Patents

Literature

282results about How to "Excellent Adhesive Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

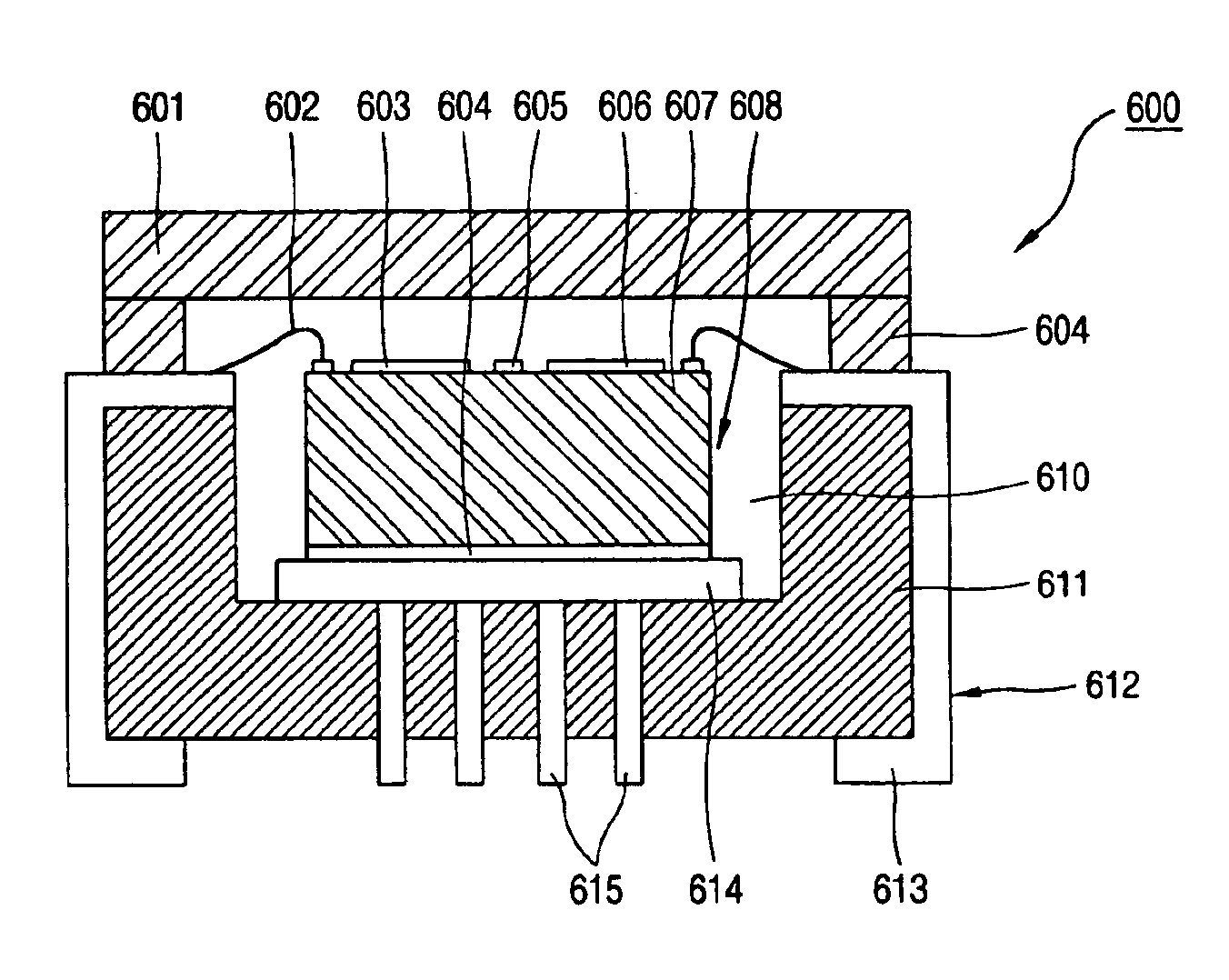

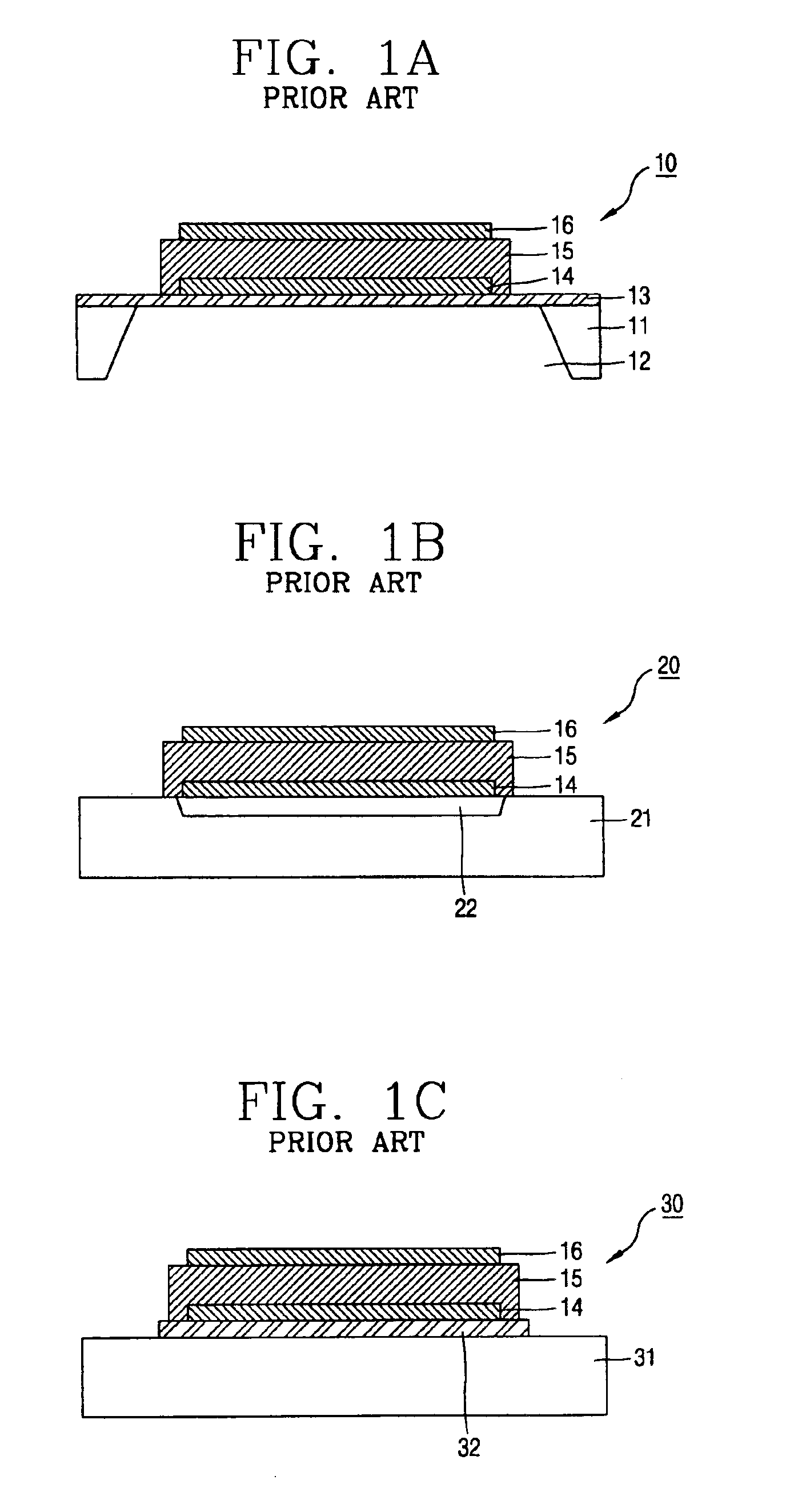

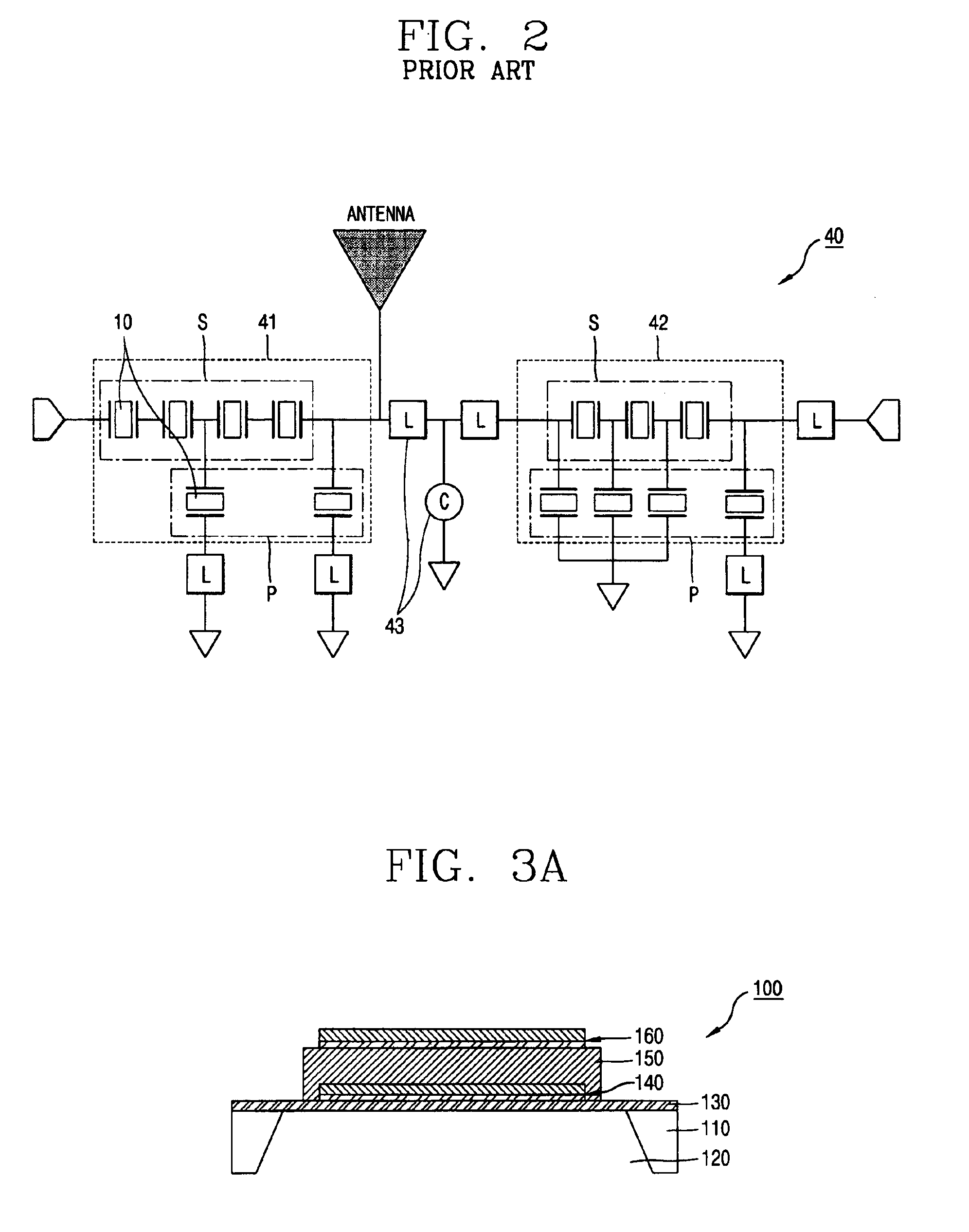

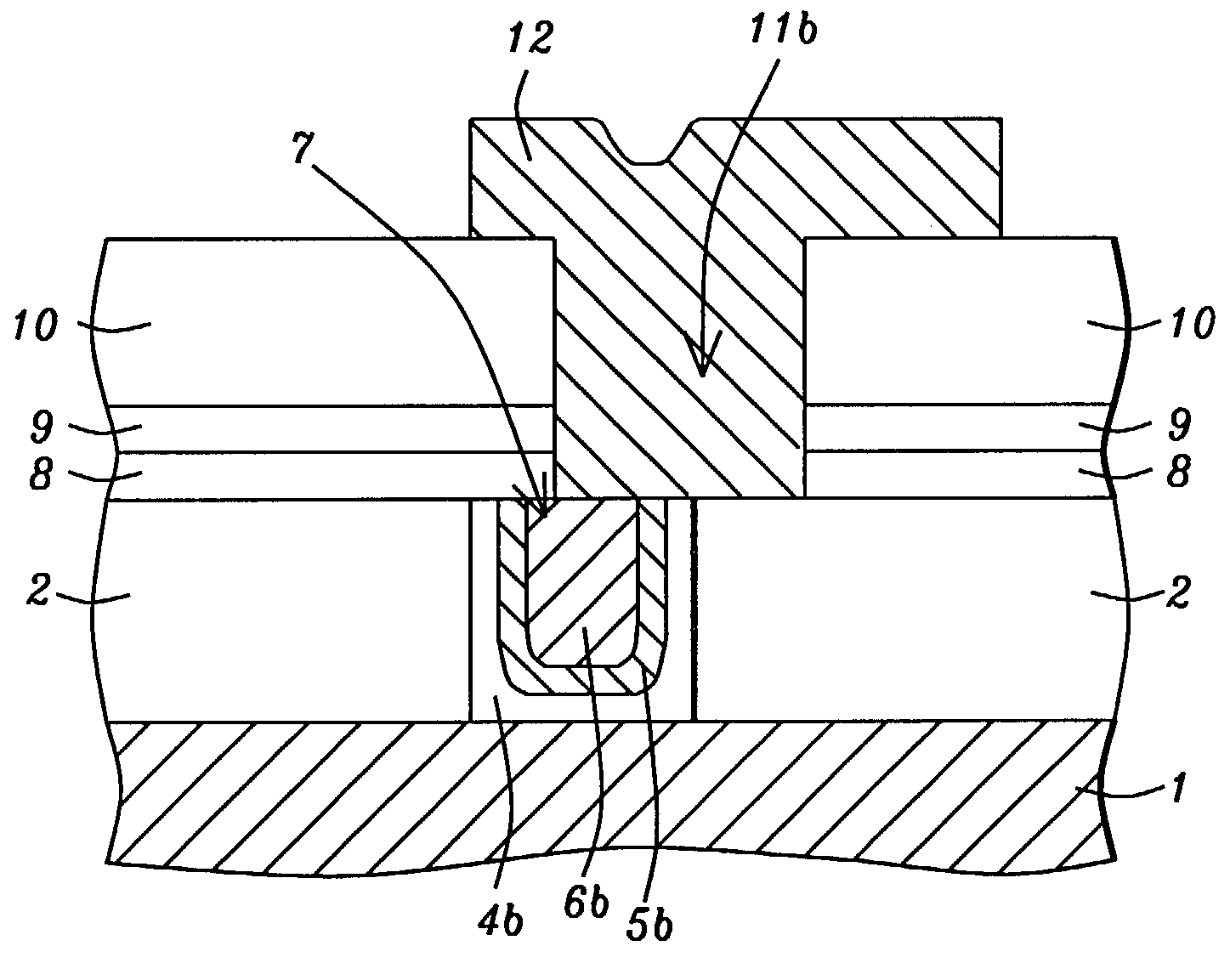

Duplexer filter having film bulk acoustic resonator and semiconductor package thereof

InactiveUS6911708B2Excellent Adhesive PropertiesStructuredImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThin-film bulk acoustic resonatorSemiconductor chip

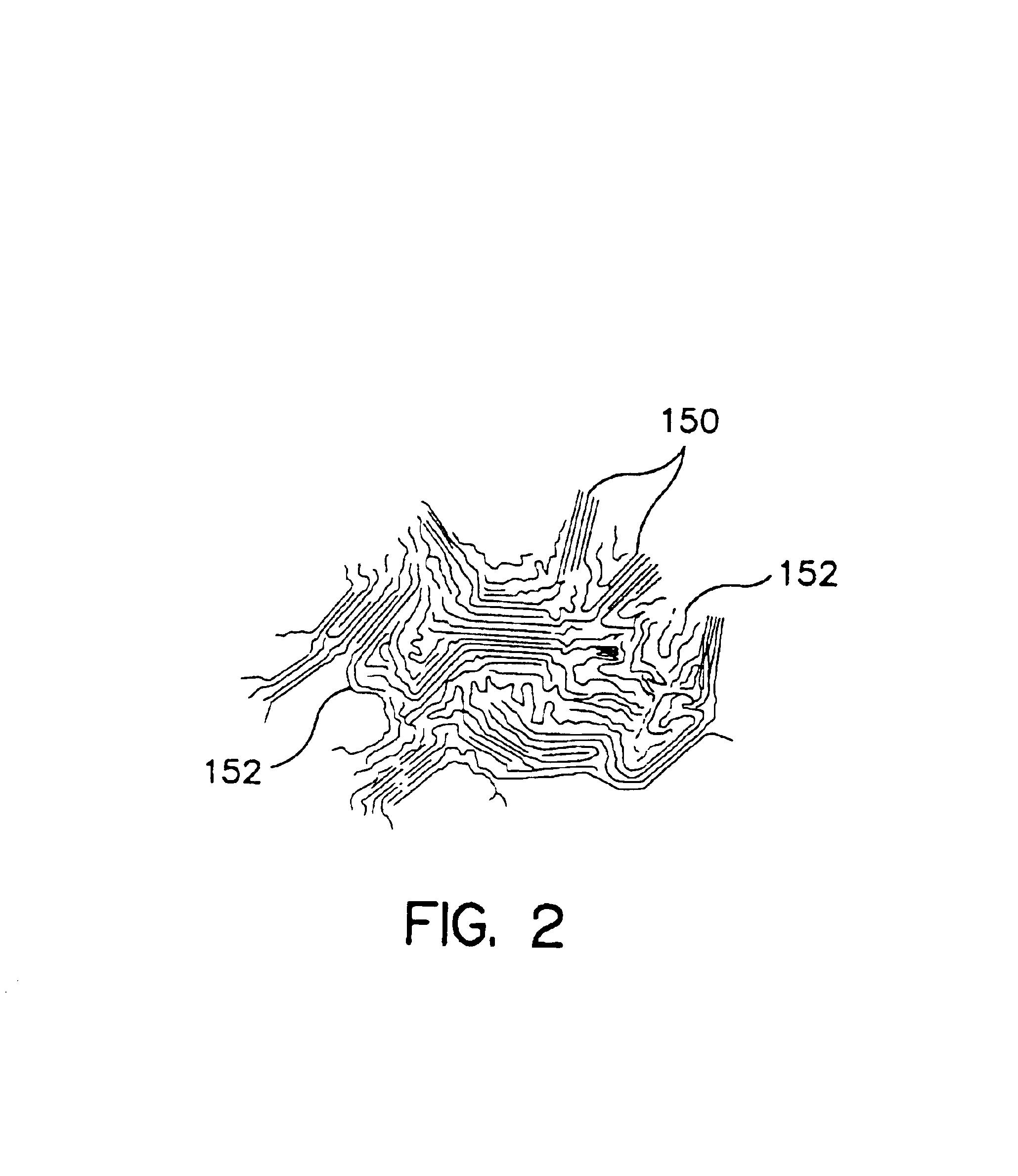

Disclosed are a film bulk acoustic resonator, a duplexer filter having the same, and a semiconductor package thereof. The film bulk acoustic resonator comprising: a semiconductor substrate; a lower electrode more than two layers formed at an upper surface of the semiconductor substrate; a piezoelectric layer deposited on an upper surface of the lower electrode with a certain thickness; and an upper electrode more than two layers formed at an upper surface of the piezoelectric layer, has an excellent bonding characteristic. The duplexer filter can microminiaturize a size thereof by integrating a film bulk acoustic filter formed by connecting the plurality of film bulk acoustic resonators serially and in parallel and peripheral passive elements of the film bulk acoustic filter into one semiconductor chip. Also, the semiconductor package is suitable for the duplexer filter.

Owner:LG ELECTRONICS INC

Laminated structures

InactiveUS6887941B2High bonding strengthImproved performance characteristicsControlling laminationSynthetic resin layered productsHot meltAlpha-olefin

Hot-melt, pressure-sensitive adhesive compositions of amorphous polyalphaolefin and crystalline polypropylene have improved bond strength over the amorphous polyalphaolefin alone. The adhesive compositions improve dynamic shear strength, dynamic peel strength, as well as static peel strength. The adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Methods and devices for enhanced adhesion between metallic substrates and bioactive material-containing coatings

InactiveUS20070073390A1Reduce riskExcellent Adhesive PropertiesVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsMedical deviceMetallic substrate

Disclosed herein are methods to create medical devices and medical devices including bioactive composite structures with enhanced adhesion characteristics. The bioactive composite structures are prepared using anchors that are electrochemically codeposited into a metallic layer that is formed on the surface of implantable medical device followed by the adhesion of a bioactive material-containing coating to the substrate and anchors.

