Patents

Literature

143results about How to "Consistent tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

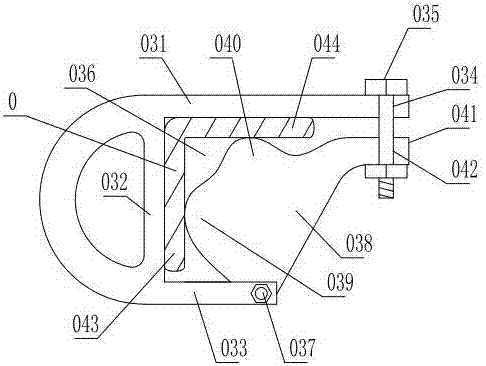

Hydraulic self-induced vibration subsoiler

InactiveCN104604365AAdjust the entry depthReduce physical discomfort and other problemsPloughsAgricultural engineeringTractor

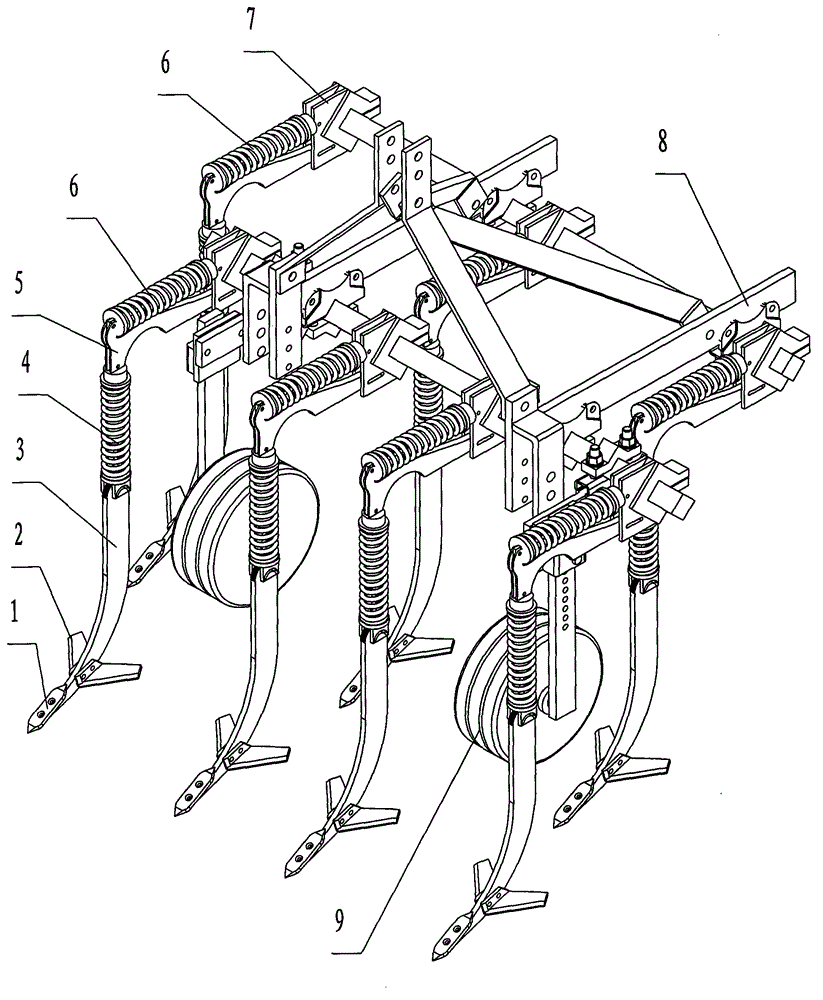

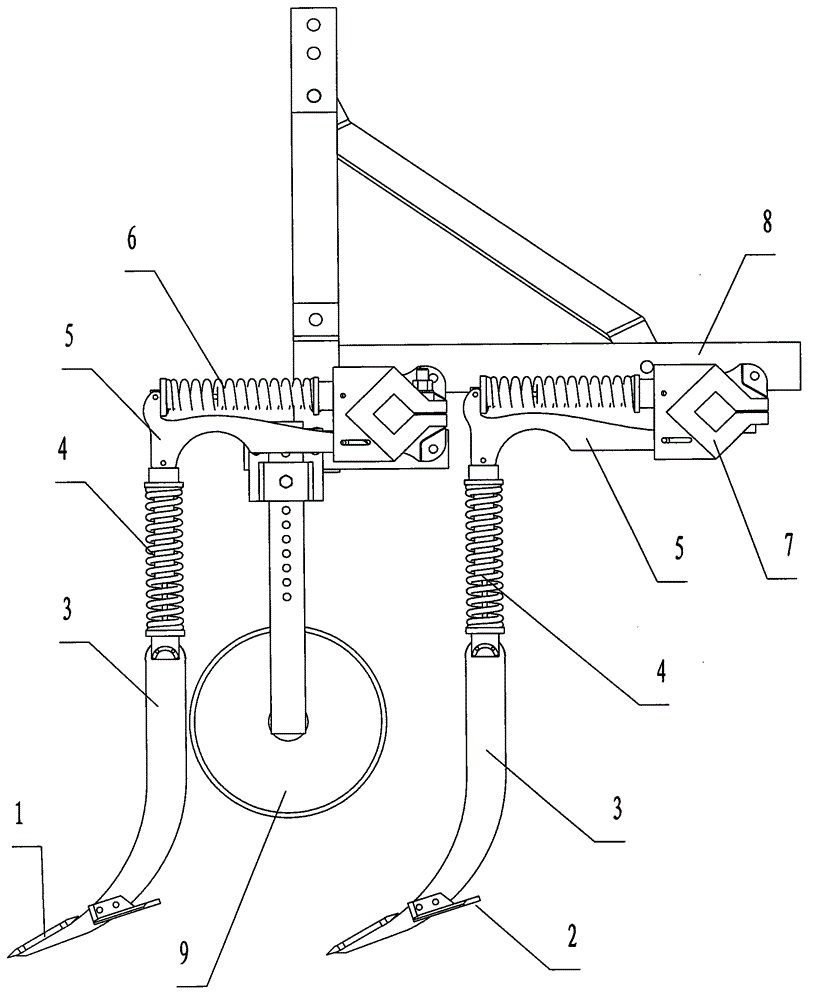

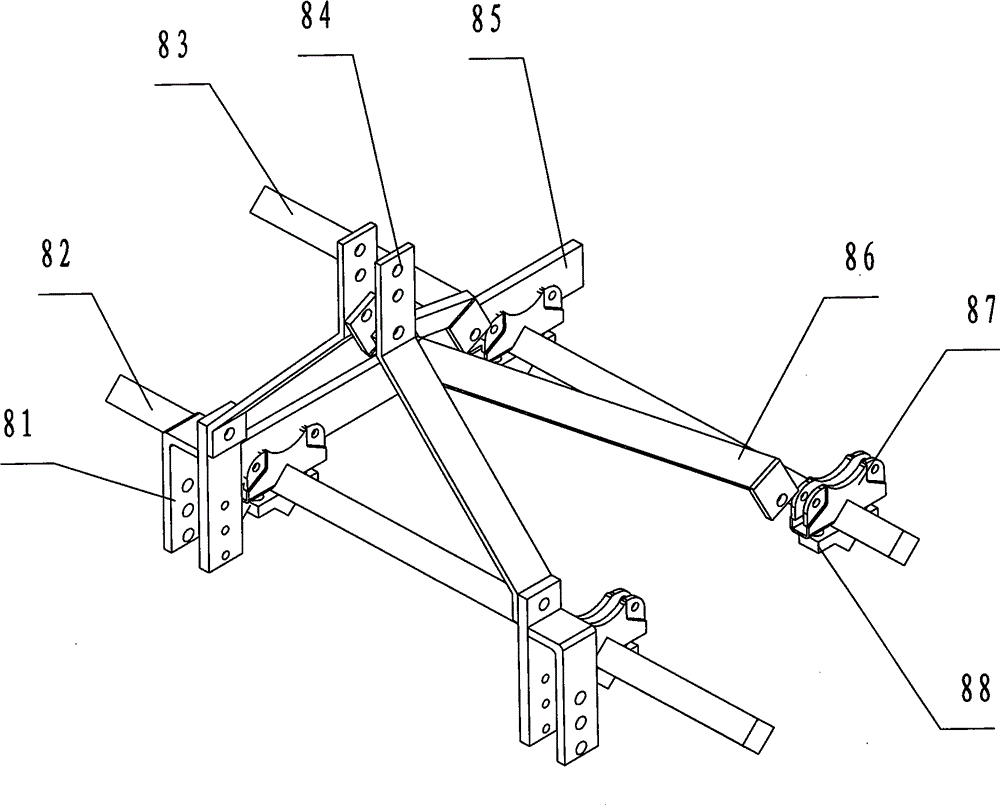

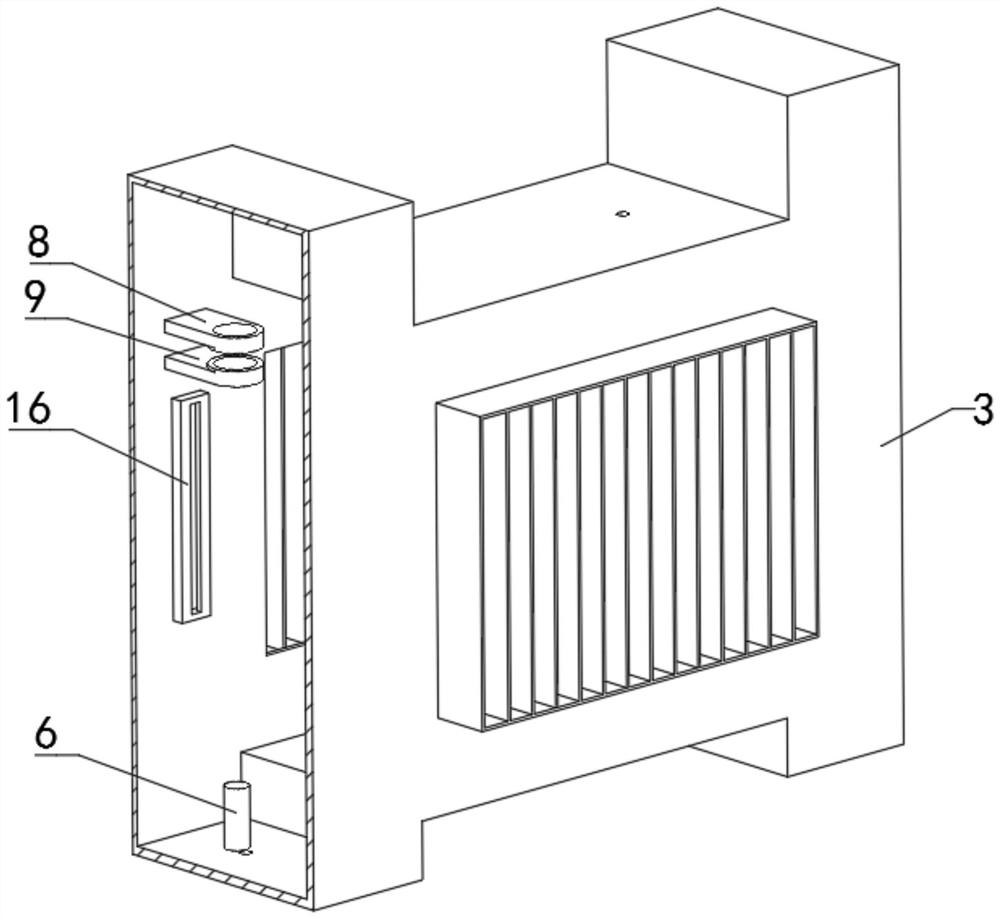

The invention relates to a hydraulic self-induced vibration subsoiler. The hydraulic self-induced vibration subsoiler is characterized by comprising a machine frame and a subsoiling device, wherein the subsoiling device is arranged at the bottom of the machine frame, the machine frame is composed of suspension pair plates, a front beam, a rear beam, an inclined traction rod, a cross beam, a cross traction rod, U-shaped groove fixing pieces and V-shaped locking pieces, and the subsoiling device is composed of shovel points, shovel wings and shovel handles. According to the hydraulic self-induced vibration subsoiler, the stretch and retraction amount of vibration springs is controlled and adjusted through hydraulic oil, the embedded depths of all subsoiling shovels are effectively adjusted, in this way, the tilling depth consistency is guaranteed during subsoiling, and the overall vibration which causes discomfort of a driver of a tractor and the like and is generated due to inconsistency of shake of mechanisms of the subsoiler is reduced; compared with a non-vibration subsoiler and a one-way vibration subsoiler under the same condition, during work, the traction resistance is remarkably reduced; to sum up, the hydraulic self-induced vibration subsoiler can reduce resistance and save energy and is good in operation effect and high in adaptability.

