Patents

Literature

87results about How to "Achieving Precise Forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

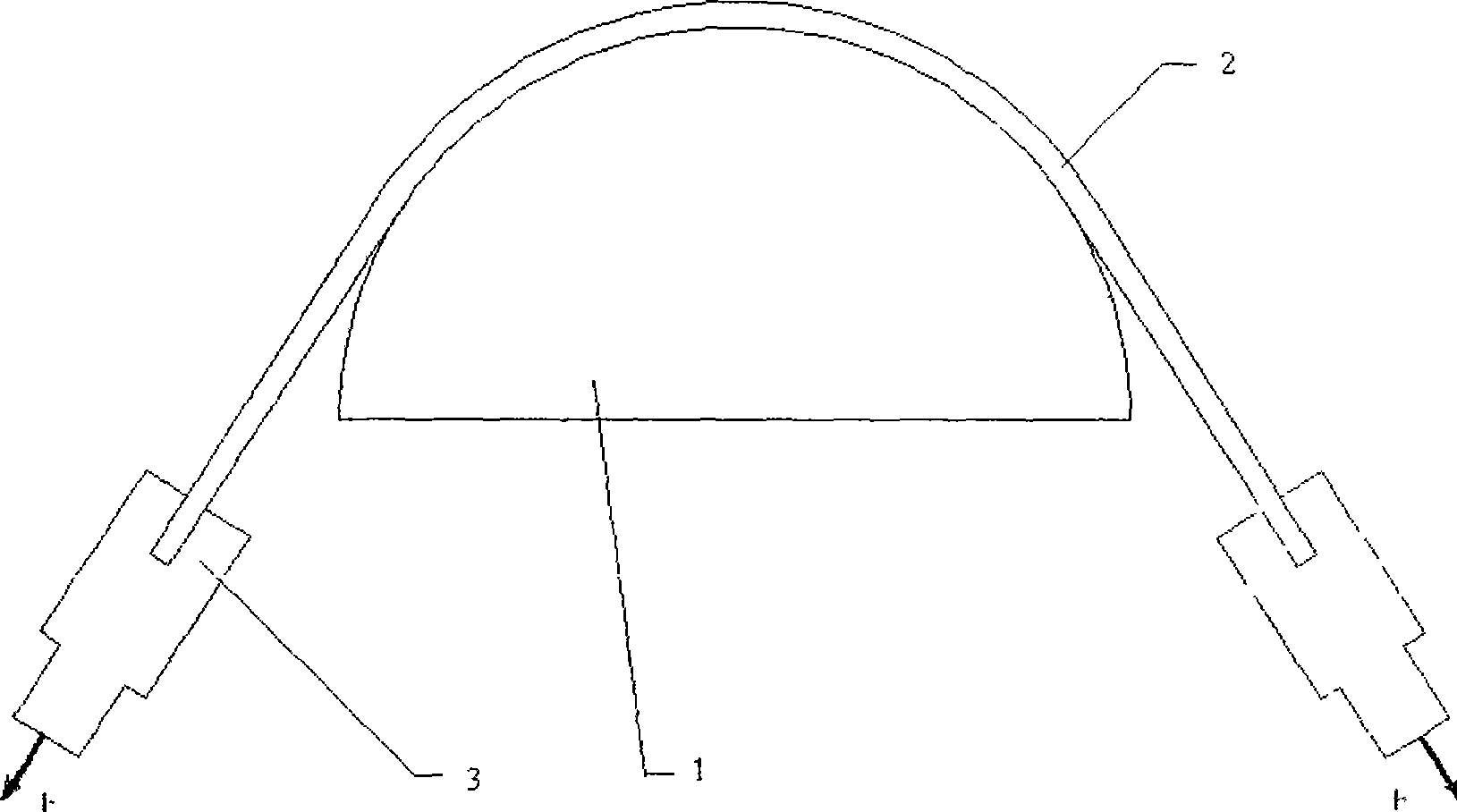

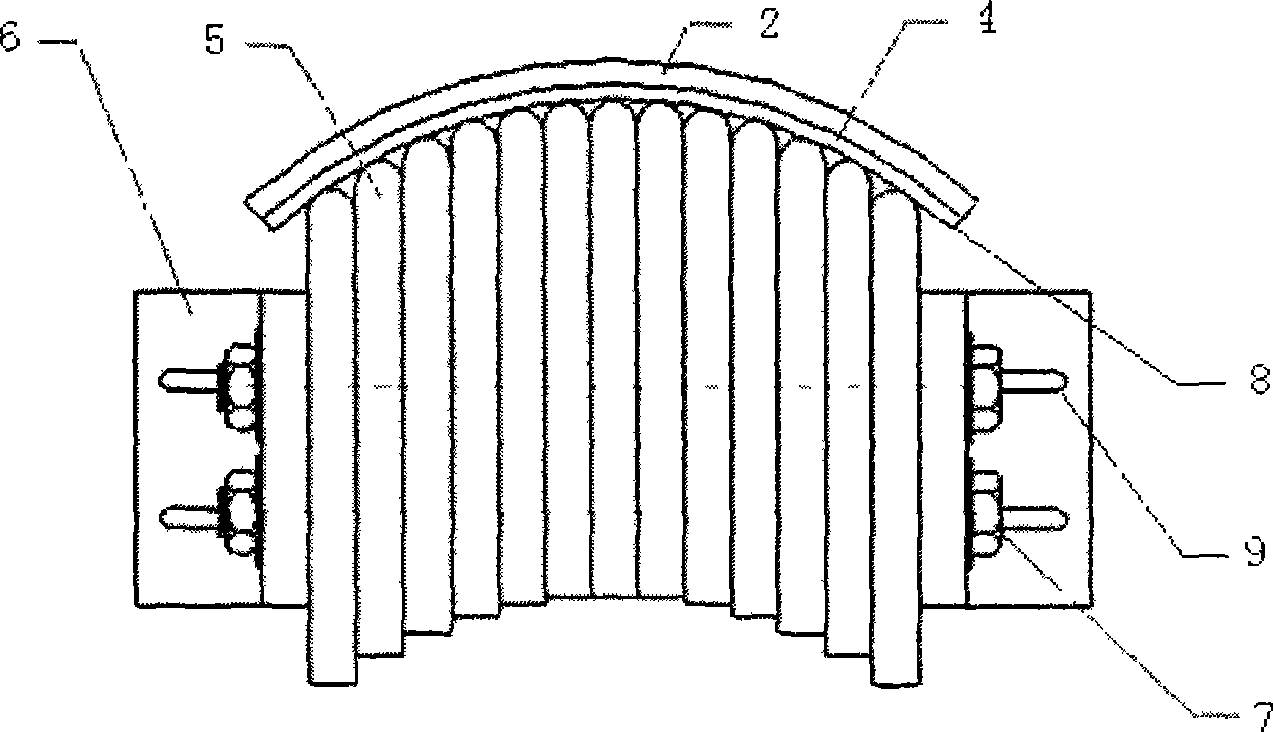

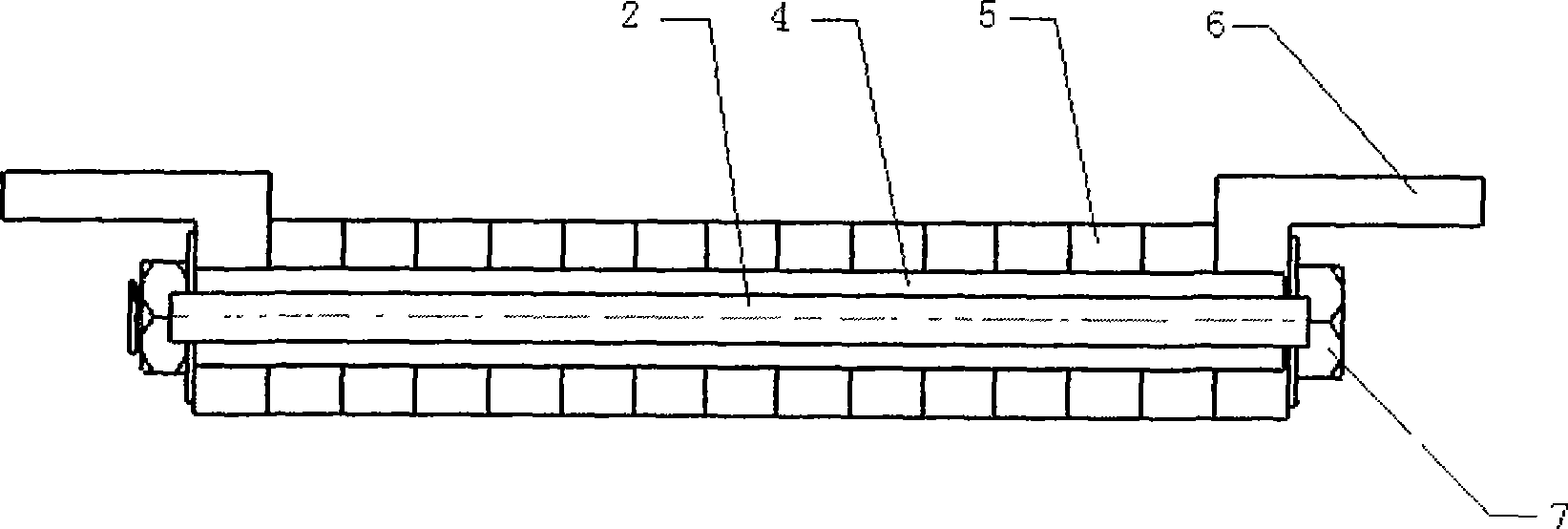

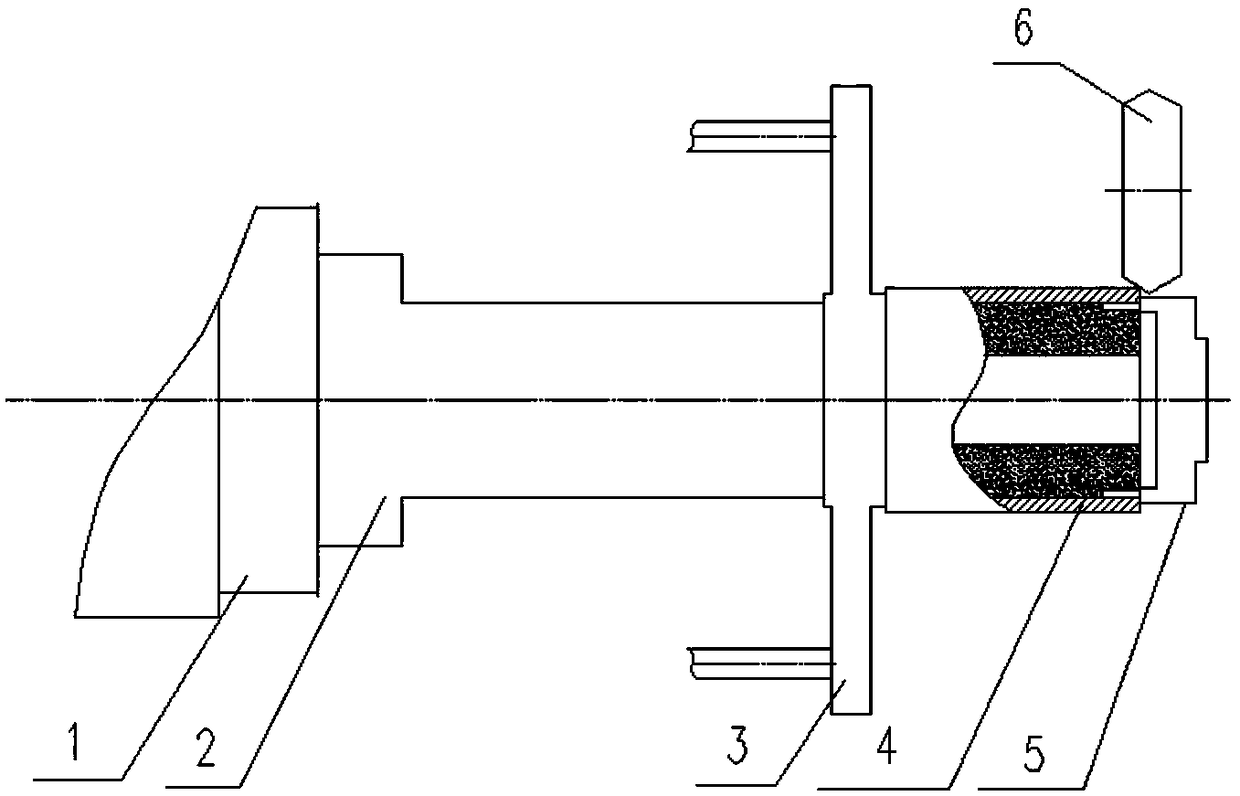

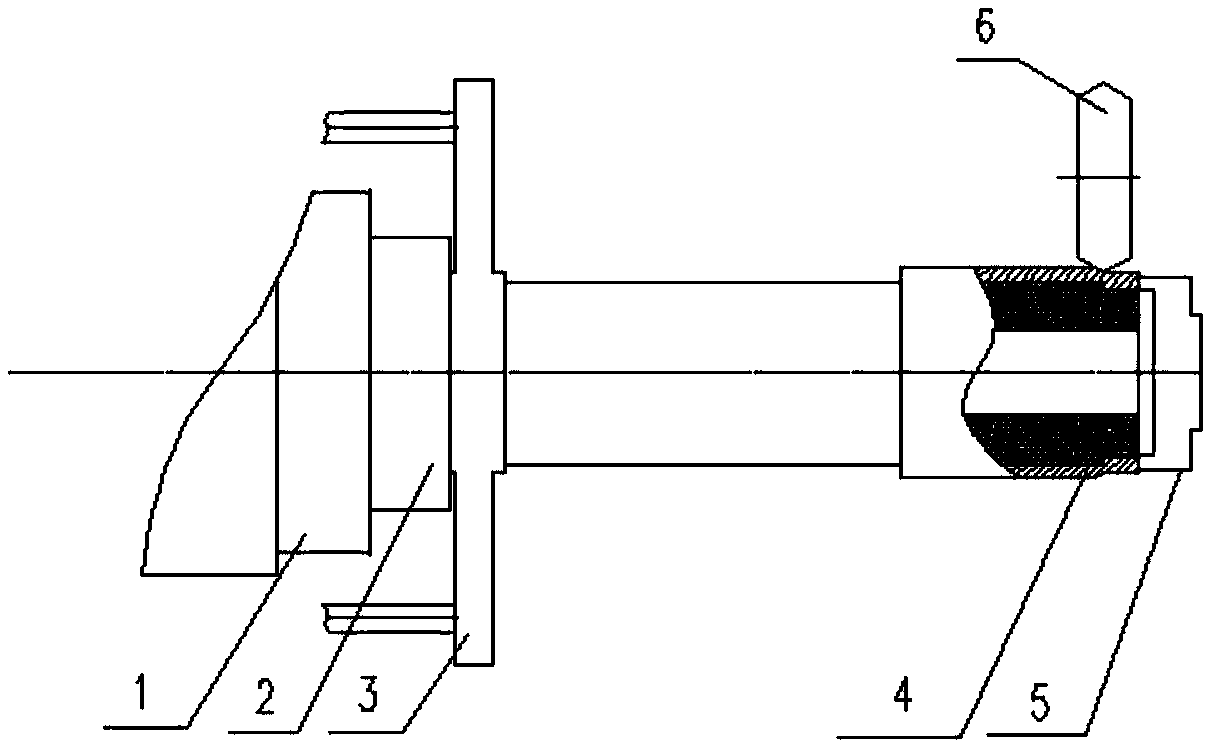

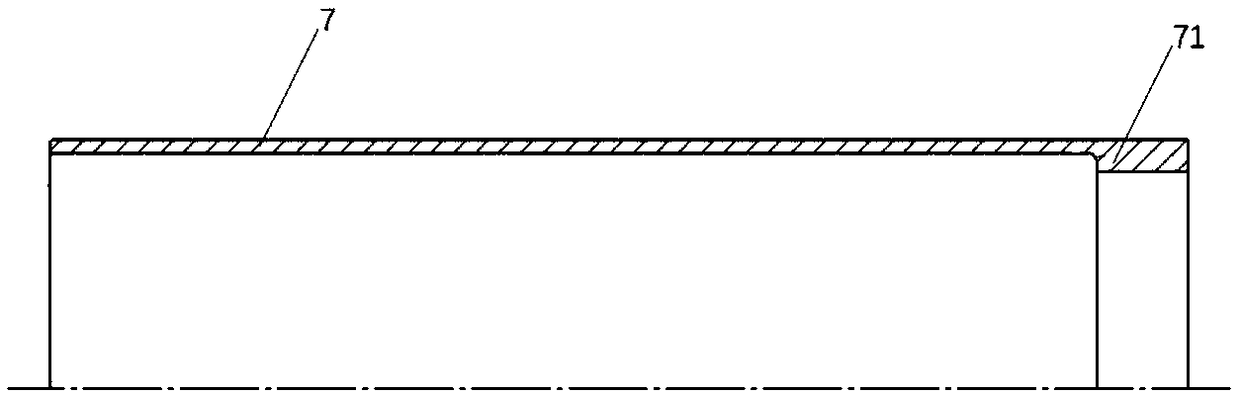

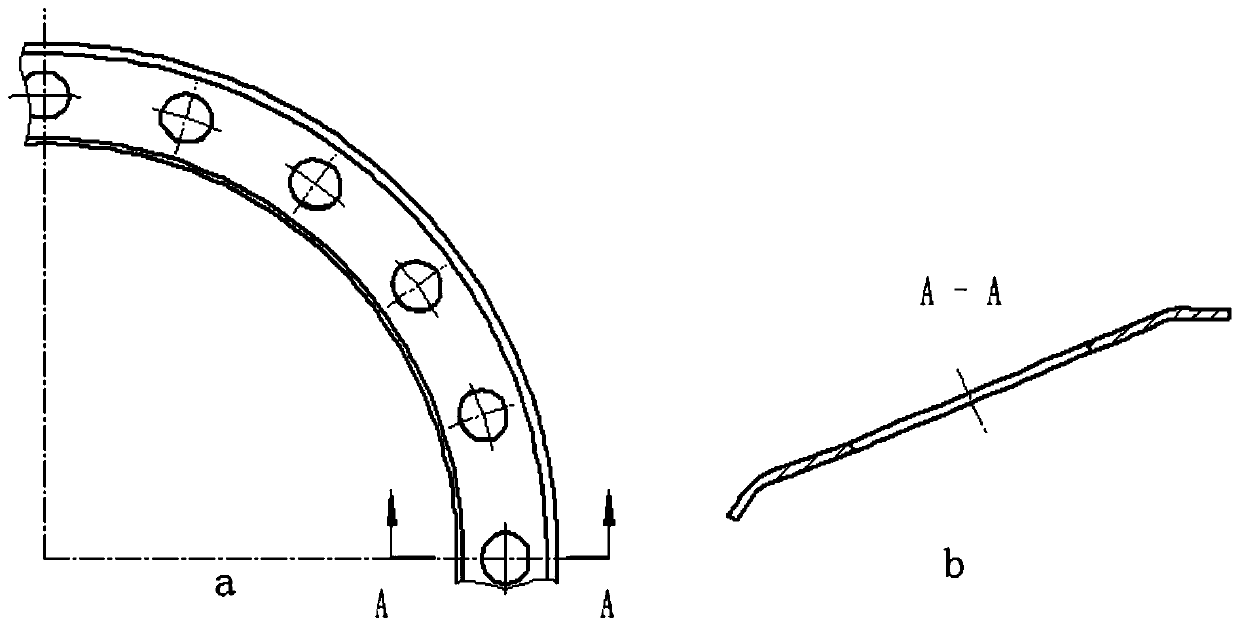

Stretch-bending forming die and forming method

InactiveCN101518802AAchieving Precise FormingShorten the design and production cycleShaping toolsEngineeringCushion

The invention discloses a stretch-bending forming die and a forming method, including a basic body (5), a cushion layer (4), a connecting bolt (7) and two clamp blocks (6). The end surface of one end of the basic body (5) is an arc working surface (10), with a through-hole (11) which is matched with the connecting bolt (7) in the middle. One clamp block, a plurality of basic bodies and another clamp block are sequentially arranged on the connecting bolt (7) in series and tightly clamped and fixed, thereby integrating a die; by adjusting the position (11) where the connecting bolt passes through a through groove on each basic body, the position of the working surface (10) of each basic body is adjusted; and by fixing the die onto the working table of a stretch bender by a mounting hole (9), the stretch-bending forming is carried out to a workpiece (2) to be formed. In the forming process, by slightly adjusting the position of the basic body (5), the shape of the external surface of the die is changed so as to compensate the rebounding effect on the forming accuracy and adapt to the rebounding control needs of different stretch-bending parts; and the invention is characterized by simple structure, convenient use, high production efficiency and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

