Patents

Literature

214 results about "Magma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magma (from Ancient Greek μάγμα (mágma) meaning "thick unguent") is the molten or semi-molten natural material from which all igneous rocks are formed. Magma is found beneath the surface of the Earth, and evidence of magmatism has also been discovered on other terrestrial planets and some natural satellites. Besides molten rock, magma may also contain suspended crystals and gas bubbles. Magma is produced by melting of the mantle and/or the crust at various tectonic settings, including subduction zones, continental rift zones, mid-ocean ridges and hotspots. Mantle and crustal melts migrate upwards through the crust where they are thought to be stored in magma chambers or trans-crustal crystal-rich mush zones. During their storage in the crust, magma compositions may be modified by fractional crystallization, contamination with crustal melts, magma mixing, and degassing. Following their ascent through the crust, magmas may feed a volcano or solidify underground to form an intrusion (e.g., an igneous dike or a sill). While the study of magma has historically relied on observing magma in the form of lava flows, magma has been encountered in situ three times during geothermal drilling projects—twice in Iceland (see Magma usage for energy production), and once in Hawaii.

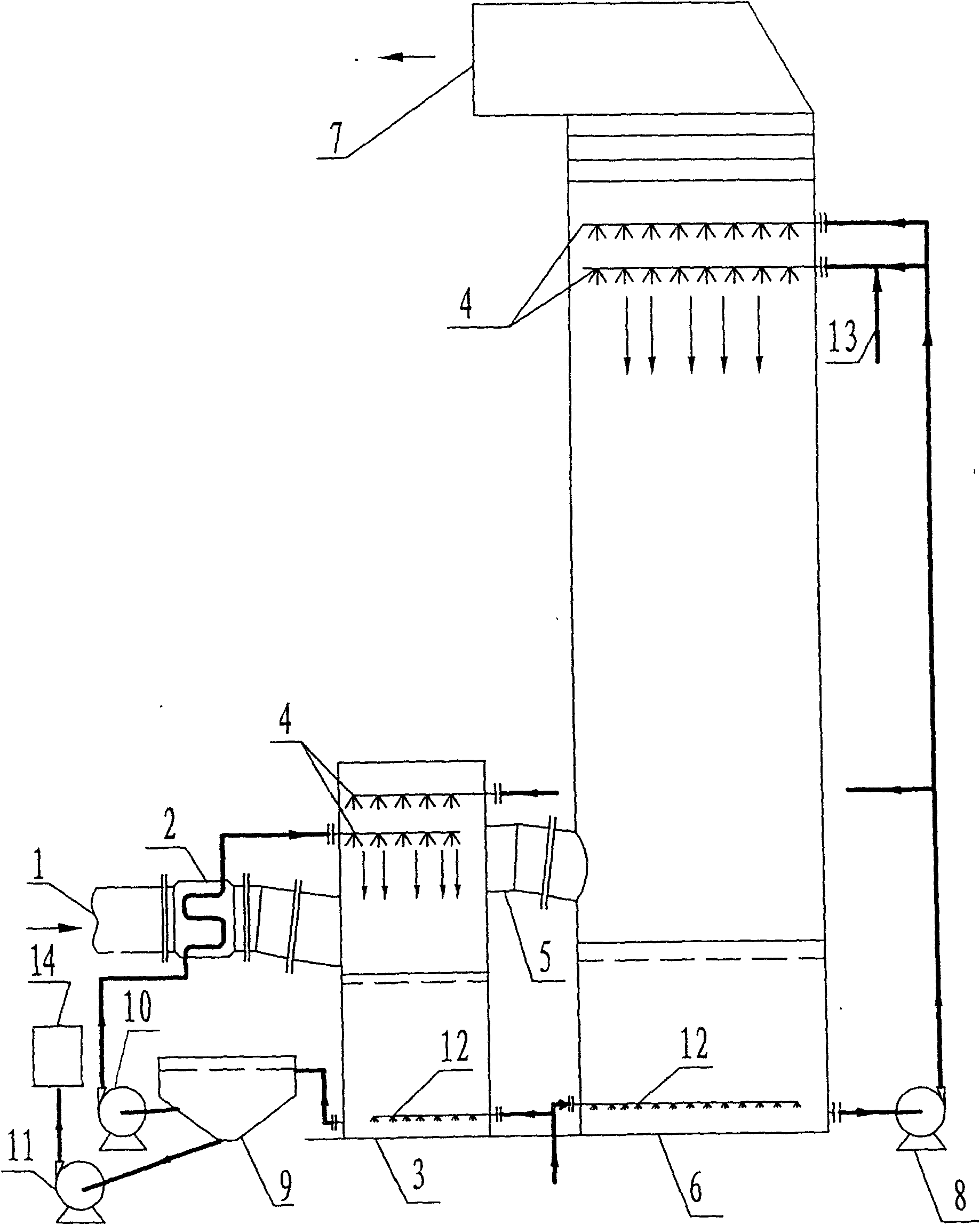

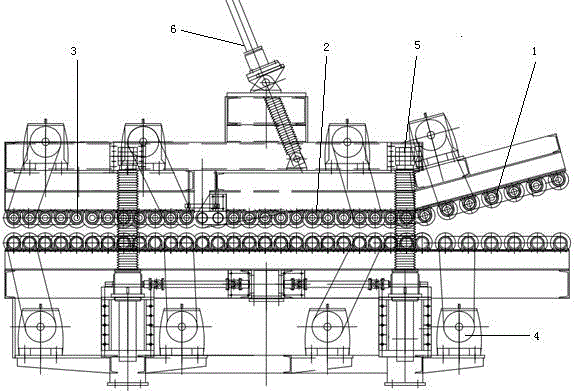

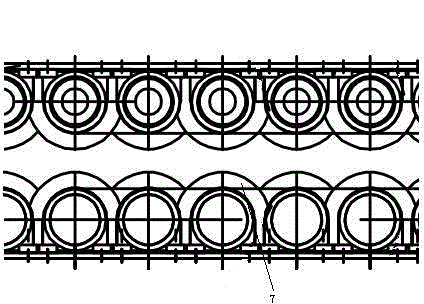

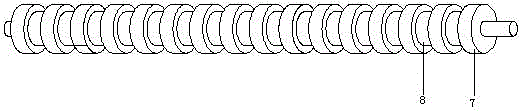

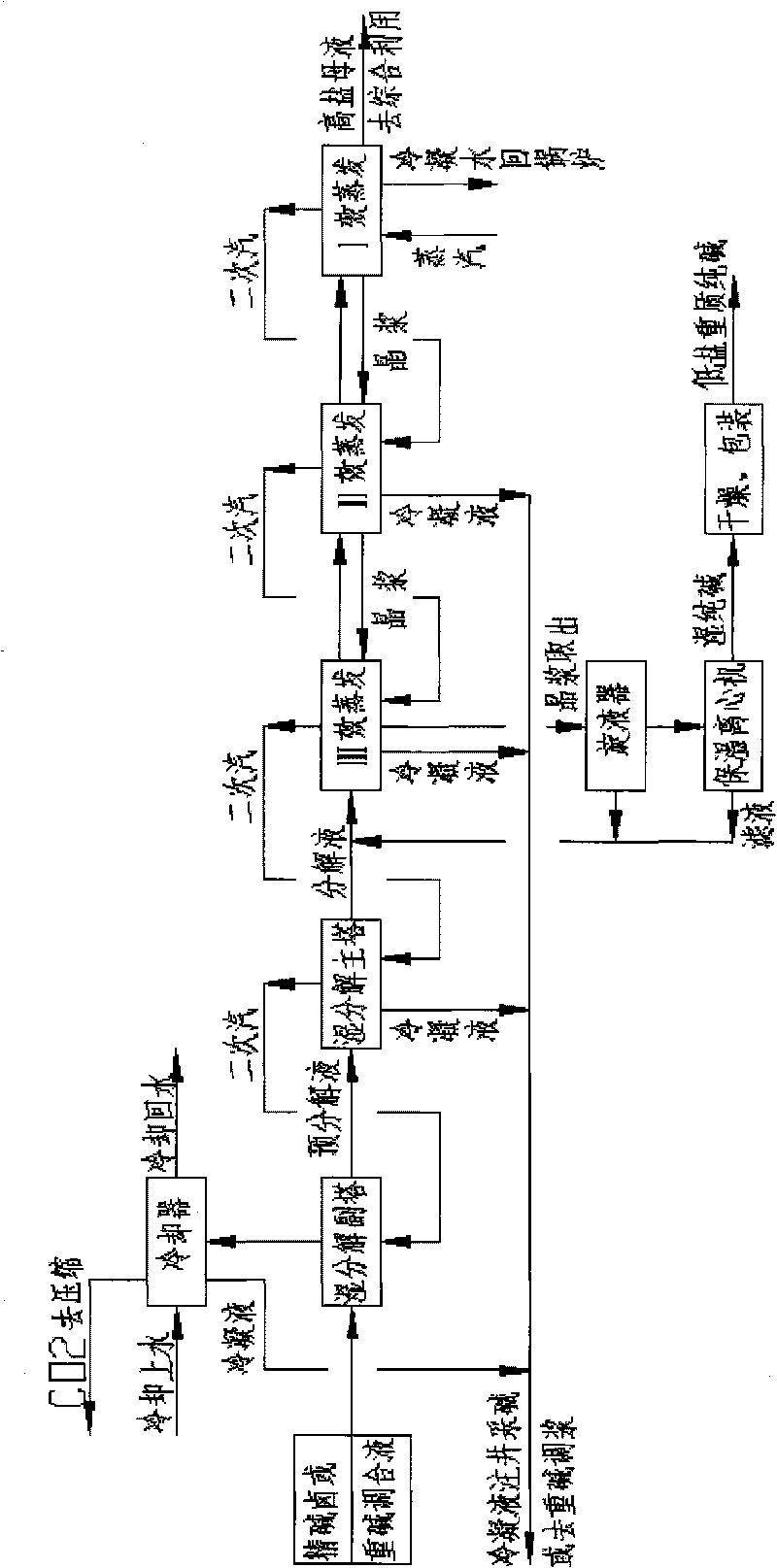

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

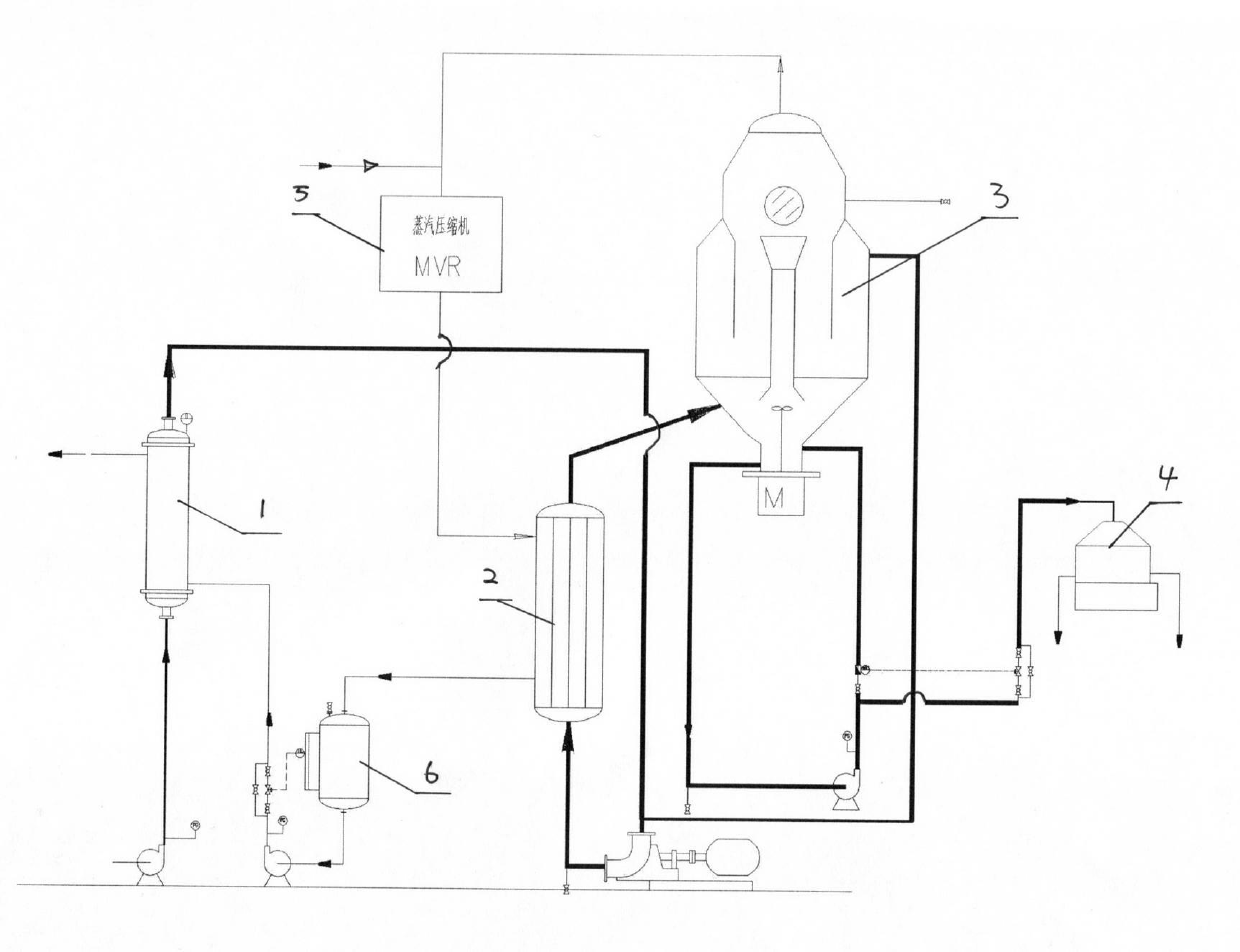

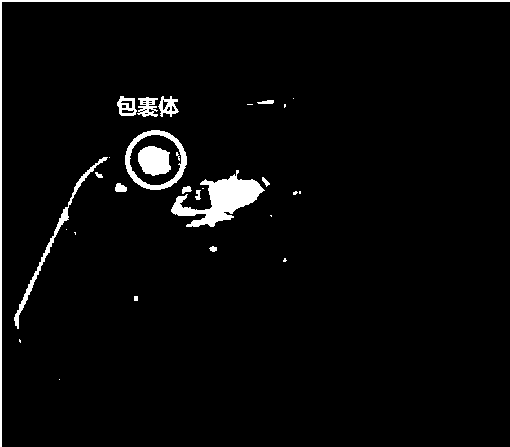

ActiveCN101670231ASolve the strength problemSolve highDispersed particle separationSolution crystallizationMagmaDistributor