Owner:SHIHEZI UNIVERSITY

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

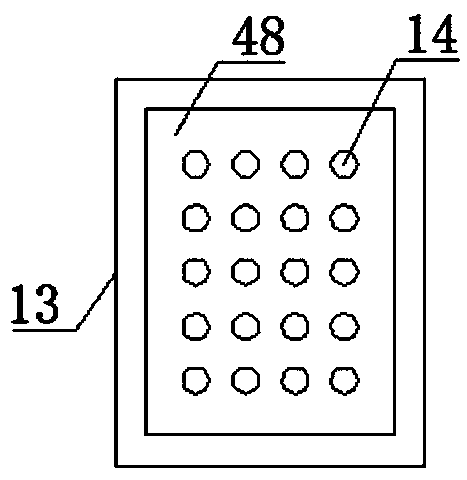

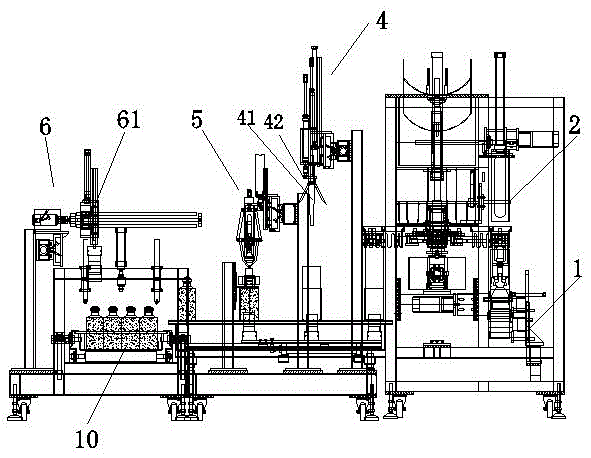

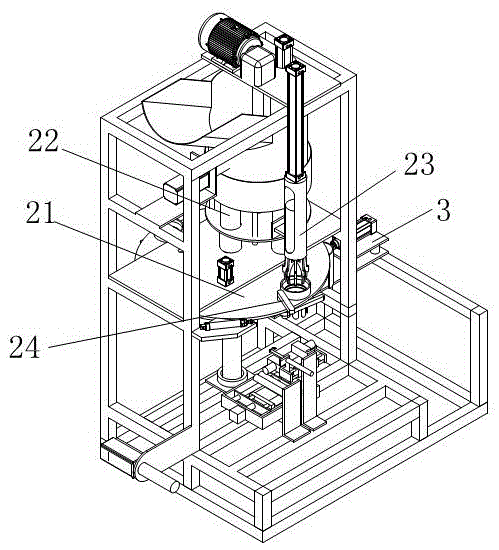

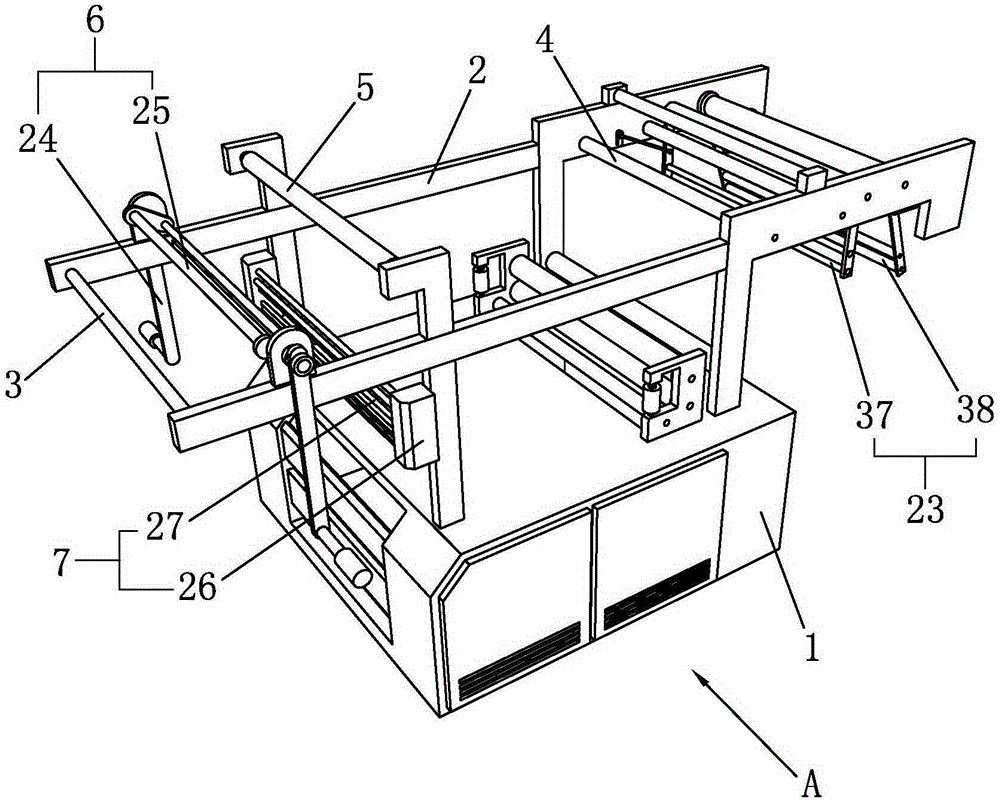

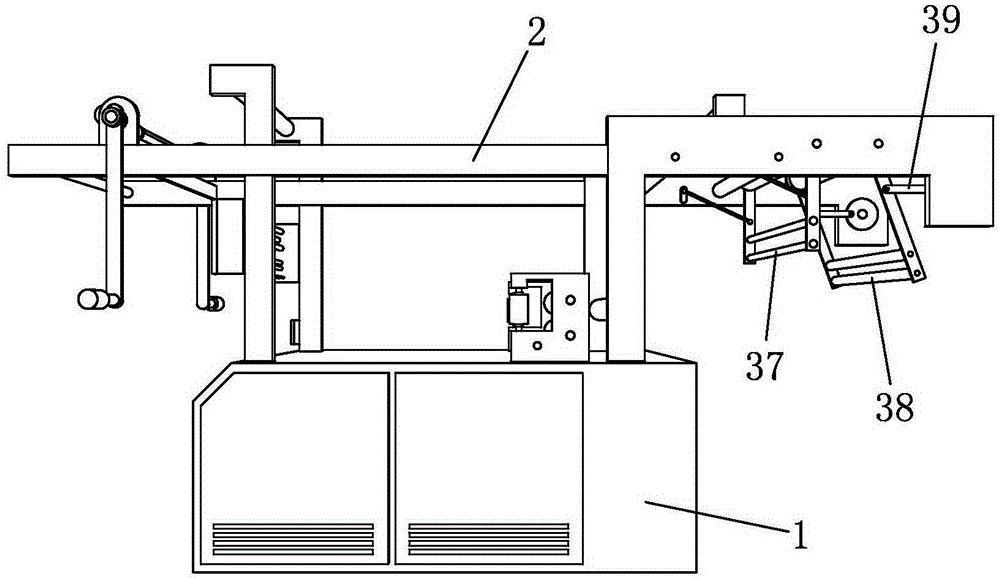

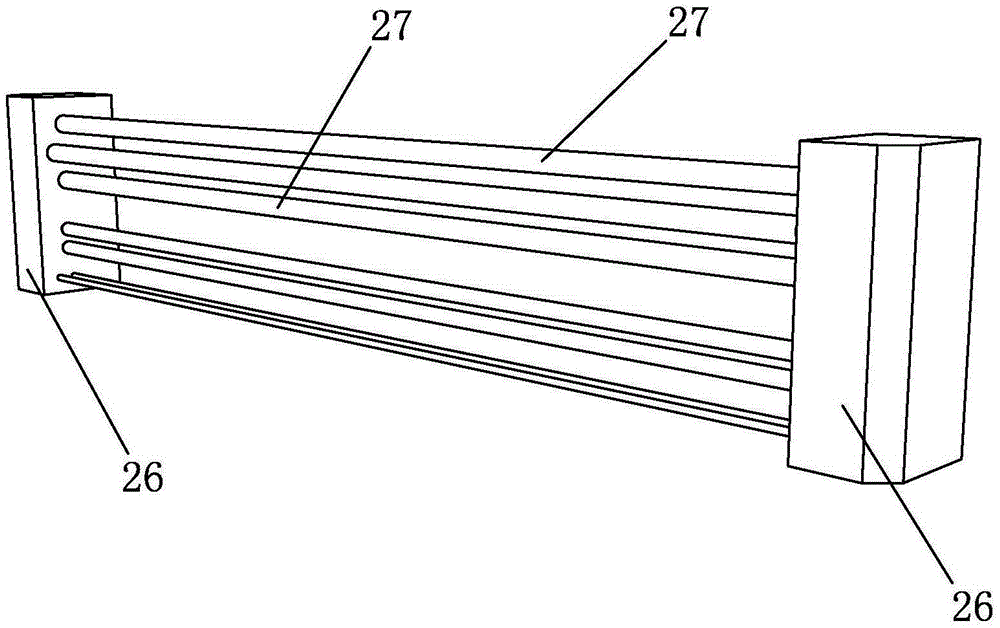

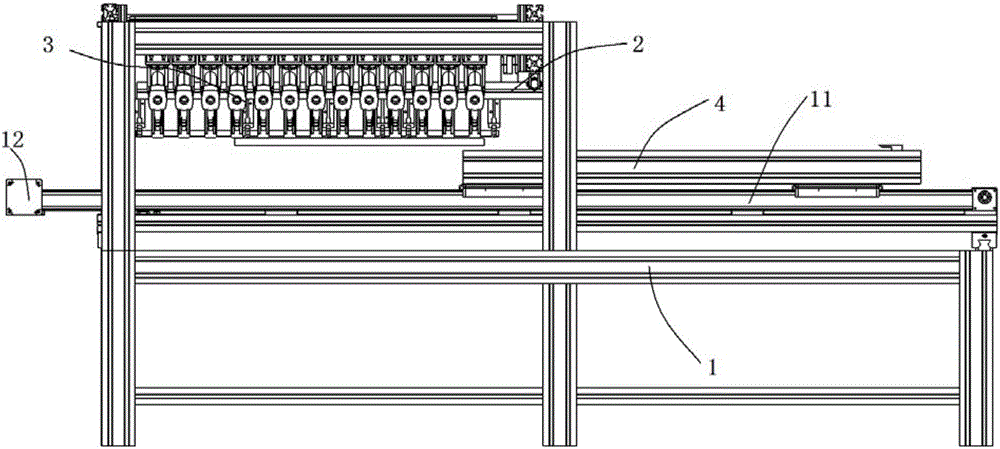

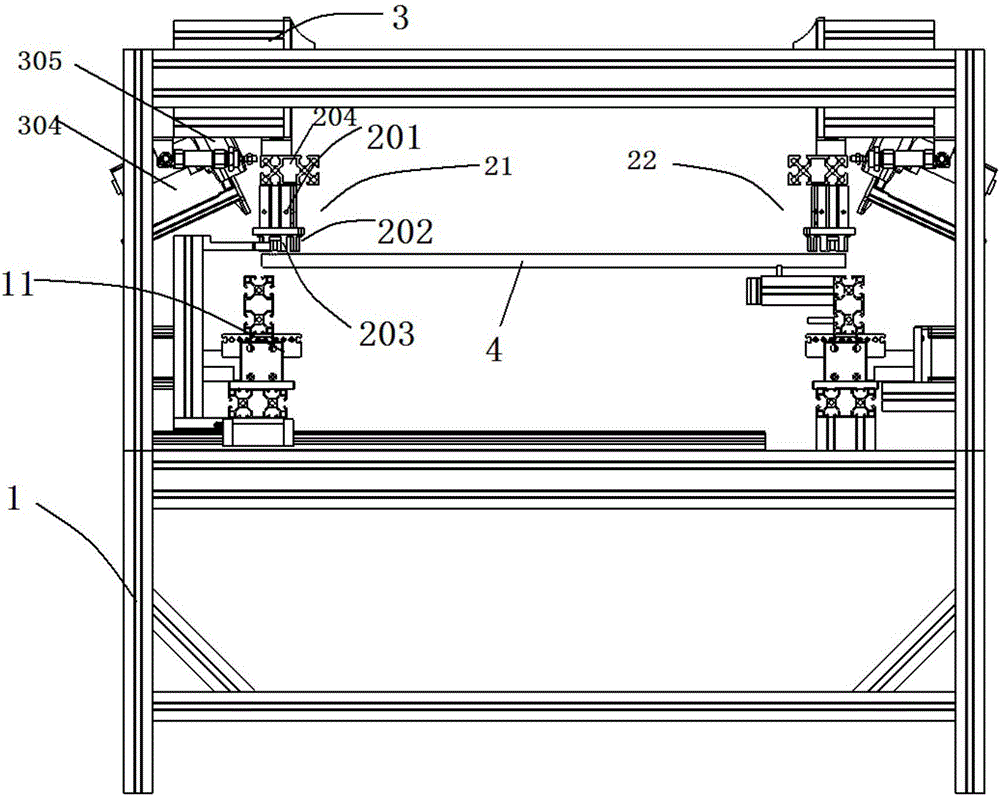

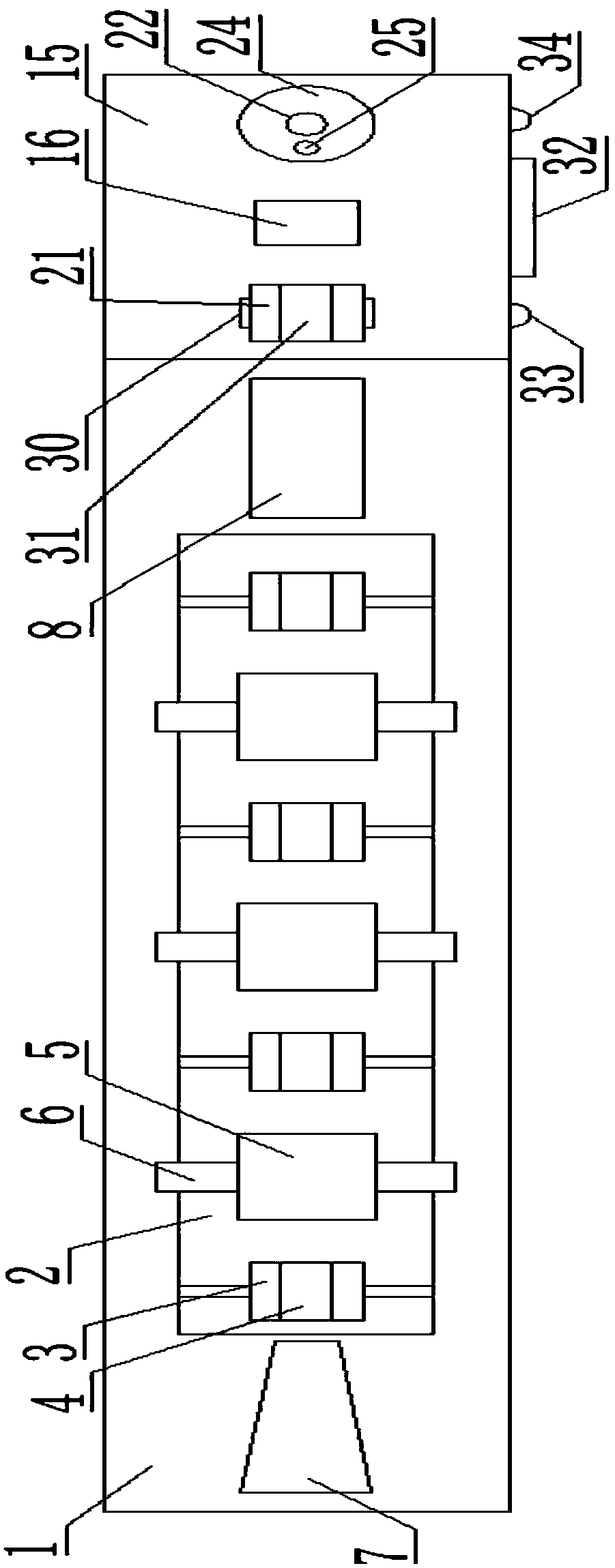

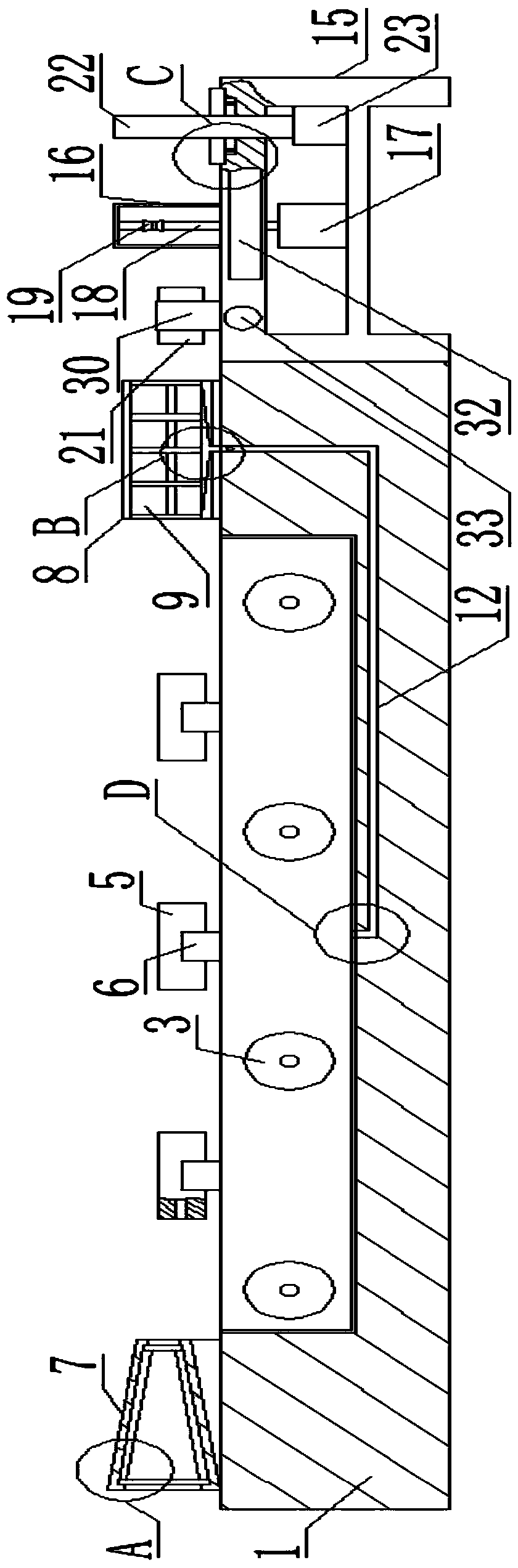

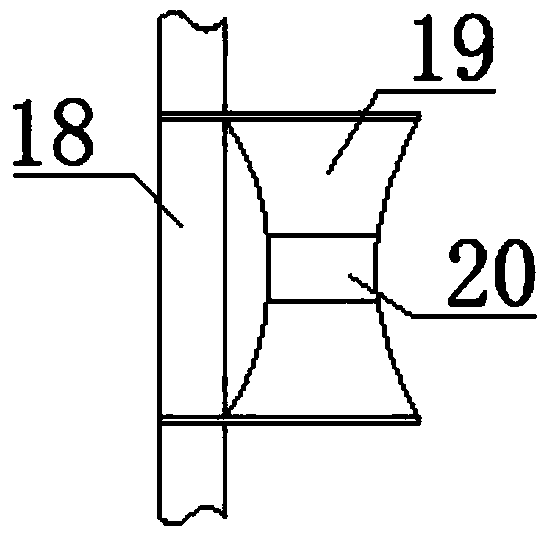

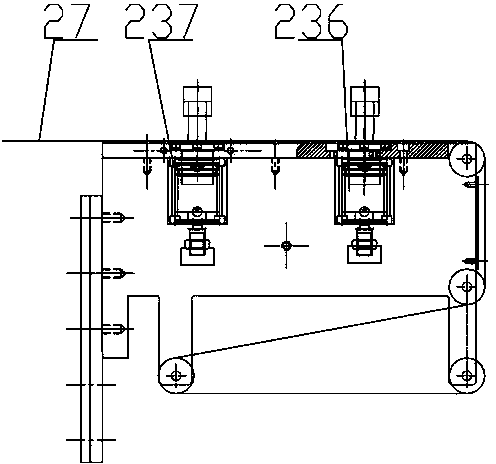

Full-automatic fungus bag production line for edible fungi

ActiveCN105564688AFully automatic production processRealize preliminary productionSuccessive articlesPulp and paper industryManufacturing line

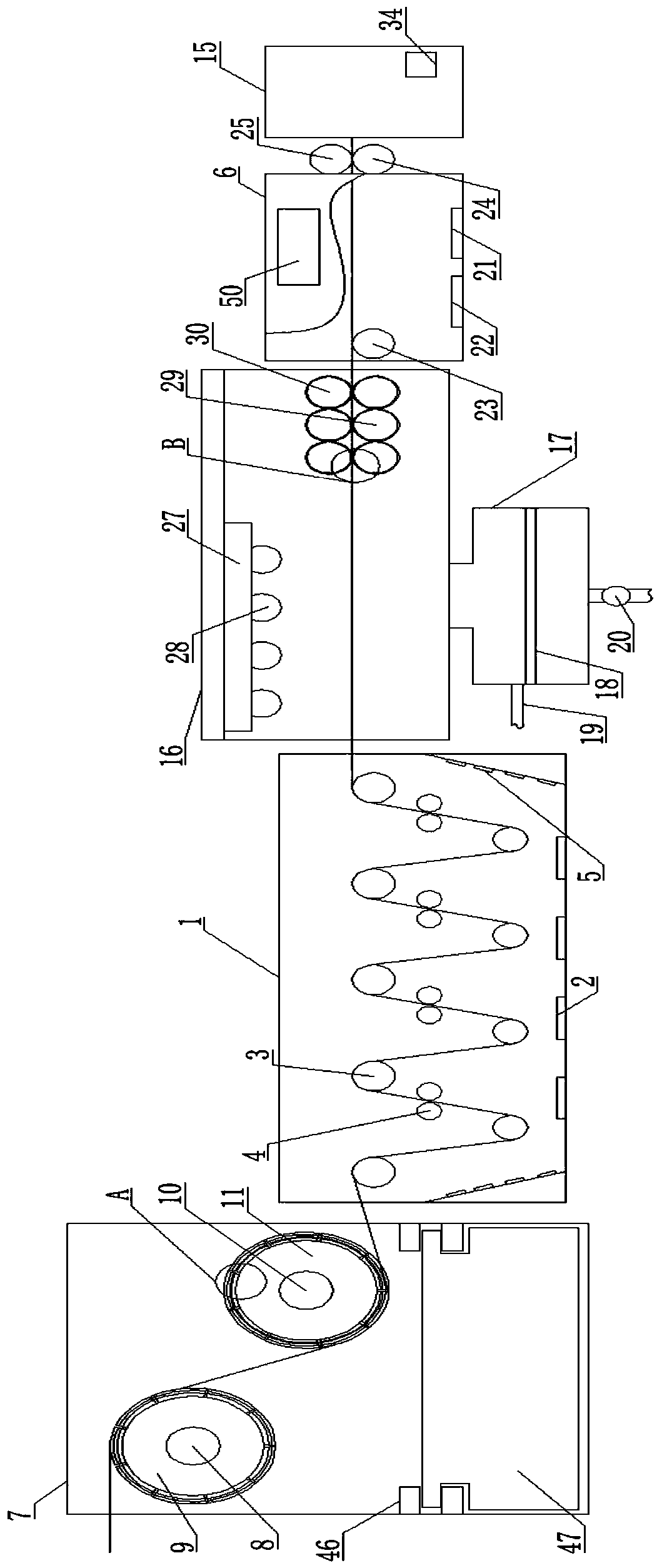

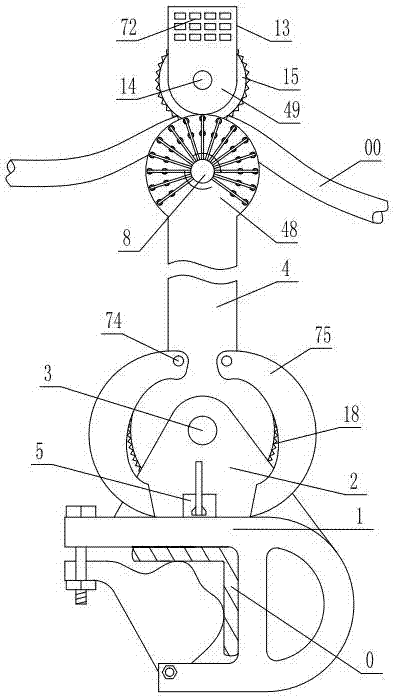

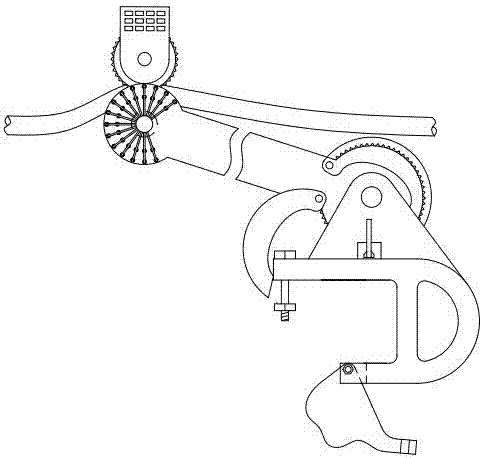

The invention relates to a full-automatic fungus bag production line for edible fungi. The full-automatic fungus bag production line comprises a bag feeding device, a bag manufacturing device, a shaping device, a ring sleeving device, a cover pressing device and a basket loading device. According to the full-automatic fungus bag production line for the edible fungi, the full-automatic fungus bag manufacturing process can be achieved; the bag taking and fixing process is completed from bag manufacturing, bag taking and bag clamping; initial manufacturing of fungus bags is achieved through discharging, shaping and compaction; the bag opening packaging process is carried out through ring sleeving and cover pressing; and finally basket loading is carried out. Full automation is achieved, and the labor force is greatly saved; errors are not likely to be made; and in addition, the looseness degree of the fungus bags is the same, the weight of the fungus bags is the same, and therefore the production quality of the fungus bags is greatly improved.

Owner:厦门祺安达自动化设备有限公司

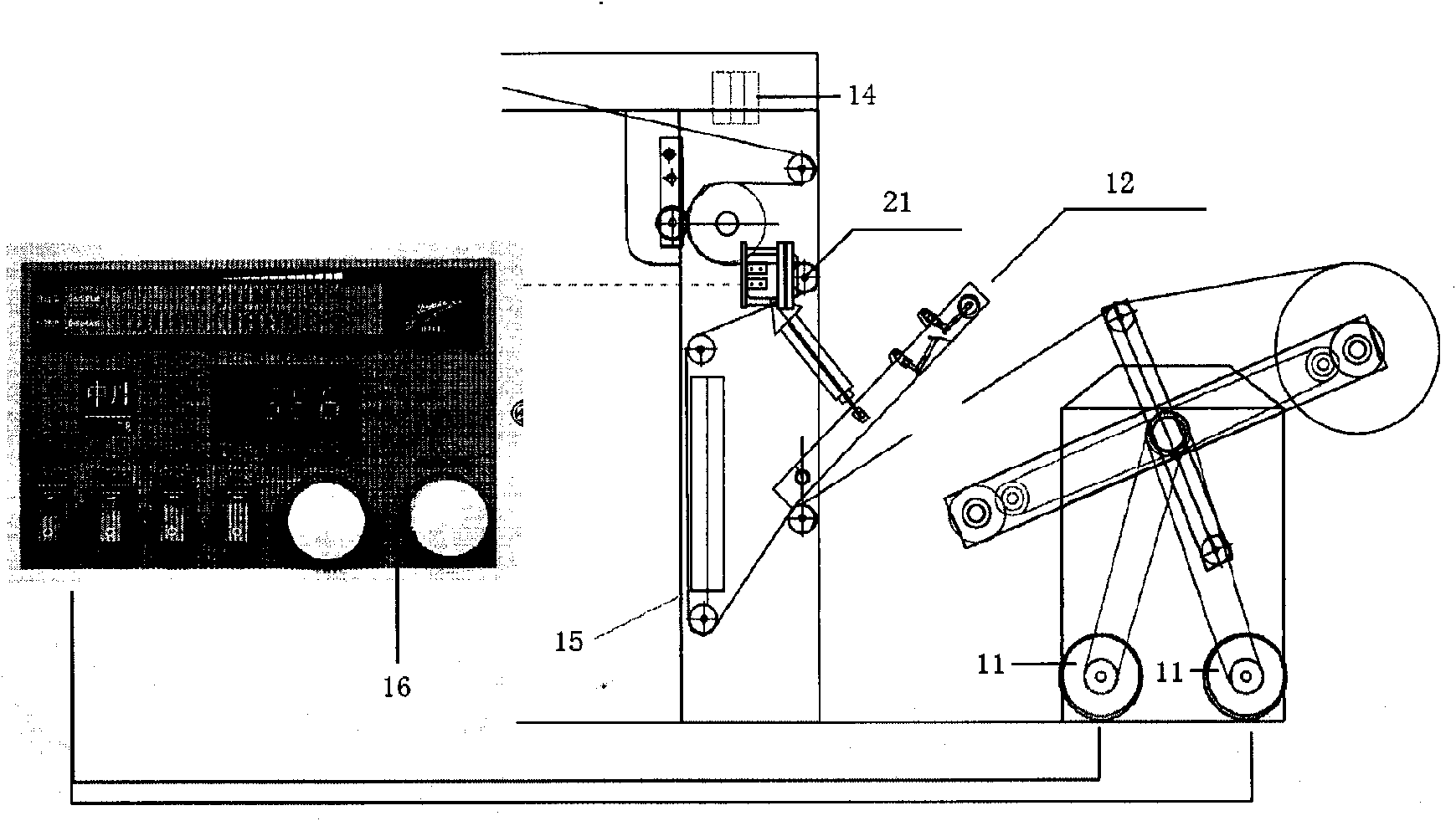

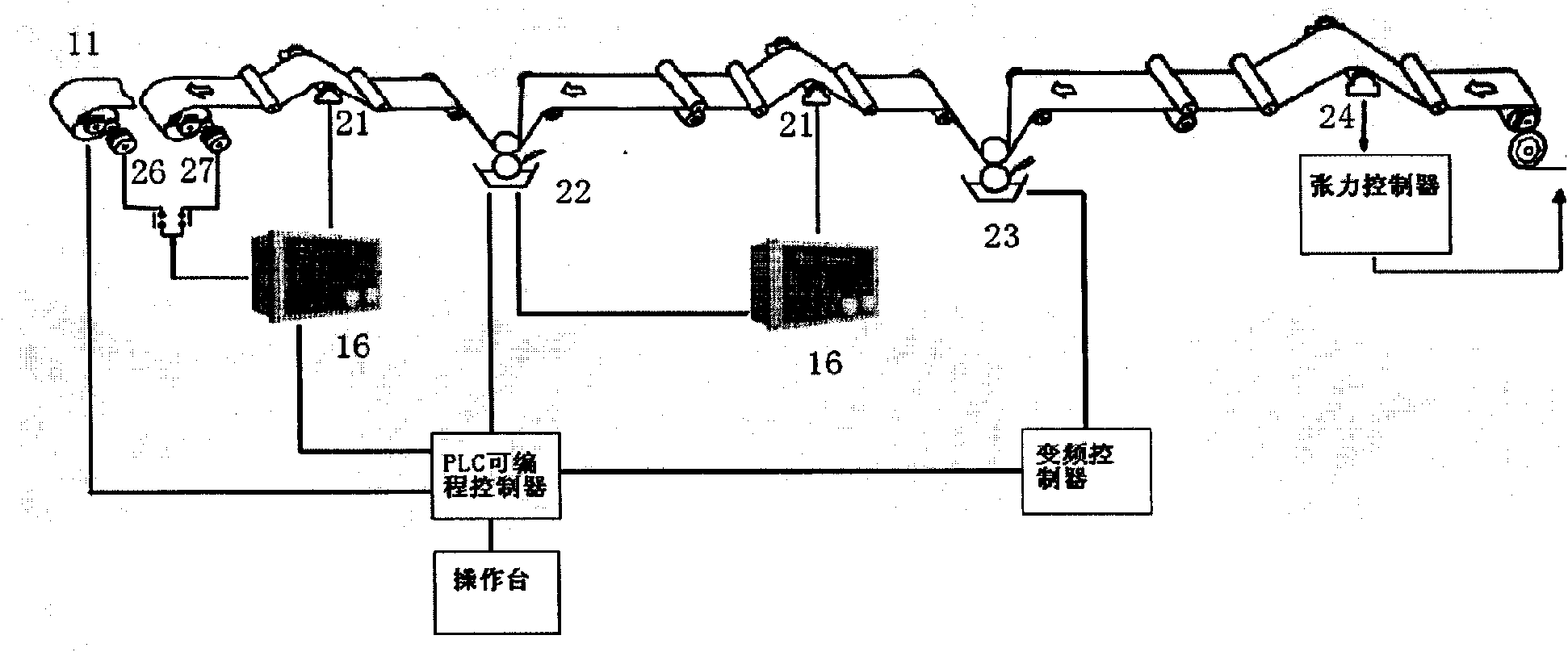

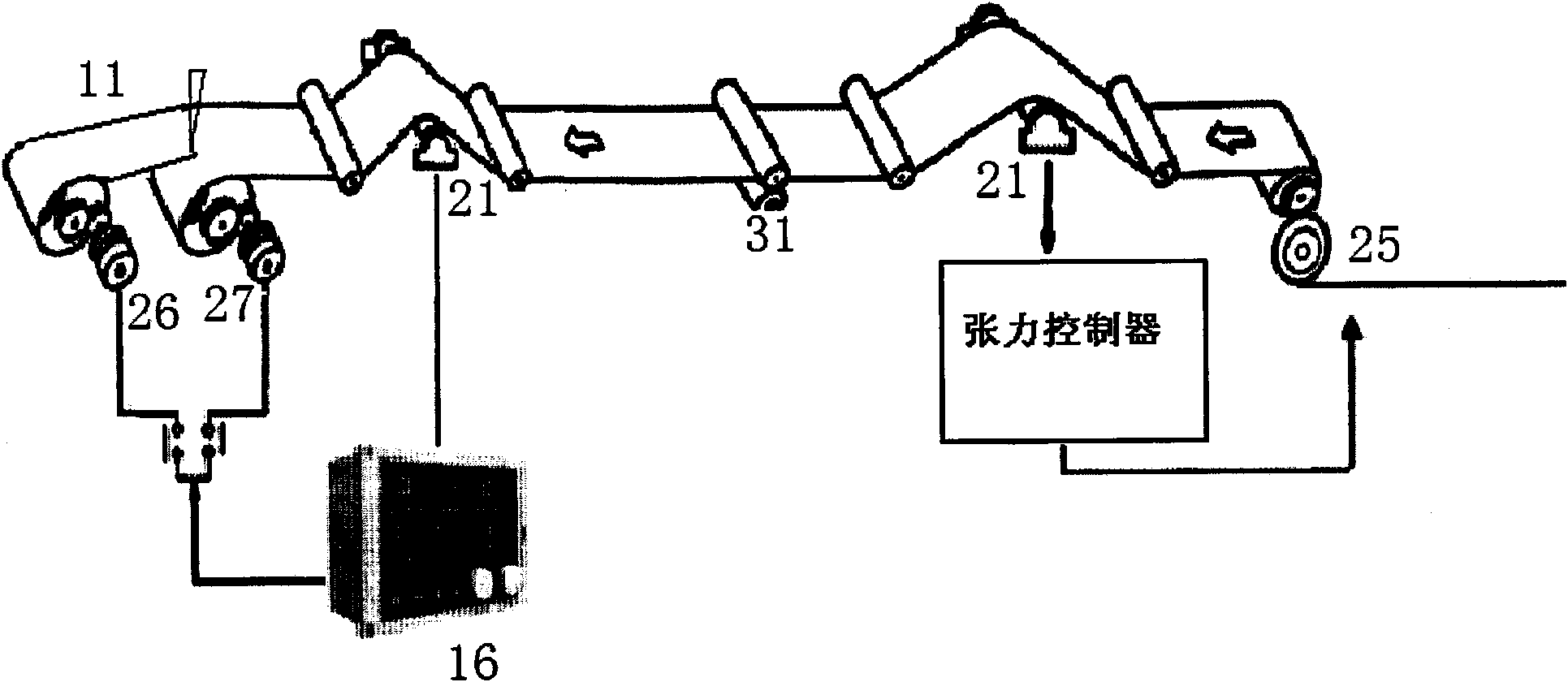

Slip motor automatic control device

InactiveCN101604952ASame torqueSynchronous control is directly effectiveDynamo-electric brake controlAutomatic controlClosed loop

The invention relates to a slip motor automatic control device. The device comprises a slip motor, a tension signal acquisition device and a slip motor controller, wherein the tension signal acquisition device is used for converting the tension expanded when materials are processed into a tension signal; and the slip motor controller is used for comparing the tension signal with the preset normal value and automatically controlling the slip motor according to the comparison result. The device adopts the closed loop tension automatic control mode, and sets the normal value according to the characteristics of the materials; and when a tension senor detects a tension error of the materials, the voltage and the current needed by the slip motor are automatically regulated and outputted after automatic comparison, so that the automatic circulation functions of target determining, automatic detection, automatic comparison and automatic regulation are achieved.

Owner:BEIJING JINPUTE PRINGTING MACHINE

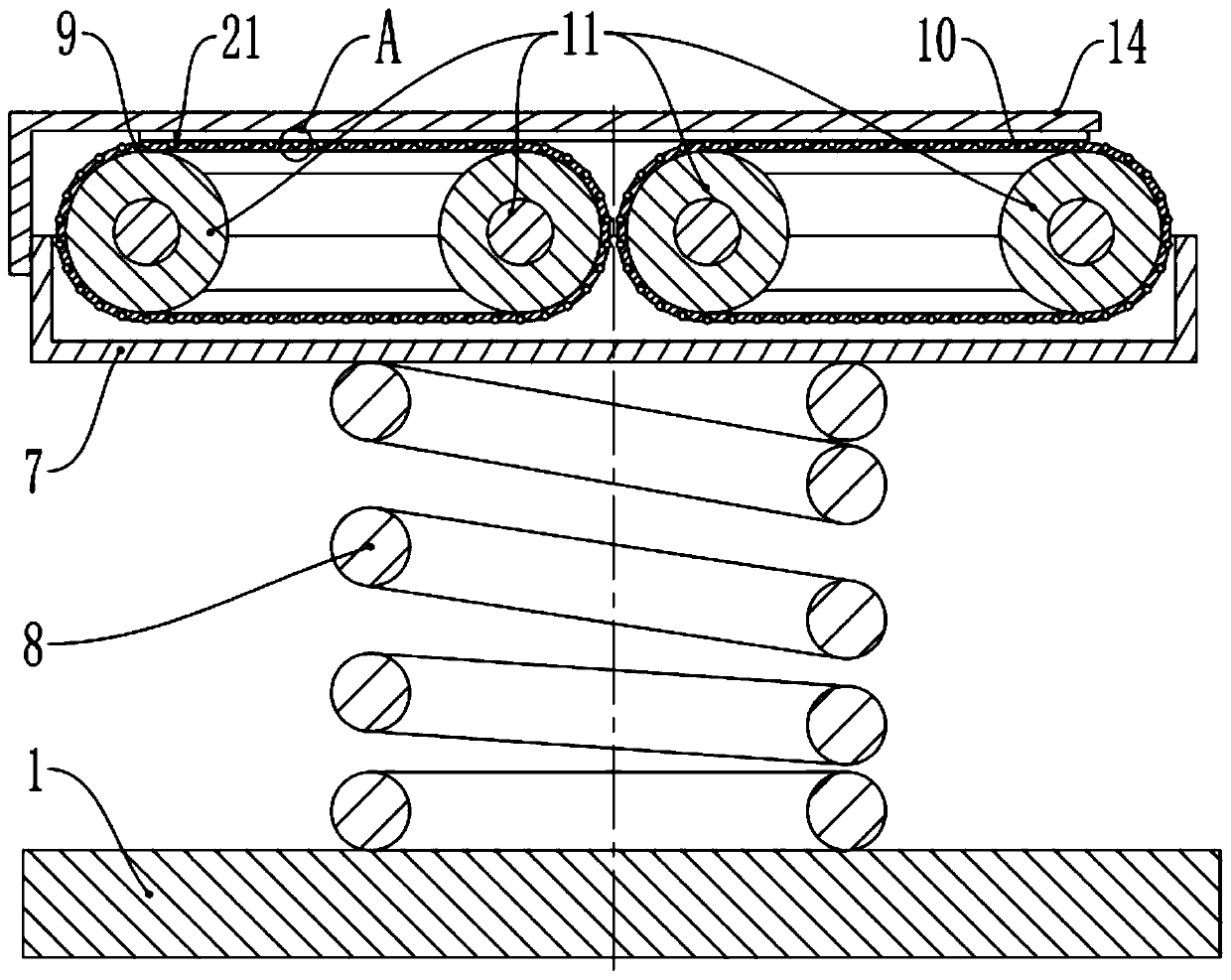

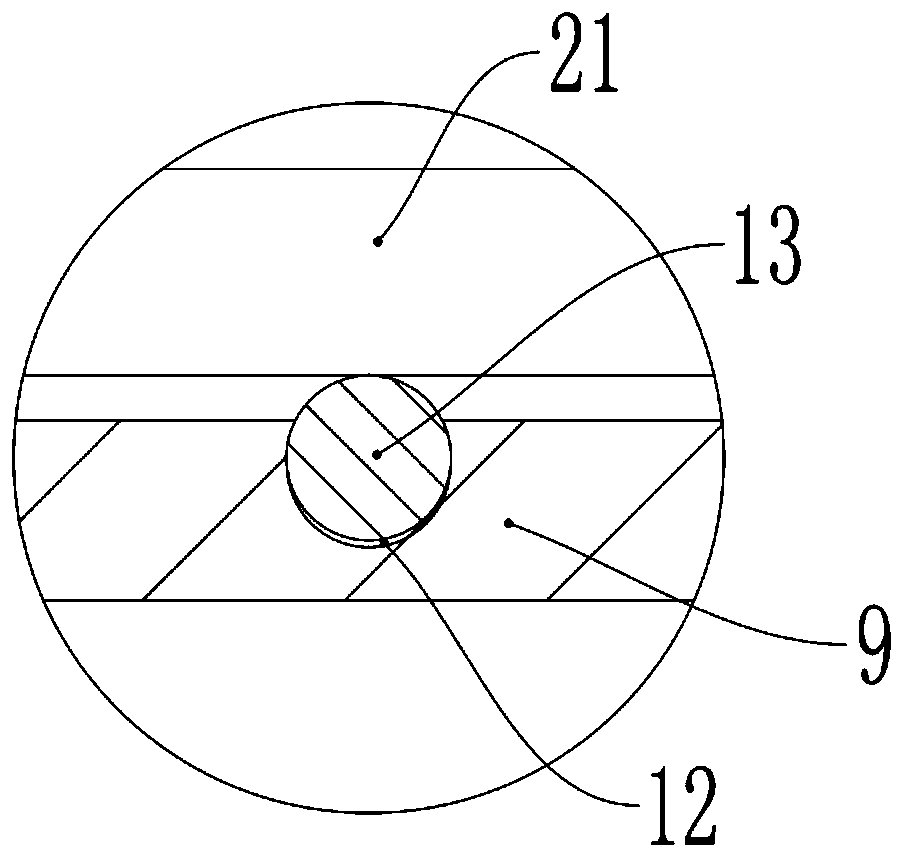

Brushing and arranging device for clothes production

The invention discloses a brushing and arranging device for clothes production. The brushing and arranging device comprises a machine body. A support is arranged on the machine body and provided with a cloth inlet roller and a cloth outlet roller. A feed roller, a tensile force control device and a fabric expanding device are arranged on the support. A transmission roller and a cleaning device are arranged in the machine body. Spray nozzles are arranged on the cleaning device. A transitional roller and a drying device are arranged in the machine body. A first brushing roller, a second brushing roller, a third brushing roller and a fourth brushing roller are arranged in the machine body. A first cloth pressing roller is arranged between the first brushing roller and the second brushing roller. A second cloth pressing roller is arranged between the third brushing roller and the fourth brushing roller. A cloth arranging device is arranged on the machine body. A cloth discharge device is arranged on a machine frame. The brushed fabric is smooth, free of creases, consistent in tightness and good in brushing effect, heat retention property and softness are improved, product quality is improved, brushing is achieved on two sides at the same time, production efficiency is improved, and the technological process is shortened.

