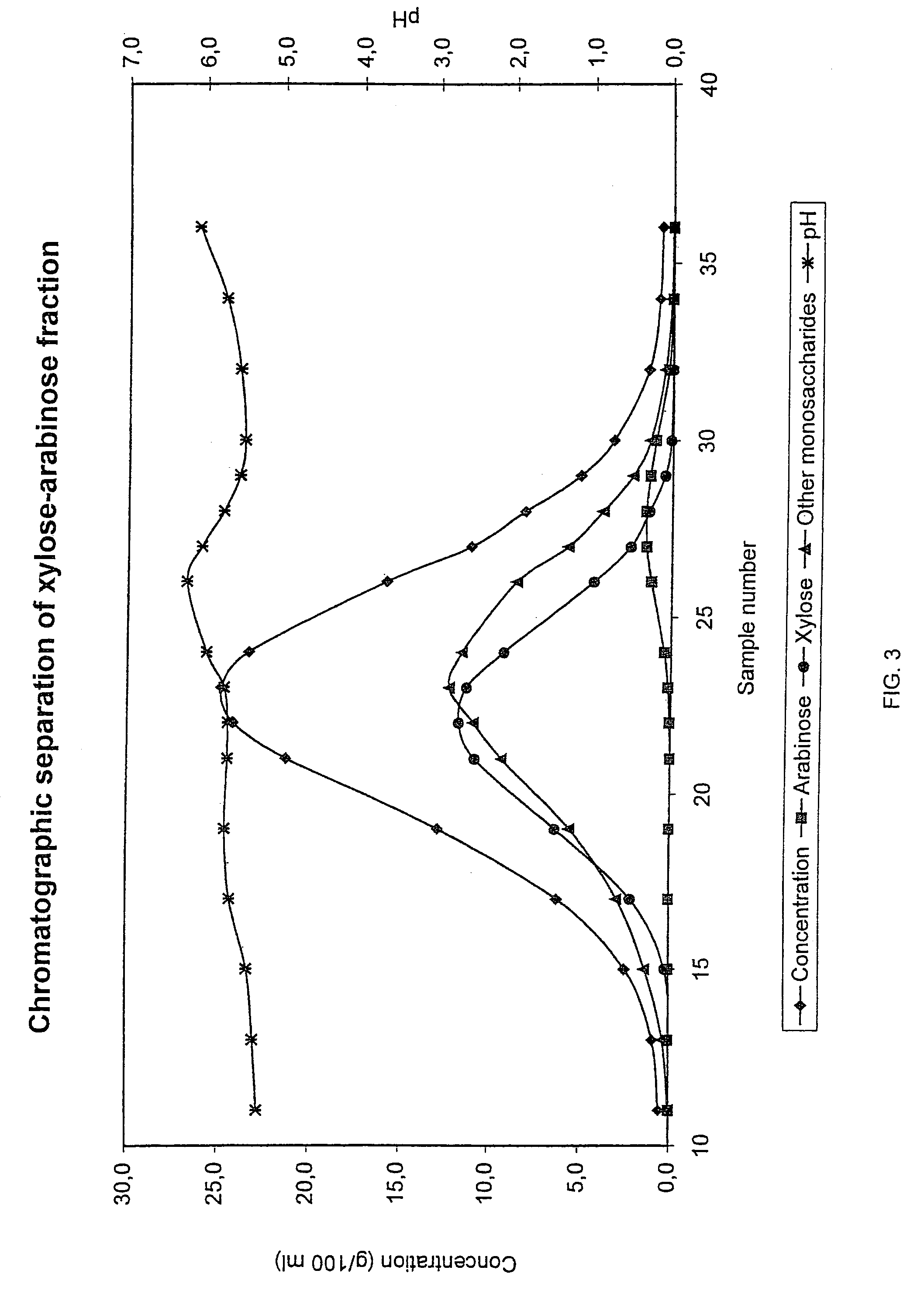

Method for recovering products

InactiveUS6987183B2Ion-exchanger regenerationSugar crystallisationChromatographic separationArabinose

The present invention is directed to a method comprising a multistep process for recovering one or more monosaccharides from a solution containing at least two monosaccharides selected from the group consisting of rhamnose, arabinose, xylose and mixtures thereof by using chromatographic separation comprising at least one step, where a weak acid cation exchange resin is used for the chromatographic separation.

