Patents

Literature

35results about How to "Solve processing deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aviation aluminum alloy pre-stretching plate and production method thereof

InactiveCN101037747AAvoid deformationReduce residual stressTemperature control deviceAviationQuenching

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention is steady without deforming in machining.

Owner:NORTHEAST LIGHT ALLOY CO LTD

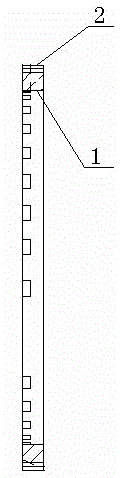

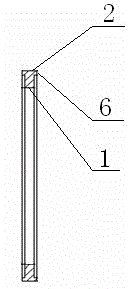

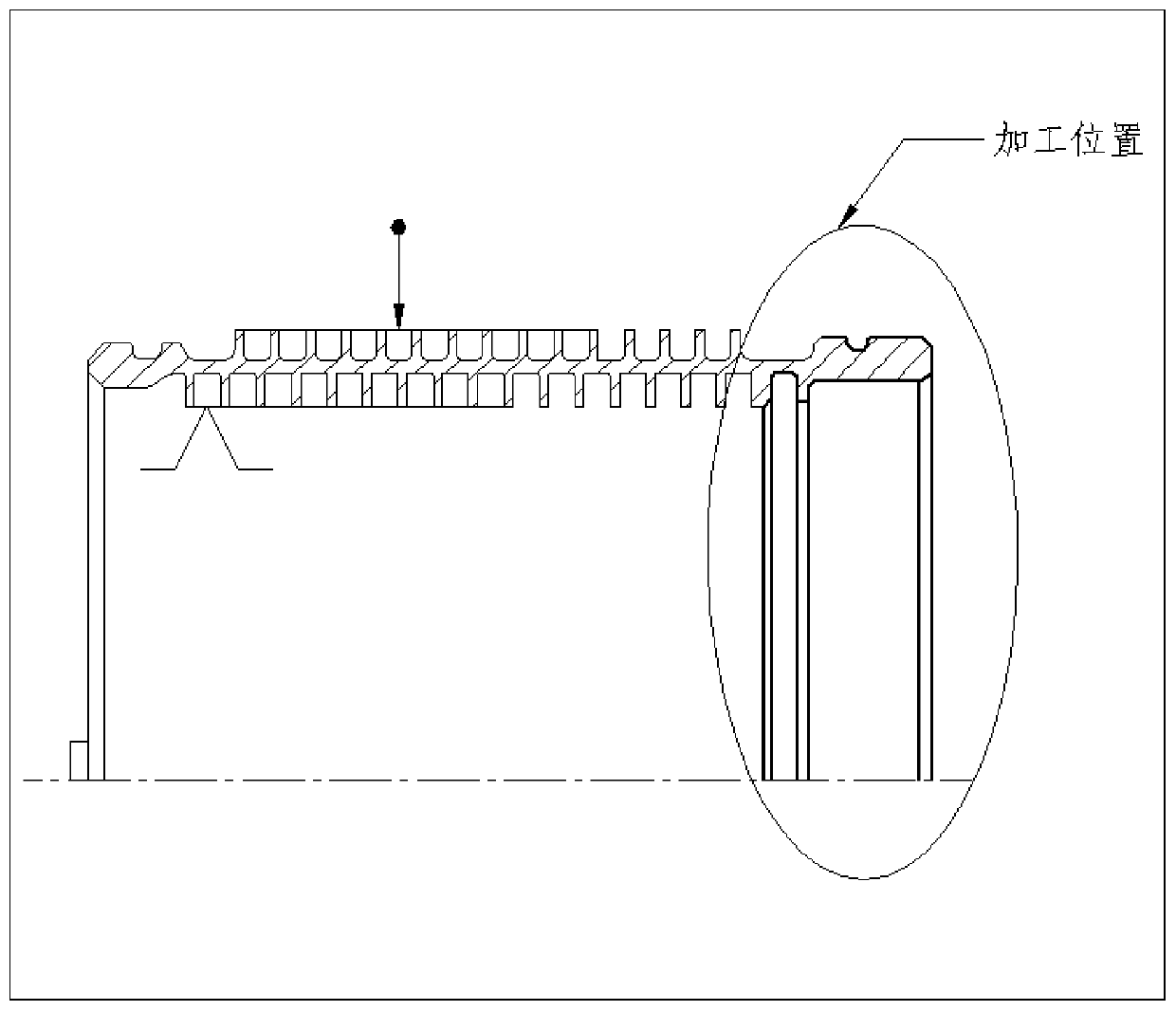

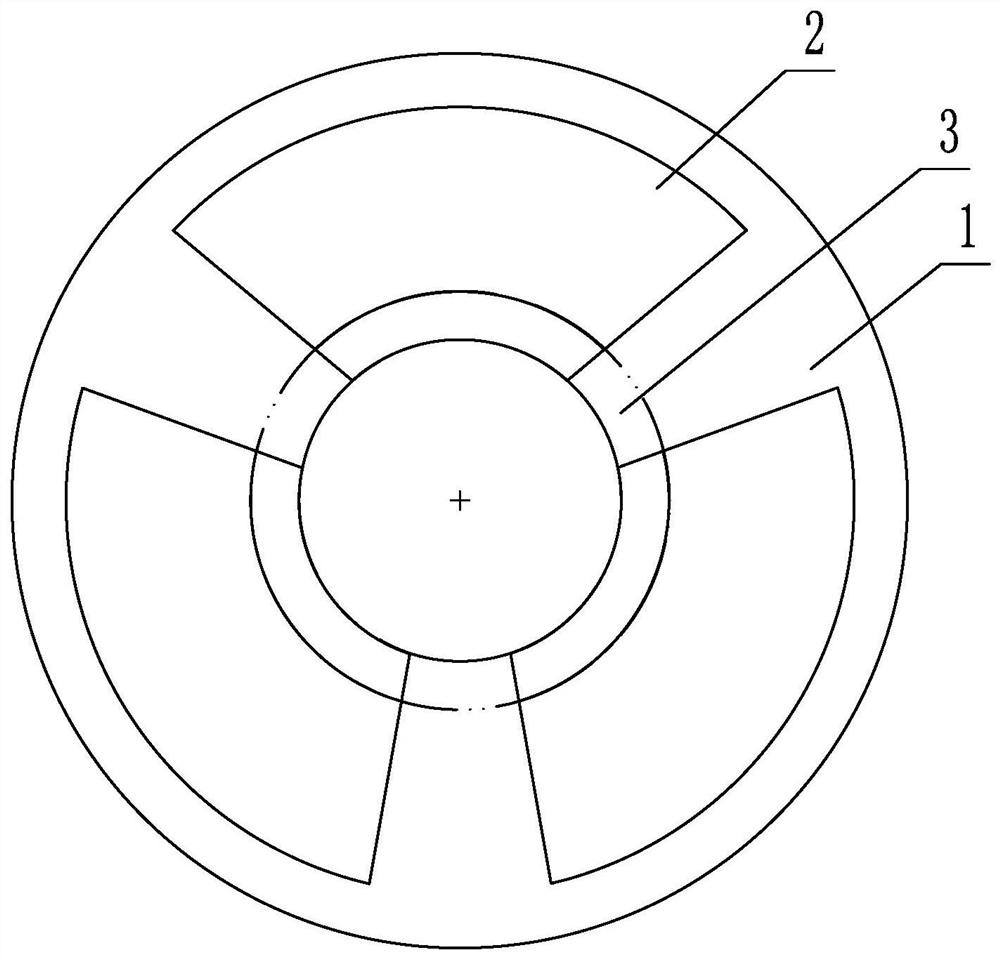

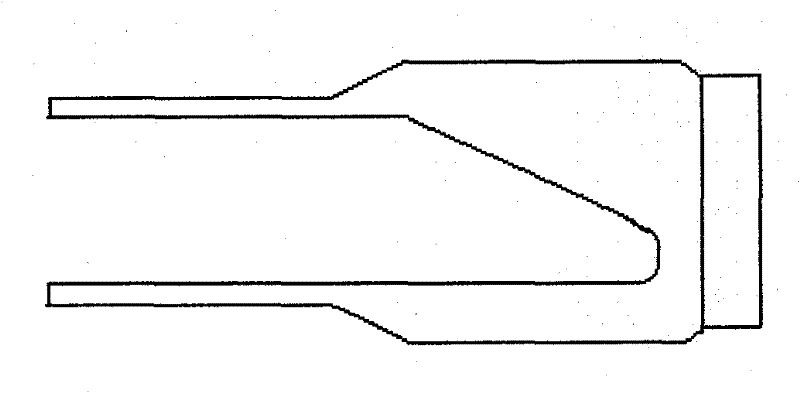

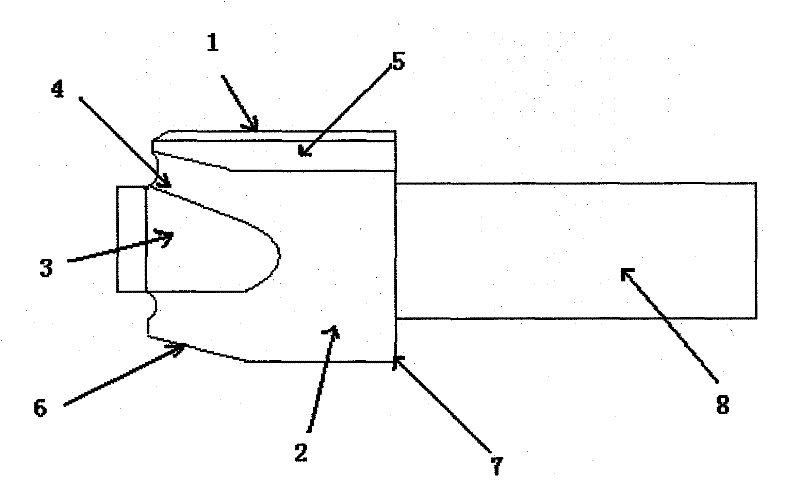

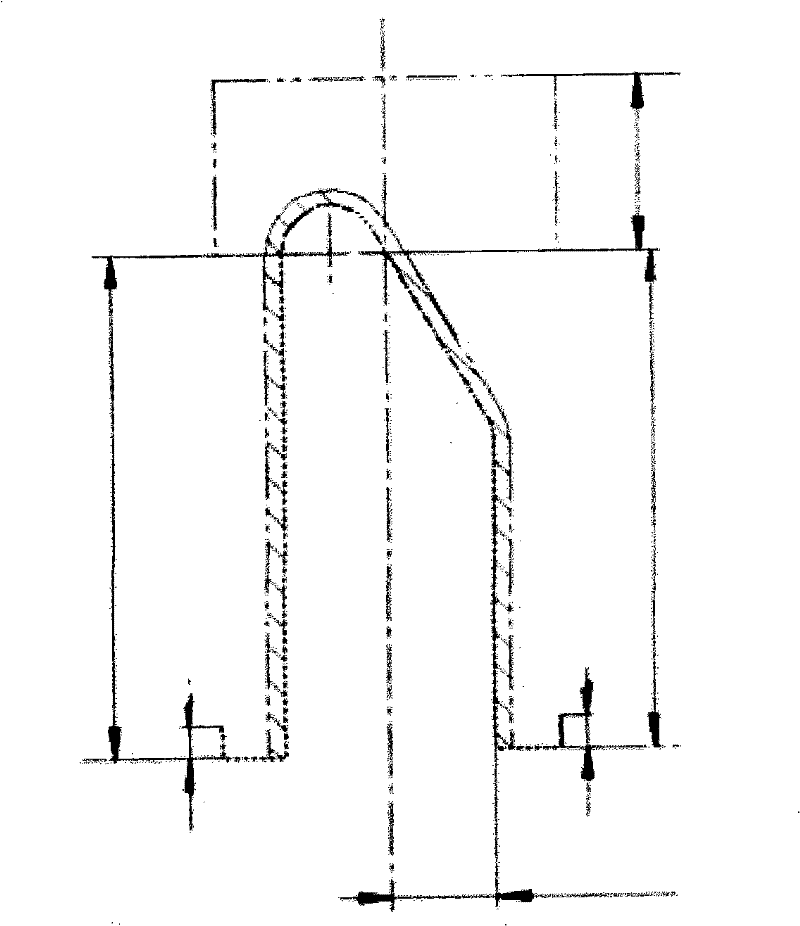

NC (numerical control) processing method for special-shaped joint part

InactiveCN101767264ASolve processing deformationMeet the design requirementsNumerical controlMachining process

