Patents

Literature

429results about How to "Excellent gas barrier properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

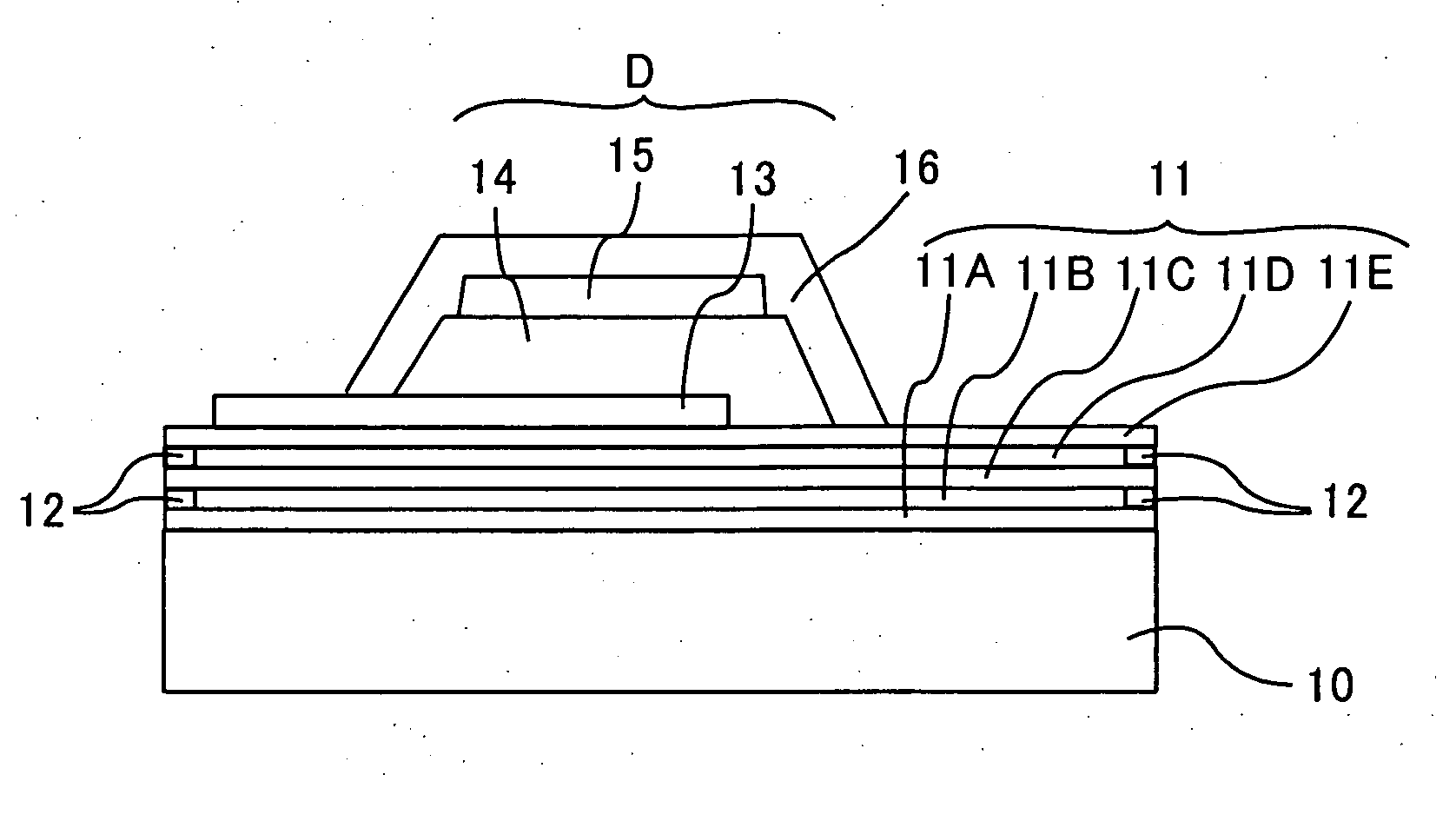

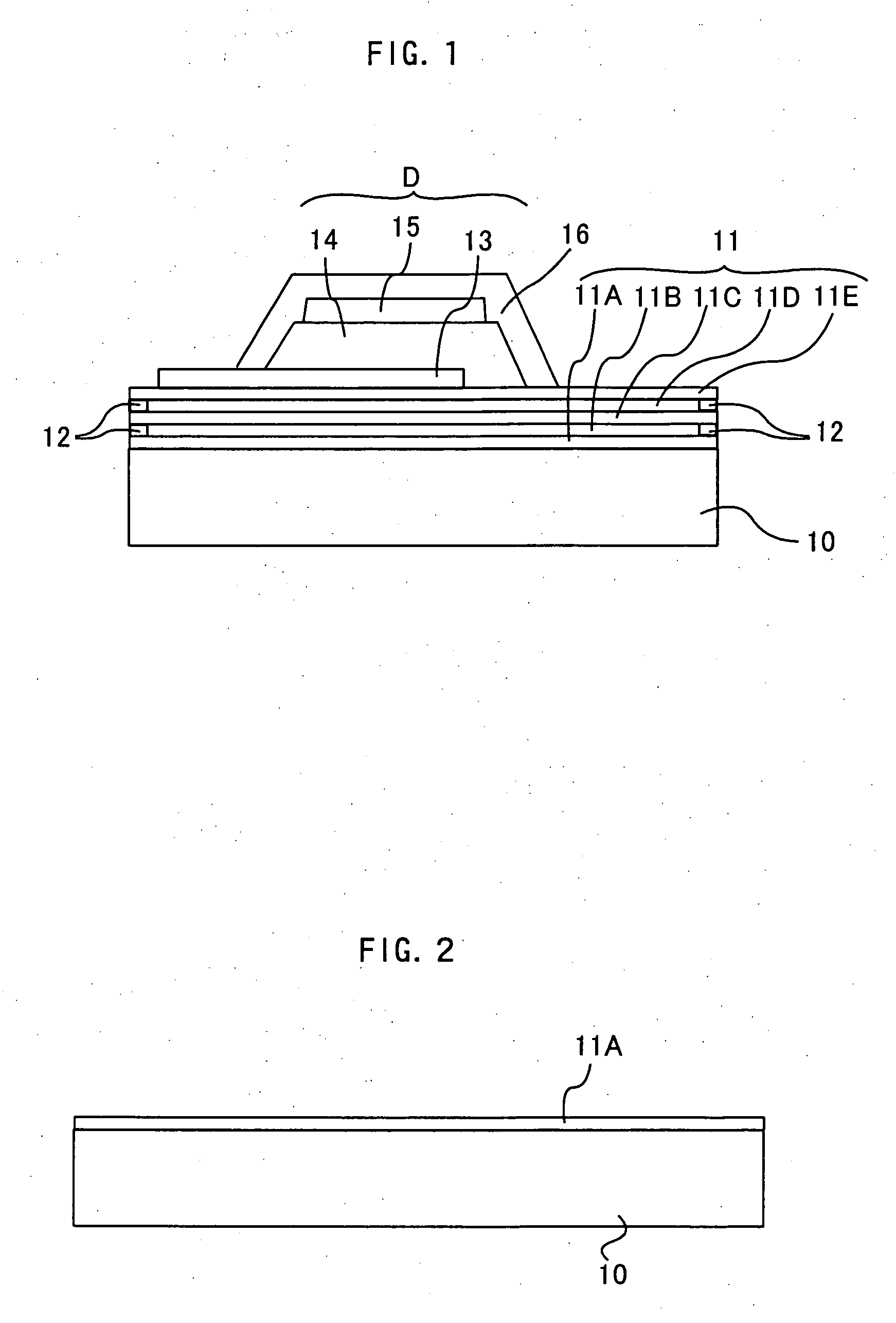

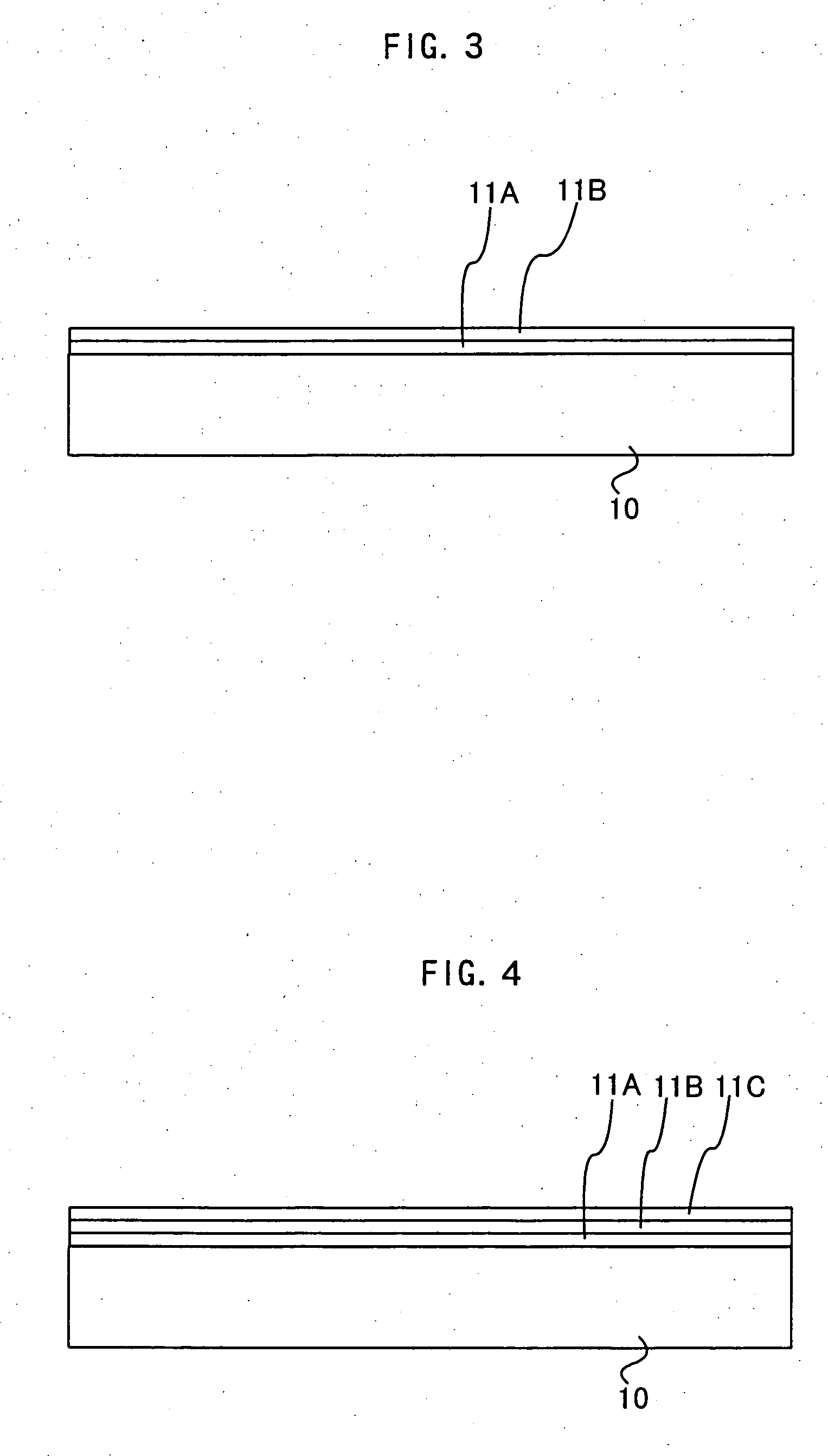

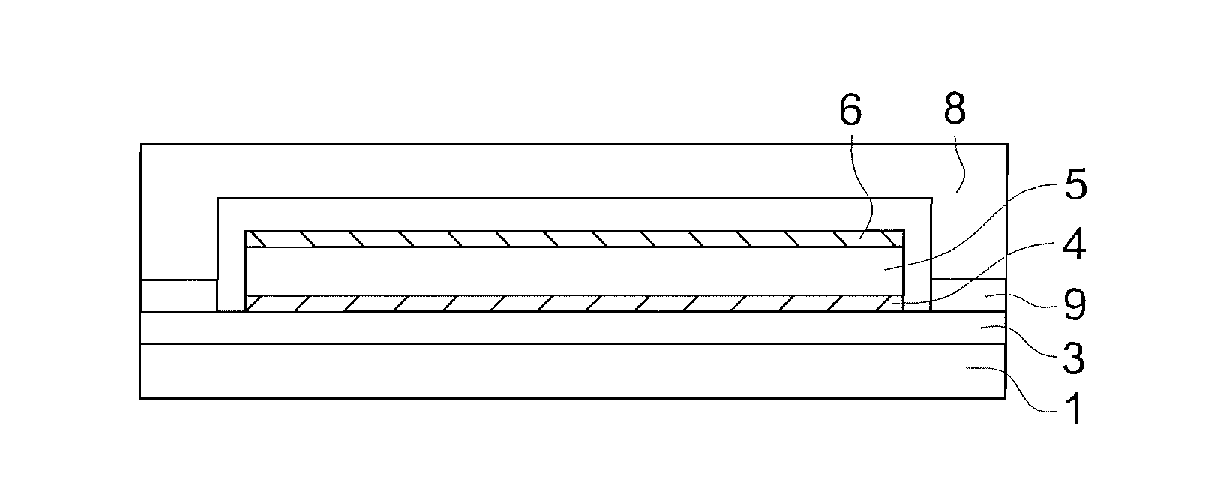

Multilayer barrier film structure and organic electroluminescent display panel and manufacturing method thereof

InactiveUS20050017633A1High gas barrier abilityNo deteriorationDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceChemistry

