Patents

Literature

43results about How to "Good Pigment Dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified polyamine

ActiveUS20130126804A1Good dispersionImprove heat resistanceTransportation and packagingInksPolyesterHeat resistance

A pigment dispersant which includes a modified polyamine obtained by the reaction of a polyamine having two or more primary and / or secondary amino groups per molecule and containing 2 to 1800 nitrogen atoms per molecule, a polyester, and a phosphorus-containing compound. The modified polyamine exhibits excellent pigment dispersion performance, shows little change in color tone upon heating, and has excellent heat resistance.

Owner:AJINOMOTO CO INC

Graft copolymers having excellent pigment-dispersing ability, production process of the graft copolymers, production method of emulsions by use of the graft copolymers, and pigment dispersions making use of the graft copolymers or emulsions

InactiveUS20050159555A1No good dispersion of the pigment was feasibleGood storage stabilityInksOrganic dyesEmulsionAcid value

A graft copolymer is formed by copolymerization of (A) a macromonomer and (B) a monomer. The macromonomer (A) is a polymer of (a) an ester monomer between an addition-polymerizable, unsaturated carboxylic acid and an aliphatic alcohol and (b) an addition-polymerizable monomer having an acidic group. The polymer contains an addition-polymerizable group at an end thereof, and has an acid value of from 100 to 300. The monomer (B) is an addition-polymerizable monomer. Units of the macromonomer (A) amount to from 20 to 50 wt. % of the whole graft copolymer, and units of the monomer (B) amount to from 50 to 80 wt. % of the whole graft copolymer.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Energy ray-curable ink composition

An active energy ray-curable ink composition comprising a colorant, a monomer and a photopolymerization initiator, in which the monomer contains an acrylamide derivative in an amount of 10 to 90% by weight based on the whole weight of the ink composition, and the ink composition has a viscosity of 3 to 35 mPa·s at 25° C. The ink composition has a low viscosity without dilution by a diluent solvent, good storage stability, good pigment dispersibility when a pigment is used as a colorant and also good continuous ejection stability to a printing medium, has a good curing property at a low energy level such as a cumulative amount of light of 150 mJ / cm2 or less, and it can attain good printing quality on nonabsorbable printing medium and achieves good adhesion of printed images to the printing medium.

Owner:HITACHT MAXELL LTD

Aqueous emulsion and coating

ActiveCN101133117AImprove mechanical stabilityGood Pigment DispersionEmulsion paintsMethacrylatePolymer science

To provide an aqueous emulsion having excellent mechanical stability, pigment compatibility and, when formed into a film, capable of providing excellent film transparency and solvent resistance; and a coating prepared using the aqueous emulsion. [MEANS FOR SOLVING PROBLEMS] An aqueous emulsion comprising: a polymer comprising at least one monomer unit selected from the group consisting of a (meth)acrylate ester monomer unit, a styrene monomer unit and a diene monomer unit as a dispersoid; and (A) a vinyl alcohol polymer having 1.9 mol% or more of a 1,2-glycol bond and a saponification degree of 70 mol% or higher and (B) a surfactant as dispersants, the ratio of (A) / (B) being 50 / 50 to 95 / 5 by weight and the average particle diameter of the particles dispersed in the emulsion being 0.5 [mu]m or smaller. A coating prepared using the aqueous emulsion.

Owner:KURARAY CO LTD

Process for improving carbon black dispersion

ActiveUS20130018137A1Good dispersionGood Pigment DispersionPigmenting treatmentFatty acid chemical modificationMasterbatchPolyolefin

A masterbatch comprising pigment and demoulding agent is provided. The demoulding agent is selected from the group comprising low molecular weight polyolefin oils, low molecular weight polyolefin waxes, montan waxes and aliphatic or aromatic carboxylic acid esters of fatty acids and / or fatty alcohols, wherein the pigment content of the masterbatch is from 3 to 70 wt. %, based on the total weight of the masterbatch. The masterbatch is suitable for preparation of a polymer composition having improved pigment dispersion.

Owner:COVESTRO DEUTSCHLAND AG

Process for Producing Resin-Coated Pigment, Resin-Coated Pigment, Aqueous Pigment Dispersion and Aqueous Colorant Composition Containing the Same

ActiveUS20080262122A1Good storage stabilityHigh densityDuplicating/marking methodsInksDispersion stabilityOrganic solvent

A process for producing a resin-coated pigment capable of providing an ink and a paint being superior in dispersion stability of a pigment and having rapid drying property, high gloss and density without containing those such as an organic solvent and a salt that cause the lowering of performance of pigment dispersion, characterized in that a pigment is dispersed in an aqueous solution in which an anionic group-containing resin is dissolved in the presence of a basic compound and then, the anionic group-containing resin is precipitated on the surface of the pigment by removing the basic compound in the aqueous solution, using an ion exchange means.

Owner:SAKATA INX

Treated water-insoluble solid particles, preparation and use

InactiveUS20030049447A1Good dispersionGood moisturizing effectCosmetic preparationsBiocideWater insolubleSolid particle

The present invention relates to water-insoluble solid particles, especially pigments, which characteristically are coated with at least one layer of at least one product resulting from the reaction between at least one molecule capable of becoming hydrated in contact with water and at least one lipophilic molecule. It further relates to cosmetic, pharmaceutical and agricultural compositions comprising such particles and to the manufacture and use of said particles.

Owner:BASF BEAUTY CARE SOLUTIONS FRANCE SAS

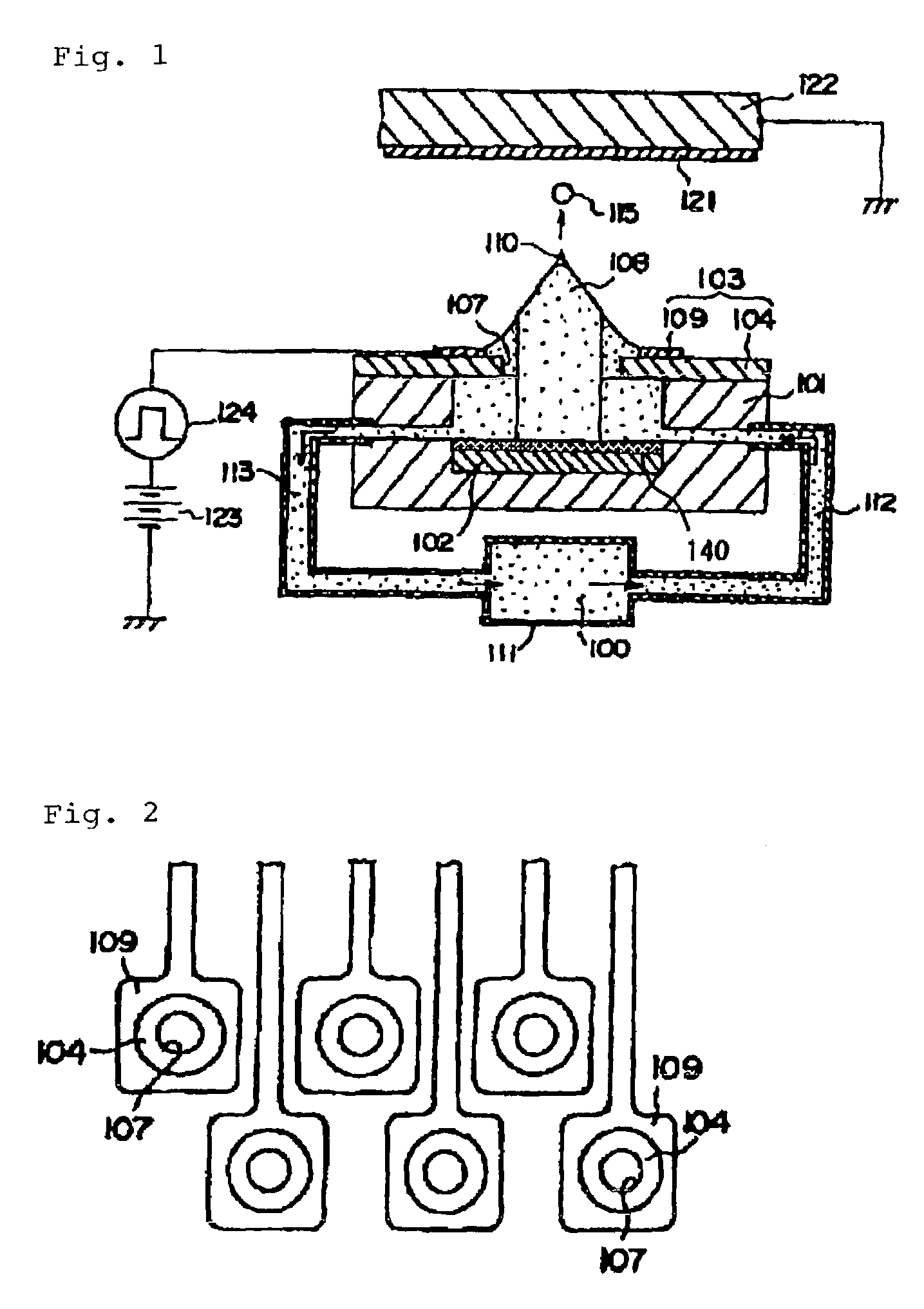

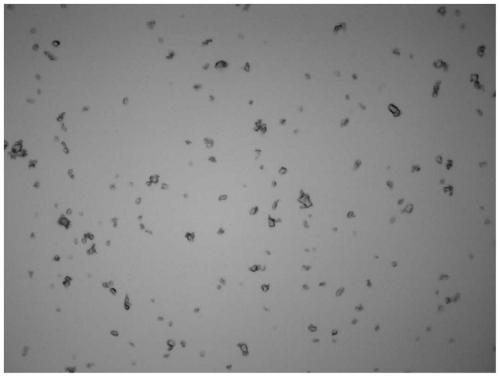

Oil based ink composition for inkjet printer

InactiveUS7008744B2Improve stabilityGood Pigment DispersionDuplicating/marking methodsInksInk printerMicroparticle

An oil based ink composition for inkjet printer comprising colored resin particles obtained by dispersion polymerization of a monofunctional polymerizable monomer (A) and a macromonomer (M) copolymerizable with the monomer (A) with coloring component fine particles comprising a surface-treated coloring agent, which are dispersed in a non-aqueous solvent having a dielectric constant of from 1.5 to 20 and a surface tension of from 15 to 60 mN / m at 25° C., as seed particles, in the presence of a dispersion stabilizer (P) soluble in the non-aqueous solvent and a polymerization initiator.

Owner:FUJIFILM CORP

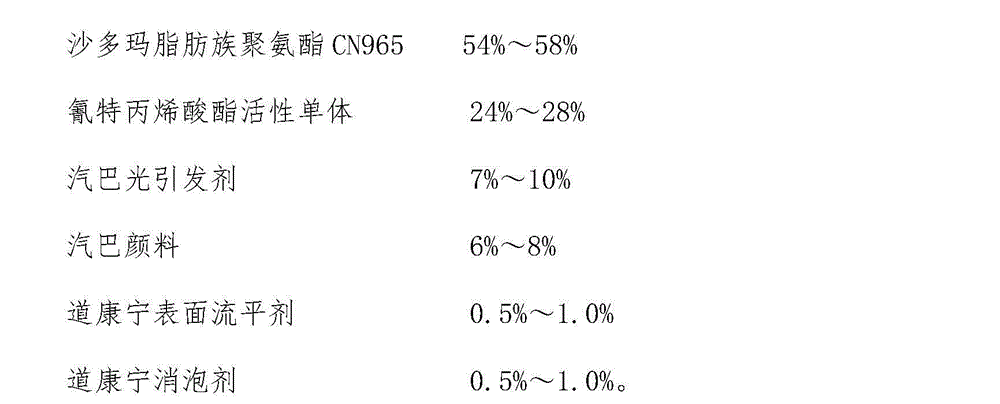

Ultra violet (UV) silk screen printing ink

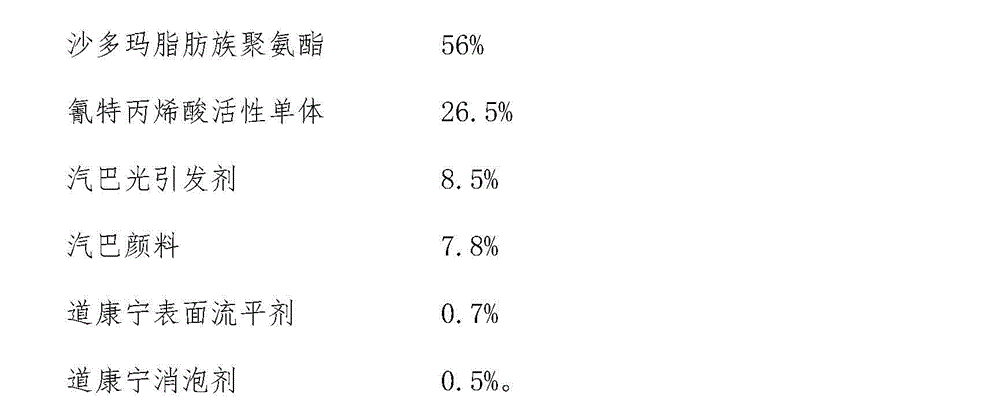

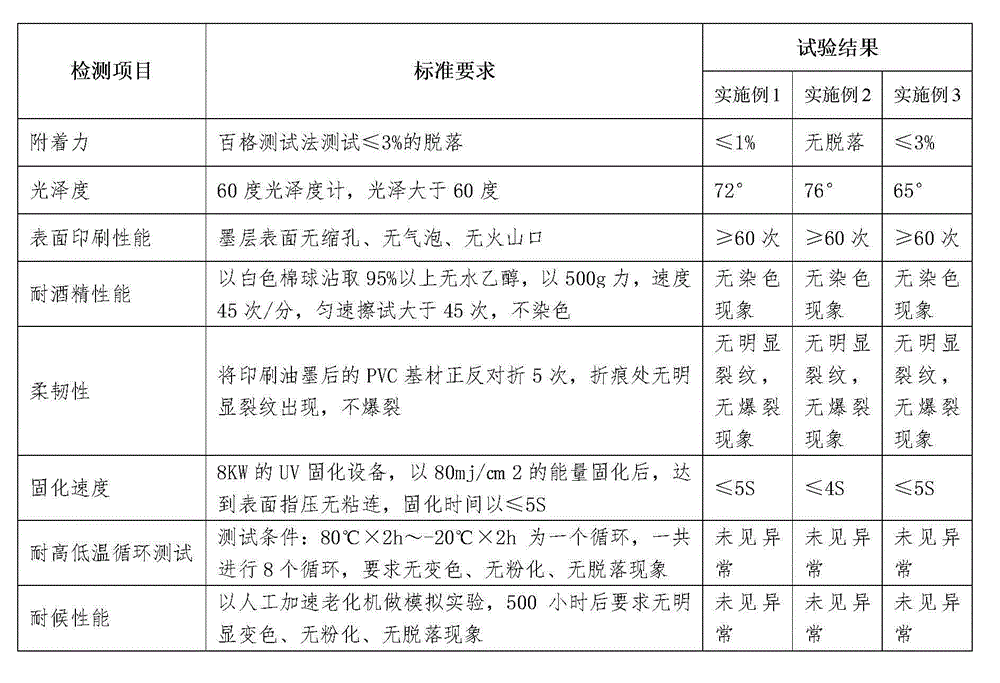

The invention relates to an ultra violet (UV) silk screen printing ink. The UV silk screen printing ink comprises components of, by weight, 54%-58% of Sartomer aliphatic polyurethane CN965, 24%-28% of Cytec acrylic ester activated monomers, 7%-10% of Ciba photoinitiators, 6%-8% of Ciba pigments, 0.5%-1.0% of Dow Corning surface flatting agents and 0.5%-1.0% of Dow Corning antifoaming agents, wherein the Cytec acrylic ester activated monomers are formed by mixing propoxylate oneopentylglycol diacrylate and ethoxylated trimethylolpropane triacrylate according to the ratio of 1: 1, adding the components into a stirrer to be dispersed until the temperature reaches 50 DEG C, and putting the components into a three-roller machine to be ground until the fineness of the components is smaller than or equal to 5 mu m. The UV silk screen printing ink is good in adhesive force and bending resistance performance.

