Automotive clamping method for elastic sealing backing ring

An elastic sealing gasket and elastic sealing technology, applied in the direction of expanding the mandrel, etc., can solve the problems of difficult to ensure the processing quality, the elastic gasket ring does not clamp the vehicle fixture, etc., to improve product quality and processing efficiency, compact structure , easy to use and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

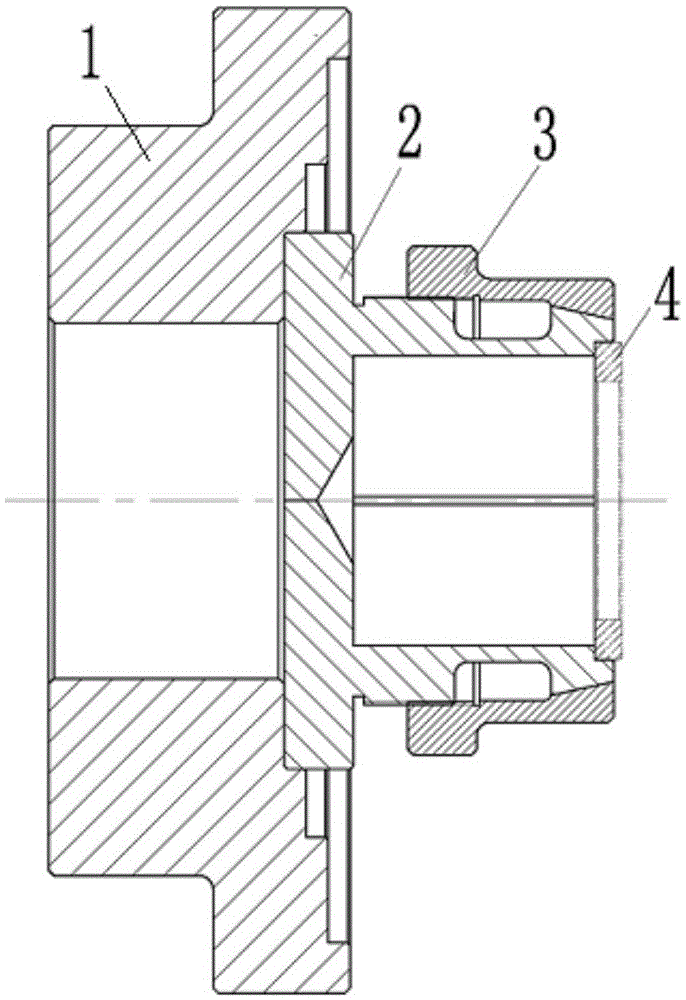

[0018] refer to figure 1 , the vehicle fixture structure that the inventive method adopts is, comprises chuck seat 1, elastic chuck 2 and taper lock cap 3,

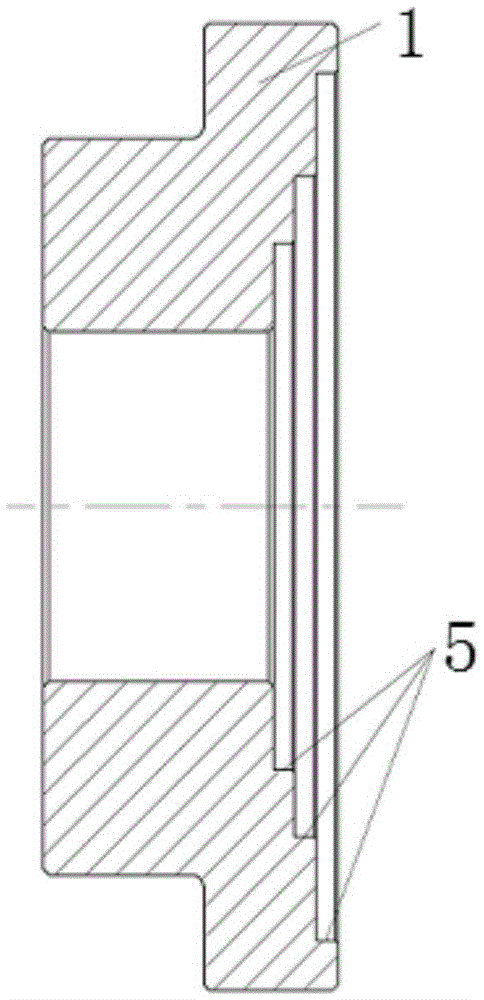

[0019] refer to figure 2 , the front face of the chuck seat 1 (the right end in the figure) is provided with a plurality of positioning notches-5 of different diameters, the chuck seat 1 is installed and positioned in conjunction with the elastic chuck 2 through the positioning notch-5, which can meet different specifications and the same type of elasticity The processing of gasket ring; the end of the chuck seat 1 (the left end in the figure) is the clamping end of the lathe. In the working state, it only needs to be clamped and aligned once, so as to ensure that the positioning datum of the workpiece is consistent and the reuse rate is high. Higher, easy to use;

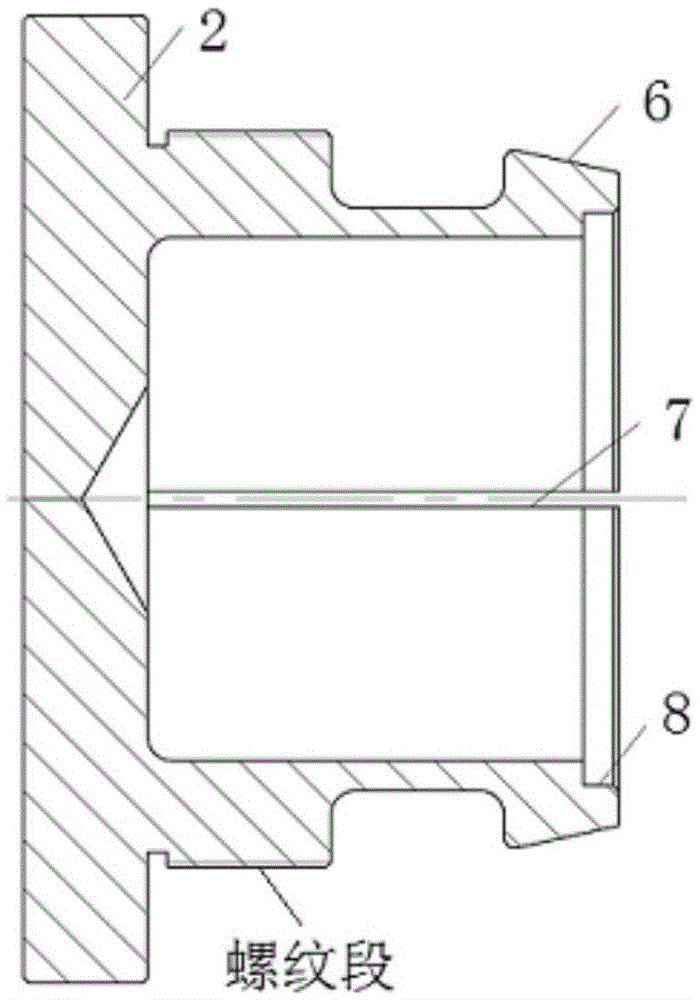

[0020] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com