Patents

Literature

12967 results about "Pipe fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks. Pipe fitting work is done in many different settings: HVAC, manufacturing, hydraulics, refineries, nuclear-powered Supercarriers and Fast Attack Submarines computer chip fab plants, power plant construction and other steam systems. Pipe fitters are represented in the USA and Canada by the United Association of Journeymen and Apprentices of the Plumbing and Pipe Fitting Industry of the United States and Canada. Fitters work with a variety of pipe and tubing materials including several types of steel, copper, iron, aluminium, and plastic. Pipe fitting is not plumbing; the two are related but separate trades. Pipe fitters who specialize in fire prevention are called Sprinklerfitters, another related, but separate trade. Materials, techniques, and usages vary from country to country as different nations have different standards to install pipe.

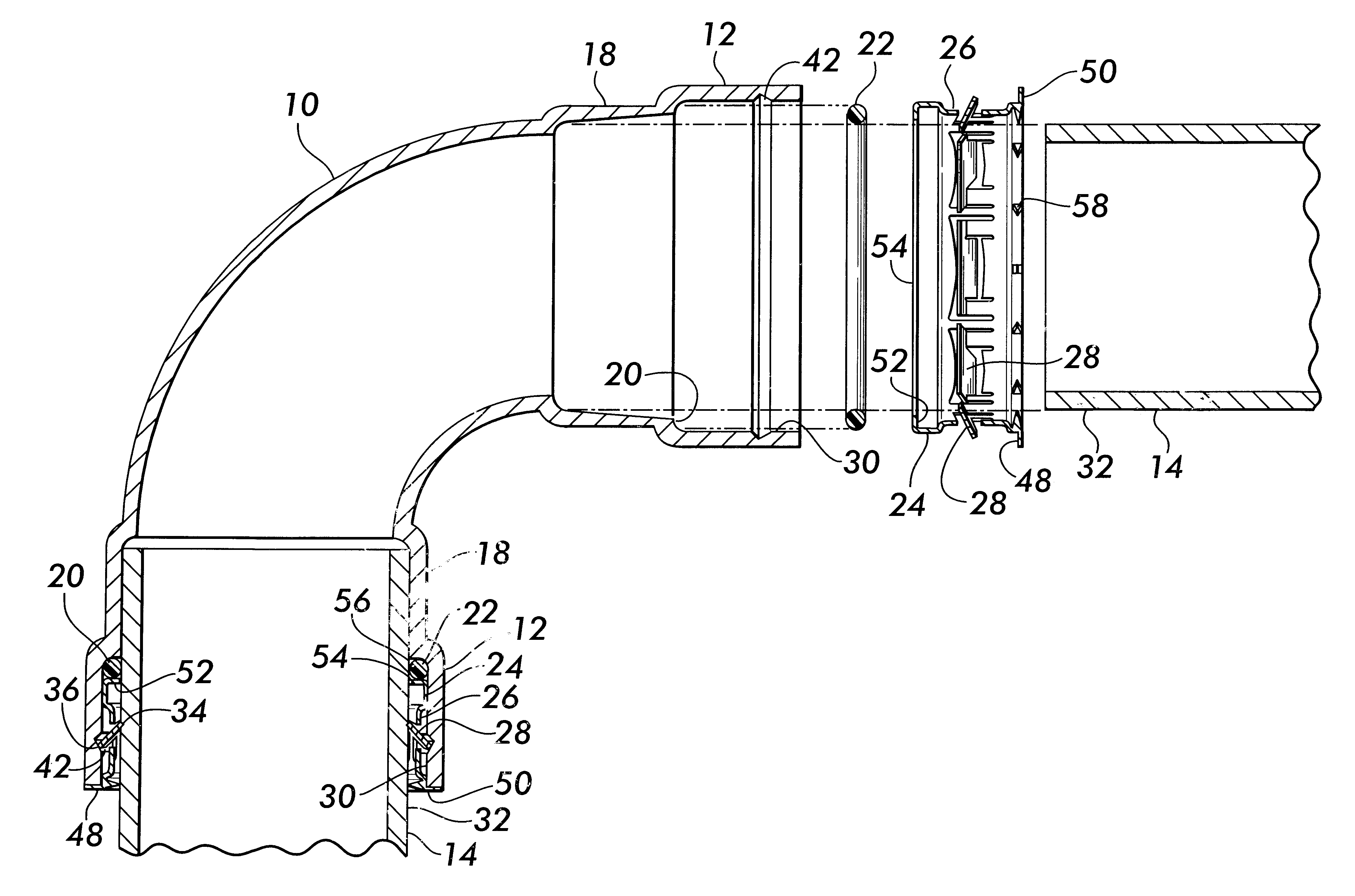

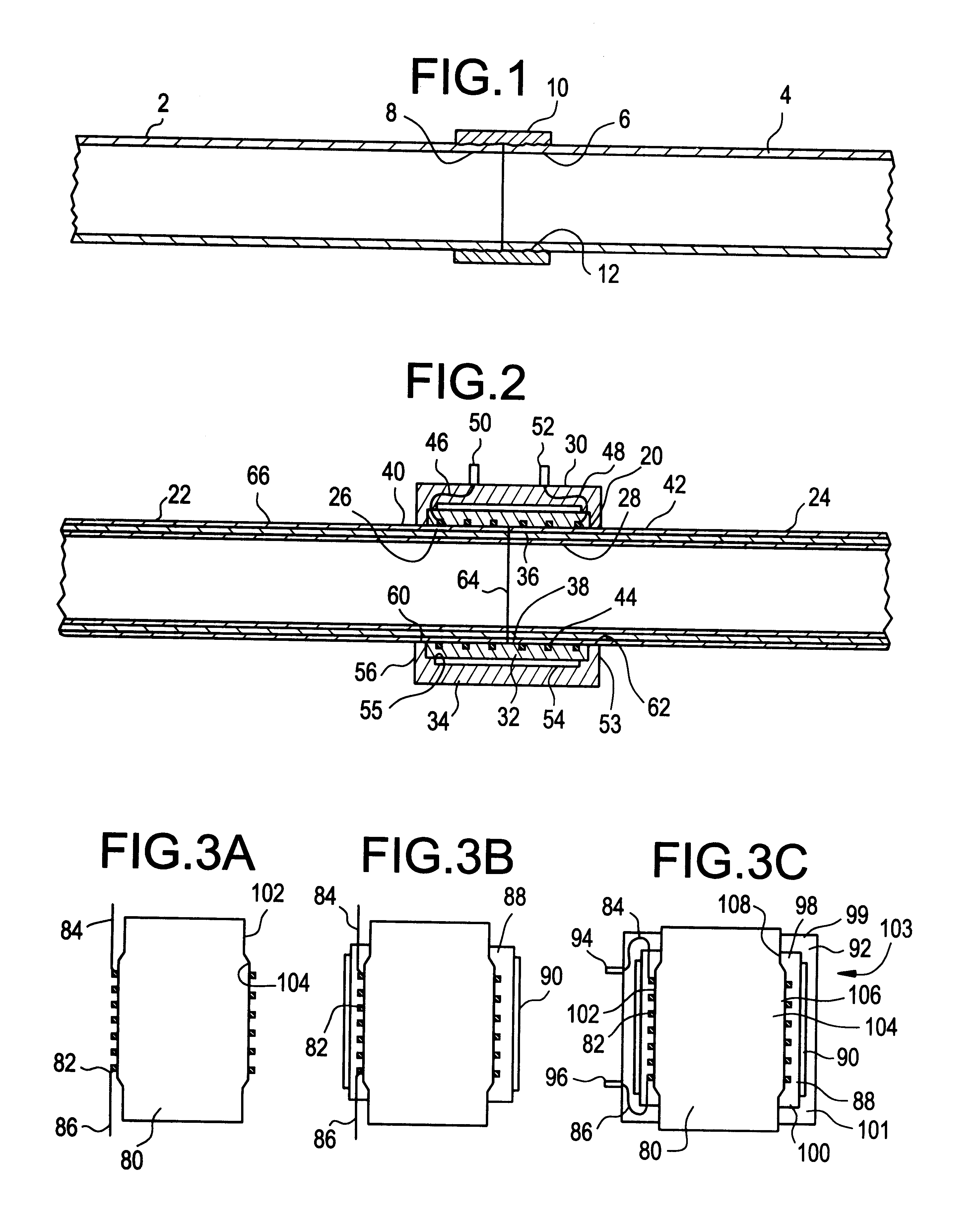

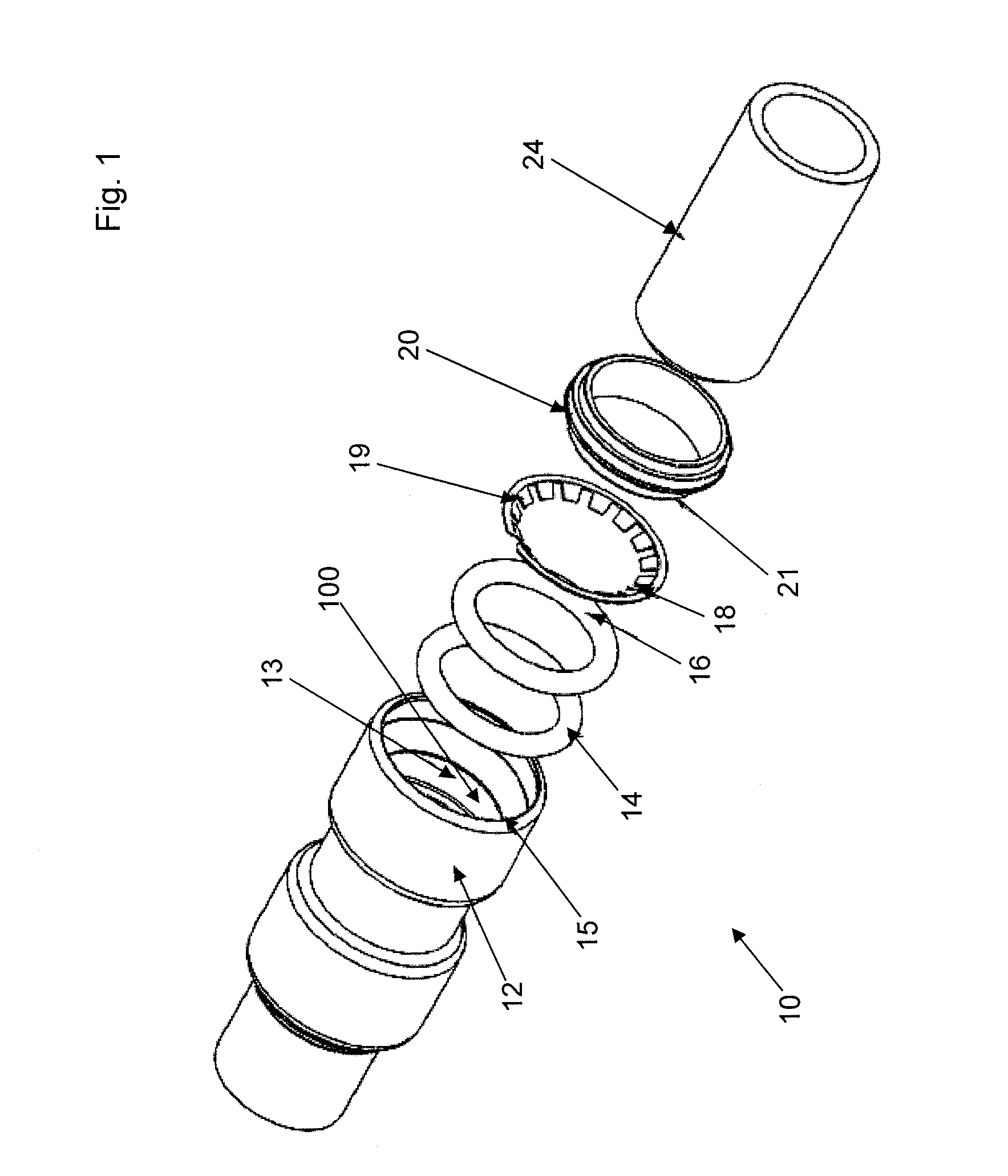

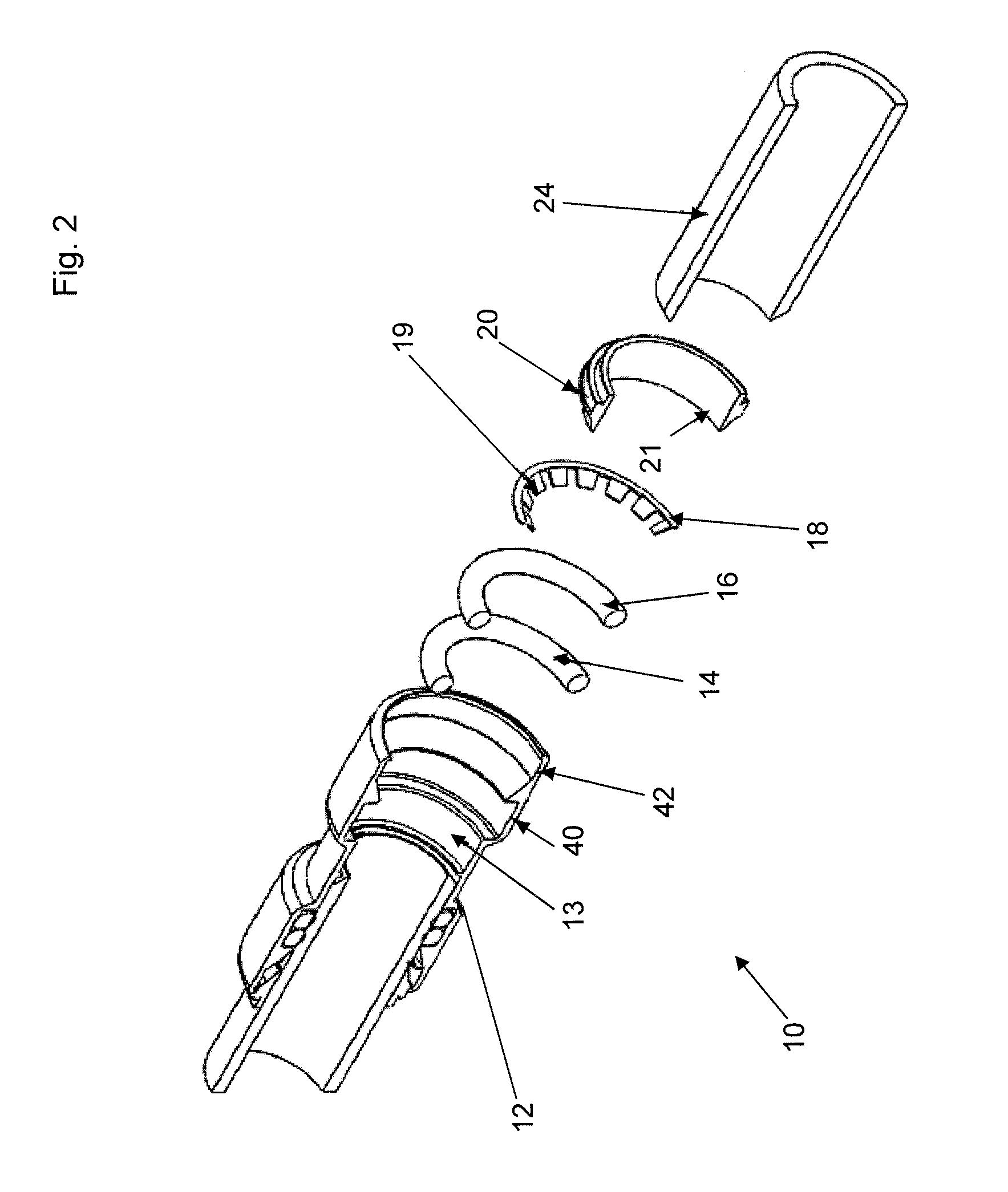

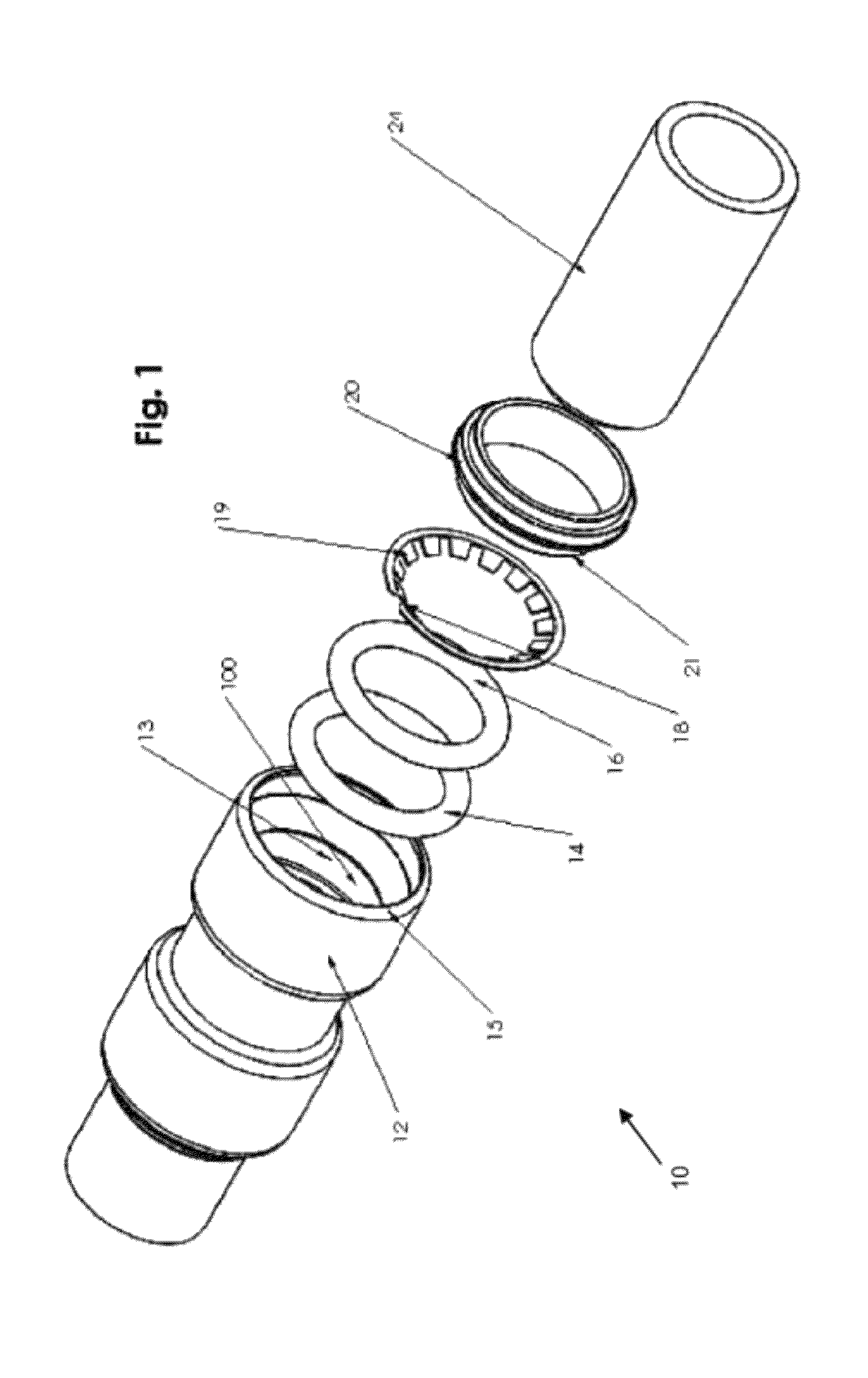

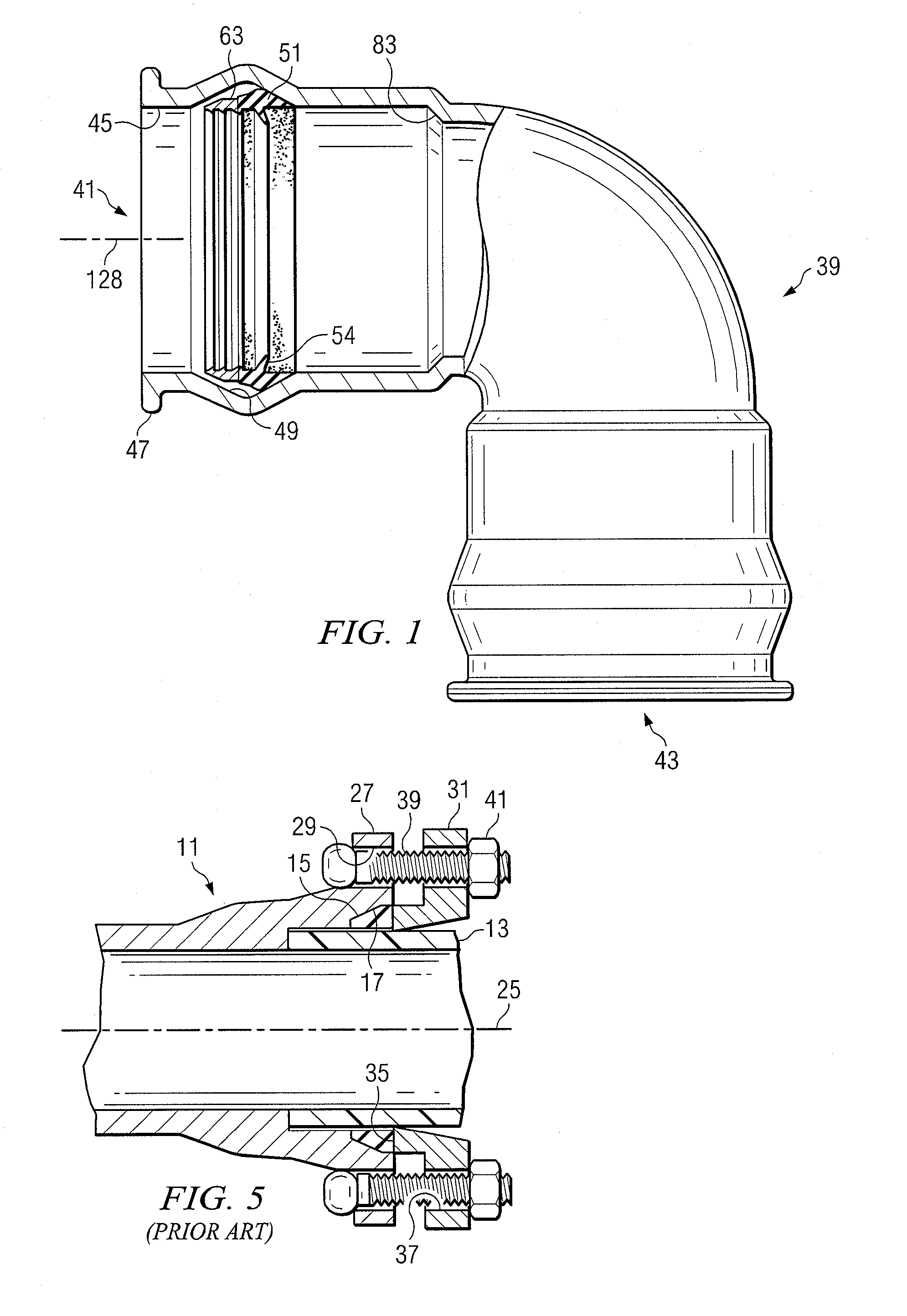

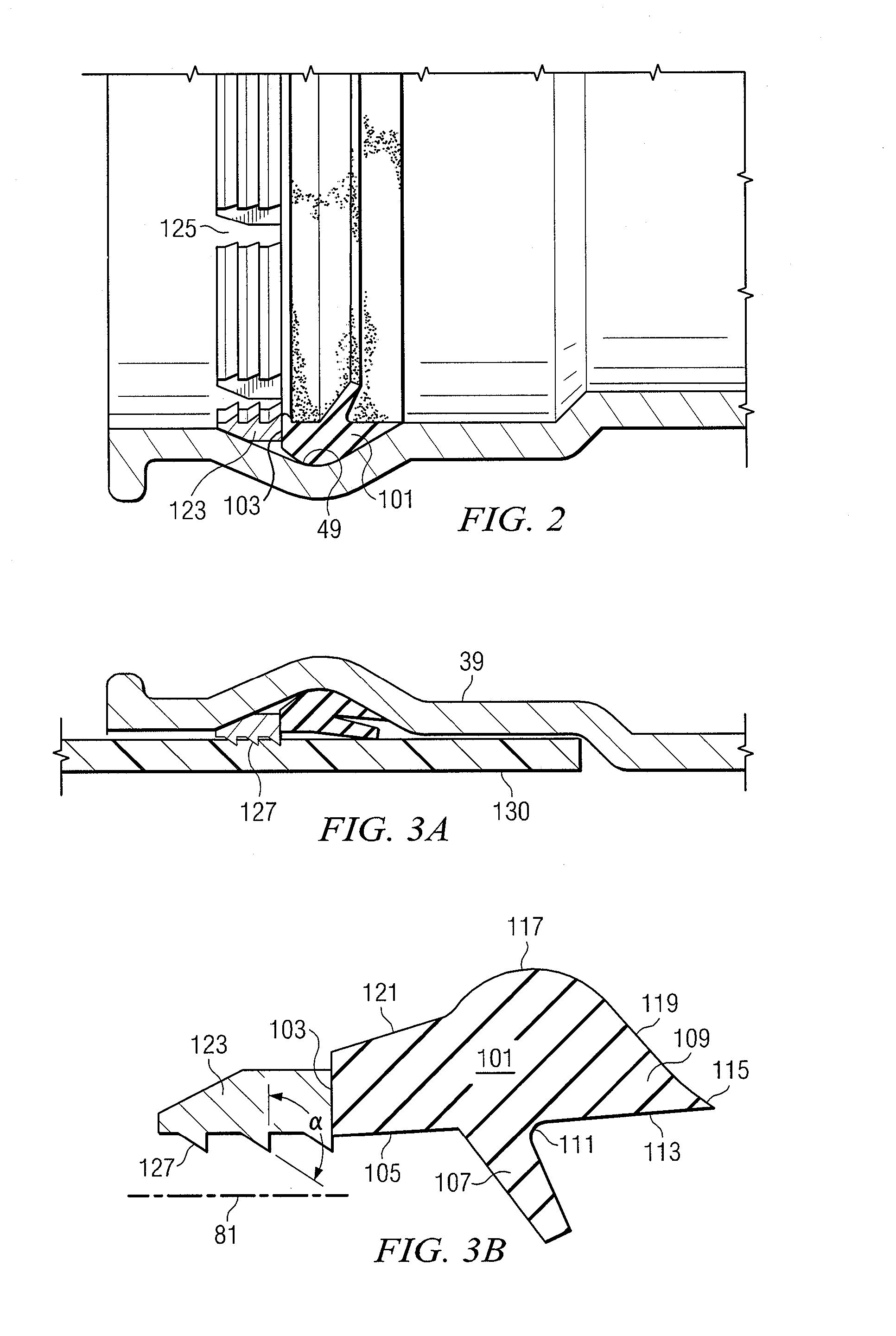

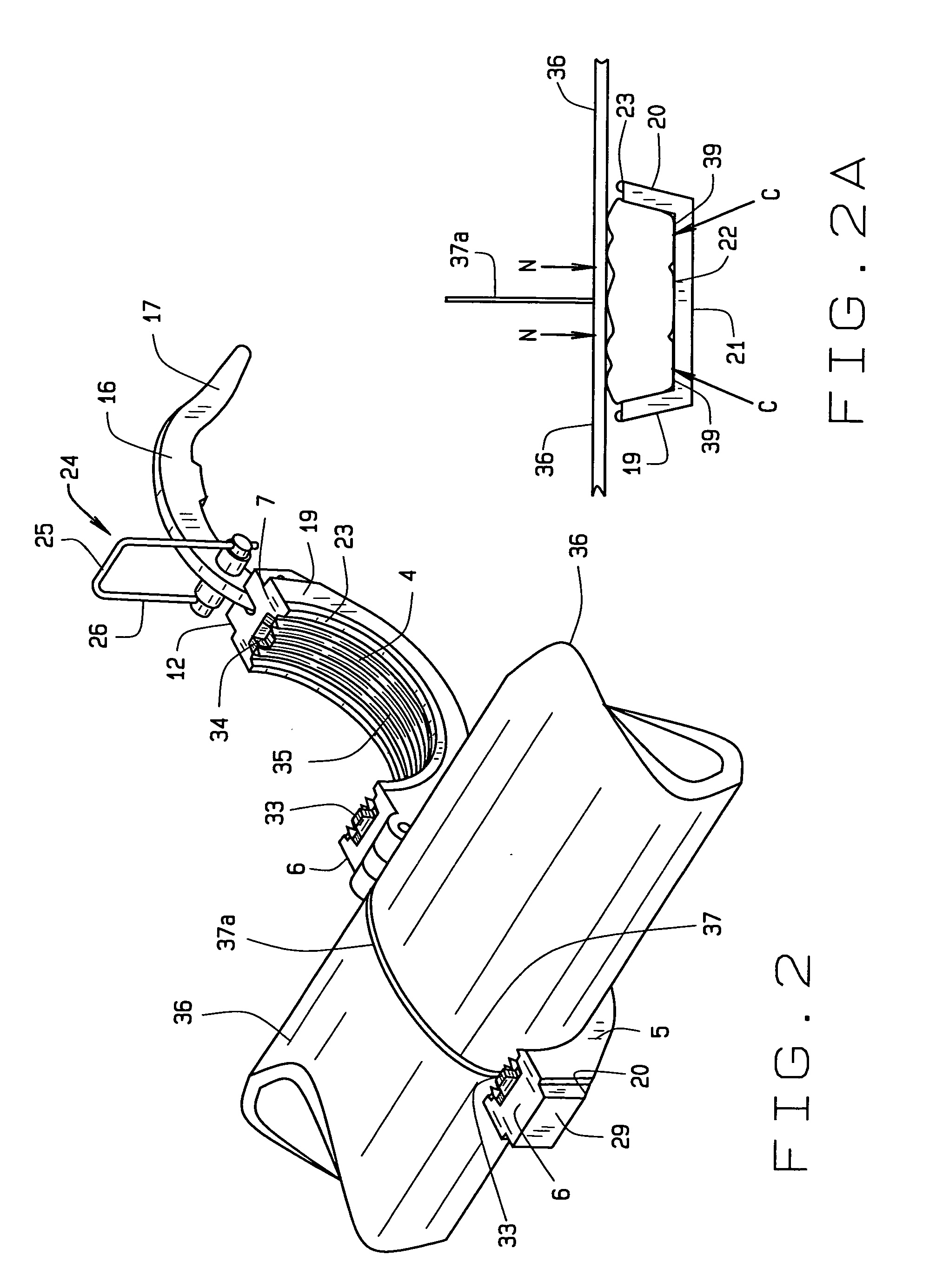

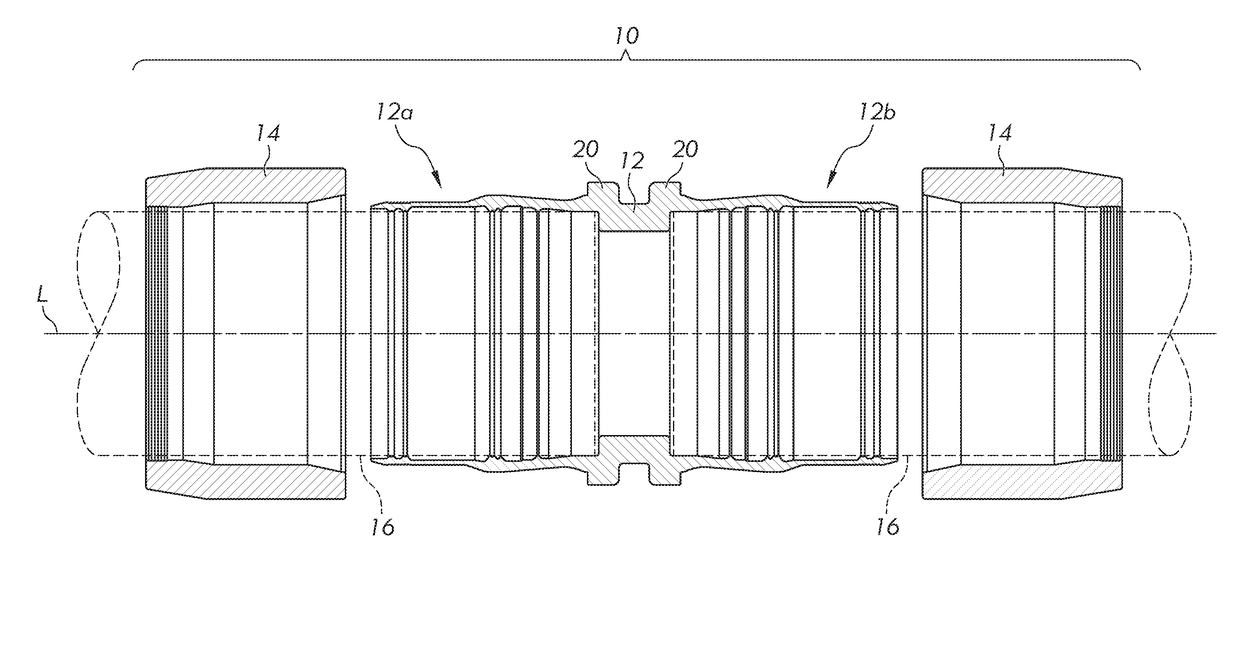

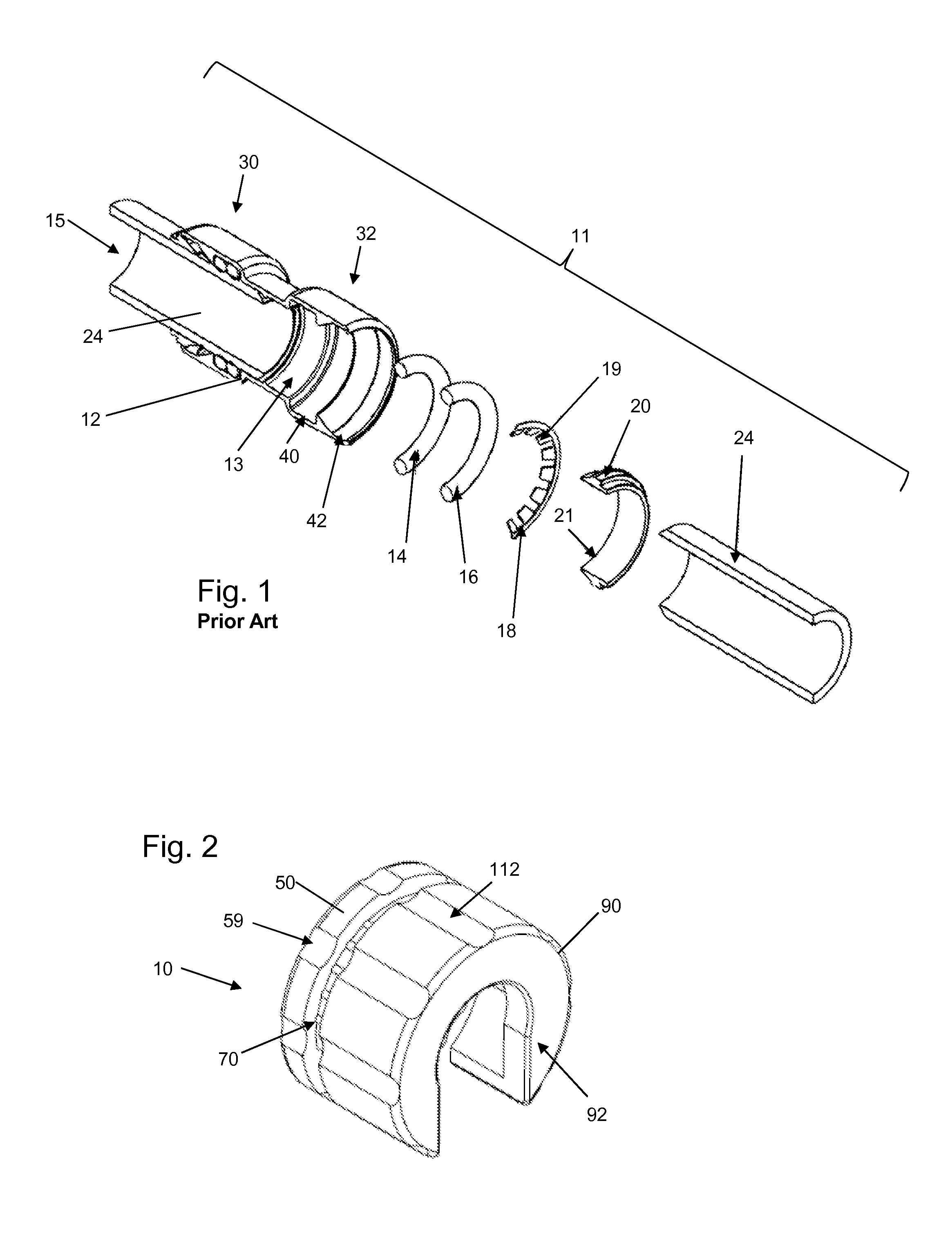

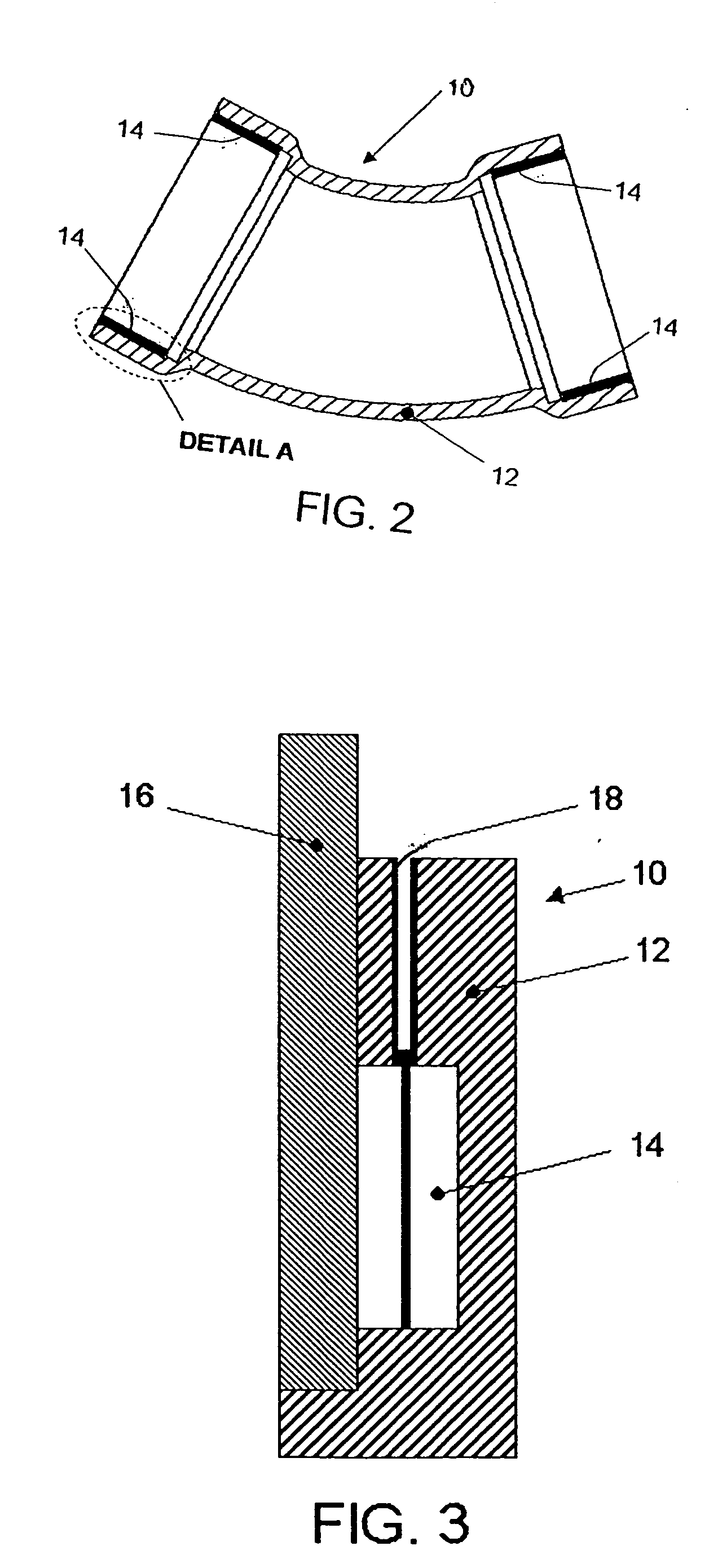

Mechanical pipe coupling with toothed retainer

InactiveUS6499771B1Reduce energy lossPositive engagementSleeve/socket jointsFluid pressure sealed jointsPipe fitting

An open end of a standard pipe fitting is enlarged in diameter to coaxially receive an O-ring and a retainer having a cylindrical surface. A plurality of locking teeth project from the cylindrical surface and are engageable with both the inner surface of the fitting and an outer surface of a pipe end inserted coaxially into the fitting open end. Each of the locking teeth have oppositely disposed edges facing obliquely inwardly and outwardly to engage both the pipe end and the fitting and resisting motion of the pipe end relatively to the fitting. In an alternate embodiment, a first plurality of teeth each have an edge facing obliquely inwardly of the fitting to engage the pipe end and resist motion tending to withdraw the pipe end from the fitting. A second plurality of teeth each have an edge facing obliquely outwardly of the fitting and resist motion tending to withdraw the retainer from the fitting.

