Patents

Literature

339results about How to "Improve flow uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

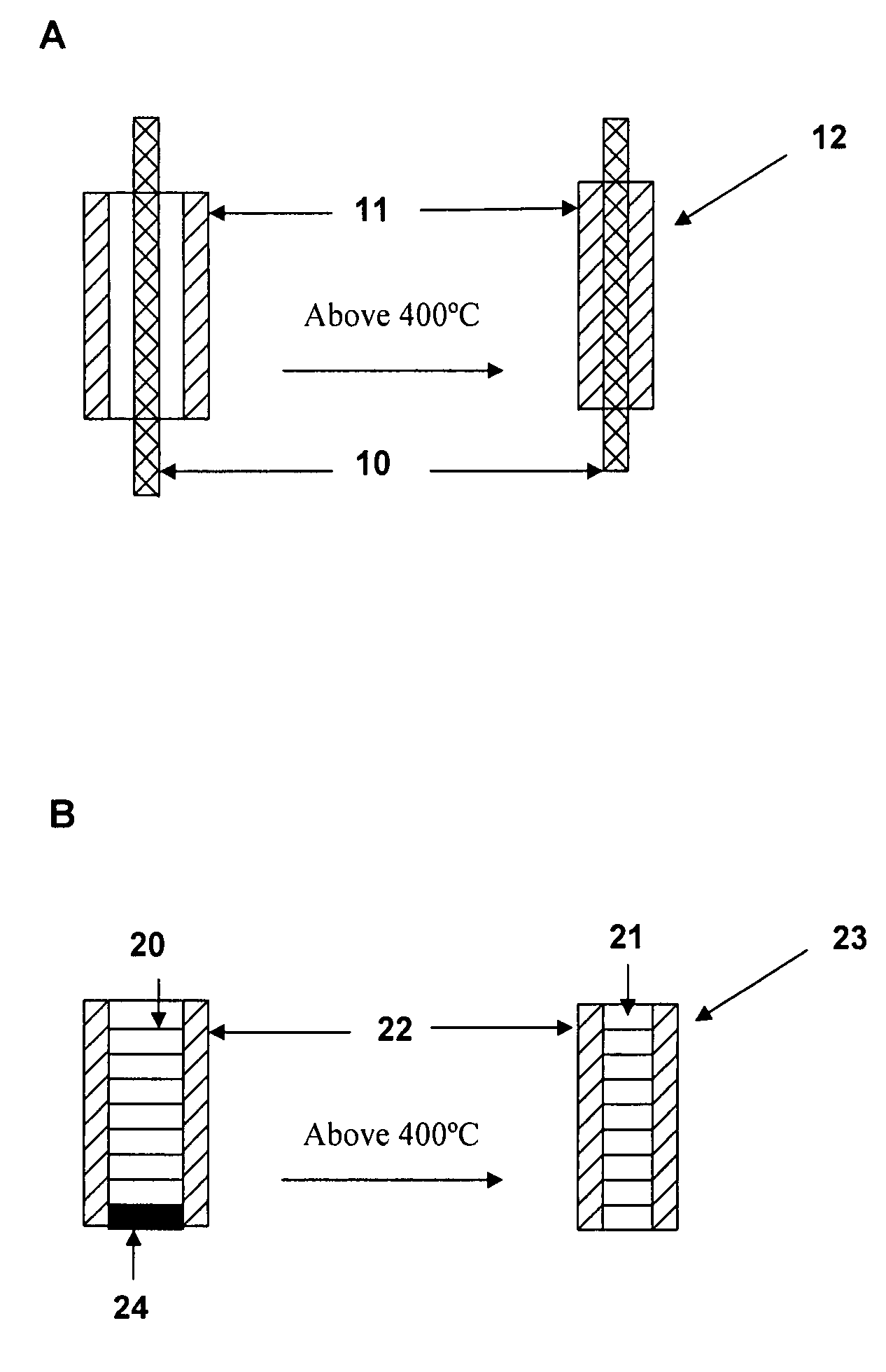

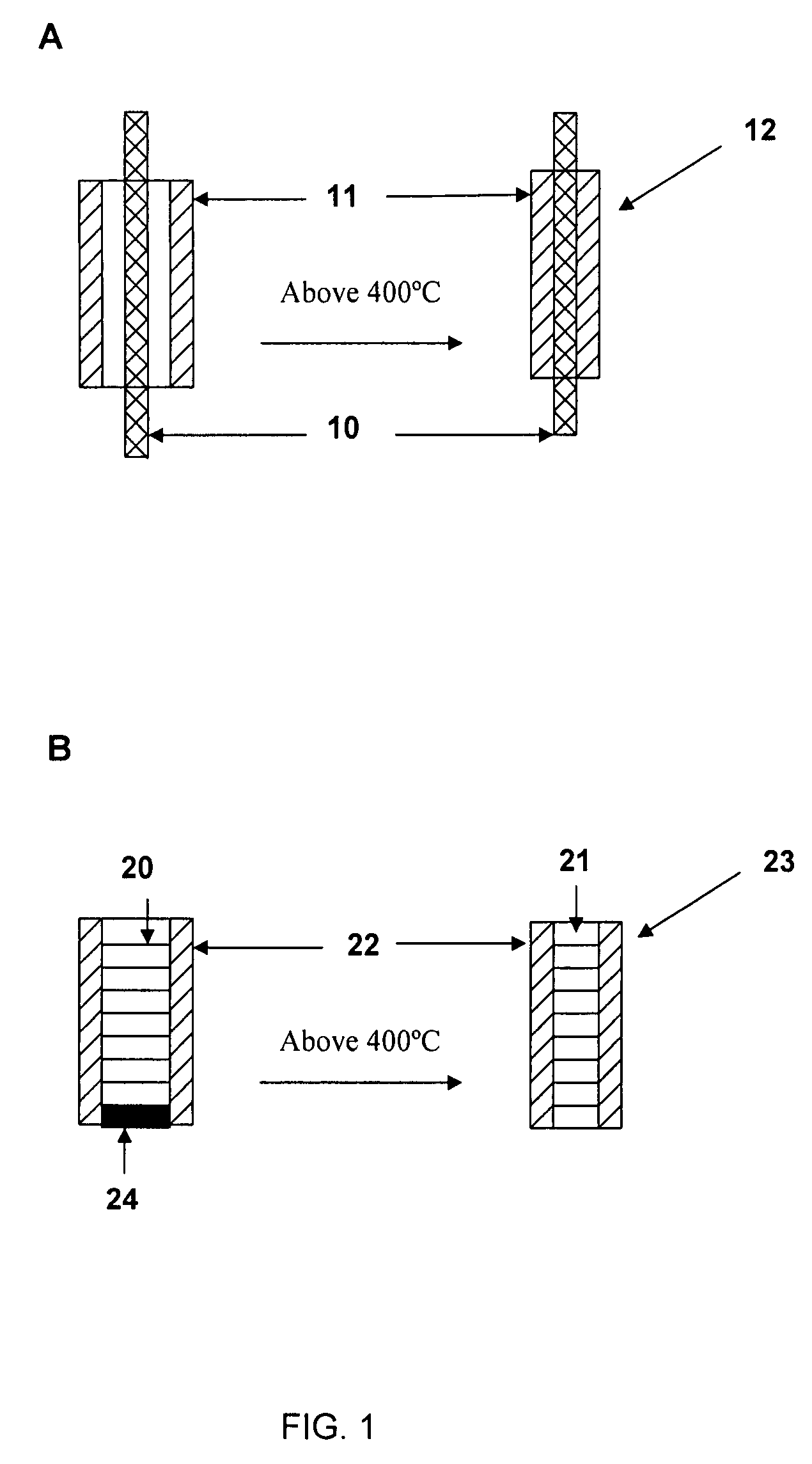

Methods and devices using a shrinkable support for porous monolithic materials

ActiveUS7651762B2Smooth inner surfacePromote resultsIon-exchange process apparatusPhysical/chemical process catalystsPorous substrateFiltration

Articles of manufacture and devices and methods of forming and using the same are provided, wherein the article comprises a porous inorganic substrate contained in or bounded by a support made from an inorganic material are provided, wherein said porous substrate and support are heated to a temperature effective to shrink the support onto the porous substrate such that liquid tight contact is formed between the porous substrate and the support. In a preferred aspect, the porous inorganic substrate has a porosity of at least 5%, and is a porous monolith formed using a sol-gel method. The articles thus formed provide a confined fluid flow through the porous substrate, providing superior performance in separations, catalysis, filtration, and the like.

Owner:AGILENT TECH INC

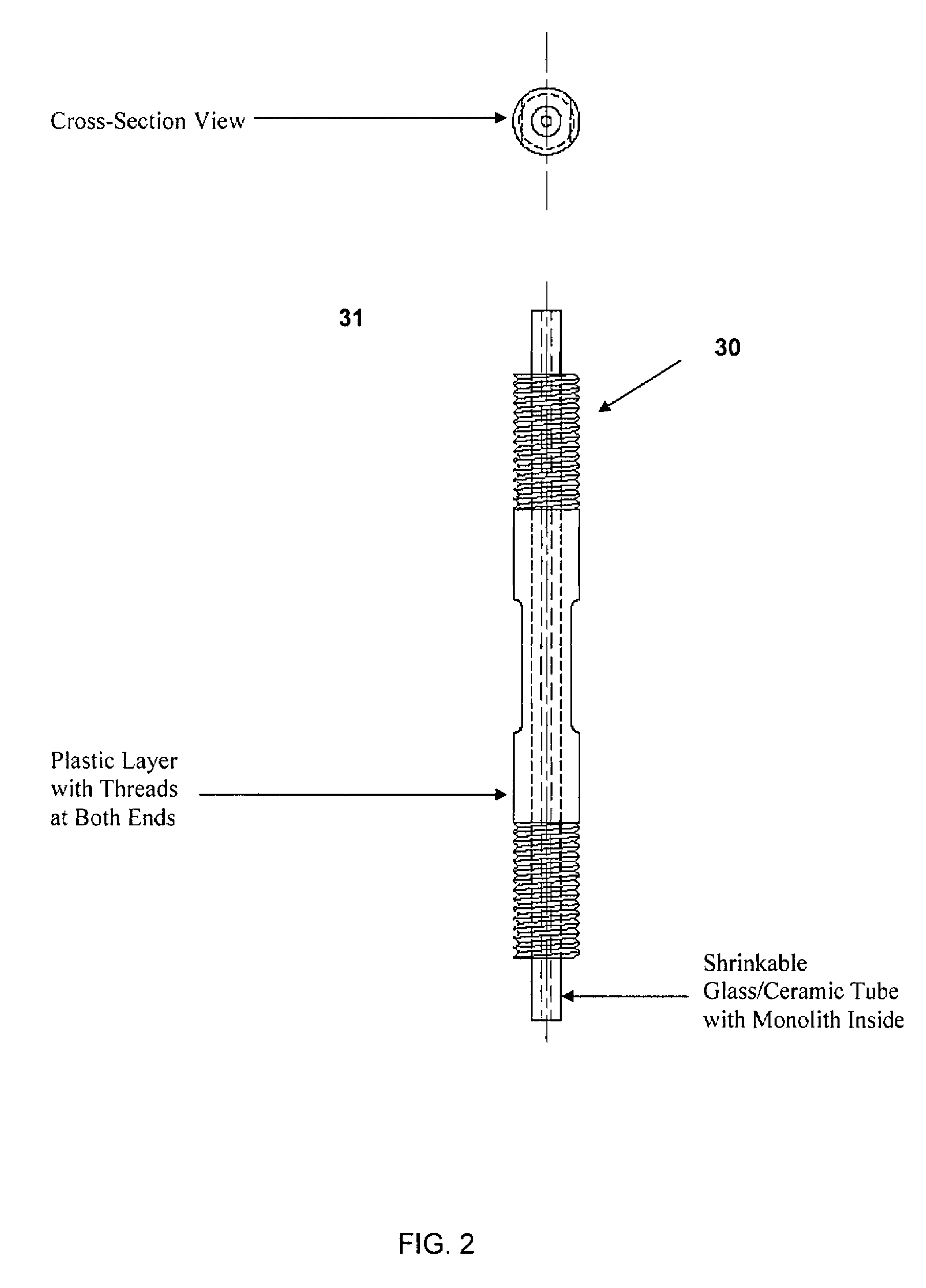

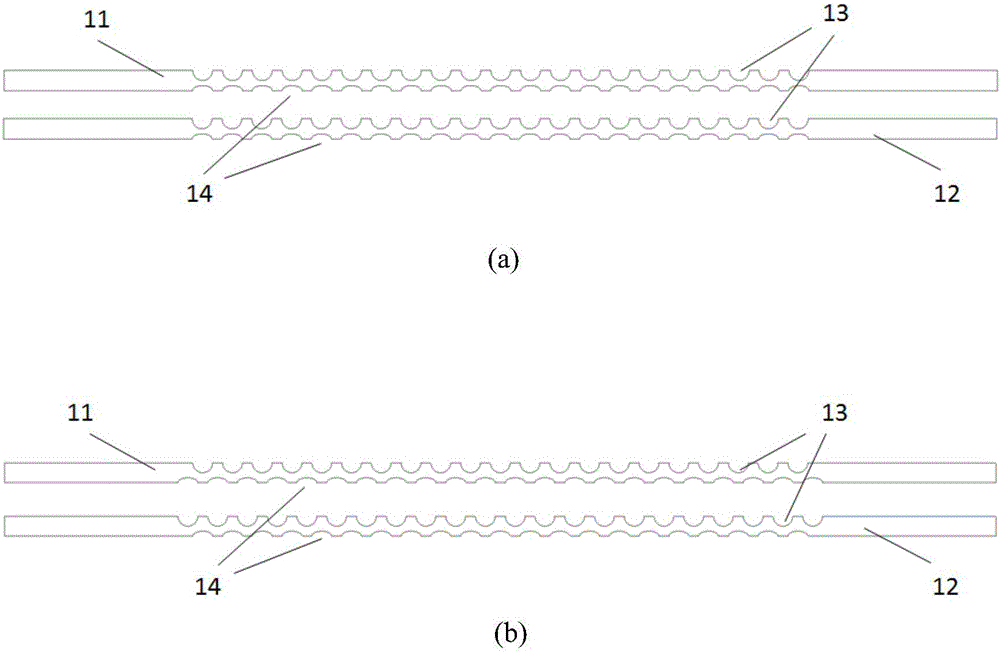

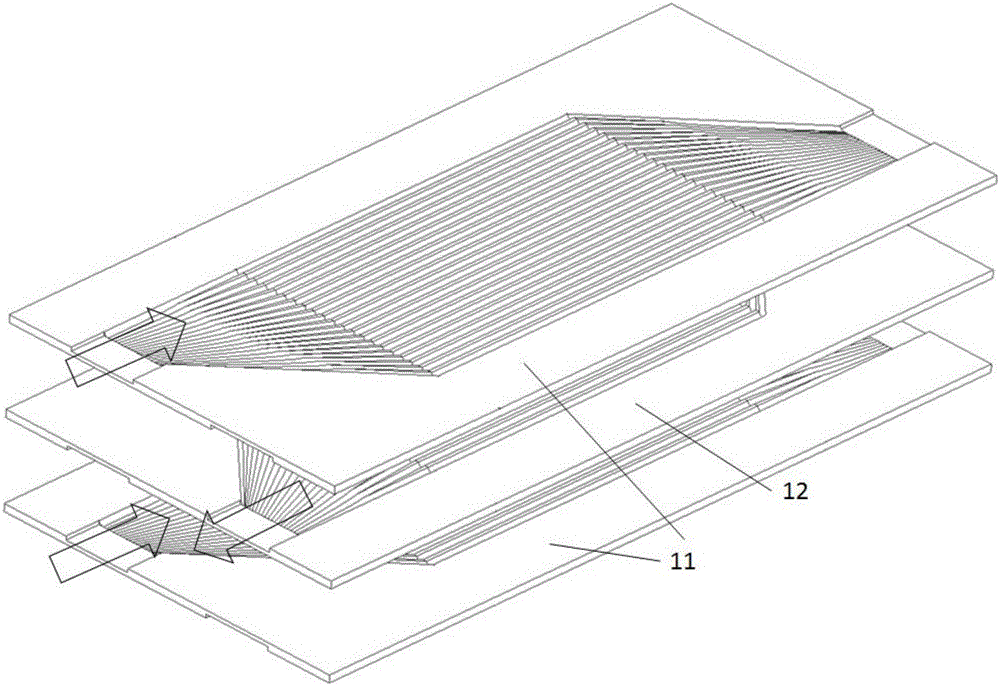

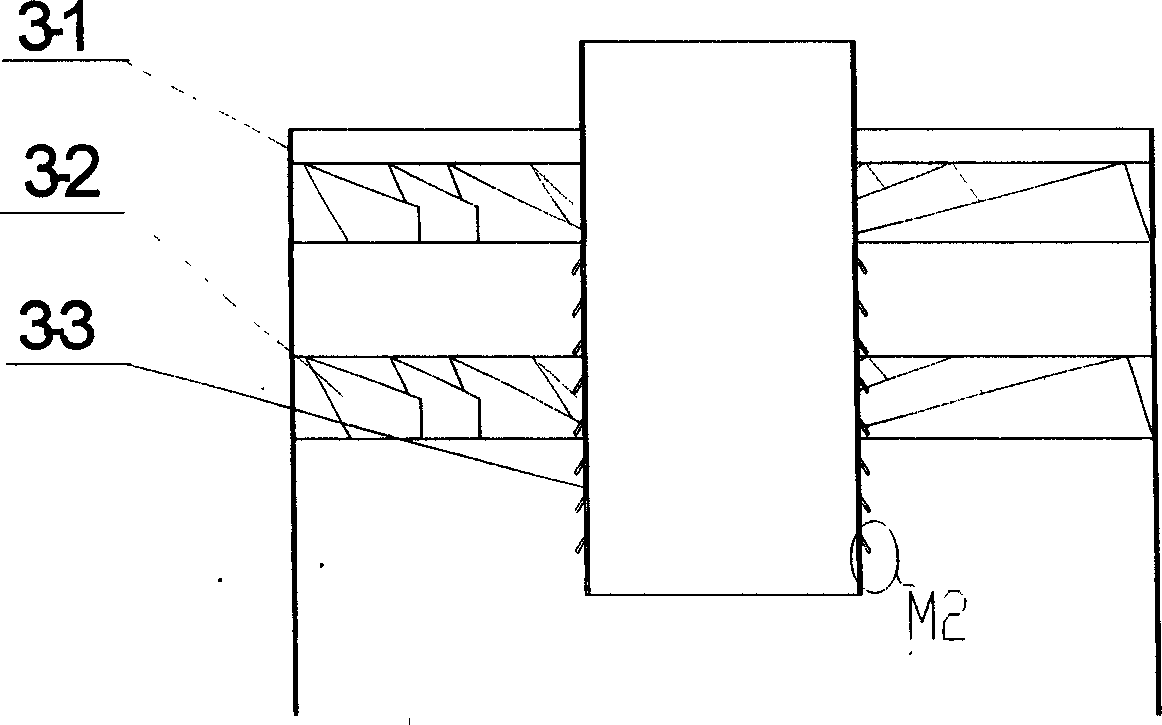

Double-side etching high-temperature and high-pressure printed circuit board heat exchanger

InactiveCN105043144AReduce thermal stressAvoid plastic deformationLaminated elementsStationary plate conduit assembliesStress distributionStress concentration

The invention relates to a double-side etching high-temperature and high-pressure printed circuit board heat exchanger. The double-side etching high-temperature and high-pressure printed circuit board heat exchanger is composed of a heat exchanging core, a flow equalizing section, a hot fluid inlet and outlet port and a cold fluid inlet and outlet port. The core is divided into an inlet section, a core heat exchanging section and an outlet section. According to the heat exchanger, runners are machined in the double sides of heat exchanging plates with a certain thickness in a photochemistry manner, a laser etching manner, a machining manner and the like. The first heat exchanging plate and the second heat exchanging plate are arranged in a spaced manner. A fusion type channel novel structure is adopted in an inlet distribution section, and fluid in the heat exchanger can be easily distributed more evenly. The heat exchanging efficiency of the heat exchanger can be improved, the thermal stress damage at an existing channel sharp corner is effectively avoided, the circulation section area of the heat exchanger is increased, and the compactness of the heat exchanger is improved; thermal stress distribution at the sharp corner is improved, plastic deformation caused by stress concentration is avoided, and the even distribution of fluid in the heat exchanger is improved; and the safety performance of the heat exchanger is improved, and the service life of the heat exchanger is prolonged.