Owner:SHAOXING HENRY TIE FASHION

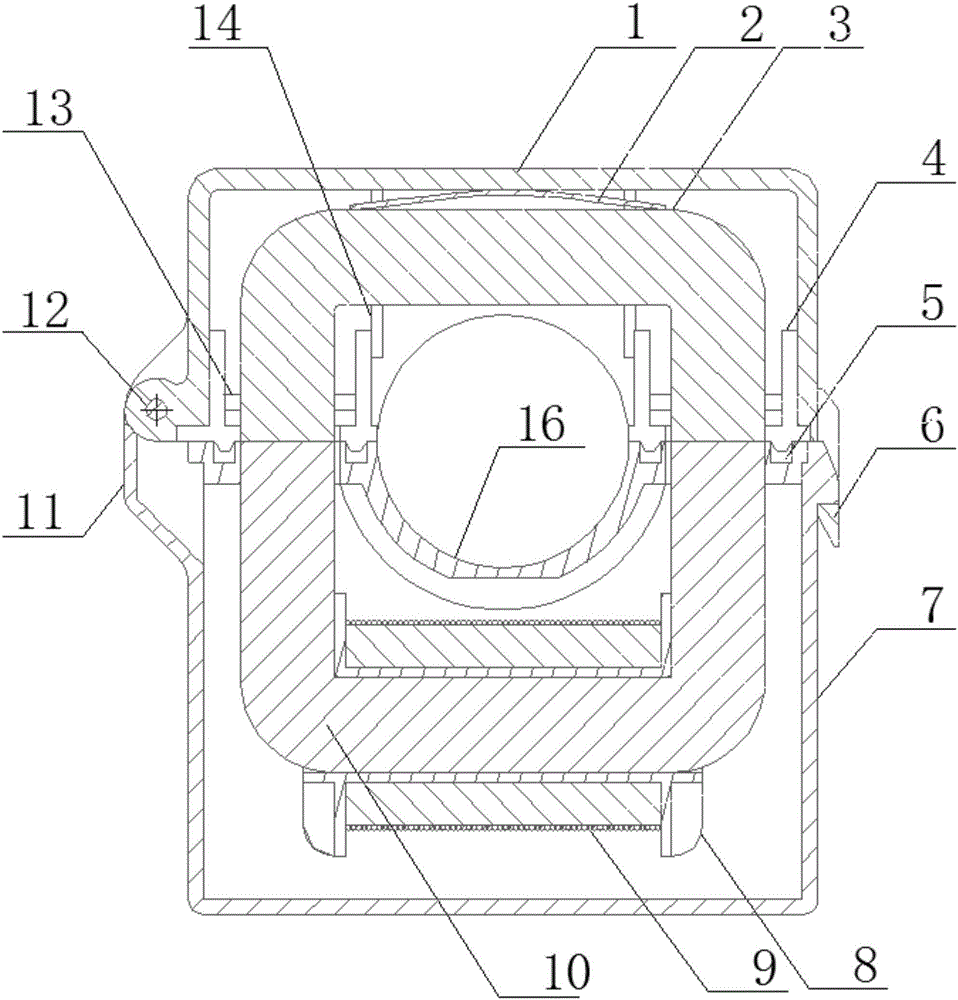

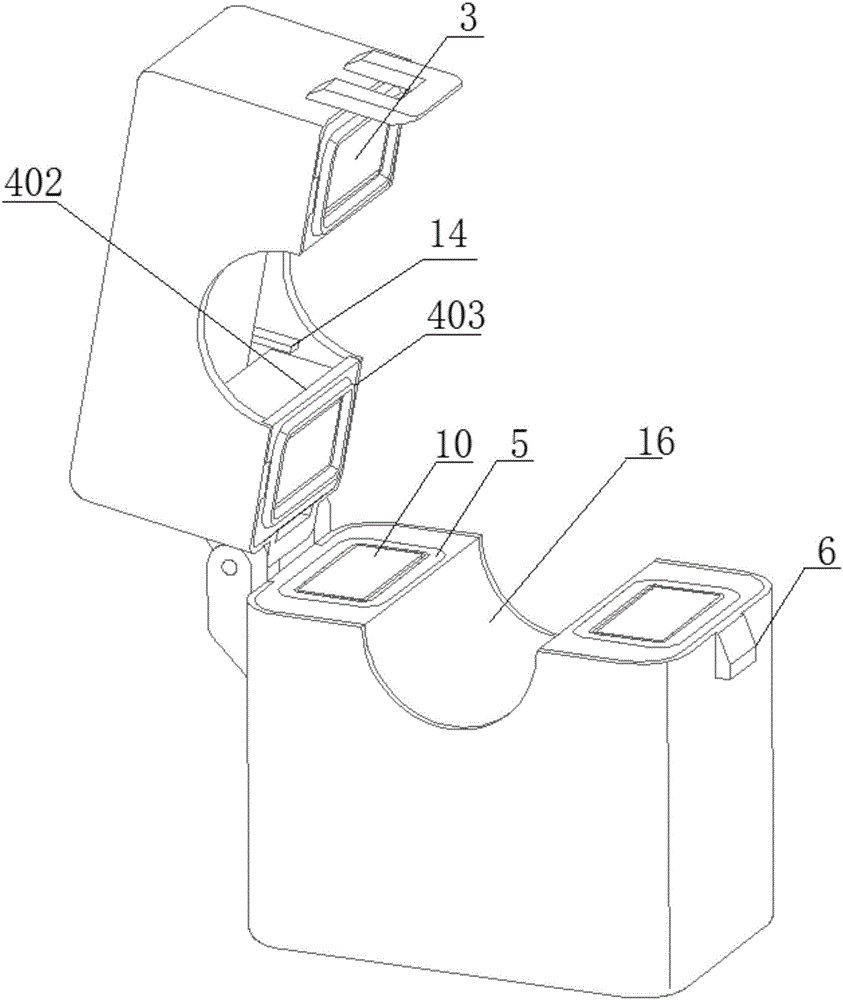

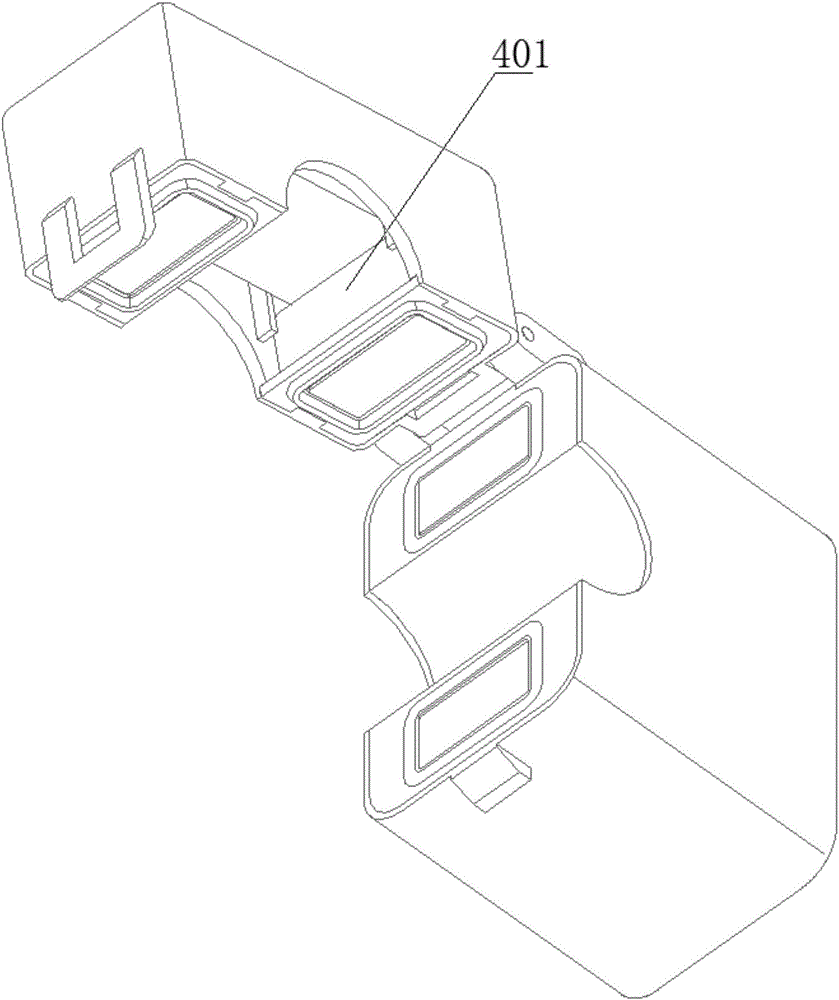

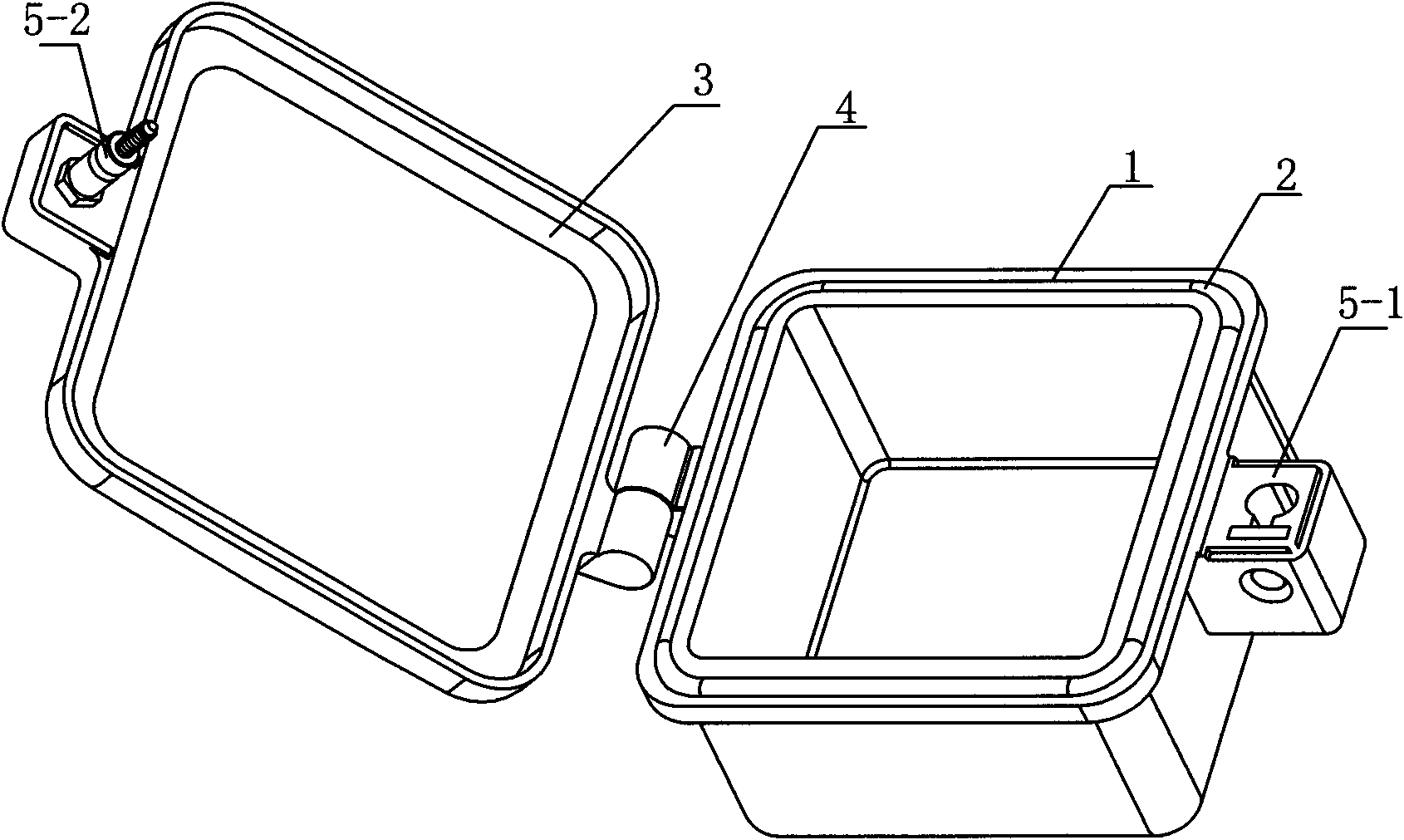

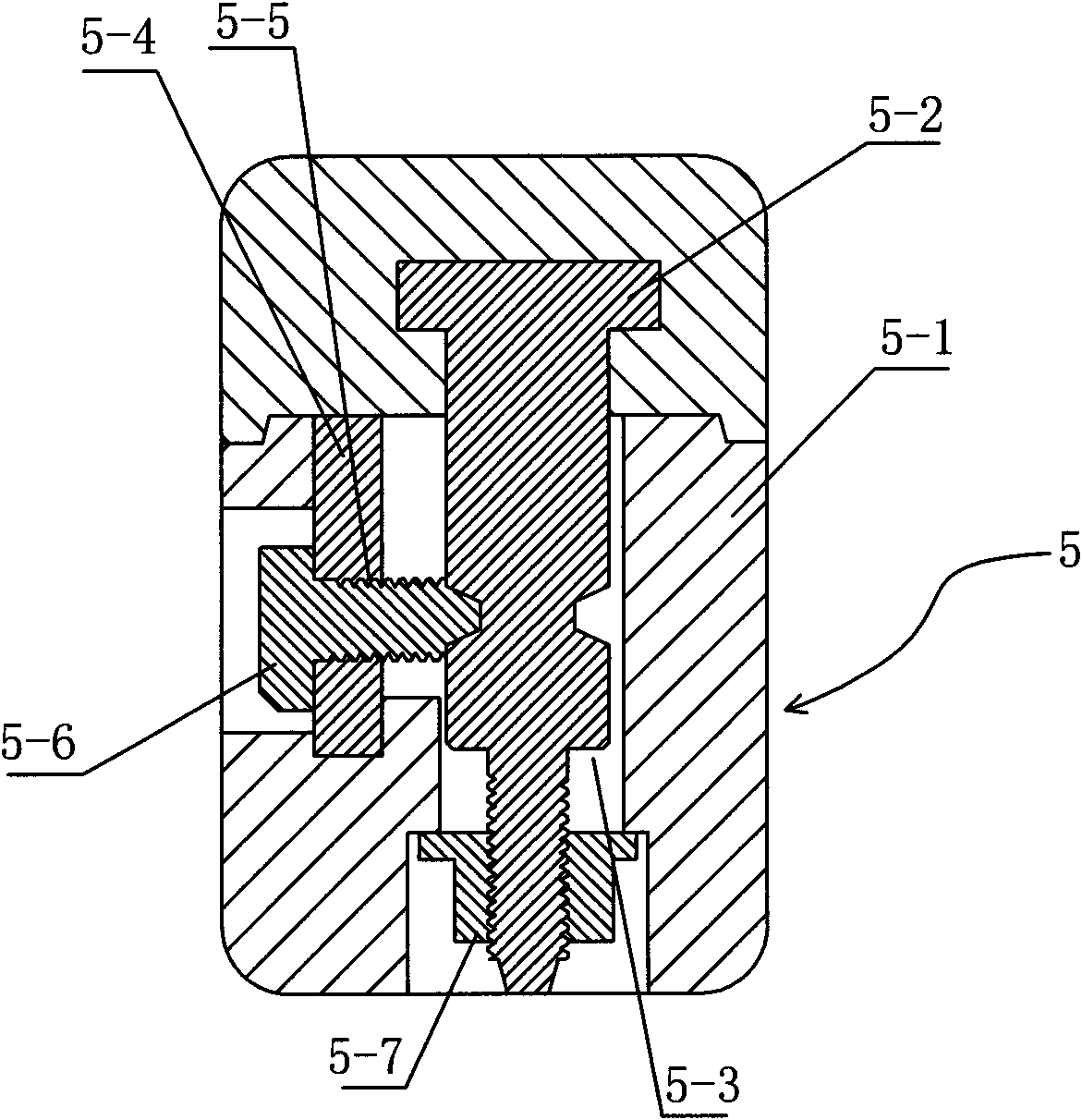

Waterproof open current transformer and sealing method

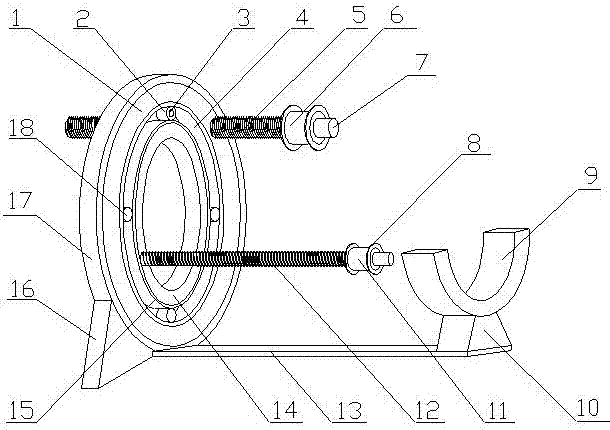

ActiveCN106847469AGuaranteed service lifePrevent rustTransformersTransformers/inductances casingsEngineeringMechanical engineering

The invention discloses a waterproof open current transformer and a sealing method. The waterproof open current transformer comprises a shell I and a shell II, wherein the shell I and the shell II are hinged; an iron core I is arranged in the shell I; an iron core II is arranged in the shell II; two ends of the iron core I are provided with at least one sealing ring I respectively in a loop overlapping manner; the outer side of each sealing ring I is provided with a sealing sleeve in the loop overlapping manner; the sealing sleeves are connected onto the shell I; an elastic sheet is arranged between the bottom of the iron core I and the shell I. The two ends of the iron core I pass through the sealing sleeves and the sealing rings I in the sealing sleeves to be closely abutted with two ends of the iron core II respectively; the elastic sheet tightly presses the iron core I; under the action of elastic force, the iron core I can be furthest combined with two sections of the iron core II with equal tightness; the combination is closer; the two ends of the iron core II pass through a sealing cover; due to the sealing action of the sealing rings I, the sealing sleeves and sealing rings II, the position where the iron core I and the iron core II are combined is sealed, and is isolated from an external environment; the damage of the external environment to an iron core section is prevented; a joint of the iron core I and the iron core II is prevented from rusting; the service life of the iron core is guaranteed.