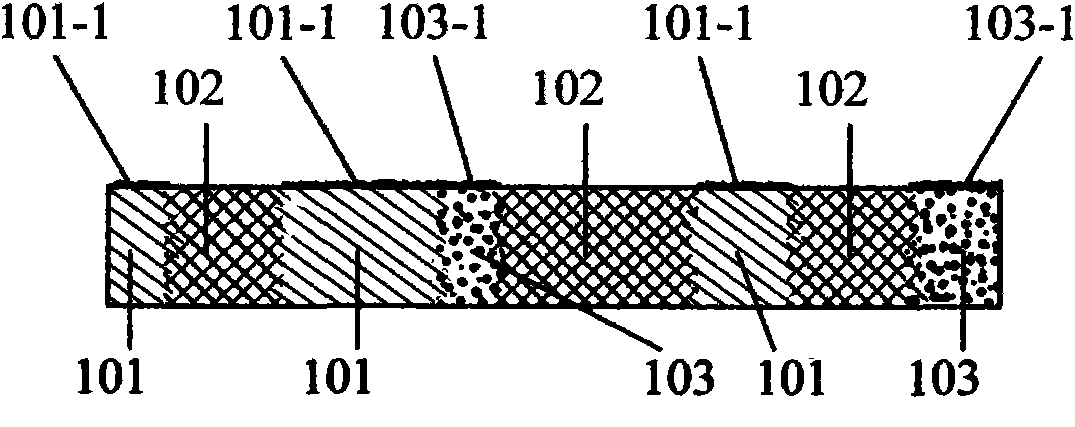

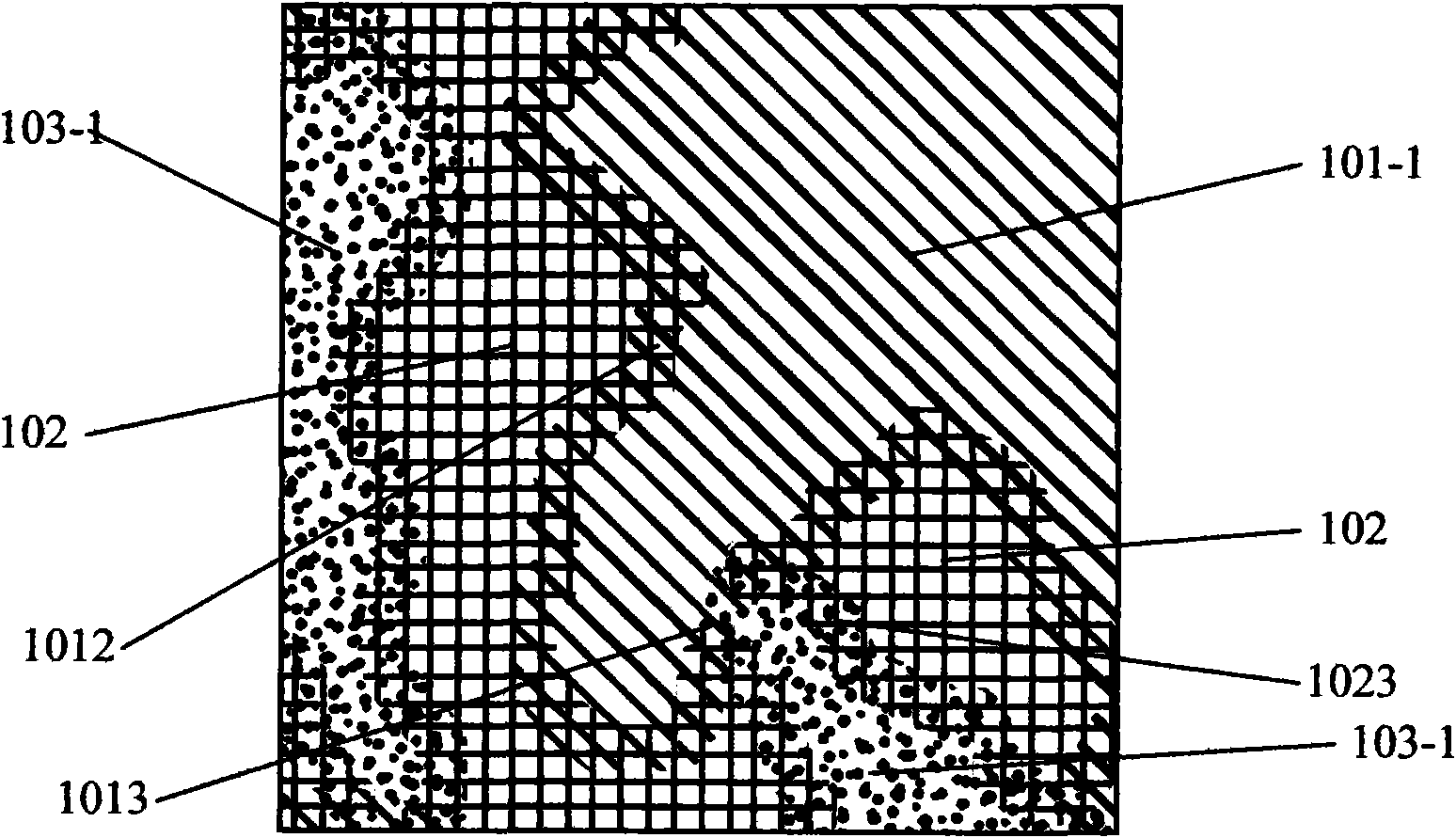

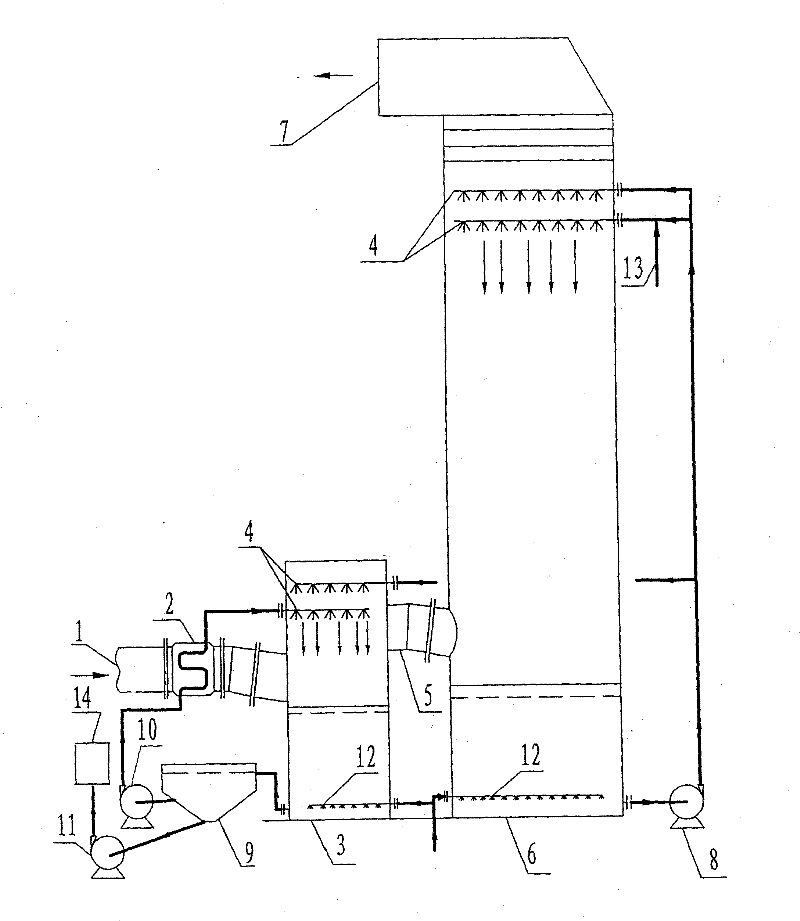

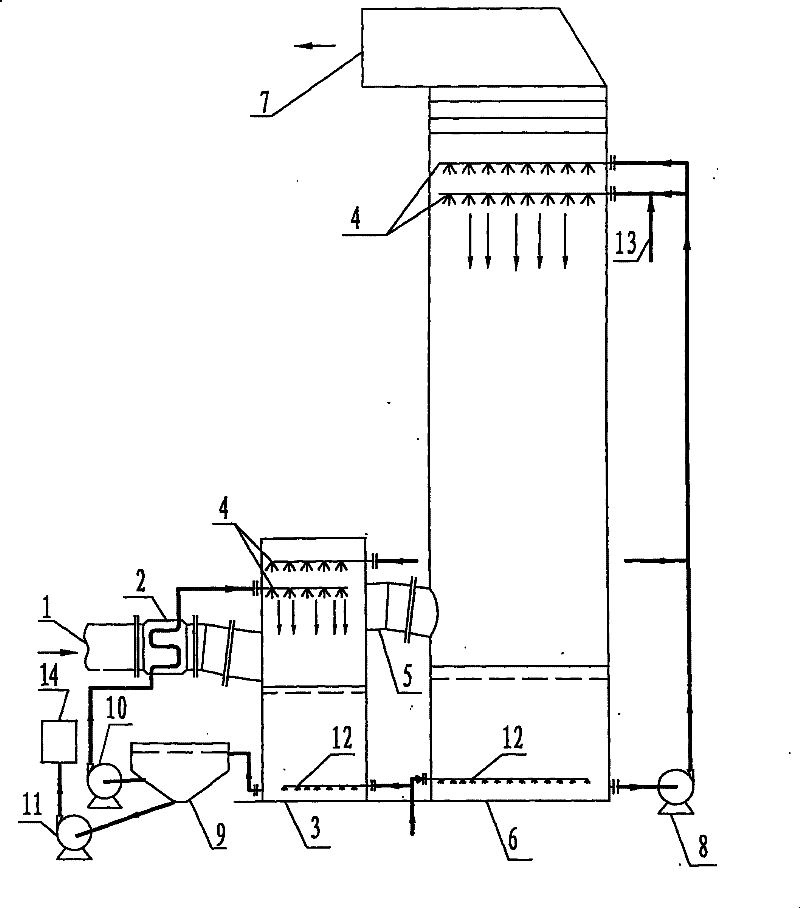

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, andthe upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

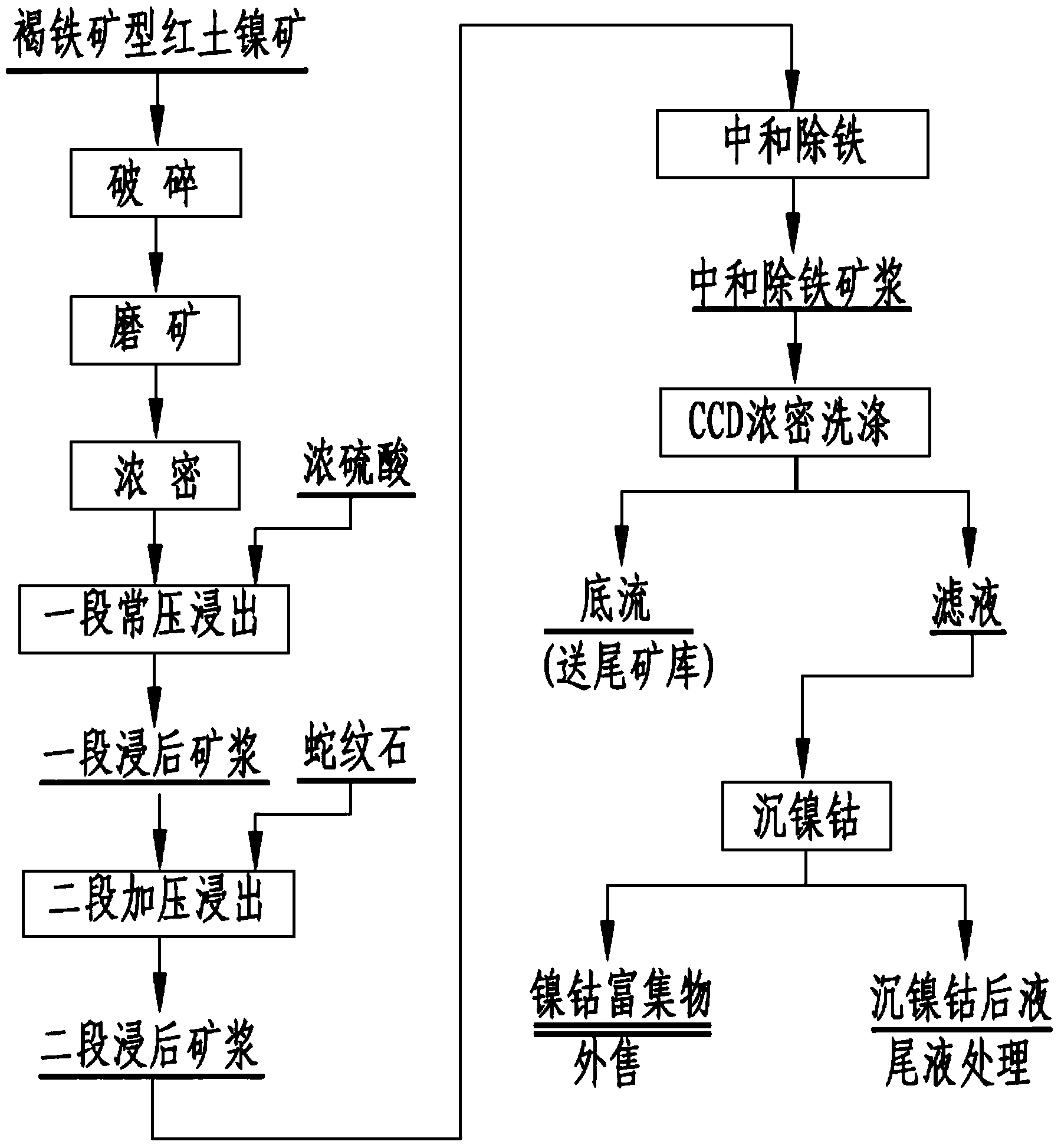

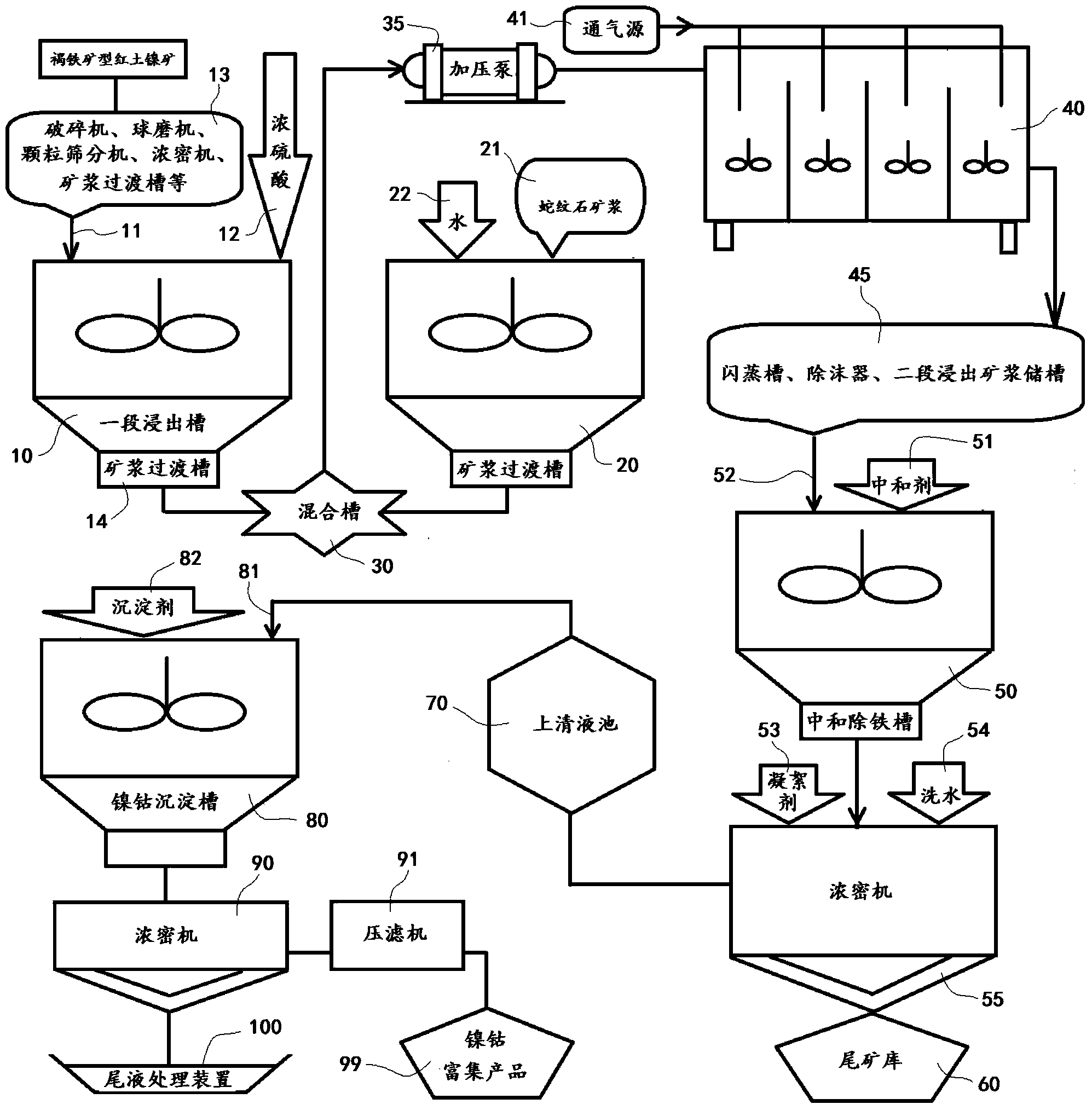

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

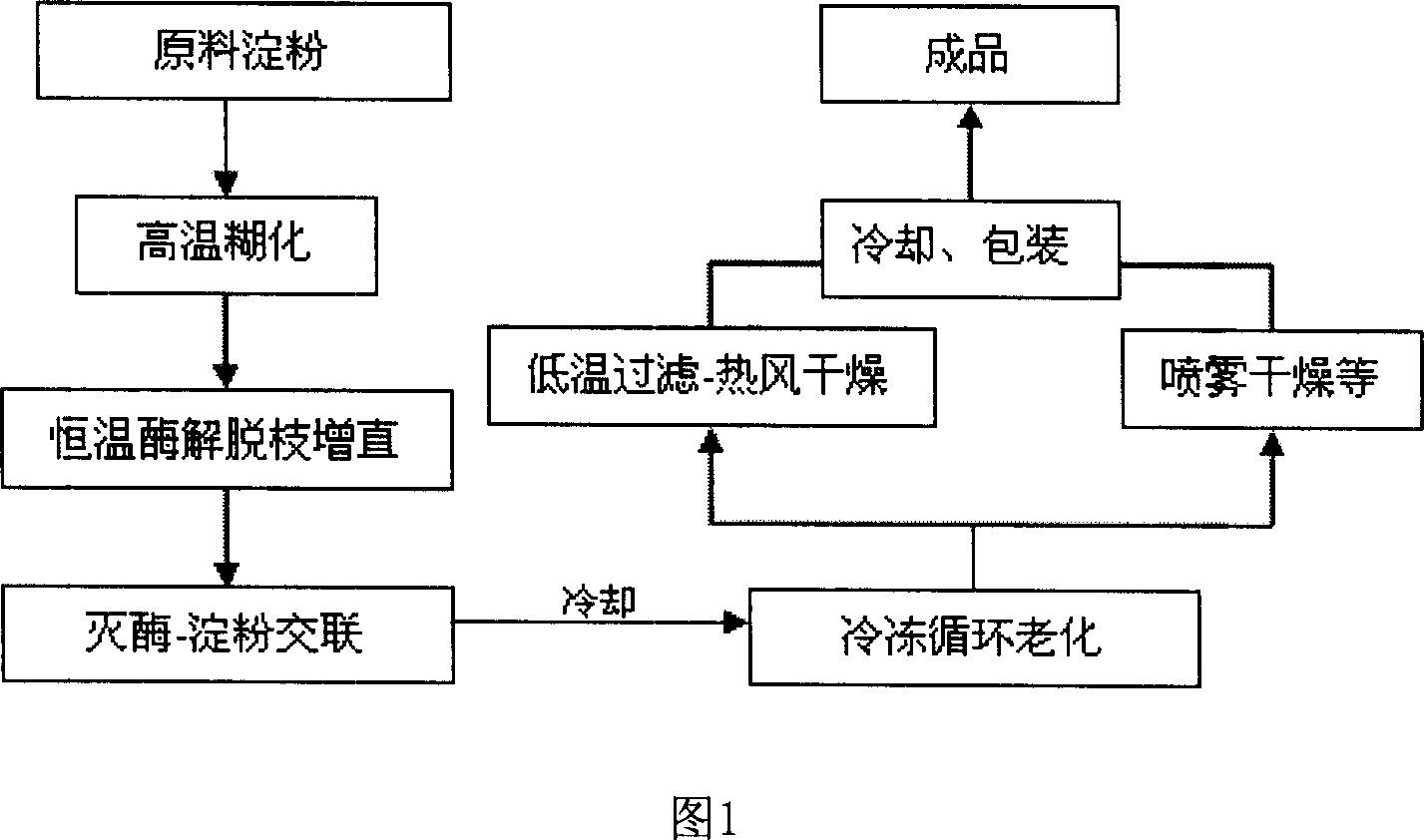

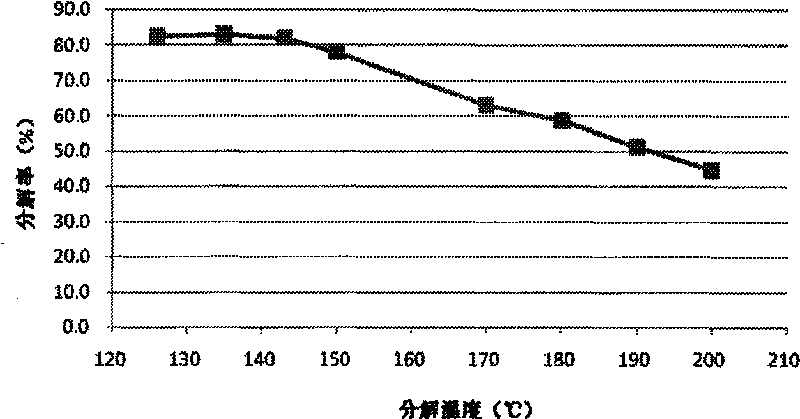

Method for promoting resistant starch content of starch

The invention discloses an improving method of resistant starch content, which is characterized by the following: adopting starch of straigt-chain starch with content more than 10% as raw material; allocating 3%-25% starch magma; gelatinizing over 78 deg. c; decomposing starch to form multiple straight-chain starch through proflavine enzyme or degrafting hydrolytic starch enzyme; using acid environment with pH value at 3. 5-6. 5 and second and third carboxylic acid functional groups of citrate to crosslink; setting the density of functional group ion at 1%-15% corresponding to starch density; adopting circulating aging technique for 3-4 times under icy point; spraying to dry starch magma; drying in the cylinder and fluid bed; filtering; drying through hot wind.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

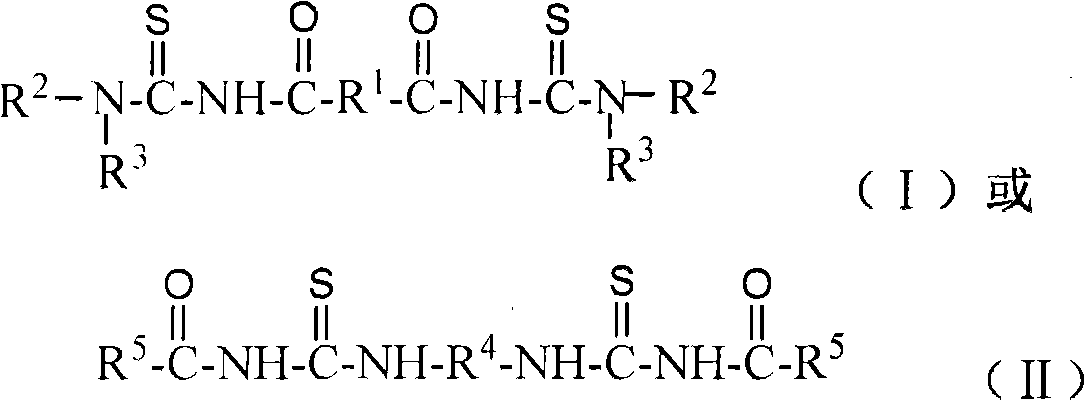

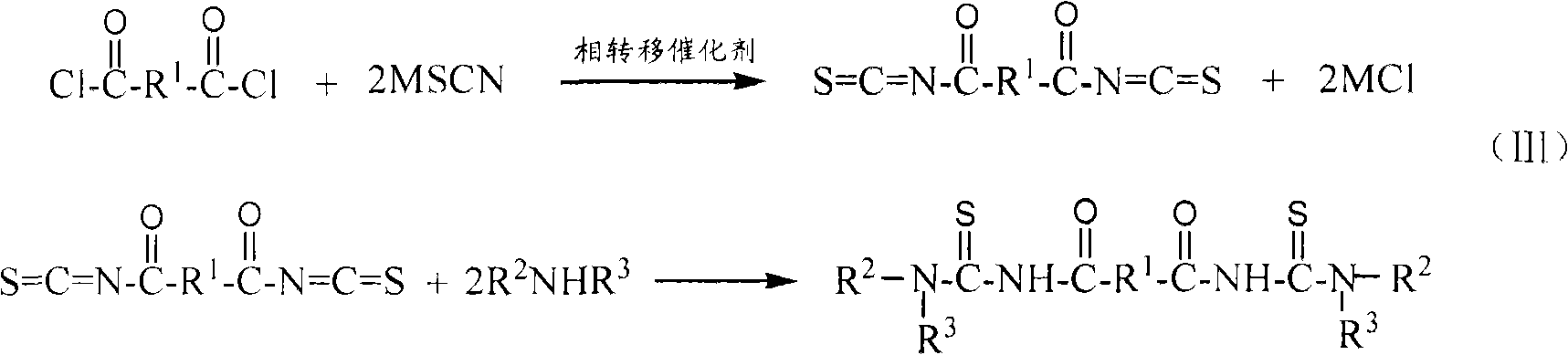

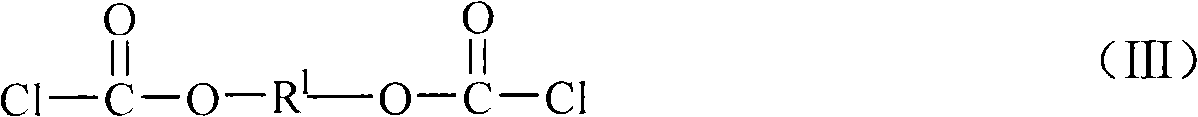

Sulphide ore floation collector and use method of diacyl bis-thiourea and preparation method thereof

InactiveCN101337206AEasy to makeEfficient flotation separationOrganic chemistryFlotationMagmaThiourea

The invention discloses the application processes and the preparation methods of a sulphide ore flotation collector as well as a diacyl bis-thiourea. The invention relates to a novel collector used for high efficiently recycling valuable sulfide minerals from metal sulphide ores; the compositions of the sulphide ore flotation collector include diacyl bis-thiourea surface active agents; the diacyl bis-thiourea compound is shown in the constitutional formula (1) or (2). The collector has strong collecting ability to copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and has good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc., thereby realizing the high efficient flotation separation of the copper sulphide minerals and ferric sulfide minerals when the pH value of ore magma is below 11, reducing the used amount of lime, and improving the comprehensive recovery of copper sulphide ores.

