Medical scaffold with inner coating film, and preparation method for medical scaffold

An inner coating and medical technology, applied in the field of medical devices, to achieve the effect of promoting rapid endothelialization, improving biocompatibility, and inhibiting the formation of embolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation of the medical stent covered with a film is as follows:

[0027] a Preparation of electrospinning solution

[0028] The silk fibroin powder and medical polyurethane are formulated into an electrostatic spinning solution, the medical polyurethane is dissolved in a solvent, and the solution is stirred at room temperature for 5-8 hours to obtain a uniform medical polyurethane solution. The silk fibroin powder with a particle size of 50nm-500nm Mix into the same solvent, ultrasonically disperse for 10 minutes to 30 minutes, so that the silk fibroin powder is fully dispersed in the solvent, then mix the medical polyurethane solution with the silk fibroin powder dispersion, and mechanically stir for 3 hours to 6 hours to obtain medical Polyurethane concentration percentage is 2wt%-12wt%, silk fibroin powder concentration percentage is 1wt%-8wt% uniform and stable dispersion composite electrospinning solution, solvent is 1,4-dioxane; dimethyl sulfoxide; tetrahydrofu...

Embodiment 1

[0044] a Preparation of electrospinning solution

[0045] Weigh medical polyether polyurethane and add it to N,N-dimethylformamide, stir at 15℃ for 5 hours at room temperature to obtain a uniform medical polyether polyurethane solution, and mix 50nm mulberry silk fibroin powder into the same Disperse the mulberry silk fibroin powder in the solvent by ultrasonic for 10 minutes in the solvent, then mix the medical polyether polyurethane solution with the mulberry silk fibroin powder dispersion and stir mechanically for 3 hours to obtain the medical polyether type The polyurethane concentration percentage is 2wt%, and the mulberry silk fibroin powder concentration percentage is 1wt% uniform and stable dispersion composite electrostatic spinning solution.

