Patents

Literature

1529results about How to "Guaranteed size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

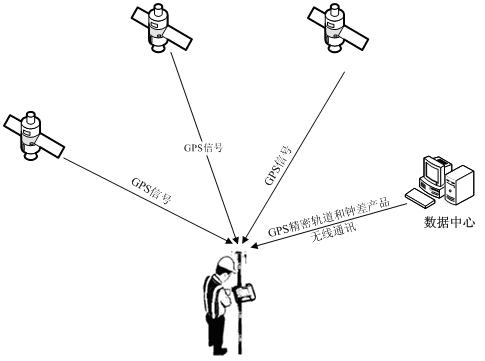

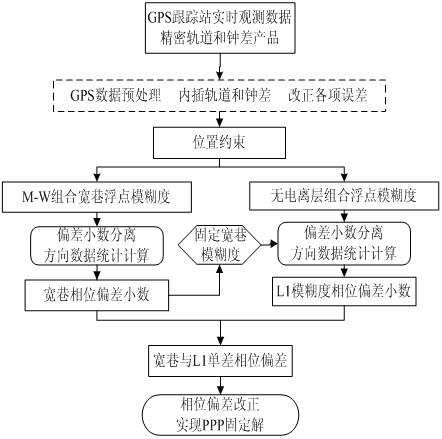

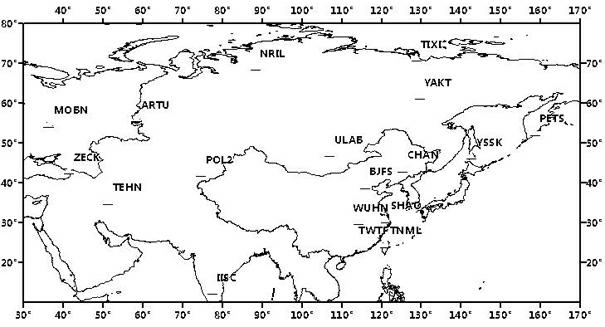

Method for estimating phase deviation in precise single-point positioning technology

InactiveCN102353969AImprove robustnessGuaranteed sizeSatellite radio beaconingPoint-to-Point ProtocolIonosphere

The invention discloses a method for estimating a phase deviation in a precise single-point positioning technology, which comprises the steps of: firstly, carrying out parameter estimation on single-difference non-ionized layer combined ambiguity by using a position as a restraint condition according to data of a reference station in a tracking network; secondly, carrying out parameter estimationon single-difference wide-lane ambiguity by adopting an M-W combination, separating out a decimal part of the single-difference wide-lane ambiguity, and carrying out decimal deviation calculation by using a directional data statistic theory, modifying and fixing the single-difference wide-lane ambiguity as an integer; thirdly, resolving a single-difference L1 ambiguity floating point solution according to a single-difference non-ionized layer ambiguity estimation value and a single-difference wide-lane ambiguity integer solution, separating the decimal part, carrying out decimal deviation calculation by using the direction data statistic theory; and finally, broadcasting the wide-lane and the L1 phase deviation decimal part to a user of a roving station so as to be used for fixing the single-difference integral ambiguity solution of the wide lane and the L1 and further obtaining a PPP (Point to Point Protocol) static solution.

Owner:SOUTHEAST UNIV

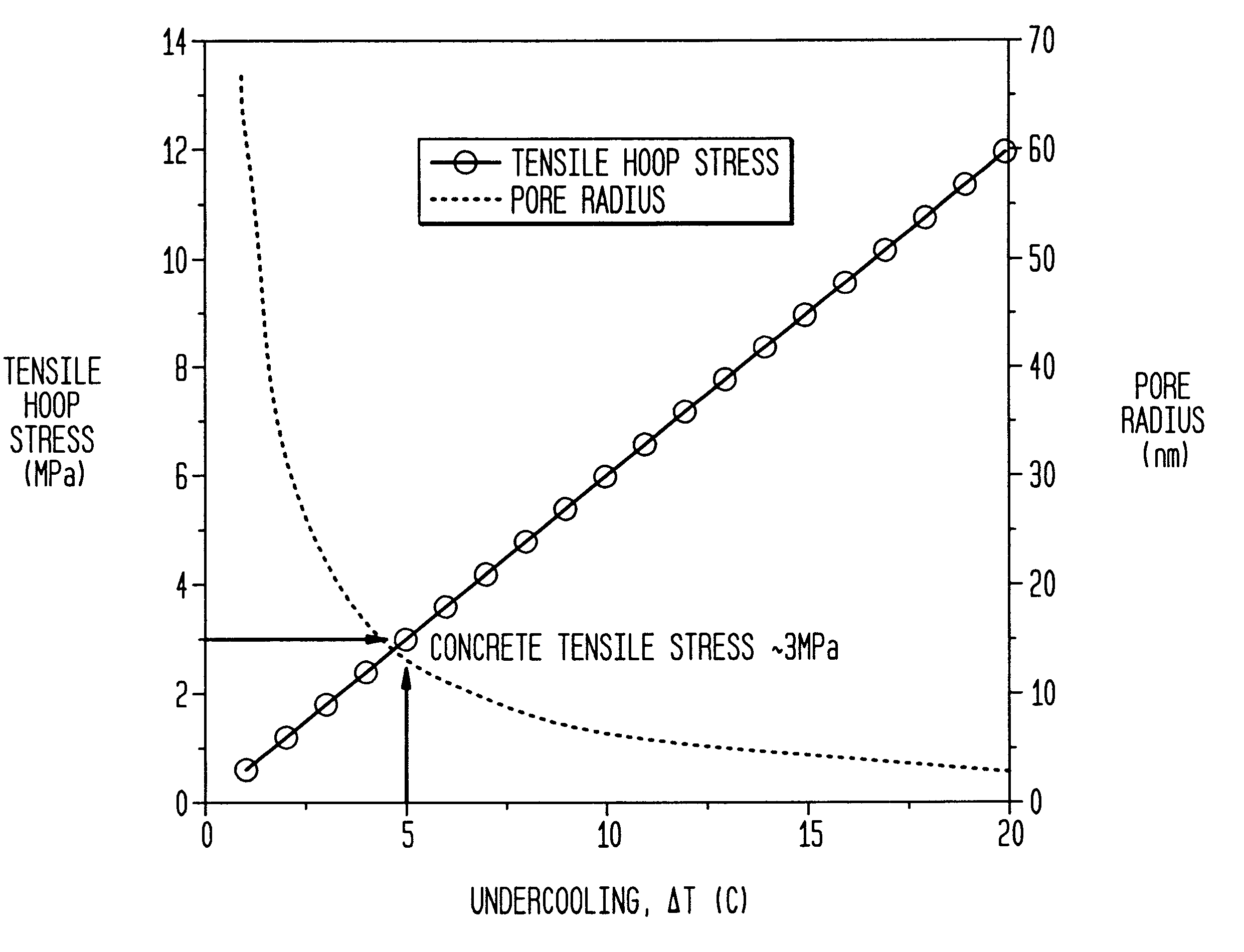

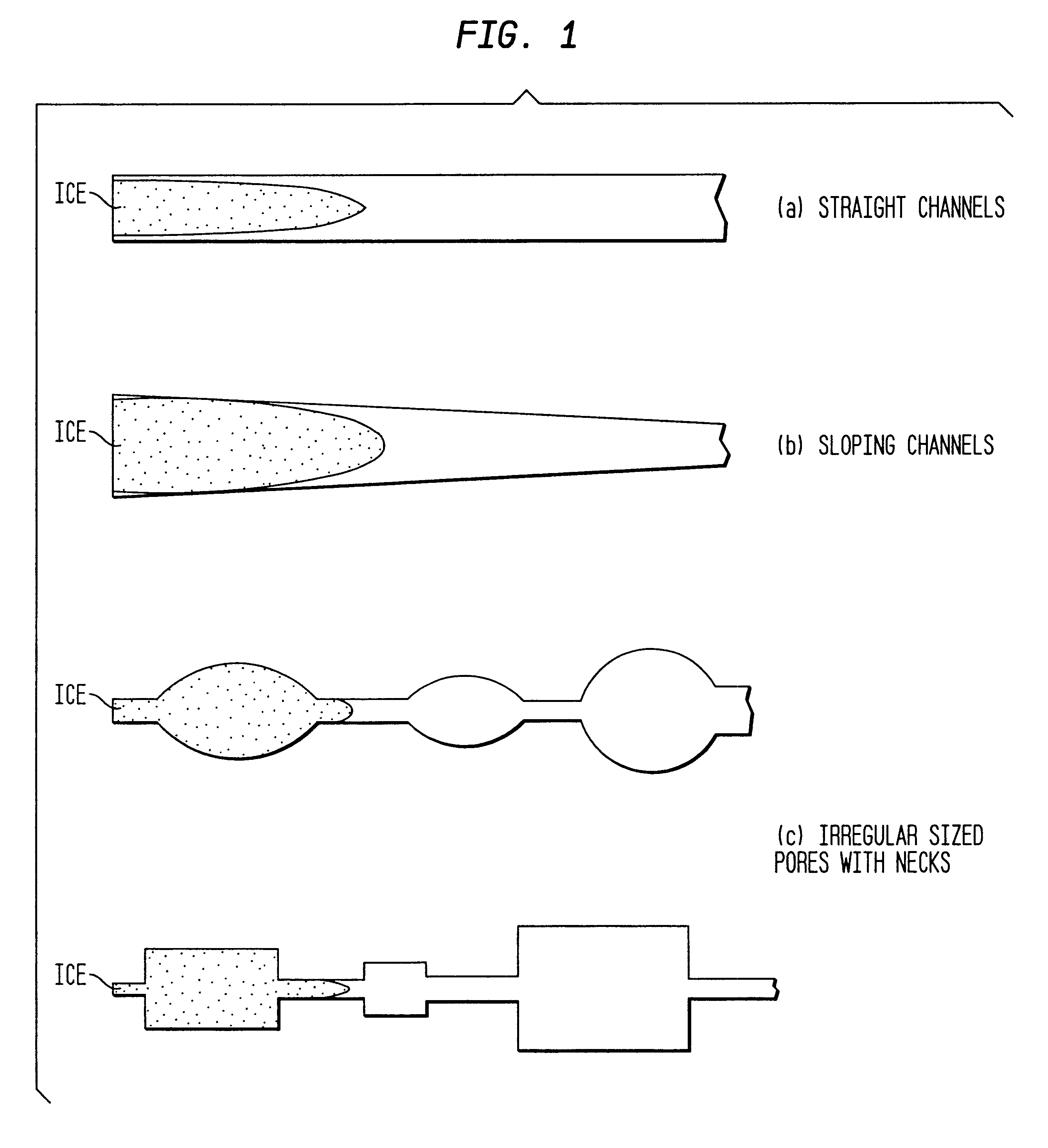

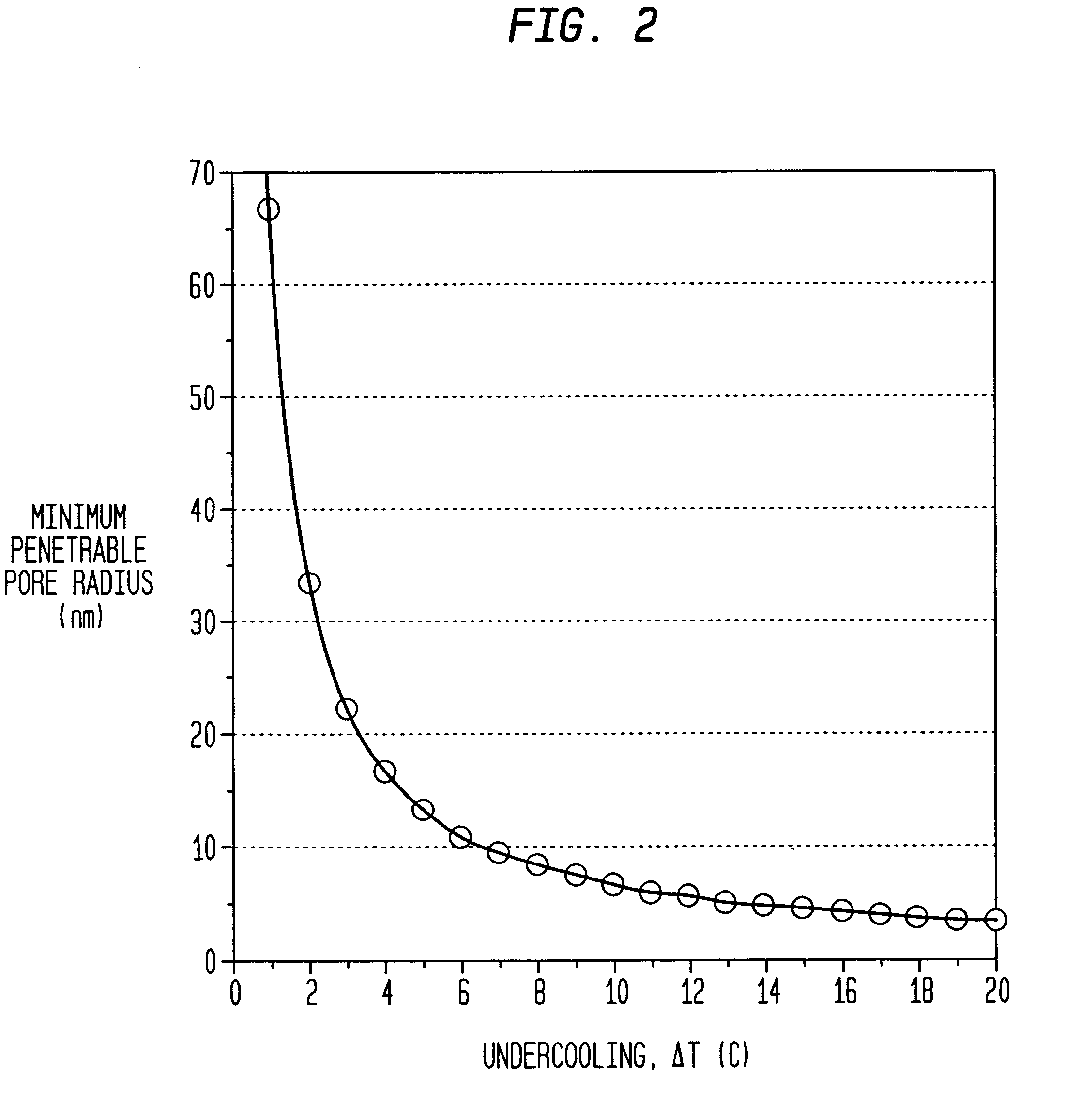

Methods of protecting concrete from freeze damage

A method of protecting a cementitious mixture from freeze damage is provided. The method consists of incorporating an entrainment air composition into the cementitious mixture to form air voids in the concrete, and further adding an effective agent for nucleating ice, preferably, in the air voids, such that upon the freezing of concrete formed from the cementitious mixture, ice is nucleated in the air voids. In one embodiment, the air entrainment composition includes ceramic shells, which could be impregnated with an agent for nucleating ice such as metaldehyde.