Owner:郓城铂晶电子科技有限公司

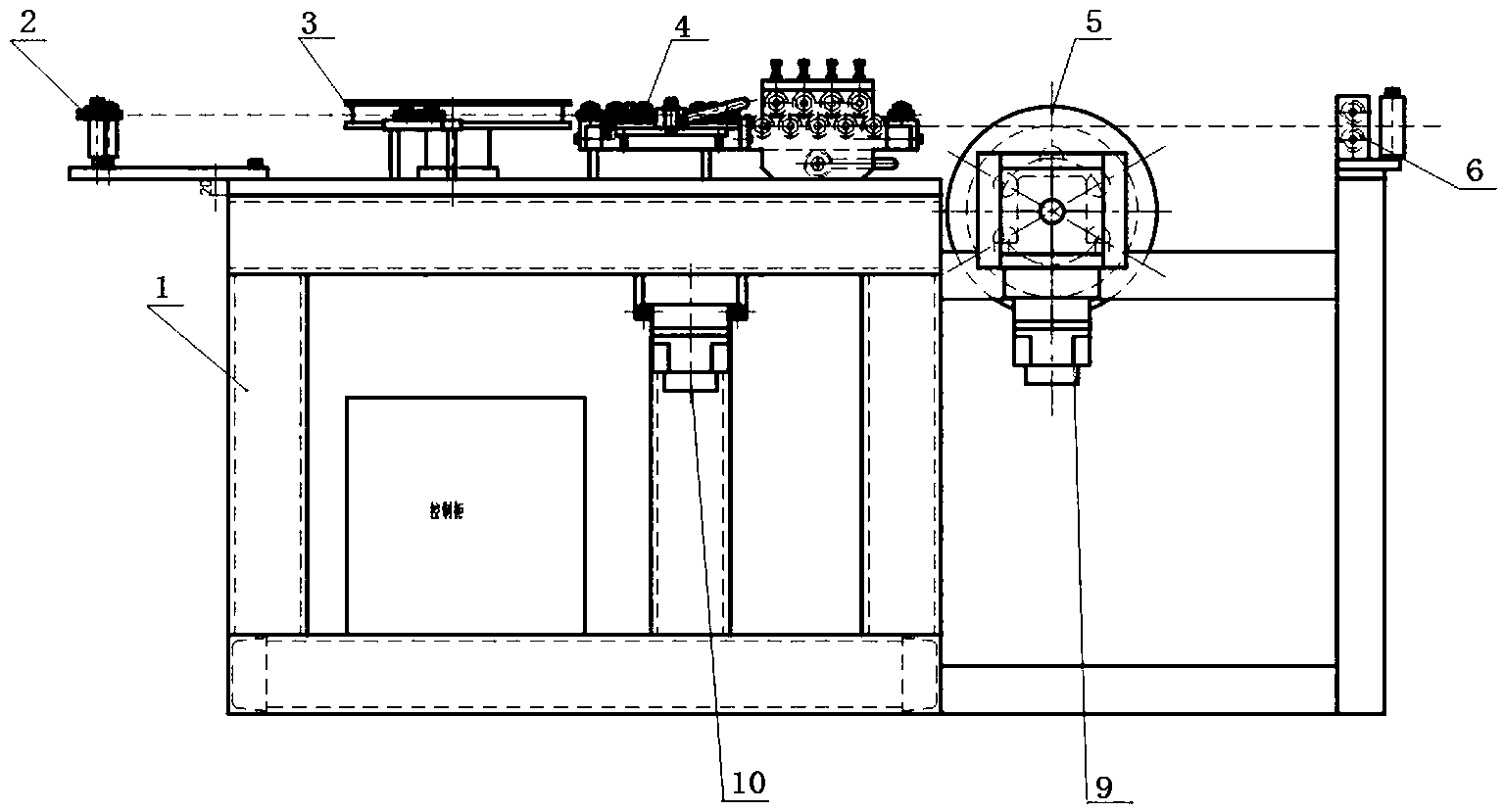

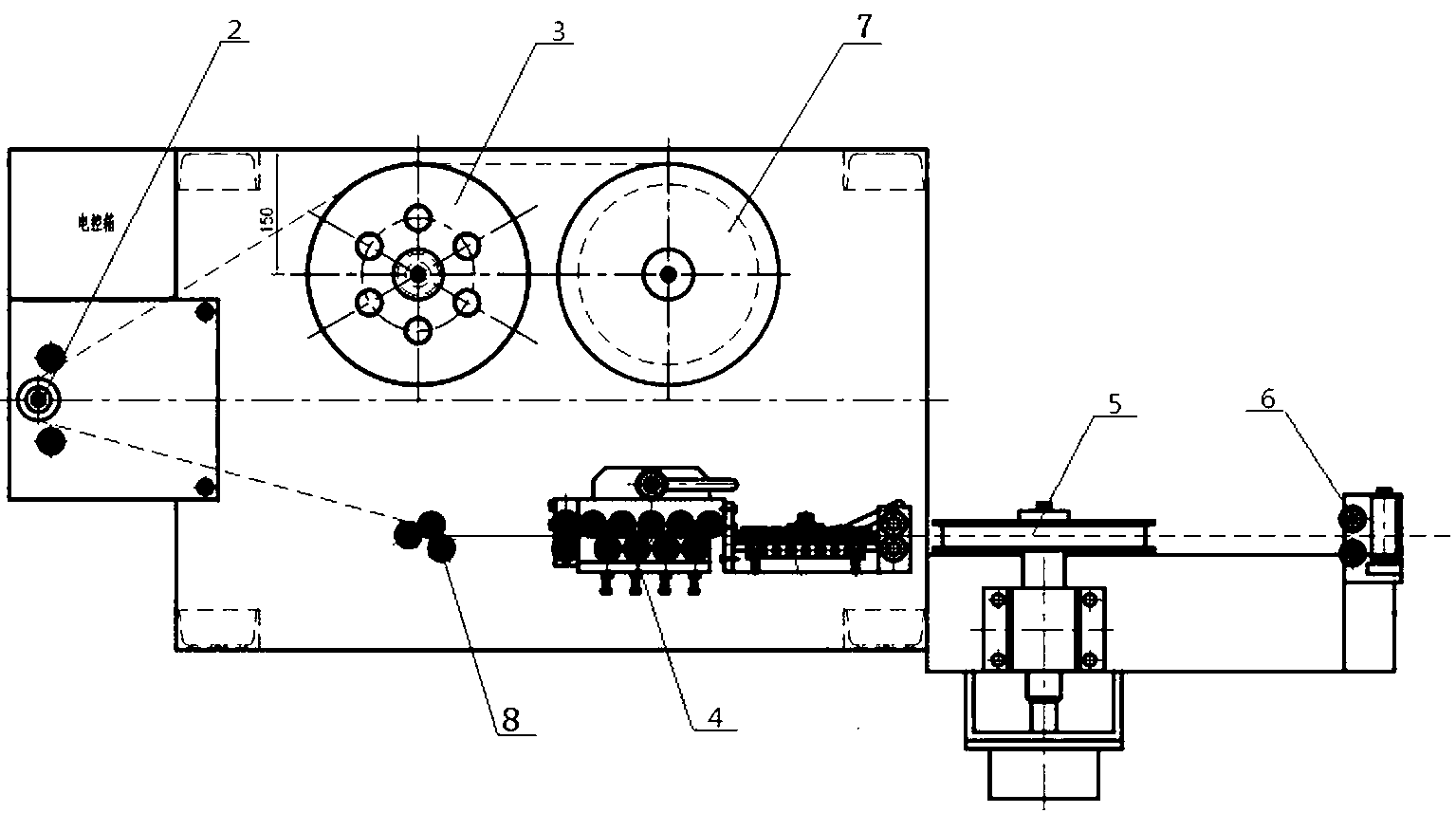

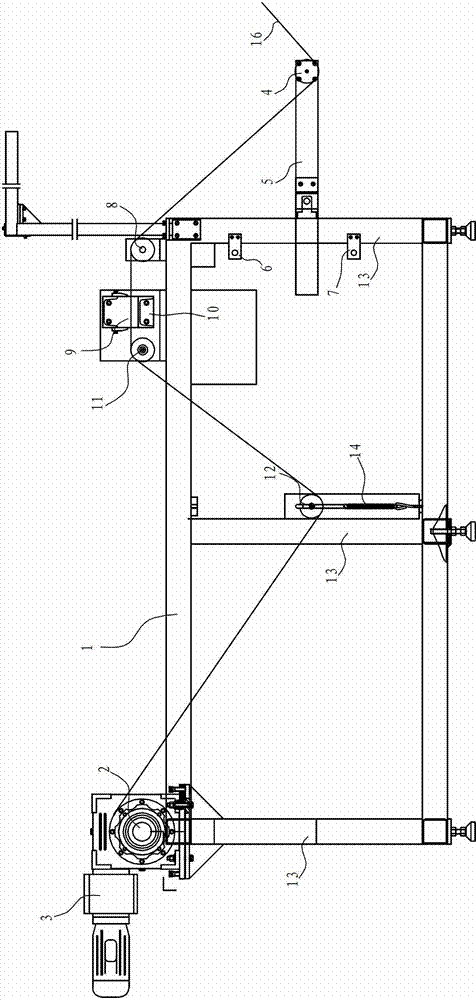

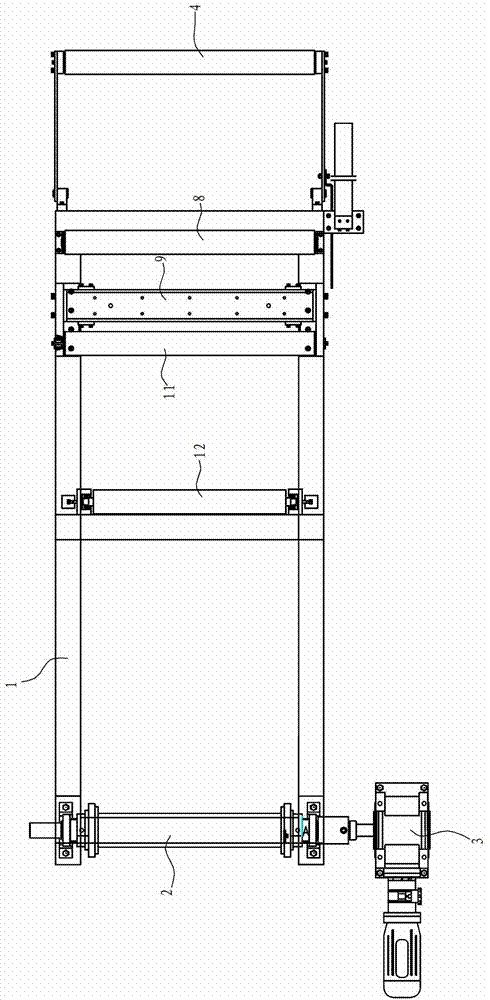

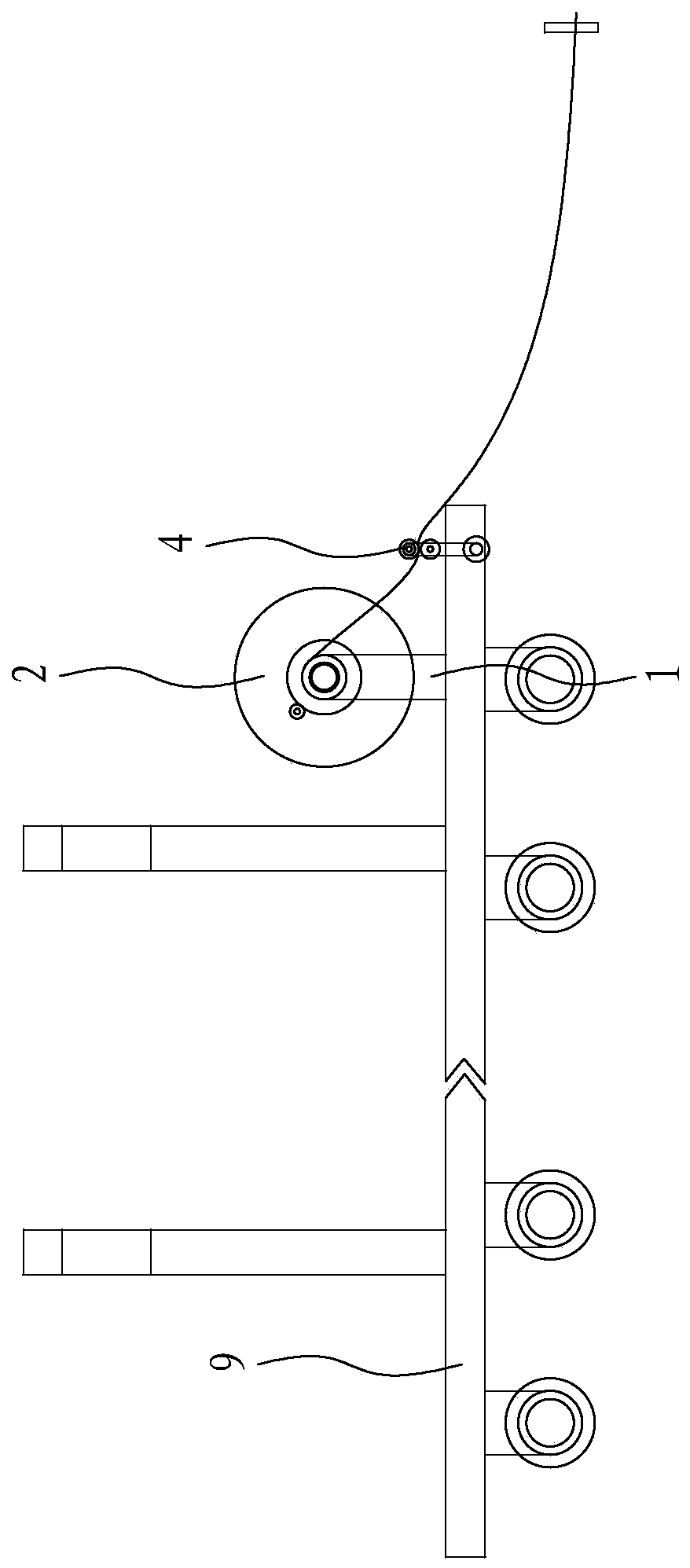

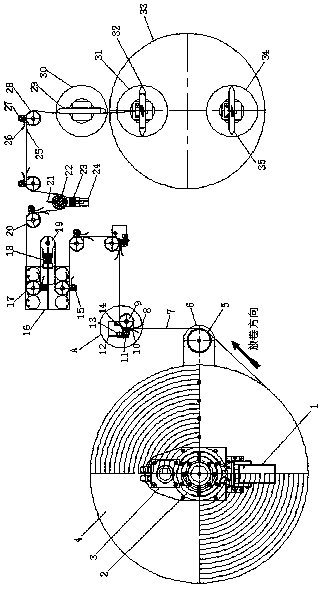

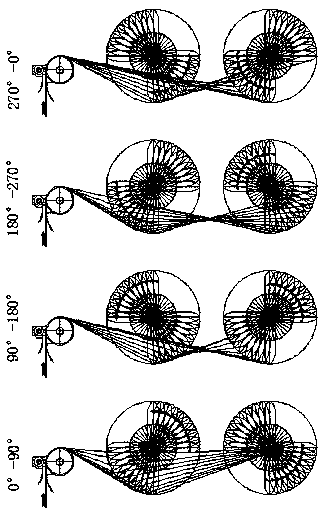

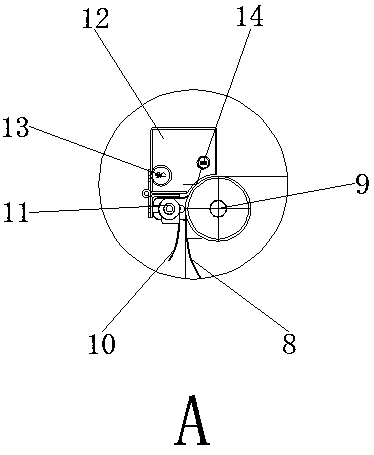

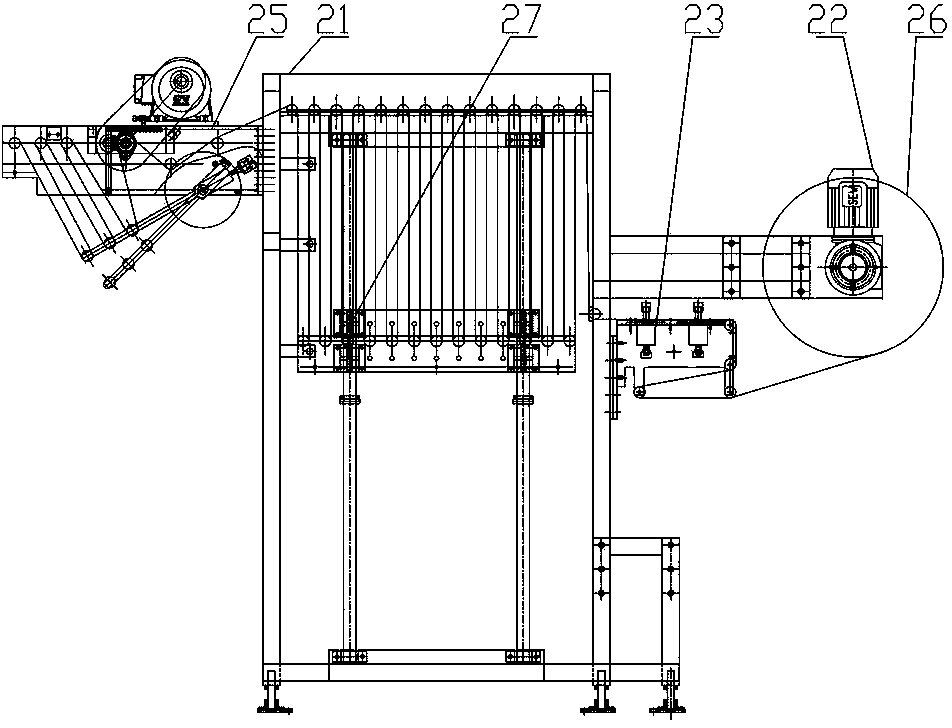

Disc separating take-up machine

ActiveCN103072847AThe tightness of the winding is consistentConsistent tightnessFilament handlingSteering wheelEngineering

The invention provides a disc separating take-up machine which comprises a frame assembly, a well-shaped frame wheel assembly, a traction wheel assembly, a straightener assembly, a wire roller assembly, a steering wheel assembly, a driven wheel assembly and a take-up pulley assembly, wherein the well-shaped frame wheel assembly is installed on one end of a frame; the traction wheel assembly, the steering wheel assembly, the driven wheel assembly, the wire roller assembly and the take-up pulley assembly are axially arranged in parallel to wheels of the well-shaped frame wheel assembly; the well-shaped frame wheel assembly, the traction wheel assembly, the straightener assembly and the wire roller assembly are arranged on a same straight line in sequence; the driven wheel assembly and the take-up pulley assembly are arranged on a same straight line in sequence; the steering wheel assembly is arranged on the other end of the frame; and the take-up pulley assembly and the traction wheel assembly are respectively provided with speed reducers. The disc separating take-up machine has the advantages of simplicity in operation, convenience in use, high disc changing efficiency, uniform winding tightness of steel wires, time saving and labor saving.

