Vertical type adjustable take-up reel

A take-up reel, vertical technology, applied in the field of vertical adjustable take-up reel, can solve the problems of copper wire being stretched or even broken, unable to wind the cable, messy, etc., to avoid being pulled Stretch or even be broken, better take-up effect, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

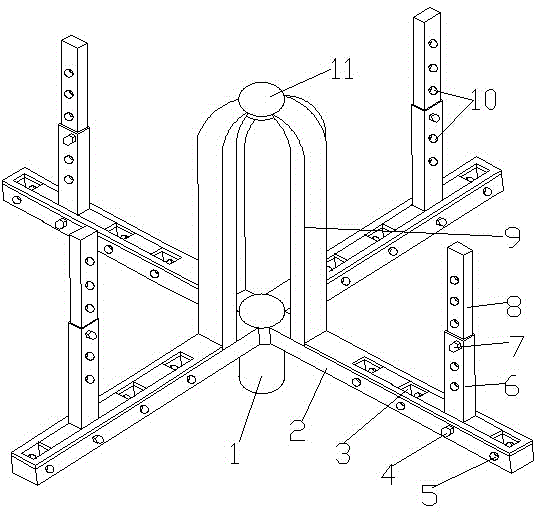

[0018] Such as figure 1 As shown, a vertical adjustable take-up reel includes a rotating shaft 1 and a take-up chassis 2. There are 3-6 take-up chassis 2 which are horizontally fixed on the top of the rotating shaft 1 at equal intervals. The wire chassis 2 includes a limit roller and a take-up roller 9. The limit roller includes a roller sleeve 6 and a roller rod 8. The roller sleeve 6 is sheathed with the roller rod 8, the roller sleeve 6 and the roller rod 8. The same side is horizontally provided with several second threaded holes 10 at equal intervals, and the second screw 7 passes through the second threaded holes 10 on the same side of the roller sleeve 6 and the roller rod 8 and then is fixed by a nut; A take-up roller 9 is vertically fixed on the upper end surface of the wire take-up chassis 2 on the side close to the rotating shaft 1, and the upper end surface of the wire take-up chassis 2 facing away from the shaft 1 is provided with several grooves 3 at equal interva...

Embodiment 2

[0022] Same as Embodiment 1, the difference is that there are three wire take-up chassis 2, which can realize the completion of the basic wire take-up operation, save steel materials, and reduce costs.

Embodiment 3

[0024] The same as Embodiment 1, the difference is that there are 5 wire take-up chassis 2, which can ensure a more stable wire take-up process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com