Owner:中山市中益油墨涂料有限公司

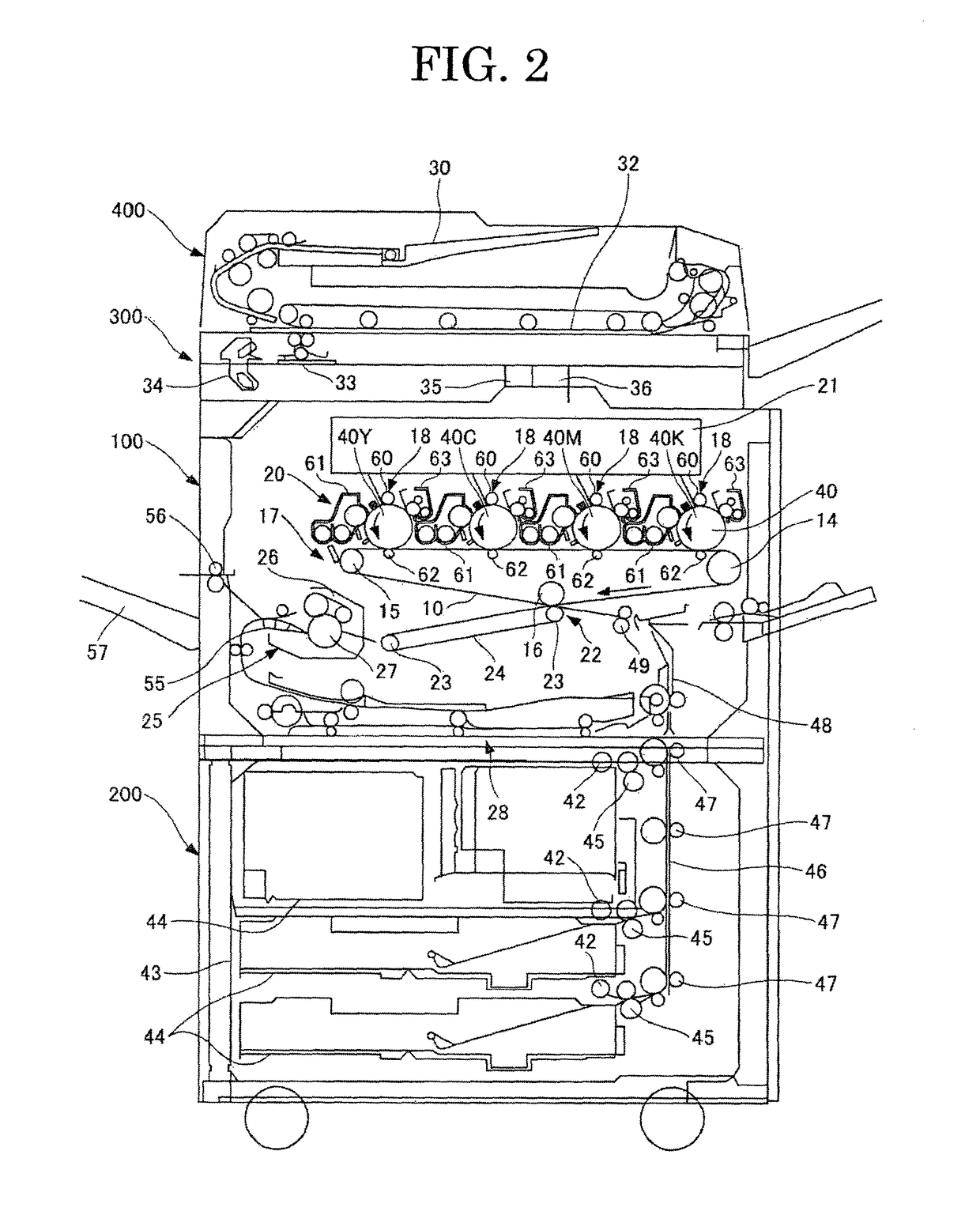

Resin composition for toner, toner, developer and image forming apparatus

InactiveUS20150153671A1Good Pigment DispersionExcellent low temperature fixabilityDevelopersAcetic acidTransmittance

A resin composition for a toner including a polyester resin and a colorant, wherein the polyester resin has A(10)-A(180) of 70 or greater, where A(10) (%) is a transmittance of light having a wavelength of 500 nm through a mixture of 20 parts by mass of the polyester resin added to 80 parts by mass of ethyl acetate and stirred at 25° C. for 10 minutes, and A(180) (%) is the transmittance after the mixture is left to stand for 3 hours.