Owner:XI AN JIAOTONG UNIV

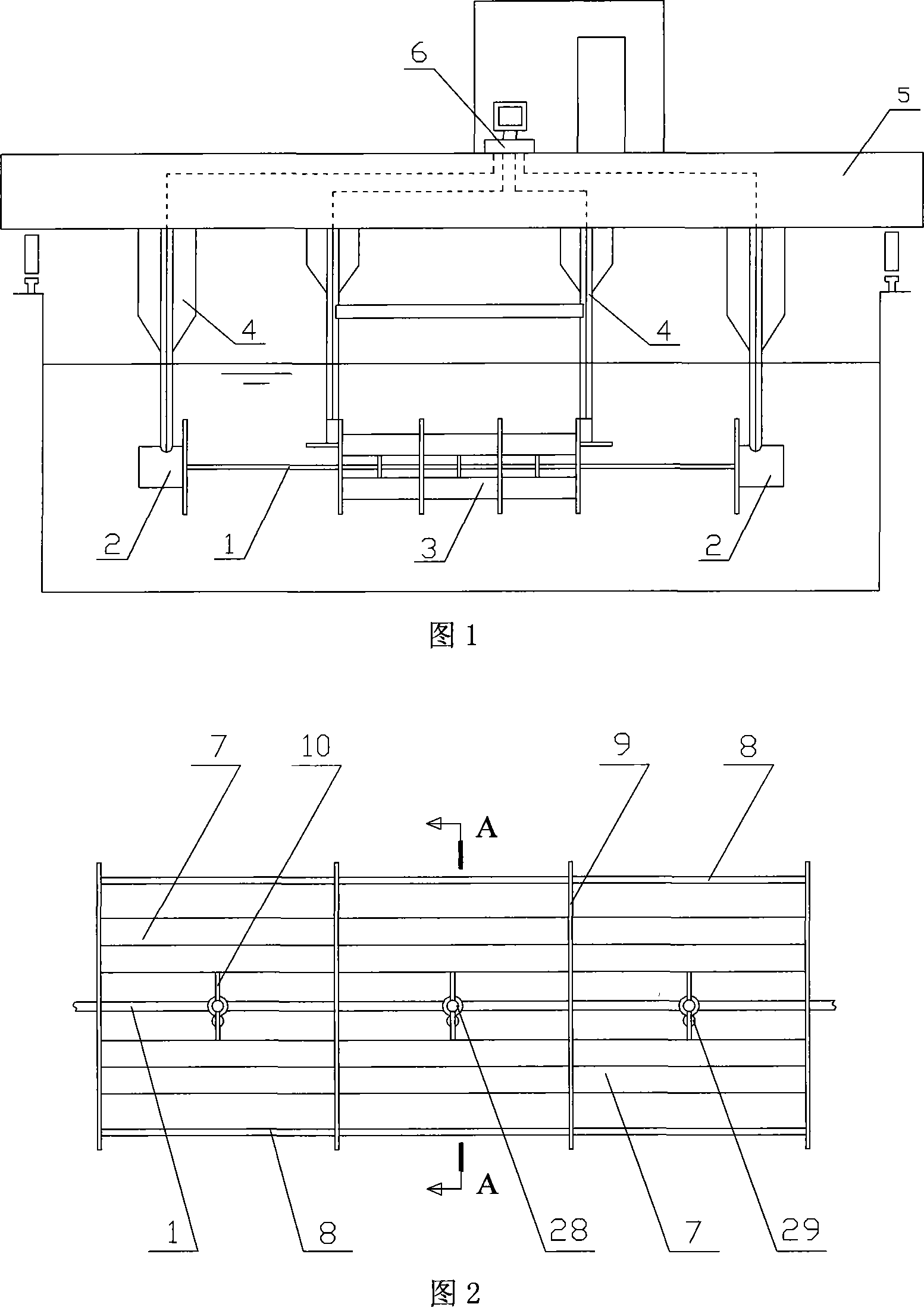

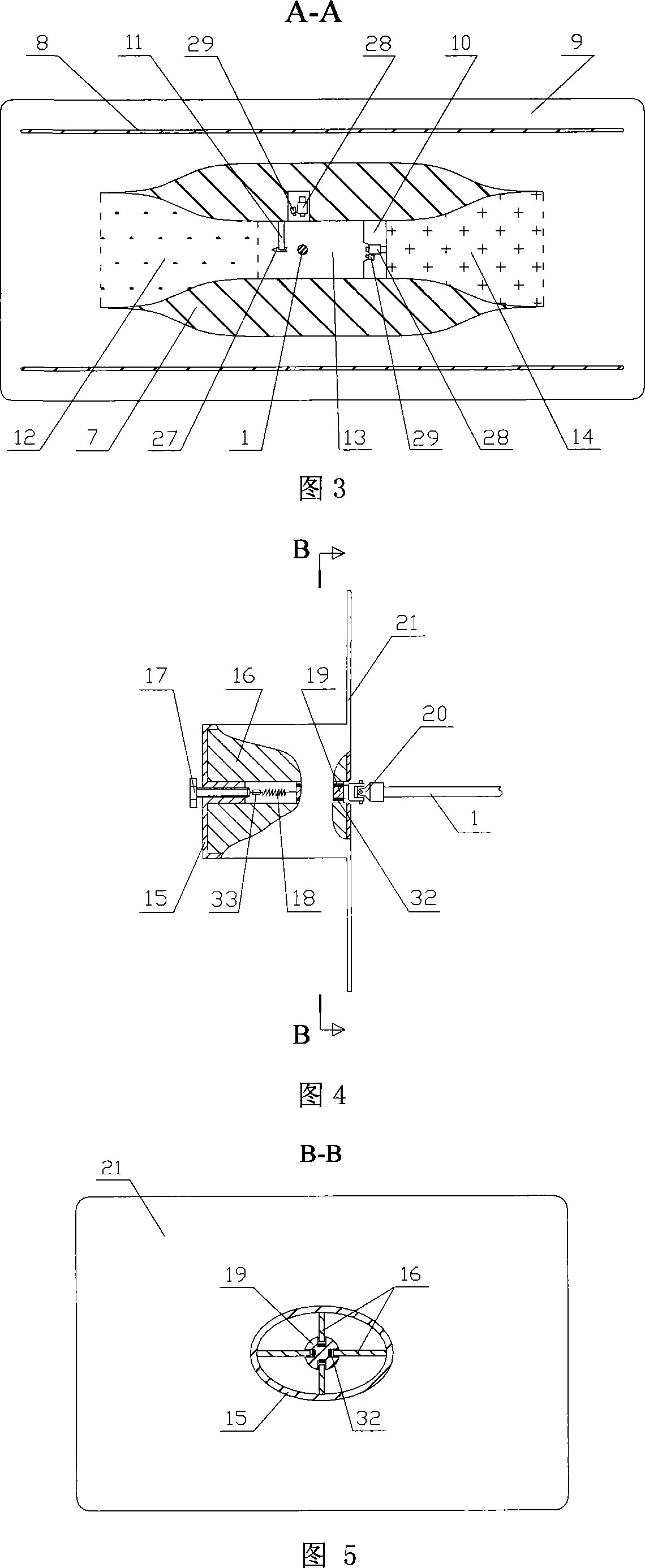

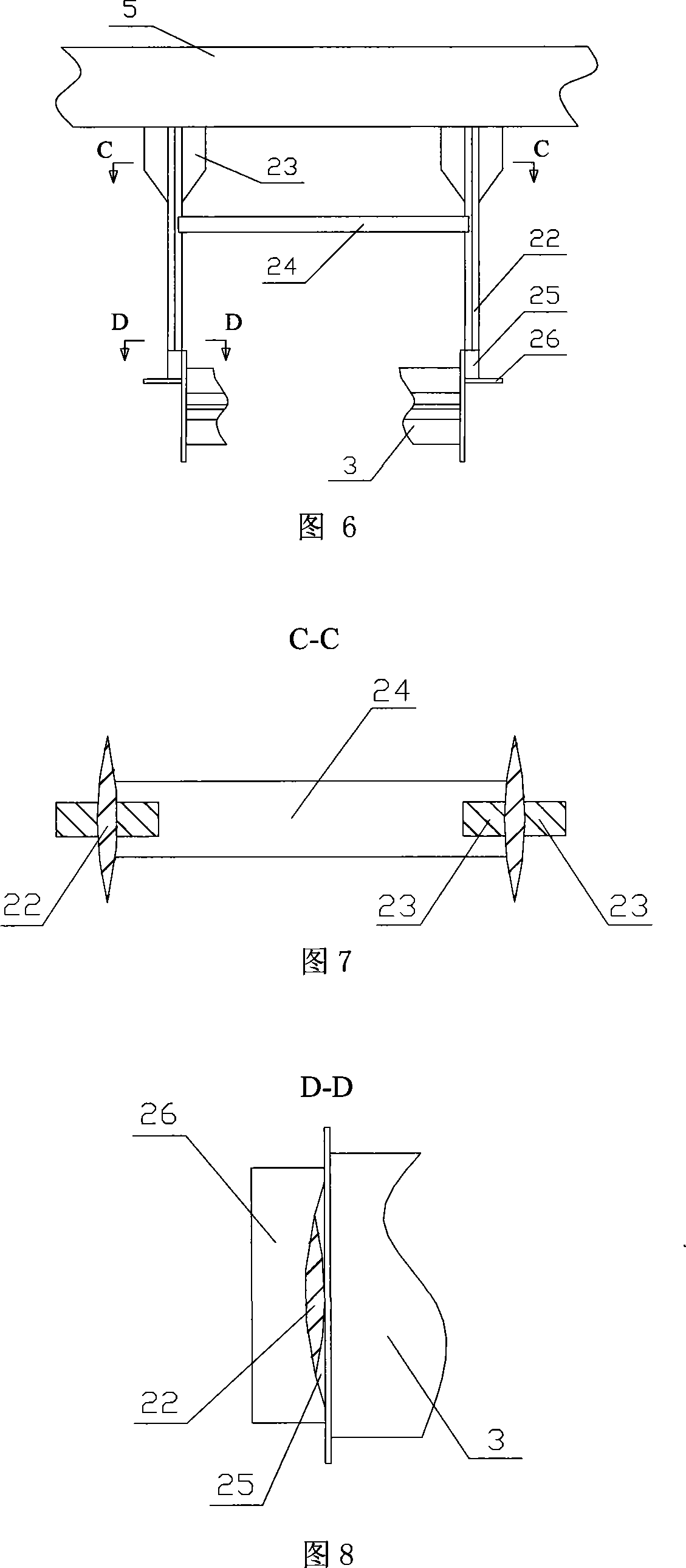

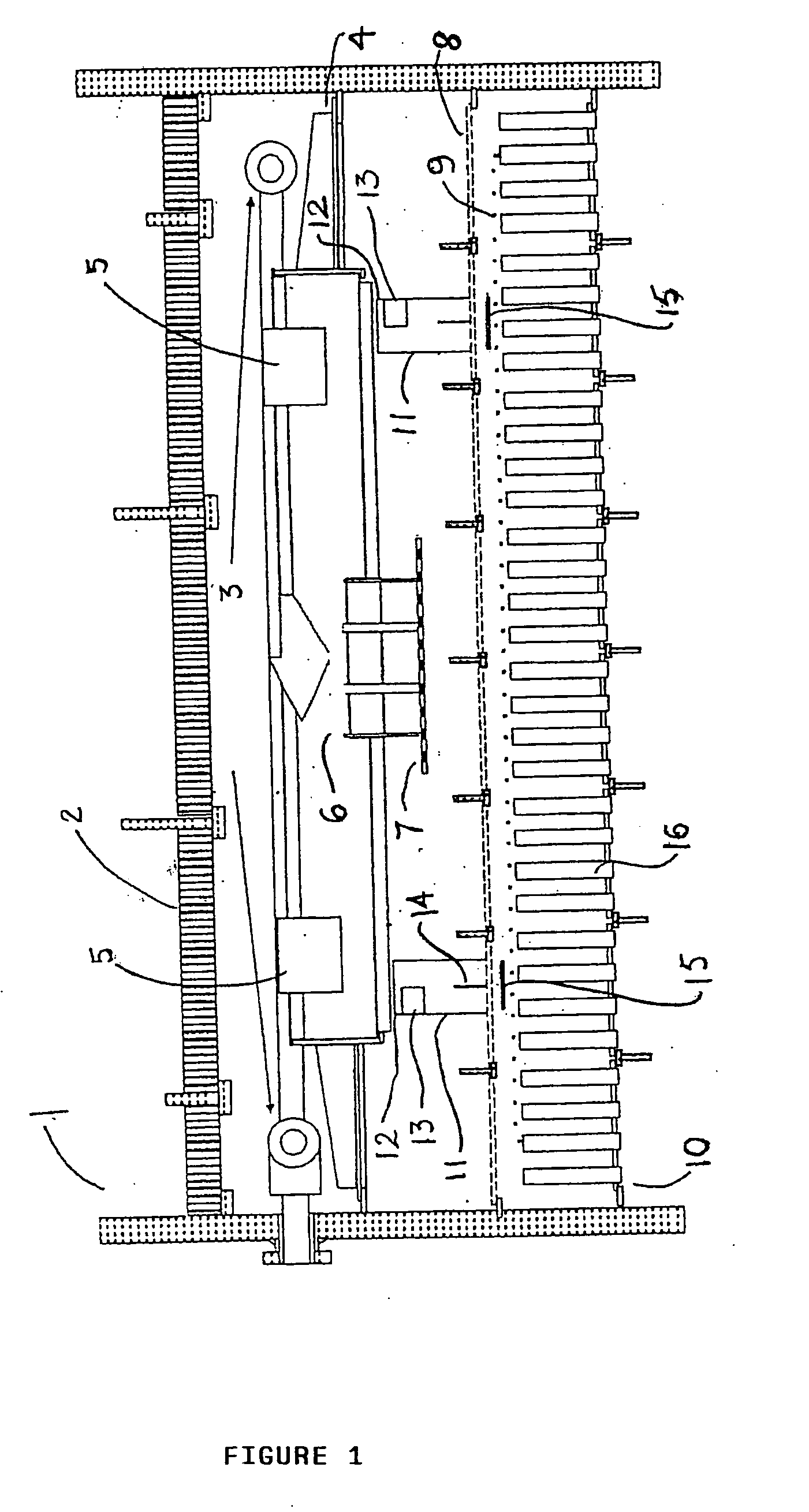

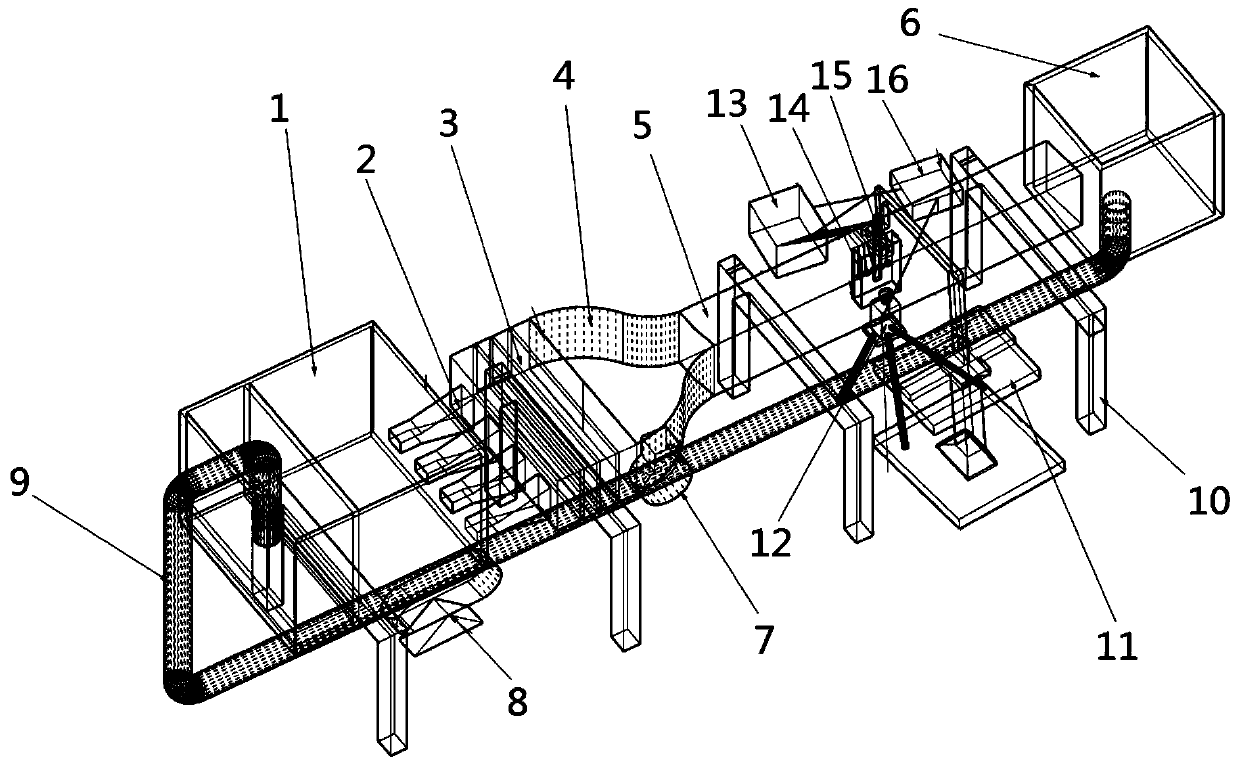

Vortex vibration testing device for flexible pipe mould vertical in towing pool

ActiveCN101089578AIncrease the Reynolds numberImprove flow uniformityVibration testingPipe fittingEngineering

A vortex-exciting vibration test device of flexible pipe fittings mode set horizontally in pull water pool is prepared as passing pipe fittings model through flow-speed increasing unit; setting said model and said unit vertically in pull water pool; supporting two ends of said model by support mechanism; using horizontal test support to connect said unit and support mechanism with trailer and distributing various instruments of measurement-analysis system in said model, said units, said mechanism, said support and said trailer.

Owner:SHANGHAI JIAO TONG UNIV

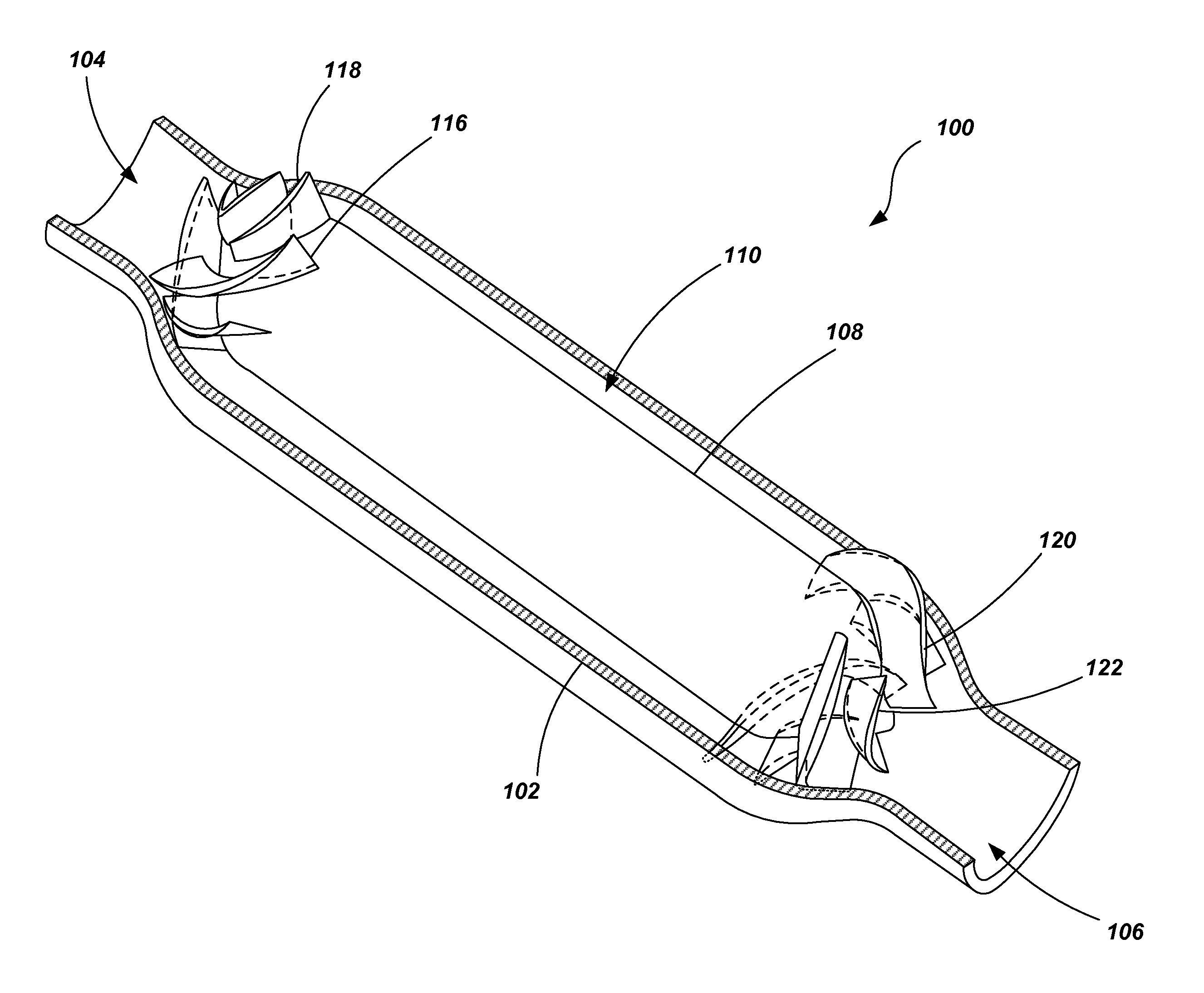

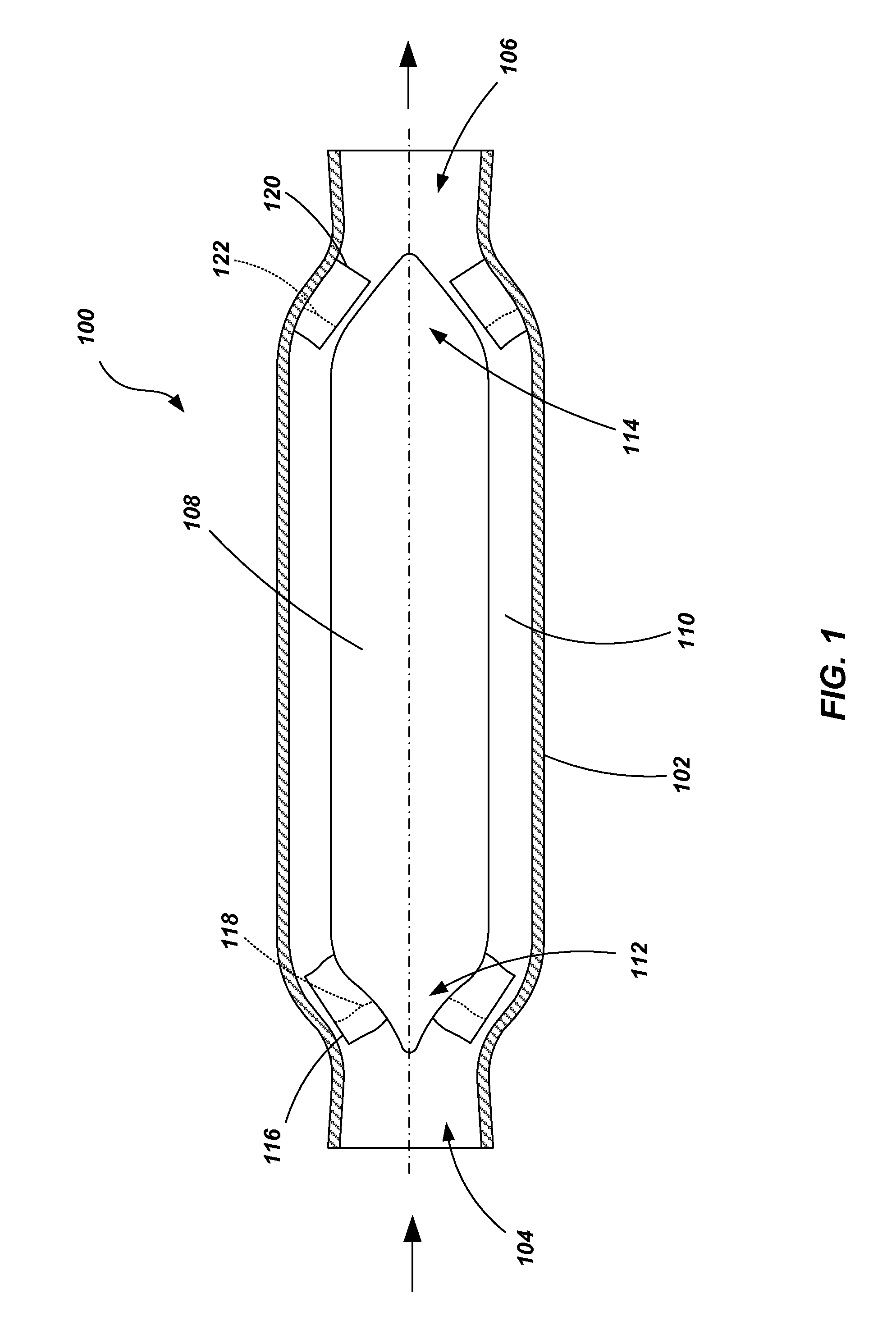

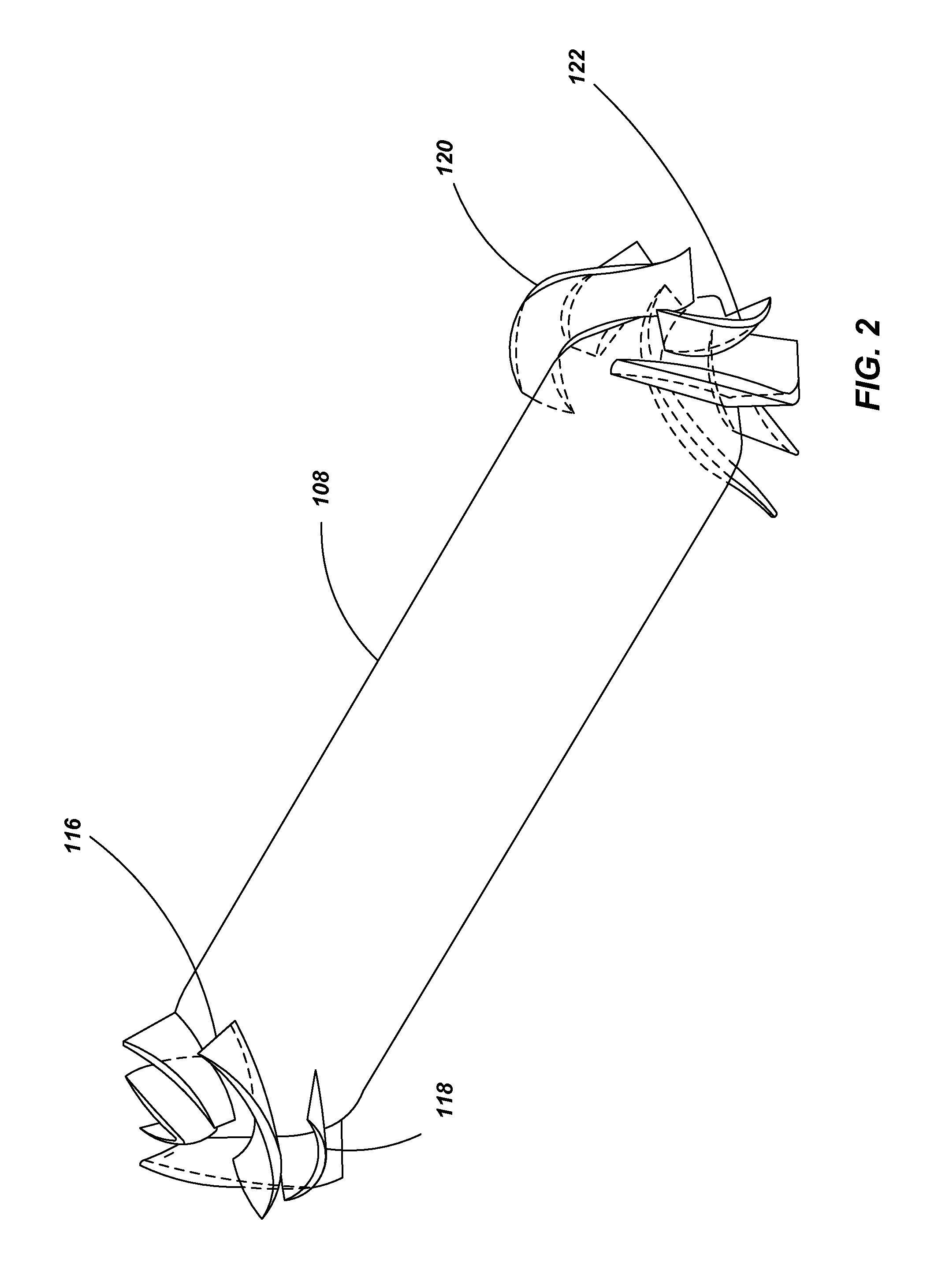

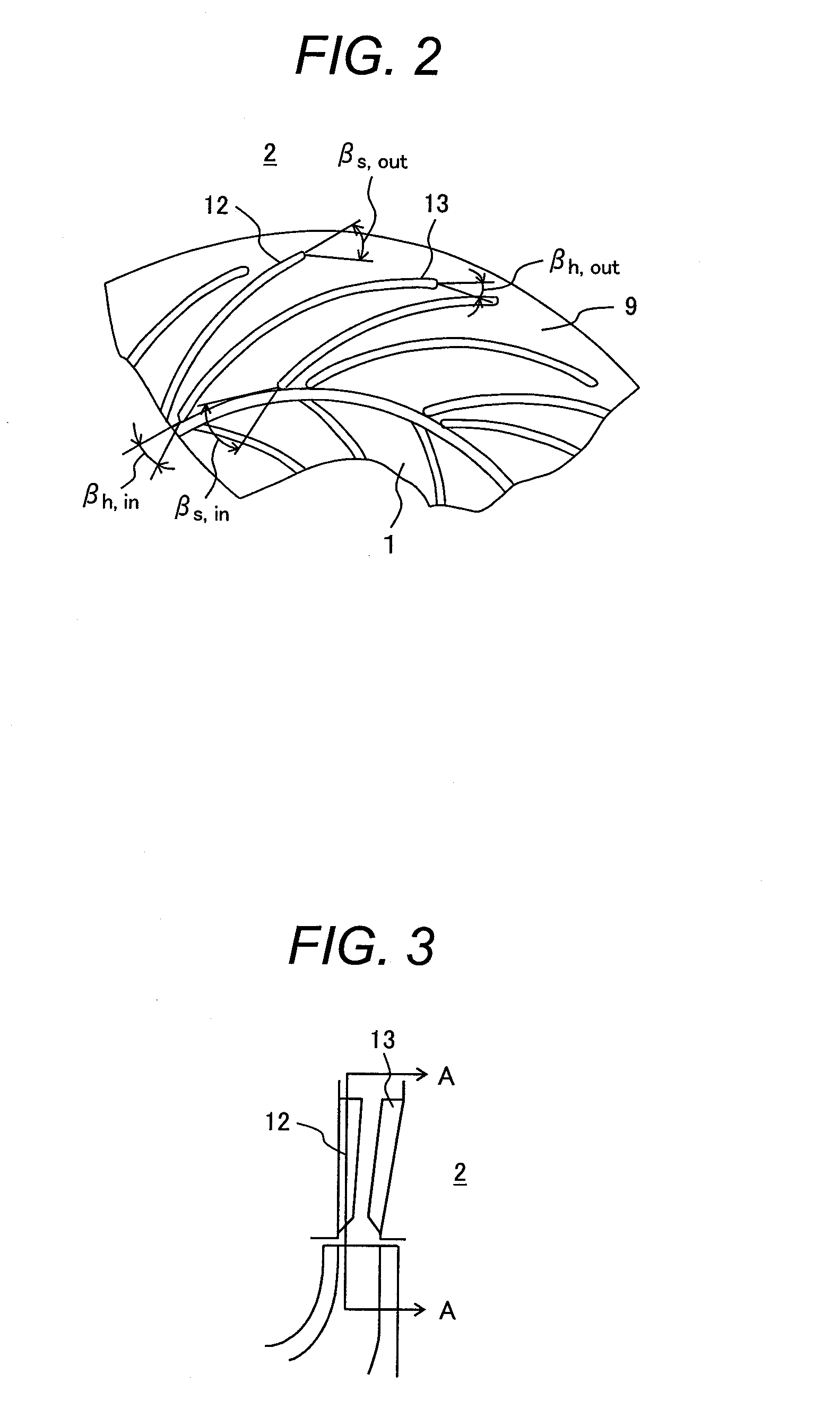

Blood pump with splitter impeller blades and splitter stator vanes and related methods

InactiveUS20120134832A1Low blood damageGuaranteed uptimePump componentsBlood pumpsImpellerMixed flow

A rotordynamic pump for delivering continuous flow of fluids, such as blood, is provided. In one embodiment, the pump includes a stator housing having an inlet and an outlet. A rotor hub is disposed within the stator housing having a mixed-stage or mixed-flow impeller. The mixed flow impeller includes both principle blades and splitter blades, the splitter blades exhibiting a shorter axial length than the principle blades. One or more stator vanes and extend radially inwardly from the stator housing. The splitter blades and principle blades are arranged in a circumferentially alternating pattern. The stator vanes include principle stator vanes and splitter stator vanes, the splitter stator vanes exhibiting a shorter axial length than the principle stator vanes. The splitter vanes and principle vanes are arranged in a circumferentially alternating pattern. The rotor hub may be magnetically suspended and rotated within the stator housing.