Owner:CENT SOUTH UNIV

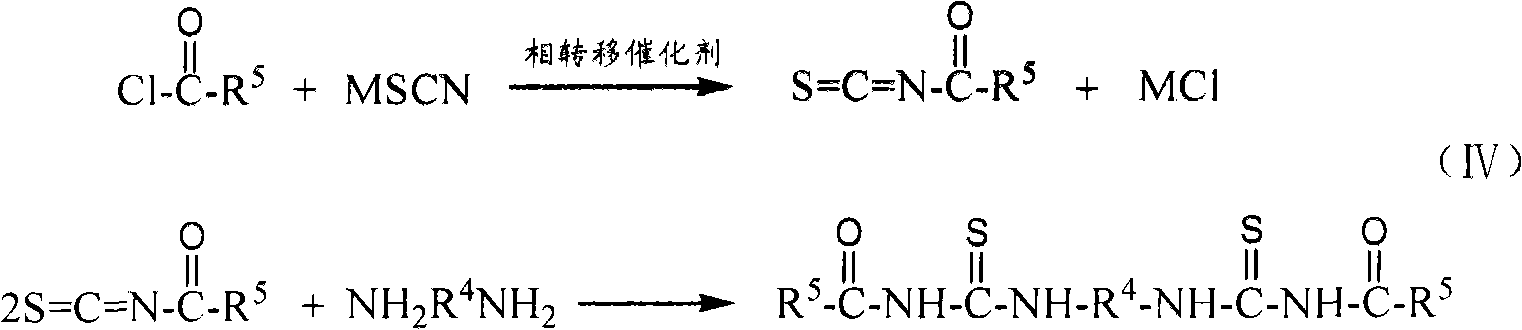

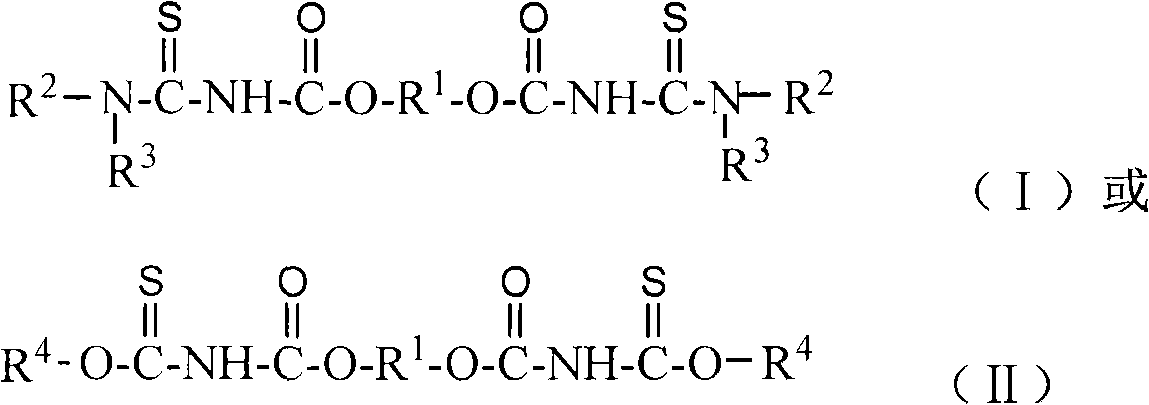

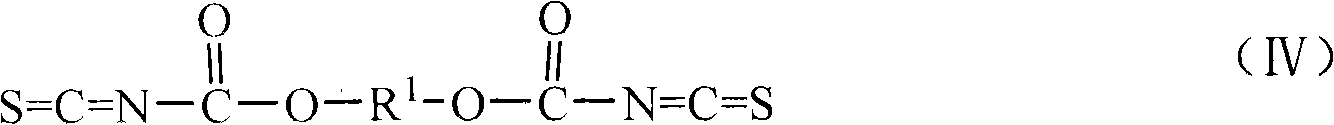

Use of diester isosulfocyanate in sulphide ore floation and preparation method thereof

InactiveCN101337205AEasy to makeStrong harvesting abilityOrganic chemistryFlotationMagmaSulfide minerals

The invention discloses a diester-based 2-thiocyanate ester derivate applied in sulphide flotation, and the preparation method thereof. Diester-based 2-thiourea (the formula one) or diester-based 2-ethionine ester (the formula two) is applied as a novel collector for high efficiently recycling valuable sulfide minerals from metal sulphide ores by floatation. The collector has wide pH range in ore magma, thereby having strong ability to collect copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and having good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc.

Owner:CENT SOUTH UNIV

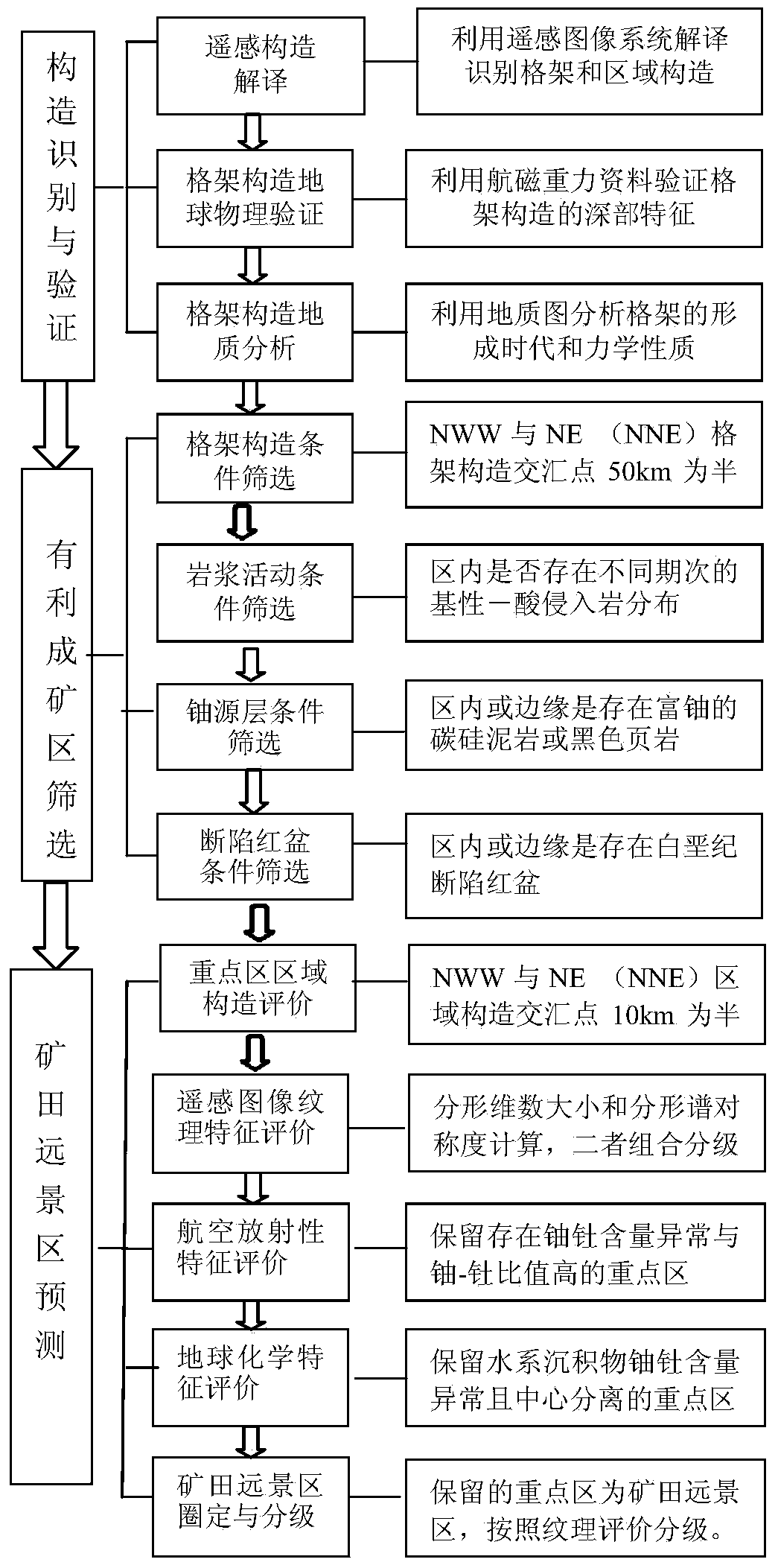

Comprehensive prediction method for prospective area of granite type uranium mine field

The invention belongs to the field of mineral exploration, and in particular relates to a comprehensive prediction method for a prospective area of a granite type uranium mine field, which aims at improving the space positioning accuracy and reliability of a metallogenic prediction area by virtue of remote sensing, geophysical, geological and geochemical methods. The method comprises the following steps: identifying and verifying structures, namely interpreting a remote sensing structure, and geophysically verifying and geologically analyzing a framework structure; screening metallogenic areas, namely screening the framework structure conditions, magmatic activity conditions, uranium source layer conditions and faulted red basin conditions of metallogenic parts; and predicting the prospective area of the mine field, namely grading key area structure conditions, evaluating remote sensing image texture characteristics, aero-radioactive characteristics and geochemical characteristics, and delimitating and grading the prospective area of the mine field. The method can be applied to evaluation and prediction of the metallogenic prospective area of the hydrothermal uranium mine field, especially the granite type uranium mine field.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

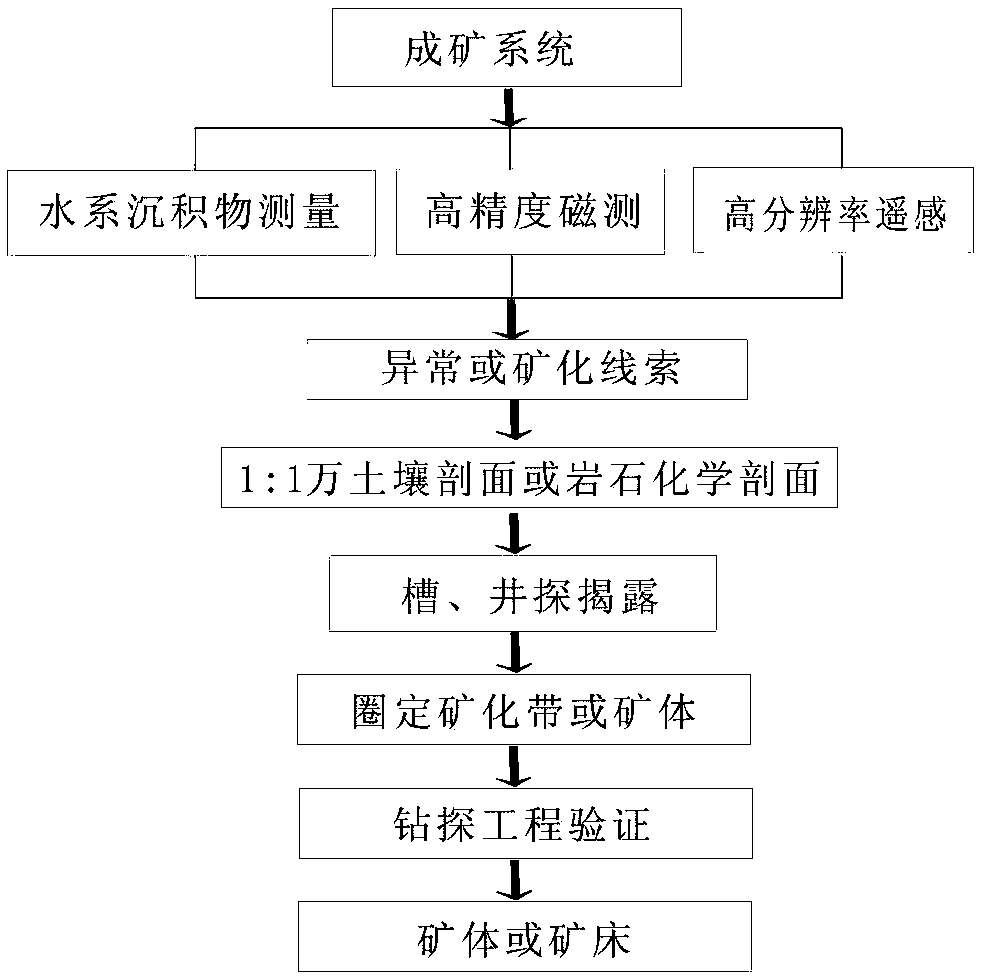

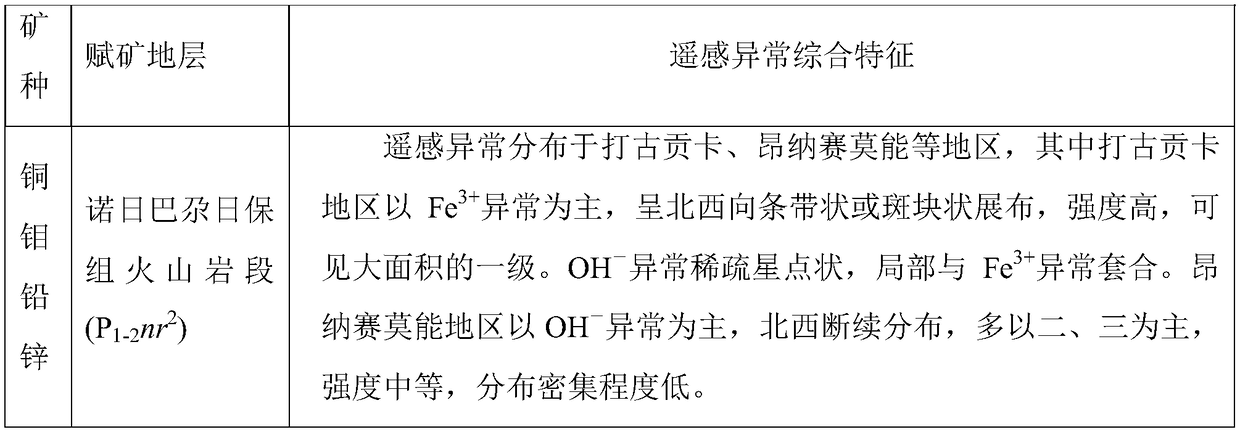

Cenozoic magmatic copper polymetallic ore prospecting method

InactiveCN108761564AGreat Prospecting BreakthroughEarth material testingGeological measurementsPetrochemicalCenozoic

The invention discloses a cenozoic magmatic copper polymetallic ore prospecting method. The method comprises the following steps: determining a magmatic zone or an abnormal area (zone) according to magmatic ore deposit and spot output space-time and geological background; preliminarily determining prospecting targets and target classification by virtue of stream sediment measurement; selecting zones having excellent copper mineralization or molybdenum mineralization or excellent abnormality in target classification for performing magnetic survey verification, and determining a first precedencetarget area or a first abnormal area; determining a second precedence target area or a second abnormal area in the first precedence target area or the first abnormal area by adopting high resolutionremote sensing; performing on-the-spot survey inspection on the second precedence target area or the second abnormal area, and finding out a geologic abnormal area (zone) or a mineralization clue area; performing soil profile or petrochemical profile measurement according to 1:10000, and determining the ore-bearing geological body position on the surface and mineralized body features; performing shallow exposure recourse to control the specific location and shape of the mineralized zone or mineralized body by utilizing trenching; and determining the depth grade thickness scale and occurrence conditions of the mineralized body by utilizing drilling, and discovering the metal ore or ore deposit.

Owner:青海省地质调查院

Productive technology for magma fruit 1iquor

The production process of raw nectar fruit white liquor mainly includes the procedures of raw material preparation, fermentation and distillation, etc. and it is characterized by that it includes thefollowing steps: cleaning fruit, cutting the fruit into small blocks; saccharifying glutinous rice or rice and converting it into mixed pulp containing dextrine and glucose; adding double-functional distiller's yeast, adding clean water and making fermentation, then making distillation, filtering and removing impurities so as to obtain the invented product with palatable taste.