Owner:RICOH KK

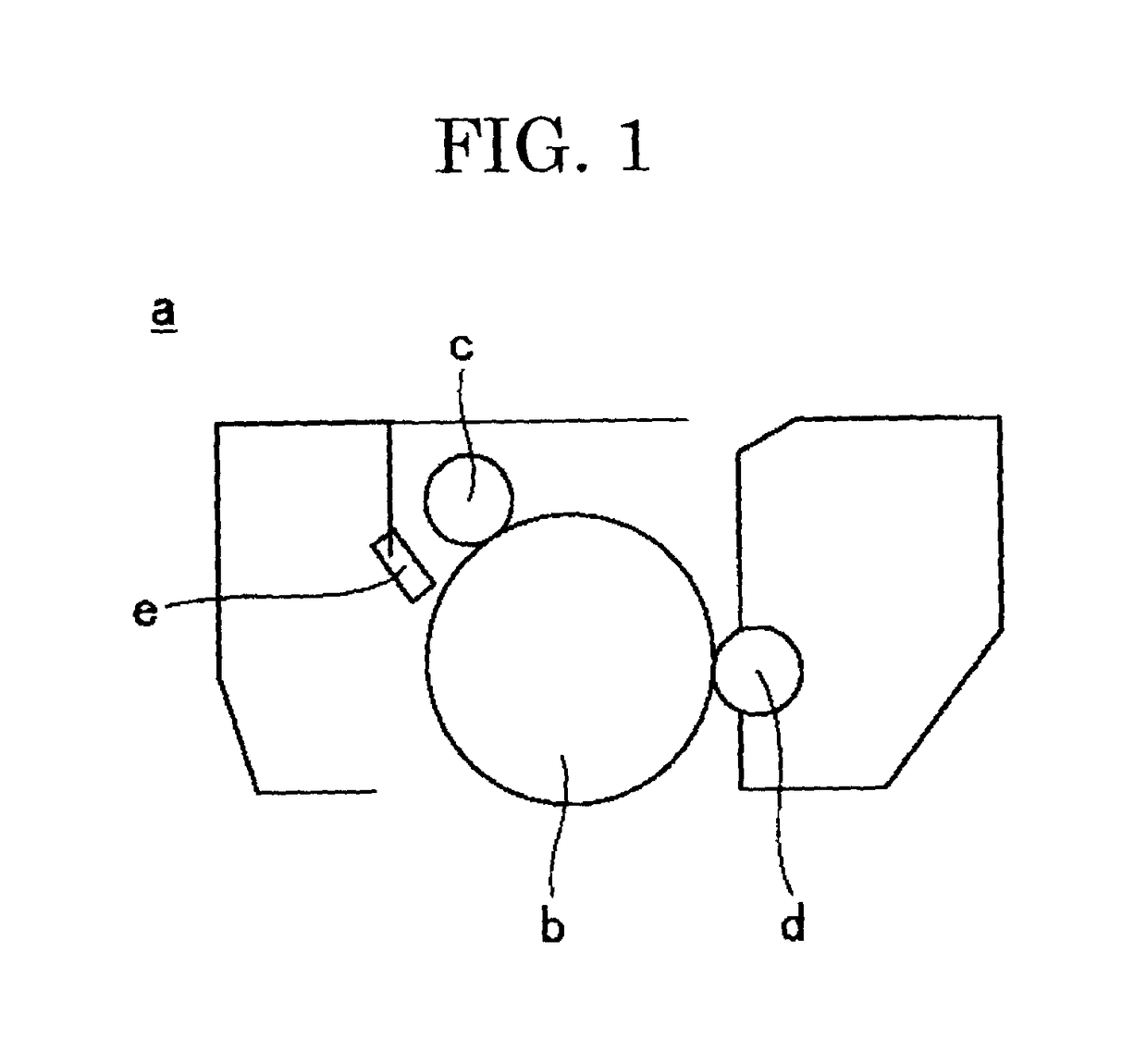

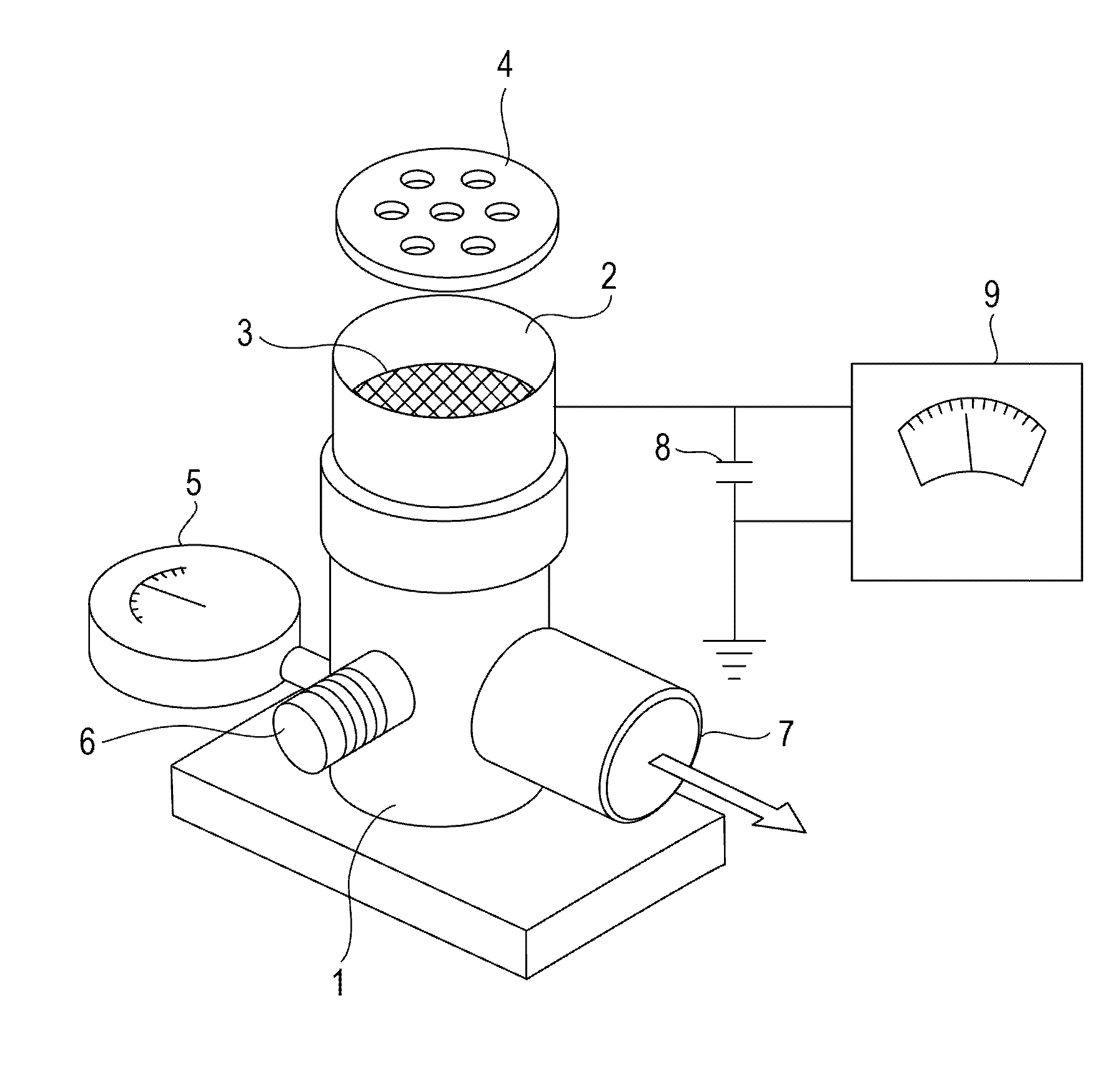

Method for manufacturing dispersion and ink using dispersion obtained thereby

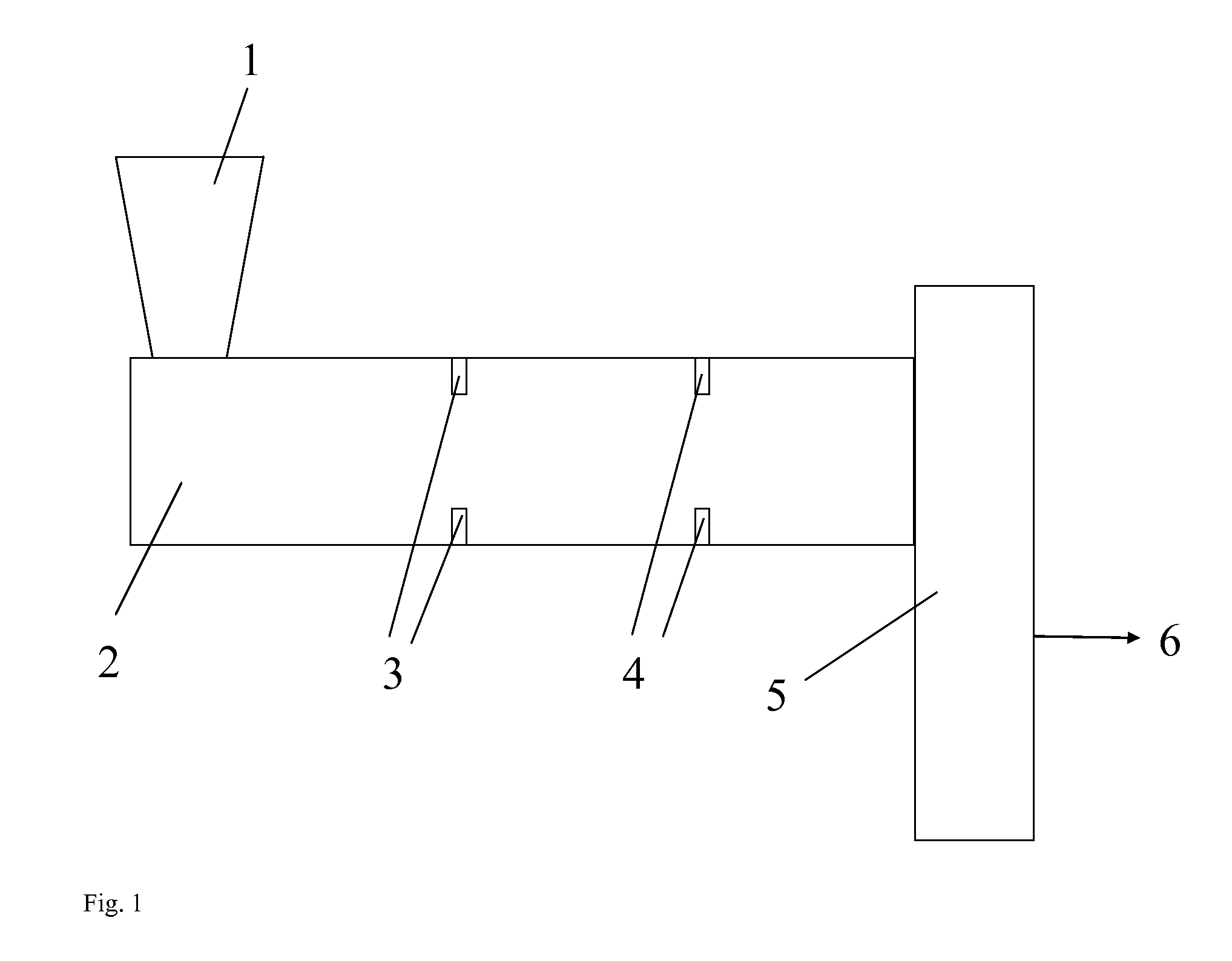

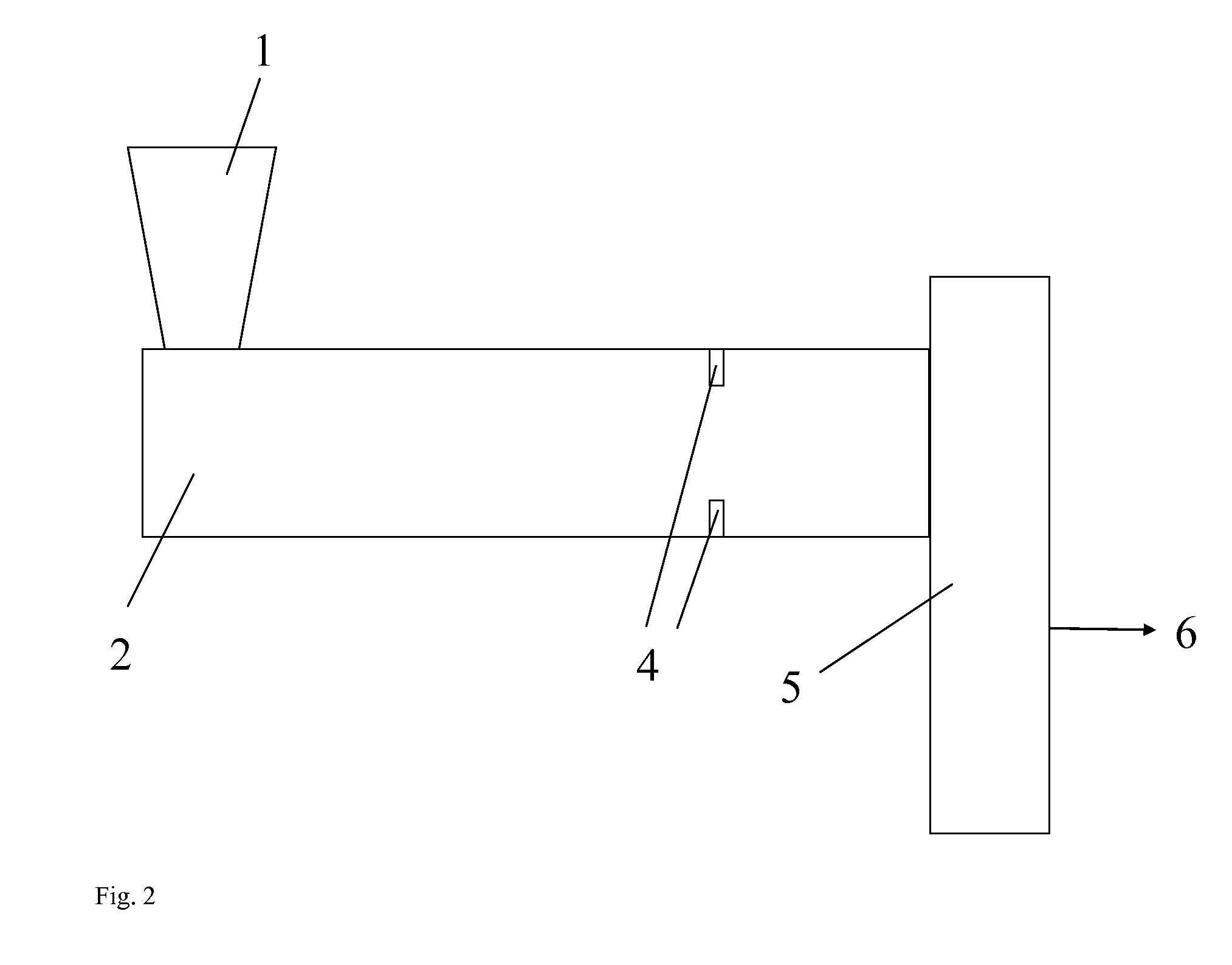

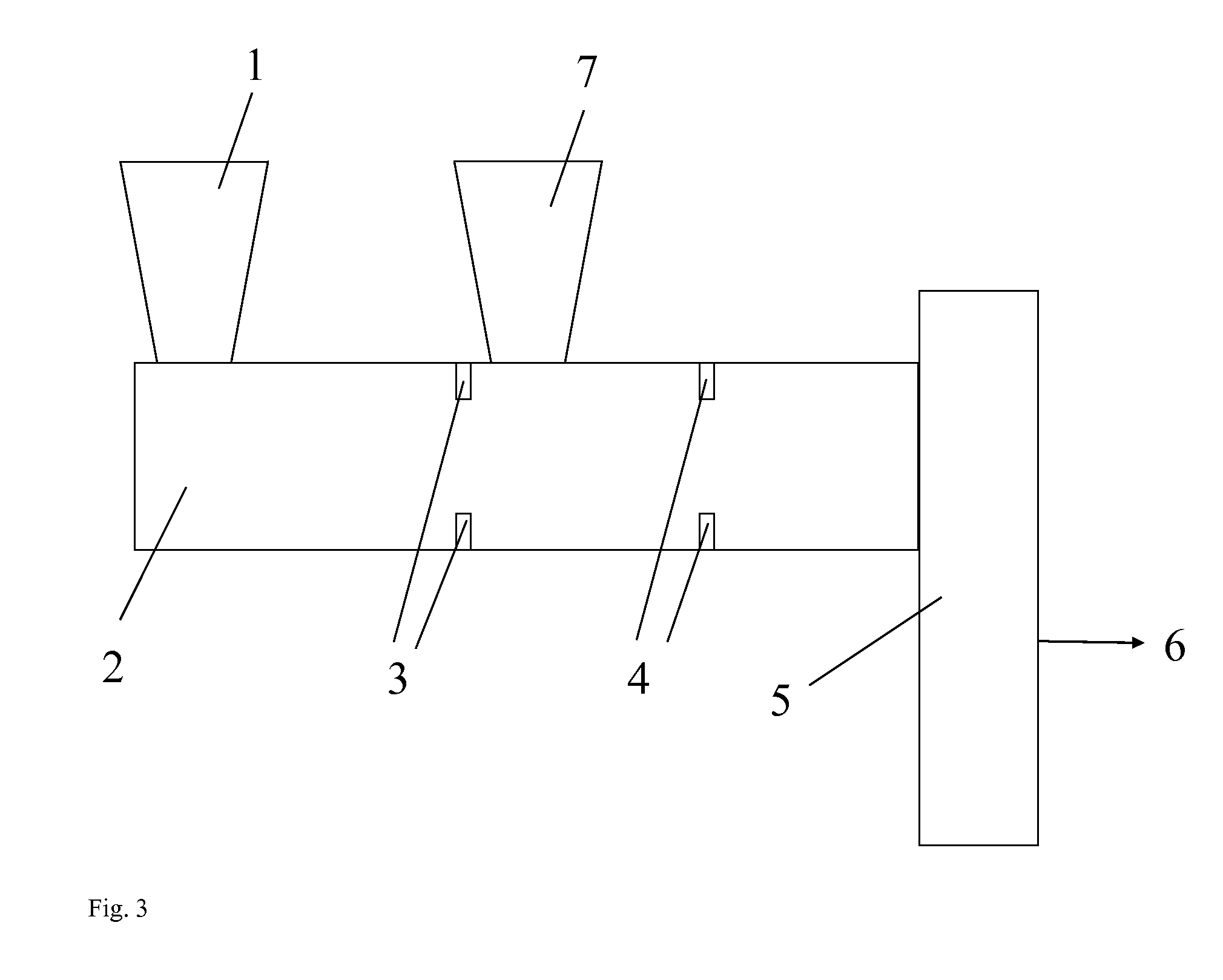

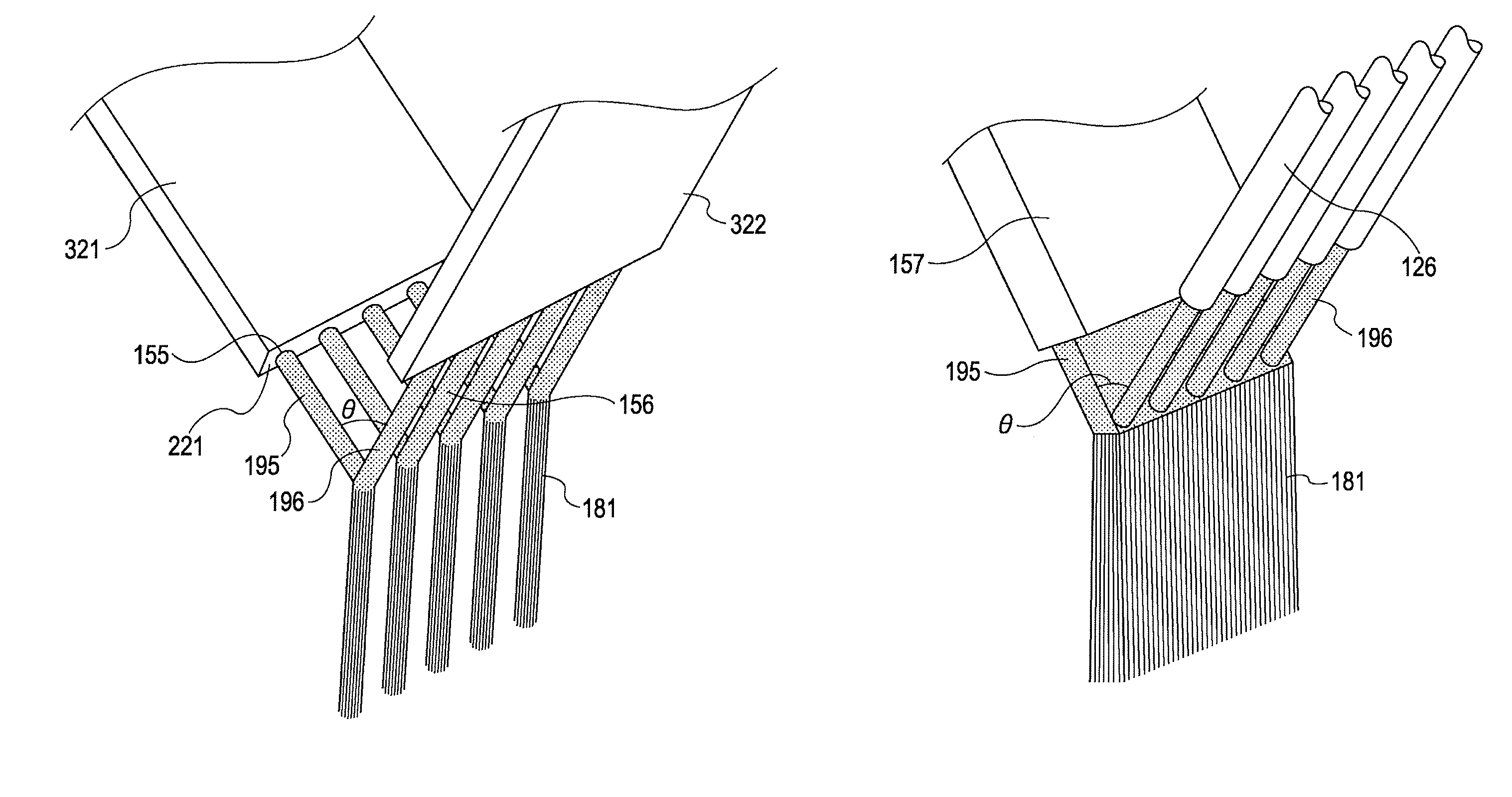

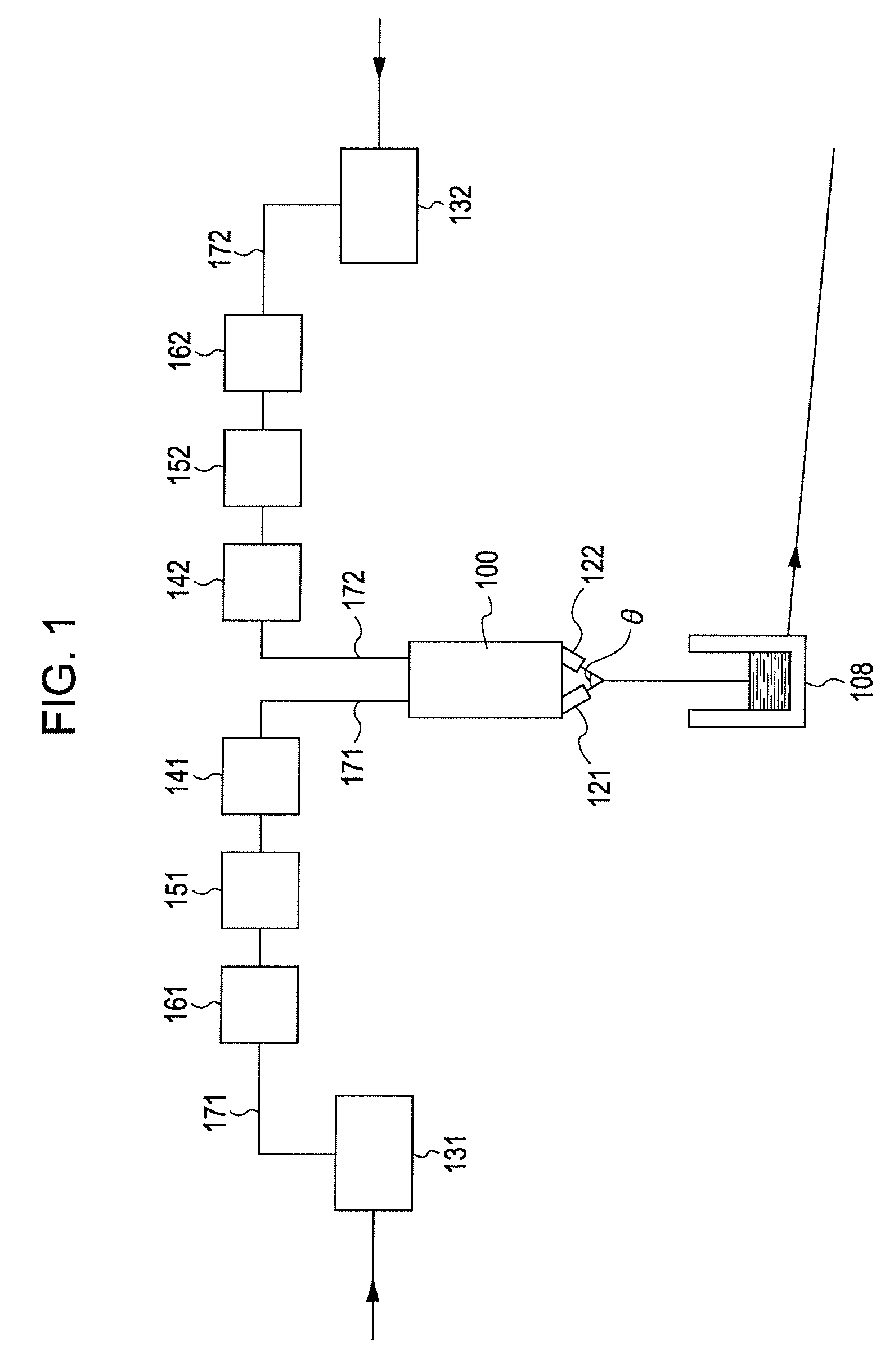

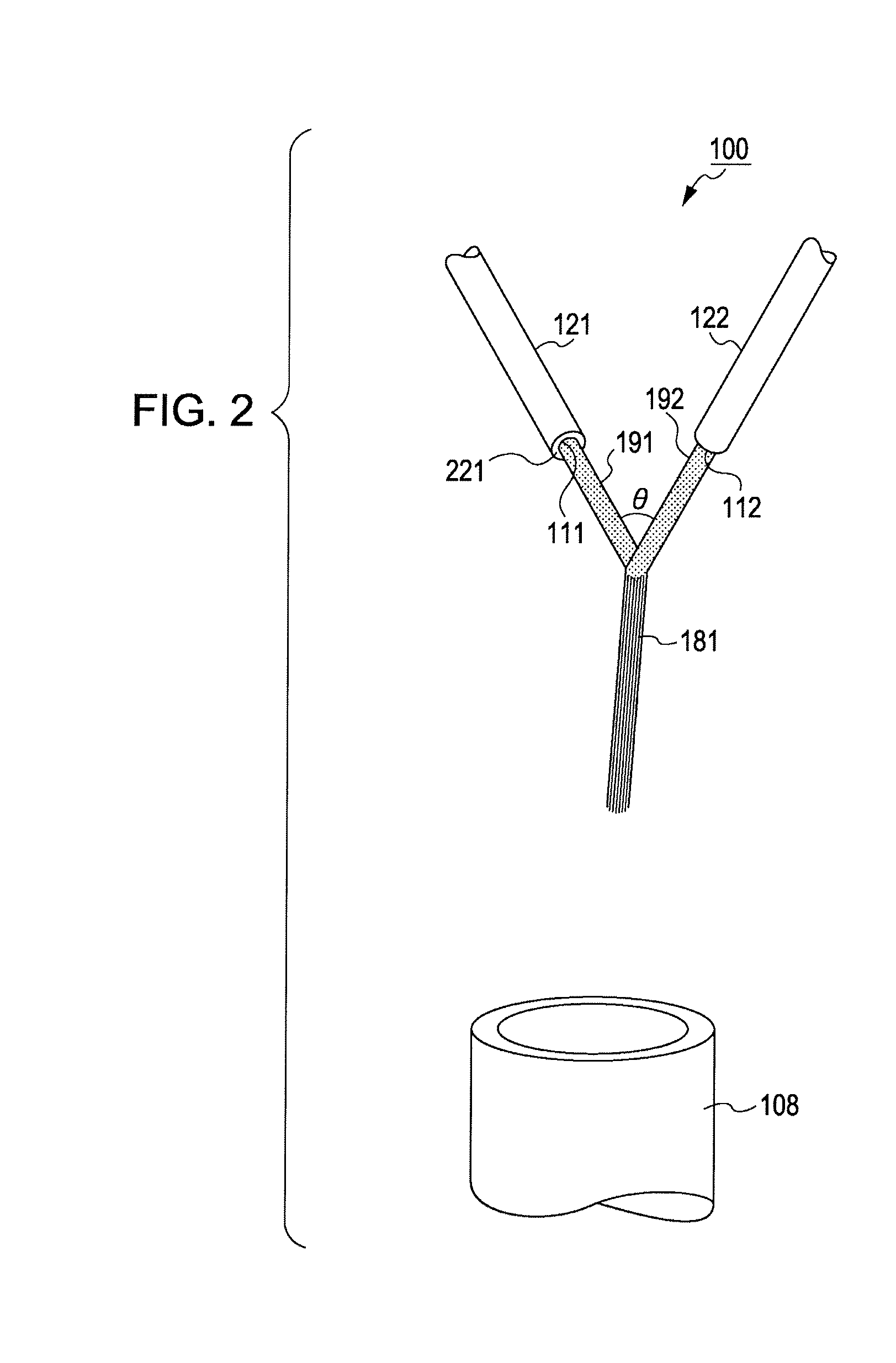

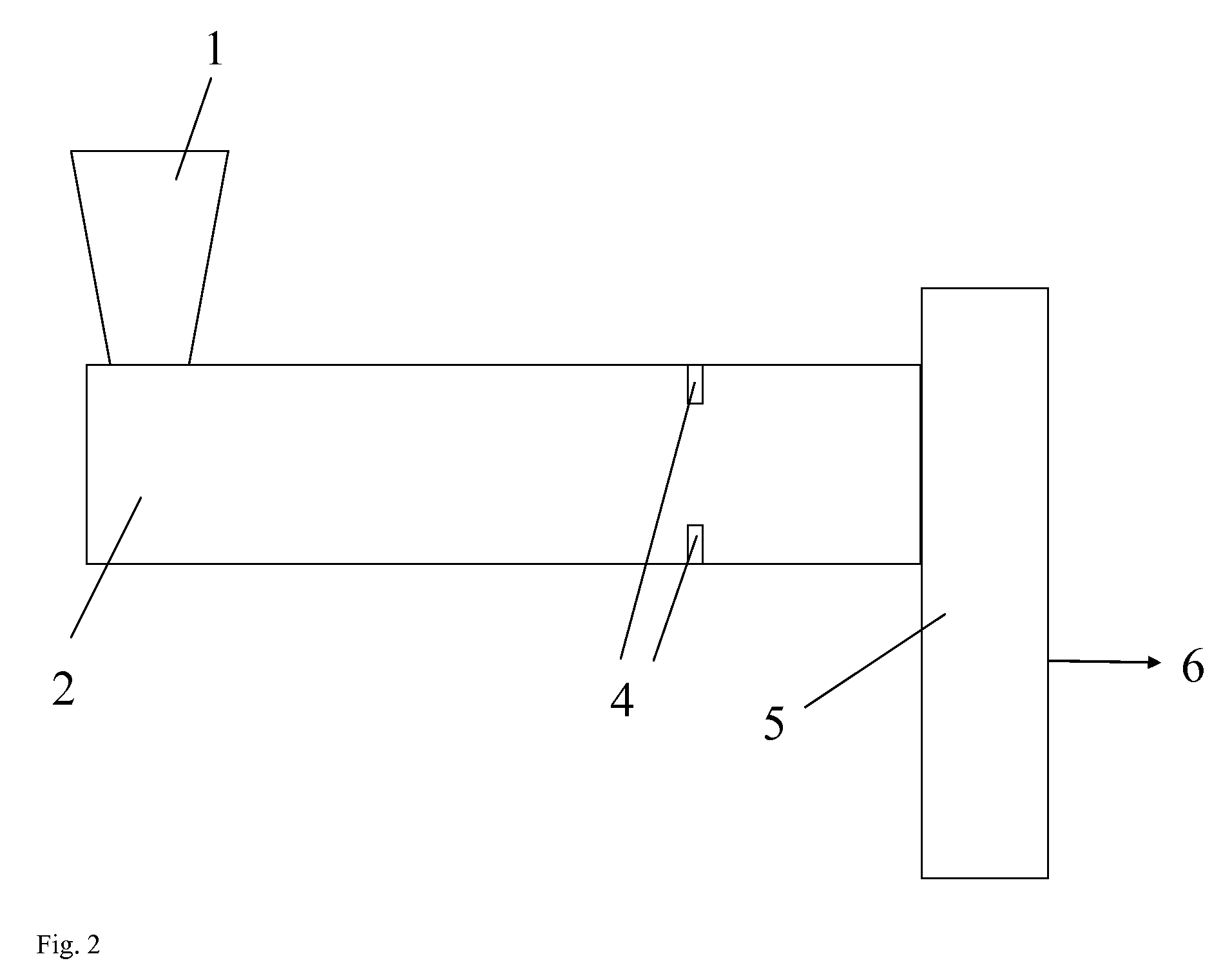

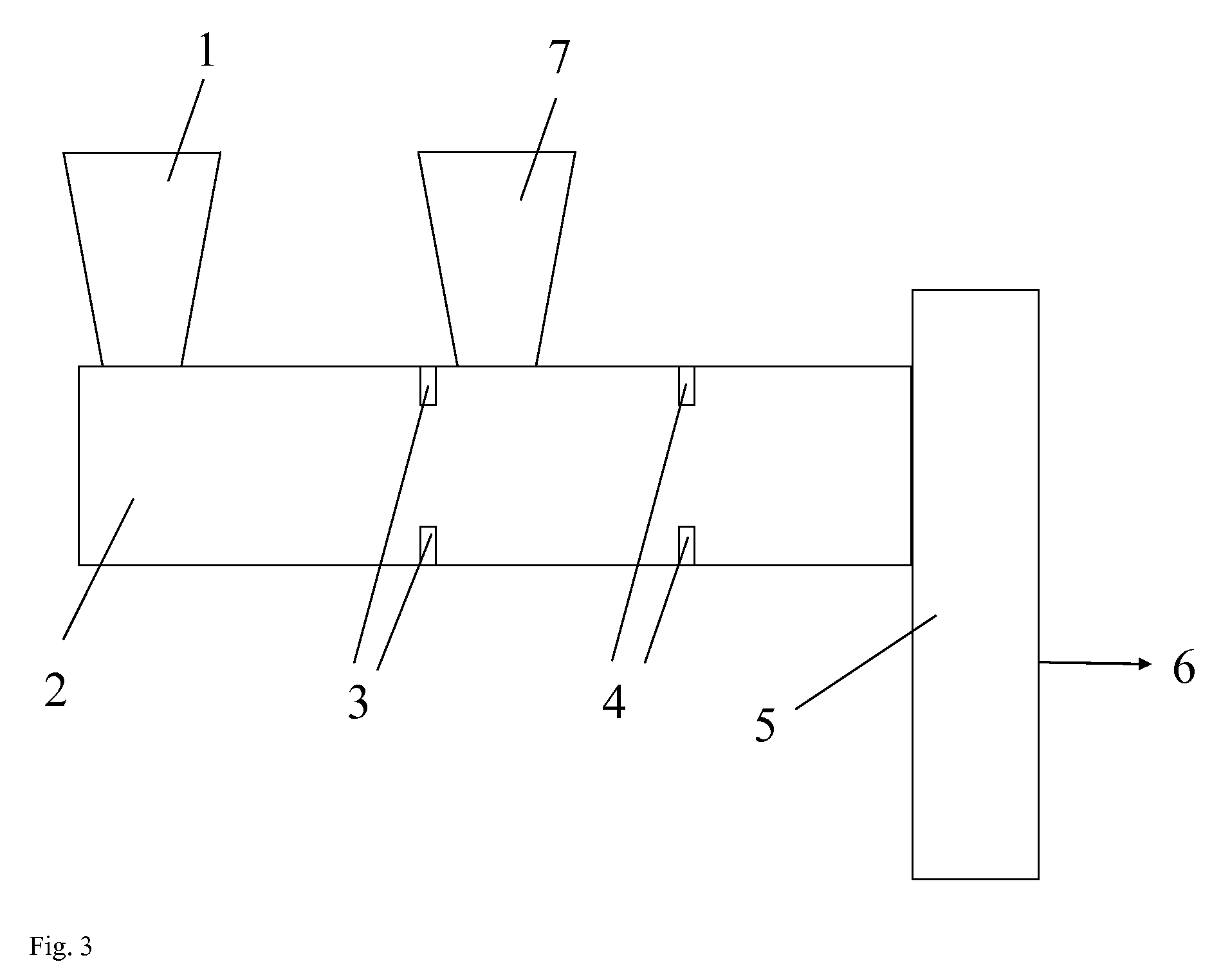

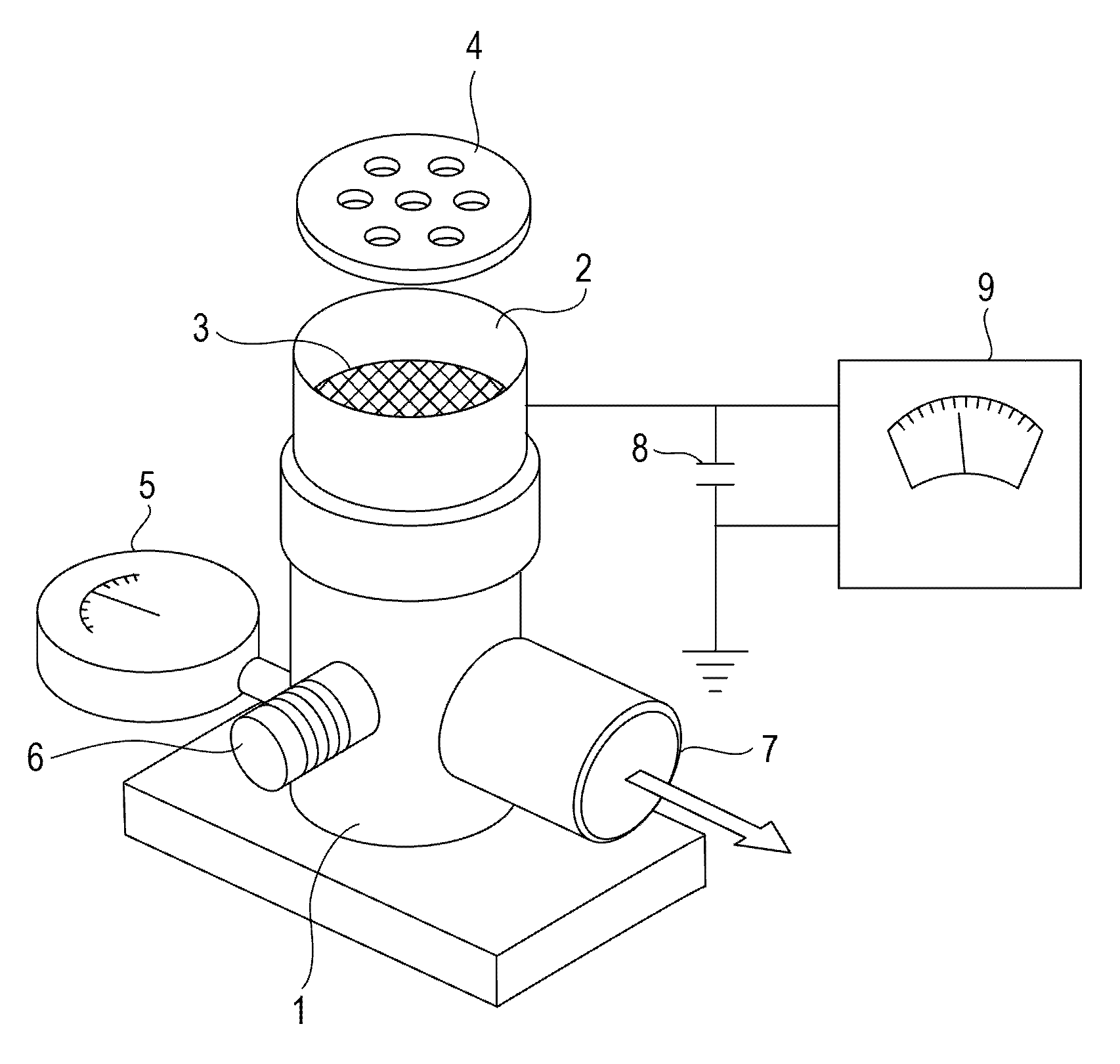

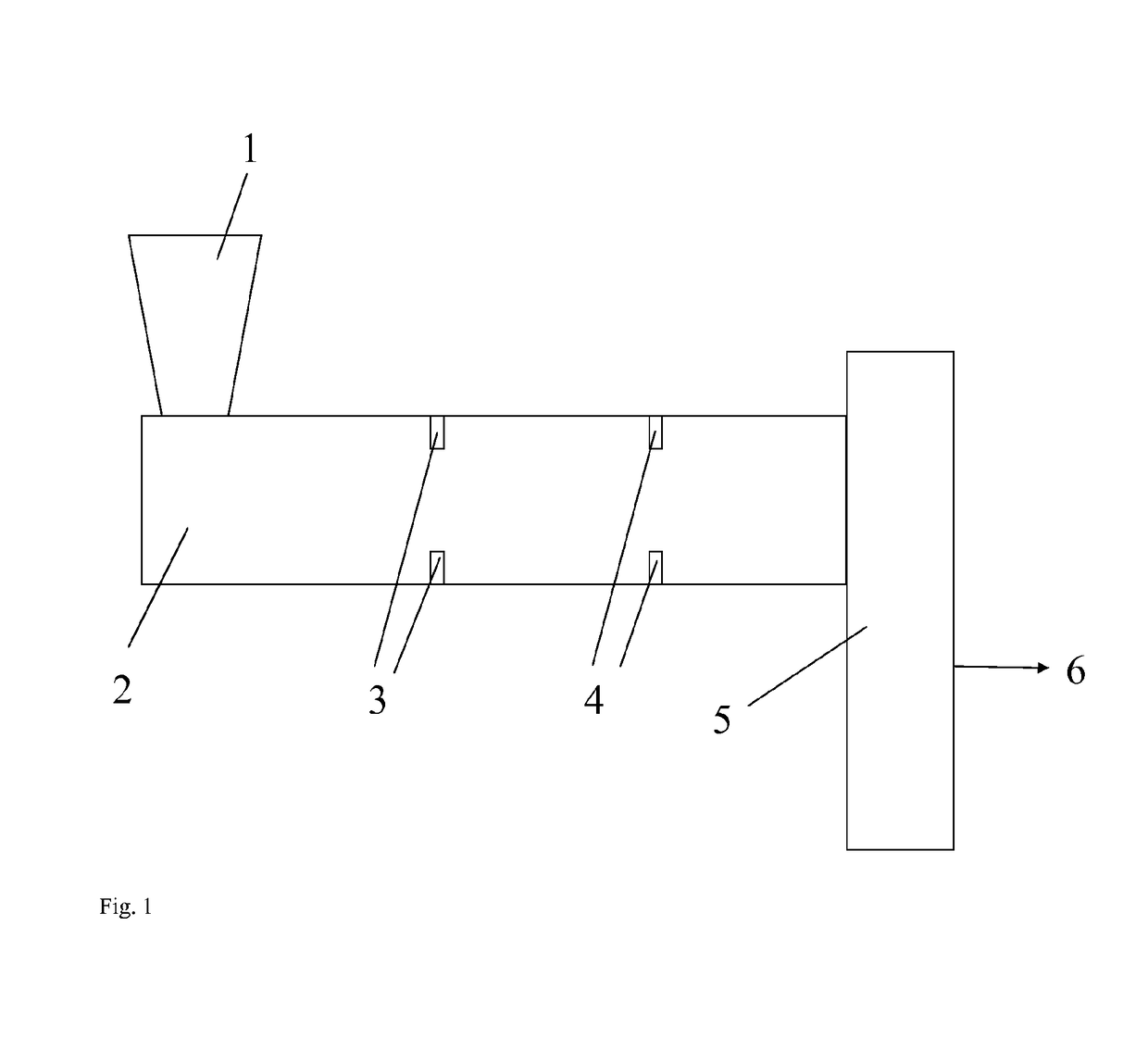

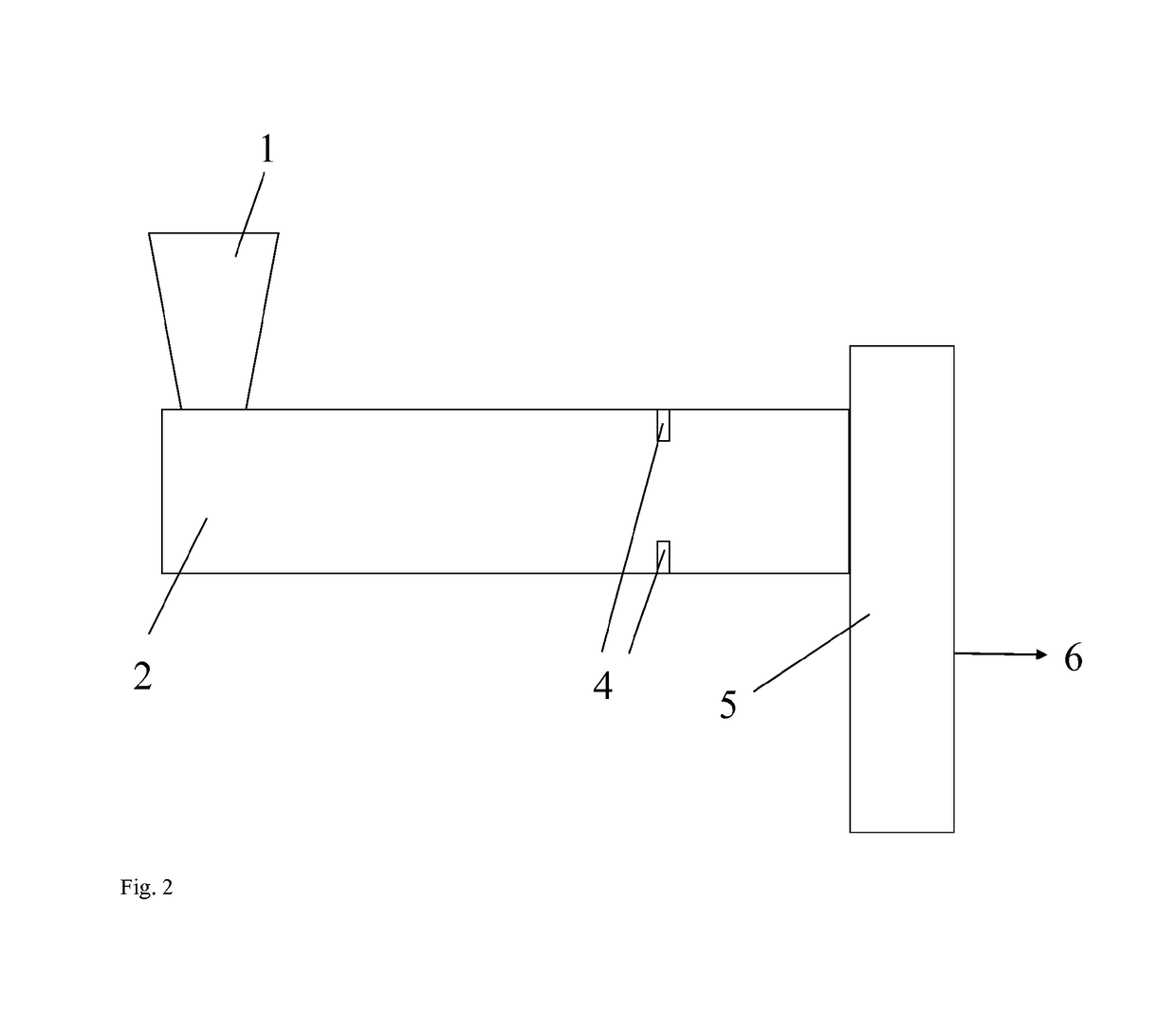

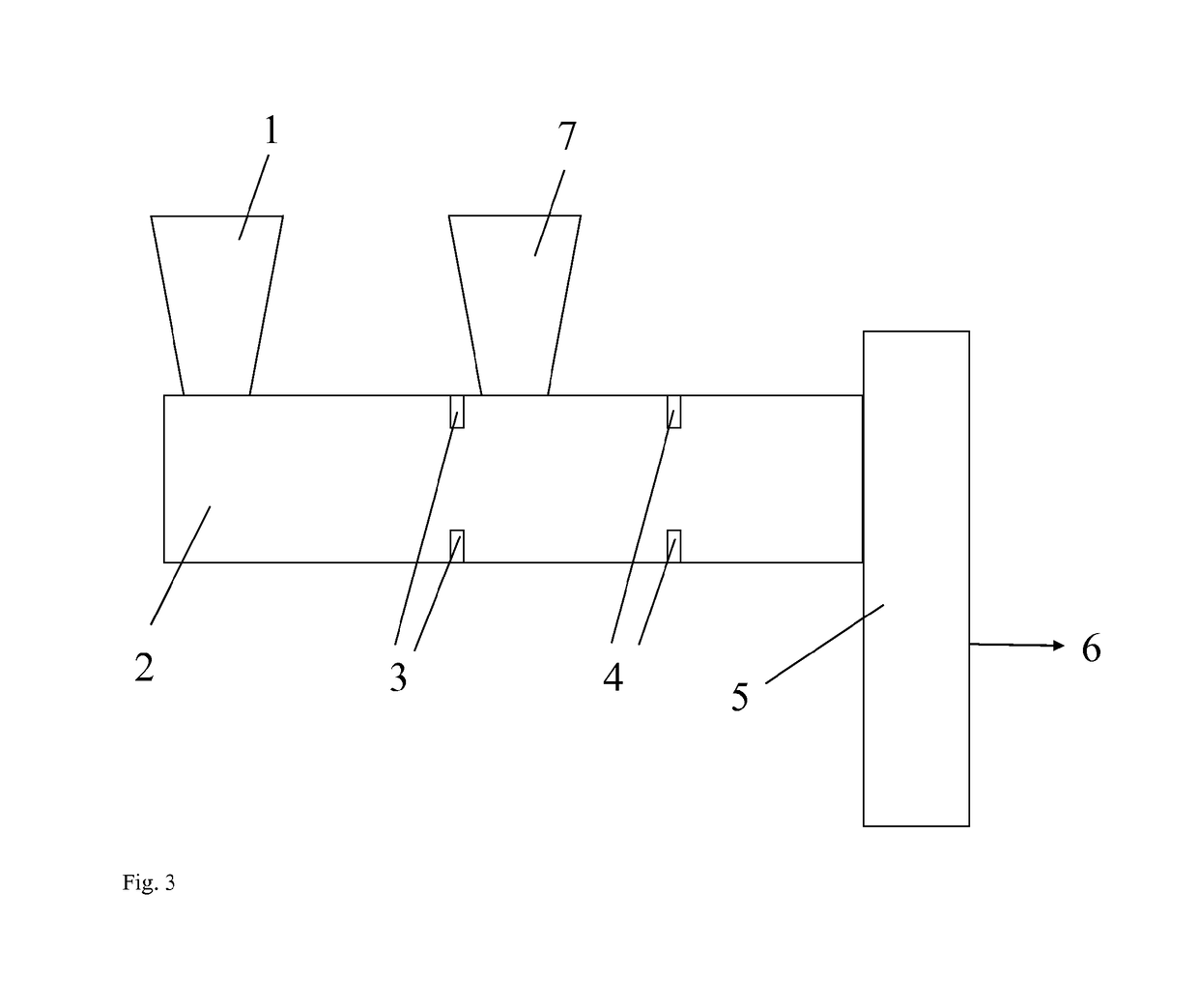

InactiveUS7557150B2Suppress scatterGood Pigment DispersionFlow mixersTransportation and packagingEngineeringReaction product

A method for manufacturing a dispersion, the method including a step of forming a reaction product by allowing at least two types of liquids to react with each other, the dispersion including a dispersion medium and particles formed from the reaction product dispersed therein. In the method described above, the at least two types of liquids are ejected from independently provided respective nozzles so that traveling directions of the liquids ejected therefrom intersect with each other at an angle of 120° or less and so that the liquids then flow in an integrated manner, whereby the reaction product is generated.

Owner:CANON KK

Process for improving carbon black dispersion

ActiveUS9056957B2Good dispersionGood Pigment DispersionPigmenting treatmentFatty acid chemical modificationMasterbatchPolymer science

A masterbatch comprising pigment and demolding agent is provided. The demolding agent is selected from the group comprising low molecular weight polyolefin oils, low molecular weight polyolefin waxes, montan waxes and aliphatic or aromatic carboxylic acid esters of fatty acids and / or fatty alcohols, wherein the pigment content of the masterbatch is from 3 to 70 wt. %, based on the total weight of the masterbatch. The masterbatch is suitable for preparation of a polymer composition having improved pigment dispersion.

