Patents

Literature

213 results about "Montan wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Montan wax, also known as lignite wax or OP wax, is a hard wax obtained by solvent extraction of certain types of lignite or brown coal. Commercially viable deposits exist in only a few locations, including Amsdorf, Germany, and in the Ione Basin near Ione, California. High-graded lignite wax are also found in Yunnan and Jilin, China.

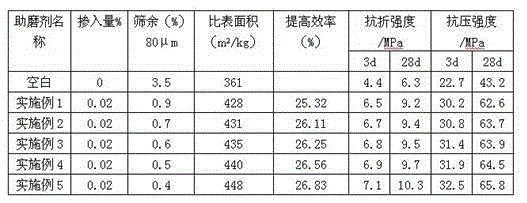

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

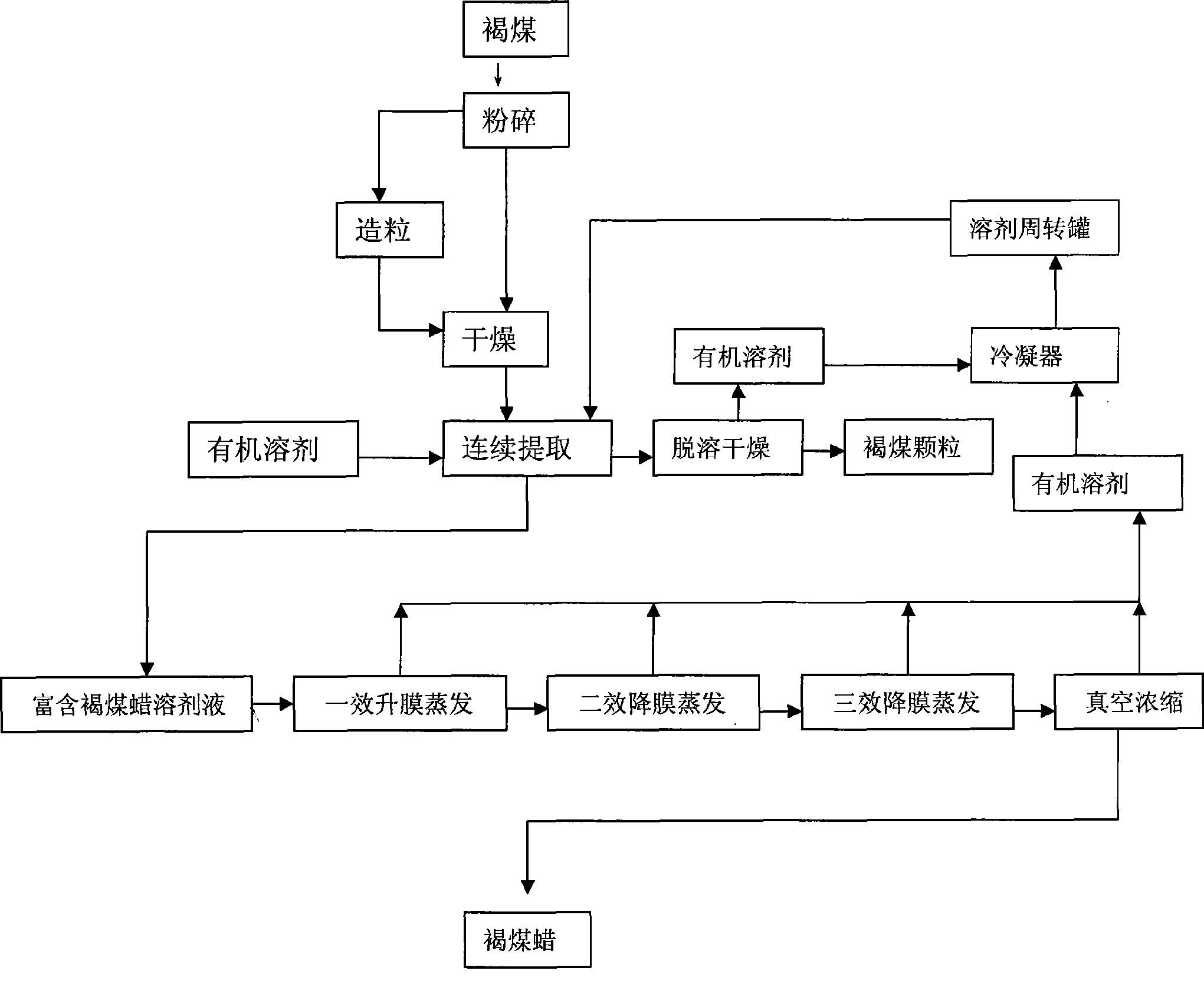

Method for extracting montan wax from lignite

ActiveCN101434868ANo pollution in the processSimple processMineral wax recovery/refiningSocial benefitsComing out

The invention relates to a production method used for extracting lignite wax from lignite, which can effectively solve the problems that the lignite wax is difficult to be prepared, has small yield and can not meet the practical requirements. The technical proposal used for solving the problems is as follows: the lignite is crushed and prepared into grains, dried and sent to an extractor for carrying out extraction; the lignite grains with the lignite wax extracted are sent to a continuous dry desolventizer so as to remove an organic solvent; the lignite grains coming out of the dry desolventizer are used for extracting a humic acid; three-effectiveness separation of the organic solvent rich in lignite wax is carried out so as to remove 95 percent of the organic solvent; subsequently, vacuum condensation is carried out so as to obtain the lignite wax; and subsequently, the solvent is recovered and circularly used. The method has simple process, can carry out production of large scale in batches, has high production efficiency, low cost and no environmental pollution, saves material, is a great creation on the preparation of lignite wax, and the application of the method has huge economical and social benefits.

Owner:河南华泰粮油机械股份有限公司

Wax emulsion for use in building products

Provided herein is an aqueous wax emulsion, comprising water; a paraffinic hydrocarbon; polyvinyl alcohol and a wax component comprising synthetic olefin wax component. The synthetic olefin wax component may be selected from the group consisting of (i) a synthetic normal α-olefin wax; (ii) a synthetic olefin wax of a carbon chain length of about 20 or more carbon atoms, that is modified by oxidizing and / or by refining through distillation or stripping; and (iii) combinations thereof. Such emulsions are also useful for settable gypsum compositions and water-resistant wallboard formed therefrom. Also included herein is a montan wax substitute for use in an aqueous montan-based wax emulsion.

Owner:OU HENRY

Wax emulsion for manufacture of composite boards

Wax emulsions useful for manufacture of a composite board are described which include water; a lignosulfonic acid or a salt thereof; and at least one wax selected from the group consisting of slack wax, paraffin wax and montan wax. Such emulsions are useful in composite board formulations and methods for making composite boards such as oriented strand boards.

Owner:OU HENRY

Wax polish and preparation method thereof

The process provides one kind of polishing wax and its preparation process. The polishing wax consists of silicone oil 3-8 wt%, vaseline 0.2-5 wt%, polyethylene 0.1-8 wt%, montan wax 0.1-0.5 wt%, coumarone-indene resin 0.1-5 wt%, carnauba wax 0.1-1 wt%, C12 fatty alcohol polyoxyethylene ether 0.5-3 wt%, nonylphenol polyoxyethylene ether 1-5 wt%, alkyl alcohol amide 2-5 wt%, ammonium hexadecyl trimethyl chloride or ammonium octadecyl trimethyl chloride 2-8 wt%, bentonite 1-5 wt%, glutaraldehyde 0.05-0.1 wt% and water 46.4-89.85 wt%. The polishing wax has no corrosion to the paint surface, and can eliminate dirt from paint surface, make paint surface clean and bright, and form protecting film with high heat resistance, less ageing and good luster.