Owner:李松林

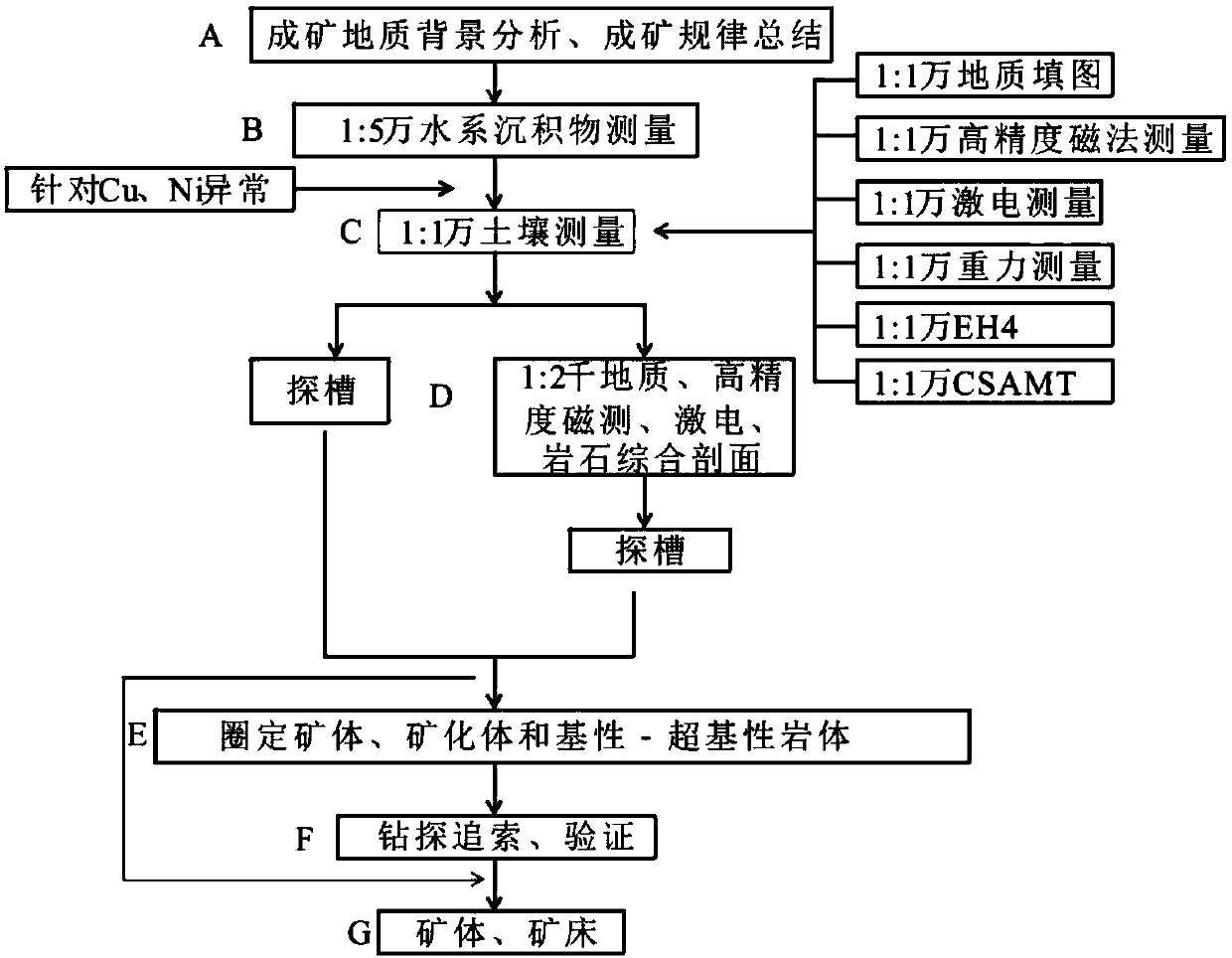

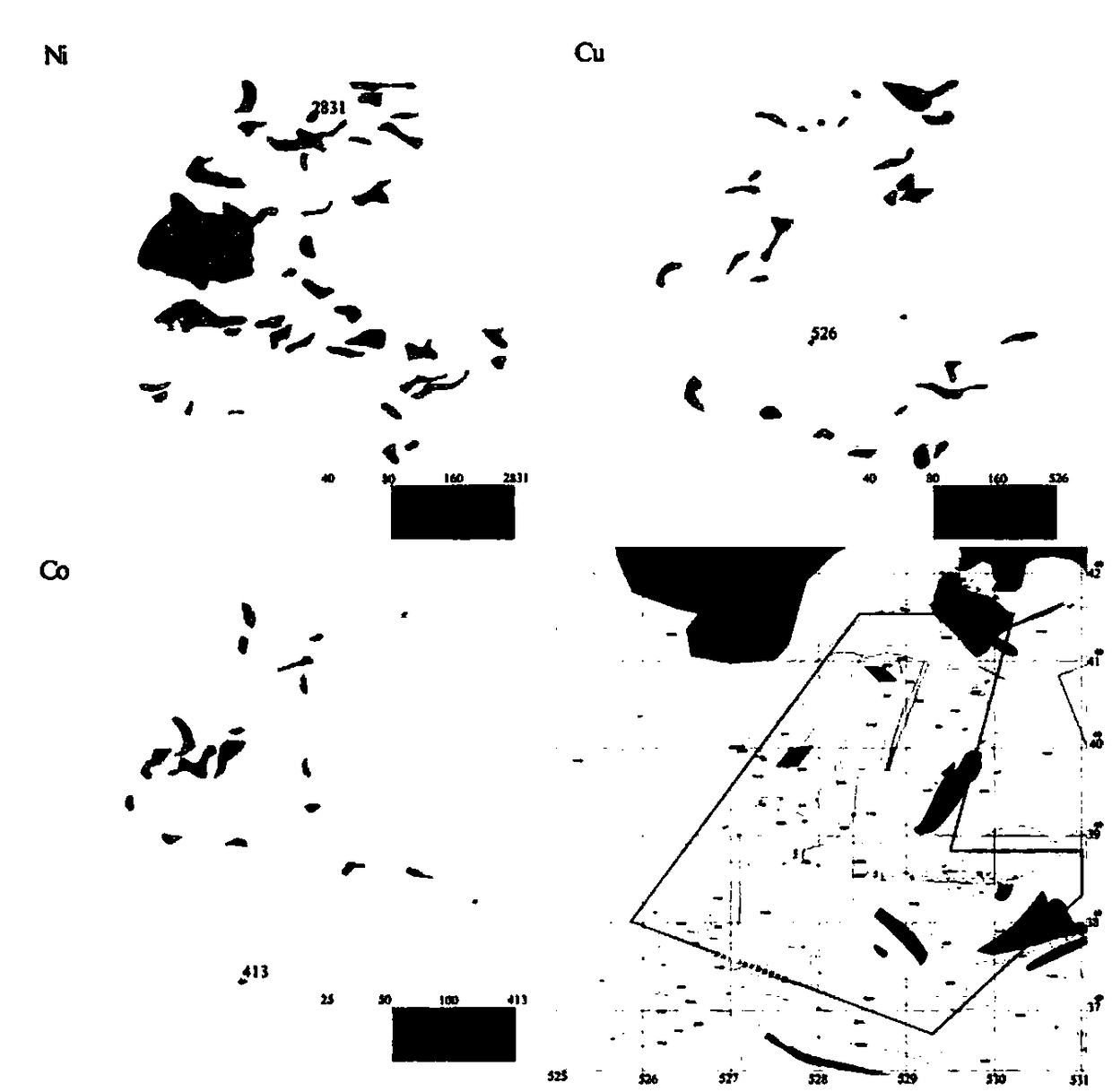

Magma type copper-nickel ore exploration method

InactiveCN107589472AImprove exploration efficiencyNarrow down the scope of prospectingGeological measurementsMagmaSediment

The invention discloses a magma type copper-nickel ore exploration method. The magma type copper-nickel ore exploration method comprises steps of A, analyzing a geological setting of an ore-forming process of a magma type copper-nickel mineral deposit and summarizing its ore-forming pattern, B, carrying out 1:50000 stream sediment measurement with an aim to observe a geochemical halo on the upperpart of a rock mass, marking abnormities of Cu and Ni, C, performing 1:10000 soil measurement by targeting an area where the Cu and Ni are abnormal, D performing trenching reveal on abnormalities anda mineralized clue or performing 1:2000 geologic measurement, high accuracy magnetic survey, induced polarization sounding and rock comprehensive profile measurement and revealing through trenching engineering, E, marking ore bodies, mineralized bodies and basic and ultra-basic rock bodies, F, using drilling to perform verification on the marked ore bodies or mineralized bodies, and G, determiningthe ore body or the mineral deposit. The magma type copper-nickel ore exploration method can improve a success rate of ore prospecting, can effectively shorten a construction period of ore prospecting and can find various kinds of metal mineral bodies.

Owner:青海省第三地质矿产勘查院

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Preparation method of oil ceramic

ActiveCN101982440AExcellent drying and firing processMeticulous drying and firing processClaywaresMagmaPetroleum

The invention discloses a preparation method of oil ceramic, which comprises the following steps of: selecting raw material soil which is acquired between the deep soil layer and the magma; adding the dried and smashed raw material soil into stone powder to prepare into ceramic mud; shaping the ceramic mud to be a blank body; and redrying the blank body to obtain a ceramic blank. The preparation method further comprises the following steps of: drying the ceramic blank, modifying, drawing, calendering, carving, re-calendering, drying at three times, inputting the dried blank into a kiln, and burning with oil to obtain the finished oil ceramic. The method can prepare the oil ceramic with the crude oil or the oil dreg produced by the oil field; and the prepared oil ceramic is black in surface, has the unequal blackness from the outer to the inner, and is unique and novel. The preparation method is energy-saving and environment-friendly, reduces the burning cost, and leads the obtained oil ceramic to be firmer and more durable.

Owner:NANTONG HUAXING OIL EQUIP

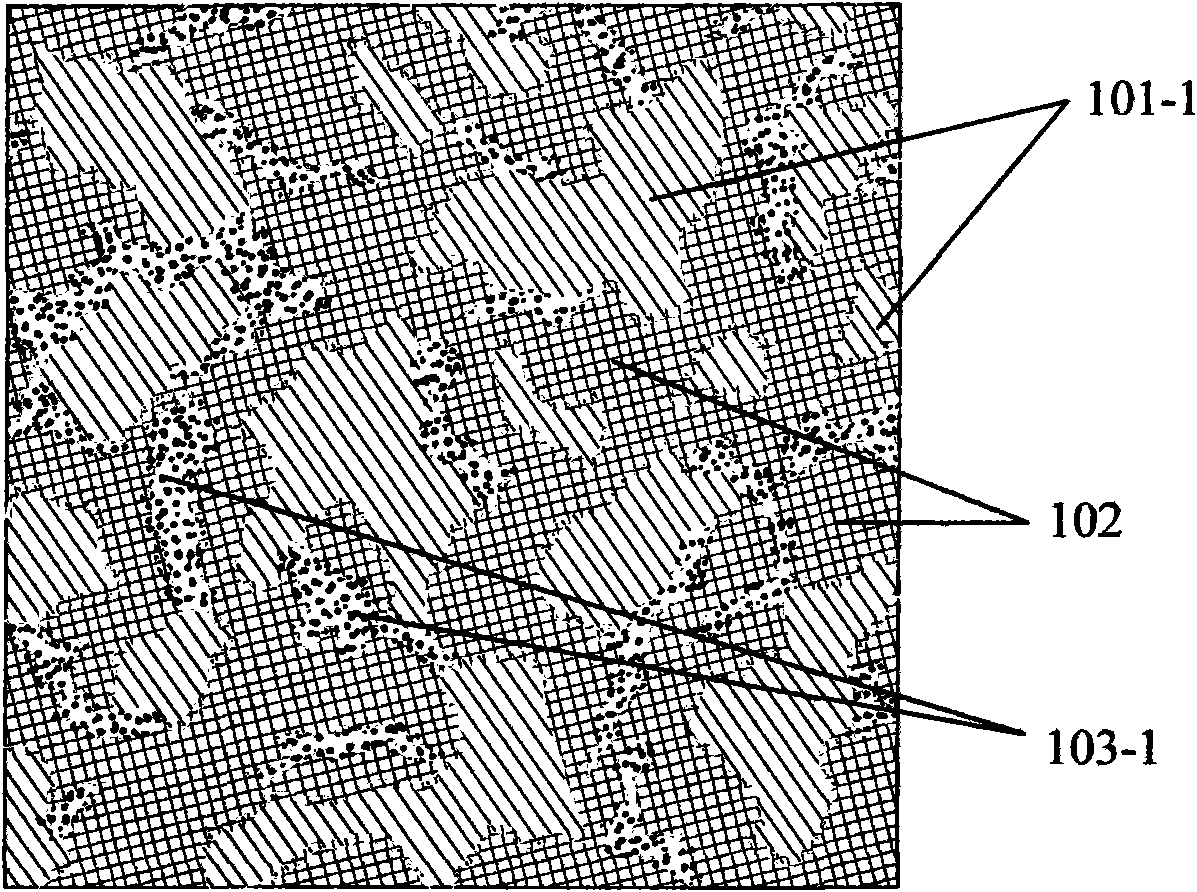

Three-dimensional antique stone produced by flowing-imitating magma and producing method thereof

InactiveCN101554821AAccurate and fast vertical stackingAchieving Precise FormingNatural patternsOrnamental structuresMagmaNatural stone

The invention relates to a three-dimensional antique stone produced by flowing-imitating magma and a producing method thereof. The three-dimensional antique stone is characterized in that the prepared product comprises patterns with 2-10 obvious billet colors, wherein in at least two colors, 1-10000 billet color pattern regions with thickness reaching 2-30mm and area being 2cm to 0.5m exist; powder materials with different colors have the characteristic of mixing mutually, wherein the edge of at least one pattern region is provided with 10-1000 color powder particles, 2 / 3-3 / 3 of edges of the peripheries of which are covered by the other adjacent color region; and a billet color pattern layer of the product is provided with a colored glaze pattern layer with 1-10 colors. The method can greatly improves the imitation expressive ability of mixing transition of colorful natural stones and color region borders, and has the characteristics of the patterns nearly never being worn and torn because of the billet thickness of the pattern layers, thereby being more suitable for the practicability.

Owner:杨德宁

Brain tonic walnut cream

InactiveCN101317677ALower blood sugarImprove immunityNervous disorderFood preparationIodised saltYolk

The invention relates to a brain strengthening walnut pulp, which is characterized in that: concentrated magma is extracted from the mixture of longan, malt, gingkgo, potato, mulberry, lily, bamboo leaves and tuchahoe and then is mixed with walnut kernel (particles), powdered mixture of black sesame and walnut kernel, sea backthern powder, powdered glucose, yolk powder, yeast extract, and edible iodated salt; the mixture are fully stirred into pasty status, sterilized at high temperature, bottled, disinfected, sealed and stored, and finally the products are prepared.

Owner:王跃进

Device and process for converting calcium process desulfurization into temperature difference crystallizing ammonia process desulfurization

ActiveCN101670231BEliminate secondary pollutionImprove environmental performanceDispersed particle separationSolution crystallizationMagmaDistributor

The invention belongs to the technical field of environment protection, and relates to a device and a process for temperature difference crystallizing ammonia process desulfurization, which is especially suitable for the ammonia process modification and newly-built desulfurization of the original calcium process desulfurization device. The device comprises a desulfurization tower, a densifying device, a gas-liquid heat exchanger, a circulating pump, a concentration circulating pump, a magma pump, a concentration crystallization tank and a drying system, wherein the desulfurization tower, the circulating pump, the magma pump and the drying system adopt the devices in the original calcium process desulfurization; the lower part of the densifying device is provided with a gas distributor, and the upper part thereof is provided with spray heads which are arranged in 2-3 layers; spray heads in the desulfurization tower are arranged in 2-4 layers, a liquid supplementation pipe is connected with the spray heads at the lowest layer in the desulfurization tower; the concentration crystallization tank is a tank with a conical bottom part; and the upper part of the concentration crystallization tank is provided with a pipeline to be connected with the bottom of the densifying device, the middle of the concentration crystallization tank is provided with a pipeline to be connected with theconcentration circulating pump, and the bottom is provided with a pipeline to be connected with the magma pump. The invention can farthest utilize the original devices on the premise of guaranteeing the normal desulfurization efficiency, thereby saving the investment, reducing the energy consumption and eliminating the secondary pollution.

Owner:江苏世纪江南投资有限公司

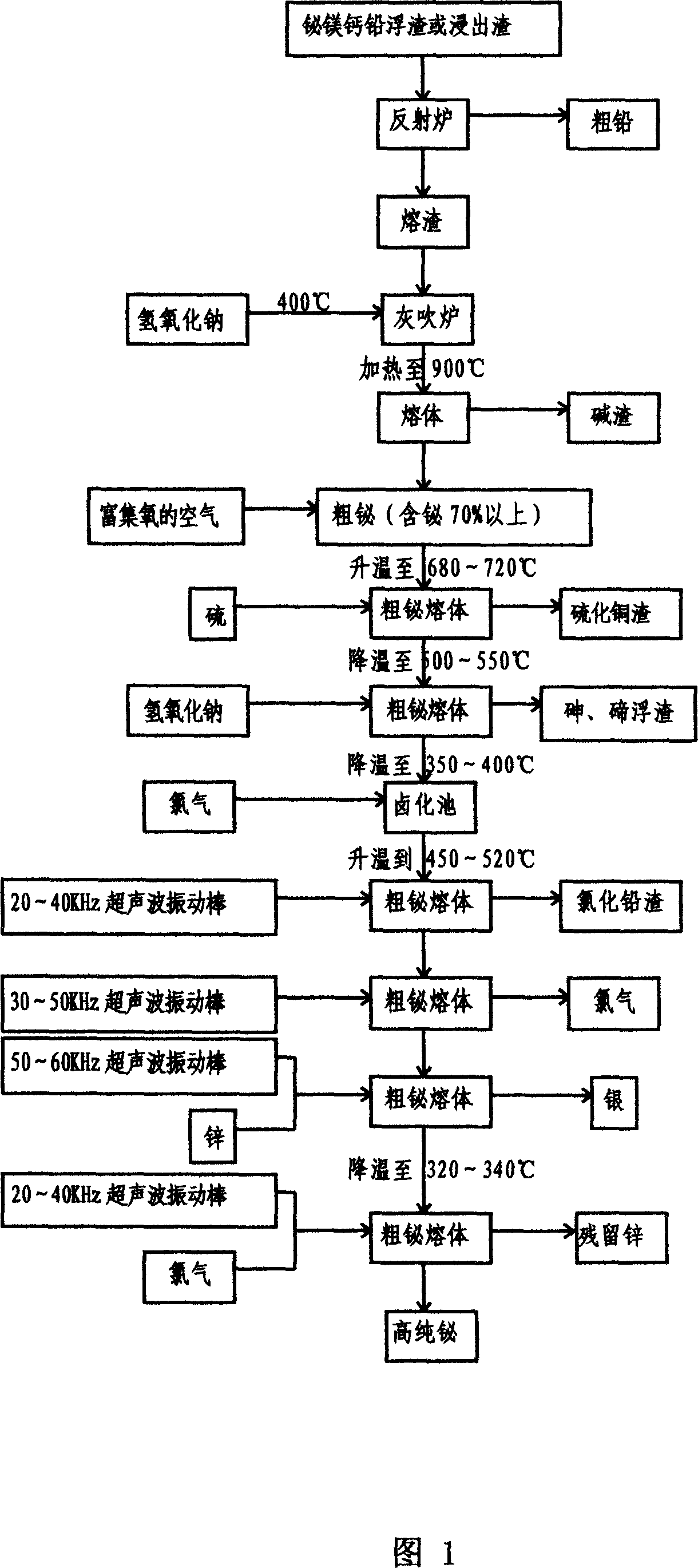

Impurity removing refining process of high pure bismuth

This invention relates to an electrolysis technique of ore magma of fluorosilicic acid of bismuth mine. Bismuth concentrate is used as raw material of ore magma to enter into slurry tank, after slurry and add chlorhydric acid to adjust acid, the above-mentioned serofluid is consecutively added into electrolyte tank of ore magma, extraction and electroextraction of bismuth are completed simultaneously by effect that electrolyte tank is imported direct current, cathode that has electrolysed scorifys bismuth powder falling on bottom of membrane bag with sponginess, spongio-bismuth is pressed into pressure filter of spongio-bismuth by equipment of drawing powder and spongio-bismuth is pressed to be block and dewatered, smelted to metallic crude bismuth, hypso-pure bismuth of which the final content is 99.999% is epurated by importing chlorine gas, natrium hydroxydatum to eliminate miscellaneous object.