Owner:MEDLOGICS DEVICE CORP

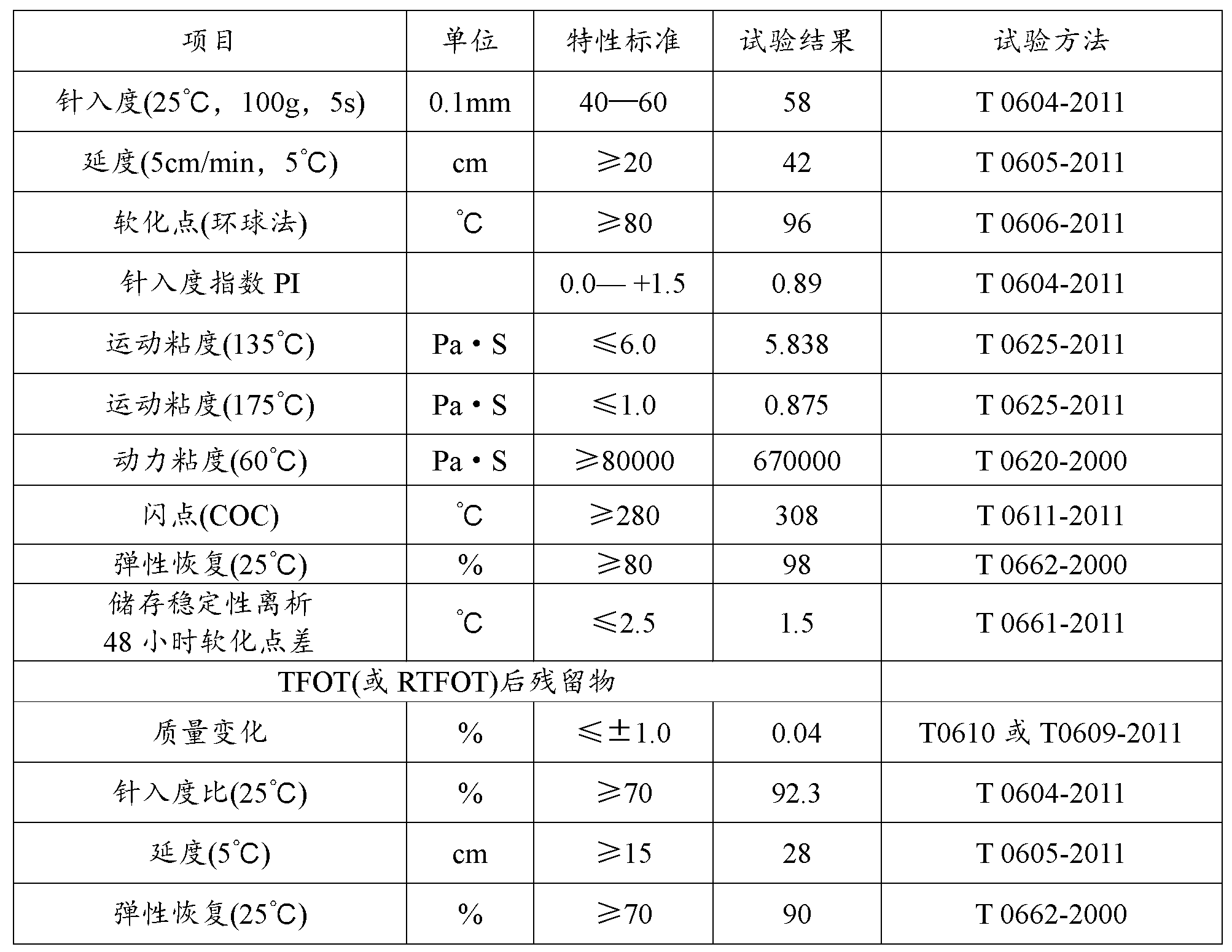

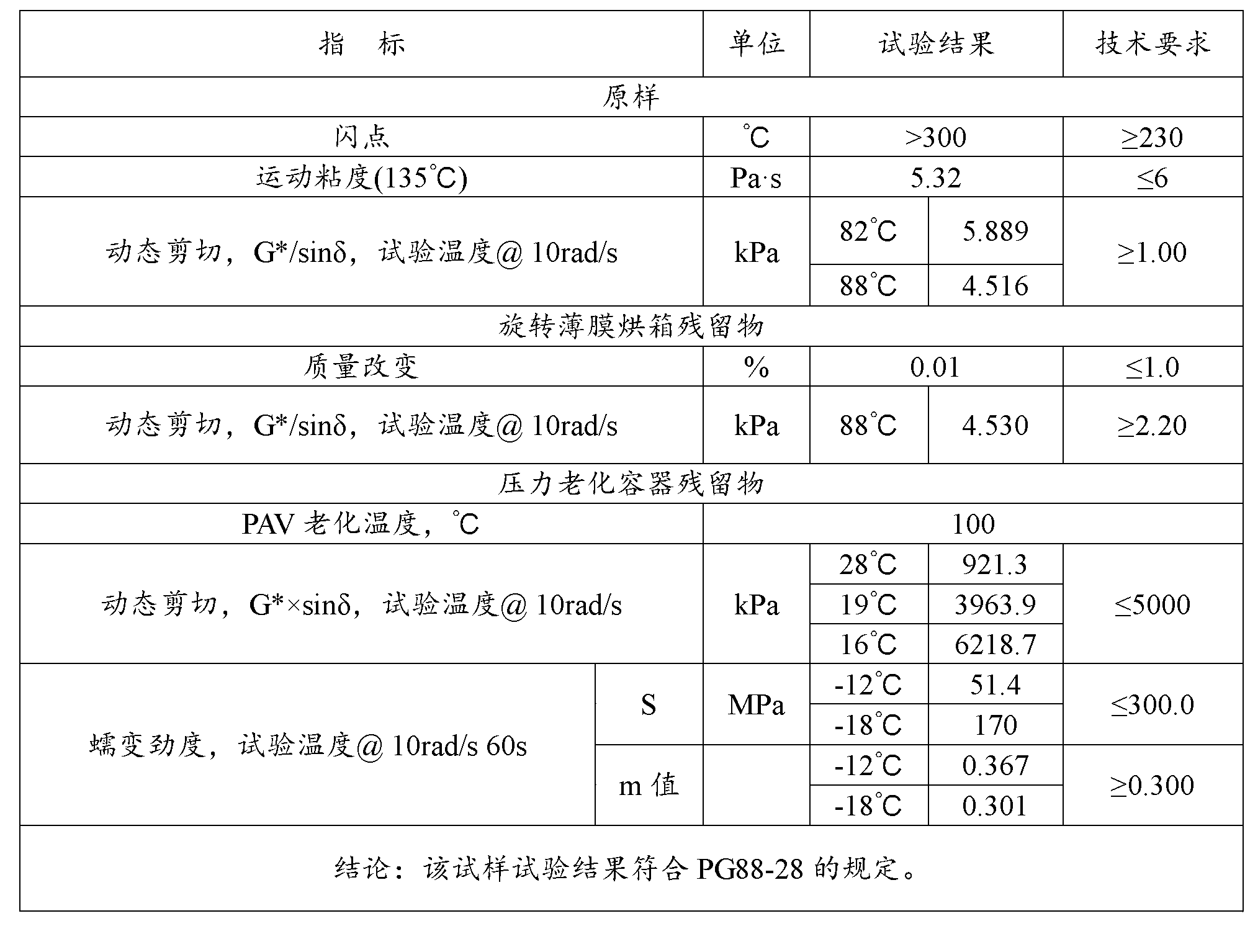

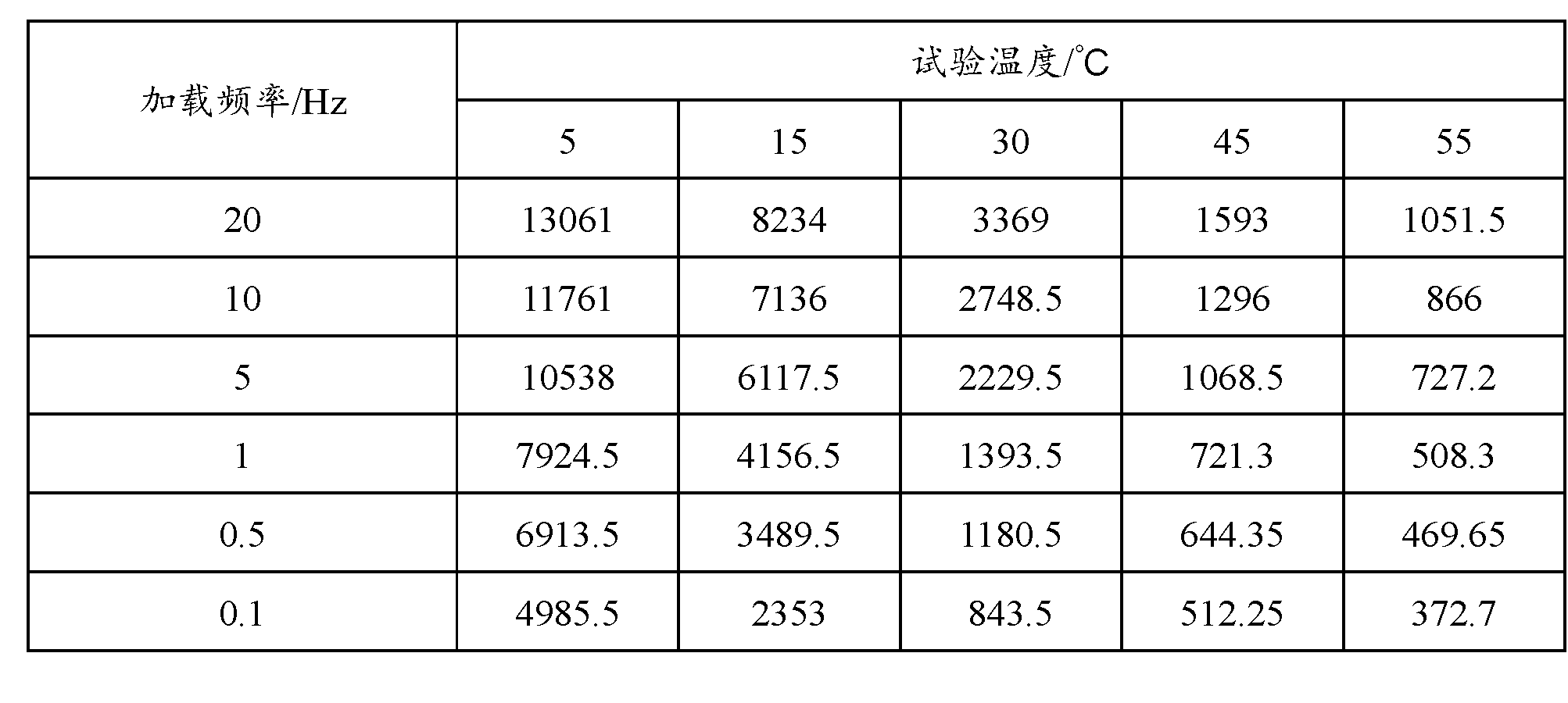

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

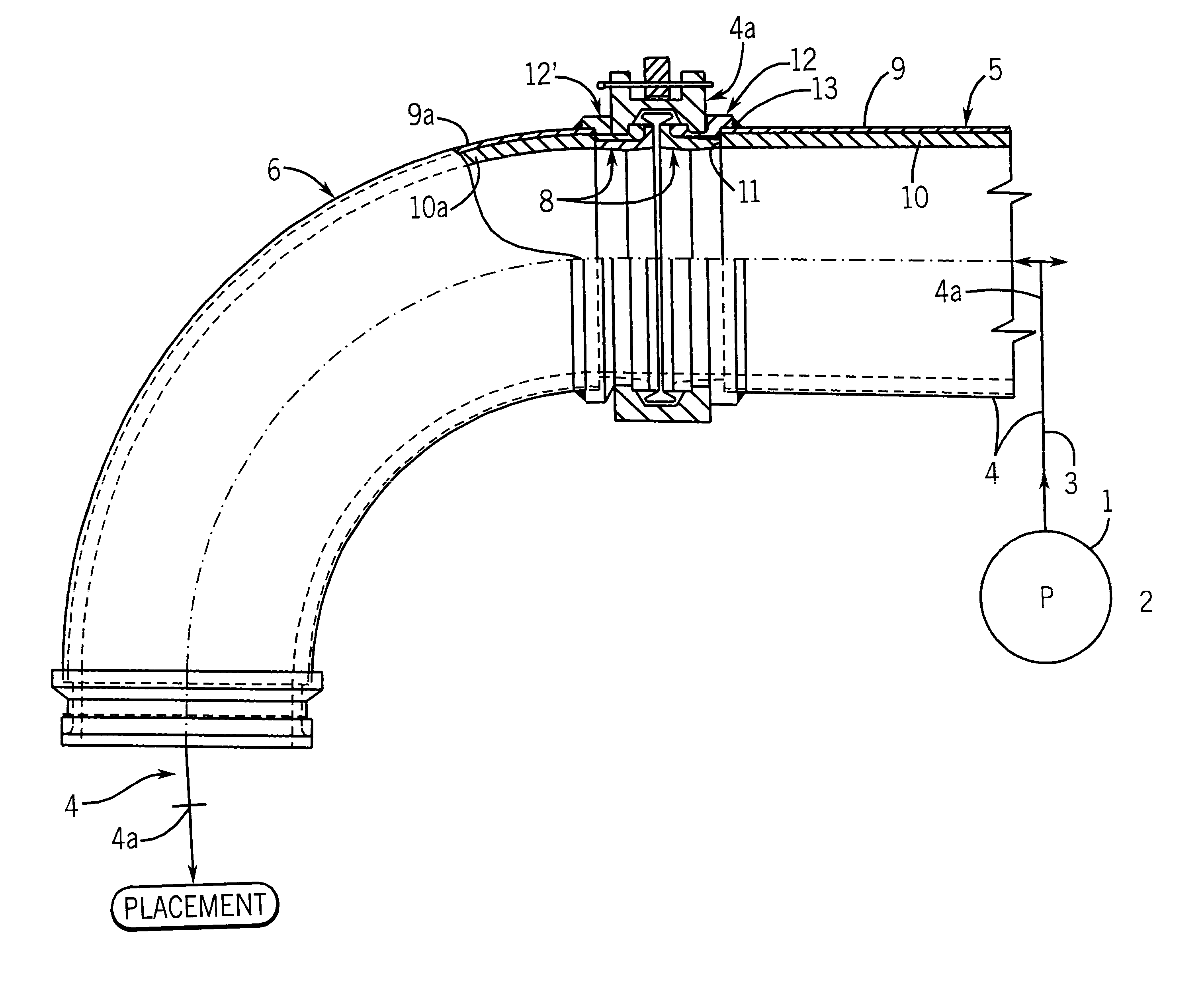

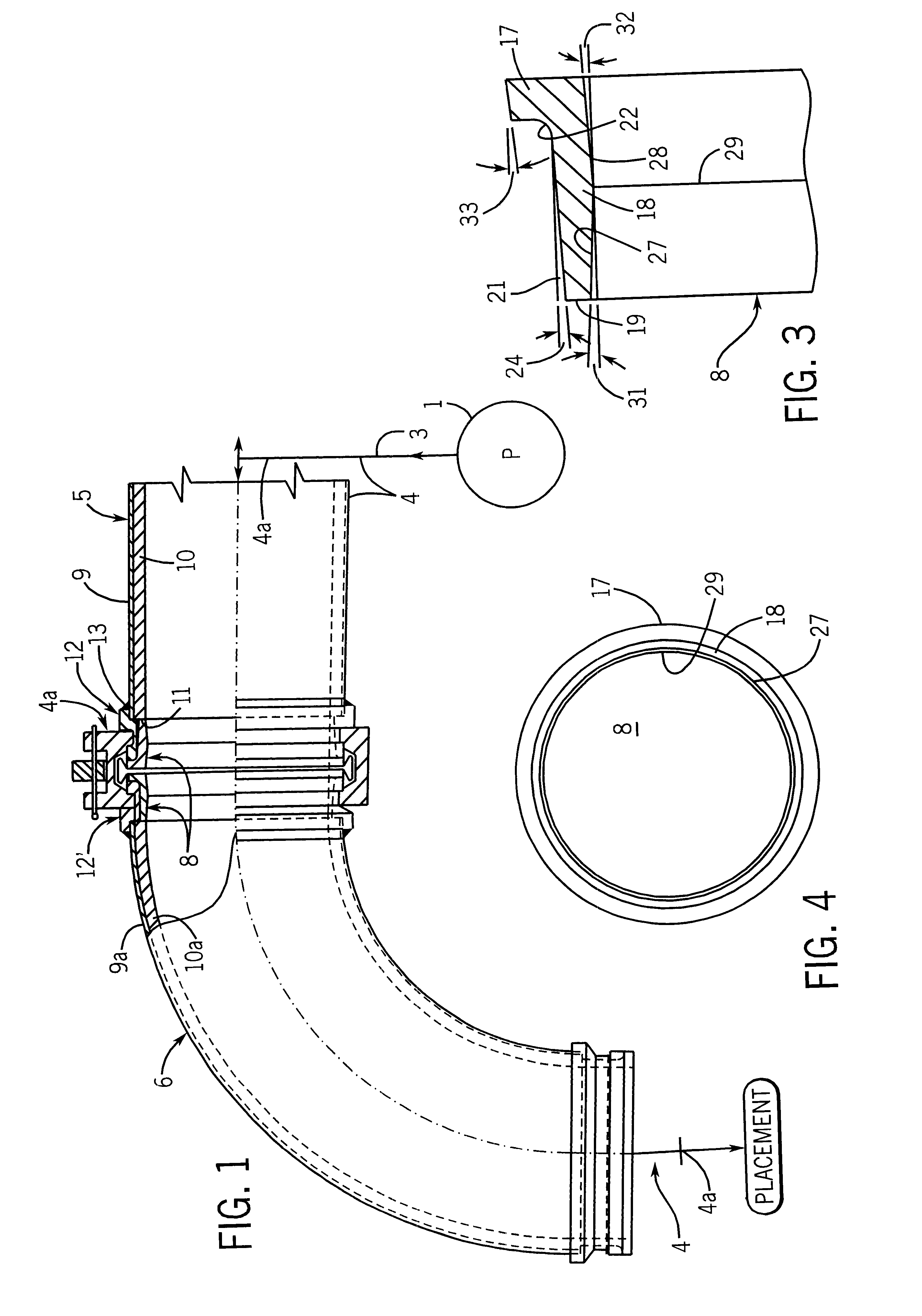

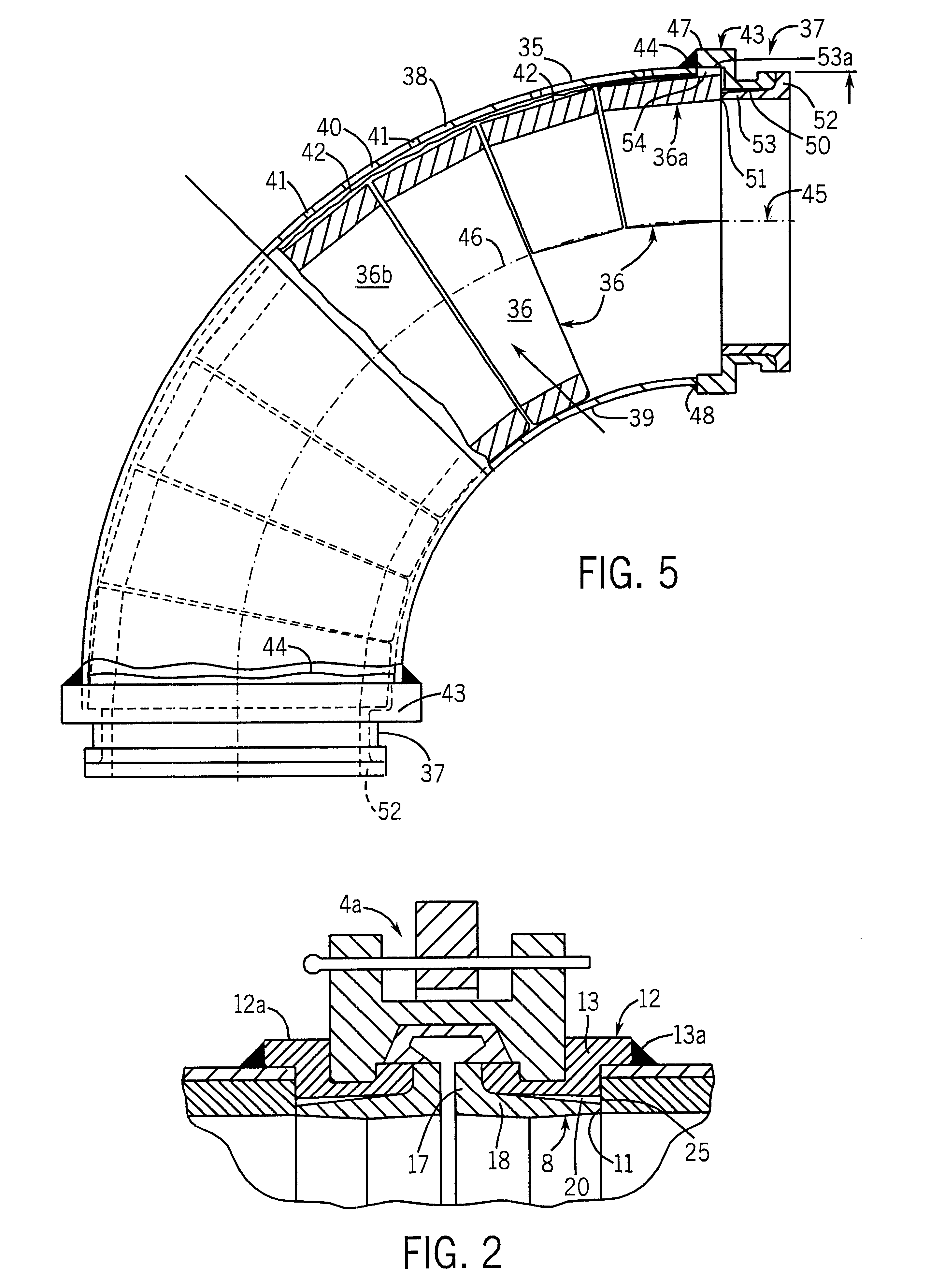

Pipe having replaceable wear resistant lined coupler

InactiveUS6467812B1Rapid and cost-effective formationQuick inexpensive replacementFlanged jointsThermal insulationWear resistantEngineering

A pipe section for concrete includes an end coupler interconnecting to another pipe section in a flow line. The coupler has an outer clamp secured extended from the pipe end with a coupling groove. An encircling clamp has sides located in the grooves of adjacent pipe sections to lock the pipe section together. The body and pipe end form an inner recess extending from the pipe end. An insert liner has a tubular portion matching the recess, with the outer surface of the tubular portion tapered to form a gap within the recess. The insert liner has an outer flange matching the outer diameter of the body and abuts the body. The inner wall of the liner has a central transition point from which the wall tapers inwardly in opposite directions to the outer end. The body member is formed of a high strength ductile steel. The insert liner is formed of a wear resistant material having a Rockwell hardness of 80 to 90. A carbide alloy consisting essentially of carbides, martensite, bainite and austenite, and 12-15% chromium, 2-3% carbon and traces nickel, molybdenum and austenite. A toughened ceramic is disclosed. The liner is adhesively bonded to the body using an epoxy adhesive which is responsive to heat for release of the liner. The liner is inserted by applying adhesive on the tubular portion and then pushing the liner into the recess.

Owner:CONSTR FORMS

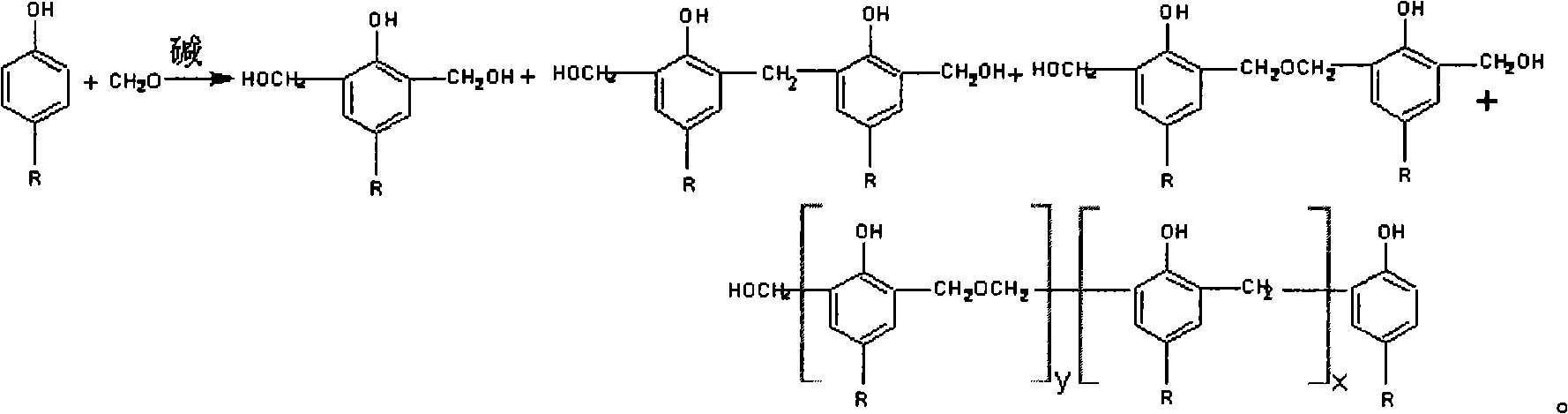

Modified phenolic tackifying resins for rubber compounding applications

This invention is related to modified alkylphenol aldehyde resins and a method for preparing them from the reactions of alkylphenols, aldehydes, amines, rosins and fatty acids. When used in rubber compounds, these modified alkylphenol aldehyde resins provide much improved tack properties.

