Patents

Literature

1089 results about "Hydraulic equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

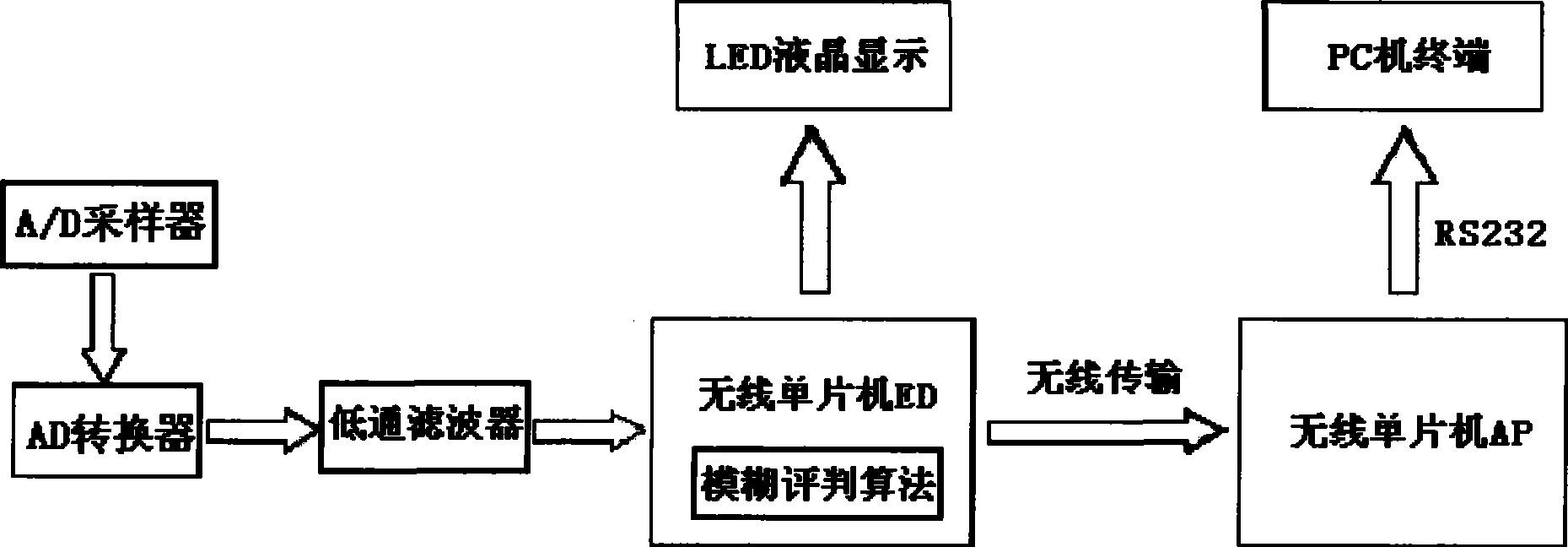

Application of deep learning based on fuzzy processing in fault diagnosis of hydraulic equipment

ActiveCN106555788ARealize fault classification and diagnosisRealize intelligent diagnosisFluid-pressure actuator testingData setHydraulic equipment

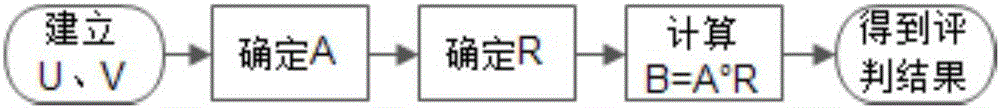

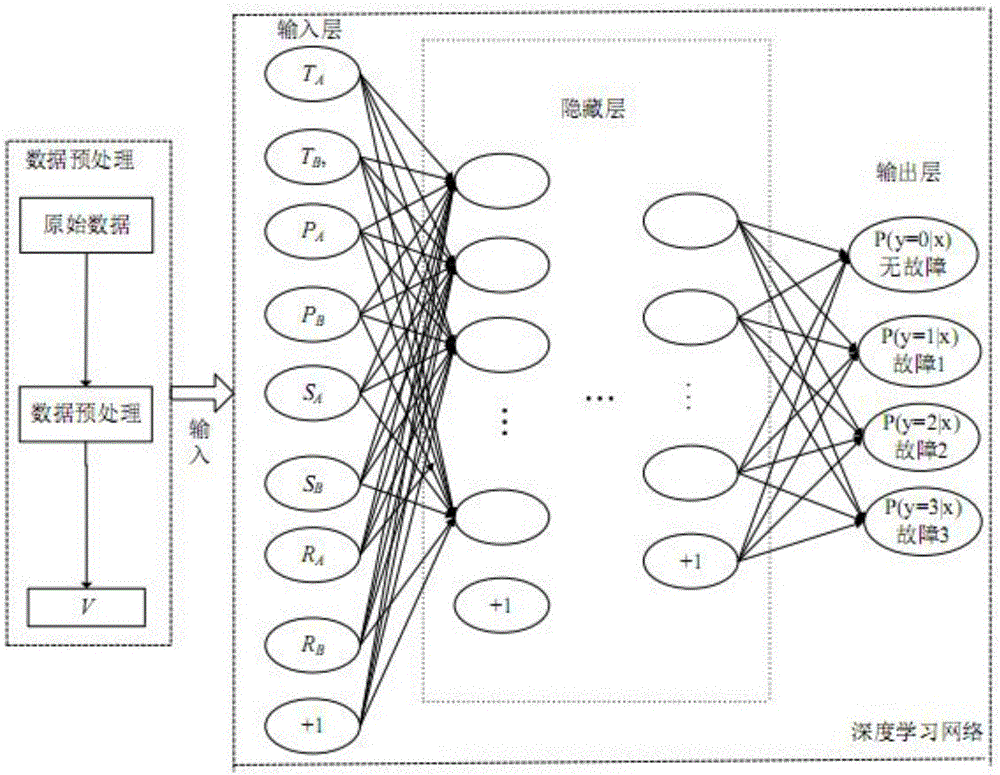

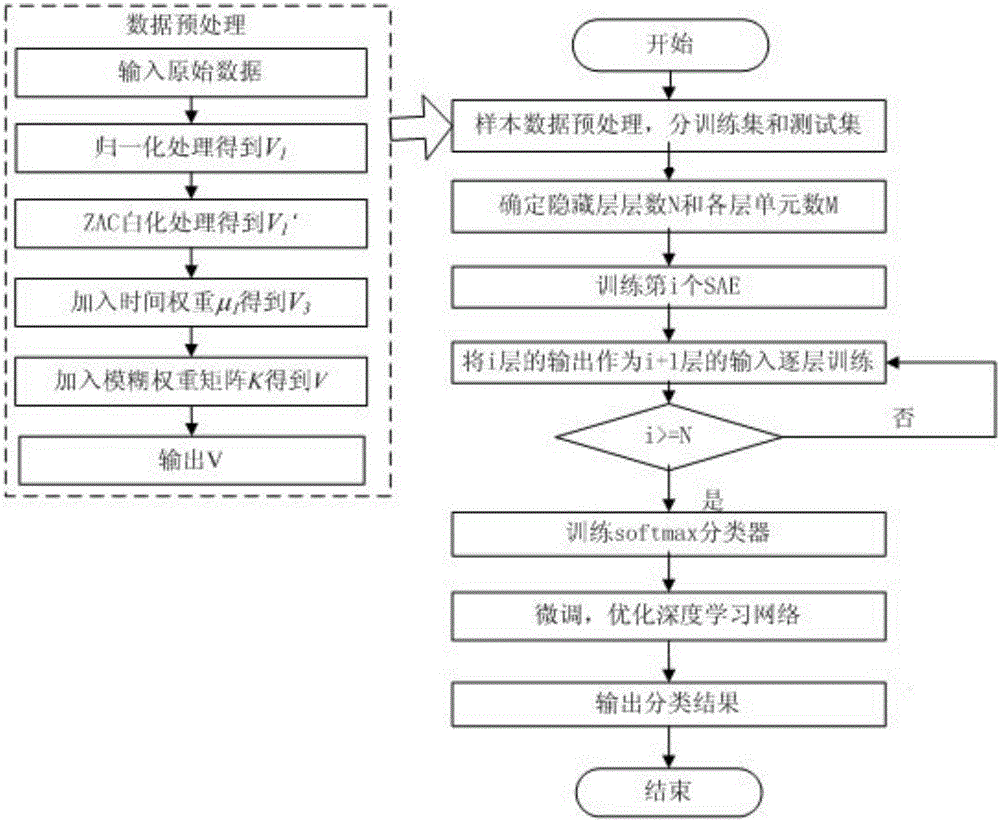

The invention discloses application of deep learning based on fuzzy processing in fault diagnosis of hydraulic equipment. The application comprises the following steps of: (1) introducing a time label and fuzzy weight to pre-process operation monitoring data of the hydraulic equipment, and dividing the operation monitoring data into a training data set and a test data set; (2) taking the training data set as an input vector of a sparse self-coding network to carry out non-supervision pre-training; (3) taking label data and no-label data as an input vector training Softmax classifier of a Softmax classifier; (4) utilizing a BP algorithm to carry out fine adjustment on deep learning network parameters; and (5) carrying out intelligent diagnosis on a fault condition. According to the application disclosed by the invention, firstly, a method of introducing the time label and fuzzy weight is adopted to carry out pre-processing on data; then, sparse self-coding is used to complete high-level feature extraction of sample data, and the Softmax classifier is used to carry out classifying diagnosis on an equipment fault state to construct an ICM model; and finally, the BP algorithm is utilized to carry out fine adjustment on global optimal parameters of the whole network, so that intelligent diagnosis on the fault state is realized.

Owner:天津开发区精诺瀚海数据科技有限公司

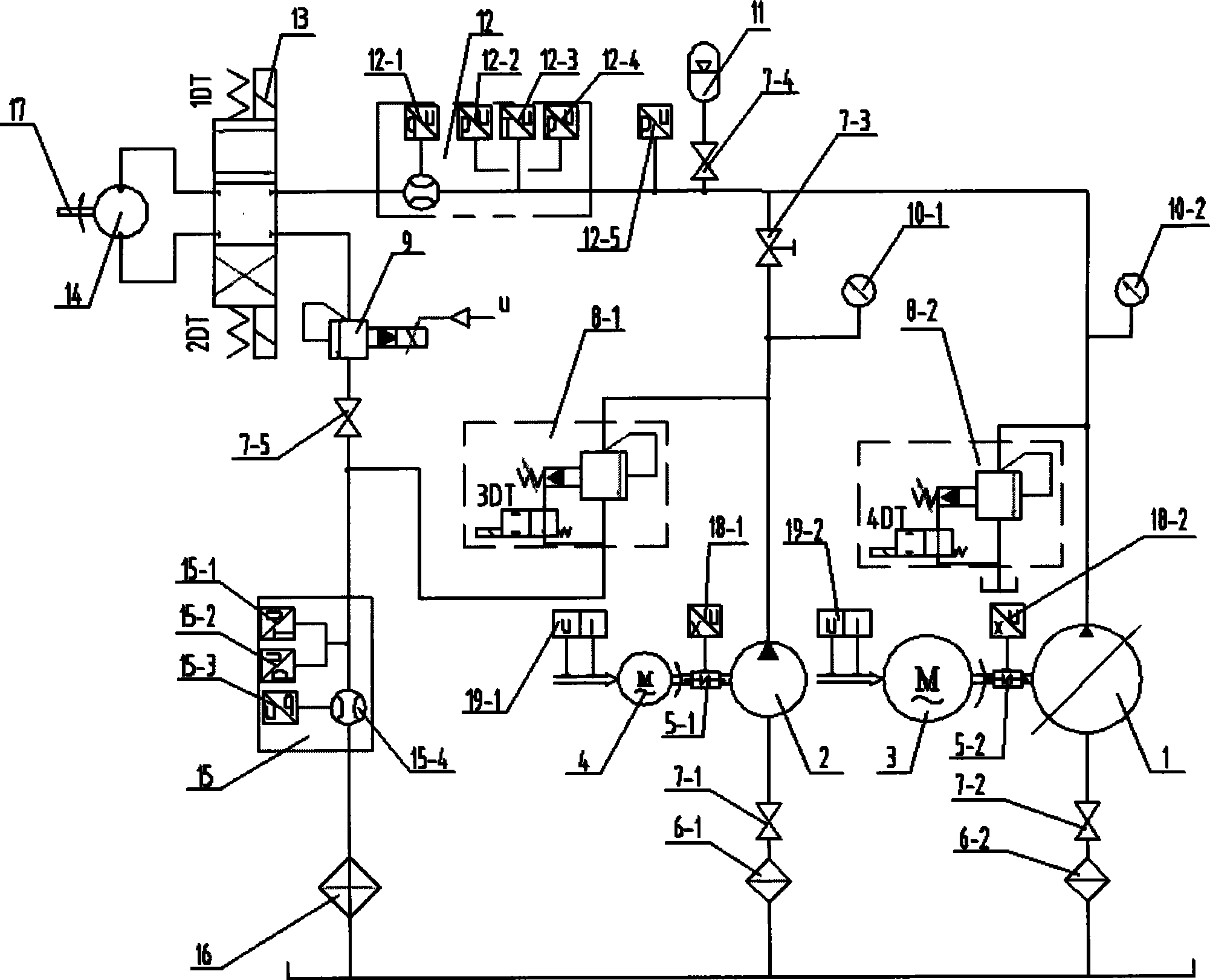

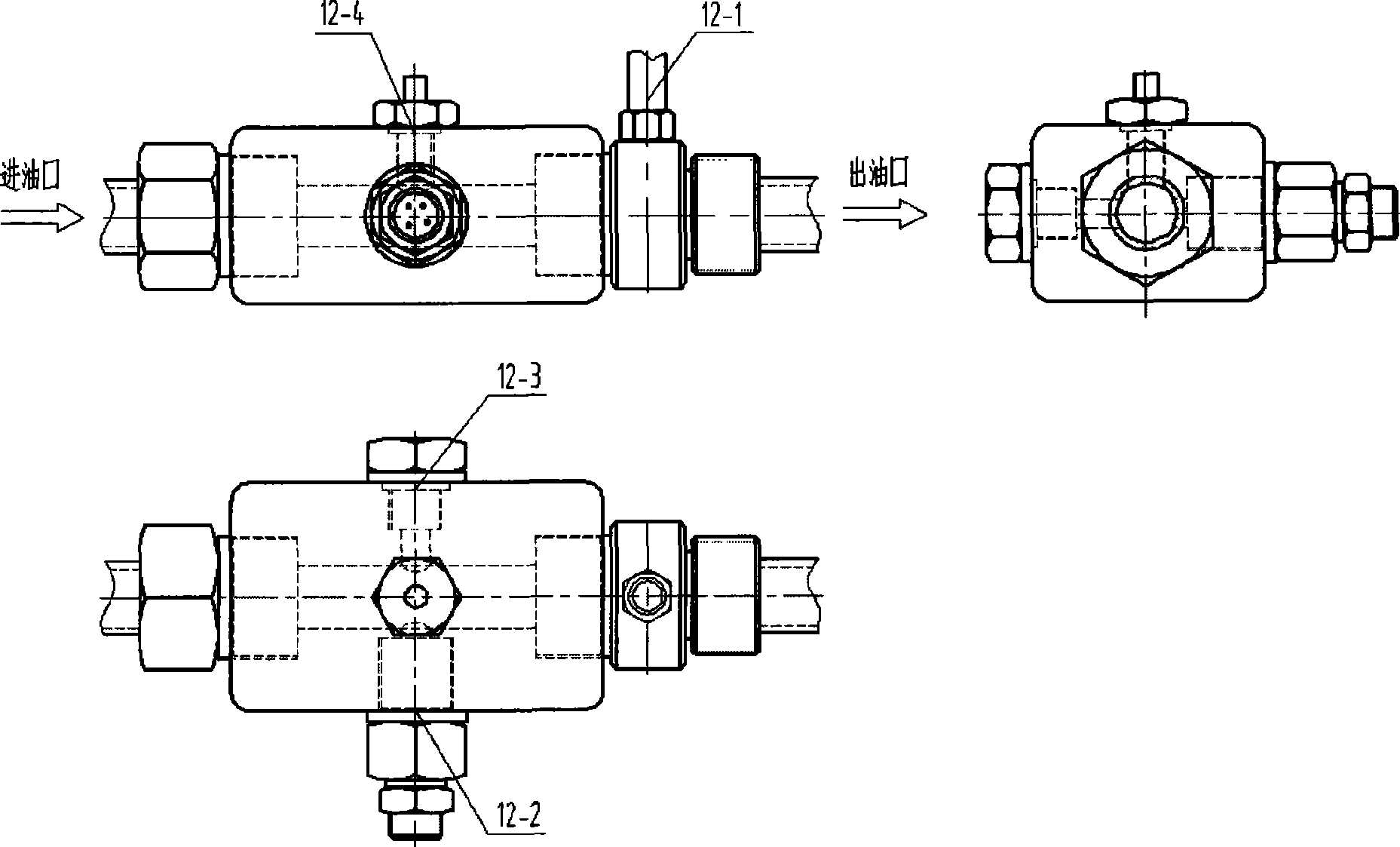

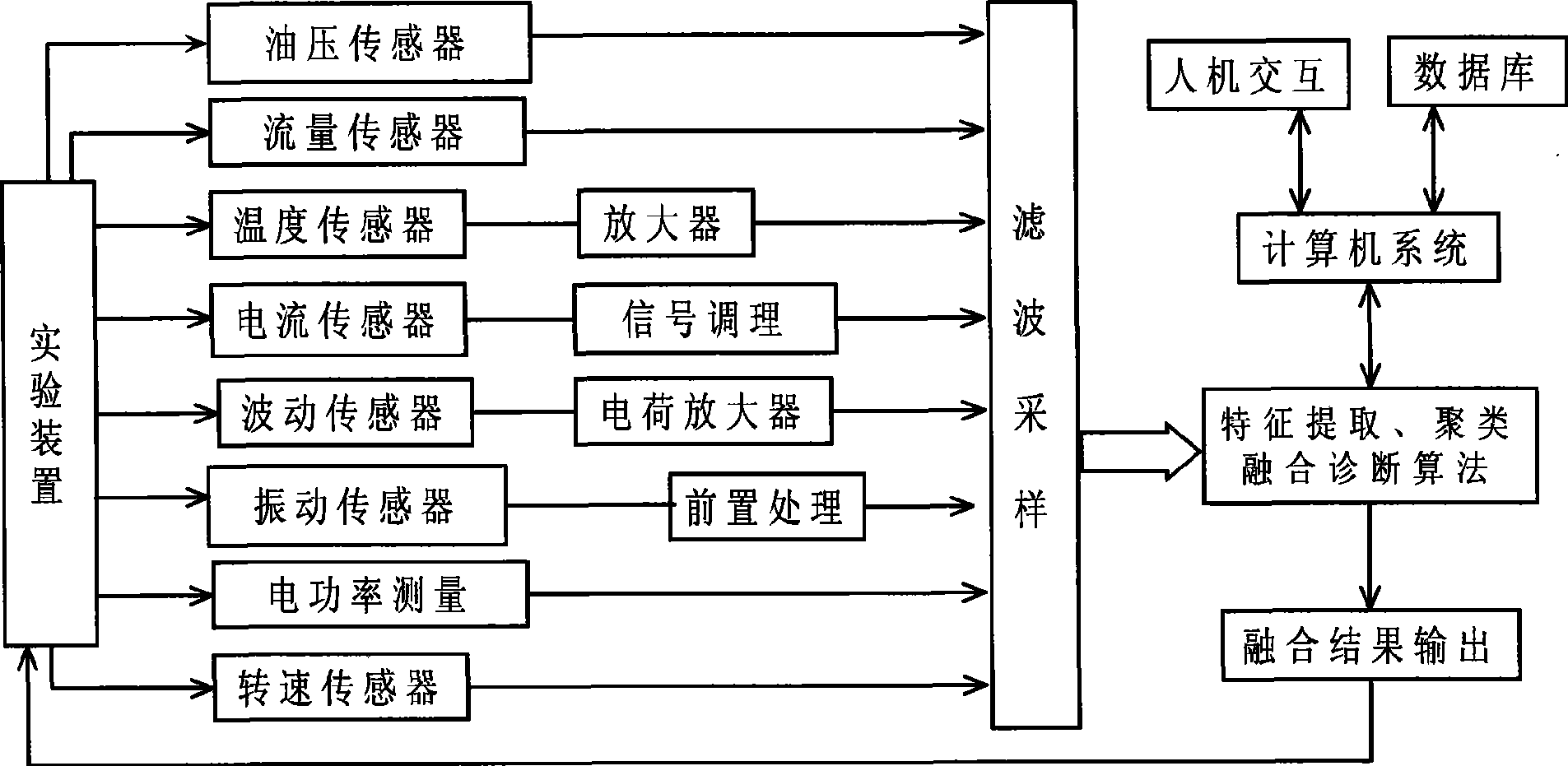

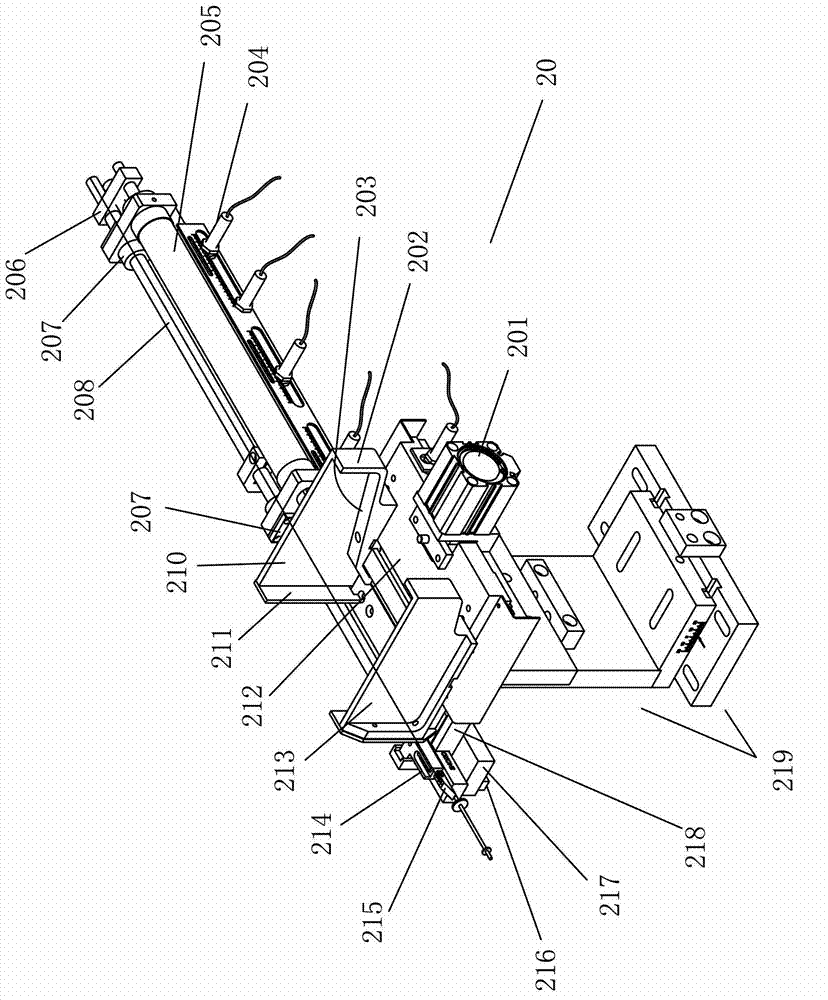

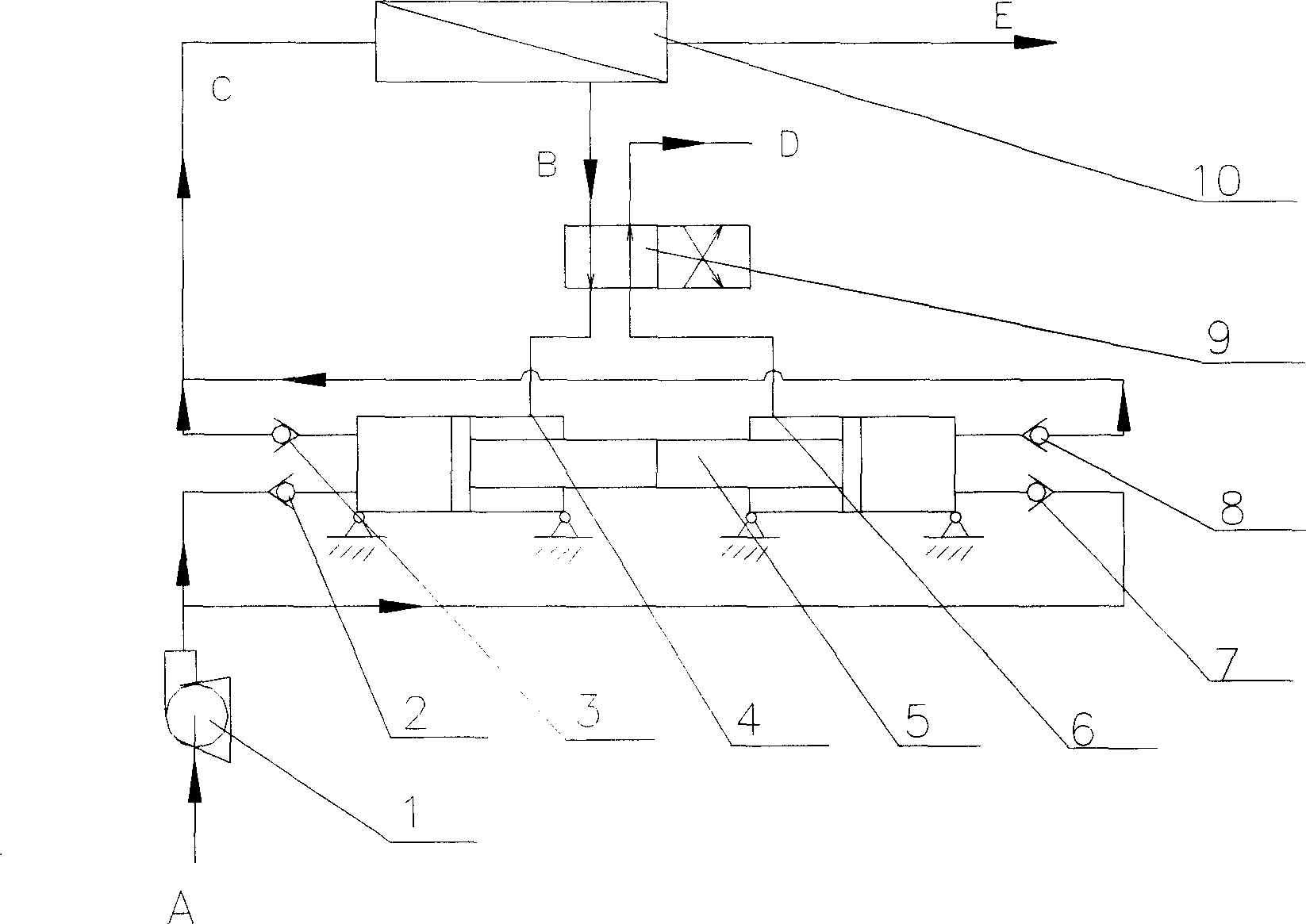

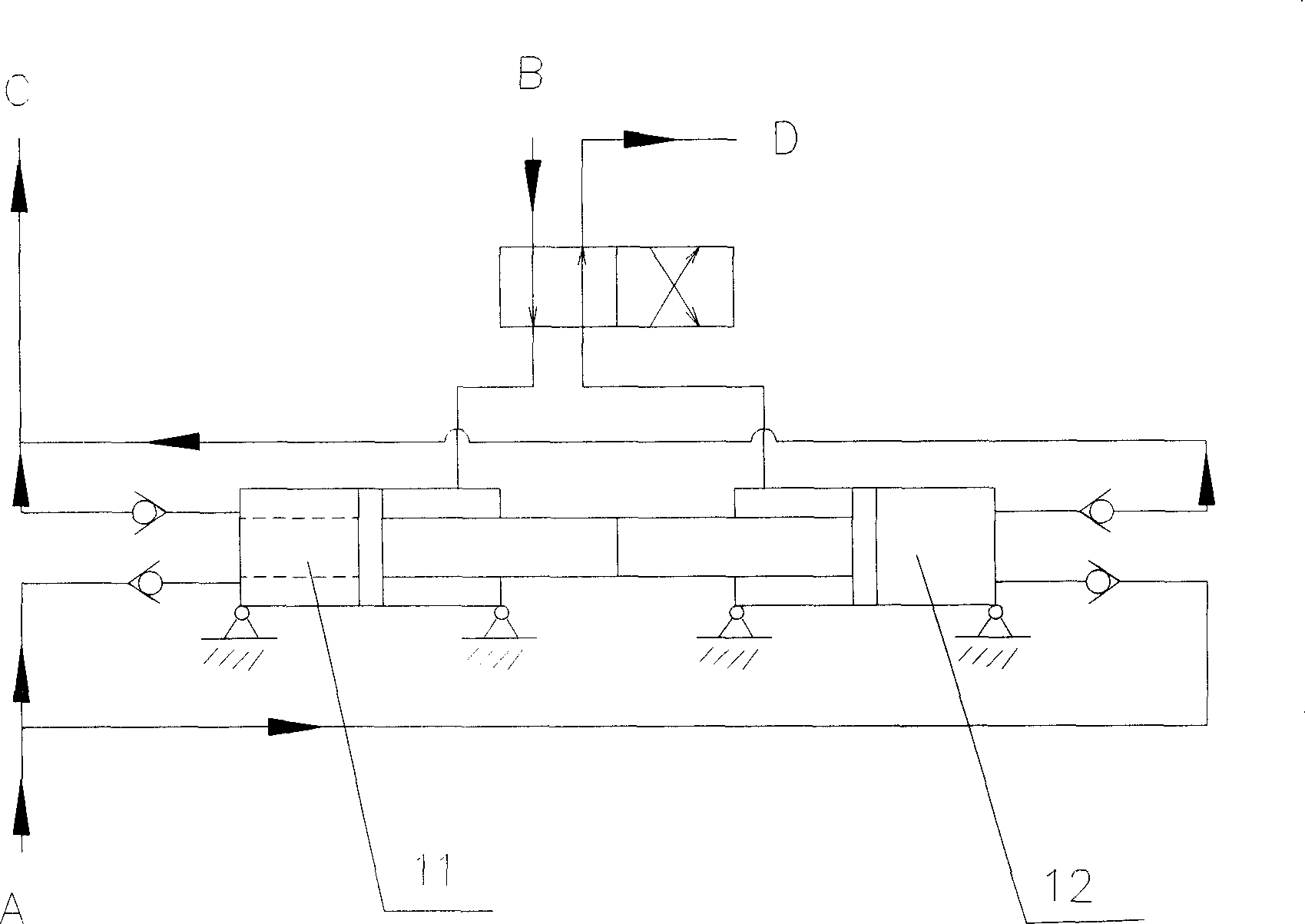

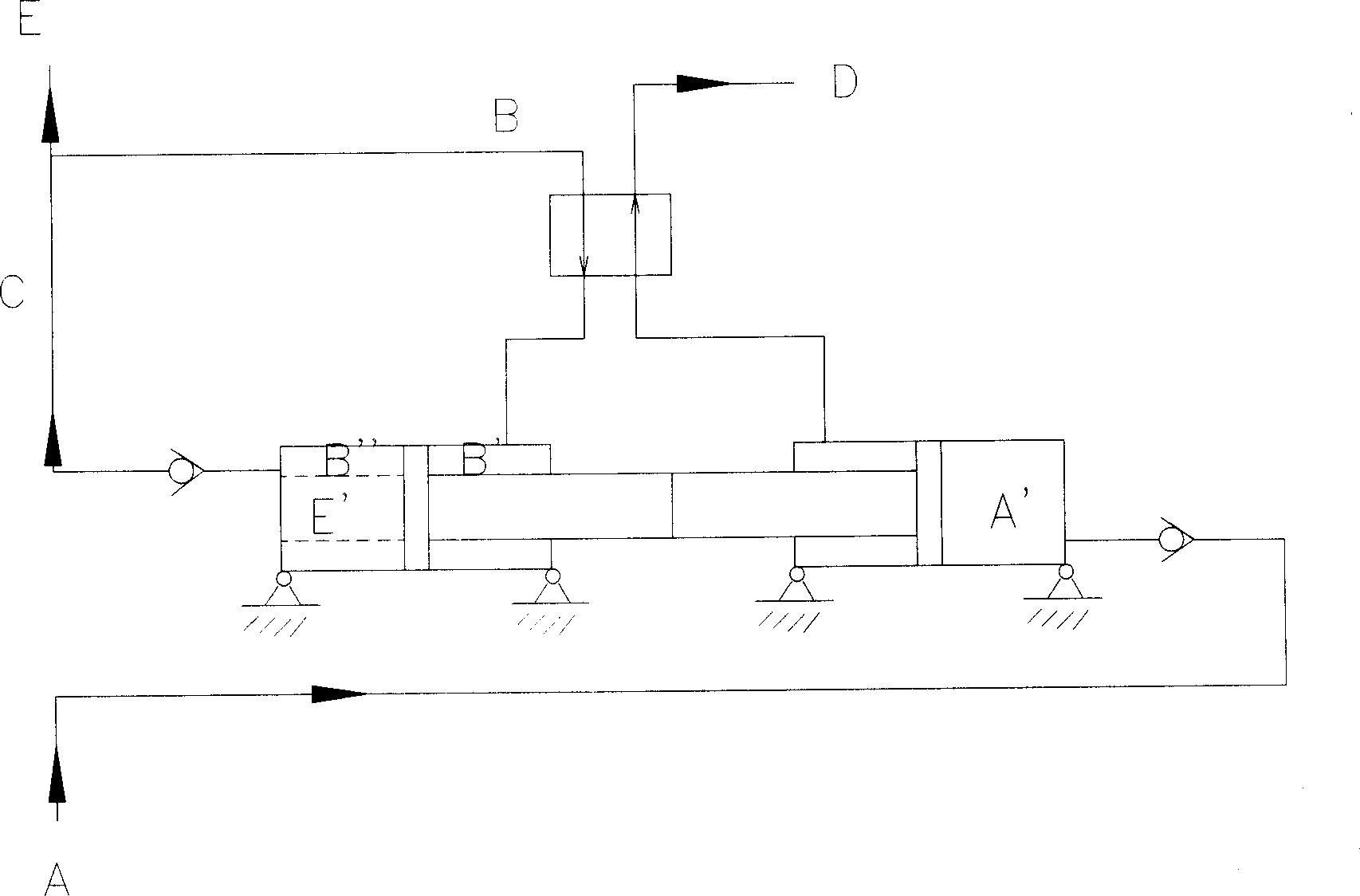

Experimental apparatus and method for obtaining multi-source diagnostic information of hydraulic equipment

InactiveCN101413521ALow efficiencySimple and fast operationFluid-pressure actuator testingSelf organizing map neural networkGear pump

The invention relates to an experimental device and an experimental method for multi-source information fusion for fault diagnosis of a hydraulic device. The device comprises the following elements: a variable plunger pump, a gear pump, two motors, two suction filters, five throttle and stop valves, two electromagnetic relief valves, an electromagnetic proportional relief valve, two pressure meters, an energy accumulator, two sets of combined sensors, a three-position four-way electromagnet directional valve, a hydraulic motor and a cooler. The experimental device can simulate eight typical running states (faults) of the hydraulic device, including low efficiency, oil and liquid pollution, air suction, leakage, oil pump fault, relief valve failure, motor failure and mechanical failure and can perform cluster analysis and fusion diagnosis to characteristics of the eight faults through a self organizing maps neural network.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

