Patents

Literature

48 results about "Hexahydrophthalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

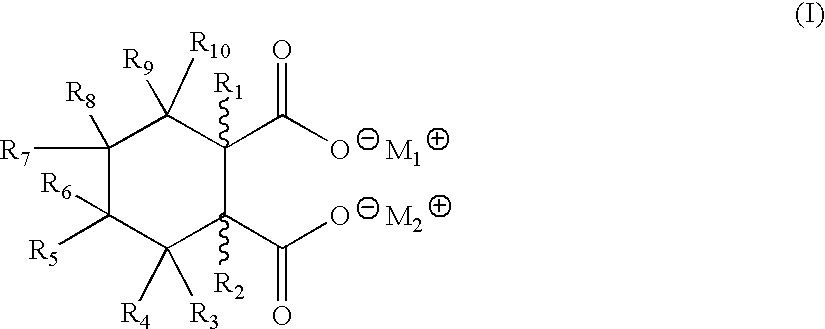

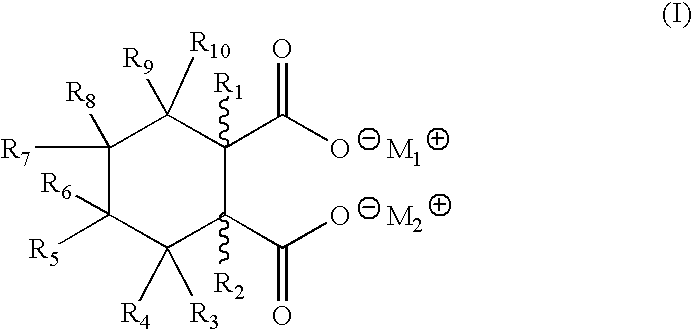

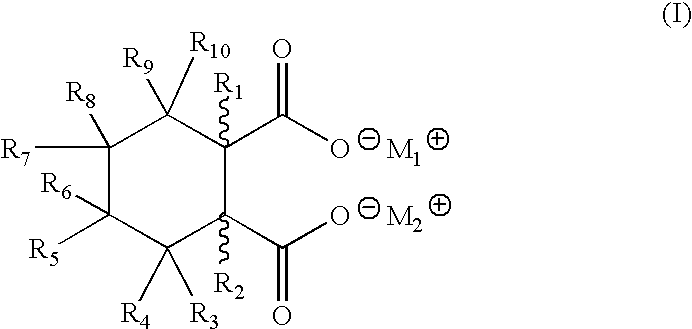

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

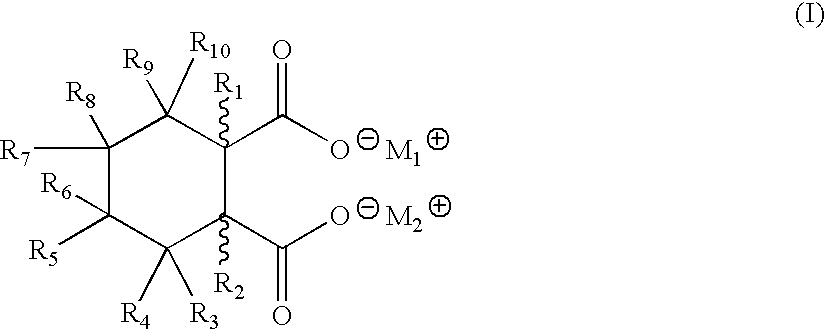

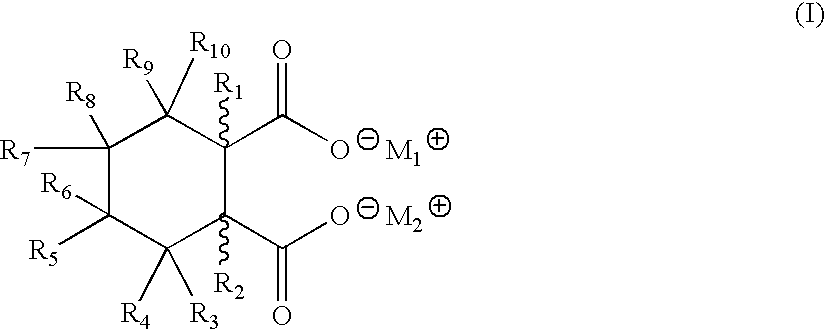

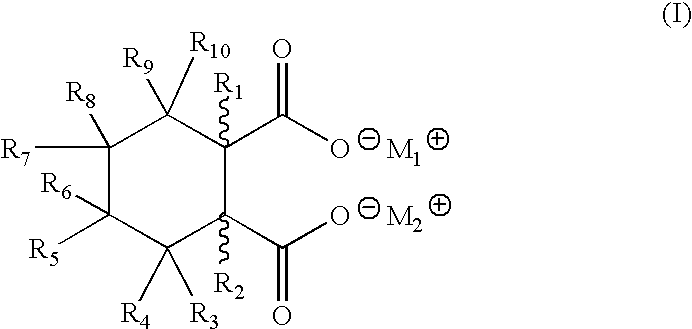

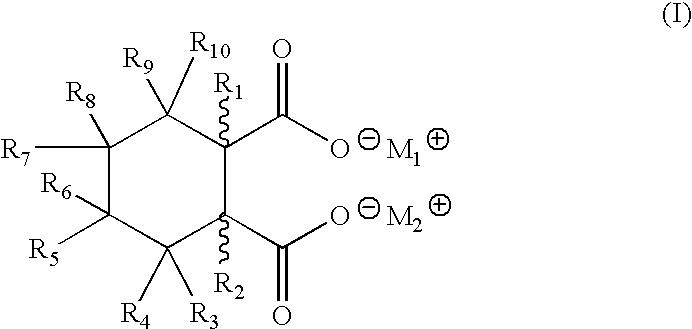

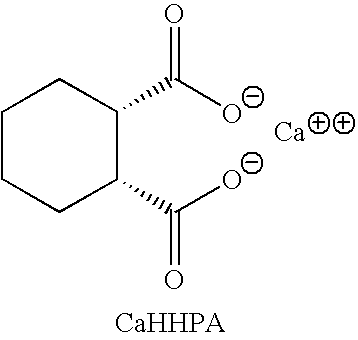

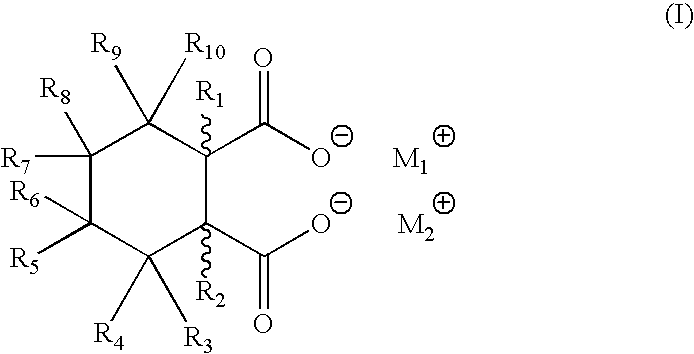

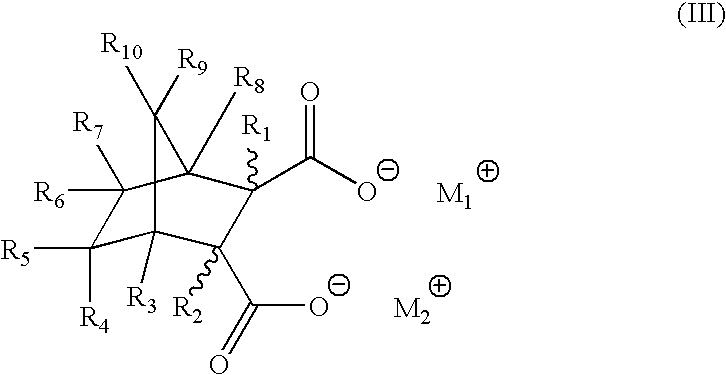

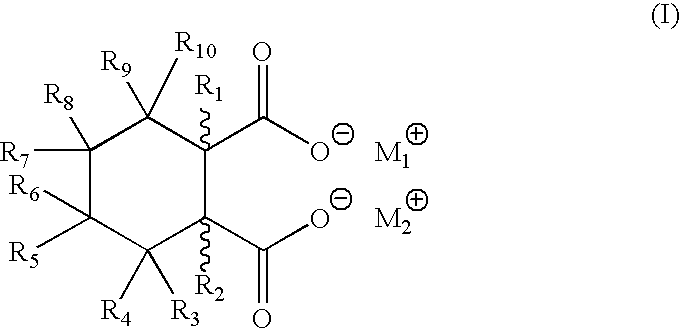

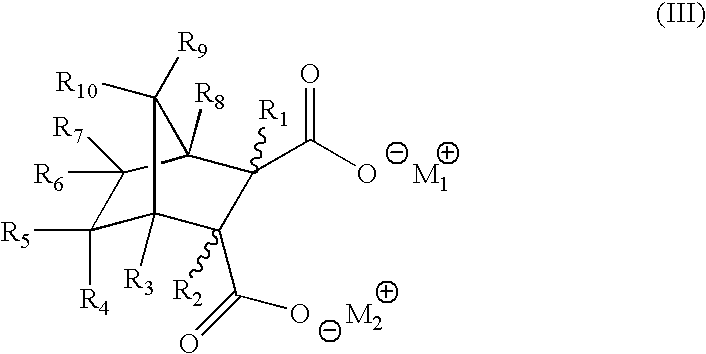

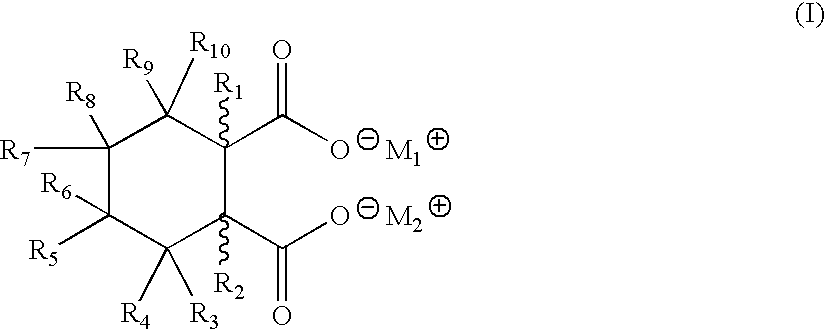

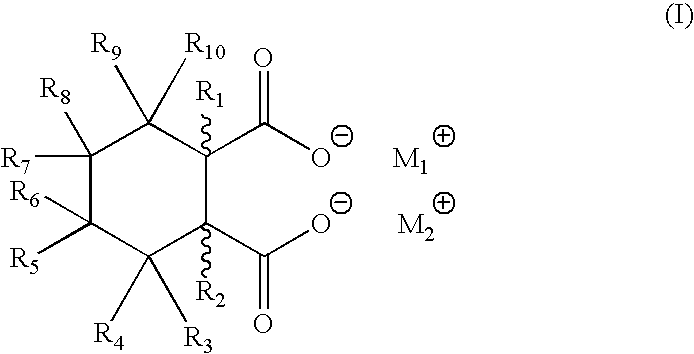

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS6562890B2Improve compatibilityExcellent high peak crystallization temperatureChemical/physical processesScavengerPolyolefin