Owner:SINO LEGEND CHINA CHEM

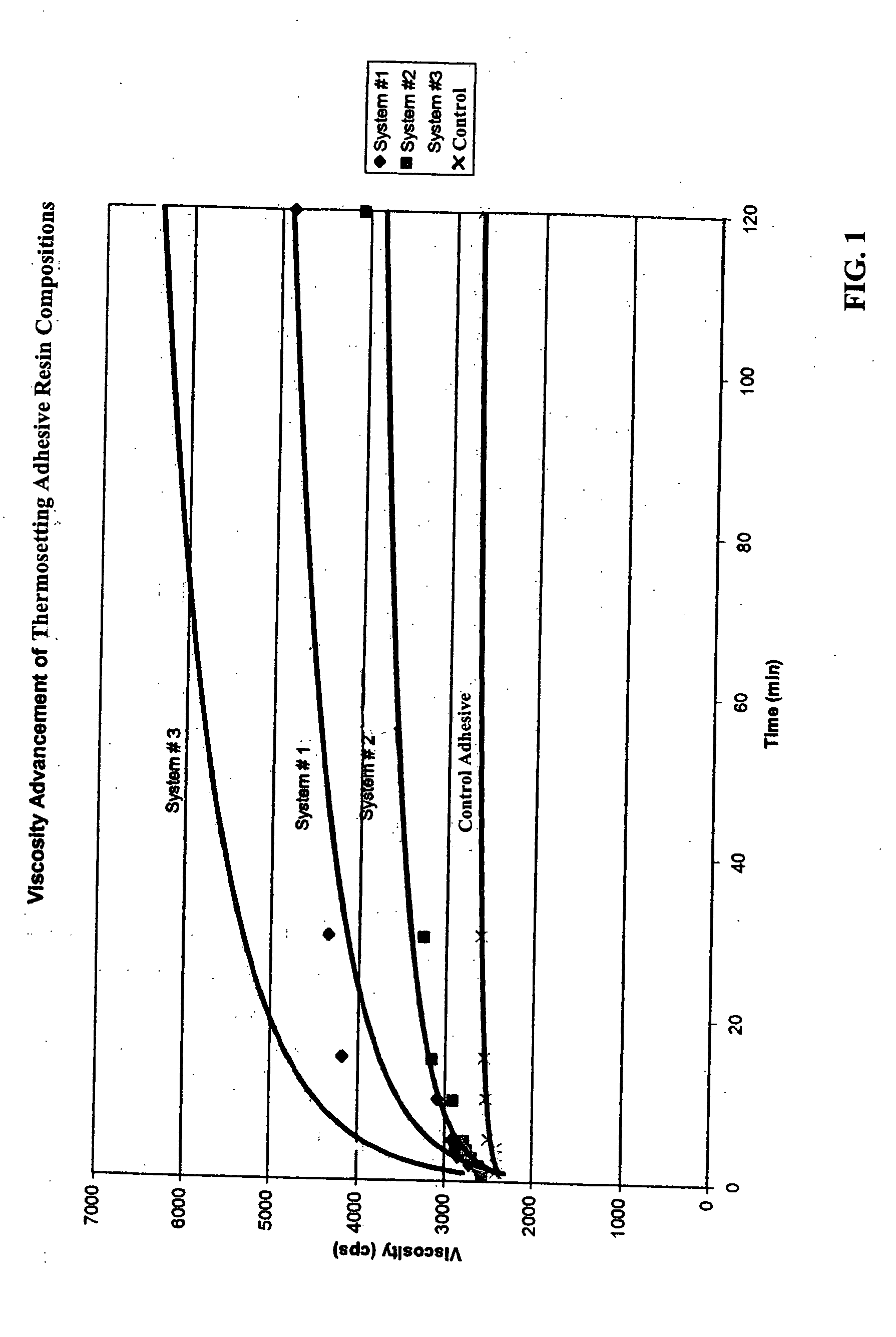

Phenolic resin-based adhesives and methods of using same in preparing laminated veneer lumber (LVL)

InactiveUS20050257888A1Fast tack build and curingGood bonding characteristicLaminationAdhesive processes with adhesive heatingPHENOL LIQUIDKetone

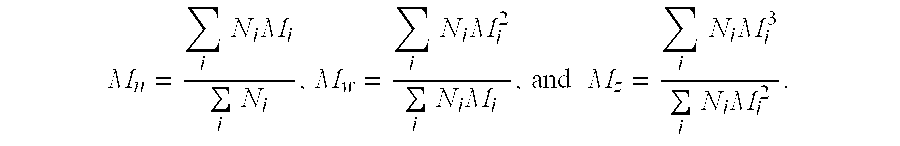

Adhesive compositions and methods of using the compositions in the production of laminated veneer lumber (LVL) are disclosed. The adhesive compositions comprise a thermosetting phenol-aldehyde resin having at least one of (A) a number average molecular weight (Mn) of at least about 450, (B) a weight average molecular weight (Mw) of at least about 2000, and (C) a Z-average molecular weight (Mz) of at least about 6000, wherein said Mn, Mw, and Mz are measured using gel permeation chromatography (GPC), a ketone-aldehyde resin cure promoter, and optionally other components (e.g., a tack-promoter or a catalyst). The adhesive compositions minimize or eliminate the art-recognized problems of glue line dryout and steam blowout, associated with LVL manufacture from both low-moisture veneers and high-moisture veneers, respectively. Furthermore, the adhesive compositions provide fast tack-build and curing as well as ultimately good bonding characteristics.

Owner:GEORGIA PACIFIC CHEM LLC

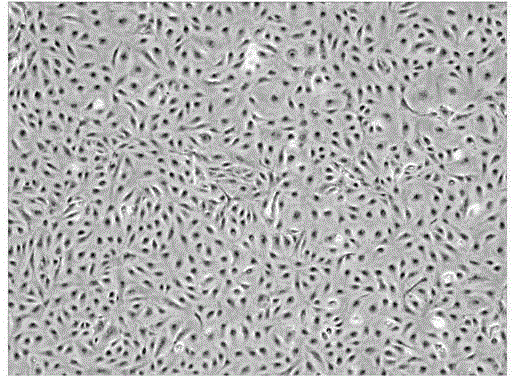

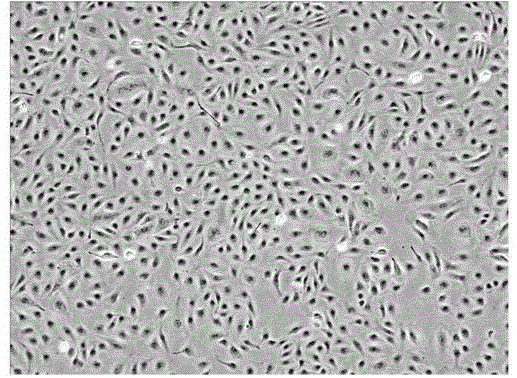

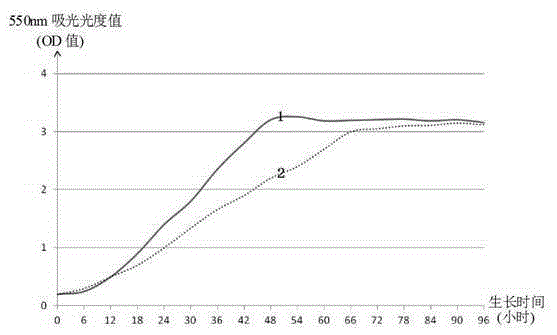

Serum-free medium for umbilical cord mesenchymal stem cells

InactiveCN105420182AOvercoming pollutionOvercoming Cell Expansion NumbersSkeletal/connective tissue cellsPancreatic hormoneStem cell culture

The invention provides a serum-free medium for umbilical cord mesenchymal stem cells and belongs to the technical field of cell culture. The serum-free medium for umbilical cord mesenchymal stem cells comprises a basal culture medium body and added ingredients, wherein the basal culture medium body is a DMEM culture medium; the added ingredients include a basic fibroblast growth factor hFGF, a epidermal growth factor hEGF, insulin hI, a leukaemia inhibitory factor hLIF and astragalus polysaccharide. The umbilical cord mesenchymal stem cells are subjected to subculture and amplification in the medium, and the surfaces of the cultured cells are marked and analyzed. The serum-free medium for umbilical cord mesenchymal stem cells overcomes the defect of exogenous pollution of serum and solves the problem of contradiction between the cell expansion number and cost reduction. The medium is free of serum, thereby preventing influence of animal-derived serum ingredients on cell culture. The medium can be used for studying the differentiation and proliferation adjusting mechanism of the umbilical cord mesenchymal stem cells.

Owner:SHANDONG JINGYUAN BIOTECH CO LTD

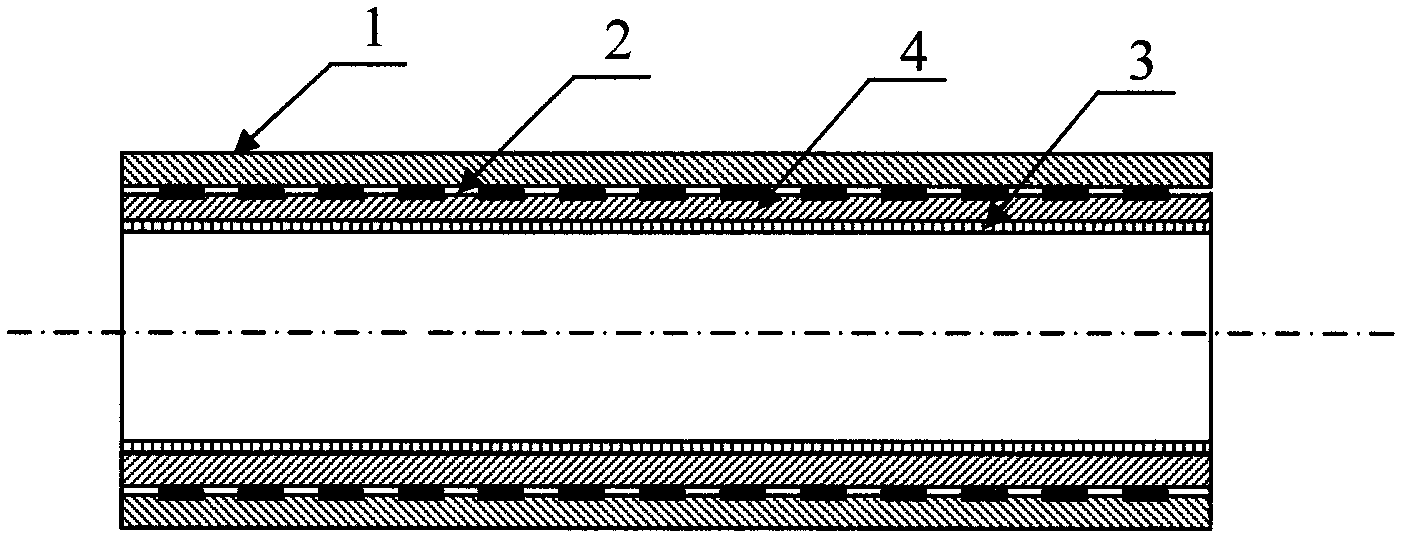

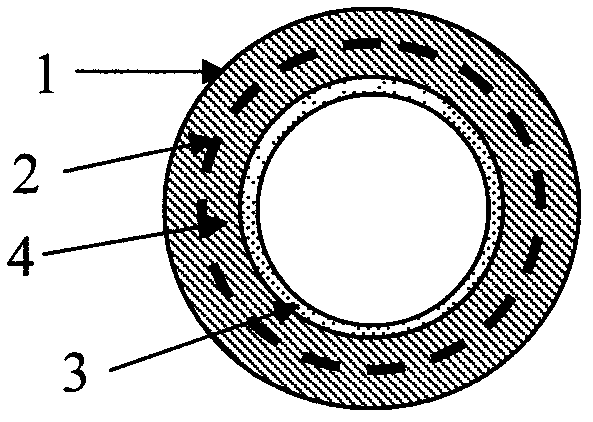

Medical scaffold with inner coating film, and preparation method for medical scaffold

InactiveCN102430157ALittle elasticityEliminate defects with high embolism rateStentsCoatingsFiberMedical equipment

The invention relates to medical equipment, particularly a medical scaffold with an inner coating film, and a preparation method for the medical scaffold, and belongs to the field of medical equipment. In the medical scaffold with the inner coating film, a non-woven inner coating film of which fibers are distributed on the axial direction of the medical scaffold is prepared on the inner surface of an inner film by an electrospinning method by taking a coating film scaffold as a basis, wherein the coating film scaffold consists of a netlike scaffold which is formed by weaving medical alloy wires, an electrospinning non-woven inner film and an electrospinning non-woven outer film; and the thickness of the inner coating film is 2 to 6 mu m. During preparation of the medical scaffold with the inner coating film, the inner coating film, the inner film and the outer film are prepared sequentially, and the inner coating film in the medical scaffold improves the biocompatibility with tract tissues of a human body, facilitates adhesion, migration and reproduction of endothelial cells at two ends of the medical scaffold, promotes quick endothelialization of the medical scaffold, and prevents the medical scaffold from becoming narrow again. The preparation method for the medical scaffold is simple, convenient to operate, and low in cost, and suitable for preparation of medical scaffolds with different diameters and lengths.

Owner:WUHAN TEXTILE UNIV

Binding wood using a thermosetting adhesive composition comprising a protein-based component and a polymeric quaternary amine cure accelerant

InactiveUS7736559B2Fast curingExcellent Adhesive PropertiesWood working apparatusCeramic shaping apparatusSynthetic resinEpichlorohydrin

Thermosetting adhesive compositions for use in e.g., particleboard or fiberboard, wherein the compositions comprise a blend of a protein-based component and a polymeric quaternary amine cure accelerant, can provide the fast tack-building and curing, as well as ultimately good bonding characteristics normally associated with synthetic resin compositions. Preferably, the polymeric quaternary amine cure accelerant is the reaction product of a polyamidoamine and epichlorohydrin.

Owner:GEORGIA PACIFIC CHEM LLC

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres having a moisture content of about 10 to about 16%; and compressing and extruding the agricultural fibre feedstock through a die to obtain fuel pellets in the form of small cylinders having a diameter of about ⅜ inch to ¾ inch or more, said pellets having an ash content of about 1.1% to about 20% by weight and a calorific value of about 7,000 BTUs per pound of fuel on a dry basis. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran fibre, rye bran fibre; oat bran fibre, rice bran fibre, soy bran fibre, canola bran fibre and wheat bran fibre. The method may include the step of pre-treating the agricultural whole grain and seed hull fibre feedstock with high temperature steam before being formed into pellets at a sufficient temperature and sufficient time to activate hemicellulose within the fibre as a binding agent. The method may include the step of mixing the agricultural whole grain and seed hull fibre feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides and alter the fusion point of the inorganic elements present in the fuel.