Owner:THE TRUSTEES FOR PRINCETON UNIV

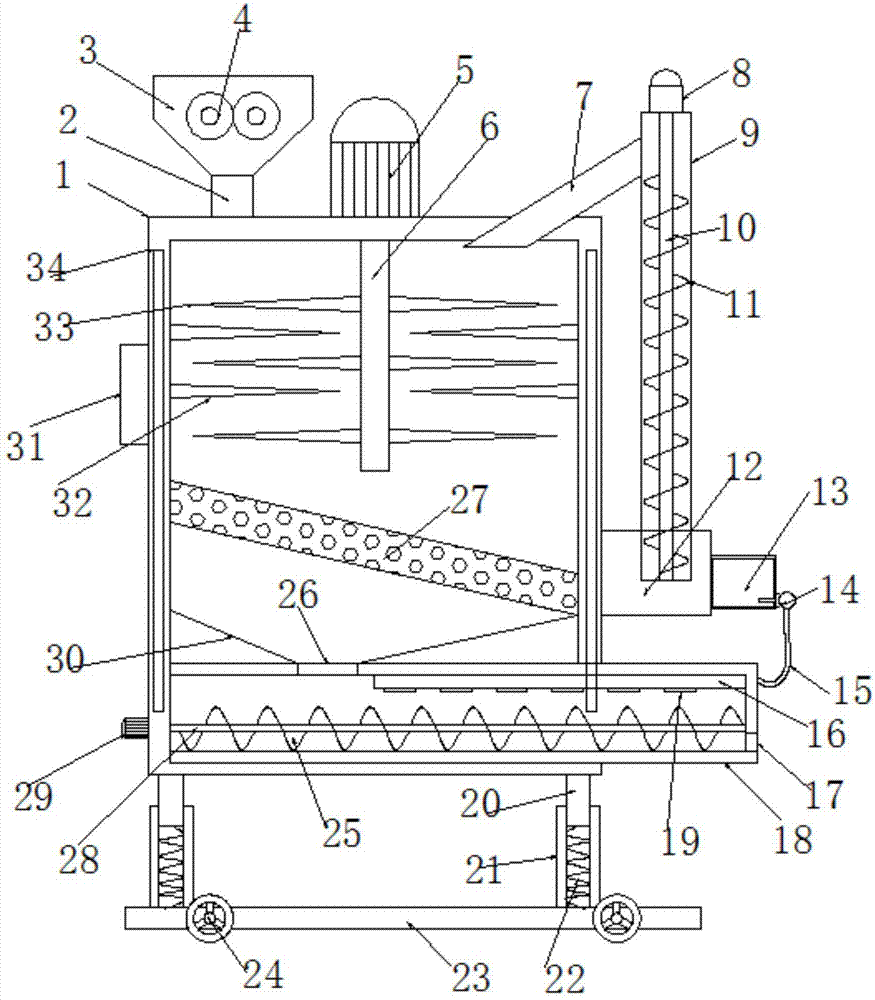

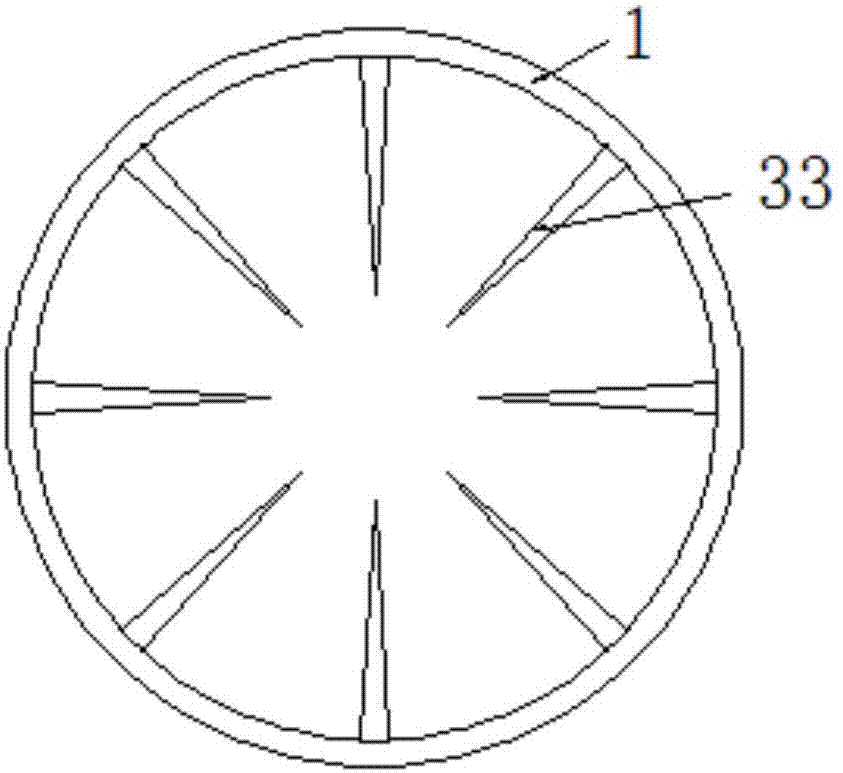

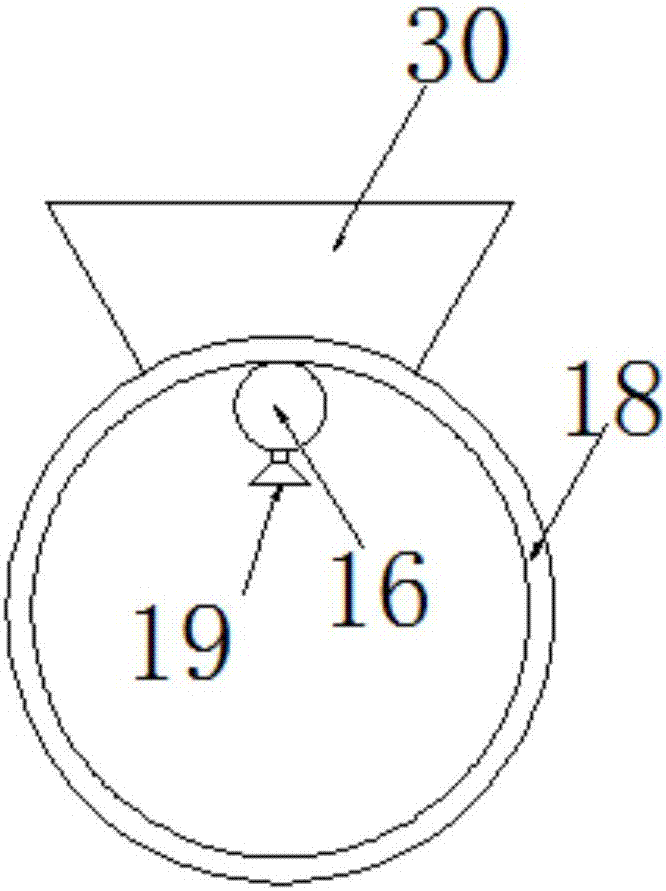

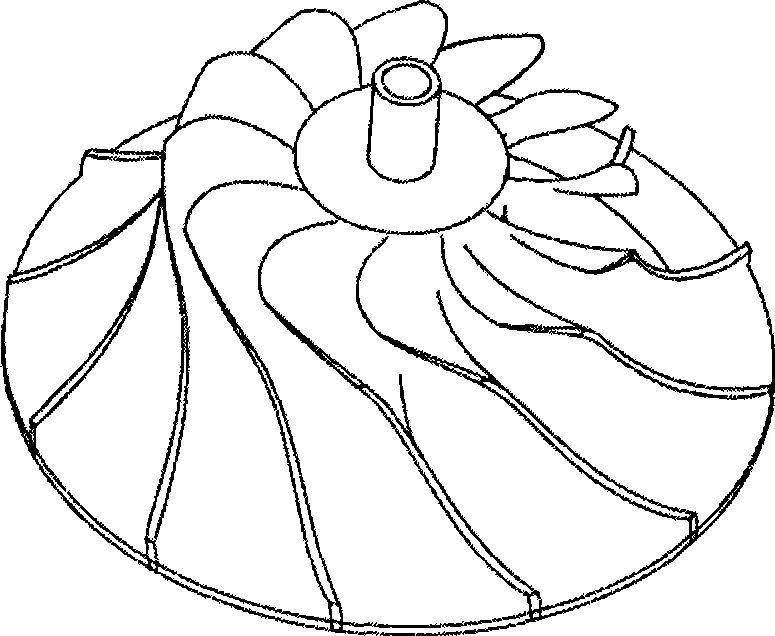

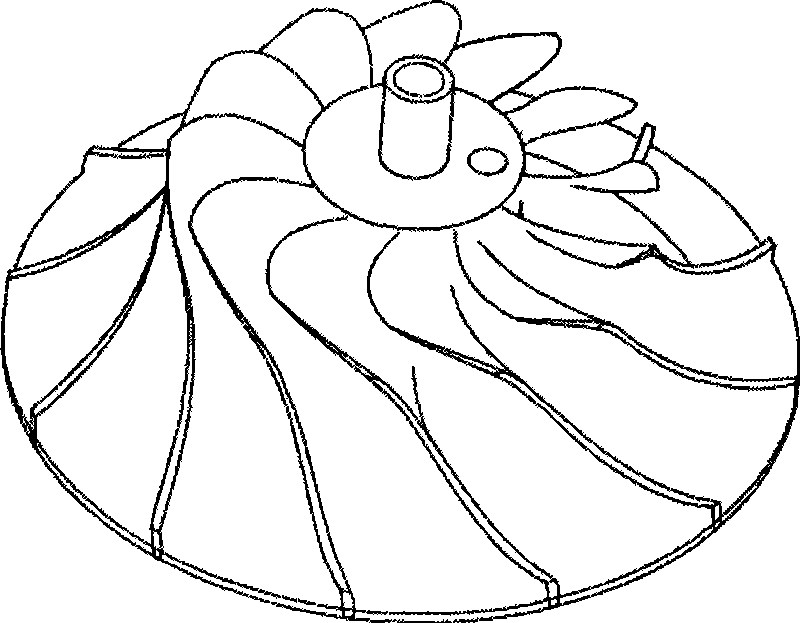

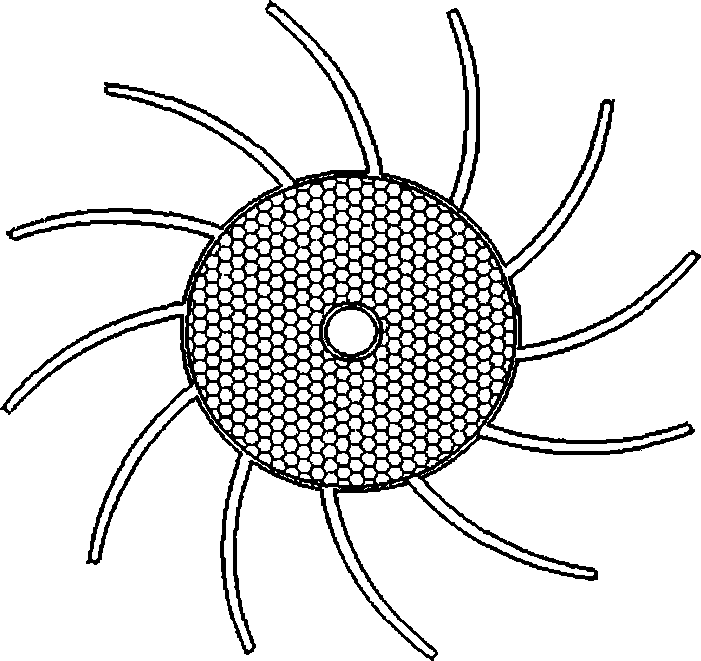

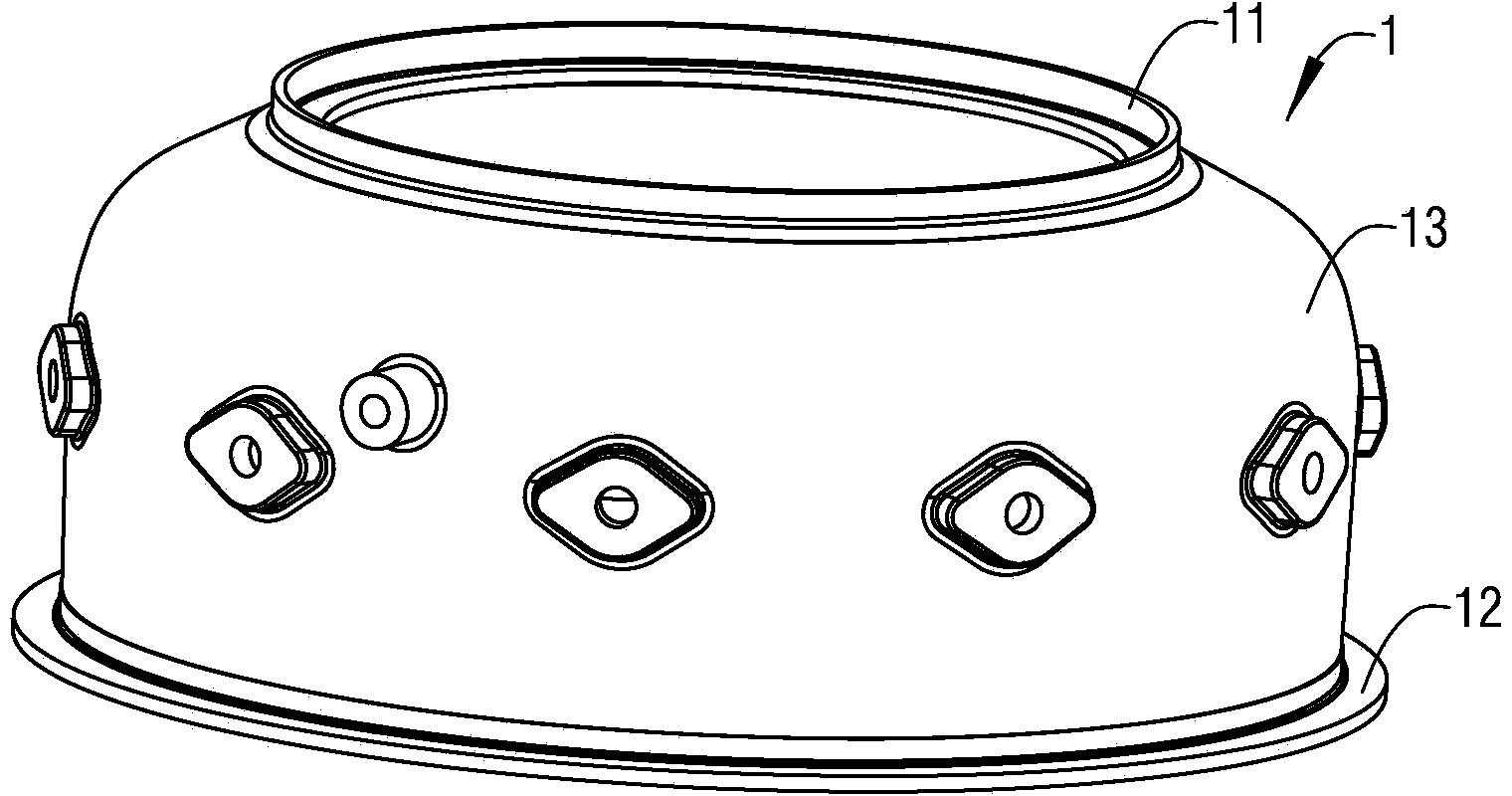

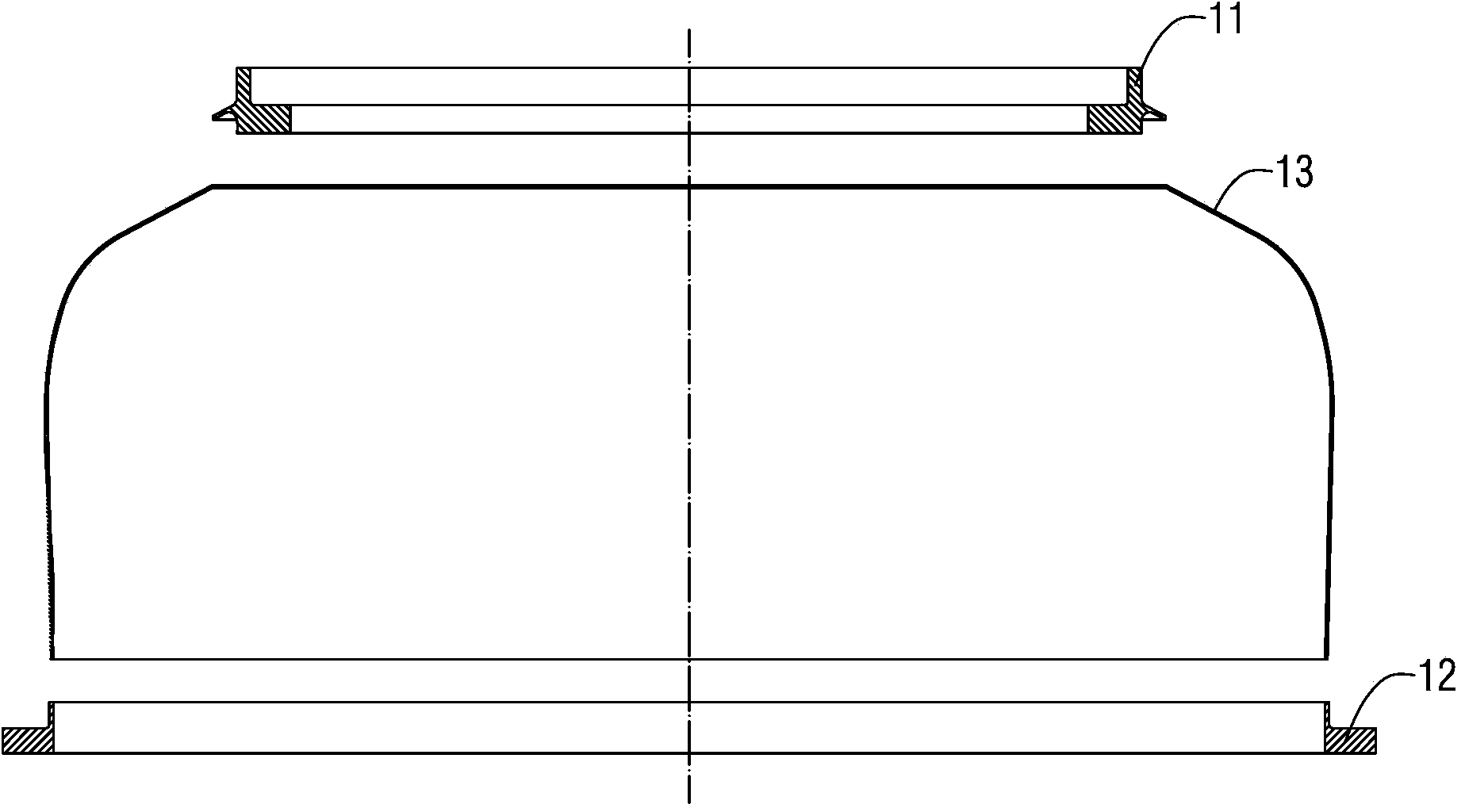

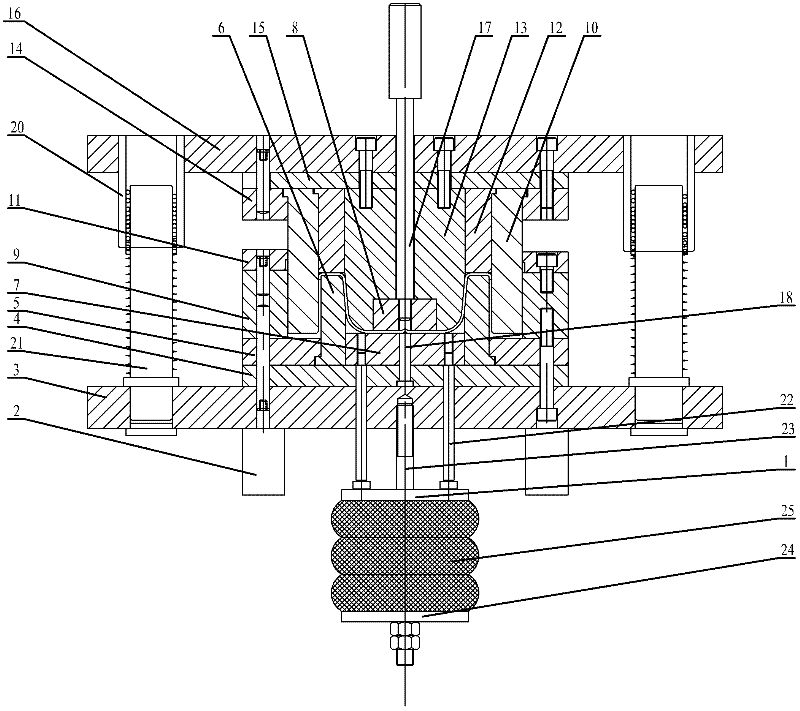

Municipal landscaping soil environment-friendly repairing device

InactiveCN107398471ASimple structureGood shock absorptionContaminated soil reclamationGrain treatmentsEngineeringLandscaping

The invention discloses an environmental protection restoration device for municipal landscaping soil, which comprises a processing box, the processing box is a cylindrical body, a feeding pipe is arranged at the upper left end of the processing box, a feeding hopper is arranged at the upper end of the feeding pipe, and a feeding hopper is arranged at the upper end of the feeding pipe. There is a crushing roller in the bucket, a crushing motor is fixed in the middle of the upper end of the processing box, a crushing shaft is set at the output end of the crushing motor, movable crushing knives are arranged symmetrically on both sides of the crushing shaft, and several fixed crushing knives are arranged in an array inside the processing box. The knives, the fixed pulverizing knives and the movable pulverizing knives are distributed at cross intervals. The structure of the invention is simple and reasonable, the shock absorption effect is good, and it is easy to carry. The size of the soil particles when mixed with the remediation fluid helps to ensure the remediation effect of the soil, and the unqualified soil will enter the collection box, and then be sent back by the lifting cylinder, so as to realize the circular crushing of the soil, which has strong practicability.

Owner:卢杰

Entirety quick manufacture method of hot isostatic pressing metal wrapps

InactiveCN101391302ARelief of restrictions that make it difficult to make complex envelopesHot isostatic pressing process goes smoothlyAdditive manufacturing apparatusIncreasing energy efficiencyVacuum pumpingData information

The invention discloses an integral rapid manufacturing method of a hot isostatic pressing metal sheath, comprising the steps: (1) a CAD three-dimensional model of the metal sheath is designed by adopting three-dimensional molding software, and is then processed by slicing software and saved as an STL file, and the data information of the STL file is transmitted to an SLM rapid forming machine; (2) a forming chamber is vacuumized; (3) a metal powder layer is spread on a work platform flatly; (4) a semiconductor pumping YAG laser or a fiber laser is adopted to scan the metal powder positioned at the boundary of the slice layer, and the powder material at the boundary is melted; and (5) the step (3) and the step (4) are repeated until the compact sheath is manufactured. Powder inlet holes can be reserved on the sheath when designing the three-dimensional model of the sheath, so as to facilitate the subsequent processes such as powder filling, compaction by vibration, vacuum pumping and encapsulation. The sheath is compact and has a controllable shape, and can form parts with any complex shapes and structures, and can realize the high utilization rate of material.