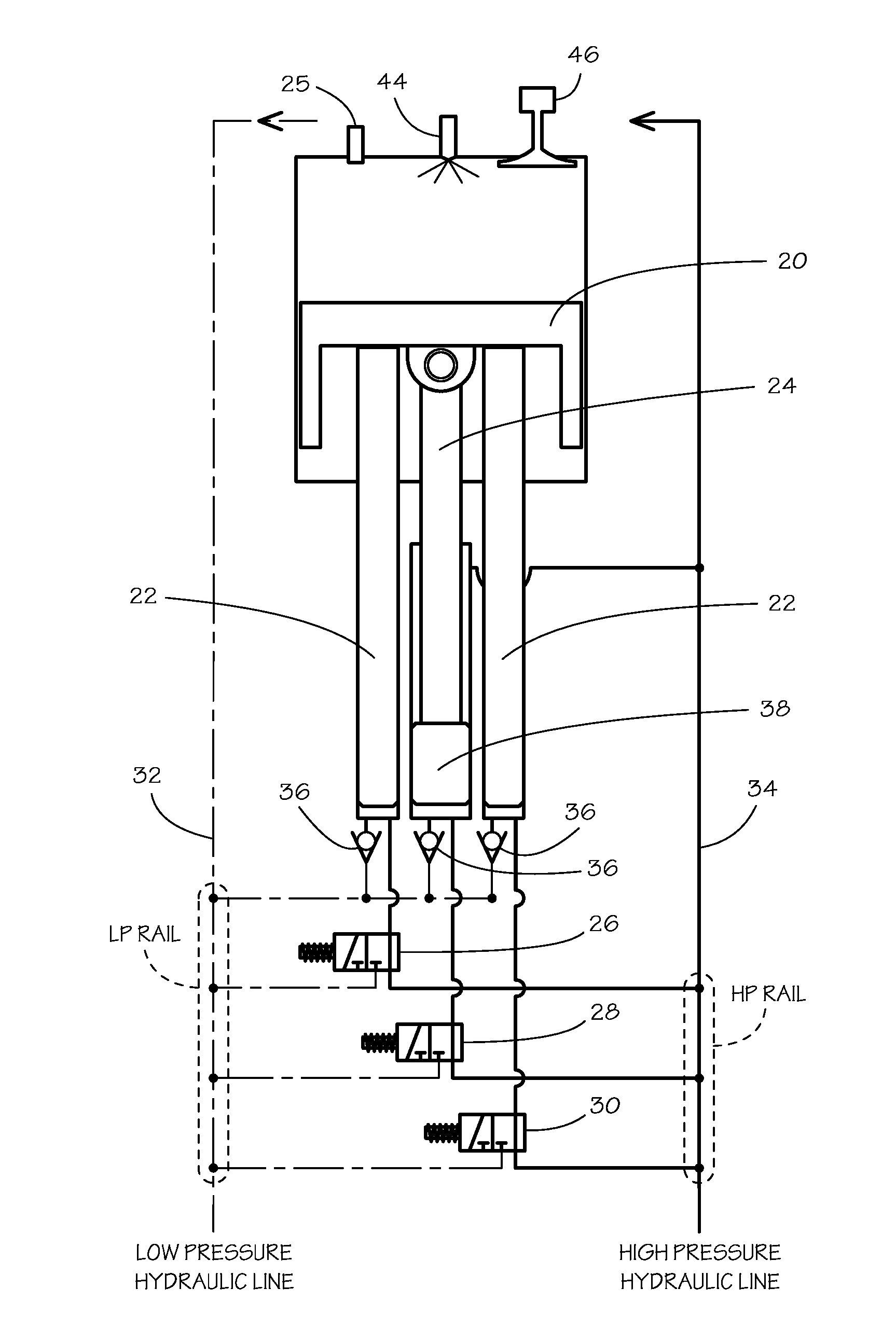

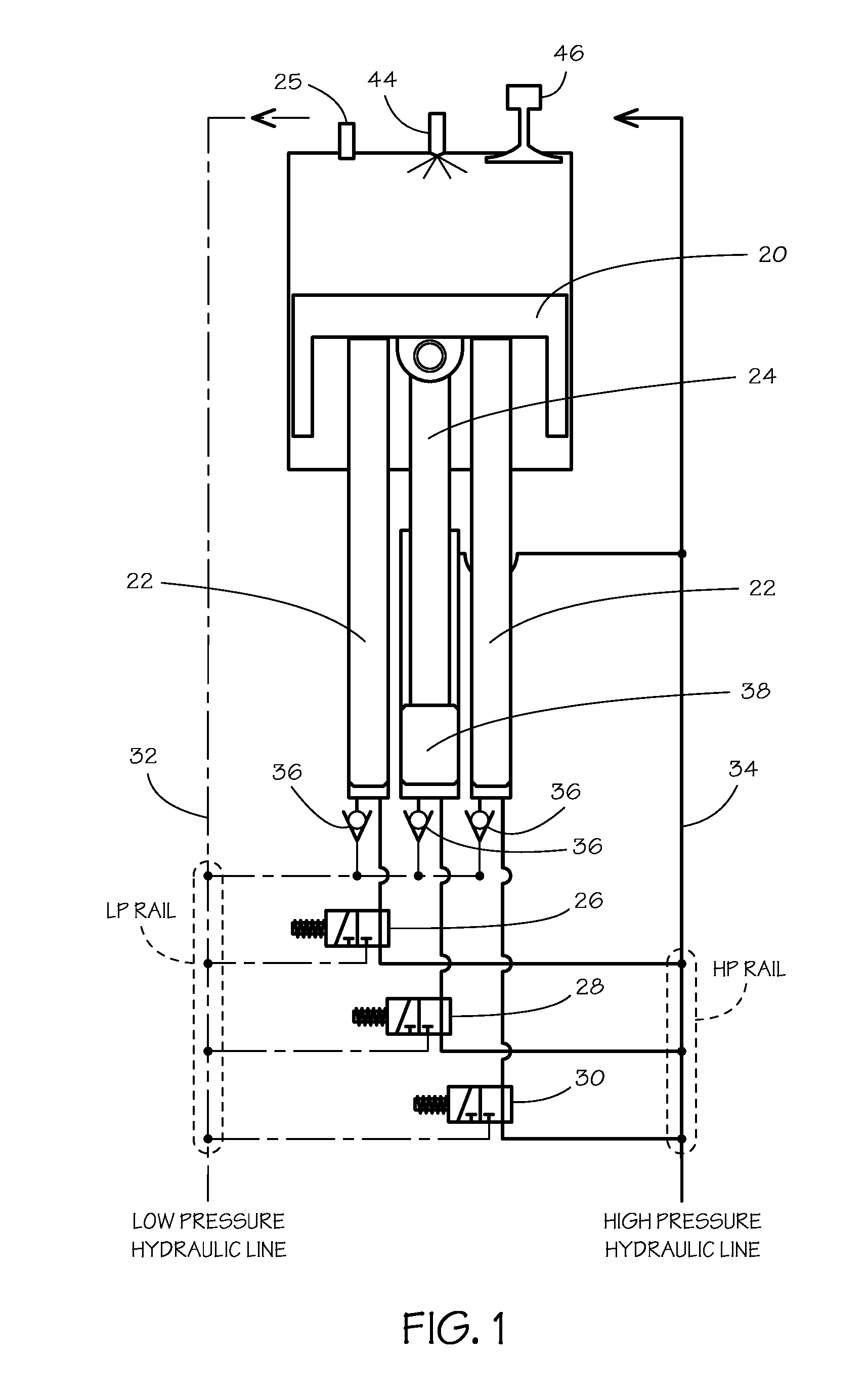

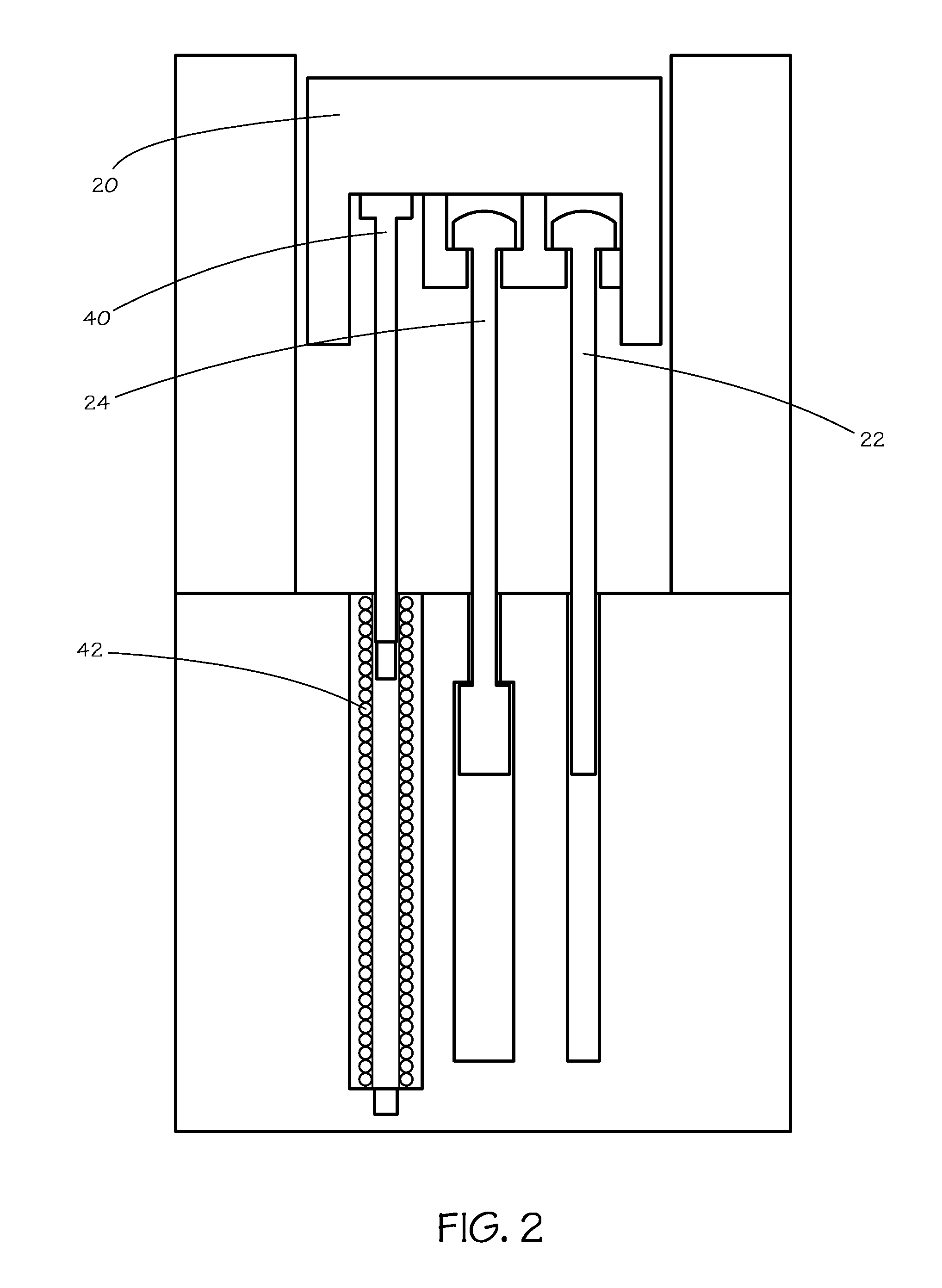

Hydraulic Internal Combustion Engines

ActiveUS20110083643A1Free piston enginesEngines without rotary main shaftHydraulic equipmentHydraulic fluid

Hydraulic internal combustion engines having at least one combustion piston not mechanically connected to a crankshaft or any other combustion piston, but instead acting on hydraulic plungers through valving that is electronically controlled to control the piston position and velocity, typically through an intake stroke, a compression stroke, a combustion or power stroke and an exhaust stroke. Electronically controlled fuel injection and electronically controlled engine valves provided great flexibility in the operating cycles that may be used, with the engine pumping hydraulic fluid to a high pressure accumulator for use in hydraulic motors or other hydraulic equipment. Embodiments using high pressure air injection to sustain combustion are also disclosed.

Owner:STURMAN DIGITAL SYST

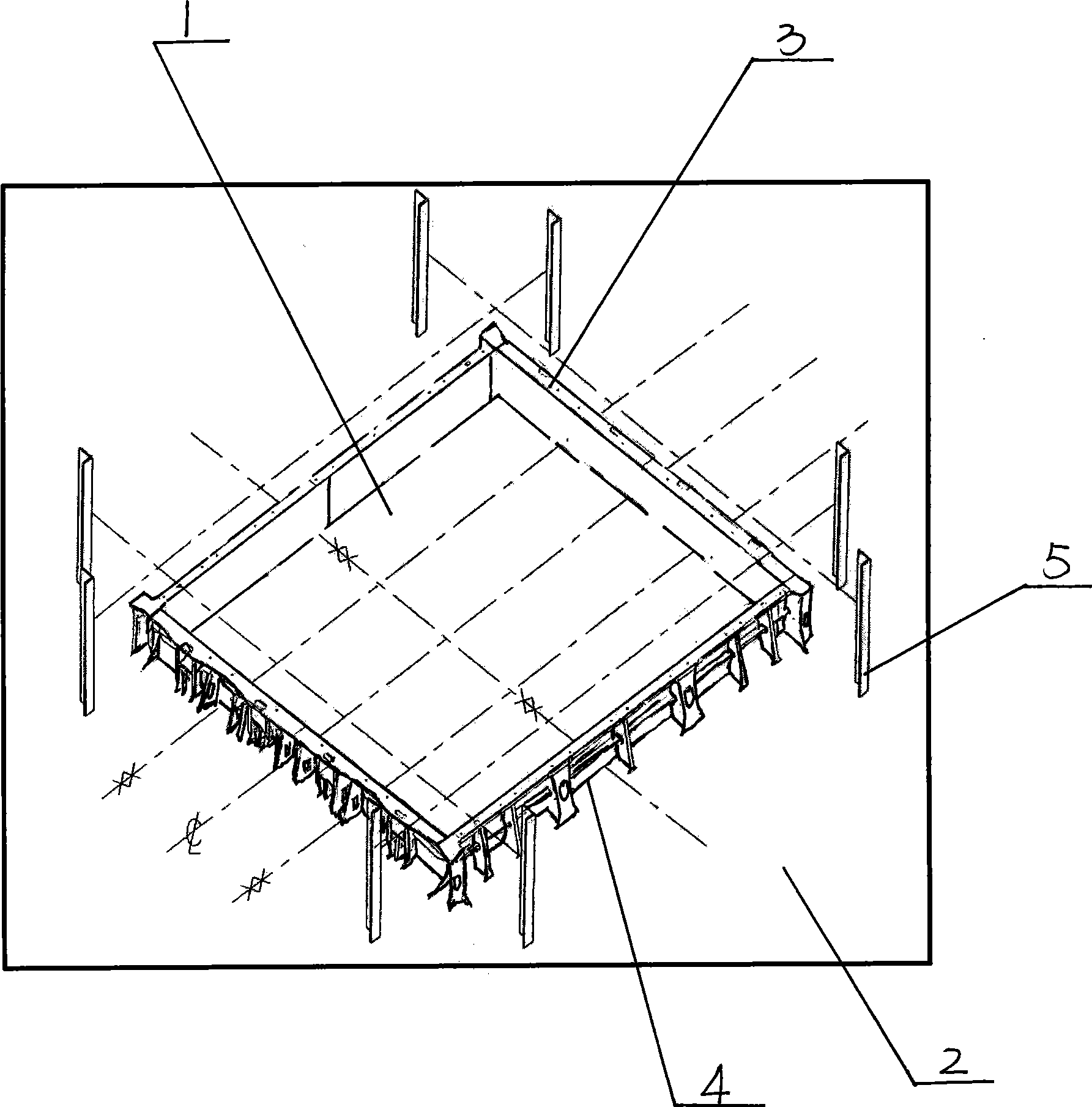

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

Method for optimal maintenance decision-making of hydraulic equipment with risk control

ActiveCN101950382ASolve the problem of processing impreciseIn line with the actual situationBiological neural network modelsSpecial data processing applicationsRisk ControlHydraulic equipment

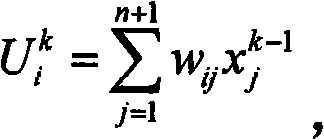

The invention belongs to the field of maintenance decision-making of hydraulic equipment, and relates to a method for the optimal maintenance decision-making of hydraulic equipment with risk control. The method mainly comprises three steps: 1) judging whether a system is in a status of defect by using a variable-weight association rule algorithm, if so, calculating the probability values of occurrences of latent faults of the system; 2) calculating the comprehensive evaluation value for the consequence of each latent fault by using a BP neural network; and 3) multiplying the probability values obtained in step 1 by the comprehensive evaluation values obtained in step 2 so as to obtain the VaRs (values-at-risk) of the latent faults, judging whether the VaRs are more than a specified threshold, if so, ranking the VaRs in descending order so as to determine the maintenance sequence; otherwise, returning to the step of monitoring. The method can judge whether a device is in a status of defect, judge the type of the latent fault and calculate the probability values of occurrences of latent faults only through a calculation; and compared with traditional risk maintenance methods, the method of the invention improves the accuracy of fault diagnosis, speeds up the diagnosis speed, and provides a better reference for online decision-making.

Owner:天津开发区精诺瀚海数据科技有限公司

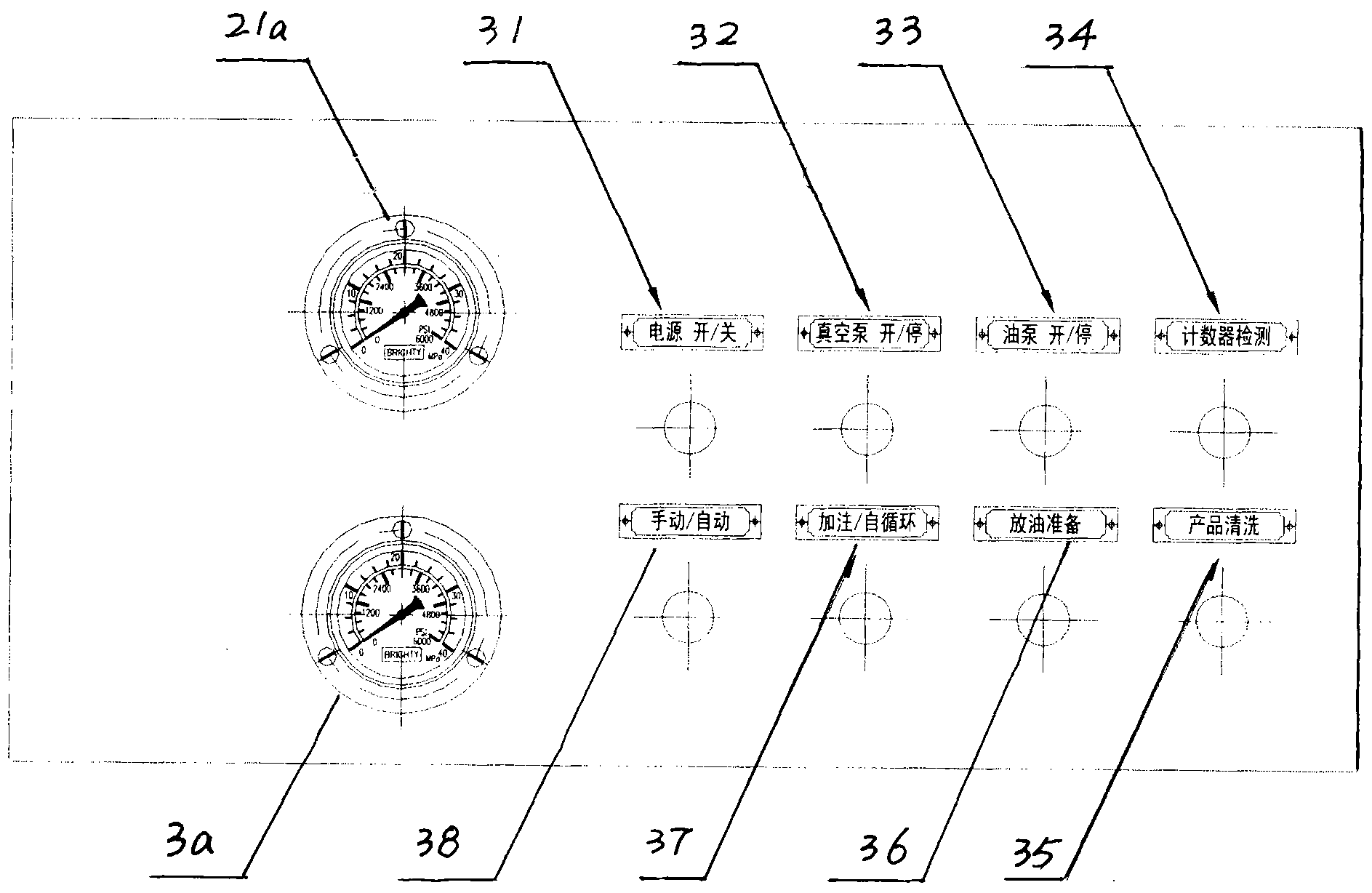

Online oil filling and purifying device for hydraulic equipment

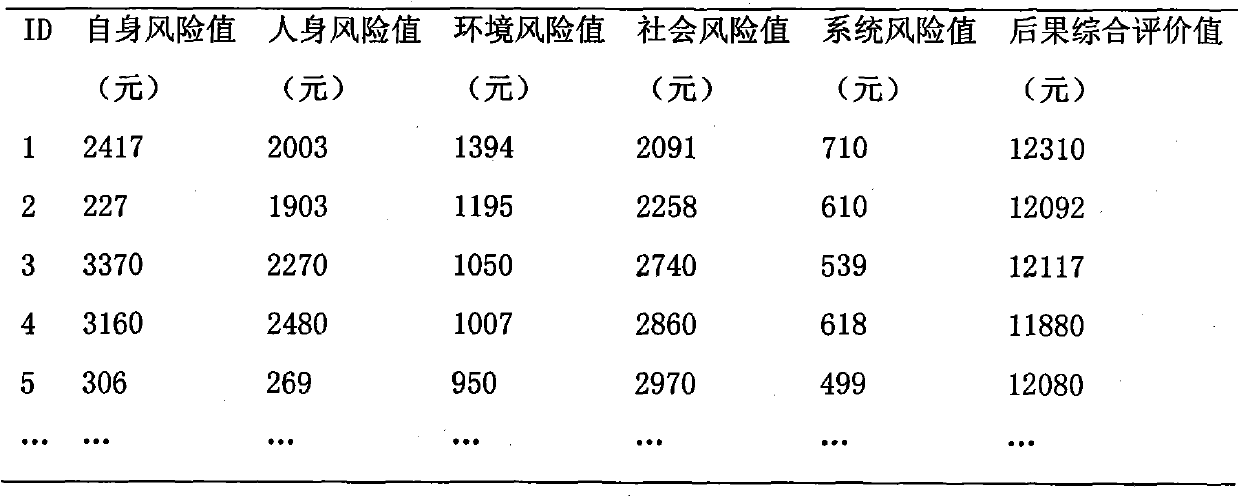

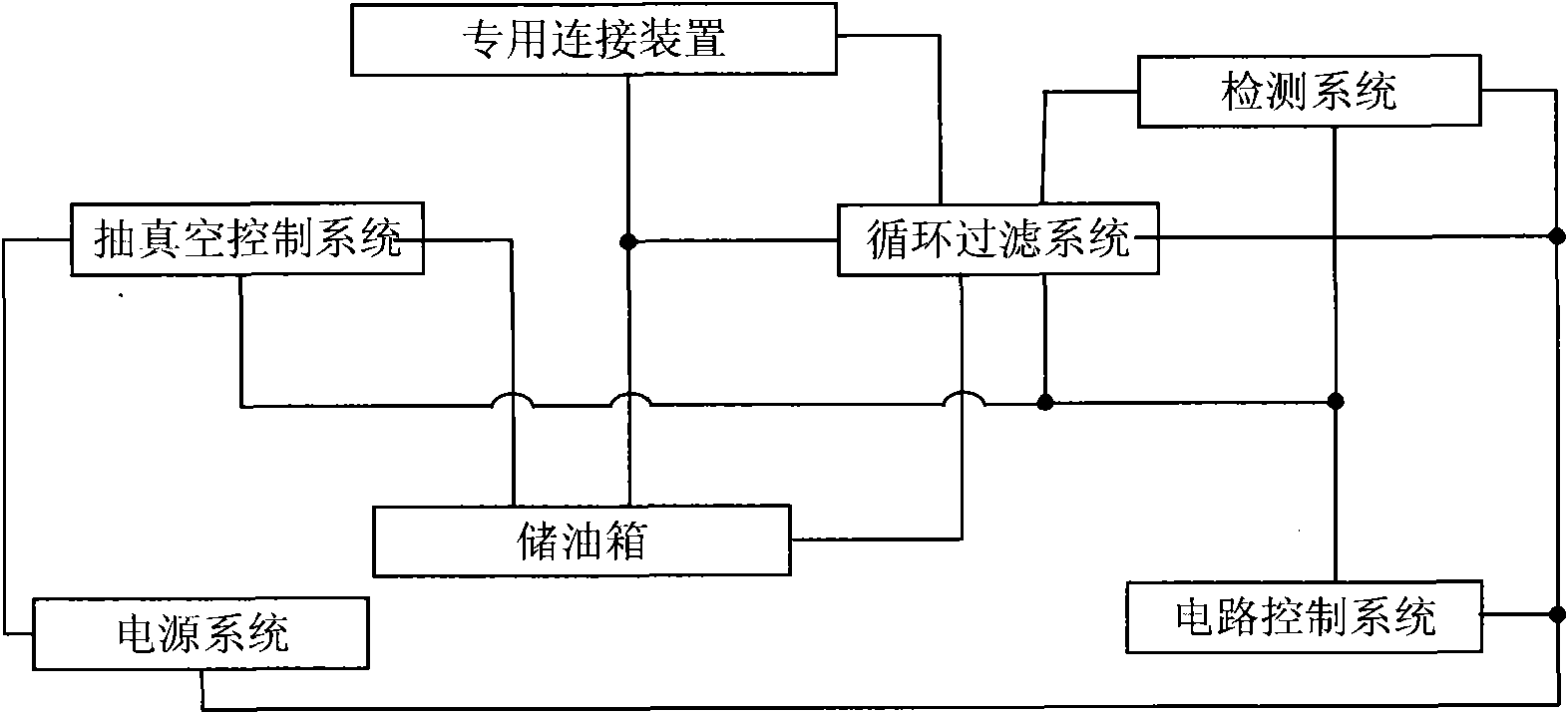

InactiveCN101865186AHigh degree of integrationFunction increaseFluid-pressure actuator testingFluid-pressure actuator componentsFiltrationControl system

The invention discloses an online oil filling and purifying device for hydraulic equipment. The main design points are that: an oil tank is provided with a vacuumization control system; the oil tank is divided into an absolute oil tank and a dirty oil tank; the absolute oil tank is provided with an oil inlet pipeline; the dirty oil tank is provided with an oil drain valve; an online circulating filtration system comprises a dirty oil pipeline communicated with the dirty oil tank and an absolute oil pipeline communicated with the absolute oil tank; the dirty oil pipeline is provided with a dirty oil electromagnetic control valve; the tips of the dirty oil pipeline and the absolute oil pipeline are respectively provided with a dirty oil pipeline quick connector and an absolute oil pipeline quick connector which are communicated with the oil tank of the hydraulic equipment; the dirty oil pipeline is communicated with the absolute oil pipeline through an isolation electromagnetic valve, aone-way valve and a gear pump; and a pressure filter is arranged in the absolute oil pipeline. The online oil filling and purifying device for the hydraulic equipment designed in the invention has the characteristics of high integration degree, complete functions, compact structure, and high maneuverability and maintainability.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

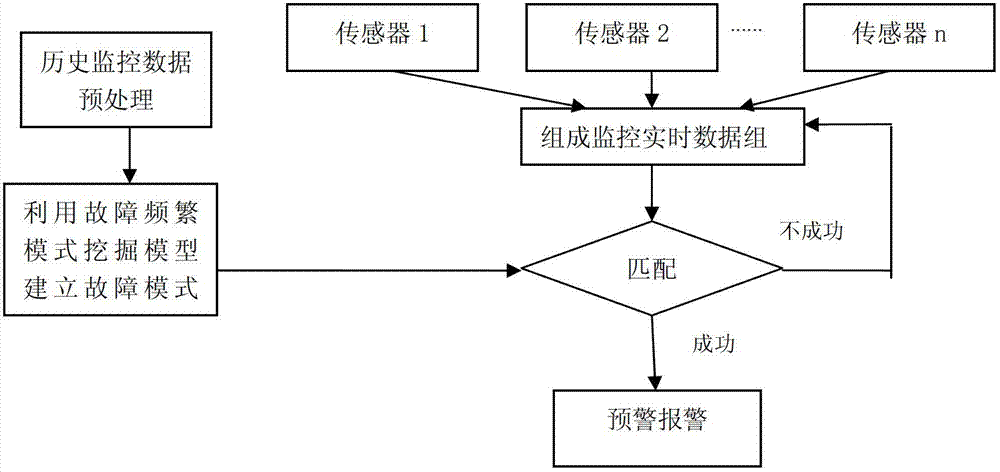

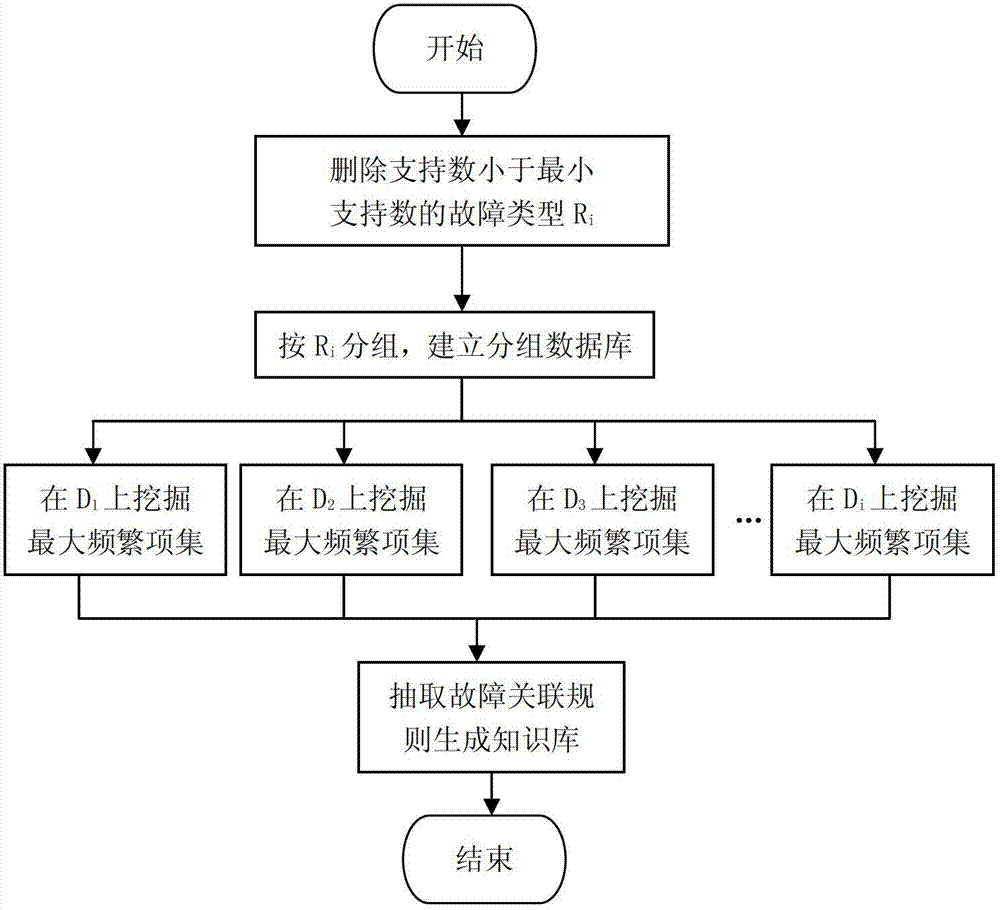

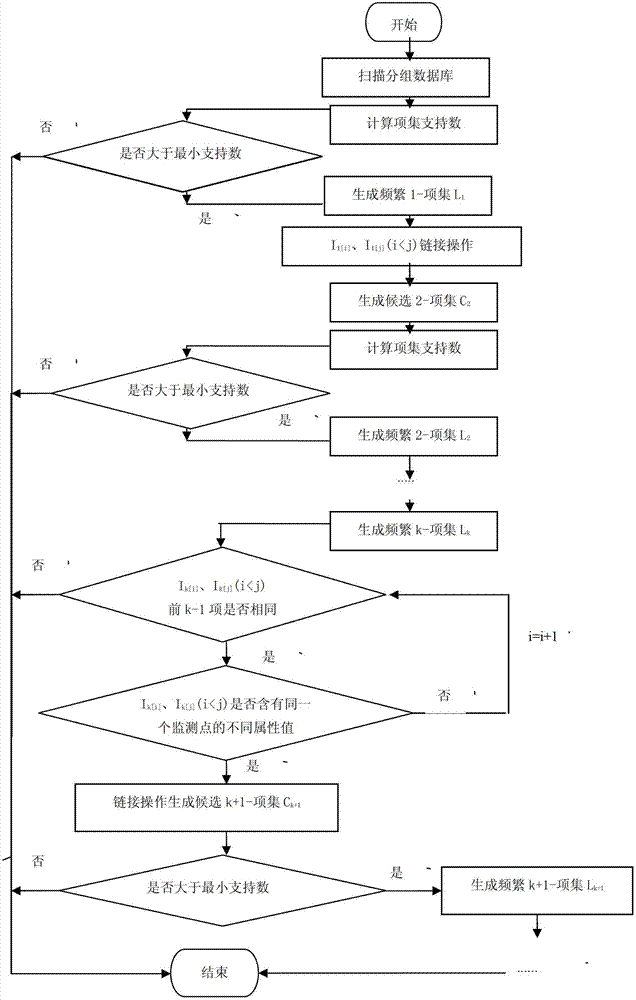

Fault early warning method for hydraulic equipment based on fault frequent pattern

InactiveCN102809965AReduce false positivesImprove accuracyElectric testing/monitoringData setError reporting

The invention discloses a fault early warning method for hydraulic equipment based on a fault frequent pattern, and aims at providing a method which can reduce the occurrence of error reporting and failure in report of early warning and increase the accuracy rate in fault diagnosis. The key point of the technical scheme is that the method comprises the steps of preprocessing the historical monitoring data of equipment, wherein preprocessing comprises removing singular value and normalizing; establishing a fault frequent pattern mining model (FFPMM for short), and mining the historical monitoring data processed in step 1 by utilizing the fault frequent pattern mining model so as to establish a fault mode base; extracting a real-time monitoring data set of the equipment, comparing the real-time monitoring data with the fault mode base in the step 2; if the real-time monitoring data set and the fault mode base fails to be matched successfully, returning the operation to monitor the data of the equipment again; however, if the matching is successful, determining that the detected equipment is in a defect state even if still showing a fault-free state, thereby accomplishing the step 4; obtaining a potential fault occurrence probability value by taking the fault mode base for reference, and then performing early-warning.

