Method for semi-solid formation and connection integration of titanium alloy and aluminum alloy

A semi-solid forming, aluminum alloy technology, applied in the field of semi-solid forming and connecting integration of titanium alloy and aluminum alloy, and semi-solid forming and connecting integration, can solve the problem that the uniformity of the joint material bonding strength is difficult to meet the requirements, the flexibility is poor, and the connection It can avoid the formation of large thickness brittle compound layer, achieve precise forming and high connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

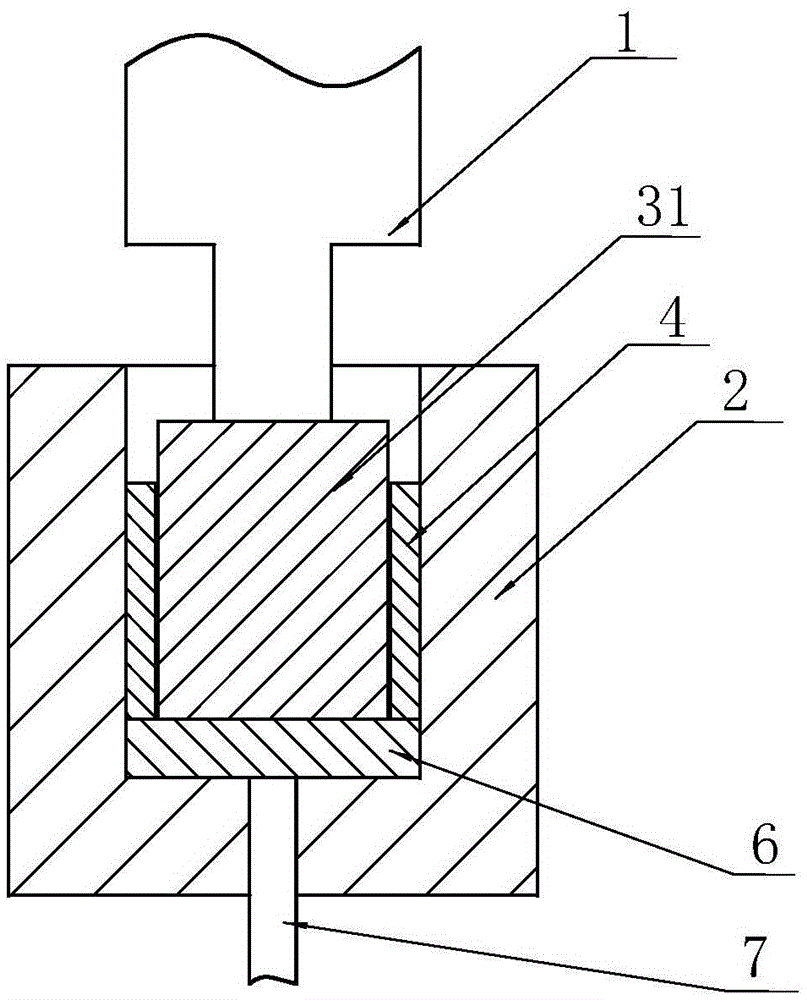

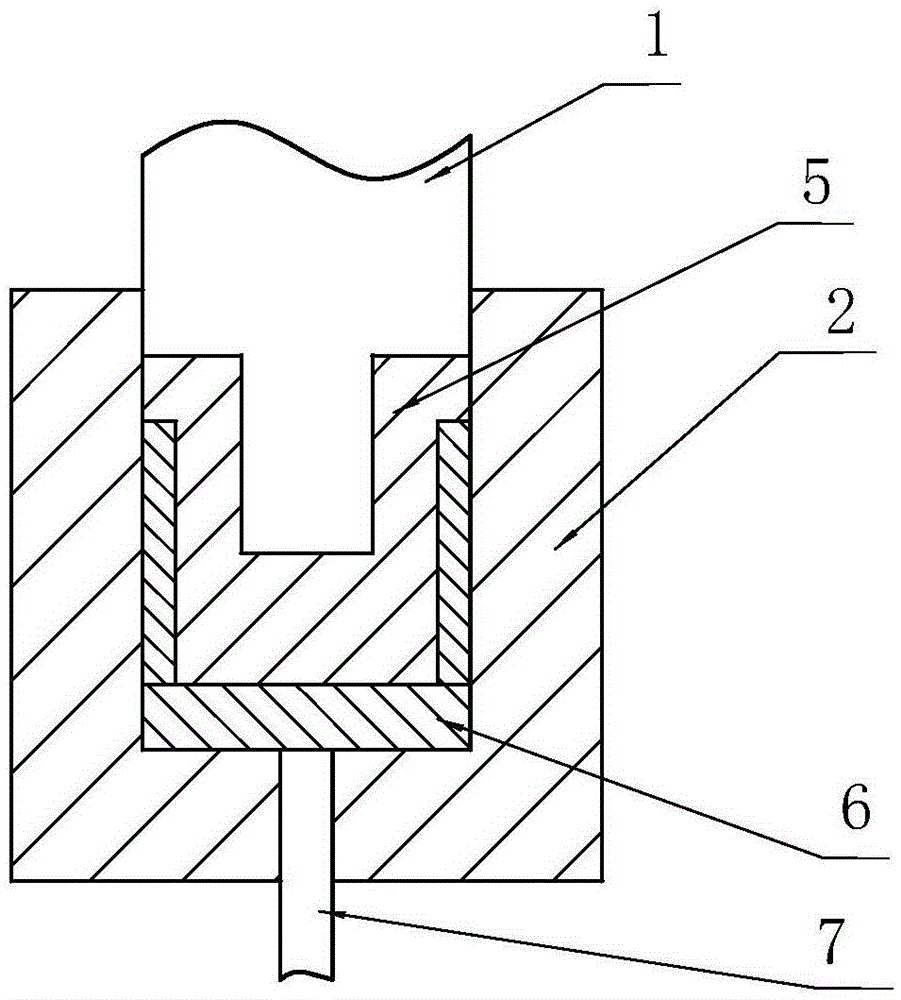

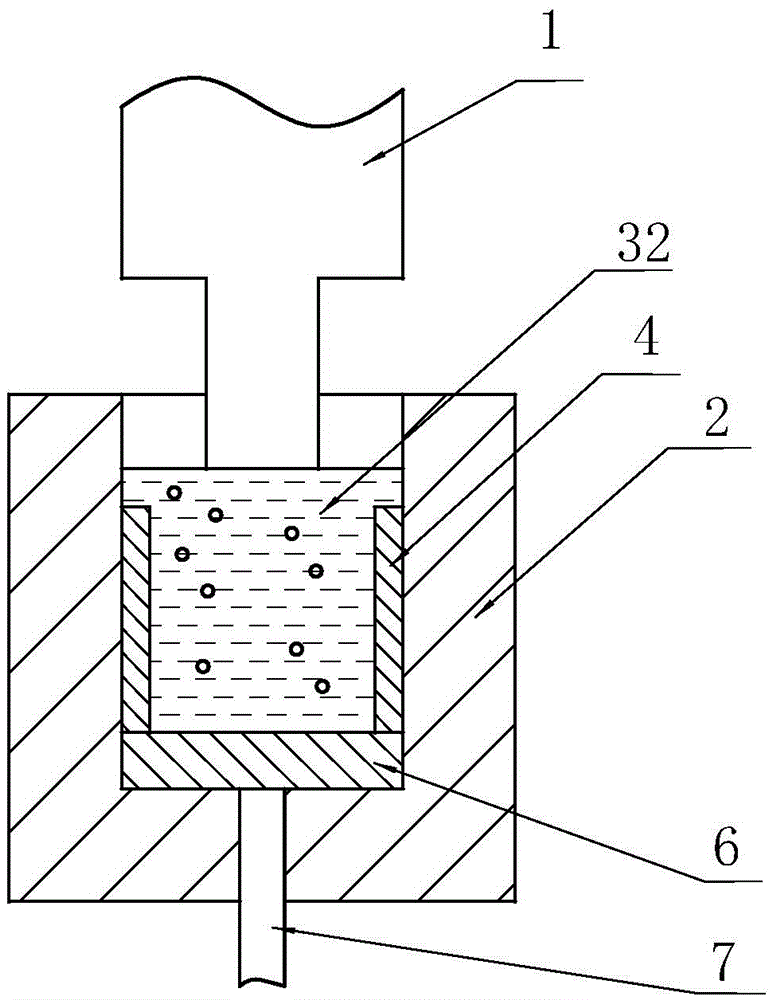

[0027] Embodiment one: TA2 titanium alloy and 6063 aluminum alloy

[0028] a. In order to facilitate putting the preheated aluminum alloy semi-solid billet into the titanium alloy tube, consider that the coefficient of thermal expansion is 2.3×10 -5 Factors, the TA2 titanium alloy pipe is processed into a TA2 titanium alloy pipe with a size of φ50mm×5mm×h40mm; the 6063 aluminum alloy bar is processed into a 6063 aluminum alloy billet with a size of φ39mm×h50.6mm;