Owner:CHENZHOU YUTENG CHEM IND

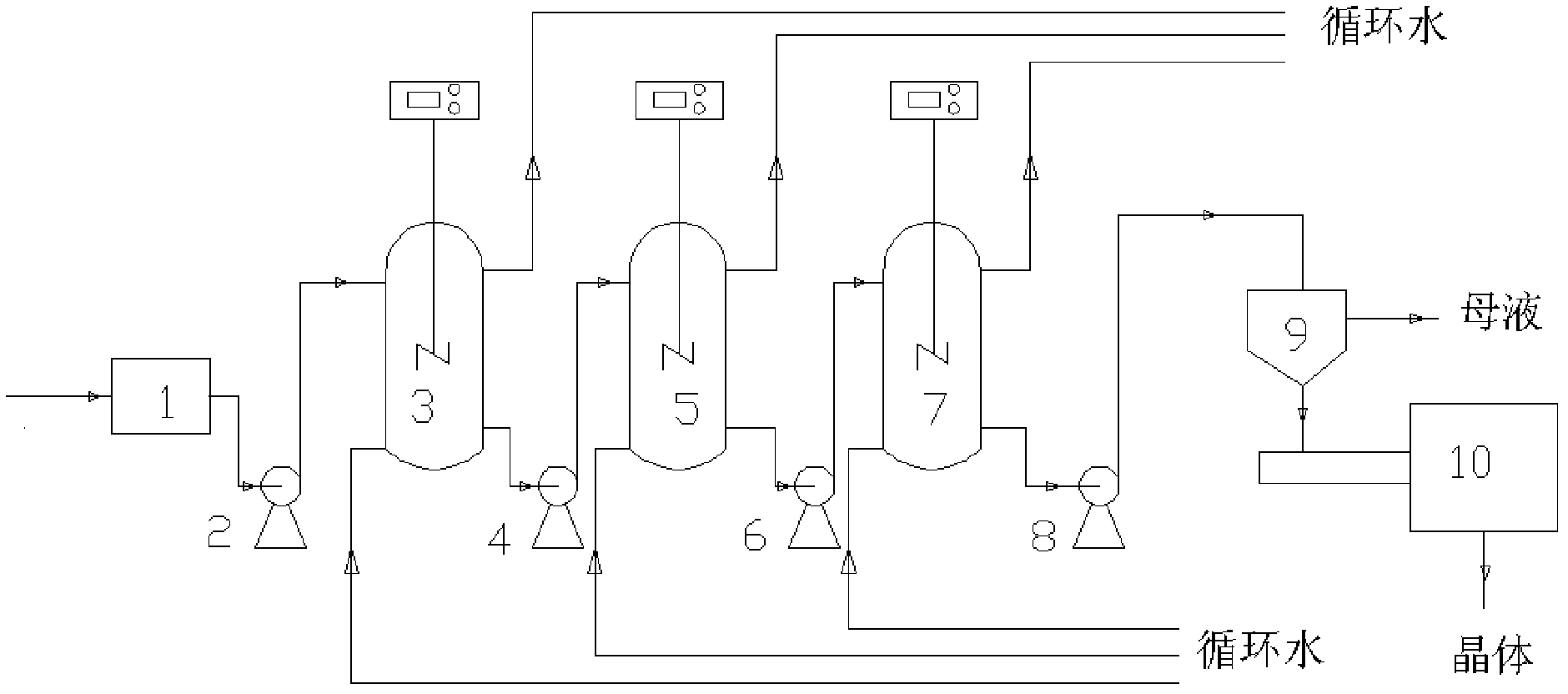

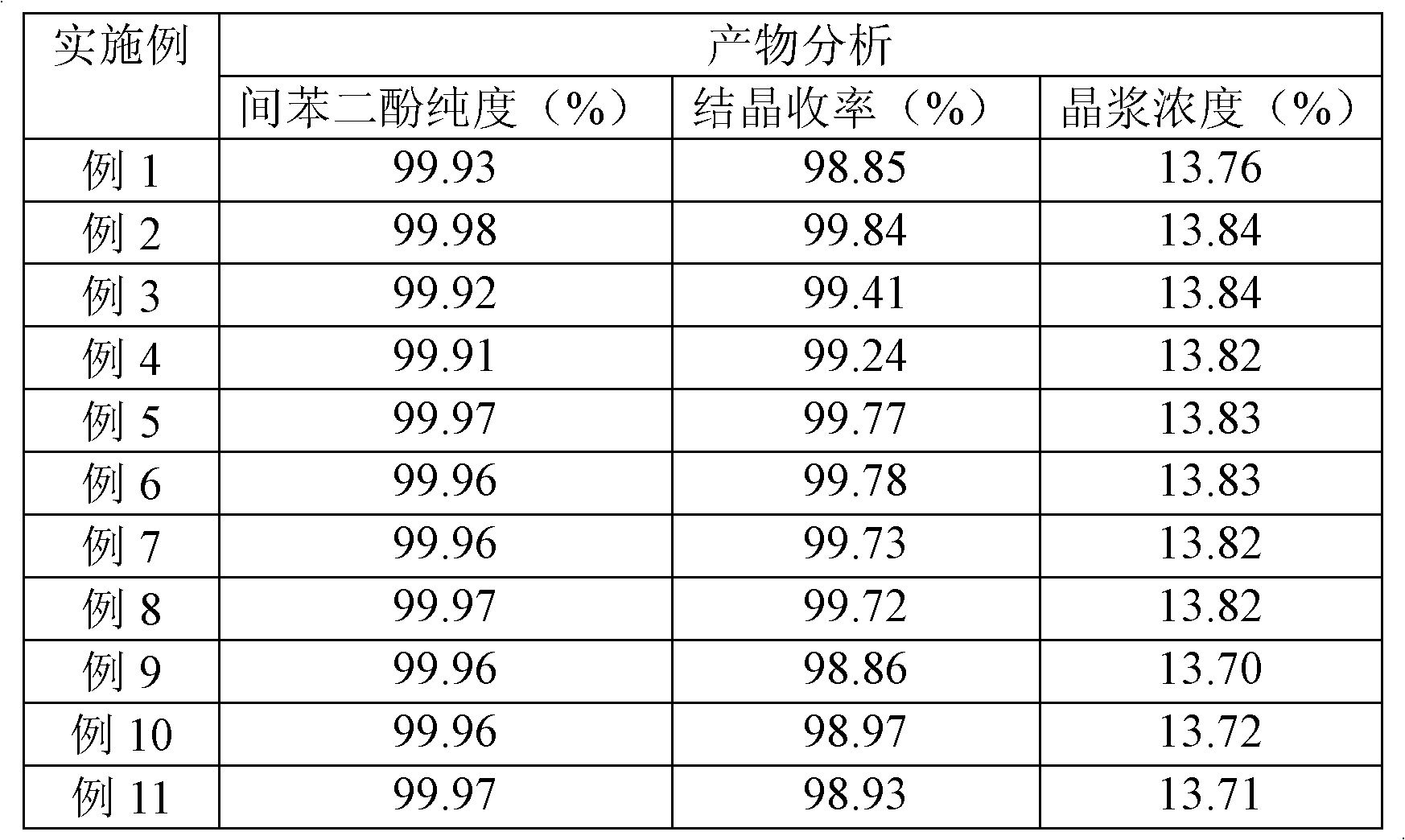

Method for purifying resorcinol by means of continuous crystallization

InactiveCN102643169AEffective growth rate controlGuaranteed stabilityOrganic chemistryOrganic compound preparationMagmaToluene

A method for purifying resorcinol by means of continuous crystallization belongs to the technical field of separation and purification of resorcinol, and includes: dissolving the resorcinol into methylbenzene in weight ratio of (6.0-6.1):1, and enabling solution to enter a primary crystallizer to crystallize with the temperature and stirring speed of the primary crystallizer constant; enabling magma to enter a secondary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop; enabling magma to enter a tertiary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop, wherein the temperature of the primary crystallizer, the temperature of the secondary crystallizer and the temperature of the tertiary crystallizer are sequentially decreased; and subjecting the magma to solid-liquid separation, and then scrubbing and drying obtained crystals by the methylbenzene. The method realizes continuous operation of crystallization and purification, operating cost is reduced, production capacity is improved, and stability of operating parameters is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH

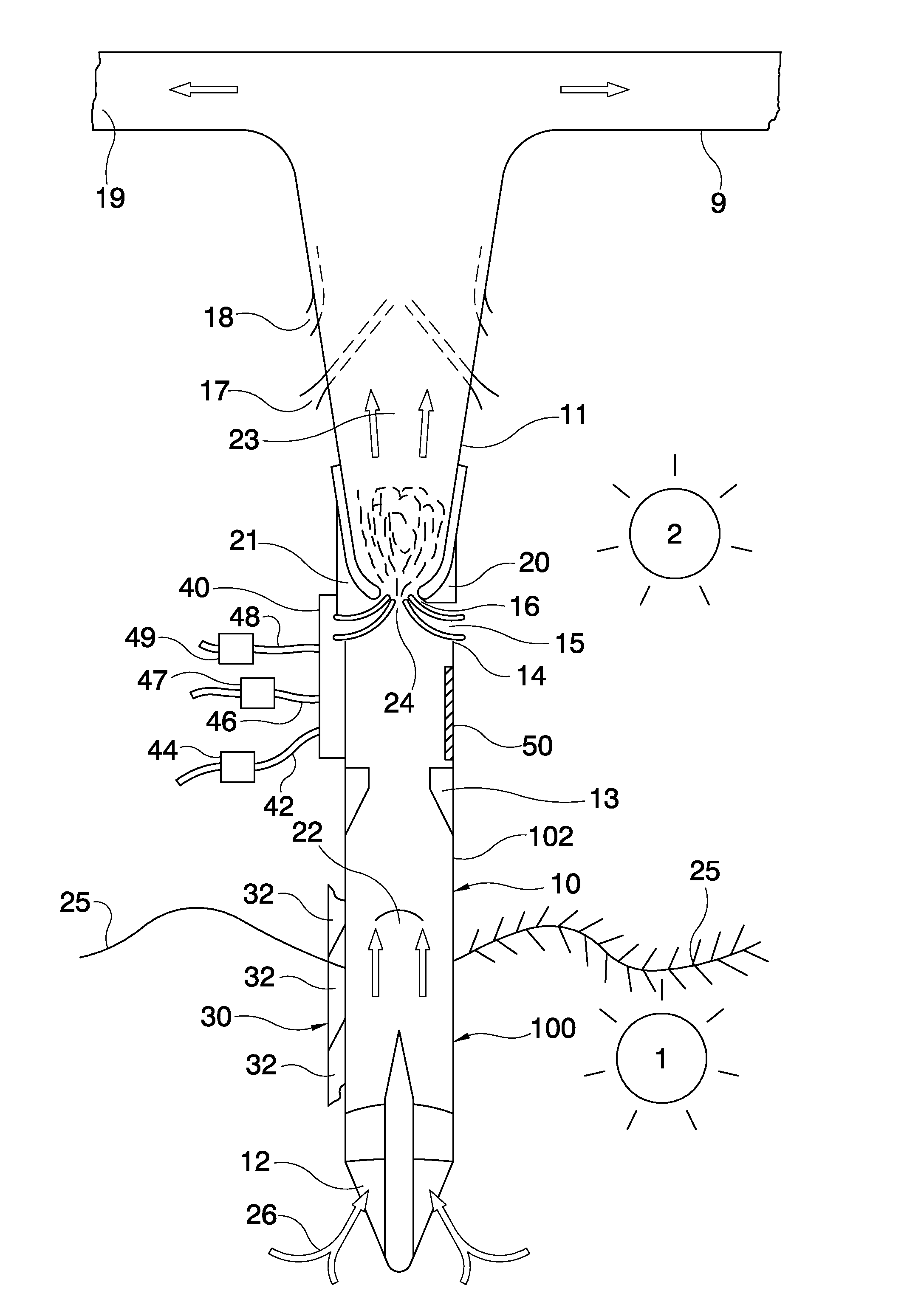

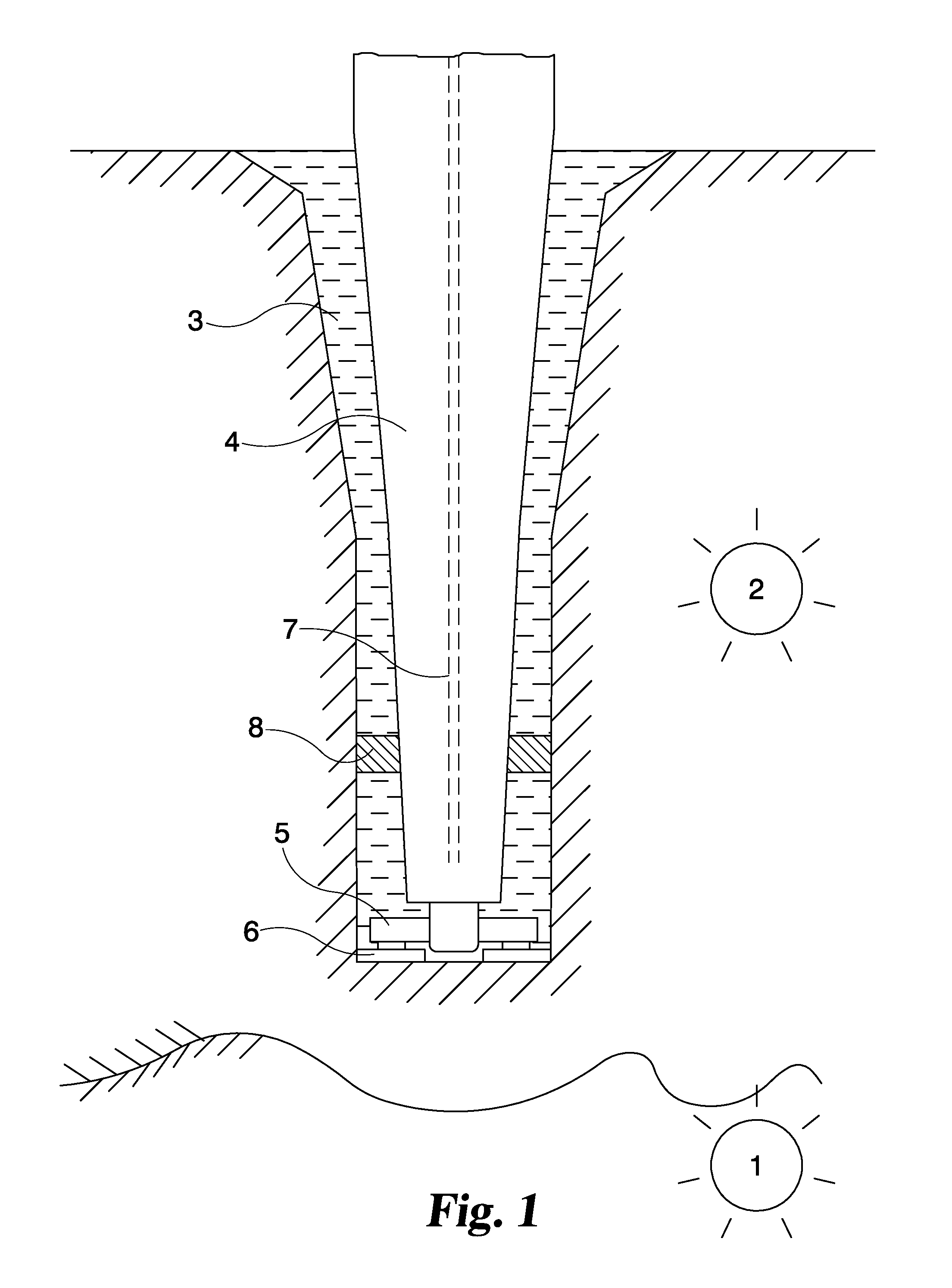

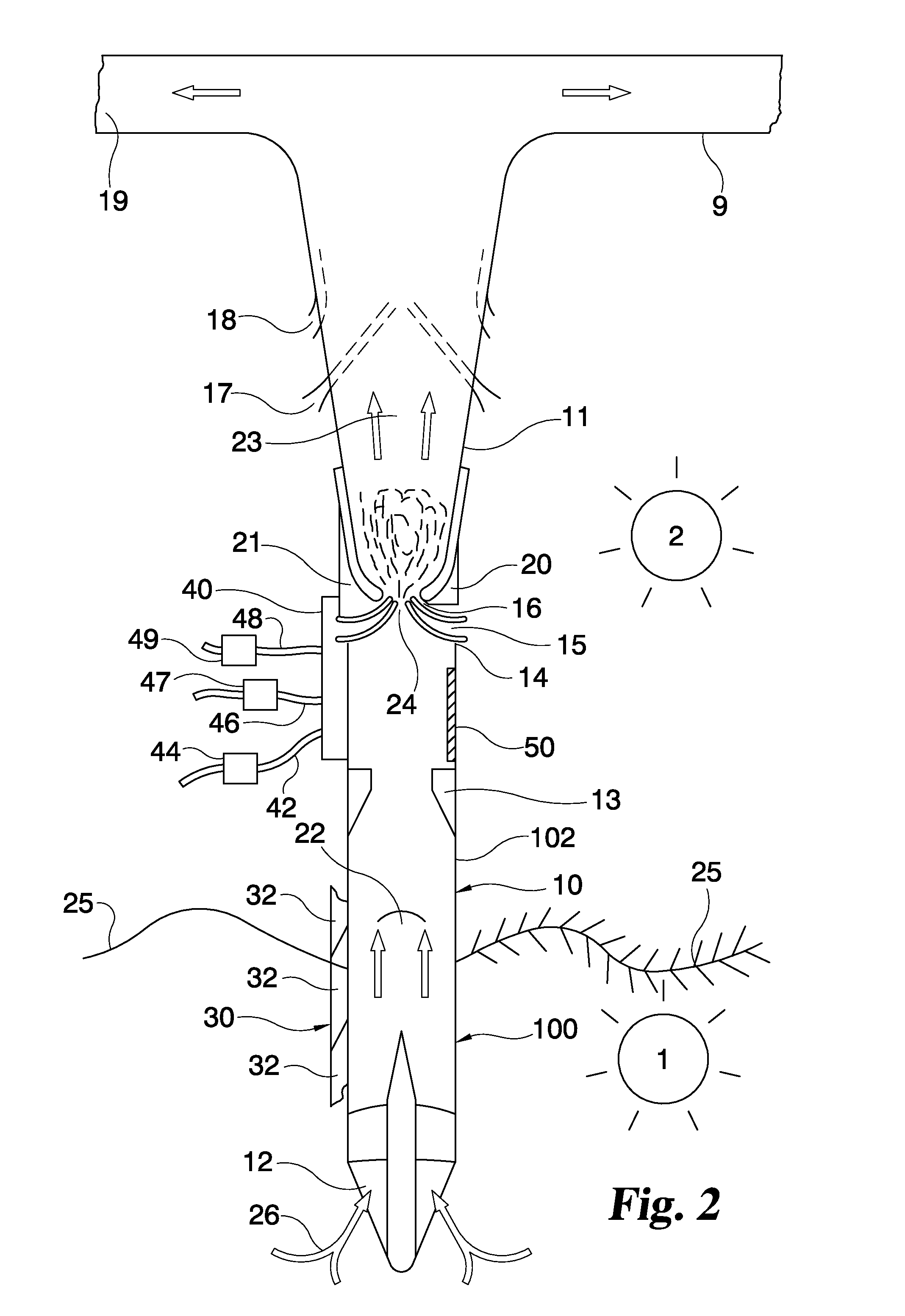

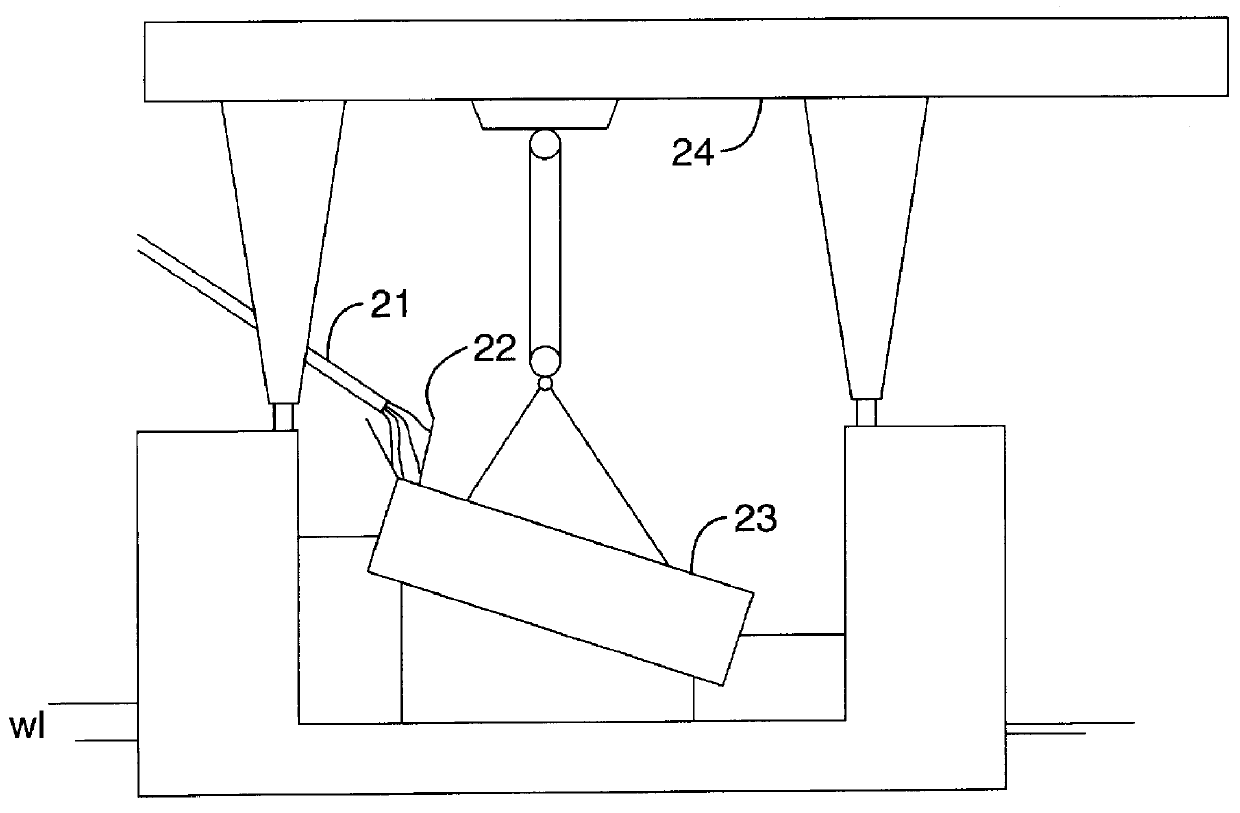

Magma evacuation systems for the prevention of explosions from supervolcanoes

InactiveUS7284931B2Avoid explosionOther heat production devicesGeothermal energy generationMagmaCombustion chamber

An apparatus controls the evacuation of volcanic magma to prevent explosions. Magma evacuation is through a single evacuation tube that heats the magma flow within the tube to prevent stickiness of the magma in the tube. The heating may use small combustion chambers to heat steam, which in turn heats and stabilizes the magma flow. Stability is aided by central cooling, where needed, using water jets from nozzles located at the wall of the tube.