Owner:EVERGREEN BIOFUELS

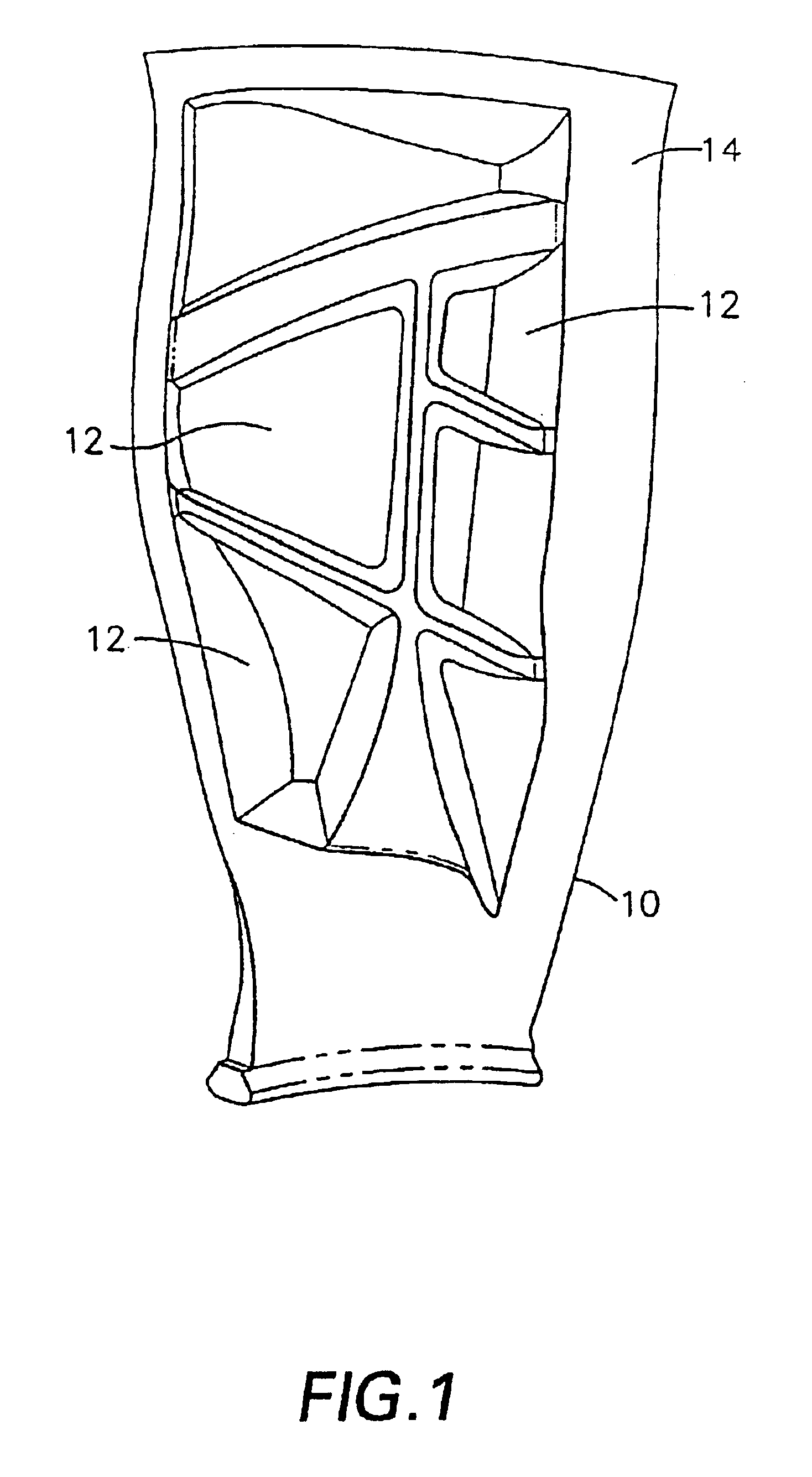

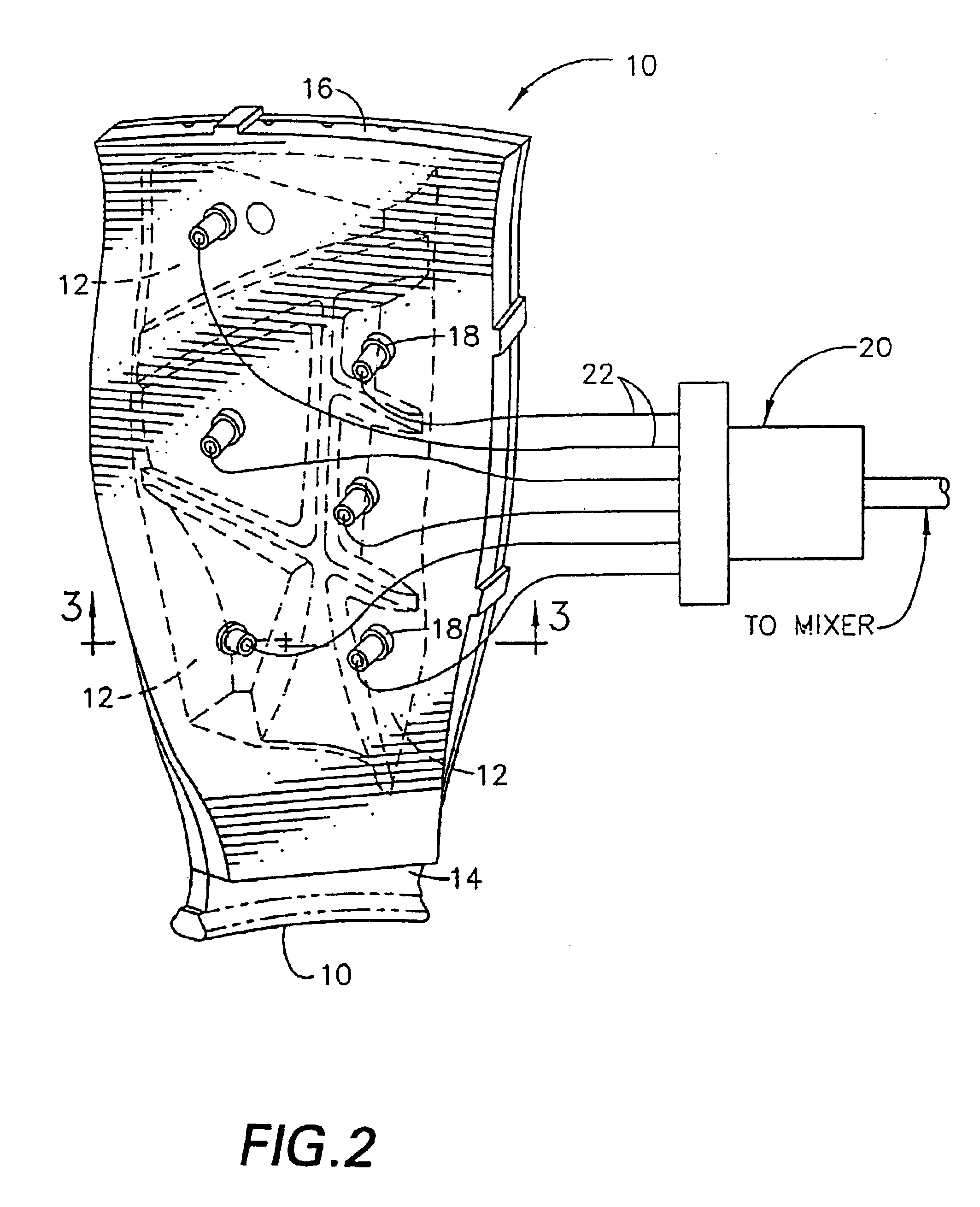

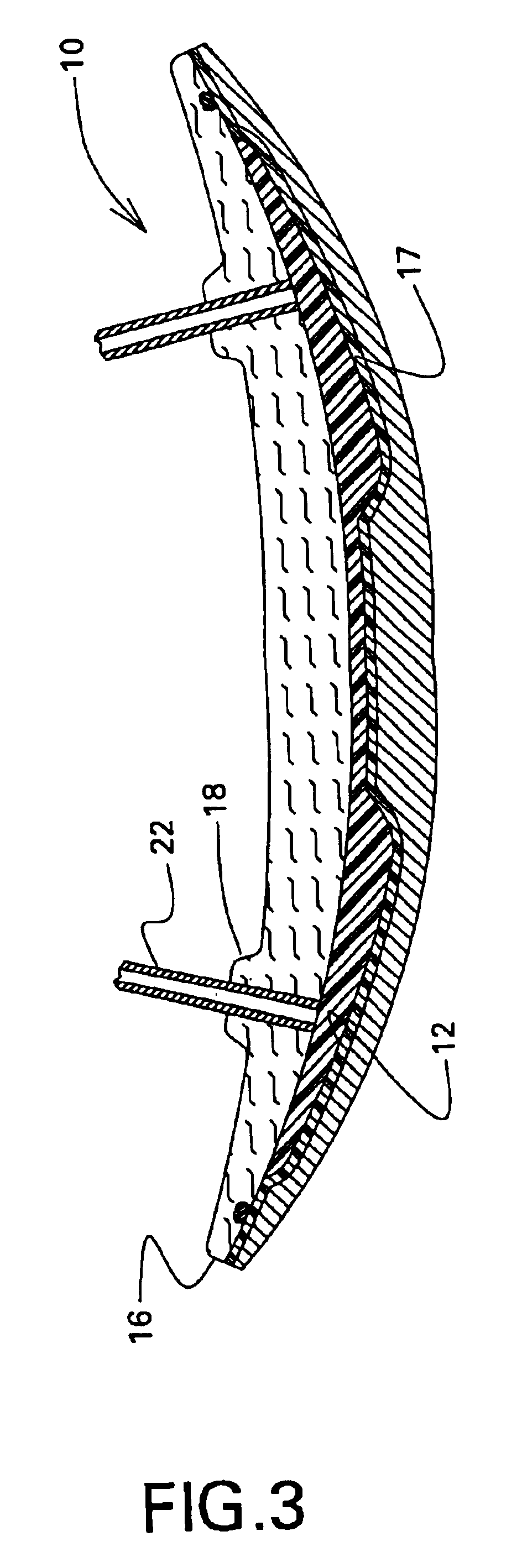

Use of high modulus, impact resistant foams for structural components

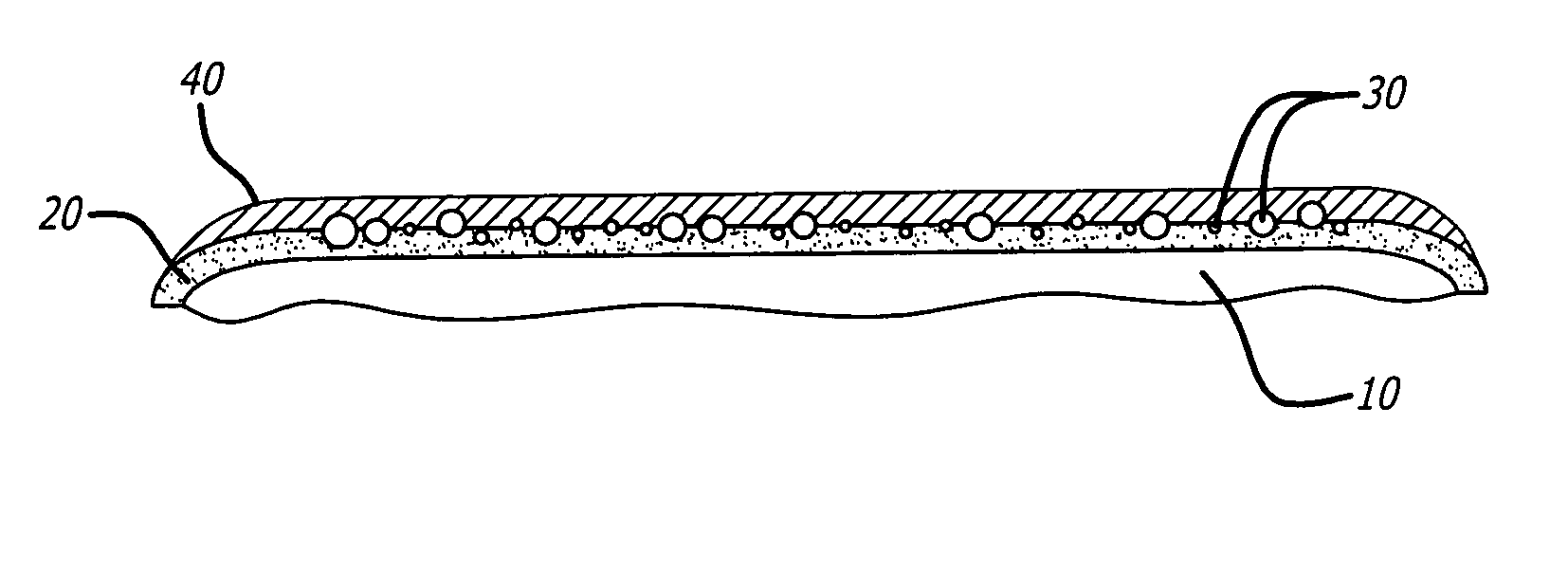

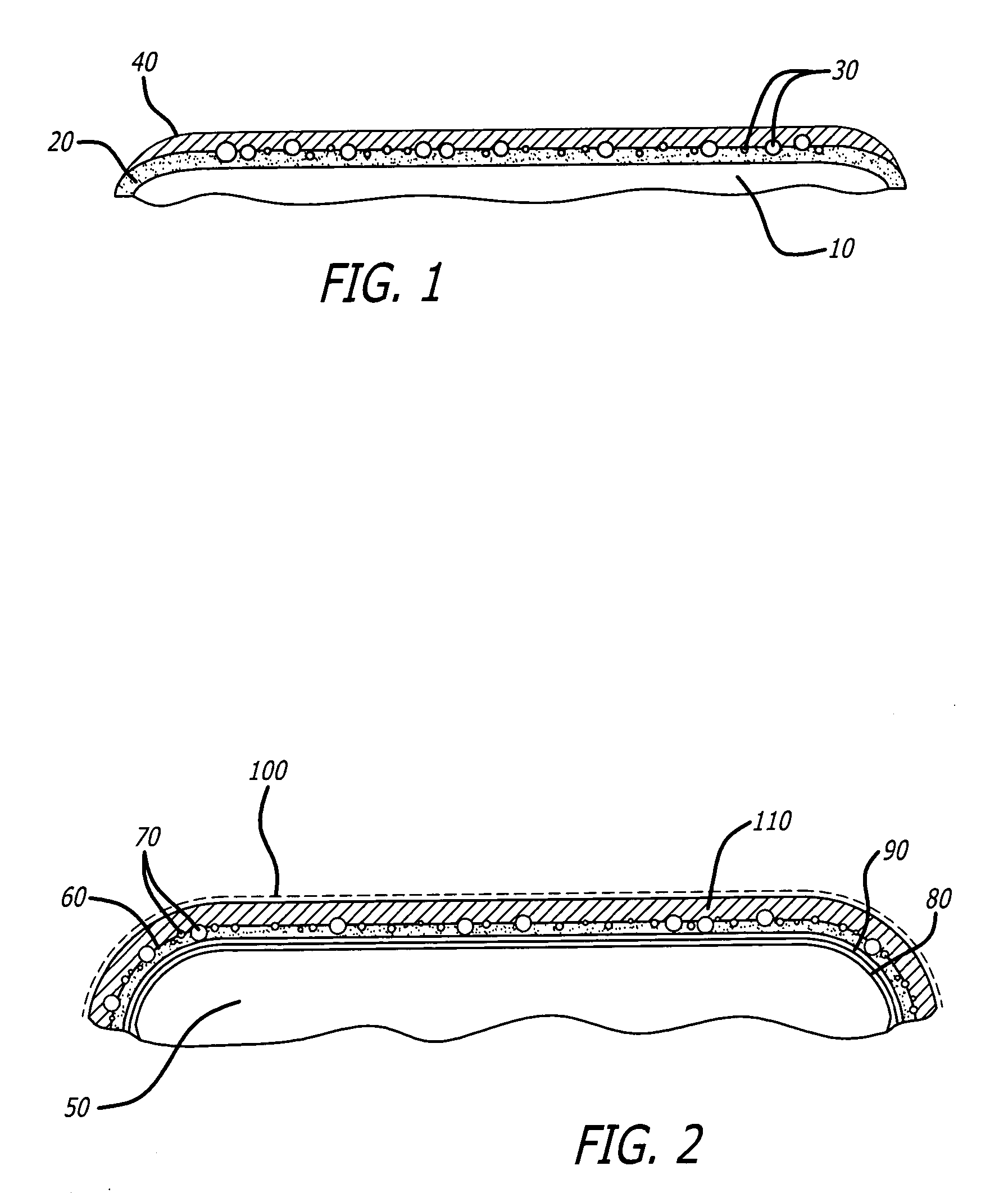

InactiveUS6884507B2Excellent Adhesive PropertiesMaximizes surface area contactSynthetic resin layered productsBlade accessoriesInjectorPolymer composition

The present invention provides tough, high modulus, low density thermoset polyurethane compositions which are useful in general as, for example, cast structural materials and in a preferred embodiment can be cured directly onto an aircraft engine fan blade, thereby providing a lighter blade, without concomitant loss in structural integrity or blade performance due to, for example, resistance to foreign object impacts and fuel efficiency. In a preferred embodiment, the composition is comprised of bis-amine compounds reacted with isocyanate-functional polyether polymers in the presence of hollow polymeric microspheres. The thermoset polymer compositions are formed by casting into a mold which is formed by a cavity within the metallic or composite fan blade or guide vane in the form of a pocket and a removable caul sheet. After the elastomeric polyurethane foam is injected through at least one injector port into the mold, the foam is cured.

Owner:GENERAL ELECTRIC CO

Thermosetting Adhesive Compositions Comprising a Protein-Based Component and a Polymeric Quaternary Amine Cure Accelerant

InactiveUS20080027159A1Fast curingExcellent Adhesive PropertiesProtein adhesivesGlue/gelatin preparationSynthetic resinEpichlorohydrin

Thermosetting adhesive compositions for use in e.g., particleboard or fiberboard, wherein the compositions comprise a blend of a protein-based component and a polymeric quaternary amine cure accelerant, can provide the fast tack-building and curing, as well as ultimately good bonding characteristics normally associated with synthetic resin compositions. Preferably, the polymeric quaternary amine cure accelerant is the reaction product of a polyamidoamine and epichlorohydrin.