Owner:VICTAULIC

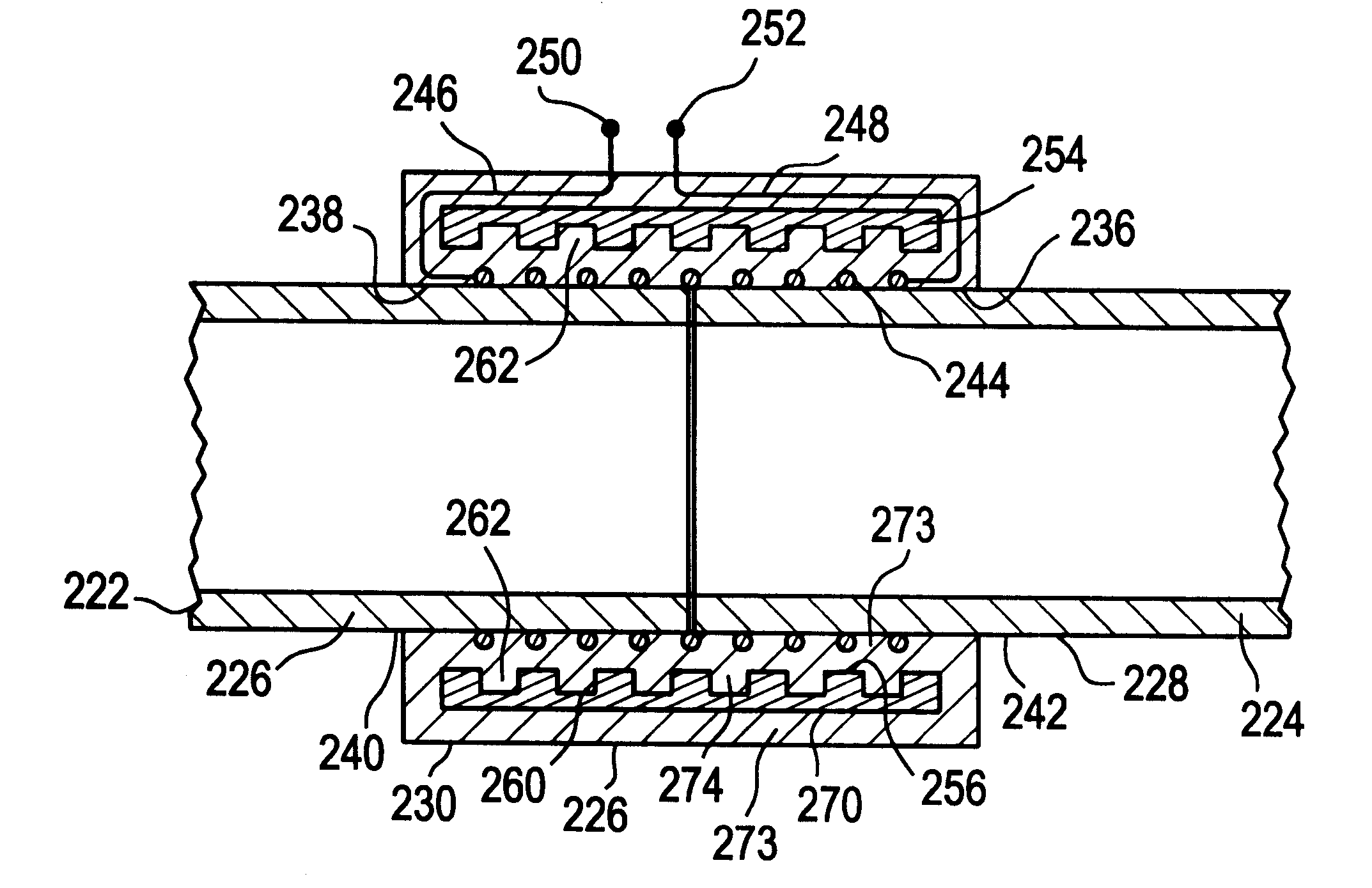

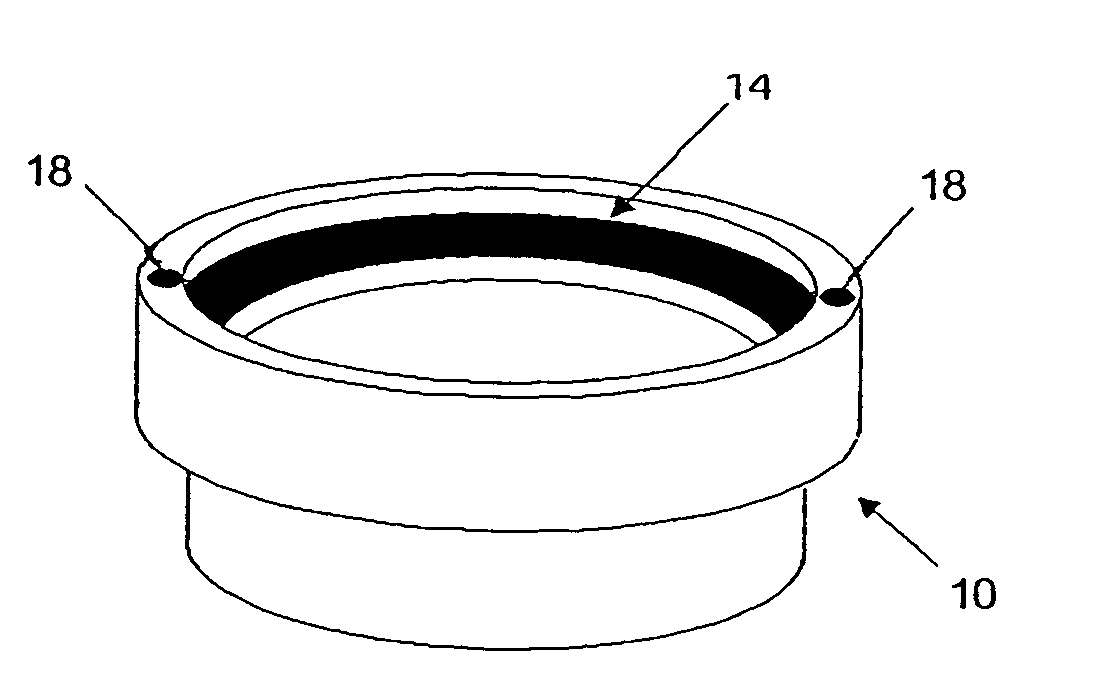

Pipe fittings

A pipe fitting for coupling together opposed ends of two plastics pipes by fusion welding, the pipe fitting comprising an annular body having an inner cylindrical surface of plastics material surrounding a cylindrical cavity for receiving opposed ends of two plastics pipes to be coupled together, an electrically conductive coil provided in said inner cylindrical surface and surrounding the cylindrical cavity, the coil having opposed ends, a pair of terminals each connected to a respective end of the coil and provided on the body for connection to a source of controlled electrical power, and an annular reinforcing member disposed in the body and surrounding the coil, the annular reinforcing member having a grooved surface which interfaces the annular body, the grooved surface defining a plurality of axially facing surfaces.