Owner:DANISCO SWEETENERS

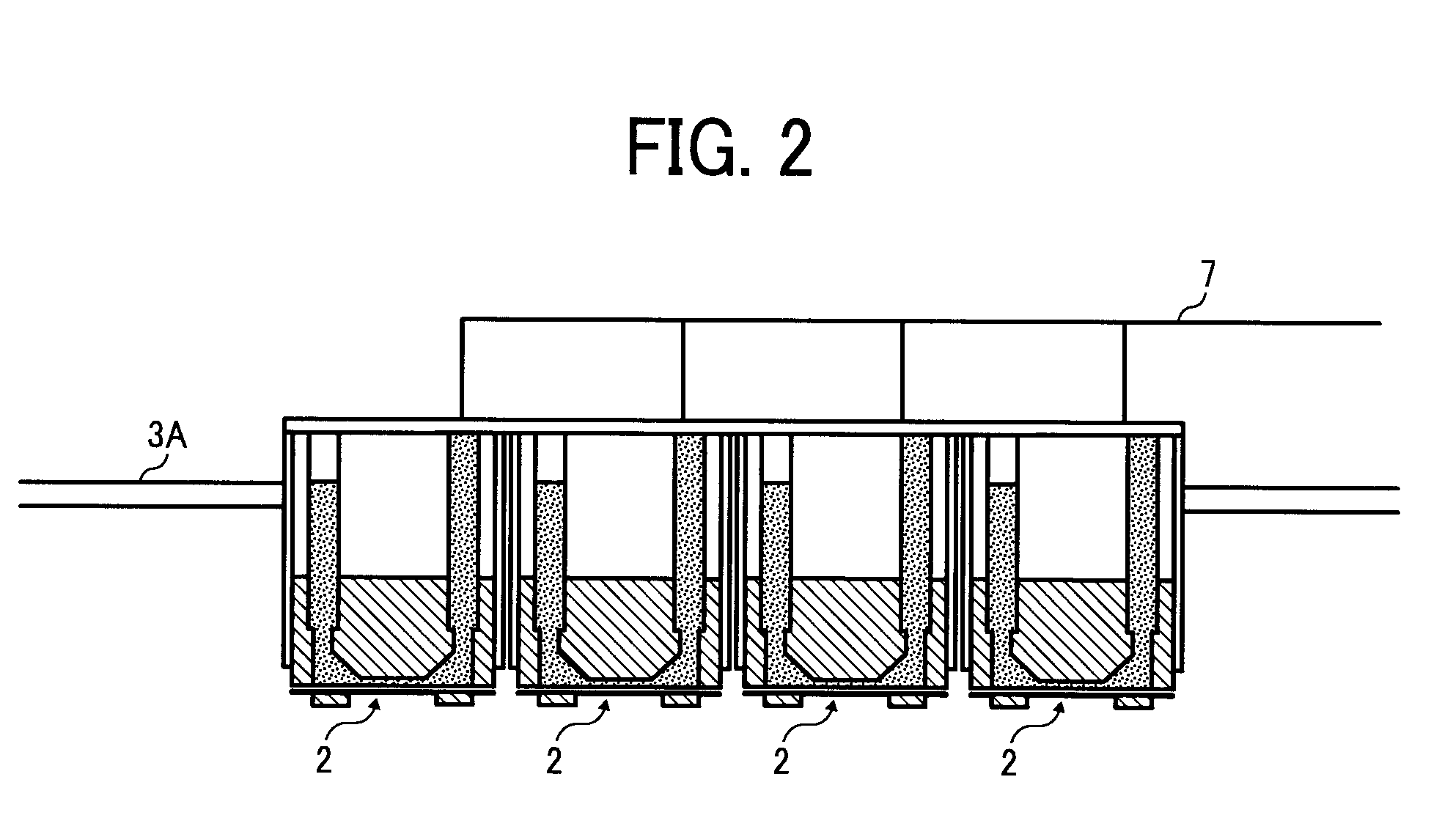

Toner preparation method and apparatus, and toner prepared thereby

ActiveUS20080286679A1Stable preparationUniform particle sizeGranulation by liquid drop formationSolution crystallizationColoring agentsLiquid drop

A method of preparing a toner, including periodically dripping and discharging droplets of a toner constituent liquid comprising a resin and a colorant with a dripper comprising a thin film comprising plural nozzles configured to discharge the droplets, and an electromechanical converter configured to oscillate the thin film; and solidifying the droplets to form toner particles, wherein the nozzle has an aperture discharging the droplet, having a circular or an ellipsoidal cross-sectional shape and cross-sectional area smaller than a cross-sectional area of another aperture contacting the toner constituent liquid.

Owner:RICOH KK

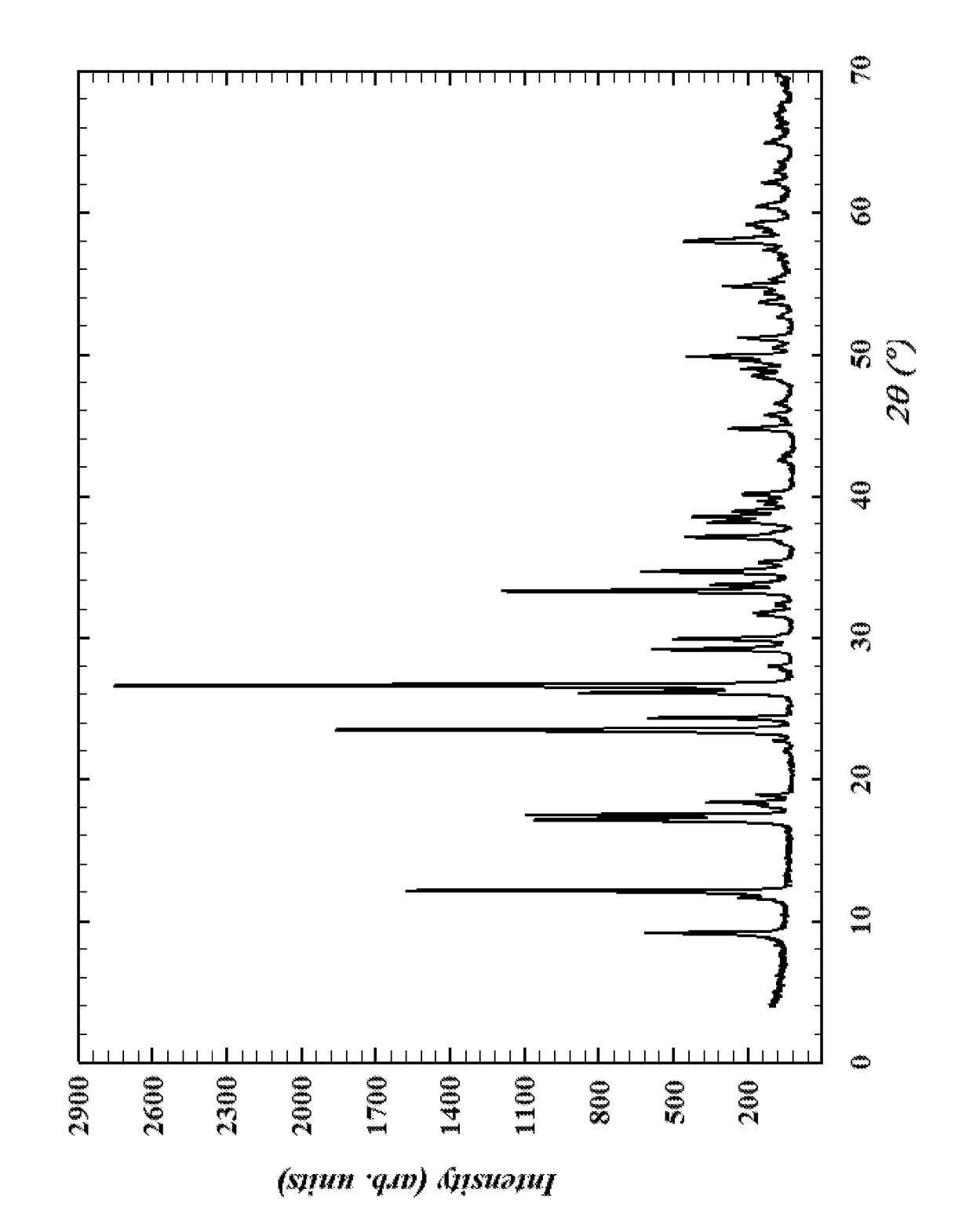

Crystalline transition metal oxy-hydroxide molybdotungstate

ActiveUS20170165648A1Polycrystalline material growthTungsten oxides/hydroxidesHydrodesulfurizationPhysical chemistry

A hydroprocessing catalyst has been developed. The catalyst is a unique crystalline transition metal oxy-hydroxide molybdotungstate material. The hydroprocessing using the crystalline ammonia transition metal oxy-hydroxide molybdotungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Process and device for production of lng by removal of freezable solids

ActiveUS20050072186A1Reducing and eliminating foulingSolidificationLiquefactionWorking pressureThermal conductivity

Novel processes and devices for the removal of freezable species such as carbon dioxide, water and heavy hydrocarbons from a natural gas feed stream during liquefaction to produce LNG are disclosed. The freezable species are able to be removed as a solid, avoiding the costly step of pretreatment to remove the freezable species from the natural gas feed stream prior to the liquefaction stage. The freezable species may be removed on a continuous basis being separated as solids following liquefaction of the natural gas feed stream with subsequent separation of the solids. The solid freezable species may then be liquefied on a continuous basis if required with natural gas recycled to the process. Continuous removal of the freezable species from the natural gas feed stream is achievable by maintaining cooling and separation apparatus at the same working pressure. Advantageously, at least part of the cooling vessel is constructed from a material having a low thermal conductivity which discourages formation of the solids of the freezable species on the walls of the cooling vessel.