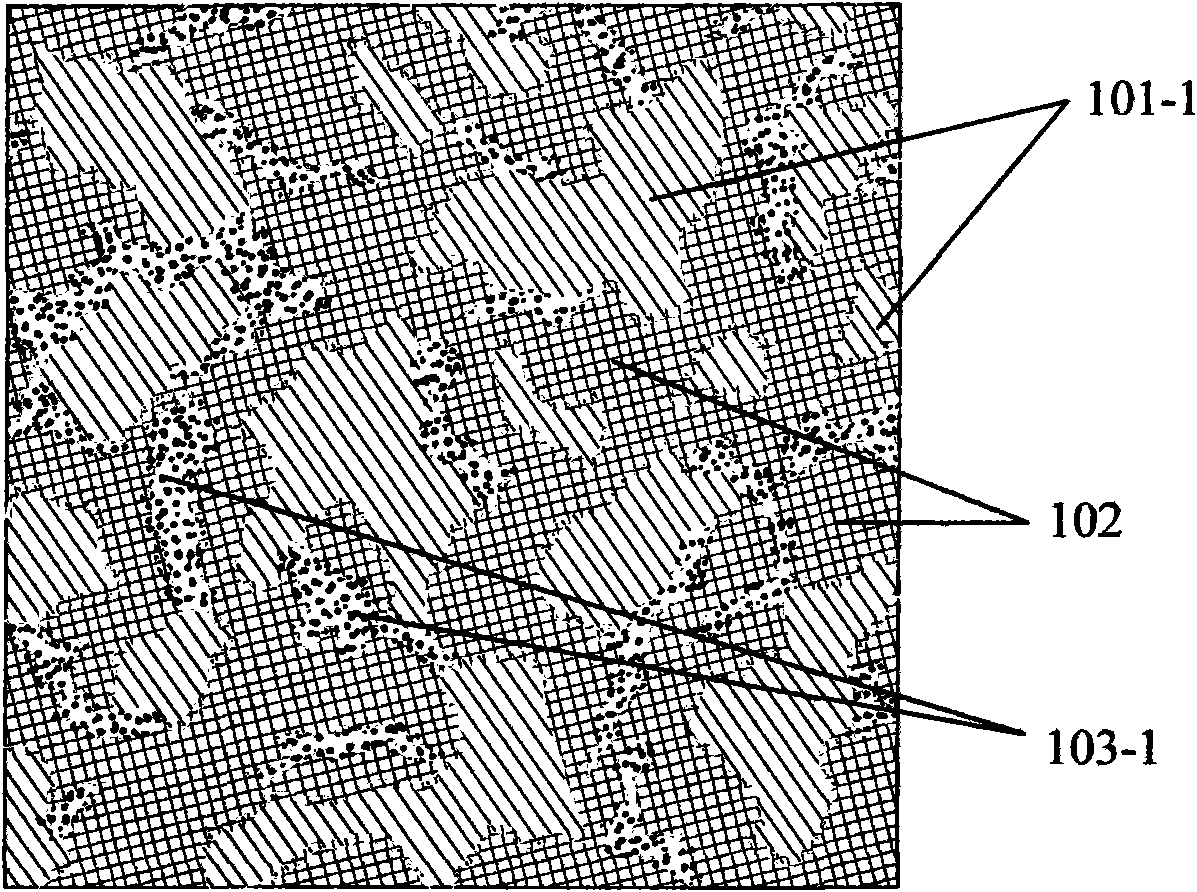

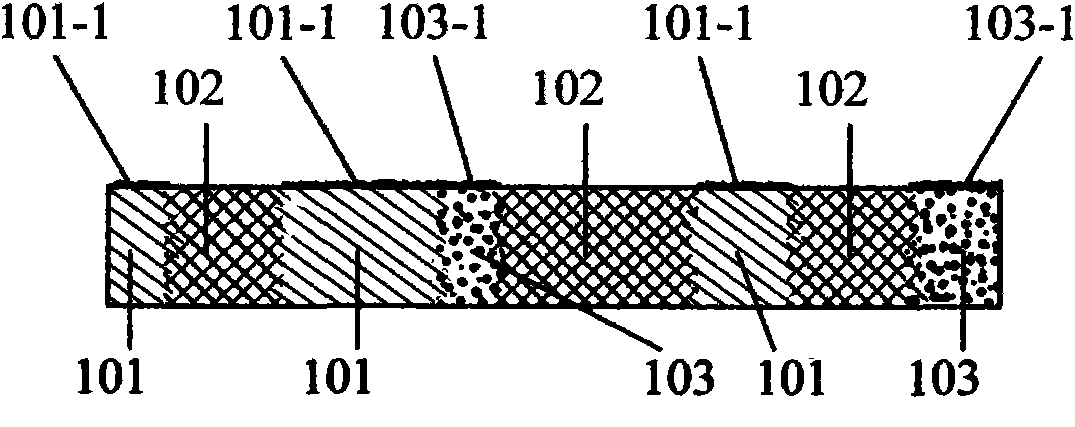

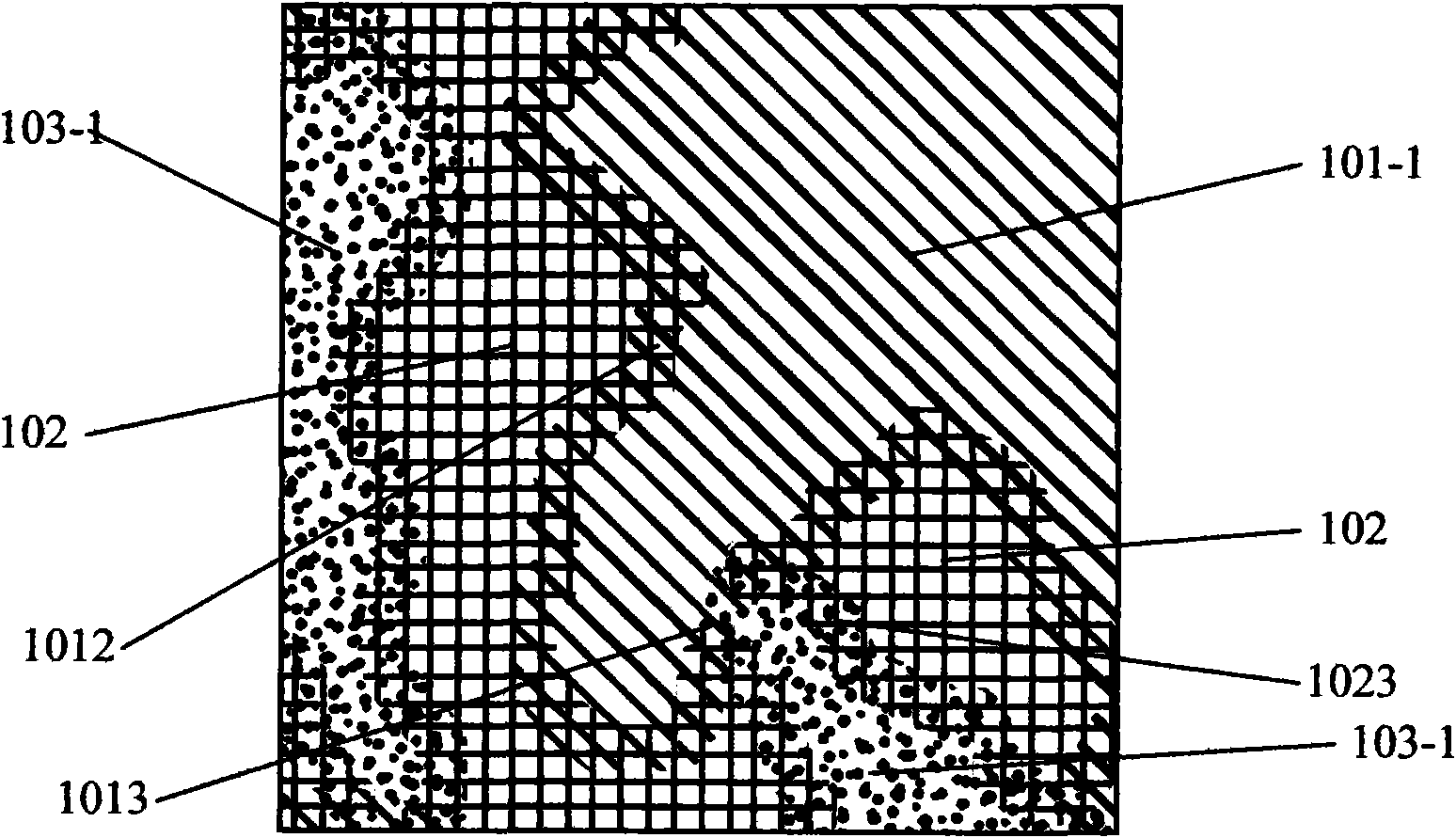

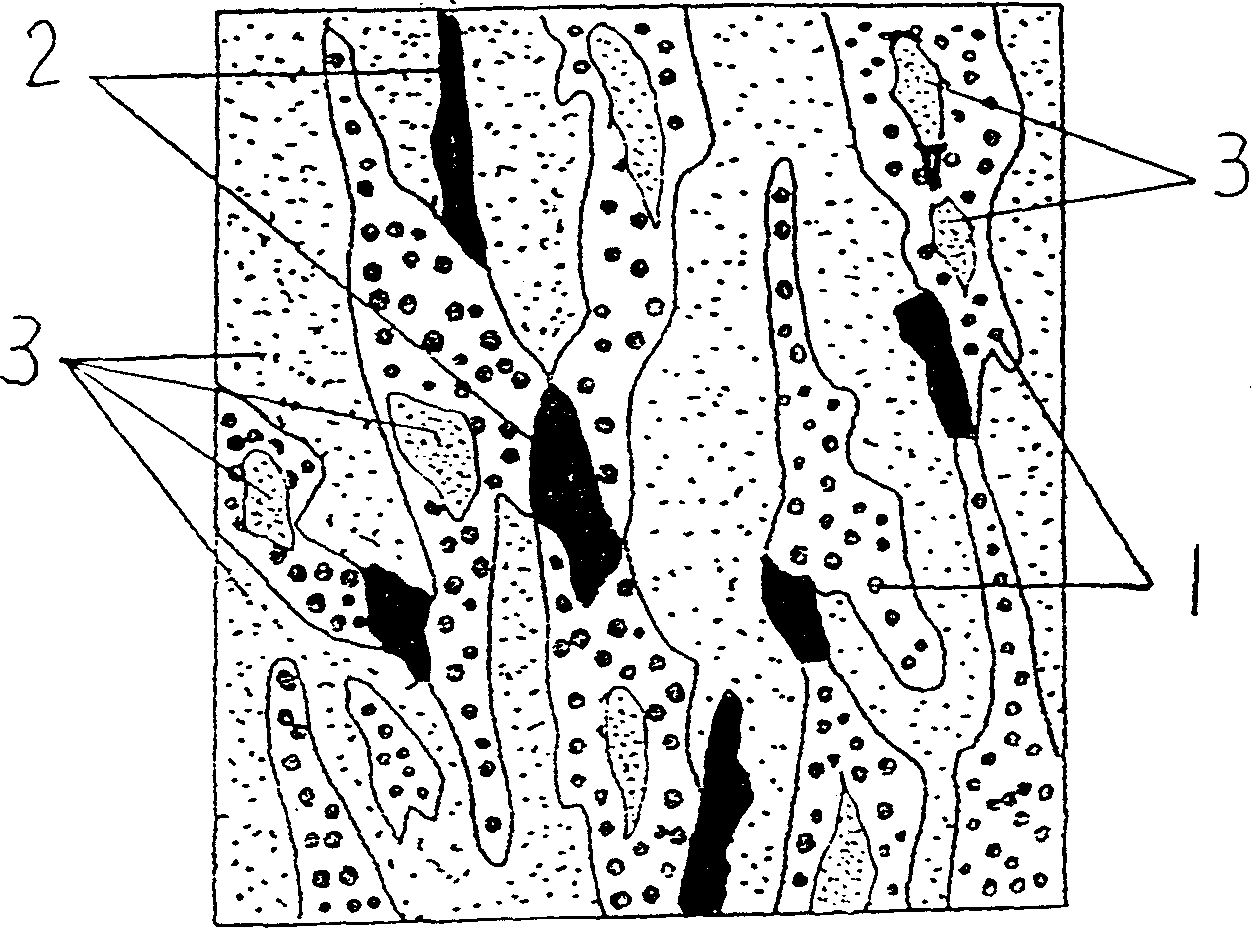

Three-dimensional antique stone produced by flowing-imitating magma and producing method thereof

InactiveCN101554821AAccurate and fast vertical stackingAchieving Precise FormingNatural patternsOrnamental structuresMagmaNatural stone

The invention relates to a three-dimensional antique stone produced by flowing-imitating magma and a producing method thereof. The three-dimensional antique stone is characterized in that the prepared product comprises patterns with 2-10 obvious billet colors, wherein in at least two colors, 1-10000 billet color pattern regions with thickness reaching 2-30mm and area being 2cm to 0.5m exist; powder materials with different colors have the characteristic of mixing mutually, wherein the edge of at least one pattern region is provided with 10-1000 color powder particles, 2 / 3-3 / 3 of edges of the peripheries of which are covered by the other adjacent color region; and a billet color pattern layer of the product is provided with a colored glaze pattern layer with 1-10 colors. The method can greatly improves the imitation expressive ability of mixing transition of colorful natural stones and color region borders, and has the characteristics of the patterns nearly never being worn and torn because of the billet thickness of the pattern layers, thereby being more suitable for the practicability.

Owner:杨德宁

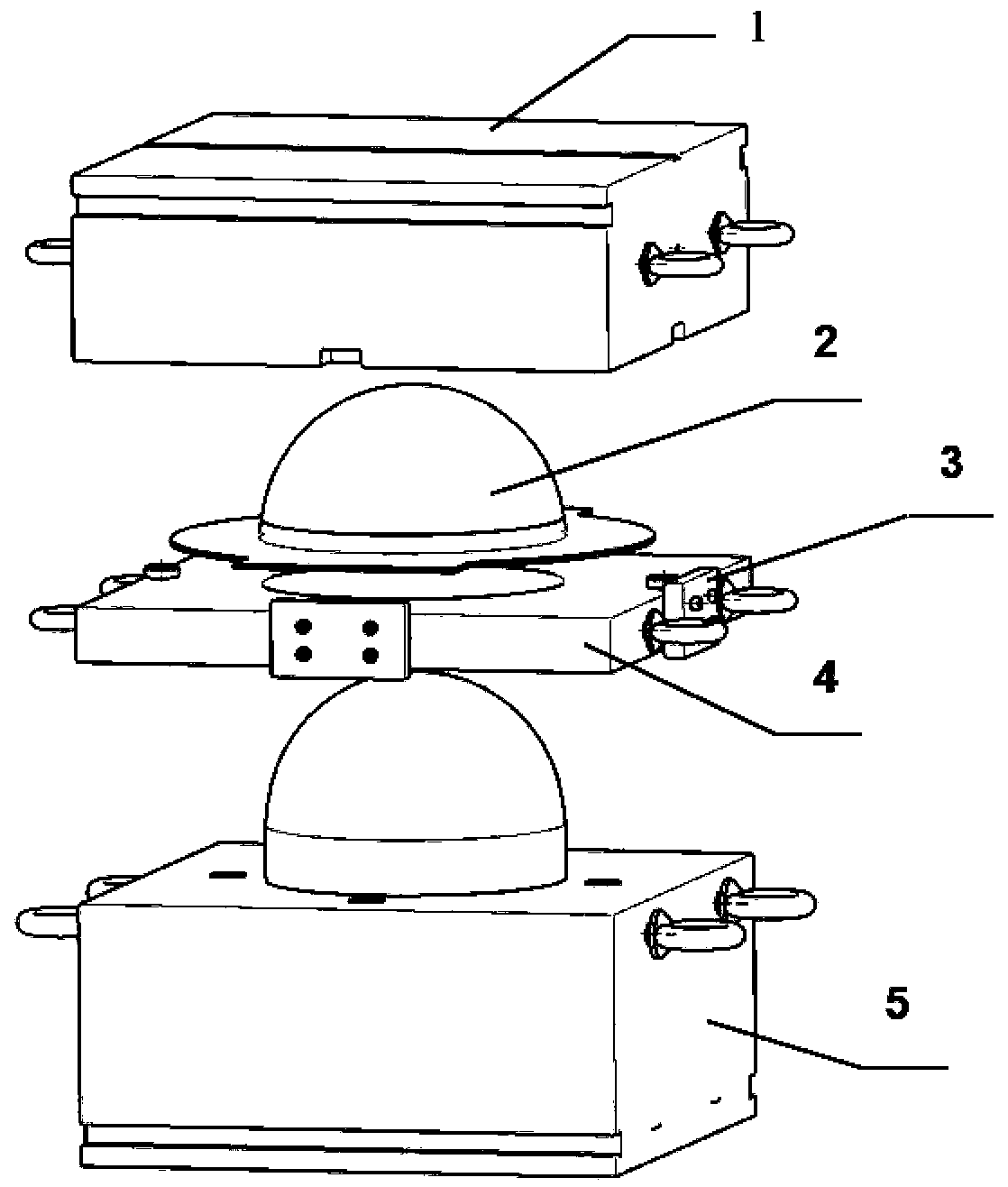

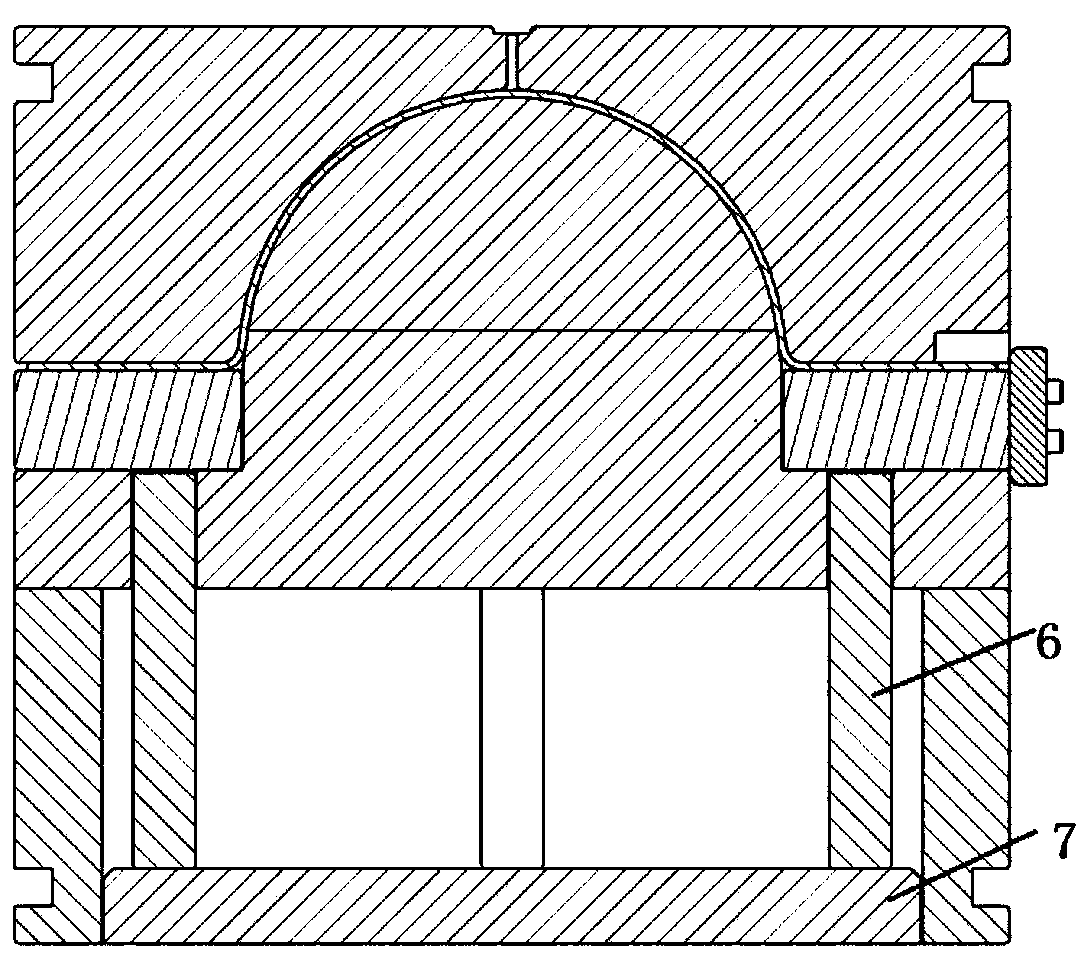

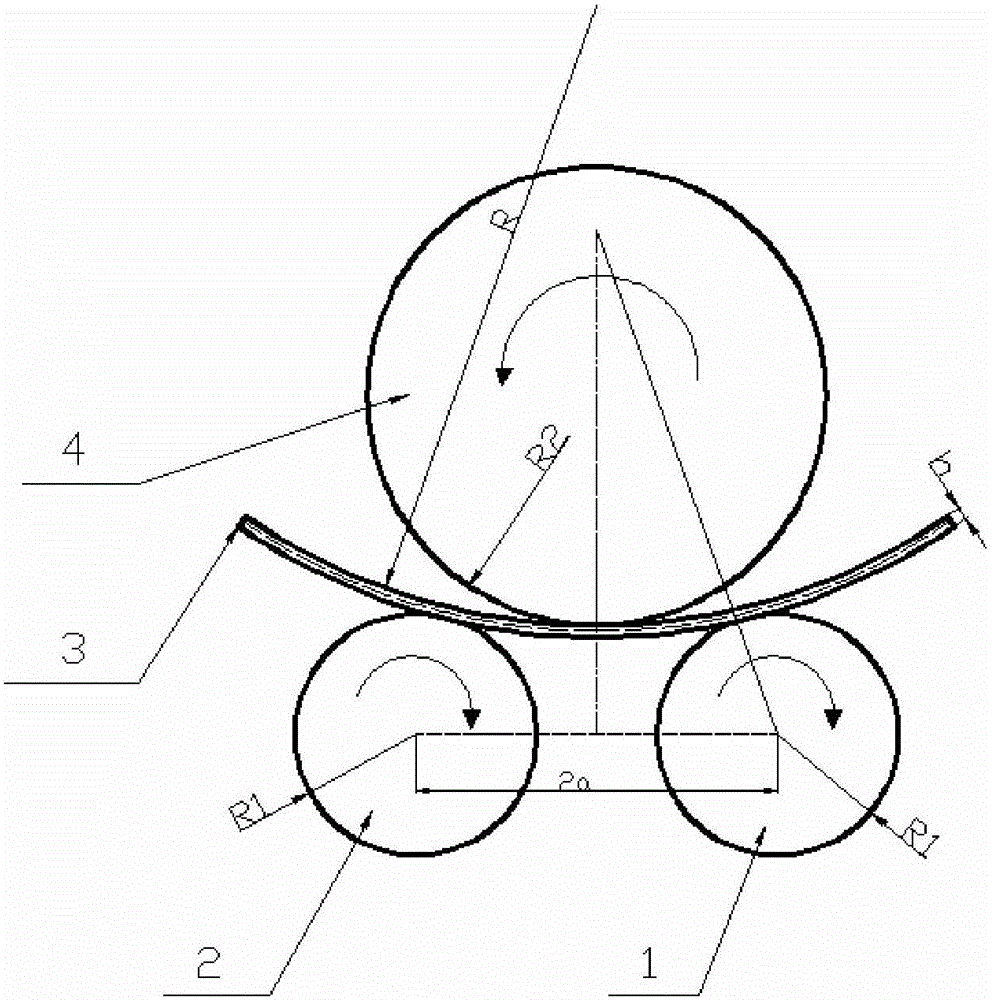

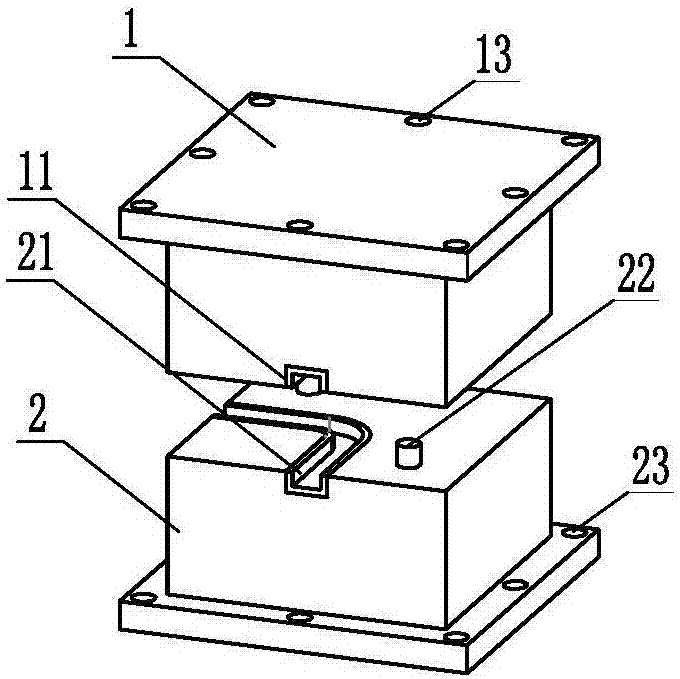

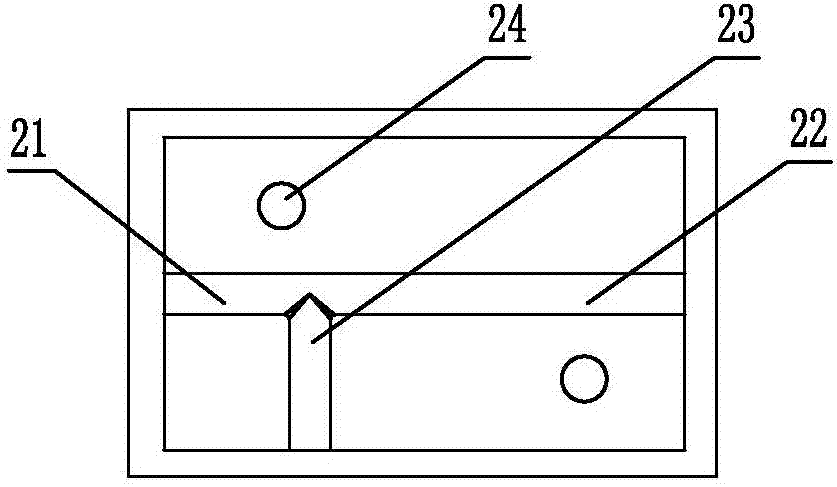

Forming mold for semi-spherical components and multi-pass forming method

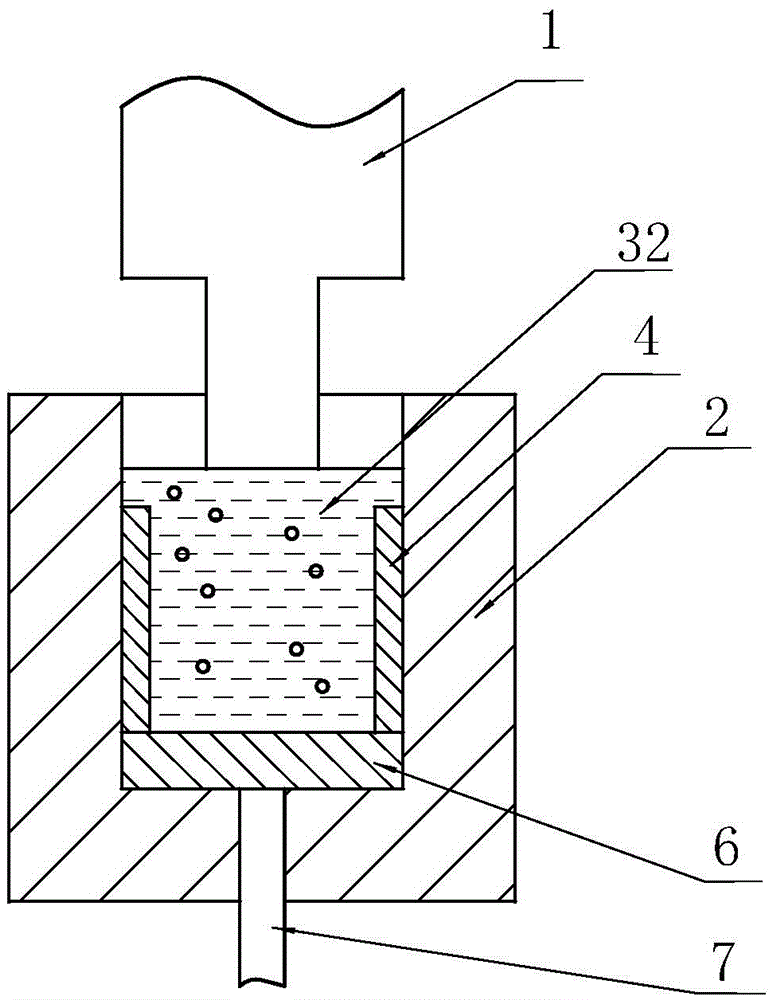

ActiveCN110479843AAchieving Precise FormingBreak through the bottleneck of forming technologyShaping toolsDiameter ratioSpherical shaped

The invention discloses a forming mold for semi-spherical components and a multi-pass forming method, belongs to the technical field of semi-sphere formation, and solves the problems of corrugation and cracking in deep drawing formation of high-height-diameter-ratio semi-spherical components, difficult control of deep drawing process parameters and weaker wall thickness uniformity in the prior art. The forming mold comprises a concave mold, a convex mold, a blank holder and a positioning plate; the concave mold and the convex mold are used for forming the semi-spherical components; the blank holder is arranged between the concave mold and the convex mold, and is matched with the concave mold to tightly press blanks to prevent corrugations of the blanks in the forming process; the blank holder is provided with a positioning plate; and the positioning plate is used for positioning an upper mold and a lower mold. The forming mold and the forming method are suitable for formation of high-height-diameter-ratio semi-spherical components.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