Owner:YANSHAN UNIV

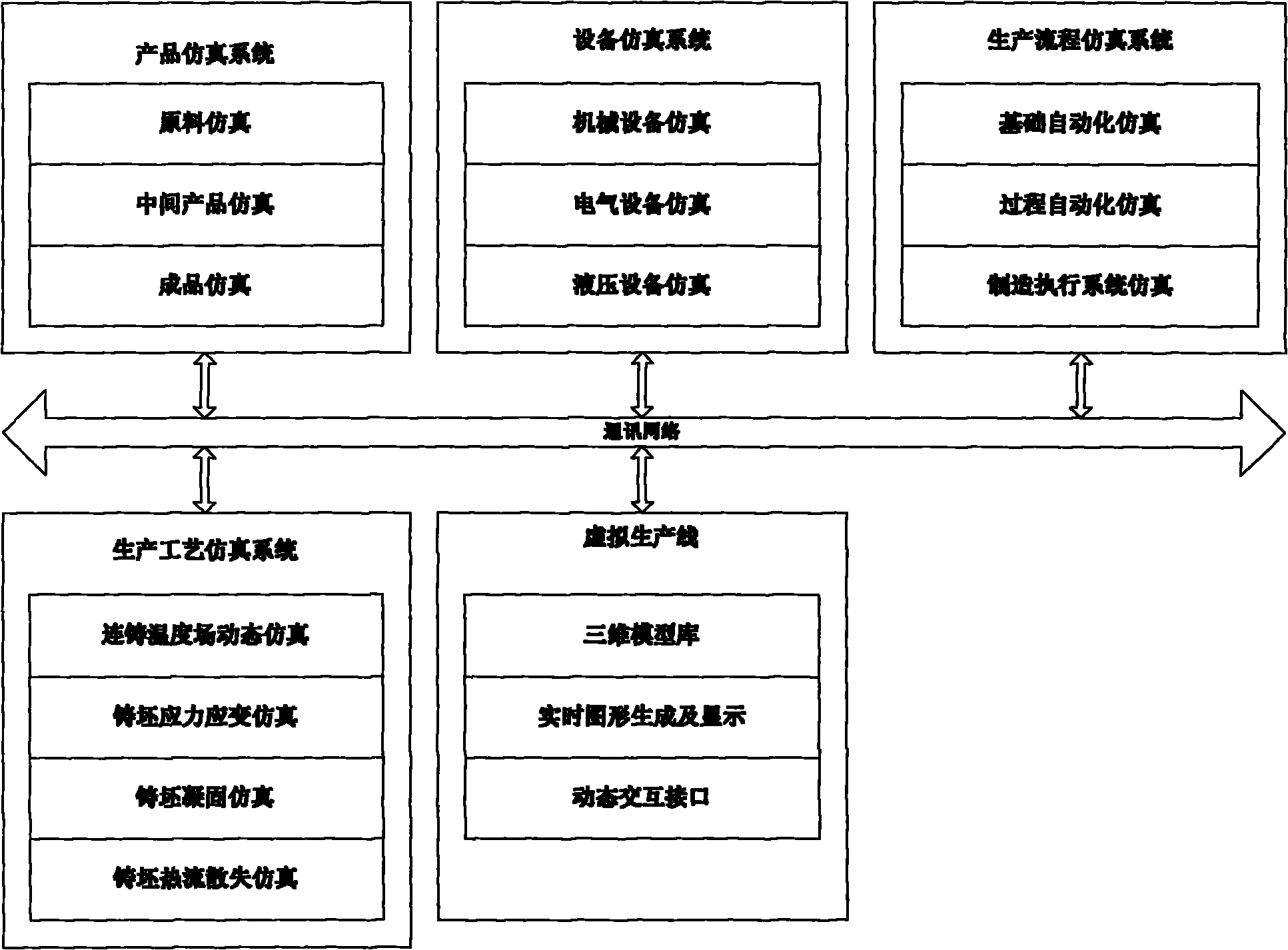

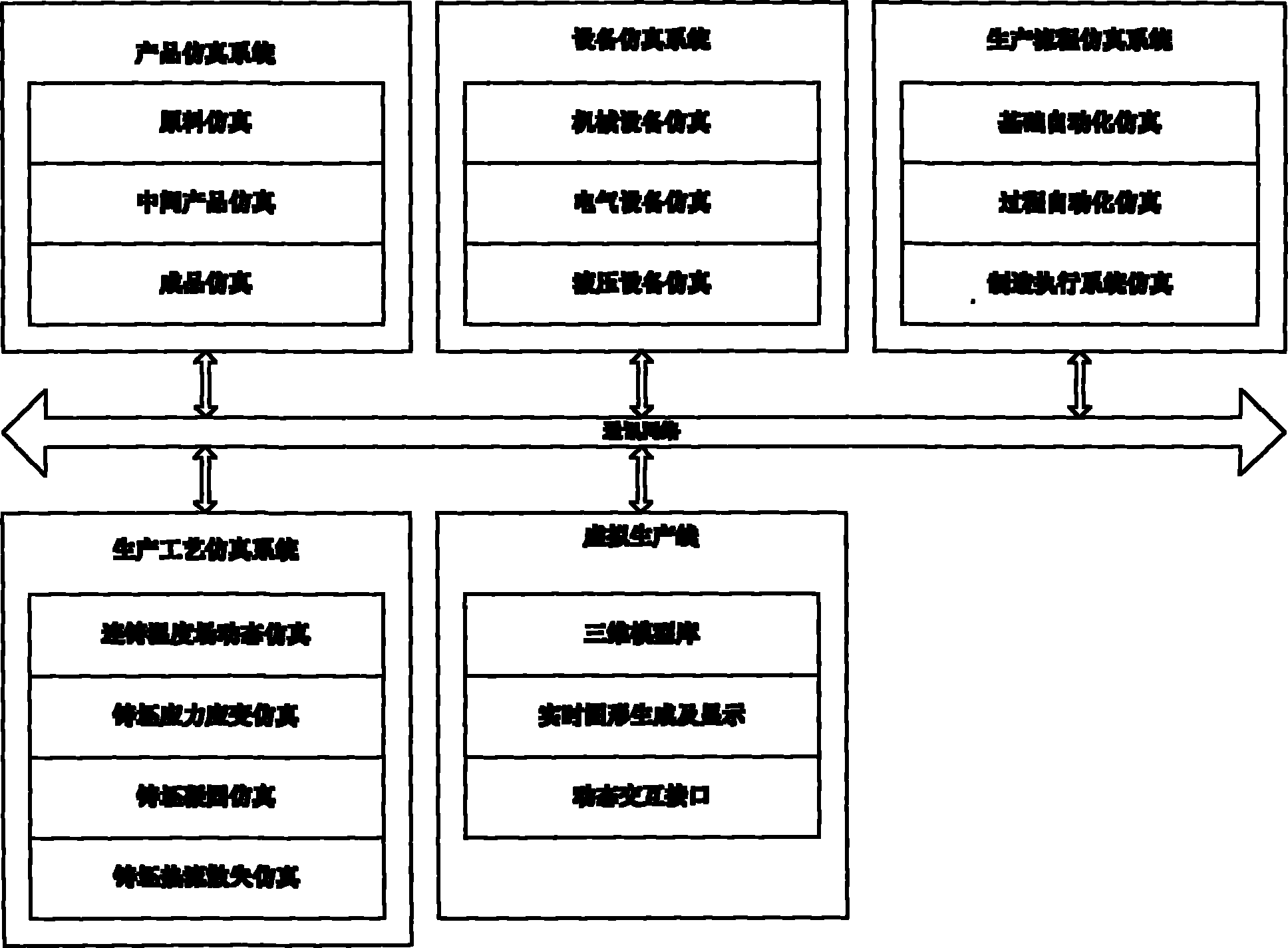

Continuous casting entity simulation and virtualization realization platform

ActiveCN101966570ARealize dynamic interactionHelp developmentHydraulic equipmentSoftware development

The invention discloses a continuous casting entity simulation system. The system comprises a production process simulation system, an equipment simulation system, a product simulation system and a production flow control simulation system which are connected on a communication network, wherein the production process simulation system is used for simulating a continuous casting production process; the equipment simulation system is used for simulating mechanical, electric and hydraulic equipment involved in production; the product simulation system is used for simulating raw materials, intermediate products and finished products; and the production flow control simulation system is used for simulating the flow control of the continuous casting production process. The system realizes digital dynamic simulation of continuous casting production based on a real continuous casting production line and can integrally simulate a continuous casting process; and control technology and application software verified by a real platform can be applied in engineering practice directly, which shortens the development cycle of a model and the application software, improves efficiency and reduces development cost.

Owner:CISDI ENG CO LTD +1

Solenoid actuator

InactiveUS7973627B2Operating means/releasing devices for valvesMagnetic materialsHydraulic equipmentEngineering

Owner:KYB CORP

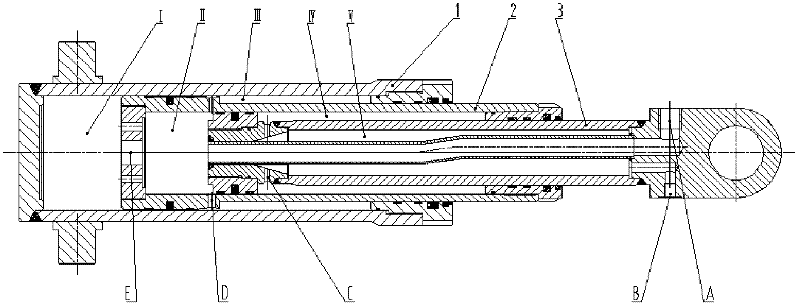

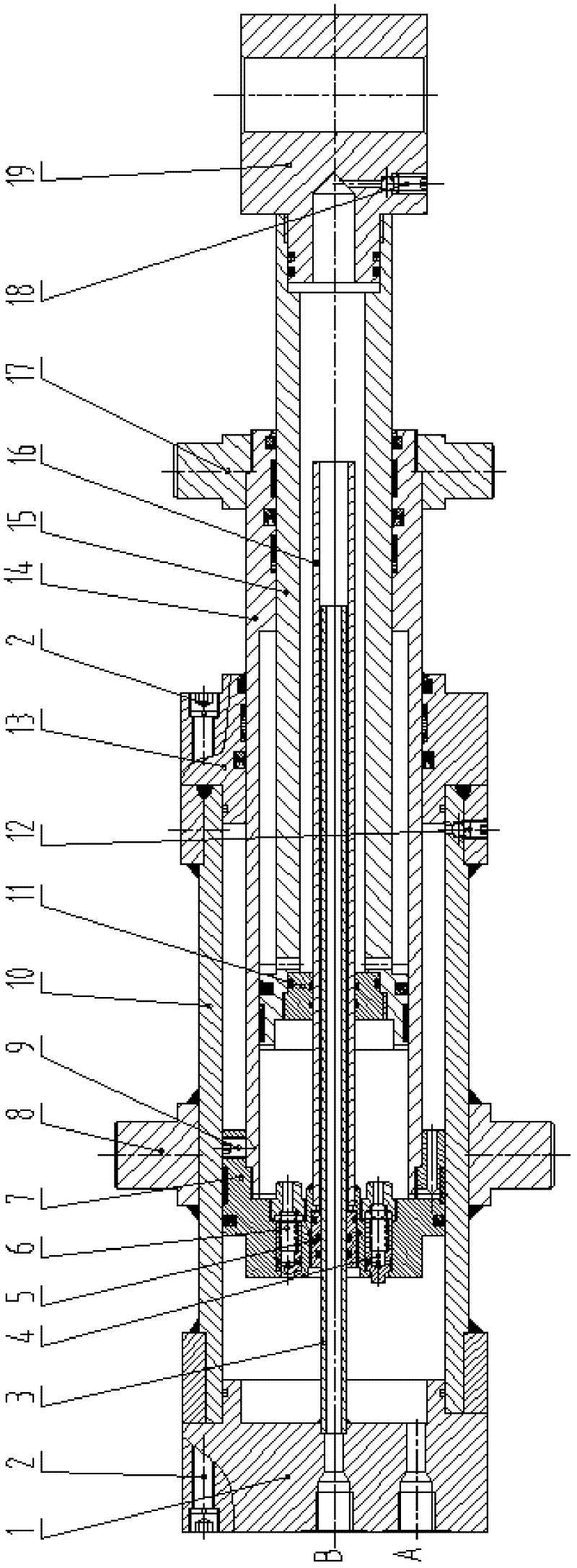

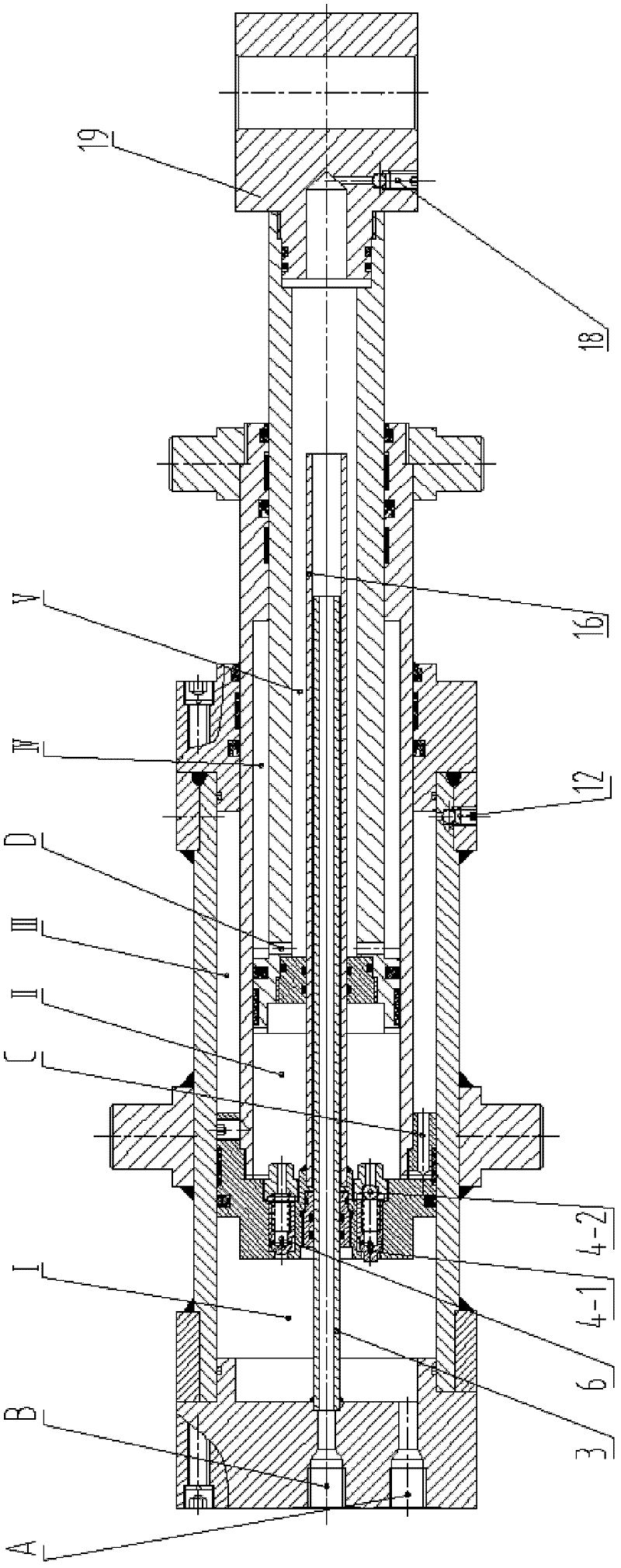

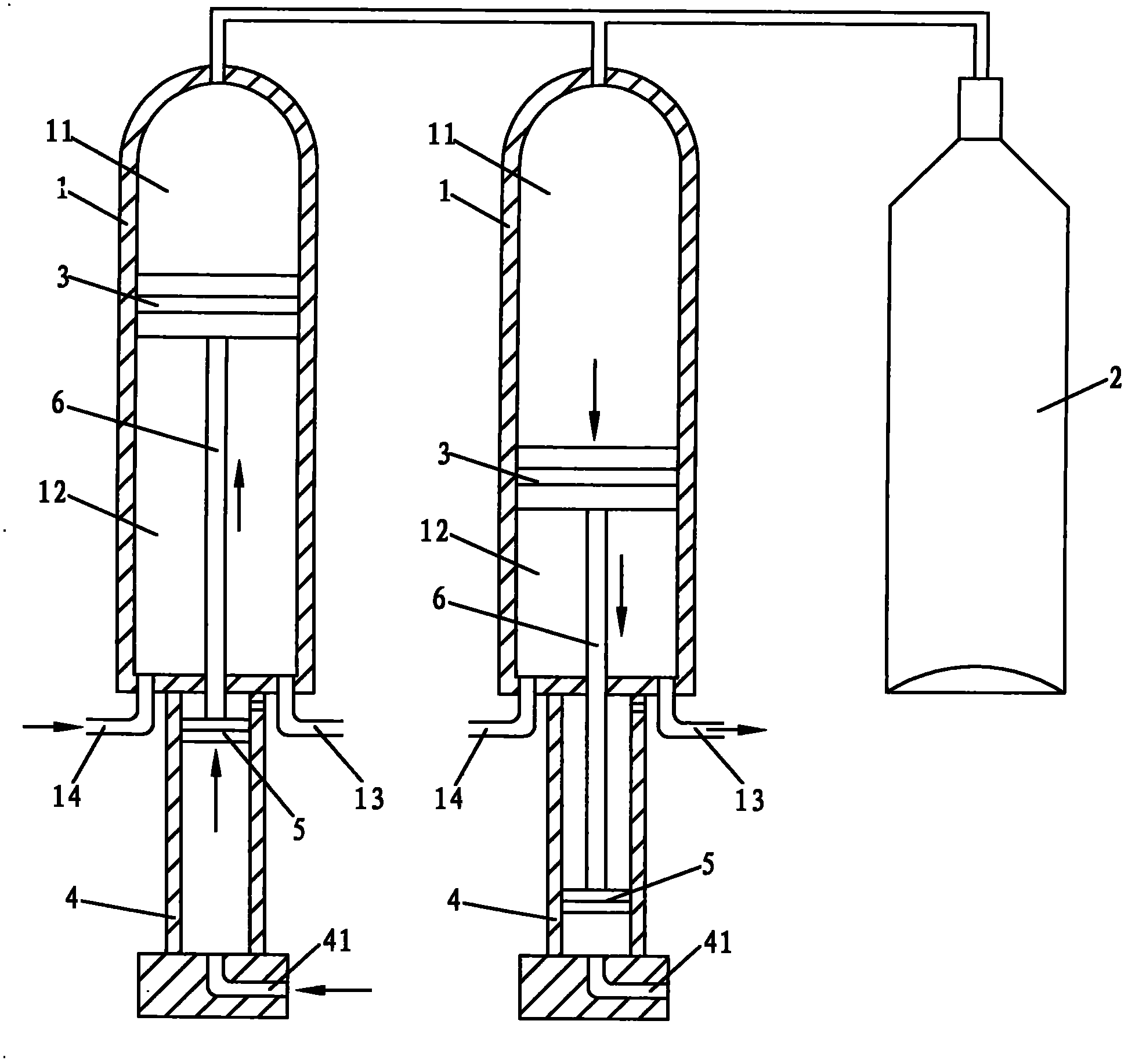

Difunctional synchronous telescopic type multistage hydraulic cylinder and hydraulic device

The invention relates to a difunctional synchronous telescopic type multistage hydraulic cylinder. The difunctional synchronous telescopic type multistage hydraulic cylinder comprises an outer cylinder barrel (10), at least one stage of middle cylinder barrel (14) and a piston rod (15), wherein a rod cavity of the outer cylinder barrel is communicated with a rodless cavity of the first-stage middle cylinder barrel to form a communication cavity, and a rod cavity of each stage of middle cylinder barrel is respectively communicated with a rodless cavity of each adjacent next-stage middle cylinder barrel to respectively form a corresponding communication cavity; and each communication cavity respectively keeps sealing when being full of hydraulic oil. In addition, the invention further provides a hydraulic device comprising the difunctional synchronous telescopic type multistage hydraulic cylinder. According to the difunctional synchronous telescopic type multistage hydraulic cylinder and the hydraulic device, disclosed by the invention, synchronous extension or shrinkage of a multistage hydraulic cylinder is realized, the multistage hydraulic cylinder runs stably and operates precisely, and can remarkably improve operation efficiency of the hydraulic device through synchronous extension and shrinkage, thus exact control of the multistage hydraulic cylinder is possible; in addition, the multistage hydraulic cylinder and the hydraulic device, disclosed by the invention, have excellent technical practicability and remarkably important technical application value.

Owner:HUNAN TELI HYDRAULIC

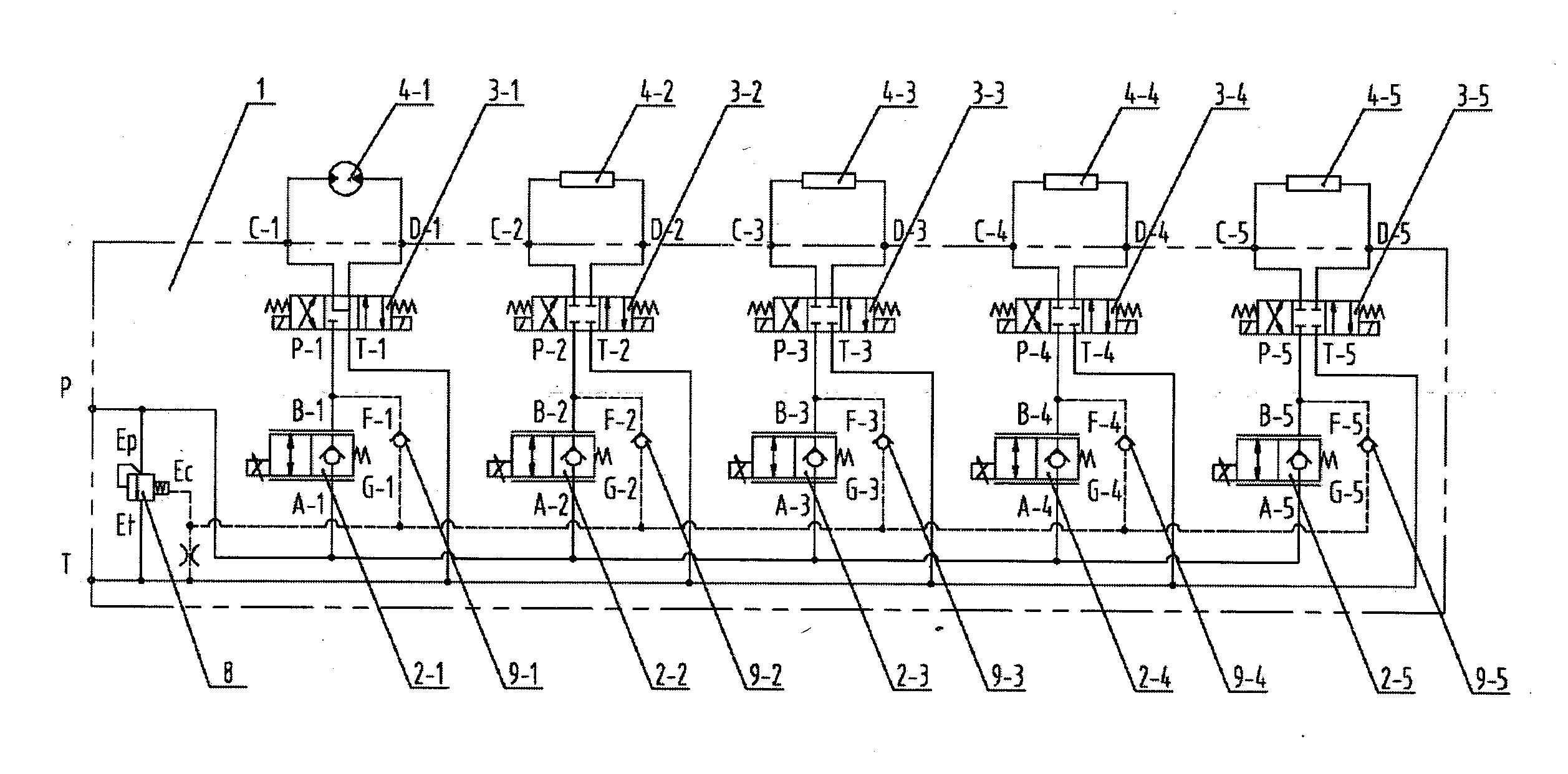

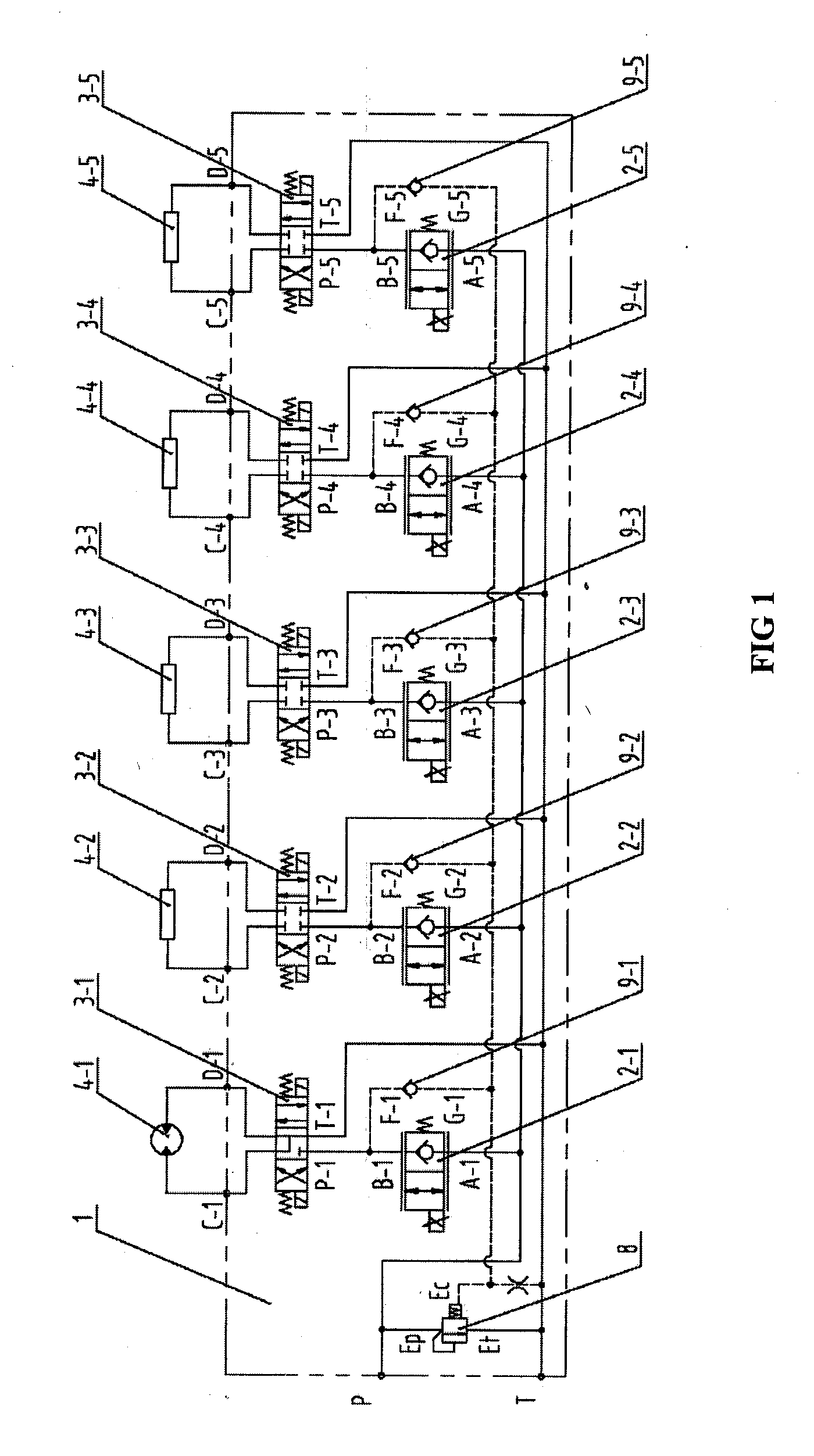

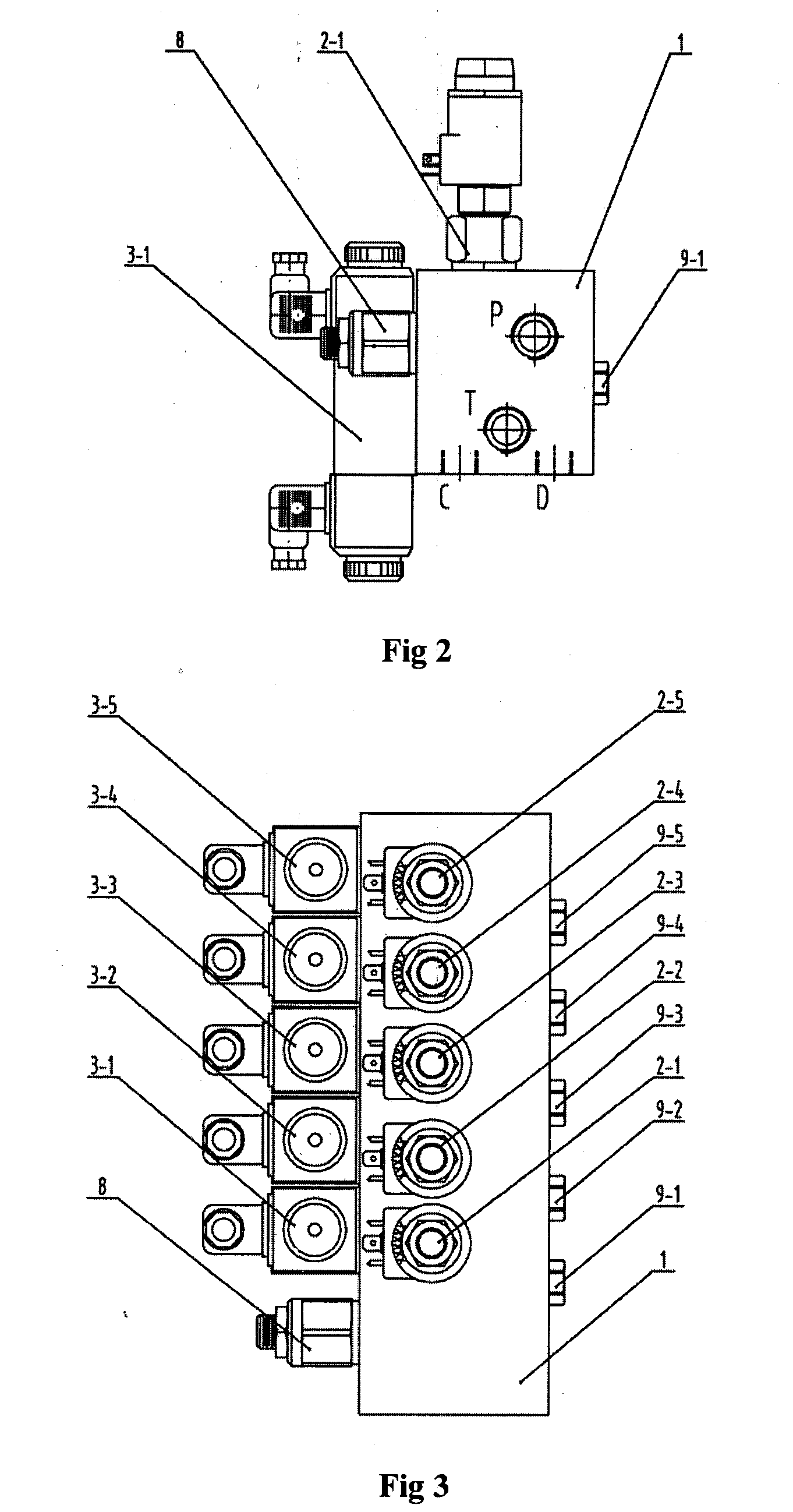

Multi-way valve, hydraulic device and concrete pump vehicle

InactiveUS20120224983A1Weaken energyDecrease productivityOperating means/releasing devices for valvesFluid couplingsProduction rateHydraulic equipment

A multi-way valve includes a plurality of parallel combination valves for controlling corresponding actuators (4-1-4-5). Each combination valve comprises proportional throttle valves (2-1-2-5) and reversing valves (3-1-3-5). An oil inlet of the proportional throttle valve is communicated with a main oil inlet (P), and an oil outlet of the proportional throttle valve is communicated with an oil inlet of the reversing valve. An oil outlet of the reversing valve is communicated with the main oil return port (T). Wherein, each combination valve further comprises a one-way control valve (9-1-9-5, 10-1-10-5) for obtaining the load pressure of corresponding actuator. One side of the one-way control valve is communicated with a pipeline between the proportional throttle valve and the actuator. The multi-way valve further includes a control element (8) which receives the load pressure fed back by each one-way control valve and responds to the load pressure to control the supply of hydraulic oil for the actuators. The multi-way valve has the load-sensitive function, thereby reducing energy loss and system heat productivity. A hydraulic equipment and a concrete pump vehicle corresponding to the multi-way valve are also provided.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP +1

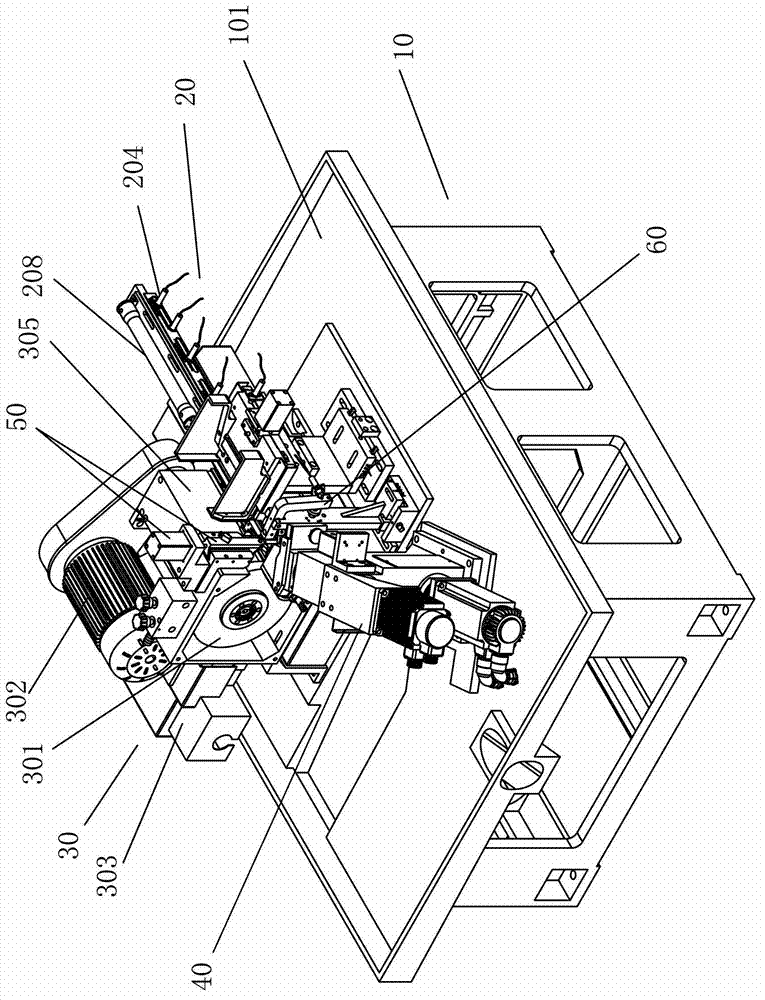

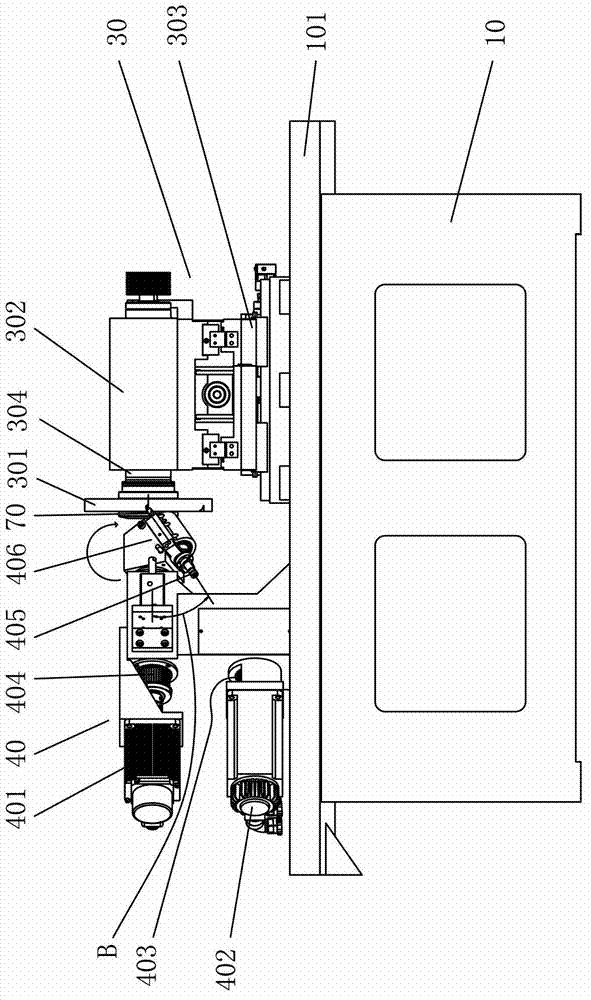

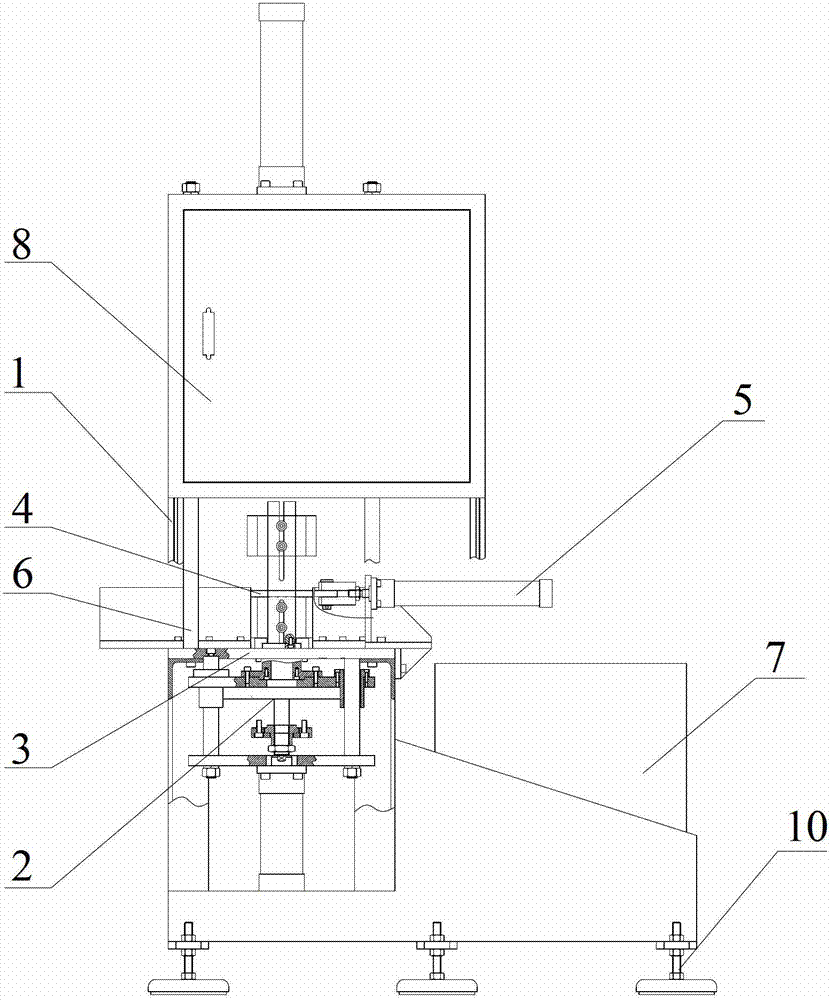

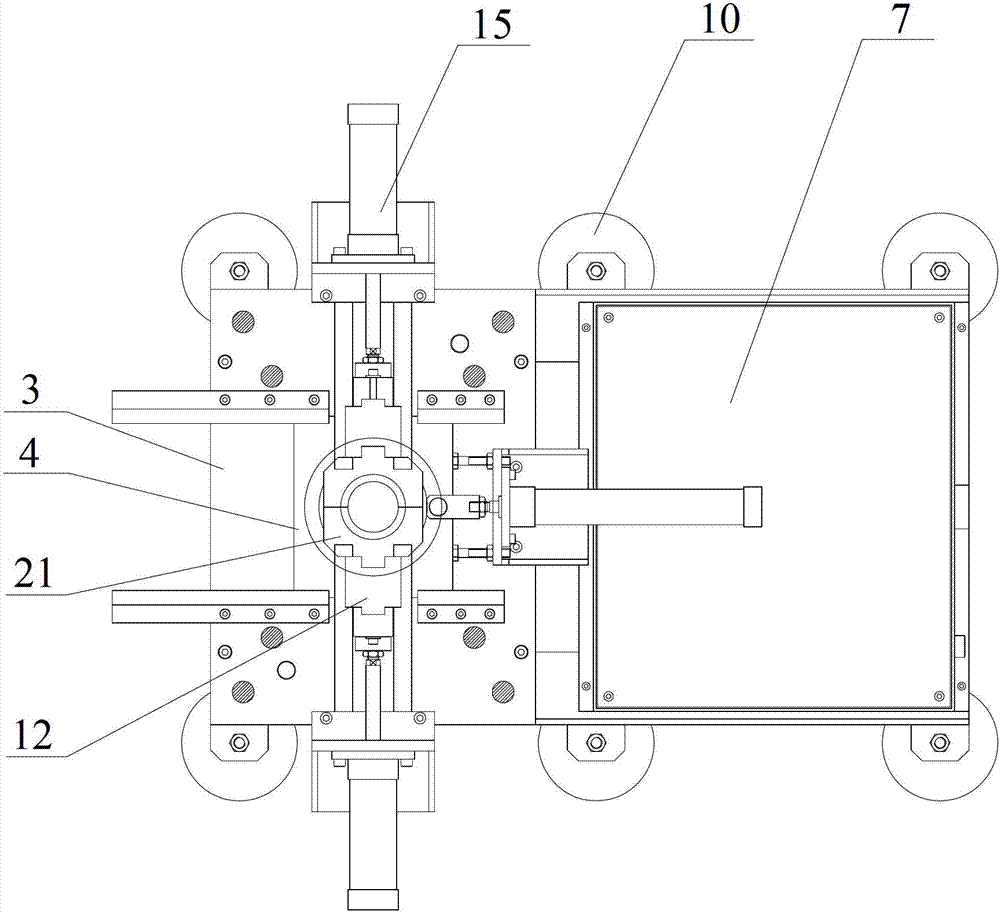

Fully automatic numerical control drill cutter grinding machine

ActiveCN102896561AOutstanding and Beneficial Technical EffectsRealize fully automatic processingDrilling toolsNumerical controlEngineering

The invention belongs to the technical field of grinding machines, and relates to a fully automatic numerical control drill cutter grinding machine, wherein a grinding component is arranged on the upper side of a machine base; the grinding component comprises a cross supporting plate capable of displacing in an X direction and a Y direction under the driving of a power device and a grinding wheel which is driven by a variable frequency motor; a working platform at one side of the grinding wheel is provided with a double-axle planet wheel type rotary clamp driven by two powers; an automatic feeding device is arranged on the opposite side of the rotary clamp; the cross supporting plate at the upper side of the grinding wheel is provided with a grinding wheel trimming device; a cooling conduct of a cooling system which is arranged on the machine base is led to a nozzle on the grinding part; a drilling bit locating device is arranged between the automatic feeding device and the rotary clamp; and actions of the cross supporting plate, the variable frequency motor, the rotary clamp, the automatic feeding device, the drilling bit locating device and the grinding wheel trimming device are controlled by a controller. The fully automatic numerical control drill cutter grinding machine has the advantages that: a fully automatic processing on the drilling bit is realized after loading, and the purpose of operating on multiple machines by one person is implemented; the fully automatic numerical control drill cutter grinding machine is high in efficiency, good in fineness and low in labor intensity, and the machine doubles the efficiency in comparison with the conventional hydraulic equipment.