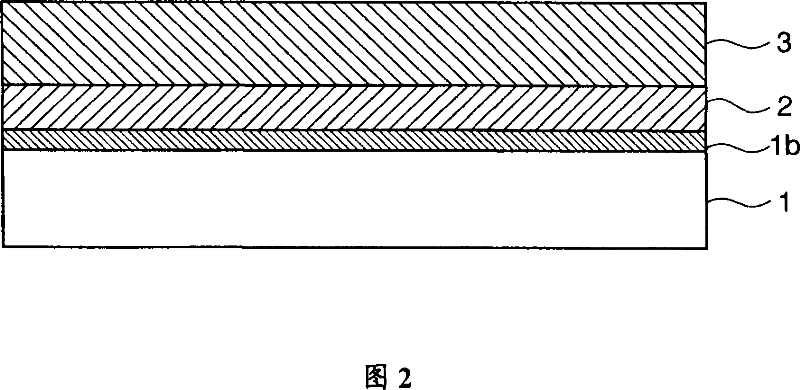

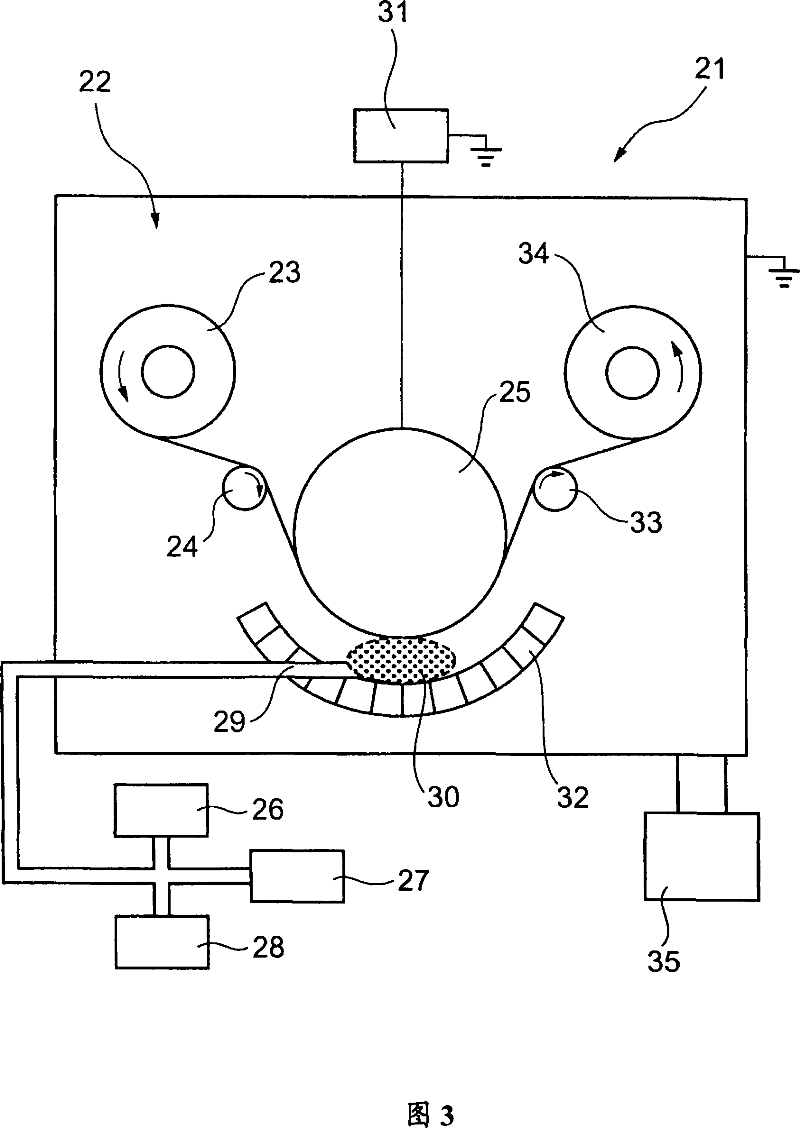

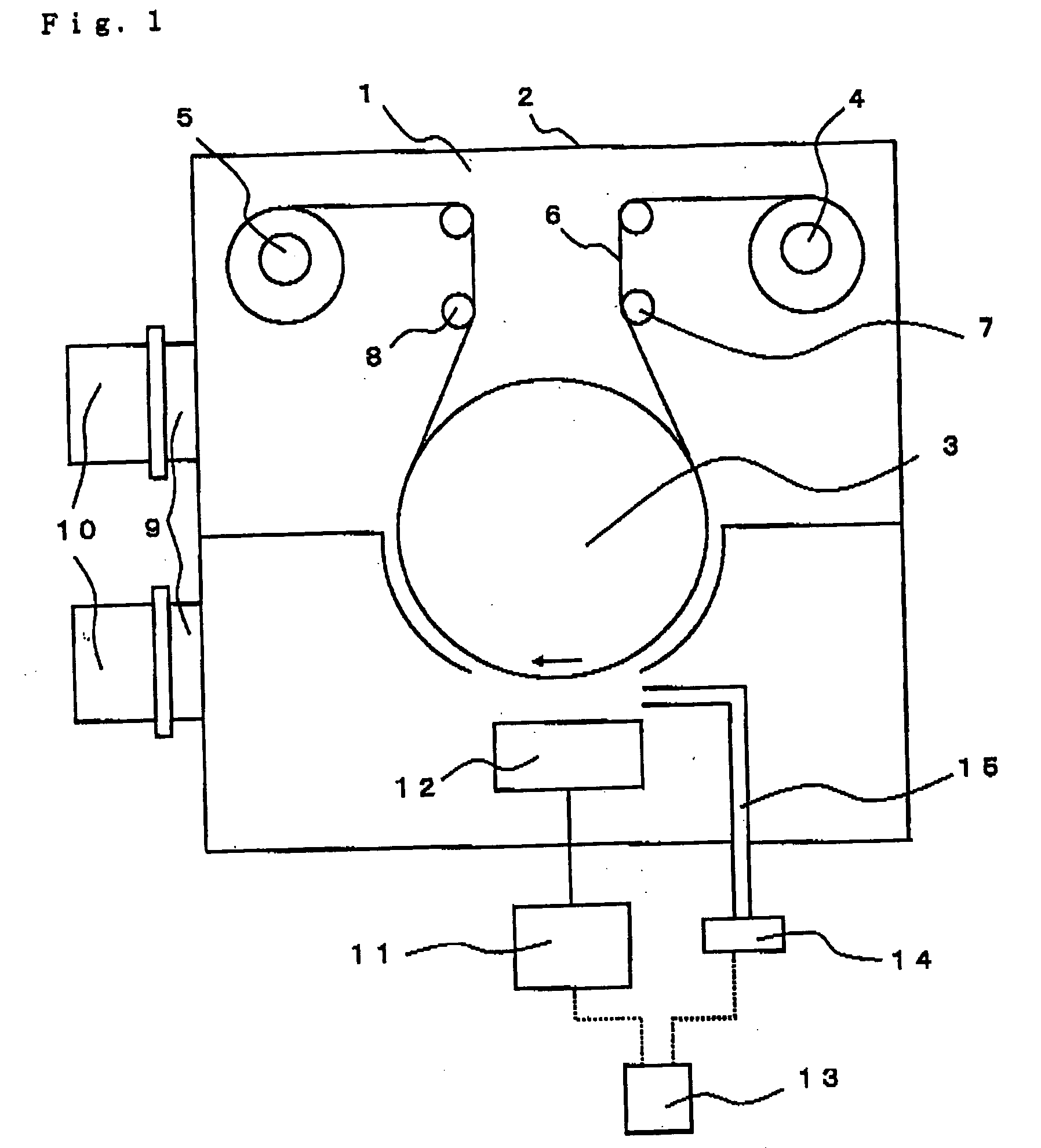

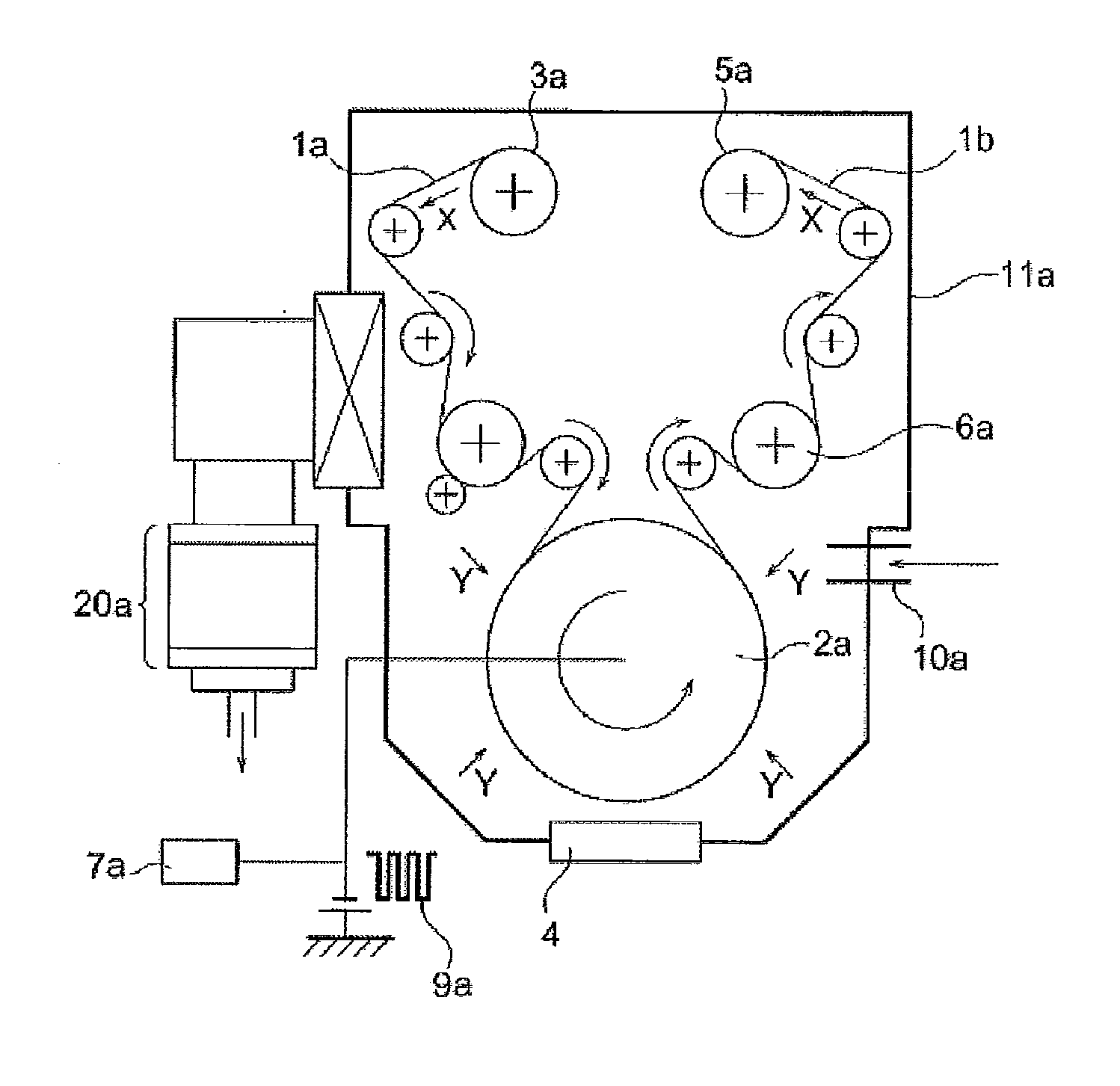

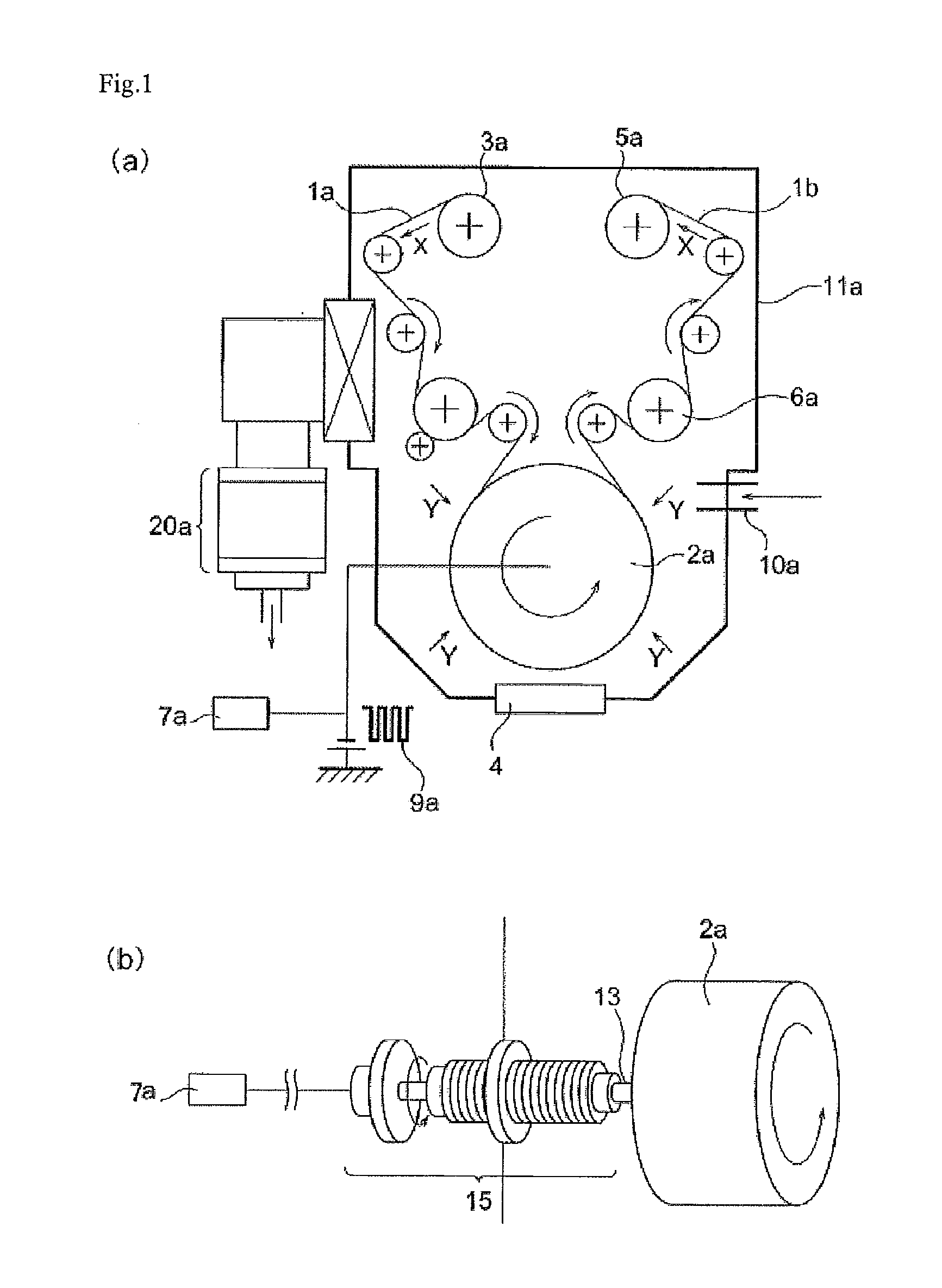

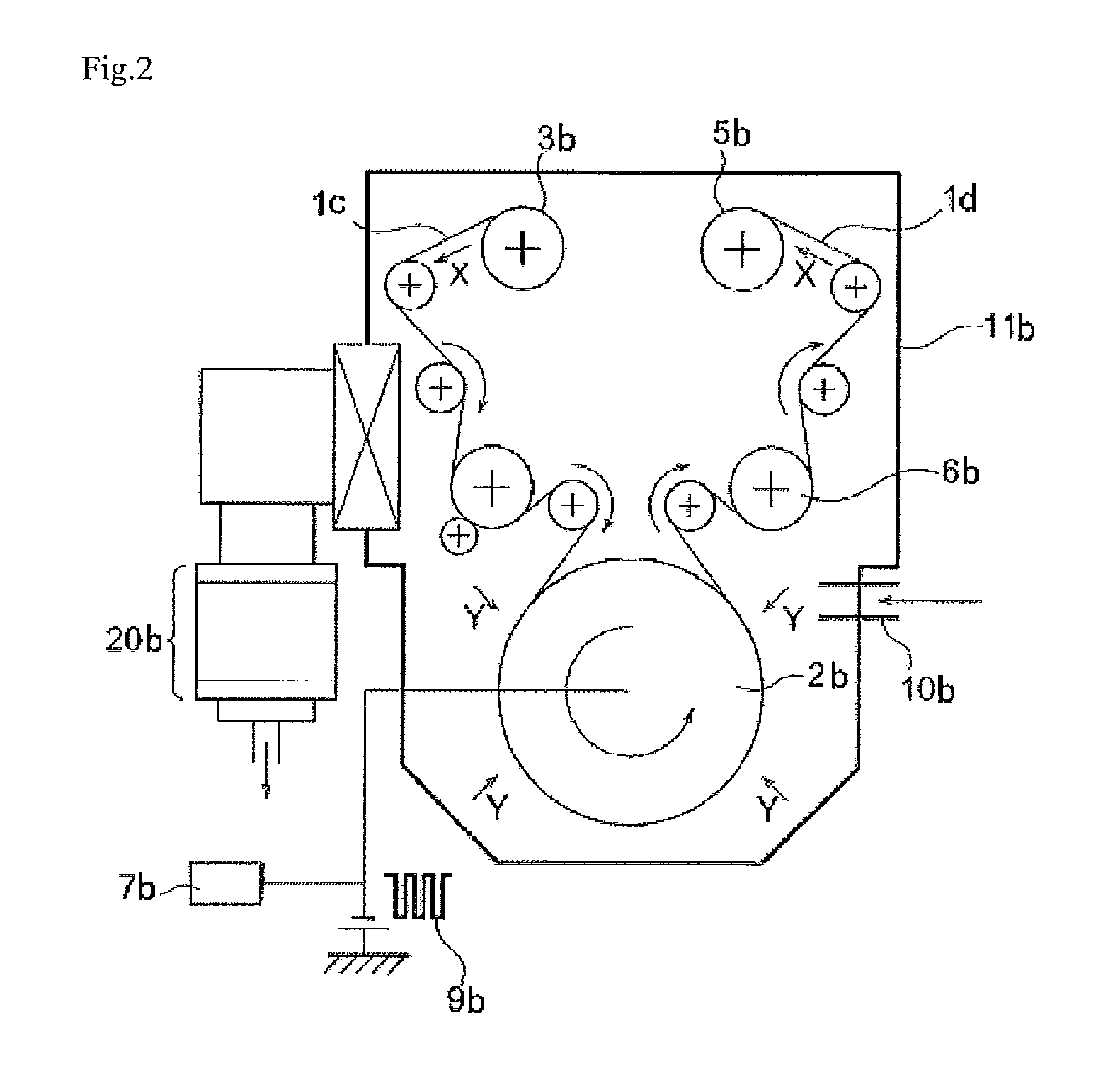

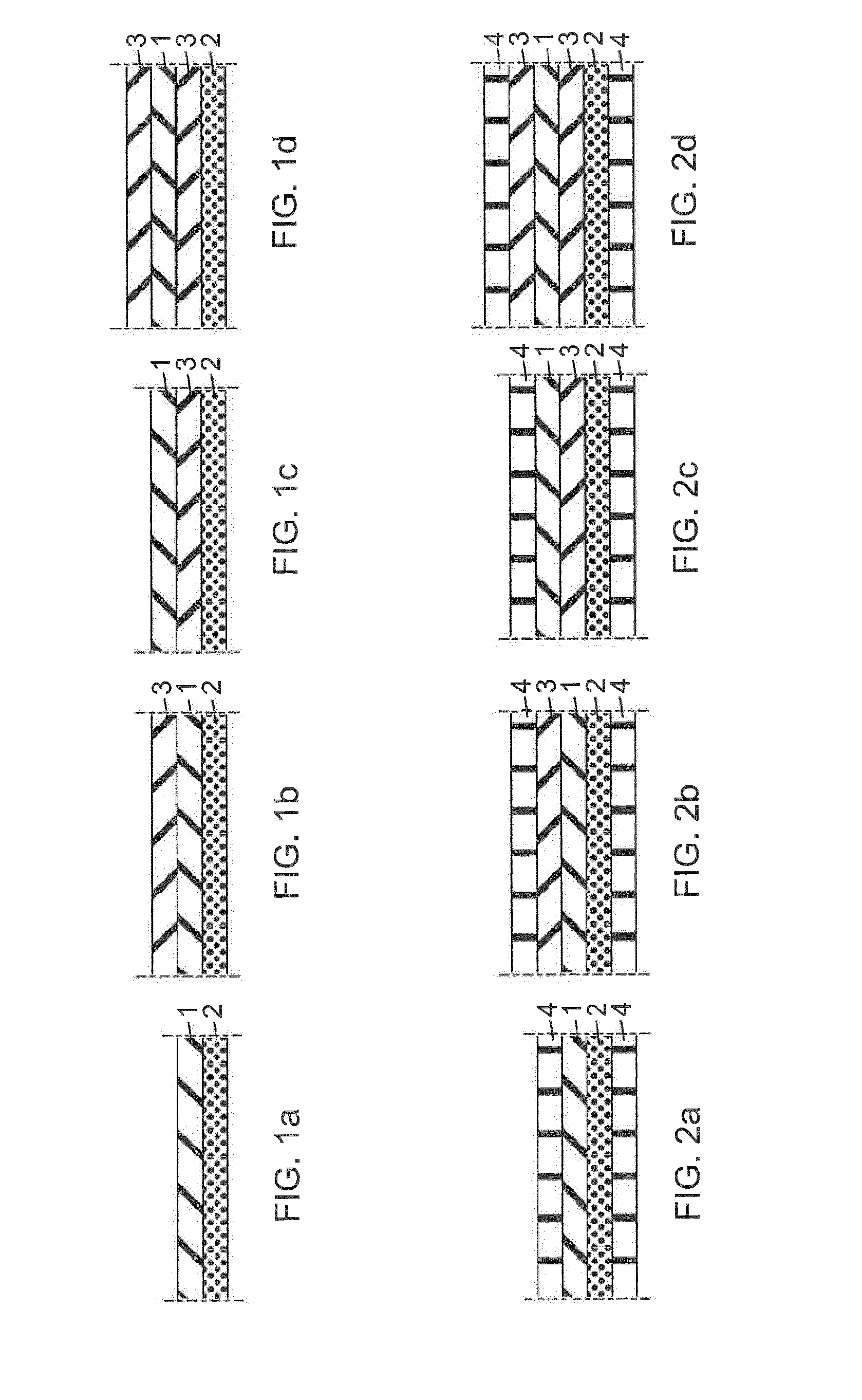

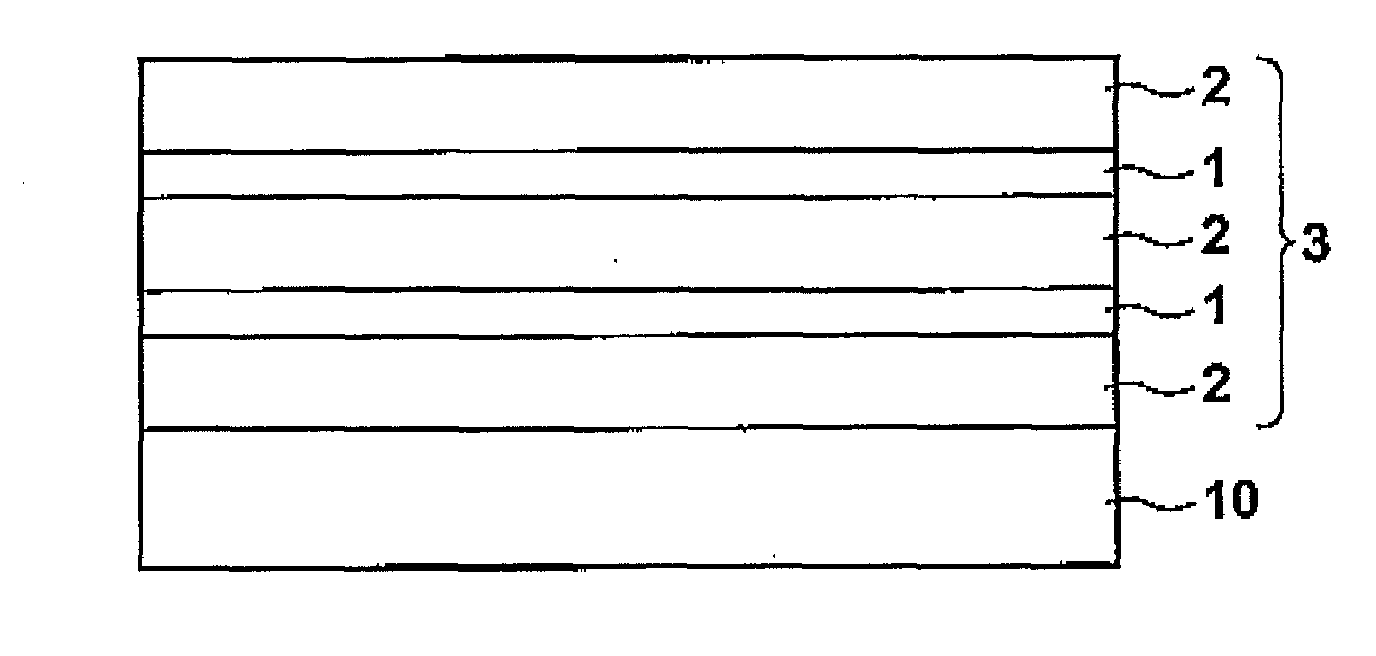

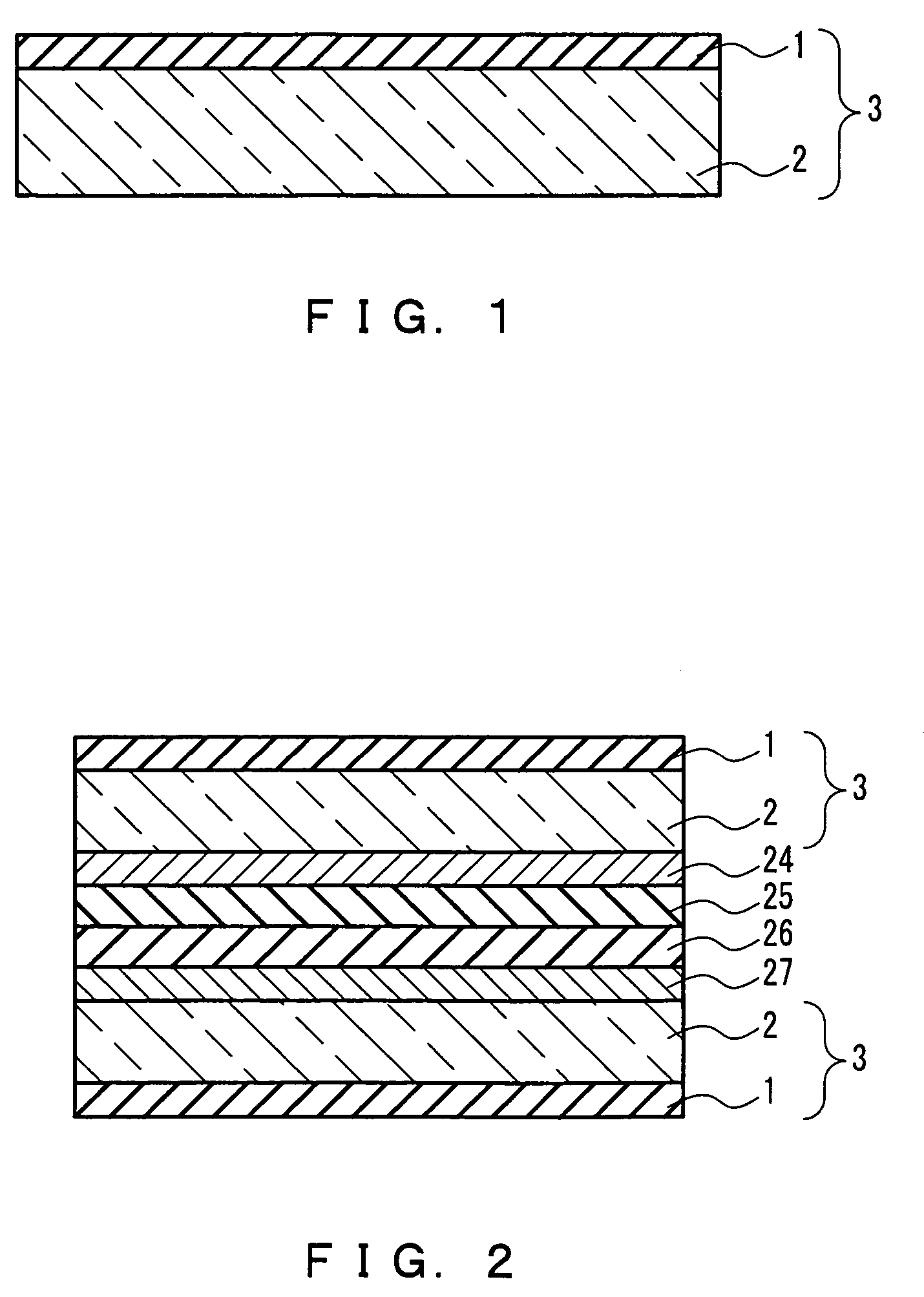

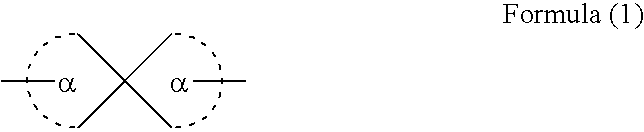

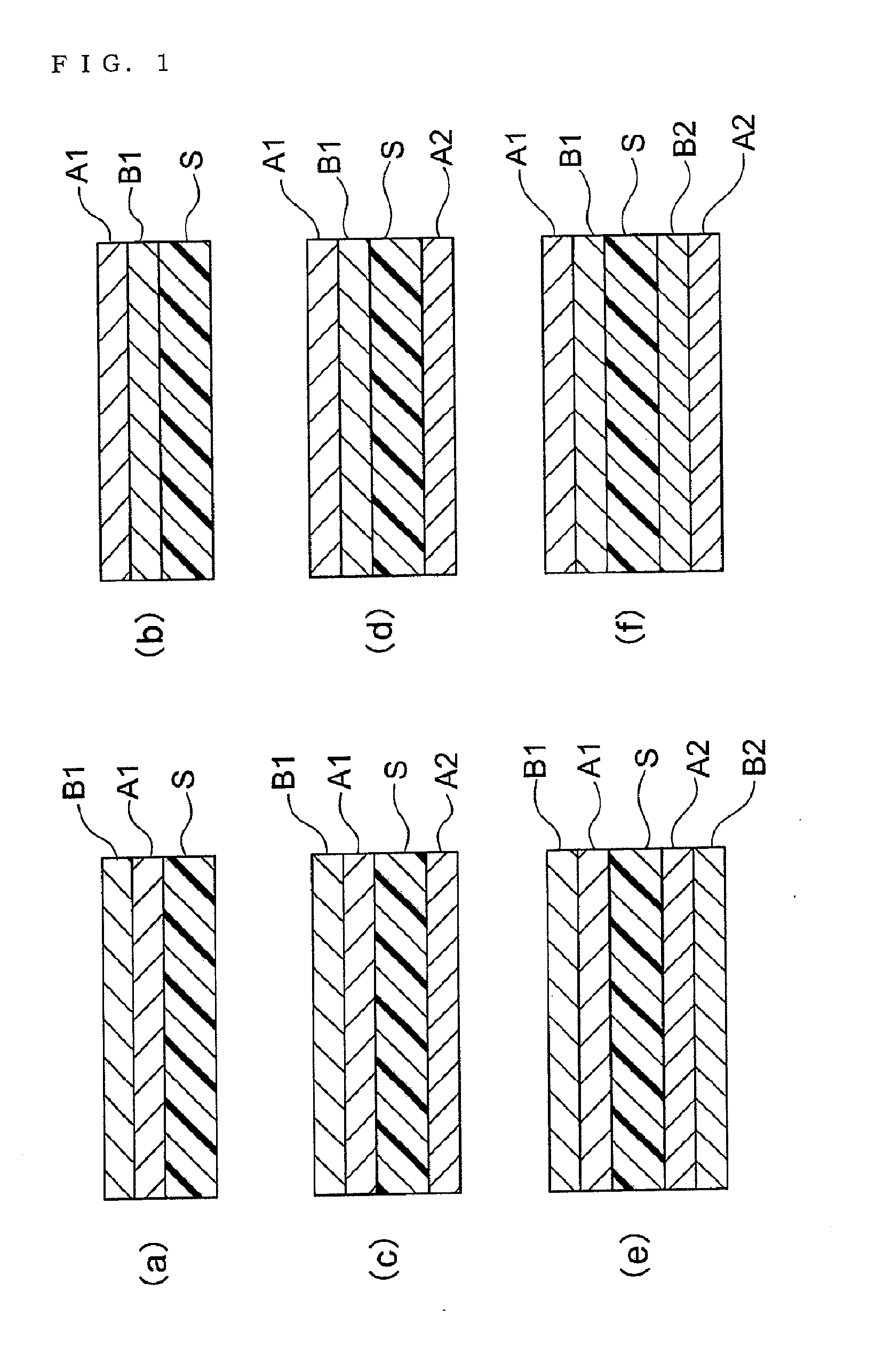

A multilayer barrier film structure of an organic. EL display panel has a multilayered body formed on a surface of a supporting substrate. The multilayered body includes an intermediate film for which the number of molecules of oxygen, water and the like permeating through is reduced upon heating or irradiation and inorganic films formed so as to sandwich the intermediate film. The film structure includes a sealing region where the intermediate film has been transformed by heating or irradiation provided so as to surround the multilayered body on the surface of the supporting substrate. In a method of manufacturing an organic EL display panel comprising an organic EL device and a supporting substrate supporting the organic EL device, a first inorganic film is formed so as to cover a surface of a supporting substrate, an intermediate film for which the number of molecules of oxygen, water and the like permeating through is reduced upon heating or irradiation is formed on the first inorganic film, a second inorganic film is formed on the intermediate film, an organic EL device comprising first and second display electrodes and at least one organic functional layer comprising an organic compound formed so as to be sandwiched between the first and second display electrodes is formed on the second inorganic film, and a perimeter outside the organic EL device is subjected to heating or irradiation, to form a sealing region where the intermediate film has been transformed surrounding the organic EL device.

