Polyurethane resin, adhesive, film and paint containing said resin for lamination

A polyurethane resin and coating technology, which is applied in the fields of gas barrier films, adhesives for gas barrier lamination, gas barrier films and coatings, and can solve the problems of undiscovered materials and insufficient gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0236] 100 parts by weight of the active hydrogen-containing compound A and 342 parts by weight of the organic polyisocyanate compound A were mixed, and a solution of acetone / ethyl acetate=1 / 0.3 was used to adjust the solid content to 35% by weight. 0.02 parts by weight of an acrylic wetting agent (manufactured by BYK Chemie GmbH: BYK381) was added thereto, and the mixture was sufficiently stirred to prepare a coating liquid.

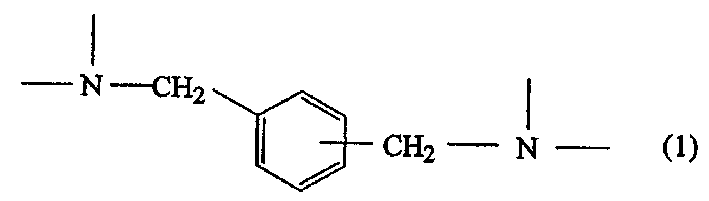

[0237] Using bar coater No. 6, the coating solution was applied to a 20μm thick stretched polypropylene film (coating amount: 3g / m 2 (Solid matter)) After drying at 85°C for 10 seconds, a 30 μm-thick polypropylene film was bonded with a nip roll and cured at 40°C for 3 days to obtain a laminated film. The content of the skeleton structure (1) in the adhesive layer was 55.3% by weight.

[0238] The gas barrier properties of the obtained laminate film, the gas barrier properties after Gelb0 treatment, the water vapor permeability, and the adhesiveness immedia...

Embodiment 2

[0242] Except having used 401 parts by weight of the organic polyisocyanate compound B instead of the organic polyisocyanate compound A, it was produced in the same manner as in Example 1. The content of the skeleton structure (1) in the adhesive layer was 48.0% by weight. The evaluation results are shown in Table 1 and Table 2.

Embodiment 3

[0244] Except that 347 parts by weight of the organic polyisocyanate compound C was used instead of the organic polyisocyanate compound A, it was produced in the same manner as in Example 1. The content of the skeleton structure (1) in the adhesive layer was 53.6% by weight. The evaluation results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com