Owner:HUAZHONG UNIV OF SCI & TECH

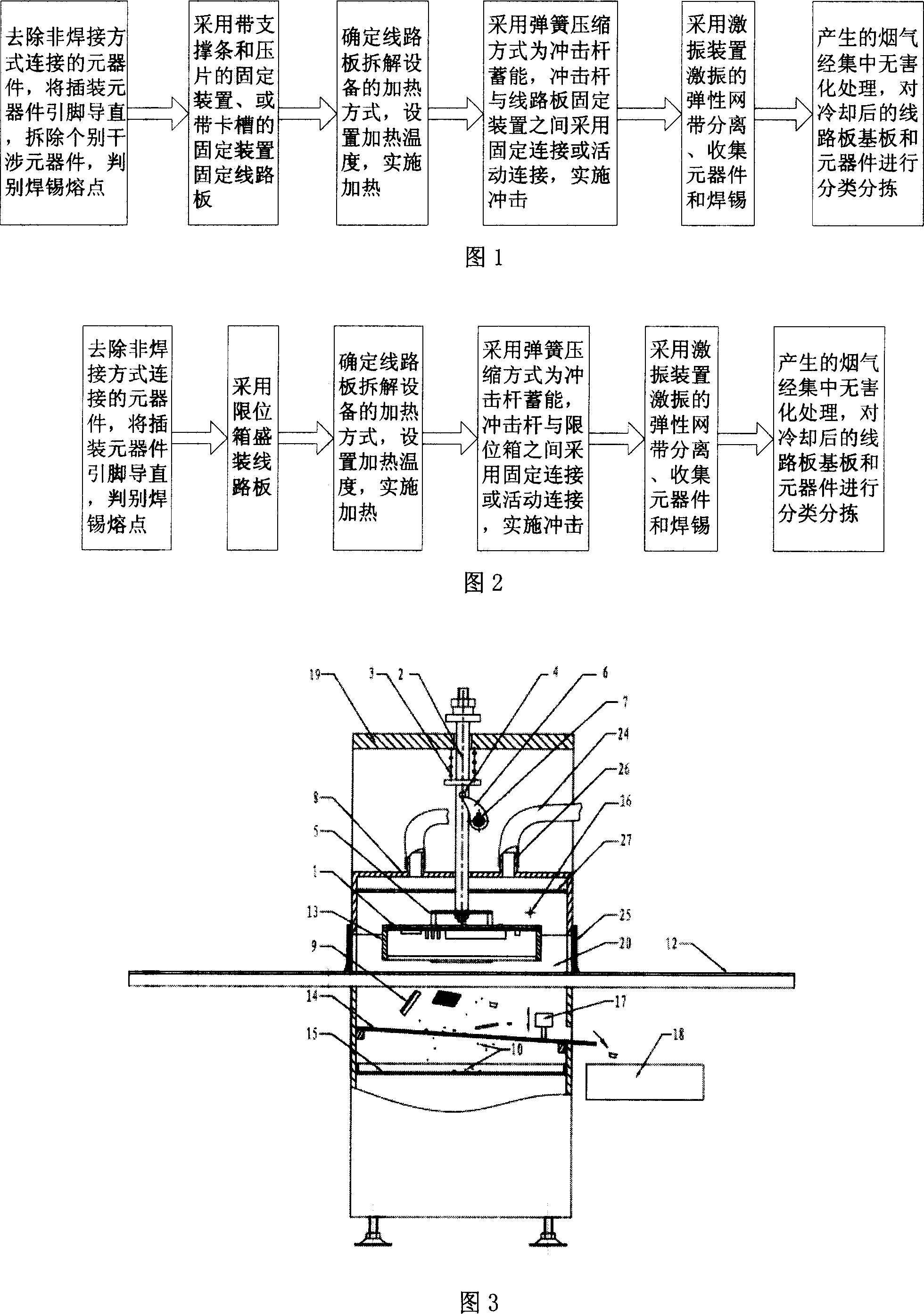

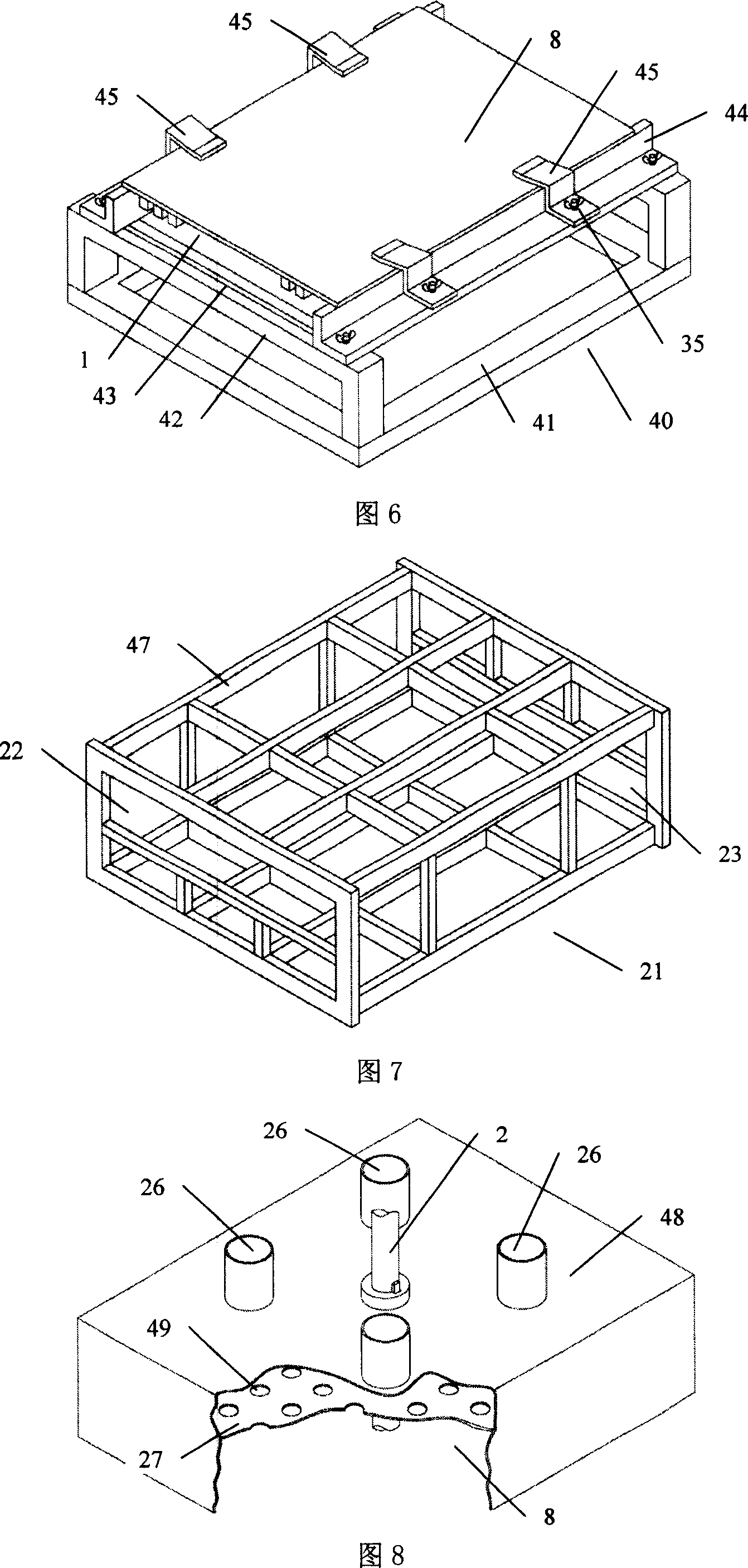

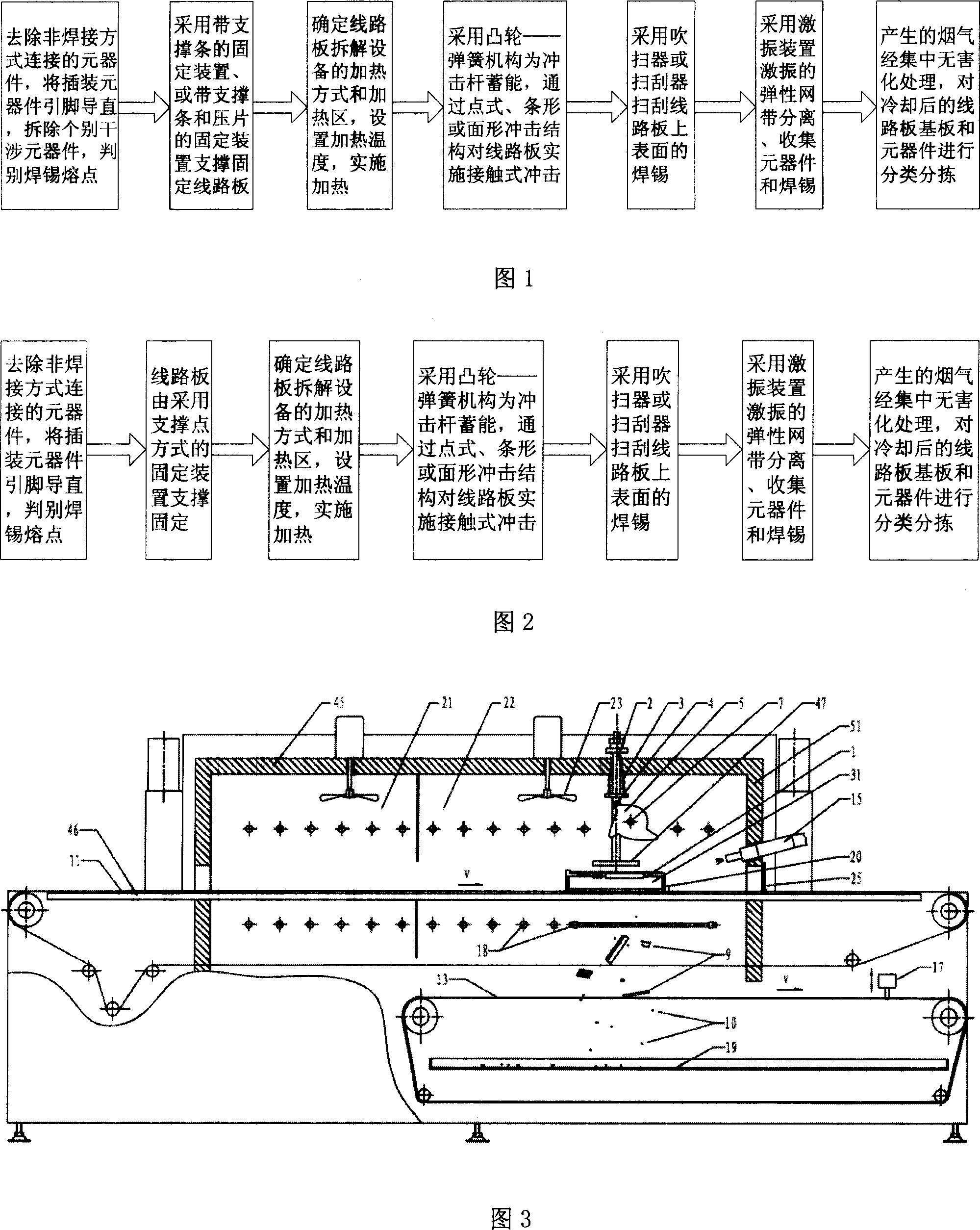

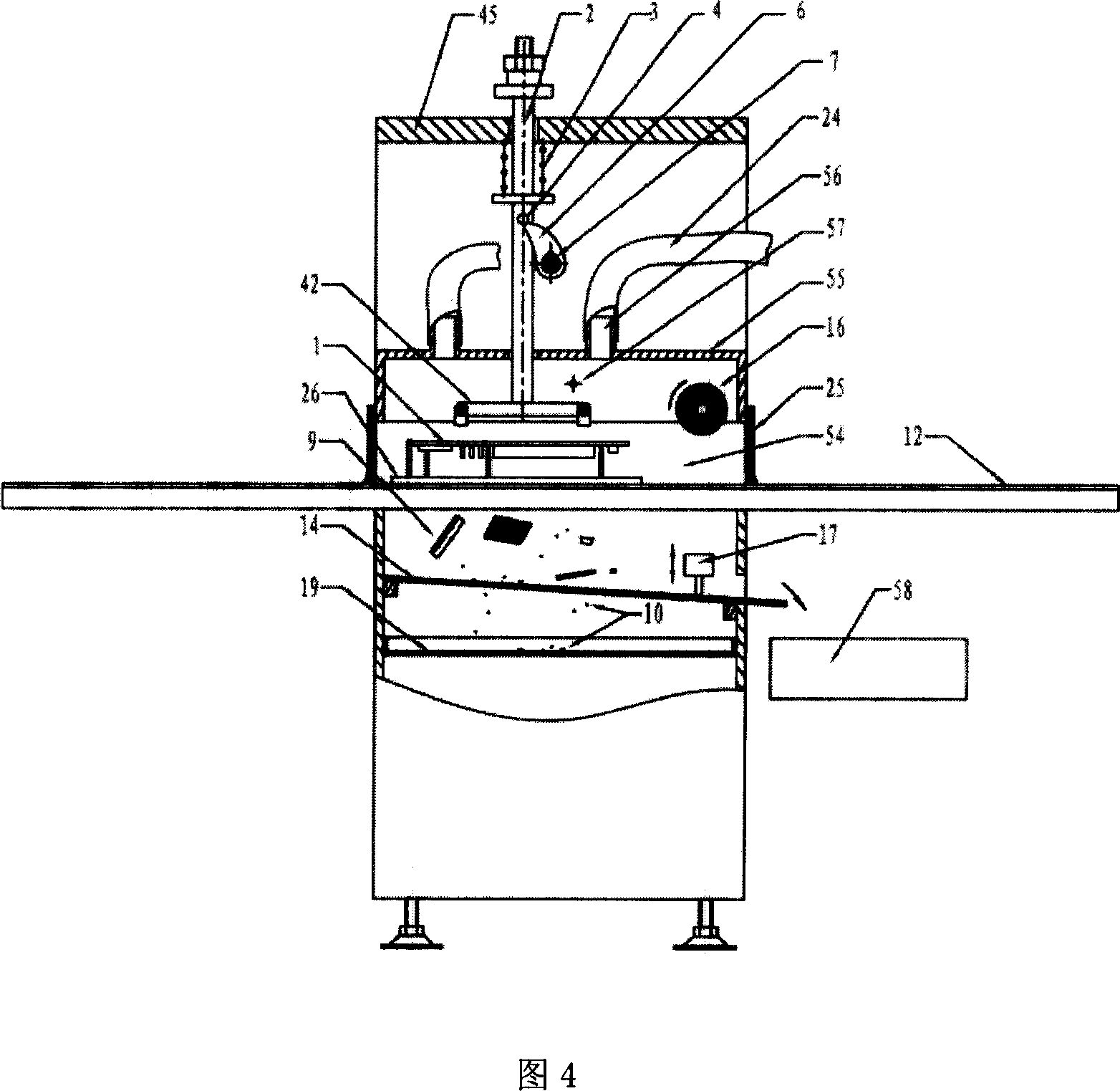

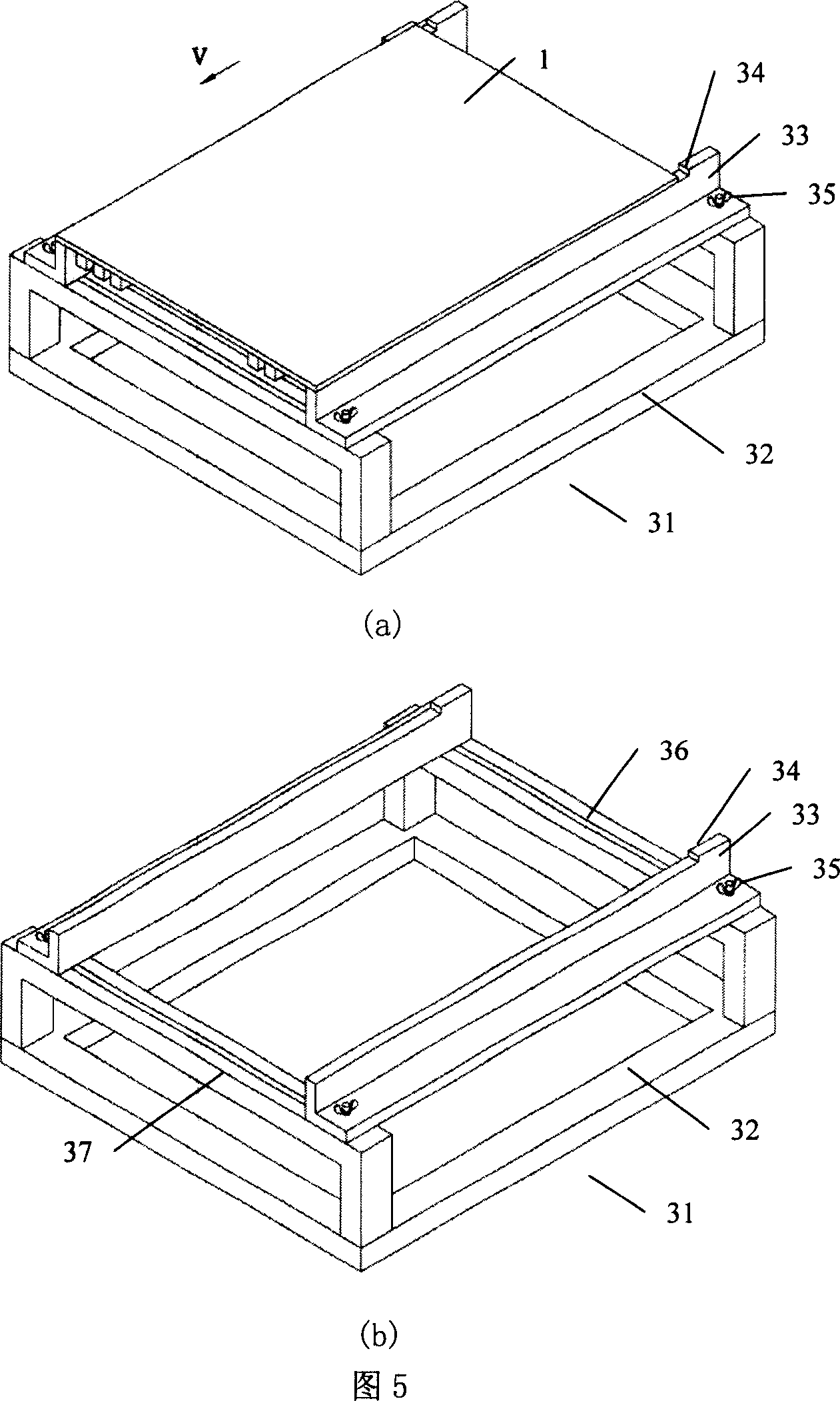

Method and equipment for disassembling components entirely from waste circuit board

InactiveCN101014229AImprove efficiencyGuaranteed functionSoldering apparatusPrinted circuit manufactureWaste productPrinted circuit board

The invention relates to one method and device to disable elements from old circuit board, which comprises the following steps: fixing circuit board or using limit box container circuit board; heating; fixing or connecting impact lever and circuit board fix device for impact; using oscillation device spring network band isolation, collection part and welding; after cooling to sort the circuit base board and element. The device comprises impact lever, compression spring, circuit board fix device, protruding wheel, guide rail, spring net band, and hot wind entrance hole.

Owner:TSINGHUA UNIV

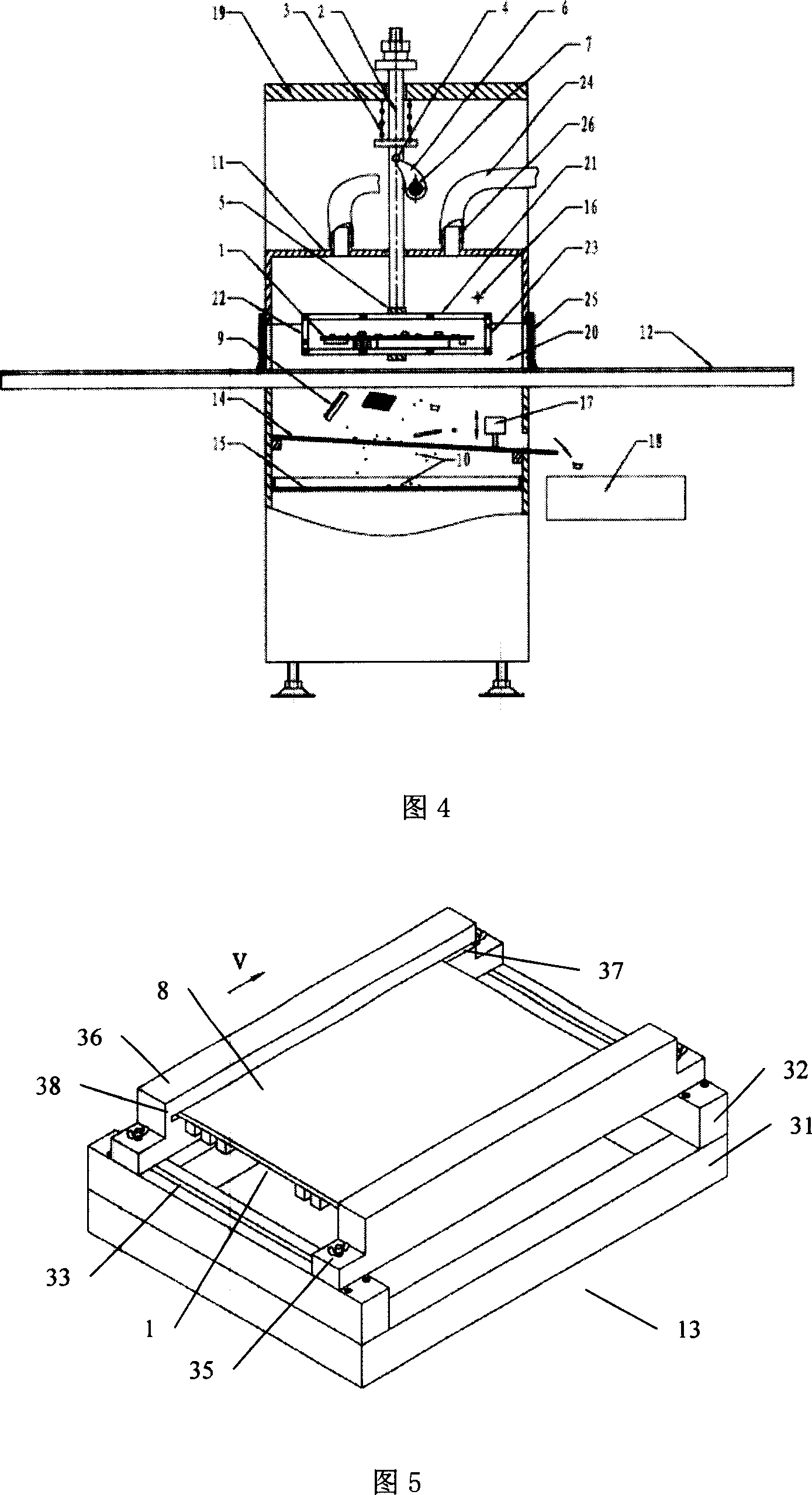

Method and equipment for disassembling circuit board using contacted impact

InactiveCN101014227AImprove efficiencyGuaranteed functionSoldering apparatusPrinted circuit manufacturePre treatmentImpact structure

The invention relates to one method and device to process disable by contact impact on circuit board, which comprises the following steps: fixing circuit board; heating on circuit board; adopting impact structure on circuit board for contact impact; adopting blower and collecting element parts and welding; after cooling processing the sort of circuit board and elements. The device comprises impact lever, compression spring, circuit board fix device, protruding wheel, guide rail, spring net band, and hot wind entrance hole.