Owner:GEORGIA PACIFIC RESINS INC

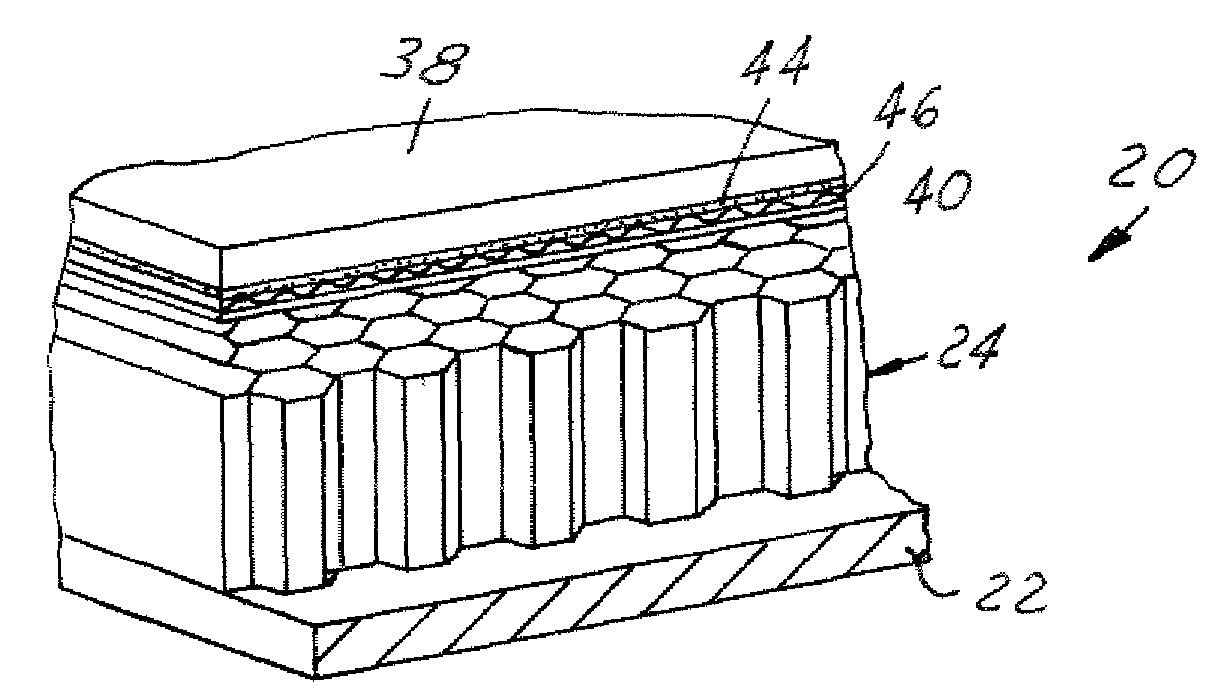

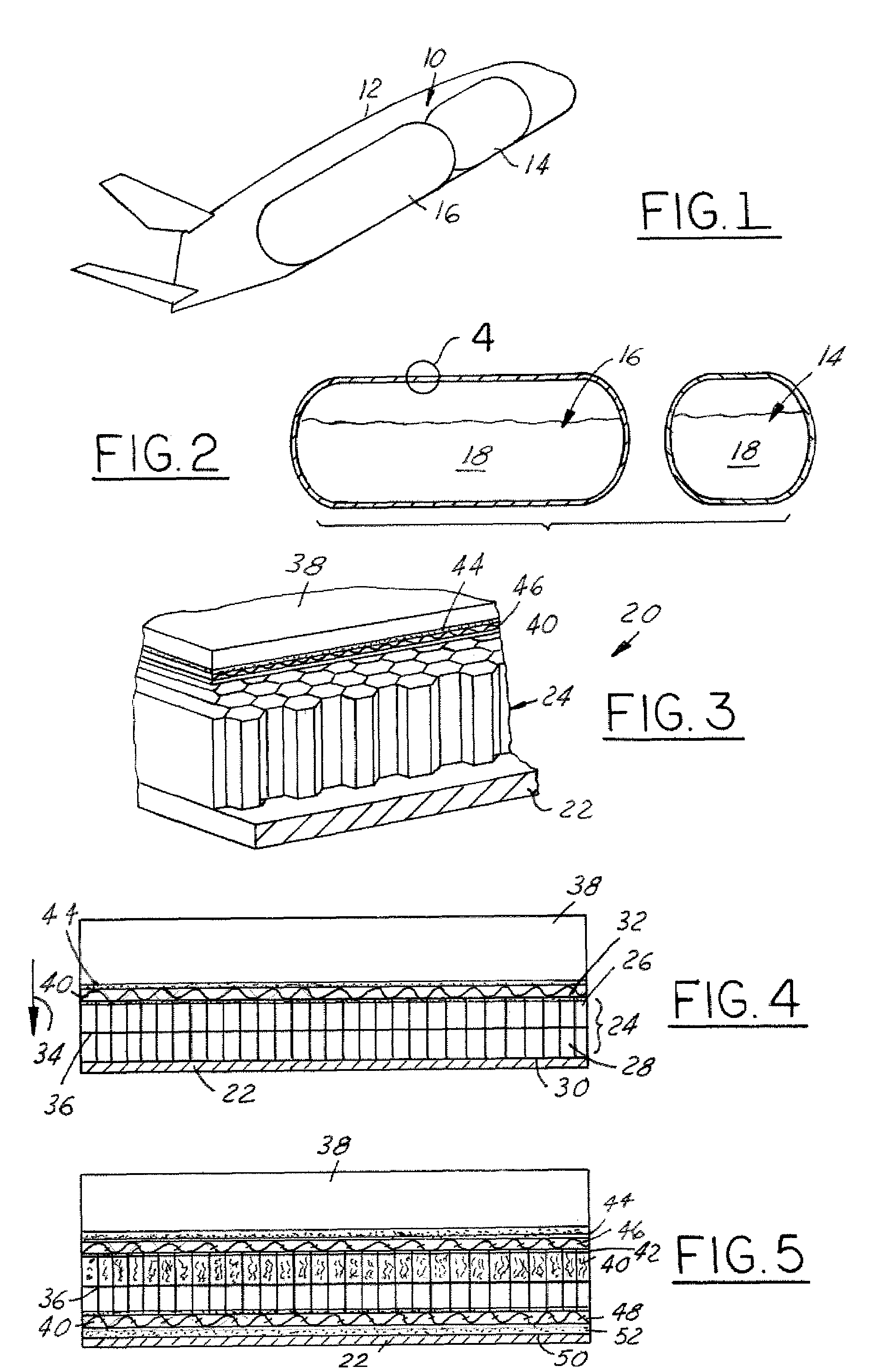

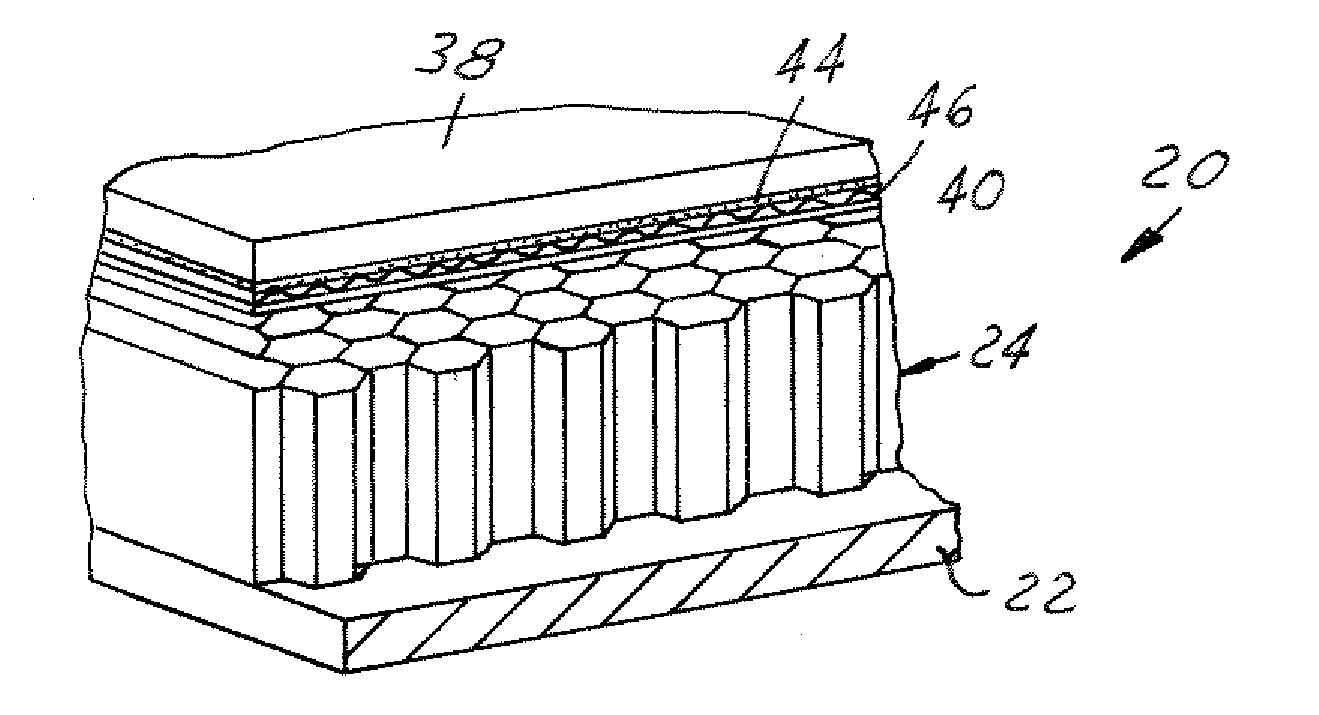

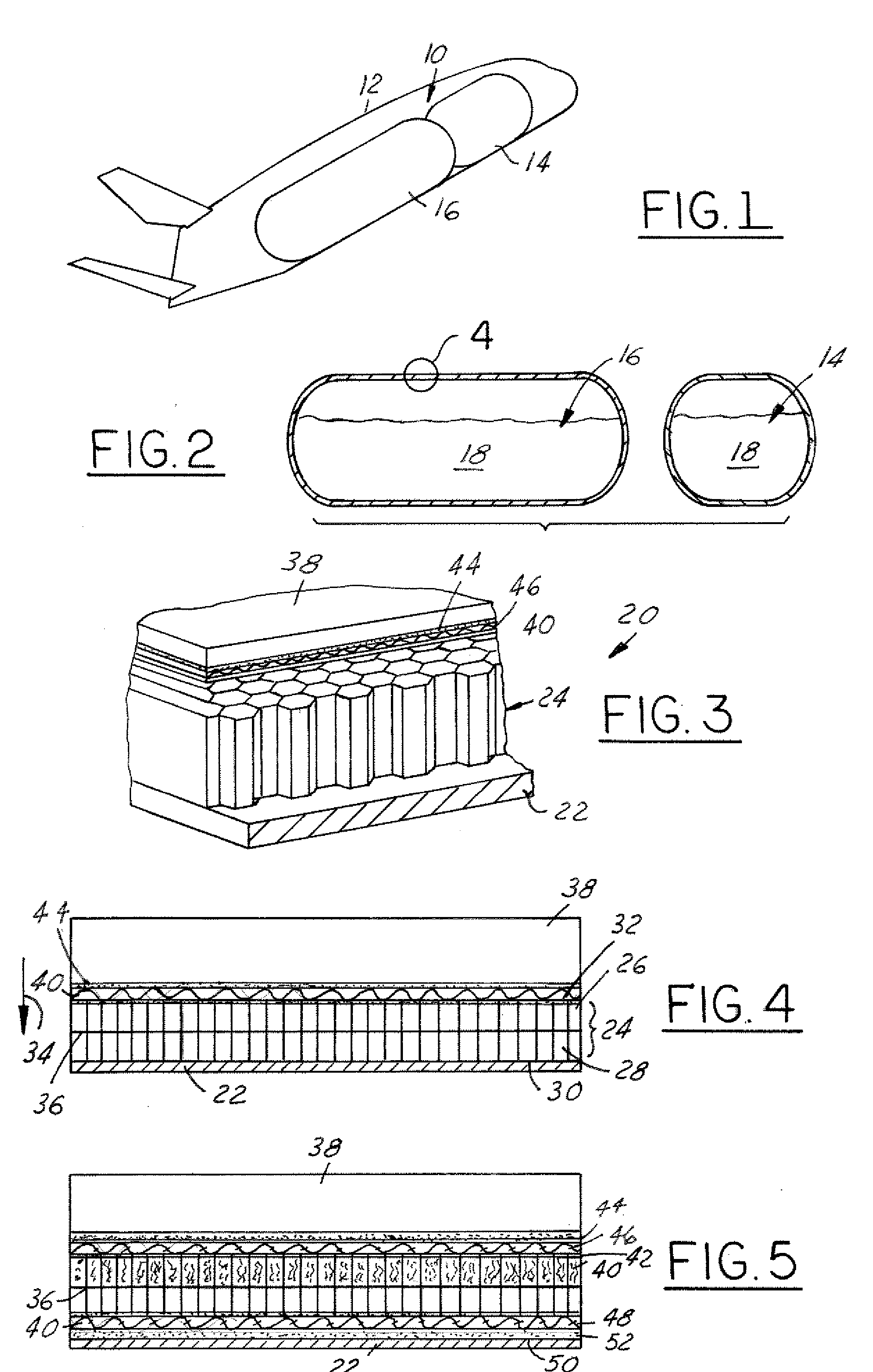

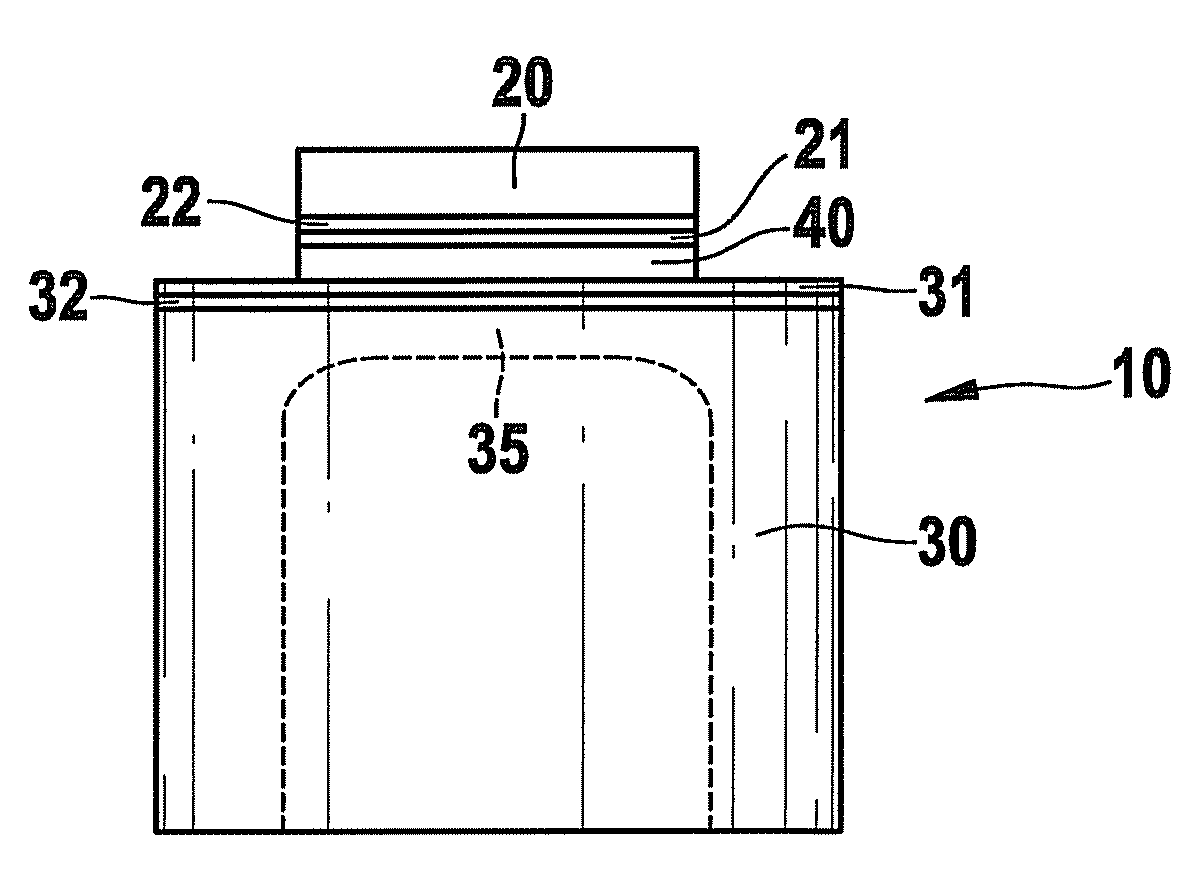

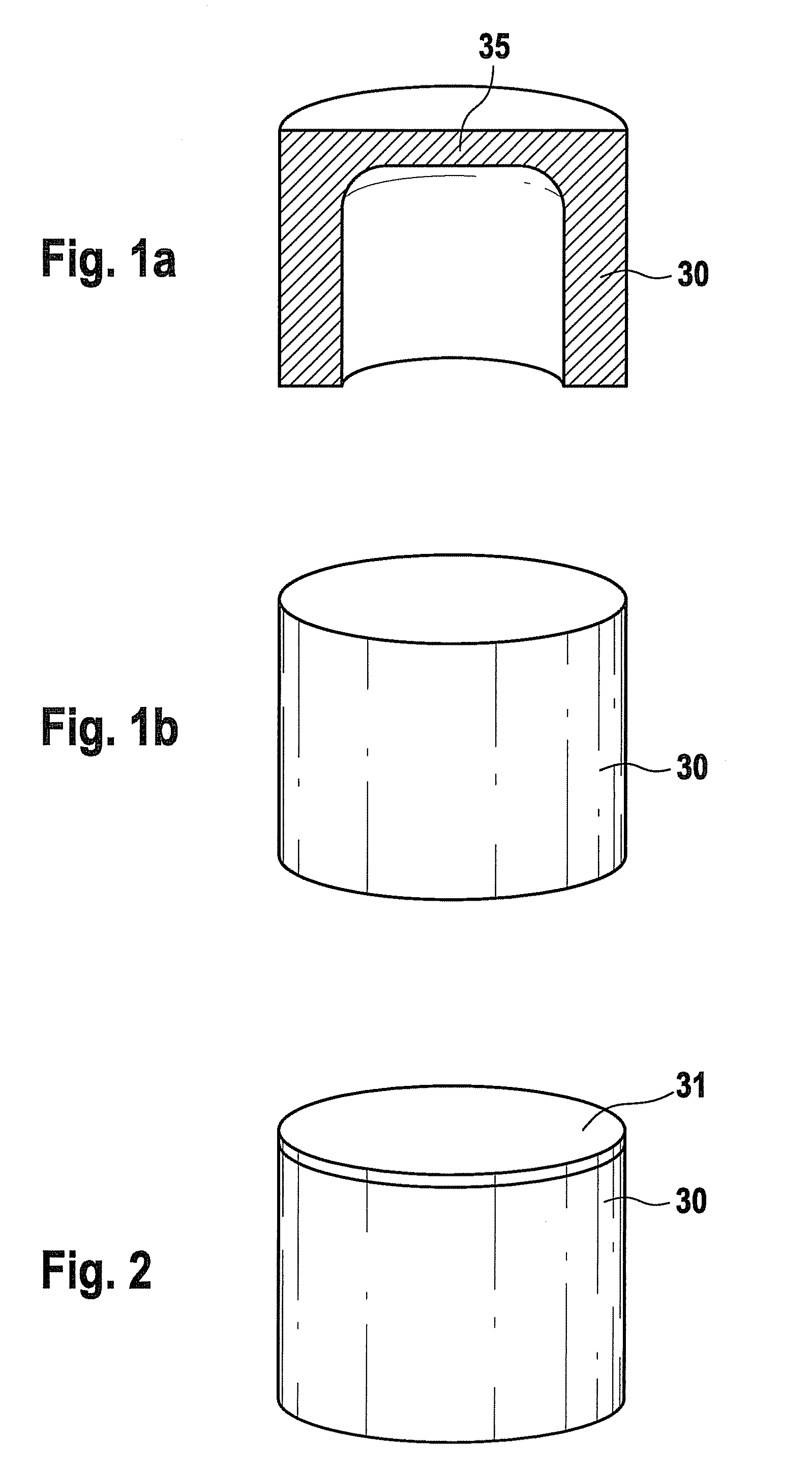

Cryogenic fuel tank insulation assembly

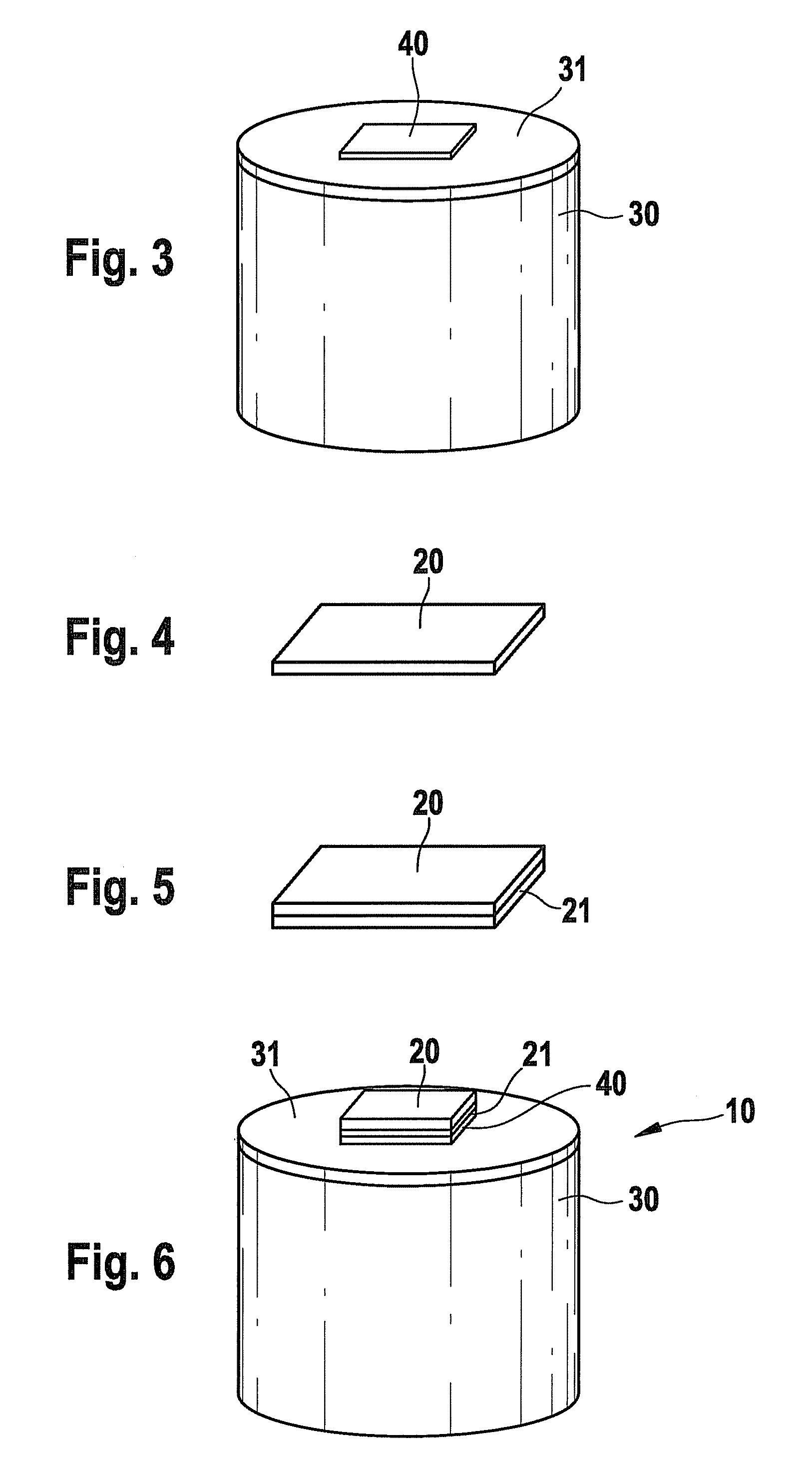

ActiveUS7296769B2Excellent Adhesive PropertiesImprove the immunityCosmonautic vehiclesCosmonautic safety/emergency devicesFuel tankProcess engineering

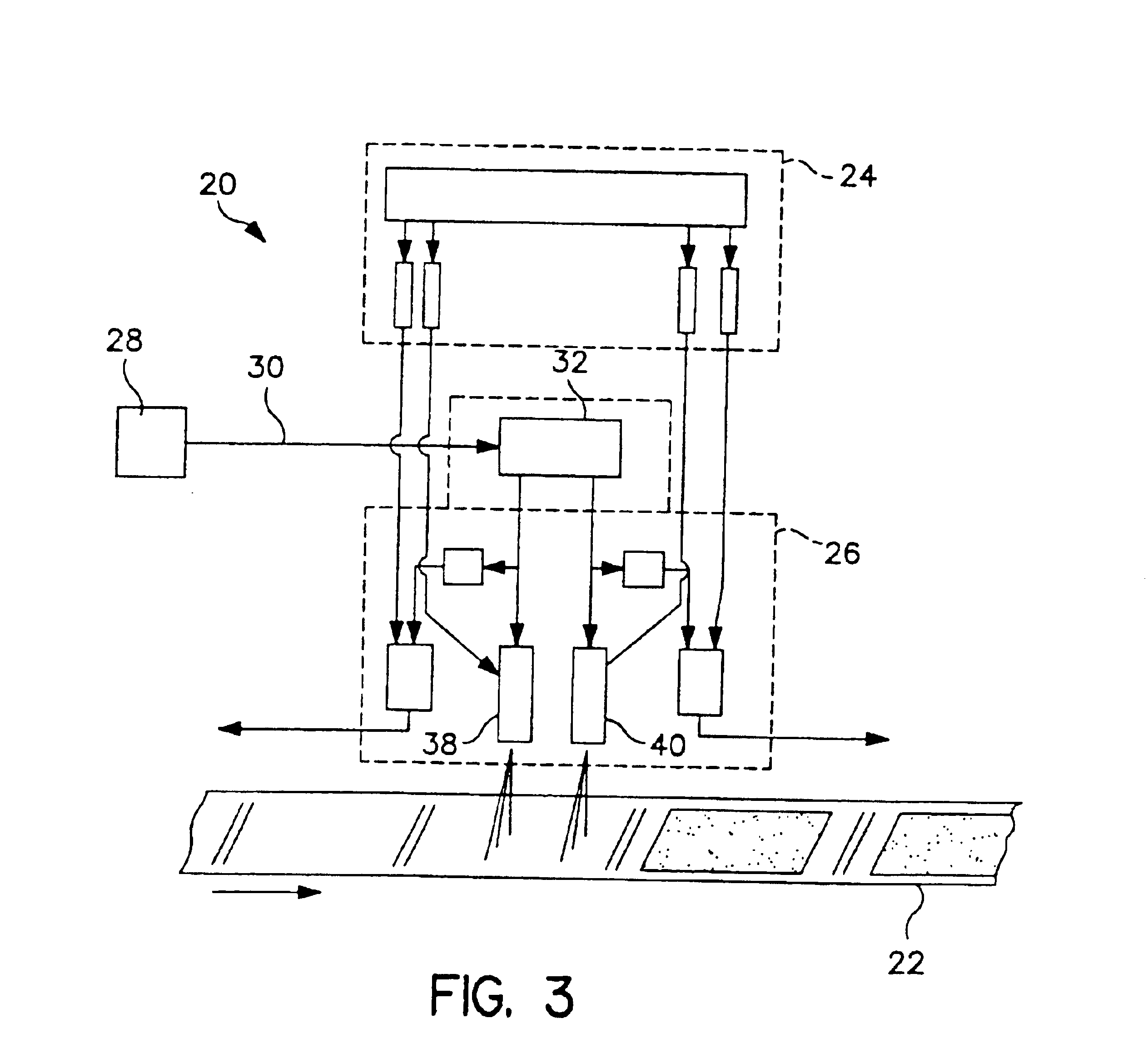

A cryogenic fuel tank assembly 10 is provided comprising a cryogenic fuel tank wall 22. A foam assembly 24 is affixed to the cryogenic fuel tank wall 22, the foam assembly 24 having an inner surface 30 and an outer surface 32. A first solid film 40 bonded to the outer surface 32 to provide a uniform outer bonding surface 42. A thermal protection system assembly 38 is bonded to the uniform outer bonding surface 42.

Owner:THE BOEING CO

Negative electrode of lithium ion battery and preparation method thereof

InactiveCN103985841AImprove convenienceImprove adhesionCell electrodesSecondary cellsAdhesivePhysical chemistry

The invention belongs to the field of materials of lithium ion batteries, and particularly relates to a negative electrode of the lithium ion battery and a preparation method thereof. The negative electrode of the lithium ion battery comprises a current collector and negative electrode paste for coating the current collector, wherein the negative electrode paste comprises the following dry ingredients by weight percent: 92-99% of active material and 1-8% of an adhesive; the active material is graphite or graphite alloy; the adhesive is waterborne multi-component copolymerization emulsion. The waterborne multi-component copolymerization emulsion is used for replacing conventional butadiene styrene rubber and serves as the adhesive for the lithium ion battery, so that the more excellent adhesive performance is realized in comparison with the adhesive performance of a conventional adhesive, and meanwhile, the prepared battery has prominently excellent performances such as good low temperature characteristics, low circulation expansion rate, good long cycling performance and relatively excellent processing characteristics; the negative electrode prepared by using the method has relatively small impedance and relatively good dynamic performance and is capable of effectively solving the problem of risk of separation of lithium in the lithium ion battery at low temperature; the prepared battery has the characteristics of safety, reliability and long cycle life.