Owner:ZHEJIANG WEIKE MACHINERY TECH

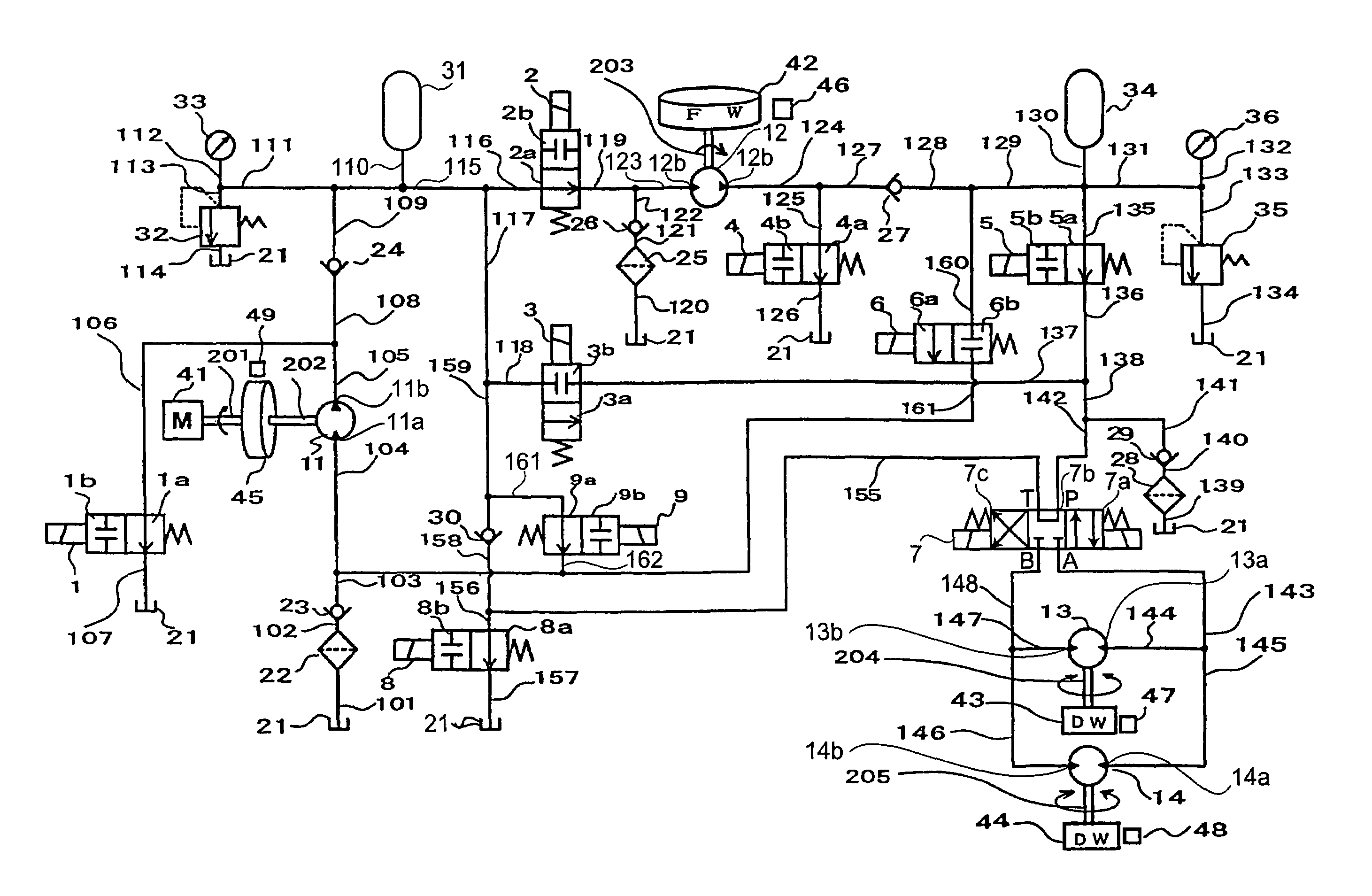

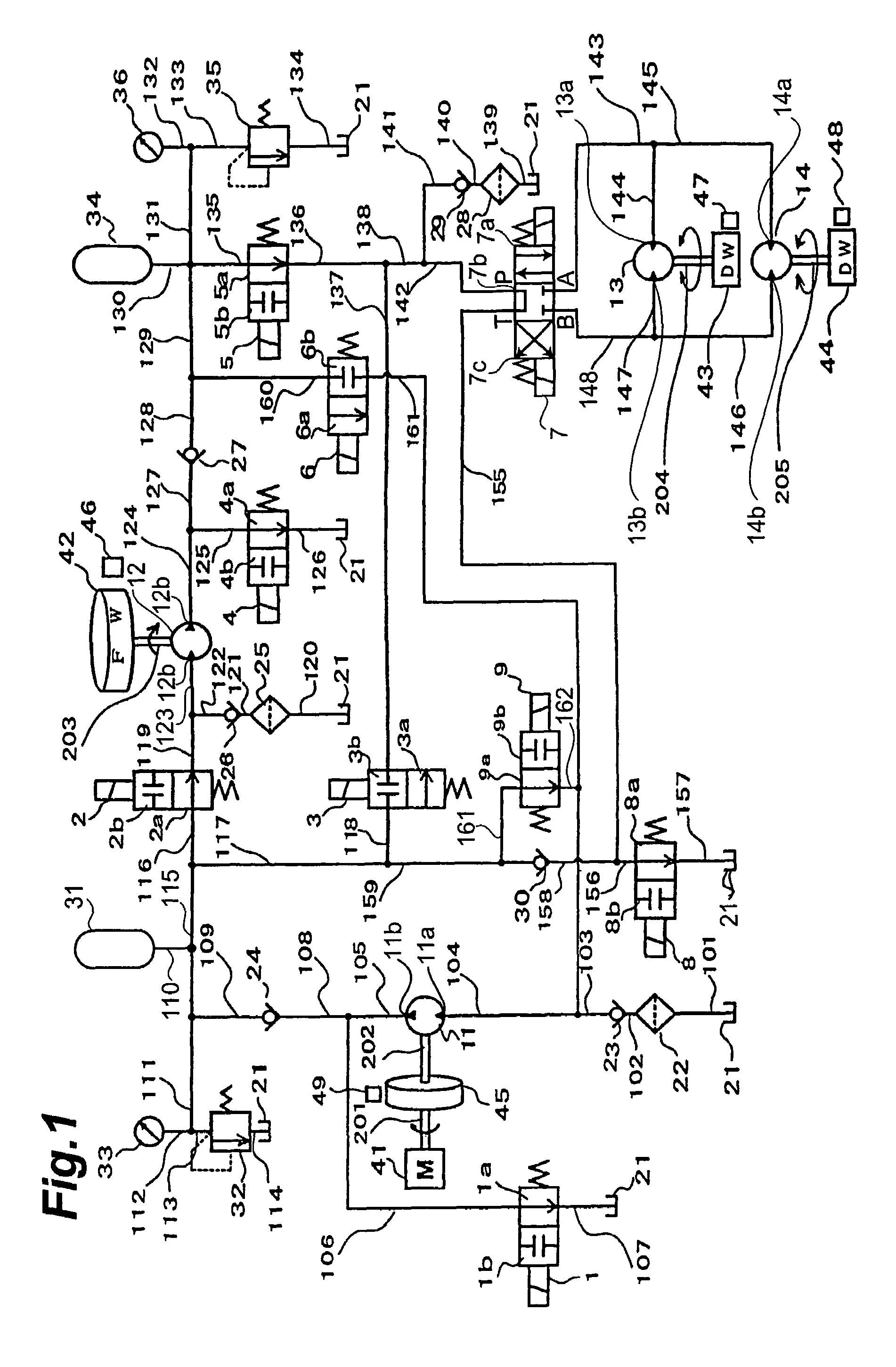

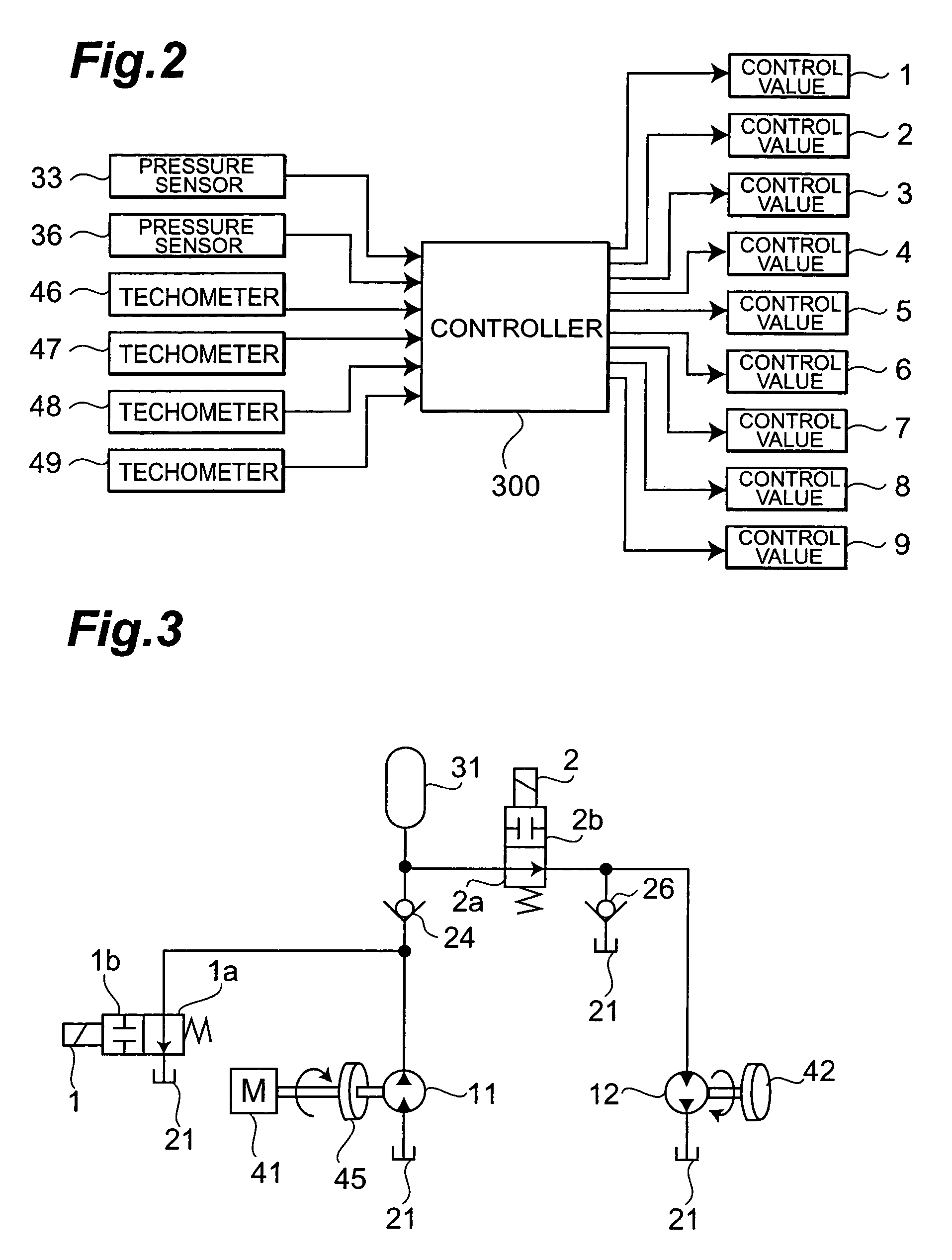

Hydraulic equipment

A hydraulic apparatus realizes the same function as that of a variable discharge pump by regulating a hydraulic device such as a control valve in a state always operated at a substantially constant number of revolutions with a high efficiency regardless of the type of a hydraulic pump driven by a driving source such as a heat engine or electric motor. This hydraulic apparatus drives a hydraulic pump with a driving source internally or additionally provided with a predetermined amount of inertia, so as to construct a fixed pressure hydraulic source, and further provides peripheral devices corresponding to a required load, so as to open / close a control valve according to a state of a load including an energy accumulating device, a hydraulic motor, or the like such that the load can be supplied with an operating fluid ranging from a low flow rate at a high pressure to a high flow rate at a low pressure.

Owner:SAXA +1

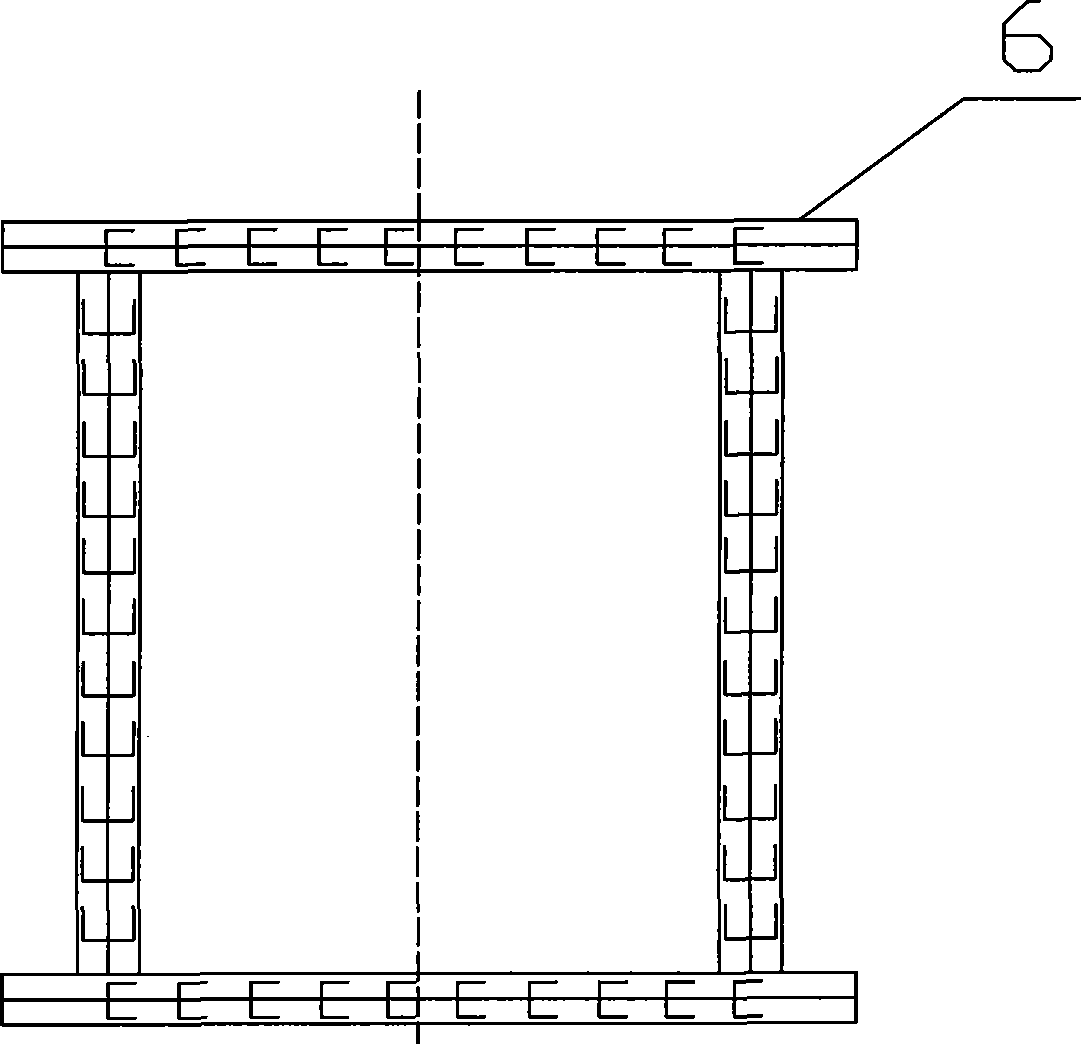

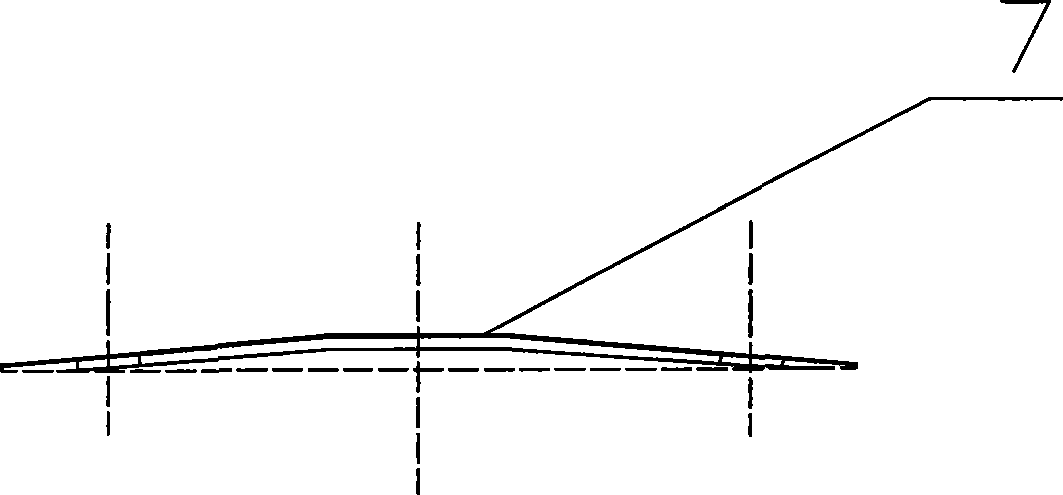

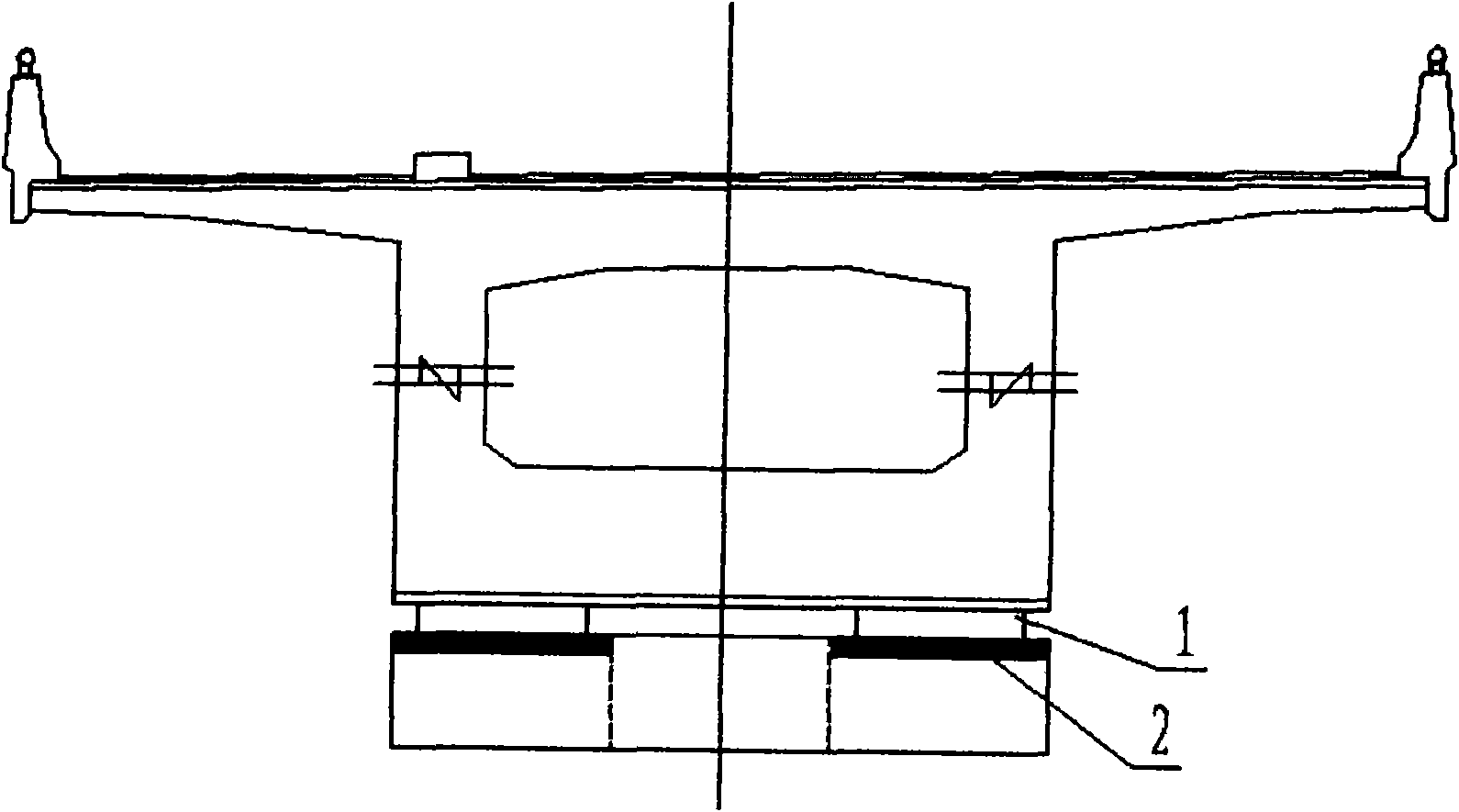

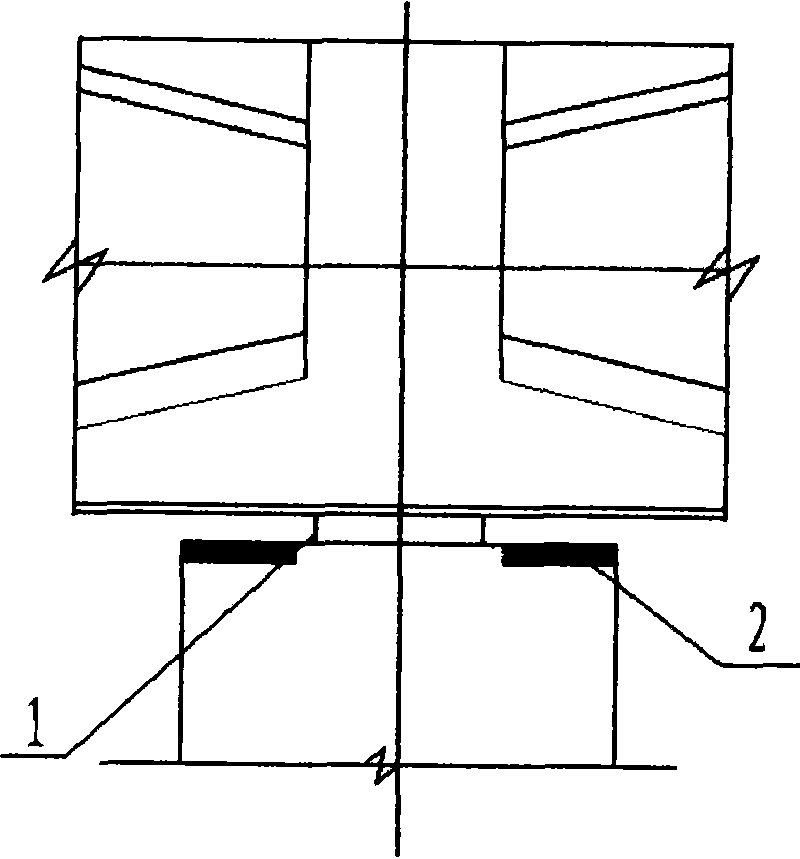

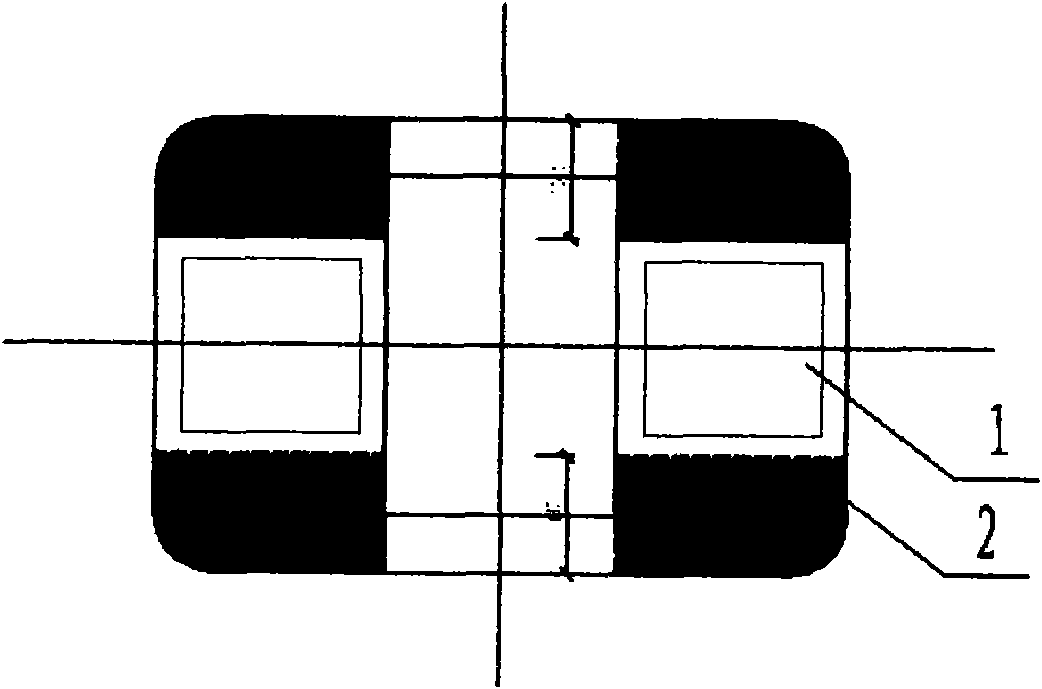

Integral lifting reconstruction method for high-span overweight continuous box girder

InactiveCN101892636ASolve the problem of setting up a reliable jacking systemAddress the risk of collapseBridge structural detailsBridge erection/assemblyReconstruction methodHydraulic equipment

The invention discloses an integral lifting reconstruction method for a high-span overweight continuous box girder. The method comprises the following steps of: cutting the top of a pier; reinforcing an upper box girder; welding a limiting device on the outer side of an upright post hoop, and integrating the limiting structure and a concrete pier into a whole to limit the lifting of the girder; debugging a lifting jack and a follow-up jack; lifting formally until the girder is lifted to a position which is 1cm higher than a designed elevation, screwing up a self-threaded device of the lifting jack, disassembling the follow-up jack, arranging a support and a permanent cushion block; loosening the self-threaded device on the lifting jack and allowing the jack to drop for 1 cm to the designed elevation; and disassembling the lifting device, the hoop and the limiting device and joining the lifted pier. The method can adapt to the high-span continuous box girder with limited height at the support, heavy weight, high requirements on a lifting hydraulic device and small width at the ribbed part of the box girder and can realize safe integral lifting of the continuous box girder with an accurate position.