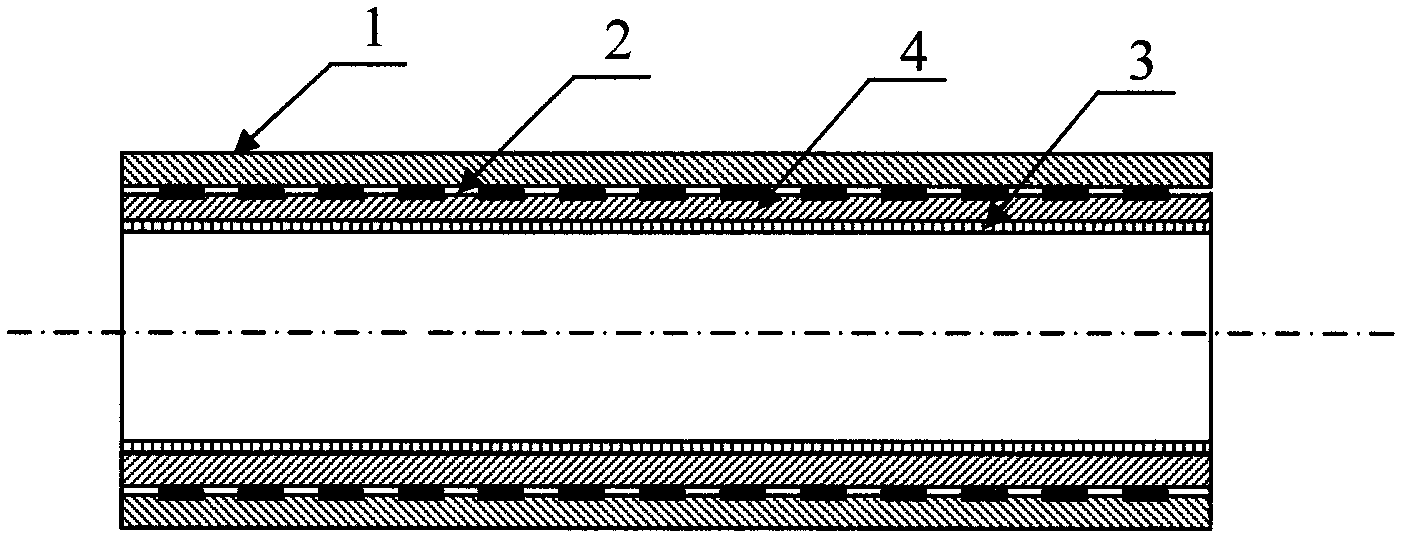

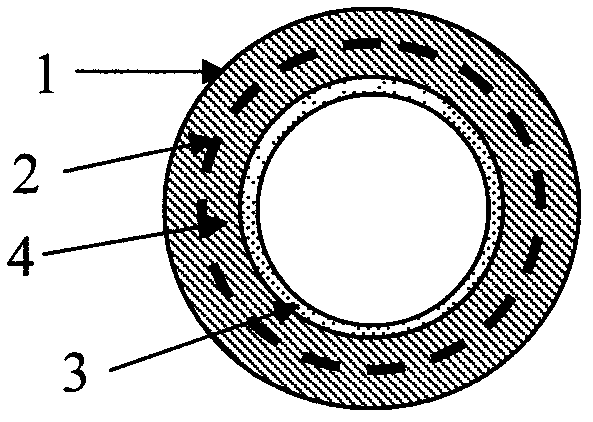

[0046] b Preparation of electrospun nonwoven inner film 3

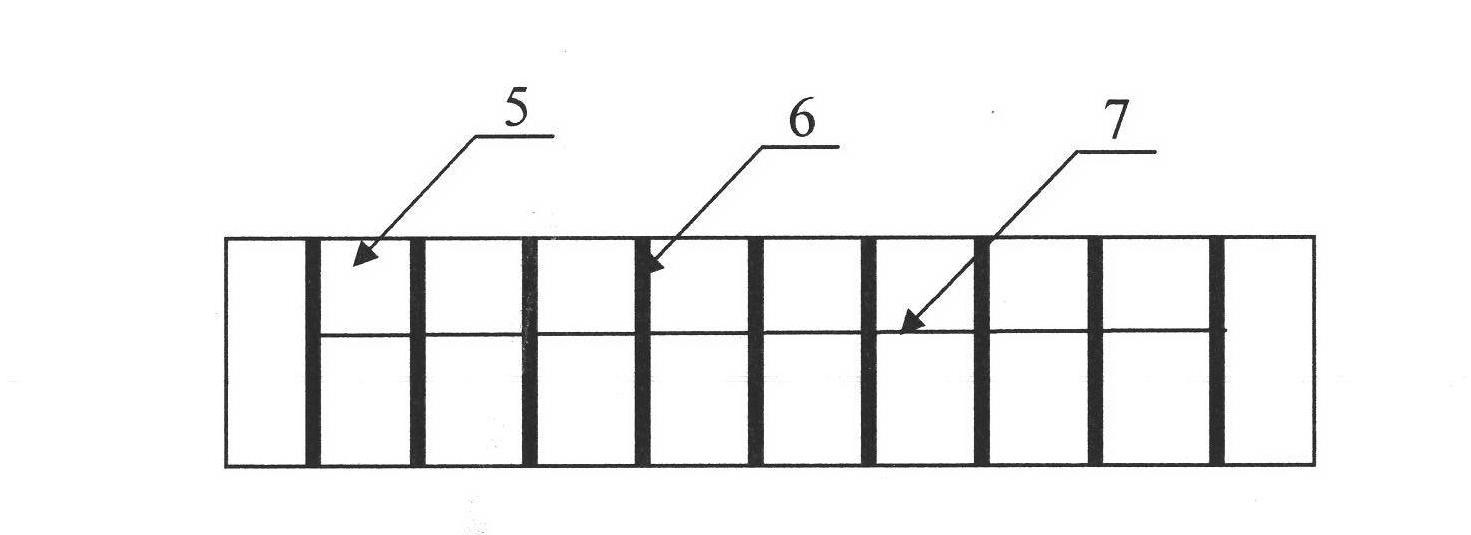

[0047] The electrospinning liquid obtained in step a is sucked into the electrospinning liquid pipe, and the mold rod with the inner diameter of the mesh support 2 and the s...

Embodiment 2

[0054] a Preparation of electrospinning solution

[0055] Weigh the medical polyester polyurethane into tetrahydrofuran, stir at room temperature 20℃ for 5 hours to obtain a uniform medical polyester polyurethane solution, mix 250nm mulberry silk fibroin powder into the same solvent, and ultrasonically disperse for 20 minutes , The mulberry silk fibroin powder is fully dispersed in the solvent, and then the medical polyester polyurethane solution is mixed with the mulberry silk fibroin powder dispersion, and mechanically stirred for 4.5 hours to obtain a medical polyester polyurethane concentration percentage of 7wt%. A uniform and stable dispersion composite electrospinning solution with a silk fibroin powder concentration percentage of 4wt%.

[0056] b Preparation of electrospun nonwoven inner film 3

[0057] The electrospinning liquid obtained in step a is sucked into the electrospinning liquid pipe, and the mold rod with the inner diameter of the mesh support 2 and the smooth su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com