Patents

Literature

2297 results about "Crystallization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature of melting and crystallization — temperature at which solid crystalline solid makes transition to a liquid state and vice versa. The crystallization temperature of tin is + 231, 93 0C.

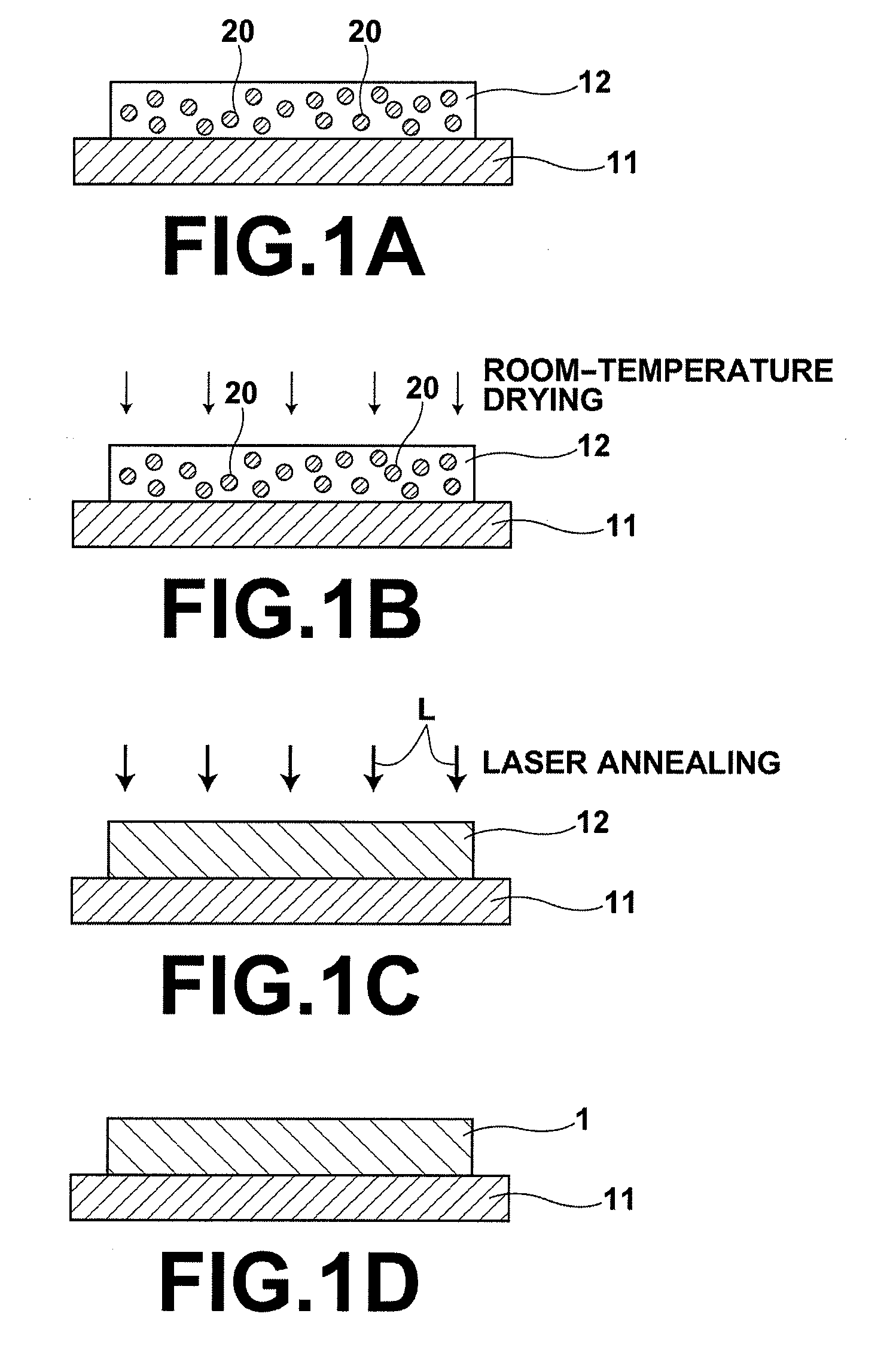

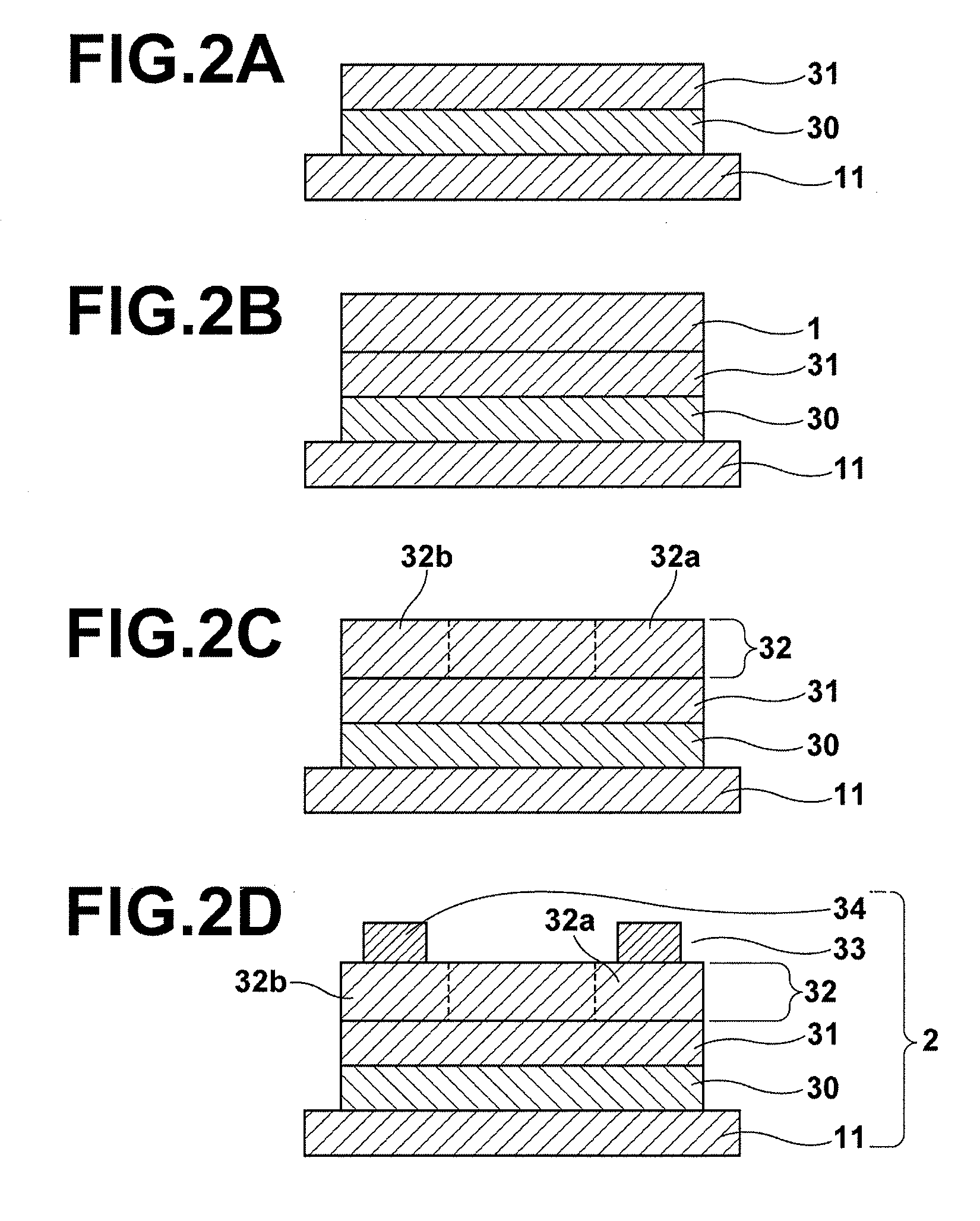

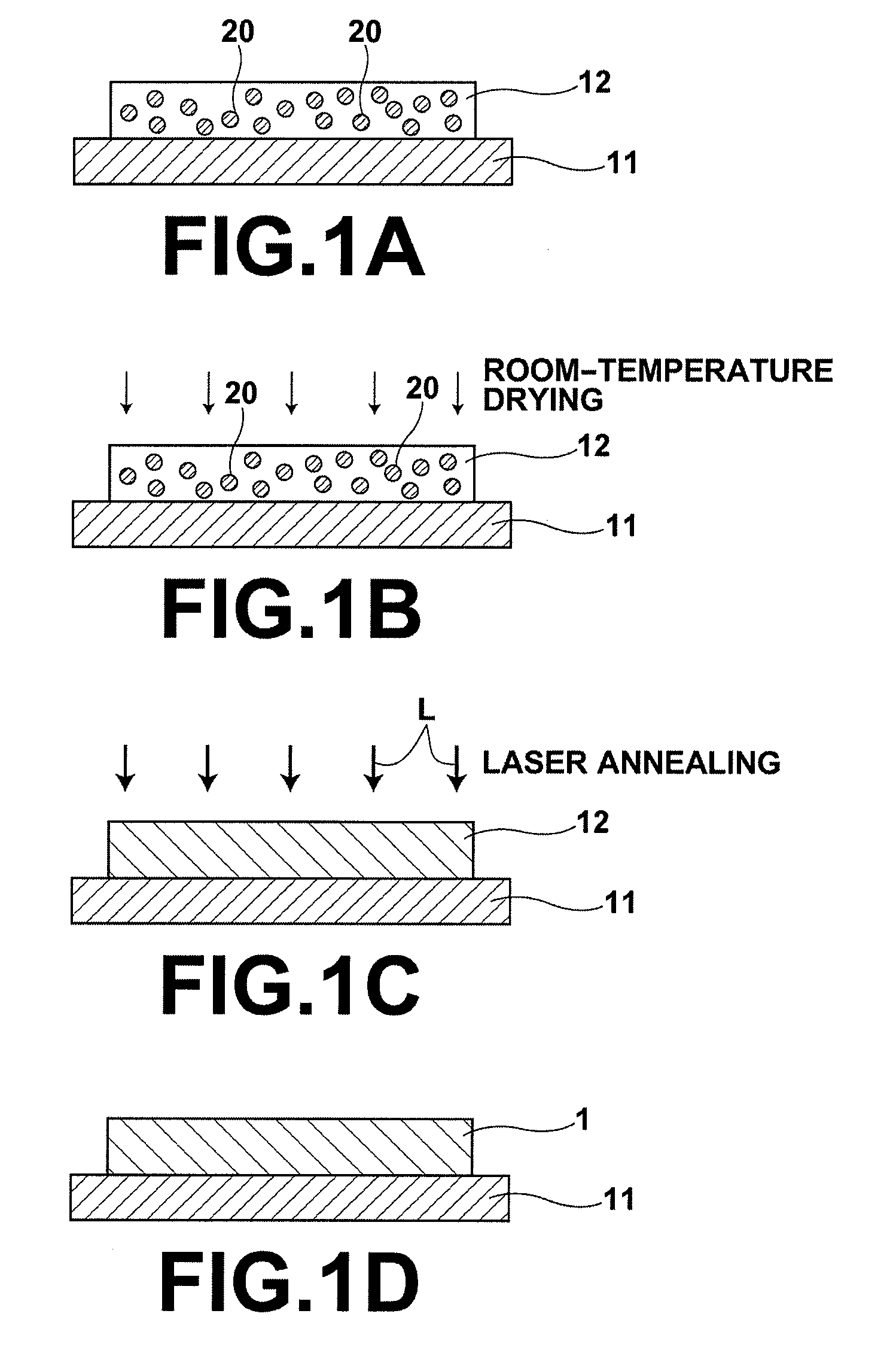

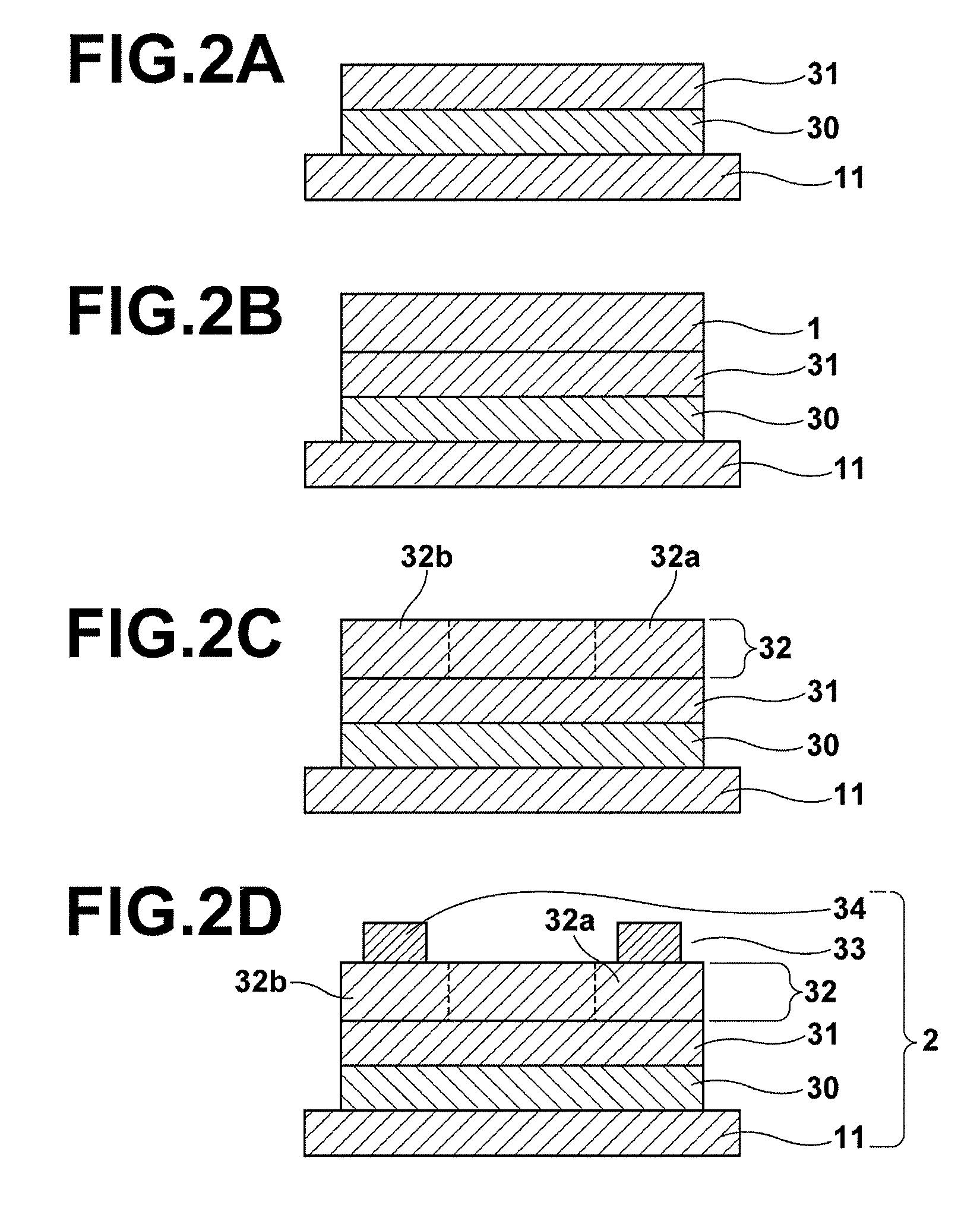

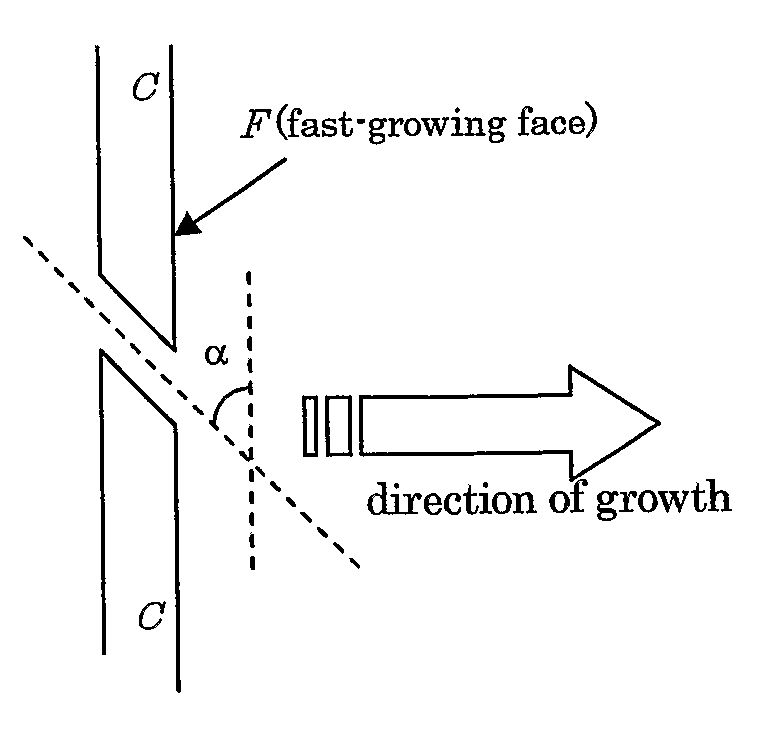

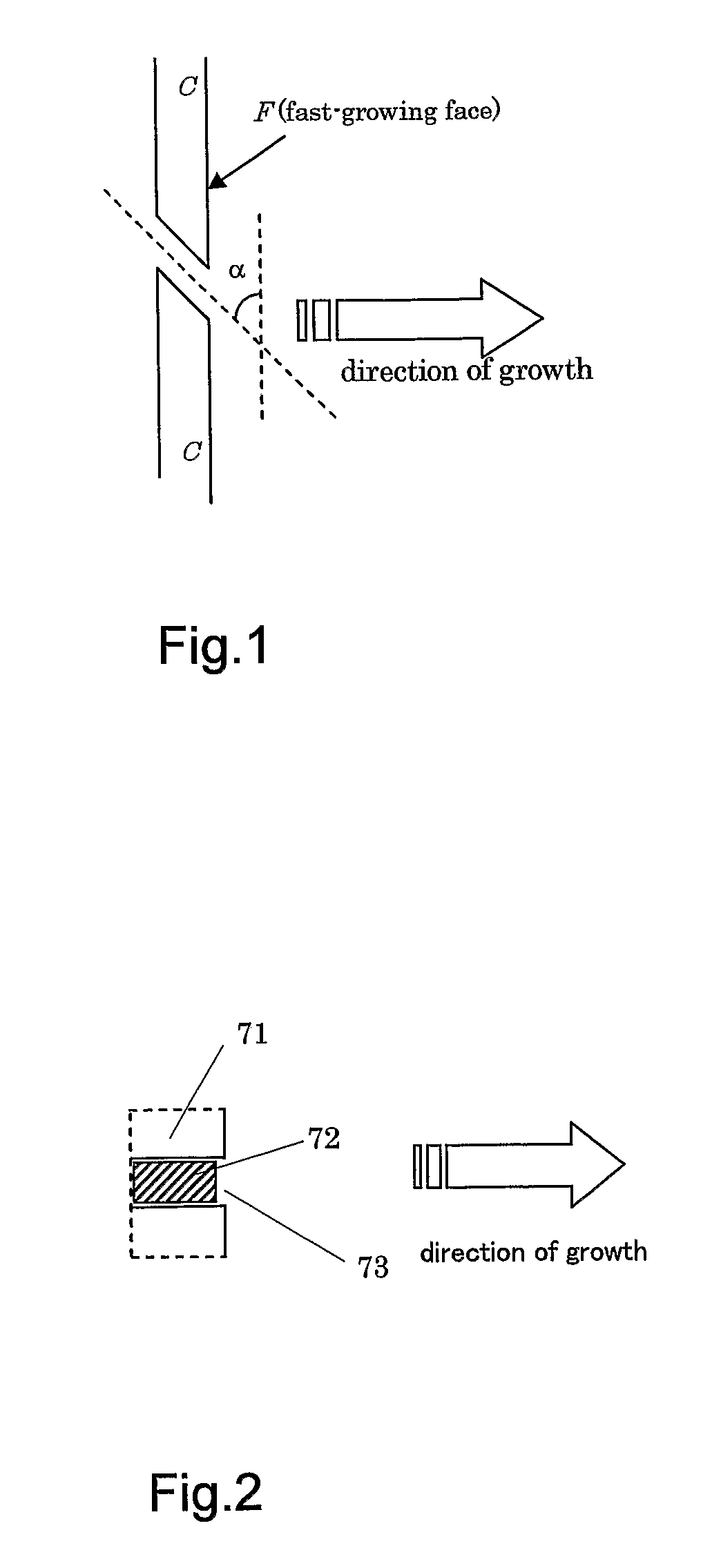

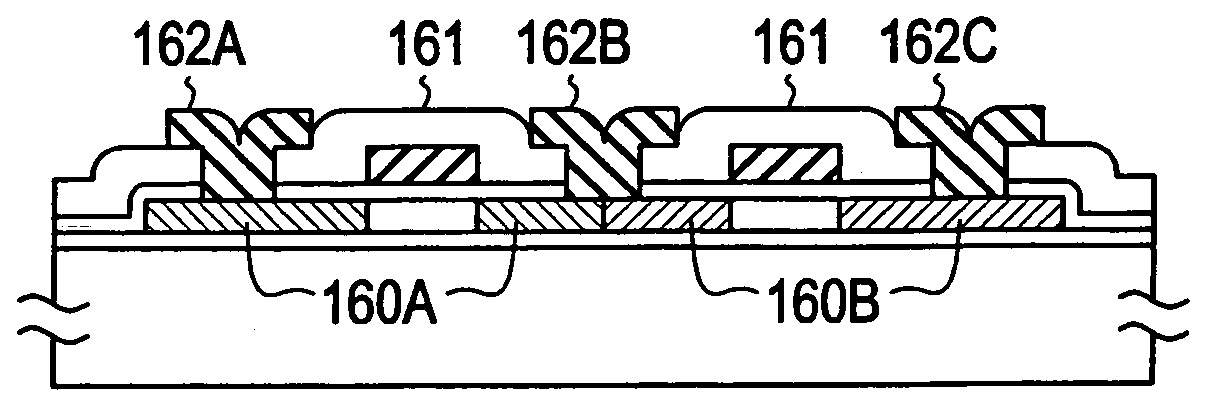