Owner:COVESTRO DEUTSCHLAND AG

Toner binder and process for producing the same

InactiveUS6992150B2Good pigment dispersibilityGood Pigment DispersionDevelopersPowdery paintsPolyesterEngineering

A toner binder for dry toners which comprises a polyester; and a process for producing the toner binder. A known conventional technique for imparting low-temperature fixing property and anti-hot offset property to a toner binder is to use a mixture of two powdery polyesters. However, when the two polyesters mixed differ greatly in softening point, the effect of mixing is not obtained and pigments show poor dispersibility during toner production. The toner binder and the process eliminate these problems. The toner binder comprises aggregates of binder resin particles comprising two polyesters (A) and (B), wherein the polyester (A) has a higher softening point than the polyester (B) and the polyesters (A) and (B) have been evenly mixed in each particle. The process for producing a toner binder is characterized by melt-mixing the two polyesters (A) and (B) at 80 to 180° C. The toner binder is used mainly as an ingredient for dry toners.

Owner:SANYO CHEM IND LTD

Ultra-high whiteness aqueous white color paste for digital textile printing ink and an ink composition using the same

InactiveUS20190345354A1Improve stabilityUltra-high whitenessInksDyeing processDigital textile printingRutile

An ultra-high whiteness aqueous white color paste for digital textile printing ink is provided, which comprises: 40 wt % to 70 wt % of TiO2 powders; 1 wt % to 5 wt % of a wetting agent; 2 wt % to 12 wt % of a dispersant; and rest of water. Herein, the TiO2 powders are rutile TiO2 powders, the wetting agent is a fatty acid derivative, and the dispersant is an acrylic acid copolymer. In addition, the present disclosure thrther provides an ink composition using the aforesaid ultra-high whiteness aqueous white color paste.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

Oily base for a cosmetic and a cosmetic comprising the same

The present invention provides an oily base for a cosmetic comprising an ester compound made from a multivalent alcohol and a fatty acid, characterized in that the ester compound is made from dipentaerythritol and at least one fatty acid selected from the group consisting of fatty acids having 5 to 16 carbon atoms and a molar ratio of a dipentaerythritol residue to a fatty acid residue having 5 to 16 carbon atoms in the ester compound is 1.0:3.0 to 1.0:6.0. The aforesaid oily base for a cosmetic has proper oily feeling with moistness, no uncomfortable sticky feeling, excellent safety to the skin and adhesion to the skin, excellent gloss-holding ability after application to the skin, and excellent compatibility with various oil agents. In addition, upon blending the ester compound in various cosmetics, the cosmetics also have proper emollient property.

Owner:KOKYU ALCOHOL KOGYO

Oily base for a cosmetic and a cosmetic comprising the same

ActiveUS20110034723A1Readily availableImprove adhesionCosmetic preparationsHair removalPentaerythritolAlcohol

The present invention provides an oily base for a cosmetic comprising an ester compound made from a multivalent alcohol and a fatty acid, characterized in that the ester compound is made from dipentaerythritol and at least one fatty acid selected from the group consisting of fatty acids having 5 to 16 carbon atoms and a molar ratio of a dipentaerythritol residue to a fatty acid residue having 5 to 16 carbon atoms in the ester compound is 1.0:3.0 to 1.0:6.0. The aforesaid oily base for a cosmetic has proper oily feeling with moistness, no uncomfortable sticky feeling, excellent safety to the skin and adhesion to the skin, excellent gloss-holding ability after application to the skin, and excellent compatibility with various oil agents. In addition, upon blending the ester compound in various cosmetics, the cosmetics also have proper emollient property.

Owner:KOKYU ALCOHOL KOGYO

Oil based ink composition for inkjet printer

InactiveUS20050192380A1High discharge stabilityGood Pigment DispersionDuplicating/marking methodsInksInk printerMicroparticle

An oil based ink composition for inkjet printer comprising colored resin particles obtained by dispersion polymerization of a monofunctional polymerizable monomer (A) and a macromonomer (M) copolymerizable with the monomer (A) with coloring component fine particles comprising a surface-treated coloring agent, which are dispersed in a non-aqueous solvent having a dielectric constant of from 1.5 to 20 and a surface tension of from 15 to 60 mN / m at 25° C., as seed particles, in the presence of a dispersion stabilizer (P) soluble in the non-aqueous solvent and a polymerization initiator.

Owner:FUJIFILM CORP

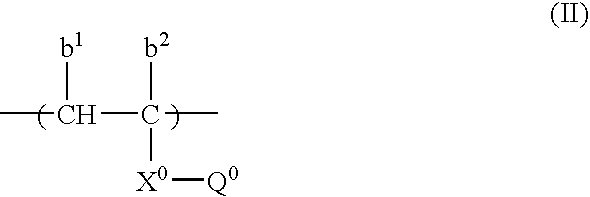

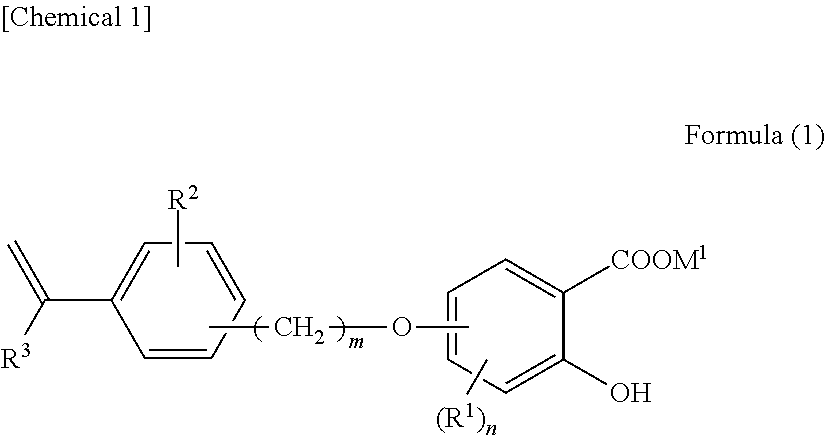

Inkjet ink

ActiveUS20100159212A1Deformation of paper is preventedGood Pigment DispersionLayered productsDecorative surface effectsWater solubleOrganic solvent

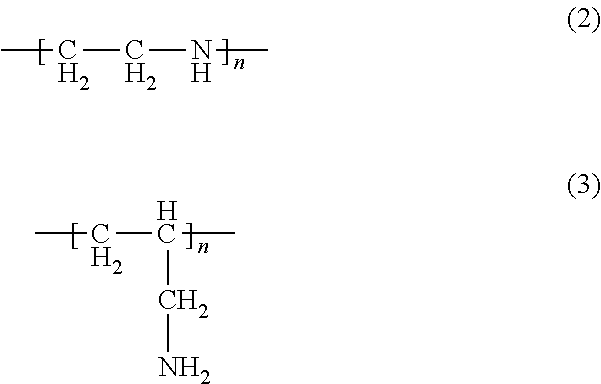

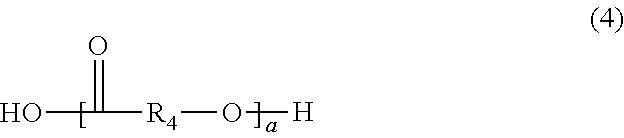

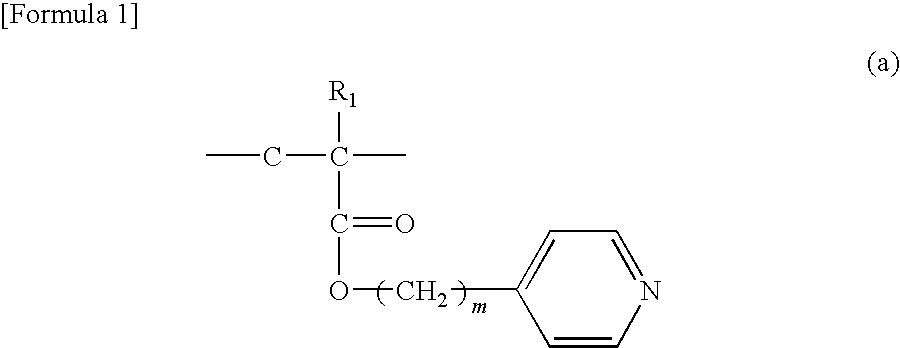

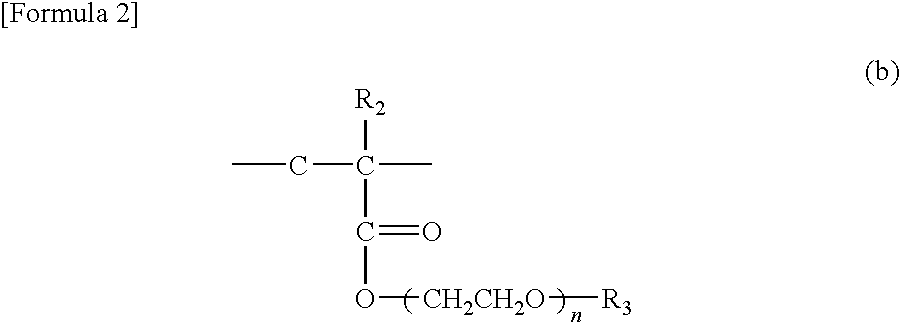

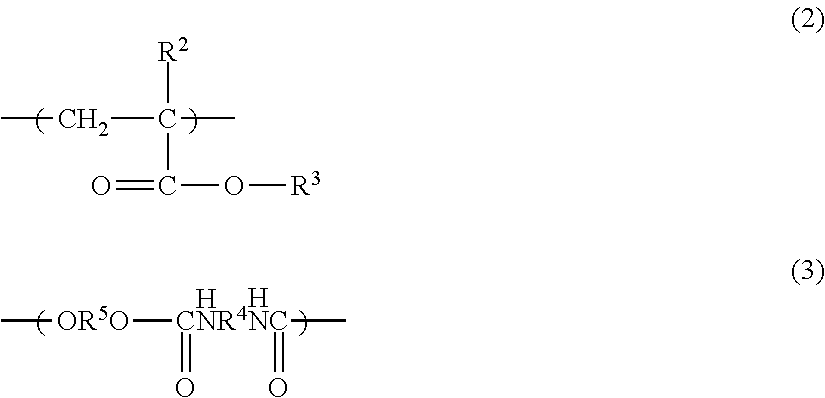

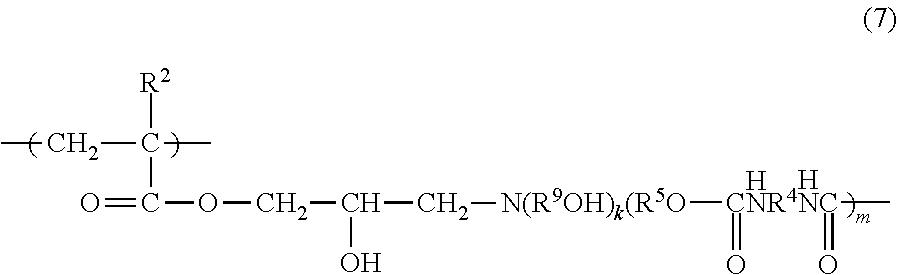

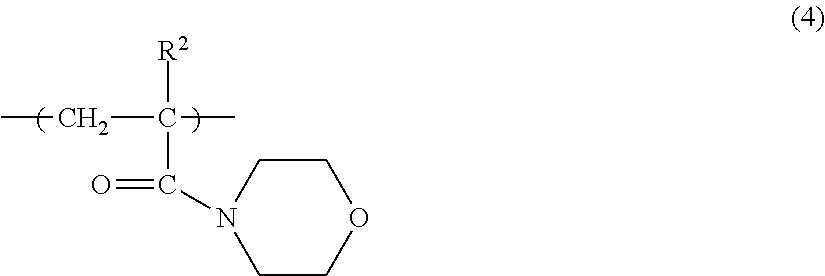

An inkjet ink that prevents paper deformation such as curling, and also exhibits favorable pigment dispersibility. The inkjet ink includes at least a pigment, water, a water-soluble organic solvent having an α value of not more than 65, and a dispersant, wherein the dispersant is a copolymer having a unit A represented by general formula (a) shown below and a unit B represented by general formula (b) shown below, and the mass ratio between the water-soluble organic solvent and the water satisfies (water-soluble organic solvent) / water=5 / 5 to 8 / 2.[In general formula (a), R1 represents a hydrogen atom or a lower alkyl group, and m represents an integer of 1 to 3.][In general formula (b), R2 and R3 each represents a hydrogen atom or a lower alkyl group, wherein R2 and R3 may be the same or different, and n represents an integer of 1 to 250.]

Owner:TOKYO UNIV OF SCI EDUCATIONAL FOUND ADMINISTRATIVE ORG +1

Resin composition for toner, toner, developer and image forming apparatus

InactiveUS9606464B2Good Pigment DispersionLow-temperature propertyDevelopersAcetic acidTransmittance

A resin composition for a toner including a polyester resin and a colorant, wherein the polyester resin has A(10)-A(180) of 70 or greater, where A(10) (%) is a transmittance of light having a wavelength of 500 nm through a mixture of 20 parts by mass of the polyester resin added to 80 parts by mass of ethyl acetate and stirred at 25° C. for 10 minutes, and A(180) (%) is the transmittance after the mixture is left to stand for 3 hours.