Owner:SHELL USA INC

Continuously controllable acesulfame crystallization device

ActiveCN106267879AIncrease productivityQuality improvementOrganic chemistrySolution crystallizationGranularityEngineering

The invention discloses a continuously controllable acesulfame crystallization device. The continuously controllable acesulfame crystallization device comprises: a crystal growing device, a first conveying pump, a first-grade crystallizer, a second conveying pump, a second-grade crystallizer, a third conveying pump, a thickening device, a fourth conveying pump and a crystal slurry tank; the crystal growing device comprises at least one crystal growing kettle; a discharging hole of each crystal growing kettle is connected with a stop valve in series and then is communicated with an inlet of the first conveying pump; the first-grade crystallizer comprises a first-grade crystallizing kettle, a first-grade cooler and a first-grade circulating pump; an outlet of the first conveying pump is communicated with a lower circulating hole of the first-grade crystallizer; the second-grade crystallizer comprises a second-grade crystallizing kettle, a second-grade cooler and a second-grade circulating pump; the discharging hole of the first-grade crystallizing kettle is communicated with the inlet of the second conveying pump; the outlet of the second conveying pump is communicated with the lower circulating hole of the second-grade crystallizer; the discharging hole of the second-grade crystallizing kettle is communicated with the thickening device through the third conveying pump; the outlet of the thickening device is communicated with the inlet of the crystal slurry tank through the fourth conveying pump. The crystallization device provided by the invention is high in production efficiency and an obtained acesulfame crystal has good quality and large granularity.

Owner:南通宏信化工有限公司

High molecular weight ionized water

ActiveUS7513987B1Increase oxidation potentialAvoid inclusionsPolycrystalline material growthFrom normal temperature solutionsHydronium ionHigh molecular mass

A method for generating a multihydrated hydronium ion including the steps: agitating water to reduce cluster size, mixing sulfuric acid in the water, adding a solution containing Ca3+ ions, removing precipitated Ca sulfate, cooling the resultant liquid to a form a slush, filterin out ice from the slush, distilling free water from the remaining liquid wherein the remaining liquid is H9O4+.