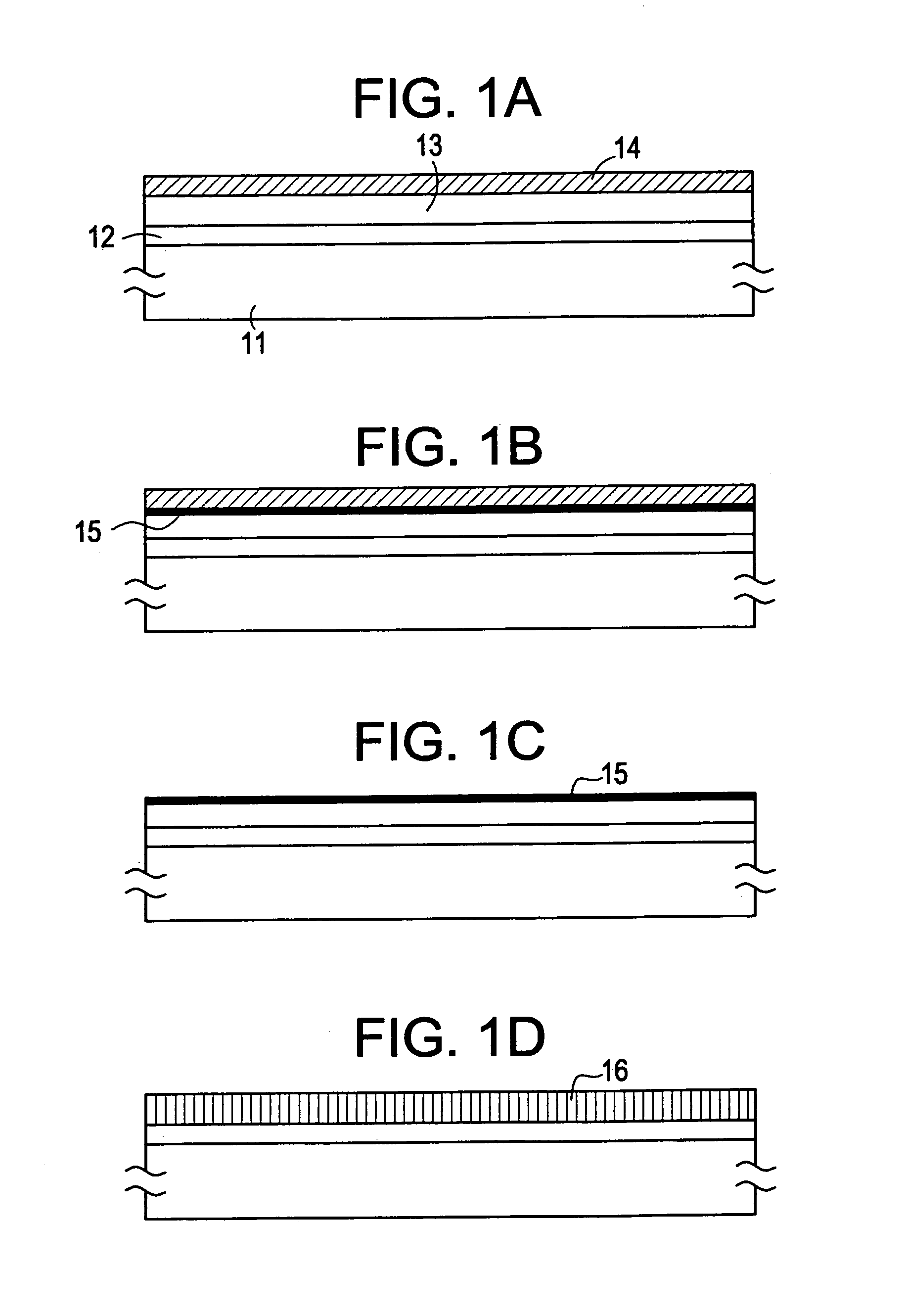

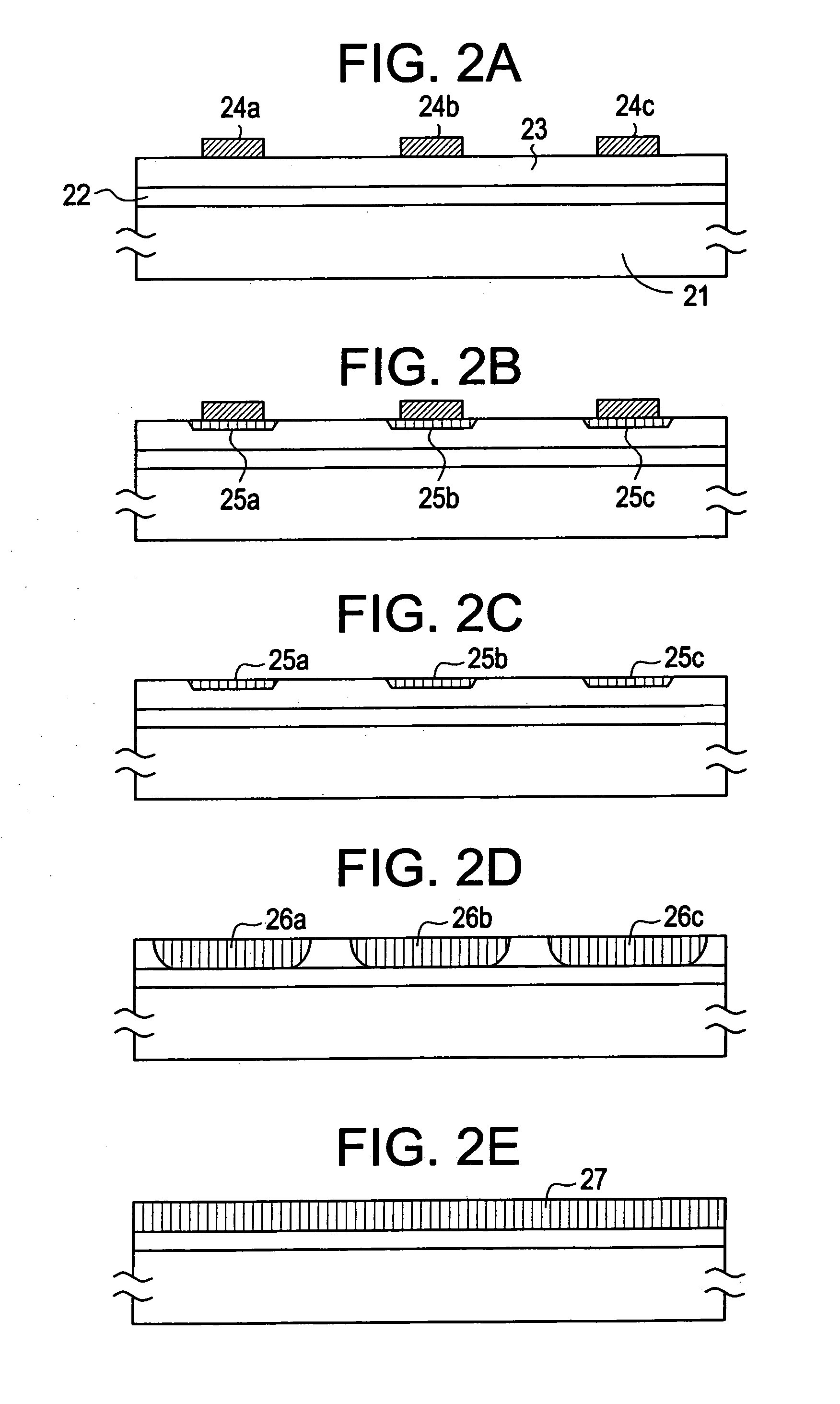

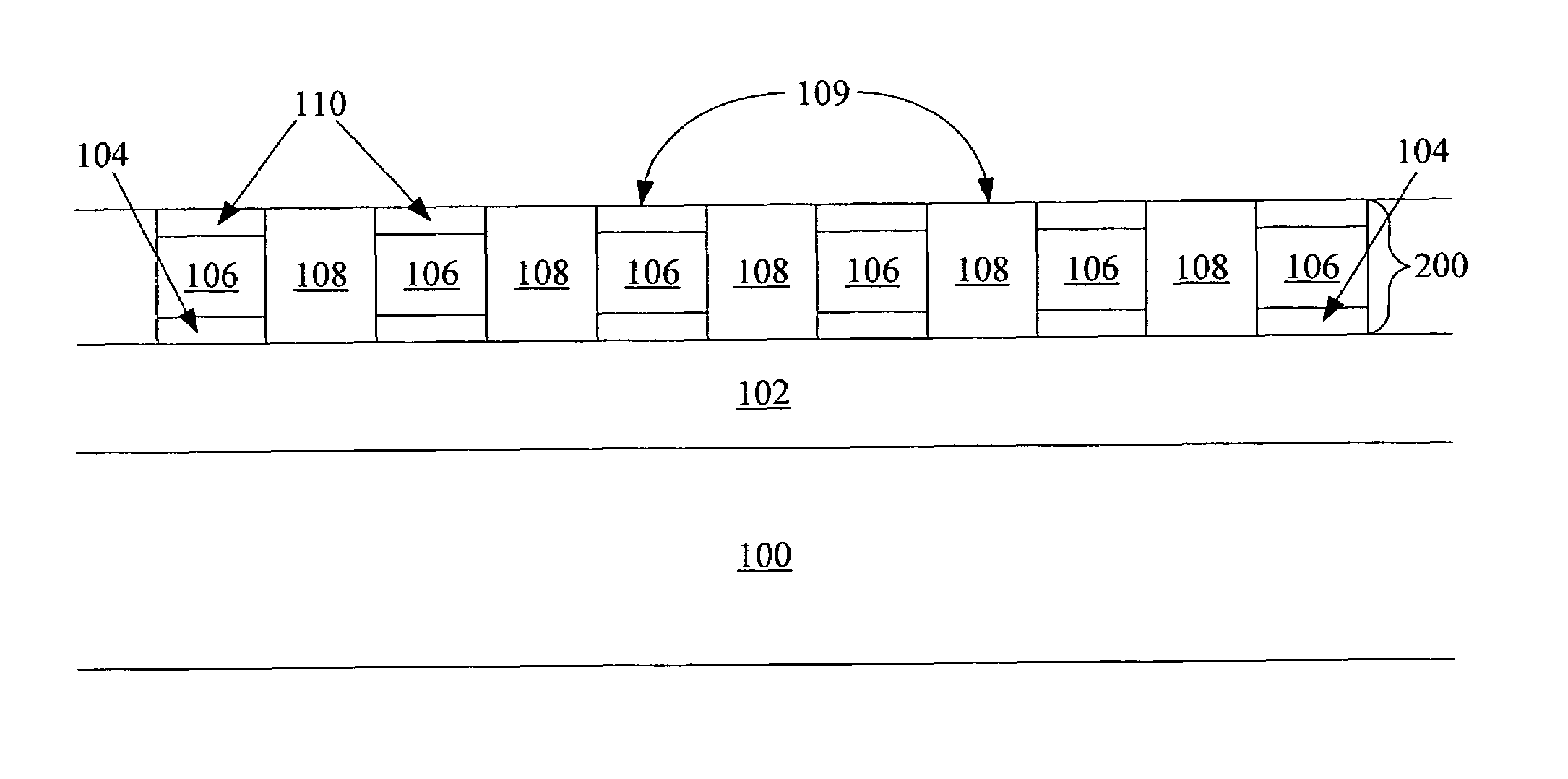

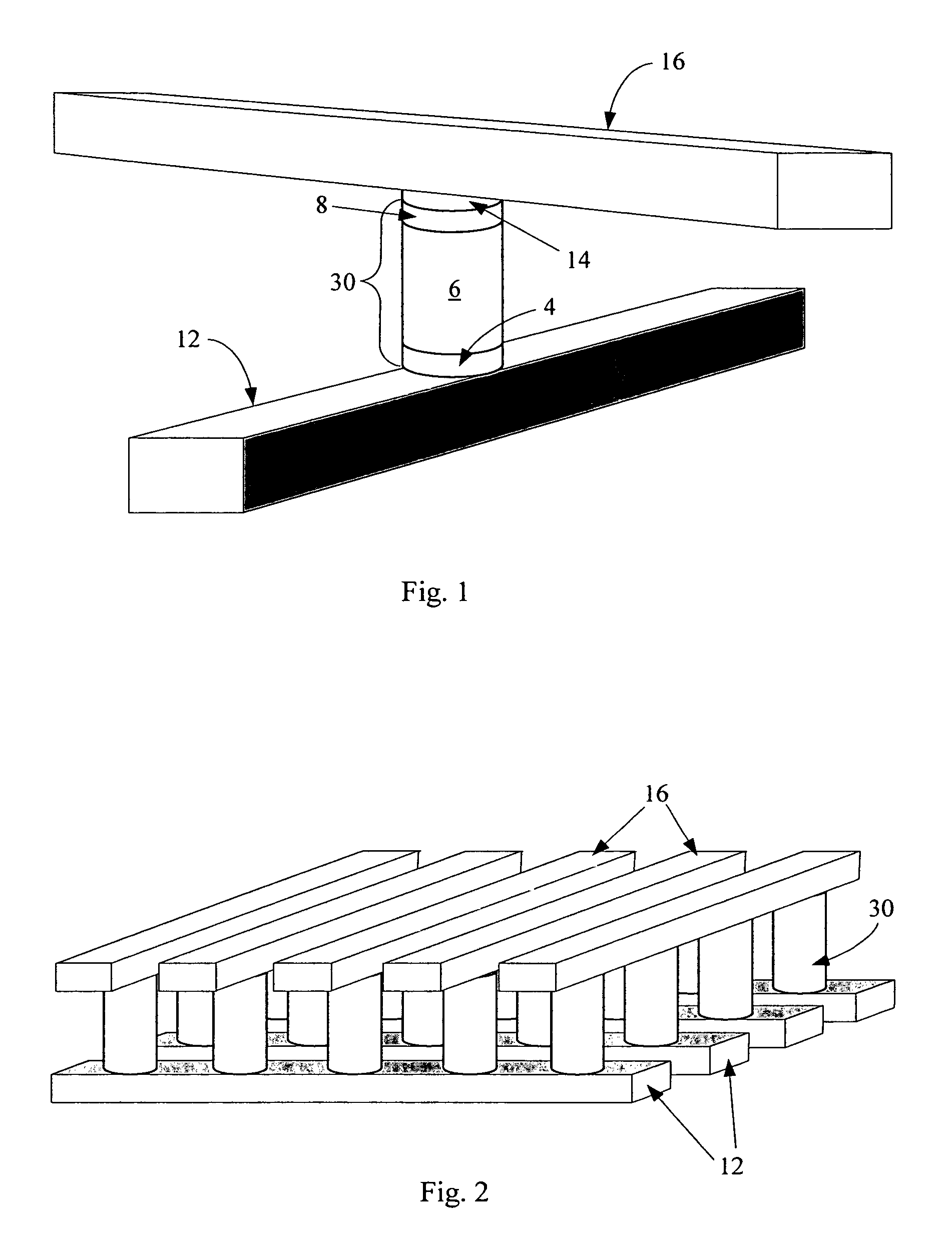

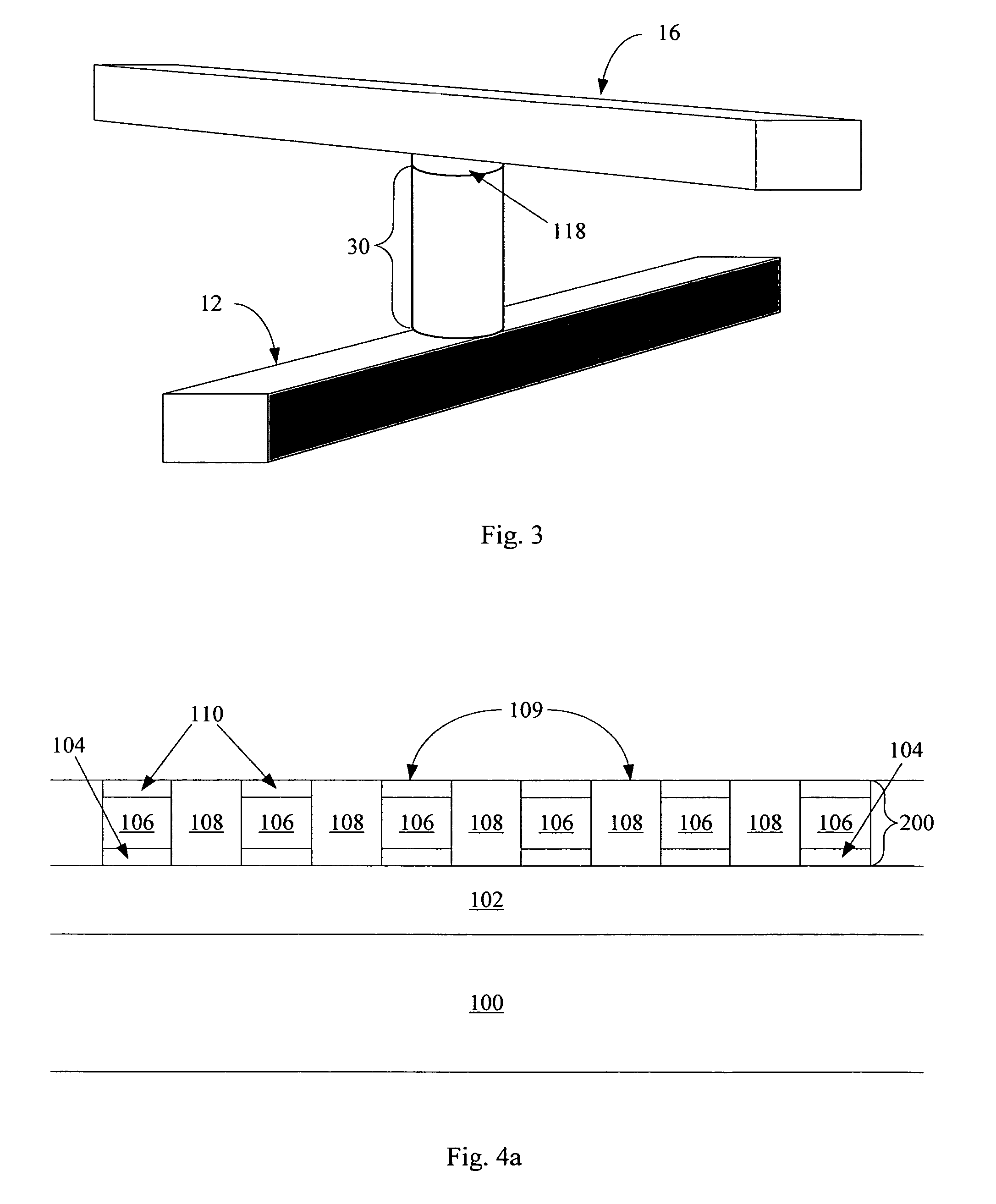

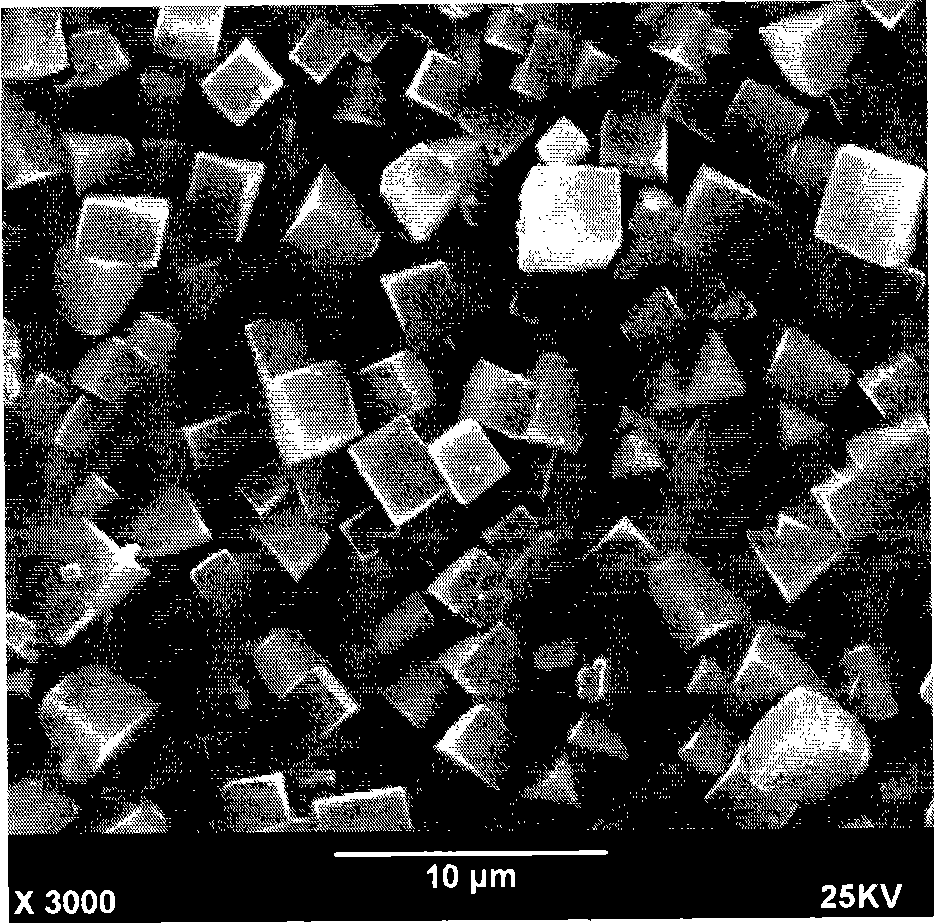

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

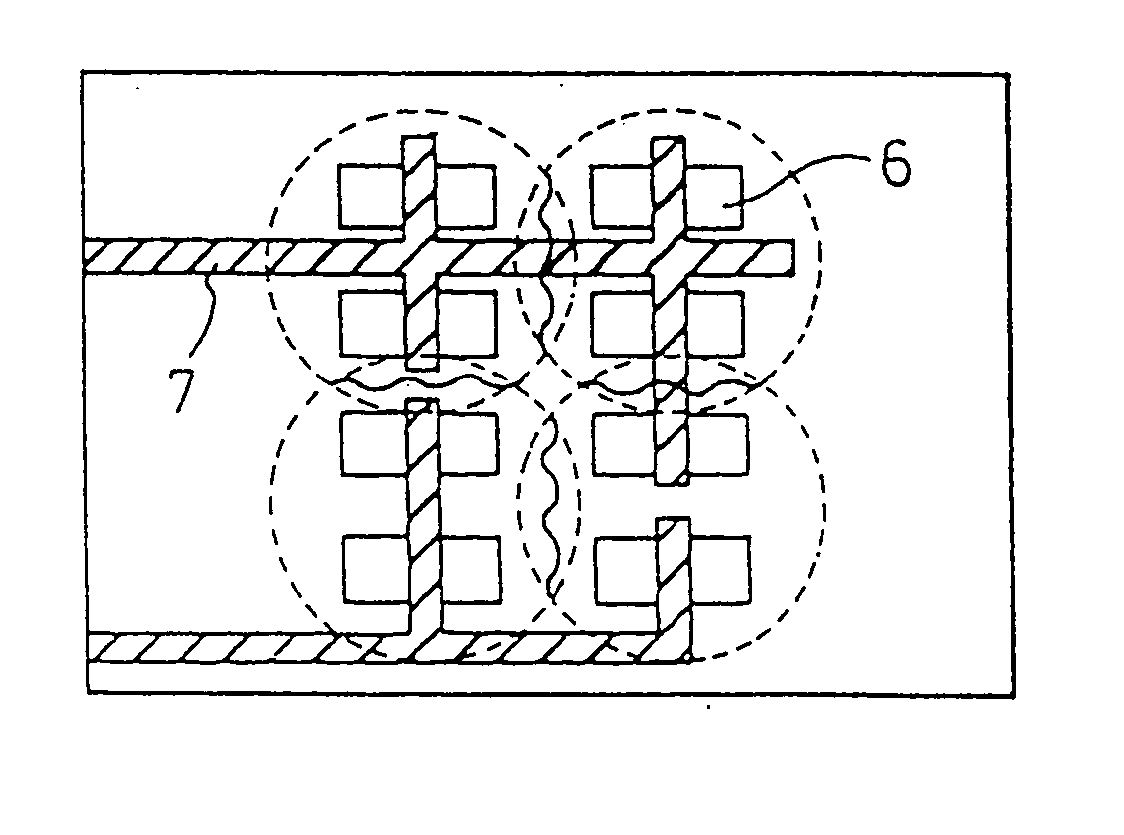

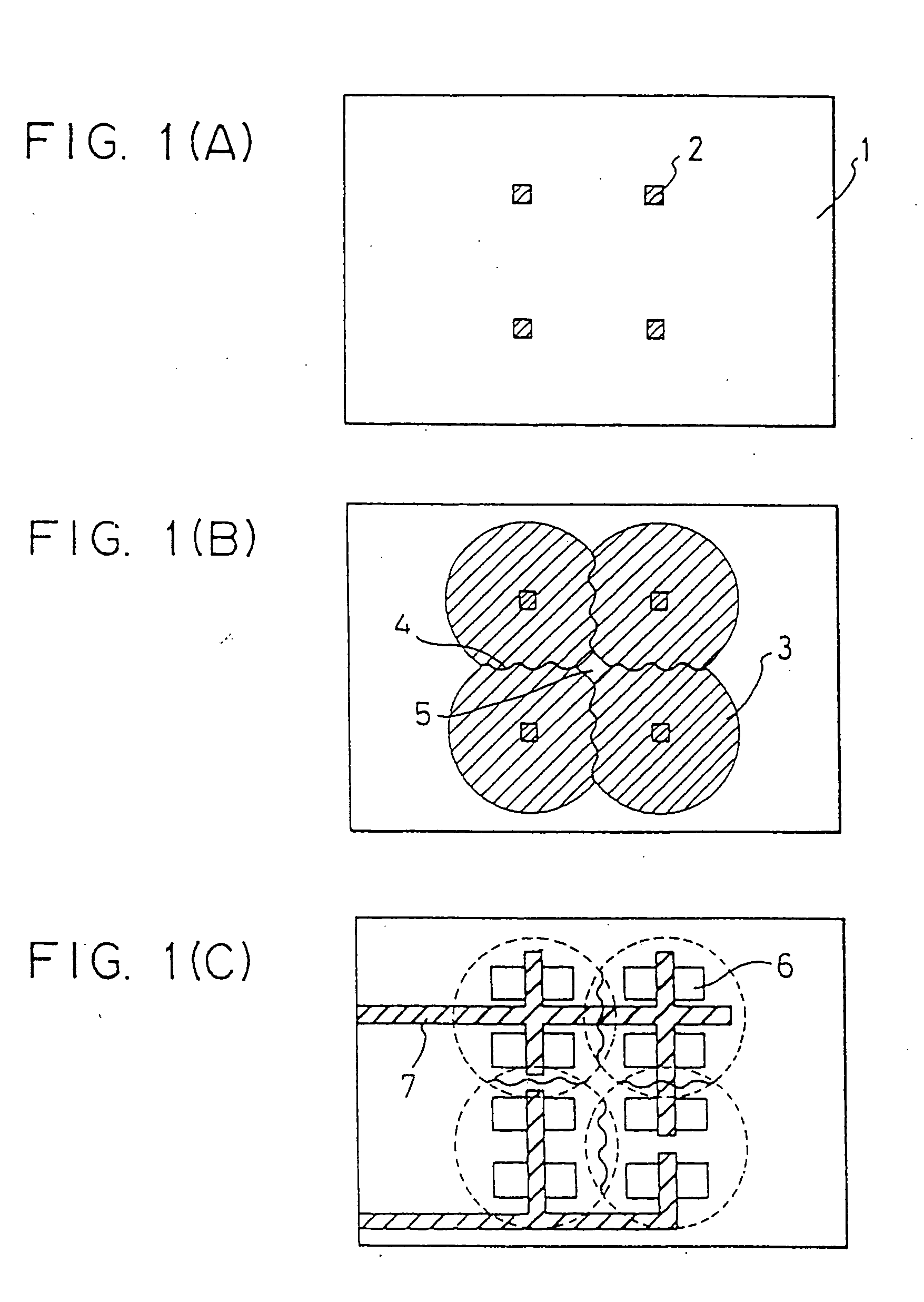

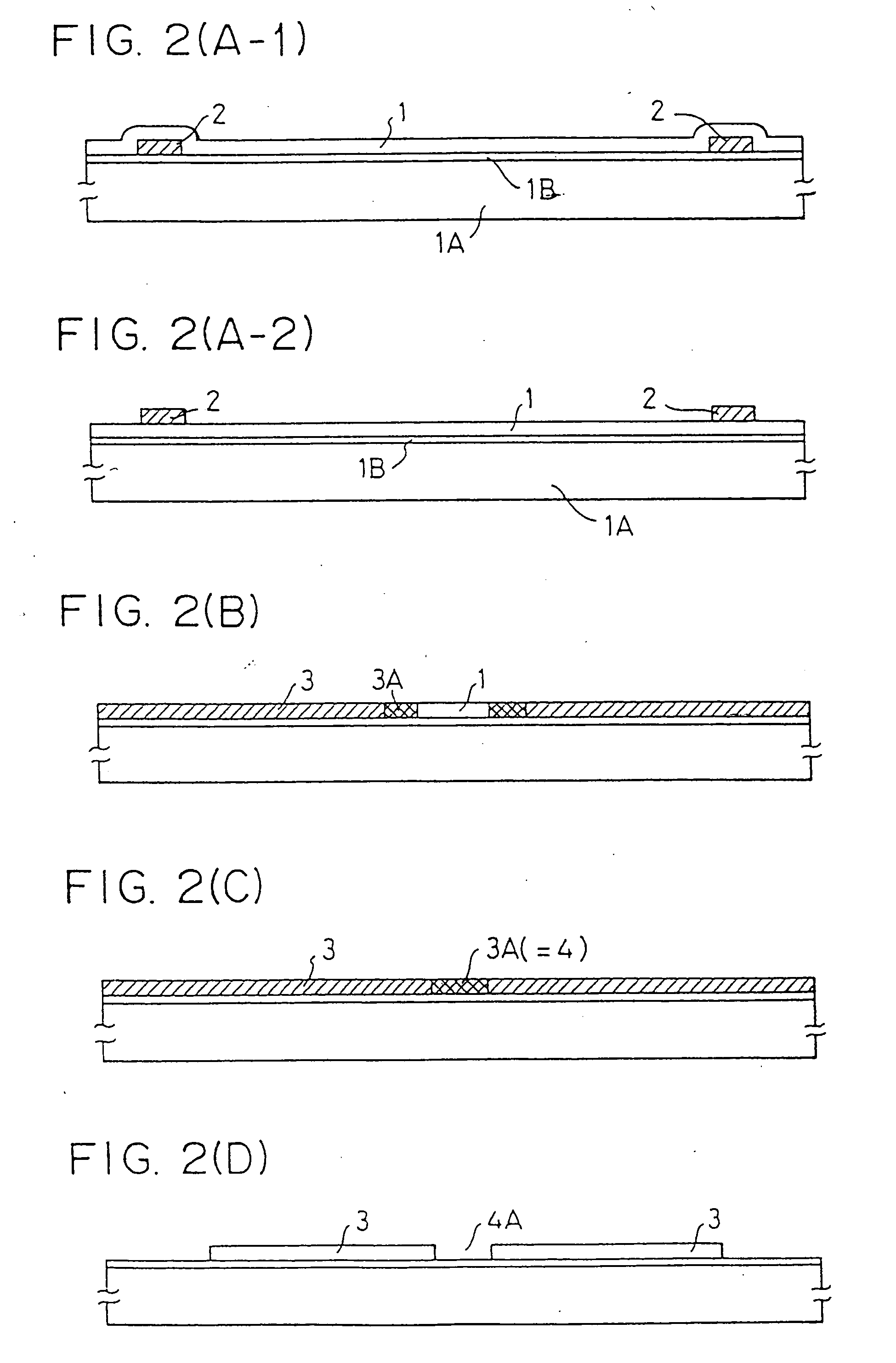

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS8202365B2Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventCrystal structure