Owner:李而淮

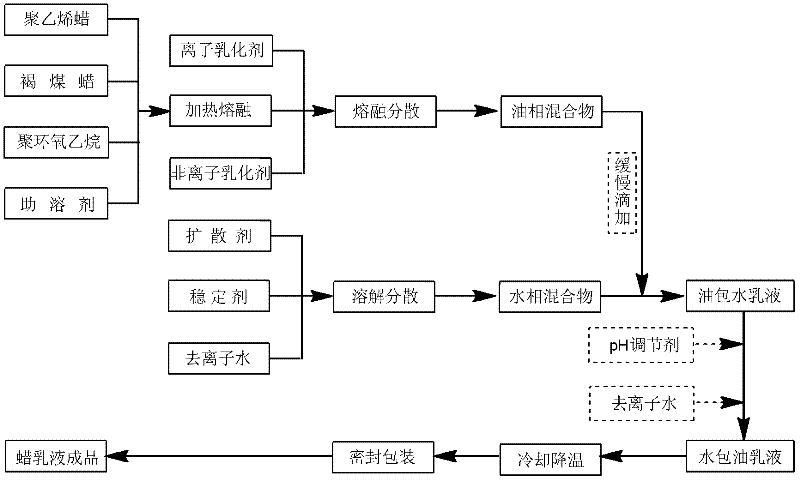

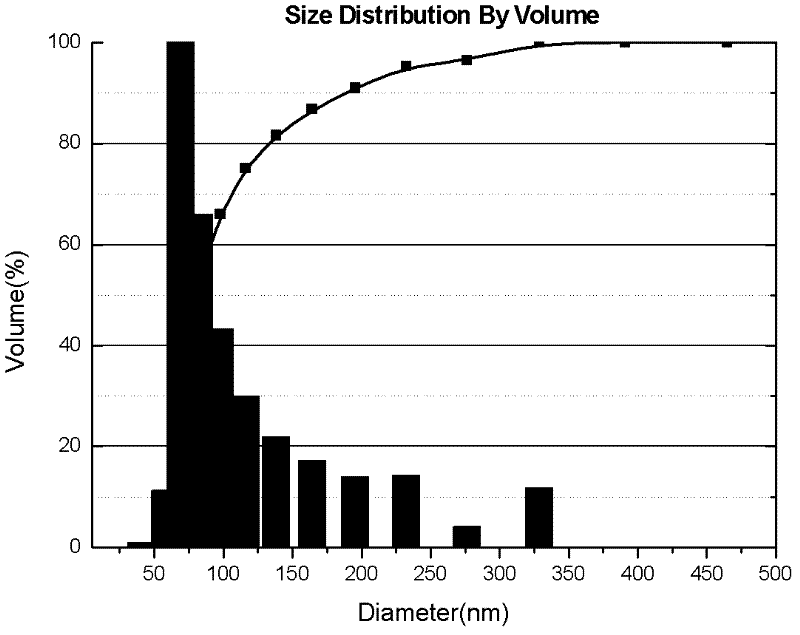

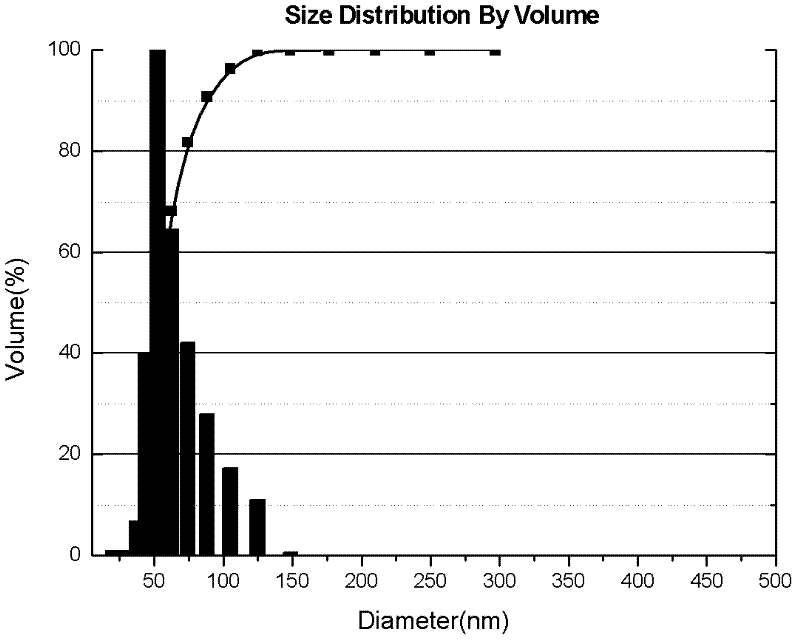

Nano wax emulsion and preparation method for nano wax emulsion

The invention provides nano wax emulsion which comprises the following components: polyethylene wax, montan wax, polyethylene oxide, cosolvent, ionic emulsifying agent, non-ionic emulsifying agent, dispersing agent, stabilizing agent, pH (potential of hydrogen) modifier and deionized water. The invention further provides a preparation method for the nano wax emulsion, the preparation method comprises the steps of (1) preparing oil-phase dispersing mixture, (2) preparing water-phase dispersing mixture, (3) preparing nano wax emulsion, and then finally obtaining high melting point and high solid content nano wax emulsion of which the wax content is 30-48%. The wax emulsion prepared in the invention solves the problem that high melting point wax is hard to emulsify; the wax content can reach 30-48%; and additive amount of the emulsifying wax in the using process and production cost are reduced, meanwhile, the prepared wax emulsion has good stability and narrow particle diameter distribution and is little influenced by multivalent metal ions; and the average particle diameter is 50-120 nm, and the nano wax emulsion is convenient for storage and transportation and can be used in continuous industrial production.

Owner:GUANGDONG LEPUTAI NEW MATERIAL TECH

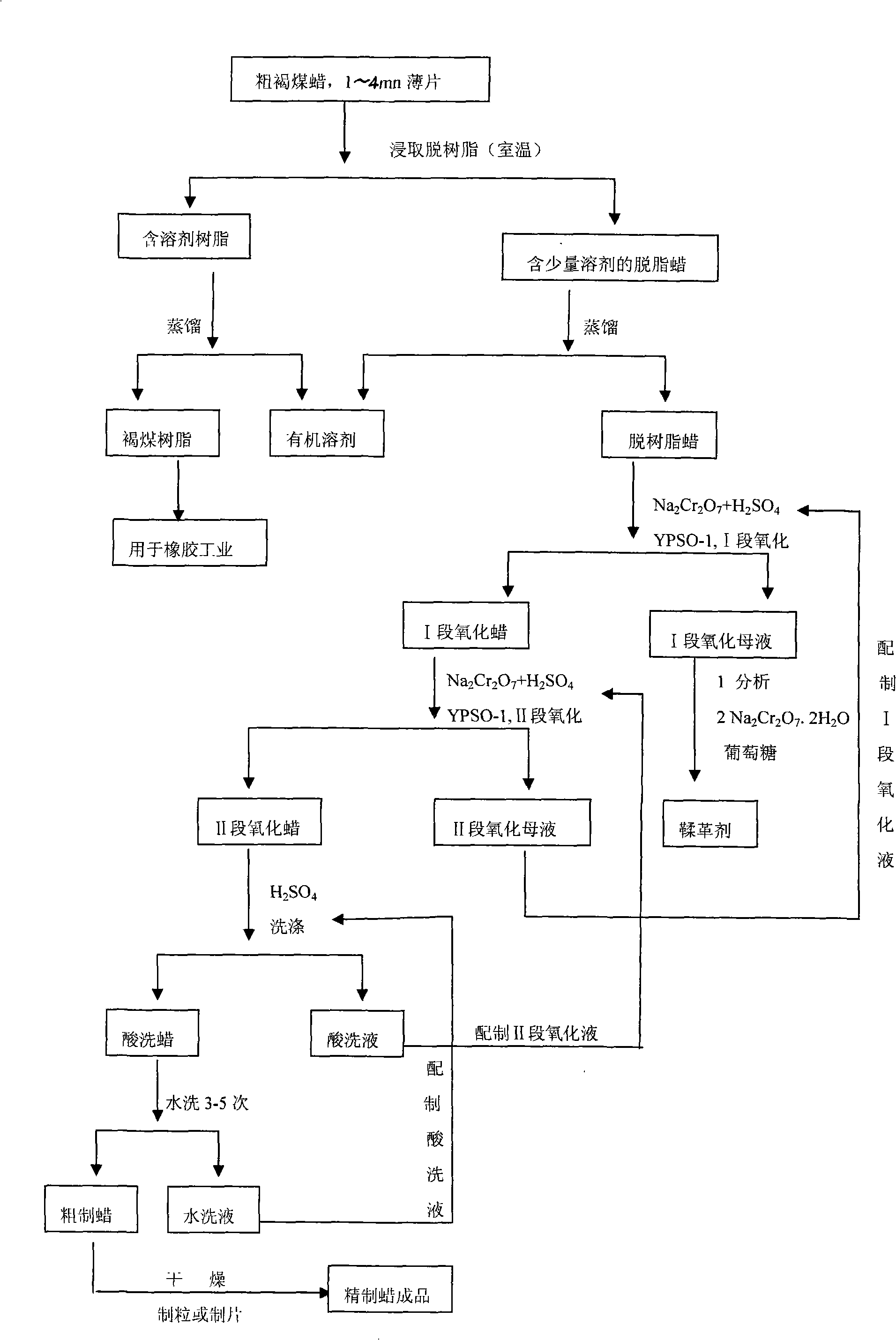

Oxidization fine purification albefaction method for montan wax

The invention provides an oxidation refined blanching method of lignite wax; coarse lignite wax is used as a material; resin is removed by adopting an ethyl acetate solvent; section oxidation is carried out on the degreased wax by using the mixed liquid of bichromate and sulphuric acid; then acid washing, water washing, drying and shaping are carried out on the oxidized wax to obtain the finished product of refined lignite blanching wax. The Cr<6+> in the oxidation liquid during the oxidation process is basically reduced to Cr<3+>; a tannage liquid can be prepared by carrying out treatment on the oxidation liquid. The production technique of the method is convenient to be operated; the technology can be practical; the cost is low and the practicability is high; and the method can produce a tannage agent needed by the tannage production industry simultaneously when producing the refined lignite wax. Considering from the aspects of environment protection and pollution control, the technique has a realistic meaning.

Owner:KUNMING UNIV OF SCI & TECH

Low-precipitate flame-retarded polyamide composition and preparation method thereof

The invention relates to the technical field of a high polymer material and especially relates to a low-temperature flame-retarded polyamide composition, and the composition includes the raw materials based on the following mass percentage: 20-70% of nylon resin, 10-30% of main flame retardant, 0-15% of synergistic agent, 10-40% of alkali-free glass fiber, 0-1% of antioxidant, and 0-2% of lubricant, wherein the nylon resin is one of nylon 66 and nylon 6 or their mixture; the main flame retardant is a brominated flame retardant; the synergistic agent is selected from one of compounds of antimonous oxide master batch, zinc borate, silicon dioxide and metallic oxide or the mixture prepared by more than one compound; the lubricant is a lubricant with high molecular weight and dispersion and includes one of polyethylene wax, modified PE wax, OP wax and lignite wax. The polyamide composition isn't easily migrated or precipitated at high-temperature moisture conditions and low in material cost, the preparation method is simple and beneficial to popularization and application.

Owner:江苏晋伦塑料科技有限公司

Method for producing high purity montan wax

InactiveCN101906320ALow impurity contentImprove product qualityMineral wax recovery/refiningSolventImpurity

The invention provides a method for producing high purity montan wax, including solvent extraction; wherein no solvent for submerging montan is added in the extraction process, the solvent is composed of the following components by mass ratio: 20-100% of isopropanol and 0-80% of alcohol or hydrocarbon or water, the alcohol is one or more than one of methyl alcohol, ethyl alcohol and tertiary butanol, and the hydrocarbon is one or more than one of petroleum ether, solvent No. 6, normal hexane and cyclohexane. The invention thoroughly solves the problems that the existing extraction solvent benzene has high toxicity, pollutes the environment and is harmful to human body health. Besides, non-toxic isopropanol or isopropanol mixed solvent with extremely low toxicity is used for extracting montan wax in montan, impurity content in montan wax is effectively reduced, resin content is lower than 16%, asphaltos is lower than 6%, high purity product is obtained, product quality of montan wax isgreatly improved, and the difficult problem of the current montan wax extraction technology is solved, thus providing a beneficial approach for producing high quality montan wax in scale.

Owner:李定忠 +2

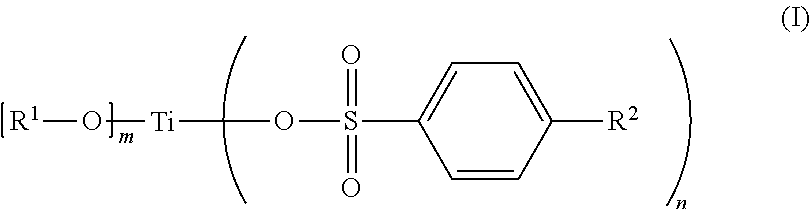

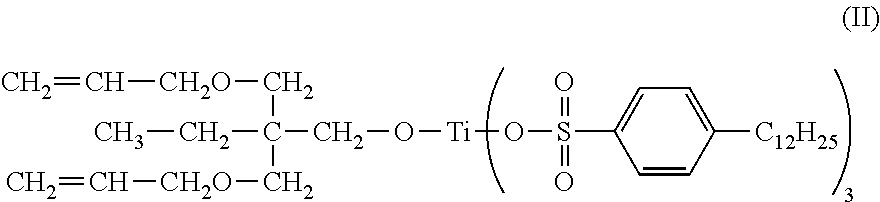

Special composite emulsifier for wax emulsion, and preparation method thereof

The present invention provides a special composite emulsifier for a wax emulsion. The special composite emulsifier is characterized by comprising, by weight, 45-50 parts of peregal, 20-25 parts of stearic acid, and 25-30 parts of fatty alcohol polyoxyethylene ether. The process comprises: sequentially adding peregal, stearic acid and fatty alcohol polyoxyethylene ether to a reaction kettle, heating to achieve a temperature of 60-70 DEG C until completely melting the material, and stirring to achieve a uniform state so as to discharge the material. According to the present invention, during preparation of various wax emulsions, the emulsifier having the amount of 8-10% of the mass of wax and the wax are co-melted and then uniformly stirred, and hot water with a temperature of 90-95 DEG C is added until the solid content is 50% so as to obtain the corresponding wax emulsion, or deionized water can be added according to requirements so as to adjust the wax emulsion content to 5-50% and the like. The special composite emulsifier can be provided for emulsifying paraffin wax, polyethylene wax, palm wax, montan wax, beeswax, rice bran wax, candelilla wax, shellac wax, and other types of waxes, such that material preparation of wax emulsion manufacturers is simply, and the prepared emulsion is translucent, has blue light , and has characteristics of good stability and small particle size; and the emulsifying system is consistent, such that various wax emulsions can be compounded according to any ratios without generation of phenomena such as precipitation, flocculation, layering and the like, and the special composite emulsifier can be conveniently used in various fields.