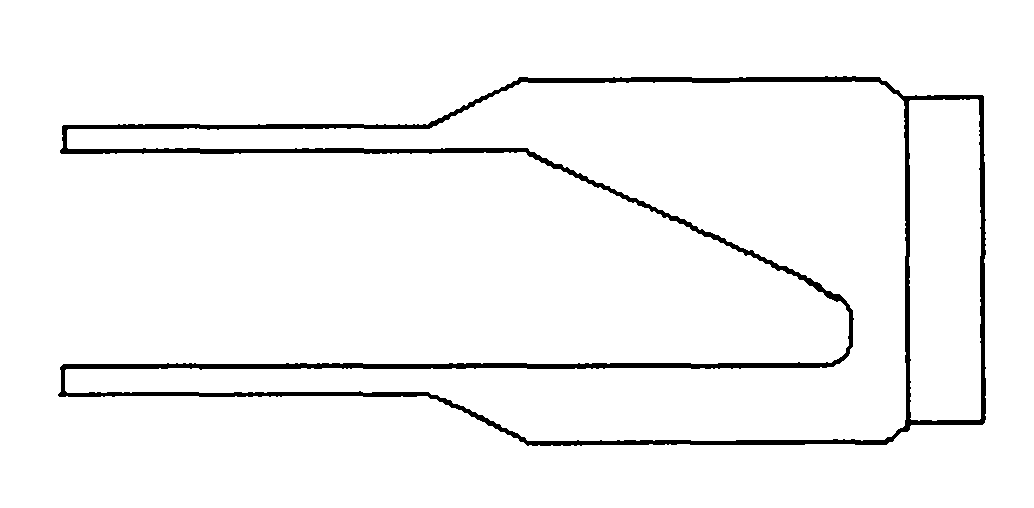

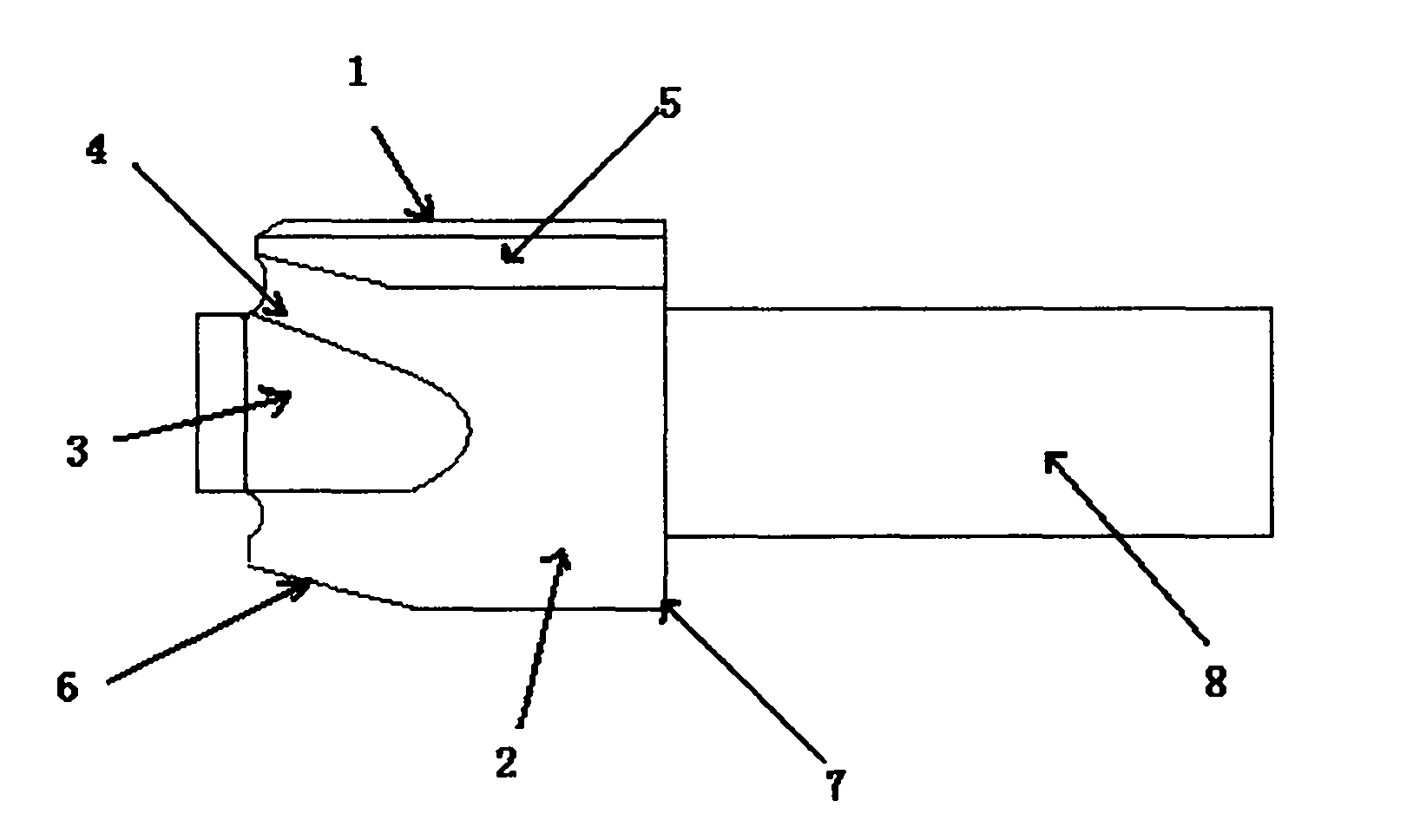

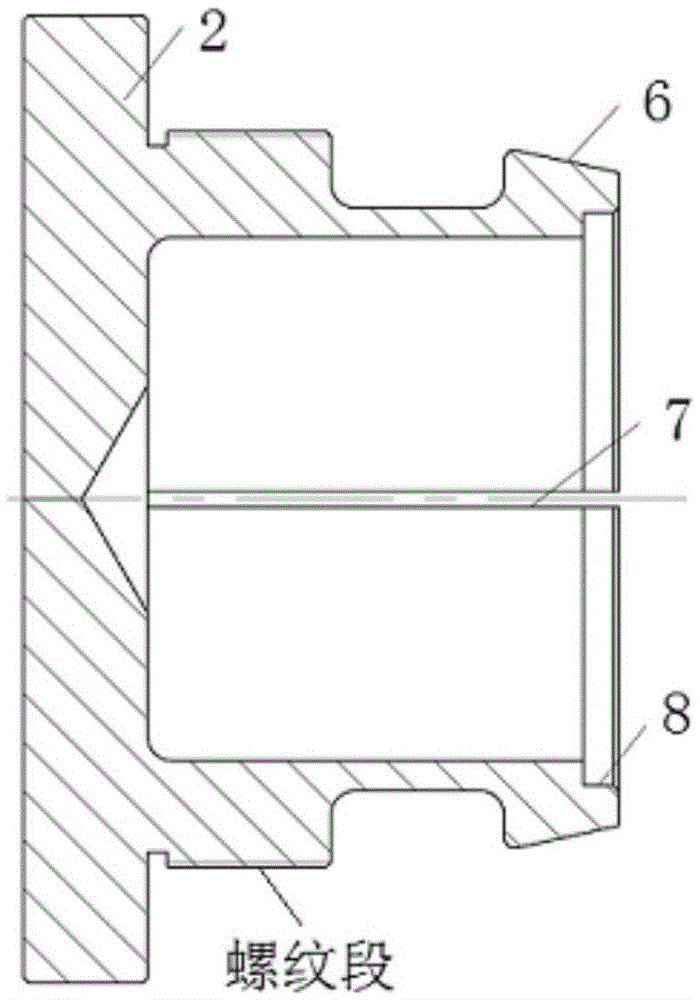

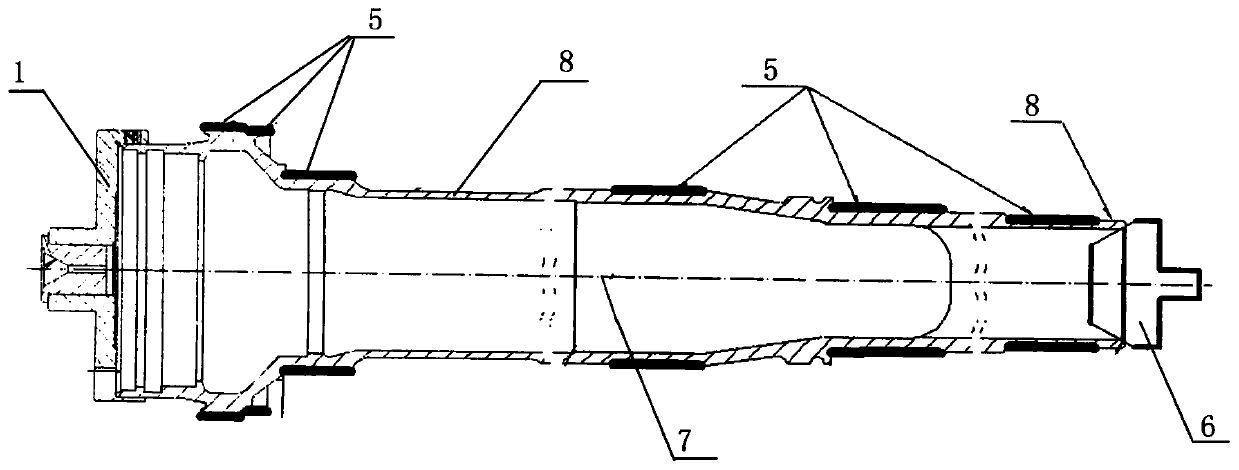

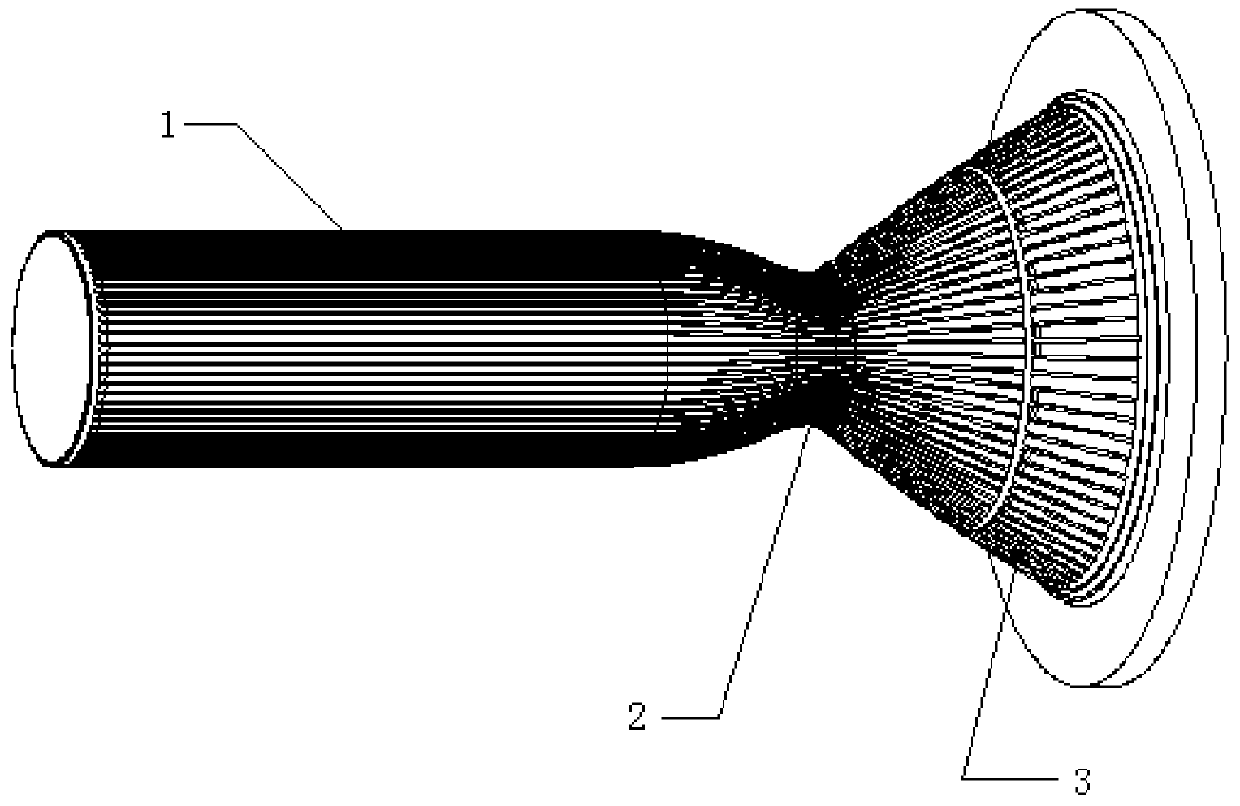

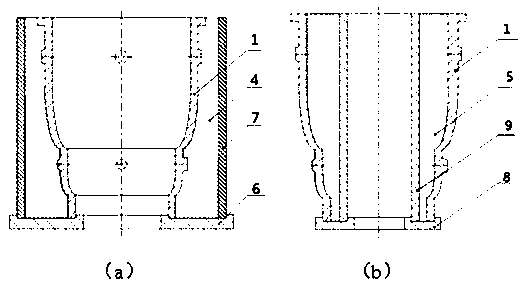

The invention provides an NC (numerical control) processing method for a special-shaped joint part. The profile surface of a tee joint is divided into the following parts: a side wall 1, an upper-lower profile 2, an upper-part circular arc 3, a through-connection circular arc 4, a profiled groove 5, a spigot outer wall 6, a root part 7 and a technical chuck 8. The NC processing method is characterized in that: a part blank is adopted to reserve the technical chuck, so as to solve the problem of clamping deformation of the part; the outer profile surface is first processed through NC milling and then the inner profile surface is processed through NC linear cutting. The NC processing method overcomes the disadvantage that the part is difficult to meet the requirement of the special-shaped profile surface for the wall thickness due to having extremely poor rigidity during the processing. The NC processing method in the invention can be applied for manufacturing the special-shaped joint part of a stress application main pipe of a certain machine, and can solve the deformation problem without stress processing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Finish machining die and method for titanium alloy thin-walled shell casting blank

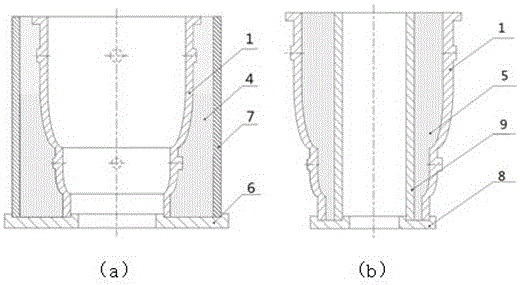

The invention provides a finish machining die and method for a titanium alloy thin-walled shell casting blank. The finish machining die is characterized in that the titanium alloy thin-walled shell casting blank is externally coated with an external casting mold and internally contains an internal casting mold. A fusible alloy is externally cast on the outer surface of the titanium alloy thin-walled shell casting blank, so that the outer surface of a titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the inner surface. Similarly, the fusible alloy is internally cast on the inner surface of the titanium alloy thin-walled shell casting blank, so that the inner surface of the titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the outer surface. By adoption of the finish machining die and method, the rigidity and the strength of parts can be effectively improved, the working procedures are reasonably arranged, the working efficiency is high, the machining cost is low, and not only can the problem of machining deformation of titanium alloy thin-walled shell parts be solved, but also the machining precision and the surface quality of the parts are greatly improved.

Owner:XIJING UNIV

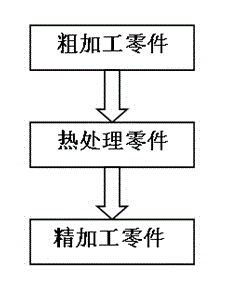

Thin-walled part machining method

InactiveCN104959786ASolve processing deformationImprove machining accuracyMachining deformationProcessing accuracy

The invention provides a thin-walled part machining method. A thin-walled part is an aluminum alloy thin-walled cavity part. The machining method comprises the first step of rough part machining, the second step of thermal processing of the part and the third step of fine part machining. According to the thin-walled part machining method, the machining method is reasonable in procedure arrangement and high in working efficiency; the problem of machining deformation of the part is effectively solved, and the machining precision and the surface quality of the part are greatly improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Method for improving sheet annular titanium alloy gear part machining precision

ActiveCN103240575ASolve processing deformationMeet processing requirementsCold treatmentRoom temperature

The invention relates to a method for improving the sheet annular titanium alloy gear part machining precision. The method includes the following steps: (1) rough turning a blank, pressing a part through a pressing plate along the axis direction, and conducting rough machining on the part; (2) recrystallization annealing; (3) rough turning a gear bank again; (4) thermocycling; (5) semi-finish-turning the gear blank; (6) stress relief annealing; (7) conducting auxiliary procedures, and machining and finishing other structural elements of the part thoroughly; (8) conducting subzero treatment; (9) finishing machining the gear blank; and (10) manufacturing teeth and conducting thermo-cold cycling. After the teeth are manufactured, conducting twice thermo-cold cycling, conducting cold treatment at the temperature of -50- -60 DEG C, keeping the temperature for 1.3-1.7h, air cooling to the room temperature for 1.5h, heating to 80-100 DEG C in a thermostat, keeping the temperature for 2.8-3.2h, air cooling to the room temperature, and finishing finish machining. By means of the method, deformation in a machining process can be eliminated.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

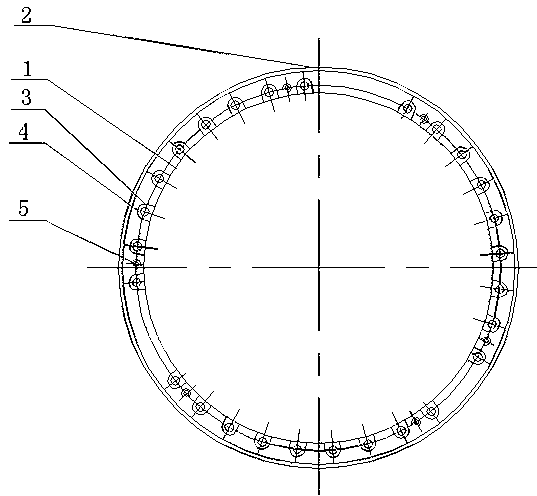

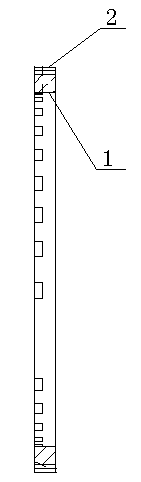

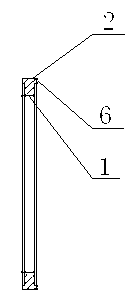

Adjustable self-centering inner supporting device for machining thin-wall tubular part

InactiveCN103433765AHigh strengthExtended service lifeAuxillary equipmentPositioning apparatusEngineeringMechanical engineering

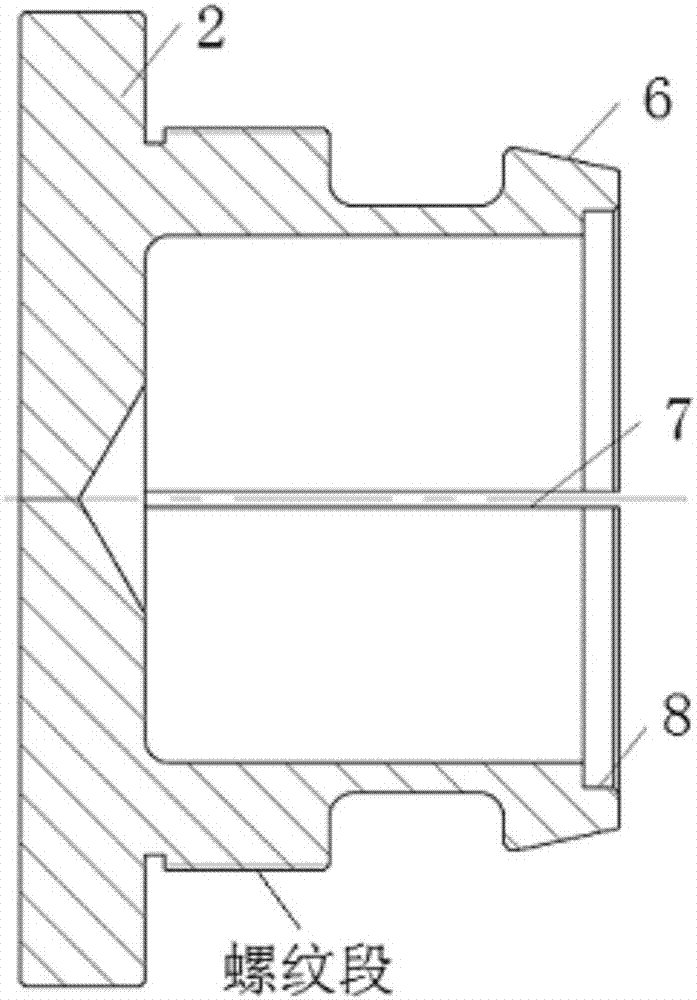

The invention discloses an adjustable self-centering inner supporting device for machining a thin-wall tubular part. The adjustable self-centering inner supporting device for machining the thin-wall tubular part is characterized in that the adjustable self-centering inner supporting device comprises an outer cylinder, a core shaft and at least three supporting bar blocks, guide grooves which are matched with the supporting bar blocks respectively are formed in the outer cylinder, a conical shaft section which is inserted into the outer cylinder and a circular shaft section which is exposed out of the outer cylinder are arranged on the core shaft, conical threads are formed in the conical shaft section, a pull tool connecting structure is arranged at the outer end portion of the conical shaft section, a tip hole is formed in the outer end face of the circular shaft section, the conical shaft section is connected with the supporting bar blocks in a threaded mode, the supporting bar blocks are arranged in the guide grooves in the outer cylinder respectively, the supporting bar blocks are matched with the guide grooves in the outer cylinder respectively in a sliding mode, the supporting bar blocks are evenly distributed in the circumferential direction of the outer cylinder, the outer surface of each supporting bar block is exposed out of the outer circumferential face of the outer cylinder, the cross section of the outer surface of each supporting bar block is in an arc shape, and the supporting portions of the outer surfaces of all the supporting bar blocks are placed in the cylindrical face concentric with the outer cylinder. The adjustable self-centering inner supporting device is convenient to use and low in cost.

Owner:TIANJIN UNIV

Aviation aluminum alloy pre-stretching plate and production method thereof

ActiveCN101037752AAvoid deformationReduce residual stressTemperature control deviceAviationQuenching

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.2, Cu of 4.2, Mn of 0.70, Mg of 1.5, Ni of 0.6, Zn of 0.1, Ti of 0.1, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hot rolling and cutting; 5) quenching, straightening, and pretensioning, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention has steady properties, and the plates can not be deformed in machining, while the machining yield can be improved.

Owner:NORTHEAST LIGHT ALLOY CO LTD

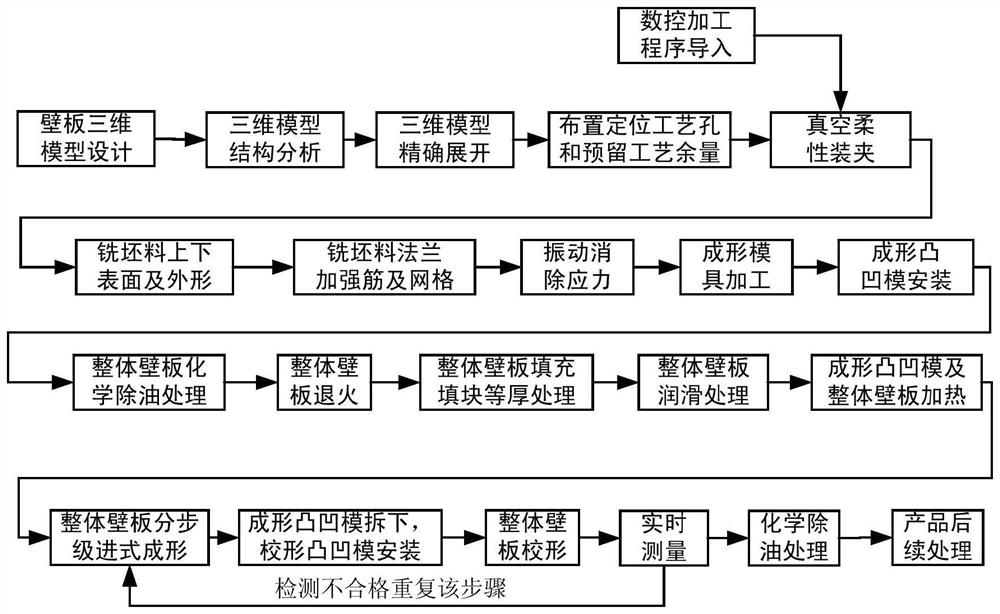

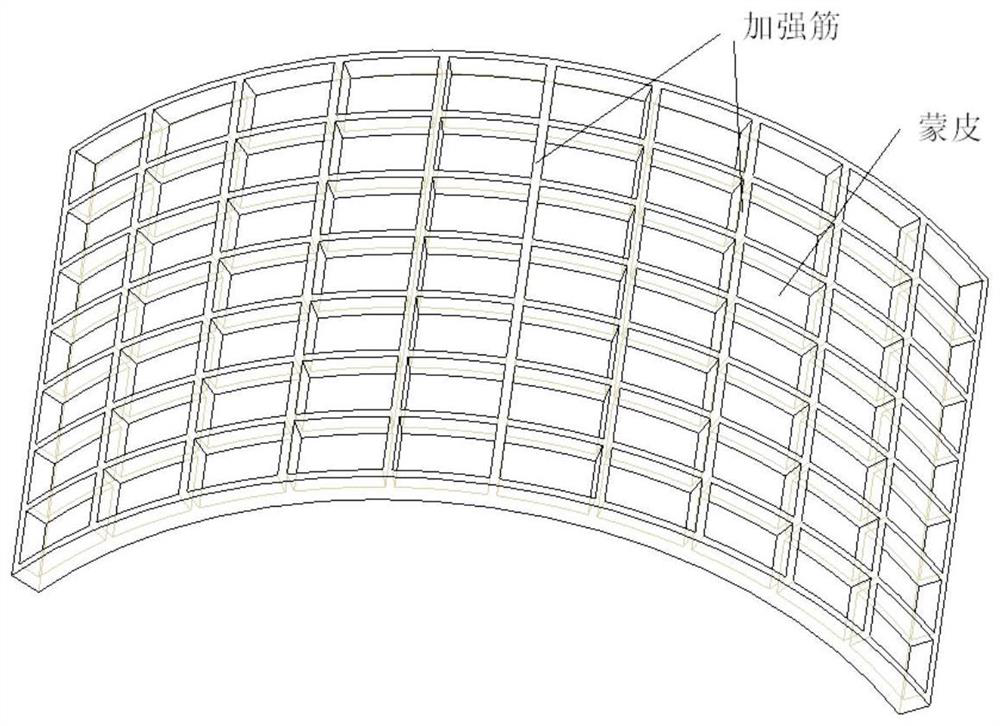

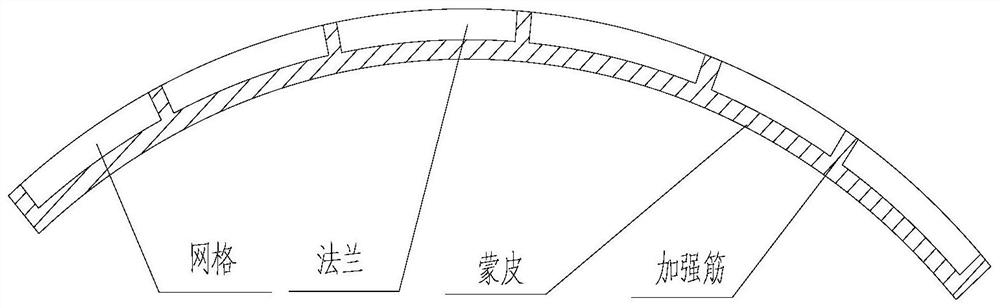

Step-by-step progressive hot forming and hot correcting integrated method for thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges

ActiveCN111804786AImprove processing efficiencySimple methodShaping toolsMetal working apparatusThin walledHomogeneous deformation

The invention provides a step-by-step progressive hot forming and hot correcting integrated method for a thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges. An original blank of the integral wall plate in a flat state is clamped on a three-axis numerical control machine tool through a vacuum flexible clamping technology, and numerical control milling machining is conducted on the ultrahigh reinforcing ribs, the oversized flanges and grids of the thin-wall integral wall plate. Then, vibration is adopted for stress relieving, the influence of material internal stress on machining deformation is eliminated. Through the equal-rigidity reinforcing technology and the step-by-step progressive hot forming and hot correcting integrated technology, the following problems are solved that when the aluminum alloy thin-wall integral wall plate with the ultrahigh reinforcing ribs and the oversized flanges is formed, the forming resistances of the reinforcing ribs andthe flanges of the wall plate are greatly different, serious uneven deformation is likely to happen, a transition area around the flange is likely to break in the deformation process, and the formingdifficulty is very large. The method achieves low-stress manufacturing of the thin-wall integral wall plate structure with the ultrahigh reinforcing ribs and the oversized flanges.

