Patents

Literature

149results about How to "No clutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

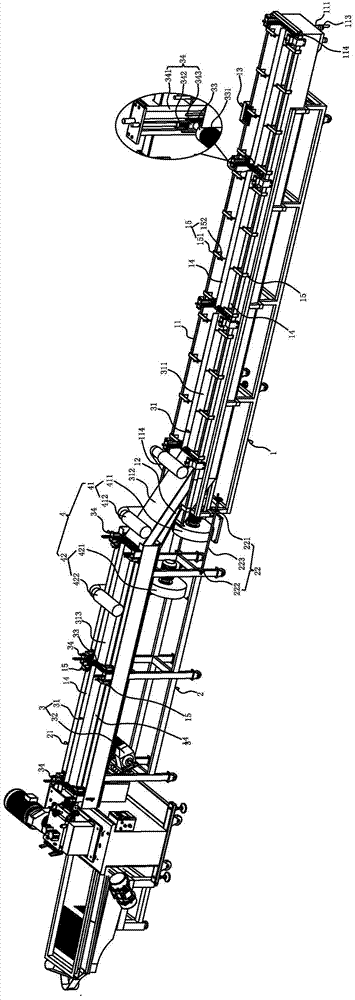

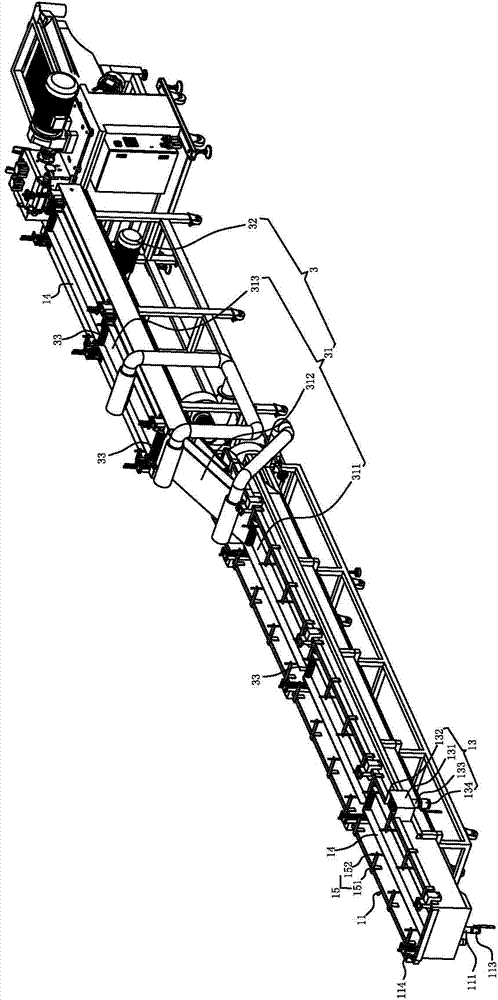

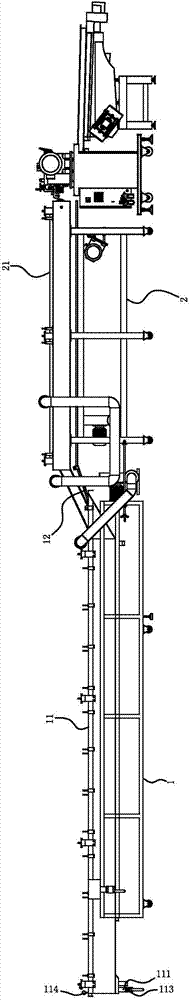

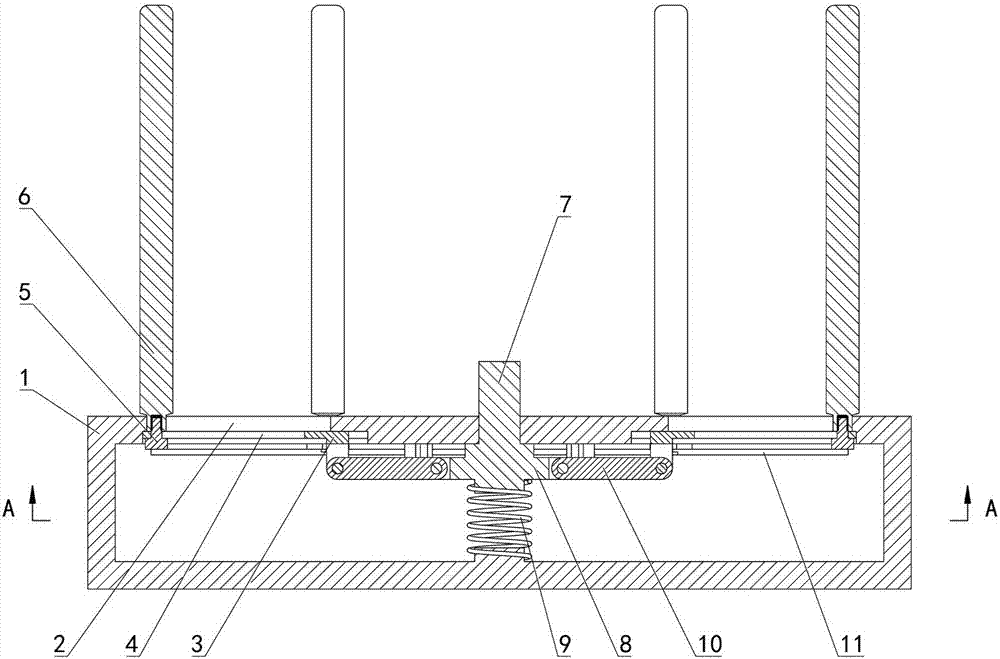

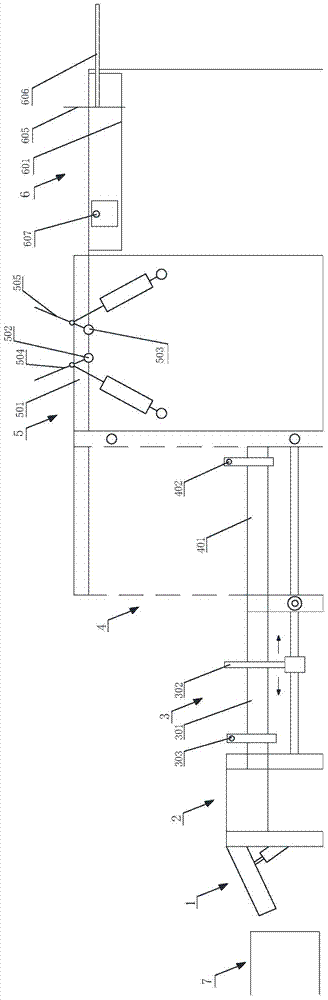

Material strip granulation production process and material strip traction equipment used in material strip granulation production process

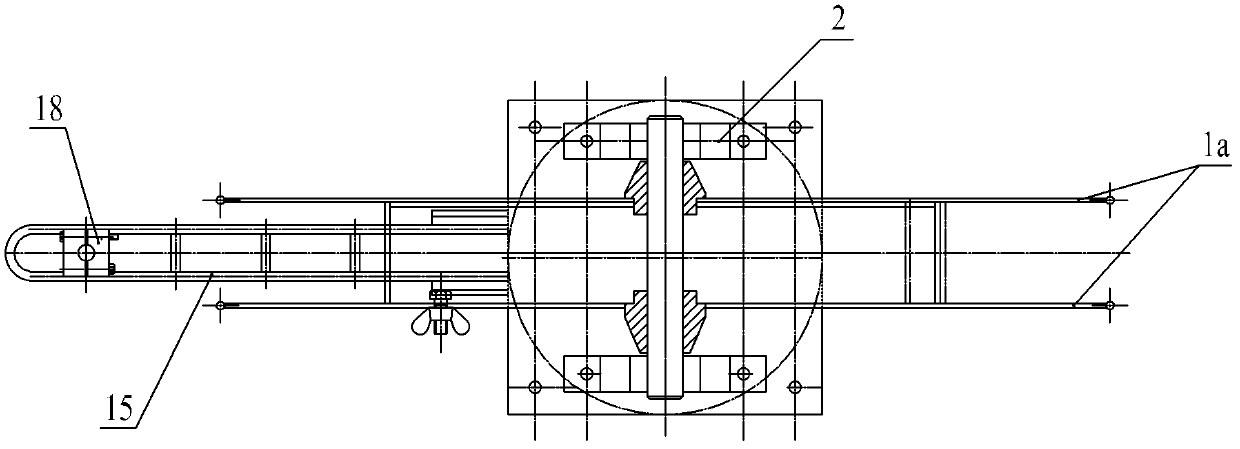

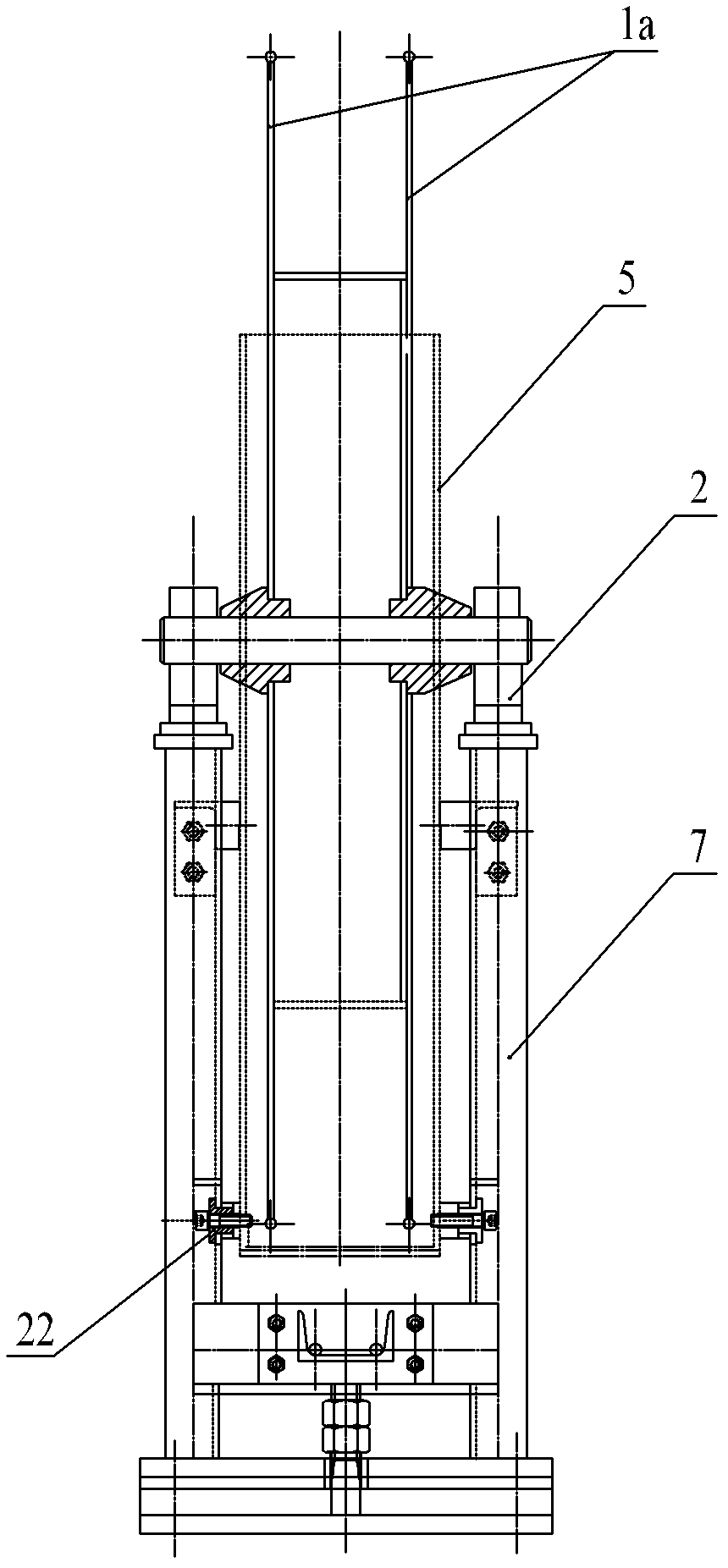

The invention discloses a material strip granulation production process. The material strip granulation production process comprises the following steps: step 1, processing plastic raw materials by a material strip extruder and extruding plastic material strips; step 2, conveying the plastic material strips to a cooling water tank of material strip traction equipment to be cooled, and conveying the cooled plastic material strips by matching of a first section of conveying crawler belt and rotary rollers; step 3, conveying the plastic material strips to a second section of conveying crawler belt in an inclined state in the material strip traction equipment and carrying out air drying treatment on the plastic material strips by an air drying device; step 4, conveying the plastic material strips which are dried by air into a plate slot in the material strip traction equipment, and reshaping and conveying the plastic material strips by the matching of the second section of conveying crawler belt and the rotary rollers; and step 5, carrying out granulation treatment on the plastic material strips by a granulator. A complete stainless steel net crawler belt is composed of the first section of conveying crawler belt, the second section of conveying crawler belt and a third section of conveying crawler belt; the widths of holes in the stainless steel net crawler belt is less than 2mm; the stainless steel net crawler belt, the material strip extruder and the granulator are synchronously operated at an uniform operating speed.

Owner:DONGGUANG HUI RU LAI POWER TECH CO LTD

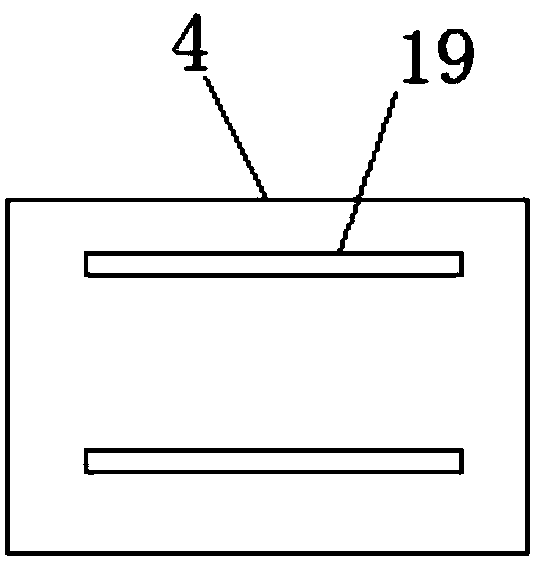

Flat-plat membrane module and casting method thereof

ActiveCN104888607ABeautiful appearanceReduce the process of man-made membrane filamentSemi-permeable membranesBiological water/sewage treatmentYarnManufacturing engineering

The invention relates to the technical field of wastewater treatment, in particular to a casting method of a flat-plate membrane module. The casting method is particularly a process for fixing two ends of membrane yarns of a hollow-fiber membrane and the membrane shell of a flat-plate membrane in a casting manner. A rotatable inner bracket serves as a support, mechanism pieces are used for fixing membrane yarn tows in a divisional manner, and the hollow-fiber membrane yarns are subjected to rough handling by a flexible glue; the glue insertion process is carried out after the flexible glue is cured, and a hard glue is subjected to preliminary treatment to speed up curing; the flexible glue is added after the hard glue is cured; after the two-end casting is finished, the membrane module is cut to complete casting of the flat-plate membrane module. The casting method not only improves the working efficiency but also solves the problems that the flowing uniformity of the flexible glue, the fatigue resistance of the root parts of the membrane yarns, and the adhesion between the membrane yarns and the flexible glue are influenced by yarn climbing of the hard glue, and can be applied to obtain the high-performance flat-plate membrane module.