Owner:山东力厚轻工新材料有限公司

Leather cup rubber material for brake of automobile and preparation method thereof

The invention discloses a leather cup rubber material for a brake of an automobile. The leather cup rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of nitrile rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 10-30 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorine rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 15-20 parts of modified white carbon black, 3-4 parts of graphite, 8-10 parts of modified wood ash, 4-6 parts of vermiculite, 4-6 parts of quartz sand, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of sulfur, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BPP, 1-2 parts of stearic acid, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of lignite wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent RD, 2-3 parts of phenyl triethoxysilane and 16-18 parts of acetyl triethyl citrate. The rubber material disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber material can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Aqueous Wax Emulsions Having Reduced Solids Content for Use in Gypsum Compositions and Building Products

ActiveUS20120216722A1Low solid contentRetaining or improving its ability to resist absorption of waterInksCeramicwareBuilding productEmulsion

Aqueous wax emulsions are disclosed herein for use in gypsum formulations and other building products which emulsions include water; a paraffinic hydrocarbon; a montan wax component; and a hydrocarbon component. Optional emulsion and strength additives may be included in the emulsion or in a slurry formed from such emulsion for preparing a settable gypsum composition herein. The hydrocarbon component is at least one hydrocarbon compound having from 5 to 20 carbon atoms or at least one hydrocarbon resin which is based on the at least one hydrocarbon compound as a monomer, wherein the resin is at least a dimer comprising the hydrocarbon compound and the resin has a molecular weight (Mw) of no greater than about 3,000, wherein the hydrocarbon compound is saturated or unsaturated, functionalized or nonfunctionalized and is aliphatic, alicyclic, or aromatic, wherein the hydrocarbon component has a softening point of from about 22° C. to about 110° C.

Owner:OU HENRY

Process for improving carbon black dispersion

ActiveUS20130018137A1Good dispersionGood Pigment DispersionPigmenting treatmentFatty acid chemical modificationMasterbatchPolyolefin

A masterbatch comprising pigment and demoulding agent is provided. The demoulding agent is selected from the group comprising low molecular weight polyolefin oils, low molecular weight polyolefin waxes, montan waxes and aliphatic or aromatic carboxylic acid esters of fatty acids and / or fatty alcohols, wherein the pigment content of the masterbatch is from 3 to 70 wt. %, based on the total weight of the masterbatch. The masterbatch is suitable for preparation of a polymer composition having improved pigment dispersion.

Owner:COVESTRO DEUTSCHLAND AG

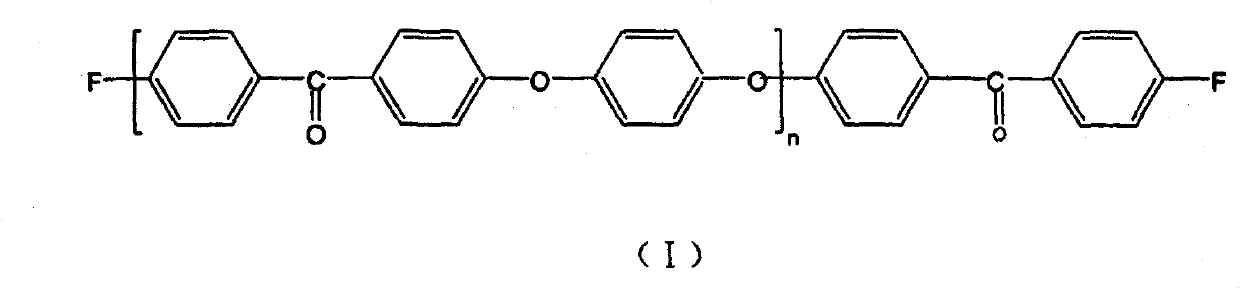

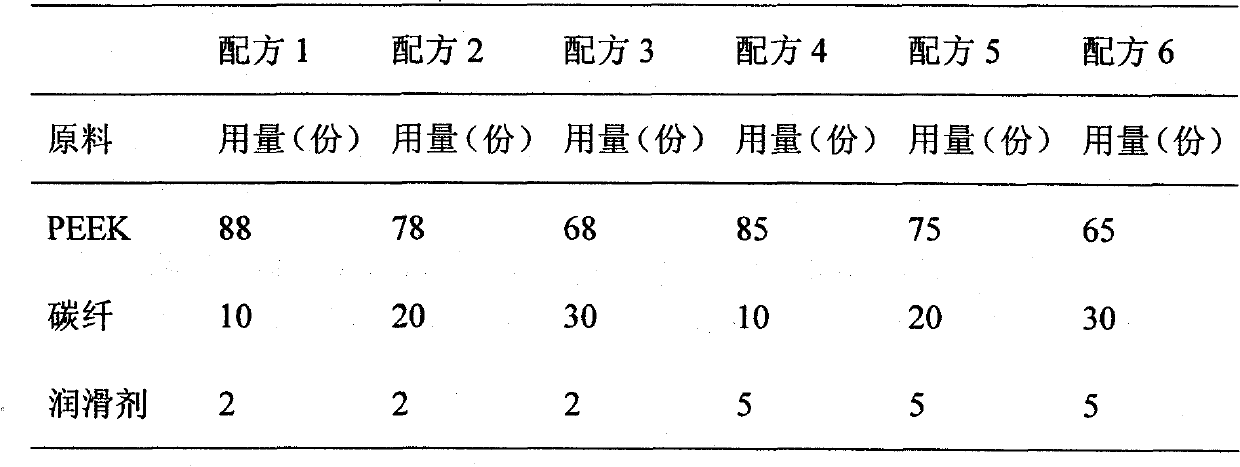

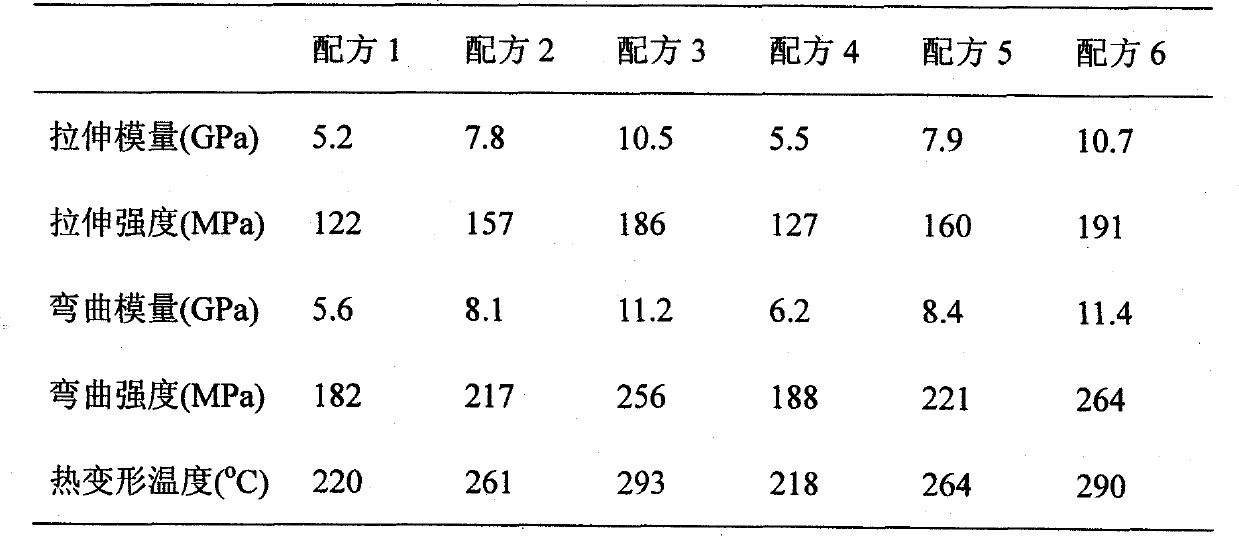

High-strength carbon fiber reinforced polyether-ether-ketone composite material and preparation method thereof

The invention belongs to the field of special engineering plastic, and in particular relates to a high-strength carbon fiber reinforced polyether-ether-ketone composite material and a preparation method thereof. The composite material contains 65-90wt% of polyether-ether-ketone resin, 0-5wt% of high temperature resistant lubricant and 10-30wt% of high-strength carbon fiber. The melt index of the polyether-ether-ketone resin is 12-80g / 10min, and the high temperature resistant lubricant is composed of high-molecular-weight polysiloxane and montan wax in the Clariant Corporation. The carbon fiber used is high-strength chopped carbon fiber of the SGL Carbon, and the surface of the fiber is subjected to coating modification. The prepared polyether-ether-ketone composite material has the characteristics of high strength, high modulus and high heat resistance, and can be widely used for aerospace, weaponry and high-end civil use field, such as a high temperature resistant connector.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

High-activity humic acid bio-fertilizer preparation method

InactiveCN106242904AImprove physical and chemical propertiesPromote absorptionBio-organic fraction processingExcrement fertilisersHigh activityINCREASED EFFECT

The present invention discloses a high-activity humic acid bio-fertilizer preparation method, and belongs to the technical field of agriculture. The high-activity humic acid bio-fertilizer is prepared by completely fermenting lignite, maifanite, a montan wax resin, traditional Chinese medicine residue, silkworm excrement, oil cake and compound bacteria. According to the present invention, with the high-activity humic acid bio-fertilizer, the physical and chemical properties of soil can be significantly improved, the absorption of crops on nutrients can be promoted, and the utilization rate of the chemical fertilizer can be increased; the fertilizer efficiency period is lasting and stable, the disease resistance and the stress resistance of crops are enhanced, and the yield increasing effect and the quality improving effect are significant; and the high-activity humic acid bio-fertilizer can be widely used in grain, vegetables, melon fruits and other field and cash crops, meets the development trend of green agriculture, has characteristics of wide raw material source, easy industrialization achieving, and broad application prospect.

Owner:YUNNAN SHANGCHENG BIOTECH

Non-washing type automobile essence and preparation method thereof

ActiveCN102586036AEffective maintenanceWon't scratchAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsGlycerolFatty alcohol

The invention relates to a non-washing type automobile essence and a preparation method thereof. The non-washing type automobile essence mainly comprises the following components in percentage by weight: 15 percent of sodium dodecyl benzene sulfonate, 5 percent of aqueous montan wax, 20 percent of dimethicone, 3 percent of oleic acid, 15 percent of glycerol, 5 percent of fatty alcohol-polyoxyethylene ether, 3 percent of emulsifier, 32.5 percent of ionic water, and 1.5 percent of waterproofing agent. The invention has the advantages that the non-washing type automobile essence quickly penetrates, ensures that a gap is generated between stains and an automobile paint, and forms a protective layer between sandy soil particles and the automobile paint, the generated wax water isolates the stains from the automobile paint at the periphery of the stains, a surfactant is used for removing the stains, a phenomenon that sand and stains slide and flow on the paint surface is generated, and the sand and the stains are lightly wiped by a towel and adhered to the towel; meanwhile, a polishing towel is used for drying and attaching a layer of protective film, so that the automobile film is bright; the harm of rain, snow, wind, sand and the like to an automobile body is effectively reduced, and the luster of the mirror surface of the automobile paint is protected against damage; and the invention has the greatest advantage of saving water resources.