Owner:MILLSTONE PROPERTIES

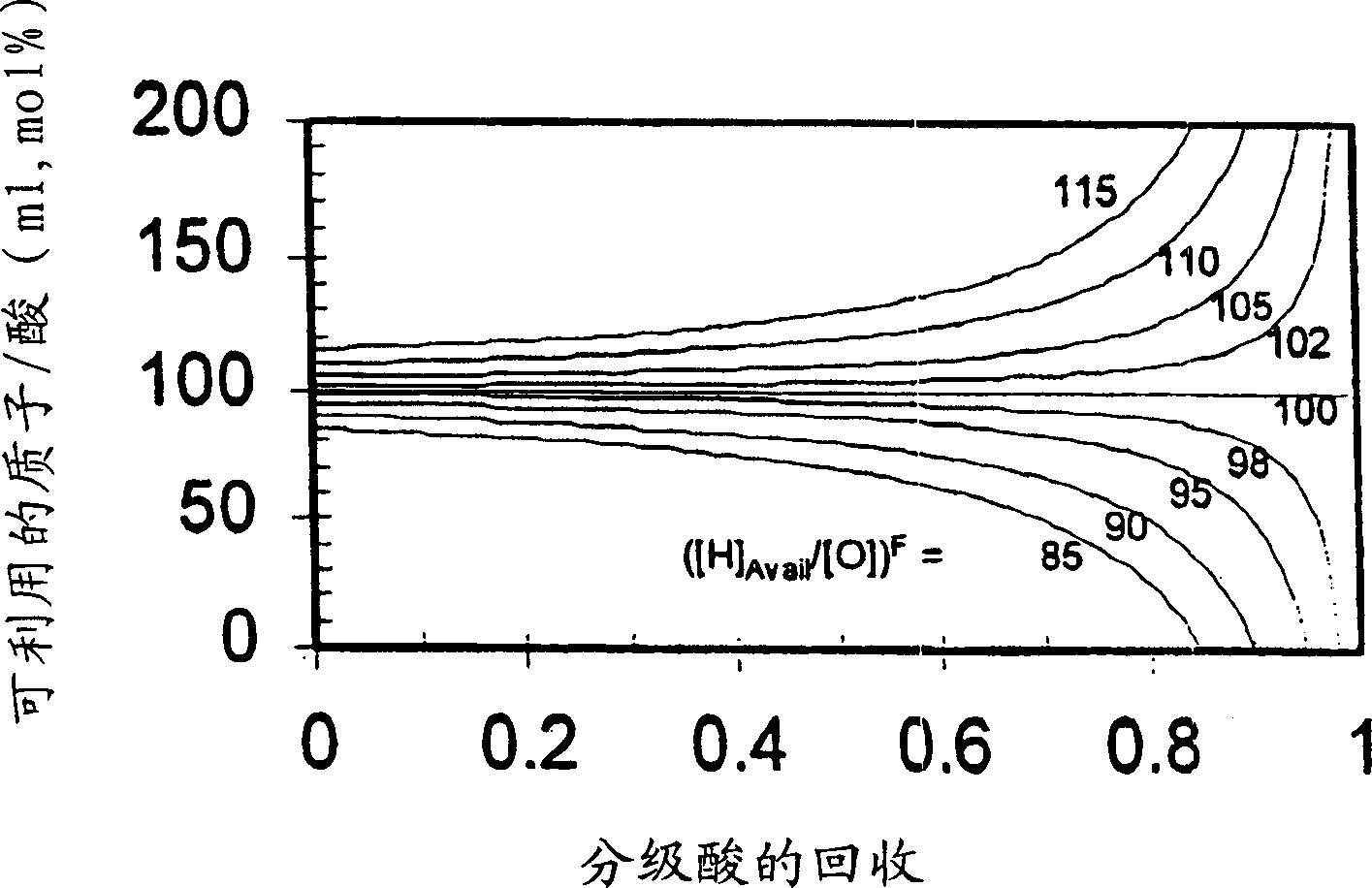

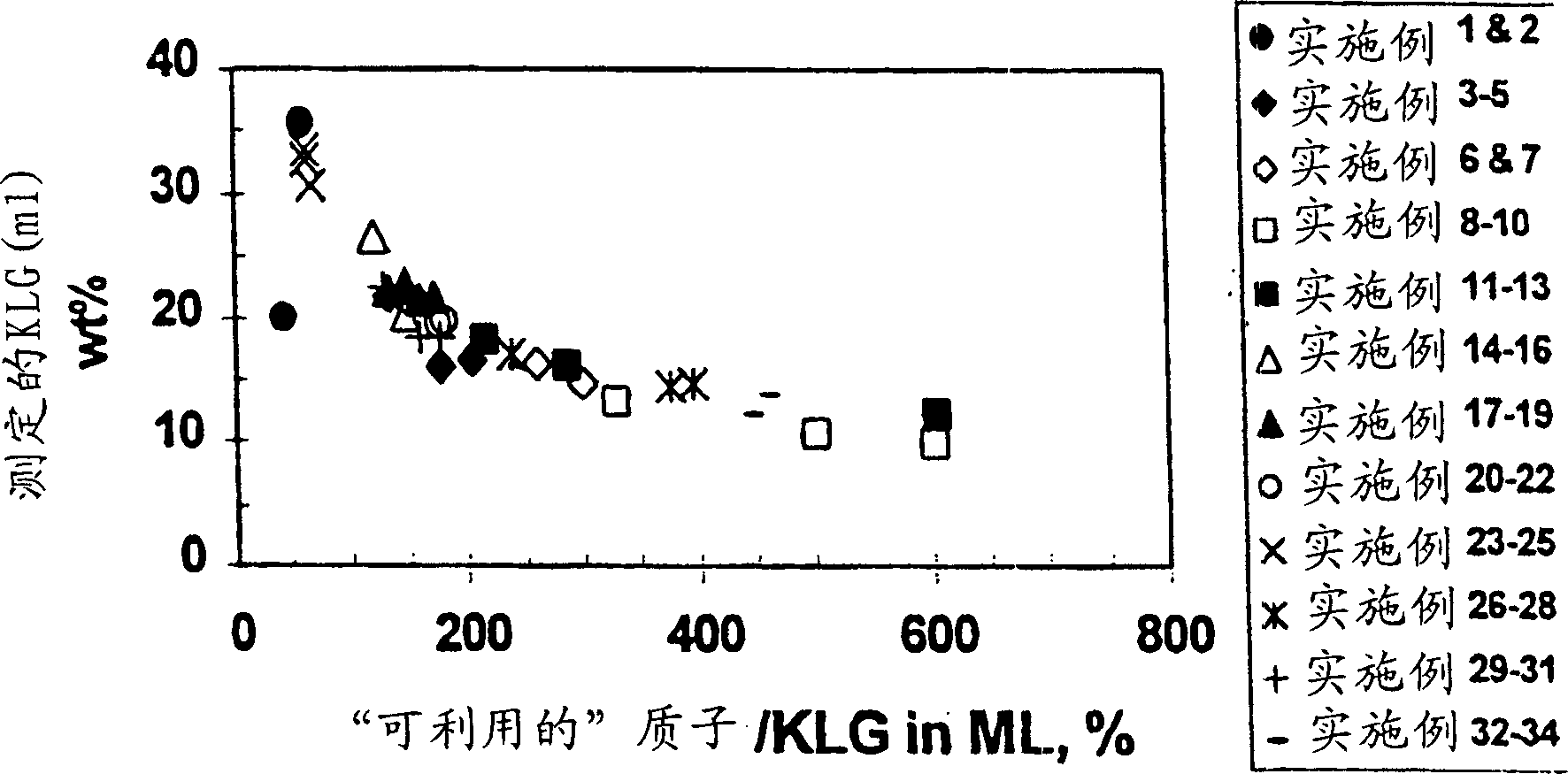

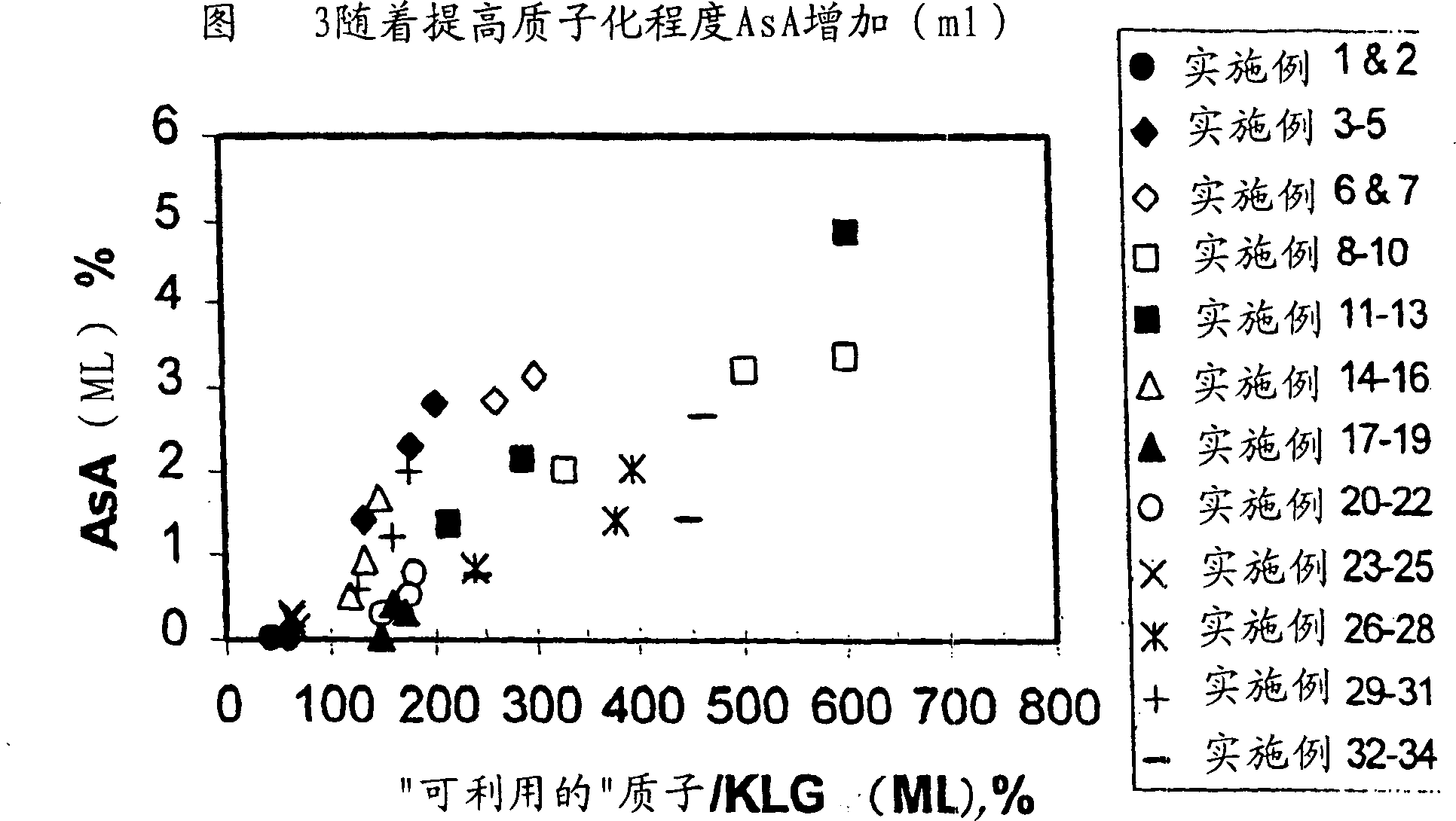

Process for recovery of organic acids from aqueous solutions

A process for recovering a desired organic acid from a solution includes the steps of: providing an aqueous solution including at least one desired organic acid or its acid anion; adjusting the proton concentration in the aqueous solution to a desired level, with the desired proton concentration being selected, at least in part, by the amount of available protons needed to associate with the acid anions of the desired organic acid(s) to be recovered and / or acid anions that are weaker than the desired organic acids; and recovering at least a portion of the at least one desired organic acid from the aqueous phase. The desired proton concentration can be based on the amount of available protons being greater than, less than or substantially equal, to the amount of protons needed to associate with the anion of the desired organic acid(s) and acid anions that are weaker than the desired organic acid(s).Specific examples of suitable organic acids include, but are not limited to, ascorbic, succinic, tartaric, glyconic, gulonic, citric, lactic, hialic, maleic, acetic, formic, gluconic pyruvic, propionic, butyric, itaconic acids and mixtures thereof. One embodiment of the present invention relates to the recovery of 2-keto-L-gulonic acid (KLG) from aqueous solutions such as fermentation baths.