Owner:FINA RES SA

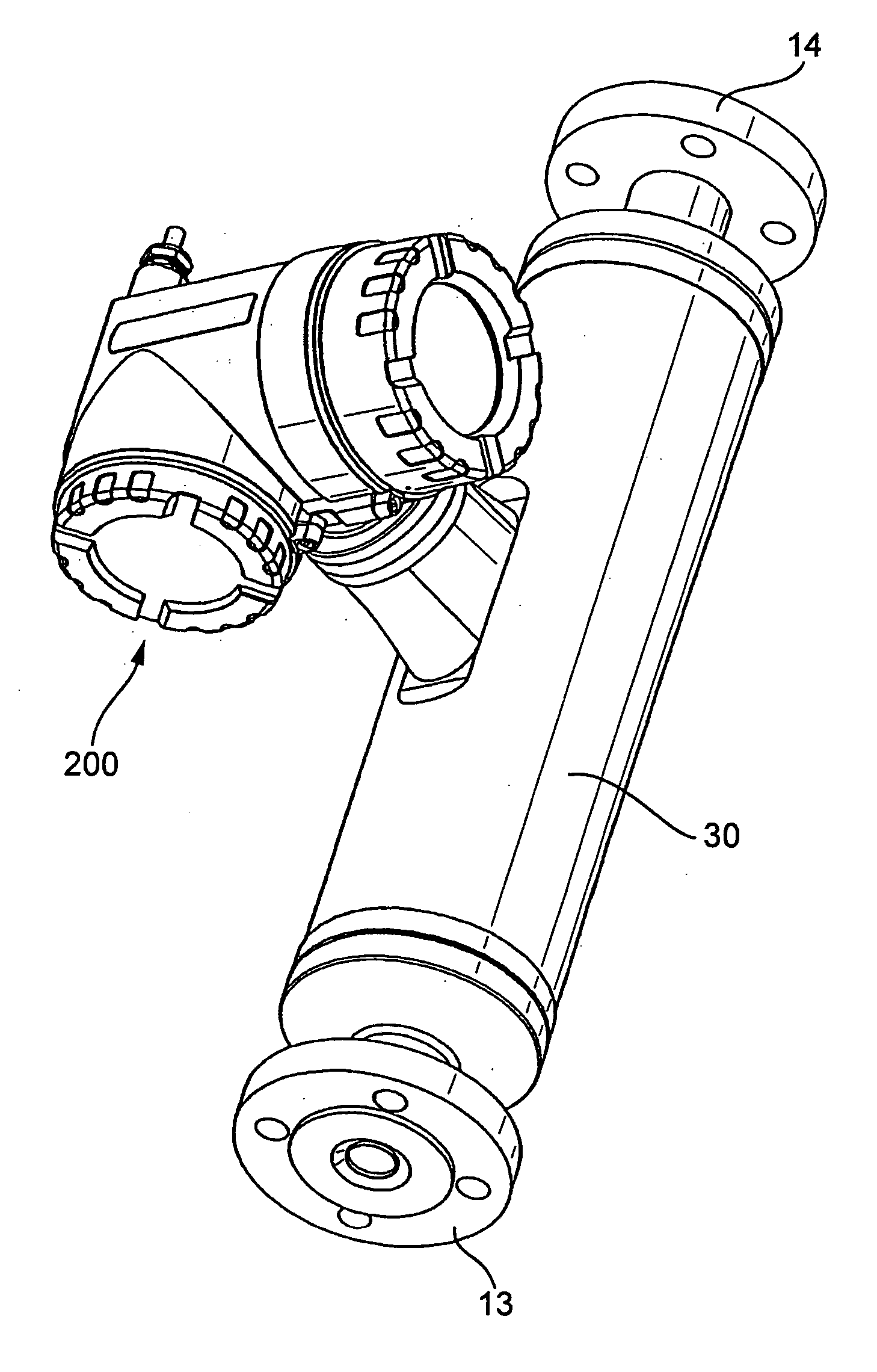

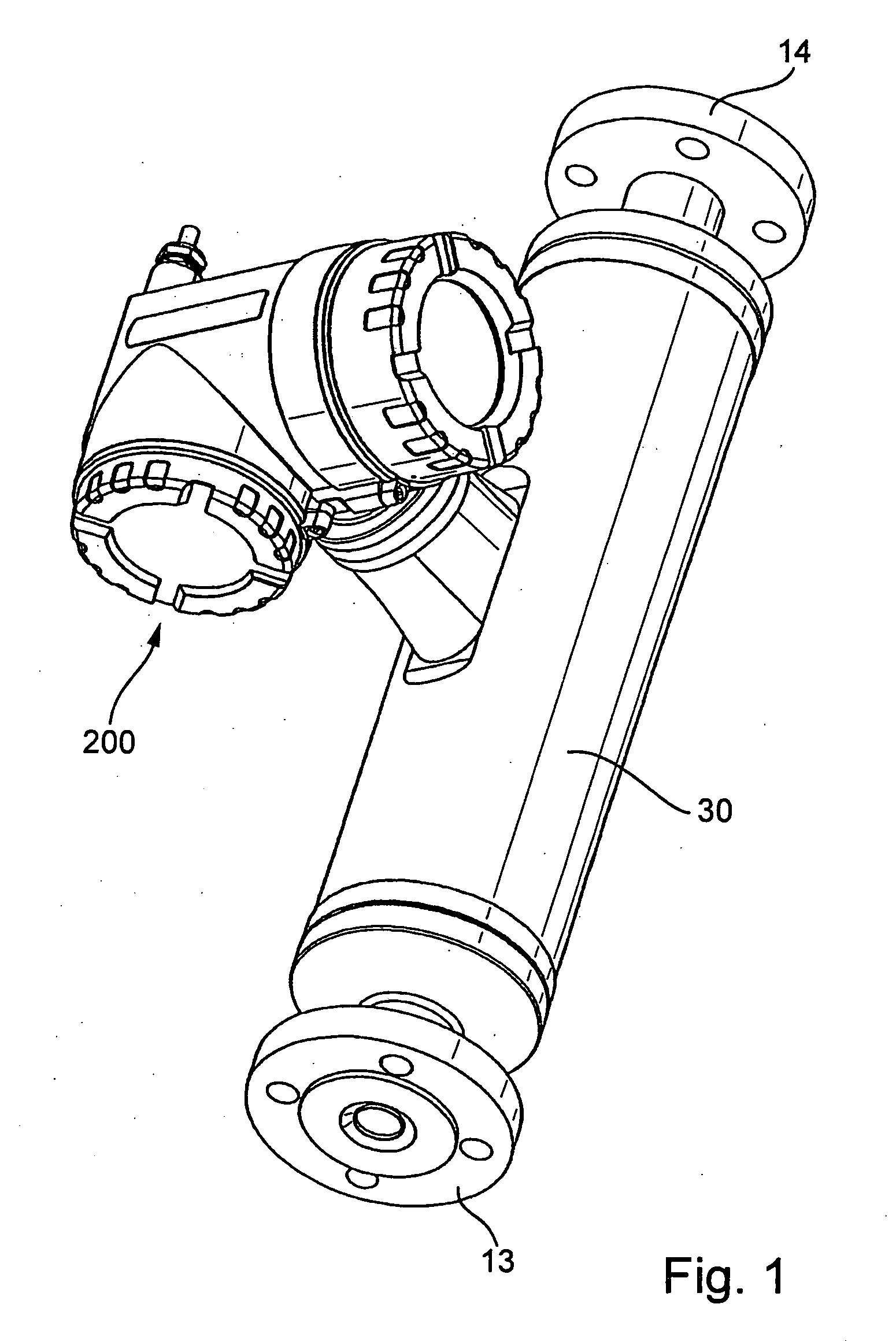

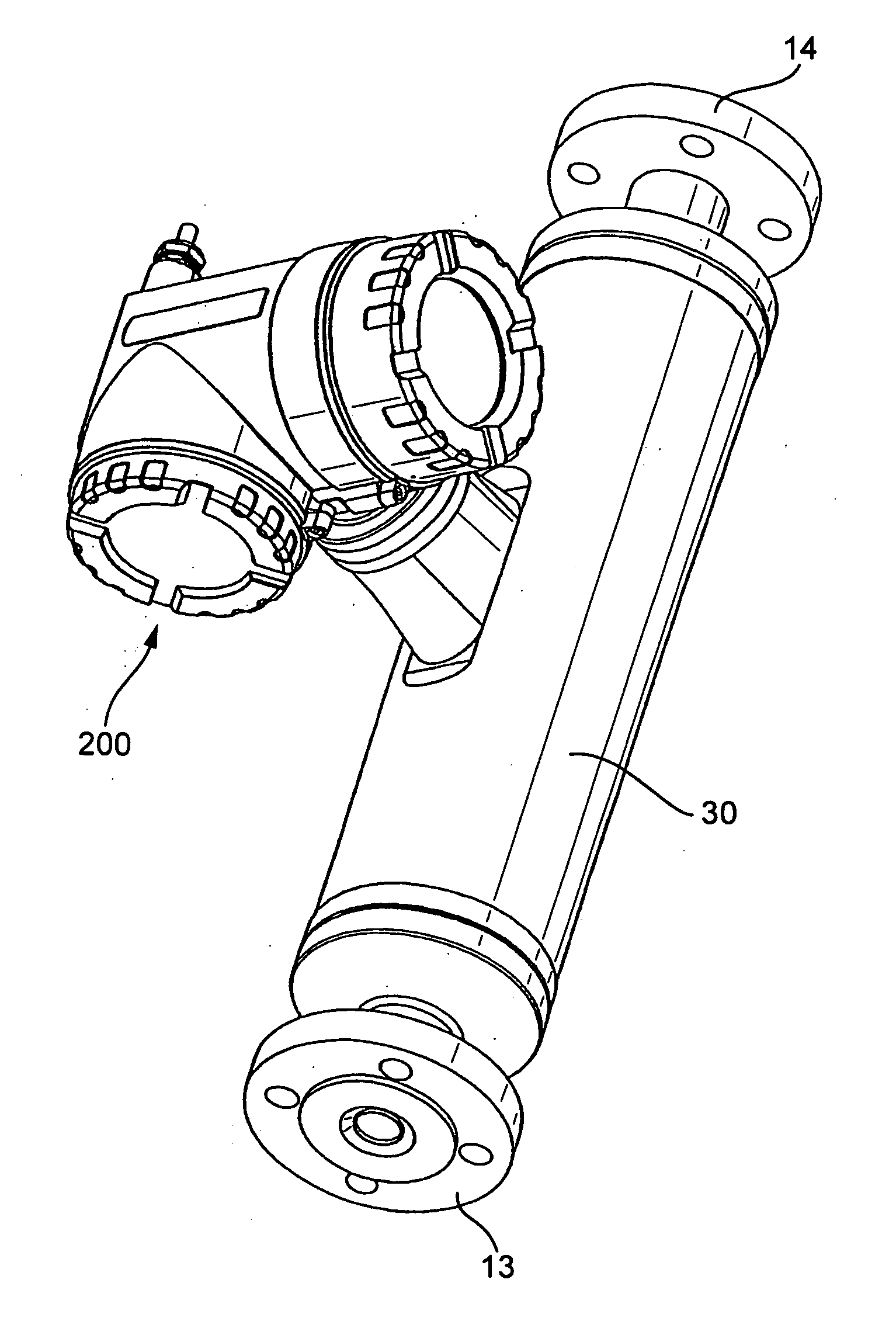

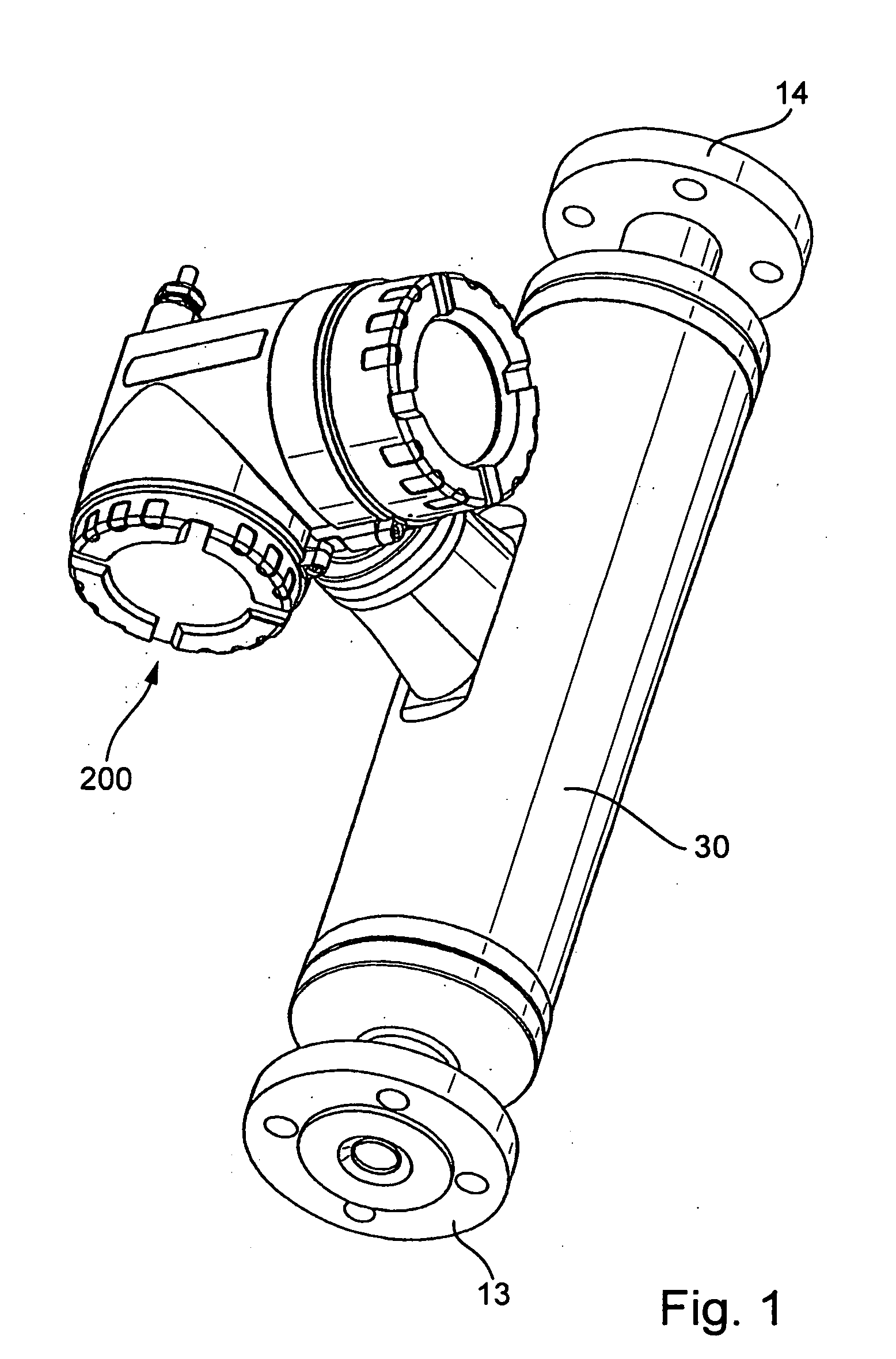

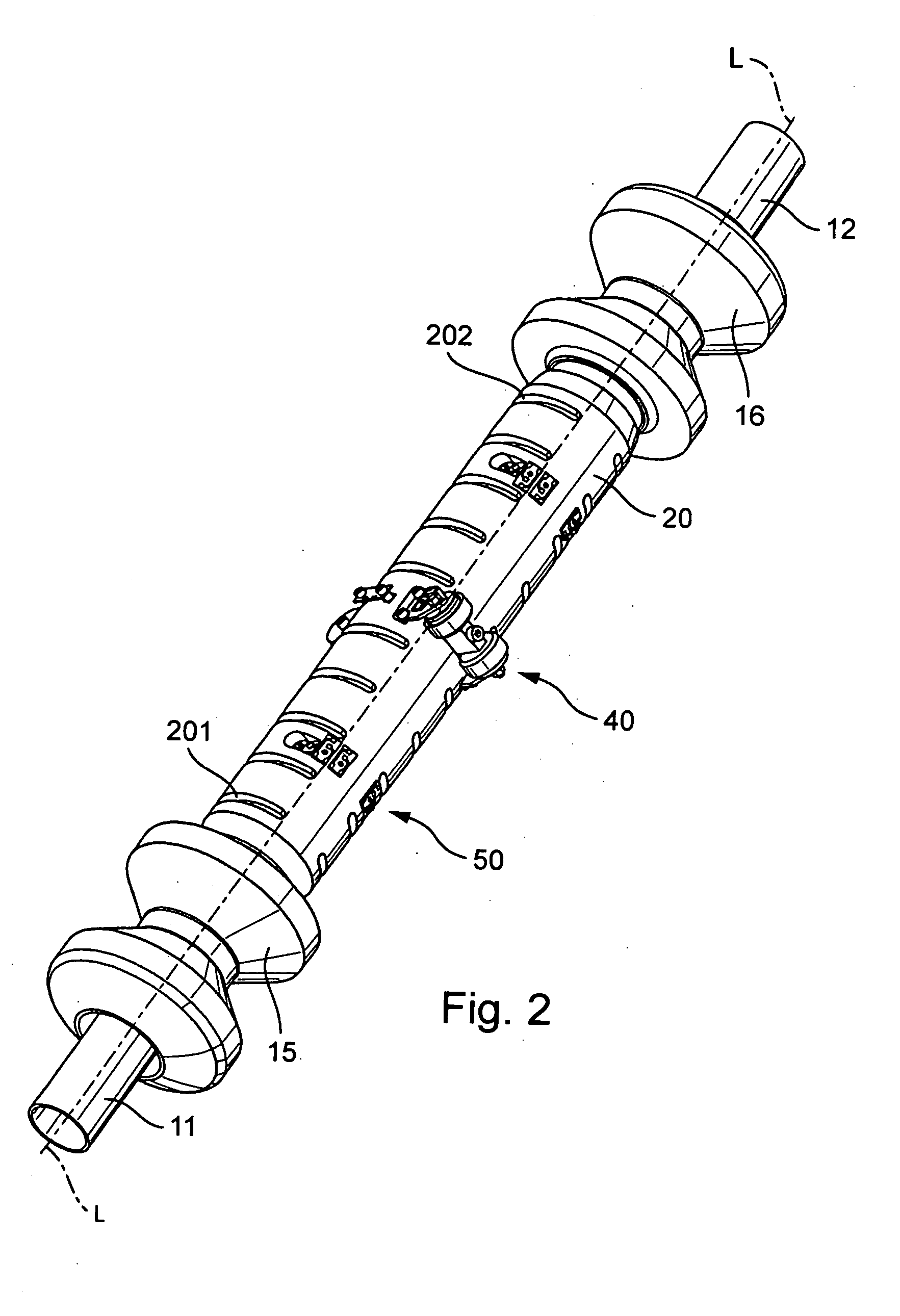

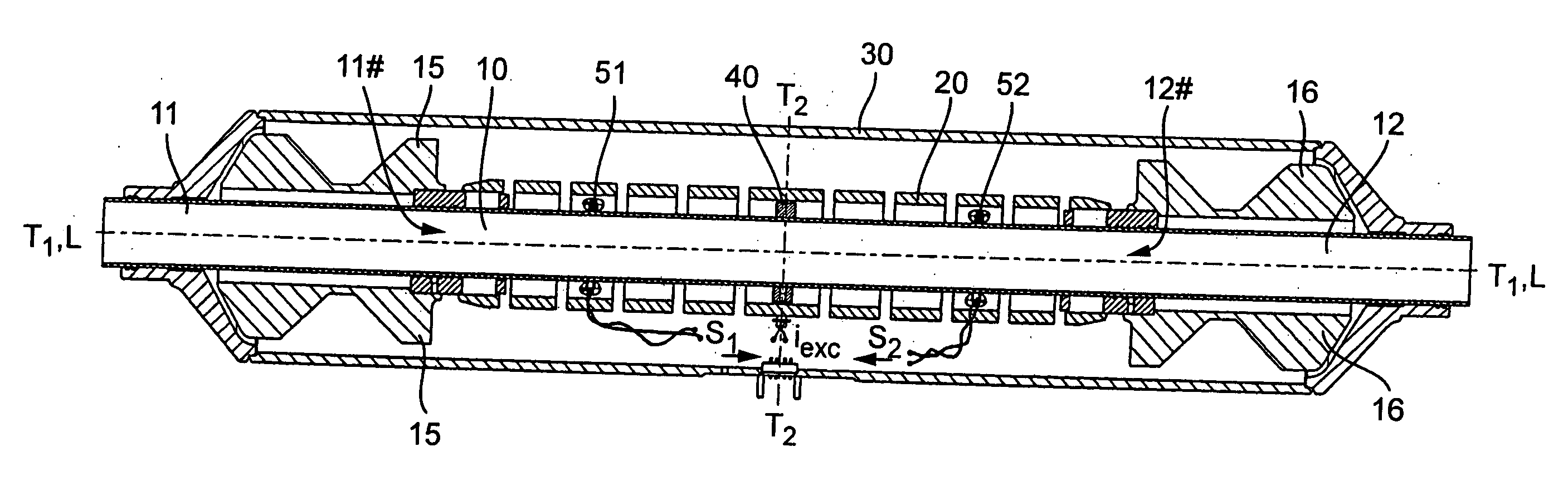

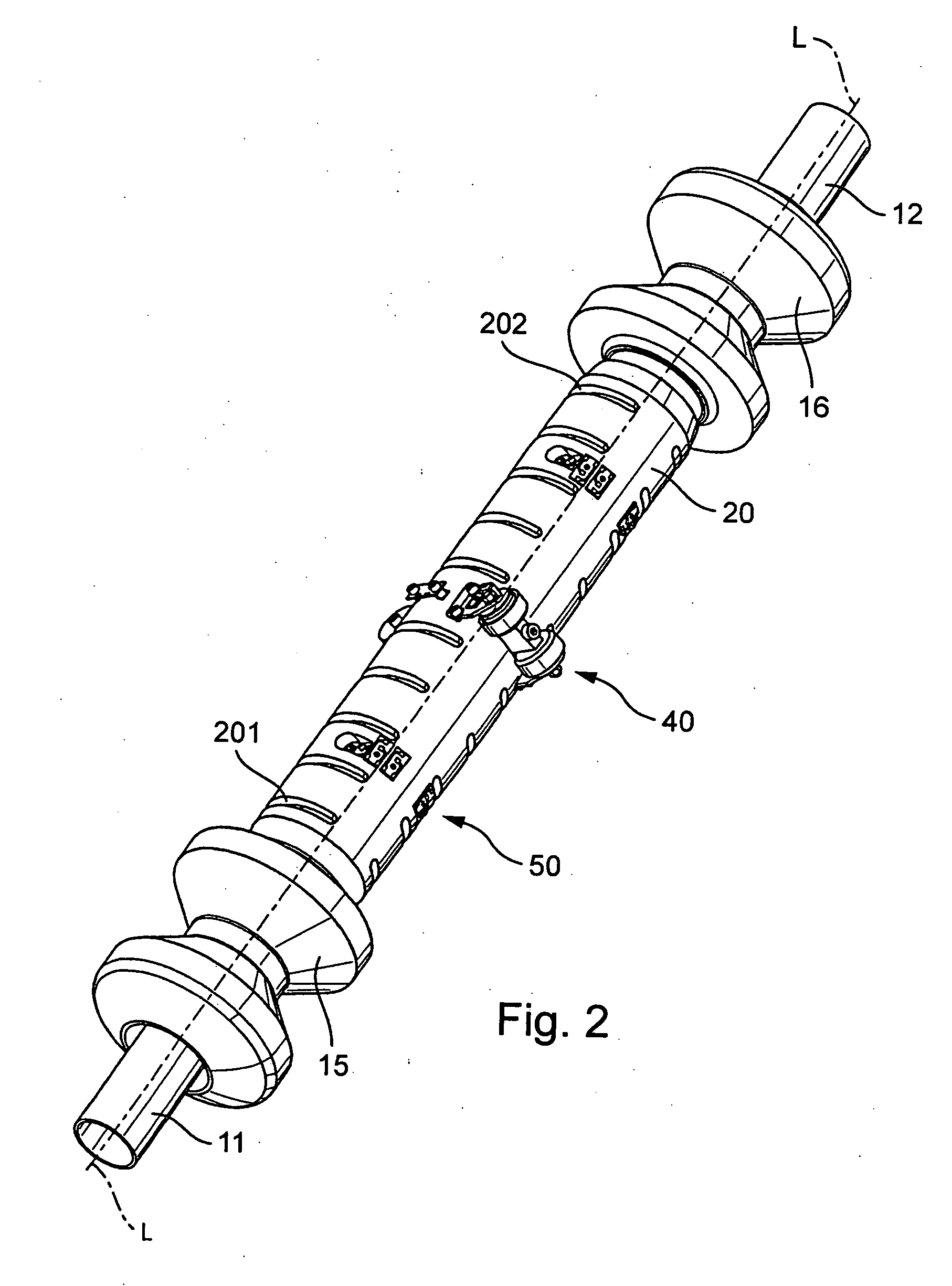

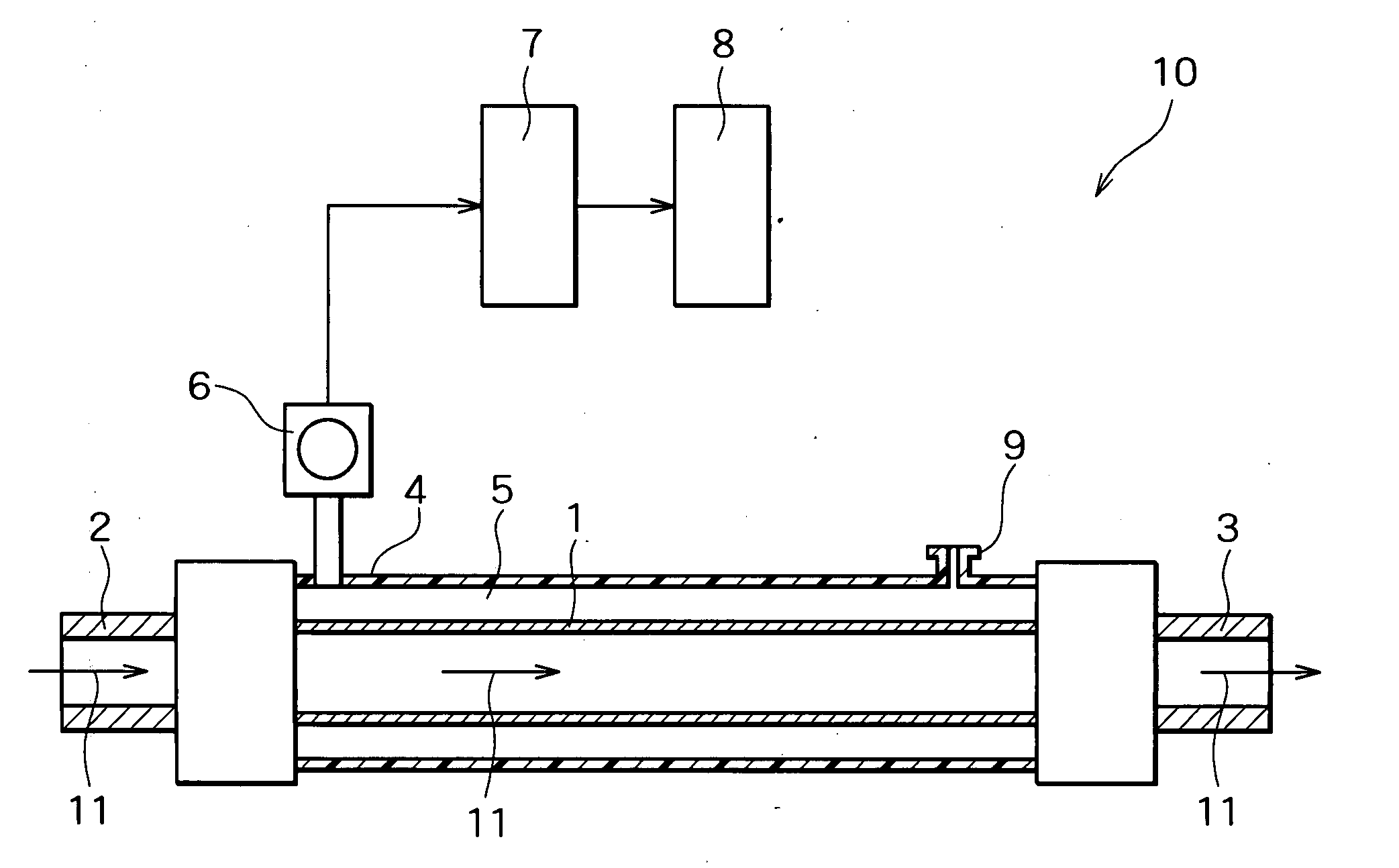

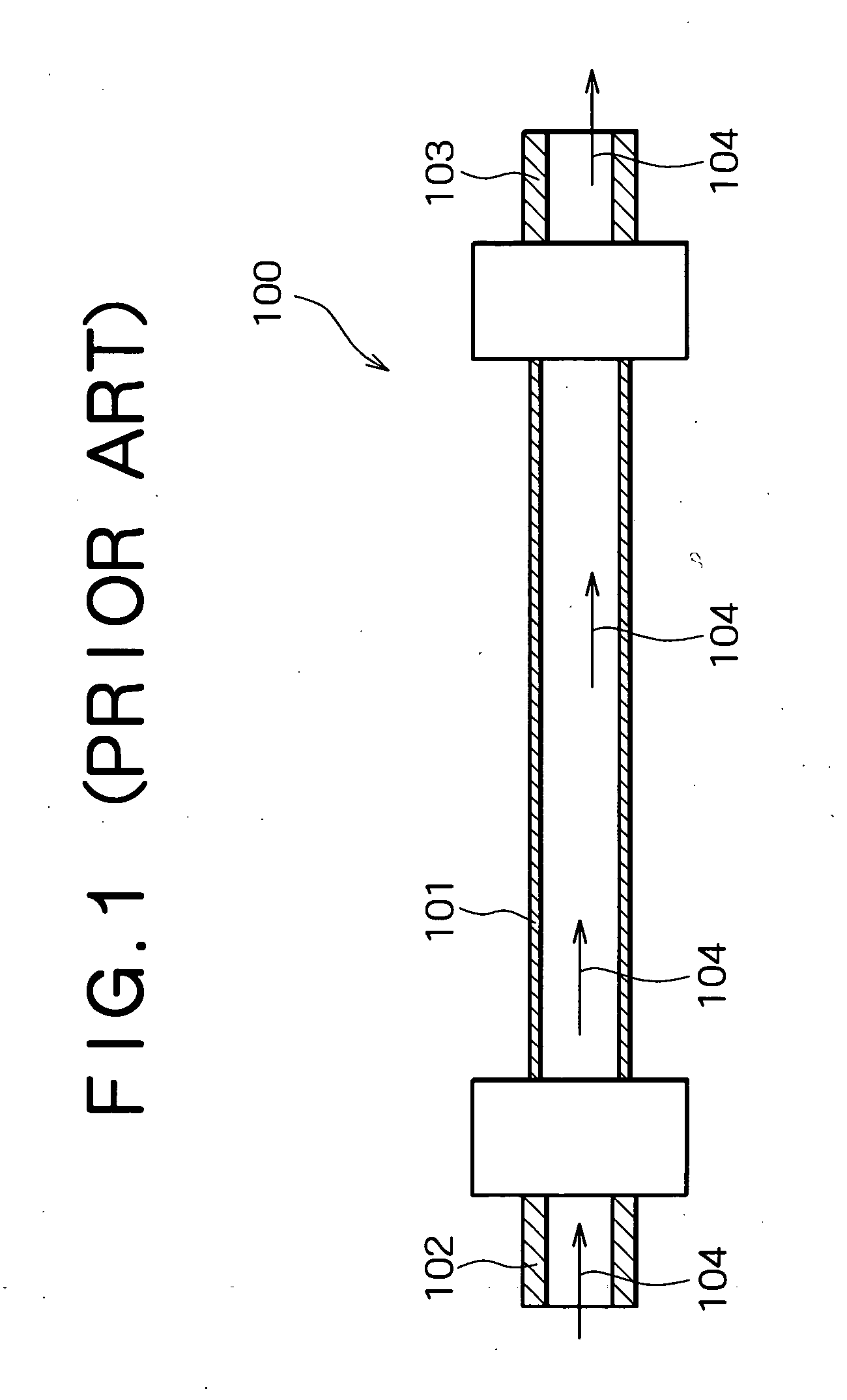

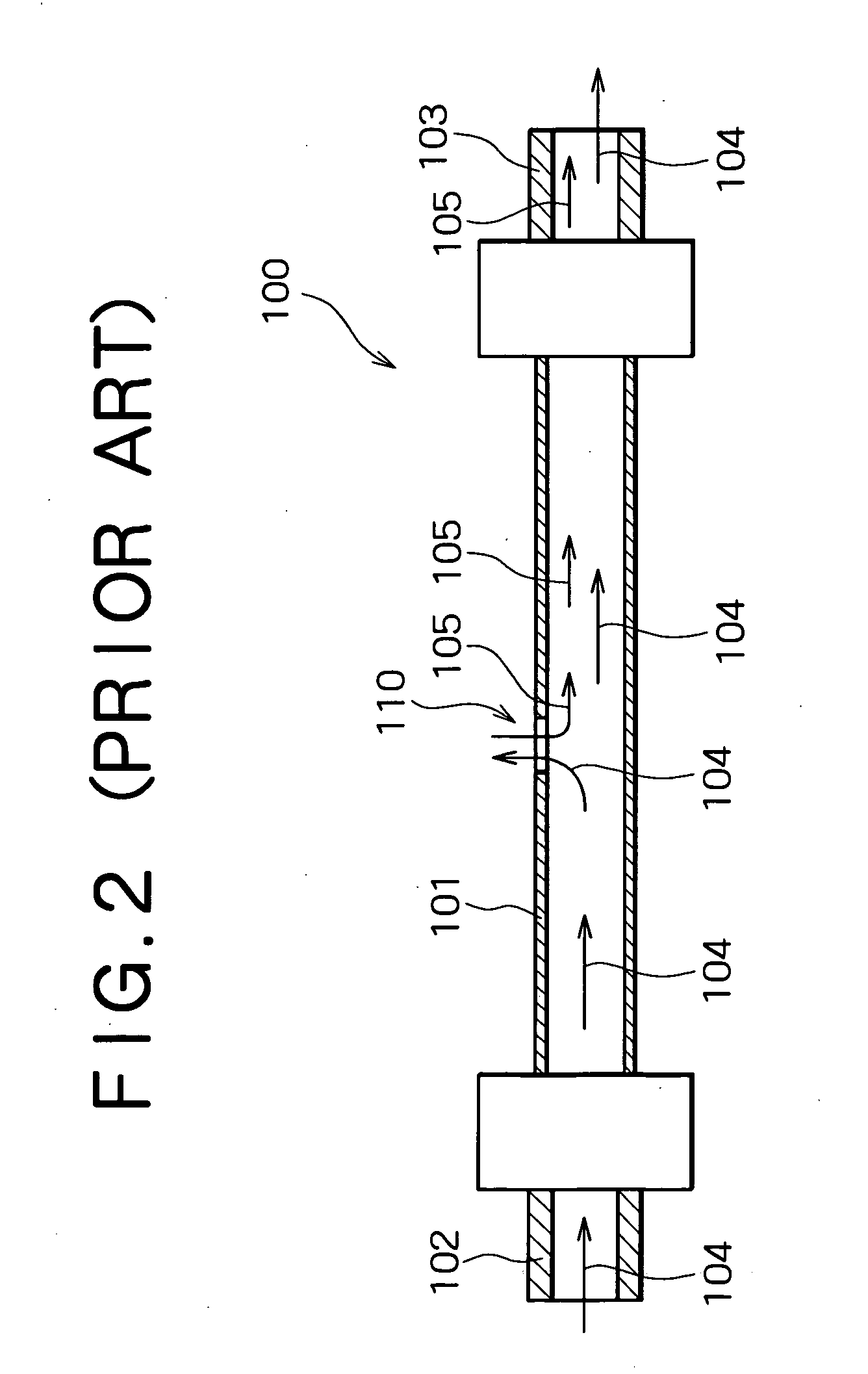

Measurement transducer of vibration-type

ActiveUS20070119264A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

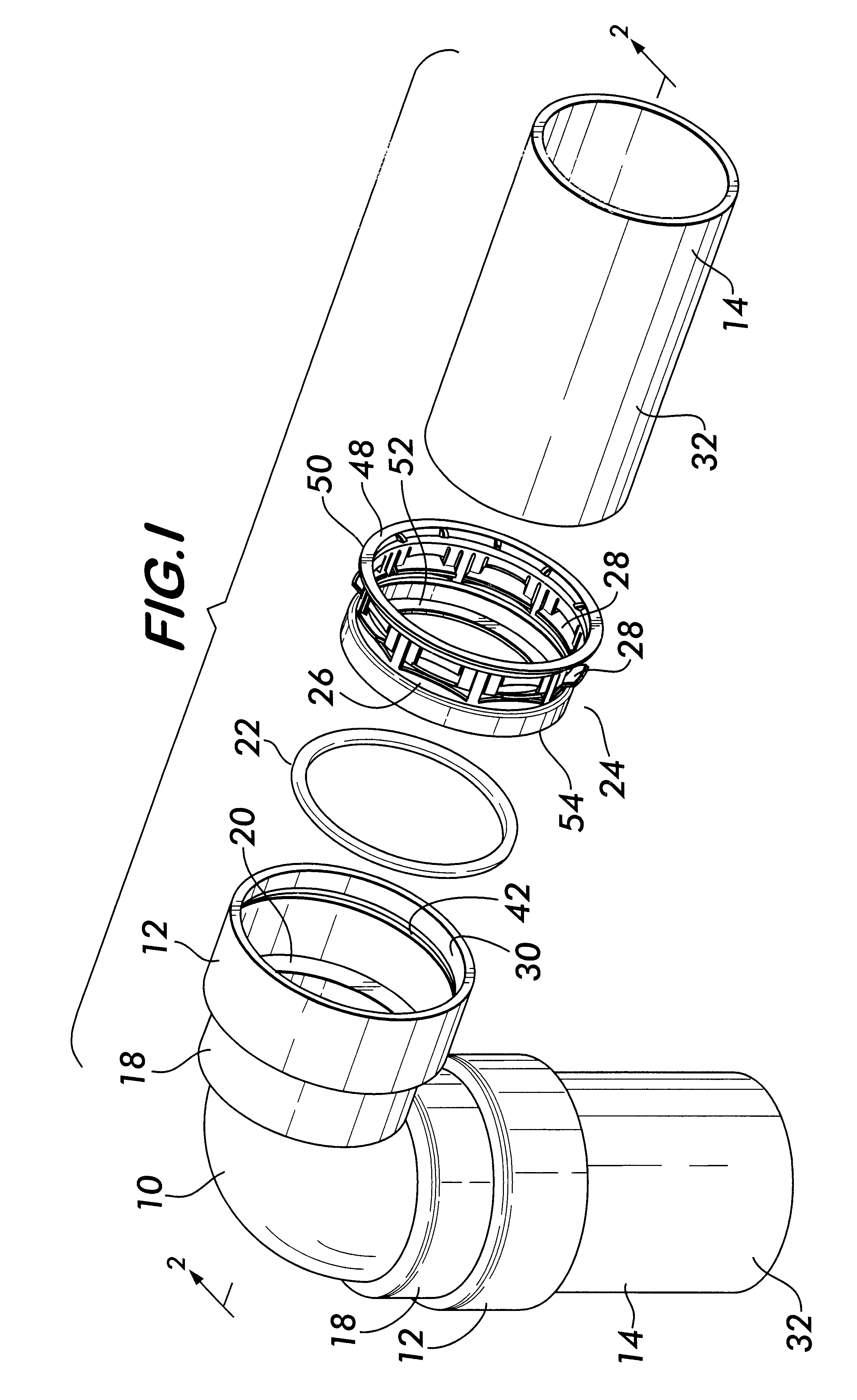

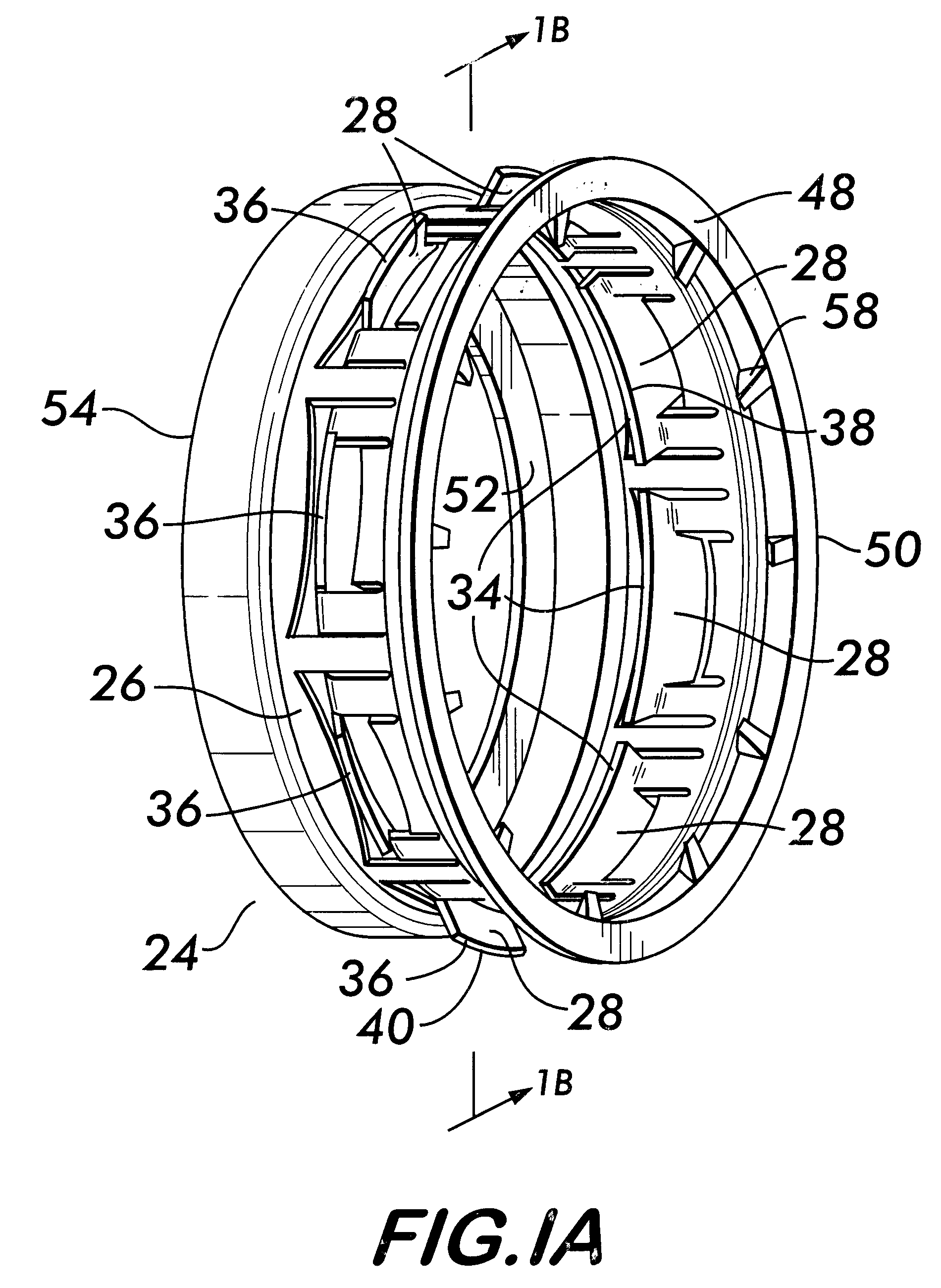

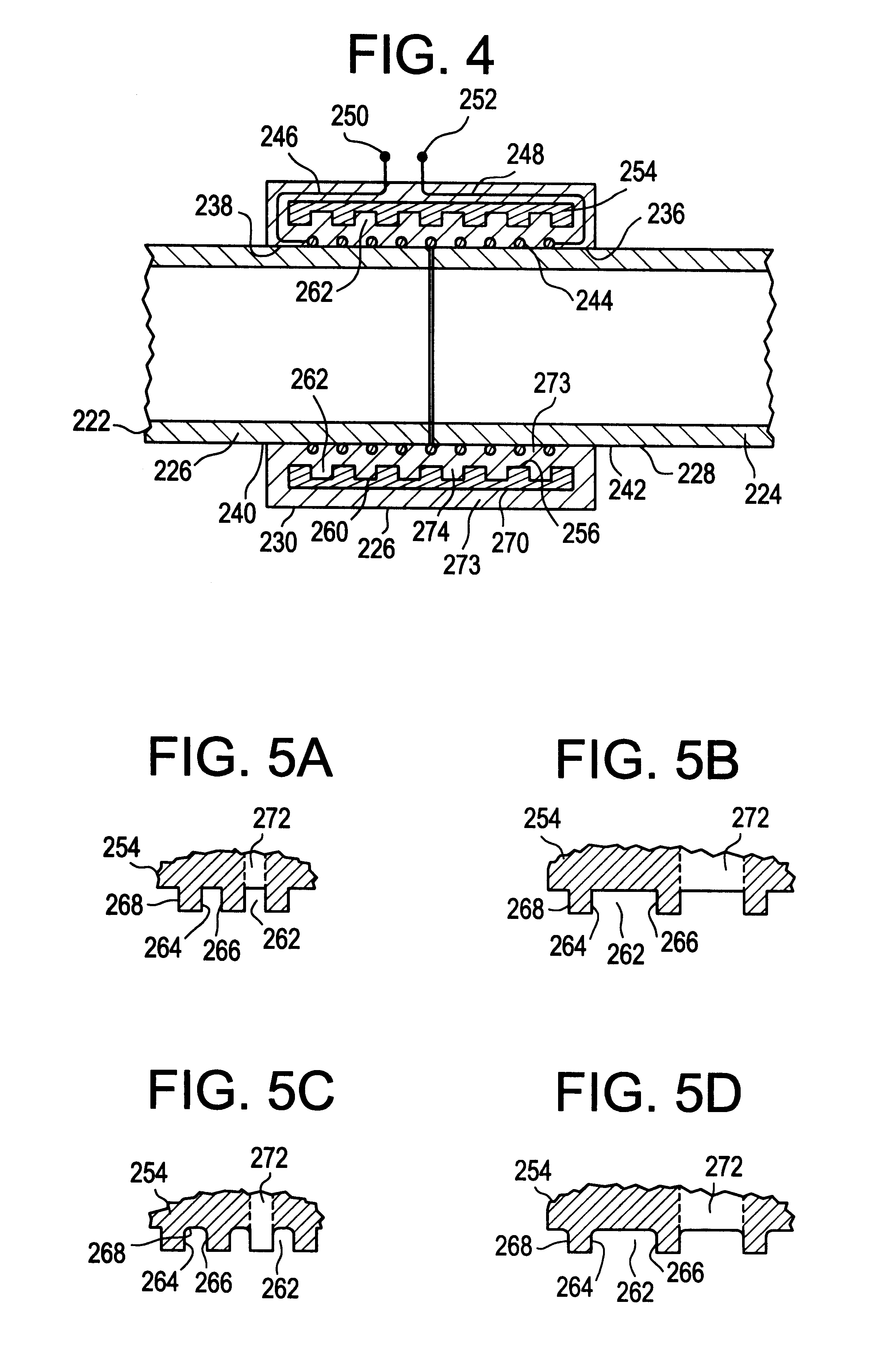

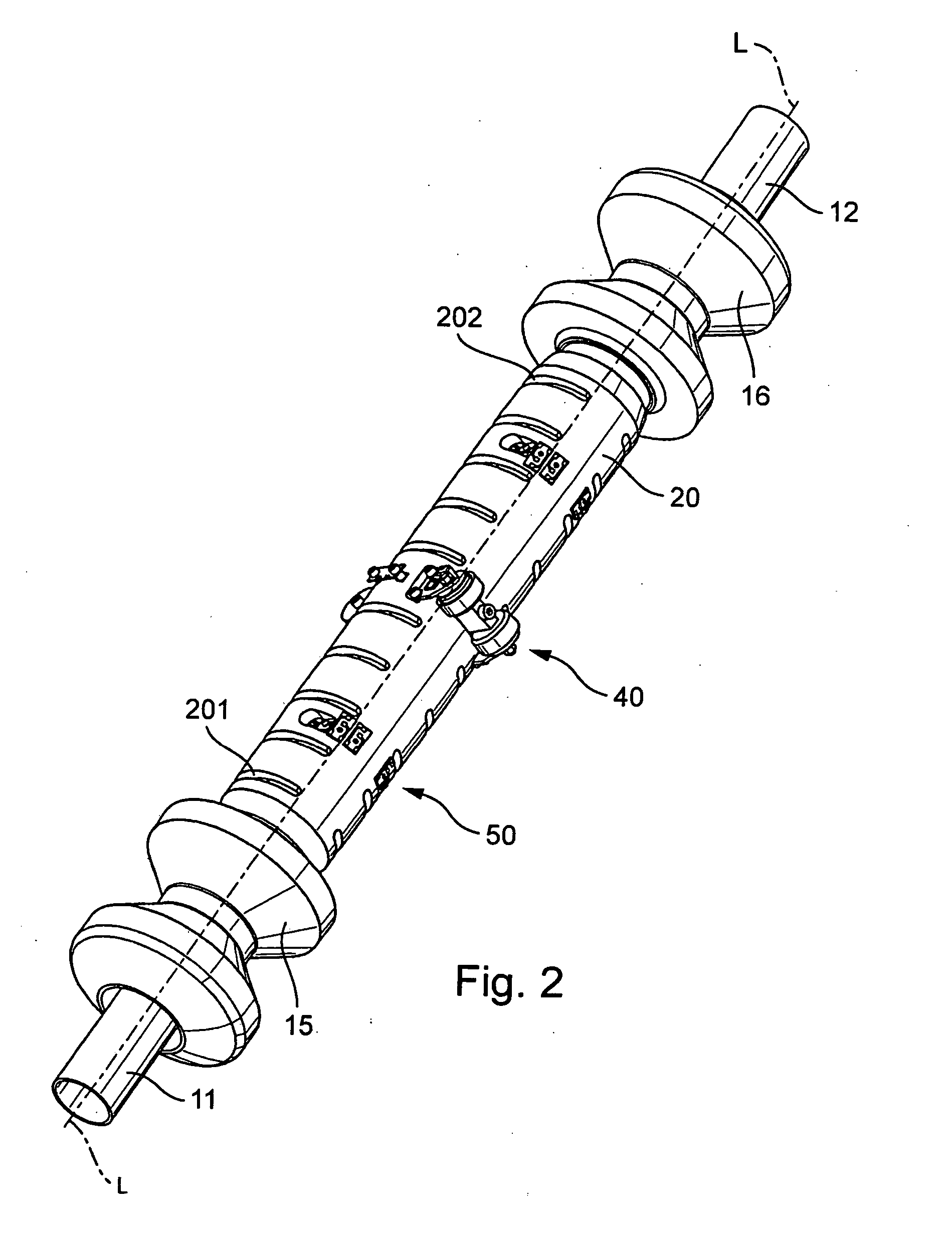

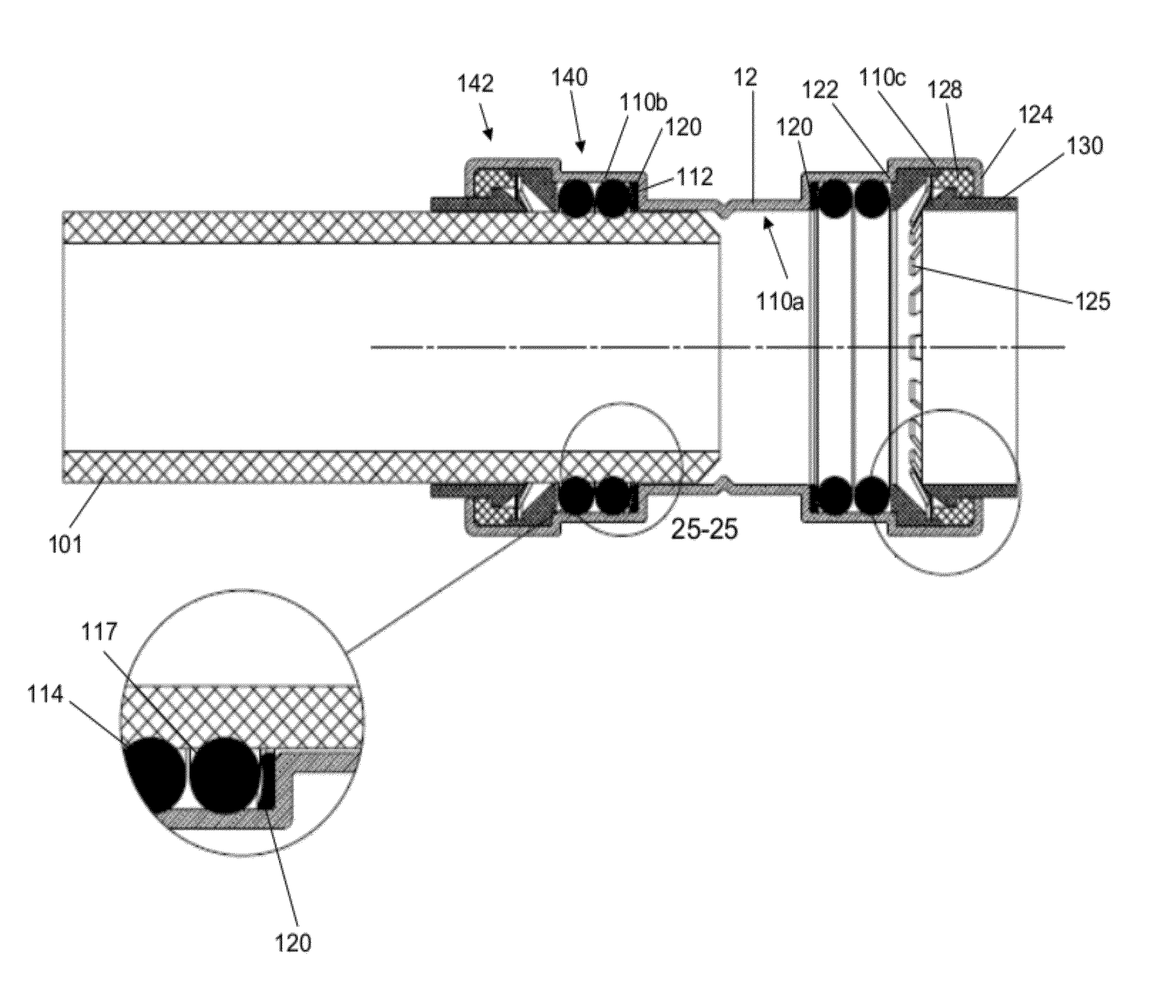

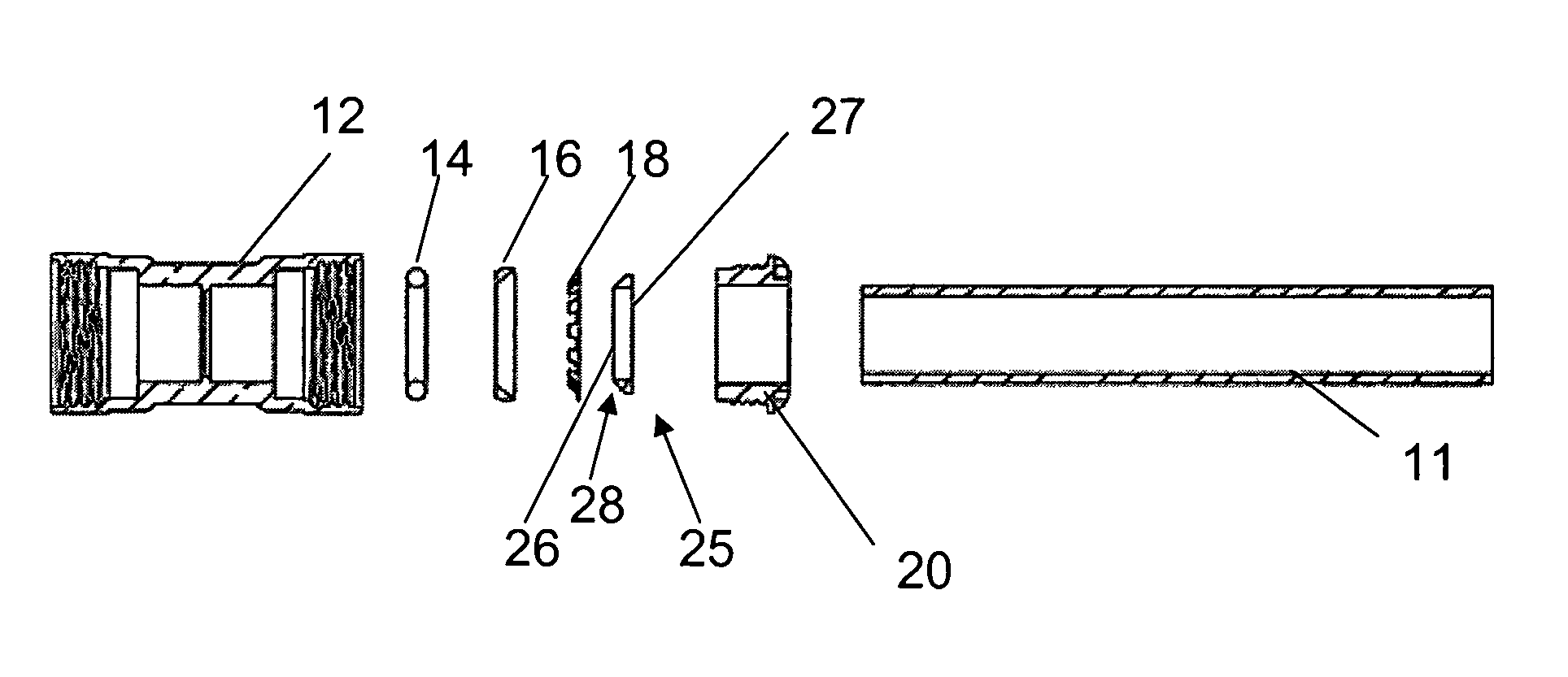

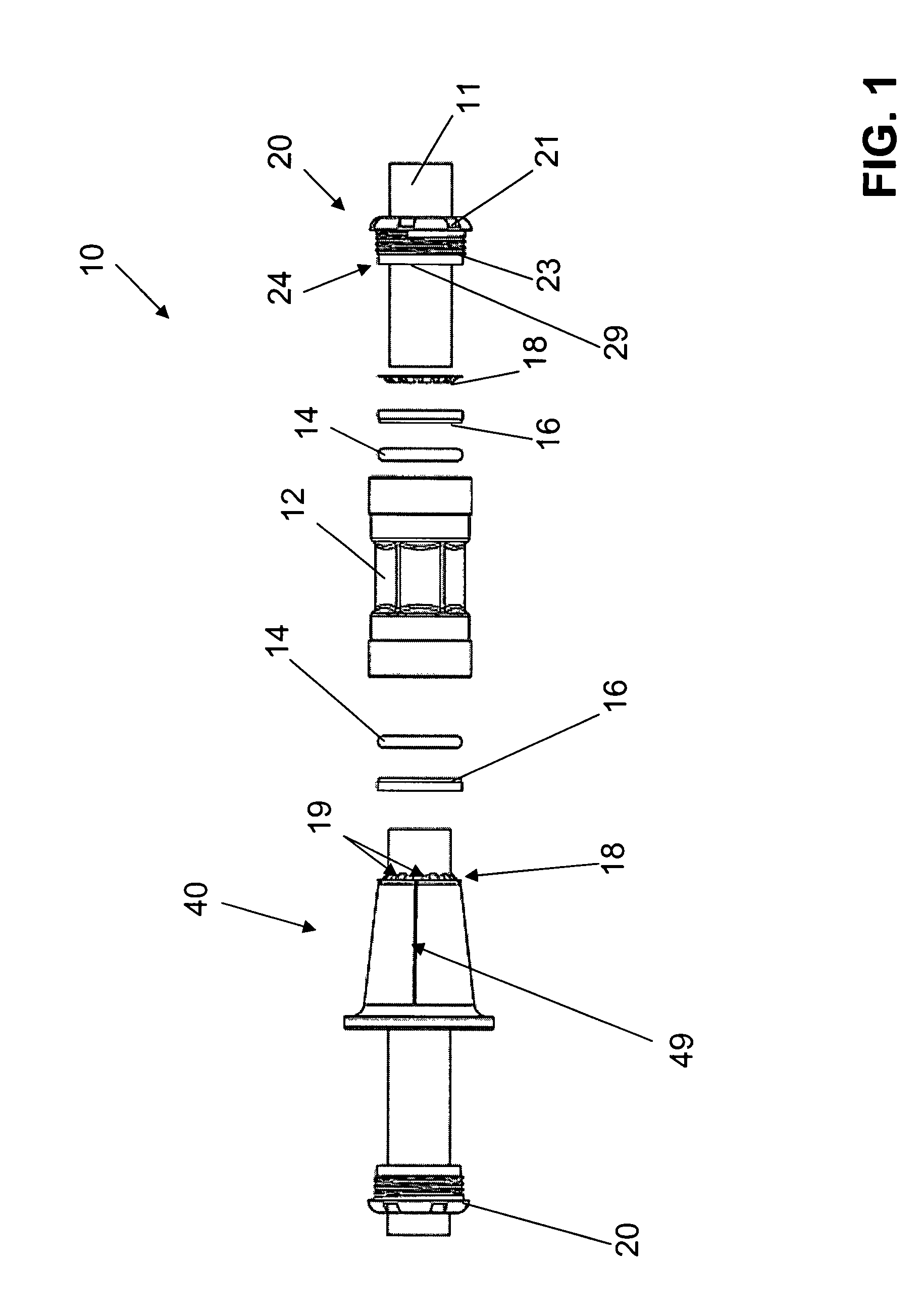

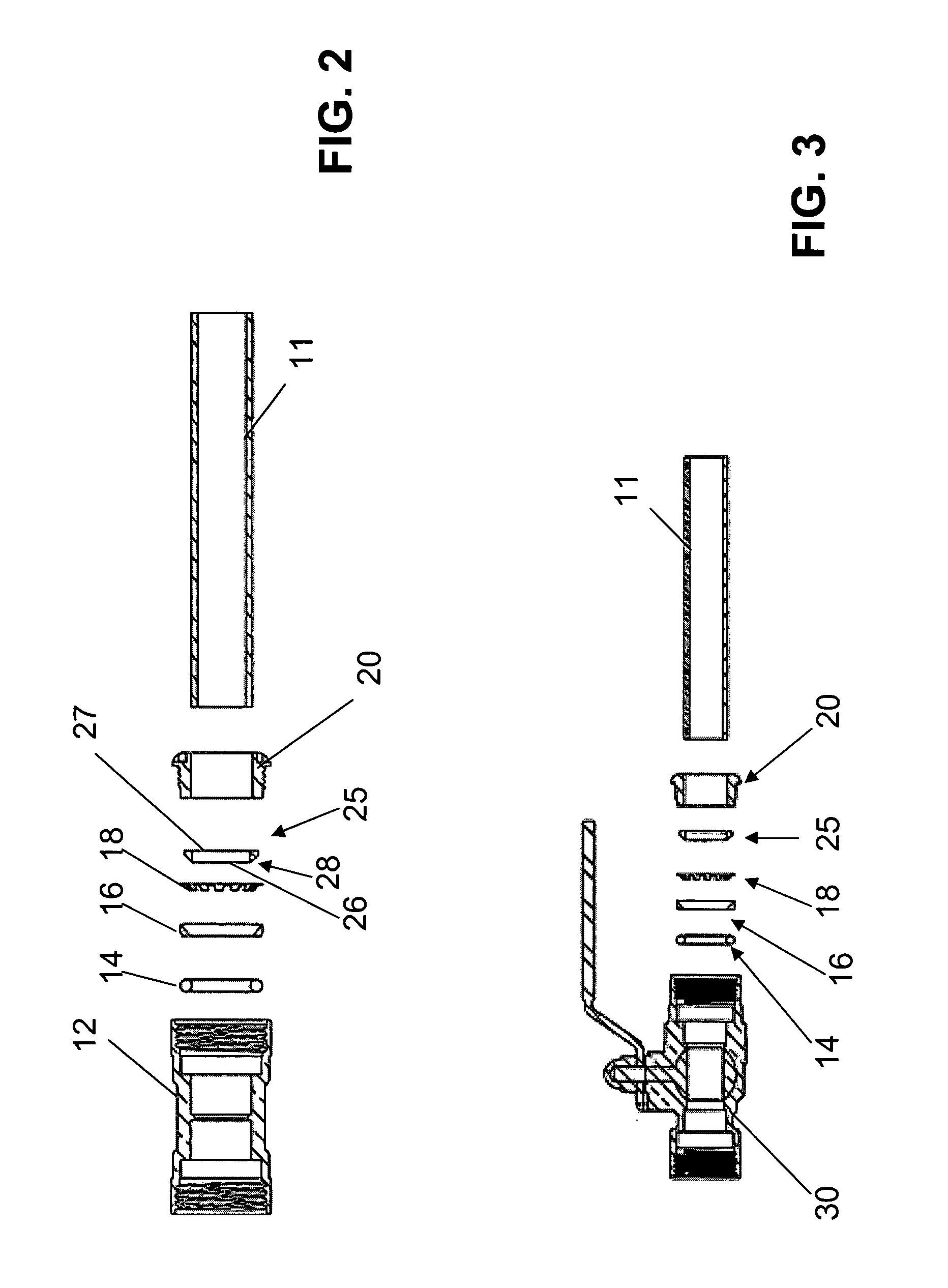

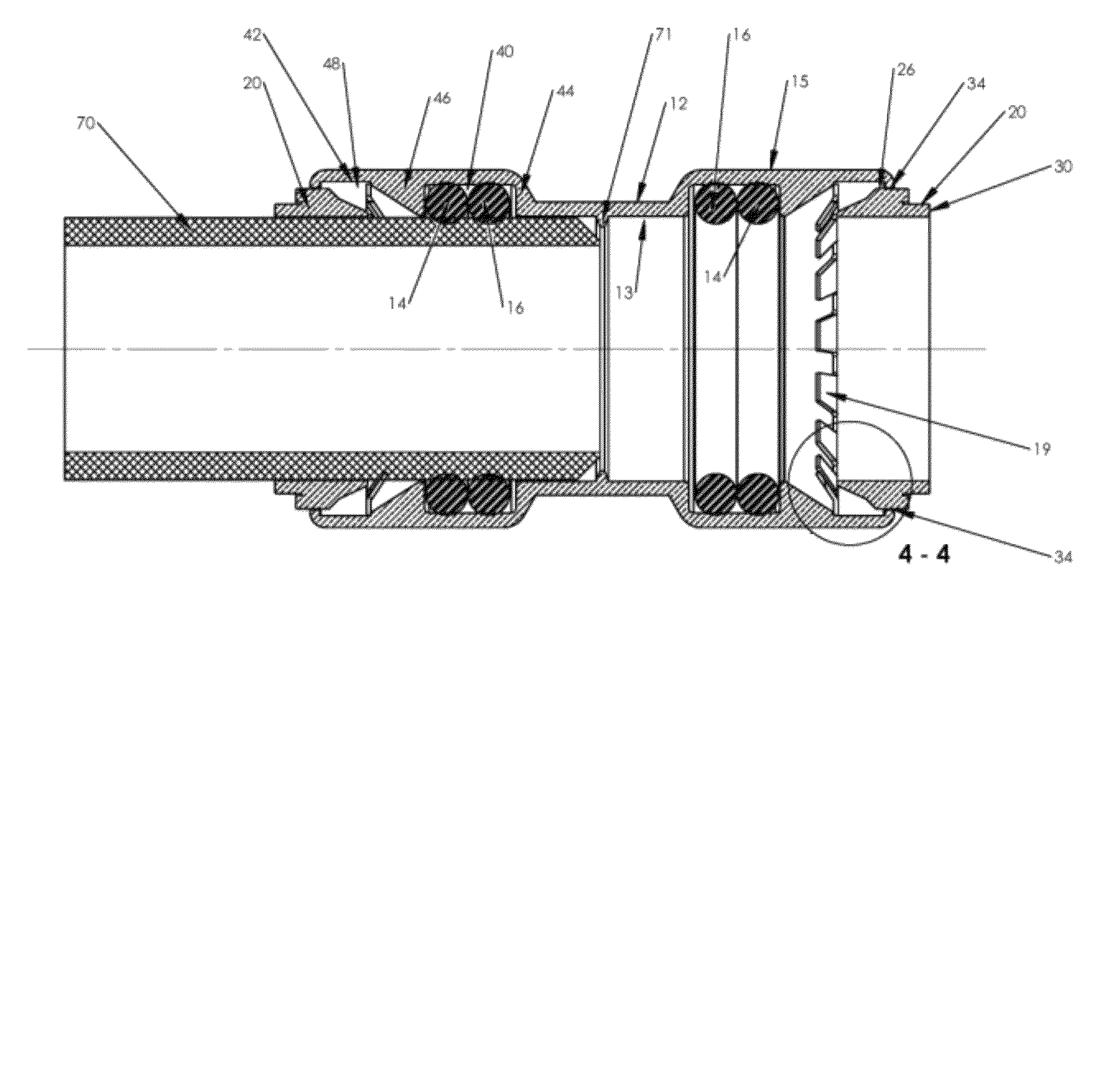

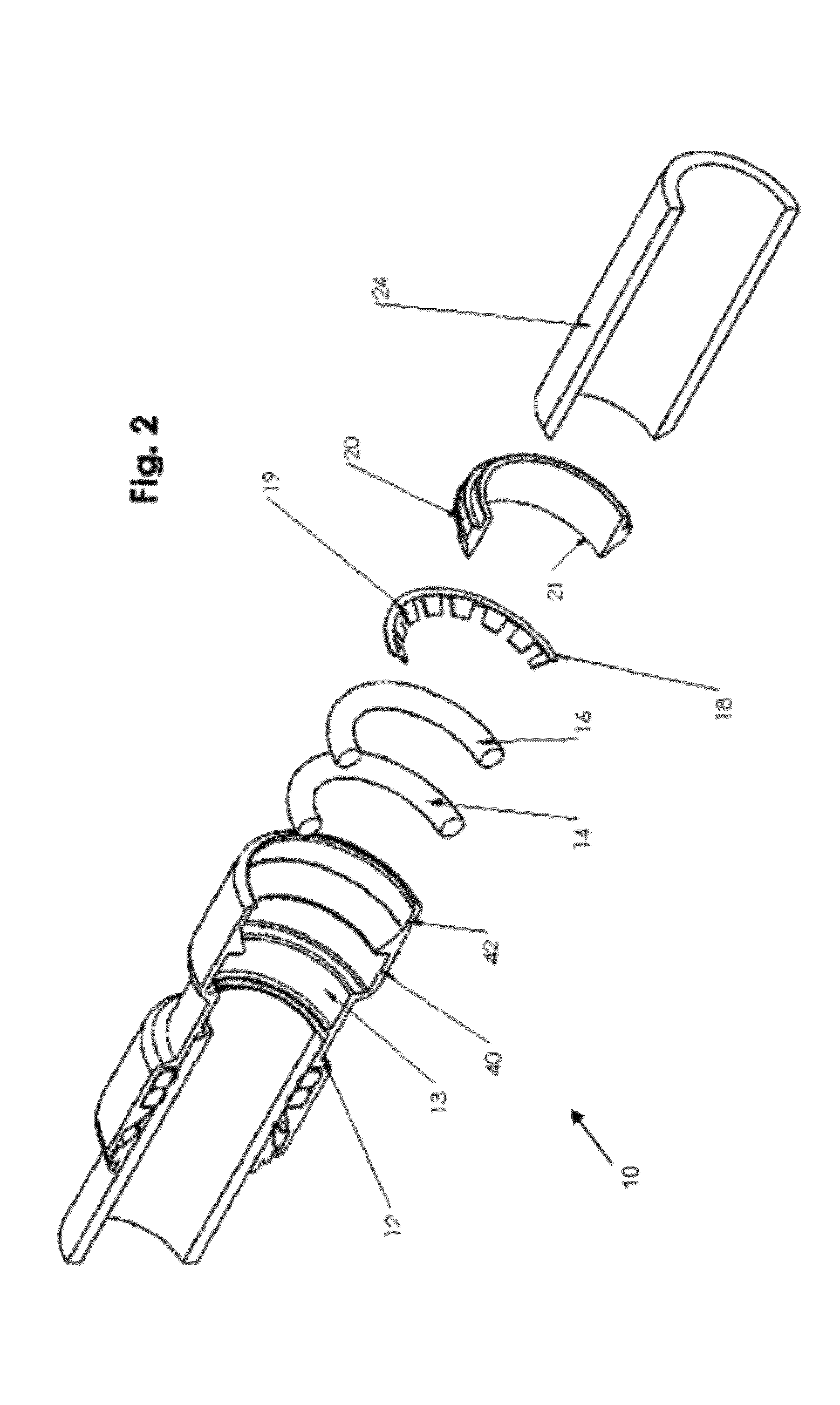

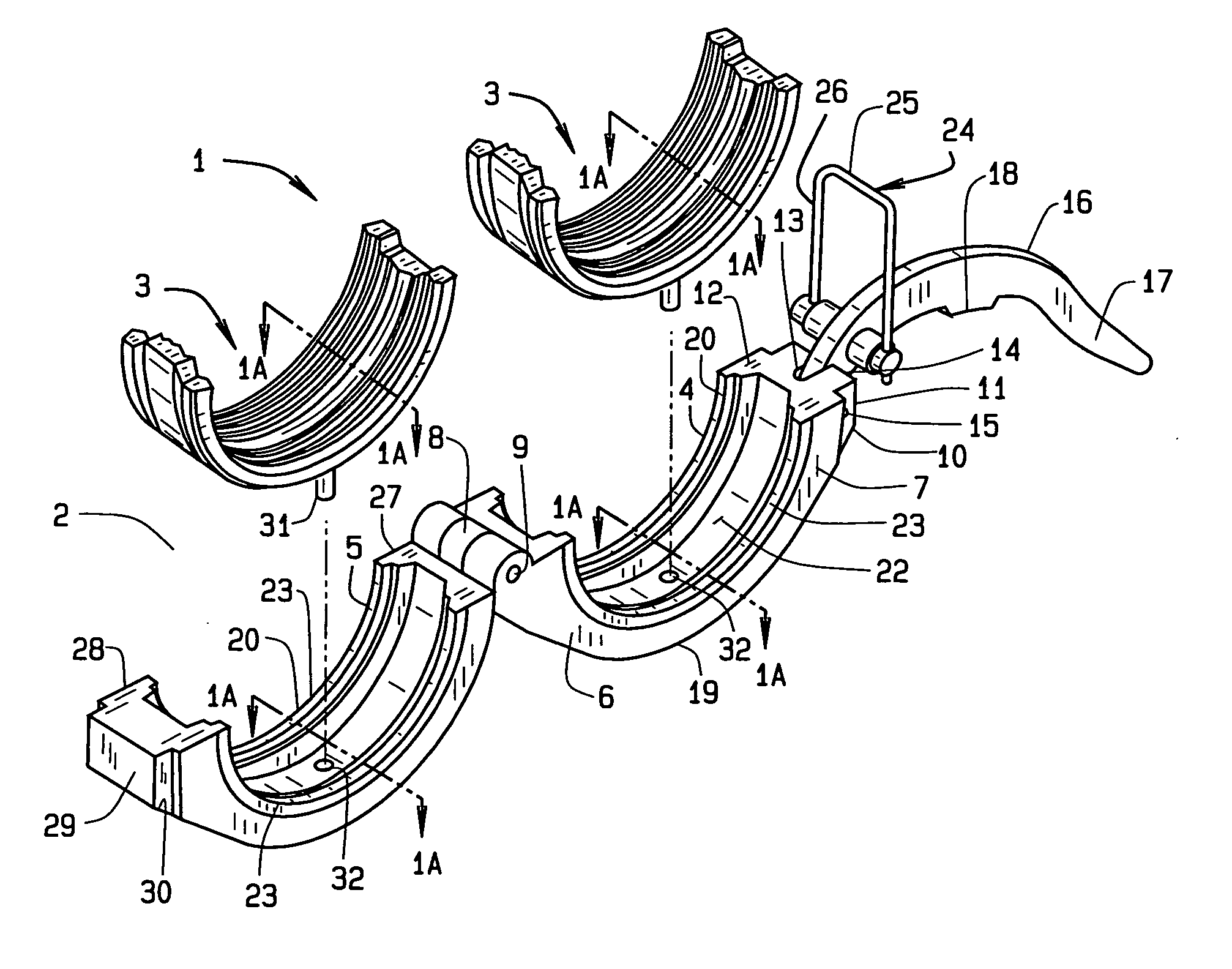

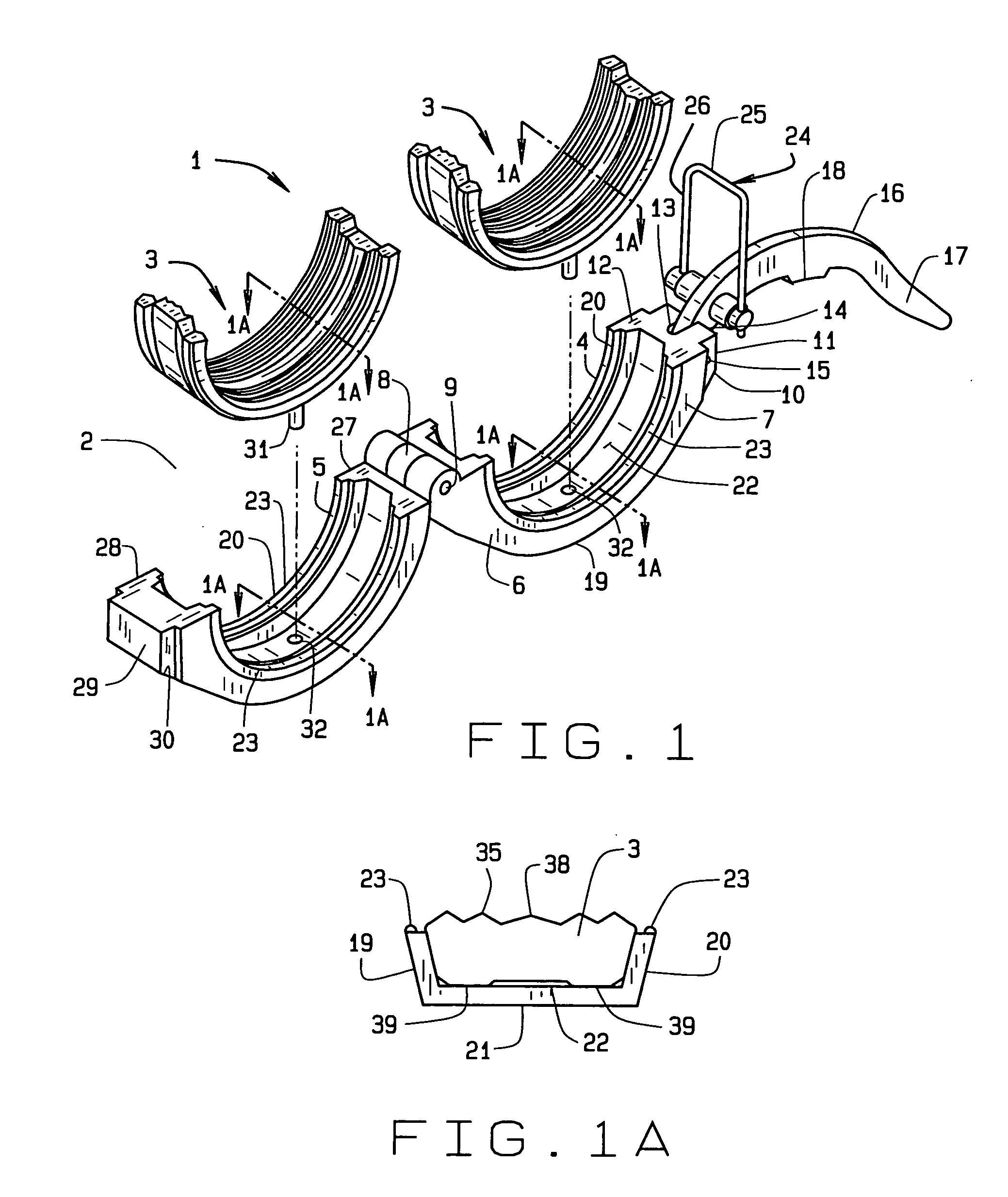

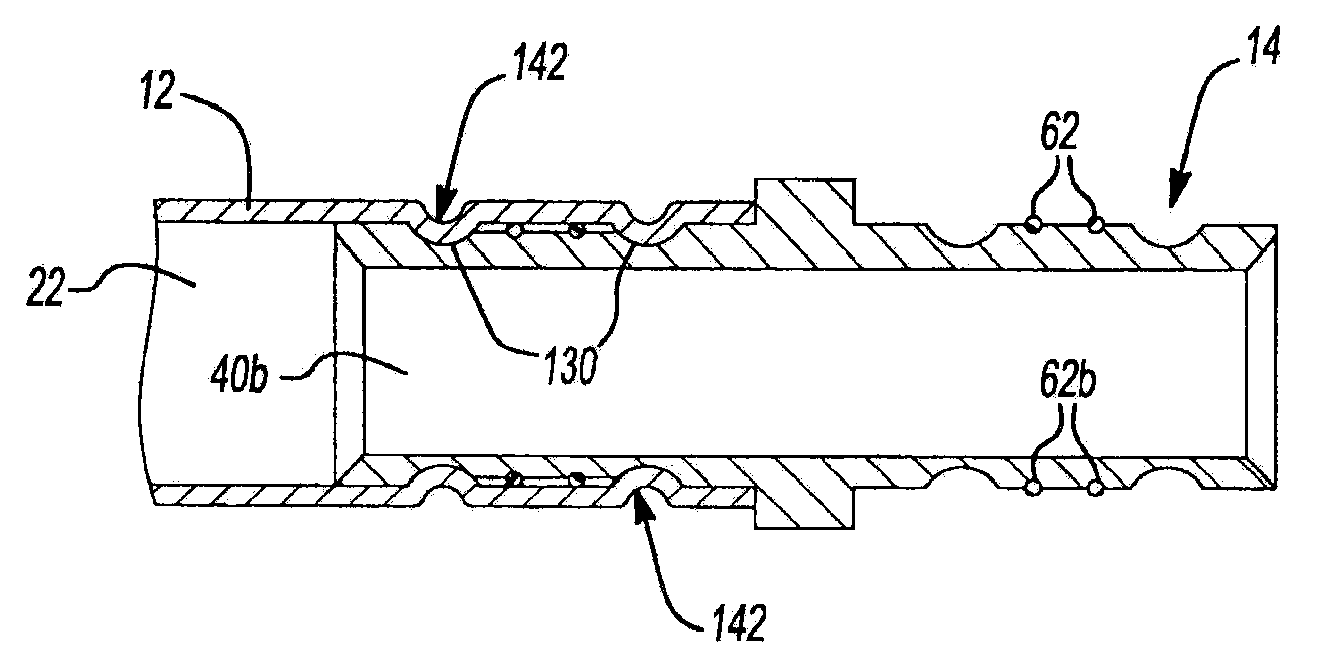

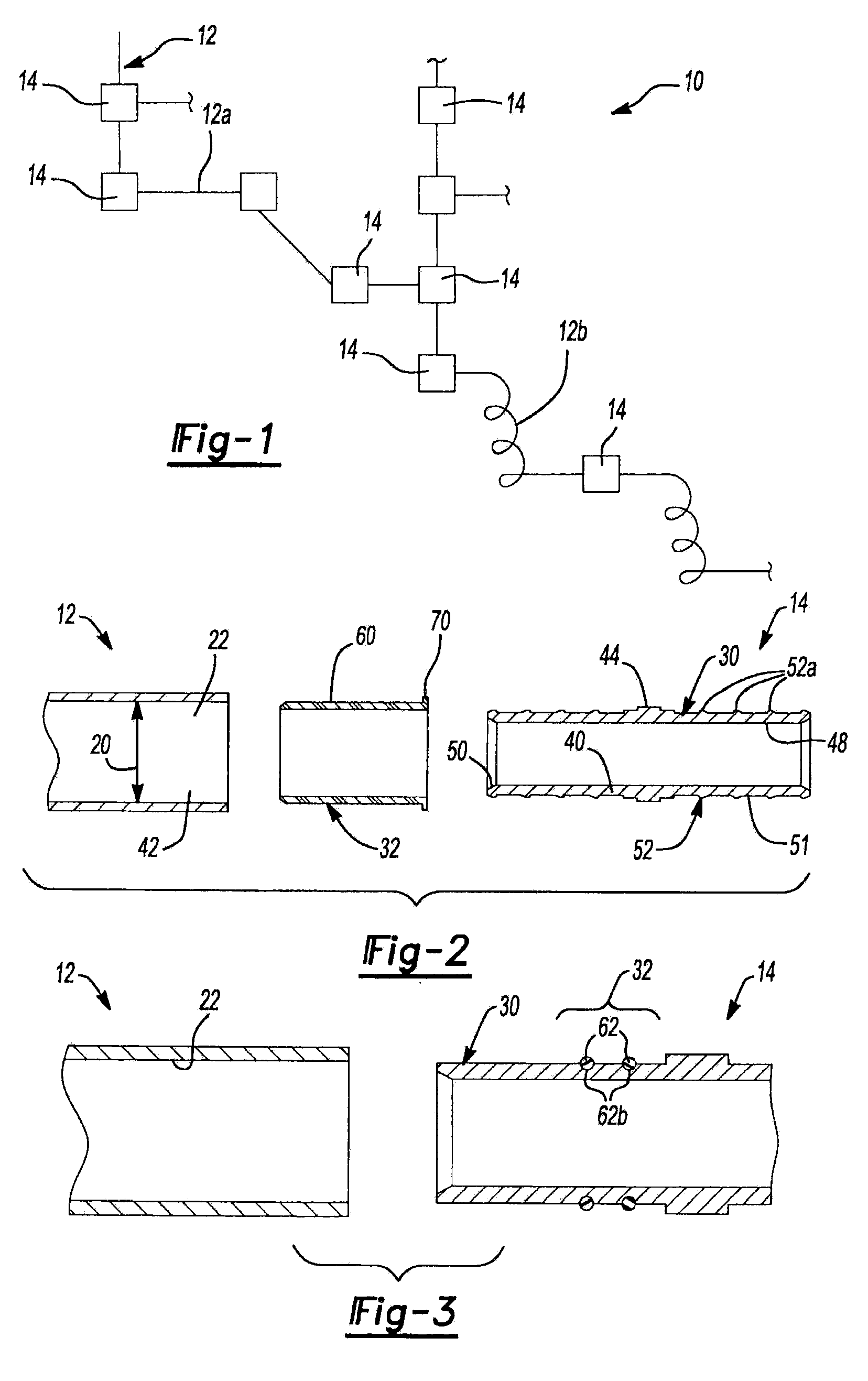

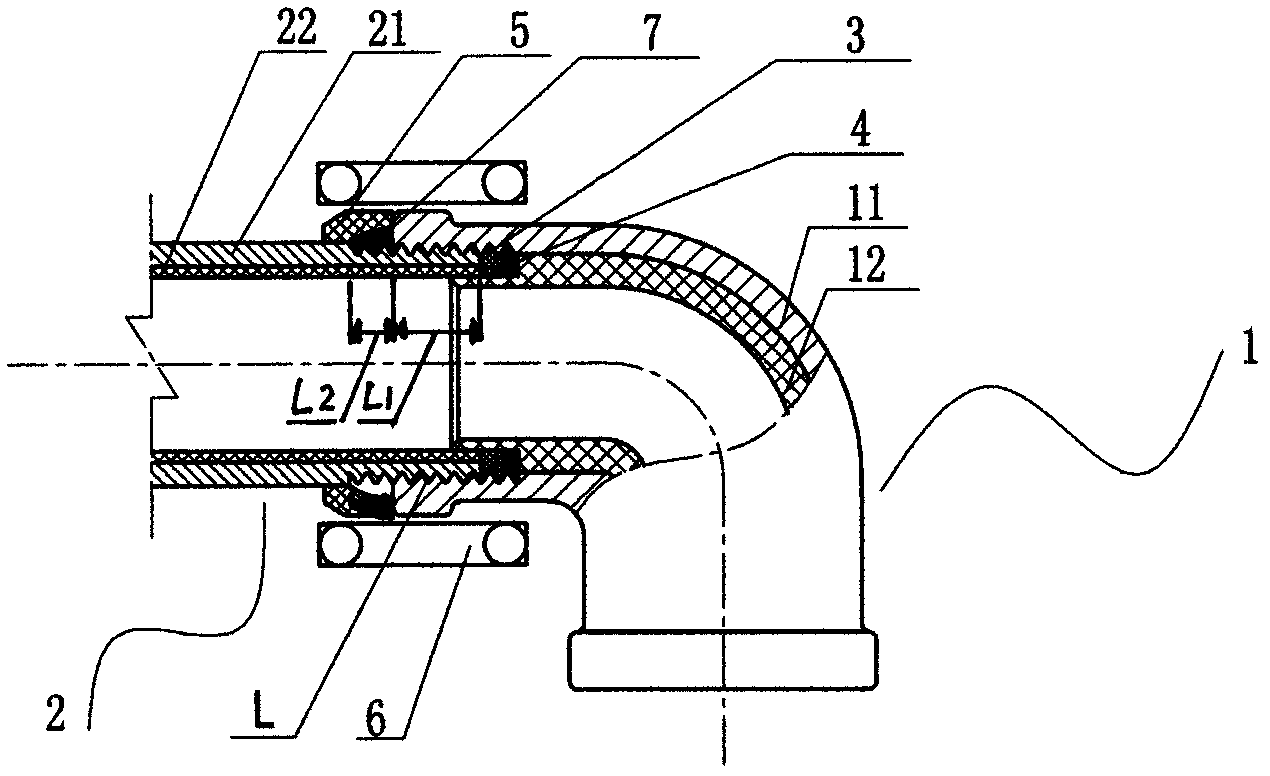

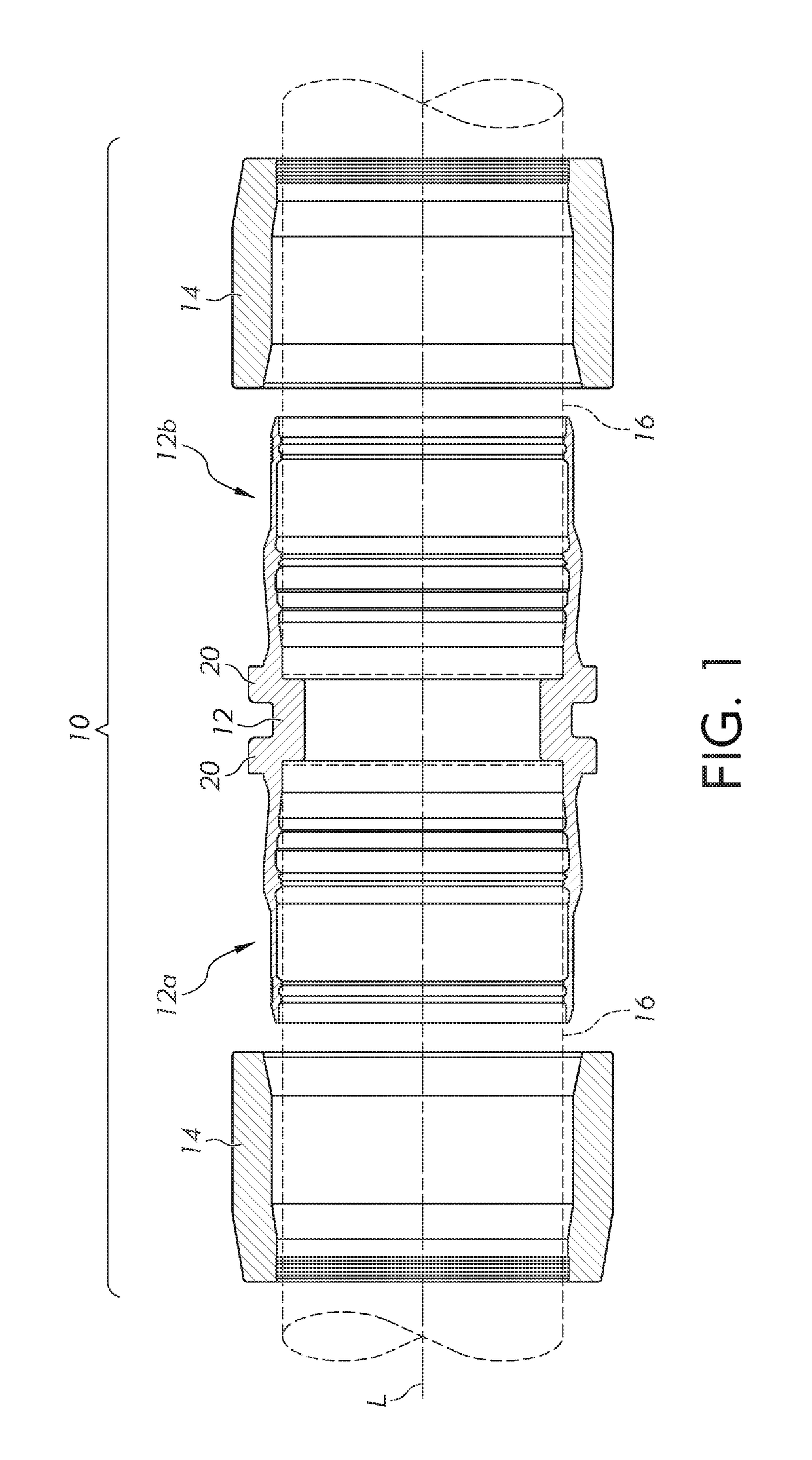

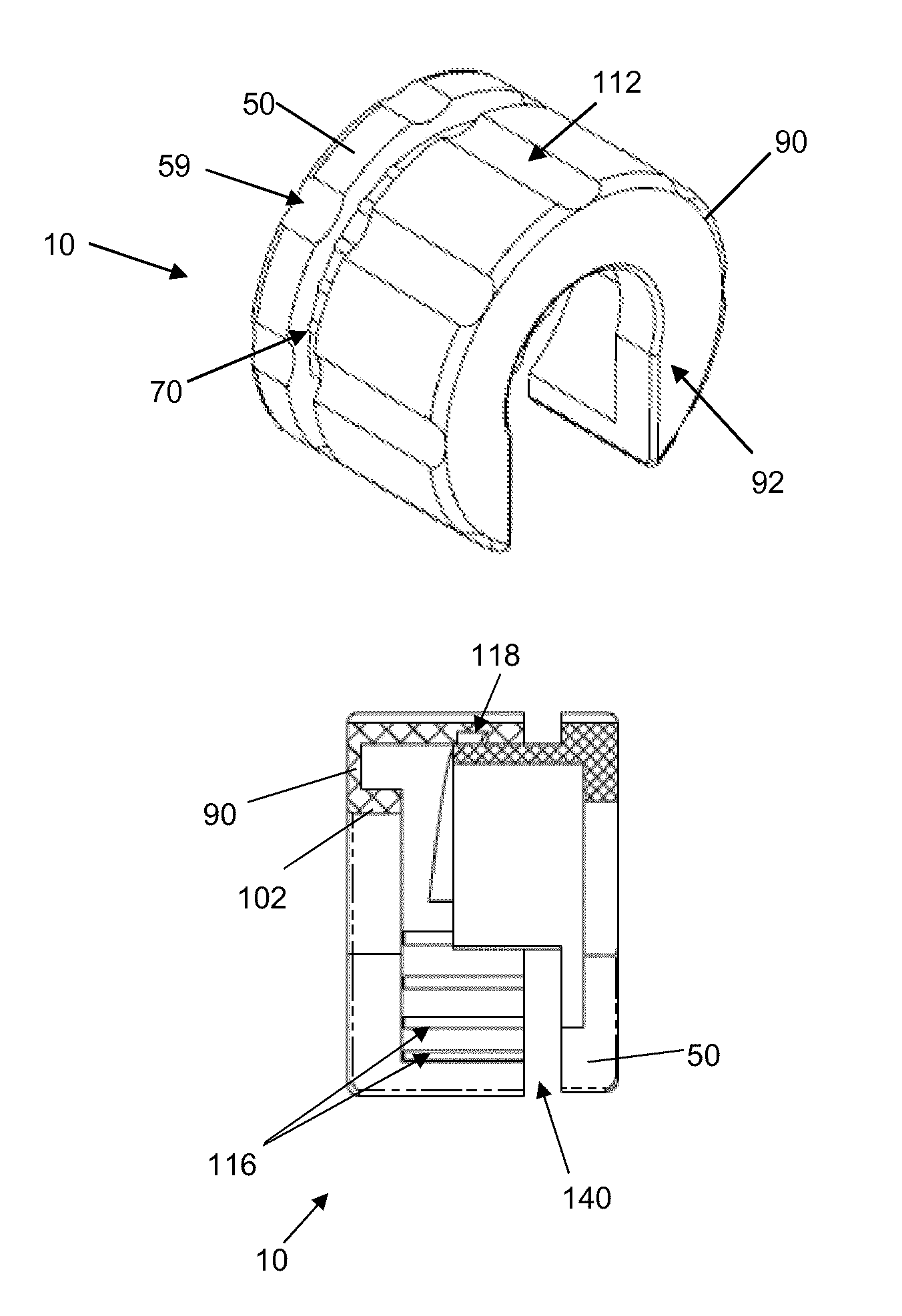

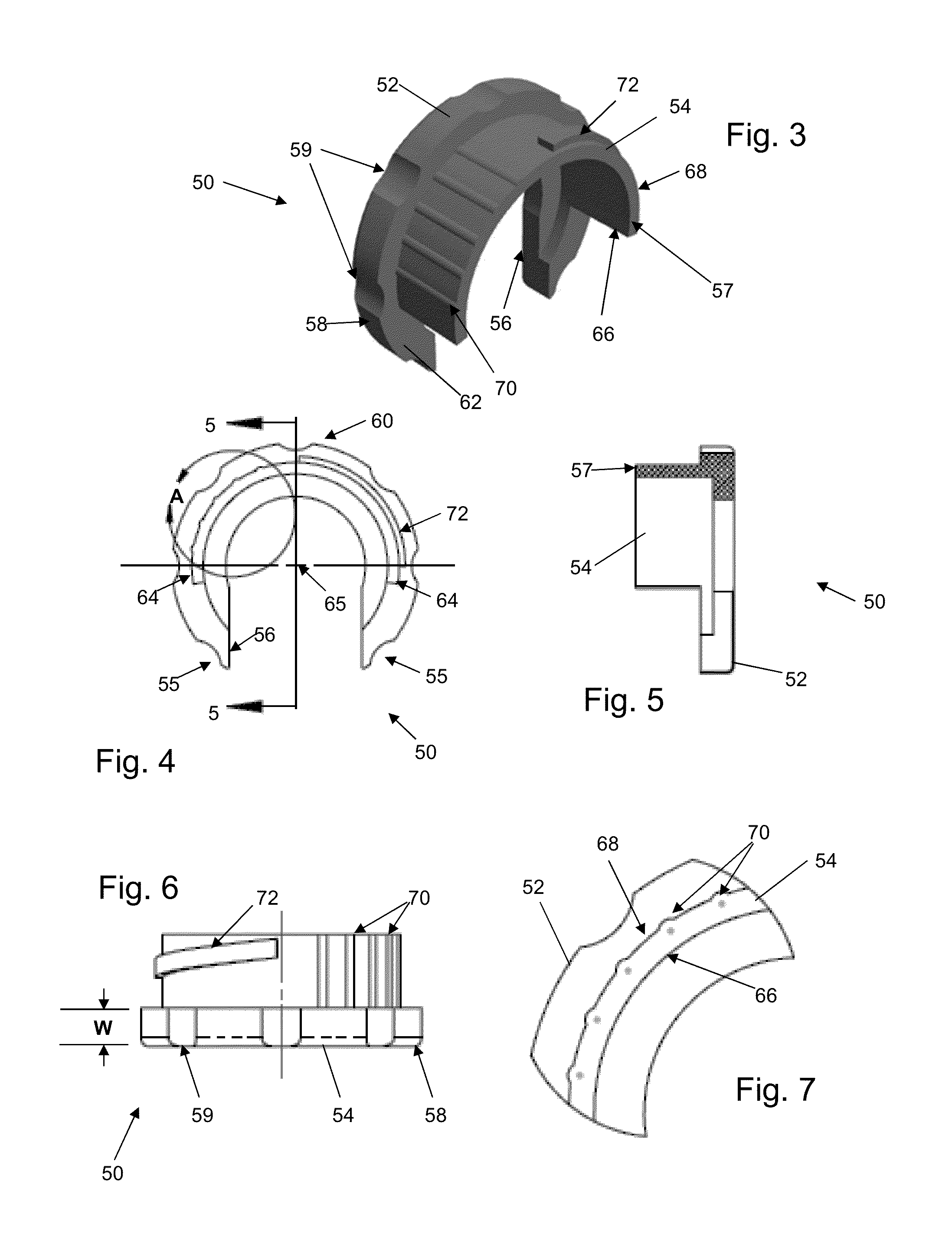

Piping joint assembly system and method with sealing ring stabilizer

ActiveUS8480134B2Facilitated releaseSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe fitting and associated piping joint assembly package allow re-use and repair of push-fit, formed piping elements without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment, the present invention includes a pipe fitting having first and second radial