Step-by-step progressive hot forming and hot correcting integrated method for thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges

A technology of integral wall panels and super-large flanges, applied in metal processing, forming tools, metal processing equipment, etc., can solve problems such as rib instability, large residual stress of wall panels, and poor plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

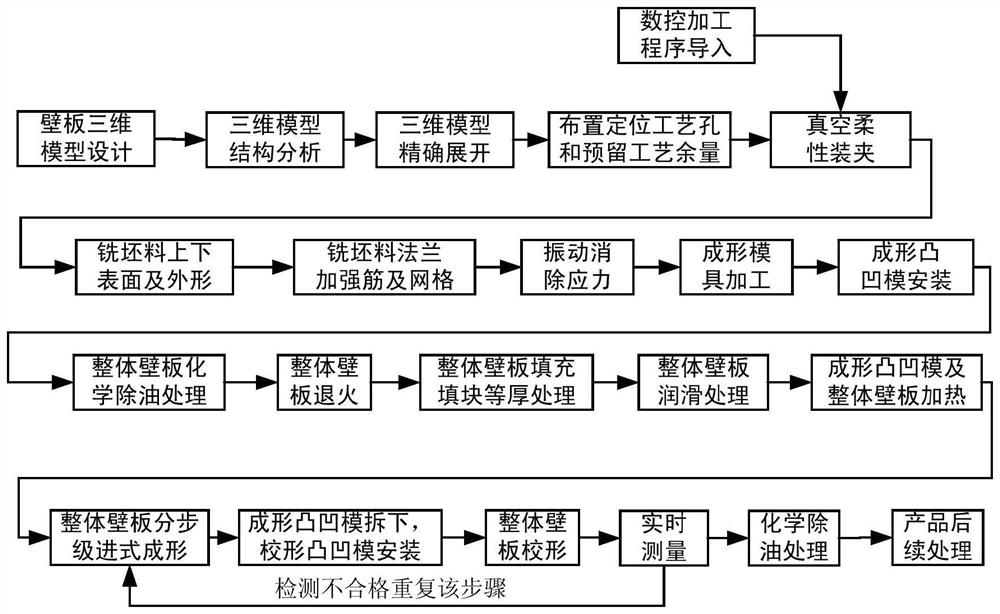

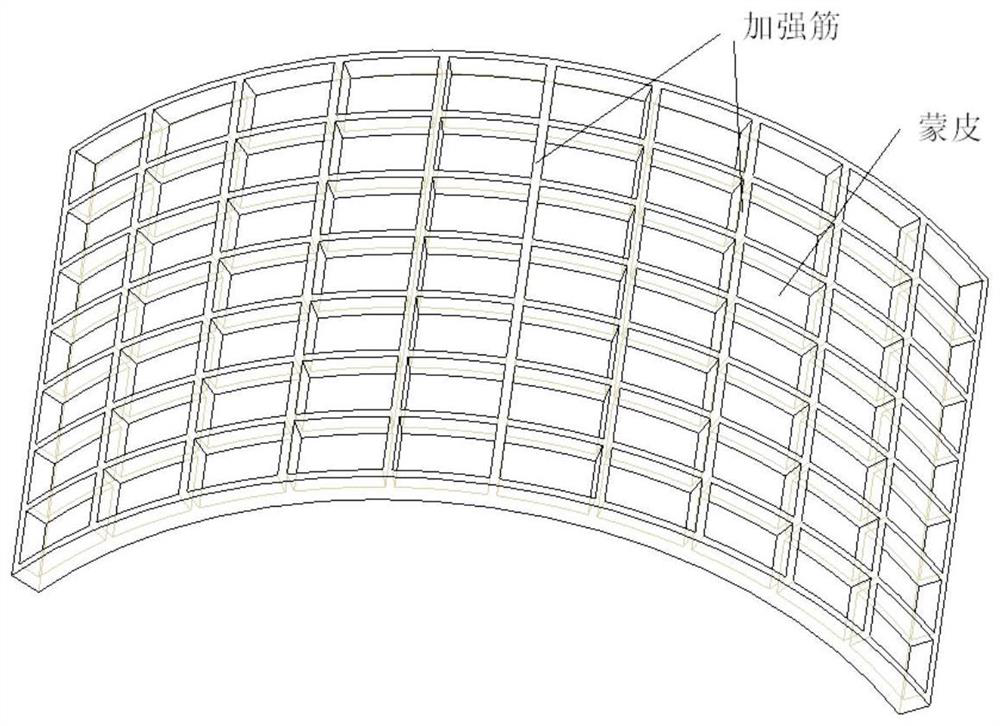

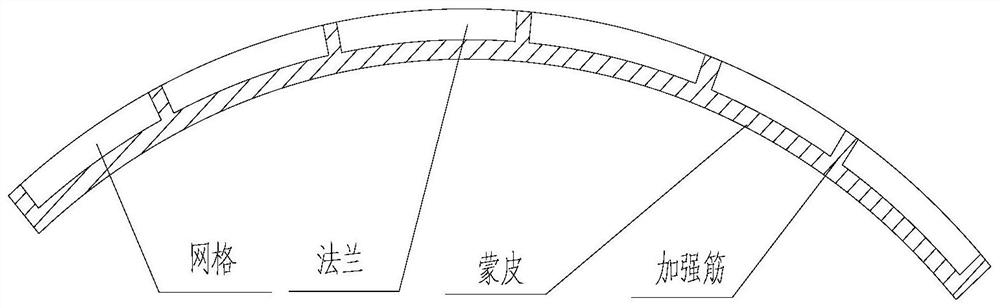

[0047] The present invention is a method for stepwise and progressive thermoforming of thin-walled integral wall panels with ultra-high reinforcement ribs and ultra-large flanges, which uses vacuum flexible clamping technology to clamp the original blank of the integral wall panel in a flat state on a three-axis CNC machine tool On the above, CNC milling with ultra-high ribs, ultra-large flanges and their grids is carried out, followed by vibration stress relief technology to eliminate the influence of material internal stress on processing deformation, and then through equal stiffness reinforcement technology and step-by-step The hot forming technology solves the problem of the large difference in the forming resistance of the wall plate reinforcement and the flange when forming the thin-walled integral wall panel with ultra-high ribs and ultra-large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com