Owner:WORLD HEART

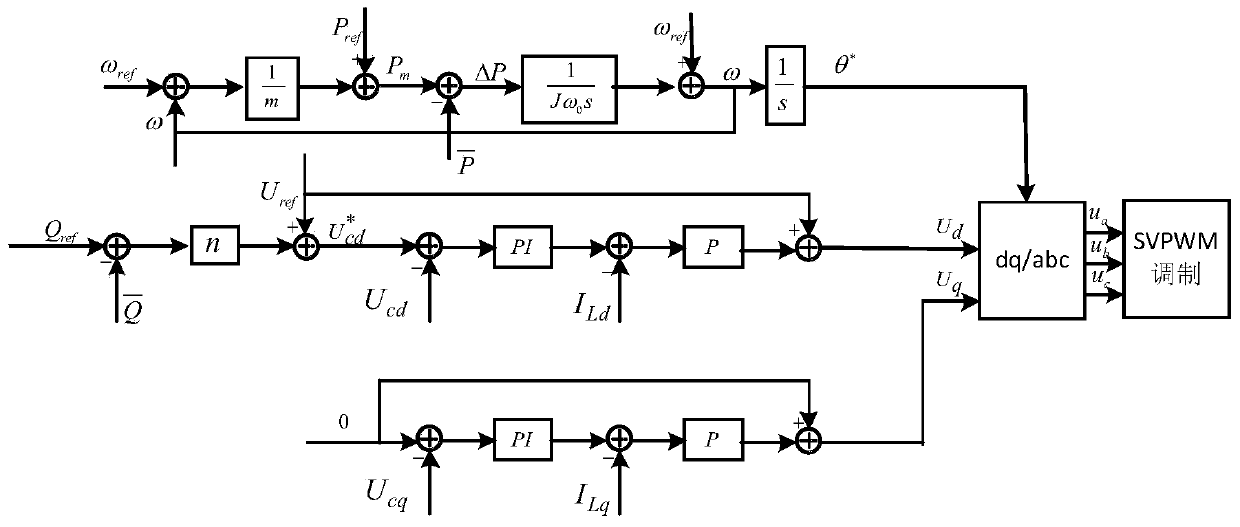

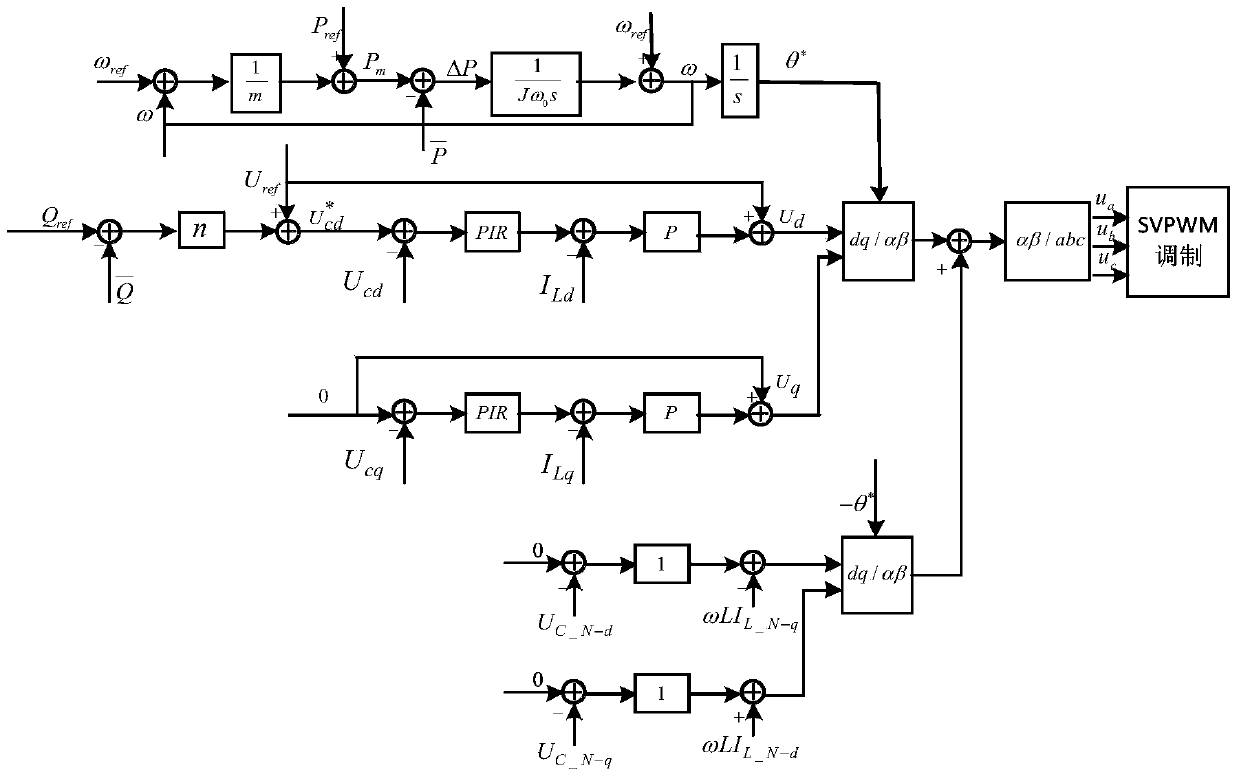

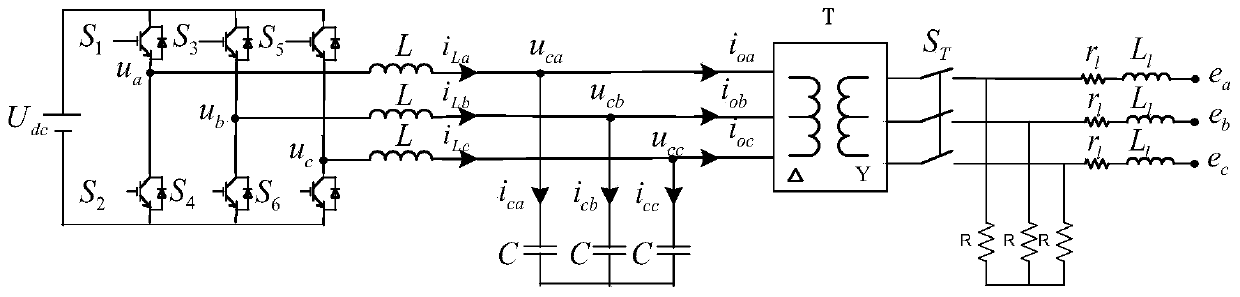

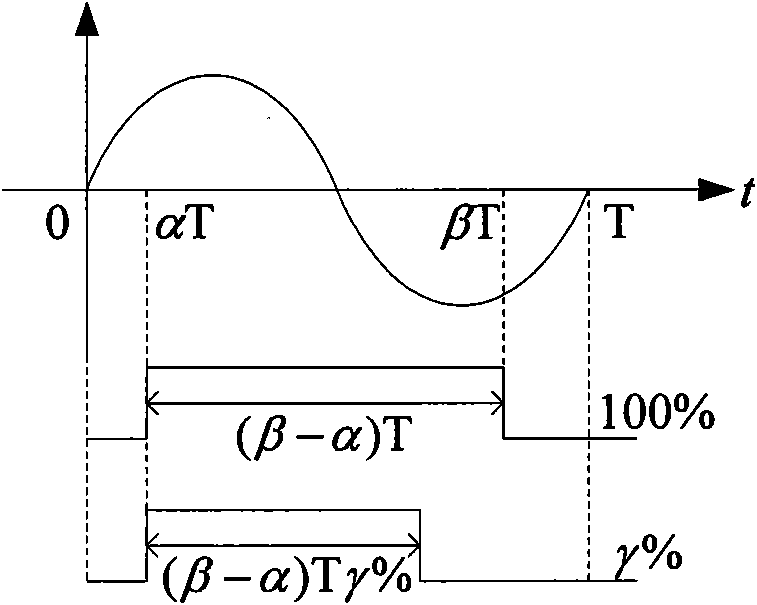

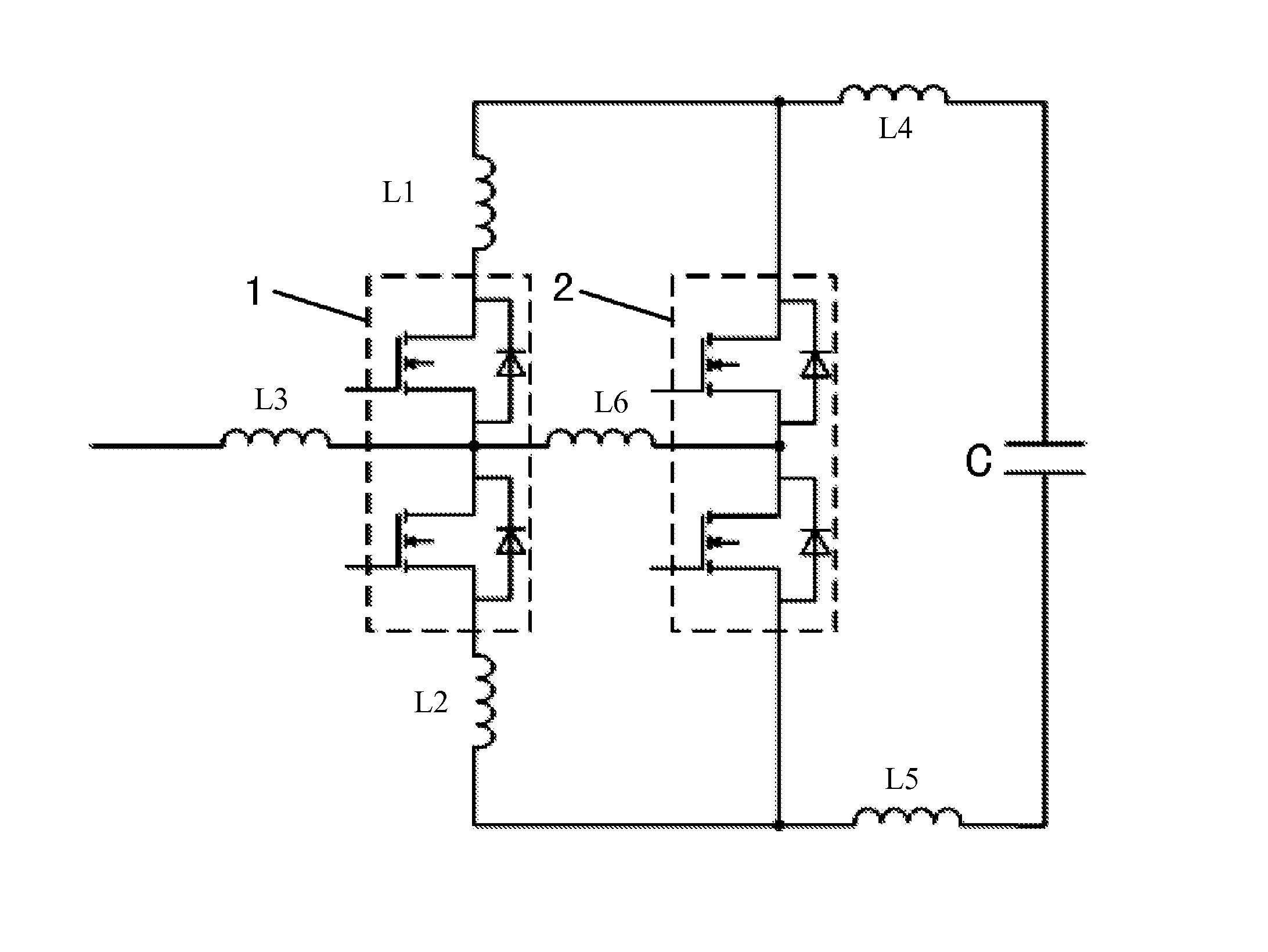

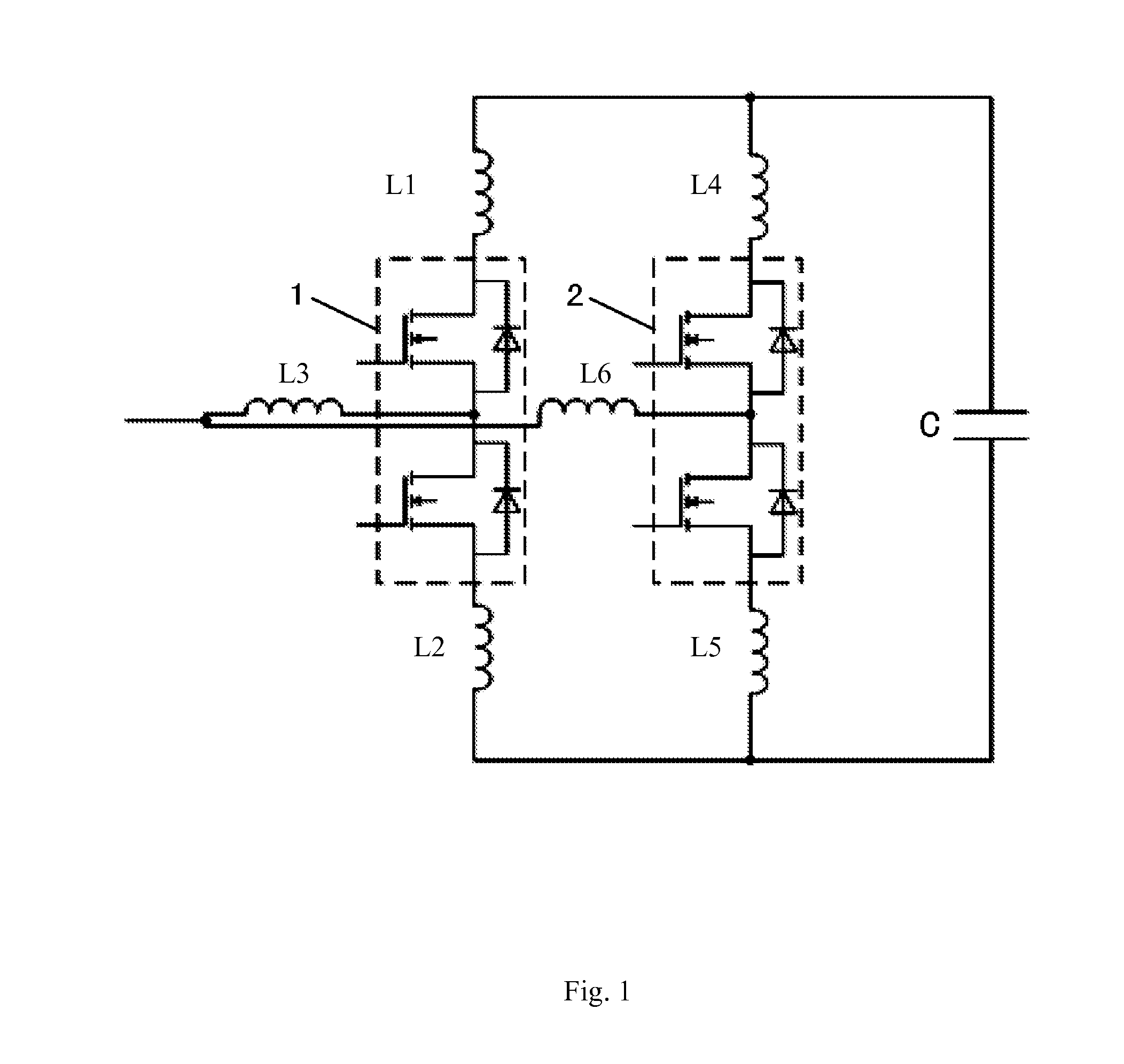

Unbalance voltage compensation and control method based on virtual synchronous machine

ActiveCN104218590AImprove flow uniformityLow costEnergy industryAc network voltage adjustmentVirtual synchronyMulti machine

The invention discloses an unbalance voltage compensation and control method based on a virtual synchronous machine. According to the method, the power calculating method on the basis of notch filter is adopted, the problems that a first order low pass filter is low in responding speed and stability and cannot eliminate secondary harmonic caused by unbalance load can be eliminated, the calculated total active power and reactive power serves as the feedback input of droop control, and part of produced unbalance voltage is suppressed by the proportional integral and the resonance control method; meanwhile, an unbalance voltage compensation controller is adopted to eliminate the unbalance quantity. The unbalance voltage can be compensated, the fine equalizing current balance of parallelly-connected multiple machines can be maintained, the method can be widely applied to micro grid inverter control on the unbalance loaded condition so as to maintain the output voltage balance during off-grid operation, and parallelly-connected operation of multiple machines is allowed.

Owner:HEFEI UNIV OF TECH

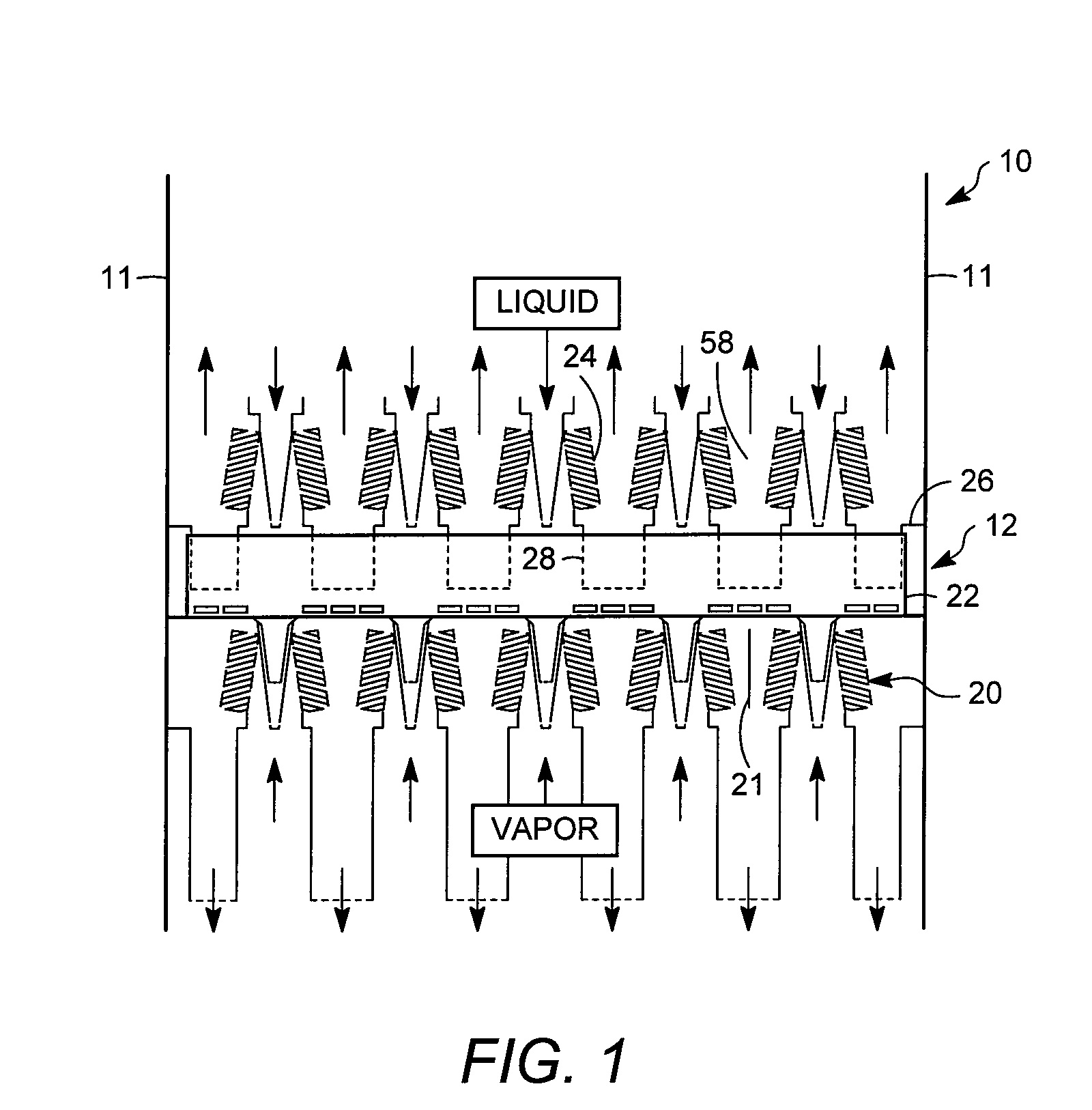

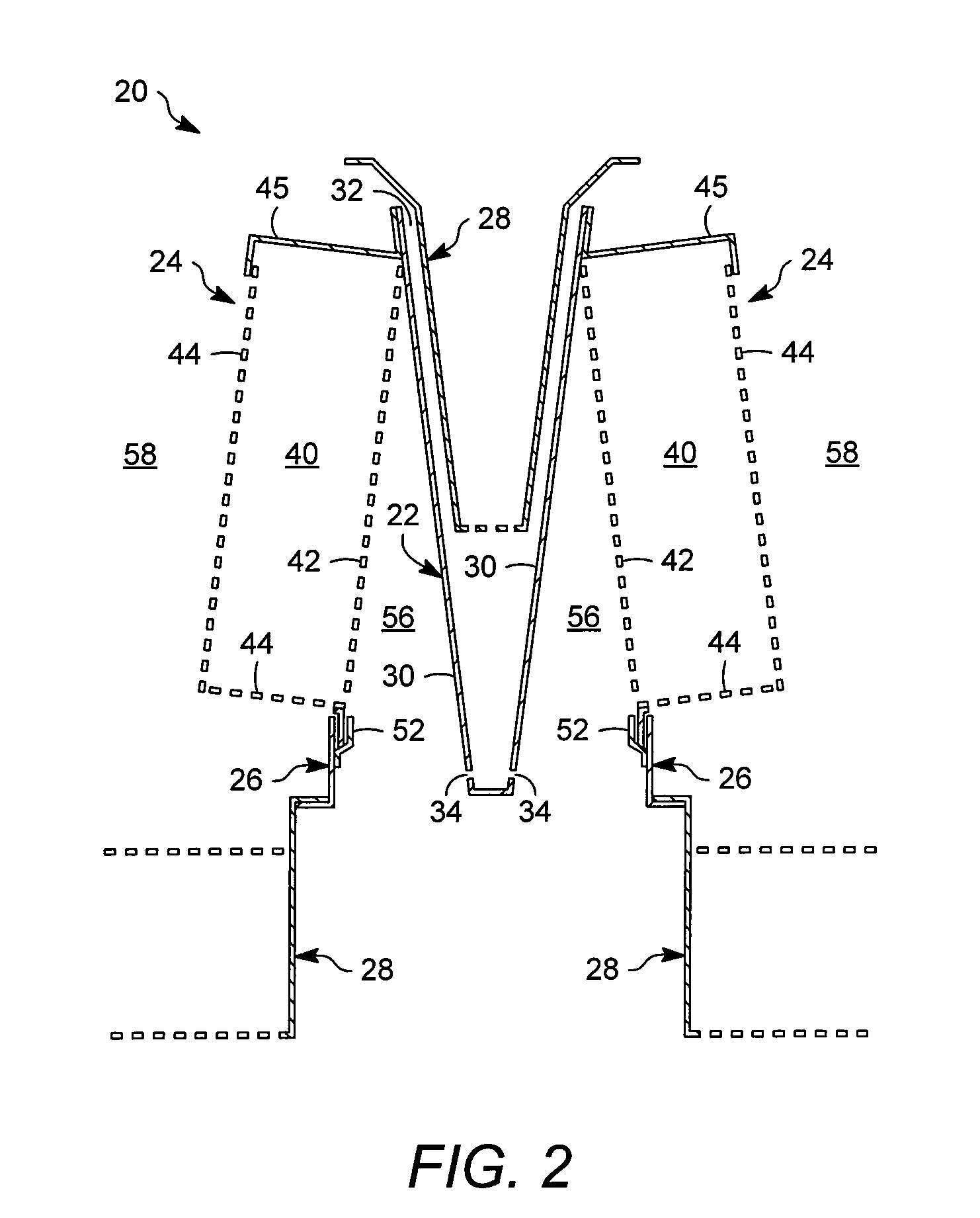

Vapor-liquid contacting in co-current contacting apparatuses

InactiveUS20100162891A1Reducing liquid handling capabilityLarge capacityCarburetting airLiquid degasificationVapor liquidEngineering

Improved contacting modules and apparatuses containing the modules, for carrying out vapor-liquid contacting, are described. In representative contacting modules, liquid (and possibly vapor) are discharged into co-current flow channels in a non-uniform manner (e.g., from only one side of the channels). Particular contacting modules comprise at least one liquid downcomer and a demister, wherein the liquid downcomer and an inlet surface of the demister define a co-current flow channel and wherein liquid is discharged from an outlet of the downcomer. The use of one or more added liquid distribution devices to more uniformly distribute the discharged liquid improves vapor-liquid contacting efficiency in the co-current flow channel and consequently vapor-liquid mass transfer and approach to equilibrium for the contacting stage.

Owner:UOP LLC

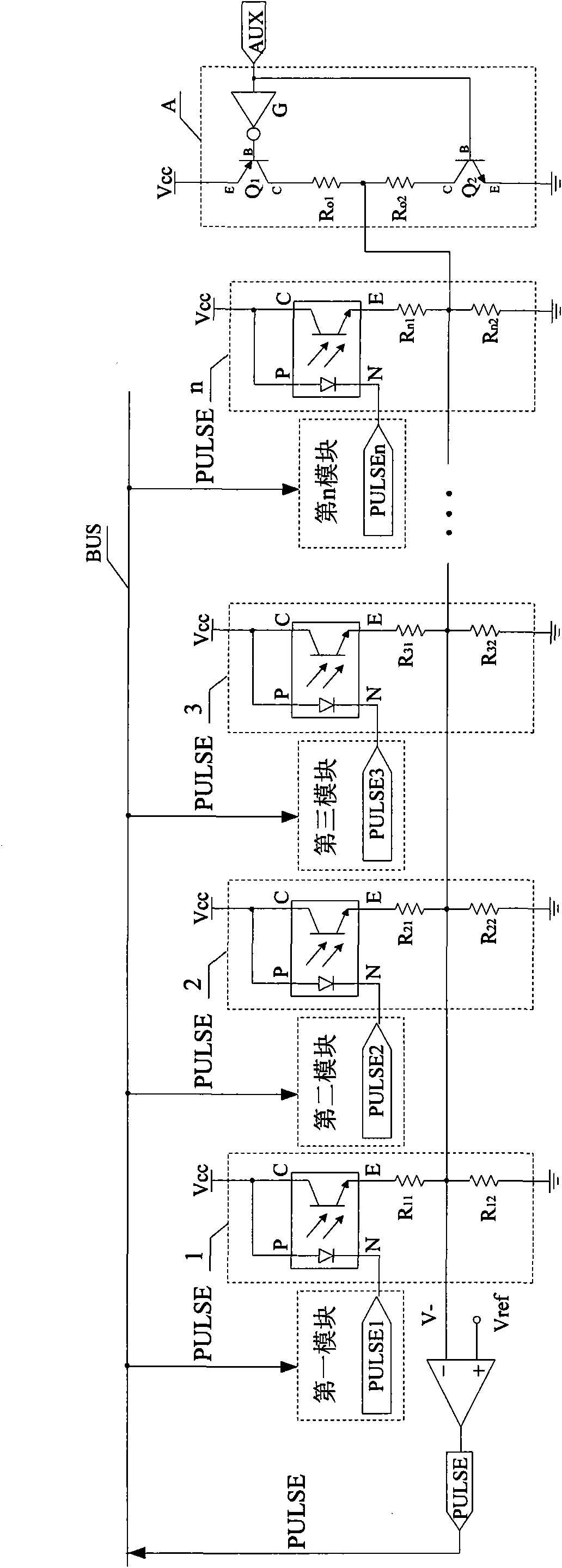

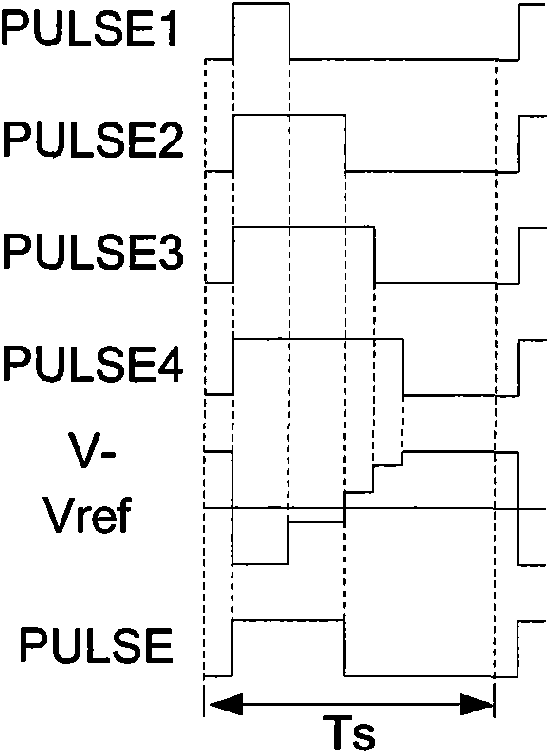

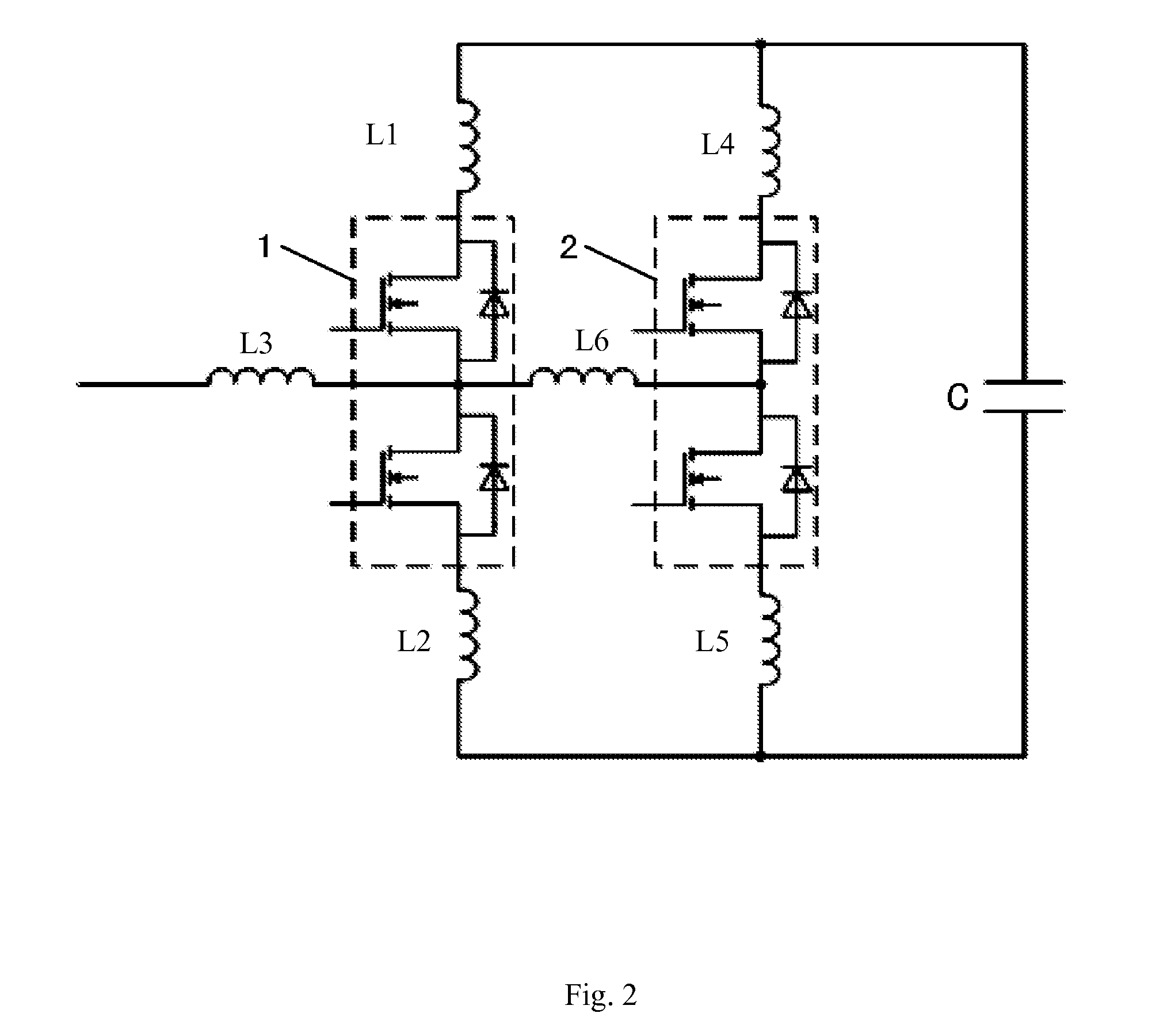

Multi-module inverter wired parallel digital control method

ActiveCN103280999ASame output frequencySame amplitudeDc-ac conversion without reversalPower inverterComputer module

The invention discloses a multi-module inverter wired parallel digital control method. The method can be applicable to a single-phase inverter parallel system or a three-phase inverter parallel system. Connecting wires among the inverter modules are composed of a communication bus, a synchronizing signal bus and an output side alternating current bus, and the control part of the inverter modules mainly consists of a homogenization voltage-stabilizing loop, virtual impedance calculation and inverter voltage current double loop control. The reference voltage phases of the inverter modules are enabled to be the same through the synchronizing signal bus, a master machine guarantees the voltage effective value of the output alternating current bus to be constant, and a slave machine traces the master machine to enable the power of the inverters to be uniformly distributed. According to the multi-module inverter wired parallel digital control method, the output frequencies, the amplitudes and the phases of the modules can be enabled to be identical, the current sharing effect is good, the control method is simple and easy to implement and the reliability is high.