Owner:南京万瑞环境科技有限公司

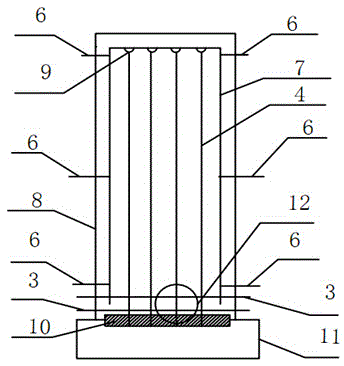

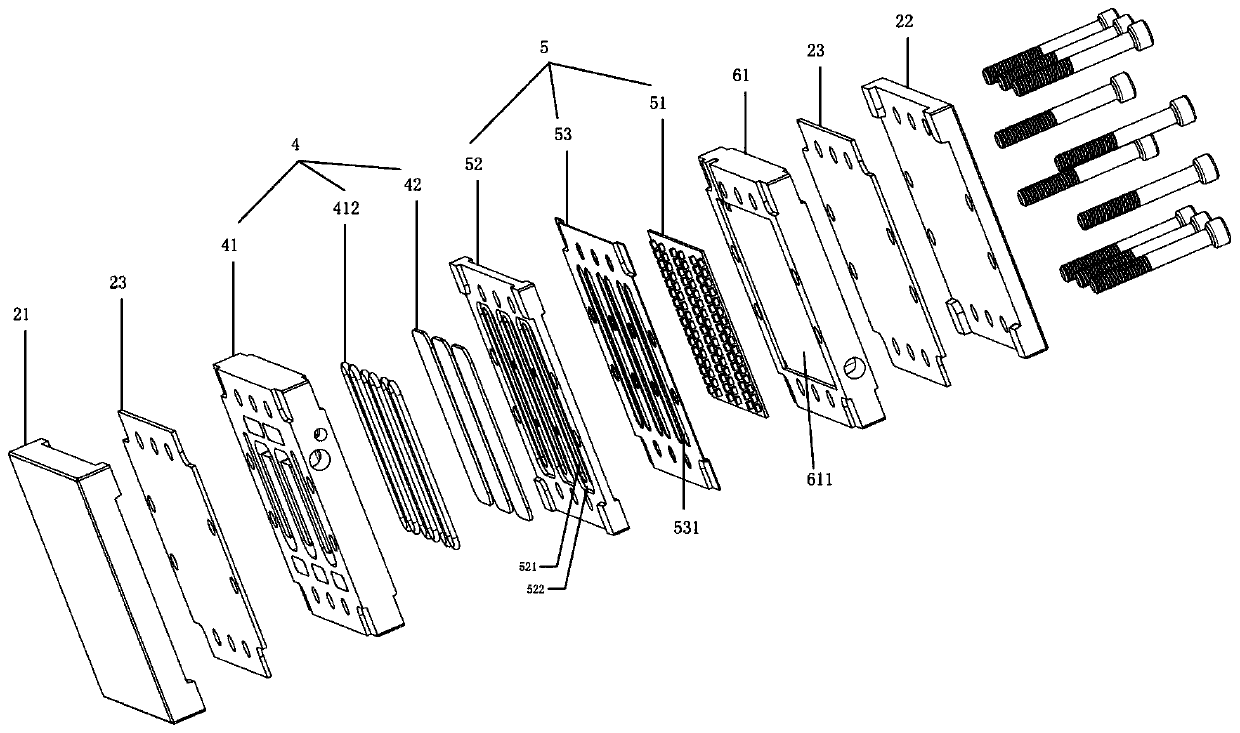

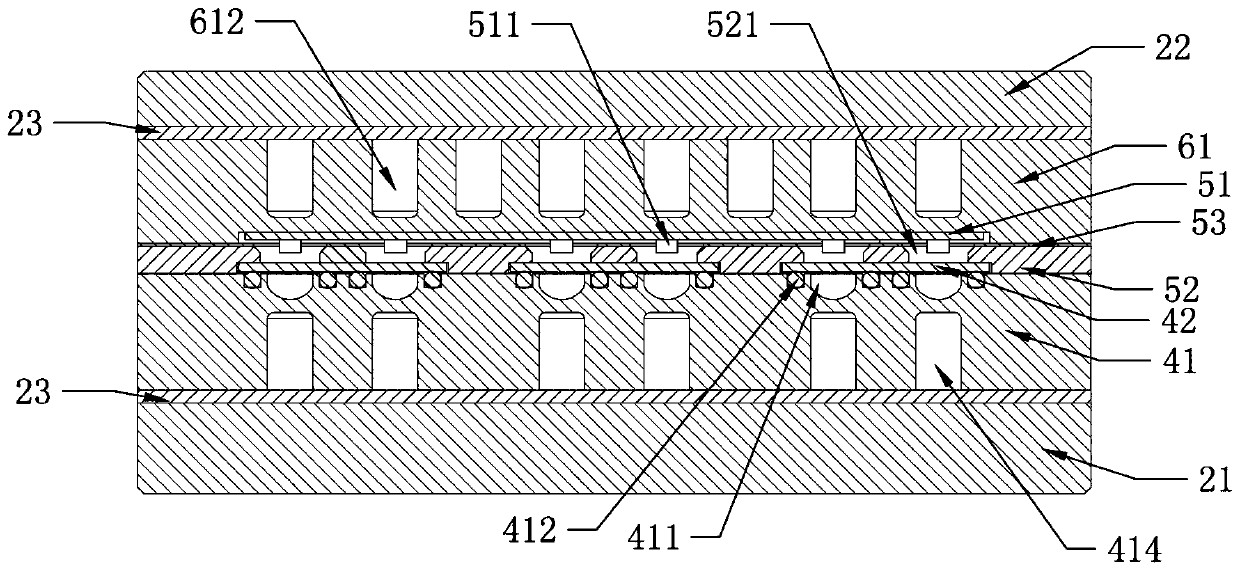

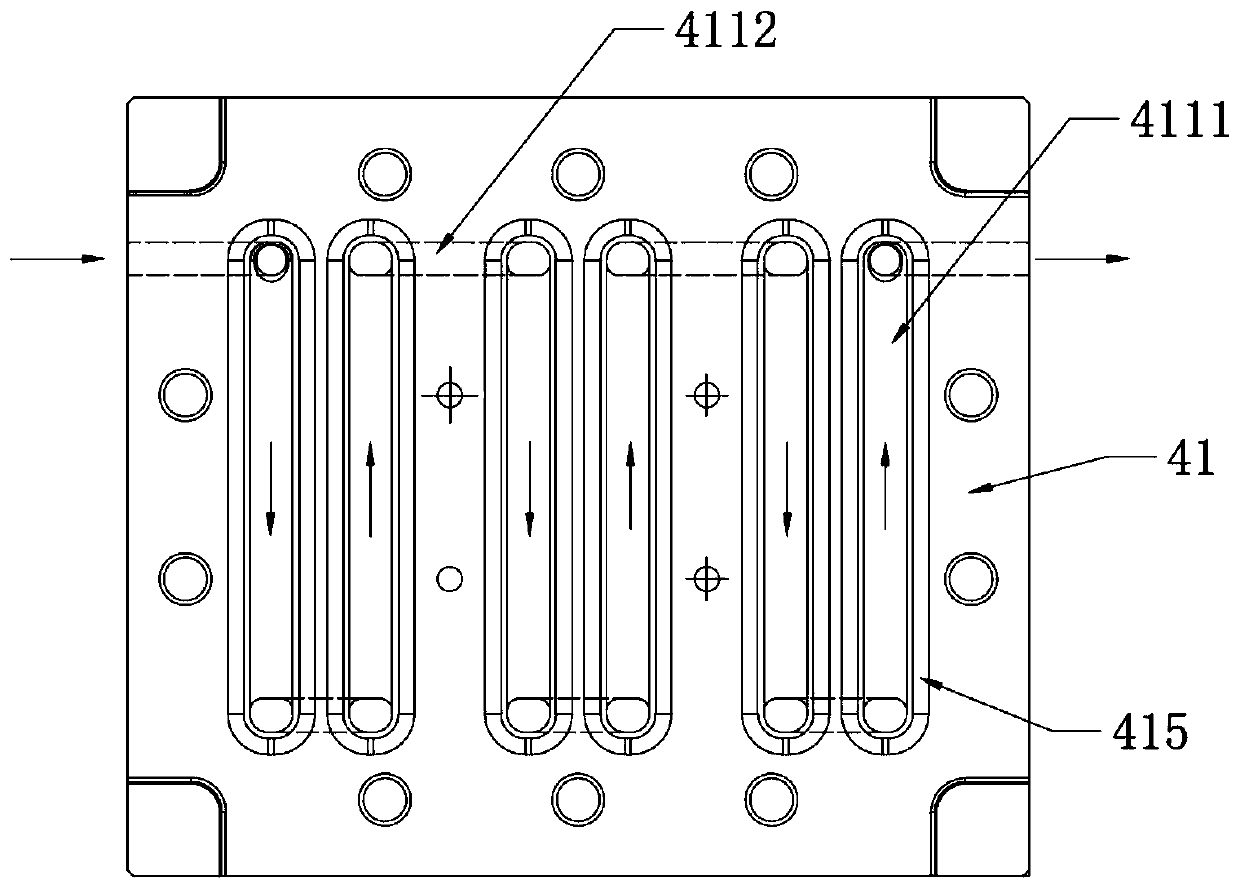

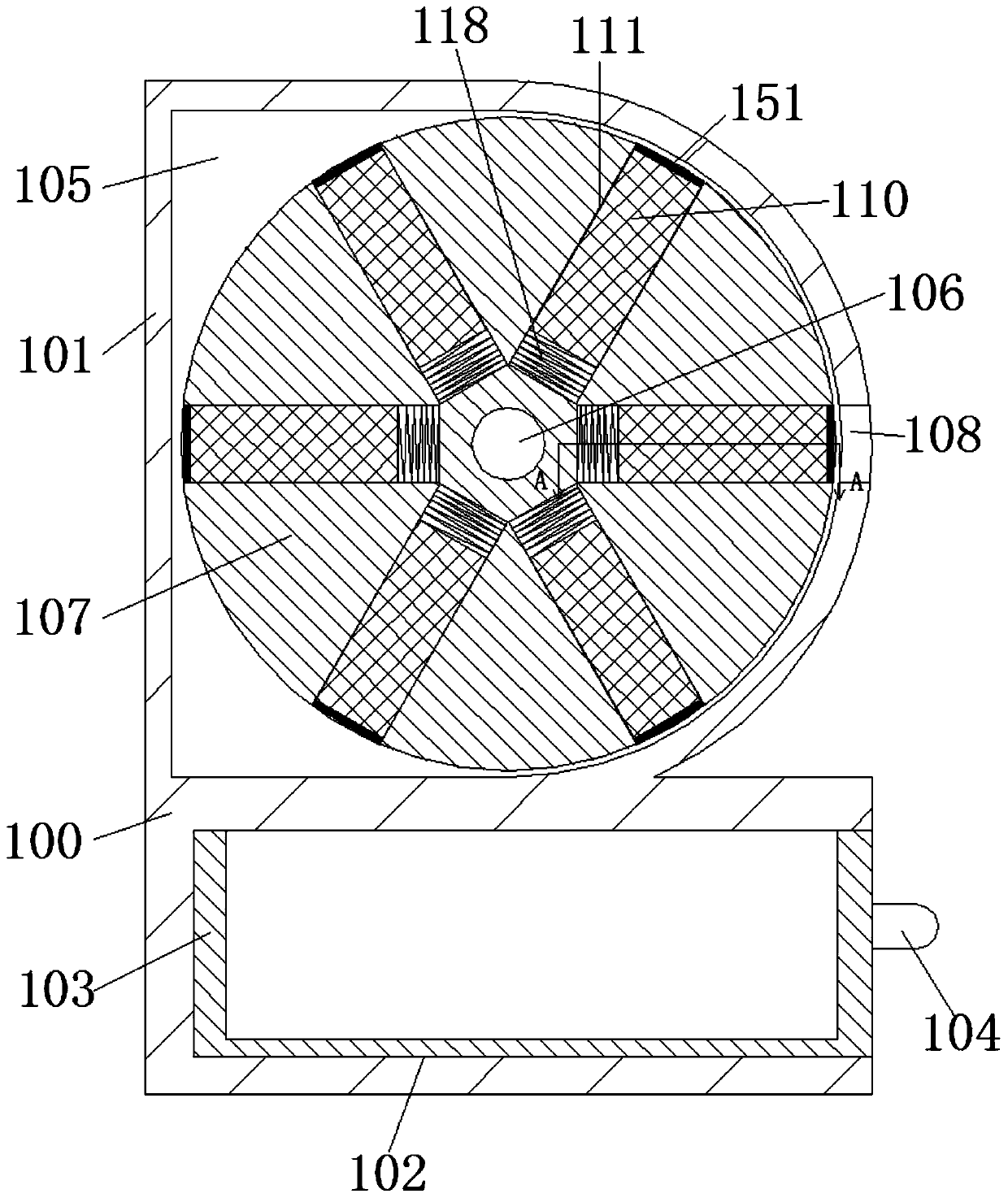

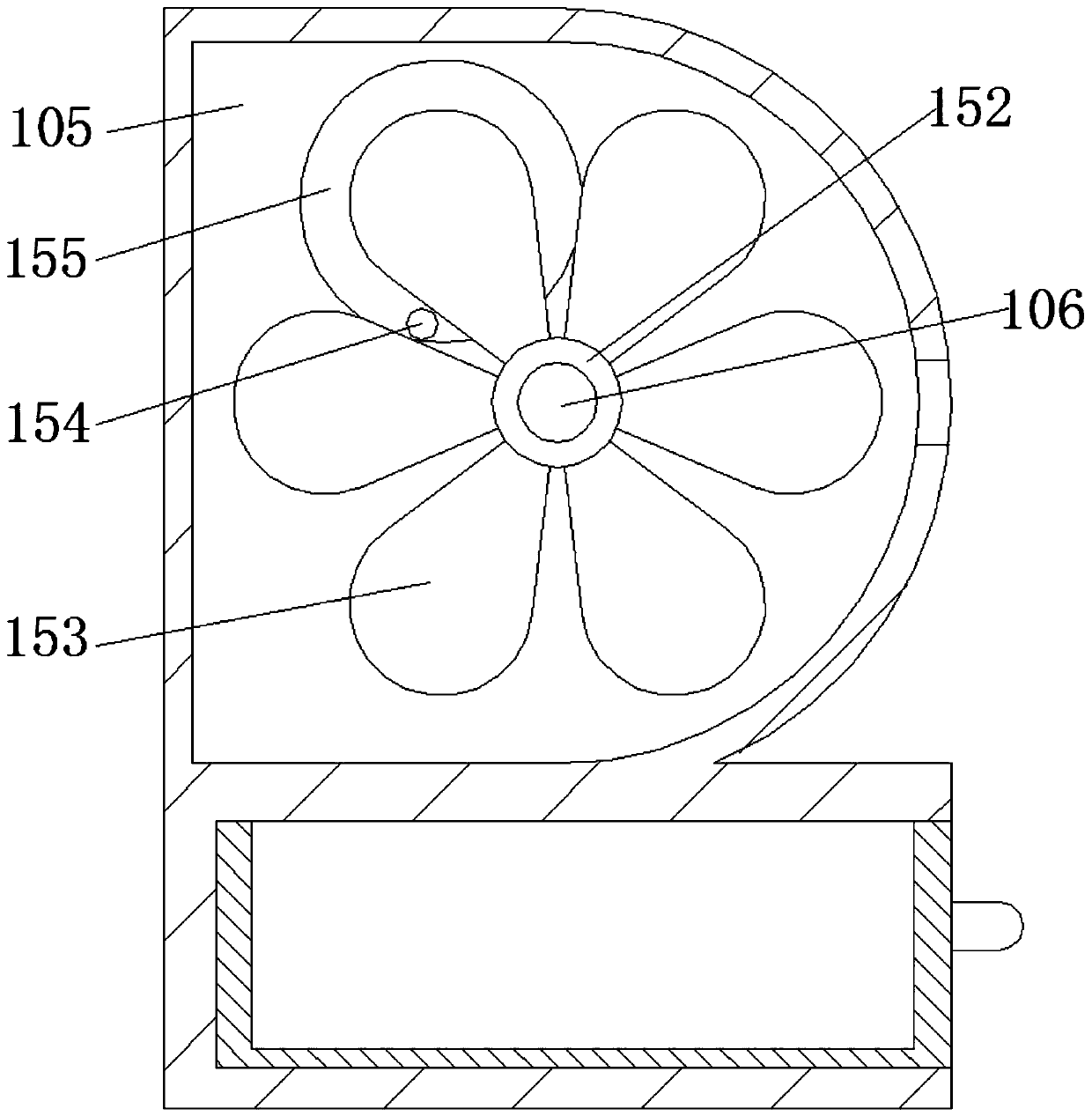

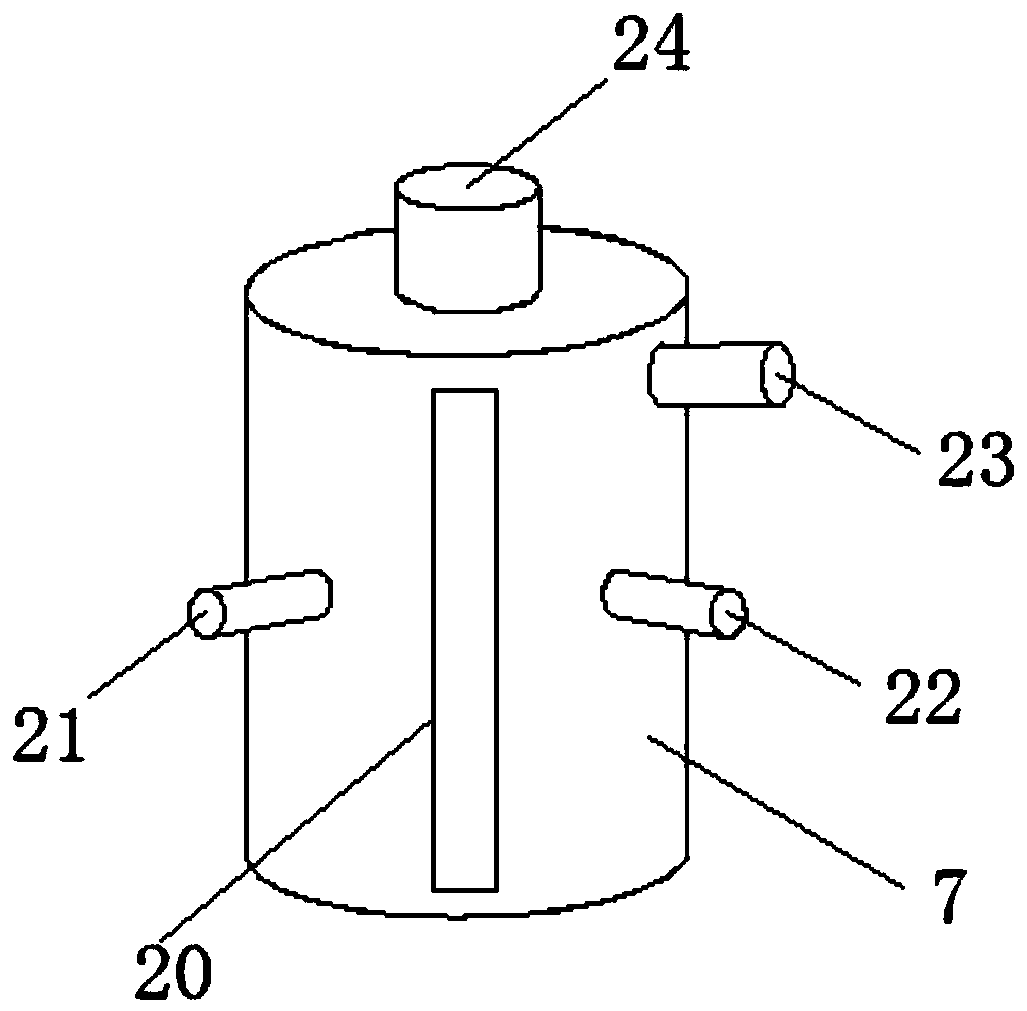

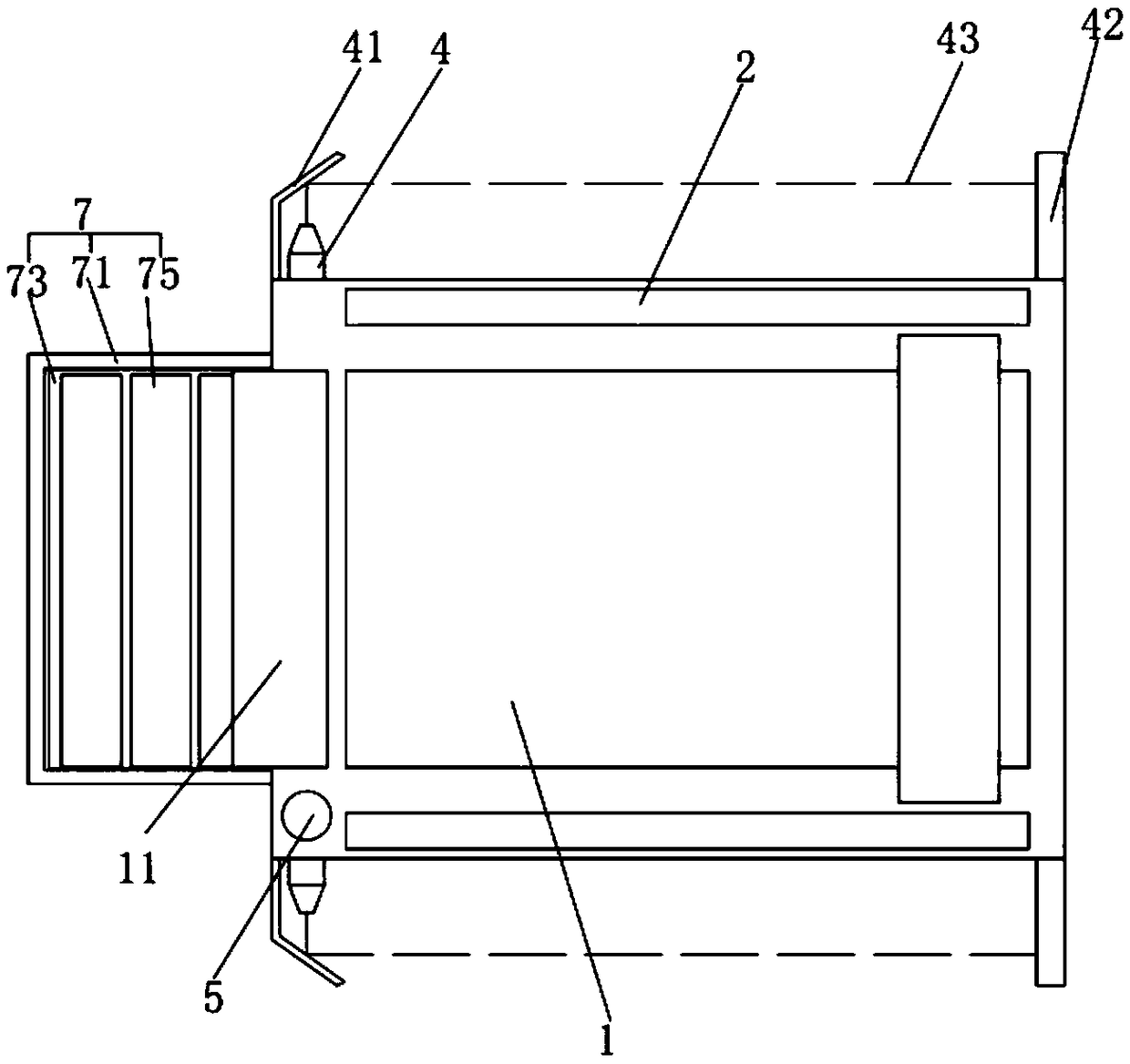

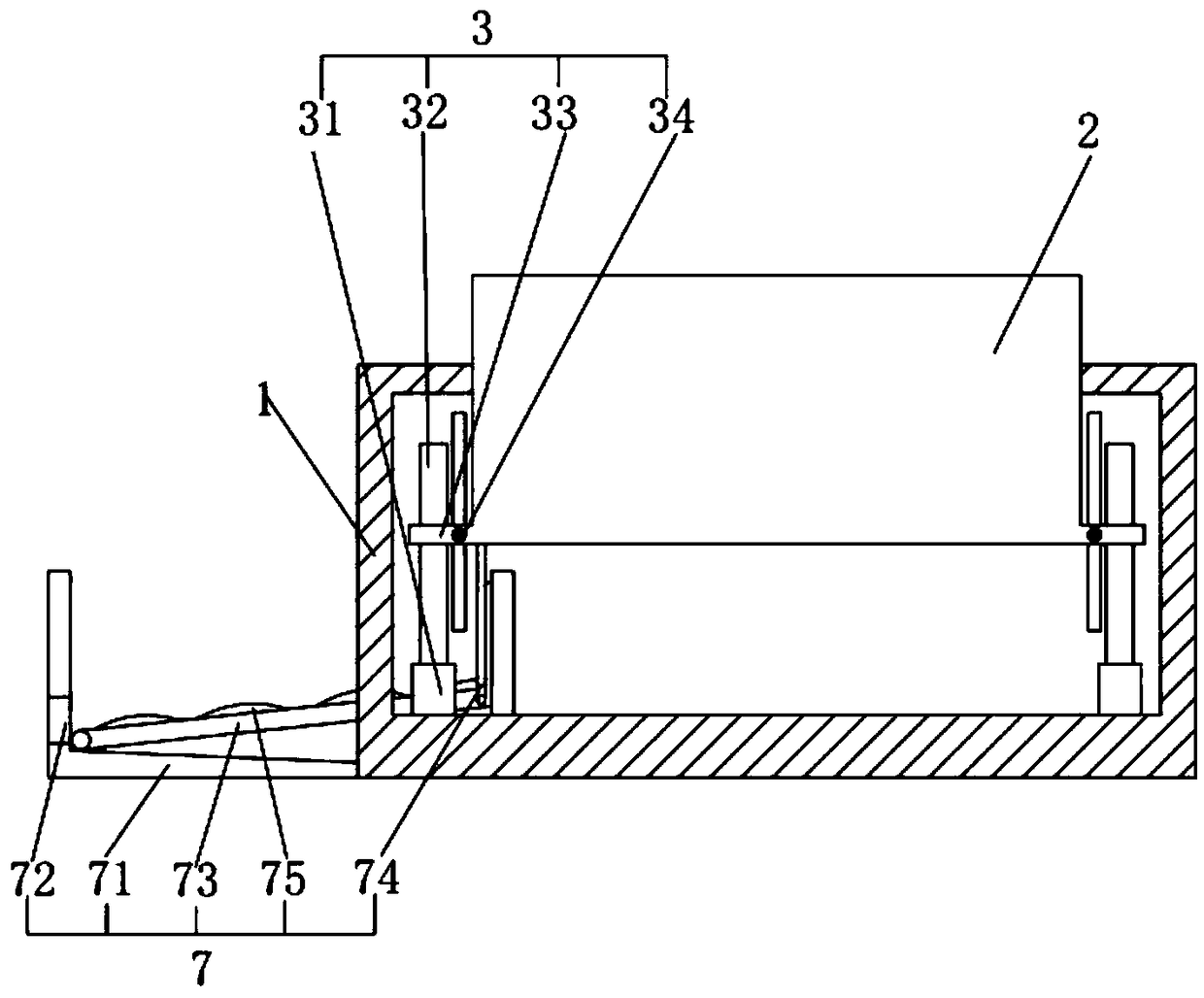

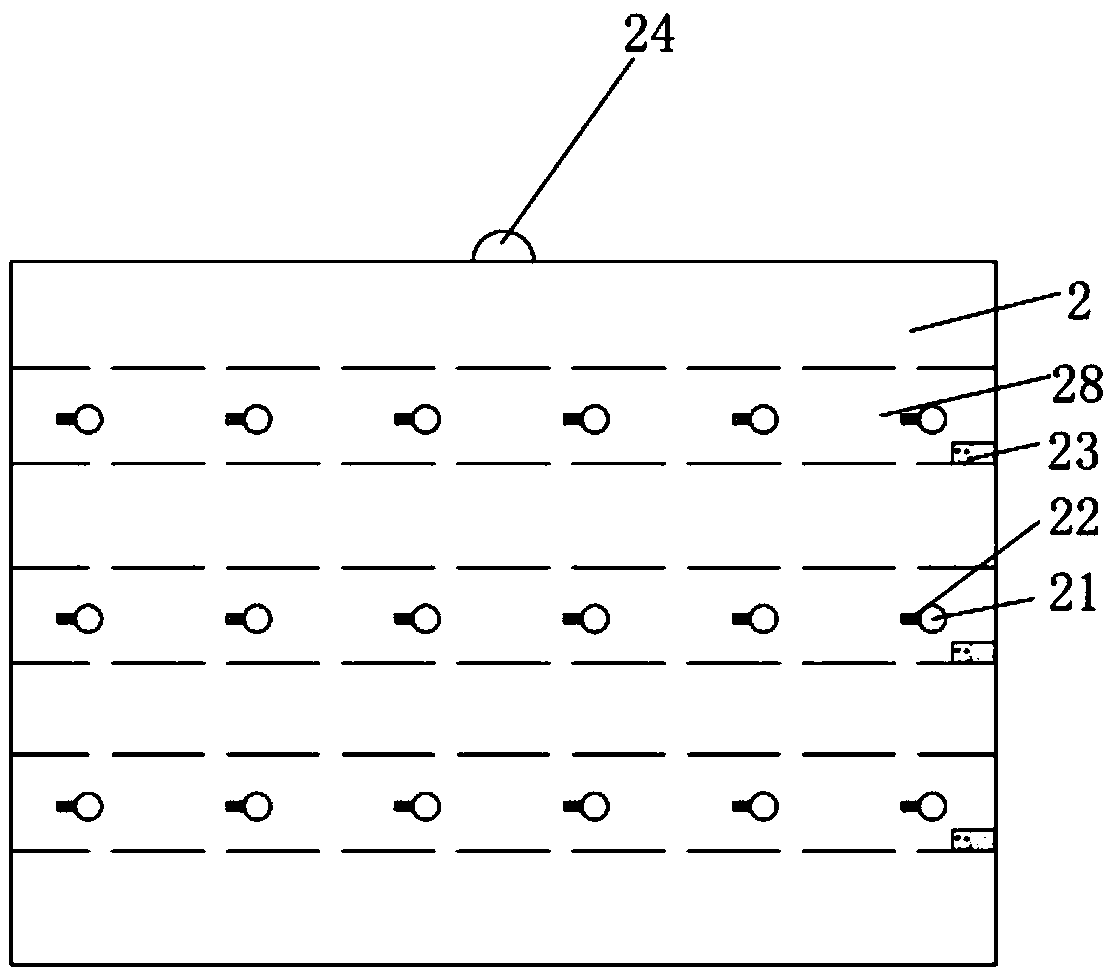

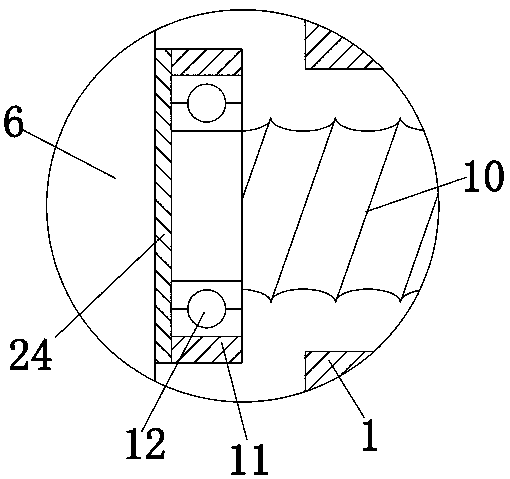

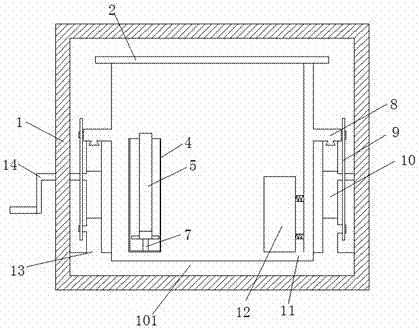

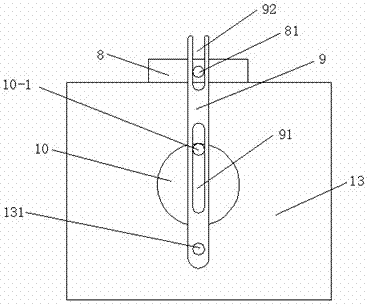

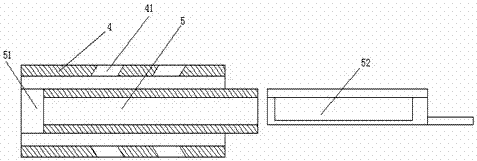

Continuous flow photochemical reactor

ActiveCN110252224ASmall device sizeCompact structureEnergy based chemical/physical/physico-chemical processesContinuous flowLight source

The invention discloses a continuous flow photochemical reactor, which comprises a reaction chamber for photochemical reaction, a temperature control chamber for temperature control of the reaction chamber and a light source control chamber for light source regulation. Specifically, the reaction chamber comprises a shell and a reactor module located in the shell, and the reactor module comprises a photochemical reaction unit, a light source module arranged outside the photochemical reaction unit, a light source heat dissipation module and a reactant temperature control module. Specifically, the reactor module comprises a reaction bin plate, a quartz glass board, a quartz plate fixed cover plate and a light source plate that are stacked sequentially. The continuous flow photochemical reactor not only can realize all-range photochemical reaction in all-ultraviolet band and visible light band, but also has the advantages of compact structure, small volume, good sealing performance, high product yield, large output, long service life, convenient maintenance, highly controllable temperature and reaction process, is suitable for industrial application, and meets the requirements of green chemical pharmacy.

Owner:黄位凤

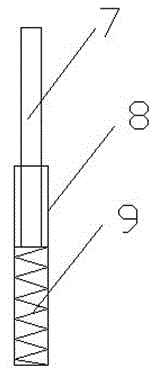

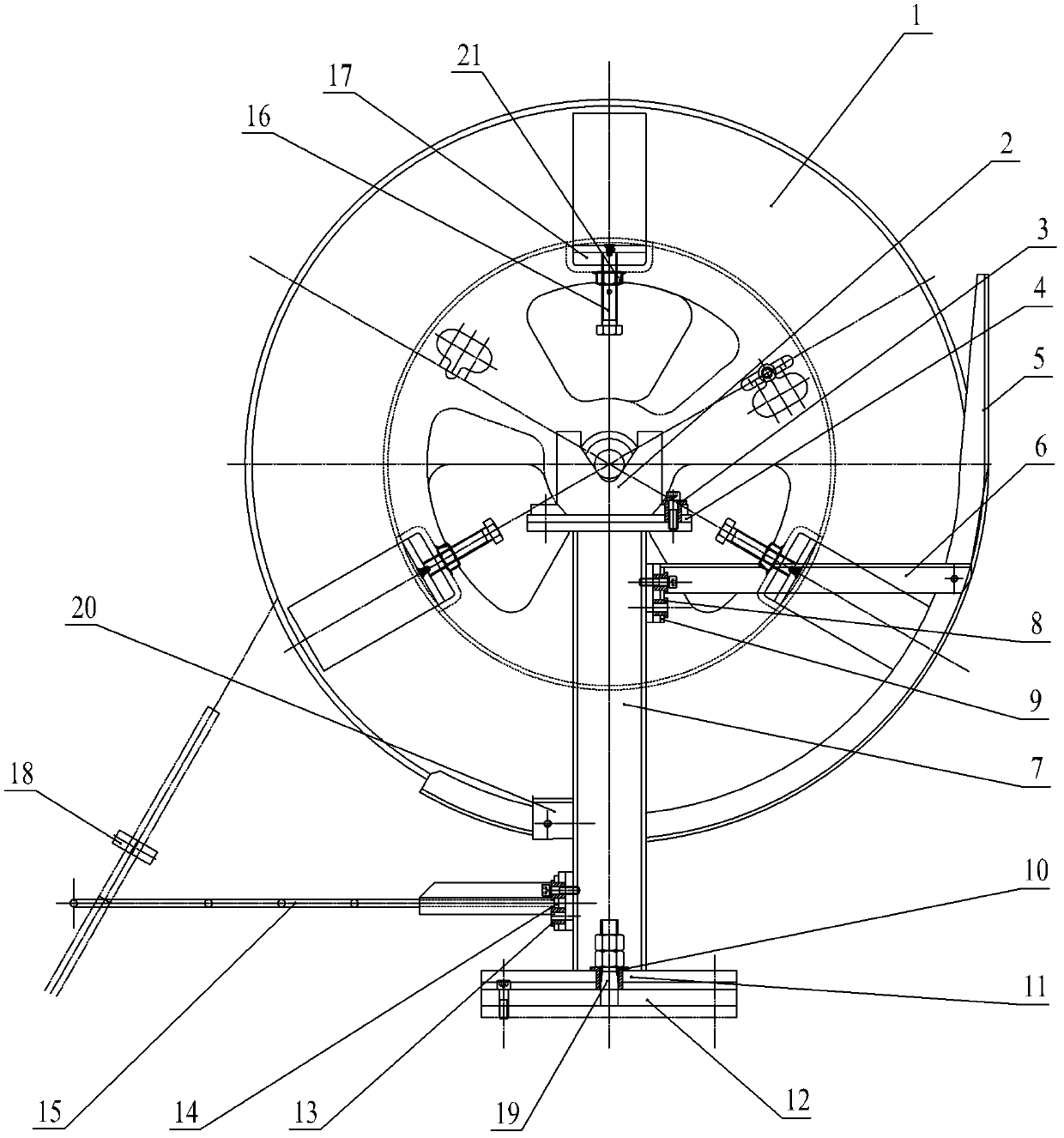

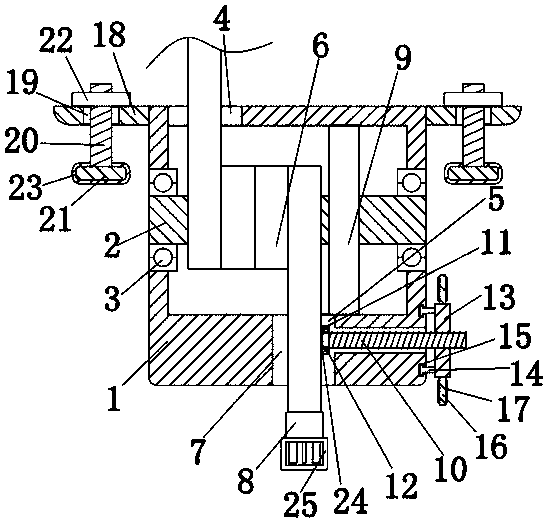

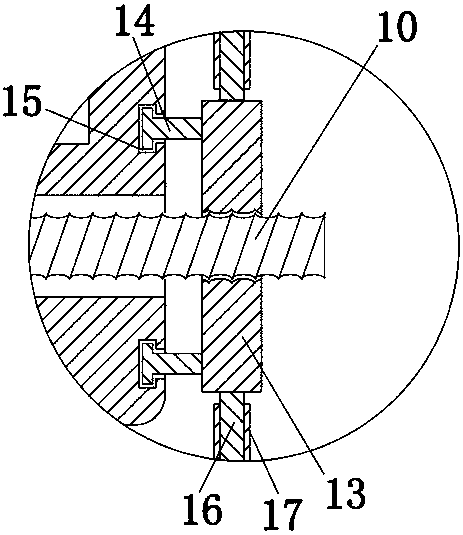

Vertical type adjustable take-up reel

ActiveCN104464953AGood take-up effectAvoid being stretchedFilament handlingCable/conductor manufactureMachiningScrew thread

The invention discloses a vertical type adjustable take-up reel and belongs to the field of machining equipment. The vertical type adjustable take-up reel comprises a rotating shaft and three to six take-up base plates, each take-up base plate comprises limiting rollers and a take-up roller, the take-up base plates are fixed to the top end of the rotating shaft, each limiting roller comprises a roller sleeve and a roller rod, each roller rod is sleeved with the corresponding roller sleeve, second threaded holes are formed in the same side faces of each roller rod and the corresponding roller sleeve, and each roller rod and the corresponding roller sleeve are fixed through a second screw; the upper end face of each take-up base plate is fixedly provided with the corresponding take-up roller and grooves, the roller sleeves are arranged in the grooves, first threaded holes are formed in the side faces of each take-up base plate and penetrate through the corresponding grooves, threaded holes are also formed in the positions, corresponding to the first threaded holes, of the roller sleeves when the roller sleeves are disposed in the grooves, and the roller sleeves are fixed in the grooves through first screws. The limiting rollers are arranged on the upper end faces of the take-up base plates, so that adjustability of the distance between the take-up rollers and the limiting rollers and the overall height of the limiting rollers is achieved; thus, taking up of cable coils of different sizes and heights can be achieved, and the limiting rollers can also prevent the phenomenon that cables get rid of restraint in the transverse direction and are in a mess when plenty of winding is conducted.