Owner:SHANDONG SNTON STEEL CORD

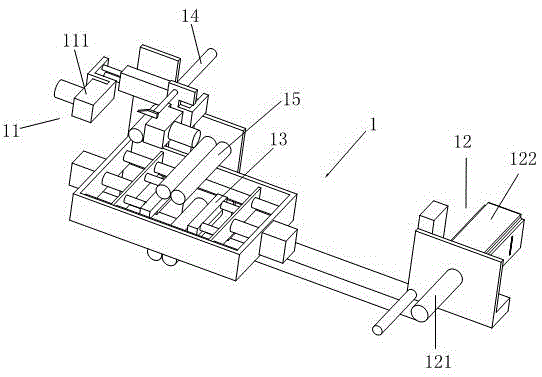

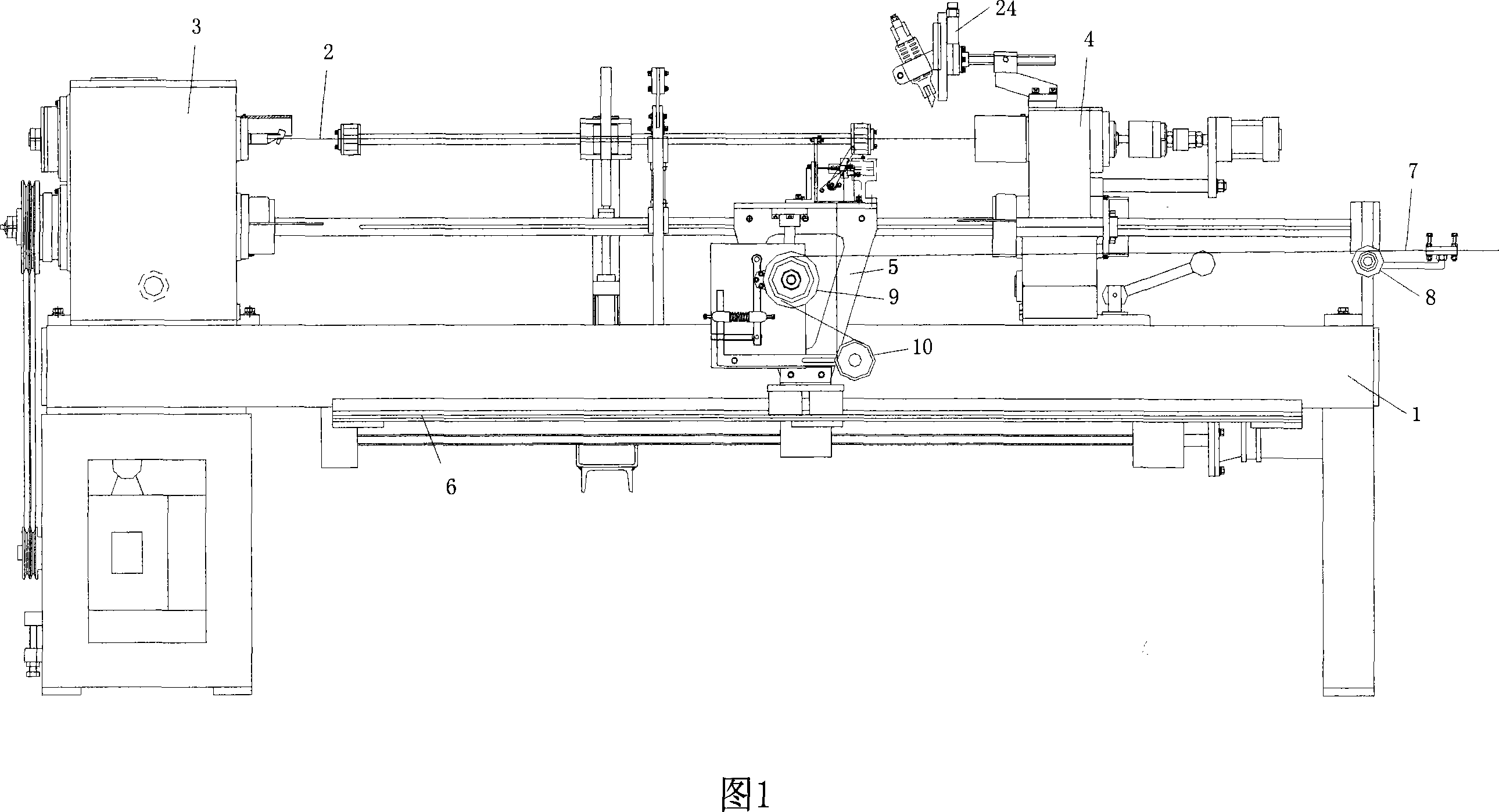

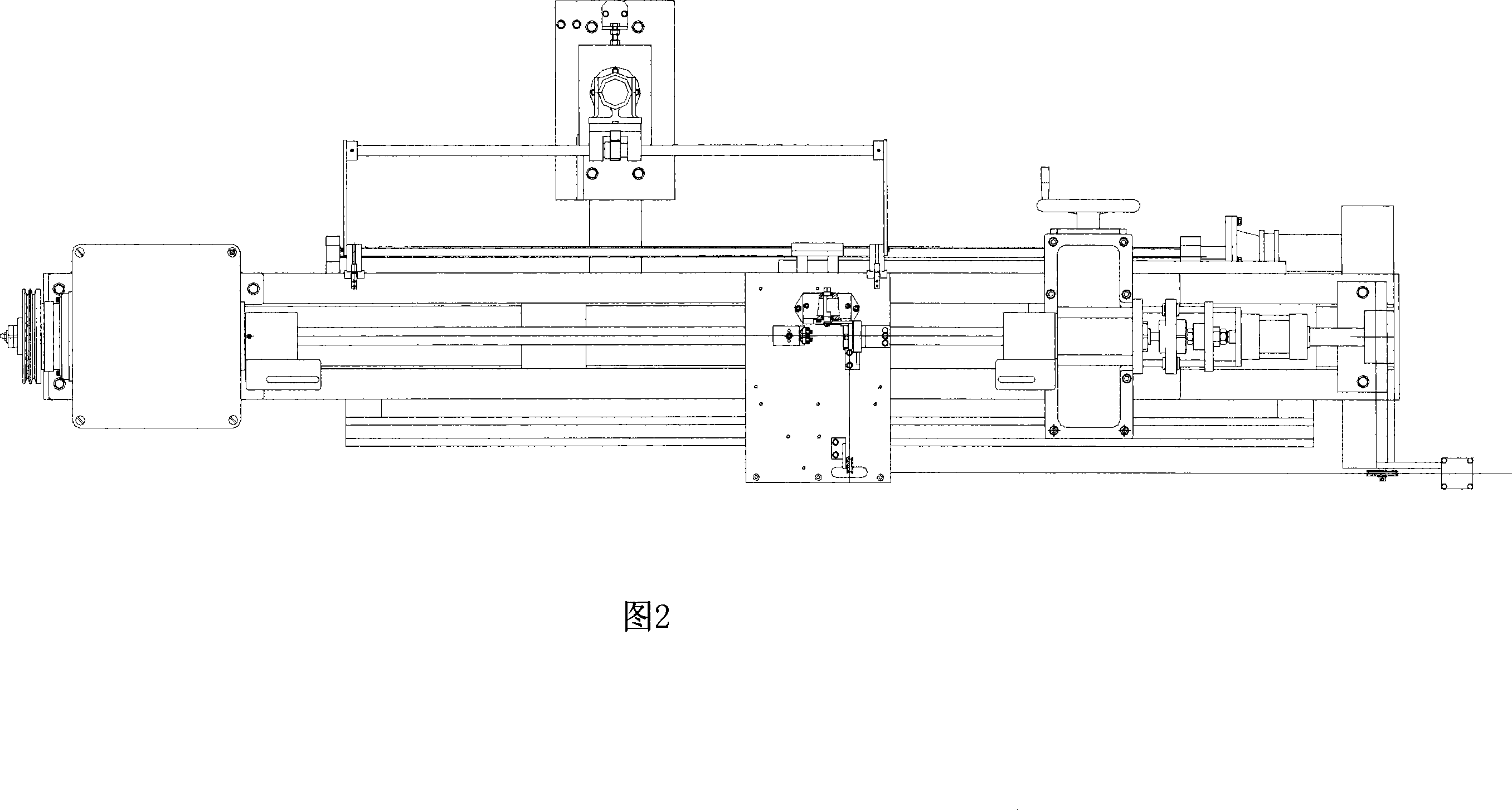

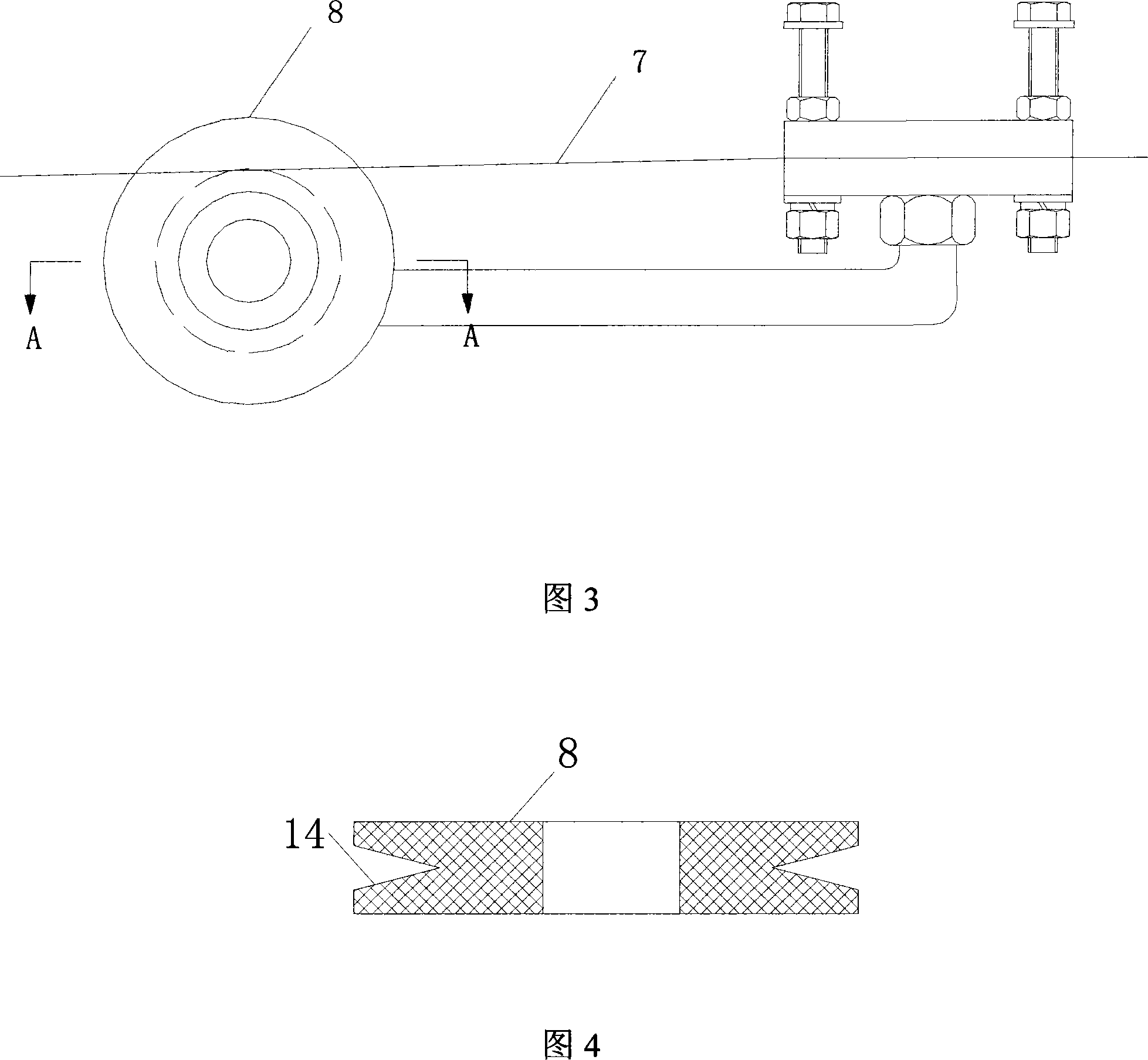

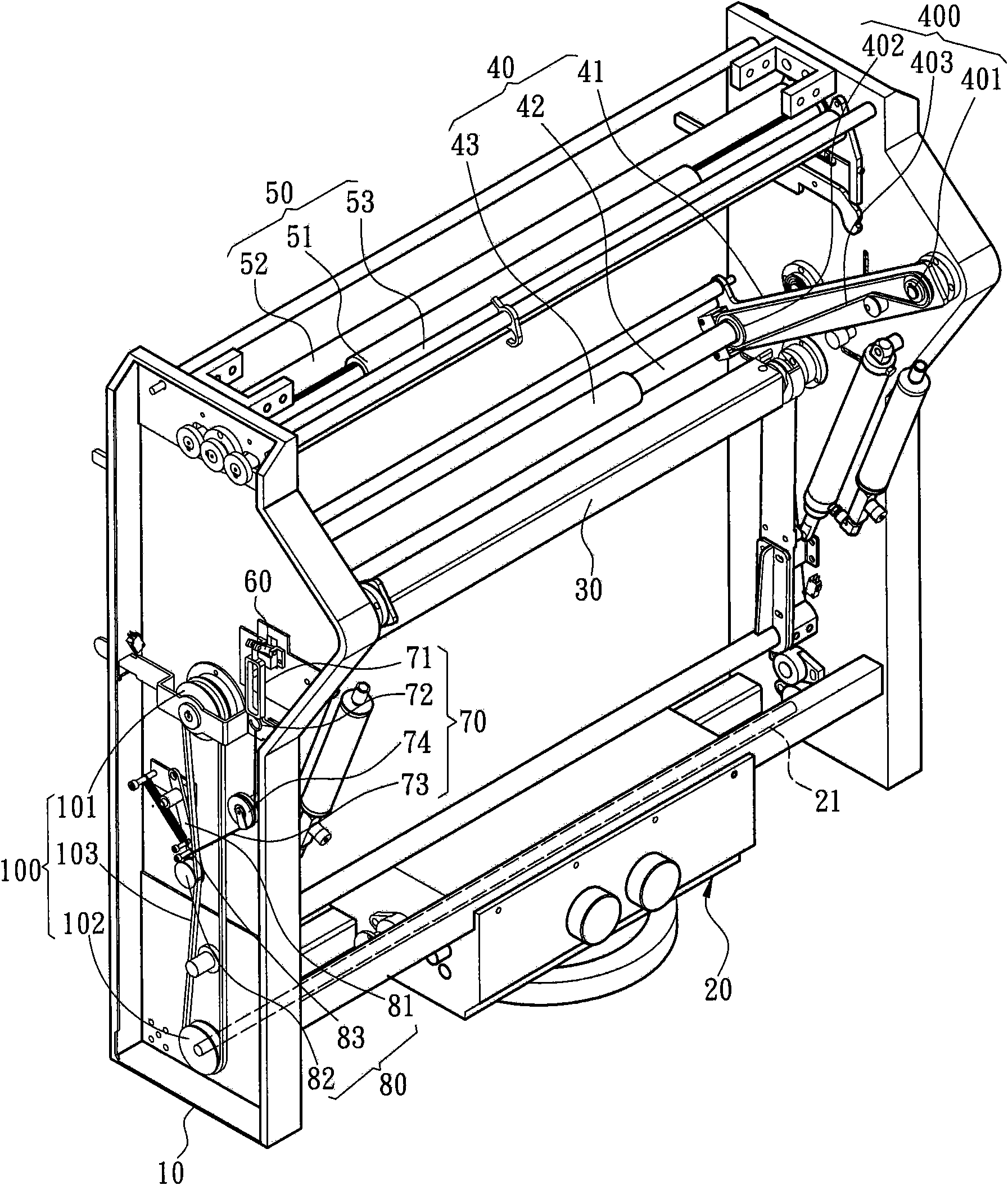

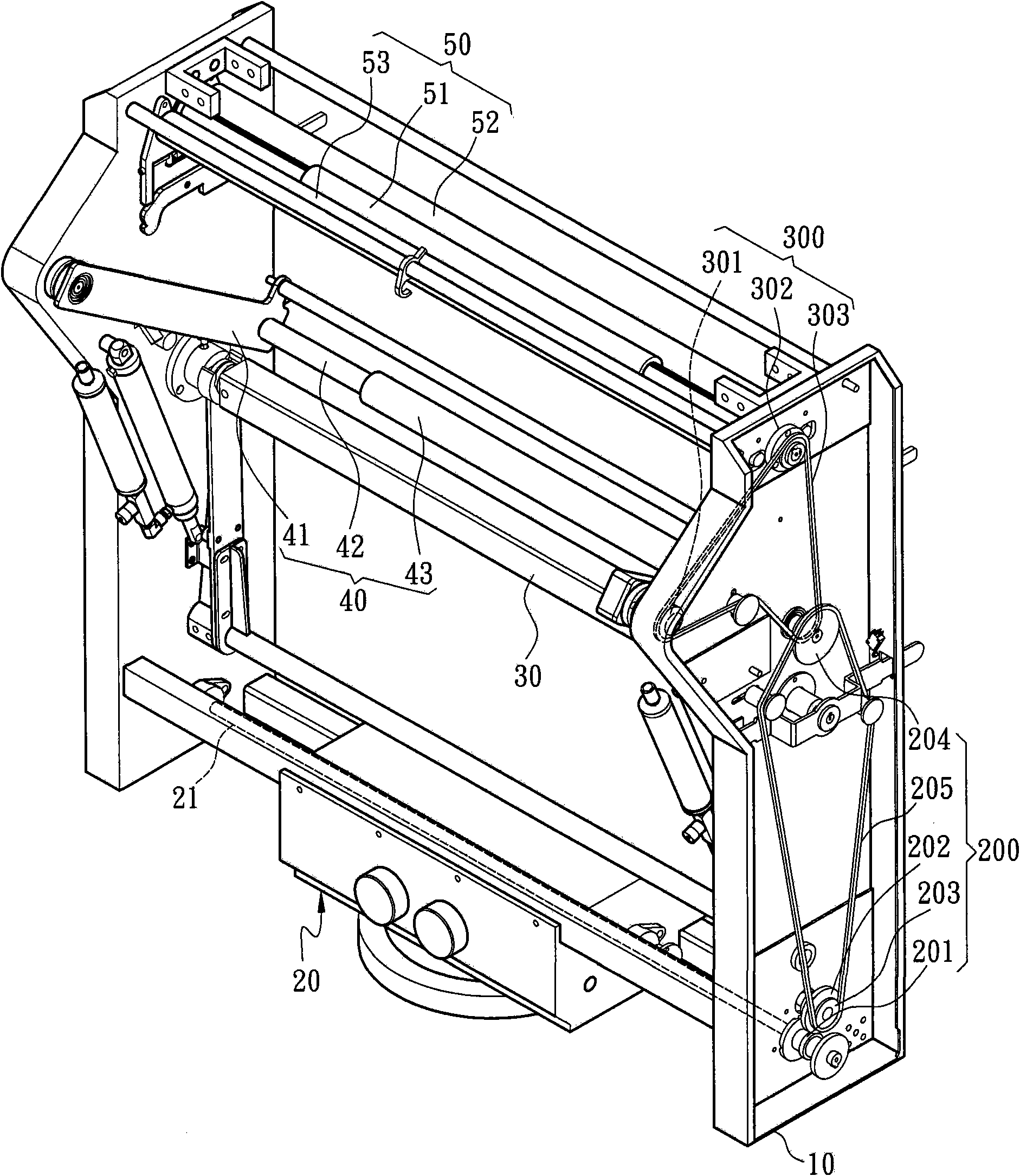

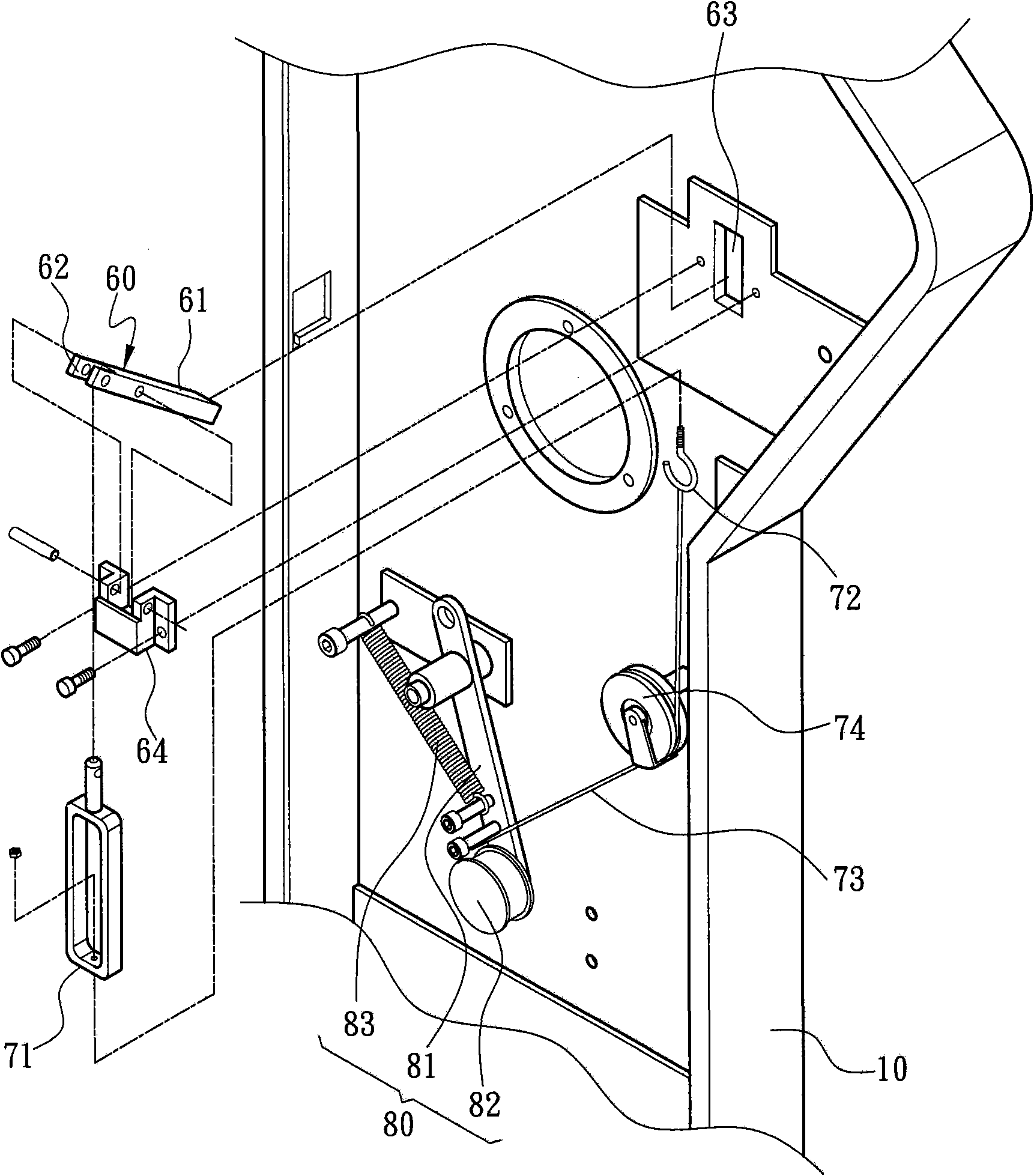

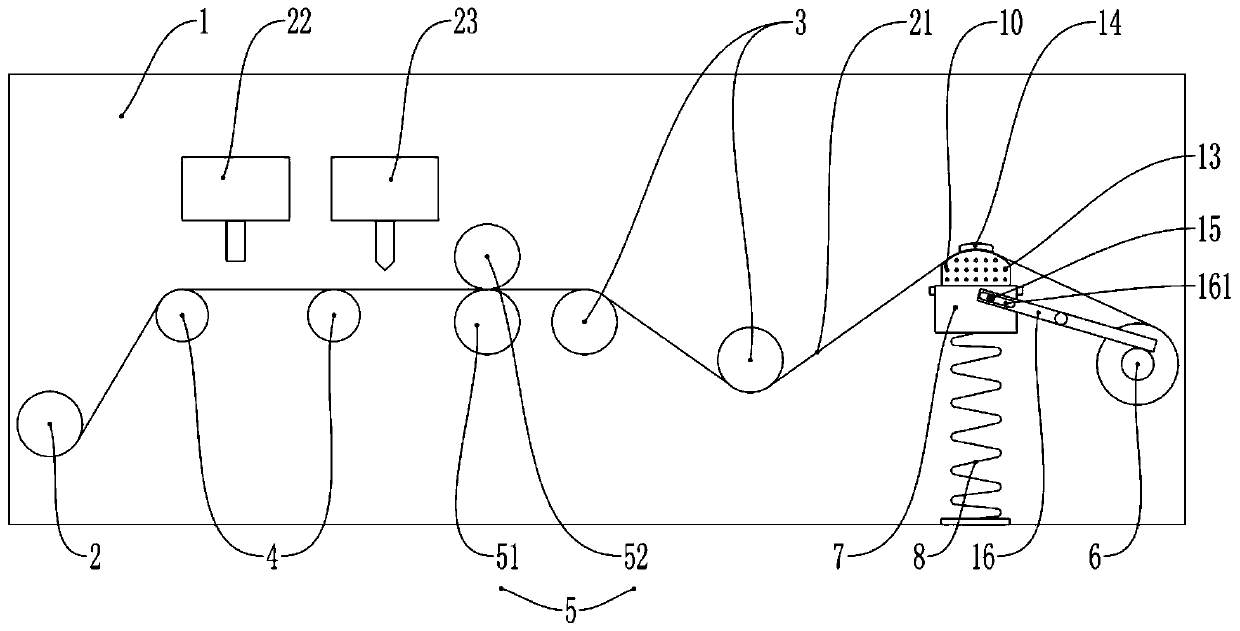

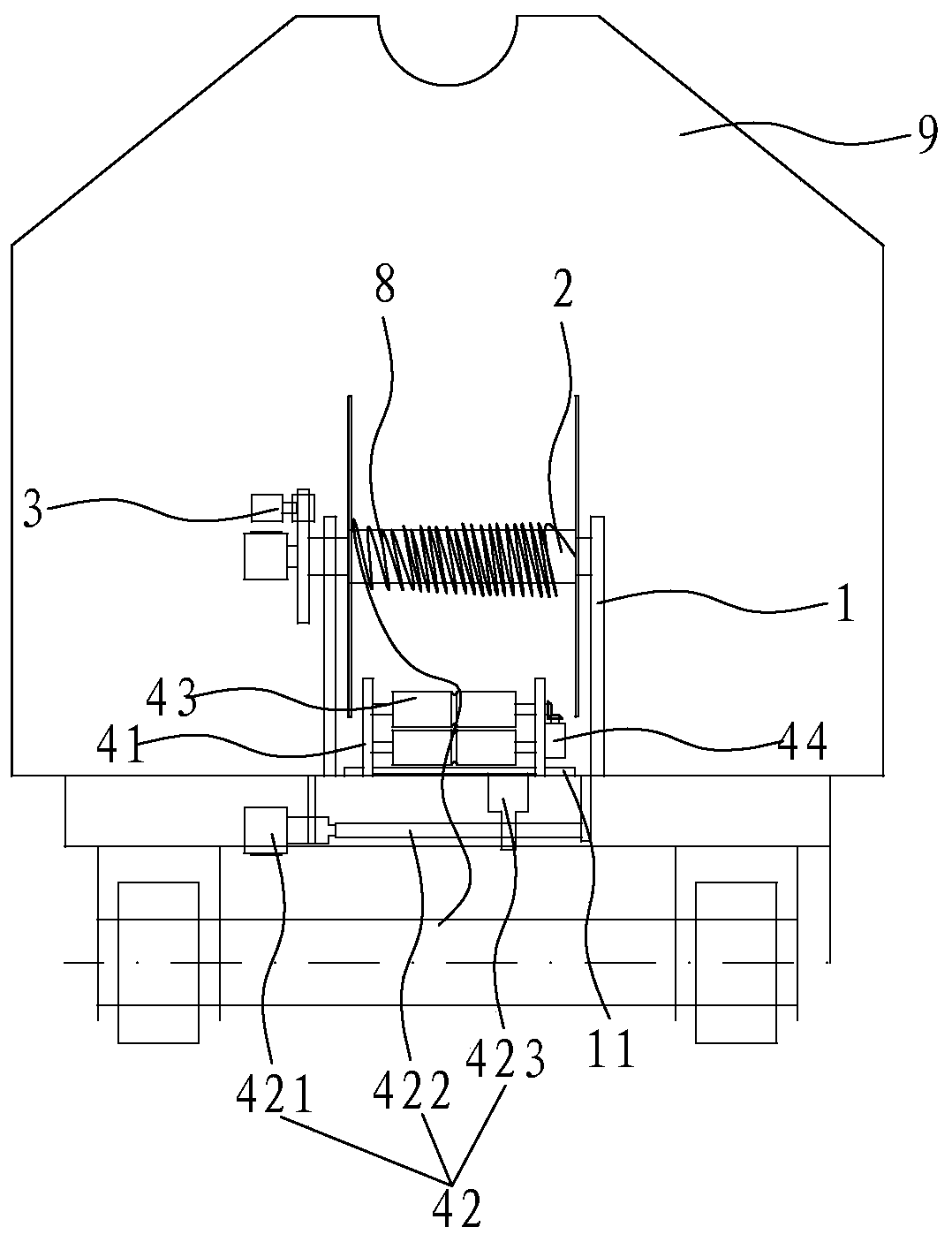

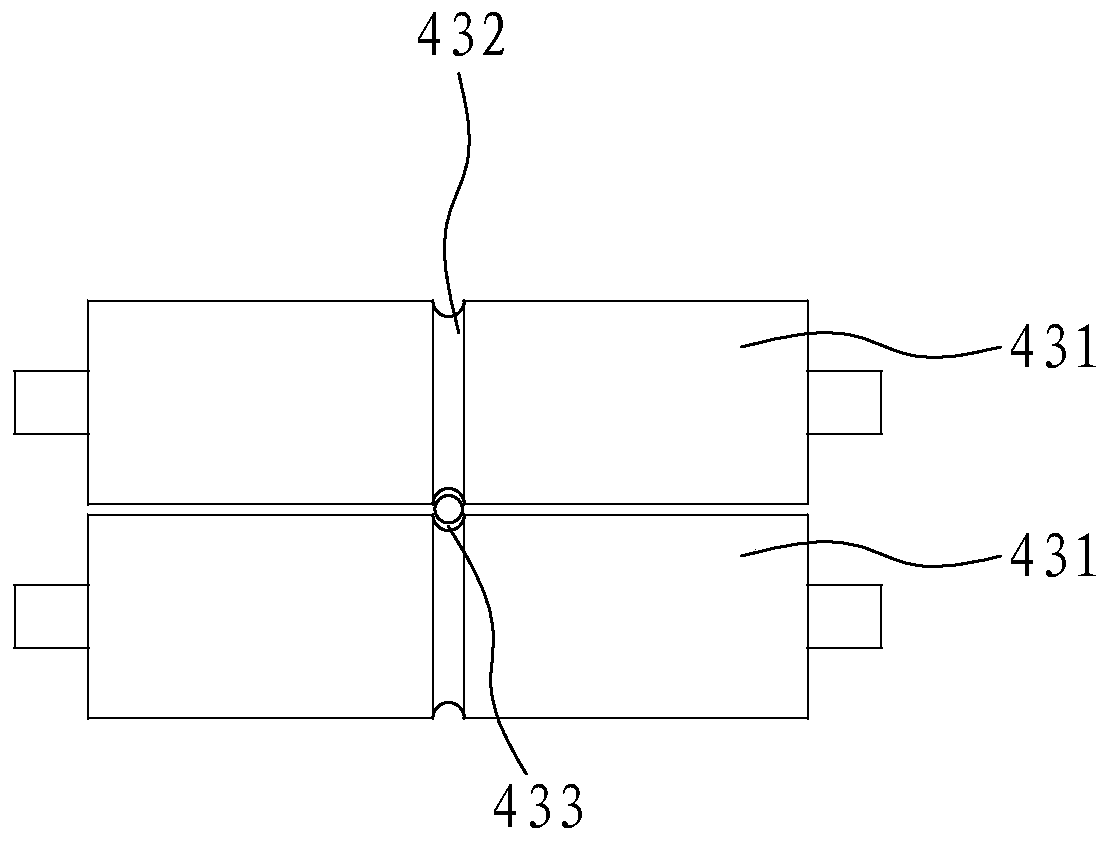

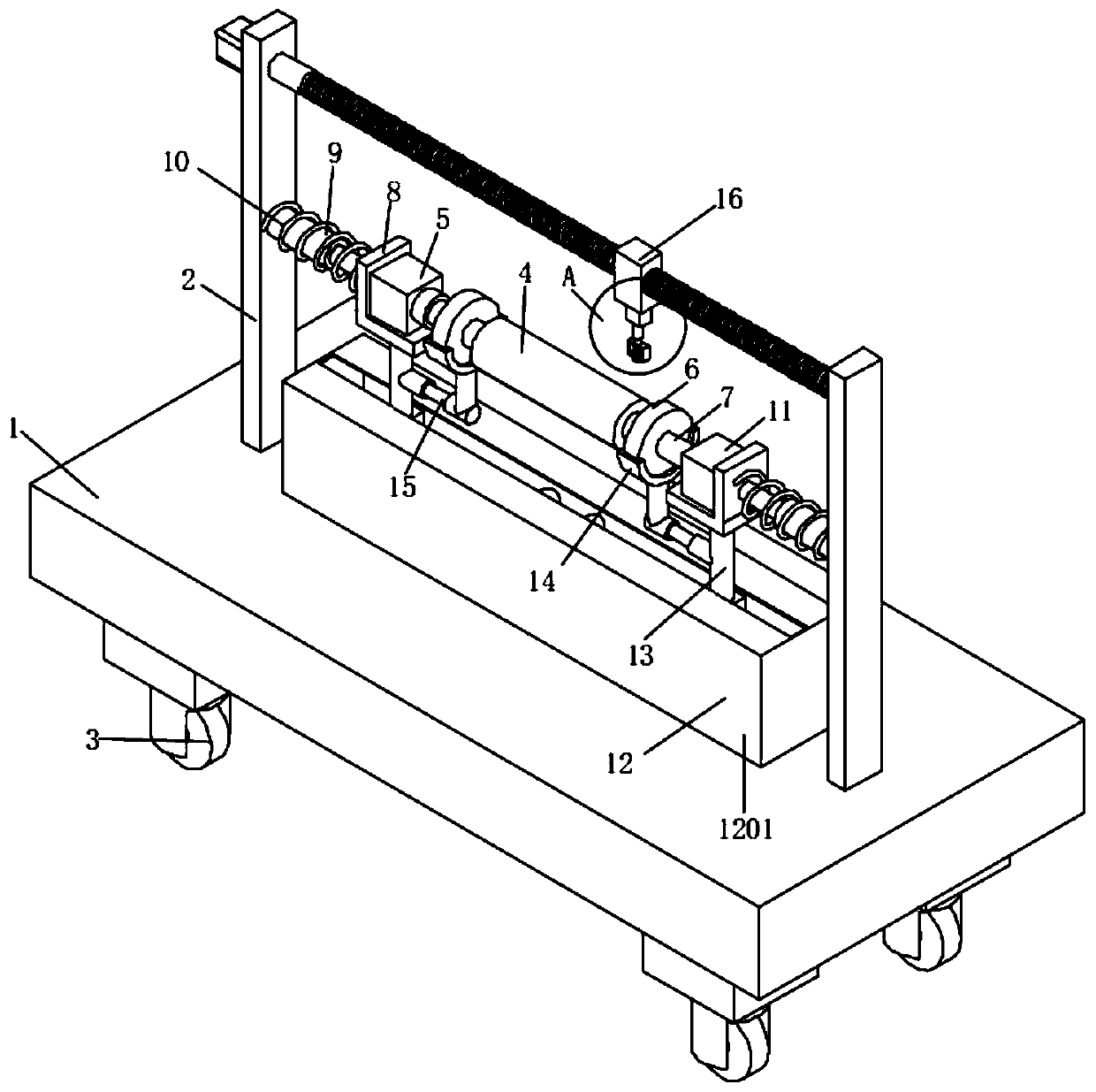

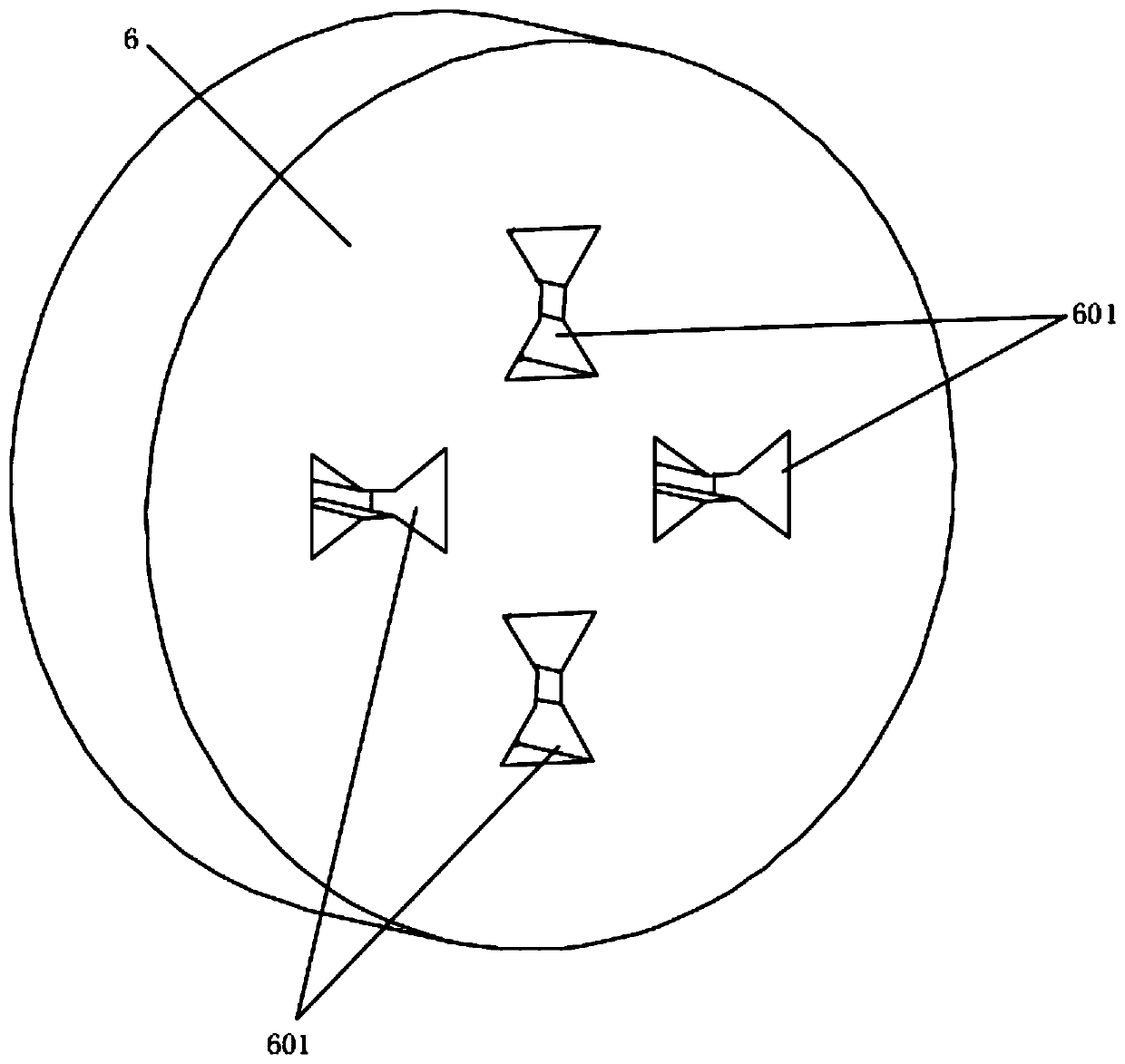

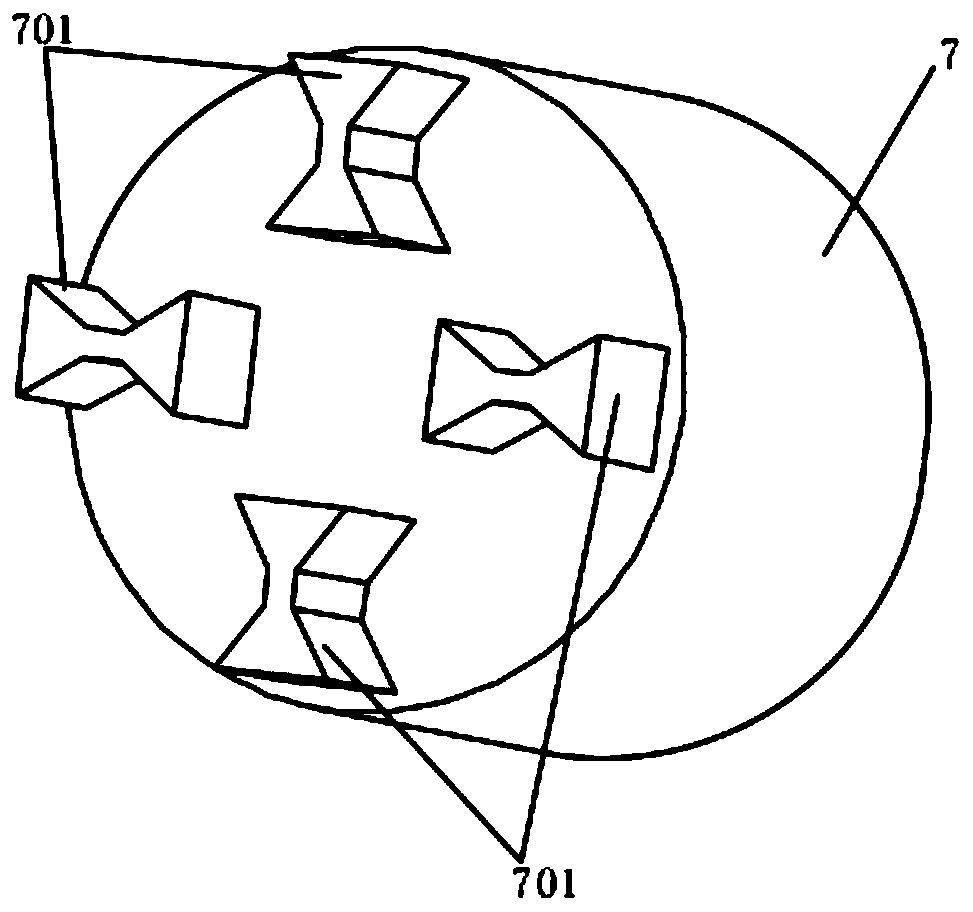

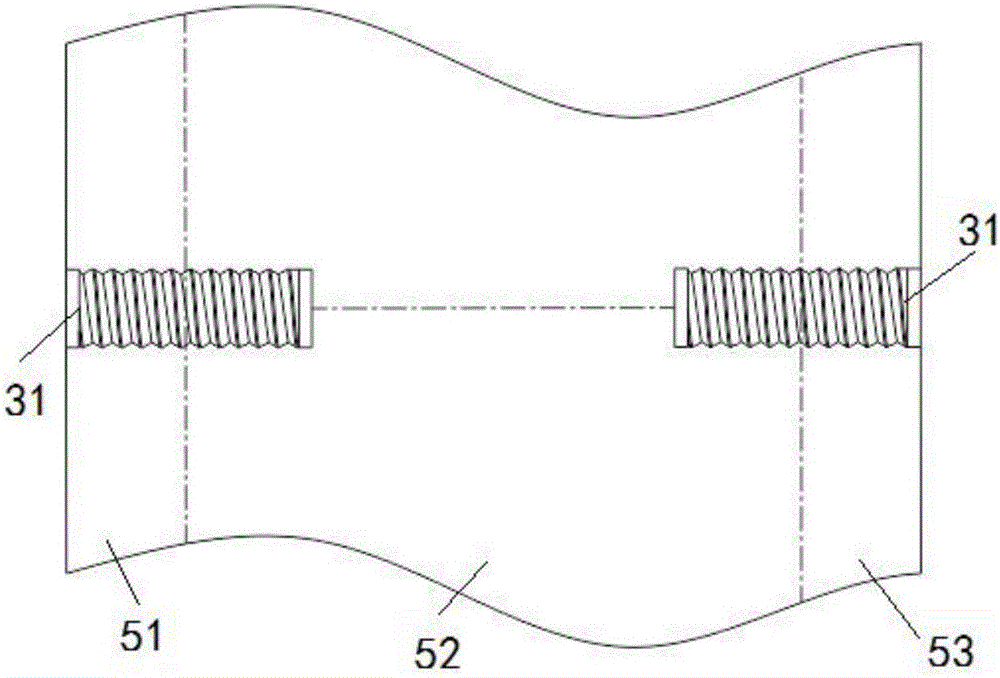

Piano automatic chord wrapping machine

The invention discloses an automatic string winder of a piano, which comprises a bedframe, a headstock for fixing one end of a string wire, a tailstock for fixing the other end of the string wire. The head stock and the tailstock are arranged on both ends of the bedframe. The bedframe is provided with a mobile worktable. The mobile worktable is arranged between the headstock and the tailstock. The bedframe and the mobile worktable are provided with tightener mechanisms to lead copper wires. The automatic string winder of the piano can wind copper wires evenly on a string wire so that the copper wires are not loose or overlapped. Copper wires are led through the tightener mechanisms. The pull force of the copper wires is stable. The tightness of the copper wires wound on the string wire is uniform. The ends of the copper wires on all of the finished string wires are the same in size, and the length of the copper wires is the same. The automatic string winder of the piano is stopped automatically, and the string is broken automatically, thus improving the working efficiency. One operator can control three automatic string winders with high work efficiency and low labor intensity. A green hand can be familiar with the skill to wind string easily.