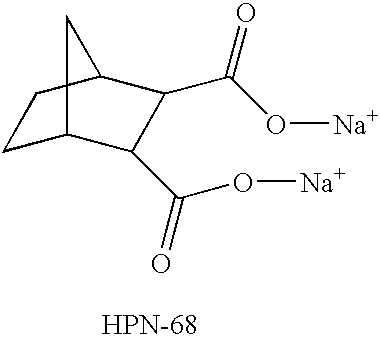

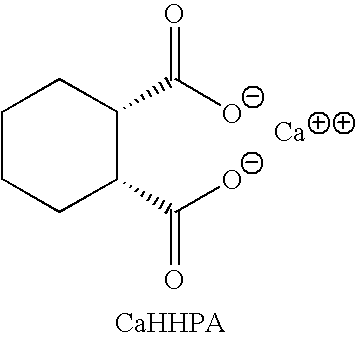

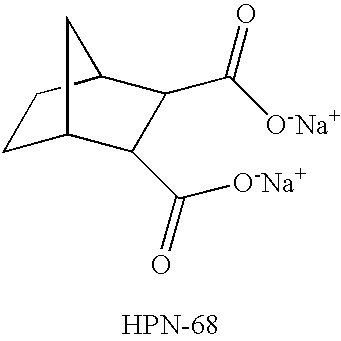

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

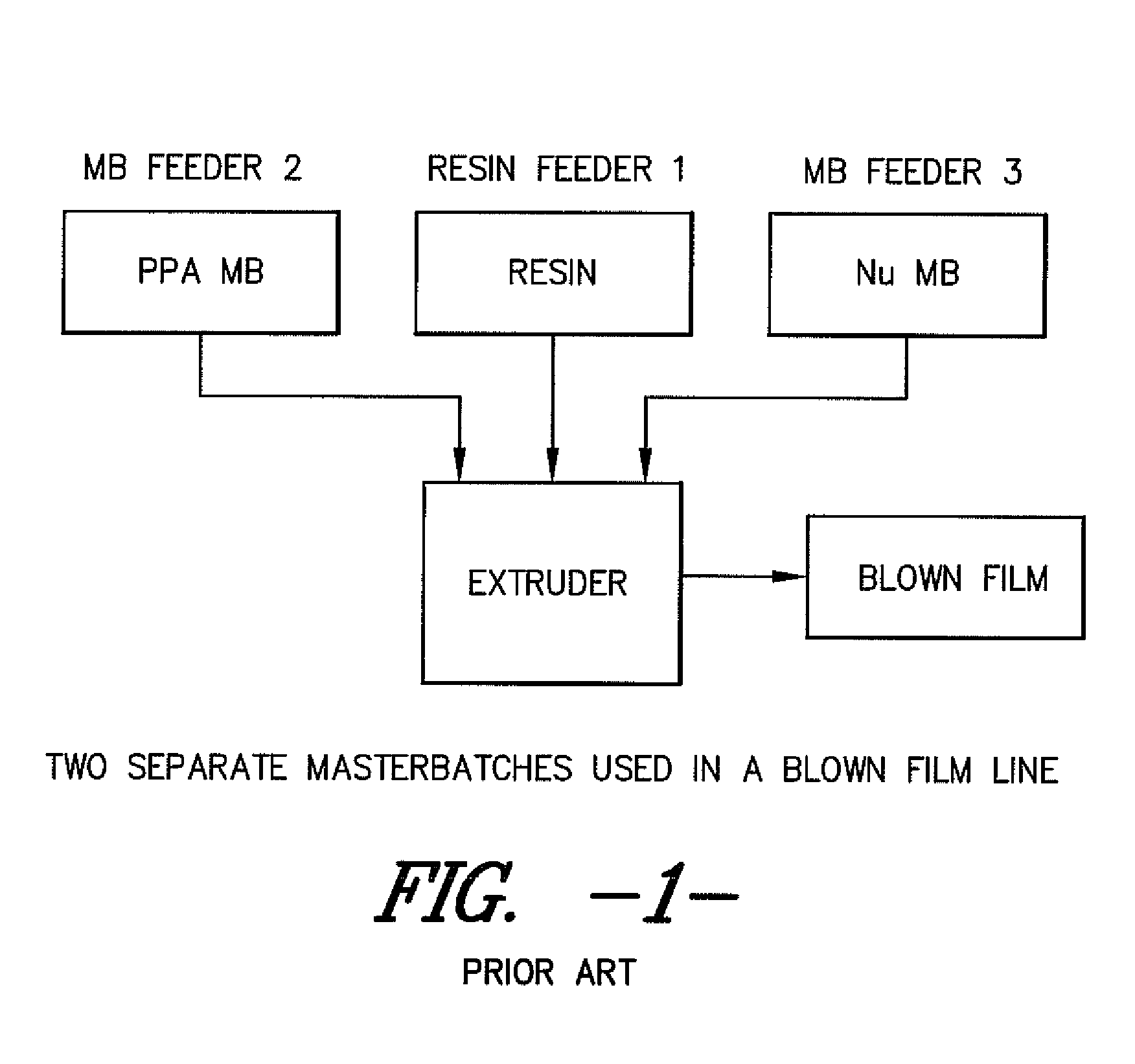

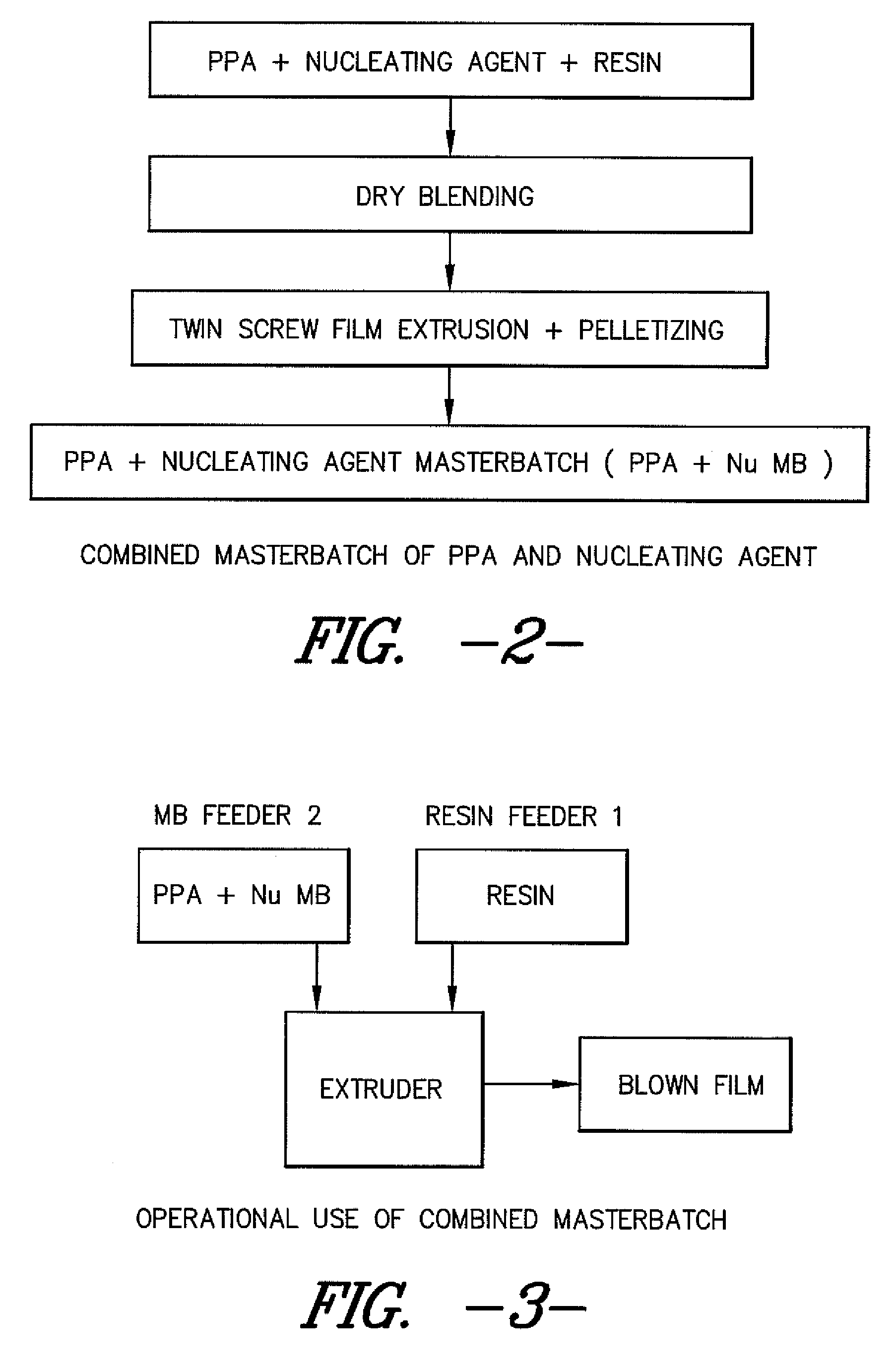

Polymer additive compositions and methods

Compositions comprising hexahydrophthalate (HHPA) metal salts may be useful as nucleating agents in polyolefins. Masterbatch compositions containing such salts and with additives may be useful in reducing haze and improving properties of manufactured polyolefin articles or film.

Owner:MILLIKEN & CO

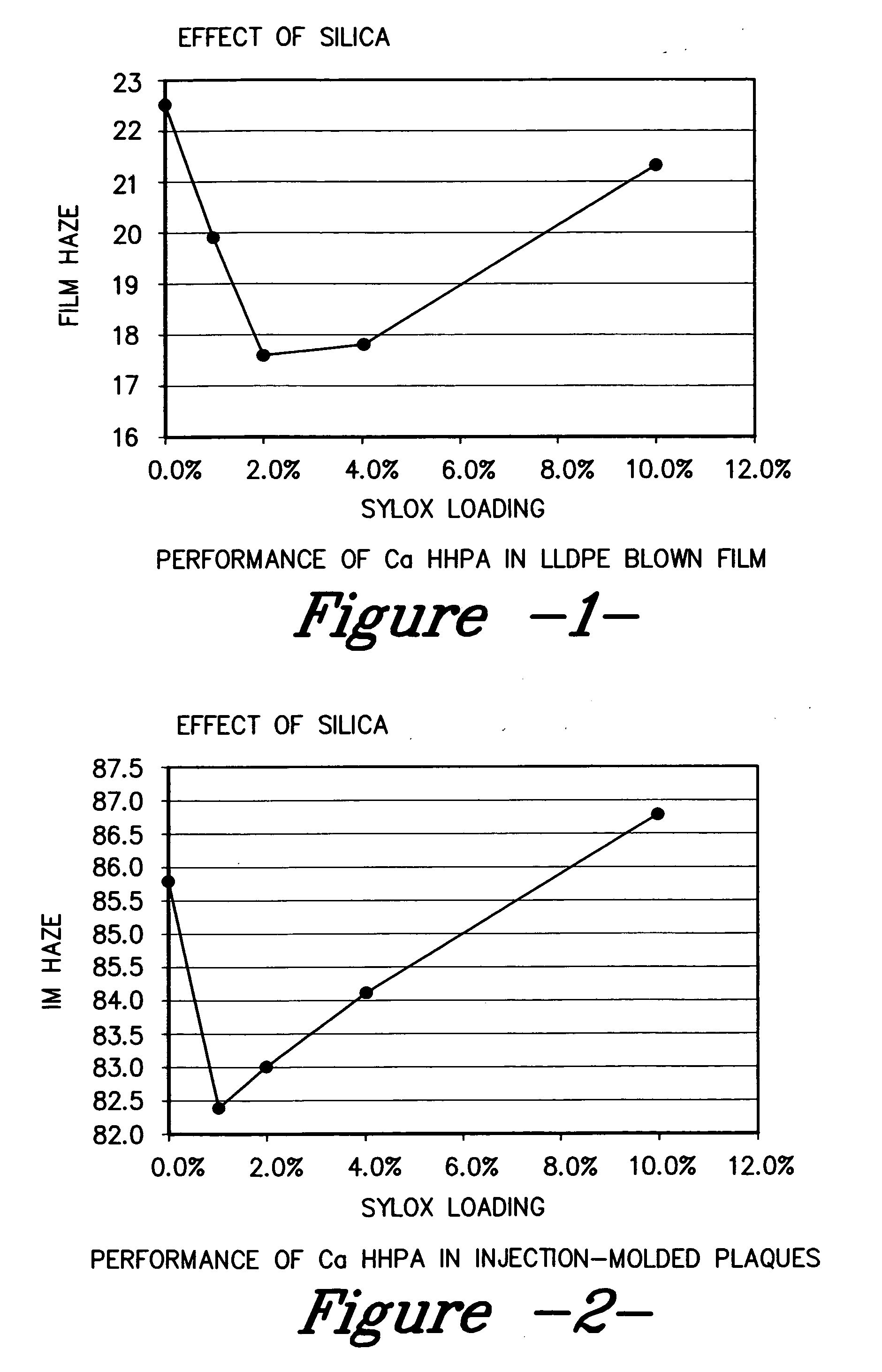

Compositions comprising metal salts of hexahydrophthalic acid and methods of employing such compositions in polyolefin resins

ActiveUS20080004384A1Easily “ let down ”Good dispersionOther chemical processesFibre treatmentPolymer sciencePolyolefin

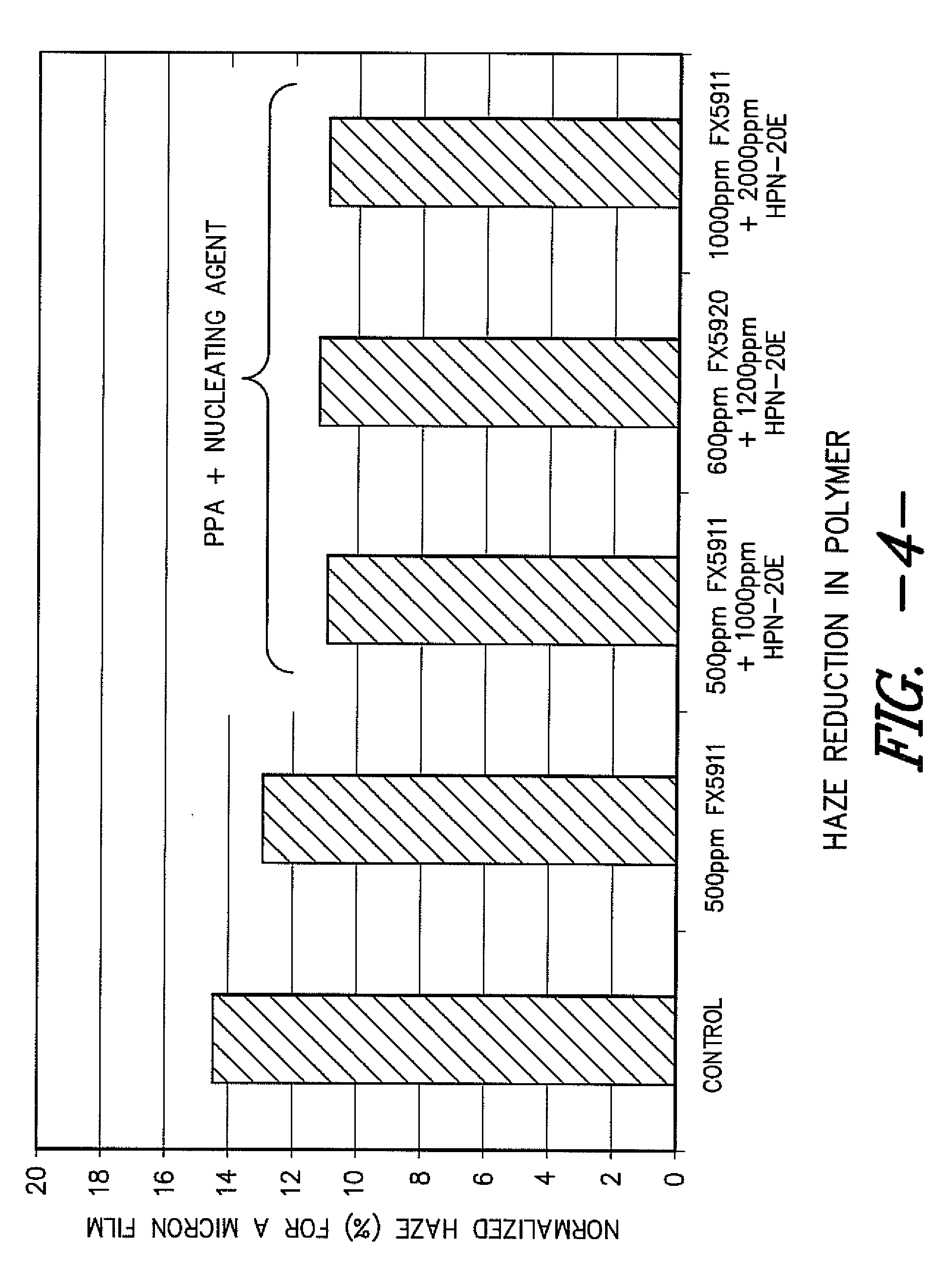

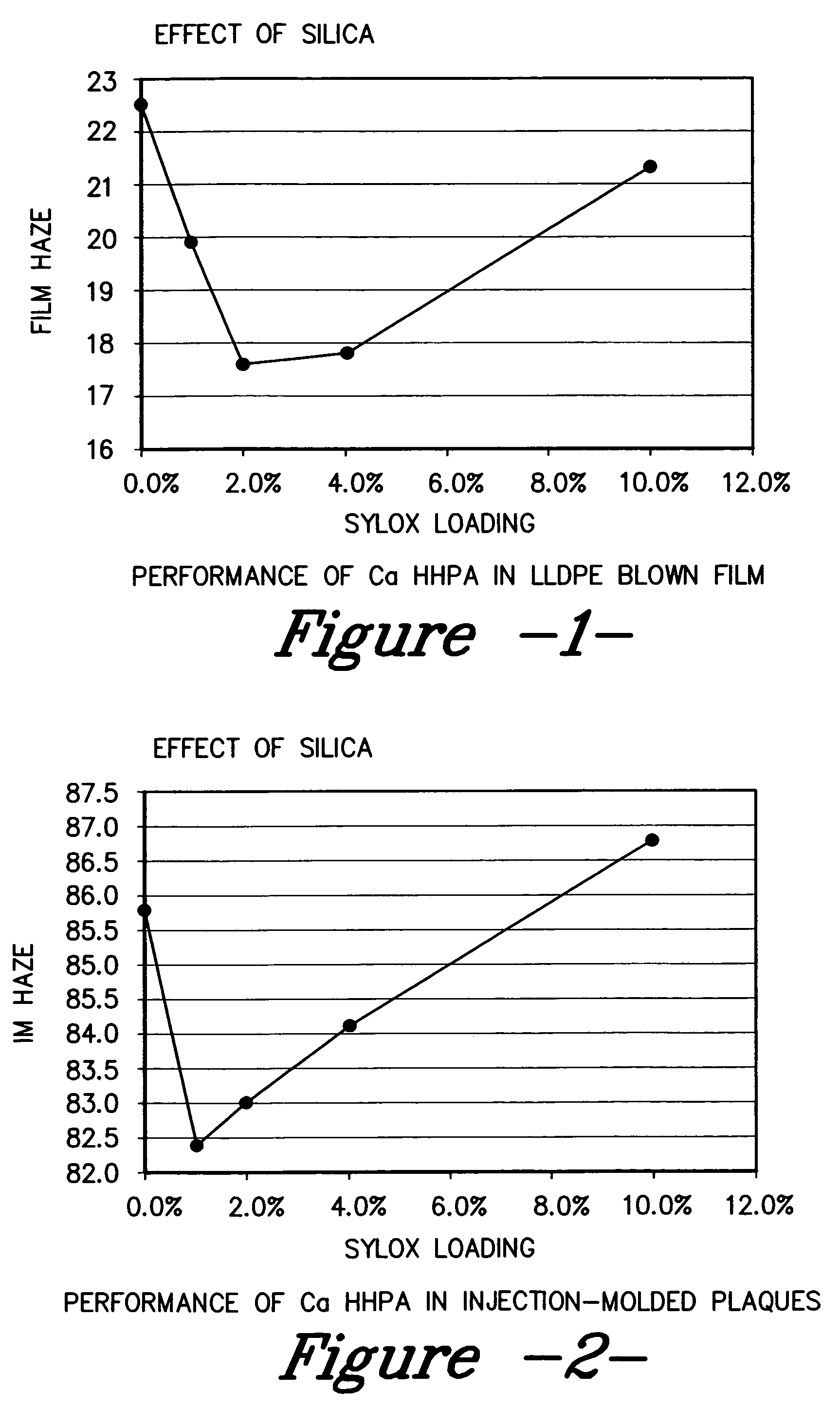

Compositions comprising hexahydrophthalate (HHPA) metal salts may be useful as nucleating agents in polyolefins. Masterbatch compositions containing such salts and silica and / or hydrotalcite are particularly useful in reducing haze and improving properties of manufactured polyolefin articles or film. Such compositions may be dispersed effectively and efficiently into resin during manufacturing operations in the form of a masterbatch, thereby providing excellent polymer crystallization temperatures, improved polymer physical properties, improved dimensional stability, and improved transparency.