Owner:WUHU CHANGRUN SPECIAL COPPER

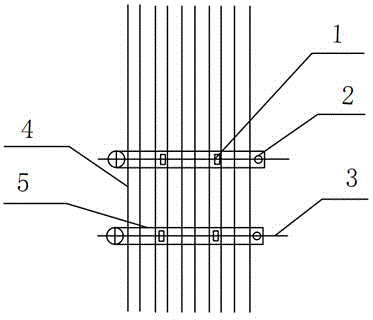

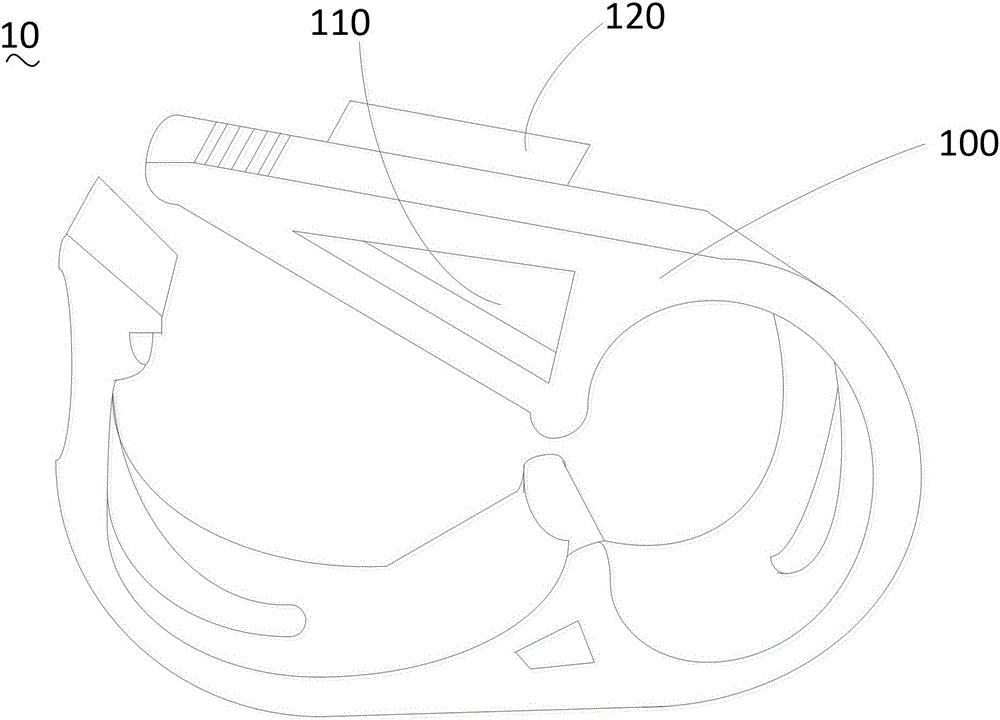

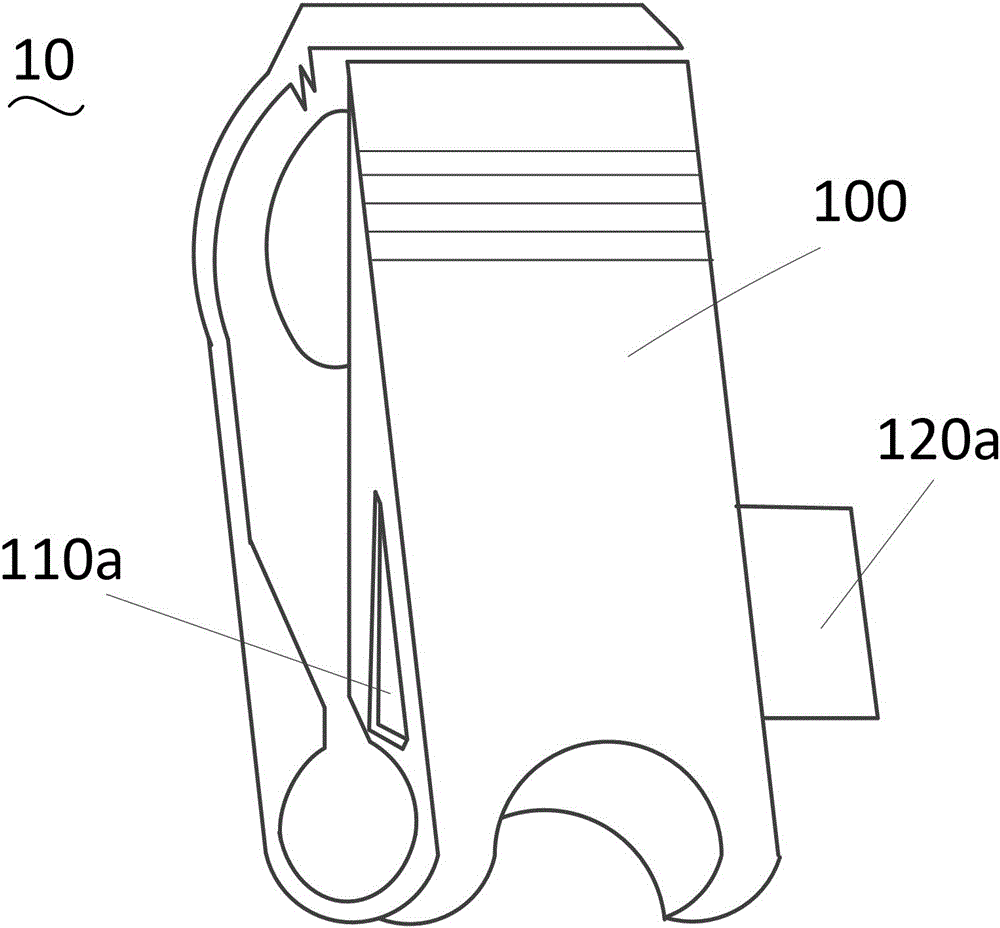

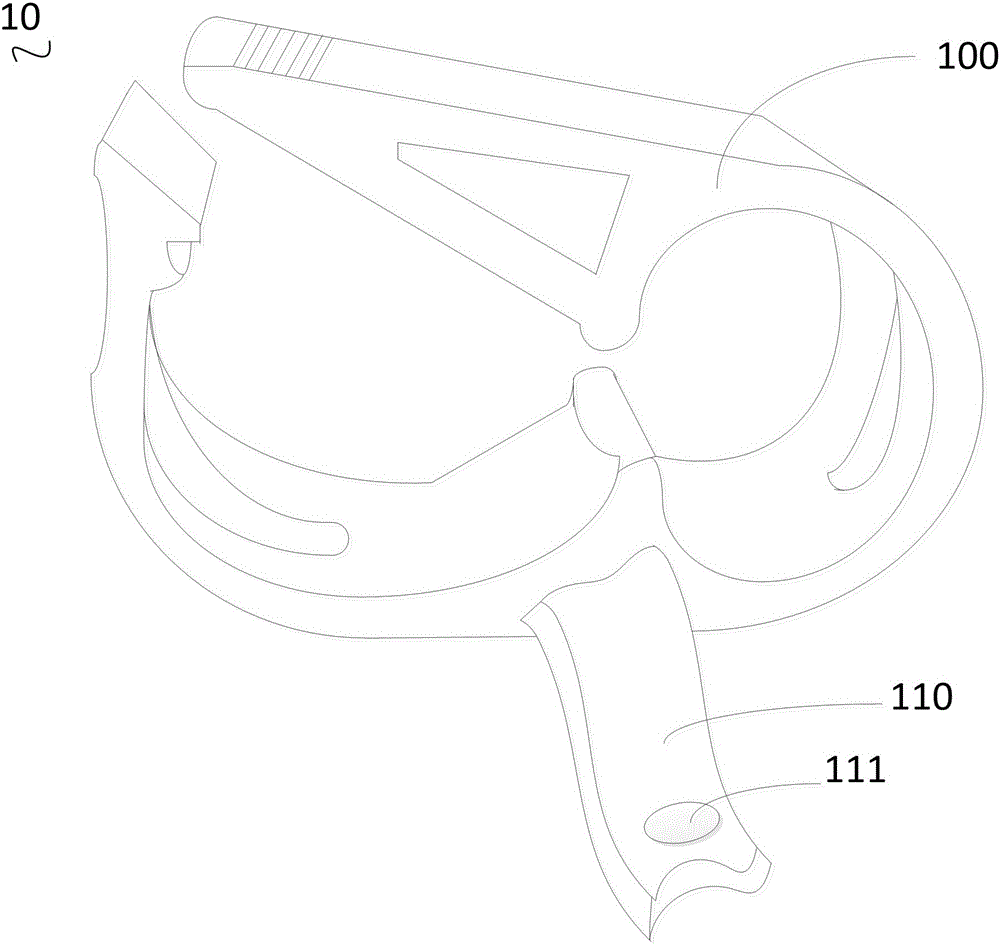

Fluid pipe clamp and attached pipe clamp for peritoneal dialysis

InactiveCN104984428AEasy to useReduce adverse effectsCatheterPeritoneal dialysisPeritoneal dialysisEngineering

The invention provides a fluid pipe clamp for peritoneal dialysis. The pipe clamp comprises a clamp body used for clamping fluid pipelines. A first connecting piece is arranged on one side of the clamp body and used for being connected with a first pipe clamp adjacent to the pipe clamp in a matched mode. Besides, a second connecting piece is arranged on the other side of the clamp body and used for being connected with a second pipe clamp adjacent to the pipe clamp in a matched mode. The fluid pipe clamp has the following advantages that the fluid pipelines can be distributed in order to be conveniently used by operators. Meanwhile, misoperation caused due to the fact that the pipelines are not easy to distinguish can be avoided, and therefore adverse effects on treatment of a patient can be avoided.

Owner:KUNSHAN VR MEDICAL TECHNOLOGY CO LTD

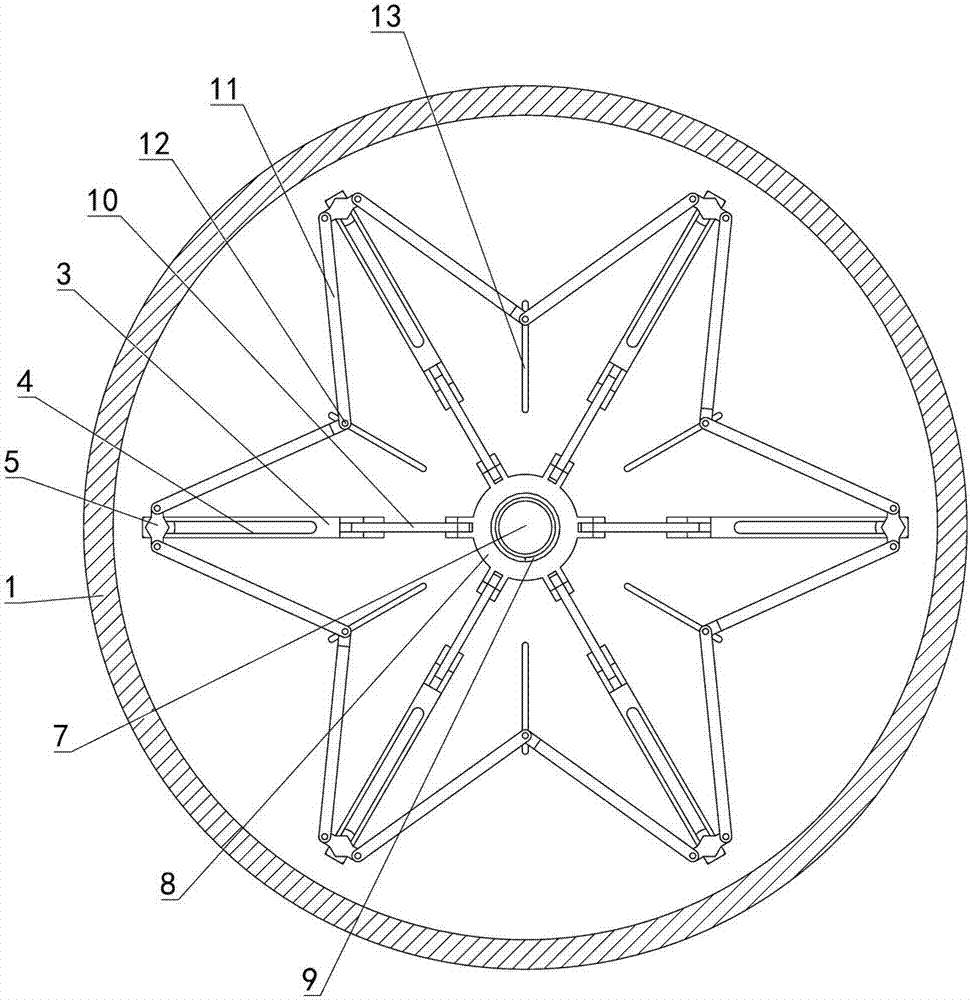

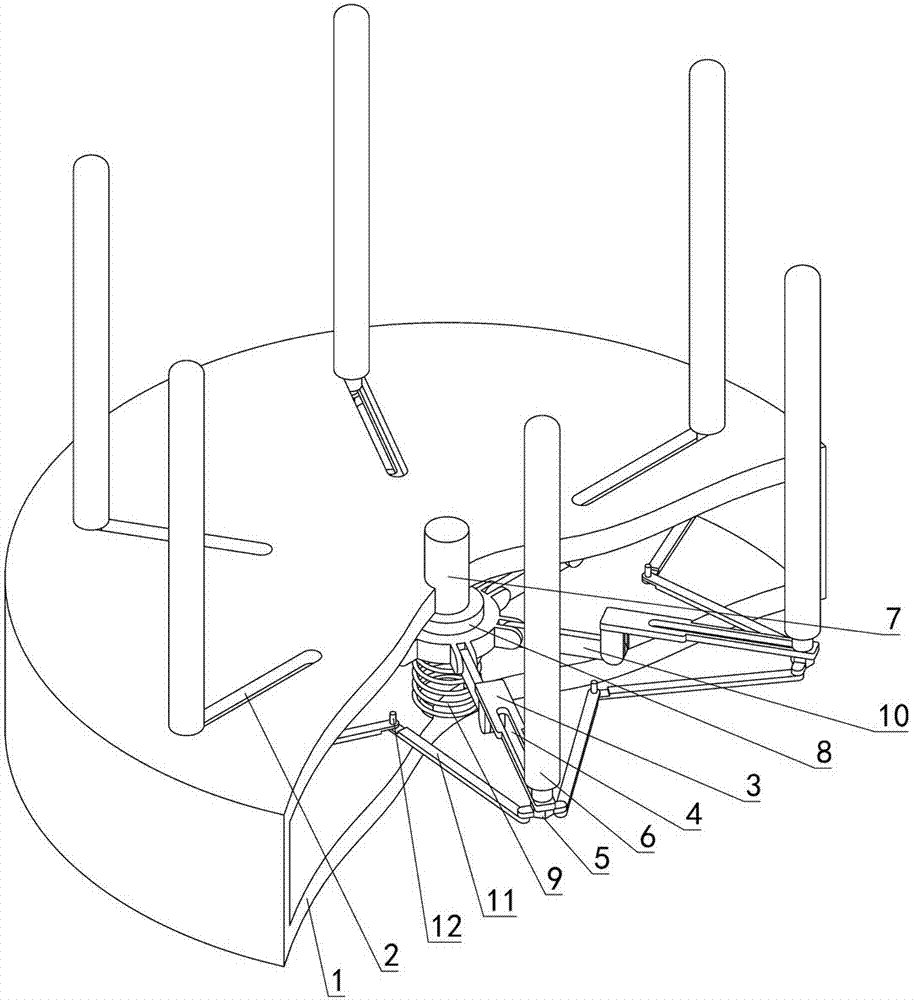

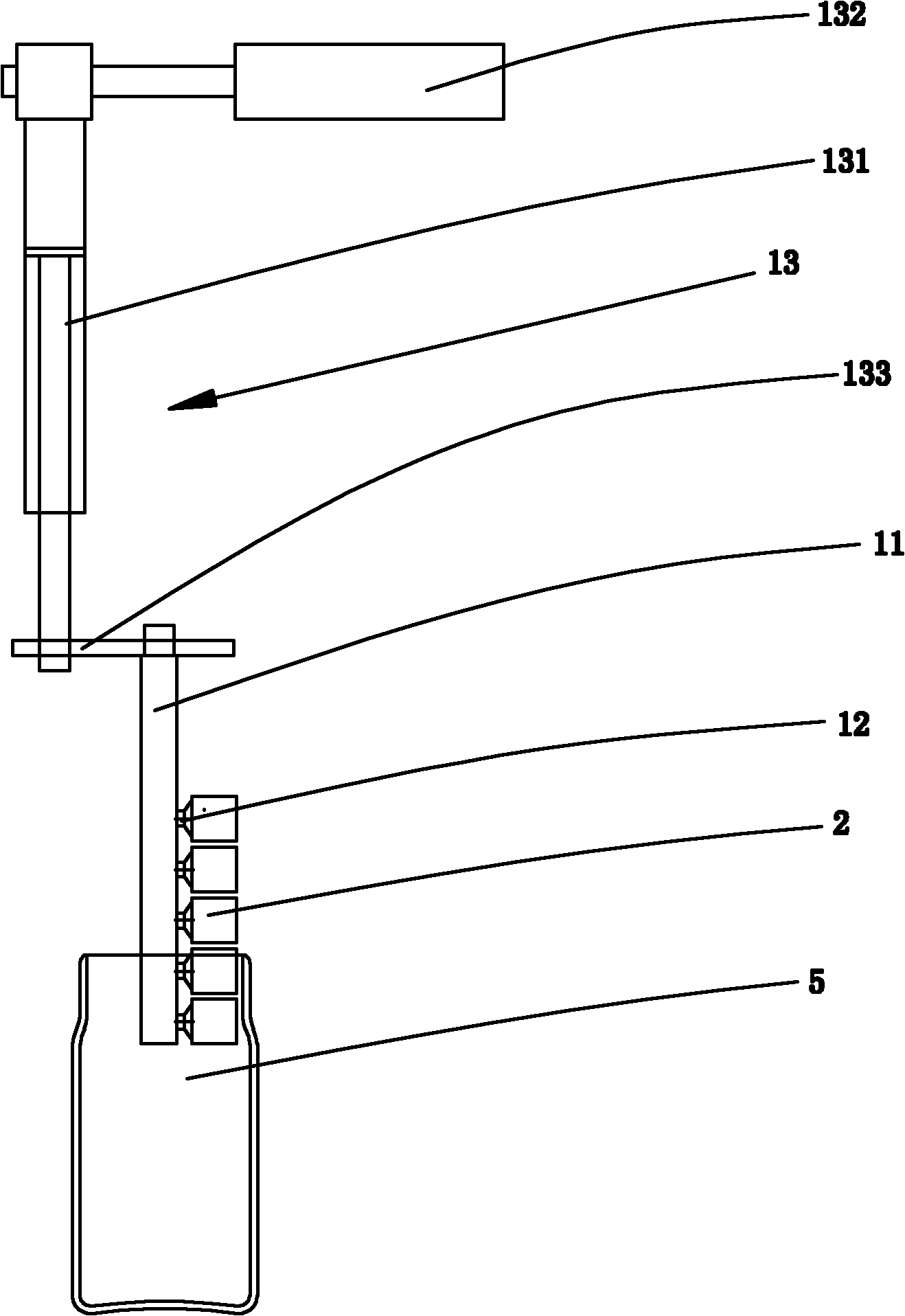

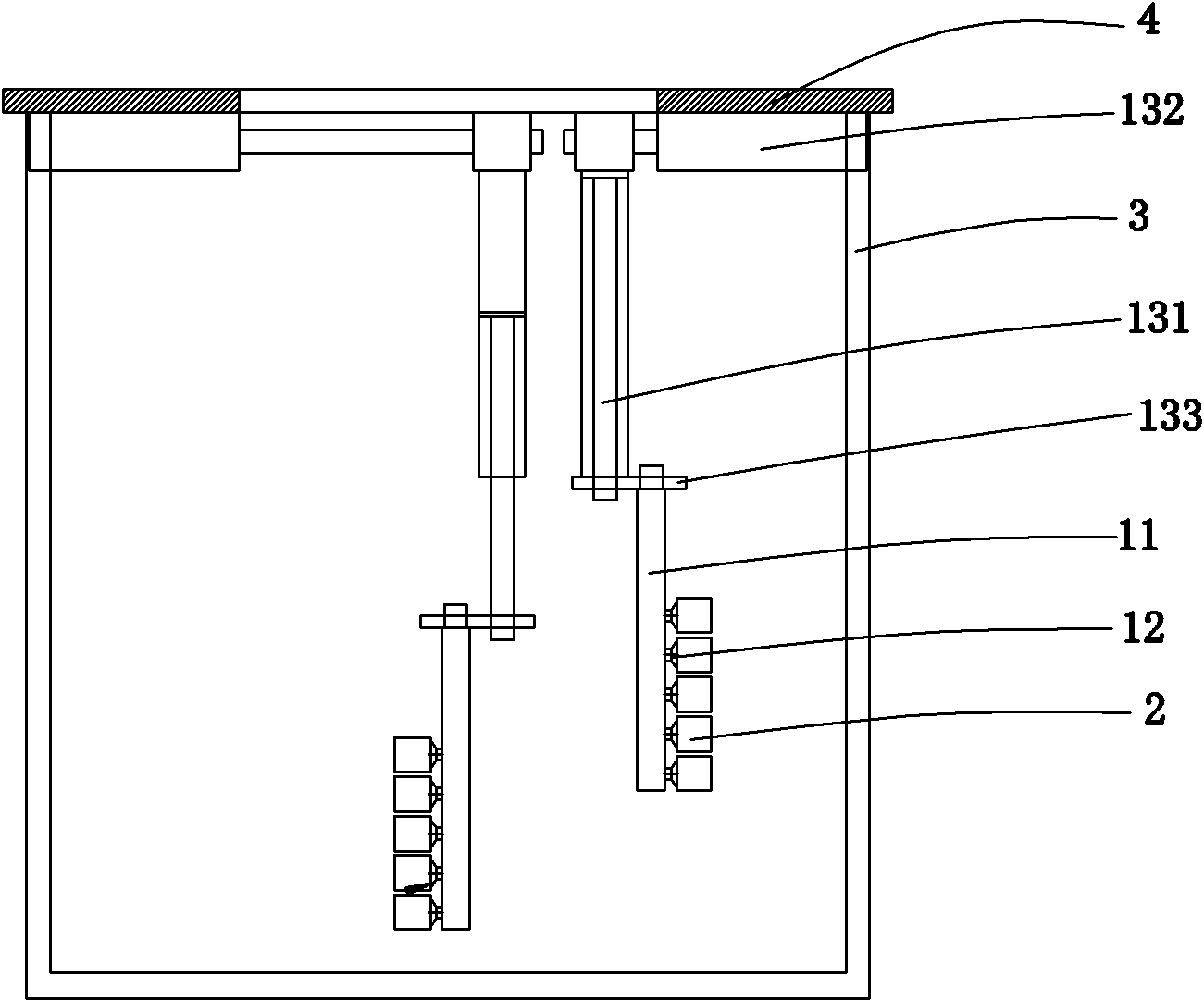

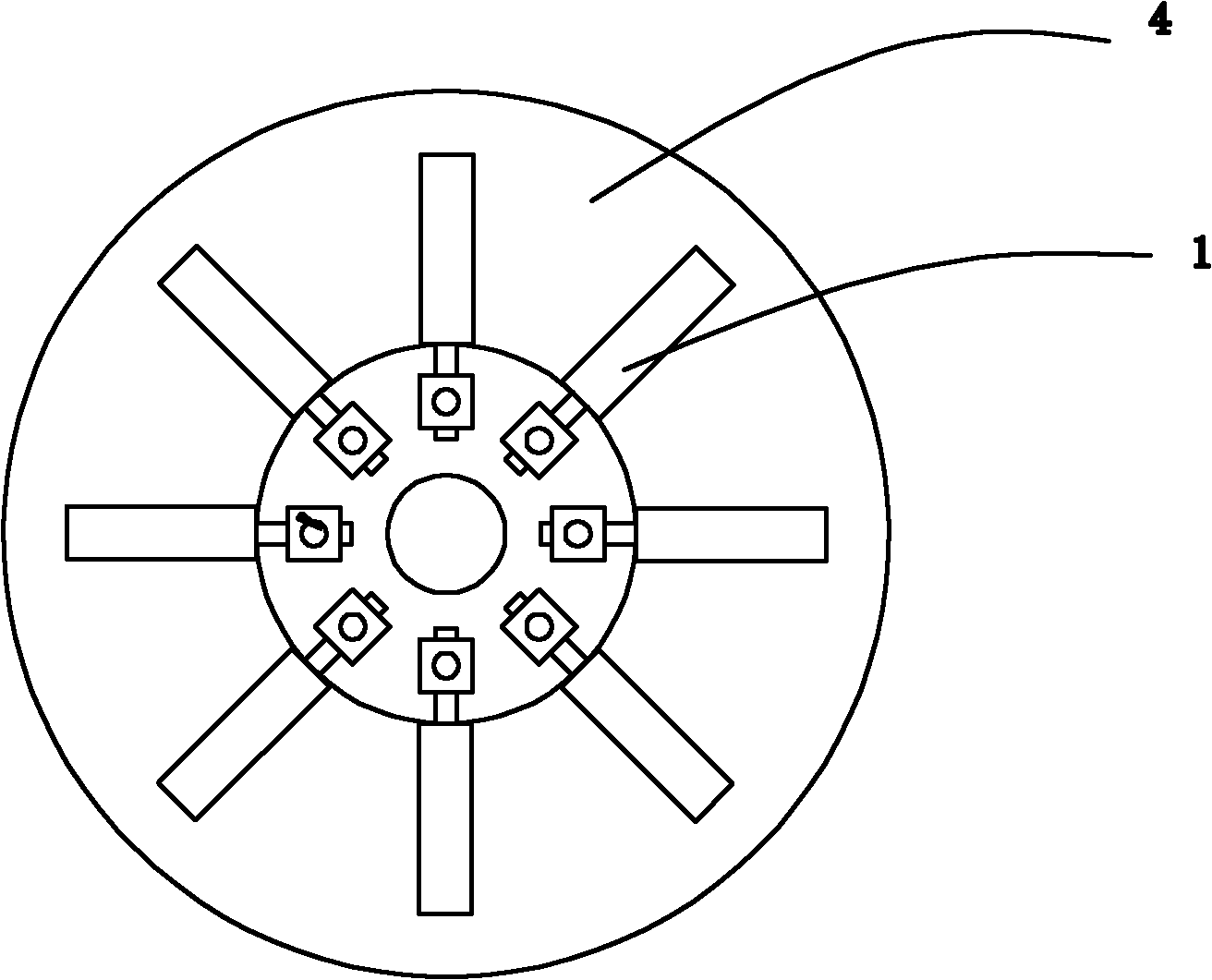

Medical catheter winding rotary table used for automatic production

The invention relates to a medical catheter winding rotary table used for automatic production. The medical catheter winding rotary table comprises a rotary table body with a cavity. Multiple centripetal slide grooves are formed in the upper end face of the rotary table body. Slide blocks capable of sliding in the centripetal slide grooves are installed in the centripetal slide grooves. Vertical through straight grooves are formed in the slide blocks. Bolts capable of sliding in the straight grooves are arranged in the straight grooves. Supporting rods vertically arranged are arranged above the slide blocks. The lower ends of the supporting rods are connected with the bolts through threads. A pressing rod vertically piercing into the cavity downwards is arranged on the rotary table body. A flange arranged in the cavity is arranged on the pressing rod. The pressing rod is sleeved with a spring. The two ends of the spring make contact with the flange and the lower end face of the cavity correspondingly. Multiple connection rods arranged in the cavity are installed on the pressing rod. Each connection rod corresponds to the corresponding centripetal slide groove in a one-to-one correspondence manner. One end of each connection rod is hinged to the pressing rod, and the other end of each connection rod is hinged to the corresponding slide block. The medical catheter winding rotary table is ingenious in structure, convenient and rapid to operate, not capable of causing the situation that it is difficult to take out catheters or surfaces of the catheters are damaged, and high in universality.