Owner:PEARL RIVER PIANO GROUP

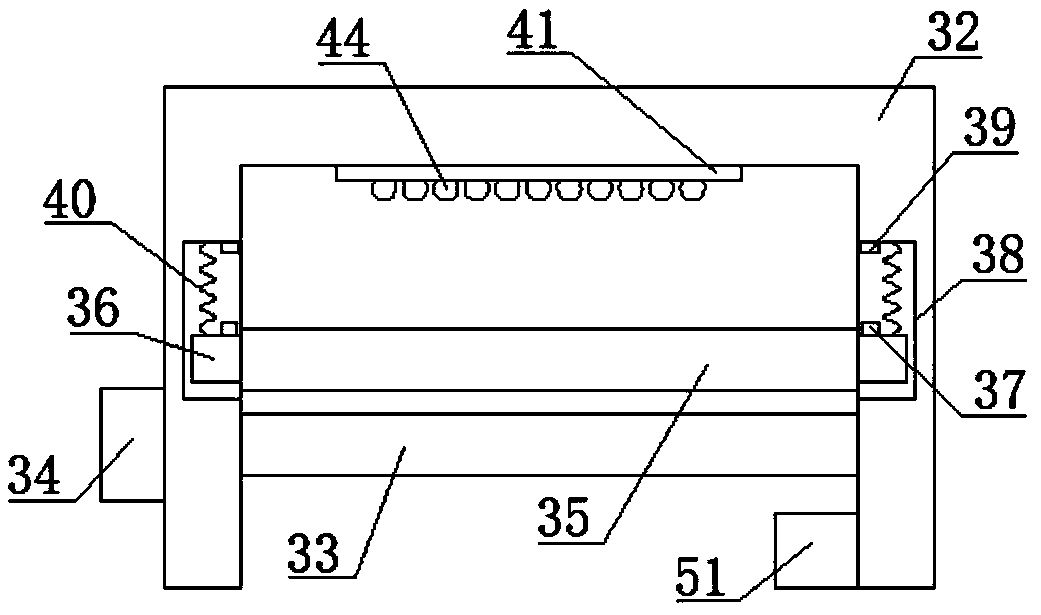

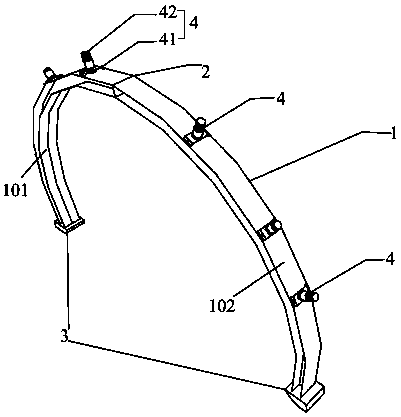

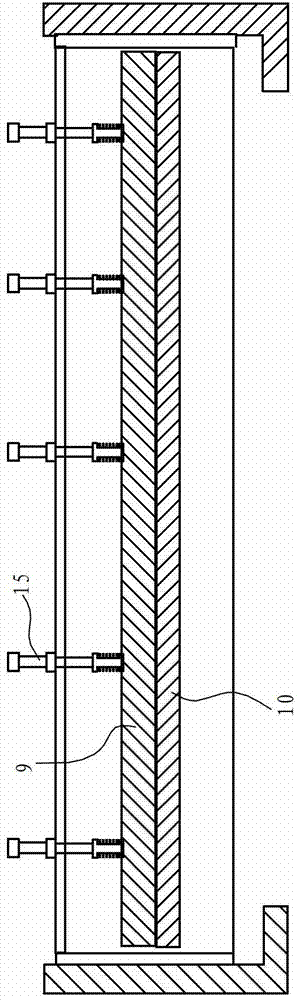

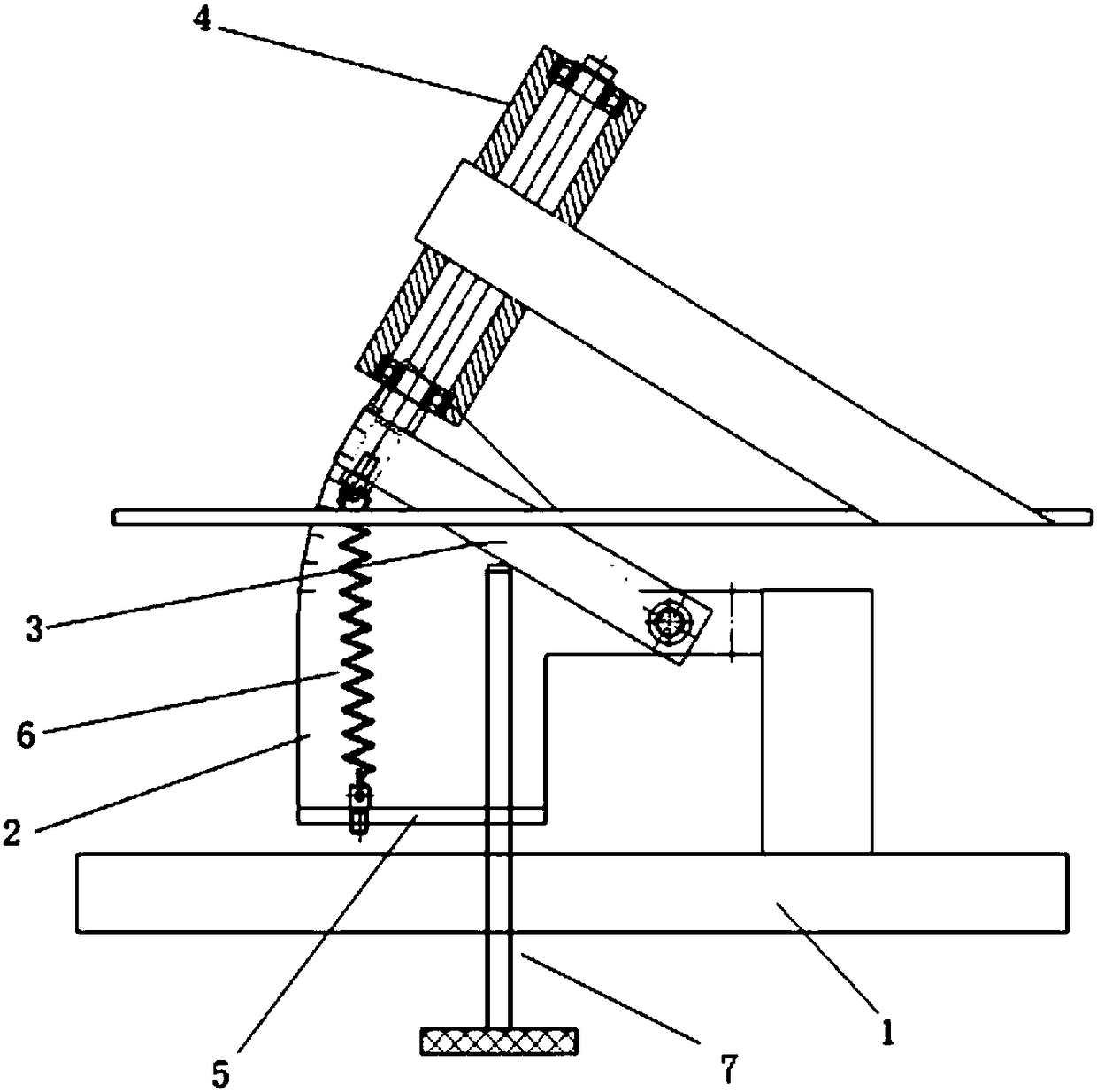

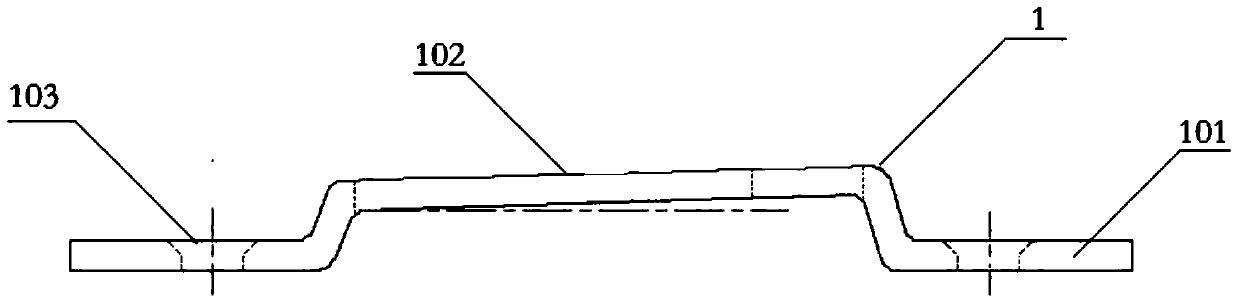

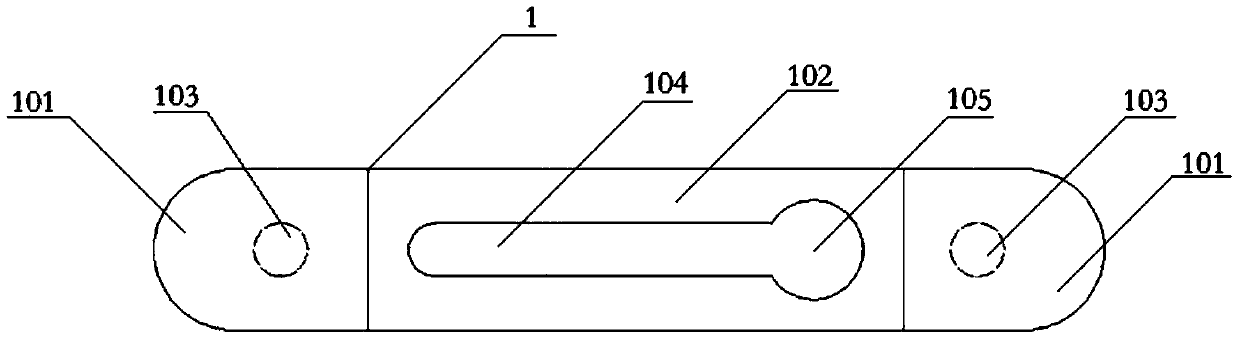

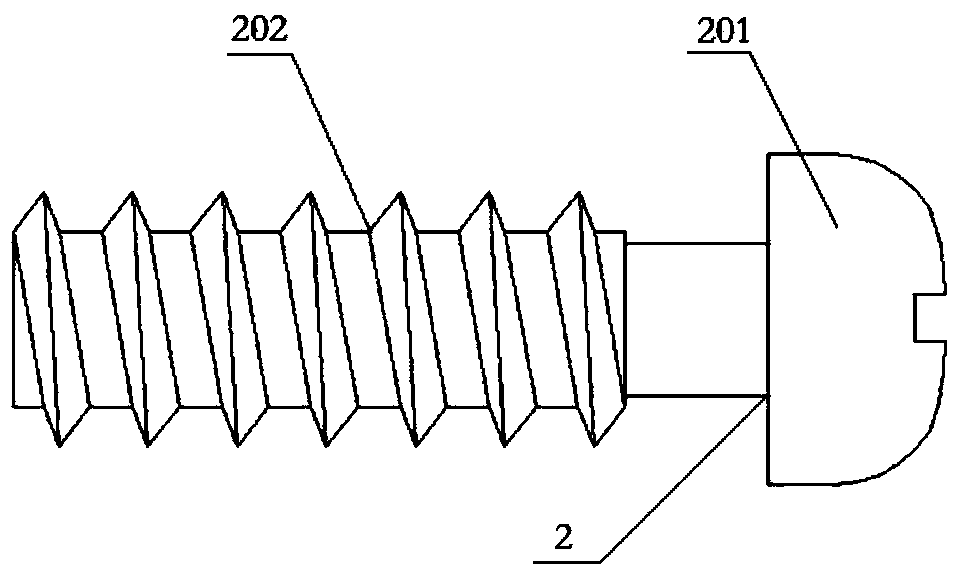

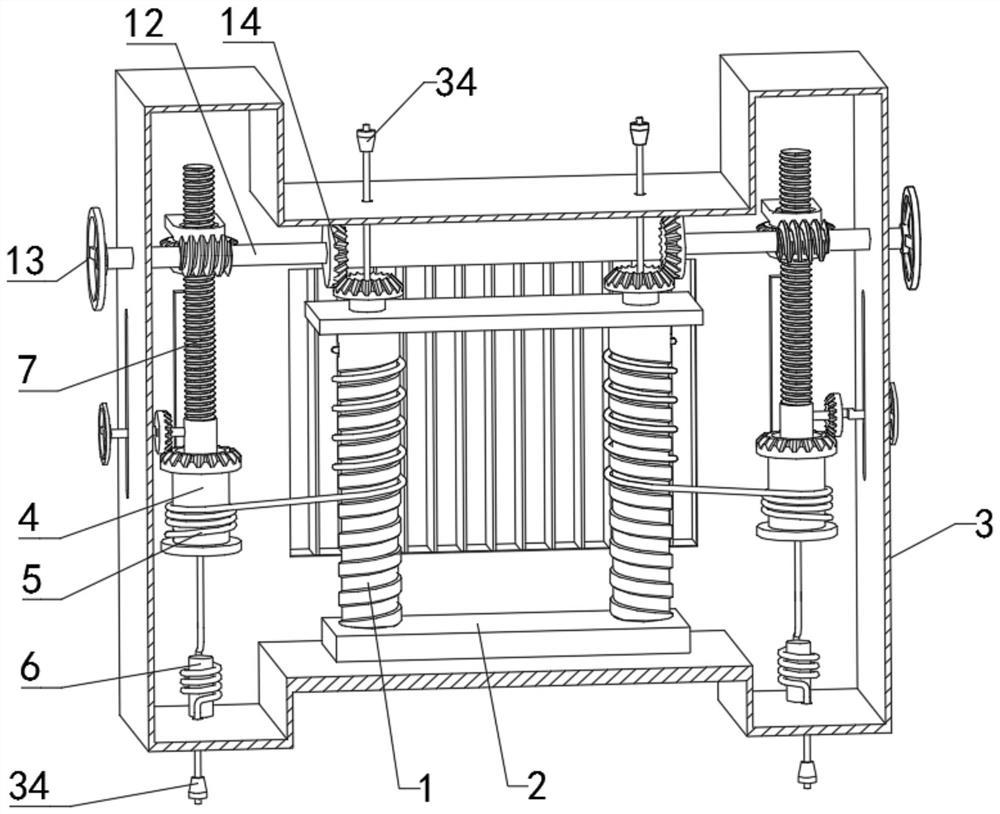

Tunnel supporting lagging jack and using method

InactiveCN108150200ASolve the problem that the tightness is difficult to controlConsistent tightnessUnderground chambersTunnel liningBuilding constructionTunnel engineering

The invention relates to the technical field of tunnel engineering construction, in particular to a tunnel supporting lagging jack and a using method. The tunnel supporting lagging jack comprises an annular lagging jack main body structure arranged along the inner wall of a tunnel, and a plurality of supporting structures connected to the lagging jack main body structure. One ends of the supporting structures are connected to the lagging jack main body structure, and the other ends of the supporting structures are provided with telescopic devices stretching out and drawing back towards one side of surrounding rock so that the supporting structures can extend to reach the surrounding rock and in contact with the surrounding rock to form an effective support. According to the tunnel supporting device, by arranging the telescopic structures, control over the attaching tightness degree is conducted on an excavation face of the surrounding rock through the telescopic structures, the problemthat loads are concentrated when a steel lagging jack supports the excavation face of the surrounding rock is solved, it is ensured that the supporting device provides annular support along the crosssection of the tunnel, and the construction quality and construction safety are ensured.

Owner:SOUTHWEST PETROLEUM UNIV

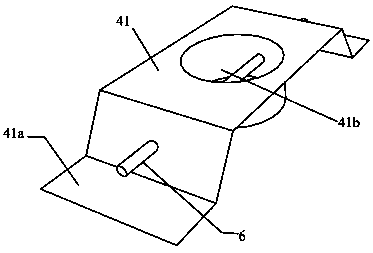

Canvas stretching and nailing device

InactiveCN106347013AConsistent tightnessGuaranteed smoothSpecial ornamental structuresEngineeringNail gun

The invention discloses a canvas stretching and nailing device which comprises a bottom moving track, a clamping and pushing device and a stretching and nailing device, wherein the moving track pushes a canvas and a frame to the bottom of the clamping and pushing device, the canvas is delivered to an accommodating space between clamping jaws, a clamping cylinder drives the clamping jaws to clamp the edge of the canvas, a pushing cylinder pushes a pushing plate profile, the clamping cylinder moves along with the pushing plate profile, the clamping jaws wrap the edge of the canvas on the frame; a cylinder drives a heavy sliding block to drive an aluminium profile to move downwards, and a nail gun falls to the stretching and nailing position along with the aluminium profile, and stretches and nails the canvas on the frame. The device disclosed by the invention can automatically complete the process flows of wrapping the frame and stretching and nailing, realize uniform tightness of stretching and nailing, and ensure the levelness of stretching and nailing, thus improving the stretching and nailing efficiency and reducing investment of labor force.