Owner:PIONEER CORP

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

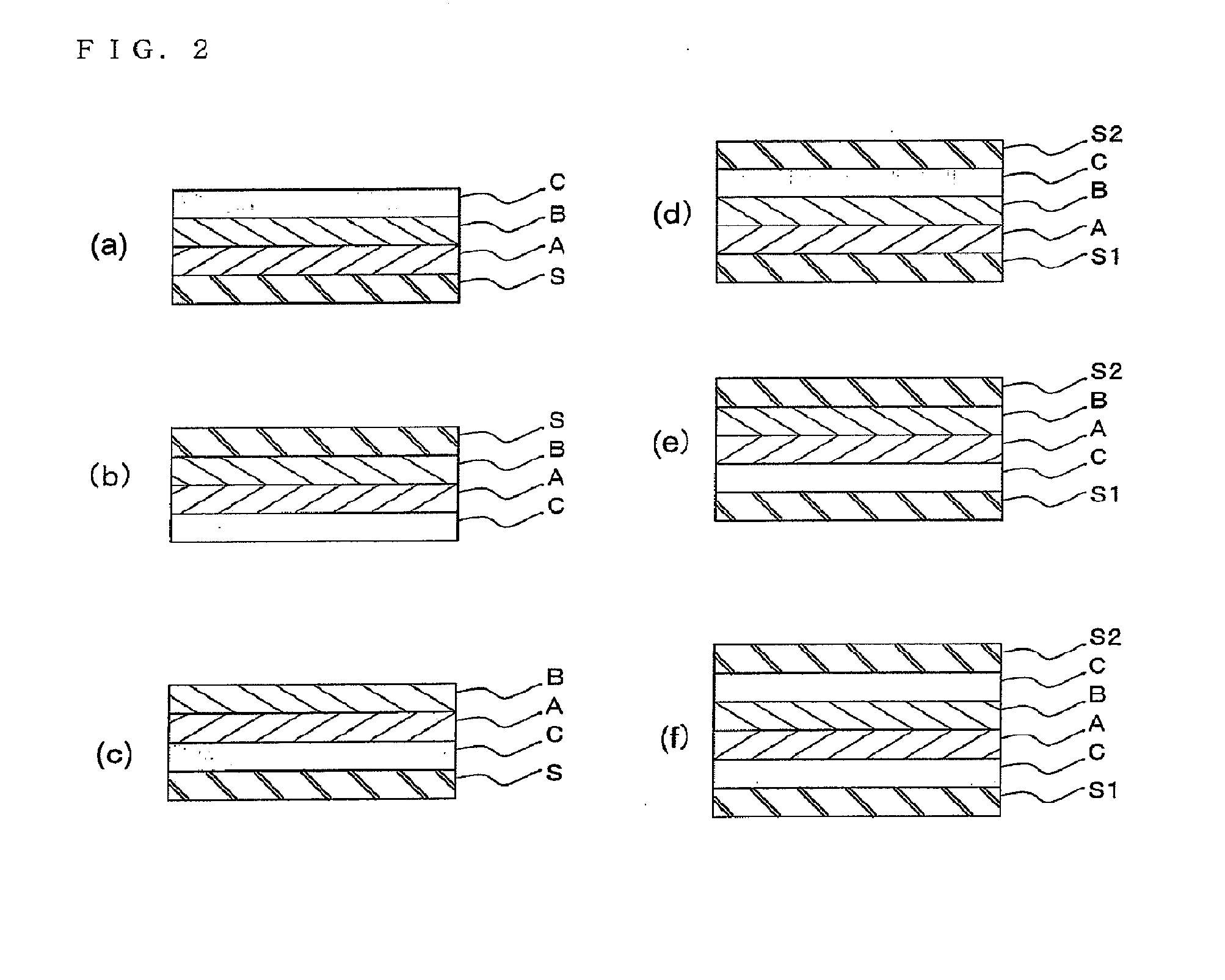

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

Packaging film or sheet

InactiveUS6416832B1Good formabilityExcellent gas barrier propertiesFlexible coversWrappersCopolymerPolymer chemistry

The invention provides a single-layer or multi-layer packaging film or sheet having at least one layer formed of a polyamide resin composition, wherein the layer formed of the polyamide resin composition is a layer (A) formed of a polyamide resin composition comprising a copolymer nylon (c) composed of an aliphatic nylon (co)polymer component (1) and an aromatic nylon (co)polymer component (2) in a proportion of at least 5 wt. %.

Owner:KUREHA KAGAKU KOGYO KK

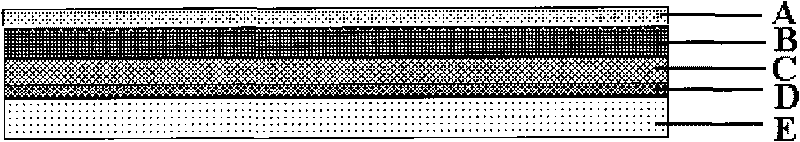

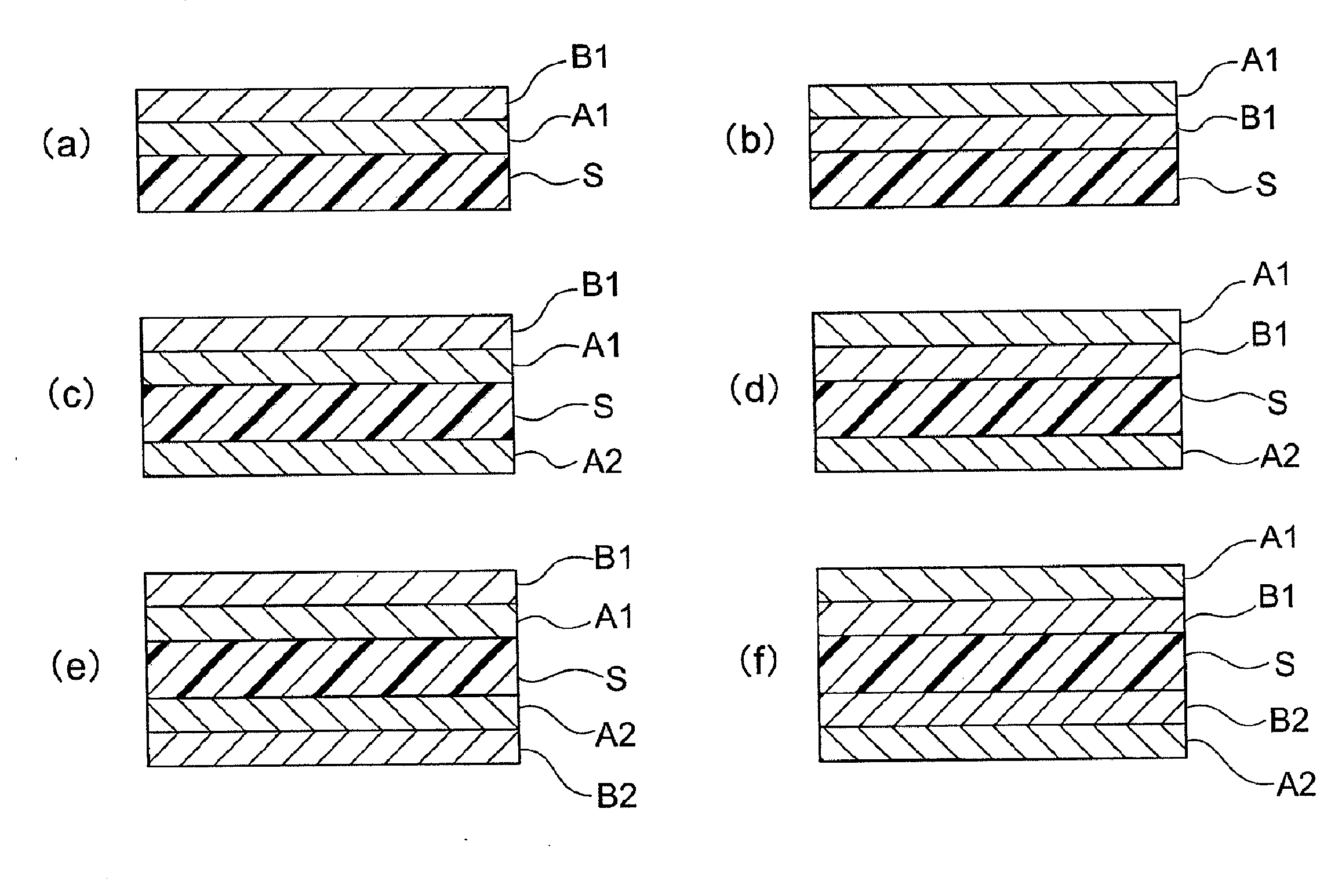

Laminated film having gas barrier characteristics

InactiveUS20090022981A1Excellent gas barrier propertiesLiquid surface applicatorsLayered productsUltimate tensile strengthStructural unit

Provided is a laminated film which exhibits high gas barrier performance immediately after the production and has excellent adhesive strength between constitutional layers, while maintaining the excellent gas barrier performance. The laminated film has at least one constitutional unit layer on an inorganic thin film formed at least on one surface of a base film. The constitutional unit layer is composed of an anchor coat layer having a thickness of 0.1 to 10 nm and an inorganic thin film formed on the anchor coat layer. A method for producing the laminated film is also provided.

Owner:MITSUBISHI PLASTICS INC

Gas barrier laminated film and laminated material using it

ActiveCN101039801AExcellent gas barrier propertiesImprove impact resistanceLayered productsVacuum evaporation coatingChemistryProduct gas

Disclosed is a gas barrier multilayer film having excellent gas barrier properties, transparency and excellent impact resistance. Also disclosed is a method for producing such a gas barrier multilayer film. Specifically disclosed is a gas barrier multilayer film wherein a vapor deposition film of an inorganic oxide is formed on a base and a gas barrier coating film is formed on the vapor deposition film. Such a gas barrier multilayer film is characterized in that a side of the base on which the vapor deposition film is to be formed is subjected to a pretreatment or a primer coating treatment and the gas barrier coating film is formed by applying a gas barrier coating liquid on the inorganic oxide film and then heating the thus-applied coating liquid.

Owner:DAI NIPPON PRINTING CO LTD

Gas barrier film and method for producing the same

InactiveUS20050112378A1Excellent gas barrier performanceImprove heat resistanceSynthetic resin layered productsGlass/slag layered productsVitrificationLiquid-crystal display

Disclosed is a gas barrier film alternately comprising at least one inorganic layer and at least one organic layer on a resin base material having a glass transition temperature of 250° C. or higher. The gas barrier film can exhibit superior gas barrier property when it is used in image display devices such as liquid crystal display devices and organic EL devices.

Owner:FUJIFILM HLDG CORP +1

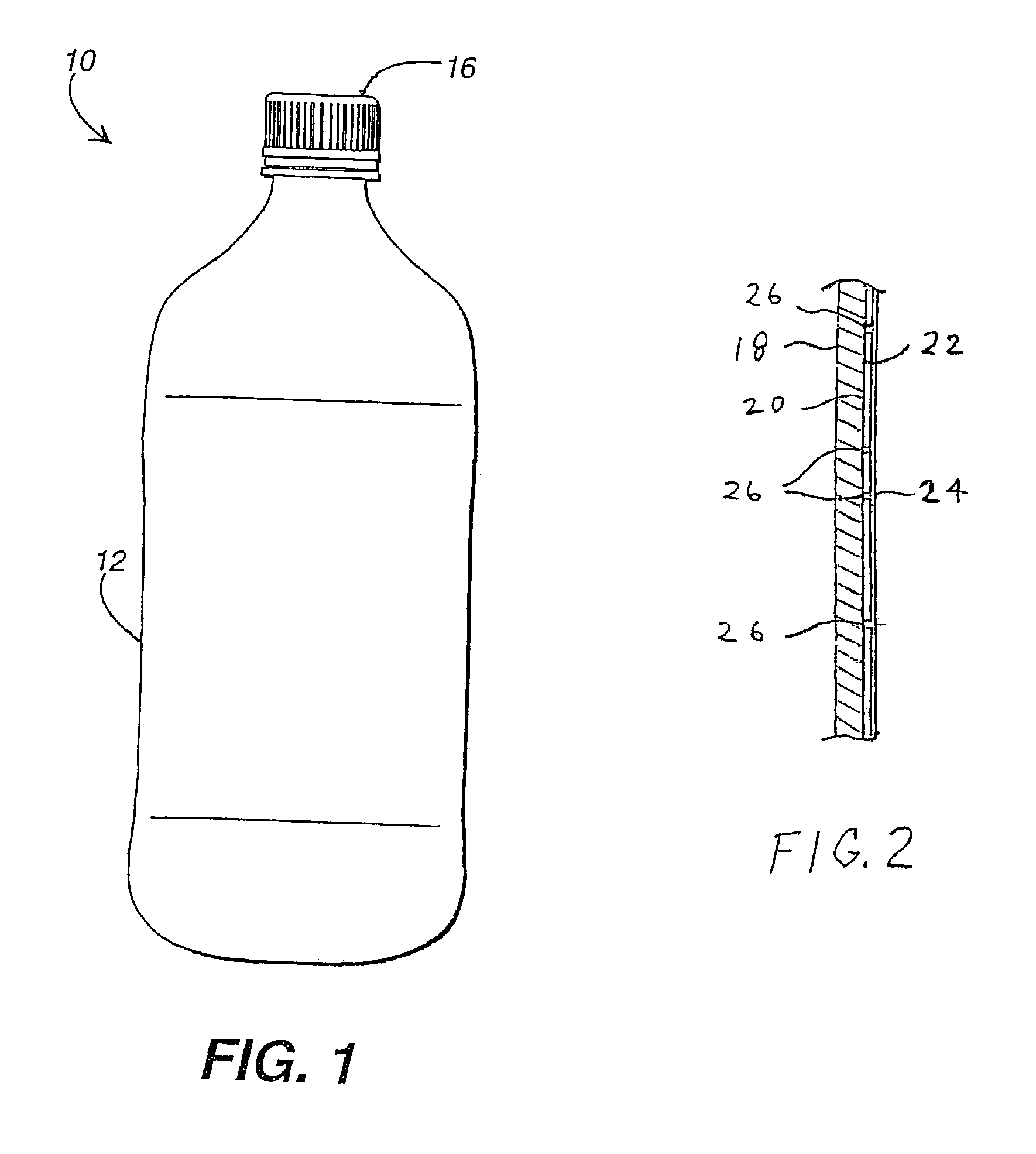

Multi-layered article

InactiveUS6344249B1Excellent appearancePrevent with reliabilityEnvelopes/bags making machineryConfectioneryEngineeringSurface layer