Owner:MILLIKEN & CO

Bimolecular nucleation methods for thermoplastics

InactiveUS20030236332A1Exceptional nucleation efficacyImprove mechanical propertiesFibre treatmentThermoplasticPolyolefin

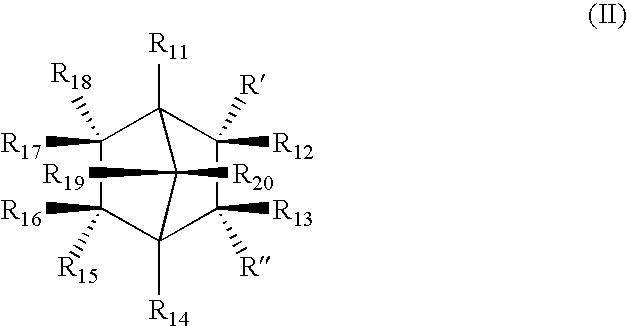

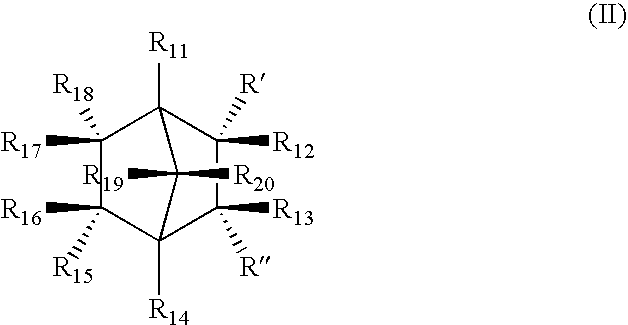

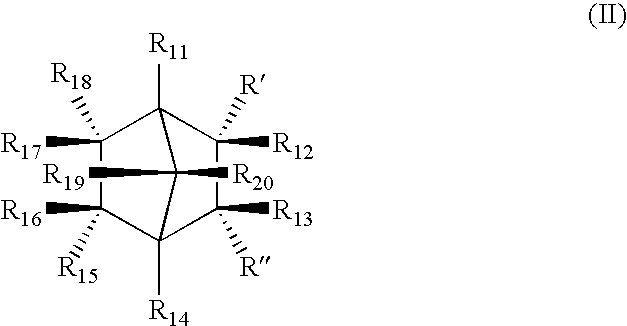

Specific methods of inducing high nucleation rates in thermoplastics, such as polyolefins, and particularly, though not necessarily, polypropylenes, through the introduction of two different compounds that are substantially soluble within the target molten thermoplastic resin (such as, as one non-limiting example, an added compound including at least one acid group and an added organic salt) are provided. Such introduced components react to form a nucleating agent in situ within such a target molten thermoplastic resin which is then allowed to cool. Preferably, one compound is an acid, preferably bicyclic (i.e., two cyclic systems sharing at least three carbon atoms) or monocycloaliphatic (i.e., a single, saturated ring system) in nature, such as, without limitation, bicyclo[2.2.1]heptane dicarboxylic acid or hexahydrophthalic acid, and the other compound is an organic salt, such as a carboxylate, sulfonate, phosphate, oxalate, and the like, and more preferably selected from the group consisting of metal C8-C22 esters. Such a production method thus provides a manner of generating in Situ the desired nucleating agent through reaction of such soluble compounds. Kits (e.g., masterbatch methods, for example) comprising such components for easy introduction within target molten polyolefin resins are also contemplated within this invention.

Owner:MILLIKEN & CO

Compositions comprising metal salts of hexahydrophthalic acid and methods of employing such compositions in polyolefin resins

ActiveUS7491762B2Easily “let downGood dispersionOther chemical processesFibre treatmentPolyolefinPolymer science

Compositions comprising hexahydrophthalate (HHPA) metal salts may be useful as nucleating agents in polyolefins. Masterbatch compositions containing such salts and silica and / or hydrotalcite are particularly useful in reducing haze and improving properties of manufactured polyolefin articles or film. Such compositions may be dispersed effectively and efficiently into resin during manufacturing operations in the form of a masterbatch, thereby providing excellent polymer crystallization temperatures, improved polymer physical properties, improved dimensional stability, and improved transparency.

Owner:MILLIKEN & CO

Polymer additive compositions for bimolecular nucleation in thermoplastics

InactiveUS20050197435A1Improve mechanical propertiesExceptional nucleation efficacyFibre treatmentThermoplasticPolyolefin

Specific methods of inducing high nucleation rates in thermoplastics, such as polyolefins, and particularly, though not necessarily, polypropylenes, through the introduction of two different compounds that are substantially soluble within the target molten thermoplastic resin (such as, as one non-limiting example, an added compound including at least one acid group and an added organic salt) are provided. Such introduced components react to form a nucleating agent in situ within such a target molten thermoplastic resin which is then allowed to cool. Preferably, one compound is an acid, preferably bicyclic (i.e., two cyclic systems sharing at least three carbon atoms) or monocycloaliphatic (i.e., a single, saturated ring system) in nature, such as, without limitation, bicyclo[2.2.1]heptane dicarboxylic acid or hexahydrophthalic acid, and the other compound is an organic salt, such as a carboxylate, sulfonate, phosphate, oxalate, and the like, and more preferably selected from the group consisting of metal C8-C22 esters. Such a production method thus provides a manner of generating in situ the desired nucleating agent through reaction of such soluble compounds. Kits (e.g., masterbatch methods, for example) comprising such components for easy introduction within target molten polyolefin resins are also contemplated within this invention.

Owner:DOTSON DARIN L +3

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

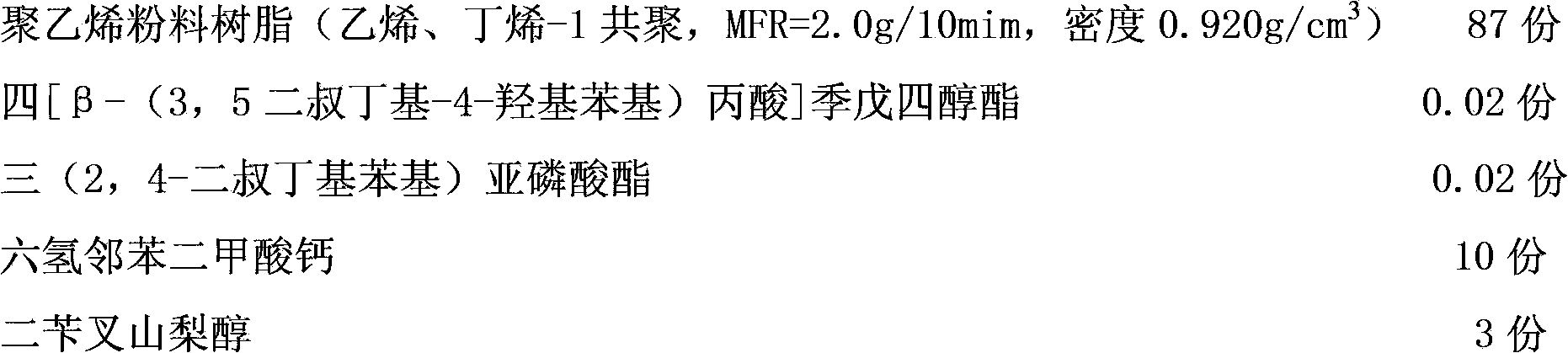

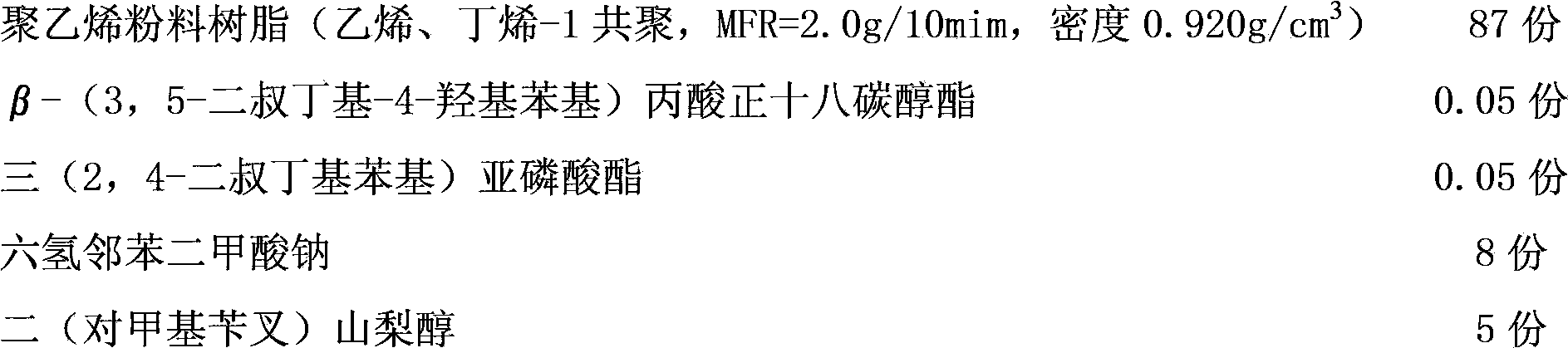

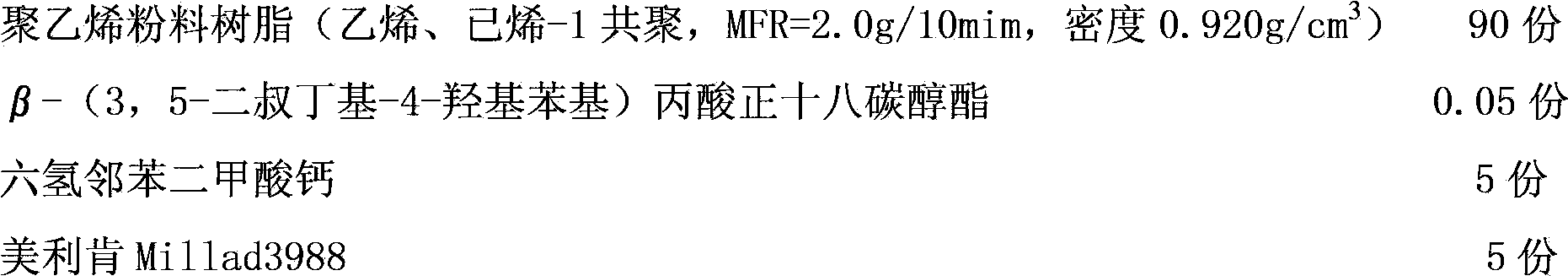

Modified master batch for polyethylene films as well as preparation and use methods thereof

The invention relates to processing fields of such polyethylene films as agricultural films, packaging films, stretching and wrapping films, and the like, and in particular relates to a modified master batch for polyethylene films as well as preparation and use methods thereof. The modified master batch is characterized by being prepared from the following raw materials in parts by weight: 100 parts of polyethylene powder resin, 0.025-0.15 part of antioxidant, 3-15 parts of nucleating agent A and 3-15 parts of nucleating agent B, wherein the nucleating agent A is selected from hexahydrophthalic acid metal salts, and the nucleating agent B is selected from sorbitols and derivatives thereof. The modified master batch for polyethylene films provided by the invention has the advantages that a polyethylene composition containing the modified master batch can be used as a film product including an agricultural film, a packaging film, a stretching and wrapping film, and the like, the tearing resistance force of the film prepared by polyethylene resin added with the modified master batch provided by the invention can be increased by more than 40%, the haze is decreased by 60% to the uttermost, and the film clarity is increased by more than 10%, so that the comprehensive performance of the film product is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Ceramic slurry for photocuring and preparation method thereof

InactiveCN110128116AHigh solid contentImprove reaction efficiencyAdditive manufacturing apparatusPentaerythritolMetallurgy

The invention discloses ceramic slurry for photocuring and a preparation method thereof. By controlling the contents of the main ceramic slurry, a dispersing agent, a monomer and a photoinitiator, thehigh-solid-content ceramic slurry for photocuring is prepared; wherein the dispersing agent can enable the solid to be better dispersed in the liquid, so that the dispersion of the main ceramic slurry in the monomer is more uniform; the monomer is selected from a mixture of free radical type photosensitive resin and cationic type photosensitive resin with different functions and reaction efficiencies; wherein hexahydro-o-phthalic acid diglycidyl ether can make the finally prepared ceramic slurry for light curing not liable to deform, the 1,6-hexanediol diacrylate can make the viscosity of a monomer to be suitable for uniform dispersion of ceramic powder in the monomer and improves the solid phase content of the slurry; and dipentaerythritol hexaacrylate can improve the reaction efficiency; by selecting each substance in the monomer, the prepared ceramic slurry has high solid-phase content, high reaction efficiency and high printing precision.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Preparation methods of castor oil base carboxylate radical intercalated hydrotalcite for PVC (Polyvinyl Chloride) and compound heat stabilizer thereof