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

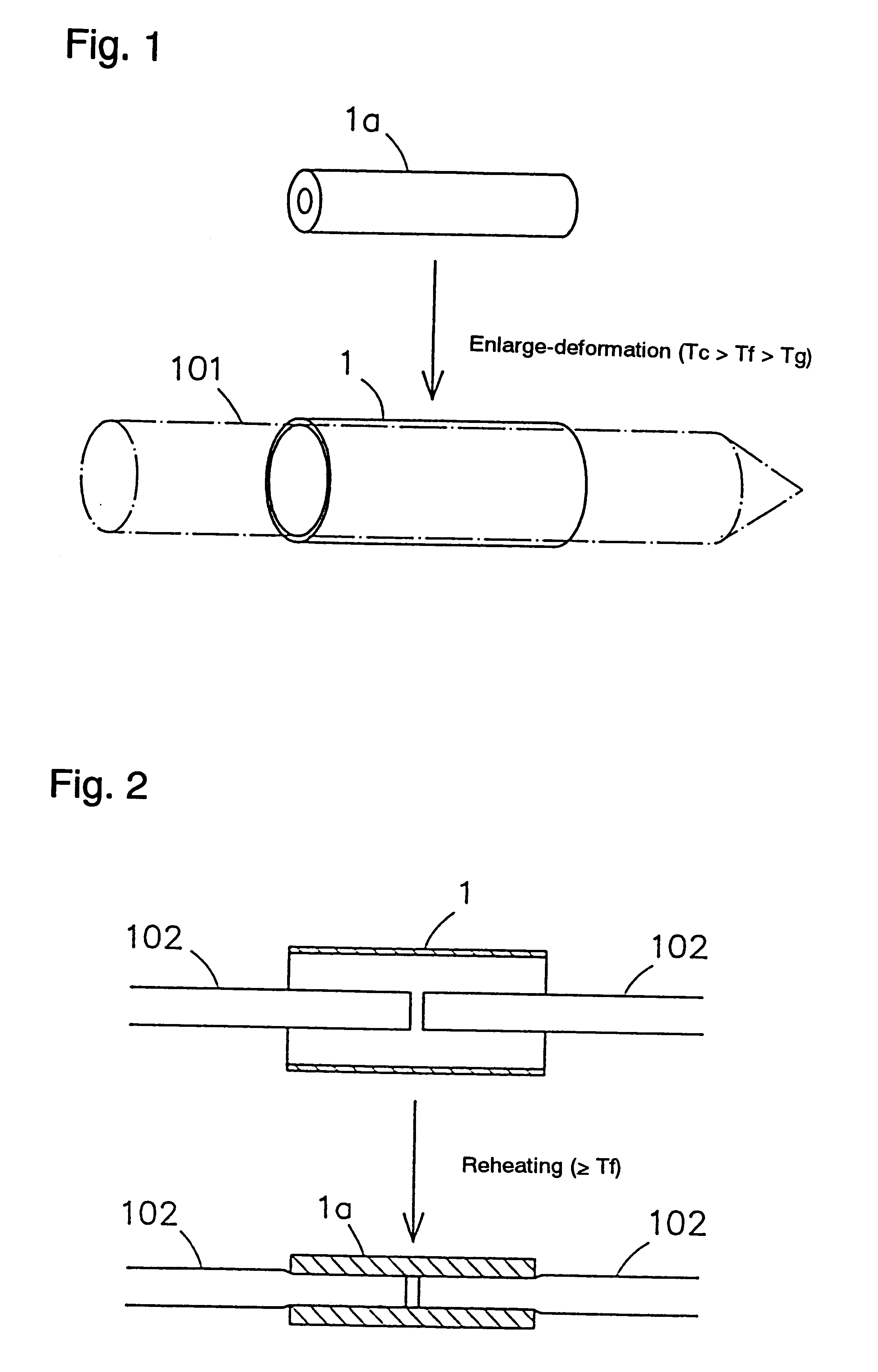

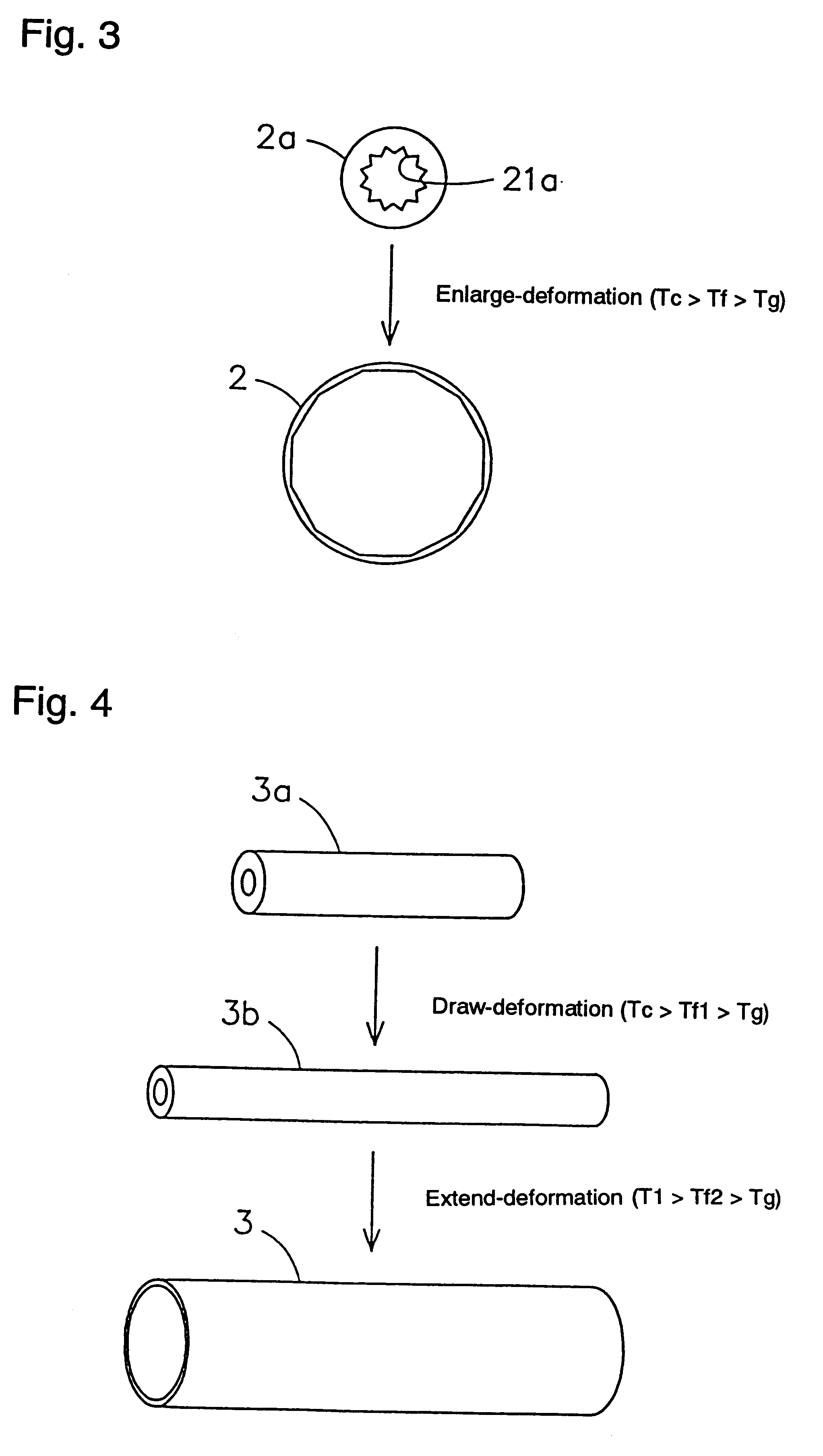

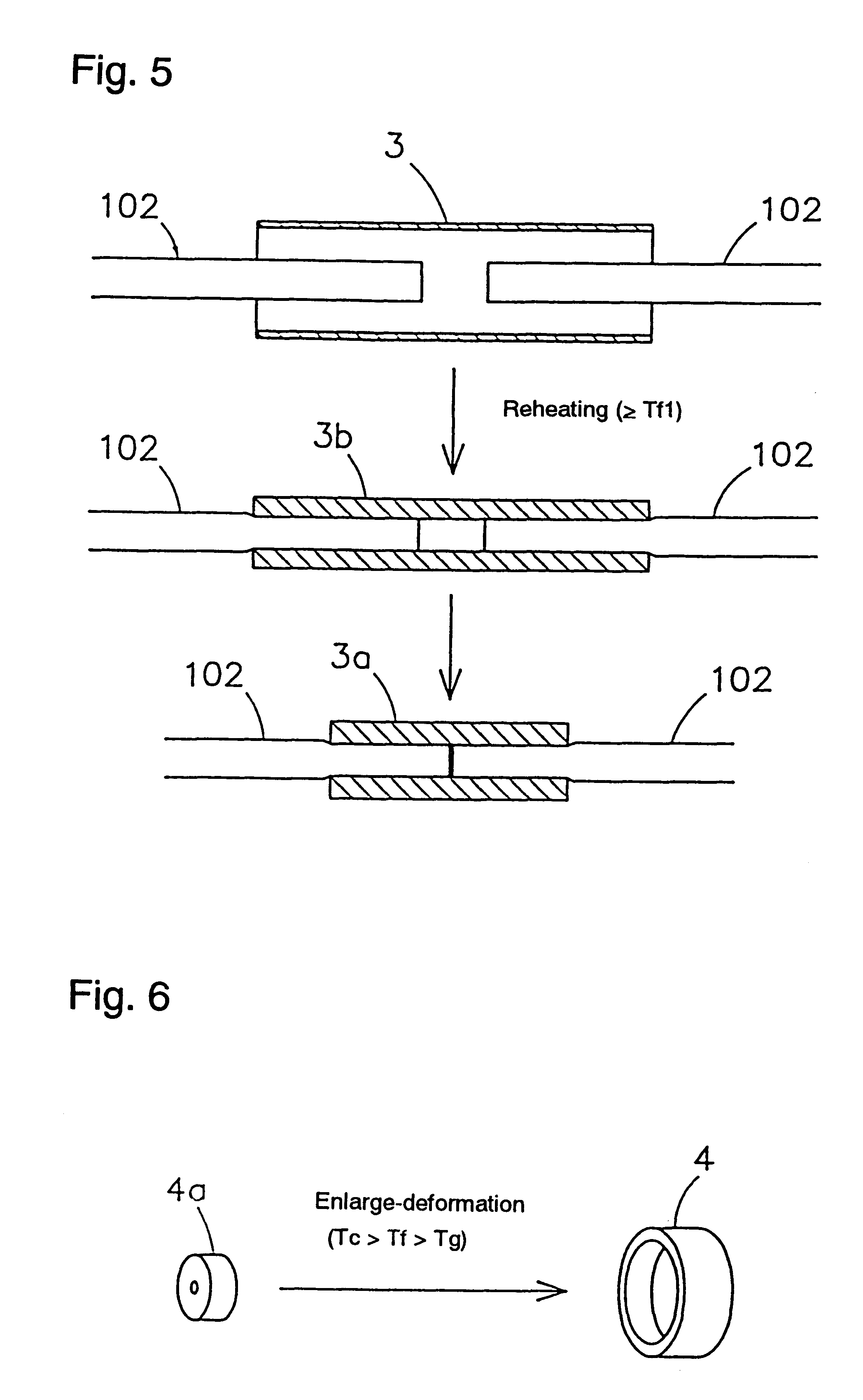

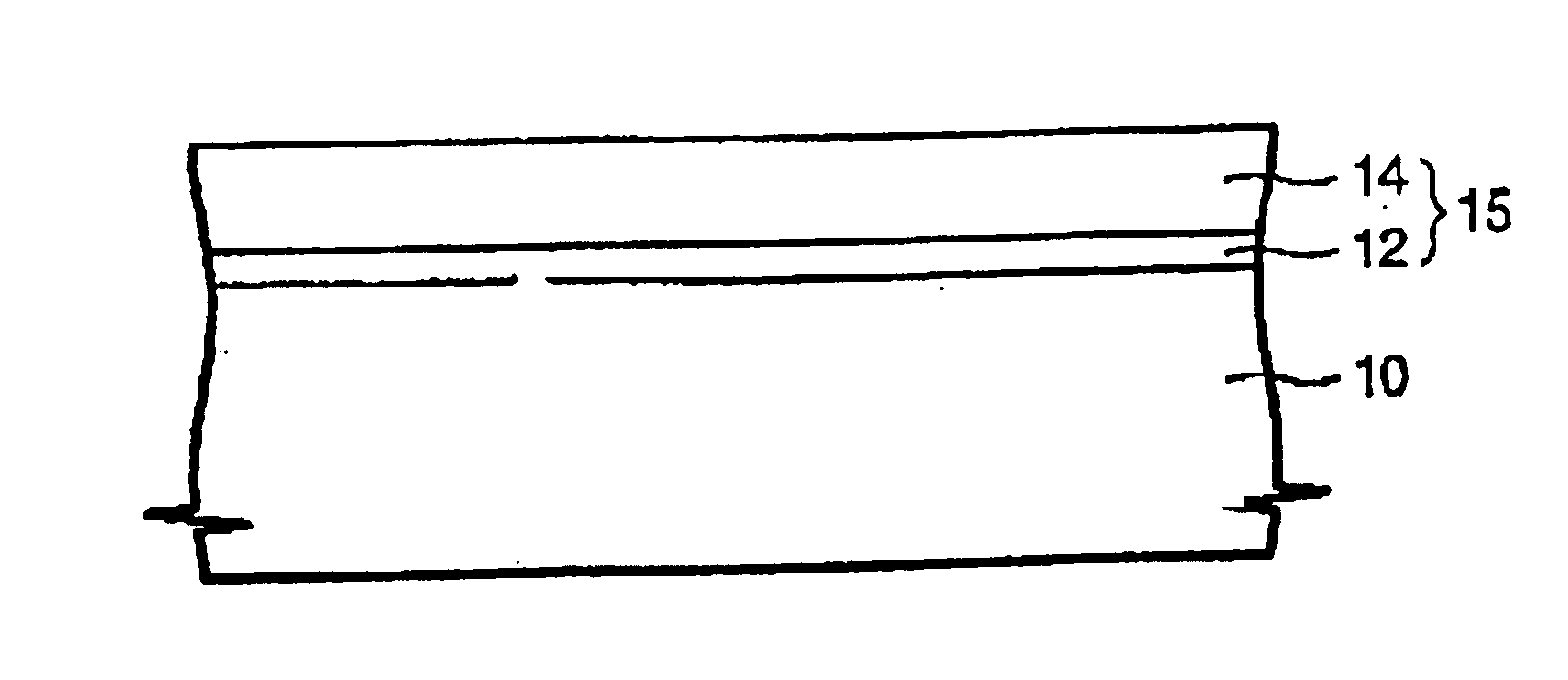

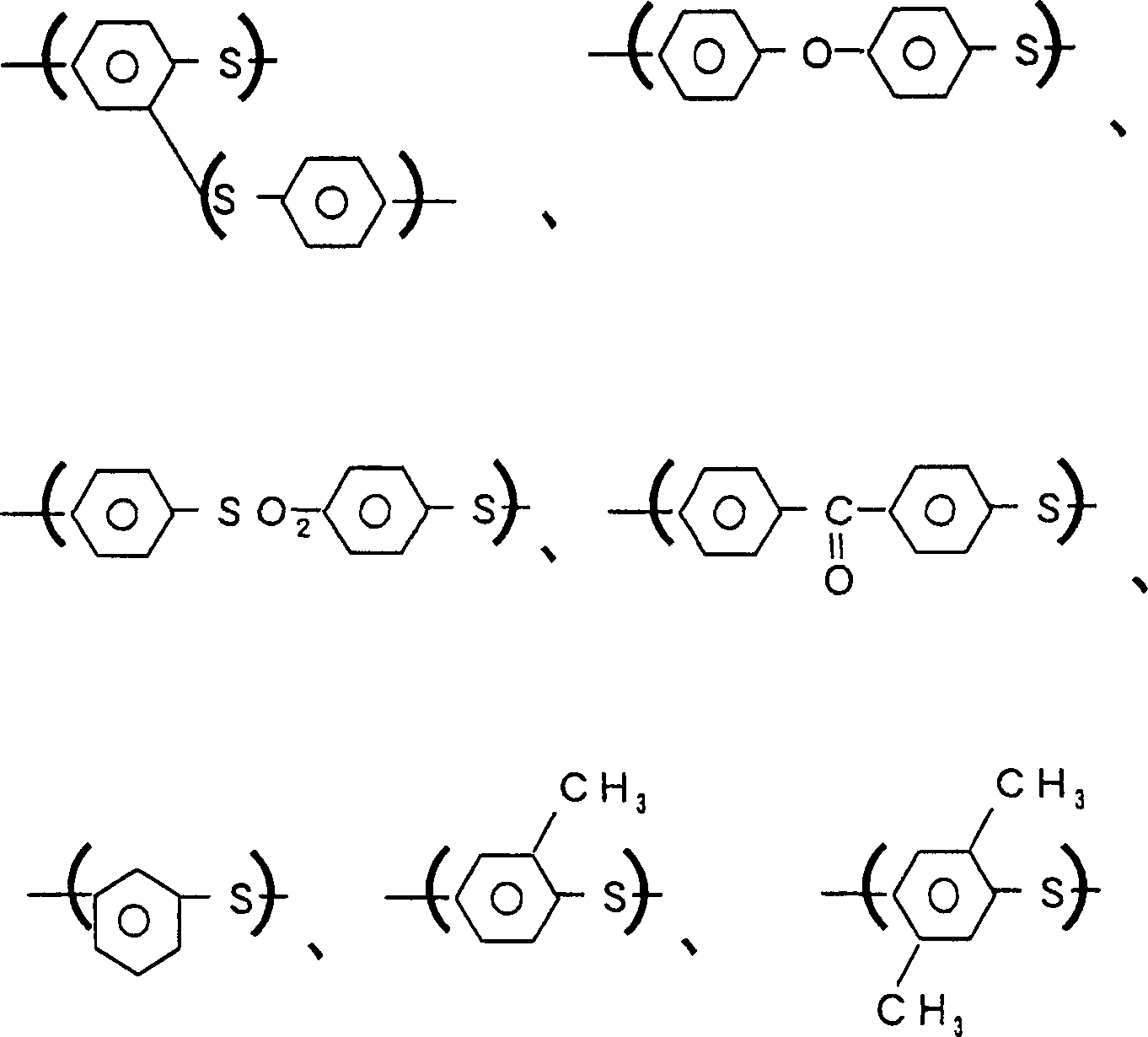

Shape-memory, biodegradable and absorbable material

InactiveUS6281262B1Easily and surely performSuture equipmentsCosmetic preparationsVitrificationPolymer science

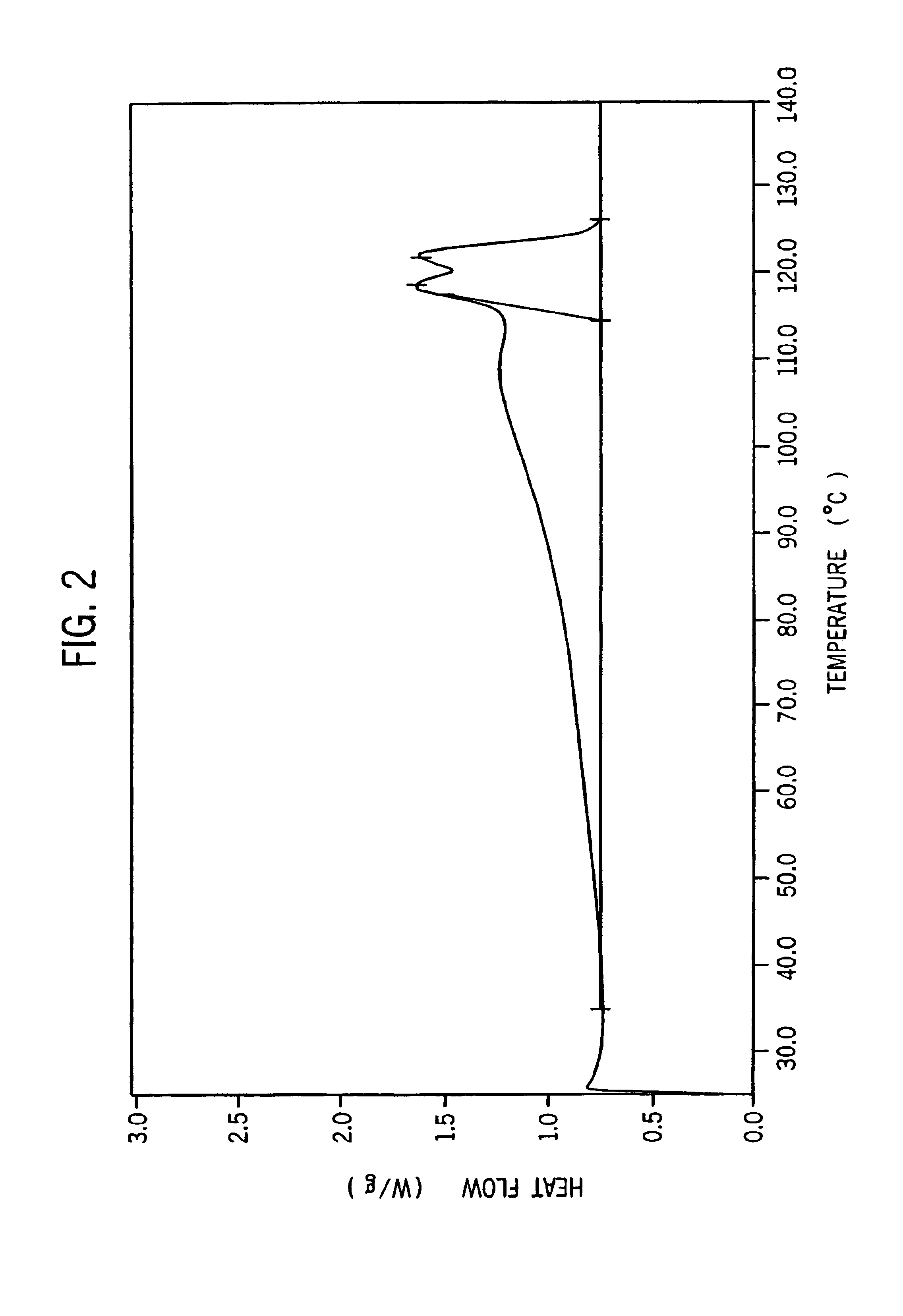

Shape-memory biodegradable and absorbable materials which make it possible to easily treat vital tissues by suture, anastomosis, ligation, fixation, reconstitution, prosthesis, etc. without causing burn. These materials never induce halation in MRI or CT and never remain in vivo. Such a shape-memory biodegradable and absorbable material is a material made of a molded article of lactic acid-based polymer and can be recovered to the original shape without applying any external force thereto but heating to a definite temperature or above. It is obtained by deforming a molded article (a primary molded article) made of a lactic acid-based polymer and having a definite shape into another molded article (a secondary molded article) having another shape at a temperature higher than the glass transition temperature thereof but lower than the crystallization temperature thereof (or 100.degree. C. when the molded article has no crystallization temperature) and then fixing said molded article to the thus deformed shape by cooling it as such to a temperature lower than the glass transition temperature. When this material is heated to the above-mentioned deformation temperature or above, it is immediately recovered to the original shape. The lactic acid-based polymer is hydrolyzed and absorbed in vivo.

Owner:TAKIRON CO LTD

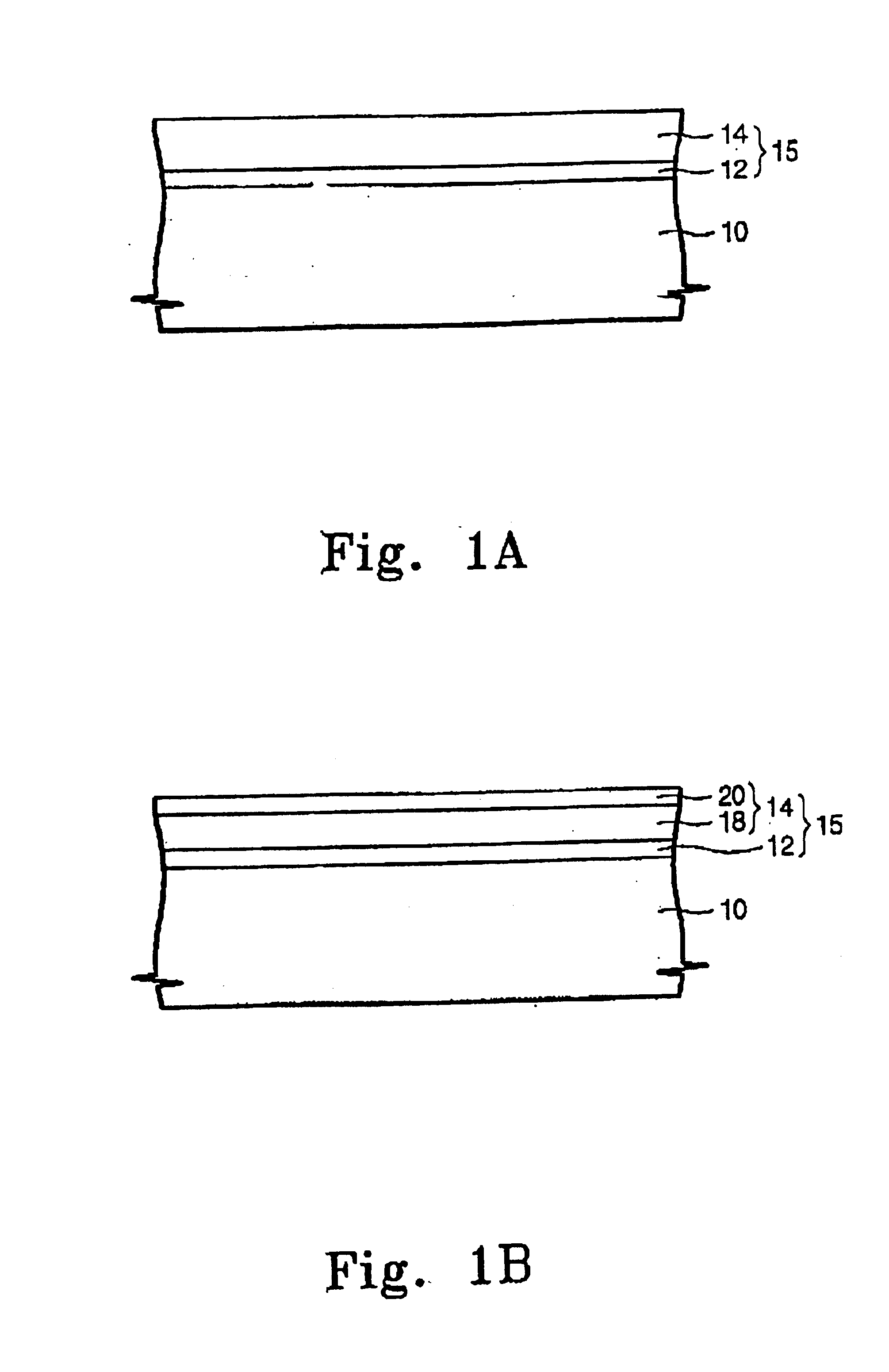

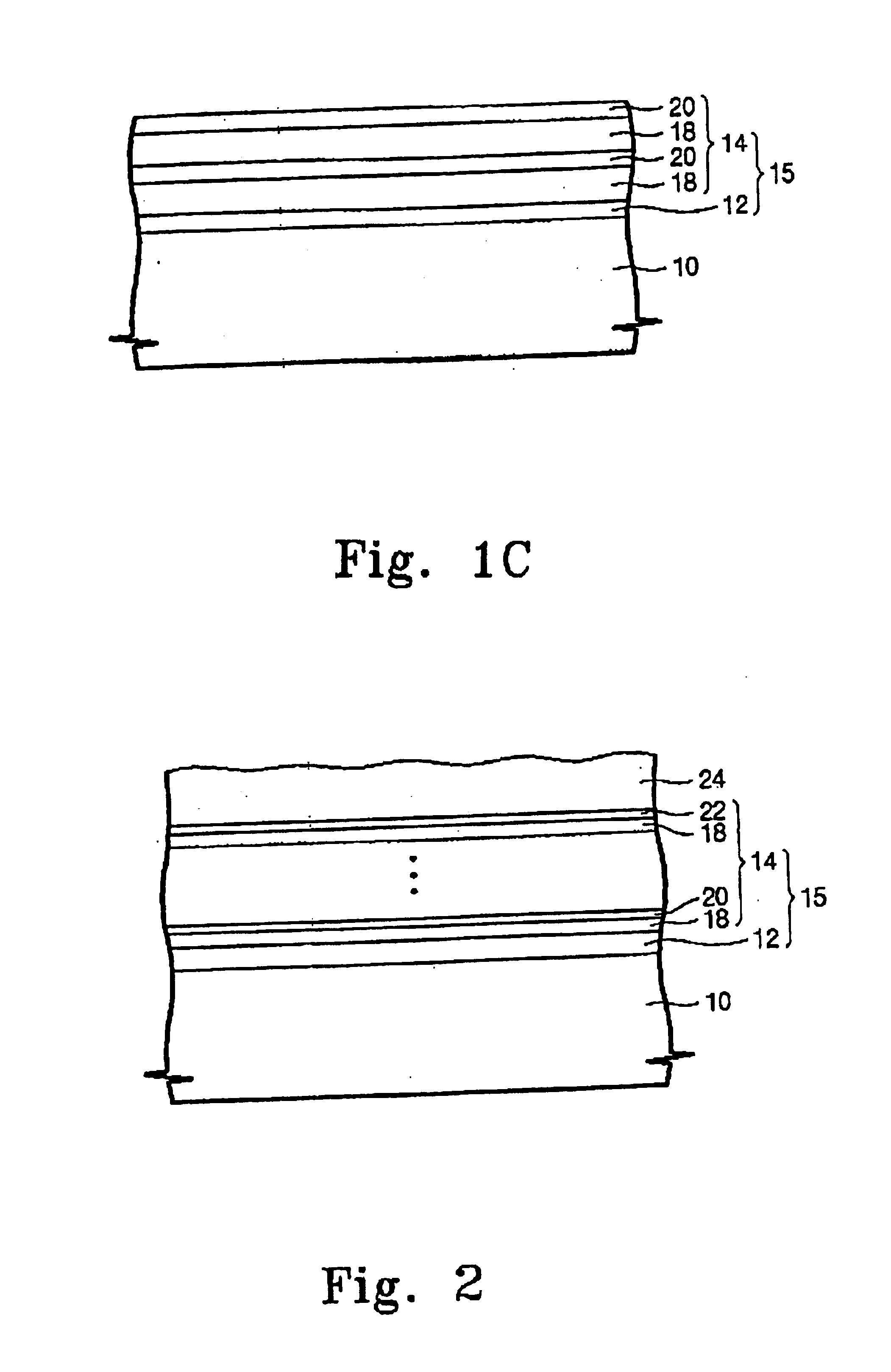

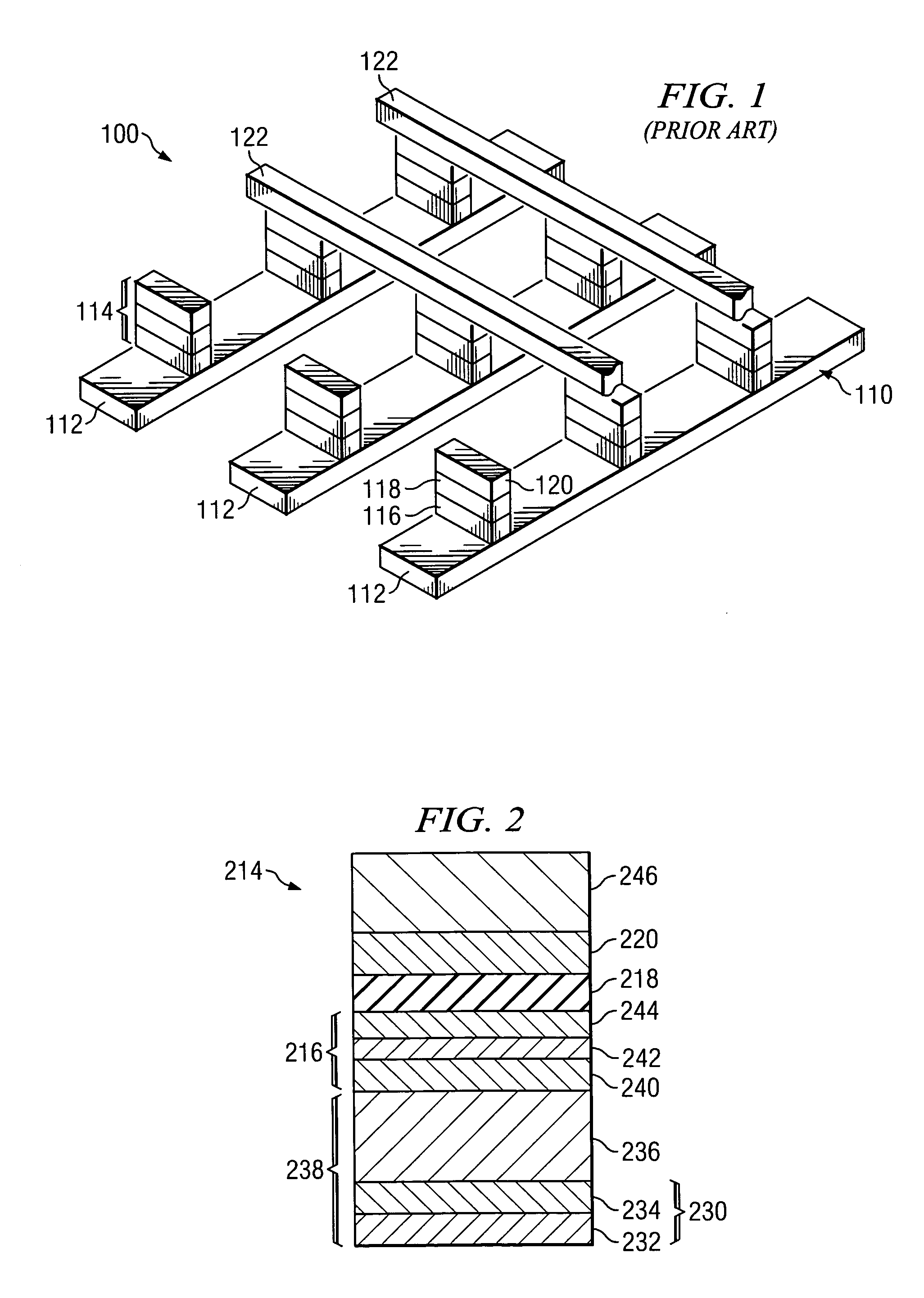

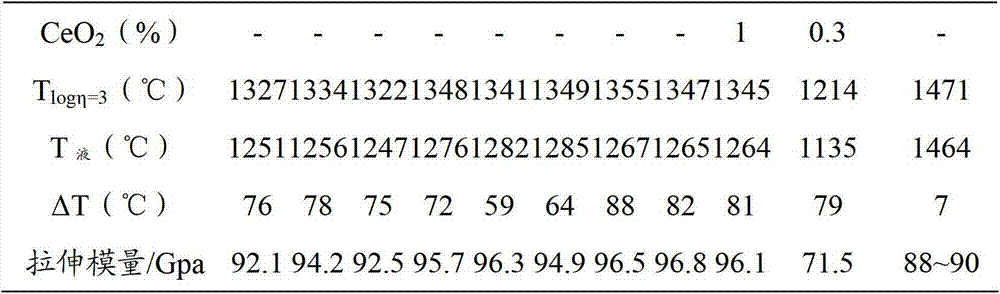

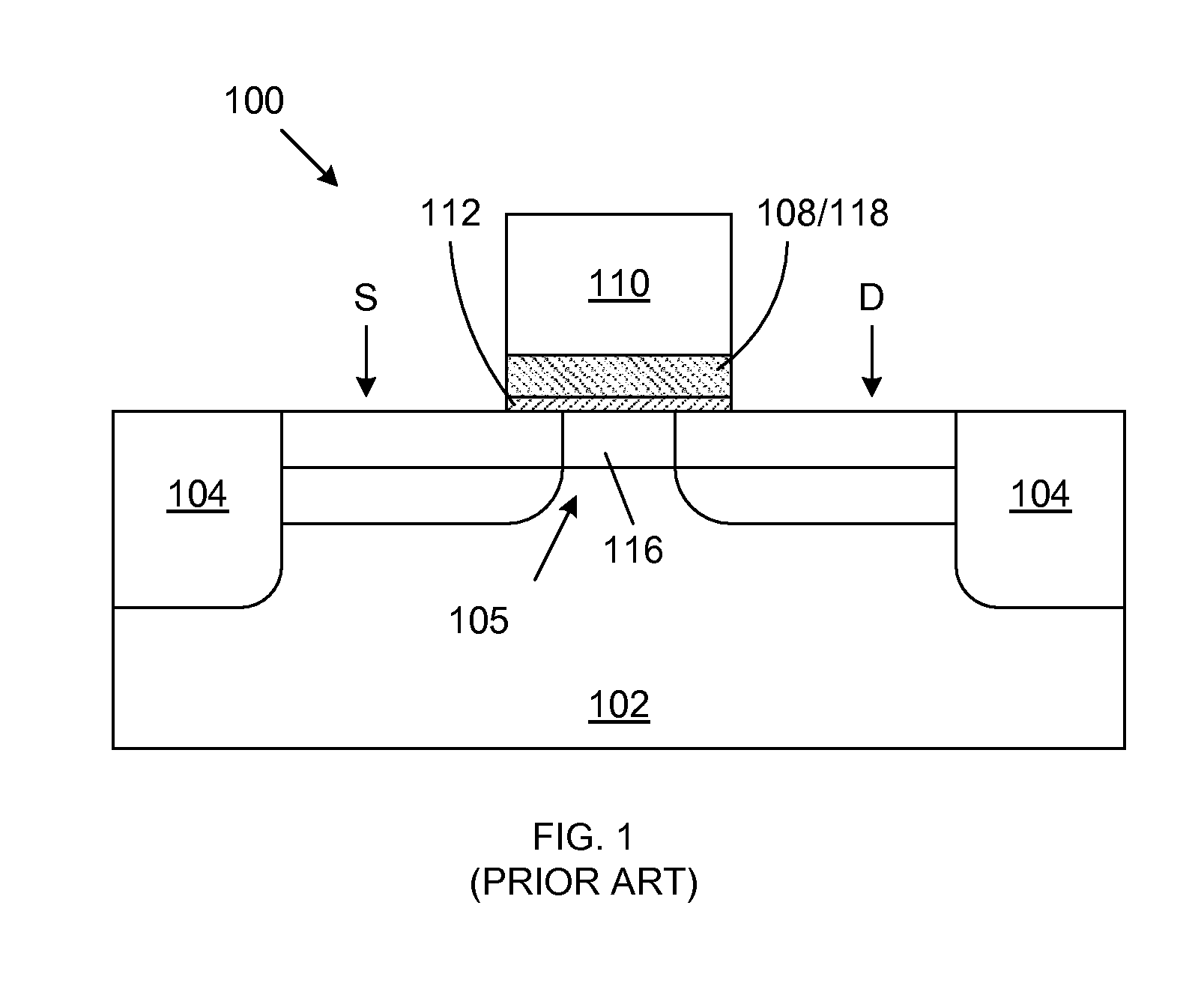

Dielectric layer for semiconductor device and method of manufacturing the same

InactiveUS6844604B2Improving interface characteristicReduce maintenanceTransistorSolid-state devicesDevice materialInterface layer

A multi-layer dielectric layer structure for a semiconductor device. The multi-layer dielectric layer structure comprises a silicate interface layer having a dielectric constant greater than that of silicon nitride and a high-k dielectric layer overlying the silicate interface layer. The high-k dielectric layer comprises one or more ordered pairs of first and second layers. With the present invention, the dielectric constant of the high-k dielectric layer can be optimized while improving interface characteristics. With a higher crystallization temperature realized by forming the multi-layer structure, each of whose layers is not more than the critical thickness, leakage current can be reduced, thereby improving device performance.