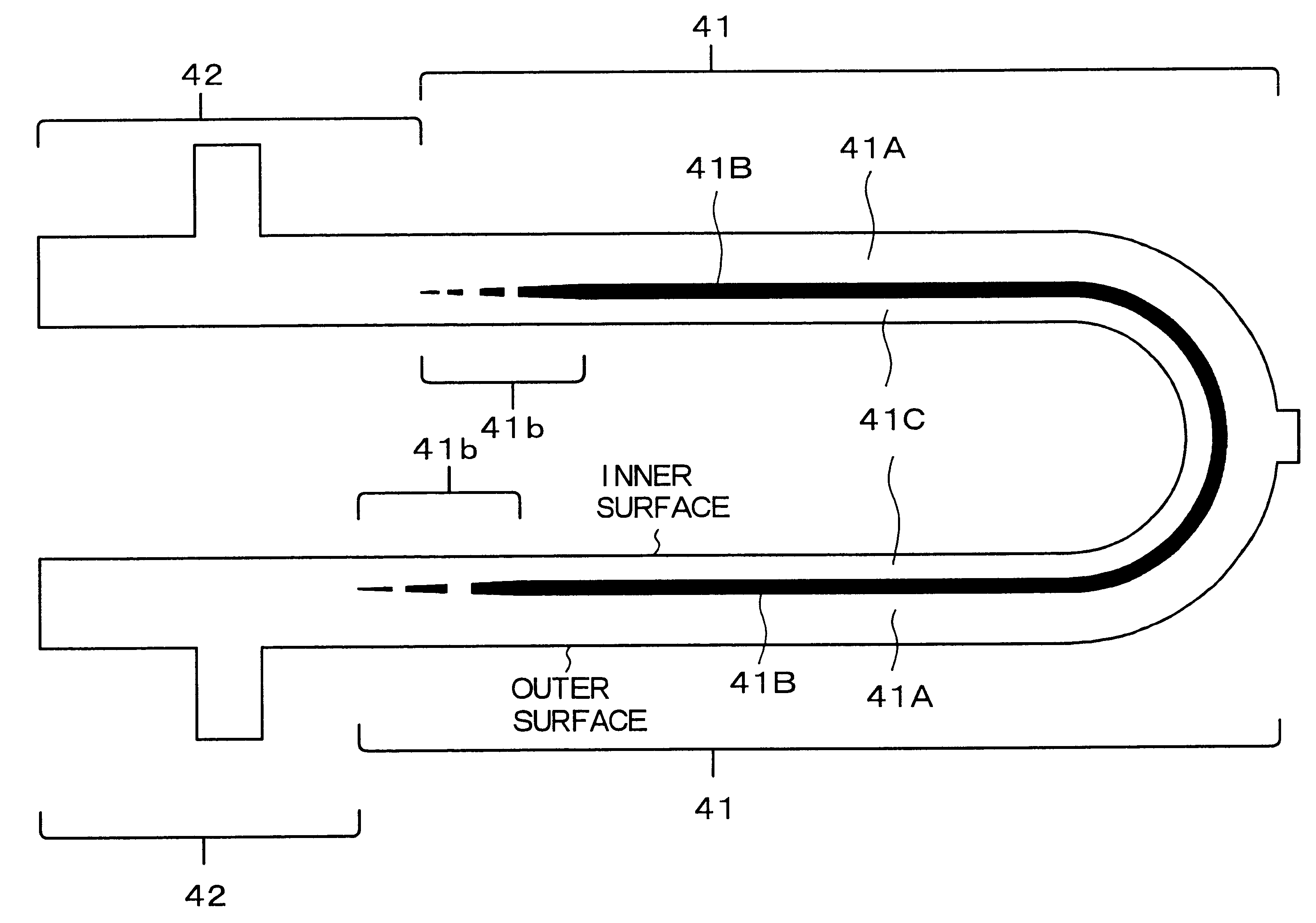

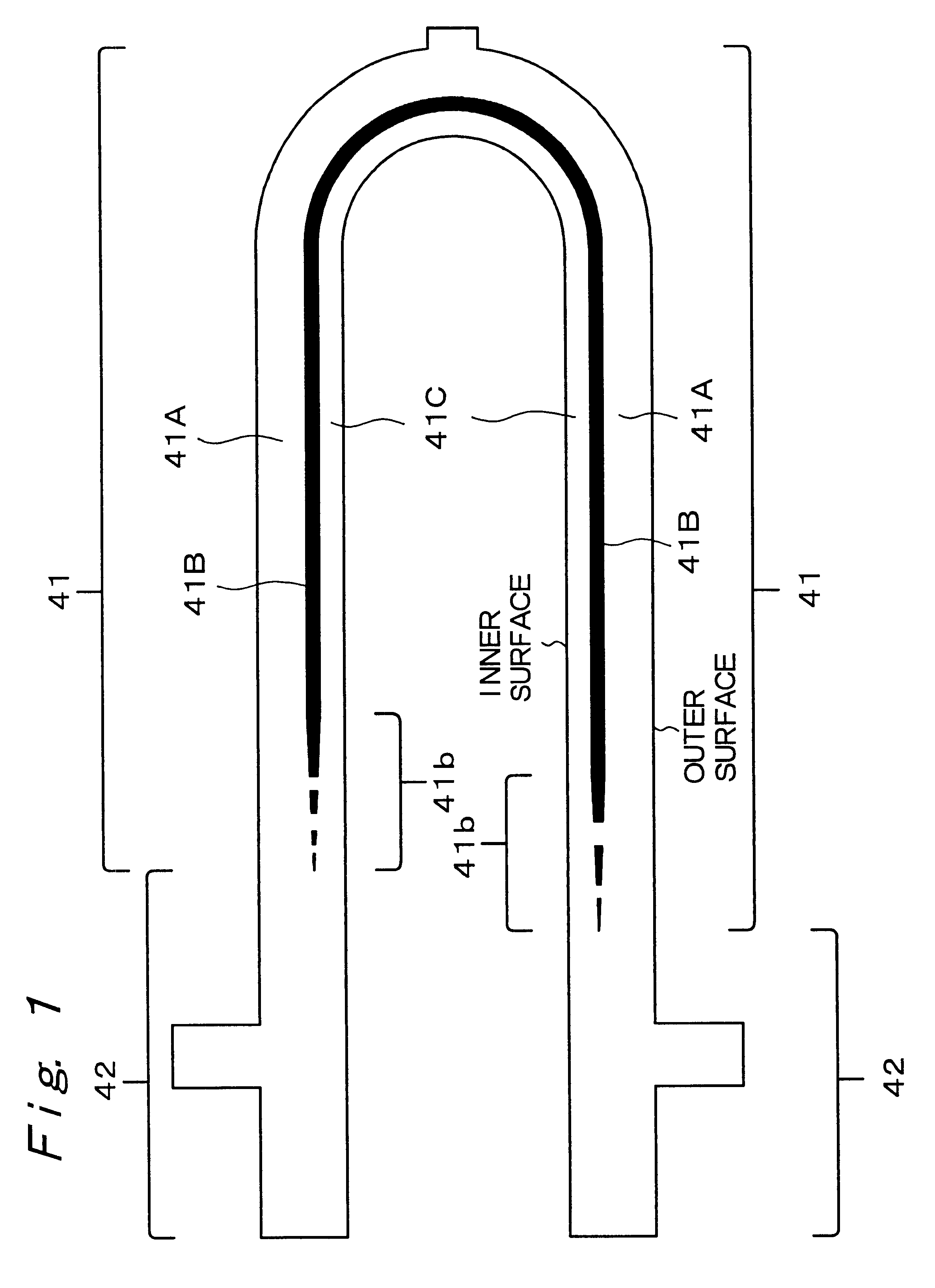

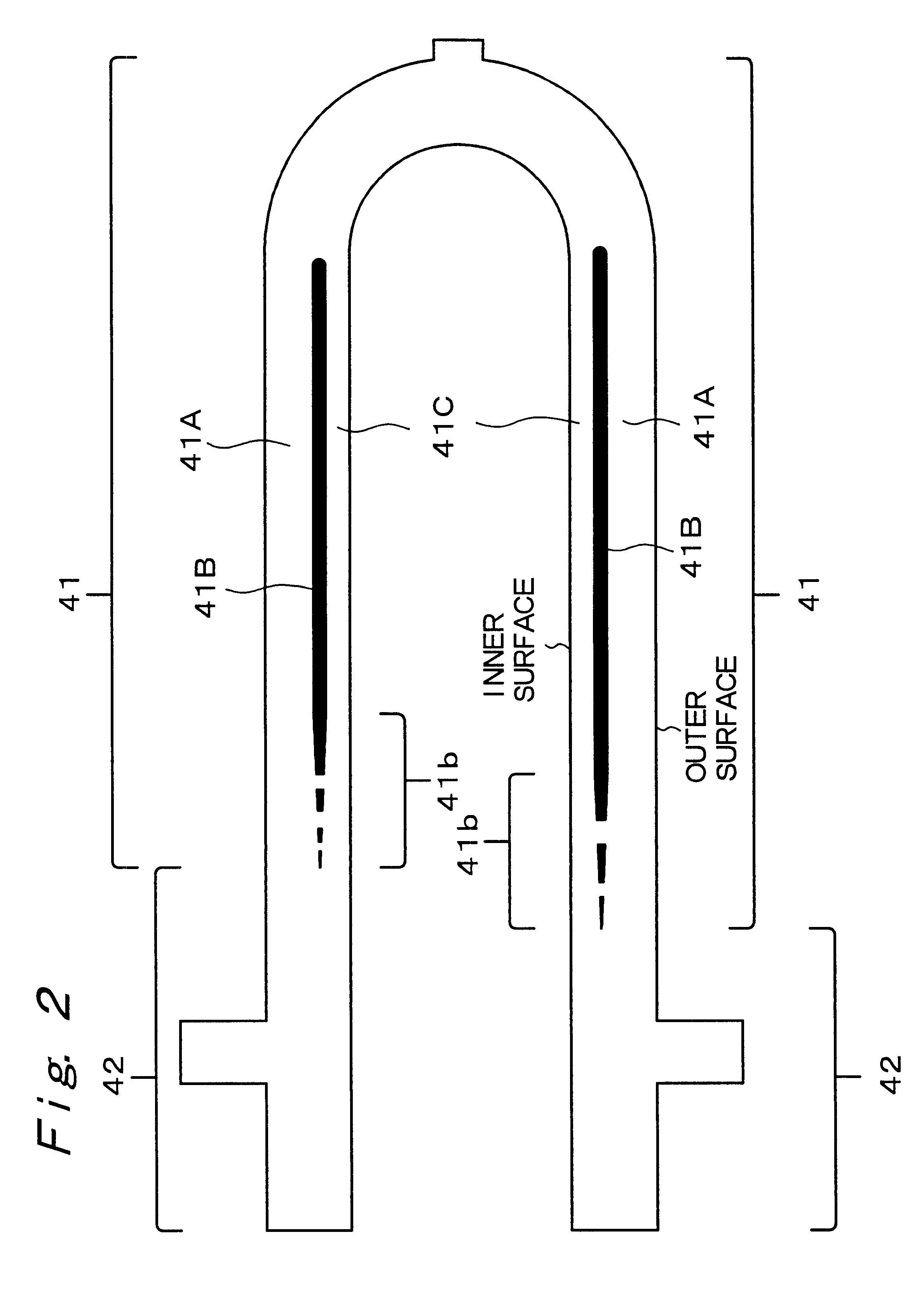

A multi-layered article having a first portion constituted of laminated three resin layers and a second portion extending from the first portion, the first portion being constituted mainly of consecutively laminated resin layers composed of a first resin layer formed of a first resin, a second resin layer formed mainly of a second resin and a third resin layer formed of the first resin, the second portion being constituted of resin layers extending from the first resin layer and the third resin layer which constitute the first portion, the first resin layer constituting the outer surface layer of the multi-layered article, the third resin layer constituting the inner surface layer of the multi-layered article which inner surface layer is opposed to said outer surface layer, the second resin layer being encapsulated with the first resin layer and the third resin layer, the second resin layer having a thickness which decreases towards the second portion, and being discontinued, in a region of the first portion in the vicinity of the second portion.

Owner:MITSUBISHI GAS CHEM CO INC

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

Formed article, method for producing the formed article, member for electronic device, and electronic device

ActiveUS20120064321A1Excellent gas barrier capabilityExcellent resistanceSynthetic resin layered productsVacuum evaporation coatingOxygen atomChemistry

A formed article includes a gas barrier layer that is formed of a material including at least an oxygen atom and a silicon atom, a surface area of the gas barrier layer having an oxygen atom content rate of 60 to 75%, a nitrogen atom content rate of 0 to 10%, and a silicon atom content rate of 25 to 35%, based on the total content of oxygen atoms, nitrogen atoms, and silicon atoms, and having a film density of 2.4 to 4.0 g / cm3. A method of producing a formed article includes implanting ions into a surface layer part of a polysilazane compound-containing layer of a formed body that includes the polysilazane compound-containing layer in its surface layer part. An electronic device member includes the formed article. An electronic device includes the electronic device member. The formed article exhibits an excellent gas barrier capability, excellent folding resistance, and excellent transparency.

Owner:LINTEC CORP

Coating composition, a method for coating a substrate, a coated substrate, a packaging material and a liquid package

InactiveUS20140251856A1Improving gas barrier functionExcellent gas barrier propertiesLiquid surface applicatorsWrappersAlcoholPolyvinyl alcohol

The present invention relates to a curtain coatable gas barrier coating composition comprising a polymer and a surfactant, wherein the polymer is selected from a group consisting of polyvinyl alcohol and polysaccharides, or mixtures thereof, wherein said polysaccharides are soluble or dispersable or suspendable in water and the surfactant is a water soluble non-ionic ethoxylated alcohol. The present invention also relates to a method for providing a substrate with a gas barrier layer by means of the coating composition, and a coated substrate having at least one gas barrier layer obtained by coating the substrate with the coating composition. Further, the invention relates to a packaging material comprising a coated paperboard coated with the coating composition, and a liquid package comprising such a packaging material.

Owner:BILLERUDKORSNES SKOG & IND AB

Film, inner liner for tire, and tire using the same

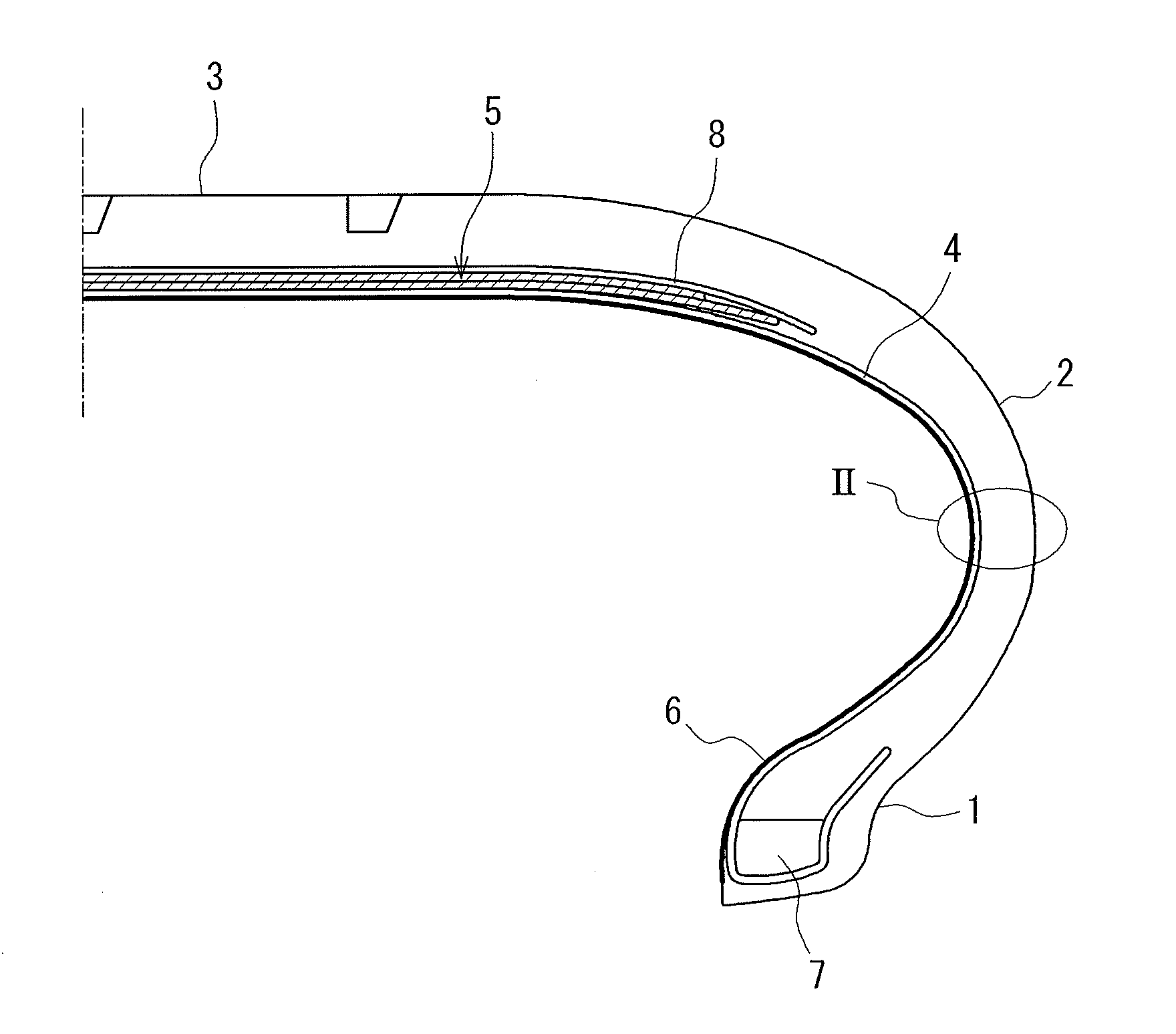

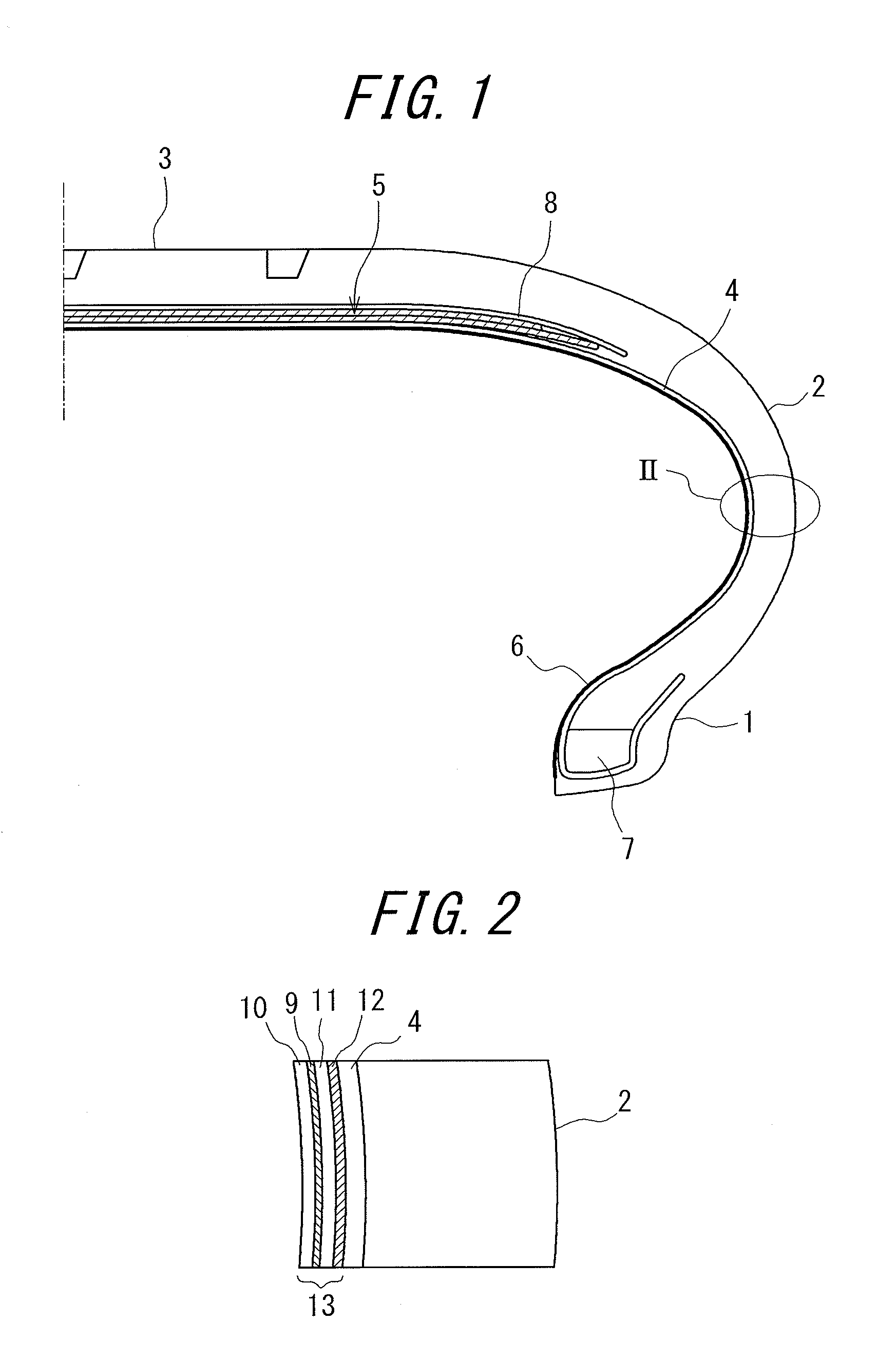

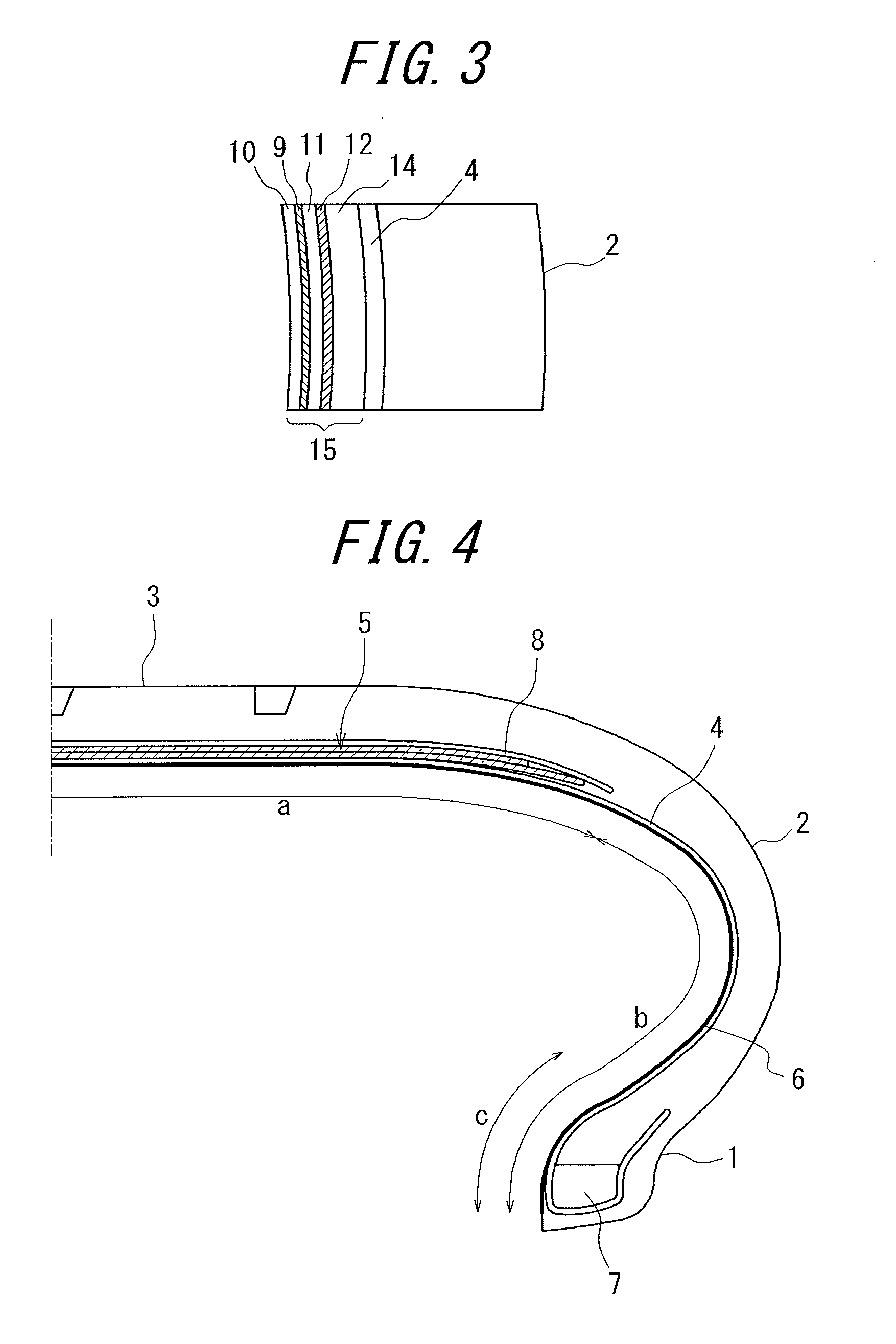

InactiveUS20110024015A1Excellent gas barrier propertiesImprove bending resistanceWithout separate inflatable insertsWith separate inflatable insertsInternal pressureEngineering

An object of the present invention is to provide: a film which is applicable to a tire, has excellent gas barrier properties and bending resistance, allows weight of a tire to be reduced with improving internal pressure retainability of the tire at both the brand-new stage and the used stage thereof, and is capable of demonstrating good gas barrier properties without breaking especially in a running condition at a relatively low temperature in winter time or the like; an inner liner for tire, using the film; and a tire provided with the inner liner for tire. The film of the present invention comprises at least a layer composed of resin composition (D) produced by dispersing viscoelastic substance (C) in a resin containing modified ethylene-vinyl alcohol copolymer (B) obtained by subjecting ethylene-vinyl alcohol copolymer (A) to a reaction, wherein 100% modulus at −30° C. of the viscoelastic substance (C) is smaller than 6 MPa. The inner liner for tire, and the tire, of the present invention are an inner liner for tire, using said film, and a tire provided with said inner liner for tire, respectively.

Owner:BRIDGESTONE CORP +1

Resin composition and a multilayered container

InactiveUS20030018114A1Excellent gas barrier propertiesHigh transparencySynthetic resin layered productsConductive materialPolymer scienceDouble bond

The present invention provides a resin composition having an oxygen scavenging function. The resin composition comprises a gas barrier resin (A), a thermoplastic resin (B) other than the gas barrier resin (A), and a compatibilizer (C), wherein the gas barrier resin (A) has an oxygen transmission rate of 500 ml.20 mum / m2.days.atm (20° C., 65% RH) or less, the thermoplastic resin (B) has a carbon-carbon double bond, and an oxygen absorption rate of the resin composition is 0.001 m / m2.day or more.

Owner:KURARAY CO LTD

Coating composition containing an epoxide additive and structures coated therewith

InactiveUS6982119B2Excellent gas barrier performanceImprove water resistanceSynthetic resin layered productsCellulosic plastic layered productsEpoxideFood products

Coatings are provided to give polymeric structures a top coat that improves the gas barrier properties of the structure while enhancing the water resistance of the top coating and while improving the adhesion of the top coat to an underlying layer of the structure. These top coat compositions comprise an organic barrier coating material in combination with an epoxide additive which enhances the water resistance, adhesion, gas barrier, or a combination thereof, of the top coat barrier layer. Multilayer structures having this top coat are also provided, particularly in the form of containers for food and beverage packaging.