Owner:WUXI ACP STEEL CORE

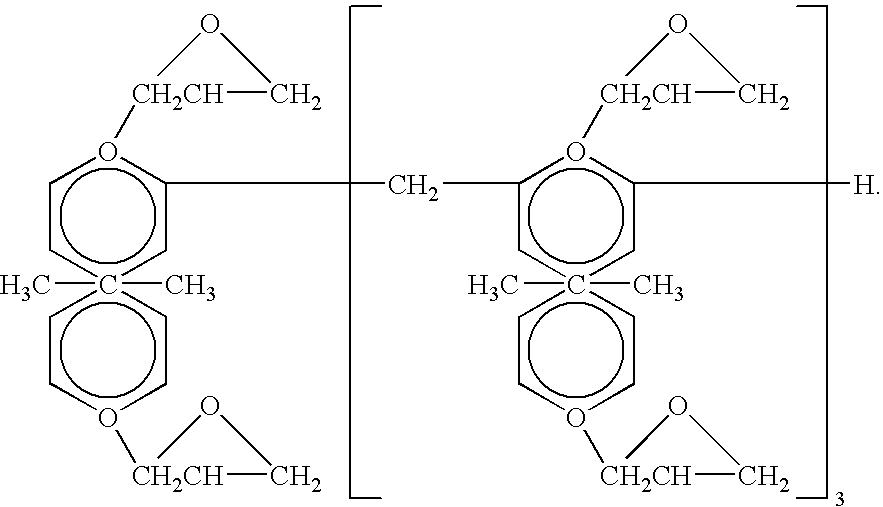

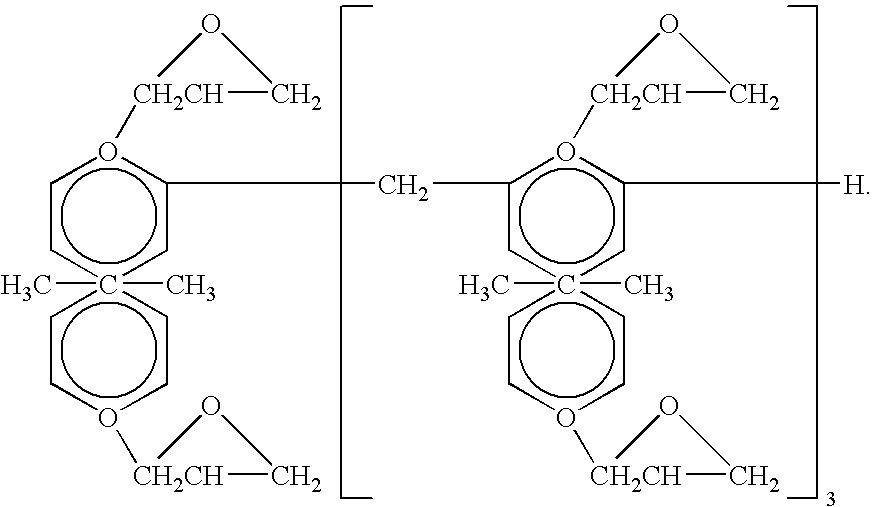

Photoresist formulation for high aspect ratio plating

InactiveUS7005233B2High aspect ratio lithographyImprove adhesionImpression capsPhotosensitive materialsResistPlasticizer

SU-8 photoresist compositions are modified to improve their adhesion properties by adding 1% to 6% of an adhesion promoter selected from the group consisting of glycidoxypropanetrimethoxysilane, mercaptopropyltrimethoxysilane, and aminopropyltrimethoxysilane. SU-8 photoresist compositions are modified to improve their resistance to cracking and film stress by adding 0.5% to 3% of a plasticizer selected from the group consisting of dialkylphthalates, dialkylmalonates, dialkylsebacates, dialkyladipates, and diglycidyl hexahydrophthalates. The improvements can be obtained simultaneously by adding both the adhesion promoter and the plasticizer to SU-8 photoresist compositions.

Owner:FORMFACTOR INC

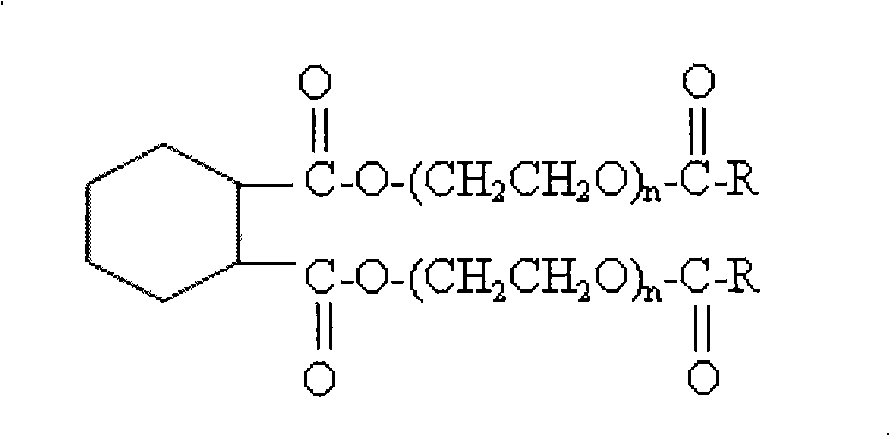

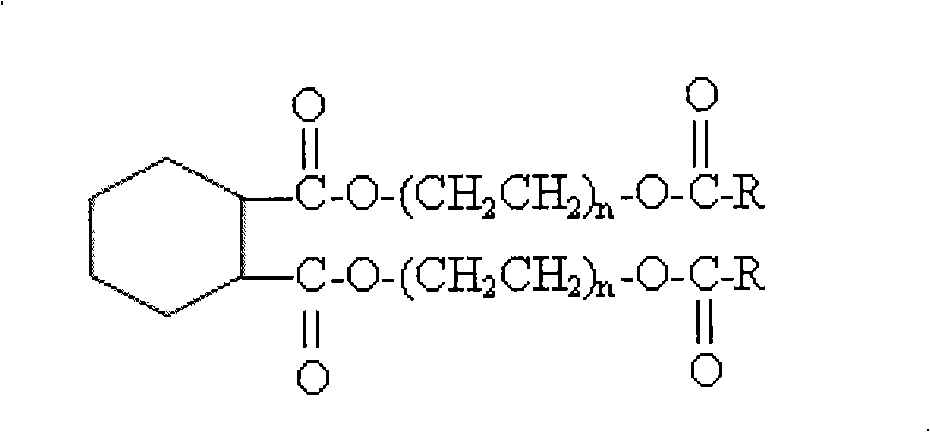

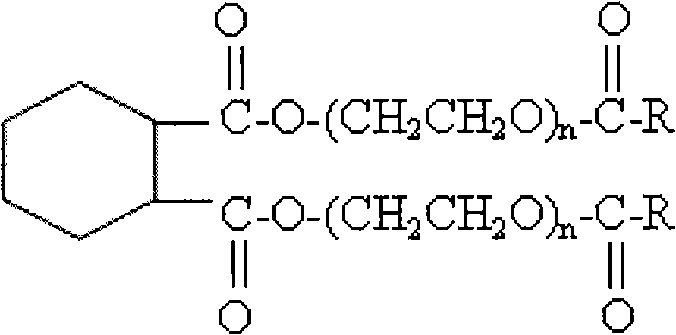

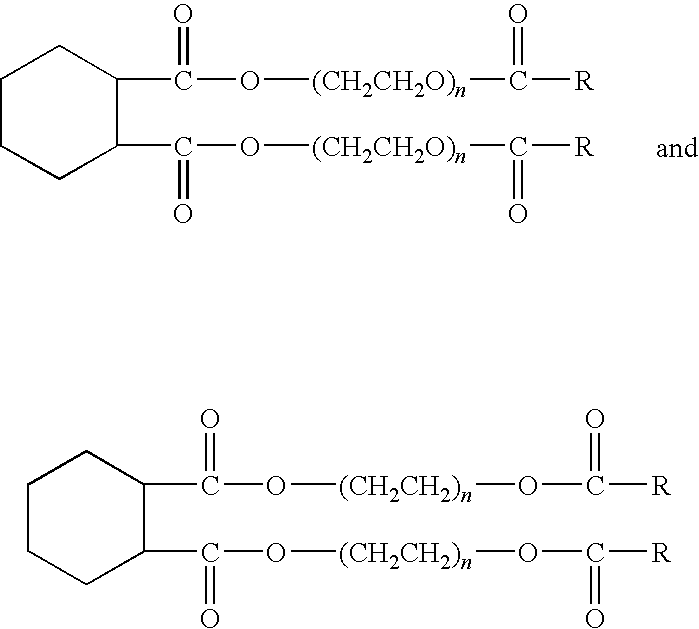

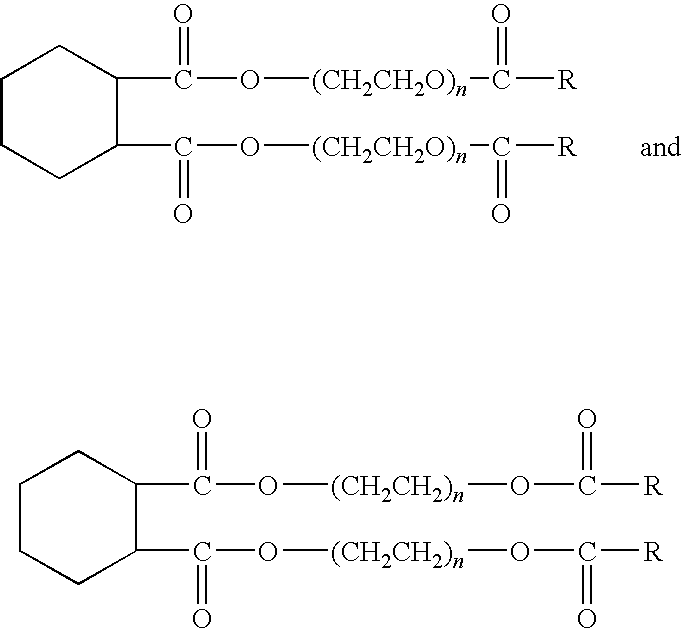

Hexa-hydrogen phthalate compound and preparation thereof

The invention relates to hexahydrophthalic acid ester compound used for preparing the plasticizer without phthalic acid and benzoic acid, which can not cause damage to the organism and the environment. The invention adopts the preparation method that firstly, the esterifying reaction is performed to hexahydrophthalic anhydride and diatomic alcohol and catalyzator, after acid radical is removed, the hexahydrophthalic acid ester alcohol is synthetized, then monoprotic acid is added into the synthetized hexahydrophthalic acid ester alcohol to continue the esterificating reaction, and finally, the hexahydrophthalic acid ester compound is produced.

Owner:NANYA PLASTICS CORP

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS20030027909A1Improve compatibilityReduce moisture absorption performanceFibre treatmentGroup 3/13 element organic compoundsScavengerPolyolefin

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

Hexahydrophthalate based compound and process for producing the same

ActiveUS20090281349A1Quality improvementImproved processing physical propertyOrganic chemistryOrganic compound preparationBenzoic acidAlcohol

A hexahydrophthalate based compound is adapted to use as a plasticizer that contains no phthalic acid and benzoic acid, possess physical properties superior to DEHA and DINA in transparency and adhesion and is friendly to organisms and the environment; and a process for producing the hexahydrophthalate based compound includes esterifying hexahydrophthalic anhydride, a diol, and a catalyst for decarboxylation to get hexahydrophthalic alcohol, and adding a monoacid into the hexahydrophthalic alcohol for further esterification, thereby obtaining the hexahydrophthalate based compound.

Owner:NANYA PLASTICS CORP

Aqueous polyester resin paint and preparation method thereof

InactiveCN106916517APromote environmental protectionImprove hydrolysis resistancePolyester coatingsAdipic acidHydrolysis

The invention discloses an aqueous polyester resin paint. The aqueous polyester resin paint comprises polyol, polybasic acid, 8-16% of catalyst, 6-12% of a curing agent, 6-10% of a filler and 60-80% of water; the polyol comprises 8-12% of trimethylolpropane, 12-24% of neopentyl glycol, 6-12% of ethylene glycol and 8-12% of propylene glycol, and the polybasic acid comprises 5-15% of purified terephthalic acid, 12-24% of m-phthalic acid, 6-12% of phthalic acid, 10-18% of trimellitic anhydride, 6-12% of hexahydrophthalic acid, 10-20% of maleic anhydride and 5-10% of adipic acid; and the aqueous polyester resin paint also includes 0.1-0.3% of p-methoxyphenol, 6-24% of ethylene glycol monobutyl ether, 8-16% of dimethylethanolamine and 60-100% of deionized water. The aqueous polyester resin paint improves the stability of the hydrolysis of a polyester main chain in order to improve the aqueous insulation property of the polyester resin paint, can be widely used in aqueous insulation devices, and meets practical use requirements.

Owner:滁州市全丰物资有限公司

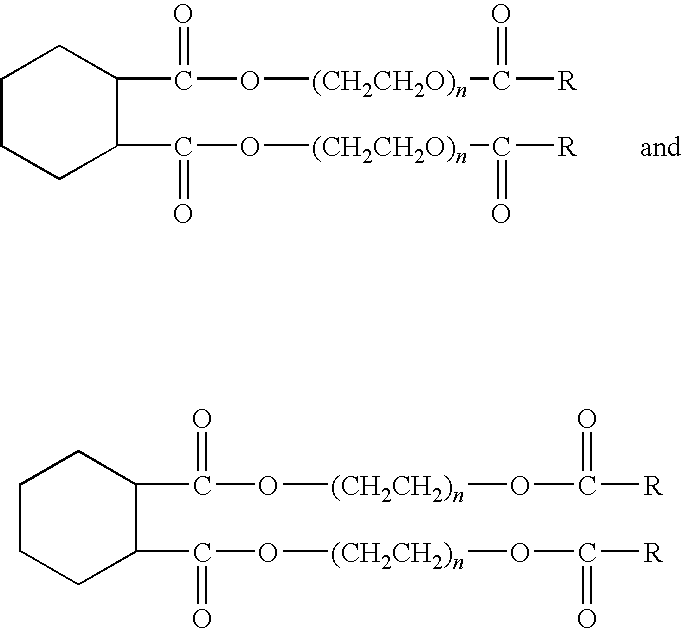

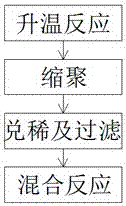

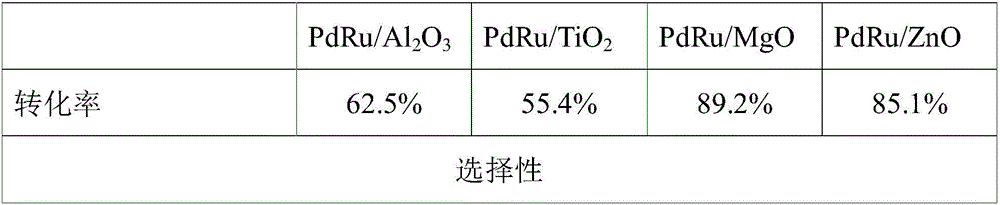

Method for preparing hexahydrophthalic anhydride

ActiveCN106674172AHigh yieldFlexible operationOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedCyclohexanecarboxylic acid

The invention provides a method for preparing hexahydrophthalic anhydride, belonging to the field of synthesis of fine chemicals. The method comprises the steps: phthalic anhydride is heated to 50 DEG C and injected into a phthalic anhydride dissolving tower, the phthalic anhydride is dissolved with a solvent, the temperature of the dissolving tower is 50-70 DEG C, the dissolved phthalic anhydride solution is pressurized and injected into a constant-pressure reaction kettle or a fixed bed reactor filled with a selective hydrogenation catalyst to carry out selective hydrogenation reaction, the product directly enters a solvent recovery column after hydrogenation reaction, the solvent is distilled off at the tower top, the materials at the tower bottom enter a hexahydrophthalic anhydride rectifying tower, the hexahydrophthalic anhydride is obtained at the tower bottom, and a mixture of phthalide, o-toluic acid and o-methyl cyclohexanecarboxylic acid is obtained at the tower top; and the mixture obtained at the top of the rectifying tower is recrystallized to crystallize phthalide. The method has the advantages of simple operation, favorable economic benefit and industrial application prospects.