Owner:STRATFORD BRIAN STAPLETON

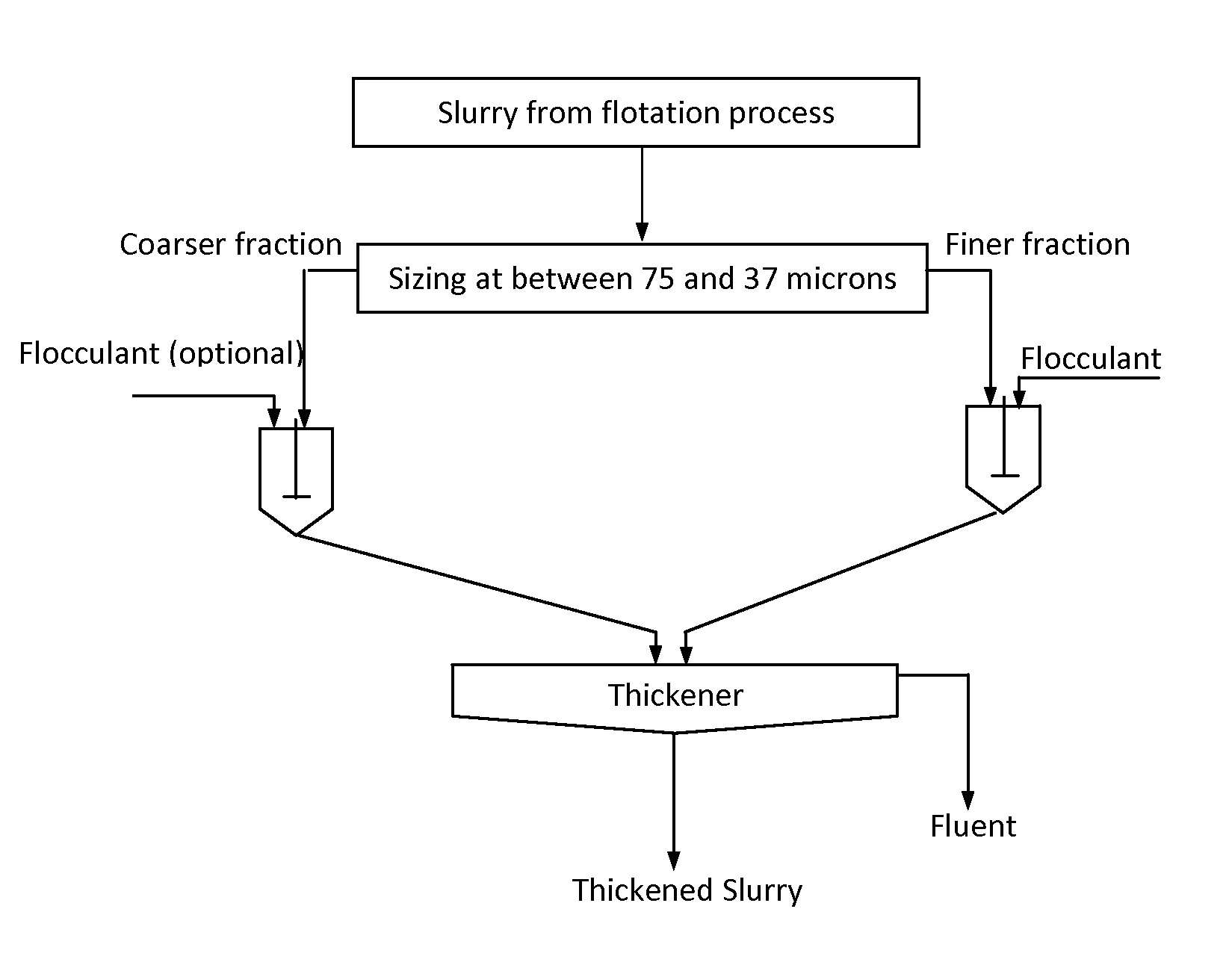

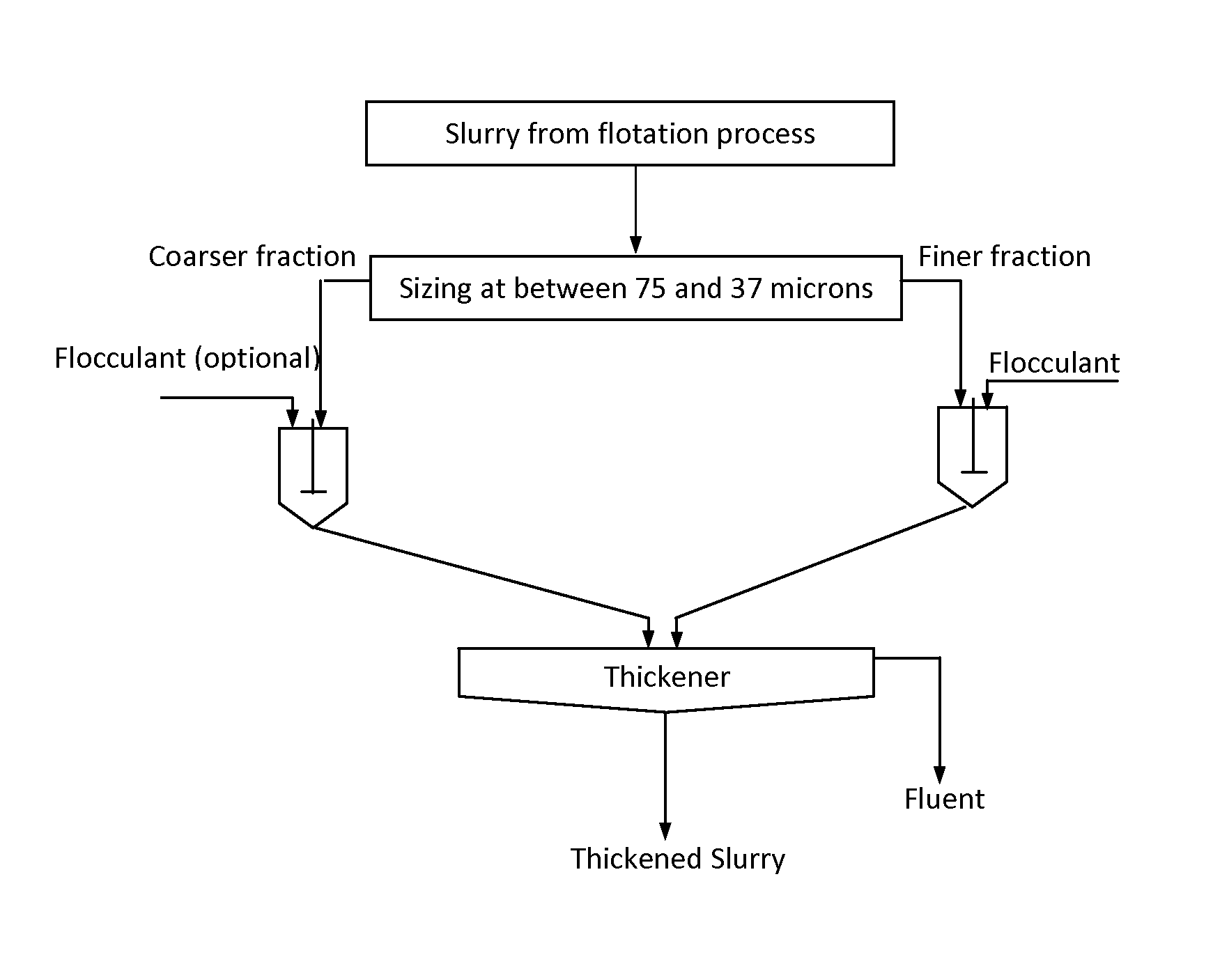

Enhancing sedimentation performance of clarifiers/thickeners

ActiveUS8187470B2Improve performanceInhibition formationSludge treatment by de-watering/drying/thickeningSedimentation separationMagmaPulp and paper industry

Owner:ARR MAZ CUSTOM CHEM

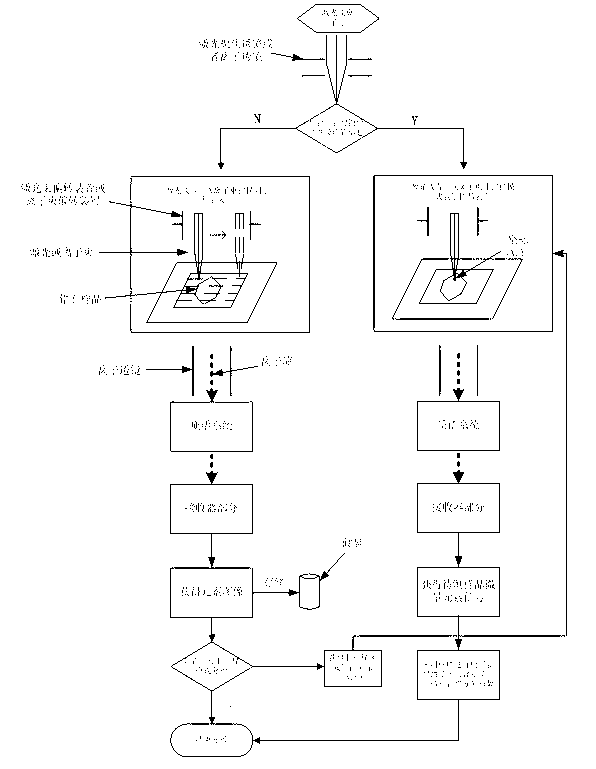

Method for predicting shrinkage cavity defect of TC4 titanium alloy casting through BP neural network

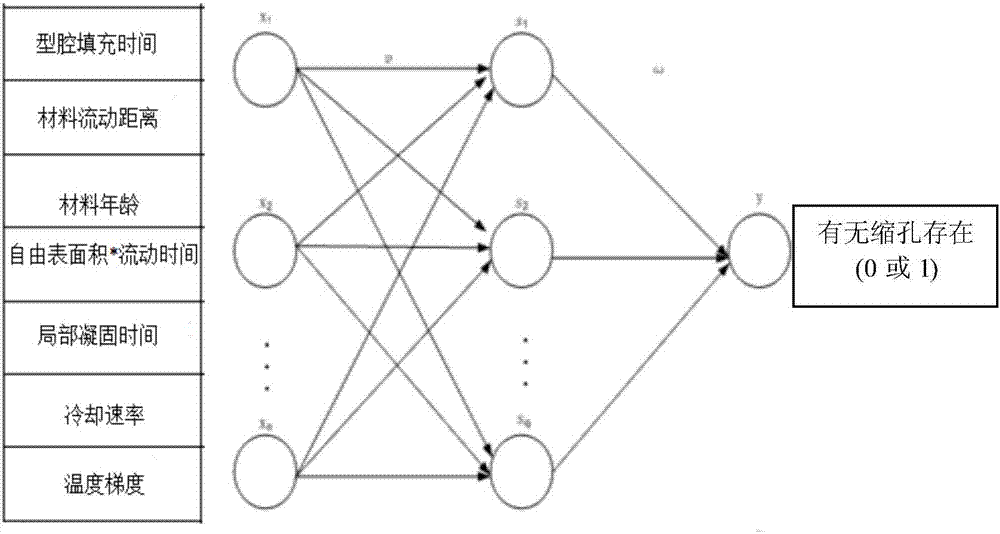

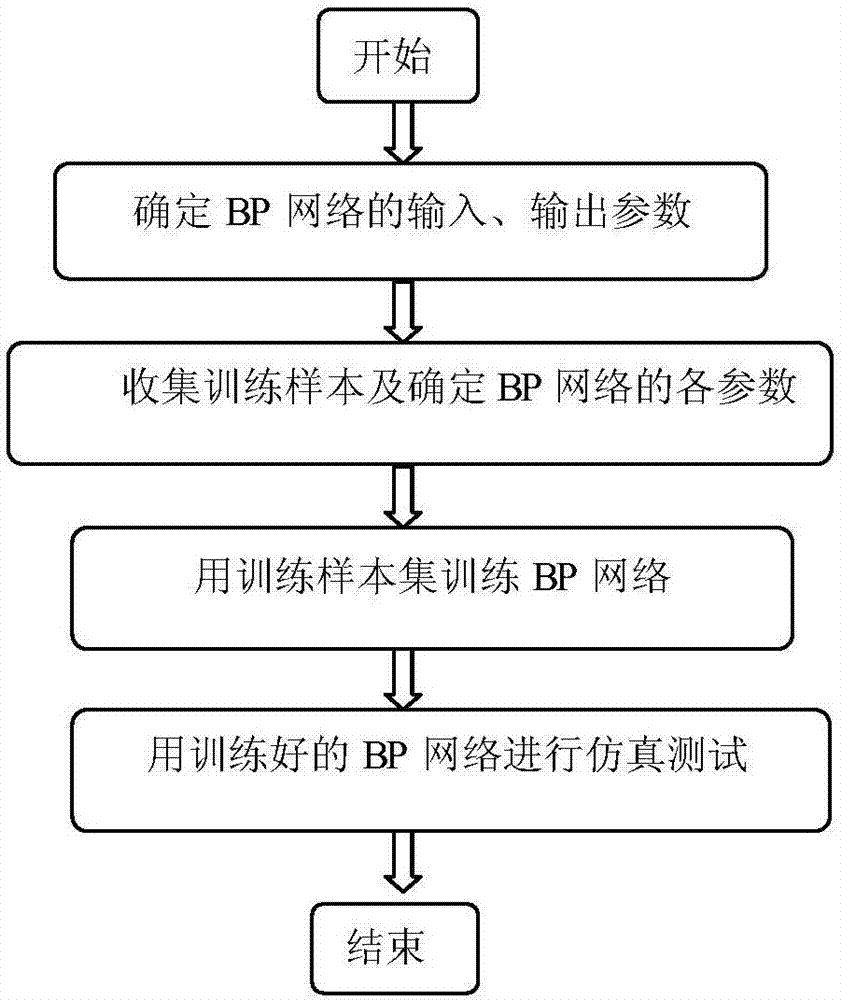

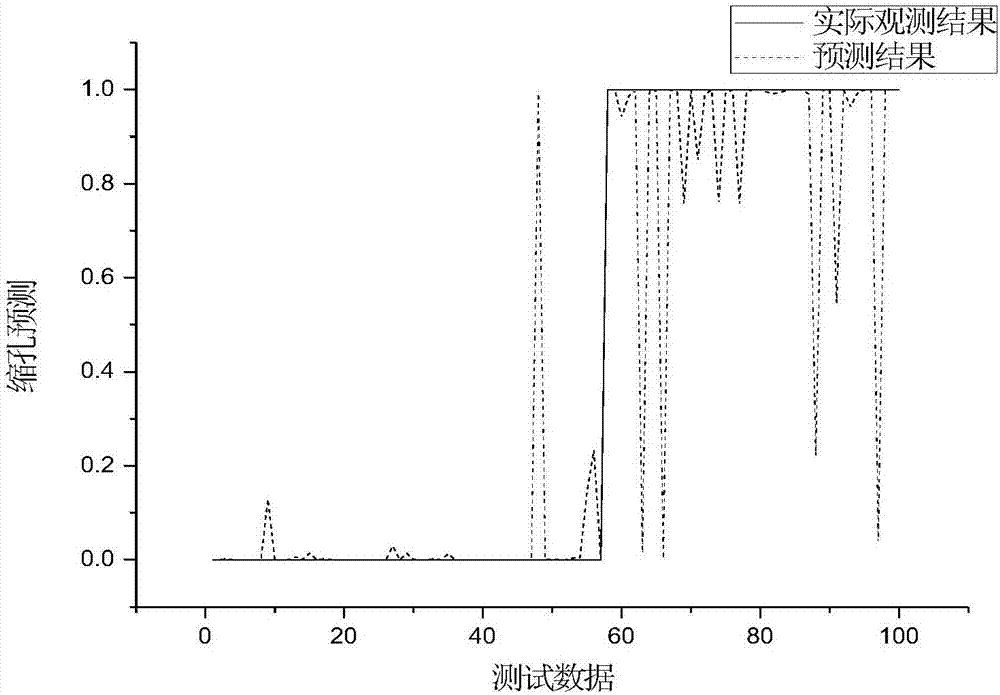

PendingCN107577850ASolve the problem of insufficient prediction accuracyImprove casting qualitySpecial data processing applicationsNeural learning methodsMagmaInvestment casting

The invention belongs to a method for predicting a shrinkage cavity defect of a TC4 titanium alloy casting through a BP neural network. According to the method, the BP neural network is applied to shrinkage cavity position prediction of the TC4 titanium alloy casting; according to formation reasons of a shrinkage cavity and the characteristics of titanium alloy investment casting, the seven parameters of cavity filling time, material flowing distance, material age, free surface area*flowing time, local solidification time, cooling rate and temperature gradient are selected the first time to serve as input of the BP neural network; and by using the judgment of whether a corresponding position has a shrinkage cavity as output of the BP neural network, the method for effectively predicting the shrinkage cavity defect of the TC4 titanium alloy casting is established. Through the method, the position of the shrinkage cavity of TC4 titanium alloy in the casting process can be predicted moreaccurately, the difficulty in titanium alloy casting shrinkage cavity detection and the problem that prediction results of MAGMA, TSolver, ProCAST and other casting simulation software are insufficient in accuracy are solved, and a data basis is provided for precisely predicting and effectively avoiding the defect of the TC4 titanium alloy in the casting process.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

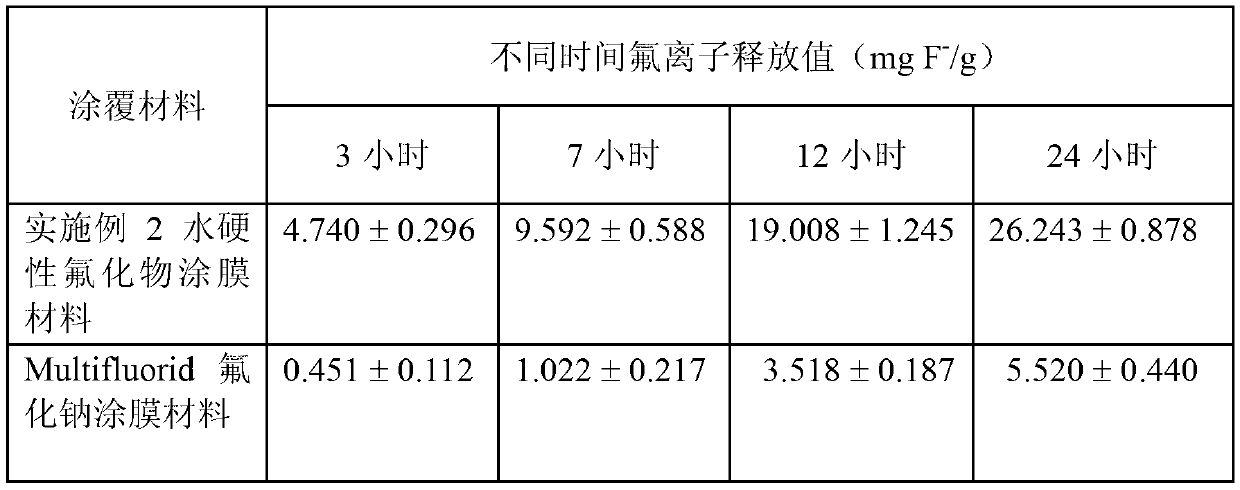

Hydraulic fluoride varnish material

InactiveCN103211710ARelease fullyImprove hydrophilicityImpression capsDentistry preparationsSolubilityMagma

The invention relates to a hydraulic fluoride varnish material, which includes a film-forming material, a fluoride and a volatile solvent, and also includes an adhesion promoter and a suspending aid. The fluoride is superfine inorganic fluoride powder with good water solubility and its adding amount in a coating material is 1-7mg / ml; the particle size of the inorganic fluoride powder is 0.1-10.0 micrometers; and the content of the film-forming material in the coating material is 20%-90%. The hydraulic fluoride varnish material provided in the invention is a premixed single-component fluoride particle suspending magma and contains 5% of fluoride. During application, the hydraulic fluoride varnish material is directly daubed on a tooth surface, needs no blow drying, and gradually hardens into a film after encountering saliva in the oral cavity. The hardened varnish has a porous microstructure, and has good hydrophilicity, can fully release fluorine ions, and bring tooth fluorination and caries prevention functions into play.