Owner:ZHEJIANG UNIV

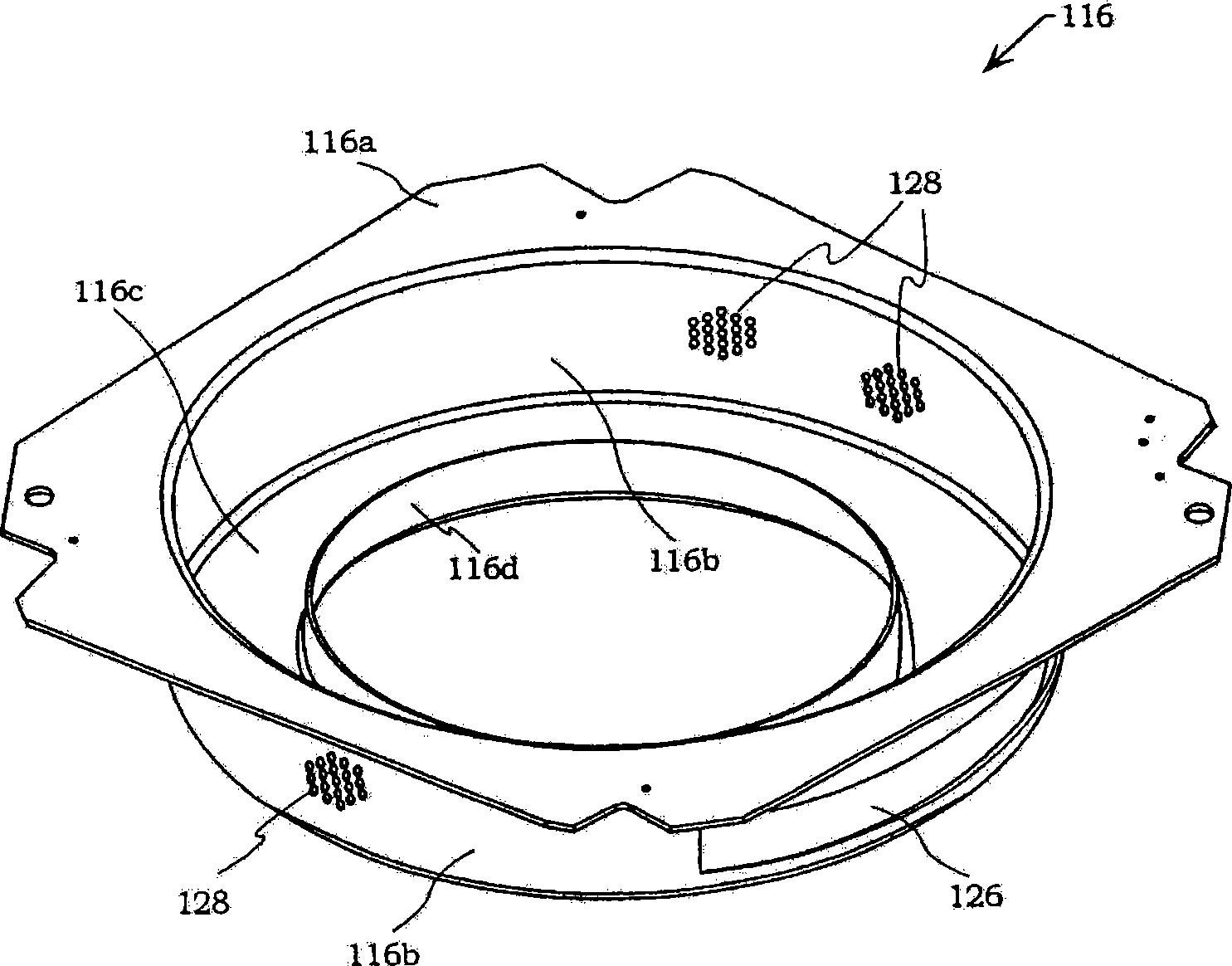

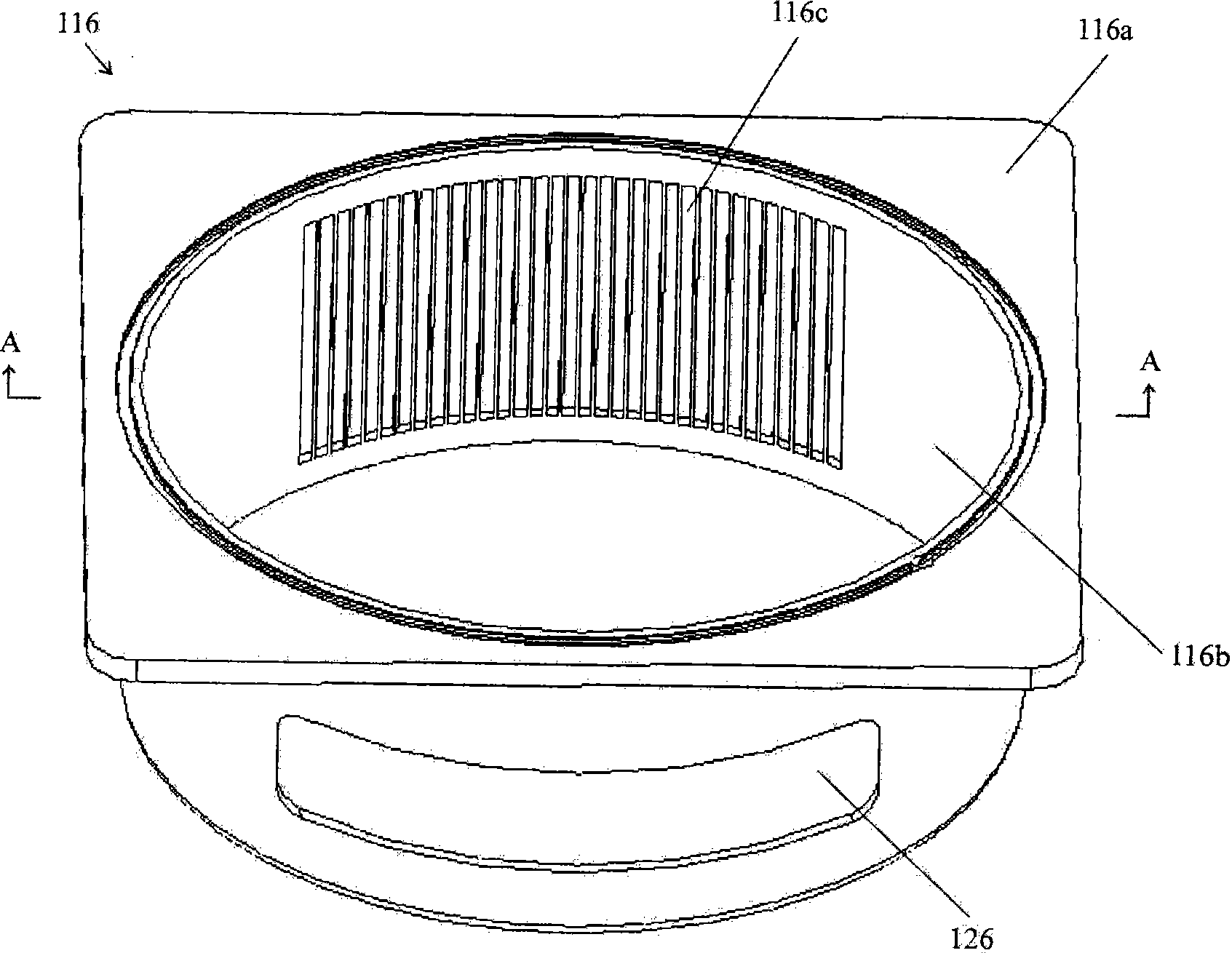

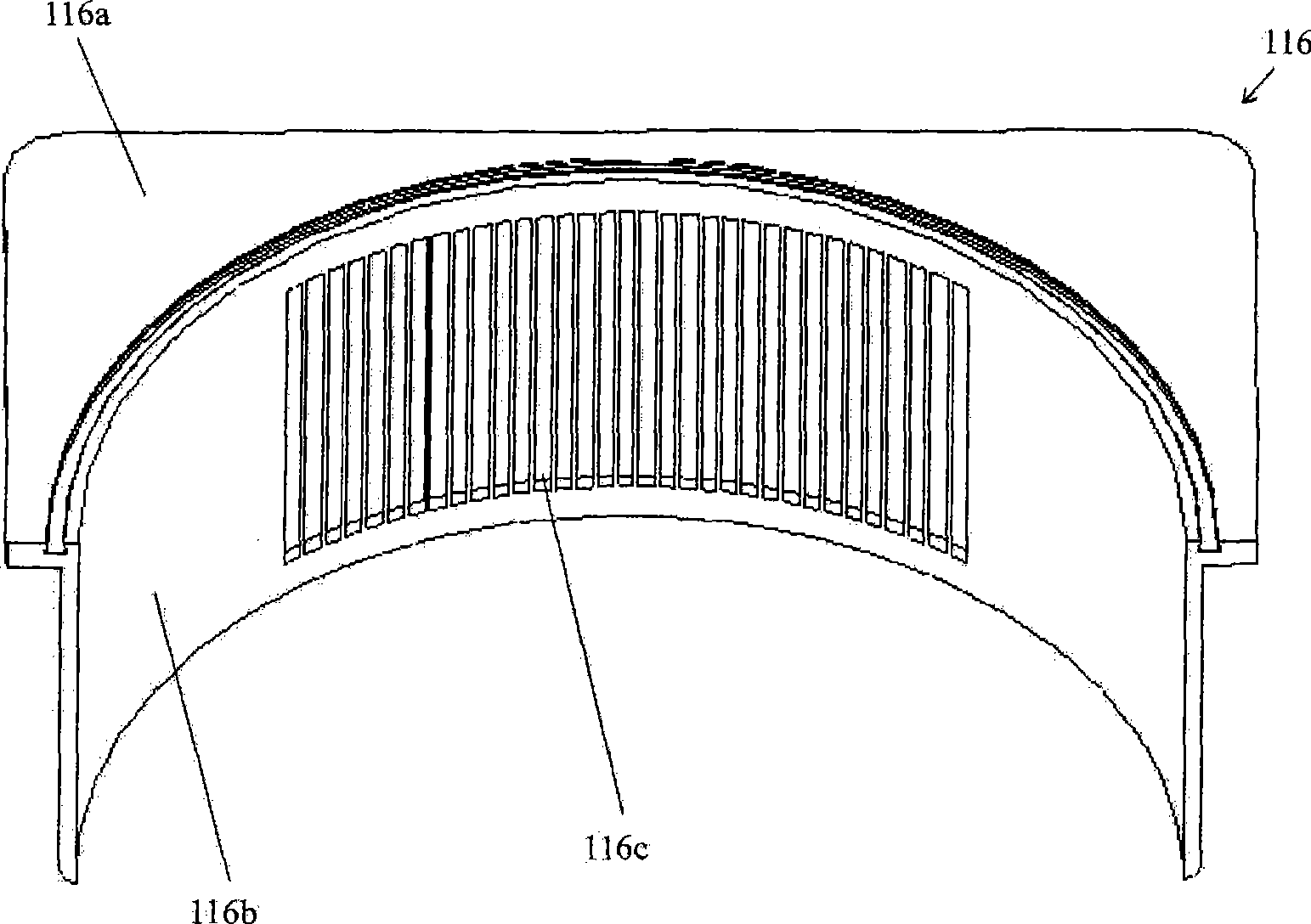

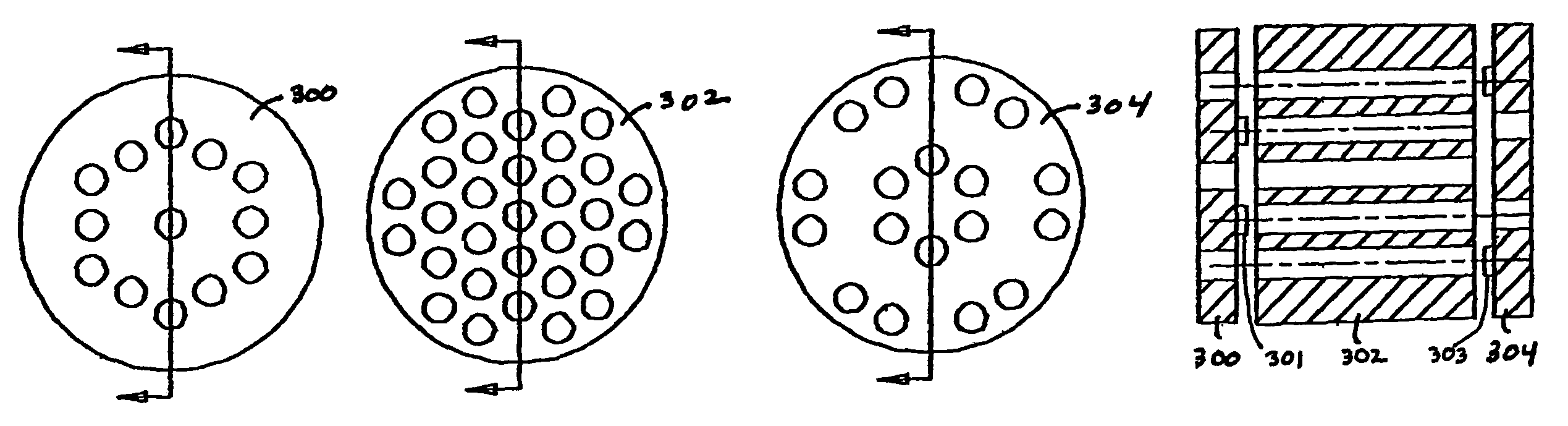

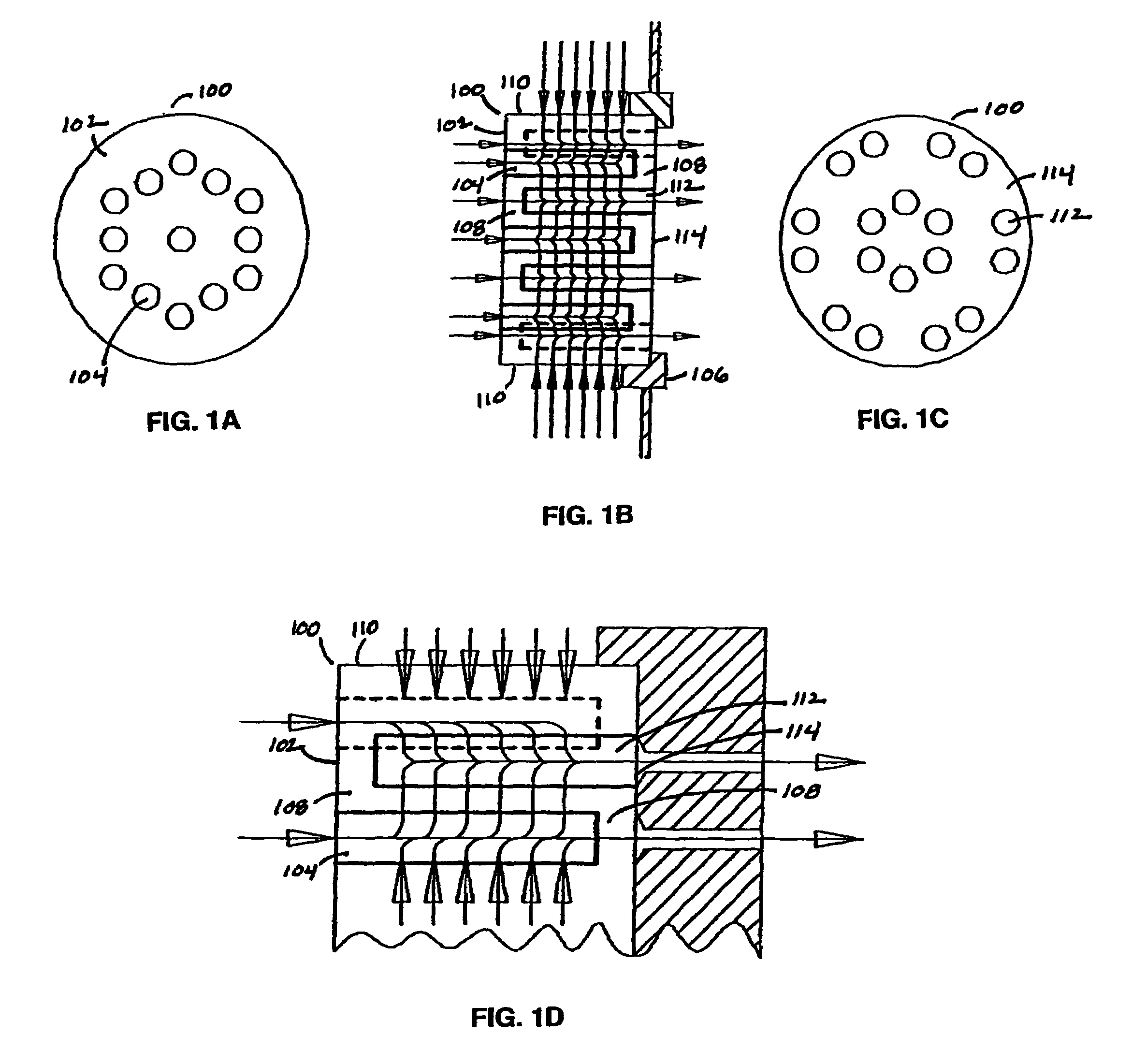

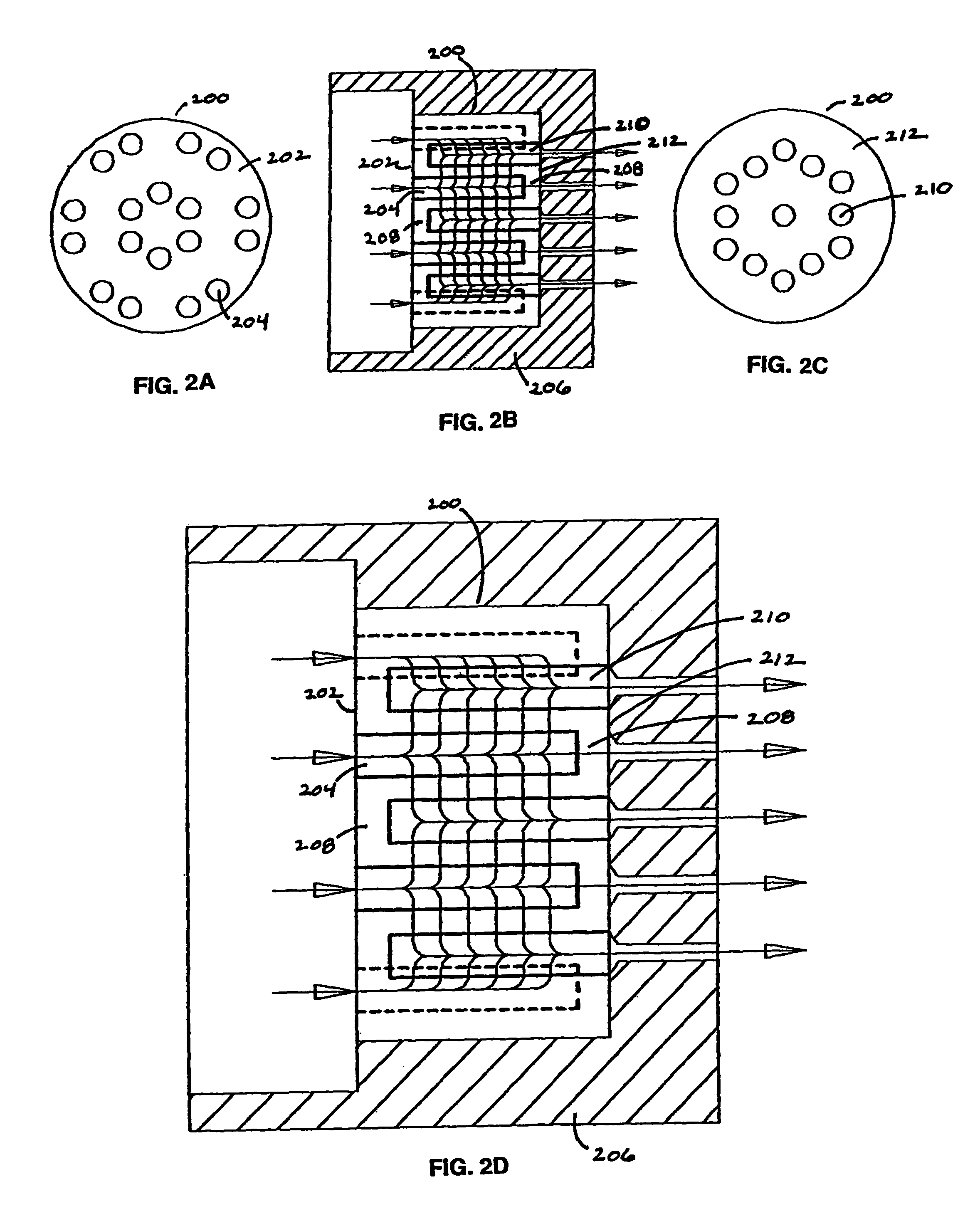

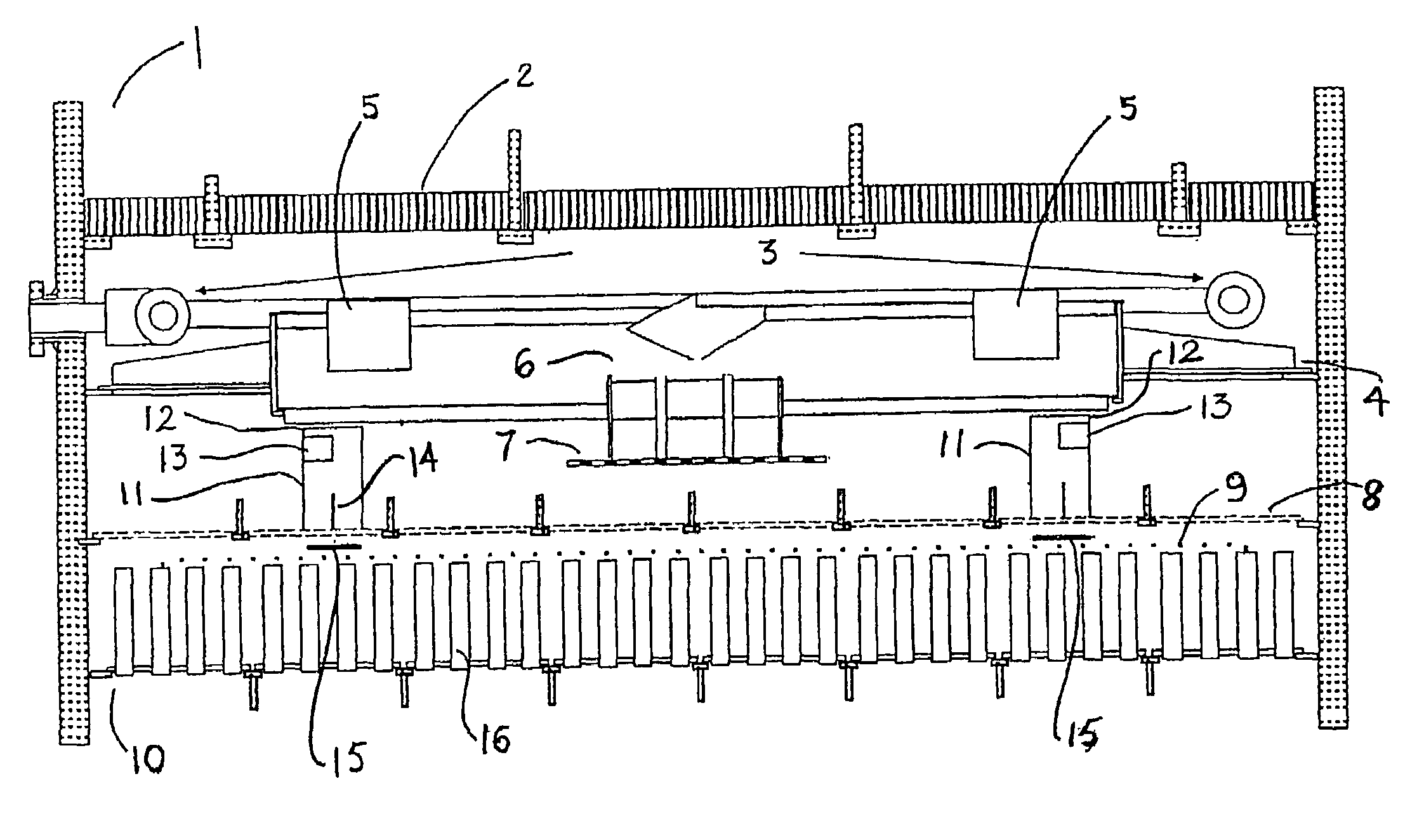

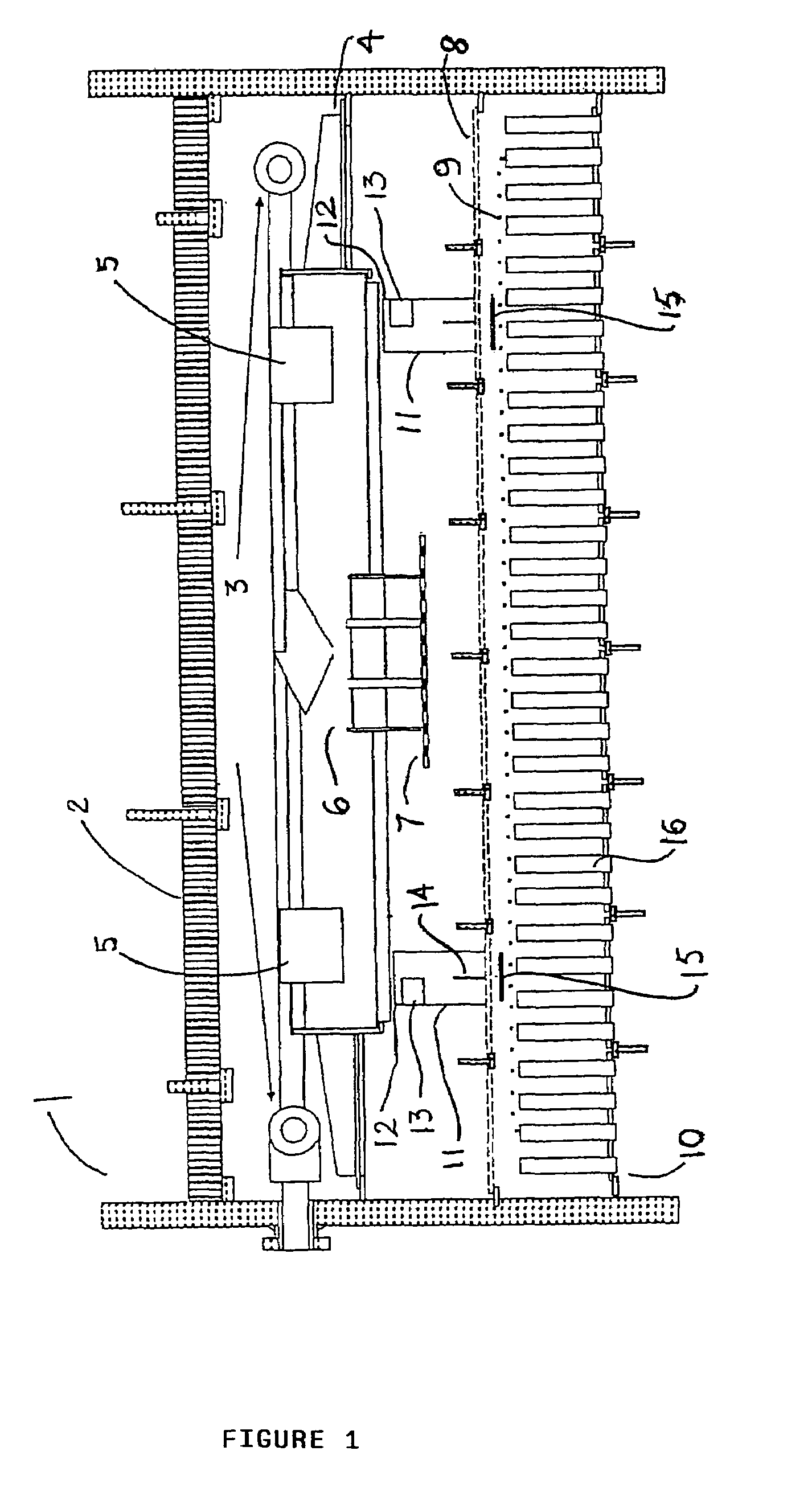

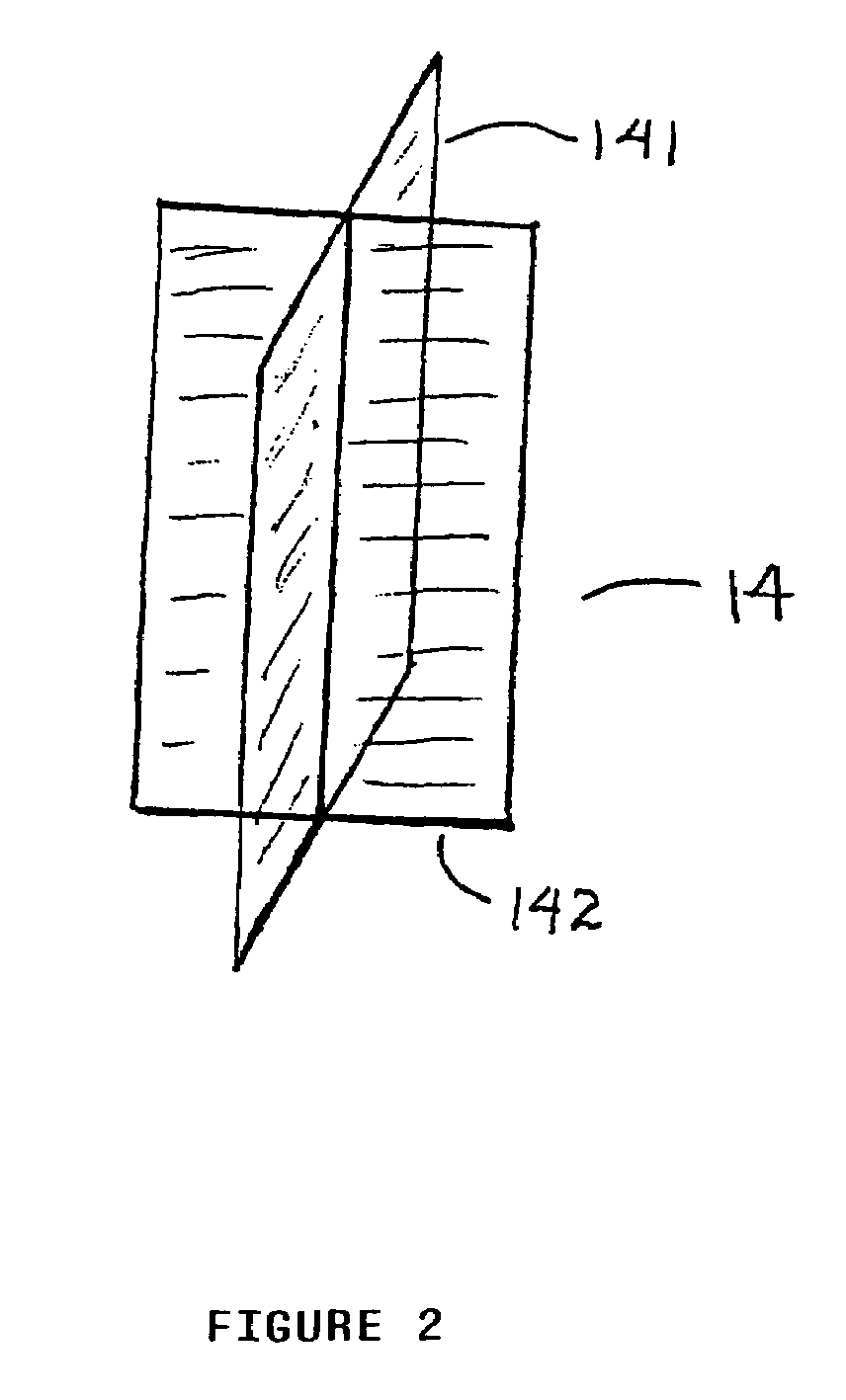

Method of making extended area filter

InactiveUS20050035052A1Improve flow uniformityImprove throughputSpinning solution de-aeratingSpinnerette packsEngineeringMetal powder

Methods are provided for making a porous filter that is useful in polymer melt spinning. The methods include pressing particles, such as a metal powder, to form a filter having a filter body integrally formed with a top cap and a bottom cap. The filter body and caps are formed as a single component or, alternatively, are formed as two or three separate parts that are fitted and pressed together to form a single component having blind inlet and outlet cavities. After pressing, the component is sintered to form the porous filter. The particles are pressed and cohere to form the caps and filter body without the use of a polymeric binder, and the inlet and outlet cavities are formed substantially without machining.

Owner:MOTT CORP

Pure titanium two-step plastic deformation processing method

The invention relates to a pure titanium two-step plastic deformation processing method in the technical field of metallic material plastic deformation; the method comprises the following steps: level-3 industrial pure titanium block is taken as the raw material, after being coated with graphite lubricant, the material is extruded on a 300KN hydraulic pressure universal experimental machine and then is subjected to rolling treatment at liquid nitrogen temperature to carry out deformation treatment on submicron crystal industrially pure titanium block, thus obtaining the superfine crystal pure titanium. The superfine crystal pure titanium of the invention features a tensile strength of 1218MPa and a specific elongation of 12.6%.