Owner:DALIAN UNIV OF TECH +1

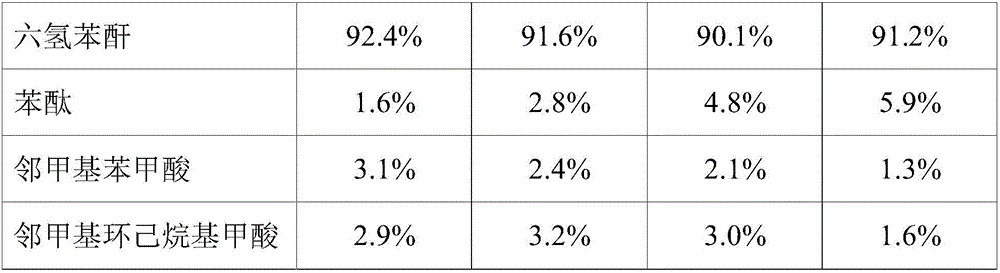

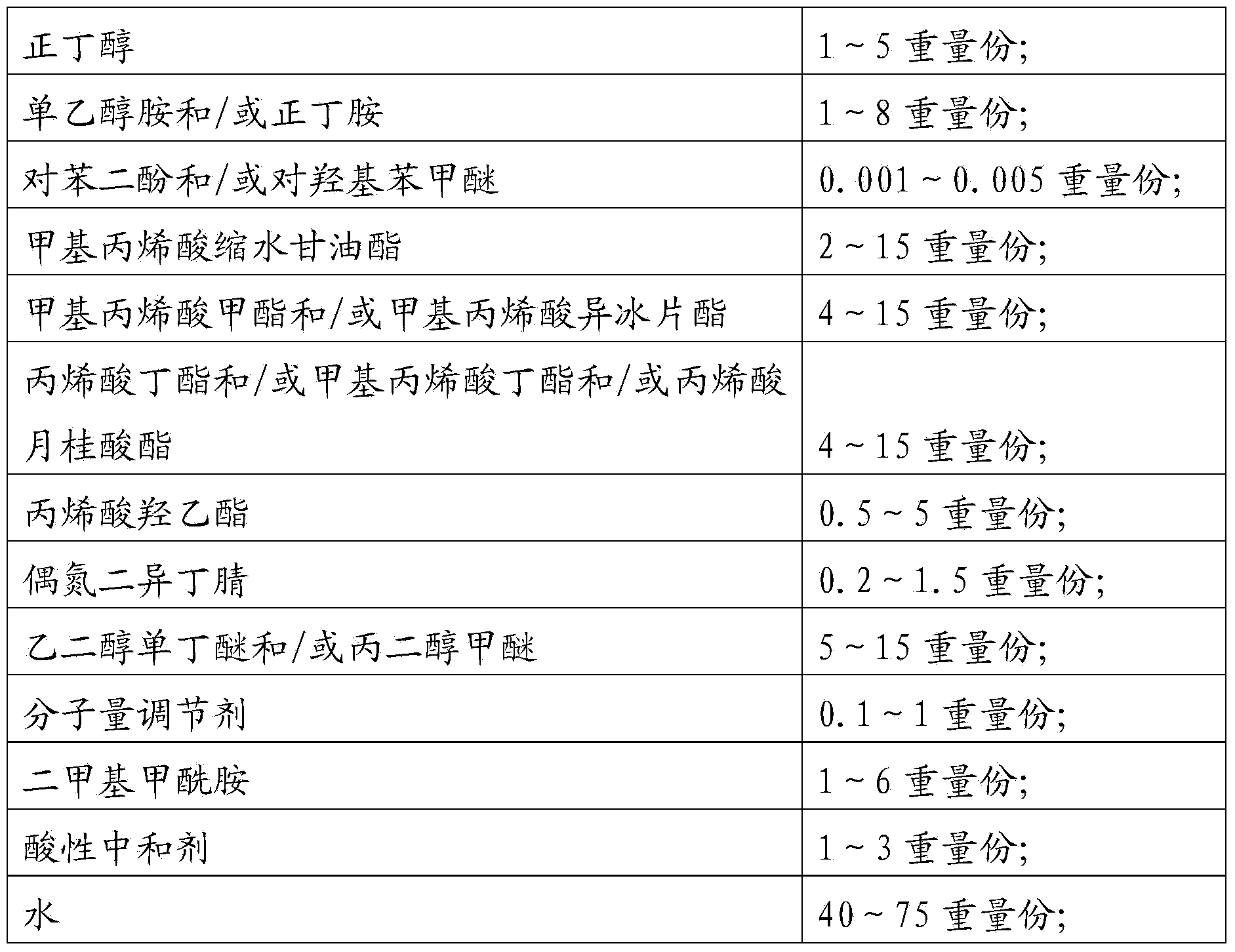

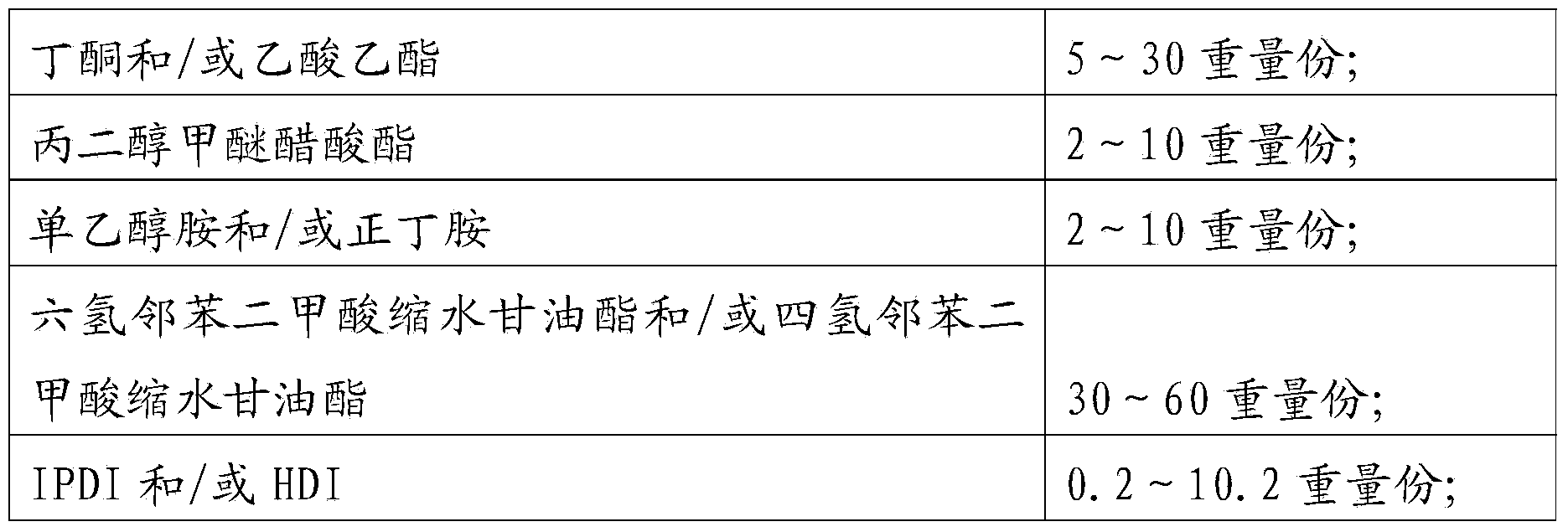

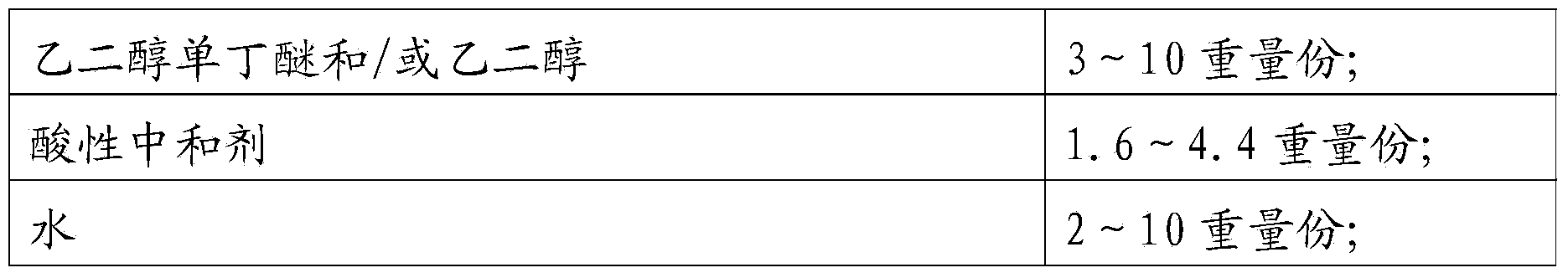

Aqueous bi-component acrylic acid-polyurethane resin and preparation method thereof

ActiveCN103554412ANo foamingPolyurea/polyurethane coatingsGlycidyl methacrylateIsophorone diisocyanate

The invention relates to an aqueous bi-component acrylic acid-polyurethane resin and a preparation method thereof. The aqueous bi-component acrylic acid-polyurethane resin comprises a component A and a component B, wherein the component A comprises n-butyl alcohol, monoethanolamine and / or n-butyl amine, hydroquinone and / or p-hydroxyanisole, glycidyl methacrylate, methyl methacrylate and / or isobornyl methacrylate, butyl acrylate and / or butyl methacrylate and / or acrylic acid laurate, hydroxyethyl acrylate, azodiisobutyronitrile, butylcellosolve and / or propylene glycol monomethyl ether, a molecular weight regulator, dimethylformamide, an acid neutralizer and water; the component B comprises butanone and / or ethyl acetate, propylene glycol methyl ether acetate, monoethanolamine and / or n-butylamine, cis-hexahydrophthalic acid glycidyl ester and / or tetrahydrophthalic acid glycidyl ester, IPDI (Isophorone Diisocyanate) and / or HDI (Hexamethylene Diisocyanate), ethylene glycol monobutyl ether and / or ethylene glycol, the acid neutralizer and the water; and the weight ratio of the component A to the component B is (4-7):1. A coating prepared from the aqueous bi-component acrylic acid-polyurethane resin is more than 150 microns in thickness and cannot generate bubbles or pinholes.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD +1

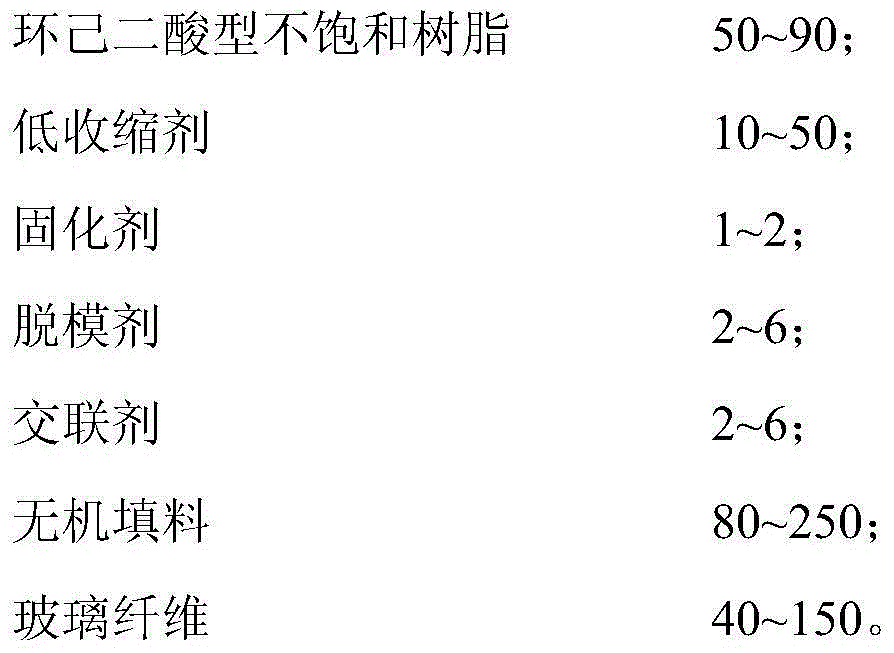

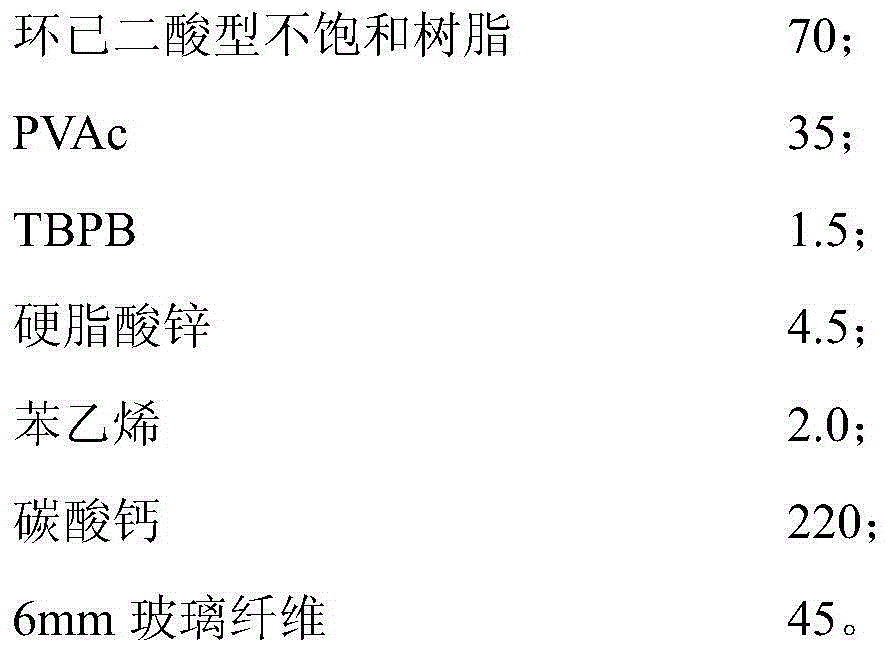

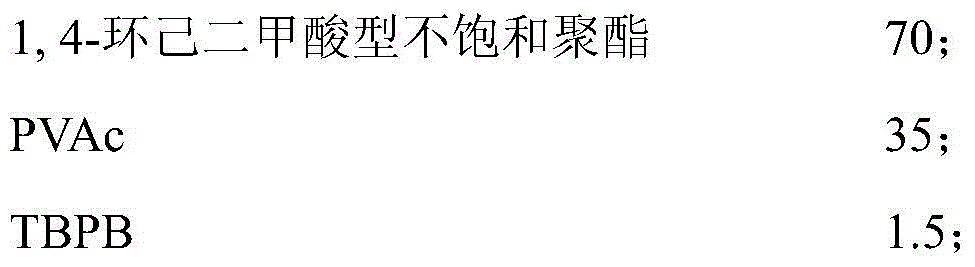

High-weather-proof bulk molding compound

InactiveCN104927001AGood weather resistanceGuaranteed mechanical propertiesGlass fiberWeather resistance