Owner:TSINGHUA UNIV

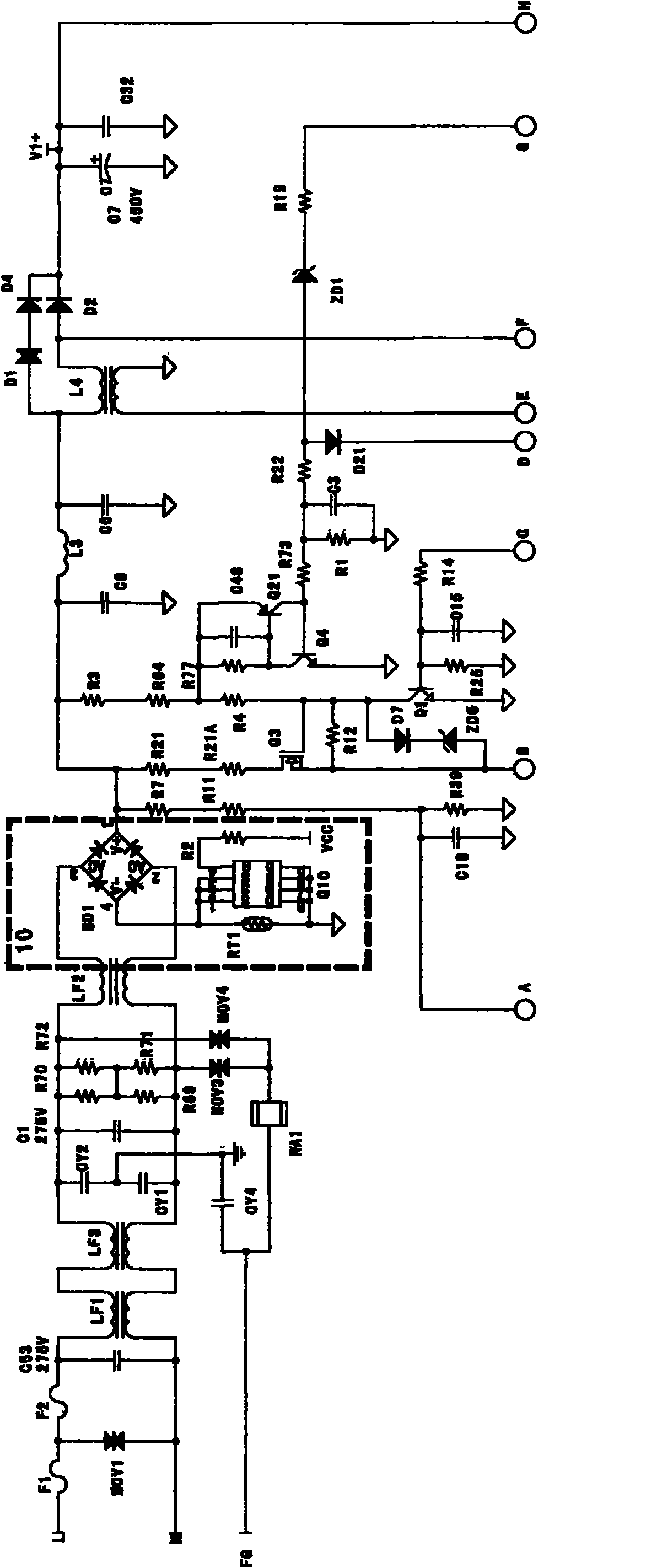

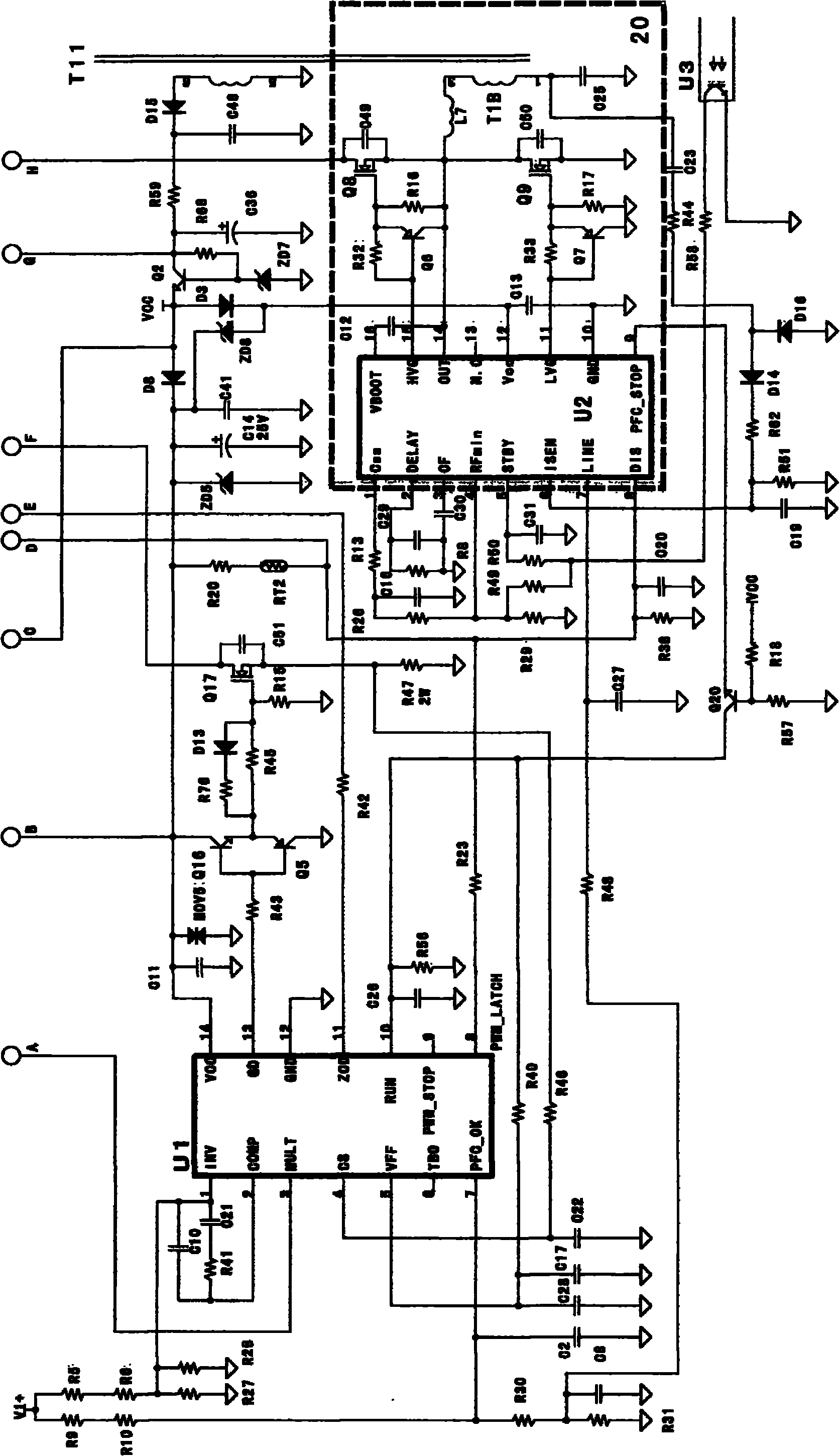

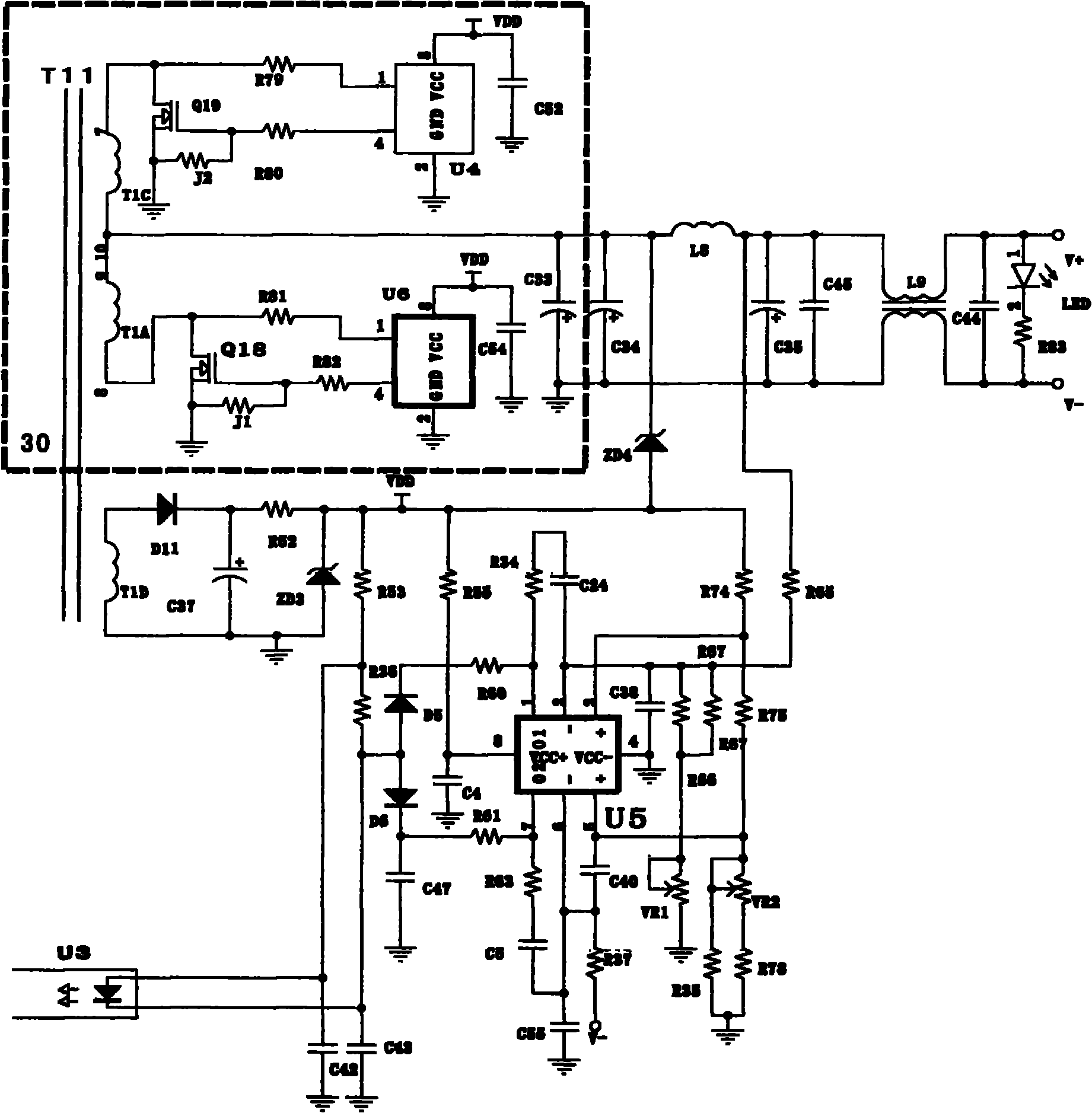

Large-power intelligent dimming multiple-output power supply for suppressing electric surge with field-effect transistor

ActiveCN101917804AGuaranteed sizeImprove efficiencyElectric light circuit arrangementEnergy saving control techniquesInfraredResonance

The invention provides a large-power intelligent dimming multiple-output power supply for suppressing electric surge with a field-effect transistor. The power supply comprises an electric surge suppression unit, an LLC (Inductor-Inductor-Capacitor) resonance conversion unit, a synchronous rectification unit and more than one constant-current-output intelligent dimming unit, wherein a power resistor in the electric surge suppression unit is connected in parallel with the source electrode and the drain electrode of a field-effect transistor, and the loss of an electric surge suppression circuit is very low due to the extremely small on-resistance of the field-effect transistor so that the whole efficiency of the power supply is improved. The invention acquires the output efficiency up to 95 percent by the optimization design of parameters of an LLC resonance network, the constant-current-output intelligent dimming unit circuit of the invention increases the mean value of the output current by increasing the duty cycle of an output current when sensing infrared rays of a human body; and otherwise, the constant-current-output intelligent dimming unit circuit decreases the duty cycle of the output current but not decreases the peak value while no body passes by so as to ensure LED luminous power and prevent light from scattering over the ground.

Owner:DONGGUAN SHILONG FUHUA ELECTRONICS

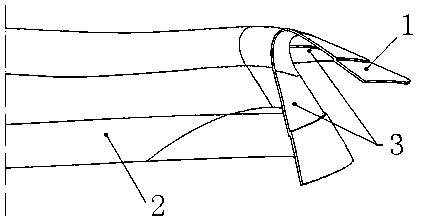

Manufacturing process for high-curvature full-profile thin-wall part

ActiveCN103639655ASolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalNatural aging

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

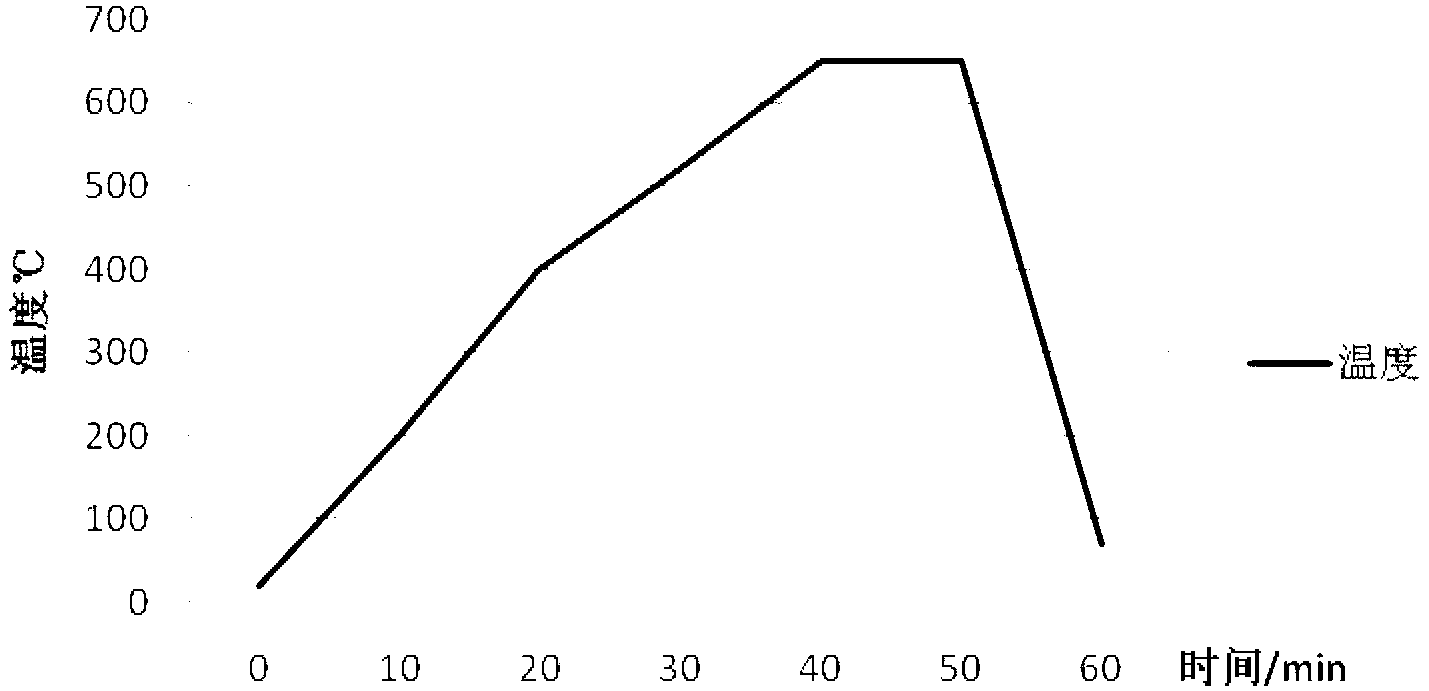

Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

InactiveCN103009270ALow shrinkageHigh strengthAbrasion apparatusGrinding devicesPolyvinyl alcoholDecomposition

The invention provides an online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and a preparation method thereof and belongs to the technical field of precision grinding pellets. Raw materials of the precision grinding pellet comprise a super-hard abrasive and a metallic bond, wherein the super-hard abrasive is diamond micro-powder; the diamond concentration falls within a range of 75-100 %; and the metallic bond uses a multicomponent alloy bond whose main components are copper powder, tin powder, aluminum powder, copper-clad ball shaped graphite powder, silicon dioxide and ferroferric oxide powder. The preparation method comprises the following steps: uniformly mixing and stirring the diamond micro-powder as well as the copper powder, the tin powder and the aluminum powder; adding polyvinyl alcohol to a mixture and mixing the polyvinyl alcohol and the mixture; adding the silicon dioxide, the copper-clad ball shaped graphite powder and the ferroferric oxide powder to an obtained mixture and mixing these materials and the obtained mixture; filling the mixture into a graphite mold; maintaining the pressure of the graphite mold for 5-10 minutes after pressurizing the graphite mold to 100-250 MPa; and carrying out hot pressing sintering on the graphite mold in a sintering furnace, wherein the sintering atmosphere is ammonia decomposition gas. Through the adoption of the online self-sharpening metallic bond and super-hard abrasive precision grinding pellet provided by the invention, online automatic sharpening can be achieved without blockage and offline repairing.

Owner:BEIJING UNIV OF TECH

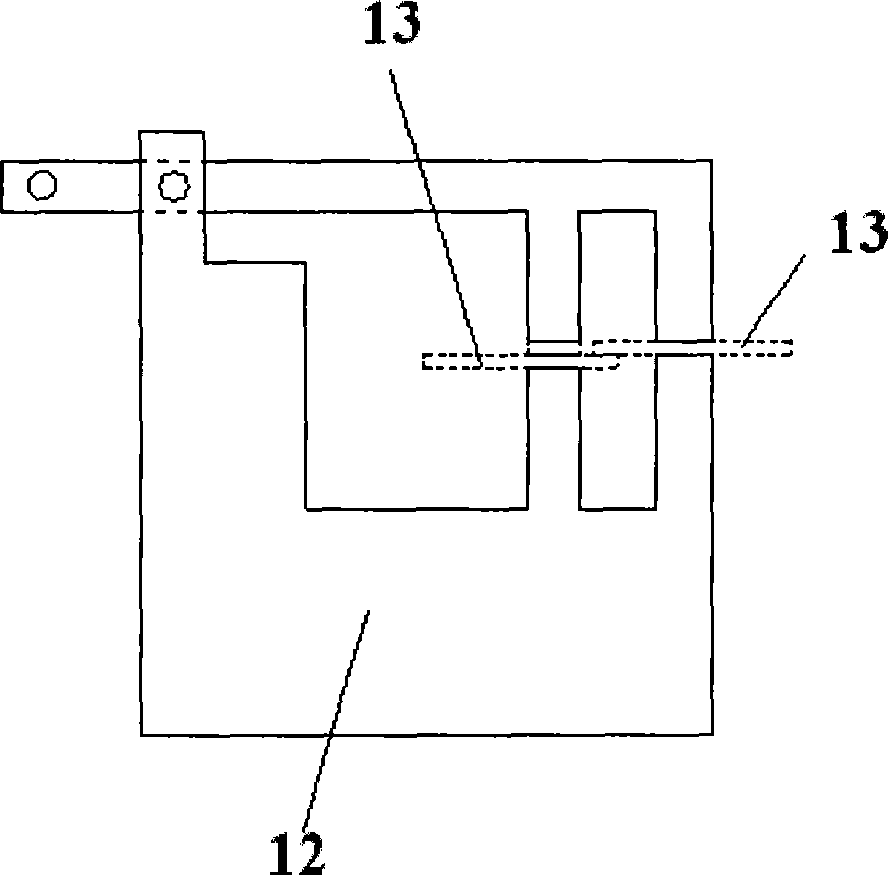

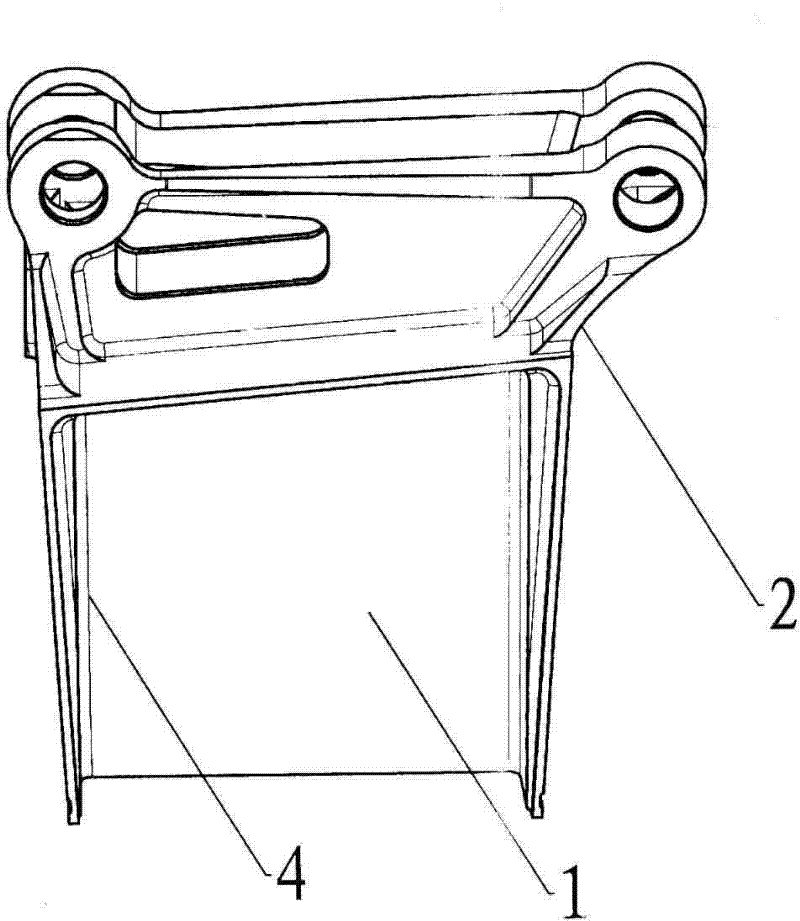

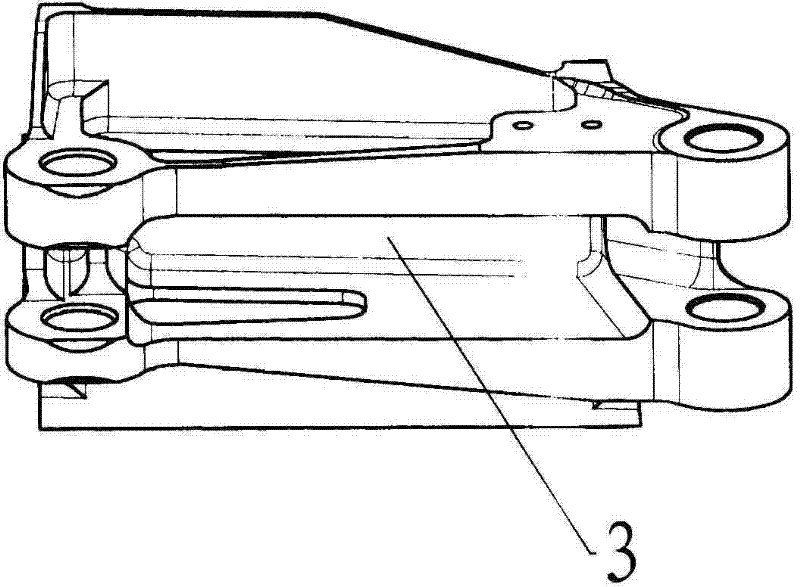

Cartridge receiver welding method and clamp applied to same

ActiveCN104162759AGuaranteed sizeGuaranteed contourWelding/cutting auxillary devicesArc welding apparatusPunchingButt joint

The invention provides a cartridge receiver welding method. The cartridge receiver welding method includes the following steps that during installation, it is guaranteed that an upper installation side and a lower installation side are higher than the wall of a cartridge receiver by 0-0.2 mm; manual argon arc welding positioning welding is conducted, and weld joint rolling and profile correction are conducted by a bench worker; through automatic argon arc welding and weld joint rolling and profile correction which are conducted by the bench worker, punching is conducted at the positions, to be welded and corresponding to twelve bosses, of the wall of the cartridge receiver through laser cutting; manual argon arc welding positioning welding is conducted on the twelve bosses, weld joints are leveled by the bench worker, and it is guaranteed that the bosses at the butt joint positions are higher than the wall of the cartridge receiver by 0-0.2 mm; manual argon arc welding is conducted on the twelve bosses; weld joints are leveled by the bench worker, the profile tolerance of a part is corrected, and it is guaranteed that gaps between the part and a model is not larger than 0.5 mm; welding of the cartridge receiver is completed. According to the cartridge receiver welding method, welding deformation can be well controlled, and therefore it is guaranteed that the size and the profile tolerance of the finished cartridge receiver meet requirements. The invention further provides a special clamp applied to the welding method.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

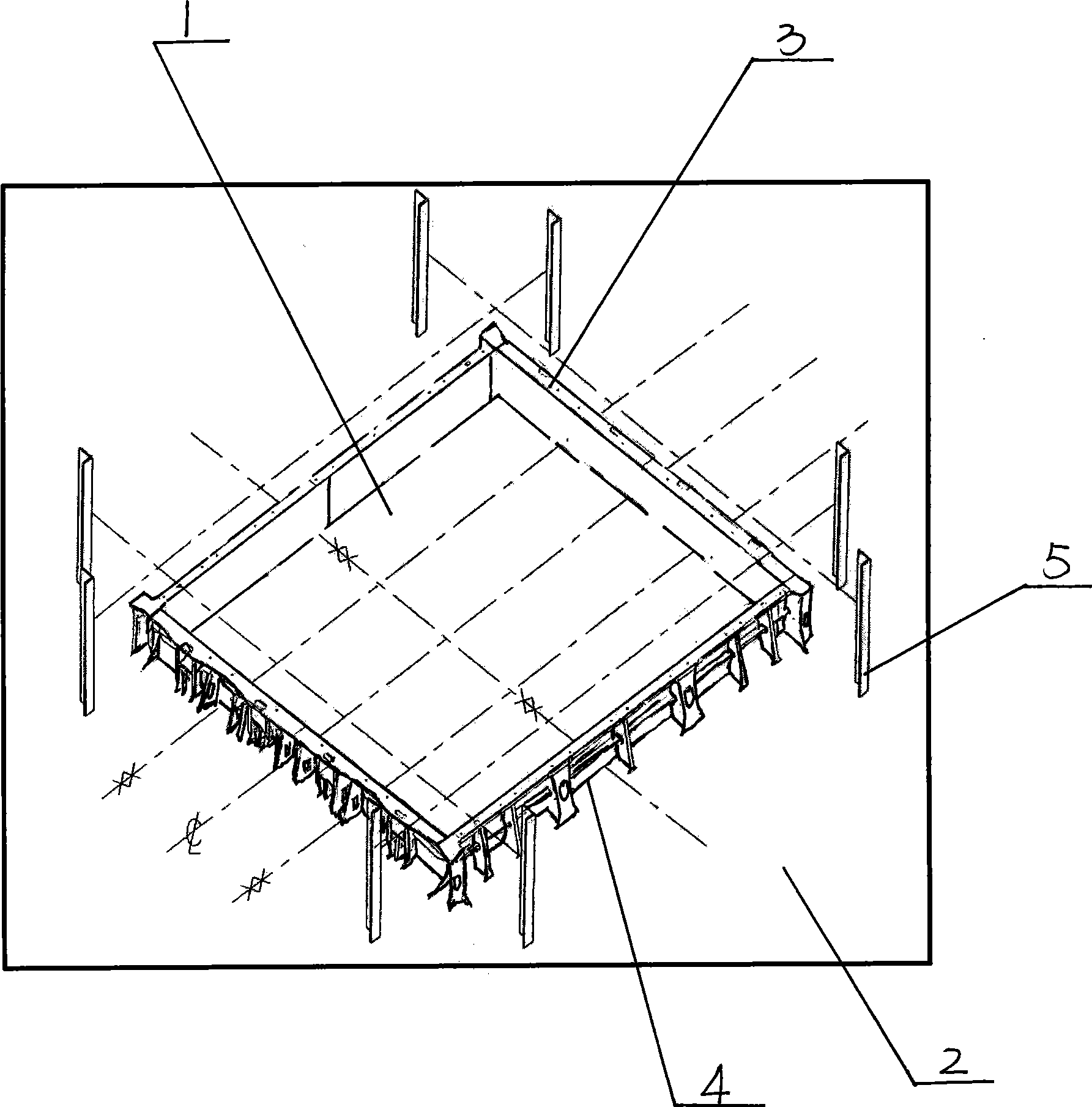

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

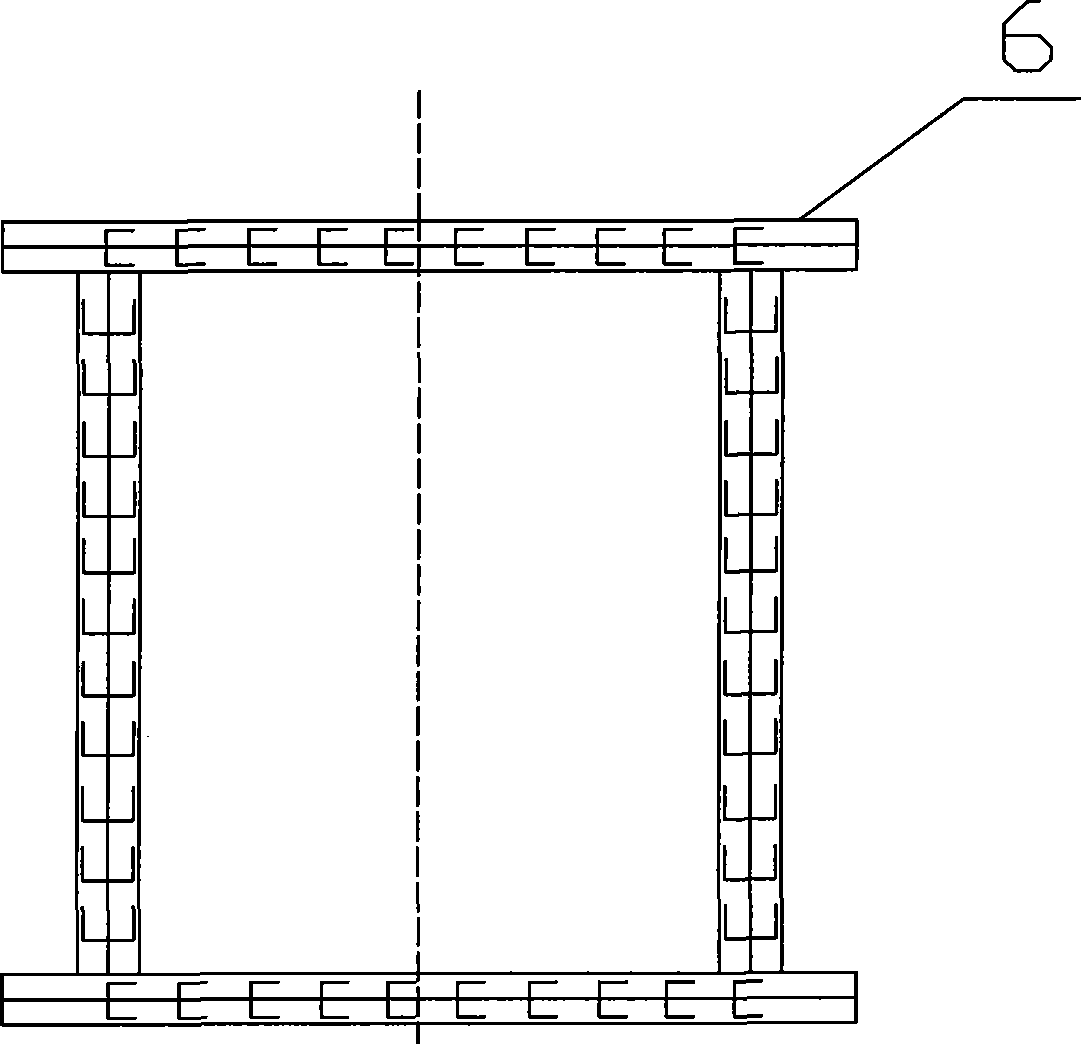

Abnormal shape box column and processing craft thereof

InactiveCN106884498ASimple structureGuaranteed sizeStrutsWelding apparatusEngineeringAbnormal shapes