Owner:BEIJING SATELLITE MFG FACTORY

Aviation aluminum alloy pre-stretching plate and production method thereof

ActiveCN101037748AAvoid deformationReduce residual stressTemperature control deviceQuenchingInternal stress

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention has steady properties, flat surface, and low internal stress.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method for machining thin-wall separation type solid retainer

ActiveCN109732293ASolve processing deformationImprove machining accuracyManufacturing technologySolid solution strengthening

The invention discloses a method for machining a thin-wall separation type solid retainer, and relates to the technical field of design and manufacture of retainers. According to the method, the problems that an existing thin-wall separation type bearing solid retainer is large in machining difficulty, easy to deform, the interior of the retainer, the outer diameter precision and the rivet hole machining precision are low, and the product machining quality is difficult to guarantee are solved; the method for machining the thin-wall separation type solid retainer is realized through the following steps that 1, finely turning is sequentially carried out on a first plane and a second plane, the outer diameter is coarsely ground and finely turning is carried out on the inner diameter; 2, solidsolution strengthening is carried out; 3, turning are both carried out on two planes ; 4, the finely turning is carried out on the outer diameter; 5, the inner diameter is finely ground; 6, a rivet hole is drilled; 7, a bolt is inserted; 8, a pocket is drilled and milled; 9, the outer diameter is finally milled; 10, final turning is carried out on the inner diameter; 11, the bolt is removed, deburring is carried out, and finishing is carried out; and 12, fluorescent permeation flaw detection is carried out. The method is used for improving the interior of the retainer, the outer diameter precision and the rivet hole machining precision of the thin-wall separation type solid retainer.

Owner:AVIC HARBIN BEARING

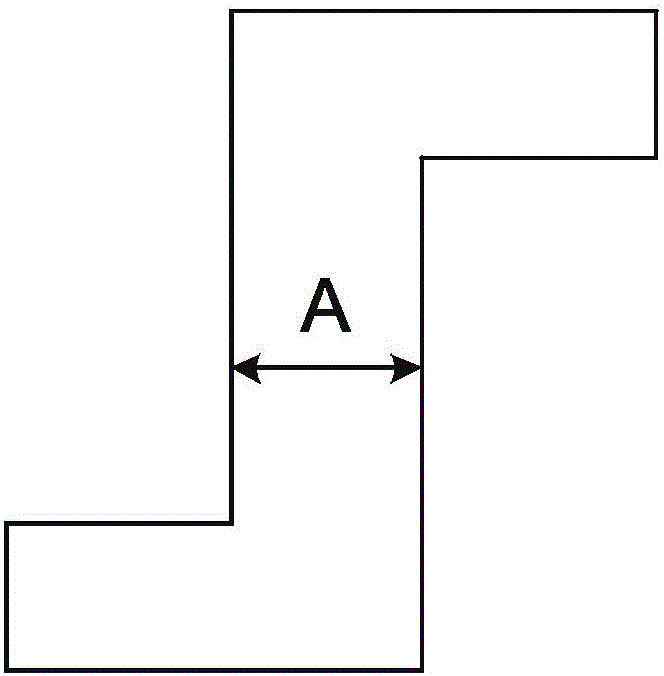

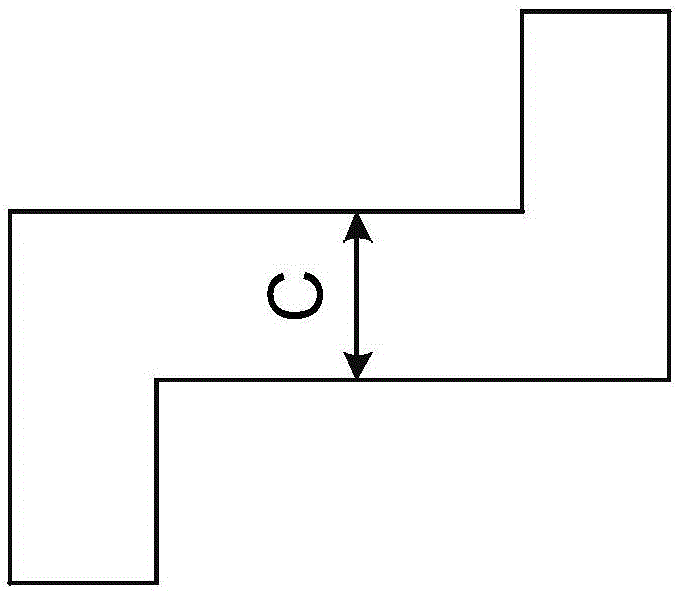

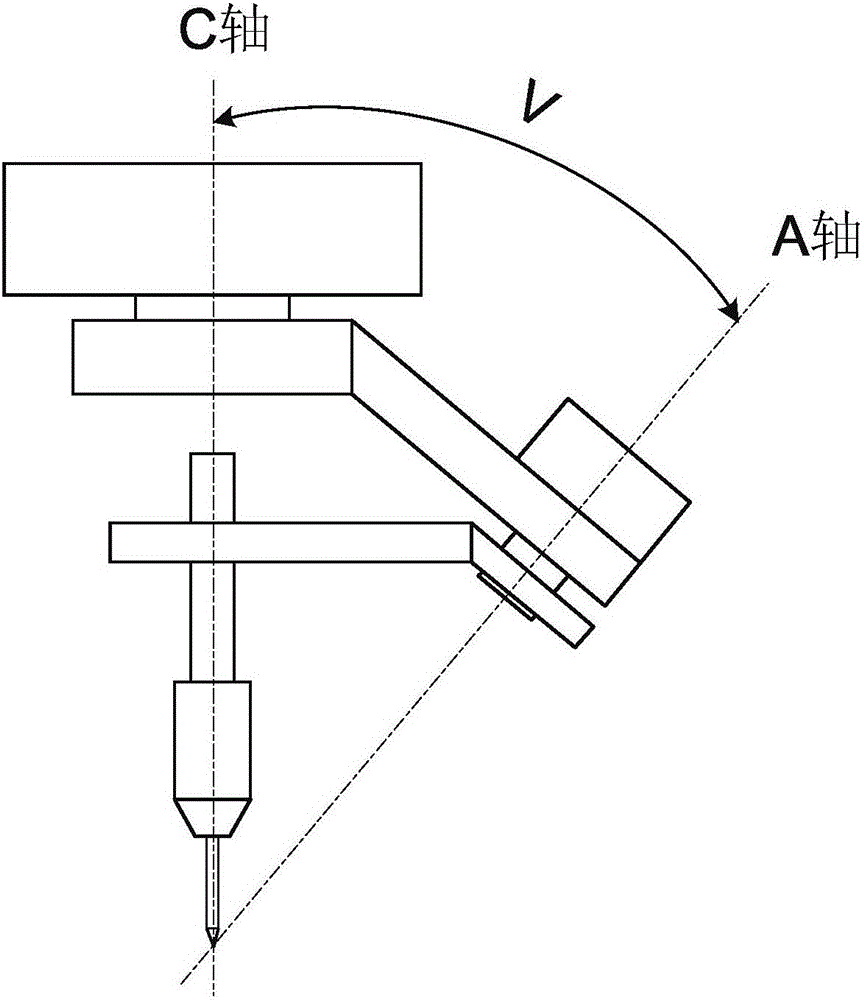

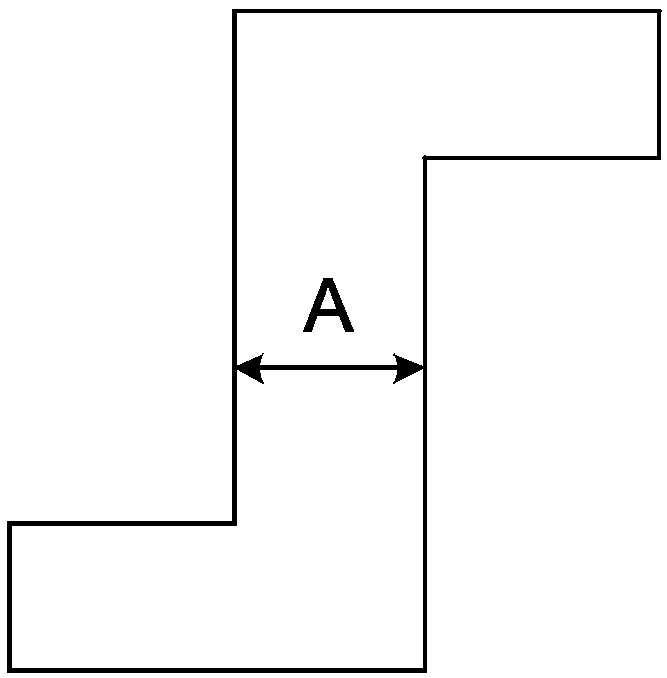

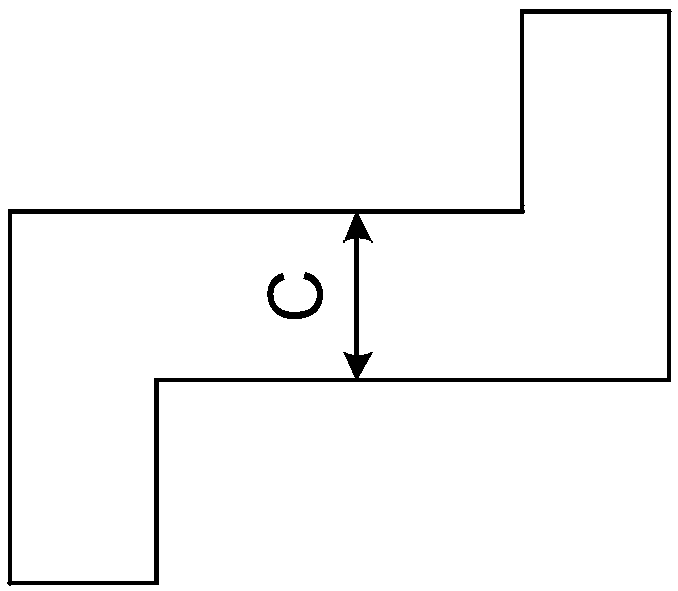

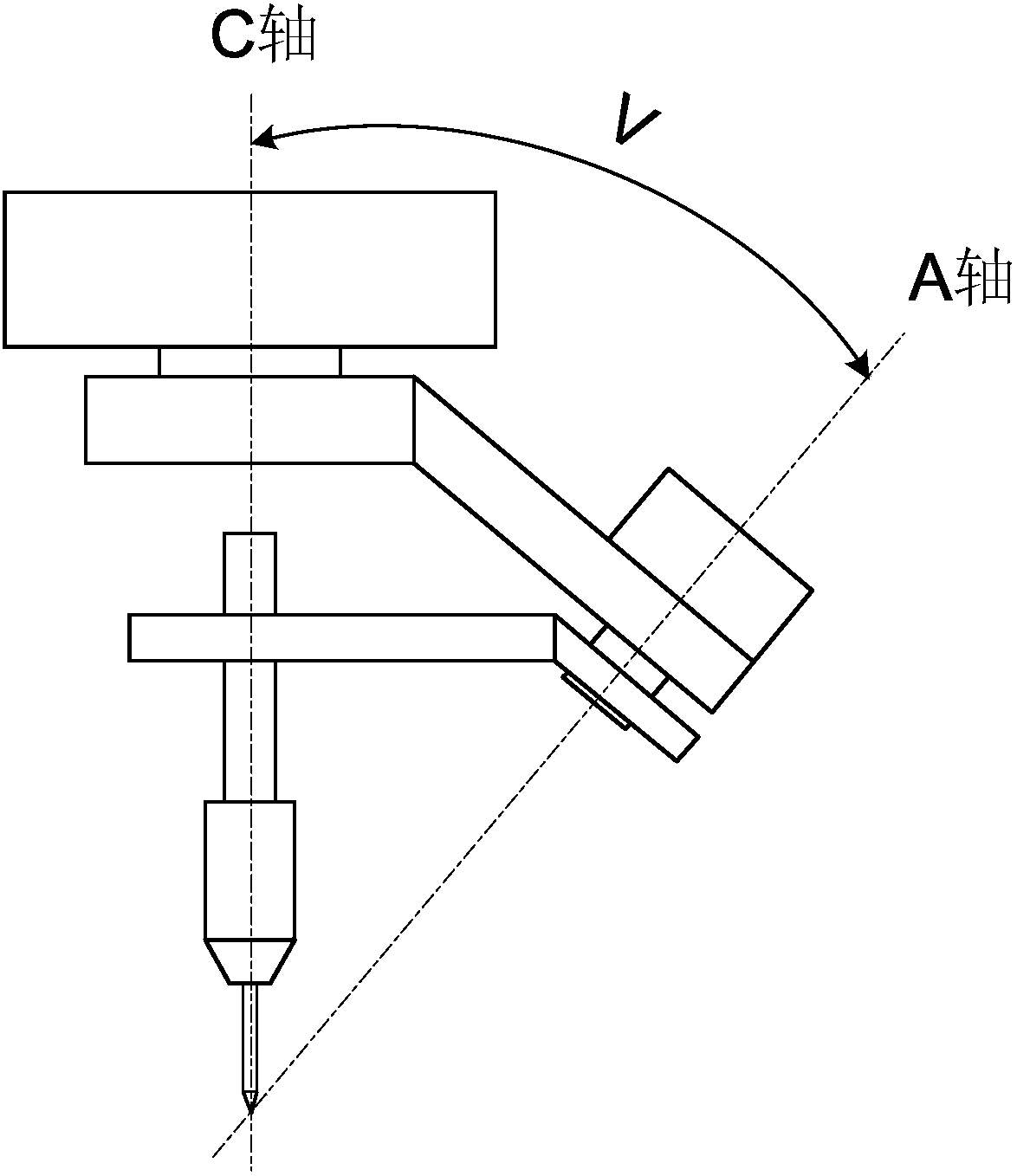

AC five-axis water cutting error compensation method and system

The invention relates to an AC five-axis water cutting error compensation method which comprises the following steps that (1) a first trial cutter path is determined and a first workpiece is processed perpendicularly according to the first trial cutter path; (2) a second workpiece is processed according to the first trial cutter path; (3) a down-look surface is subjected to axial symmetry and rotated by 90 degrees counterclockwise to be taken as a second trial cutter path, and a third workpiece is processed with an inclined angle V1 according to the second trial cutter path; (4) the widths of the second rectangles of the first workpiece, the second workpiece and the third workpiece are measured respectively and marked as L1, L2 and L3 respectively, and an included angle of the A axis and the C axis in the cutter bit structure is recorded as V2; (5) error compensation is performed according to the V1, V2, L1, L2 and L3. The invention further discloses an AC five-axis water cutting error compensation system. With the adoption of the method and the system, the problem that processing deformation caused by the error of a non-cutter-length AC five-axis water cutting head mechanism is solved, the processing accuracy is improved, and the method and the system have a wide application range.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