The invention discloses a high-weather-proof bulk molding compound. The high-weather-proof bulk molding compound comprises, by weight, 50-90 parts of hexahydrophthalic acid type unsaturated resin, 10-50 parts of low-shrinkage agents, 1-2 parts of curing agents, 2-6 parts of release agents, 2-6 parts of cross-linking agents, 80-250 parts of inorganic filler, and 40-150 parts of fiberglass. Compared with the prior art, the high-weather-proof bulk molding compound has the advantages that weather resistance is quite high, mechanical property, physical property and chemical property can be maintained for a long time in any environments, and yellowing, embrittlement, cracking and performance reduction are avoided.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Photoresist formulation for high aspect ratio plating

InactiveUS7238464B2High aspect ratio lithographyImprove adhesionPhotosensitive materialsRadiation applicationsResistPlasticizer

Owner:FORMFACTOR INC

Photoresist formulation for high aspect ratio plating

InactiveUS20060141394A1High aspect ratio lithographyImprove adhesionRadiation applicationsPhotomechanical apparatusPlasticizerPhthalic acid

SU-8 photoresist compositions are modified to improve their adhesion properties by adding 1% to 6% of an adhesion promoter selected from the group consisting of glycidoxypropanetrimethoxysilane, mercatopropyltrimethoxysilane, and aminopropyltrimethoxysilane. SU-8 photoresist compositions are modified to improve their resistance to cracking and film stress by adding 0.5% to 3% of a plasticizer selected from the group consisting of dialkylphthalates, dialkylmalonates, dialkylsebacates, dialkyladipates, and diglycidyl hexahydrophthalates. The improvements can be obtained simultaneously by adding both the adhesion promoter and the plasticizer to SU-8 photoresist compositions.

Owner:FORMFACTOR INC

Tubing with high strength and high toughness for mining and preparation method thereof

InactiveCN106674811AGood compatibilityImprove dispersion stabilityPolyvinyl chlorideShock resistance

The invention discloses tubing with high strength and high toughness for mining and a preparation method thereof. The tubing is prepared by the following raw materials in parts by weight: 50-70 parts of polyvinyl chloride, 10-15 parts of diglycidyl 1,2-cyclohexanedicarboxylate, 18-26 parts of oxidized graphene, 11-18 parts of sub white corundum fine powder, 4-7 parts of tristearin, 10-15 parts of basic magnesium sulfate whisker, 9-14 parts of bis(2-ethylhexyl) phthalate, 12-19 parts of aerosol, 5-8 parts of montan wax, 24-37 parts of montmorillonite, 2-4 parts of aluminium stearate, 1-3 parts of magnesium stearate, and 16-23 parts of white onyx powder. Based on a high-molecular blend system of polyvinyl chloride, diglycidyl 1,2-cyclohexanedicarboxylate and bis(2-ethylhexyl) phthalate, the sub white corundum fine powder, the basic magnesium sulfate whisker, the white onyx powder, and other raw materials are added, so that tensile strength and toughness of the material are improved, and heat resistance, wear resistance and shock resistance of the material are improved.

Owner:宋志勇

Outer power line sheath for rechargeable battery charger of battery cart

InactiveCN107652597AStrong impact resistanceImprove impact resistanceRubber insulatorsBuilding insulationsPolyvinyl alcoholButylated hydroxytoluene

The invention discloses an outer power line sheath for a rechargeable battery charger of a battery cart. The outer power line sheath comprises the following raw materials in parts by weight: 60-70 parts of main materials, 1-2 parts of hexahydrophthalic anhydride, 0.5-1.2 parts of cyclohexane peroxide, 1-2 parts of trimethylol propyl triacrylate, 2-6 parts of composite flexibilizer, 85-95 parts offilling reinforcing agent, 1-2 parts of aluminum-zirconium coupling agent, 1-2 parts of stearic acid, 0.1-0.8 part of yttrium oxide, 0.5-1.5 parts of pine tar, 1-2 parts of disproportionated rosin, 1-2 parts of an antioxidant TNP (trinitrophenyl group), and 1-2 parts of an antioxidant BHT (butylated hydroxytoluene), wherein the composite flexibilizer is prepared by the following processes: uniformly mixing a yeast extract, glucose and water; inoculating gluconacetobacter xylinus; dynamically culturing through a shaking table; filtering; washing with water; adding polyvinyl alcohol, ethylene glycol and p-toluenesulfonic acid; adding epoxidized soybean oil and triphenyl phosphorus under nitrogen protection; cooling; and filtering to obtain the composite flexibilizer.

Owner:天长市平康电子科技有限公司

Bimolecular nucleation methods for thermoplastics

InactiveUS7129323B2Improve mechanical propertiesExceptional nucleation efficacyFibre treatmentThermoplasticPolyolefin