Owner:泰兴市智谷科技孵化器中心

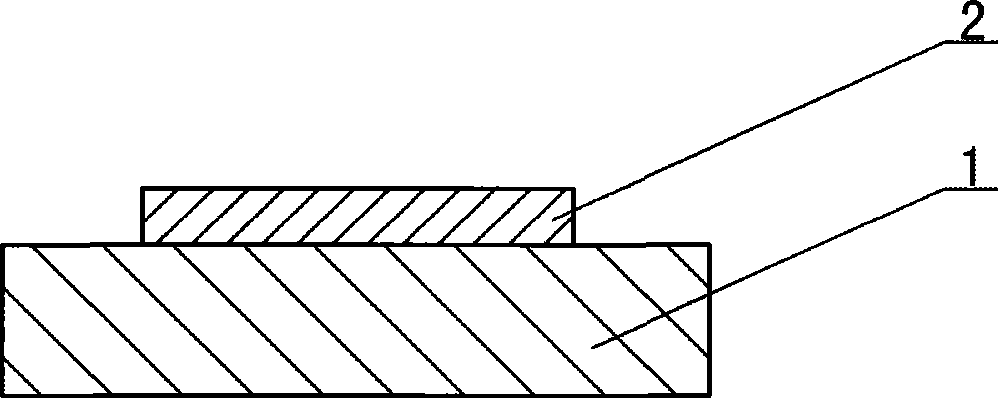

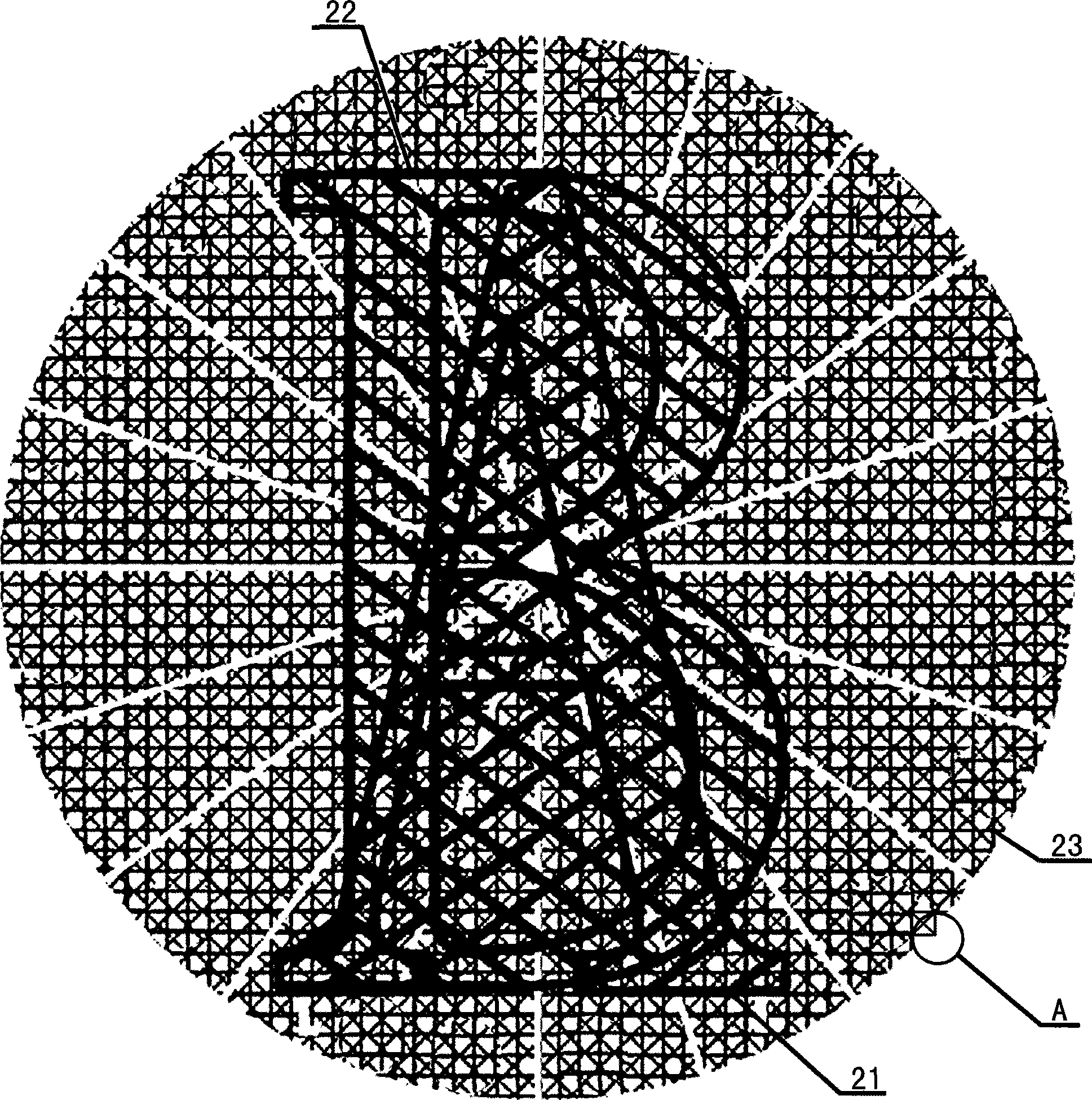

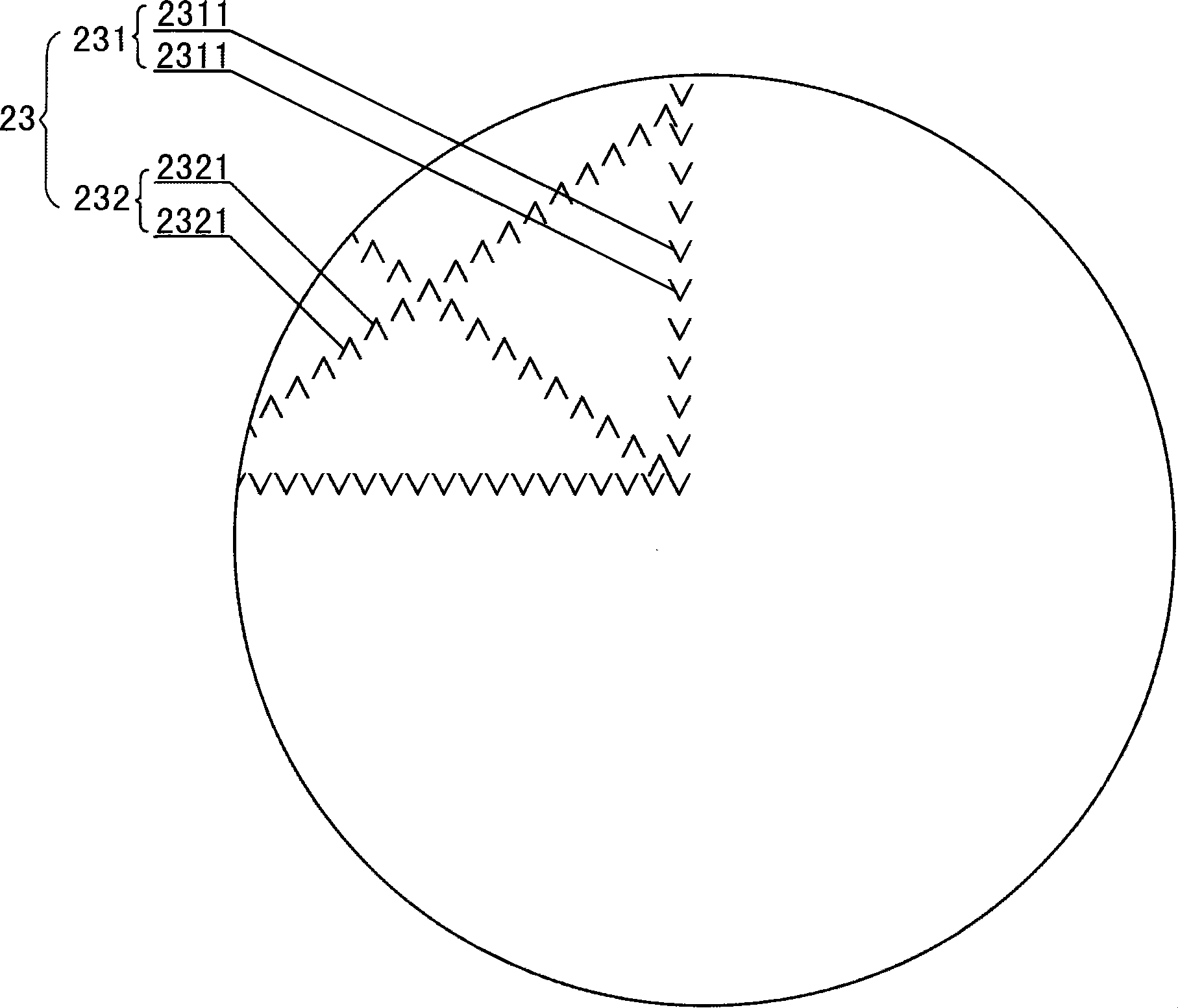

Anti-counterfeit mark article

InactiveCN101364359APrevent counterfeitingIncrease the difficulty of counterfeitingStampsIdentification meansOrganic solventMulti method

An anti-fake label comprises a base layer; an anti-fake label layer is arranged on the surface of the base layer; the anti-fake label layer comprises at least one anti-fake pattern which is composed of a plurality of lines; and each line of the same anti-fake pattern comprises a plurality of identical line units which are parallel with each other. The anti-fake label has the following beneficial effects: (1) the anti-fake patterns adopt the single line style design, so as to actually achieve the anti-fake effects for seeing, understanding and identify easily; (2) the anti-fake label can be manufactured by multiple methods, and the base layer can be made from multiple materials; (3) the anti-fake label can be manufactured without toxic chemicals such as ink, dye and organic solvent, so as to be environment-friendly and remarkably reduce production cost for manufacturers; (4) a plurality of patterns can be overlapped in a same position without mutual interference to generate an indistinct picture, thereby resulting in good anti-fake effect; and (5) the anti-fake label can effectively prevent being counterfeited by outlaws and reduce production cost.

Owner:林扬凰

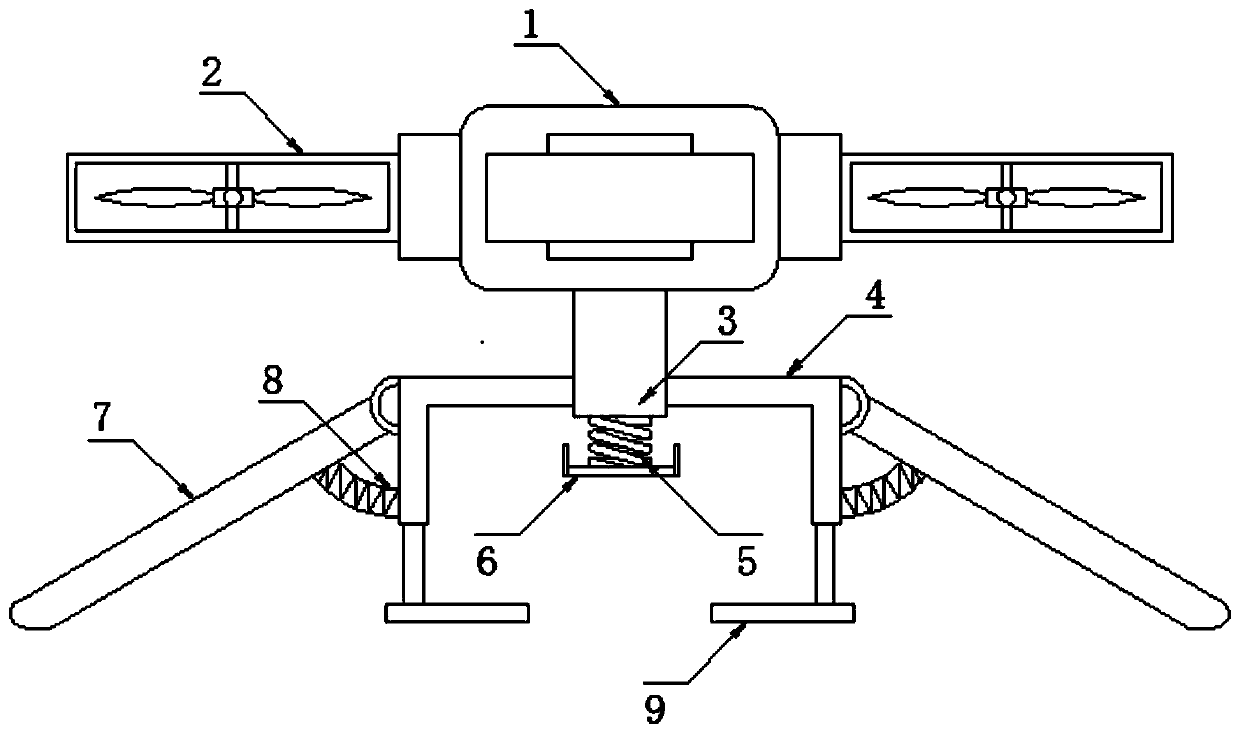

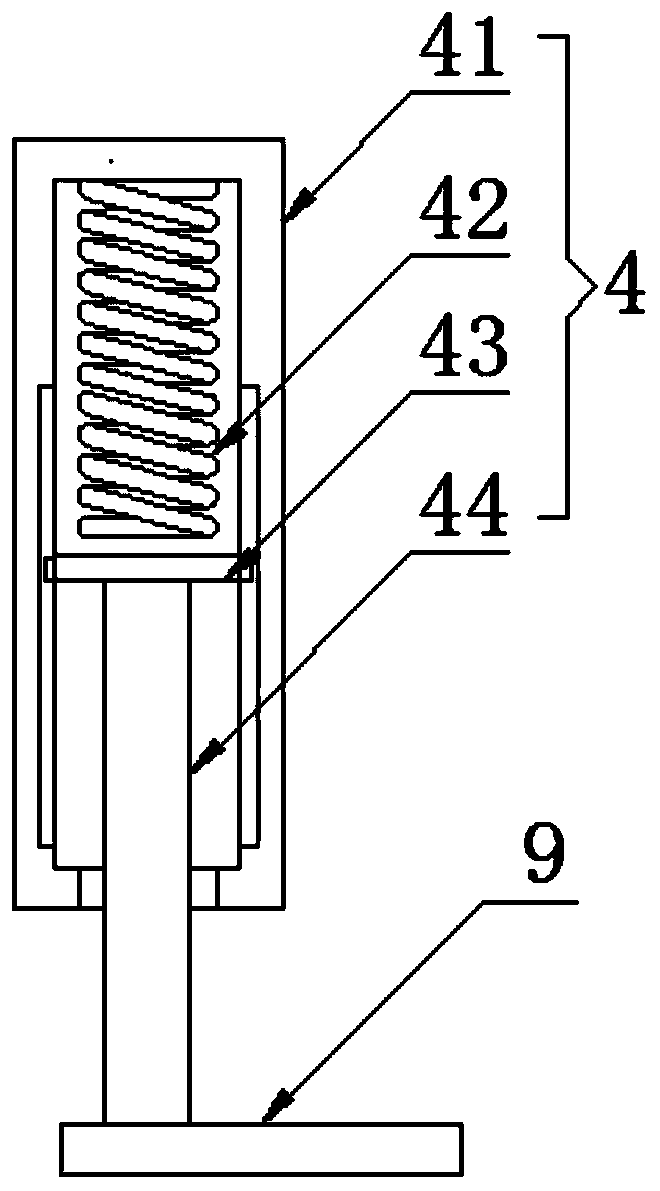

Unmanned aerial vehicle stable in operation and convenient for carrying auricle

InactiveCN109808892ANo falling phenomenonSmooth landingFreight handlingAlighting gearEngineeringOff phenomenon

The invention discloses an unmanned aerial vehicle stable in operation and convenient for carrying an auricle in the technical field of unmanned aerial vehicles. The unmanned aerial vehicle comprisesan unmanned aerial vehicle body; wings are arranged on outer walls on the four sides of the unmanned aerial vehicle body; a supporting column is arranged at the bottom of the unmanned aerial vehicle body; telescopic supports are arranged on outer walls on the left side and the right side of the supporting column; a buffer spring is arranged at the bottom of the supporting column; a hanging plate is connected with the bottom of the buffer spring; a buffer rod is movably arranged at one end, far away from the outer wall of the supporting column, of each of the telescopic supports through a connecting shaft; a telescopic spring is arranged at one end, close to the outer wall of each of the telescopic supports, of the buffer rod, and the other end of the telescopic spring is connected with theouter wall of the corresponding telescopic support; a supporting plate is arranged at the bottom of each of the telescopic supports. The unmanned aerial vehicle disclosed by the invention has the beneficial effects that the shaking amplitude of the article during transportation is reduced, and the falling-off phenomenon cannot appear; the unmanned aerial vehicle is more smoothly landed, the article can be smoothly landed, the messy phenomenon cannot appear inside the article, and the quality when the unmanned aerial vehicle carries the article is ensured.

Owner:南通亿思特机器人科技有限公司

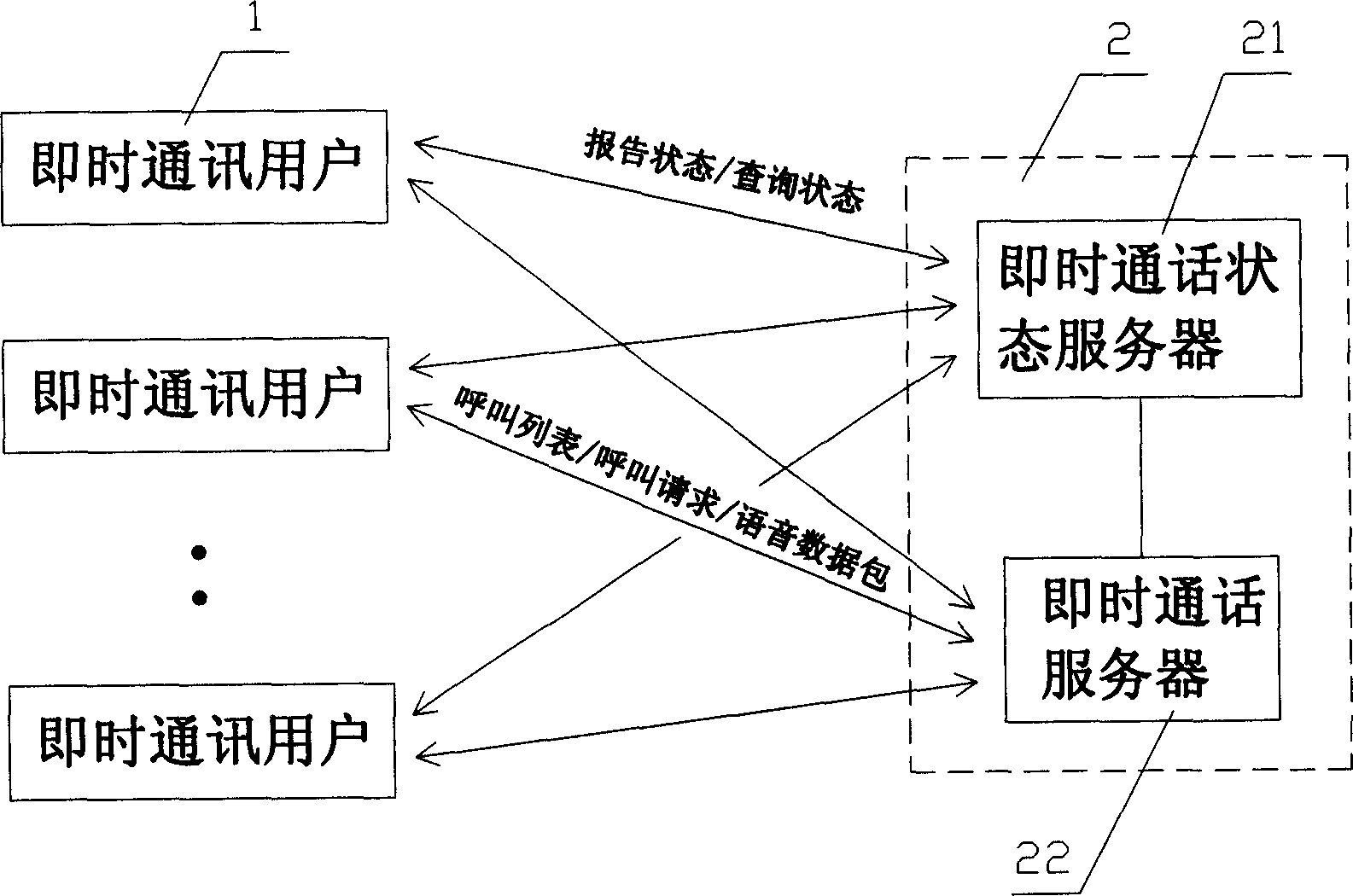

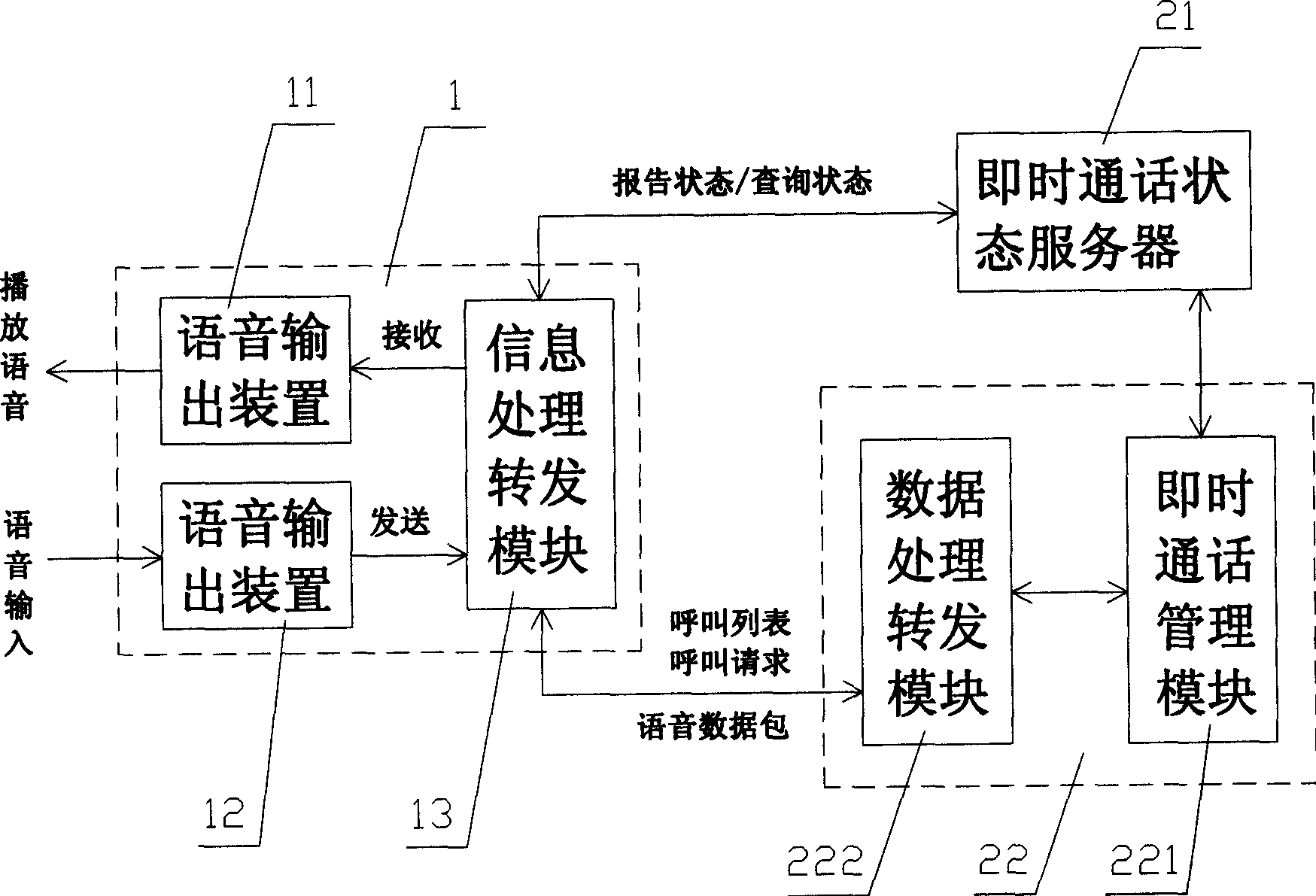

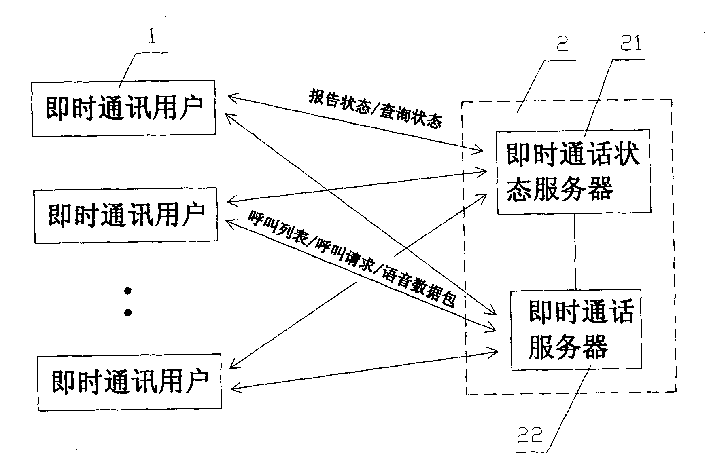

A method and system for instant calling of instant messaging subscriber

InactiveCN1523866ANo clutterImprove immediacySpecial service for subscribersSubscriber signalling identity devicesNetwork packetCommunications server

A demand session method and system for demand communication users is that a demand communication user transfers a calling list containing other demand users to a demand communication server. The user sending the list and the said other users form a communication group, the server system receives the phonetic calling request of the users one by one at the same time and receives the phonetic data packet sent by the said user than to transfer the said packet to other demand communication users, realizing phonetic communication among multiple demand communication users.