Owner:SAMSUNG ELECTRONICS CO LTD

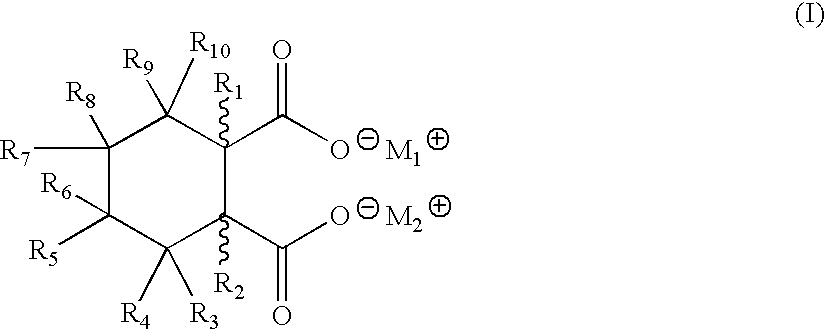

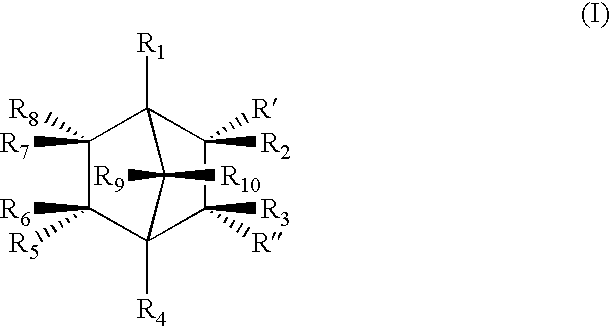

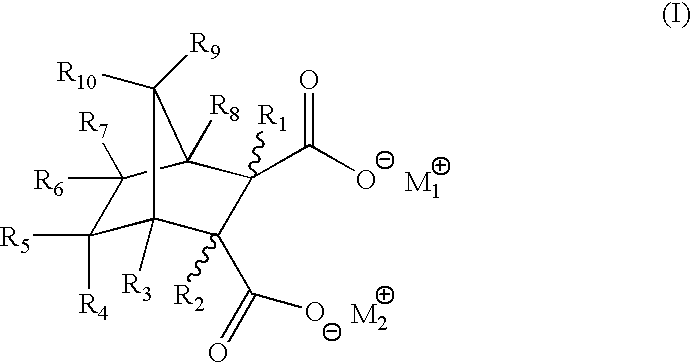

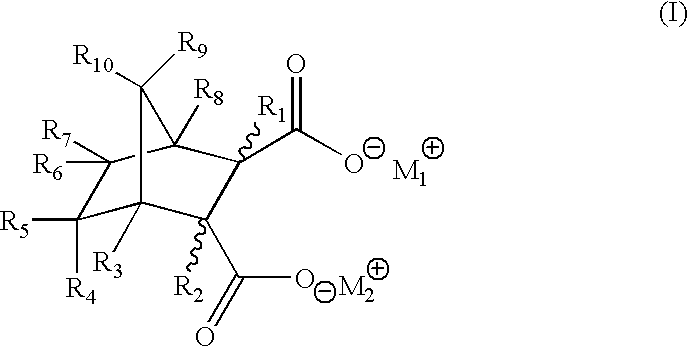

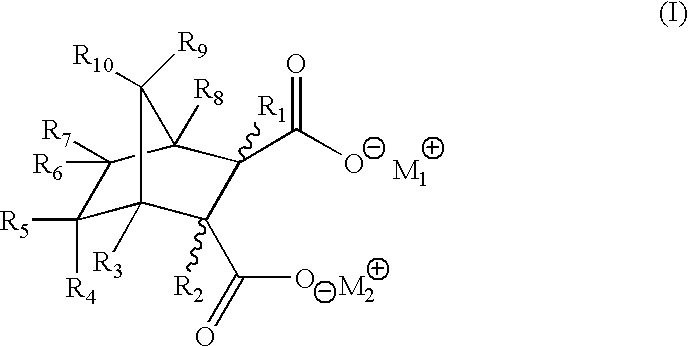

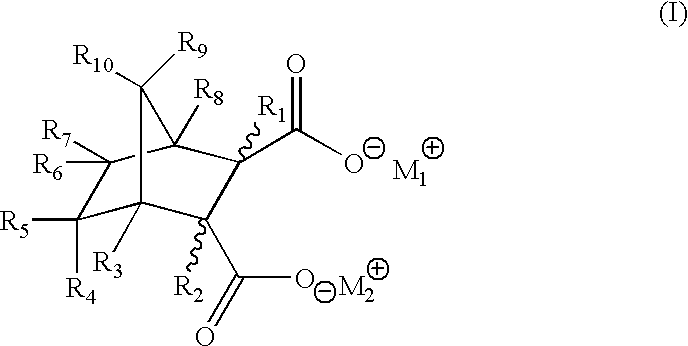

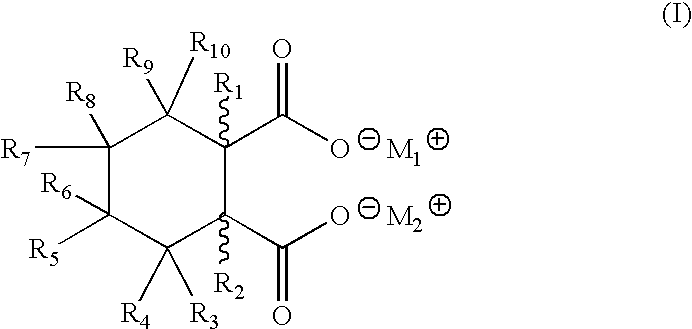

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

MTJ stack with crystallization inhibiting layer

InactiveUS6977181B1Improve thermal stabilityImprove compatibilityNanoinformaticsSolid-state devicesHeat stabilityCrystallization temperature

A method of forming a magnetic stack and a structure for a magnetic stack of a resistive memory device. A crystallization inhibiting layer is formed over the free layer of a magnetic stack, improving thermal stability. The crystallization inhibiting layer comprises an amorphous material having a higher crystallization temperature than the crystallization temperature of the free layer material. The crystallization inhibiting layer inhibits the crystallization of the underlying free layer, providing improved thermal stability for the resistive memory device.

Owner:POLARIS INNOVATIONS

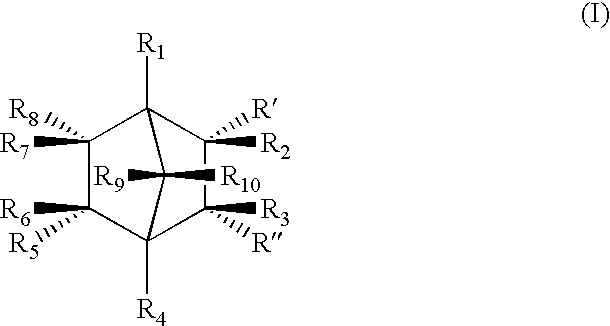

Highly nucleated thermoplastic articles

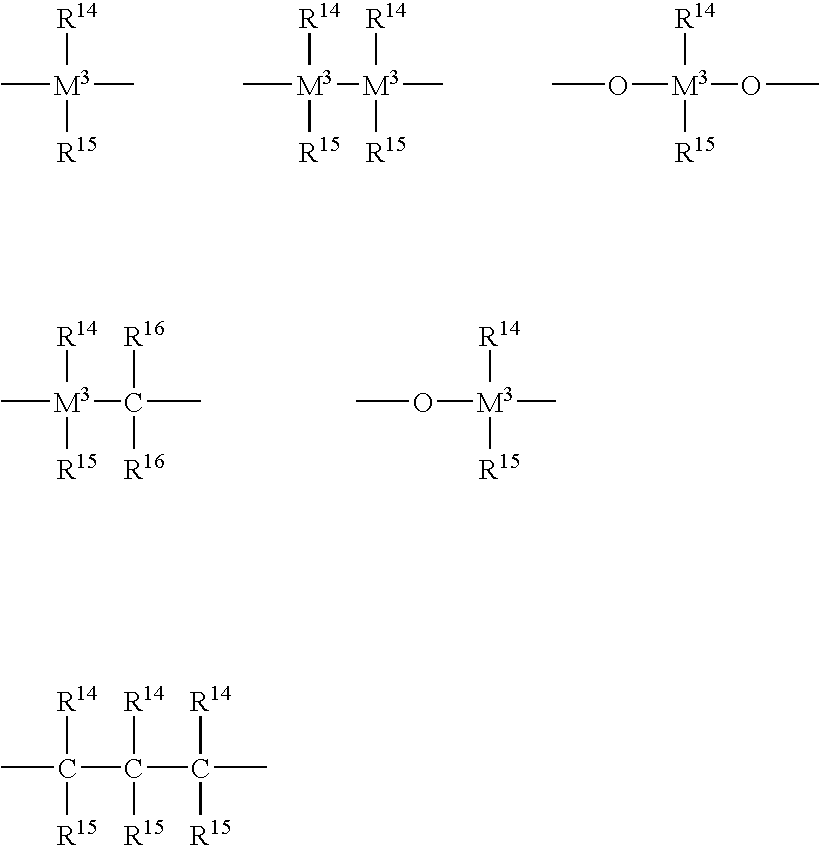

InactiveUS6534574B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic active ingredientsOrganic chemistryPolyolefinCrystallization temperature

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

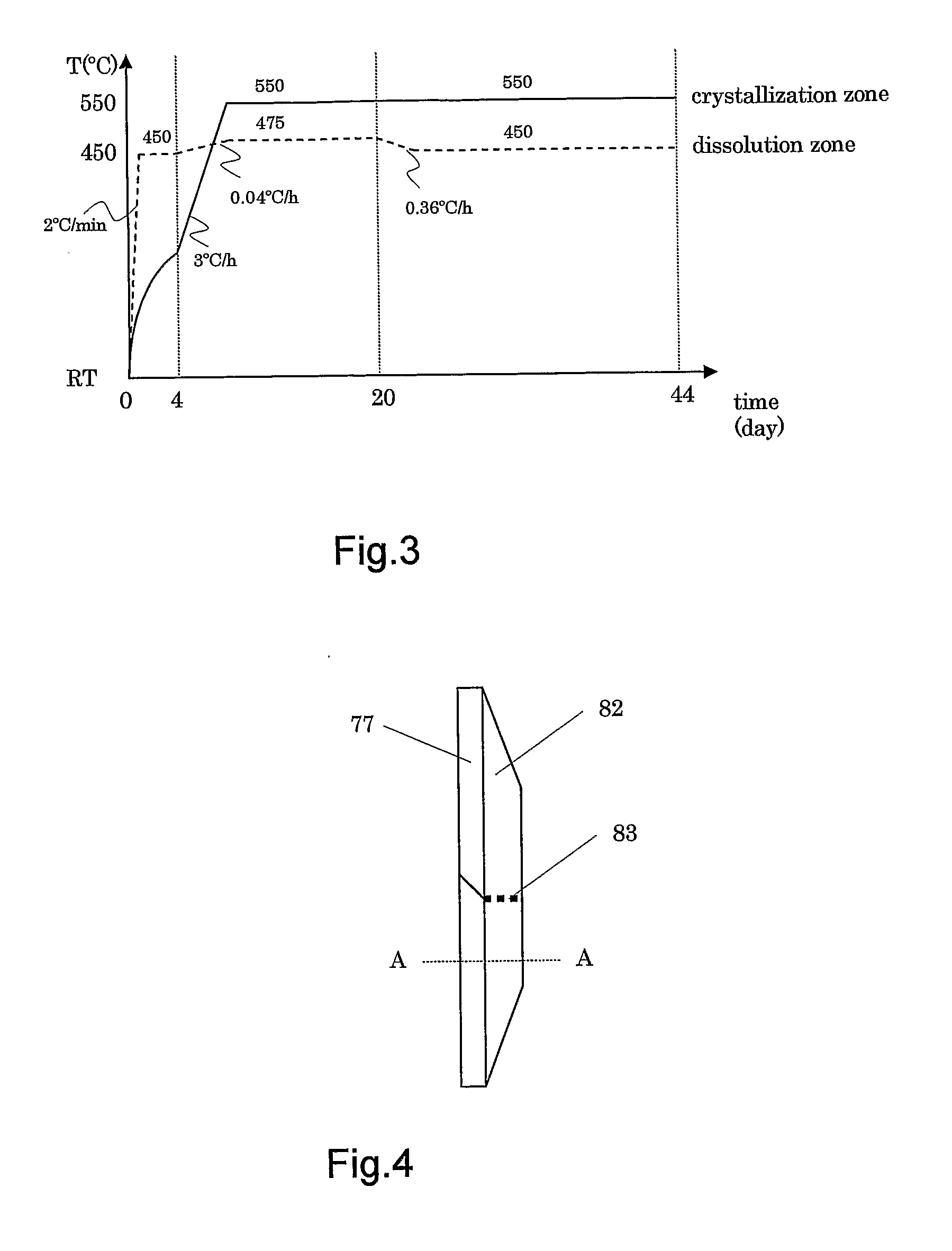

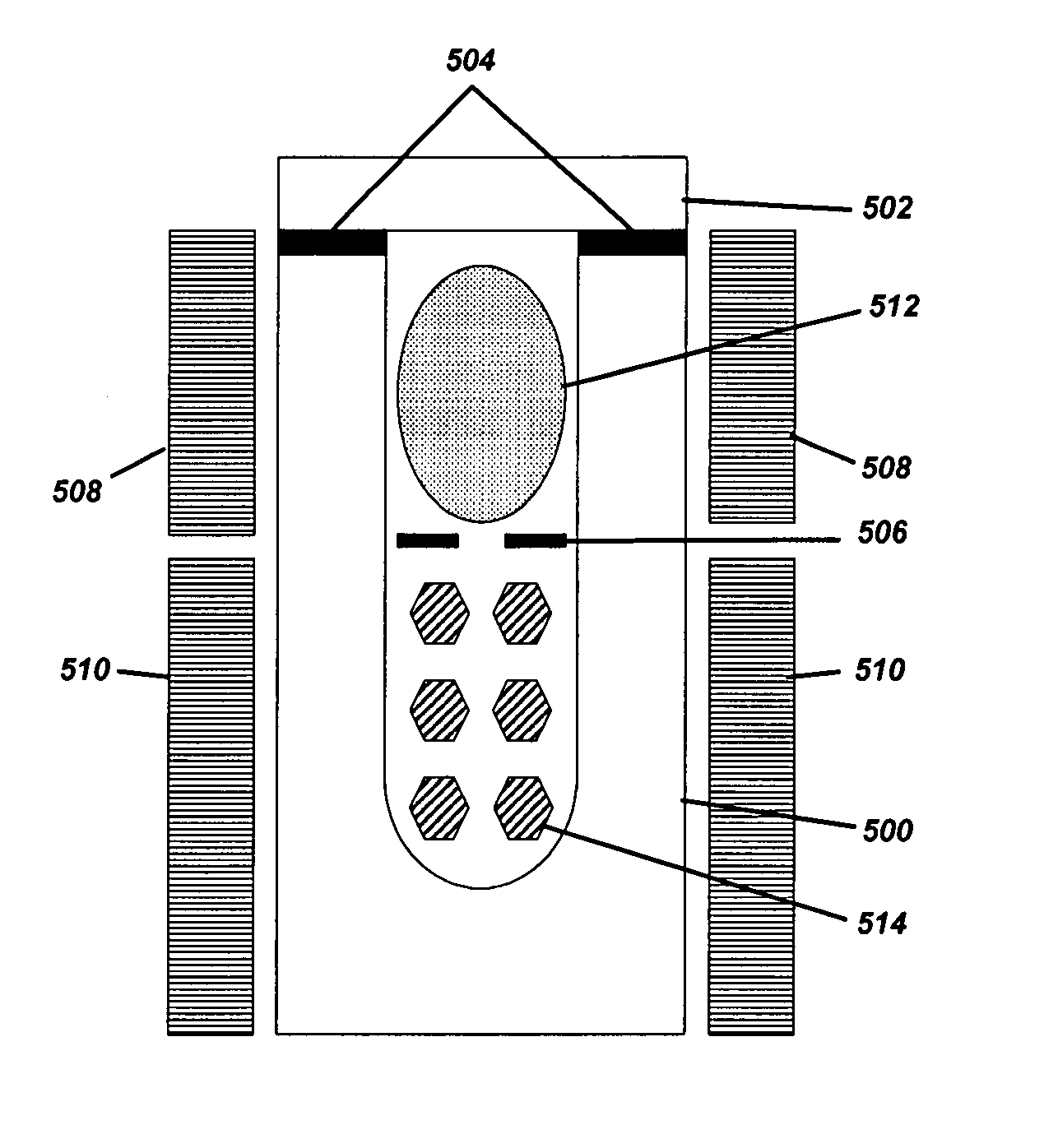

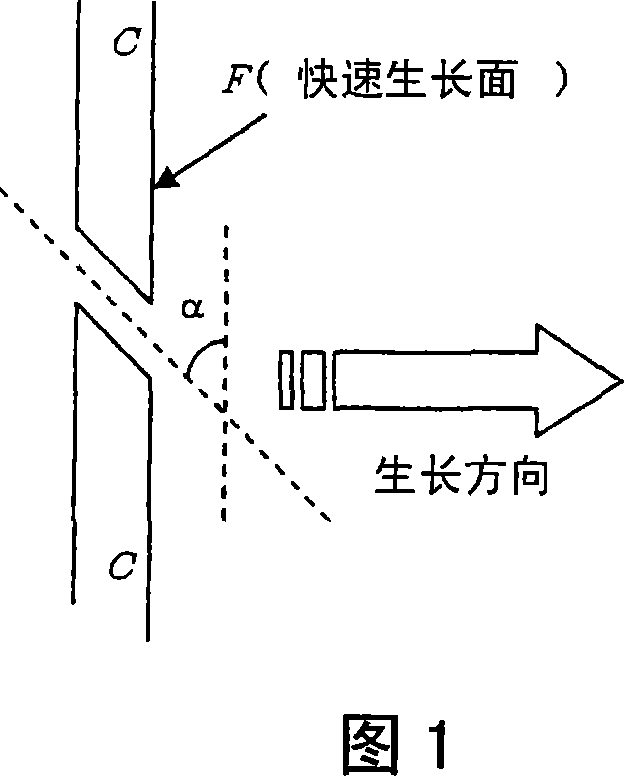

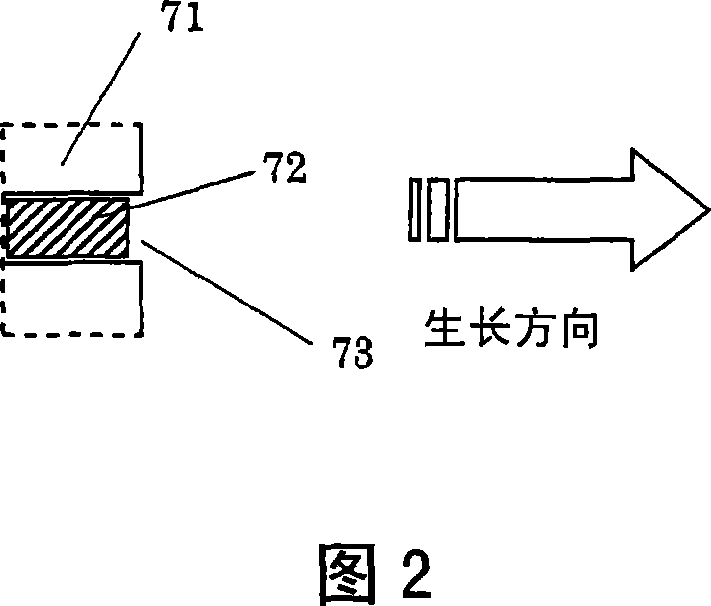

Nitride Single Crystal Seeded Growth in Supercritical Ammonia with Alkali Metal Ion

ActiveUS20080156254A1Increase in sizeShorten the timePolycrystalline material growthLaser detailsDissolutionSingle crystal

The present invention is related to a process for obtaining a larger area substrate of mono-crystalline gallium-containing nitride by making selective crystallization of gallium containing nitride on a smaller seed under a crystallization temperature and / or pressure from a supercritical ammonia-containing solution made by dissolution of gallium-containing feedstock in a supercritical ammonia-containing solvent with alkali metal ions, comprising: providing two or more elementary seeds, and making selective crystallization on the two or more separate elementary seeds to get a merged larger compound seed. The merged larger compound seed is used for a seed in a new growth process and then to get a larger substrate of mono-crystal gallium-containing nitride.

Owner:AMMONO SP Z O O (PL) +1

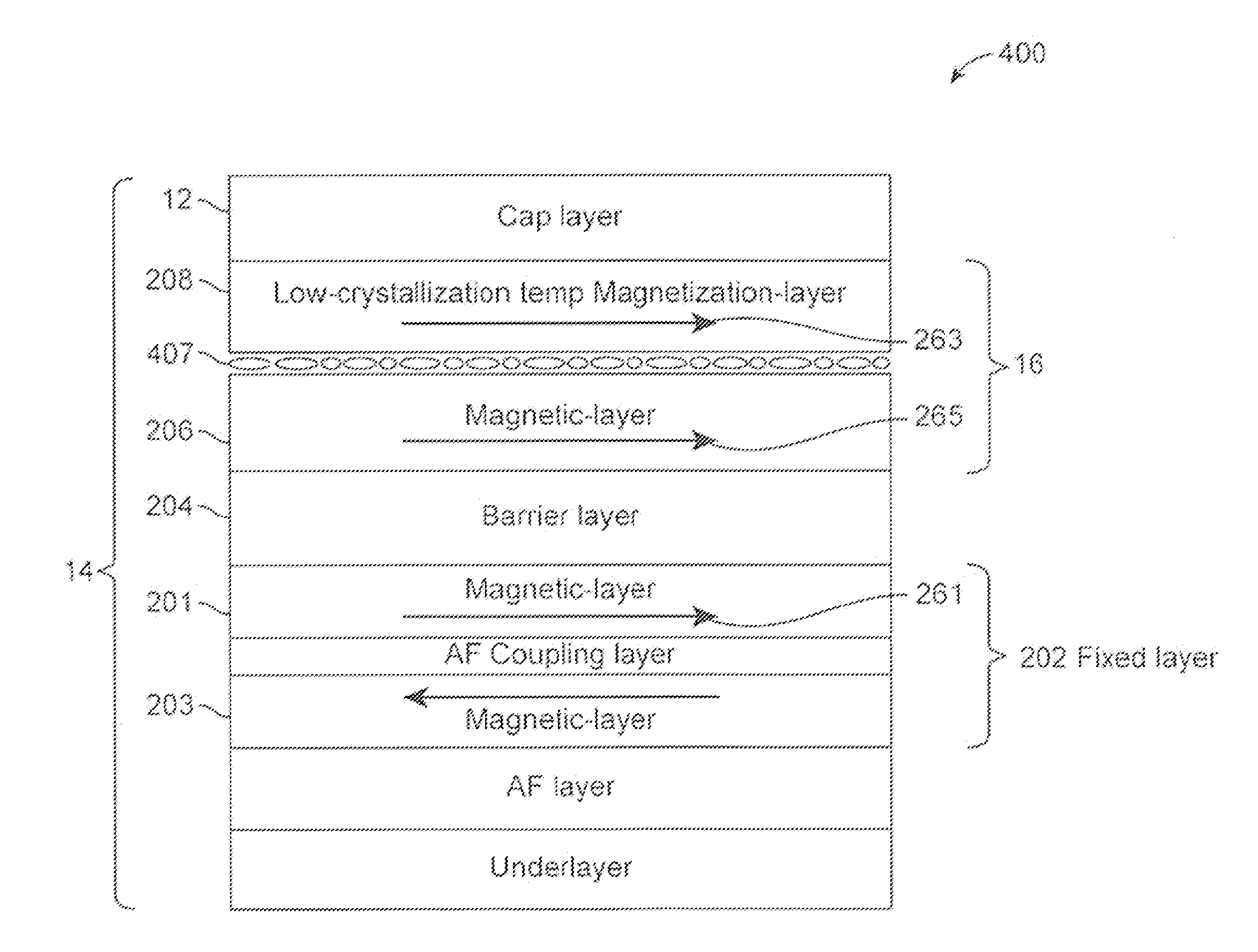

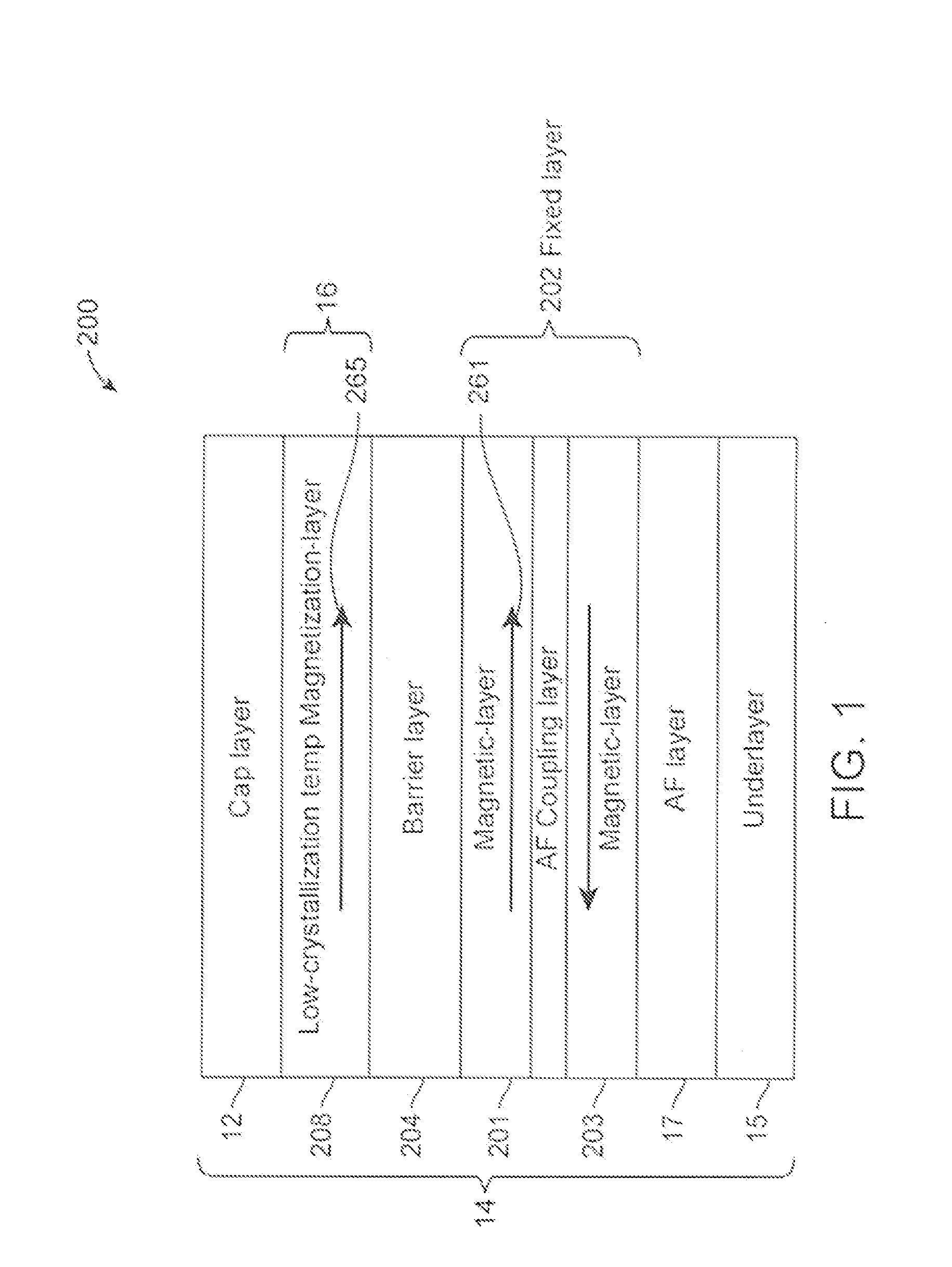

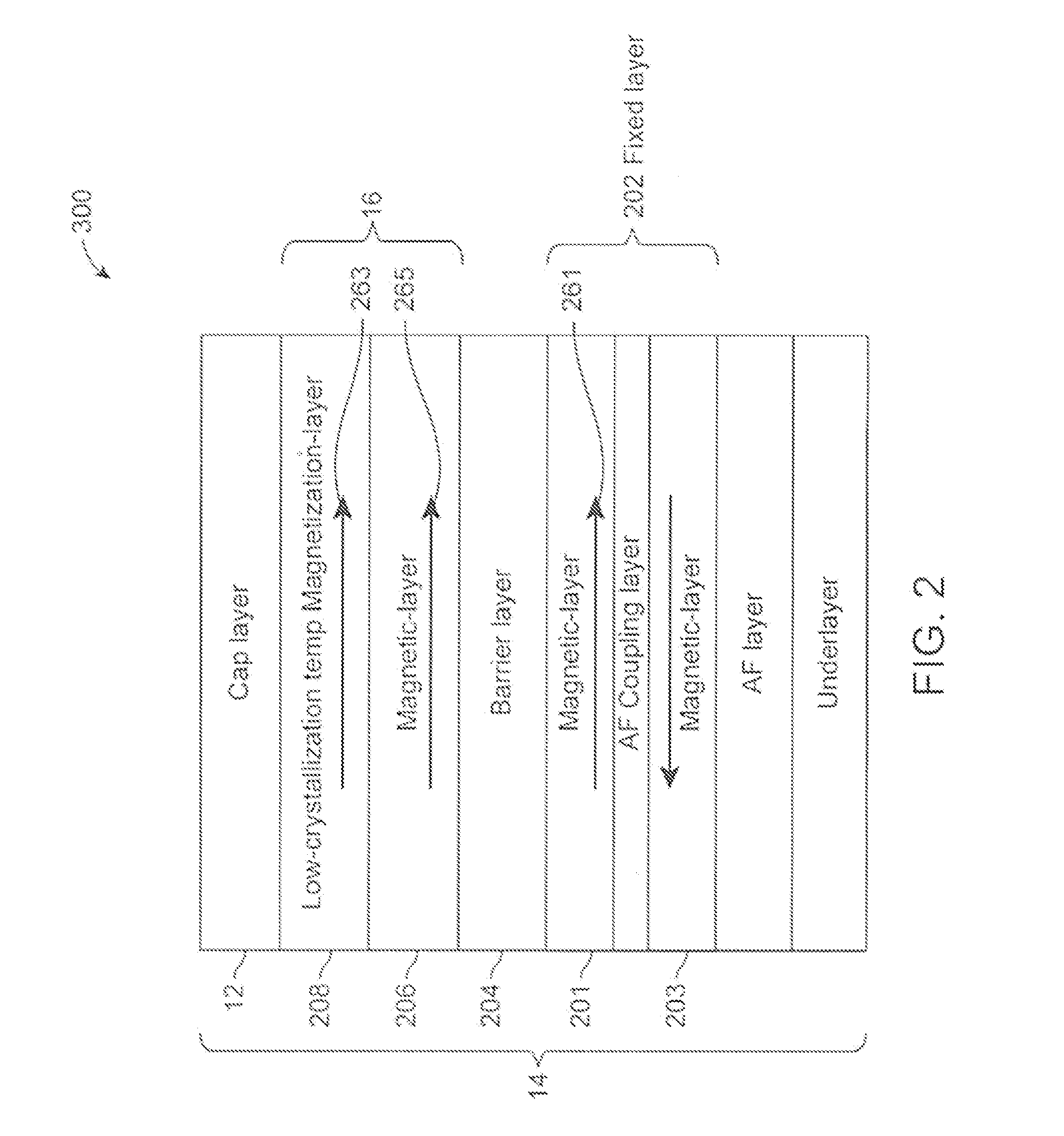

Low-crystallization temperature MTJ for Spin-Transfer Torque Magnetic Random Access Memory (STTMRAM)

A spin-torque transfer memory random access memory (STTMRAM) element is disclosed and has a fixed layer, a barrier layer formed upon the fixed layer, and a free layer comprised of a low-crystallization temperature alloy of CoFeB—Z where Z is below 25 atomic percent of one or more of titanium, (Ti), yittrium (Y), zirconium (Zr), and vanadium (V), wherein during a write operation, a bidirectional electric current is applied across the STTMRAM element to switch the magnetization of the free layer between parallel and anti-parallel states relative to the magnetization of the fixed layer.