Owner:SHANGHAI XIANWEI CIVIL ENG

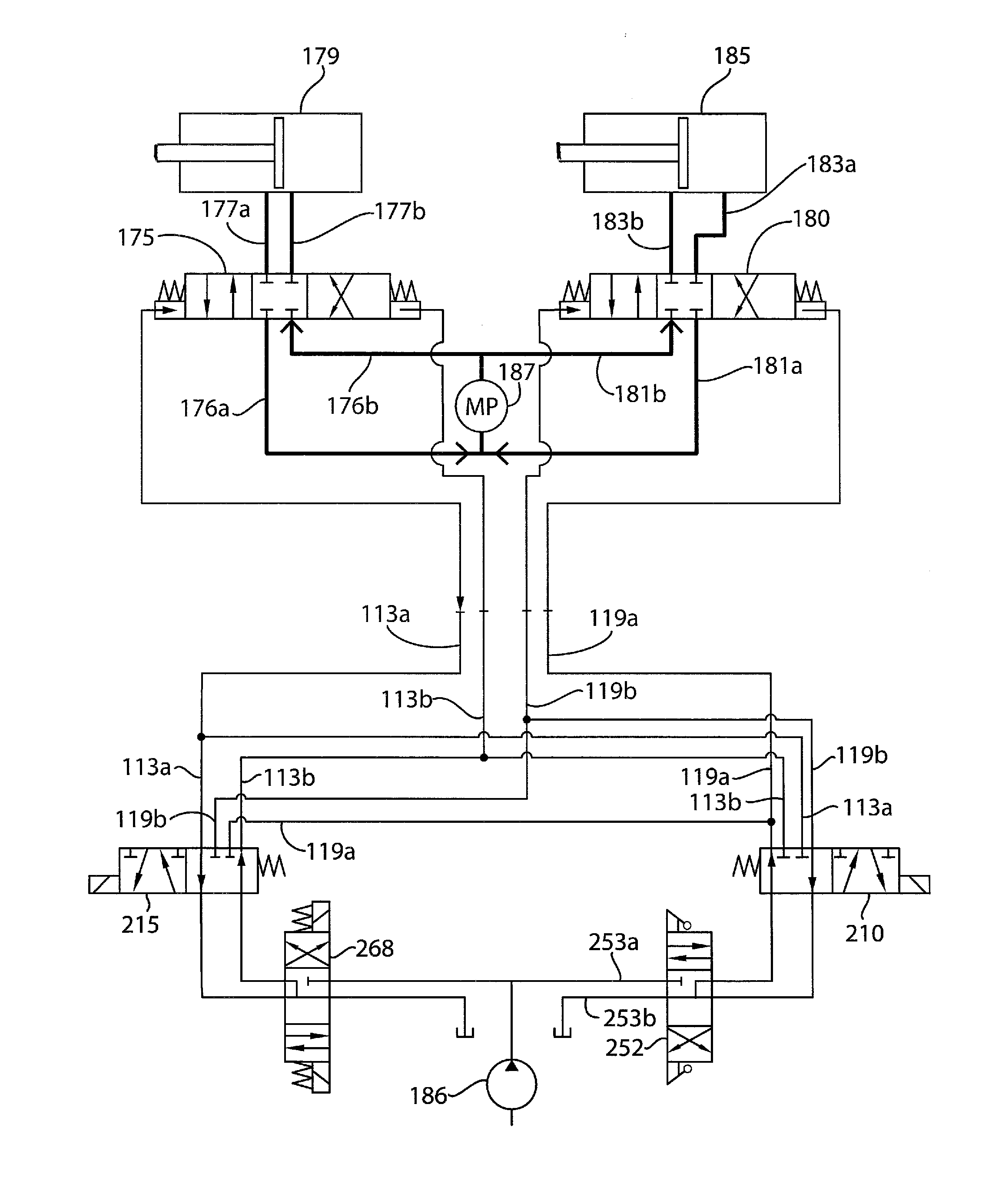

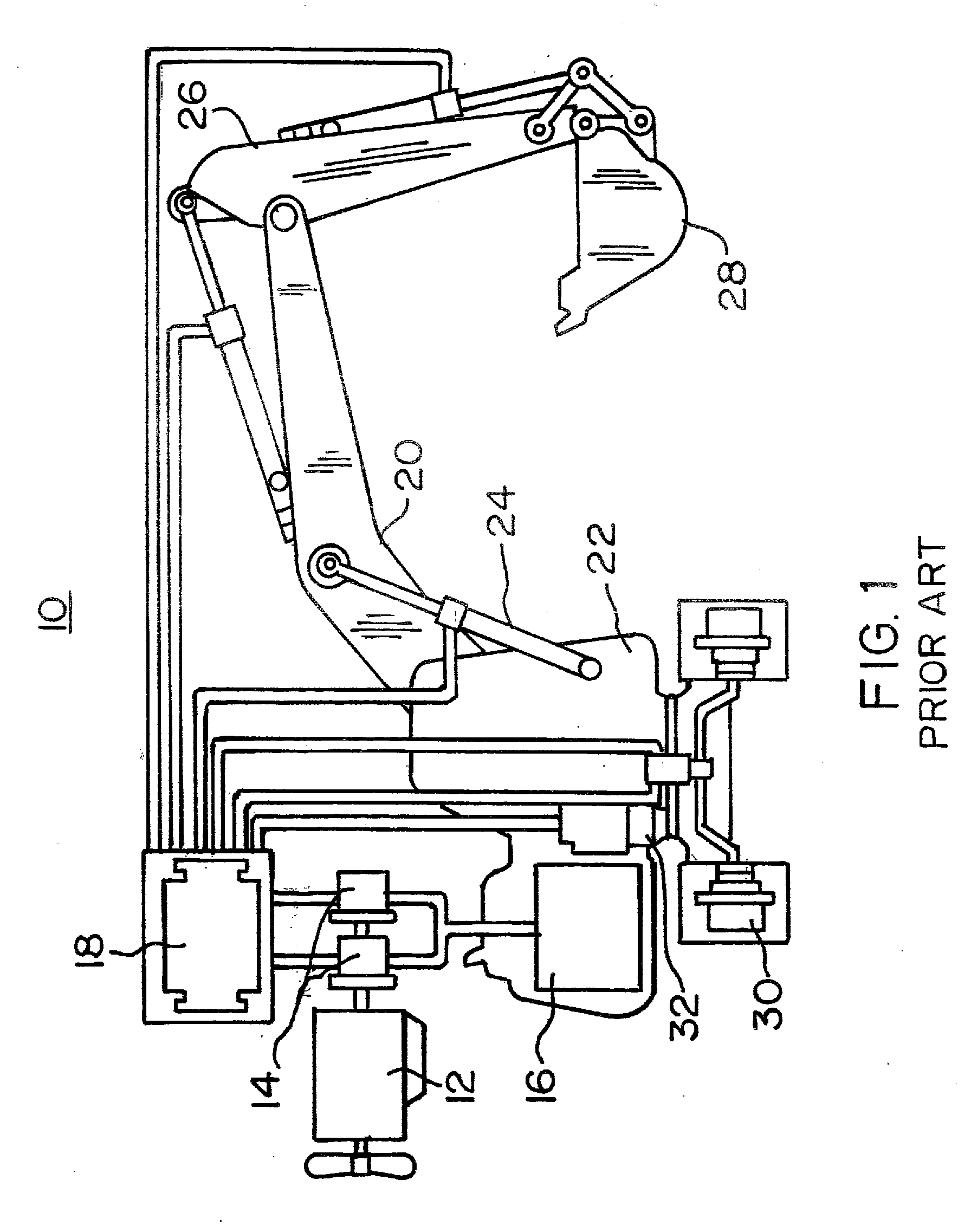

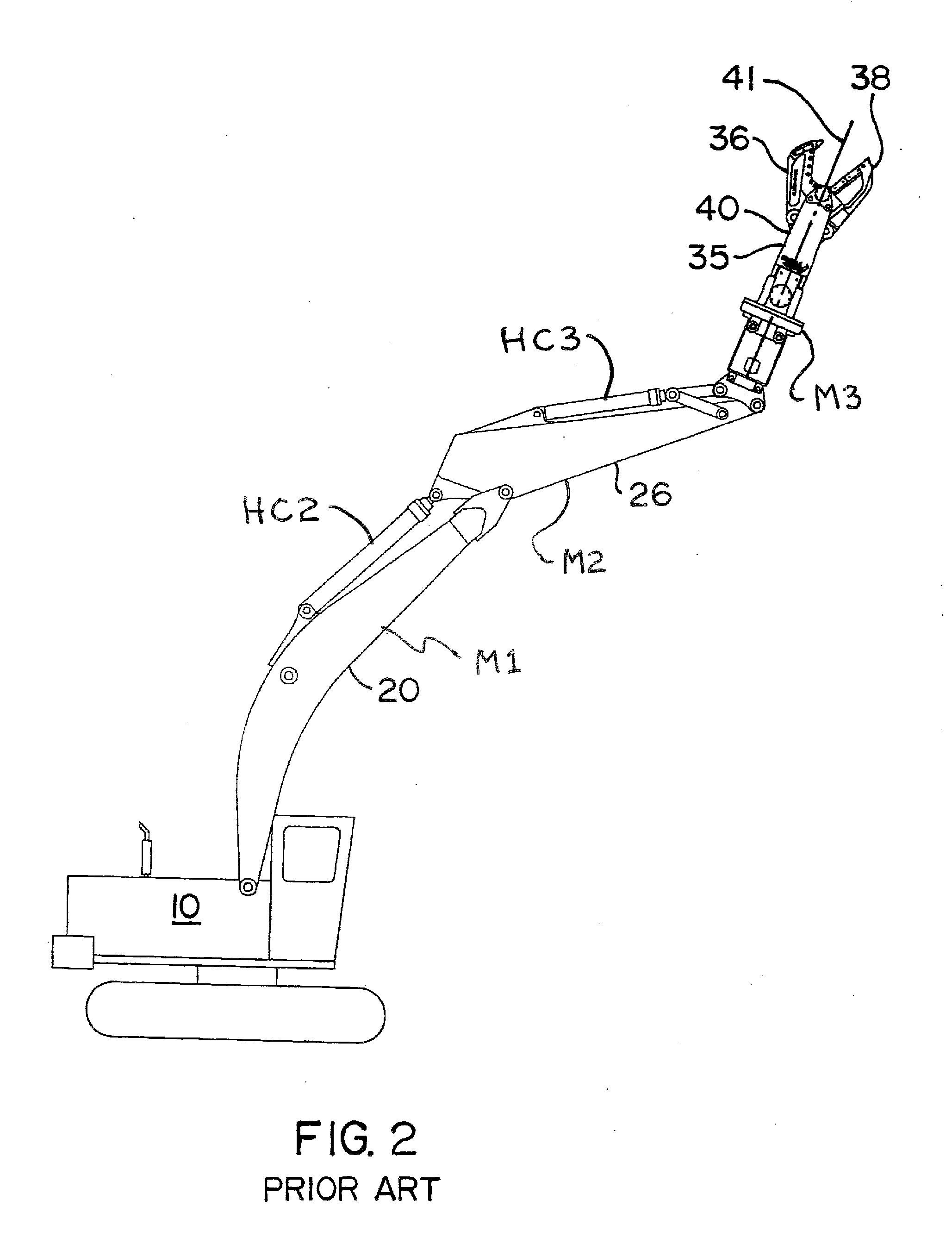

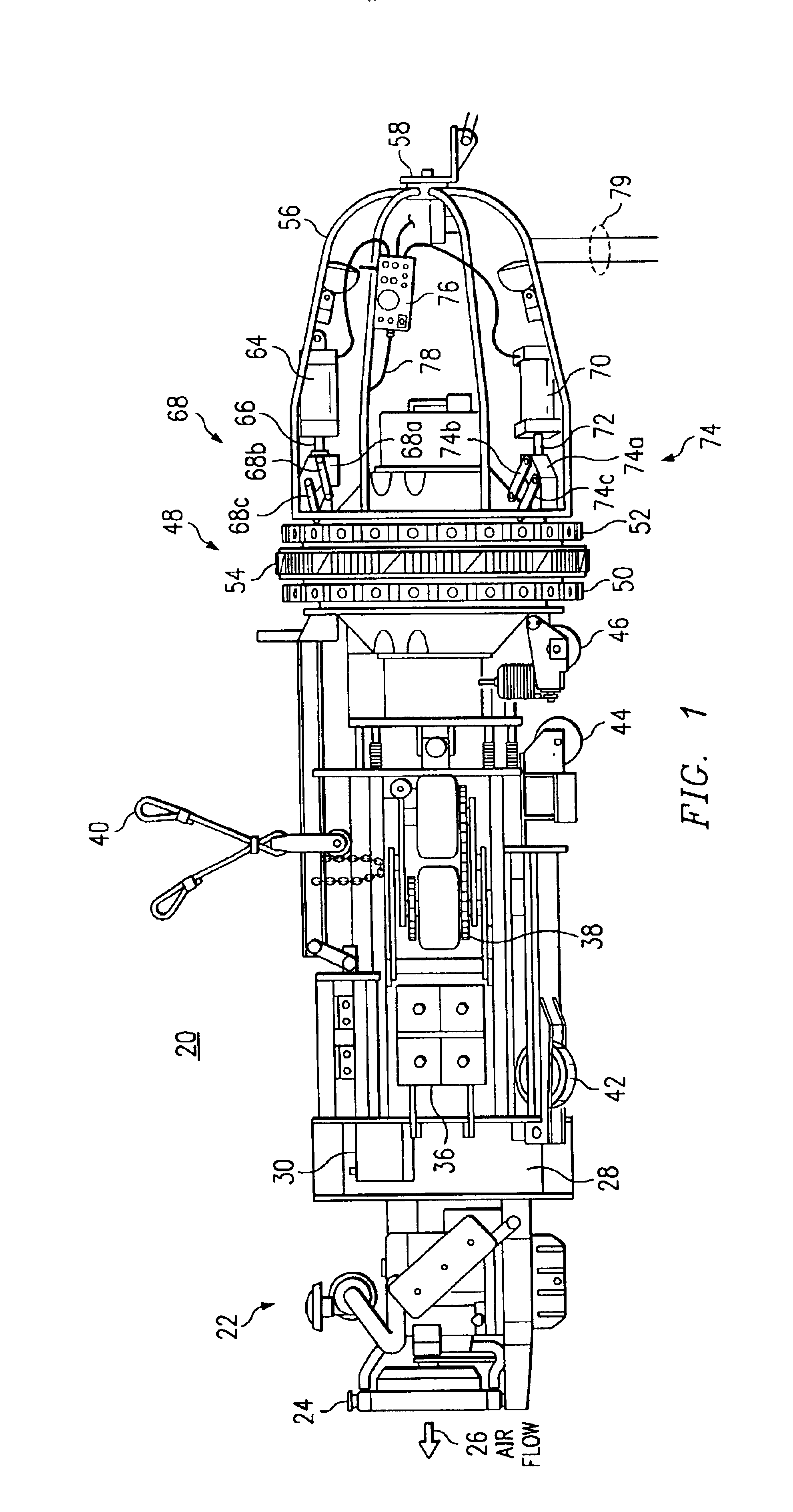

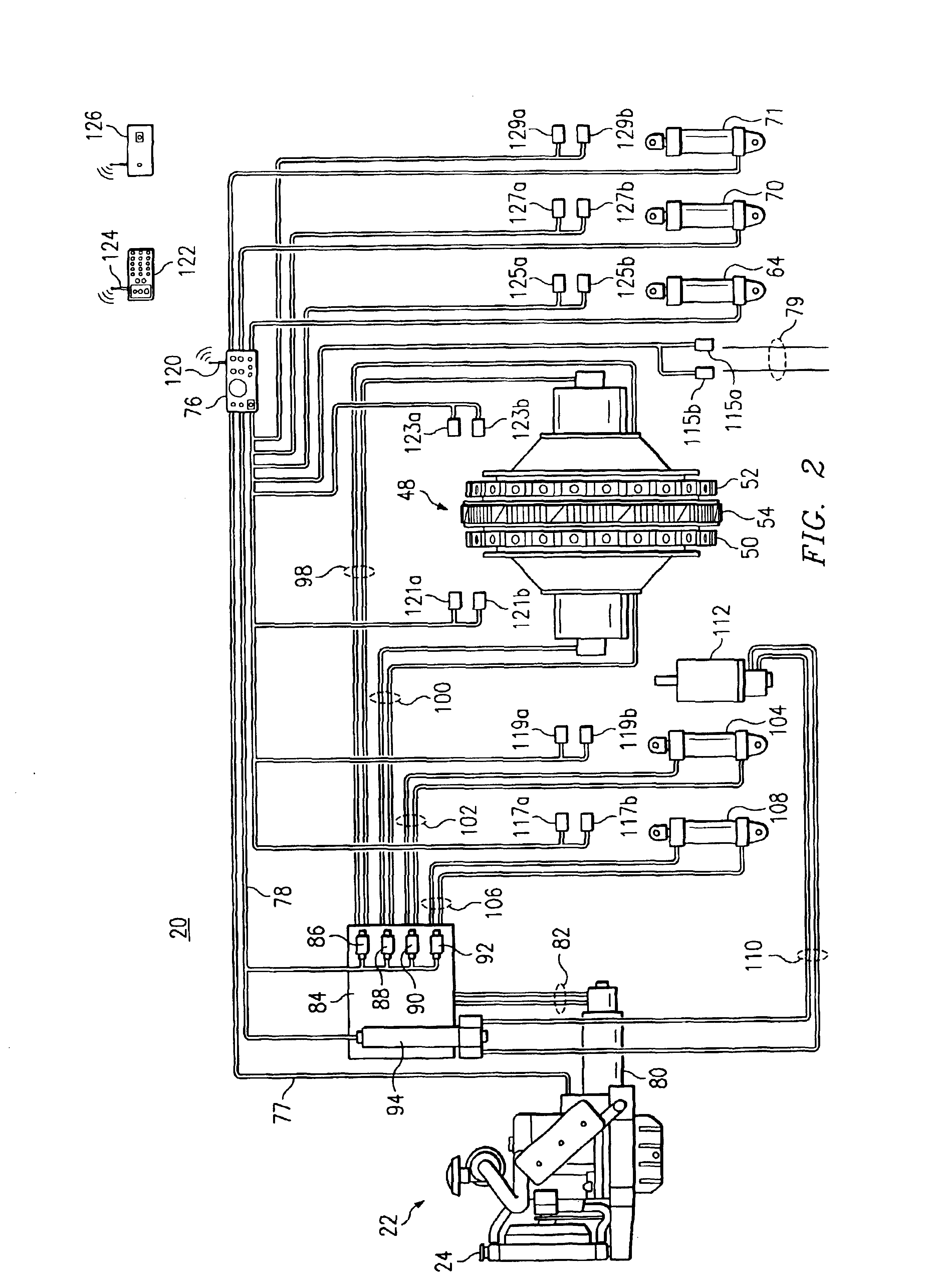

Universal Control Scheme For Mobile Hydraulic Equipment And Method For Achieving The Same

A universal control scheme for mobile hydraulic equipment has switches to activate and / or control any number of different tools or accessories that may be used to configure the equipment. Additionally, a single controller command may be reassigned from one set to another set of hydraulic line pairs. Furthermore, at different times, two separate controller commands may be used to control the same hydraulic line pair. The control scheme also provides for consolidating hydraulic line pair functions to separate for dedicated use those line pairs associated with operating hydraulic cylinders to extend or retract a member and those line pairs used to provide hydraulic fluid for operating tools.

Owner:RAMUN MICHAEL R RAMU

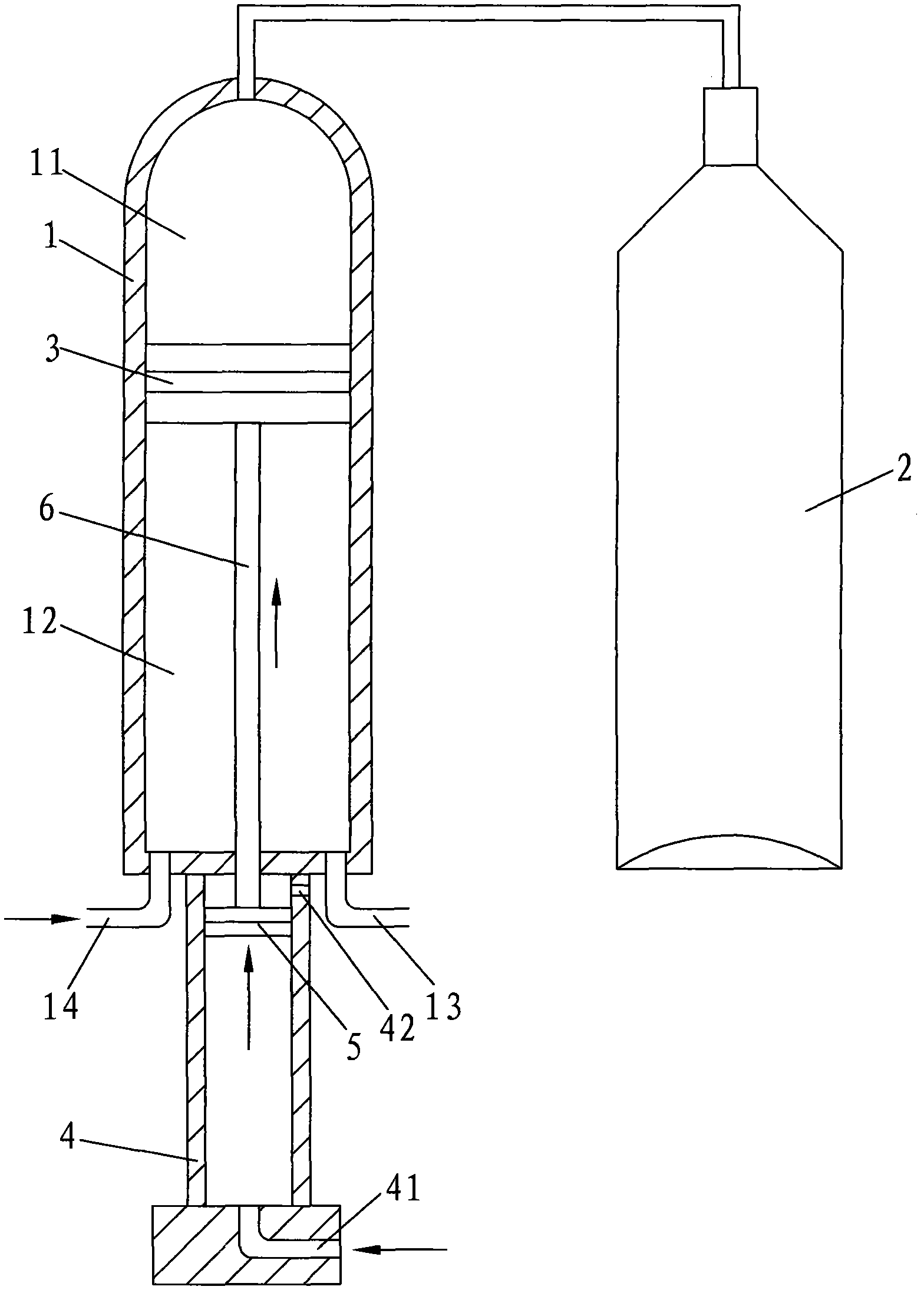

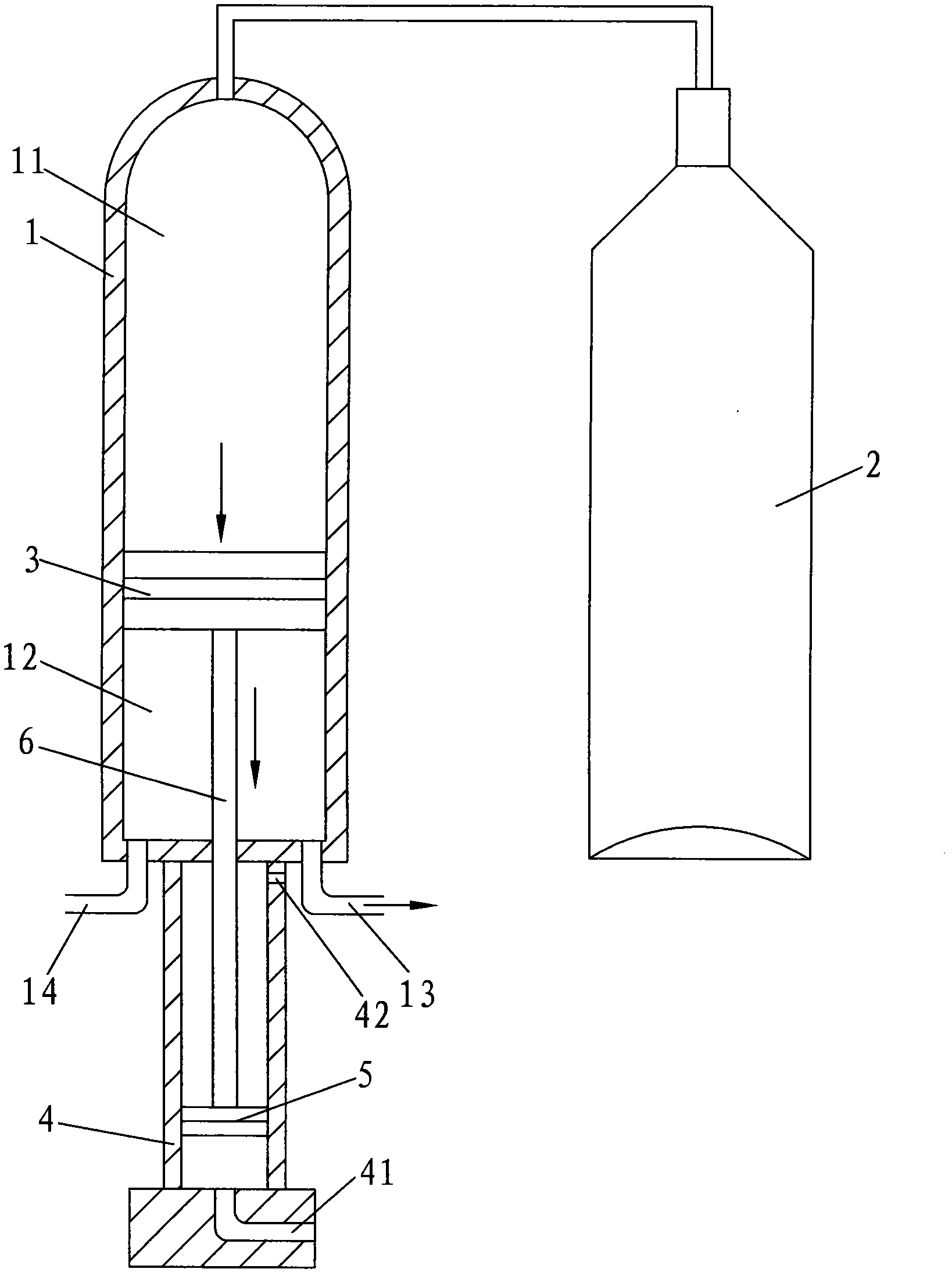

Hydraulic pressure booster for ultra-high pressure tool

InactiveCN101498324AAchieve low pressure unloadingImprove reliabilityServomotor componentsFluid-pressure convertersUltra high pressureEngineering

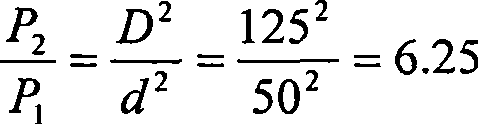

The invention belongs to the field of the hydraulic device, in particular relates to a hydraulic intensifier (8) of a superhigh pressure tool. The hydraulic intensifier (8) adopts a pressure cylinder (3), a reversing valve (1) and a hydraulic control one-way valve (2) to form a pressurizing loop, a pressure cylinder piston is arranged in the pressure cylinder (3) and is used for dividing the pressure cylinder into a poleless cavity, a pole cavity and a pressurizing cavity, a top pole (4) is arranged on an end cover of the poleless cavity of the pressure cylinder, the pressure cylinder piston is a hollow part, an one-way valve (5), a center hole (7) and the pressurizing cavity are arranged in the hollow, and the inlet end of the one-way valve (5) is positioned in a position which opposites to the top pole (4). When the piston completely withdraws, the top pole can touch the one-way valve (5) to communicate the one-way valve, the outlet end of the one-way valve (5) is communicated with the pressurizing cavity by the center hole (7), and the hydraulic control one-way valve (2) is arranged on an oil circuit of the pole cavity of the pressure cylinder (3). The hydraulic intensifier has compact structure, and the pipeline connection between the valves and the pressure cylinders is saved to reduce system leakage. The invention has the advantages of convenient installation, low cost, stable operation, long service life, high work efficiency, strong temperature variation resistance, strong environmental pollution resistance, convenient maintenance, and the like and is suitable for the outdoor service on building sites for a long period.

Owner:BEIJING UNION UNIVERSITY

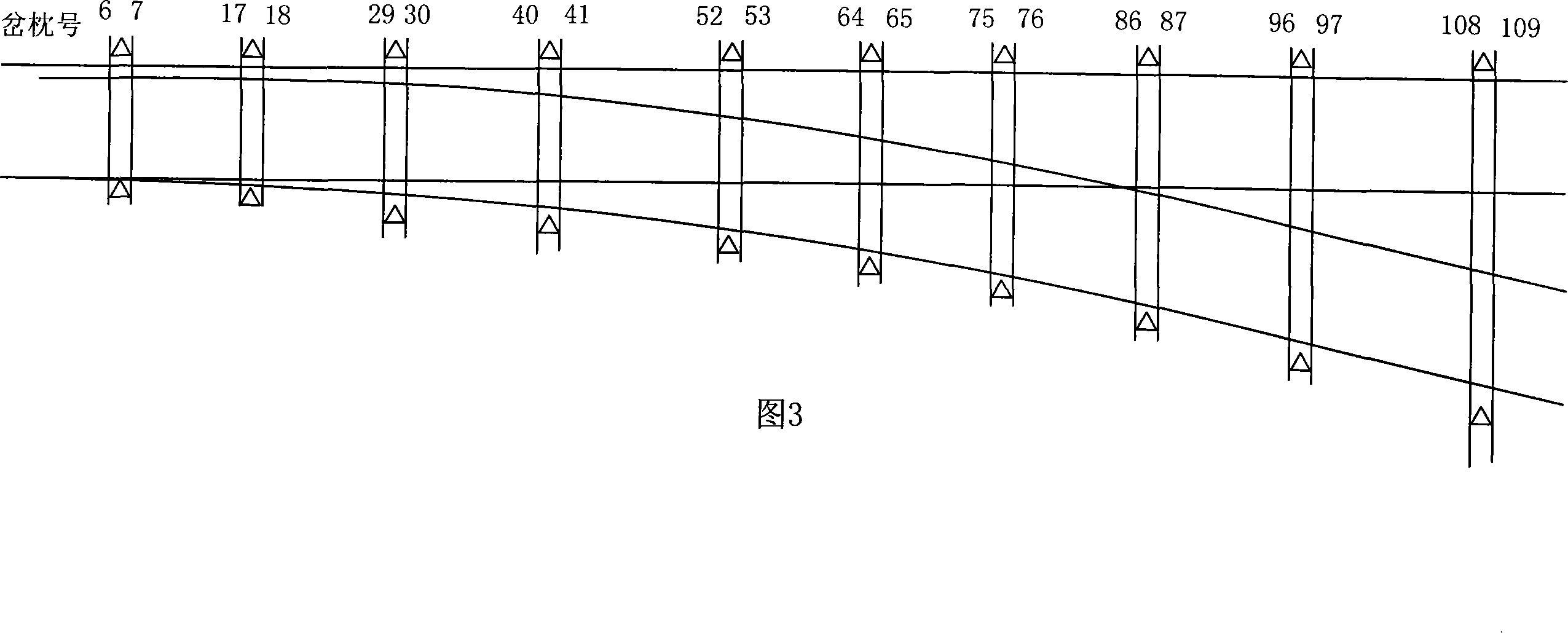

Runway switch laying method for ballast track passenger special line

ActiveCN101173492AHigh adjustment accuracyAvoid deformationRailway track constructionHydraulic equipmentEngineering

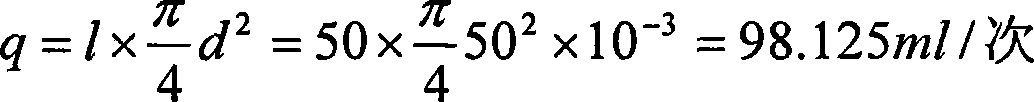

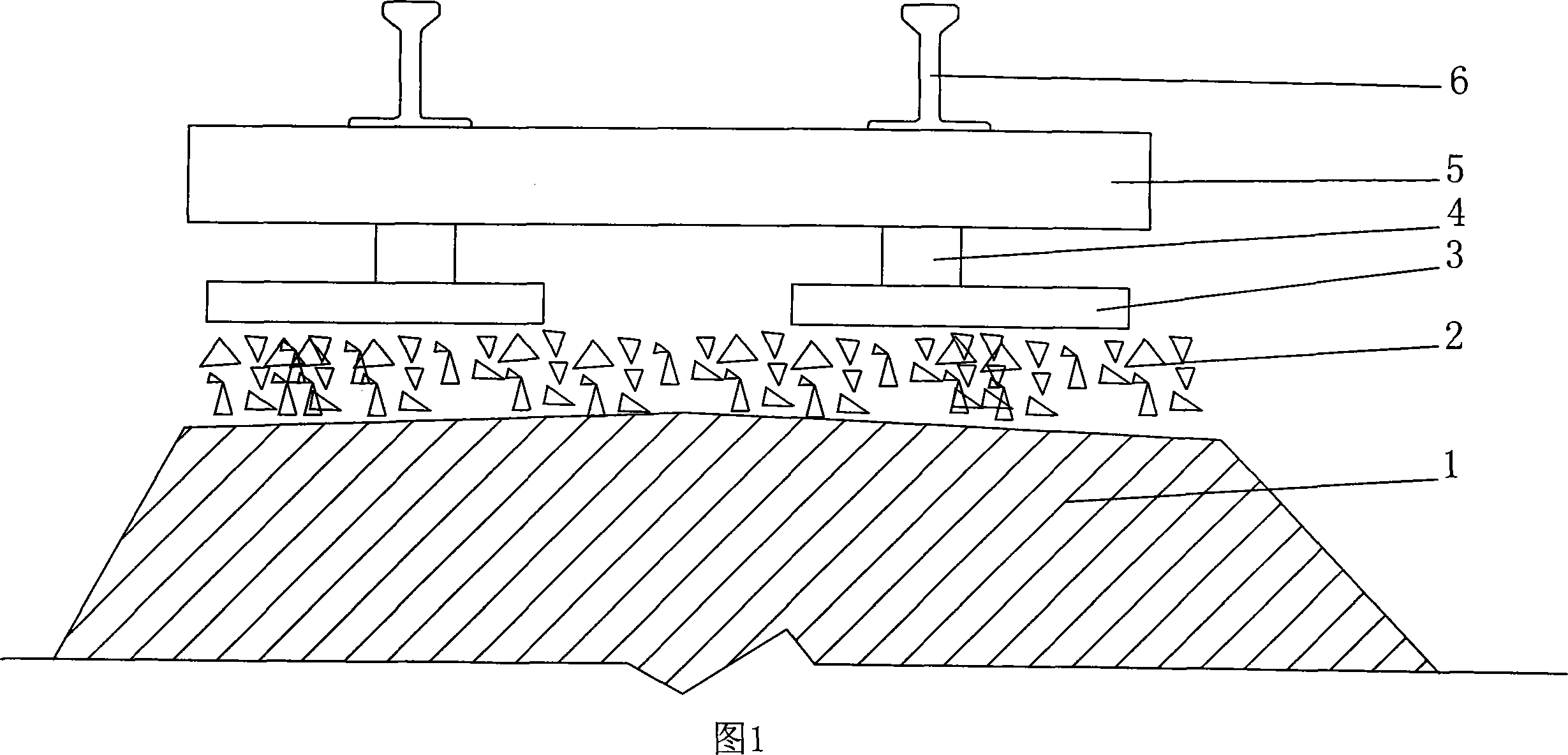

The invention relates to an in-situ laying method for the turnouts of ballast track dedicated passenger lines, which is characterized in that: a plurality of temporary track panels are laid at the original positions of the turnouts for transitive purposes, and a piece of large mechanical road maintenance equipment is adopted to tamp the track panels to stabilize the ballast bed; then the temporary track panels are removed, a turnout assembling platform is arranged at the original position of the turnout, and the overall assembly and fine adjustment of the turnout are carried out on the turnout assembling platform. Then a piece of synergic hydraulic equipment is used to jack up the assembled turnout as a whole, the operations of charging ballast and tamping are performed after removing the turnout assembling platform, and the turnout should be repaired and maintained regularly while in service. The invention has the advantages of tremendously improving the adjusting precision of the turnout, effectively preventing the turnout from deforming, enabling the positioning of the turnout to be more accurate, and maintaining the integrity of the turnout.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