Owner:ALLIO ROBOT TECH (CHANGSHU) CO LTD

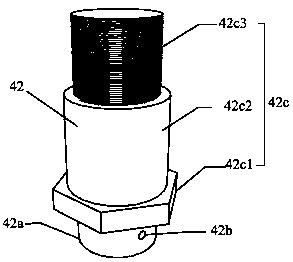

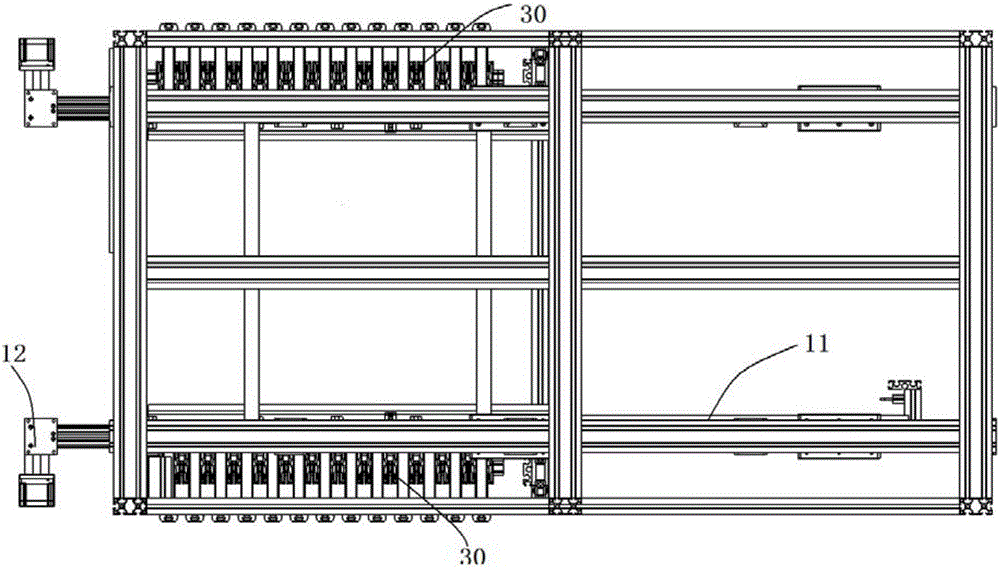

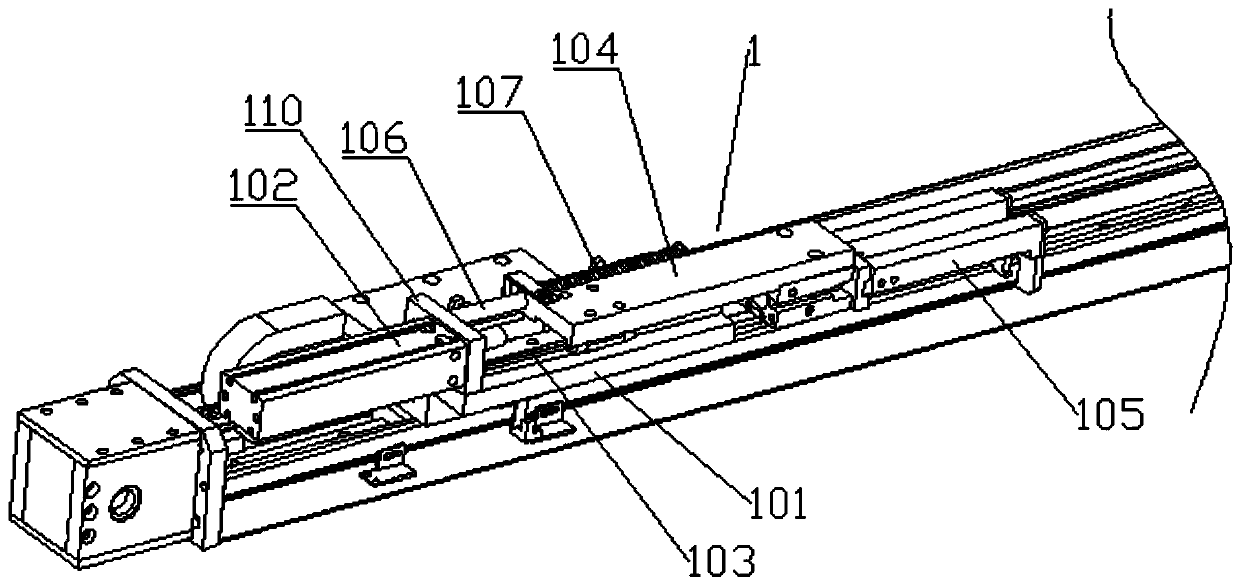

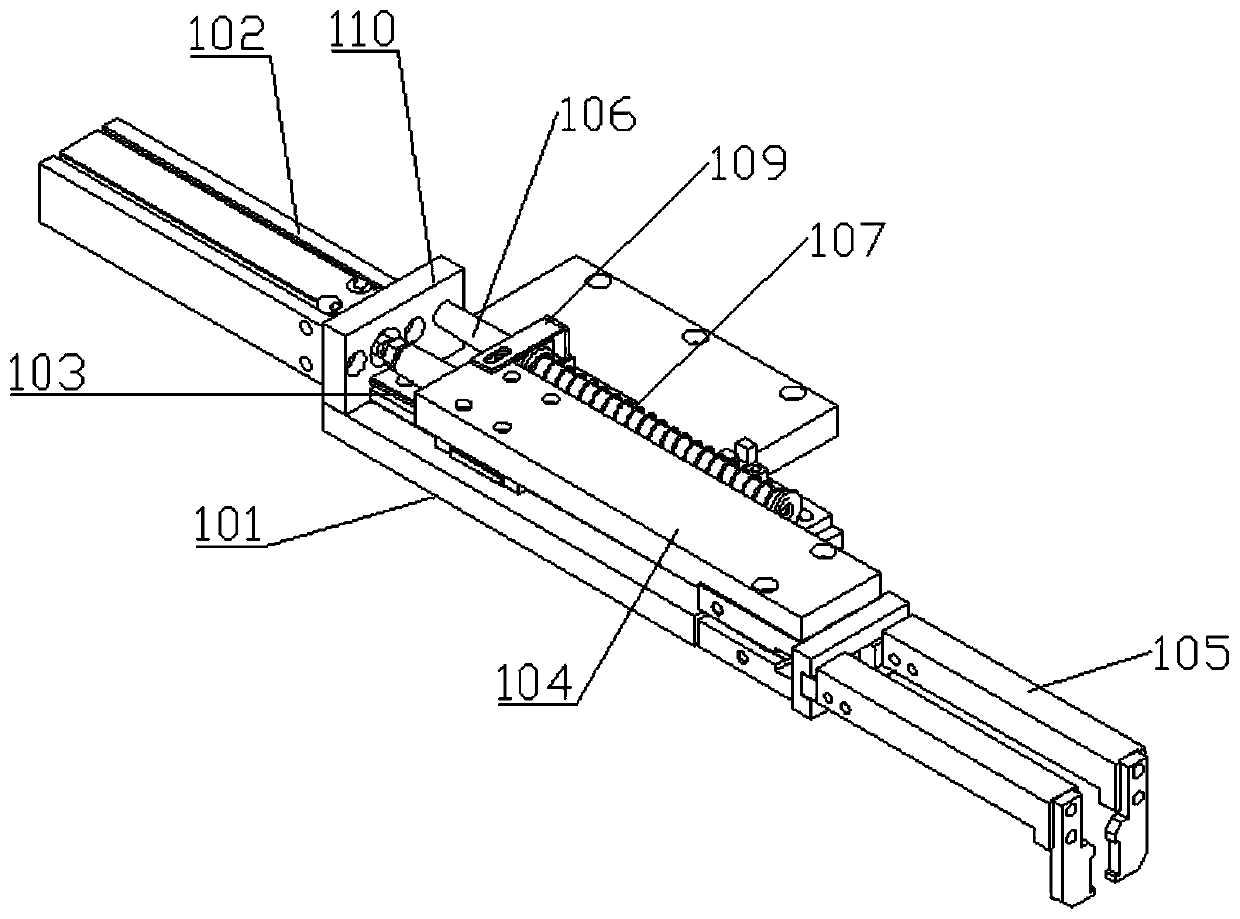

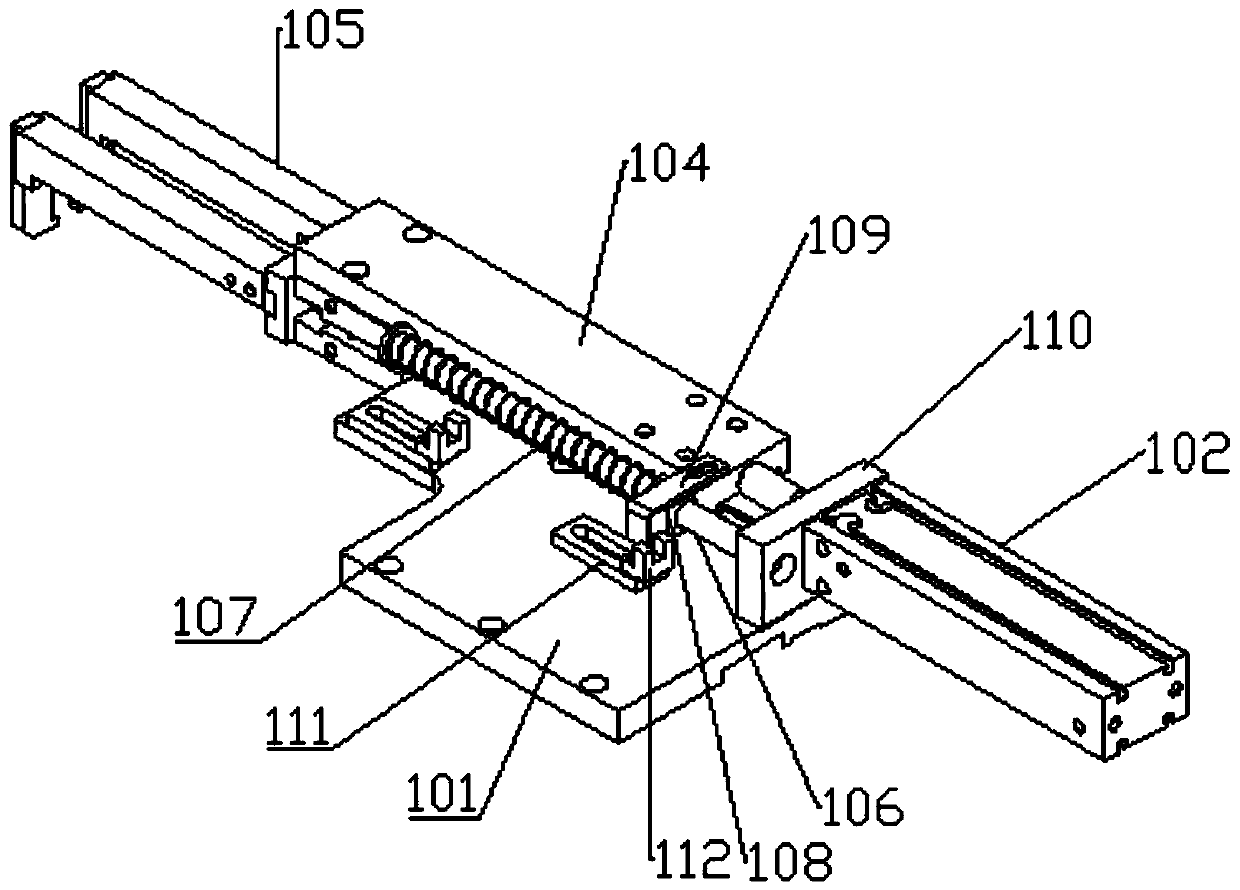

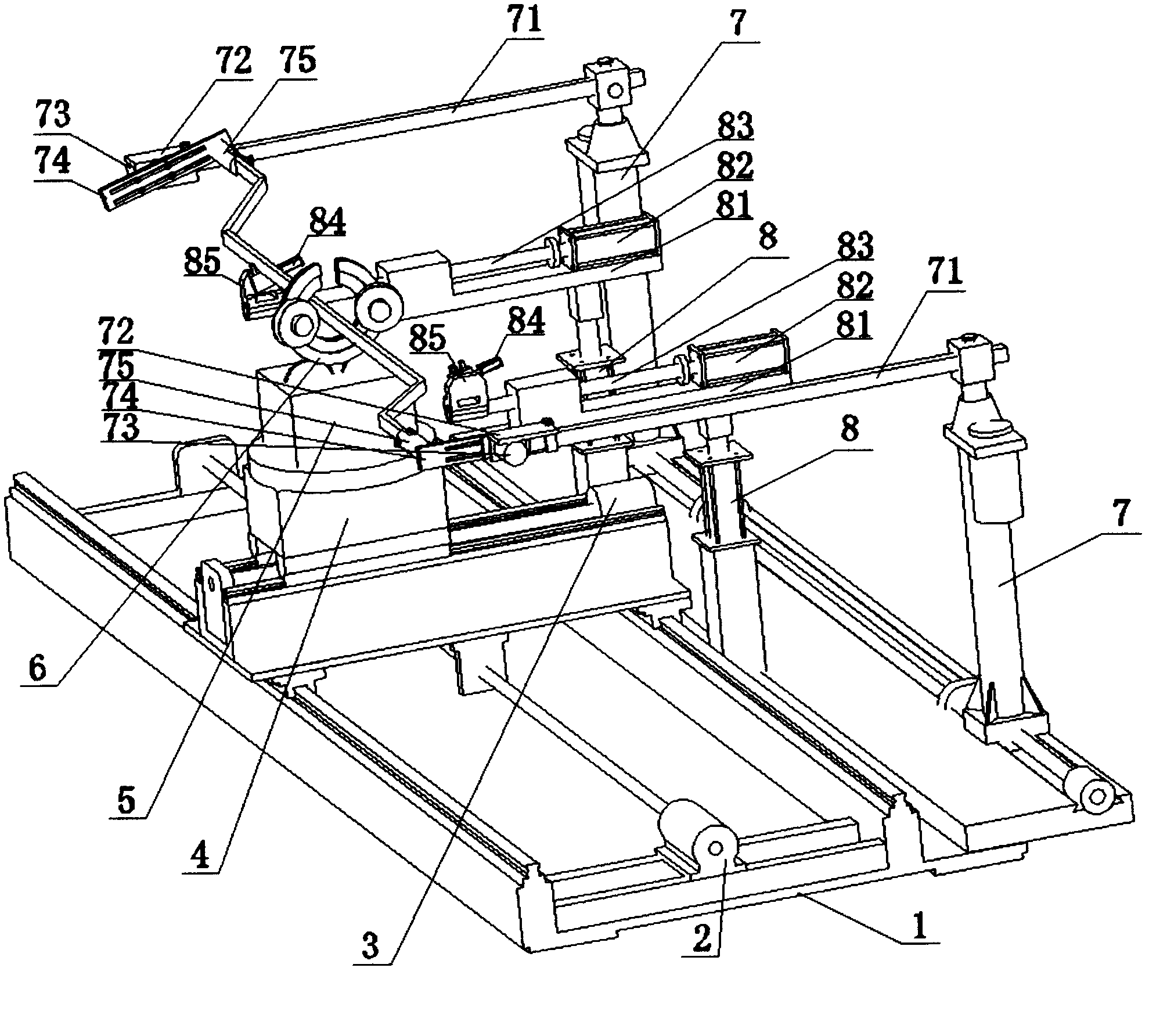

Automatic taking, winding and bagging device for infusion set

The invention relates to the technical field of packaging devices, in particular to an automatic taking, winding and bagging device for an infusion set. The automatic taking, winding and bagging device for the infusion set comprises a rack, an infusion set tensioning mechanism, an infusion set tail taking mechanism, an infusion set head taking mechanism, an infusion set automatic winding mechanism, an infusion set roll transferring mechanism, a bag entering mold and a bag entering pushing mechanism, wherein the infusion set tensioning mechanism, the infusion set tail taking mechanism, the infusion set head taking mechanism, the infusion set automatic winding mechanism, the infusion set roll transferring mechanism, the bag entering mold and the bag entering pushing mechanism are sequentially arranged on the rack from back to front in the X-axis direction. According to the automatic taking, winding and bagging device for the infusion set, the whole taking, winding and bagging process ishigh in process continuity and operation stability; a drip chamber of the infusion set is stably fixed in the winding process, the infusion set is wound tidily, the tightness of coils is consistent, the wound infusion set is tidy and tight, and an infusion set catheter cannot be damaged; and the equipment is high in automation degree, rapid to operate and high in stability in the whole transferring process.

Owner:YANTAI KAIBO AUTOMATION TECH

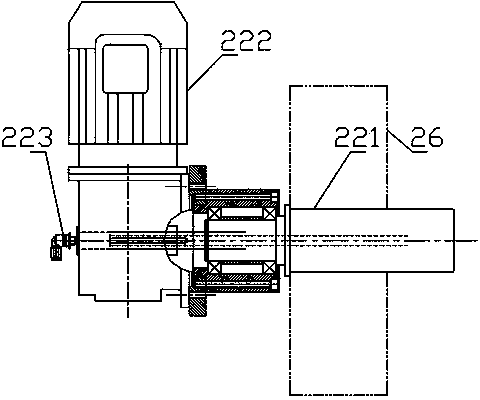

CNC taping machine for winding bar of wind turbine rotor winding bar

InactiveCN102983691AConsistent tightnessQuality improvementApplying solid insulationNumerical controlMotor drive

The present invention discloses a CNC (computerized numerical control) taping machine for a rotor bar of a wind generator. The taping machine comprises a base, a taping operation mechanism and a bar fixture. the taping operation mechanism comprises a horizontal servo motor- and a vertical servo motor-driven platform base on the base, a rotary servo motor-driven rotating operation platform on the platform base, and a taping machine head on the rotating operation platform. the bar fixture comprises two stand columns with horizontally adjustable space and vertically adjustable height; the upper end of each column is provided with a retractable fixed rod via fasteners; a bar clamping mechanism is arranged at the front end of each fixed rod; and the bar clamping mechanism is a bar fixing clamp which is driven by a stepper motor or a cylinder, and can swing up and down. The CNC taping machine is simple in structure and easy for operation, with high degree of automation and resulting good taping quality.

Owner:上海闵行机械工程技术研究所有限公司

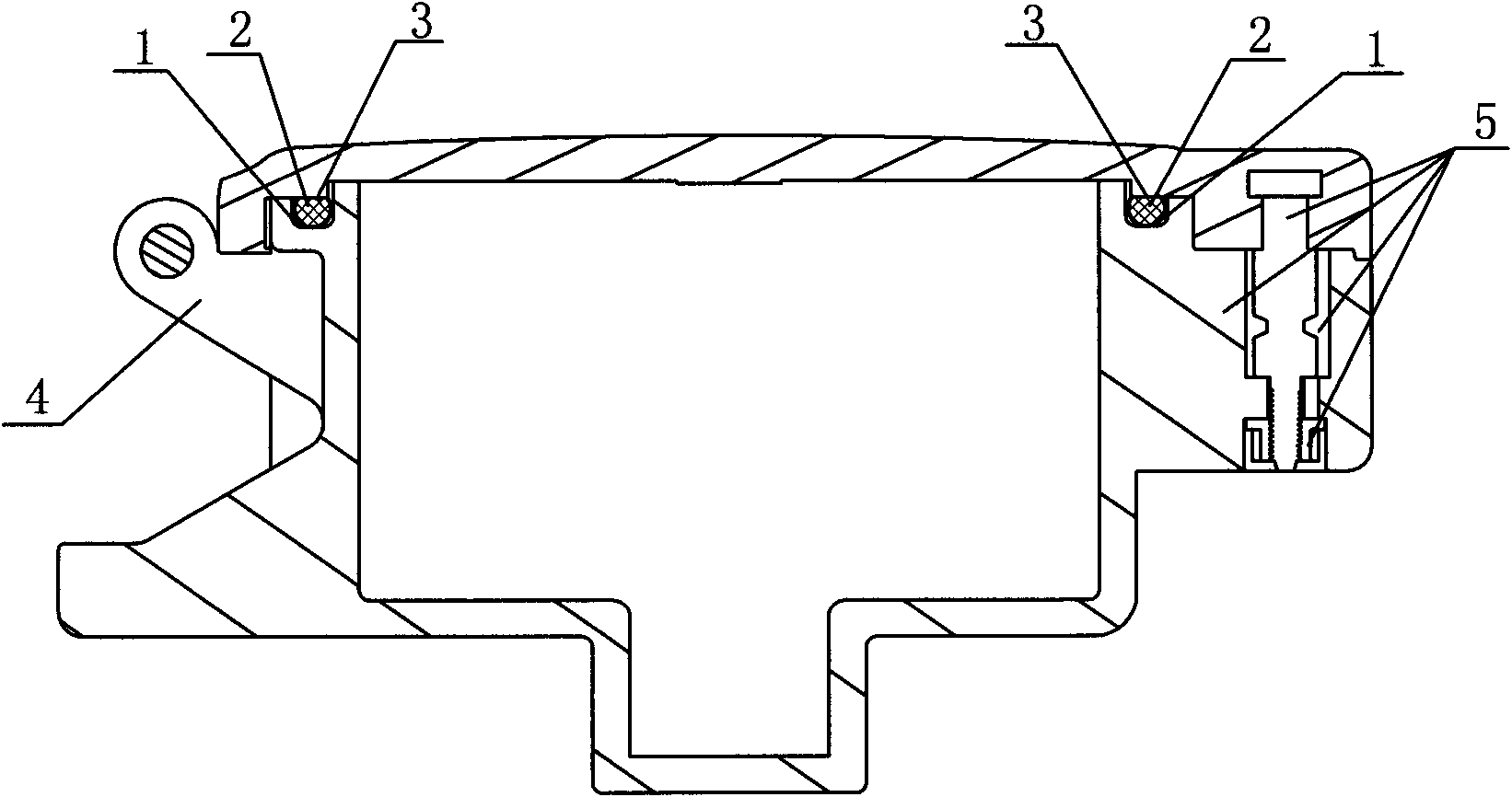

Sealing structure for sealing box

InactiveCN102182825AConsistent compressionNot easy to ageEngine sealsNutsEngineeringMechanical engineering

The invention discloses a sealing structure for a sealing box. The sealing structure comprises an annular accommodating groove (1) positioned on an upper edge of a box body, an annular elastic sealing piece (2) accommodated in the accommodating groove (1), and a pressing plate (3) which is arranged on a box cover and is used for pressing against the elastic sealing piece (2), wherein a contact surface between the pressing plate (3) and the elastic sealing piece (2) is a plane; the elastic sealing piece (2) and the pressing plate (3) are pressed against each other through a pressing device arranged on the box body and the box cover; the elastic sealing piece (2) has the hardness of 45-50 degrees and the compression of 1-1.5mm; and the pressing plate (3) has the surface flatness of not more than 0.4. The sealing structure for the sealing box is good in sealing effect and high in insulating level, and has a protection level of IP67.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

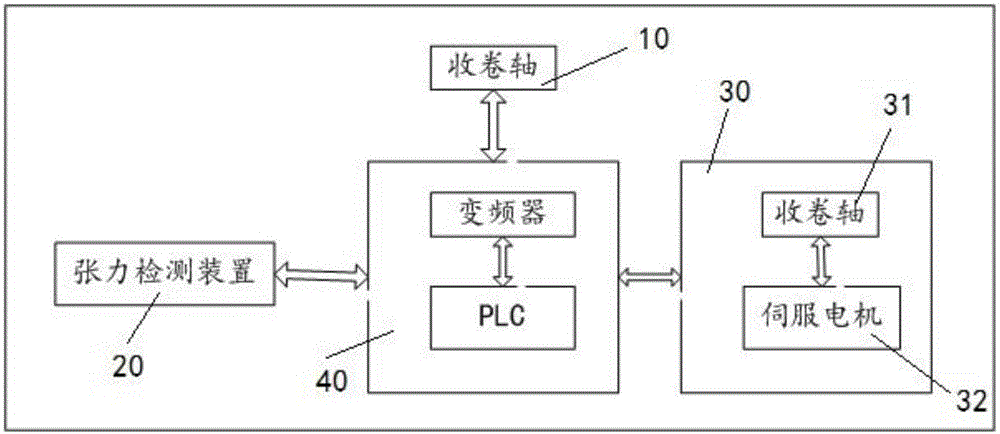

Cloth rewinder tension force adjusting framework

InactiveCN101934946AVolume stabilityConsistent tightnessKnittingWebs handlingDrive wheelConductor Coil

The invention discloses a cloth rewinder tension force adjusting framework comprising a driving mechanism, a cloth winding rod, a cloth pressing mechanism and an adjusting mechanism, wherein the driving mechanism is arranged on the cloth rewinder; the cloth winding rod and the driving mechanism are provided with corresponding driving wheels on which belts are straddled to cause the driving mechanism to drive the cloth winding rod to furl cloth; the cloth pressing mechanism is provided with an action arm and a cloth pressing rod, wherein the action arm is arranged on the cloth rewinder, and the cloth pressing rod is arranged on the action arm; the cloth pressing rod is provided with a first position which does not contact with the cloth, and a second position which contacts with the cloth and is supported by the cloth; the adjusting mechanism is pressed by the action arm on the first position of the cloth pressing rod so as to abut against the belt to increase the initial driving force for the cloth winding rod to coil cloth; the second position of the cloth winding rod is driven by the action arm to separate from the belt; and the cloth is under the active control of the cloth pressing rod to obtain the effect of consistent compactness of the cloth, thus improving cloth coiling quality.

Owner:PAI LUNG MACHINERY MILL CO LTD

Thin film rolling equipment of food packaging bag

The invention relates to the technical field of packaging bags, in particular to thin film rolling equipment of a food packaging bag. The thin film rolling equipment comprises a machine frame, whereina guide roller, a transmission roller, a traction roller and a winding roller are arranged on the machine frame, an adjusting unit is arranged between the winding roller and the guide roller, the adjusting unit comprises an adjusting seat and a first elastic part, the first elastic part is located below the adjusting seat, one end of the first elastic part is connected with the adjusting seat, the other end of the first elastic part is connected with the machine frame, and the adjusting seat is internally provided with a first a belt line and a second belt line; the rotating central axis of the first belt line and the second belt line is perpendicular to the traction roller, and the transmission directions of the first belt line and the second belt line are opposite. According to the scheme, the tension adjusting and anti-wrinkle processing in the winding process of the packaging bag is achieved through the adjusting unit, and the problems that in the prior art, the packaging bag is deformed, broken and wrinkled in the winding process of the packaging bag are solved.

Owner:重庆富美包装印务有限公司

Belt collecting and winding machine structure

InactiveCN103043483AConsistent tightnessGood belt tensioning effectWebs handlingWinding machineConductor Coil

The invention relates to a belt collecting and winding machine structure. The belt collecting and winding machine structure comprises a support, a collecting barrel and a collecting driving mechanism, wherein the collecting barrel is arranged on the support, and the collecting driving mechanism controls the collecting barrel to rotate. The belt collecting and winding machine structure is characterized by further comprising a first roller, a first limit switch, a second limit switch, a second roller, an upper press plate, a lower press plate, a third roller and a fourth roller, wherein the first roller is fixed at a first end of a swing rod, the middle of the swing rod is rotationally arranged on the support, conveyed belts firstly wind on the first roller, the upper press plate and the lower press plate are fixed on the support, the lower press plate is arranged below the upper press plate and tightly arranged with the upper press plate, the third roller and the fourth roller are fixed on the support, the axis of the fourth roller is lower than the axis of the collecting barrel, and output ends of both the first limit switch and the second limit switch are connected with the collecting driving mechanism. Compared with the prior art, the belt collecting and winding machine structure can always guarantee constant tightness degree of belt winding.

Owner:NINGBO NINGCHUANG AUTOMATION DEVICE

Cable winding disc

InactiveCN111204609AWinding effectContinuous and orderly winding and tilingFilament handlingControl theoryElectric cables

The invention relates to the field of tissue manufacturing equipment, in particular to a cable winding disc. The cable winding disc comprises a rack, a winding disc body rotationally arranged on the rack and used for winding a cable, a winding servo motor arranged on the rack and used for driving the winding disc body, and a guide device arranged on the rack, located in front of the winding disc body and used for guiding the cable, a sliding rail parallel to the axial direction of the winding disc is arranged at the position, in front of the winding disc, of the rack, the guiding device comprises an installation base capable of sliding along the sliding rail, a sliding driving device arranged on the rack and used for driving the installation base to slide, a clamping guiding wheel set arranged on the installation base and a guiding servo motor used for driving the clamping guiding wheel set to rotate, the clamping guiding wheel set comprises two guide wheels close to each other, arc-shaped guide grooves are formed in the circumferences of the guide wheels, and the arc-shaped guide grooves of the two guide wheels are matched to form a guide channel allowing the cable to pass through. According to the cable winging disc, the technical problems that cable winding tightness degree is inconsistent, and cables are stacked in a certain area are solved.

Owner:HENGAN (CHINA) PAPER IND CO LTD

Convenient and fast yarn winding roller mounting frame

The invention discloses a convenient and fast yarn winding roller mounting frame. The frame comprises a base, two supporting rods vertically and fixedly arranged on the surface of the base, a windingroller installed between the two supporting rods, a first motor arranged at one end of the winding roller and used for driving the winding roller to rotate, a first component, a second component and amoving seat which is used for driving the second component to move to realize clamping or separation of the first component and the second component. The frame is simple in structure and convenient to operate, by arranging the first component, the second component, the moving seat and a driving mechanism which are matched with one another for use, and a mortise and a tenon are adopted to performfixing between the first component and the second component through clamping, so that the first component and the second component can be locked and fixed without the aid of other auxiliary fixing components, the winding roller can be conveniently disassembled or installed, and the frame can be suitable for winding rollers of different sizes.

Owner:宿迁至诚纺织品股份有限公司

Efficient heat-setting spinning thread processing machine with uniform oil

The invention discloses an efficient heat-setting spinning thread processing device with uniform oil, which comprises a shell, wherein a first groove is arranged on the shell; an oil roller, a heatingplate and a support rod are arranged inside the first groove; a dust removal channel and an oil return channel are arranged on the two sides of the first groove. A first sponge ring, an oil outlet, an oil tank and an oil return pipe are installed on the oil return channel. A second sponge ring and an electrostatic precipitator are arranged inside the dust removal channel. A winding base is arranged at one side of the shell. A lead frame, a hydraulic cylinder, a telescopic rod, a lead wheel and a tension sensor are arranged on the winding base. Directional wheels and winding rods are arrangedon both sides of the lead frame. A variable speed motor, a clamp and a pressure sensor are arranged on each winding rod. The efficient heat-setting spinning thread processing device with uniform oil not only can improve oil uniformity and work efficiency, but also has the advantages of simple structure, low labor intensity, saving oil, good winding effect, long service life and convenient use.

Owner:湖州织里凯狄酷娃服饰有限公司

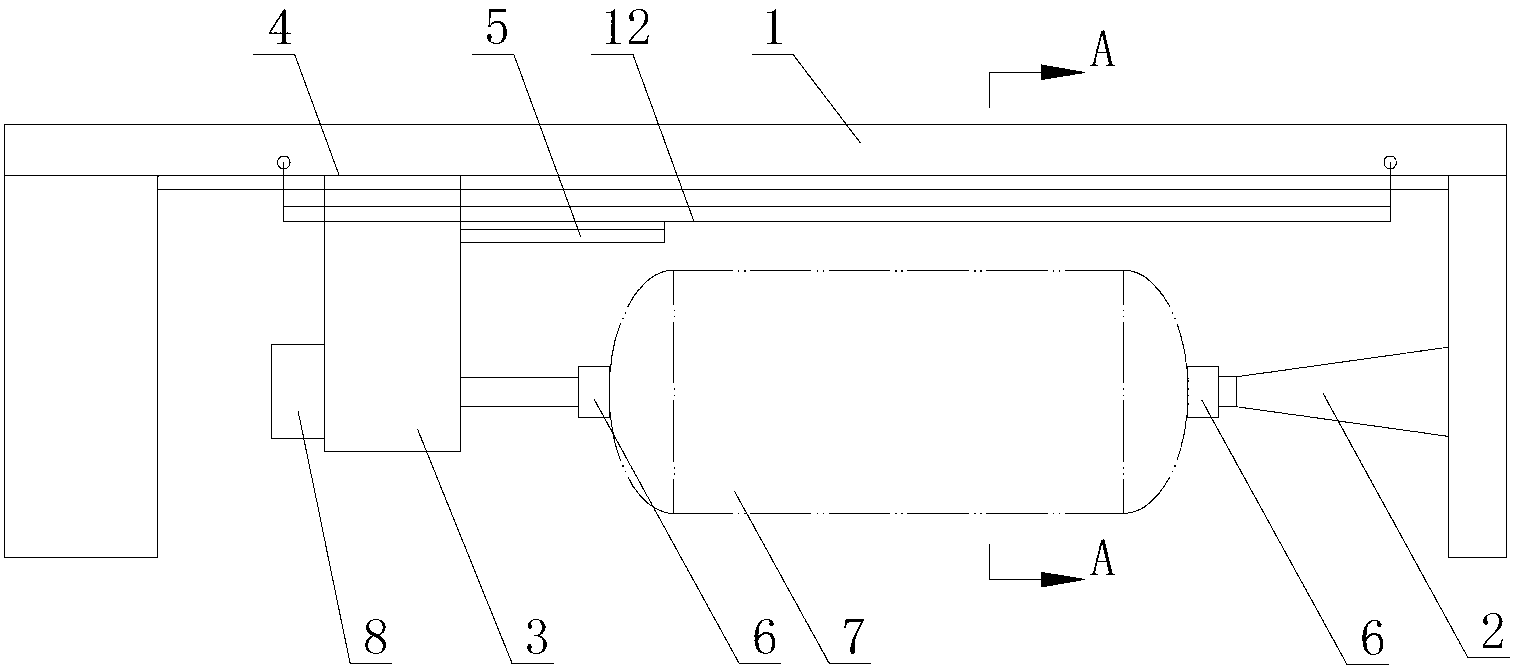

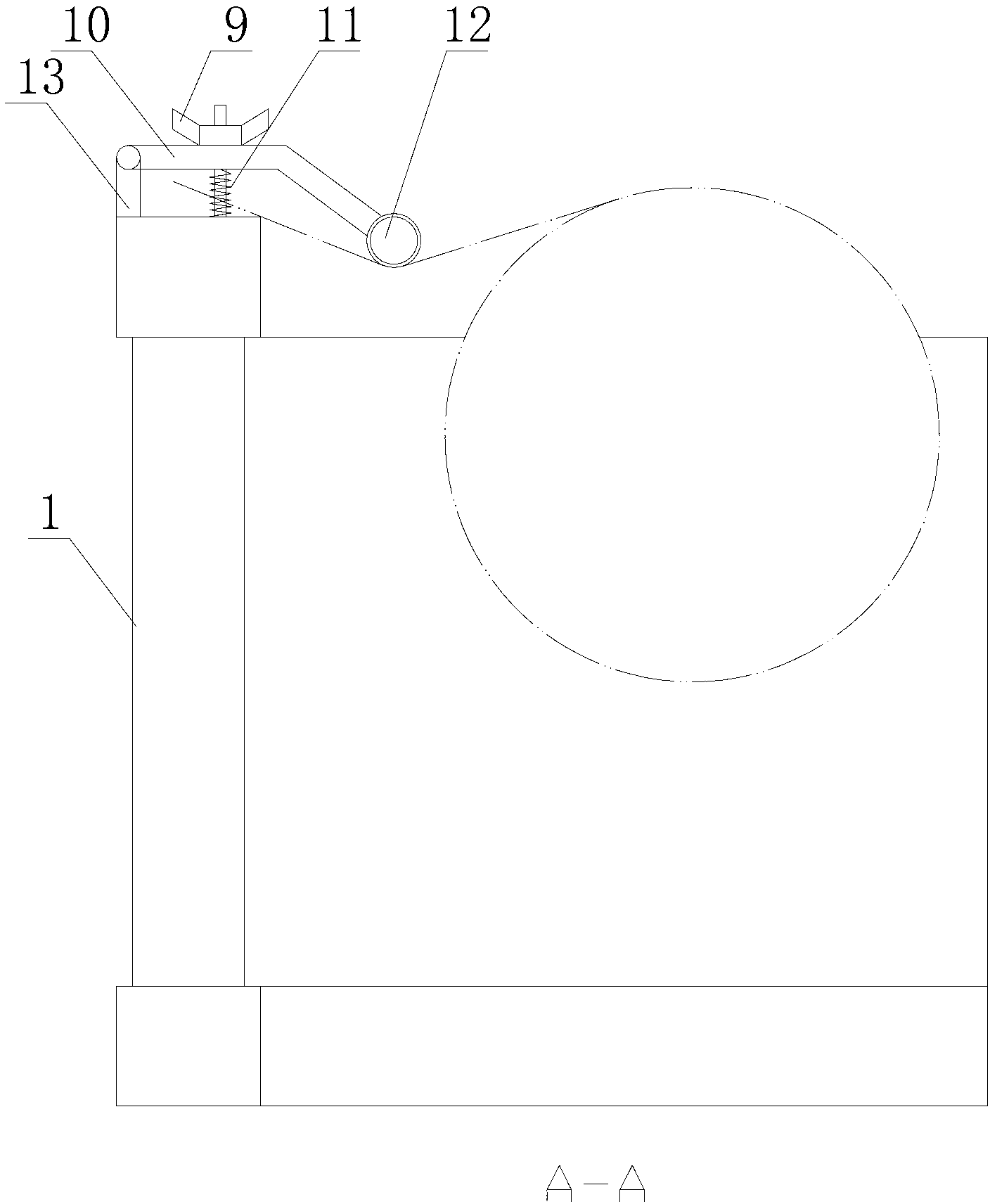

Automatic winding device of low-temperature insulation gas cylinder liner heat-preservation film

InactiveCN103322404ARealize automatic film windingConstant tensionPressure vesselsGas cylinderEngineering

The invention discloses an automatic winding device of a low-temperature insulation gas cylinder liner heat-preservation film. The automatic winding device is good in winding tightness, and comprises a rack, wherein the rack is provided with a fixed clamping part and a movable clamping part for clamping a gas cylinder, a first chunk is rotatably arranged on the fixed clamping part, the movable clamping part is rotatably provided with a second chunk and a power device for driving the second chunk to rotate, the rack is provided with a film-winding tension regulating device close to the gas cylinder, the film-winding tension regulating device comprises two regulating bolts respectively arranged at the positions of the rack, close two ends parts of the gas cylinder, regulating rods are sleeved on the regulating bolts, springs are sleeved on the regulating blots below the regulating rods, and a film-pressing shaft is arranged between the end parts of two regulating rods.

Owner:ZHANGJIAGANG FREE TRADE ZONE CHANGJIANG NEW ENERGY EQUIP

Steering guide wheel set

ActiveCN108492930AConsistent tightnessEliminate breaksInsulating conductors/cablesState of artMechanical engineering

The invention discloses a steering guide wheel set. The steering guide wheel set comprises an adjusting platform arranged on a wrapping machine rack; an angle adjusting arm is arranged on the adjusting platform; one end of the angle adjusting arm is movably connected onto the adjusting platform and the other end is provided with a guide rod; the edge of one side, close to the wrapping machine rack, of the adjusting platform is provided with a vertical plate; a pull spring is arranged between the vertical plate and the guide rod; a screw hole is arranged in the vertical plate; an adjusting ejector rod passes through the screw hole and is arranged; and the end part of the adjusting ejector rod is contacted with the angle adjusting arm. In comparison with the prior art, according to the steering guide wheel set, the angle adjusting arm is pushed through the adjusting ejector rod, the guide rod thus adjusts the output angle of a belt, the winding angle of a cable coated with the belt is adjusted, the tightness of the belt coating the cable is thus ensured to be consistent, the whole belt surface is ensured to thoroughly coat the wire passing guide rod, and a phenomenon that the belt isunevenly stressed as the belt is stressed at one side and the belt is broken during a production process can be eliminated.