Owner:THE COCA-COLA CO

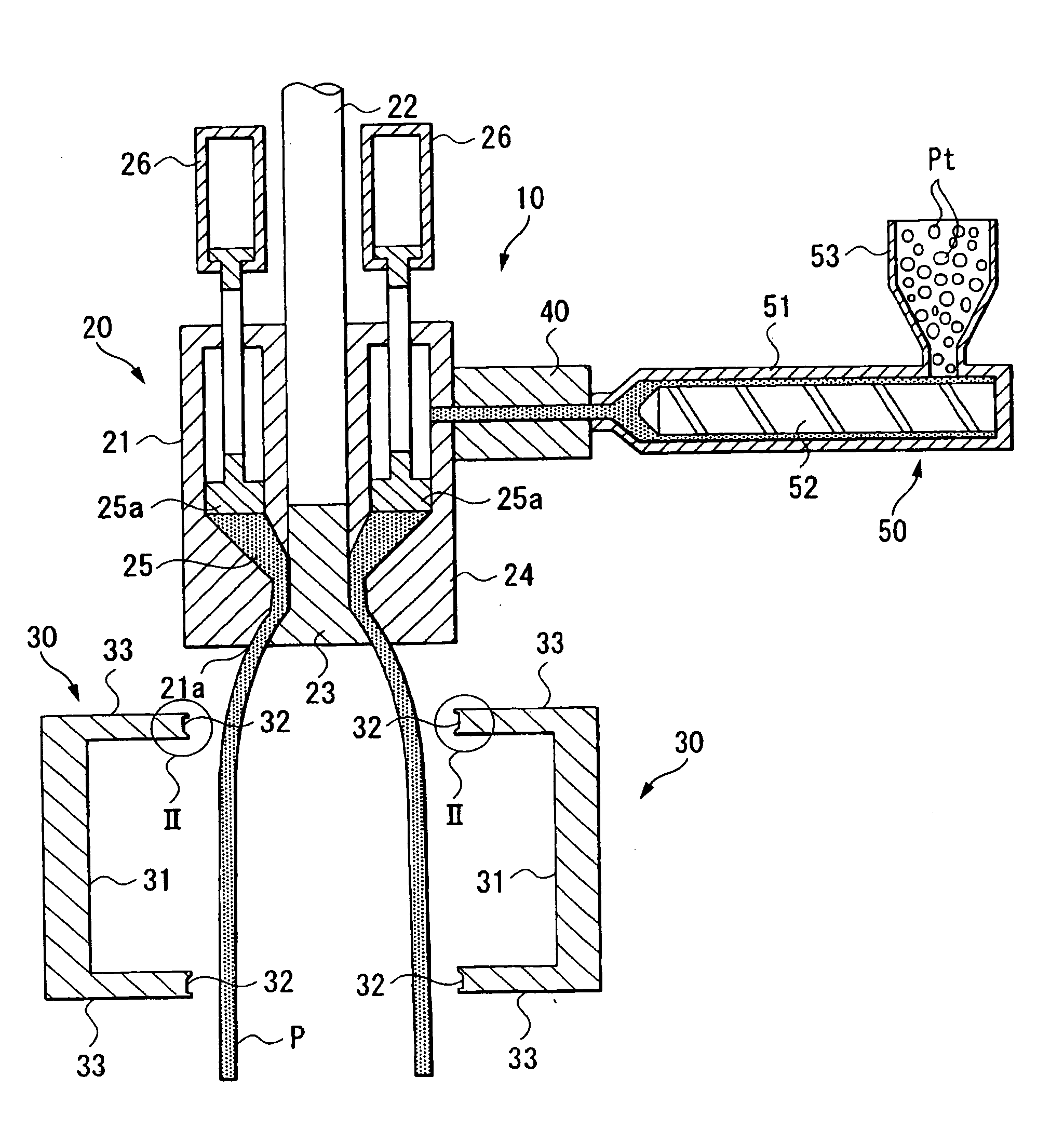

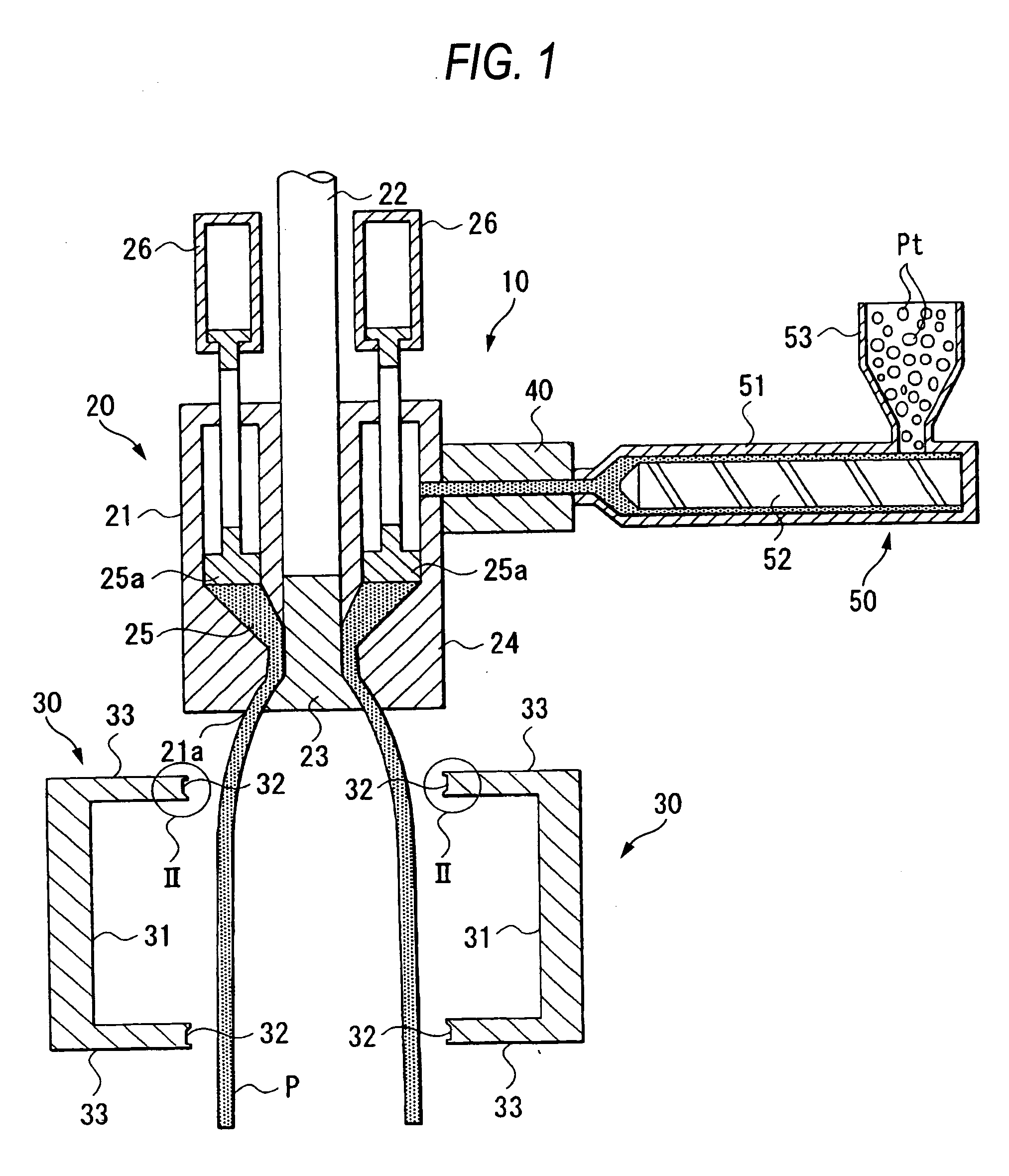

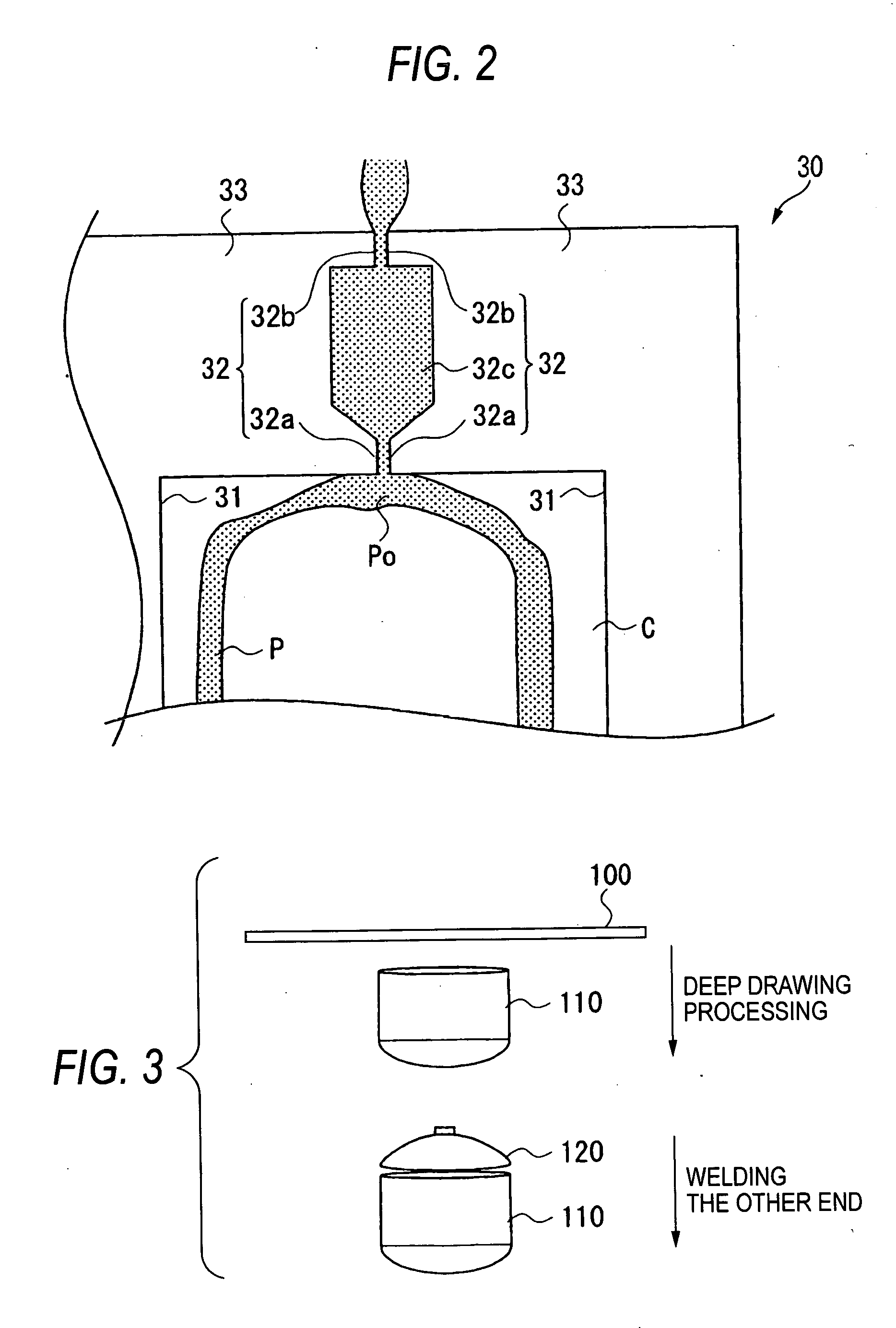

Method for manufacturing liner for pressure resistant container and liner made of liquid crystal resin

InactiveUS20050260372A1Favorable blow molding characteristicExcellent gas barrier propertiesLiquid crystal compositionsThin material handlingPolyesterPolymer science

A wholly aromatic polyester amide liquid crystal resin including repeating units of: (I) a 6-hydroxy-2-naphthoic acid residue: 1 to 15 mol %, (II) a 4-hydroxybenzoic acid residue: 40 to 70 mol %, (III) an aromatic diol residue: 5 to 28.5 mol %, (IV) a 4-aminophenol residue: 1 to 20 mol %, and (V) an aromatic dicarboxylic acid residue: 6 to 29.5 mol %, and having a melting point of 270° C. to 370° C., and having a melt viscosity of 60 Pa.s to 200 Pa.s at a shear rate of 1000 / sec at a temperature higher by 10° C. to 20° C. than this melting point is molten at a temperature of the melting point +40° C., and extruded at a rate of 0.3 kg / min or more and less than 5 kg / min to form a parison. A pair of molds arranged with the parison interposed there between are closed under a prescribed mold closing pressure, so that air is blown into the interior of the parison.

Owner:SUBARU CORP +1

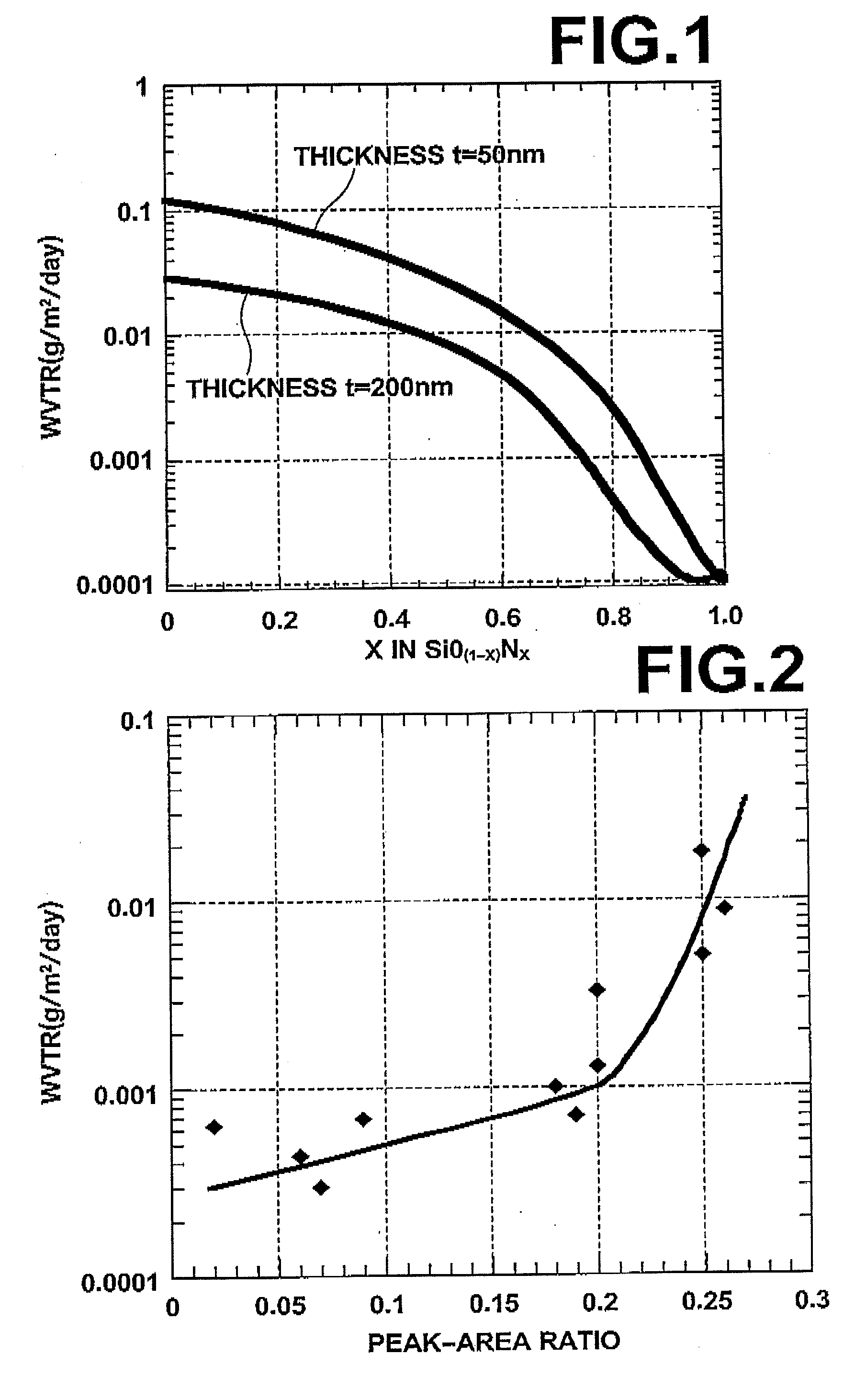

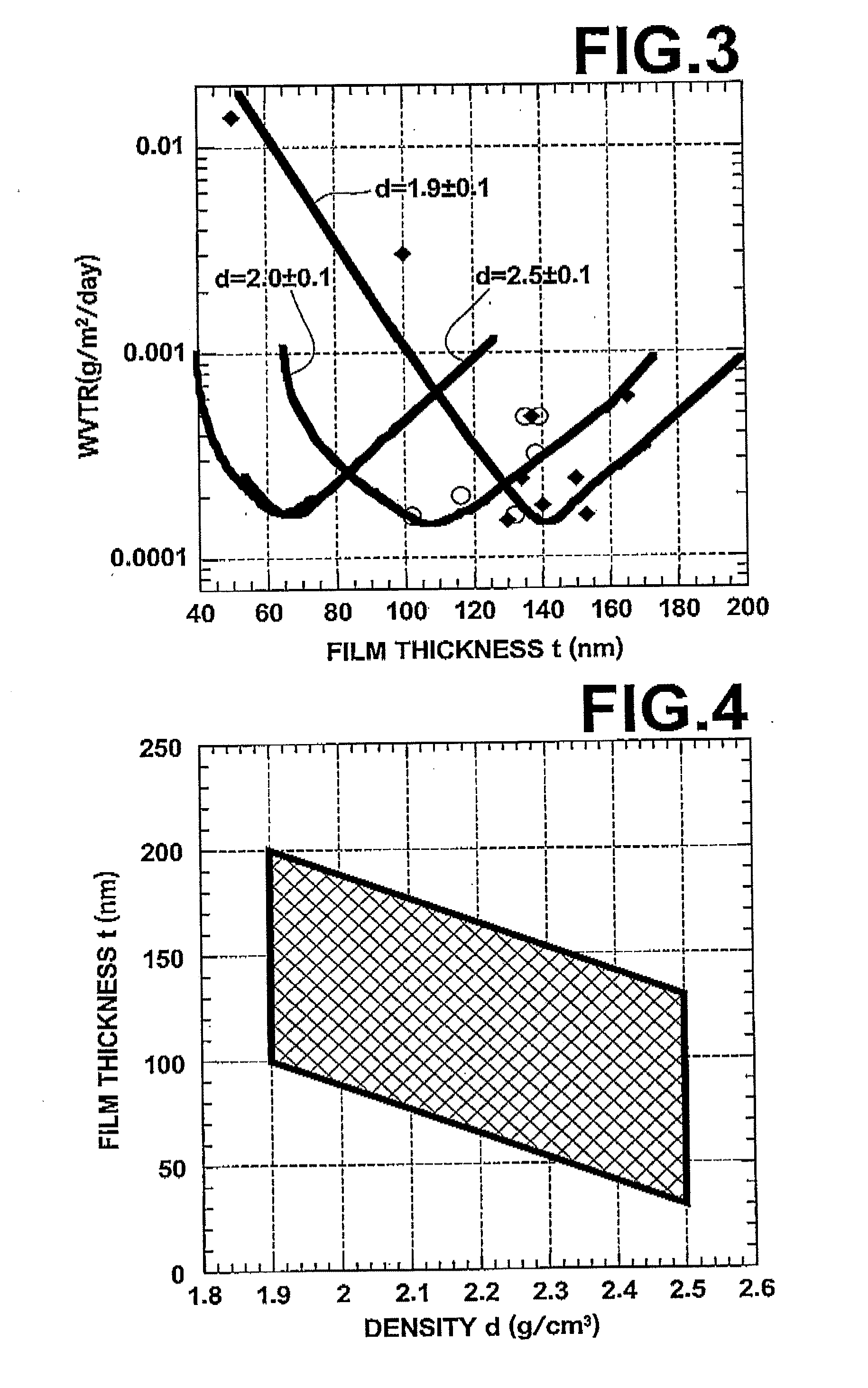

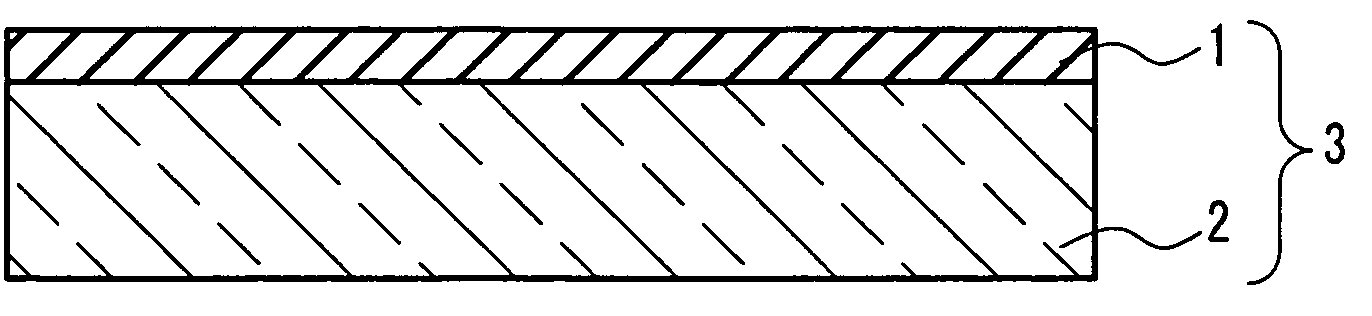

Silicon -nitrogen compound film, and gas-barrier film and thin-film device using the silicon-nitrogen compound film

ActiveUS20090110896A1Satisfactory gas-barrier performanceEasy to produceSynthetic resin layered productsSolid-state devicesNitrogenVolumetric Mass Density

A silicon-nitrogen compound film according to the first aspect of the present invention is made of a material expressed by a compositional formula Si3NxOyHz, where 10≦(3x+2y)≦12, 3.4≦x≦4.0, 0≦y, 0≦z≦2.0, the peak-area ratio of a first area of a first peak appearing near a wave number of 2150 cm−1 in a Fourier-transform infrared absorption spectrum of the material and corresponding to a Si—H stretching vibration to a second area of a second peak appearing near a wave number of 810 cm−1 in the Fourier-transform infrared absorption spectrum and corresponding to a Si—N stretching vibration is smaller than 0.2, and the silicon-nitrogen compound film has a thickness t (in nanometers) and a density d (g / cm3) which satisfy the inequalities,1.9≦d≦2.5, and−700d+1930≦6t≦−700d+2530.