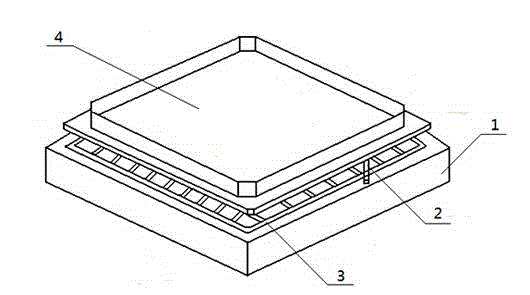

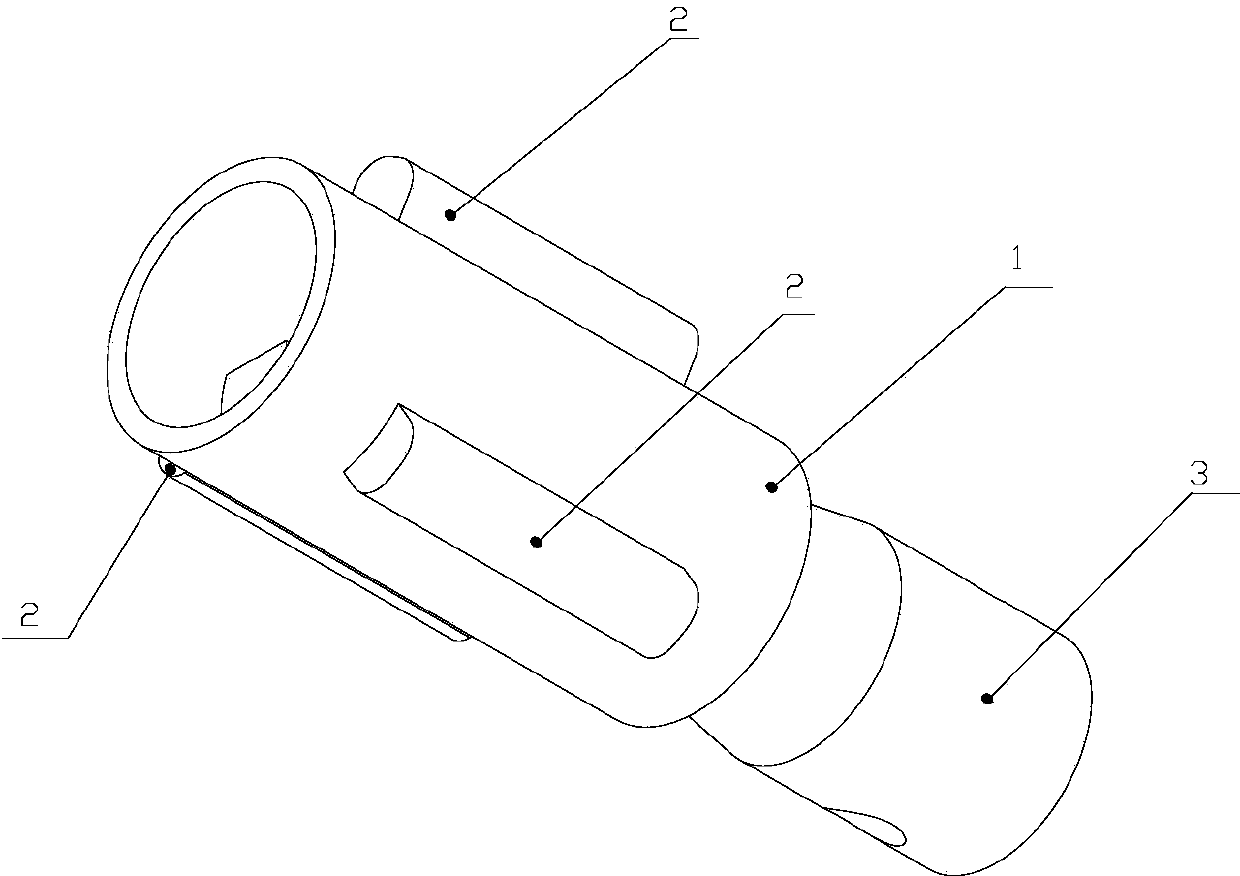

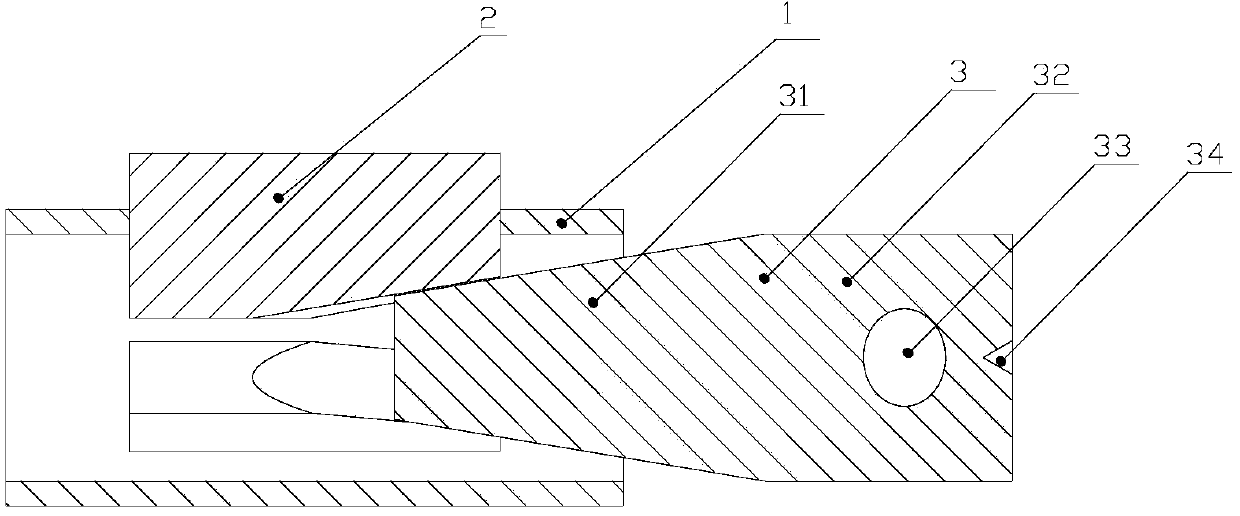

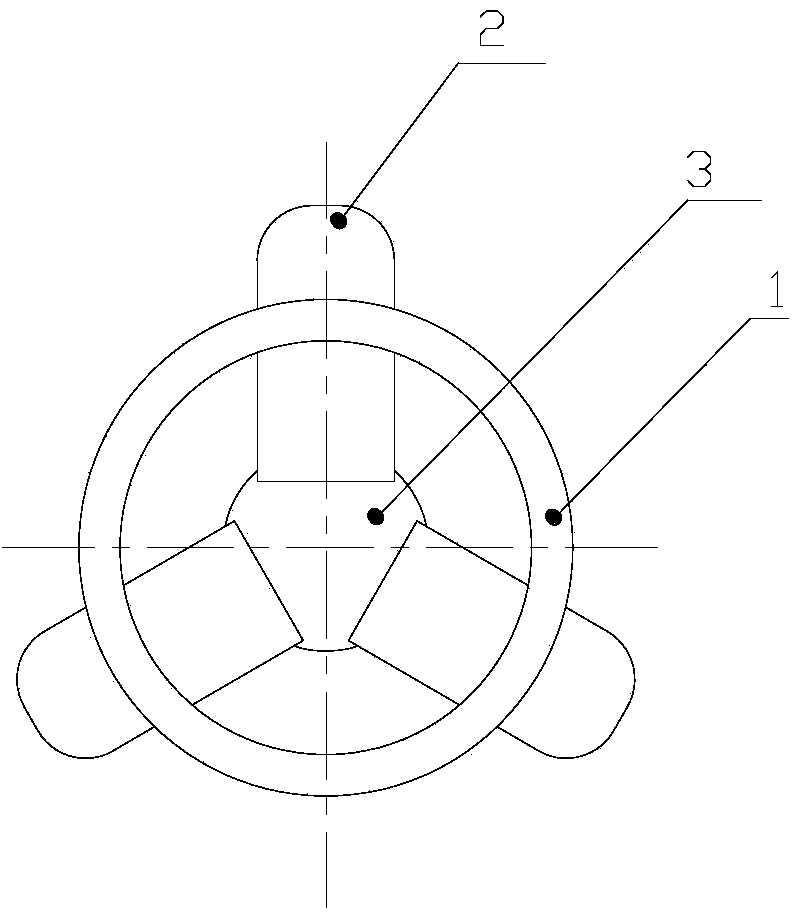

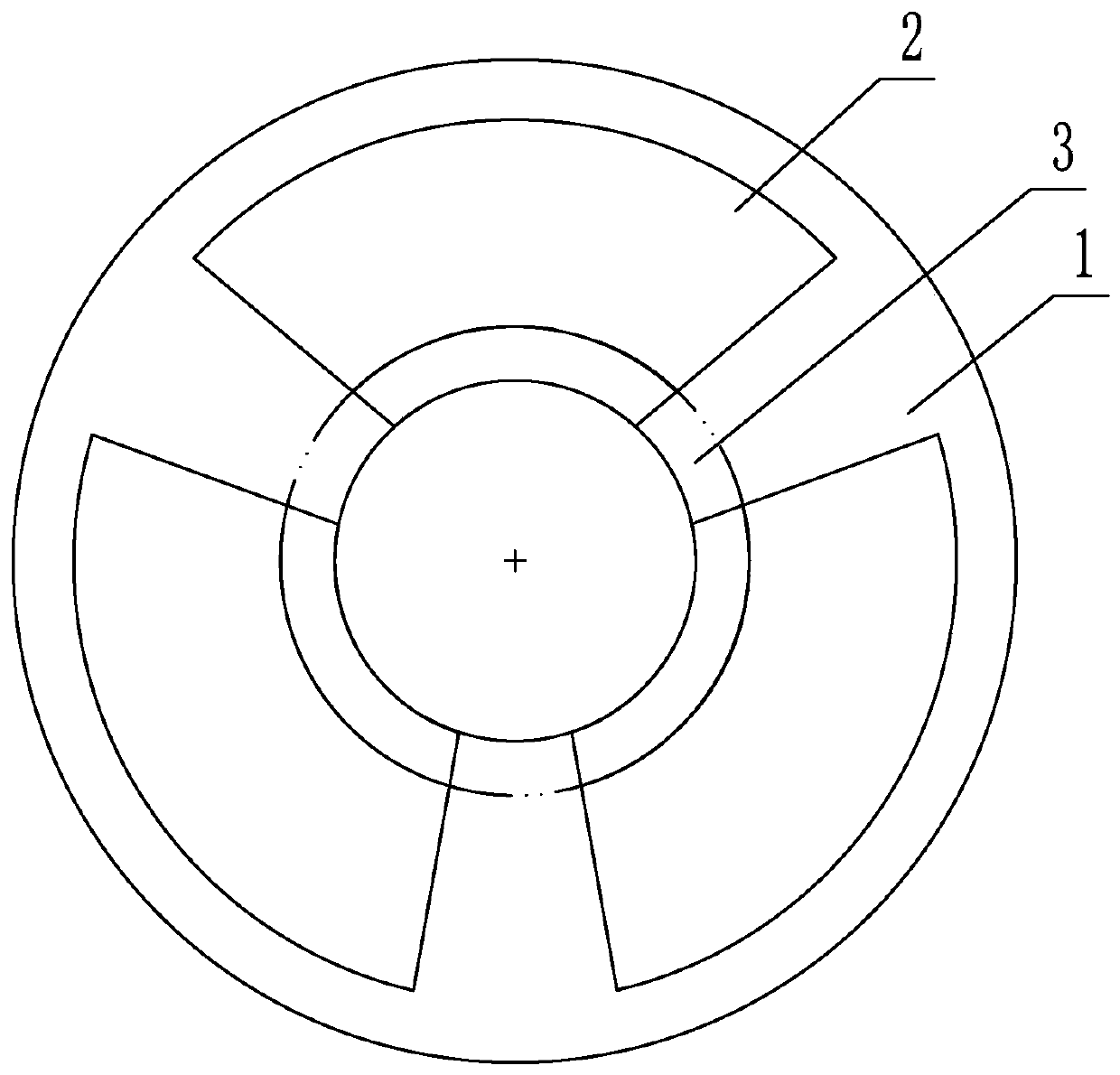

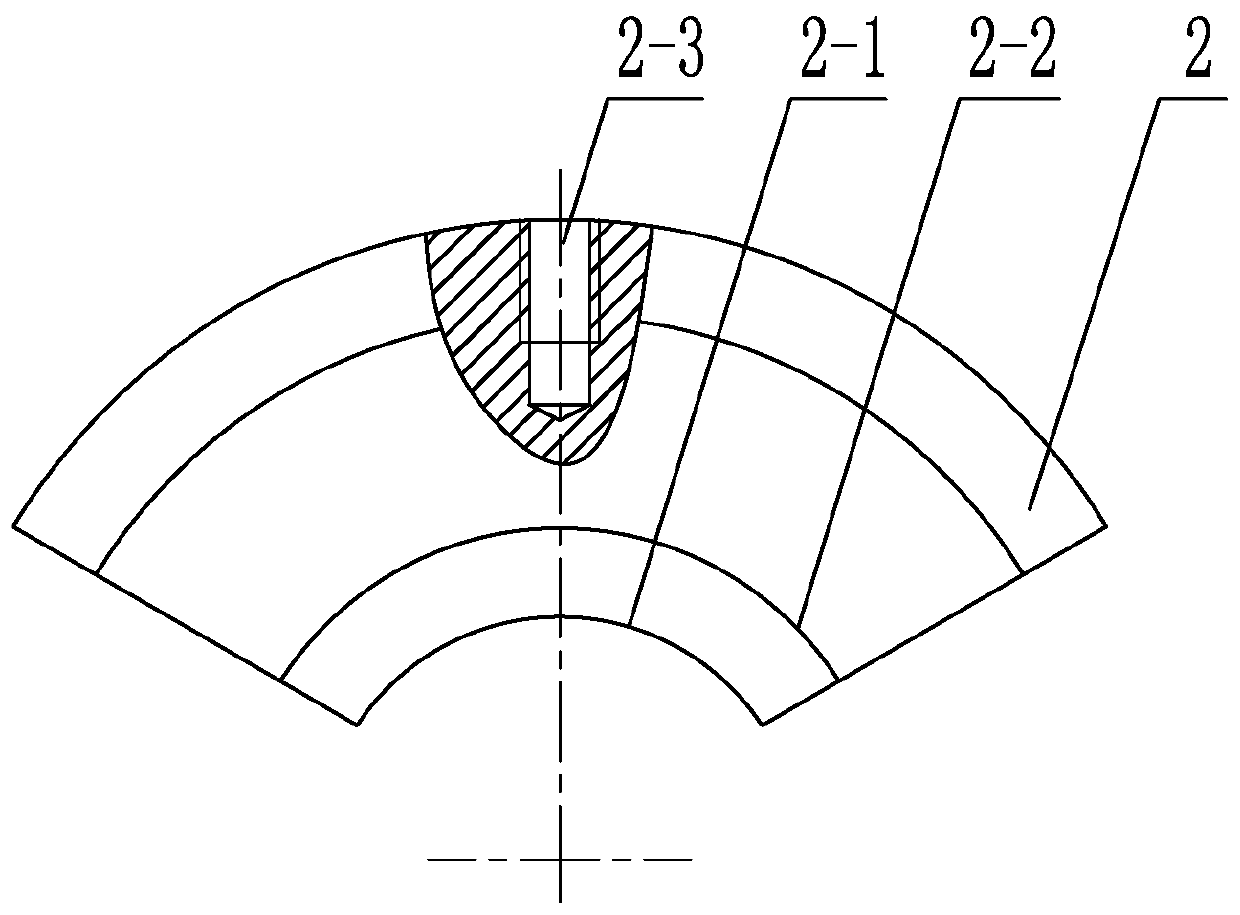

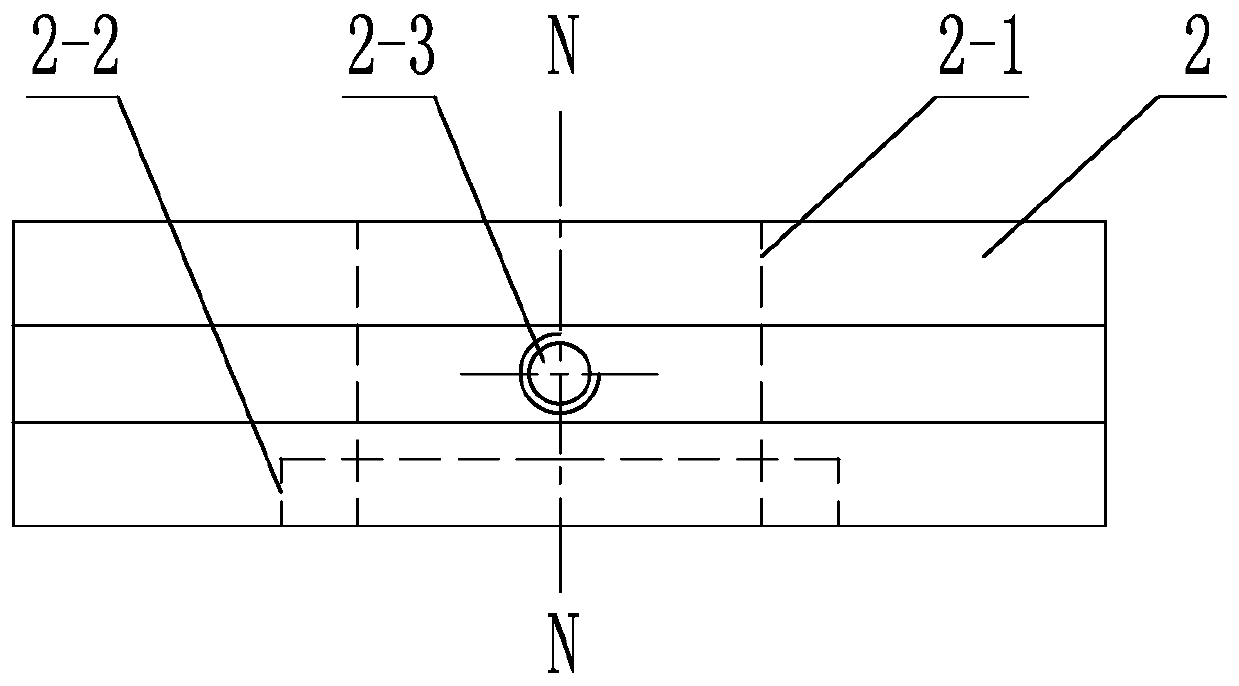

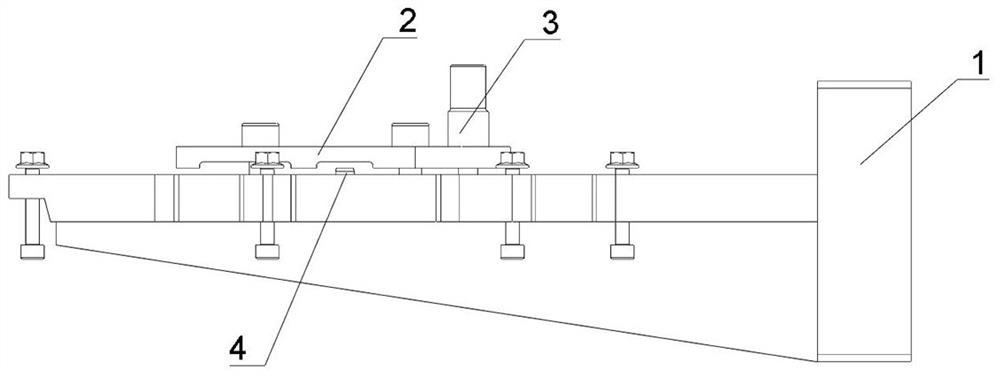

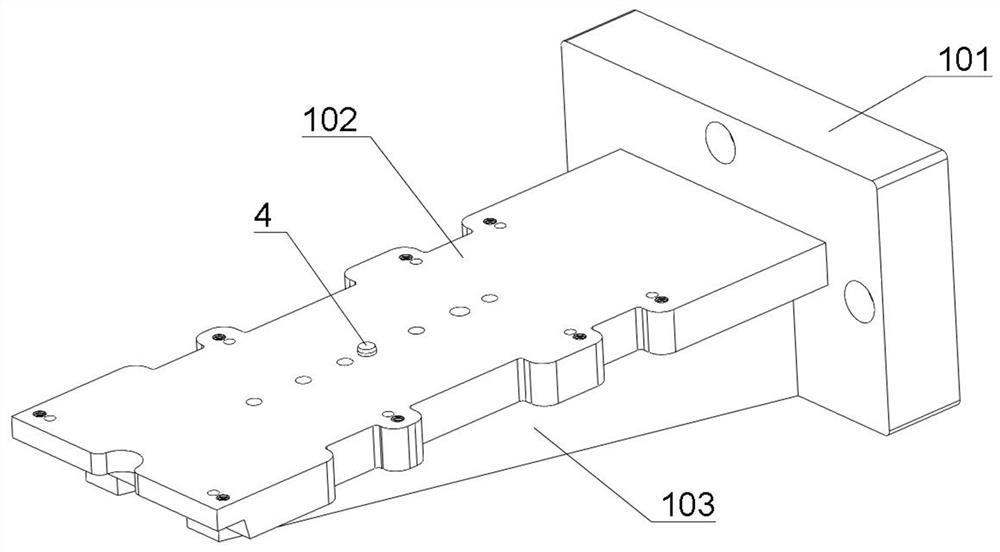

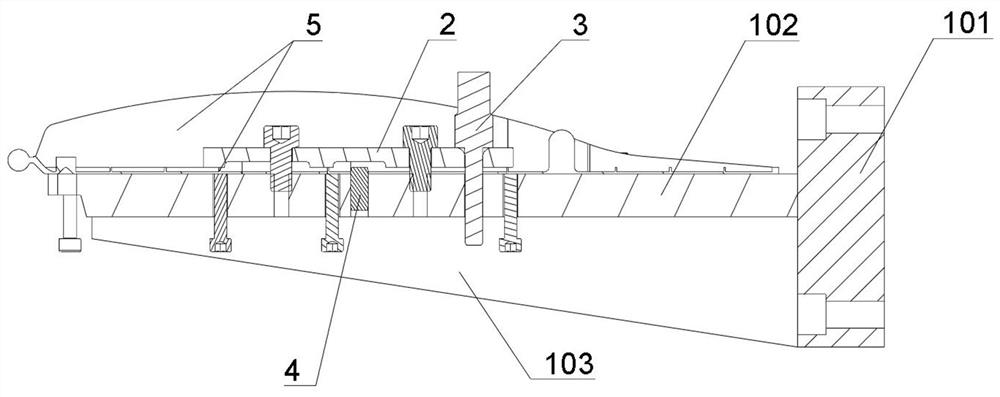

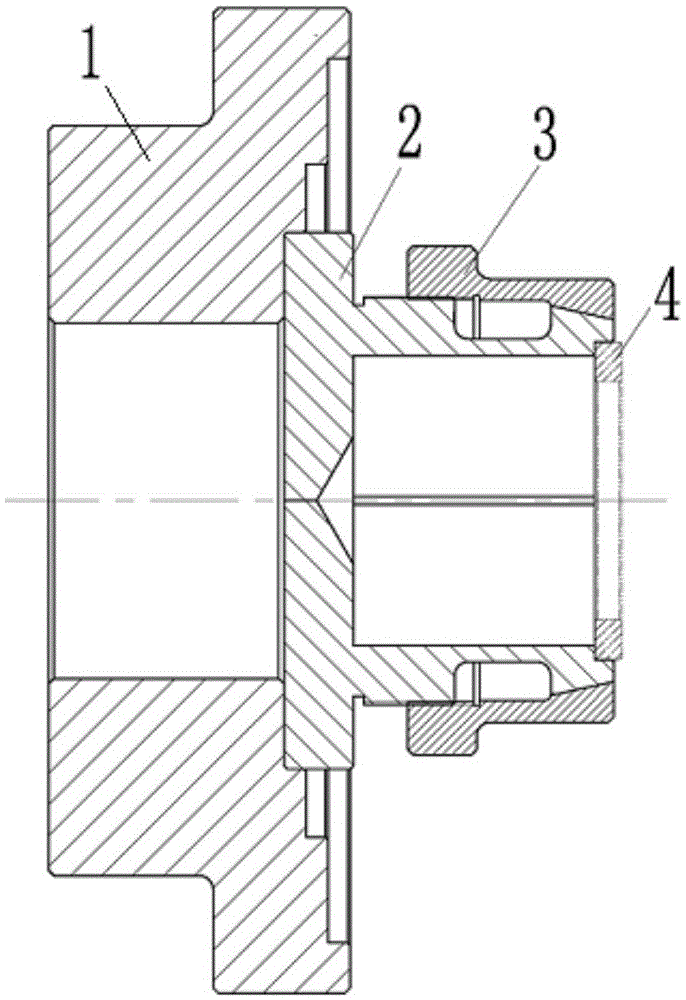

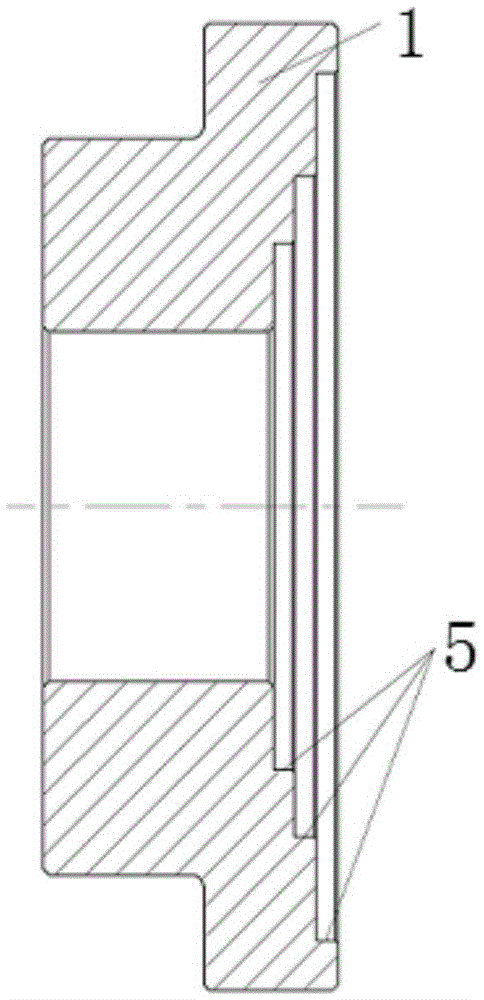

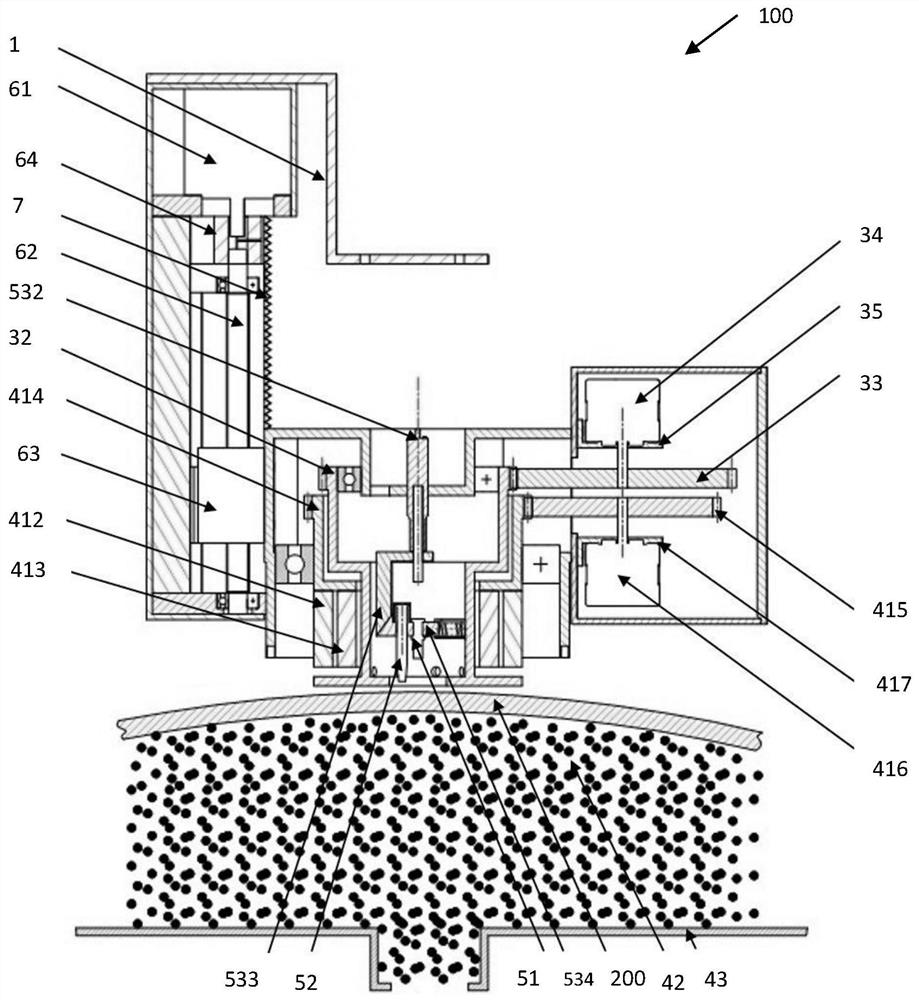

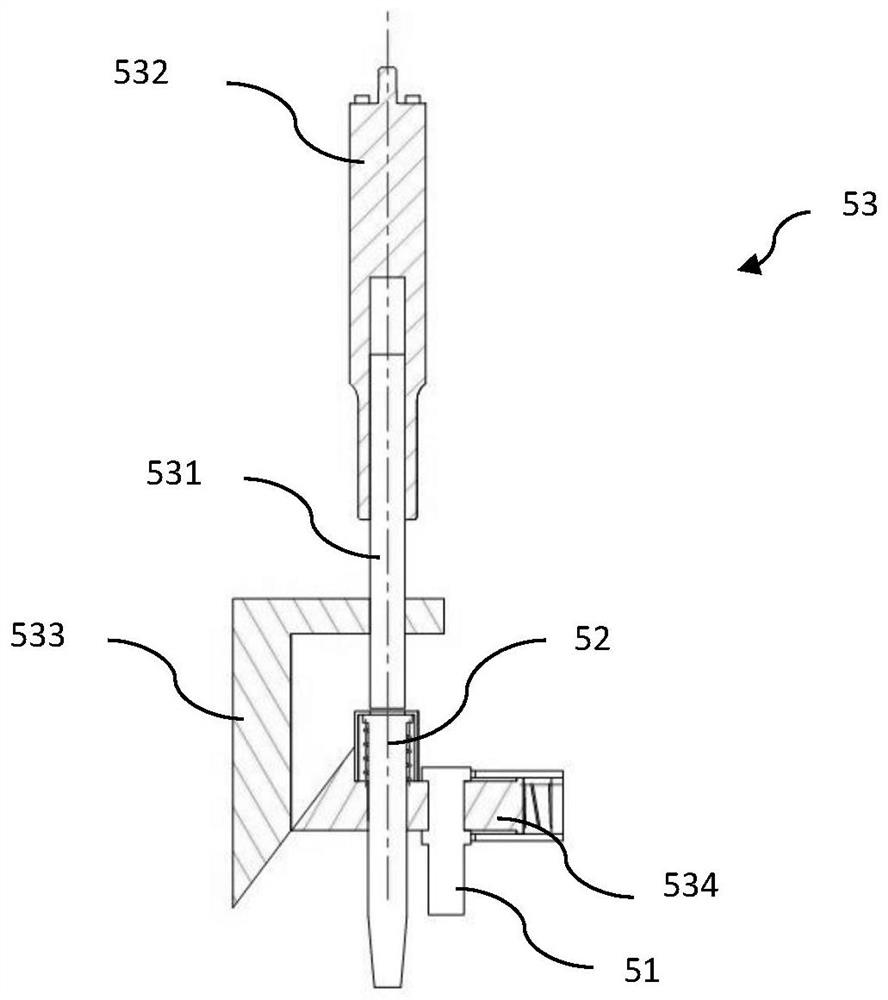

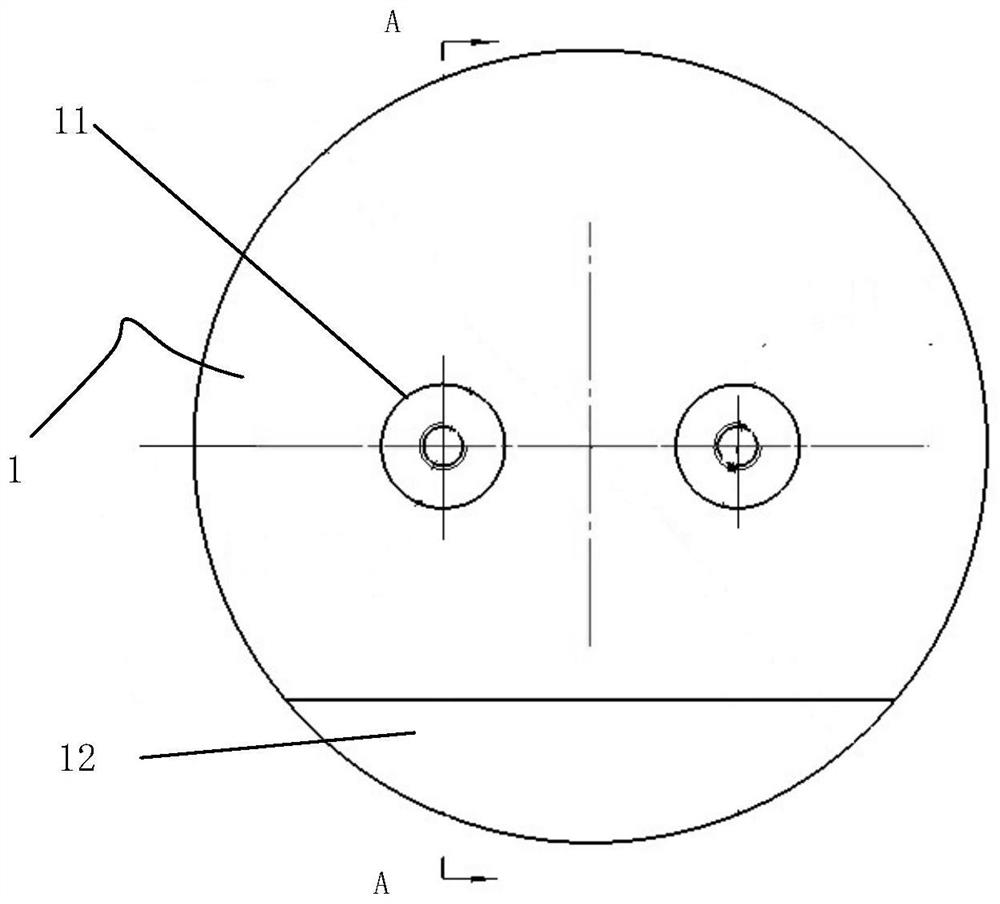

Machining tool and machining method for adjusting piece of aero-engine

ActiveCN114654278AReasonable structureLow manufacturing costWeight reductionPositioning apparatusPhysicsMachine tool

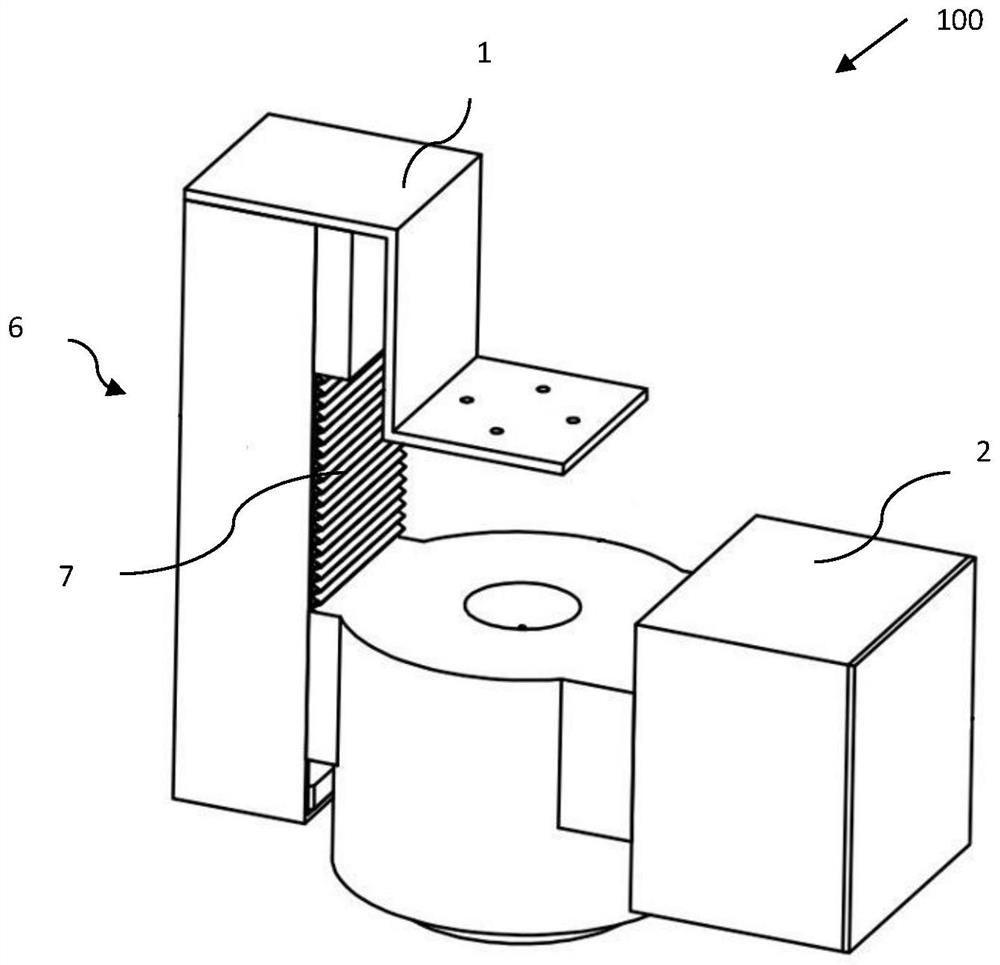

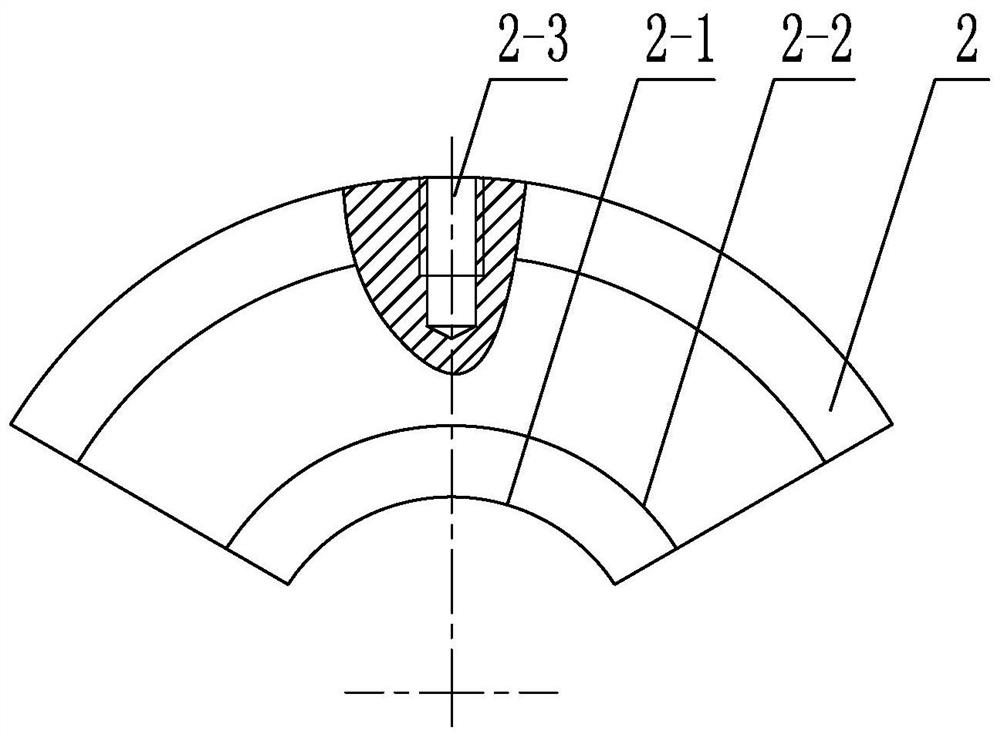

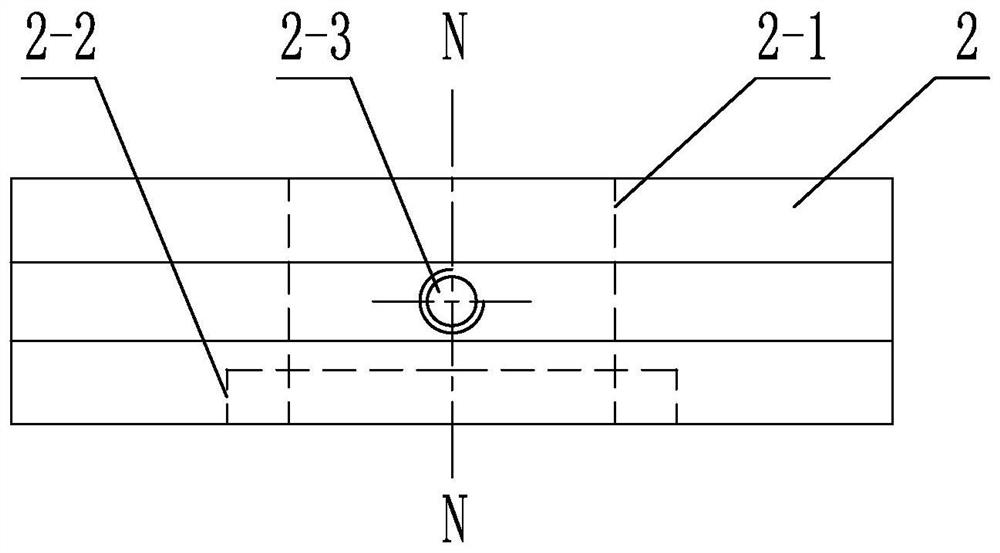

The invention provides an aero-engine adjusting sheet machining tool and method, and relates to the technical field of machining. The machining tool comprises a clamp body (1), a pressing block (2), a taper positioning pin (3) and a cylindrical positioning pin (4), and a plurality of screw holes and a plurality of pin holes are formed in the center of the clamp body (1); the cylindrical positioning pin (4) is arranged in the pin hole; the pressing block (2) is arranged in the middle of the clamp body (1). The taper positioning pin (3) penetrates through the pressing block (2) and the clamping plate (102) at the same time. By means of the machining tool, the problems that machining procedures of the aviation adjusting piece are scattered, clamping is difficult, and machining efficiency is low are solved. The machining method is convenient to operate, the machining precision can be effectively improved, and the product machining quality is improved.