Owner:EASTMAN CHEM CO

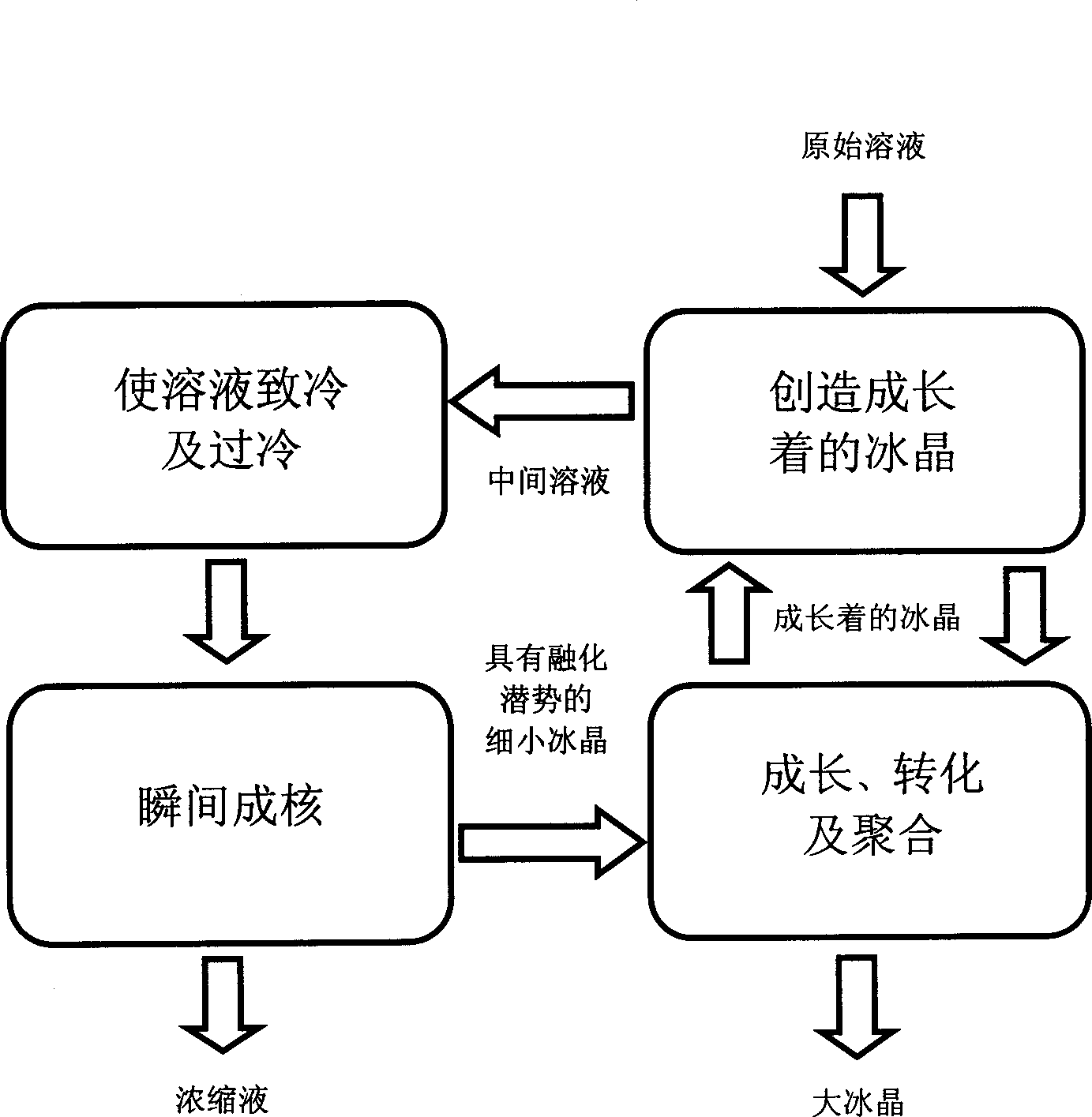

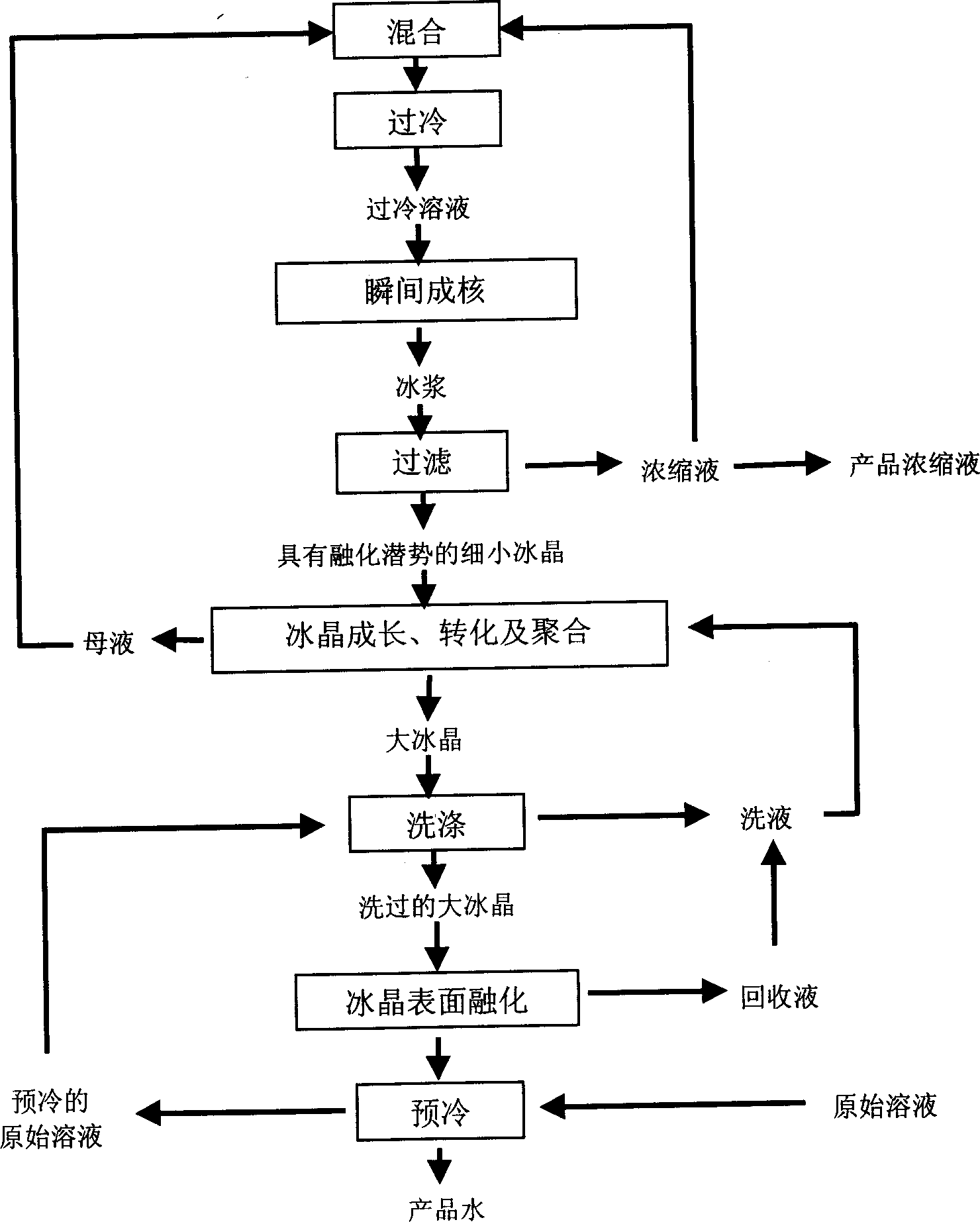

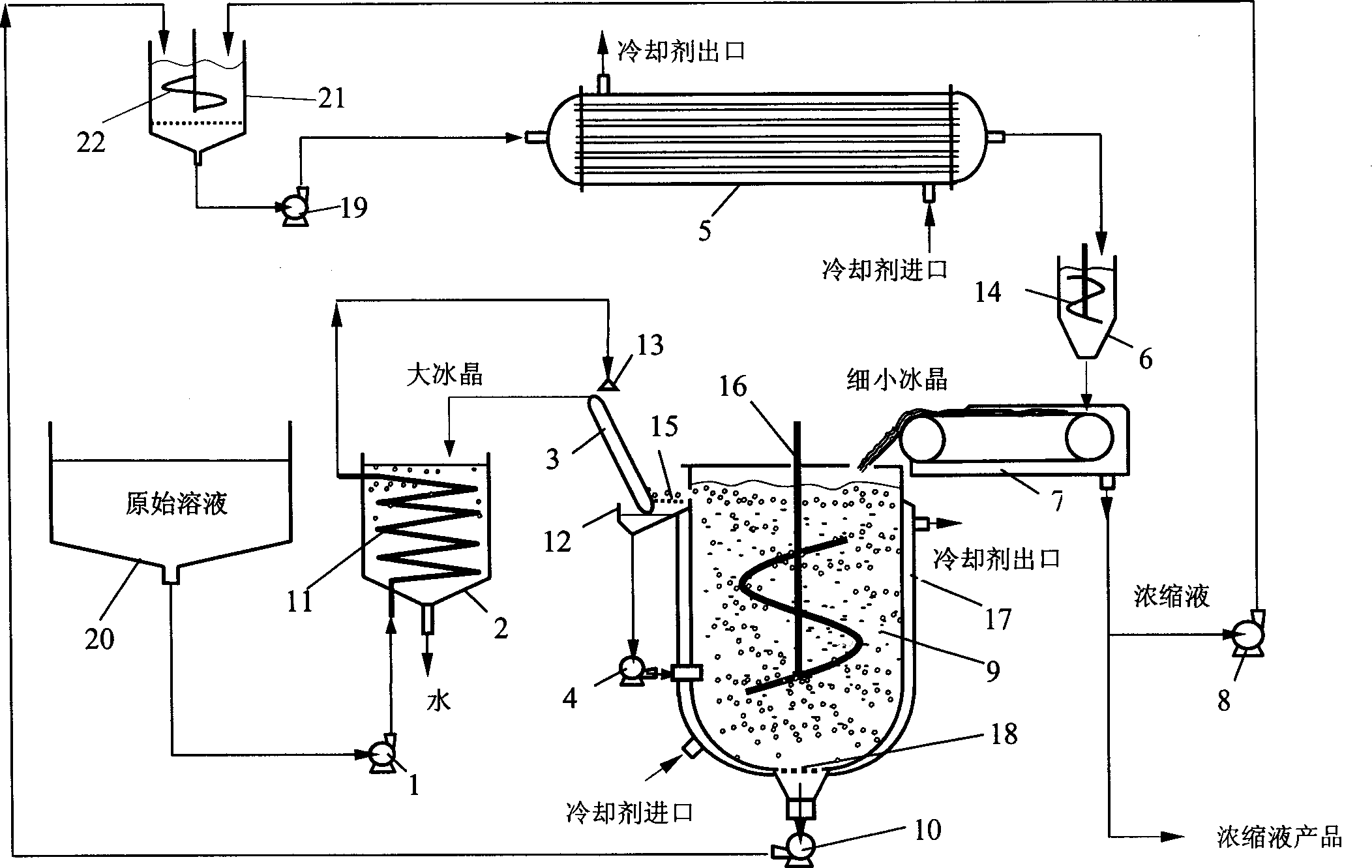

Freeze concentration for aqueous solutions

The invention is an efficient physical method of freezing and concentrating aqueous solutions based on the transformation of ice crystals. It results in a very high ice crystal growth rate, produces granular, aggregated large ice crystals without internal entrainment, and avoids scraping of ice crystals during freezing to save energy. The method mainly consists of the following processes: cooling the solution to a supercooled state without nucleation or ice formation on the heat transfer surface; instantly nucleating the supercooled solution to produce fine ice crystals and concentrating the solution; with the help of absorption-exotherm The growth, transformation and polymerization of ice crystals in a well-balanced and controlled environment produce large, granular or spherical ice crystals at high rates. Both single-stage and multi-stage operations can be used in this method and the main steps can be arranged flexibly. The equipment for implementing this method mainly includes refrigeration heat exchangers, nucleators, filters and multifunctional crystallizers, each of which has its own characteristics to meet the requirements of the method.