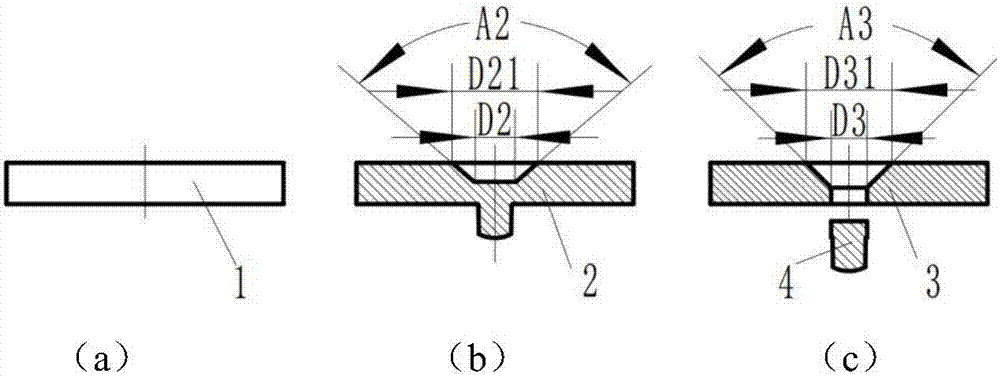

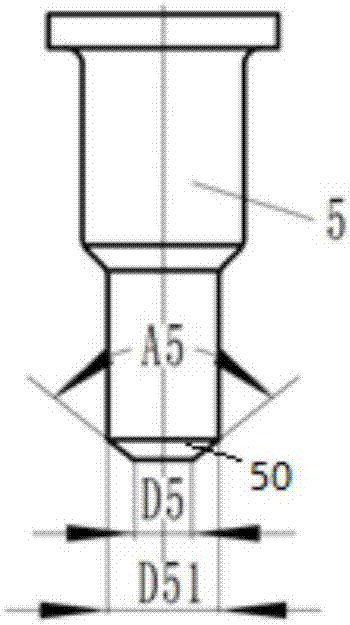

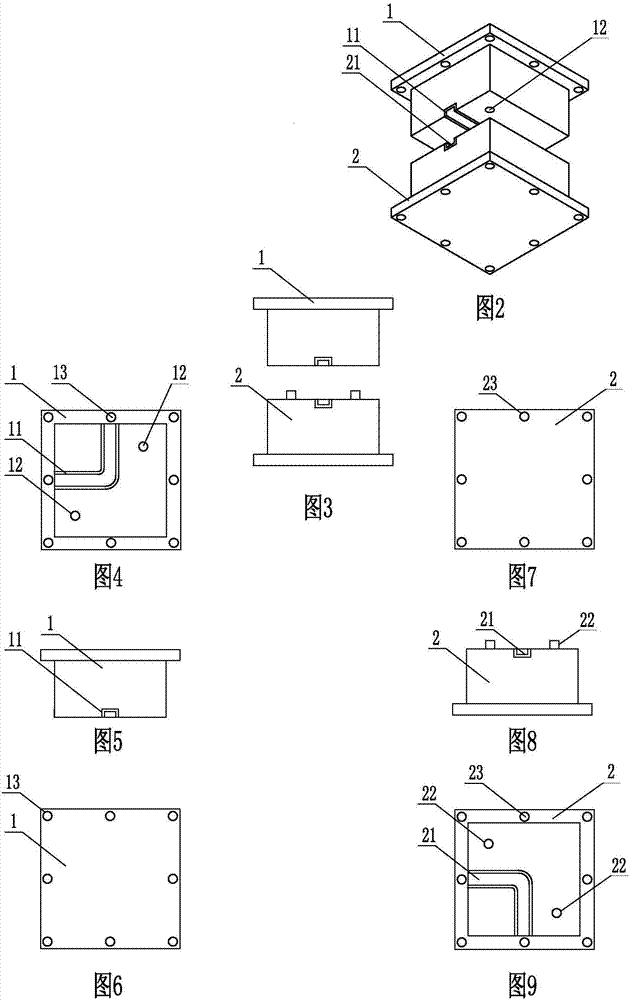

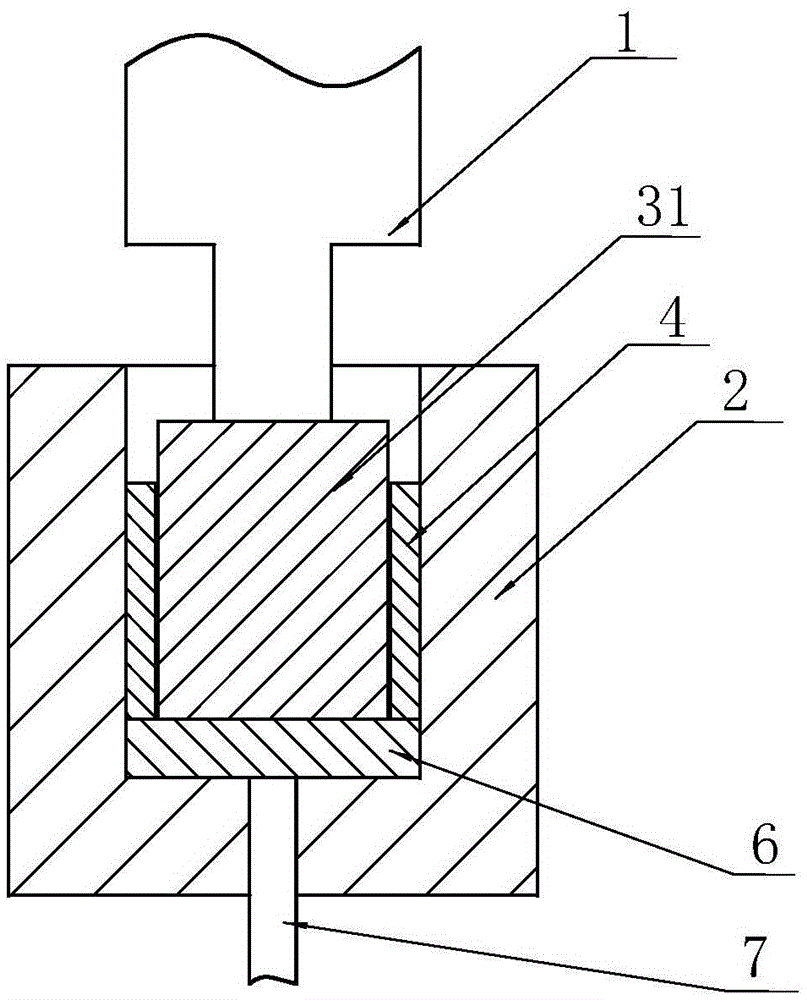

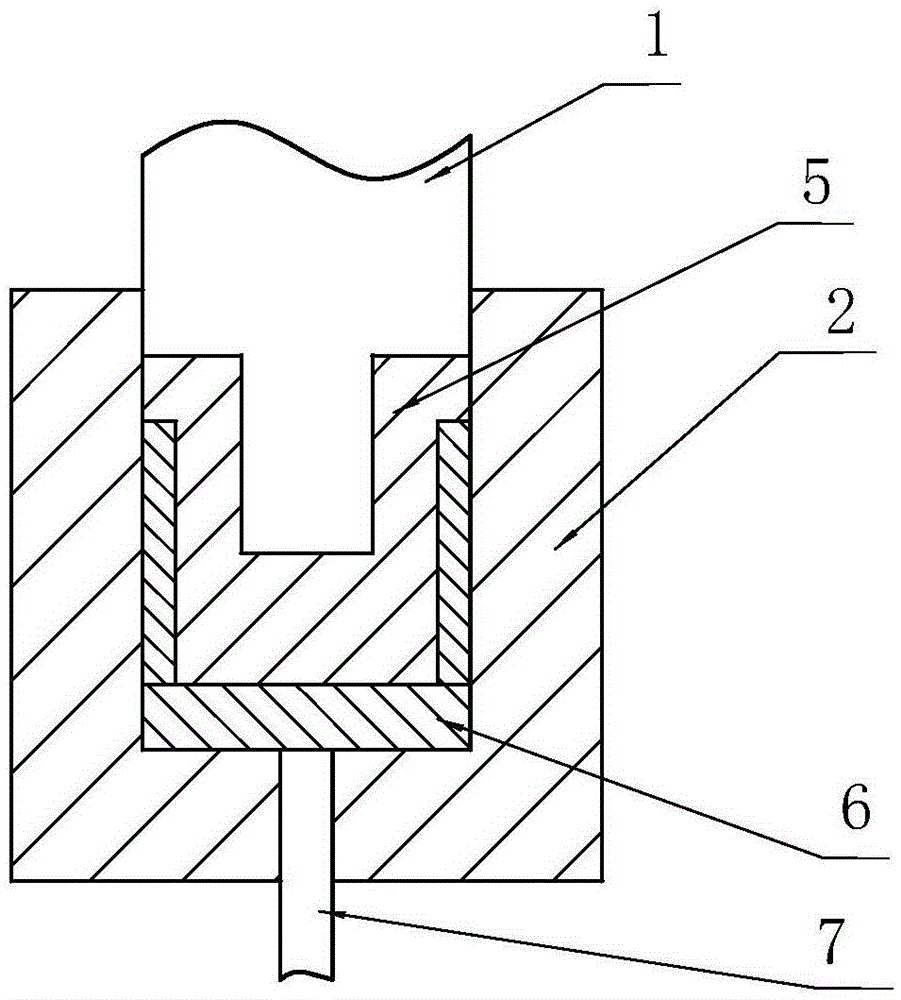

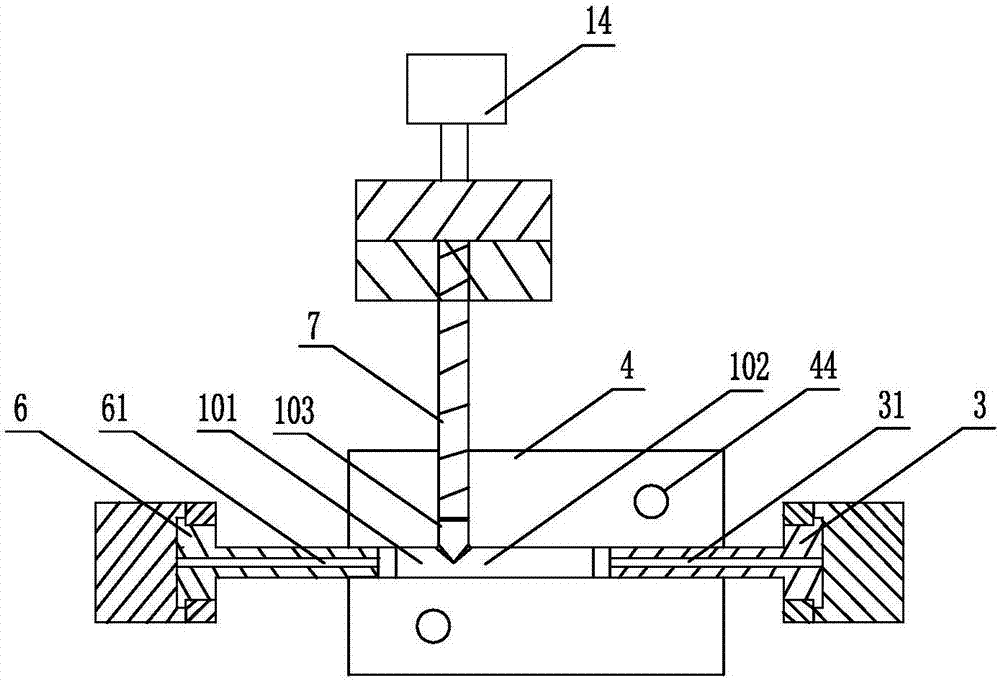

Counterbore stamping forming mould and process

ActiveCN106862374ASmall shape deformationAvoid problems such as swelling and crackingShaping toolsPerforating toolsPunchingCounterbore

The invention discloses a counterbore stamping forming mould and process. The counterbore stamping forming mould comprises an extrusion mould and a punching and sizing mould, wherein the extrusion mould is used for extruding a blank to form a workpiece, and the punching and sizing mould is used for punching and sizing the workpiece to obtain a finished product; the extrusion mould comprises an extrusion punch and an extrusion concave die, and the end part of the extrusion punch is an extrusion circular platform; an extrusion cutting edge is arranged at the top of the extrusion concave die, and a push rod hole is formed in the lower part of the extrusion cutting edge; the punching and sizing mould comprises a punching and sizing punch and a punching concave die; the bottommost part of the punching and sizing punch is a cylinder, and the upper part of the cylinder is connected with a sizing circular platform; a punching cutting edge is arranged at the top of the punching concave die. The taper angle of a workpiece counterbore is A2, the diameter at the large end is D21, and the diameter at the small end is D2. The taper angle of a finished product counterbore is A3, the diameter at the large end is D31, and the diameter at the small end is D3. The counterbore stamping forming mould and process realize the precise forming of counterbores under small deformation and low loading, avoid hole bursting, etc., improve the processing efficiency of the counterbores, and reduce the reject rate and the manufacture cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

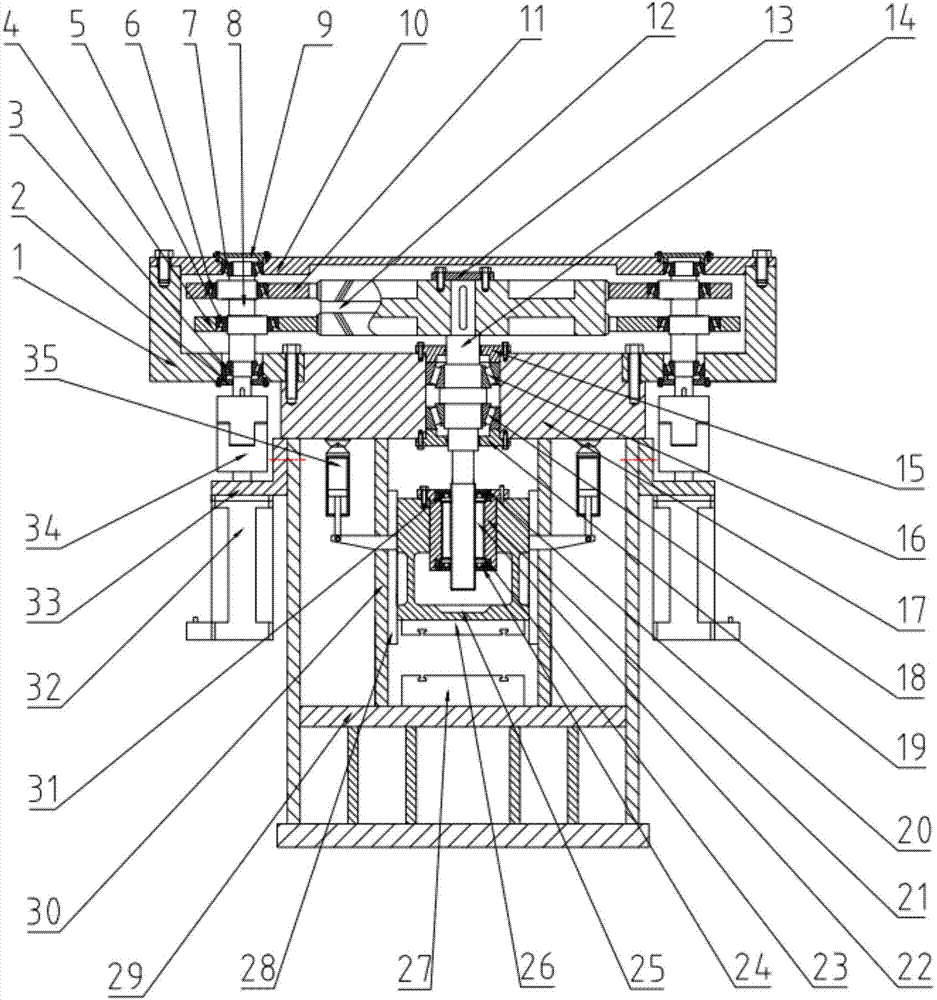

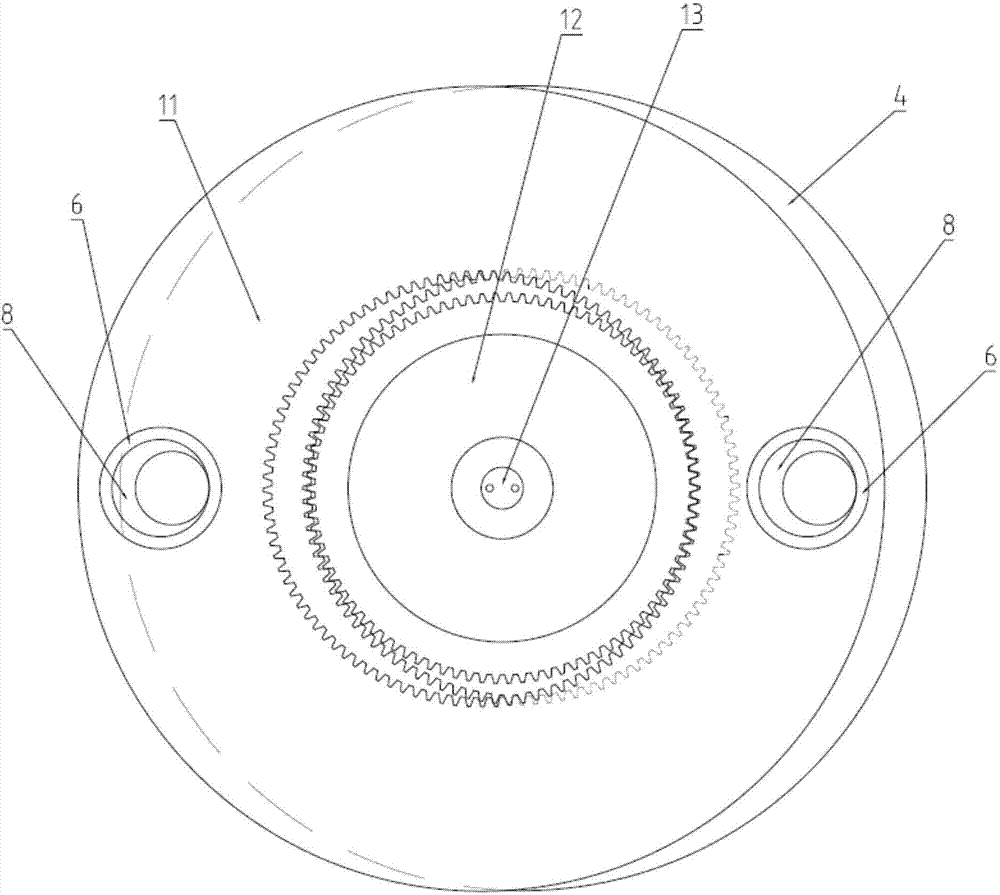

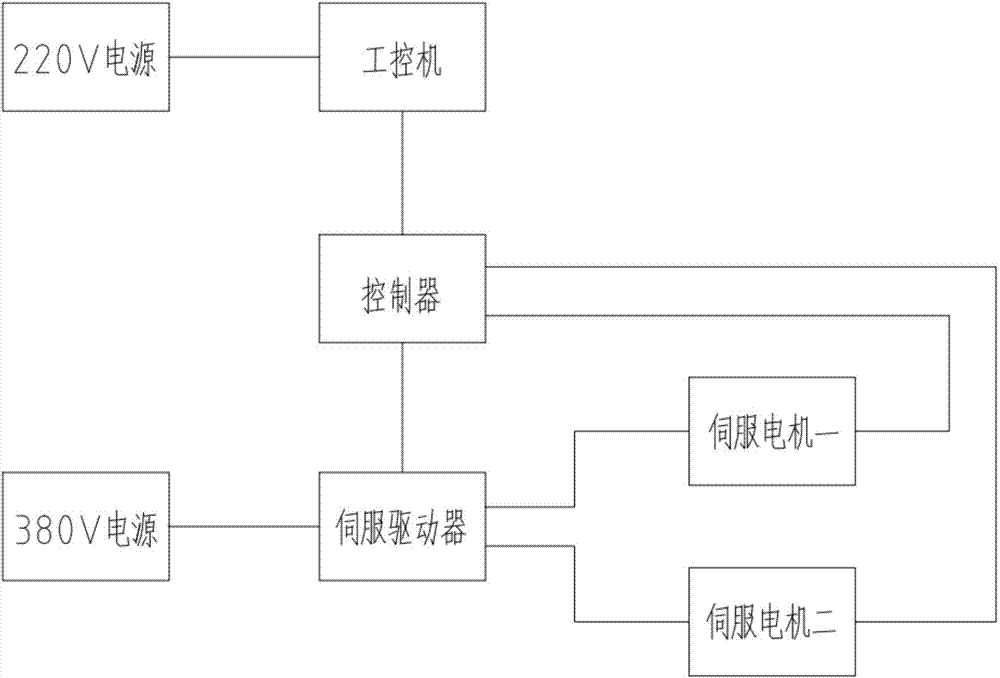

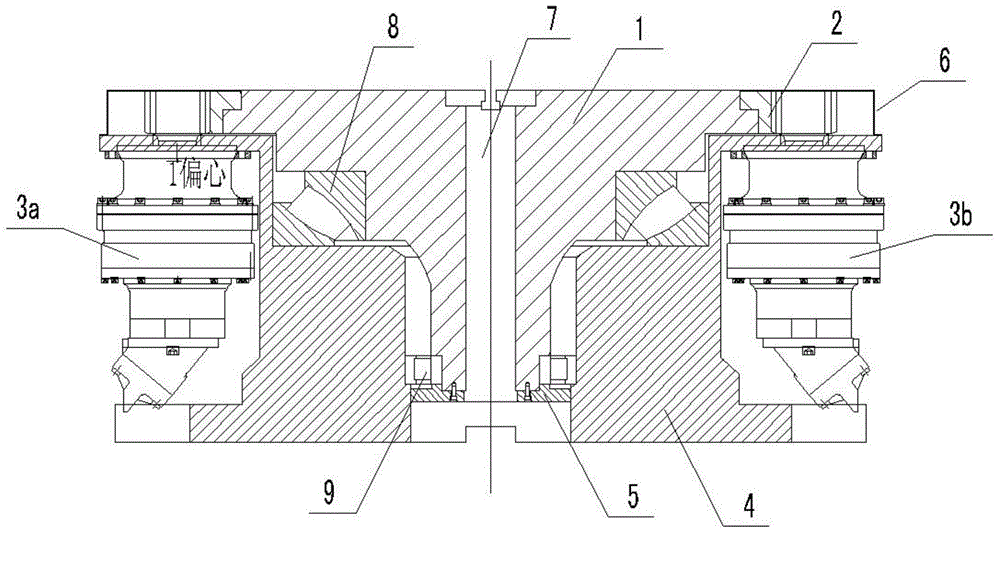

Helical-tooth few tooth difference planetary gear transmission electric servo screw press

The invention discloses a helical-tooth few tooth difference planetary gear transmission electric servo screw press. After being powered on, servo motors drive a driving crank shaft to rotate, an inner-toothed ring plate is made to transversely move in a planar circular mode, then a center gear drives a lead screw shaft to slowly rotate, the rotation of the lead screw shaft enables a nut to drive a sliding block to move up and down, a die is installed on an upper die base and a lower die base, and the sliding block moves up and down to achieve plastic forming on a workpiece. According to the helical-tooth few tooth difference planetary gear transmission electric servo screw press, helical-tooth few tooth difference planetary gear transmission is adopted, the transmission ratio can be larger, and the precision requirement of large-scale metal parts is met; helical-tooth design is adopted, and the unbalance load on an input shaft is improved; the multiple servo motors are adopted, the power requirement of the press for each motor is lowered, and impact of the press on a power grid is small; the movement precision of a planetary roller screw is higher than that of a screw and a nut, and precision forming can be achieved through the roller screw in cooperation with a servo control system.

Owner:XI AN JIAOTONG UNIV

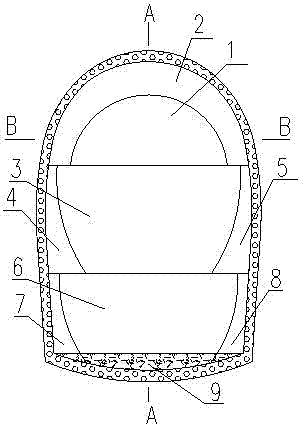

Medium ground tunnel milling excavating and mating mechanized construction method

InactiveCN103899318AAchieving Precise FormingReduce disturbanceTunnelsWorking environmentEngineering

The invention discloses a medium ground tunnel milling excavating and mating mechanized construction method. The construction method includes the steps that the center of an upper step is excavated by a large breaking hammer to be in a paraboloid shape, after the outer portion of the center of the upper step is excavated and trimmed by a milling excavator to form an excavation face perpendicular to the tunnel axis, the upper step is supported to form a stable bearing arch, then the core soil part of a middle step is excavated by the large breaking hammer until a drill rod of the large breaking hammer is drifted, the edge wall parts on the left side and the right side of the middle step are excavated and trimmed by the milling excavator, initial supporting is carried out, the core soil part of a lower step is excavated by the large breaking hammer, the edge wall parts on the left side and the right side of the lower step are excavated and trimmed by the milling excavator, initial supporting is carried out, deslagging is carried out, and the steps are repeated until excavation of a whole tunnel is completed. By means of the medium ground tunnel milling excavating and mating mechanized construction method, the advantages of mating mechanized construction of the milling excavator are sufficiently exerted, accurate molding of the tunnel profile is achieved, surrounding rock is small in disturbance, back break control is good, the working environment is good, the construction safety is high, and influences of vibration of blasting are avoided.