Owner:FUJIFILM CORP

Organic luminescence device and its production method

InactiveUS20050122039A1Excellent gas barrier propertiesDischarge tube luminescnet screensLayered productsWater vaporOxygen

An organic luminescence device uses a substrate with a gas-barrier film in which a gas-barrier film containing an amorphous oxide and at least two kinds of oxides selected from the group consisting of boron oxide, phosphorus oxide, sodium oxide, potassium oxide, lead oxide, titanium oxide, magnesium oxide, and barium oxide is formed on a substrate. The selected two kinds of oxides are a combination of an oxide of an element having a large atomic radius and an oxide of an element having a small atomic radius. The substrate is made of glass or plastic. As a result, the organic luminescence device using a substrate excellent in gas-barrier capability to prevent the infiltration of oxygen, water vapor, etc. from outside is provided.

Owner:PANASONIC CORP

Gas barrier laminate film, method for producing the same and image display device utilizing the film

InactiveUS20050238846A1High yieldAvoid crackingSynthetic resin layered productsRecord information storageWrinkle skinRoll film

In a gas barrier laminate film comprising a gas barrier layer laminated on at least one surface of a support, the surface of the support on the side opposite to the surface laminated with the gas barrier layer is made to have an Ra value of 1 to 20 nm. A gas barrier laminate film that can prevent cracks generated by displacement of rolled film, slacks and wrinkles during rolling up and transportation in the production process of the film and thus can be produced with a high yield, a method for producing the same and an image display device utilizing the film are provided.

Owner:FUJIFILM CORP

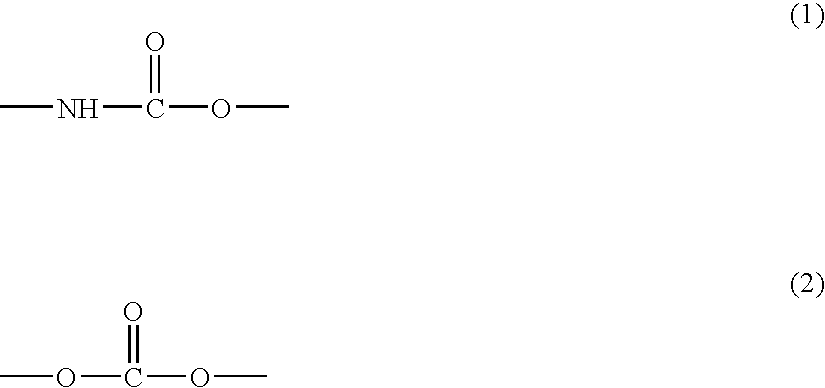

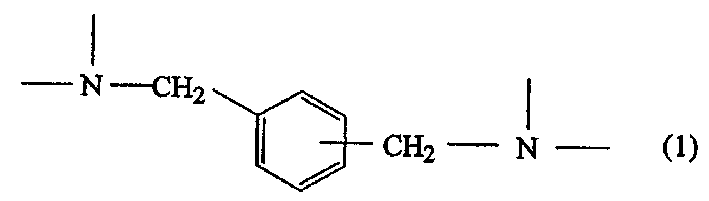

Amine epoxy resin curing agent, gas barrier epoxy resin composition comprising the curing agent, coating agent, and adhesive agent for laminate

ActiveUS20100160494A1Excellent gas barrier performanceOvercome short pot lifeSynthetic resin layered productsDomestic containersCarbamateAdhesive

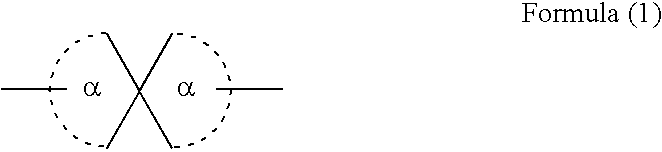

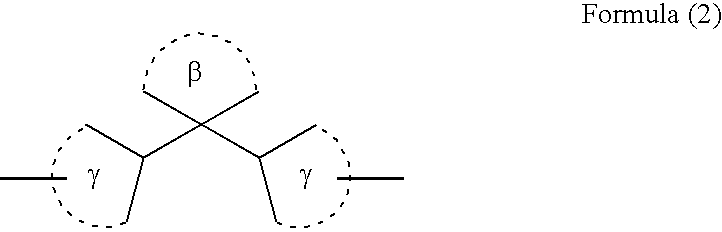

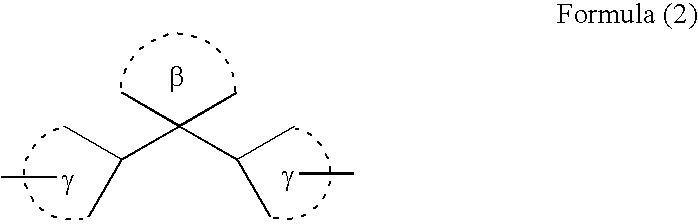

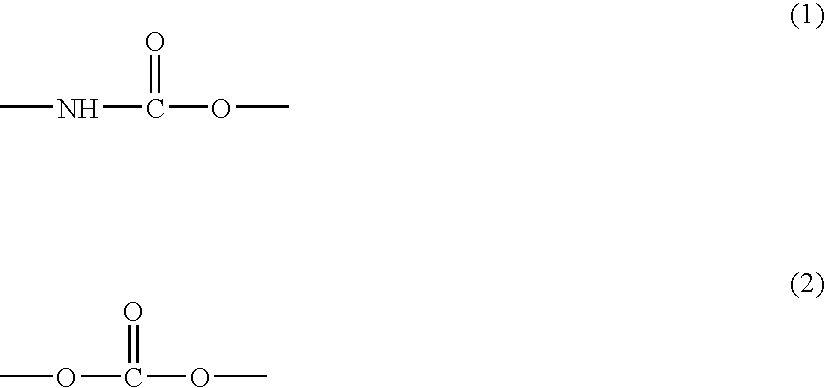

The present invention provides an amine based epoxy resin curing agent containing an epoxy resin and an amine compound capable of imparting a high gas barrier performance and a long pot life, in addition to excellent performances which an epoxy resin conventionally possesses, and an epoxy resin composition with a high gas barrier performance and a long pot life, which contains the subject curing agent. Also, the present invention provides an adhesive for laminate with excellent adhesiveness to various polymers, papers, metals, etc., which contains, as a main component, an epoxy resin composition containing an amine based resin curing agent with a high gas barrier performance and a long pot life.The amine based epoxy resin curing agent of the present invention is composed of a reaction product of the following (A), (B) and (D) or a reaction product of the following (A), (B), (C) and (D):(A) m-xylylenediamine or p-xylylenediamine,(B) a polyfunctional compound having at least one acyl group, which is capable of forming an amide group site through a reaction with a polyamine and forming an oligomer,(C) a monovalent carboxylic acid having from 1 to 8 carbon atoms and / or its derivative, and(D) a functional compound having at least one carbonate site represented by the formula (2), which is capable of forming a carbamate site represented by the formula (1) through a reaction with a polyamine:

Owner:MITSUBISHI GAS CHEM CO INC

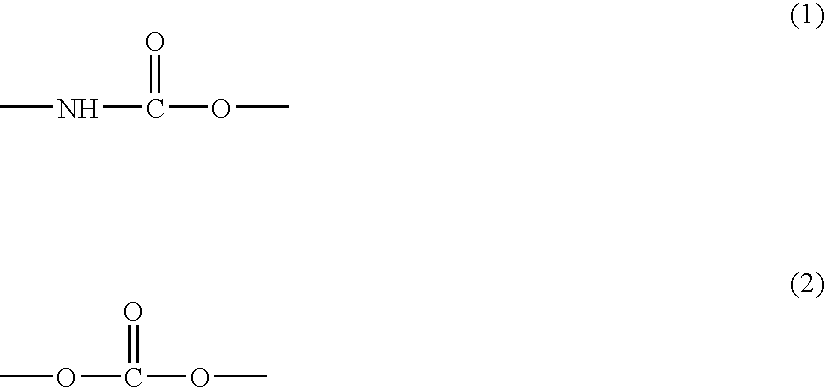

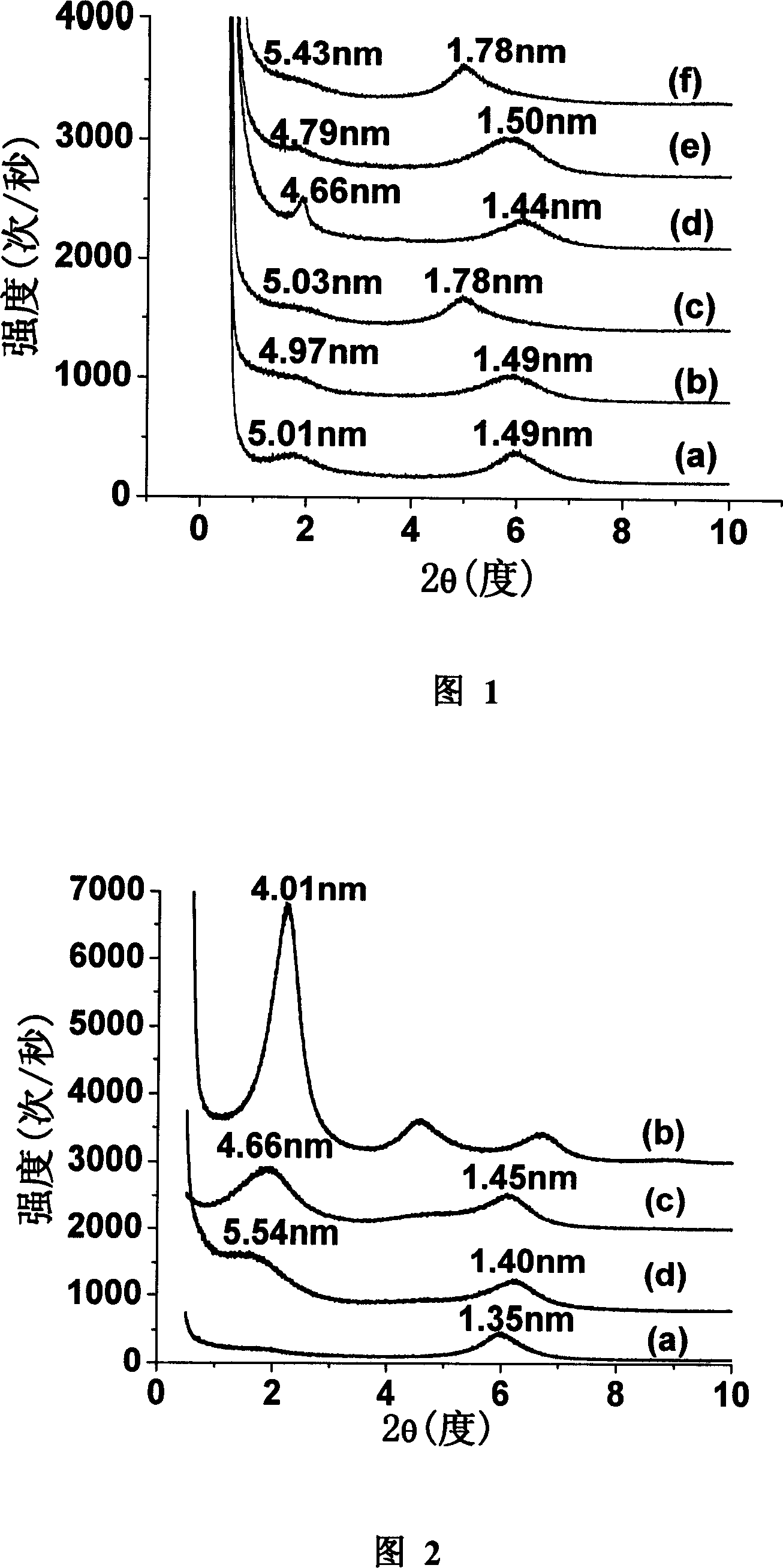

Silane coupling agent modified clay and butadiene styrene rubber nanometer composite material preparation method

InactiveCN1970607AImprove interface strengthImprove mechanical propertiesMaterials preparationPolymer science

The invention discloses a making method of clay modified by silane coupling agent with butadiene styrene rubber nanometer composite material, wherein the silane coupling agent is gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide, which comprises the following steps: making gamma-aminotriethylene silane modified clay liquid suspension under normal temperature; blending with butylbenzene rubber emulsion completely; flocculating; washing; drying; fusing; sulfurizing to obtain the product; adding di-(gamma-triethylene propyl) tetrasulfide to obtain the modified clay and butadiene styrene rubber nanometer composite material of gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide.

Owner:BEIJING UNIV OF CHEM TECH

Gas barrier multilayer film

ActiveUS20090214854A1Excellent gas barrier performanceHigh strengthFlexible coversWrappersPolymer sciencePolyvinyl alcohol

Provided is a film which can be industrially coated easily and exhibits excellent gas barrier performance without being subjected to a high-temperature heat treatment. The film exhibits good gas barrier performance immediately after the production, and maintains the excellent gas barrier performance while exhibiting excellent hot water resistance and printing resistance. More specifically, provided are: a gas barrier laminated film including a resin layer on an inorganic thin film formed on at least one surface of a support film, the resin layer being formed by applying: (1) an aqueous dispersion containing polyvinyl alcohol (a), an ethylene-unsaturated carboxylic acid copolymer (b), and inorganic particles (c); (2) an aqueous dispersion containing an ethylene-unsaturated carboxylic acid copolymer (b), inorganic particles (c), and / or a cross-linking agent (d); or (3) an aqueous dispersion containing polyvinyl alcohol (a), an ethylene-unsaturated carboxylic acid copolymer (b), inorganic particles (c), and a cross-linking agent (d), to the inorganic thin film surface; and a method of producing the gas barrier laminated film.

Owner:MITSUBISHI CHEM CORP

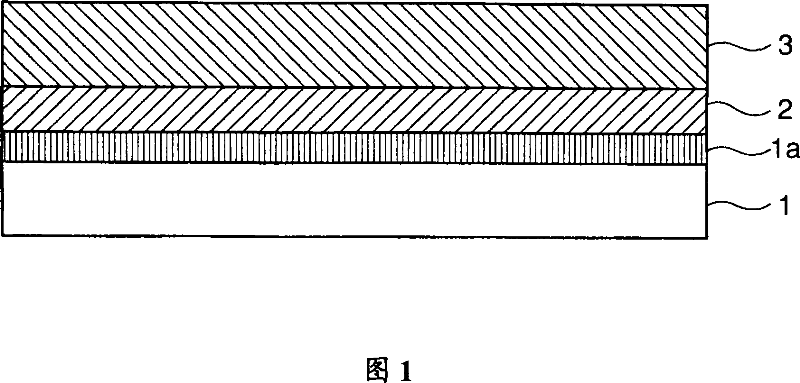

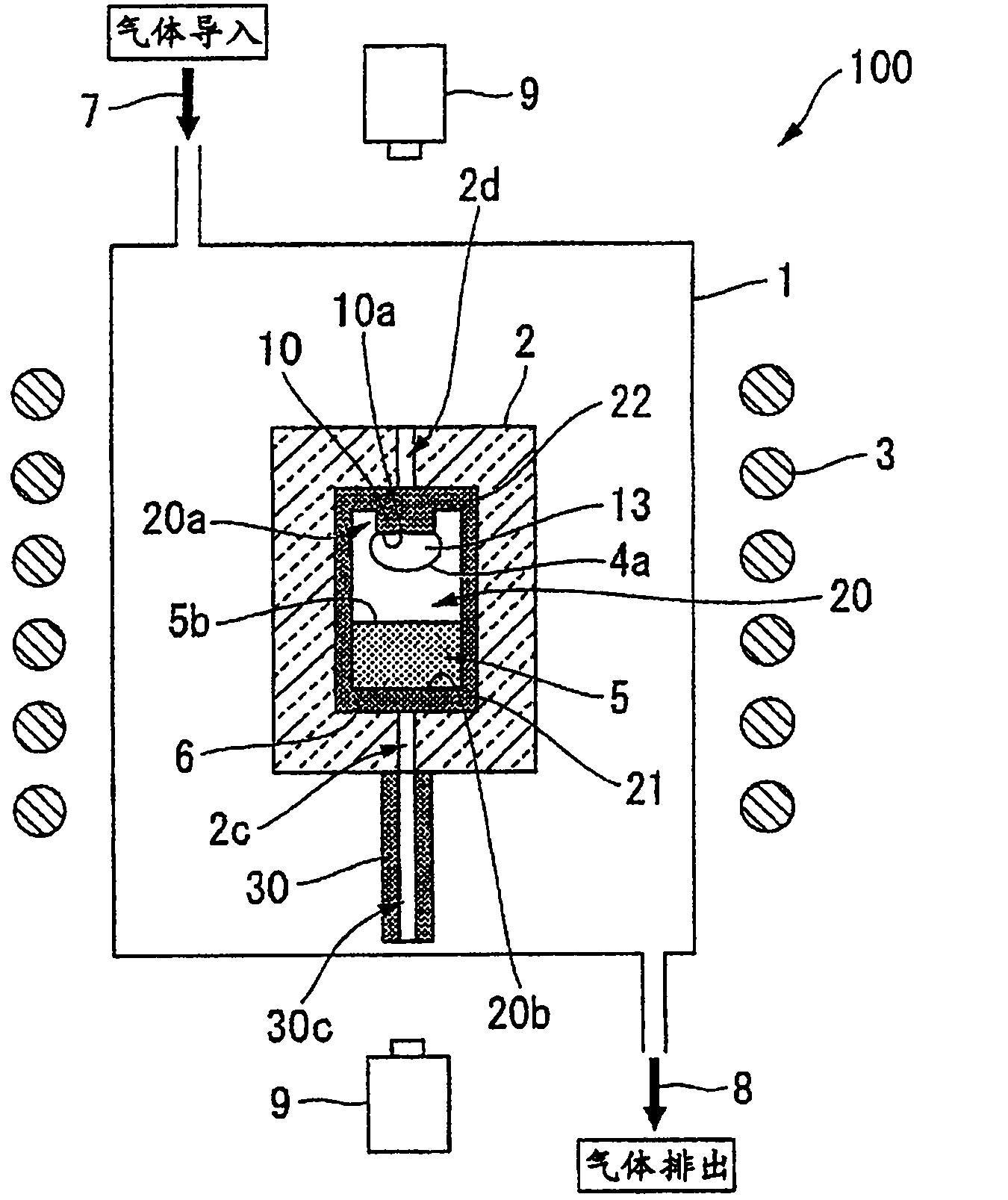

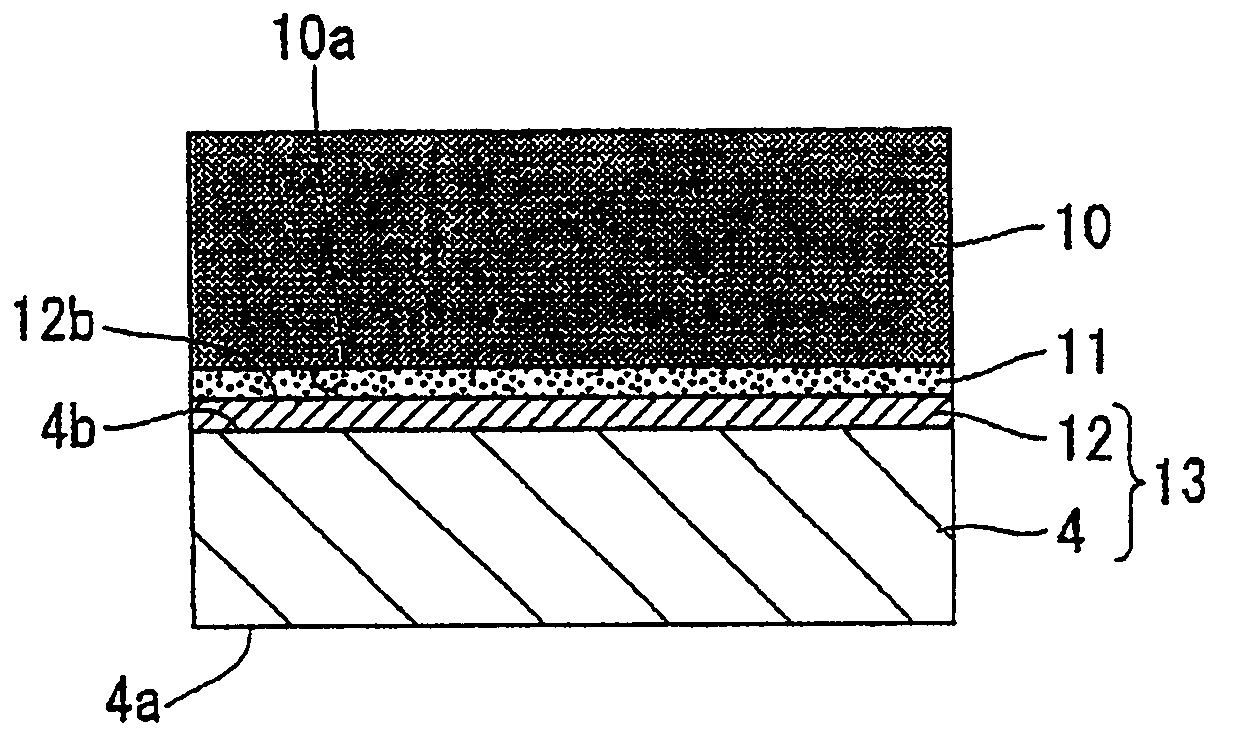

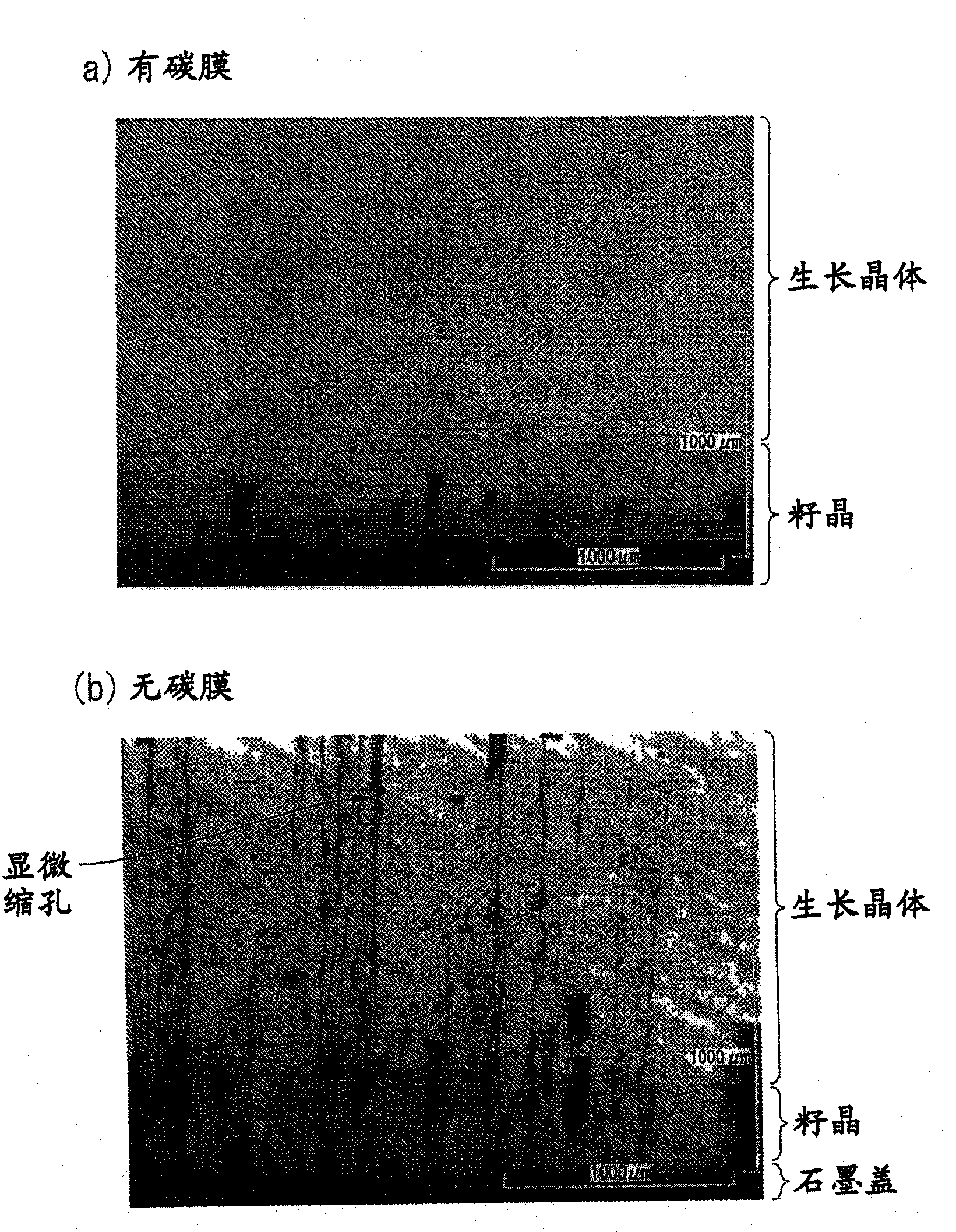

Seed crystal for growth of silicon carbide single crystal, process for producing the same, and silicone carbide single crystal and process for producing the same