Owner:ZHANGJIAGANG TWENTSCHE CABLE

Buckle type connecting structure of solid wood or raw wood furniture

The invention discloses a buckle type connecting structure of solid wood or raw wood furniture. The buckle type connecting structure comprises a first furniture sheet material, a second furniture sheet material and a connecting piece which are connected correspondingly, wherein the connecting piece consists of two parts, namely a buckling plate and buckling screws; each buckling screw comprises a bolt and an embedded nut; the buckling plate comprises two fixed parts positioned at two ends, and a convex connecting part positioned in the middle; a clamping groove is formed in the connecting part, and is arranged in an inclined slope manner; the height is gradually decreased from the inlet end to the buckling end by taking the plane of the two fixed parts as basic reference. The buckle type connecting structure ensures the high-grade quality of solid wood and raw wood furniture, and is simple in structure and convenient to install, use and detach, thus the labor intensity is alleviated and the labor cost is reduced, the problems of great processing difficulty and low production efficiency in the traditional process are solved, the limitation of bearing capacity and stability for the three-in-one connecting piece is broken through, and a foundation is laid for realizing factory scale production of solid wood and raw wood furniture.

Owner:长沙凌志装饰有限公司

Constant-speed winding type winding needle combination mechanism

PendingCN108461826AIncrease winding speedConsistent tightnessFinal product manufactureSecondary cellsPole pieceWind speed

The invention relates to a constant-speed winding type winding needle combination mechanism. The constant-speed winding type winding needle combination mechanism comprises an unwinding correction execution mechanism, wherein a battery pole piece is arranged at the outside wall of an unwinding servo motor; an unwinding passing roll support plate is arranged above a first unwinding passing roll; theoutside wall of the unwinding passing roll support plate is connected with an unwinding pole piece; the top end of the unwinding pole piece is connected with a pole lug flattening plate A of a pole piece passing roll; the pole piece passing roll is arranged at the upper side wall of the pole lug flattening plate A of the pole piece passing roll; a pole lug flattening plate B of the pole piece passing roll is arranged at the left side wall of the pole piece passing roll; a pole lug flattening adjusting mechanism is arranged at the side wall of the top part of the pole lug flattening plate B ofthe pole piece passing roll; a pole piece dedusting mechanism is arranged above the pole lug flattening adjusting mechanism. The constant-speed winding type winding needle combination mechanism has the advantages that the winding speed is effectively improved; a battery cell is wound within constant tension value; the looseness of the inner layer and outer layer of the battery cell is uniform; the quality of the wound finished product battery cell is stable; the efficiency is improved by one time or more; the winding speed can reach 1400mm / s.

Owner:GUANGDONG JITI SMART EQUIP CO LTD

Binding machine for cigarette case paperboard stacks and binding system

ActiveCN103803110AReasonable structureSimple pipeline layoutWrapping material feeding apparatusConveyor wrappingPhysicsEngineering

The invention discloses a binding machine for cigarette case paperboard stacks. The binding machine comprises a machine frame, wherein a working platform is arranged in the middle part of the machine frame, the front part of the working platform is designed to be a film band drooping supply area, a liftable film pushing mechanism is mounted above the working platform, a liftable cutting mechanism and a heat sealing mechanism are mounted on the inner side of the film pushing mechanism, the heat sealing mechanism is used for performing the heat seal operation, and the cutting mechanism is used for cutting film bands. The invention also discloses a binding system which comprises a film conveying device, a cigarette case paperboard stack conveying mechanism and the binding machine, wherein the film bands conveyed by the film conveying device are supplied to the drooping supply area of the banding machine, the cigarette case paperboard stacks conveyed by the cigarette case paperboard stack conveying mechanism are pushed by the pushing mechanism to the working platform, the film conveying device and the cigarette case paperboard stack conveying mechanism are distributed in parallel, and the conveying direction of the film bands is consistent to that of the cigarette case paperboard stacks. The machine has the advantages of simple structure, high degree of automation, convenience in operation, good working stability and the like.

Owner:HUNAN KENON AUTOMATIC EQUIP

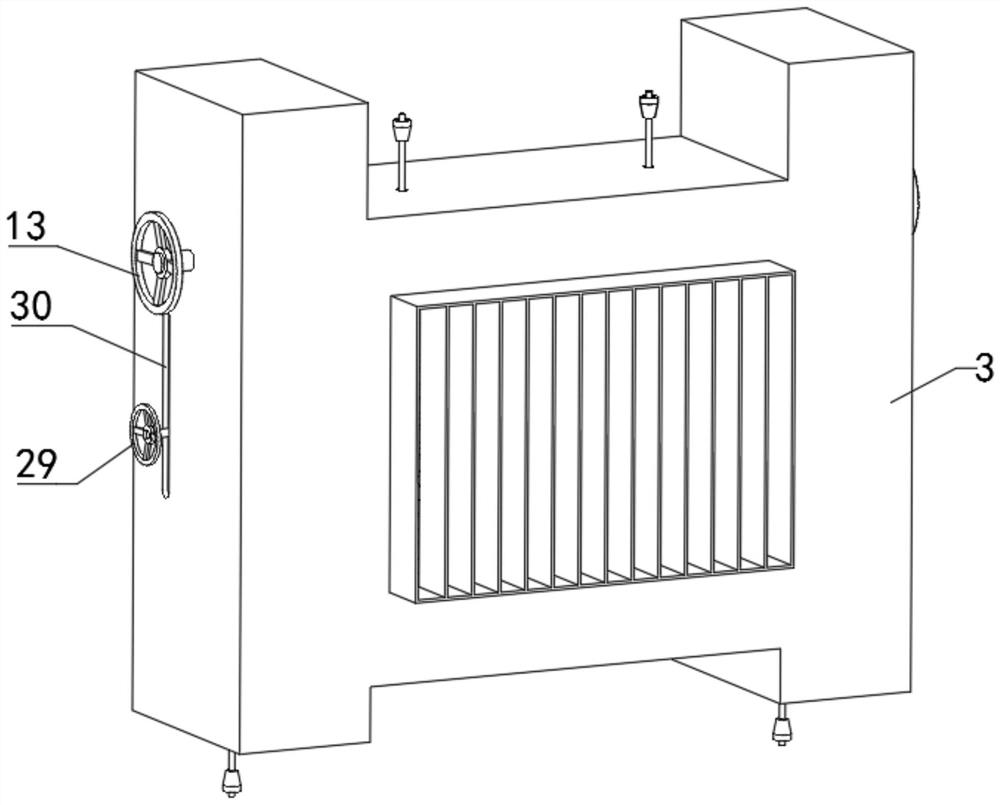

Transformer with adjustable turns

ActiveCN112712979AAdjustable densityConsistent tightnessTransformers/inductances coils/windings/connectionsVariable inductancesTransformerControl theory

The invention discloses a transformer with the adjustable number of turns. The transformer comprises a shell, an iron core, a standby spool, a lifting rotating unit and a take-up and pay-off unit, wherein the lifting speed of the standby spool and the autorotation speed of the iron core are in a preset proportion, and wound coils are spiral, consistent in tightness and adjustable in density. According to the transformer, the number of turns of the coil in the transformer can be adjusted without opening the transformer shell, and then voltage transformation operation can be completed conveniently and rapidly.

Owner:重庆重变电器有限责任公司

Protection belt winding device for petroleum transport pipeline

The invention discloses a protection belt winding device for a petroleum transport pipeline. The protection belt winding device for the petroleum transport pipeline protection belt winds a protectionbelt around the outer side of the petroleum pipeline by two layers through two-way rotation. The winding layer is thick, the protection effect is better, and the efficiency is high. The protection belt winding device is characterized in that a supporting plate is placed on a fixing frame; the fixing frame is of a circular ring structure; the bottom of the supporting plate is tangent to the outer circle of the fixing frame; one end of a connection plate is connected with the supporting plate; a supporting block is placed on the connection plate; an arc-shaped bracket is placed on the supportingblock; a plurality of rubber bulges are placed on the inner side of the arc-shaped bracket; an outer fixing ring is placed on the fixing frame through a bearing; an inner gear ring is placed on the inner side of the outer fixing ring; a through hole is formed in the outer fixing ring; one end of a main screw rod penetrates through the outer fixing ring and the fixing frame in sequence, the main screw rod is in threaded fit with the outer fixing ring, and a fixing rod is placed at the other end of the main screw rod; a main winding roller is rotatably placed on the fixing rod connected with the main screw rod; limiting rings are placed on the two sides of the main winding roller correspondingly; and an inner fixing ring is placed in the inner gear ring.

Owner:赣州江投石化有限公司

Wire paying-off lifting tool of power system

InactiveCN107293993AReduce volumeEasy to installApparatus for overhead lines/cablesElectric power systemQuality assurance

The invention discloses a lifting tool for unwinding wires in an electric power system, which comprises a base, a lower locking device which is arranged on the bottom of the base to lock and cooperate with the pole cross-arm, a bracket is fixed on the base, and the bracket is hinged to a support tube through a bracket shaft , the bracket is provided with a lower positioning device for positioning and matching the support cylinder, the upper end of the support cylinder is installed with an upper gear that rotates close to the outer surface of the main support plate through a rotating connection device, and the support cylinder is equipped with a gear that is snapped and positioned with the teeth of the upper gear In the upper positioning device, an upper bracket is hinged on the upper part of the upper gear, and an upper locking device is arranged between the auxiliary support plate and the upper bracket. The advantages are convenient installation, reliable fixation, simple disassembly, free adjustment of the pay-off height according to the actual height of the pole insulator, automatic determination of the length of the pay-off cable, and only one installation and disassembly for one set-up. Yes, the tightness of the wires before and after the tightening is consistent to ensure the quality, and one person can operate it.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

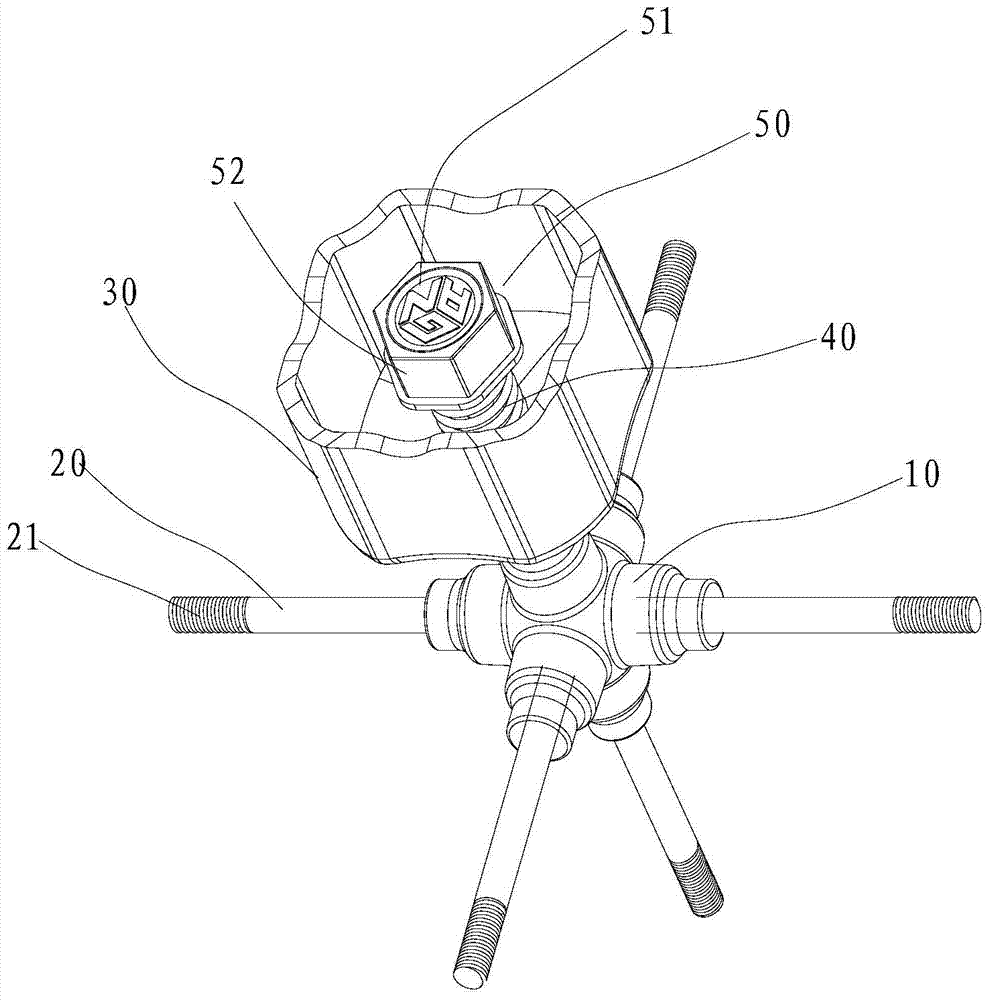

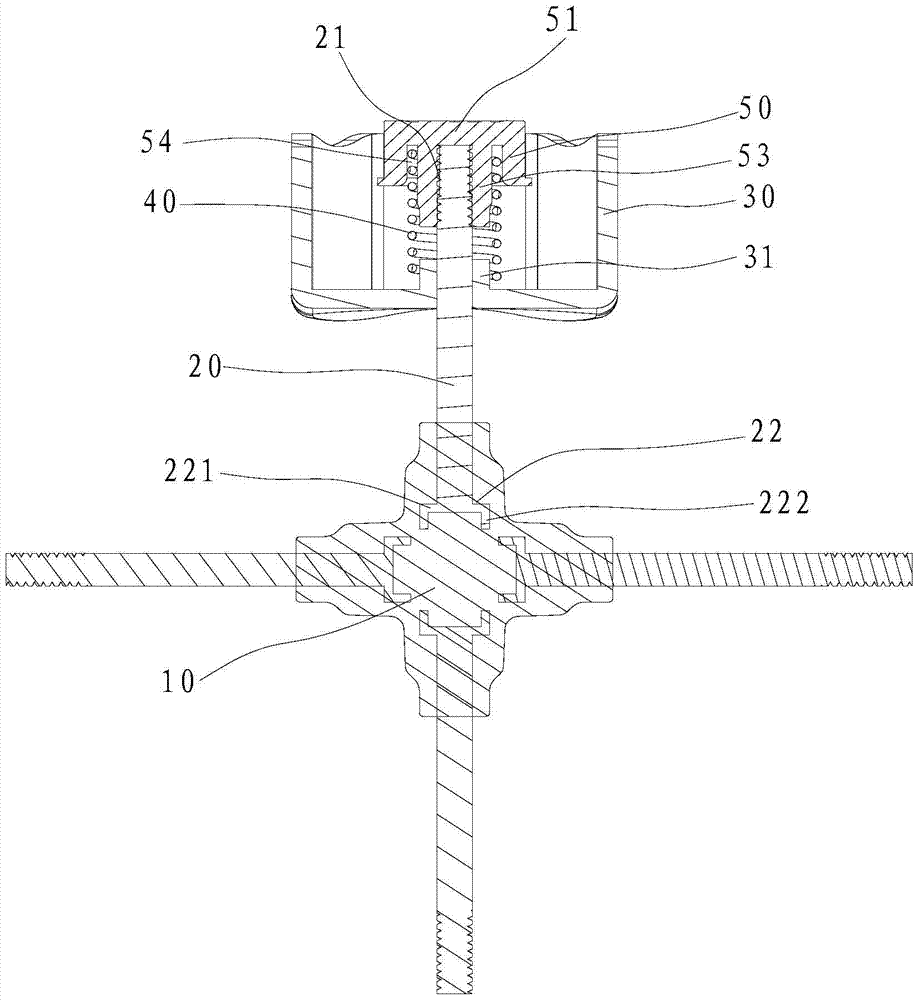

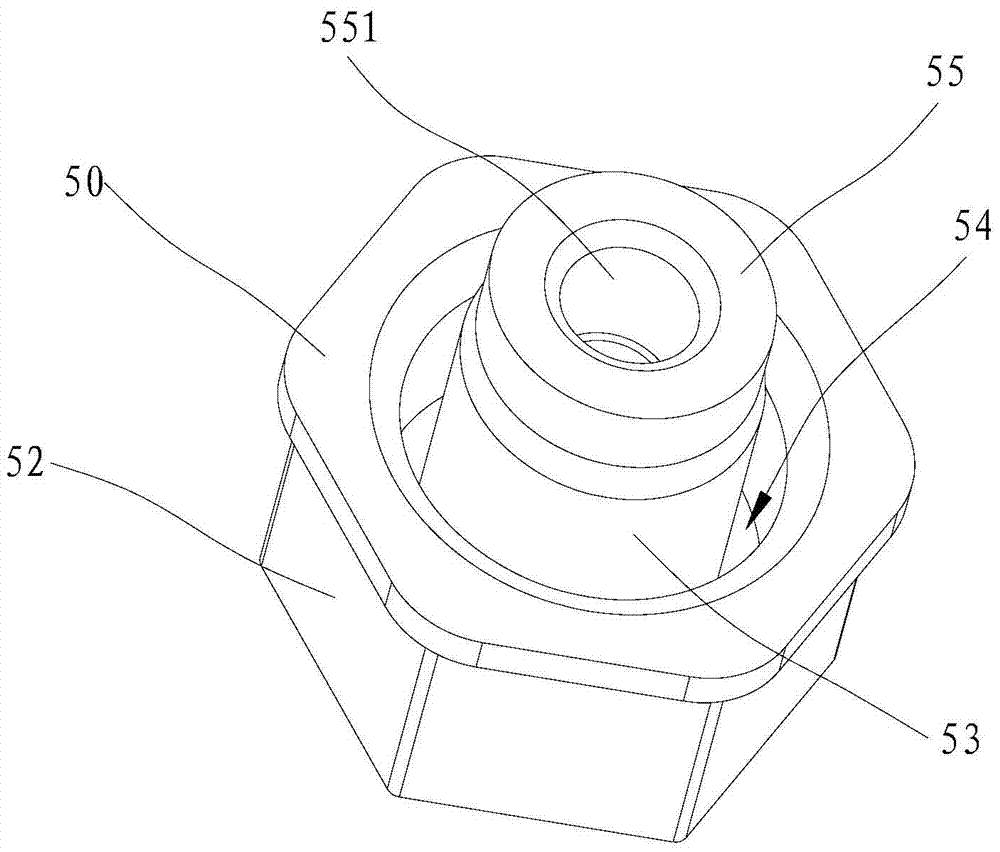

The installation structure of Rubik's cube center block

An installation structure for magic cube center blocks comprises a shaft center, the center blocks, connecting rods and elastic parts, one end of each connecting rod is provided with an embedded portion which is embedded in the shaft center, and each embedded portion comprises an extending portion and an inserting portion; the other end of each connecting rod is connected into the corresponding center block in a penetrating mode, an outer thread is formed in the outer surface of the portion, connected into the corresponding center block in a penetrating mode, of each connecting rod, an adjusting block is arranged on the portion, connected into the corresponding center block in a penetrating mode, of each connecting rod, and each adjusting block comprises a top wall, side walls located on the periphery of the lower surface of the top wall and a first sleeving installation portion which extends downwards from the lower surface of the top wall and is installed on the outer surface of the corresponding connecting rod in a sleeving mode; the inner surface of each sleeving installation portion is provided with an inner thread matched with the corresponding outer thread, and an installation groove is formed between the outer surface of each sleeving installation portion and the corresponding side walls; one end of each elastic part is arranged in the corresponding installation groove and abuts against the lower surface of the corresponding top wall, and the other end of each elastic part abuts against the inner side end wall of the corresponding center block. According to the installation structure for the magic cube center blocks, the center shaft structure is stable, the degrees of tightness of all faces of a magic tube are consistent, and the assembly is convenient.

Owner:江淦源

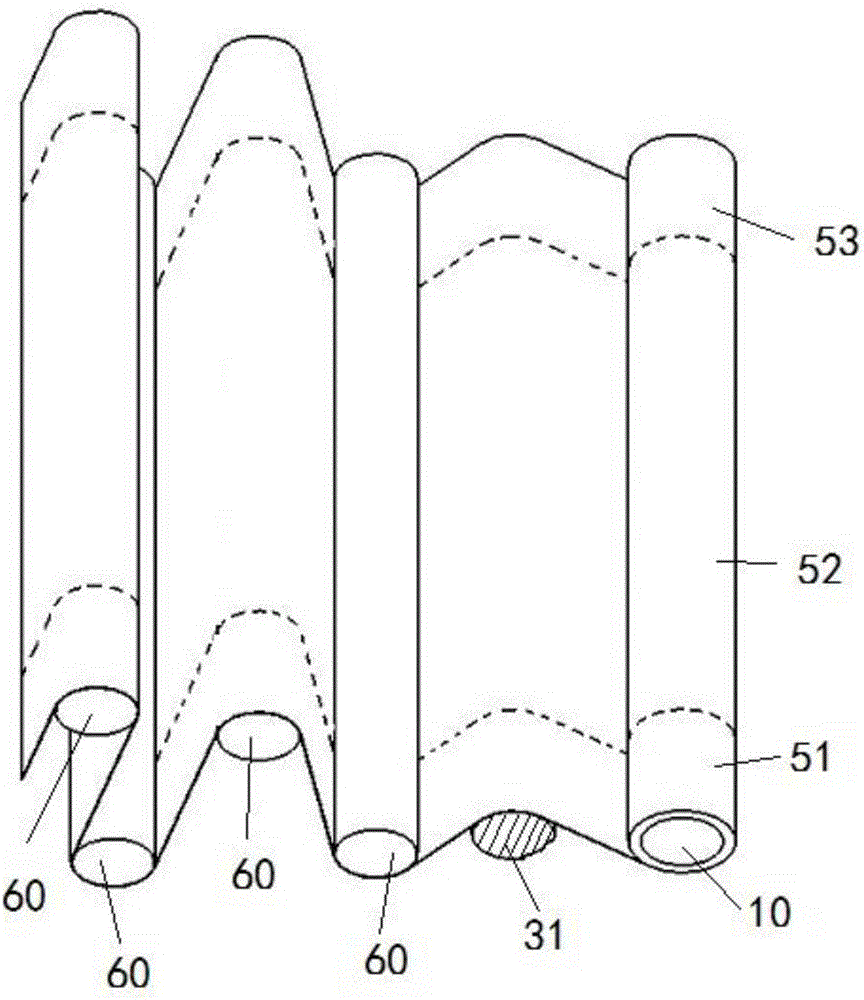

Pearl wool winding treatment method and system

The invention discloses a pearl wool winding treatment method and system. The pearl wool winding treatment method comprises the steps that according to the property of pearl wool, the pearl wool is divided into three zones, namely a left marginal zone, a middle zone and a right marginal zone in the width direction of the pearl wool for tension detection; the instantaneous radius of a winding shaft is obtained according to the volume of wound pearl wool on the winding shaft, and the torque of the winding shaft is adjusted in real time with a detected initial tension value of the middle zone being considered also; and detected tension values of the left side edge zone and the right side edge zone of the pearl wool are compared with the detected tension value of the middle zone of the pearl wool, and if the comparison difference of one side exceeds a preset threshold value, a deviation correction device arranged on the marginal zone on the side in advance is started to adjust the tension of the pearl wool on the edge of the side. By adjusting the torque of the winding shaft, the deviation correction device applies external force to the pearl wool for adjustment, so that the tensions of all the zones of the pearl wool are constant in the winding process.

Owner:厦门谱睿科技有限公司

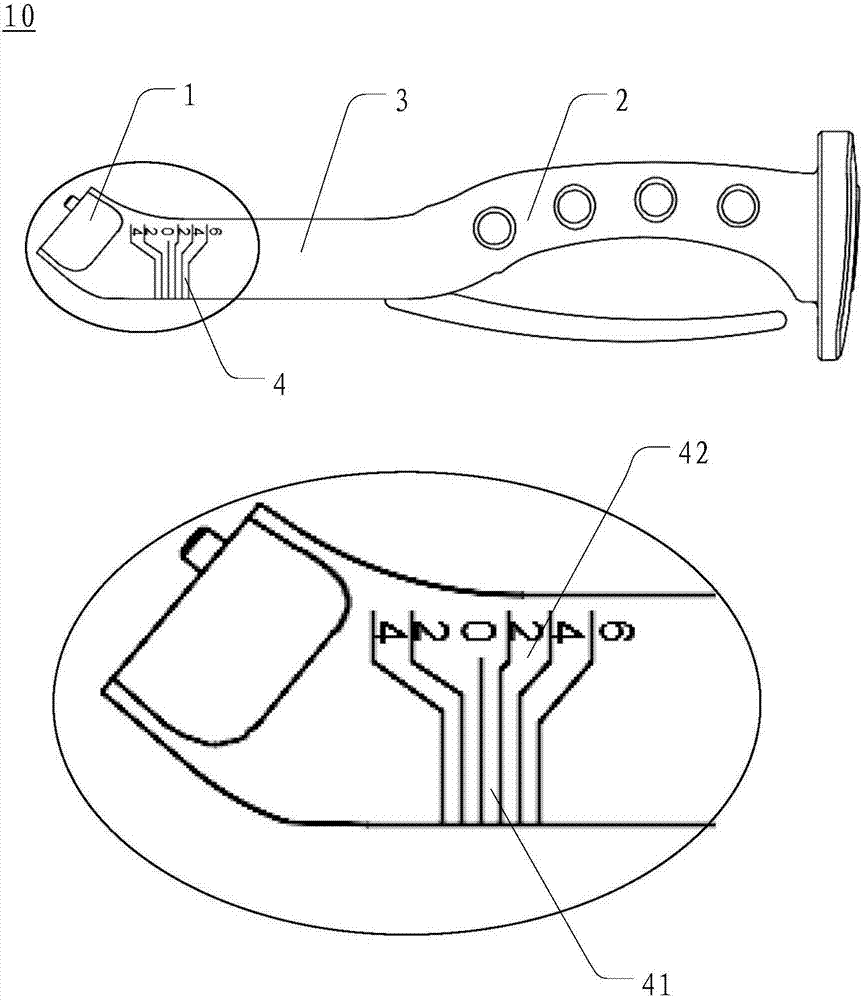

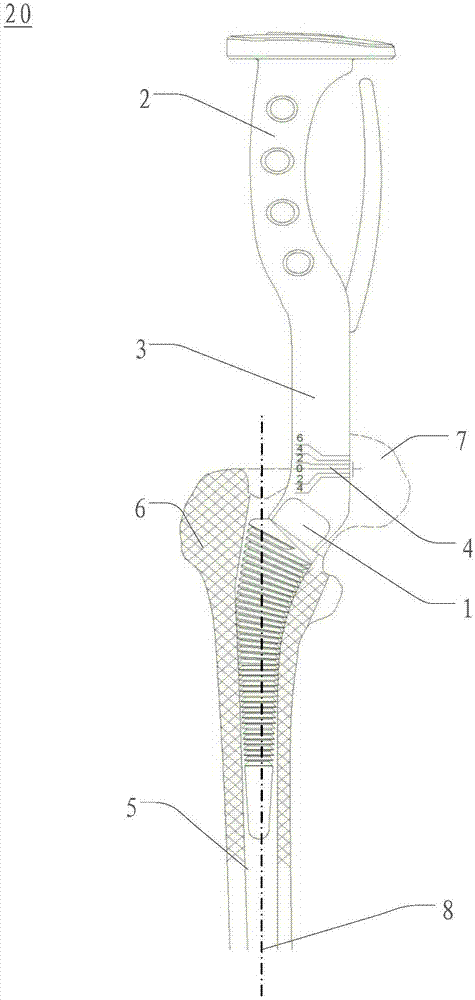

File handle and file for total hip replacement arthroplasty

The invention provides a file handle for total hip replacement arthroplasty. The file handle comprises a handle body, wherein the handle body is provided with a connecting portion connected with a file, a handholding portion, and a transition portion arranged between the connecting portion and the handholding portion, and scale marks for calibrating the position of the center of a ball of a hip prosthesis are arranged on the transition portion. When the file is inserted into the femoral medullary cavity through the file handle and the corresponding scale mark is aligned with the vertex of the greater trochanter of the human femur, the center of the ball of the hip prosthesis which is about to enter the femoral medullary cavity can be aligned with the vertex of the greater trochanter of the human femur. The position of the center of the ball of the hip prosthesis is predetermined by means of the scale marks arranged on the transition portion, and the insertion depth of the file into the femoral medullary cavity is controlled, so that surgery efficiency is improved and surgery precision is improved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com