Owner:SHENHUA BAOSHEN RAILWAY

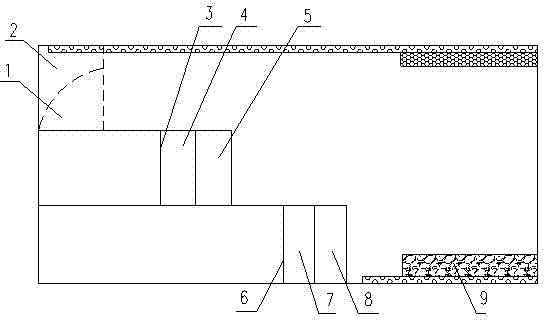

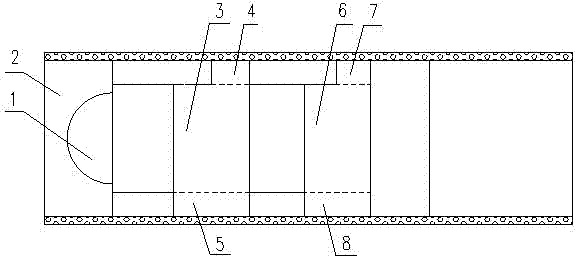

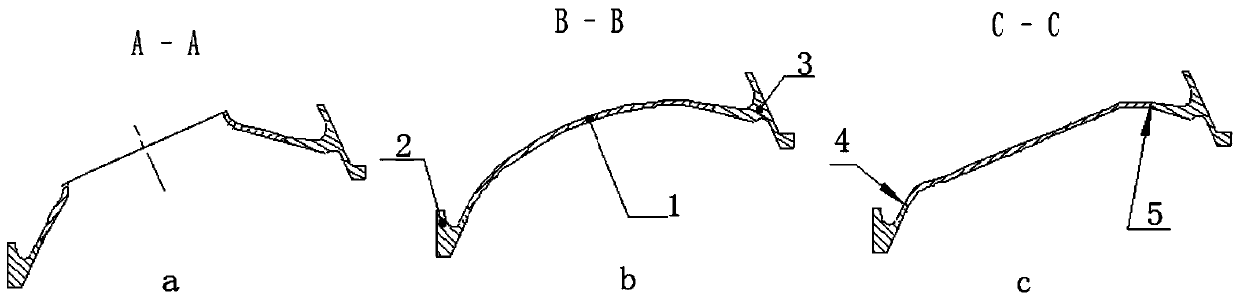

Forming method of titanium alloy oil tank shell

InactiveCN105033568AImproved precision forming processAchieving Precise FormingDrive wheelButt welding

The invention belongs to the field of precise panel machining, and discloses a forming method of a titanium alloy oil tank shell. The forming method comprises the following steps that firstly, the shape of an unfolded material of a component is calculated according to the theoretical diameter of the neutral plane of the titanium alloy oil tank shell, blanking is carried out in the direction of fiber of a rolled blank, and a panel material is obtained; secondly, the cold roll bending diameter of the oil tank shell is determined according to the structural parameters of a cold roll machine; thirdly, roll bending forming is carried out on the panel material through the cold roll machine according to the cold roll bending diameter of the oil tank shell; fourthly, butt welding is carried out on the panel material formed through roll bending; and fifthly, thermal correcting and stabilizing processing are carried out on a cylindrical piece formed through welding. The technology allowance and machining procedures needed by the thermal forming technology are greatly saved through unfolded material calculation, drive wheel pressing displacement compensation calculation, electron beam butt welding and the composite technology of thermal correcting and stabilizing processing; and according to the precise forming technology of the whole oil tank shell, the production efficiency is greatly improved, and the producing and manufacturing cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Method for manufacturing cylinder with circumferential inner reinforcing rib

In order to overcome the deficiencies of the prior art, the present invention provides a method for manufacturing a cylinder with a circumferential inner reinforcing rib with high material utilizationrate, high production efficiency and good product quality. A blank partially sleeves the end of a core mold; a main shaft is driven to rotate and drives the core mold, a limiting device and the blankto rotate. Under the blocking of the limiting device and the axial pushing of a tail tip, the axial length of the blank becomes shorter, the radial thickness increases, and then a rotating wheel is controlled to close radially and press the end wall of the blank relative to the port in the rear end of the blank. Under the action of the limit action of an annular groove at the end of the core moldand the thrust of the tail tip, the port in the rear end of the blank is radially fed along with the rotating wheel to radially thicken and fill and form a radially inwardly protruding circumferential inner reinforcing rib b to control the axial movement of the rotating wheel relative to the primary cylinder. When the rotating wheel is close to make the wall thickness of the cylinder reach a preset value, the rotating wheel stops closing and keeps axially moving to make the wall thickness of the cylinder uniform, thereby obtaining a cylinder with a circumferential inner reinforcing rib.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Electric fluid dynamic spray printing equipment for flexible dielectric substrate and control method

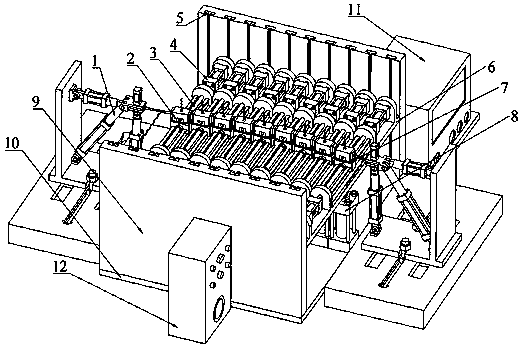

ActiveCN108162595AImprove pattern printing qualityAchieving Precise FormingTypewritersPower drive mechanismsDielectric substrateElectrical and Electronics engineering

In order to solve the problem that existing electric fluid dynamic spray printing equipment cannot meet electric fluid dynamic spray printing of a flexible dielectric substrate, the invention provideselectric fluid dynamic spray printing equipment for the flexible dielectric substrate and a control method. The electric fluid dynamic spray printing equipment comprises a support, a spray printing module and a spray printing platform. The spray printing module is arranged on the support through an X-axis slipping mechanism and a Z-axis slipping mechanism, and a spray head is arranged on the spray printing module, and a working platform is arranged on the spray printing platform. The working platform comprises a bottom plate and a plurality of supporting assemblies, and each supporting assembly comprises a first position in mounting and a second position for supporting the flexible dielectric substrate to be subjected to spray printing to form a hook face in working. According to the method, the equipment is adopted to conduct spray printing. According to the electric fluid dynamic spray printing equipment and the control method, the flexible dielectric substrate to be subjected to spray printing can be arranged into the hook face of a preconceived object subjected to spray printing, the spray printing effect of the flexible dielectric substrate is good, and accurate forming of apattern on the complex hook face is achieved.

Owner:JIAXING UNIV

Thin-wall rectangular-cross-section pipe bending method

InactiveCN107052124AAchieving Precise FormingGuaranteed dimensional accuracyEngineeringHigh pressure

The invention provides a thin-wall rectangular-cross-section pipe bending method. The thin-wall rectangular-cross-section pipe bending method comprises the following steps that (1), a conventional pipe bending method is adopted, a thin-wall rectangular-cross-section pipe blank is bent in advance, and a pipe pre-bending piece with folds is obtained; (2), a corresponding shaping die is selected and installed on a pressure bulging pressing machine; (3), the pre-bending piece is installed to the shaping die and is connected with a high-pressure-oil oil way; (4), a high-pressure oil pump is started to eliminate air in the pipe pre-bending pipe, an exhausting hole is sealed, a pipe is filled with oil liquid; (5), pressure is exerted for bulging till the folds of the pipe pre-bending piece are eliminated; (6), pressure is relived, oil is discharged, and die sinking is performed. By means of the method, two types of process technologies are comprehensively utilized, on one hand, the advantage that the conventional bent pipe is easy to form is utilized, the blank is bent in advance in the first place, then the inner-high-pressure forming technology is utilized, high pressure is exerted on the interior of the pipe so that the pipe can be bulged and attached to the die to eliminate the folds, disadvantages of the conventional bent pipe are overcome, a thin-wall rectangular-cross-section pipe bending piece is formed accurately, forming quality and precision are high, the surface is neat and smooth, and the appearance is attractive.

Owner:柳州科瑞科技有限公司 +1

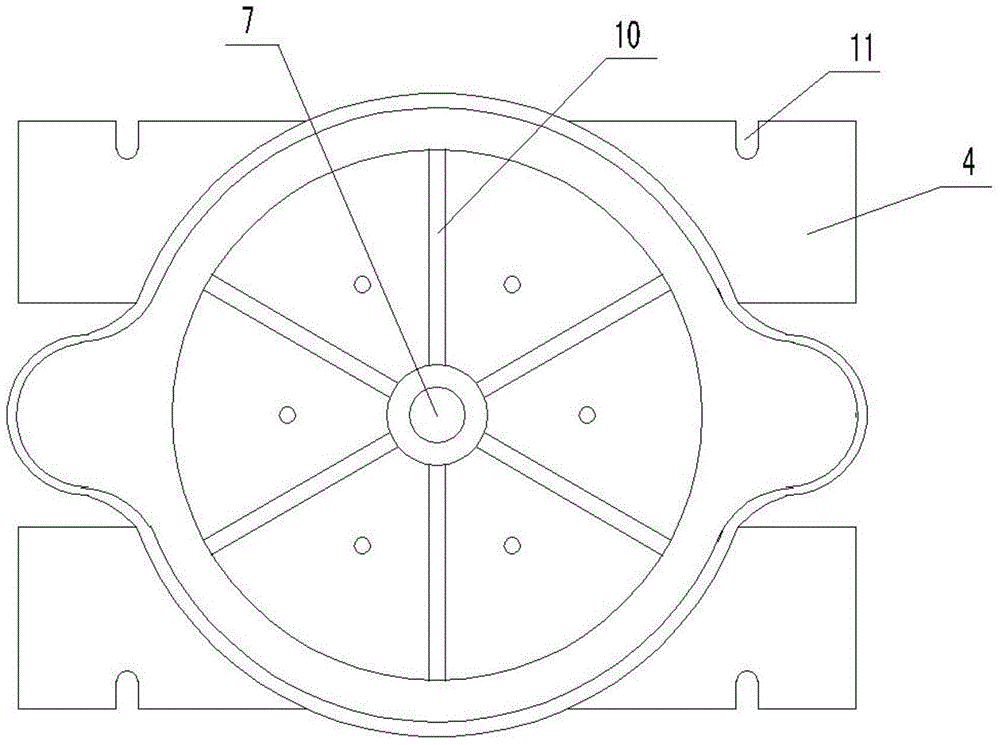

Device for realizing high-pressure twisting process on hydraulic press

ActiveCN104399808ARealize the pressure torsion forming processVersatileShaping toolsForging/hammering/pressing machinesHydraulic motorControl engineering

The invention discloses a device for realizing a high-pressure twisting process on a hydraulic press. The device is characterized by comprising a revolving table, wherein the revolving table is horizontally supported on a turntable base through a waist centering bearing; a transmission gear ring is arranged on the top peripheral surface of the revolving table; hydraulic motor hanging devices are arranged at the left and right sides of the revolving table on the turntable base respectively; a first hydraulic motor and a second hydraulic motor are independently fixed on the hydraulic motor hanging devices at the corresponding sides respectively, so that the first hydraulic motor and the second hydraulic motor are positioned at the left and right sides of the revolving table respectively; driving torques of the first hydraulic motor and the second hydraulic motor are transferred to the revolving table through the transmission gear ring; and a first motor matched with the first hydraulic motor and a second motor matched with the second hydraulic motor are arranged respectively. The device can realize the high-pressure twisting process on a general hydraulic press, can provide sufficient torques, and can achieve the precise forming purpose through speed adjustment.

Owner:HEFEI UNIV OF TECH

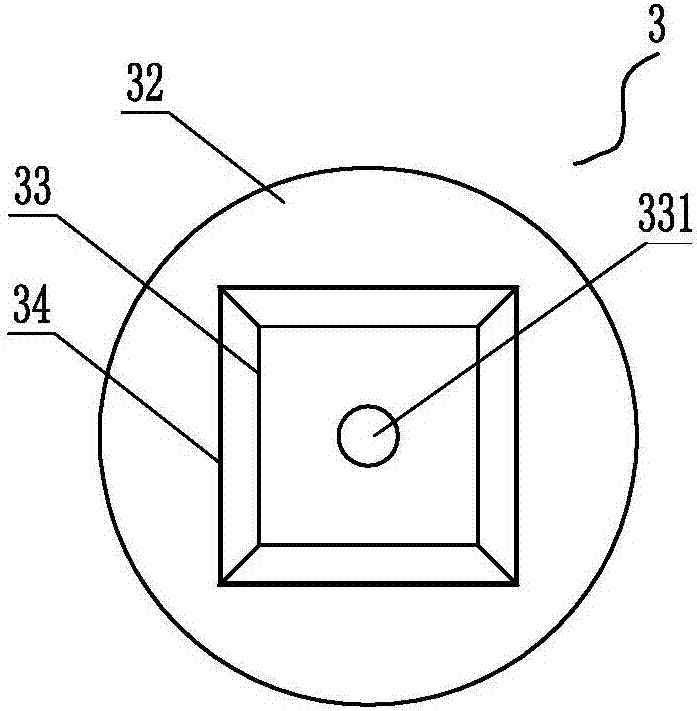

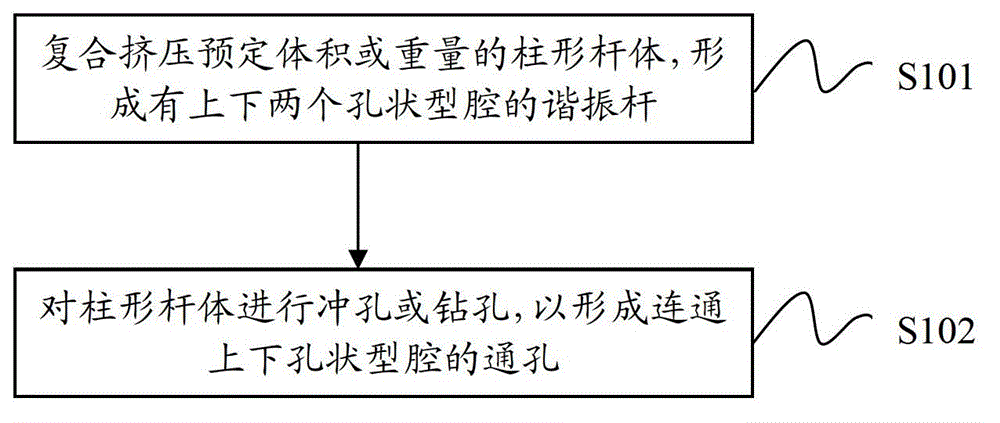

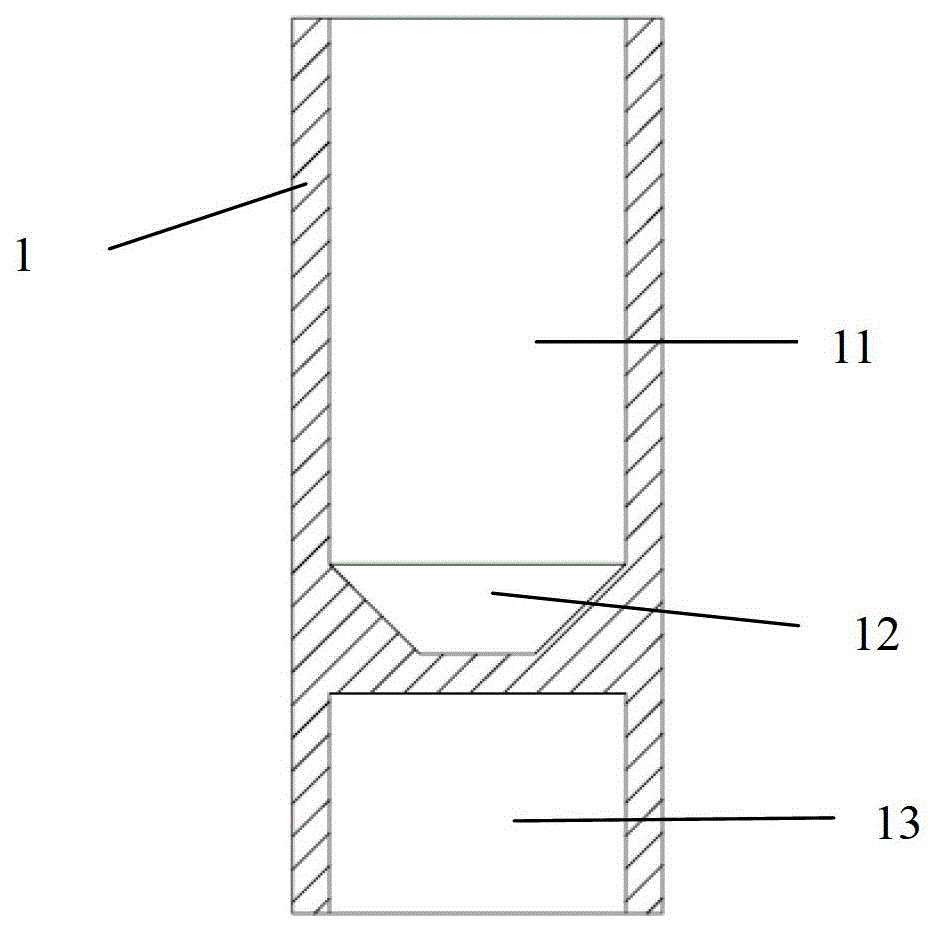

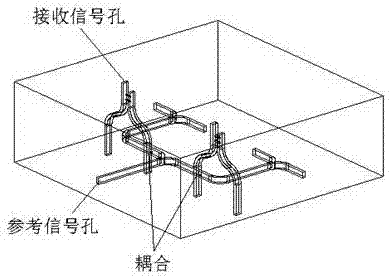

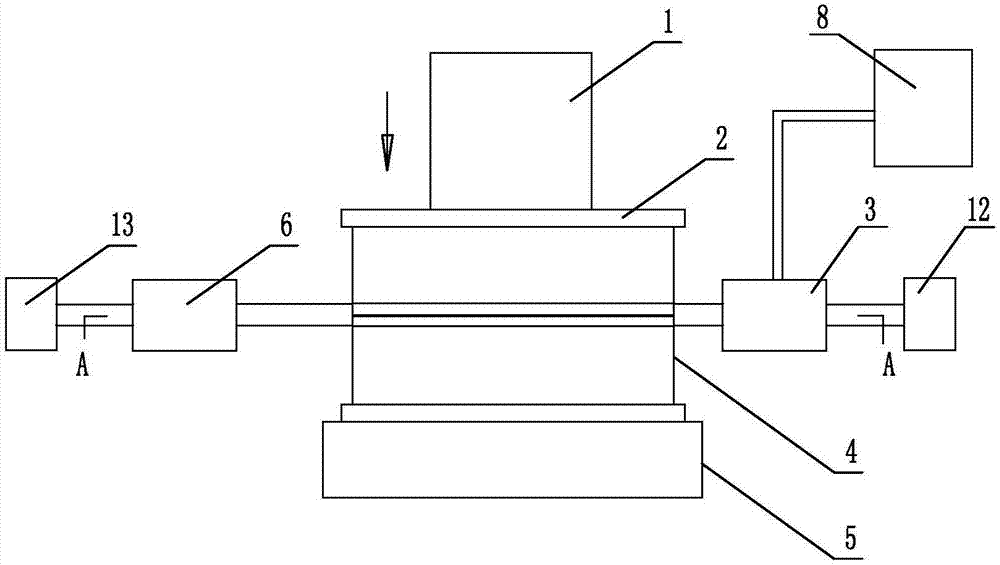

Method for molding and producing resonance rod by adopting flow control

InactiveCN103182632APrecise control of non-uniform plastic flowImprove mechanical propertiesPunchingResonance

The invention provides a method for molding and producing a resonance rod by adopting flow control. The resonance rod comprises a rod body and hole-shaped cavities positioned at the two ends of the rod body. The method comprises the following steps: extruding a column-shaped rod body with predetermined weight or size in a combined manner; forming a first column hole and an annular cone hole both axially arranged inside one side of the column-shaped rod body and forming a second column hole axially arranged inside the other side of the column-shaped rod body, wherein the first column hole and the second column hole are positioned at the two ends of the rod body; and punching or drilling the column-shaped rod body to form a through hole for communicating the annular cone hole with the second column hole. According to the method, no cuttings are produced during the production process of combined extrusion; material and labor cost is saved; the minimum order quantity of products is not required; the much debug time of dies is saved; and besides, the combined extrusion can realize once formation at one position, thus, the machining efficiency is higher; and nonferrous metals such as copper and aluminum, and ferrous metal raw materials made of mild carbon steel of various grades can be machined.