housing elements for receiving one or more sealing members and a fastening ring, respectively. In one embodiment, the present invention further includes a sealing member stabilizer element, a housing divider element and a snap ring support member cooperatively engageable so as to facilitate the secure retention and optional removal of an inserted piping element.

Owner:QUICK FITTING

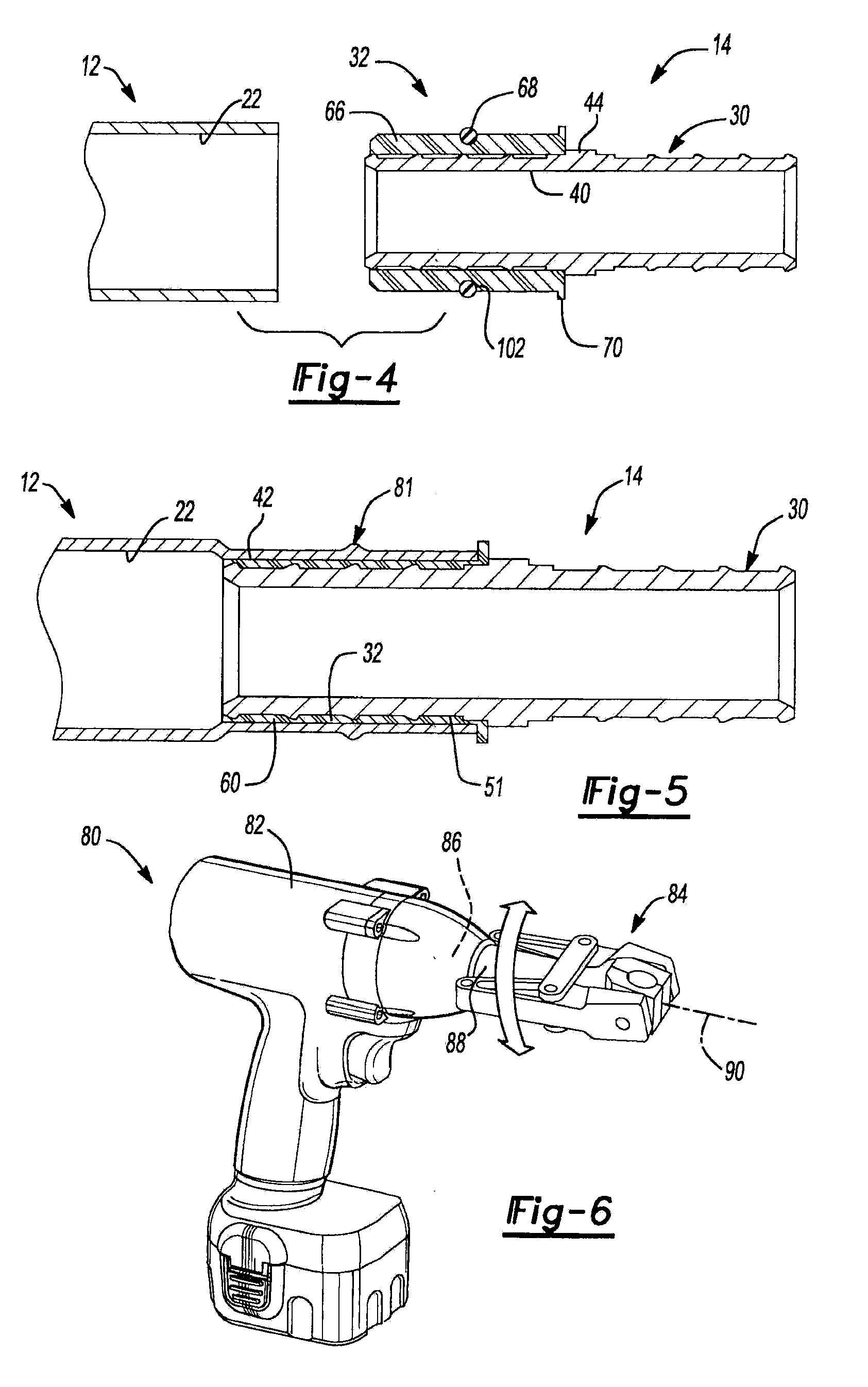

Piping joint assembly system and method

A pipe fitting assembly package and fastening ring removal tool allow re-use and repair of push-fit piping fittings and valves without damage to the fitting or valve elements or the pipe. The quick connection pipe fitting assembly package of the present invention employs a threaded retaining cap that when removed, exposes the clamping, sealing and fastening mechanism of the fitting or valve. In one embodiment, the present invention further includes a removable packing gland mounted on a body about an axis of an orifice. The fastening ring removal device provided as part of the present invention is manually pushed onto the cylindrical object and is capable of expanding to traverse over the installed fastening ring. The fastening ring removal device includes a parallel angular surface to lift the fastening ring off of the pipe member. In one embodiment of the present invention, the removal device has a plurality of cut areas or slits extending axially along its surface to allow for the expansion of the upper rim portion of the fastener removal tool as it slides over a remaining fastening ring. The present invention facilitates re-use of existing fittings and valves by allowing the internal components to be removed, repaired and / or replaced.