The invention discloses an abnormal shape box column. The abnormal shape box column comprises a panel, partition plates, web plates and an upper flange plate, the partition plates are arranged on the panel, the web plates are arranged on the two sides of the partition plates and are fixedly connected with the panel, the upper flange plate is arranged at the upper parts of the two web plates, technical partition plates are arranged at the two ends of the panel, and the partition plates and the web plates are matched with the upper flange plate. According to the abnormal shape box column, the web plates are arranged on the panel to form a box body, the parathion plates are arranged in the box body, the upper flange plate is arranged at the upper part of the box body, and the technical partition plates are arranged at the two ends of the box body, so that the structure of the box column is improved, moreover, the size of the end part of the box body is effectively guaranteed, the processing of a large connector is facilitated on site, the supporting performance and the stability are also greatly improved, and the construction requirement is further better met.

Owner:JIANGSU HUNING STEEL MECHANISM

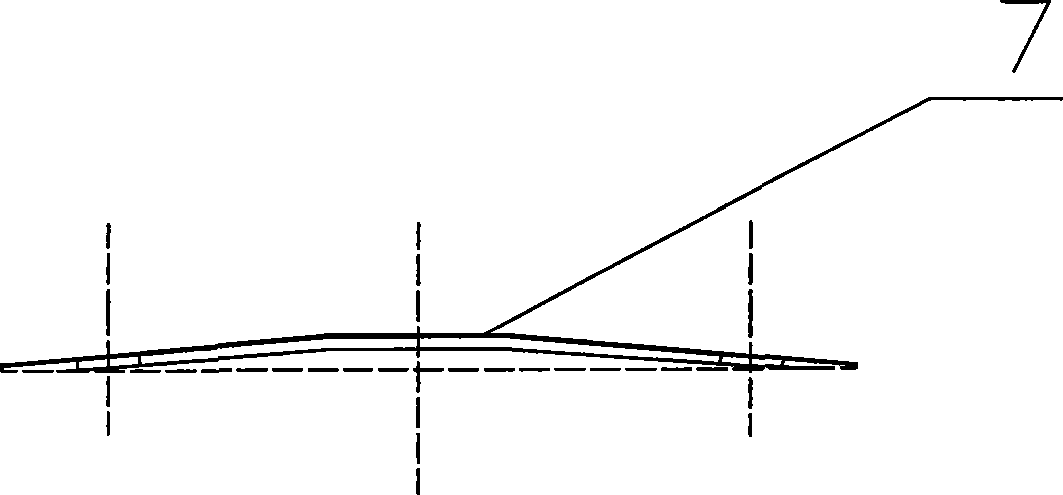

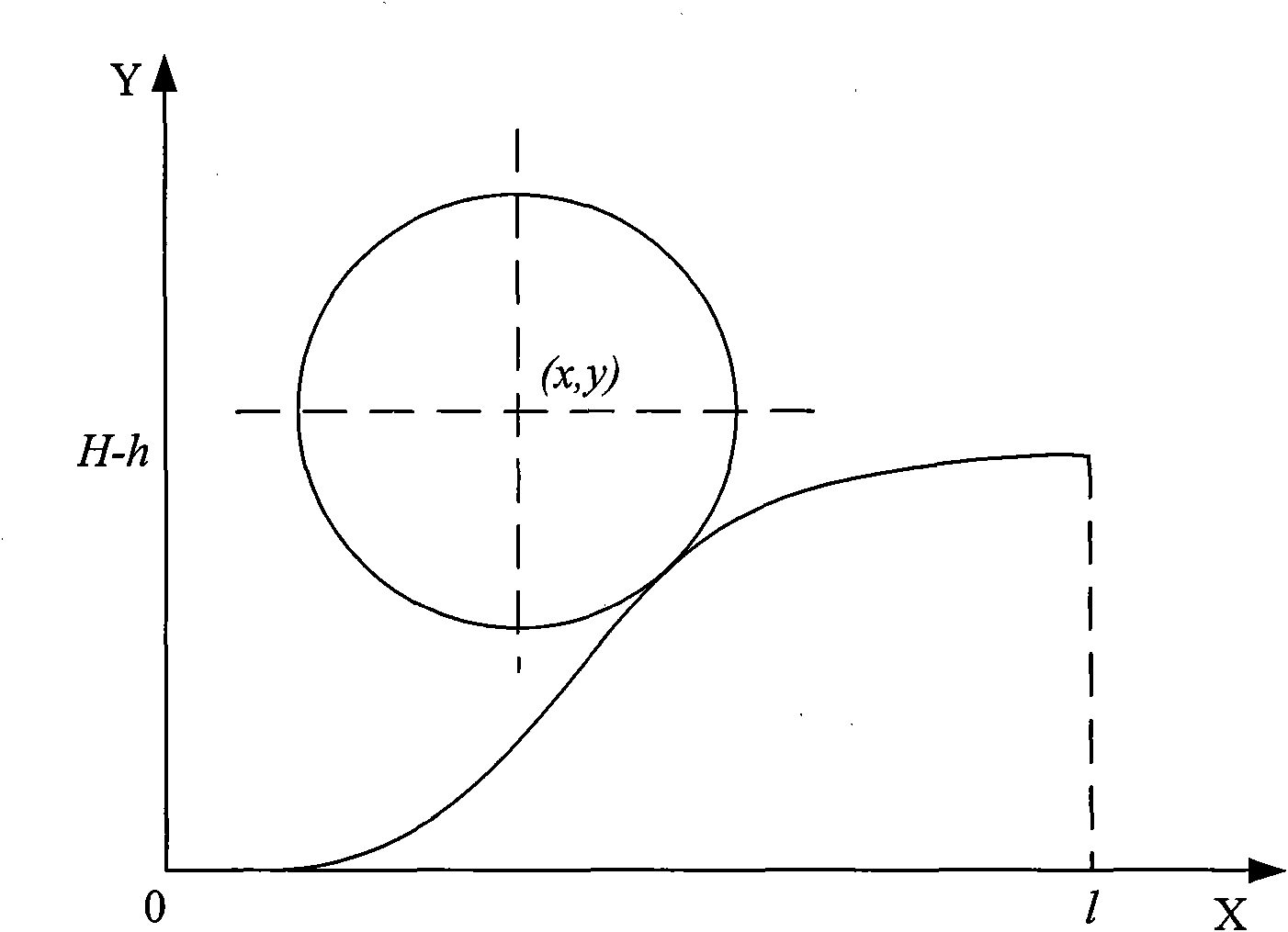

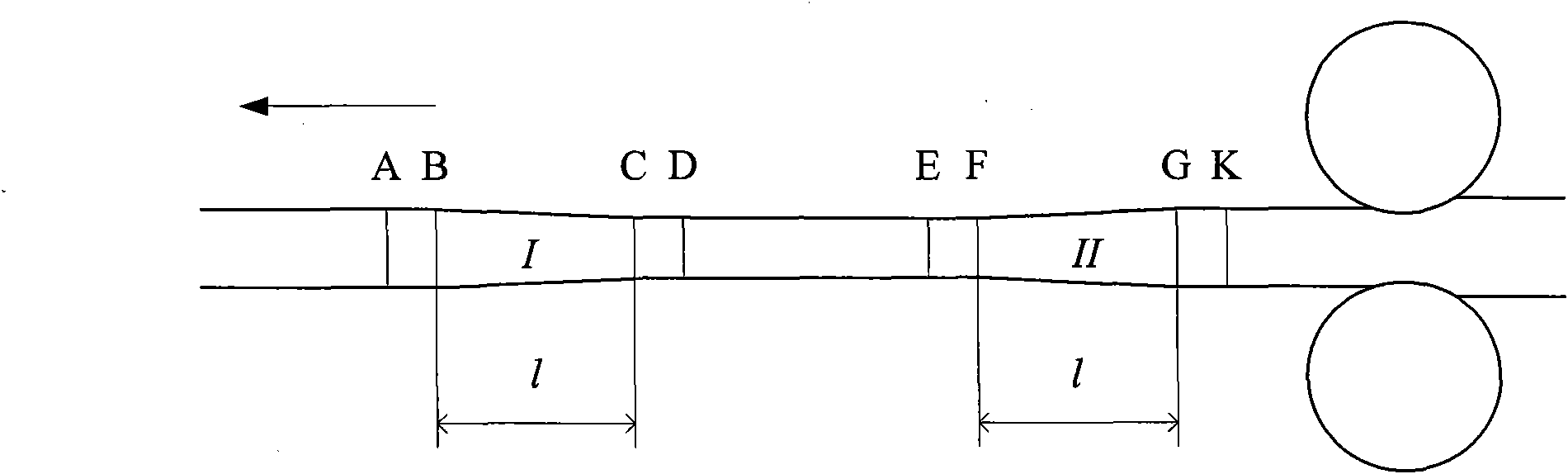

Control method for periodic variable-thickness strip rolling speed

ActiveCN101890434AGuaranteed shapeGuaranteed sizeMetal rolling arrangementsRoll speed control deviceVariable thicknessControl theory

The invention discloses a control method for a periodic variable-thickness strip rolling speed, and belongs to the technical field of rolling. The control method comprises horizontal rolling speed control and the vertical rolling speed control of a roller, wherein the horizontal rolling speed control is performed in a way that: a thick region of a strip is rolled at a thick region rolling speed; the rolling speed starts to decrease at a near point A of a transition region and decreases to VB at a starting point B of the transition region; at the transition region, the horizontal rolling speed at the transition region is calculated according to a transition region curvilinear equation and a second flow equivalence principle; and the rolling speed starts to increase after an end point C of the transition region and increases to a thin region rolling speed at a far point D of the transition point to start to roll a thin region; the vertical rolling speed control of the roller is performed in the way that: the vertical rolling speed of the roller is 0 when the thick region of the strip is rolled; after the thick region is rolled and a rolled piece reaches the starting point B of the transition region, the roller starts downward pressing, and the vertical rolling speed of the transition region is Vdy(x); the Vdy(x) starts to decrease after reaching a maximum point Q1 and decreases to 0 at the end point C of the transition region; and the steps are repeated periodically.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

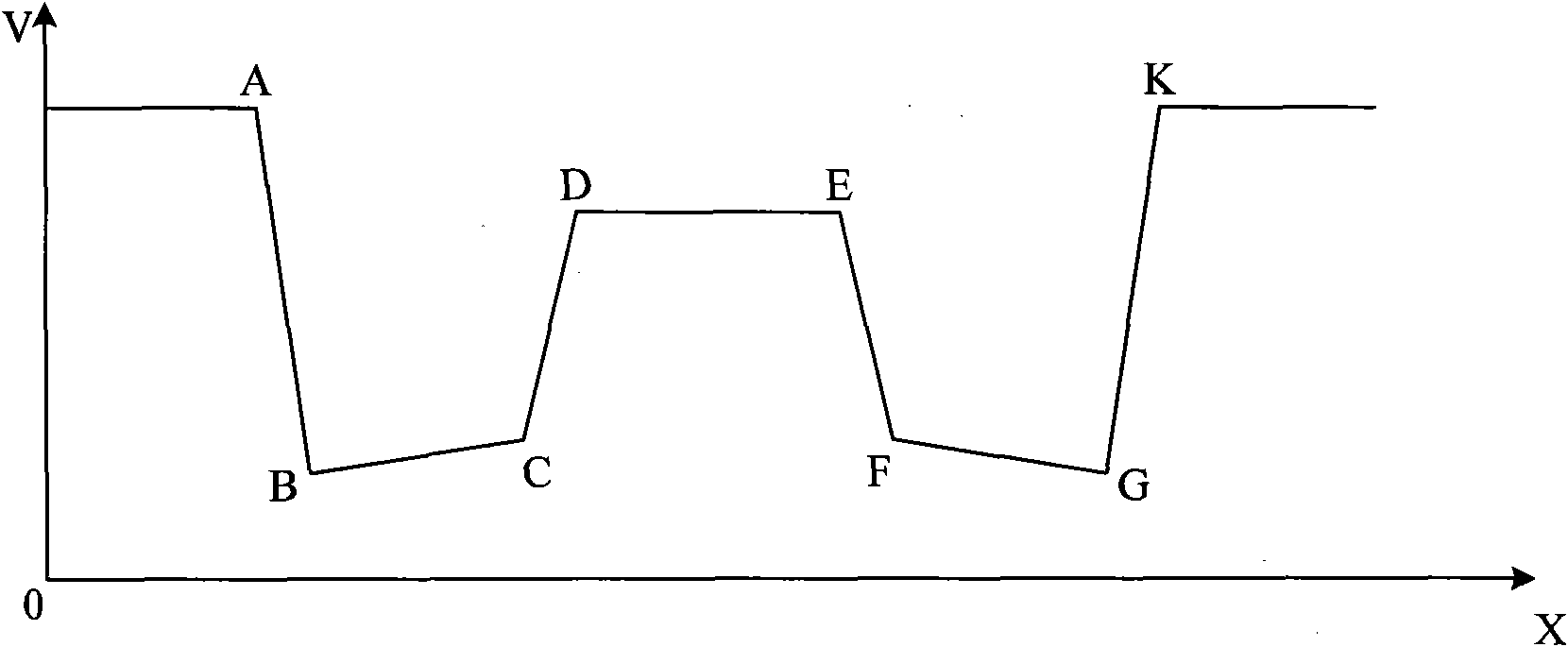

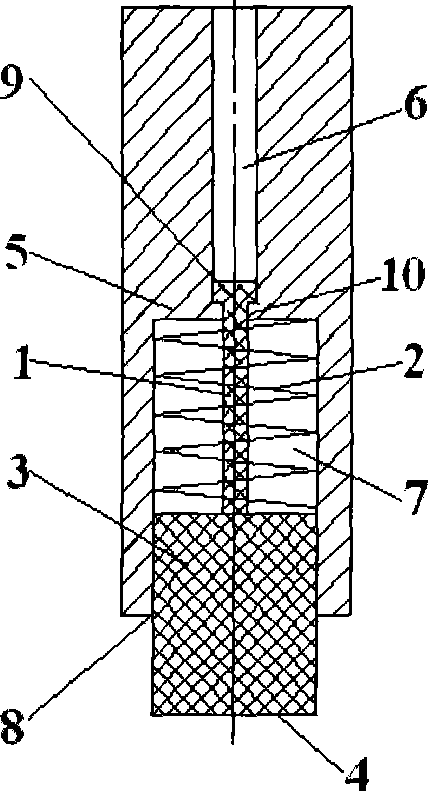

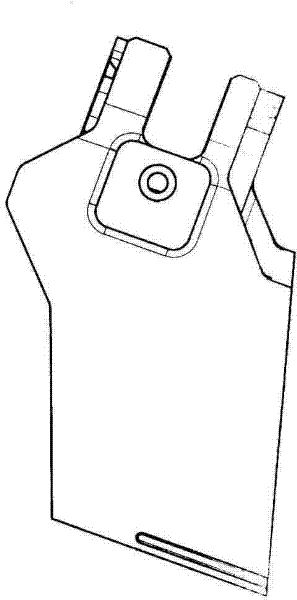

Clamping structure for fastening motion self-compensation

InactiveCN101367171AGuaranteed sizeEliminate misalignmentWelding/cutting auxillary devicesAuxillary welding devicesSelf compensationEngineering

The invention discloses a clamp structure for clamping and autocompensation; a clamping block (3) is arranged on a clamp; the surface of the clamping block (3) for clamping a workpiece is a clamping surface (4); and the clamping block (3) is made of an elastic material. With the technical proposal adopted, abrasion occurring in a clamping part and the change of the surface of the clamped workpiece are subjected to compensation by a simple elastic structure so as to ensure that a gripping jaw has enough clamping force in clamping and to guarantee the dimension of the workpiece after various machining processes (such as welding).