ActiveCN102057084ASuppression of crystal defectsHigh strengthPolycrystalline material growthFrom condensed vaporsCarbon filmCarbide

A seed crystal for the growth of a silicon carbide single crystal is provided which inhibits crystal defects from generating at the interface between the seed crystal and graphite and with which a high-quality silicon carbide single crystal having a low crystal defect density can be produced with satisfactory reproducibility. The seed crystal for the growth of a silicon carbide single crystal is a seed crystal (13) for silicon carbide single-crystal growth which is to be attached to the lid of a graphite crucible filled with a raw silicon carbide powder. The seed crystal (13) comprises: a seed crystal (4) which is constituted of silicon carbide and one side of which is a growth surface (4a) where a silicon carbide single crystal is to be grown by the sublimation method; and a carbon film (12) formed on the side (4b) opposite to the growth surface of the seed crystal (4), the carbon film (12) having a density of 1.2-3.3 g / cm3.

Owner:RESONAC CORPORATION

Multilayer coextruding pyrocondensation film

ActiveCN101306593AOvercoming low shrinkageOvercome barrierFlexible coversWrappersSurface layerCopolymer

2499. The invention provides a multilayer coextrusion heat shrinking film which comprises a surface layer, a sandwich layer and a heat-sealing layer. The surface layer and the heat-sealing layer are respectively bonded with the sandwich layer through a bonding layer; the sandwich layer comprises a mixture composed of 98Wt% of PVDC resin and 2Wt% of processing aid, wherein, the PVDC resin is a VDC-MA copolymer, the melting point is 150 DEG C, the density is 1.7g / cm<3>, and the processing aid is epoxidized soybean oil or other plasticizing agent systems. The proposal increases the shrinkage factor of the multilayer coextrusion heat shrinking film, and improves the barrier property; the multilayer coextrusion heat shrinking film has excellent heat sealing performance, and is widely applied to the vacuum shrink package.

Owner:SUZHOU TIPACK

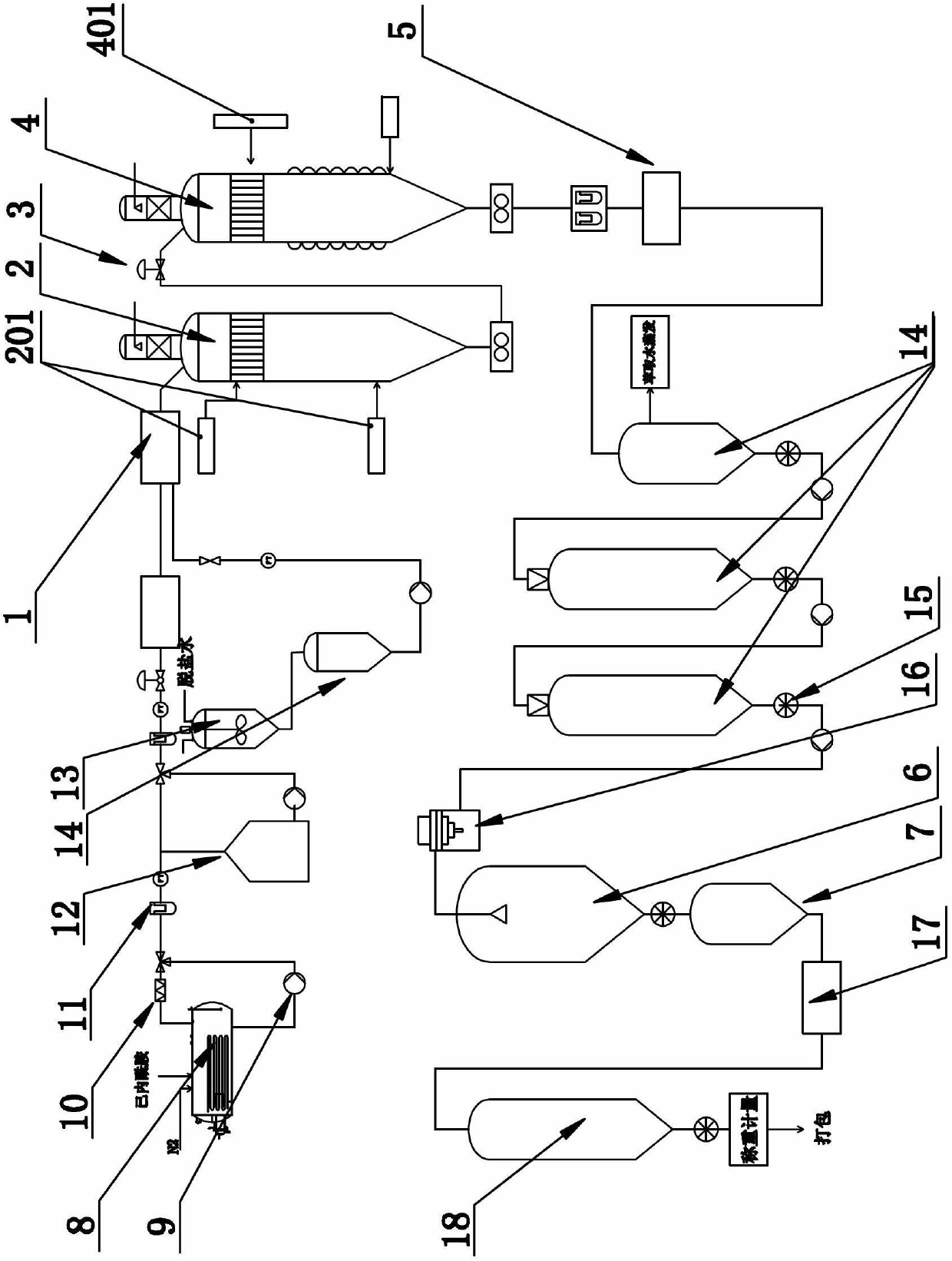

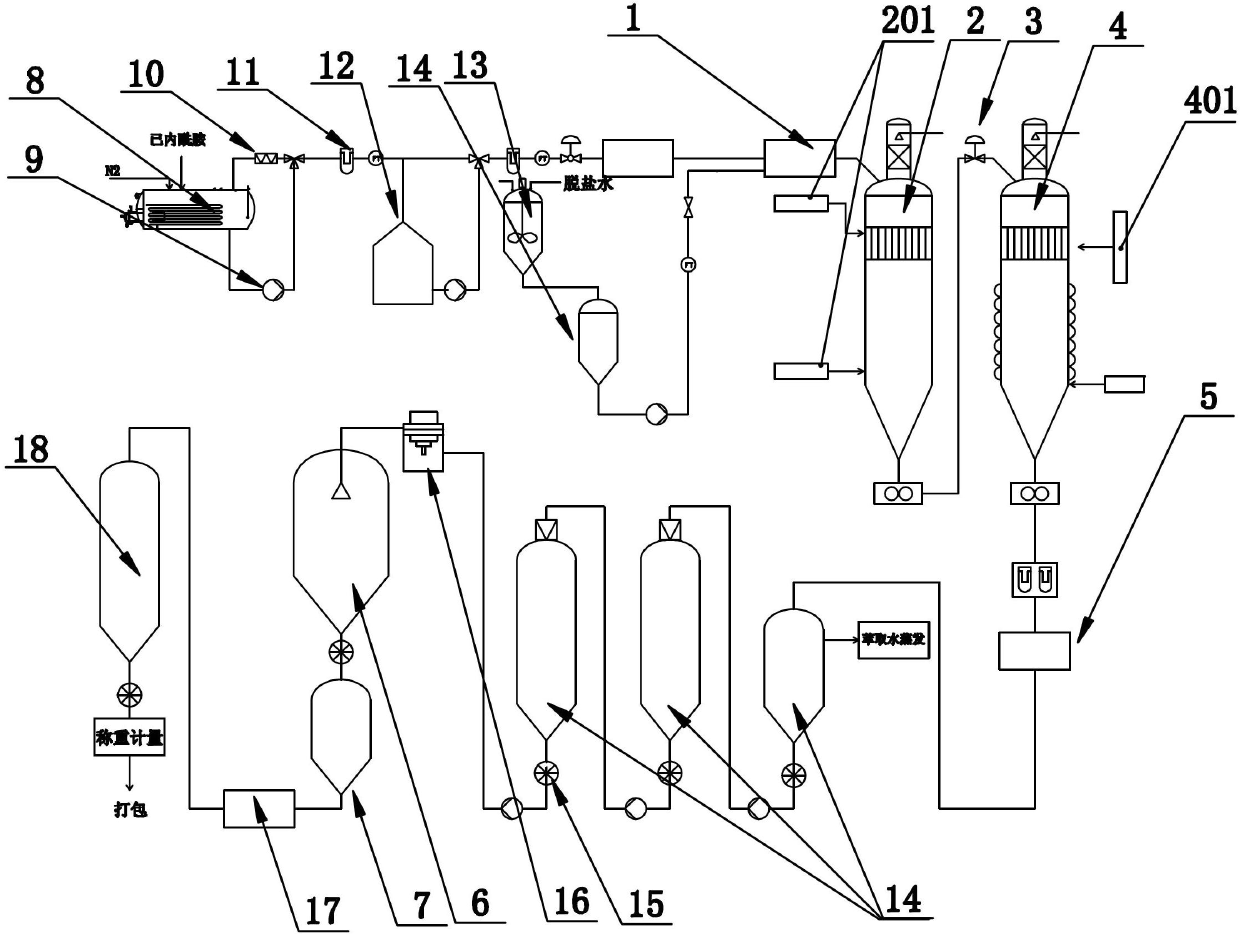

Process for producing caprolactam and nylon 66 salt copolymer slice

The invention relates to a process for producing a caprolactam and nylon 66 salt copolymer slice. The process comprises the following steps of: 1) preparing raw materials, namely respectively preparing caprolactam melt, a nylon 66 salt aqueous solution and an additive; 2) mixing the raw materials prepared in the step 1) in a mixer; 3) reacting the raw materials mixed in the step 2) in a pre-polymerization tower; 4) reacting the materials treated in the step 3) in a post-polymerization tower for reaction; 5) slicing the materials prepared in the step 4); 6) extracting the slices prepared in the step 5); 7) drying the extracted slices in the step 6); and 8) cooling the slices dried in the step 7), thus obtaining the caprolactam and nylon 66 salt copolymer slice finished product. According to the technical scheme, the caprolactam and nylon 66 salt copolymer slice has the characteristics of outstanding tensile strength, anti-impact strength and anti-puncturing strength, high gas isolation performance, high heat resistance, high mist degree, high glossiness, low temperature performance, flexibility, high transparency, high printablility and the like.

Owner:浙江华建尼龙有限公司

Back film for solar module

ActiveCN101764163AHigh gas barrierGood mechanical strengthSynthetic resin layered productsPhotovoltaic energy generationChemistryWater vapor

The invention discloses a back film for a solar module; the back film comprises an outer surface fluoride containing layer, a middle layer and an inner surface ethylene- vinyl acetate copolymer layer; the middle layer comprises a polyester layer, an ethylene-vinyl alcohol copolymer layer and a bonding layer; the middle layer is prepared by co-extruding the polyester material layer, the ethylene-vinyl alcohol copolymer layer and the bonding layer; the outer surface fluoride containing layer is a fluoride containing film compounded on the polyester layer of the middle layer or the fluoride containing coating coated on the polyester layer of the middle layer; and the inner surface ethylene- vinyl acetate copolymer layer is applied on the bonding layer of the middle layer by curtain coating. The back film of the solar module provided by the invention has the advantages of low water vapor transmission rate and high insulation performance, not only has excellent barrier and insulation performance, but also has the packaging performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Polyurethane resin, adhesive, film and paint containing said resin for lamination

InactiveCN1473861AGood adhesionExcellent gas barrier propertiesPolyurea/polyurethane coatingsAdhesiveHigh adhesion

The polyurethane resin produced by reacting a component composed mainly of an active hydrogen-containing compound with a component composed mainly of an organic polyisocyanate compound which contains a backbone structure represented by the formula: in an amount of 20% by weight or higher, exhibits a high gas-barrier property and a high adhesion property. Accordingly, the present invention provides: (A) a two-part liquid curable polyurethane resin composition having an excellent adhesion property to various polymers, papers, metals, etc., especially after boiling and retort treatments, and an adhesive for gas-barrier laminate containing such a composition; (B) a heat-curing gas-barrier polyurethane resin useful as a packaging material for foodstuffs or drugs for the purpose of preserving contents thereof by preventing various gases from penetrating therethrough, which is capable of maintaining its high gas-barrier property; and (C) a paint having excellent properties such as rust-proofing property, corrosion resistance and aesthetic decorating property that are inherent to polyurethane resin, and being applicable to packaging materials for foodstuffs or drugs that are required to show a high gas-barrier property by shielding various gases.