Owner:TENCENT TECH (SHENZHEN) CO LTD

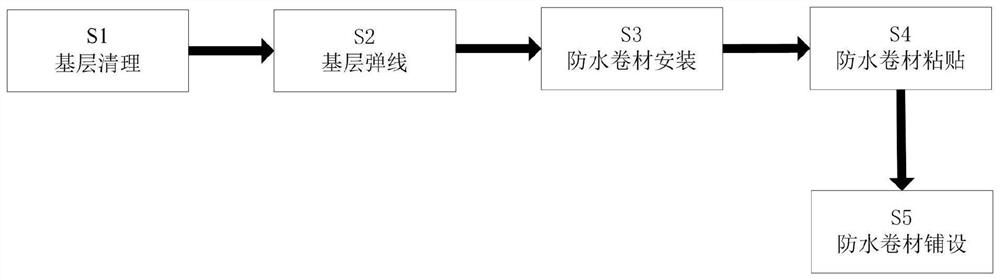

Self-adhesive waterproof roll construction process

ActiveCN111945962ANo position changeImprove laying effectRoof covering using flexible materialsProtective foundationAdhesiveConstruction engineering

The invention relates to a self-adhesive waterproof roll construction process. The self-adhesive waterproof roll construction process adopts the following waterproof roll construction device, and thewaterproof roll construction device comprises a supporting frame, a movable vertical plate, movable wheels, a limiting plate, a locking supporting plate, a connecting transverse plate and a roll coil.The construction process for the self-adhesive waterproof roll by adopting the waterproof roll construction device comprises the following steps of S1, base layer cleaning; S2, base layer line snapping; S3, waterproof roll installation; S4, waterproof roll pasting; and S5, waterproof roll laying. According to the self-adhesive waterproof roll construction process, the problems that in the existing manual laying process of the waterproof roll, long-distance waterproof roll laying needs to be carried out in a segmented mode, the waterproof roll can be twisted when a self-adhesive layer of the waterproof roll is integrally torn off, or sundries are adhered to a pasting layer, so that the laying of the waterproof roll is influenced, the waterproof roll is twisted due to the fact that the waterproof roll is not limited during pasting, and then the laying effect of the waterproof roll is poor can be solved.

Owner:邵阳市兴源新型建材有限公司

Novel accounting management data storage device

PendingCN110547610AEasy accessTime-consuming and laborious to solveBook cabinetsDrawersEngineeringData storing

Owner:MINJIANG UNIV

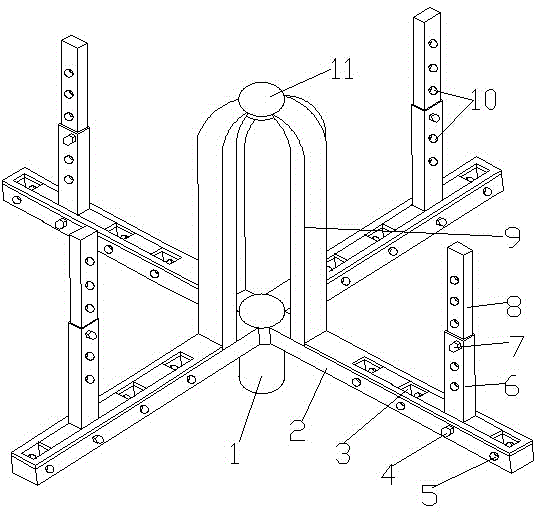

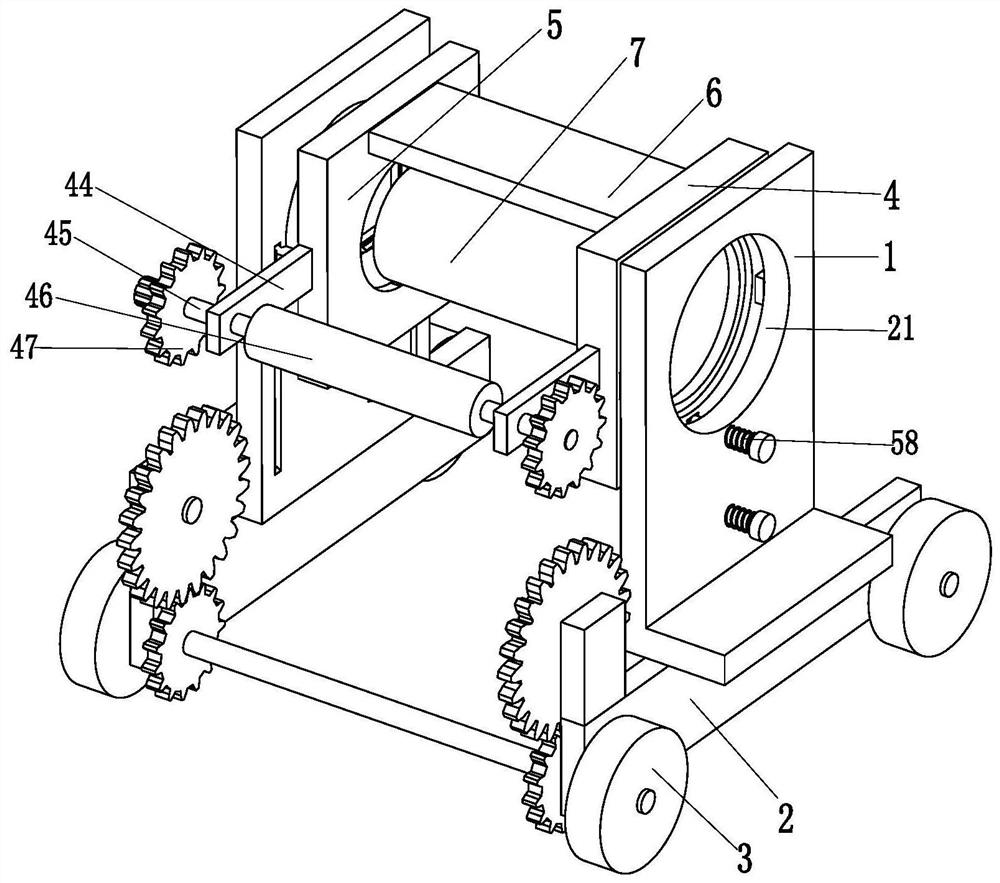

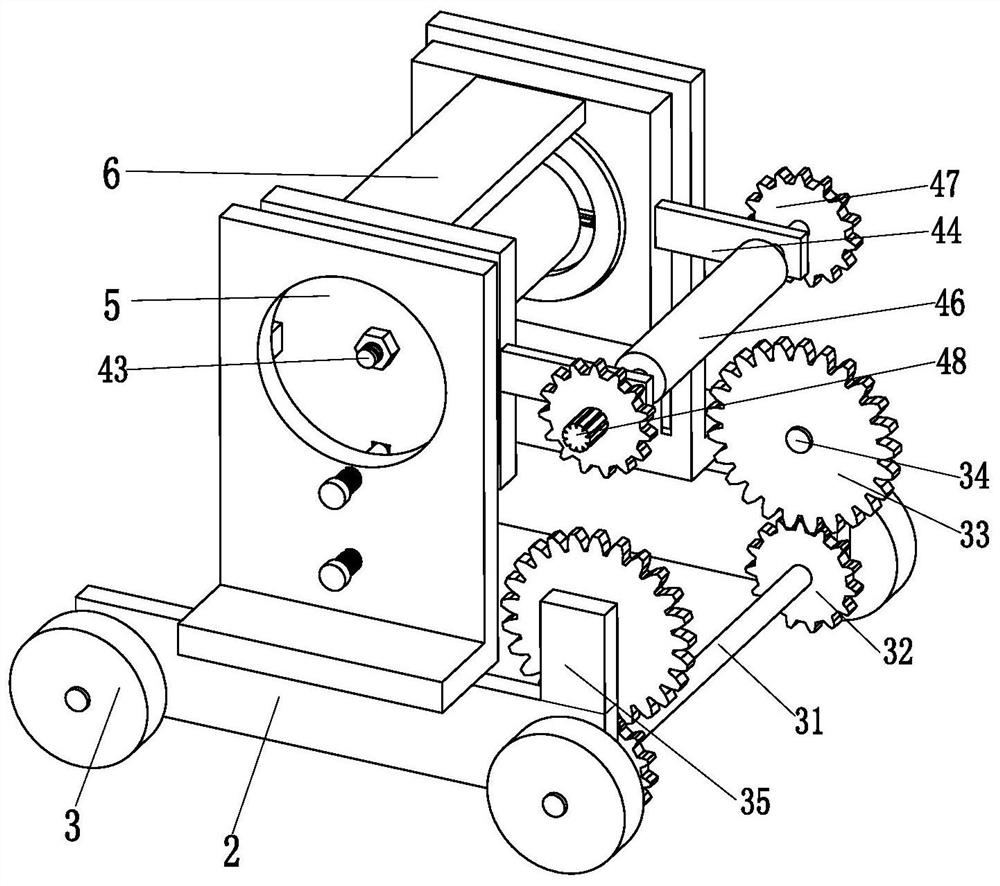

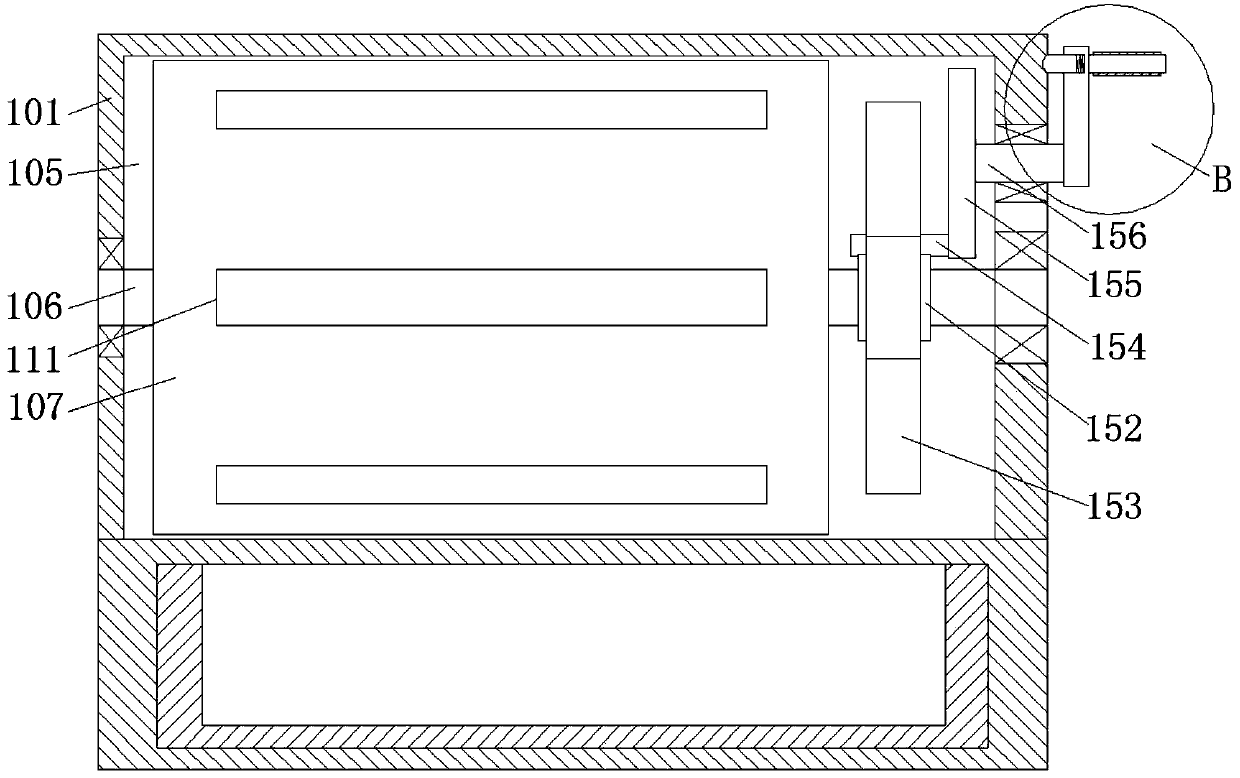

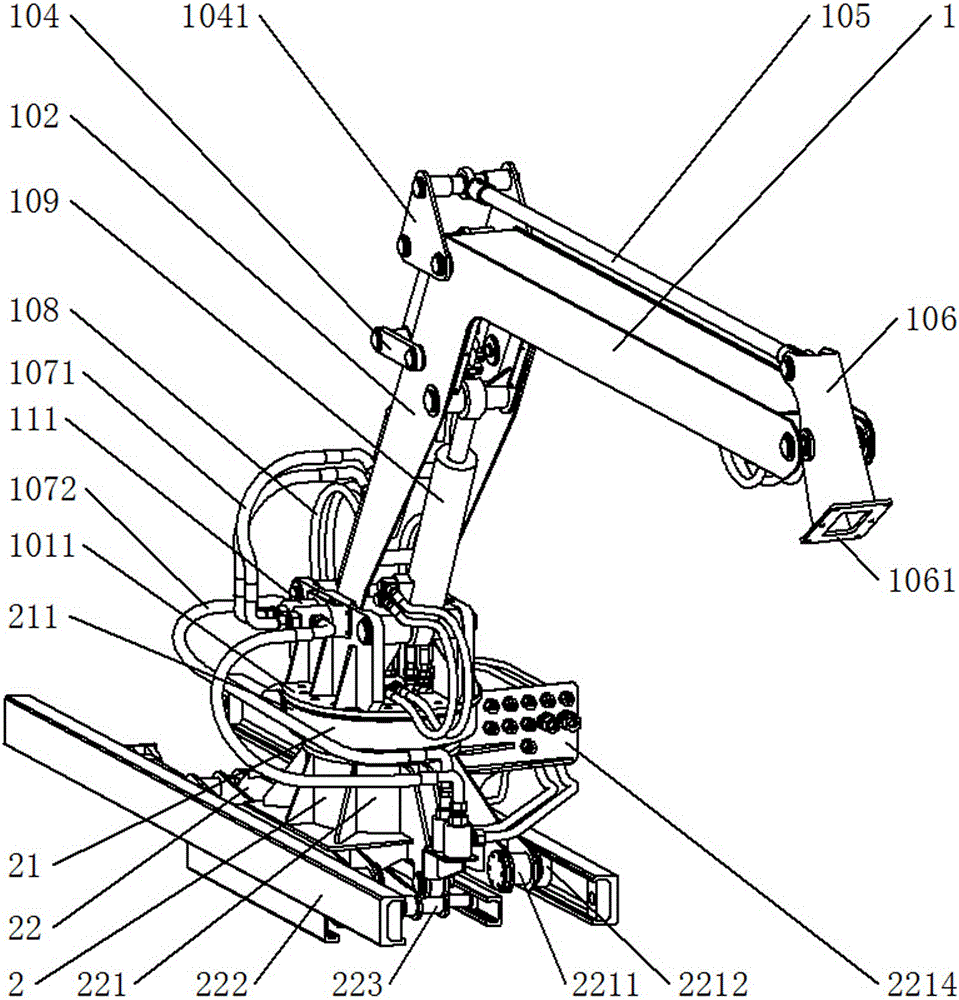

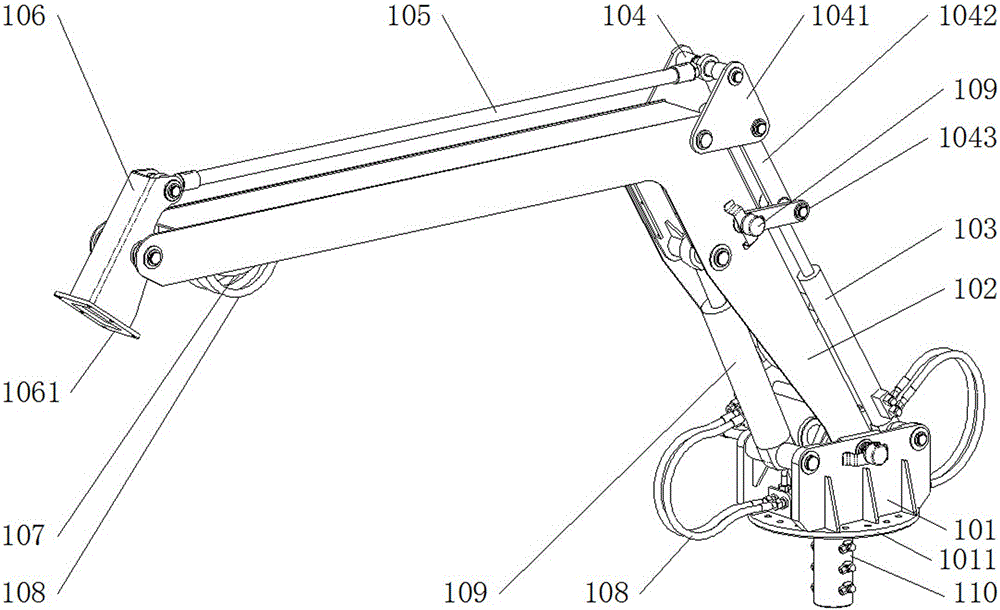

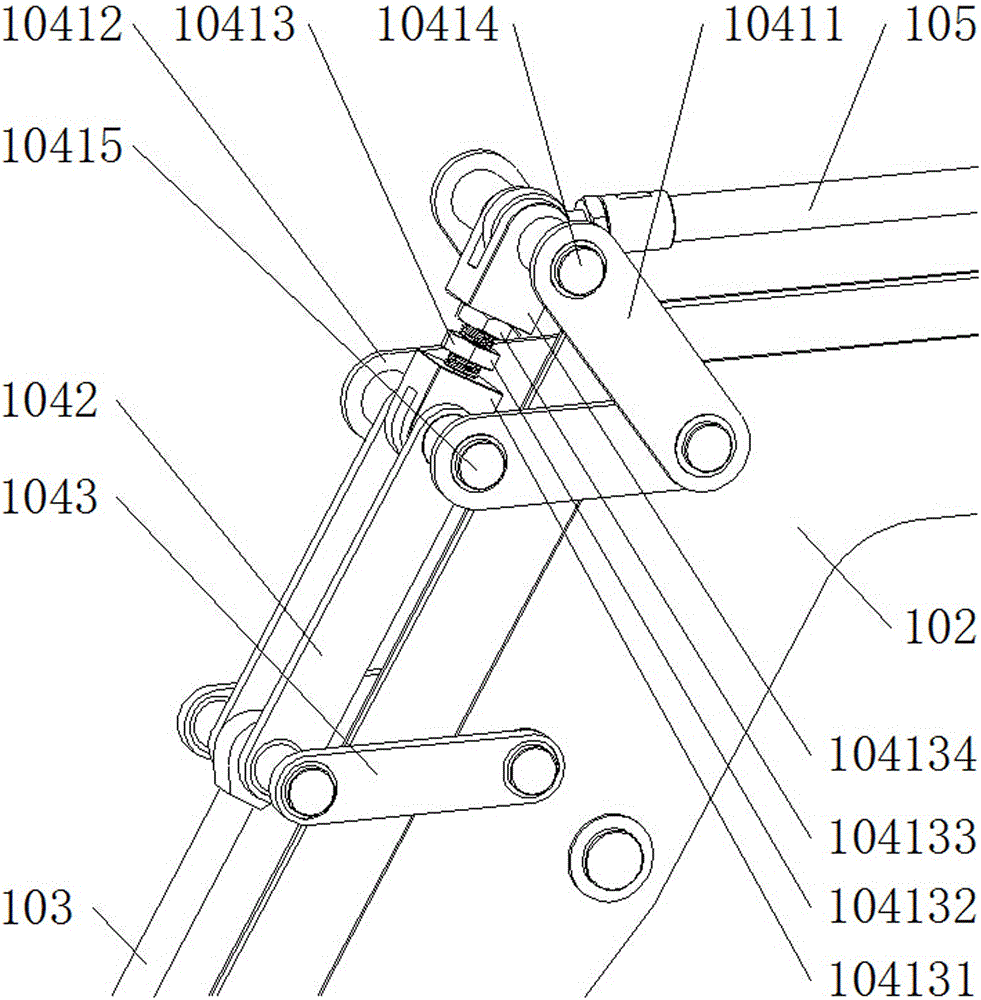

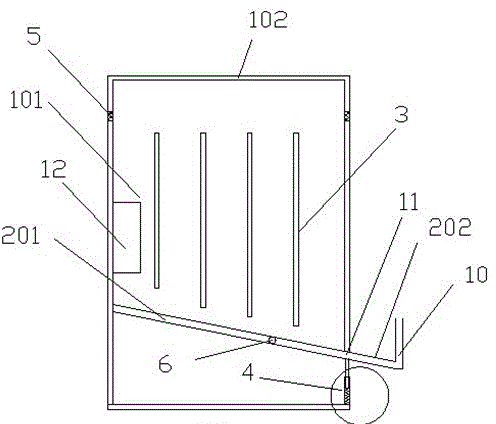

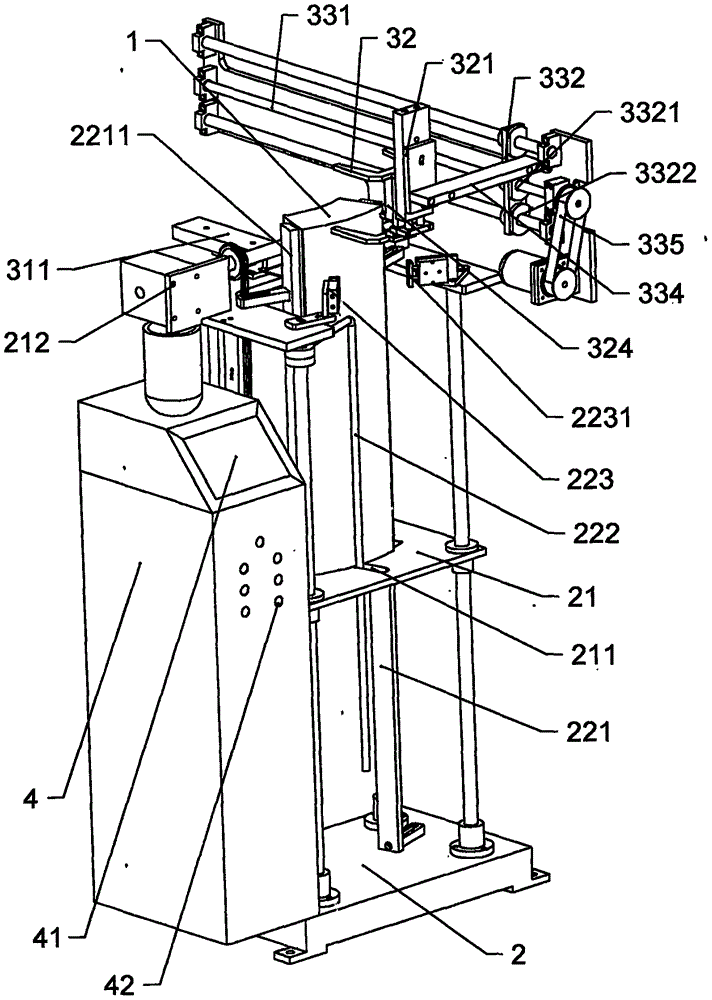

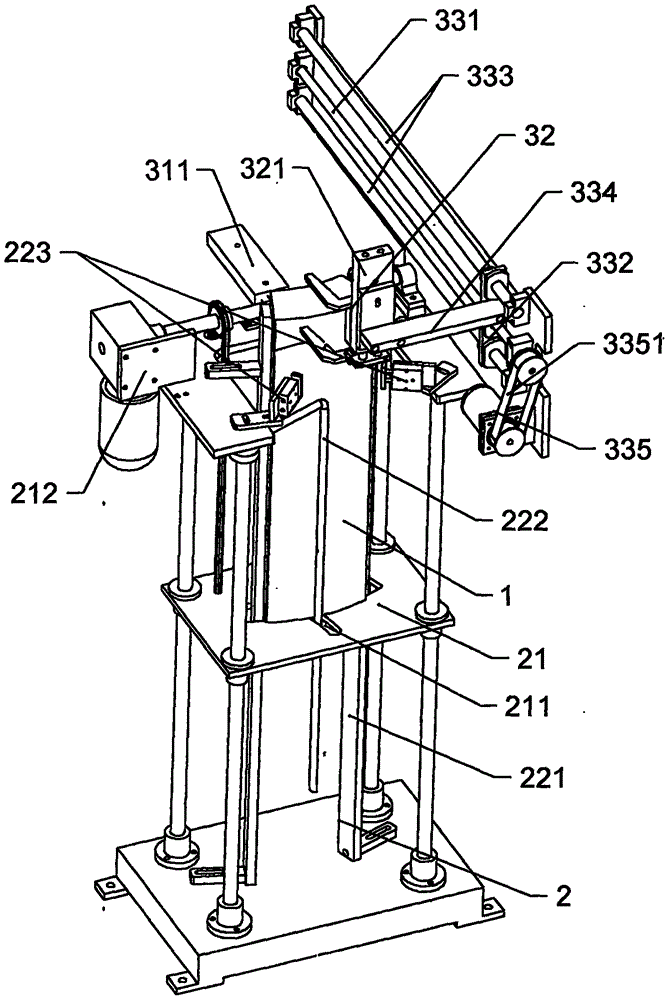

Device for supporting and positioning of cleaning terminal of photovoltaic array cleaning vehicle

ActiveCN105107812AModule function independentThe interface is clearCleaning processes and apparatusHydraulic cylinderPush pull

A device for supporting and positioning of a cleaning terminal of a photovoltaic array cleaning vehicle comprises a working arm set and a movable base. The movable base comprises a slewing device and a horizontal moving device, and is installed on a device bottom rack. The working arm set is installed on the movable base and includes an arm set base, a main arm, an end arm with execution terminal installation interface, an adapter rocker assembly, a push-pull rod, a main arm pitching hydraulic cylinder and an end arm posture-alignment hydraulic cylinder, wherein the root of the main arm is hinged to the arm set base; the main arm pitching hydraulic cylinder is hinged between the main arm and the arm set base; the end arm is hinged to one end of the main arm; the adapter rocker assembly is hinged to the position between the end and root of the main arm; the push-pull rod is hinged between the end arm and the adapter rocker assembly; the end arm posture-alignment hydraulic cylinder is hinged between the adapter rocker assembly and the arm set base. The device can meet the demand for cleaning any side of the vehicle, the structure is simple, the interface is distinct, the degree of automation is set reasonably, and the device is neat in appearance, flexible to operate, convenient to control and high in adaptability.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

Electronic mutual inductor working power supply

InactiveCN102244418ASingle frequencyReduce the impactElectromagnetic wave systemCircuit arrangementsSpecial designTransceiver

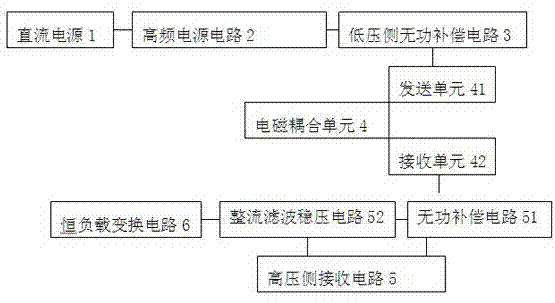

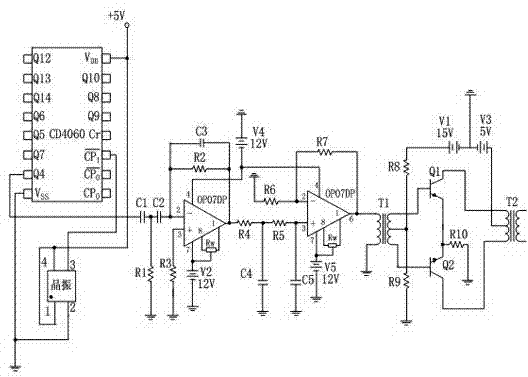

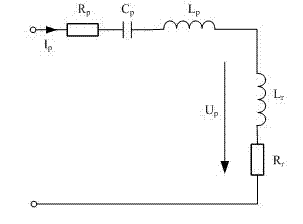

The invention discloses an electronic mutual inductor working power supply, which comprises: a direct-current power supply, a high frequency power supply circuit, a low-tension-side reactive compensation circuit, an electromagnetic coupling unit, a high-tension side receiving circuit and a constant load conversion circuit. The direct-current power supply supplies power for the high frequency power supply circuit. The high frequency power supply circuit is electrically connected with the low-tension-side reactive compensation circuit. The electromagnetic coupling unit comprises a sending unit and a receiving unit. The low-tension-side reactive compensation circuit is connected into the sending unit of the electromagnetic coupling unit. The high-tension side receiving circuit is connected into the receiving unit of the electromagnetic coupling unit. And the high-tension side receiving circuit is electrically connected with the constant load conversion circuit. In the invention, special design structure is used to realize high concentration transceiver of energy of electromagnetic coupling coils and reliable transmission of electric energy from the low tension side to the high-tension side can be realized through a special designed working circuit. Therefore, the invention is worth popularizing.