Owner:危宾

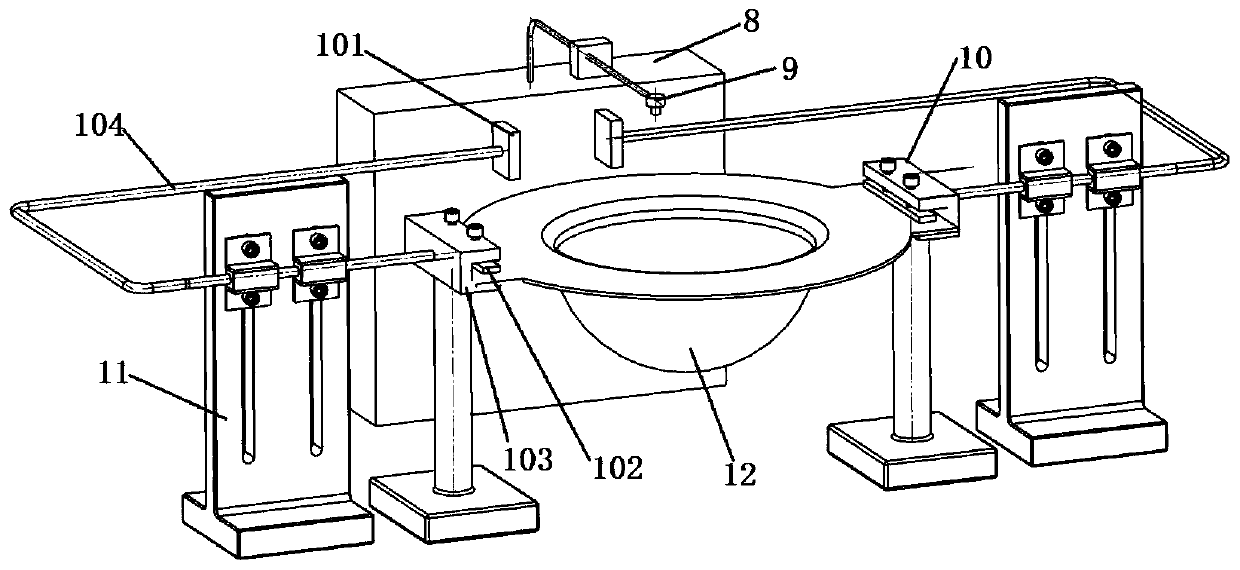

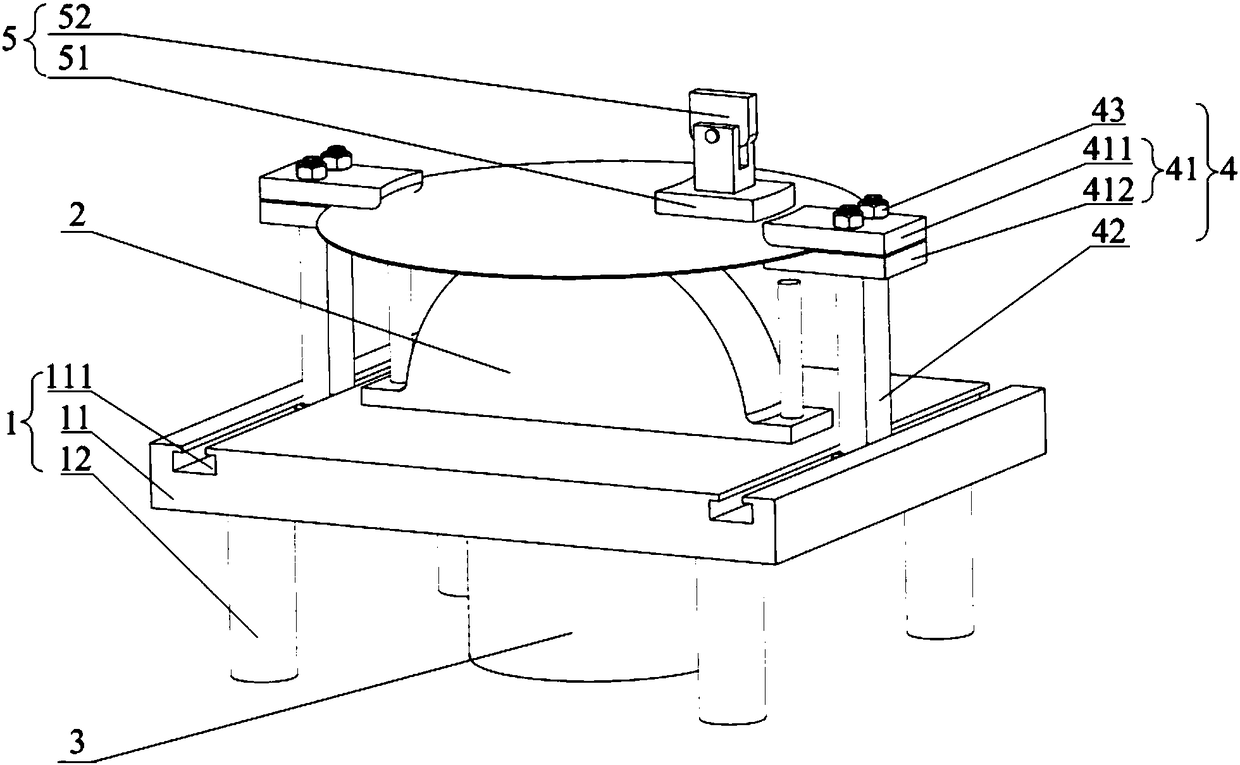

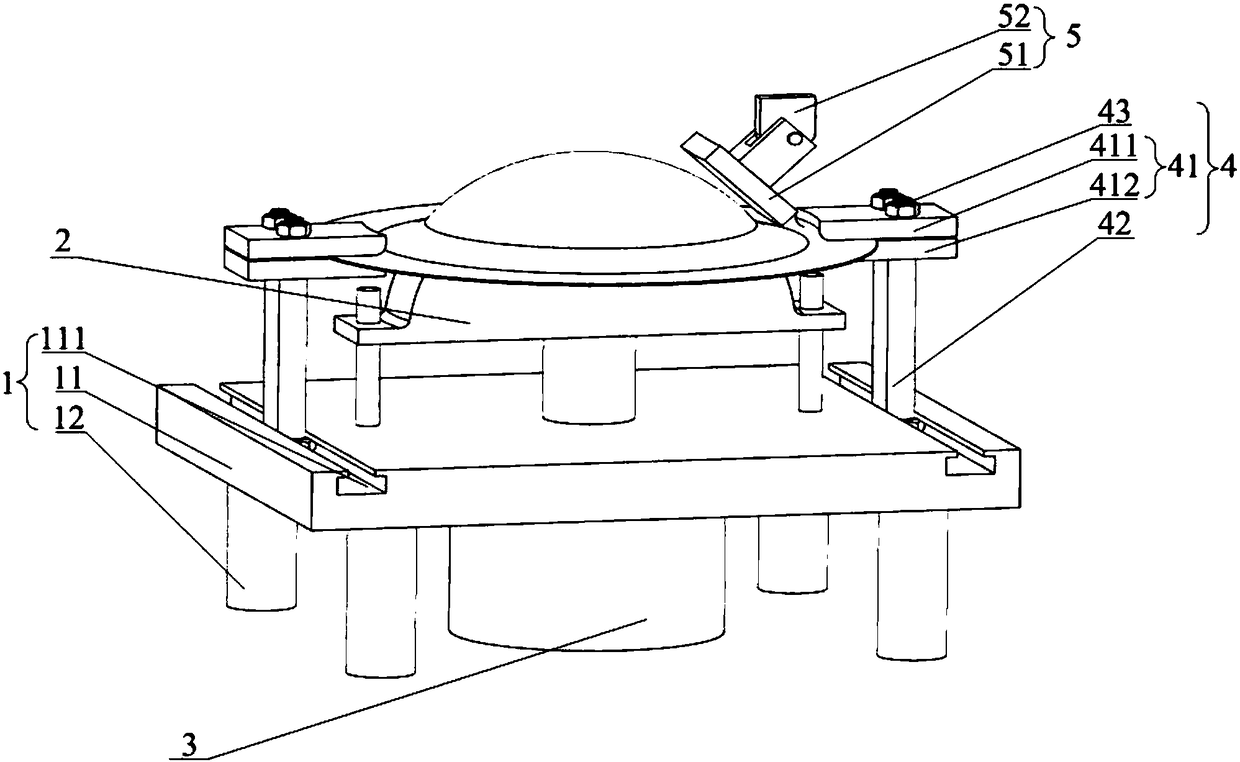

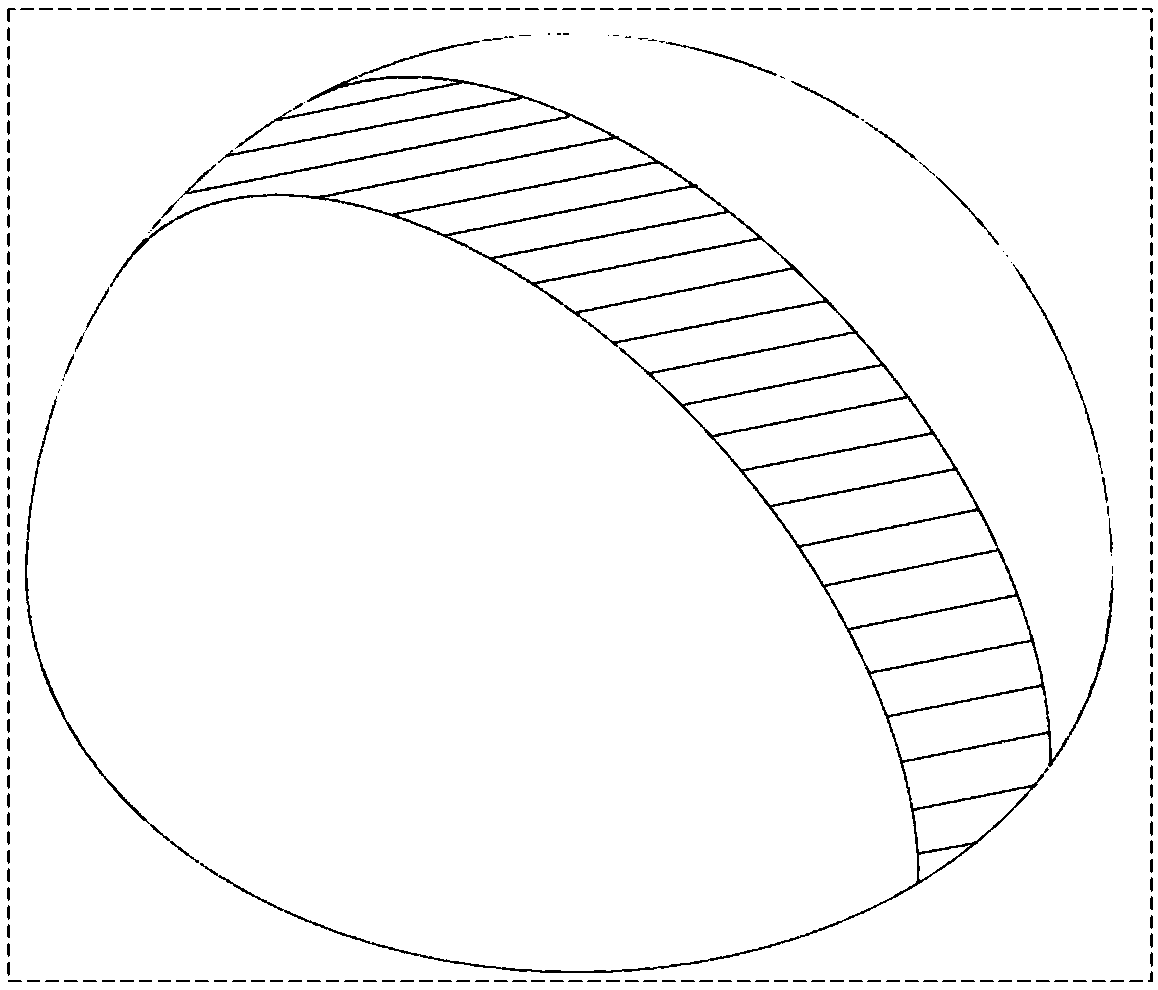

Electromagnetic pulse forming device of plate type part and forming method thereof

ActiveCN108435874AAchieve preparationHigh precisionShaping toolsMetal-working feeding devicesElectromagnetic pulseLarge size

The invention discloses an electromagnetic pulse forming device of a plate type part. The electromagnetic pulse forming device comprises a supporting frame, a male die, a lifting mechanism, clamping mechanisms and an electromagnetic pulse element, wherein the male die is arranged on the supporting frame, the upper portion of the lifting mechanism is connected with the lower portion of the male die, the number of the clamping mechanisms is two, the clamping mechanisms are symmetrically distributed on the two sides of the male die respectively, clamping elements are arranged at the top ends of the clamping mechanisms, the electromagnetic pulse element is located above the male die, a gap is formed between the electromagnetic pulse element and the male die, and the gap is used for containingplate materials to be formed. The invention further provides a forming method adopting the same. The electromagnetic pulse forming device can effectively reduce the size of the die, is beneficial to reducing the manufacturing cost of the die, and high in forming precision and facilitates accurate forming of large-size plate materials.

Owner:CENT SOUTH UNIV

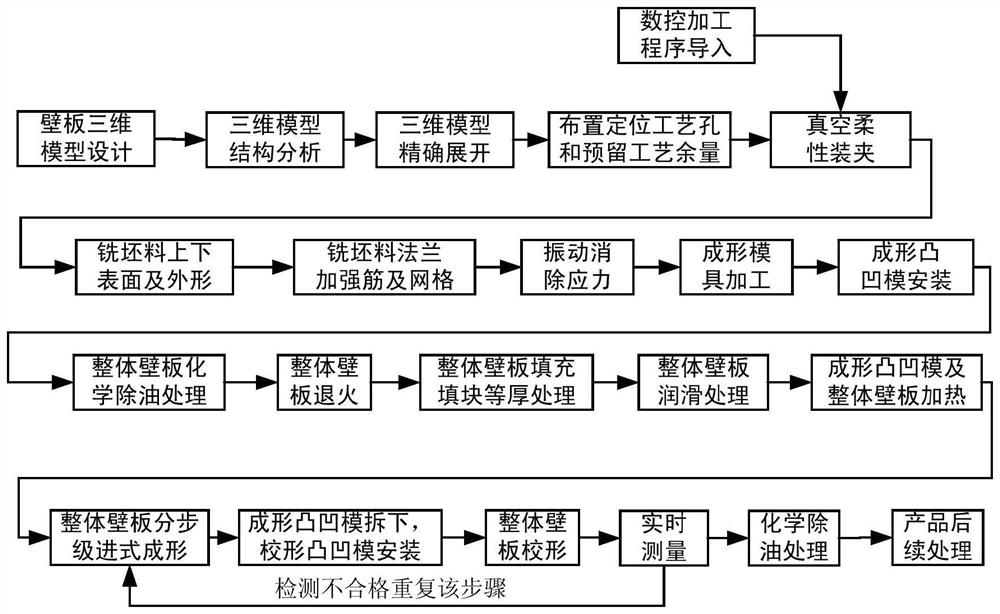

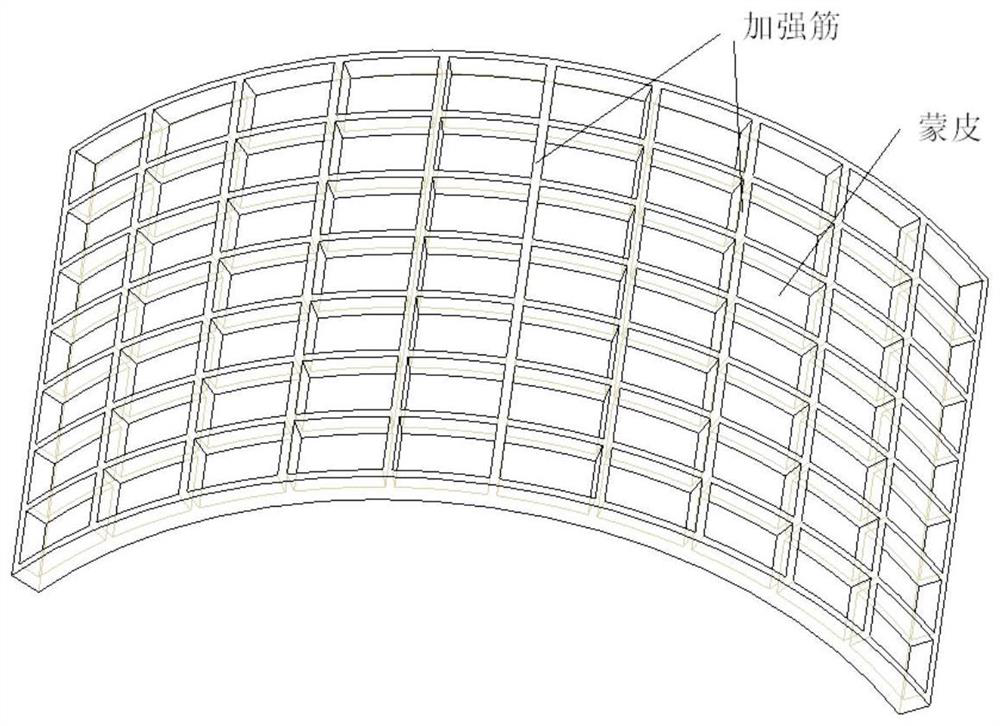

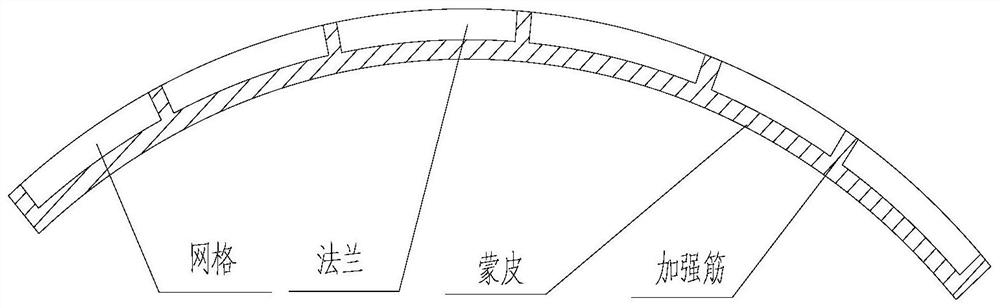

Step-by-step progressive hot forming and hot correcting integrated method for thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges

ActiveCN111804786AImprove processing efficiencySimple methodShaping toolsMetal working apparatusThin walledHomogeneous deformation

The invention provides a step-by-step progressive hot forming and hot correcting integrated method for a thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges. An original blank of the integral wall plate in a flat state is clamped on a three-axis numerical control machine tool through a vacuum flexible clamping technology, and numerical control milling machining is conducted on the ultrahigh reinforcing ribs, the oversized flanges and grids of the thin-wall integral wall plate. Then, vibration is adopted for stress relieving, the influence of material internal stress on machining deformation is eliminated. Through the equal-rigidity reinforcing technology and the step-by-step progressive hot forming and hot correcting integrated technology, the following problems are solved that when the aluminum alloy thin-wall integral wall plate with the ultrahigh reinforcing ribs and the oversized flanges is formed, the forming resistances of the reinforcing ribs andthe flanges of the wall plate are greatly different, serious uneven deformation is likely to happen, a transition area around the flange is likely to break in the deformation process, and the formingdifficulty is very large. The method achieves low-stress manufacturing of the thin-wall integral wall plate structure with the ultrahigh reinforcing ribs and the oversized flanges.

Owner:BEIJING SATELLITE MFG FACTORY

Silicon-oxygen-carbon ceramic products and preparing method thereof

The invention discloses a siloxicon ceramic part product and a process for preparation thereof. The process employs organosiloxane as ceramic precursor, and another organosiloxane precursor as a forming die, shaping organosiloxane ceramic precursor and preparing molded siloxicon ceramic parts via crosslinking, solidifying and pyrolising. The employed organosiloxane ceramic precursor is an organicmonomer or polymer containing Si-O main chains or a skeletal structure. A molding material precursor of organosiloxane ceramic precursor is one component which contains polysiloxane of at least two alkenyls per molecule. The other component contains at least two poly-organo-hydrogen-siloxanes hydrogen atoms of which are bound to the same silicon atoms or to different silicon atoms. The invention has the advantages that the ceramic precursor and the molding material are all siloxane, which can be perfectly wet and have the similar thermal expansions, thereby meeting the requirement of the precursor on molding accuracy and avoiding the problem of cracking of shaped bodies. Siloxicon ceramics with complex shapes can be accurately prepared, in particular to preparing tiny siloxicon ceramic parts and patterns.