Owner:CHERY AUTOMOBILE CO LTD

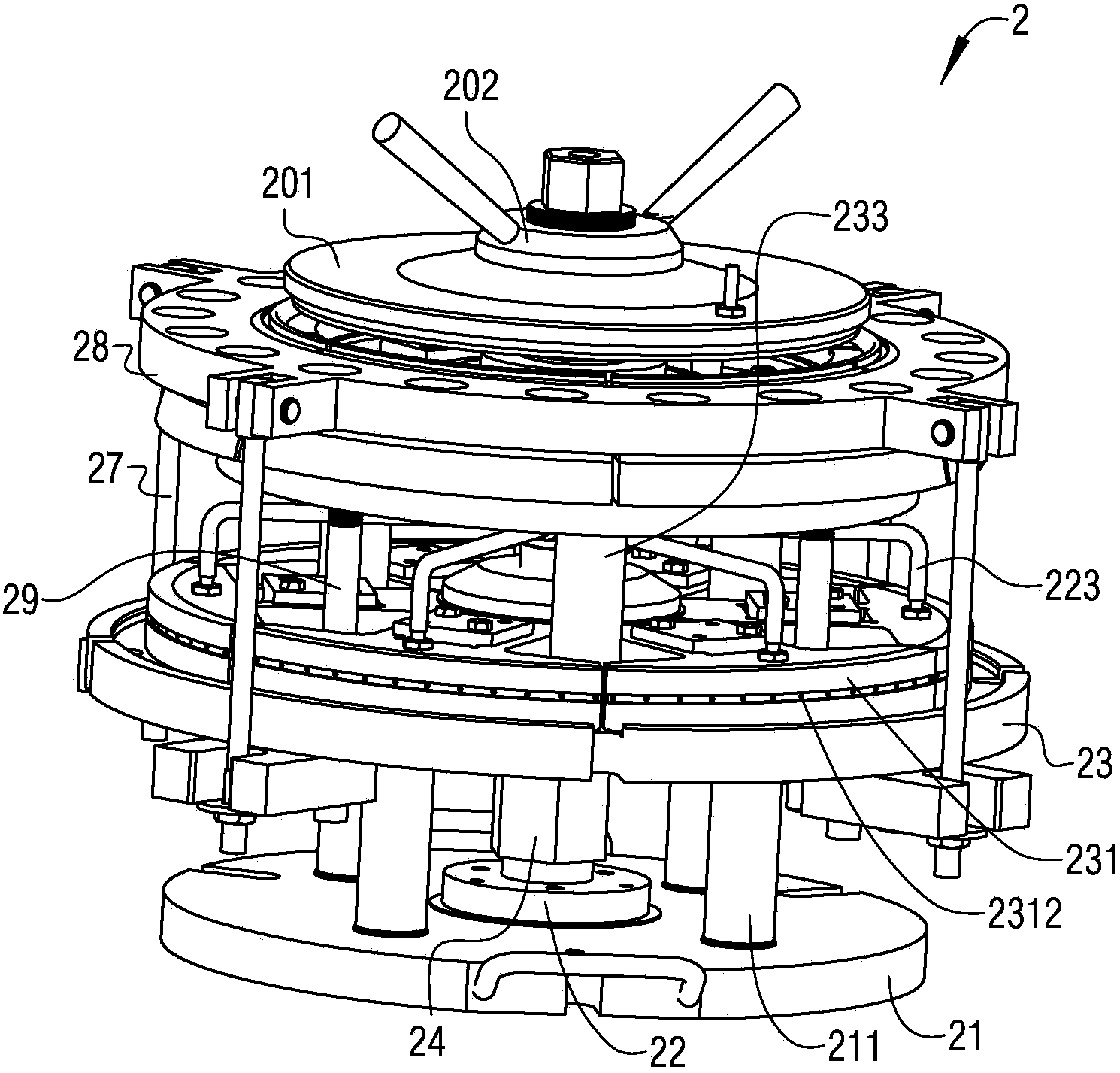

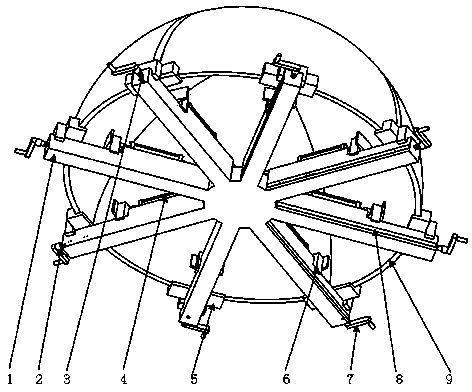

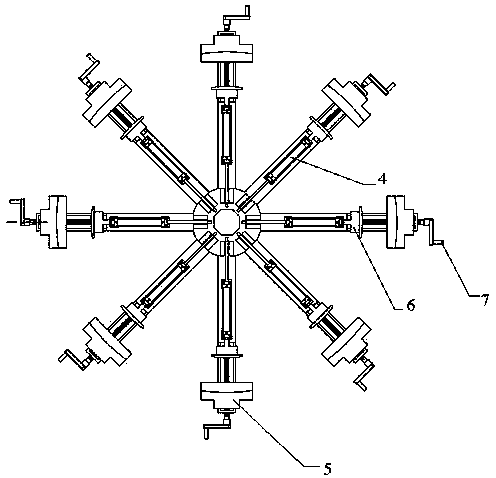

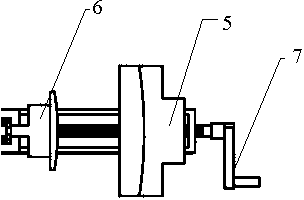

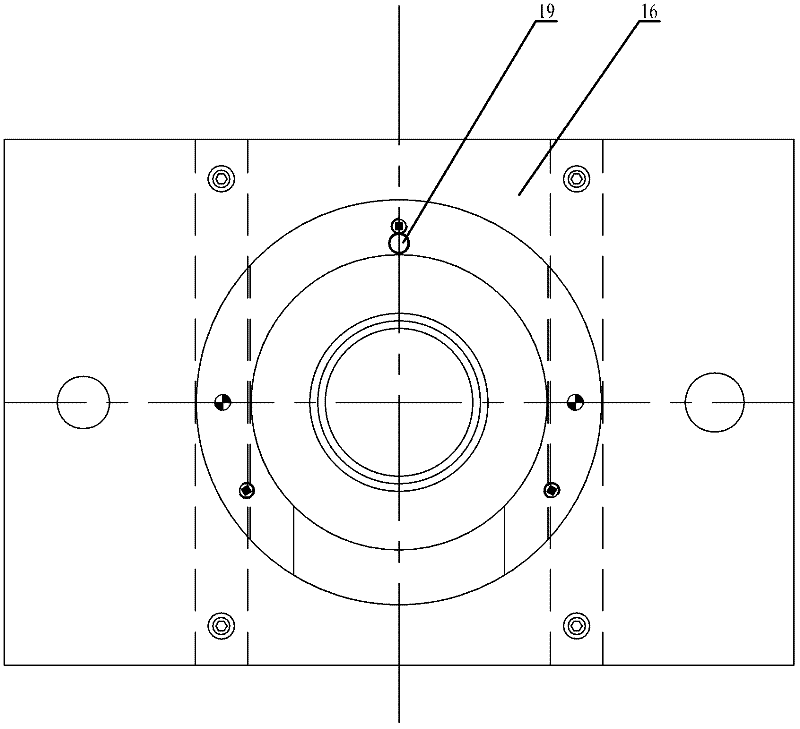

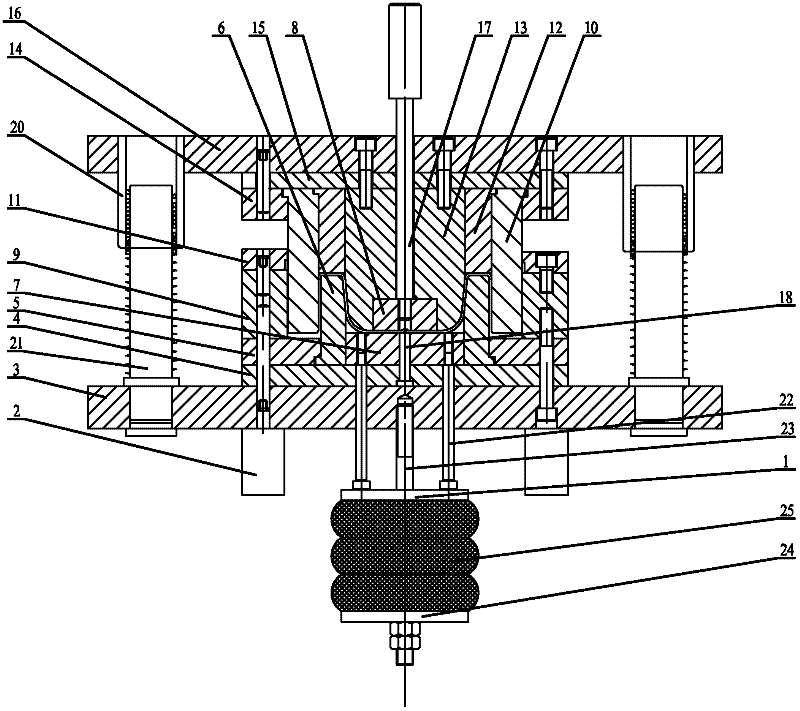

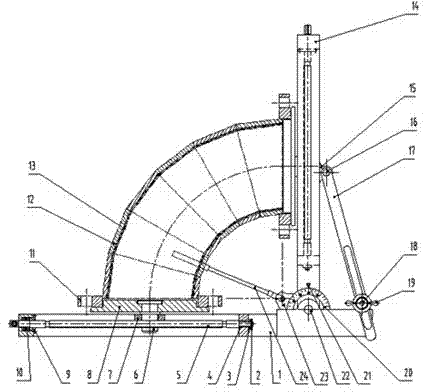

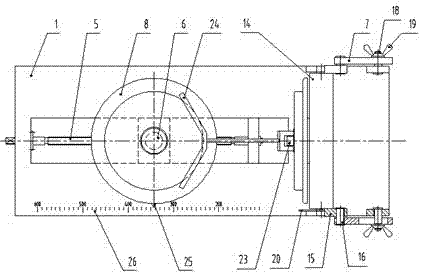

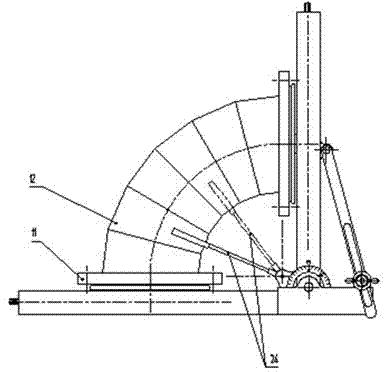

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

Integral sand core, mould for casting coupler knuckle, producing method and coupler knuckle

InactiveCN101402131AGuaranteed No Flying SpursGuaranteed uniformityFoundry mouldsFoundry coresCasting moldKnuckle

The invention discloses an integral core and a mold for casting a coupler knuckle and a coupler knuckle casting method. The disclosed integral core for casting the coupler knuckle is provided with an S surface which is the same as a matching surface of the coupler knuckle, and can be placed into a mold cavity of a coupler knuckle casting mold during the casting, the S surface of the integral core is taken as an S surface of the mold cavity of the casting mold, and the S surface of the integral core for casting the coupler knuckle is a whole, has no parting surfaces, and also has no stripping taper, thereby ensuring that the S surface of a coupler knuckle casting piece has no stripping taper and burrs; the disclosed mold for casting the coupler knuckle is matched with the integral core for casting the coupler knuckle and can cast the coupler knuckle casting piece with the S surface without stripping taper; and the disclosed S surface part of the coupler knuckle comprises two joined cylindrical curve surfaces and has no stripping taper, so as to ensure that the matching surface of the coupler knuckle has evener contact and improves the service performance of the coupler knuckle.

Owner:CRRC QIQIHAR ROLLING CO LTD

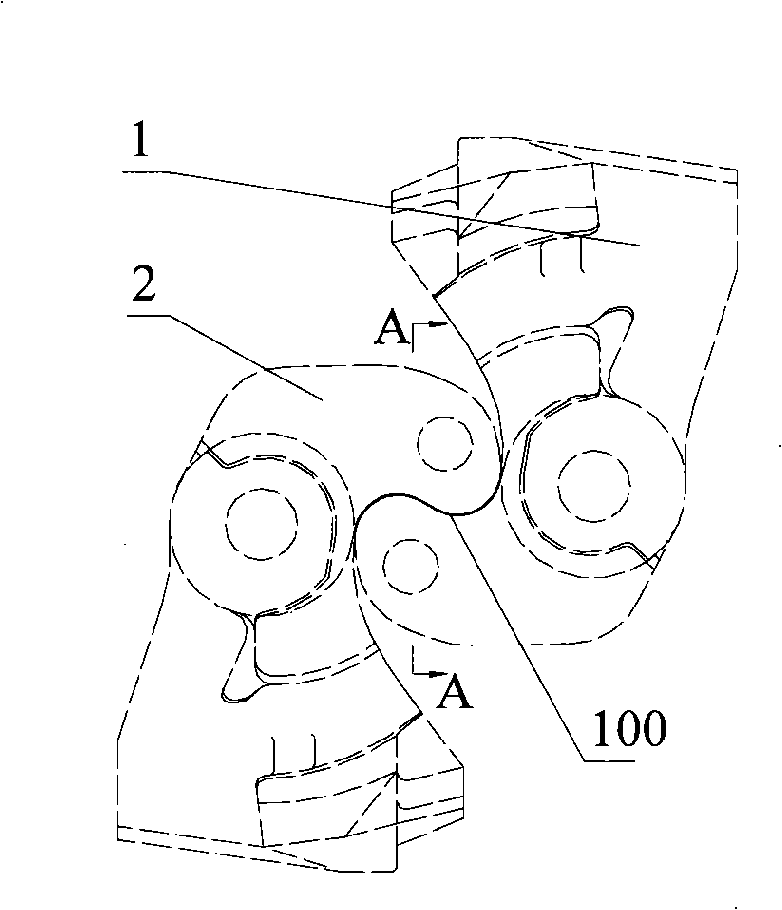

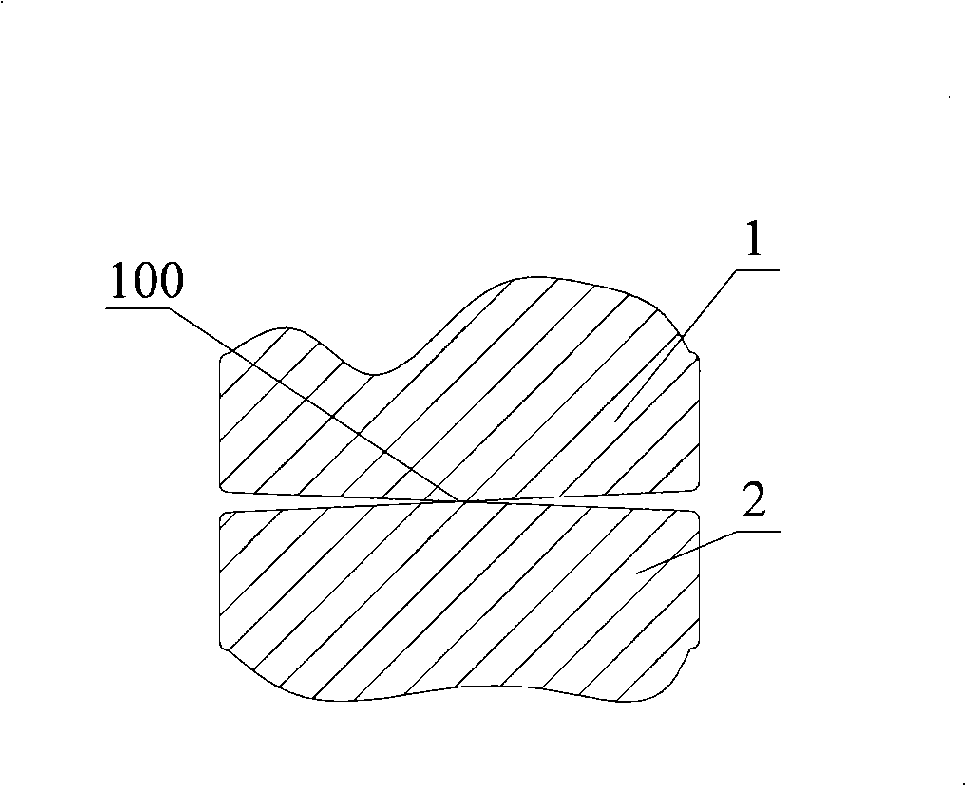

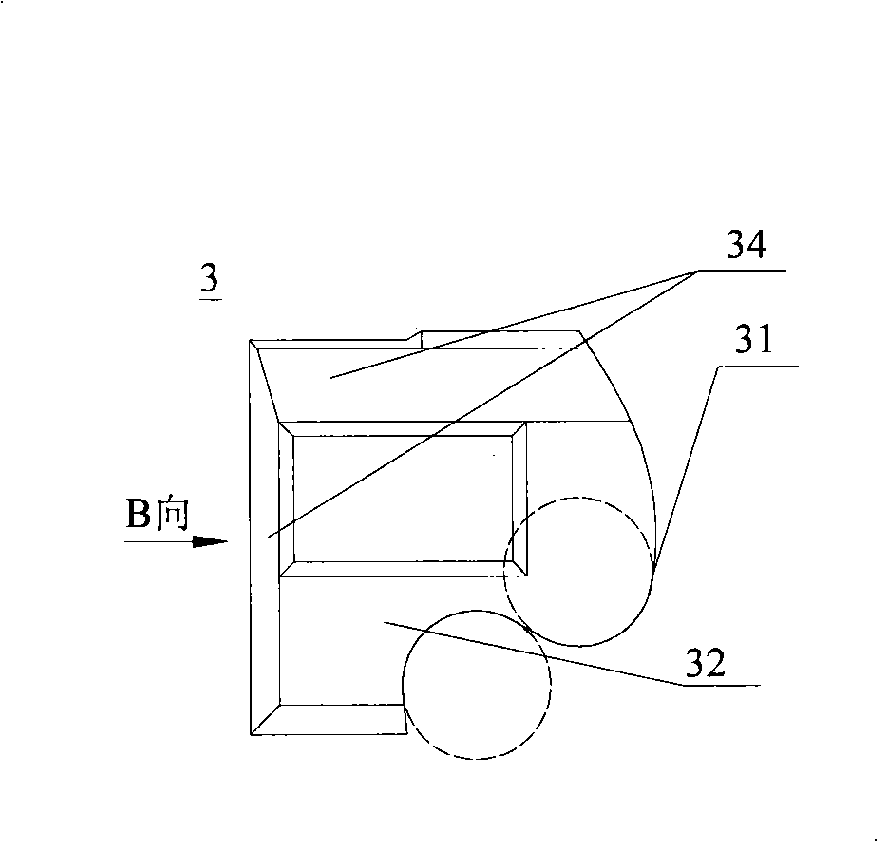

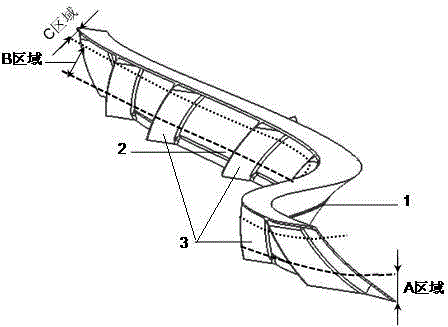

Double-S-shaped double-curve thin-walled part manufacturing process

ActiveCN104526270AImprove clamping stabilityImprove processing rigidityMachining deformationVibration Problem

The invention relates to the technical field of mechanical machining, in particular to a double-S-shaped double-curve thin-walled part manufacturing process. A five-coordinate high-speed mill is adopted to conduct rough machining on an inner curve and an outer curve with ribs and conduct semi-finish machining and finish machining on the inner curve and the outer curve with ribs, and a step cushion block positioning and gypsum filling method is adopted to perform clamping and positioning. The part clamping and positioning problems are solved, and part clamping stability and machining rigidity are improved. Regional segmented and layered machining is adopted for parts, machining deformation of ultra-complicated thin-walled curved surfaces is effectively controlled, the vibration problem in the machining process is avoided, and part size and accuracy are ensured.

Owner:JIANGXI HONGDU AVIATION IND GRP

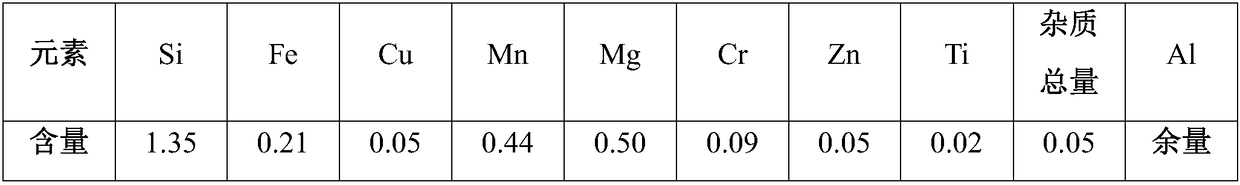

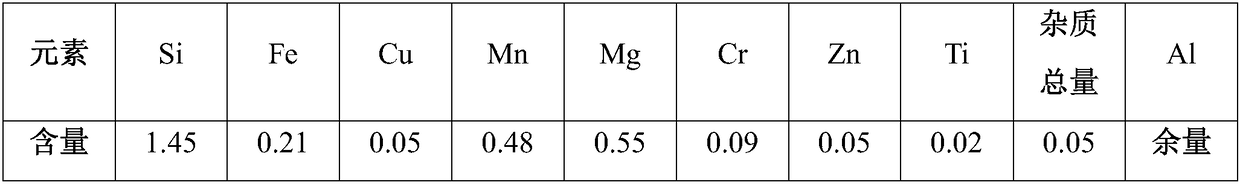

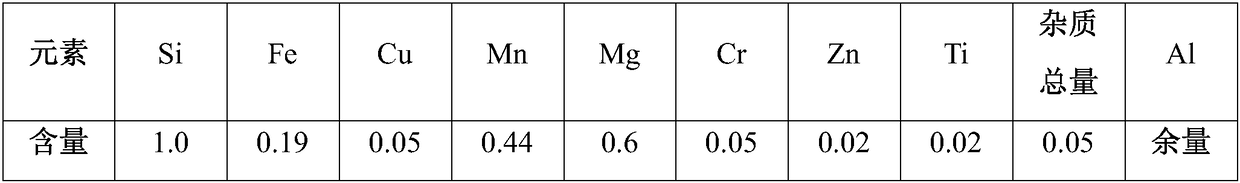

Production process of 6-series aluminum alloy ultra-thin round tube extrusion profile

The invention belongs to the technical field of aluminum alloy production, and relates to a production process of a 6-series aluminum alloy ultra-thin round tube extrusion profile, aluminum alloy rawmaterials comprise 1.35-1.45% of Si, 0.21% of Fe, 0.05 % of Cu, 0.44 to 0.48% of Mn, 0.50 to 0.55% of Mg, 0.09% of Cr, 0.05% of Zn, 0.02% of Ti, <= 0.05% of other single impurities, <=0.15% of total impurities, and balance of Al, an aluminum alloy ingot prepared by the formula is subjected to extrusion, on-line water mist quenching treatment, stretching and straightening, and artificial aging, andthe aging system for the artificial aging is 145+ / -5DEG C *11h, existing quenching method and aging system are changed, the size and the mechanical properties of a finally prepared aluminum alloy ultra-thin round tube can meet the requirements of production preparation, the aluminum alloy tube is thin in wall, and the elongation after fracture is greatly improved.

Owner:CHINA ZHONGWANG

One-piece forming die with multiple functions

The invention relates to a one-piece forming die with multiple functions, in particular to one-piece forming cup die for use in fields of blanking, stretching, raising, lettering, flanging and the like. In the technical scheme, the one-piece forming die with multiple functions comprises an upper die plate and a lower die plate, wherein a guide sleeve is fixed to the edge part of the upper die plate; a stretching male die is fixedly arranged on the middle part of the lower surface of the upper die plate; a punching block is arranged inside the bottom end part of the stretching male die; a flanging female die insert is sleeved outside the stretching male die; a blanking flanging female and male die is sleeved outside the flanging female die insert; an upper fixed plate is sleeved outside the blanking flanging female and male die; a punching rod is arranged in the stretching male die and the upper die plate in a sliding mode; and the bottom end part of the punching rod is connected with the punching block. By the one-piece forming die, products can be formed in one piece, so that the yield and quality of the products can be improved.