Owner:QUICK FITTING HOLDING COMPANY LLC

Piping joint assembly system and method

ActiveUS8205915B1Facilitated releaseSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe fitting and associated piping joint assembly package allow re-use and repair of push-fit piping fittings and valves without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment, the present invention includes a pipe fitting having first and second radial housing elements for receiving one or more sealing members and a fastening ring, respectively. The fastening ring can be a split fastening ring. The split fastening ring and the sealing members provided as part of the present invention are capable of being removed and / or replaced.

Owner:QUICK FITTING

Measurement transducer of vibration type

ActiveUS20070186685A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

Measurement transducer of vibration type

ActiveUS20070119265A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

A kind of polybutene alloy material and preparation method thereof

The invention discloses a polybutene alloy material and a preparation method thereof, and belongs to the field of polyolefin material, specifically relates to a polybutene alloy material and a preparation method thereof. The polybutene alloy material provided by the present invention comprises, by mass, 50-99% of poly-1-butene, 1-40% of polypropylene and 0-10% of a butane-propylene copolymer. Thepreparation method is characterized by: adopting a TiCl4 / MgCl2 supported titanium catalyst for synthesis of the polybutene alloy material through a two-phase polymerization method. The polybutene alloy material provided by the present invention has a core-shell structure, and has advantages of the combination of the excellent impact resistance of the poly-1-butene, the heat resistance and creep property of the poly-1-butene, the low shrinkage rate of the poly-1-butene, the high modulus of the polypropylene, the high surface hardness of the polypropylene, the rapid shaping of the polypropylene, and the like, such that the polybutene alloy material can replace the partial use of the poly-1-butene and the polypropylene. In addition, the polybutene alloy material can be applicable for preparation of the pipe and the pipe fitting, toughening modification of the polypropylene, or the polybutene alloy material can be used as the general polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

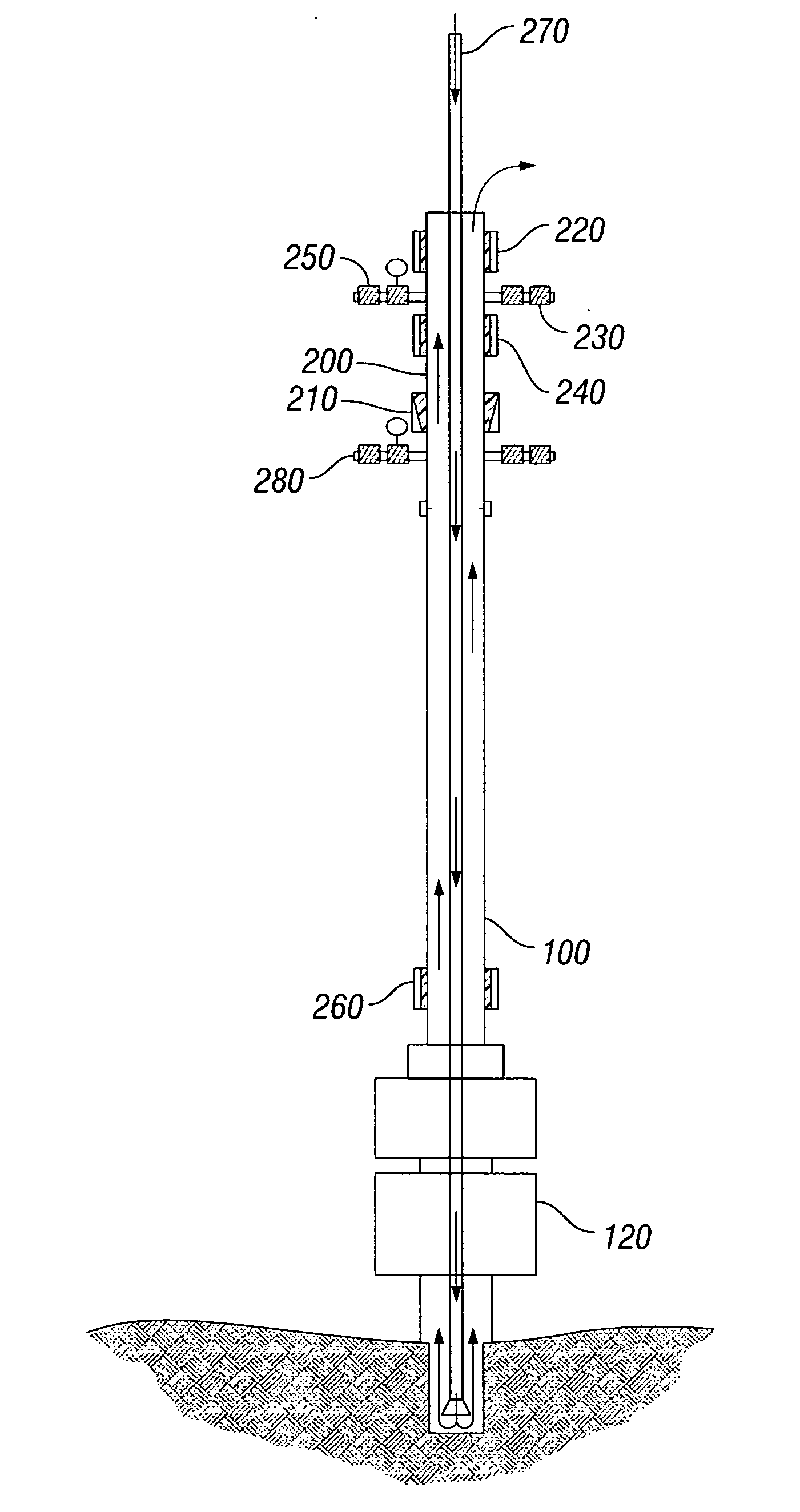

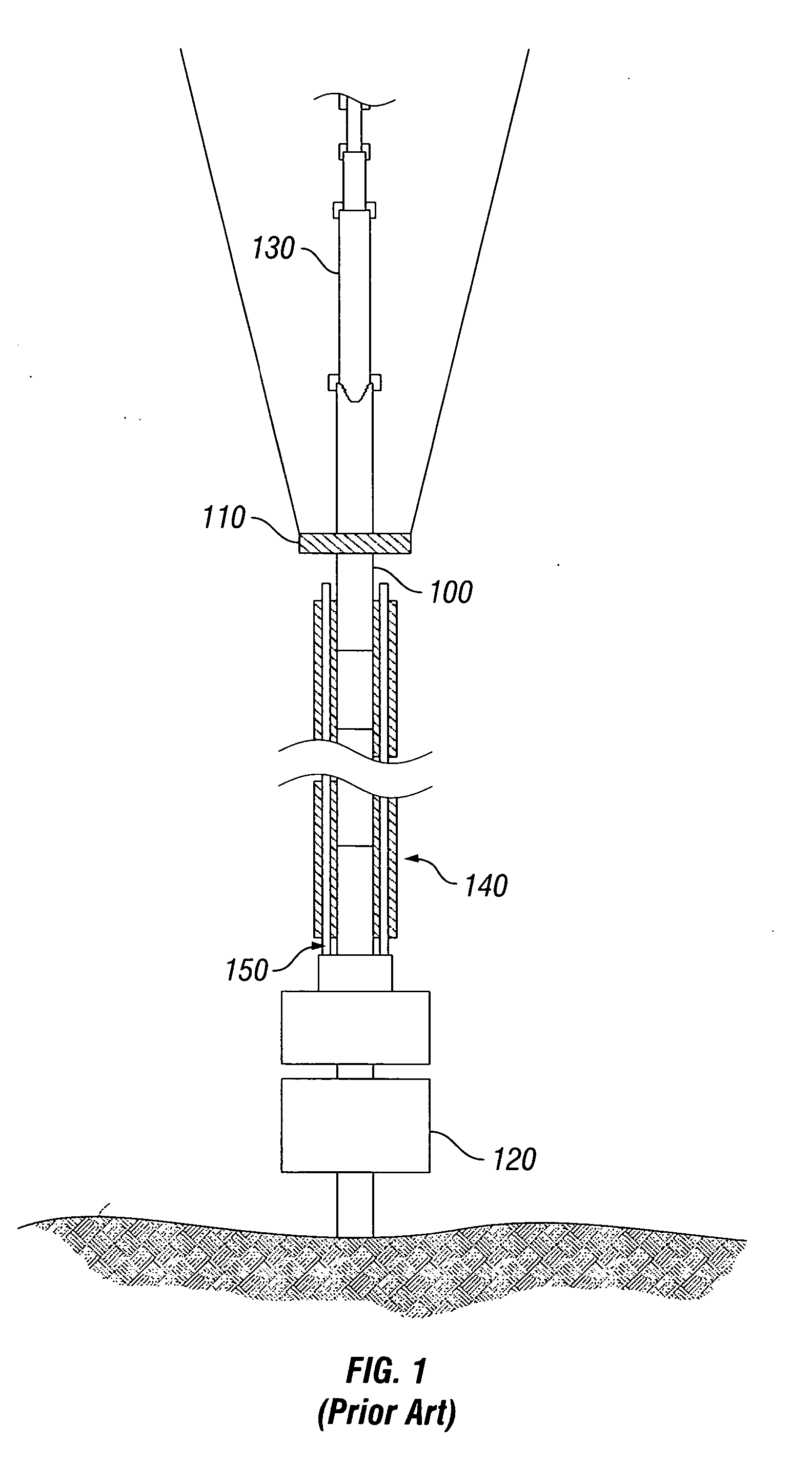

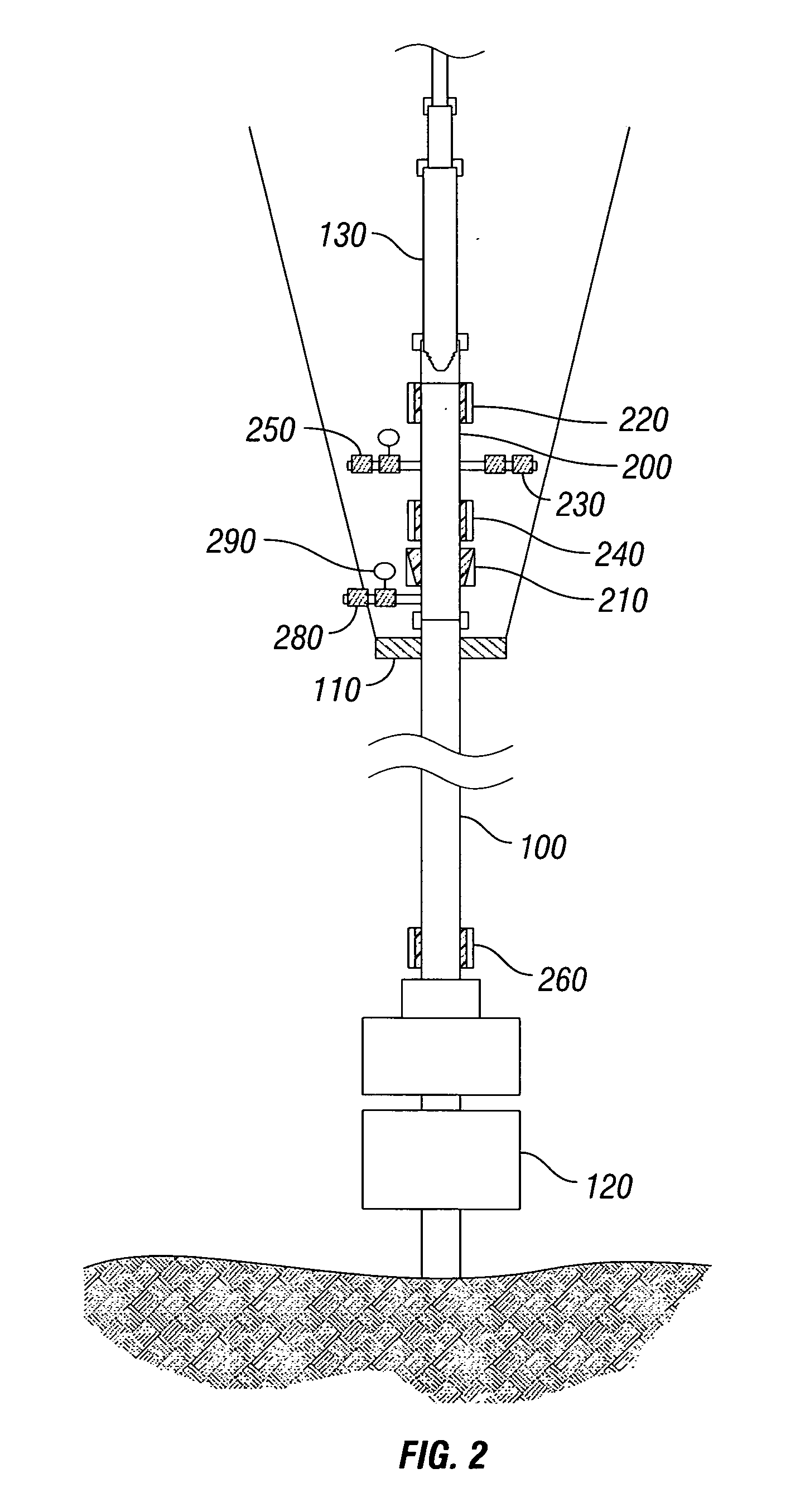

Apparatus and method for managed pressure drilling

A drilling system employing a main tubular having a plurality of fluid inlet and outlet conduits positioned thereon and a concentric inner tubular having a plurality seals for sealing the annular space between the concentric inner and main tubulars. The fluid inlet and outlet conduits work in cooperation with the annular seals to selectively open and close for effective management of pressure within the tubulars.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD +1

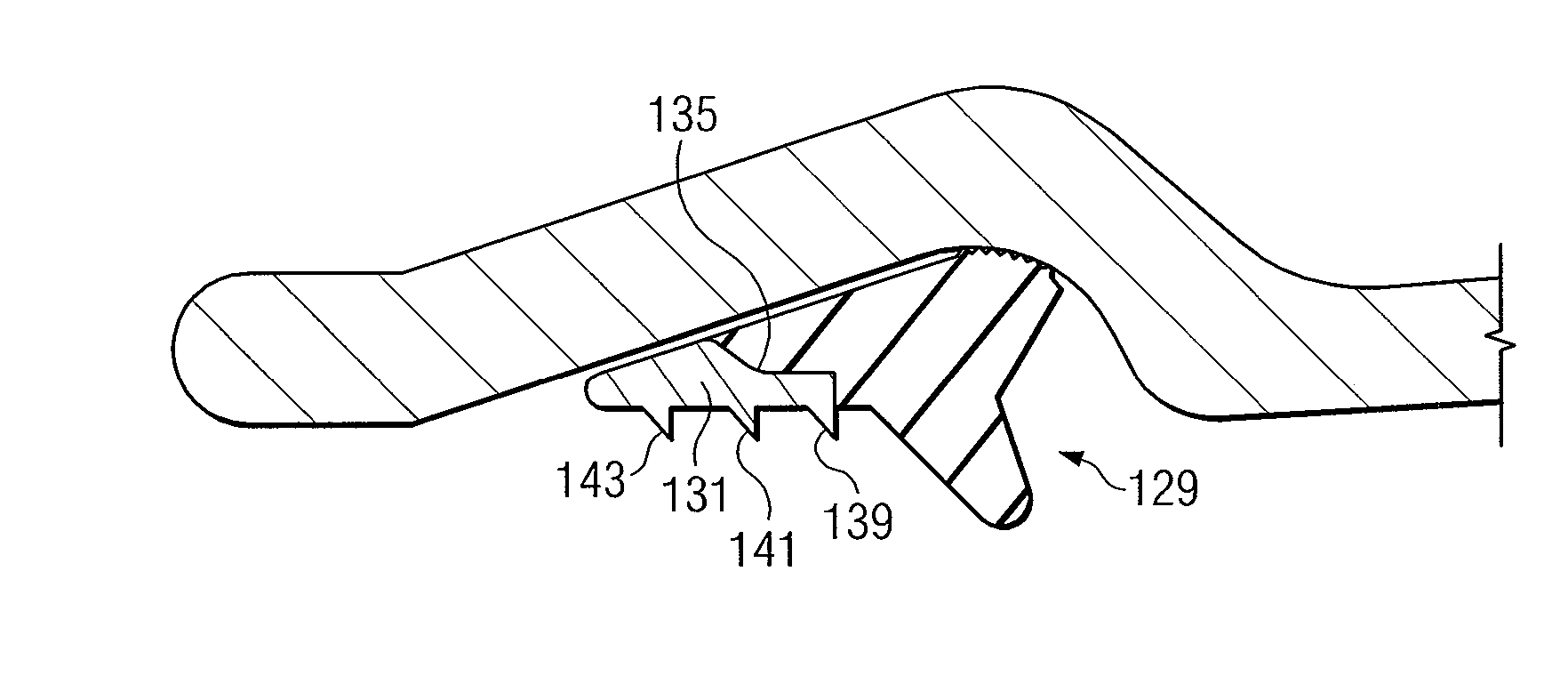

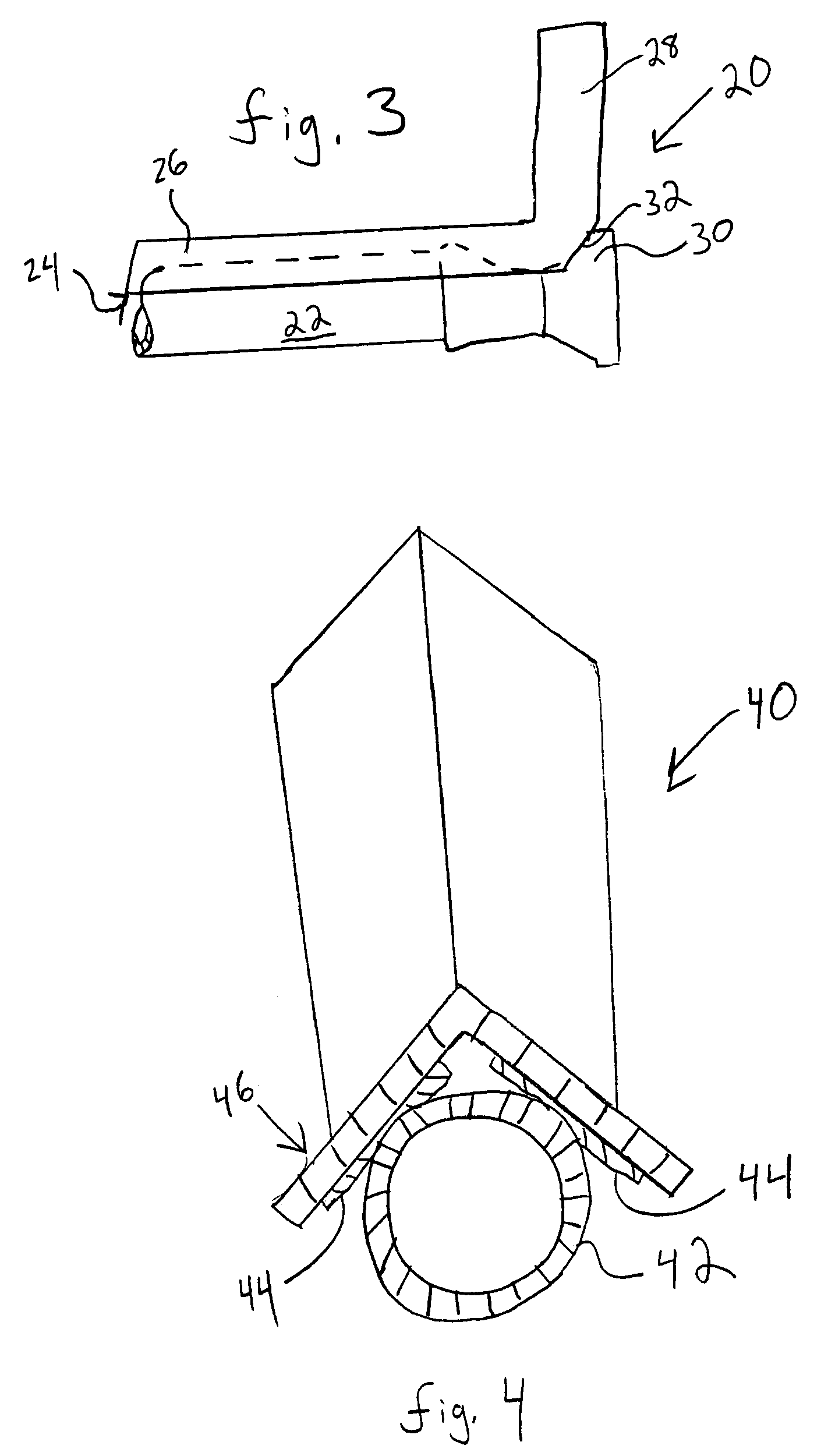

Self restrained ductile iron fitting

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. A ring-shaped body is installed within a mating groove provided in a mouth region of the as-cast fitting after the fitting has been cast at the manufacturing plant. The ring-shaped body carries a gripping member with teeth on an inner surface thereof which are initially angled away from an outer surface of a mating male pipe. The teeth are forced into engagement with the exterior surface of the mating male pipe as the pipe joint at the fitting is assembled. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening of the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The ring-shaped body also includes a relatively flexible portion formed of an elastomer which forms a sealing member with the mating male pipe.