Owner:AVALANCHE TECH

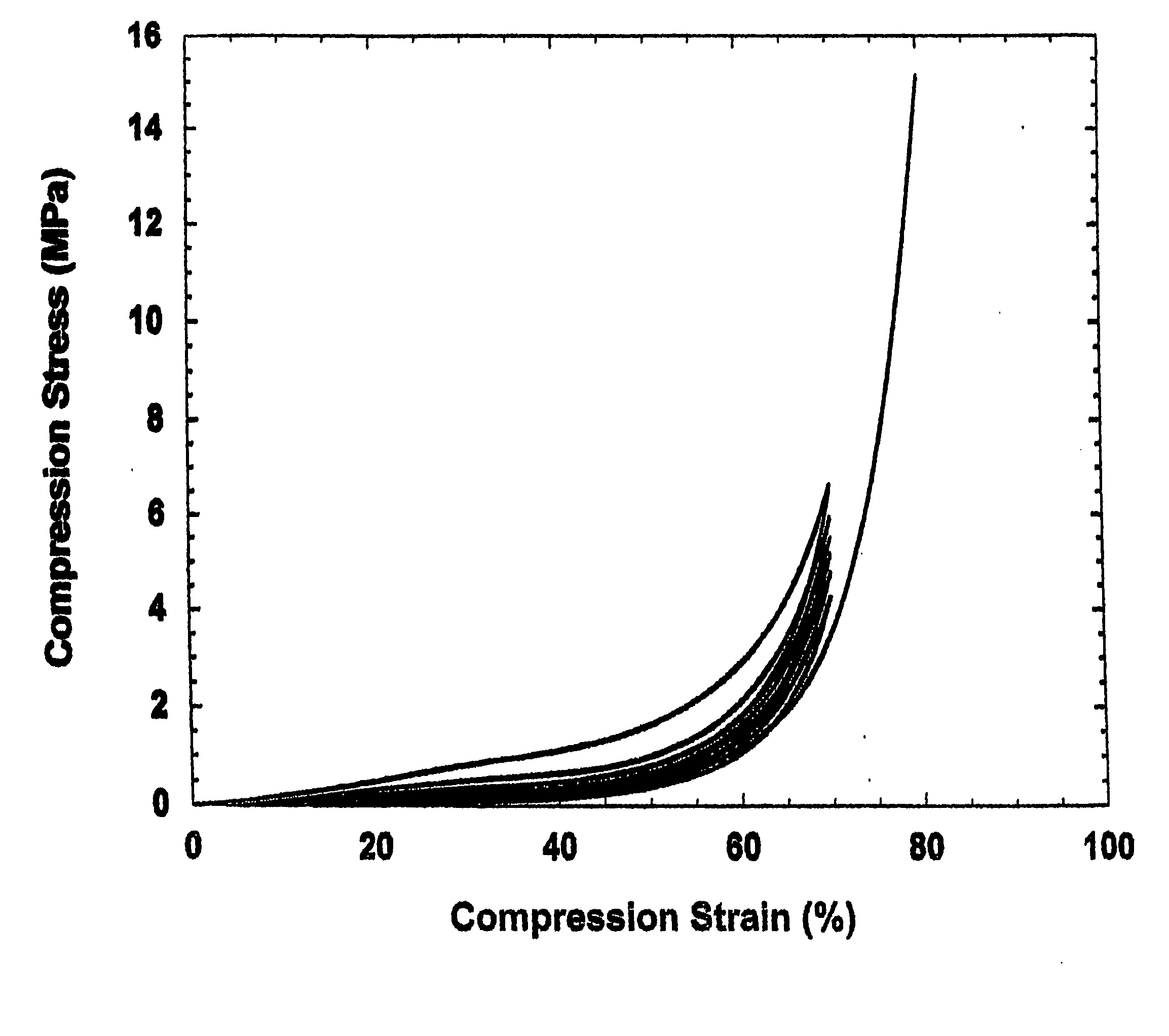

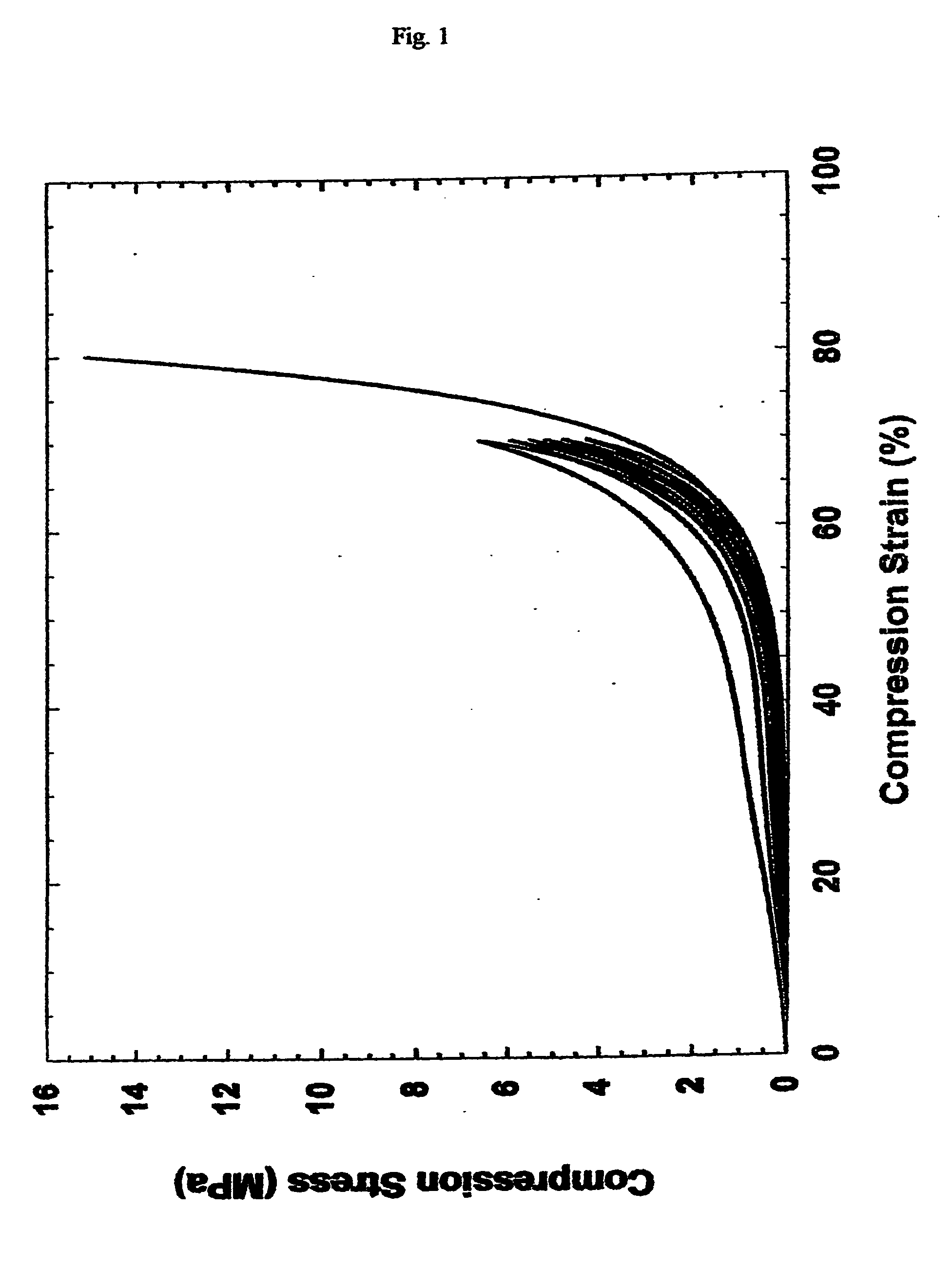

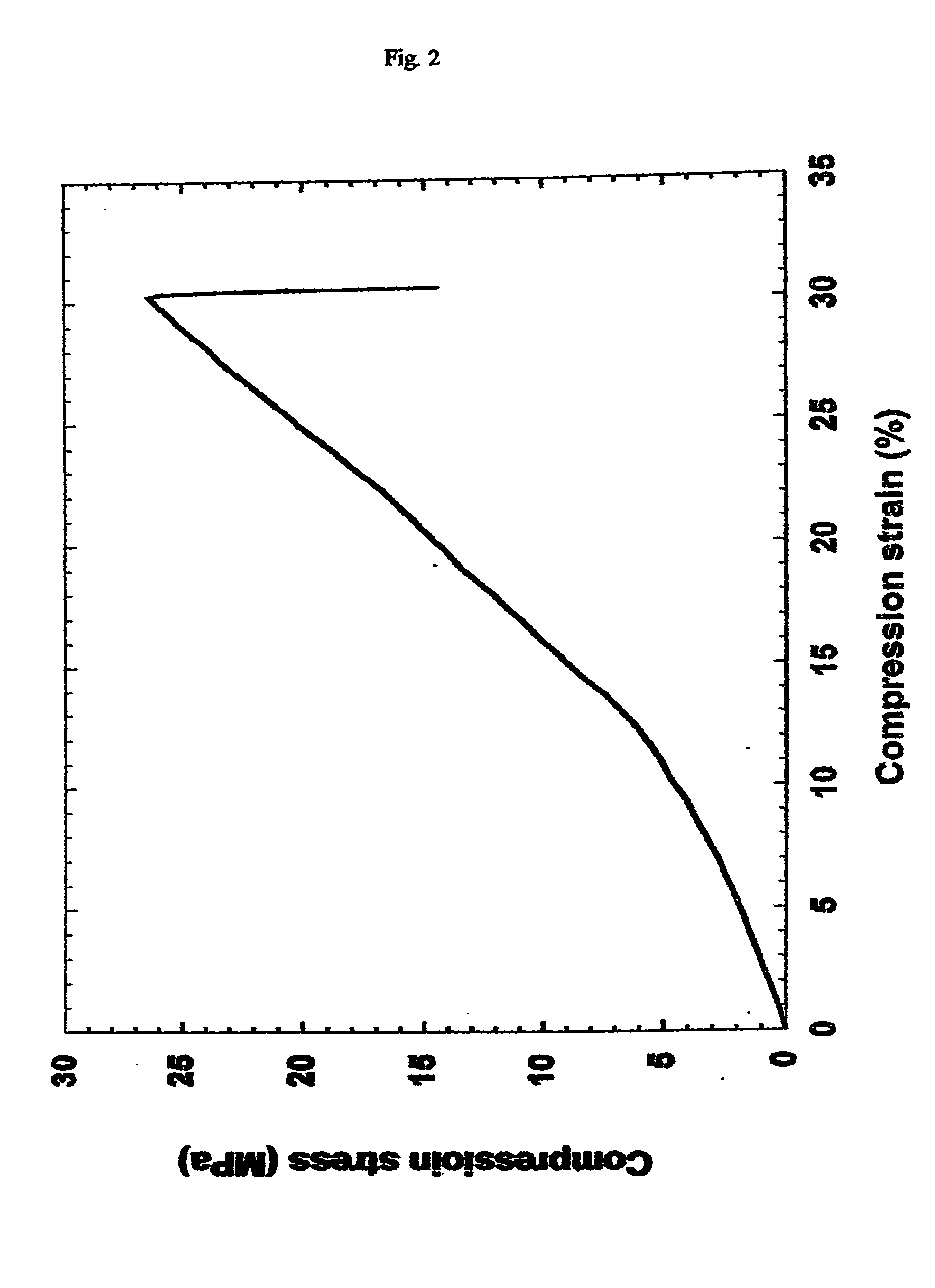

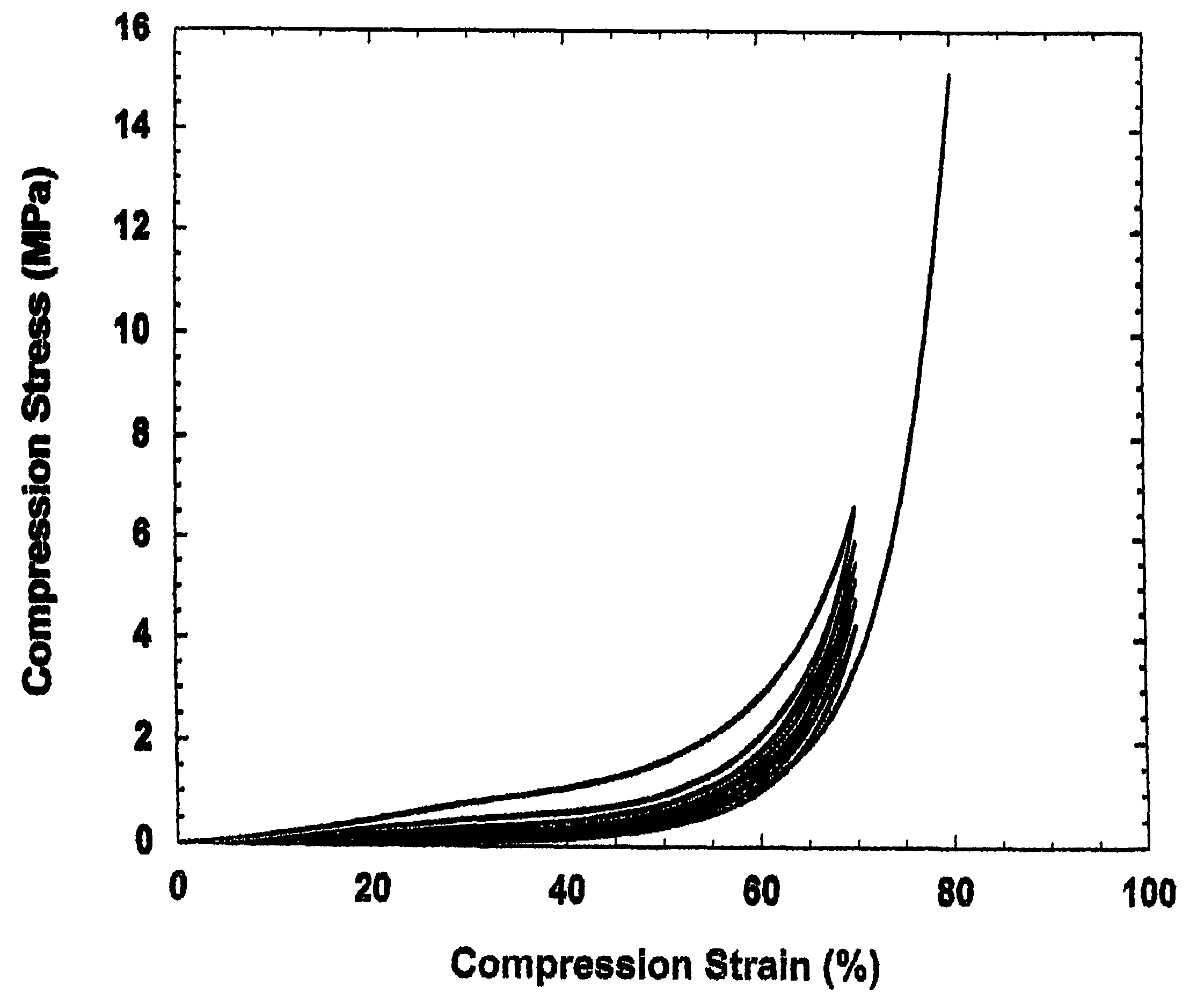

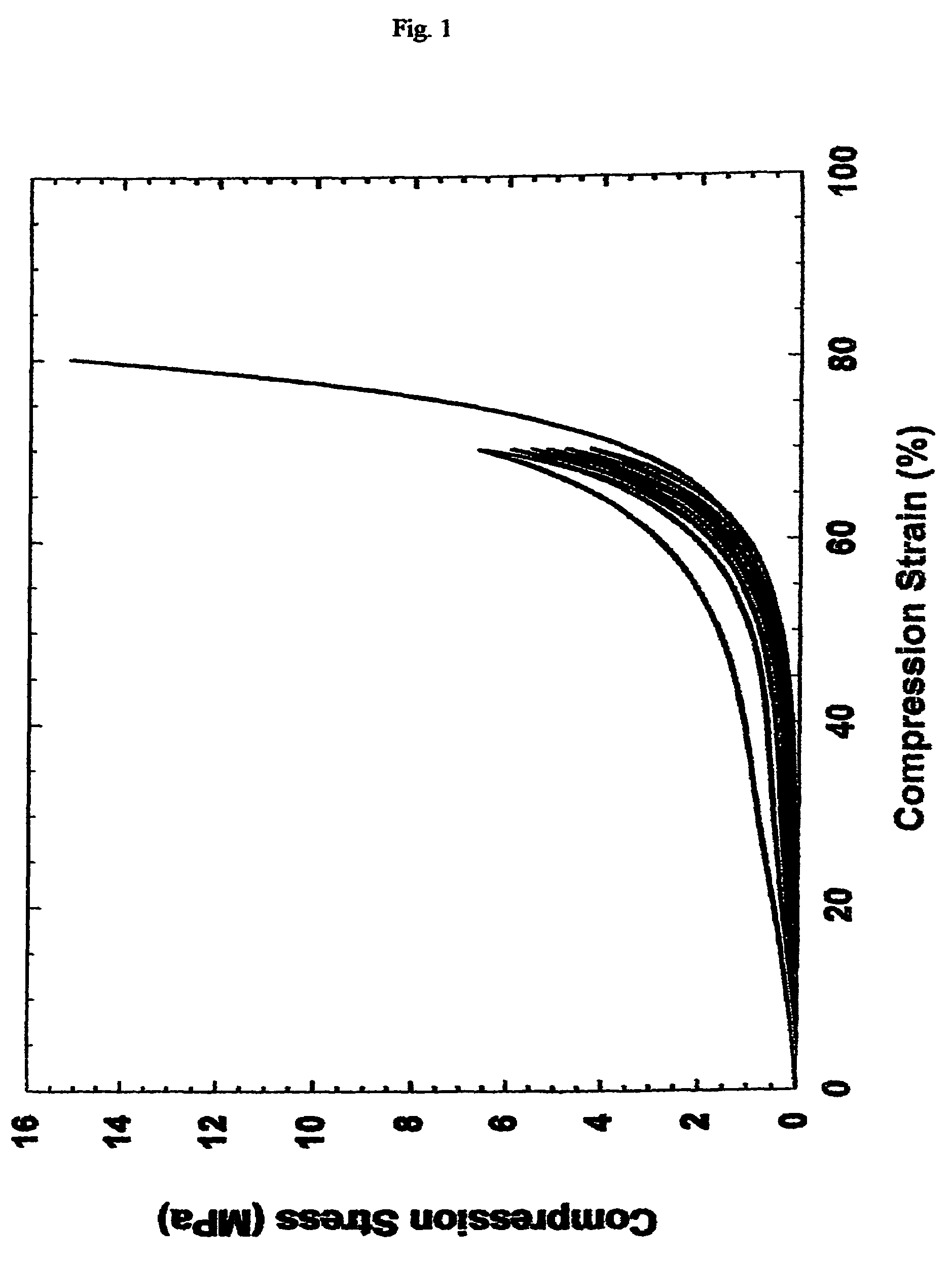

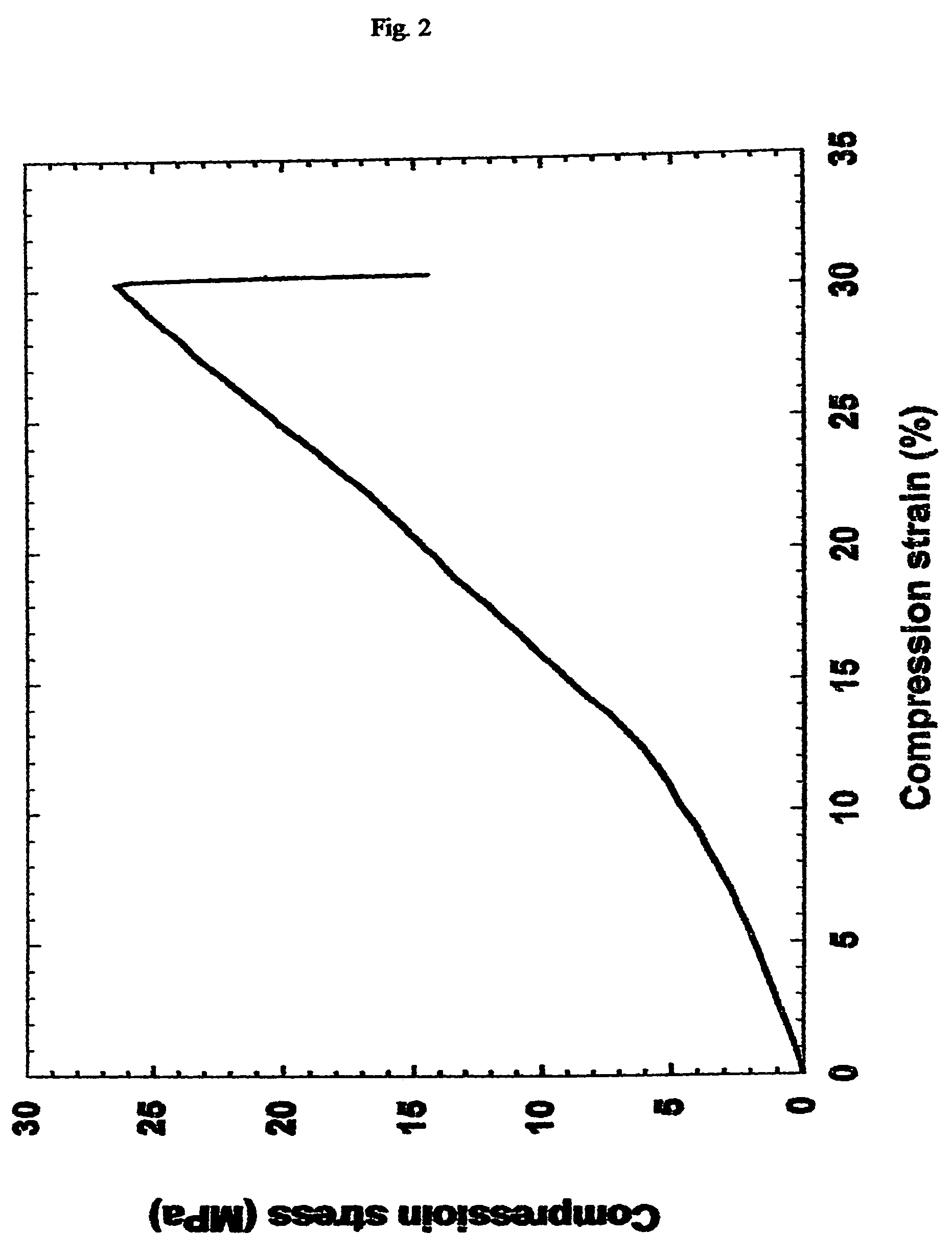

Highly convertable endolumenal prostheses and methods of manufacture

Endolumenal prostheses that readily and extensively convert from a delivery configuration to a deployed configuration are disclosed. Endolumenal prostheses may be fabricated from one or more shape memory polymers, a high modulus elastomer, a polymer that is both elastomeric and exhibits shape memory behavior, a hydrogel, or some combination thereof. Polymers used to fabricate the prostheses are selectively synthesized to exhibit desired characteristics such as crystallinity, strain fixity rate, strain recovery rate, elasticity, tensile strength, mechanical strength, cross-linking density, extent physical cross-linking, extent of covalent cross-linking, extent of interpenetrating networks, rate of erosion, heat of fusion, crystallization temperature, and acidity during erosion. The endolumenal prostheses convert to the deployed configuration following delivery to a treatment site, upon exposure to an initiator either present within the body naturally or introduced into the body.

Owner:SYNECOR LLC

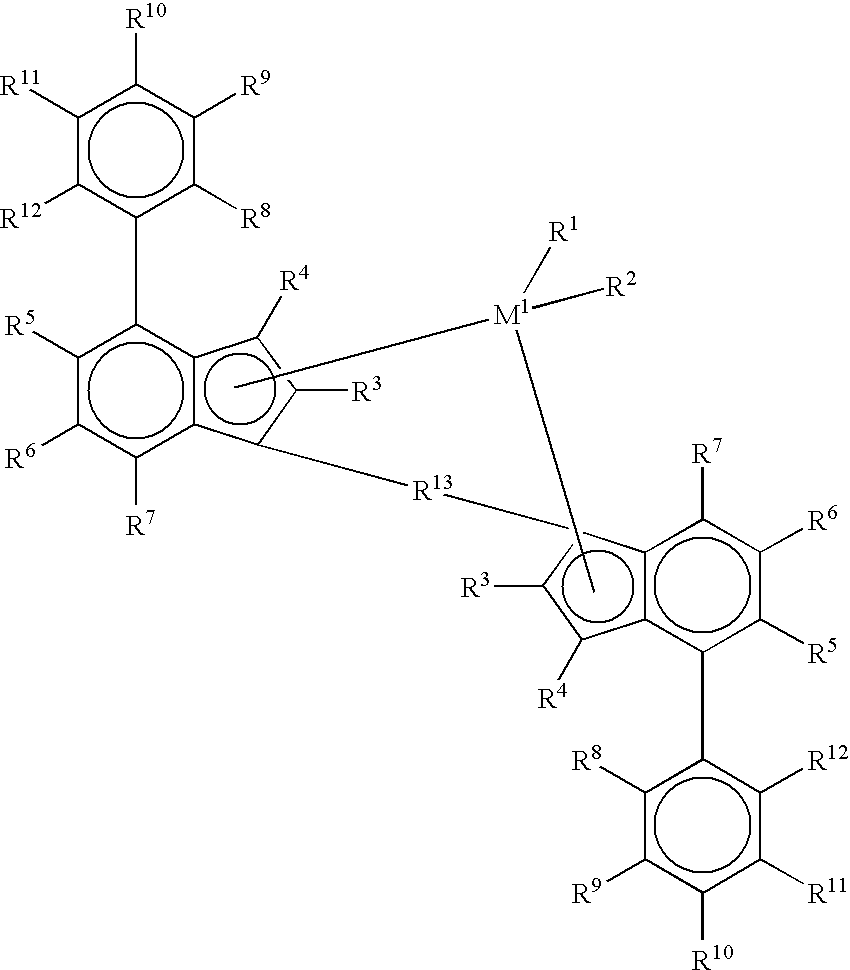

Polypropylene composition useful for making solid state oriented film

Disclosed is a polypropylene composition useful for making solid state oriented film. The composition comprises two predominantly isotactic polypropylenes with the melting point temperature of one of the polypropylenes being substantially lower than the melting point temperature of the other. In one embodiment of the composition the higher melting point polypropylene is made by Ziegler-Natta catalysis, while the lower melting point polypropylene is made by metallocene catalysis. Compared to polypropylene with similar melt flow rate and made by Ziegler-Natta catalysis, and solid state oriented film thereof, the composition provides a better balance of elevated temperature draw characteristics and physical properties of oriented film made therefrom. Thus, at the same or lower elevated temperature yield stress, oriented film of the composition exhibits improved properties such as stiffness, elongation-at-break, dimensional stability, and oxygen barrier. Also disclosed is a method for the manufacture of oriented, flexible packaging film. In the method a cast sheet is melt extruded from the composition, and, after cooling until it is solid, the cast sheet is stretched to the desired extent of orientation at a temperature which the sheet does not break while being stretched, but below the Tm of the composition. The resulting film then is cooled to at least the crystallization temperature of the lower melting point polypropylene.

Owner:MONTELL TECH CO BV

Highly versatile thermoplastic nucleators

InactiveUS6559211B2Improve mechanical propertiesIncrease temperatureOrganic chemistryOrganic compound preparationPolyolefinCrystallization temperature

Bicyclic nucleator compounds that provide highly versatile nucleation benefits for different polyolefins are provided. Such nucleator compounds provide very high peak crystallization temperatures and significantly reduced crystallization cycle time for certain thermoplastic formulations with or without the presence of other calcium stearate and / or peroxide components within the same type of formulation. Furthermore, such inventive nucleator compounds exhibits very little if any fugitivity from such thermoplastic formulations thereby providing excellent processing characteristics as well as excellent nucleation capabilities for a variety of different thermoplastic resins, independent of the presence of different, potentially necessary, additives (such as calcium stearate). Thermoplastic compositions as well as thermoplastic additive packages comprising such inventive nucleator compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