Owner:孔国星

Special material for waste ABS (acrylonitrile butadiene styrene) plastic regenerated and modified automobile and preparation method of special material

The invention discloses a special material for a waste ABS plastic regenerated and modified automobile and a preparation method of the special material, and solves the problem that the recovery rate of a waste ABS plastic is lower, and resources are wasted in the prior art. The special material comprises the components in parts by weight as follows: 100 parts of a waste ABS broken material, 1-8 parts of ABS, 0.1-0.3 parts of EBS (ethylene bis stearamide), 0.1-0.2 parts of zinc stearate, 0.1-0.2 parts of calcium stearate, 0.1-0.2 parts of antioxidant 10100, 0.2-0.6 parts of antioxidant 168 and 0.1-0.4 parts of montan wax, wherein the waste ABS broken material is obtained by picking, breaking, cleaning, dehydrating, absorbing and drying the waste ABS plastic. The preparation method of the special material for the waste ABS plastic regenerated and modified automobile is further provided. The special material for the waste ABS plastic regenerated and modified automobile and the preparation method of the special material have the advantages that the waste ABS plastic can be recycled, resources are saved, the environment is protected, the cost is reduced, the preparation process is simplified, and the like.

Owner:四川塑金科技有限公司

Wax emulsion for manufacture of composite boards

Wax emulsions useful for manufacture of a composite board are described which include water; a lignosulfonic acid or a salt thereof; and at least one wax selected from the group consisting of slack wax, paraffin wax and montan wax. Such emulsions are useful in composite board formulations and methods for making composite boards such as oriented strand boards.

Owner:OU HENRY

Environment-friendly water-based composite wax emulsion release material for electric aluminum and preparation method of material

ActiveCN104726022AImprove alcohol resistanceEvenly distributedWax coatingsEmulsionFilm-coated tablet

The invention relates to the technical field of film coating products, and provides an environment-friendly water-based composite wax emulsion release material for electric aluminum and a preparation method of the material. The composite wax emulsion release material is characterized in that the composite wax emulsion release material is prepared from the following raw materials in parts by weight: 10-25 parts of montan wax, 2-8 parts of water-based resin, 2-7 parts of emulsifying agents, 1-5 parts of PH conditioning agents, 1-5 parts of wetting agents and 60-80 parts of water. Compared with the prior art, the composite wax emulsion release material has good alcohol tolerance; the composite wax emulsion release material is diluted with alcohol and water according to a ratio of 3:2, and then flocculated by a non-breaking emulsion, and wax particles coated on a film are distributed uniformly, so that the problem that the peeling effect of the wax emulsion release material is affected due to the fact that the coating quantity in a unit area is not stable is solved; water-based resin is matched reasonably, so that the surface tension of a coating layer is improved; the recoatability is excellent; the film coating appearance of a dark product is improved effectively; the water serves as a dispersion medium, so that the influence to the environment is little; the production cost is low; and the wax emulsion release material has the advantages of environmental protection and low cost.

Owner:云南玉溪东魅包装材料有限公司

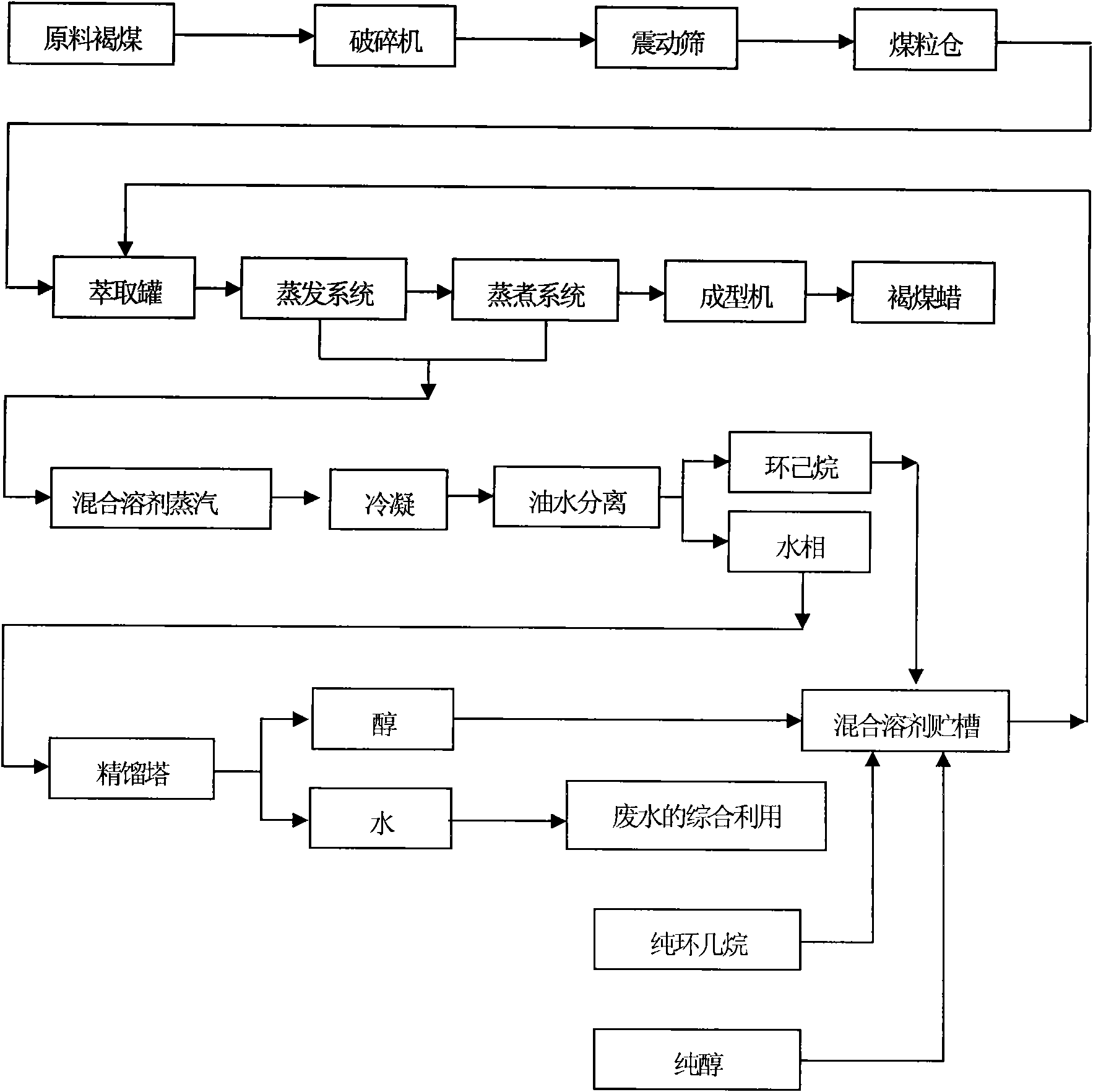

Mixed solvent and method for extracting montan wax

The invention provides mixed solvent extracting lignite wax and an extraction method, wherein the mixed solvent comprises the following raw materials: 10-70 mass percent of octanol, 10-70 mass percent of methylbenzene and 10-70 mass percent of alcohols. Lignite is pelletized and then is extracted by the mixed solvent, and the lignite wax is obtained by dehydration, concentration, evaporation and dryness. The lignite wax is extracted in the innoxious environment, and the extracted solvent can be recovered, thereby the mixed solvent is safe and reliable, the extraction cost is low, the process condition during the whole extraction process is more common, the process is simple, the operation is convenient, the comprehensive processing cost is low, the processing ability is strong, and the product yield is higher; in addition, the extraction method can not produce emulsion phenomenon during the whole extraction process, and is an effective, low-cost, massive and innoxious extraction process.

Owner:刘润民 +4

Lignite wax oxidizing and refining method

ActiveCN103525462AReduce usageShort reaction timeMineral wax recovery/refiningProcess engineeringIndustrial engineering

The invention discloses a lignite wax oxidizing and refining method which comprises the following steps: on the basis of taking degreased lignite wax as a raw material, refining the lignite wax by using a sectional method, firstly, performing primary rinsing by using peracetic acid and assistant, subsequently performing secondary rinsing by using hydrogen peroxide and hydrogen peroxide assistant, and finally drying and preparing a refined lignite wax product in a hot melting mode. The method disclosed by the invention is simple, feasible in technique, environment-friendly and energy-saving, the prepared wax is excellent in quality, and the method is an effective method for oxidizing and refining lignite wax of a non-chromium system.

Owner:KUNMING UNIV OF SCI & TECH

Alloy material and method for manufacturing forklift beam by use of same

InactiveCN103266273AGood workmanshipFoundry moulding apparatusFurnace typesParaffin waxInvestment casting

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

Multifunctional shoe polish for sneakers and preparation method for multifunctional shoe polish

InactiveCN102382577ALow costStrong decontaminationSurface-active non-soap compounds and soap mixture detergentsPolishing compositionsPentachlorophenolShoe polish

The invention discloses a multifunctional shoe polish for sneakers and a preparation method for the multifunctional shoe polish, which belong to the field of domestic chemistry engineering. The multifunctional shoe polish comprises, by weight, 20-30 parts of lithopone, 30-50 parts of microcrystalline wax, 20-40 parts of carnauba wax, 10-20 parts of montan wax, 5-10 parts of beeswax, 10-30 parts of silicon oil, 30-60 parts of glycerol, 5-8 parts of fatty alcohol-polyoxyethylene ether, 10-15 parts of turpentine, 2-5 parts of bactericide, 2-5 parts of sodium pentachlorophenol, 10-20 parts of stearic acid and 20-50 parts of deionized water. The preparation method for the multifunctional shoe polish includes steps of heating and smelting oil-phase materials in an oil-phase pot and uniformly mixing and emulsifying the melted oil-phase materials with water. The multifunctional shoe polish for sneakers and the preparation method for the multifunctional shoe polish have advantages of low cost of raw materials, high detergency, wide application of products and easiness in popularization.