Owner:CHENGDU HOLY AVIATION SCI & TECH

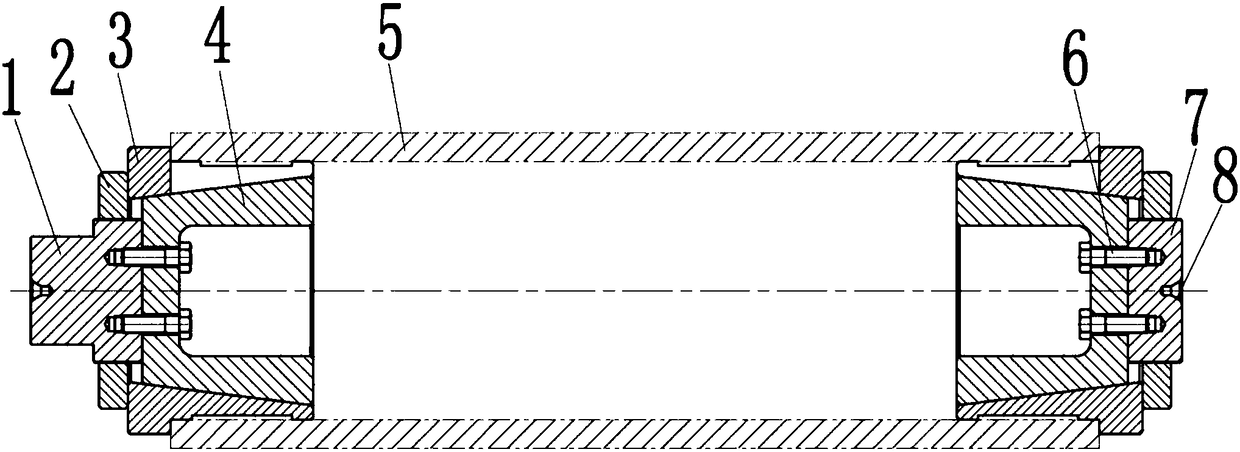

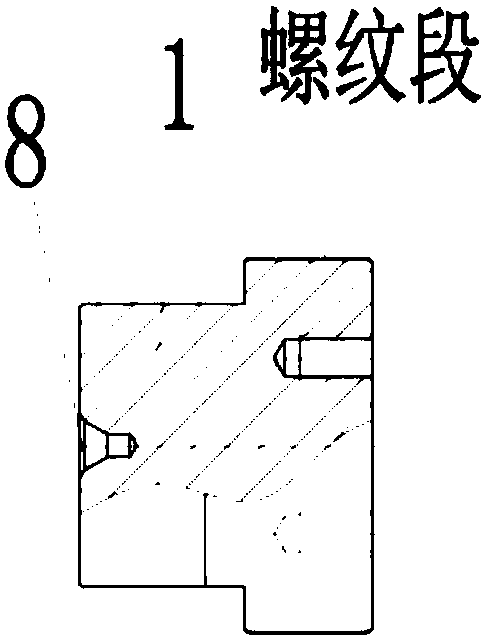

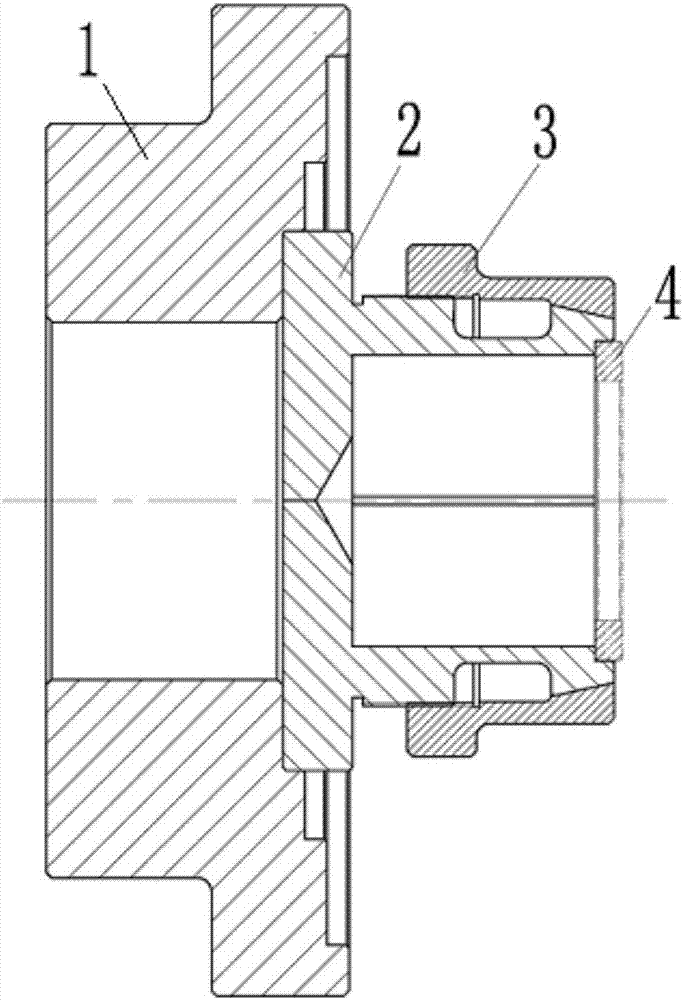

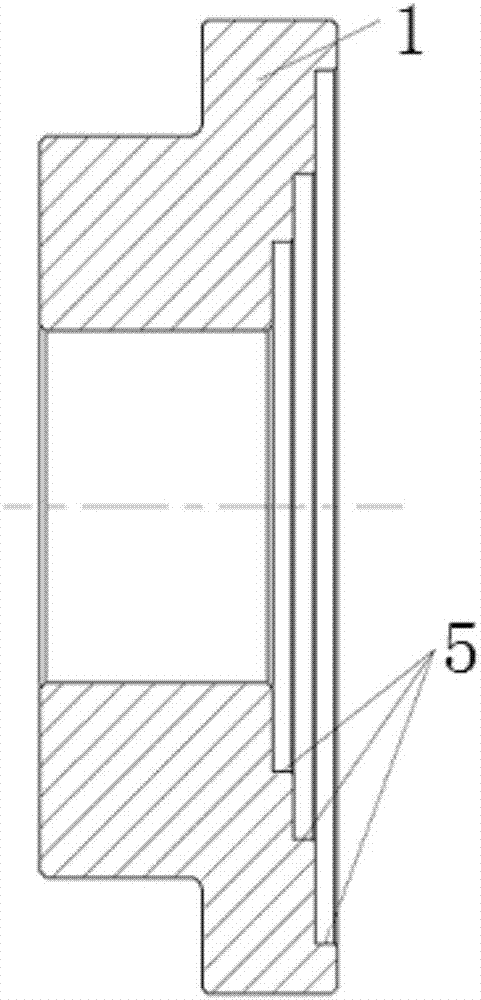

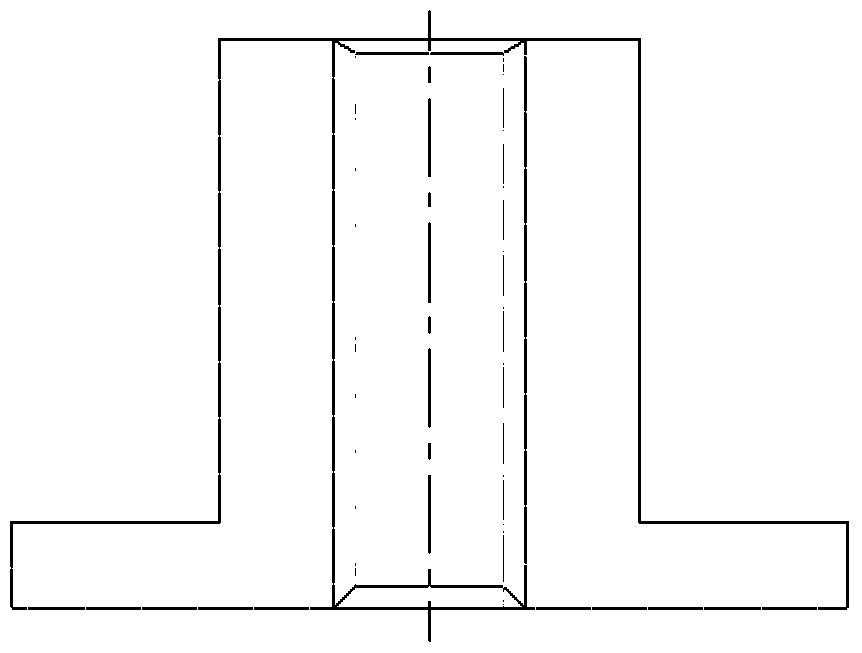

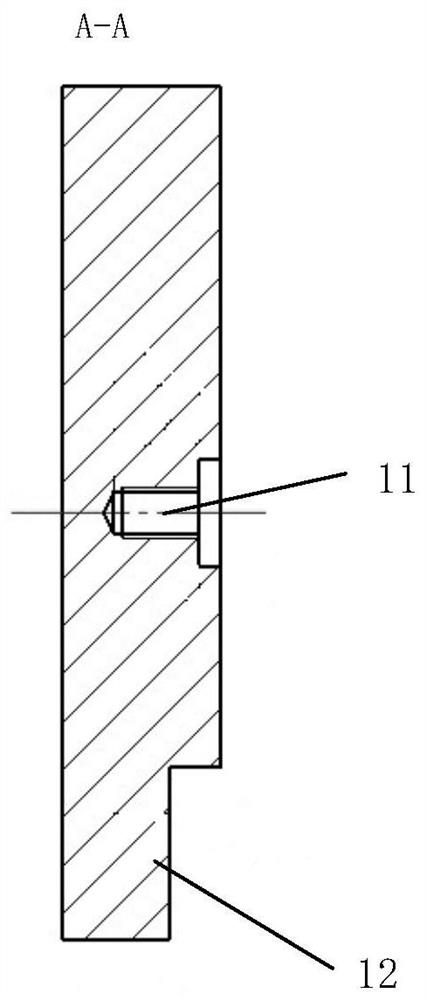

Grinding clamp and clamping method suitable for thin-wall long spacer bush

ActiveCN108481192ACompact structureEasy to useGrinding work supportsMechanical engineeringGrinding process

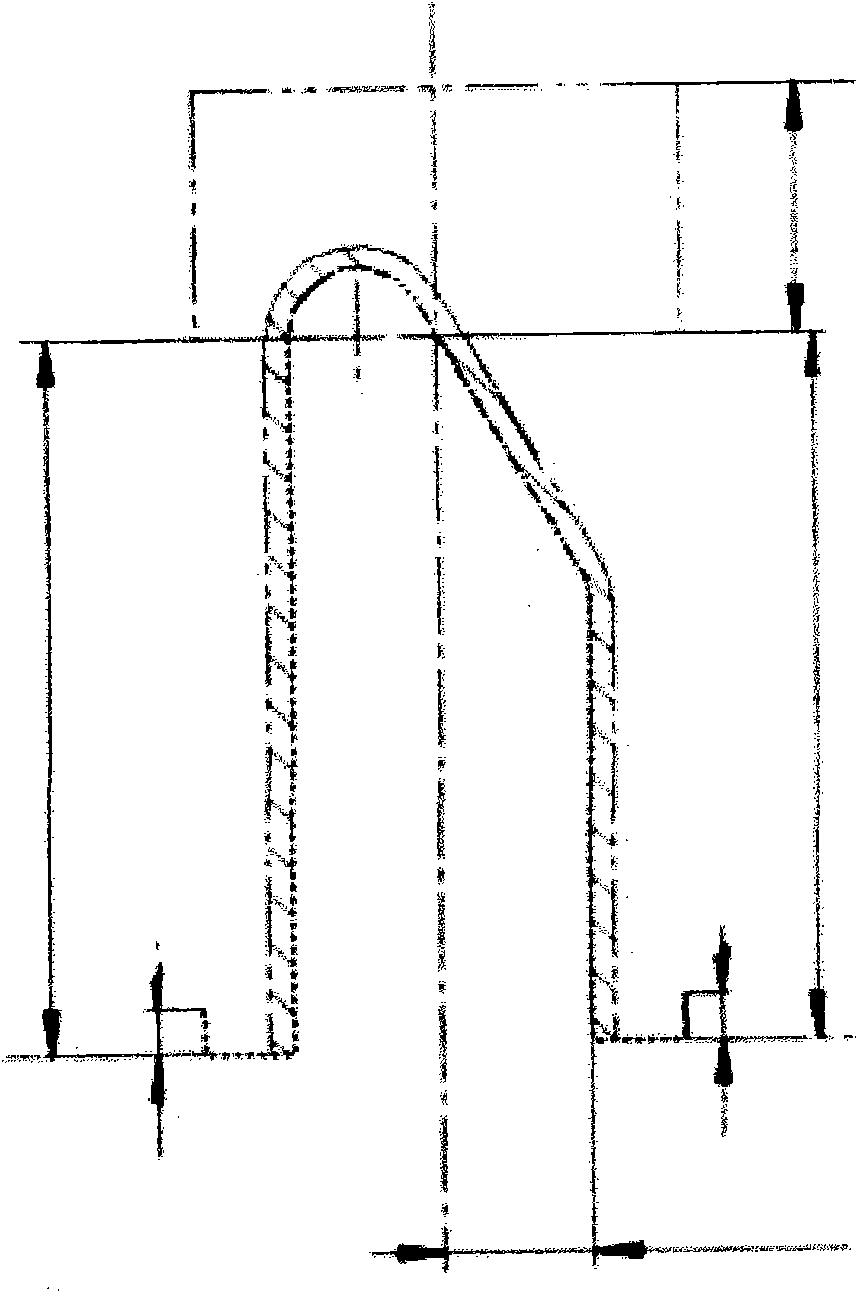

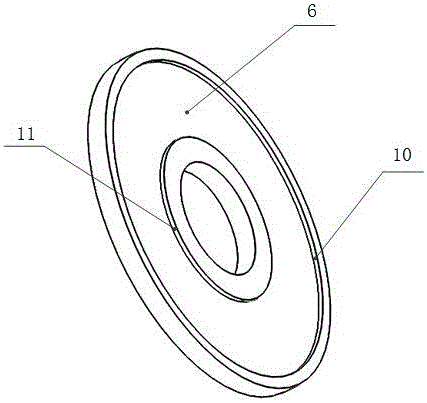

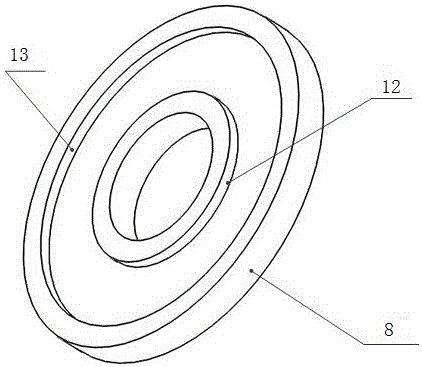

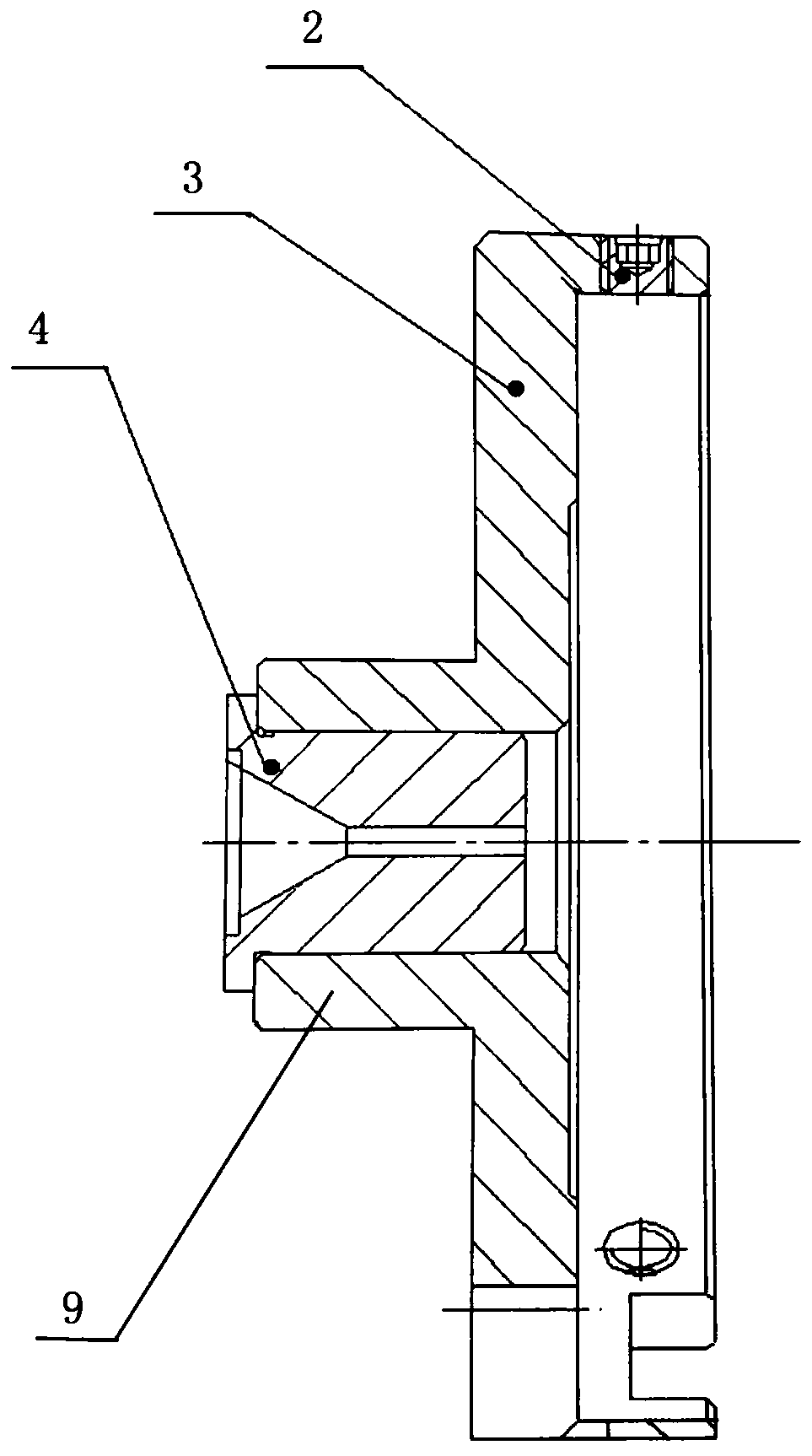

The invention discloses a grinding clamp suitable for a thin-wall long spacer bush. The clamp comprises a moving disc base and a top disc base which are oppositely arranged on the left side and the right side, adjusting round nuts are connected to the moving disc base and the top disc base through threads, transition cone caps with the outer surfaces as the outer conical faces are detachably connected to the right end face of the moving disc base and the left end face of the top disc base, section diameters of the outer conical faces of the transition cone caps are sequentially increased in amanner of extending from the mounting face, the cone faces of the transition cone caps are sleeved with elastic cone sleeves matched with the faces, the corresponding ends of the two elastic cone sleeves are jointly sleeved with the thin-wall long spacer bush, and the other ends of the elastic cone sleeves are located between the adjusting round nuts and the thin-wall long spacer bush. According to the grinding clamp suitable for the thin-wall long spacer bush, deforming caused by clamping in the grinding process of the thin-wall long spacer bush can be effectively reduced. The invention further discloses a grinding clamping method suitable for the thin-wall long spacer bush