[0029] b. Put the TA2 titanium alloy tube into the mold and preheat together, the preheating temperature is 300°C;

[0030] c. Using an electromagnetic induction heating device to preheat the 6063 aluminum alloy billet to 620°C and keep it warm for 20 minutes, the 6063 aluminum alloy billet is converted into a semi-solid billet with a liquid phase rate of 60%;

[0031] d. Move the 6063 aluminum alloy semi-solid blank 3 that has been preheated and insulated into the TA2 titanium alloy tube in the mould, ensuring tha...

Embodiment 2

[0033] Embodiment 2: TA7 titanium alloy and 7075 aluminum alloy

[0034] a. Process the TA7 titanium alloy pipe into a TA7 titanium alloy pipe with a size of φ60mm×5mm×h45mm.

[0035] b. Put the TA7 titanium alloy tube into the mold for preheating together, the preheating temperature is 320°C;

[0036] c. Process the 7075 aluminum alloy bar into a billet with a size of φ49mm×h62mm, preheat the 7075 aluminum alloy billet to 620°C with an electromagnetic induction heating device, and keep it warm for 18 minutes. The conversion rate of the 7075 aluminum alloy billet to liquid phase is 56%. semi-solid billet;

[0037] d. Move the preheated and heat-preserved 7075 aluminum alloy semi-solid blank into the TA7 titanium alloy tube in the mould, ensuring that the 7075 aluminum alloy semi-solid blank is adjacent to the TA7 titanium alloy tube;

[0038] e. The punch goes down quickly and pressurizes 190KN, the speed of the punch down is 10mm / s, and the holding time is 15s, so that the ...

Embodiment 3

[0039] Embodiment three: TB2 titanium alloy and 2024 aluminum alloy

[0040] a. Process the TB2 titanium alloy pipe into a TB2 titanium alloy pipe with a size of φ40mm×5mm×h35mm;

[0041] b. Put the TB2 titanium alloy tube into the mold and preheat together, the preheating temperature is 350°C;

[0042] c. Process the 2024 aluminum alloy bar stock into a billet with a size of φ29mm×h50mm, preheat the 2024 aluminum alloy billet to 630°C with an electromagnetic induction heating device, and keep it warm for 15 minutes. The 2024 aluminum alloy billet is converted into a liquid phase rate of 50%. semi-solid billet;

[0043] d. Move the preheated and heat-preserved 2024 aluminum alloy semi-solid blank into the TB2 titanium alloy tube in the mould, ensuring that the 2024 aluminum alloy semi-solid blank is adjacent to the TB2 titanium alloy tube;

[0044] e. The punch goes down rapidly and pressurizes 180KN, the speed of the punch is 10mm / s, and the holding time is 20s, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com