Owner:TIANJIN UNIV

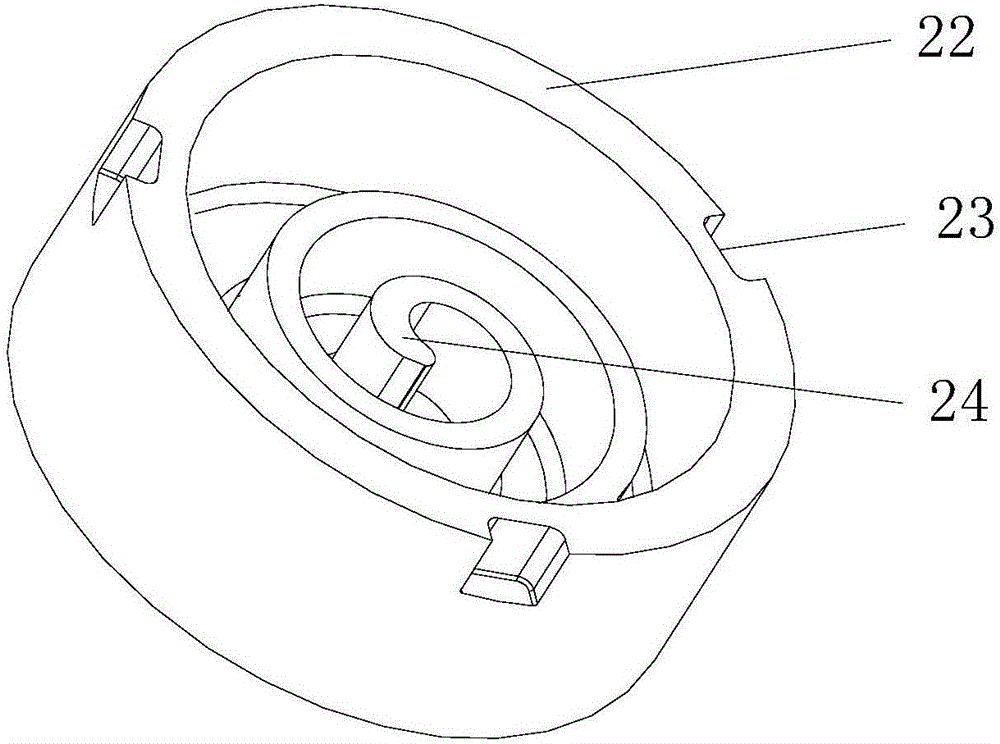

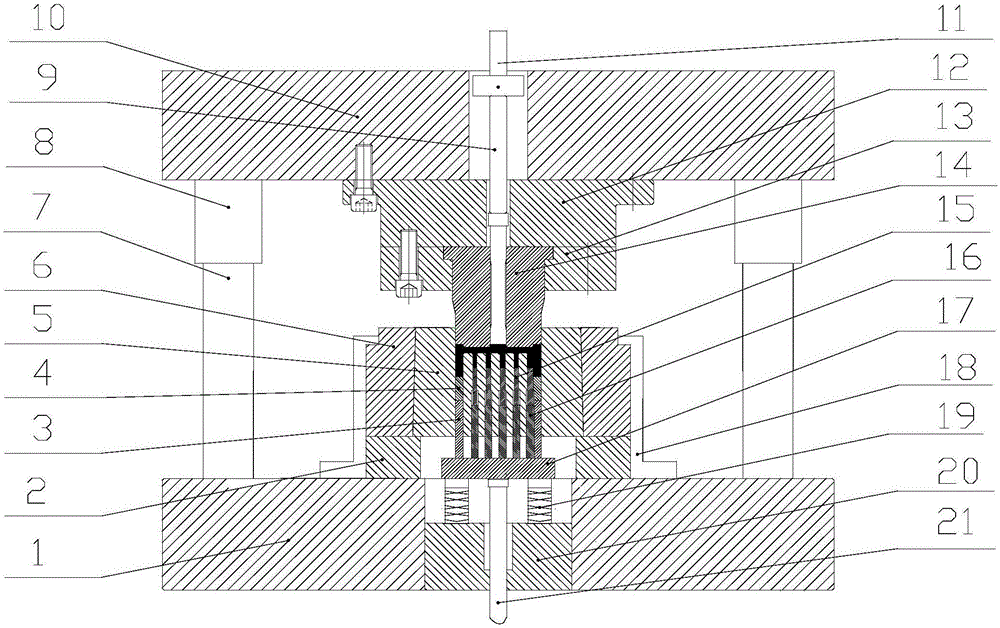

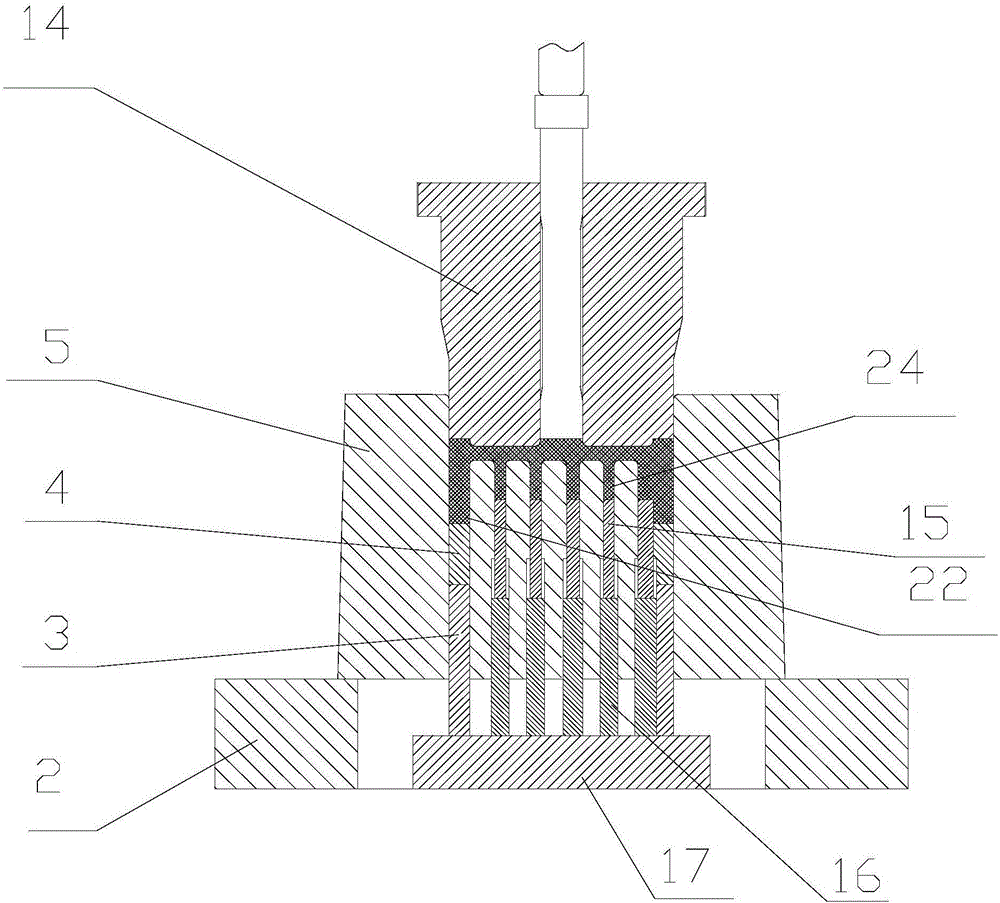

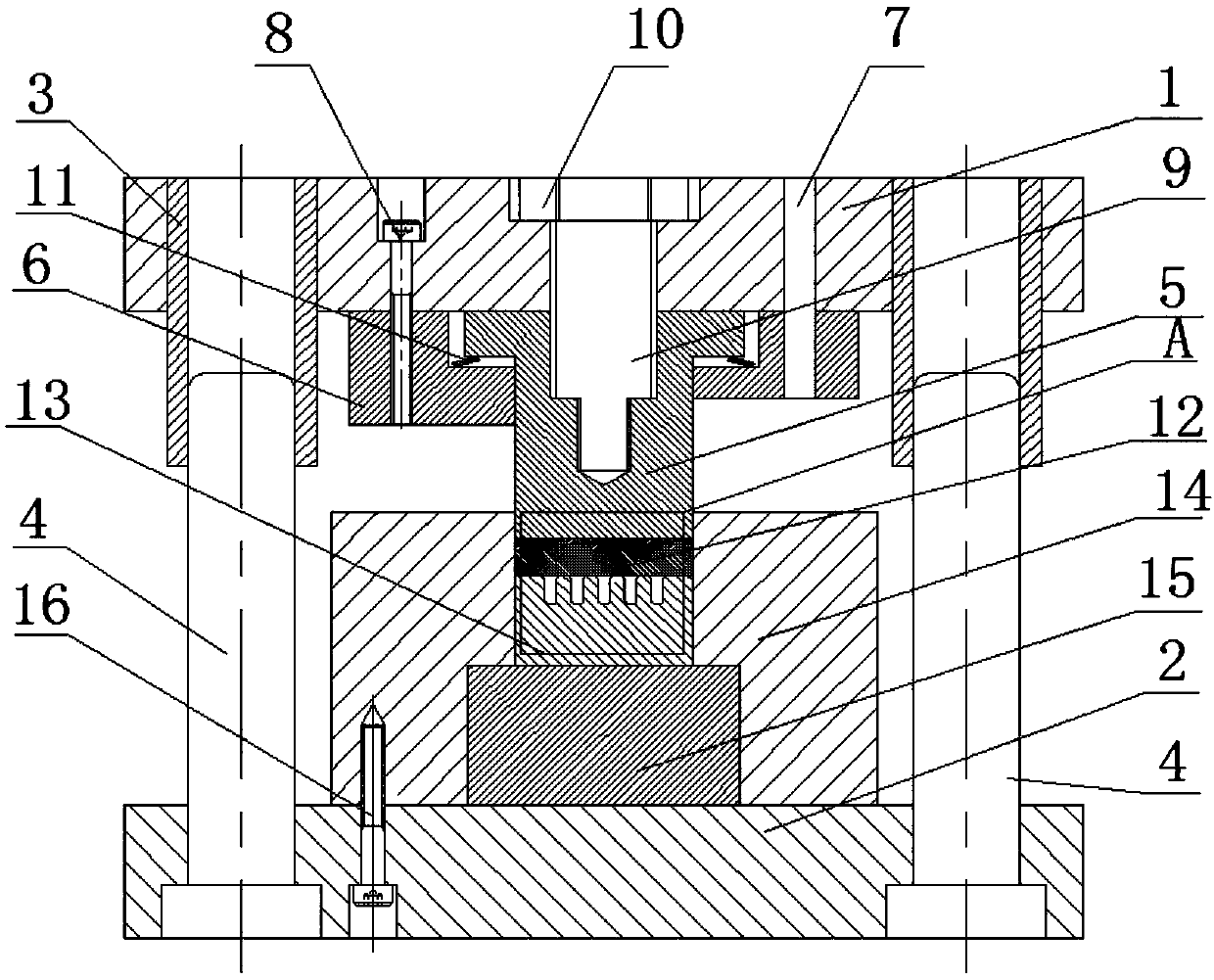

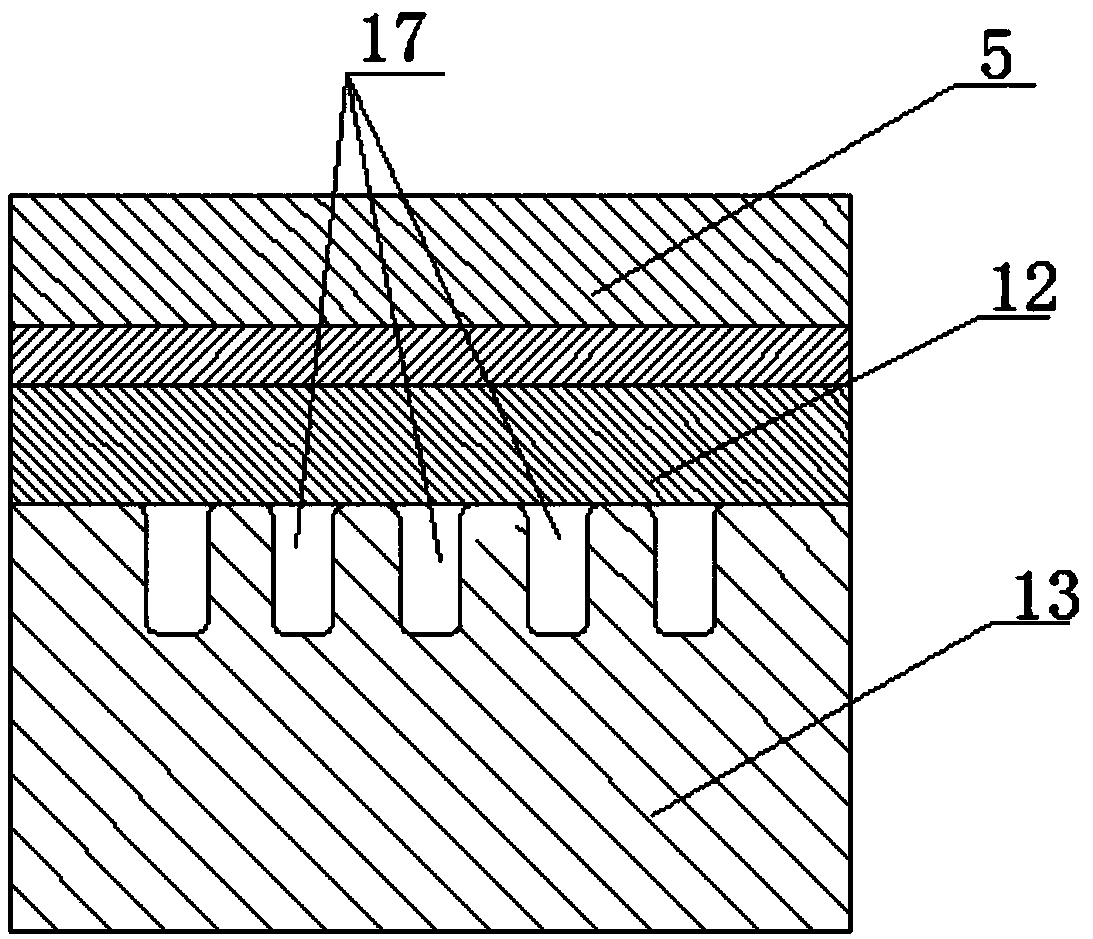

Accurate forming die structure for stator disc of air conditioner compressor of new energy automobile

ActiveCN106583619AControl flow irregularitiesAchieving Precise FormingForging/hammering/pressing machinesWheelsFiberNew energy

The invention discloses an accurate forming die structure for a stator disc of an air conditioner compressor of a new energy automobile. The die structure comprises a convex die, a concave die and a backpressure structure, wherein the backpressure structure comprises a spiral backpressure body, an outer ring backpressure body, ejection rods, an ejection rod supporting plate, a spring and a cushion plate; the outer ring backpressure body is located at the periphery of the spiral backpressure body; the spiral backpressure body corresponds to a spiral bulge of the stator disc; the outer ring backpressure body corresponds to an outer ring bulge of the stator disc; the ejection rods are arranged at the lower ends of the spiral backpressure body and the outer ring backpressure body; the ejection rod supporting plate is arranged at the lower ends of the ejection rods; the cushion plate is located below the ejection rod supporting plate; the spring is arranged between the ejection rod supporting plate and the cushion plate; and the ejection rod supporting plate in the backpressure mechanism is located below the concave die. Compared with the prior art, the die structure disclosed by the invention has the following advantages: accurate forming for the stator disc can be realized, destroy for a metal fibre flow line due to the subsequent machining is avoided, the utilization rate of materials and the mechanical property of the stator disc are increased, and the cost is reduced.

Owner:HEFEI UNIV OF TECH

Method for semi-solid formation and connection integration of titanium alloy and aluminum alloy

The invention discloses a method for semi-solid formation and connection integration of a titanium alloy and an aluminum alloy. The method comprises the following steps: a preconnected titanium alloy is prepared to a titanium alloy pipe with a certain size and shape; the titanium alloy pipe is put in a mold for preheating; an aluminum alloy is prepared to a semi-solid blank or semi-solid slurry with a liquid phase rate of 50-60%; the aluminum alloy semi-solid blank or semi-solid slurry is shifted into the titanium alloy pipe of the mold; and a convex mold quickly moves downwards, and is pressed to realize die-forging connection integral formation. The method realizes precise formation of the aluminum alloy by using excellent fluidity of the aluminum alloy in the semi-solid state, prevents formation of a high-thickness brittle compound layer, can form a stable interface through a reaction between a liquid phase in the aluminum alloy semi-solid blank and the titanium alloy, and is high in connecting reliability. In addition, the method is simple and feasible, needs no special equipment, and adopts a common hydropress to realize the formation and connection integration of the titanium alloy and the aluminum alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

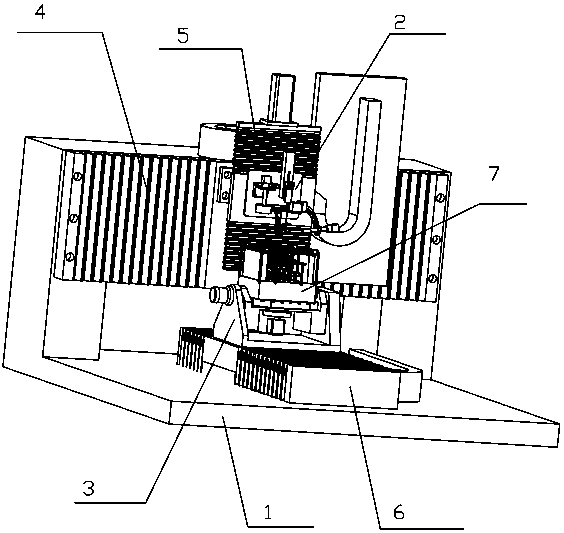

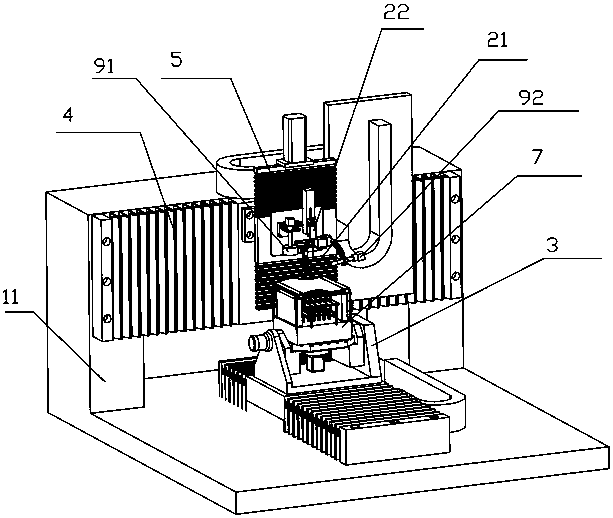

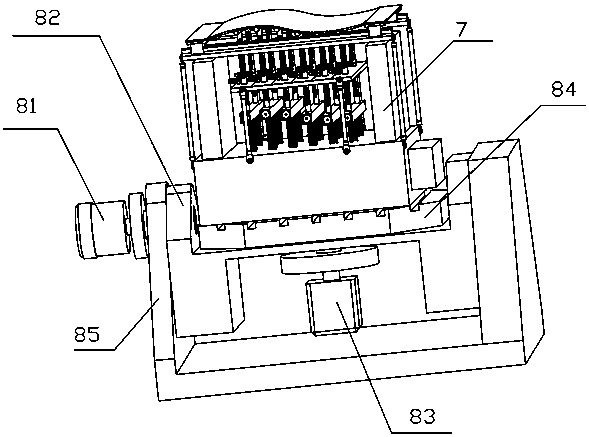

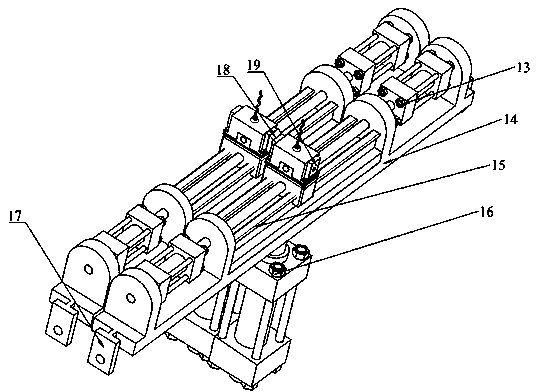

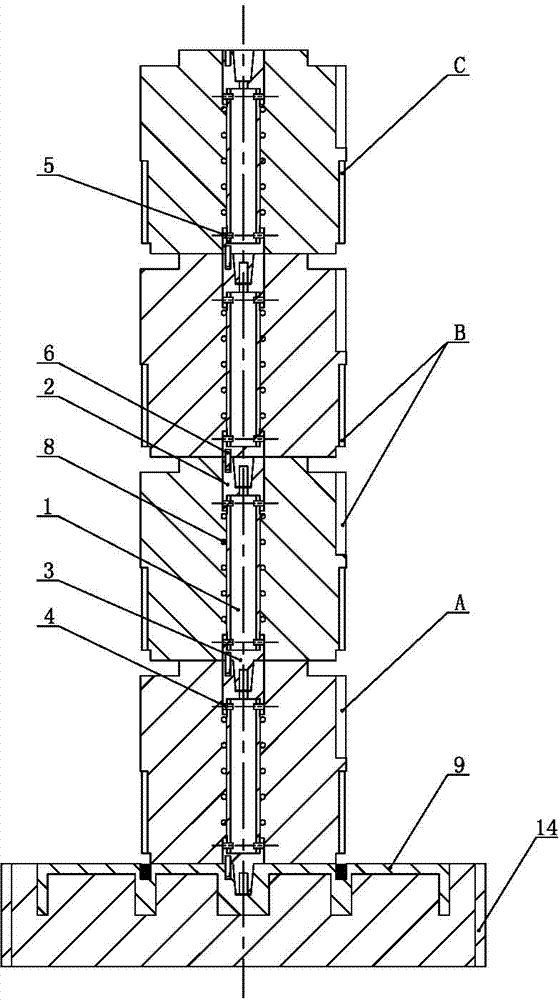

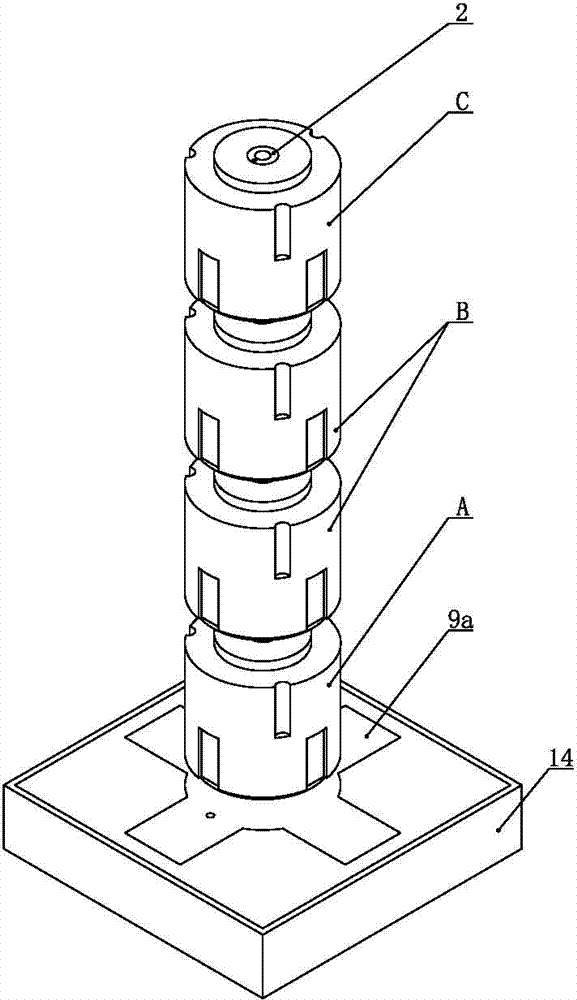

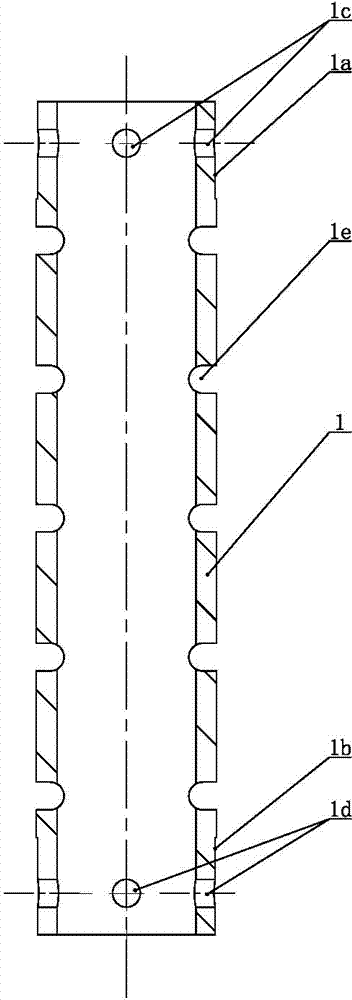

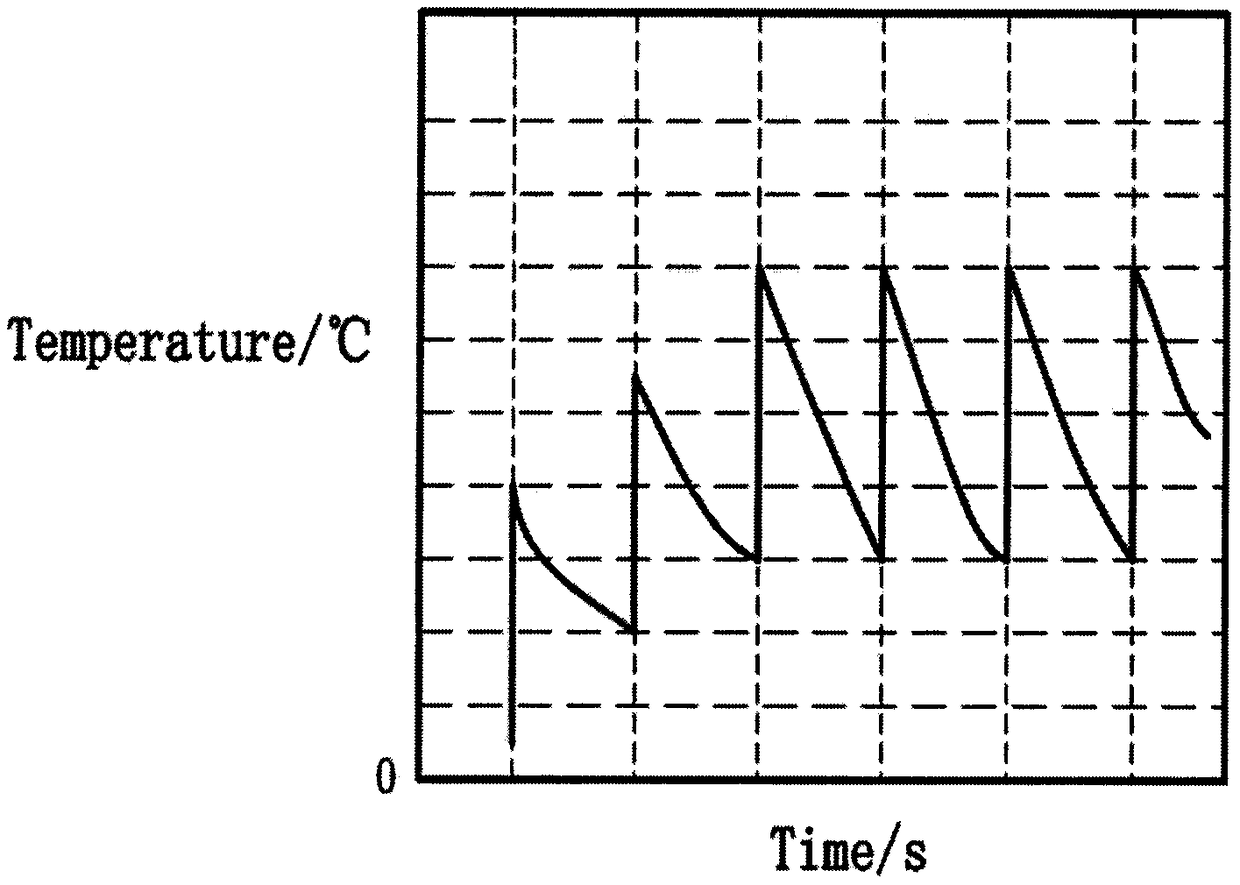

Multi-point three-dimensional electrothermal drawing-pressing composite bending forming device based on independent heat preservation mode

ActiveCN109877199AReduce consumptionReduce deformation resistanceGlass productionTemperature controlControl arm

The invention discloses a multi-point three-dimensional electrothermal drawing-pressing composite bending forming device based on independent heat preservation mode. The composite bending forming device mainly comprises a stretch bending control arm, a support, a bottom plate, a basic body, a lifting oil cylinder, a press bending oil cylinder, a die unit body, a temperature control cabinet, a power supply box and the like. According to the device, three-dimensional stretch bending forming of a section bar is achieved by adopting a vertical stretch-bending mode and a horizontal press-bending mode, and flexible forming of a three-dimensional bent workpiece with a complex geometric shape is achieved by adjusting use number of the basic body, the enveloping surface shape of a multi-point die and number of press bending oil cylinder actuating mechanisms at the two ends of the basic body; through the designed independent insulation box structure, temperature distribution on the section bar is more uniform, energy consumption is reduced, and forming precision is improved; in addition, temperature in each heat preservation box is monitored in real time, so that effective control of temperature in the whole forming process is achieved; and according to the self-resistance heating mode adopted to heat the metal section bar made of difficult-to-process material, plasticity of the formed workpiece is improved, deformation resistance of the workpiece is reduced, and accurate forming of three-dimensional hot stretch bending is achieved.

Owner:CHANGCHUN UNIV OF TECH

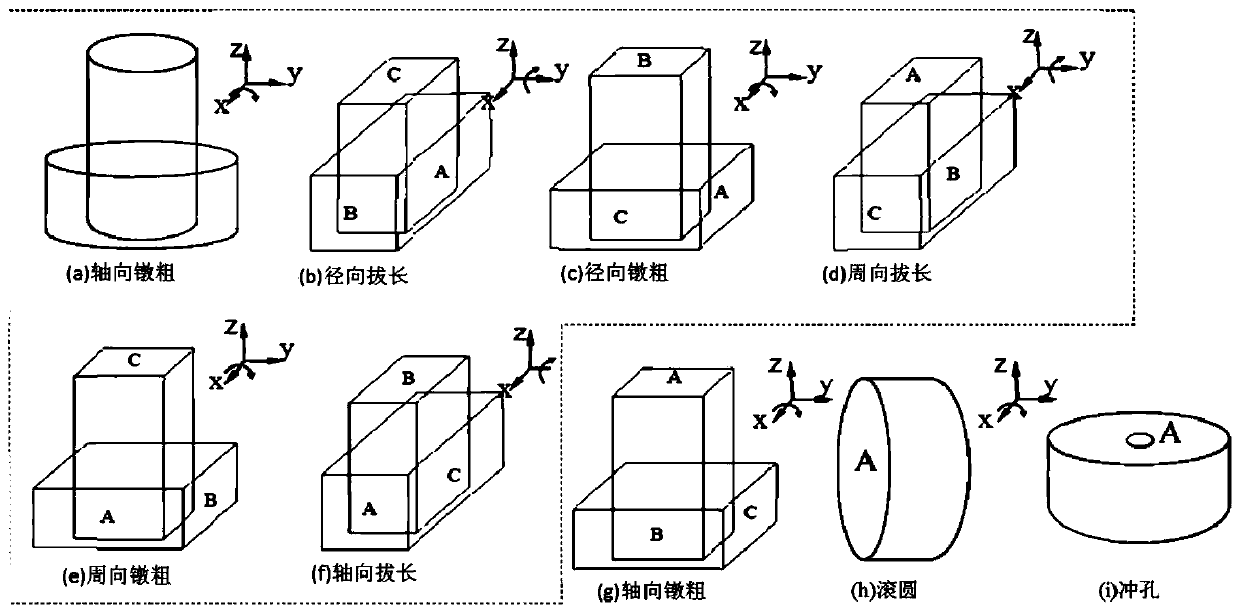

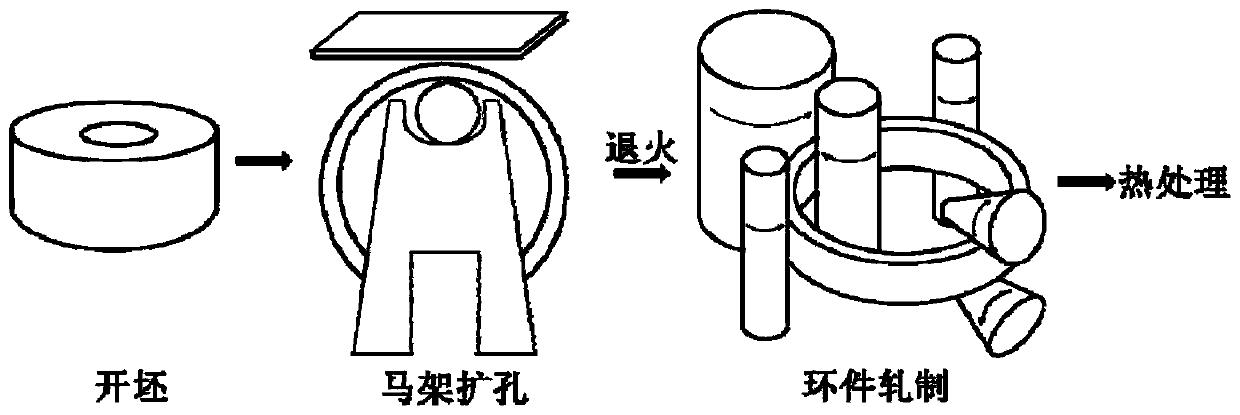

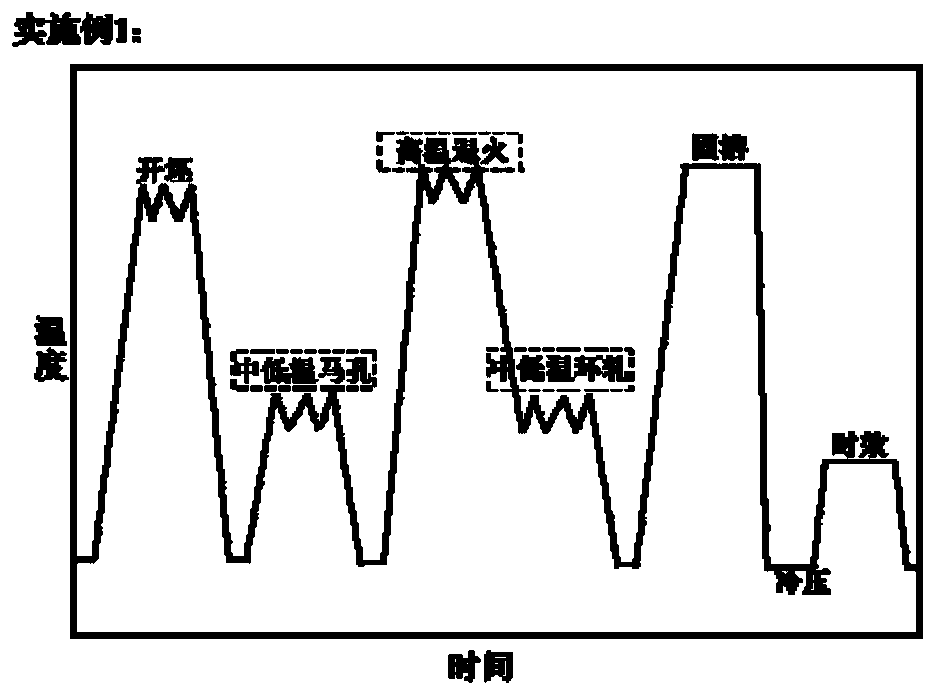

Method for adjusting and controlling coarse second phase of 2219 aluminum alloy ring part

ActiveCN110144533AImprove mechanical propertiesImprove dissolution efficiency2219 aluminium alloyHigh density

The invention discloses a method for adjusting and controlling the coarse second phase of a 2219 aluminum alloy ring part. The method comprises the processes of multi-direction forging cogging, medium-low-temperature shack reaming, high-temperature annealing, medium-low-temperature ring part rolling and heat treatment. The method adopts medium-low-temperature shack reaming+ high-temperature annealing and medium-low-temperature ring part rolling-solid solution, the coarse second phase is thoroughly crushed through the lower-temperature deformation shearing function, the dynamic recovery is suppressed by using the lower temperature condition to generate a high-density element diffusion misalignment channel, in the follow-up high-temperature annealing process, the thorough dissolution of thesecond phase after crushing is achieved, and the mechanical properties of the ring part are improved accordingly.