Owner:胡辉

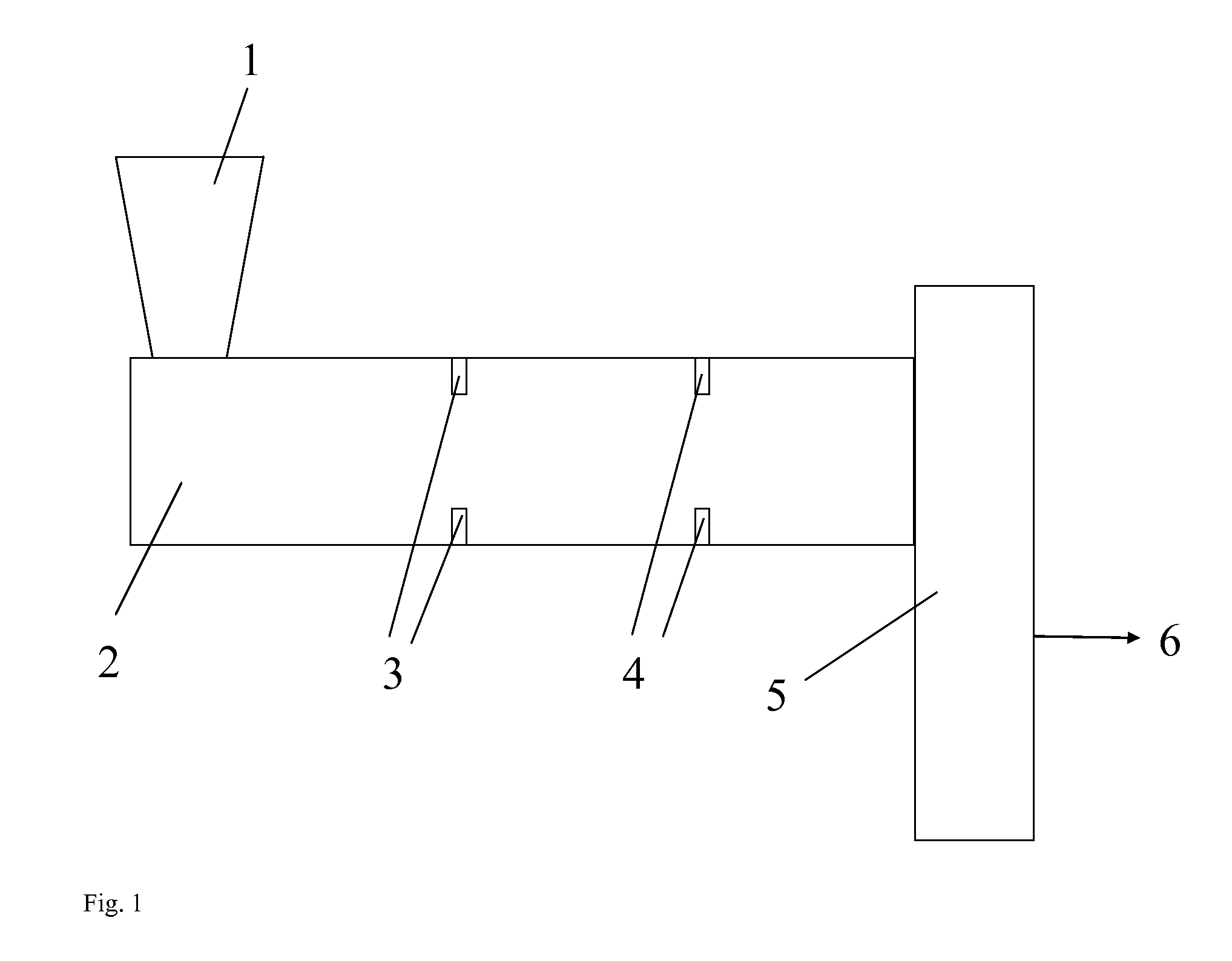

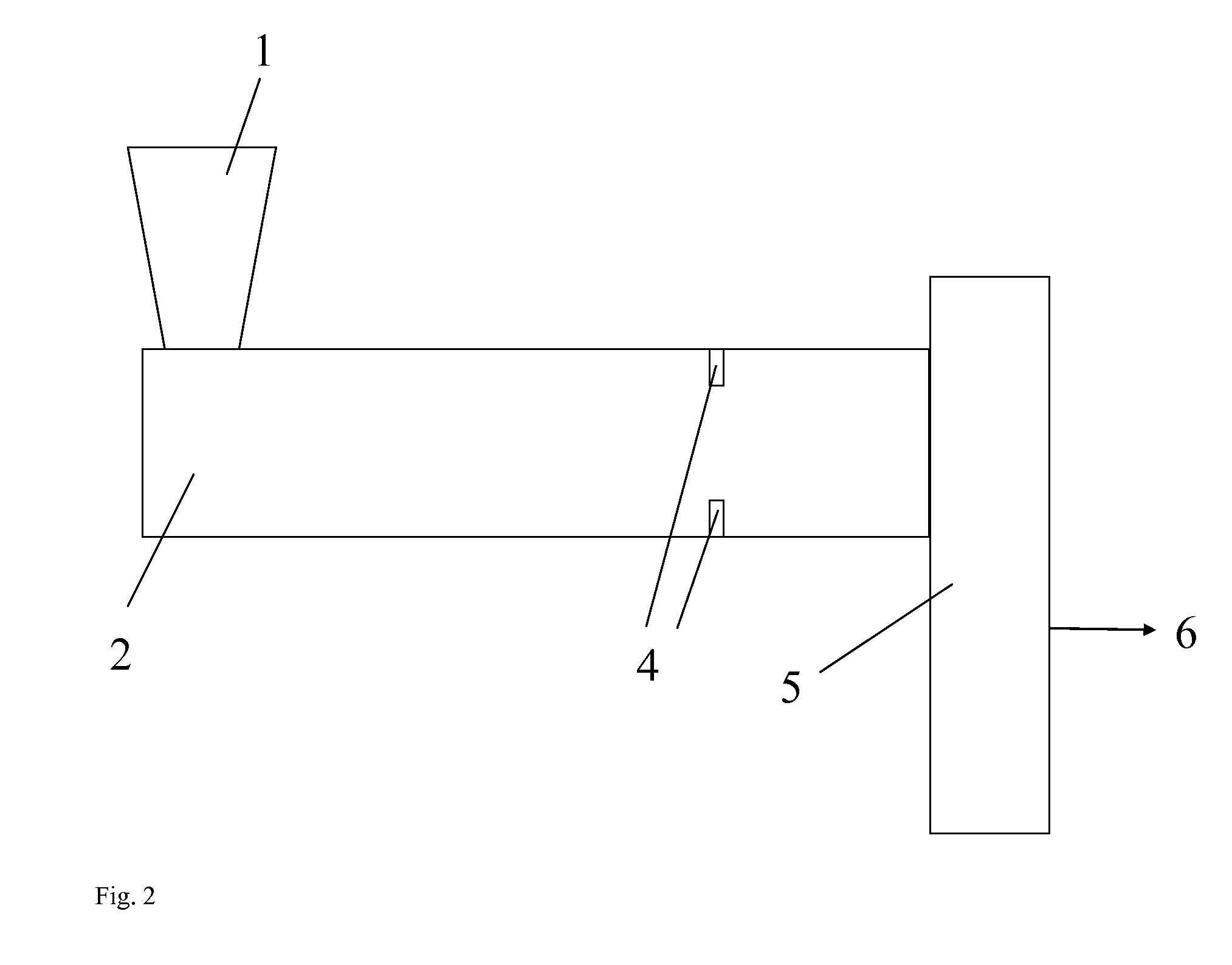

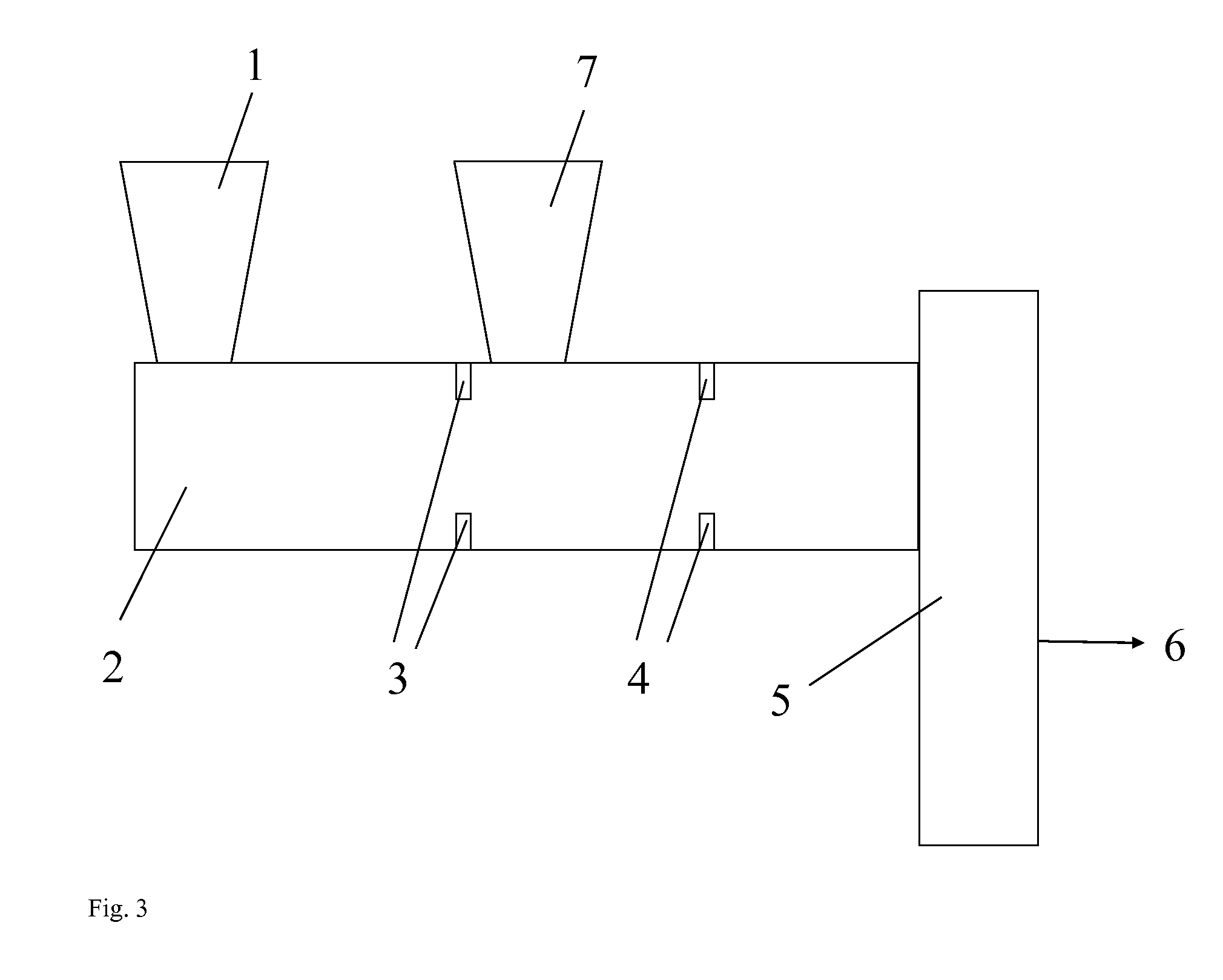

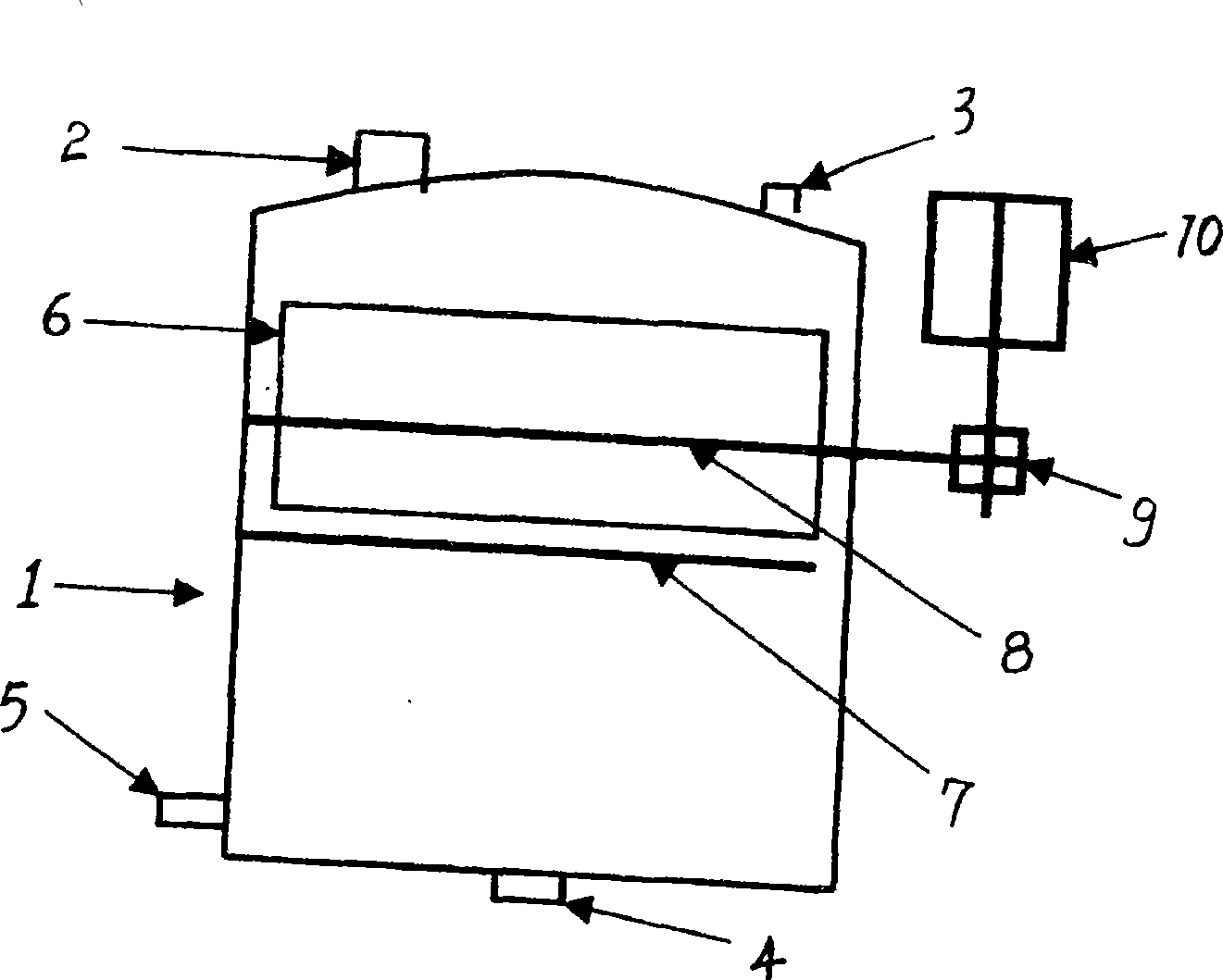

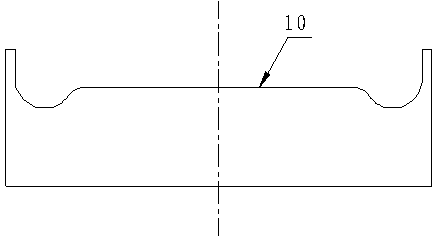

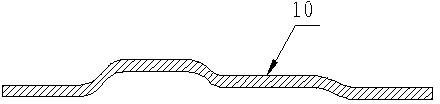