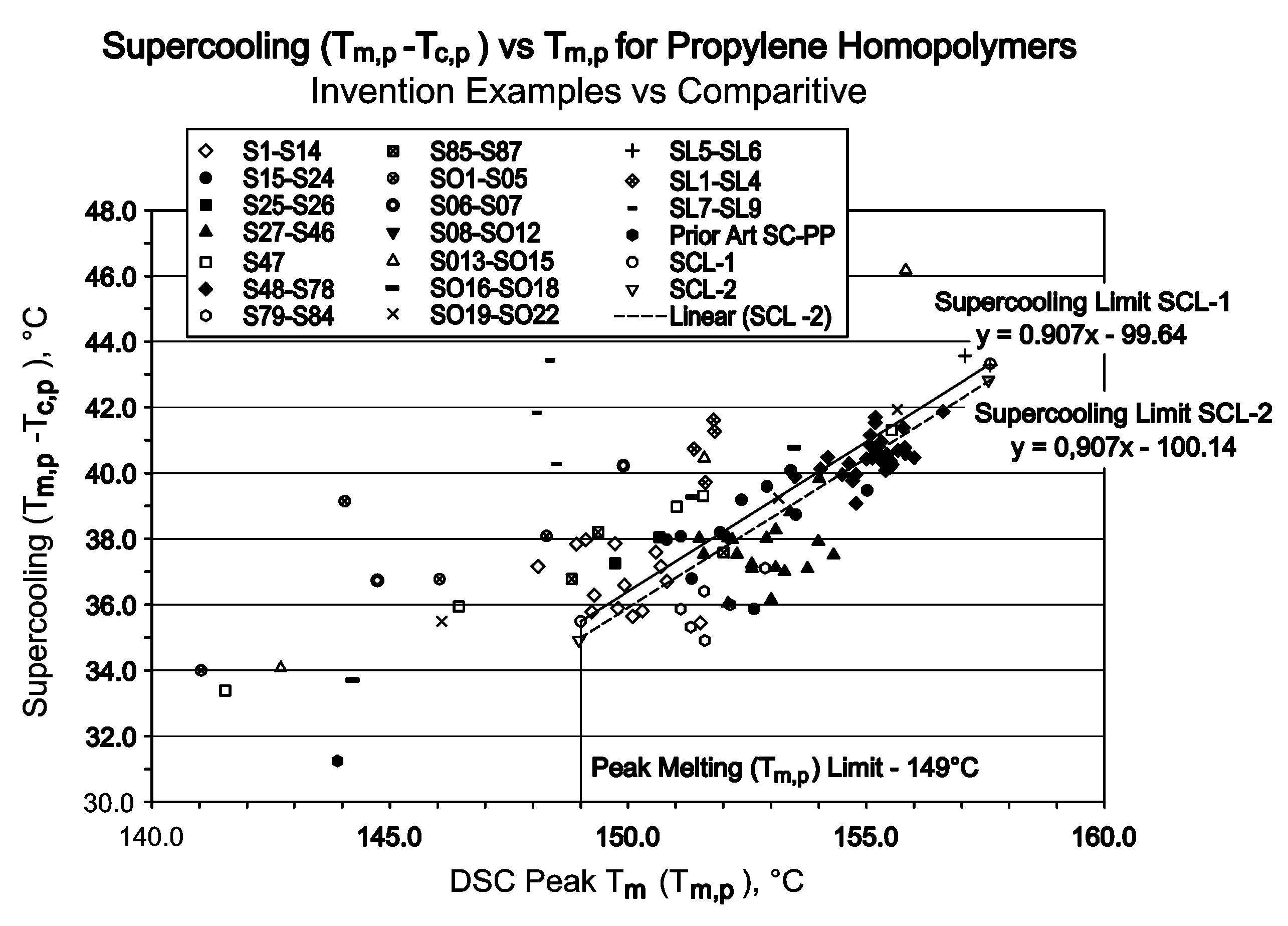

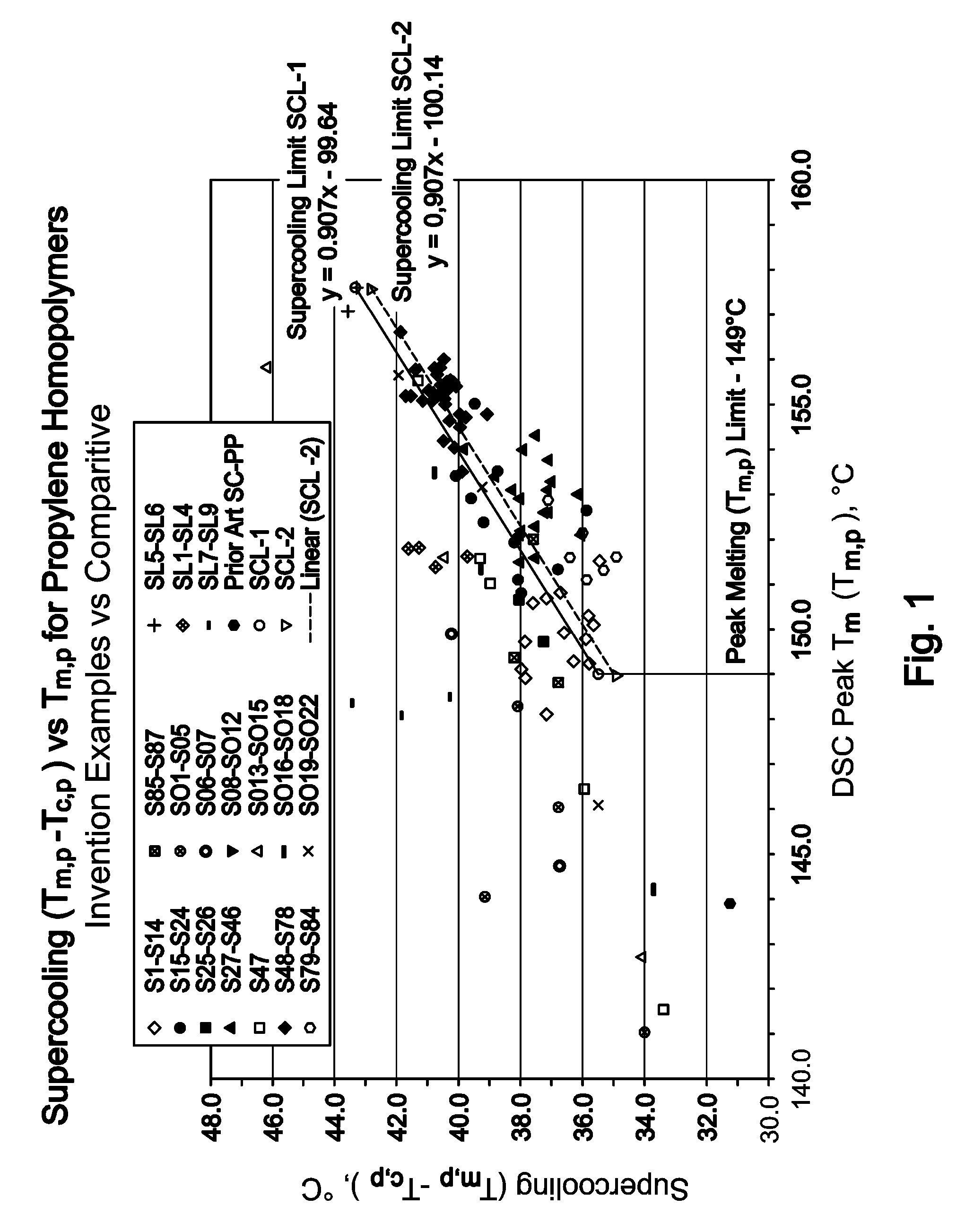

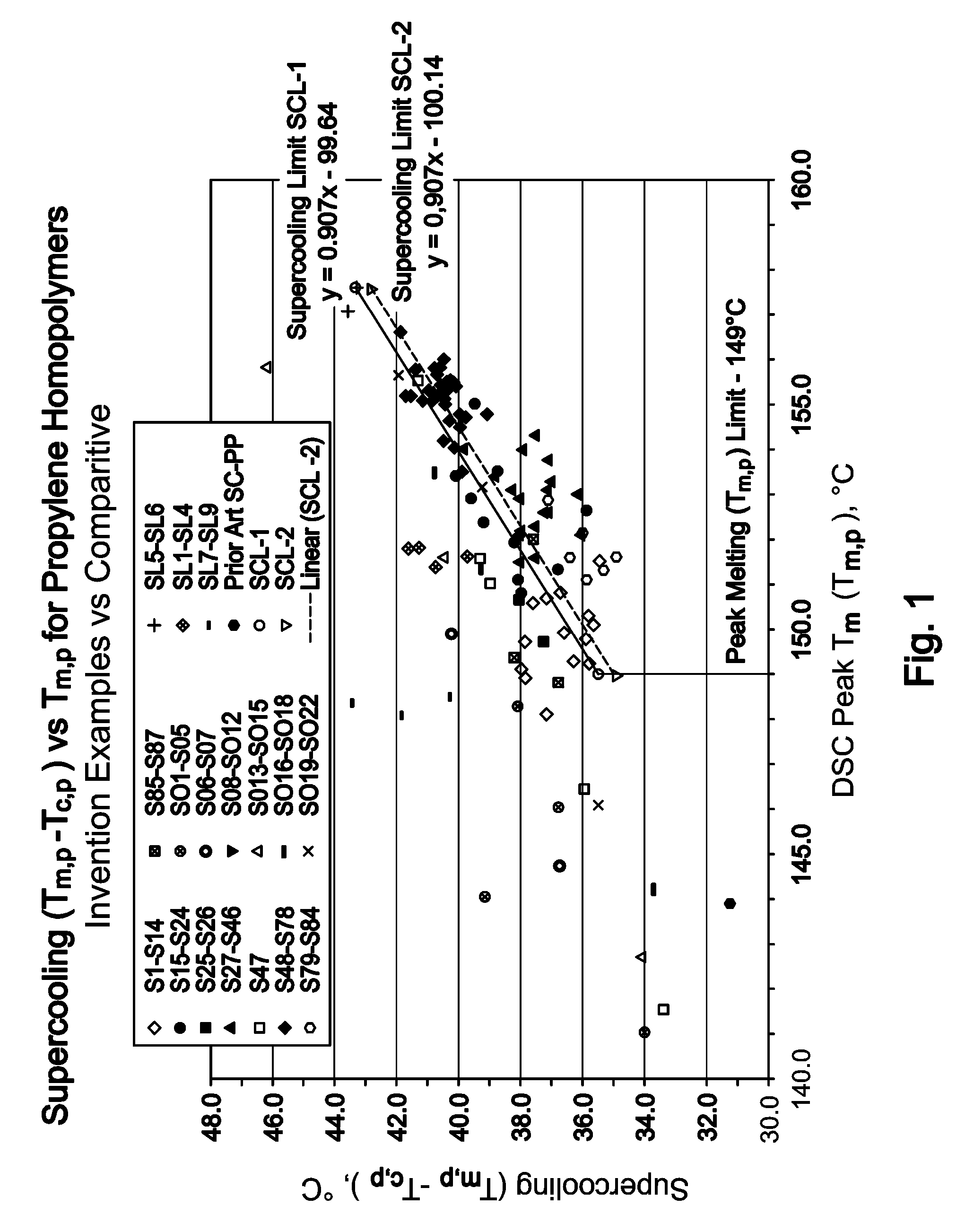

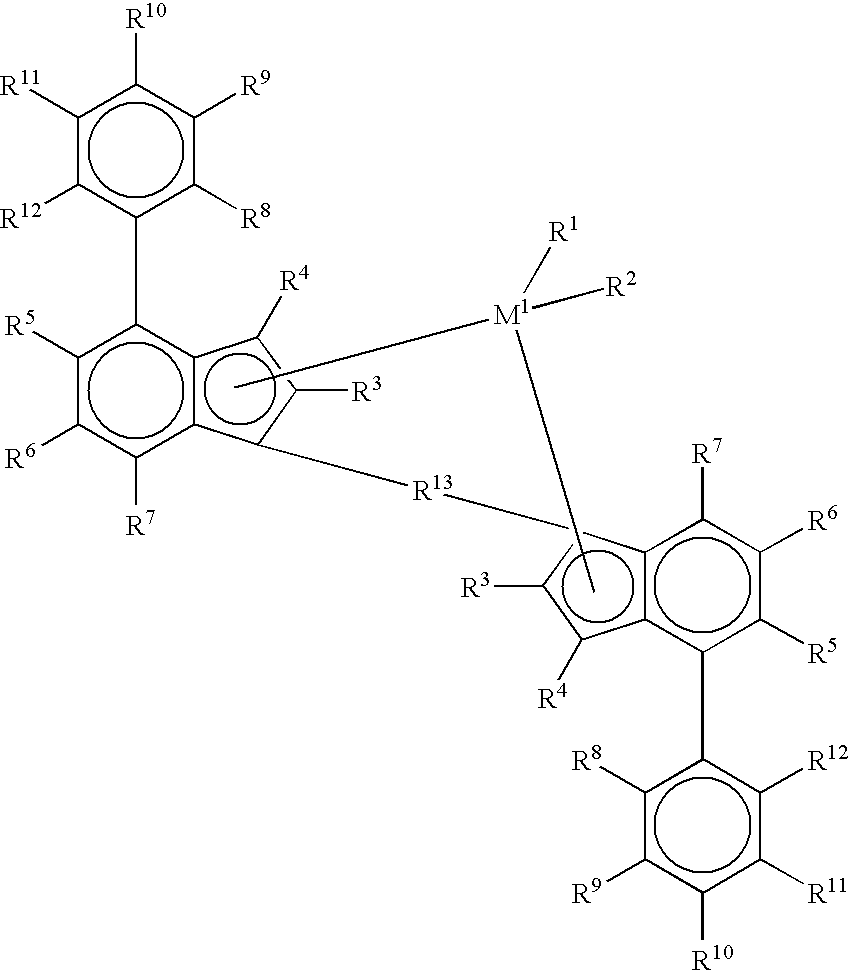

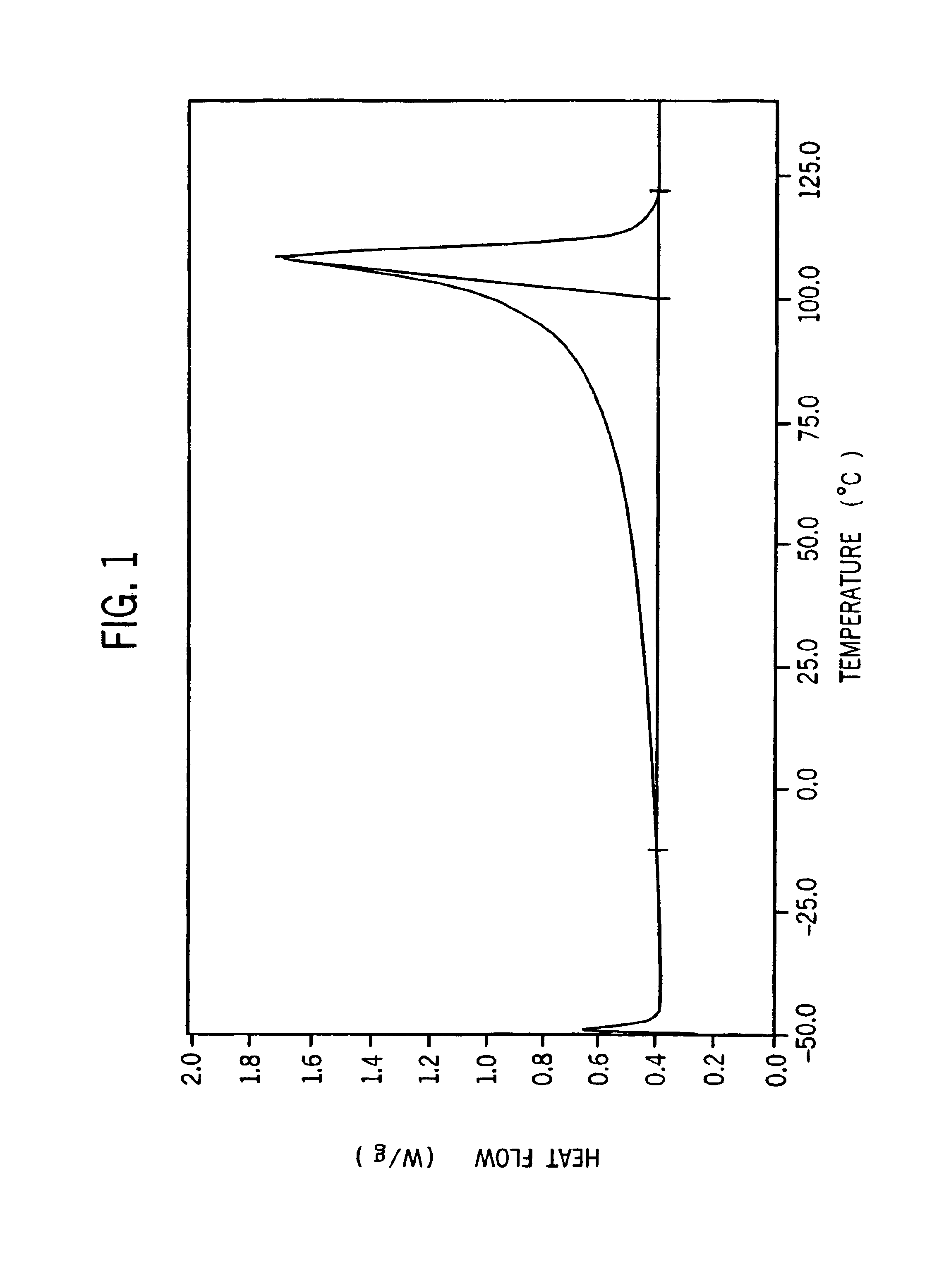

Isotactic Polypropylene Produced From Supercritical Polymerization Process

This invention relates to an isotactic propylene homopolymer having:more than 15 and less than 100 regio defects (sum of 2,1-erythro and 2,1-threo insertions and 3,1-isomerizations) per 10,000 propylene units;an Mw of 35000 g / mol or more;a peak melting temperature of greater than 149° C.;an mmmm pentad fraction of 0.85 or more;a heat of fusion of 80 J / g or more; anda peak melting temperature minus peak crystallization temperature (Tmp−Tcp) of less than or equal to (0.907 times Tmp) minus 99.64 (Tmp−Tcp<(0.907×Tmp)−99.64), as measured in ° C. on the homopolymer having 0 wt % nucleating agent.

Owner:EXXONMOBIL CHEM PAT INC +1

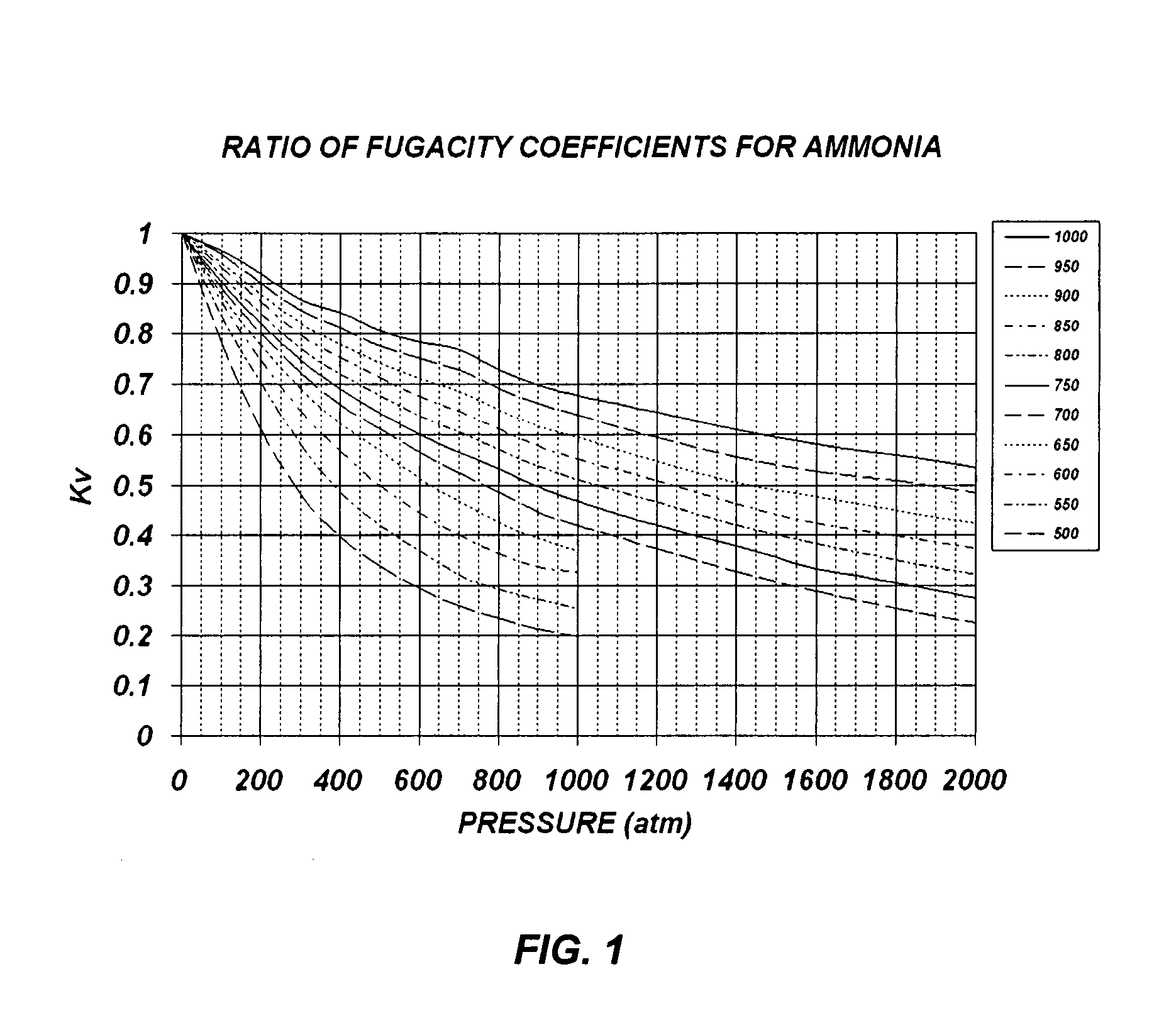

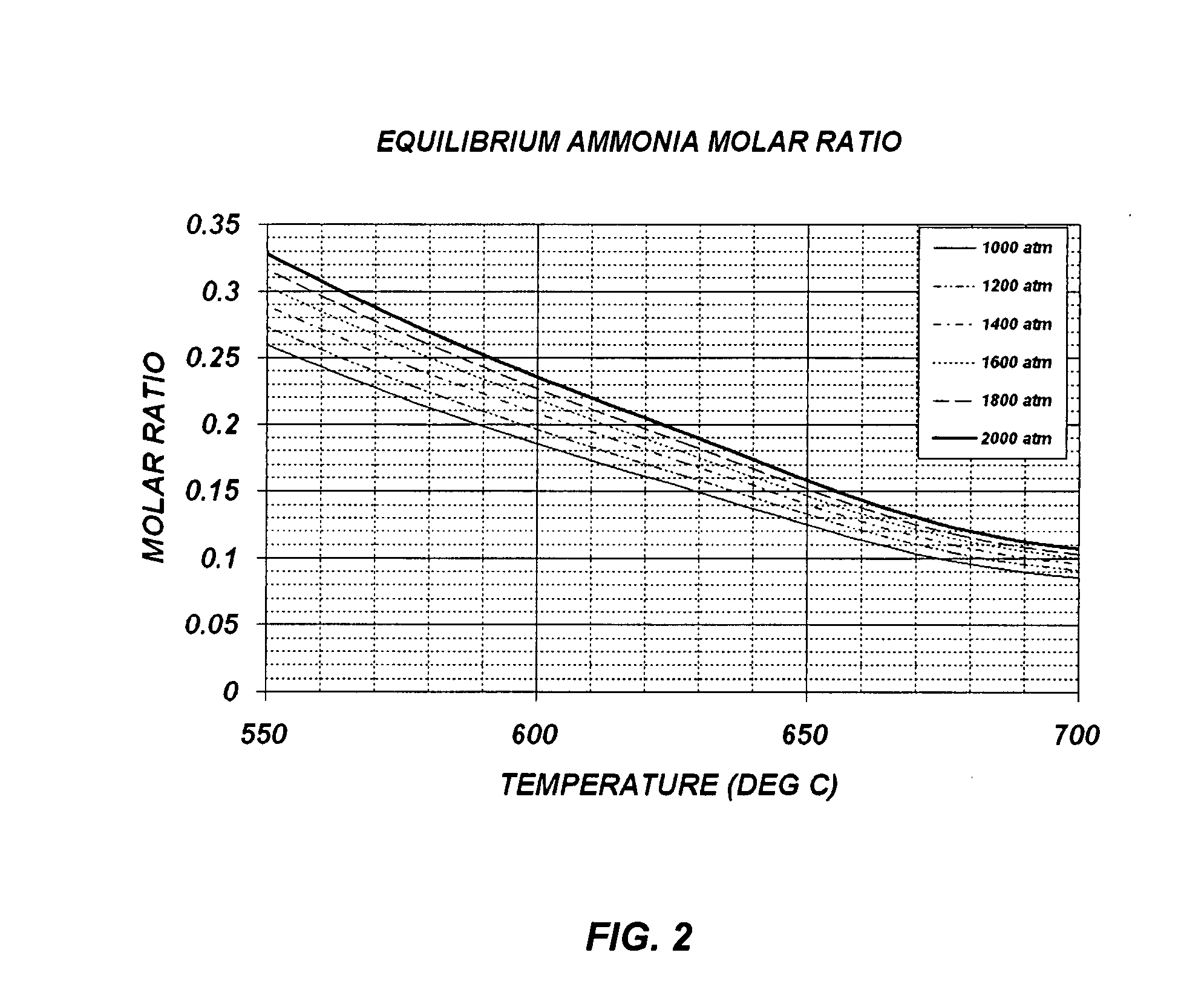

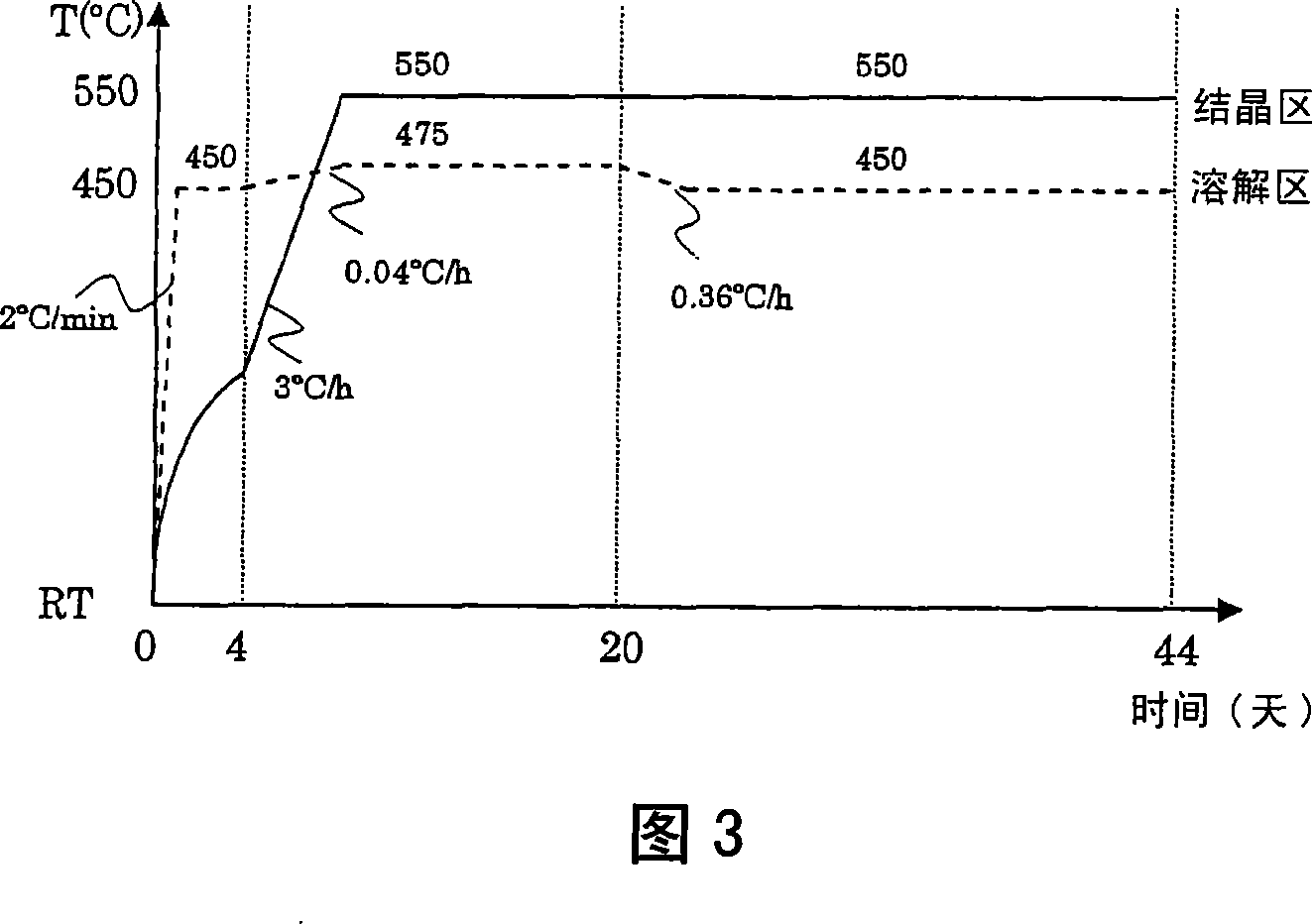

Method for growing group III-nitride crystals in a mixture of supercritical ammonia and nitrogen, and group III-nitride crystals grown thereby

ActiveUS20080102016A1Avoid dissociationHigh speed growthPolycrystalline material growthAluminium compoundsSource materialNitrogen

A method of growing group III-nitride crystals in a mixture of supercritical ammonia and nitrogen, and the group-III crystals grown by this method. The group III-nitride crystal is grown in a reaction vessel in supercritical ammonia using a source material or nutrient that is polycrystalline group III-nitride, amorphous group III-nitride, group-III metal or a mixture of the above, and a seed crystal that is a group-III nitride single crystal. In order to grow high-quality group III-nitride crystals, the crystallization temperature is set at 550° C. or higher. Theoretical calculations show that dissociation of NH3 at this temperature is significant. However, the dissociation of NH3 is avoided by adding extra N2 pressure after filling the reaction vessel with NH3.

Owner:JAPAN SCI & TECH CORP

Semiconductor, semiconductor device, and method for fabricating the same

InactiveUS6997985B1Improve continuityImprove solubilityTransistorFrom gel stateGlass transition pointCobalt

Method of fabricating semiconductor devices such as thin-film transistors by annealing a substantially amorphous silicon film at a temperature either lower than normal crystallization temperature of amorphous silicon or lower than the glass transition point of the substrate so as to crystallize the silicon film. Islands, stripes, lines, or dots of nickel, iron, cobalt, or platinum, silicide, acetate, or nitrate of nickel, iron, cobalt, or platinum, film containing various salts, particles, or clusters containing at least one of nickel, iron, cobalt, and platinum are used as starting materials for crystallization. These materials are formed on or under the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

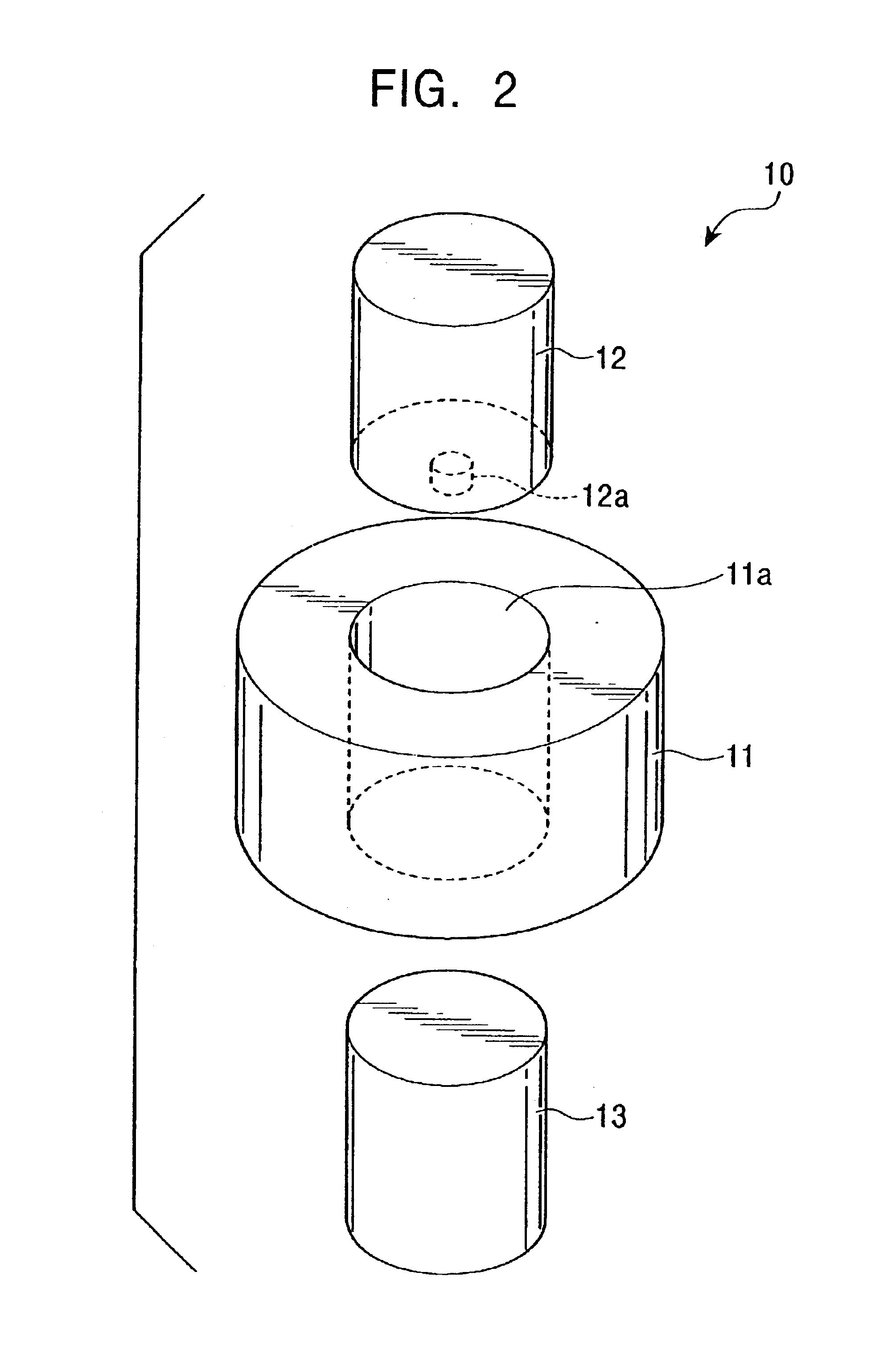

Low-loss magnetic powder core, and switching power supply, active filter, filter, and amplifying device using the same

InactiveUS6897718B2Reduced core lossLess distortionDc-dc conversionInorganic material magnetismMetallurgyAlloy

A magnetic powder core comprises a molded article of a mixture of a glassy alloy powder and an insulating material. The glassy alloy comprises Fe and at least one element selected from Al, P, C, Si, and B, and has a texture primarily composed of an amorphous phase. The glassy alloy exhibits a temperature difference ΔTx, which is represented by the equation ΔTx=Tx−Tg, of at least 20 K in a supercooled liquid, wherein Tx indicates the crystallization temperature and Tg indicates the glass transition temperature. The magnetic core precursor is produced mixing the glassy alloy powder with the insulating material, compacting the mixture to form a magnetic core precursor, and annealing the magnetic core precursor at a temperature in the range between (Tg−170) K and Tg K to relieve the internal stress of the magnetic core precursor. The glassy alloy exhibits low coercive force and low core loss.

Owner:ALPS ALPINE CO LTD

Isotactic polypropylene produced from supercritical polymerization process

This invention relates to an isotactic propylene homopolymer having:more than 15 and less than 100 regio defects (sum of 2,1-erythro and 2,1-threo insertions and 3,1-isomerizations) per 10,000 propylene units;an Mw of 35000 g / mol or more;a peak melting temperature of greater than 149° C.;an mmmm pentad fraction of 0.85 or more;a heat of fusion of 80 J / g or more; anda peak melting temperature minus peak crystallization temperature (Tmp−Tcp) of less than or equal to (0.907 times Tmp) minus 99.64 (Tmp−Tcp<(0.907×Tmp)−99.64), as measured in ° C. on the homopolymer having 0 wt % nucleating agent.