Owner:MITSUBISHI GAS CHEM CO INC

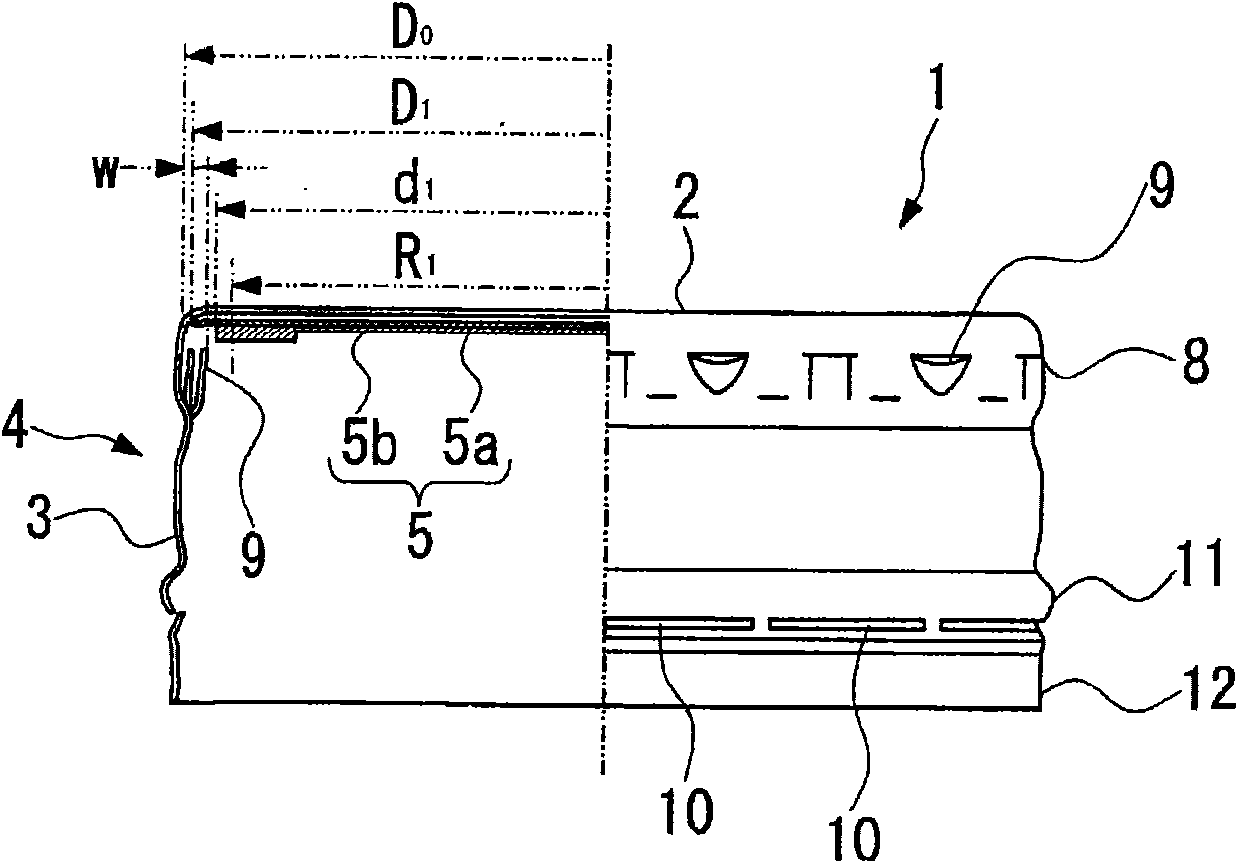

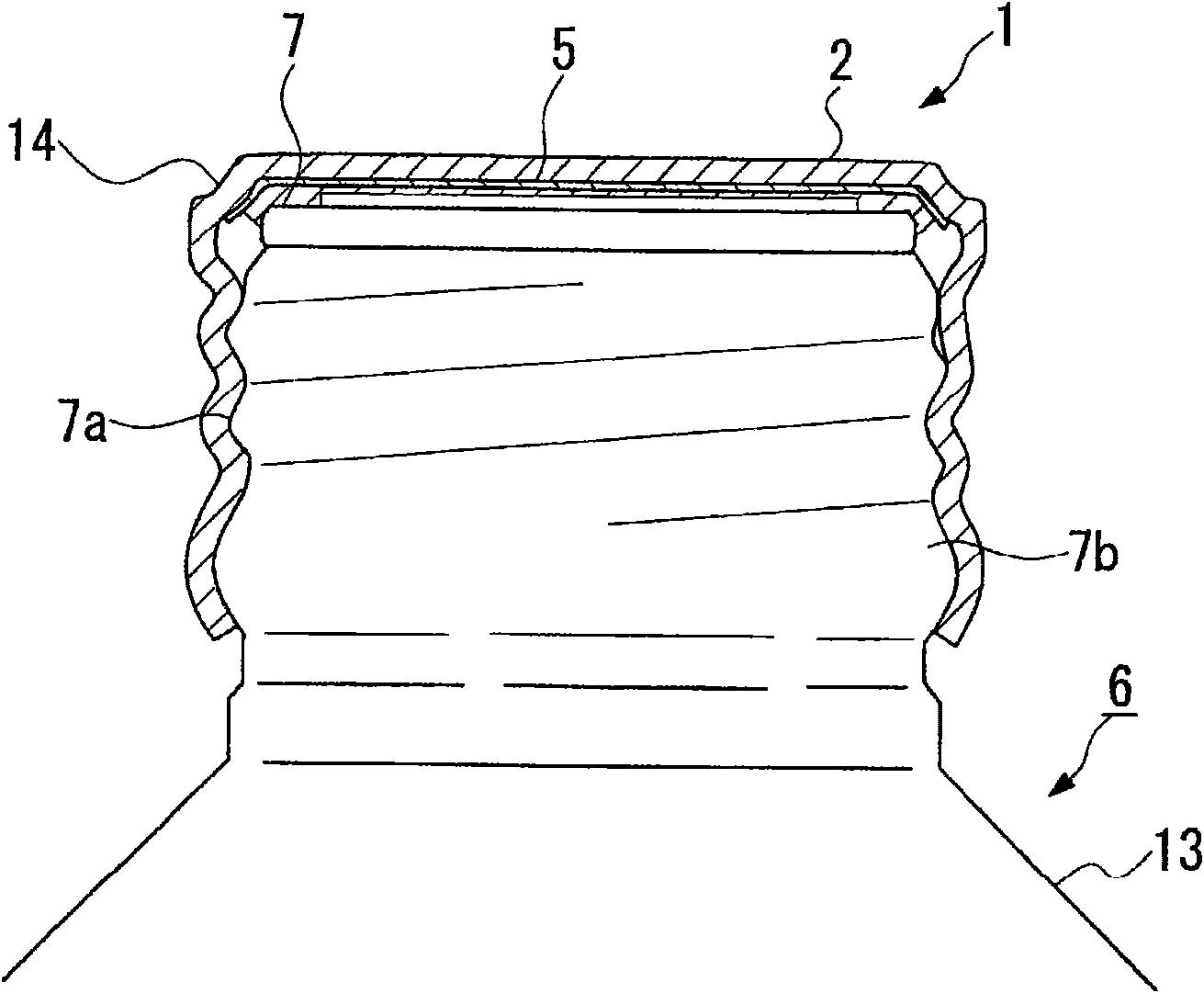

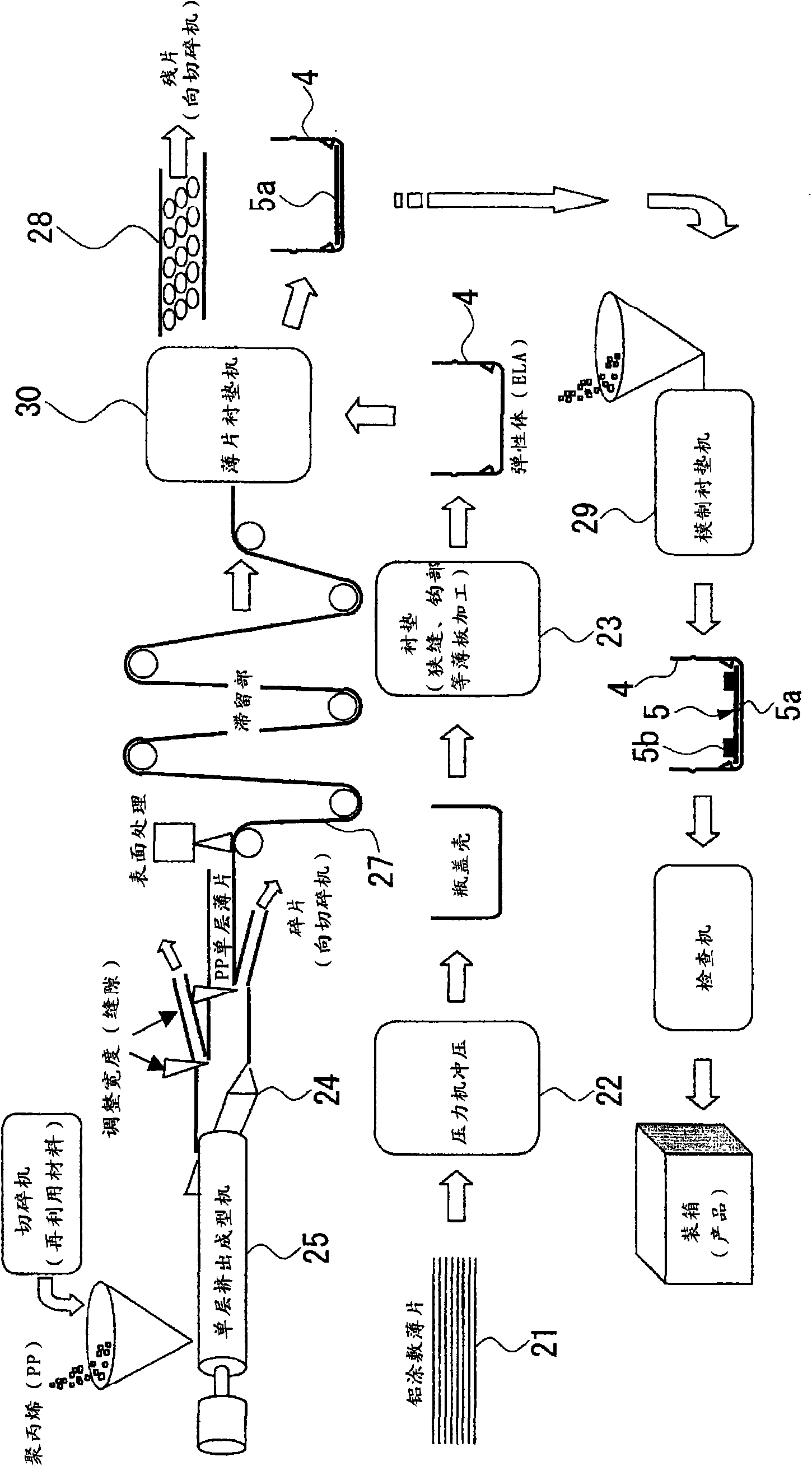

Liner-provided cap and cap-provided threaded container

ActiveCN101891031AHigh suitability for installationSmall unseal torque valueCapsClosure capsSoft layerEngineering

The present invention discloses a liner-provided cap and a cap-provided threaded container. The liner-provided cap for sealing the mouthpiece of the threaded container includes the cap shell (4) consisting of the top plate (2) and the tubular peripheral wall section (3) that hangs from the peripheral edge of the top plate (2), and the synthetic resin liner (5) provided on the inner surface of the top plate (2). The liner (5) includes the disk-shaped rigid sheet (5a) disposed in contact with the inner surface of the top plate (2), and the soft layer (5b) that is laminated to the rigid sheet (5a) and is more flexible than the rigid sheet (5a). The soft layer (5b) is concentric with the rigid sheet (5a) and is formed in an annular or disk shape with a diameter smaller than that of the rigid sheet (5a) so that the soft layer (5b) can be brought into contact with at least the mouthpiece.

Owner:UNIVERSAL CAN CORP

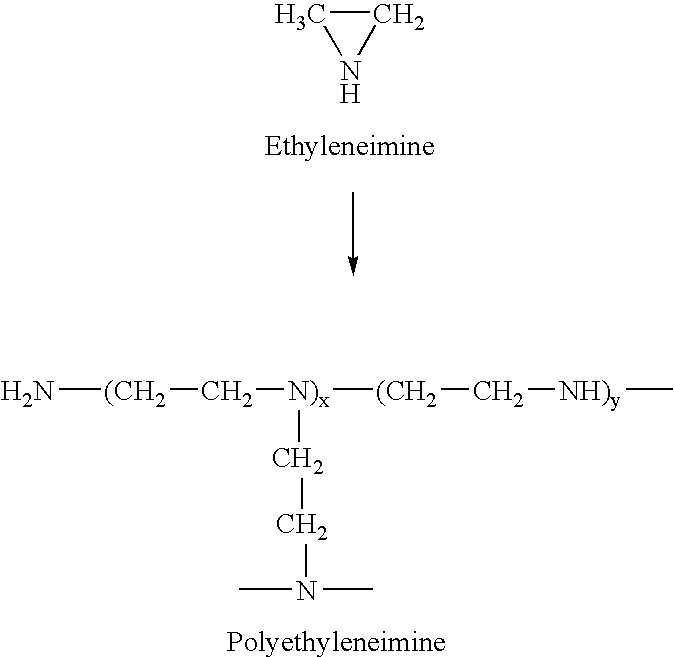

Methods for intercalating, exfoliating and/or dispersing clay particles, and articles incorporating such clay particles

InactiveUS20070106005A1Excellent gas barrier propertiesGood physical propertiesBottlesSynthetic resin layered productsPolymer scienceNanoparticle

Methods are provided for intercalating, exfoliating and / or dispersing clay particles with a cationic polymer for form clay nanoparticles. The resulting clay nanoparticles may be incorporated in various polymeric articles, such as a container, preform, closure, liner, sheet or film.

Owner:GRAHAM PACKAGING PET TECH

Laminate, method for producing same, electronic device member, and electronic device

InactiveUS20110274933A1Excellent gas barrier capabilityGreat capabilitySynthetic resin layered productsElectrical equipmentOxygen atomCarbon atom

A laminate comprises a gas barrier layer and an inorganic compound layer, the gas barrier layer being formed of a material that includes at least an oxygen atom, a carbon atom, and a silicon atom, the gas barrier layer having an oxygen atom content rate that gradually decreases from the surface of the gas barrier layer in the depth direction, and having a carbon atom content rate that gradually increases from the surface of the gas barrier layer in the depth direction. An electronic device member includes the laminate, and an electronic device includes the electronic device member. The laminate exhibits an excellent gas barrier capability and excellent transparency, and does not produce cracks (i.e., the gas barrier capability does not deteriorate) even when the laminate is folded. The laminate exhibits an excellent gas barrier capability and an excellent impact-absorbing capability even if an impact is applied from the outside.

Owner:LINTEC CORP

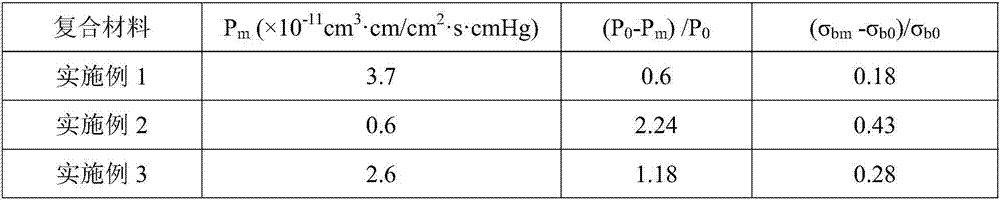

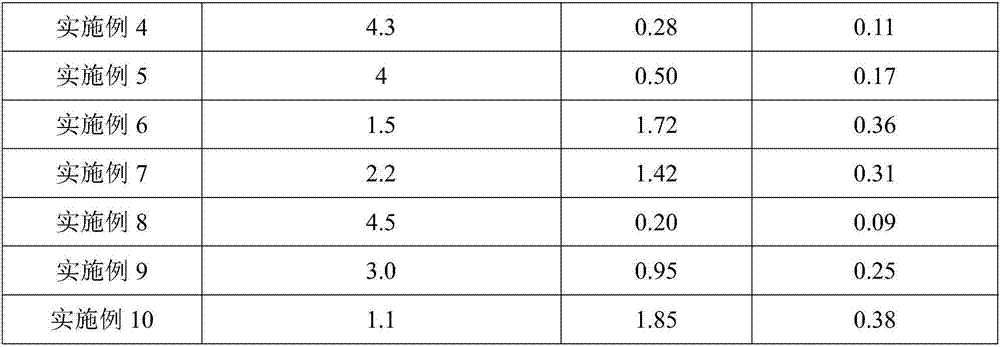

Nanometer composite material high in air barrier property and preparation method thereof

The invention discloses a nanometer composite material high in air barrier property and a preparation method thereof, and belongs to the technical field of nanometer composite materials. The method comprises the following steps that firstly, laminar nanometer filler is dispersed into a surface modifier solution, stirred for a time after ultrasonic treatment and then filtered, washed and dried to obtain surface modified laminar nanometer filler; secondly, the surface modified laminar nanometer filler is pre-mixed with a polymer, then placed in an internal mixer, mixing is conducted after heating and fusion to obtain a nanometer composite material, the nanometer composite material is subjected to hot-press molding, and the nanometer composite material high in air barrier property is obtained. The nanometer composite material high in air barrier property has the advantages of being excellent in barrier property, low in filler consumption, easy to process and good in integrated mechanicalproperty and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

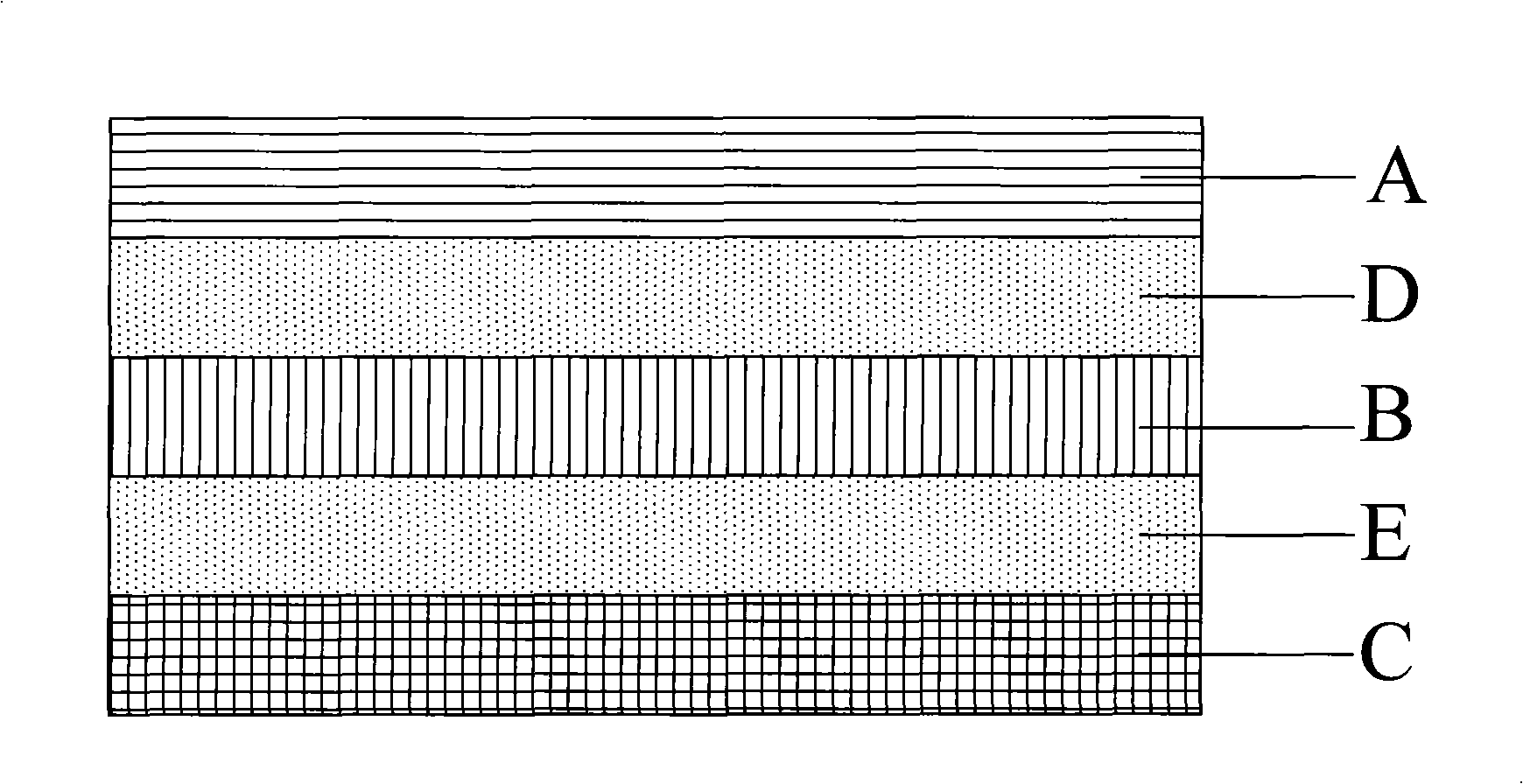

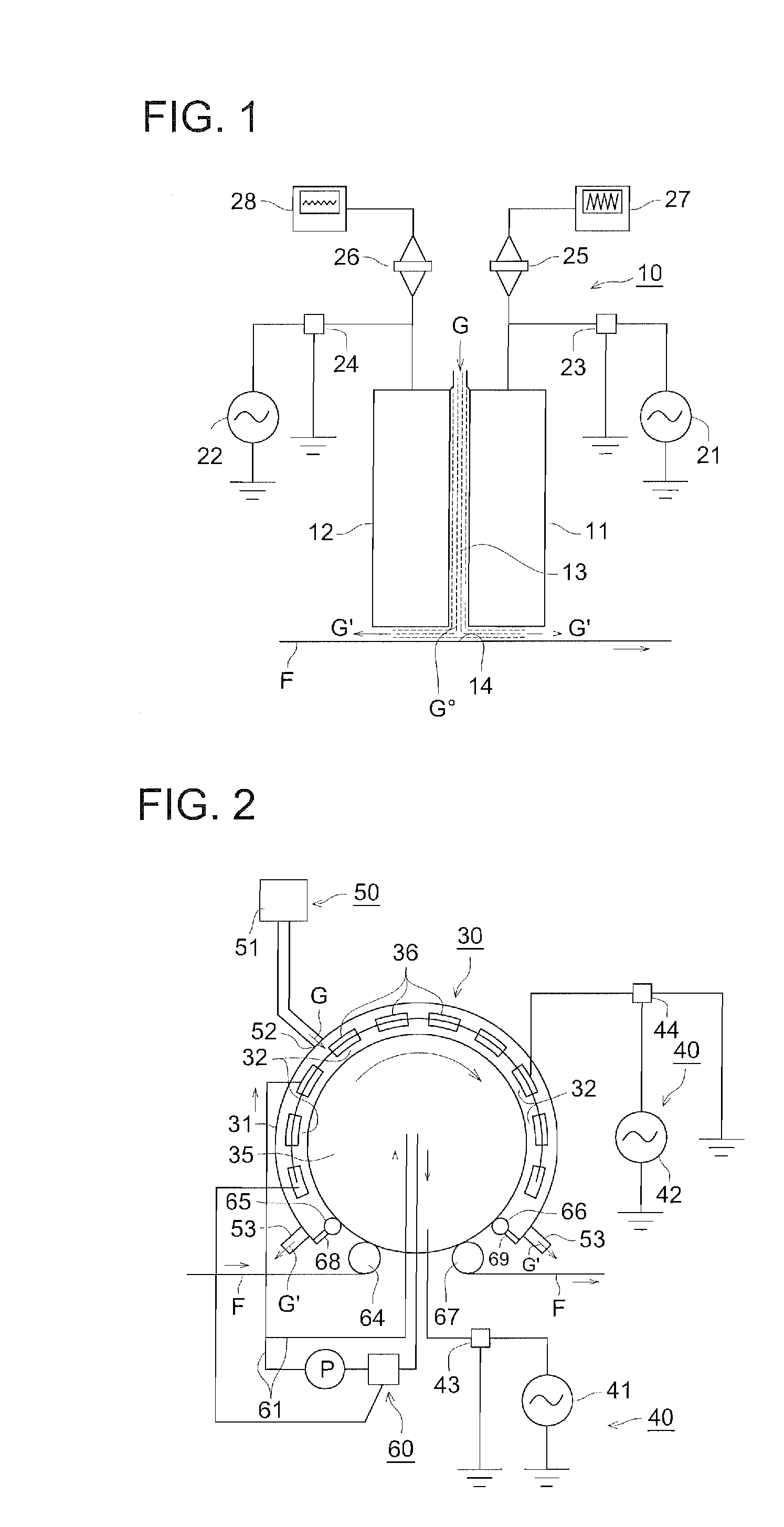

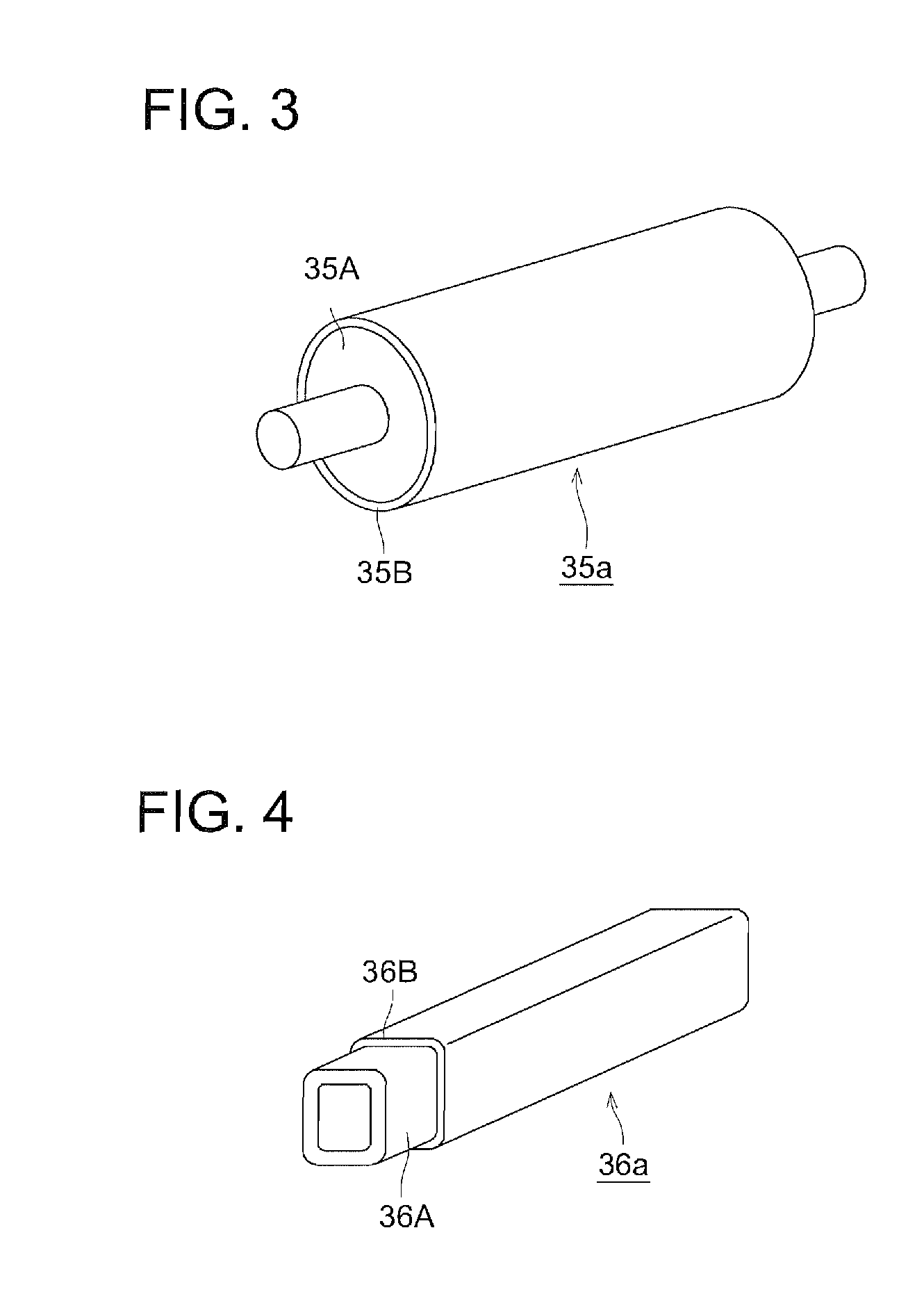

Gas barrier thin film laminate, gas barrier resin substrate and organic el device

InactiveUS20090267489A1Excellent gas barrier propertiesReduce weightDischarge tube luminescnet screensLamp detailsElectric fieldEnvironmental resistance

Disclosed is a gas-barrier thin film laminate which can be produced with high yield while having higher gas barrier properties than the conventional ones. The gas barrier properties of this gas-barrier thin film laminate do not deteriorate even when the laminate is bent. Also disclosed is an organic EL device (hereinafter also referred to as OLED) with excellent environmental resistance which uses the gas-barrier thin film laminate. The gas-barrier thin film laminate having at least one inorganic film and at least one stress relaxation film is characterized in that at least one stress relaxation film is formed by an atmospheric pressure plasma method wherein two or more electric fields of different frequencies are applied.

Owner:KONICA MINOLTA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com