Owner:MCNAIR TECH +1

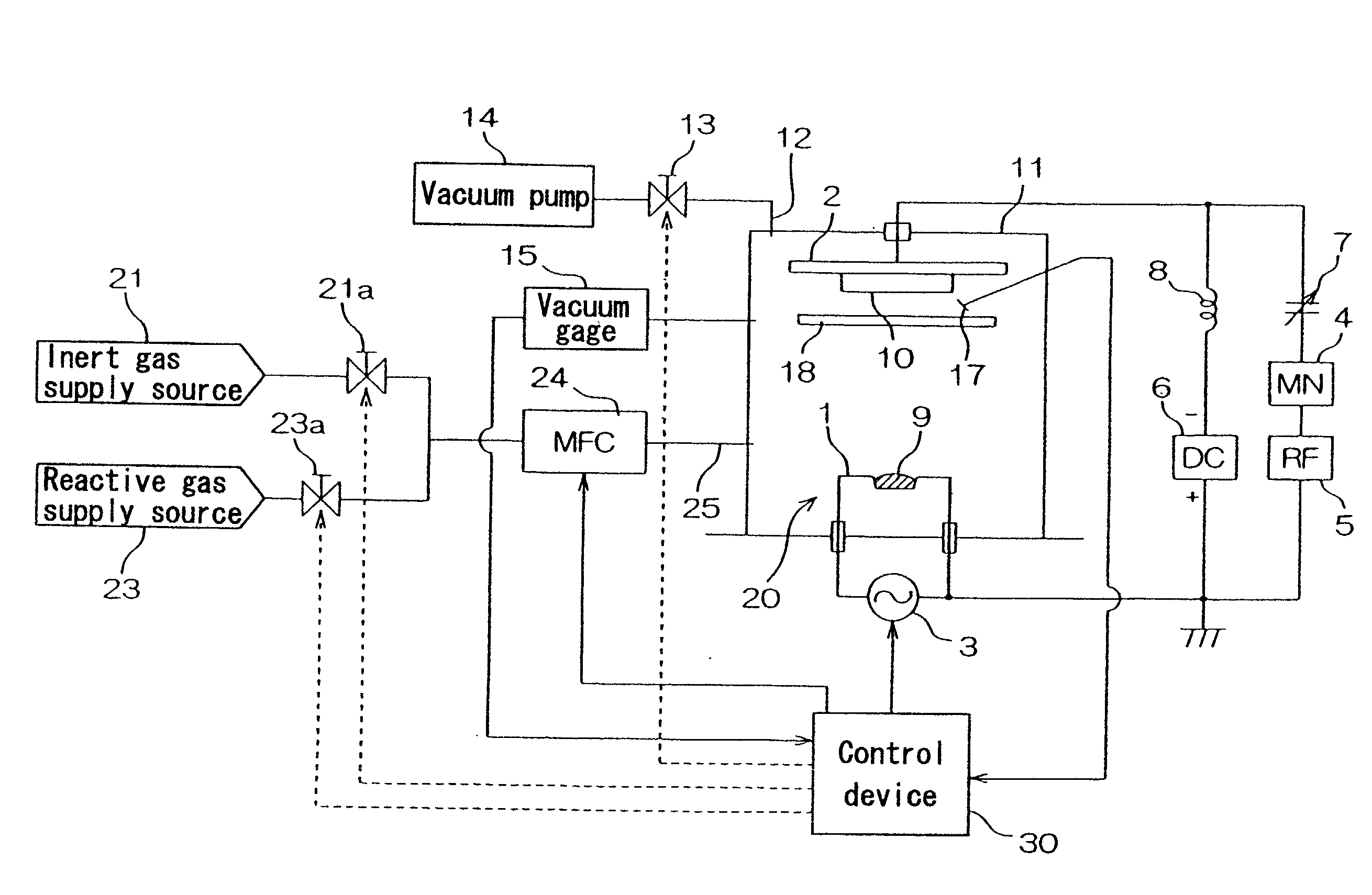

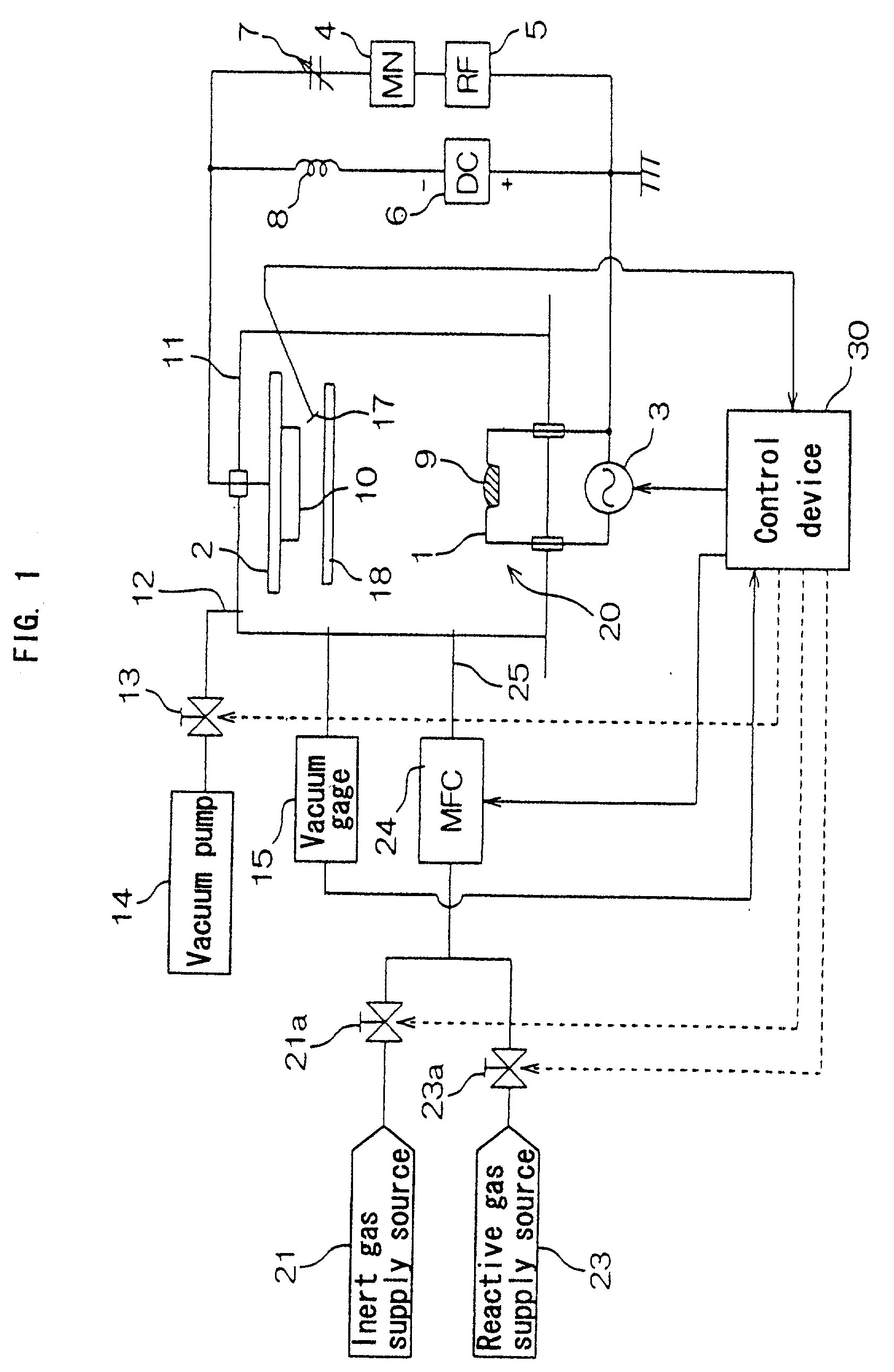

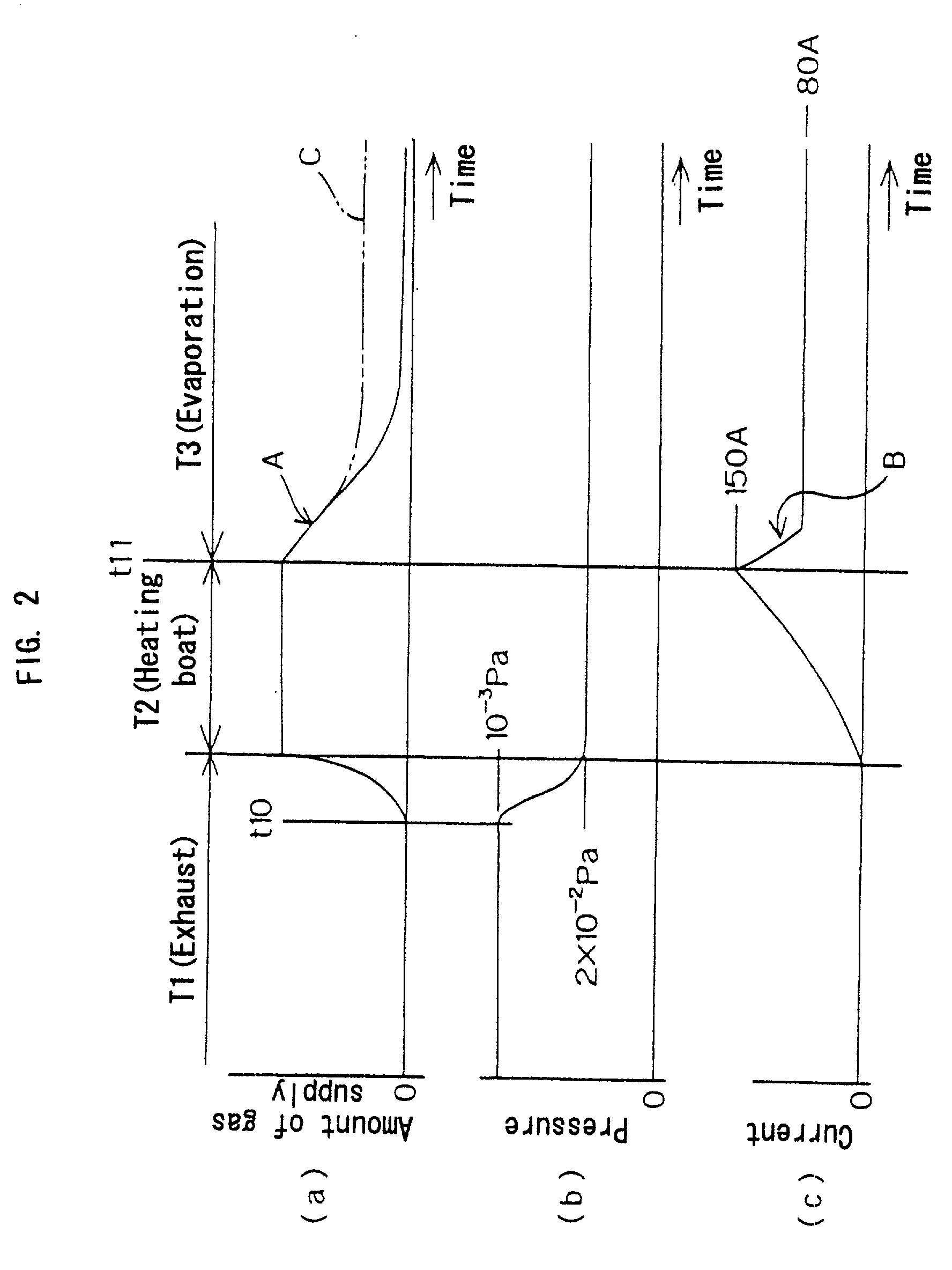

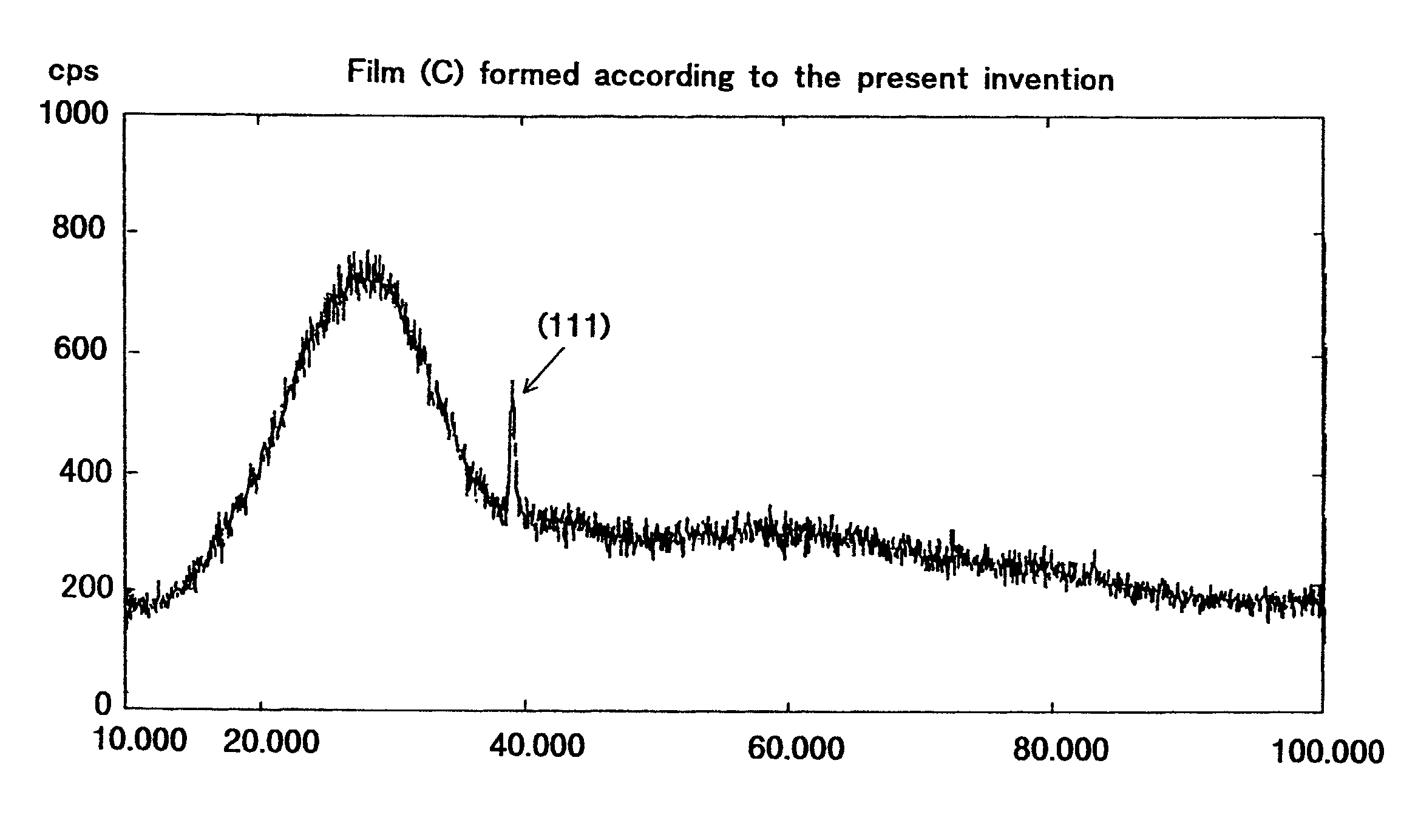

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member , thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

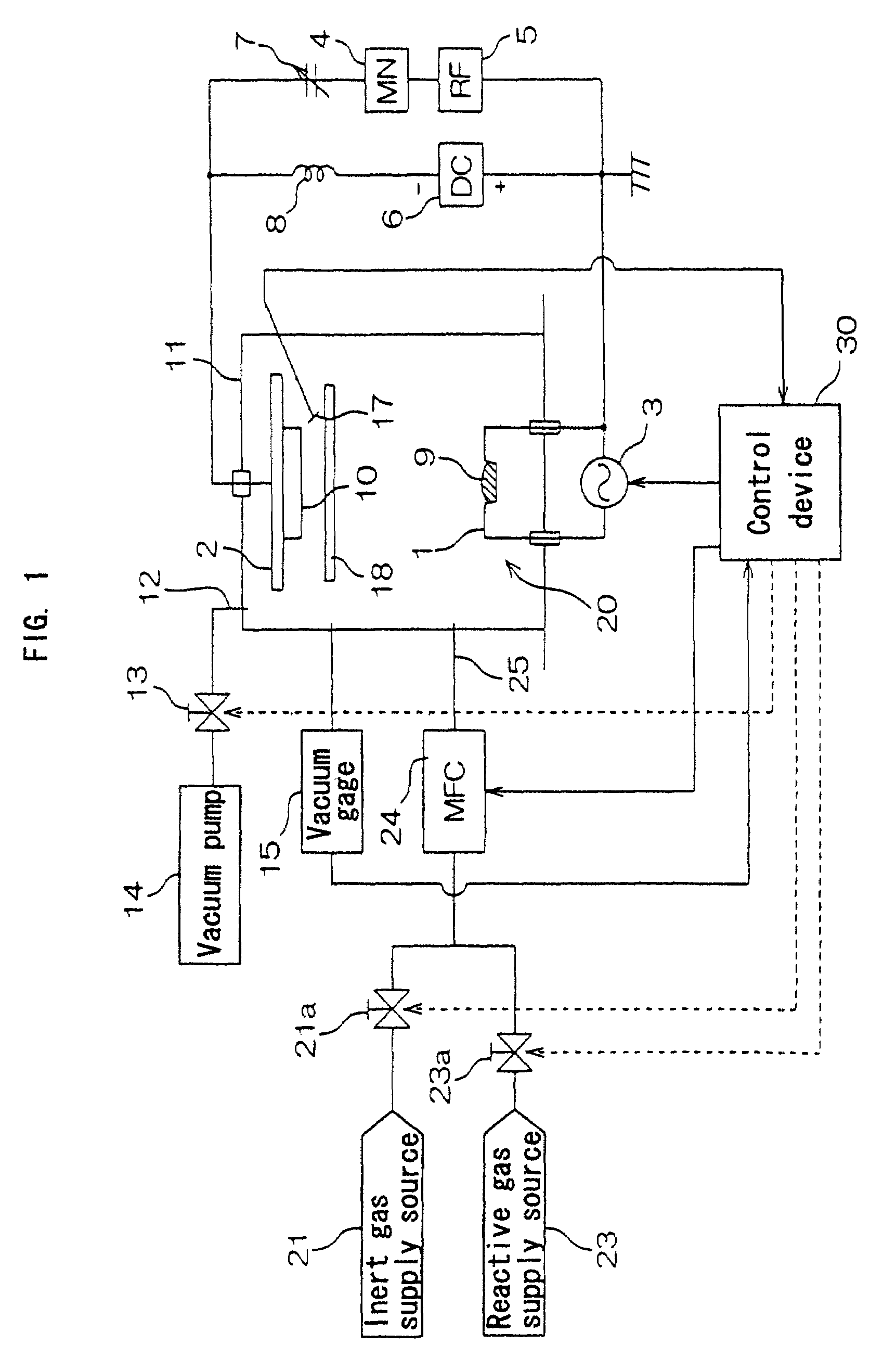

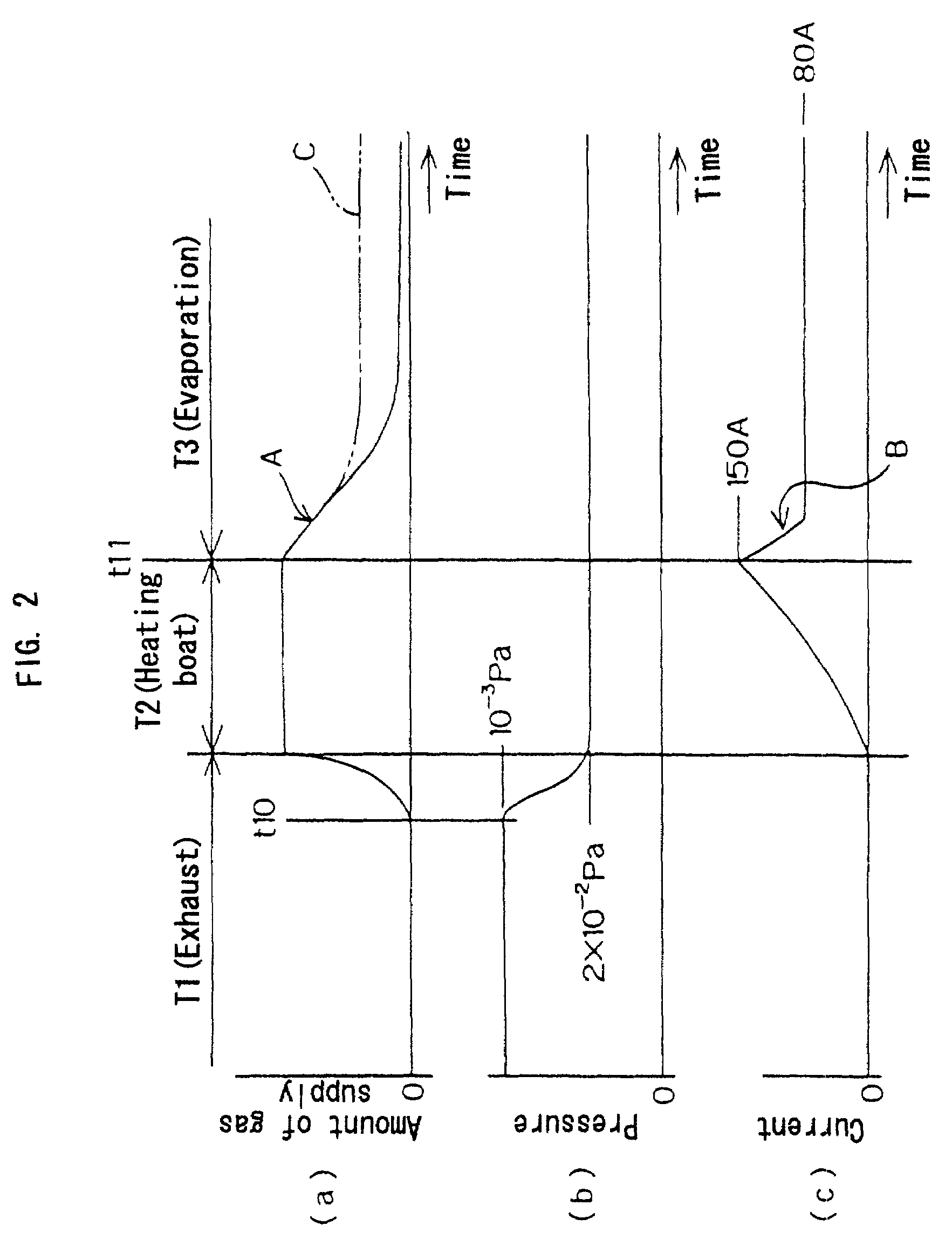

ActiveUS20020126265A1Low surface roughnessGood crystal orientationVacuum evaporation coatingSputtering coatingCrystal orientationSingle crystal

The metal film of the present invention is a dense film of a single crystal that has very low surface roughness and very good crystal orientation because an arithmetic mean roughness of the surface is not larger than 2 nm and a (111) peak intensity of X-ray diffraction is not less than 20 times the sum of all other peaks. Also the metal oxide film of the present invention is a dense film that includes less oxygen defects and almost no voids therein because a content of a non-oxidized metal is not higher than 1 mole % of a metal component that constitutes the metal oxide and a packing density is 0.98 or higher.

Owner:KYOCERA OPTEC

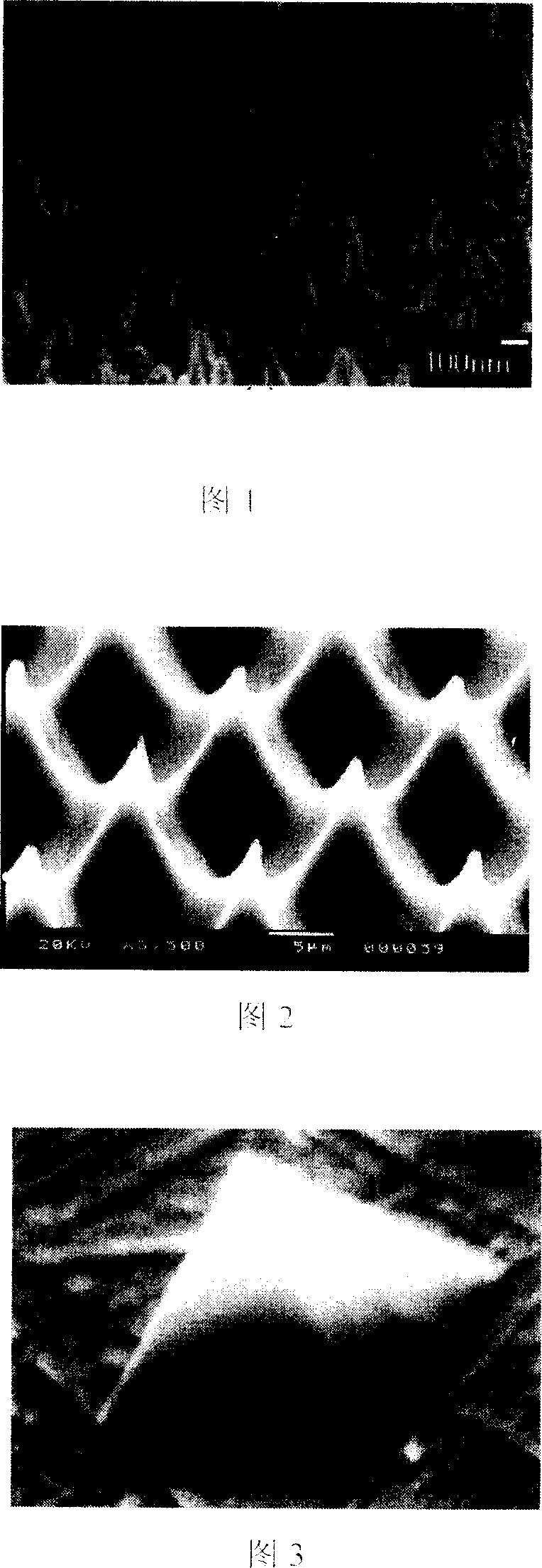

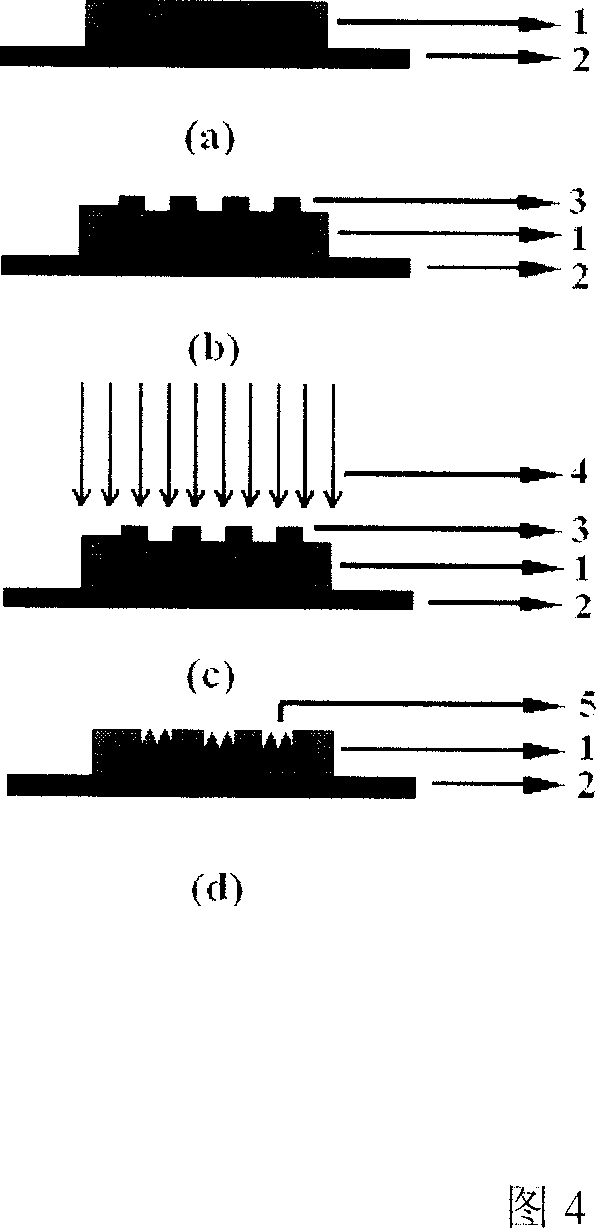

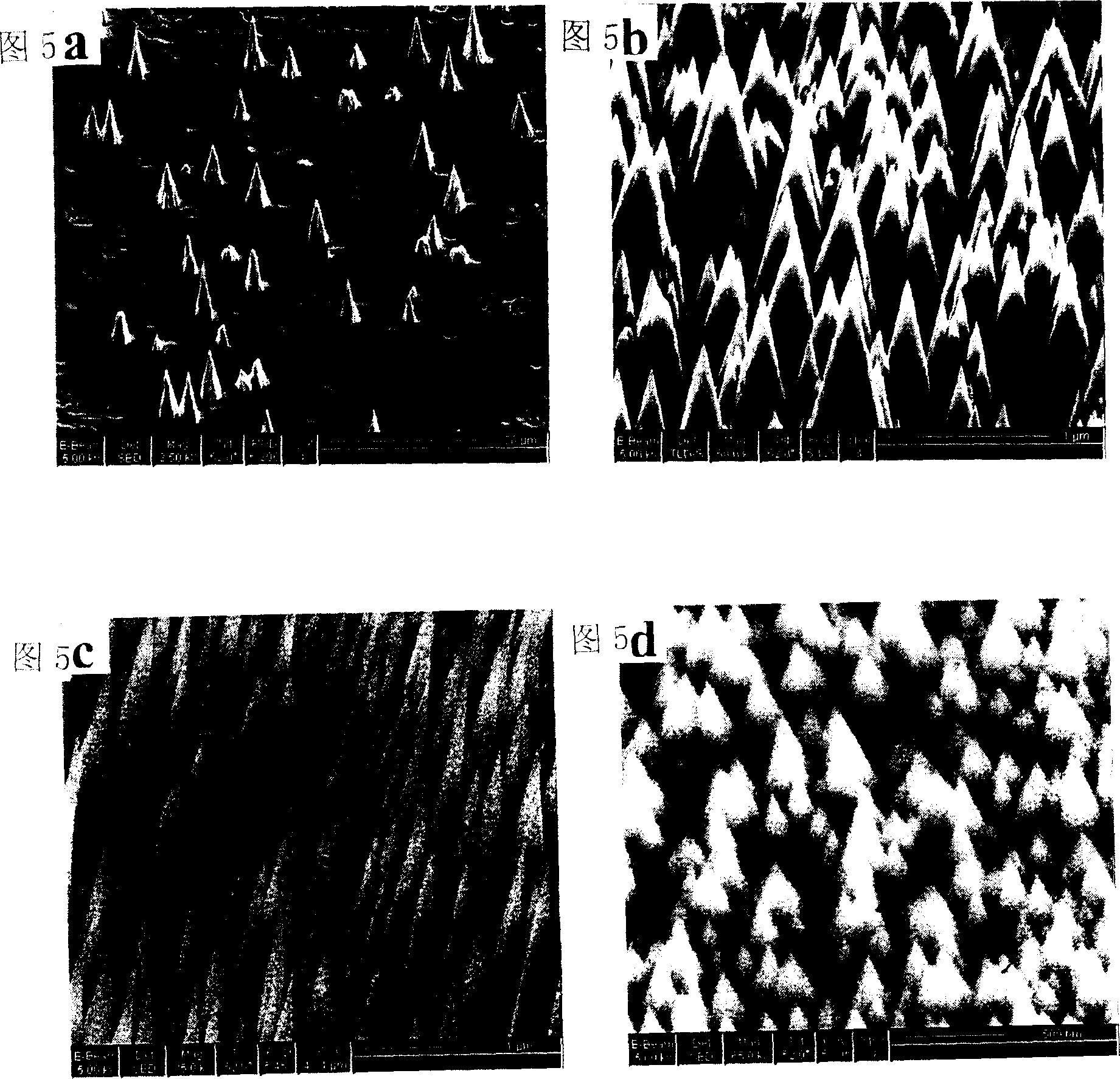

Surface nano tip array and its preparing method

InactiveCN1978310AControllable aspect ratioSmall tip curvature radiusIndividual molecule manipulationGas phaseDiameter ratio

This invention relates to a surface nm cone array and its manufacturing method, in which, said surface nm conical array is formed by applying a plasma etching technology and preparing nm conical array on a substrate with the major diameter ratio between 50-8000, the curvature radius on the tip lower than 5 nm, the bottom diameter of 200-2000 nm, the cone angle of 16-72 deg. and the density of 109 cm2-105 cm2, the preparation method includes: putting it in a CVD device after cleaning the substrate in a biased chemical gas phase deposition device, vacuumizing it to 10-2 Torr, applying plasma pre-etching process, then turning off the bias and filament current then to re-vacuumize it to 10-2 Torr then to etch it to form a surface nm cone array.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Cryogenic fuel tank insulation assembly

ActiveUS20050089661A1Excellent Adhesive PropertiesImprove the immunityCosmonautic vehiclesCosmonautic safety/emergency devicesFuel tankProcess engineering

A cryogenic fuel tank assembly 10 is provided comprising a cryogenic fuel tank wall 22. A foam assembly 24 is affixed to the cryogenic fuel tank wall 22, the foam assembly 24 having an inner surface 30 and an outer surface 32. A first solid film 40 bonded to the outer surface 32 to provide a uniform outer bonding surface 42. A thermal protection system assembly 38 is bonded to the uniform outer bonding surface 42.

Owner:THE BOEING CO

Surface treated copper film

InactiveUS7651783B2Improve acid resistanceHigh bonding strengthInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisHeat resistance

A surface treated copper foil with improved adhesion to the insulating resin of a copper-clad laminate for higher frequency applications contains a copper foil provided with a heat-resistant layer and an olefin-based silane coupling agent layer sequentially on at least one side thereof. An anticorrosive treatment may be performed after the heat resistance treatment. The copper foil is preferably an electrolytic copper foil, and these layers can be provided on the S side and / or the M side thereof. The copper foil has an adequate adhesive strength, even without the roughening treatment that has been performed in the past. A film of zinc, zinc-tin, zinc-nickel, zinc-cobalt, copper-zinc, copper-nickel-cobalt, or nickel-cobalt can be used favorably as the heat-resistant layer, and a film that has undergone a zinc-chromate or a chromate treatment can be used favorably as the anticorrosive layer.