Owner:EXXONMOBIL CHEM PAT INC +1

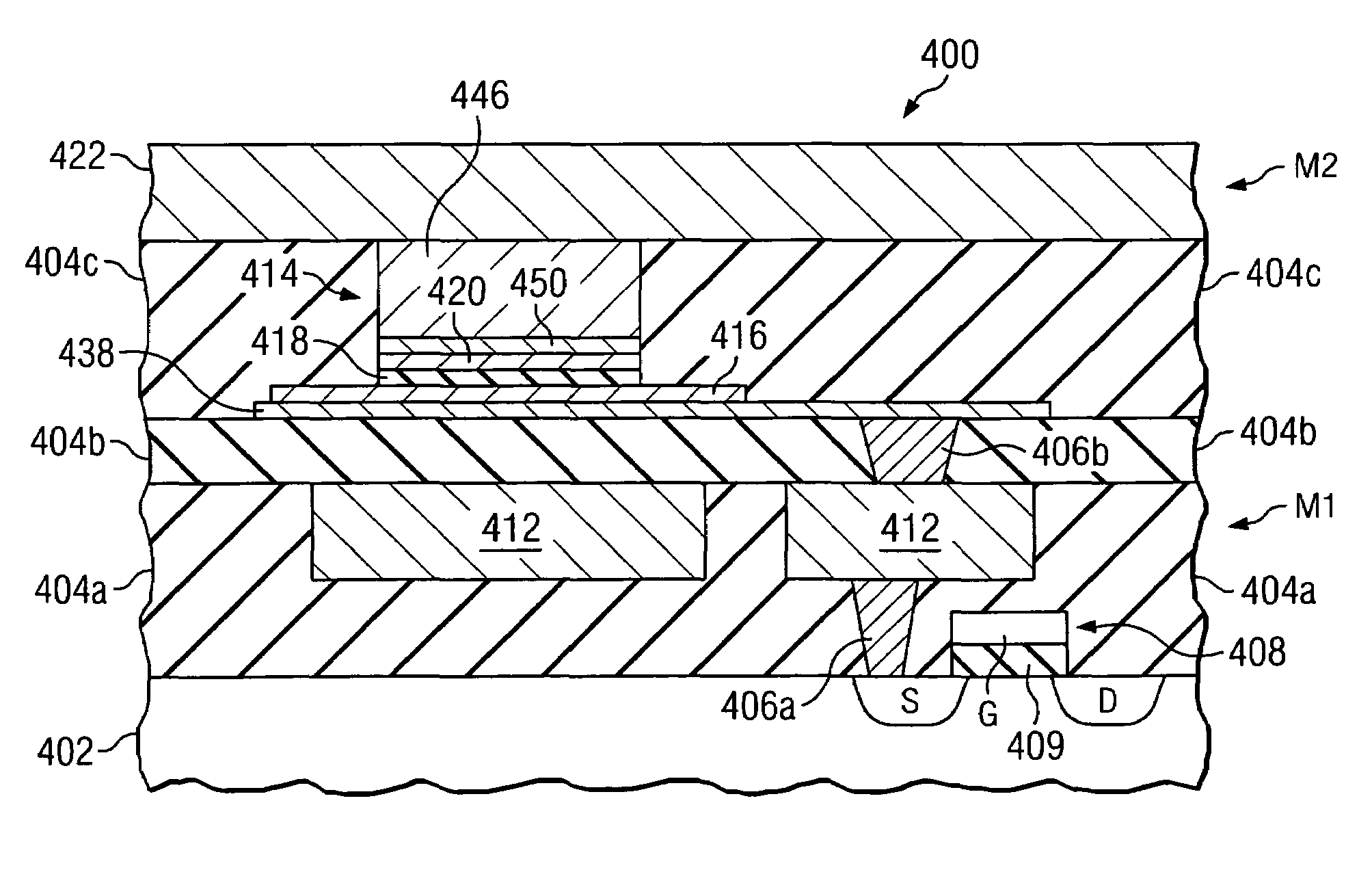

Semiconductor device and method for manufacturing the same

InactiveUS20050020006A1Small amount of resistanceImprove mobilityStatic indicating devicesSolid-state devicesIridiumManganese

A method for manufacturing a semiconductor device such as a thin film transistor using a crystal silicon film is provided. The crystal silicon film is obtained by selectively forming films, particles or clusters containing nickel, iron, cobalt, ruthenium, rhodium, paradium, osmium, iridium, platinum, scandium, titanium, vanadium, chrome, manganese, copper, zinc, gold, silver or silicide thereof in a form of island, line, stripe, dot or film on or under an amorphous silicon film and using them as a starting point, by advancing its crystallization by annealing at a temperature lower than a normal crystallization temperature of an amorphous silicon. A transistor whose leak current is low and a transistor in which a mobility is high are obtained in the same time in structuring a dynamic circuit having a thin film transistor by selectively forming a cover film on a semiconductor layer which is to become an active layer of the transistor and by thermally crystallizing it thereafter.

Owner:SEMICON ENERGY LAB CO LTD

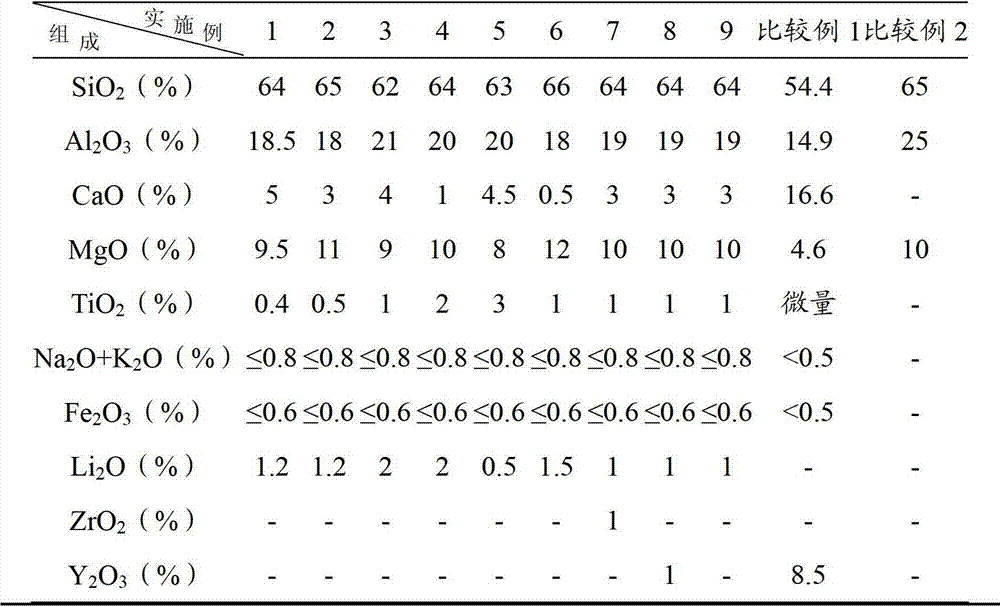

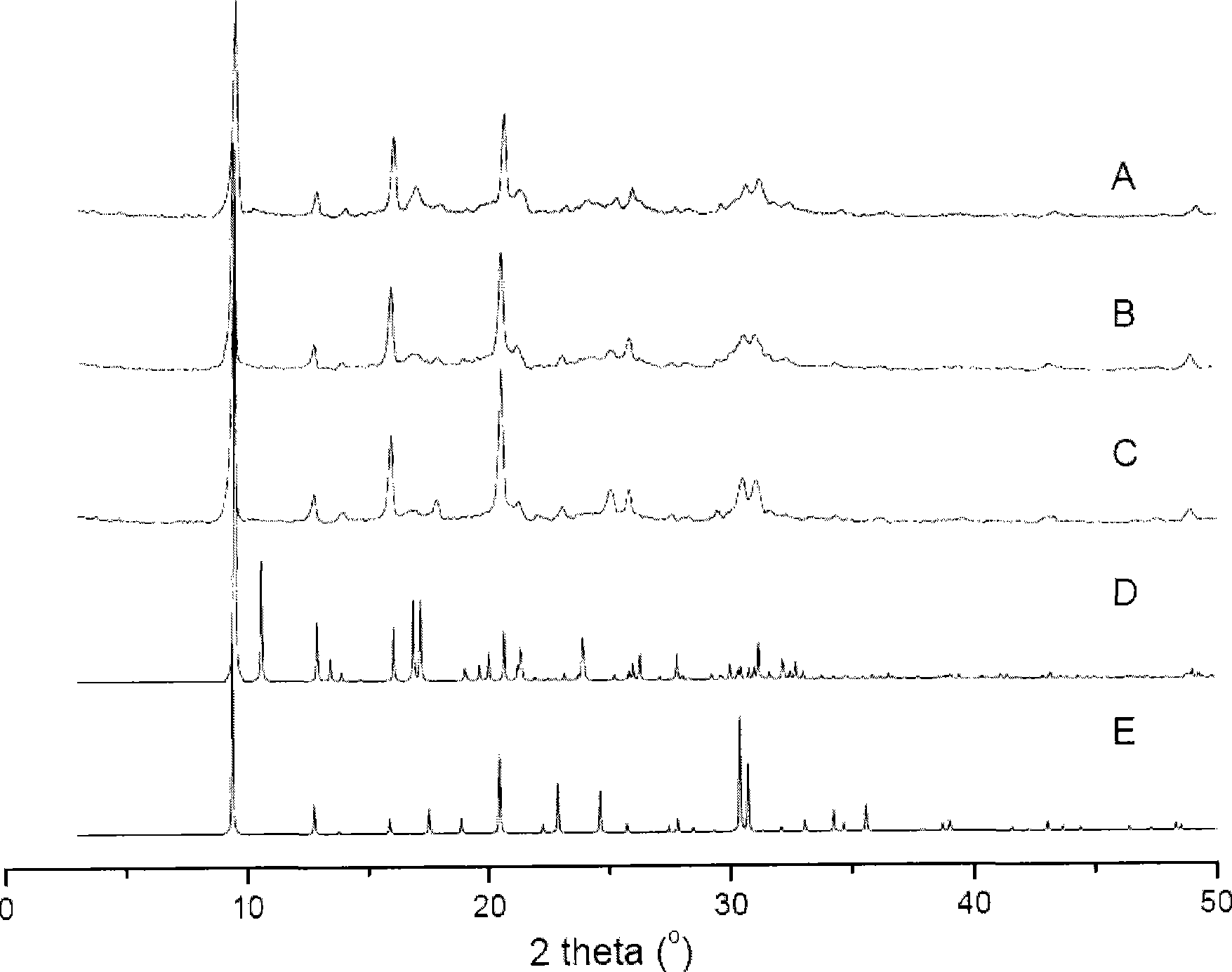

Glass fiber

InactiveCN103086605AHigh tensile modulusLow molding temperatureGlass fiberCrystallization temperature

The invention provides a glass fiber which comprises 62-66 wt% of SiO2, 18-21 wt% of Al2O3, 0.5-5 wt% of CaO, 8-12 wt% of MgO, 0.5-2 wt% of Li2O, 0.4-3 wt% of TiO2, 0.1-0.6 wt% of Fe2O3 and 0.1-0.8 wt% of Na2O and K2O. The total mass content of the Na2O, K2O and Li2O is 0.5-3 wt%. Therefore, the glass fiber provided by the invention has low forming temperature and upper limit crystallization temperature on the premise of having high tensile modulus, so that the glass fiber is applicable to large-scale industrial production.

Owner:CHONGQING POLYCOMP INT

Low-temperature metal-induced crystallization of silicon-germanium films

Owner:SANDISK TECH LLC

Nitride single crystal seeded growth in supercritical ammonia with alkali metal ions

Composite compounds of tin and lithium, silicon and lithium, or tin, silicon, and lithium having tin and silicon nano-dispersed in a lithium-containing matrix may be used as electrode materials and particularly anode materials for use with rechargeable batteries. Methods of making the composite compounds include the oxidation of alloys, the reaction of stabilized lithium metal powder with tin and silicon oxides, and the reaction of inorganic salts of lithium with tin and silicon containing compounds.

Owner:AMMONO SP Z O O (PL) +1

Co-additive compositions and methods for applying co-additive compositions into nucleated polymer compounds

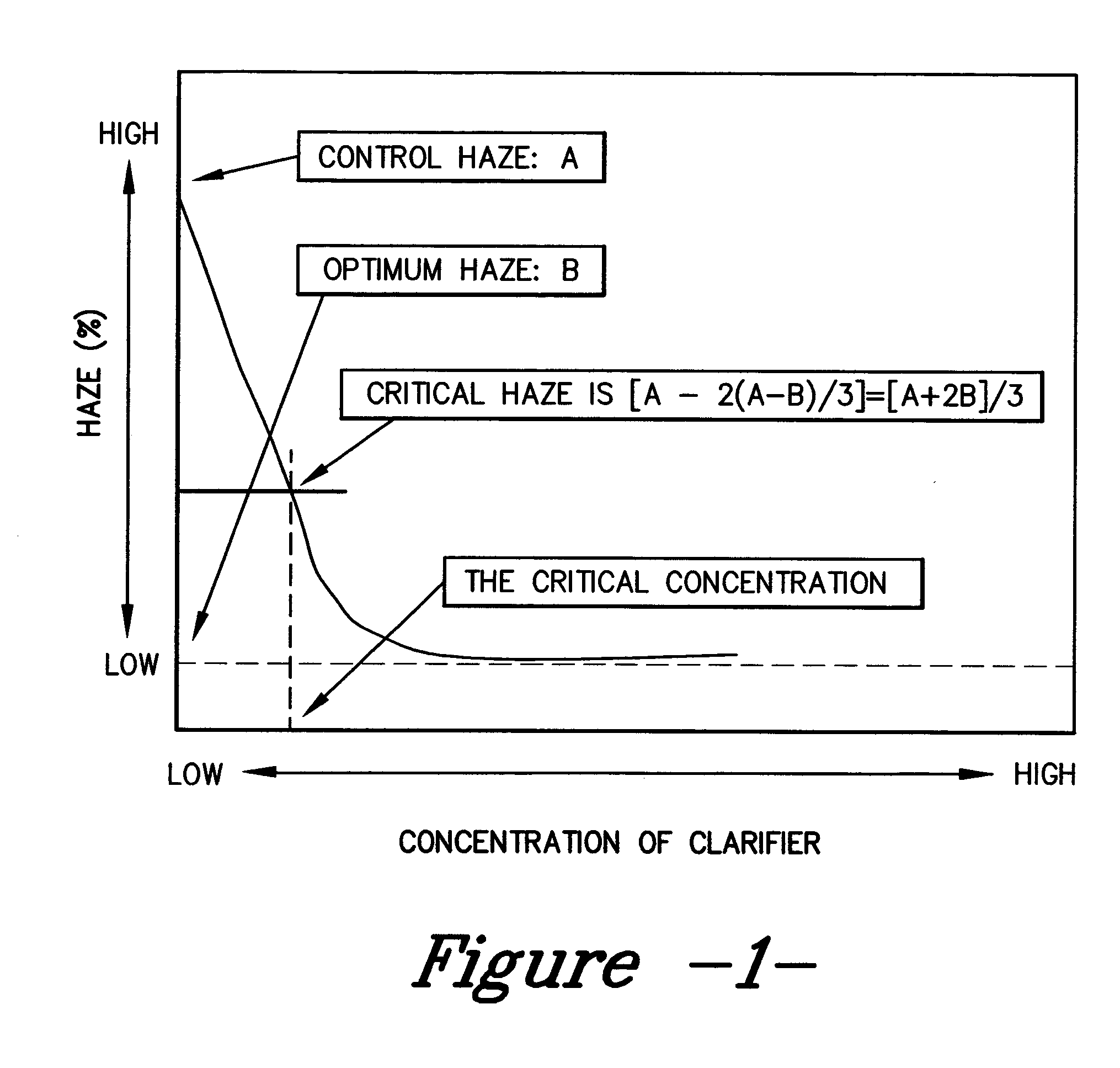

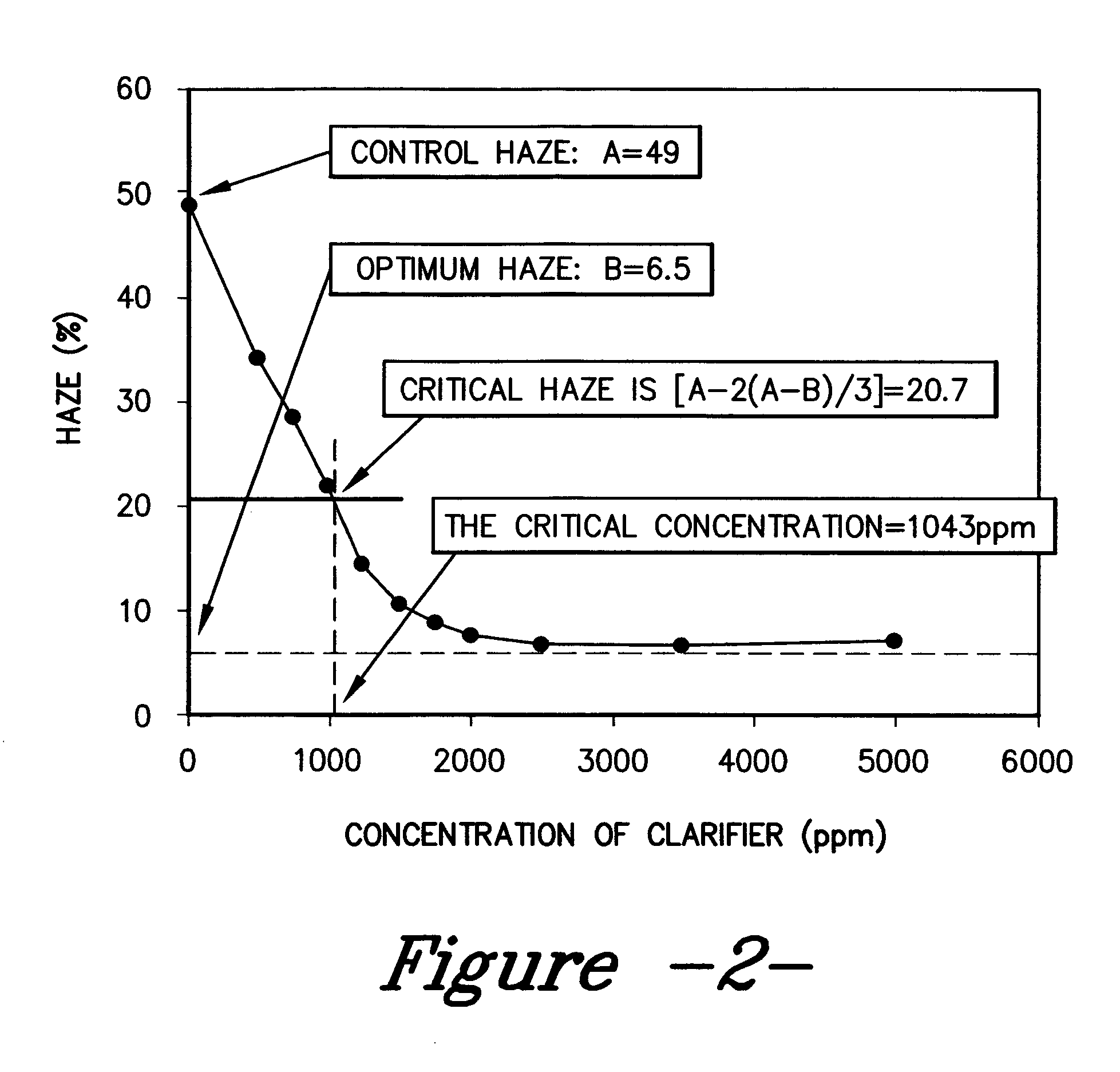

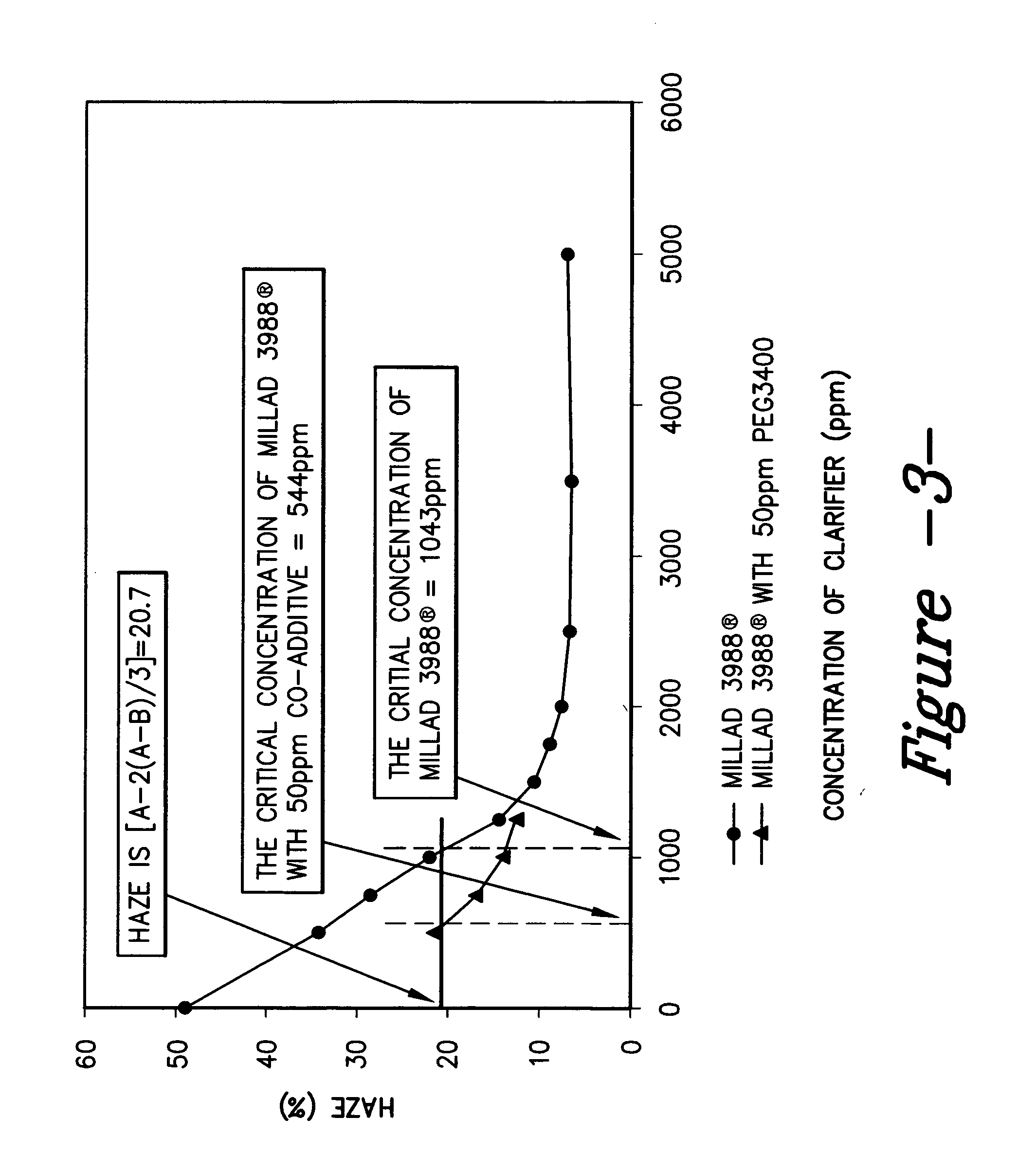

ActiveUS20060173108A1Improving haze performanceReducing critical concentrationMixingCLARITYPlastic materials

It is possible to improve significantly the optical performance of diacetal or DBS-based nucleating or clarifying agents using a co-additive. Haze is a measure of the lack of clarity in a thermoplastic or plastic material. A low level of haze is usually quite desirable, and nucleating / clarifying agents are designed to reduce the degree of haze in a plastic or thermoplastic material. A co-additive may be used in connection with a nucleating / clarifying agents in a polymer or copolymer to achieve even greater results in terms of improved clarity (reduced haze), or in terms of a higher crystallization temperature (Tc) of the polymer. A method for reducing haze in polymer articles using a co-additive composition in addition to nucleating and clarifying agents is disclosed.

Owner:MILLIKEN & CO

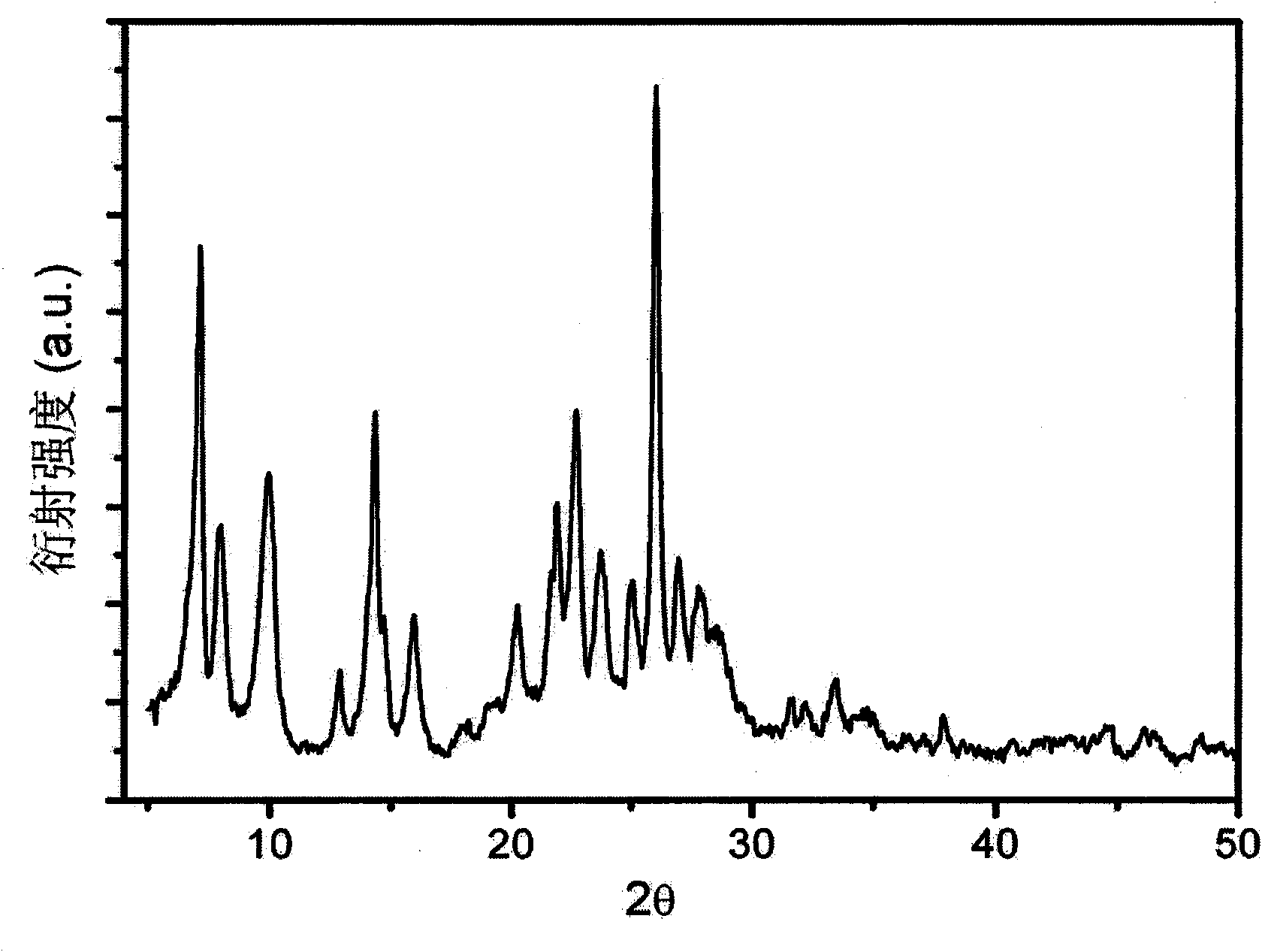

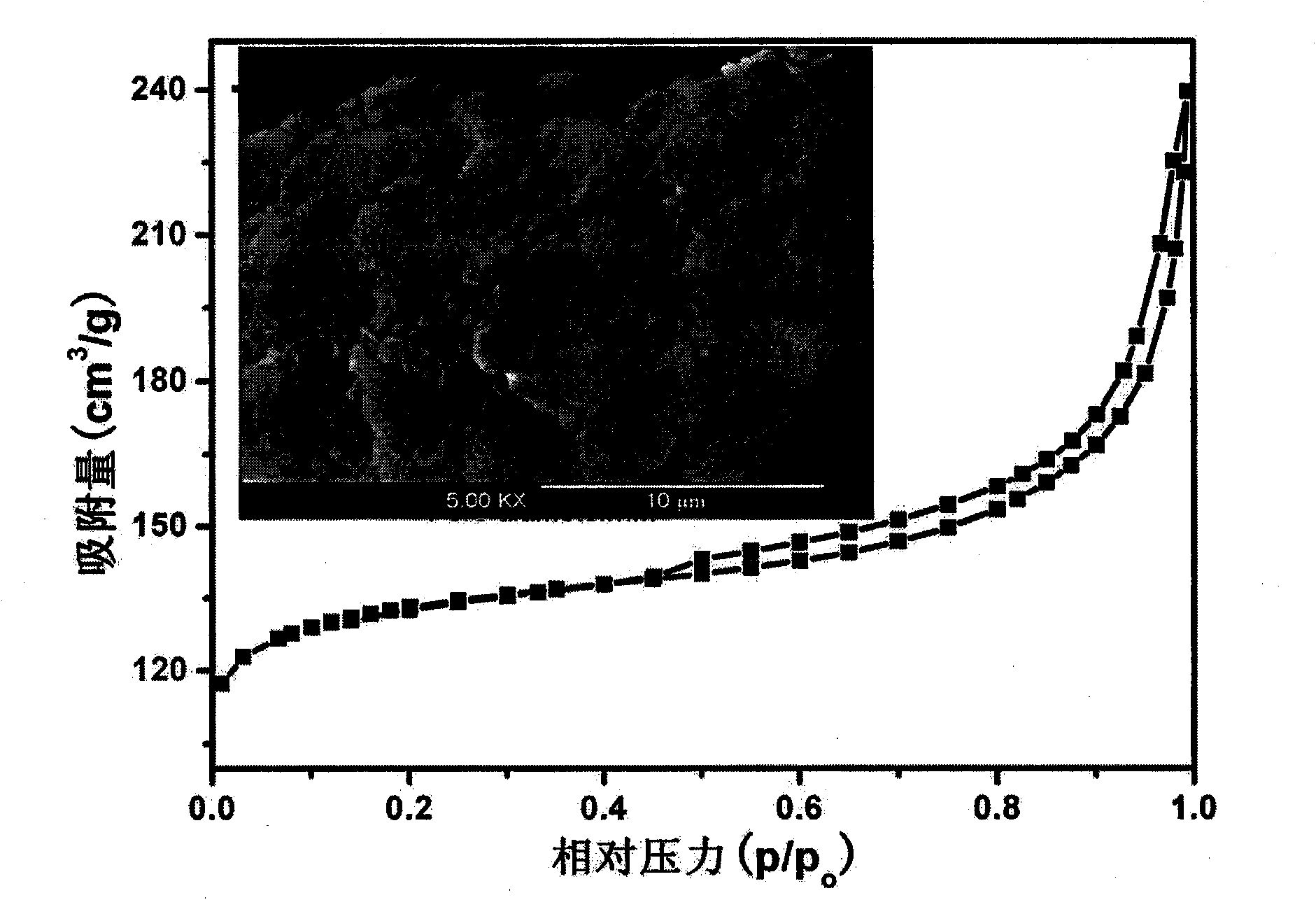

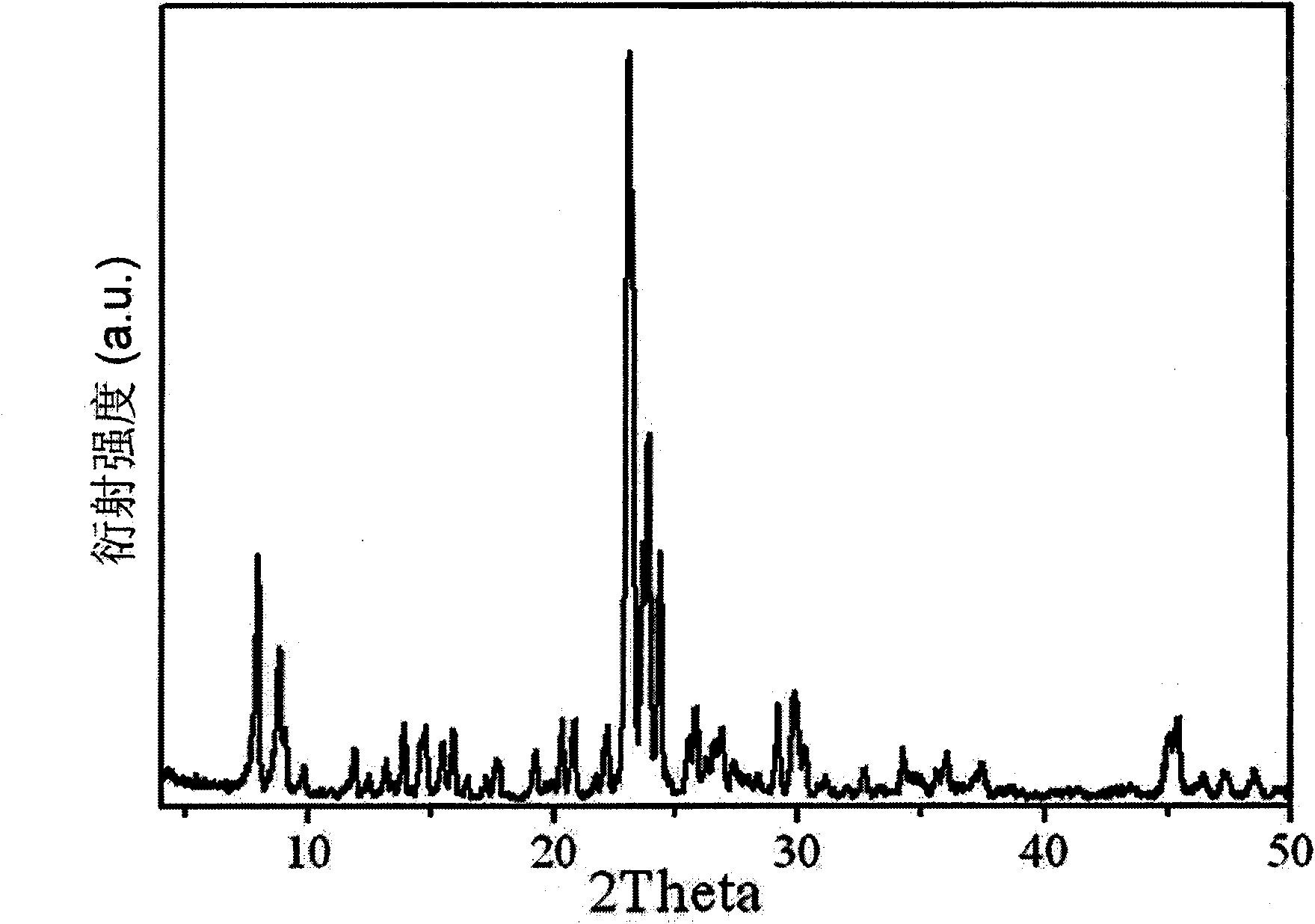

AEI/CHA eutectic molecular sieve containing triethylamine and synthetic method thereof

