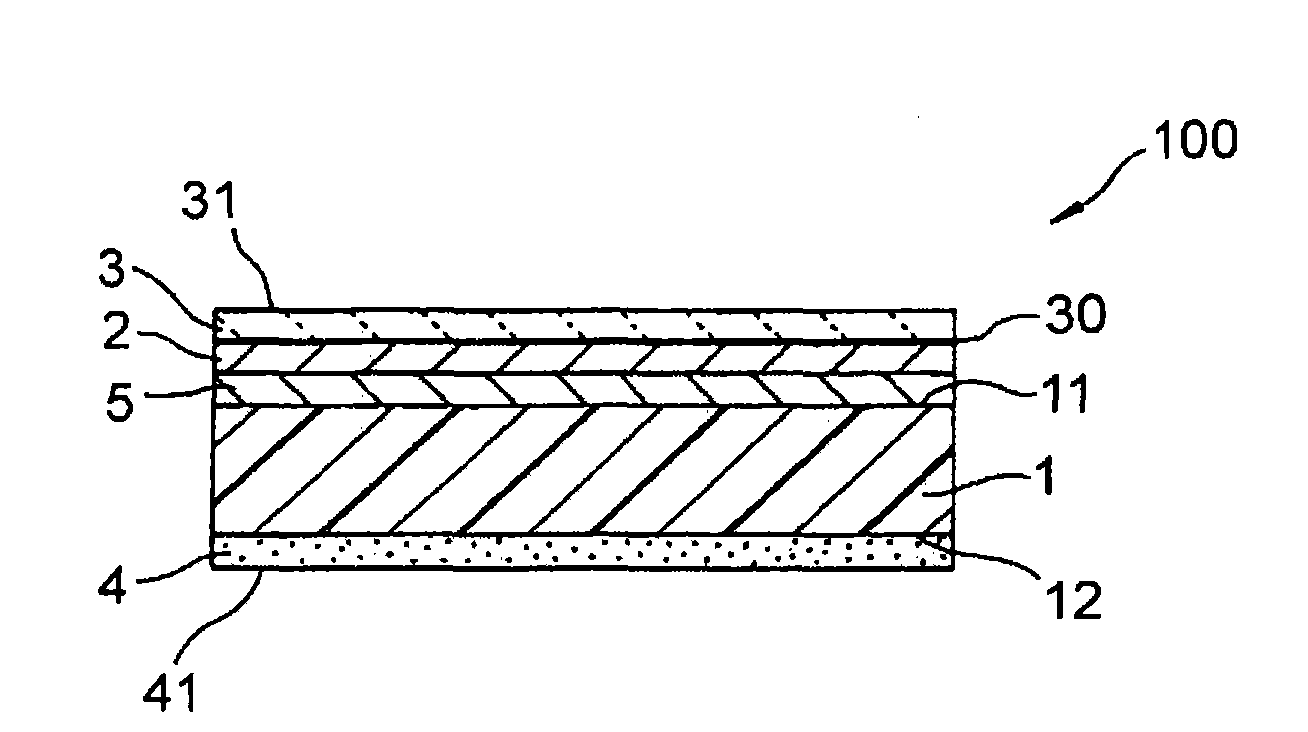

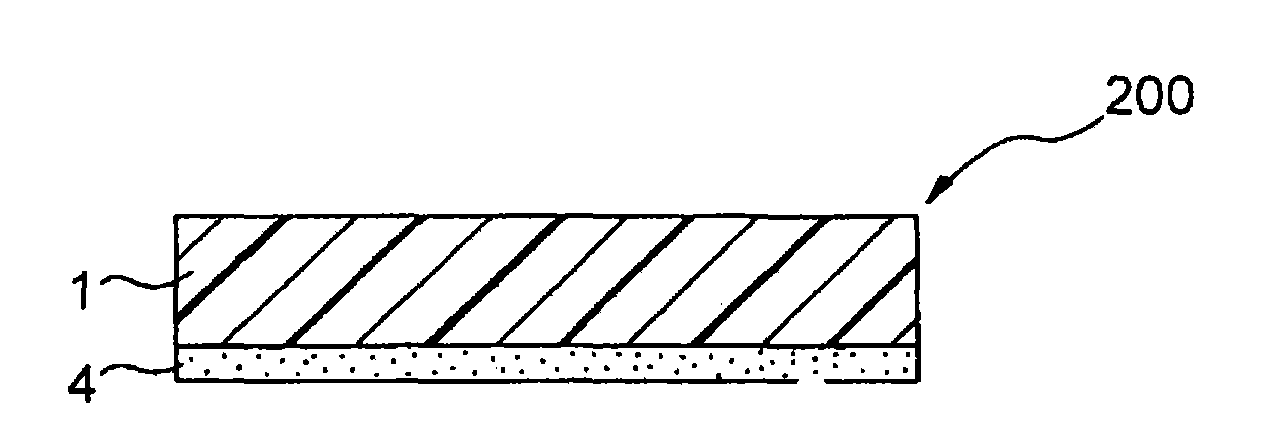

(meth)acrylic pigmented film, marking film, receptor sheet and method for preparing the same

An acrylic and acrylic technology, applied in the field of acrylic colored film, can solve the problems of migration, insufficient pigment dispersion, difficult compatibility of pigment concentrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0073] The present invention will be described in more detail below based on the examples of the present invention, but the present invention is not limited by the examples.

[0074] 1. Preparation of (meth)acrylic polymer

[0075] 1.1 Acrylic resin 1

[0076] First, 60 parts by weight of methyl methacrylate (MMA), 34 parts by weight of n-butyl methacrylate (BMA) and 6 parts by weight of dimethylaminoethyl methacrylate (DMAEMA) were dissolved in 150 parts by weight in ethyl acetate, and adding 0.6 parts by weight of the polymerization initiator 2,2'-azobis-(2-methylpropionate methyl ester) (manufactured by Wako Pure Chemical Industries, Co., Ltd., After product name V-601), the mixture was allowed to react at 65° C. for 24 hours in a nitrogen atmosphere to prepare an ethyl acetate solution of acrylic resin 1 (solid content: 39%). Its weight average molecular weight (Mw) was 68,000, and its Tg was 63°C. Tg is calculated according to the FOX equation (equation below):

...

example 1