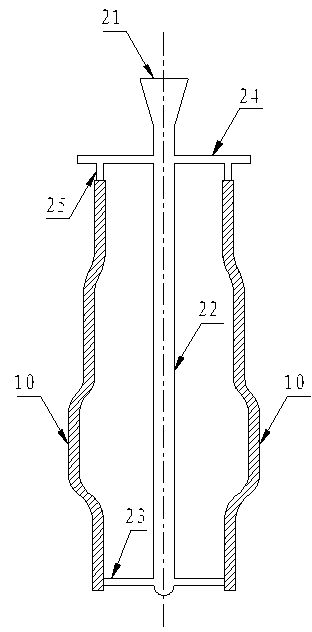

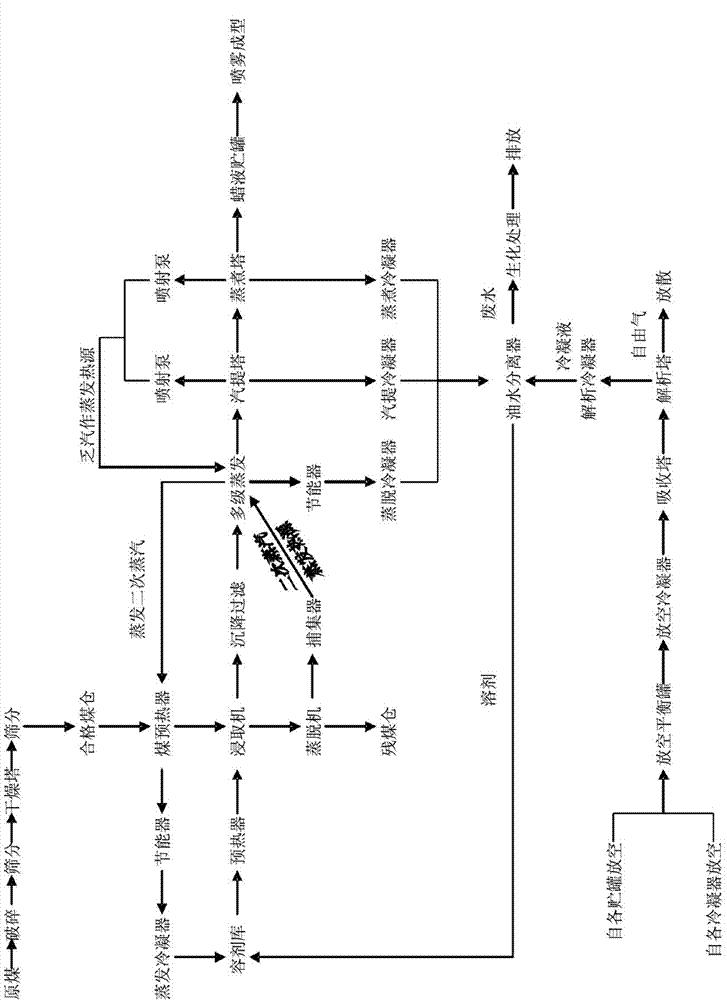

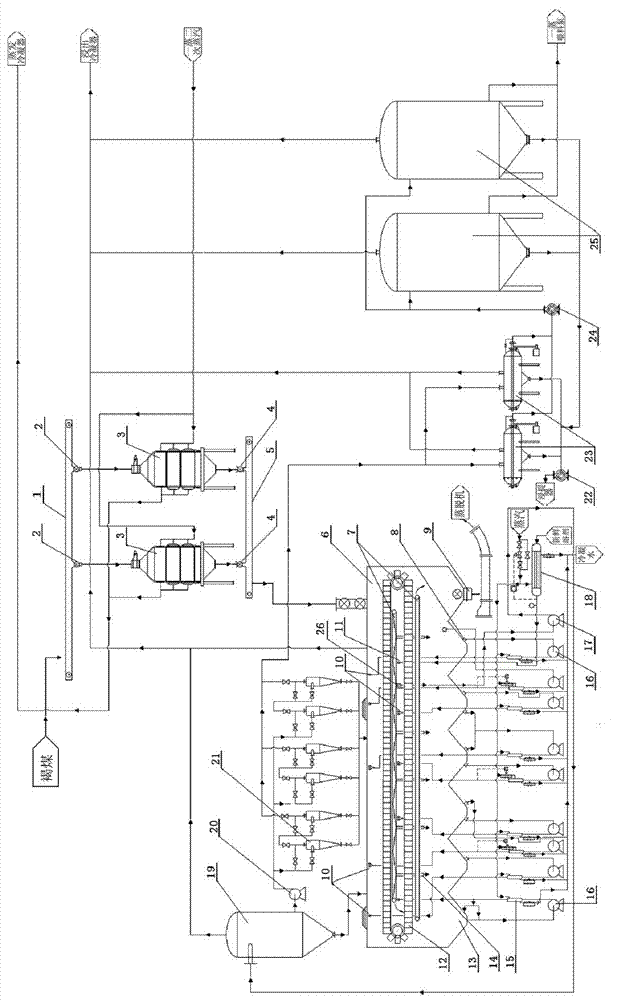

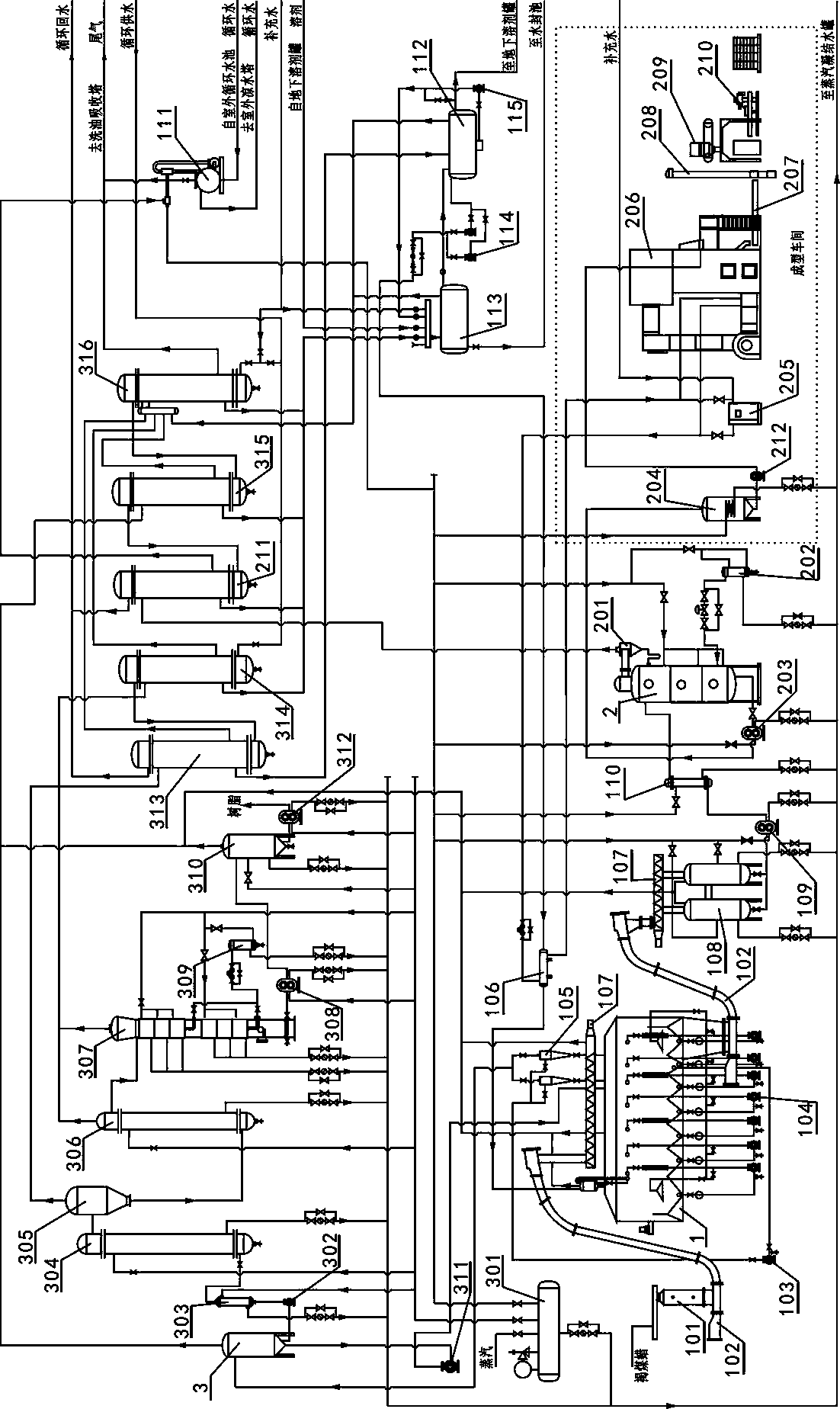

Method for efficiently extracting fossilized plant wax from brown coal and device thereof