Owner:JX NIPPON MINING& METALS CORP

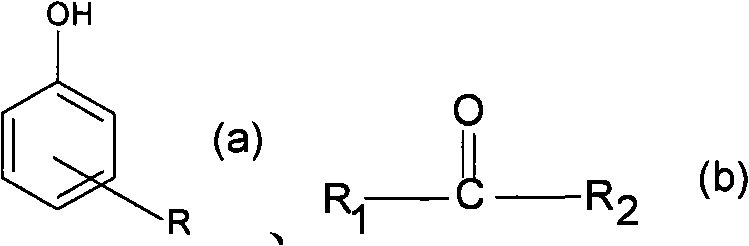

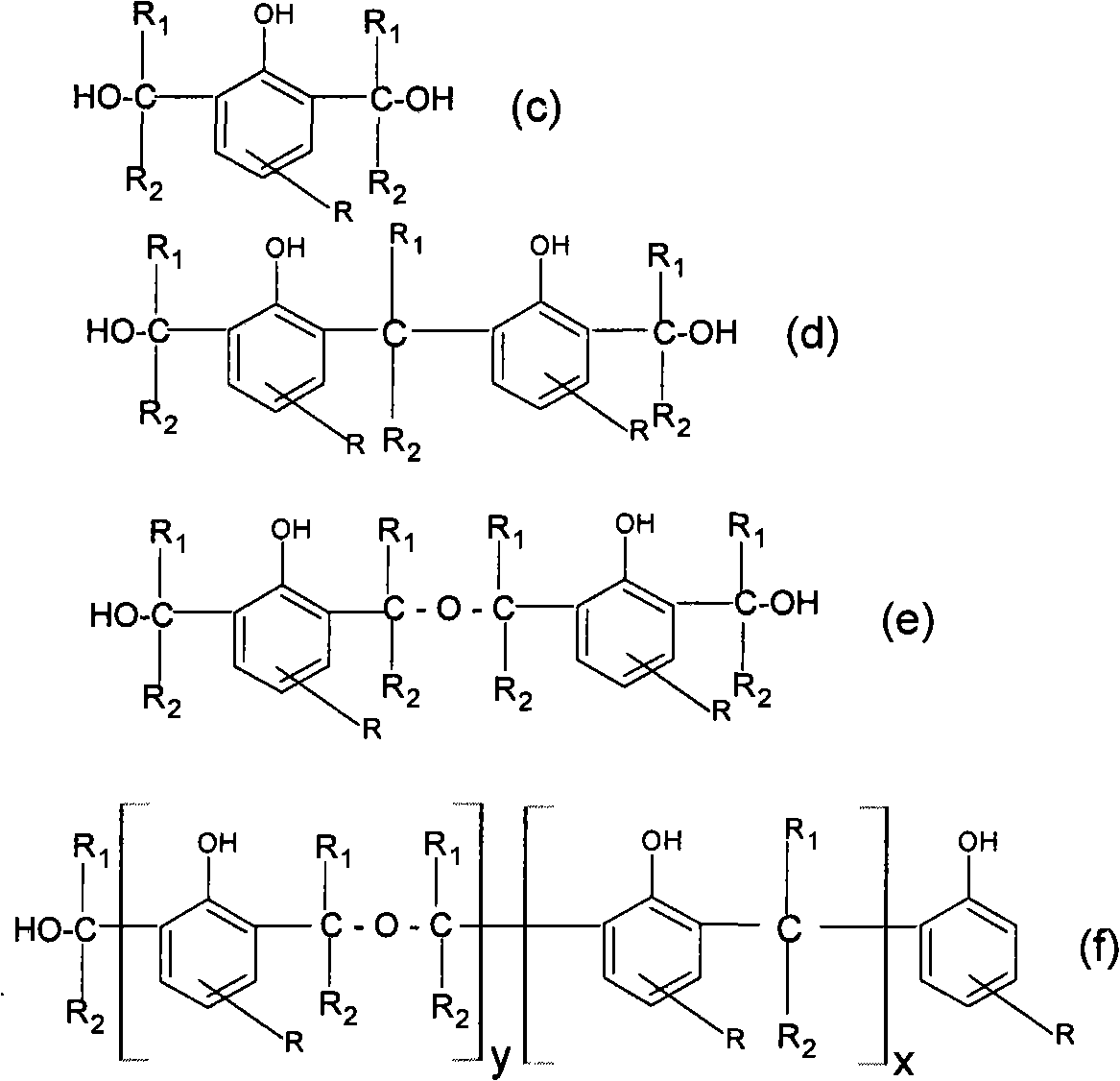

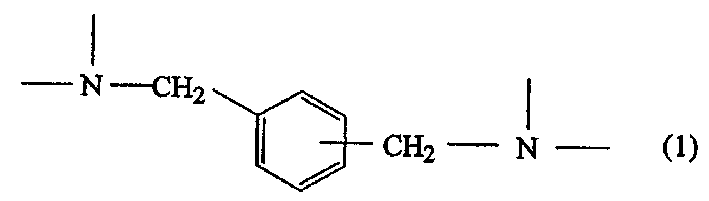

Polyurethane resin, adhesive, film and paint containing said resin for lamination

InactiveCN1473861AGood adhesionExcellent gas barrier propertiesPolyurea/polyurethane coatingsAdhesiveHigh adhesion

The polyurethane resin produced by reacting a component composed mainly of an active hydrogen-containing compound with a component composed mainly of an organic polyisocyanate compound which contains a backbone structure represented by the formula: in an amount of 20% by weight or higher, exhibits a high gas-barrier property and a high adhesion property. Accordingly, the present invention provides: (A) a two-part liquid curable polyurethane resin composition having an excellent adhesion property to various polymers, papers, metals, etc., especially after boiling and retort treatments, and an adhesive for gas-barrier laminate containing such a composition; (B) a heat-curing gas-barrier polyurethane resin useful as a packaging material for foodstuffs or drugs for the purpose of preserving contents thereof by preventing various gases from penetrating therethrough, which is capable of maintaining its high gas-barrier property; and (C) a paint having excellent properties such as rust-proofing property, corrosion resistance and aesthetic decorating property that are inherent to polyurethane resin, and being applicable to packaging materials for foodstuffs or drugs that are required to show a high gas-barrier property by shielding various gases.

Owner:MITSUBISHI GAS CHEM CO INC

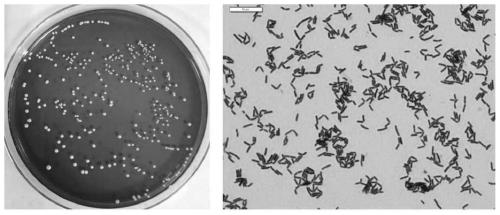

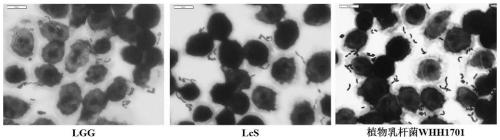

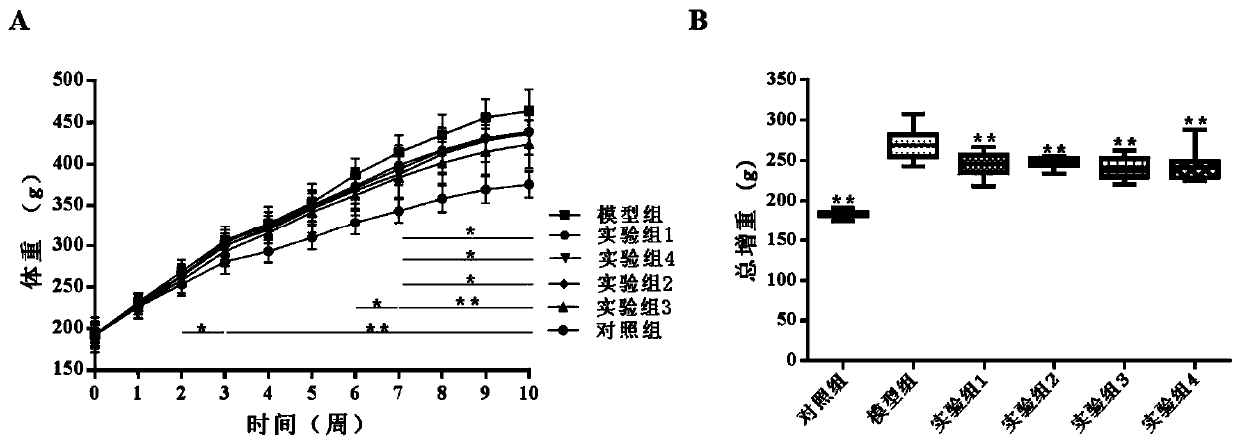

Lactobacillus plantarum with weight reducing function and application thereof

The invention relates to the field of microorganisms and discloses lactobacillus plantarum with a weight reducing function and application thereof. The lactobacillus plantarum 1701 strain is separatedfrom a yogurt powder sample collected from rural areas of Shigatse in the Tibet Autonomous Region. The strain is preserved in the China General Microbiological Culture Collection Center on October 23, 2019, and the microorganism has the preservation number of CGMCC NO.18728. The lactobacillus plantarum 1701 has excellent tolerance and adhesion, can remarkably reduce the weight of a rat, reduce fat accumulation in a body, reduce the viscera ratio and body fat ratio, reduce the leptin level and reduce blood lipid and can be used in medicines, health-protecting products and health foods for preventing and treating obesity. Furthermore, the strain still has a weight reducing function after inactivation, thus having rich product mode, wide application range, high product stability and long preservation period.

Owner:HANGZHOU WAHAHA TECH +1

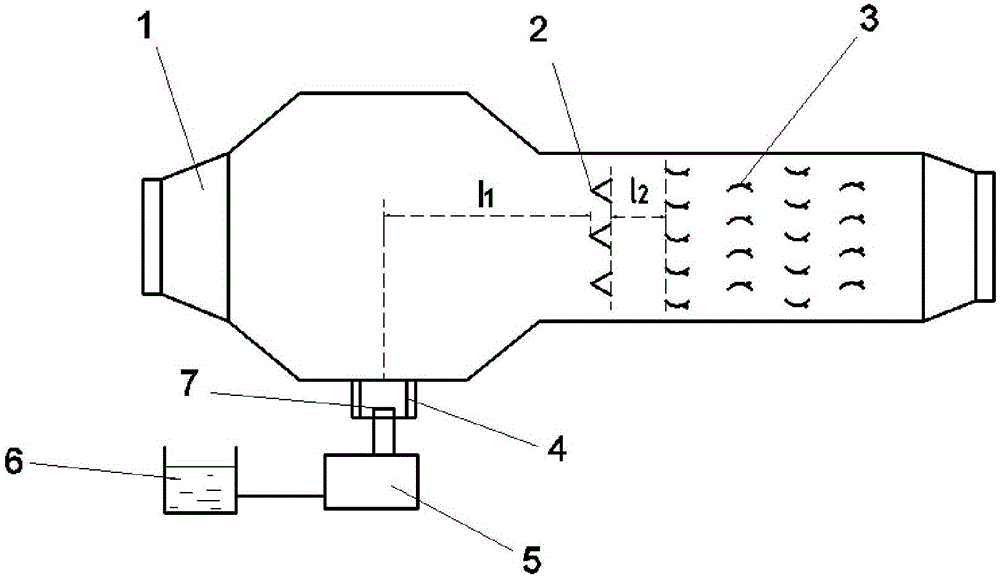

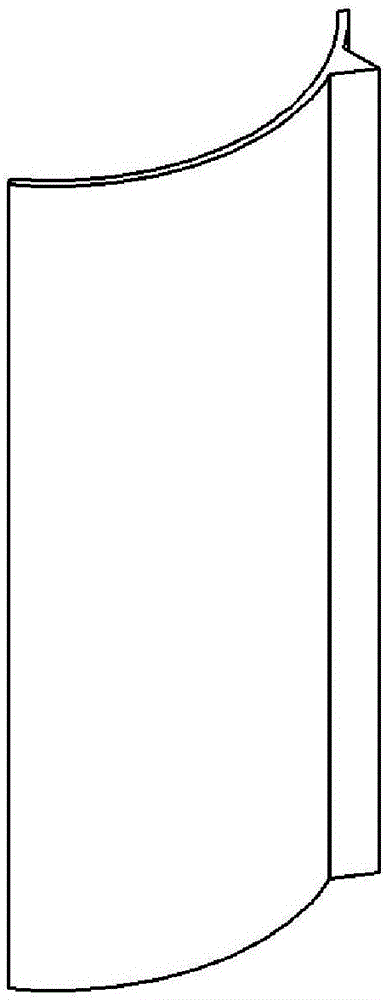

System and method for agglomerating particulate matters through ultrasonic atomization of charged turbulence

ActiveCN106823652AIncrease the chance of sticking to each otherIncreased chance of collisionCombination devicesExhaust gasEngineering

The invention relates to a system and method for agglomerating particulate matters through ultrasonic atomization of charged turbulence. The system comprises a runner main body, an entrance section, an atomization charging device, a premixing section and a turbulence disturbance section, wherein the entrance section, the atomization charging device, the premixing section and the turbulence disturbance section are sequentially arranged on the runner main body; the atomization charging device is used for spraying charged ultrasonically-atomized drops into the runner main body; a plurality of V-shaped mixing blades are distributed in the premixing section, openings of the V-shaped mixing blades back to an incoming flow direction, and two ends of the V-shaped mixing blades are fixedly arranged on the inner wall of the runner main body; the turbulence disturbance section comprises a plurality of turbulence disturbance components; the turbulence disturbance components include round arc plate surfaces and protruded bluff bodies; the protruded bluff bodies are arranged on arched side surfaces of the round arc plate surfaces; the turbulence disturbance components are distributed in the runner main body by taking the flow direction of exhaust gas as a row and the flow direction of vertical exhaust gas as a column; and the turbulence disturbance components in the same row are distributed along the same direction, and the turbulence disturbance components in the adjacent rows are distributed along the opposite direction.

Owner:XI AN JIAOTONG UNIV

Polyurethane laminates made with a double belt press

InactiveUS20130115412A1Excellent Adhesive PropertiesFine surfaceSynthetic resin layered productsPaper/cardboard layered productsComposite laminatesResin matrix

A fiber reinforced composite laminate with fibers generally oriented along two major axes and having a polyurethane resin matrix suitable for reinforcing wood based substrates such as trailer / container flooring, glulams, plywood, particle boards, laminated veneer lumber, and oriented strand board, is provided. The laminate is produced by pulling the fibers through a resin injection box, where a polyurethane resin is injected into the box to wet the fibers. The polyurethane resin wetted fiber layer is then covered with a release media on the top and bottom sides of the layer. The sandwich of fiber, resin and release media is fed to a double belt press capable of applying pressure and heat to consolidate and cure the laminate. The laminate thus made can be thinner than 0.080 inch and provides excellent flatness compared to pultruded thin laminates.

Owner:HAVCO WOOD PRODS

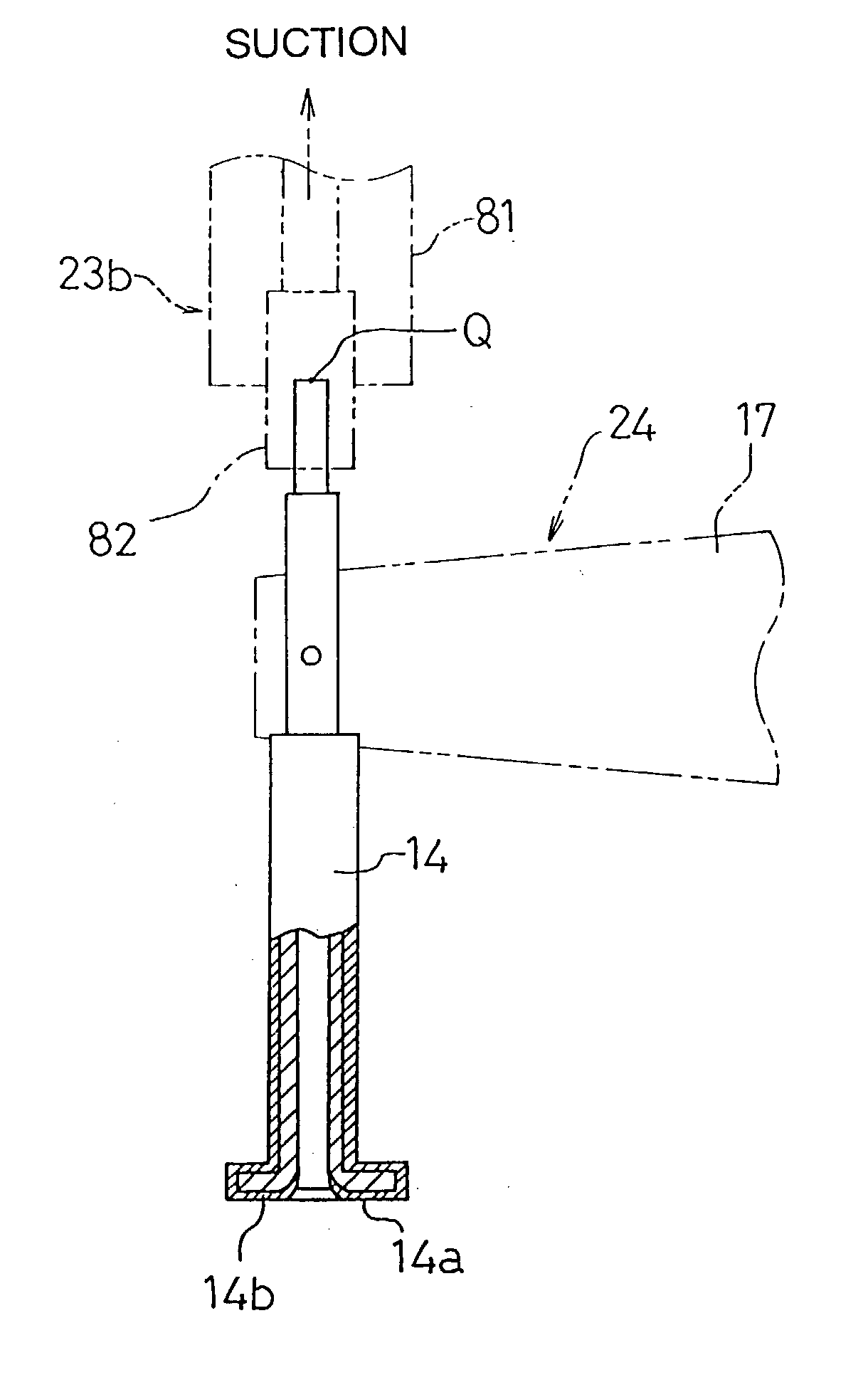

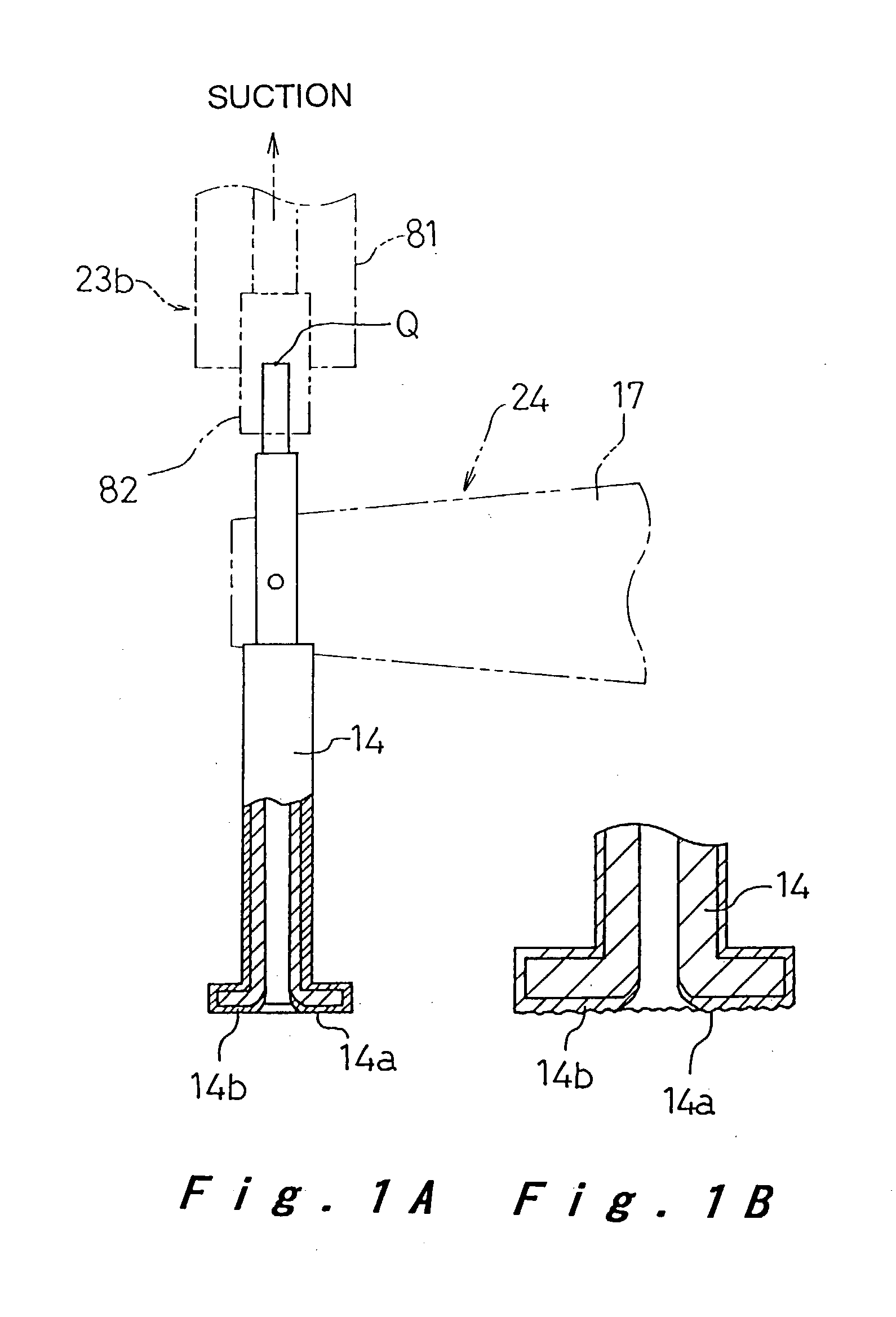

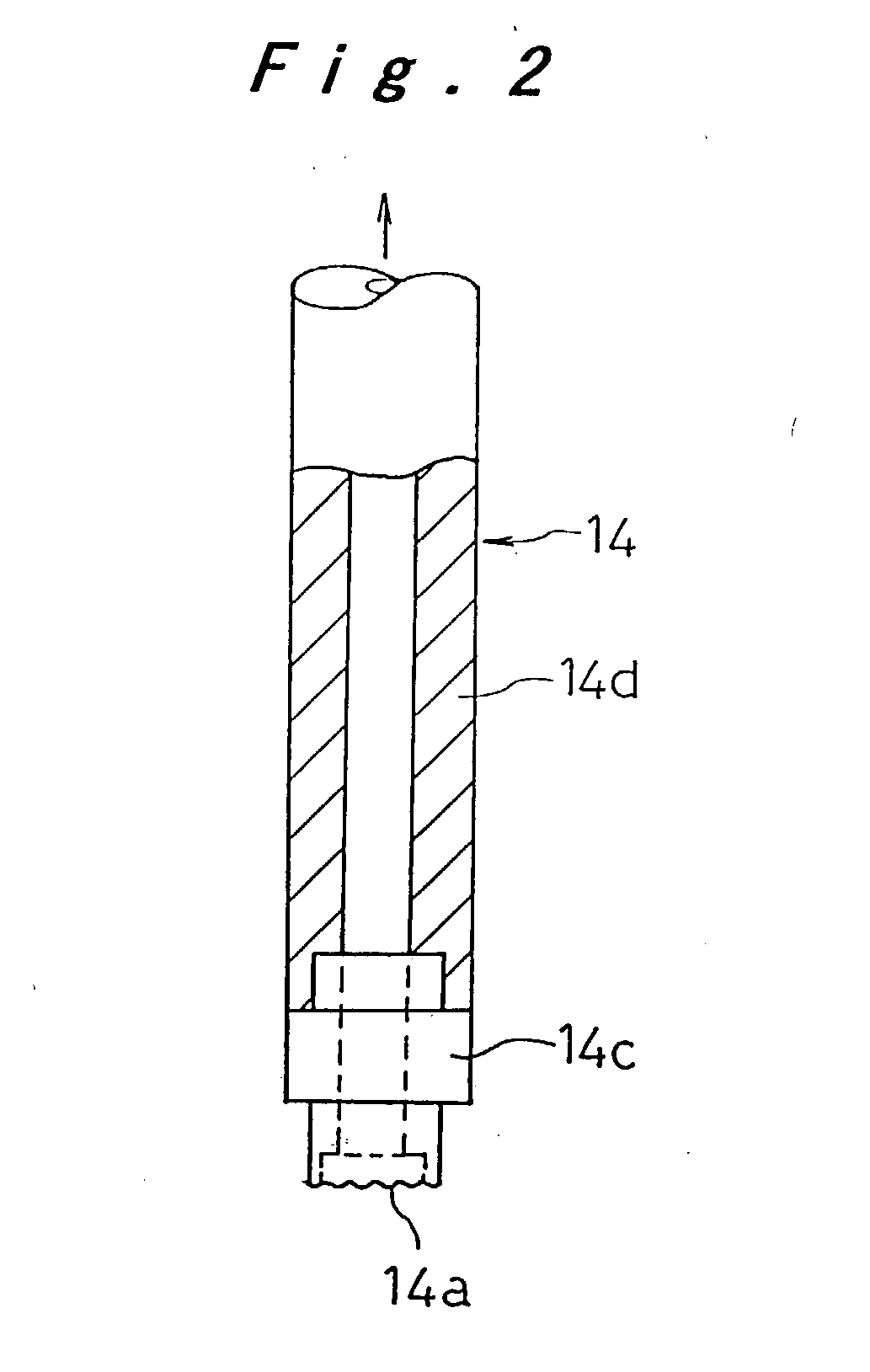

Component mounting tool, and method and apparatus for mounting component using this tool

InactiveUS20030150108A1Deterioration of surface regularity and flatnessExcellent Adhesive PropertiesWelding/cutting auxillary devicesSolid-state devicesMetal interconnectUltrasonic vibration

Component 3 is pressed onto a circuit board 4 so that their respective metal interconnects 5, 6 are in close contact with each other, and ultrasonic vibration is applied to the suction nozzle 14 holding the component 3. Friction is thereby generated between metal interconnects 5, 6 whereby the component 3 is bonded on circuit substrate. Suction nozzle 14 for handling components is made of stainless steel and has a working face 14a provided with a hardened layer 14b, or alternatively, suction nozzle 14 may have a suction head 14c having a working face 14a made of cemented carbide. Working face 14a of suction nozzle 14 is refined by polishing as required during the mounting operation.