Owner:SHANGHAI JIAO TONG UNIV

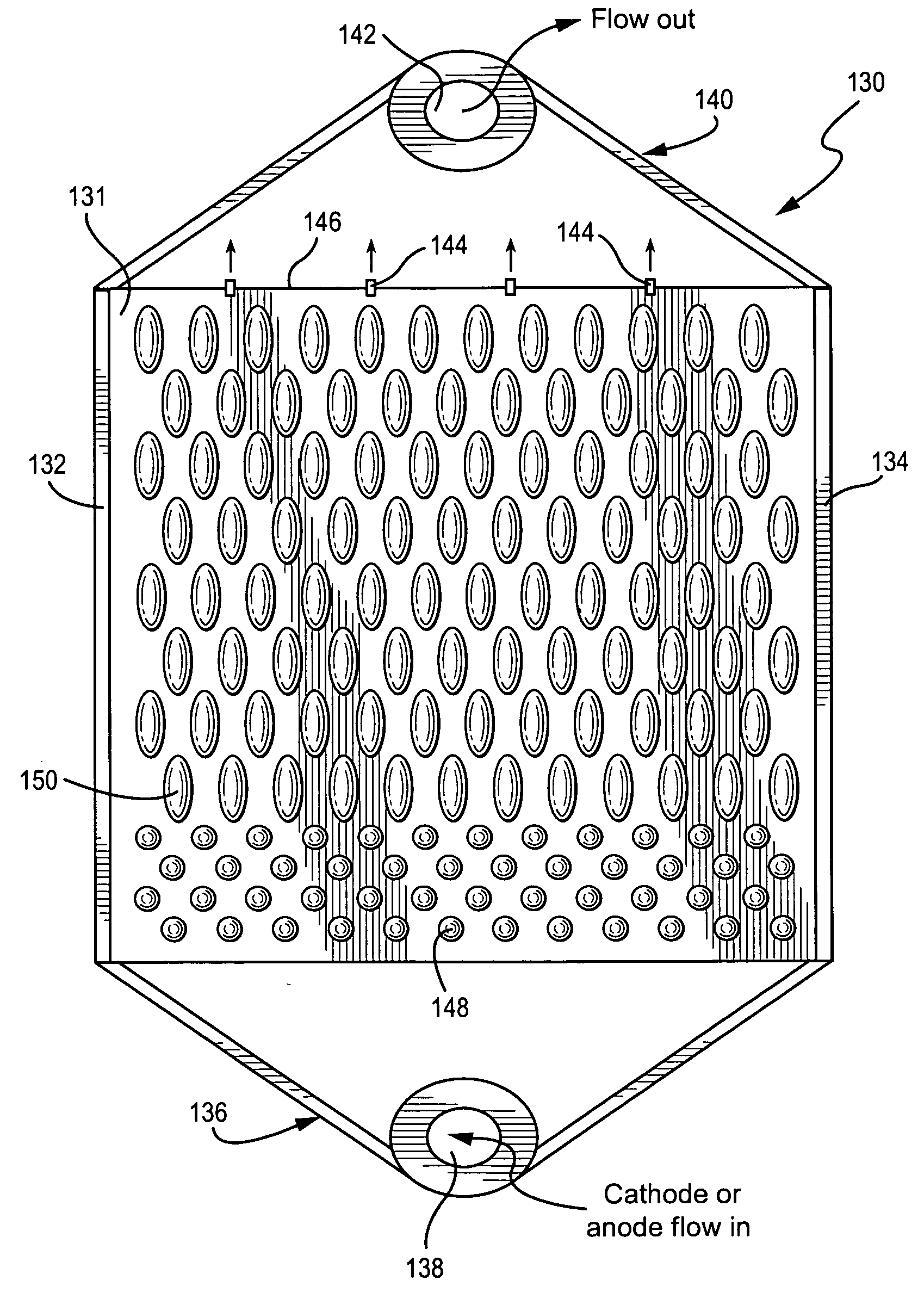

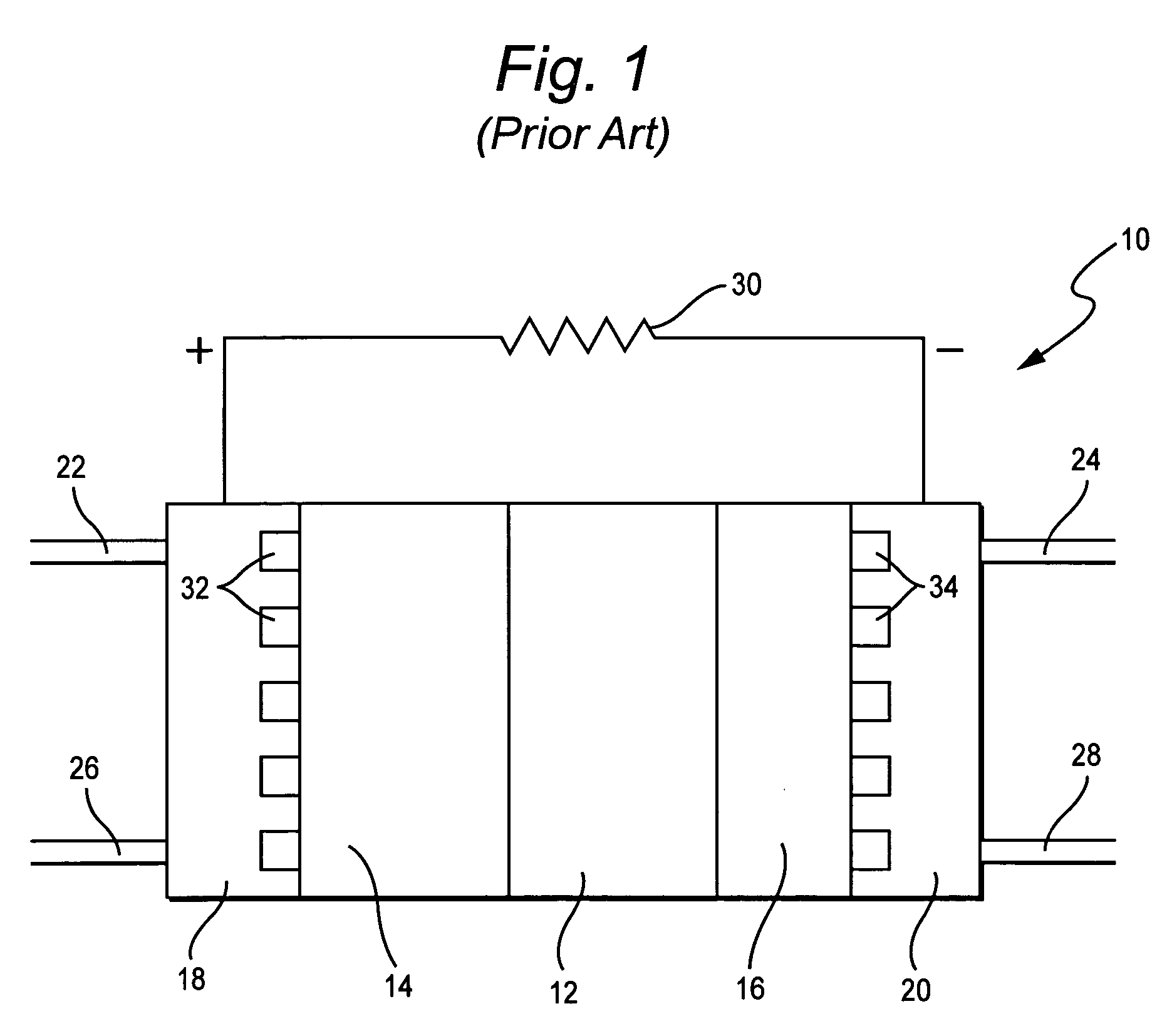

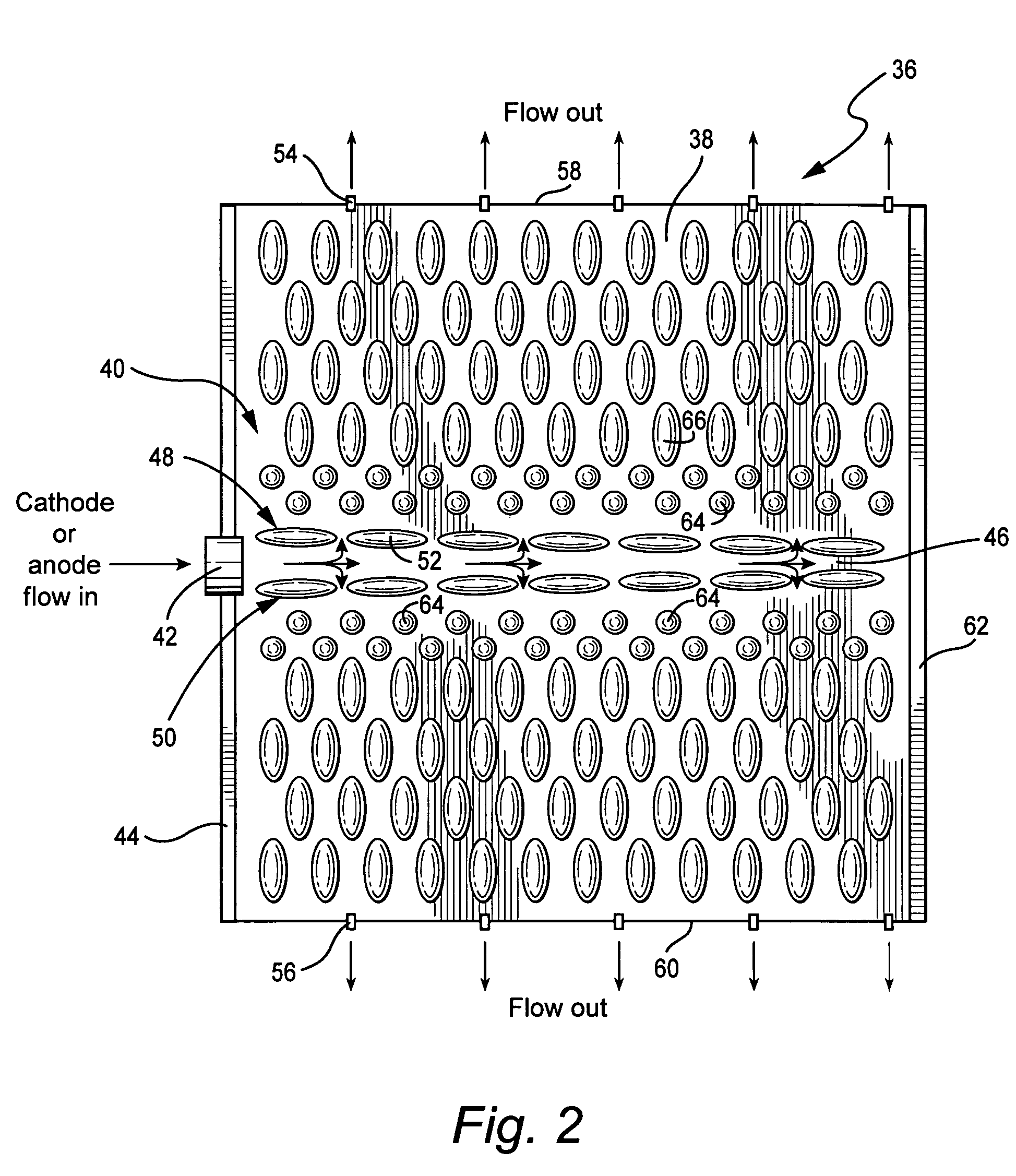

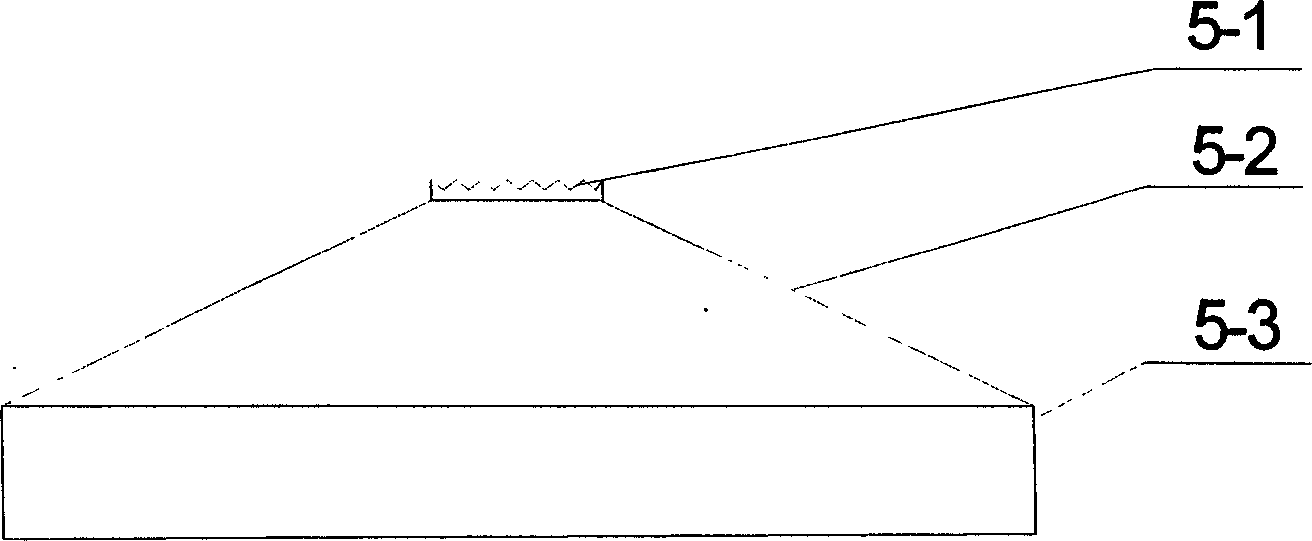

Flow field design for high fuel utilization fuel cells

InactiveUS20060093891A1Improved fuel cell performanceImprove flow uniformityFuel cell auxillariesSolid electrolyte fuel cellsFluid fieldEngineering

A flow field forming one wall of a channel in a flow field plate of a solid oxide fuel cell, the flow field includes a flat substrate having a patterned array of differently-shaped flow barriers projecting from the substrate into the channel, the flow field channel decreases in cross-sectional area in a flow direction.

Owner:GENERAL ELECTRIC CO

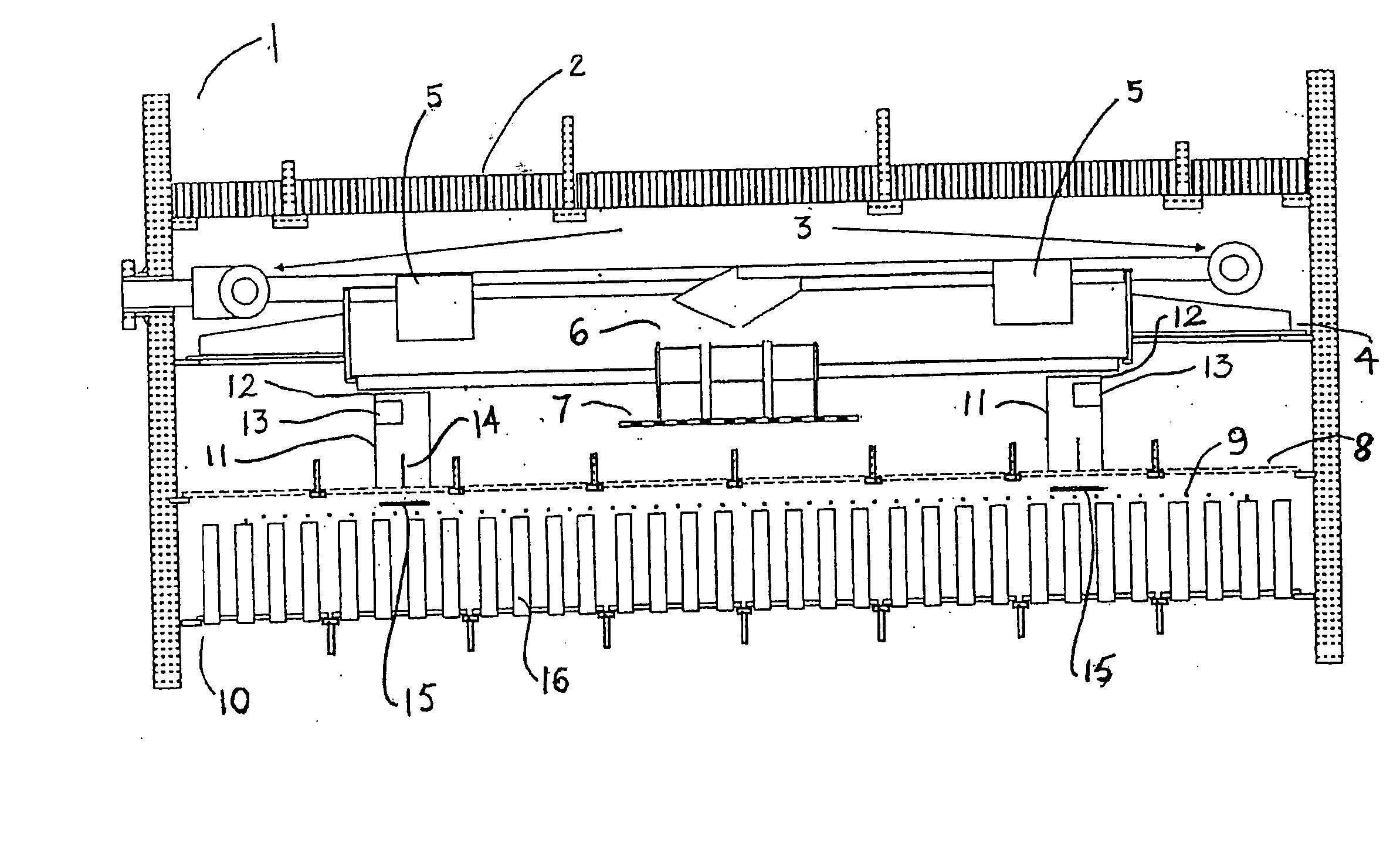

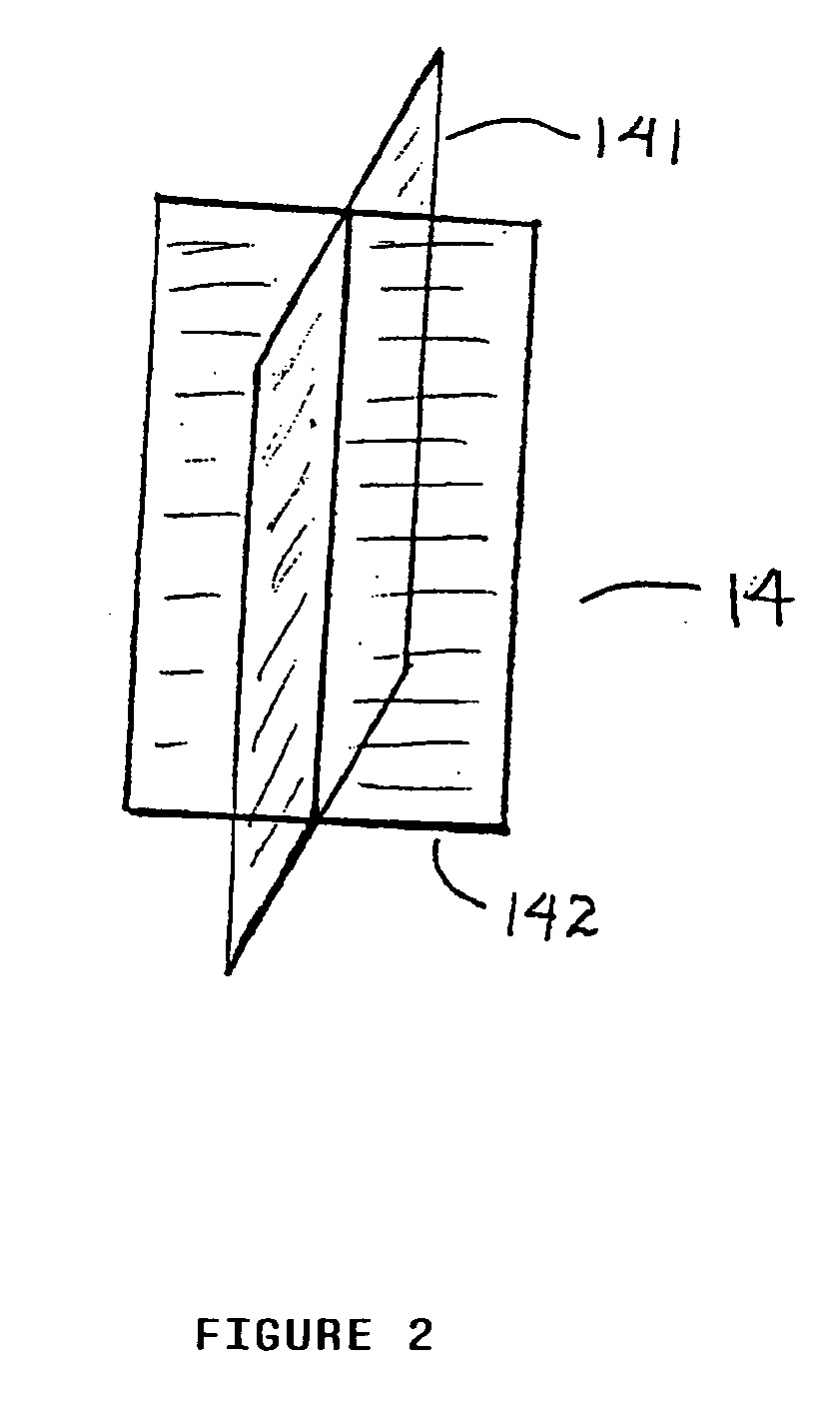

Distributor system for downflow reactors

ActiveUS20060257300A1Increase the sectionImprove flow uniformityChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical nozzle-type rreactorsLine tubingProcess engineering

Downflow catalytic reactor having a plurality of catalyst beds in which a mixture of gas and liquid are passed, the region in between subsequent catalyst beds being provided with a distributor system for the distribution and mixing of gas and liquid prior to contact with a subsequent catalyst bed, said region comprising: (a) gas injection line arranged below a catalyst support tray, (b) collector tray adapted to receive gas and liquid, (c) spillway collectors extending above the level of said collecting tray, (d) mixing chamber adapted to receive the gas and liquid descending from said spillway collectors, (e) impingement plate below said mixing chamber, (f) first distributor tray arranged below said impingement plate having a number of apertures throughout and a number chimneys, and (g) second distributor tray arranged below said first distributor tray for the redistribution of gas and liquid prior to contact with the subsequent catalyst bed, wherein the at least one chimney is provided with a distributor device that is able to divide the chimney chamber into at least two chambers.

Owner:TOPSOE AS

Flow controller for gas turbine combustors

InactiveUS20050044842A1Uniform flow distributionUniform flowContinuous combustion chamberFurnace componentsInjectorGas turbines

A flow controller is disposed between a preburner section in a diffuser and prior to the main fuel injector and catalytic sections in a turbine combustor. The flow from the burner section is typically not uniform in temperature and velocity and the flow splitter renders the flow substantially uniform at the fuel injector and catalyst inlet. The flow splitter comprises substantially equal mass annular flow areas defined by a first outer frustoconical element and the diffuser wall, a second element defining with the first element a second annular area and a central bluff disk defining with the second element the interior annular area. Vanes are provided on the flow splitter to enhance turbulent flow and substantially preclude swirling flow. As a result, flow uniformity at the catalyst inlet and main fuel injection is achieved.

Owner:GENERAL ELECTRIC CO

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

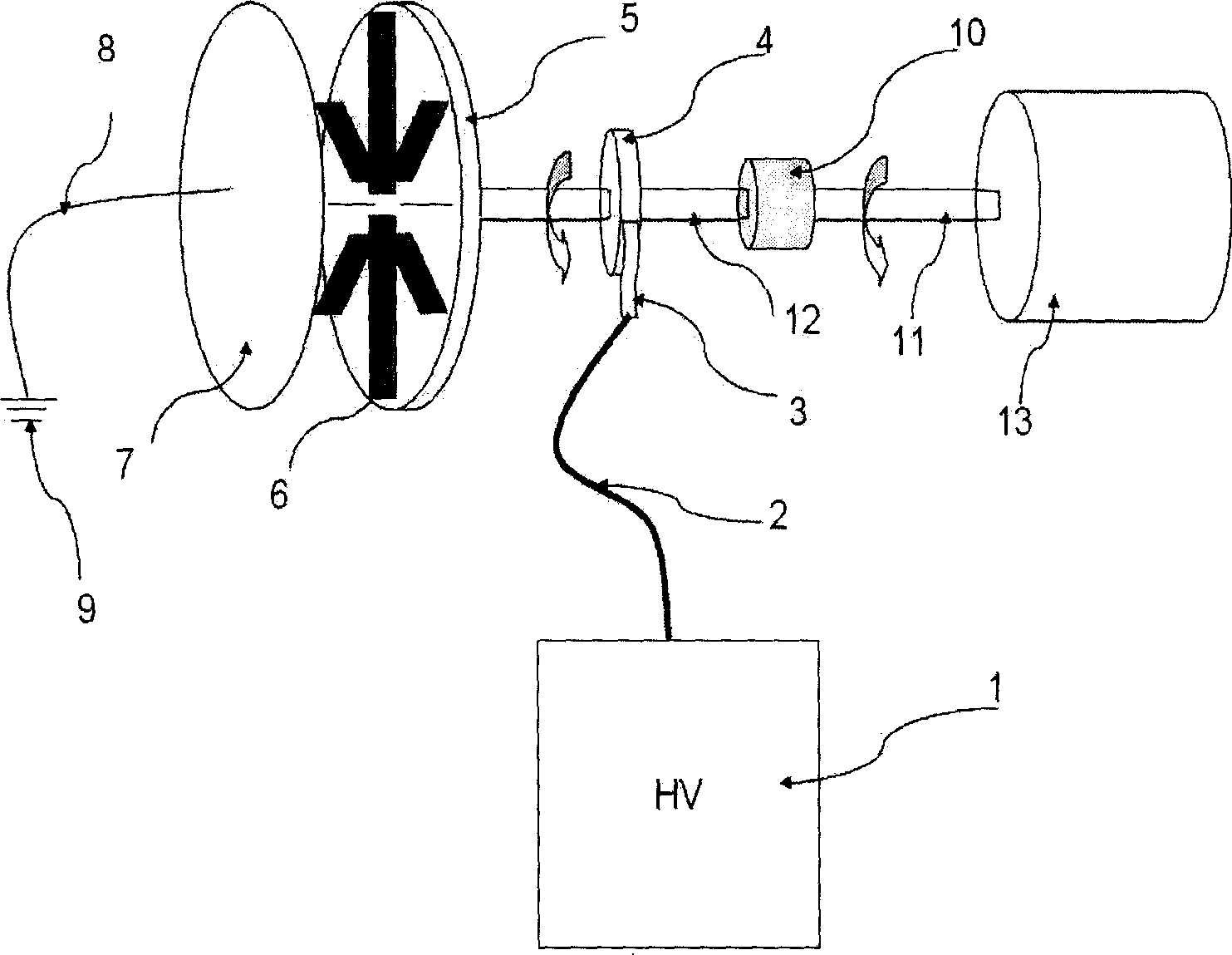

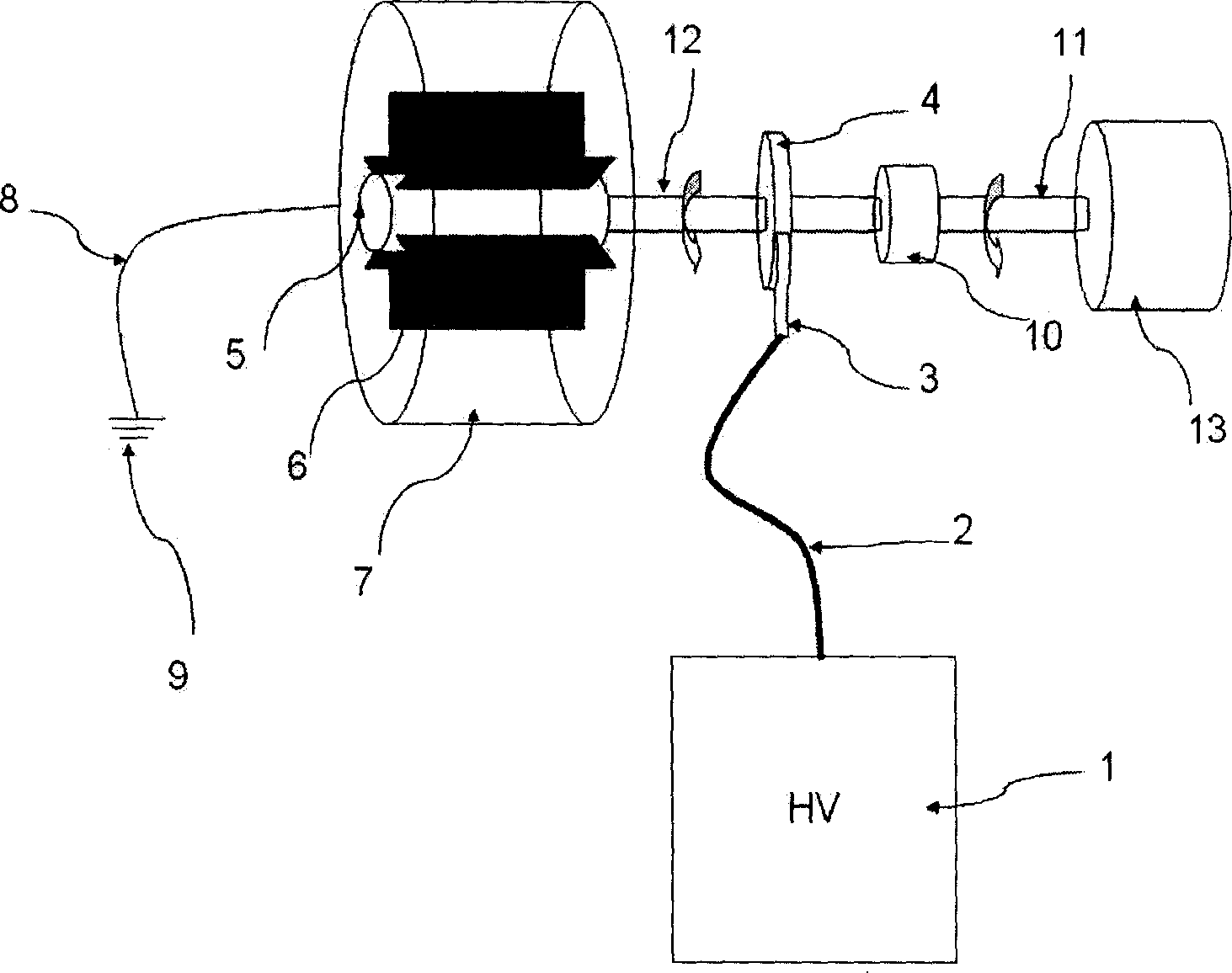

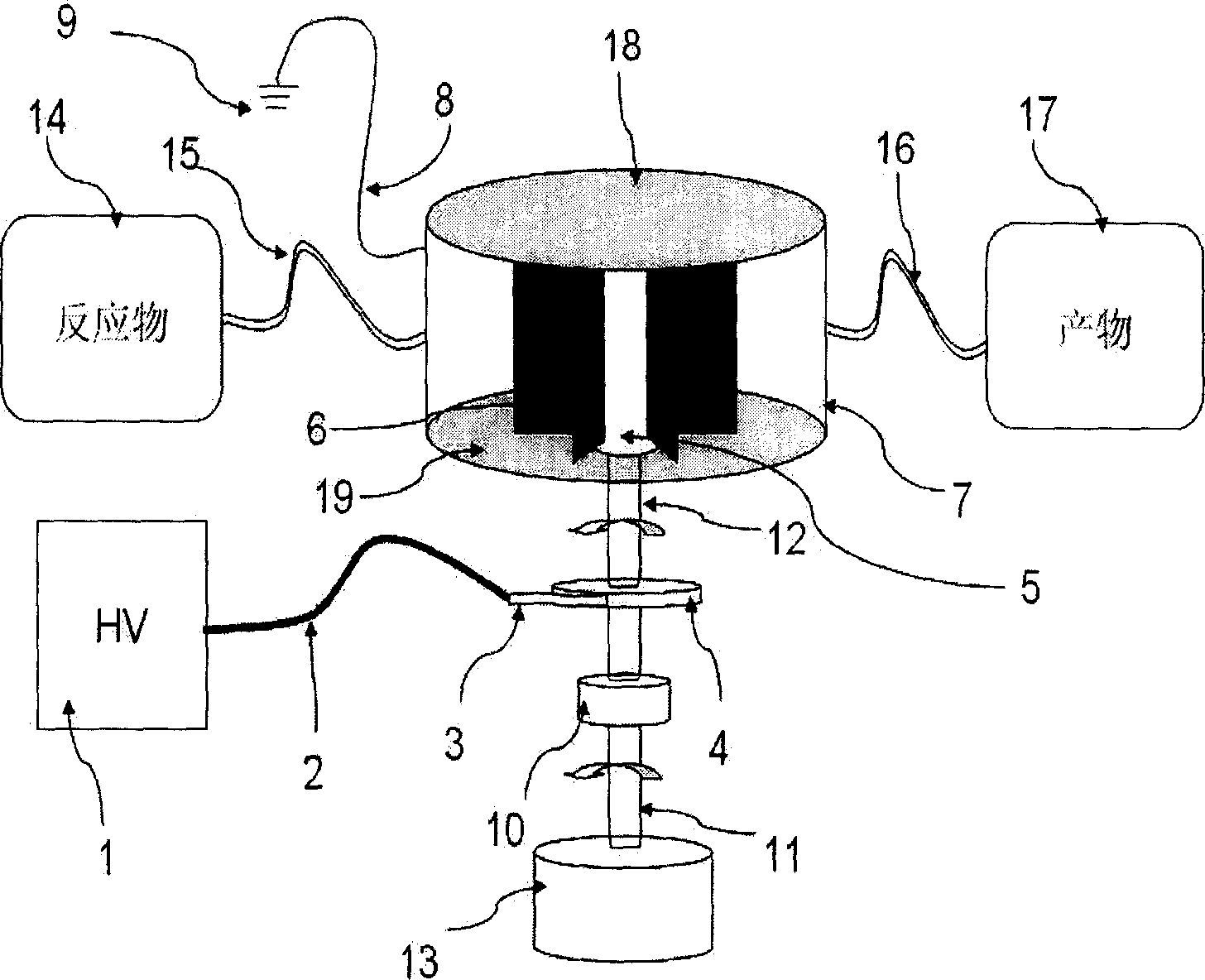

Rotary corona discharge low temp plasma source apparatus

InactiveCN1719964AHigh discharge energy densityIncrease the concentration of active particlesElectric discharge tubesPlasma techniqueCorona dischargeHigh pressure

This invention relates to a rotary corona discharge low temperature plasma source device, in which, the high voltage electrode is composed of a super thin sheet electrode curved plate, an earth electrode is composed of related earth electrode curved plates, the high voltage electrode drive device drives the high voltages electrode to rotate quickly, the high voltage electrode supply device provides energy to the high voltage electrode.

