Multifunctional multiple-effect automatic continuous evaporative crystallization technique and crystallization device

A technology of evaporation crystallization and multi-effect evaporator, which is applied in the field of multi-functional multi-effect automatic continuous evaporation crystallization process and crystallization equipment, can solve the problems of difficult control of crystallization temperature, increase of production cost, no utilization, etc., and reduce the labor cost of enterprises , reduce emissions, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

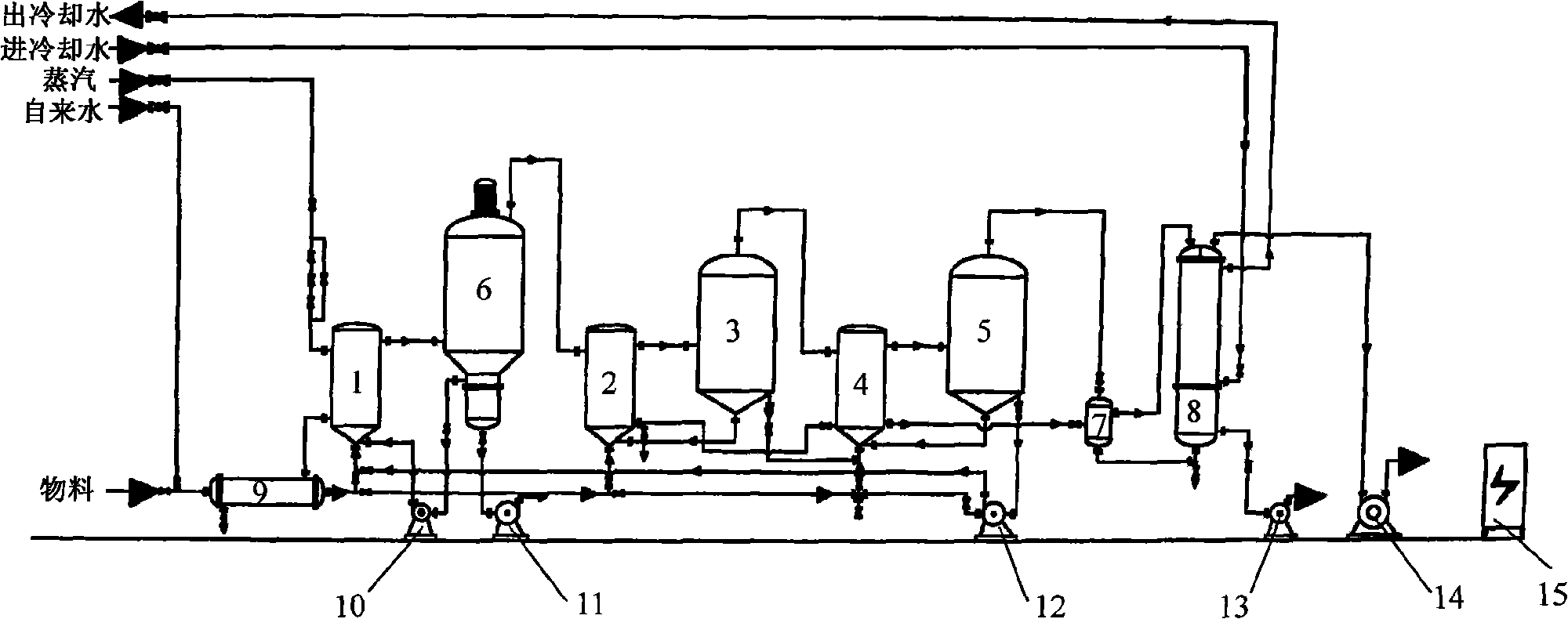

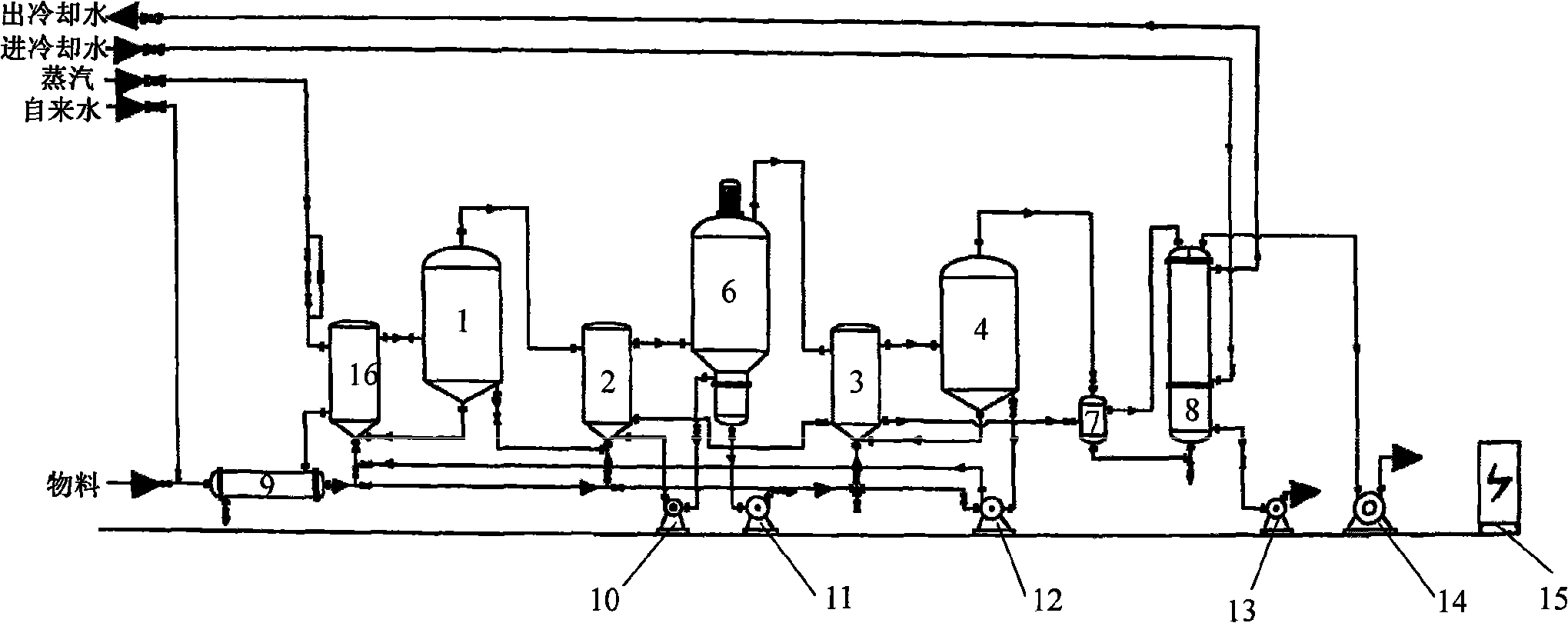

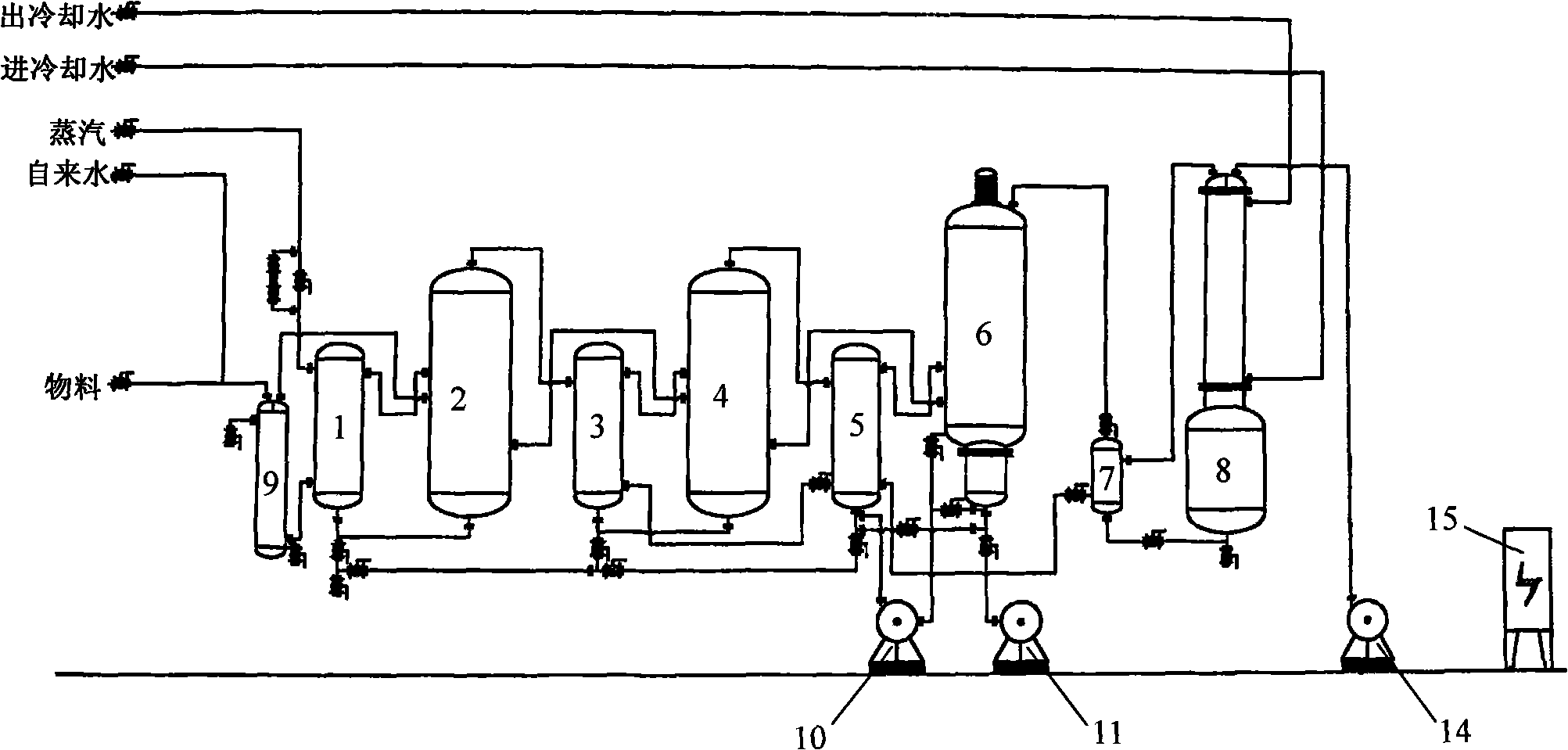

[0019] The total process of the present invention is as follows: unsaturated aqueous solution or organic solution (concentration is 5-20%) enters preheater under the action of vacuum pump and after preheating, enters first-effect evaporator and enters second-effect evaporator after reaching certain concentration, in After continuous evaporation in the second-effect evaporator to reach a certain concentration, it enters the three-effect evaporator, and then enters the four-effect and five-effect evaporators in turn. The temperature of each effect evaporator gradually decreases, and the vacuum degree gradually increases; when the material concentration reaches saturation Enter the crystallizer for flash crystallization. After crystallization, the thick slurry is pumped to the centrifuge for solid-liquid separation. The evaporated water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com