Owner:CENT SOUTH UNIV

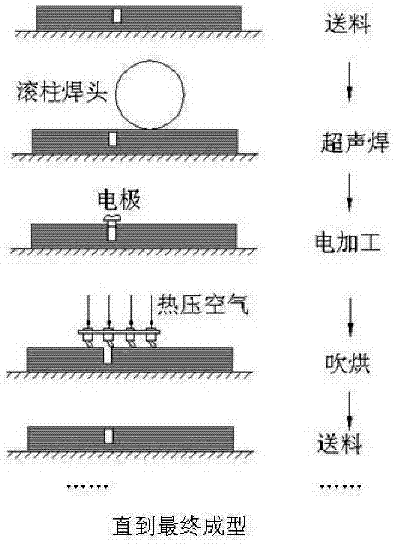

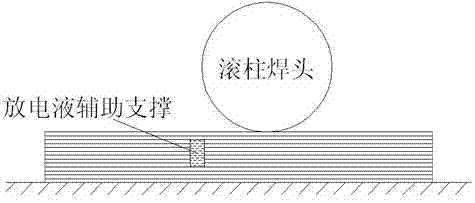

3D printing method based on ultrasonic welding additive manufacturing and electric spark forming

ActiveCN106881509AUniform textureReduce the temperatureAdditive manufacturing apparatusUltrasonic weldingMetal sheet

The invention discloses a 3D printing method based on ultrasonic welding additive manufacturing and electric spark forming. According to the method, the two high and new technologies of ultrasonic welding additive manufacturing and electric spark forming are combined, and a high-precision ultrathin metal sheet is subjected to layered ultrasonic welding; and after each layer is welded, the spark erosion technique is adopted to form a vacant part on the cross section of the layer according to the component CAD model cross section needs, and forming is performed layer by layer until final forming is completed. The 3D printing method has the advantages of being small in ultrasonic welding pressure, low in temperature, firm in solidification and the like together with the characteristics that an electric spark forming electrode is low in vibration, small in size, high in forming precision and the like. The defects that common 3D printing precision is low, bonding is not firm, the inside is hollow and the suspended portion needs to be supported are overcome. The difficulties that tool fillets occur in other 3D printing, the tool size cannot be small, tool vibration is high, and the precision of a top layer 'ceiling' cannot be guaranteed are eliminated. Overall precision forming of a component with a 3D inner cavity can be achieved, and a breakthrough is provided for simplifying the component structure, reducing the component size and improving product accuracy.

Owner:NANCHANG UNIV

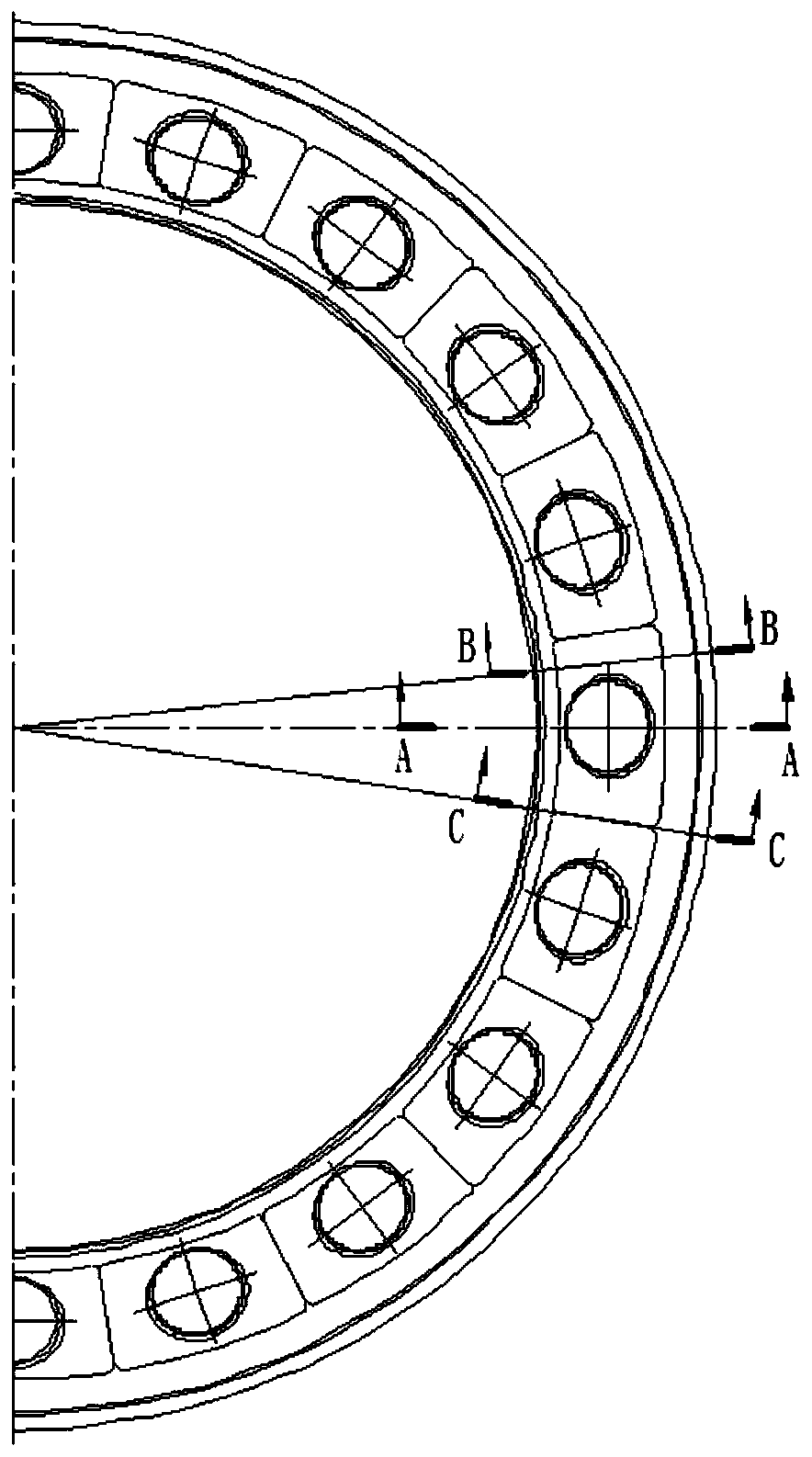

Method for improving manufacturing precision of components at head switching section of annular flame cylinder

ActiveCN110238617AImprove manufacturing precisionIncrease productivityStructural engineeringWelding deformation

The invention discloses a method for improving the manufacturing precision of components at a head switching section of an annular flame cylinder. The method comprises the following steps of first, pre-forming the head switching section to form a primary head switching section with a turbulator mounting hole, meanwhile pre-processing an internal cooling ring and an external cooling ring to form an internal cooling ring coarse structure and an external cooling ring coarse structure, and separately welding the internal cooling ring coarse structure and the external cooling ring coarse structure to the primary head switching section to form primary welding components; and positioning the profile of the formed head switching section and the turbulator mounting hole, and processing and forming the internal cooling ring coarse structure and the external cooling ring coarse structure to form a final internal cooling ring and a final external cooling ring. At first, the head switching section is pre-formed, and the head switching section is finally formed in the component state, so that the influence of welding deformation and heat treatment deformation on the profile tolerance of the head switching section and the location degree of the turbulator mounting hole is avoided, the manufacturing precision of the component is improved, and meanwhile, the method is higher in production efficiency.

Owner:AECC AVIATION POWER CO LTD

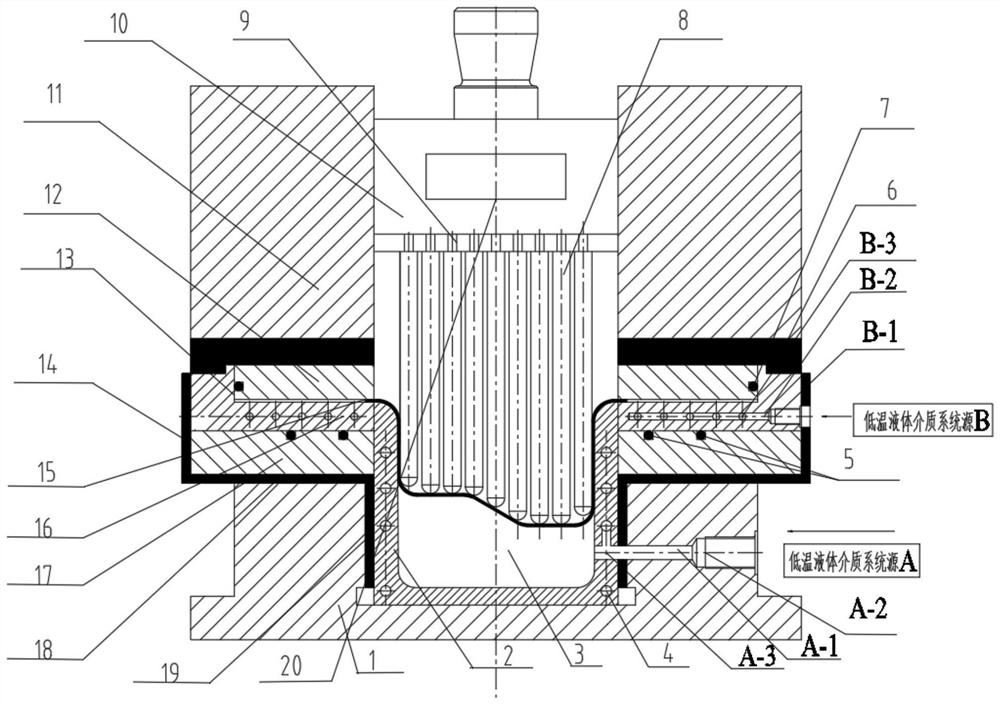

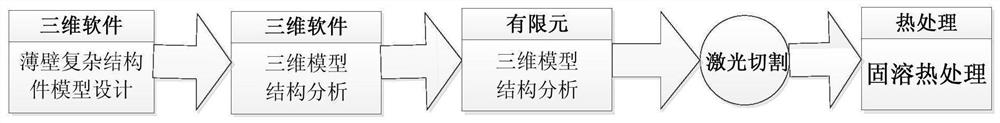

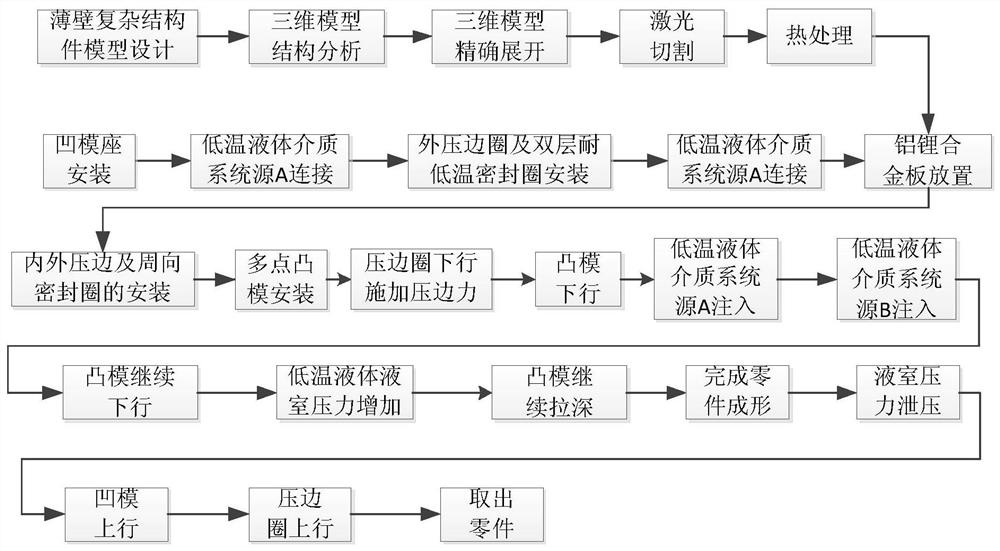

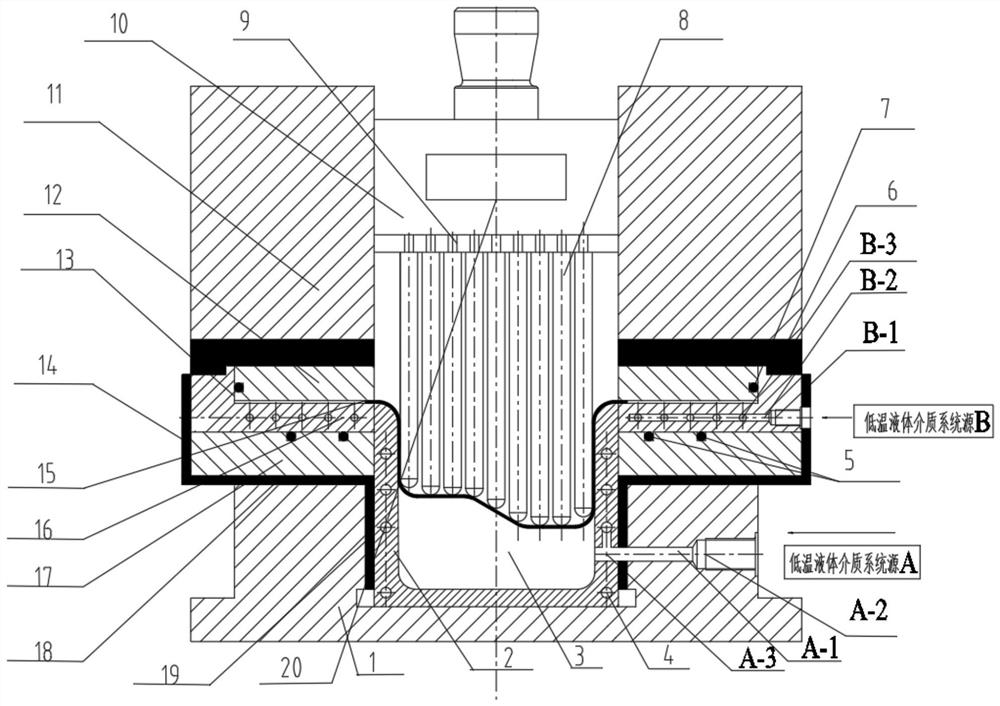

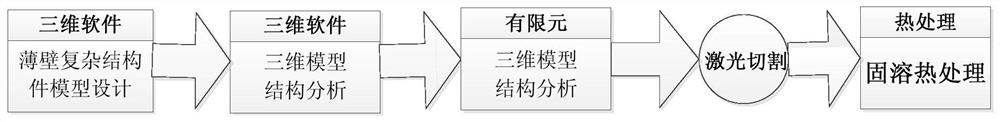

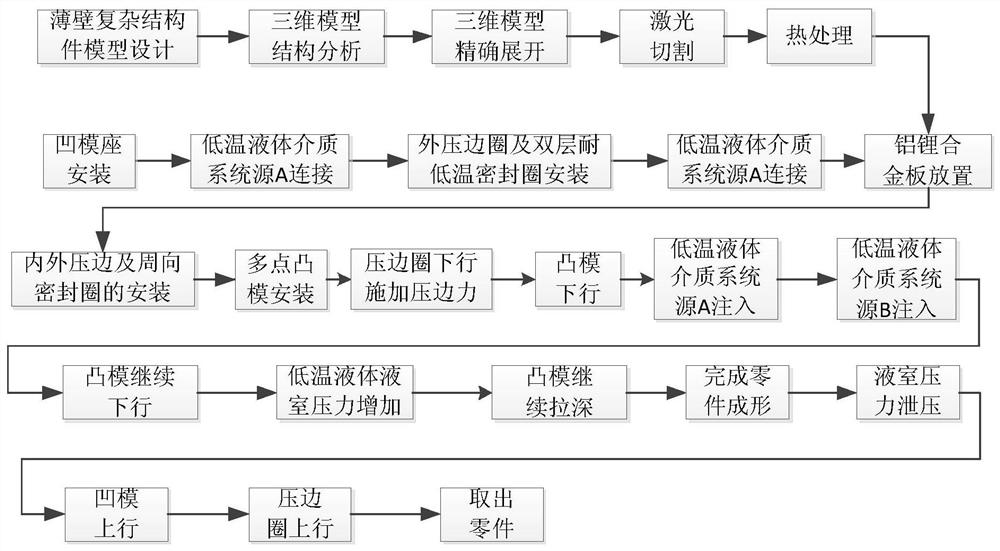

Ultralow-temperature flexible forming method for aluminum-lithium alloy complex thin-wall structural part

ActiveCN112676459ASolve the problem that the accuracy of shape and size is difficult to be guaranteedReduce manufacturing costShaping toolsAluminium-lithium alloyMaterials science

The invention relates to the technical field of special forming manufacturing processes of aluminum-lithium alloy complex thin-wall structural parts, in particular to an ultralow-temperature flexible forming method for an aluminum-lithium alloy complex structural part, the wall thickness of the structural part is not larger than 5 mm, and the complex structural part is of a spatial curved surface structure in appearance. The device is particularly suitable for forming aluminum-lithium alloy thin-wall complex structural parts. By utilizing the characteristics of plasticization and reinforcement of the aluminum-lithium alloy at ultralow temperature, the aluminum-lithium alloy plate is flexibly formed by adopting an ultralow-temperature flexible forming method, so that the defects that the aluminum-lithium alloy complex thin-wall structural part is difficult to form a complex-shaped component, poor in fracture toughness, easy to generate microcracks during room-temperature forming and the like can be overcome, the forming resilience is large, and the shape and size precision of the component is difficult to guarantee.

Owner:BEIJING SATELLITE MFG FACTORY

Ultralow-temperature flexible forming device for complex thin-walled aluminum-lithium alloy structural part

InactiveCN112676460ASolve the problem that the accuracy of shape and size is difficult to be guaranteedReduce manufacturing costShaping toolsAluminium-lithium alloyThin walled

The invention relates to the technical field of special forming manufacturing processes of complex thin-walled aluminum-lithium alloy structural parts, in particular to an ultralow-temperature flexible forming device for the complex thin-walled aluminum-lithium alloy structural part. The thin wall refers to that the wall thickness of the structural part is not larger than 5 mm, and the complex structural part refers to that the shape of the structural part is of spatial curved surface structure. The ultralow-temperature flexible forming device is particularly suitable for forming the thin-walled complex aluminum-lithium alloy structural part. By utilizing the characteristics of plastification and reinforcement of the aluminum-lithium alloy at ultralow temperature, an ultralow-temperature flexible forming method is adopted to conduct flexible formation of an aluminum-lithium alloy plate, and then the problems that when indoor-temperature formation is conducted on the complex thin-walled aluminum-lithium alloy structural part, a complex-shaped component is difficult to form, fracture toughness is poor, defects such as microcracks are prone to generation during indoor-temperature forming, the forming resilience is large, and the shape and size precision of the component is difficult to guarantee are solved.