Owner:MILLIKEN & CO

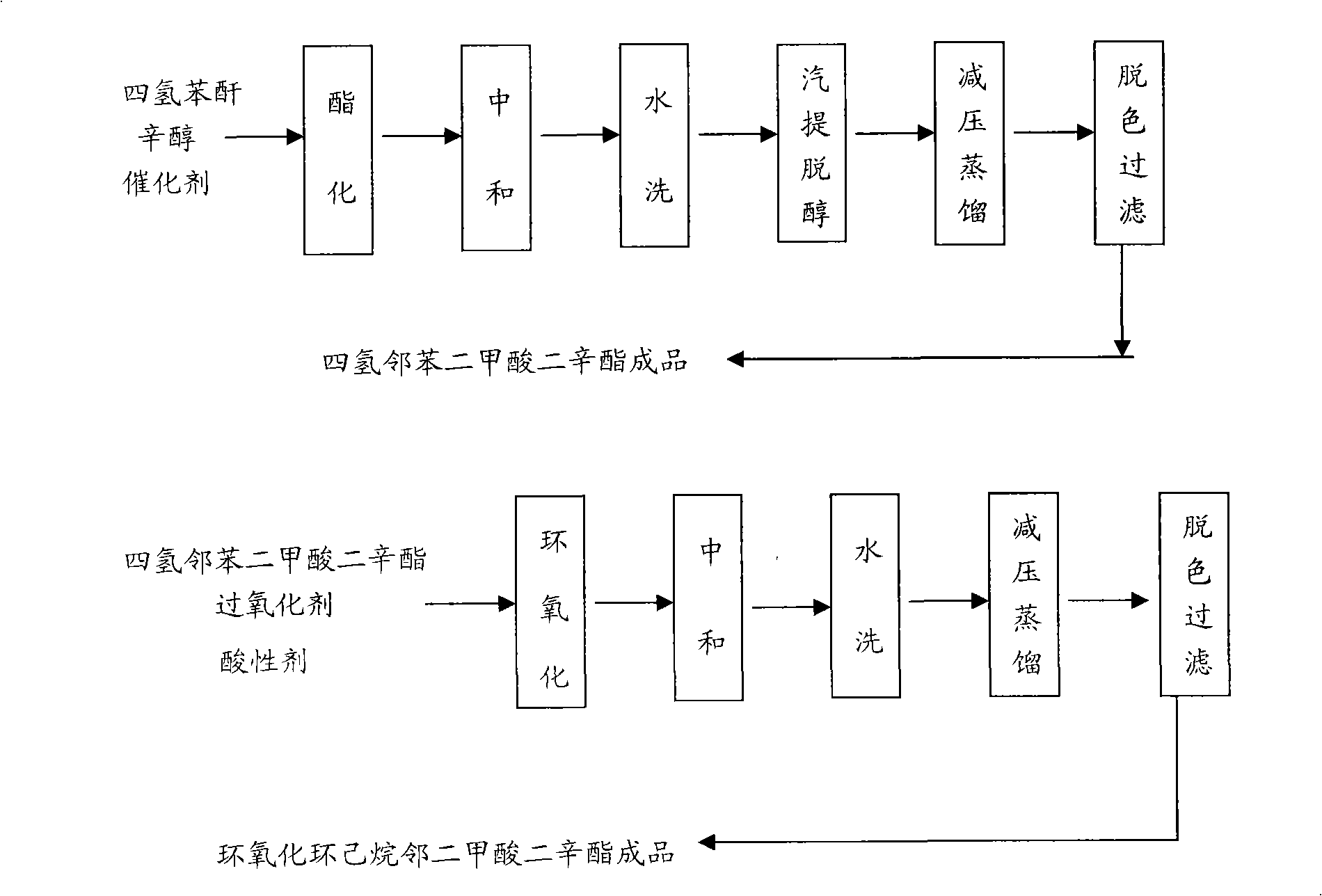

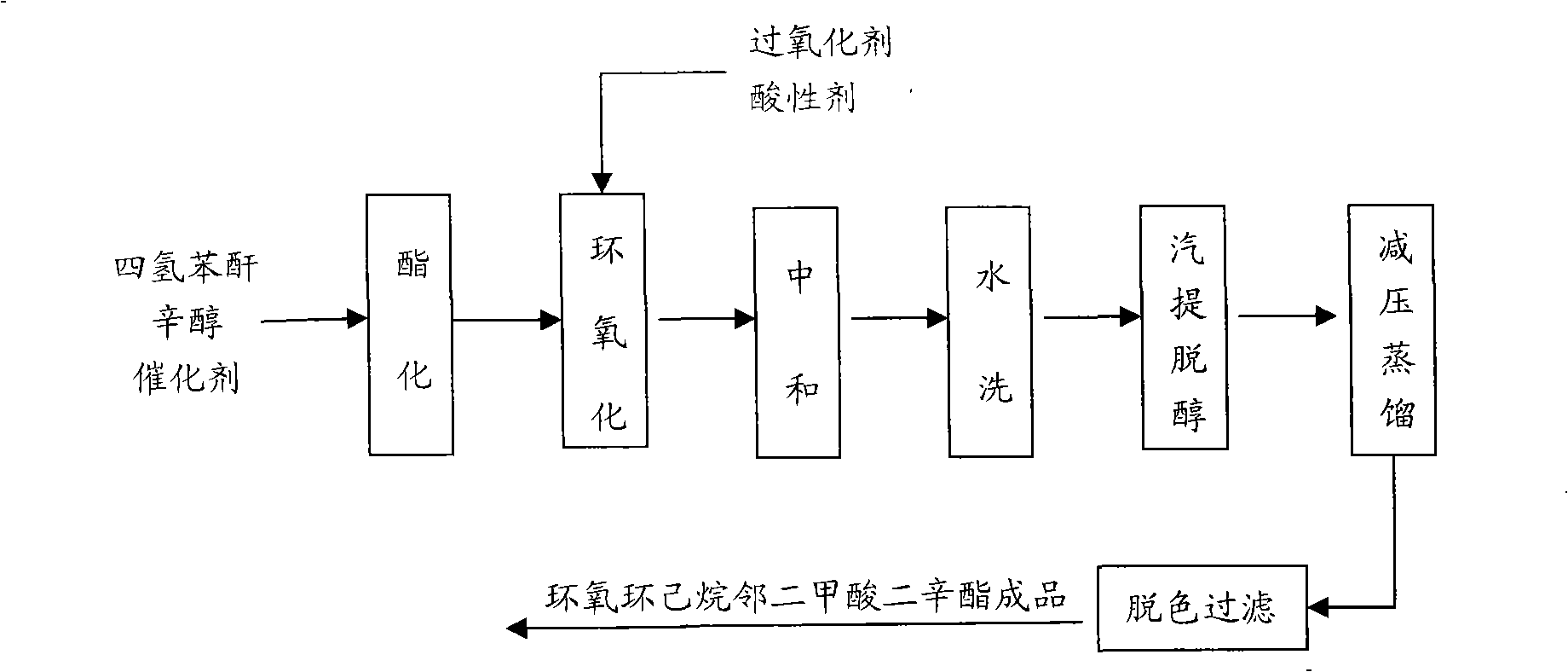

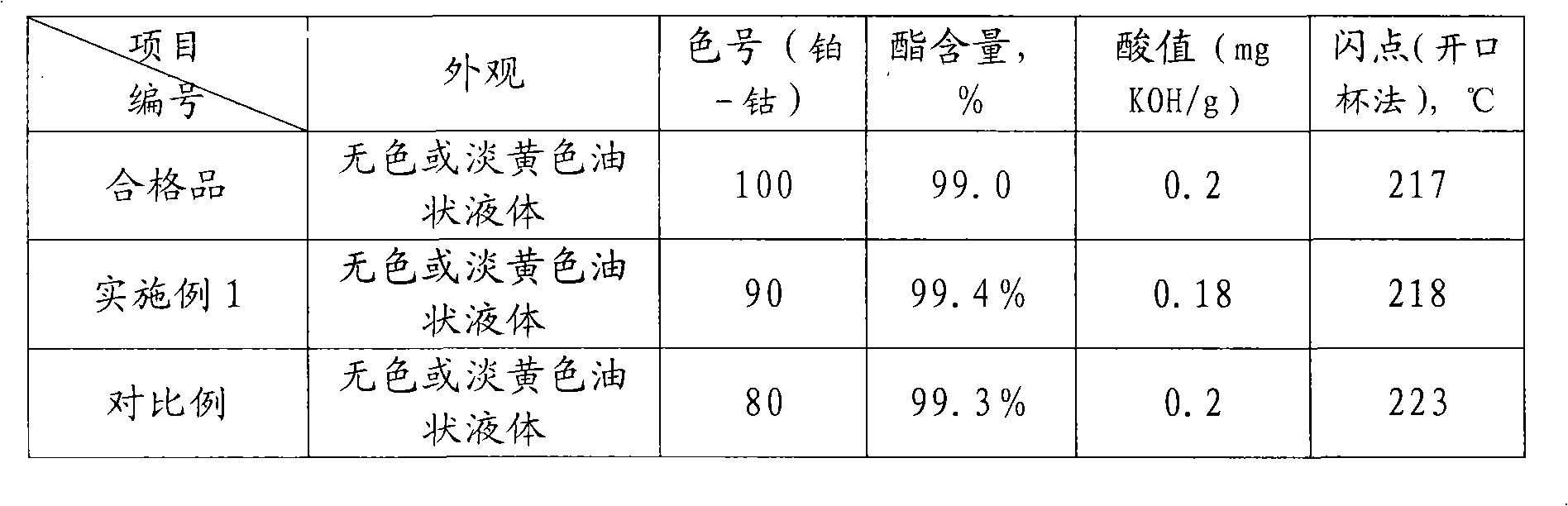

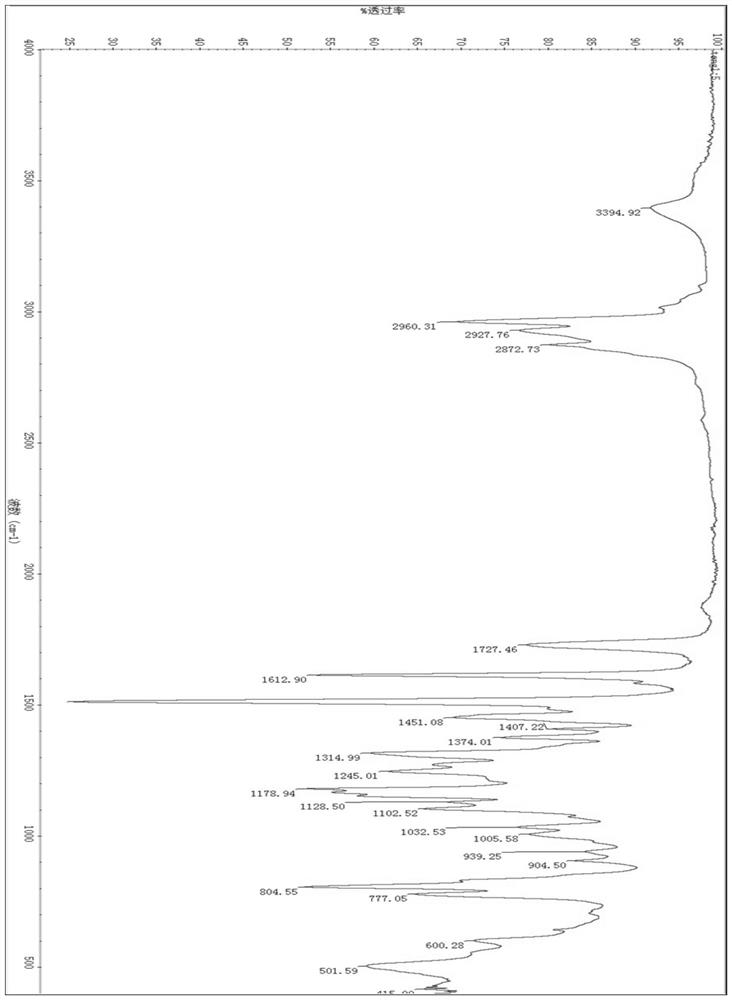

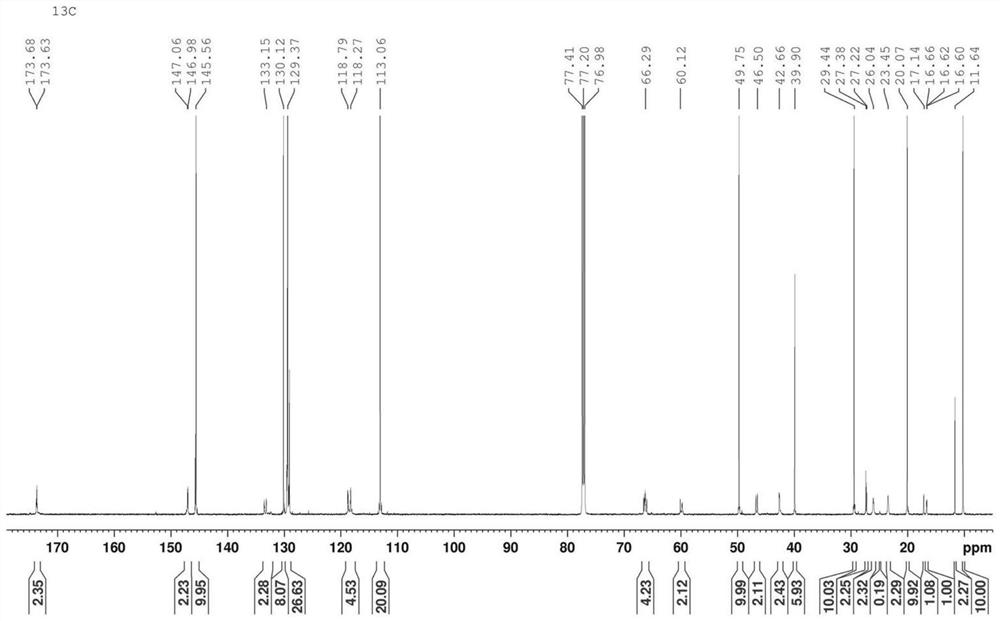

Process for producing epoxidation hexahydrophthalic acid di-octyl

InactiveCN101402617AEmission reductionReduce lossOrganic chemistryWater dischargeTetrahydrophthalamic acid

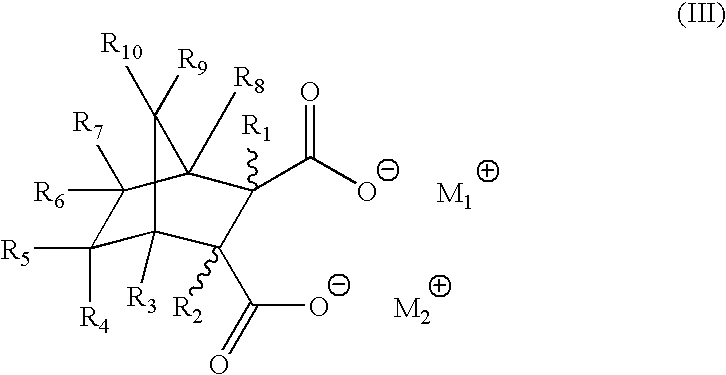

The invention relates to a process for producing epoxidationdioctyl cyclohexane phthalate. THPA and octanol are used as raw materials, and have esterification reaction under the action of catalyst to produce tetrahydrochysene dioctylphthalate; when the esterification reaction finishes, an overoxidation agent and an acidizer are added to the tetrahydrochysene dioctylphthalate for epoxidation reaction, and are subjected to neutralization, washing, steam stripping and dealcoholization, decompression and distillation, and decolorization and filtration to obtain epoxidationdioctyl cyclohexane phthalate. The process has the advantages of simple processing, short production period which is shorted by approximately two hours, less equipment investment, less waste water discharge which is reduced by approximately 20 percent, small energy consumption, and reduction of production cost by approximately 10 percent.

Owner:河南庆安化工高科技股份有限公司

High tensile strength rubber material

The invention discloses a high tensile strength rubber material, which is prepared from the following raw materials in parts by weight: 40-60 parts of hydrogenated nitrile rubber, 15-25 parts of epichlorohydrin rubber, 20-40 parts of ethylene propylene diene monomer, 0.5-1 part of epoxy fatty acid methyl ester, 1-2 parts of trioctyl phosphate, 1-2 parts of chlorinated paraffin, 10-20 parts of modified humic acid, 8-22 parts of carbon fibers, 10-18 parts of anthracite, 2-8 parts of sodium antimonate, 5-12 parts of antimony trioxide, 0.5-1.5 parts of epoxidized soybean oil, 0.1-0.6 part of trimethyl phosphate, 1-2 parts of microcrystalline wax, 1-3 parts of an antioxidant DNP, 0.5-1.5 parts of di-tert-butyl peroxide, 1-2 parts of hexahydrophthalic anhydride and 1-2 parts of sulphur. The high tensile strength rubber material has very good hardness, toughness and tensile strength as well as very high density, is excellent in corrosion resistance and ageing resistance, and has higher impact resistance.