Owner:梁保民 +1

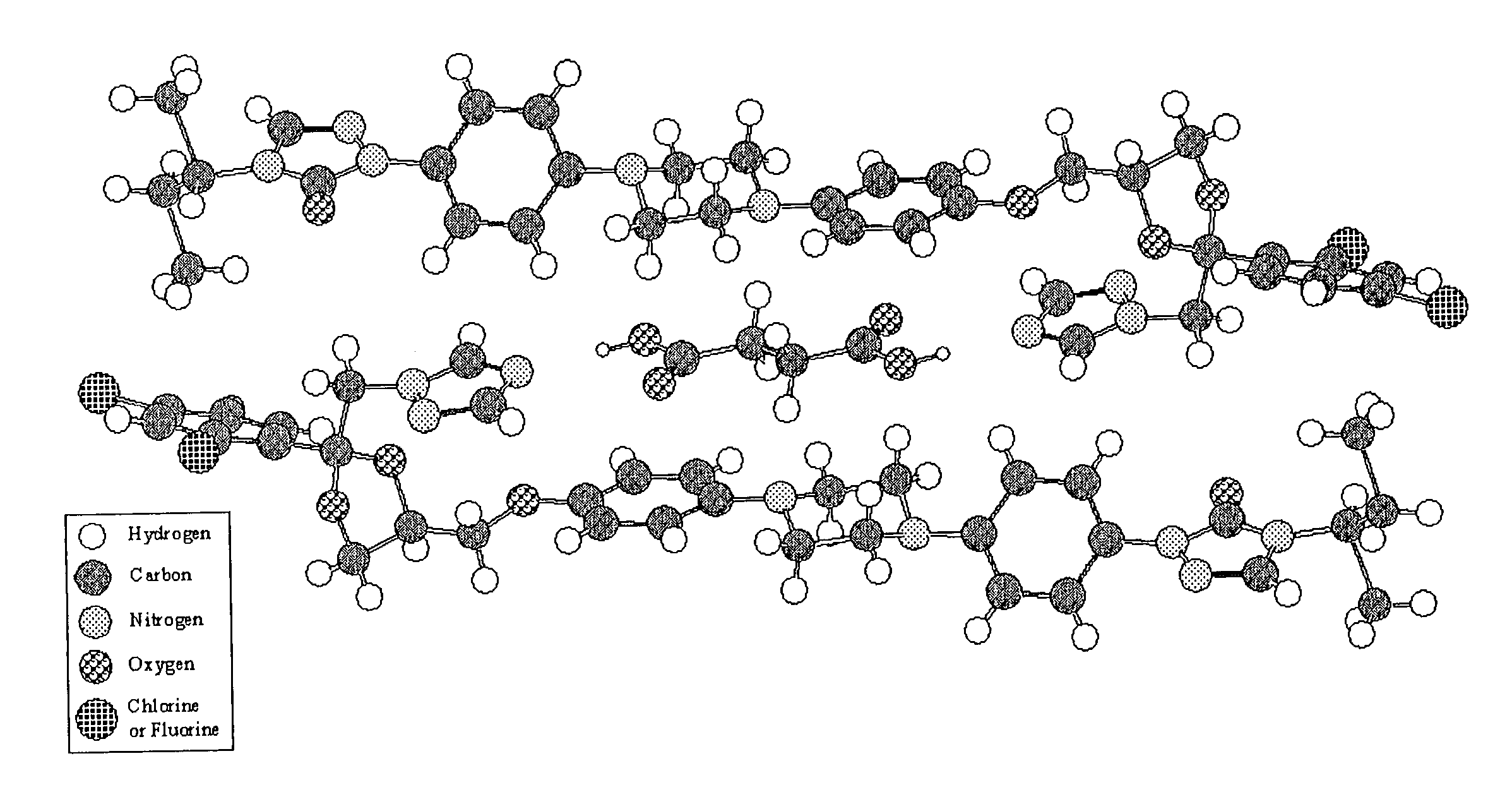

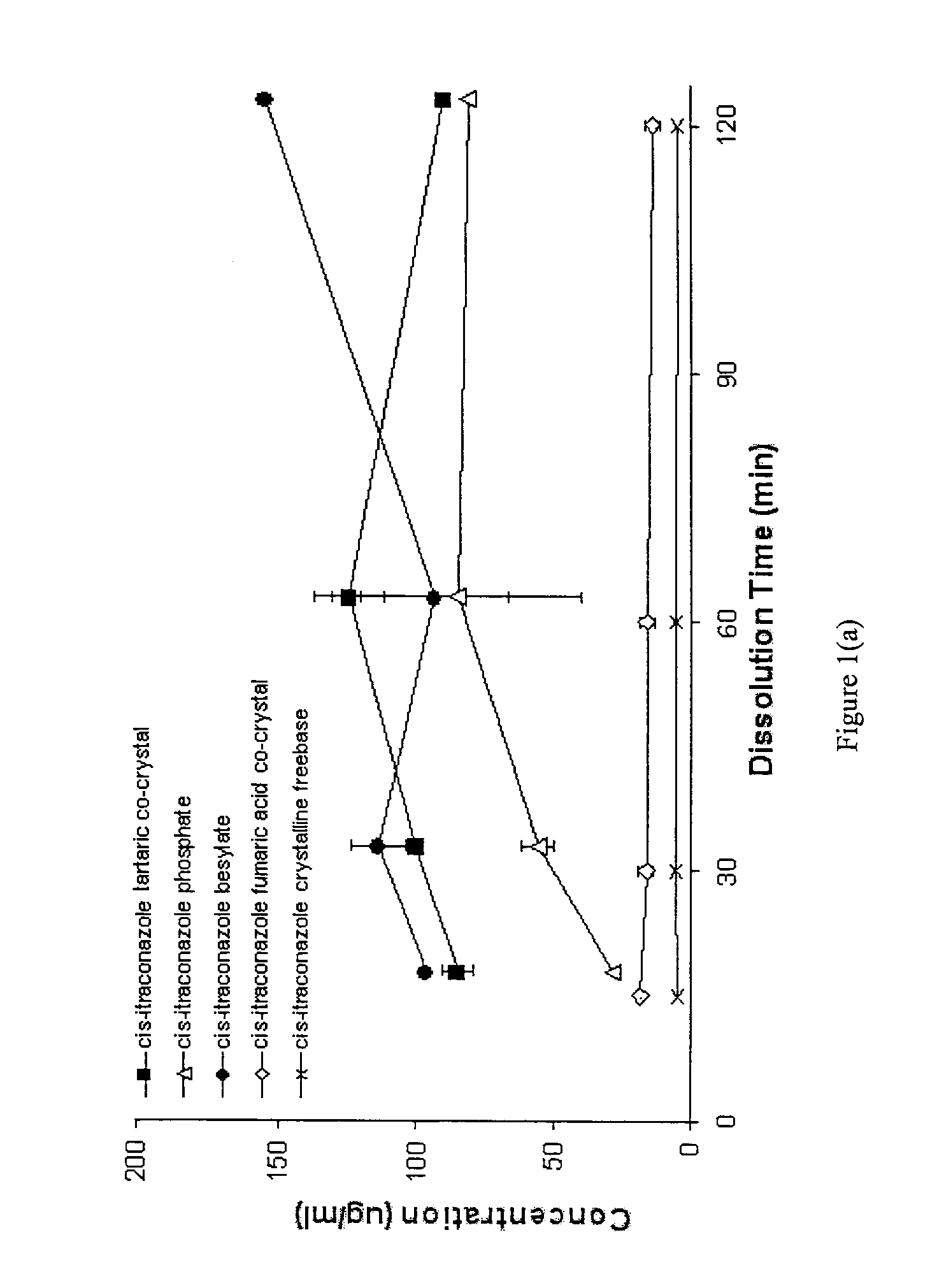

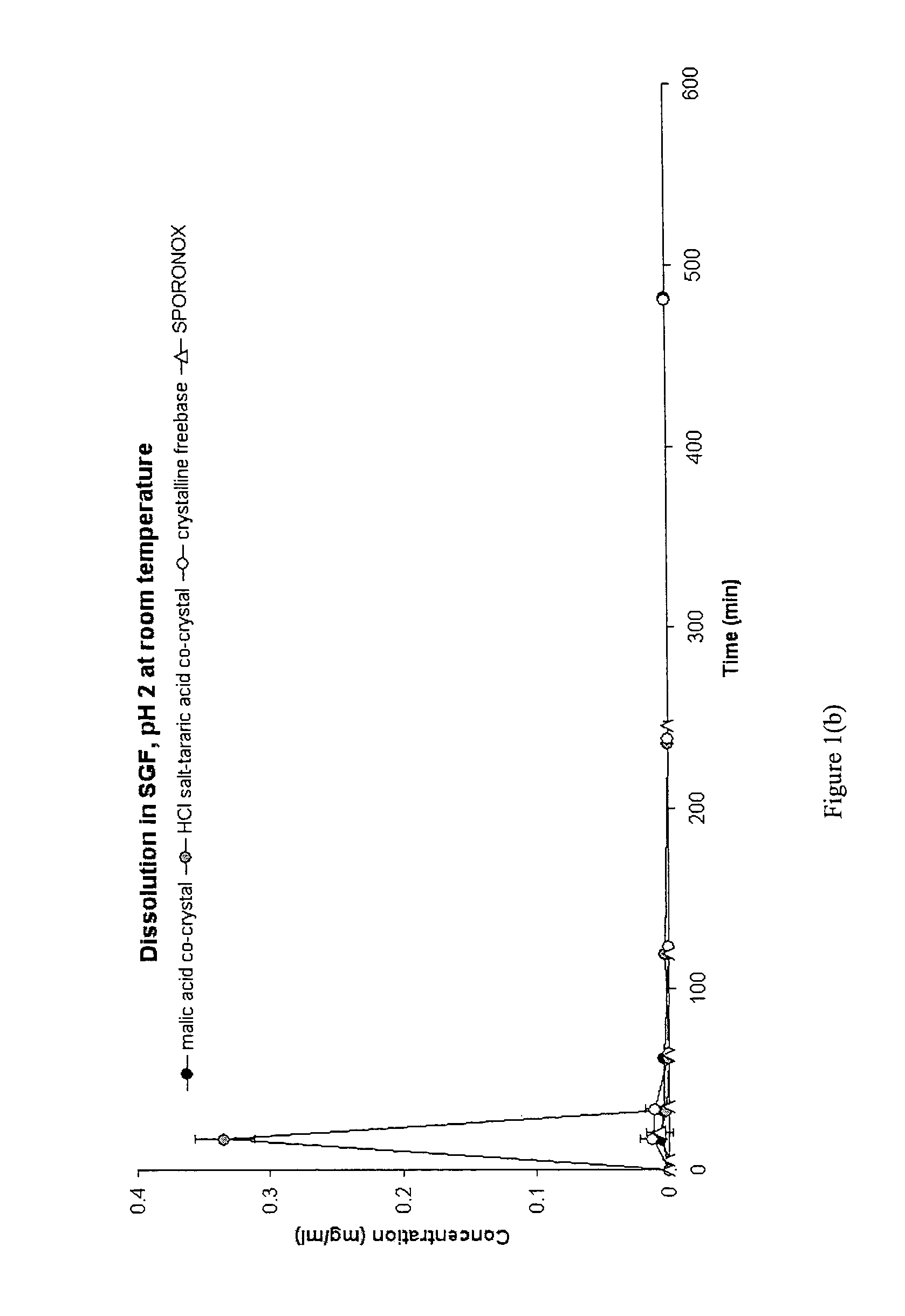

CIS-itraconazole crystalline forms and related processes, pharmaceutical compositions and methods

The invention provides novel soluble conazole crystalline forms (e.g. itraconazole, posaconazole and saperconazole) that include salts, co-crystals and related solvates useful as pharmaceuticals. The invention also provides pharmaceutical compositions comprising, and processes for making, these conazole crystalline forms. Methods of using such compositions for the treatment or prevention of systemic and local fungal, yeast, and dermatophyte infections are also provided.

Owner:TRANSFORM PHARMACEUTICALS INC

Removing Contaminants from Natural Gas

A process is described for removing contaminants from a natural gas feed stream including water. The process includes the steps of cooling the natural gas feed stream in a first vessel to a first operating temperature at which hydrates are formed, heating the hydrates to a temperature that is above the first operating temperature by introducing a warm liquid to the first vessel so as to melt the hydrates and liberate a dehydrated gas and a water-containing liquid, and removing from the first vessel a stream of dehydrated gas.

Owner:WOODSIDE ENERGY

Lyophilization method and apparatus for producing particles

Owner:FERRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com