Owner:王晓臣

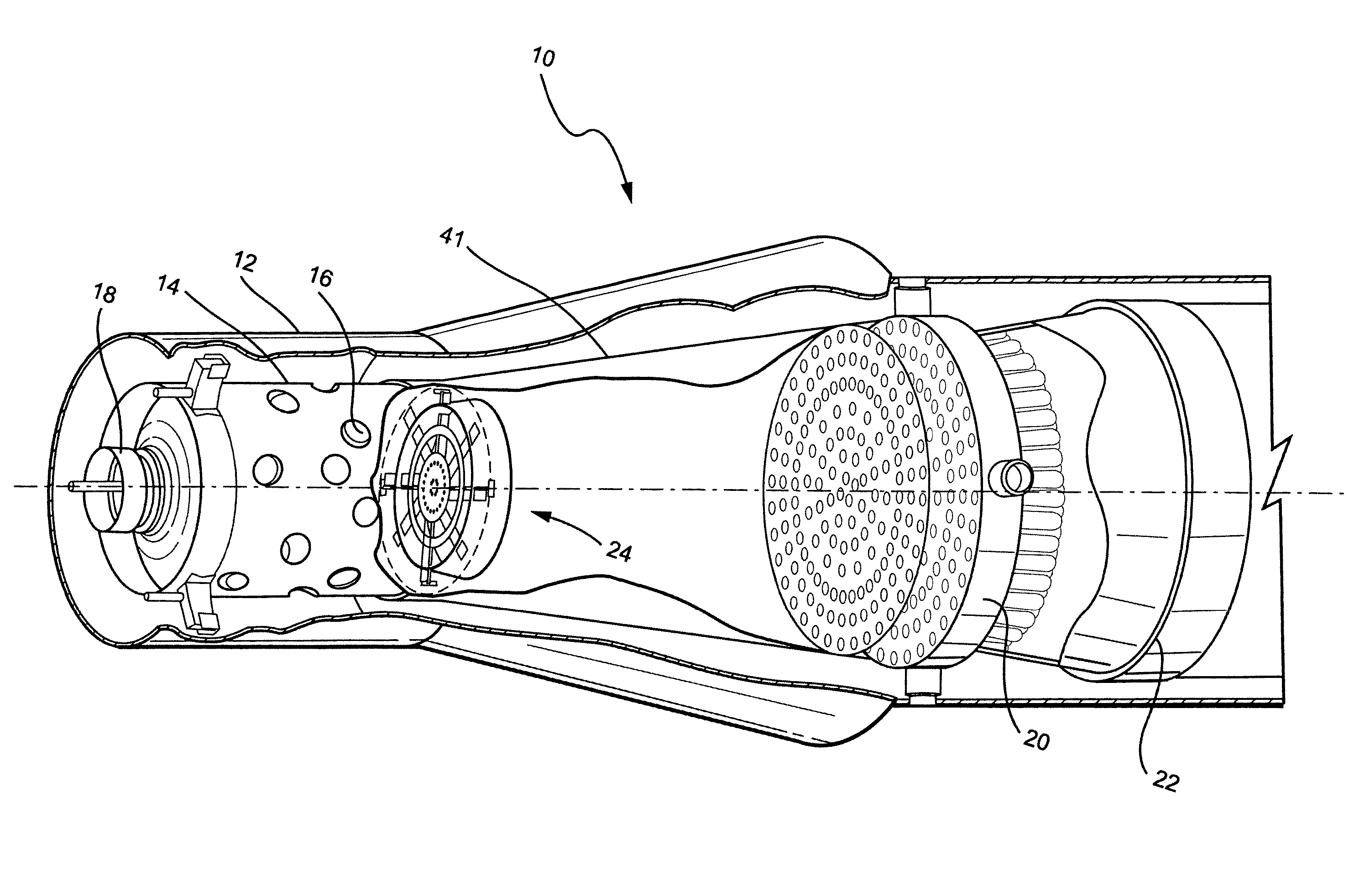

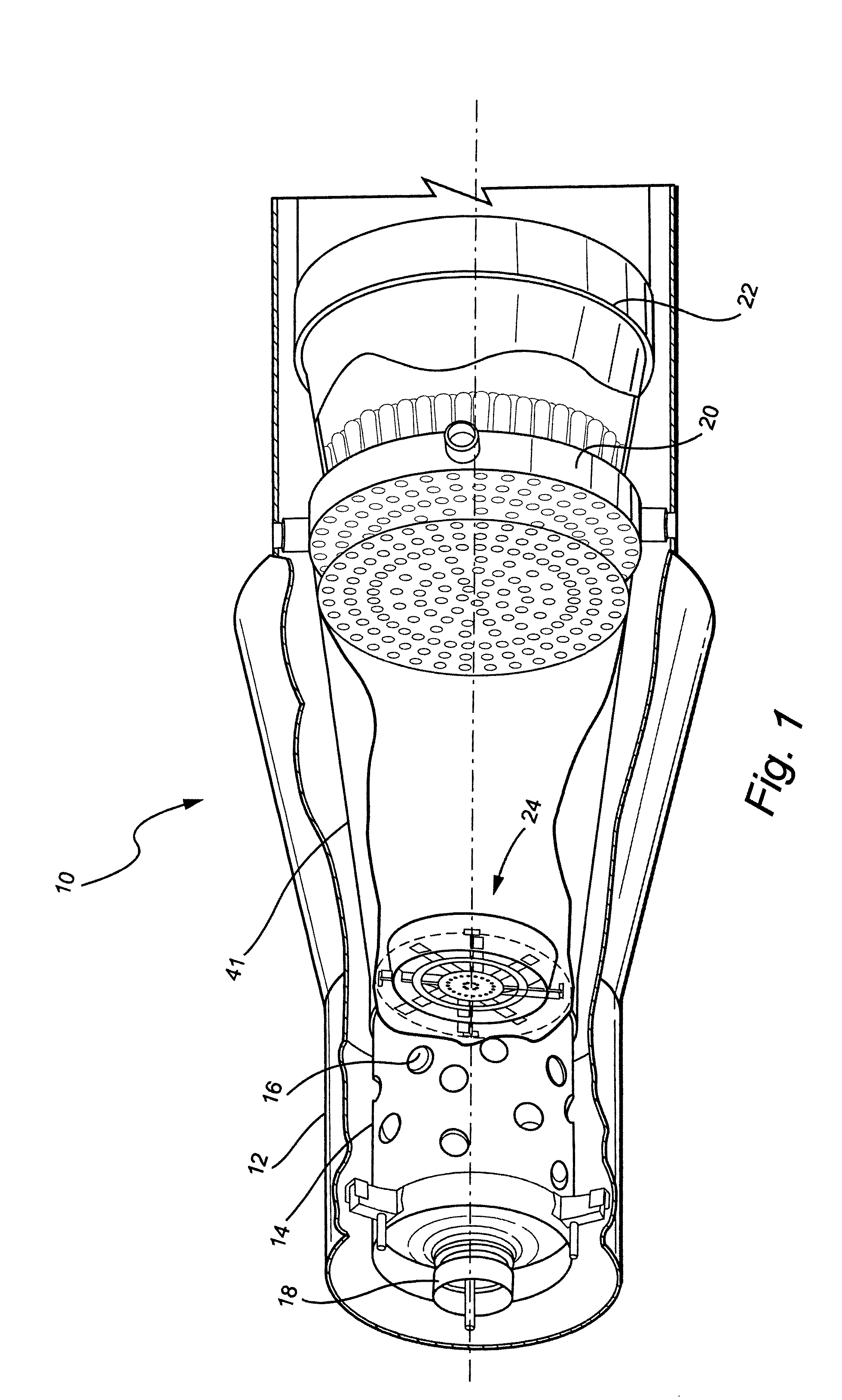

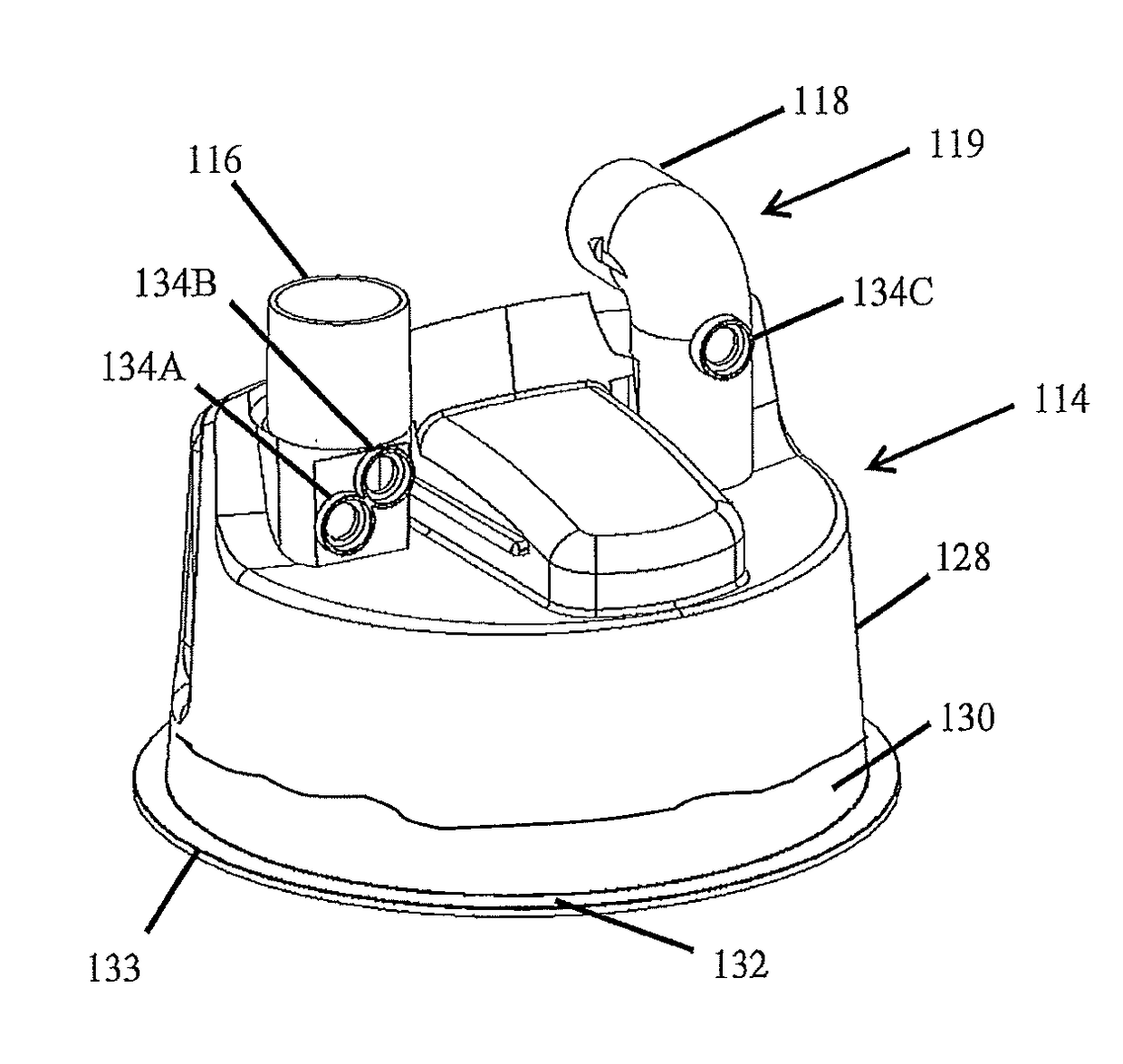

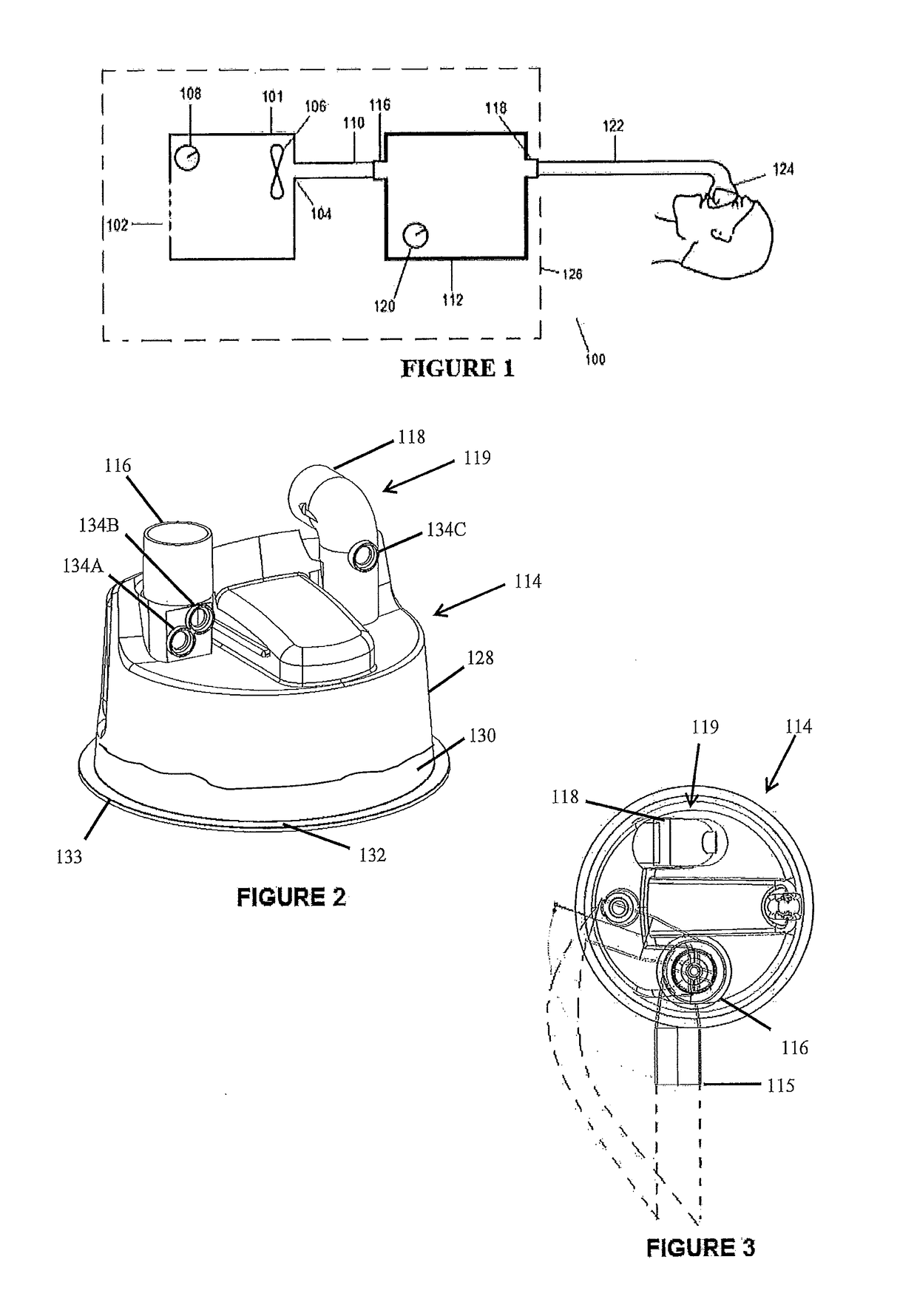

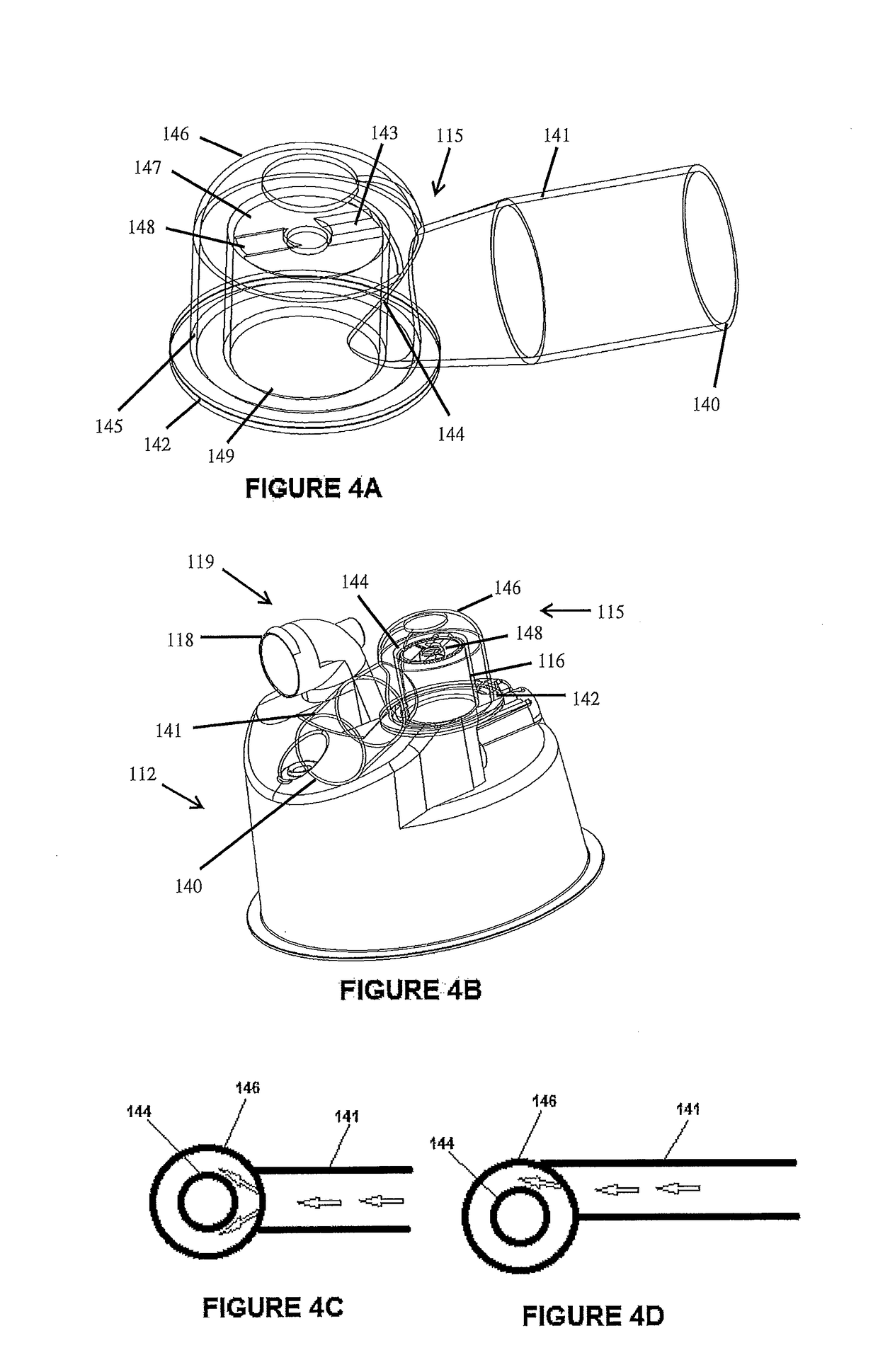

Flow mixers for respiratory therapy systems

ActiveUS20170197057A1Improve accuracyImprove flow uniformityRespiratorsElectrocardiographyEngineeringBreathing treatments

A flow of gases in a respiratory therapy system can be conditioned to achieve more consistent output from sensors configured to sense a characteristic of the flow. The flow can be mixed by imparting a tangential, rotary, helical, or swirling motion to the flow of gases. The mixing can occur upstream of the sensors. The flow can be segregated into smaller compartments to reduce turbulence in a region of the sensors.

Owner:FISHER & PAYKEL HEALTHCARE LTD

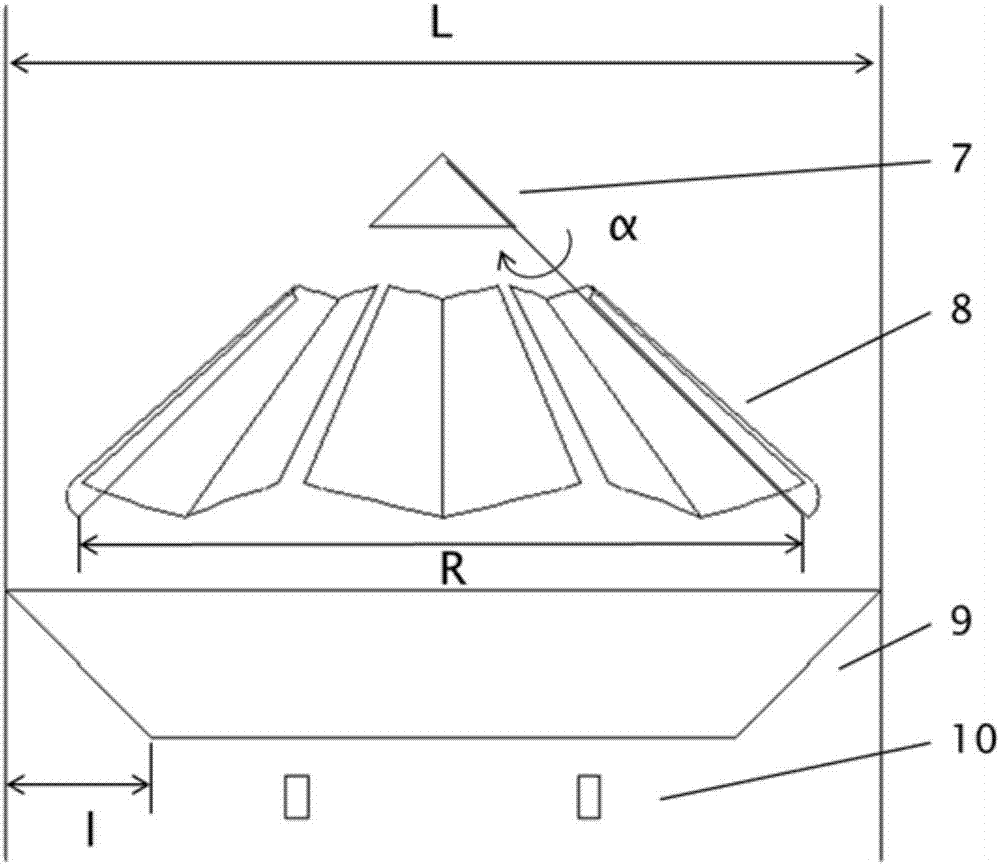

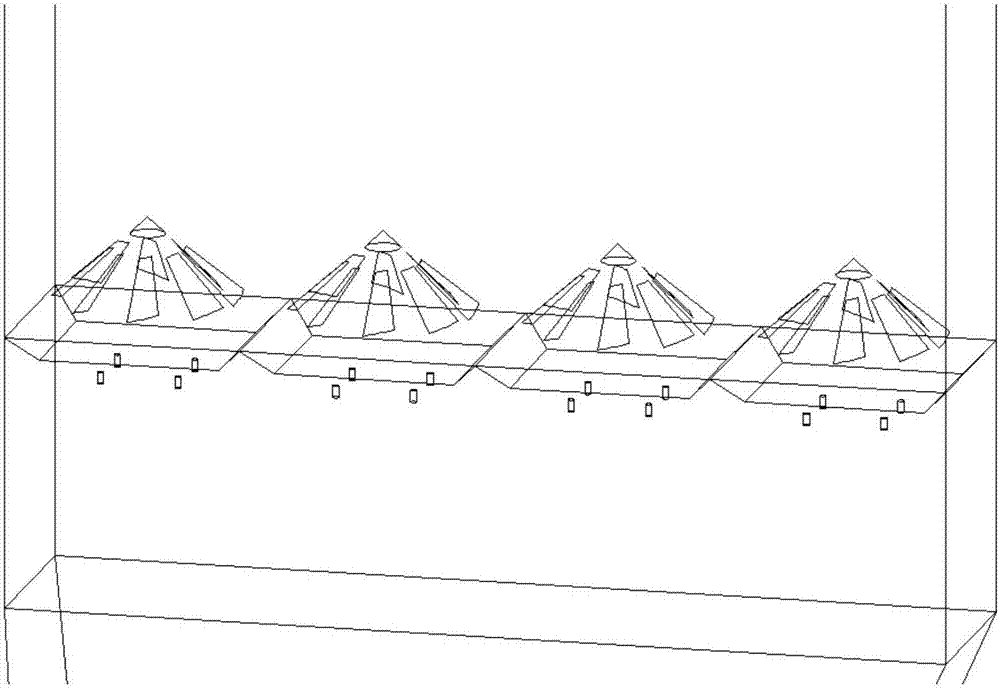

Pyramidal laying liquid typed high performance mass transfer tray with central downcast pipe

InactiveCN1695768AIncrease the effective areaImprove tray efficiencyFractional distillationRetaining ringProduct gas

Owner:BAYER TECH & ENG SHANGHAI

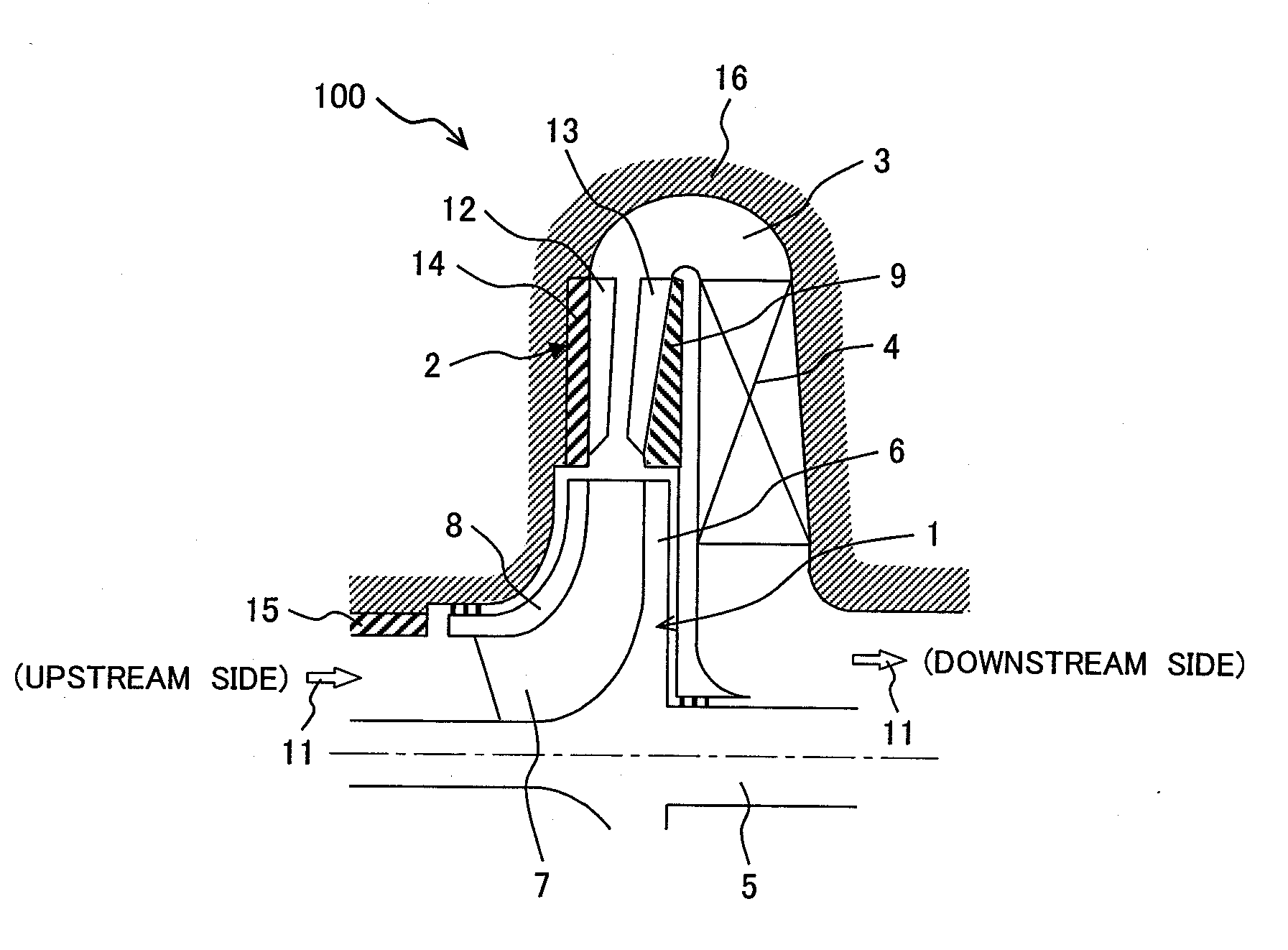

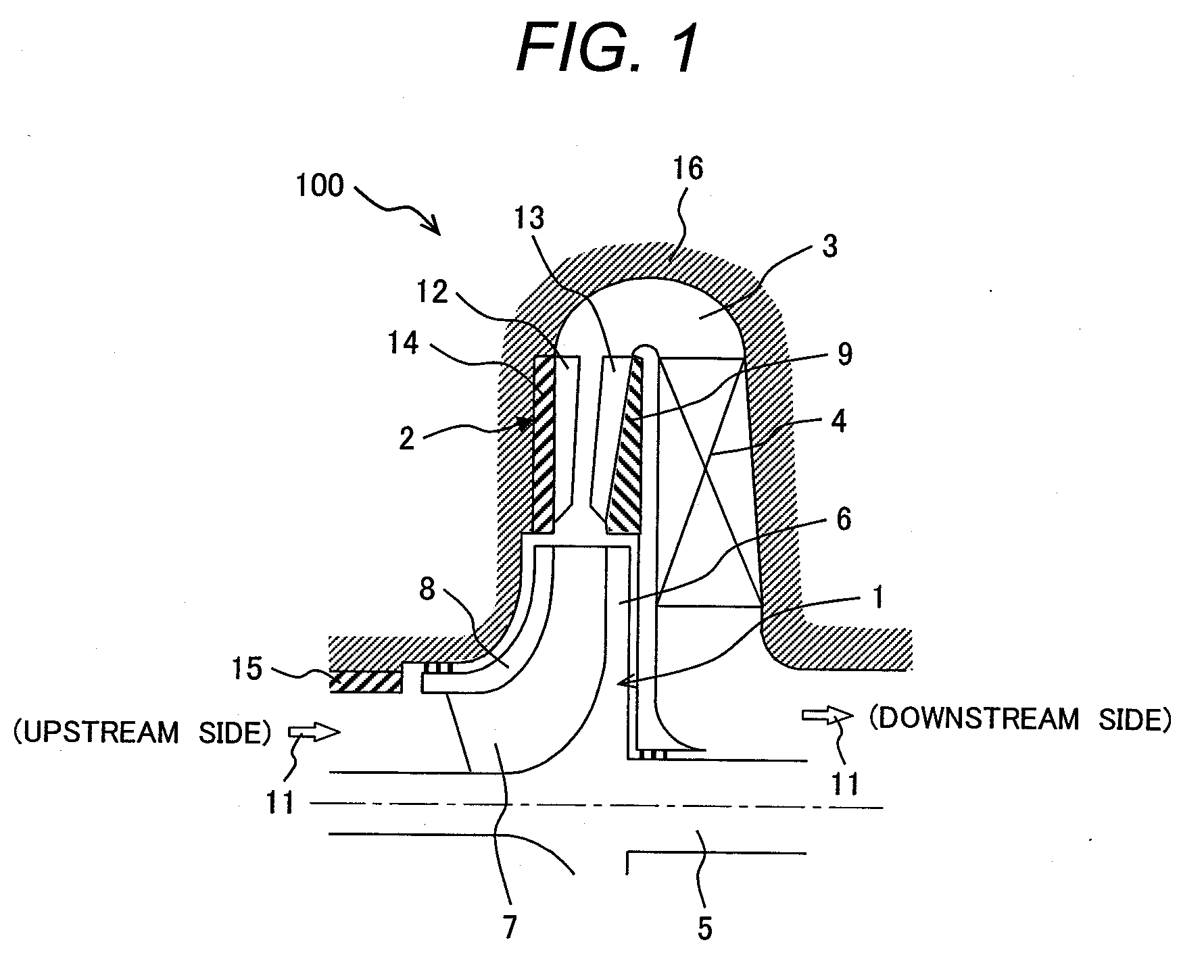

Turbo machinery

InactiveUS20110097203A1Improve uniformity of flowReduce case diameterEngine manufacturePump componentsChannel widthImpeller

Turbo machinery comprising an impeller and a diffuser positioned on a downstream side of the impeller that a channel wall surface of the diffuser is composed of a pair of a shroud side diffuser plate and a hub side diffuser plate which surface each other and a channel width is formed so as to be increased downstream, characterized in that guide vanes in a circular arc shape lower in height than the channel width are installed in a line of a plurality of vanes on both channel walls of the shroud side diffuser plate and hub side diffuser plate of the diffuser, and a total of vane heights of the two guide vanes at an outlet of the diffuser is set so as to be within a range from 30 to 70% of the channel width at the outlet of the diffuser.