Owner:BAOJI PETROLEUM MASCH CO LTD +2

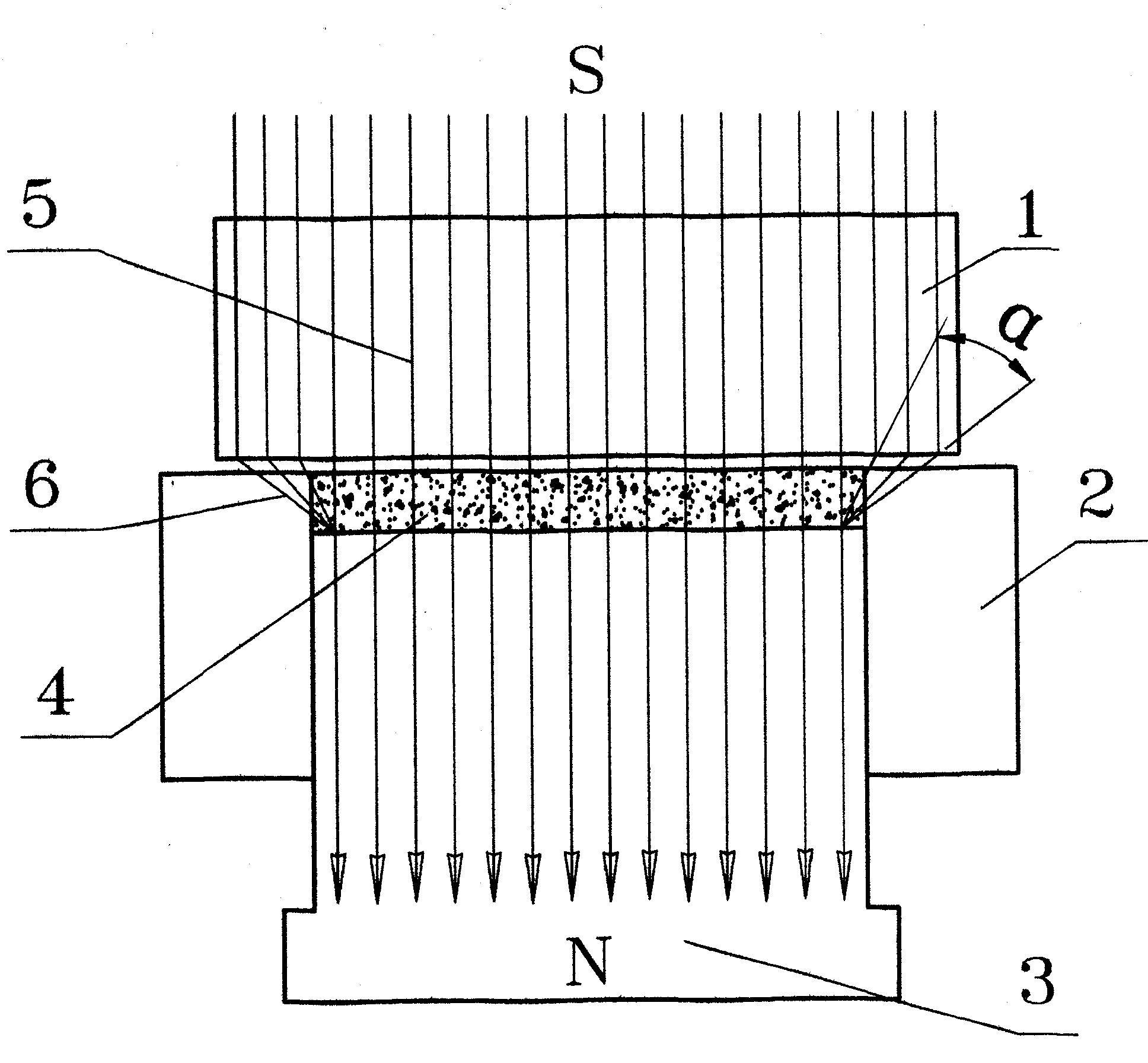

Mold for rectifying deformation of permanent magnetic ferrite product

InactiveCN103213191ASolve processing deformationImprove yieldCeramic shaping apparatusFerrite (magnet)Materials science

The invention relates to a mold for rectifying deformation of a permanent magnetic ferrite product. The mold for rectifying deformation of the permanent magnetic ferrite product is characterized by comprising an upper puncher pin of the mold, a concave mold and a lower puncher pin of the mold. The upper puncher pin of the mold is made of magnetism conducting materials. The lower puncher pin of the mold is made of magnetism conducting materials and included in the concave mold of the mold, wherein the concave mold is made of materials which do not conduct magnetism. Two types of magnetic fields in time of pressing products are the following two types: one is a parallel uniform orientation magnetic field in the concave mold of the mold and the other is a non-uniform orientation magnetic field outside the concave mold of the mold. Magnetic lines of force of the parallel uniform orientation magnetic field in the concave mold of the mold and the non-uniform orientation magnetic field outside the concave mold of the mold form included angles. The included angles range from 0 degree to 45 degrees from inside to outside. According to the mold for rectifying deformation of the permanent magnetic ferrite product, the problem that deformation occurs when the permanent magnetic ferrite product is machined is fundamentally solved, the rate of finished products and production efficiency are improved and production cost is reduced.

Owner:鞍山市德康磁性材料有限责任公司

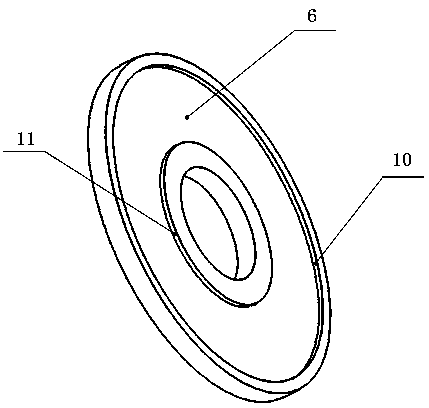

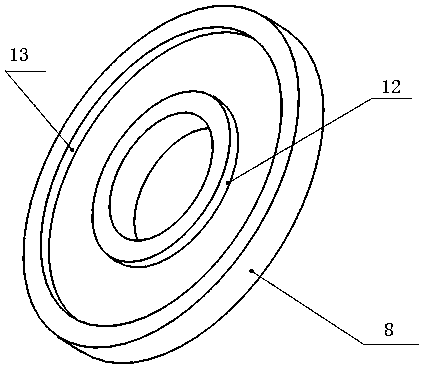

Automotive clamping method for elastic sealing backing ring

The invention discloses an automotive clamping method for an elastic sealing backing ring. The automotive clamping method comprises the steps that 1, a chuck seat is clamped on a common lathe, and after centering is conducted on the chuck seat, an elastic chuck with the corresponding size is installed at first positioning spigots in the front end; 2, a conical locking cap and the elastic chuck are connected through a thread, when the thread is screwed on the elastic chuck and multi-section elastic cutting grooves are deformed, the outer diameter size of the elastic sealing backing ring is machined as needed, a second positioning spigot in the right end of the elastic chuck is machined, and the effect that the size of the second positioning spigot is consistent with the outer diameter size of the elastic sealing backing ring is ensured; and 3, after machining of the second positioning spigot is completed, the conical locking cap is loosened, the to-be-machined elastic sealing backing ring is encased into the second positioning spigot, the conical locking cap is tightly screwed again, and thus machining of the elastic sealing backing ring can be conducted. According to the automotive clamping method for the elastic sealing backing ring, finish machining of elastic sealing backing rings with different specifications and the same type can be achieved through transformation of the structure.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Aviation aluminum alloy pre-stretching plate and production method thereof

The invention relates to aluminium alloy pretensioning plates for aviation and a method for producing the same in order to solve the problem that the existing aluminium alloy plates are easy to be deformed in the machining and machining yield is low. The aliminium alloy pretensioning plates for aviation comprise, based on weight shares, Si of 0.20, Fe of 0.3, Cu of 1.7, Mn of 0.10, Cr of 0.22, Ti of 0.06, Mg of 2.5, Zn of 5.6, and the residuel of Al, the total of 100. The method for producing the aliminium alloy pretensioning plates for aviation includes the steps of : 1) admixture; 2) casting; 3) soak heating treat; 4) heating, hor rolling and cutting; 5) quenching, straightening; 6) pretensioning, ageing, sawing the plates according to the requirement of the product to produce aliminium alloy pretensioning plates for aviation. The plates product of the invention is steady without deforming in machining.

Owner:NORTHEAST LIGHT ALLOY CO LTD

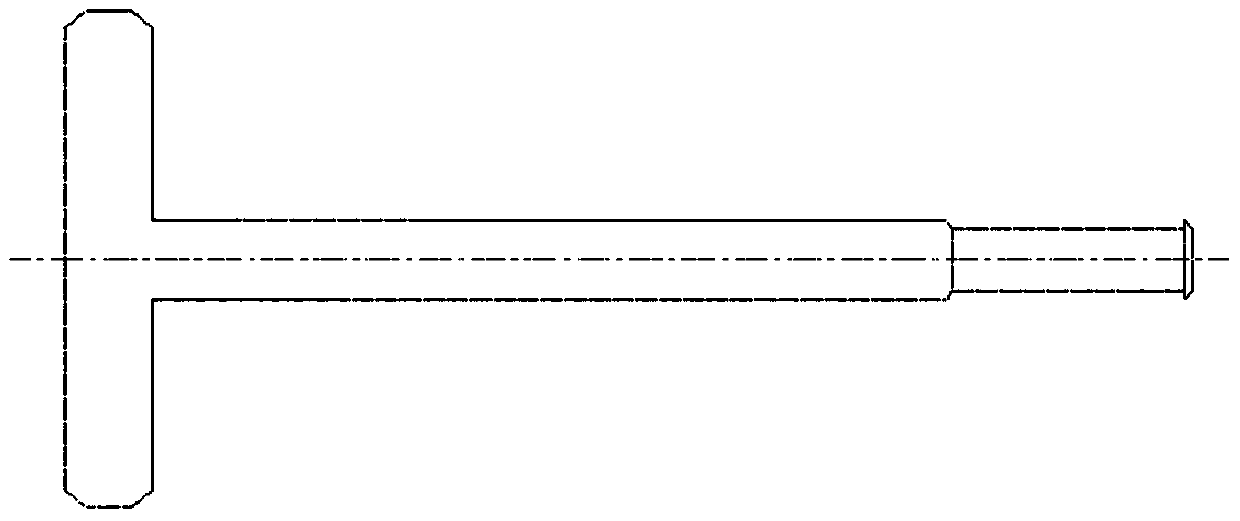

Alignment tool capable of achieving cylindrical grinding on long-axis-type part and using method of alignment tool

InactiveCN110814874ASolve processing deformationReduce pass rateRevolution surface grinding machinesGrinding work supportsPhysicsCylindrical grinding

The invention relates to the technical field of mechanical machining, in particular to an alignment tool capable of achieving cylindrical grinding on a long-axis-type part and a using method of the alignment tool. The alignment tool is installed at the outer side of one side of the installation end of the long-axis-type part and is close to one end of a grinding machine head, and comprises a sleeve and a snap ring which are integrally connected, wherein the inner diameter of the snap ring is equal to the outer diameter of the installation end of the long-axis-type part. A replaceable centre stand can be inserted in the sleeve, and a conical groove of the replaceable centre stand is matched with a centre. Four through holes with inner threads are uniformly and symmetrically formed in the snap ring, and can be in thread fit with jacking screws to squeeze the installation end of the long-axis-type part tightly. The alignment tool is utilized, and the cross alignment method of utilizing four symmetric points for clamping the part by 90 degrees is adopted. The alignment operation is precise and convenient.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Manipulator composite grinding tool for thin-wall part

ActiveCN113561017ANormal pressure reductionReduce vibrationEdge grinding machinesPolishing machinesEngineeringManipulator

The invention provides a manipulator composite grinding tool for a thin-walled part, and belongs to the field of grinding and polishing. The manipulator composite grinding tool is characterized by comprising a bracket, a base, a grinding device, a magnetic grinding device and a control device; the bracket is used for being connected with a manipulator, the base is mounted on the bracket in a lifting manner; the grinding device is arranged on the base and is provided with a grinding part for polishing the thin-wall part from one side of the thin-wall part; the magnetic grinding device is arranged on the base and provided with a rotatable magnet assembly arranged on one side of the thin-wall part and magnetic abrasive particles arranged on the other side of the thin-wall part, and the magnetic abrasive particles are matched with the rotating magnet assembly to be used for grinding the other side of the thin-wall part; and the control device is used for controlling double-sided grinding of the grinding device and the magnetic grinding device. According to the grinding tool, the normal pressure on the thin-wall part is reduced, the stress deformation in the grinding process is reduced, the design difficulty and the manufacturing cost of a thin-wall part clamp are reduced, and the process efficiency is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

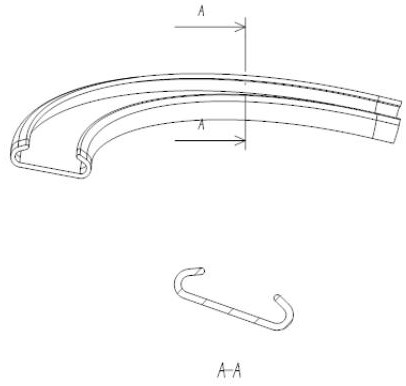

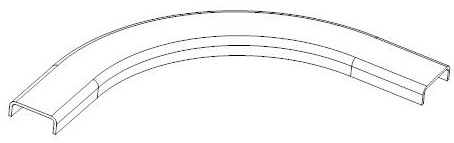

A forming method and forming device for a slender C-shaped cross-section sheet metal part

ActiveCN110756689BImprove forming efficiencyImprove forming qualityAircraft componentsShaping toolsEngineeringHydroforming

The invention belongs to the field of aviation parts processing, and specifically relates to a processing method for slender strip parts. It is characterized in that the forming method includes the following steps: A. pre-forming the U-shaped transition shape of the part; B. unfolding the part for the blank when using The positioning pin is positioned on the mold body, and the cover plate and the mold body are positioned with the mold positioning pin; C. After the installation is completed, the U-shaped pre-formed shape of the part is flexibly packaged with a rubber bag hydroforming machine; D. The manual forming mold is used Bend at the two closed corners of the formed part; E. Complete the final shape of the part and realize the smooth pick-up, a forming device for thin and thin C-shaped cross-section sheet metal parts, which is characterized in that it includes: a mold body and a base, the The mold body includes: a cover plate, a part positioning pin, a mold positioning pin and a preformed shape of a part, and the base includes: a mushroom pin, a part, a first core block, a second core block and a third core block.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

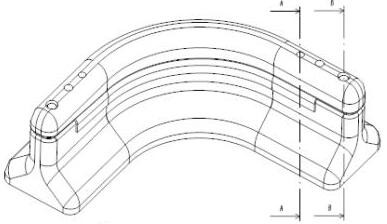

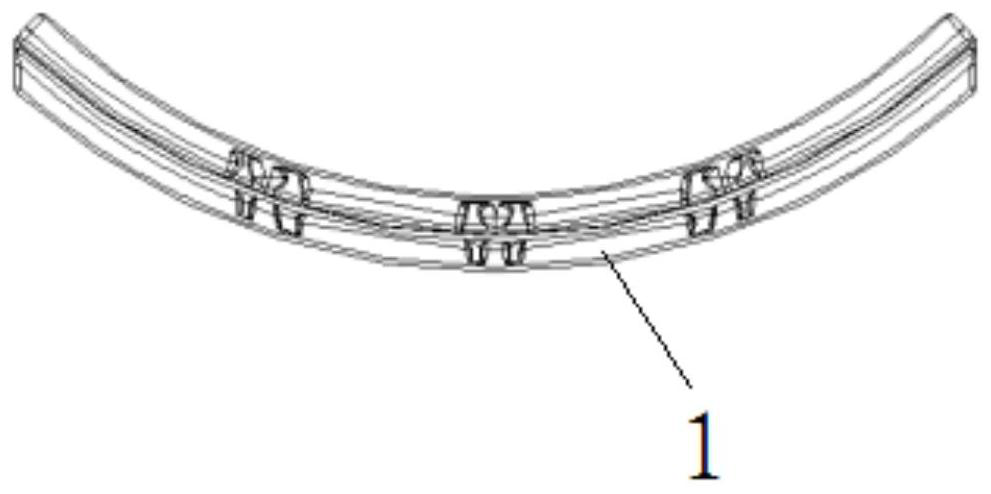

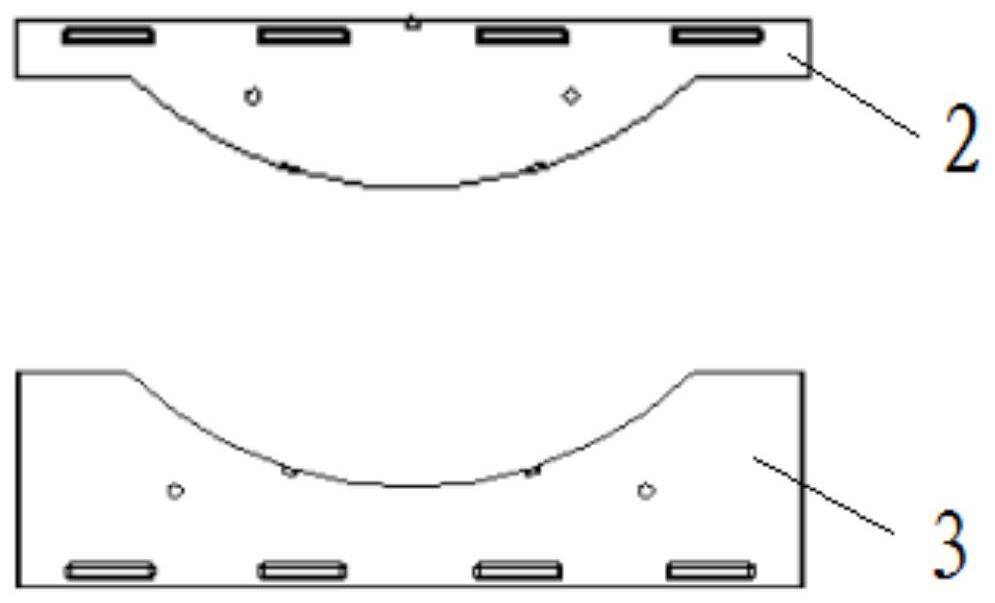

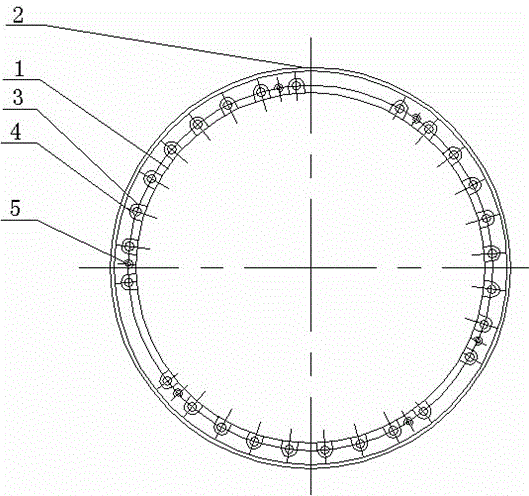

Arc-shaped forge piece machining system and method

PendingCN112705658ASolve processing deformationReduce residual stressUpsetting pressesFurnace typesMachining deformationEconomic benefits

The invention discloses an arc-shaped forge piece machining system and method. The machining system comprises a forge piece machine used for machining an arc-shaped forge piece and a cold deformation die used for conducting cold deformation and straightening on the arc-shaped forge piece, and a die cavity with the same shape and size as a finished arc-shaped forge piece is formed in the cold deformation die. According to the arc-shaped forge piece machining system, the cold deformation die is additionally arranged, the die cavity of the cold deformation die is adopted for limiting the appearance of the arc-shaped forge piece, stress of the arc-shaped forge piece is stable, meanwhile, the required arc-shaped size, namely the size of the finished arc-shaped forge piece, is preset in the die cavity, it is further guaranteed that the arc-shaped forge piece is deformed in the product size direction meeting the requirement in the cold deformation process, the technical bottleneck that machining deformation and straightening of the arc-shaped forge piece are difficult is effectively solved, qualified products are produced, and remarkable economic benefits are obtained.

Owner:SOUTHWEST ALUMINUM GRP

Method for improving sheet annular titanium alloy gear part machining precision

ActiveCN103240575BSolve processing deformationMeet the process requirementsCold treatmentRoom temperature

The invention relates to a method for improving the sheet annular titanium alloy gear part machining precision. The method includes the following steps: (1) rough turning a blank, pressing a part through a pressing plate along the axis direction, and conducting rough machining on the part; (2) recrystallization annealing; (3) rough turning a gear bank again; (4) thermocycling; (5) semi-finish-turning the gear blank; (6) stress relief annealing; (7) conducting auxiliary procedures, and machining and finishing other structural elements of the part thoroughly; (8) conducting subzero treatment; (9) finishing machining the gear blank; and (10) manufacturing teeth and conducting thermo-cold cycling. After the teeth are manufactured, conducting twice thermo-cold cycling, conducting cold treatment at the temperature of -50- -60 DEG C, keeping the temperature for 1.3-1.7h, air cooling to the room temperature for 1.5h, heating to 80-100 DEG C in a thermostat, keeping the temperature for 2.8-3.2h, air cooling to the room temperature, and finishing finish machining. By means of the method, deformation in a machining process can be eliminated.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

A kind of clamping method for elastic gasket ring vehicle

The invention discloses an automotive clamping method for an elastic sealing backing ring. The automotive clamping method comprises the steps that 1, a chuck seat is clamped on a common lathe, and after centering is conducted on the chuck seat, an elastic chuck with the corresponding size is installed at first positioning spigots in the front end; 2, a conical locking cap and the elastic chuck are connected through a thread, when the thread is screwed on the elastic chuck and multi-section elastic cutting grooves are deformed, the outer diameter size of the elastic sealing backing ring is machined as needed, a second positioning spigot in the right end of the elastic chuck is machined, and the effect that the size of the second positioning spigot is consistent with the outer diameter size of the elastic sealing backing ring is ensured; and 3, after machining of the second positioning spigot is completed, the conical locking cap is loosened, the to-be-machined elastic sealing backing ring is encased into the second positioning spigot, the conical locking cap is tightly screwed again, and thus machining of the elastic sealing backing ring can be conducted. According to the automotive clamping method for the elastic sealing backing ring, finish machining of elastic sealing backing rings with different specifications and the same type can be achieved through transformation of the structure.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Processing method of thin-walled vase-shaped cooling chamber

The invention discloses a processing method of a thin-walled vase-shaped cooling room. The method comprises the steps of firstly, manufacturing a workblank of the thin-walled vase-shaped cooling room; filling an inner cavity of the cooling room with gypsum; and finally, carrying out rough processing and finish processing to obtain the thin-walled vase-shaped cooling room. According to the processing method provided by the invention, the procedures are reasonably arranged, the working efficiency is high, the manufacturing cost is low, the problem that parts deform during processing is effectively solved, the utilization rate of raw materials is greatly increased, and the processing accuracy and surface quality of parts are improved.