Owner:GUANGDONG UNIV OF TECH

Multifunctional auxiliary anesthetizing device for clinical anesthesiology department

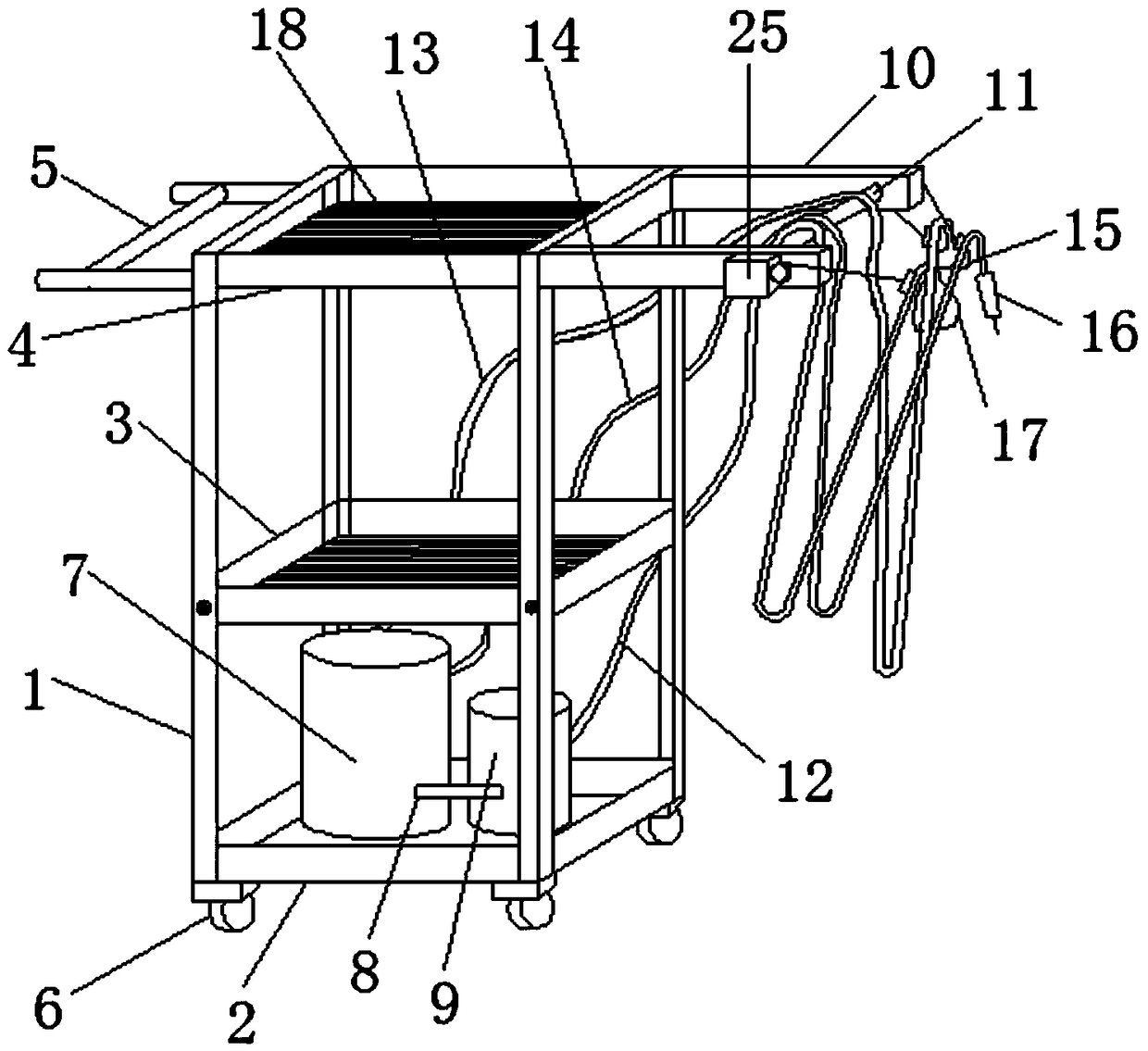

The invention discloses a multifunctional auxiliary anesthetizing device for the clinical anesthesiology department. The multifunctional auxiliary anesthetizing device comprises a movable frame, a bottom storage rack fixed on an inner side of the movable frame, a middle storage rack above the bottom storage rack, an upper storage rack above the middle storage rack, a push handle fixed on one sideof a top portion of the movable frame and universal wheels fixed on a bottom portion of the movable frame, an anesthetizing liquid storage barrel is fixed on a surface of the bottom storage rack, an nebulizer is connected to one side of the anesthetizing liquid storage barrel through a connection pipe, a support is fixedly welded to the other side of the top portion of the movable frame, a rollingshaft is welded to inner sides of the support, wire coilers are fixed on both sides of the support, and a first liquid supplying pipe is connected to the other side of the anesthetizing liquid storage barrel in a communicated manner. The multifunctional auxiliary anesthetizing device for the clinical anesthesiology department is convenient to move, wide in application range and capable of workingin three anesthetizing manners including body surface rubbing anesthetization, body surface injecting anesthetization and breathing anesthetization, difficulty in operation can be lowered, a space inan operating room can be saved, and an operation efficiency can be improved.

Owner:单晓辉

Welding rod box

The invention relates to a welding rod collecting device, and in particular relates to a welding rod box. The welding rod box comprises a box body, the box body is composed of a box cover body and a box main body, the box cover body and the box main body are connected in a dismountable and adaptive mode, the side wall of the box body is provided with a material outlet; an inclined supporting plate is arranged in the inner cavity of the box body, and the end of the supporting plate extends outside the outer side of the box body from the material outlet; the side wall of the box body at the lower part of the supporting plate can flexible up and down, the supporting plate is divided into the fixed supporting plate and the movable supporting plate, and the fixed supporting plate is connected with the movable supporting plate through a hinge; a baffle is fixed at the end of the movable supporting plate; an electric heater is arranged at the inner wall of the box body. By adopting the structure, the welding rods are arranged in the welding rod box at the welding site, so that the disorder placing phenomenon of the welding rods can be avoided at the site, the problems that the welding rods are easy to affect with damp, easy to lose due to disorder placing and easy to conflict for bringing the safety accidents can be avoided.

Owner:李虎林

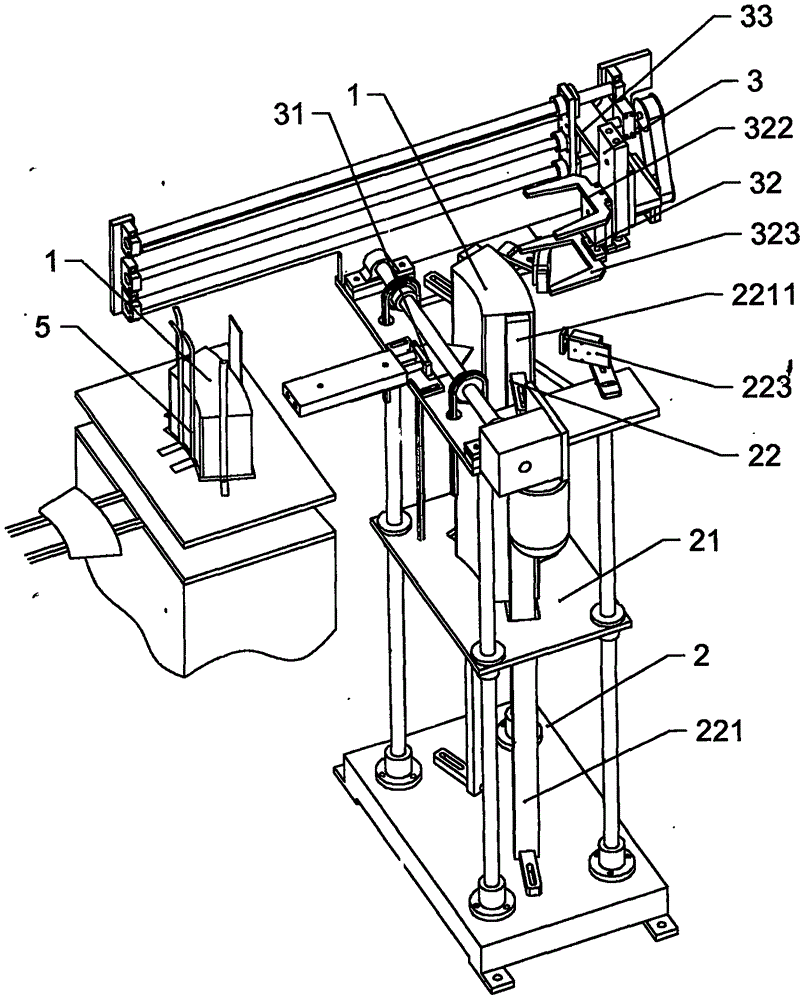

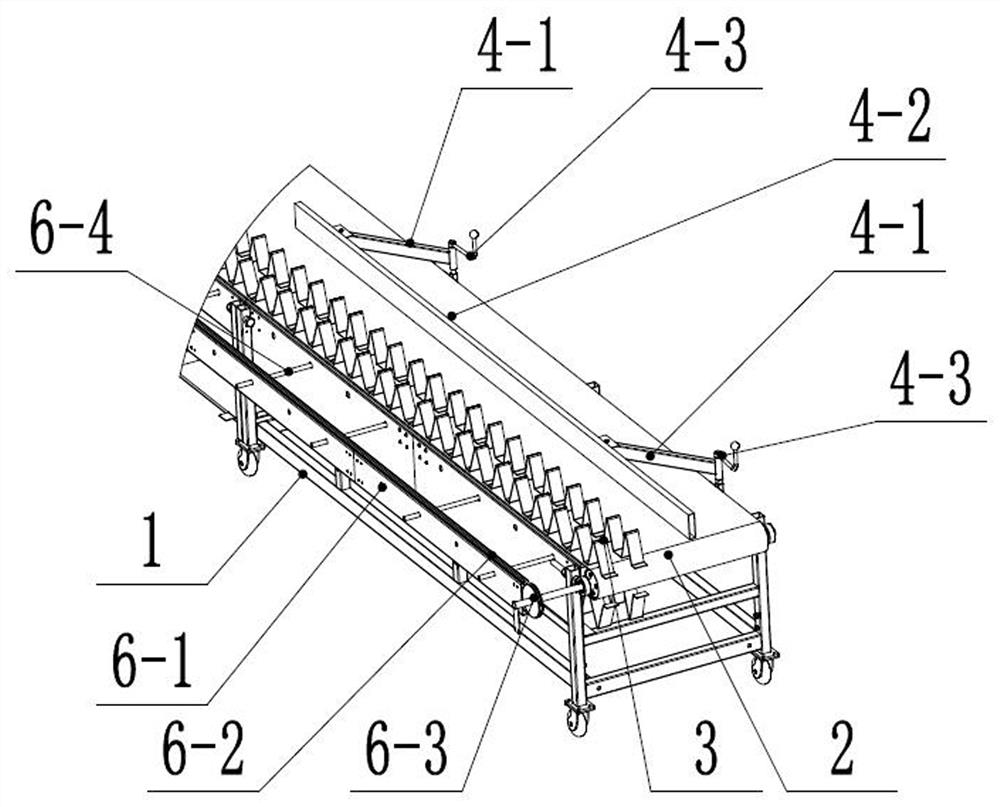

Paper scrap conveying device of dixie cup machine

InactiveCN106044194AReduce labor intensityNo clutterConveyorsDe-stacking articlesPulp and paper industryWorking hours

The invention discloses a paper scrap conveying device of a dixie cup machine. The paper scrap conveying device comprises a rack, a transmission mechanism and a control box, wherein the rack comprises a paper storage lifting platform and a positioning assembly; the paper storage lifting platform can be used for placing and lifting a paper scrap; the positioning assembly is arranged on the peripheral side of the paper scrap in a matching manner; the transmission mechanism comprises a paper spading piece, a paper clamping arm and a guiding and transporting assembly; the positioning assembly comprises two side positioning pieces fixed on the rack, a rotary rod and air cylinder positioning pieces; the two side positioning pieces comprise two positioning pieces; the rotary rod is rotated and propped against the arc-shaped outer side face of the paper scrap after the paper scrap is placed; the air cylinder positioning pieces are symmetrically arranged on the arc-shaped outer side face of the paper scrap above the rotary rod; air cylinder back up plates are arranged on the air cylinder positioning pieces; and the paper clamping arm can move in the space between the two air cylinder back up plates. The paper scrap conveying device is used on the dixie cup machine to continuously and automatically supplement the carrying capacity of paper scraps on a paper scrap transferring device, and can increase the continuous working hours.

Owner:WENZHOU JUNENG MACHINERY CO LTD

Overturning stacking machine

The invention discloses an overturning stacking machine. The overturning stacking machine comprises a buffering paper separation part, a collection and piling part, an overturning part and a stacking part, wherein a hoisting conveying part is arranged between the collection and piling part and the overturning part; the overturning part comprises an overturning mechanism and a plurality of overturning part conveyor belts which are arranged in parallel along the conveying direction of a paperboard; the overturning mechanism comprises a first rotary shaft and a second rotary shaft which are located under the overturning part conveyor belts and are arranged along the radial direction of the overturning part conveyor belts; the first rotary shaft is located in front of the second rotary shaft; first baffle teeth and second baffle teeth are arranged on the first rotary shaft and the second rotary shaft between the adjacent overturning part conveyor belts respectively; and the positions and quantity of the first baffle teeth correspond to those of the second baffle teeth respectively. According to the overturning stacking machine, the first baffle teeth are matched with the second baffle teeth, so that the corrugated paperboard can be easily overturned; the overturning stacking machine has a simple structure, is in low cost and has high production efficiency.

Owner:ZHEJIANG UNIV OF TECH

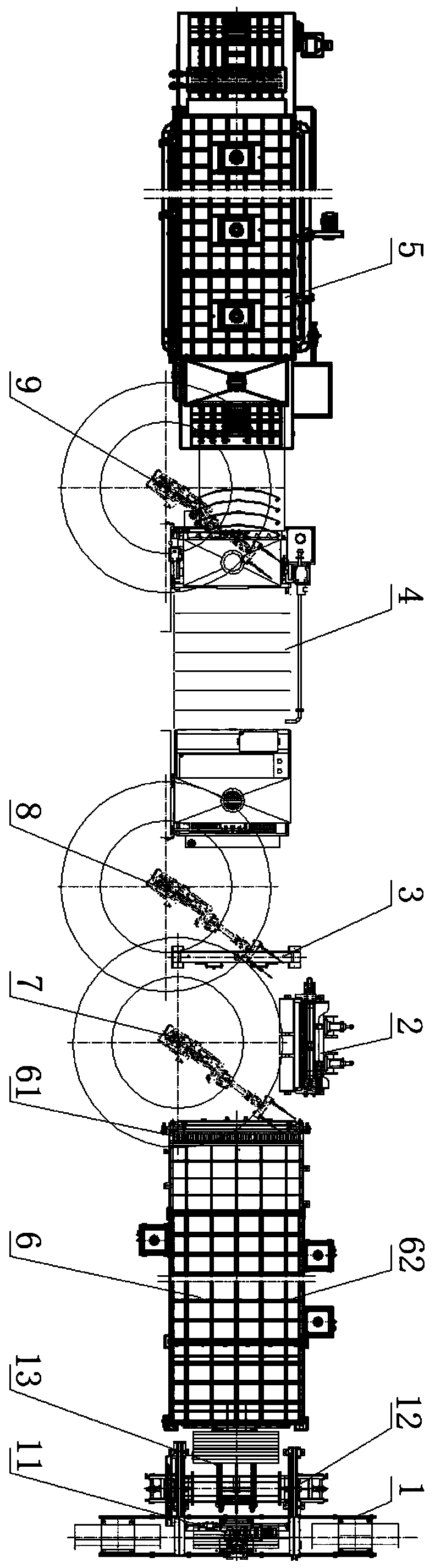

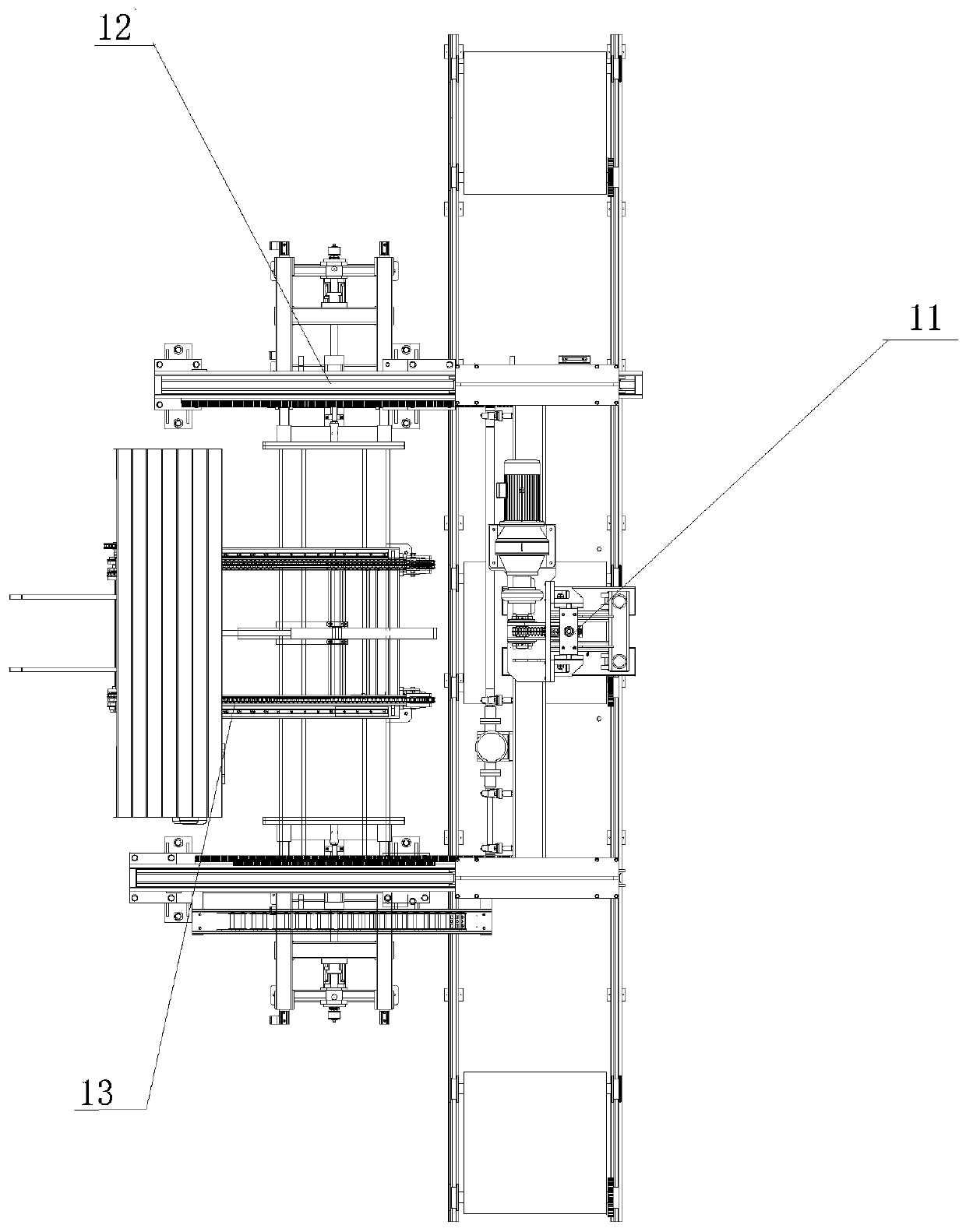

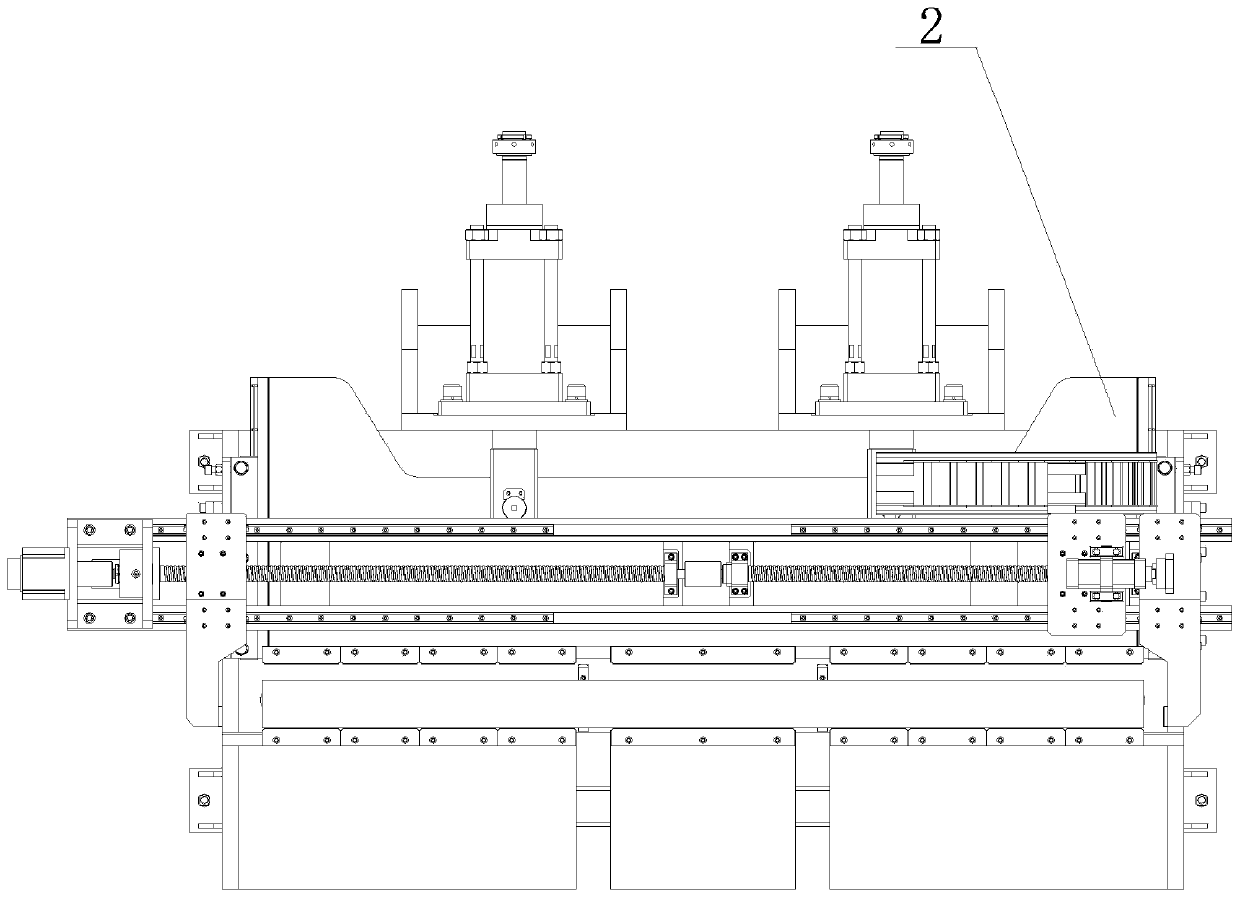

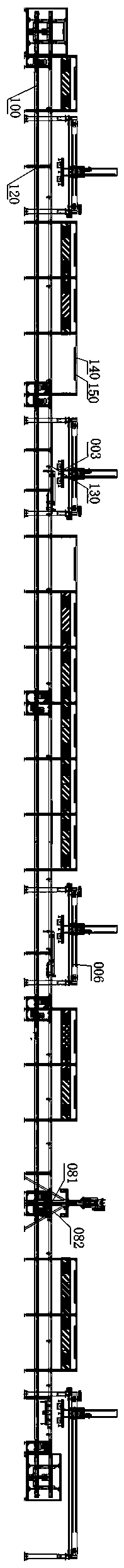

Automatic automobile plate spring forming heat treatment line and work method thereof

PendingCN111455153ASave adjustment timeRealize automated productionFurnace typesHeat treatment furnacesThermodynamicsTempering

The invention relates to an automatic automobile plate spring forming heat treatment line and a work method thereof. An automatic feeding device, a plate spring quenching heating furnace, a plate spring straightening machine, a plate spring forming machine, a quenching device and a tempering heating furnace are included. The automatic feeding device conveys reeds to a feeding port of the quenchingheating furnace after centring the reeds, and the reeds are conveyed to a quenching heating furnace discharging port to be heated from the quenching heating furnace via a stepping mechanism. A firstcarrying robot conveys the reeds at the quenching heating furnace discharging port to the plate spring straightening machine, and the straightened reeds are conveyed to the plate spring forming machine. A second carrying robot conveys the formed reeds to a workpiece oil inlet mechanism of the quenching device, the workpiece oil inlet mechanism places the reeds on a stepping conveying mechanism, the quenching device brings the reeds into oil for quenching, and a workpiece oil discharging mechanism is used for supporting out the quenched reeds from the stepping conveying mechanism. A third carrying robot places the quenched reeds on the tempering heating furnace from the workpiece oil discharging mechanism, and automatic reed forming heat treatment is finished.