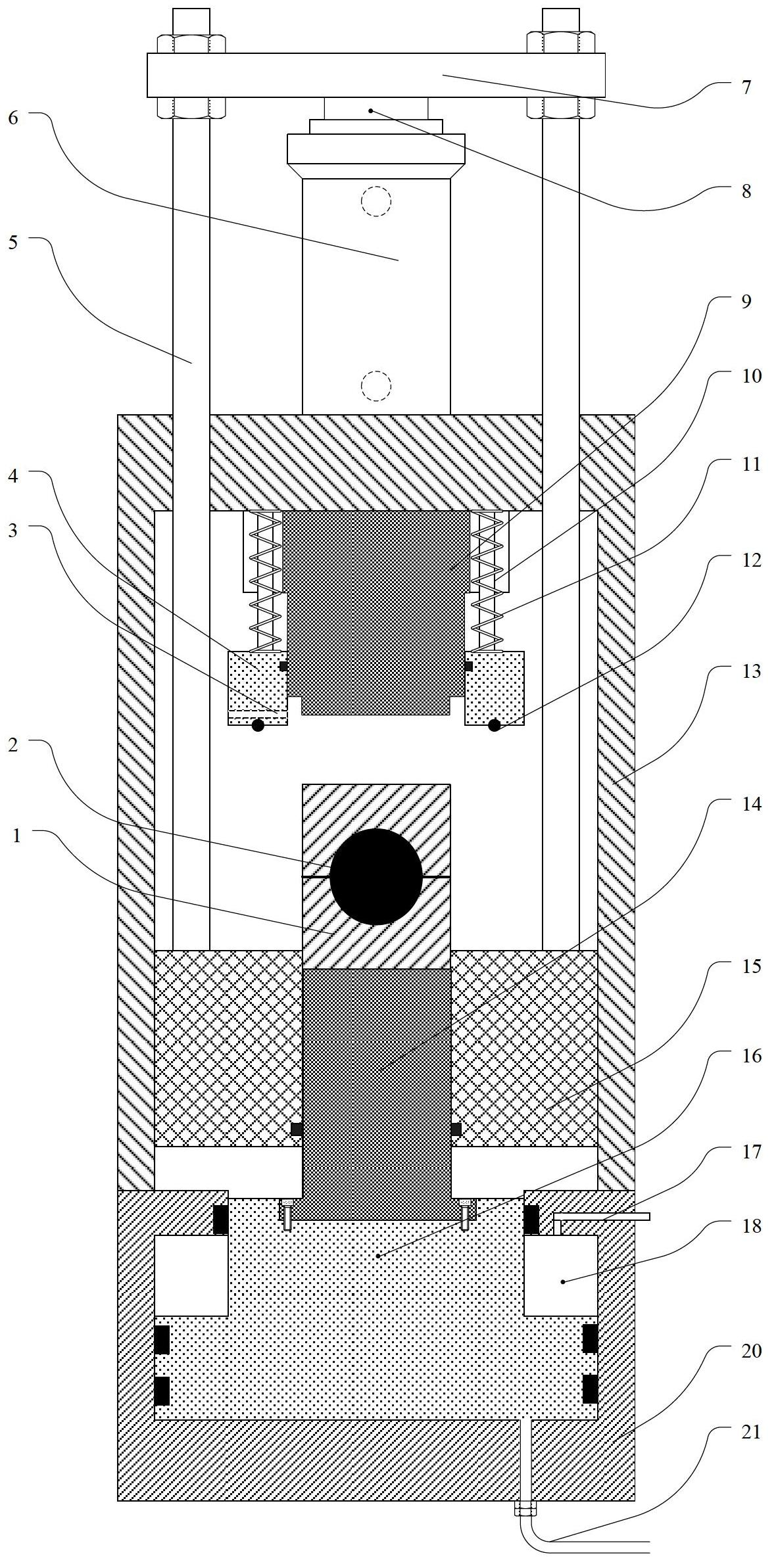

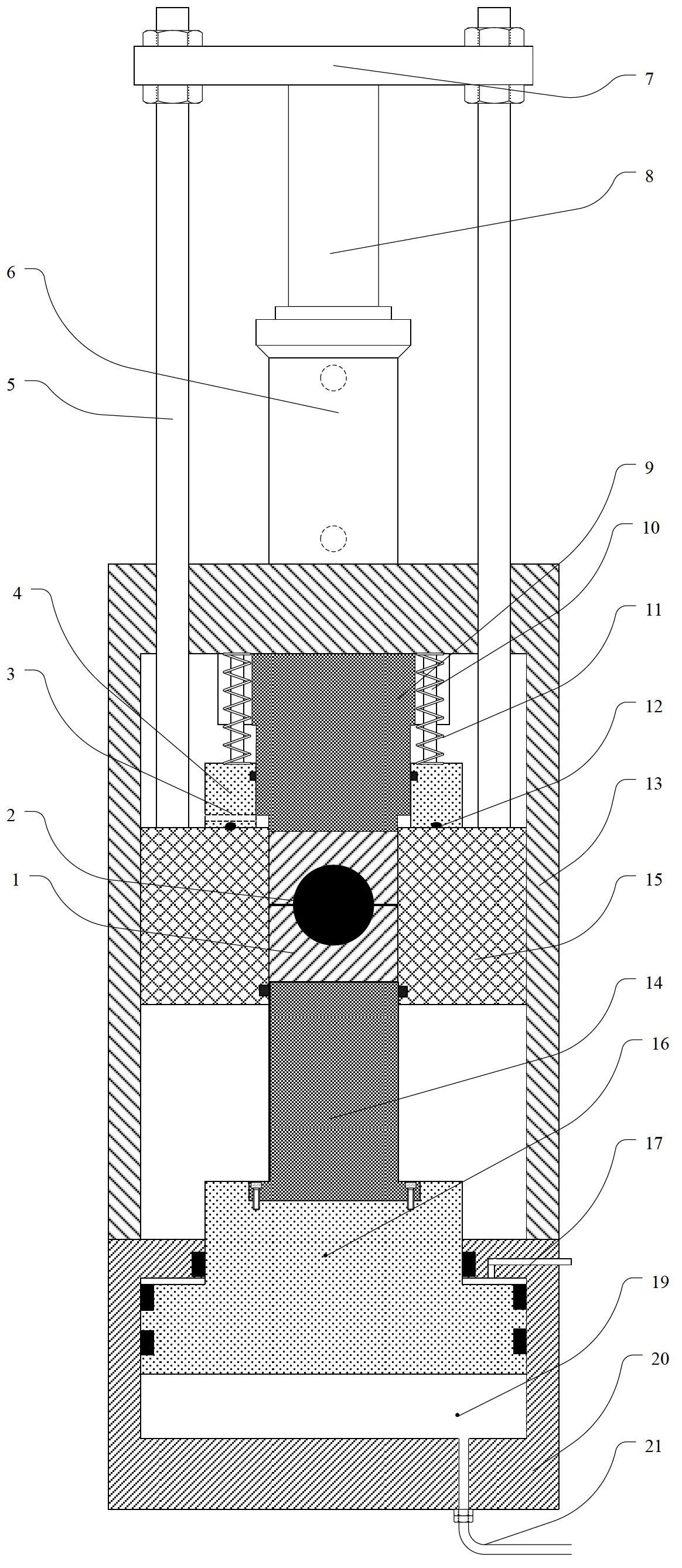

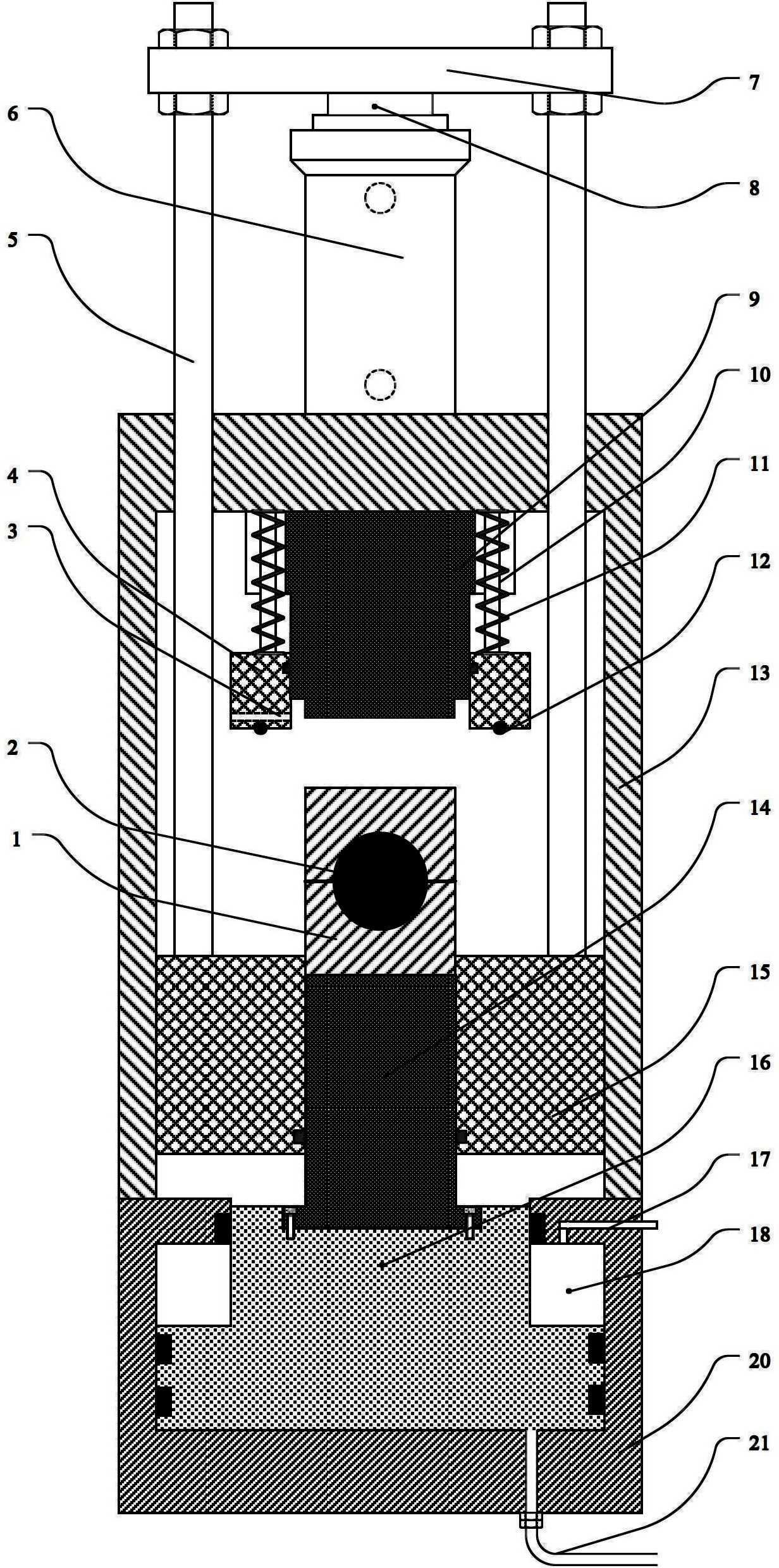

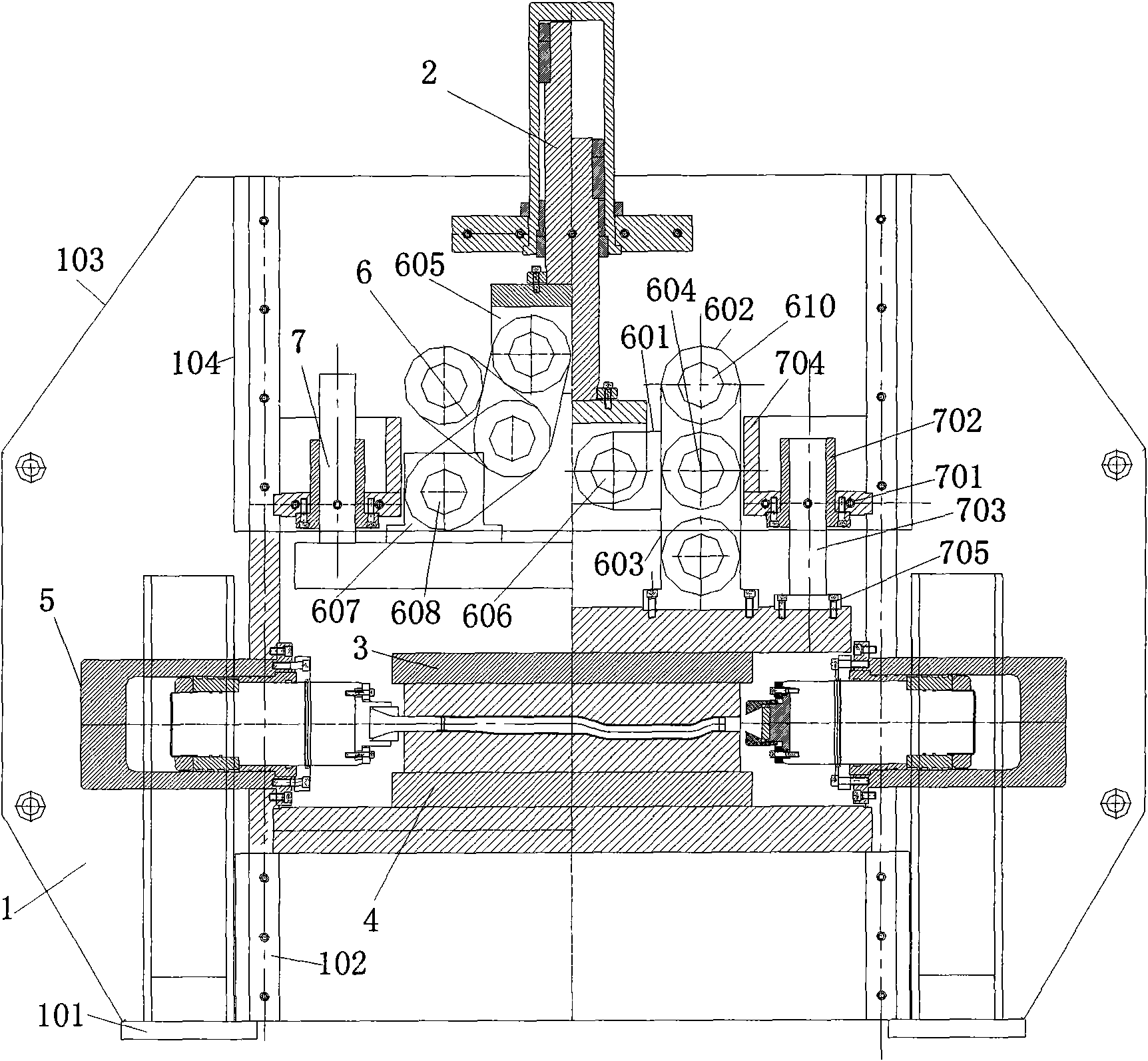

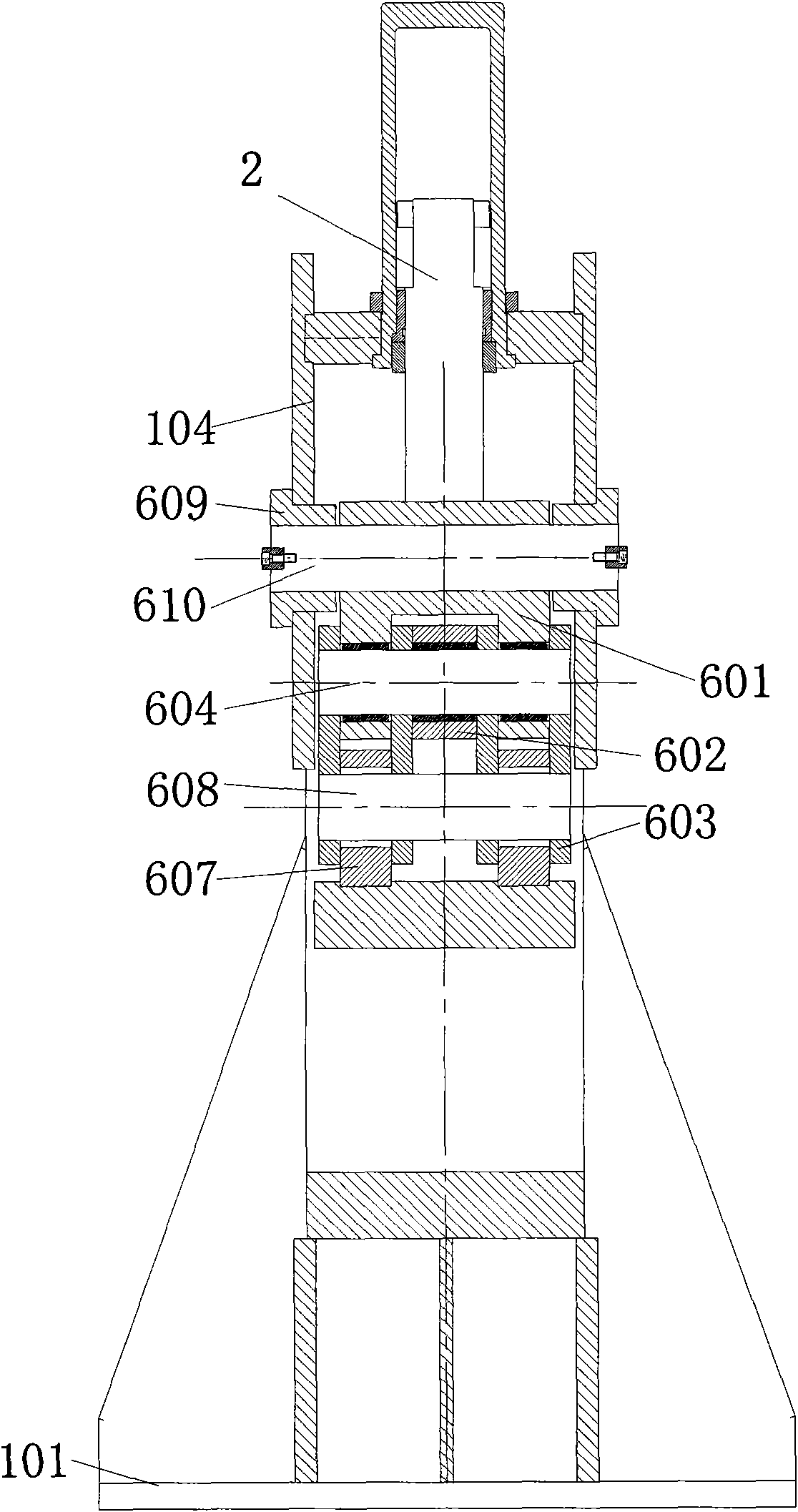

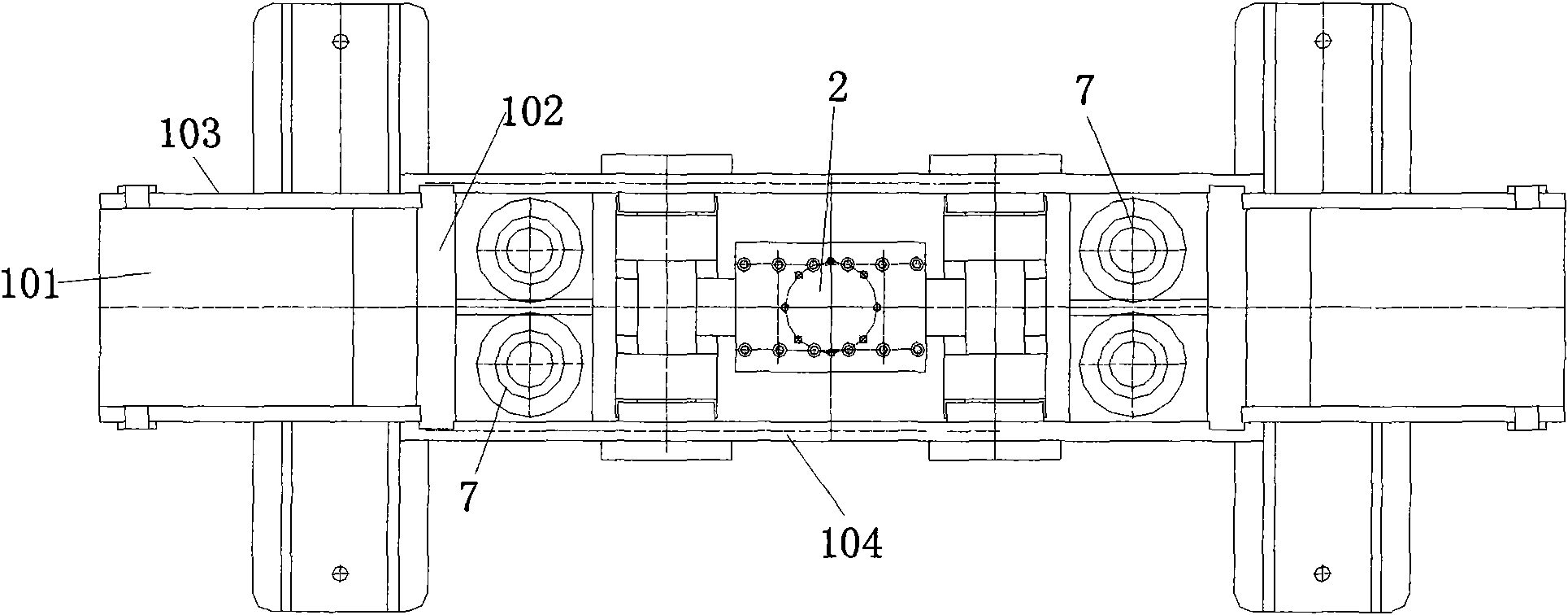

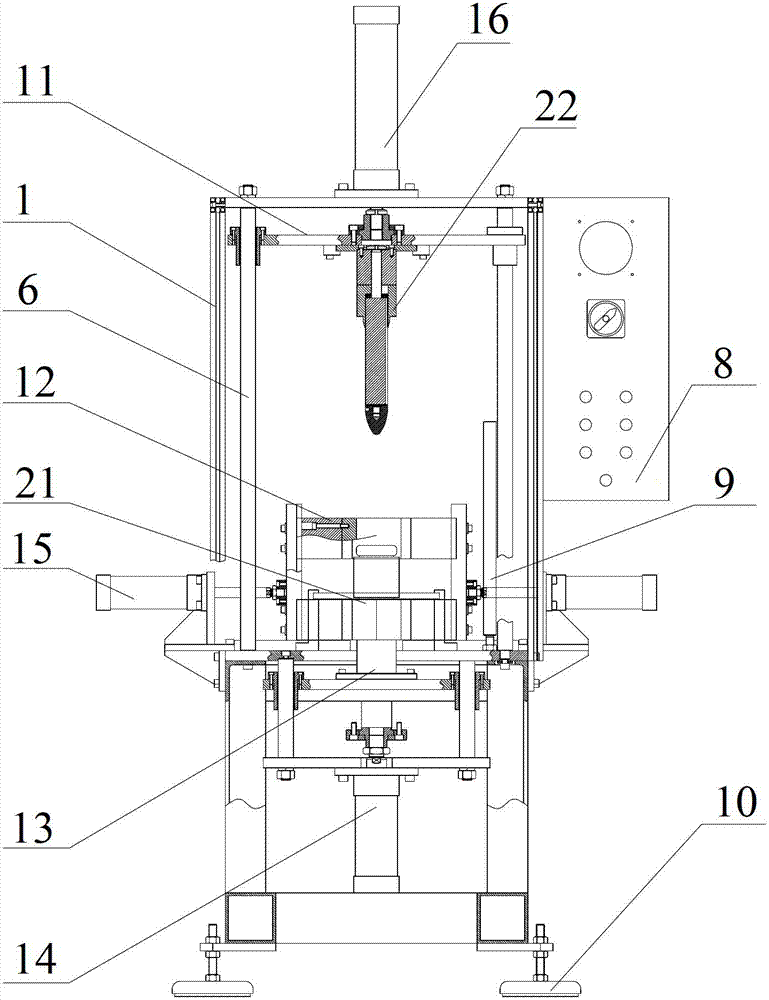

Quasi-isostatic pressing vacuum hydraulic machine

The invention relates to the field of hydraulic equipment, in particular to a quasi-isostatic pressing vacuum hydraulic machine. The hydraulic machine comprises a main machine body, a hydraulic transmission system, a vacuum system and an electric control system, wherein the main machine body comprises a machine body, a lower main hydraulic cylinder, an upper auxiliary hydraulic cylinder, a lower punch, an upper punch, a steel die barrel and a vacuum cover; the machine body is connected to the lower main hydraulic cylinder; the auxiliary hydraulic cylinder is arranged on the machine body; the lower punch is fixed at the upper end of a piston of the main hydraulic cylinder and can move together with the piston of the main hydraulic cylinder under the guidance of the internal surface of the steel die barrel; the upper punch is fixed below the plane on the top of an inner cavity of the machine body; the steel die barrel and the vacuum cover are arranged in the cavity of the machine body; and the vacuum cover is connected with the top of the inner cavity of the machine body through a sliding column and a spring and can passively ascend along the sliding column under the push of the steel die barrel and passively descend under the reset action of the spring. The quasi-isostatic pressing vacuum hydraulic machine can press a rubber die in a vacuum state, has the characteristic of compact structure and is convenient to operate.

Owner:TSINGHUA UNIV

Energy-saving reverse osmosis treatment system

InactiveCN1721047ALess investmentSave energyWater/sewage treatment bu osmosis/dialysisReverse osmosisDecreased energyEnergy recovery

The invention discloses energy-saving reverse osmosis treatment system. It uses high pressure operation condition of itself, recoveries and uses the residual pressure energy to achieve purpose. According to fluid pressure principle, connect two hydraulic equipments to form energy recovery device; uses reverse osmosis dense water pressure as drive force to complete conveying process and recovery. The advantage of this invention is that decreases energy consumption, convenient to operate and simple, and fits to all kinds situations for reverse osmosis system.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

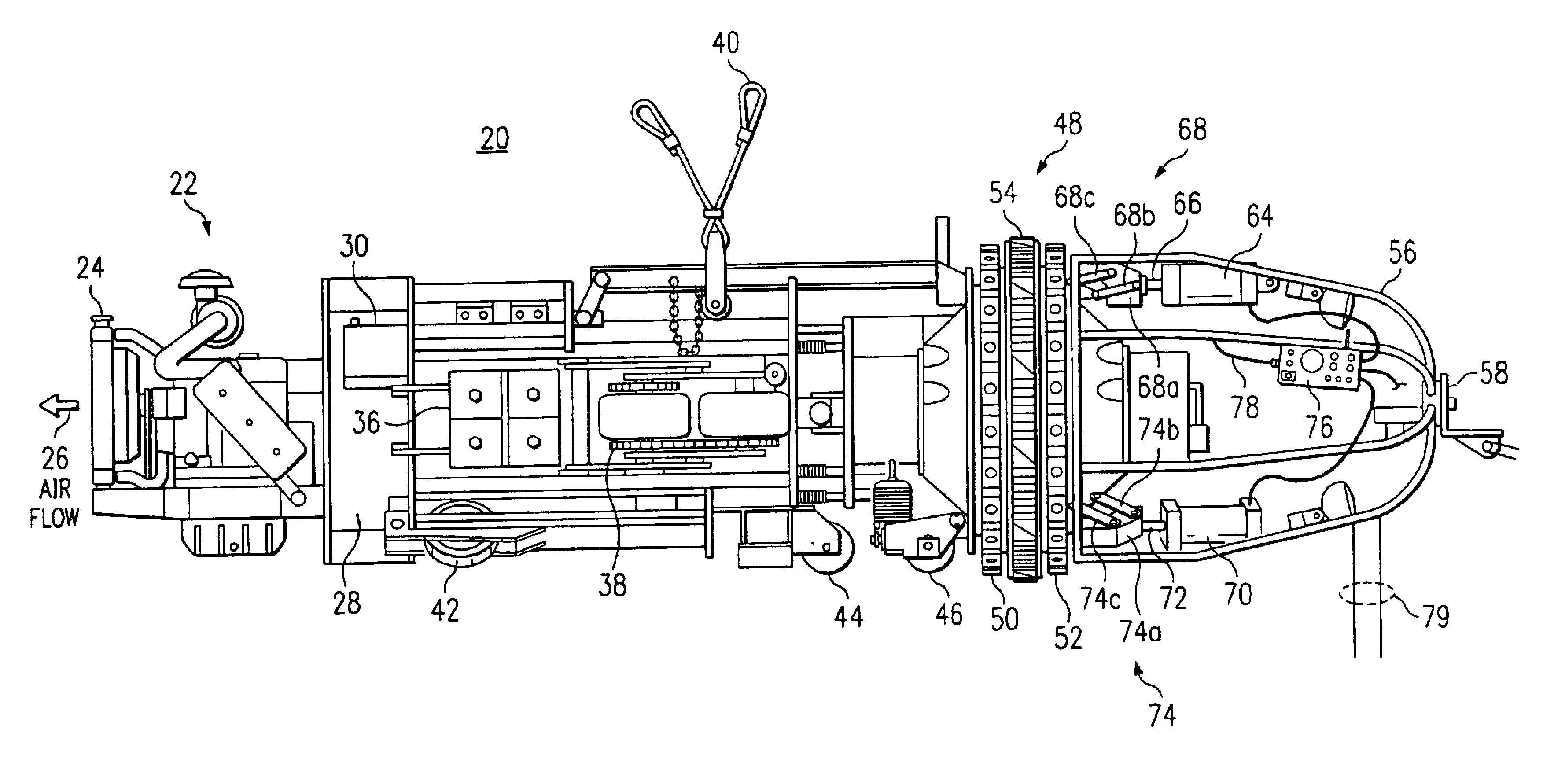

Tetherless internal line-up unit for pipeline welding

ActiveUS6915943B2Welding/cutting auxillary devicesAuxillary welding devicesDrive wheelRadio receiver

A line-up clamp unit is powered by a diesel engine which drives a hydraulic pump for operating hydraulic equipment in the unit. The unit includes a line-up clamp which has front shoes, rear shoes and expanding copper back-up tiles. Drive wheels are deployed by a hydraulic cylinder and operated by a hydraulic drive motor. A group of aligning assemblies are electrically operated and fiction to extend L-shaped members to beyond the diameter of the pipe being welded so that the unit can be automatically positioned at the end of a pipe section. A control box includes a radio receiver for receiving control signals and producing corresponding electric control commands for operating the line-tip unit. A remote control radio transmitter has operating, mechanisms, including push buttons and toggle switches, for operating the line-up unit, including the engine, drive motor, brakes, line-up clamp and aligners.

Owner:CRC EVANS PIPELINE INT INC

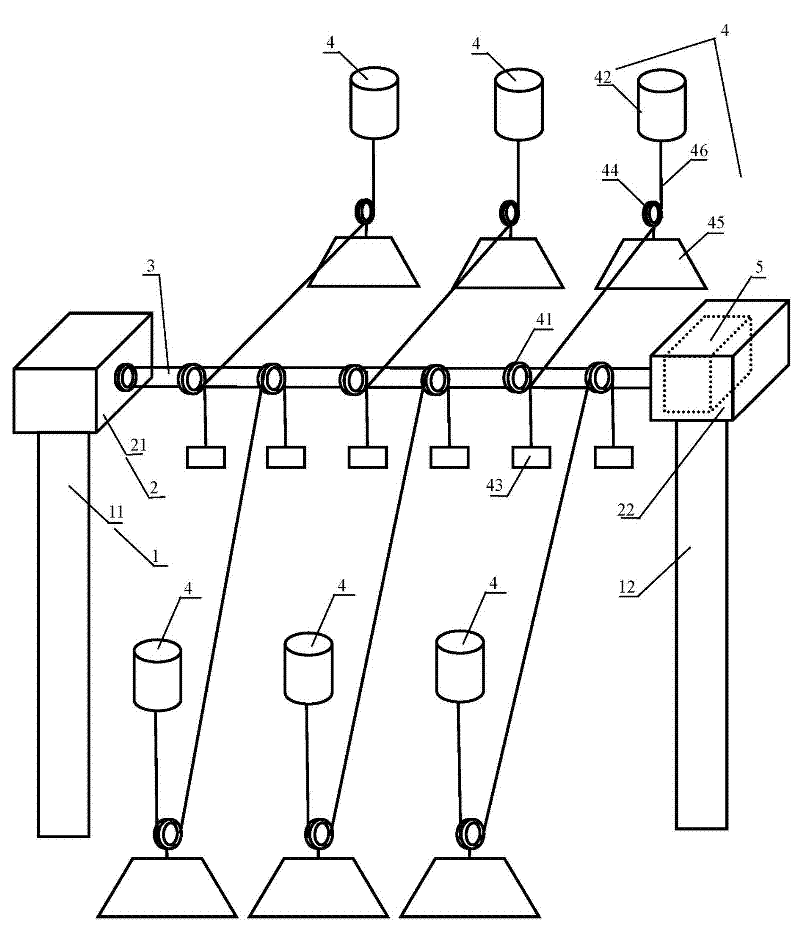

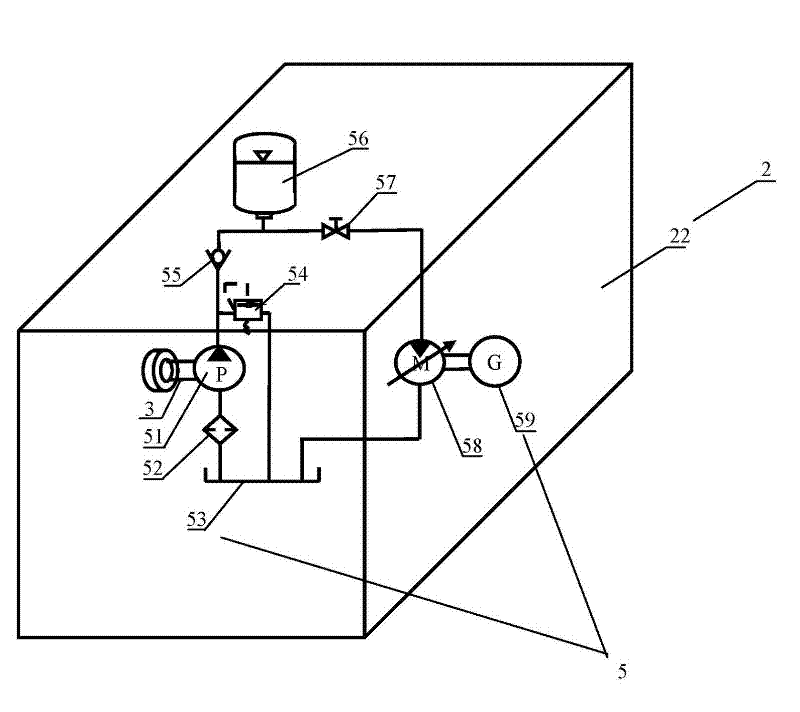

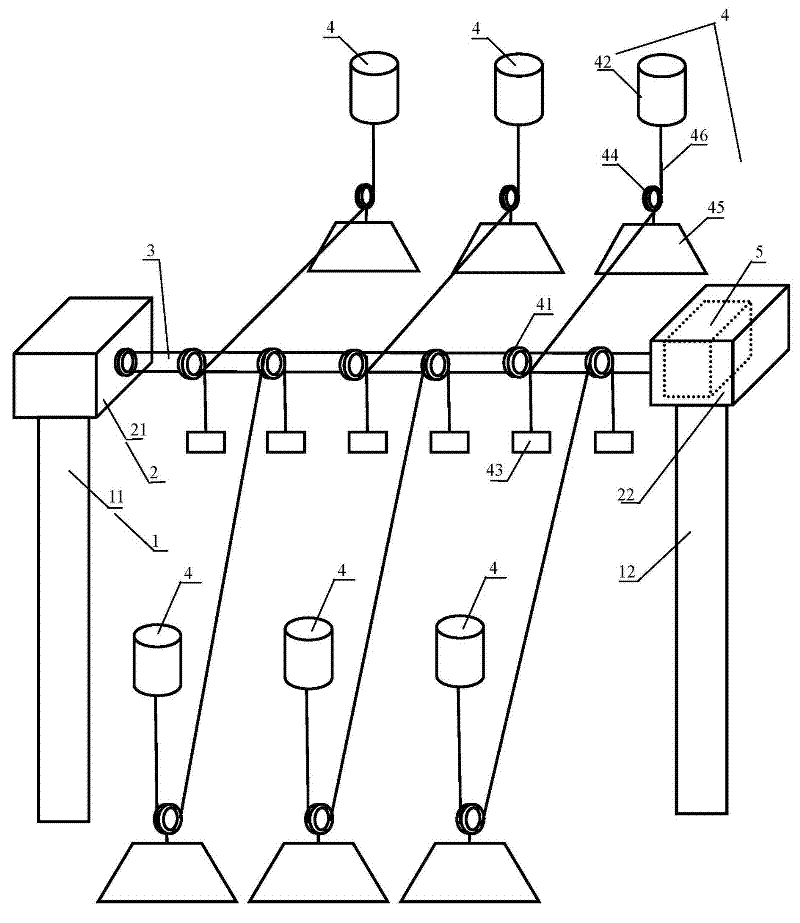

Multi-oscillating floater wave-driven hydraulic power generating device

InactiveCN102410134AIncrease powerImprove stabilityMachines/enginesFluid-pressure actuatorsMechanical energyEngineering

The invention discloses a multi-oscillating floater wave-driven hydraulic power generating device. The multi-oscillating floater wave-driven hydraulic power generating device comprises an installing platform, a generator cabin, a rotating shaft, a plurality of oscillating floater sets and a hydraulic power generating device, wherein the plurality of oscillating floater sets are arranged into an array on a sea surface, and can collect wave energy at different positions at the same time and drive an overrunning coupler by a transmission rope to synchronously convert the wave energy into the mechanical energy of the rotating shaft; and the rotating shaft drives a permanent-magnet generator to generate power. The multi-oscillating floater wave-driven hydraulic power generating device can collect the wave energy of a plurality of oscillating floaters at the same time, so that large-scale wave-driven power generation is realized, the cost performance of the wave-driven power generation and the wave energy collecting stability are improved; all hydraulic equipment and power generating equipment is arranged on the sea surface and does not contact sea water, so that the multi-oscillating floater wave-driven hydraulic power generating device is difficult to corrode and convenient to install and regulate and maintain.

Owner:JIMEI UNIV

Mechanical pipe fitting bulging device

The invention discloses a mechanical pipe fitting bulging device which comprises a stand main body, a main pressure oil cylinder, an upper die block, a lower die block, closed hydraulic plungers, a hydraulic system, a clamping control switch and an electric control system. The closed hydraulic plungers are arranged on both sides of the upper die block and the lower die block. The mechanical pipe fitting bulging device is characterized by also comprising a crank arm link mechanism and a guide mechanism, the crank arm link mechanism is hinged with the main pressure oil cylinder, the stand main body and the upper die block respectively. One end of the guide mechanism is fixedly connected with the stand main body, and the other end is fixedly connected with the upper die block. The mechanical device can increase the forming force of equipment and has the same effect on high pressure bulging in pipe fittings as big tonnage hydraulic equipment, so that the purchase cost of the equipment is reduced; and the production efficiency is improved due to the mechanical device. Compared with similar equipment, the mechanical pipe fitting bulging device has the advantages of small size and low energy consumption; and the performance conforms to production requirements, and the cost is reduced to 10-20% that of the similar equipment.