Owner:HITACHI LTD

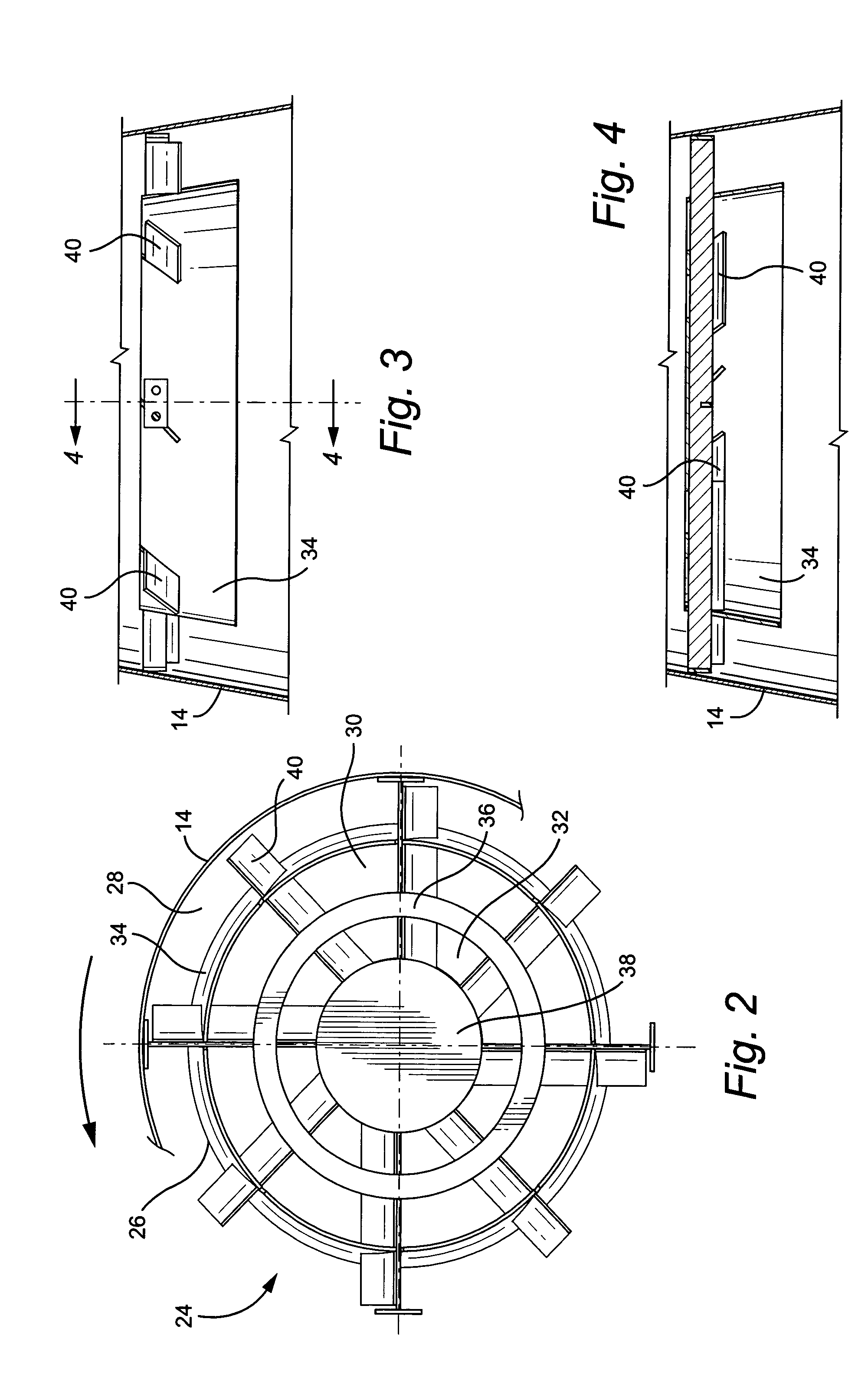

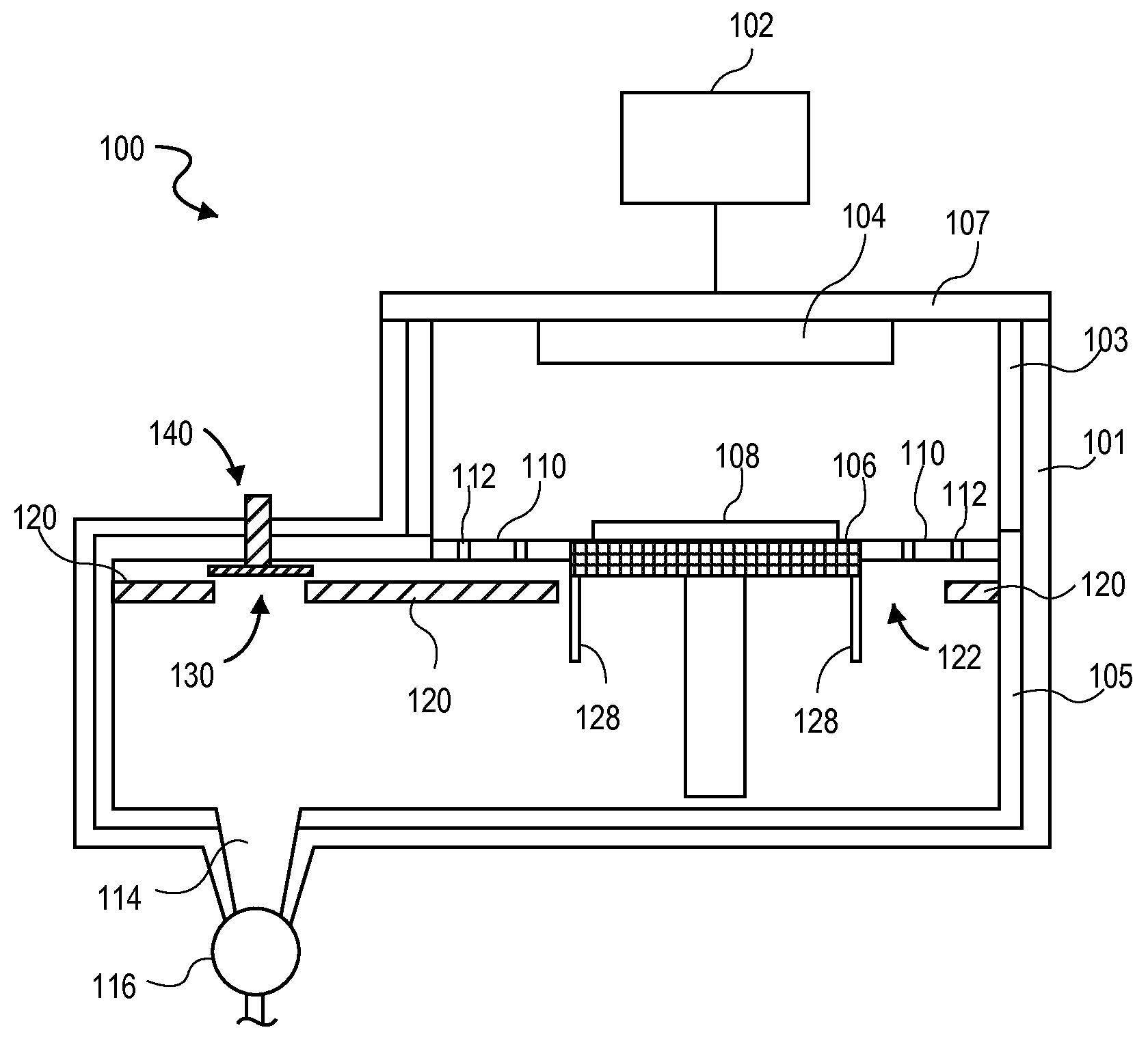

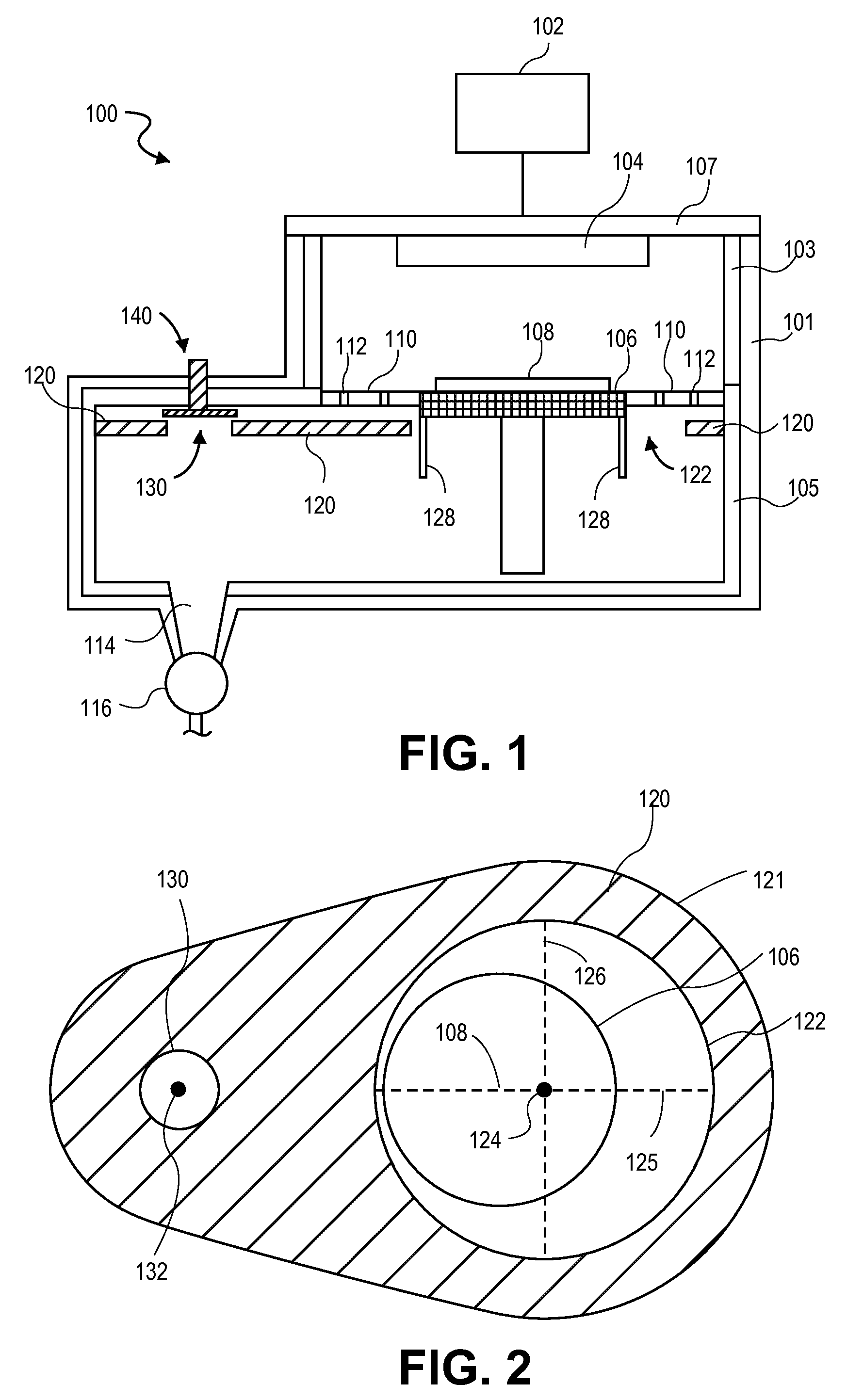

Tunable gas flow equalizer

InactiveUS20110005680A1Improve flow uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringStreamflow

A tunable gas flow equalizer is described. In an embodiment, the tunable flow equalizer includes a gas flow equalizer plate having primary opening and a secondary opening. The primary opening may surround a substrate support, and the secondary opening may be configured with a tuner. In an embodiment, the substrate support may be vertically adjustable with respect to the gas flow equalizer plate. The flow uniformity may be fine tuned by adjusting a tuner configured with a secondary opening in the gas flow equalizer plate and / or by adjusting the height of a vertically positionable substrate support plate having an inwardly tapered skirt 528 with respect to the gas flow equalizer plate 520.

Owner:APPLIED MATERIALS INC

Chamber lining

ActiveCN101399197AReduce pollutionAvoid generatingSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a chamber liner which is used for lining in a semiconductor chamber. The liner comprises a side wall, the shape and the size of which match with those of the inner wall of the semiconductor chamber, and the side wall of the liner is provided with a shield pore. The chamber liner provided by the invention is suitable for the side pulling semiconductor chamber, and film accumulation generated on the inner wall of the chamber can be reduced or even avoided, thus protecting the inner wall of the chamber effectively, reducing particle contamination and further improving the processing / treating quality of semiconductor devices, wafer, etc.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Parallel current sharing method for converters with weighted average of per-unit values of output current

InactiveCN101604922AImprove rationalityImprove flow uniformityDc-ac conversion without reversalPower inverterComputer module

The invention belongs to the technical field of parallel control of inverters, and relates to a parallel current sharing method for converters with the weighted average of per-unit values of output current. The widths of pulse signals of various inverter modules are used to represent per-unit values of output current, namely the percentage that the output current of a module accounts for the rated current thereof, the average value of the per-unit values of the output current of various modules is obtained through a mode of performing weighted voting on various pulse width signals, and the modules are converted into current values according to the average value to adjust respective output current to finally achieve that the per-unit values of the output current of the modules are equal within the allowed error range and realize the current sharing control of parallel inverters. The method is applicable to the parallel current sharing control of a plurality of inverter modules, particularly to the parallel current sharing control of a plurality of inverter modules with partially equal power. The current sharing control method can remarkably improve current sharing control accuracy, and ensure that the inverter modules bear corresponding output current according to the rated values thereof at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

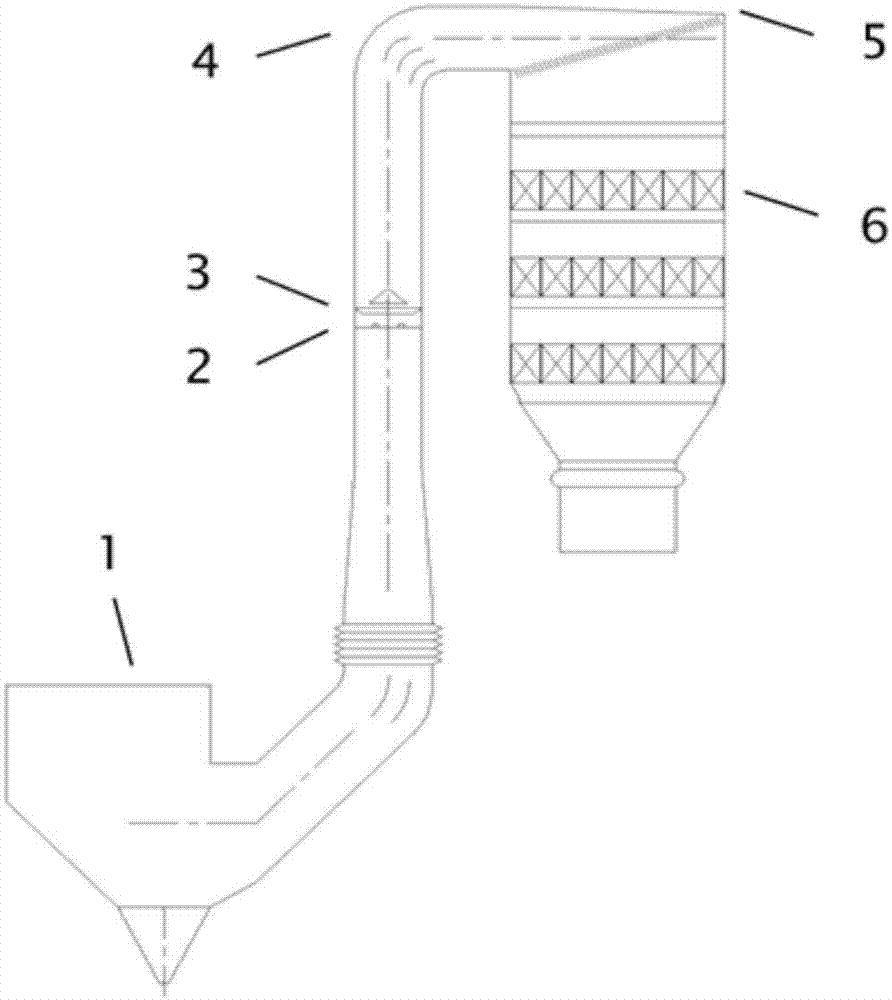

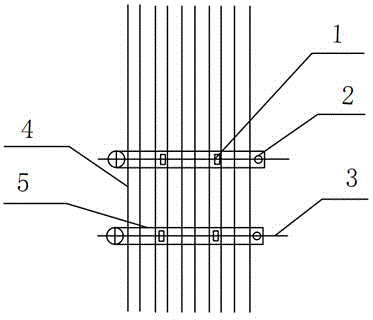

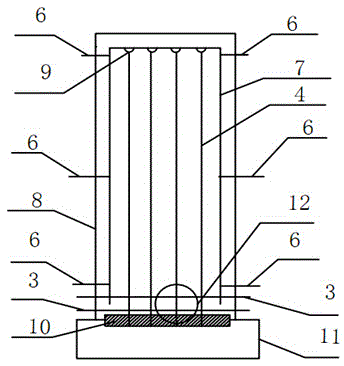

Vortex combined SCR static mixer

The invention discloses a vortex combined SCR static mixer, comprising a tip body, a plurality of arc flow deflectors with an axis where the tip body is located as a center axis, and a plurality of baffle plates uniformly distributed, with the axis as a center axis, on the lower ends of the flow deflectors, wherein the baffle plates allows flue gas to gather at an ammonia gas nozzle; the arc flow deflectors allow flue gas and ammonia gas to generate transverse speed and to spirally flow upward; and gas flow located at a central area and not directly influenced by the arc flow deflectors staggerly flows relative to peripheral gas flow after bumping onto the tip body, so flue gas and ammonia gas are mixed. The vortex combined SCR static mixer provided by the invention is beneficial for promoting diffusion of ammonia gas, greatly improves mixing effect, enhances the mol ratio uniformity of ammonia and nitrogen and exerts good effect on optimization and synergism of a SCR denitration system.

Owner:SHANDONG UNIV

Flat-plat membrane module and casting method thereof

ActiveCN104888607ABeautiful appearanceReduce the process of man-made membrane filamentSemi-permeable membranesBiological water/sewage treatmentYarnManufacturing engineering

The invention relates to the technical field of wastewater treatment, in particular to a casting method of a flat-plate membrane module. The casting method is particularly a process for fixing two ends of membrane yarns of a hollow-fiber membrane and the membrane shell of a flat-plate membrane in a casting manner. A rotatable inner bracket serves as a support, mechanism pieces are used for fixing membrane yarn tows in a divisional manner, and the hollow-fiber membrane yarns are subjected to rough handling by a flexible glue; the glue insertion process is carried out after the flexible glue is cured, and a hard glue is subjected to preliminary treatment to speed up curing; the flexible glue is added after the hard glue is cured; after the two-end casting is finished, the membrane module is cut to complete casting of the flat-plate membrane module. The casting method not only improves the working efficiency but also solves the problems that the flowing uniformity of the flexible glue, the fatigue resistance of the root parts of the membrane yarns, and the adhesion between the membrane yarns and the flexible glue are influenced by yarn climbing of the hard glue, and can be applied to obtain the high-performance flat-plate membrane module.

Owner:南京万瑞环境科技有限公司

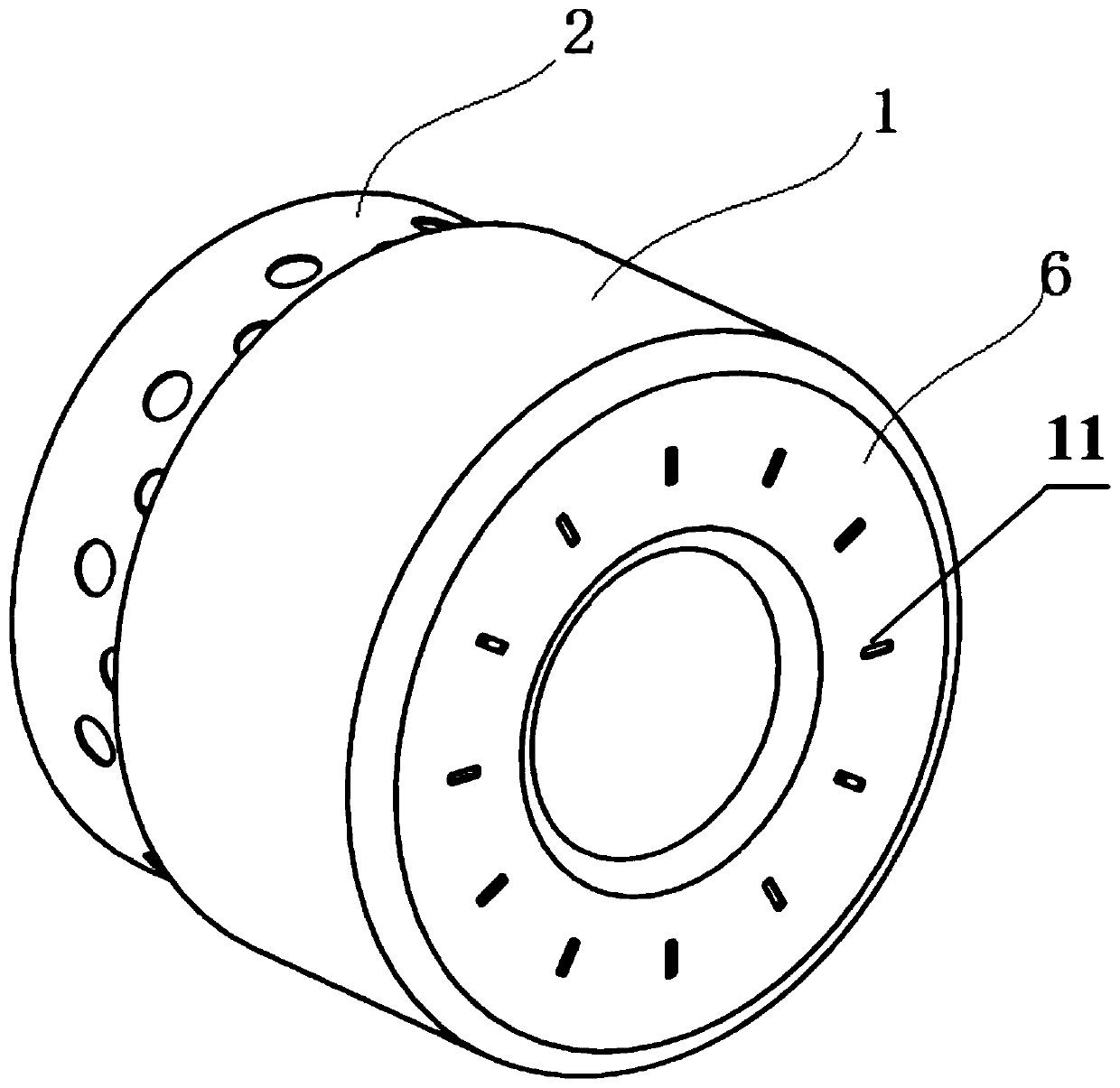

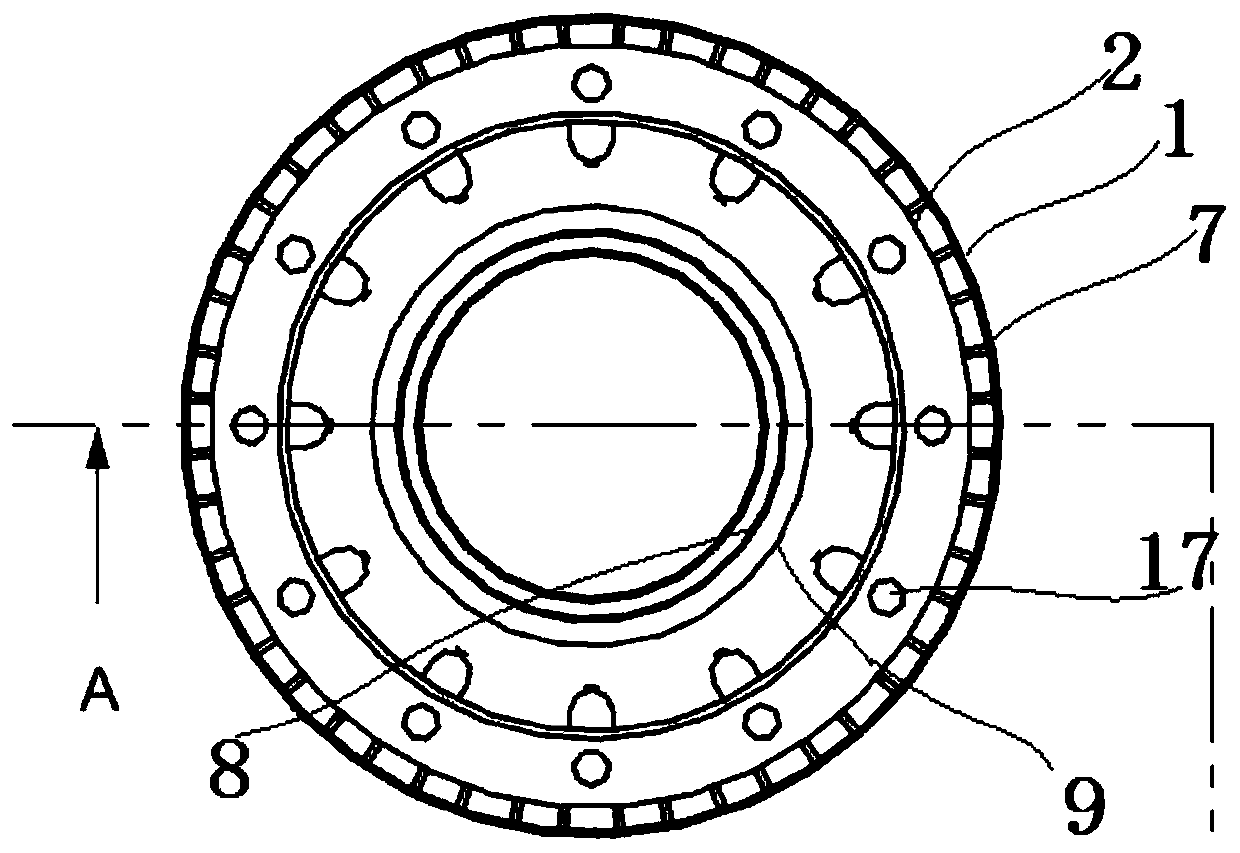

Current equalizing busbar

ActiveUS20140362627A1Simple structureImprove flow uniformitySingle bars/rods/wires/strips conductorsConversion constructional detailsPower flowEngineering

The present application discloses a current equalizing busbar for a converter comprising: a direct current busbar connected to a DC terminal of the converter and positive terminals and negative terminals of respective power modules; and an alternate current busbar connected to AC terminals of the respective power modules and a load; wherein, when the converter operates, a sum of an inductance caused by the DC busbar between the DC terminal and a positive terminal or a negative terminal of a power module and an inductance caused by the AC busbar between the load and an AC terminal of the power module is equal to a sum of an inductance caused by the DC busbar between the DC terminal and positive terminals or negative terminals of other power modules and an inductance caused by the AC busbar between the load and AC terminals of said other power modules.