Owner:山东森德数控机械有限公司

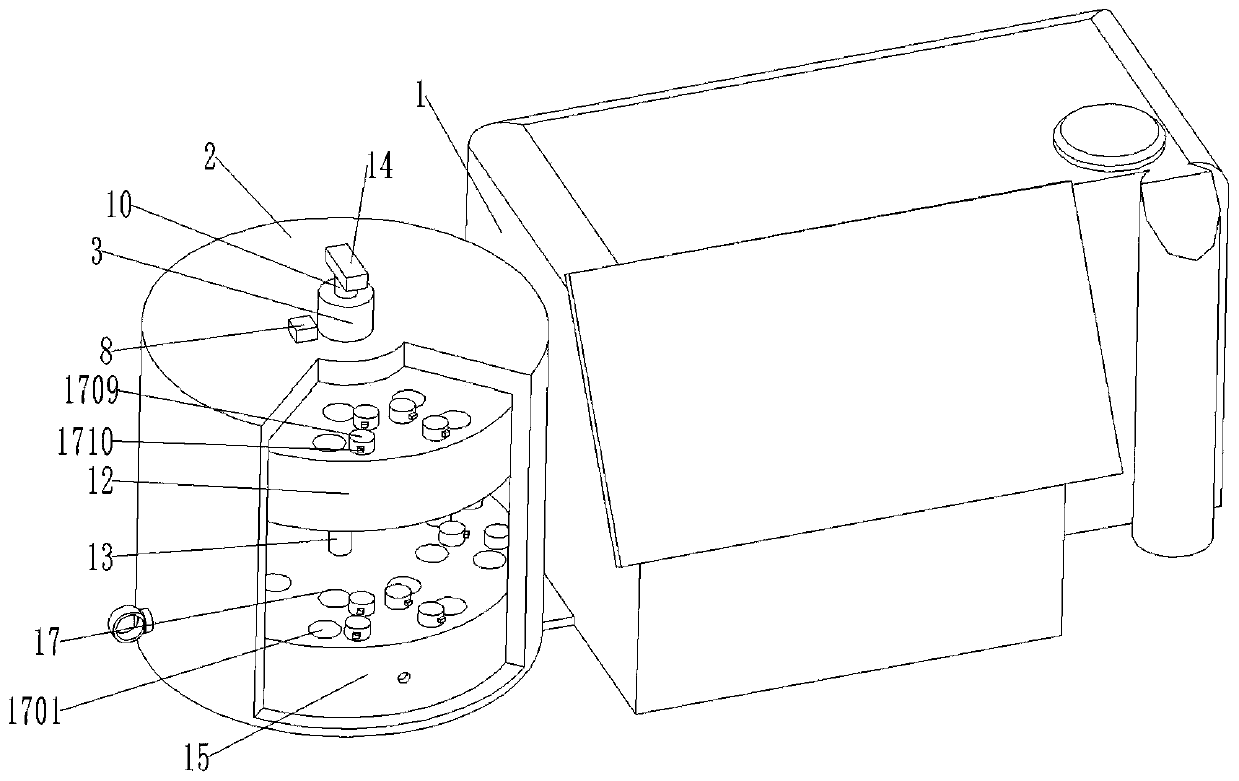

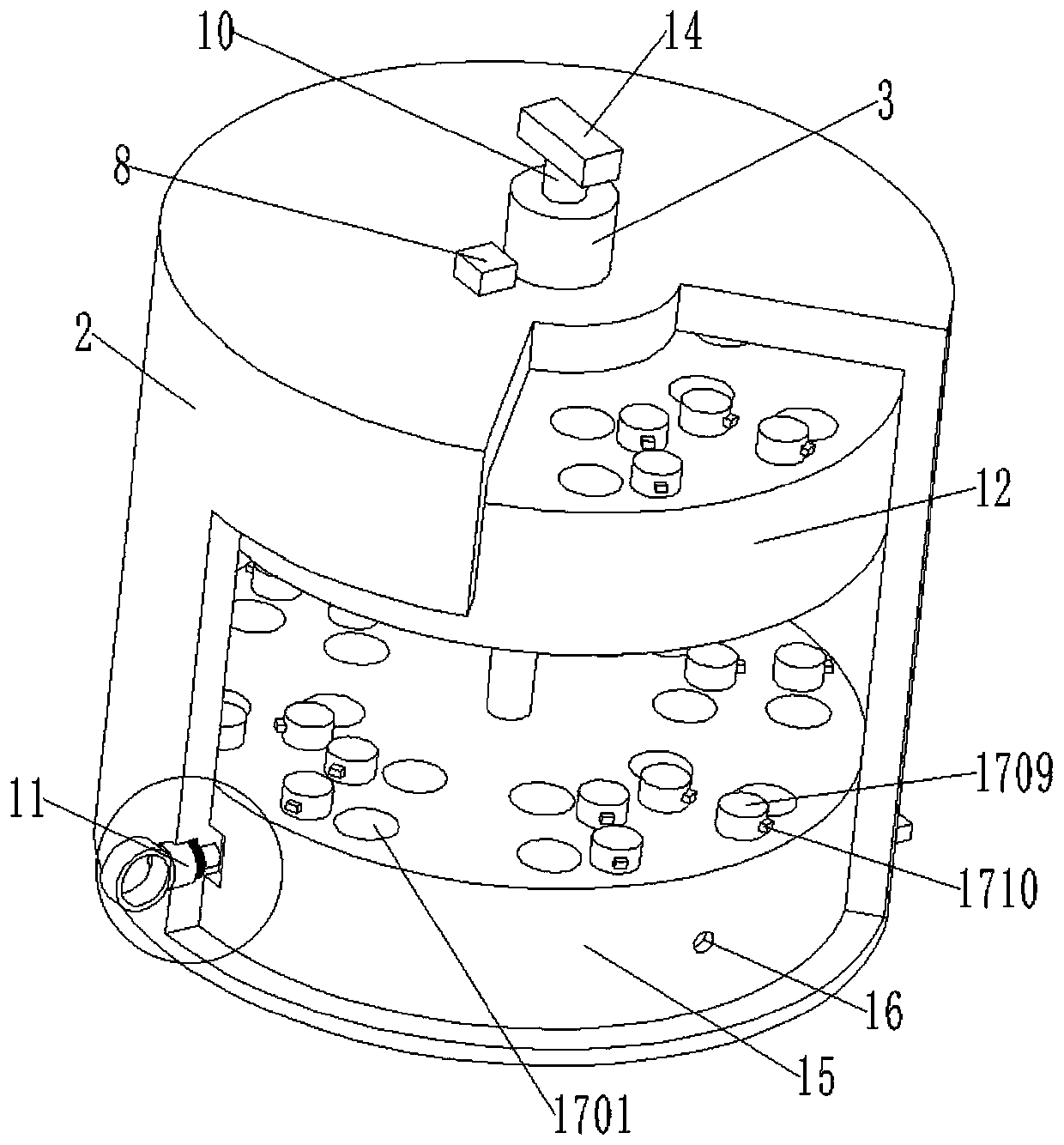

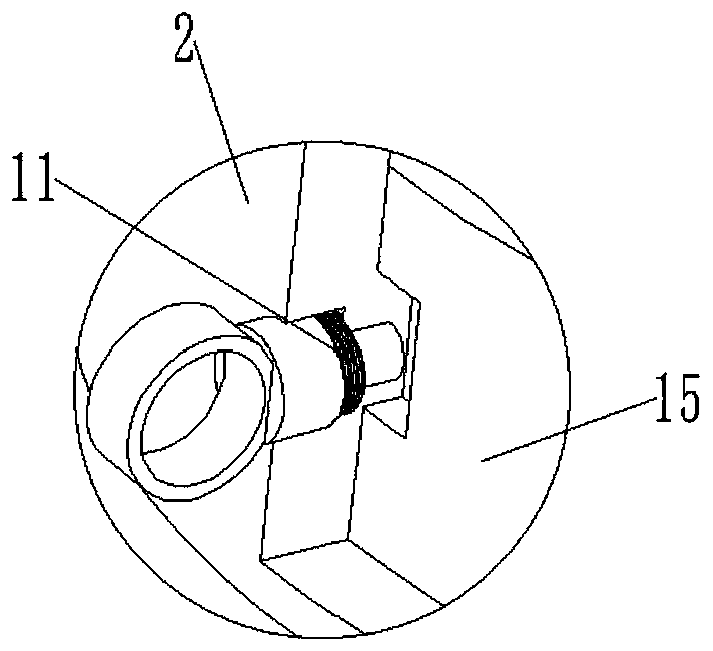

Cell detection device with partitioned sampling private bin

InactiveCN111595759AImprove detection efficiencyConvenience guaranteedIndividual particle analysisTest tube stands/holdersComputer hardwareEmbedded system

The invention discloses a cell detection device with a partitioned sampling private bin. According to the cell detection device, a sample placing bin, a first storage disc and a second storage disc are arranged, samples for cell sampling can be placed in a differentiated manner during cell detection, further the samples can be distinguished and sampled in a detection test, the convenience of the test is ensured, great convenience is brought to detection of workers and cells, the cell detection working efficiency is further improved, the working effectiveness is guaranteed, placement positioning connecting mechanisms arranged in the first storage disc and the second storage disc have a very good auxiliary effect on differentiated placement of the cell samples, the cell samples are preventedfrom being scattered, differentiated detection of the cell samples is facilitated, on one hand, the safety of the collected samples in the using process is ensured, on the other hand, the collected samples are better distinguishing differentiation, and detection work is facilitated.

Owner:李五世

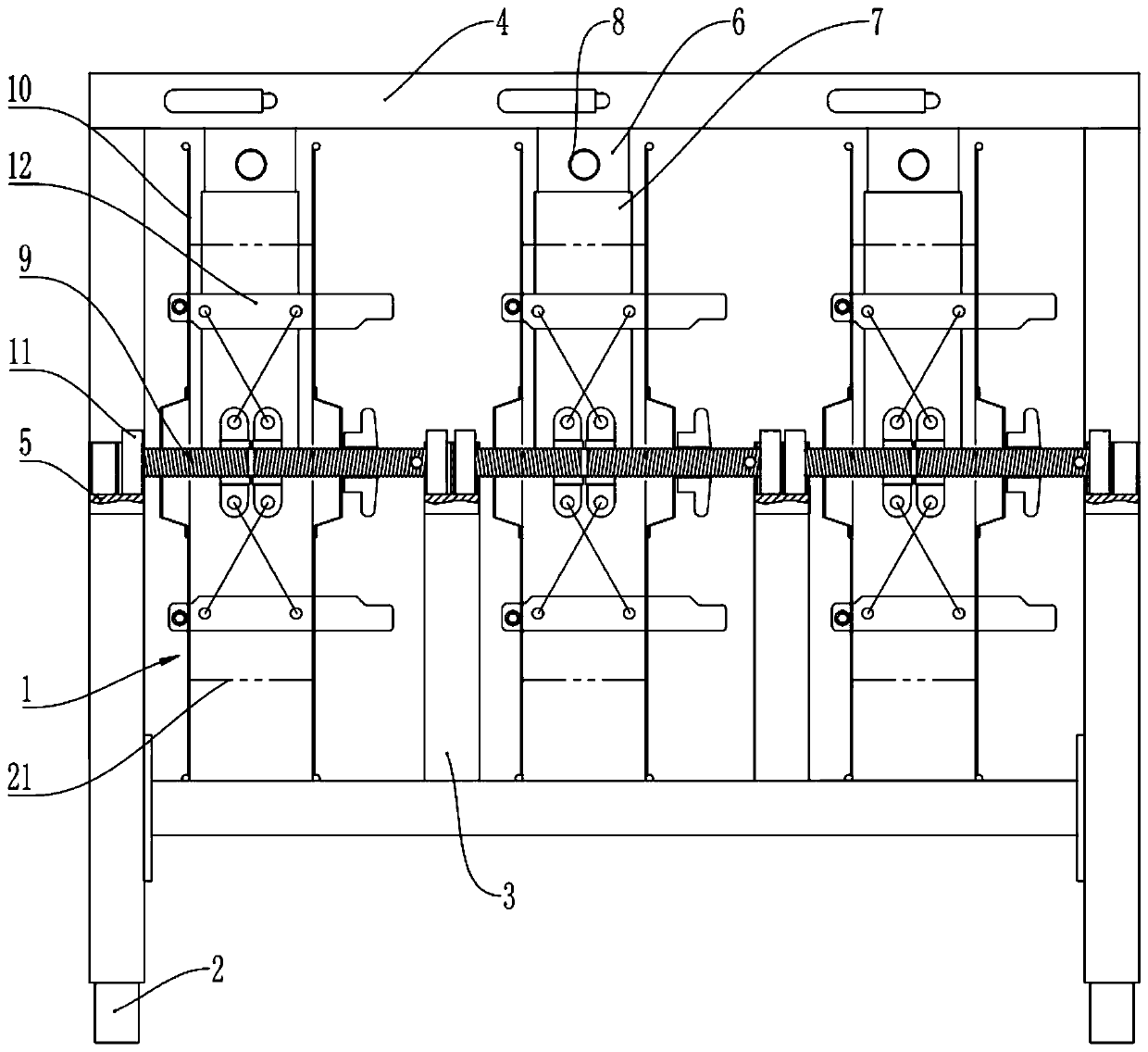

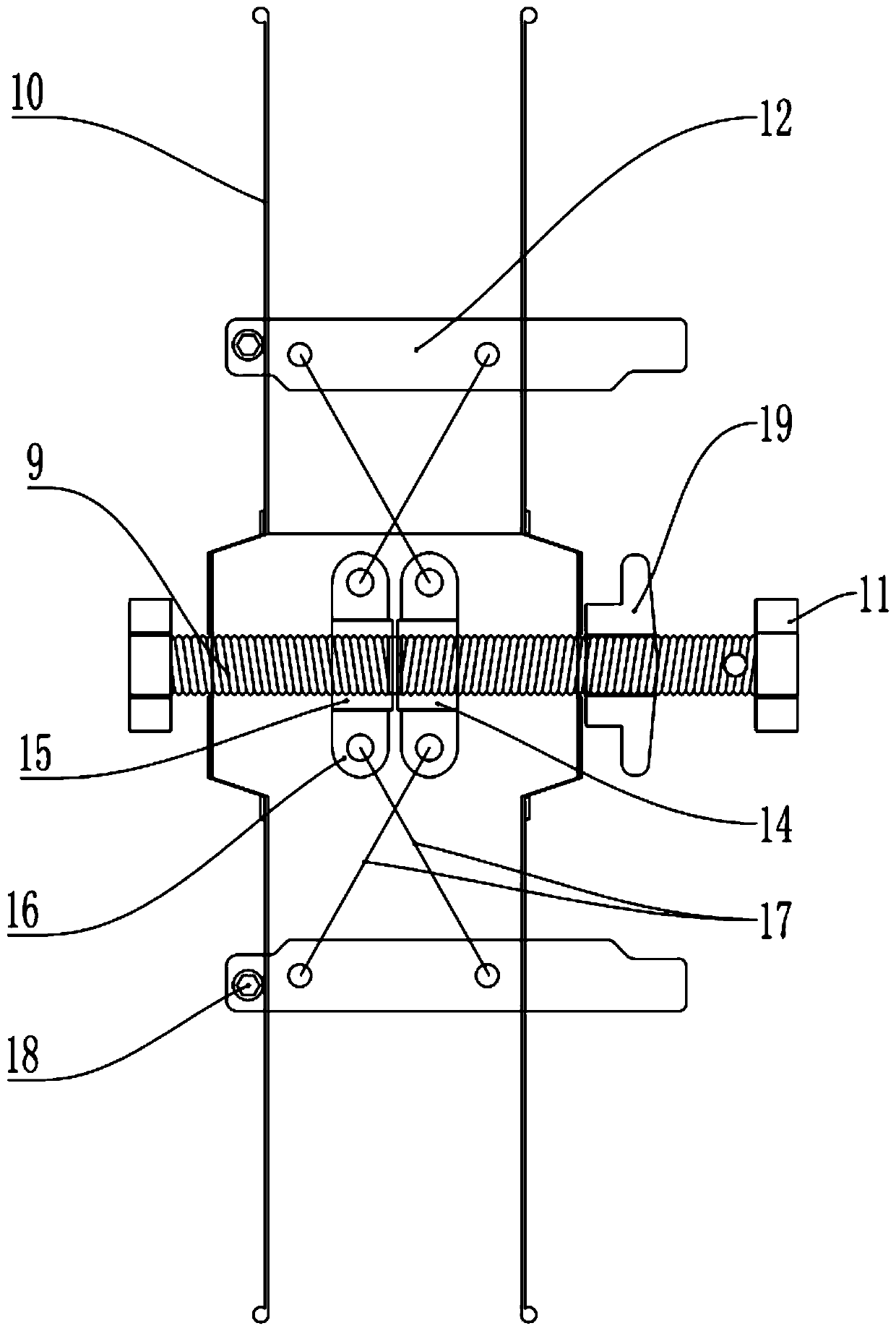

Wire feed plate mechanism for submerged-arc welding

InactiveCN102601495AEasy loadingNo clutterArc welding apparatusStructural engineeringMechanical engineering

The invention relates to a wire feed plate mechanism for submerged-arc welding. A plate rail is supported and installed on a shaft base through a central shaft of the plate rail. The shaft base is fixed at the top of a channel steel leg. The bottom of the channel steel leg is connected with a bottom plate. The plate rail is provided with two side plates. One of the side plates is moveably detectable so as to load a welding stick. One end of a conduit frame is connected with the channel steel leg. A conduit clamp is installed on the conduit frame and loaded with a conduit where the welding stick passes through. At least three tightly pushing assemblies for keeping an inner ring of the welding stick maintaining certain tensile are installed on the plate rail. The three tightly pushing assemblies are uniformly distributed in the peripheral direction of the plate rail. Each tightly pushing assembly comprises a fixed nut, a tightly pushing screw and a pressing piece. The fixed nut is fixed on the plate rail, the tightly pushing screw is installed in the fixed nut, and the pressing piece is fixed at the end of the tightly pushing screw. The wire feed plate mechanism for the submerged-arc welding has a simple, compact and reasonable structure, is convenient and rapid to operate, is capable of reducing the labor intensity of workers greatly and has high degree of automation.

Owner:WUXI HUALIAN SCI & TECH GROUP

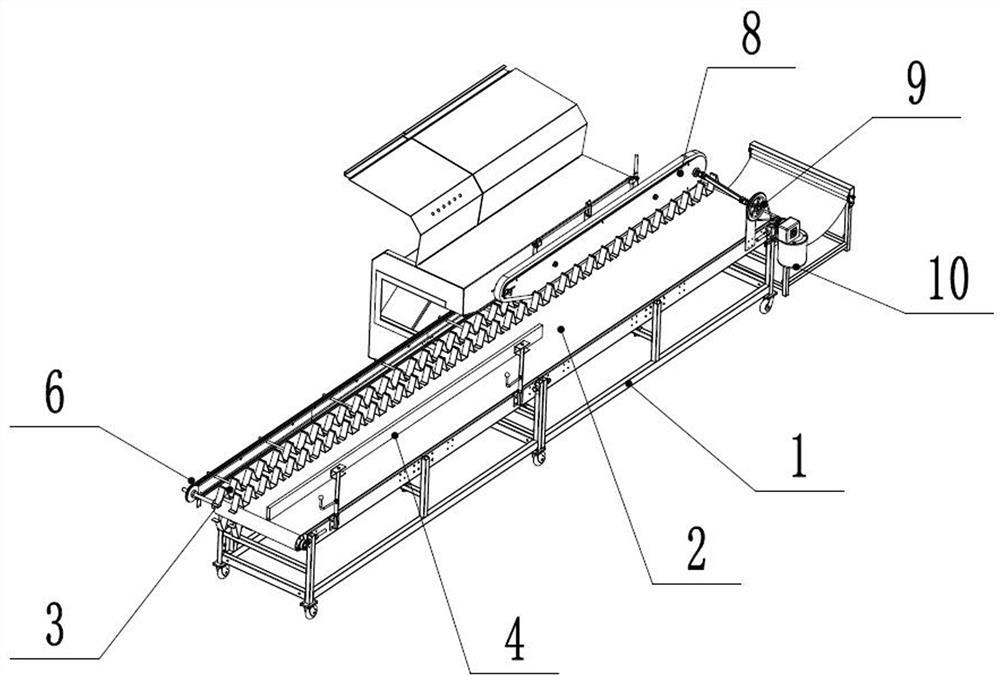

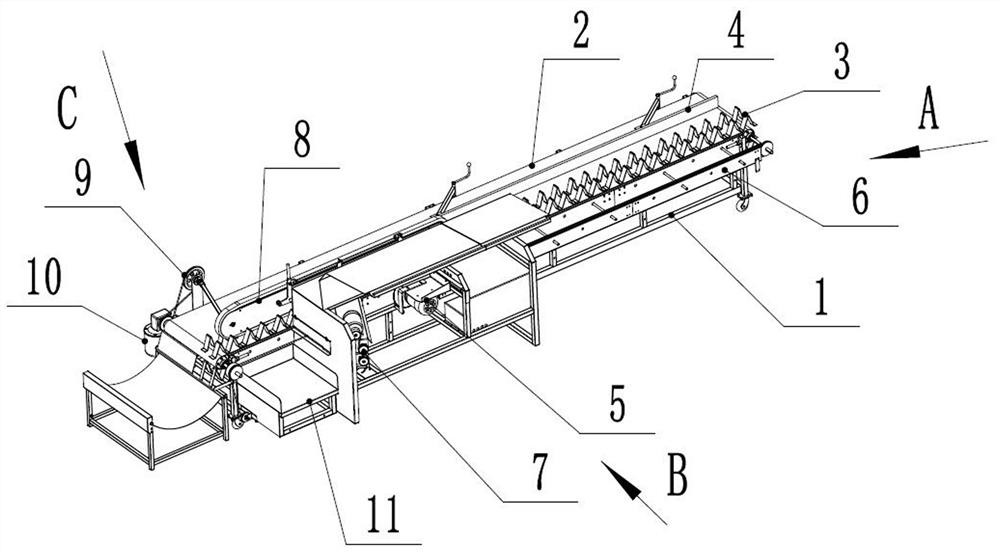

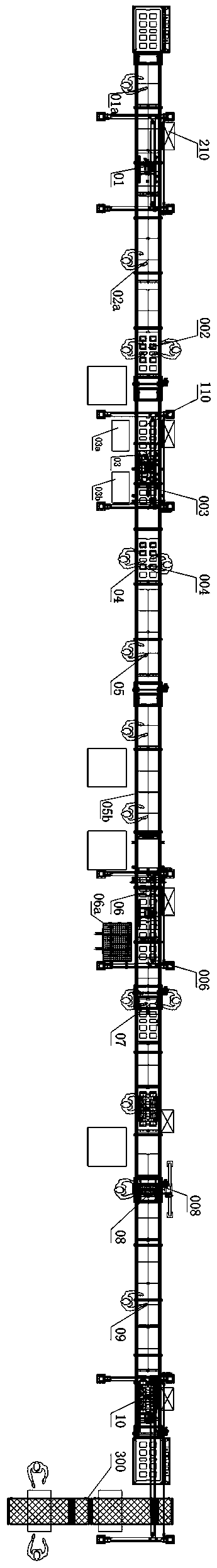

Bouquet processing production line and production method

PendingCN111837690AFully automatedGuaranteed adjustabilityThorn removersPackagingProcess engineeringManufacturing line

The invention discloses a bouquet processing production line and production method. The production line comprises a machine frame; the machine frame is installed with a conveying belt; several partitions are arranged on the conveying belt along the conveying direction; an empty slot for placing a bouquet is formed between the partitions; the machine frame further comprises a translational positioning device, a cutting device, a carding device and an automatic binding machine, which are sequentially arranged along the conveying direction of the conveying belt; the translational positioning device is used for aligning tops of fresh flowers; the cutting device is used for cutting roots of the fresh flowers; the carding device is used for removing excess branches and needles from the fresh flowers in a beating manner; and a pressing device positioned over the conveying belt is also arranged near the cutting device and the carding device. By means of the bouquet processing production line and production method in the invention, automation of bouquet production is realized; operations including root cutting, removing of excess branches and needles, binding and the like, can be automatically completed; and furthermore, the length adjustability and the length consistency of bouquets also can be ensured.