Owner:S & B TECHN PRODS

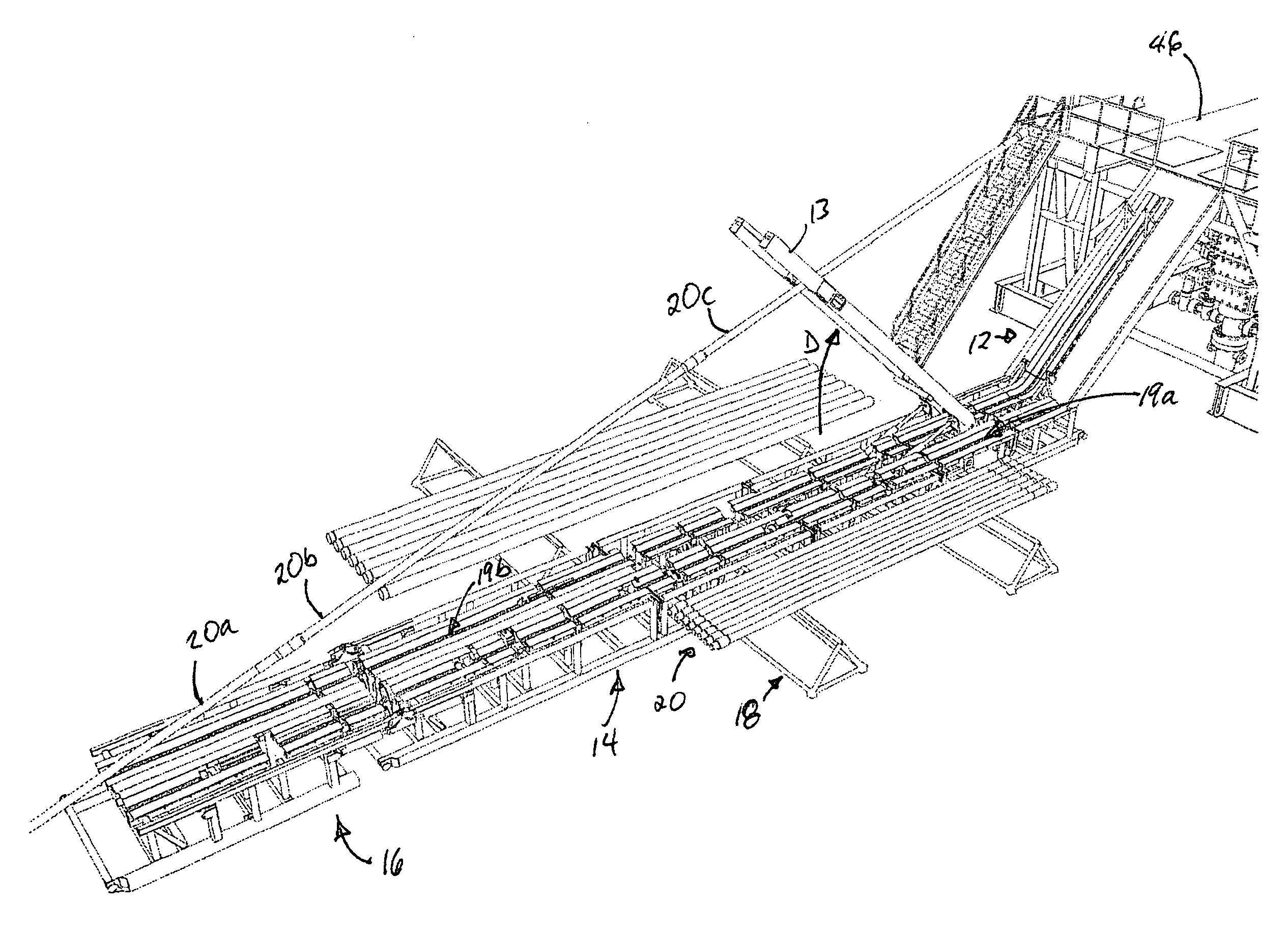

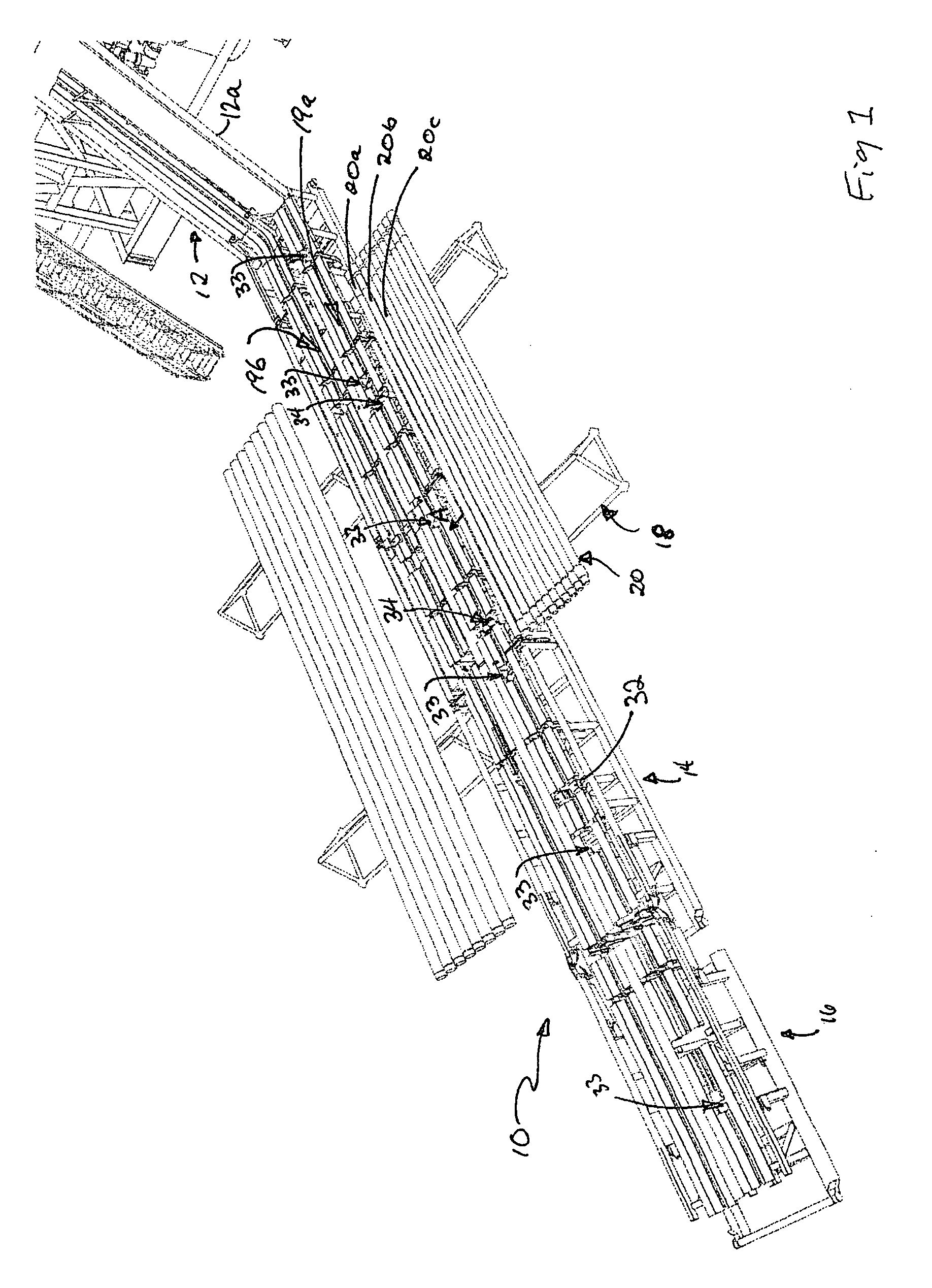

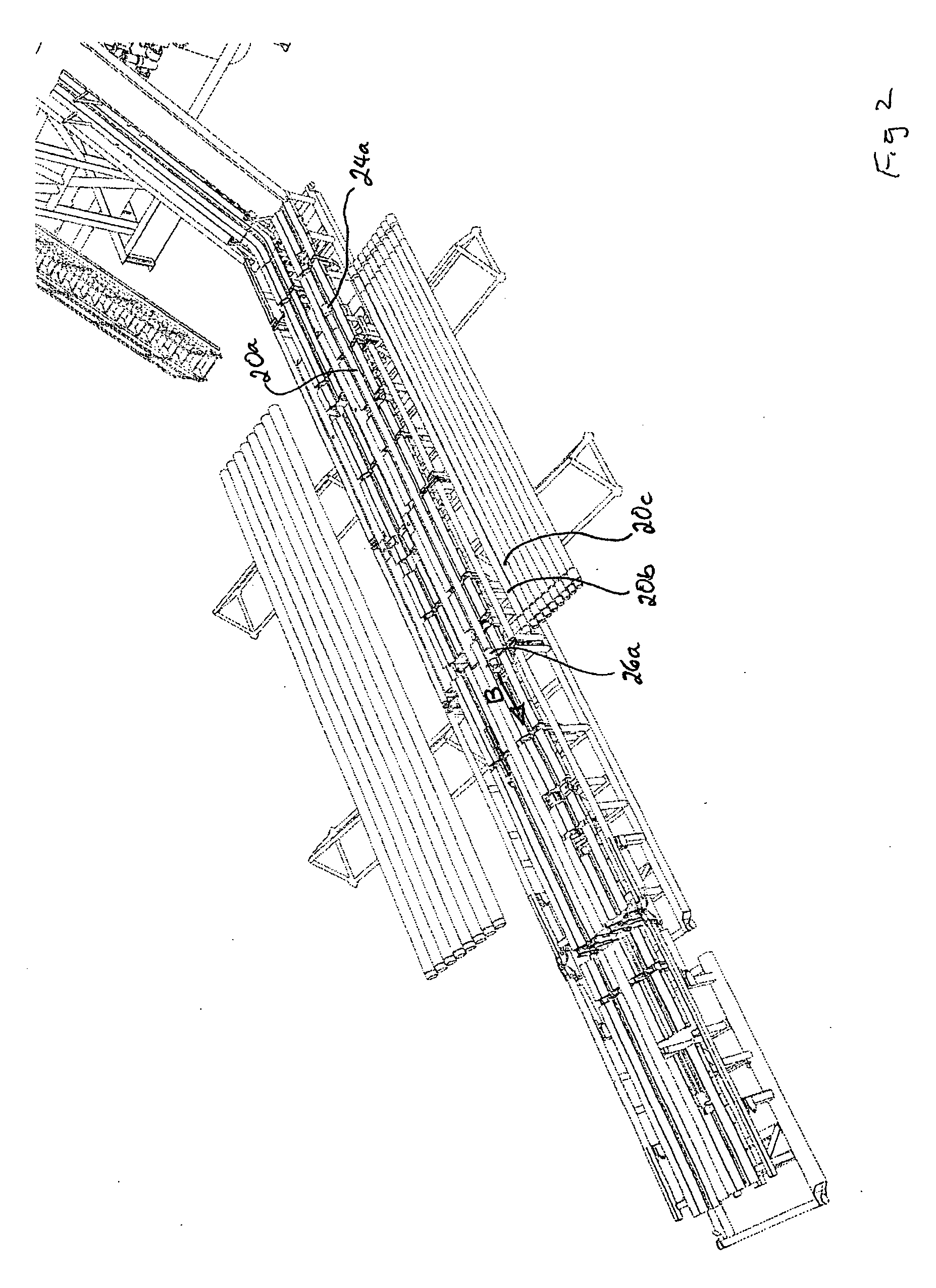

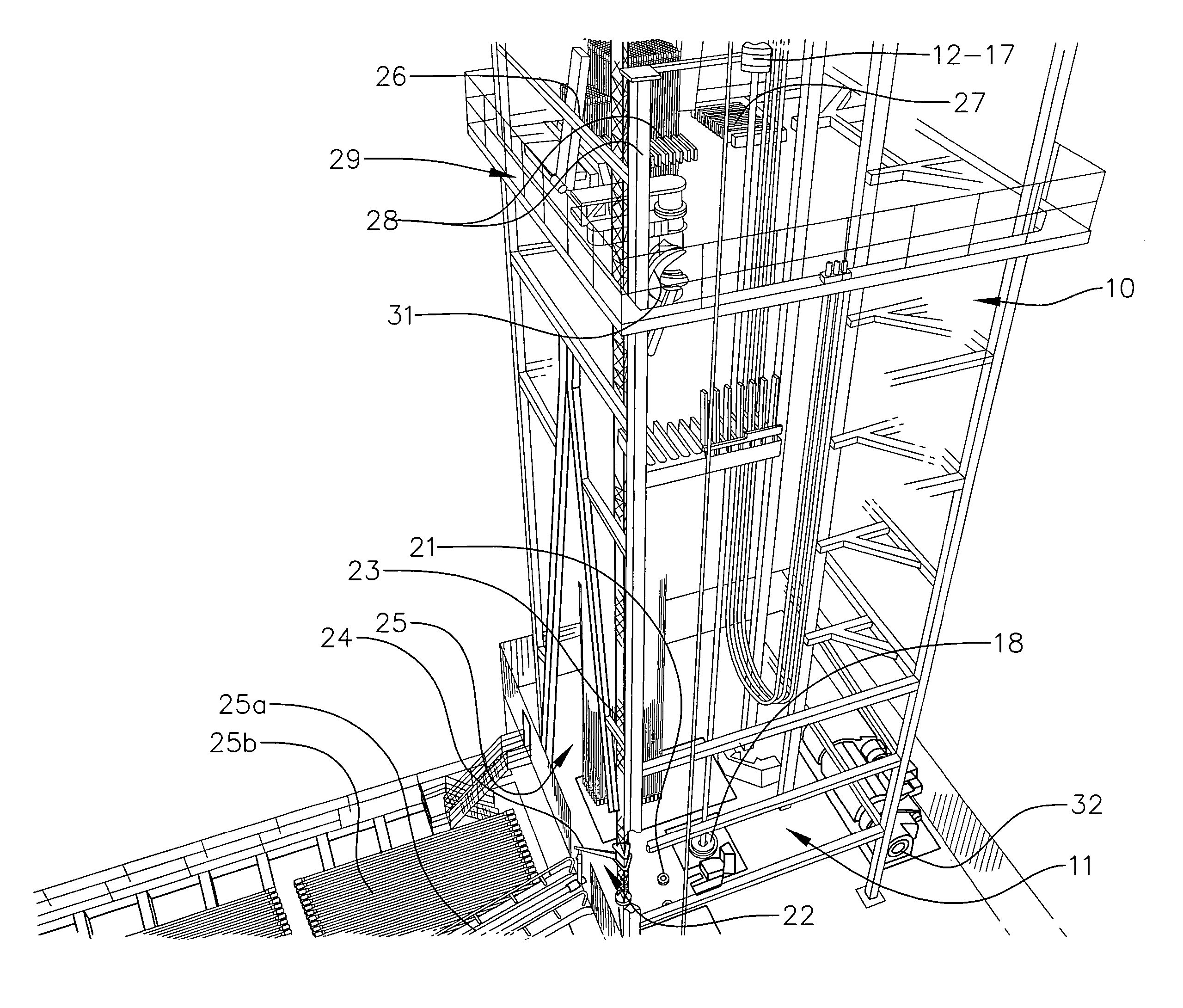

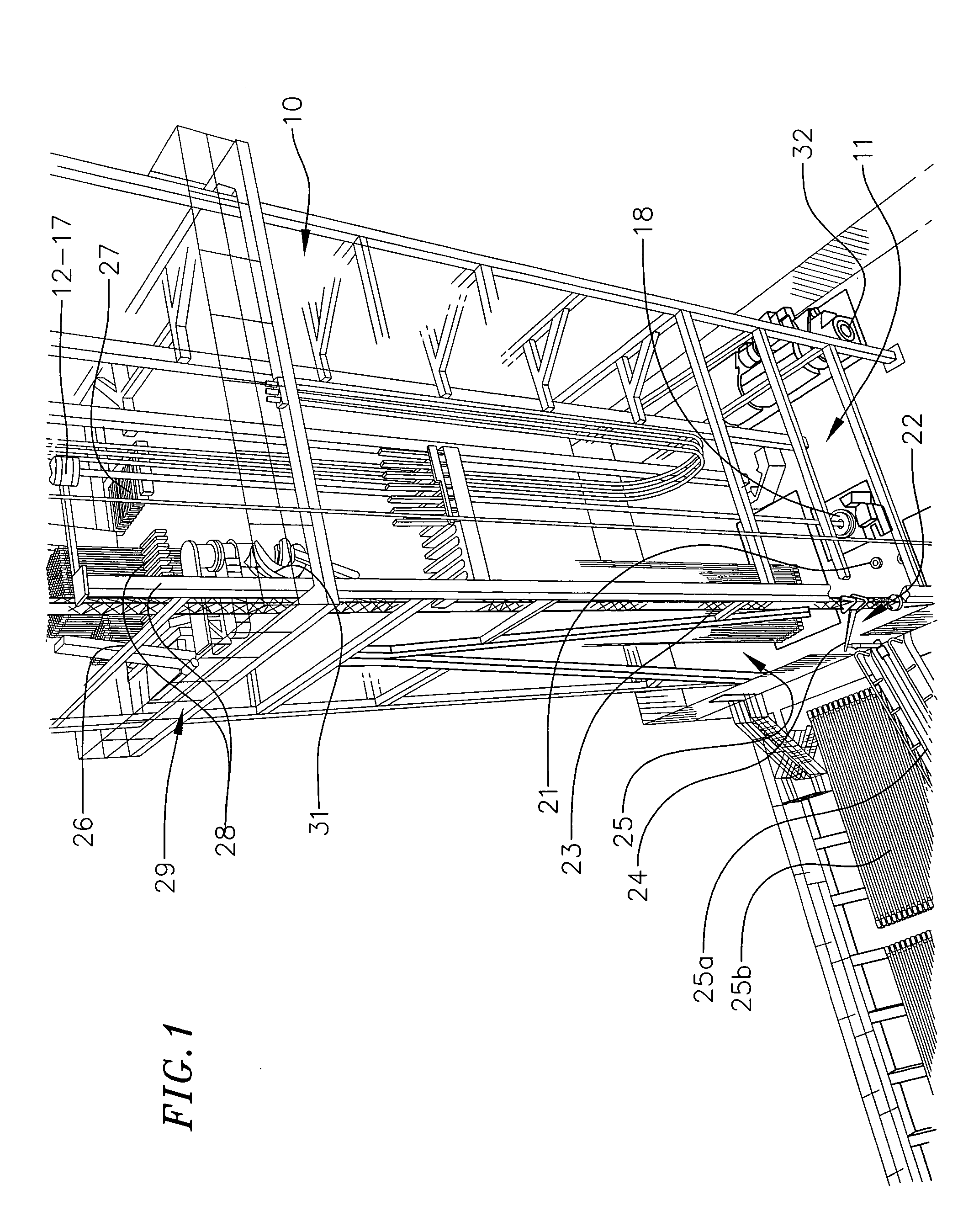

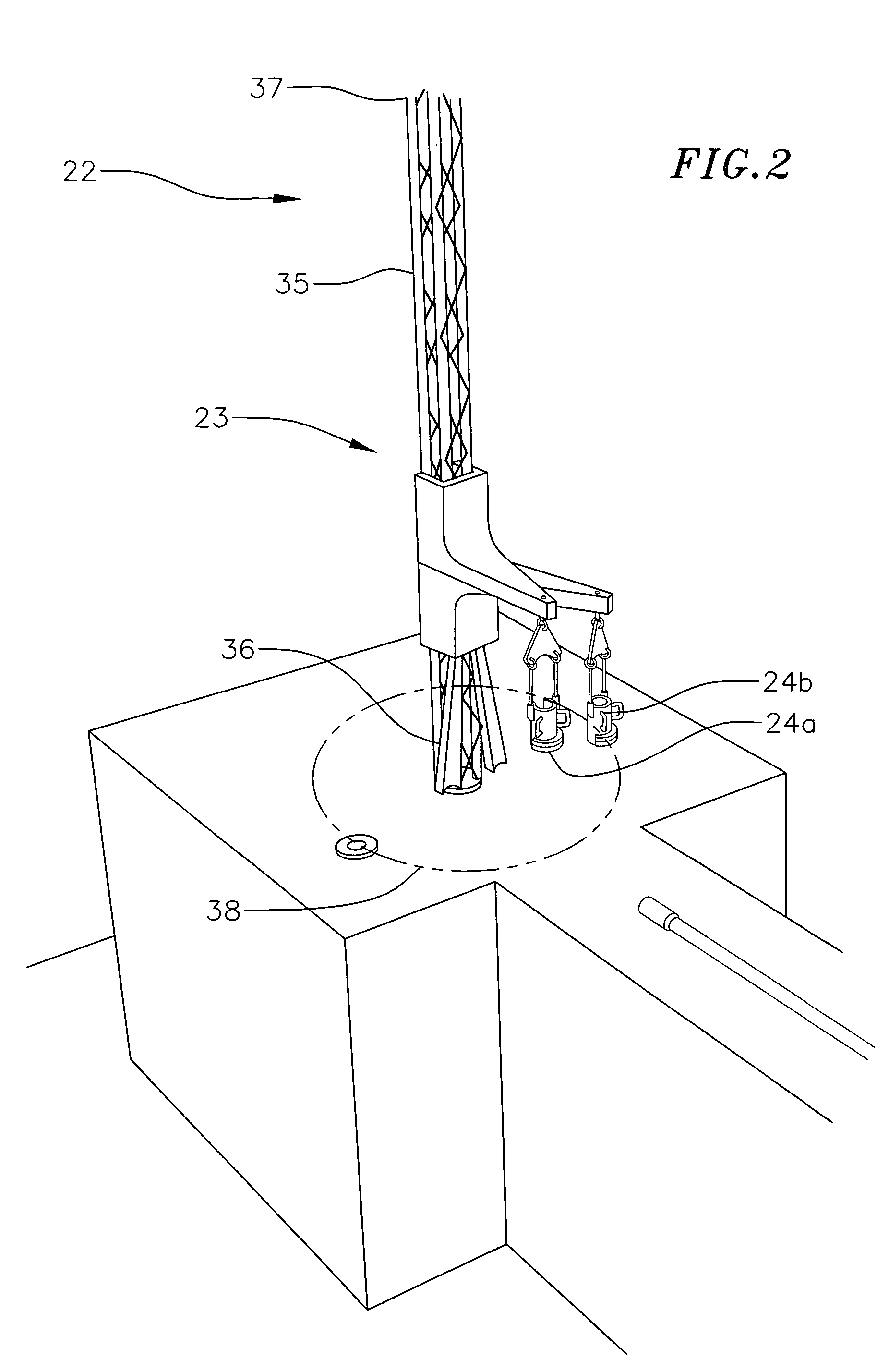

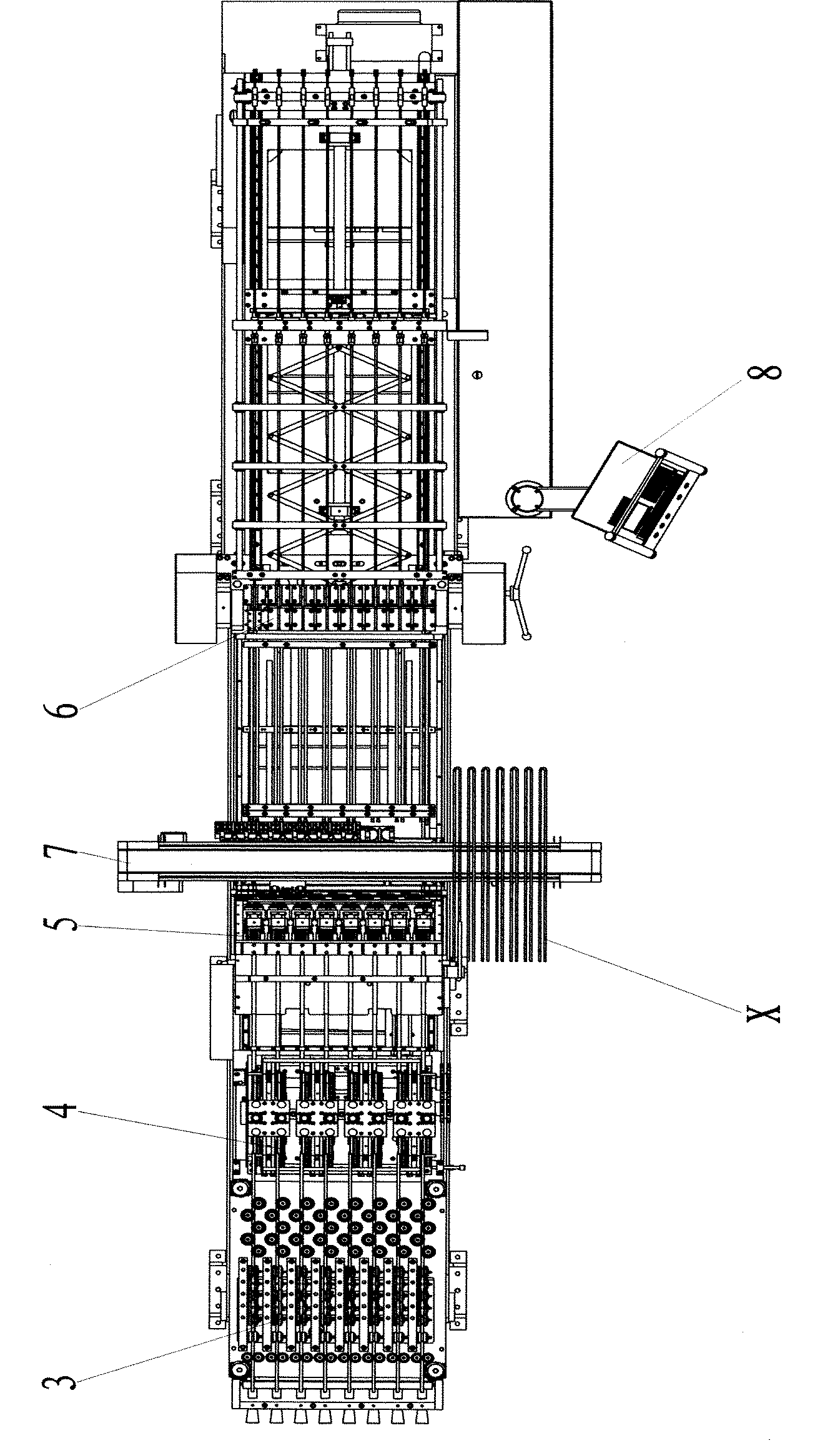

Horizontal offline stand building system

InactiveUS20100163247A1Reduce human contactReduce the possibilityDrilling rodsFluid removalEngineeringPipe fitting

A horizontal offline stand building system includes a substantially horizontal, elongate catwalk having a frame and a stand lifting arm. The catwalk has a top surface adapted to receive at least two tubluars aligned coaxially along a linear path in a make-up channel on said top surface. The tubulars are threaded together to form preferably at least a triple pipe stand in the make-up channel. The completed stand is then transferred laterally to a delivery channel containing the stand lifting arm. The stand lifting arm is selectively actuable lifting arm for selectively elevating a rig end of a pipe stand from said top surface of the catwalk to the deck of a drilling rig, and then for supporting the mid and rear sections as the stand is hoisted from the delivery channel up the derrick of the drilling rig.

Owner:WEATHERFORD CANADA

Method and apparatus for offline standbuilding

A method and apparatus for moving pipe on a rig floor between a number of different stations including an off-floor rack, a preparation opening, a borehole, and a storage area, such that tubulars can be loaded onto the drill floor, prepared at the preparation opening, loaded onto or off of the storage rack, and connected to a drill string while drilling is simultaneously conducted at the borehole, comprising at least two pipehandling devices, at least one of the pipehandling devices having multiple independent gripping arms, the pipehandling devices being arranged for communicating pipe between a storage area off the drill floor, a storage area on the drill floor, at least one preparation opening, and a drill opening are provided.

Owner:VARCO I P INC

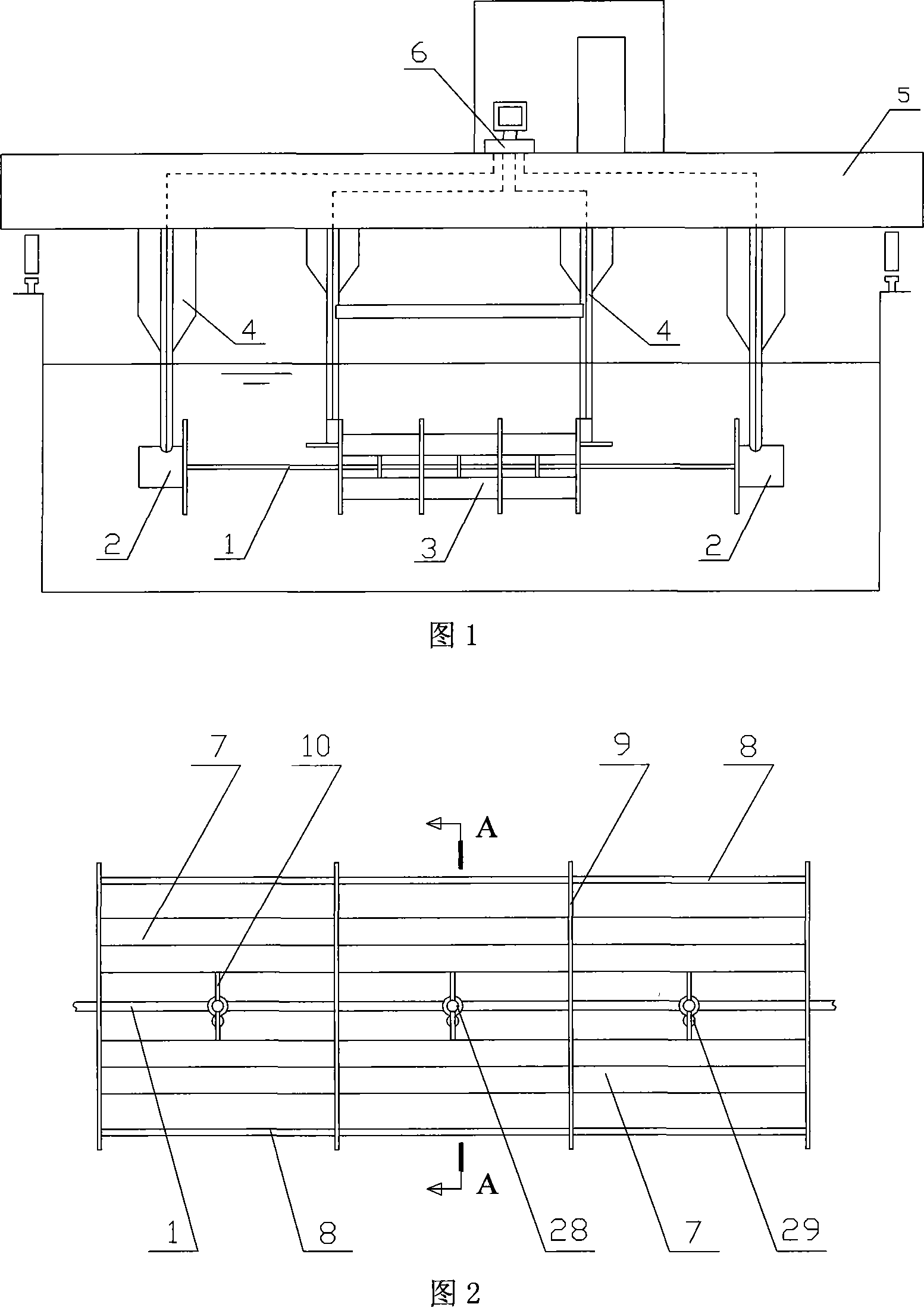

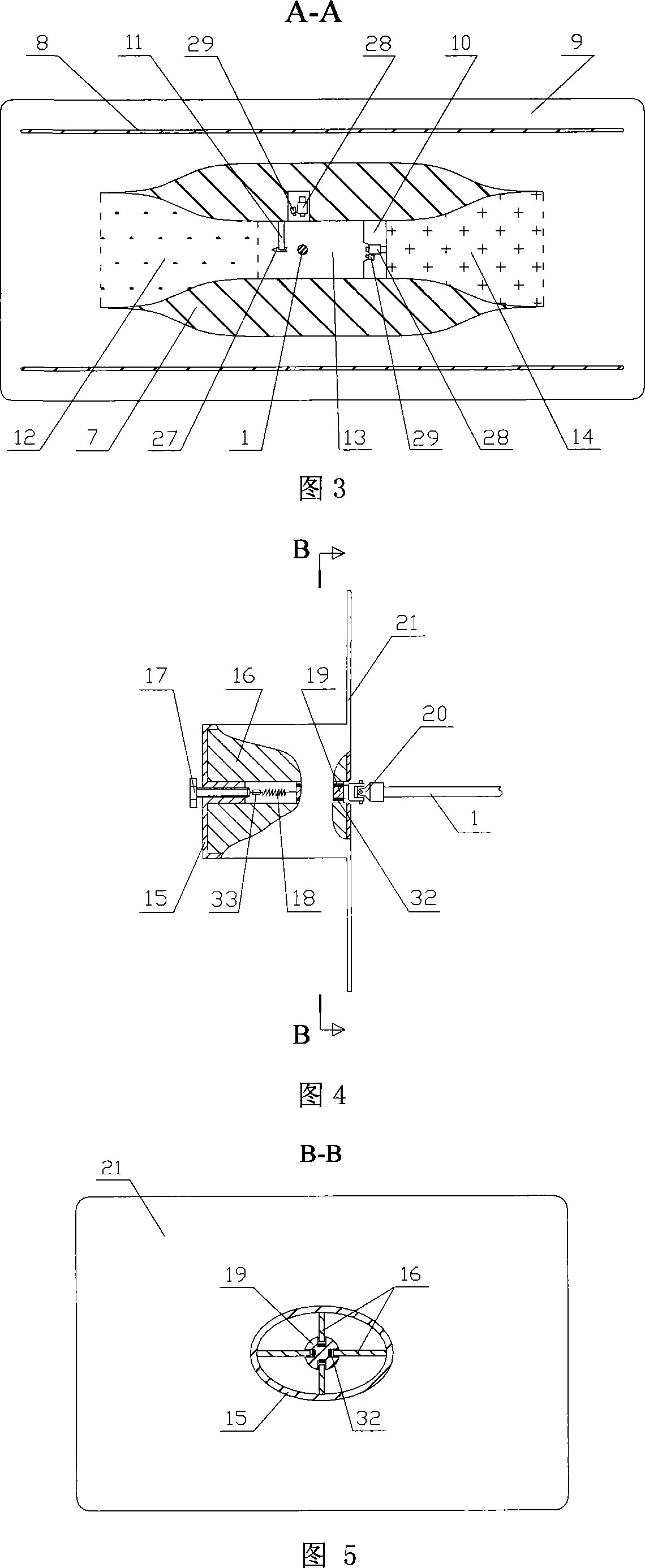

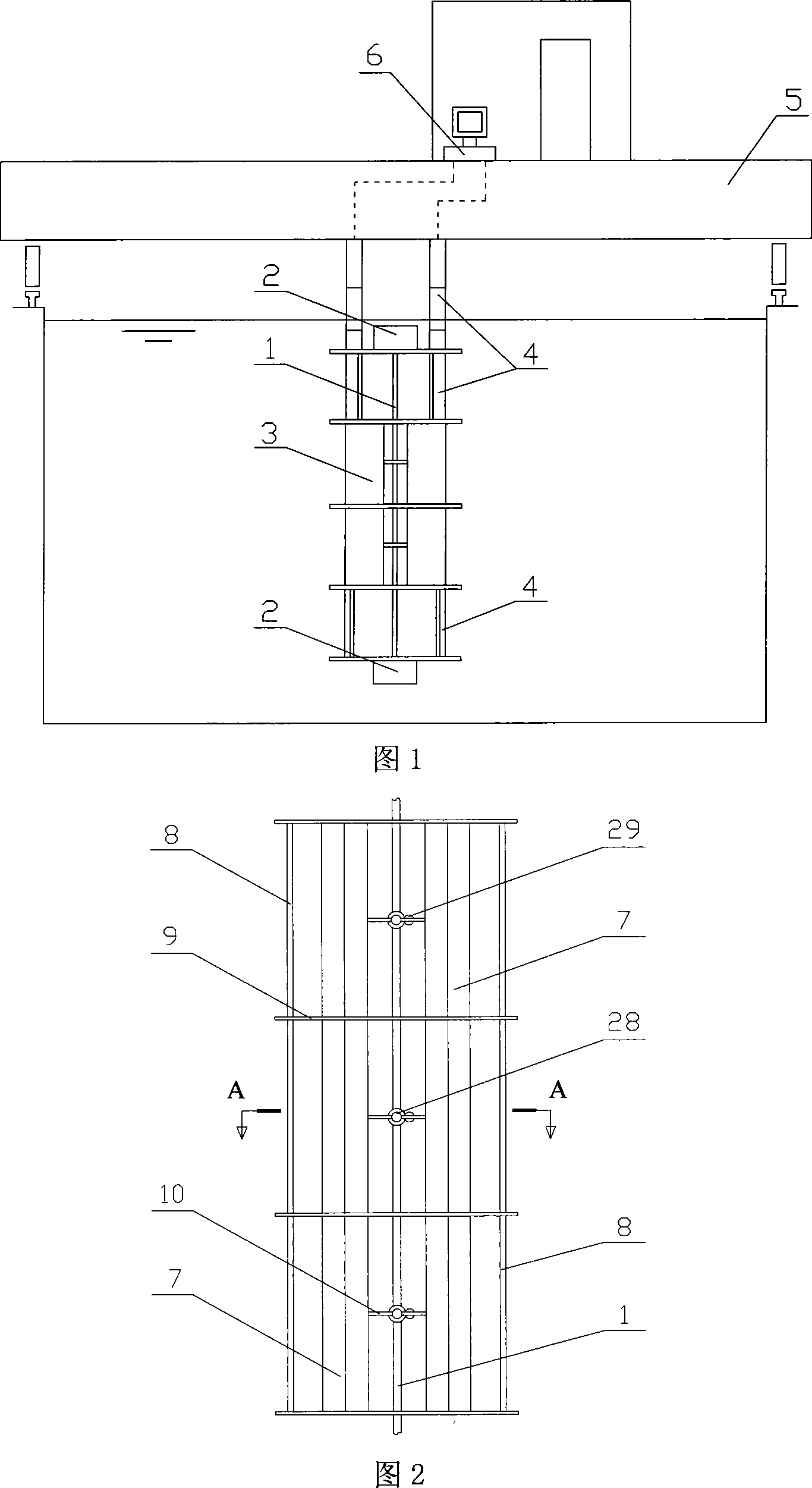

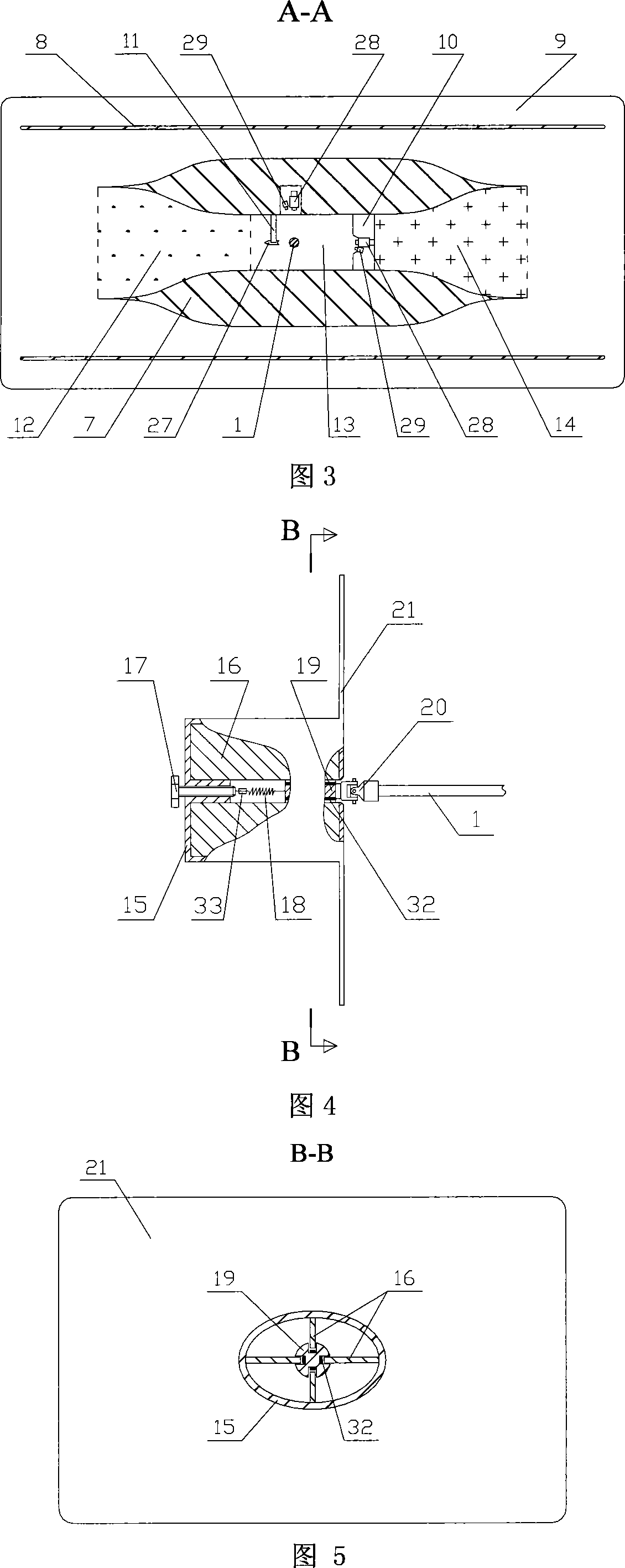

Vortex vibration testing device for flexible pipe mould vertical in towing pool

ActiveCN101089578AIncrease the Reynolds numberImprove flow uniformityVibration testingPipe fittingEngineering

A vortex-exciting vibration test device of flexible pipe fittings mode set horizontally in pull water pool is prepared as passing pipe fittings model through flow-speed increasing unit; setting said model and said unit vertically in pull water pool; supporting two ends of said model by support mechanism; using horizontal test support to connect said unit and support mechanism with trailer and distributing various instruments of measurement-analysis system in said model, said units, said mechanism, said support and said trailer.

Owner:SHANGHAI JIAO TONG UNIV

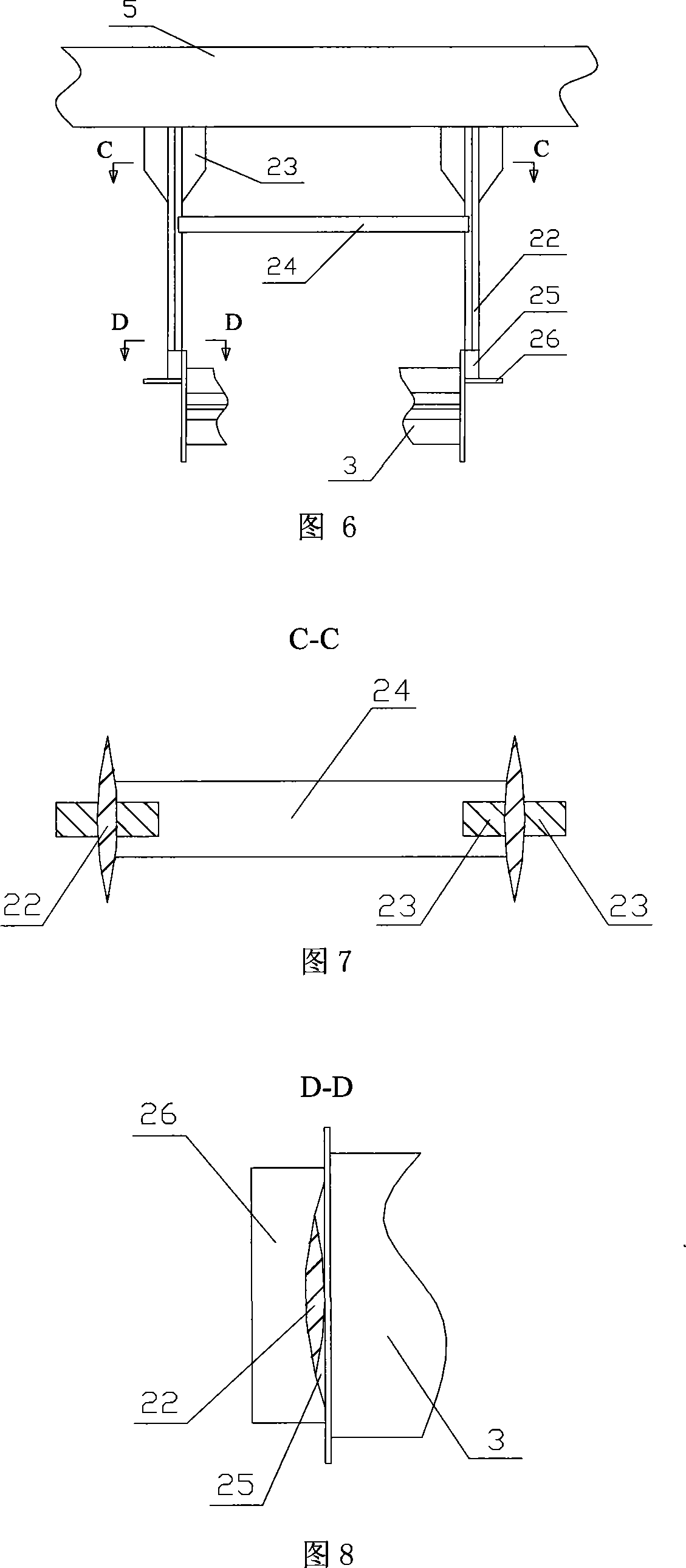

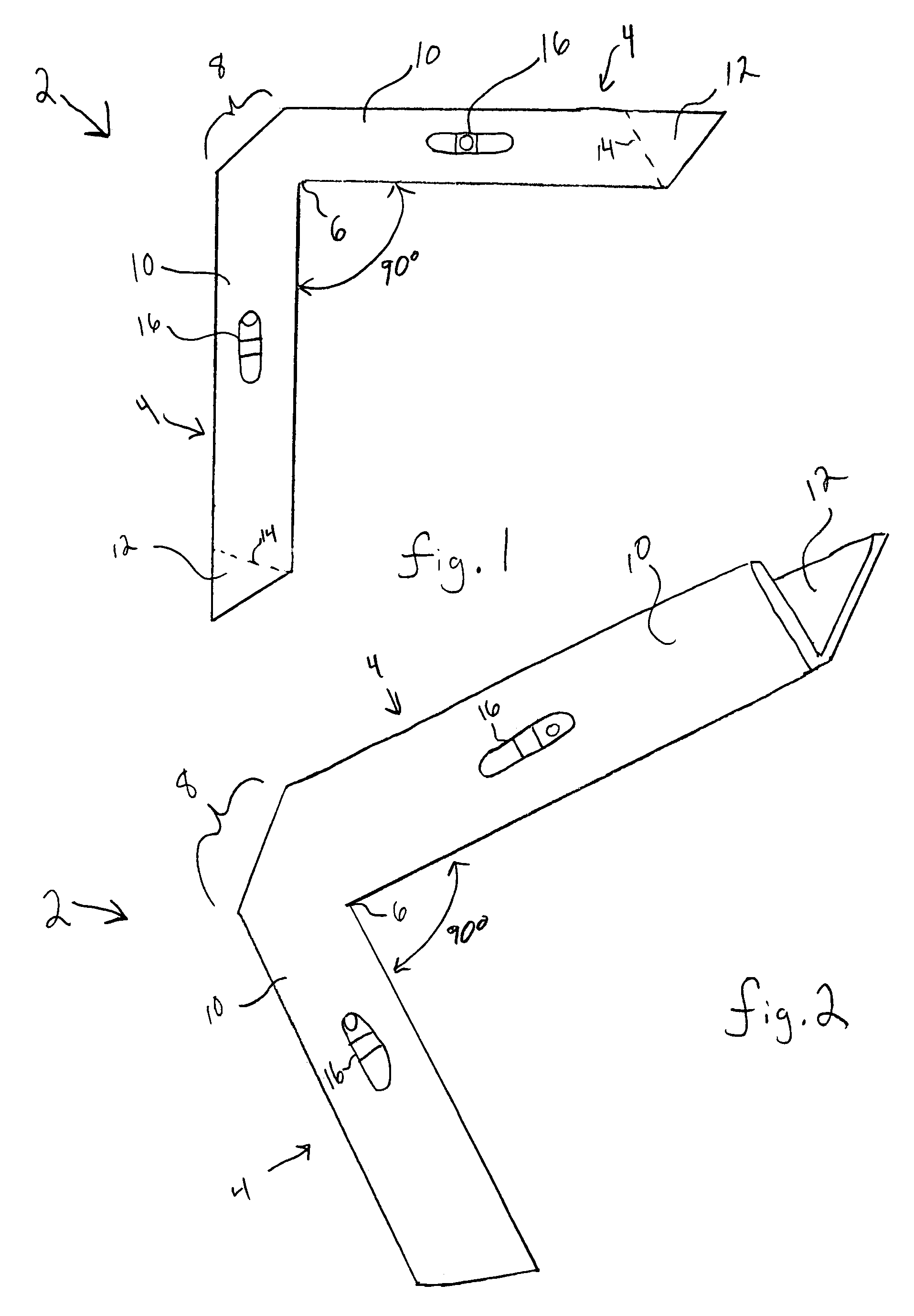

Combination level and squaring tool

A square that includes two rigid, channeled members having an interior and an exterior, with the two members being joined at a ninety-degree angle to form a one-piece L-shaped tool having an elbow and a notch disposed on an exterior corner opposite the elbow. The invention also features a bubble level attached to the exterior of each member and a releasable adhesive member disposed upon the interior of each member, such as magnets, tapes, or adhesive plastic materials. Methods for pipe-fitting and for holding pipes or joints in place with the invention are also provided.

Owner:DINIUS MICHAEL J

Gasket for a coupler upon a rail car, tank trailer, or related means

InactiveUS20050248098A1Great sealing surfaceSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe coupler interconnects pipes and fittings and sections of pipe end to end for transferring bulk dry and fluid materials. The coupler connects various pipe ends, grooved, smooth, and ground, together. The coupler also connects various fittings such as tees and valves to pipe ends. Two arms clamp upon the two pieces of a gasket to seal the connection of pipes and fittings within the coupler. A plurality of ridges upon both surfaces of the piece grasp and seal the end of a pipe. The gasket removes any gaps in the connection that would have trapped material and contaminated later loads of material.

Owner:SISK DAVID E +1

Piping structure having leak detection function and leak detector

InactiveUS20050166666A1Minimize impactIncrease pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateDouble tubePipe fitting

A covering member having a valve encloses a flexible hose to form a double pipe. Gas supply pipe fittings are attached to respective ends of the double pipe to form a hermetic space between the flexible hose and covering member. The covering member also has a pressure-measuring device to which a decision unit equipped with an alarm device is connected. The same gas or liquid as the one flowing through the flexible hose is introduced to the hermetic space from the valve provided in the covering member, and sealed in the hermetic space by closing the valve. The pressure in the hermetic space is set so as to be higher than the pressure produced in the flexible hose when the gas or liquid is flowing. The pressure-measuring device measures the pressure in the hermetic space while the gas or liquid flows in the flexible hose, and the decision unit compares the measured value with a reference value. As a result, if the value measured by the pressure-measuring device is lower than the reference value, the decision unit decides that a breakage has occurred and then the alarm device activates an alarm.

Owner:LASERFRONT TECH

Fluid conduit system and fittings therefor

InactiveUS20080048448A1Joints with sealing surfacesNon-disconnectible pipe-jointsPipe fittingEngineering

A fluid conduit system that employs fittings having ends with a structural portion and a seal portion. The ends of the fittings are inserted into a tube, which may be a hard, i.e., rigid, or soft, i.e., flexible, tube. The seal portion sealingly engages the inner diameter of the tube upon its insertion into the tube. The tube is deformed to prevent the fitting from being withdrawn from the tube; the portion of the tube in the immediate vicinity of each seal that forms the seal portion is not deformed. A method for forming a fluid conduit system is also provided.

Owner:JAMISON TOMMY L +2

Vortex vibration testing device for flexible pipe mould vertical in towing pool

ActiveCN101089577AIncrease the Reynolds numberImprove flow uniformityVibration testingPipe fittingEngineering

A vortex-exciting vibration test device of flexible pipe fittings model set vertically in pull water pool is prepared as passing pipe fittings model through flow-speed increasing unit; setting said model and said unit vertically in pull water pool; supporting two ends of said model by support mechanism; using vertical test support to connect said unit and support mechanism with trailer and distributing various instruments of measurement-analysis system in said model, said units, said mechanism, said support and said trailer.