[0105] Pigment Concentrate 2 and Acrylic Resin 1 and Acrylic Resin 2 as film-forming resins were prepared. Next, Pigment Concentrate 2, Acrylic Resin 1 and Acrylic Resin 2 were mixed such that 100 parts by weight of Acrylic Resin 1 (including Acrylic Resin 1 in Pigment Concentrate 2), 100 parts by weight of Acrylic Resin Resinoid 2 and Pigment 1 in 100 parts by weight. With respect to 100 parts by weight of acrylic resin 2, 5 parts by weight of a crosslinking agent (epoxy crosslinking agent manufactured by Soken Chemical Co., Ltd., trade name E-AX, 5% solid content in toluene solution) was added in this mixture. Pigment concentrates have good compatibility with film-forming resins. Compatibility was rated as "good" if no gelation, color separation, or precipitation of the pigment was observed by visual inspection, and "poor" if gelation, color separation, or precipitation of the pigment was observed. The resulting mixture was coated on a 50 μm release-treated polyester film...

example 2

[0117] A (meth)acrylic colored film and a receptor sheet were obtained by the same method as in Example 1 except for the following points. Pigment Concentrate 3, Acrylic Resin 1 and Acrylic Resin 2 were mixed such that 100 parts by weight of Acrylic Resin 1 (including Acrylic Resin 1 in Pigment Concentrate 3), 100 parts by weight of Acrylic Resin 2 and 100 parts by weight of Pigment 2. To this mixture was added 0.5 parts by weight of a bisamide crosslinking agent, which was the same bisamide crosslinking agent used in the pressure-sensitive adhesive of Example 1, relative to 100 parts by weight of the acrylic resin 2 . Compatibility, tensile strength and elongation are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition point | aaaaa | aaaaa |

| Glass transition point | aaaaa | aaaaa |

| Glass transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com