ActiveCN102851076AImprove processing powerImprove equipment utilization efficiencyMineral wax recovery/refiningWaxSolvent

The invention discloses a method for efficiently extracting fossilized plant wax from brown coal and a device thereof. The method comprises the steps of pretreating the brown coal, conducting gradient leaching, recovering the solvent to precipitate the wax, desolventing residual coal, and molding and packaging. The device comprises a feeding unit, a leaching unit, an evapo-separated unit, a disolventing unit, and a condensation system. According to the invention, by using a mixed solvent comprising toluene and ethanol or tert-butyl alcohol as the extraction solvent, the toxicity is lower than that of toluene, the latent heat of vaporization is lower than that of toluene, thus the energy consumption of mass transfer process is reduced; by adopting a large liquid-solid ratio cycle work mode to carry out gradient continuous cycle leaching on the brown coal particles, the leaching rate can reach more than 85%, and wax content in the coal dry basis after leaching is less than 0.8%; the technology leaching temperature is lower than the solvent boiling point, thus isopropanol and other insoluble substances in the lignite wax are greatly reduced; the negative desolventing process can effectively prevent wax pyrolysis, raise the acid value and saponification value of the was, so as to raise the quality of the obtained wax; the brown coal throughput per unit reaches 60T / h, and the automation and large scale production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

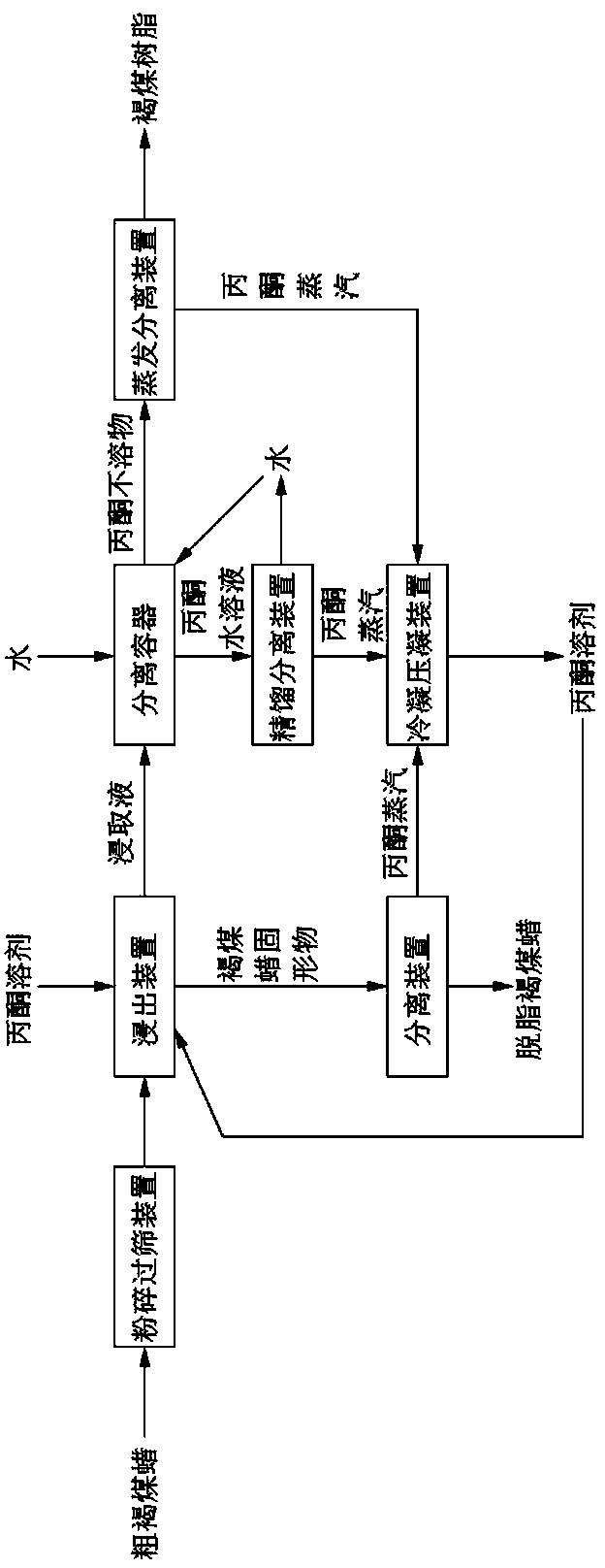

Energy-saving efficient resin-removing method and device for coarse lignite wax

ActiveCN103897734AEasy to recycleConsumableMineral wax recovery/refiningAqueous acetoneAqueous solution

The invention discloses an energy-saving efficient resin-removing method and device for coarse lignite wax. The resin-removing method comprises the following steps: smashing coarse lignite wax and sieving the smashed coarse lignite wax by a 0.5-3.0mm sieve; then, leaching the sieved lignite wax particles and acetone in a solid-to-liquid ratio of 1:1-1:8kg / L at constant temperature for 2-4 hours and separating to obtain a leaching liquid and a solid; placing the solid in a separating device, and heating, evaporating and removing residual acetone to obtain degreased lignite wax; placing the leaching liquid in a separating container, adding water to separate resin from acetone, and carrying out solid-liquid separation to obtain acetone insolubles and an acetone aqueous solution; and recovering acetone by rectifying the acetone aqueous solution; and evaporating the acetone insolubles to obtain walchowite. The degreasing device comprises a degreasing kettle, a ceride-removing desolventizing tank, a resin desolventizing separating tank, a rectifying device, an acetone storage tank and a condenser. According to the energy-saving efficient resin-removing method and device disclosed by the invention, as resin in lignite wax is easy to dissolve in acetone at constant temperature, wax and asphaltos are not dissolved, and the resin content in wax is reduced by digestion and separation at constant temperature, so that the device is simple and energy-saving and environment-friendly in process.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Solvent and method for extracting montan wax

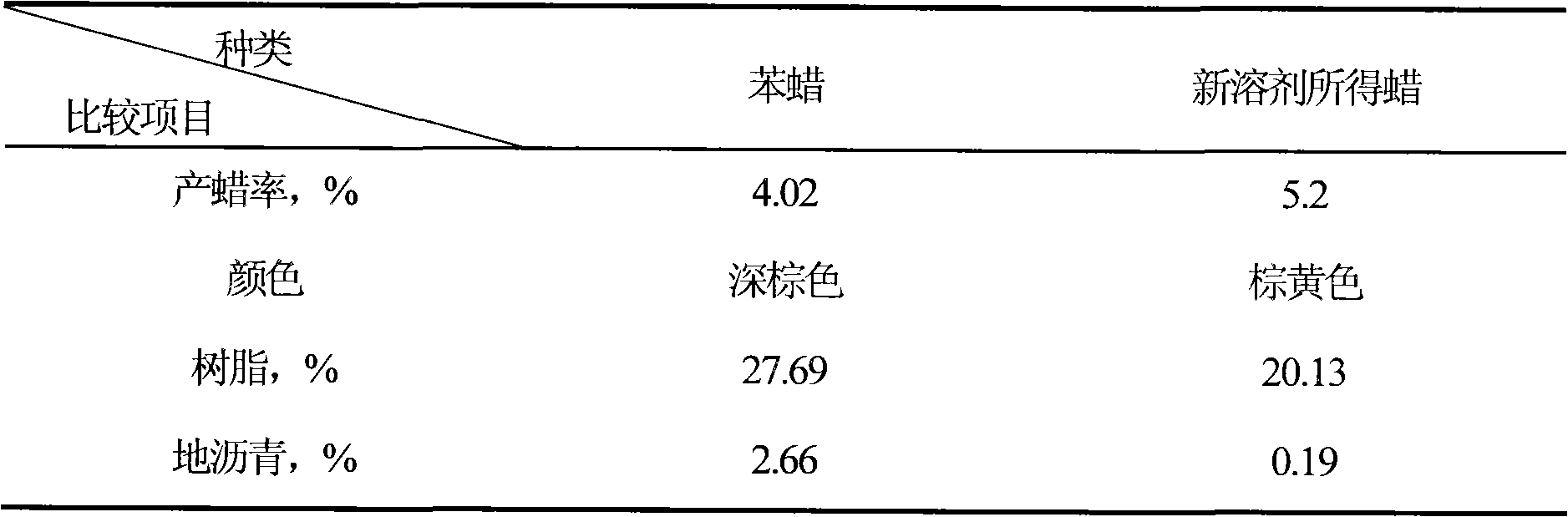

The invention provides a solvent and a method for extracting montan wax, which is characterized in that: the solvent is prepared by 1, 2-dichloroethane and alcohol according to the volume ratio of 3:7 to 10:0; grinding, extracting, filtering, concentrating and drying are carried out to obtain the brown montan wax. Under same production conditions, the solvent and the method increase the yield of the montan wax by 2 to 3 percentage and reduce the cost of the solvent by 10 to 20 percent compared with the benzene extraction method. Moreover, with high quality, the extracted montan wax has lighter brown color. The extracting solvent used by the invention causes no pollution to the environment and does not harm the human health. Changing the solvent into the nontoxic and harmless one provided by the invention and not changing the existing production equipment or technological conditions, the solvent and the method can save energy and reduce consumption, improve the quality of the products and bring no pollution to the environment.

Owner:李定忠

Color layer paint and PET (polyethylene terephthalate) heat transfer film for thermally transferring color layer onto PVC (polyvinyl chloride)

InactiveCN102504663AImproves UV resistanceGood acid and alkali resistanceWax coatingsDuplicating/marking methodsCyclohexanonePolymer science

Color layer paint comprises 50-65 parts of acrylic resin, 20-35 parts of ethyl acetate, 5-15 parts of organic pigment, 0.3-2 part of UV (ultraviolet) absorbent, and 0.5-2 parts of inorganic filler. A PET (polyethylene terephthalate) heat transfer film for thermally transferring color layer onto PVC (polyvinyl chloride) comprises a PET base film, a release layer coated on the PET base film, and a color layer formed by coating the release layer with the color layer paint, wherein the PET base film is 10-18 micrometers in thickness, and the release layer paint is made of montan wax, butanone and cyclohexanone according to a mass ratio 10:(6-9):(0.5-3). The color layer is thermally transferred onto a PVC board through the PET heat transfer film, and a product made has high ultraviolet resistance and acid and alkali resistance.