Owner:SHANGHAI JIAO TONG UNIV

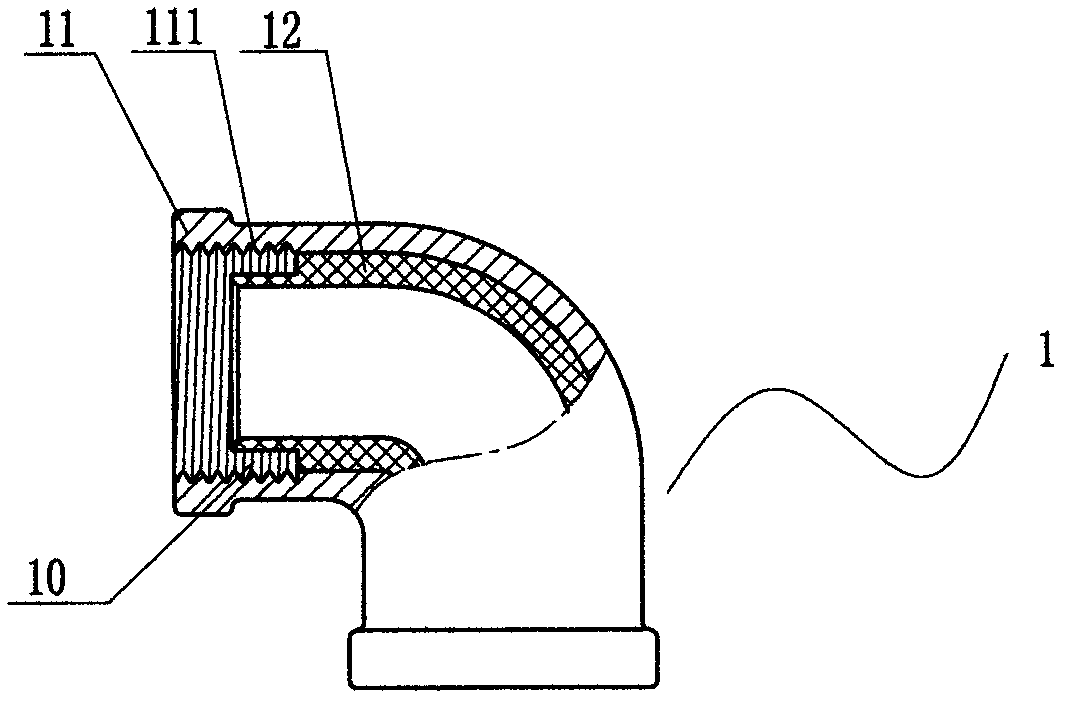

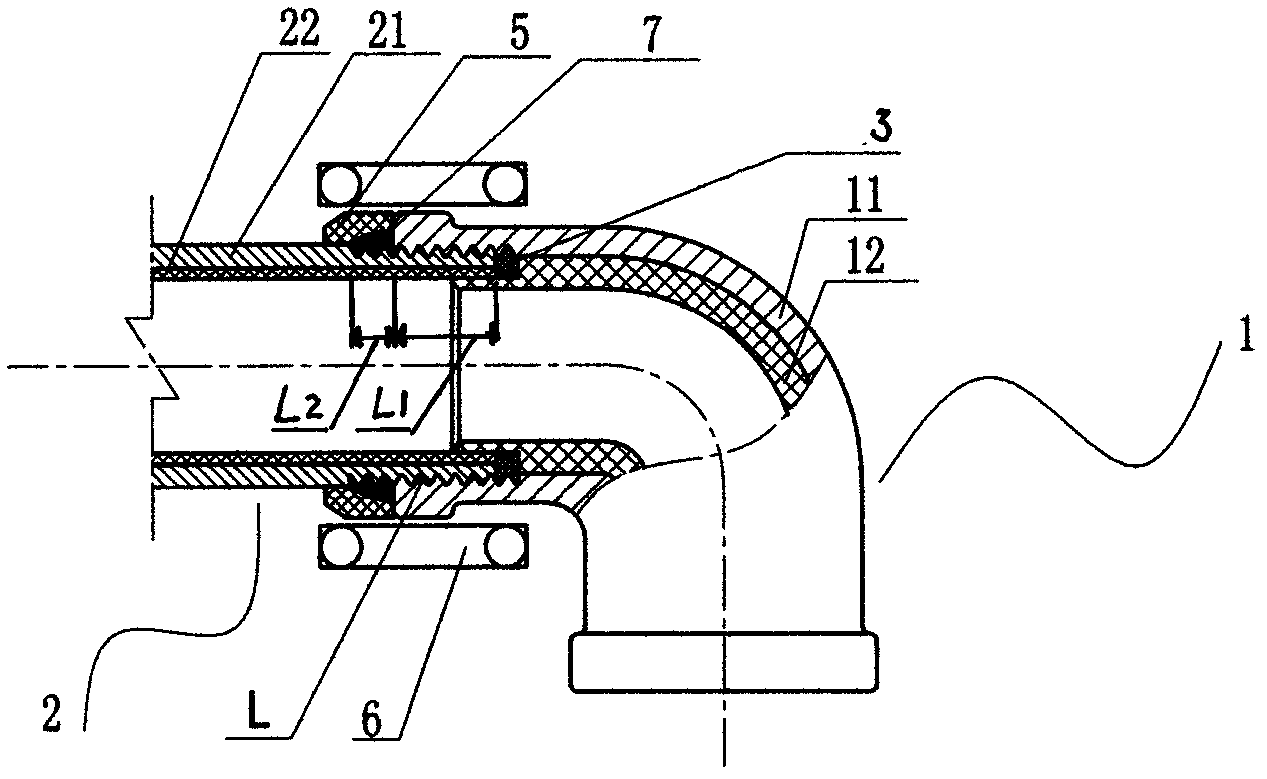

Full corrosion-resistant connection structure of steel lining plastic composite pipeline

InactiveCN102359697AReduce the chance of secondary pollutionEliminate interface rustCorrosion preventionPipe protection against corrosion/incrustationPipe fittingHot-melt adhesive

The invention discloses a full corrosion-resistant connection structure of a steel lining plastic composite pipeline, and belongs to the technical field of connection of the steel lining plastic composite pipeline. The structure comprises a corrosion-resistant ring sleeved on a non-meshing section of an external thread of a steel outer layer, a steel lining plastic composite pipe fitting consisting of a steel outer ring part and a plastic inner ring part, and a composite pipe consisting of the steel outer layer with the external thread, and a plastic inner layer, wherein the external thread consists of a meshing section and the non-meshing section; an annular cavity of which the inner wall is provided with an internal thread section is formed between the steel outer ring part and the plastic inner ring part; the pipe is in threaded connection with the pipe fitting; a solid hot melt adhesive is arranged in the annular cavity; when an alternating magnetic field is formed at the periphery of the joint of the pipe fitting and the pipe, the solid hot melt adhesive is in thread engagement with the steel outer ring part and in sealed connection with the end faces of the steel outer layer and the plastic inner layer; and the corrosion-resistant ring is in sealed connection with the non-meshing section of the pipe. After the scheme is adopted, the problem that the threads of the pipe and the pipe fitting are easily corroded and rusted is solved, and a full corrosion-resistant threaded connection effect is achieved.

Owner:HUAHUI CONSTR GROUP

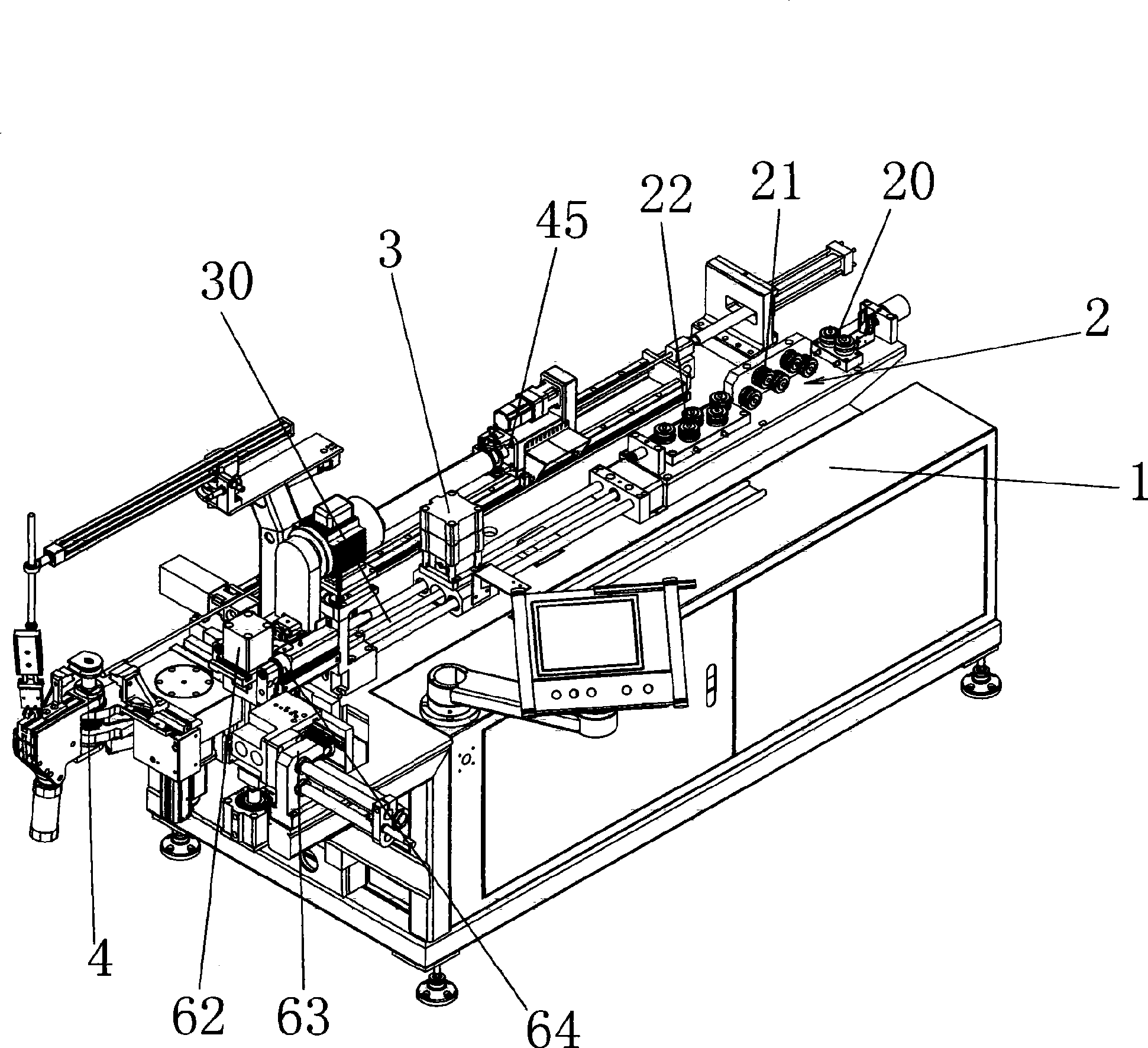

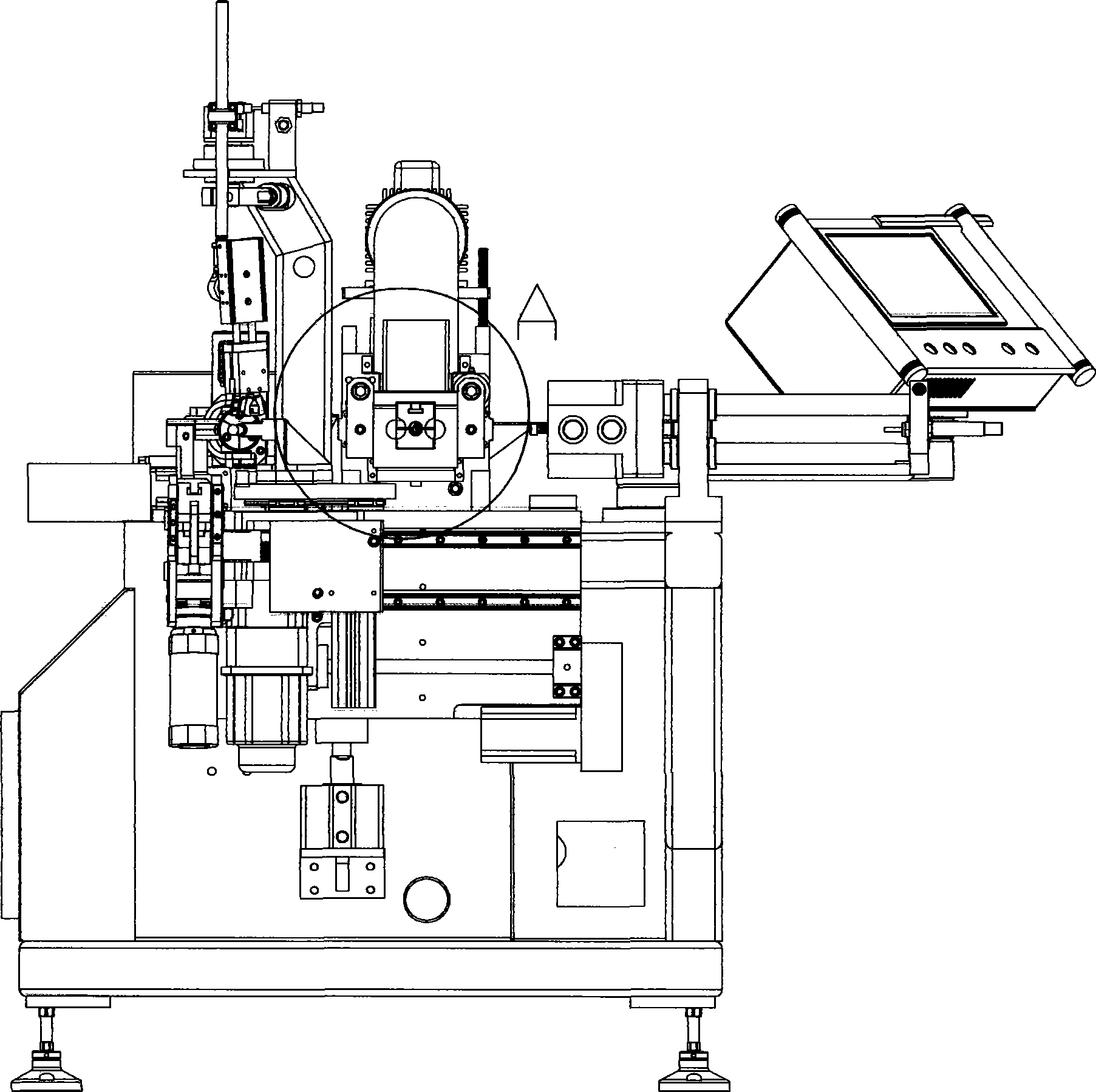

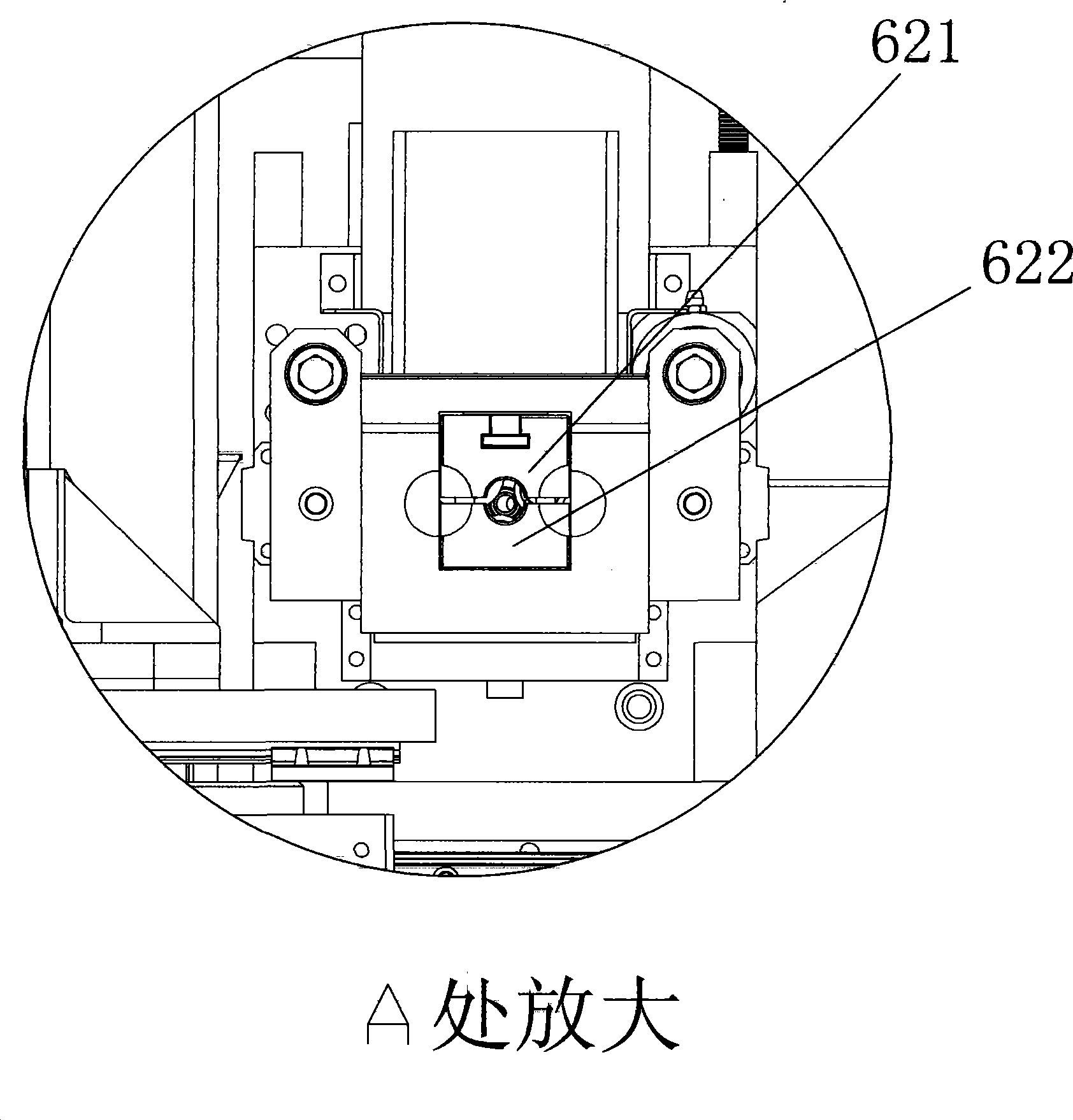

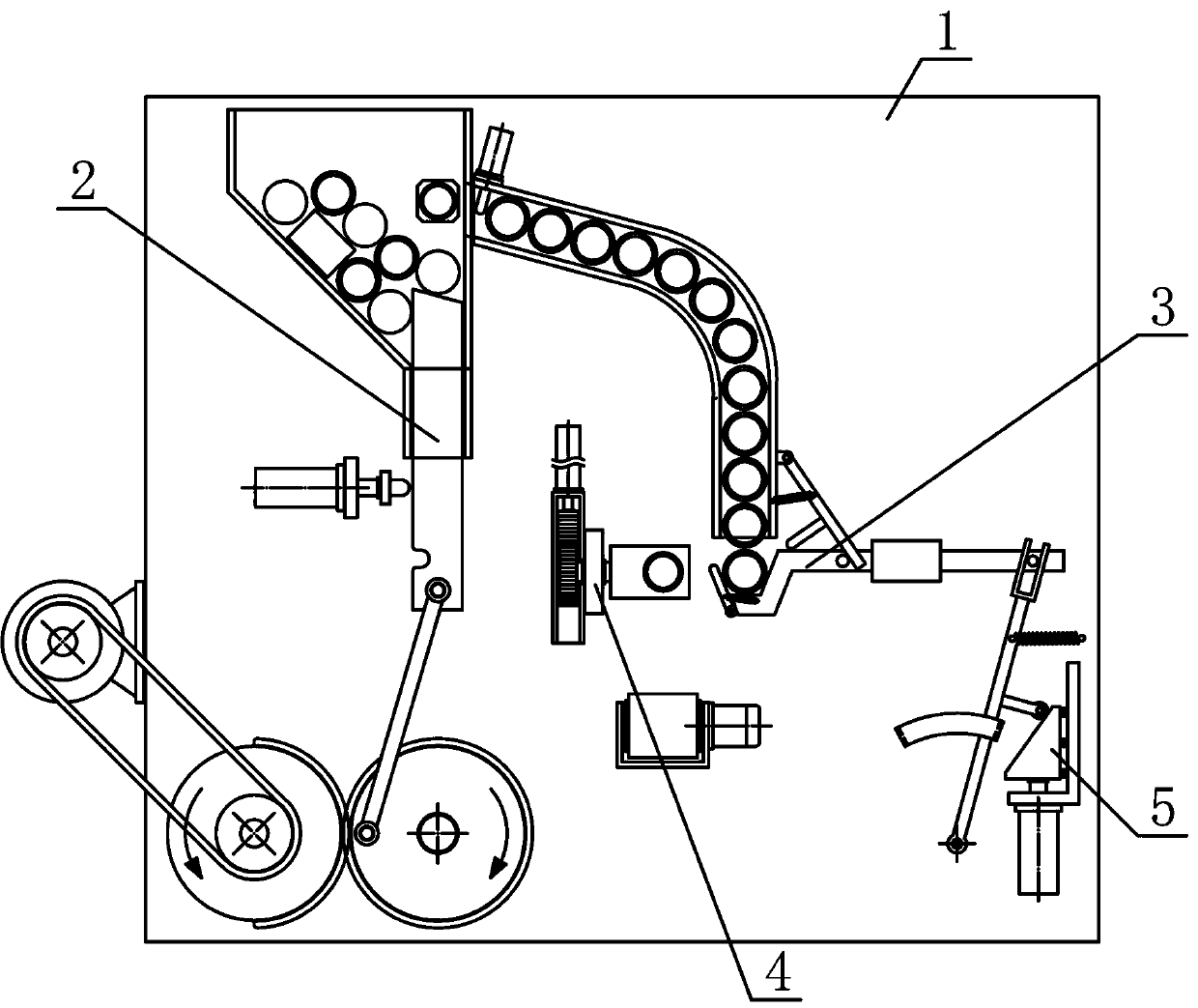

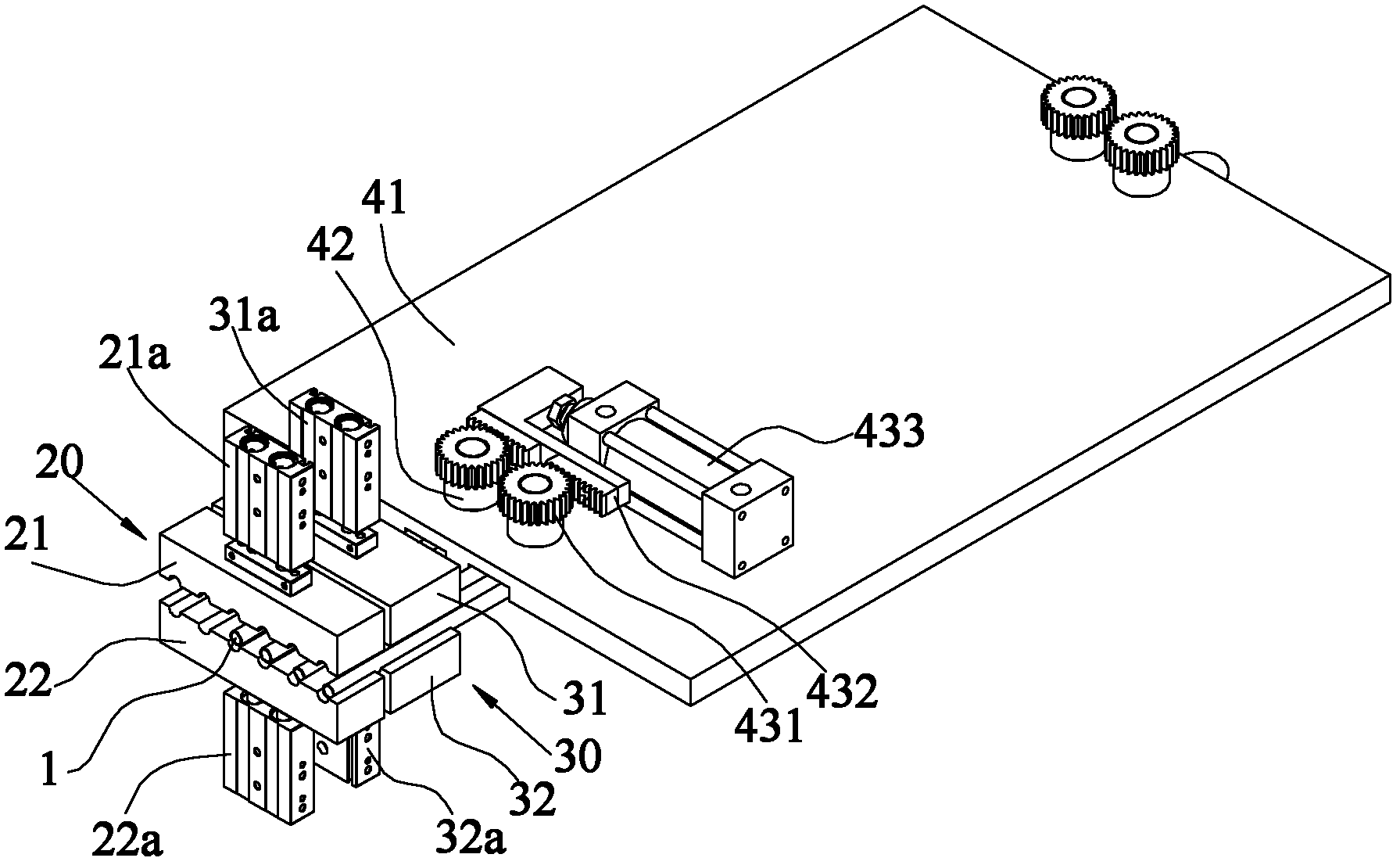

Integrated pipe bender

ActiveCN101474651AHigh degree of collectionAvoid uncertaintyMetal-working feeding devicesPositioning devicesRotational axisPipe fitting

The invention relates to an integrated pipe bender. The pipe bender comprises a machine tool working table which is sequentially provided with a pipe fitting straightening mechanism, a pipe fitting feeding structure and a bent pipe forming mechanism. The main design points are characterized in that a blanking device and a tubing head flaring device are arranged between the pipe fitting feeding structure and the bent pipe forming mechanism, and the blanking device comprises a hollow rotating shaft which is used for passing through by pipe fittings, a cutting knife which is positioned on the rotating shaft and a control mechanism which controls the opening and closing of the cutting knife head; and the tubing head flaring device comprises a flaring punch head capable of shift, a flaring clamping die mechanism and a drive mechanism which drives the flaring punch head to move, and the flaring punch head can prop against one side of the flaring clamping die mechanism. The purpose of the invention aims at providing the integrated pipe bender which can perform once forming on the flaring and the bent pipe of pipe fitting materials.

Owner:OMS MASCH CO LTD

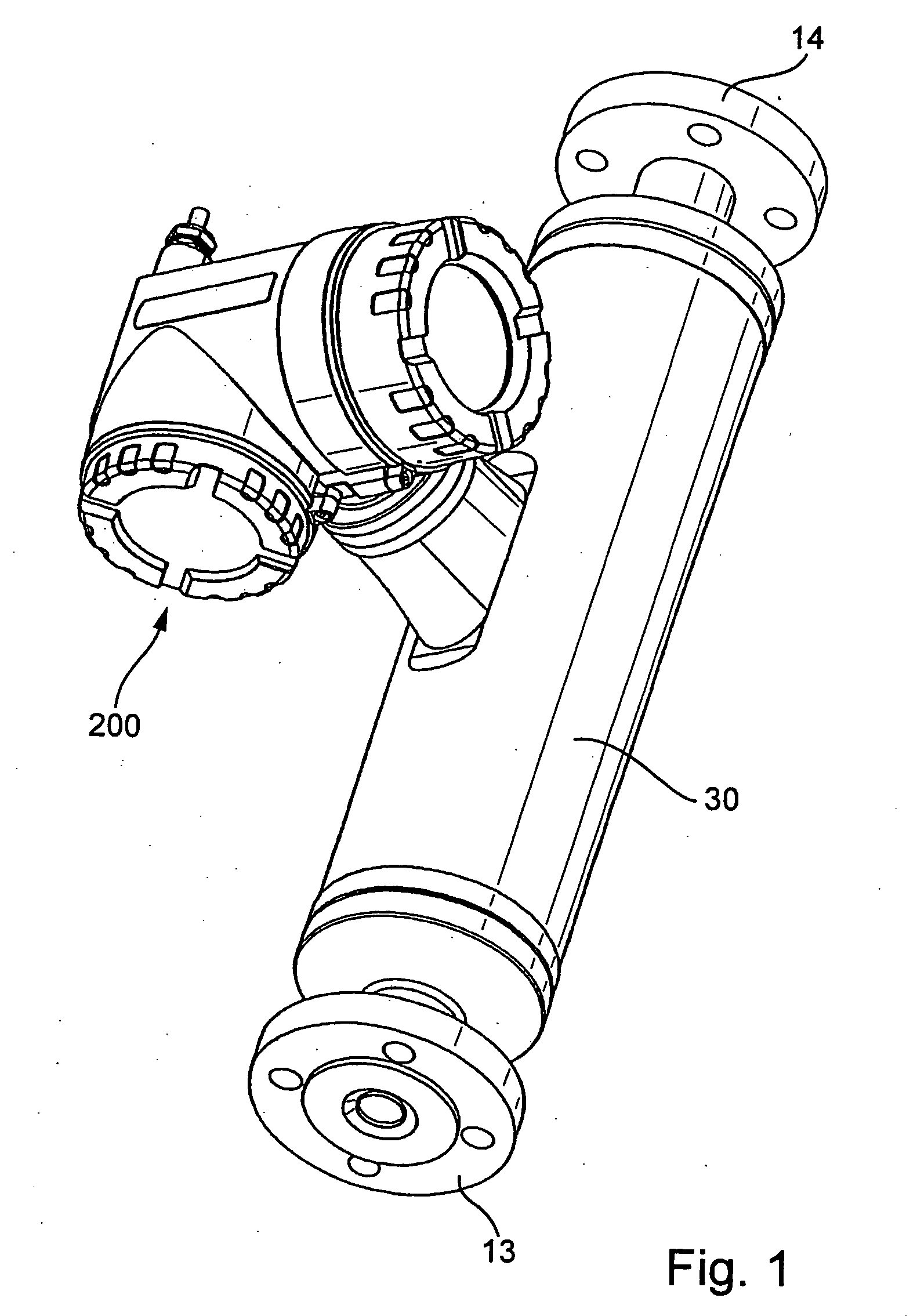

Pipe Fitting With Sensor

A fluid fitting is provided that is mechanically attached to a pipe, including a coupling body having an inner surface defining a bore for receiving the pipe therein. A ring is positioned to fit over the at least one end of the coupling body for mechanically attaching the coupling body to the pipe, and a main seal formed on the inner surface of the coupling body to engage the pipe. When installed, the ring and coupling body apply a compressive force to the main seal sufficient to attach the pipe to the coupling body in a non-leaking manner. An electrically operated sensor device is fixed to a surface of one of the coupling body or ring that, when the ring is installed on the coupling body, produces an electrical parameter in response to physical movement of the coupling body or ring to which the sensor device is fixed.

Owner:LENLOK HLDG LLC

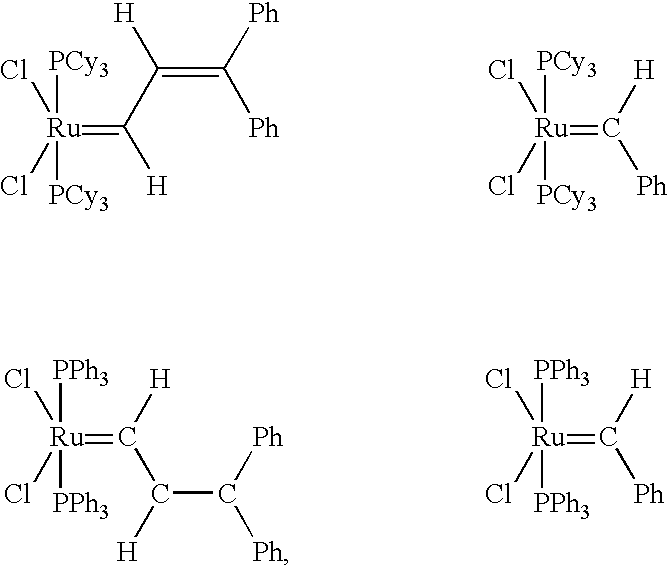

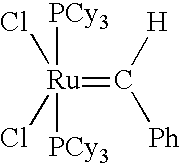

Pipe made from metathesis polymerized olefins

InactiveUS6410110B1Extended validity periodImprove responseLayered productsBottlesPolymer sciencePipe fitting

Thermosetting resin pipes and pipe fittings are provided which are prepared by polymerizing a cyclic olefin monomer in the presence of a ruthenium or osmium metathesis polymerization catalyst. These articles may be prepared by various methods, such as centrifugal casting. Reinforced articles may also be prepared by filament winding.

