Flat-plat membrane module and casting method thereof

A casting method and curtain film technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Non-uniformity, decreased membrane filament protection performance, etc., to achieve the effect of reducing the process of artificially arranging membrane filaments, having a beautiful appearance and reducing the time required for curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Casting of Curtain Membrane Modules

[0039] The materials and specifications of the curtain membrane module are as follows:

[0040] The overall length of the curtain membrane module: 0.5m;

[0041] Hollow fiber membrane filament: PVDF material, quantity 100 pieces;

[0042] Hard glue: epoxy resin, soft glue: polyurethane.

[0043] Module performance: the number of broken membrane filaments ≤ 99.5%.

[0044] The casting process is as follows:

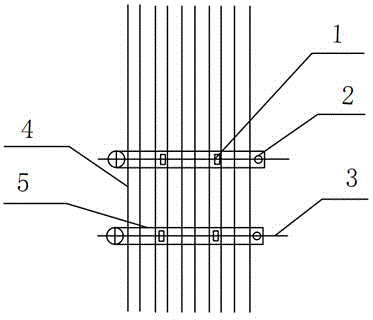

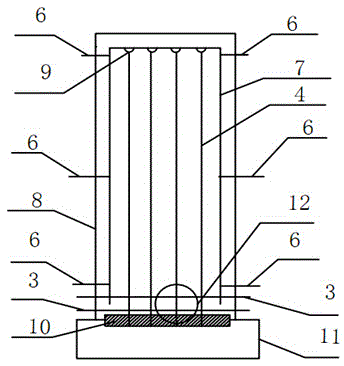

[0045] (1) Suspend the membrane filaments and partition the membrane filaments; hang 100 hollow fiber membrane filaments (4) on the 2 hooks (9) of the rotatable inner support (7);

[0046] (2) Take a 0.5m-long hollow fiber membrane, bind the membrane filament bundle at the same position with a nylon cable tie, cut the membrane filament and plug the hole;

[0047] (3) Use free clips (5) to partition the membrane filaments, the number of partitions is 2 groups, each group of partitions uses two free clips, each o...

Embodiment 2

[0058] Example 2: Casting of Curtain Membrane Modules

[0059] The materials and specifications of the curtain membrane module are as follows:

[0060] Curtain membrane module overall length: 2m;

[0061] Hollow fiber membrane filament: PTFE material, quantity 3000 pieces;

[0062] Hard glue: epoxy resin, soft glue: polyurethane.

[0063] The casting process is as follows:

[0064] (1) Suspend the membrane filaments and partition the membrane filaments, hang 3000 hollow fiber membrane filaments (4) on the 6 hooks (9) of the rotatable inner support (7);

[0065] (2) Take a 2m long hollow fiber membrane, bind the membrane filament bundle at the same position with nylon cable ties, cut the membrane filament and plug the hole;

[0066] (3) Use free clips (5) to partition the membrane filaments. The number of partitions is 8 groups. Two free clips are used for each group of partitions. The distance between the free clips is 30mm and 60mm from the bottom of the membrane filame...

Embodiment 3

[0077] Example 3: Casting of Curtain Membrane Modules

[0078] The materials and specifications of the curtain membrane module are as follows:

[0079] Curtain membrane module overall length: 2.5m

[0080] Hollow fiber membrane filament: PVDF material, quantity 6000 pieces

[0081] Hard glue: epoxy resin, soft glue: polyurethane.

[0082] The casting process is as follows:

[0083] (1) Suspend the membrane filaments and partition the membrane filaments, hang 6000 hollow fiber membrane filaments (4) on 8 hooks (9) of the rotatable inner support (7);

[0084] (2) Take a 2.5m long hollow fiber membrane, tie the membrane filament bundle at the same position with nylon cable ties, cut the membrane filament and plug the hole;

[0085] (3) Use free clamps (5) to partition the membrane filaments, the number of partitions is 8 groups, and each group partition uses two free clamps, each of which is 30mm and 60mm away from the bottom of the membrane filaments, and the vertical ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Overall length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com