Owner:STOMATOLOGICAL HOSPITAL NO 4 ARMY SURGEON UNIV PLA

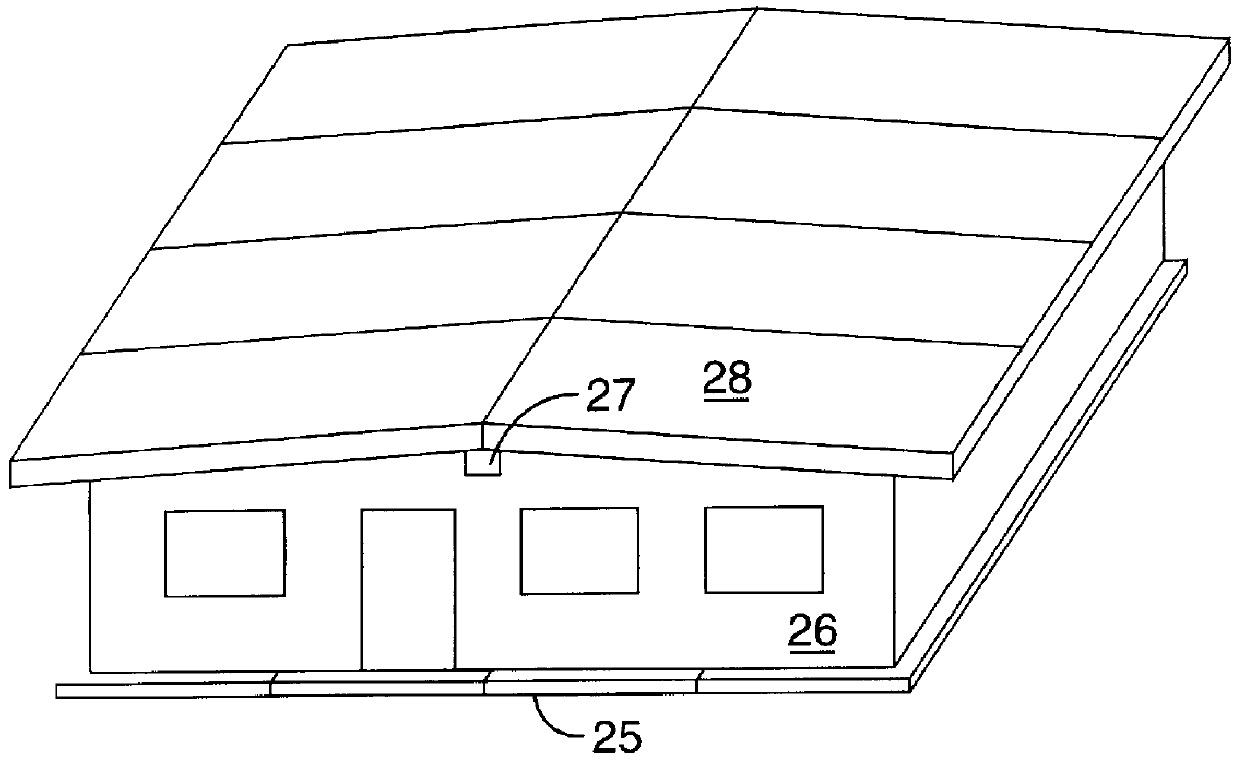

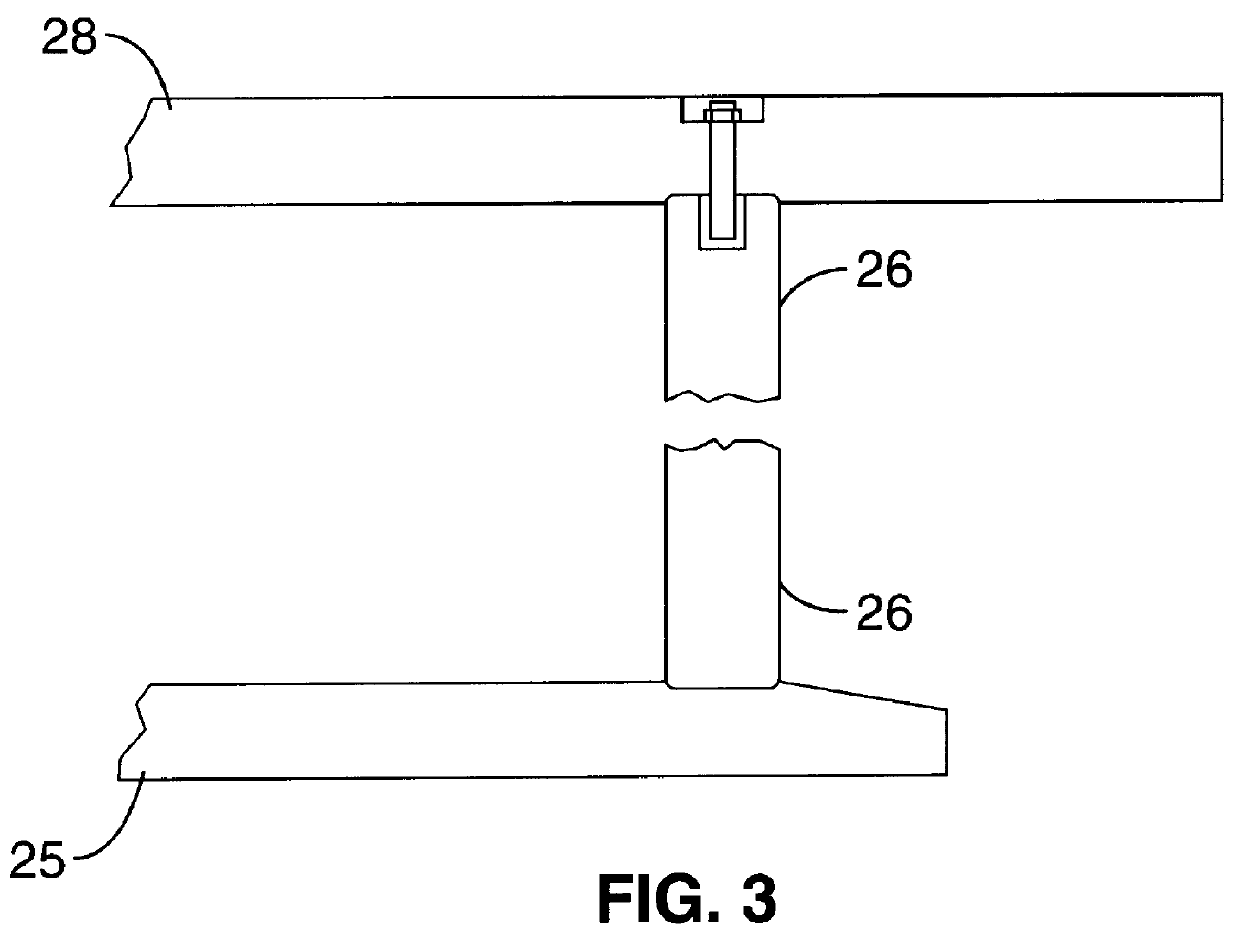

Method of manufacturing a building material from volcanic magma

A method of manufacturing a building material includes the steps of directing molten volcanic magma from an underwater volcanic magma vent to a level above sea level via a tube formed from the magma; directing the molten volcanic magma into a mold on a floating barge; cooling the magma in the mold to form a building material; and removing the building material from the mold. The tube is formed by lowering a cap assembly over an underwater flowing volcanic magma vent and raising the cap such that the magam solidifies inside the cap perimeter where it is cold.

Owner:WATSON LOUIS L

Process for preparing low-salt heavy soda ash

The invention relates to a method for preparing low-salt heavy soda ash by applying a multi-temperature phase diagram of a Na2CO3-NaHCO3-H2O ternary system, utilizing the feature that the system can precipitate anhydrous sodium carbonate crystals at the appropriate temperature and the composition and adopting the anhydrous sodium carbonate flow process. The method comprises the following steps: carrying out pressure wet decomposition on mixed solution of the heavy soda ash which is rich in sodium bicarbonate or refined natural alkali halide, leading the content of the sodium bicarbonate and the content of sodium carbonate in the solution to achieve the corresponding proportion, further leading the solution to enter into a multi-effect evaporator for evaporation and concentration, controlling the crystallization temperature to be above the phase transition point from anhydrous sodium carbonate to sodium carbonate monohydrate, and ensuring that the precipitated solid phase is the anhydrous sodium carbonate; and taking out a magma by self-pressure, carrying out thermal insulation and separation, obtaining a filter cake which mainly contains the anhydrous sodium carbonate, and drying the filter cake for preparing the low-salt heavy soda ash. The process can change the traditional two-step dry calcination to one-step wet calcination, simplify and shorten the process flow, reduce the area occupied by devices, improve the operation environment, simultaneously improve the quality of a product and reduce the energy consumption.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

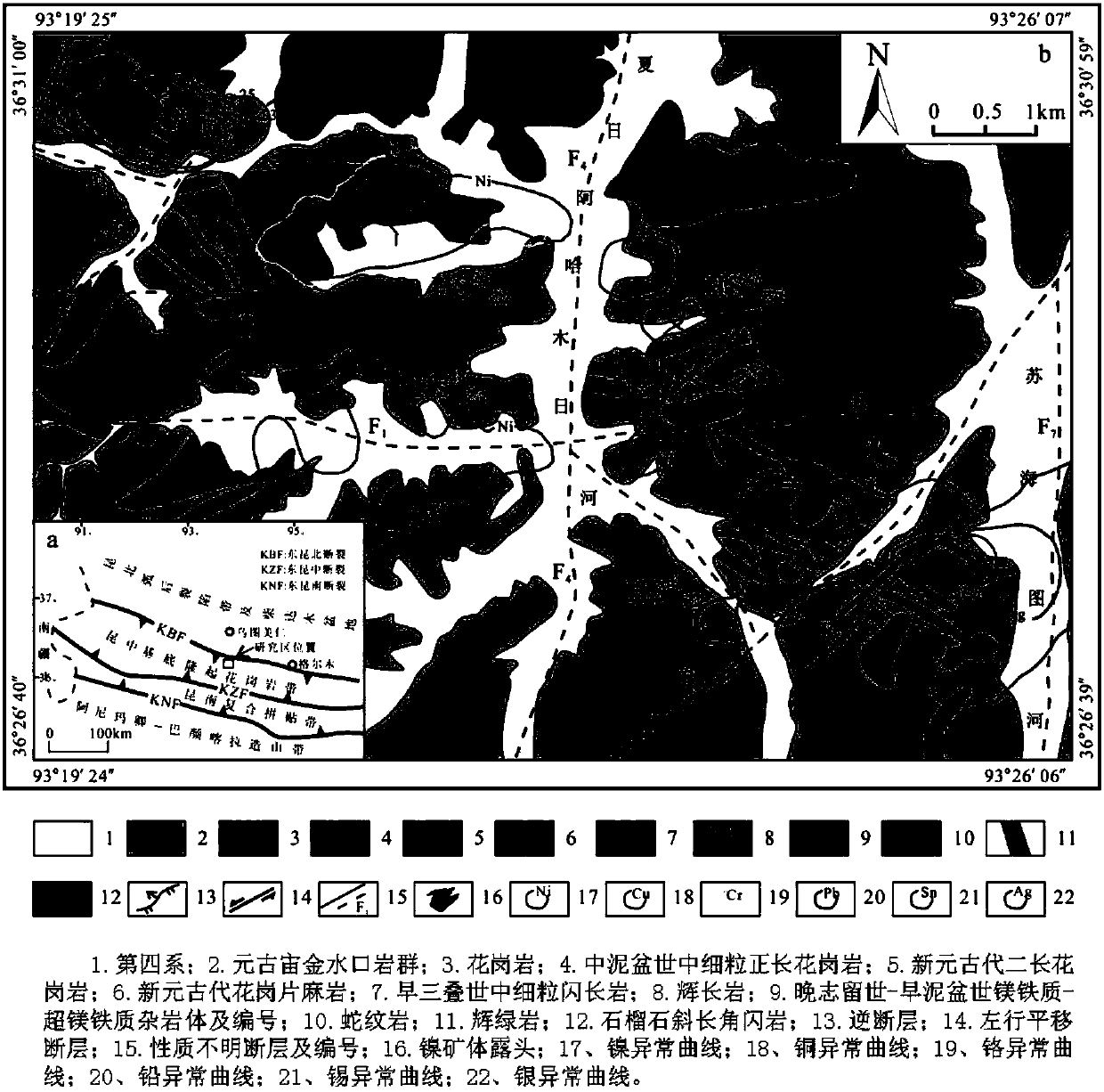

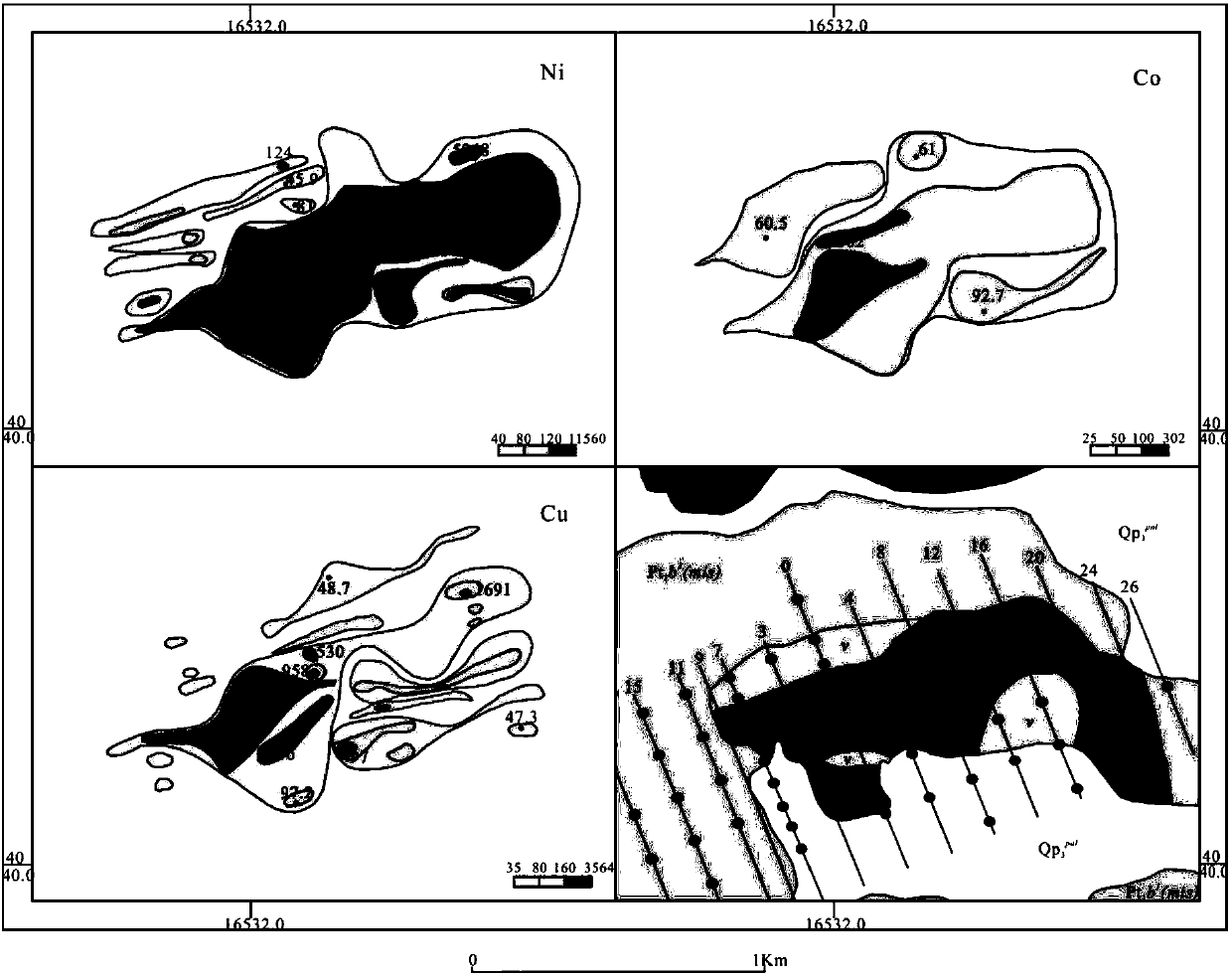

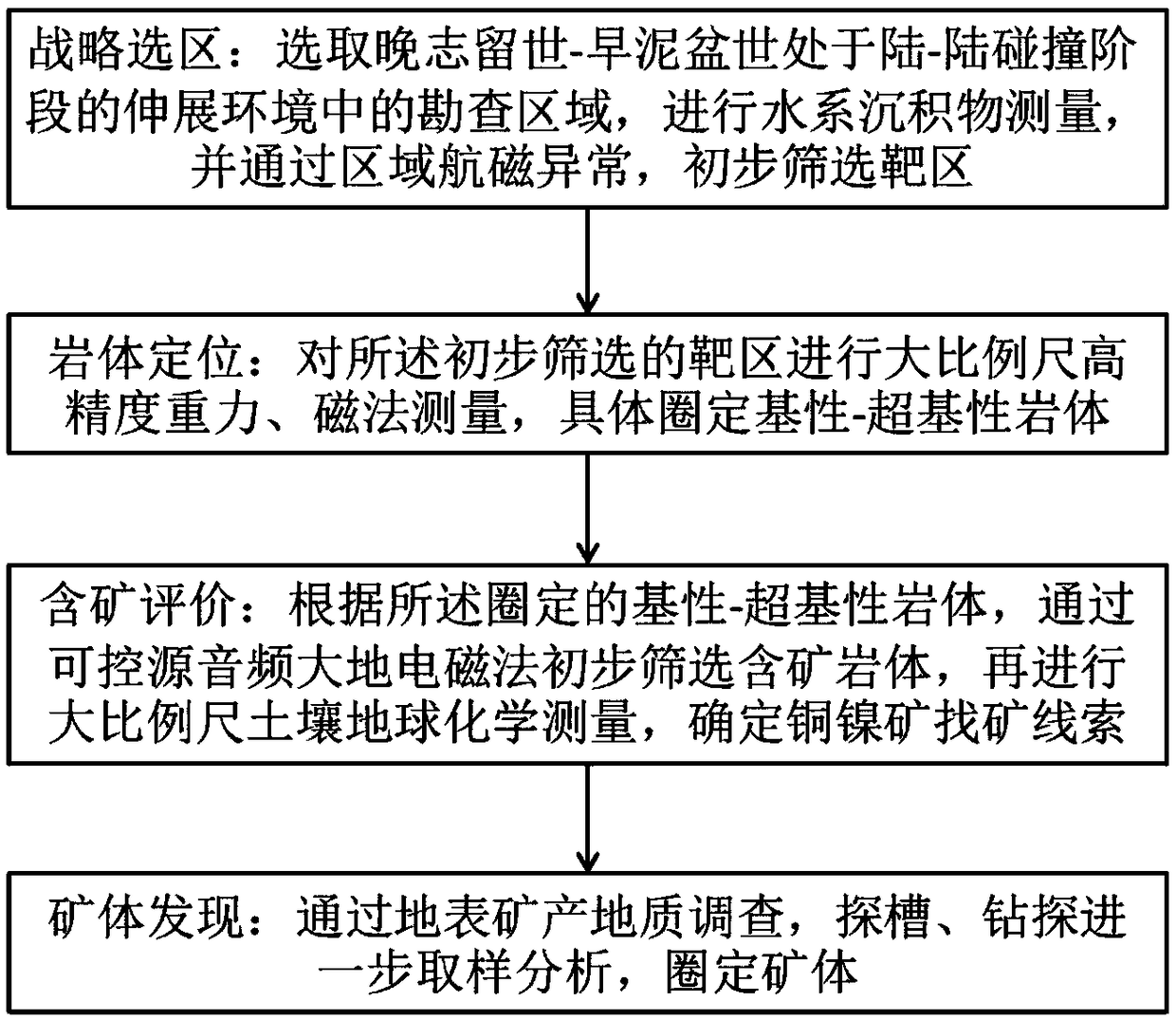

Prospecting method for orogenic magmatic melting nickel ore

InactiveCN108802830AWidely applicable to prospectingImprove the success rate of prospectingElectric/magnetic detectionAcoustic wave reradiationWater basedMagma

Provided is a prospecting method for orogenic magmatic melting nickel ore. The method comprises the following steps: selecting the exploration area in the extended environment of the Late Devonian andthe Early Devonian in the land-continent collision phase, performing the water-based sediment measurement, and preliminarily screening the target area through regional avionic abnormality; carrying out large-scale high-precision gravity on the preliminarily screened target area, and specifically delineating the basicity- ultrabasic rock mass; according to the delineated basicity- ultrabasic rockmass, preliminarily screening the ore-bearing rock mass by a controllable source audio magnetotelluric method, and then carrying out the large-scale soil geochemical measurements to identify copper-nickel ore prospecting clues; and through surface geological survey of minerals, further sampling and analyzing trenches and drilling, and delineating ore bodies. According to the method, the prospecting range can be reduced, the exploration period is short, and the prospecting success rate is improved, the exploration efficiency is high, and meanwhile, the method can be widely applied to the searchfor various metal mines in the magnesium-iron-supermafic rock area.