Owner:A O SMITH +1

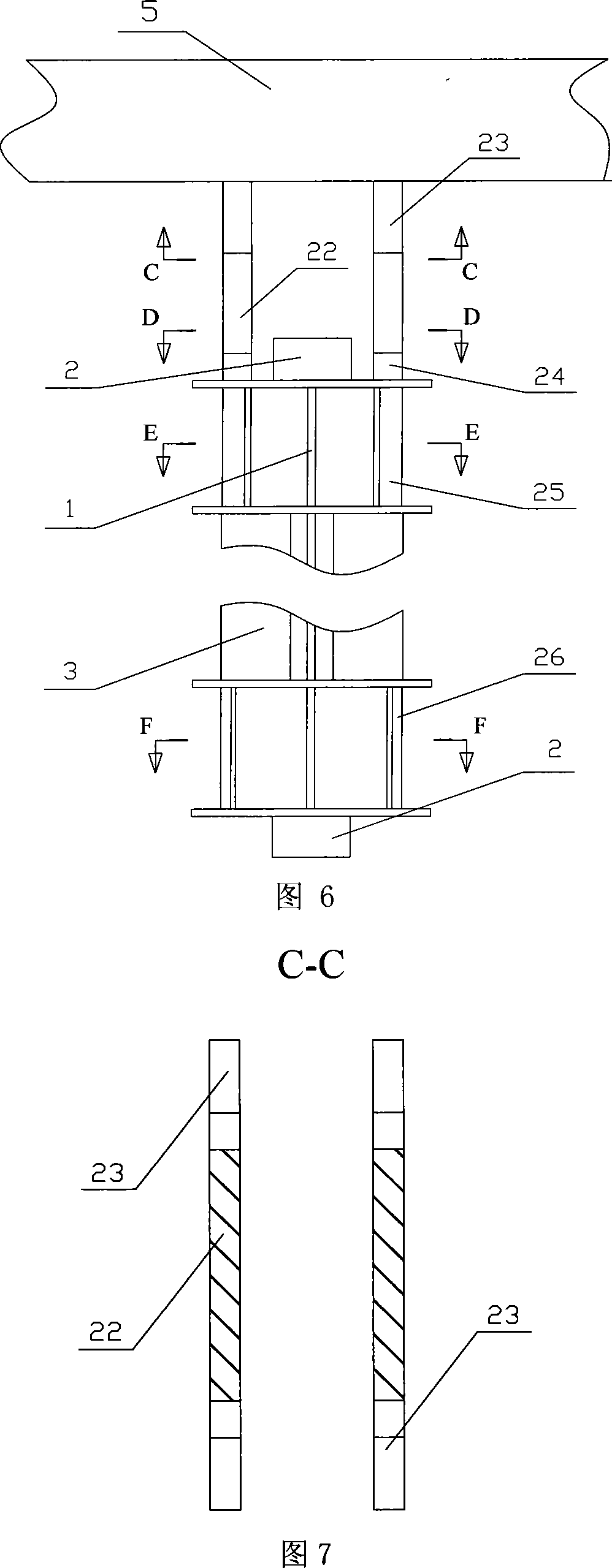

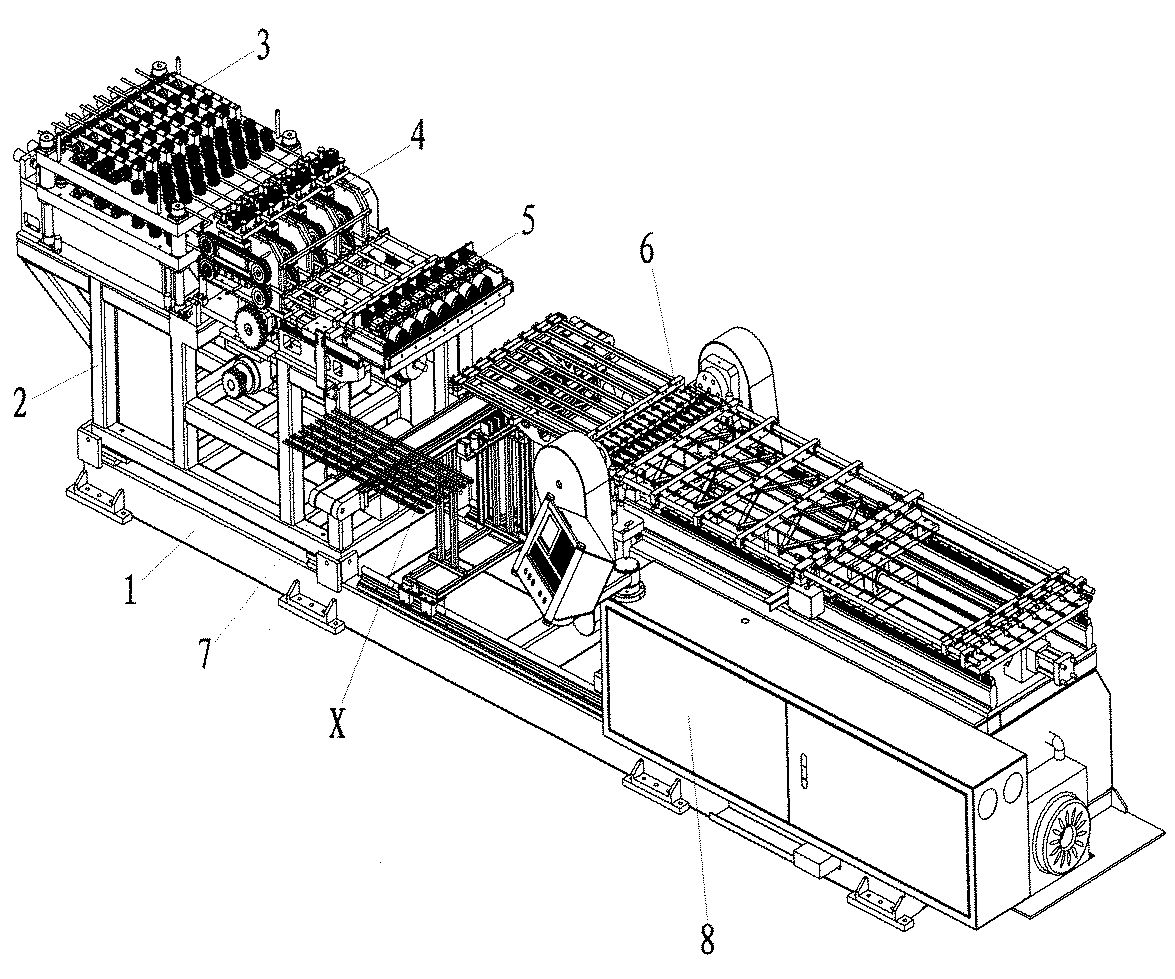

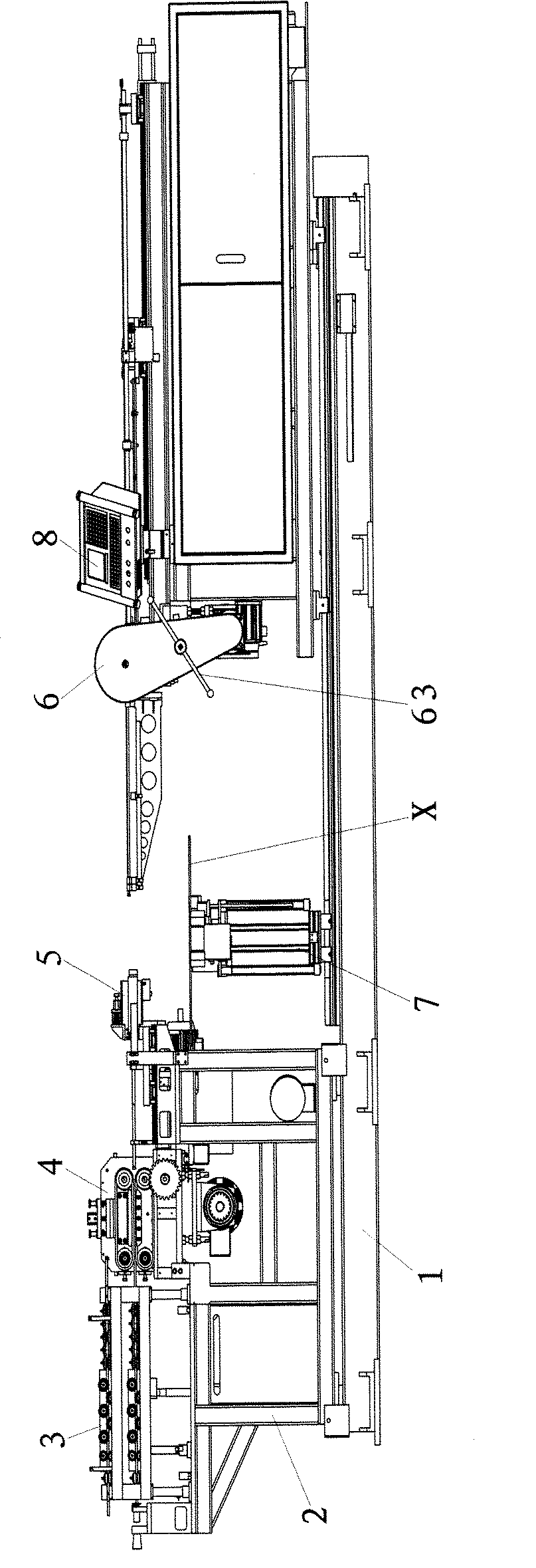

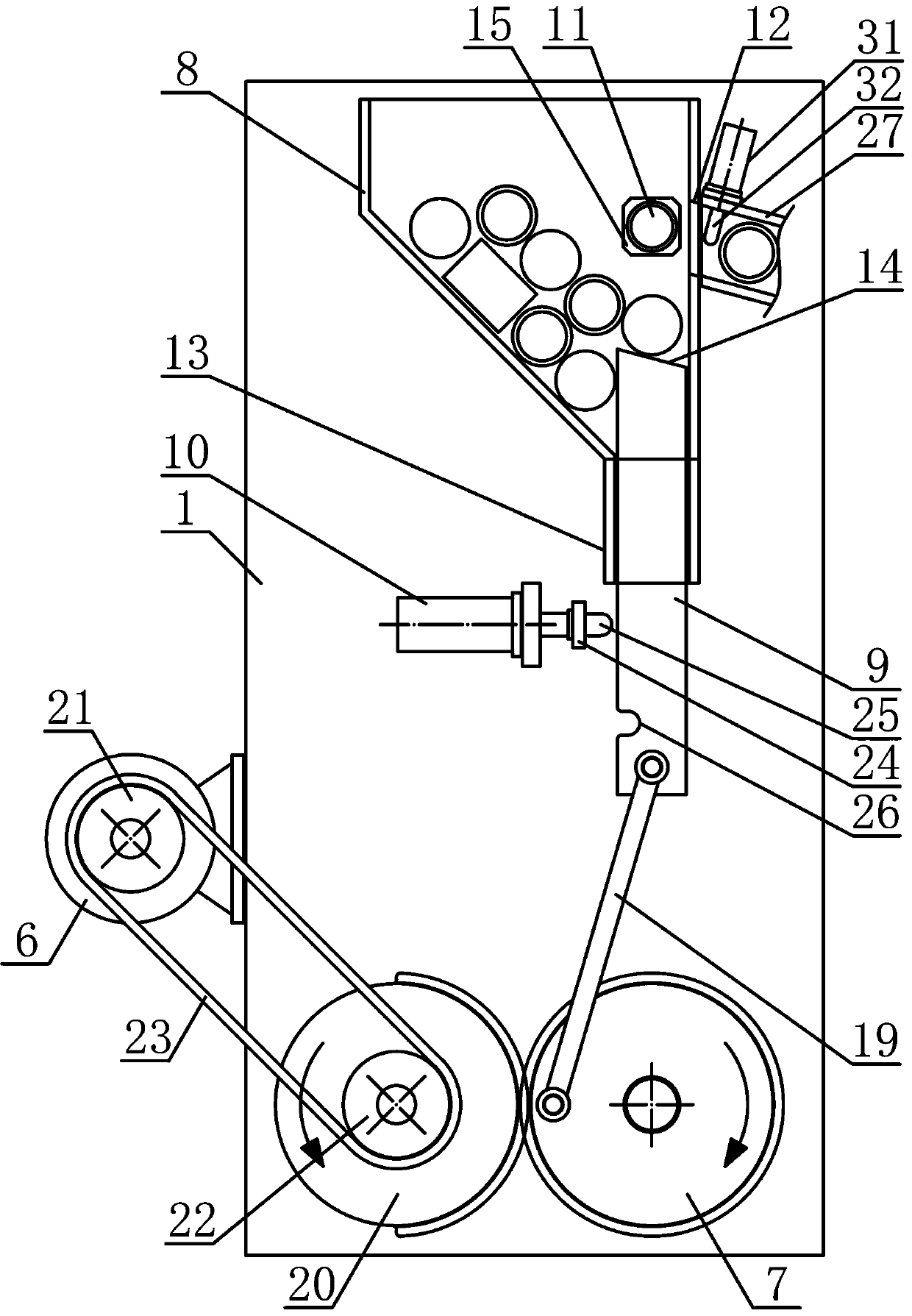

Long U-shaped tube bender

ActiveCN102139301ASimple structurePrecise positioningShaping toolsMetal-working feeding devicesPipe fittingEngineering

The invention relates to a long U-shaped tube bender, in particular to the long U-shaped tube bender capable of processing two tubes in different pipe diameters. The long U-shaped tube bender comprises a base, a stand, a rounding and straightening device, a feeding device, a cutting device, a feeding path, a bending device, a receiving device and a controller, wherein the rounding and straightening device comprises two sets of rounding and straightening mechanisms; the stand is provided with a position switching mechanism for adjusting positions of the two sets of rounding and straightening mechanisms; the feeding device comprises two kinds of feeding channels for conveying pipe fittings in different pipe diameters; a position switching part for adjusting the positions of the two feeding channels is arranged on the stand; the bending device comprises two kinds of bending channels for bending pipe fittings in different pipe diameters; and a bending bracket is arranged on the stand and is provided with a position switching part for adjusting the positions of the two bending channels. The long U-shaped tube bender has a simple and reasonable structure, is accurately positioned, is convenient to operate and easy for manufacture. On the basis of no dismount and replacement of main parts, the long U-shaped tube bender can be used for processing the pipes in different pipe diameters and has wide processing range.

Owner:OMS MASCH CO LTD

Cross platform grip ring release device and method

The present invention provides, in part, a device that can fit around a fitting retention compartment of a pipe fitting, apply axial pressure to a pipe insertion component so as to flex the teeth of a fastening ring inwardly, which permits smooth insertion and removal of piping elements. In embodiments, the device comprises a two-piece device with mating threads that permit the pieces to move toward and away from one another with minute adjustments.

Owner:QUICK FITTING

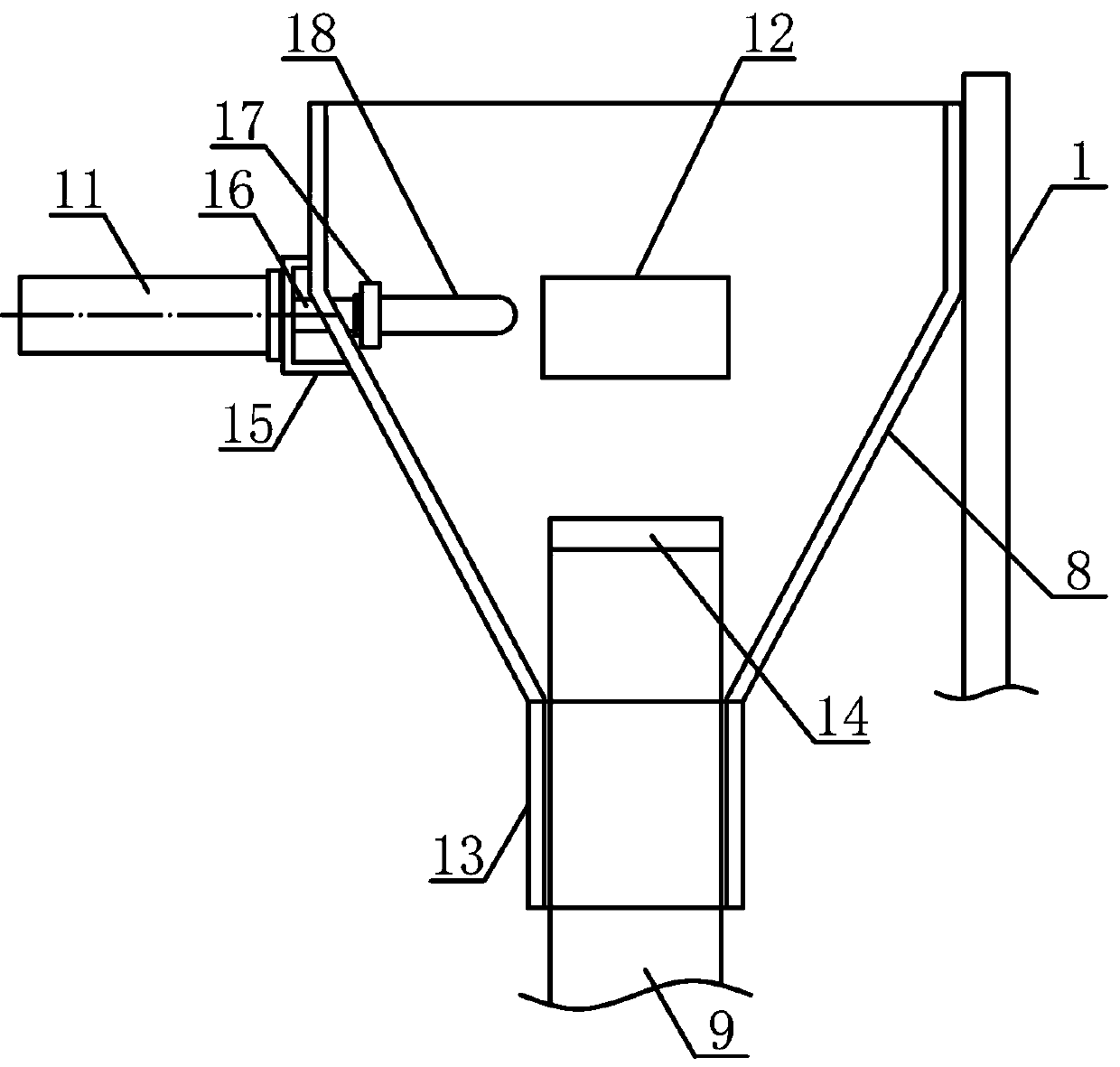

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

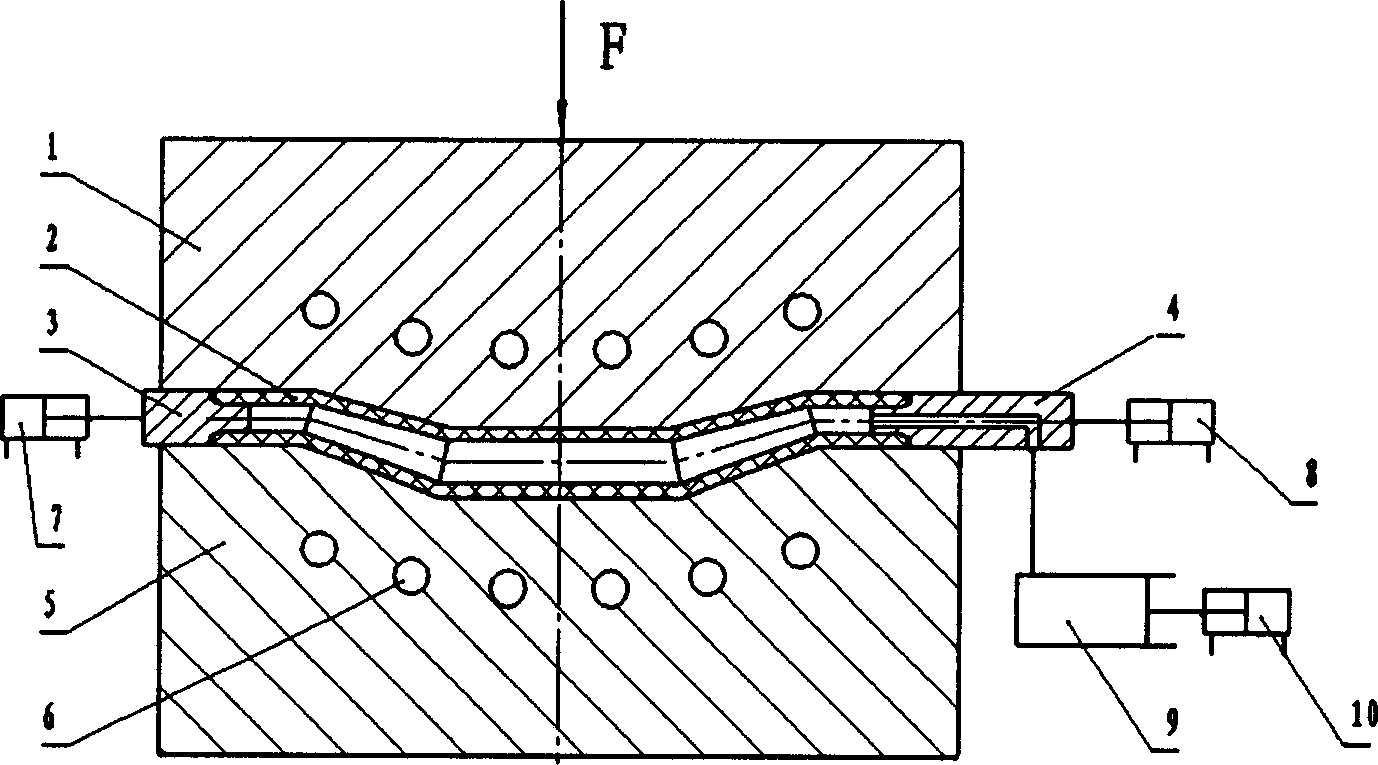

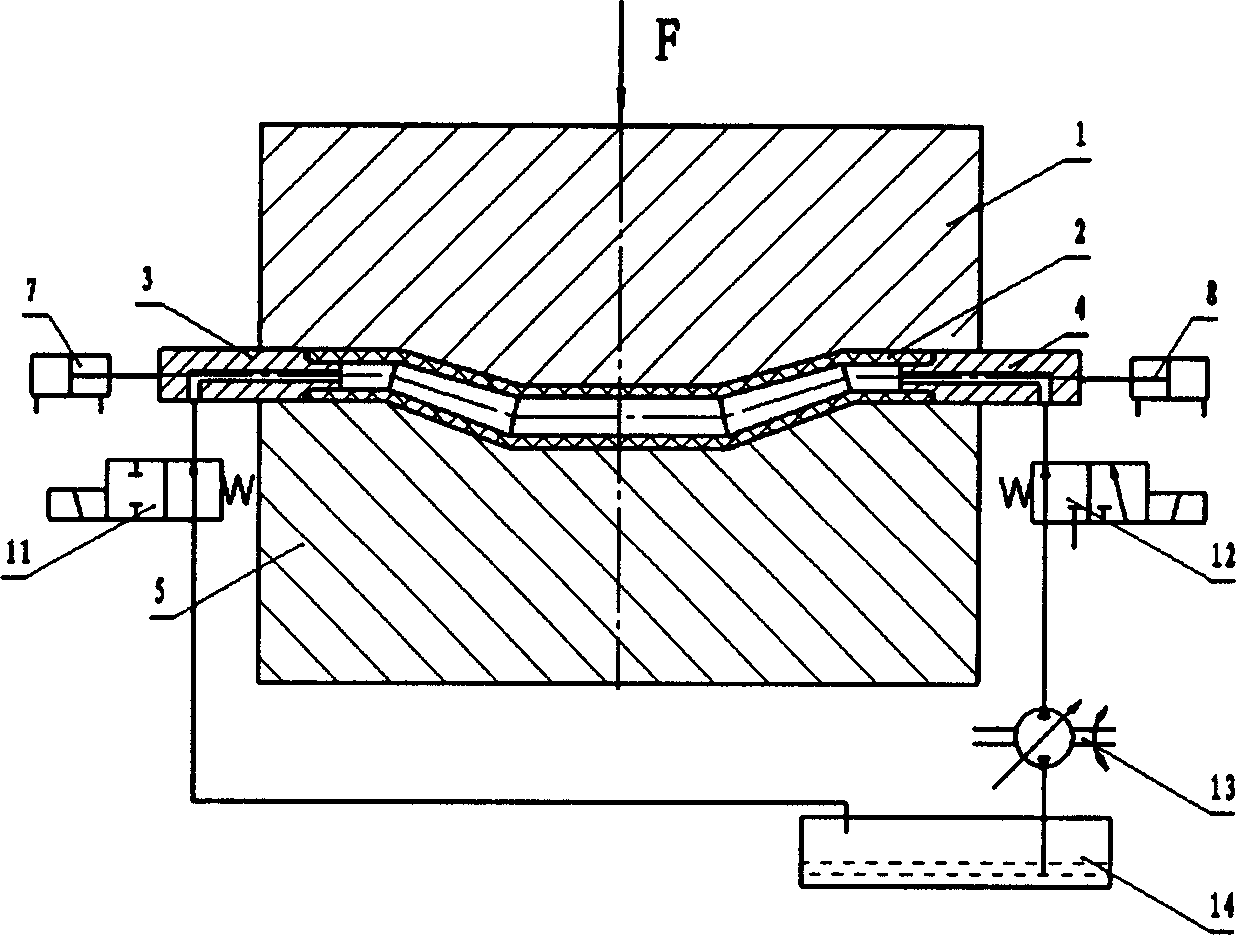

Method for forming magnesium alloy pipe fitting

InactiveCN1792493AMeet the requirements of superplastic formingHigh dimensional accuracyShaping toolsHydraulic cylinderPipe fitting

A method for shaping a Mg-alloy pipe includes such steps as putting a Mg-alloy pipe blank in a mould for generating superplastic bending, and introducing a pressure medium to the inside of said pipe blank for generating superplastic expansion to form a Mg-alloy pipe. Its apparatus is composed of mould consisting upper and lower moulds, sealing unit consisting of sealing block and two hydraulic cylinders, pressure medium source, and heating unit.

Owner:HENAN UNIV OF SCI & TECH

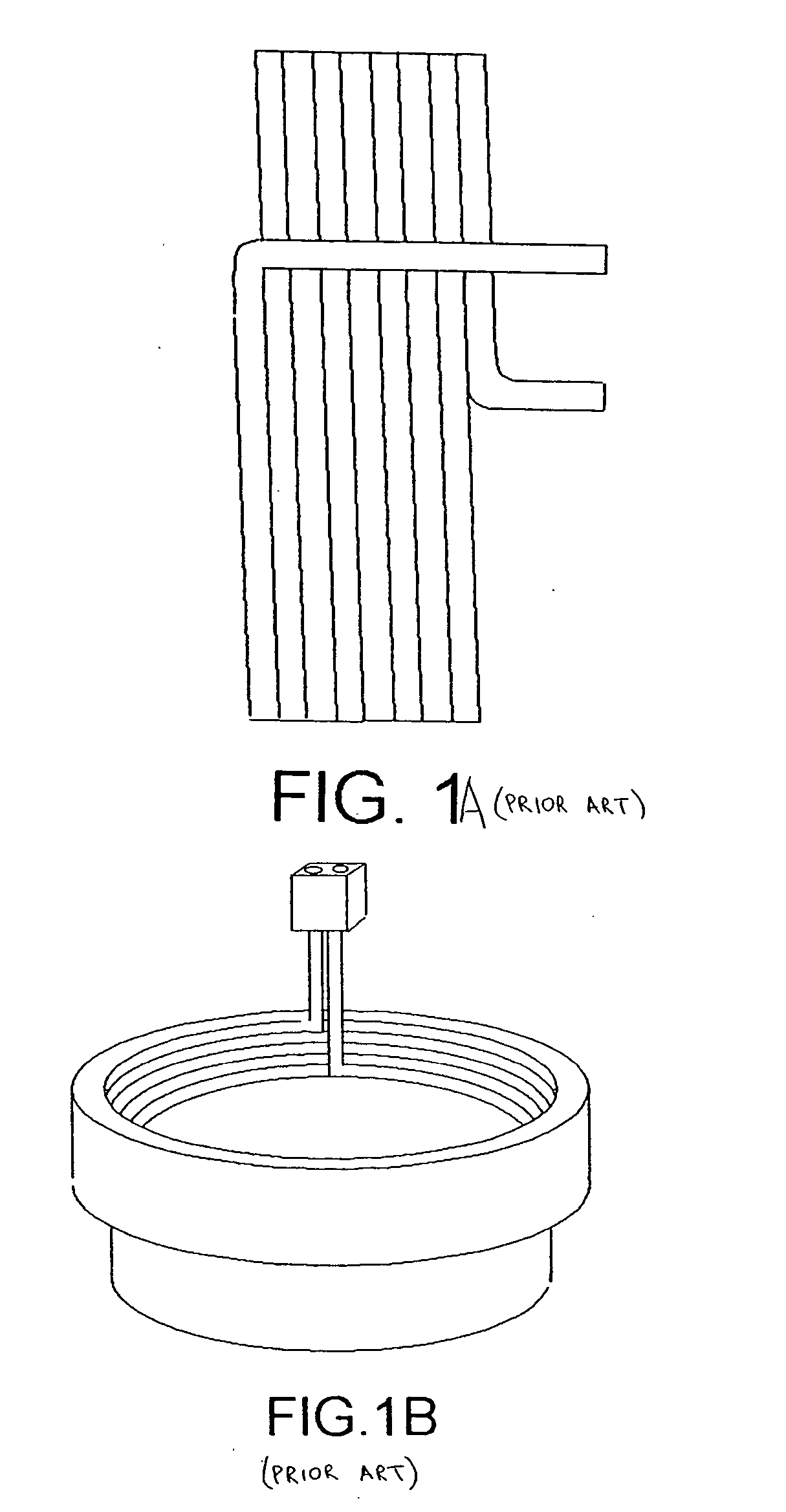

Electrofusion pipe-fitting joining system and method utilizing conductive polymeric resin

InactiveUS20060016552A1Material nanotechnologyMechanical working/deformationConductive polymer compositePipe fitting

A joining device for electrofusion of at least one end of a pipe to a fitting is provided which includes a fitting of a polymeric material and a collar adapted to receive the end of the pipe. The collar is fabricated from a conductive polymer composite material and positioned within the fitting. A connector for connecting the collar to a source of current may be provided which may be integral to the fitting. Likewise, the collar may be integral to the fitting. All three of the connector, collar and fitting are preferably an integral unit. A method of making the joining device and a method of using the joining device are also provided.

Owner:GEORGE FISCHER SLOANE

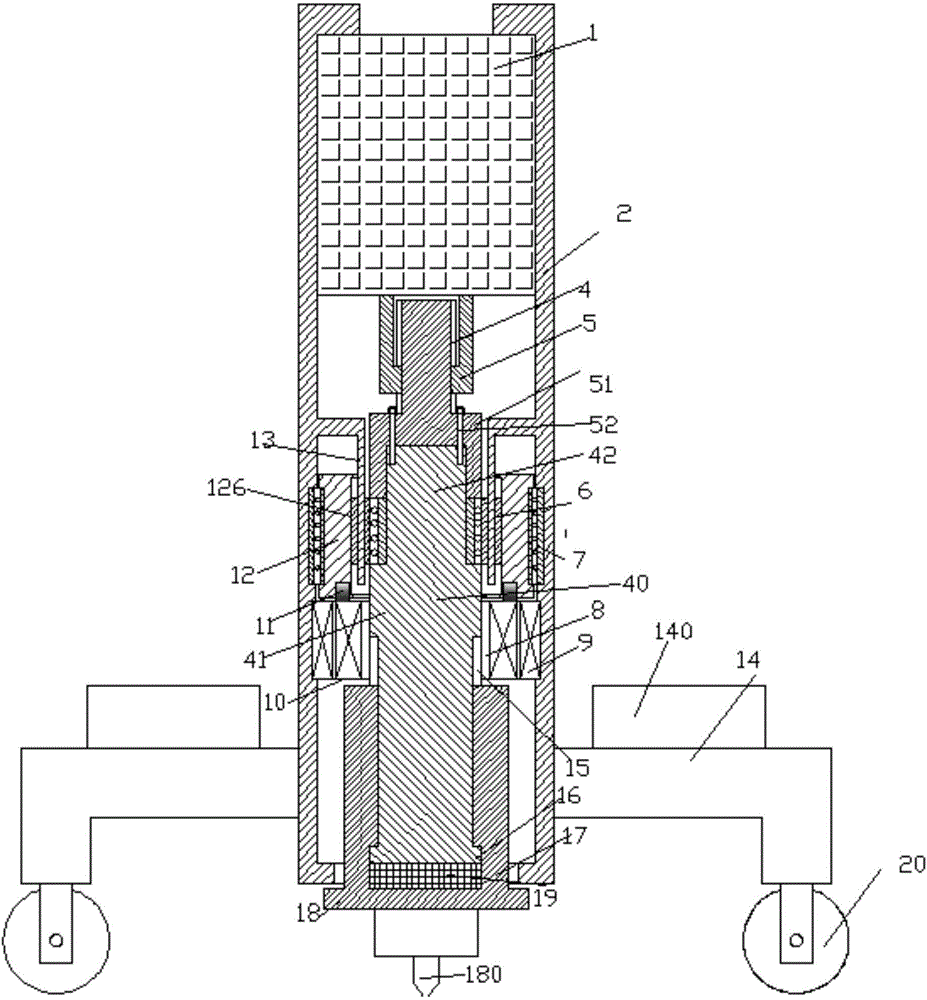

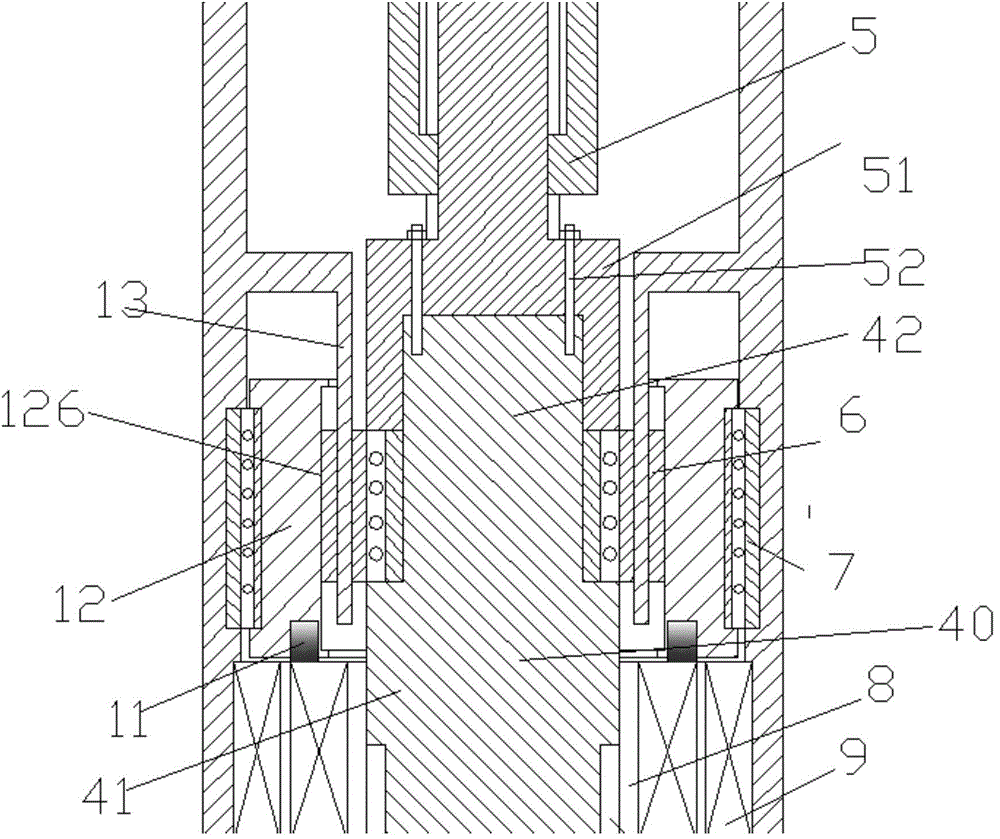

Movable type hole drilling device

InactiveCN104526004AAvoid hard contactEasy to assembleBoring/drilling componentsBoring/drilling machinesCouplingPipe fitting

Provided is a movable type hole drilling device. The movable type hole drilling device comprises a shell (2). The lower portion of the shell (2) is fixedly connected with an idler wheel installation part (14). The lower portion of the idler wheel installation part (14) is provided with idler wheels (20) used for moving the hole drilling device. The upper portion of the idler wheel installation part (14) is capable of removably placing weight blocks (140) used for providing downward pressure during the hole drilling process. The upper portion of the shell (120) is provided with a hole drilling driving motor (2). The hole drilling driving motor (2) is in power connection with spline housing pipe fittings (5). The spline housing pipe fittings (5) are matched with spline shafts arranged on the upper portions of spline shaft connecting pieces (4). The lower portions of the spline shaft connecting pieces (4) are provided with a coupling sleeve. A concave portion of the coupling sleeve is used for containing a minor diameter part (42) on the upper portion of a drill driving shaft (40), and the coupling sleeve is fixedly connected with the drill driving shaft (40) through longitudinal extending fastening bolts (52).

Owner:王达

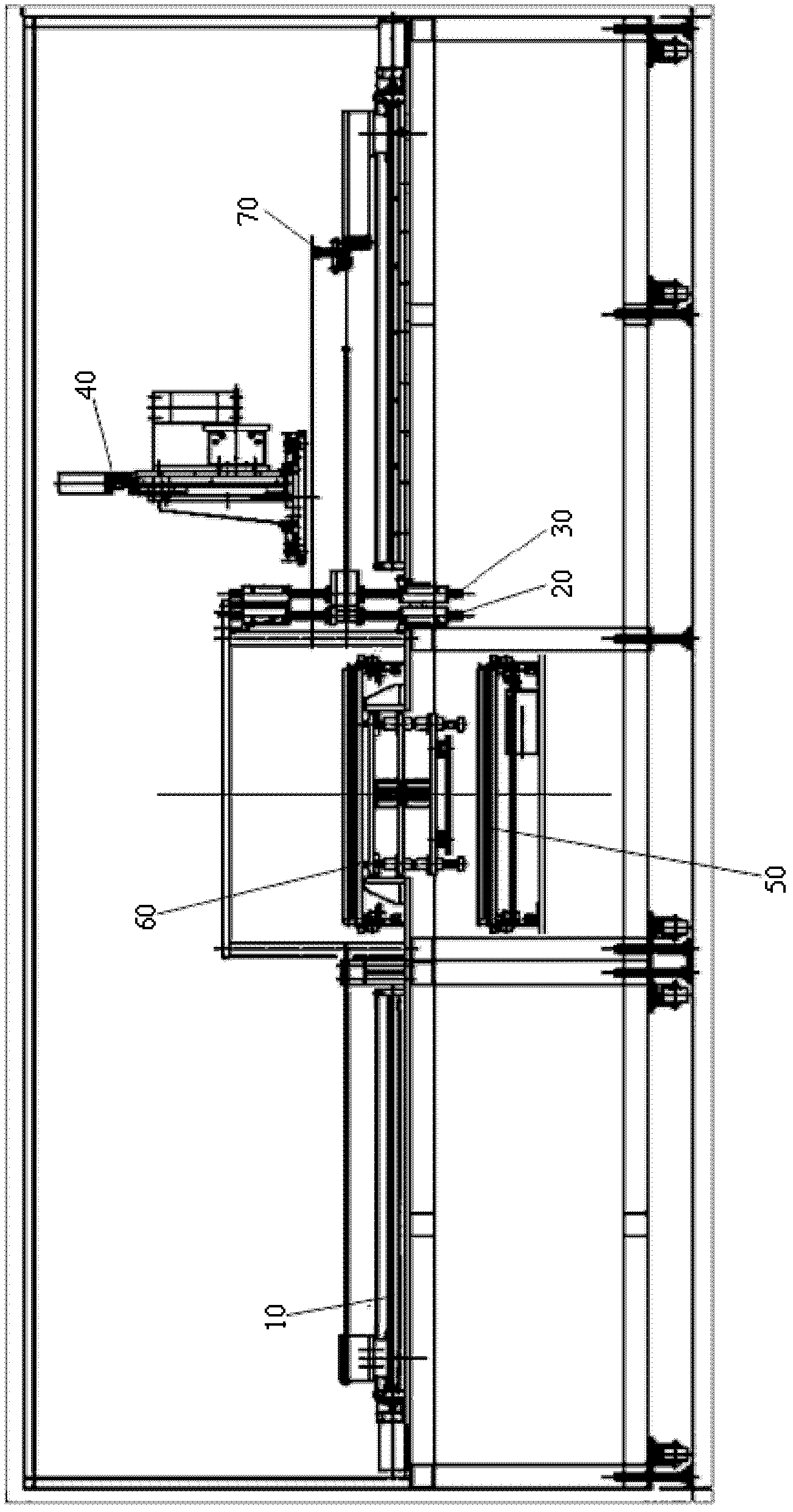

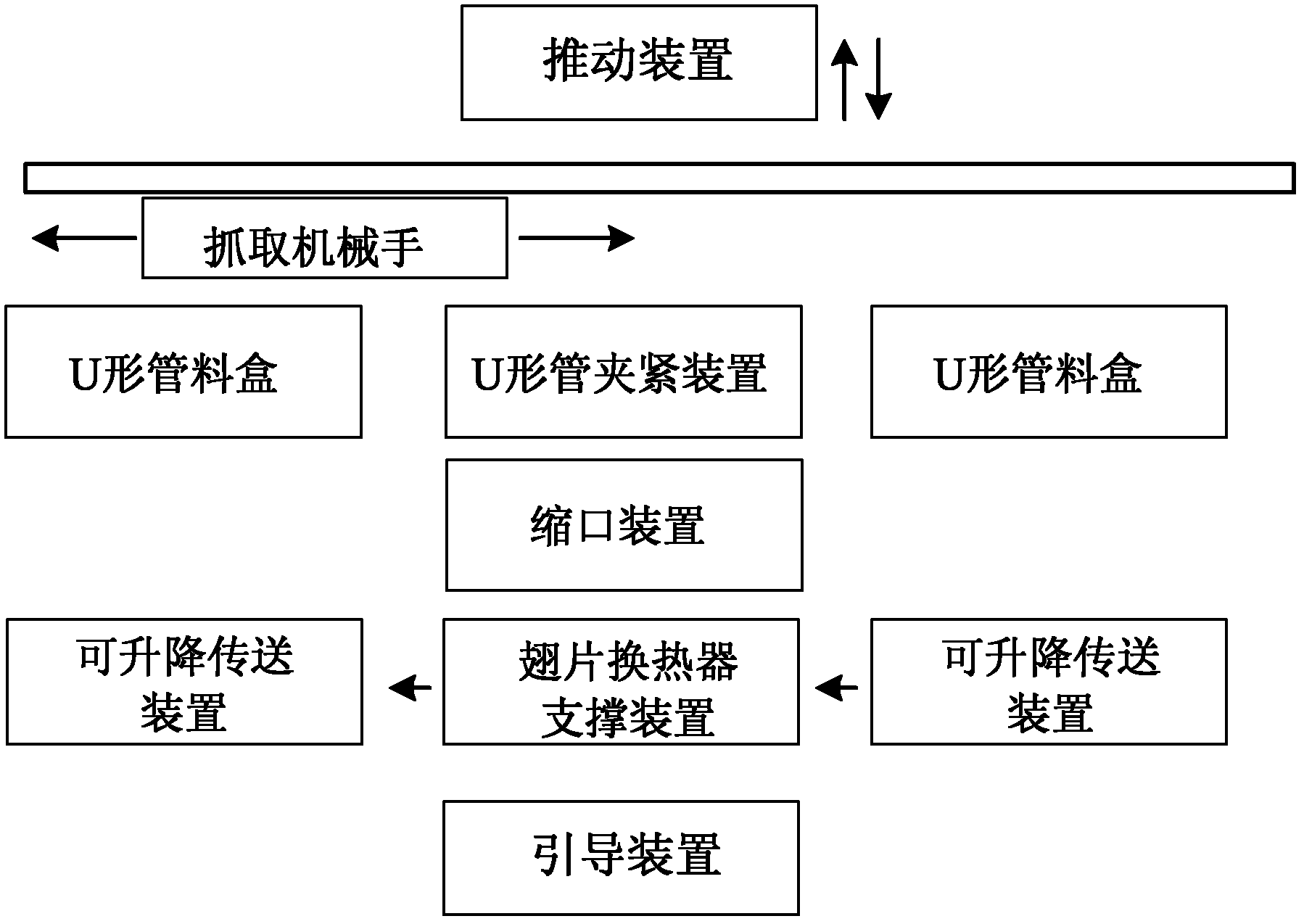

Tube penetrating device and method for fin type heat exchanger

ActiveCN103182637ANot easy to damageImprove pipe penetration efficiencyWork holdersMetal working apparatusPipe fittingEngineering

The invention provides a tube penetrating device and a tube penetrating method for a fin type heat exchanger. The tube penetrating device comprises a fin type heat exchanger support device, a pipe fitting support device arranged at a first end of the former, and a guidance device (10) arranged at the second end, opposite to the first end, of the fin type heat exchanger support device, wherein the guidance device is provided with a connecting seat (11) and a plurality of guidance units (12) connected with the former and adjacent to each other in sequence. The tube penetrating device can effectively improve the tube penetrating efficiency, and has low probability of fin damage with guidance of the guidance units.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com