Owner:上海交运集团股份有限公司

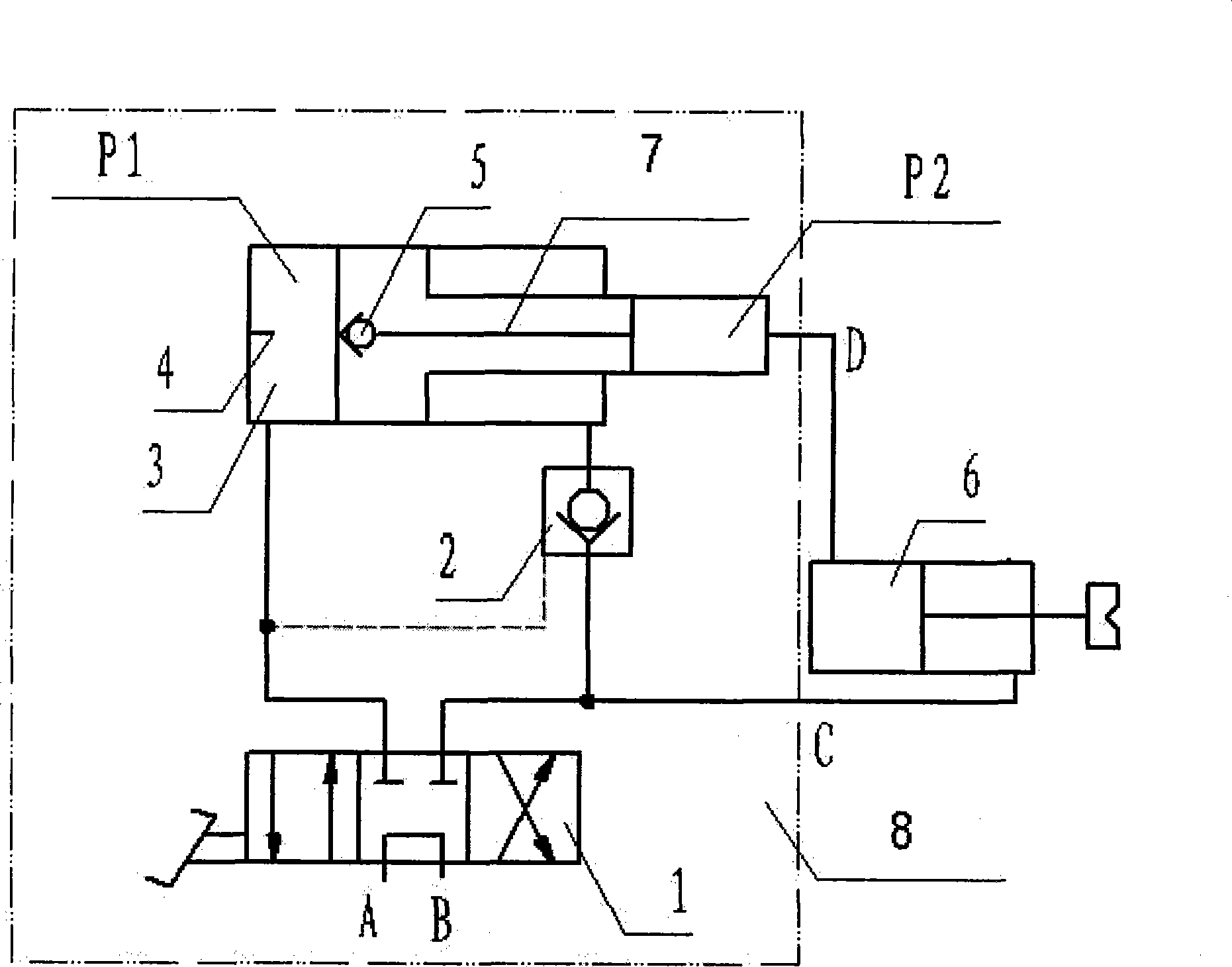

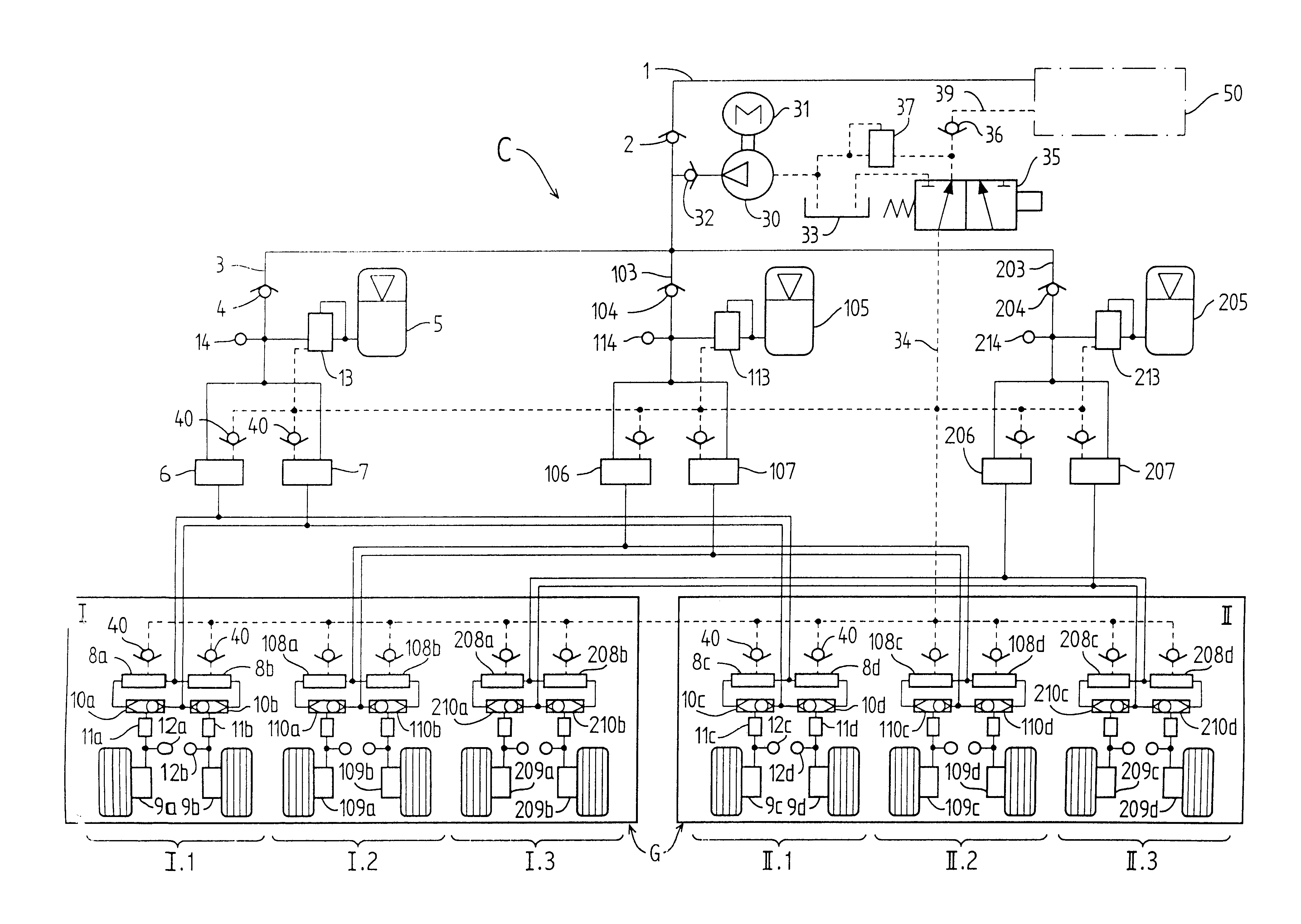

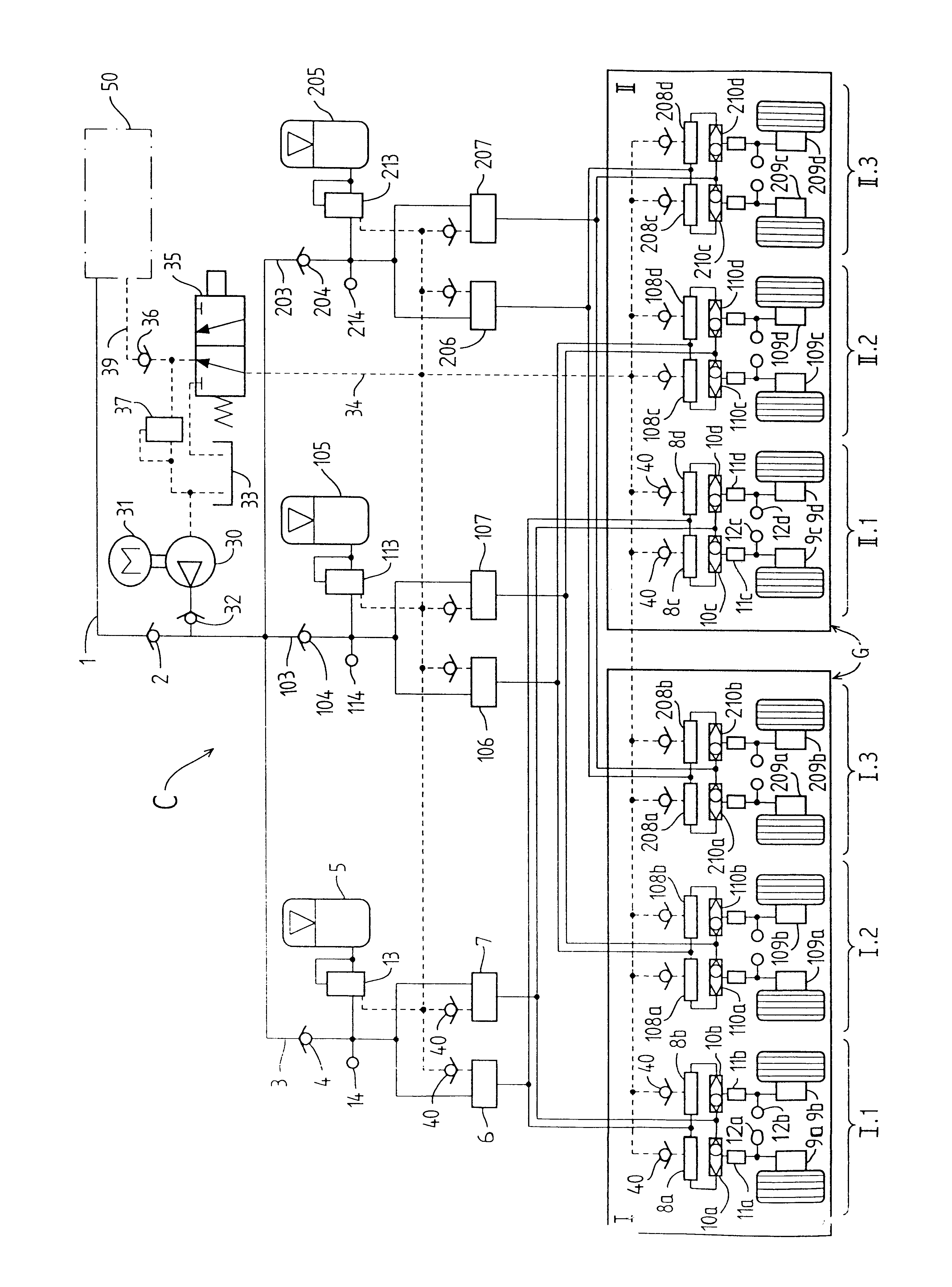

Architecture for the hydraulic braking system of an aircraft

InactiveUS6663192B2Light weightHydraulic pipework to be simplified considerablyFluid-pressure actuator safetyServomotorsHydraulic circuitHydraulic equipment

The invention relates to an architecture for a hydraulic braking system suitable for an aircraft of the type having at least one group of main landing gear units, each landing gear unit comprising a determined number of wheels each provided with a hydraulically actuated brake, the or each landing gear group being associated with a hydraulic circuit provided with hydraulic equipment and adapted to deliver hydraulic fluid under pressure to all of the brakes of the landing gear group, the hydraulic fluid being pressurized by at least one aircraft pressure generator system associated with an aircraft hydraulic fluid supply. According to the invention, accumulators are connected on the or each circuit in sufficient number for each accumulator to feed two pairs of brakes, each pair of brakes being mounted on a distinct landing gear unit, and an electrically-driven pump being arranged to maintain a predetermined pressure level in all of the accumulators of the circuit in question.

Owner:MESSIER HISPANO BUGATTI SA

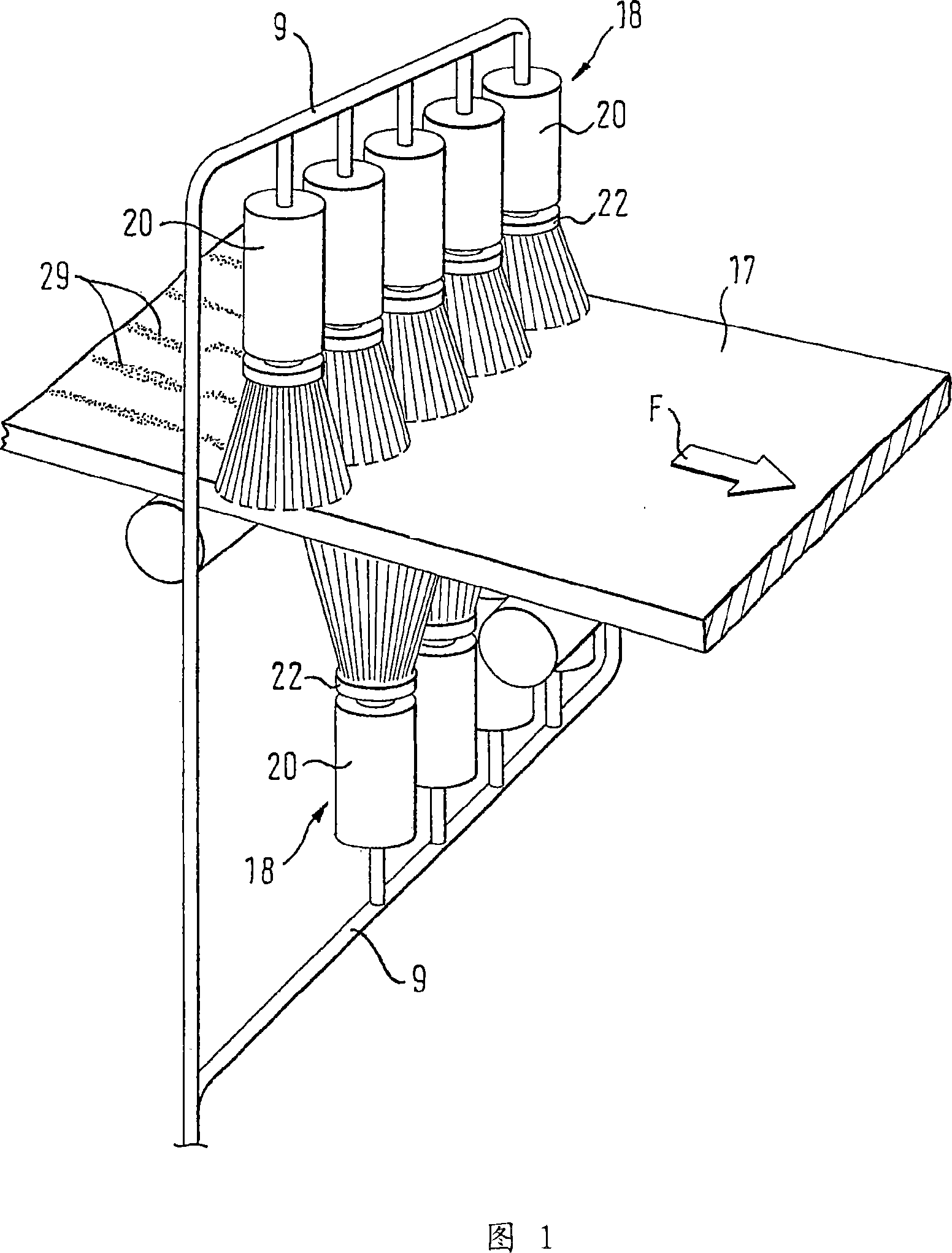

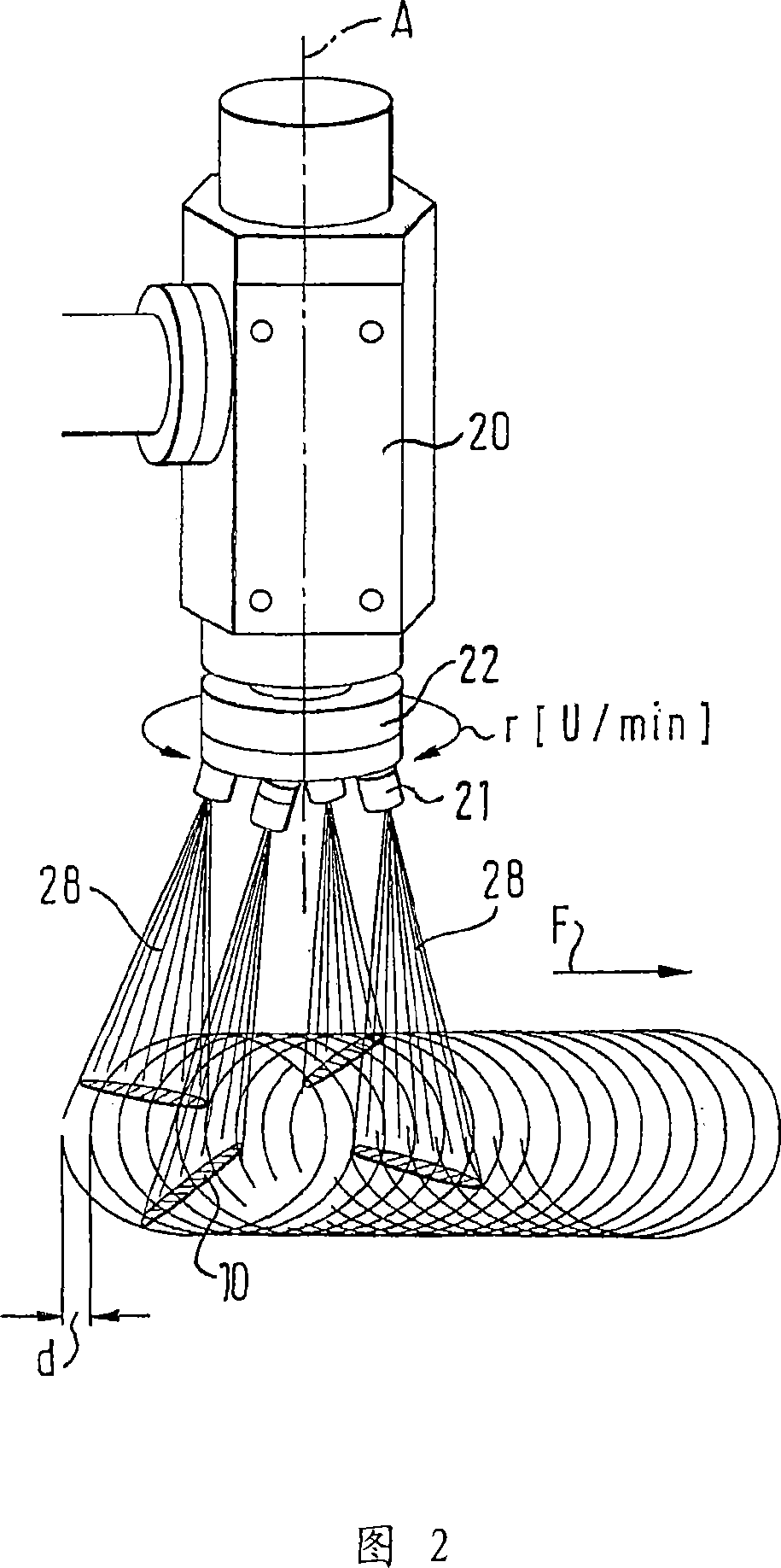

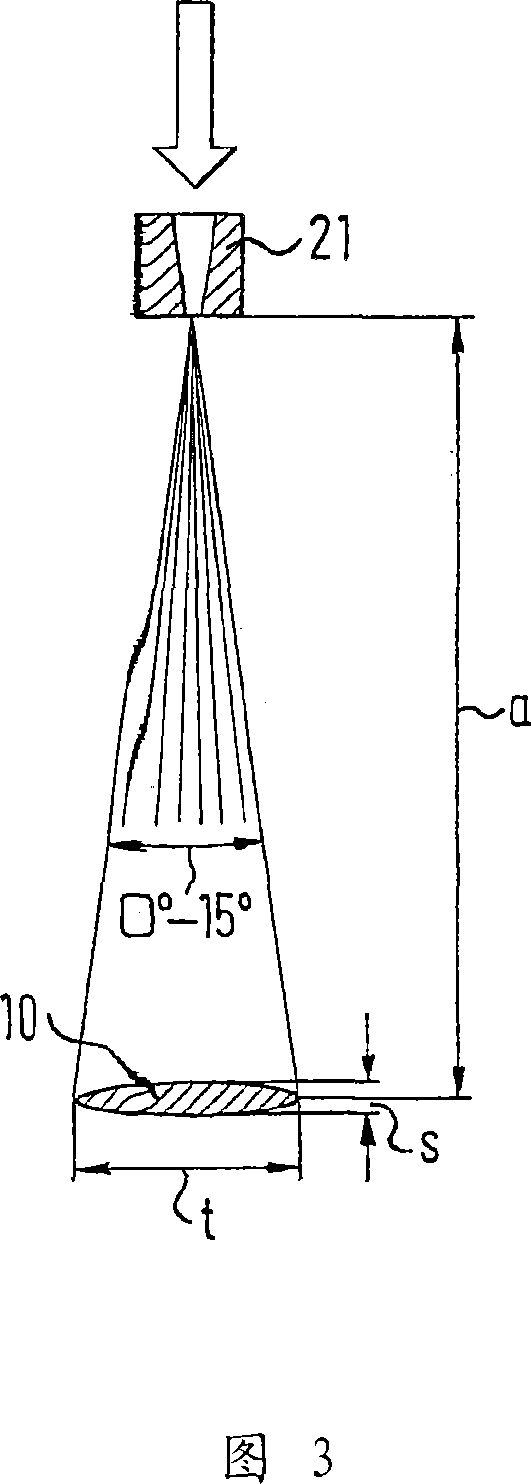

Hydraulic equipment for hot-rolled member scale removal

The invention relates to a device which is used to descale warm rolling products (17) which can be displaced in relation to the device by high pressure water projection. Said device comprises at least one row of nozzle heads which cover the width of the rolling products, said row of nozzle heads comprising several nozzle heads (20). Each nozzle head is driven in a rotational manner by a motor about a rotational axis (A) which is essentially perpendicular to the surface to the rolling products and comprises at least two nozzles (1 8) which are disposed in an eccentric manner in relation to the rotational axis. The invention is characterised in that the nozzles (1 -8) of each nozzle head (20) are arranged as close as constructively possible on the periphery (25) of the nozzle head in such a manner that the nozzle head produces an injection image on the surface of the rolling product, said injection image at least touching the injection image of the nozzle head which is next in the row of nozzle heads.

Owner:HERMETIK HYDRAULIK

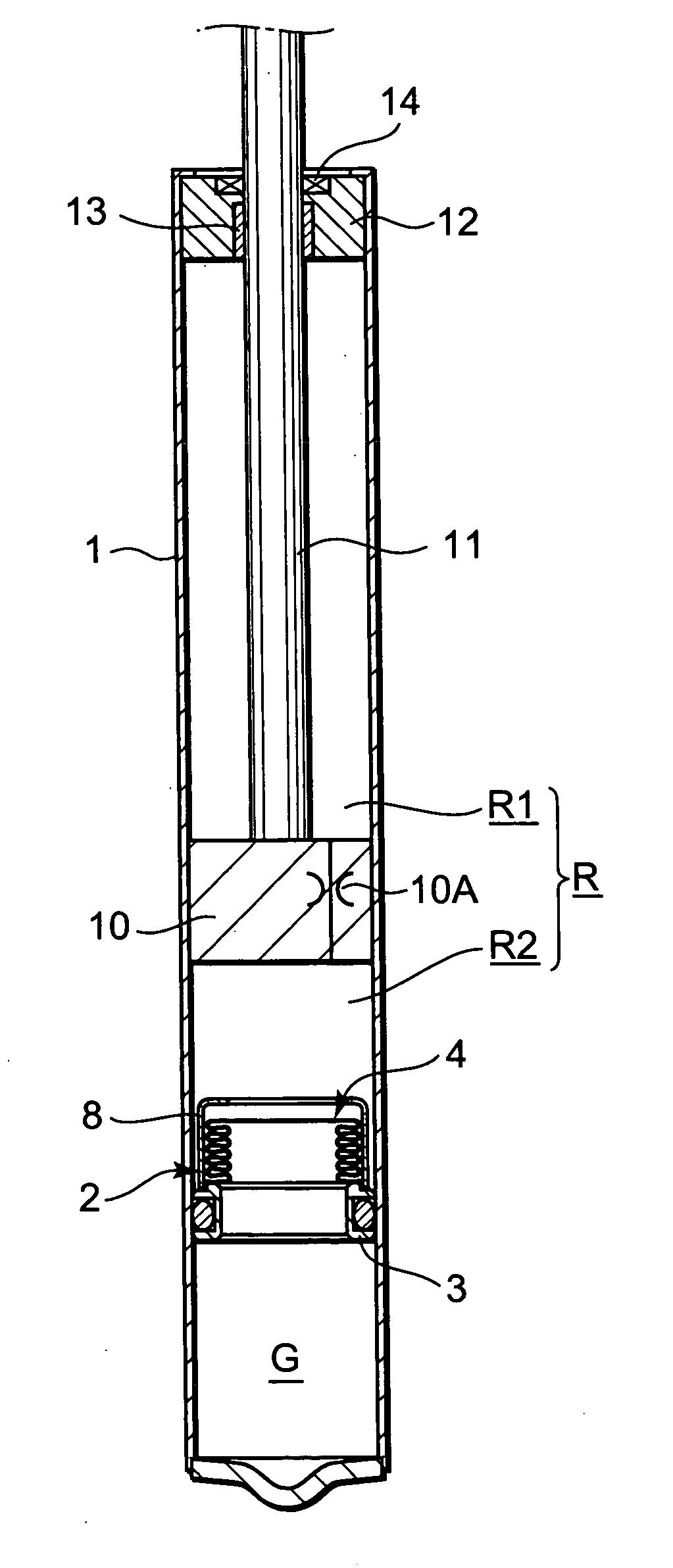

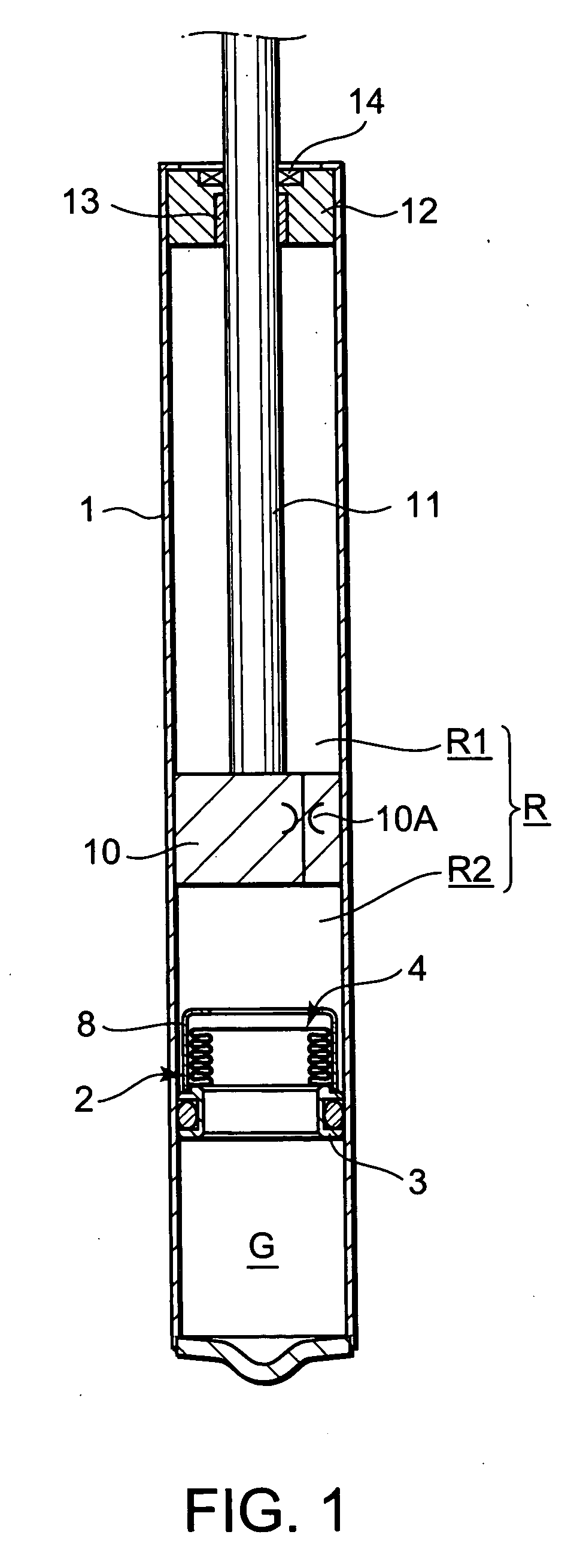

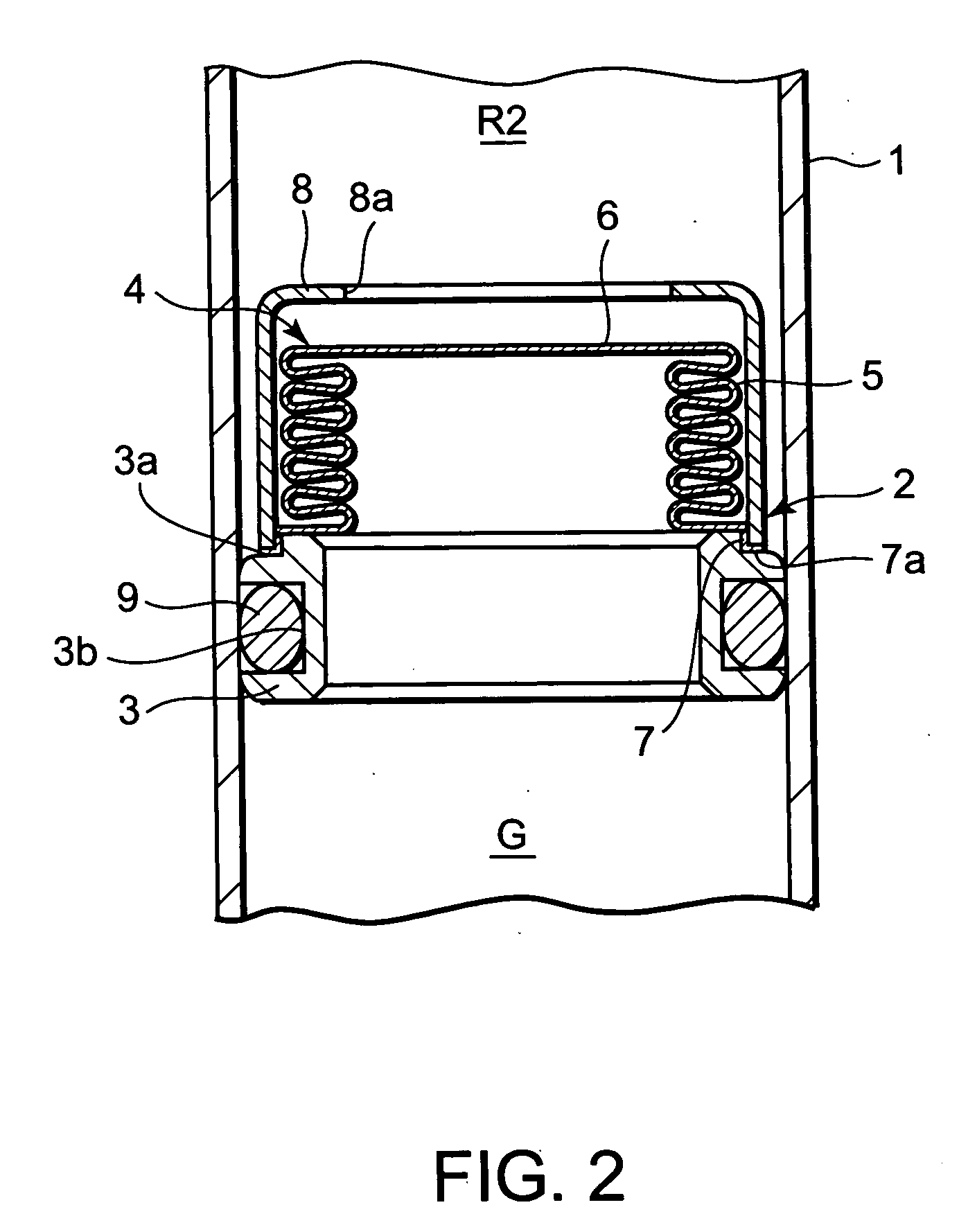

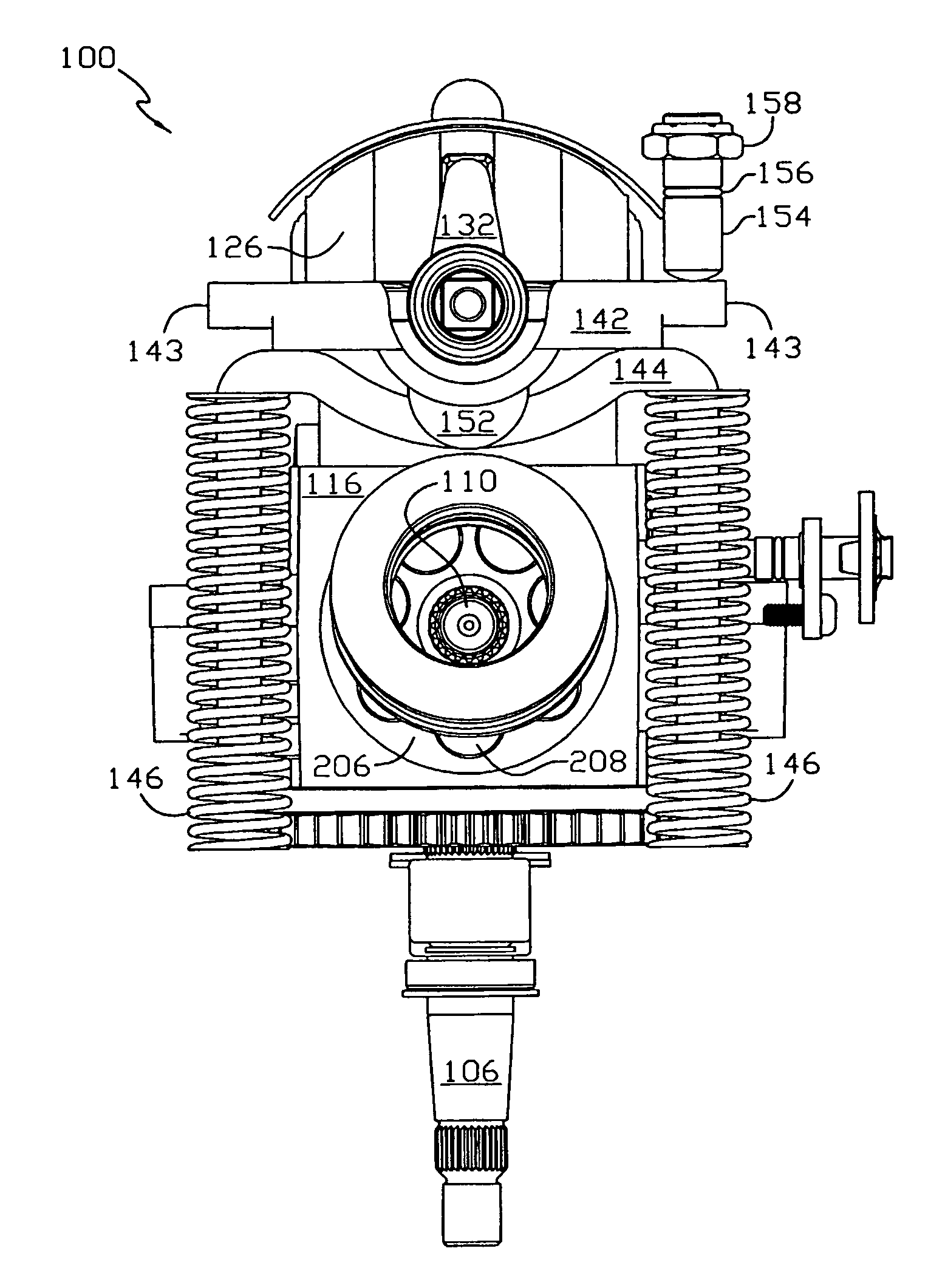

Hydraulic equipment with built-in free piston

InactiveUS20060180418A1Improve responseIncrease elasticitySpringsAccumulator installationsHydraulic equipmentGas chamber

A gas chamber (G) and a liquid chamber (R) are separated by a free piston (2) in a cylinder (1) of a hydraulic damper. The free piston (2) comprises a hollow main body (3), a metal bellows (4) which elongates and contracts according to a pressure balance between the gas chamber (G) and liquid chamber (R), and a stopper (8) fixed to the main body (3) for preventing the metal bellows (4) from elongating beyond a predetermined length. By compensating for variation in the capacity of the liquid chamber (R) caused by a displacement of the piston (10) in the cylinder (1) by elongation or contraction of the metal bellows (4), the damping characteristic of the damper is prevented from becoming unstable due to a frictional force acting on the free piston (2). The stopper (8) prevents excessive stress from being exerted on the metal bellows (4).