Owner:青海省地质矿产勘查开发局

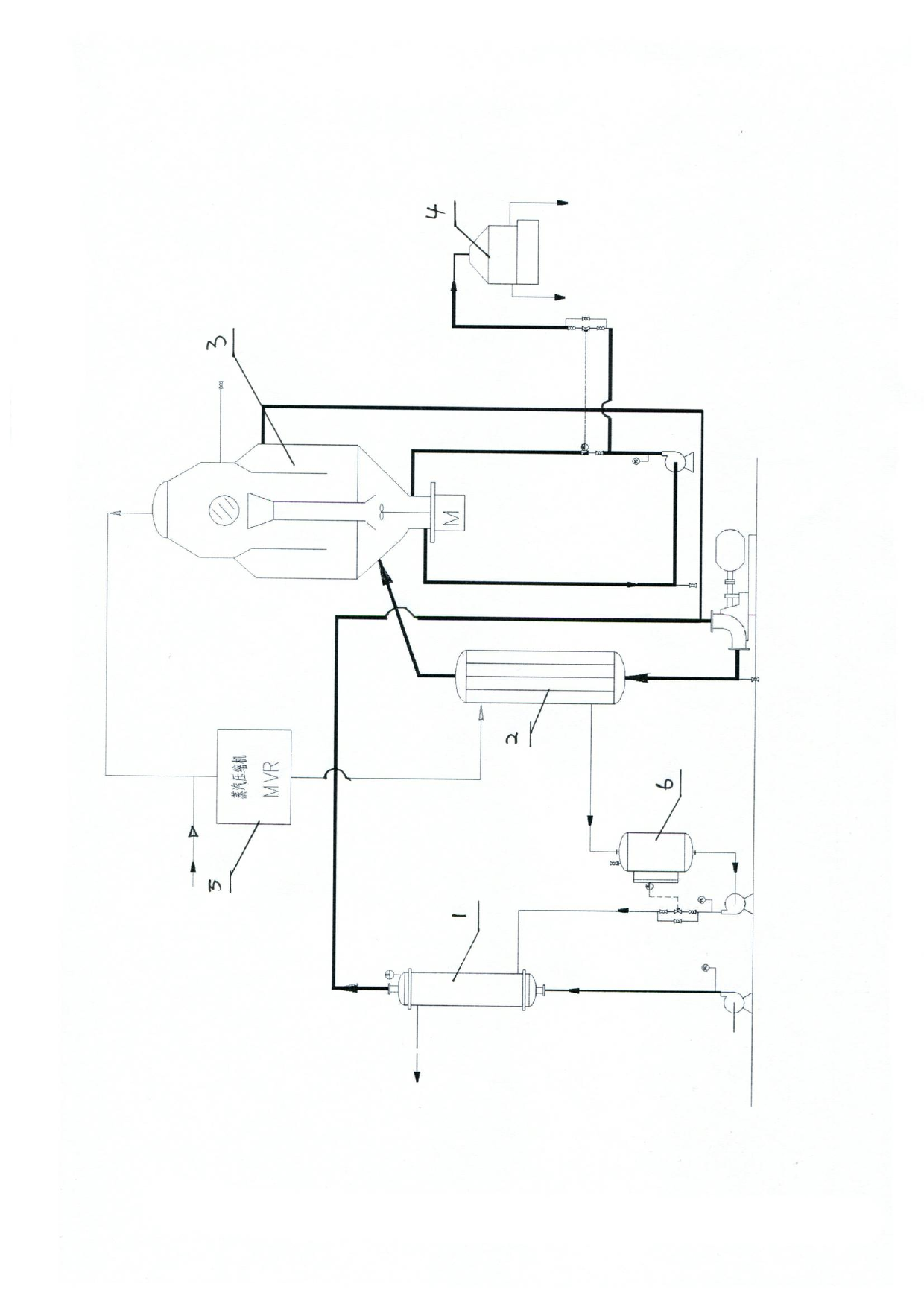

New energy-saving technology for producing edible potassium chloride

InactiveCN102167363AAccelerate evaporationEvenly distributedChemical industryAlkali metal halide purificationMagmaNew energy

The invention provides a new energy-saving technology for producing edible potassium chloride. The technology comprises the steps of: leading dissolved and decontaminated potassium chloride solution to enter a preheater for preheating; mixing mother liquor overflowed out of a DTB (draft tube) crystallizer with materials discharged out of the preheater, and transporting the mixture by a forced circulation pump to enter a heating evaporator; heating by the heating evaporator, and warming by absorbing the heat energy; and crystallizing in the DTB crystallizer; transporting magma to a centrifugal machine to separate by the transport of a magma pump so as to obtain a potassium chloride crystalloid; warming secondary vapor discharged out of the DTB crystallizer in a compressing way by a vapor compression machine, transporting the warmed secondary vapor into the heating evaporator to indirectly heat up the materials; and leading condensed water to enter a collector for preheating the preheater. The new energy-saving technology is stable and reliable in operation, large in crystallizing grain sizes, high in yield, and low in energy consumption.

Owner:LIANYUNGANG SHUREN KECHUANG FOOD ADDITIVE

Distille's yeast for brewing magma fruit liquor

InactiveCN1465688AIncrease varietyMeet needsMicroorganismsAlcoholic beverage preparationMagmaAlpha-amylase

The composition of distillers' yeast for making raw material fruit white liquor includes (by weight portion) 12.5-17.5 portions of mixed type saccharifying enzyme, 3-6 portions of acid-resistant dried yeast, 6-7.5 portions of rhizomycin, 3-6 portions of aspergillin, 1-3.5 portions of flavouring yeast, 1.5-3 portions of acid proteinase and 1-3 portions of cellulase, in which the mixed type saccharifying enzyme is respectively formed from the following components: 25-30 portions of glucose anylase, 2.5-5 portions of alpha-amylase, 10-13 portions of beta-amylase and 1-3 portions of proteinase.

Owner:李松林

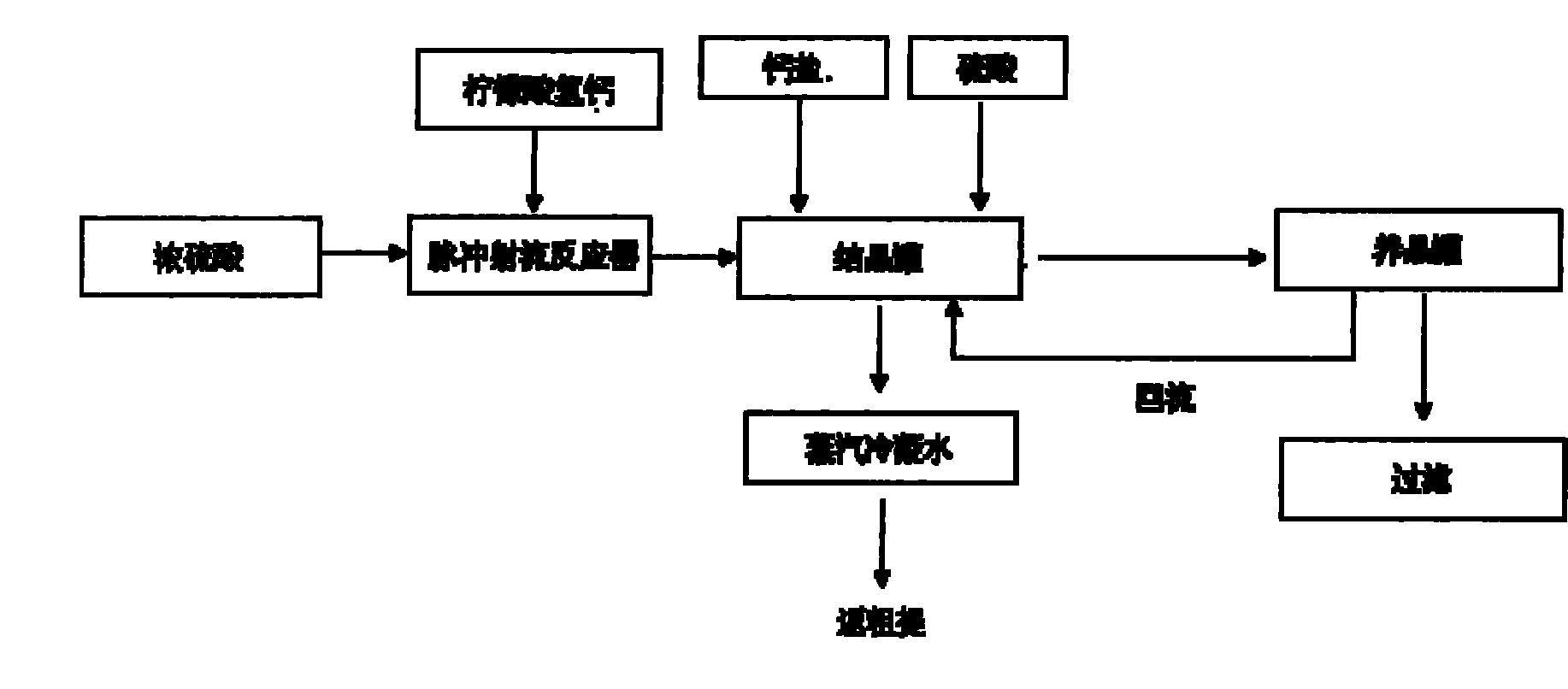

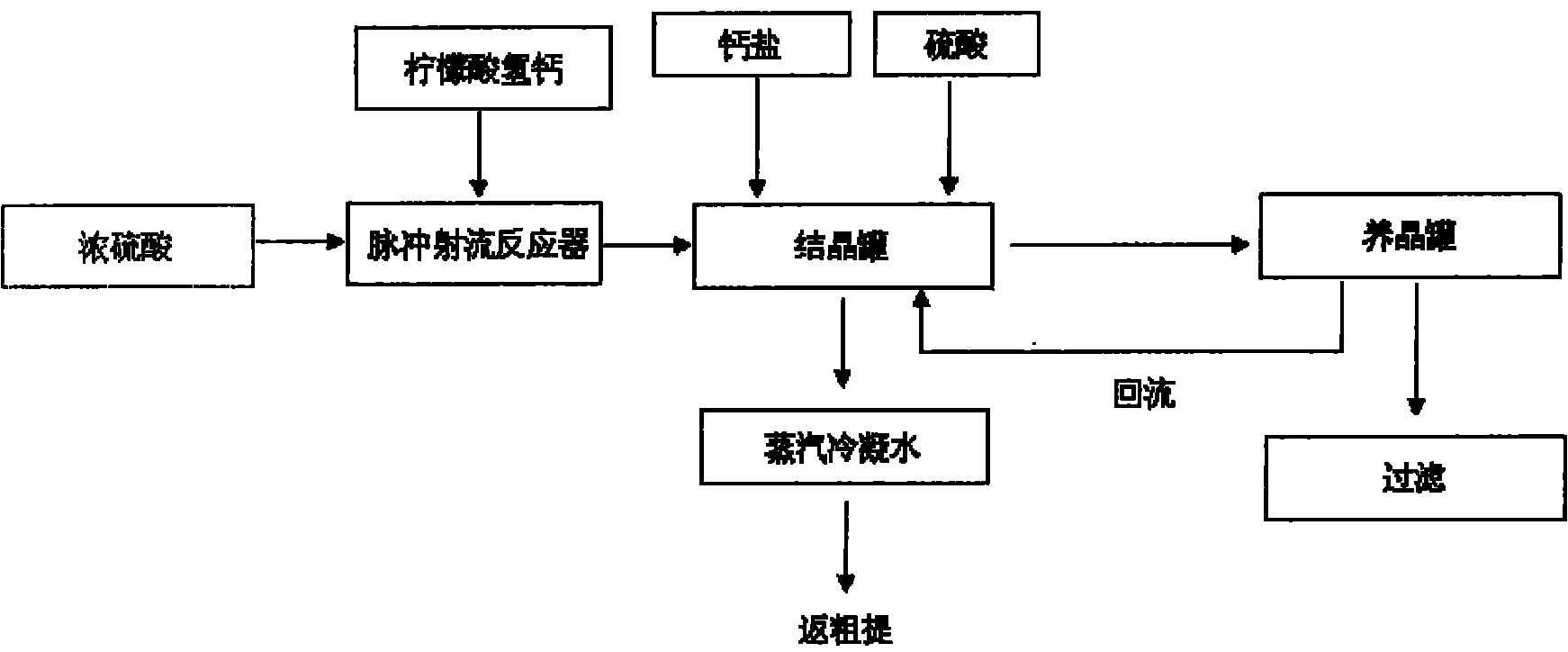

Continuous acidolysis process for calcium hydrogen citrate

ActiveCN102060691AHigh degree of automationContinuous stable operationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationMagmaCITRATE ESTER

The invention relates to a continuous acidolysis process for calcium hydrogen citrate. The process mainly the following steps of: 1, respectively feeding calcium hydrogen citrate and concentrated sulfuric acid into a pulse jet reactor through pipelines for finishing an instantaneous acidolysis reaction in the reactor; 2, performing fine adjustment on the pH value of reaction solution in a crystallizer and finishing a crystallization process; and 3, finishing coarse-fine granule grading of the magma liquid in a maturing tank, and making the magma liquid enter a filtering process to finish solid-liquid separation. The process has the advantages of thorough reagent reaction, high automation degree, high acidity of acidolysis liquid, good crystal form of byproducts such as calcium sulphate, controllable granularity and the like.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Measuring method for distribution coefficient of zircon microelement and zircon magma microelement

The invention discloses a measuring method for a distribution coefficient of a zircon microelement and a zircon magma microelement. The method comprises the steps of scanning the surface of a sample through a laser beam or a primary ion beam to obtain images of microelements and background elements, determining an analysis position through obtained image information of the microelements, deflecting the laser beam or the primary ion beam to the selected analysis position, and measuring the content of the zircon microelement and the content of the magma glass microelement in a non-scanning mode.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

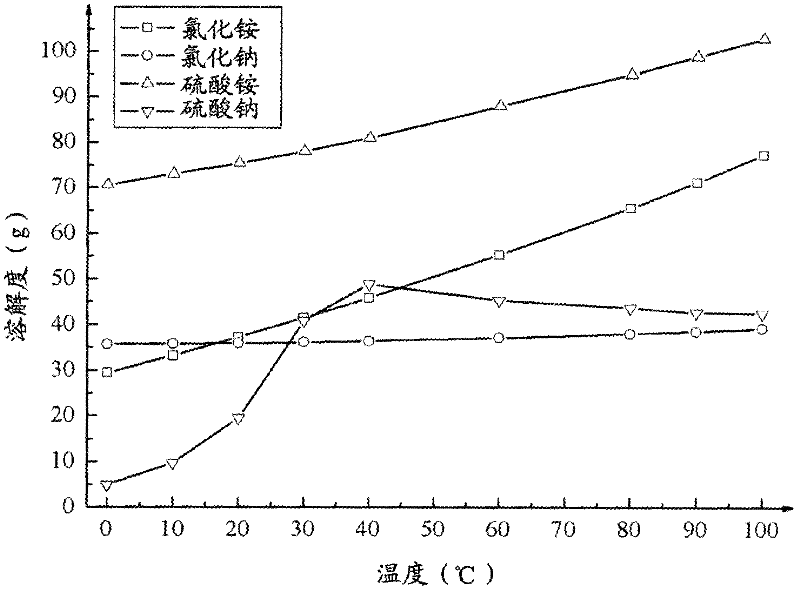

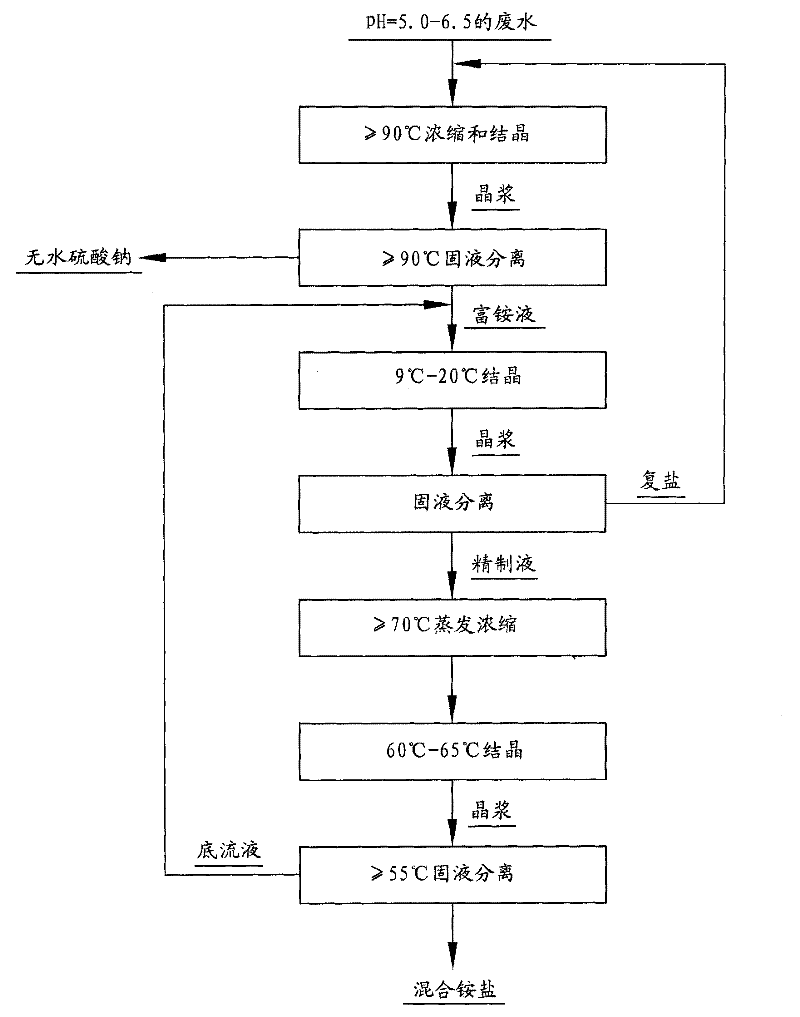

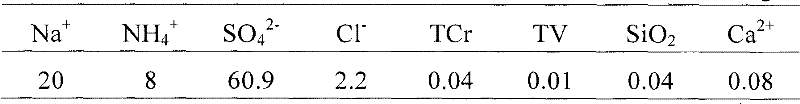

Treatment method of sodium-roasted-leached-acid ammonium salt vanadium precipitation waste water

The invention provides a treatment method of sodium-roasted-leached-acid ammonium salt vanadium precipitation waste water. The method comprises the following steps of: (a) concentrating and crystalizing waste water of which the pH value is 5.0-6.5 at the temperature of over 90 DEG C to obtain first magma, and performing solid-liquid separation at the temperature of not lower than 90 DEG C to obtain an anhydrous sodium sulfate crystal and a first solution; (b) crystalizing the first solution at the temperature of 9-20 DEG C, and performing solid-liquid separation to obtain a complex salt of sodium sulfate and ammonia sulfate; and (c) evaporating and concentrating the second solution at the temperature of over 70 DEG C, crystalizing at the temperature of 60-65 DEG C to obtain second magma, and performing solid-liquid separation on the second magma at the temperature of over 55 DEG C to obtain a mixed ammonia salt containing ammonia sulfate and ammonium chloride, and a third solution.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Double dating method for single-particle monazite

The invention discloses a double dating method for single-particle monazite. The method includes the steps that the crystallization age, namely the occurrence time of a magmatic intrusion incident , of a granite geologic body where the monazite is located can be obtained; (U-Th) / He age of the monazite can be obtained and represents the uplift-related cooling age, namely the time of fast tectonic uplift of the geologic body. The intrusion history and the tectonic uplift history of the geologic body where the monazite is located can be obtained through U-Pb and (U-Th) / He double dating of the single monazite at the same time, and the double dating method is of important geological significance.

Owner:HEBEI UNIV OF ENG

Magma diluent

A condensed-oil diluting agent for improving steam throughout effect and recovery rate driven by auxiliary chemical steam in condensed-oil thermal extraction is prepared by analyzing partial transition metal element in crude-oil molecular structure chain for crude-oil viscosity influence, controlling object element content variation by physical chemical method and decreasing viscosity and flowing resistance. The condensed-oil diluting agent consists of complexone III, low-grade fatty acid, chelate dispersant and sulfosalt discharging aid. It can eliminate close-well block, inhibit clay expansion and improve stratum permeability, back-extraction speed and rate and restore oil-well production.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com