Owner:RICOH KK

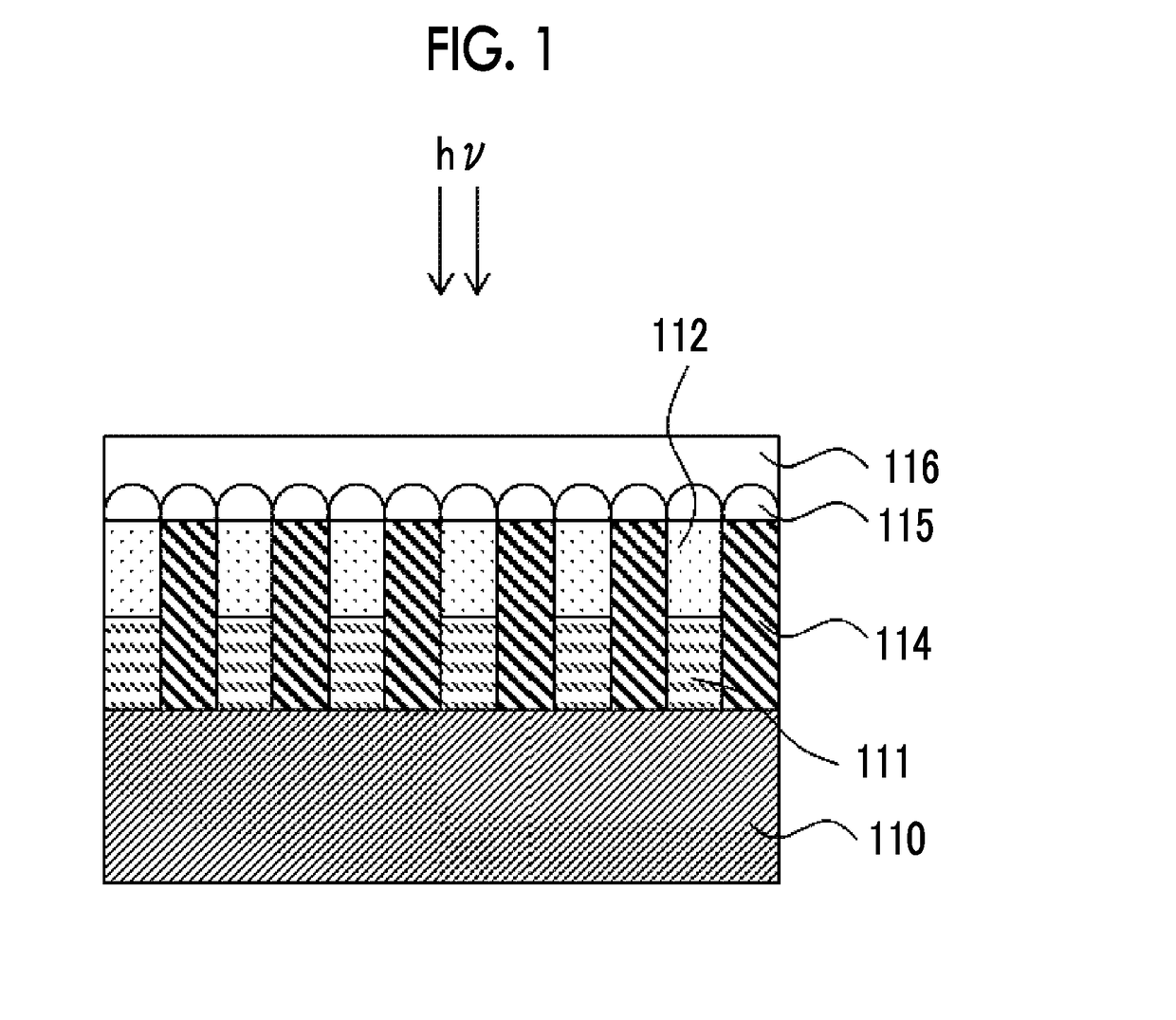

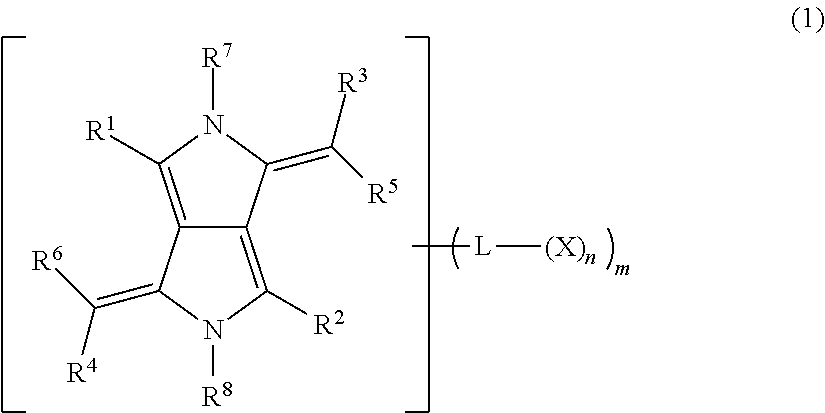

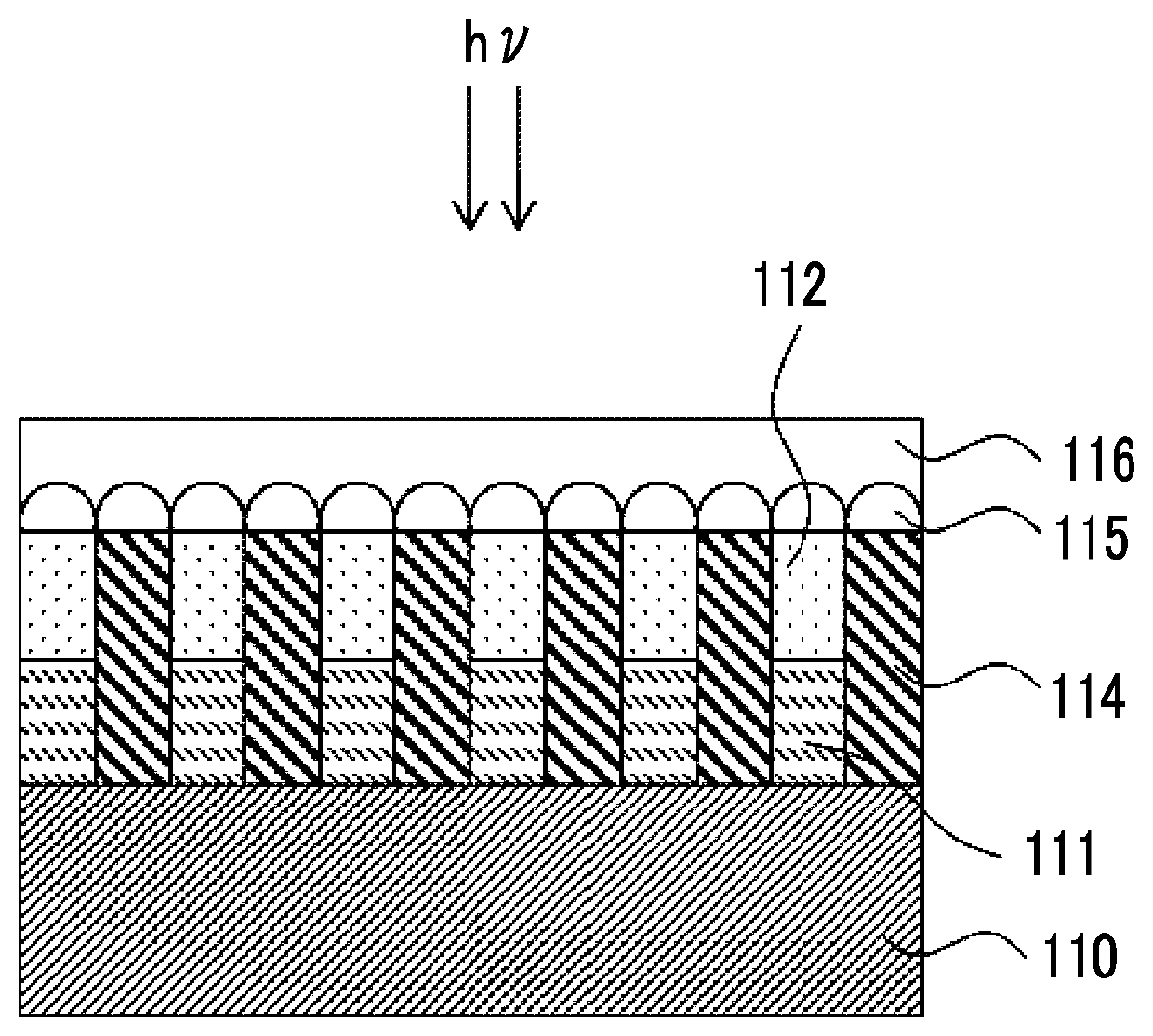

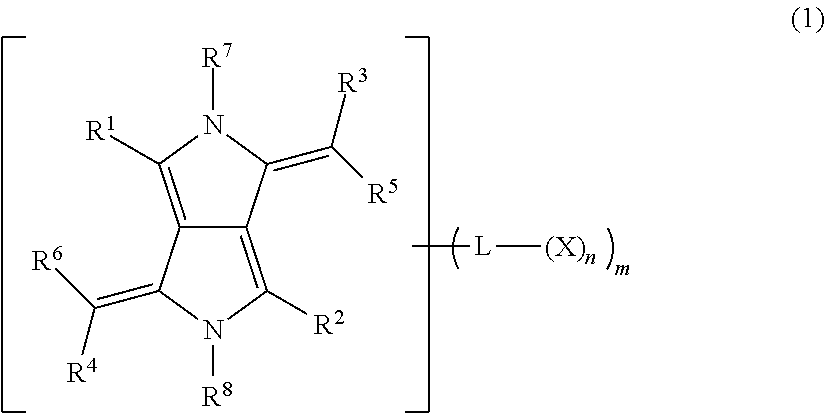

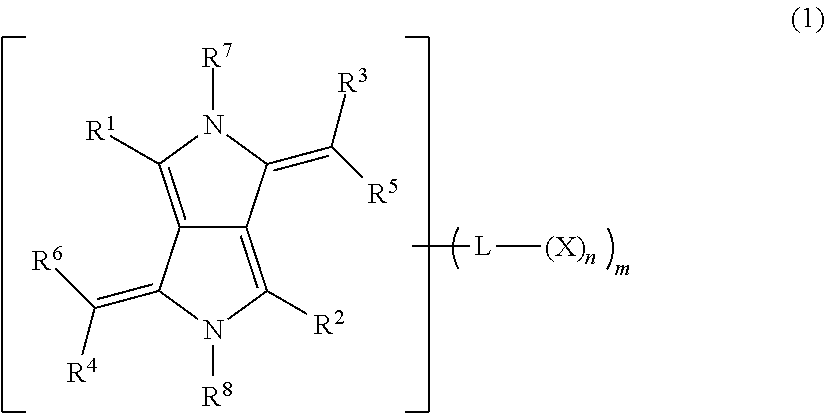

Composition, curable composition, cured film, near infrared cut filter, infrared transmitting filter, solid image pickup element, infrared sensor, and camera module

ActiveUS20180356573A1Improve stealth performanceGood Pigment DispersionOptical filtersSolid-state devicesInfraredPhotopigment

Provided are a composition that has excellent pigment dispersibility without affecting the color of a pigment in a visible range, a curable composition, a cured film, a near infrared cut filter, an infrared transmitting filter; a solid image pickup element, an infrared sensor, and a camera module. The composition includes: a pigment; a pigment derivative that includes a compound represented by Formula (1); and a solvent, in which R1 and R2 represent an aryl group or the like, R3 to R6 represent a cyano group, a heteroaryl group, or the like, R7 and R8 each independently represent —BR9R10 or the like, R9 and R10 each independently represent a hydrogen atom, a halogen atom, an alkyl group, an aryl group, a heteroaryl group, an alkoxy group, an aryloxy group, or a heteroaryloxy group, L represents a single bond or a linking group, X represents an acidic group or the like, m represents an integer of 1 to 10, and n represents an integer of 1 to 10.

Owner:FUJIFILM CORP

Non-aqueous ink composition for inkjet printing

ActiveUS8765838B2Good storage stabilitySuppresses viscosity changesMeasurement apparatus componentsDuplicating/marking methodsPolyesterOrganic solvent

A non-aqueous ink composition for inkjet printing, comprising 5 to 15% by mass of pigment relative to a mass of the non-aqueous ink composition, a pigment dispersant in such an amount that a mass ratio of the pigment dispersant to the pigment ranges from 0.2 to 2.0, and an organic solvent, the pigment dispersant comprising(A) a polyamide having a polyester side chain and / or a copolymer of vinylpyrrolidone and a C10-40 alkene, and(B) an alkyl(alkyl)acrylate copolymer having a C12-25 alkyl group and a nitrogen-containing groupin such an amount that a mass ratio of the dispersant (B) to a total of the dispersant (A) and the dispersant (B), (B) / [(A)+(B)], ranges from 0.75 to 0.99. The ink composition has good storage stability and causes no satellite even printed in an environment of a low temperature.

Owner:RISO KAGAKU CORP

Toner

Since a charge amount of a toner and a charge rise characteristic thereof are liable to be influenced by the change in temperature and humidity condition, the change in image density occurs in printing, and in particular, in high temperature and high humidity environment, inconveniences, such as image fogging, occur due to non-uniformity of the charge amount distribution. In a toner including toner particles obtained by dispersing a monomer composition containing a polymerizable monomer and a colorant in an aqueous medium to form droplets and polymerizing the polymerizable monomer in the droplets, the toner particles contain a polymer formed by a polymerization reaction of the polymerizable monomer and a metal compound having a vinyl group.

Owner:CANON KK

Modified barium sulfate for heavy anti-corrosion coating

InactiveCN111574853ABright colorIncrease the amount of fillerRubber derivative coatingsAnti-corrosive paintsModified carbonPhysical chemistry

The invention discloses modified barium sulfate for heavy anti-corrosion coating. The average particle size of the modified barium sulfate is smaller than 2.0 micrometers, the maximum particle size ofthe modified barium sulfate is smaller than 5 micrometers, and the content of the modified barium sulfate with the particle size being 2 micrometers is larger than 25%. The oil absorption amount is less than 10g / 100g, and the specific gravity is 4-4.5 g / cm < 3 >; and the pH value is 6-9. The modified barium carbonate is obtained by taking barium sulfate raw powder as a raw material and modifyingthe powder. The modified barium sulfate disclosed by the invention is used as a filler of a heavy anti-corrosion coating, so that the heavy anti-corrosion coating is fine, uniform and high in whiteness. And the strength, acid and alkali resistance, water resistance and the like of a paint film can be improved.

Owner:JIANGSU QUNXIN POWDER TECH CO LTD

(meth)acrylic pigmented film, marking film, receptor sheet and method for preparing the same

InactiveCN101622304AGood Pigment DispersionHigh tensile strengthThin material handlingAcrylic polymerMeth-

The present invention provides a film having a superior pigment dispersibility, and a high tensile strength and elongation characteristics, and a method for preparing such a film. Generally, the application is directed to a meth)acrylic pigmented film comprising a film forming resin. The film forming resin comprises a (meth)acrylic polymer containing a unit derived from a carboxyl group-containing monomer and a (meth)acrylic polymer containing a unit derived from an amino group-containing monomer. The pigmented film additionally comprises a dispersant selected from the group consisting of a (meth)acrylic polymer containing a unit derived from a hydroxyl group-containing monomer and a (meth)acrylic polymer containing a unit derived from an amino group-containing monomer. Also, the pigmented film comprises a pigment concentrate comprising a pigment dispersed in said dispersant.

Owner:3M INNOVATIVE PROPERTIES CO

Composition, curable composition, cured film, near infrared cut filter, infrared transmitting filter, solid image pickup element, infrared sensor, and camera module

ActiveUS11209582B2Improve stealth performanceGood Pigment DispersionOptical filtersSolid-state devicesInfraredPhotopigment

Provided are a composition that has excellent pigment dispersibility without affecting the color of a pigment in a visible range, a curable composition, a cured film, a near infrared cut filter, an infrared transmitting filter; a solid image pickup element, an infrared sensor, and a camera module. The composition includes: a pigment; a pigment derivative that includes a compound represented by Formula (1); and a solvent, in which R1 and R2 represent an aryl group or the like, R3 to R6 represent a cyano group, a heteroaryl group, or the like, R7 and R8 each independently represent —BR9R10 or the like, R9 and R10 each independently represent a hydrogen atom, a halogen atom, an alkyl group, an aryl group, a heteroaryl group, an alkoxy group, an aryloxy group, or a heteroaryloxy group, L represents a single bond or a linking group, X represents an acidic group or the like, m represents an integer of 1 to 10, and n represents an integer of 1 to 10.

Owner:FUJIFILM CORP

Cosmetic composition comprising an alkyl phosphate and a fatty alkyl ether of polyethylene glycol, processes therefor and uses thereof

ActiveUS9687426B2Good Pigment DispersionCosmetic preparationsHair cosmeticsAlkylphosphatePolyethylene glycol

Composition containing an aqueous phase and an emulsifying system, where the emulsifying system contains at least one C10-C30 alkyl phosphate and at least one C8-C24 fatty alkyl ether of polyethylene glycol, the ether comprising from 1 to 19 ethylene glycol units and having an HLB<8 at 25° C. Process for making up or for non-therapeutically caring for keratin fibres, via the application to keratin fibres of the composition. Uses of the composition in particular for obtaining uniform and / or thick makeup on keratin fibres, and as mascara for making up keratin fibres.