Owner:湖北三江航天江北机械工程有限公司

A titanium alloy thin-wall shell billet finishing mold and processing method thereof

The invention provides a finish machining die and method for a titanium alloy thin-walled shell casting blank. The finish machining die is characterized in that the titanium alloy thin-walled shell casting blank is externally coated with an external casting mold and internally contains an internal casting mold. A fusible alloy is externally cast on the outer surface of the titanium alloy thin-walled shell casting blank, so that the outer surface of a titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the inner surface. Similarly, the fusible alloy is internally cast on the inner surface of the titanium alloy thin-walled shell casting blank, so that the inner surface of the titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the outer surface. By adoption of the finish machining die and method, the rigidity and the strength of parts can be effectively improved, the working procedures are reasonably arranged, the working efficiency is high, the machining cost is low, and not only can the problem of machining deformation of titanium alloy thin-walled shell parts be solved, but also the machining precision and the surface quality of the parts are greatly improved.

Owner:XIJING UNIV

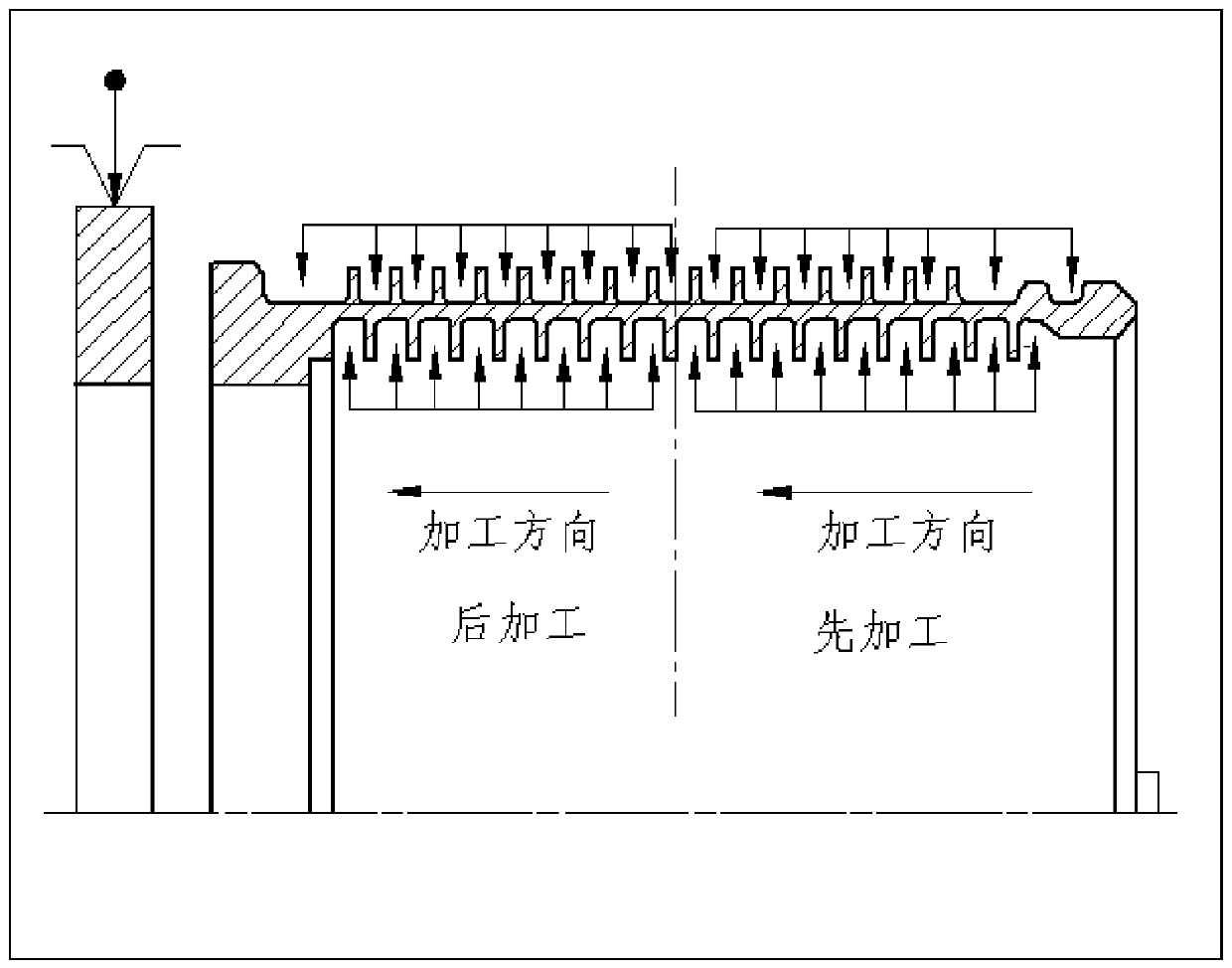

Method for machining thin-wall special-shaped part

ActiveCN111299986ASolve processing problemsSolve processing deformationMachining deformationStructural engineering

The invention relates to a technology for machining a thin-wall special-shaped part and provides a method for machining the thin-wall special-shaped part. The method comprises steps as follows: for apart forming an internally and externally symmetric structure window by milling, an internal and outer diameter ring groove at the front part is subjected to finish turning firstly, clamping force forthe part is increased, and then an internal and outer diameter ring groove at the rear part is subjected to finish turning. The problem of machining deformation of the type of thin-wall special-shaped part is effectively solved, the machining problems caused by part structure are solved by arranging a reasonable process route and selecting a unique moving path, and reference method and basis canbe provided for machining of other parts with the similar structure.

Owner:HARBIN DONGAN ENGINE GRP

Method and system for error compensation of ac five-axis waterjet cutting

The invention relates to an AC five-axis water cutting error compensation method which comprises the following steps that (1) a first trial cutter path is determined and a first workpiece is processed perpendicularly according to the first trial cutter path; (2) a second workpiece is processed according to the first trial cutter path; (3) a down-look surface is subjected to axial symmetry and rotated by 90 degrees counterclockwise to be taken as a second trial cutter path, and a third workpiece is processed with an inclined angle V1 according to the second trial cutter path; (4) the widths of the second rectangles of the first workpiece, the second workpiece and the third workpiece are measured respectively and marked as L1, L2 and L3 respectively, and an included angle of the A axis and the C axis in the cutter bit structure is recorded as V2; (5) error compensation is performed according to the V1, V2, L1, L2 and L3. The invention further discloses an AC five-axis water cutting error compensation system. With the adoption of the method and the system, the problem that processing deformation caused by the error of a non-cutter-length AC five-axis water cutting head mechanism is solved, the processing accuracy is improved, and the method and the system have a wide application range.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

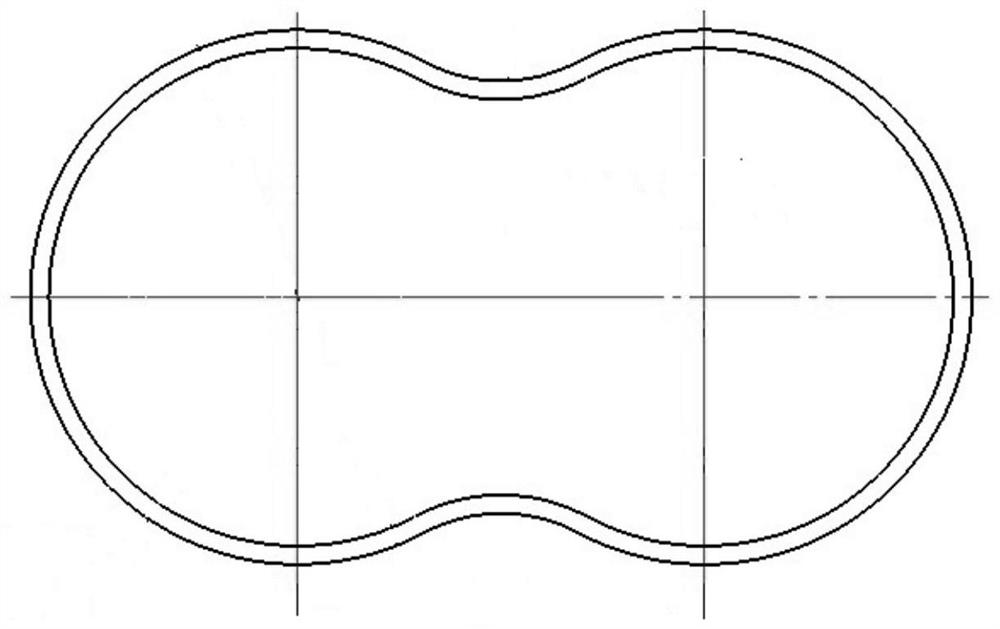

Processing method of special-shaped sealing ring and process pressure plate and positioning plate for processing

ActiveCN112589485BSolve difficultyReduce machining errorsMilling equipment detailsPositioning apparatusFluoroplastMachining

The invention belongs to the technical field of mechanical processing of sealing rings, and in particular relates to a processing method and tooling for special-shaped sealing rings, which process an 8-shaped groove on a raw material plate, and use the inner surface and outer surface of the groove as the reference roughness. The prototype of the special-shaped sealing ring is milled out, and the inner surface of the prototype of the special-shaped sealing ring is fine-milled to the required size, and then the inner cavity is filled with a process pressure plate, and the outer surface is fine-milled to obtain the finished product of the special-shaped sealing ring. Plate and process platen are clamped at one time, divided into rough milling and fine milling, which effectively solves the problem of difficult positioning and clamping when processing fluoroplastic special-shaped sealing rings, and its positioning is accurate, and the processing error of special-shaped sealing rings is small. High efficiency ensures the sealing performance of the special-shaped sealing ring.

Owner:XIAN AERO ENGINE CONTROLS

A processing method for a thin-wall separated solid cage

The invention discloses a method for machining a thin-wall separation type solid retainer, and relates to the technical field of design and manufacture of retainers. According to the method, the problems that an existing thin-wall separation type bearing solid retainer is large in machining difficulty, easy to deform, the interior of the retainer, the outer diameter precision and the rivet hole machining precision are low, and the product machining quality is difficult to guarantee are solved; the method for machining the thin-wall separation type solid retainer is realized through the following steps that 1, finely turning is sequentially carried out on a first plane and a second plane, the outer diameter is coarsely ground and finely turning is carried out on the inner diameter; 2, solidsolution strengthening is carried out; 3, turning are both carried out on two planes ; 4, the finely turning is carried out on the outer diameter; 5, the inner diameter is finely ground; 6, a rivet hole is drilled; 7, a bolt is inserted; 8, a pocket is drilled and milled; 9, the outer diameter is finally milled; 10, final turning is carried out on the inner diameter; 11, the bolt is removed, deburring is carried out, and finishing is carried out; and 12, fluorescent permeation flaw detection is carried out. The method is used for improving the interior of the retainer, the outer diameter precision and the rivet hole machining precision of the thin-wall separation type solid retainer.

Owner:AVIC HARBIN BEARING

A kind of CNC machining method for special-shaped joint parts

InactiveCN101767264BSolve processing deformationMeet the design requirementsNumerical controlEngineering

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

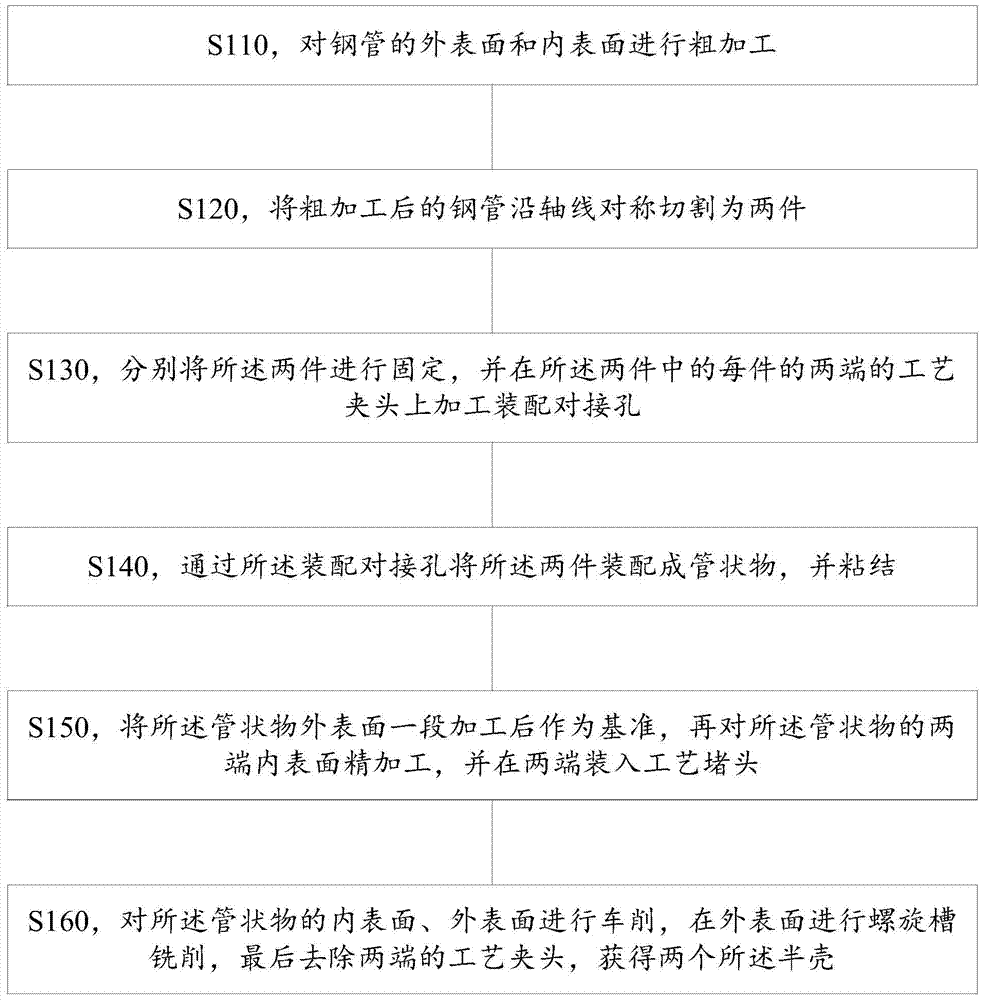

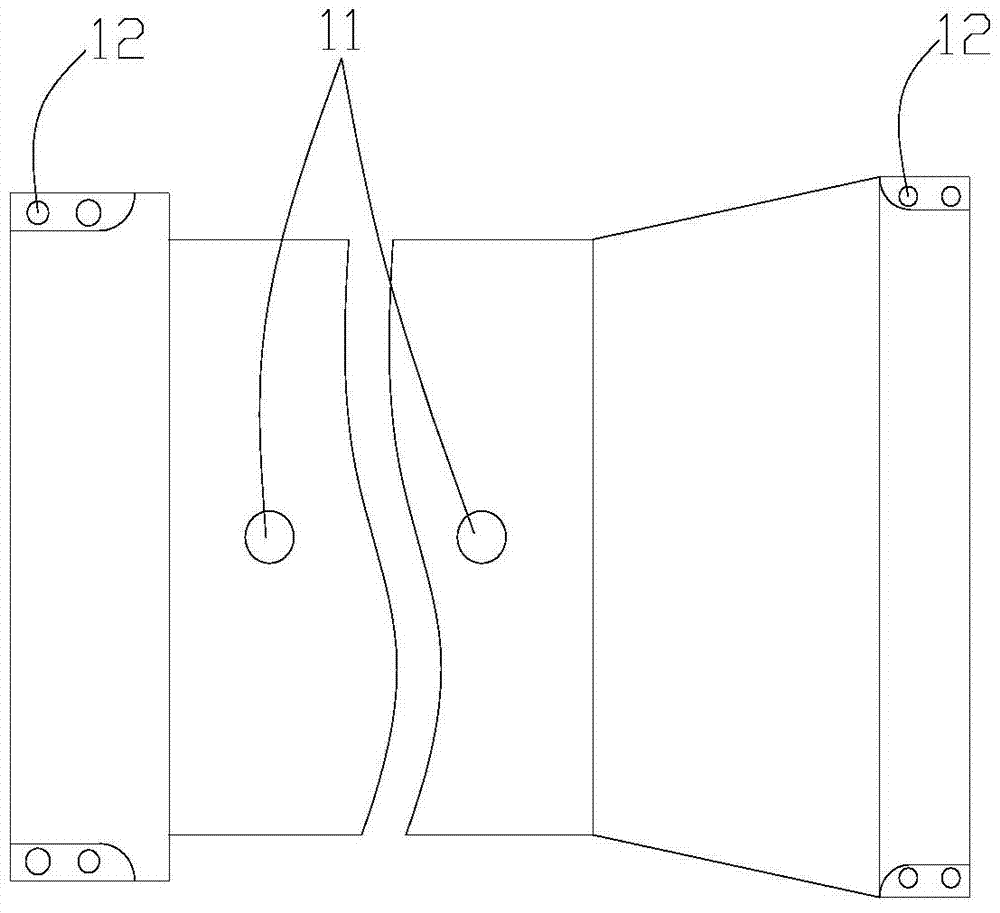

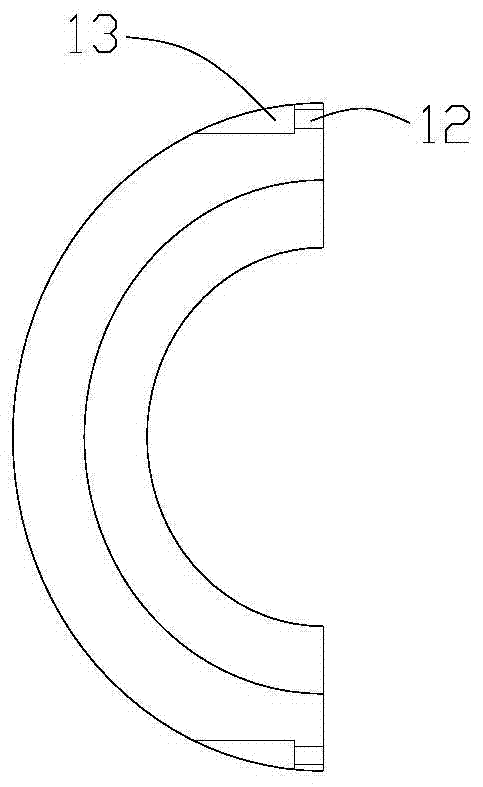

A half-shell processing method with multiple spiral grooves distributed on the outer circle

ActiveCN105033587BSolve processing deformationImprove machining accuracyButt jointArchitectural engineering

The invention discloses a half-shell processing method with a plurality of spiral grooves distributed on the outer circle. The method comprises: rough machining the outer surface and the inner surface of a steel pipe; cutting the roughly machined steel pipe symmetrically along the axis into two pieces; Fix the two pieces, and process assembly butt joint holes on the process chucks at both ends of each of the two pieces; assemble the two pieces into a tubular object through the assembly butt joint holes, and bond them; After a section of the outer surface of the tubular is processed as a reference, the inner surfaces of both ends of the tubular are finished, and technical plugs are installed at both ends of the tubular; the inner surface of the tubular, Turning is performed on the outer surface, and spiral groove milling is performed on the outer surface. Finally, the process chucks at both ends are removed to obtain two half-shells, which solves the problem of deformation of the thin-walled long half-shell and improves the processing accuracy and quality of the product.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com