Owner:无锡绿缘汽车零部件有限公司

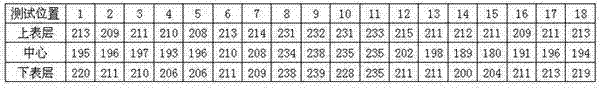

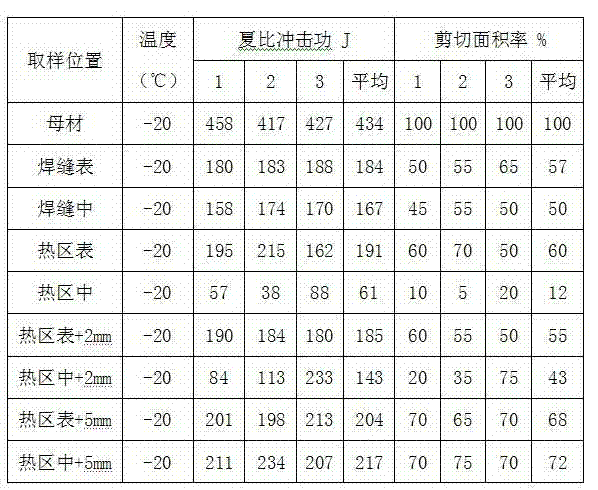

Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

ActiveCN102310119AUniform deformationUniform performanceArc welding apparatusUltrasound testMagnetic particle inspection

The invention discloses a manufacturing method of an X65 pipeline steel longitudinal submerged arc welded pipe for undersea use. The manufacturing process of the steel pipe comprises: edge milling, edge prebending, JCO moulding, prewelding, inside welding, outside welding, first ultrasonic inspection, first x-ray inspection, mechanical expanding, hydrostatic test, chamfering, groove machining, second ultrasonic inspection, second x-ray inspection, pipe end magnetic particle inspection and appearance quality inspection. The method of the invention makes each part of the X65 steel grade ongitudinal submerged arc welded pipe with a diameter of phi 762mm and wall thickness of 28.6-30.2mm has uniform deformation and performances in the process of JCO moulding; the method in the invention solves the problem that local heating of the steel pipe during welding results in severely reduced strength and toughness as well as elongation; the method provided in the invention also provides a solution to the problems of increased strength and reduced toughness and uniform elongation caused by work hardening during steel pipe mechanical expanding.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

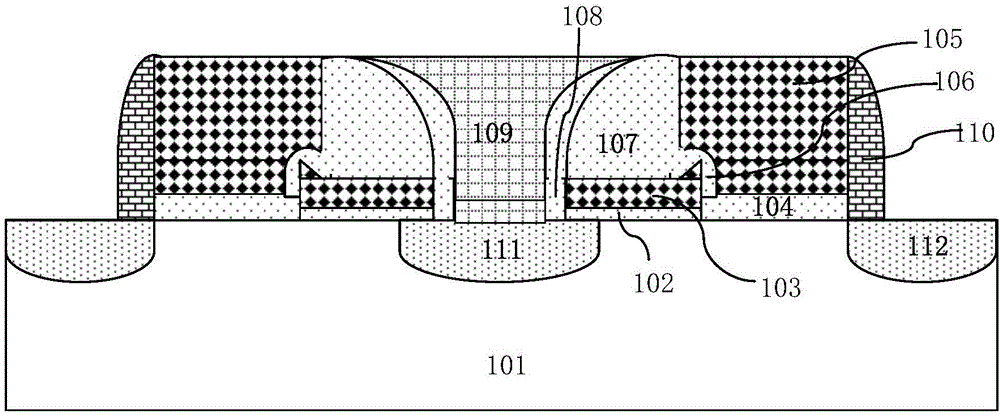

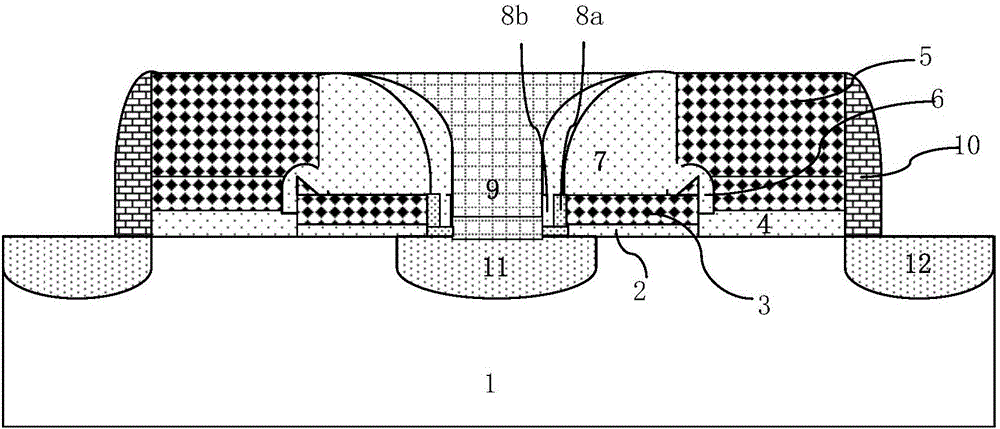

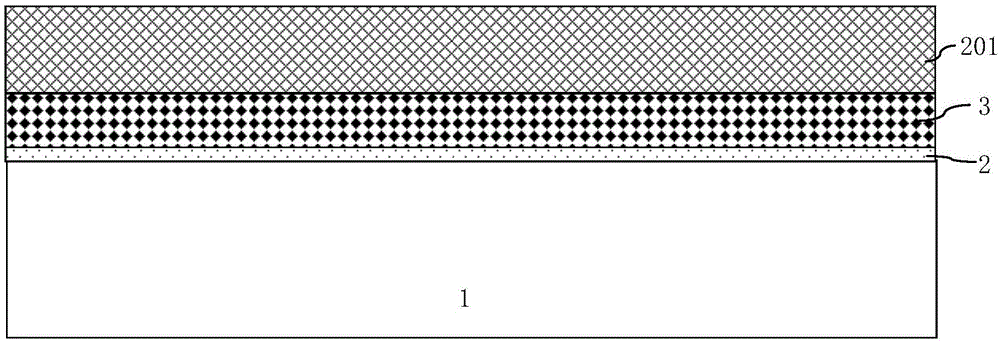

Self-aligned split gate flash memory device and manufacturing method thereof

ActiveCN106298793AAvoid direct contactAvoid it happening againTransistorSolid-state devicesUnit structureData retention

The invention discloses a self-aligned split gate flash memory device. One unit structure comprises a polysilicon word line, a polysilicon floating gate and source polysilicon, wherein a first floating gate sidewall covers a top surface of the polysilicon floating gate and a first side surface of the polysilicon word line; a second floating gate sidewall is formed on the first side surface of the polysilicon floating gate; the first floating gate sidewalls and the second floating gate sidewalls of two adjacent unit structures define a forming region of the source polysilicon in a self-aligned manner and the width of the bottom of the source polysilicon is defined by each second floating gate sidewall in a self-aligned manner; a second floating gate sidewall material comprises a first oxide layer and a second oxide layer formed by CVD HTO; and the first oxide layer is formed by carrying out thermal oxidation on silicon on the first side surface of the polysilicon floating gate. The invention further discloses a manufacturing method of the self-aligned split gate flash memory device. According to the self-aligned split gate flash memory device and the manufacturing method thereof, the data retention capacity of the device can be improved and good control on the width of the bottom of the source polysilicon and the length of the polysilicon floating gate can be ensured.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method for machining joint with deep and narrow groove complicated structure

InactiveCN102225480AGuaranteed sizeReduce the risk of qualityMilling equipment detailsMilling cutterEnd mill

The invention relates to a method for machining a joint with a deep and narrow groove complicated structure, and the method is characterized by comprising the following steps of: 1) extending a joint web plate during design, forming a positioning hole on the extended web plate, and machining by taking the positioning hole as a process original point; 2) machining a part web plate; 3) carrying out rough and finish milling on lug slots and machining lug slot notches; and 4) machining an internal camber surface by adopting profile segmentation, carrying out half-finish machining by layers by virtue of a vertical milling cutter with the length of 45mm, and carrying out non-layered finish machining by virtue of a vertical milling cutter with the edge length of 90mm. The method can be used for not only effectively solving the problem of poor thickness of lugs, and a more reasonable method is provided for machining the rotating angles of the part, thus improving the integral machining precision of the part and increasing the production efficiency.

Owner:SHENYANG AIRCRAFT CORP

Multi-specification combined elbow welding tool and welding method for same

ActiveCN103692128AImprove quality and efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a multi-specification combined elbow welding tool, which comprises a base and an upper seat, wherein the base is connected with the upper seat in a rotating way; a screw rod is arranged on the base, and is also connected with a positioning flange on the base through a connecting nut; the structure of the upper seat is the same as that of the base; a positioning seat is also arranged on the base; a positioning shifting fork is connected to the positioning seat through a pin shaft; a locking mechanism is arranged on the positioning shifting fork and the base; an angle adjustment mechanism is also arranged between the base and the upper seat. According to the multi-specification combined elbow welding tool, the size and the angle of a finished product elbow is directly determined through the tool, and flanges and elbow pieces are placed on the tool for integral assembly-welding, so that the angle and the size of the elbow can be ensured, and the finished product elbow can be ensured to be qualified.

Owner:NANJING MEISHAN METALLURGY DEV

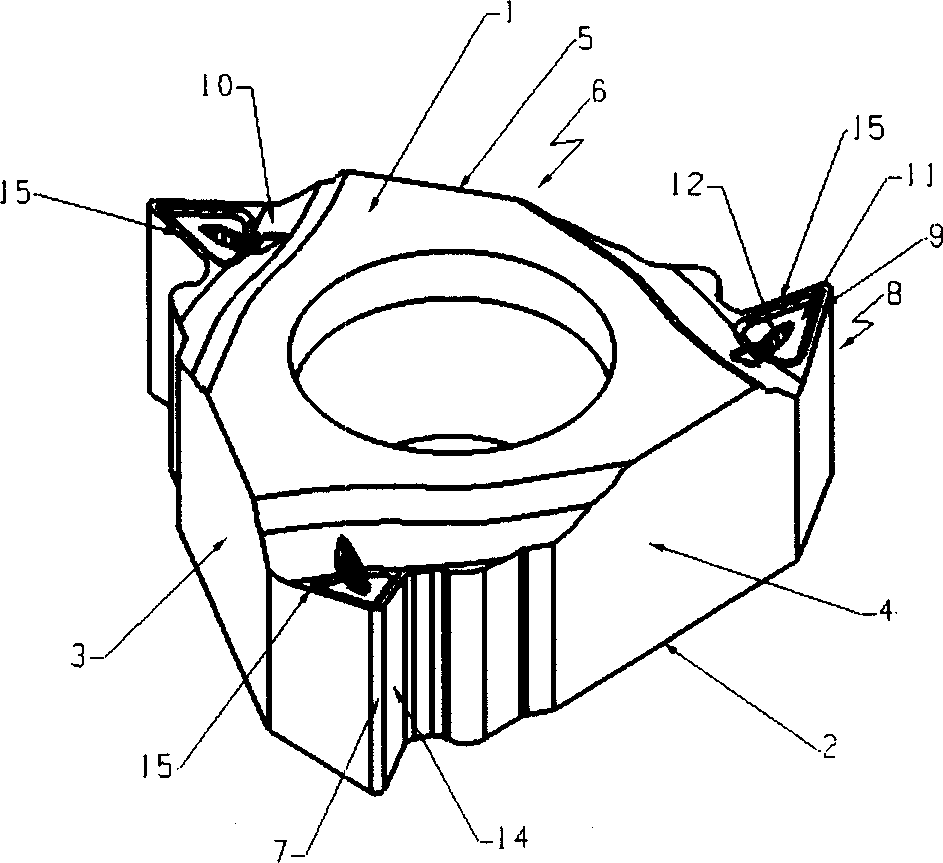

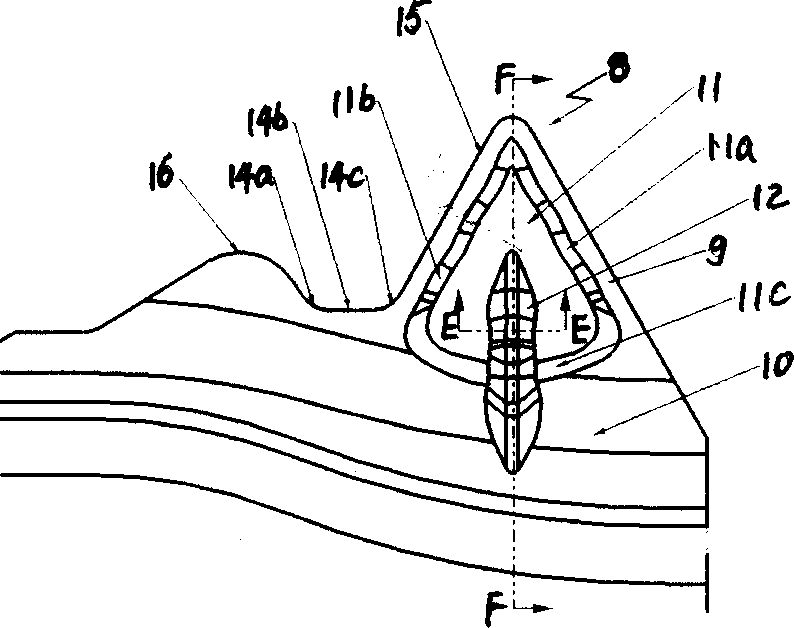

Cutting blade for machining screw thread

The thread machining cutter with unique groove form includes upper surface, lower surface and three side surfaces constituting cutter body and cutting bit angle. Any two side surfaces are connected by arced surface to constitute cutting bit angle, the top is the front edge surface connected to the cutter body via an arced surface, the front cutter surface and the side surface form cutting edge, and each of the cutting edge is provided with one trimming edge. The front cutting surface has one fanned notch with wavy side walls and one boss with front end extending to inside the notch and tail end extending backwards and ending in the arced surface. The present invention can control the cutting scrap direction and shape during machining, raise the smoothness of the machined surface and the machining efficiency, and may be used in triangular, rectangular, trapeziform and other shaped thread.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

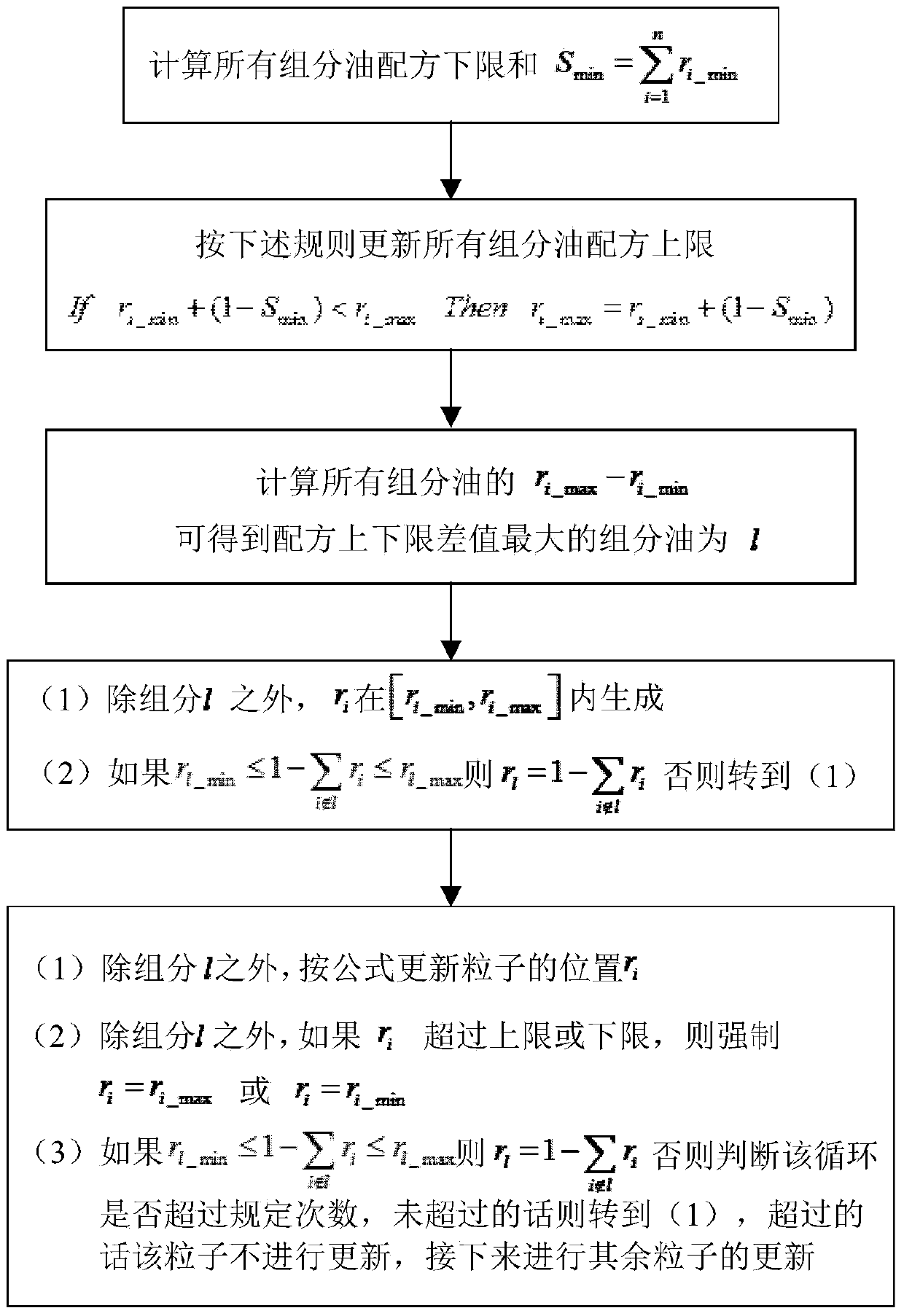

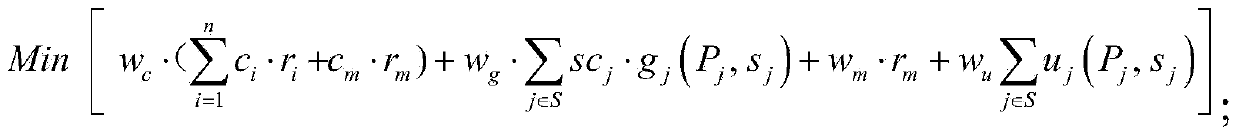

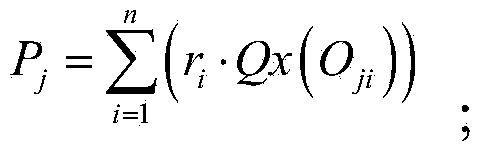

Method for optimizing gasoline blending in offline manner

InactiveCN103745115AReduce dosageGuaranteed sizeBiological modelsSpecial data processing applicationsMaterial balanceGasoline

The invention discloses a method for optimizing gasoline blending in an offline manner. The method includes building a gasoline blending model; optimally computing the built model by the aid of a particle swarm optimization algorithm. The minimum blending cost, the minimum product mass surplus and the minimum manganese-additive dosage are comprehensively taken into consideration in the model on the premise that requirements of product index constraints, component inventory constraints, manganese-additive dosage limit and material balance constraints are met. The method has the advantages that equality constraints in the blending model are processed by the aid of the particle swarm optimization algorithm in a novel processing mode, so that a result obtained after particle swarms are updated at every turn can assuredly meet conditions of the equality constraints, the scale of population can be guaranteed, and the arithmetic speed can be increased.

Owner:EAST CHINA UNIV OF SCI & TECH

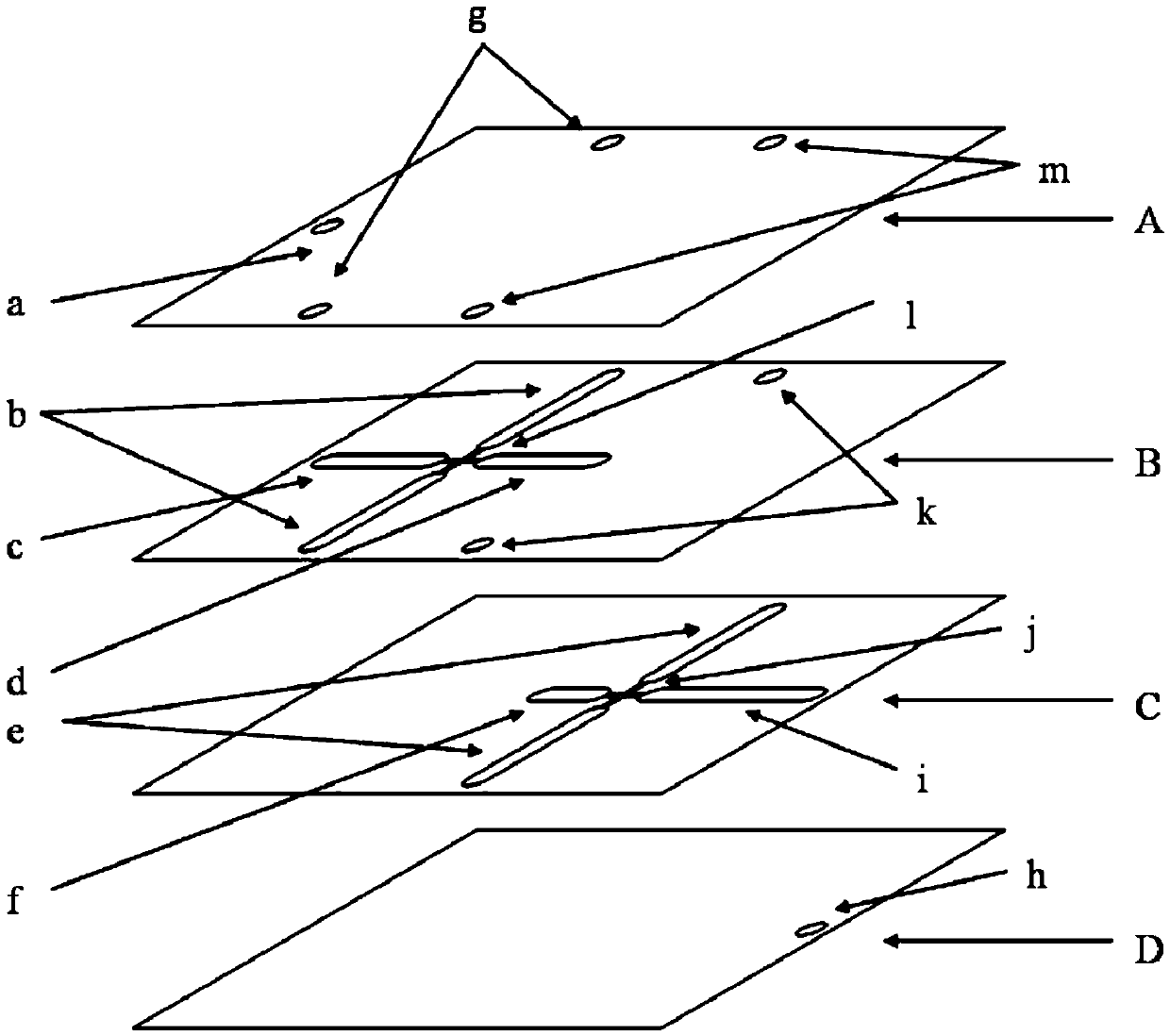

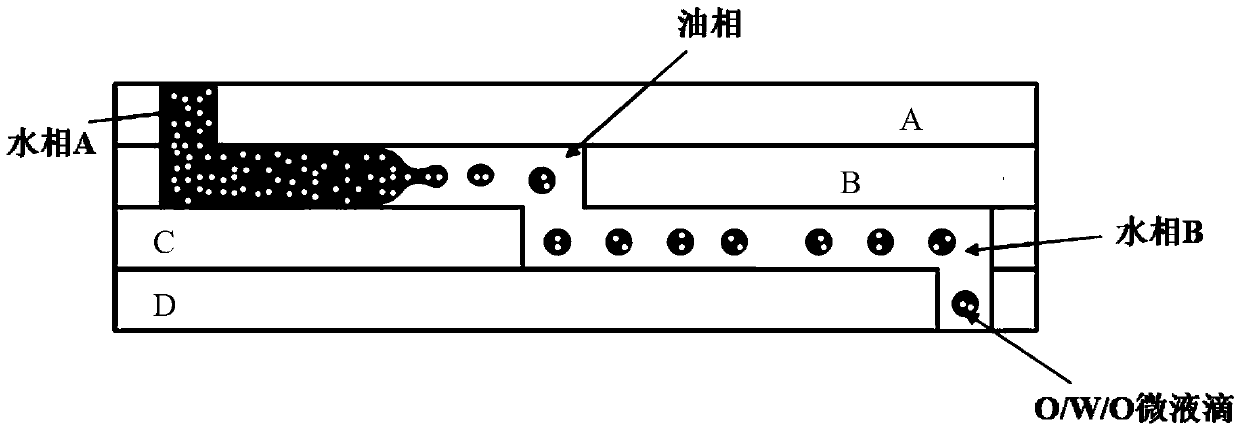

Multicomponent micro droplet microfluidic chip and processing method thereof

The invention relates to a multicomponent micro droplet microfluidic chip and a processing method thereof. The provided multicomponent micro droplet microfluidic chip is formed by a covering layer (A), a hydrophobic chip layer (B), a hydrophilic layer chip layer (C) and a base layer (D) which are stacked sequentially. The invention further provides a processing method of the multicomponent micro droplet microfluidic chip.