Owner:LOREAL SA

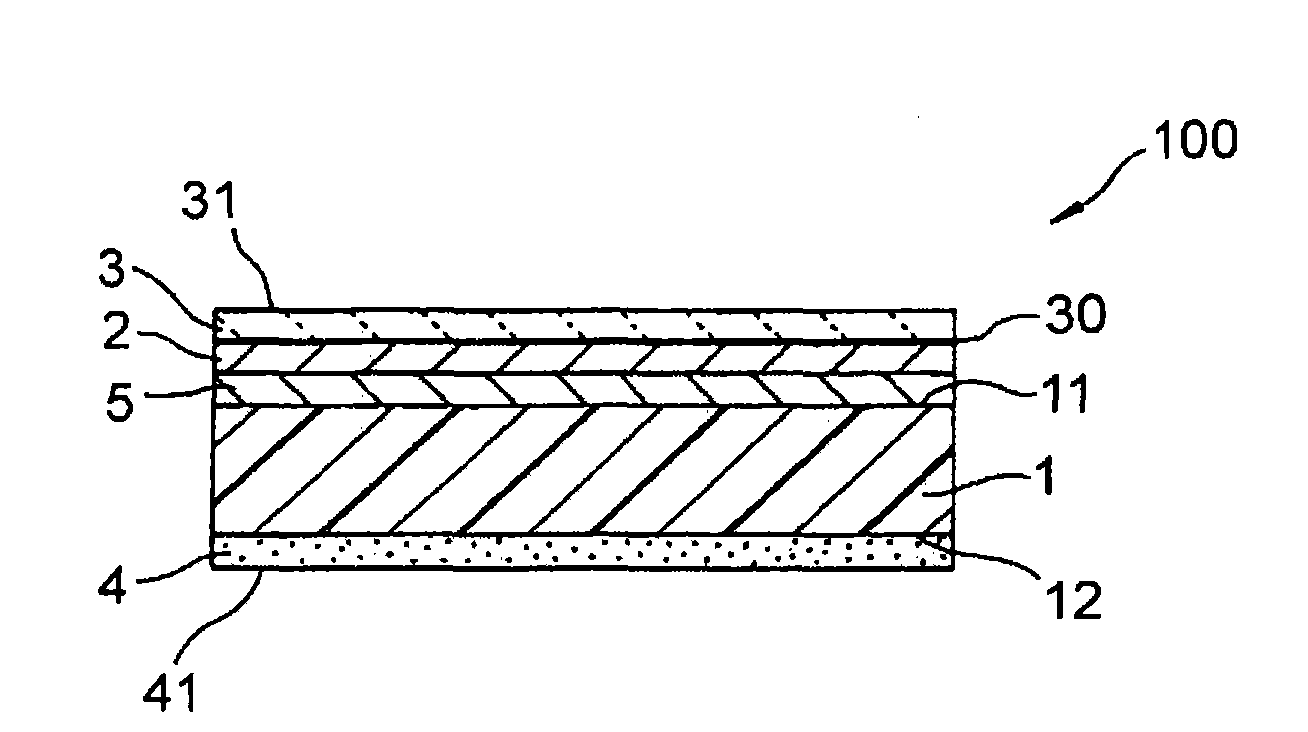

Container for medical products

InactiveUS20110284559A1Excellent in impact resistance strengthExcellent gas barrier propertiesSynthetic resin layered productsLarge containersPolymer sciencePigment dispersion

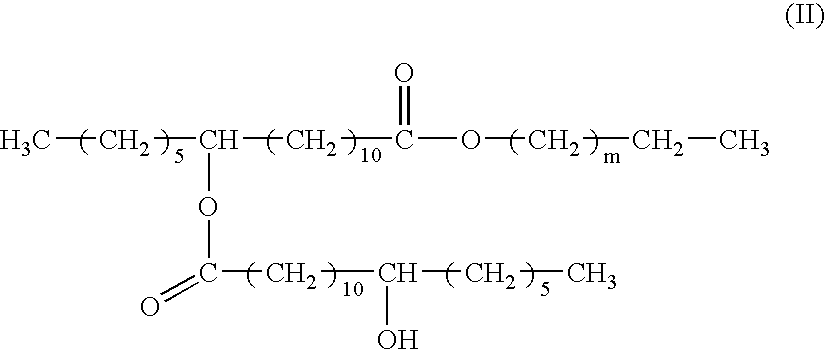

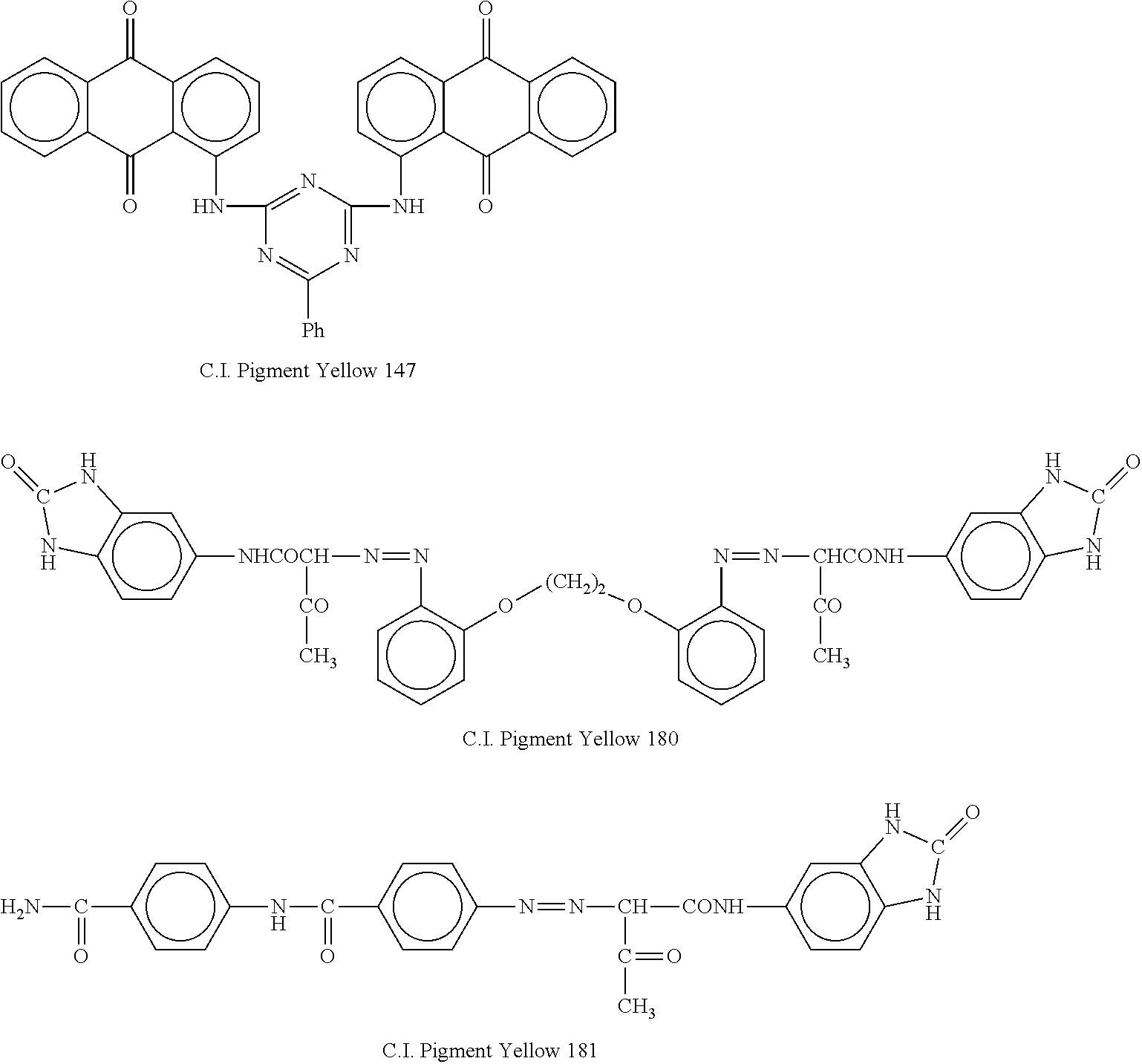

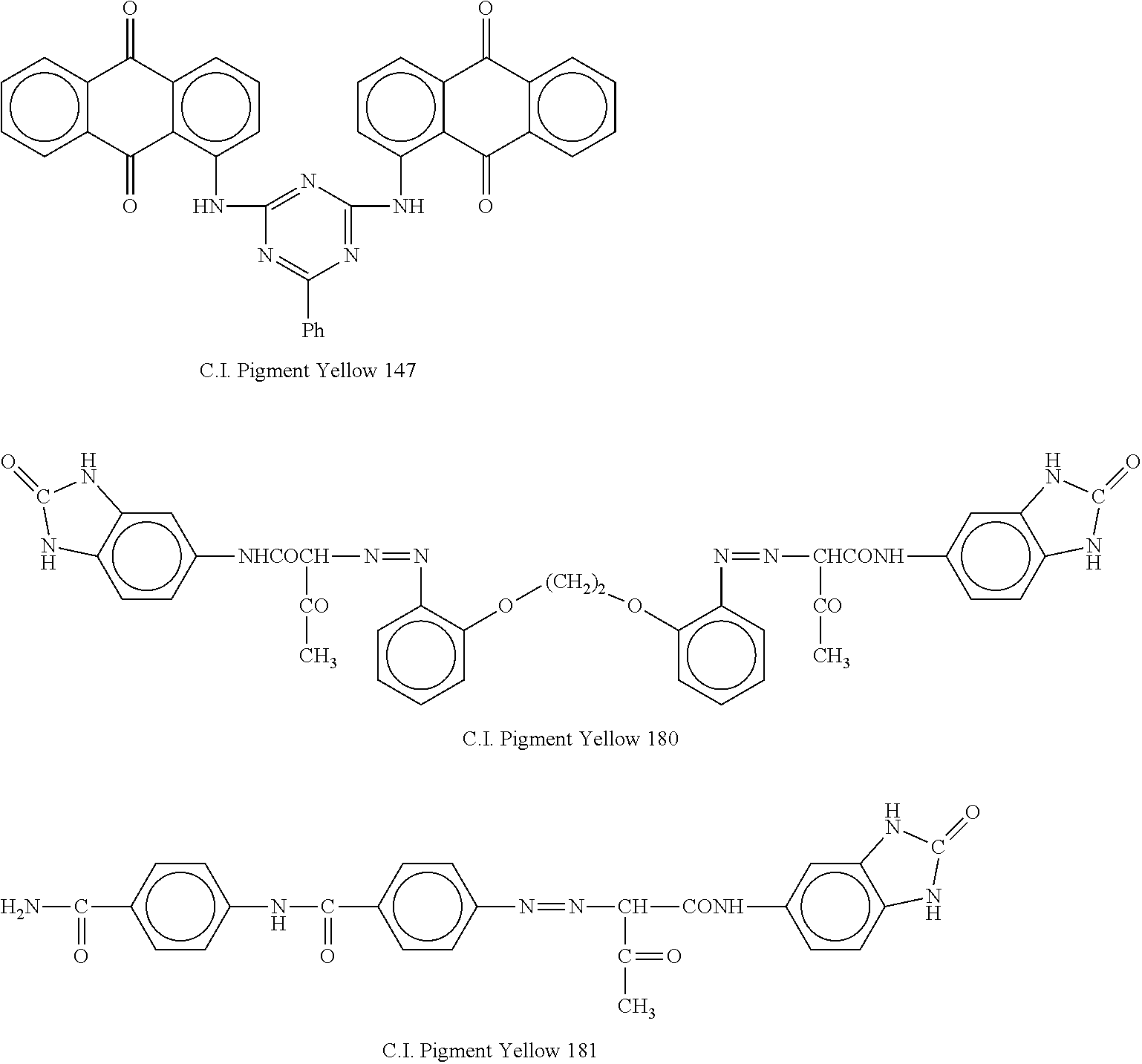

A sanitary container has a hollow cavity for storing a product in cleanliness. A wall portion of the container has a laminated structure of an inner layer and an outer layer. The outer layer is made of a cyclic olefin polymer containing at least one pigment selected from the group consisting of C.I. Pigment Yellow 147, C.I. Pigment Yellow 180 and C.I. Pigment Yellow 181 and added therein. The inner layer is made of a cyclic olefin polymer free of the at least one pigment. The sanitary container is superb in pigment dispersion (ultraviolet ray blocking property), is free of troublesome contamination of its content with pigment particles, and is also excellent in impact resistance strength, gas barrier properties and interface bonding.

Owner:DAIKYO SEIKO LTD

Process for improving carbon black dispersion

ActiveUSRE47079E1Good dispersionGood Pigment DispersionPigmenting treatmentOrganic dyesMasterbatchPolymer science

A masterbatch comprising pigment and demolding agent is provided. The demolding agent is selected from the group comprising low molecular weight polyolefin oils, low molecular weight polyolefin waxes, montan waxes and aliphatic or aromatic carboxylic acid esters of fatty acids and / or fatty alcohols, wherein the pigment content of the masterbatch is from 3 to 70 wt. %, based on the total weight of the masterbatch. The masterbatch is suitable for preparation of a polymer composition having improved pigment dispersion.

Owner:COVESTRO DEUTSCHLAND AG

Process for producing resin-coated pigment, resin-coated pigment, aqueous pigment dispersion and aqueous colorant composition containing the same

ActiveUS9156991B2Good dispersionEasy to dryDuplicating/marking methodsInksDispersion stabilityOrganic solvent

A process for producing a resin-coated pigment capable of providing an ink and a paint being superior in dispersion stability of a pigment and having rapid drying property, high gloss and density without containing those such as an organic solvent and a salt that cause the lowering of performance of pigment dispersion, characterized in that a pigment is dispersed in an aqueous solution in which an anionic group-containing resin is dissolved in the presence of a basic compound and then, the anionic group-containing resin is precipitated on the surface of the pigment by removing the basic compound in the aqueous solution, using an ion exchange means.

Owner:SAKATA INX

Container for medical products

InactiveUS8563107B2Excellent in impact resistance strength and gas barrier property and interface bondingGood chemical stabilitySynthetic resin layered productsLarge containersPolymer sciencePigment dispersion

A sanitary container has a hollow cavity for storing a product in cleanliness. A wall portion of the container has a laminated structure of an inner layer and an outer layer. The outer layer is made of a cyclic olefin polymer containing at least one pigment selected from the group consisting of C.I. Pigment Yellow 147, C.I. Pigment Yellow 180 and C.I. Pigment Yellow 181 and added therein. The inner layer is made of a cyclic olefin polymer free of the at least one pigment. The sanitary container is superb in pigment dispersion (ultraviolet ray blocking property), is free of troublesome contamination of its content with pigment particles, and is also excellent in impact resistance strength, gas barrier properties and interface bonding.

Owner:DAIKYO SEIKO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com