Owner:DELTA ELECTRONICS INC

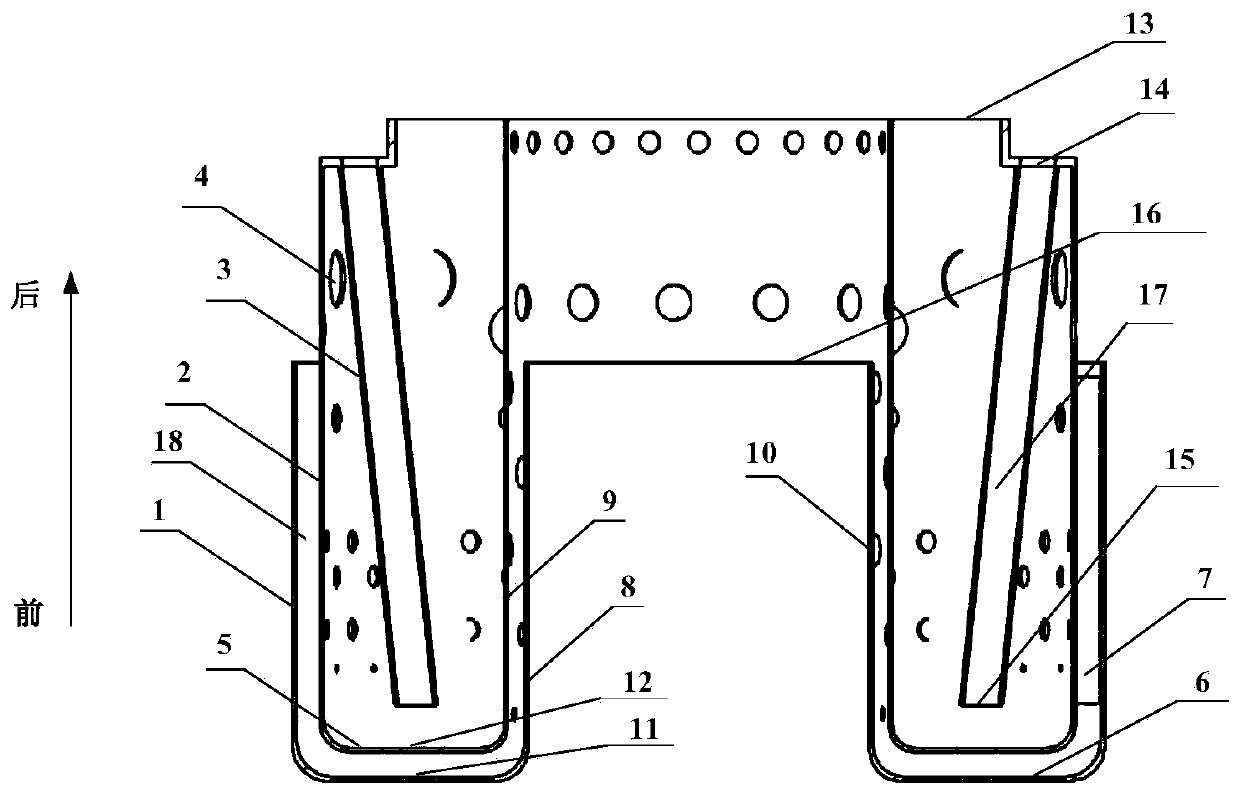

Secondary-flow evaporation tube type combustion chamber structure

ActiveCN111023155AReduce the chance of ablationSmall sizeContinuous combustion chamberCombustion chamberMechanical engineering

The invention discloses a secondary-flow evaporation tube type combustion chamber structure. A combustion chamber body and a baffle plate are adopted, wherein the front end of the combustion chamber body is shaped like a cylinder, and the upper end of the baffle plate is provided with an annular groove; the baffle plate is additionally arranged on an outer wall surface of a combustion chamber, andair film holes are formed in the annular cylindrical barrel wall and the groove wall of the annular groove, so that the reverse air flow of a secondary flow in a casing is heated and heated again after being injected by a primary air flow at the head of the combustion chamber and mixed; and then the combustion flame temperature field is more uniform, the heat transfer of the fin reinforced wall surface enables the temperature of the wall surface to be effectively decreased, the uniformity of the flow field is optimized, the combustion efficiency is improved, and the emission of pollutants such as NOx is greatly reduced while fuel is saved. The annular cylindrical outer wall and the inner wall of the annular groove are connected through fins to form an integrated forming structure, the overall weight of the device is reduced, the outline size of the combustion chamber is decreased, the thrust ratio of an engine is effectively increased, and the maneuverability of the engine is increased; and the using number of connecting parts between structural members is decreased at the same time, and the overall performance is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

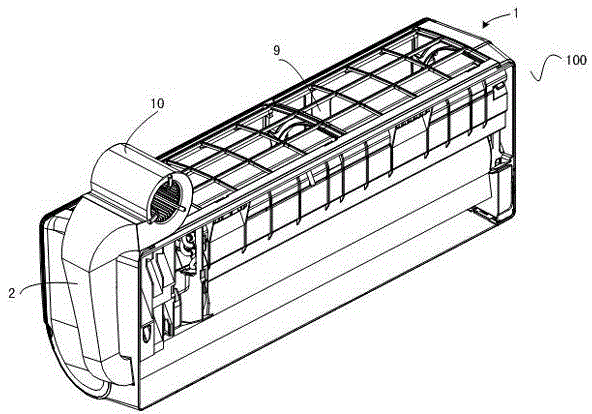

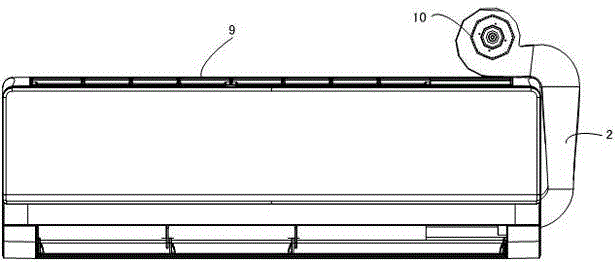

Wall-hung air conditioner with drainage structure

InactiveCN105698267AImprove comfort experienceSpeed up the flowDucting arrangementsLighting and heating apparatusEngineeringFlue

The invention discloses a wall-hung air conditioner with drainage structure. The wall-hung air conditioner comprises an indoor unit; the indoor unit includes a shell; a cross flow fan and a heat exchanger are formed in the shell; a strip-shaped air outlet is formed in the shell; an air guide port is formed in a back volute, provided with an air supply flue of the main cross flow fan, along the length direction of the air outlet; and an induced draft fan is arranged above the shell, and is communicated with the air guide port through an air guide channel. The wall-hung air conditioner can solve the problems of insufficient softness of exhaust and low air supply quantity in a traditional wall-hung air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

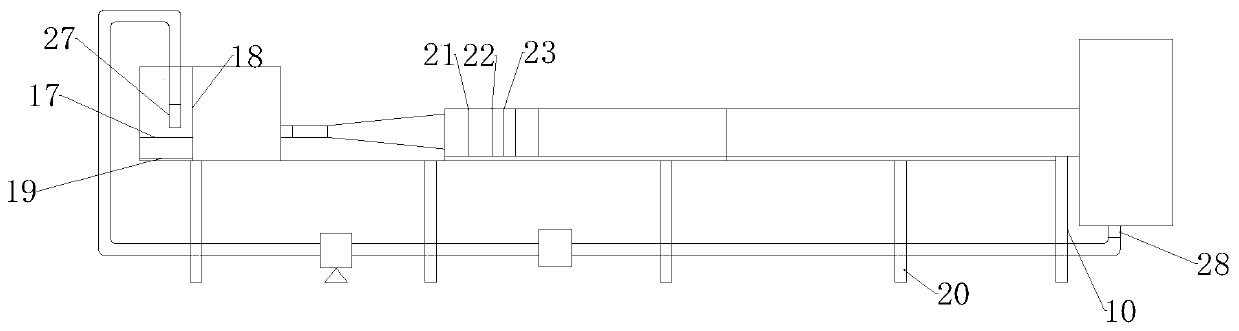

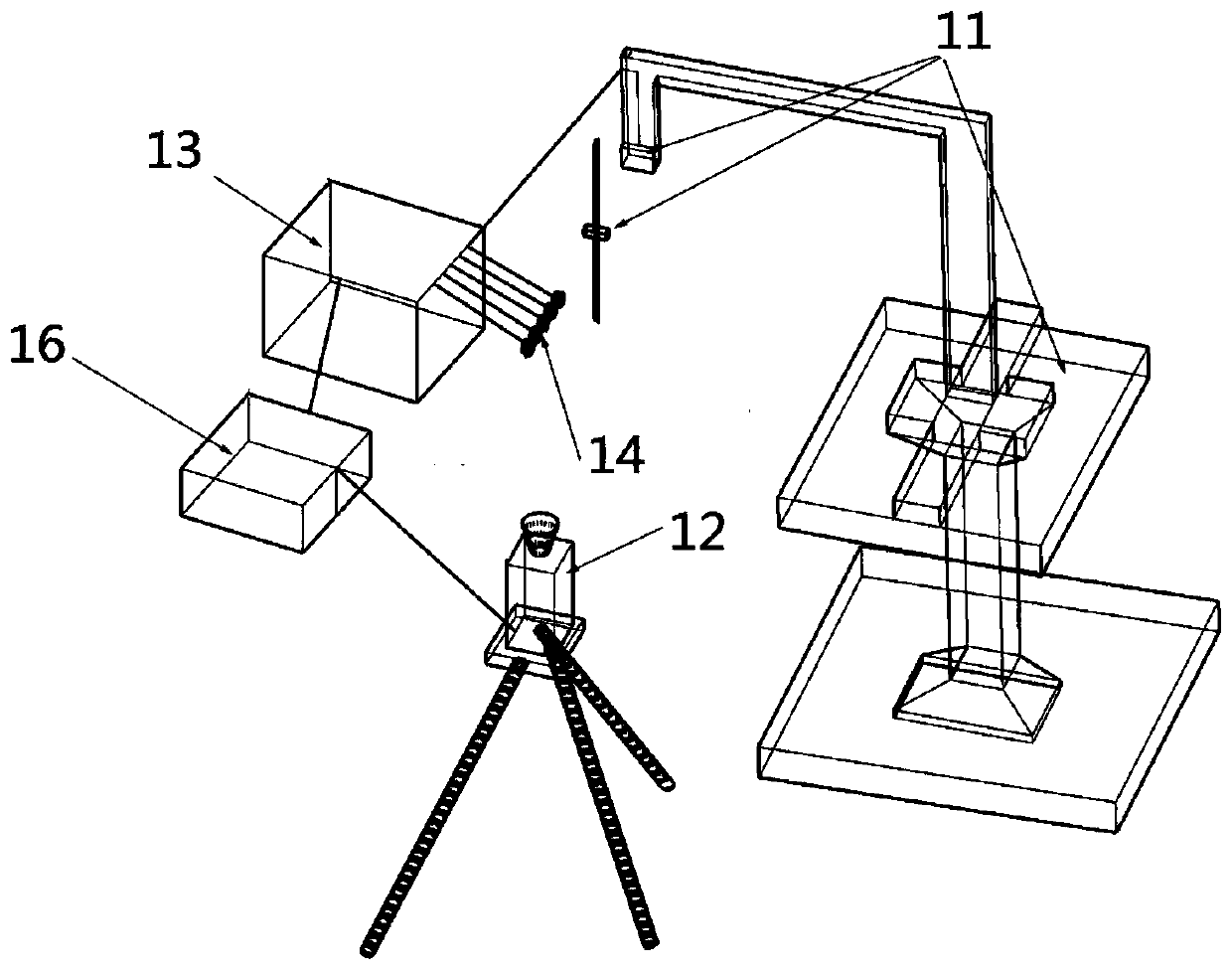

Pressure high chord thickness ratio empty box bluff body streaming flow induced vibration test device

ActiveCN111537190AHigh precisionImprove uniformitySubsonic/sonic/ultrasonic wave measurementHydrodynamic testingTest measurementSensor array

The invention discloses a pressure high chord thickness ratio empty box bluff body streaming flow induced vibration test device. An empty box is arranged in a test section water tank, the empty box isof a cuboid, cylinder or irregular structure with openings in the top end and the bottom end, and holes consistent in size and shape are formed in the portion, corresponding to the opening area in the top end of the empty box, of a top plate of the test section water tank; a test measurement part is arranged outside the test section water tank, and comprises a vibration displacement measurement system, a micro pulsating pressure sensor array, a PIV system, a multifunctional dynamic measurement instrument and a synchronous clock; oscillating bar vibration signals obtained by the vibration displacement measurement system and water flow pulsating pressure change signals detected by the micro pulsating pressure sensor array are transmitted to the multifunctional dynamic measuring instrument respectively and recorded, and signals of the multifunctional dynamic measurement instrument and the PIV system are synchronized through the synchronous clock. The device has the advantages of both contact measurement and non-contact measurement, and improves the precision of vibration displacement measurement while not interfering with a flow field.

Owner:NANJING HYDRAULIC RES INST

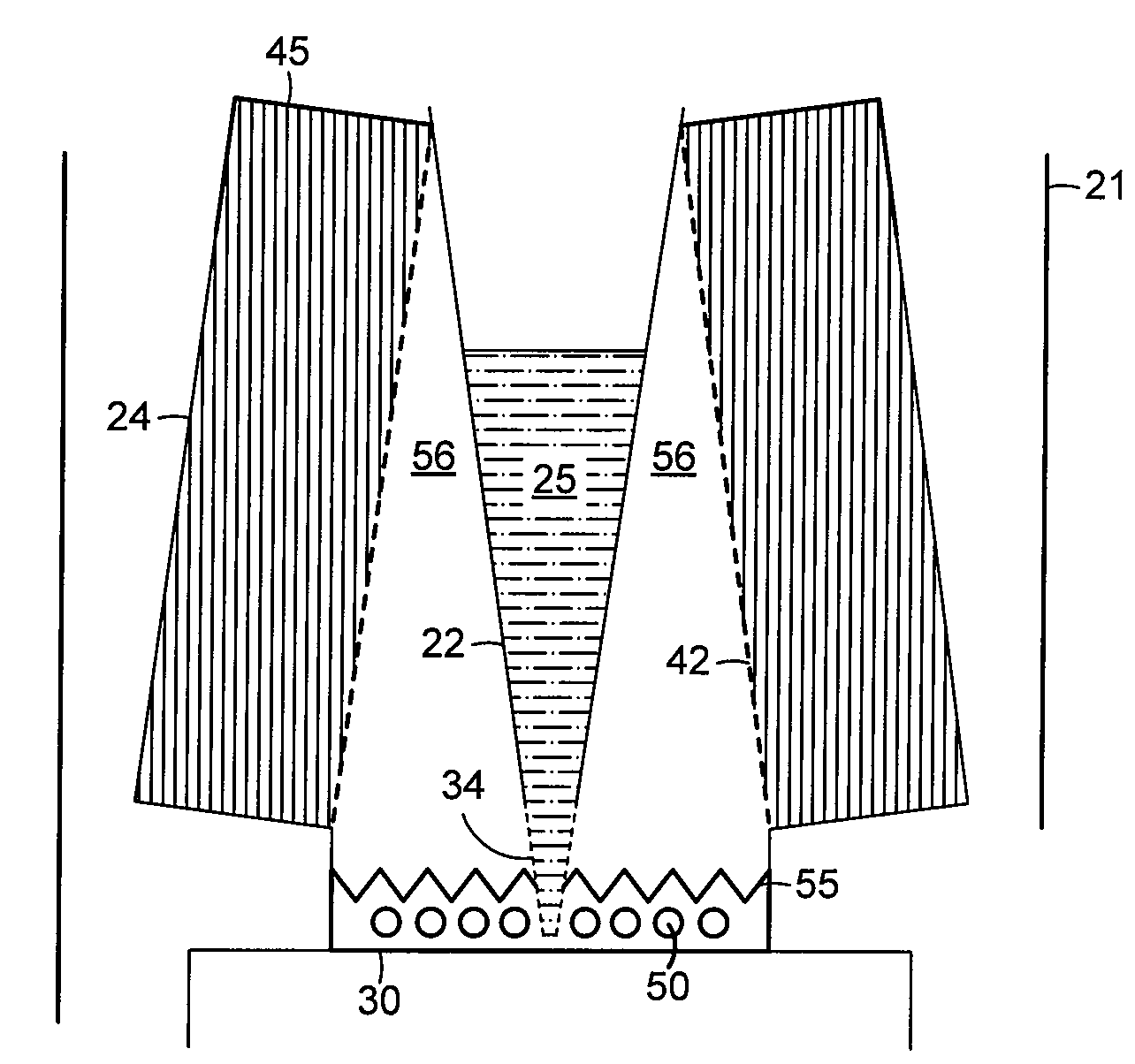

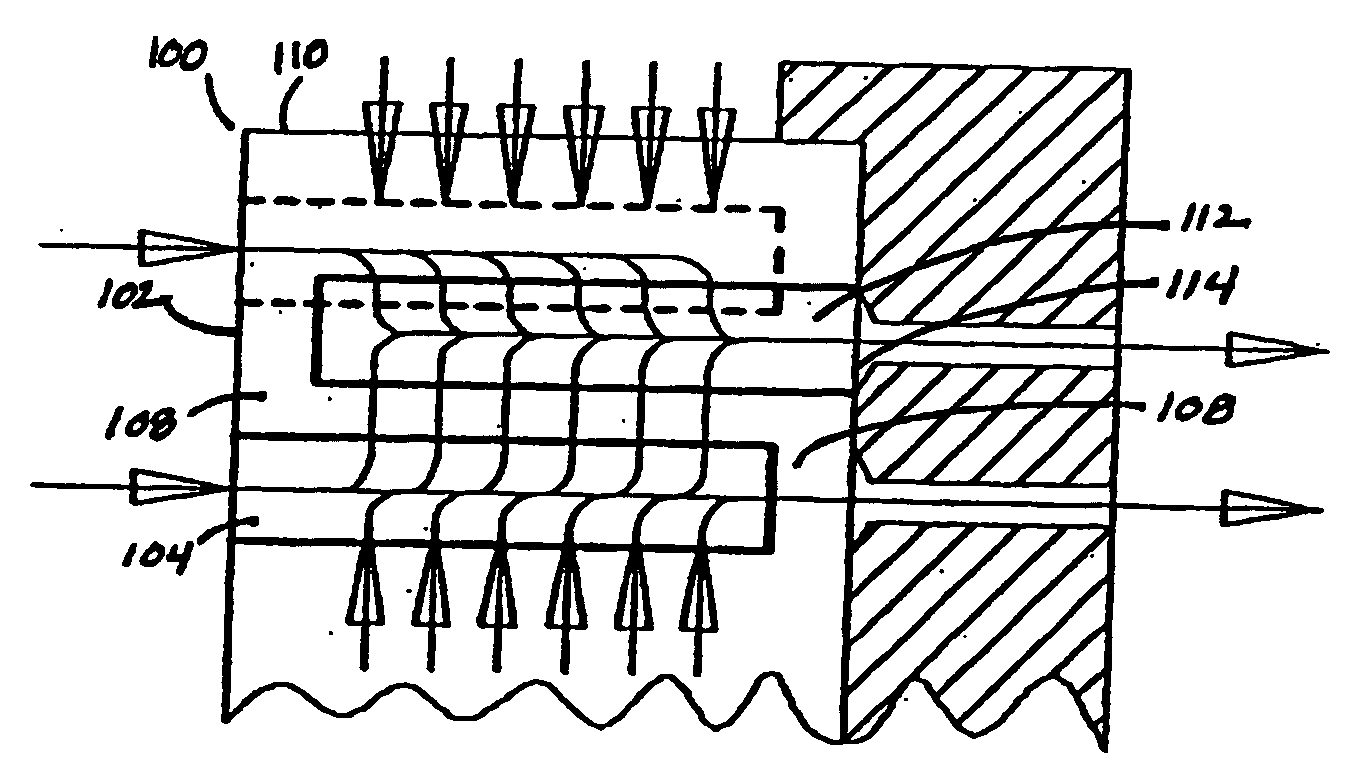

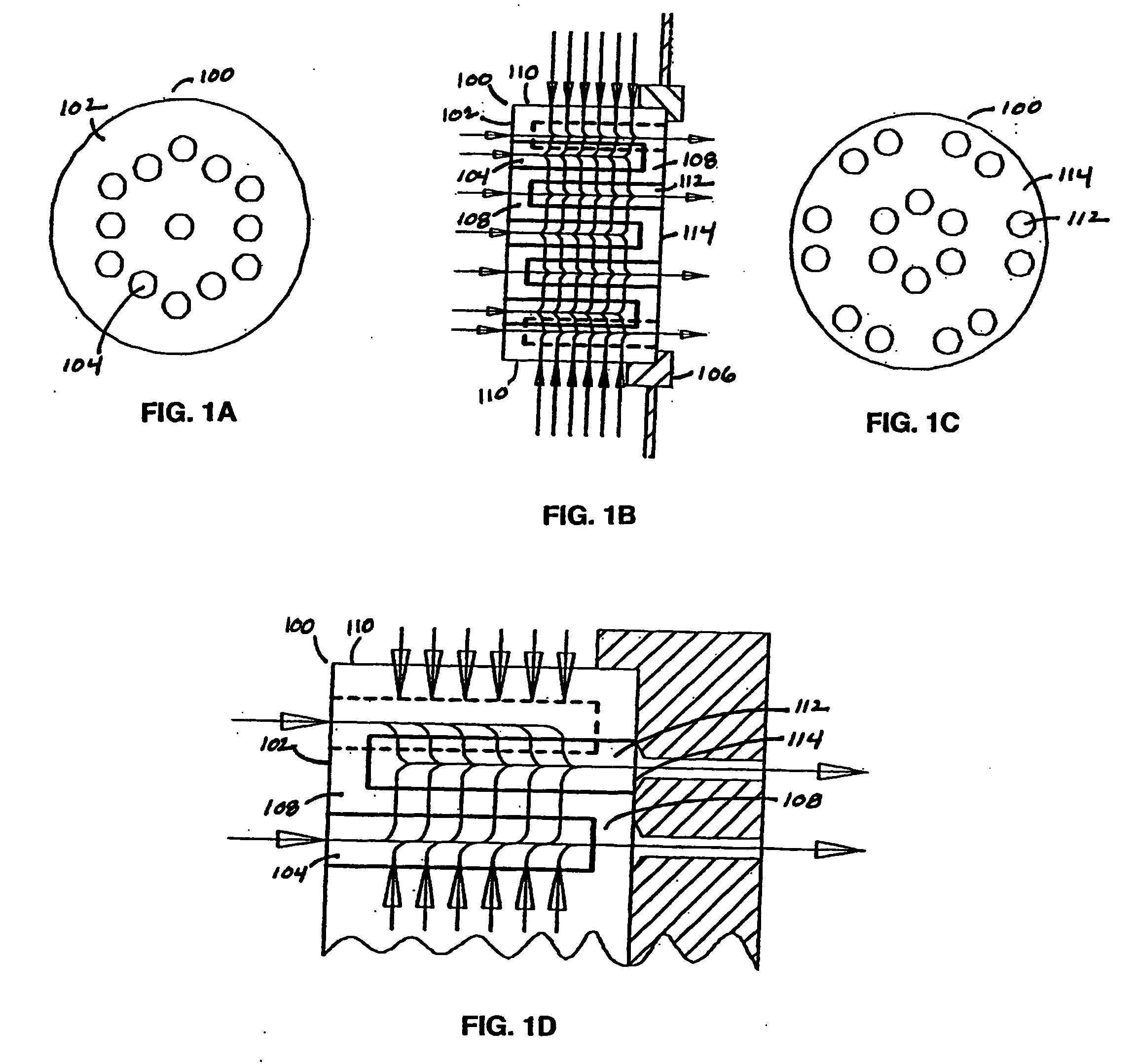

Method of making extended area filter

InactiveUS7361300B2Improve flow uniformityEfficiently and economically produced and and maintained and replacedSpinning solution de-aeratingSpinnerette packsMetal powderPolymer melt

Methods are provided for making a porous filter that is useful in polymer melt spinning. The methods include pressing particles, such as a metal powder, to form a filter having a filter body integrally formed with a top cap and a bottom cap. The filter body and caps are formed as a single component or, alternatively, are formed as two or three separate parts that are fitted and pressed together to form a single component having blind inlet and outlet cavities. After pressing, the component is sintered to form the porous filter. The particles are pressed and cohere to form the caps and filter body without the use of a polymeric binder, and the inlet and outlet cavities are formed substantially without machining.

Owner:MOTT CORP

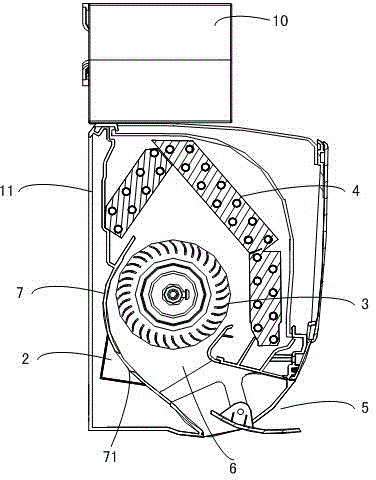

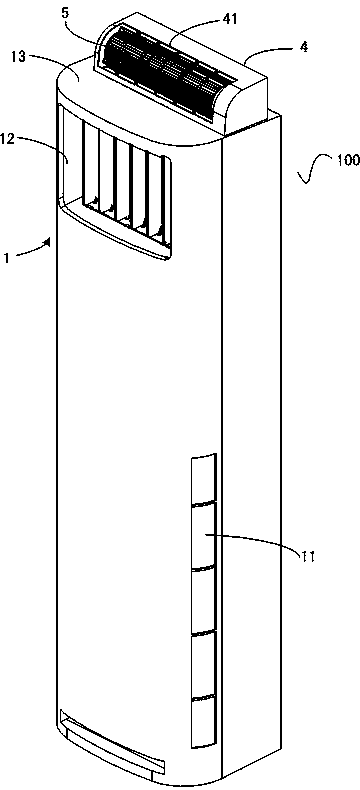

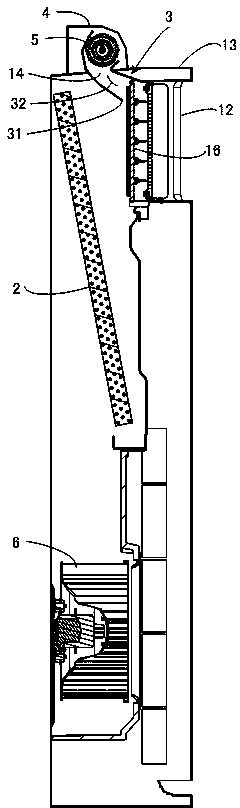

Vertical air conditioner indoor unit with drainage structure

InactiveCN105698264AImprove comfort experienceLarge amount of induced airLighting and heating apparatusAir conditioning systemsEngineeringHeat exchanger

The invention discloses a vertical air conditioner indoor unit with a drainage structure. The vertical air conditioner indoor unit comprises a cabinet; a heat exchanger is formed in the cabinet; an air outlet is formed in the cabinet opposite to the heat exchanger; an air guide port is formed in a top plate of the cabinet; an air guide channel is formed in the cabinet; the starting end of the air guide channel is connected with the air guide port, and the tail end of the air guide channel extends to the air outlet; an induced draft fan is formed on the top plate; and an air outlet end of the induced draft fan is towards the air guide port, and is communicated with the air guide channel. The vertical air conditioner indoor unit can solve the problems of insufficient softness of exhaust and low air supply quantity in a traditional vertical air conditioner indoor unit.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Constant diameter right-angle extruding production of micro/nanometer crustal industrial pure titanium block

An isometric angle squeezing technology for preparing micron / nano-crystal industrial-purity Ti block includes such steps as providing an industrial-purity Ti block, annealing, holding its temp, cutting it to become blanks, polishing the surface of blank, coating glass lubricant, coating graphite lubricant on the inner surface of an isometric angle squeezing die with a squeezing channel angle of 90-120 deg, heating said blank and die, and isometric angle squeezing. Its product has high strength, plasticity, biocompatibility and anticorrosion nature, the elastic modulus similar to that of bone, and low cost.

Owner:SHANGHAI JIAO TONG UNIV

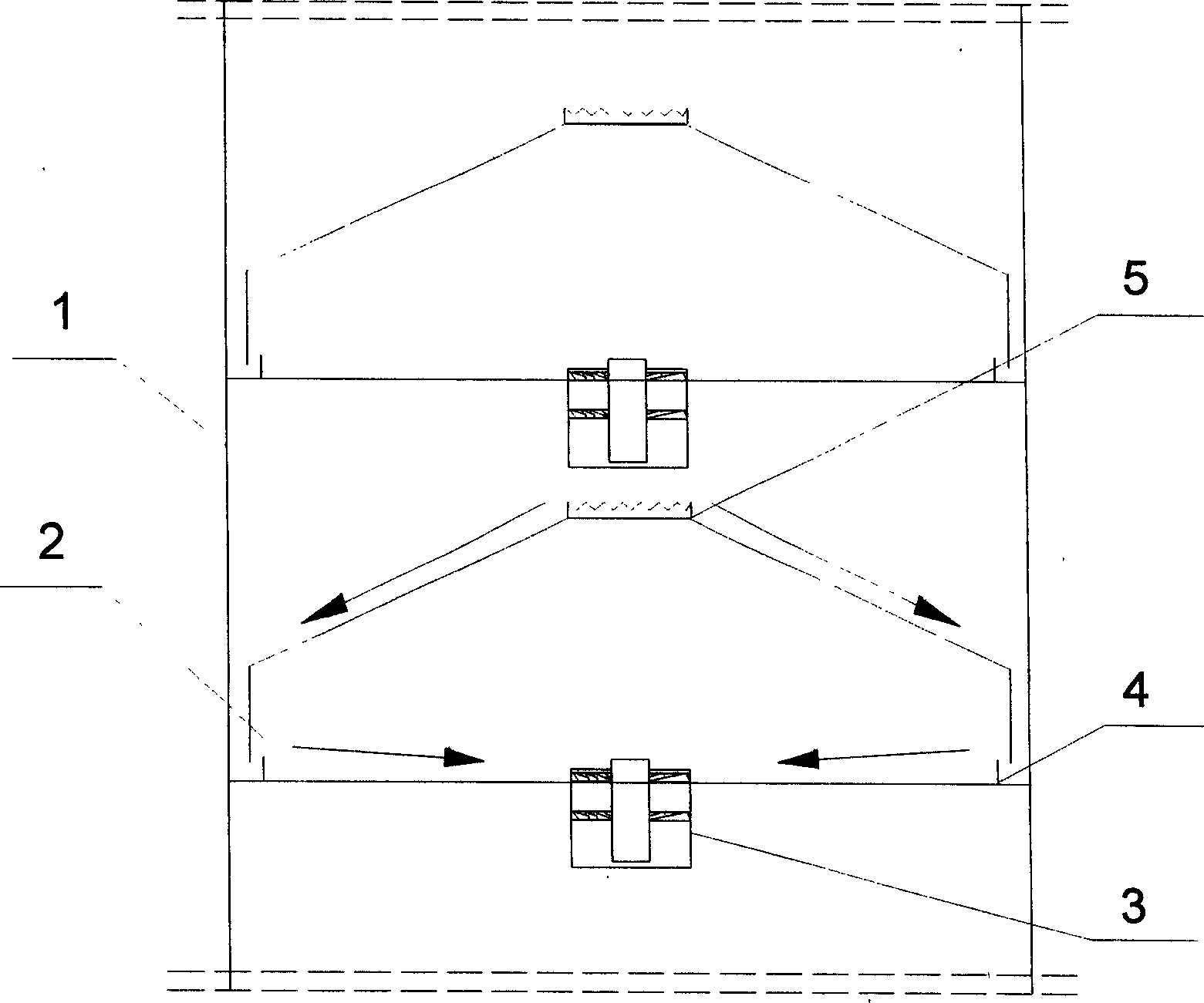

Distributor system for downflow reactors

ActiveUS7601310B2Increase the sectionImprove flow uniformityChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical nozzle-type rreactorsLine tubingProcess engineering

Downflow catalytic reactor having a plurality of catalyst beds in which a mixture of gas and liquid are passed, the region in between subsequent catalyst beds being provided with a distributor system for the distribution and mixing of gas and liquid prior to contact with a subsequent catalyst bed, said region comprising:(a) gas injection line arranged below a catalyst support tray,(b) collector tray adapted to receive gas and liquid,(c) spillway collectors extending above the level of said collecting tray,(d) mixing chamber adapted to receive the gas and liquid descending from said spillway collectors,(e) impingement plate below said mixing chamber,(f) first distributor tray arranged below said impingement plate having a number of apertures throughout and a number chimneys, and(g) second distributor tray arranged below said first distributor tray for the redistribution of gas and liquid prior to contact with the subsequent catalyst bed, wherein the at least one chimney is provided with a distributor device that is able to divide the chimney chamber into at least two chambers.

Owner:TOPSOE AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com