Owner:FSPG HI TECH

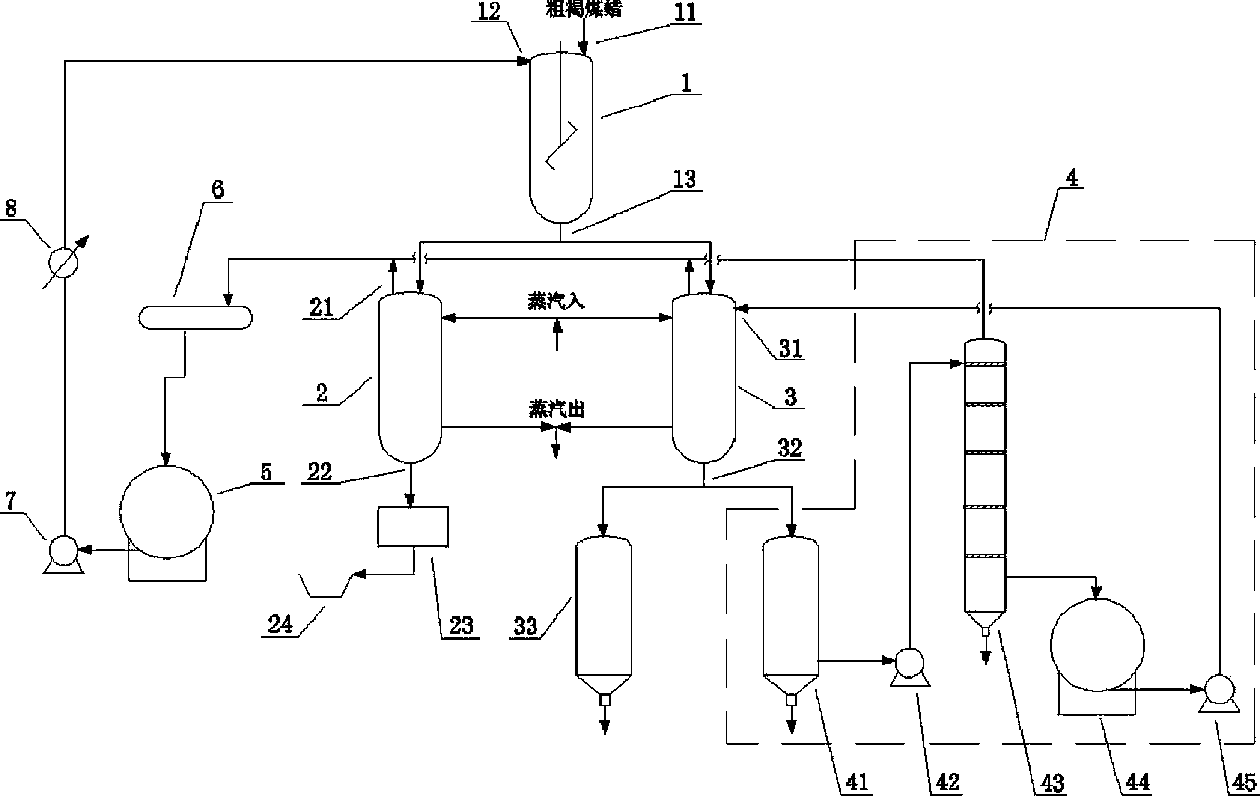

Production process of montan wax

InactiveCN101671574ALow asphalt contentImprove product qualityMineral wax recovery/refiningOil waterSolvent

The invention discloses a production process of montan wax, adopting mixed solvent of cyclohexane and alcohol. The production process comprises the following steps: smashing and screening lignite, putting coal particles of lignite into an extraction tank, putting mixed solvent in a volume ratio of solid to liquid of 1:1 to 1:4 for extraction and flash evaporating the extracted solution to recoverthe solvent; evaporating residual mixed solvent by a stewing system to obtain crude montan wax; vapor condensing the evaporated mixed solvent by a heat exchanger, then separating oil and water, and feeding upper-layer cyclohexane to a solvent feed tank; and separating tertiary butanol in lower-layer liquid from water by a rectification method, and introducing the separated tertiary butanol into the solvent feed tank; detecting the content of cyclohexane or tertiary butanol in the solvent feed tank, supplementing pure cyclohexane solvent and pure tertiary butanol solvent to lead the proportionof the two solvents to meet requirements, and then using the two solvents continuously. The extraction solvents of the production process have safety and reliability, simple extraction process, high wax yield, economy and environment protection, high reuse rate of solvents and low cost, thereby having wide practicability.

Owner:GUODIAN FUEL +1

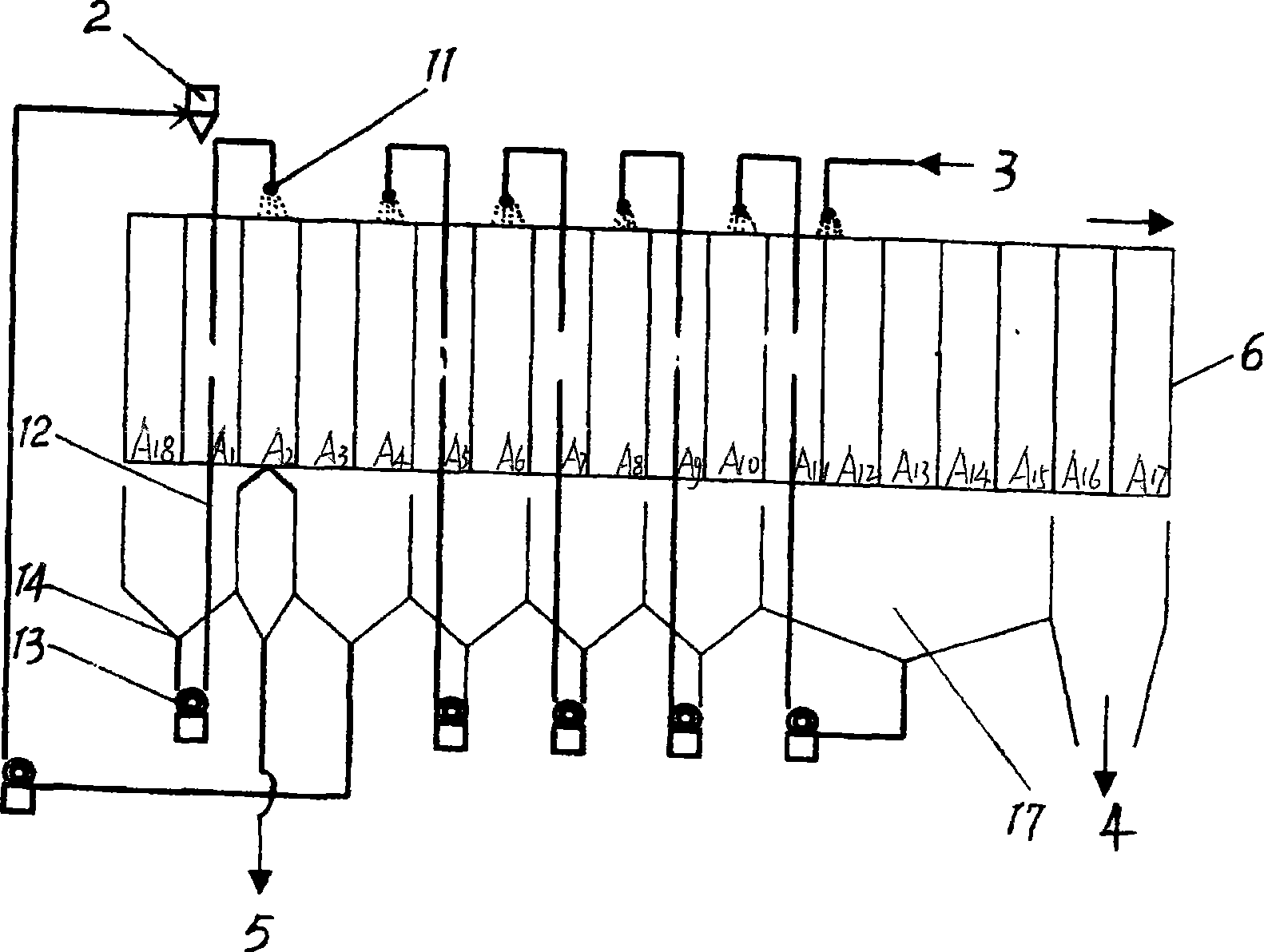

A method of continuously producing resin-removed lignite wax and resin and a device thereof

ActiveCN103666561AReduce consumptionPrevent decarboxylationMineral wax recovery/refiningNatural resin purificationSolventWax

The invention discloses a method of continuously producing resin-removed lignite wax and resin and a device thereof. The method includes continuously leaching lignite wax in a rotocel extractor by utilization of organic solvent, and removing the resin and recovering the solvent. The device comprises a solvent turnover pot, a leaching system, a solvent removing system of resin-removed lignite wax, a resin solvent removing system, a vacuum system and a steam distributor. According to the method and the device, a manner of low-temperature (lower than 20 DEG C) counter-current mass transfer and cyclic leaching is adopted. Benzene, toluene or ethyl acetate is adopted as the solvent, or a mixture of ethyl acetate and benzene or toluene is adopted as the solvent to highly dissolve the resin to be removed. The resin-removed lignite wax with high quality and the byproduct resin can be obtained by solvent removing treatment. The leaching efficiency is high and operation is cyclic. Large-scale continuous production is achieved. The yield of the resin-removed lignite wax is more than 80%. The resin content is lower than 5%. The solvent consumption is low with less than 100 kg of the solvent being consumed by per ton of the wax. A manner of removing the solvent under negative pressure is utilized, and therefore the solvent removing efficiency is high and the solvent removing temperature is low, decarboxylation of the lignite wax is prevented effectively and the acid value and the saponification number of the wax are guaranteed.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

High temperature resistant and wear resistant rubber material for oil sealing

The invention discloses a high temperature resistant and wear resistant rubber material for oil sealing. The rubber material comprises the following raw materials in parts by weight: 50 to 70 parts of hydrogenated nitrile rubber, 30 to 50 parts of fluororubber, 10 to 20 parts of polytetrafluoroethylene, 40 to 60 parts of composite filling material, 10 to 20 parts of microencapsulated red phosphorus, 5 to 15 parts of zinc borate, 20 to 30 parts of ammonium polyphosphate, 15 to 25 parts of acetyl trioctyl citrate, 1 to 3 parts of benzoyl peroxide, 0.2 to 0.4 part of dibutyl tin dilaurate, 0.3 to 0.5 part of promoter D, 0.1 to 0.2 part of promoter ZDC, 1 to 2 parts of Ca / Zn composite stabilizer, 1 to 2 parts of dibutyl tin dichloride, 1 to 2 parts of rare earth stabilizer, 0.2 to 0.4 part of anti-aging agent MB, 0.2 to 0.4 part of anti-aging agent 445, and 2 to 4 parts of montan wax; wherein the composite filling material comprises aerosil, modified molybdenum disulfide, modified graphite, and modified silicon carbide.

Owner:宁国天运橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com