Owner:PANASONIC CORP

Metal film and metal film-coated member, metal oxide film and metal oxide film-coated member, thin film forming apparatus and thin film forming method for producing metal film and metal oxide film

ActiveUS7033679B2Reduce surface roughnessGood crystal orientationVacuum evaporation coatingGas discharge lampsPhysical chemistryCrystal orientation

The metal film of the present invention is a dense film of a single crystal that has very low surface roughness and very good crystal orientation because an arithmetic mean roughness of the surface is not larger than 2 nm and a (111) peak intensity of X-ray diffraction is not less than 20 times the sum of all other peaks. Also the metal oxide film of the present invention is a dense film that includes less oxygen defects and almost no voids therein because a content of a non-oxidized metal is not higher than 1 mole % of a metal component that constitutes the metal oxide and a packing density is 0.98 or higher.

Owner:KYOCERA OPTEC

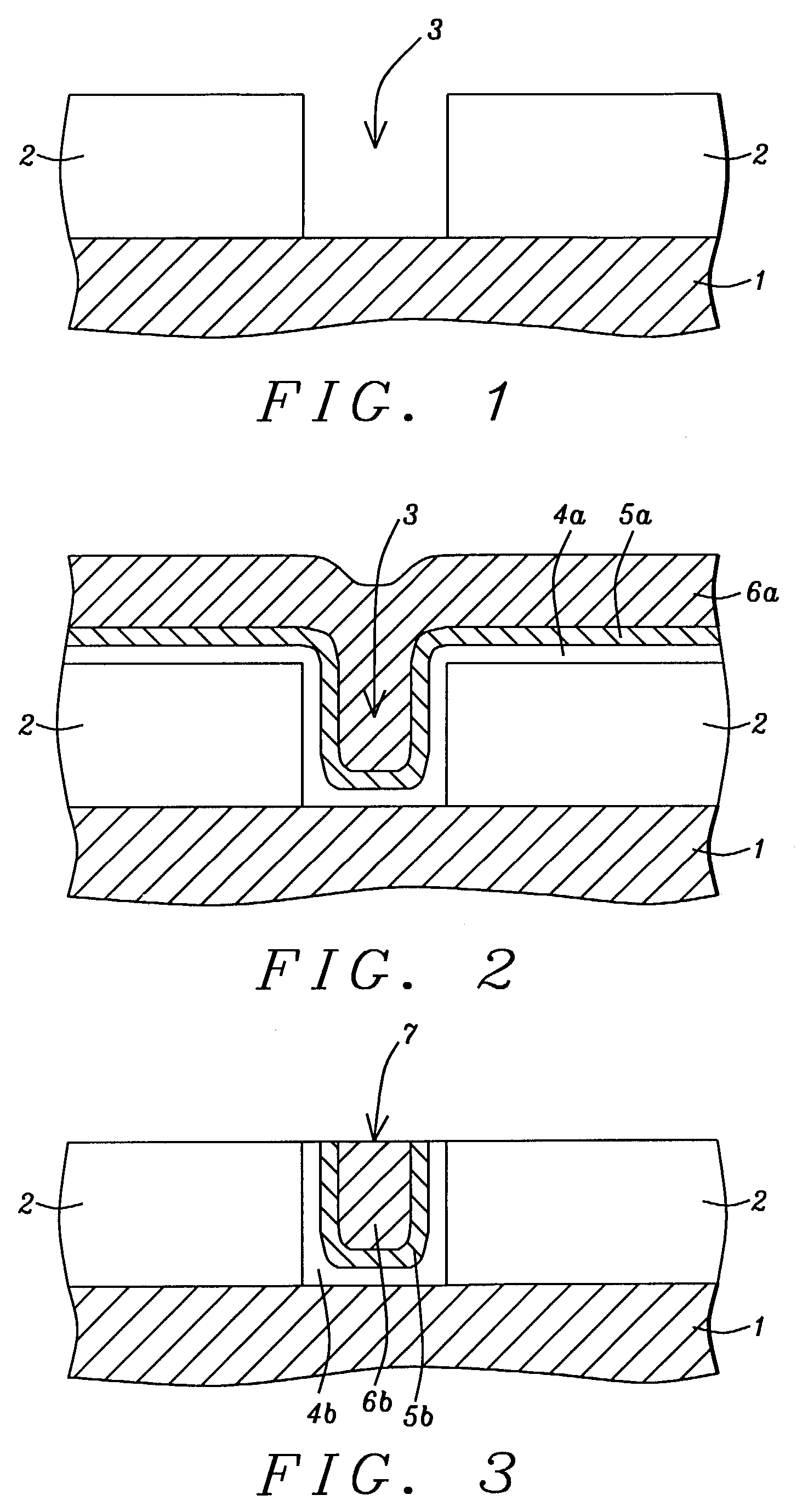

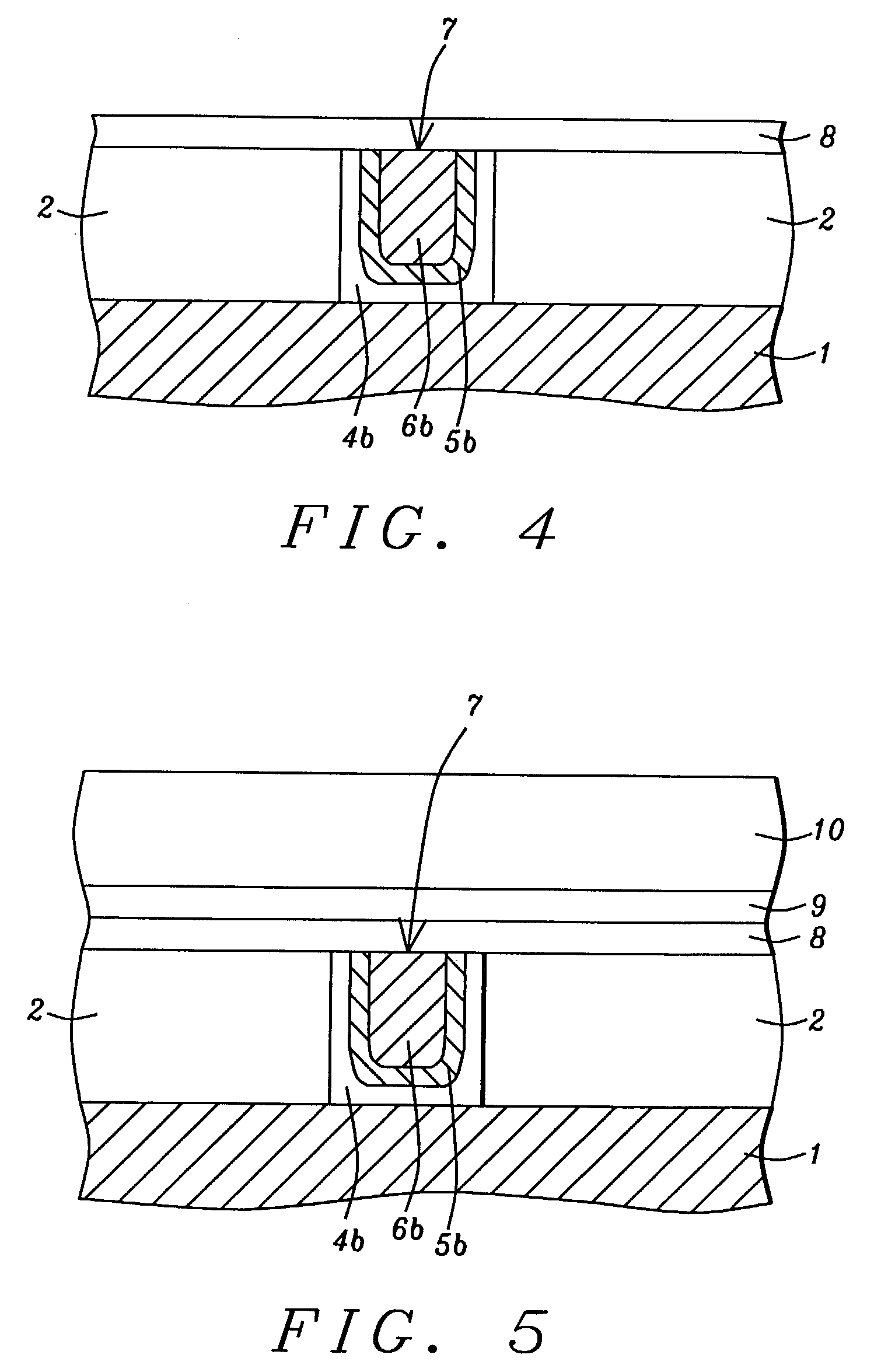

Method for manufacturing a sensor component and sensor component

InactiveUS20100219487A1High stress reversal strengthHigh strengthFluid pressure measurement by electric/magnetic elementsSolid-state devicesMetallurgyMetal particle

A method for manufacturing a sensor component and a sensor component. The sensor component has a semiconductor substrate and a metal substrate. The semiconductor substrate and the metal substrate are bonded together with the aid of a low-temperature process. A bonding material containing metal particles is applied in a first step to the semiconductor substrate and / or the metal substrate and a sintering process is used in a second step for producing the bond between the semiconductor substrate and the metal substrate.

Owner:ROBERT BOSCH GMBH

Textile-elastomer composite preferable for transfer or film coating and method of making said composite

InactiveUS6475562B1Easy to produceControl more effectively the amount of coating appliedSynthetic resin layered productsPretreated surfacesProduct gasFilm coating

The present invention relates to a process-for producing a fabric-elastomer composite that, when transfer or film coated, is preferable for use as an artificial leather substrate. The inventive procedure involves (a) producing an elastomer composition of at least four ingredients (an anionically-stabilized waterborne polymer dispersion, an acid-generating chemical, a cloud-point surfactant, and a foam-stabilizing surfactant); (b) incorporating sufficient gas into the liquid mixture to generate a spreadable foam; (c) applying the foam onto a porous textile substrate; (d) heating said foamed fabric until the elastomer coagulates over the fabric substrate; and (e) drying the resultant composite without destroying the coagulated structure. The resultant composite obtains a suppleness that is similar to that of leather and a surface that is suitable for transfer coating to produce artificial leather. The composite may be utilized as upholstery fabric in furniture or in automobiles, apparel, and the like. The particular composites produced are also contemplated within this invention.

Owner:SAGE AUTOMOTIVE INTERIORS INC

Atomic layer deposition tantalum nitride layer to improve adhesion between a copper structure and overlying materials

ActiveUS7202162B2Improve adhesionExcellent Adhesive PropertiesSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectTantalum nitride

A process for improving the adhesion between an underlying copper structure, and overlying materials and structures, has been developed. The process features formation of a tantalum nitride layer on a copper structure, wherein the copper structure is located in a damascene type opening. To obtain the maximum adhesion benefit the tantalum nitride layer is formed via an atomic deposition layer procedure, performed at specific deposition conditions. The adhesion between the underlying copper structure and overlying materials such as a silicon nitride etch stop layer, as well the adhesion between the lower level copper structure and overlying upper level metal interconnect structures, is improved as a result of the presence of the atomic layer deposited tantalum nitride layer.

Owner:TAIWAN SEMICON MFG CO LTD

Superconducting wire material and method for preparation thereof, and superconducting magnet using the same

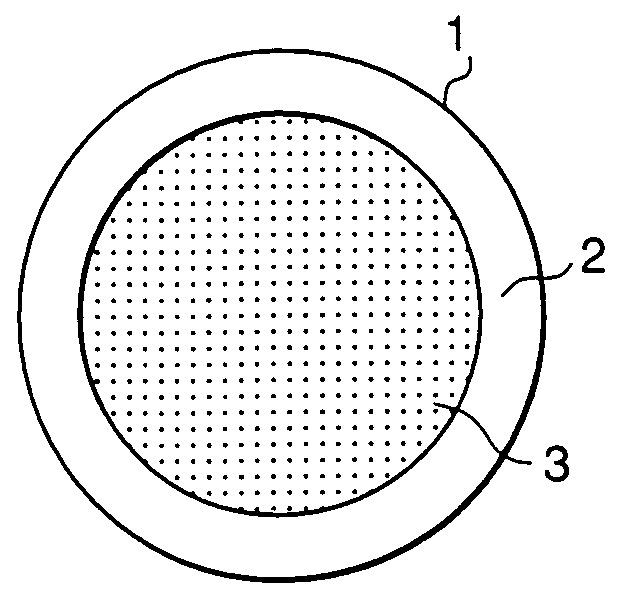

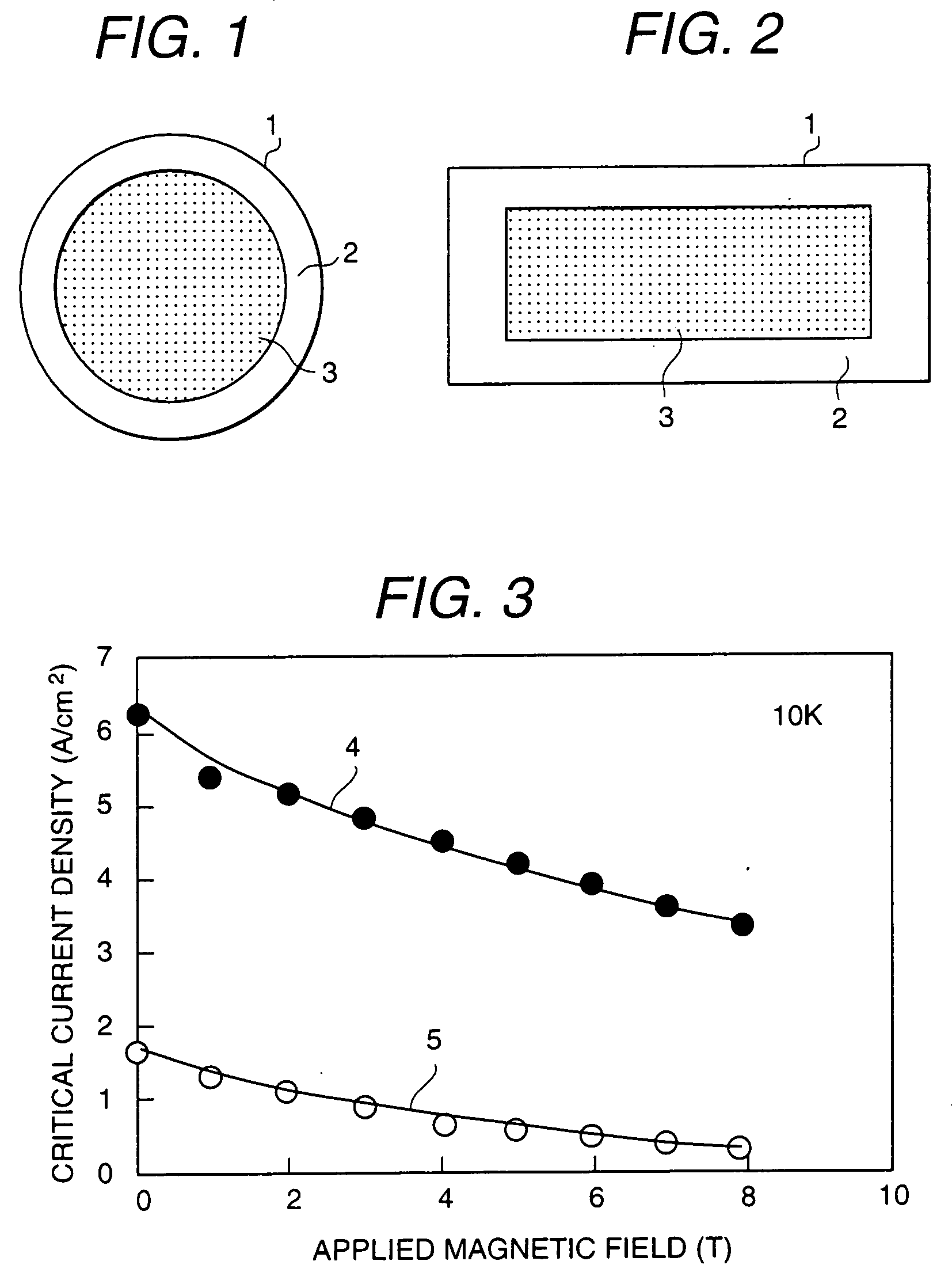

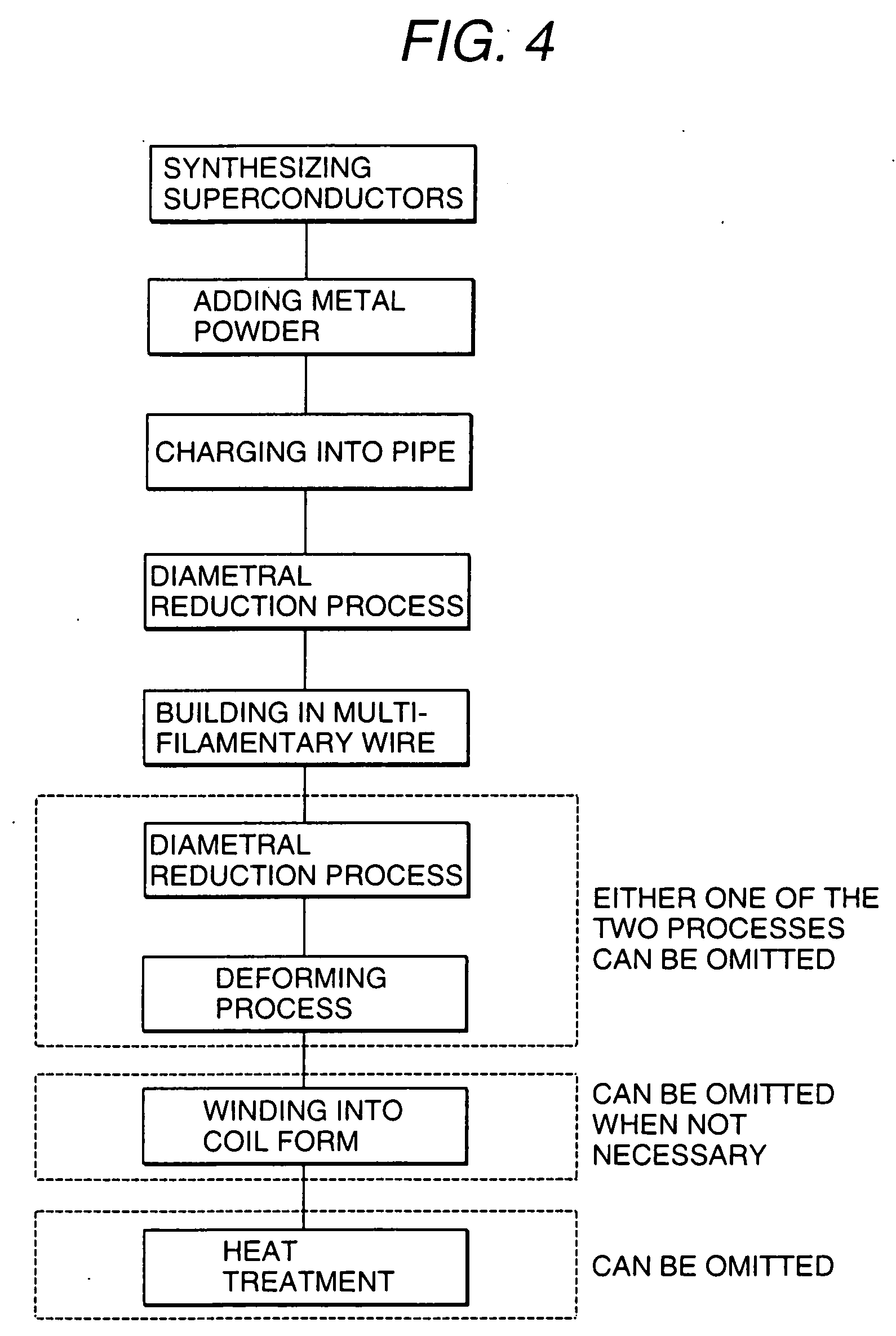

InactiveUS20050174202A1Improve performanceExcellent Adhesive PropertiesCircuit-breaking switches for excess currentsSuperconductors/hyperconductorsElectrical conductorNiobium

An object of the present invention is to provide: a superconducting wire with a boron-containing superconductor charged or included therein, the superconducting wire further being able to have a practical critical current density; a method for manufacturing the superconducting wire, and; a superconducting magnet using the superconducting wire. The present invention is characterized in that: in a superconducting wire which has a boron-containing superconductor charged or included therein, a metal-sheathing material made of either a single metal selected from a group consisting of gold, silver, aluminum, copper, iron, platinum, palladium, nickel, stainless steel, chromium, magnesium, tantalum, niobium, titanium, tin, beryllium, tungsten, and cobalt, or an alloy consisting of a plurality of metals selected from this group, is disposed on the outer surface of the foregoing superconducting wire, the density of the superconducting wire after it has been finally processed is 80% or more of its theoretical density, and the critical temperature of the superconducting wire is 30K or more.

Owner:HITACHI LTD

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran, rye bran; oat bran, rice bran, soy bran, canola bran and wheat bran. The method may include the step of mixing the feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides.

Owner:EVERGREEN BIOFUELS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com