InactiveCN101450806AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveChemical composition

The invention discloses an AEI / CHA eutectic molecule sieve containing triethylamine. An anhydrous chemical composition of the AEI / CHA eutectic molecule sieve is expressed as mR.(Six.Aly.Pz)O2, wherein x, y and z are molar fractions of Si, Al and P respectively; the x is between 0.001 and 0.98; the y is between 0.01 and 0.6; the z is between 0.01 and 0.6, x+y+z is equal to 1; the R is a template agent, and the m is a mole number of the R; and the value of the m is between 0.02 and 0.6. A preparation method for the AEI / CHA eutectic molecule sieve comprises the following steps: a) according to the mol ratio of oxides of various components, stirring and mixing evenly a silicon source, an aluminum resource, a phosphorus source, the template agent, and water are to obtain an initial gel mixture; and b) transferring the initial gel mixture into a stainless steel synthesis kettle to be sealed, then heating the kettle to a crystallization temperature of between 160 and 250 DEG C, and performing crystallization at constant temperature for 1 to 120 hours under the self-generated pressure, and separating a solid product, washing the solid product to be neutral, and drying the solid product to obtain the AEI / CHA eutectic molecule sieve. The molecule sieve can be used as a catalyst for an acid catalytic reaction after the template agent is removed through the baking.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS6562890B2Improve compatibilityExcellent high peak crystallization temperatureChemical/physical processesScavengerPolyolefin

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

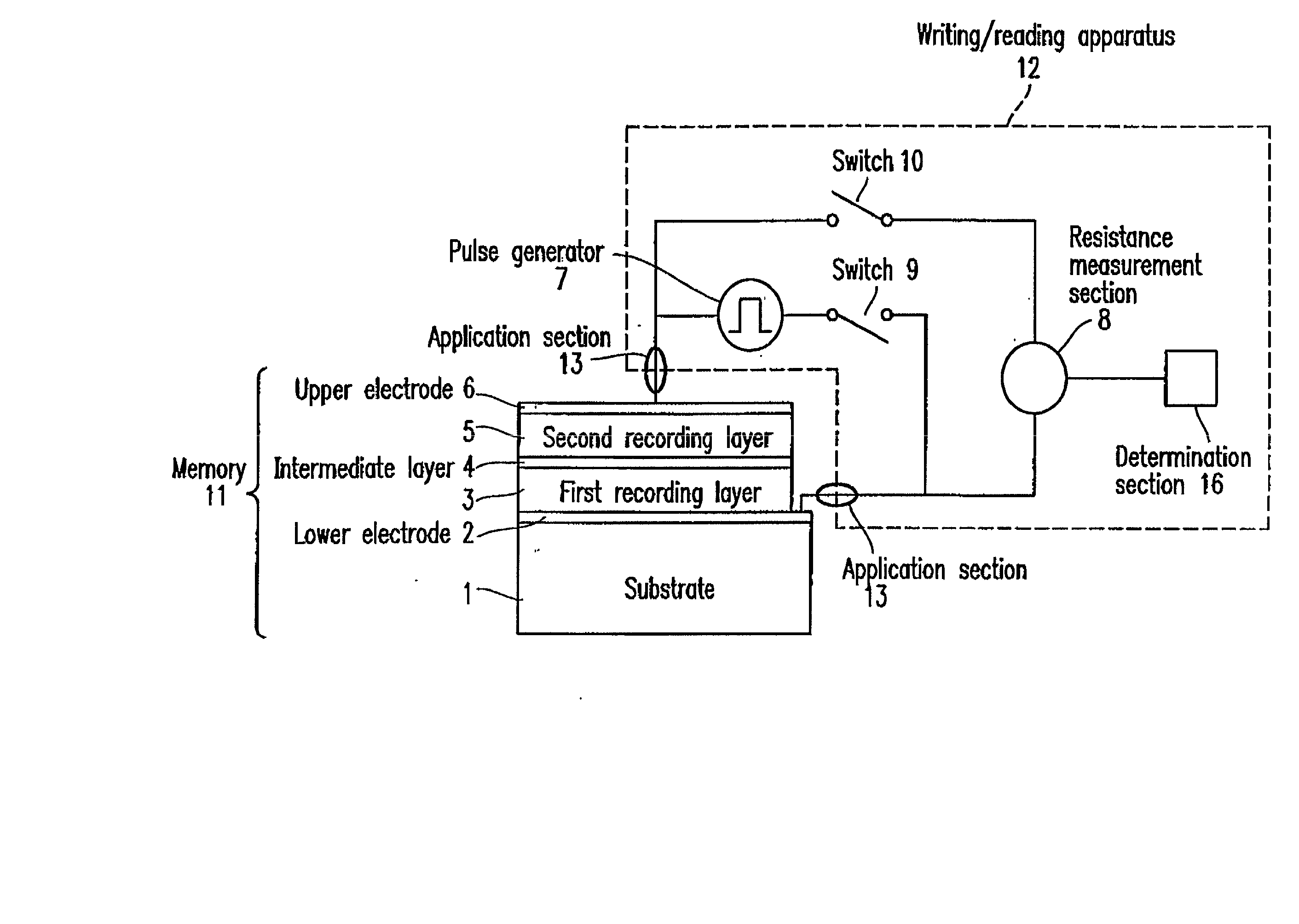

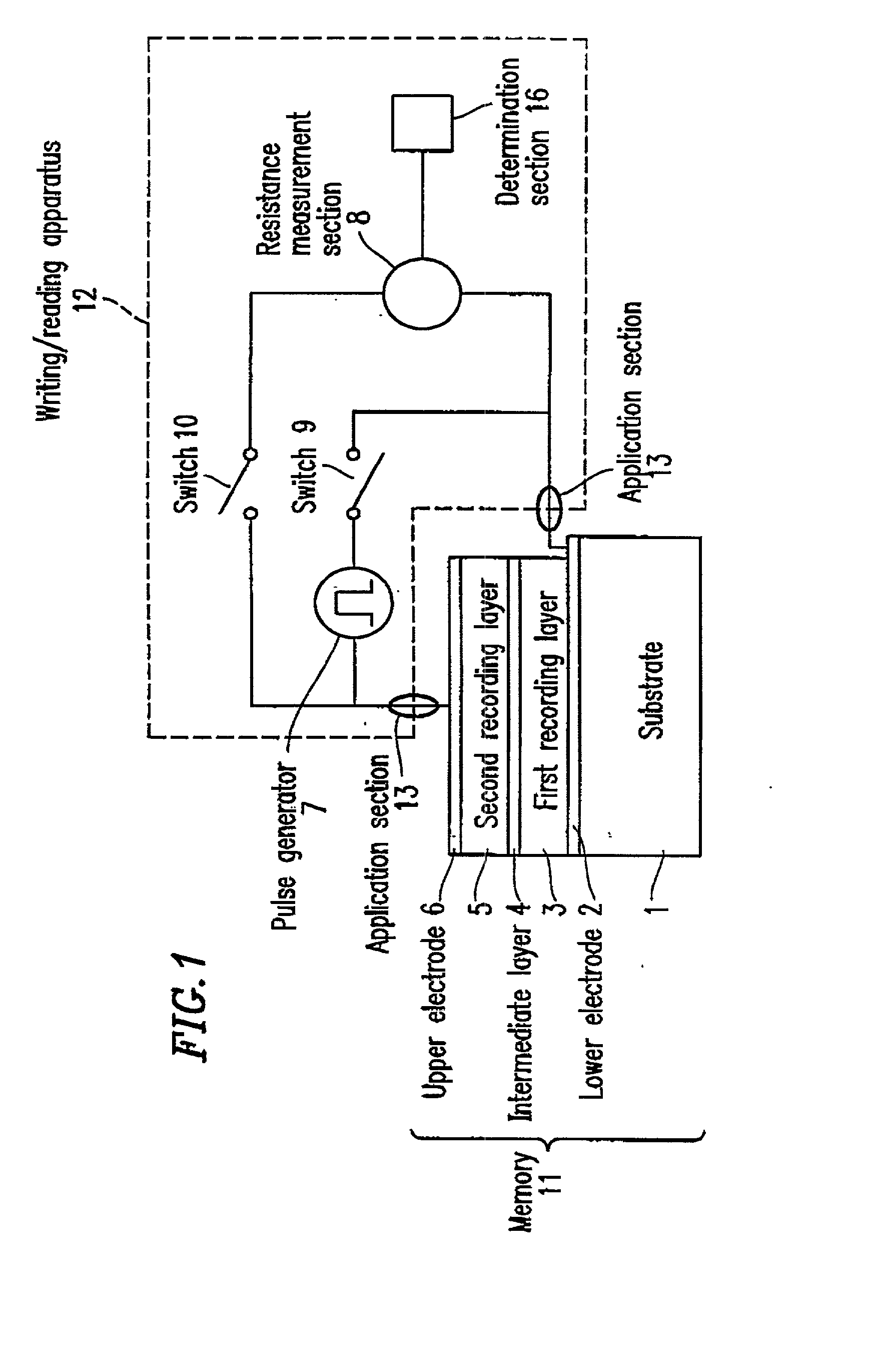

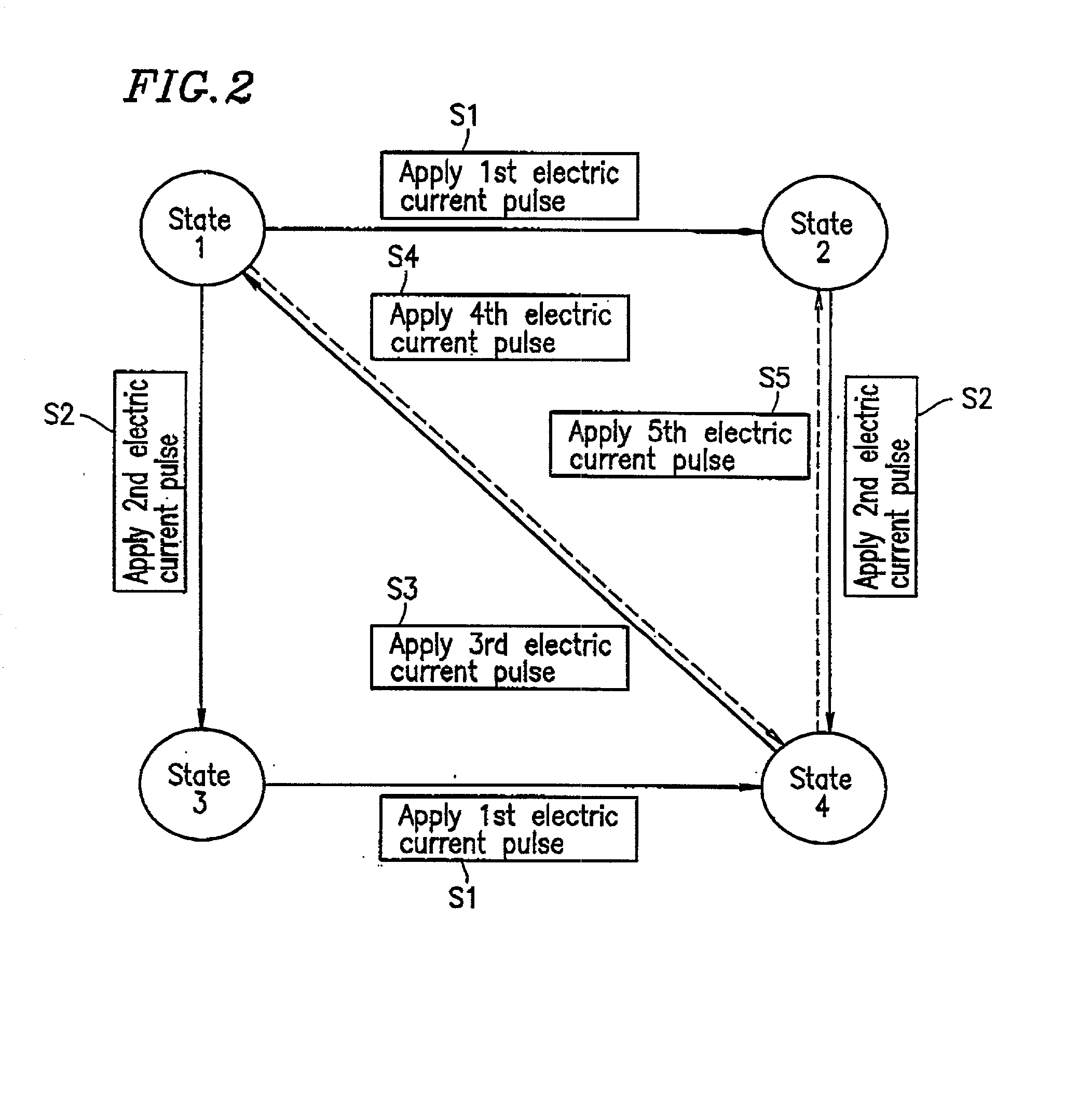

Memory, writing apparatus, reading apparatus, writing method, and reading method

InactiveUS20020131309A1Easy to implementElectrical apparatusRead-only memoriesAmorphous phaseCrystallization temperature

A memory includes: first and second recording layers for recording information by utilizing a reversible phase change between a crystalline phase and an amorphous phase which occurs due to increases in temperature caused by application of an electric current pulse. The crystallization temperatures of the first and second recording layers, Tx1 and Tx2 have the relationship Tx1<Tx2. The crystallization times of the first and second recording layers, tx1 and tx2, have the relationship tx1>tx2. Ra1+Ra2, Ra1+Rc2, Rc1+Ra2, and Rc1+Rc2are different from one another where the resistance value of the first recording layer in the amorphous phase is Ra1: the:resistance value of the first recording layer in the crystalline phase is Rc1, the resistance value of the second recording layer in the amorphous phase is Ra2 and the resistance value of the second recording layer In the crystalline phase is Rc2.

Owner:PANASONIC CORP

Method for improving catalytic property of methane aromatization catalyst

InactiveCN101618337AImprove catalytic performanceImprove bindingMolecular sieve catalystsHydrocarbonsLevel structureActive component

The invention relates to a method for improving the catalytic property of methane aromatization catalyst, belonging to the technical field of molecular sieve catalysis. The invention is characterized in that on the condition of no-second template, the crystal growth of zeolite molecular sieve is controlled by reasonablely controlling zeolite molecular sieve synthesis conditions such as synthesis formulation, charging sequence, ageing time, crystallization temperature, crystallization time and the like, small molecular sieve crystal is used for assembly and intergrowth to form MCM-22 and ZSM-5 molecular sieve assembly with multi-stage pore path structure, Mo or Re used can be adopted as active component to perform loading and modification to the prepared molecular sieve assembly, and the invention provides Mo-based MCM-22 and ZSM-5 molecular sieve assembly catalysts and an application thereof in methane non-oxidative aromatization reaction. The effects and the benefits of the invention is that the operation is simple, the cost is low and in methane non-oxidative aromatization reaction, the multi level structure assembly catalyst prepared by the method of the invention has better catalytic performance compared with the traditional catalyst.

Owner:DALIAN UNIV OF TECH

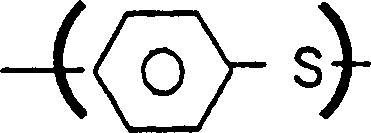

Polyphenylene sulfide resin compositions

A polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 12 [mu]m or lager and has a crystallization temperature during cooling of 205 DEG C or lower. Also provided is a polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 10 to 12 [mu]m, excluding 12 [mu]m, has a crystallization temperature during cooling of 205 DEG C or lower and a chloroform-extractable content of 0.5 wt.% or lower, and gives a 2 mm-thick molding which has a transmittance of 15% or higher for laser light having a wavelength of 940 nm and a heat distortion temperature of 230 DEG C or higher under a load of 1.82 MPa.

Owner:TORAY IND INC

Ethylene interpolymer polymerizations

InactiveUS6916883B2Raise the crystallization temperatureImprove propertiesPolymer scienceCrystallization temperature

Owner:DOW GLOBAL TECH LLC

Highly convertible endolumenal prostheses and methods of manufacture

Endolumenal prostheses that readily and extensively convert from a delivery configuration to a deployed configuration are disclosed. Endolumenal prostheses may be fabricated from one or more shape memory polymers, a high modulus elastomer, a polymer that is both elastomeric and exhibits shape memory behavior, a hydrogel, or some combination thereof. Polymers used to fabricate the prostheses are selectively synthesized to exhibit desired characteristics such as crystallinity, strain fixity rate, strain recovery rate, elasticity, tensile strength, mechanical strength, cross-linking density, extent physical cross-linking, extent of covalent cross-linking, extent of interpenetrating networks, rate of erosion, heat of fusion, crystallization temperature, and acidity during erosion. The endolumenal prostheses convert to the deployed configuration following delivery to a treatment site, upon exposure to an initiator either present within the body naturally or introduced into the body.

Owner:SYNECOR LLC

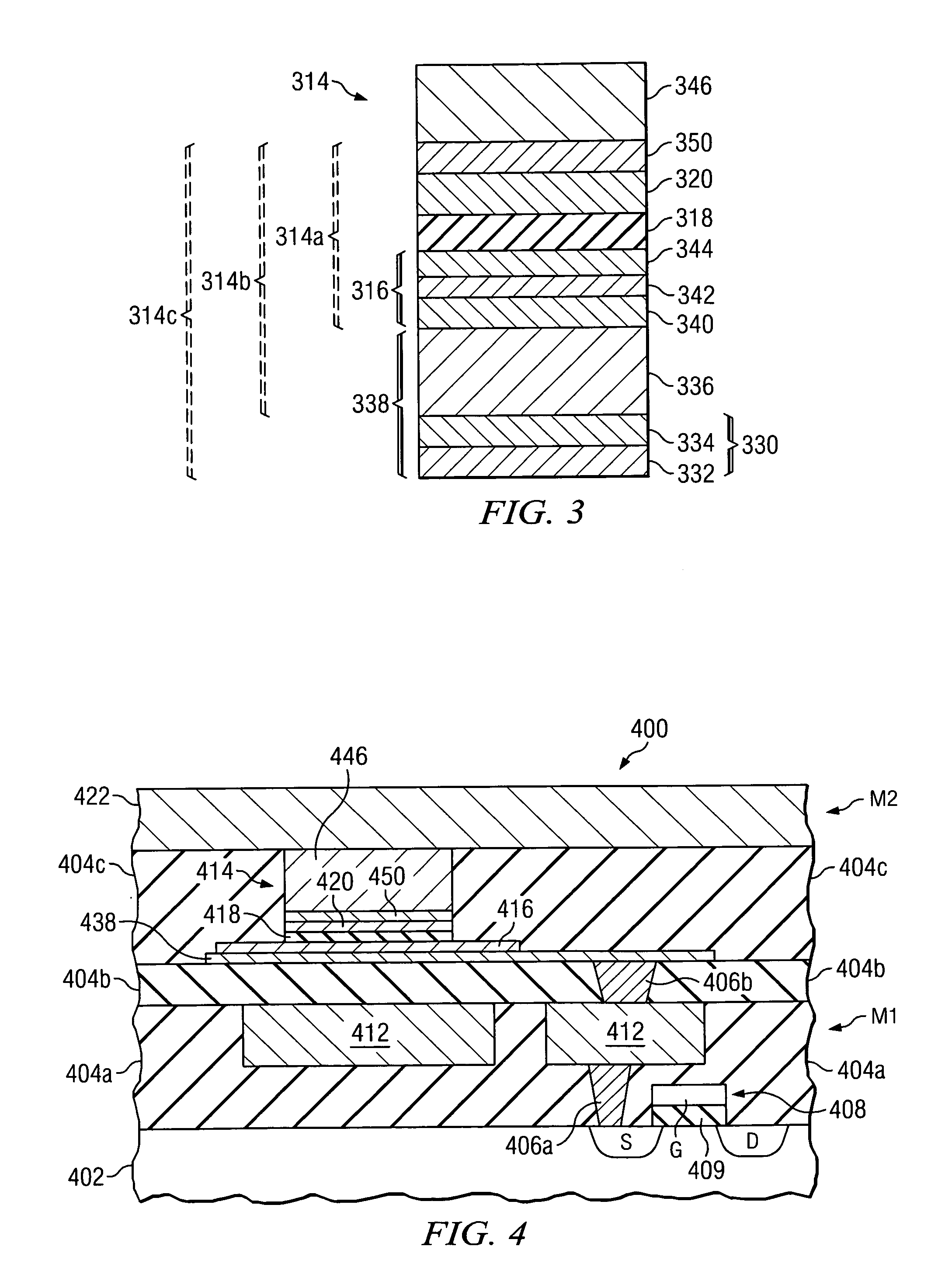

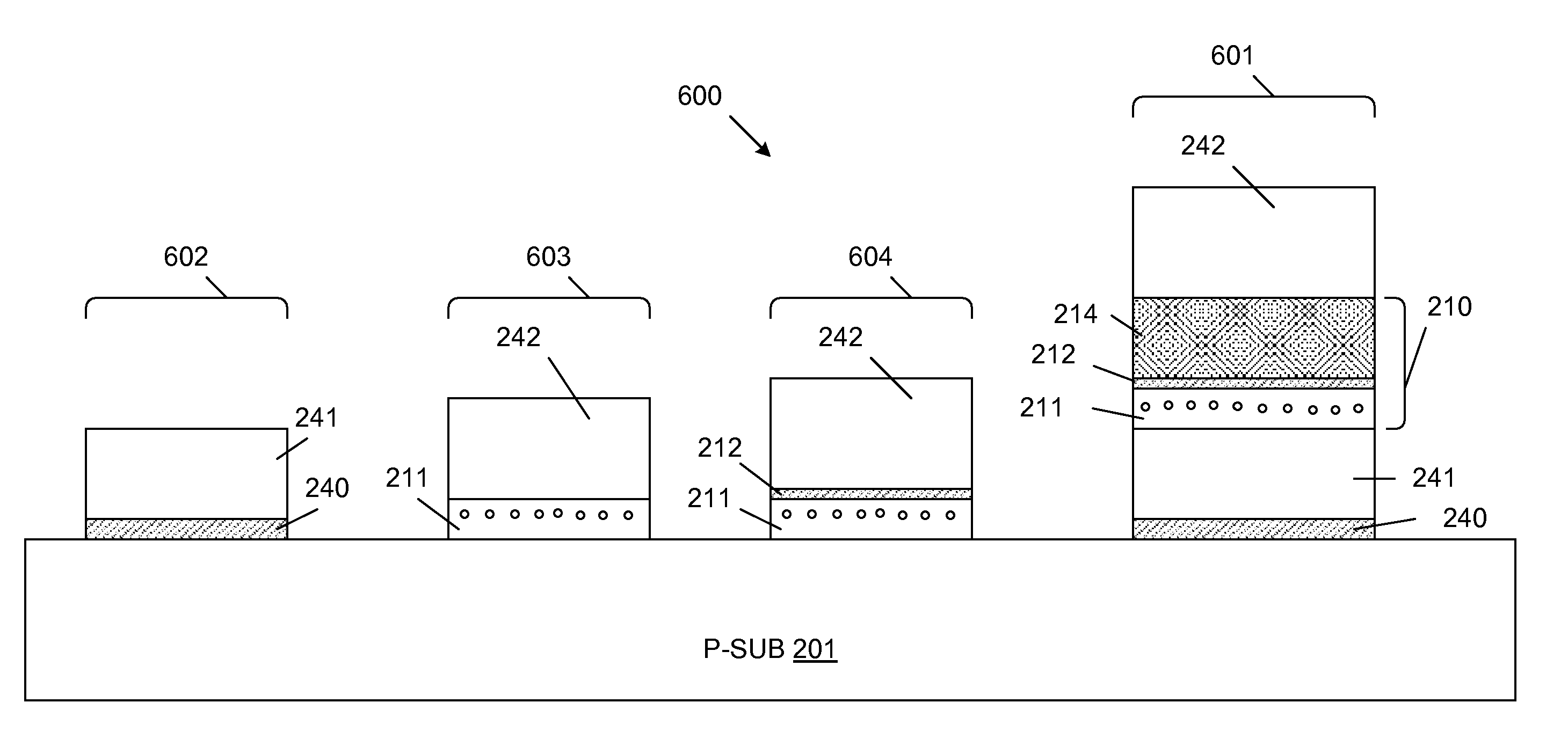

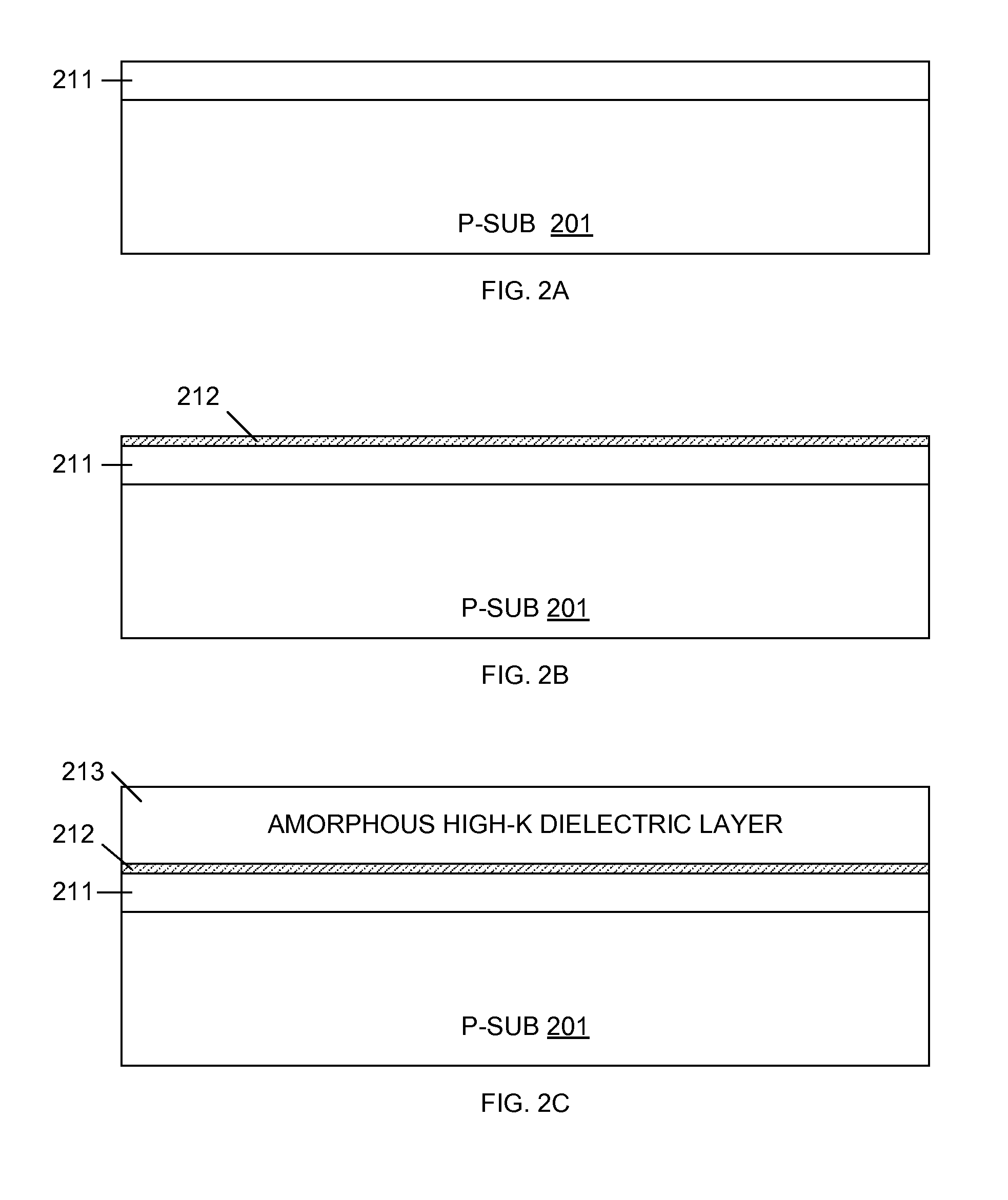

High-K Dielectric Stack And Method Of Fabricating Same

ActiveUS20090181530A1Improve reliabilityIncrease capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenCrystallization temperature

A method for improving the reliability of a high-k dielectric layer or a high-k dielectric stack by forming an amorphous high-k dielectric layer over an insulating layer, doping the amorphous high-k dielectric layer with nitrogen atoms, and subsequently heating the resulting structure at a temperature greater than or equal to the crystallization temperature of the high-k dielectric material, thereby transforming the high-k dielectric material from an amorphous state to a crystalline state, and causing nitrogen atoms to diffuse into the insulating layer.

Owner:TOWER SEMICONDUCTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com