Owner:EAST CHINA UNIV OF SCI & TECH

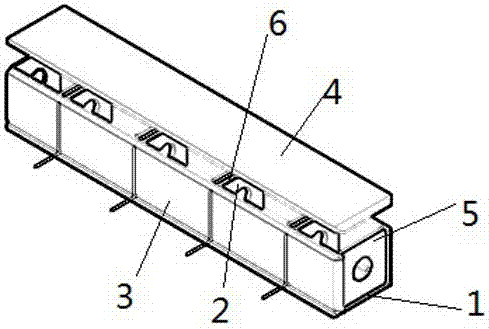

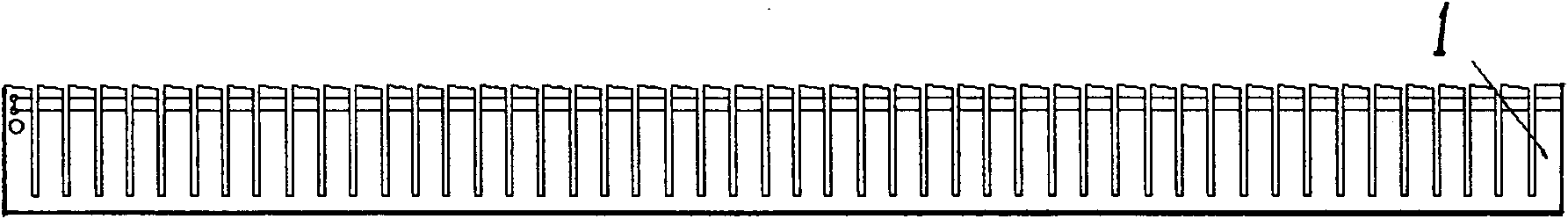

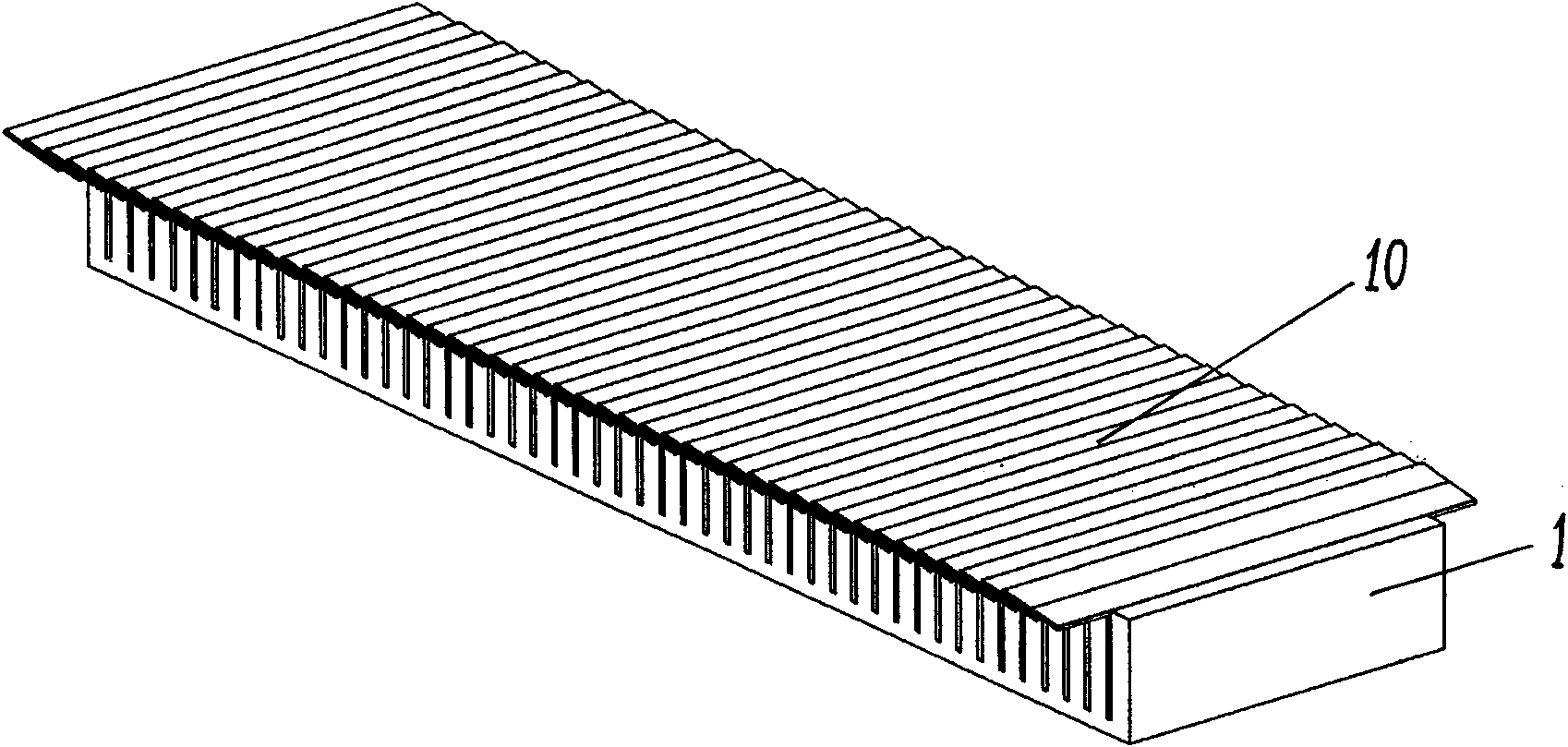

Method and device for collecting fins and arranging and combining fins and flat pipes

ActiveCN101913077AReasonable production processReduce transit proceduresAssembly machinesLean manufacturingMarine engineering

The invention discloses a method for collecting fins and arranging and combining the fins and flat pipes, which comprises the following steps of: (1) finishing equidistant arrangement of the flat pipes by using a pipe-arranging mold; (2) covering a large tray on the arranged flat pipes, turning, and putting the flat pipes into a fin and flat pipe collecting device assembly; (3) pushing a movable block to make the large tray support the flat pipes so as to clamp front ends of the flat pipes in a clamping groove of a guide block, and taking the pipe-arranging mold out; (4) automatically guiding the fins into a guide groove which is composed of the guide block and the flat pipes, and finishing the fin collection and arrangement of the flat pipes; and (5) loosening the movable block, collecting the arranged fins and flat pipes in a small tray or directly assembling the fins and the flat pipes, or stacking and storing the fins and the flat pipes. The invention also provides a corresponding device according to the method, which mainly comprises a pipe-arranging mold, a fin and flat pipe collecting device assembly and a small tray. The method for collecting the fins and arranging and combining the fins and the flat pipes has the advantages of no need of manually collecting the fins, reduction of a transfer program, capacity of preventing adhesion between the fins, automatically arranging the fins and the flat pipes, improving the product quality, along with low equipment investment and contribution to lean production.

Owner:SONGZ AUTOMOBILE AIR CONDITIONING

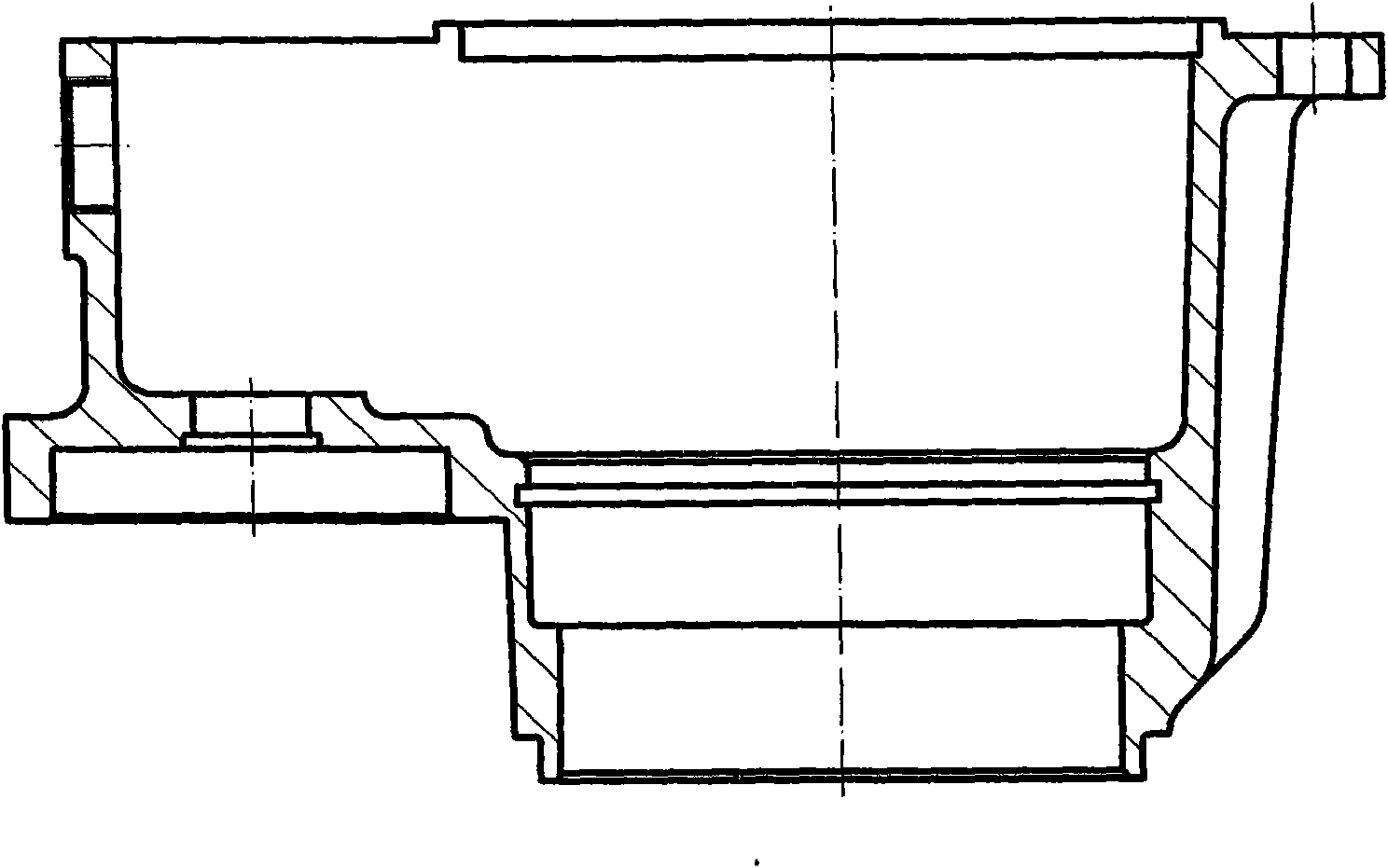

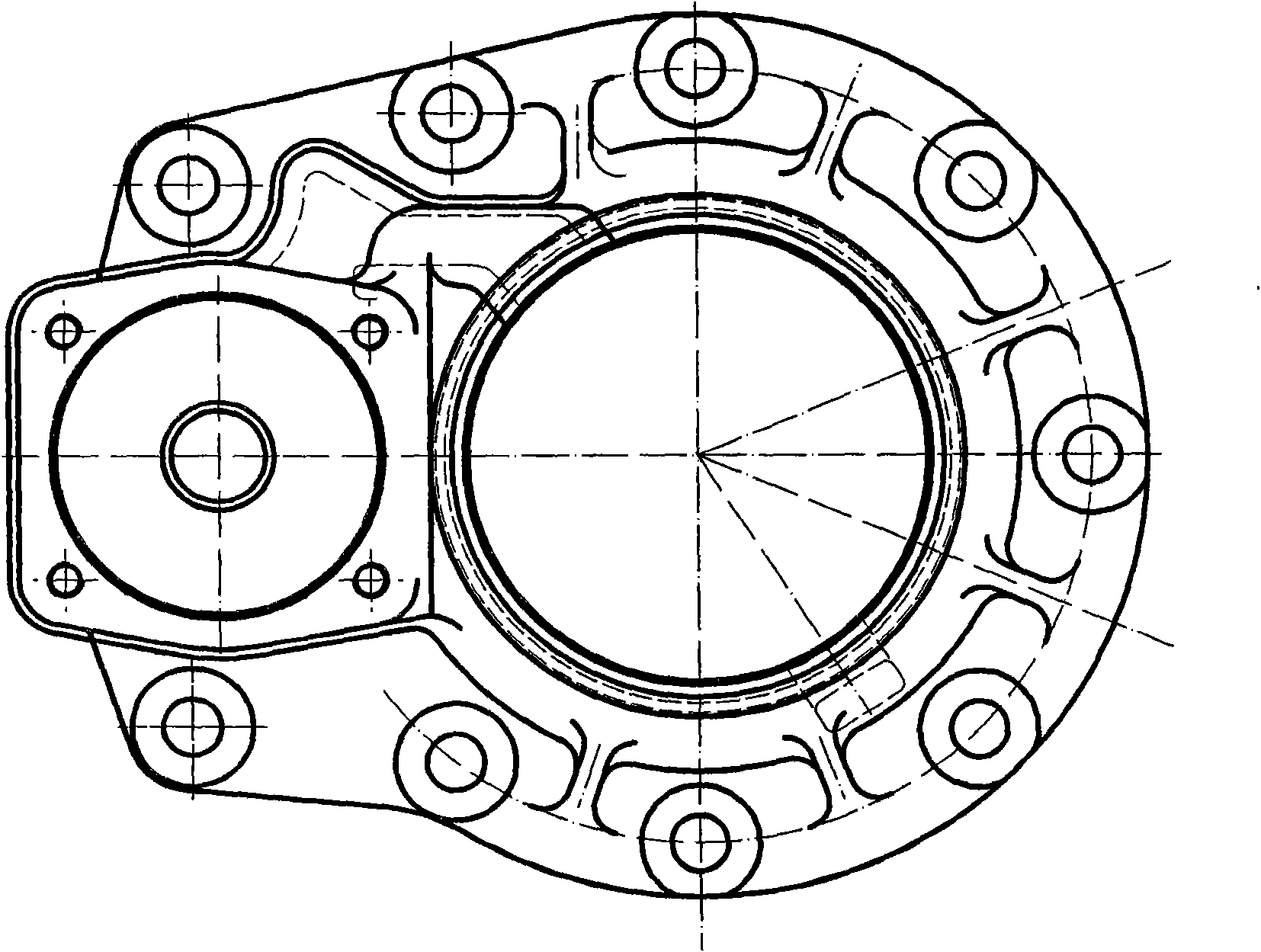

Method for processing main reducing gear front shell of automobile parts

The invention provides a method for processing a reducing gear front shell of automobile parts, which comprises the following steps: according to the requirements of a drawing, roughly and finely lathing the end face of a small end and the smallest outer circle, lathing a large plane and a retainer, boring an inner hole, lathing feet R and cutting grooves; finely boring two smallest inner holes while ensuring the coaxiality of the two holes is no more than phi0.04; drilling nine phi12.5 holes and four phi6.7 holes on a central line shown in the drawing; milling a left side small plane parallel to a big plane and roughly and finely boring inner holes on the small plane; milling a small boss plane on an upper right part and rilling a phi22.5 through hole; reaming a phi26 holes on in the nine phi12.5 holes; tapping threads; doing tests by using corresponding measuring tools and apparatuses; and doing a leakage test by applying a pressure of 8 bar without leakage. The method fully guarantees the product in hole-to-hole center line parallelism and coaxiality as well as pressure leakage and high quality, prolongs the service life of the product and meets the requirement for the rapid development of the automobile industry.

Owner:鞠小平

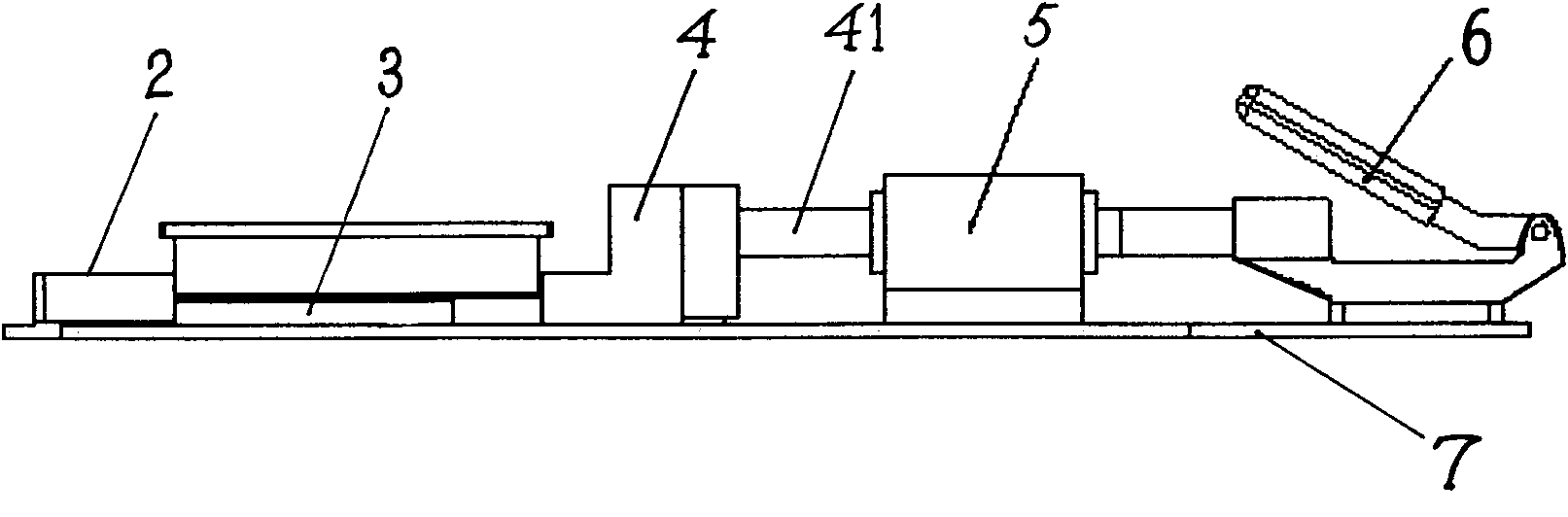

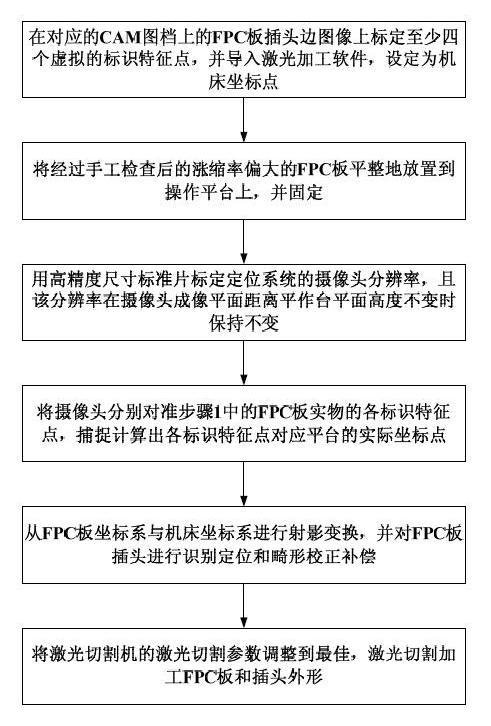

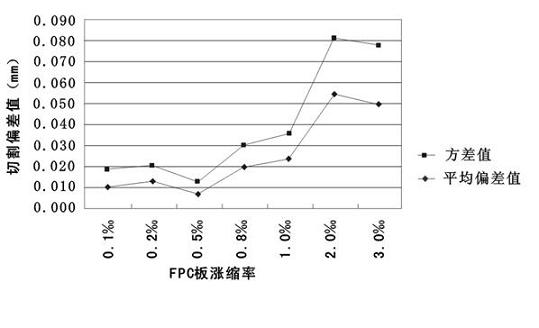

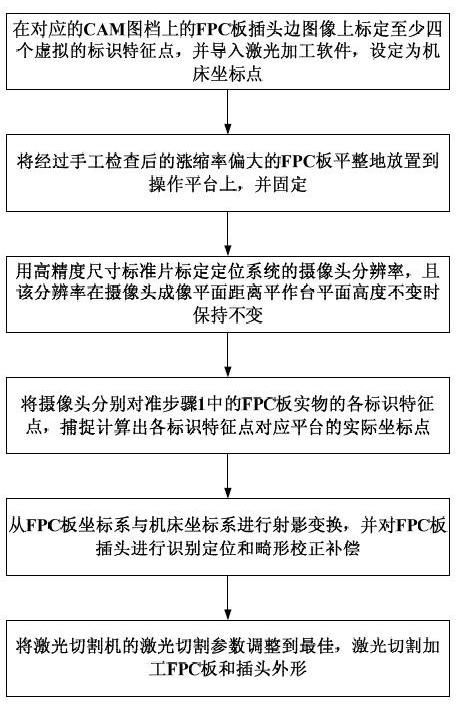

Method for identifying and positioning flexible printed circuit (FPC) board plug

InactiveCN102248288AImprove the problem of cutting deviationGuaranteed sizeLaser beam welding apparatusComputer hardwareCamera image

The invention relates to a method for identifying and positioning a flexible printed circuit (FPC) board plug. The method comprises the following steps of: 1, calibrating at least four virtual identifier characteristic points on an image of the edge of an FPC board on a corresponding computer aided manufacturing (CAM) figure file and importing laser processing software to set the virtual identifier characteristic points as machine tool coordinate points; 2, flatly placing the FPC board with slightly large expansion ratio after manual detection on a platform and fixing the FPC board; 3, calibrating the camera resolution ratio of a positioning system by using a high-precision dimension standard sheet, wherein the resolution ratio remains unchanged when the height from a camera imaging plane to a platform plane is not changed; 4, aligning the camera with each identifier point of the FPC board real object obtained in the step 1 and capturing and calculating the actual coordinate point, corresponding to the platform, of each identifier point; 5, performing projective transformation on an FPC board coordinate system and a machine tool coordinate system, identifying and positioning the FPC board plug, and performing malformation correction compensation; and 6, adjusting laser cutting parameters acquired from cutting system software to be optimum and performing laser cutting processing on the FPC board and the plug appearance. The method is simple and convenient in operation and high in precision.

Owner:KUSN ZHENGYE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com