Owner:BEIJING SATELLITE MFG FACTORY

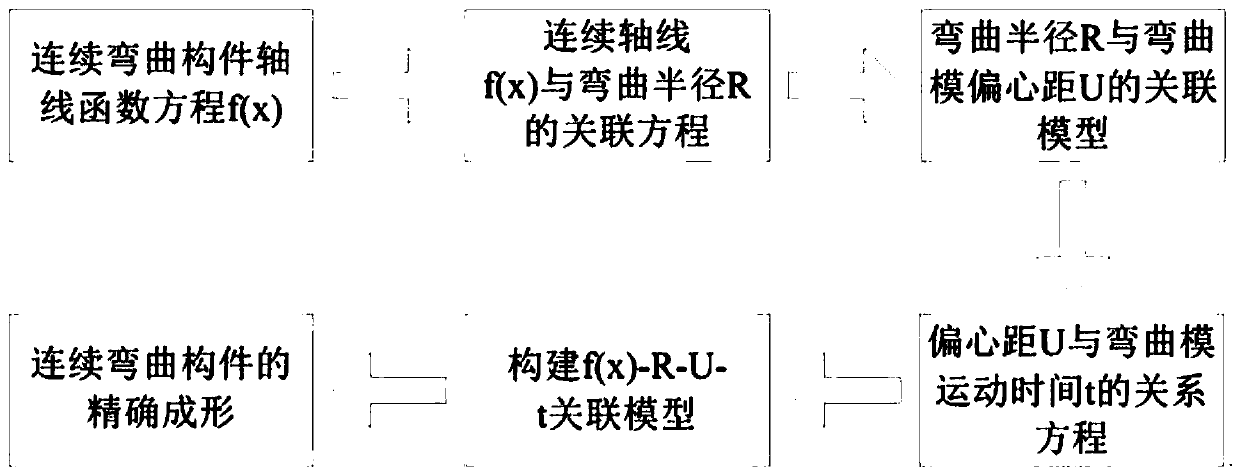

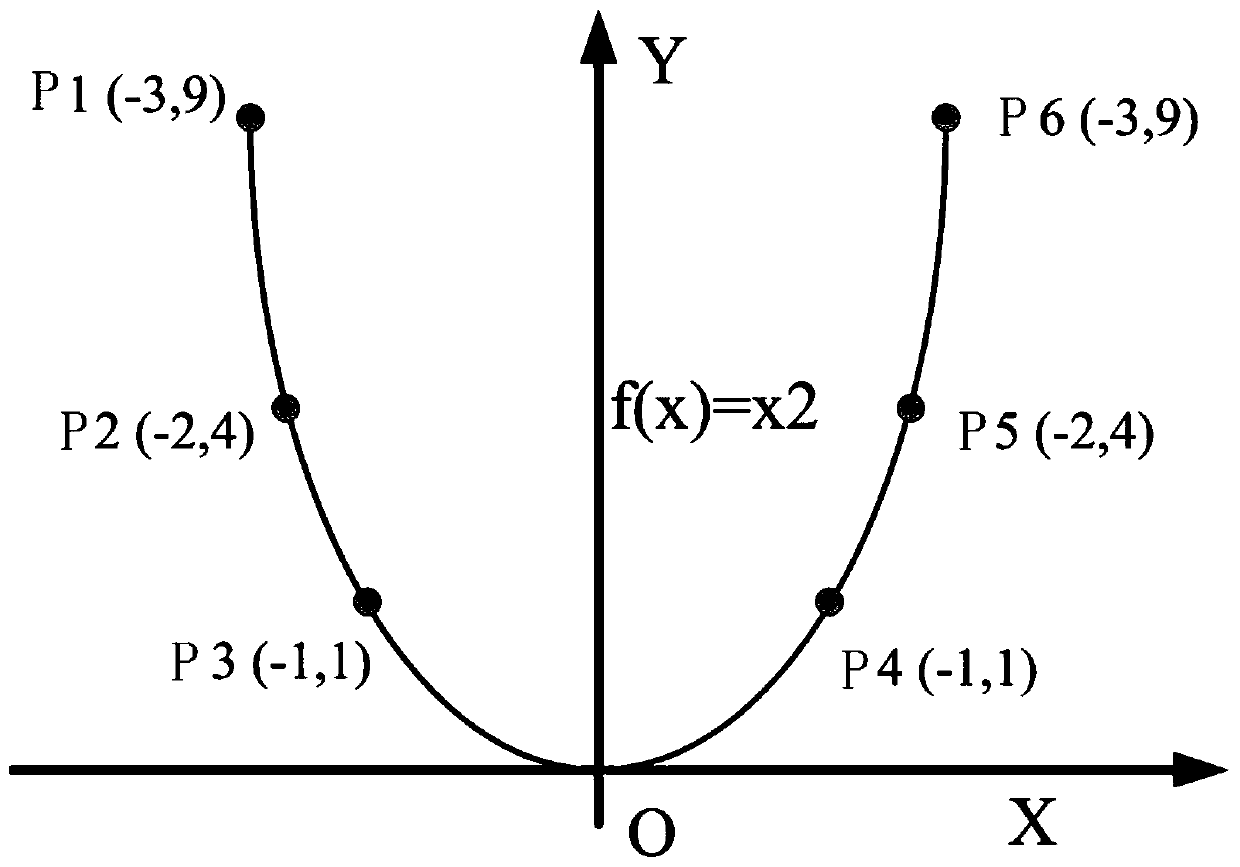

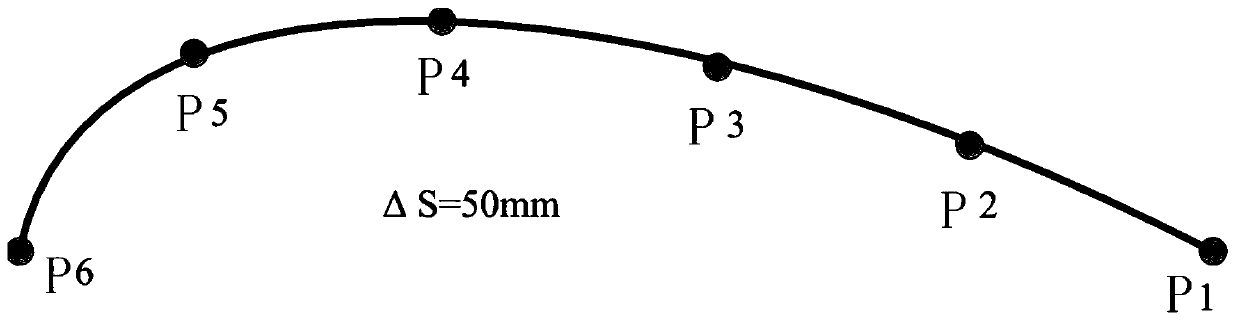

Continuous free bending precise forming method

InactiveCN111085580AAchieving Precise FormingImprove forming qualityAdaptive controlBend radiusMechanical engineering

The invention discloses a continuous free bending precise forming method. The method comprises the following steps of firstly, establishing a relation equation of a continuous axis f (x) and a bendingradius R, and determining the bending radius R of the real-time position of the axis; and establishing a correlation model between the real-time bending radius R of the pipe and the eccentric distance U of the bending die through a free bending technology, further establishing a relation between an equation of an axis and free bending parameters, completely constructing a correlation model amongf (x)-R-U-t through a relation equation between the eccentric distance U and the movement time t of the bending die, and realizing the accurate forming of complex continuous bent components. Accordingto the method, production efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

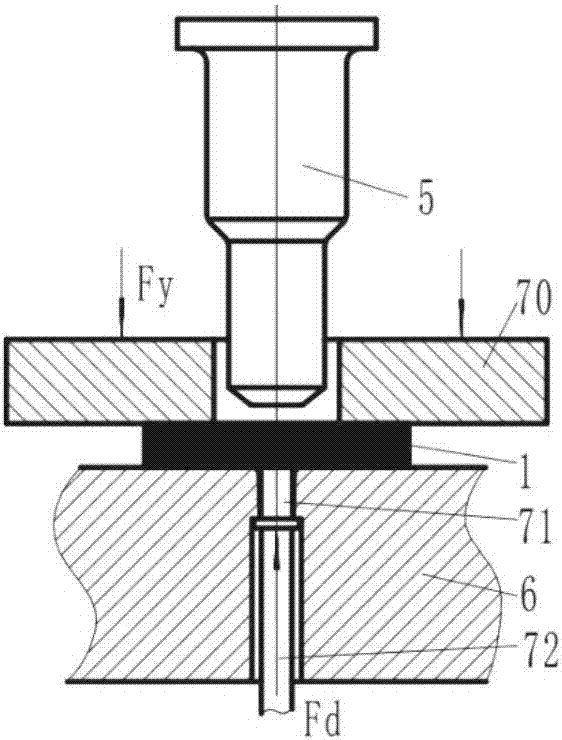

Compounding and forming integrated device and method for multi-layer metal micro-channel structure

ActiveCN109647986AReduce deformation resistanceReduce coefficient of frictionShaping toolsReciprocating motionEngineering

The invention discloses a compounding and forming integrated device and method for a multi-layer metal micro-channel structure. The device and method solve the technical problems that in existing structure design, a mold device is complex in structure, the machining process of the metal micro-channel structure is complex in procedure and high in manufacturing cost, a micro-channel structure formedby independent machining of mono-metal materials is poor in quality, and the performance of the structure is not improved. The compounding and forming integrated device comprises an upper mold base and a lower mold base which are matched; the upper mold base achieves vertical reciprocating movement through a guide sleeve and a guide column; a convex mold is fixedly arranged on the lower surface of the upper mold base; a concave mold is fixedly arranged on the upper surface of the lower mold base; the concave mold and a concave mold fixing board define a mold cavity; a micro-channel groove isformed in the upper surface of the concave mold in an inwards concave mode; the convex mold is fixedly arranged on the lower surface of the upper mold base through a convex mold fixing board; a grooveis formed in the position of the upper surface, making contact with the upper mold base, of the upper end of the convex mold in an inwards concave mode; a vibrator penetrating through the upper moldbase is fixedly connected with the interior of the groove; and the compounding and forming integrated device and method for the multi-layer metal micro-channel structure can be widely applied to the field of precision manufacturing of bi-metal micro-channel structures.

Owner:HARBIN INST OF TECH AT WEIHAI

Mold core of multi-inner-cavity revolving body structural component

ActiveCN104493099AImprove integrityReduce weightFoundry mouldsFoundry coresMaterials scienceStructural component

The invention relates to a mold core of a multi-inner-cavity revolving body structural component. The mold core comprises a sand core base which is embedded into the top of lower box molding sand, wherein a bottom sand core is superimposed on the center of the upper end surface of the sand core base, a middle sand core is superimposed on the bottom sand core, and a top sand core is superimposed on the middle sand core; the sand core base, the bottom sand core, the middle sand core and the top sand core are coaxial; the shape of the bottom sand core is consistent with that of a lower revolving inner cavity of the structural component, the shape of the middle sand core is consistent with that of a middle revolving inner cavity of the structural component, and the shape of the top sand core is consistent with that of an upper revolving inner cavity of the structural component. The center of each sand core is provided with a mandrel, the mandrel comprises a mandrel main rod as well as a mandrel concave end and a mandrel convex end, which are connected to two ends of the mandrel main rod, and the upper mandrel convex end can be inserted into the lower mandrel concave end. A core box comprises a core box soleplate and a core box side plate, and the mandrel is inserted in the center of the core box soleplate. By adopting the mold core, the formation of a complicated inner cavity structure of a large-sized multi-section high-precision revolving body casting can be realized.

Owner:YANGZHOU FENG MING METAL PROD

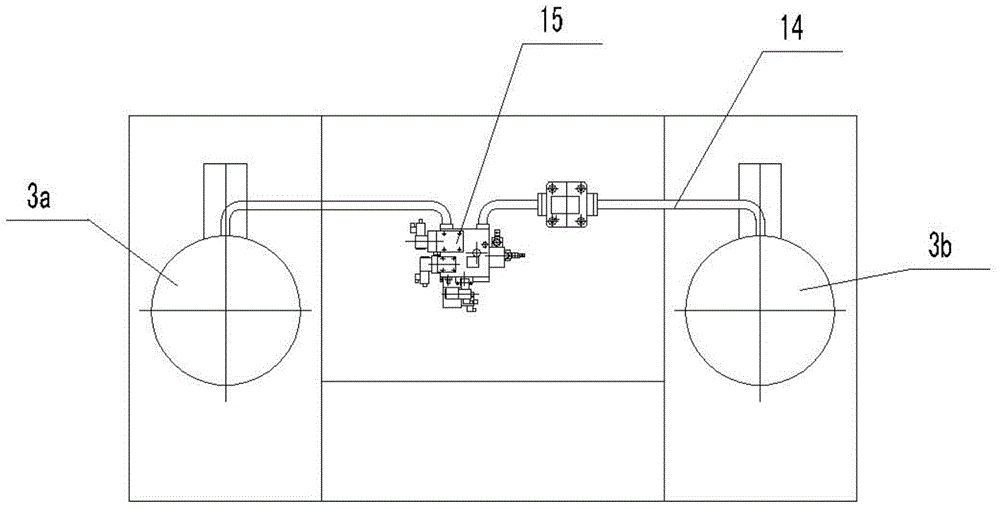

Forming device for faucet pipe body and method for forming faucet pipe body through forming device

A faucet pipe body forming device, including a hydraulic pressure generating system, a hydraulic bulging press, and an internal high-pressure forming die. The internal high-pressure forming die includes an upper die and a lower die. Die holes, including short and long end round die holes and vertically arranged manifold circular grooves, long and short end round die holes are installed with left and right push heads for tight sealing, the oil inlet channel of the right push head is connected with the high-pressure oil circuit, and the manifold is round A back pressure piston is installed in the die hole, and the left and right push heads and the back pressure piston are respectively connected with the left and right oil cylinders and the back pressure oil cylinder of the hydraulic bulging press. The method for manufacturing the faucet body includes the steps of: S1 using the internal high pressure forming technology to manufacture the semi-finished faucet body, S2. using the conventional bending process to form the finished faucet body. The design of the device is scientific, and the method of using the forming device to manufacture the complex-shaped faucet body fully utilizes the advantages of the internal high-pressure forming technology and the conventional pipe bending process, which can make the manifold end precisely formed, and the quality of the formed pipe body is good.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Preparation method of alloy cranial prosthesis

InactiveCN105893769ABest manufacturing stepsImplement the repair functionMedical simulationImage enhancementProsthesisBiocompatibility Testing

The invention relates to a preparation method of an alloy cranial prosthesis. The method mainly comprises the steps of acquiring skull image data of a patient, generating a skull model by means of three-dimensional reconstruction, obtaining a two-dimensional prosthesis and carrying out shaping production to obtain the alloy cranial prosthesis. The preparation method provided by the invention covers the shortage of the traditional preparation technology, and is used for efficiently preparing the alloy cranial prosthesis which has a complicated shape and can meet the biocompatibility and mechanical compatibility requirements of a medical material. Furthermore, the preparation method is lower in cost, high in manufacturing accuracy and high in molding efficiency.

Owner:刘国远 +2

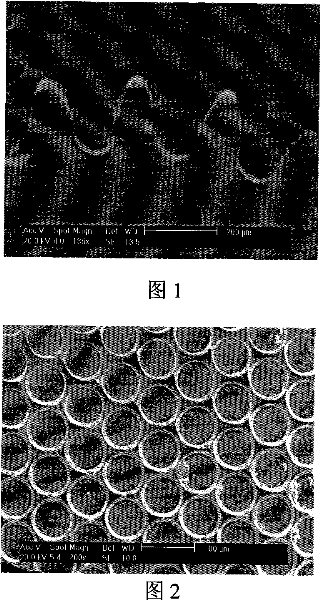

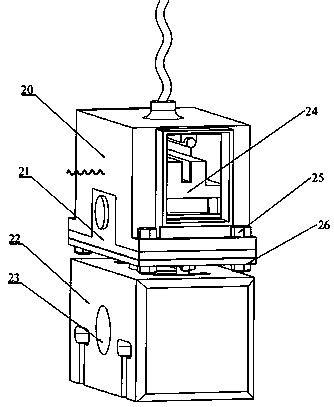

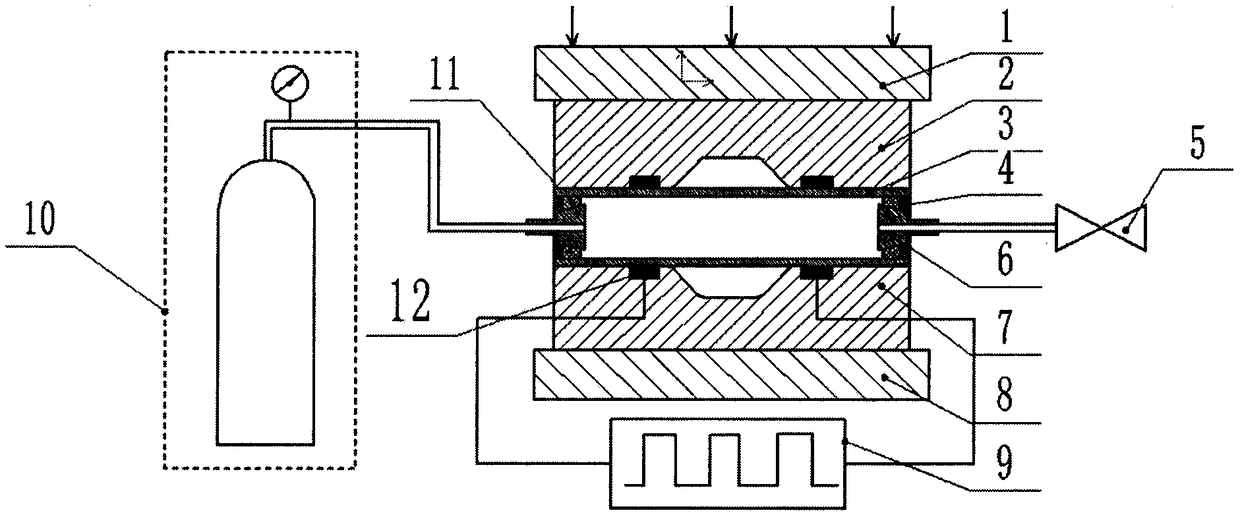

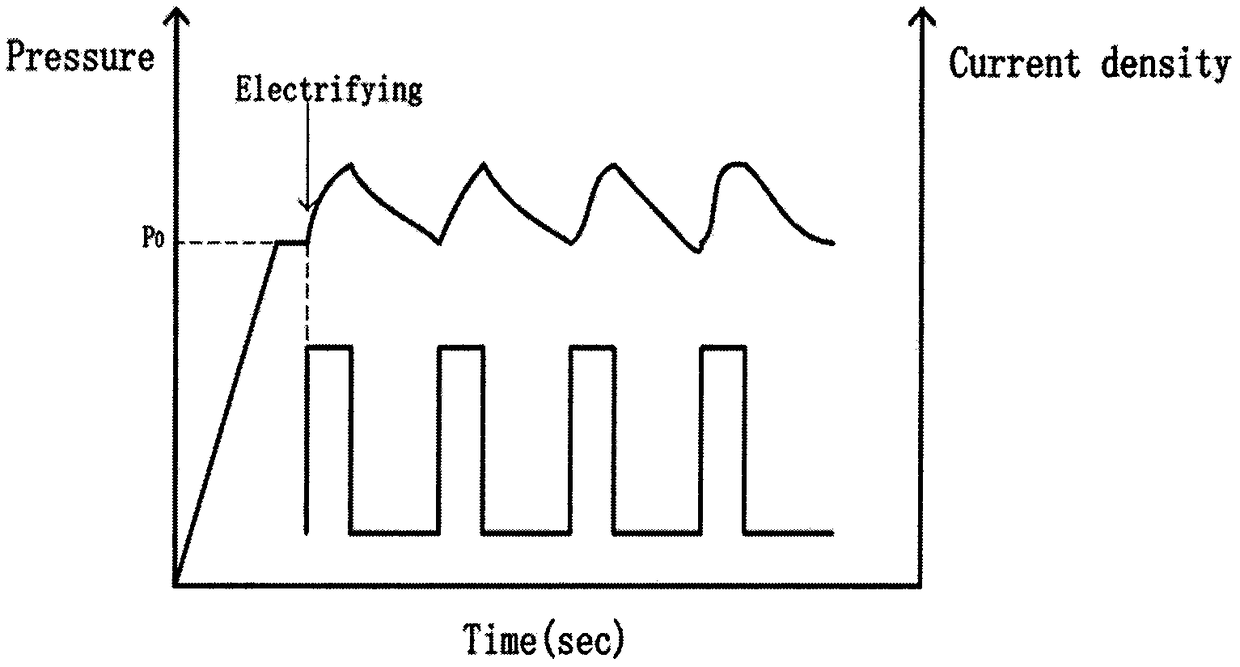

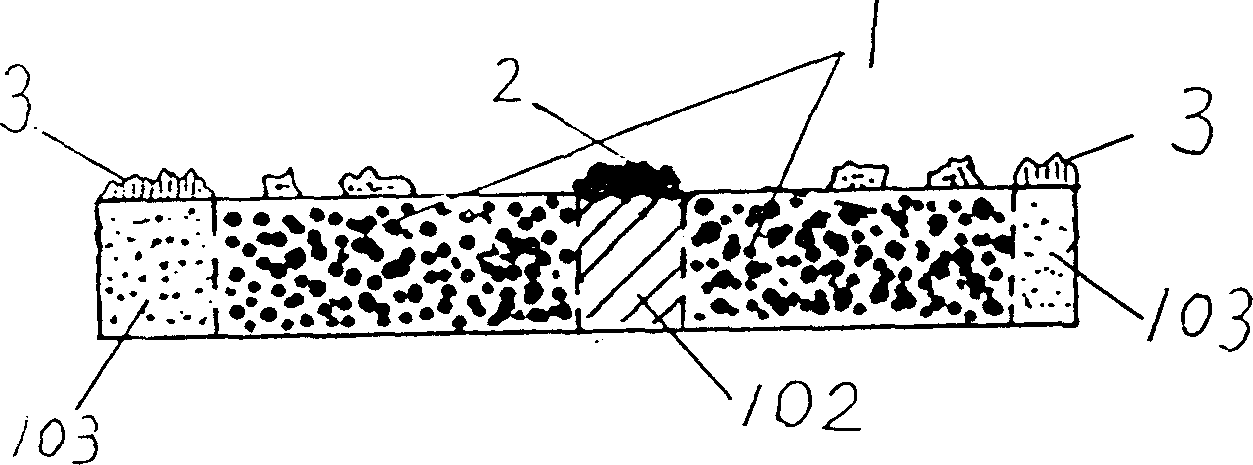

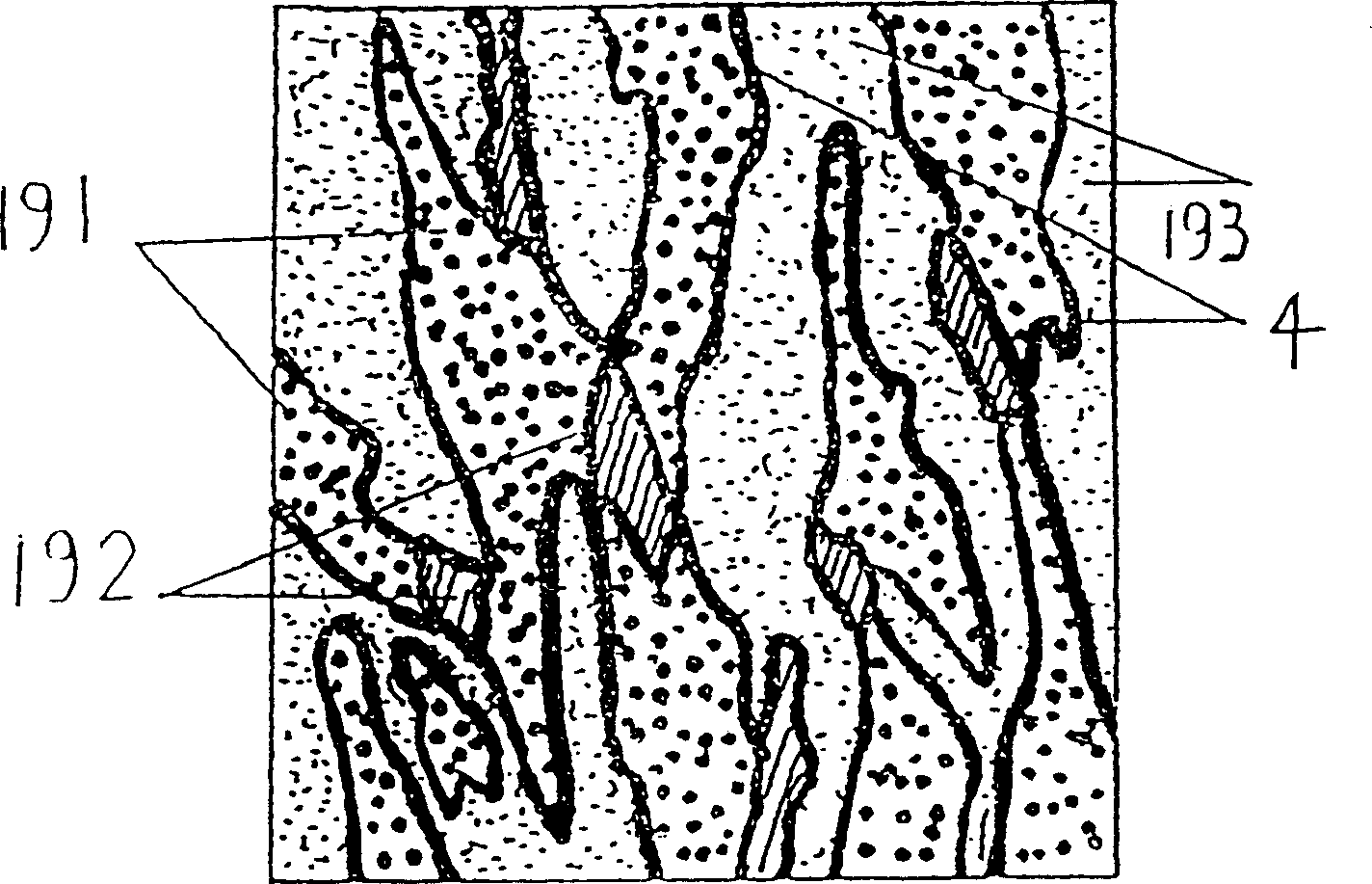

Pulse-current pulse heating and gas-pressure forming device and method for difficult-to-deform alloy pipe fitting

InactiveCN109465322AHomogeneous temperature distribution around theImproves wall thickness uniformityShaping toolsAlloyPulse power supply

The invention discloses a pulse-current pulse heating and gas-pressure forming device and method for a difficult-to-deform alloy pipe fitting. As shown in figure 1, an upper mould and a lower mould are separately arranged at upper and lower sides of a to-be-formed pipe fitting, and formed parts are placed in cavities of the moulds; two semi-circular electrodes are separately embedded into the upper mould and the lower mould, and separately correspond to the two ends of a pipe; when the upper mould fits to the lower mould, the corresponding semi-circular electrodes define a circular ring shapeso as to be in sufficient contact with the pipe; the electrodes are externally connected with a high-frequency pulse power supply; and argon gas supercharging systems are connected to the two ends ofa sealed pipe. Low-pressure argon gas is firstly filled into the pipe, so that pressure in the pipe reaches a set value; then, the power supply is accessed, and the high-frequency pulse power supply emits low-frequency pulse current to heat the pipe, so that pressure in the pipe, the pipe surface temperature and relative load are in periodic fluctuation along with low-frequency pulse current, which are separately as shown in figures 2, 3 and 4; and pipe ring-direction temperature distribution is more uniform, the pipe is repeatedly expanded in an expanding process through pulsation changes ofload, expanding uniformity of the pipe expanding area is improved, and the local wall thickness is prevented from being reduced, so that forming performance of the pipe fitting is greatly improved, and precise forming for the pipe fitting with a complex shape is favorably realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Tridimonsional antique brick and its production method

InactiveCN1830689AVertically accurate and fastAccurate and fast vertical stackingOrnamental structuresSpecial ornamental structuresPattern recognitionBrick

A pseudo-classical 3D brick features that is has a color pattern layer with obviously recognized 2-10 colors and a color enamel pattern layer on said color pattern layer. It has high anti-wear performance.

Owner:杨德宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com