Owner:KYB CORP

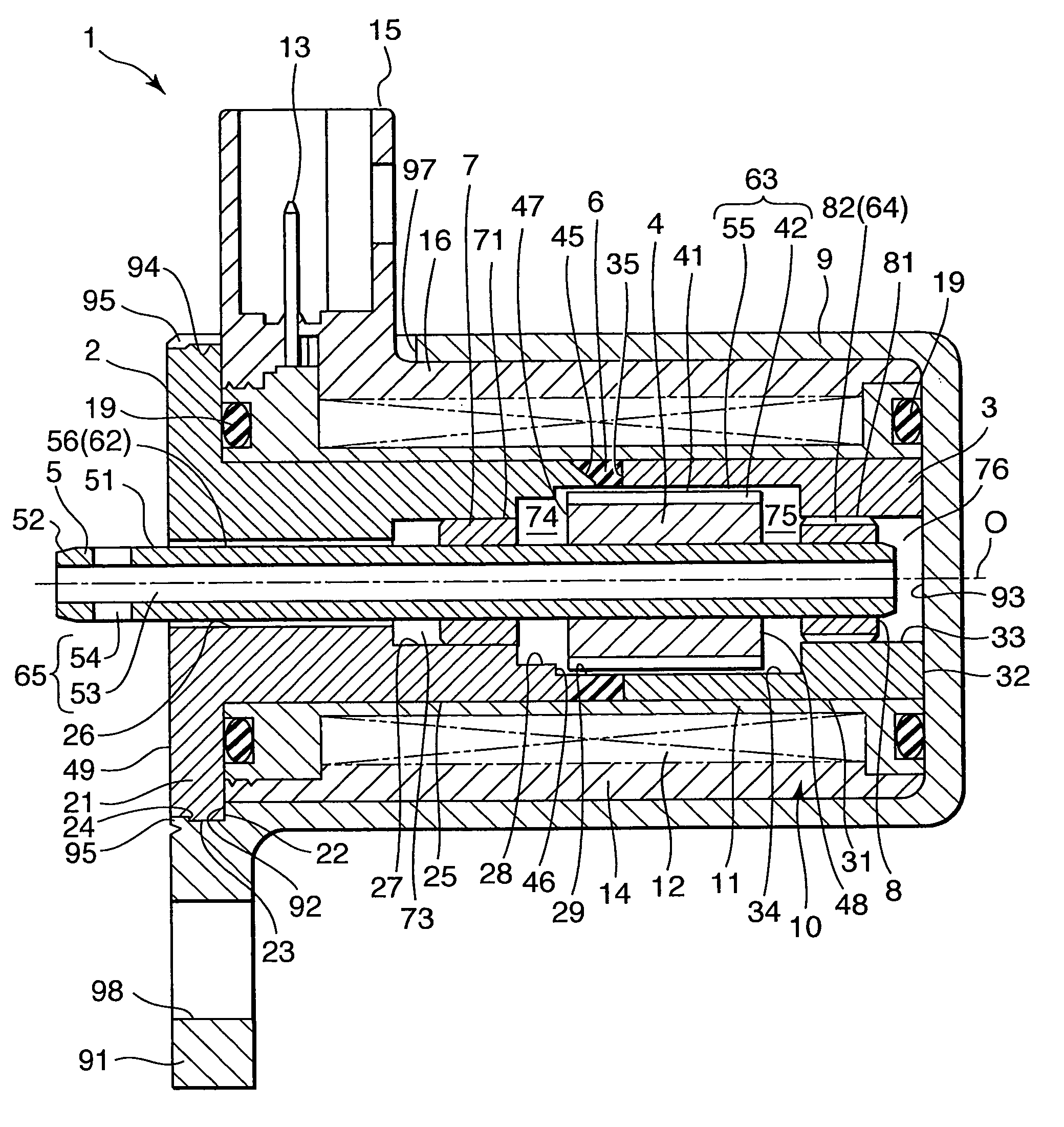

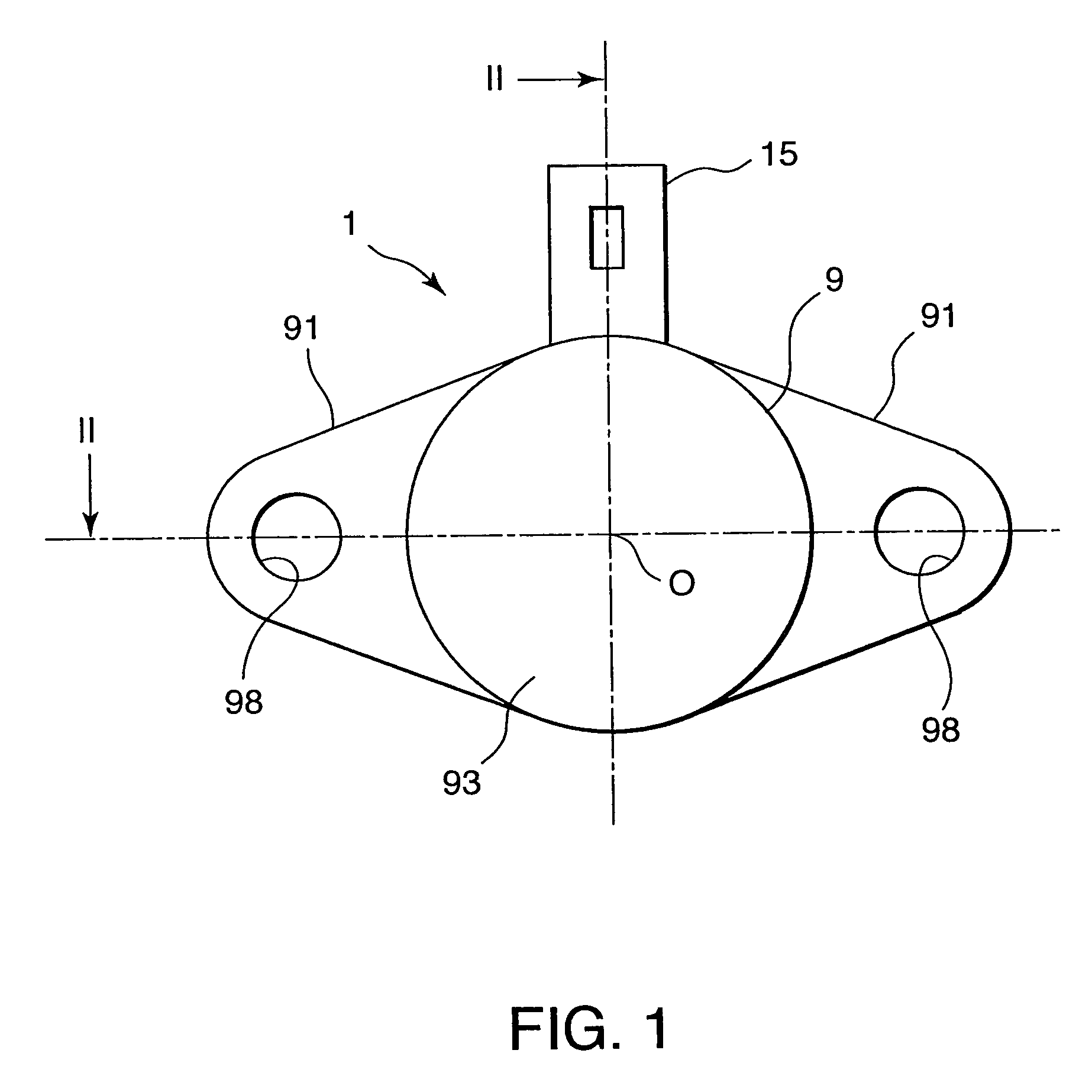

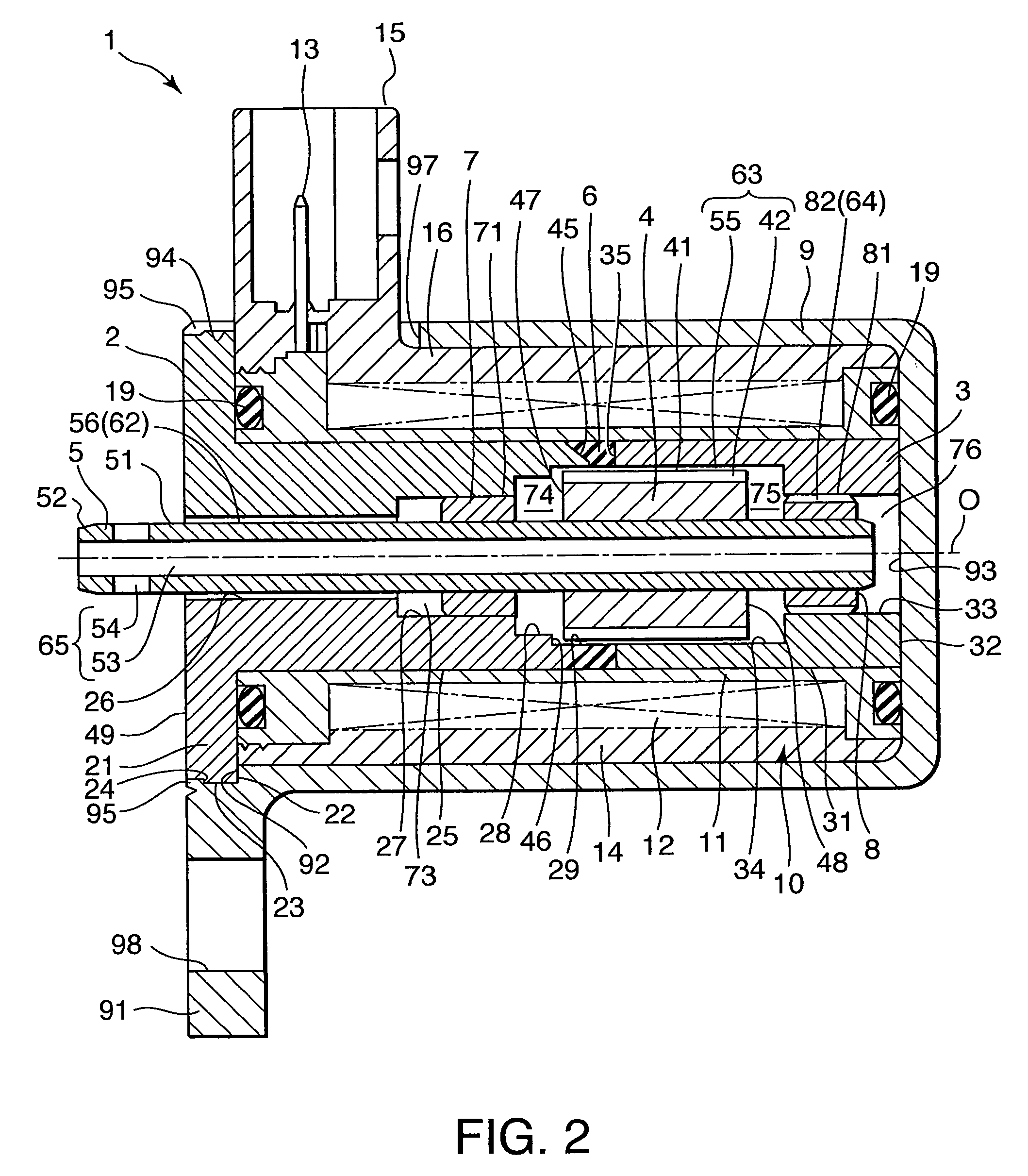

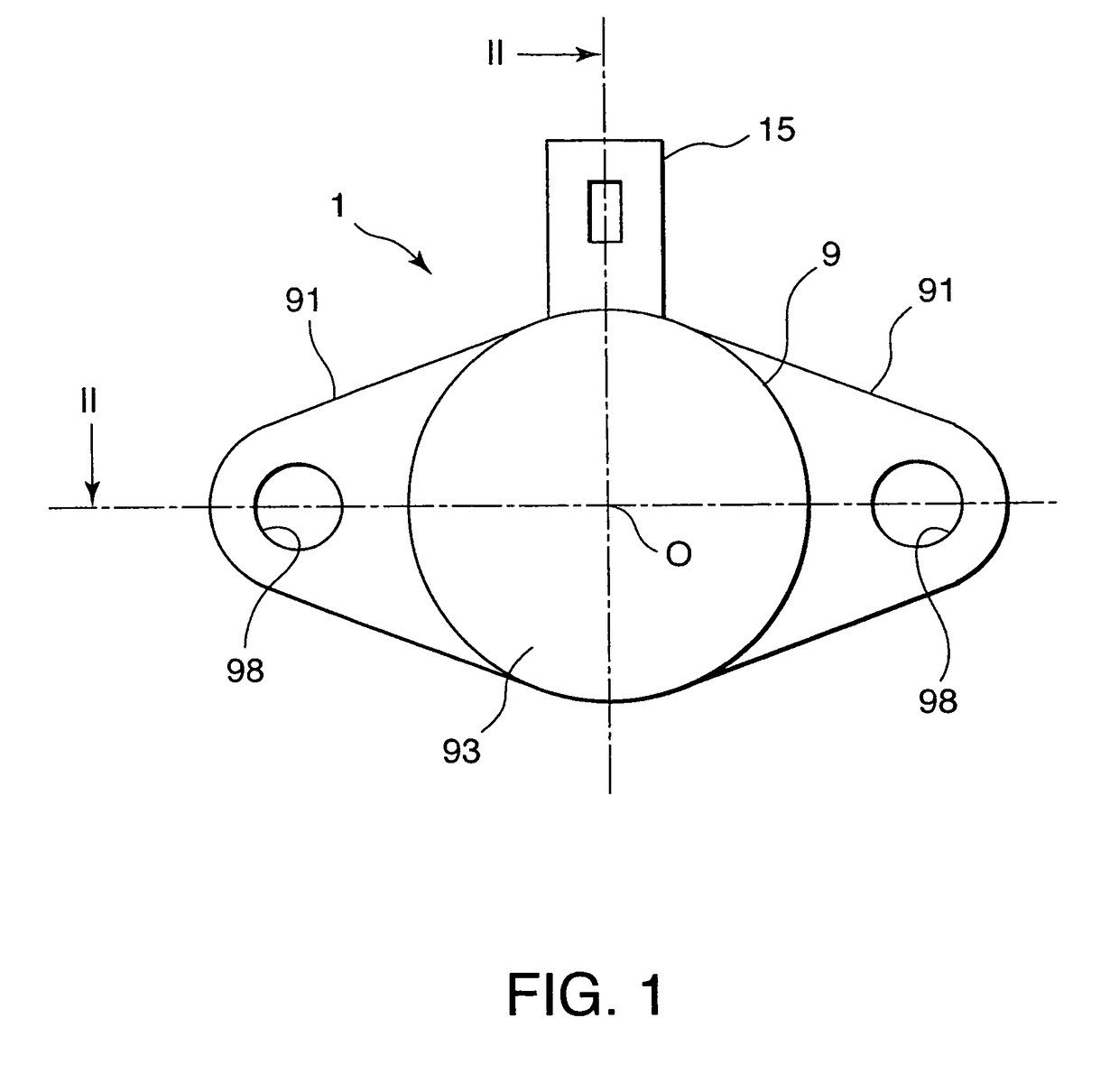

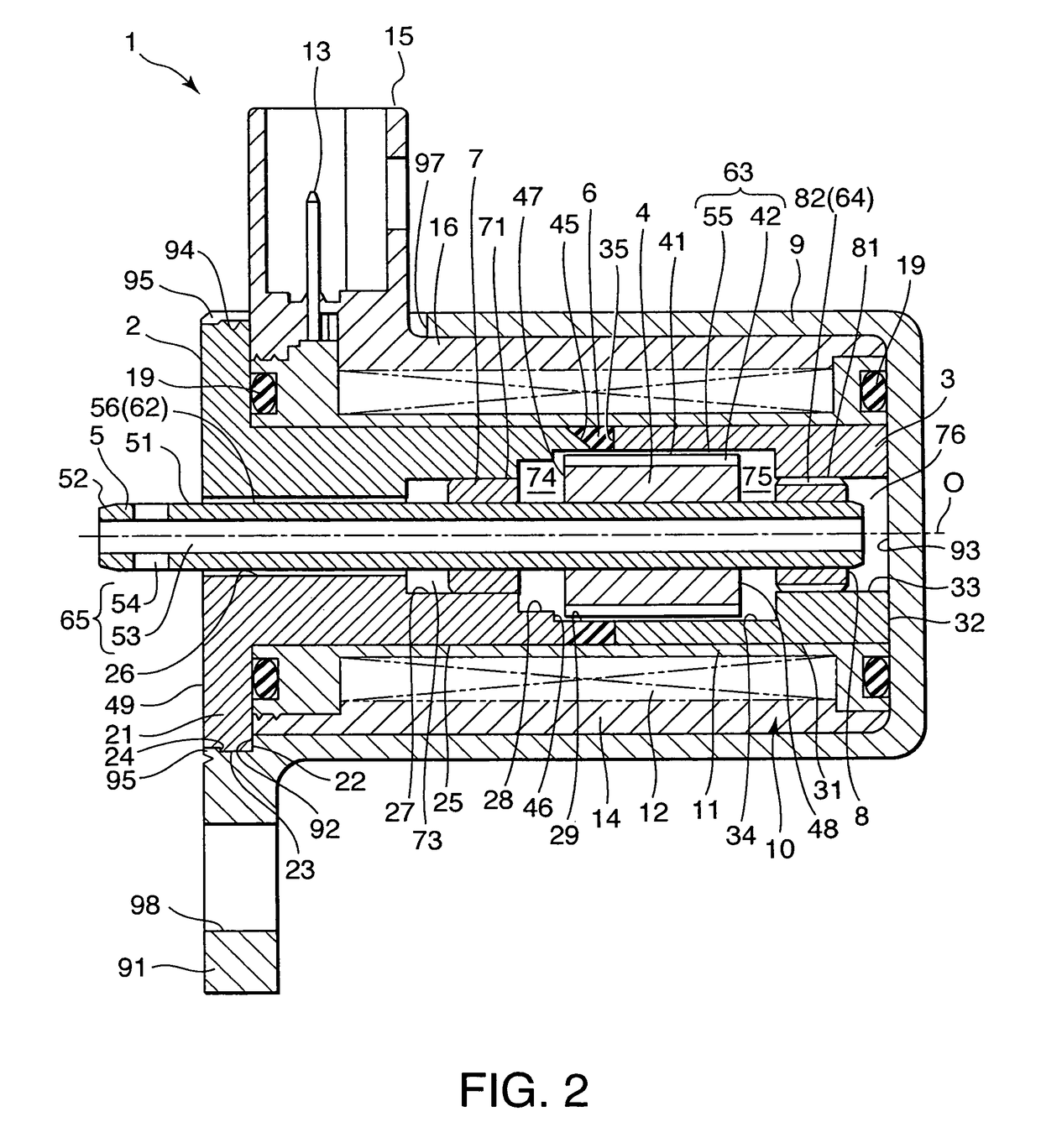

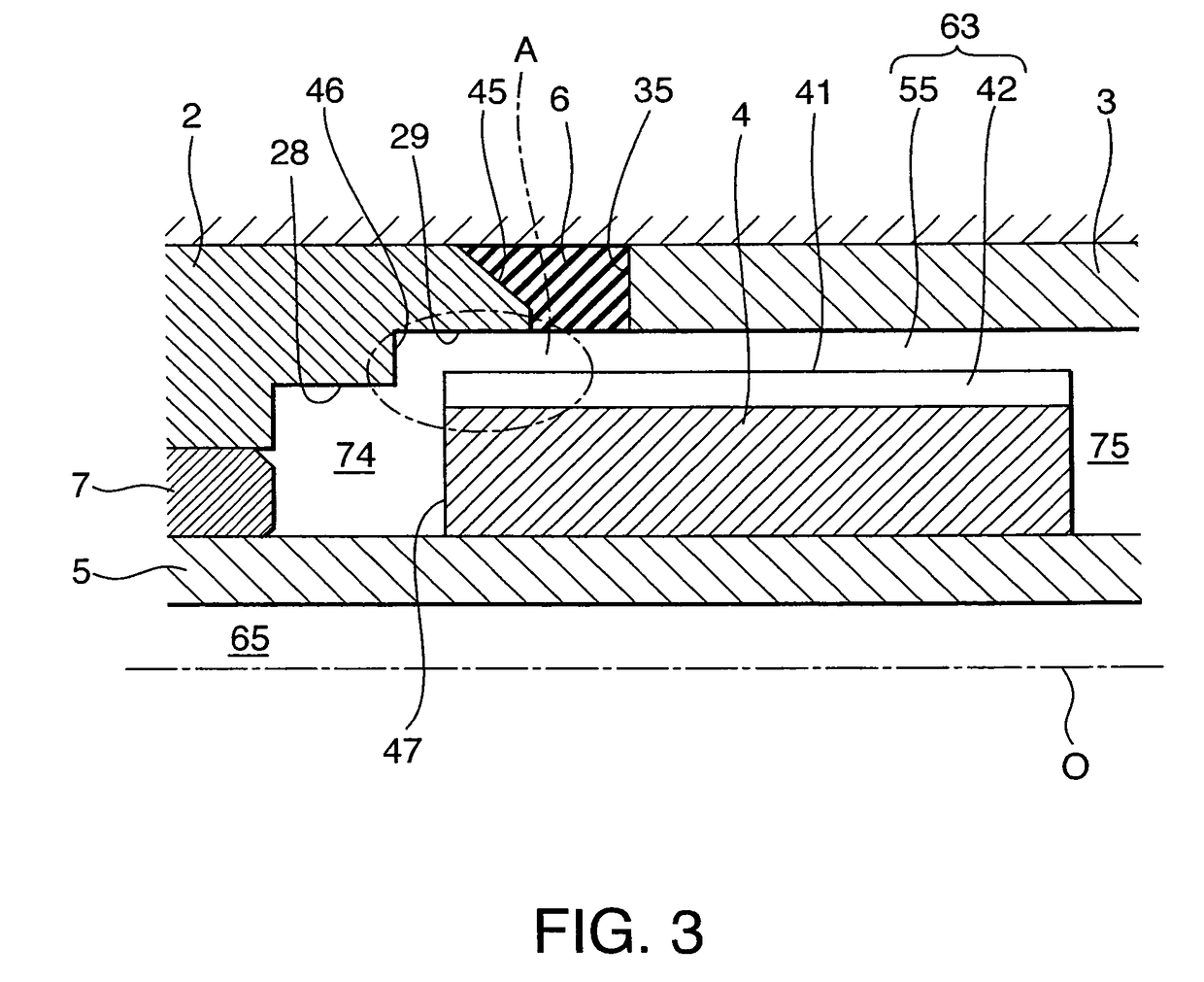

Solenoid actuator

InactiveUS8469334B2Increase sliding resistanceOperating means/releasing devices for valvesPiston pumpsEngineeringHydraulic equipment

A solenoid actuator (1) attached to hydraulic equipment comprises a shaft (5) connected to the hydraulic equipment, a plunger (4) fixed to the shaft (5), a coil (12) which magnetically drives the plunger (4), and a first bearing (7) and a second bearing (8) supporting the shaft (5) on either sides of the plunger (4). A plunger front chamber (74) is formed between the first bearing (7) and the plunger (4), and a plunger rear chamber (75) is formed between the plunger (4) and the second bearing (8). By providing a plunger exterior oil passage (63) on the outside of the plunger (4) to connect the plunger front chamber (74) to the plunger rear chamber (75), working oil flows through the plunger exterior oil passage (63) every time the plunger (4) strokes, thereby preventing a deposit of contaminant on the plunger (4) without increasing a stroke resistance of the plunger (4).

Owner:KYB CORP

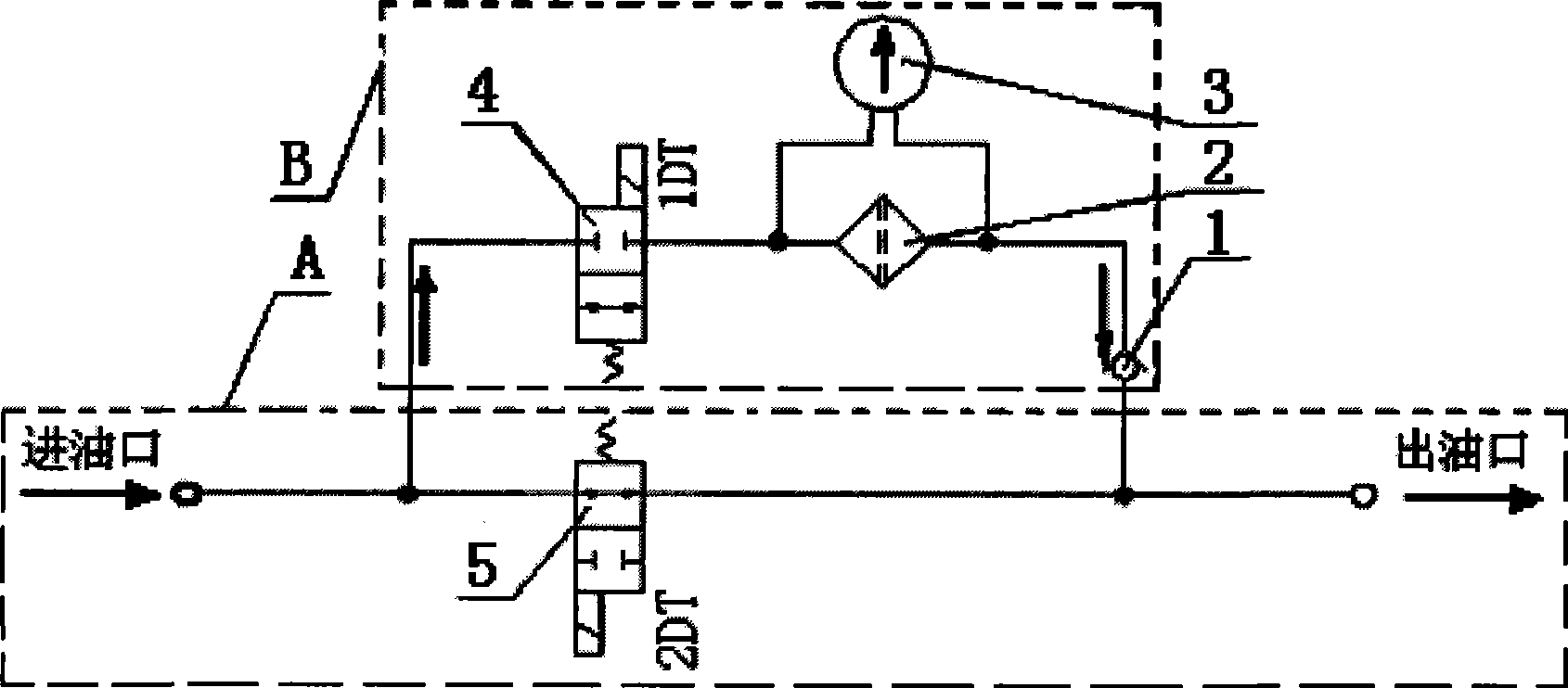

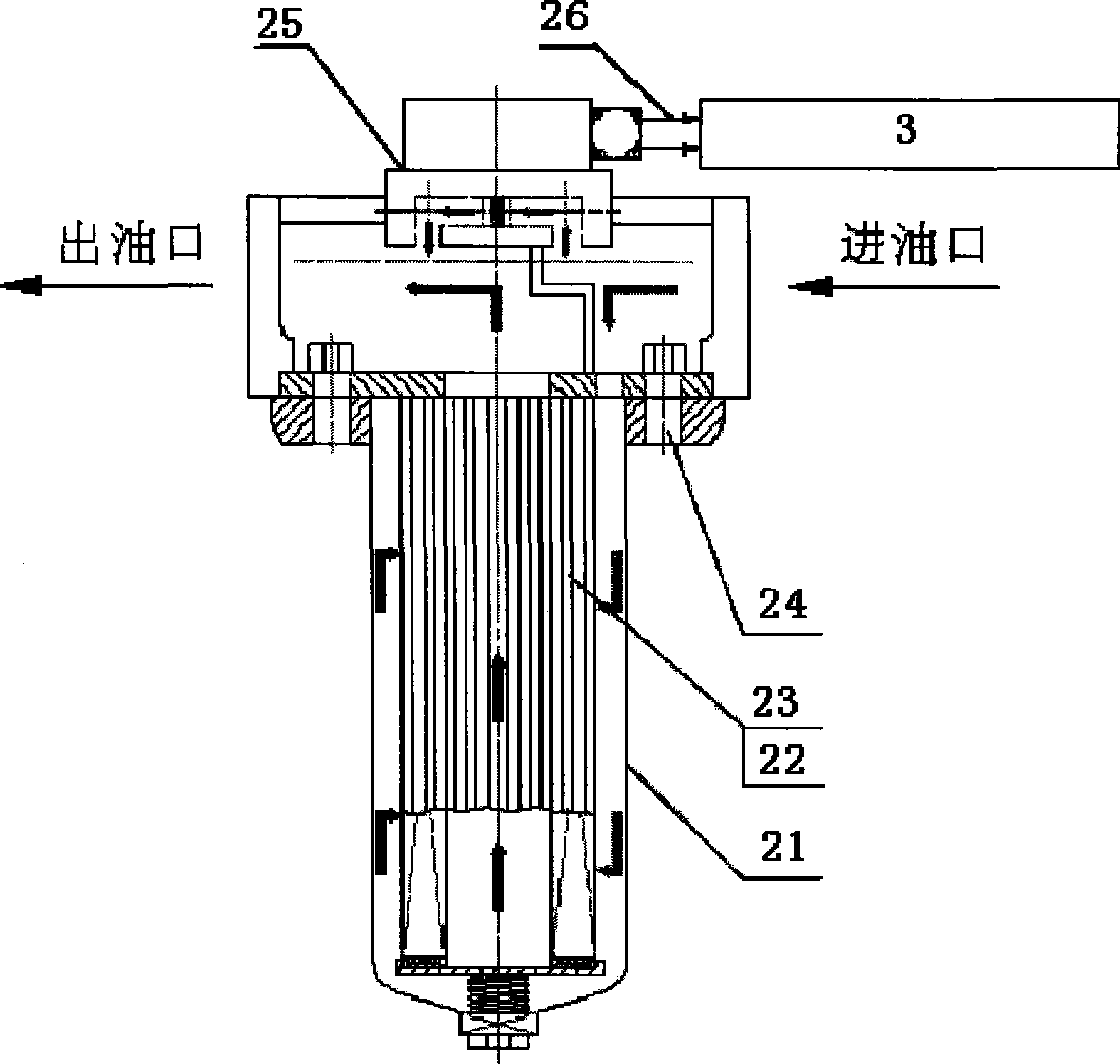

Oil liquid pollution monitoring, cleaning and filtrating apparatus for embedded hydraulic power system

InactiveCN101363464ADoes not affect actual operating conditionsAchieve reuseFluid-pressure actuator componentsDisplay deviceHydraulic equipment

The invention discloses an oil pollution monitoring and cleaning and filtering device of an embedded hydraulic power system, which comprises a main oil way A of the hydraulic system, a second electronic-magnetic or electronic-liquid steering valve which is arranged between the inlet and the outlet of the main oil way A of the hydraulic system. The device is characterized in that a branch oil way B is parallelly arranged on the inlet and the outlet of main oil way A of the hydraulic system, a branch oil way B is provided with a first electronic-magnetic or electric-liquid steering valve, a filter or a one-way valve and the filter is parallelly connected with a pressure gradient oil pollution monitoring and display device. The filtering device aims at not influencing the normal operation of the system when the attachment as the hydraulic equipment is embedded into the design of the hydraulic power system, monitoring results can better show the practical operation of oil.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Motor stator coil shaping machine

InactiveCN103095062AImprove work efficiencyGuaranteed dimensional accuracyManufacturing dynamo-electric machinesHydraulic cylinderElectric machine

The invention provides a motor stator coil shaping machine which comprises a machine frame, support feet, a control box and a hydraulic equipment box. A working table which is arranged on the middle portion of the machine frame is provided with a vertical sliding guide pillar. The working table is provided with a light rail sliding panel which is pushed by a hydraulic cylinder. A radial shaping device is arranged above the light rail sliding panel. The radial shaping device comprises a shaping half module and a shaping mandrel. The edge of the worktable is further provided with a stator stack thickness locating rod. Due to the method, the motor stator coil shaping machine utilizes the shaping mandrel to guarantee an inner ring size of a coil. Meanwhile, the motor stator coil shaping machine achieves a goal of radial shaping of the coil through a shaping half module compacted coil, coordinates with the stator stack thickness locating rod to detect the thickness of the coil and effectively guarantees size accuracy of the coil in the radial direction.

Owner:NIDE MECHANICAL EQUIP

High-speed heavy-duty linear reciprocating body operation energy storage device

InactiveCN102102688AImprove work efficiencyFast pushMechanical apparatusEngineeringHydraulic equipment

The invention relates to the technical field of hydraulic equipment, in particular to a high-speed heavy-duty linear reciprocating body operation energy storage device. The device comprises a tank body, an air storage tank and a high-pressure hydraulic cylinder, wherein an inner cavity of the tank body is separated into an air pressure chamber and a liquid storage chamber through an air pressure piston; the air storage tank is communicated with the air pressure chamber through a pipeline; the liquid storage chamber is provided with a liquid outlet and a liquid reflux inlet; the high-pressure hydraulic cylinder is provided with a liquid inlet and a hydraulic piston; and the air pressure piston is connected with the hydraulic piston through a piston rod. Because the area of the air pressurepiston is greater than that of the hydraulic piston, the air pressure piston has a large pressure area to push the liquid in the liquid storage chamber to have a high speed, the stored energy can be simultaneously and rapidly released together with the high-pressure hydraulic cylinder, the working efficiency is high, and the high-pressure hydraulic cylinders are pushed to exchange by a low-power small-flow pump, so that two liquid storage chambers alternately inhale liquid discharged by a working motion body cylinder in a reciprocating mode, and the working motion body can be pushed to move at a high speed. Therefore, the pressure and flow of the hydraulic cylinder of the working motion body are improved, the working operation speed is improved, and the electric energy is saved.

Owner:广东尚正堂集团股份有限公司

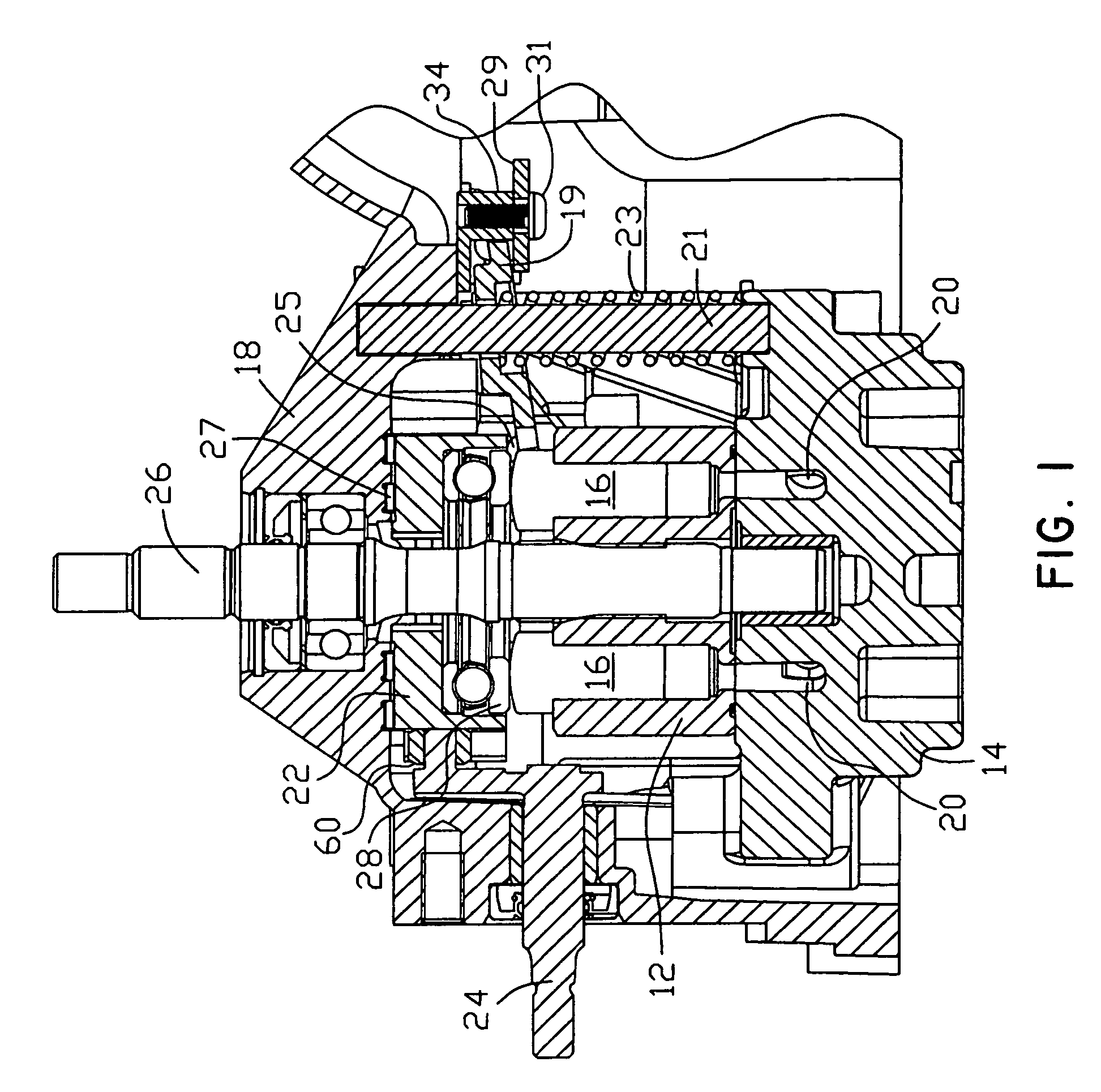

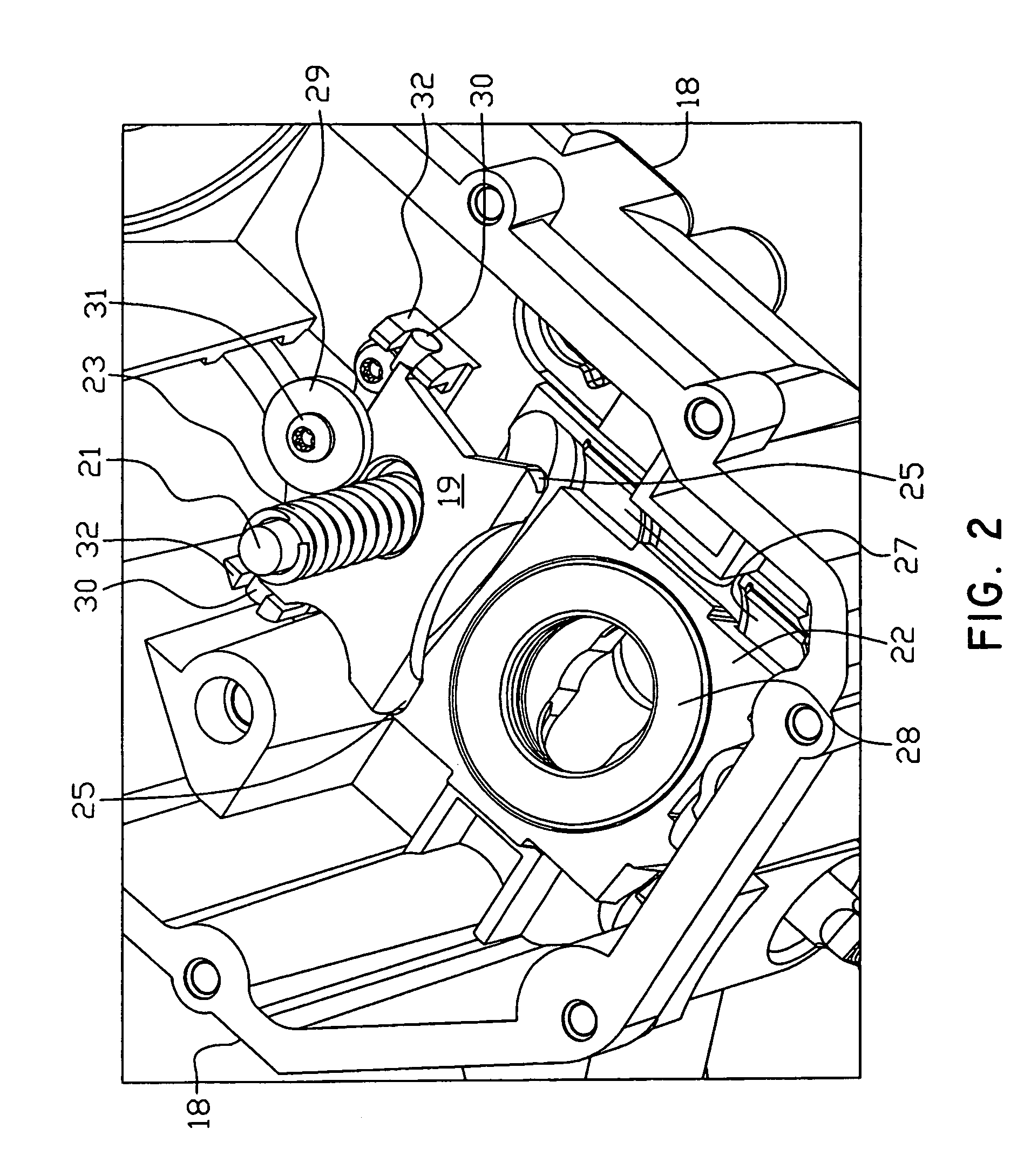

Return to neutral device for a hydraulic apparatus

InactiveUS7111545B1Maintain positionEliminate the problemFluid couplingsPositive-displacement liquid enginesHydraulic equipmentEngineering

In a hydrostatic device using an axial piston pump, a return plate is mounted so that it contacts the movable swash plate of the hydrostatic transmission. The plate is biased by a spring-type mechanism to force the swash plate to return to neutral, and the set position of the plate may be externally adjusted. A bias arm comprising a generally U-shaped member having spring mounted on either leg thereof may be engaged to the return plate.

Owner:HYDRO GEAR PARTNERSHIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com