Owner:烟台方程机械技术有限公司

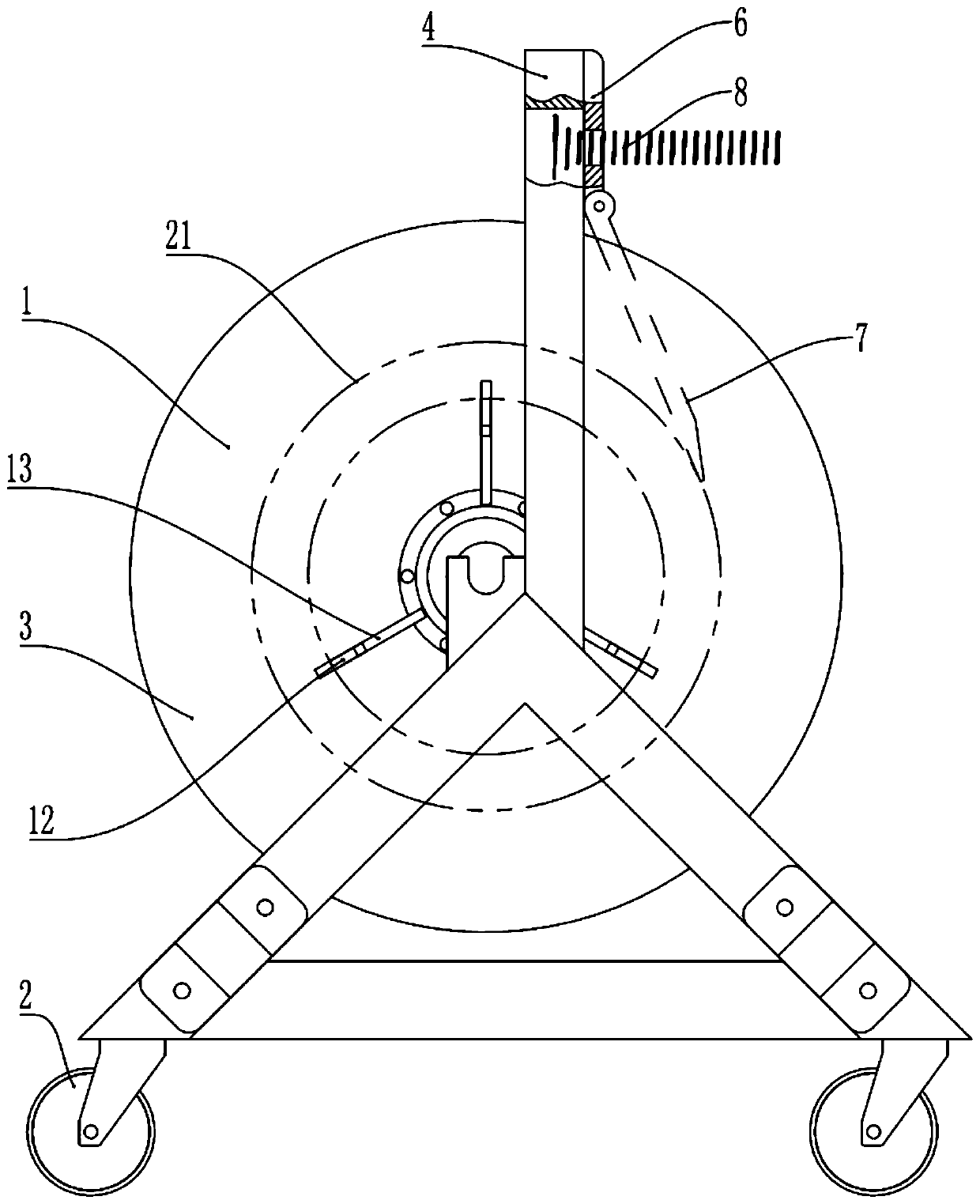

Rapid fixing type paying-off construction process

ActiveCN110203755AScattered situations will not occurRealize the needs of coiling and unwindingFilament handlingApparatus for laying cablesEngineeringElectric power

The invention relates to the technical field of electric power paying-off, and particularly discloses a rapid fixing type paying-off construction process. The rapid fixing type paying-off constructionprocess comprises the following steps that S1, a rapid fixing type paying-off device is taken, wherein the rapid fixing type paying-off device comprises a support and a cable installing disc, the cable installing disc is rotationally connected to the support, and the cable installing disc comprises a supporting shaft and two baffle discs which are distributed in the axial direction of the supporting shaft; S2, a cable coil is installed, wherein the cable installing disc is taken down from the support, the baffle discs are taken down from the cable installing disc, the cable coil which needs to be installed sleeves expanding rods, then the taken-down baffle discs are installed back, stretching and retracting units are adjusted, so that the inner ring of the cable coil is tightened throughthe expanding rods, the baffle discs are adjusted, so that the baffle discs tightly press against the two sides of the cable coil, and the cable installing disc are installed on the support; and S3, paying-off is prepared, wherein a cable head of the outer ring of the cable coil is sorted out, and a section of cable is pulled out for later use. According to the scheme, the problems that the cablecoil is scattered, the paying-off speed of the cable is low and the manual labor intensity is large in the prior art are solved through the cable installing disc, the stretching and retracting units and the expanding rods.

Owner:CHONGQING CONSTR NINTH ENG

Novel intelligent laser cutting machine

InactiveCN109332915AIsolate the dangerAvoid getting in the wayLaser beam welding apparatusInfraredLaser cutting

The invention discloses a novel intelligent laser cutting machine, which includes a machine tool body. The feeding end of the machine tool body is provided with a driving roller, both sides of the machine tool body in the length direction are internally and slidably provided with lifting type protective isolation plates correspondingly, the machine tool body is internally provided with a driving mechanism which drives the lifting type protective isolation plates to slide up and down, and infrared ray alarms connected with driving mechanism circuit signals are fixedly arranged on both sides, near the driving roller, of the machine tool body in the length direction correspondingly; and the infrared ray alarms are vertically arranged with the side wall of the machine tool body, mirror face refracting plates are fixedly arranged on both sides, near the infrared ray alarms, of the machine tool body correspondingly, the mirror face refracting plates are obliquely arranged at 45 degrees, andinfrared ray receiving plates are vertically fixedly arranged on both sides, away from the driving roller, of the machine tool body correspondingly. According to the novel intelligent laser cutting machine, the condition that apprentice inadvertently closes to observe laser cutting head work can be effectively avoided, and safety is improved.

Owner:应娉

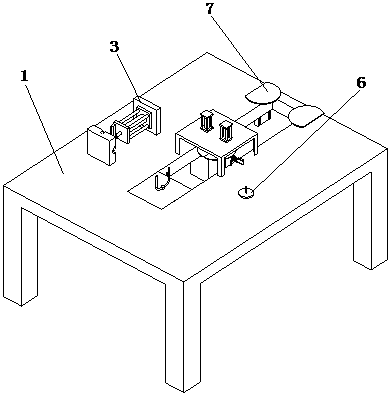

Wire winding equipment for wire processing

ActiveCN110127139AAffect the winding effectNo clutterFilament handlingWrapping with article rotationEngineeringConductor Coil

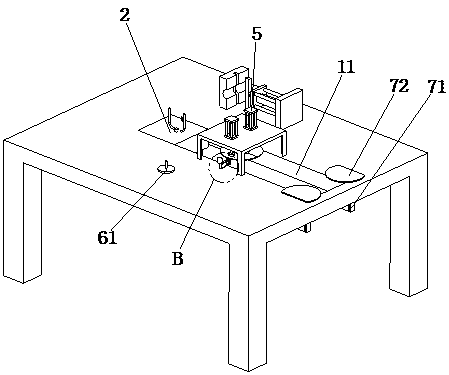

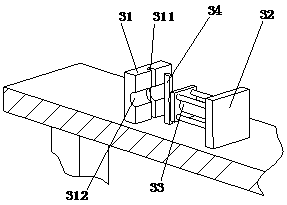

The invention discloses wire winding equipment for wire processing, and belongs to the technical field of wire processing. The wire winding equipment comprises a workbench, a wire winding assembly, ashearing assembly, a moving assembly, a pressing assembly, a tightening assembly and a lifting assembly; the workbench is vertically arranged, the top of the workbench is provided with a rectangular through groove, the shearing assembly is arranged at the top of the workbench, the wire winding assembly is arranged in one end of the rectangular through groove, the moving assembly is arranged besidethe rectangular through groove and located at the bottom of the workbench, the moving end of the moving assembly is fixedly connected with the wire winding assembly, the pressing assembly is arrangedat the top of the workbench, the tightening assembly is arranged at the top of the workbench, and the lifting assembly is arranged at the other end of the rectangular through groove. According to thewire winding equipment for wire processing, the two semicircular pressing plates are driven by the output ends of two pressing air cylinders to compress winded wire, so that electric wire can be fitclosely together and can be prevented from being loosened after being wound, and the influence of the winding effect of the electric wire is avoided.

Owner:ZHEJIANG KANGWEISHENG HIGH TEMPERATURE CABLE

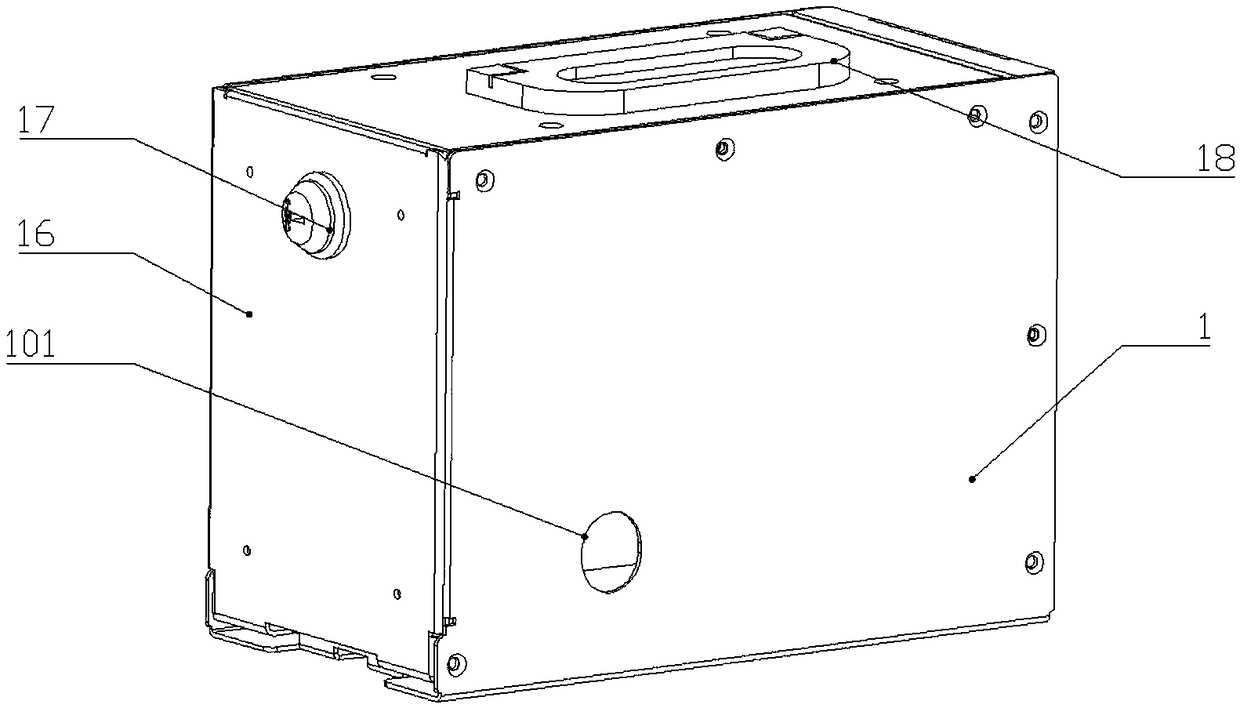

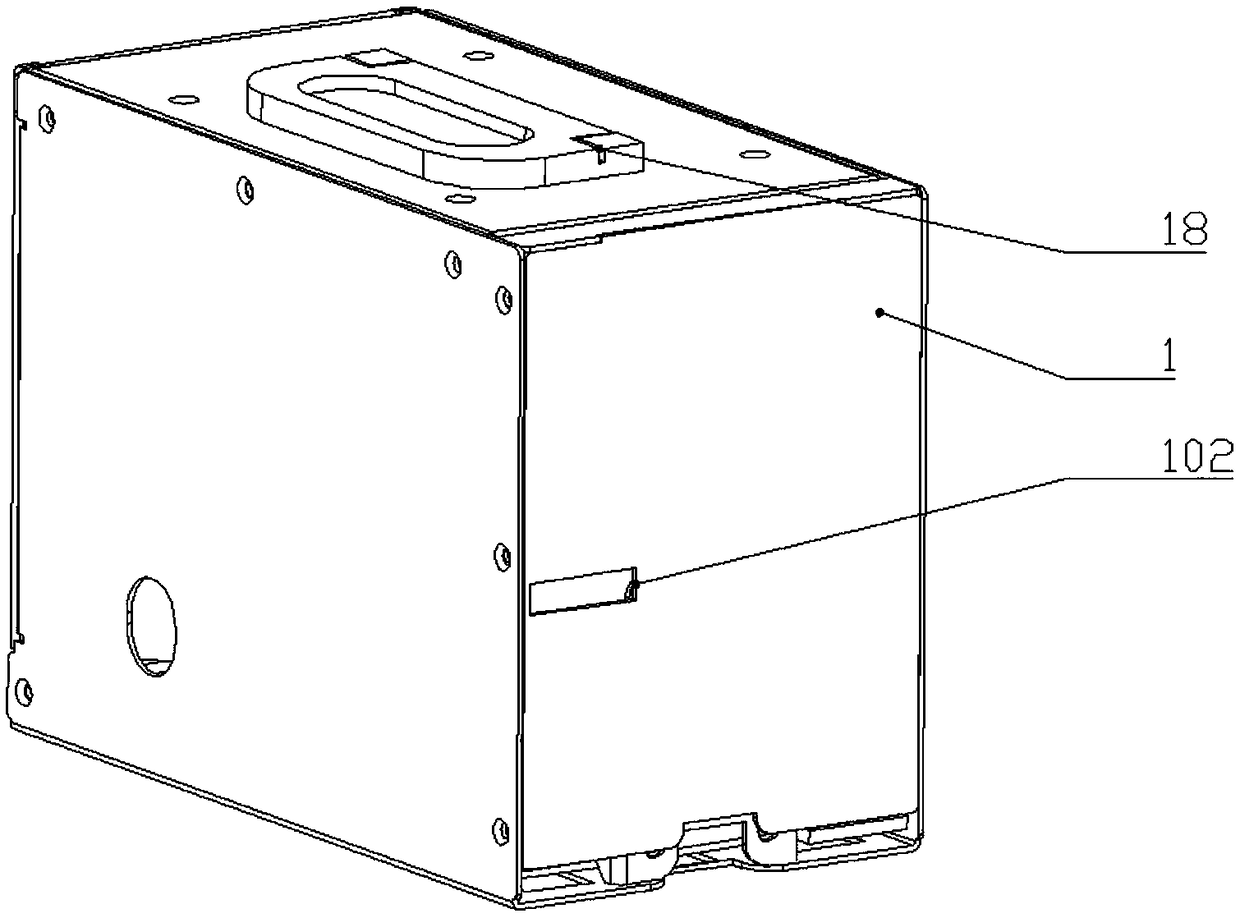

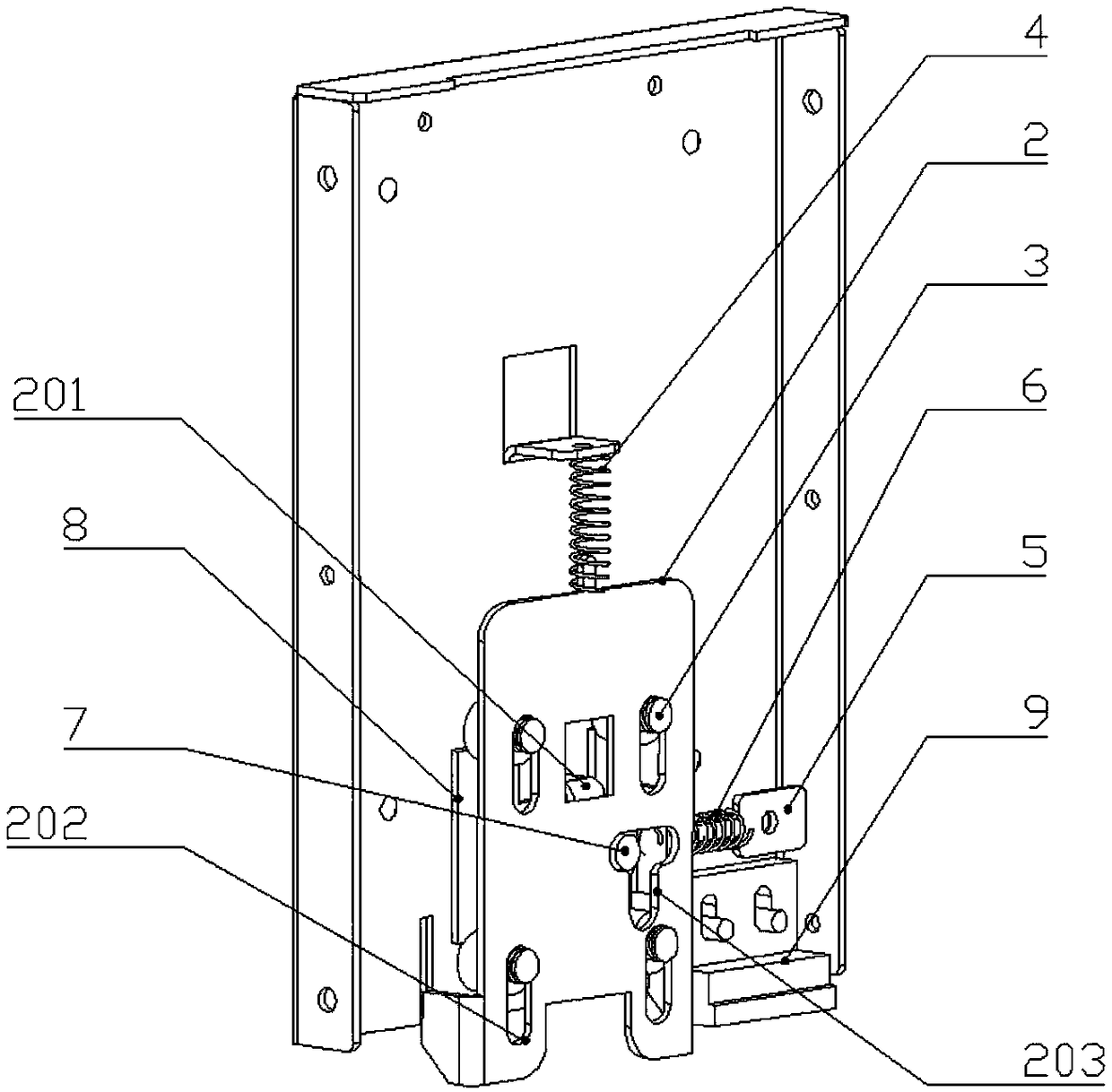

Bankbook storage box and automatic bankbook issuing device containing bankbook storage box

PendingCN108961608AImprove securityThere will be no loose passbooksComplete banking machinesEngineeringSelf-service

Owner:BEIJING C&W ELECTRONICS GRP

Mechanical arm and fermented beancurd bottling mechanism applying same

InactiveCN102152296AWill not damage the structureWon't break shapeProgramme-controlled manipulatorEngineeringManipulator

The invention discloses a full-automatic fermented beancurd bottling mechanical arm and a fermented beancurd bottling mechanism applying the same. The mechanical arm comprises a longitudinal fixed base, the fixed base is longitudinally provided with a plurality of suckers for sucking fermented beancurds, the suckers are distributed on the fixed base at equal distance, the upper end of the fixed base is connected with a transverse connecting rod, the other end of the connecting rod is connected with a longitudinal air cylinder, and the other end of the longitudinal air cylinder is connected with transverse air cylinders, wherein the transverse air cylinders are dual-stroke air cylinders, and the longitudinal air cylinder is a single-stroke air cylinder; and the fermented beancurd bottling mechanism comprises a plurality of the mechanical arms and a rack for fixing the mechanical arms, the upper end of the rack is provided with a circular air-cylinder fixed tray, and the transverse air cylinders of the mechanical arm are respectively fixed on the air-cylinder fixed tray at equal distance in a star shape. In the invention, the mechanical arm clamps the fermented beancurds by using the suckers, so that the clamping is more steady and firmer, the structures of the fermented beancurds are not damaged, the bottling efficiency is high and the bottling effect is good; and in the fermented beancurd bottling mechanism, a plurality of the mechanical arms work coordinately so that the fermented beancurd bottling efficiency is greatly increased.

Owner:GUANGDONG JINOU MACHINERY MFG CO LTD

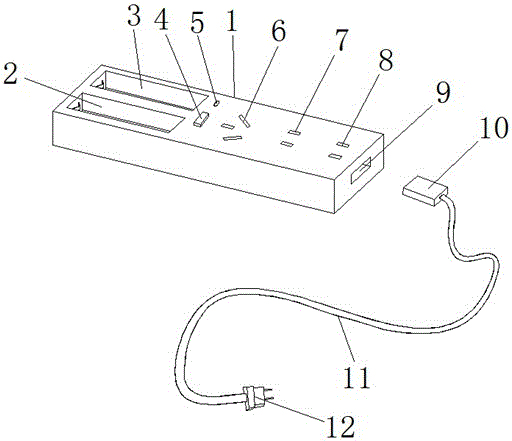

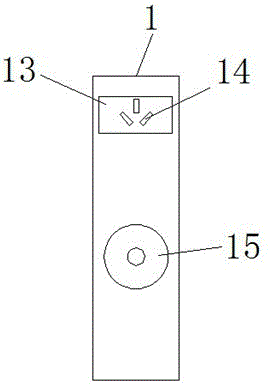

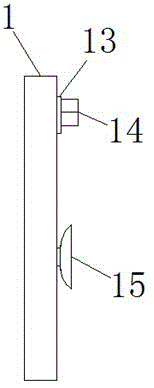

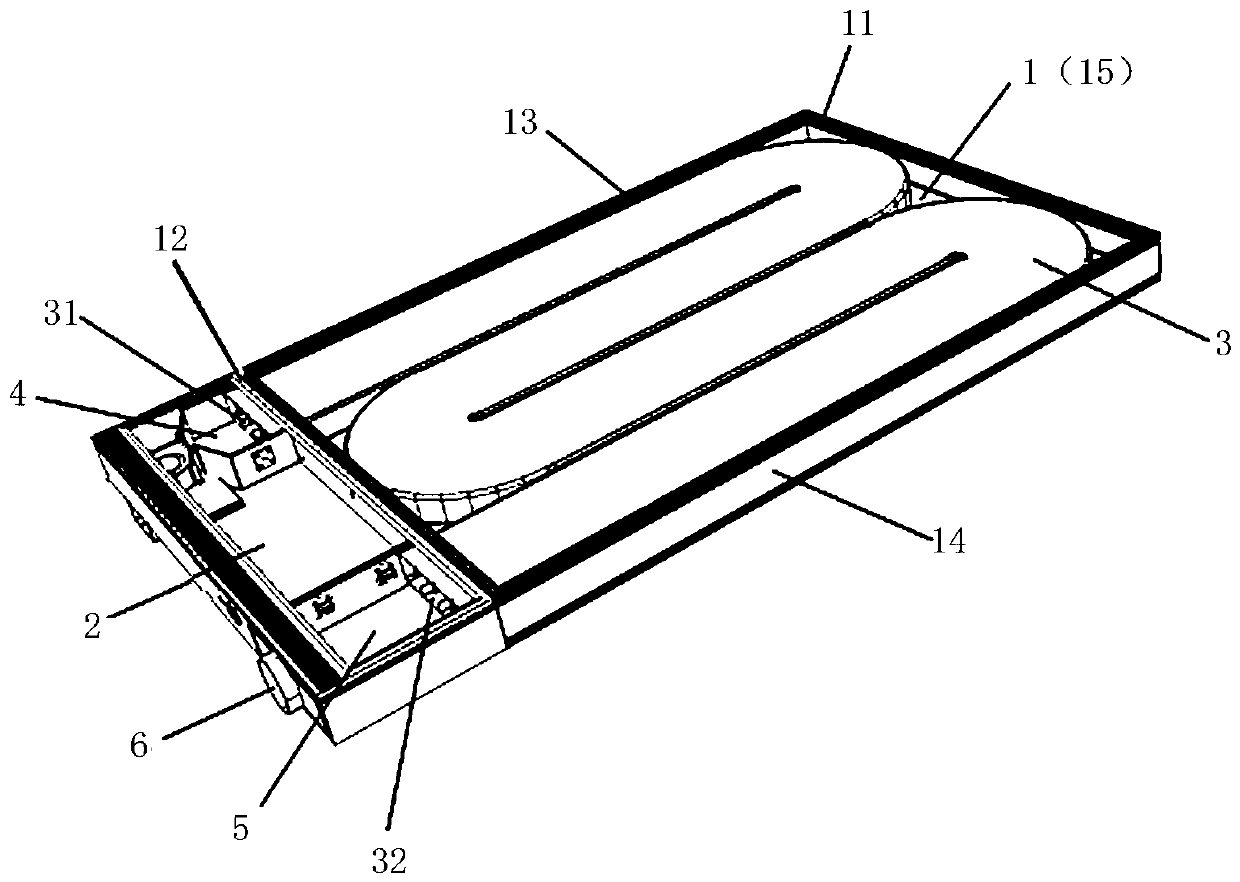

Multifunctional battery charging device

InactiveCN106849249AReasonable structureImprove user experienceCircuit monitoring/indicationDifferent batteries chargingBattery chargeLithium battery

The invention discloses a multifunctional battery charging device including a socket box and a power line. The upper end face of the socket body is provided with a first battery groove. The other side of a first jack is provided with a second jack. One side of the second jack is provided with a third jack. The tail end of the socket box is provided with a wiring hole. A connection base plate is connected to the back face of the socket box fixedly. A second plug is mounted on the connection base plate. A sucker is mounted in the middle position of the back face of the socket box. One end of the power line is equipped with a connector while the other end of the power line is connected with the first plug electrically. The multifunctional battery charging device is reasonable in structure and can charge a lithium battery when serving as a socket. At the same time, two connection modes, namely, wired connection and wireless connection, can be provided for a user through different wiring ways. The sucker arranged on the back face can solve a problem of fixation of the patch board effectively, so that the patch board placement disorder is avoided during use and a user can have better use experience.

Owner:陈萍

Automatic assembly line and technology for solar photo-thermal heating equipment

PendingCN111421339ATo achieve the purpose of automated assemblyImprove assembly efficiencyAssembly machinesThermodynamicsControl system

The invention provides an automatic assembly line and technology for solar photo-thermal heating equipment. The automatic assembly line comprises a plurality of stations, a transporting system and a control system; the transporting system comprises a plurality of pallets moving in the forward direction of the operation working procedure, and the pallets are suitable for supporting the solar photo-thermal heating equipment in the assembly process; and the control system controls start and stop of the transporting system so as to enable a bottom plate to serve as an assembly standard piece of the whole assembly process to complete the assembly working procedure of the solar photo-thermal heating equipment starting from the bottom plate. According to the automatic assembly line and technology, assembly is started from the bottom plate of the solar photo-thermal heating equipment, the bottom plate serves as the assembly standard piece of the whole assembly process, the solar photo-thermalheating equipment is assembled in a mode of transmitting of the transporting system, assembly operation is achieved in a form of automatic transferring of a conveying system, thus the purpose of automatic assembly is achieved, assembly operation on the assembly line is achieved through cooperation of labor, and the purposes of high assembly efficiency and high quality are achieved.

Owner:河南日昇源集成科技有限公司

Power line collecting and releasing device for building machine

InactiveCN109160392ARewind fast and orderlyGuaranteed to workEngineeringElectrical and Electronics engineering

The invention discloses a power line collecting and releasing device for a building machine. The power line collecting and releasing device comprises a box body. A rotating rod is arranged in the boxbody. The rotating rod is rotationally connected with the box body through first bearings. A first through hole is formed in the left side of the upper surface of the box body, and a second through hole is formed in the lower surface of the box body. The outer wall of the rotating rod is movably sleeved with a power line which is attached to the first through hole. The power line is attached to the second through hole. According to the power line collecting and releasing device for the building machine, when line collecting and releasing work is conducted, due to cooperation of the box body, aspring, the rotating rod and the bearings, the power line is stored in the box body when work is not needed, and the service life of the power line can be prolonged; and due to cooperation among a first screw rod, a rotary disc, the power line, the rotating rod, the spring and the first bearings, the power line can be rapidly collected and released in order, and the phenomenon that the power lineis disordered cannot happen.

Owner:谢兵

Cosmetic container convenient for use

The invention discloses a cosmetic container convenient for use. The cosmetic container convenient for use comprises an external box body; a supporting seat is arranged in the external box body; two supporting plates are arranged on the left side and the right side of the supporting seat respectively; each supporting plate is rotatingly connected with a slide rail working plate via a limit shaft, wherein the slide rail working plate is only capable of moving forward and backward; each supporting plate is provided with a circular rotating platform, when one of the circular rotating platforms rotates, the corresponding slide rail working plate is driven to move forward and backward; the top of each supporting plate is provided with a rectangular slide block; an internal box body is arranged between the two rectangular slide blocks; a barrel body and a lipstick box are arranged in the internal box body; the upper end of the internal box body is rotatingly connected with a cosmetic mirror. The cosmetic container is capable of avoiding defects in the prior art, and is convenient for taking and storing of cosmetic pens, and no messy feeling is caused.

Owner:马苏怡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com