Owner:TIANCHANG KANGNING PLASTIC TECH

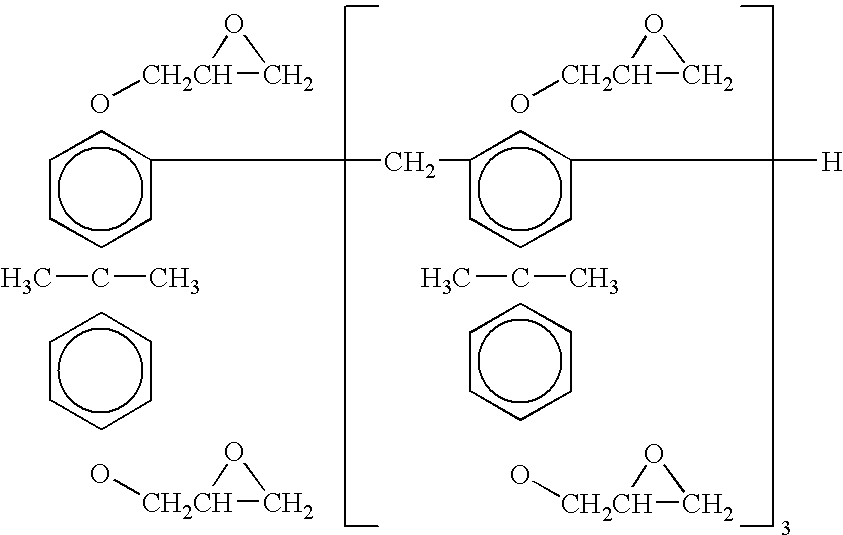

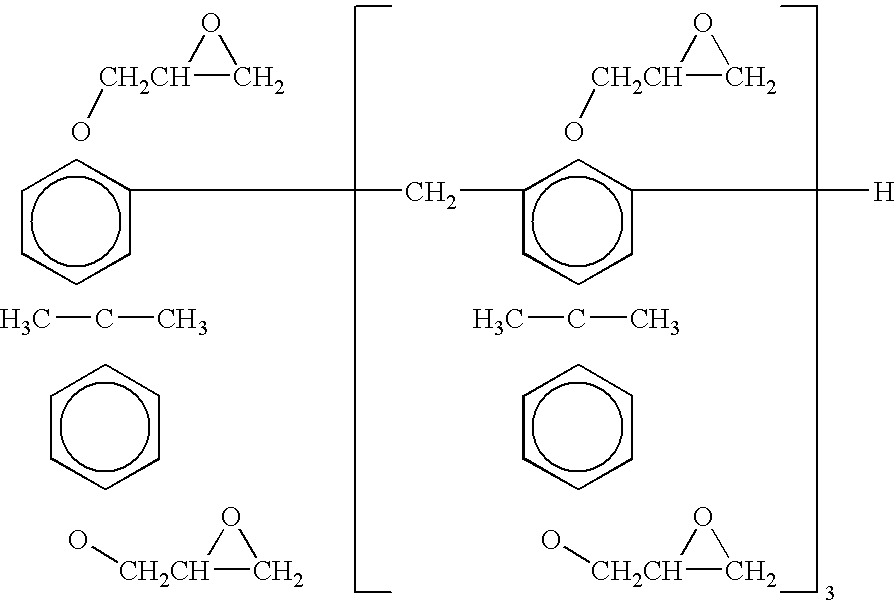

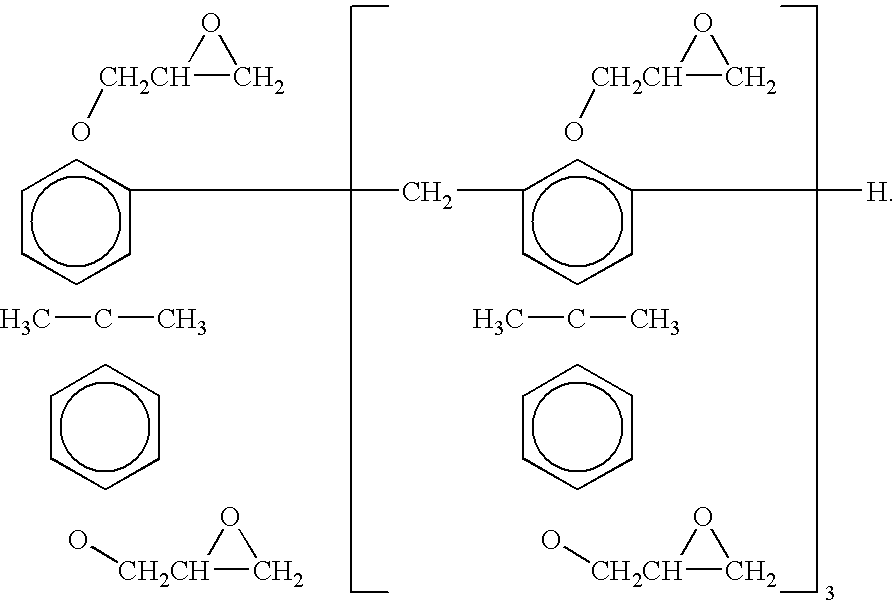

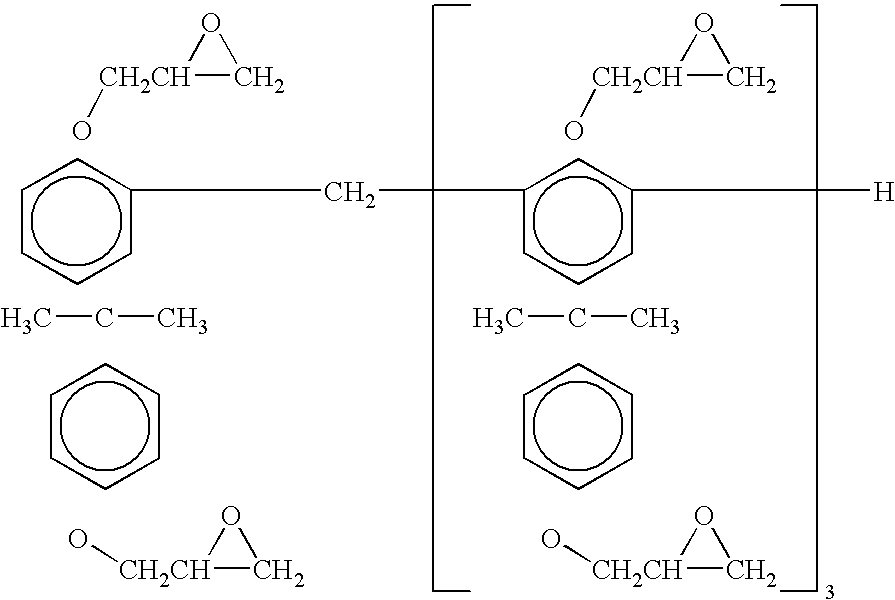

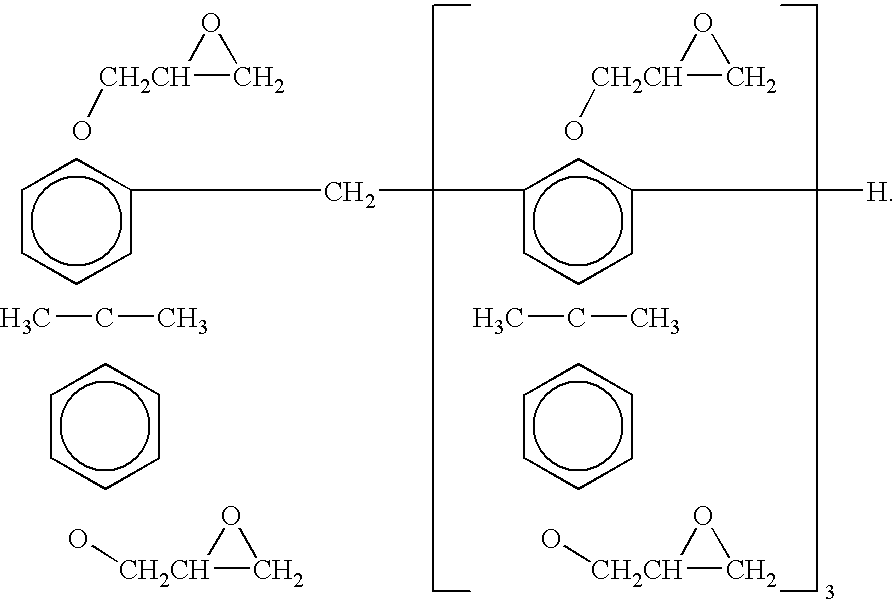

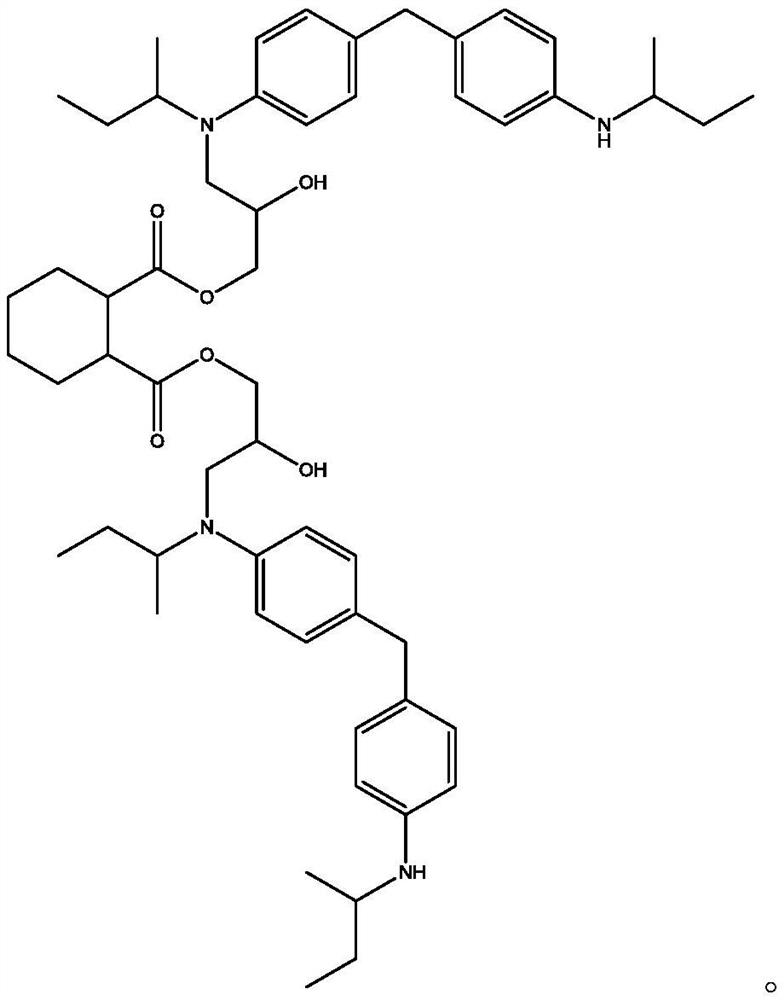

Secondary amine chain extension cross-linking agent and polyurethane elastic material

ActiveCN114044869AHigh molecular weightReduce reactivityOrganic compound preparationAmino-hyroxy compound preparationPolymer sciencePtru catalyst

The invention discloses a secondary amine chain extension cross-linking agent and a polyurethane elastic material. The structural formula of the secondary amine chain extension cross-linking agent is shown in the specification, and the preparation method comprises the following step: in the presence of a catalyst, reacting 4, 4'-bis(sec-butylamino) diphenyl methane with hexahydrophthalic acid diglycidyl ester. The operability of the secondary amine chain extension cross-linking agent and the strength, heat resistance and the like of the prepared polyurethane elastic material can be improved.

Owner:WANHUA CHEM GRP CO LTD

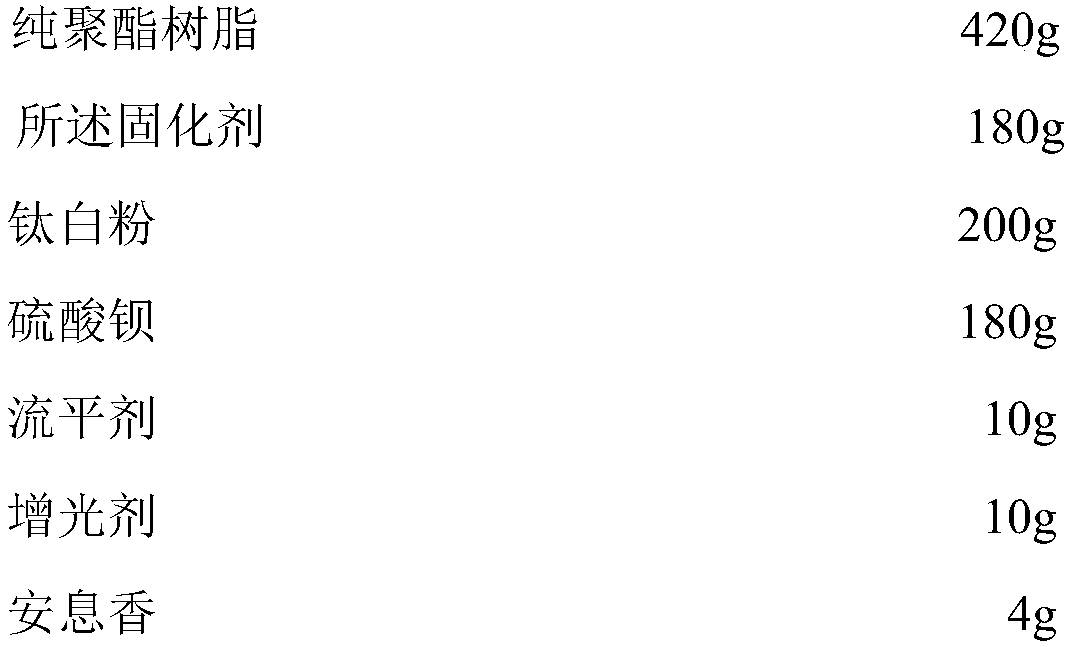

Epoxy powder coating for pipeline and preparation method of epoxy powder coating

InactiveCN107141959ANo pollution in the processImprove adhesionAnti-corrosive paintsPowdery paintsAnticaking agentPrecipitated calcium carbonate

The invention discloses an epoxy powder coating for pipelines and a preparation method thereof. Diglycidyl hexahydrophthalate, polyester resin, choline chloride, benzoin, titanium dioxide, light calcium carbonate, Leveling agent, powder flow aid, talcum powder, edge covering agent, anti-caking agent, and pigments are mixed at high speed, melted and extruded, pressed into tablets, crushed, sieved and filtered to make powder coatings; it has no pollution, It has the characteristics of energy saving and environmental protection, good bonding performance, good weather resistance, long service life, and low production cost.

Owner:安徽颐鑫节能材料有限公司

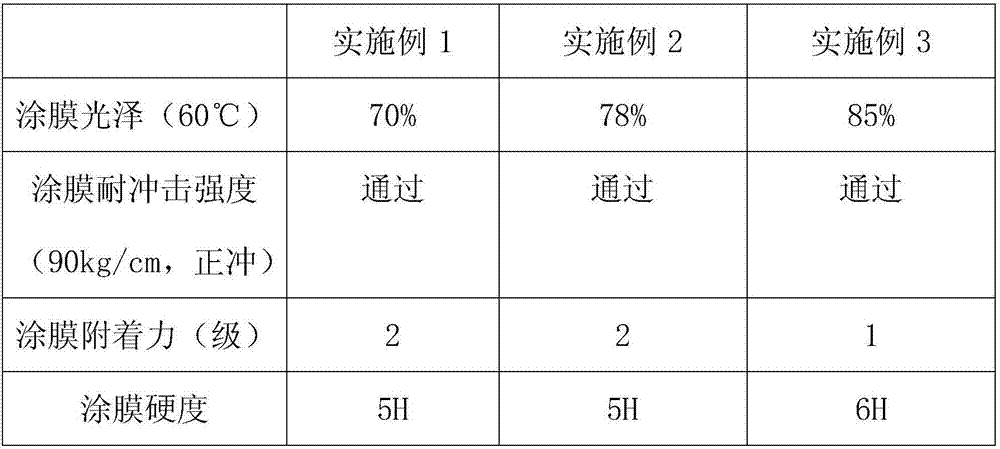

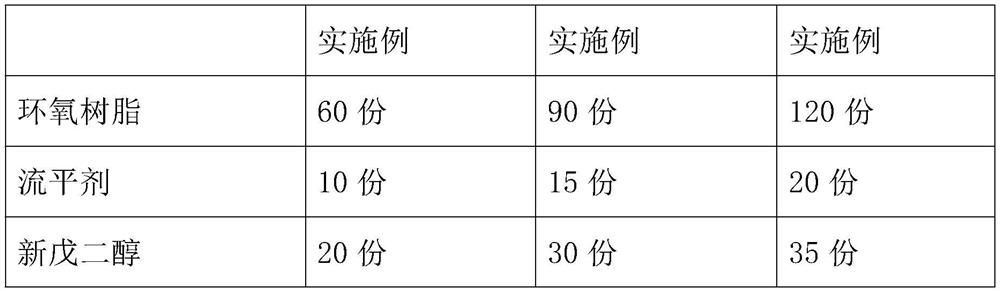

High-performance water-based resin and preparation method thereof

The invention discloses a high-performance water-based resin and a preparation method thereof. The high-performance water-based resin is prepared from the following components in parts by weight: 60 to 120 parts of epoxy resin, 10 to 20 parts of flatting agent, 20 to 35 parts of neopentyl glycol, 15 to 35 parts of isophthalic acid, 10 to 22 parts of hexahydrophthalic acid, 10 to 15 parts of phthalic anhydride, 11 to 18 parts of trimellitic anhydride, 20 to 30 parts of adipic acid, 10 to 15 parts of p-methoxyphenol and 10 to 13 parts of base material wetting agent. The invention relates to an environment-friendly adhesive which is prepared from the following raw materials in parts by weight: 15-25 parts of dimethylethanolamine, 10-14 parts of a dry crosslinking enhancer, 11-16 parts of a wetting dispersant, 20-35 parts of vegetable oil fatty acid, 30-50 parts of alkyd resin, 10-15 parts of an initiator, 10-20 parts of a surfactant and 10-30 parts of a catalyst. According to the high-performance water-based resin, the hardness, the corrosion resistance, the weather resistance, the dryness and the adhesive force performance are correspondingly improved, and compared with existing water-based resin, the film drying time is shortened.

Owner:南京杰腾新材料科技有限公司

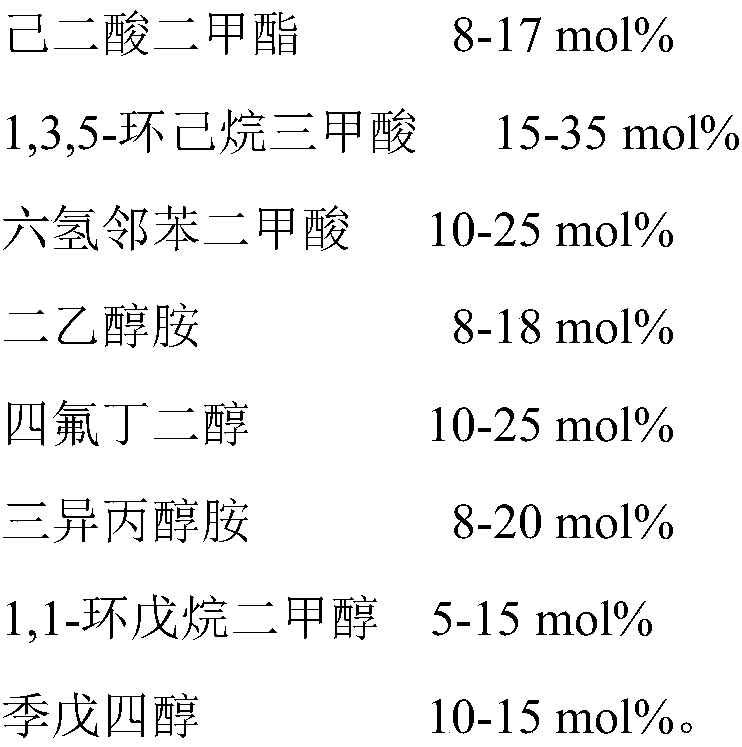

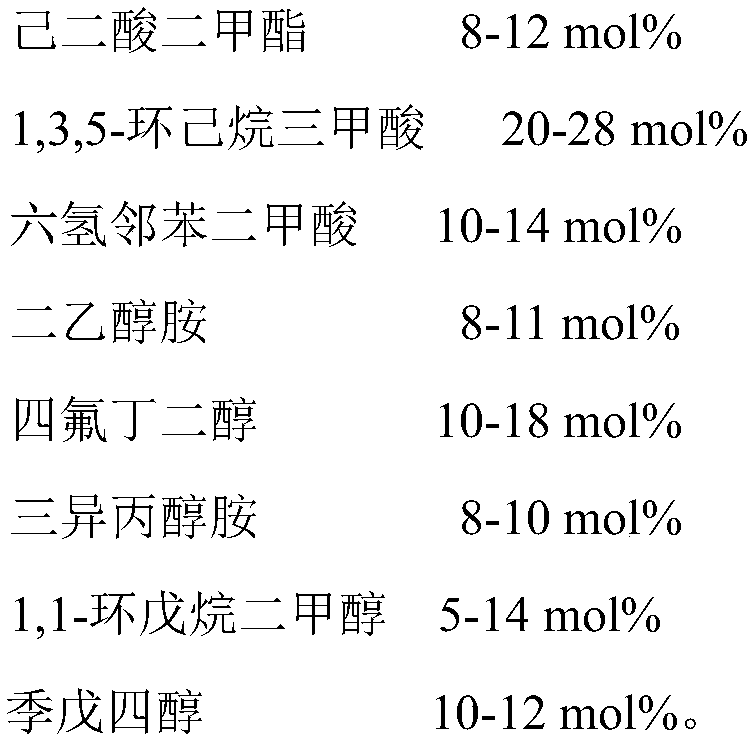

Curing agent for pure polyester powder coating system and preparation method thereof

ActiveCN109111783AImprove outdoor weather resistanceImprove the level ofPowdery paintsPolyester coatingsCross-linkButanediol

The invention relates to a curing agent for a pure polyester powder coating system and a preparation method thereof. The curing agent is prepared by polymerizing dimethyl adipate, 1,3,5-cyclohexanetricarboxylic acid, cis-hexahydrophthalic acid, diethanol amine, tetrafluoro-butanediol, tri-isopropanolamine, 1,1-cyclohexanedimethanol and pentaerythritol. The final curing agent is colorless transparent particles with a hydroxyl value of 200-250 mgKOH / g and a softening point of 110-125 DEG C; the curing agent can be subjected to cross-linked curing with powder coating pure polyester resin, whereinthe curing speed is relatively moderate, and a film with perfect levelling property can be obtained; pinholes rarely appear when the curing agent is applied to the coating of a 130 mu m thick film. Meanwhile, due to the introduction of a fluorine-containing material, tetrafluoro-butanediol, the outdoor weather resistance of the film is enhanced.

Owner:安徽徽州正杰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com